TN THE

MATTER

OF:

)

NITROGEN

OXIDES

EMISSIONS

FROM

)

VARIOUS

SOURCE

CATEGORIES:

)

AMENDMENTS

TO

35 ILL. ADM.

CODE

)

PARTS

211

AND 217

NOTICE

OF

FILING

TO:

Mr.

John T. Therriault

Assistant

Clerk

of

the Board

Illincis

Pollution

Control

Board

100 W.

Randolph

Street

Suite

11-500

Chicago,

Illinois

60601

(VIA HAND

DELIVERY)

Timothy

Fox,

Esq.

Hearing

Officer

Illinois

Pollution

Control

Board

100

W. Randolph

Street

Suite

11-500

Chicago,

Illinois 60601

(VIA

U.S.

MAIL)

(SEE

PERSONS

ON

ATTACHED

SERVICE

LIST)

PLEASE

TAKE

NOTICE

that

I

have today

filed

with the

Office of

the Clerk

of the

Illinois

Pollution

Control

Board

PRE-FILED

COMMENTS

FOR

THE ILLINOIS

ENVIRONMENTAL

PROTECTION

AGENCY

SUBMITTED

BY

ARCELORMITTAL

USA,

INC.

a copy of

which

is herewith

served upon

you.

Dated:

Respectfully

submitted,

By:

CLLL

Christina

L. Archer

Christina

L.

Archer

Associate

General

Counsel

ARCELORMITTAL

USA, INC.

1.

South

Dearborn,

19

th

Floor

Chicago,

Illinois

60603

(312)

899-3865

CEV

CLERK’S

OFFICE

BEFORE

THE

ILLINOIS

POLLUTION

CONTROL

BOARD

25

2008

)

R08-l9

(Rulemaking

- Air)

STATE

OF

(LL(NOIs

Potluton

Control

Board

THIS FILING

SUBMITTED

ON RECYCLED

PAPER

CERTIFICATE

OF SERVICE

I, Christina L.

Archer, the

undersigned, hereby

certify

that I have

served

the

attached

PRE-FILED

COMMENTS.

FOR THE ILLINOIS

ENVIRONMENTAL

PROTECTION

AGENCY SUBMITTED

BY

ARCELORMITTAL

USA, INC:

upon:

Mr. John T.

Therriault

Assistant Clerk

of the Board

Illinois

Pollution Control

Board

100 West Randolph

Street,

Suite 11-500

Chicago,

Illinois 60601

via hand

delivery. on

November

25,

2008 (original plus 9

copies);

and upon:

Timothy Fox, Esq.

Hearing

Officer

Illinois Pollution

Control Board

100

WtRandolph,

Suite 11-500

Chicago,

Illinois

60601

Gina

Roccaforte,

Esq.

Ms. Dana

Vetterhoffer

Division of Legal

Counsel

Illinois

Enviromental

Protection

Agency

1021 North

Grand

Avenue East

Post Office

Box

19276

Springfield,

Illinois

62794-9276

Virginia

Yang. Esq.

Deputy

Legal

Counsel

Illinois

Department

of Natural

Resources

One

Natural Resources

Way

Springfield,

Illinois

62701-1271

Mathew

J. Dunn,

Esq.

Chief,

Environmental

Bureau

North

Office of

the

Attorney General

69

West

Washington

Street,

Suite

1800

Chicago,

Illinois

60602

Kathleen

C.

Bassi,

Esq.

Stephen

J.

Bonebrake,

Esq.

SchiffHardin,

LLP

6600

Sears

Tower

233

South

Wacker

Drive

Chicago,

Illinois

60606-6473

Alec M. Davis,

Esq.

General Counsel

Illinois

Environmental

Regulatory Group

215

East Adams

Street

Springfield,

Illinois

62701

by

depositing

said

documents in the

United

States Mail, postage

prepaid,

in

Chicago,

Illinois on

November 25,

2008.

CLL

Christina

L.

Archer

THIS

FILING

SUBMITTED

ON

RECYCLED

PAPER

BEFORE

THE ILLINOIS POLLUTION

CONTROL

BOA1D

•

iN

THE MATTER OF:

)

NOV

25

2OO

NITROGEN

OXIDES EMISSIONS

FROM

)

(Rulemaking-Air)

VARIOUS SOURCE

CATEGORIES:

)

V

AMENDMENTS

TO 35

ILL. ADM CODE

).

•

PARTS

211 AND

217

V

)

V

V

PRE-FILED

COMMENTS

FOR

THE

V

ILLINOIS ENVIRONMENTAL

PROTECTION

AGENCY

•

SUBMITTED

BY

ARCELORMITTAL

USA,

INC.

NOW

COMES

ARCELORMITTAL

USA

INC.

(ArcelorMittal)

and submits the

following

Pre-Filed Comments

for

the

Illinois Environmental

Protection Agency

(Illinois

EPA or

Agency)

for presentation

at the

1

st

round

of hearings

scheduled in the

above-referenced

matter

for

December

9,

2008.

Specifically,

the proposed

regulations at 35 Ill.

Adm. Code

Part

217,

Subpart

H apply to iron

and steel and

aluminum

manufacturing

and

regulate reheat,

annealing

and

galvanizing

furnaces. ArcelorMittal’s

Riverdale,

Illinois facility has

a permitted

roller-

hearth

tunnel

furnace

equipped with ultra-

low NOx

tube burners (ULNBs),

which processes

cast

steel

slabs.

However,

the tunnel furnace

cannot be

considered as a

reheat, annealing,

or

galvanizing

furnace

and the arbitrary

NOx

reduction

proposed is

inappropriate for the

tunnel

V

V

furnace

in

operation

at ArcelorMittal’s

Riverdale

facility.

ArcelorMittal

finds

that based

on the

applicability

provisions

provided in

the proposed

regulation

at 35 JAC

217.150, the

tunnel

furnace

is not subject to this

regulation.

Should the

Agency

deem that

ArcelorMittal’s

tunnel

furnace requires

regulation

under the

proposed rule, it will

be

necessary

for the. Agency

to

include

a

specific

defmition

and emission factor

for the

existing

tunnel furnace

at

ArcelorMittal’s

Riverdale,

Illinois

facility, recognizing

the unique

nature of

the

operation

and the advanced

NOx

/

control

technologies

already

in

use.

V

THIS FILING

SUBMITTED ON

RECYCLED PAPER

1.

For

clarification purposes,

a brief

background

on

these

types

of furnaces

within

the

iron

and

steel

industry

is provided

herein.

Annealing

and

galvanizing

furnaces

are

used

to

further

process

steel

that

has

already

been

hot-rolled

and

exists

as

a

steel

strip,

while

reheat

furnaces are

used

to

process

steel

slabs,

billets

and

blooms,

which

are

typically

considered

intermediate

products.

At

traditional

mills,

liquid

steel

is

cast

into

slabs;

the

slabs

are

then

stored

in

a slab

yard,

transported to

a reheat

furnace,

heated

to

a

temperature

sufficient

for

rolling,

rolled

into

a

strip,

and

fmally

coiled

as a

finished

product.

In 1986,

new

technology

was

developed

that

allowed

continuous

casting

of

thin

slabs.

At

the Riverdale

facility,

a

state

of

the

art

compact

strip

production

(CSP)

facility

was

constructed

and began

operation

in 1996.

The CSP

process

allows

liquid

steel

to

be

cast

into

thin

slabs,

which

then

directly

enter

a

tunnel

furnace,

before

being

rolled

into

a strip

and

coiled.

ArcelorMittal

Riverdale

casts

a

thin

slab

with

a

2-inch

height,

which

is

then cut

to

length

by the

shear,

and

conveyed directly

into

the

tunnel

furnace

which

serves

to

equalize

slab

temperature

prior

to

rolling

at the

hot

strip

mill

(HSM):

The

CSP

design

represents

advanced

energy

efficiency

process

technology

(and

emission

reductions)

compared

to

traditional

methods

of

making

“hot

bands.”

Clearly,

the tunnel

furnace

is

not an

annealing

or galvanizing

furnace.

ArcelorMittal

has

prepared

the

remainder

of

these

comments

to further

illustrate

that

a

tunnel

furnace

cannot

be

coisidered

as a

reheat

furnace.

-

2.

The

Technical

Support

Document

(TSD)

prepared

in

support

of

the

rulemaking

provides

a

general

description

of

reheat

furnaces;

however,

the Illinois

EPA

provides

no

proposed

definition

of

reheat

furnaces

in

35

Iii.

Adm.

Code

Part

211.

Temperature

and

fuel

mixture

are

two

components

used

in

defining

a

reheat

furnace.

As

described

in

Section

6.2.1

of

THIS

FILING

SUBMITTED

ON

RECYCLED

PAPER

the

TSD, the

typical temperature

range for a reheat

furnace is a

continuous 2150

to

2450°F.

A

typical

reheat

furnace must

increase the slab to

this

temperature

from

ambient

levels;

however,

the

tunnel

fuinace

at ArcelorMittal’s

Riverdale

facility

maintains

the

slab

at its cast

temperature

with

only.

a

small

increase

in

temperature from

approximately

1800-1900°F to

2040-2146°F.

The

maximum

temperature of the

tunnel furnace

is 2150°F, well below

a

typical reheat

furnace’s

capacity.

Additionally,

while

traditional reheat

furnaces use fuel-rich

mixtures,

the tunnel

furnace

uses

a leaner fuel mixture.

3.

Design parameters

also

differ in

the tunnel furnace

versus a

traditional

reheat

furnace:

ArcelorMittal’s

predecessor,

Acme Steel

Company,

applied for a construction

permit

for

the CSP facility, including

the tunnel furnace,

on

April 12,

1993. The application

stated that

“The

Tunnel Furnace NOx

control technology

is

planned to

consist of low NOx

burners and

burner

càntrol

equipment.

In the

unlikely

event of burner(s)

or associated burner

control(s)

malfunctiOflor

breakdown,

the tunnel

furnace

must continue

to operate because it

is

in-line

with

the

cOntinuous., caster and

is the only

outlet for cast steel

slabs. The

tunnel furnace

is not

designed

as a conventional

reheat furnace;

therefore, any slabs

that must be

diverted

are not

recoverable

by Acme.” In

review, it

was found that the burners

are equivalent

in design

and

operation

to

ULNB, not

LNBs (See

paragraph #4 below

for more

details).

As

previously

indicated,

the , tunnel furnace

receives

slabs

directly from

the continuous caster.

Unlike a

traditional caster

which produces

a slab that’ is

stored prior

to processing, there is

no place to

store the

slabs

and no way to

“reheat”

a slab

from

ambient temperature.

The

entire CSP process

operates

as one

continuous process

and all sections must

be operating

optimally to produce

a

quality

finished product.

Further,

the tunnel furnace oflen

holds

the

slabs

until

they

can be

‘processed

at the

downstream

HSM.

Slabs

are

only

held

to accommodate maintenance

of HSM

THIS

FILING

SUBMITTED

ON

RECYCLED

PAPER

equipment;

any

lengthy holding

time

is

detrimental

to

the quality

of the

slab and

thus

the final

product.

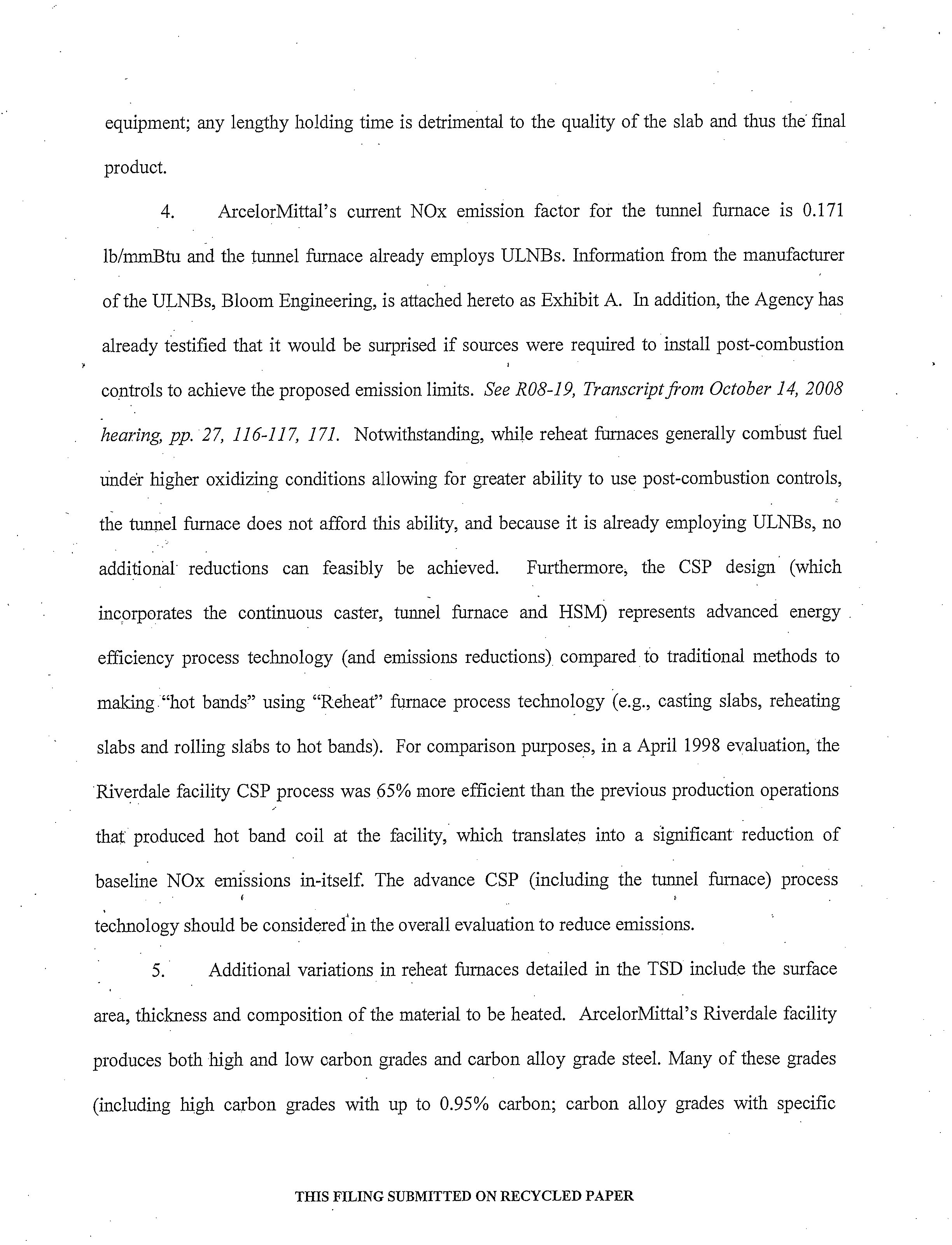

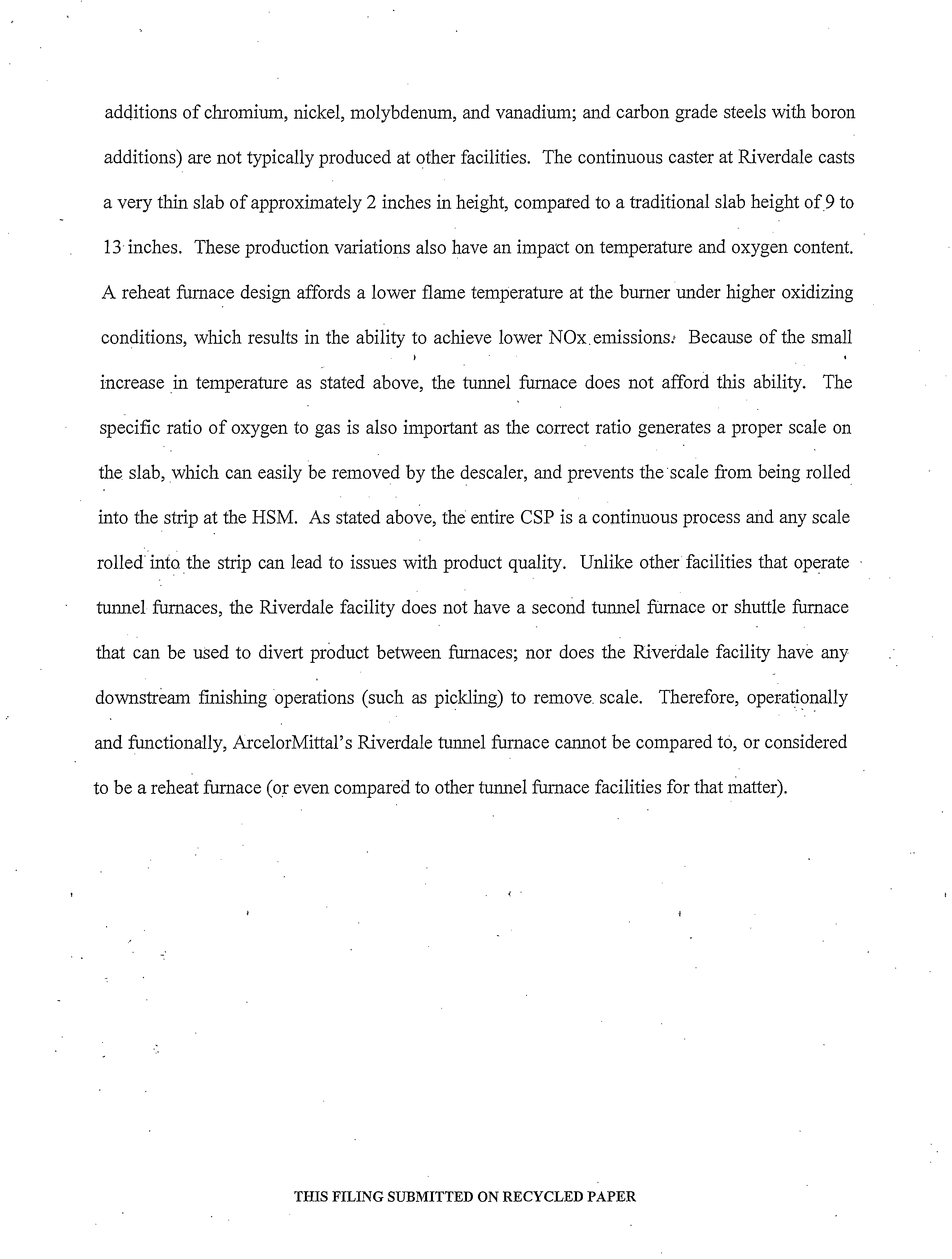

4.

ArcelorMittal’s

current

NOx

emission

factor

for the

tunnel

furnace

is 0.171

lb/mrnBtu

and

the

tunnel

furnace

already

employs

ULNBs.

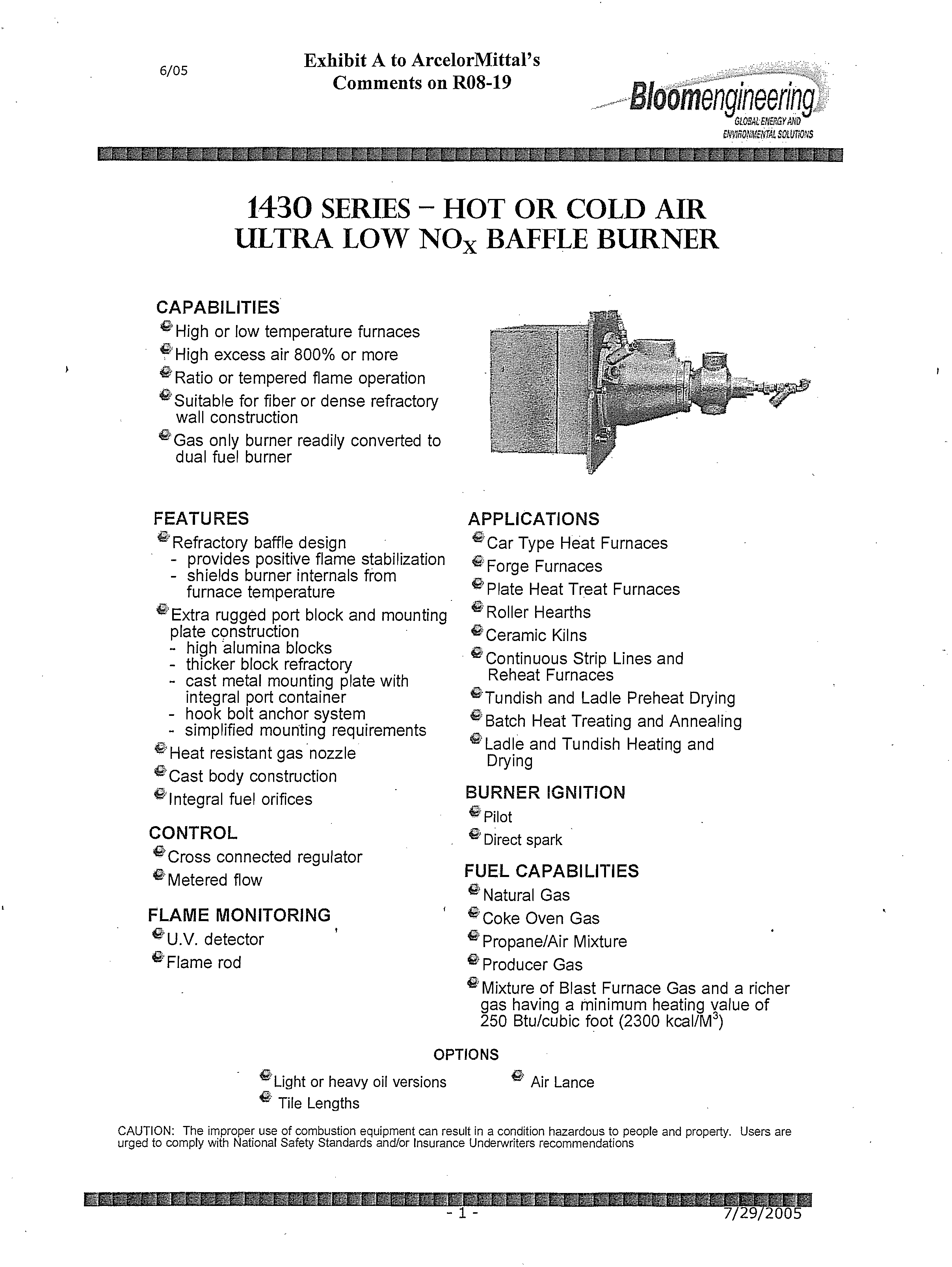

Information

from

the manufacturer

of the

ULNBs, Bloom

Engineering,

is

attached hereto

as Exhibit

A.

In addition,

the Agency

has

already

testified

that

it

would

be

surprised

if

sources

were

required

to install

post-combustion

controls

to achieve

the

proposed

emission

limits.

See

R08-19,

Transcrzpt

from

October

14,

2Q08

heariiig,

pp.

27, 116-117,

171.

Notwithstanding,

while

reheat

furnaces generally

combust

fuel

under

higher

oxidizing

conditions

allowing

for

greater

ability

to use

post-combustion

controls,

the

tunnel

furnace

does

not

afford

this ability,

and

because

it is

already

employing

ULNBs,

no

additional

reductions

can

feasibly

be

achieved.

Furthermore,

the CSP

design (which

incorporates

the

continuous

caster,

tunnel furnace

and

HSM)

represents

advanced

energy

efficiency

process

technology

(and

emissions

reductions)

compared

to

traditional

methods

to

making.”hot

bands” using

“Reheat”

furnace

process technology

(e.g.,

casting slabs,

reheating

slabs

and

rolling

slabs

to

hot

bands).

For comparison

purposes, in

a April

1998 evaluation,

the

Riverdale

facility

CSP

process was

65%

more efficient

than

the

previous

production

operations

that

produced

hot

band

coil at

the

facility,

which

translates

into

a significant

reduction

of

baseline

NOx

emissions

in-itself.

The

advance

CSP (including

the

tunnel

furnace) process

technology

should

be considered

in

the

overall

evaluation

to

reduce emissions.

5.

Additional

variations

in

reheat furnaces

detailed

in the

TSD include

the surface

area,

thickness

and

composition

of

the

material

to

be heated.

ArcelorMittal’s

Riverdale

facility

produces

both

high

and

low carbon

grades

and carbon

alloy

grade steel.

Many

of

these

grades

(including

high

carbon

grades with

up to

0.95%

carbon; carbon

alloy

grades

with

specific

THIS

FILING

SUBMITTED

ON RECYCLED

PAPER

additions

of chromium, nickel, molybdenum, and vanadium;

and carbon

grade

steels with boron

additions)

are not typically produced at other facilities. The

continuous caster at Riverdale casts

a very thin

slab of approximately 2 inches in height,

compared

to

a traditional slab

height

of

9

to

13 inches.

These

production

variations also have

an impact

on

temperature and oxygen content.

A

reheat

furnace design affords a lower flame temperature at

the burner under higher oxidizing

conditions, which results in the ability to achieve lower

NOx.emissions. Because of the small

increase in temperature as stated above, the tunnel furnace does

not afford this ability. The

specific ratio of oxygen to gas is also important as the correct

ratio generates a proper scale

on

the slab, which can easily be removed by the descaler, and

prevents the scale from being rolled

into the strip at the HSM. As stated above, the

entire

CSP is a continuous

process and

any

scale

rolled into the strip can

lead

to issues with

product

quality. Unlike other

facilities

that operate

tunnel

furnaces, the Riverdale facility

does not

have

a second tunnel

furnace

or

shuttle furnace

that

can

be used to

divert

product

between

furnaces; nor does the

Riverdale facility

have any

downstream

fmishing operations

(such

as

pickling) to remove, scale.

Therefore, operationally

and functionally,

ArcelorMittal’

s

Riverdale tunnel furnace cannot be

compared

tO, or

considered

to be a reheat

furnace (or

even

compared to other tunnel furnace

facilities

for

that matter).

THIS FILING

SUBMITTED ON

RECYCLED PAPER

For

the above reasons, AtcelorMittal USA, Inc. requests

the

Agency recognize the unique

differences

in the tunnel furnace design and propose a specific definition for the existing tunnel

furnace recognizing

the unique nature of

ArcelorMittal’s

operation

and the advanced

NOx

control technologies

already

in use.

Respectfully submitted,

ARCELORMITTAL

USA,

INC.

By:

)

RL

Christina L. Archer

Dated:

<S

Christina

L. Archer

Associate General Counsel

ARCELORMITTAL USA, INC.

1 South Dârborn,

19

th

Floor

Chicago, Illinois

60603

(312) 899-3865

THIS

FILING SUBMITTED

ON

RECYCLED PAPER

Exhibit

A to

ArcelorMittal’s

Comments

on

R08-19

BIoôiTih

&OBALEIEPWAN

1345VTALSOLUVOS

1430

SERIES

- HOT OR COLD

AIR

ULTRA

LOW

NO

BAFFLE

BURNER

CAPABILITIES

High

or low temperature

furnaces

High excess air

800%

or more

Ratio

or tempered

flame operation

Suitable for fiber

or dense refractory

wall

construction

Gas only burner

readily converted

to

dual fuel burner

FEATURES

Refractory baffle

design

- provides

positive flame

stabilization

- shields

burner internals

from

furnace temperature

Extra rugged

port block

and mounting

plate construction

- high alumina blocks

- thicker block

refractory

- cast metal mounting

plate

with

integral port container

-

hook bolt anchor system

- simplified

mounting requirements

CHeat

resistant gas nozzle

Cast

body

construction

lntegral

fuel orifices

CONTROL

Cross

connected

regulator

Metered

flow

FLAME MONITORING

@UV

detector

Flame

rod

Light or

heavy oil

versions

Tile Lengths

6/05

APPLICATIONS

SCar Type

Heat Furnaces

Forge

Furnaces

Plate Heat Treat

Furnaces

Roller Hearths

Ceramic Kilns

Continuous

Strip Lines and

Reheat Furnaces

Tundish

and Ladle Preheat

Drying

Batch

Heat Treating

and

Annealing

Ladle and

Tundish

Heating

and

Drying

BURNER IGNITION

Pilot

Direct spark

FUEL

CAPABILITIES

Natural Gas

Coke

Oven

Gas

Propane/Air Mixture

Producer

Gas

Mixture of

Blast

Furnace

Gas and

a richer

gas

having

a

minimum

heating

value

of

250

Btu/cubic

foot (2300 kcal/M

3

)

OPTIONS

Air Lance

CAUTION:

The improper use of combustion

equipment

can result

in a condition hazardous to

people

and property.

Users are

urged to comply

with National Safety Standards

and/or

Insurance

Underwriters recommendations

.

q•• •

-1

7/05

Bloohiengineering;

GWEAL

ENtOY4’a

1430

SERIES

-

HOT

OR

COLD

AIR

ULTRA

LOW

NO

BAFFLE

BURNER

MAXIMUM

CAPACITIES

100°F

(38°C)

Combustion Air

800°F

(427°C)

Combustion

Air

Caalo

Capacity

Air

Flow

Air

Capacity

Air

Flow

Air

Pressure

ILOtt

iO.

MM

Pressure

MM

VV

1430-

BTU/HR

SCFH

Nm

3

/hr

“

mBar

BTU/HR

SCFH

Nm

3

/hr

mBar

(9.95mBar)

wC

,

02O,0.315

3,465

68

15

3,465,

92.90

,13.5

33,5801Q,

025

0.506

5,565

149.20

5.9

0.506

•5

.122p

1

QO

.

000550

6,050,

1,62.20

S.5

05Q

6,Q59

162p,1

,4 3QL.

QQz..

030A

0 710

7,810

209.38

5.5

1168

0.710

7.810

209.38,

12.4

30.85

q

035

0

947 10,417

279

28 5

6

13 93

0

947

10,417

279

28

12

6

31 34

010

040

1.300

14,300

383.38

5.7

14.18

1.300

14,300

383.38

12.9

32.09

020

045

2.000

22,000

589.81

6.8

16.92

2.000

22,000

589.81

15.5

38.56

020

FLAME

SIZES

Catalog

No.

Capacity

100°F

(38°C)

800°F

(427°C)

1430-

MM

Air

10%

Air

10%

BTU/HR

Excess

Excess

020

028’

30”x12”

28”x

12”,

025

0

45

36” x

14”

33”

x

14”

030B

052

39”x15”

35”x15”

030A

067

44”x17”

39”x17”

,

035

.

.

0.98

‘.

52”x20”:

.

45”x20”

040

1.20

60”

x 33”

50”

x 24”

‘

045.

1.60

‘

72”x28”

66”x28”

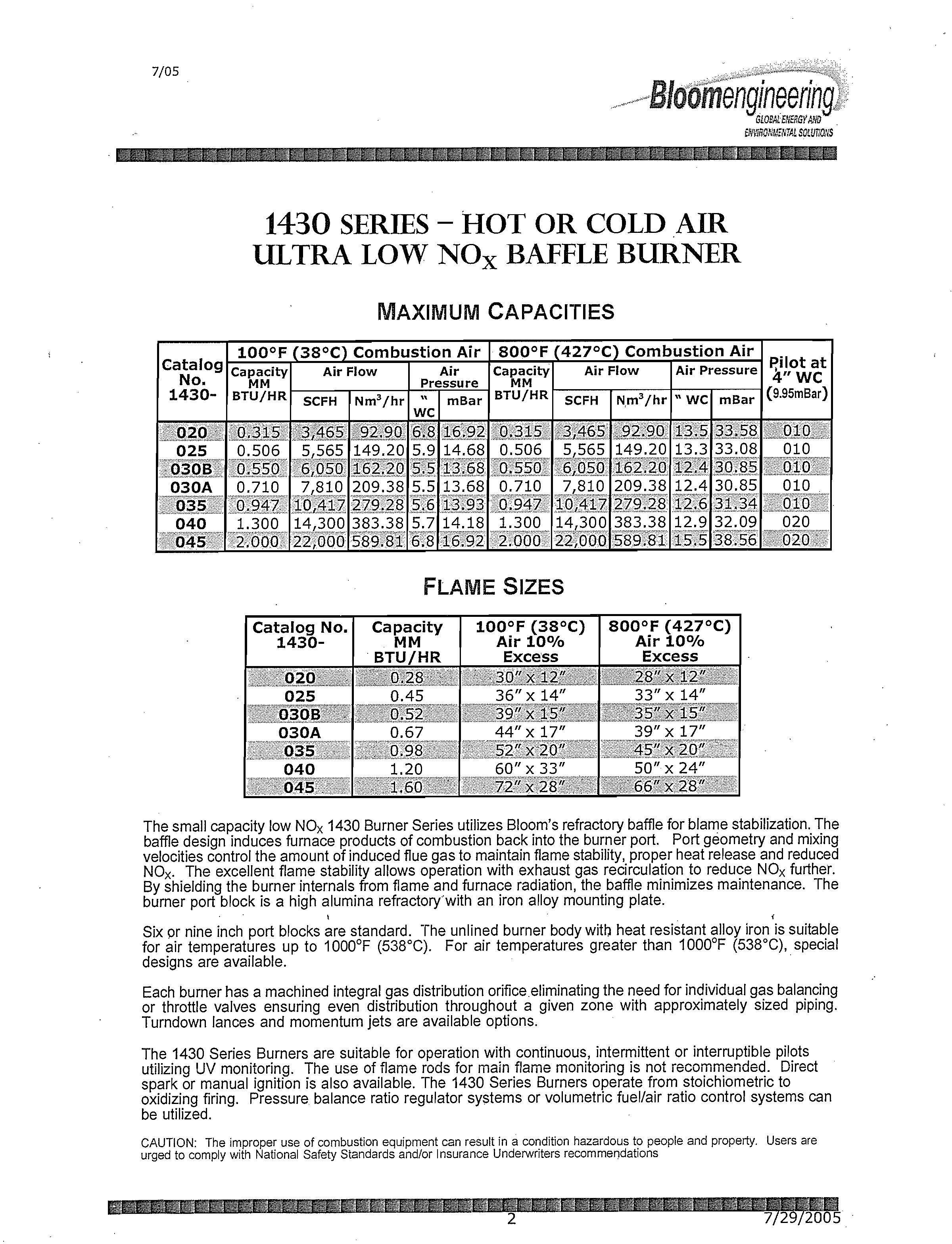

The

small

capacity

low

NOx

1430

Burner

Series

utilizes

Bloom’s

refractory

baffle

for

blame

stabilization.

The

baffle

design

induces

furnace

products

of combustion

back

into

the burner

port.

Port

geometry

and

mixing

velocities

control

the

amount

of

induced

flue

gas

to

maintain

flame

stability,

proper

heat

release

and reduced

NOx.

The excellent

flame

stability

allows

operation

with

exhaust

gas recirculation

to

reduce

NOx

further.

By

shielding

the

burner

internals

from

flame

and

furnace

radiation,

the baffle

minimizes maintenance.

The

burner

port

block

is

a

high alumina

refractorywith

an

iron

alloy

mounting

plate.

Six or

nine inch

port

blocks

are

standard.

The

unlined

burner

body

with

heat

resistant

alloy

iron is

suitable

for

air

temperatures

up to

1000°F

(538°C).

For

air

temperatures

greater

than

1000°F

(538°C),

special

designs

are

available.

Each

burner

has

a machined

integral

gas distribution

orifice

eliminating the need

for

individual

gas

balancing

or throttle

valves

ensuring

even

distribution

throughout

a

given

zone

with

approximately sized

piping.

Turndown

lances

and

momentum

jets are

available

options.

The 1430

Series

Burners

are

suitable

for operation

with

continuous,

intermittent

or

interruptible

pilots

utilizing

UV monitoring.

The

use

of flame

rods

for

main flame

monitoring

is

not

recommended.

Direct

spark

or

manual

ignition

is

also available.

The

1430

Series

Burners

operate

from

stoichiometric to

oxidizing

firing.

Pressure

balance

ratio regulator

systems

or

volumetric

fuel/air

ratio control

systems

can

be utilized.

CAUTION:

The improper

use of

combustion

equipment

can

result

in

a condition

hazardous

to people

and

property.

Users are

urged

to

comply

with

National

Safety

Standards

and/or

Insurance

Underwriters

recommendations

205

7/05

BIoohhginoering.

&OHALENEAYiN9

MThIAL

SOLUROS

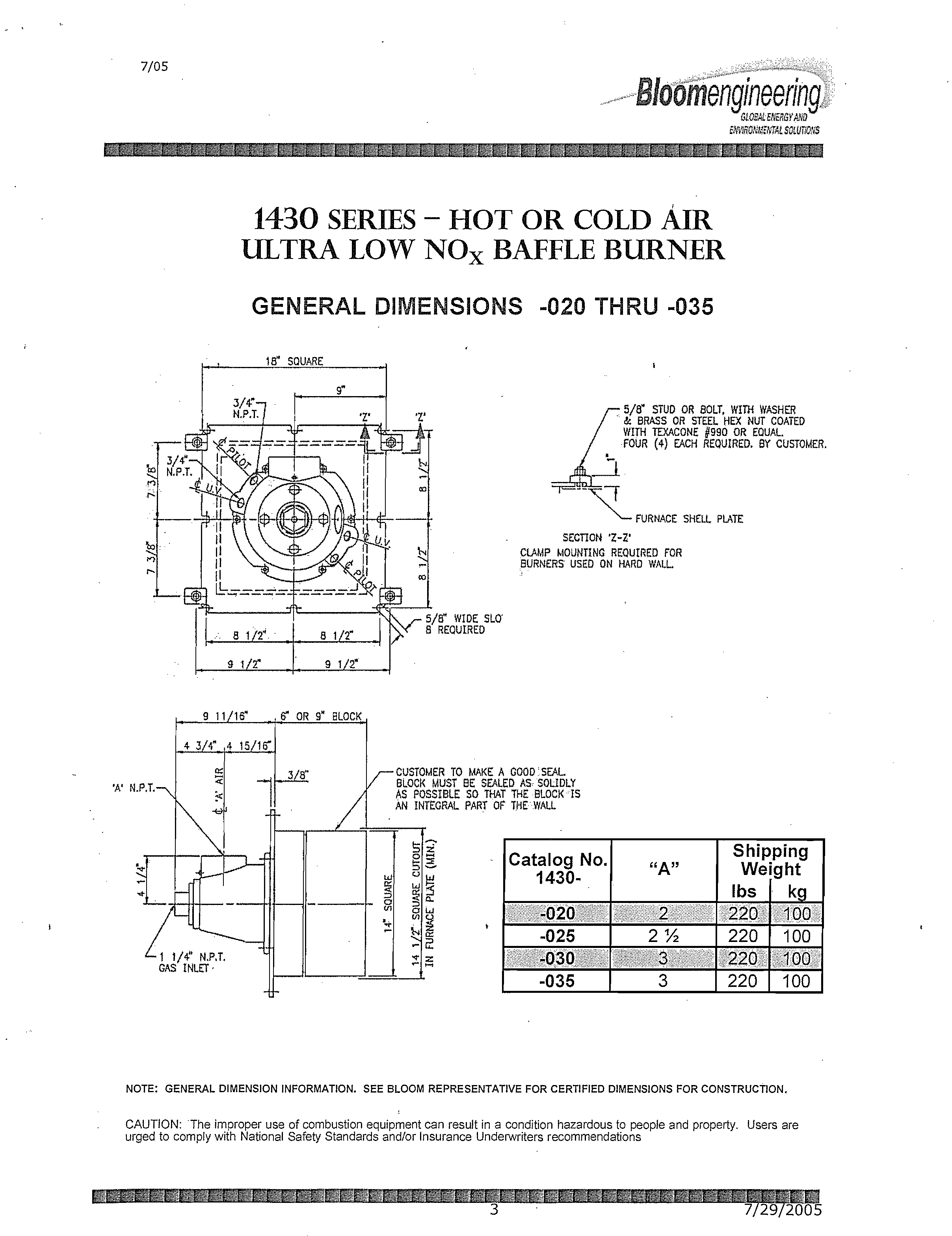

1430

SERIES - HOT OR COLD AIR

ULTRA LOW

NO

BAFFLE BURIR

GENERAL DMENSONS

-020

THRU

-035

5/8W WIDE SL

B

REQUIRED

5/8W

STUD OR BOLT,

WITH WASHER

&

BRASS

OR STEEL HEX NUT COATED

WITH

TEXACONE

#990

OR EQUAL

FOUR

(4)

EACH

REQUIRED. BY

CUSTOMER.

FURNACE

SHELL

PLATE

SECTION

Z-Z

CLAMP MOUNTING

REQUIRED FOR

BURNERS

USED

ON HARD

WALL

Catalog

No.

Shipping

1430-

“A”

Weight

lbs

kg

2

220.

100

2%

220

100

3

220

100

3

220

100

NOTE:

GENERAL

DIMENSION

INFORMATION. SEE BLOOM REPRESENTATIVE

FOR

CERTIFIED DIMENSIONS

FOR

CONSTRUCTION.

CAUTION:

The

improper

use of

combustion equipment can

result in a condition hazardous to people and property. Users

are

urged to comply with National Safety Standards and/or Insurance

Underwriters

recommendations

3

7/29/2005

7/05

-BIoomêngineering.

GLOPALERERfANS

MEATALSOWWWS

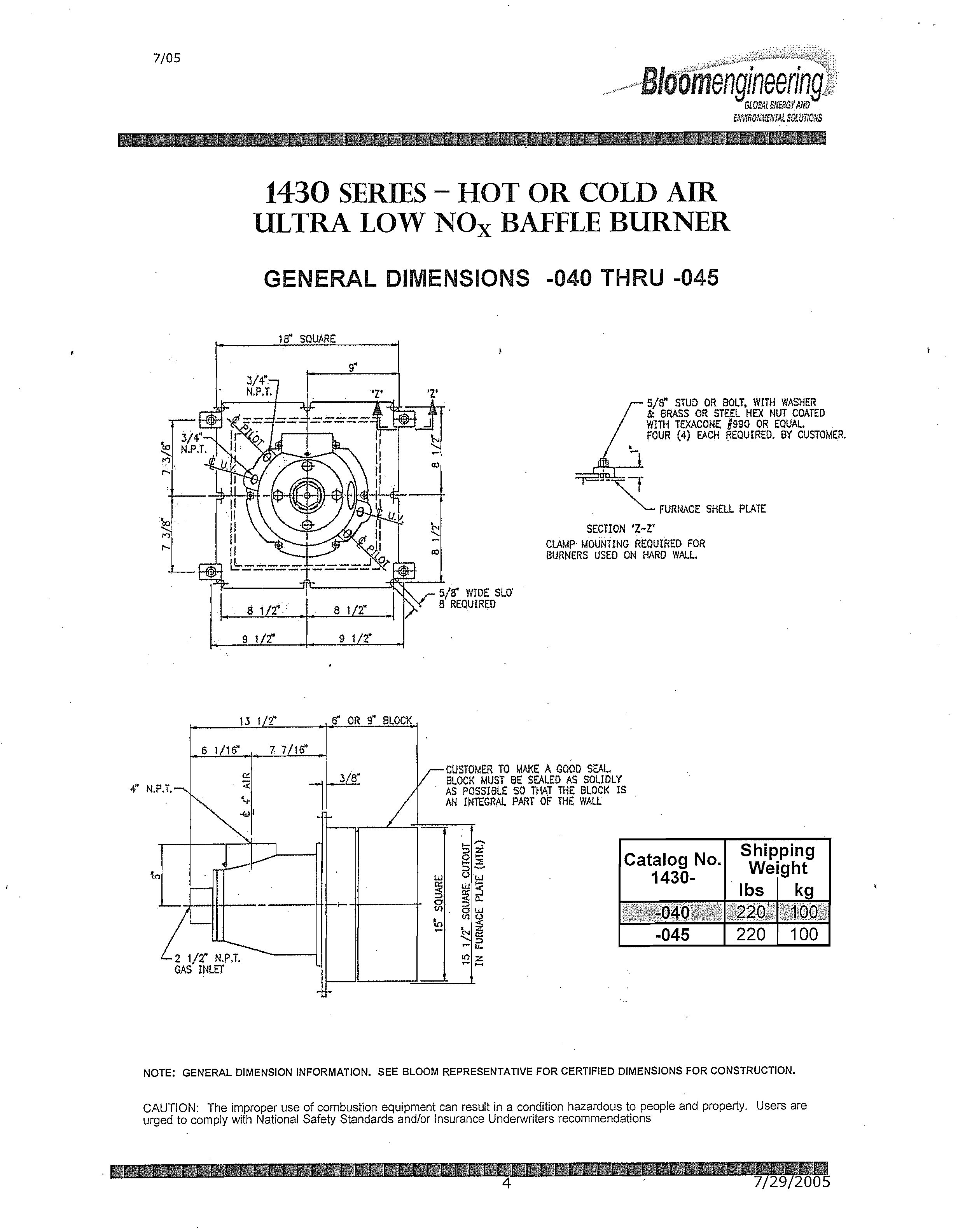

1430

SERIES

-

HOT

OR

COLD

AIR

ULTRA

LOW

NO

BAFFLE

BURNER

GENERAL

DIMENSIONS

-040

THRU

-045

S/8•’

WIDE

SL0

B REQUIRED

,—

5/Sn

STUD

OR

BOLT

WITH

WASHER

I

&

BRASS OR

STEEL

HEX

NUT

COATED

I

WITH

TEXACONE

S9O

OR

EQUAL

/

FOUR

(4)

EACH REQUIRED.

BY

CUSTOMER.

,

FURNACE

SHELL

PLATE

SECTION

1-Z’

CL4MP

MOUNTING

REOUIRED

FOR

BURNERS

USED ON

HARD

WALL

Catalog

No.

Shipping

1430-

Weight

lbs

kg

-040

100

-045

220

I

100

NOTE:

GENERAL

DIMENSION

INFORMATION.

SEE

BLOOM

REPRESENTATIVE

FOR

CERTIFIED

DIMENSIONS

FOR

CONSTRUCTION.

CAUTION:

The

improper

use

of combustion

equipment

can result

in a

condition

hazardous

to

people

and

property.

Users

are

urged to

comply

with National

Safety

Standards

and/or

Insurance

Underwriters

recommendations

N

4

I’LP.T

4

//9/2UU5