Exhibit E

Sanitary District of Decatur

Second

erim Report

0

Electronic Filing - Received, Clerk's Office, June 15, 2009

* * * * * PCB 2009-125 * * * * *

June 18 , 2008

sanitary District

of

Decatur

5 01 DIPPER LANE - DECATUR, ILLINOIS 62522 .

217/422.6931 " FAX: 217/4238171

o tec

Attn.: Michael S. Garretson

Bureau of

'ýATater

Compl

No

P .O. Box 19276

Springfield, Illinois 62794-1

R e:

Dear Mr. Garretson:

Enclosed is the Interim Report reg

by Special Condition 1 8 of the S

c

c t of Decatur's NPDES

Perm

Please contact me at 422-6931 ext. 214 or at

tirnk

t.il.us

if you have any questions

Sanitary District of Decatur

Nickel and Zinc Limits

June 2008 Interim Report

The reissued NPDES permit for the Sanitary District of Decatur that became effective

July 1, 2007 contains new limits for nickel and zinc and a two-year compliance schedule

for meeting the limits. Special Condition 18 requires that an interim progress report be

submitted to Illinois EPA by July 1, 2008. A summary of information gathered and

activities since the January 1, 2008 report is provided below.

Plant Influent and Effluent Sampling

Nickel and zinc have been included in quarterly plant influent and effluent sampling for

many years. During 2007, effluent sampling frequency increased to twice weekly as part

of the translator study. Ongoing influent and effluent sampling for nickel and zinc is

planned to continue at a frequency of twice monthly. The District is investigating

purchase of an ICP instrument to perform metals analysis in-house.

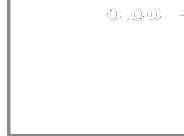

An updated summary of influent and effluent values is shown below. Review of past

data shows that the plant discharge would not be able to consistently meet the expected

nickel limit calculated on a hardness of 359 mg/L (per 1/2/08 email from Scott Twait of

Illinois EPA). Recent zinc concentrations appear to be near the expected limit with a few

exceptions.

Influent and Effluent Nickel

0

0.01

0.02

0.03

0.04

0.05

0.06

0.07

1

9

9

8

2

0

0

1

2

0

0

3

2

0

0

6

2

0

0

7

2

0

0

7

2

0

0

7

2

0

0

7

2

0

0

7

2

0

0

7

2

0

0

8

2

0

0

8

Date

Concentration, mg/L

Influent

Effluent

Expected

Permit Limit

Electronic Filing - Received, Clerk's Office, June 15, 2009

* * * * * PCB 2009-125 * * * * *

Influent and Effluent Zinc

0

0.05

0.1

0.15

0.2

0.25

0.3

0.35

0.4

0.45

1998

2001

2003

2006

2007

2007

2007

2007

2007

2007

2008

2008

Sample Date

Concentration, mg/L

Influent

Effluent

Expected Permit

Limit (avg.)

Expected Permit

Limit (max.)

Industrial Source Sampling

Analyses for metals including nickel and zinc have been performed semi-annually as part

of the District’s industrial pretreatment program. Sampling of the major industries

(ADM and Tate & Lyle) has been increased to monthly and other industries discharging

metals are now sampled quarterly.

Receiving Stream Sampling

Upstream and downstream sampling at the locations described in the translator study will

be continued at a twice monthly frequency to provide a more complete picture of nickel

and zinc in the Sangamon River.

Chronic WET Testing

Chronic toxicity tests were conducted in July and September 2007. An additional chronic

toxicity test using EDTA to chelate metals in the samples was conducted in December

2007. The EDTA treated tests showed more chronic toxicity than the untreated effluent,

which the laboratory attributed to the possibility that EDTA itself was causing toxicity.

No additional toxicity testing is currently planned.

Industrial Source Investigations

Tentative pretreatment local limits have been calculated based on the expected permit

limits for nickel and zinc. The District’s two major industrial users have been made

aware of the tentative limits and several meetings have been held with each to review

treatment options. Both industries utilize zinc as part of their cooling tower treatment

Electronic Filing - Received, Clerk's Office, June 15, 2009

* * * * * PCB 2009-125 * * * * *

programs, and sampling has not identified any other significant zinc sources at the two

facilities. Each of the industries has been consulting with their cooling tower treatment

supplier, and both expect to be able to achieve the tentative pretreatment limit through

reduced zinc usage and better control of cooling tower operation. Both also have the

option of switching to either a phosphate or a silicate-based treatment program in the

event that zinc control alone is not sufficient.

ADM is the only significant industrial source of nickel, which is used as a catalyst in

hydrogenation processes. Two potential changes to reduce nickel discharges are being

investigated. In one area, improved housekeeping procedures are being implemented to

prevent nickel from entering the wastewater stream. The improved housekeeping will be

followed with testing to determine success. In the second area, dissolved nickel is

proposed to be recovered using a combination of ion exchange to concentrate the nickel,

followed by an electroplating process for removal. While both processes are relatively

common, ADM reports that they have not been used together in this application. They

still anticipate a reasonable probability of success and are currently beginning bench

testing.

Several other industrial users would also be impacted by reduced pretreatment limits for

nickel and zinc. While their concentrations are a concern, they discharge a very small

volume of wastewater relative to the two large users and have an insignificant impact on

concentrations in the plant influent. Use of mass rather than concentration pretreatment

limits is being considered for these small users.

Compliance Plan

Based on current information, the measures necessary to comply with final nickel and

zinc limitations will include a combination of the following:

1. Continued effluent and stream monitoring to determine whether further

adjustment of NPDES permit limits may be justified.

2. Finalization of local pretreatment limits for nickel and zinc, and ongoing

discussions with industrial users to verify that they will be able to meet the limits

by the compliance deadline of July 1, 2009.

3. Ongoing review and analysis of technical information that would be needed to

support a site-specific water quality standard.

The next interim report will be submitted by January 1, 2009 as required by our NPDES

permit.

Exhibit F

itary District

of Decatur

Third Interim Report

December 29,

2008

Electronic Filing - Received, Clerk's Office, June 15, 2009

* * * * * PCB 2009-125 * * * * *

Sanita

5 01 DIPPER LANE " DECATUR, ILLINOIS 62522 . 2171422-6931 "

FAX: 2171423.8171

D

ecember

2

al Protection Agency

Attn.: Michael S. Garretson

Bureau of Water Compliance Assurance Section,

MC

#19

1021 North Grand Avenue East

P .O. B ox 19276

4 -9276

Re: NPDES Permit IL0028321

erim Report

Dear Mr.

Garretson:

regarding compliance with nickel

and zinc limits required

by Special Condition 18 of the Sanitary District of Decatur's NPDES Permit.

Sincerely,

Timothy R.

Technical Director

cc: Bob Mosher, DWPC Standards

Rick Pinneo, DWPC Permits

J oe Koro kowski, Champaign Region

Electronic Filing - Received, Clerk's Office, June 15, 2009

* * * * * PCB 2009-125 * * * * *

Sanitary District of Decatur

Nickel and Zinc Limits

December 2008 Interim Report

The reissued NPDES permit for the Sanitary District of Decatur that became effective

July 1, 2007 contains new limits for nickel and zinc and a two-year compliance schedule

for meeting the limits. Special Condition 18 requires that an interim progress report be

submitted to Illinois EPA by January 1, 2009. A summary of information gathered and

activities since the July 1, 2008 report is provided below.

Plant Influent and Effluent Sampling

Nickel and zinc have been included in quarterly plant influent and effluent sampling for

many years. During 2007, effluent sampling frequency increased to twice weekly as part

of the translator study. Ongoing influent and effluent sampling for nickel and zinc is

planned to continue at a frequency of twice monthly. The District will begin performing

metals analysis in-house in early 2009.

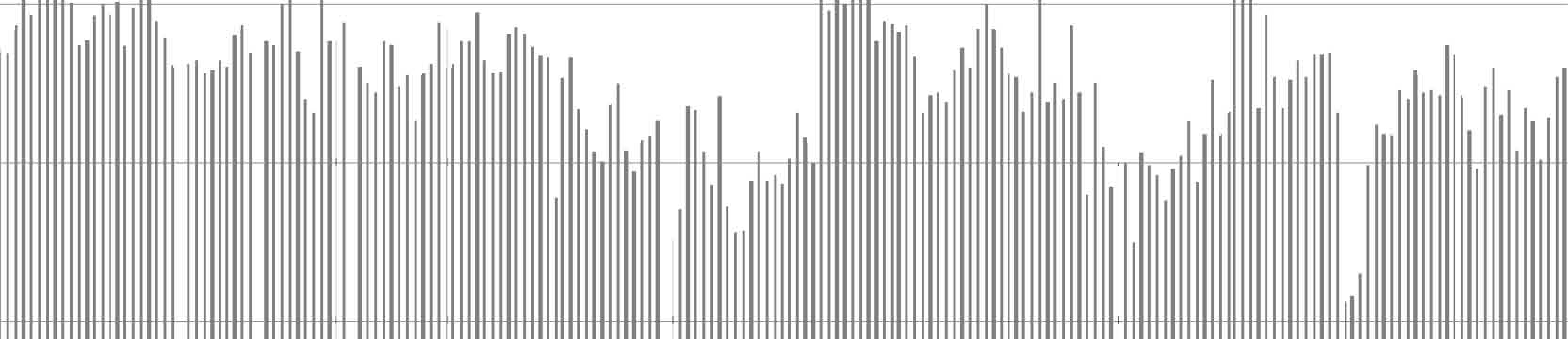

An updated summary of influent and effluent values is shown below. Review of past

data shows that the plant discharge would not be able to consistently meet the expected

nickel limit calculated on a hardness of 359 mg/L (per 1/2/08 email from Scott Twait of

Illinois EPA). Recent zinc concentrations appear to be below the expected limit.

Influent and Effluent Nickel

0

0.01

0.02

0.03

0.04

0.05

0.06

0.07

0.08

0.09

19

98

20

02

20

06

20

07

20

07

20

07

20

07

20

08

20

08

Date

Concentration, mg/L

Influent

Effluent

Expected

Permit Limit

Electronic Filing - Received, Clerk's Office, June 15, 2009

* * * * * PCB 2009-125 * * * * *

Influent and Effluent Zinc

0

0.05

0.1

0.15

0.2

0.25

0.3

0.35

0.4

0.45

1998

2002

2005

2007

2007

2007

2007

2007

2008

2008

Sample Date

Concentration, mg/L

Influent

Effluent

Expected Permit

Limit (avg.)

Expected Permit

Limit (max.)

Industrial Source Sampling

Analyses for metals including nickel and zinc have been performed semi-annually as part

of the District’s industrial pretreatment program. Sampling of the major industries

(ADM and Tate & Lyle) has been increased to monthly and other industries discharging

metals are now sampled quarterly.

Receiving Stream Sampling

Upstream and downstream sampling at the locations described in the translator study will

be continued at a twice monthly frequency to provide a more complete picture of nickel

and zinc in the Sangamon River.

Chronic WET Testing

Chronic toxicity tests were conducted in July and September 2007. An additional chronic

toxicity test using EDTA to chelate metals in the samples was conducted in December

2007. The EDTA treated tests showed more chronic toxicity than the untreated effluent,

which the laboratory attributed to the possibility that EDTA itself was causing toxicity.

Results of the toxicity testing have been reviewed by Illinois EPA personnel.

Industrial Source Investigations

Tentative pretreatment local limits have been calculated based on the expected permit

limits for nickel and zinc. The District’s two major industrial users have been made

aware of the tentative limits. During 2008, three formal meetings have been held with

ADM personnel and one with Tate & Lyle; inspections and other contacts with each

during the year also oncluded discussion of nickel and zinc issues. Both industries

formerly utilized zinc as part of their cooling tower treatment programs, and both have

eliminated or greatly reduced zinc in their towers. At this time, both industries are

meeting the expected zinc pretreatment limit. ADM is continuing to ivestigate the

possible impact of the zinc limit on their planned wasting of solids from the pretreatment

system to the District.

ADM is by far the most significant industrial source of nickel. While it is primarily used

as a catalyst in hydrogenation processes, investigations have found that even very small

amounts that exist in other plant waste streams become important when pretreatment

limits are very low. Incoming grain and sodium hydroxide used in the plant contain

small but significant amounts of nickel. Production swings and changes in product mix

present sampling challenges. A summary of ADM’s investigations and findings to date is

attached. A meeting with ADM early in January 2009 is planned to further review their

investigations and plans for compliance.

Several other industrial users would also be impacted by reduced pretreatment limits for

nickel and zinc. While their concentrations are a concern, they discharge a very small

volume of wastewater relative to the two large users and have an insignificant impact on

concentrations in the plant influent. Use of mass rather than concentration pretreatment

limits is being considered for these small users.

Water Quality Standard Investigations

The year 2008 was unusually wet, and did not present the opportunity to gather additional

data related to a translator for nickel and zinc under critical low flow conditions.

Following consultation with Illinois EPA, the District is continuing to investigate

approaches to a water quality standard adjustment including the biotic ligand model and

the water effect ratio approach. An initial contact has been made with a consultant that

seems to be very familiar with these approaches, and information is being gathered to

evaluate their possible application. In addition, the District has begun to consider what

information might be needed to justify a standard based on a different level of water

quality protection, as allowed for by state and federal regulations.

Compliance Plan

During the next reporting period, the District will continue to work toward compliance

with final nickel and zinc limitations by means of the following activities:

1. Request a modification of the District’s NPDES permit extending the compliance

schedule for meeting the nickel and zinc limits. In spite of ongoing investigations

by the District and ADM, it appears that the current nickel limit cannot be

achieved without changes to treatment processes, operations (in particular,

operations at industrial users), a site-specific adjustment of the water quality

standard, or some combination of these three actions.

Electronic Filing - Received, Clerk's Office, June 15, 2009

* * * * * PCB 2009-125 * * * * *

2. Continued effluent and stream monitoring to determine whether further

adjustment of NPDES permit limits may be justified.

3. Finalization of local pretreatment limits for nickel and zinc, and ongoing

discussions with industrial users regarding pollution prevention or control

measures to enable reductions of nickel and zinc.

4. Ongoing review and analysis of technical information that would be needed to

support a site-specific water quality standard. This information includes both

biological and toxicity data related to the standard, and economic data that would

also be required for a legal proceeding.

The next report will be submitted by July 1, 2009 as required by our NPDES permit.

CURRENT ADM DECATUR COMPLEX BALANCE - 11/2008

Lbs / day

MGD

ppm Ni

lbs Ni / day ppm Zn lbs Zn / day % of Ni from Grain

Ni from Grain, Lbs / day

ALL Water into Complex

18.5

0

0

50% Sodium Hydroxide

215,000

1.7

0.4

ALL Grains into Complex

36,500,000

57

1300

Corn Plant

5.1

0.040

1.70

0.40

16.9

50%

0.85

East Plant

2.5

0.20

4.15

0.80

16.6

100%

4.15

Biochem

1.65

0.030

0.41

0.30

4.1

100%

0.41

West Plant

0.9

0.090

0.67

0.40

3.0

0%

0

TOTAL to ADM WWTP

6.9

40.6

5.4

Clarifier Carryover - Bugs

35,000

100

3.5

800

28.0

Effluent, Soluble Portion

9.3

0.091

7.0

0.11

8.5

C. Twr Blowdown Residual

2.7

0.020

0.45

0.15

3.4

FINAL EFFLUENT to SDD

35,000

12.0

0.11

11.0

0.40

39.8

SDD Avg Limit (Proposed)

0.0365

3.588

0.352

34.605

These numbers represent our best estimates of the current balance however these numbers may not take into account various factors inlcuding:

Storm Water

Future Soy Expansion

Glycol Plant Start-up (Ni Catalyst)

50% NaOH contains nickel & Soda Ash availability

Complex Variability:

Future In-plant Water Re-use efforts, reduced Effluent flow

--- Fructose Production swings

--- New Ion Exchange product, Feb09

--- Changes in IX / Non-IX balance

IN

TO ADM WWTP

EFFLUENT

Electronic Filing - Received, Clerk's Office, June 15, 2009

* * * * * PCB 2009-125 * * * * *

A

ppm Nickel

ppm Zinc

Lbs Dry

Lbs

Lbs

Dry Basis

Dry Basis

Bushels / day

Grain / day

Nickel / day

Zinc / day

Corn:

0.53

32

550,000

26,026,000

14

833

Soybeans:

4.1

46

200,000

10,440,000

43

480

TOTAL with GRAIN

36,466,000

57

1,313

Effluent, Lbs / day Max @ 12 MGD

3.6

34.6

Additional Nickel & Zinc Sources:

-- Nickel Catalysts used at Corn and West Plants.

-- Residual nickel & zinc at Corn Plant Towers, residual zinc at Bio Products Towers.

SOURCES

B

Co-gen:

Boiler Blowdown

RO Reject water

IX Waste Neutralization

#6 Cooling Tower

East Plant:

Refinery (low salt)

Biochem:

Bio Condensate (low salt)

Cooling Tower Blowdowns

Corn Plant:

Mill Hotwell condensate

Feed Scrubber discharge

Waste Heat condensate

Alcohol waste

Cooling Tower Blowdowns

West Plant:

Greasy Tower

Split Box

Car Washer (?)

Bean & Germ Plant Split Boxes

SFI

THESE STREAMS ARE OK

C

Co-gen:

None

East Plant:

8" & 12" Isolate (high salt)

0.2 to 0.3 ppm Ni and 1 ppm Zn.

Biochem:

Biochem Waste (high salt)

Nickel at 0.02 - 0.04ppm. Zinc in 0.3 - 0.6 ppm range.

Corn Plant:

Refinery Fructose & Sorbitol IX regen waste

High Ni and Zn, varies with batch IX operation

Average Ni is 0.15ppm and zinc is 0.14 ppm

West Plant:

24 hour composite at Corn Plant

1st DAF, 2nd DAF and Primary Skimmer

Periods of high Ni and Zn.

Periods of high nickel.

Packaging Plant

SSL waste

Zinc excursions > 1ppm.

Zinc excursions > 1ppm.

Vitamin E

Storm Water

Nickel as high as 0.2 ppm.

Nickel excursions > 0.1ppm.

STREAMS that have shown HIGH LEVELS

Electronic Filing - Received, Clerk's Office, June 15, 2009

* * * * * PCB 2009-125 * * * * *

D

Nickel & Zinc Chronology

2006-2007

●►

Investigated nickel recovery by electroplating…cost savings.

Jan-08

●►

New SDD specs on nickel and zinc: 0.17 to 0.037ppm Ni and 0.45ppm Zn.

●►

Effluent was 0.06 to 0.10 ppm Ni at that time.

●►

Nickel found in West Plant stream & CP Cooling Towers.

Mar - Apr 2008

●►

Hired nickel consultant at Corn Plant.

●►

Ran West Plant High Salt trial.

May-08

●►

Met with SDD representatives.

●►

Began sampling program throughout Corn Plant & Sewer Plant.

●►

Ceased all zinc addition to Cooling Towers.

●►

West Plant in-process sampling began.

●►

Identified zinc analysis issues.

June - July 2008

●►

Opened dialog with nickel catalyst supplier.

●►

Nickel precipitation problems surfaced…nickel-gluconate complex.

●►

Hydrogenation pH looked at again.

●►

SDD changed testing basis.

Aug-08

●►

Widened scope of sampling.

●►

Began sharing samples with EPA lab.

●►

Streams of interest confirmed by EPA lab.

●►

Pursuing nickel-gluconate oxidation.

●►

Sought participation by ADM Research & GE Betz

Sept - Nov 2008

●►

Turned Complex-wide sampling over to individual plants.

●►

Each plant responsible for determining reduction methods.

●►

Determined degree of Sludge nickel and zinc levels.

●►

Learned of lower nickel limit…3.7 lbs / day to 2.3 lbs / day.

●►

Began calculations on effect of Sludge wasting on effluent nickel & zinc.

●►

Ran bench and plant trials on nickel removal methods at Corn Plant.

●►

Determined approx % reduction necessary at each plant to reach nickel limit.

●►

Chemistry change on #4 Tower lowered zinc ppm to <0.5 ppm.

E

●►

Incoming Water (SWTP, NWTP and Well Water) not an issue.

●►

Zinc analysis had issues through mid-summer 2008.

●►

ADM ICP method will under-report nickel vs. EPA lab --- use multiplier.

●►

Both nickel & zinc will bleed from Cooling Tower systems.

●►

Streams with significant zinc-containing suspended solids are very difficult to filter.

●►

Nickel reclamation via electroplating has many issues in facilities of our kind.

Chelating IX resins are not food grade. Expect high Acid / Base usage for any IX system.

Nickel will precipitate at ~9.5 - 10.5 pH if it is not complexed with organic material.

Organic matter can be oxidized with ozone and H2O2 to allow nickel precipitation. Very high ozone usage.

●►

In some plants, there are intermittent processes & discharges which complicate discovery of sources.

●►

Short-term, select streams can be sent to a Co-product, given FDA and quality compliance.

●►

Zinc can be brought under the limit by wasting sludge by removal from the effluent.

Clarifier operation will be critical and may require additional drying equipment with signficant capital expenditure.

●►

If all Corn Plant acid IX waste is treated, approx 2.5MM lbs of 35% HCl per month must be raised to 10pH.

●►

Soy-based operation will need to find a feed / fertilizer outlet to reduce nickel & zinc.

●►

Oil refining operation believes that moving the entire catalyst handling system may significantly reduce nickel.

Electronic

REDUCING

Filing -

NICKEL

Received,

&

Clerk's

ZINC

Office, June 15, 2009

* * * * * PCB 2009-125 * * * * *

F

1.2

MGD

0.03

MGD

2.0

MGD

0.6

MGD

0.9

MGD

1.25

MGD

0.4

MGD

MGD

0.35

MGD

1.6

MGD

MGD

0.5

MGD

POND OVERFLOW

ZEEWEED REJECT

1.3

MGD

0.35

MGD

0.1

MGD

2.2

MGD

0.1

MGD

11.5

MGD

0.65

MGD

0.15

MGD

0.5

MGD

TO LOW SALT

BIOCHEM #4 / #5 TOWER BD

CO-GEN NEUT TO CITY

POTABLE AS SANITARY

POLYOL

EAST COMPLEX STORM WTR

BIOCHEM WASTE

BIOCHEM STORM WATER

CORN PLT COOLING TOWER BD

WEST PLT STORM WATER

CO-GEN NEUT WATER

CORN PLANT

TOWERS

FRONT PUMP

STATION

DAMON PUMP

STATION

DECATUR SANITARY DISTRICT

CO-GEN #6 TOWER BD

CORN PLT ALCOHOL

2008

BASIC WASTE WATER TREATMENT LAYOUT

CORN PLT MILL COND

LOW SALT

ANAEROBIC &

AEROBIC

TREATMENT

HIGH SALT

ANAEROBIC &

AEROBIC

TREATMENT

BIOCHEM CONDENSATE

POND &

ZEEWEED

CORN PLT WASTE HEAT

CORN PLT FEED HOUSE

WEST PLANT + VITAMIN E

CORN PLT REFINERY

EAST PLANT REFINERY

EAST PLT 8" & 12" ISOLATE

TRUCK WASH

Electronic Filing - Received, Clerk's Office, June 15, 2009

* * * * * PCB 2009-125 * * * * *

Electronic Filing - Received, Clerk's Office, June 15, 2009

* * * * * PCB 2009-125 * * * * *

Exhibit

G

Sanitary

ary

of Sample Data

Presented to

Illinois

EPA on October 30,

2007

SDD Nickel & Zinc Limits

Influent and Effluent Nickel

0

0.01

0.02

0.03

0.04

0.05

0.06

1

9

9

8

2

0

0

1

2

0

0

3

2

0

0

5

2

0

0

7

2

0

0

7

2

0

0

7

2

0

0

7

2

0

0

7

2

0

0

7

2

0

0

7

Sample Date

Concentration, mg/L

Influent

Effluent

Permit Limit

Influent and Effluent Zinc

0

0.05

0.1

0.15

0.2

0.25

0.3

0.35

0.4

0.45

1998

2001

2003

2006

2007

2007

2007

2007

2007

2007

Sample Date

Concentration, mg/L

Influent

Effluent

Permit Limit (avg.)

Permit Limit (max.)

“Domestic” wastewater concentrations

Nickel – below detection limit

Zinc – approximately 0.066 mg/L

Drinking water supply concentrations

Nickel – below detection limit

Zinc – approximately 0.011 mg/L

Electronic Filing - Received, Clerk's Office, June 15, 2009

* * * * * PCB 2009-125 * * * * *

Major Industries Nickel

0.000

0.020

0.040

0.060

0.080

0.100

F

irst

h

al

f

1

99

9

March 2000

April 200

1

March 20

0

2

M

a

y

2

0

03

Ap

ri

l

2

004

March 2005

January 2006

Jan

u

ary

2

00

7

Sample Date

Nickel, mg/L

ADM Point A

ADM Point D

T&L Point A

T&L Point C

Permit Limit

(ADM permit limit for Ni is 0.17 mg/L)

Major Industries Zinc

0.000

0.200

0.400

0.600

0.800

1.000

Fir

st

ha

l

f

199

9

March 2

0

0

0

April 2001

March 2002

May 2003

April 2004

March 2005

January 2006

January

2

0

0

7

Sample Date

Zinc, mg/L

ADM Pt. A

ADM Pt. D

T&L Pt. A

T&L Pt. C

Permit Limit

Ongoing information gathering

Influent, effluent, stream sampling

Industrial and domestic wastewater sampling

Chronic toxicity testing

EIU stream biosurveys

Calculation options

Translator study

Hardness

Biotic ligand model

Questions

Other dischargers affected?

Any federal updates on Ni and Zn criteria scheduled?

Relief options potentially available – site-specific standards, use designation?

Others? Which could IEPA support?

Other information needed?

Five day/week monitoring?

Electronic Filing - Received, Clerk's Office, June 15, 2009

* * * * * PCB 2009-125 * * * * *

Exhibit

Public Notice / Fact Sheet of

Draft Modified NPDES Permit for the Sanitary District

of

Decatur

Posted

on Illinois EPA's Website on May S, 2009

NPDES Permit No. IL0028321

Notice No. REP:06120503.bah

Public Notice Beginning Date: May 7, 2009

Public Notice Ending Date: June 8, 2009

National Pollutant Discharge Elimination System (NPDES)

Permit Program

PUBLIC

NOTICE/FACT SHEET

of

Draft Modified NPDES Permit to Discharge into Waters of the State

Public Notice/Fact

Sheet Issued By:

Illinois EPA

Division of Water Pollution Control

Permit Section

1021 North Grand Avenue East

Post Office Box 19276

Springfield, Illinois 62794-9276

217/782-0610

Name and Address of Discharger:

S anitary District of Decatur

Sanitary District o

501 Dipper Lane

501 Dipper Lane

Decatur,

Illinois 62522

Decatur, Illinois

(Macon County)

i lity:

T he Illinois Environmental Protection Agency (IEPA) has made a tentative determination

to

issue

a

NPDES

Permit to discharge into the

waters of the state and has prepared a draft Permit and associated fact sheet for

the above named discharger. The Public Notice period

will begin and end

on the dates

indicated in

the heading of this Public Notice/Fact Sheet. All comments on the draft Permit and requests

for hearing must be received

by the

IEPA

by U.S. Mail, carrier mail or hand delivered by the Public Notice Ending Date. Interested

rsons are invited to submit written comments

on the draft

Permit

to the

IEPA

at the above address. Commentors shall provide his or

nd

address and the nature of the issues proposed to be raised and the evidence proposed to be presented with regards to

issues.

Commentors may include a request for public hearing. Persons submitting comments and/or requests for public hearing

a lso

send

a

copy of such comments or requests to the Permit applicant. The NPDES Permit and notice numbers must appear on

m ent page.

The application, engineer's review notes including load limit calculations, Public Notice/Fact Sheet, draft Permit, comments received, and

other documents are available for inspection and may be copied at the IEPA between 9:30 a.m. and 3:30 p.m. Monday

through Friday

when scheduled by the interested person.

If written comments or requests indicates a

significant degree of

public interest

in the draft Permit, the permitting authority may, at its

discretion, hold a public hearing. Public notice will

be given

45

days before any

public

hearing. Response to comments will be provided

when the final Permit is issued. For further information, please

call

Richard E. Pinneo

at 217/782-0610.

The following water quality

and effluent standards and limitations were applied to the discharge:

Title 35: Environmental Protection, Subtitle C: Water Pollution, Chapter I: Pollution Control Board and the Clean Water Act were

applied in determining the applicable standards, limitations and conditions contained in the draft Permit.

The applicant is engaged in treating domestic and industrial wastewater for the City of Decatur and the Villages of Forsyth

and Mt.

Zion.

The length of the Permit is approximately 3 years.

The main

discharge number is 001. The seven day once in ten year low flow (7Q10) of the receiving stream, Sangamon River, is 0 cfs.

Electronic Filing - Received, Clerk's Office, June 15, 2009

* * * * * PCB 2009-125 * * * * *

Public Notice/Fact Sheet -- Page 2 -- NPDES Permit No. IL0028321

The design average flow (DAF) for the facility is 41.0 million gallons per day (MGD) and the design maximum

flow (DMF) for the facility is

125.0 MGD. Treatment consists of screening, grit removal, primary clarification,

two-stage activated sludge, secondary clarification,

disinfection, discharge to surface water, anaerobic digestion, flotation

thickening, land application of sludge.

This treatment works has an approved pretreatment

program. There are 16 noncategorical SIUs and 7 CIUs.

This modified NPDES Permit

does not increase the facility's DAF, DMF, concentration limits, and/or load limits.

The following modifications are proposed:

1. Extend the existing compliance schedule for nickel and zinc from two years to

three years. This extension is necessary because

work performed to date has not allowed achievement of numeric limitations for nickel

or zinc. Work performed includes a translator

study, source investigation and source elimination or reduction including change

of cooling water additives containing zinc,

housekeeping practices, pH addition and other investigations. The

additional time will be used to investigate other treatment

techniques that would include electro-coagulation

and methods to break the glutin nickel chealating bond.

2.

3.

4.

To place outfall 006 back in

the permit since it was inadvertently removed.

To add seven (7)

existing stormwater discharges to the permit and place stormwater requirements as

a Speci

Removal of Special Condition 8 because a reasonable potential to exceed analysis was performed

showing no potential existed to

exceed water quality

standards for fluoride and dichlorobromomethane.

5 . To change nic

A pplication i

d zinc

d ischarge point, receivi

based on the metals translator.

discharge(s) which is (are) located in Macon County, Illinois. The

following information iden

nd stream classifications:

ies the

Biological Stream

Characterization

0 07 & A07

U nnamed tributary I 39E

52' 12" North ( 88E 57'55" West (

General Use

I

Not Rated

of Spring Creek

The permit authorizes the discharge of stormwater at six locations and stormwater and groundwater at one location.

Stormwater and

groundwater discharges are directed to the Sangamon River, tributaries of the Sangamon River, Stevens Creek or

tributaries of Stevens

Creek.

This permit authorizes discharge from 5 CSOs in accordance with 35 Ill. Adm. Code

306.305 and PCB Order AS 91-7, dated June 23,

1992 into the following waters:

Sangamon River, Unnamed tributary of Spring

Creek and Stevens Creek.

CSO controls consist of first flush storage and pri

flow).

nt utilizing vortex separators (for up to 10 times the average

dry weather

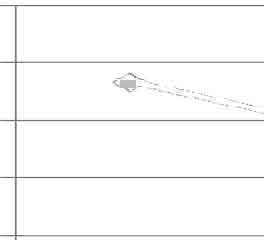

you further in identifying the location of the discharge(s) please see the attached map.

Public Notice/Fact

Sheet --

Page

3 --

NPDES Permit No. IL0028321

The stream segment(s) receiving the discharge from out¬all(s) 001, 002, 003, A03, 004, A04, 008 and A08 is (are)

on the 303 (d) list of

impaired waters.

The following parameters have

been

identified as the pollutants causing impairment:

Potential Causes

Designated Use Impairments

Manganese, nitrogen (total), dissolved

oxygen, PCBs and fecal coliform

Aquatic Life, Fish Consumption, Primary Contact Recreation

The

stream segment receiving the discharge from outfalls 007 and A07 is not on the 303(d) list o¬ impaired streams.

The stream segment receiving the discharge from outfall A06 is on the 303(4) list of impaired streams.

Potential Causes

Methoxychlor

Monthly

Average

The

discharge(s) from the facility is (are) proposed to be men

Discharge Number(s) and Name(s): 001 STP Outfall

ed and limited at all times as follows:

Load limits computed based on a design average flow (DAF) of 41.0 MGD (design maximum flow (DMF) of 125.0 MGD).

The effluent of the above discharge(s) shall be monitored and limited at all times as follows:

LOAD LIMITS Ibs/day*

DAF (DMF)

Parameter

CBOD$

S uspended Solids

Dissolved Oxygen

pH

Fecal Coliform

Chlorine Residual

Ammonia Nitrogen:

March-May/Sept.-O

ct.

June-August

Nov.-Feb.

Zinc

6,839

(20,850)

8,549

(26,063)

Designated

Use

Impairments

Aquatic Life

Weekly

Average

13.678

(41,700)

1 5,387

(46,913)

Shall not

be less than 6 mg/L

S hall be in the range of 6 to 9 Standard Units

CONCENTRATION

LIMITS mq/L

M onthly

Average

20

2 5

W eekly

Average

40

0 .05

Regulation

3 5 IAC 304.120 40

CFR 133.102

D

aily

Maximum

shall

not

exceed

400

per

100

mL

(May

through October)

513 (1,564)

445 (1,355)

513 (1,564)

26(78)

1,026 (3,128)

1,026 (3,128)

1,026 (3,128)

142 (434)

1.5

1.3

1.5

0 .075

45

3.0

3.0

3.0

0.416

35

IAC

304.120 40

CFR 133.102

35 IAC 302.206

3 5 IAC 304.125

3 5 IAC 304.121

35 IAC 302.208

35 IAC 355 and

35 IAC 302

35 IAC 302.208(e)

Nickel

1

5.1 (16)

1

1

1 0.015 1

1

1351AC

302.208(e)

*Load Limits are calculated by using the formula: 8.34 x (Design Average and/or Maximum Flow in MGD) x (Applicable Concentration in

mg/L).

Electronic Filing - Received, Clerk's Office, June 15, 2009

* * * * * PCB 2009-125 * * * * *

Public Notice/Fact Sheet -- Page 4 -- NPDES Permit No.

IL0028321

This Permit contains an authorization to treat and discharge excess flow as follows:

Discharge Numbers) and Name(s): 003 Oakland Avenue

Treated Combined Sewage Outfall

004 South Edward

Street Treated Combined Sewage Outfall

007 McKinley Avenue Treated Combined Sewage Outfall

008 Seventh Ward Treated Combined Sewage Outfall

CONCENTRATION

LIMITS mq/L

Parameter

BOD5

S uspended

Solids

Monthly Average

Shall be in the range of

6 to 9 Standard Units

This draft Permit also contains the following requirements as special conditions:

Reopening of this Permit to include different final effluent limitations.

2.

Operation of the facility by or under the supervision

of a certified operator.

Regulation

40 CFR 133.102

40 CFR 133.102

35 IAC 304.125

Submission of the operational data

in a specified form and at a required frequency at any time during the effective

term of this

Permit.

More frequent monitoring requirement

without Public Notice in the event of operational, maintenance or other problems

resulting in

possible effluent deterioration.

Prohibition

against causing or contributing to violati

Effluent sampling point location.

Seasonal fecal coliform I

The Permittee implements

and administers an industri

10. Submission of annual fiscal data.

11

q uality standards.

ment program pursuant to 40 CFR 3403.

1 2. Conditional authorization to discharge from high level

emergency bypasses) based on 40 CFR.

13. Submission of semi annual reports

indicating the quantities of sludge generated and disposed.

14. An

authorization of combined sewer and treatment plant discharges.

for biomonitoring of the effluent.

15. Recording

the monitoring results on Discharge Monitoring Report Forms using one such form for

each outfall each month and

submitting the forms to IEPA each month.

16.

17.

Compl e schedule for nickel and zinc.

Stormwater pollution preven

Electronic Filing - Received, Clerk's Office, June 15, 2009

* * * * * PCB 2009-125 * * * * *

Public Notice/Fact Sheet -- Page 5 -- NPDES Permit No. IL0028321

. .. ý` i

V.':

KGS'auirah' I)

-=N I)FS

? MaCo11

Col

i

wt c

-r

'^-ZR'

107

A A '77

t

istlicr of Decahu ' ý.

zz:aa_S_ _ 1

u ttti

^'

k ':': "-

a l J ..:

0 4 An

I L

F

R.,

Tr

1

a a?

M

'ý

,t :gas

aa3 .t

e ý+,ý-

0

ý 'j

'-sue

ENS

¬ , W

J

1

L . '

r

c

7 1

l

t

.x

Electronic Filing - Received, Clerk's Office, June 15, 2009

* * * * * PCB 2009-125 * * * * *

NPDES Permit No. IL0028321

Illinois Environmental Protection Agency

Division of Water Pollution

Control

1021 North Grand Avenue East

Post Office Box 19276

d, Illinois 62794-9276

Modified (NPDES) Permit

Expiration Date: June 30, 2012

Issue

Date:

April 20, 2007

Effective Date:

July 1, 2007

Modification Date:

Name and Address of Permittee:

Facility Name and Address:

Sanitary District of Decatur

Sanitary District of Decatur Main STP

501 Dipper Lane

501 Dipper Lane

Decatur, Illinois 62522

Decatur, Illinois

(Macon County)

Receivinq Waters: Sanoamon River

NATIONAL POLLUTANT DISCHARGE ELIMINATION SYSTEM

In compliance with the provisions of

the

Illinois Environmental

Protection Act, Title 35 of the Ill. Adm. Code, Subtitle C, Chapter I, and the

Clean Water Act (CWA),

the above-named Permittee is hereby authorized to discharge at the above location to the above-named

receiving stream in accordance

with the standard conditions and attachments herein.

ex

horized to discharge after the above expiration date. In order to receive authorization to discharge beyond the

mit the proper application as required by the Illinois Environmental Protection Agency

(IEPA) not

later than 180 days

pr

t ion date.

A lan Keller, P.E.

Manager, Permit Section

Division

of

Water

Pollution Control

SAK:REP:06120503.bah

Electronic Filing - Received, Clerk's Office, June 15, 2009

* * * * * PCB 2009-125 * * * * *

Page 2

Modification Date:

NPDES Permit

No. IL0028321

Effluent Limitations Monitoring,

and Reporting

FINAL

Discharge Number(s) and Name(s): 001 STP Outfall

Load limits computed based on a design average flow

(DAF) of 41.0 MGD (design ma

flow (DMF) of

125.0 MGD).

Excess flow facilities (if

applicable) shall not be utilized until the

main treatment facility is receiving its maximum

practical flow.

From the modification date of

this Permit until the expiration date, the effluent

of the above discharge(s) shall be monitored

and limited at

all times as follows:

LOAD LIMITS Ibs/day

(DMF)`

CONCENTRATION

LIMITS MG/L

*Load limits

based on design maximum flow shall apply

only when flow exceeds design average flow.

"Carbonaceous BOD5

(CBOD5) testing shall be in accordance

with 40 CFR 136.

**'*See Special Condition

7.

****See Special Condition

17.

Flow shall be reported on the Discharge

Monitoring Report (DMR) as monthly

average and daily maximum.

Fecal Coliform shall be reported on the DMR as daily

ma

pH shall be

reported on the DMR as a minimum and a

maximum.

Chlorine Residual shall be

reported on DMR as daily maximum.

Dissolved oxygen shall be

reported on DMR as minimum.

Page 3

Modification Date:

NPDES Permit No. IL0028321

Effluent Limitations Monitoring, and Reporting

FINAL

Discharge Number(s) and Name(s): 003 Oakland Avenue Treated Combined

Sewage Outfall

004 South Edward Street Treated

Combined Sewage Outfall

007 McKinley Avenue Treated Combined

Sewage Outfall

008 Seventh Ward Treated Combined Sewage

Outfall

These flow facilities shall not be utilized until the main treatment facility is receiving

its maximum practical flow.

From the

modification date of this Permit until the expiration date, the effluent of the above discharge(s) shall be monitored

and limited at

all times as follows:

CONCENTRATION

LIMITS mg/L

Parameter

Total Flow (MG) I See Below

B OD,

Suspended Solids

pH

Monthly Average

S hall be

in

the

range of 6 to 9 Standard Units

Sample Frequency

Daily When Discharging

Daily When Discharging

Daily When Discharging

Grab

G rab

D aily When Discharging I

Grab

Total flow in million gallons shall be reported on the Discharge Monitoring Report (DMR)

in the

quantity

maximum column.

Report the

number

of days

of discharge in the comments section of the DMR,

pH shall be

reported

on the

DMR as a minimum and a maximum.

Sample Type

and Suspended Solids shall be

reported on the DMR as a monthly average concentration.

Page 4

Modification Date:

NPDES Permit No. IL0028321

Influent Monitoring, and Repa

The

influent

to the plant shall be monitored as

follows:

g

P arameter

Sample Frequency

Sample Type

F low (MGD)

Continuous

*RIT

BOD5

2 days/week

Composite

S uspended Solids

2 days/week

(

- ---- - - - ----------

I

Composite

__ __--

I nfluent samples shall be taken at a point representative of the influent.

Flow (MGD) shall be reported on the Discharge Monitoring Report (DMR) as monthly average and daily maximum.

BOD5 and Suspended Solids shall be reported on the DMR as a monthly average concentration.

*Recording, Indicating, Totalizing.

Page 5

NPDES Permit No. IL0028321

Special Conditions

The Permittee shall implement and enforce its approved Pretreatment Program which was approved on

September 3, 1985 and all

SPECIAL CONDITION 1. This Permit maybe modified to include different final effluent limitations or requirements which are consistent

with applicable laws, regulations, or judicial orders. The I EPA will public notice the permit modification.

SPECIAL CONDITION 2. The use or opera of this facility shall be by or under the sup

of a Certified Class 1 operator.

SPECIAL CONDITION 3. The IEPA may request in writing submittal of operational information in a specified form and at a required

frequency at any time during the effective period of this Permit.

SPECIAL CONDITION 4. The IEPA may request more frequent monitoring by permit modification pursuant to 40 CFR 3 122.63 and

hout Public Notice in the event of operational, maintenance or other problems resulting in possible effluent deterioration.

SPECIAL

CONDITION

5. The effluent,

alone

or in

combination

with

other sources, shall

not

cause a violation of any applicable water

quality standard outlined in 35 111. Adm. Code 302.

SPECIAL CONDITION 6. Samples taken in compliance with the effluent monitoring requirements shall betaken at a point represen

of the discharge, but prior to entry into the receiving stream.

SPECIAL CONDITION 7. Fecal Coliform limits for Discharge Number 001 are effective May thru October. Sampling of Fecal Coliform

is only required during this time period.

The total residual chlorine limit is applicable at all times. If the Permittee is chlorinating for any purpose during the months of November

through April, sampling is required on a daily grab basis. Sampling frequency for the months of May through October shall be as

indicated on effluent limitations, monitoring and reporting page of this Permit.

S PECIAL CONDITION 8.

A.

1.

a pproved subsequent modifications thereto. The Permittee shall maintain legal authority adequate

to

fully i

Pretreatment Program in compliance with Federal (40 CFR 403), State, and local laws. The Permittee shall:

inspection and

monitoring

procedures at

least

once per year, which will determine whether each

dustrial user (SIU) is in compliance with applicable pretreatment standards;

b .

Perform an evaluation, at least once every two (2) years, to determine whether each SIU needs a slug control plan. If needed,

the SIU

slug control

plan

shall

include

the

items specified in 40 CFR 3 403,8 (f)(2)(v);

U pdate its inventory of Industrial Users (IUs) at least annually and as needed to ensure that all SIUs are properly iden

characterized, and categorized;

Receive and review self monitoring and other IU reports to determine compliance with all pretreatment standards and

requirements, and obtain appropriate remedies for noncompliance by any IU with any pretreatment standard and/or

requirement;

Investigate instances of noncompliance, collect and analyze samples, and compile other

9.

2 .

p roduce evidence admissible in enforcement proceedings, including judicial act

e:

rmation with sufficient care

as

to

Require development, as necessary, of compliance schedules by each industrial user for the installation

of control

technologies to meet applicable

pretreatment

standards; and,

Maintain an adequate revenue structure for continued operation of the Pretreatment Program.

The Permittee shall issue/reissue permits or equivalent control mechani

to commencement of discharge in the case of new discharges. The perm

CFR 3 403.8(f)(1)(iii).

o all SIUs prior to expiration of existing permits or prior

is at a minimum shall include the elements listed in 40

3. The Permittee shall develop, maintain, and enforce, as necessary, local limits to implement the prohibitions in 40 CFR 3 403.5 which

prohibit the introduction of specific pollutants to the waste treatment system from any source of nondomestic discharge.

Electronic Filing - Received, Clerk's Office, June 15, 2009

* * * * * PCB 2009-125 * * * * *

Page 6

Modification Date:

NPDES Permit No. 10028321

Special Conditions

4. In addition to the general limitations expressed in Paragraph 3 above, applicable pretreatment standards must be met by all industrial

users of the POTW. These limitations include specific standards for certain industrial categories as determined by Section 307(b)

and (c)

of

the

Clean Water Act, State limits, or local limits, whichever are more stringent.

5. The USEPA and

IEPA individually retain the right to take legal action against any industrial user and/or the POTW for those cases

where an industrial user has failed to meet an applicable

pretreatment standard by the deadline

date regardless of

whether

or

not

such failure has resulted in a permit

violation.

6. The Permittee shall establish agreements with all contributing jurisdictions, as necessary, to enable it to fulfill its requirements with

respect to all IUs discharging to its system.

7. Unless already completed, the Permittee shall within six (6) months of the effective date of this Permit submit to USEPA and IEPA a

proposal to modify and update its approved Pretreatment Program to incorporate Federal revisions to the general pretreatment

regulations. The proposal shall include all changes to the approved program and the sewer use ordinance which are necessary to

incorporate the regulations commonly referred to as PIRT and DSS, which were effective November 16, 1988 and August 23, 1990,

respectively. This includes the development of an Enforcement Response Plan (ERP) and a technical re-evaluation of the

Permittee's local Ii

8. The Permittee's Pretreatment Program

has

been

modified to incorporate a Pretreatment Program Amendment

approved

on February

6, 1995. The amendment became effective

on the date of approval and is a fully enforceable provision of your Pretreatment

Program.

Modifications of your Pretreatment Program shall be submitted in accordance with 40 CFR 3 403.18, which established conditions for

substantial and

nonsubstantial modifications.

B. Repo

rds

Requirements

1. The Permittee shall provide an annual report briefly describing the permittee's pretreatment program activities over the pre

calendar year. Permittees who operate multiple plants may provide a single report providing all

plant-specific

reporting requirement

are met. Such report shall be submitted no later than

April 28

of each

year,

and shall be in the

format

set forth in [EPA's POTW

Pretreatment Report Package which contains information regarding:

An updated lis of the Permittee's industrial users.

y of the compliance activities including numbers of any major enforcement actions, (i.e., administrative

ions, etc.), and the outcome of those actions. This includes an assessment of the compliance status

trial users and the effectiveness of the Permittee's Pretreatment Program in meeting its needs and

ption of

all substantive changes made to the Permittee's Pretreatment Program. Changes which are "substantial

" as described in 40 CFR 3 403.18(c) must receive prior approval from the Approval Authority.

Results of sampling

and analysis of POTW influent, effluent, and sludge.

A summary of the findings from the priority pollutants

sampling. As sufficient data becomes available the

IEPA may modify

this Permit to incorporate additional

requirements relating to the evaluation, establishment, and enforcement of local limits for

organic pollutants. Any permit modification is subject to formal due process procedures

pursuant

to

State

and Federal law

and regulation. Upon a determination that an organic pollutant

is

present that causes

interference

or pass through, the

Permittee shall establish

local limits as required by 40 CFR 3 403.5(c).

2. The Permittee shall maintain all pretreatment data and records for a minimum of three (3) years. This period shall be extended

during the course of unresolved litigation or when requested by the IEPA or the Regional Administrator of USEPA. Records shall be

available to USEPA and the IEPA upon request.

Electronic Filing - Received, Clerk's Office, June 15, 2009

* * * * * PCB 2009-125 * * * * *

Page 7

Modification Date:

NPDES Permit No. IL0028321

Special Conditions

3. The Permittee shall establish public participation requirements of 40 CFR 25 in implementation of its Pretreatment Program. The

Permittee shall at least annually, publish the names of all ]U's which were in significant noncompliance (SNC), as defined by 40 CFR

3 403.8(f)(2)(vii),

in the largest daily paper in the municipality in which the POTW is located or based on any more restrictive definition

of SNC that the POTW may be using.

4. The Permittee shall provide written notification to the Deputy Counsel for the Division of Water Pollution Control, IEPA, 1021

North

Grand Avenue East, P.O. Box 19276, Springfield, Illinois 62794-9276 within five (5) days of receiving notice

that any Industrial User

of its sewage treatment plant is appealing to the Circuit Court any condition imposed by the Permittee in

any permit

issued

to the

Industrial User by Permittee. A copy

of the

Industrial

User's appeal and all other

pleadings

filed by all parties shall be mailed to the

Deputy Counsel within five (5) days of

the pleadings being filed

in

Circuit Court.

C. Monitorinq Requirements

1. The Permittee

shall

monitor its

influent, effluent and sludge and report concentrations of the following parameters on monitoring

report forms provided by the IEPA and include them in its annual report. Samples shall be taken at quarterly (four times per year)

intervals at the indicated reporting limit or better and consist of a 24-hour composite unless otherwise specified below. Sludge

samples shall be taken of final sludge and consist of a grab sample reported on a dry weight basis.

STORET

CODE

01097

01002

01007

01012

01027

01032

01034

01042

00718

00720

00951

0104.5

01046

01051

01055

71900

01067

00556

32730

01147

01077

01059

01092

PARAMETER

Antimony

Arsenic

Barium

Beryllium

Cadmium

Chromium (hex - grab not

to exceed

24 hours)*

Chromium (total)

Copper

Cyanide (grab) (weak acid disso

Cyanide (grab) (total)

Fluoride*

Iron (total)

Iron (Dissolved)*

Lead

Manganese

Mercury (effluent grab

Nickel

USEPA Method 1631 or equivalent)***

Oil (hexane soluble or equivalent) (Grab Sample only)*

Phenols (grab)

Selenium

Silver

(total)

Thallium

Zinc

* Influent and effluent only

**1 ng/L

_

1 part per trillion.

*** Other approved methods may be used for influent (composite) and sludge

Minimum

reporting limit

0.07 mg/L

0.05 mg/L

0.5 mg/L

0.005 mg/L

0.001 mg/L

0.01 mg/L

0.05 mg/L

0.005 mg/L

5.0 ug/L

5.0 ug/L

0.1 mg/L

0.5 mg/L

0.5 mg/L

0.05 mg/L

0.5 mg/L

1.0 ng/L**

0.005 mg/L

5.0 mg/L

0.005 mg/L

0.005 mg/L

0.003 mg/L

0.3 mg/L

0.025 mg/L

Unless otherwise indicated, concentrations refer to the total amount of the constituent present in all phases, whether solid, suspended or

dissolved, elemental or combined including all oxidation states. Where constituents are commonly measured as

other than total, the

phase is so indicated.

2.

The Permittee shall conduct an analysis for the one hundred and ten (110) organic priority pollutants identified in 40 CFR 122

Appendix D, Table II as amended. This monitoring shall be done once per year and reported on monitoring report forms

provided by the IEPA and shall consist of the following:

The influent and effluent shall be sampled and analyzed for the one hundred and ten (110) organic priority pollutants.

The sampling shall be done during a day when industrial discharges are expected to be occurring at normal

to

maximum levels.

Electronic Filing - Received, Clerk's Office, June 15, 2009

* * * * * PCB 2009-125 * * * * *

Page 8

NPDES Permit No. IL0028321

Special Conditions

Samples for the analy

Modifica Date:

id and base/neutral extractable compounds shall be 24-hour

composites.

Five (5) grab samples shall be collected each monitoring day to be analyzed for volatile

organic compounds. A single

analysis for volatile pollutants (Method 624) may be run for each monitoring day by

compositing equal volumes of each

grab sample directly in the GC purge and trap apparatus in the laboratory, with

no less than one (1) mL of each grab

included in

the composite.

Wastewater samples must be handled,

prepared, and analyzed by GC/MS in accordance with USEPA Methods 624

and 625 of 40 CFR 136 as amended.

The sludge shall be sampled and analyzed for the one hundred and ten (110) organic priority pollutants. A sludge

sample shall be collected concurrent with a wastewater sample and taken as final sludge.

Sampling and analysis shall conform to USEPA Methods 624 and 625 unless an alternate method has been

approved

by IEPA.

c. Sample collection, preservation and storage shall conform to approved

USEPA

procedures

and requirements.

In addition, the Permittee shall monitor any new

toxic substances as defined by the Clean Water Act, as amended, following

notification by the IEPA.

Permittee

shall report any noncompliance with effluent or water quality standards in accordance with Standard Condition

12(e)

of this Permit.

5.

Analytical

detection limits shall be in accordance with 40 CFR 136. Minimum detection limits for sludge analyses shall be in

accordance with 40 CFR 503.

SPECIAL CONDITION 9. The Permittee has undergone a Monitoring Reduction review and the influent and effluent sample frequency

has

been

reduced

for CBODS, BOD5, suspended solids, dissolved oxygen, pH, fecal coliform, chlorine residual and ammonia nitrogen

due

t o sustained compl

to the Illinois Environmental Protection Agency/Division

of

Water

Pollution Control/Compliance Assurance Section. The

days/week if effluen

The IEPA will require that the influent and effluent sampling frequency for these parameters be increased

to 5

monitoring will be required Wit

tion occurs due to increased wasteload, operational, maintenance or

other

problems.

The increased

is Notice when a permit modification is received by the Permittee from the IEPA.

SPECIAL CONDITION 10. During January of each year

the

Permittee

shall submit annual fiscal data regarding sewerage system

use any fiscal year period provided the period ends within twelve (12) months of

the submission date,

ion shall be

on

forms

provided by IEPA titled "Fiscal Report Form For NPDES Permittees".

SPECIAL CONDITION

11. The Permittee shall conduct biomonitoring of the effluent from Discharge Number(s) 001.

BiomonitoriM

1.

Acute Toxicity - Standard definitive acute toxicity tests shall be run on at least two trophic levels of aquatic

species (fish,

invertebrate) representative of the aquatic community of the receiving stream. Testing must be consistent with Methods

for

Measurinq the Acute Toxicity of Effluents and Receiving Waters to Freshwater and Marine Organisms

(Fifth Ed.)

EPA/821-R-02-012. Unless substitute tests are

pre-approved; the

following

tests are

required:

a.

Fish - 96 hour static LC50 Bioassay using fathead minnows (Pimephales promelas).

b.

Invertebrate

48-hour static LC50 Bioassay using Ceriodaphnia.

Testing Frequency - The above tests shall be conducted using 24-hour composite samples unless otherwise authorized by

the IEPA. Samples must be collected in the 18th, 15th, 12th, and 9th month prior to the expiration date of this Permit.

Electronic Filing - Received, Clerk's Office, June 15, 2009

* * * * * PCB 2009-125 * * * * *

Page 9

Modification Date:

NPDES Permit

No. IL0028321

vial Conditions

Reporting - Results shall be reported according to EPA/821-R-02-012, Section

12, Report Preparation, and shall be submitted

to IEPA, Bureau of Water, Compliance Assurance Section within one

week of receipt from the laboratory. Reports are due to

the I EPA no later than

the 16th, 13th, 10th, and 7th month prior to the expiration date of

this Permit.

Toxicity Reduction

Evaluation - Should the results of the biomonitoring program identify toxicity, the ]EPA

may require that the

Permittee prepare a plan for toxicity

reduction evaluation and identification. This plan shall be developed in accordance

with

Toxicity Reduction Evaluation Guidance

for Municipal Wastewater Treatment Plants, EPA/833B-99/002, and shall

include an

evaluation to determine which chemicals

have a potential for being discharged in the plant wastewater, a monitoring

program

to determine their presence or absence and to identify other compounds

which are not being removed by treatment, and other

measures as appropriate. The Permittee shall submit to the

IEPA its plan for toxicity reduction evaluation within ninety (90)

days following notification by the IEPA. The Permittee shall

implement the plan within ninety (90) days or other such date as

contained in a notification letter received from the IEPA.

The IEPA may modify this Permit during its term to incorporate additional

requirements or limitations based on the results of

the biomonitoring. In addition, after review of the monitoring results, the IEPA

may modify this Permit to include numerical

limitations for specific toxic

pollutants. Modifications under this condition shall

follow public notice and opportunity for

hearing.

ONDITION 12. Discharge Number 002

is an emergency high level bypass, Discharges from this overflow

are subject to the

conditions:

(1)

A Bypass- means the intentional diversion of waste streams

from any portion of a treatment facility.

li) ASevere property damage- means substantial physical damage

to property, damage to the treatment facilities which

causes them

to become inoperable, or substantial and permanent

loss of natural resources which can reasonably be

expected

to occur in the absence of a bypass. Severe property damage does not

mean economic loss caused by

delays in production.

(2)

Bypass not exceeding limitations.

The Permittee may allow any bypass to occur which does not cause effluent limitations

to

be exceeded, but only if it also is for essential

maintenance to assure efficient operation. These bypasses are not subject

to

the provisions of paragraphs (3) and (4)

of this section.

(3)

Notice

(1)

A nticipated bypass. If the Perm ittee knows

in

advance

of the need for a bypass, it shall s

at least ten days before the date of the bypass.

if possible

(Ii) Unanticipated bypass. The Permittee shall submit

notice of an unantici

Condition 12(e) of this

Permit (24-hour notice).

ed bypass as required in Standard

(4)

Prohibition of bypass.

Bypas

unless:

(1)

, and the IEPA may take enforcement

action against a Permittee for bypass,

Bypass was unavoidable to prevent

loss of life, personal injury, or severe property damage;

(Ii) There was no feasible alternatives to the bypass,

such as the use of auxiliary treatment facilities, retention of untreated

wastes, or maintenance during normal periods of

equipment downtime. This condition is not satisfied if adequate

back-up equipment should have been installed in the exercise of

reasonable engineering judgment to prevent a bypass

which occurred during normal periods of equipment downtime or

preventive maintenance; and

(Iii) The Permittee

submitted notices as required under Standard Condition 12(e) of this

Per

(5)

Emergency Bypass when discharging,

shall be monitored daily by grab sample for

BOD5

and

Suspended Solids. The

Permittee shall submit the monitoring

results on Discharge Monitoring Report forms using one such

form

for each month

in

which bypassing occurs. The Permittee shall

specify the number of discharges per month that occur and shall report this

number in the quantity daily maximum column.

The Permittee shall report the highest concentration value of BOD5 and

Suspended Solids discharged in the concentration daily

maximum column.

Electronic Filing - Received, Clerk's Office, June 15, 2009

* * * * * PCB 2009-125 * * * * *

Page 10

NPDES

Permit No. IL0028321

Special Conditions

SPECIAL CONDITION

13. For the duration of this Permit, the

Permittee shall determine the quantity of sludge

produced by the

treatment facility in dry tons

or gallons with average percent total

solids analysis. The Permittee shall maintain adequate

records of the

quantities of sludge produced

and have said records available

for IEPA inspection. The Permittee shall submit to the IEPA,

at a

minimum, a semi-annual summary report

of the quantities of sludge generated

and disposed of, in units of dry tons or gallons (average

total percent solids) by different disposal

methods including but not limited to

application on farmland, application on reclamation

land,

landfilling, public distribution, dedicated

land disposal, sod farms, storage

lagoons or any other specified disposal method. Said reports

shall be submitted to the IEPA by January 31 and July

31 of each year reporting the preceding

January thru June and July thru December

interval of sludge disposal operations.

Duty to Mitigate. The Perm

s hall take all reasonable

steps

to

ize any sludge use or disposal

in violation of this Permit.

Sludge monitoring

must be conducted according to test procedures

approved under 40 CFR 136 unless

otherwise spec

503, unless other

test procedures have been specified in this Permit.

in 40 CFR

Planned Changes. The Permittee

shall give notice to the I EPA on the

semi-annual report of any changes in sludge

use and disposal.

The Permittee shall retain records of

all sludge monitoring, and reports required

by the Sludge Permit as referenced in Standard

Condition

23 for a period of at least five (5) years

from the date of this Permit.

If the Per

in the report

Ilutant

more frequently than required by the Sludge

Permit, the results of this monitoring shall be included

ng of data submitted to the

IEPA.

reports for sludge shall be reported on the

form titled "Sludge Management Reports" to

the following address:

Illinois Environmental

Protec

Bureau of Water

Agency

Compliance Assurance Section

Mail Code #19

1021 North Grand Avenue East

Post Office Box 19276

Springfield, Illinois 62794-9276

S PECIAL CONDITION 14.

A UTHORIZATION

OF

COMBINED

SEWER AND TREATMENT

PLANT DISCHARGES

The IEPA has determined that at least a portion of

the collection system consists of

combined sewers. References to the collection

system

and the sewer system refer only to those parts

of the system which are owned

and operated by the Permittee unless otherwise

indicated.

The Permittee is authorized to discharge

from the overflow(s)lbypass(es)

listed below provided the diversion structure is

located on a

combined sewer and the following terms and conditions

are met:

D ischarge Number

A03

A04

A06

A07

A08

Treatment Requirements

1.

of applicable water quality

standards. Sufficient treatment shall co

Location

Oakland Avenue CSO

Treatment Bypass

South Edward Street CSO

Treatment Bypass

Fairview Park CSO

McKinley Avenue CSO Treatment

Bypass

Seventh Ward CSO Treatment Bypass

All combined sewer

overflows and treatment plant bypasses

shall be

Receiv

ncLWater

S angamon

River

Sangamon

River

Stevens Creek

Unnamed tributary of Spring Creek

Sangamon River

en sufficient treatment to prevent pollution

and the violation

of the following:

Treatment as described

in PCB AS 91-7 and dated June

23, 1992 shall be provided. The terms and conditions of this

Board Order are hereby

incorporated by reference as if fully set

forth herein; and,

Electronic Filing - Received, Clerk's Office, June 15, 2009

* * * * * PCB 2009-125 * * * * *

Page

11

Modification

Date:

NPDES Permit No. IL0028321

Special Conditions

Any additional treatment,

necessary to comply with applicable water quality standards and the federal Clean Water Act,

including any amendments

made by the Wet Weather Water Quality Act of 2000.

All CSO discharges authorized by this

Permit shall be treated, in whole or in part, to the extent necessary to prevent accumulations

of sludge deposits, floating debris and solids in accordance

with 35 Ill. Adm. Code 302.203 and to prevent depression of oxygen

levels below the applicable water quality standards.

Overflows during dry weather are prohibited. Dry weather overflows

shall be reported to the ]EPA pursuant to Standard Condition

12(e) of this Permit (24 hour notice).

4.

The

collee

Proper operation and maintenance programs for the sewer

system and the CSOs (Compliance with this Item shall be met

through the requirements imposed by Paragraph 8 of this

Special Condition);

5.

The

treatment system shall

be operated to maximize treatment of wastewater flows.

Nine Minimum Controls

The Permittee shall comply with the nine minimum controls

contained in the National CSO Control Policy published in the Federal

Register on April 19, 1994. The nine minimum controls

are:

use of the collection system for storage (Compliance

with

this

Item shall be met through the requirements

imposed by Paragraphs 1, 4, and 8 of this Special Condition);

shall be met through the requirements imposed by Paragraph 9 of this Special Con

Review and modification of pretreatment requirements to assure CSO impacts are

min

perated to optimize transport of wastewater flows and to minimize

CSO discharges,

raphs 4, 5, and 8 of this Special Condition);

Prohibition of CSOs during dry

weather (Comp)

Paragraph 3 of this Special Condition);

zed (Compli

m

of flow to the POTW for treatment (Compliance with this Item shall be

met through the requirements

Item shall be met through the requirements imposed by

lids and floatable materials

in CSOs (Compliance with this Item shall be met through the requirements

mposed by Paragraphs 2 and 8 of this Special

Condition);

9.

Pollution prevention programs which focus on source control activities

(Compliance with this Item shall be met through the

requirements imposed by Paragraph 6 of this

Special Condition, See Below);

Public notification to ensure that citizens receive adequate information regarding

CSO occurrences and CSO impacts

(Compliance

with this Item shall be met through the requirements imposed by

Paragraph 12 of this Special Condition);

and,

Monitoring to characterize impacts and

efficiency of CSO controls (Compliance with this Item shall be met through the

requirements imposed by Paragraphs

10 and 11 of this Special Condition).

Page 12

Modification Date:

NPDES Permit No. IL0028321

Special Conditions

A pollution prevention plan (PPP) shall be developed by the Permittee

unless one has already been prepared for this collection

system. Any previously-prepared PPP shall be

reviewed, and revised if necessary, by the Permittee to address the

contained in Chapter 8 of the U.S. EPA guidance document, Combined Sewer Overflows

Guidance For Nine Minimum Controls,

and any items contained in previously-sent review documents from the

IEPA concerning the PPP. Combined Sewer Overflows

Guidance For Nine Minimurn Controls is available online at http://www.epa.gov/NPDES/pubs/owm0030.pdf,

The PPP (or revised

PPP) shall be presented to the general public at a public information meeting conducted by the Permittee within nine (9) months of

the effective date of this Permit. The Permittee shall submit documentation that the pollution prevention plan complies with the