12/18/2888

11:16

3175698451

TERRA

GROUP

PAGE

02/15

-r

--

11550

N.

MERIDIAN

STREETS

SUITE

180

CPJriEL

INDIANA

46032

PH

317.660.6868

Fx

317.569.0451

Mate

ti

15, LLC

CEVED

CLERK’S

OFFICE

cem

17,2008

DEC

.1

8

2008

Royal

Coulter,

President

STATE

OFIWNOIS

Peoria

Disposal

Company

oUutjon

Control

Board

4700

North

Sterling

Avenue

Peoria,

Illinois

61615-3652

RE:

NOTICE

OF

EXCLUSIVE

LICENSE

United

States Patents

6,191,068

and

6,313,368

Dear

Mr.

Conker:

Terra

Materials,

LLC

has

recently

become

aware

of

your

company’s

interest

in

using

a

magnesium

sulfite/magnesium

scrubber

residue

(MSR)

in

conjunction

with

your proposed

“delisting

permit”

now

pending

before

the

Illinois

Environmental

Protection

Agency

(Case

No.

AS 2008-010

-

In

the

Matter

of

RCRA

Delisting

Adjusted

Standard

Petition

of

Peoria

Disposal

Company).

Terra

Materials,

LLC

is

not fully

familiar

with your

company’s

proposed

treatment

regime,

but

has

reviewed

sworn

testimony

presented

on

your

company’s

behalf

at

the August

18, 2008

hearing

before

the

Illinois

Pollution

Control

Board.

Specifically, begimtirig

on

page

33

of

the

testimony, Dr.

Ajit

Chowdbury

described

the

proposed

treatment

to

be

used

by

Peoria

Disposal

as:

“The new

chemical

treatment

regimen PDC

utilized

for

the

trials

incorporated

addition

of

reagents

involving

sulfur

oxy-anion

compounds

of

alkaline-earth

metals

along

with

agents

for

p11

control

which

included

calcined

and

uncalcined

lime.

As

necessary,

the

pH

control

agents

which

may

be

used

include

various

phosphate

and iron

compounds.

The

additive

mix ratio

and

dosage

were

controlled

to

provide

a

robust

chemistry

such

that

the

potential

for leaching

of

heavy

metals

of

concern

are

minimized

under

various

natural

and

induced

leaching

scenarios.

During

this

treatment,

the heavy

metals

are

stabilized

through

a

series

of

complex

precipitation

and

adsorption-coprecipitation

reactions

in

a

pH

regime

of

very

low

solubility

of

the

metals,

The

material

after

stabilization

is

characterized

by low

potential

for

leaching

of

heavy

metals

as

indicated

by

the

TCLP

(U.S.

EPA

Toxicity

Characteristic

Leaching

Procedure)

which

is

TCLP,

analysis

with

using

different

8

extraction

fluids

like

acidic,

neutral

and a

pH

11.0

solution

and

also

the

corresponding

MEP

tests

which

is

a

multiple extraction

procedure

of

U.S.EPA”

After

discussing

this

matter

with

our supplier

of

MSR and

reviewing

the

public

record

of

your

proposed

de1istin

permit,

we

concluded

we

should

advise

you

that

Terra

Materials,

LLC

is

the

exclusive

licensee

of:

12/18/2008

11:16

3175690451

TERRA

GROUP

PAGE

03/15

-r

11550

N.

MERIDIAN

STREET

SurE

180’

CARMEL-

INDIANA

46O32

PH

31

7.66O86B’

Fx

317.569.0451

Mfeii

Is,

LL(

United

States

Patent

6,191,068

relating

to

compositions

comprising

magnesium

sulfite,

triple

super

phosphate,

and

at

least

one

of

limestone

and

hydroboracite,

methods

for

the

treatment

of

heavy

metal-containing

matrices,

methods

for

controlling

the

pH

of

matrices,

and

methods

for

removing

acid

gases

from

solid,

semi-solid,

liquid

or

gaseous

matrices;

and,

United

States

Patent

6,313,368

relating

to

methods

of

stabilizing

heavy

metal-

containing

matrices

comprising

mixing

with

such

matrices

an

effective

amount

of

sulfonated

calcium

aluminum

magnesium

phosphate

to

render

such

matrices

inert,

methods

of

stabilizing

heavy

metal-containing

matrices

comprising

mixing

with

such

matrices

an

effective

amount

of

magnesium

sulfite

to

render

such

matrices

inert,

and

methods

of

stabilizing

heavy

metal-containing

matrices

comprising

mixing

with

such

matrices

an

effective

amount

of

hydroboracite

to

render

such

matrices

inert.

Copies

of

the

referenced

patents

are

attached

for

your

convenience.

In

addition

to

these

exclusive

licenses,

Terra

Materials,

LLC

has

also

filed

patent

applications

for

methods

for

the

stabilization

and/or

fixation

of

leachable

metals

on

its

own

behalf.

These

patent

applications

describe

the

use

of

magnesium-based

scrubber

byproducts

and

calcium-based

products

and

byproducts

either

individually

or

in

various

combinations

for

the

stabilization

and/or

fixation

of

heavy

metal-containing

matrices,

other

contaminants

arid

chemicals

matrices.

Terra

Materials,

LLC

desires

to

maximize

the

use

of

the

inventions

disclosed

and

protected

by

these

patents

and

applications

though

sale

and

use

of

products

incorporating

these

technologies,

as

well

as

through

sub-licensing,

sales

agreements,

and

other

arrangements

with

others.

It

is

in

this

spirit

that

we

are

notifying

you

and

others

of

these

matters.

We

look

forward

to

working

with

your

company

to

achieve

this

goal.

Please

contact

us

so

we

can

amicably

reach

a

mutually

profitable

agreement.

Sincerely,

TERRA

MATERiALS,

LLC

.

Thomas

P.

McCullough

Managing

Partner

cc:

Steve

Thomas,

Headwaters

Resources,

Inc.

Tom

JYAnnunzio,

Exelon

Supply

Management

Dr.

Ajit

Chowdbury,

Trishul

Technologics,

LLC

Clerk’s

Office,

Illinois

Pollution

Control

Board

Enclosures:

US

Patent

Nos.

6,191,068

and

6,313,368

12/18/2008

11:16

31

756’30451

TERRA

GROUP

PAGE

04/15

inn

iiinurnan

US006313368B1

(12)

United

States

Patent

Rhat

(10)

Patent

No.:

(45)

Date

of

Patent

US

6,313,368

111

*Nov.

6,

2001

(54)

METHOD

AND

COMPOSITIONS

FOR

STABilIZATION

OF

HEAVY

METALS,

ACID

GAS

REMOVAL

AND

PH

CONTROL

IN

CONTAMINATED

MATRiCES

(75)

Inventor:

Vasantlx

K.

flat,

9

Be]saw

P1.,

Cincinnati,

OH

(US)

45220

Assignee:

Vasantb

K-

flat

Subject

to

any

disclaimer,

the

term

of

this

patent

is

extended

or

adjusted

under

35

USt.

154(b)

byo

days.

This

patent

is

subject

to

a

terminal

dis

claimer.

(21)

App!.

No.:

09/404,531

(22)

Filed:

Related

US.

Application

Data

(60)

Continuation

of

application

No.

08/96

1,823,

flIed

on

Oct.

31,

1997,

now

Pat.

No-

5,985,778,

which

is

a

division

of

application

No-

08/790,700,

filed

on

ian.

29,

1997,

now

Pat.

No.

5,719,099

Provisional

application

No.

60/028,935,

filed

on

Oct.

22,

1.996.

Jjt.

CL

7

-.

4.621)

3’OO

US.

Cl

588/231;

588/236;

588/252

Field

of

Search

502/3,

14,

414,

5021415,

521;

423/424.1;

501/48;

588/231,

236,

252,

257,

901

(56)

Refetences

Cited

U.S.

PATENT

DOCUMENTS

53

08

2052

a

7/1978

(3

-

OTHER

PUBLICATIONS

Etzel

.1

.E

Industrial

Pretreatment

Technologies

for

Heavy

Metal

Removal

and

Treatment

of

Heavy

Metal

Sludge

to

Render

Them

Non

hazardous,

Virginia

Water

Pollution

Control

Assn,

Nov.

31,

j9$,x

Teriogo,

Ill

Magnesium

Hydroxide

Reduces

Sludge

Improves

Filtering

Pollution

Engineering,

Apr.

1987’

Tallman,

P-N.,

Pablroan,

hi,

and

Kbalafalla

Reclaiming

Heavy

Metals

Prom

Waste

Water

Using

Magnesium

Oxide

US

Dept

of

Interior,

Bureau

of

Mines

Report

of

Investiga

tion

9023,

1986,

cited

by

examiner

Enmaty

Examiner—Steven

P.

Griffin

Asslrtant

&aminer—Eileen

E.

Nave

(57)

ABSTRACT

A

one-step

method

and

compositions

for

stabii.zatioo

of

heavy

metals,

acid

gas

removal

and

pH

control

in

hazardous

and

toxic

solid,

semi-solid,

liquid

and/or

gaseous

matrices

using

a

mixture

of

reactive

agents

in

a

single

product,

for

the

broader

purpose

of

enhancing

environmental

pollution

control,

prevention

and

remediatiun

are

described.

The

product

contains

sulfottated

calcium

aluminum

magnesium

phosphate.

This

material

may

be

used

alone

or

in

combina

tion

with

magnesium

sulfIte

and/or

hydroboracite.

3

ClaIms,

No

Drawings

(-73)

(

j

Notice:

4,950,409

—

8/1990

5,039,499

*

8/1991

5,087,375

•

2/1992

5,156,746

10/1992

5,162,600

11/1992

5,202,083

4/1993

5,220,111

6)1993

3,368,741

11/1994

5,389,233

•

2/1995

5,397,478

3/1995

5,422,015

•

6/1995

5,439,656

8/1995

5,491,281

2/1996

5,637,355

‘

6/1997

5,700,107

•

12/1997

5,719,099

“

2/1998

5,860,908

1/1999

5,935,778

-

11/1999

5,986,161

11/1999

Sanfogth

210/751

Stowe,

it

423/242

Weinwunn

210/688

Maree

at

al

210/712

Cody

et

a)

588/236

Sanfoeth

et

al

210/747

Rued

et

al

Munday

at

at

210/724

Seen

208/120

Pal

at

a)

2101710

Angell

ci

at.

—

2101151

Johnson

at

al

423/243.07

Rhat

588/207

$snforth

ci

al

..

c88i236

Newton

588/231

Rhat

5021444

Forreater

588,256

l3hat

0z’4S

Akae

itt

at

588,231

Sep.

24,

1999

FOREIGN

PAFENT

DOCUMENTS

(60)

(51)

(57)

(58)

4,108,596

•

8/1978

4,132,558

1/1919

4.354,942

10/1982

4,356,036

10/1982

4,388,283

-

G/1983

4,465,597

‘

8/1984

4,474,595

-

10/1984

4,515,696

5/1985

4,652,381

3/1987

4,671,882

•

6/1987

4,737,356

“

4/1988

4,764,284

8/1988

4,889,640

‘

12/1989

4,919,787

4/1990

Hemming

at

a)

8/94.27

Uchilcawa

at

al

106/104

jØczun

et

at

2101712

Haiphin

et

al

75/21

Abrams

et

al

..

423/242

Herman

ci

at

2101713

Lawbon,

Jr

at

at

71/28

Matthew

at

at

210/713

laglis

210/713

Douglas

at

al

210/720

O’Hara

at

al

423/659

.Iansen

2201115

Sanforib

210/751

Chester

208/52

12/18/2@8

11:16

31756S0451

TERRA

GROUP

PAGE

05/15

US

6,313,368

Bi

I

MENOD

AND

COMPOSITIONS

FOR

STABILIZATION

OF

HEAVY

METALS,

ACID

GAS

REMOVAL

AND

PH

CONTROL

IN

CONTAMINATED

MATRICES

This

application

is

a

Continuation

of

applicatioti

Ser.

No.

08/961.823

fIled

on

Oct.

31,

1997,

now

U.S.

Pat.

No.

5,985.778

which

is

a

Divisional

of

application

Scr.

No.

08/790,700

filed

Jan.

29,1997,

now

U.S.

Pat,

Nø.

5,719,099.

This

application

cia.tms

priority

of

provisional

application

Serial

No

60/028,935

filed

Oct.

22,

1996.

TECHNICAL

FIELD

This

invention

relates

to

the

treatment

of

contaminated

materials..

SpecIcally,

it

relates

to

methods

and

composi

tions

for

rendering

inert

a

broad

spectrum

of

heavy

metals

that

may

be

present

in

hazardous

and/or

toxic

matrices,

such

as

fly

ash

and

alag

from

incinerators,

process

water

from

ftk

and

paint

manufacturing,

process

dust,

water

and

sludge

from

fertou

and

non-ferrous

foundnes,

electric

arc

furnace

dust,

for

erample,

from

steel

mills,

hazardous

waste,

toxic

WaSte,

soils,

sludges

and

sediments.

Heavy

metals

like

antimony,

arseruc,

barium,

beryllium,

cadmium,

chromium.

cobalt,

copper,

lead,

mercury,

molybdenum,

nickel,

selenium,

civar,

thallium,

vanadiwn

and

zinc

are

reduced

to

a

level

of

permanent

stability

meeting

the

glacial

acetic

acid

leathatc

criteria

set

forth

by

the

U.S.

EPA

In

the

‘Ibxicity

Characteristic

Leaching

Procedure

(TCLP)

and

the

water

leach

tests,

for

example,

California

or

Indiana

Water

Leach

Tests,

ejmulating

leaching

due

to

rain

as

ft

actually

occurs

in

the

environment.

The

invention

also

relates

to

industrial

processes

that

require

acid

gas

removal

from

the

contami

nated

matrix

and

p11

control

of

the

contaminated

matrix

BACIcCIROUND

OF

THE

INVENTION

When

biologically

available,

heavy

metals

leachIng

from

soil,

water

or

waste,

as

well

as

those

released

into

the

ai,

arc

detrimental

to

all

living

beings.

Permissible

levels

of

heavy

metal

pollutioo

are

regulated

by

the

local,

state

and

federal

authorities.

The

important

sets

of

federal

regulations

sic

the

Resource

Conscivation

and

Recovery

Act

(RCRA)

ad

the

Comprehensive

Envirnnmental

Re

ponse,

Compensation,

and

Liability

Act

(CERCLA),

which

governs

the

Suparfund

program.

One

of

the

er1jost

reiediatioO

methods,

the

removal

and

hauling

of

heavy

metal

contained

waste

and

soil

to

a.

land.ll,

while

still

iO

use,

is

more

frequently

being

viewed

by

the

public

as

unacceptable.

New

regulations

and

continued

desire

to

find

better

and/or

itlcxpcnsivn

environ

mental

pollution

control,

prevention

and

remediatlon

tech

ntques

have

driven

potential

hazardous

and/or

toxic

waste

generators

toward

new

technologies.

Encapsulation

of

heavy

metal-containing

waste

in

portland

cement,

for

example,

though

weeling

the

letter

of

the

environmental

law,

does

not

meet

the

spirit

of

the

law

when

the

encapsulated

waste

is

exposed

to

rain.

Under

those

circumstances,

heavy

metals

go

ifltO

solution

and

become

biologically

available.

Pennauest

stahili7,anon

by

forotirig

geocttemically

stable

compounds

of

heavy

metsl.s

is

by

far

the

best

solution

to

this

challenge.

Certain

industrial

processes

may

also

release

acid

gases

which

need

to

be

removed.

Often

pH

control

of

the

con

taminated

matrix

is

also

required.

Numerous

methods,

mostly

multi-step

and

sequential

step,

have

been

utilized

to

prevent

the

leaching

of

hazardous

heavy

metals

in

solid,

semi-solid,

liquid

and/or

gascous

complex

matrices

so

that

(flu

waste

is

rendered

suitable

for

disposal

10

a

satary

land6.ll.

There

has,

however,

been

no

2

suggestion

to

use

sulfonated

calcium

alui.num

magnesium

phosphates,

byd.roboracite

or

serubber

magnesium

product

(magnesium

sulfite)

for

the

plupose

of

providing

heavy

metal

stabilization,

together

with

the

additional

benefits

of

5

acid

gas

removal

and

pH

control,

to

contaminated

or

treated

matrices

in

a

one-step

metbod

or

singlc-prodcuzt

composi

tion.

U.S.

Pat.

No.

4,671,882,

Douglas

et

a!.,

issued

June,

1987,

discloses

a

multi-step

process

for

heavy

metal

stabi

ligation.

Douglas

does

not

prefer

to

use

limestone

because

he

in

believes

that

the

use

of

limestone

results

in

the

production

of

carbon

diozide

gas

when

added

to

acid

solutiu

and

such

gas

would

adversely

affect

the

pH

increasing

step

essential

to

his

multi-step

heavy

metal

stabilization

process.

Both

U.S.

Pat.

Nos.

4,889,640

and

5,037,479,

Stanforth,

suggest

that

lime

is

stone

is

not

effective

in

the

disclosed

heavy

metal

stabili

zation

processes

because

it

is

a

non-reactive

form

of

calcium

and/or

magnesium

carbonate.

The

above-mentioned

patents

do

not

suggest

any

products

Or

processes

for

acid

gas

removal.

20

SUMMARY

OF

THE

INVENTION

It

is.

the

primary

object

of

the

present

invention

to

provide

a

one-step

method

and

single-product

compositions

that

2

simultaneously

stabilize

heavy

metals,

remove

acid

gases

and

control

p11

in

contaminated

Solid,

semi-solid,

liquid

and/or

gaseous

complex

matrices,

It

is

a

further

object

of

the

present

invention

to

provide

a

new

method

tot

the

simultaneous

treatment

of

a

wide

variety

of

matrices

including

in-process

and

waste

materials

con

taminated

with

a

bread

range

of

heavy

metals

classified

by

the

U.S.

EPA

a

hazardous,

such

that

gcochernically

stable,

substantially

non-leaching

compounds

of

heavy

metals

arc

formed

aod

the

contaminated

matrices

are

rendered

inert.

is

It

is

another

object

of

the

present

invemion

to

provide

a

new

family

of

compositions

that

achieve

permanent

stability

of

leachable

heavy

metals

in

complex

matrices

exposed

to

actual

environmental

coDditiOs.

it

is

still

another

hject

of

the

present

Invention

to

provide

40

a

method

and

a

general

range

of

compositions

that

stabilize

more

heavy

metals

than

those

in

the

prior

art

using

ozle$tcp

treatment

and

using

a

single

product

which

may

contain

one

or

more

reactive

agents.

It

is

yet

another

objOct

of

the

present

invention

to

provide

a

method

and

compositions

that

are

more

cost-eective

than

those

of

the

prior

azt

is

stabilizing

heavy

metals

in

a

wide

variety

of

complex

matrices.

in

accordance

with

the

present

invention

there

is

provided

a

method

and

compositions

for

the

treatment

of

in-process

hazardous

materials

and

waste

materials

contaminated

with

hazardous

heavy

metals

to

tevels

of

local,

state

and

federal

regulatory

limits,

Simultarteously,

this

invention

provides

a

singly-step

method

and

single-product

compositions

for

heavy

metal

stabilization,

acid

gas

removal

and

pH

control

in

contaminated

complex

matrices.

Specifically,

th

present

inventioO

encompasses

a

com

position

for

the

treatment

of

heavy

metal-containing

matri

ces

comprising

an

effective

amount

of

sultonated

calcium

aluminum

magnesium

phosphate.

The

composition

may

optionally

include

magnesium

sulfite

and/or

bydroboracite.

The

invention

also

relates

to

a

method

for

maiming

a

composition

for

the

treatment

of

heavy

metal-containing

mariees

comprising

the

steps

of

mIxing

the

following

matetials

(a)

a

phosphate-containing

material

selected

from

the

group

consisting

of

phosphoric

acid,

rock

phosphate,

12/19/2008

11:16

3175690451

TERRA

GROUP

PAGE

06/15

05

6,313,368

81

3

apatitc,

triple

super

phospbate,

calcium

magnesium

monobydrogen

phosphate

dihydrate,

alkali

phosphate,

and

mixtures

(hereof;

(b)

an

aluminum-containing

material

selected

from

the

group

consisting

of

kaoliriite,

bauxite,

alumina

dihydrate,

bentonite,

zeolites,

and

mixtures

thereof;

and

(c)

an

alkaline

earth-containing

material

selected

from

the

group

consisting

of

dolomite,

dolime,

quicklime,

fly

ash,

limestone,

brucite,

niagnesite,

periclase,

dolomitic

limestone,

magnesia,

magnesium

hydroxide,

bydroboracitc,

colenianite,

and

mixtures

thereof;

and

sulfi,nating

the

product(s)

of

said

mixing

step.

DETAILED

DESCRIFUON

OF

THE

INVENTION

The

goals

set

fonb

above

are

accomplished

using

a

single

product

and

a

one-step

application

method,

as

opposed

to

using

scveral

diflrent

reagents

and

multi-step

or

sequential

application

method

to:

(1)

stabilize

a

broad

spectrum

of

heavy

metals

(Table

I)

listed

by

the

US.

EPA

as

hazardous;

(2)

control

acid

gases

found

in

complex

matrices,

includ

ing

industrial

processes

and

waste;

and

(3)

control

pH

of

the

contaminated

and

treated

matrices.

This

invention

relates

to

compositions

and

methods

for

accomplishing

these

goals,

as

well

as

to

method

for

prepar

ing

those

compositions.

Table

I—U.S.

EPA

List

of

Hazardous

Heavy

Metals

Antimony,

Arsenic,

Barium,

Beryllium,

Cadmium,

Chromium,

Cobalt,

Copper,

Lead,

Mercury,

Molybdenuxn,

Nickel,

Selenium,

Silver,

Thallium,

Vanadium,

and

Zinc.

In

developing

the

heavy

metal

stabilizing

product

com

positions

of

this

invention,

economic

considerations

were

applied

to

the

following

technical

cnncegtual

basis:

Ingre

dients

that

form

salts

of

low

sohibility

with

the

heavy

metals

in

qutstiun

will

also

produce

permanently

stable,

pH

independent,

complex,

non-leaching

compounds

that

immo

bilize

the

heavy

metals

when

they

contain

glass

(non-

crystalline)

network

forming

catirins

(such

as

Si,

13,

F’,

Ge

and

mixtures

thereot)

arid

glass

(non-crystalline)

network

forming

anions

(such

as

0,5,

Se,

Te

and

mixtures

thereof).

In

conjunction

with

ingredients

containing

the

glass

(non-

crystalline)

network

forming

ions,

those

containing

network

dwellers

(such

as

Al,

Mg,

Ga

and

mixtures

thereof)

and

network

modifiers

(such

as

Ca,

Mg

and

mixtures

thereof)

arc

also

found

to

help

in

stabilizing

heavy

metals

contained

in

contaminated

matrices.

It

is

not

necessary

that

glass

actually

be

formed

as

a

reault

of

the

reaction

between

heavy

metals

and

the

heavy

metal

stabilizer,

but

rather

that

the

ingredients

used

to

prepare

the

heavy

metal

stabilizers

be

capable

of

forming

glass.

It

is

important

that

salts

of

low

solubi.lity

are

formed

as

a

result

of

the

reaction

between

these

ions

and

the

heavy

metals.

Thus,

the

technical

concept

of

this

invention

advances

two

essential

conditions

kit

the

production

of

permanently

stable,

pH

independent,

complex,

non-leaching

compounds

to

that

immobilize

the

heavy

metals:

(1)

in

selecting

the

ingredients

for

heavy

metal

stabilizing

product

compositions,

it

is

important

that

they

are

capable

of

form

ing

glass

(that

is,

they

contain

glass

network

forming,

network

dwelling

or

network

modif’ing

ions),

and

(2)

that

65

salts

of

low

solubility

be

formed

as

a

result

of

the

reaction

between

these

ions

and

the

heavy

metals

in

question.

4

Sulfouated

Calcium

Aluminum

Magnesium

Phosphate

(SCAMP)

is

a

product

composition

that

fits

the

technical

concept

by

itself,

as

well

as

in

conjunction

with

other

ingredients.

SCAMP

can

be

described

by

the

general

for

S

mula

.

(C

15

Hz,(C

6

HJSO

3

Na)

(Ca

3

AI

Mg

3

(P0j

5

9H

2

0),

wherein

s-il,

It

can

also

be

described

as

a

sulfonated

phosphate

or

a

sulfonated

mixture

of

phosphates,

with

ingredienLs

containing

calcium,

aluminum

and

magnesium

ions.

The

sulfonate

in

this

case

is

sodium

dodecylbenzene

in

sulfooate.

‘Ibe

presence

of

SCAJYIP

can

be

detected

directly

by

the

combination

of

powder

x-ray

diraction

technique

for

calcium

aluminum

magnesium

phosphate

and

wet

chemical

analysis

for

the

sulfonate.

SCAMP

prepared

according

to

the

present

application

is

an

effective

stabilizer

for

a

broad

15

spectrum

of

heavy

metals.

In

water,

the

sulfonate

behaves

tote

soap

in

forming

micelles,

but

has

an

advantage

over

soap

in

not

forming

precipitates

with

calcium

ions.

Additiousily,

the

sulfonate

being

a

surfactant,

reduces

the

surface

tension

of

the

par-

20

tides

coated

with

it,

accelerates

reactions

between

acidic

and

basic

ingredients

in

a

given

mixture

to

form

complex

salts,

prevents

caking,

and

improves

fiowability

of

the

product.

The

sul.fnnate

also

promotes

the

formation

of

heavy

metal

complex

salts

of

very

low

solubility

by

facilitating

the

25

sequestering

and

6,xing

of

heavy

metal

leachates

from

a

contaminated

matrix.

These

practically

iosohd,le

complex

salts

confirm

pH

independent

and

permanent

hxing

of

leachates

in

a

landfill.

Sulfonates

useful

in

the

present

invention

include

any

salt

of

the

reaction

product

oIsulfnnic

in

acid

and

hydrocarbons,

such

as

long

chain

alkylbenrene

suifonates,

with

sodium

dodecybenzene

sulfonate

being

preferred.

SCAMP

can

be

prepared

in

a

number

of

ways.

As

an

example,

to

produce

one

mole

of

SCAMP,

combine

1

Va

moles

of

dolomitic

limestone

or

3

moles

of

dolnmitic

lime;

wIth

½

mole

of

either

kaolinite,

bauxite

or

alumina

trihy

drate;

react

the

same

with

5

moles

of

phosphoric

acid

and

treat

the

reaction

prodtzct

with

less

than

one

mole

of

the

sulfonate.

As

another

example,

to

produce

one

mole

of

SCAMP,

combine

and

react

1

¼

moles

of

dolomitin

lime

stone

or

3

moles

of

dolomitic

lime;

with

½

mole

of

either

kaolinite,

bauxite

or

alumina

tmihydrate;

and

with

2

½

moles

of

either

triple

super

phosphate

or

rock

phosphate,

along

with

an

apprnpriate

amount

of

water,

if

needed,

sad

less

than

one

mole

of

the

sujfonate,

The

solid

raw

materials

are

ground

or

pulverized

to

fine

powder

to

provide

high

surface

area

for

the

required

reaction(s)

to

take

place.

Tt

is

some

times

helpful

to

add

heat

to

the

reaction,

although

frequently

the

increased

temperatures

caused

by

grinding

and

the

heat

Lu

of

reaction

between

ingredients

are

sufficient

to

provide

the

desired

end

product.

In

general,

a

SCAMP-containing

single

product

compo

sition

for

the

treatment

of

heavy

metal-containing

matrices

ç

may

be

prepared

by

combining,

mixing

and

reacting

the

following

materials:

(a)

a

phosphate-containing

material

selected

from

the

group

consisting

of

phosphoric

acid,

rook

phosphate,

apat.ite,

triple

super

phosphate,

calcium

magnesium

monohydrogen

phosphate

dihydrate,

alkali

phosphate,

and

mixtures

thereof

(preferably

phosphoric

acid,

rock

phosphate

or

triple

super

phosphate,

and

most

prefer

ably

rock

phosphate);

(b)

an

alurui.aumn-contstnlng

material

selected

from

the

group

consisting

of

kaolinjte,

bauxite,

alumina

tritiydrate,

bentonite,

zeolites,

and

mixtures

thereof

(preferably

bauxite

or

kaolinite);

and

12/18/200B

11:16

31756S0451

TERRA

GROUP

PAGE

07/15

US

6,313,368

Bi

5

(c)

an

alkaline

earth-containing

material

selected

from

the

group

consisting

of

ciolomitic

limestone

(doLomite),

dolomitic

lime

(doliine),

quicklime,

fly

ash,

limcstoOe,

brucite,

magrissite,

periclase,

magnesia,

magnesium

hydroxide,

hydroboracite,

eplemanite,

and

mixtutes

S

thereof

(preferably

dolomitic

limestone,

d&imIic

lime

or

hydroboracite,

and

most

preferably

dolomitic

lime.ctciie);

and

sulfonating

the

product(s)

of

said

combining,mixing

and

reacting

steps.

10

The

proportions

of

the

mdividual

reactions

listed

above

may

be

varied

depending

on

the

properties

required

for

the

ual

product.

For

example,

for

optimal

heavy

metal

stabilization,

the

amount

of

mnaterixi(e)

from

group

(a)

above

in

ptoportion

to

groups(b)

and

(c)

should

be

about

3:3.

For

s

optimal

acid

gas

control,

the

ratio

should

be

about

6:1:12,

For

optimal

pU

control

of

the

contaminated

and

treated

matrices,

the

ratio

should

be

about

6:1:3.

SCAMP

is

an

essential

active

agent

w

the

product

composition

of

the

invention

that

assures

in

a

single

step,

simultaneous

and

eflctive

stabilization

of

at

lea.t

8

of

the

17

heavy

metals

listed

in

Table

I

(see

Table

U

below),

as

well

as

acid

gas

and

pH

control.

Materials

from

groups

(a),

(I,)

or

(c)

used

in

excess

of

that

required

atoichiomctdca]ly

fr

the

fomn1atou

of

SCAl4P

are

essentially

for

fine

tuning

the

heavy

metal

25

stabilization,

acid

gas

control

or

pH

control

characteristics

of

the

final

product.

or

example,

formulating

a

product

such

that

it

contains

excess

phosphate

material

provides

extra

henefii

in

terms

of

pH

control

ad

in

the

stabilization

of

heavy

metals

that

form

phosphates

of

tow

solubijity.

Excess

30

alumiiiuut-wntainiflg

material

helps

in

pH

control

ad

in

the

stabilization

of

heavy

metals

that

form

oxides

or

hydroxides

of

low

solubility,

while

excels

alkaline

earth-containing

material

helps

in

pH

control

and

acid

gas

control.

Stabilization

of

all

1?

heavy

metals

hated

as

hazardous

by

s

the

U.S.

EPA

can

be

accomplished

in

a

single-step,

along

with

acid

gas

and

p11

control,

using

a

product

composition

that

comprises

SCAMP

and

sulfur-containing

materIals

such

as

magnesium

suthte,

calcium

sulfite,

magnesium

sulfate,

sodium

metabisulfate,

calcium

magnesium

sulilte,

epsorn

40

salt,

gypsum,

and

mixtures

thereof.

Pteferred

sulfur-

containing

materials

include

magnesium

sulfate,

calcium

sulfate

and

calcium

magnesium

sulfite,

and

mixtures

thereof,

with

magnesIum

sulfite

being

most

preferred.

An

inexpen

sive

source

of

magnesium

sulfite

that

also

contains

minor

45

arncnifltll

of

magnesium

sulfate

is

Scrubber

Magnesium

6

Produat

(SMP).

This

material

is

a

by-product

of

scmbbiug

acid

gases,

like

sulfur

dioxide

and

oxides

of

nitrogen,

with

magnesium-containing

reagents,

such

as

magnesia,

magne

siutu

hydroxide,

calcium

magnesium

oxide

(dolime),

cal

cium

magnesium

borate

(hydroboracite),

and

calcium

mag

nesium

carbonate

(dolomite).

The

ue

of

sutfur-.conraioing

material

(for

example,

SMP)

alone,

stabilizes

iS

of

the

17

lw,.ivy

metals

fairly

well.

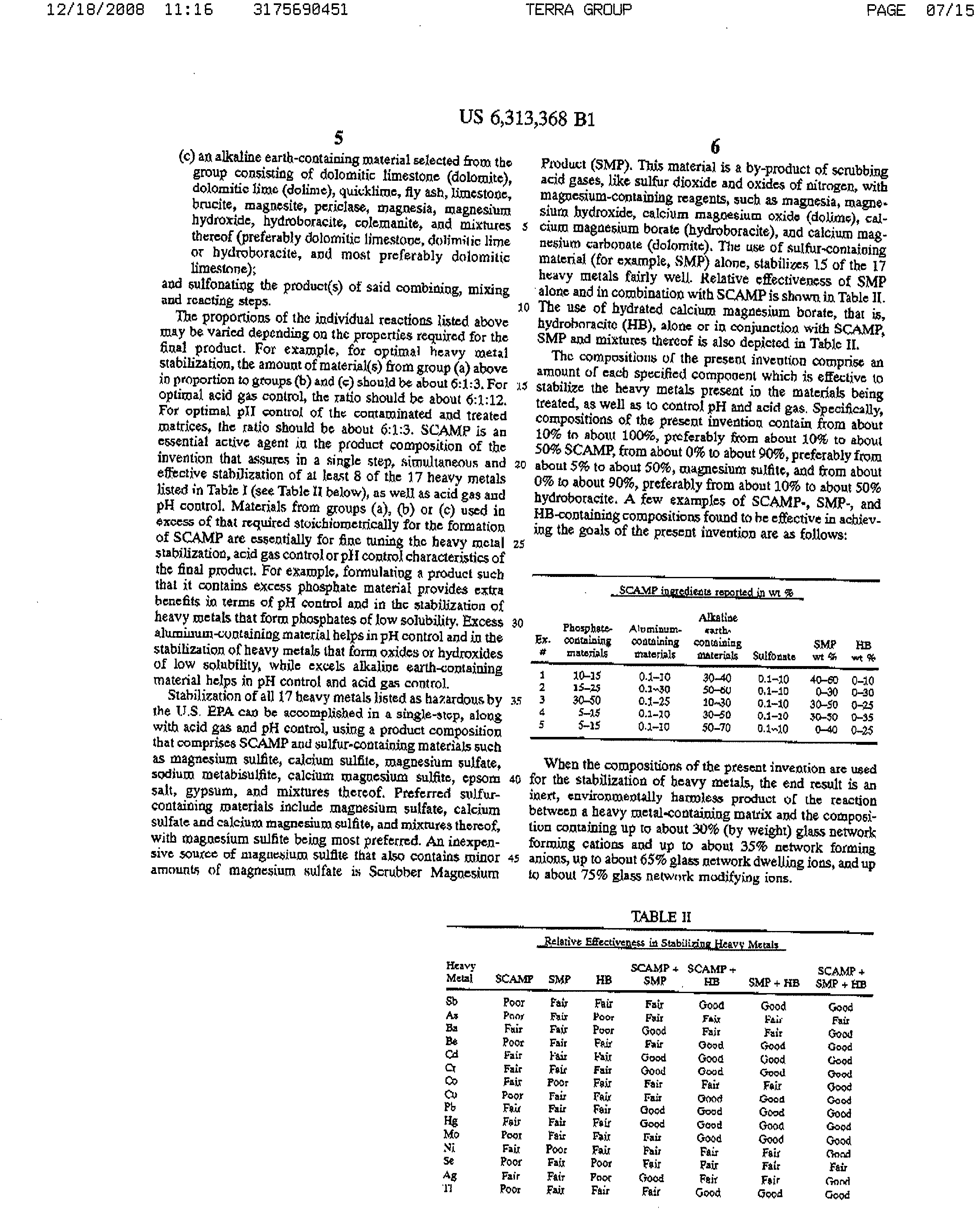

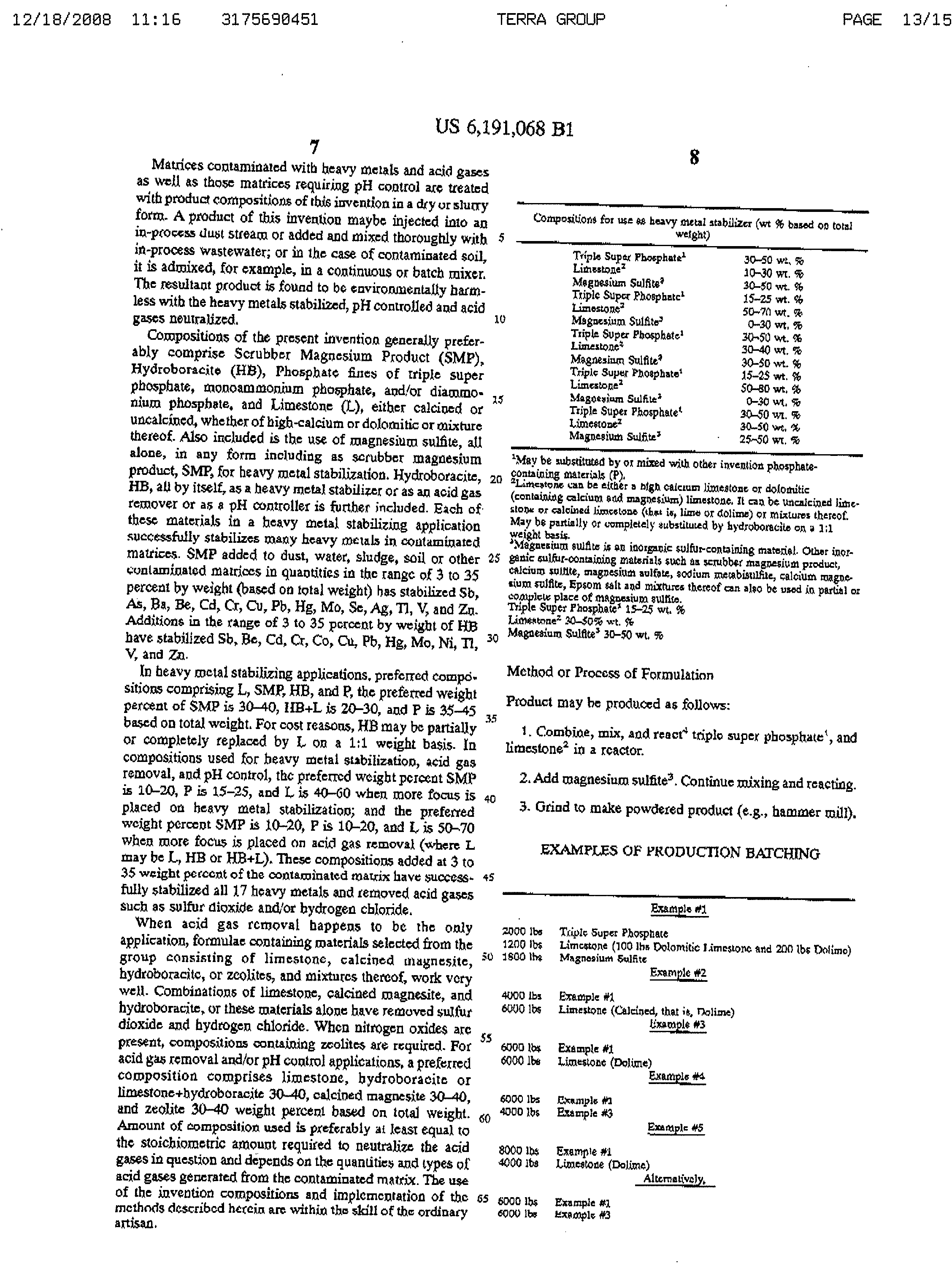

Relative

effectiveness

of

SMP

alone

and

in

combinatio

with

SCAMP

is

shown

in

Table

II.

The

use

of

hydrated

calcium

magnesium

borate,

that

is,

hydrobriracito

(HB),

alone

or

in

conjunction

with

SCAMP,

SMP

and

mixtures

thereof

is

also

depicted

in

Table

U.

The

coinpositkni

of

the

present

iflVeDtiOO

comprise

an

amount

of

each

specified

component

which

is

effective

to

stabilize

the

heavy

metals

present

in

the

materials

being

treated,

as

well

as

to

control

pH

and

acid

gas.

Specifically,

compositions

of

the

present

invention

contain

from

about

10%

to

aboi.tt

100%,

preferably

from

about

10%

to

about

50%

SCAMP

from

about

0%

to

about

p0%,

preferably

from

about

5%

to

about

50%,

criagnesium

sulfite,

and

&om

about

0%

to

about

90%,

preferably

from

about

10%

to

about

50%

hydrobozacite.

A

few

examples

of

SCAMP.,

SMP-,

and

HB-containing

compositions

found

to

he

effective

in

achiev

ing

the

goals

of

the

present

invention

are

as

foJlows

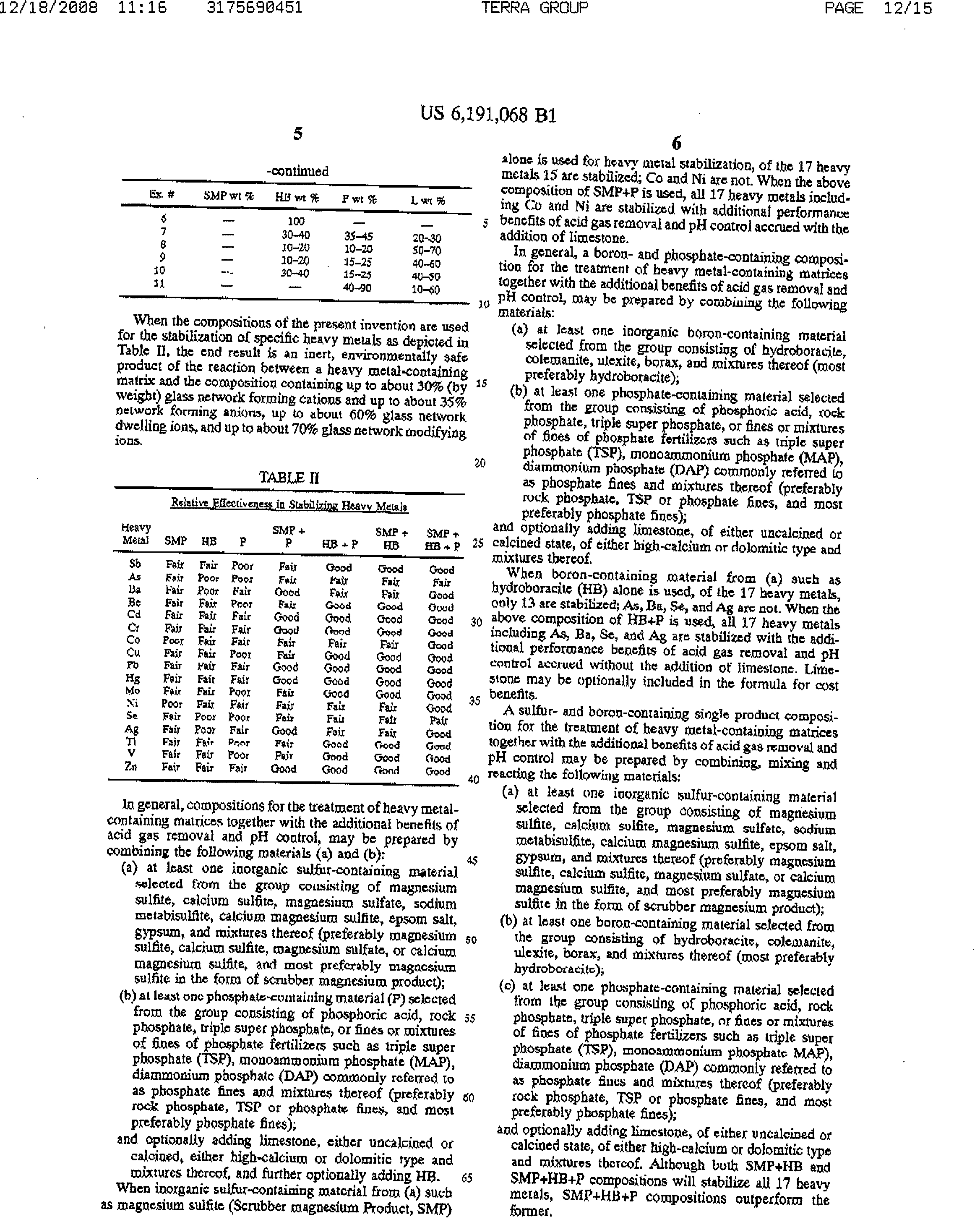

..

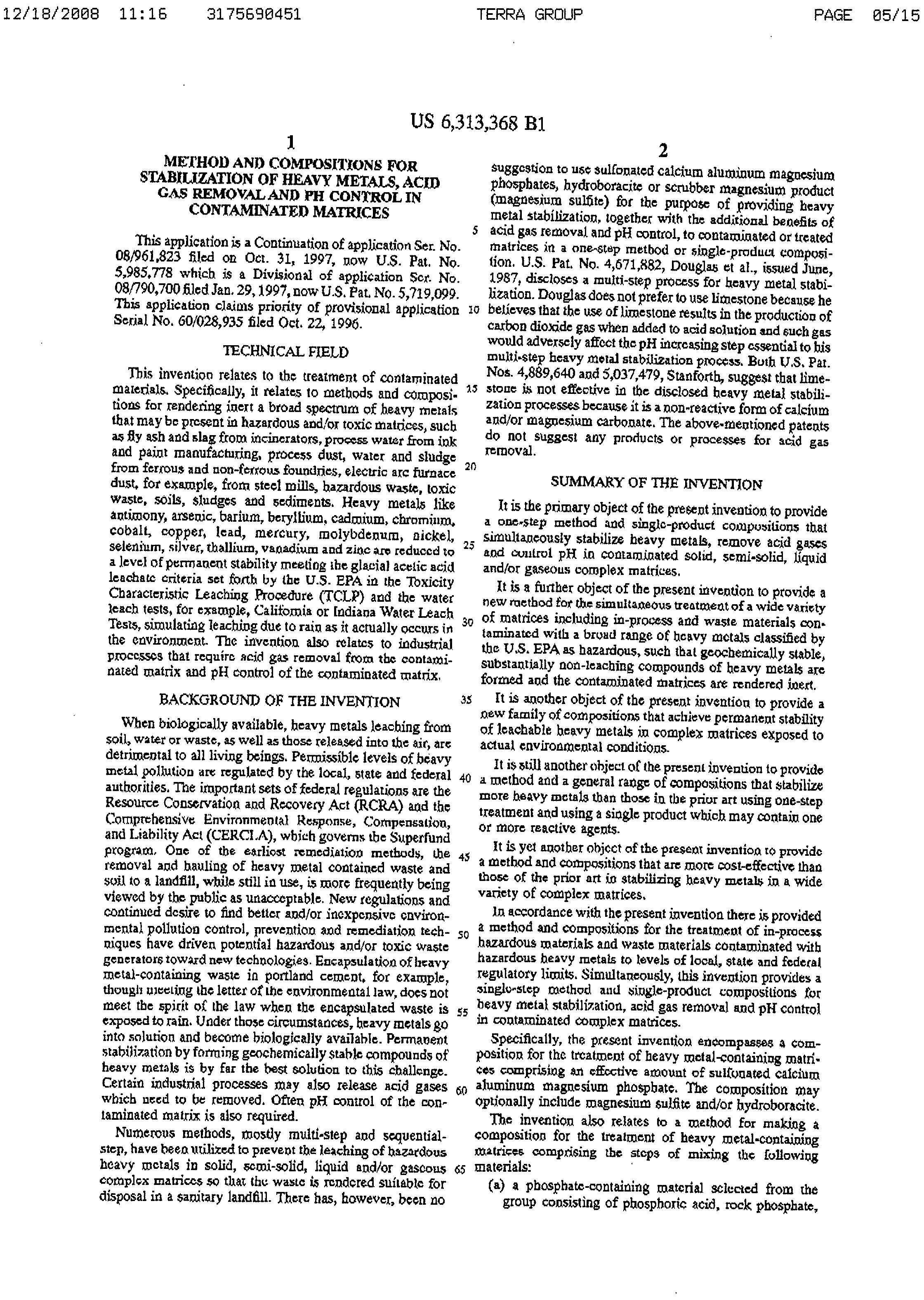

SCAMP

iraredieei*

oriadi

wt

%

A&EUOS

Phoaphata-

Alumiauni.

arrh’

P,r.

coataioi,nj

containing

containing

SMP

RS

#

aiatenalt

materj1a

lMnrlStS

Selfirnara

wt

,

“r

%

I

10—iS

04—20

30—40

0.1—10

40—

0—jo

2

25.45

0.—30

50—60

ol—lO

0—30

0—30

3

30-40

0.1—25

IO30

0.1—10

30—SO

0-.5

4

5.,5

0.—0

30—50

0.1—10

30-30

0—35

5

5—IS

0.1—10

50—70

0.1—10

0—40

0—25

When

the

compositions

of

the

present

inveOtiGn

arc

used

for

the

stabilization

of

heavy

metals,

the

end

result

is

an

lOert,

ciavironweol.ally

harmless

product

ot

the

reaction

between

a

heavy

metal-containing

matrix

and

the

composi

lion

containing

up

t

about

30%

(by

weight)

glass

network

forming

cations

and

up

to

about

35%

network

forming

anions,

up

to

about

65%

glass

network

dwelling

ions,

and

up

to

about

75%

glass

netwr,rk

modifying

ions.

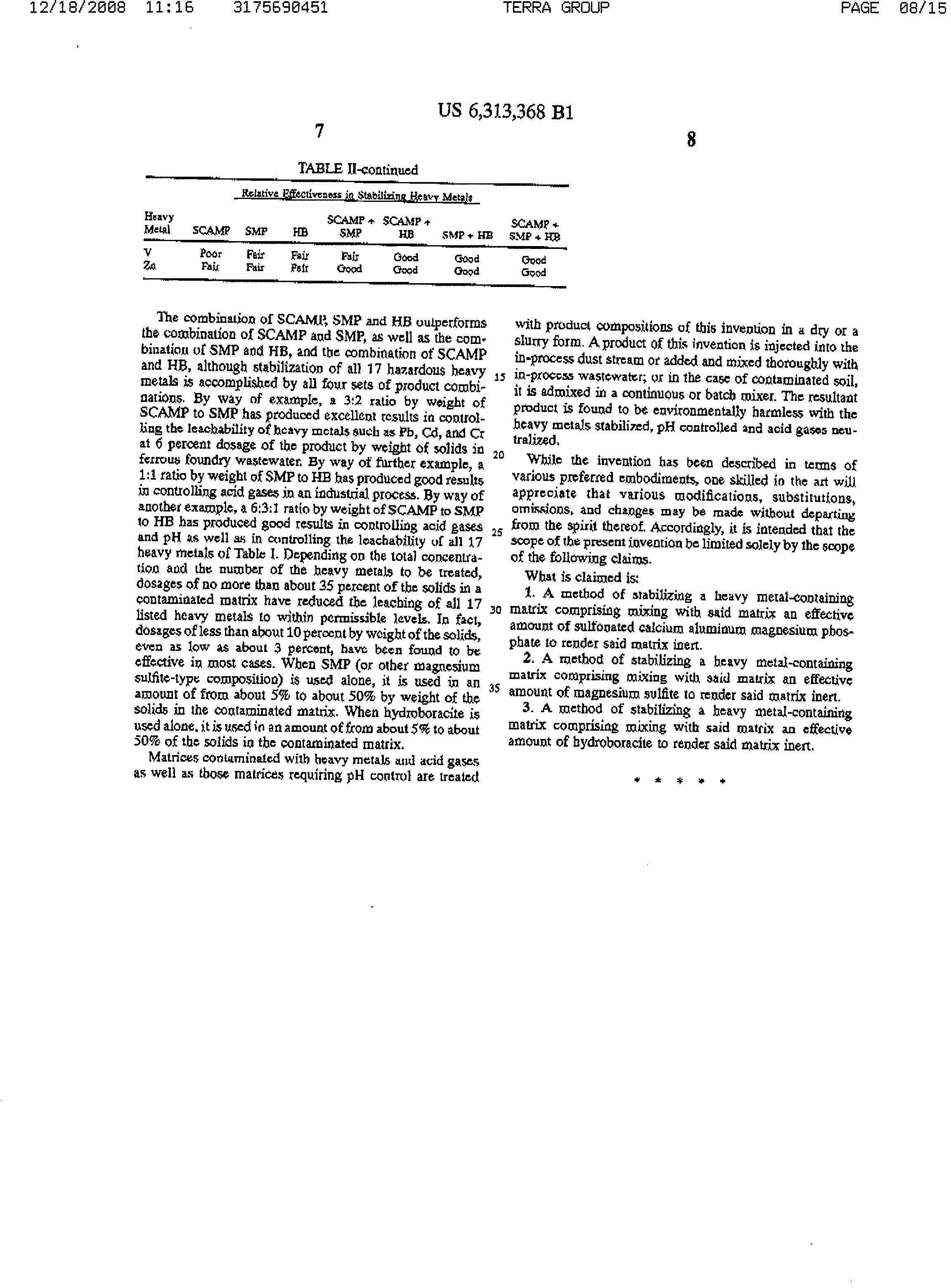

Good

FAg

Fair

GOod

Good

Good

Fair

GOod

Good

Good

Fair

Fair

Fair

Good

Good

Fair

Gc4

Good

Fair

Good

Good

Good

Fair

Fair

Fair

Good

Fair

Good

Goad

Good

Good

Good

Good

Good

Goød

Good

Fair

Good

t4BLE

II

RatarIve

eficttyentss

in

Stabili,es

Heavy

Mat

Heavy

SCA.MP

-

SCAMP

-t-

SCAMP

+

Metal

SCAMP

SMP

HB

SMP

H

SMP+HB

SMP+lB

Sb

Poor

Fair

Fair

Fair

Aa

Poor

Far

Poor

Fair

He

F

5

i

0

Fair

Poor

Good

Ba

Poor

Fair

Fair

Pair

Cd

Fair

irair

taix

Good

Cy

Fair

Fair

Fair

Good

Cd

Fair

Poor

Fair

Fair

C

Poor

Fair

Fair

Fair

Fl,

Fair

Fair

Fjr

Good

Hg

Fair

Fair

Fair

Gocd

Mo

Pot

Fair

Fair

Fair

Ni

Fair

Poor

Fats

Fair

Sr

Poor

Paix

Poor

Fair

Ag

Fair

Fair

Poor

Good

1]

Poor

Fats

Fair

Fair

12/18/2008

11:16

3175690451

TERRA

GROUP

PAGE

08/15

7

US

6,313,368

BI

8

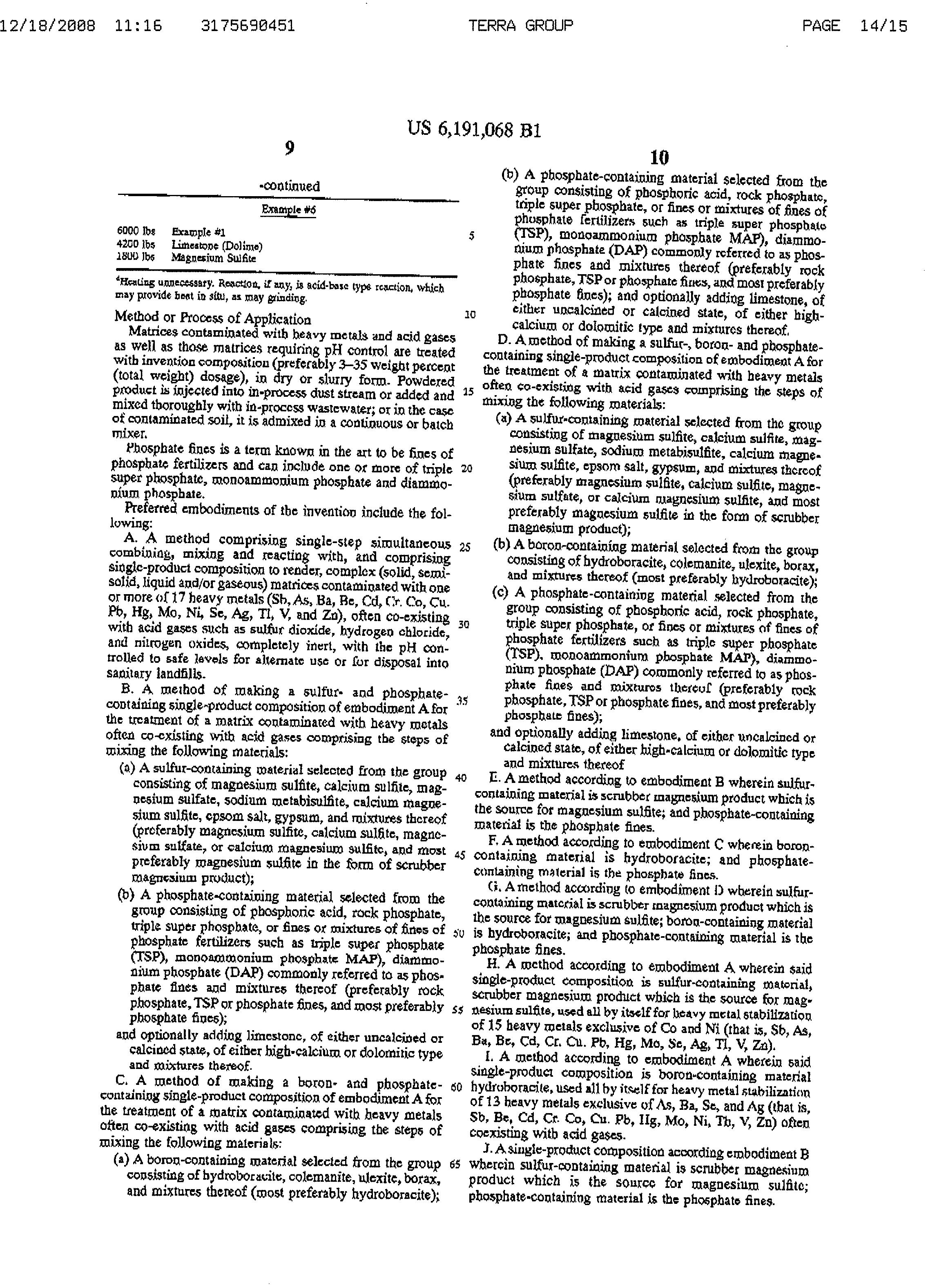

TABLE

Il-continued

S

ii

av’

Meta

B8avy

SCAMP

+

SCA).W

a

SCAMP

Metal

SCAMP

SMP

t{B

SMP

H

SMP

H

SMP

a

V

Poor

Fair

Fair

t’sfs

Oood

Oood

t3ood

-

Ze

l’air

Fair

Fair

Oood

Ovçd

Ood

C3cc4

The

combination

of

SCAMP,

SMP

and

HB

outperlbrtns

the

combination

of

SCAMP

aød

SMP,

as

well

as

the

corn

binaiieu

of

SMP

and

HB,

and

the

combrostion

of

SCAMP

and

lB,

although

stabilization

of

aT)

17

hazardous

heavy

metals

is

accomplished

by

all

føur

sets

of

product

combi

natiøns.

By

way

nf

example,

a

32

ratio

by

weight

of

SCAMP

to

SMP

has

produced

exceflent

results

in

control

hug

the

teachability

of

heavy

metals

such

as

Pb,

Cd,

and

Cr

at

6

percent

dosage

of

the

product

by

weight

of

solids

in

ferrous

foundry

wastewates

y

way

of

further

example,

a

11

ratio

by

weight

of

SMP

to

14B

has

produced

good

results

in

contzolling

acid

gases

in

an

industrial

process.

By

way

of

another

example,

a

6:3:1

ratio

by

weight

of

SCAMP

to

SMP

to

HB

has

produced

good

results

in

controlling

acid

gases

and

pH

as

well

ai

in

controlling

the

leachability

cf

all

17

heavy

metals

of

Table

I.

Depending

on

the

total

concentra

hoc

sod

the

number

of

the

heavy

metals

to

be

treated,

dosages

of

no

more

than

about

35

percent

of

the

solids

in

a

contaminated

matrix

have

reduced

the

leaching

of

all

17

listed

heavy

metals

to

wIthin

permissible

levels

I

fact,

dosages

of

less

than

about

10

percent

by

woight

of

the

solids,

even

as

low

as

about

3

percent,

have

been

found

to

be

effective

in

most

cases.

When

SMP

(or

other

magnesium

sulfite-type

composition)

is

used

alone,

it

is

used

in

an

amount

of

1mm

about

5%

to

about

50%

by

weight

of

the

sohds

in

the

cotrtaxninated

matrix.

When

bydroboracite

is

used

alone.

jt

is

treed

in

an

amount

of

from

about

$%

to

about

50%

of

the

solids

in

the

contamiatcd

matrix.

Matrices

contaminated

with

heavy

metals

and

acid

gases

as

well

as

those

matrices

requiring

pH

control

are

treated

with

product

compositions

of

this

invention

in

a

dty

or

a

slutry

form.

A

product

of

this

invention

is

injected

into

the

in-process

dust

stream

or

added

and

mixed

thoroughly

with

in-process

wastewater;

or

in

lbs

case

of

contaminated

soil,

it

is

admixed

in

a

continuous

or

batch

mixer.

The

resultant

product

is

found

t

be

environmentally

harmless

with

the

heavy

metals

stabilized,

pH

controlled

and

acid

gases

neu

iralized.

20

While

the

invention

has

been

described

in

terms

of

various

preferred

embodiments,

one

skilled

in

the

art

will

appzeciate

that

various

tnocliflcaiious,

substitutions,

onssiocs

and

changes

may

be

made

wfthout

departing

25

fron,

the

pirit

thereof.

Accordingly,

jt

is

intended

that

the

scope

of

the

present

invention

be

limited

solely

by

the

scope

of

the

folio-wing

claims.

What

is

claimed

is:

1.

A

method

of

stabilizing

a

heavy

metal-containing

x

matrix

comprising

mixing

with

said

matrix

an

effective

amount

of

sulfoated

calcium

aluminum

magnesium

phos

phate

to

render

saidmatrix

inert.

2.

A

method

of

stabilizing

a

heavy

metal-containing

matrix

compraaLrlg

mixing

with

said

matrix

an

effective

amount

of

magnesium

sulfite

to

render

said

matth

inert.

3.

A

method

of

stabilizing

a

heavy

metal-containing

matrix

comprising

mixing

with

said

matrix

an

effective

amount

of

bydroboracite

to

render

said

matrix

inert

a

*

*

a

a

12/18/28

11:16

3175690451

TERRA

GROUP

PAGE

09/15

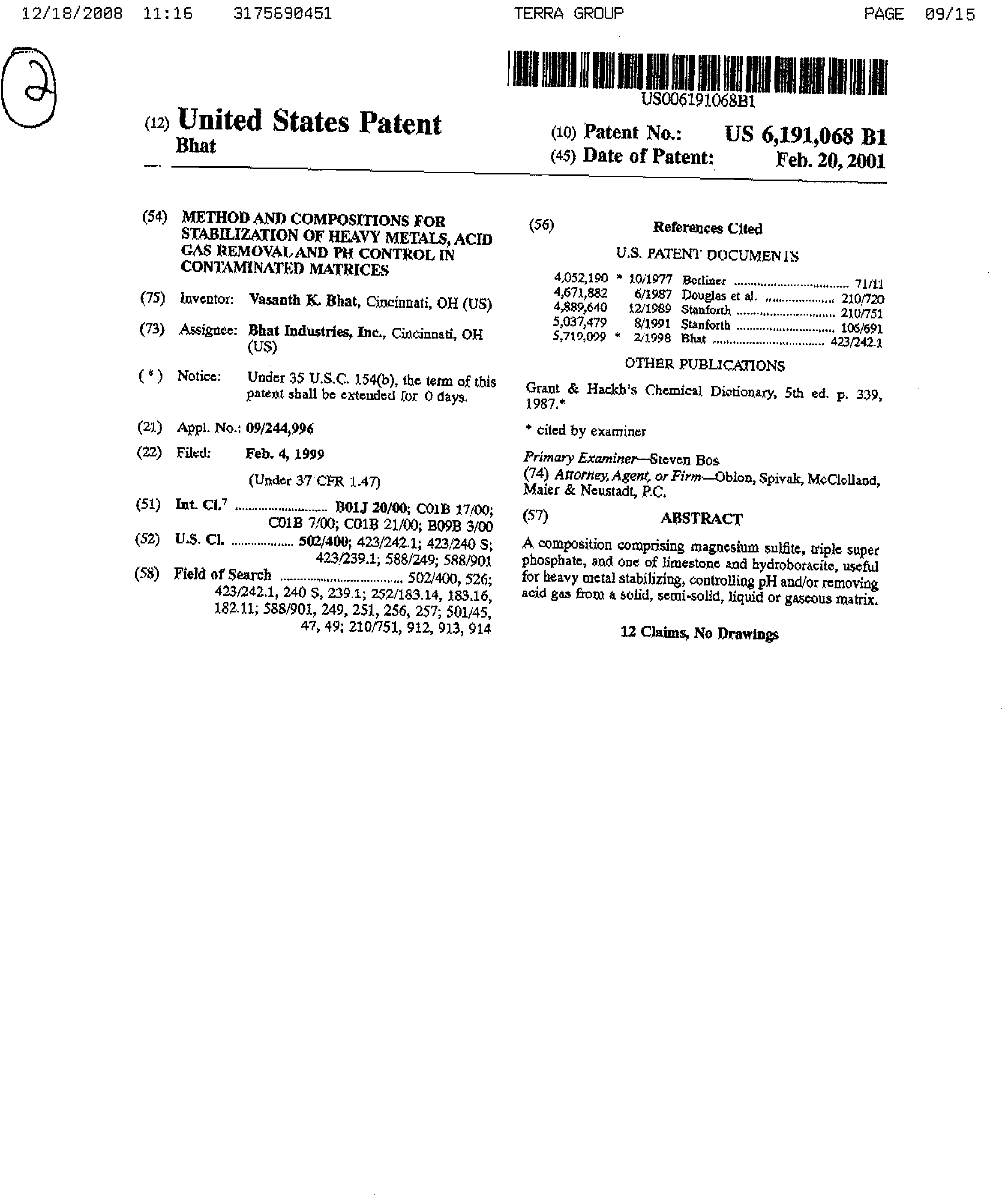

UHll1hIBI

US006191068B1

(12)

United

States

Patent

Bhat

(10)

Patent

No.:

(45)

Date

of

Patent

US

6,191,068

B!

Eeb.

20,2001

(54)

METHOD

AND

COMPOSITIONS

FOR

STABILIZATION

OF

HEAVY

METALS,

ACID

GAS

REMOVAL

AND

PH

CONTROL

IN

CONTAMINATEI3

MATRICES

(75)

Inventor:

Vasauth

K.

Bhat,

Cincinnati,

OH

(US)

(73)

seignee:

Bhat

Industries,

Inc.,

C,ncinnad,

OH

(US)

()

Notice:

Under

35

U.S.C.

154(b),

the

term

of

this

patent

shall

be

cteuded

br

0

days.

(21)

Appi.

No.:

09J244,96

(22)

Filed:

Feb.

4,

1999

(Under

37CPR

1.47)

tnt.

CI?

I401J

20100,

COIB

17/00;

COlE

7/00;

COlE

21/00;

BO9B

3/00

U.S.

CI

502/400;

42312421;

423/244)

S;

423/239.1;

588/249;

558/901

Field

of

Search

....

5021400,

52;

423,242.1,

240

S.

239.1;

252/183.14,

183.16,

182.11;

588/901,

249,

251,

256,

257;

501/45,

47,

49;

210/751,

912,

913,

914

(56)

Refemices

Cited

U.S.

PATENT

DOCUMENtS

10i1977

crtincr

71/li

6/1987

DogIes

et

i

210/720

12/1989

Stemfoc.h

2101751

8/1991

St.anforth

l06,91

2/1998

Rhat

423/242.1

OThER

PUBLICATIONS

Grant

&

Hackh’s

Chemical

Dictionary,

5th

ed.

p.

339,

1987.

died

by

examiner

Primary

Examiner—Steven

Bos

(74)

Airorney,Agent,

orFirm—Oblon,

Spivak,

MC1oUand,

Maier

&

Neustadt,

P.C.

(57)

ABSTRACT

A

composition

comprising

magnesium

sulñte,

triple

soper

phosphate,

and

one

of

limestone

a.od

hydroboracite,

useful

for

heavy

metal

stabilizing,

controUiug

pH

and/or

removing

acid

gea

from

a

solid,

semi-solid,

tiquid

or

gaseous

matrix.

4.052,190

4,671.882

4,889,640

5,037,479

5,710,099

(51)

(52

(58)

12

Claims,

No

Drawings

12/18/28

11:16

317569S451

TERRA

GROUP

PAGE

le/15

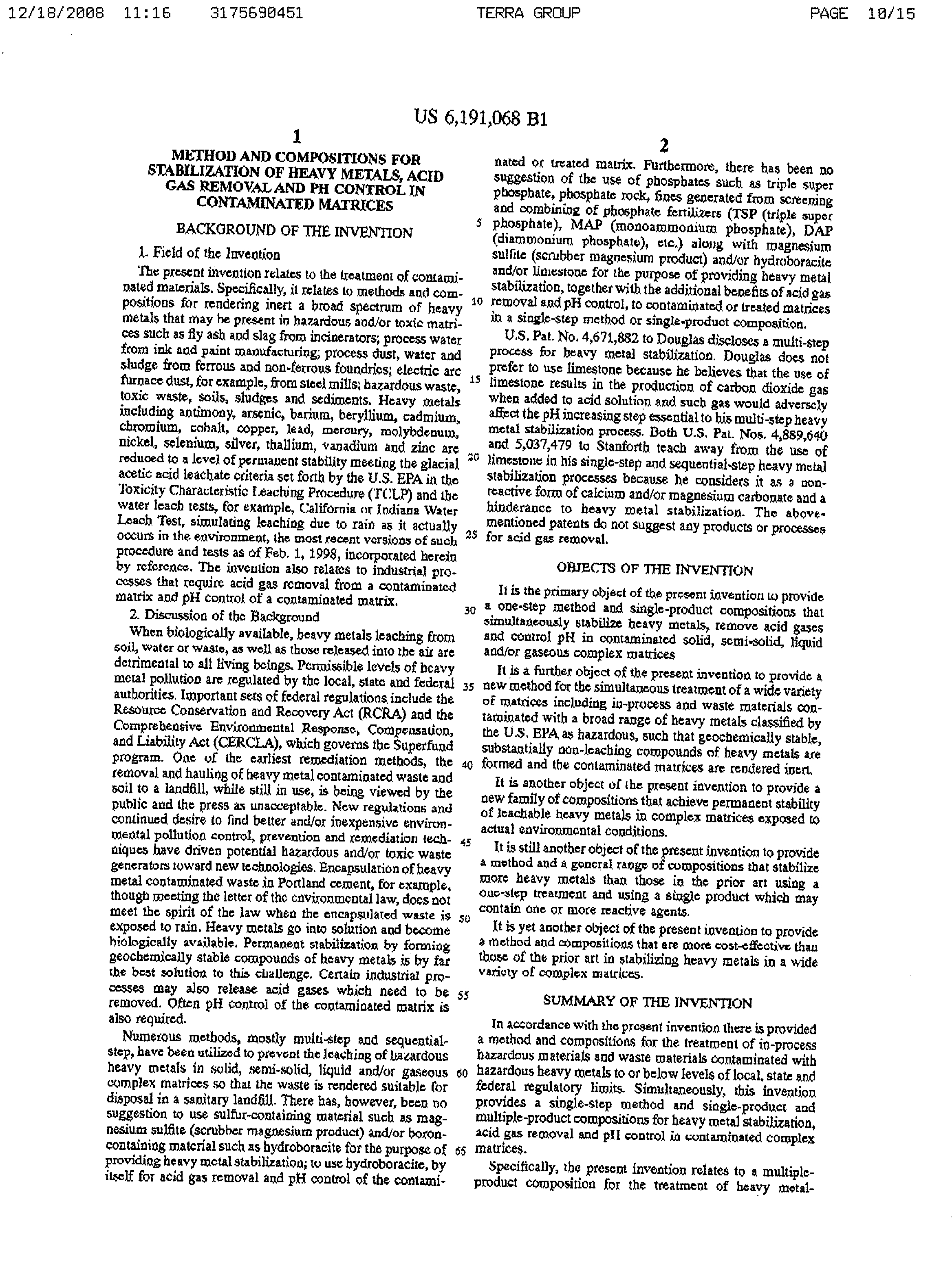

1.

METHOD

AND

COMPOSITIONS

FOR

STABILIZATION

OF

HEAVY

METALS,

ACID

GAS

REMOV4L

AND

PH

CONTROL

IN

CONTAMINATED

MATRICES

BACKGROUND

OF

THE

INVENTION

1.

Fiekl

of

the

Invemion

‘She

present

invention

relates

to

the

treatment

of

coxitawj

nated

materials.

Specifically,

It

relates

to

methods

and

corn

positions

for

rendering

inert

a

broad

spectrum

of

heavy

metals

that

may

be

present

in

hazardous

sod/or

toxic

matri

ces

such

as

fly

ash

and

slag

from

incinerators;

prOcess

water

from

ink

ad

paint

manufacteriog;

process

dust,

Water

and

sludge

from

forrous

and

non-ferrous

foimdrins;

electric

arc

furnace

dust,

for

example,

from

steel

milis

hazardous

waste,

toxic

waste,

soils,

sludges

and

sediments.

Heavy

metals

including

antimony,

arsenic,

barium,

beryllium,

cadmium,

chromium,

cobalt,

copper,

lead,

mercury,

molybcknum,

nickel,

selenium,

silver,

thallium,

vanadium

anti

zinc

are

reduced

to

a

level

of

permanent

stability

meeting

the

glacial

acetic

acid

leachate

cdtetia

set

forth

by

the

US.

EPA

it

the

‘ibxicity

Character,stic

Leaching

Procedure

(TCLP)

and

the

water

leach

tests,

(‘or

example,

California

r

Indiana

Water

Leach

l’est,

simulating

leaching

due

to

rain

a

t

actually

occurs

in

the.

Cnvironment,

the

most

tecent

versions

of

such

procedure

and

tests

as

of

Feb.

1,

1P8,

incorporated

herein

by

reference,

The

invention

also

relates

tQ

industrtal

pro

cesses

that

require

acid

gas

removal

from

a

contaminated

mairix

and

pH

control

of

a

contaminated

matrix.

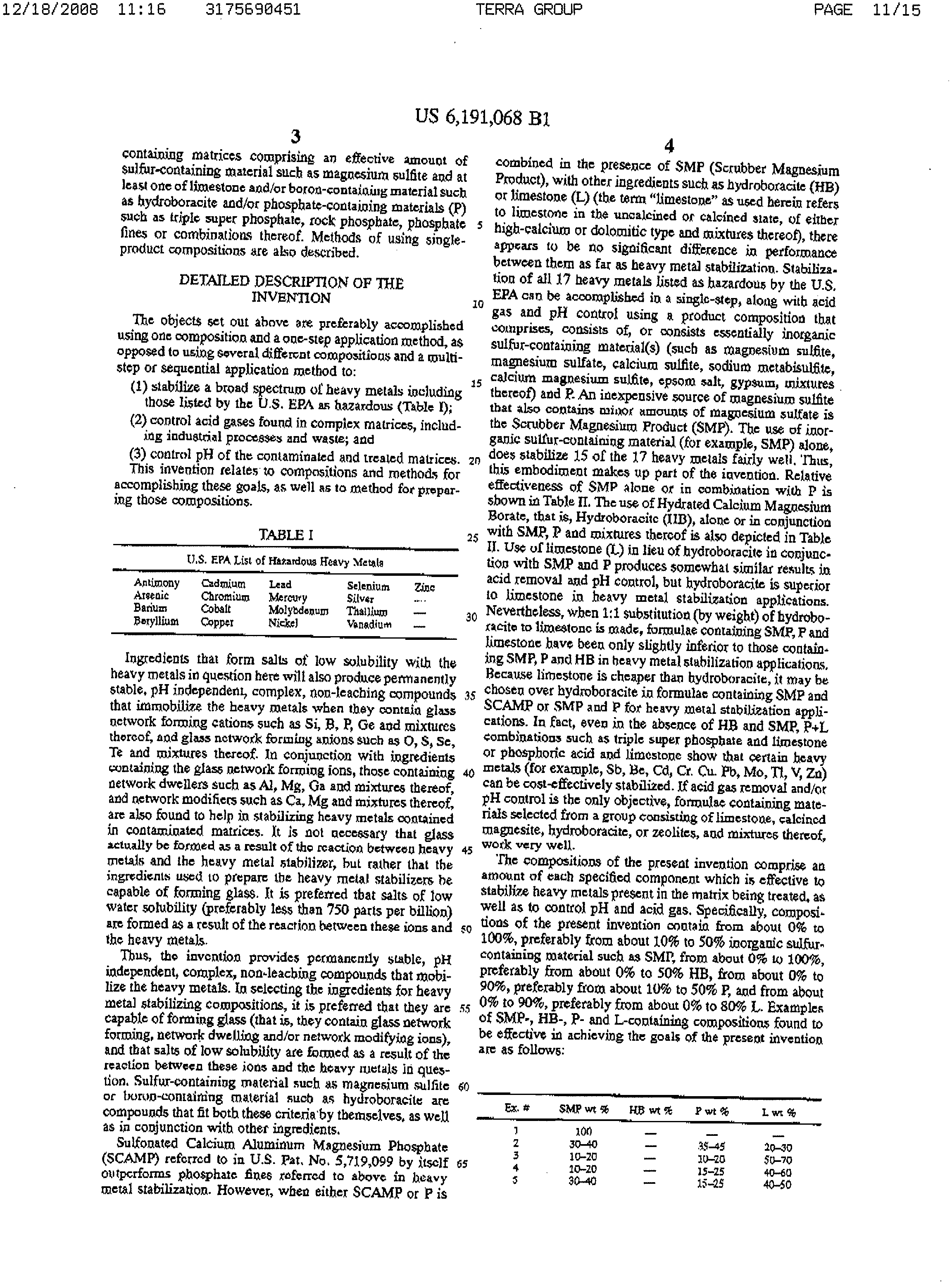

2.

Discussion

of

the

Background

When

biologically

available,

heavy

metals

leaching

from

soil,

water

or

waste,

as

well

as

those

released

into

the

aim

are

dctrjmcetal

to

a.l1

living

beings.

Permissible

levels

of

heavy

metal

pollution

are

regulated

by

the

local,

state

and

federal

authorities.

Lportant

sets

of

federal

regulations,

include

the

Resource

Conservation

and

Recovety

Act

(RCRA)

and

the

Compreheive

Environmental

Response,

Compensation,

and

Liability

Act

(CERCLA),

which

governs

the

Superfund

program.

One

of

the

earliest

rercediation

rOetbods,

the

removal

and

hauling

of

heavy

metal

contaminated

waste

and

soil

to

a

landfill,

while

still

in

use,

is

being

viewed

by

the

public

and

the

press

as

unacceptable.

New

regulaiione

and

continued

desire

to

find

better

and/or

inexpensive

environ

mental

pollution

control,

prevention

and

rentediatiun

lech

nioes

have

driven

potential

hazardous

and/or

toxic

waste

generators

toward

new

technologies.

Encapsulation

of

heavy

metal

contaminated

watc

in

Portland

cement,

for

example,

though

meeting

the

letter

of

tho

environmental

law,

does

not

meet

the

spirit

of

the

Jaw

when

the

ertcapstilared

waste

iS

exposed

to

rain.

Heavy

metals

go

intO

solution

ad

become

biologically

available.

Permanent

stabilization

by

forming

geochemically

stable

compounds

of

heavy

metals

ts

by

far

the

brat

solution

to

this

cttatlenge.

Certain

industrial

pro

cesses

may

also

release

acjd

gases

which

need

to

be

removed.

Often

pH

control

of

the

contaminated

matrix

is

also

required.

Numerous

methods,

ntc,stly

multi-step

and

sequential

step,

have

been

utilized

to

prevent

the

leaching

of

hazardous

heavy

metals

in

solid,

semi-solid,

liquid

and/or

gaseous

oornplex

matrices

so

that

the

waste

is

rendered

suitable

(‘Or

disposal

jO

a

sanitary

land8ll.

There

has,

however,

been

no

suggestion

to

use

sulfur-containing

xnatciial

such

as

mag

nesium

sulfite

(scrubber

magnesium

product)

and/or

boron-

containing

material

such

as

hydroboracite

for

the

purpose

of

providing

heavy

metal

stabihLzatioo

to

use

bydroboracite,

by

itself

for

acid

gas

removal

and

pH

control

of

the

contami

2

nated

or

treated

matrix.

Furthermore,

there

has

been

no

suggestion

of

the

use

of

phosphates

such

as

triple

super

phosphate,

phosphate

rock,

lines

generated

from

screening

and

combining

of

phosphate

fertilizers

(TSP

(triple

super

S

phosphate),

MAP

(rnonoammonium

phosphate),

DAP

(diammonium

phosphate),

etc.)

aloug

with

magnesium

sulfite

(scrubber

magnesium

product)

and/or

hydrc,boracite

and/or

limestone

for

the

purpose

of

providing

heavy

metal

stabilization,

together

with

the

additional

benefits

of

acid

gas

so

removal

and

pH

cootrol,

to

contaminated

or

treated

matrices

in

a

single-step

method

Or

single-product

composition.

U.S.

Pat.

No.

4,671,882

to

Douglas

discloses

a

multi-step

process

fur

heavy

metal

stabilization.

Douglas

does

not

prefer

to

use

limestone

because

he

believes

that

the

use

of

13

limestone

results

in

the

production

of

carbon

dioxide

gas

when

added

t

acid

solutin

and

such

gas

would

adversely

aect

the

pH

increasing

step

essential

to

his

multi-step

heavy

metal

stabilazatio

process.

Both

U.S.

PaL

Nos.

4,889,4O

and

5,037,479

to

Stanfortb

teach

away

from

the

use

of

limestone

in

his

single-step

and

sequential-step

heavy

metal

stabilization

processes

because

he

considers

it

as

a

non

reactive

form

of

calcium

and/or

magnesium

cabonate

and

a

binderance

to

heavy

metal

stabilization.

The

above-

mentioned

patents

d

not

suggest

any

products

or

processes

2$

for

acid

gas

rentoval,

O)3JECTS

OF

flIE

INVENTION

It

is

the

primary

object

of

the

present

tevanticru

Lu

provide

30

a

onestep

method

and

single-product

compositions

that

simultaneously

stabilize

heavy

metals,

remove

acid

gases

and

control

pH

in

contaminated

solid,

scnii.soli4

liquid

and/or

gaseous

complex

matrices

It

is

a

further

object

of

rise

present

invention

to

provide

a.

new

method

for

the

simultaneous

treatment

of

a

wide

variety

of

matrices

including

lu-process

and

waste

materials

con

taminated

with

a

broad

range

of

heavy

metals

classiñed

by

the

U.S.

EPA

as

hazardous,

such

that

geocbemtoally

stable,

substantially

con-leaching

compounds

of

heavy

metals

axe

40

formed

and

the

contaminated

matrices

are

rendered

inert.

it

is

another

object

of

the

present

invention

to

provide

a

new

family

of

cmpositrons

that

achieve

permanent

stability

of

leachable

heavy

metals

in

complex

matrices

exposed

to

actual

environmental

conditions.

It

is

still

another

object

of

the

present

invention

to

provide

a

method

ad

a

general

range

of

compositions

that

stabilize

more

heavy

metals

than

those

in

the

prior

art

using

a

one-step

treatment

and

using

a

single

product

which

may

contain

One

or

more

reactive

agents.

It

is

yet

another

object

of

the

present

invention

to

provide

a

method

and

compositions

that

are

more

cost-effective

than

those

of

the

prior

art

in

stabilizing

heavy

metals

in

a

wide

variety

of

complex

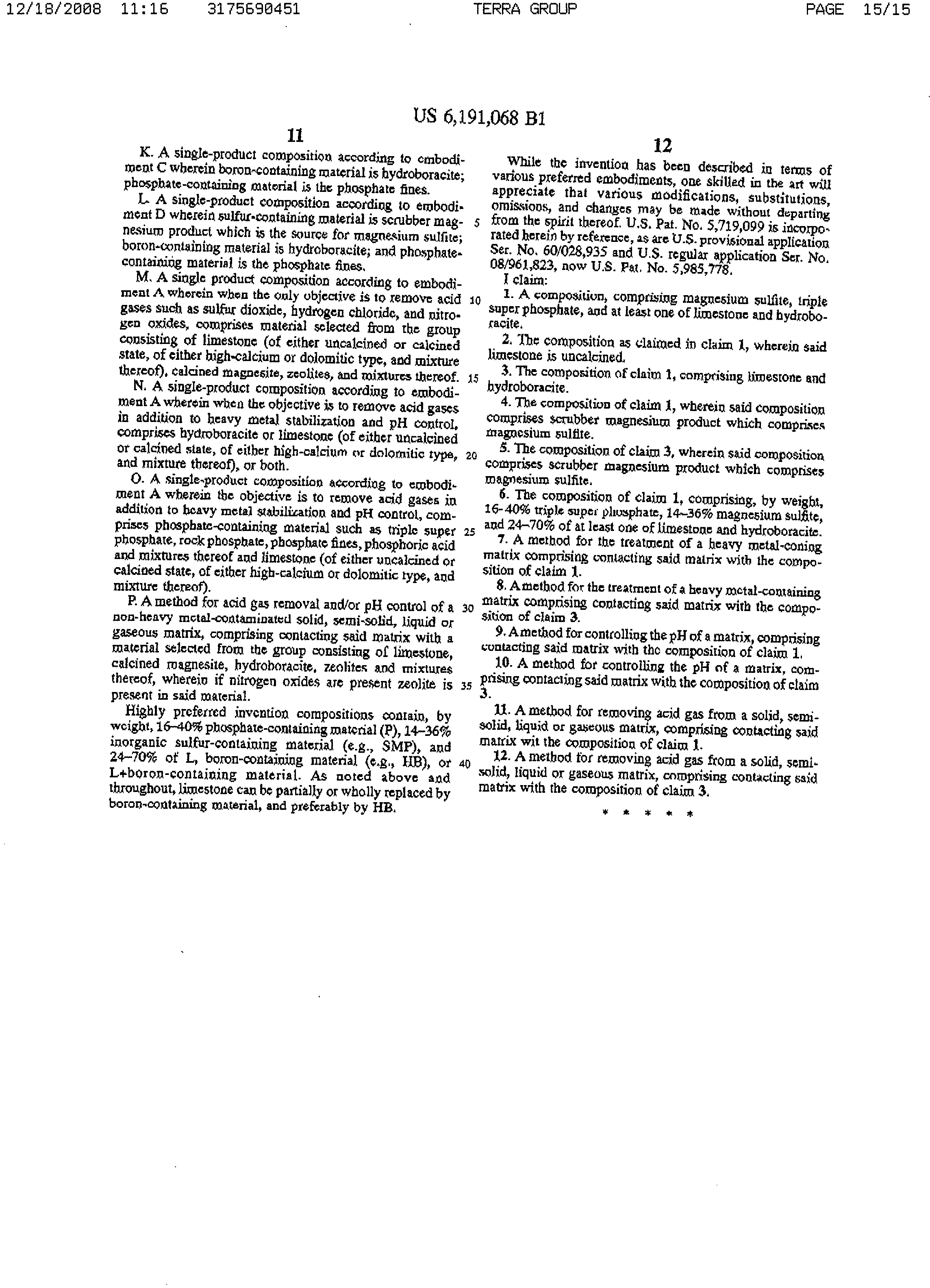

matrices.