BEFORE

THE

ILLINOIS

POLLUTION

CONTROL

BOARD

DYNEGY

MIDWEST

GENERATION,

INC.,

Petitioner,

ILLINOIS

ENVIRONMENTAL

PROTECTION

Agency,

To:

NOTICE

OF

FILING

John

Therriault,

Assistant

Clerk

Illinois

Pollution

Control

Board

James

R.

Thompson

Center

Suite

11-500

100

West

Randolph

Chicago,

Illinois

60601

Illinois

Environmental

Protection

Agency

Division

of

Legal

Counsel

1021

North

Grand

Avenue,

East

P.O.

Box

19276

Springfield,

Illinois

62794-9276

PLEASE

TAKE

NOTICE

that

we

have

today

electronically

filed

with

the

Office

of

the

Clerk

of

the

Pollution

Control

Board

PETITION

FOR

VARIANCE,

AFFIDAVIT

OF

ARIC

D.

DIERICX,

and

APPEARANCES

OF

KATHLEEN

C.

BASSI

AND

STEPHEN

J.

BONEBRAKE,

copies

of

hich

are

herewith

served

upon

you.

Dated:

January

9,

2009

Kathleen

C.

Bassi

Stephen

J.

Bonebrake

SCHIFF

HARDEN,

LLP

6600

Sears

Tower

233

South

Wacker

Drive

Chicago,

Illinois

60606

312-258-5500

V.

)

)

)

)

)

PCB

09-

)

Variance

—

Air

)

)

)

Electronic Filing - Received, Clerk's Office, January 9, 2009

BEFORE

THE

ILLINOIS

POLLUTION

CONTROL

BOARD

DYNEGY

MIDWEST

GENERATION,

INC.,

)

)

Petitioner,

)

)

v.

)

PCB

09-

)

Variance

—

Air

ILLINOIS

ENVIRONMENTAL

)

PROTECTION

AGENCY,

)

)

APPEARANCE

I,

KATHLEEN

C.

BASSI,

hereby

file

my

appearance

in

this

proceeding

on

behalf

of

Petitioner,

DYNEGY

MIDWEST

GENERATION,

INC.

Kathleen

C.

Bassi

SchiffHardin

LLP

6600

Sears

Tower

233

South

Wacker

Drive

Chicago,

Illinois

60606

312-258-5500

kbassi@schiffhardin.com

Dated:

January

9,

2009

Electronic Filing - Received, Clerk's Office, January 9, 2009

BEFORE

THE

ILLINOIS

POLLUTION

CONTROL

BOARD

DYNEGY

MIDWEST

GENERATION,

INC.,

)

)

Petitioner,

)

)

v.

)

PCB

09-

)

Variance

—

Air

ILLINOIS

ENVIRONMENTAL

)

PROTECTION

Agency,

)

)

APPEARANCE

I,

STEPHEN

J.

BONEBRAKE,

hereby

file

my

appearance

in

this

proceeding

on

behalf

of

Petitioner,

DYNEGY

MIDWEST

GENERATION,

INC.

Stfen

3.

Bonebrake

Schiff

Hardin

LLP

6600

Sears

Tower

233

South

Wacker

Drive

Chicago,

Illinois

60606

312-258-5500

sbonebrake@schiffhardiri.com

Dated:

January

9,

2009

Electronic Filing - Received, Clerk's Office, January 9, 2009

BEFORE

THE

ILLINOIS

POLLUTION

CONTROL

BOARD

DYNEGY

MIDWEST

GENERATION,

INC.,

)

)

Petitioner,

)

)

v.

)

PCB

09-

)

Variance

—

Air

ILLINOIS

ENVIRONMENTAL

)

PROTECTION

Agency,

)

)

Respondent.

)

PETITION

FOR

VARIANCE

NOW

COMES

Petitioner,

DYNEGY

MIDWEST

GENERATION,

NC.

(“Petitioner”

or

“DMG”),

by

and

through

its

attorneys,

SCHIFF

HARDFN,

LLP,

and,

pursuant

to

Sections

35

and

37

of

the

Environmental

Protection

Act

(“Act”),

415

ILCS

5/3

5,

37,

and

35

Ill.Adm.Code

Part

104,

Subpart

B,

respectfi.illy

requests

that

the

Board

grant

the

Petitioner

a

variance

from

certain

provisions

of

the

Illinois

Multi-Pollutant

Standard

(“MPS”),

35

Ill.Adm.Code

§

225.233,

as

applied

to

Unit

3

at

the

Baldwin

Energy

Complex

for

the

limited

period

beginning

July

1,

2009,

and

ending

March

31,

2010.

Specifically,

DMG

seeks

a

variance

at

Baldwin

Unit

3

from

the

MPS

requirement

in

Sections

225.233(c)(1)(A)

and

225.233(c)(2)

to

inject,

beginning

July

1,

2009,

halogenated

activated

carbon’

at

a

minimum

injection

rate

of

5.0

pounds

per

million

actual

cubic

feet

(“lbs/macf”)

exhaust

gas

flow

and

from

related

monitoring,

recordkeeping,

and

reporting

provisions

at

Sections

225

.210(b)

and

(d)

and

Note:

“halogenated

activated

carbon”

and

“sorbent”

are

used

interchangeably

in

this

Petition.

—1—

Electronic Filing - Received, Clerk's Office, January 9, 2009

225.233(c)(5).

DMG

will

suffer

arbitrary

or

unreasonable

hardship

if

the Board

does

not

grant

this

requested

variance.

In

support

of

its

Petition,

DMG

states

as

follows:

A.

DMG

GENERATES

ELECTRICITY

IN

ILLiNOIS

AT

FIVE

COAL-

FIRED

POWER

STATIONS.

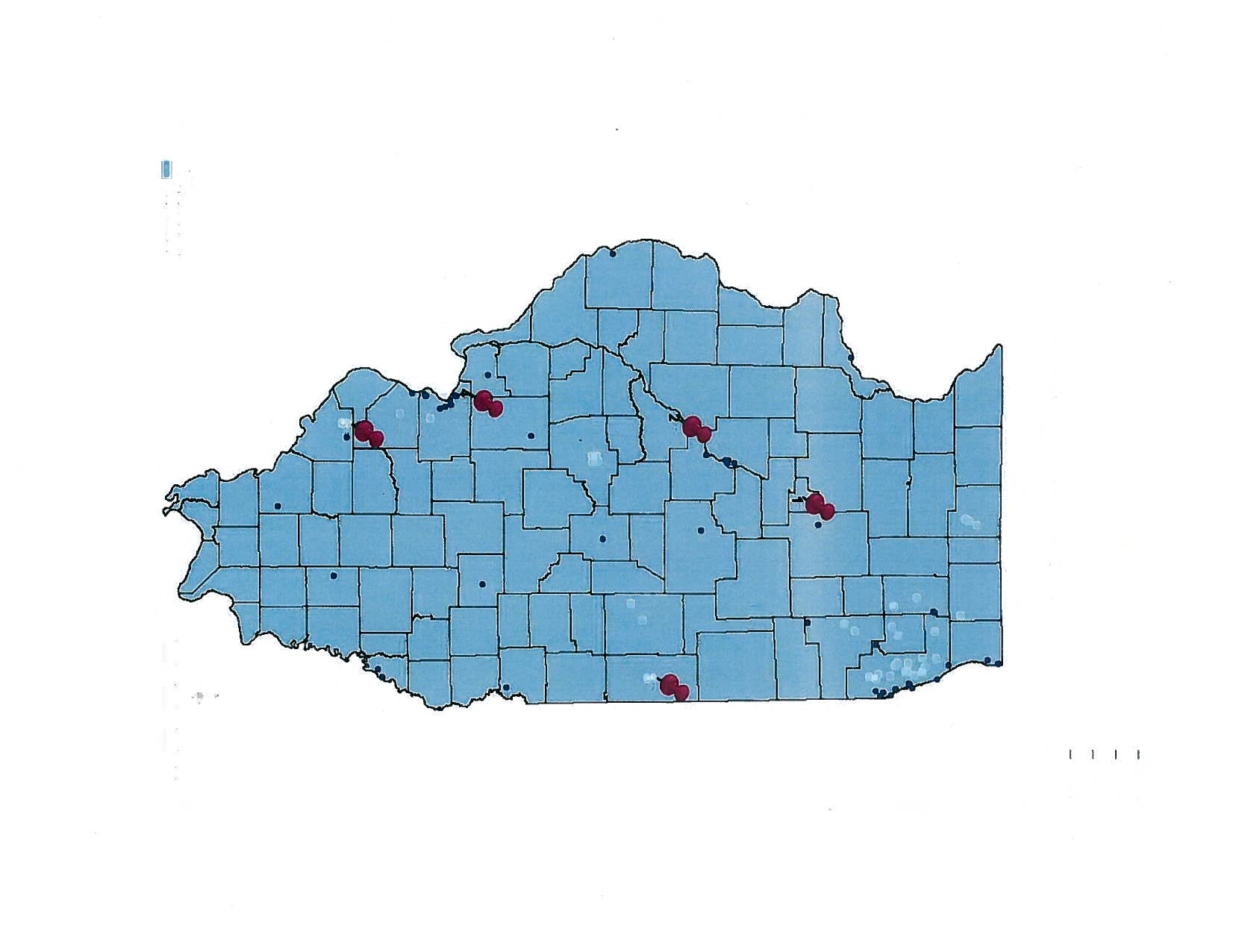

I.

DMG

owns

and

operates

five

coal-fired

electricity

generating

power

plants

in

located

in

downstate

Illinois.

The

Baldwin

Energy

Complex

(“Baldwin”),

whose

Unit

3

is

the

subject

this

variance

request,

is

located

in

Randolph

County.

The two

other

coal-

fired

power

plants

affected

by

DMG’s

proposed

conditions

to

this

requested

variance

are

the Havana

Power

Station

(“Havana”)

located

in

Mason

County

and

the Hennepin

Power

Station

(“Hennepin”)

located

in

Putnam

County.

DMG’s

other

two

coal-fired

power

plants

are

the

Vermilion

Power

Station

located

in

Vermilion

County,

and

the

Wood

River

Power

Station

located

in

Madison

County.

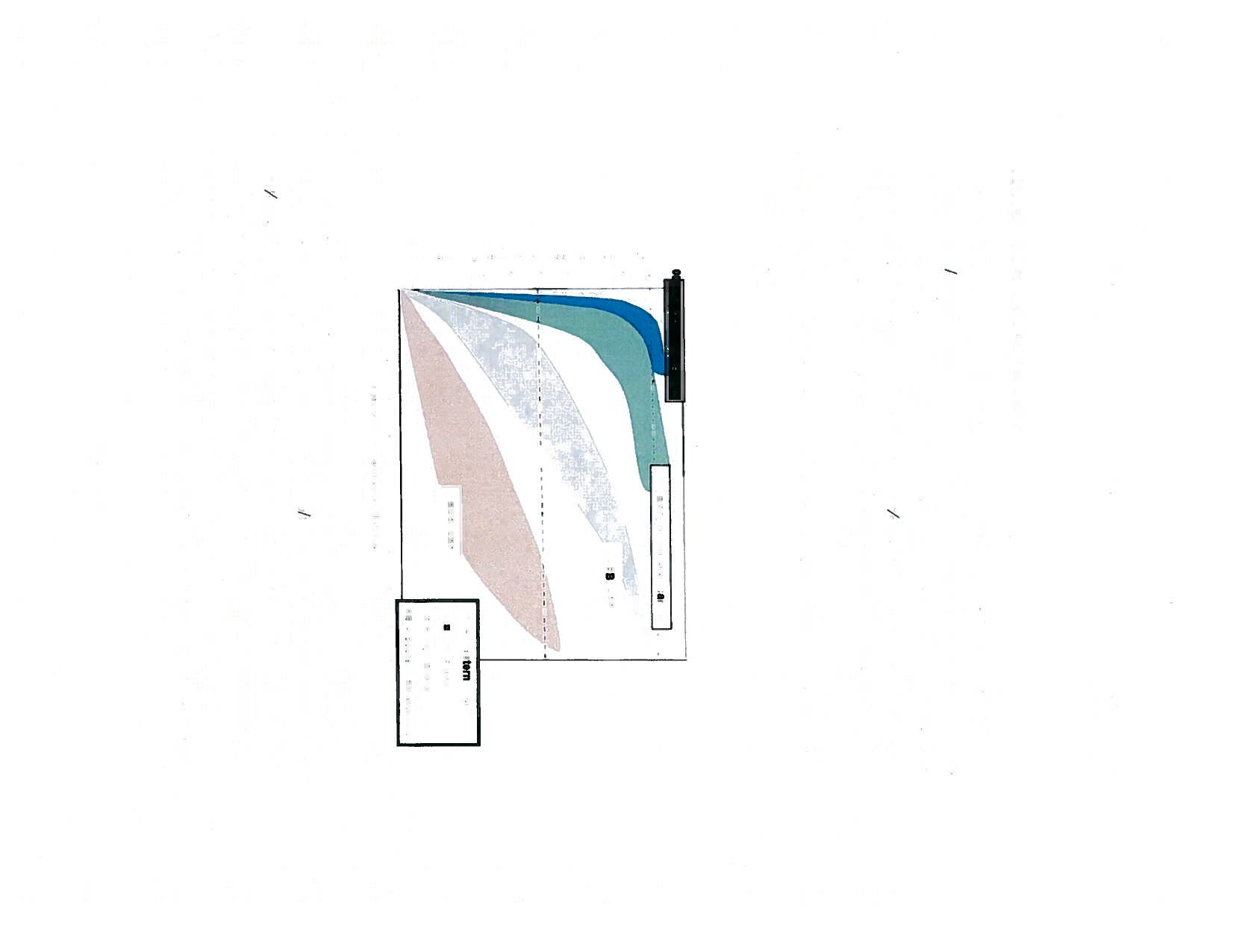

A

map

depicting

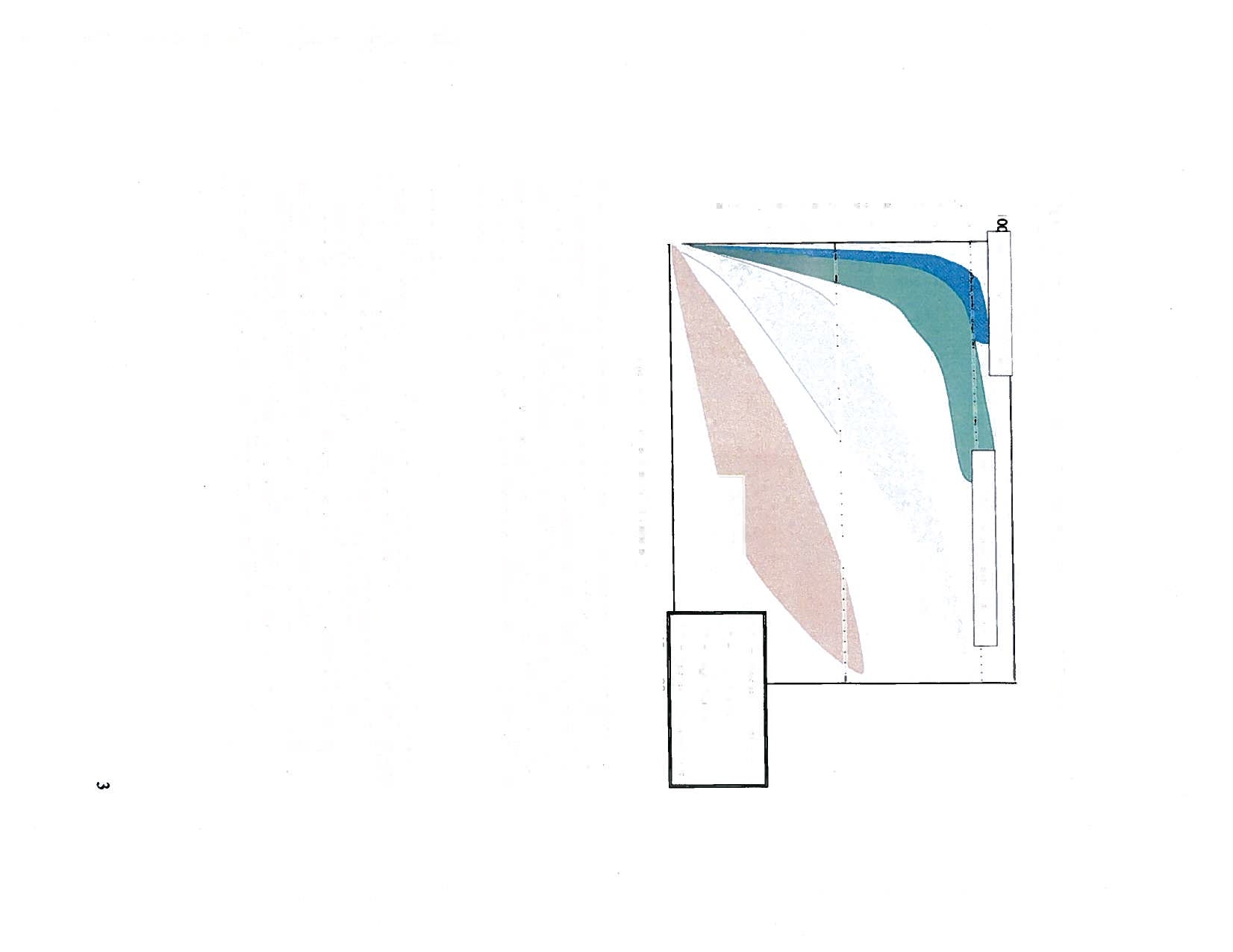

the

location

of

each

of

DMG’s

coal-fired

power

plants

is

provided

in

Exhibit

1.

The

addresses

of

the

five

power

stations,

their

identification

numbers

assigned

by

the

Illinois

Environmental

Protection

Agency

(“Agency”),

age,

permit

application

numbers,

and

other

pertinent

information

regarding

their

output,

pollution

control

equipment,

and mercury

emissions

are

provided

in

Exhibit

2.

DMG

employs

approximately

588 persons

at

these

five

power

stations,

of

whom

approximately

175

are

employed

at

Baldwin.

2.

The

air

monitoring

stations

maintained

by

the

Agency

that

are

nearest

to

Baldwin,

as

well

as

Havana

and

Hennepin,

are

identified

in

Exhibit

.

Randolph

County,

the

location

of

Baldwin,

is

designated

nonattainment

for

PM2.5

and

attainment

2

Exhibit

1

identifies

the

locations

of

all

five

of

DMG’s

coal-fired

power

plants,

including

Baldwin,

Havana

and

Hennepin,

on

a

copy

of

the

map

from

the

Agency’s

illinois

Annual

Air

Quality

Report

2006

(at

p.

34),

which

identifies

the

locations

of

the

Agency’s

air

quality

monitoring

stations.

-2-

Electronic Filing - Received, Clerk's Office, January 9, 2009

(or

unclassifiable/attainment)

for all

other

criteria

pollutants.

Mason

and

Putnam

Counties,

the respective

locations

of

Havana

and

Hennepin,

are

designated

attainment

(or

unclassifiable/attainment)

for

all

criteria

pollutants.

See

40

CFR

§

81.3

14;

USEPA’s

Green

Book

(list

of

national

attainment

and

nonattainment

designations)

at

http://www.epa.gov/oar/oagps/greenbkl.

3.

The

principal

emissions

at

DMG’s

coal-fired

power

plants

are

sulfur

dioxide

(“SO

2

”),

nitrogen

oxides

(“NOx”),

and

particulate

matter

(“PM”).

As

relevant

to

this

Petition,

coal-fired

power

plants

also emit

mercury.

SO

2

is

currently

generally

controlled

through

the

use

of

low

sulfur

coal.

Additionally,

DMG

has

construction

permits

for

and

is

constructing

spray

dryer

absorbers

(i.e.,

dry

scrubbers)

with

fabric

filter

(i.e., baghouse)

systems

on

all

three

Baldwin

units,

as

well

as

on

Havana

Unit

6,

and

DM0

is

installing

a

fabric

filter

on

Hennepin

Unit

2.

All

of

these

dry

scrubbers

are

scheduled

to

be

placed

into

service

by

December

31,

2012.

In

fact,

the

Baldwin

Unit

3

outage

scheduled

to

begin

in

March

2010

will

be

used

to

install

its

dry

scrubber

and

fabric filter.

DMG

did

not

defer

its

plans

to

install

dry

scrubbers

in

light

of

the

remand

of

the

federal

Clean

Air

Interstate

Rule

(“CAIR”)

in

North

Carolina

v.

EPA,

531

F.3d

896

(D.C.

Cir.

2008).

When

placed

into

service,

these

dry

scrubbers

will

significantly

reduce

DMG’s

system-wide

4

SO

2

emission

rate.

NOx

emissions

are

generally

controlled

by

various

combinations

of

low

sulfur

coal,

low

NOx

burners,

over-fire

air,

and

selective

As

of

the

date

of

submittal

of

this

Petition

for

Variance

to

the

Board,

the

court in

North

Carolina

has

remanded

the

CAIR

to

the U.S.

Environmental

Protection

Agency

(“USEPA”)

without

vacatur.

See

North

Carolina

v.

EPA,

No.

05-1244

((D.C.

Cir.

Dec.

23,

2008)

(Order

remanding

rule

without

vacatur).

“System-wide”

refers

only

to

DMG’s

coal-fired

units

subject

to

the

Illinois

mercury

rule,

35

Ill.Adm.Code

Part

225.Subpart

B.

-3-

Electronic Filing - Received, Clerk's Office, January 9, 2009

catalytic

reduction

systems

(“SCRs”).

PM

is

generally

controlled

through

the

use

of flue

gas

conditioning,

electrostatic

precipitators

(“ESPs”),

and

fabric

filter

systems.

In

accordance

with

the

provisions

of

the

MPS

established

in

the

Illinois

mercury rule,

DM0

will

control

mercury

emissions

by

injection

of

halogenated

activated

carbon

in

conjunction

with

SCRs,

dry

scrubbers,

ESPs,

and

fabric

filters.

4.

DM0 has

never

previously

sought

or obtained

a variance

from

the

Board.

To

the

best

of

DMG’s

knowledge,

a

prior

owner

of Baldwin

once

before

obtained

a

Board

variance

for

Baldwin

on

an

unrelated

matter

(i.e.,

PCB

1999-0002,

granting

a 45-day

provisional

variance

from

conditions

and

effluent

discharge

limits

in

35

1ll.Adm.Code

§

304.120

and

304.141(b)

in

July

1998)

but

not

concerning

similar

relief.

B.

DMG SUPPORTED

THE

MPS

IN

2006

TO

COORDINATE

MERCURY

EMISSION

CONTROLS

WITH

OTHER

EMISSION

CONTROL

REQUIREMENTS.

5.

In

May

2005, USEPA

promulgated

the

Clean

Air

Mercury

Rule

(“CAMR”),

70

Fed.

Reg.

28606 (May

18,

2005), to

reduce

mercury

emissions

from

coal-

fired

electric

generating

units

(“EGUs”)

in

the

lower

48

states.

The

federal

CAMR,

which applied

to EGUs

with

nameplate

capacities

greater

than

25

megawatts,

established

caps

on

the

mercury

emissions

for

each

affected

state

and

allowed

states

to

participate

in

USEPA-administered

emissions

trading

programs

if

their

state

programs

met

certain

minimum

requirements.

DMG’s

coal-fired

power plants

are

EGUs

that

were

subject

to

the

federal

CAMR.

6.

In

December

2006,

the

Board

adopted

the

Illinois

mercury

rule

at

R06-25

to

satisfy

the

federal

CAMR

requirements

in

Illinois.

The

rule

adopted

by

the

Board

differs

significantly

from

the

federal

CAMR in

a

very

important

way:

the

Illinois

-4-

Electronic Filing - Received, Clerk's Office, January 9, 2009

mercury

rule

adopts a

command-and-control

approach

that

requires

affected

coal-fired

power

plants

to

achieve

a

90% reduction

from

input

mercury

or

an

emission

rate

of

0.0080

lb

mercury/GWh

gross

electrical

output

5

and

rejects

participation

in

the

federal

mercury

emissions

trading

program.

6

7.

In

2006, when

the

Agency

was

developing

its

mercury

rule,

DMG

was

also

simultaneously

faced

with

developing

a

compliance

strategy

to

meet

future

emission

reduction requirements

under

both

the

Illinois

CAIR

and

the

Consent

Decree

DMG

had

entered

with,

among

others,

the

federal

government.

7

The

CAIR

establishes

a

state-wide

cap

on

SO

2

and

NOx

emissions

from

EGUs

that

must

be

implemented

through

emission

reductions

and/or

emissions

allowance

trading.

In

general,

the

Consent

Decree

requires

DM0

to

reduce

SO

2

,

NOx,

and

PM

emissions

at

its

five

coal-fired

power

plants

and

mercury

at

the

Vermilion

Power

Station

through

a

combination

of

enforceable

emission

limits,

installation

of

mandatory

pollution

control

and

monitoring

technology,

and

SO

2

and

NOx

allowance

restrictions,

with

full

compliance

to

be

achieved

by

the

end

of

2012.

8.

DM0

evaluated

its

environmental

compliance

strategy

in

light

of

the

available

pollution

control

technologies,

including

use

of

potential

co-benefit

emission

control

technologies

that

reduce

not

only

mercury

but

also

NOx

and/or

SO

2

.

DM0

Hereinafter,

this

Petition

refers

only

to

the

90% reduction

compliance

option

for

the

sake

of

simplicity.

6

The

CAMR

was

vacated

by

State

of

New

Jersey

v.

Environmental

Protection

Agency,

517

F.3d

574

(D.C.

Cir.

2008),pet.for

cert.filed,

77

U.S.L.W.

3253

(U.S.

Oct.

17,

2008) (No.

08-5

12).

‘

United States,

et

al.

v.

Illinois

Power

Co.,

et

al.,

No.

99-CV-833-MJR

(S.D.

Ill.)

(Consent

Decree

entered

May

27,

2005)

(a

copy

of

the

Consent

Decree

as

originally

entered

is

available

at

<www.epa.

gov/compliance/resources/cases/civilfcaa/

illinoispower.html

>

under

the

link

“Consent

Decree.”

-5-

Electronic Filing - Received, Clerk's Office, January 9, 2009

determined

that

the best

approach

to implementing

reasonable and effective

air

emissions

reductions

from its coal-fired

power

plants

was

for the Agency

to

adopt

a comprehensive

approach that

would address

mercury

emissions

in

coordination

with

other

air emission

reduction requirements.

While

recognizing

that

the

injection

of halogenated

activated

carbon can reduce

mercury emissions,

DM0 did not

believe that considerably

high

levels

of mercury removal

at all units

could

be achieved in the short

run or that

the

reductions

could

be

measured

with sufficient

accuracy

to

assure

compliance

with

the Illinois

mercury

emission

limits.

9.

DM0

determined that

compliance with

its Consent

Decree, the Illinois

CAIR and the

Illinois mercury nile could

require the

installation of various

combinations

of pollution control

equipment.

The pollution

control equipment

necessary

for DM0

to

meet

its

NOx

limits

(i.e.,

SCRs) and SO2 limits

(i.e.,

dry

scrubbers)

for the

CAIR,

as

well

as fabric filters

for PM control

under

the Consent Decree, also

enhance a

source’s ability

to

reduce

mercury

emissions and,

therefore,

enhance DMG’s

ability

to ensure

compliance

with

Illinois’

mercury

emissions

limits. These

same combinations

of

control

technologies

were necessary

for DMG to

comply with the

Consent Decree,

the

CAIR, and

the Illinois

mercury rule; however,

all of the pollution

control equipment

could not

be

installed

by

the

earliest compliance

date, i.e.,

July 1, 2009,

the

initial

compliance

deadline

for the

Illinois mercury

rule.

Thus,

coordination of

these separate regulatory

emission

reduction

requirements

was

essential.

10.

For these

reasons, DMG

(and

other electricity

generators

in

Illinois)

worked

with

the Agency

on

a

proposal

to coordinate

the

intertwined

mercury,

NOx,

and

SO

2

emissions

control planning.

That effort

resulted

in the

MPS,

which

was

adopted

by

-6-

Electronic Filing - Received, Clerk's Office, January 9, 2009

the

Board

as part

of the

Illinois

mercury

rule at Section

225.233.

DMG

opted in

to

the

MPS on

November

26,

2007,

see Ex.

38

11.

The

MPS

requires

DM0

to install

and operate

halogenated

activated

carbon

injection

systems

to control

mercury emissions

but extends

the

deadline

to

demonstrate

compliance

with

the rule’s

overall

90%

mercury

reduction

requirement

until

2015.

Prior to

2015

DM0

units

are subject

to

the

sorbent

injection

rate

requirements.

The

MPS also

establishes

strict, declining

emissions

limits

for NOx

and

SO2 over a

period

of time,

including

a system-wide

SO2

limit

of

0.24

lb/mmBtu

in

2013,

declining

to

a

rate of

0.19 lb/mmBtu

in 2015,

and precludes

trading

of any

excess NOx

and

SO

2

allowances

that may

be generated

by

the pollution

control

equipment

necessary

to

meet

the

applicable

emissions

limitations.

As

a

result, because

the

MPS and the

Consent

Decree each

restrict

the emissions

trading

otherwise

available

under the

CAIR,

DMG

must

install and

operate pollution

control

equipment

and

cannot rely

on

allowance

purchases

as a

compliance

strategy

or

compliance

timing tool.

12.

In order

for

it to meet

the emission

reduction

requirements

of the MPS

and

the

Consent Decree,

DM0 must

plan for

and finance

the purchase

of

the

necessary

pollution

control equipment.

Since the

MPS and

Consent

Decree

require

compliance

with

specified

emissions

rates, DM0

does not

have

the

flexibility

available to

other

companies

to

delay

this

equipment

planning

and

financing

through

purchases

of

allowances

to

satisfy its compliance

obligations

until

the

financial,

labor,

and

equipment

markets

are

more

advantageous.

The

procurement

process

for So

2

,

PM,

and

mercury

8

DMG’s

MPS

Group

includes

each of

the

10 individual

coal-fired

units located

at

its

five power

stations, as

required to

be

included

in a single

MPS

group

by

Section

225.233(a)(2).

-7-

Electronic Filing - Received, Clerk's Office, January 9, 2009

pollution

control

devices

— each of

which alone involves

significant

equipment

and

engineering —

is

approximately

three to five years.

For example,

in order for Baldwin

Unit 3 to comply

with its

SO

2

emission

rate

requirements by

the

end

of 2010, DMG

commenced

its

procurement

process

in

2007.

The estimated

time for

actual construction,

tie-in, commissioning,

startup,

and testing of

a dry scrubber is approximately

three years.

From

engineering

concept to

online operation,

including permitting,

the

period

is

approximately

four and one-half

years.

13.

DMG has

estimated that its capital

costs

of compliance

with

the

Illinois

mercury rule

(including the MPS)

and

its

Consent

Decree would

be a total of

$973

million

by

2013. These estimates

may change

depending

on

additional federal

or state

requirements

(including

any

related

to the

CAIR

remand),

the ultimate

outcome

of any

appeals

relative

to

the CAMR

vacatur, new

technology, or

variations

in costs of material

or

labor, among other reasons.

14.

Given the

large

capital

and operations and maintenance

(“O&M”) projects

involved

in

pollution

control

decisions at each

of

its

five coal-fired power

plants,

DMG

must

proceed

cautiously to

maintain its financial

resources

and

operational flexibility,

as

well

as the integrity of the

electricity

generation

system

that supports

Illinois’

economy.

DM0

continues

to

evaluate

compliance

strategies

at

each of

its

coal-fired

power

plants

to

identify

the optimal

locations

for

investments

and

expenditures

consistent

with

the goal of

maintaining

operational

flexibility

within

a competitive

energy market.

-8-

Electronic Filing - Received, Clerk's Office, January 9, 2009

C.

DMG

REQUIRES

TEMPORARY

RELIEF

FROM

SECTIONS

225.233(c)(1)(A),

SECTION

225.233(c)(2), 225.210(b),

225.210(d)

AND

225.233(c)(5)

AT

BALDWIN

UNIT

3 TO

AVOID WASTING

LIMITED

RESOURCES AND

TO

PROVIDE OPERATING

FLEXIBILITY

IN

CONJUNCTION

WITH ITS

OTHER

ENVIRONMENTAL

OBLIGATIONS.

15.

DM0

seeks

this

variance

because making

capital and operating

expenditures

to install and

operate

a

halogenated activated

carbon

injection system on

Baldwin

Unit

3

that will

need

to be removed

and

re-located

nine months

after July 1,

2009,

upon installation of the

dry scrubber and fabric

filter

systems

on Baldwin Unit 3

is

not financially

prudent, would

divert

capital

and operating

expenditures

that could

be

otherwise

better

spent,

and

will result in adverse environmental

effects. DMG faces

arbitrary

and

unreasonable hardship

if it is not granted

the variance

and allowed

to

make

responsible

operating decisions

regarding

the

best

combinations of

actions to

address

the

myriad

compliance requirements

of the MPS and Consent

Decree.

16.

Specifically,

DM0

seeks

relief

from

the

requirement

in Sections

225.233(c)(1)(A)

and

225.233(c)(2) that

it inject

halogenated

activated

carbon

in Baldwin

Unit

3

beginning

July

1, 2009,

at a rate

of

5.0 lbs/macf

exhaust

gas

and from the related

monitoring,

recordkeeping,

and

reporting

provisions of

Sections 225.210(b)

and (d) and

225.233(c)(5).

Sections

225.233(c)(l)(A)

and 225.233(c)(2)

of

the MPS provide,

in

relevant

part:

9

c)

Control Technology Requirements

for Emissions

of

Mercury.

1)

Requirements

for EGUs in

an

MPS Group.

Excluding amendments

currently proposed

in Docket

R09-10

to

add sorbent

manufacturers

to

the

approved

list;

DMG

would

expect

to be

able

to use the

additional

sorbent

manufacturers

if the

Board adopts those

amendments.

-9-

Electronic Filing - Received, Clerk's Office, January 9, 2009

A)

For

each

EGU

in

an

MPS

Group

other

than

an

EGU

that

is

addressed

by

subsection

(c)(1)(B)

of

this

Section

for

the

period

beginning

July

1,

2009...

and

ending

December

31,2014..

.

,the

owner or

operator

of

the

EGU

must

install,

to

the

extent not

already

installed,

and

properly

operate

and

maintain

one

of

the

following

emission

control

devices:

i)

A

Halogenated

Activated

Carbon

Injection

System,

complying

with

the

sorbent

injection

requirements

of

subsection

(2)

of

this

Section.

2)

For

each

EGU

for

which

injection

of

halogenated

activated

carbon

is required

by

subsection

(c)(1)

of

this

Section,

the

owner

or

operator

of the

EGU

must

inject

halogenated

activated

carbon

in

an

optimum

manner,

which,

except

as

provided

in

subsection

(c)(4)

of

this

Section,

is

defined as

all

of

the

following:

A)

The

use

of

an

injection

system

designed

for

effective

absorption

of

mercury,

considering

the

configuration

of

the

EGU

and

its

ductwork;

B)

The

injection

of

halogenated

activated

carbon

manufactured

by

Aistom,

Norit, or Sorbent

Technologies,

or

the

injection

of

any

other

halogenated

activated

carbon

or sorbent

that

the

owner or

operator

of

the

EGU

has

demonstrated

to

have

similar

or

better

effectiveness

for

control of

mercury

emissions;

and

C)

The

injection

of sorbent

at

the

following

minimum

rates,

as

applicable:

i)

For

an

EGU

firing

subbituminous

coal,

5.0

lbs

per

million actual

cubic

feet

or,

for

any

cyclone-fired

EGU

that

will

install

a

scrubber

and

baghouse

by

December

31,

2012,

and

which

already

meets

an

emission

rate

of

0.020

lb

mercury/GWh

gross

electrical

output

or

at

least

75 percent

reduction

of

input

mercury,

2.5

lbs

per

million

actual

cubic

feet;

-10-

Electronic Filing - Received, Clerk's Office, January 9, 2009

ii)

For

an

EGU

firing

bituminous

coal,

10.0

lbs

per

million

actual

cubic

feet

or

for

any

cyclone-fired

EGU

that

will

install

a

scrubber

and

baghouse

by

December

31,

2012,

and

which

already

meets

an

emission

rate

of

0.020

lb

mercurylGWh

gross

electrical

output

or

at

least

75

percent

reduction

of

input

mercury,

5.0

lbs

per

million

actual

cubic

feet;

iii)

For

an

EGU

firing

a

blend

of

subbituminous

and

bituminous

coal,

a

rate

that

is

the

weighted

average

of

the

above

rates,

based

on

the

blend

of

coal

being

fired;

or

iv)

A

rate

or

rates

set

lower

by

the

Agency,

in

writing,

than

the

rate

specified

in

any

of

subsections

(c)(2)(C)(i),

(c)(2)(C)(ii),

or

(c)(2)(C)(iii)

of

this

Section

on

a

unit-

specific

basis,

provided

that

the

owner

or

operator

of

the

EGU

has

demonstrated

that

such

rate

or

rates

are

needed

so

that

carbon

injection

will

not

increase

particulate

matter

emissions

or

opacity

so

as

to

threaten

noncompliance

with

applicable

requirements

for

particulate

matter

or

opacity.

D)

For

the

purposes

of

subsection

(c)(2)(C)

of

this

Section,

the

flue

gas

flow

rate

must

be

determined

for

the

point

of

sorbent

injection;

provided

that

this

flow

rate

may

be

assumed

to

be

identical

to

the

stack

flow

rate

if

the

gas

temperatures

at

the

point

of

injection

and

the

stack

are

normally

within

1000

F,

or

the

flue

gas

flow

rate

may

otherwise

be

calculated

from

the

stack

flow

rate,

corrected

for

the

difference

in

gas

temperatures.

Sections

225.210(b)

and

(d)

require

that

the

owners

or

operators

of

EGUs

subject

to

the

mercury

rule

comply

with

the

monitoring,

recordkeeping,

and

reporting

requirements

of

Sections

225.240

through

225.290.

Section

225.233(c)(5)

sets

forth

additional

—11—

Electronic Filing - Received, Clerk's Office, January 9, 2009

monitoring,

recordkeeping,

and

reporting

requirements

applicable

to

EGUs

that

have

opted

in

to

the

MPS.

Although

DMG

believes

that it

would

not

be

subject

to

these

monitoring,

recordkeeping,

and

reporting

requirements

if

it

were

granted

relief

from

the

underlying

substantive

requirements,

nevertheless,

DMG

is

seeking

relief

from

these

monitoring,

recordkeeping,

and

reporting

requirements

to

ensure

that

there

are

no

questions

in

this

regard.

17.

In

accordance

with

the

MPS,

DMG

must

begin

injecting

halogenated

activated

carbon

at

(i)

four

of

its

coal-fired

units

on

July

1,

2009

(Baldwin

Units

1-3,

Wood

River

Unit

5),

and

(ii)

five

of

its

units on

December

31,

2009

(Havana

Unit 6,

Hennepin

Units

1

and

2,

Vermilion

Units

1

and 2).’°

DMG

has

obtained

construction

permits

to

install

sorbent

injection

equipment

at

these

nine

units.

These

nine

units

represent

approximately

97%

of

DMG’s

installed

coal-fired

capacity.

18.

At

the

minimum

sorbent

injection

rate

specified

in

the

MPS,

DMG

estimates

it

would

need

to

inject

approximately

20

million

pounds

of

sorbent

during

each

12-month

period.

At

the

MPS’

minimum

injection

rate,

over

the

period

July

1,

2009,

through

December31,

20l4,

DMG

would

inject

more

than

115

million

pounds

of

sorbent

system-wide.

With

vendor

bids

for

halogenated

activated

carbon

plus

delivery

currently

in

excess

of

$1

per pound,

the

injection

of

sorbent

will

represent

a

significant

operating

expense

for

DMG’s

MPS

units.

At

the

minimum

injection

rate of

the

MPS,

DM0

estimates

that

sorbent

injection

at

Baldwin

Unit

3

alone,

from

July

1,

2009,

through

10

As

required

by

the

Consent

Decree,

DM0

has

already

installed

and is

operating

a

fabric

filter

system

with

sorbent

injection

at

its

Vermilion

Power

Station.

Wood

River

Unit

4

is

not

required

to

begin

injecting

sorbent

until

January

1,

2013.

-12-

Electronic Filing - Received, Clerk's Office, January 9, 2009

March

31,

2010, would

amount

to

4 million

pounds

of

sorbent

at an approximate

cost of

$4

million.”

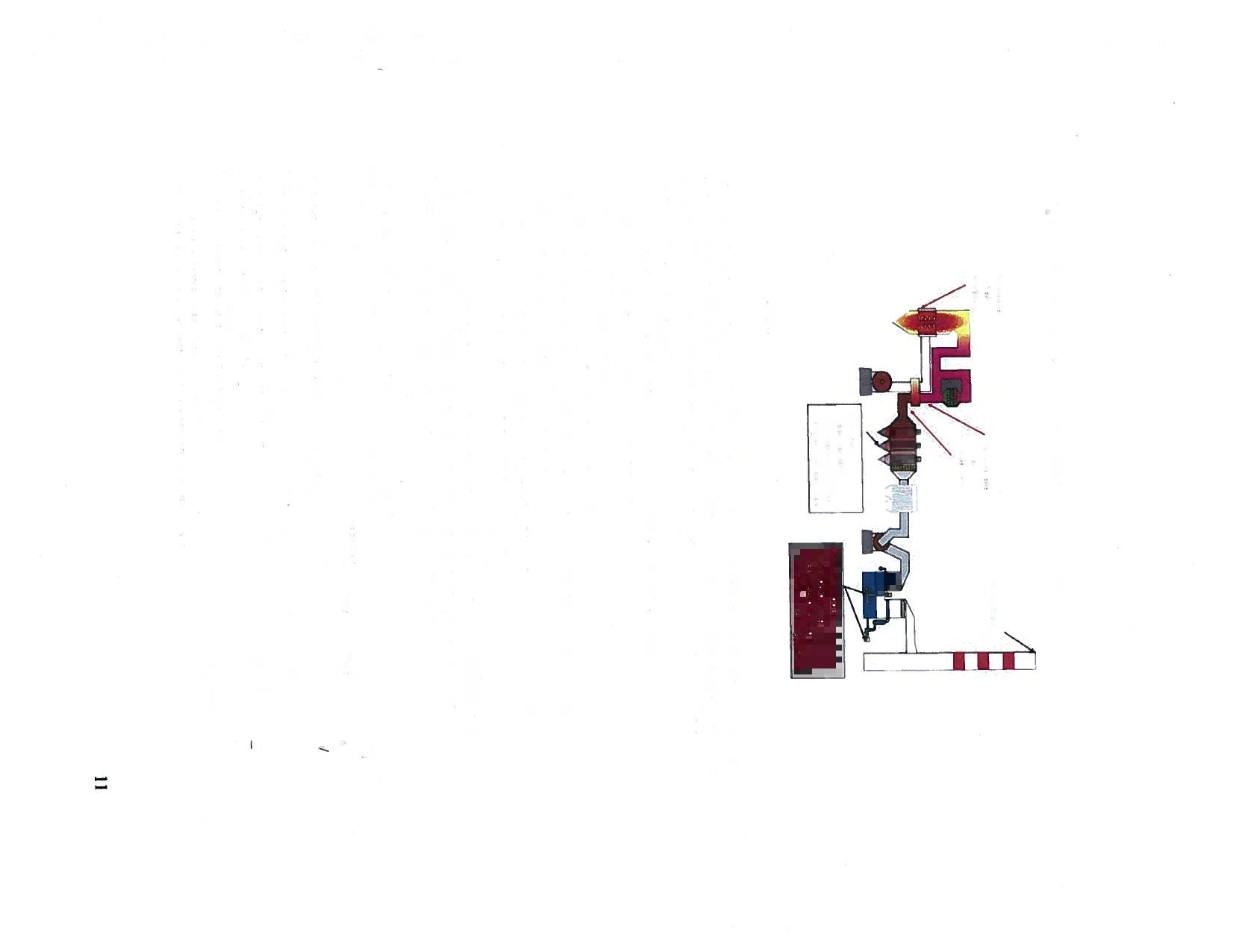

19.

Baldwin

Unit

3

emissions

are currently

controlled

by

a

cold-side

ESP,

which

includes

SO3

injection.

If

subject

to the MPS

mercury requirements

beginning

July 1,

2009,

DM0 would

be

required to

install

a sorbent

injection

system

upstream

of

the

cold-side

ESP in

order

for the

mercury/halogenated

activated

carbon

residue

to be

removed

from

the

flue

gas

prior

to

being

emitted.

In

its scheduled

spring

2010 outage,

Baldwin

Unit

3

will

be

retrofitted

with a

dry

scrubber

and

a

new

fabric

filter

system to

meet

emission

reduction

requirements

under

the Illinois

CAIR

and

the

Consent

Decree.

As

a

result,

when

Baldwin Unit

3

resumes

operation

in 2010 after

the

spring

outage,

it

will

be

re-configured

with

a

sorbent

injection

system

located

downstream

of

the ESP

and

upstream of

the

fabric

filter

system.

This configuration

will

allow DM0

to

collect fly

ash

in the

ESP

prior

to

the injection

of

activated

carbon

into the

flue gas stream,

with

the

activated

carbon

residue

removed

in

the

fabric

filter system

and

subsequently

disposed.

20.

The

installation

of sorbent injection

lances

in the ductwork

upstream

of the

ESP

on

Baldwin

Unit

3 in

order

to

meet the

MPS mercury

requirements

beginning

July

1,

2009,

would

require

a multi-day

unit

outage

and

result

in the loss

of

operating

revenue

(i.e.,

this

unplanned

outage

would not

be required

if the injection

equipment

was

installed

as

part of

the

spring

2010 fabric

filter

retrofit

outage).

DMG

estimates

that

it

will cost

approximately

$100,000

to

install

the injection

equipment

upstream

of the

ESP;

re

locating it

after

nine months

to

a

location

downstream

of

the ESP would

increase

these

Notably,

in the

economic

analysis

to

support

its mercury

rule,

the

Agency

estimated the

cost

of

halogenated

activated

carbon

at only

80

cents per

pound.

R06-25,

Tr.

at 81

(June

22, 2006).

-13-

Electronic Filing - Received, Clerk's Office, January 9, 2009

installation

costs

accordingly.

Injection

into

the

flue

gas

stream

upstream

of

an

ESP

provides

an

opportunity

for

mercury

removal

only

while

the

sorbent

is

suspended

in

the

flue

gas

stream.

In

contrast,

injection

upstream

of

a

fabric

filter

system

provides

opportunity

for

mercury

removal

while

the

activated

carbon

is

suspended

in

the

flue

gas

stream

and

even

greater

mercury

removal

when

the

sorbent

is

located

on

the

surface

of

the

bags.

The

increased

contact

between

the

flue

gas

and

mercury

particles

increases

the

mercury

removal

efficiency.

21.

An

evaluation

of

DMG’s

fleet

has

revealed

a

viable

alternative

to

the

installation

and

operation

of

a

sorbent

injection

system

on

Baldwin

Unit

3

prior

to

the

installation

of

the

fabric

filter

system

in

spring

2010.

Rather

than

wasting

resources

at

Baldwin

Unit

3

by

installing

a

sorbent

injection

system

upstream

of

the

cold-side

ESP

in

order

to

meet

the

July

1,

2009,

MPS

sorbent

injection

deadline,

only

to

have

to

remove

it

within

nine

months,

DMG

proposes

an

alternative

that

will

result

in

a

net

environmental

benefit.

22.

Specifically,

instead

of

injecting

sorbent

beginning

July

1,

2009,

at

Baldwin

Unit

3,

DMG

proposes

to

inject

sorbent

at

Havana

Unit

6

and

Hennepin

Unit

2

six

months

before

the

MPS

deadline

applicable

to

these

units.

The

overall

mercury

reductions

to

be

achieved

by

Havana

Unit

6

and

Hennepin

Unit

2

will

be

largely

contemporaneous

with

the

time

period

sorbent

would

have

been

injected

into

Baldwin

Unit

3.

In

addition,

the

proposed

variance

will

result

in

collateral

environmental

benefits

with

regard

to

fly

ash

re-use

and

carbon

dioxide

(“C0

2

”)

emission

reductions.

23.

Havana

Unit 6

and

Hennepin

Unit

2

will be

retrofitted

with

fabric

filter

particulate

collection

systems

and

sorbent

injection

systems

by

July

1,

2009.

These

two

-14-

Electronic Filing - Received, Clerk's Office, January 9, 2009

fabric

filter

and

sorbent

injection

systems

will

remove at

least

as

much

mercury

as

sorbent

injection

upstream

of

the

ESP

at

Baldwin Unit

3

and

are

likely

to

remove

more

mercury

emissions than

the

cold-side

ESP

on

Baldwin Unit

3,

which

includes

SO

3

injection

to

aid

in

particulate

collection.

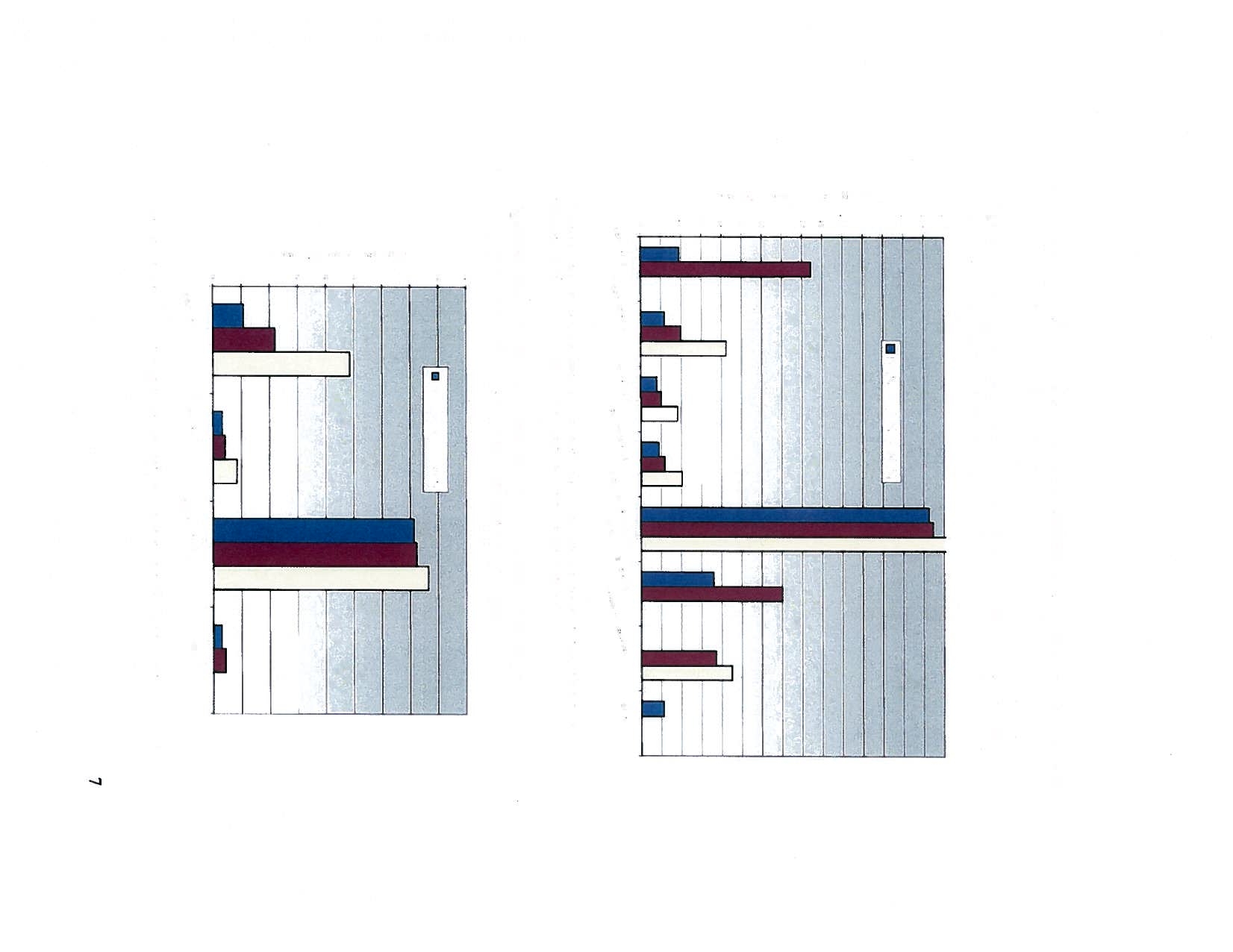

See

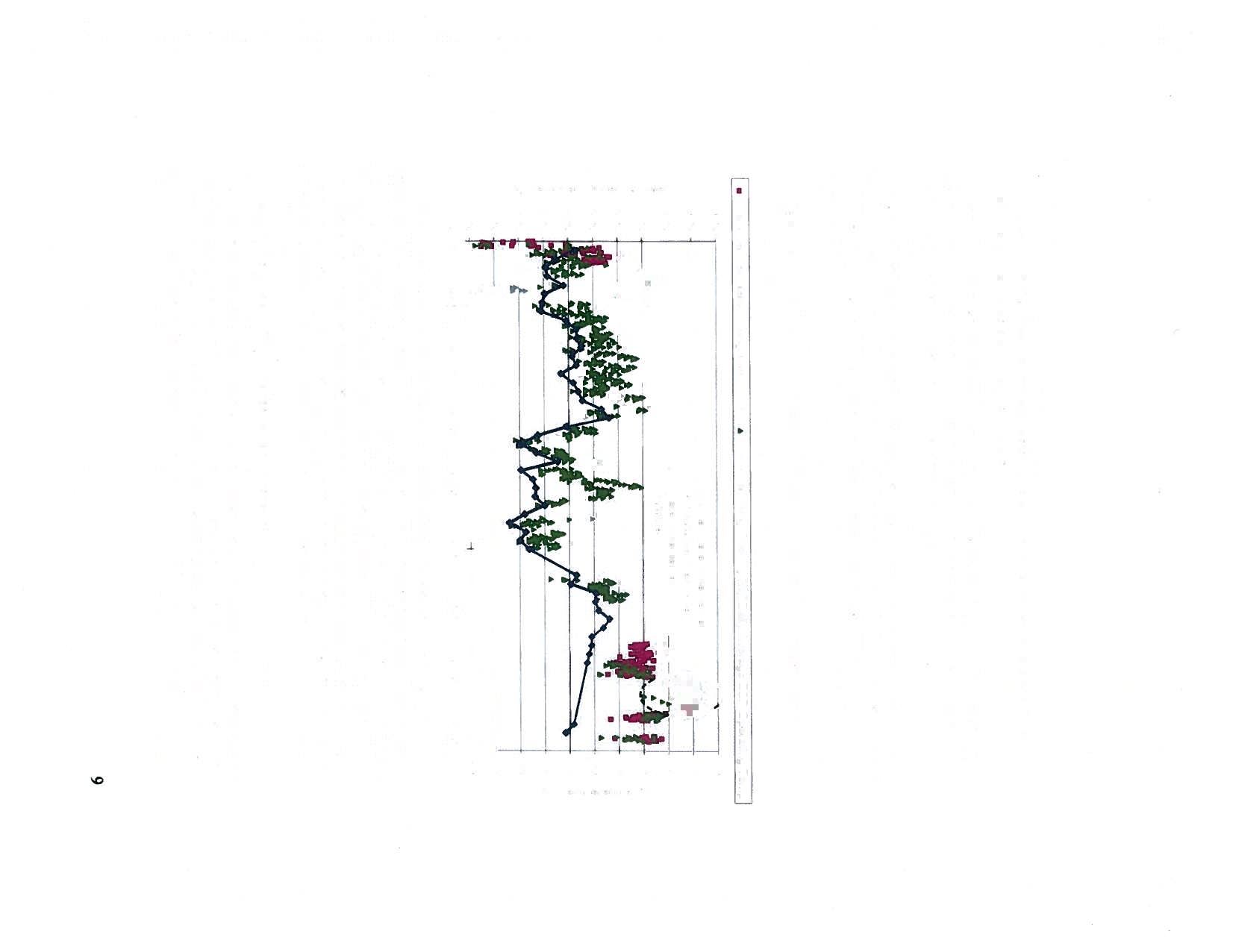

Ex.

4.

In addition,

even

at lower

injection

rates,

fabric

filter

systems

are

more

effective

at

removing

mercury

than

ESP-controlled

units

with

SO

3

injection,

which

somewhat

inhibits

mercury

removal.

See

Exs.

5

and

4.

The

net

effect

of

injecting

sorbent

upstream

of

the

Havana

Unit

6

and

Hennepin

Unit

2

fabric

filter

systems

will

be

much

more

cost-effective

mercury

removal.

Moreover,

the

combined

generating

capability

of

Havana

Unit

6

and

Hennepin

Unit

2

is

greater

than

that

of

Baldwin

Unit

3

(L e.,

645

MW

net

(aggregate)

for

Havana

Unit

6

and

Hennepin

Unit

2

compared

to

600

MW

net

for

Baldwin

Unit

3).

Therefore,

the

fabric

filter/sorbent

injection

systems

at

Havana

Unit

6

and

Hennepin

Unit

2

could

generate

even

more

mercury

reductions

than

the

cold-side

ESP

plus

sorbent

injection

system

at

Baldwin

Unit

3

alone.

DMG

estimates

that

mercury

reductions

at

Havana

Unit

6

and

Hennepin

Unit

2

from

July

1,

2009,

through

December

31,

2009,

would

aggregate

up

to

19

pounds

more

mercury

reduction

than

would

have

been

achieved at

Baldwin

Unit

3

from

July

1,

2009,

through

commencement

of

the

spring

2010

planned

outage.

See

Ex.

6.

Additionally,

relying

on

Havana

Unit

6

and

Hennepin

Unit

2, rather

than Baldwin

Unit

3,

for

mercury

reductions

would

avoid

the

need

for

an

unplanned

forced

outage

in

early

2009

and

the

cost

of

relocating

the

injection

system

on

Baldwin

Unit

3.

Under

the

proposed

alternative

of

commencing

sorbent

injection

at

Havana

Unit

6

and

Hennepin

Unit

2 on

July

1,

2009,

these

units

could

inject

about

2.5

million

fewer

pounds

of

sorbent

than at

Baldwin

Unit

3

from

July

1,

2009,

through March

31,

2010.

-15-

Electronic Filing - Received, Clerk's Office, January 9, 2009

24.

To

ensure

the

generation

of

mercury

emission

reductions

at

Havana

Unit

6

and

Hennepin

Unit

2,

DMG

would

begin

injecting

halogenated

activated

carbon

at

Havana

Unit

6

and

Hennepin

Unit

2

six

months

before

the

MPS

deadline

(on

July

1,

2009,

instead

of

December

31,

2009)

applicable

to

those

units.

DM0

would

inject

sorbent

at

Havana

Unit

6 and

Hennepin

Unit

2

at

a

rate of

5

lbs/macf

unless

or

until

DMG

informs

the

Agency

that

these

units,

individually

or

averaged

together,

achieve

mercury

reductions

of

90%

(or

comply

with the

mercury

emission

rate of

0.0080

lb/GWhr)

as

determined

by

a stack

test

performed

in

accordance

with proposed

Sections

225

.239(d)(4)

and

(5),

(e),

and

(0(1),

assuming

those

sections

adopted

are

substantially

the

same

as

proposed.

25.

Because

DM0

is

still

evaluating,

installing,

and

testing

its

mercury

control

systems,

it

is

unable

at

this

time

to

determine

exactly

how

much mercury

will

be

controlled

at

Havana

Unit 6

and

Hennepin

Unit

2.

Likewise,

DM0

is

uncertain as

to

the

precise

amount

of

mercury

that

will

be

emitted

by

Baldwin

Unit 3.

However,

on

the

basis

of

historic

operating

data

in

conjunction

with

load

forecasts

and

best engineering

judgment

concerning

the

early

operation

of

DMG’s

mercury

removal

equipment

at

Havana

Unit

6

and

Hennepin

Unit

2,

DM0

estimates

that

Havana

Unit

6

and

Hennepin

Unit

2,

in

aggregate,

will

reduce

mercury

by

up

to

19

pounds

more

than would

be

reduced

from

Baldwin

Unit

3

during

the

timeframes

covered

by

this

Petition.

See

Ex.

6.

26.

Importantly,

DM0

does

seek

changes

to

any

other

requirements

of

the

MPS.

DM0

remains

committed

to

the

previously

agreed-to

SO

2

and

NOx

reductions

reflected

in

the

MPS

rule

and

does

not

seek

a

change

to

the

requirement

that

it

install

SO

2

or

NOx

controls

on

its

coal-fired

E0Us by

any

of

the

deadlines

established

by

the

MPS.

-16-

Electronic Filing - Received, Clerk's Office, January 9, 2009

DM0

also

does

not

seek

relief

from

the

rate

at

which

sorbent

is

required

to

be

injected

at

any

other

of

its

plants

affected

by

the

MPS

rule,

including

the

requirement

that

it

inject

sorbent

at

a

rate

of

5

lbs/macf

at

Havana

Unit

6

and

Hennepin

Unit

2

beginning

December

31,

2009,

even

though

DMG

believes

the

mercuiy

removal

efficiency

at

those

two

units

will

achieve

the

mercury

removal

efficiency

anticipated

by

the

MPS.

The

only

relief

that

DMG

seeks

is

from

the

requirement

that

it

inject

sorbent

at

Baldwin

Unit

3

beginning

July

1,

2009.

27.

During

the

next

several

months,

DM0

will

continue

to

evaluate

the

best

combination

of

capital

equipment

and

operating

costs

to

comply

with

applicable

MPS

requirements.

It

will

proceed

with

the

appropriate

procurement

process

to

construct

and

install

the

equipment

and

secure

appropriate

quantities

of

sorbent

necessary

for

it

to

meet

the

remainder

of

the

MPS

requirements.

28.

DMG

has

met

with

the

Agency

to

discuss

its

requested

variance.

As

a

result

of

these

discussions,

DMG

understands

that

the

Agency

agrees

that

there

is

potentially

a

net

environmental

benefit

that

would

result

from

the

Board

granting

this

variance

and,

at

the

worst,

no

environmental

harm.

DMG

further

understands

that

the

Agency

does

not

oppose

this

variance

as

proposed,

though

it

may

not

actively

support

it.

D.

THE

VARIANCE

WILL

RESULT

IN

A

NET

ENVIRONMENTAL

BENEFIT

BECAUSE

MERCURY

EMISSION

REDUCTIONS

AT

HAVANA

UNIT

6

AND

HENNEPIN

UNIT

2

WILL

BE

GREATER

THAN

WOULD

HAVE

BEEN

ACHIEVED

BY

BALDWIN

UNIT

3.

29.

A

net

environmental

benefit

will

result

from

the

requested

relief.

During

the

requested

variance

period,

DM0

will

have

fabric

filter

controls

systems

online

at

Havana

Unit

6

and

Hennepin

Unit

2

that

will

reduce

mercury

emissions

in

an

amount

that

is

more

than

Baldwin

Unit

3

would

reduce

with

its

ESP

and

SO

3

injection.

17-

Electronic Filing - Received, Clerk's Office, January 9, 2009

30.

While

DM0

does

not

have

data

that

addresses

the

qualitative

and

quantitative

impact

of

its

mercury

emissions

on

human

health

and

the

environment,

USEPA

has

found

that

emissions

from

the

coal-fired

electric

power

generation

sector

as

a

whole

tend

to

affect

a

large

region

of

the

country

with

relatively

minimal

impacts

in

the

immediate

vicinity

of

an

individual

plant.

70

Fed.Reg.

25162,

25245-49

(May

12,

2005).

Consistent

with

that

finding,

mercury

emissions

from

the

affected

DM0

power

plants

contribute

to

themix

of

regional

pollutants

that

are

transported

on

weather

patterns

and

impact

areas

hundreds

of

miles

downwind.

In

fact,

the

purpose

of

the

vacated

CAMR

was

to

address

this

regional

impact

by

capping

regional

mercury

emissions.

In

other

words,

the

reductions

in

mercury

from

a

single

EGU

generally

have

little

measurable

effect

in

local

downwind

areas.

Moreover,

because

DM0

will

contemporaneously

offset

the

effect

of

this

variance

with

mercury

reductions

from

Havana

Unit

6

and

Hennepin

Unit

2,

the

difference

in

the

downwind

impact

may

not

even

be

measurable,

though

any

downwind

impact

should

be

lessened

because

of

the

greater

aggregate

mercury

removal

that

will

occur

from

Havana

Unit

6

and

Hennepin

Unit

2.

31.

Adverse

cross-media

impacts

are

not

an

issue

in

this

matter.

The

variance

that

DM0

seeks

does

not

impact

its

SO

2

or

NOx

reduction

obligations

under

the

MPS

or

otherwise

affect

its

SO

2

or

NOx

emissions.

Since

overall

mercury

emissions

will

decrease

or

remain

the

same

during

the

pendency

of

the

variance,

there

will

be

no

significant

impact

on

water

quality.

32.

In

addition

to

an

overall

reduction

in

mercury

emissions,

there

are

other

environmental

benefits

associated

with

granting

the

requested

variance.

Specifically,

the

requested

variance

would

avoid

wasting

the

fly

ash

from

Baldwin

Unit

3,

which

is

likely

-18-

Electronic Filing - Received, Clerk's Office, January 9, 2009

to

occur

when

contaminated

with

halogenated

activated

carbon

residue.

The

majority

of

fly

ash

from

Baldwin

Unit 3

is

currently

re-used

as

an

additive

in

the

production

of

concrete.

Injection

of

sorbent

upstream

of

the

Baldwin

Unit

3

ESP, as

would

be

required

by

the

MPS

before

Baldwin

Unit

3’s

spring

2010

outage,

will

likely

force

all

of

this

coal

combustion

by-product

to

be

disposed

rather

than beneficially

reused.

Without

the

relief

requested

by

this

variance,

the

fly

ash

contamination

would

occur

from

July

1,

2009,

until

the

start

of

the

Baldwin

Unit

3

planned

outage

when

it

will be

retrofitted

with

a dry

scrubber

and

fabric

filter

system.

The

quantity

of

fly

ash

at

risk

from

July

1,

2009

through

the

scheduled

start

of

the

Baldwin

Unit

3

outage

in

March

2010

is

over

55,000

tons.

When

Baldwin

Unit

3

resumes

operation

in

2010,

it

will

be

configured

with

sorbent

injection

downstream

of

the

ESP

and

upstream

of

the

fabric

filter

system.

This

configuration

will

allow

DM0

to

collect

fly

ash

in

the

ESP

prior to

the

injection

of

sorbent

into

the

flue

gas

stream,

with

the

halogenated

activated

carbon

residue

removed

in

the

fabric

filter

system

and

disposed.

33.

Another

potential

benefit

of

DM0’

s

variance

will

be

a

reduction

in

the

production

of

CO

2

emissions.

By

injecting

sorbent

into

fabric

filter

systems

at

Havana

Unit 6

and

Hennepin

Unit

2,

DM0

expects

to

remove

as

much

or

even

more

mercury

(than

injection

at

Baldwin

Unit

3)

while

using

substantially

less

sorbent.

According

to

Praxair,

it

typically

takes

the

combustion

of

five

pounds

of

coal

to

produce

one

pound

of

activated

carbon

(i.e.,

20%

yield).

Therefore,

a

reduction

in

sorbent

demand

will produce

a

corresponding

reduction

in

indirect

CO

2

emissions.

For

example,

avoiding

the

production

of

2

million

pounds

of

sorbent

avoids

the

release

of

over

17

million

pounds

of

Co

2

.

-19-

Electronic Filing - Received, Clerk's Office, January 9, 2009

E.

DMG’S

SUGGESTED

CONDITIONS

FOR

THE

VARIANCE

AND

COMPLIANCE

PLAN.

34.

Dynegy

requests

that

the

term

of

the

variance

for

Baldwin

Unit

3

begin

on

July

1,

2009,

and

terminate

March

31,

2010.

35.

DMG

proposes

that

the

following

conditions

apply

to

this

variance:

A.

Prior

to

and

during

the

term

of

the

variance,

Baldwin

Unit

3

shall

be

not

subject

to

the

requirements

of

Section

225.233(c)(1

)(A),

Section

225.233(c)(2),

Sections

225.210(b)

and (d),

and

Section

225.23

3(c)(5).

B.

Beginning

December

31,

2009,

Havana

Unit

6

and

Hennepin

Unit

2

shall

comply

with

all

applicable

MPS

requirements,

as

otherwise

required.

C.

Likewise,

upon

restarting

operations

following

its

spring

2010

outage,

Baldwin

Unit

3

shall

comply

with

all

applicable

MPS

requirements.

36.

The

compliance

plan

shall

include

the

following

provisions:

A.

From

July

1,

2009,

through

December

30,

2009,

Havana

Unit

6

and

Hennepin

Unit

2

shall

inject

sorbent

at

a

minimum

rate

of

5

lbs/macf

at

each

of

those

units

until

or

unless

DMG

informs

the

Agency

that

these

two

units,

either

individually

or

averaged

together,

will

achieve

mercury

reductions

of

90%

or

will

meet

the

emission

rate

of

0.0080

lb/GWhr.

Unless

expressly

stated,

such

notification

shall

not

commit

the

units

to

achieve

a

90%

reduction

or

achieve

a

rate

of

0.0080

lb/GWhr

after

December

30,

2009.

If

DMG

chooses

to

comply

with

this

variance

by

achieving

a

90%

reduction

in

mercury

emissions

at

Havana

Unit

6

or

Hennepin

Unit

2,

the

mercury

removal

rate

shall

be

determined

by

performing

a

single

stack

test

on

the

applicable

unit

or

units

in

accordance

with

proposed

Section

225.239(d)(4)

and

(5),

(e),

and

(f)(1),

assuming

those

sections

as

adopted

in

the

Board’s

Docket

R09-

10

are

substantively

the

same

as

proposed.

B.

Only

sorbents

listed

in

or

manufactured

by

the

companies

listed

in

Section

225.233(c)(2)(B)

or

demonstrated

as

effective

as

the

listed

sorbents

as

allowed

by

Section

225.233(c)(4)

may

be

injected

unless

or

until

DM0

informs

the

Agency

that

these

two

units,

either

individually

or

averaged

together,

will

achieve

mercury

reductions

of

90%

or

will

meet

the

emission

rate

of

0.0080

lb/GWhr.

C.

If

DMG

elects

to

comply

withthis

variance

pursuant

to

the

90%

removal

or

0.0080

lb/GWhr

option

under

Paragraph

36(A),

above,

-20-

Electronic Filing - Received, Clerk's Office, January 9, 2009

through

December

30,

2009,

Havana

Unit

6

and

Hennepin

Unit

2

shall

inject

sorbent

at

a

rate

no

less

than

the

rate

injected

during

mercury

removal

performance

tests

to

achieve

an

emission

rate

of

0.0080

lb/GWhr

or

90%

removal.

For

example,

if

during

stack

testing,

DMG

demonstrated

a

90%

removal

injecting

sorbent

at

a

rate

of

2

lb/macf,

then

DM0

would

continue,

throughout

the

rest

of

the

variance

period,

to

inject

at

the

minimum

two-pound

rate

rather

than

at

a

five-pound

rate.

D.

For

Havana

Unit

6

and

Hennepin

Unit

2,

DM0

shall

maintain

records

of

the

sorbent

injection

rate

and

flue

gas

flow

rate

from

July

1,

2009,

through

December

30,