ýR

flODGI

ý

DWAR

Y ZRAN

A T T O R N

E

Y

S A T L A W

K ATHERINE

D. HODGE

E-mail: khodge@hdzlaw.com

January 20, 2009

VIA FEDERAL EXPRESS

Mr. John T. Therriault

Assistant Clerk

of the Board

Illinois Pollution Control Board

100

West Randolph Street, Suite 11-500

Chicago, Illinois

60601

Timothy Fox, Esq.

Hearing Officer

Illinois Pollution Control Board

100 West Randolph

Street, Suite 11-500

Chicago, Illinois

60601

RE: Application for Non-Disclosable

Information

In the Matter of: Nitrogen

Oxides Emission from Various

Source

Categories: Amendments to

3.5 111. Adm. Code Parts 211 and

217, R08-19

Dear Sirs:

In connection with the above-referenced

rulemaking, ConocoPhillips Companv

("ConocoPhillips")

is submitting the attached Supporting

Materials to the Illinois Pollution

Control Board ("Board").

Attachments B and C of the Supporting

Materials are being submitted

as NON-DISCLOSABLE INFORMATION

to the Board pursuant

to 35 Ill. Adm. Code Part 130.

"Non-disclosable information" is defined in part

as "information concerning

secret

manufacturing

processes or confidential data submitted

by any person under the [Illinois

Environmental

Protection] Act." 35 Ill. Admin.

Code § 101.202 (citing 415 ILCS 5/7((a)).

Attachments B

and C are documents containing confidential data

and information regarding cost

evaluations of projects at ConocoPhillips'

facility, as well as a turnaround

schedule for

maintaining and/or upgrading process

heaters at the facility.

To facilitate

the Board's protection of Attachments

B and C as non-disclosable

information, we are

providing the information required by

Section 130.404 of the Board's rules.

The information in Attachments

B and C is business confidential

data and is not available

publicly outside ConocoPhillips and is restricted

information within ConocoPhillips.

3 150 ROLAND AVENUE A

POST OFFICE BOX 5776 A

SPRINGFIELD, ILLINOIS 62705-5776

TELEPHONE

217-523-4900 A FACSIMILE

217-523-4948

Electronic Filing - Received, Clerk's Office, January 20, 2009

* * * * * PC # 5 * * * * *

Mr. John T. Therriault

Timothy Fox, Esq.

January 20, 2009

Page

2

Accordingly,

access to the information included

in Attachment B is limited to

only management

level employees and

project engineers that are required

to use the information during

the course

of their job duties. Similarly,

access to information included

in Attachment

C is

limited

to only

management level employees

and other employees that are

required to use the information

during the course of their job duties

for business planning purposes.

Information provided in

Attachment

B has competitive value

based on negotiated price of

the equipment that will be

installed, and

the information in Attachment

C is vital to strategically planning

future operations

in accordance with

the company's business plan. Thus,

confidential information in

Attachments

B

and C is considered sensitive

in a competitive market

and disclosure of such information

would

provide an advantage to

competitors in terms of negotiation

of project costs and

knowledge

of when the facility will not

be operating all of its units. ConocoPhillips

treats the

information in Attachments

B and C as business

confidential and proprietary

and has no

knowledge that the information

has been published or

disseminated beyond the company,

except

to

outside counsel who are

obligated to treat the information

as protected.

As required

by the Board's rules, Attachments

B and C have been labeled

as NON-

DISCLOSABLE

INFORMATION. In addition, in

accordance with Section

130.404(e)(4), we

have enclosed the affidavit

of Mr. David Dunn verifying

the facts set forth above. This letter

constitutes

an unlimited waiver

of any statutory determination

process.

If you have any questions regarding

the above, please do not hesitate

to contact me.

KDH:MTR:db

enclosures

C NPH:OI I/Fil/R08-19/Application

for Non-Discl. Info.

Electronic Filing - Received, Clerk's Office, January 20, 2009

* * * * * PC # 5 * * * * *

STATE OF ILLINOIS

)

SS

COUNTY OF MADISON )

AFFIDAVIT OF DAVID W. DUNN

I, David W. Dunn, on behalf of

CONOCOPHILLIPS

COMPANY

("ConocoPhillips"),

being first

duly sworn, depose and state as follows:

1.

I am the Environmental Director of ConocoPhillips' Wood River Refinery.

2 .

I have reviewed the application for non-disclosable information dated January 20,

2008 and the Supporting Materials to be filed with the Illinois Pollution

Control Board in the

R08-19 rulemaking.

3 .

The

information contained in Attachments B and C of the Supporting Materials is

not available publicly outside ConocoPhillips and is restricted information

within

ConocoPhillips.

a.

Access to the information included in Attachment B is limited

to only

management level employees and project engineers that are required to

use the information during the course of their job duties.

b.

Access to the information included in Attachment C is limited to only

management level employees and other employees that are required to use

the information during the course of their job duties or for

business

planning purposes.

4.

The information provided in Attachment B has competitive

value based on the

negotiated price of the equipment that will be installed at the facility. The information in

Attachment C is vital to planning future operations in accordance with the company's

business

plan.

Electronic Filing - Received, Clerk's Office, January 20, 2009

* * * * * PC # 5 * * * * *

5.

The

information in Attachments B and C is considered sensitive

in

a

competitive

market and disclosure of such information could provide an advantage to

competitors in terms of

negotiation of project costs and knowledge of when

the facility will not be operating all of its

units.

6.

ConocoPhillips

treats the information in Attachments B and C

as business

confidential

and proprietary. I have no knowledge that the information

has been published or

disseminated beyond the company, except to outside counsel.

Under penalties as provided by law

pursuant to Section 1-109 of the Code of

Civil Procedure, the undersigned

certifies that the statements set forth in this

instrument

are true and correct, except as to matters therein stated to

be on

information

and belief and as to such matters the undersigned

certifies as

aforesaid that

he

verily

believes the same to be true.

Further Afflant Sayeth Not.

David W. Dunn

S ubscribed and sworn to before me

this 40 day of u,c

2009.

OFFICIAL SEAL

CAROL HALLOWS

NOTARY PUBLIC

- STATE OF ILLINOIS

MY COMMISSION

EXPIRES:04127112

Notary

Public

CNPH:O11/HVR08-19/Affidavit

of D. Dunn

Electronic Filing - Received, Clerk's Office, January 20, 2009

* * * * * PC # 5 * * * * *

BEFORE THE ILLINOIS POLLUTION

CONTROL BOARD

IN THE MATTER

OF:

)

NITROGEN OXIDES EMISSIONS

FROM )

VARIOUS SOURCE CATEGORIES: )

AMENDMENTS TO 35 ILL. ADM. CODE )

PARTS 211 and 217

)

R08-19

(Rulemaking - Air)

NOTICE OF FILING

TO: Mr.

John T. Therriault

Assistant

Clerk of the Board

Illinois Pollution Control Board

100 W. Randolph Street

S uite 11-500

Chicago, Illinois

60601

(VIA ELECTRONIC

MAIL)

Timothy Fox,

Esq.

Hearing Officer

Illinois Pollution Control Board

100

W. Randolph Street

Suite 11-500

Chicago, Illinois 60601

(VIA FIRST CLASS MAIL)

(SEE PERSONS ON ATTACHED SERVICE LIST)

P LEASE TAKE NOTICE

that I have today filed with the Office of the Clerk of

the Illinois Pollution Control Board

the SUPPORTING MATERIALS FROM

CONOCOPHILLIPS COMPANY, a copy of which is herewith

served upon you.

Respectfully submitted,

By:

/s/ Katherine D. Hodge

Katherine D. Hodge

Dated: January 20, 2009

Katherine D. Hodge

Monica T. Rios

HODGE DWYER

ZEMAN

3150 Roland Avenue

Post Office Box 5776

Springfield, Illinois 62705-5776

(217) 523-4900

THIS FILING

SUBMITTED ON RECYCLED PAPER

Electronic Filing - Received, Clerk's Office, January 20, 2009

* * * * * PC # 5 * * * * *

CERTIFICATE OF SERVICE

I, Katherine

D. Hodge, the undersigned, hereby certify

that I have served the

attached SUPPORTING MATERIALS

FROM CONOCOPHILLIPS COMPANY

upon:

Mr. John T. Therriault

Assistant

Clerk of the Board

Illinois Pollution

Control Board

100 West Randolph Street, Suite 11-500

Chicago, Illinois 60601

via electronic

mail on January 20, 2009; and upon:

Timothy Fox, Esq.

Hearing Officer

Illinois Pollution Control Board

100

West Randolph, Suite 11-500

Chicago, Illinois

60601

Gina Roccaforte, Esq.

John J. Kim, Esq.

Division of Legal

Counsel

Illinois Environmental Protection

Agency

1021 North Grand Avenue East

P ost Office Box 19276

Springfield, Illinois 62794-9276

Virginia Yang,

Esq.

Deputy Legal Counsel

Illinois Department of Natural Resources

One Natural Resources Way

Springfield, Illinois

62702-1271

by depositing said document in the

United

Springfield, Illinois

on January 20, 2009.

Matthew J. Dunn,

Esq.

Chief, Environmental Bureau North

Office of the Attorney General

69 West

Washington Street, Suite 1800

Chicago, Illinois 60602

Kathleen

C. Bassi, Esq.

Stephen

J. Bonebrake, Esq.

Schiff Hardin, LLP

6600 Sears Tower

233 South Wacker Drive

Chicago,

Illinois 60606-6473

Christina L. Archer, Esq.

Associate General Counsel

Arcelormittal USA, Inc.

1

South Dearborn, 19th Floor

Chicago, Illinois 60603

States Mail, postage prepaid, in

/s/ Katherine D. Hodge

Katherine

D. Hodge

CNPH:011/Fil/R08-19/NOF-COS - Supporting Materials

Electronic Filing - Received, Clerk's Office, January 20, 2009

* * * * * PC # 5 * * * * *

BEFORE THE

ILLINOIS POLLUTION

CONTROL BOARD

IN THE MATTER OF:

)

R08-19

NITROGEN

OXIDES EMISSIONS FROM ) (Rulemaking

- Air)

VARIOUS SOURCE

CATEGORIES: )

AMENDMENTS TO 35 ILL.

ADM. CODE )

PARTS

211 and 217

)

S UPPORTING MATERIALS

FROM CONOCOPHILLIPS

COMPANY

N OW COMES CONOCOPHILLIPS

COMPANY ("ConocoPhillips"),

by and through

its

attorneys,

HODGE DWYER ZEMAN, and submits

the attached SUPPORTING

MATERIALS

in the above-referenced

matter.

1 . On December 9, 2008,

Mr. David W. Dunn on

behalf of ConocoPhillips

presented

testimony in the

above-referenced matter. During

the course of his testimony,

the Illinois

Environmental Protection Agency ("Agency")

or the Illinois

Pollution Control Board

("Board")

requested additional

documents or information in

response to testimony that

Mr. Dunn provided.

2.

As stated at hearing

and in the cover letter to

this filing, two of the enclosed

Attachments are

being submitted to the Board

as NON-DISCLOSABLE INFORMATION

pursuant to 35111. Admin.

Code Part 130.

3.

The following materials

are being provided in response

to Agency or Board

requests at hearing:

a.

On pages

151 and 154 of the December

9, 2008 transcript, the

Agency requested

cost analysis information for

the boiler and

process heater examples referenced

in Mr. Dunn's pre-filed

testimony.

As Mr. Dunn stated

at hearing, such information

was

provided

to the Agency in January 2008

as confidential business

information. ConocoPhillips

has provided, as Attachment

A, a

Electronic Filing - Received, Clerk's Office, January 20, 2009

* * * * * PC # 5 * * * * *

January 8, 2008 letter

to the

Agency

regarding comments on the

R08-19 rulemaking proposal. In addition,

ConocoPhillips has

provided, pursuant to 35111. Admin. Code Part 130, its

cost

analysis data as NON-DISCLOSABLE INFORMATION, which is

attached hereto as Attachment B.

b.

On

pages

156 through 157 of the December 9, 2008 transcript, the

Board requested that the turnaround schedule for process heaters

be provided, if possible. As noted at hearing, the turnaround

schedule is confidential for business purposes. Accordingly,

ConocoPhillips

is

submitting a turnaround schedule for affected

heaters at its facility as NON-DISCLOSABLE

INFORMATION

pursuant to 35 Ill Admin. Code Part

13 0.

The confidential

turnaround schedule is attached hereto as Attachment C.

c.

On

page 153

of the

December

9,

2008 transcript,

the Agency

inquired as to the age of the burners and burner management

system for the boiler referenced on page 7 of Mr. Dunn's

testimony. Information regarding the age of the burners and

burner management system for Boiler 15, as well as information

regarding the actual emissions rate and factor for the

examples

discussed in Mr. Dunn's testimony, is attached hereto as

Attachment D.

4.

As provided in the cover letter to this filing, ConocoPhillips has submitted

Attachments B and C as NON-DISCLOSABLE INFORMATION pursuant to 35 Ill. Admin.

Code Part 130 and requests that such Attachments be handled by the Board in accordance with

35 111. Admin. Code Part 130.

Electronic Filing - Received, Clerk's Office, January 20, 2009

* * * * * PC # 5 * * * * *

5.

ConocoPhillips reserves

the right to supplement these supporting materials.

Respectfully submitted,

By: /s/ Katherine

D. Hodge

Katherine D. Hodge

D ated: January 20, 2009

K atherine D. Hodge

Monica T. Rios

HODGE DWYER ZEMAN

3150 Roland Avenue

Post

Office Box 5776

Springfield, Illinois

62705-5776

(217) 523-4900

C NPH:011/Fil/R09-19/Supporting Materials

Electronic Filing - Received, Clerk's Office, January 20, 2009

* * * * * PC # 5 * * * * *

aaoý

ooýG L

o

ýo9

ConocoPhilli s

January 8, 2008

CERTIFIED MAIL

RETURN RECEIPT REOUESTED

Mr. Rob Kaleel

Manager, Air Quality Planning Section

Illinois

Environmental Protection Agency

1021

North Grand Avenue East

P.O. Box 1276

Springfield, IL 62794-9276

Re: Draft Regulatory Proposal

NOx rule posted on July 30,2007; revised December 19, 2007

Dear

Mr.

Kaleel:

W ood River Refinery

P. O. Box 76

900 South Central

Avenue

Roxana, Illinois 62084

Enclosed for your consideration are comments

prepared by ConocoPhillips on behalf of the WRB

Refining LLC refinery in Roxana, Illinois regarding the Illinois EPA's draft NOx rulemaking (December

19, 2007 version).

The

Wood River Refinery (WRR) has operated in Illinois since 1917. It refines more than 300,000

barrels

of

crude

oil per day and currently employs more than 600 employees and a large number of

contractors.

WRR

is located

in Madison County, which is included in the St. Louis ozone moderate

nonattainment area.

WRB Refining LLC is a joint venture between ConocoPhillips and Encana that was created on January 1,

2007. ConocoPhillips is the operator of the WRR facility for the joint venture. ConocoPhillips is a

member

of the Illinois Environmental Regulatory Group.

The comments described below reflect a careful

consideration of the draft regulatory proposal and a

comparison against ongoing projects

to reduce NOx in the refinery. The regulatory proposal as drafted

could

significantly

affect

WRR operations by requiring overly stringent and unreasonable NOx controls

to be installed on many

boiler and heaters. The compliance date included in the draft is not achievable,

based

on

the remaining

time to design, plan, purchase, install the controls, and complete performance

testing on a large number of emission sources. Installation

of the controls included in the proposed draft

will require entire processing units to be shut down for several weeks.

Very

few of the affected units

are

currently scheduled for maintenance turnarounds before the compliance deadline and, therefore, any

unscheduled refinery unit shutdowns will have a significant effect on the fuel supply in the Midwest

market.

WRR supports the comments that

IERG

filed

on October 15, 2007 and subsequent IERG

comments

and

offers the following

specific

comments

on the impacts this regulatory proposal could

have

on WRR.

ATTACENENT A

Electronic Filing - Received, Clerk's Office, January 20, 2009

* * * * * PC # 5 * * * * *

Mr. Rob Kaleel

January 8, 2008

For background purposes, WRR notes that the refinery is subject to a 2005 Clean Air Act enforcement

consent decree (the Consent Decree) between ConocoPhillips, WRB, the United States and the State of

Illinois.

This Decree includes significant requirements to reduce NOx emissions from existing heaters

and

boilers throughout COPC's U.S refineries, including those in Illinois. Many of the comments

provided

herein are based on the experience we have gained in

implementing

those

Consent Decree

provisions.

Compliance

date deadline

Proposed Section 217.152 includes a compliance date of May 1, 2010 for the installation of controls and

demonstration of compliance for all affected facilities. This date is not achievable given the design,

engineering,

purchasing, and construction challenges that would

be required to meet the very stringent

emission limits noted in the draft proposal. There are several reasons why this date is not achievable,

a. As of the filing of these comments, only 28 months remain before compliance must be certified.

The regulation has not been finalized and the parties subject to the regulation are not certain with

what they must comply. WRR has not prepared a detailed compliance plan at this time, since it

is

unclear what we must include in the plan,

b. Every heater and boiler that is included in the as-yet-to-be-determined plan

must be carefully

evaluated to determine the most efficient compliance plan.

This evaluation must include

assessments of existing controls, potential future

controls, potential future process changes and

economic considerations before the plan can be

finalized. The averaging plan included in the

draft proposal

must be evaluated to determine if certain equipment can be over-controlled to

balance out under-controlled equipment. Development of the initial compliance plan

is

expected

to take WRR at least 6 months, and will probably remain open to modification

several months

after that while more detailed engineering studies are completed

on the affected boilers and

heaters.

c. An engineering study

must be completed on each heater that must be controlled after the

compliance

plan is developed. WRR

is in the process of installing NOx controls on several

heaters

at

this time as part of the above-described COP Consent Decree. The engineering phase

of these projects has been up to 10 months long, depending on whether the

heater fire box

must

be modified and how the original equipment must be changed. In

many cases, these heaters have

been chosen as the easiest and most cost-effective

sources from which to obtain NOx emissions

reductions at the refinery. Additional

heaters are likely to require even more engineering

resources and time to meet RACT emissions requirements since the retrofits are likely to be more

complicated and more difficult to complete.

d. Air construction permits may be needed on some units to ensure

that the controls and other

operational changes are federally enforceable. Permit applications

typically take 2 to 3 months to

prepare followed by another 3 months for IEPA review and approval.

e. After the design is completed, equipment must be ordered

and shutdown planning completed.

Ultra Low NOx burners, which are the apparent RACT

control technology proposed in the draft

proposal, are taking at least 6 months for delivery for

our existing projects. Shutdown planning

and preparation can occur during this time, but

very little other work can move forward.

f. In all, WRR may

need to install emission controls, or make other changes, on 19 boilers and

heaters, across

13 operating units. Typically, WRR completes maintenance turnarounds on a 5

year cycle with all units scheduled sometime during the cycle.

A

few

of the affected heaters

and

one of the boilers are scheduled for a maintenance turnaround

during 2008 and 2009. The

remaining units are not scheduled before the

2010

deadline

but instead are planned through 2011.

Early turnarounds to upgrade other heaters will

impact the Midwest fuel supply, including the

entire state of Illinois, potentially causing significantly

higher gasoline and diesel fuel costs for a

period of time.

Electronic Filing - Received, Clerk's Office, January 20, 2009

* * * * * PC # 5 * * * * *

Mr. Rob Kaleel

January 8, 2008

g. In addition, it is unlikely that sufficient contractor maintenance staff will be available to complete

all of the heater and boiler upgrades that are required. Performance testing contractors may also

not be available to certify the new controls as required in the draft proposal.

Based on these reasons, WRR suggests that the compliance deadline be extended until at least December

31, 2013. We further suggest, to show ongoing improvement during

the

intervening

period,

that

a

schedule for implementation of NOx controls could be submitted by affected parties by

January 1, 2009,

with a requirement for 25% of proposed NOx controls

in place by May 1, 2010.

This

extended schedule

would help satisfy the "reasonably available" definition for RACT.

Subpart D: Industrial Boilers

Proposed

Section 217.160 describes what

industrial

boilers

are included in the

draft

proposal and includes

an emission limit for these boilers. WRR industrial boilers burn

only gaseous fuels and our comments

will be limited to this subset. The gaseous fuel

that is

burned

on the

WRR

site includes natural gas and

refinery

gas. Refinery

gas is similar to natural gas, but includes other hydrocarbon compounds that

increase

NOx

emissions to

some

degree. Refinery gas is a co-product of the refining process and is

typically consumed by onsite heaters and boilers to improve overall refining energy efficiency and reduce

flaring.

The draft proposal includes emission limits

for boilers greater than 100 MMBTU/hr of 0.080 lb/MIVIBTU.

This proposed RACT emission limit is overly stringent for typical industrial boilers when burning

refinery fuel gas. This emission limit will require the equivalent of Ultra Low NOx

control

technology

that is well beyond RACT.

WRR is presently designing NOx controls for an existing

onsite boiler as part of its Consent Decree

requirements to reduce overall NOx emissions. This boiler

is larger than 100 MMBTU/hr and does not

have NOx emission reducing burners at this

time. The Consent Decree requires that Ultra Low NOx

burners

(ULNB)

be installed to

qualify

for NOx reduction credit. The burner vendor will guarantee

that

the boiler will perform better than 0.070 lbs NOx / MMBTU with the ULNB.

It

has

taken more than 10

months to design the retrofit for this boiler. The permit application is in preparation

and should be

submitted in 2 months. We expect it will take approximately

3 months before IEPA will issue the permit.

A three week long shutdown

is

scheduled

for the boiler during the third quarter of 2008 to modify the

boiler. Total

time for

this project to be completed will be at least 20 months. Fortunately, this emission

control

system will

be in place before May 1, 2010. The estimated cost of the control system per ton of

NOx controlled is in excess of $20,000 per ton NOx controlled, without considering the installation

of a

NOx CEMS. A summary of the cost evaluation will be provided under separate, business confidential,

cover.

The above boiler was selected for retrofitting because it

had one of the easiest configurations to make the

required changes when compared to the other boilers

on the WRR site. The cost per ton controlled for

retrofitting the other boilers is expected

to be higher.

WRR believes that the

draft proposal RACT for industrial boilers is too stringent,

based on the cost of

control and the guaranteed emission factor. RACT is defined in 40CFR51.100(o)

as:

o)

«Reasonably available control technology>> (RACT)

means devices, systems, process

modifications, or other apparatus or techniques that

are reasonably available taking into account:

`b]-,(l) The necessity of imposing such controls in order

to attain and maintain a national ambient

air quality standard;

U,(2) The social, environmental, and economic impact of such controls;

and

3

Electronic Filing - Received, Clerk's Office, January 20, 2009

* * * * * PC # 5 * * * * *

Mr. Rob Kaleel

January 8, 2008

%7?(3)

Alternative means of providing for attainment and maintenance

of such standard. (This

provision defines RACT for the purposes of §51.341(b) only.)

The term "reasonable" is

defined

in

Webster's New College dictionary as "governed by

or

in

accordance

with reason or sound thinking", "within the

bounds of common sense," and finally "not extreme

or

excessive." WRR believes that these

definitions should be used in determining what a RACT

technology

is. Using these definitions, RACT is technology where equipment

is readily available, can be obtained on

a timely basis, and can be installed for a cost is not excessive.

Common sense should prevail in making

these decisions.

Generally, RACT should not mean "best available", since this

could imply a stretch,

technically and economically, for

the facilities where the rule applies.

Item (2) says that social, environmental AND economic impact

of such controls must be taken into

account. The proposed emission factor of 0.080 for boilers

does not adequately consider the economic

consequences on the companies that are required to install these controls.

In addition, ULNB are

currently "best available control technology" (BACT) for industrial

boilers and are only required for new

or significantly modified units. A comparison of the cost of the NOx control

on this boiler is 8 to 10

times more costly than the typical RACT control cost per ton ($2,000 - 2,500) in

other

moderate

nonattainment areas.

IEPA must reconsider the economic impact that

the proposed low emission factor will have on industry.

We recommend 0.12 lb NOx/MVIBTU that is recommended

by lERG in their comments. We believe that

this emission factor can be reasonably achieved while satisfying

all the parameters that must be

considered.

Subpart E: Process Heaters

Proposed Section 217.184 describes what process heaters are

included in the draft proposal and includes

an emission limit for these heaters. WRR process heaters burn

only refinery gaseous fuels, as described

above, and our comments will be limited to this subset.

As noted above, the gaseous fuel that is

burned on the WRR site includes natural gas and refinery gas.

Refinery gas is similar to natural gas, but includes other components that increase

NOx emissions to some

degree. The draft proposal includes emission limits for boilers greater than 100 MMBTU/hr

of 0.070

lb/1VIIVIBTU. This proposed emission limit is too stringent for typical process heaters and requires Ultra

Low NOx control technology that is well beyond BACT.

WRR is in the process of installing NOx controls in an existing process heater as part of its Consent

Decree

requirements to reduce overall NOx emissions. This heater is slightly smaller than 100

MMBTU/hr, however, it serves as an excellent example

of

the

economic consequence of retrofitting

existing process heaters with ULNB. The process heater does not have

NOx emission reducing burners at

this time. The Consent Decree requires that Ultra Low NOx burners (ULNB) be installed

to qualify for

NOx reduction credit. The burner vendor will guarantee that the boiler will perform at least at 0.050

lbs

NOx / MMBTU with the ULNB. The ULNB changes to this unit were designed over a 6 month period

and are already permitted. A significant modification to the floor of the heater is required to

accommodate the ULNB. The estimated cost of the control system per ton of NOx controlled is in excess

of $15,000 per ton NOx controlled, without considering the installation of a NOx CEMS. A summary of

the cost evaluation will be provided under separate, business confidential, cover.

WRR has 16 process heaters with heat input capacities greater than 100 MMBTU/hr

and, thus, must

evaluate how to control NOx emissions under the RACT rule. The process heater described above

was

selected for early NOx emission reductions primarily because it was one of the easiest to retrofit. The

installation

of NOx emission controls on the remaining process heaters will involve more detailed

engineering to evaluate how the fire boxes

and floors must be modified to include ULNB and what other

4

Electronic Filing - Received, Clerk's Office, January 20, 2009

* * * * * PC # 5 * * * * *

Mr. Rob Kaleel

January 8, 2008

changes (heater tubes) must be moved to allow for the longer flame

front that occurs with

ULNB

use.

The cost per ton NOx controlled for each additional process

heater is expected to be significantly greater

than the heater described. We are currently evaluating

installation of NOx controls on several other

heaters

with the potential cost in

excess

of

$20,000 per

ton

NOx controlled in order to meet our Consent

Decree requirements.

We

are not required to install emission controls on all heaters to comply with the

Consent Decree. The calculated costs to achieve the IEPA proposed RACT is far above the generally

accepted US EPA guidance of $2,000 per ton controlled.

WRR believes that the draft proposed RACT of

0.0701b

NOx/MMBTU

is too stringent for process

heaters. The above example of an actual project

to retrofit an existing heater shows that the cost of this

control is far beyond what is normally considered acceptable

economic impact from a RACT rule. The

0.070

lb/MMBTU limit will require ULNB

on nearly every heater in the refinery, at a cost of tens, and

potentially hundreds, of millions

of

dollars.

Other facilities in the non-attainment areas could be similarly

affected.

This economic impact is

unacceptable since RACT must consider economic impacts when

selecting

the

technology.

WRR agrees with the IERG suggestion that the NOx emission limit for process

heaters

be

set at 0.12 lb

NOx/MMBTU. This limit will significantly lower NOx emissions from

existing process heaters and meet

the intent of RACT controls, while somewhat reducing economic

impacts. This 0.121b NOx / MMBTU

emission limit will still require a major and expensive NOx

control program, far beyond what is required

under the COP Consent Decree.

Testing

and Monitoring

Proposed Sections 217.168 and 217.188 list the proposed testing

and monitoring requirements for this

draft proposed rulemaking. These sections

require that any industrial boiler or process heater unit

over

100

MMBTU/hr must install a CEMS

to monitor and record NOx emissions. This is expected to

require

the installation of approximately 10 CEMS at WRR based on the number

of process heaters at an

estimated cost of about $500 M per installation, and a total estimated

cost of $5 MM. These heaters are

not currently required to have NOx CEMS installed, but must

only demonstrate in a performance test that

the emission factor, combined with the heater capacity will

not exceed permit limits. The installation of

CEMS on process heaters is a complicated project,

since most of these heaters do not have exhaust

stacks

designed for this installation. Purchase of

the

analyzer

is a small portion of the cost of installation,

since

the units must have appropriate power installed,

weatherproof shelters and other required

systems.

WRR

believes

that CEMS should be limited to those units greater than

250 MMBTU/hr, as discussed in

the IERG comments. In addition, we believe that annual performance

testing is sufficient for process

heaters that are included in an averaging plan, since the low

NOx burners are generally not subject to

significant variation from demonstrated emission factors

during normal operation. Annual performance

testing will provide confirmation of emission

factors and allow IEPA to adequately

monitor degradation

in emission control performance without burdening

industry with unneeded continuous

monitoring.

Case-by-Case RACT

The rule

should

contain a provision that allows for case-by-case RACT

determination through the

permitting process. The USEPA allows RACT determinations

to be contained in federally enforceable

permits for SIP purposes and the Agency believes

it is

authorized

to make case-by-case MACT

determinations by federal law. Allowing

case-by-case RACT determinations through the

permitting

process would be an

effective

and

efficient means for addressing unique situations.

Summary

Electronic Filing - Received, Clerk's Office, January 20, 2009

* * * * * PC # 5 * * * * *

WIM IS

ULLCUUCQ

Dy,ýý

t

b

1hie,

B

Uý

TTQ

eer and install the I

CO-4"

.

I

ssion fucturs

for gaseous;'

;

4 a NOx emission controls.

The

c`

CT, particularly given the

`;

exp

uirý;nent

to continuously

d oma

when annual

F -ýý

I I I III

11 1

111 11

IR

1 1

tnose, units.

ý upstlons regarding these

comments.

ý ''hý{s1ý' )2ý1

`I

I

Pý:JyiCiý ICiýEi4tP1

:M

;?C

6

Electronic Filing - Received, Clerk's Office, January 20, 2009

* * * * * PC # 5 * * * * *

ATTACHMENT B

N ON-DISCLOSABLE INFORMATION

Electronic Filing - Received, Clerk's Office, January 20, 2009

* * * * * PC # 5 * * * * *

ATTACHMENT C

N ON-DISCLOSABLE

INFORMATION

Electronic Filing - Received, Clerk's Office, January 20, 2009

* * * * * PC # 5 * * * * *

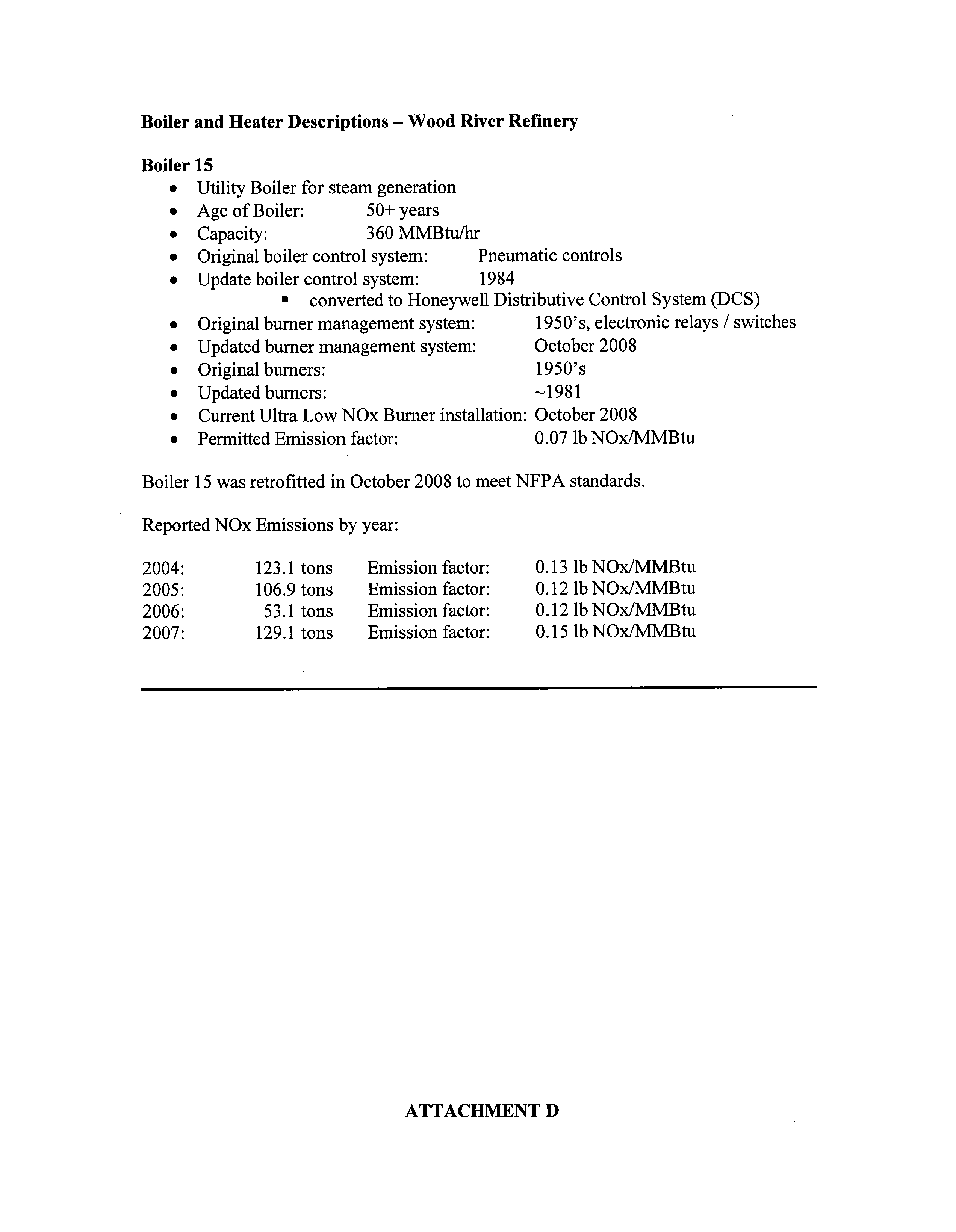

Boiler and Heater Descriptions - Wood River Refinery

Boiler 15

" Utility Boiler for steam generation

" Age of Boiler:

50+

years

" Capacity:

360 MMBtu/hr

" Original boiler control system:

Pneumatic

controls

" Update boiler control

system:

1984

" converted to Honeywell Distributive Control

System (DCS)

" Original burner management system:

1950's,

electronic relays / switches

" Updated burner management

system:

October 2008

" Original burners:

1950's

" Updated burners:

1981

" Current Ultra Low NOx Burner

installation: October 2008

" Permitted Emission

factor:

0.07 lb NOx/MMBtu

Boiler 15 was retrofitted in October 2008 to meet NFPA standards.

Reported NOx Emissions by year:

2004:

123.1 tons Emission factor:

0.13 lb

NOx/MMBtu

2005:

106.9 tons Emission

factor:

0.12 lb NOx/MMBtu

2006:

53.1 tons

Emission factor:

0.121b NOx/MMBtu

2007:

129.1 tons

Emission factor:

0.15 lb NOx/MMBtu

ATTACHMENT D

Electronic Filing - Received, Clerk's Office, January 20, 2009

* * * * * PC # 5 * * * * *

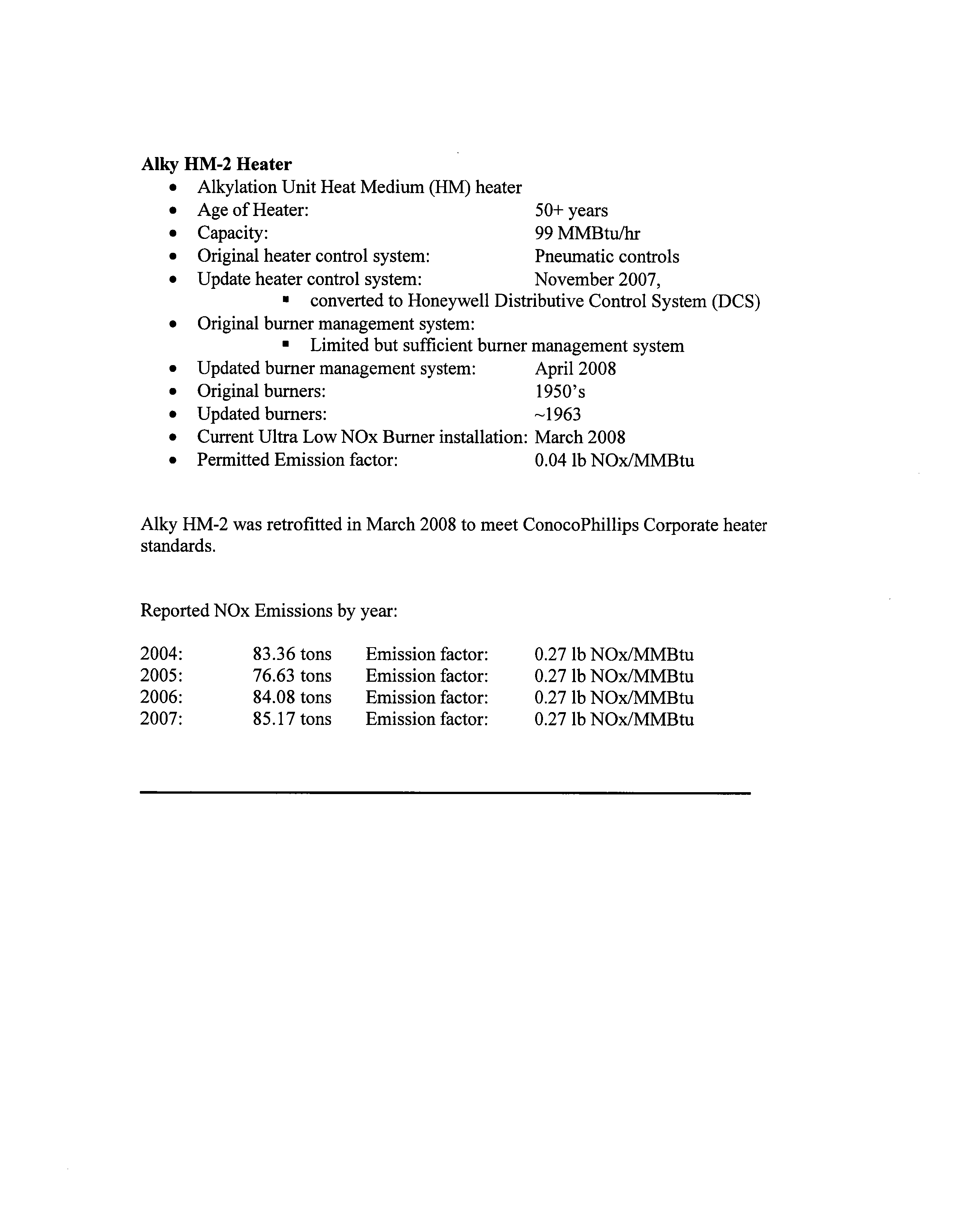

Alky HM-2 Heater

" Alkylation Unit Heat Medium (HM) heater

" Age of Heater:

50+

years

" Capacity:

99 MMBtu/hr

" Original heater control system:

Pneumatic controls

" Update heater control system:

November 2007,

" converted to Honeywell Distributive

Control System (DCS)

" Original burner management system:

" Limited but sufficient burner management system

" Updated burner management

system:

April 2008

" Original burners:

1950's

" Updated burners:

1963

" Current Ultra Low NOx Burner installation: March 2008

" Permitted Emission factor:

0.041b NOx/MMBtu

Alky HM-2 was retrofitted in March 2008 to meet ConocoPhillips

Corporate heater

standards.

Reported NOx Emissions by year:

2004:

83.36 tons Emission factor:

0.271b NOx/MMBtu

2005:

76.63 tons Emission factor:

0.271b NOx/MMBtu

2006:

84.08 tons Emission factor:

0.271b NOx/MMBtu

2007:

85.17 tons Emission factor:

0.271b NOx/MMBtu

Electronic Filing - Received, Clerk's Office, January 20, 2009

* * * * * PC # 5 * * * * *