BEFORE

THE ILLINOIS POLLUTION CONTROL

BOARD

IN THE MATTER OF:

)

NITROGEN OXIDES EMISSIONS FROM )

VARIOUS SOURCE

CATEGORIES:

)

AMENDMENTS TO

35 ILL. ADM. CODE )

PARTS 211 and 217

)

R08-19

(Rulemaking -

Air)

NOTICE

OF FILING

TO: Mr. John T. Therriault

Assistant Clerk of the Board

Illinois

Pollution Control Board

100 W. Randolph

Street

Suite 11-500

Chicago, Illinois 60601

(VIA ELECTRONIC MAIL)

Timothy Fox, Esq.

Hearing Officer

Illinois

Pollution Control Board

100 W. Randolph

Street

S uite 11-500

Chicago, Illinois 60601

(VIA FIRST CLASS MAIL)

(SEE PERSONS ON ATTACHED SERVICE LIST)

PLEASE TAKE NOTICE that

I have today filed with the Office of the Clerk

of

the Illinois Pollution Control Board the ENTRY

OF APPEARANCE OF

KATHERINE D. HODGE ON BEHALF

OF UNITED STATES STEEL

CORPORATION, ENTRY OF APPEARANCE

OF MONICA T. RIOS ON

BEHALF

OF UNITED STATES STEEL CORPORATION, PRE-FILED

TESTIMONY OF LARRY

G. SIEBENBERGER ON BEHALF OF

UNITED

STATES STEEL CORPORATION and PRE-FILED

TESTIMONY OF BLAKE E.

STAPPER ON BEHALF OF UNITED STATES

STEEL CORPORATION, copies

of which are herewith

served upon you.

Respectfully submitted,

By: /s/ Katherine D. Hodae

Katherine D. Hodge

Dated: November 25, 2008

Katherine D. Hodge

Monica T. Rios

HODGE DWYER ZEMAN

3150 Roland Avenue

Post Office Box 5776

Springfield, Illinois 62705-5776

(217) 523-4900

THIS FILING

SUBMITTED ON RECYCLED PAPER

Electronic Filing - Received, Clerk's Office, November 25, 2008

CERTIFICATE OF SERVICE

I, Katherine D. Hodge, the undersigned, hereby certify that I have served the attached

ENTRY OF APPEARANCE OF KATHERINE D. HODGE

ON BEHALF OF UNITED

STATES

STEEL CORPORATION, ENTRY OF APPEARANCE OF MONICA T. RIOS

ON

BEHALF OF UNITED STATES STEEL CORPORATION, PRE-FILED

TESTIMONY OF

LARRY G. SIEBENBERGER ON BEHALF OF UNITED STATES

STEEL CORPORATION

and PRE-FILED TESTIMONY

OF

BLAKE

E. STAPPER ON BEHALF OF UNITED STATES

STEEL CORPORATION upon:

Mr. John T. Therriault

Assistant

Clerk of the Board

Illinois Pollution Control Board

100 West Randolph Street, Suite 11-500

Chicago, Illinois 60601

v ia electronic mail on November 25, 2008; and upon:

Timothy Fox, Esq.

Hearing Officer

Illinois Pollution Control Board

100 West Randolph,

Suite 11-500

Chicago, Illinois 60601

Matthew J. Dunn, Esq.

Chief, Environmental Bureau North

Office of the Attorney

General

69 West Washington Street, Suite 1800

Chicago, Illinois 60602

Gina Roccaforte, Esq.

John J. Kim, Esq.

Division of Legal Counsel

Illinois Environmental Protection Agency

1021 North

Grand

Avenue

East

Post Office Box 19276

Springfield, Illinois 62794-9276

Virginia Yang, Esq.

Deputy Legal Counsel

Illinois Department of Natural Resources

One Natural Resources Way

Springfield, Illinois 62701-1271

Kathleen C. Bassi, Esq.

Stephen J. Bonebrake, Esq.

Schiff Hardin, LLP

6600 Sears Tower

233 South Wacker Drive

Chicago, Illinois

60606-6473

by depositing said documents in

the United States Mail, postage prepaid, in

Springfield, Illinois on November 25, 2008.

/s/ Katherine D. Hodize

Katherine D. Hodge

USSC:001/Fil/COS -EOA & Pre-Filed Testimony of Larry Siebenberger and Blake Stapper

Electronic Filing - Received, Clerk's Office, November 25, 2008

BEFORE THE ILLINOIS

POLLUTION CONTROL

BOARD

IN THE MATTER

OF:

)

R08-19

NITROGEN OXIDES EMISSIONS

FROM ) (Rulemaking

- Air)

VARIOUS

SOURCE CATEGORIES:

)

AMENDMENTS

TO 35 ILL. ADM.

CODE )

PARTS 211 and

217

)

ENTRY

OF APPEARANCE

OF KATHERINE D. HODGE

ON BEHALF

OF UNITED STATES

STEEL CORPORATION

NOW COMES

Katherine D. Hodge,

of the law firm HODGE

DWYER ZEMAN,

and hereby enters her appearance

in this matter on behalf

of UNITED STATES

STEEL

CORPORATION.

Respectfully

submitted,

Dated: November 25, 2008

Katherine D.

Hodge

HODGE DWYER

ZEMAN

3150 Roland Avenue

Post Office Box 5776

Springfield, Illinois 62705-5776

(217)

523-4900

By:

/s/ Katherine D. Hodge

Katherine D. Hodge

U SSC:001/Fil/EOA - KDH

Electronic Filing - Received, Clerk's Office, November 25, 2008

BEFORE

THE ILLINOIS POLLUTION CONTROL BOARD

IN THE MATTER OF:

)

R08-19

NITROGEN OXIDES EMISSIONS FROM ) (Rulemaking -

Air)

VARIOUS SOURCE CATEGORIES: )

AMENDMENTS TO 35 ILL. ADM.

CODE

)

PARTS 211 and 217

)

ENTRY OF APPEARANCE OF MONICA

T.

RIOS

ON BEHALF OF UNITED STATE STEEL CORPORATION

NOW COMES Monica T. Rios, of the law firm HODGE DWYER

ZEMAN, and

hereby enters her appearance in

this matter on behalf of UNITED STATES STEEL

CORPORATION.

Respectfully submitted,

By: /s/ Monica T. Rios

Monica T. Rios

Dated: November 25, 2008

Monica T. Rios

HODGE DWYER ZEMAN

3150 Roland Avenue

Post Office Box 5776

Springfield, Illinois

62705-5776

.(217)

523-4900

U SSC:001/Fi1/EOA-MTR R08-9

Electronic Filing - Received, Clerk's Office, November 25, 2008

BEFORE THE ILLINOIS POLLUTION CONTROL

BOARD

IN THE MATTER OF:

)

R08-19

NITROGEN OXIDES EMISSIONS FROM ) (Rulemaking

- Air)

VARIOUS SOURCE CATEGORIES: )

AMENDMENTS TO 35 ILL. ADM. CODE

)

PARTS 211 and 217

)

PRE-FILED

TESTIMONY OF LARRY G. SIEBENBERGER

ON BEHALF OF UNITED STATES STEEL CORPORATION

NOW COMES the UNITED STATES

STEEL CORPORATION ("U.S. Steel"),

by and

through its attorneys, HODGE DWYER ZEMAN, and submits

the following

PRE-FILED TESTIMONY OF LARRY G. SIEBENBERGER

for presentation at the

December 9,

2008, hearing scheduled in the above-referenced matter.

Pre-Filed Testimony of Larry G. Siebenberger

I. INTRODUCTION

Good

Morning. My name is Larry Siebenberger,

and I am the Manager of

Environmental Control at U.S. Steel's Granite

City Works ("GCW"). I have been

employed at GCW

in various environmental and operating positions

for the past 37 years.

I have a BA in Chemistry and an MS in Environmental

Studies from Southern Illinois

University at Edwardsville.

GCW

is the last fully integrated iron and

steel mill in Illinois. GCW is located in

Granite

City, Illinois, which is in the St.

Louis Metropolitan area. The facility

employs

approximately 2,200

employees and is one of the largest

employers in the region. GCW

was

originally founded in 1878 and operated as Granite

City Steel until 1971, when

it

was purchased by National Steel

Corporation. National Steel Corporation

filed for

Electronic Filing - Received, Clerk's Office, November 25, 2008

Chapter 11 bankruptcy in 2002, along with many other steel producers

in the United

States. U.S. Steel purchased National

Steel Corporation's assets in 2003.

II.

OVERVIEW

OF PRODUCTION OPERATIONS AT GRANITE CITY

WORKS

The GCW

facility includes two by-product coke batteries that produce

metallurgical coke and coke oven gas, a by-product fuel with about 500-600

Btu's per

cubic foot. The major components

of coke oven gas consist of approximately 52%

hydrogen, 26%

methane, and 5% carbon monoxide. Undesulfurized coke oven gas also

contains approximately 1800 ppm of hydrogen cyanide.

The hydrogen cyanide

contributes fuel bound

nitrogen during the combustion process producing NOx in

addition to the

thermal NOx normally produced. As a result, coke oven gas produces

higher NOx emissions than natural gas. Coke

oven gas is a very valuable fuel, which is

used to under fire

the coke ovens themselves (approximately 40-50% of gas produced),

and the remainder is used at various down stream

units including blast furnace stoves,

boilers, and slab

reheat furnaces in lieu of a purchased fuel such as natural gas. GCW

attempts

to use all the available coke oven gas at these units

in lieu of purchased fuels;

however, depending on operating

levels of the plant and the operating schedules of the

down steam units, excess

coke oven gas may be flared.

The next step in the production process consists

of two blast furnaces that use

metallurgical coke,

flux (lime), iron ore and hot blast air to reduce the iron ore

to

molten

iron. The blast furnace is a closed system. The reacted

hot blast air exits the furnace as a

by-product fuel called blast

furnace gas. Blast furnace gas, also a valuable

fuel, has a Btu

content of approximately

80-120 Btus per cubic foot. The gas

derives its heat content

primarily from its carbon monoxide content.

Blast furnace gas is a low NOx fuel. Blast

Electronic Filing - Received, Clerk's Office, November 25, 2008

furnace

gas is used as a fuel in the blast furnace

stoves (which heat the hot blast

air used

in the furnace) and the facility's

boilers. During a two blast

furnace operation, more blast

furnace gas is produced

than can be consumed.

The excess blast furnace gas is flared.

The

molten iron is taken to the basic

oxygen furnaces where it is charged

along

with scrap steel into the furnace.

Oxygen is blown into the

iron/scrap bath where it reacts

exothermically

with the carbon and silicon in the

molten iron resulting in a heat of

liquid

steel.

The liquid steel is processed

through a continuous caster

which forms the steel into

a solid slab.

The slabs

of steel are taken to the

hot strip mill where the slabs

are charged into

one of four slab reheat furnaces.

As the slabs move through

the slab reheat furnaces, they

are heated up

to rolling temperature. The slab reheat

furnaces are heated by coke

oven

gas and

natural gas. Once the slabs

reach rolling temperatures, they

are rolled by a series

of rolling mills into a

flat sheet of steel, which is rolled

up into a coil called a hot roll

band. Most of the

steel produced at GCW

is sold as hot roll bands.

Some of the hot roll bands

are further processed

at GCW through the pickle

line

which acid cleans

the steel sheet and recoils

it into a coil. The steel coil

is then processed

through

a cold mill, which reduces

the steel to its final thickness.

The cold reduced

coil is then processed

through one of the two galvanizing

lines

at GCW. The steel

sheet is reheated in a

furnace before being dipped

in a bath of molten

zinc

or zinc and aluminum.

A thin coating is left on the

sheet. This product is

called

galvanize or galvalume.

The coating offers corrosion

resistance.

GCW currently operates

twelve boilers. Boilers

1 through 10 were built in the

1920s and 1930s.

They have approximately

60 MMBtu/hour firing capacity

each. They

Electronic Filing - Received, Clerk's Office, November 25, 2008

combust

coke oven gas, blast furnace

gas, and natural gas. Boilers

11 and 12 are 225

MMBtu/hour boilers that

also fire coke oven gas, blast

furnace gas, and natural

gas. The

primary

purpose of the boilers is to provide

steam for the down

stream processes, plant

heating, and drive the steam

turbines, which provide the

blast air for the blast

furnaces.

The boiler loads

vary depending on the

level of production at the down

stream processes,

and

the fuel blends vary depending

on blast furnace operation

(one or two furnace

operation) and whether

the hot strip slab furnaces

are operating and consuming

coke oven

gas.

III.

RECENT IMPROVEMENTS

AT GRANITE CITY

WORKS

Since its

acquisition of the GCW

in 2003, U.S. Steel has made

major

improvements

at the facility.

These improvements include

the construction of non-

recovery coke batteries

by Gateway Energy &

Coke Company, LLC,

and the installation

of a new

cogeneration boiler ("Cogen

Boiler") and turbine.

The non-recovery batteries

will make GCW self-sufficient

with its needs for

metallurgical coke. The

new batteries

will also provide

steam for power generation.

The Cogen boiler

will combust blast

furnace

gas and a minimum amount

of natural gas. Existing

Boilers 1 through

10

will

be

shut down after full commissioning

of the Cogen

Boiler. The blast

furnace gas consumed

by Boilers

1 through 10, plus blast

furnace gas that is currently

flared, will be combusted

in the Cogen Boiler. The

steam from the Cogen

Boiler, as well as the

steam from the

non-recovery

coke batteries, will be

used to generate electricity

for GCW. The

generation of electricity

at the new turbine will be

much more efficient

than the power

currently being generated

at an outside utility

and transported

to the facility. Since

Boilers

1 through 10 consume

coke oven gas and the

Cogen Boiler will not, additional

Electronic Filing - Received, Clerk's Office, November 25, 2008

coke oven gas will be available

for use at the blast furnace stoves, slab reheat

furnaces,

and Boilers 11 and

12.

Additional projects currently being

implemented at GCW, which provide

emission reductions, include coke

oven gas desulfurization at the existing

coke by-

product batteries,

low NOx burner installation at

the slab reheat furnaces, and

replacement of the natural

gas-fired coke oven gas booster pump with an electric

drive

PUMP.

IV.

IMPACT OF THE ILLINOIS EPA'S

PROPOSED RULE

The Illinois Environmental

Protection Agency's ("Illinois

EPA" or "Agency")

current proposal

in this proceeding would apply

to the boilers, slab reheat furnaces

and

galvanizing lines at GCW. In

the event that additional regulation of NOx

emission units

is required, GCW has been

discussing the impact of the

Illinois EPA's proposal on

potentially

affected emission units at the

GCW facility. The Illinois EPA's

proposal does

not take into account the unique

characteristics of the GCW

boilers and slab reheat

furnaces.

Specifically, the

Illinois EPA's proposed limits and cited

control technologies do

not consider the combustion

of coke oven gas and

the resulting NOx emission

rate, which

is higher

than that of natural gas. Coke

oven gas NOx emissions

are the result of the

thermal NOx generated during

combustion, and the additional

NOx generated due to the

fuel bound nitrogen

as a result of the hydrogen

cyanide content of the

gas. Other unique

characteristics not adequately

considered include the variation

in load and fuel blends that

occur at the GCW

boilers, the fact that not all

reheat furnaces are alike,

and that reheat

Electronic Filing - Received, Clerk's Office, November 25, 2008

furnaces NOx emission rates while combusting natural gas

can vary widely depending on

the type of product they are processing

and the necessary operating temperatures.

A.

Boilers

GCW does not believe that the Agency's current

proposed Section 217.164(a)

limit

of 0.08

lbs/MMBtu for Industrial Boilers greater than 100 MMBtu/hr combustion

for Natural Gas or Other Gaseous Fuels takes into account

the unique characteristics of

Boilers 11 and 12. Some of the unique characteristics

include the combustion of a

varying fuel mix of desulfurized or non-desulfurized coke oven gas in combination

with

blast furnace gas and natural gas. GCW has discussed

with the Agency these unique

characteristics and

the results of a NOx control option evaluation performed by URS

Corporation for Boilers 11 and 12. The URS evaluation

concluded that the installation of

flue gas recirculation ("FGR")

in conjunction with the existing burners was the optimum

NOx RACT control technology for Boilers 11 and 12. URS testimony

discussing its

evaluation has been filed separately. Based on

the installation of FGR, GCW proposes a

NOx average limit of

0.113 lbs/MMBtu for Boilers 11 and 12. This proposed

limit takes

into account worst case NOx fuel blends during

normal operation, when one blast furnace

is down and there are increased

coke oven gas NOx emissions as the result of

maintenance outages at the coke oven gas desulfurization

facility. This limit will result

in a reduction of approximately 492 tons per

year of NOx emissions from current

levels.

See Exhibit A to

my testimony for additional details.

Electronic Filing - Received, Clerk's Office, November 25, 2008

B. Reheat Furnaces

The Illinois

EPA has agreed that due to the unique characteristics of the GCW

reheat furnaces, including the complexity of using both

desulfurized and non-

desulfurized coke oven

gas (when the coke oven desulfurization unit is down for

maintenance), the Low NOx Burner configuration currently being

installed is RACT.

While the Illinois EPA has

not to date agreed, GCW has proposed an average NOx ozone

season limit of

0.1891bs/MMBtu for slab reheat furnaces 1 through

4. This limit is based

on the burner manufacturer's warranty and

the maximum combusted blend of

desulfurized coke oven

gas and non-desulfurized coke oven gas (during desulfurized

maintenance

outage) with natural gas. This limit will result in a

reduction of

approximately 476 tons per year of NOx

emissions from current levels. See Exhibit B to

my testimony for additional

details.

V.

PROPOSED COMPLIANCE DATE

The current

Agency proposal has a May 1, 2010 compliance date.

As stated

earlier, GCW

has many capital improvement projects

underway. The GCW Engineering

Department has a great deal of

recent experience with U.S. Steel project

approval

procedures, engineering

projects, purchasing, and installation

of equipment. Based on

this

experience, the GCW Engineering Department

has estimated that it will take at least

eighteen months from

the time a final rule is promulgated to complete

the installation of

controls.

This time frame includes at least six

months for initial appropriation approval

for engineering, engineering

design, and obtaining a construction

permit. The next six

months will

include, after obtaining a construction

permit, appropriation approval to

purchase equipment, procurement,

and delivery of equipment

(estimated delivery of FGR

Electronic Filing - Received, Clerk's Office, November 25, 2008

fans is approximately six months). The last six months is for installation of equipment

and start up. Based on this estimate, and assuming

the final rule does not require items

with longer delivery times, the compliance date should be at least eighteen months from

the effective date of the rule.

VI. CONCLUSION

U.S. Steel respectfully requests that the Board consider this testimony and include

U.S. Steel's proposed emission limits for its affected emission units

in

the

proposed rule.

Further, U.S. Steel requests that the Board allow for at least an eighteen month time

frame from the effective date of the rule to comply with the final rule.

I appreciate

the opportunity to present my testimony. I am happy to answer any

questions.

U.S. Steel reserves the right to supplement this testimony.

Respectfully submitted,

By: /s/ Katherine D. Hodge

Katherine D. Hodge

Dated: November 25, 2008

Katherine D. Hodge

Monica T. Rios

HODGE DWYER ZEMAN

3150 Roland Avenue

Post Office Box 5776

Springfield,

Illinois 62705-5776

(217) 523-4900

U SSC:001/Fil/R0819/Prefiled Testimony of L. Siebenberger

Electronic Filing - Received, Clerk's Office, November 25, 2008

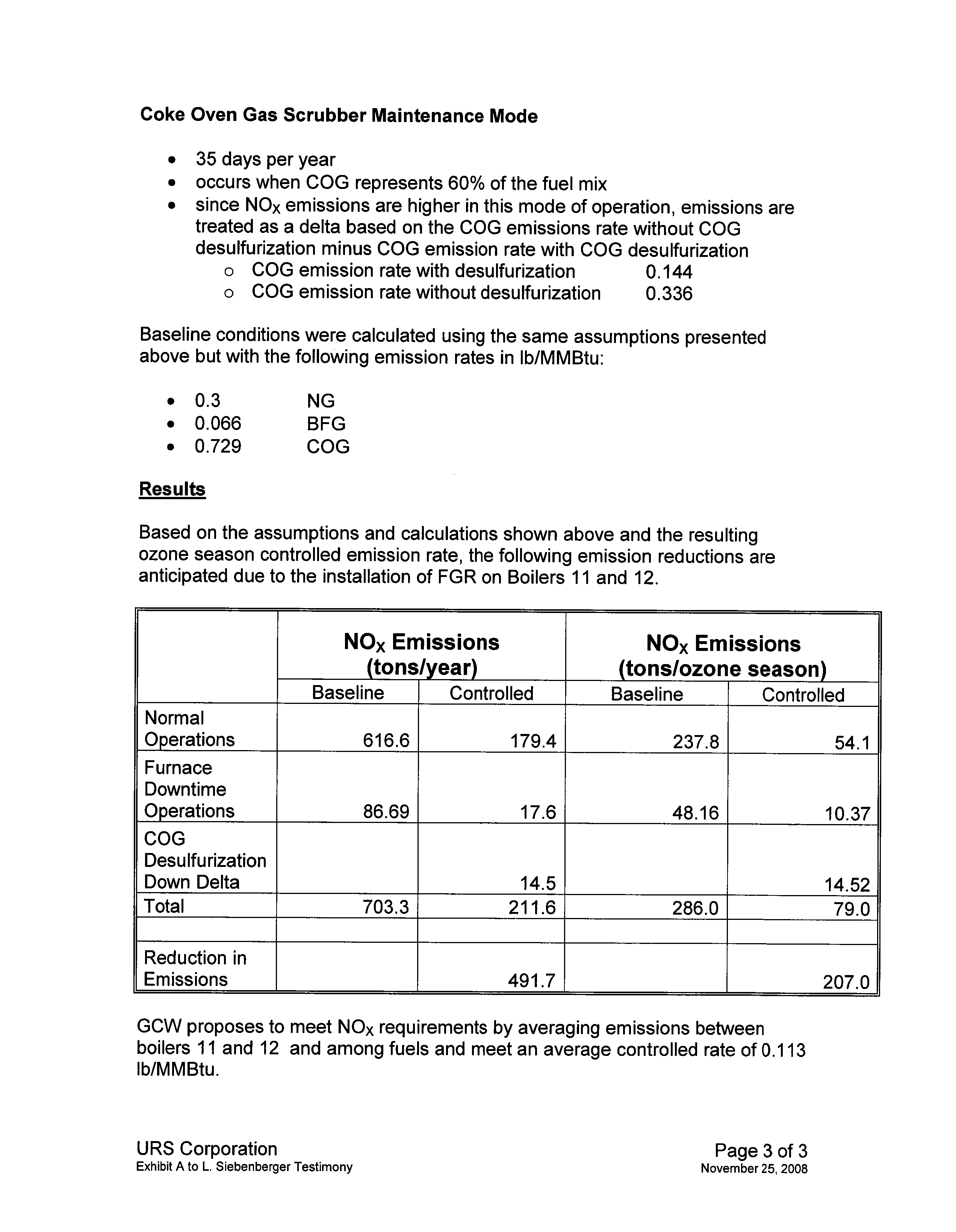

EXHIBIT A

United States Steel Corporation

Granite City Works

Description

of NOX RACT Emission Rate

and

Emission Reduction

Calculations

for Boilers 11 and 12

U.S. Steel Granite

City

Works

(GCW) has estimated the emissions for its boilers

11 and 12 in response to the Illinois Environmental

Protection Agency's proposed

rule to require that the emissions units employ Reasonably

Available Control

Technology (RACT) on these two units.

The Illinois Pollution

Control Board has proposed revisions to Title 35 Part 217

which would require these units

to meet emissions limits that have been

proposed as RACT. While these units meet the definition

of industrial boilers in

which

would be regulated under Subpart D of the proposed rule,

the fuel mix that

they fire

is unlike that of a typical industrial boiler. Therefore, an evaluation

was

undertaken

by URS Corporation for GCW to evaluate potential control

technologies applicable to the units and

estimate the resulting emissions for

technologies that are found to be feasible.

The URS evaluation found

that because of the unique mixture of fuels fired by

the units, the only technically

feasible control technology is Flue Gas

Recirculation (FGR). The potential

emissions and emissions reductions related

to the use of FGR were evaluated. The evaluation method is

described below.

RACT

emissions estimates for NOx emissions from boilers 11 and 12 were

developed

as three distinct components that represent three distinct operational

conditions that the boilers operate under. These

are:

Normal operations,

Operations while a blast furnace is out of

service (limiting the supply of

one of the fuels (blast furnace gas (BFG) used by the

boilers), and

Operations while

the desulfurization unit that is being constructed to treat

the coke oven gas (COG),

one of the fuels used by the boilers is off-line in

maintenance mode.

This

analysis was done for the two boilers in combination since that is the way

the steam produced

by the boilers is used. Each boiler has a heat input capacity

of 225 MMBtu per hour. Therefore,

the analysis has been done based on the

total heat input of 450 MMBtu per hour.

U RS Corporation

Page

1 of 3

E xhibit A to L. Siebenberger Testimony

November 25, 2008

Electronic Filing - Received, Clerk's Office, November 25, 2008

The calculation of estimated emissions for

each of these operational modes is

described

below.

Normal Operations

For this analysis, normal operations were calculated

as operations during those

times when the two blast furnaces at the facility are in

operation and providing

the full potentially

available BFG.

Key assumptions for this mode of operations

include:

" Blast furnace maintenance time as shown in table below:

Ozone

Season Annual

15

15 days Blast Furnace Rebuild

55 days Blast Furnace Down (15%) of time annual

basis

23

days Blast Furnace Down (15%) of time ozone season

basis

2

2 days maintenance outage

40

72 days Total Maintenance Outage

a fuel mix on the boilers of:

0 25% natural gas (NG)

0 35% BFG

0 40%

COG

" a capacity factor of 100%

" controlled NOX emission rates (Ibs/MMBtu) of:

0 0.084

NG

0 0.0288

BFG

0 0.144

COG

Furnace Downtime

Operations

" Furnace downtime

0 15 days furnace rebuild

0

15%

downtime per furnace (55 days for annual and 23 days for

ozone

season)

0 2 days maintenance outage

" Fuel Mix

o NG

40%

o COG

60%

Capacity factor 40%

Same emission rates

per fuel as for normal operations

U RS Corporation

Page 2 of 3

E xhibit A to L. Siebenberger Testimony

November 25, 2008

Electronic Filing - Received, Clerk's Office, November 25, 2008

Coke

Oven Gas Scrubber Maintenance

Mode

" 35 days per year

occurs when COG represents 60%

of the fuel mix

" since NOx emissions

are higher in this mode of

operation, emissions are

treated as a delta

based on the COG emissions rate

without COG

desulfurization minus COG emission

rate with COG desulfurization

o COG emission rate with desulfurization

0.144

o COG emission rate without desulfurization

0.336

Baseline conditions were

calculated using the same assumptions

presented

above but with the following

emission rates in Ib/MMBtu:

" 0.3

NG

" 0.066

BFG

0.729

COG

Results

Based

on the assumptions and calculations

shown above and the resulting

ozone season

controlled emission rate, the following

emission reductions are

anticipated due

to the installation of FGR on Boilers 11 and 12.

NOx Emissions

NOx Emissions

(tons/year)

tons/ozone

season

B aseline

Controlled

Baseline

Controlled

Normal

Operations

616.6

179.4

237.8

54.1

Furnace

Downtime

Operations

86.69

17.6

48.16

10.37

COG

Desulfurization

Down Delta

14.5

14.52

Total

703.3

211.6

286.0

79.0

Reduction

in

Emissions

491.7

207.0

GCW proposes

to

meet

NOx requirements by averaging emissions between

boilers 11 and 12 and among fuels

and meet an average controlled rate of

0.113

Ib/MMBtu.

U RS

Corporation

Page

3 of 3

E xhibit A to L.

Siebenberger Testimony

November 25, 2008

Electronic Filing - Received, Clerk's Office, November 25, 2008

EXHIBIT B

United States Steel Corporation

Granite City Works

Estimation of NOx

Emissions

and

NOx Emission Reductions

for

Slab Furnaces 1, 2, 3 and 4

U.S.Steel Granite City Works (GCW)

has estimated the emissions for its

slab

furnaces 1, 2, 3, and 4 in response to the Illinois

Environmental Protection

Agency's

proposed rule to require that the emissions

units employ Reasonably

Available

Control Technology (RACT) on these four units.

The Illinois Pollution Control Board has

proposed revisions to Title 35 Part 217

which would require these units to meet

emissions limits that have been

proposed

as RACT. These units meet the definition

of recuperative reheat

furnaces which would

be regulated under Subpart H of the proposed rule.

Therefore, an evaluation was

undertaken by GCW to evaluate potential control

technologies applicable to the units

and estimate the resulting emissions for

technologies that are found to be feasible.

The evaluation

found that for these particular units, the only technically

feasible

control technology is

the installation of low NOX burners. The potential emissions

and emissions reductions related

to the use of low NOX burners were evaluated.

The evaluation method is described below.

RACT

emissions estimates for NOX emissions from slab furnaces 1 through

4

were developed

based on a set of key assumptions. These are:

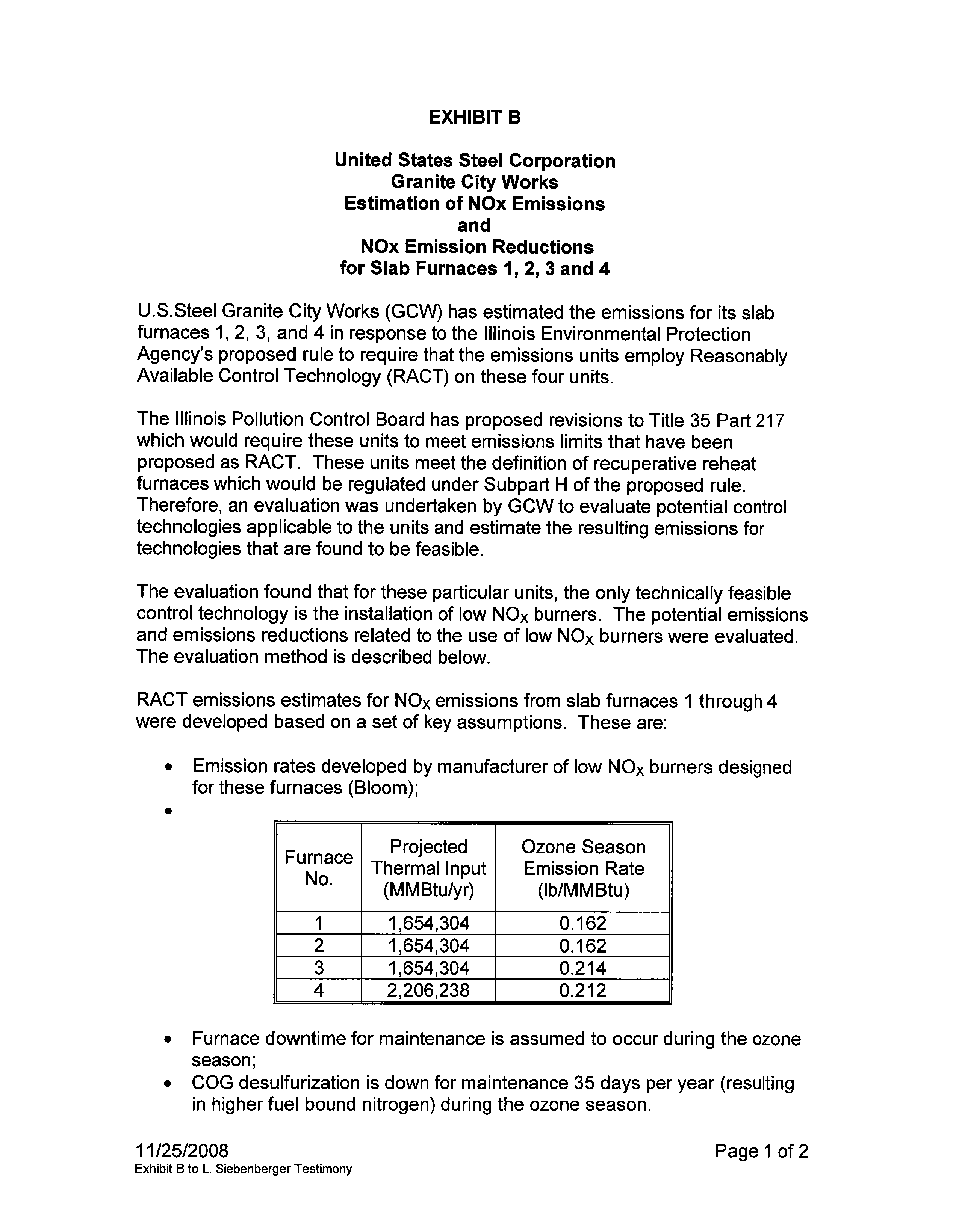

Emission rates developed by manufacturer of low NOX burners

designed

for

these furnaces (Bloom);

Furnace

No.

Projected

Thermal Input

(MMBtu/yr)

Ozone Season

Emission Rate

(Ib/MMBtu)

1

1,654,304

0.162

2

1,654,304

0.162

3

1,654,304

0.214

4- -ý 2,206,238

0.212

" Furnace downtime for maintenance is assumed to occur during the ozone

season;

" COG desulfurization is down for maintenance 35 days per year (resulting

in higher fuel bound nitrogen) during the ozone season.

1 1/25/2008

Page 1 of 2

E xhibit B to L. Siebenberger Testimony

Electronic Filing - Received, Clerk's Office, November 25, 2008

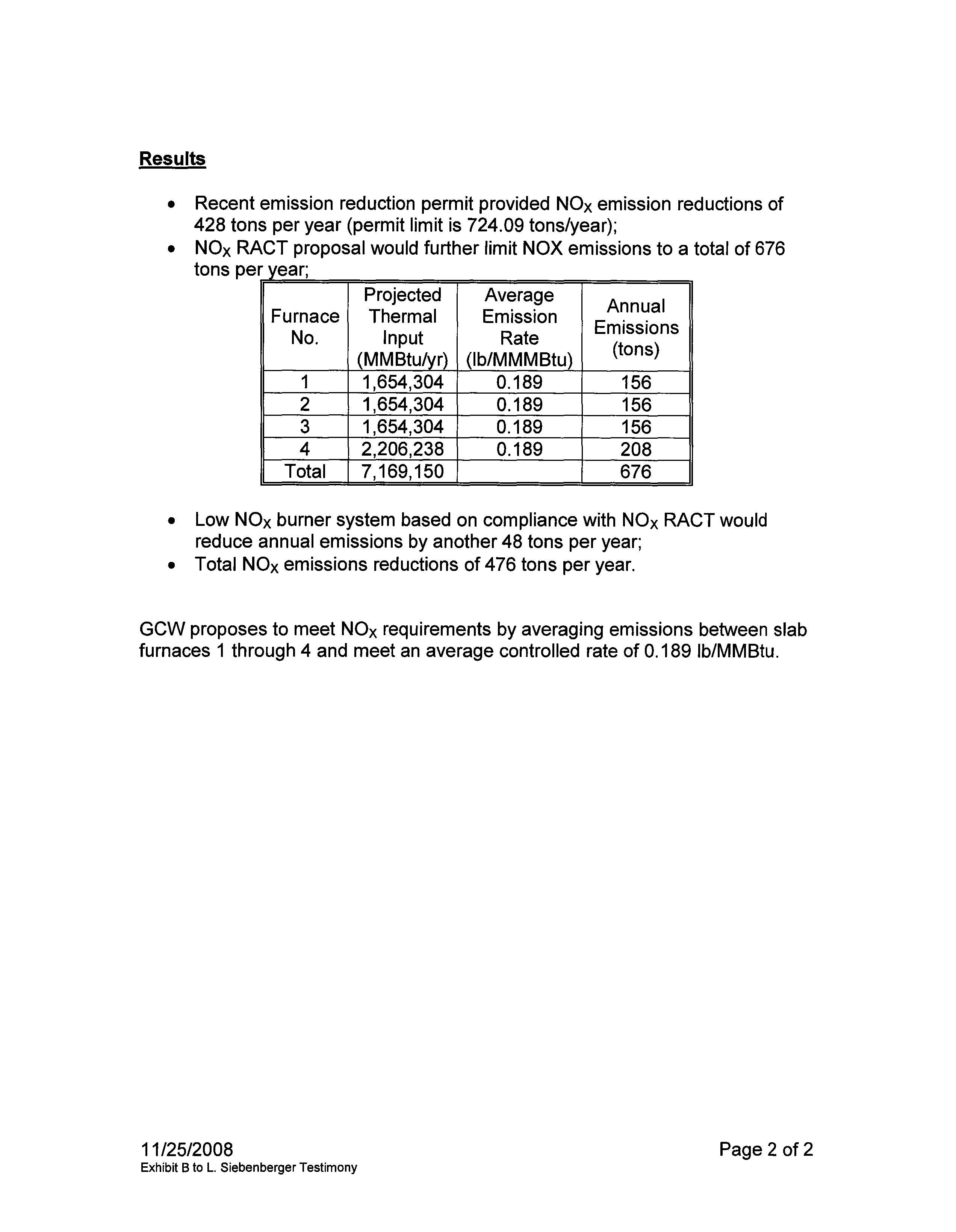

Results

" Recent emission reduction permit

provided NOx emission reductions of

428 tons per year (permit limit is 724.09 tons/year);

" NOx RACT proposal would further limit NOX emissions to a total of 676

tons

per

year;

Projected

Average

Annual

Furnace

Thermal

Emission

E missions

N o.

Input

Rate

(tons)

(MMBtu/ r) (Ib/MMMBtu)

1

1,654,304

0.189

156

2

1,654,304

0.189

156

3

1,654,304

0.189

156

4

2,206,238

0.189

208

Total 7,169,150

676

" Low NOx

burner system based on compliance with NOx RACT would

reduce annual emissions by another 48 tons

per

year;

" Total NOx emissions reductions of 476 tons per year.

GCW

proposes to meet NOx requirements

by

averaging

emissions between slab

furnaces 1 through 4 and meet an average controlled rate of

0.189 Ib/MMBtu.

1 1/25/2008

Page 2 of 2

E xhibit B to L. Siebenberger Testimony

Electronic Filing - Received, Clerk's Office, November 25, 2008

BEFORE THE ILLINOIS POLLUTION CONTROL

BOARD

IN THE MATTER OF:

)

R08-19

NITROGEN OXIDES EMISSIONS FROM ) (Rulemaking

- Air)

VARIOUS SOURCE CATEGORIES: )

AMENDMENTS TO 35 ILL. ADM. CODE

)

PARTS 211 and 217

)

PRE-FILED

TESTIMONY OF BLAKE E. STAPPER

ON BEHALF OF UNITED STATES STEEL CORPORATION

NOW COMES the UNITED STATES

STEEL CORPORATION ("U.S. Steel"),

by and

through its attorneys, HODGE DWYER ZEMAN,

and submits the following

PRE-FILED TESTIMONY OF BLAKE

E.

STAPPER

for presentation at the

December 9,

2008, hearing scheduled in the above-referenced matter.

Pre-Filed Testimony of Blake E. Stapper

I. INTRODUCTION

Good

Morning. My name is Blake Stapper,

and I am a professional engineer in

the State of Texas. I have over twenty years

of experience in the area of regulatory

compliance and combustion

engineering and have been employed

by URS Corporation

("URS"), an environmental consulting firm, since

2000. I have a BS and MS in

mechanical engineering

from the University of Texas and University

of California,

respectively.

A copy of my resume is attached

to my testimony.

My testimony today focuses

on the NOx control options that URS

evaluated for

Boilers 11 and 12

located at U.S. Steel's Granite City

Works ("GCW") in Granite City,

Illinois. I will describe the various NOx control

options that URS evaluated and explain

why such control options are

or are not reasonable NOx control

technologies for these

boilers.

Electronic Filing - Received, Clerk's Office, November 25, 2008

11. BACKGROUND

Boilers 11 and 12 are field erected boilers

rated at a steam flow of 150 klb/hr.

Boiler 11 is a Combustion

Engineering (ABB) corner fired boiler with a single level of

burners. Boiler 12 is a front wall fired boiler built by

Riley with two circular burners.

Both boilers utilize air heaters for

heat recovery and to assist in flame stability when

burning blast

furnace gas ("BFG"). Both boilers are designed to

fire natural gas ("NG"),

coke oven gas ("COG") and BFG either separately

or in combination. Both COG and

BFG are fuels that present special

combustion and pollution control issues. COG

contains fuel nitrogen components, primarily hydrogen cyanide

("HCN"). During

combustion, a fraction of the HCN is converted

to NOx, making the COG a relatively

high NOx emitting

fuel. In regards to BFG, it has a very high concentration

of inerts and

does not contain fuel nitrogen components

like HCN, and consequently BFG is an

inherently low NOx

fuel. However, BFG has a very low heating

value

(about

112

Btu/ft3), and thus, BFG is difficult to burn. Since

both COG and BFG are process gases,

particulates can be present, which

precludes burner designs having small orifices.

As discussed

in more detail in the following sections,

URS evaluated both

combustion modifications options and back-end

control technologies for Boilers 11 and

12. The combustion modifications

evaluated included flue gas recirculation

("FGR")

applied to the existing burners and burner

replacement with and without FGR.

The

back-

end control technologies evaluated

included Selective Non-Catalytic

Reduction

("SNCR").

Electronic Filing - Received, Clerk's Office, November 25, 2008

III. FLUE GAS RECIRCULATION

Based on the URS experience with various fuels, boilers, burners, and FGR

systems, a FGR addition to the existing burners was selected as the optimum NOx control

technology for Boilers 11 and 12. FGR, without burner replacement, has been

successfully applied to both corner fired boilers, which are similar to Boiler 11, and

multi-burner front wall fired boilers, which are

similar

to Boiler 12.

In similar boilers

firing either NG or refinery gas, NOx reductions ranging from 60% to 70% were obtained

with FGR.

The amount of flue gas that may be recirculated is limited by flame stability.

Increasing amounts of FGR reduce the concentration of oxygen in the combustion air,

and replaces it with the inert gases from the flue gas (primarily nitrogen and carbon

dioxide). At lower levels, the recirculated flue gas acts as a heat sink, causing the flame

temperature to decrease, and resulting in lower thermal NOx formation. However, as the

amount of FGR increases, the inerts increase to the point that it is no longer possible to

maintain a stable flame. This point of instability (and the corresponding amount of FGR

that may be safely introduced) varies based on the burner design.

The existing burners on Boilers 11 and 12 should be able to accept a significant

amount of FGR (20%), since the burners already

fire BFG with very little support fuel.

This is because the BFG is composed of a significant amount of inert gases (over 60%

nitrogen and carbon dioxide, combined). The presence of the inert gases depresses the

flame temperature, and reduces the thermal NOx formation. This is the same mechanism,

by which FGR reduces NOx emissions, only the inert gases (the

nitrogen and carbon

Electronic Filing - Received, Clerk's Office, November 25, 2008

dioxide in the flue gas) are introduced along with the combustion air.

As

such,

BFG is

effectively a gaseous fuel with the

equivalent of significant FGR. Since the existing

burners can burn large quantities of BFG, addition of FGR when burning a high

percentage of COG or NG should not present

any combustion issues. Since the boilers

are designed

for the flue gas flow present with BFG, the addition of FGR when firing

NG

or COG will also not present any boiler

heat transfer issues or affect the boiler efficiency.

Since the BFG has the equivalent

of significant FGR, it would not be wise to

implement

additional FGR when firing a high fraction of BFG, as it would

not

be

possible to maintain a stable flame. Due to the inherently

low-NOx combustion of the

BFG, this will not significantly

impact the overall reduction obtained by the

implementation of FGR.

Another factor that makes

FGR an ideal NOx control technology for the GCW

boilers

is that the amount of FGR added can easily be controlled

based on the measured

fraction of NG, COG, and BFG used, allowing

NOx control to be maximized when firing

NG or COG, but

not cause flame stability issues when firing BFG.

IV.

BURNER REPLACEMENT

URS also evaluated whether

replacing burners was a viable option for controlling

NOx from

Boilers 11 and 12 and determined that burner

replacement was not a viable

option for several reasons. First, there

is very limited recent experience in this country

applying "low

NOx burners" technologies to steel plant gases.

In addition, the

specialized fuel requirements at a

steel plant, particularly for BFG, mean many boiler

burner technologies that

have been developed for NG and/or

refinery gas are not suitable

for BFG

applications. Application of a burner

design, unproven for steel plant gases

Electronic Filing - Received, Clerk's Office, November 25, 2008

could result in a non-functional boiler and/or

a boiler explosion. Burner replacement as a

control option also

was rejected for the GCW facility because Boiler 11 is a corner

(tangentially) fired boiler. Since the existing burners for this unit are inherently

low

NOx, the application of circular low NOx burners would

mean a total rebuild of the

boiler.

Further, low NOx burners do not necessarily

provide significant NOx reductions

alone, but must be combined

with FGR. When emissions from low NOx burners with

FGR are compared to emissions from conventional burners with

FGR, in most cases, the

NOx reductions for a given FGR rate are the

same. In the URS boiler database, which

consists of

NOx data from hundreds of boilers with FGR applied to the existing burners

and retrofits of low NOx burners with FGR, there

is no

statistical

difference in the NOx

reductions achieved for a given FGR

rate when the burners were replaced versus

application of FGR alone.

V. SNCR

SNCR

systems entail the injection of a reducing agent (ammonia/urea)

into the

flue gas stream to produce a NOx

reducing atmosphere at proper temperatures. These

systems are common on

large utility boilers. SNCR systems require ample

residence

time and good mixing of ammonia and flue gases at

the ideal temperature range for

satisfactory NOx reductions to occur. If these

conditions are not met, it can result in

higher NOx, or

the emission of unreacted ammonia ("ammonia slip").

The ideal temperature range

for the SNCR reactions to occur ranges from about

1,700°F to 2,100°F.

If the ammonia/urea is injected when the temperature

is higher, it

will be oxidized and will result in higher

NOx emissions. If the ammonia/urea is

injected

Electronic Filing - Received, Clerk's Office, November 25, 2008

when the temperature is too low, the reaction will not occur, and ammonia will be

emitted from the stack. Improper

mixing

of the

ammonia/urea and NOx

can also

result in

poor SNCR performance. If the molar ratio of ammonia/urea to NOx is too high at a

given location, then the excess ammonia will be emitted.

In sulfur-containing fuel firing applications, ammonia slip results in the creation

of ammonium compounds which are emitted as condensable particulates. These

compounds typically condense at temperatures that are commonly found in the air

heaters, and the deposits that form can lead to plugging, fouling, and corrosion. Air

heater pluggage increases the pressure drop and acts to reduce the maximum steam

production from the boiler. Air heater fouling results in decreased thermal efficiency of

the boiler process. Air heater corrosion decreases the equipment life, and results in more

frequent maintenance. Each of these outcomes

will ultimately require that the unit be

shut down. Recent studies on utility boilers that inject ammonia when firing sulfur-

containing fuels suggest that even very low amounts of ammonia slip may negatively

impact the air heater.

Boilers 11 and 12 are not good candidates for SNCR application because their

operating characteristics are

not consistent with the characteristics required for SNCR

operation. As discussed in more detail below, the specific characteristics of

the boiler

operation that preclude SNCR as a viable control option

include variation in steam load,

changes

in the bound-nitrogen content of the fuel, fluctuations in fuel heating value, and

the sulfur content of the COG.

The steam loads

for Boilers 11 and 12 varies significantly, because they are

affected by other parts of the process. When both blast furnaces

are in operation, the

Electronic Filing - Received, Clerk's Office, November 25, 2008

steam demand is high. However,

when only one blast furnace is in operation, the steam

demand is relatively low.

There are other parts of the process that require steam,

which

cause the boiler load to swing. When the load changes,

the flue gas temperature also

changes. As such, the location of

the optimum temperature window for the SNCR

reactions changes.

Since the ammonia/urea injection grid

is fixed, the flue gas

temperature at the injection point

may not be ideal. On large utility-scale boilers,

multiple injection

locations may be used to overcome this problem,

but it is not practical

on smaller units, such as GCW's Boilers

11

and

12.

The COG contains bound

nitrogen, in the form of HCN, which is of particular

concern when the

H2S scrubber is out of service for maintenance

purposes. The presence

of bound-nitrogen compounds in the COG

means that changes in the COG firing rate will

also produce dramatic changes

in the uncontrolled NOx concentration.

Variations in the

NOx cause an improper molar ratio of ammonia/urea

to NOx, resulting in either

higher

NOx emissions or ammonia slip

as the COG component of the fuel

changes.

The

heating value of the three fuels being

fired in Boilers 11 and 12 is quite

different, with the BFG having

a heating value about one tenth that of NG,

and the COG

being somewhere in between.

As the fuel blend being

fired in the boilers varies, the

flame temperature

in the boiler fluctuates.

The fuel blend also affects mass

flow rate

through the boiler, which is much

higher for the BFG than for NG.

The changes in the

flame temperature

and mass flow rate not only cause

the location of the ideal SNCR

injection temperature window

to change, they also cause the NOx

mass emission rate to

fluctuate. Variations

in the NOx cause an improper

molar ratio of ammonia/urea

to NOx,

Electronic Filing - Received, Clerk's Office, November 25, 2008

resulting in either higher NOx emissions or ammonia slip during fuel composition

transitions.

The scrubbed COG contains a significant amount of hydrogen sulfide and other

sulfur-containing compounds. These concentrations are much higher when the boilers

are being operated

while the H2S scrubber is out of service for maintenance purposes. In

either case, some of the sulfur compounds will react with the ammonia/urea that is

injected to form condensable ammonium sulfates.

Ammonium bilsulfate will condense at

the temperatures present in the air heater. As such, it will form deposits on the air heater

surfaces, and will negatively affect the boiler operation, as described

previously.

Ammonium

sulfate production is also an issue that is particularly important in Granite

City since any additional fine particulate that is produced by combustion processes

and

ultimately emitted to the atmosphere

has the potential to exacerbate PM2,5 nonattainment

issues.

VI. CONCLUSION

The NOx control measure that is best applied to the GCW Boilers 11 and 12 is

FGR. This NOx control can result in significant pollutant

reductions while minimizing

potentially adverse effects

on boiler operation. Other control approaches considered for

these boilers included SNCR and low NOx burners. Neither of these

controls offer any

advantages either singularly or in combination

with FGR when compared to application

of FGR alone.

In fact, particularly SNCR has several distinct disadvantages

including the

potential to create additional PM emissions - a result that

would be directly at odds with

the Illinois Environmental

Protection Agency's goal of reducing PM emissions

in

order

to attain the PM2,5 National Ambient Air Quality Standard.

Electronic Filing - Received, Clerk's Office, November 25, 2008

Thank you for allowing me the opportunity to present my testimony. I am

happy

to answer any questions.

U.S. Steel reserves the right to supplement

this testimony.

Respectfully submitted,

By: /s/ Katherine D. Hodge

Katherine D. Hodge

Dated: November

25, 2008

Katherine D. Hodge

Monica T. Rios

HODGE DWYER ZEMAN

3150 Roland Avenue

Post Office Box 5776

Springfield, Illinois 62705-5776

(217) 523-4900

U SS0001/Fil/R0819/Prefiled

Testimony of B. Stapper

Electronic Filing - Received, Clerk's Office, November 25, 2008

Blake E. Rapper, PE

Principal Engineer

A reas

of

Expertise

N Ox, Combustion, Air Pollution

Control, Regulatory Compliance,

Compliance Strategy, Emissions

Monitoring and Prediction

Years of Experience

With URS: 16 Years

With Other

Firms: 4 Years

E ducation

MS / 1989 / Mechanical

Engineering / University of

California, Irvine

B S / 1986 / Mechanical Engineering

/ University of Texas @ San

Antonio

Registration/ Certification

1 993 / Registered Professional

Engineer / TX / 76087

O verview

Mr. Stapper has worked in the

field

of

regulatory compliance and

combustion engineering for

20 years, and currently serves as the manager

of the Air Pollution Control team for URS' Carolinas operation.

During

his career, he has performed and

managed numerous combustion and air

pollution control projects in the refining, chemicals,

utility, metals, forest

products, and aerospace

industries. The primary focus of these projects

has been to quantify and reduce the NO. emissions

from a wide variety of

sources. He has managed air

permitting projects for utilities, and

developed and taught training programs

for both air pollution control and

regulatory applicability.

Mr.

Stapper

has performed numerous BACT

analyses for multiple source types,

including boilers, process heaters, IC

engines, turbines, flares, and

painting facilities. He has worked to develop

innovative NOx control technologies, and

has conducted evaluations to

select the most suitable

technology for a particular application. He has

also performed optimization projects to

improve efficiency, both for

individual sources, and

for entire facilities. His responsibilities have

included all aspects of these

projects, including planning, testing, design,

implementation, and

project management.

C hronology

Principal Engineer, URS,

Charlotte, NC, 2007 to present

Unit Leader, URS,

Austin, TX, 2002 to 2006

P roject Manager, URS,

Austin, TX, 2000 to 2002

P roject Manager,

Pegasus Technologies, Austin, TX, 1998-2000

Senior Engineer, Radian

International, Austin, TX, 1990-1998

Research Assistant,

The University of California - Irvine, 1987-1989

Research Engineer, SwRI,

San Antonio, TX, 1986-1987

P roject Specific Experience

S ome specific examples of projects in which Mr. Stapper

has

been

involved are as follows:

"

Project Manager, Emissions Control

Study. Mr. Stapper is

currently working on a project to evaluate

the emission control

equipment that would provide the

best solution for a facility in

Texas that is burning petroleum coke

in horizontal kilns. The

objective of the project

is to identify a combination of particulate,

Electronic Filing - Received, Clerk's Office, November 25, 2008

S02,

and sulfuric acid controls that would allow the facility relief

from the

regulatory requirements that currently constrain their

operational

flexibility. The deliverable for this effort is a

recommendation

and budgetary cost estimate, for the purpose of

securing authorization to develop an Authorization For Design

engineering

package.

"

Project Manager, NOx Control Evaluation for Clean Air

Interstate Rule (CAIR) Compliance. Managed an evaluation

of

a 430 MW tangentially-fired utility boiler, to determine the

applicability

and costs of a range of NOx control technologies.

The

goal

of the project was to recommend how to implement

these technologies

in stages to provide the most cost-effective

solution

for complying with the CAIR Phase I and Phase II NOx

emission allowances.

"

Task Leader, Petcoke Gasifier Permit Application. Mr.

Stapper served

as the task leader for the analysis of the Best

Available Control Technology (BACT) for the emissions sources

at a proposed

petroleum coke gasification facility in Texas. The

sources

that were evaluated included boilers, thermal oxidizers,

material

handling, storage tanks, and IC engines.

"

Project Manager, Low-NOx Burner Retrofits for 12 Process

Heaters. Managed a project to engineer, procure, and provide

construction oversight for the installation of low-NOx burners

and burner

management systems on twelve process heaters. Mr.

Stapper was responsible for coordinating the work of URS staff

from multiple offices with a number of subcontractors, in order

to meet the regulatory compliance date of June 1, 2006. All

twelve

heaters were certified as compliant prior to the deadline.

"

Project Manager, Boiler Induced Flue Gas Recirculation

(IFGR) Retrofit. Managed the design of an IFGR system on a

steam boiler at NASA. The goal of the project was to reduce

NOx emissions to 0.035 lb/MMBtu using the existing forced

draft fan. The boiler control system was also upgraded. The

deliverable was the construction bid package

for the retrofit.

"

Project Manager, NOx Controls for Rule 4306 Compliance.

Managed a project to assess the necessary

modifications to 43

refinery combustion sources for compliance with

the

San

Joaquin

Valley Unified Air Pollution Control

District Rule

4306.

Mr.

Stapper was responsible for the technical evaluation of the

process heaters for retrofit with ultra

low-NO, burners. Two

boilers require the installation of induced flue gas

recirculation

(IFGR) to meet the new compliance

limits. A number of the

Electronic Filing - Received, Clerk's Office, November 25, 2008

larger boilers and

process heaters will require SCR. The scope

of

the project was to determine

what controls should be applied

to

each unit, and

to

provide

a total installed cost estimate.

"

Project Manager, Ultra-low

NOx Burner Retrofit for NOx

SIP Compliance.

Managed the installation of an ultra-low

NOx

RMB burner on two gas-fired

steam boilers to achieve 9 ppm

NOx emissions.

The turn-key EPC project included an

upgrade

of the boiler burner

management system, the replacement of

the

forced-draft

fans, and the installation of variable frequency

drives

to increase the operating

efficiency. The first retrofit is complete,

and installation

on the second boiler is underway.

"

Project Manager,

Low NOx Burner Retrofits. Managed

the

implementation

of ultra-low NOx burner retrofits on

a boiler and

two process

heaters for a chemical manufacturer with two

sites in

the HGA

The first part of this effort was to develop

a SIP

compliance evaluation.

This study determined the lowest

cost

options for

NOx control technologies at each of the

two sites,

and also developed

a plan that demonstrated the potential savings

if the two sites

traded NOx credits as if they were a

single

account. A project

schedule was also developed so that

the

projects could

be spread out over the duration

of the five year

interim compliance

period.

"

Project

Manager, SCR Troubleshooting.

Evaluated

performance

problems with the Selective Catalytic

Reduction

(SCR) systems

on four GE LM6000 simple

cycle gas turbines.

Although

the units had only operated about

1,000 hours since

startup,

the SCRs had not been able to

demonstrate the necessary

performance,

based on outlet NOx emissions.

URS was

contracted

to investigate the extent of

the performance problem,

to identify

the causes of the operating problems,

and to

recommend

corrective actions. The

results showed that the SCR

was not

able to achieve the performance

guarantee for outlet

NOx

and NH3 slip. The data showed

that the ammonia

vaporization

skid was undersized, and

further suggested that the

performance

problem was caused

by premature catalyst

deactivation.

URS provided recommendations

for corrective

action, which were subsequently

implemented.

"

Project Director, Passive

FTIR Phase I Testing of

Simulated and Controlled

Flare Systems. Directed the

technical tasks for an evaluation

of the use of passive Fourier

transform infrared radiometry

for measuring emissions from

process flares. Flare emission

levels are not well understood due

Electronic Filing - Received, Clerk's Office, November 25, 2008

to the difficulty in making traditional emissions measurements.

The project consisted of the development of a Quality Assurance

Project Plan (QAPP), an analytical study of the technology

to

estimate detection limits, along with field testing on a simulated

flare plume and an actual process flare. Mr. Stapper's

responsibilities included the overall management of the technical

aspects of the project, which included serving as the

leader of the

testing, data analysis, and reporting tasks.

"

Project Manager, Boiler Optimization. Testing, modeling

and

installing a neural network control system on a coal-fired, 590

MW tangentially-fired CE boiler with SOFA and CCOFA.

Initial

testing demonstrated a NOx reduction of 20%, with a

simultaneous 50 Btu/kWh improvement in unit

net heat rate.

"

Project Manager, Utility Boiler Optimization . NOx and

heat

rate improvement project on a gas-fired 430 MW tangentially-

fired CE boiler. Testing included an evaluation of reduced air

operation at low loads and an assessment of the optimum

burner

configurations to achieve minimum NOx at low loads. The

recommended changes to the unit's operating

procedures reduced

heat rate by 0.5% and lowered NOx emissions by

15%.

"

Project Manager,

Boiler

Optimization

and Emissions

Prediction. Testing, modeling and

installing a neural network

control system on a coal-fired, 590

MW tangentially-fired CE

boiler. The goal of this project was to reduce

NOx

emissions

as

much as possible with no negative

impact on heat rate. Testing

was conducted to determine the effects of

reduced

excess

oxygen,

mill biasing and air staging.

The system demonstrated an 18%

NOx reduction, with a 1.9 percent

heat rate improvement.

"

Project Manager, Consulting

Services to Evaluate NOx and

S02 Emissions Control

for Municipal Waste Gasifier.

Managed an

evaluation of the performance claims for a municipal

solid waste gasification

facility. Mr. Stapper was responsible for

reviewing the

documentation provided by the gasifier vendor for

the combustion

process to gasify the MSW, along with the post-

combustion

controls for removal of particulate, S02, and NOx.

The results of

the evaluation showed that the gasifier project was

capable of

performing at the specified production rate, while

achieving the

project goals for emission levels.

"

Task Leader, SCR Pilot Demonstration. Pilot study to

demonstrate

the applicability of a selective catalytic reduction

system

(SCR) on a high-dust, coal-fired utility boiler. Responsible

for

planning testing activities, analyzing the results, and reporting.

Electronic Filing - Received, Clerk's Office, November 25, 2008

"

Task Member, SNCR Demonstration. Demonstration of a

selective

non-catalytic reduction system (SNCR) for NOx

reduction on a 185 MW oil-fired boiler. Responsible for

conducting

test program and for collective process and emissions

data. Collected and analyzed ammonia samples to equate SNCR

NOx reduction performance with ammonia slip.

"

Task Member, System-wide NOx Control Evaluation.

Evaluated NOx control technologies for all the sources at a

utility. Specific responsibility was to assess the effectiveness of

the selective non-catalytic NOx reduction technology on

approximately 50 units.

"

Task Leader, Amine Incinerator BACT Analysis.

Recommended the best available control technology (BACT) for

NOx on a new amine incinerator at a Gulf Coast chemical plant.

The project tasks included a review of the waste stream to

estimate

the emissions loading, an evaluation of the available

NOx control technologies, and the identification of the most cost

effective

control equipment.

"

Project Director, Projected Emissions from BIF Boiler.

Analyze the potential emissions from a proposed BIF boiler (for

incinerating hazardous wastes) at a Gulf Coast refinery. The

project required an assessment of the existing BIF units and their

respective waste streams. This was coupled with the operating

characteristics of the proposed unit in an attempt to predict the

emissions once it was installed.

P rofessional Societies

/ Affiliates

Air and Waste Management Association

American Society of Mechanical Engineers

Combustion

Institute

I nstitute for Liquid Atomization Spray Studies

Carolinas

Air Pollution Control Association

S pecialized

Training

MS / 1989 / Mechanical Engineering / University

of California, Irvine

BS / 1986 / Mechanical Engineering / University

of Texas @ San

Antonio

URS Project Manager Certification,

2005

Electronic Filing - Received, Clerk's Office, November 25, 2008

Publications

John

Wester, Blake Stapper and Madhu Ramavajjala, "SCR Operational

Issues at Austin Energy's Sand Hill Energy Center", presented at the

105th Meeting of the Plant Design and Operating Committee, Austin,

TX, July 2002.

T eresa L. Wilson, Blake E. Stapper, G. Dale Roberts and Don Scruggs,

"Application of a Neural Network Based, Closed-Loop Control

Optimization System to a Load-Following Utility Boiler, to be

presented at PowerGen 2000, Orlando, FL, November 2000.

Blake E. Stapper and R.C. Booth, "Advances in the Application of Neural

Network Systems for Controlling NOx and Heat Rate in Utility

Boilers", AWMA 93rd Annual Conference and Exhibition, Salt Lake

City, UT, June 2000.

Brad J. Radl and Blake E. Stapper, "Advanced Control and Operating

Strategies for Power Generation Companies", EPRI-DOE-EPA

Combined Utility Air Pollutant Control Symposium, Atlanta, GA,

1999.

Micheal Lewis, Monte Gottier, and Blake Stapper, "Emission Solutions

Through Optimization", EPRI-DOE-EPA Combined Utility Air

Pollutant Control Symposium, Washington, D.C., 1997

S cott Briggs, Blake Stapper, and Walt Crow, "A Predictive Emissions

Monitoring System (PEMS) for a Paper Mill Power Boiler", TAPPI

Environmental Conference & Exhibit, Minneapolis, MN, 1997

Blake E. Stapper, Gordon C. Page, Robert R. Horton, and Ted S. White,

"Compliance Optimization Modeling Systems for Industrial Boilers",

CIBO Ninth Annual NOx Control Conference,

Hartford,

CT,

1996

Blake E. Stapper, Thomas P. Nelson, Ronald D. Bell, and S. Peter Barone,

"A Low- NOx, High-DRE Burner for Co-firing

Liquid Waste with

Natural Gas", AFRC Fall International Symposium,

Monterrey,

CA,

1995

Huang, C., Hargis, J., Fuller, L., Mallory, R., Stapper, B.,

and

Cichanowicz,

E., "Status of SCR Pilot Plant Tests on

High

Sulfur

Coal at Tennessee

Valley Authority's Shawnee Station," presented at

the 1993

EPRI/EPA Joint Symposium on Stationary

NOx Control, Miami, FL

B. E. Stapper and G. S. Samuelsen, "An Experimental

Study

of the

Breakup of a Two-Dimensional

Liquid Sheet in the Presence of Co-

flow Air Shear", AIAA-90-0461, Gas

Turbine and Aeroengine

Congress and Exposition, Brussels,

Belgium, 1990

Electronic Filing - Received, Clerk's Office, November 25, 2008