ew Generation Project Water S

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

February

11, 2005

3 100 Stevenson

Drive

City

Water Li

Mr. Brian

Fitzgerald

New Generation

Project

Dear . Fitzgerald:

f _.

'"!)

rd Amendment No. 2

elated De

:.

unbar

6, 20C1Q..

support

the addition of the

new electric

.-

performed

to ý<<idress wat(sul)ply,

boron

r.wmoval

and lake water

conservat

A ttachments

c

c:

Brian Basel

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

-JY$(erJ9bldy

tndex and CedifNlan

C

ity Water Light & Power

Springfield, Illinois

New Generation Project

INDEX

AND CERTIFICA rION

PAGE

NUMBER

PART 140.

PART TITLE

FO

PAOFS

PART 1.0

Executive Summary

2

P ART 2.0

Introduction

2

. ý . .ý-_-PART 3.0

,- Water Supply

P

ART 4.0

Wastewater Treatment

PART 5.0

Options

2

3

3

PART 6.0

Evaluation of Options

23

PART 7.0

Conclusions and Recommendations

3

APPENDICES

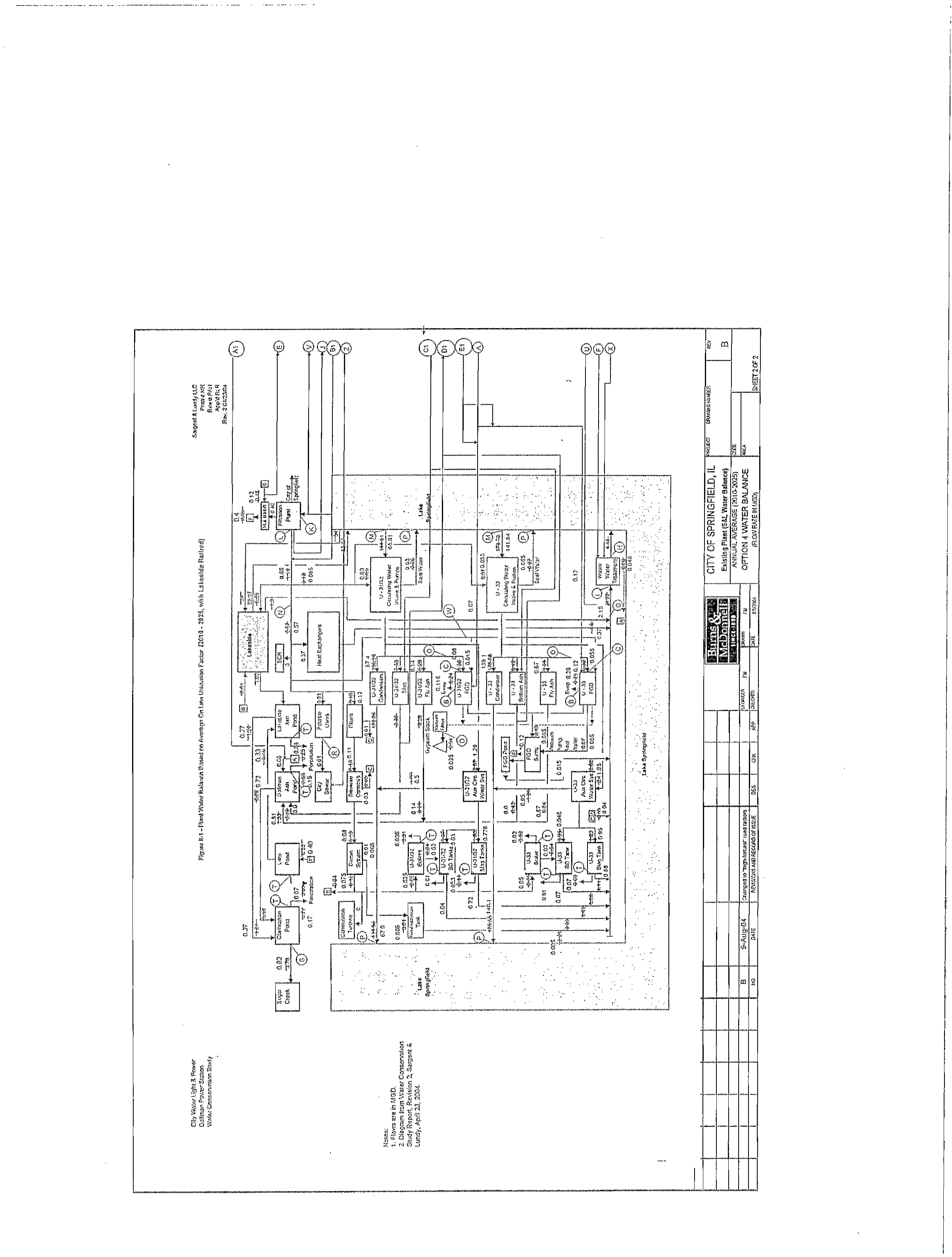

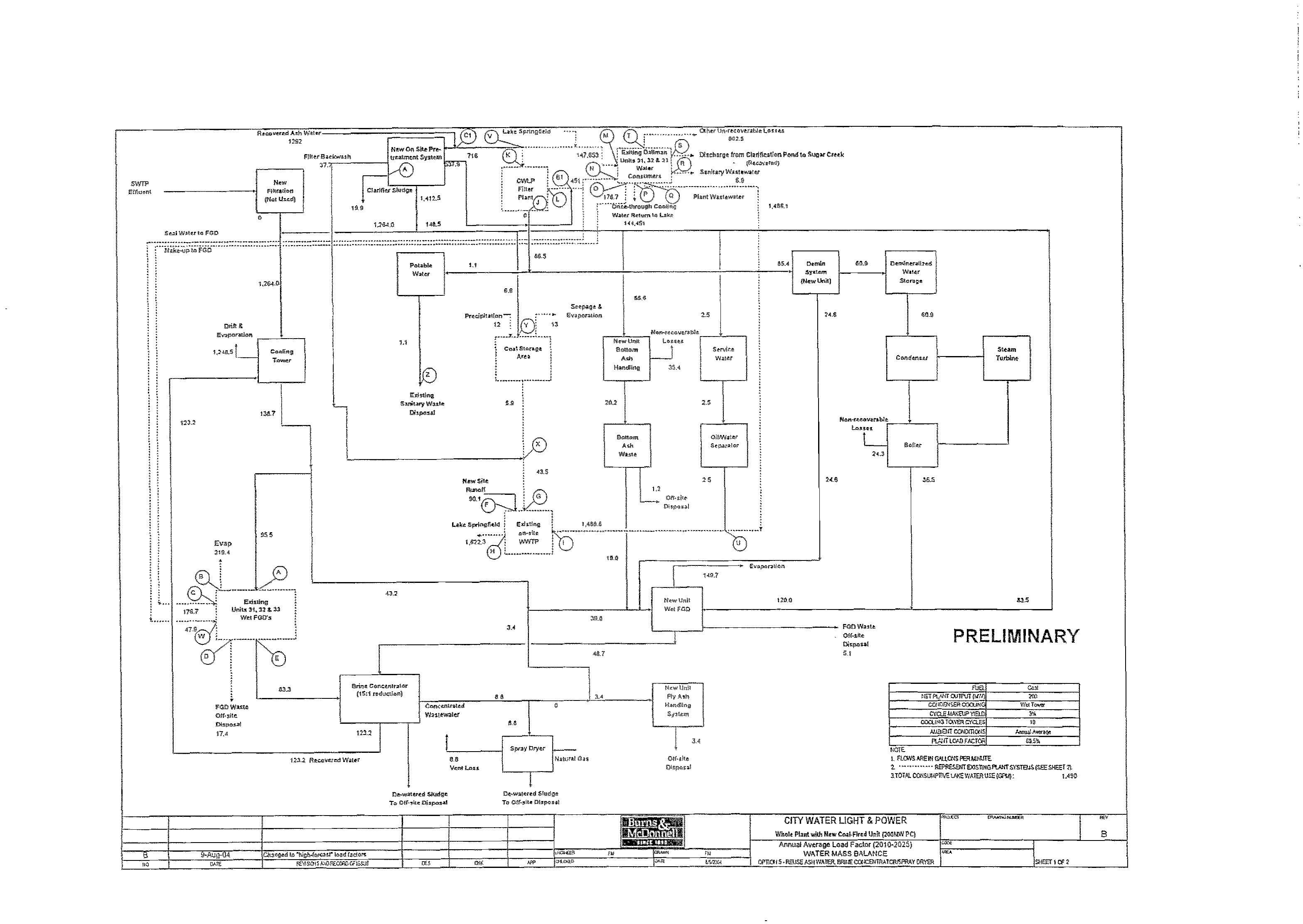

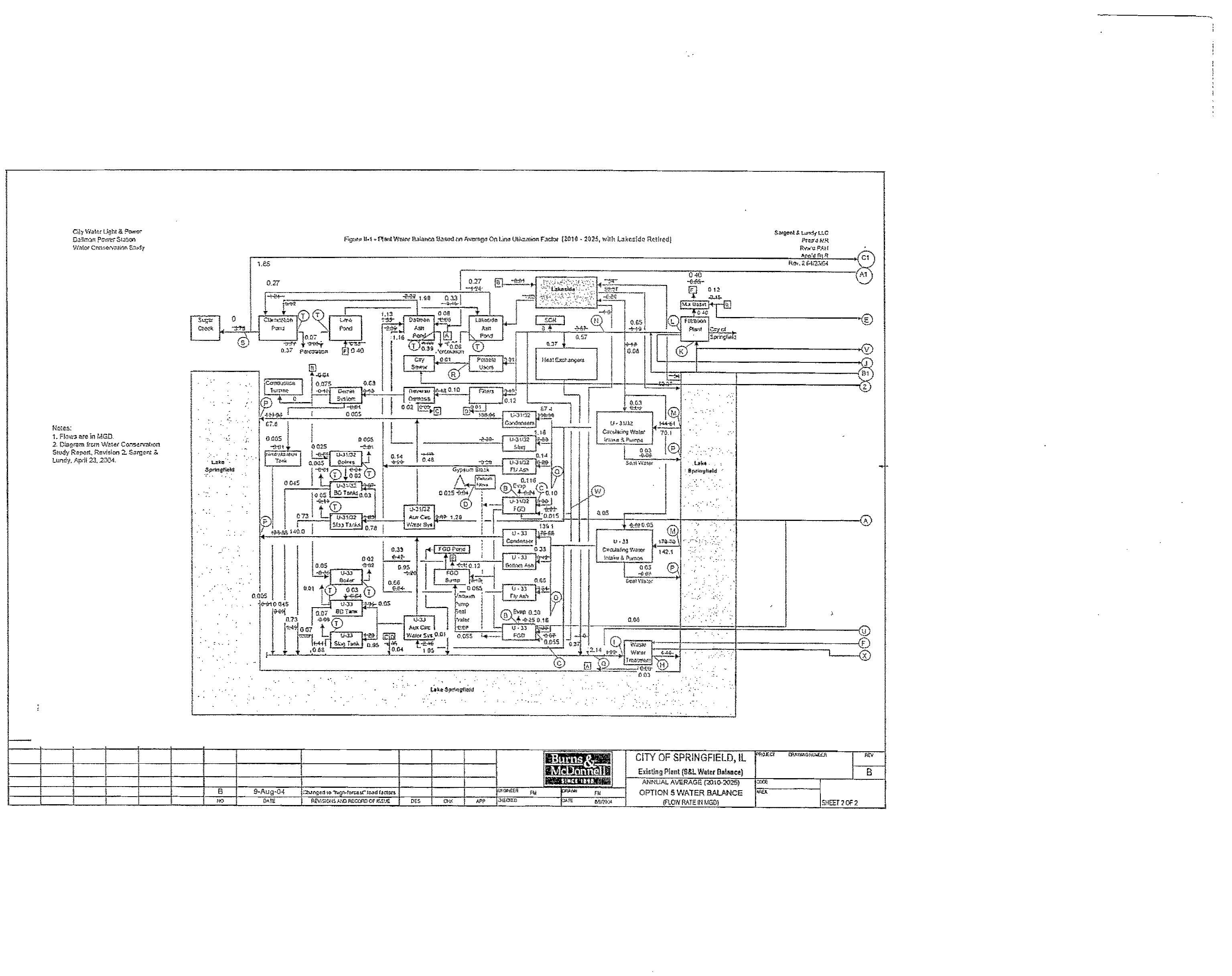

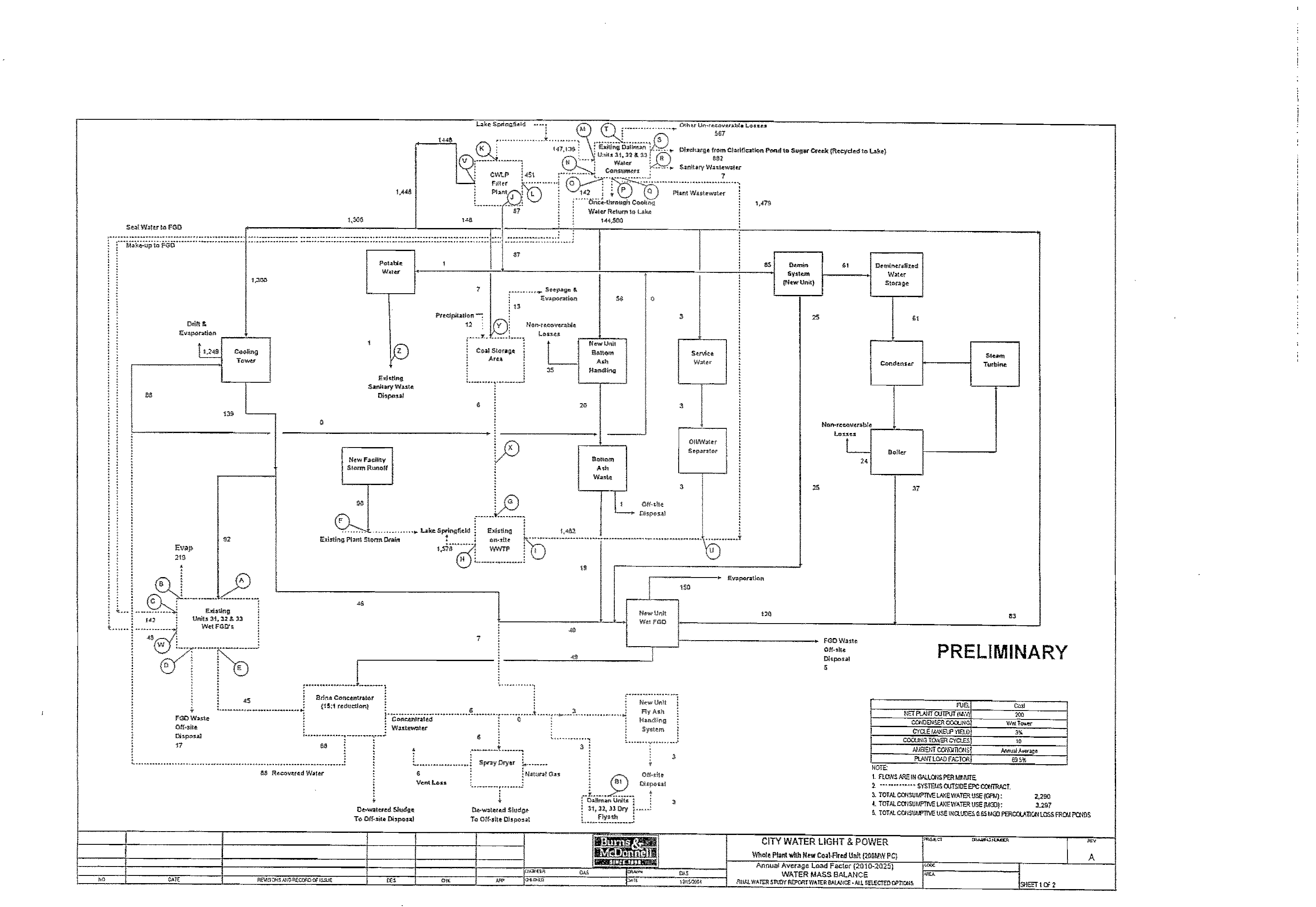

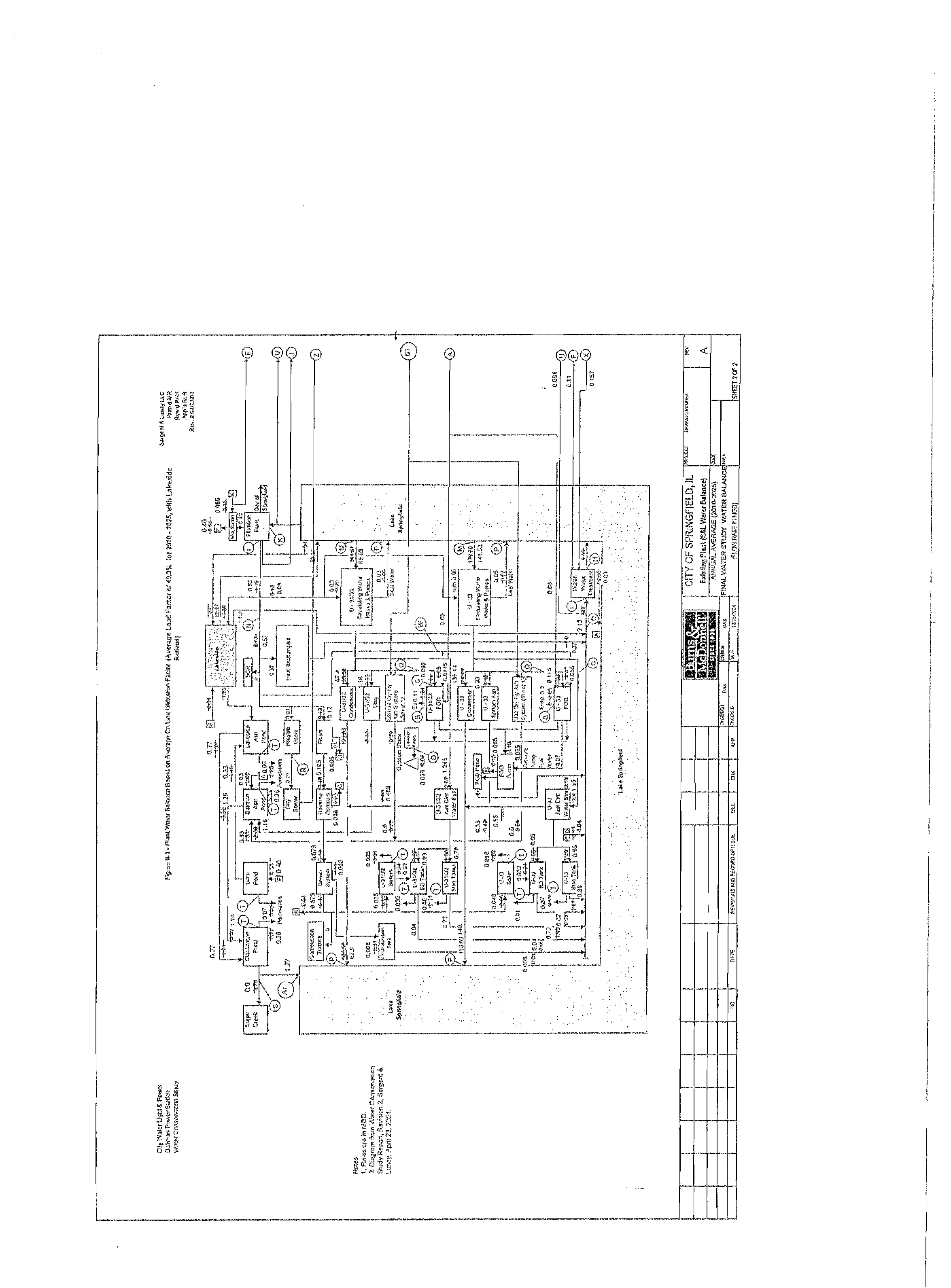

Water Balance Diagrams

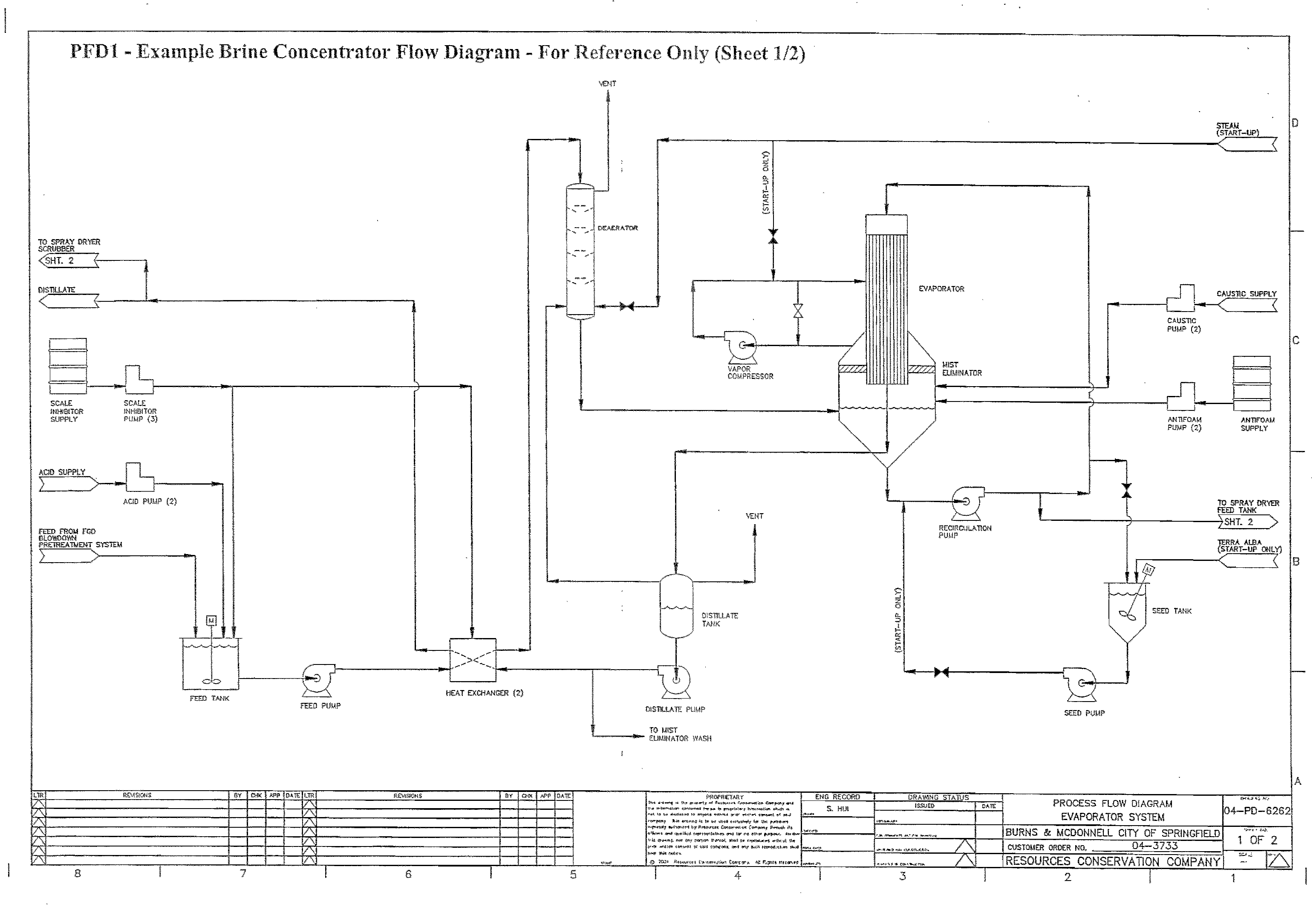

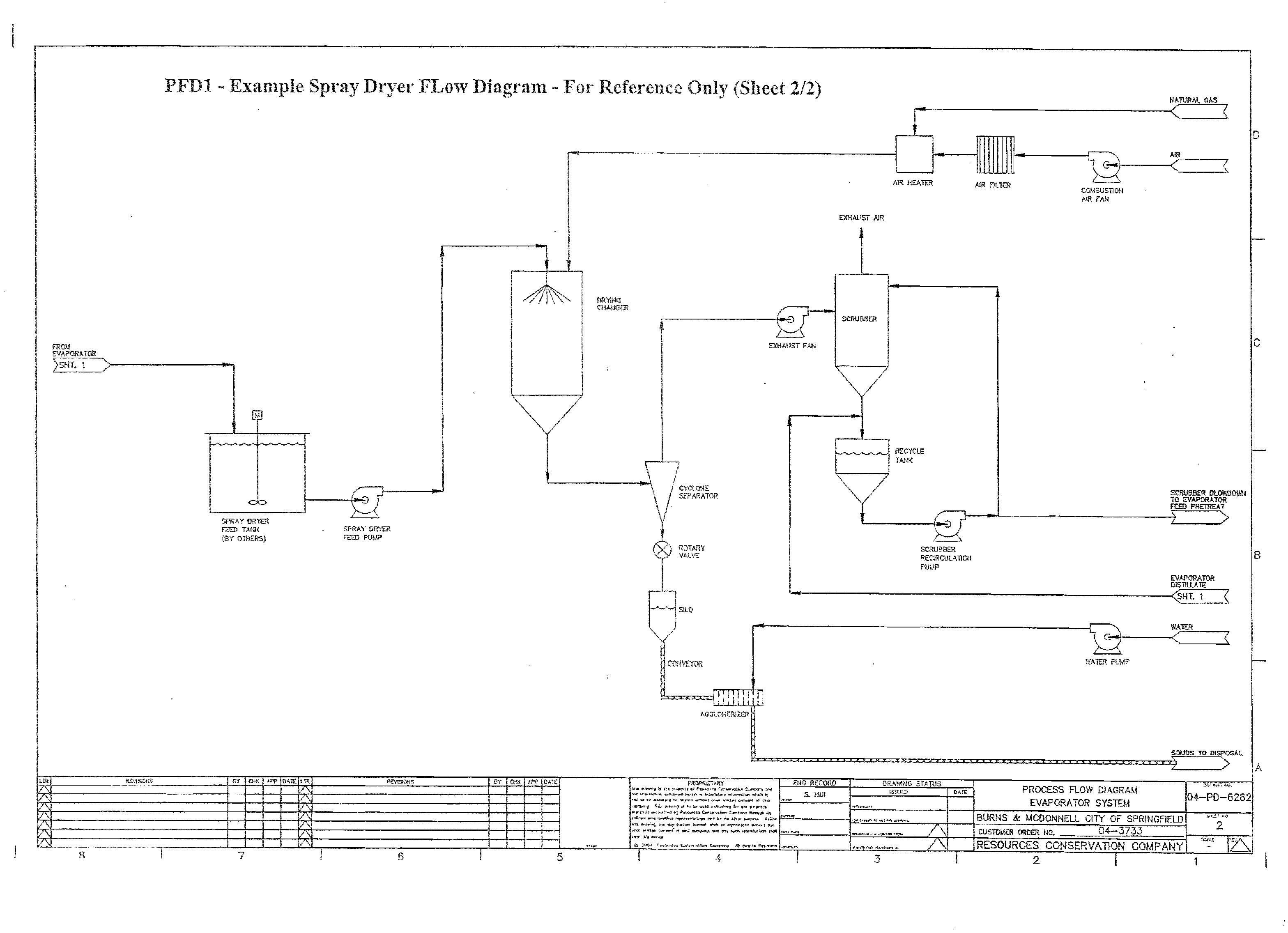

Typical Brine Concentrator/Spray

Dryer Process Flow Diagram

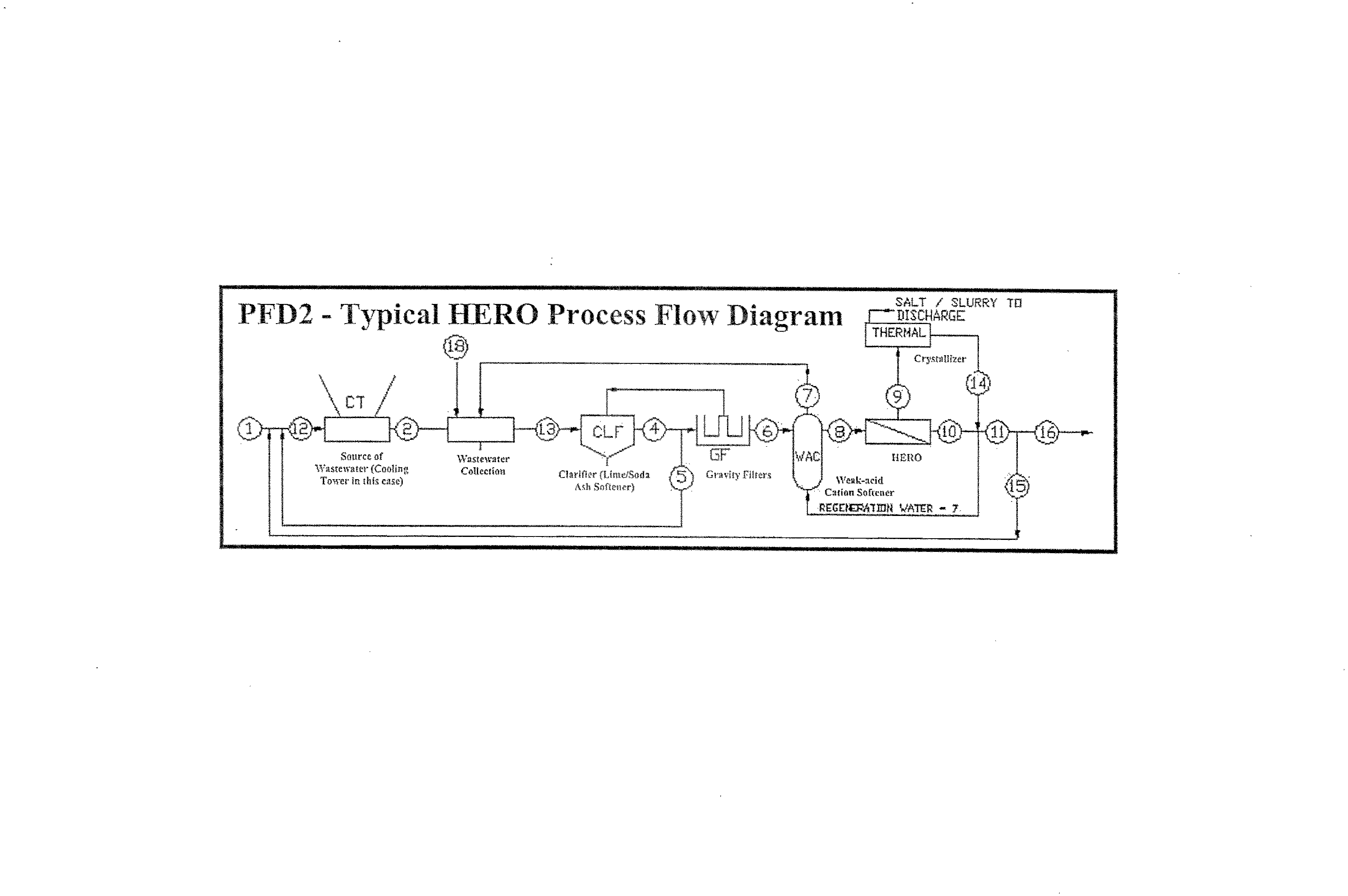

Typical HERO System Process Flow Diagram

W ater Usage Projection

for 2010-7050.

Water Usage Charts

Boron Treatment Options Cost Comparison

Water Conservation Options Cost Comparison

ICATION

7

2

1

1

3

1

2

Design Firm Registration Number: 184-001310

-

'"-CltkWeteiggd(APawaiý Spririyfeld,7gPriols

--R!0=1.._..._-..

Pr*c(34821. January 2005

Kansas ft Mlasoud

W8(erSWyCert

Page RUM

doo

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Water Study

Table

of Contents

TABLE OF

C ONTENTS

1 .0 EXECUTIVE SUMMARY.........................,...

2.0 INTRODUCTION..........,..........,...................

3.0 WATER SUPPLY ..............

...........

2-1

...,... 3-1

..................

3-1

4.0

4.1 On-Site Wastewater Treatment Plant....

... 4-

5.0

I

I .'!i' !' I,

Pro'.-i.Juý_

6.0 EVALUATION OF OPTIONS....

6.1

Wastewater Treatment Options...

6.1.1 Plant Wastewater Discharges ................ ,......... .........

.., 5-2

......

6-1

6.1.2 Ash Pond Discharges and Boron Removal Approach....

6.1.3

Boron Removal Options...

6 .2 Water

Supply

and Conservation Options..................

6 .2.1 Lake Sp

6.2.2 W itr

r

C;onserva

6.2.3 Wý<ler

7 .0

n .................

6 .;3.1 Boron-Remo

..6-11

... ....... 6-20

6.3.2 Water Conserva

C ity Water Light & Power, Springfield, Illinois

"TC)C-1

Bums

&

Mcbc,rn,-.

l

P roject 34821, REV: 1, February 2005

K&r, u iy Missouri

CWLP Water Study Feb 2005. doc

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Water Study

Table

of Contents

A PPENDICES

Water Balance

Diagrams

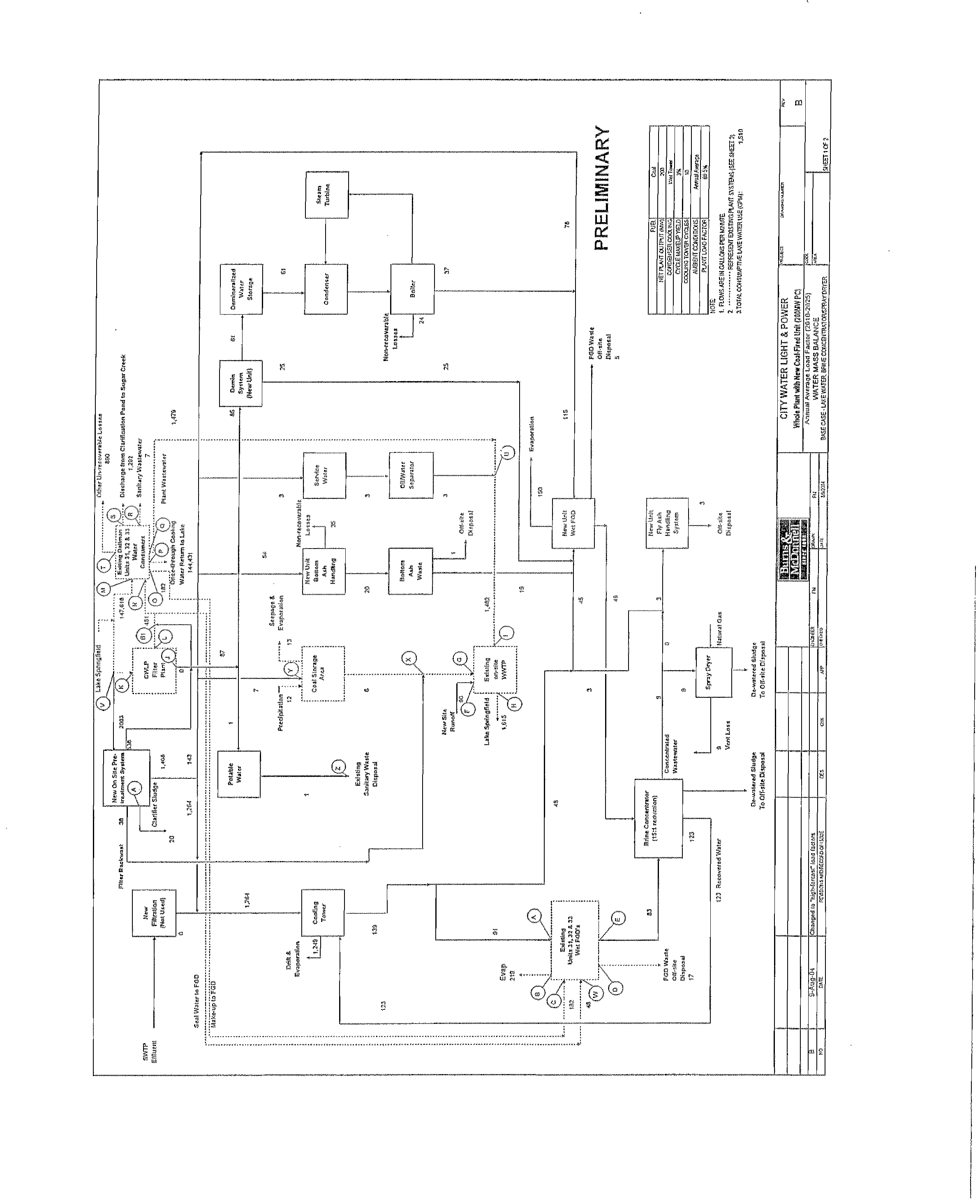

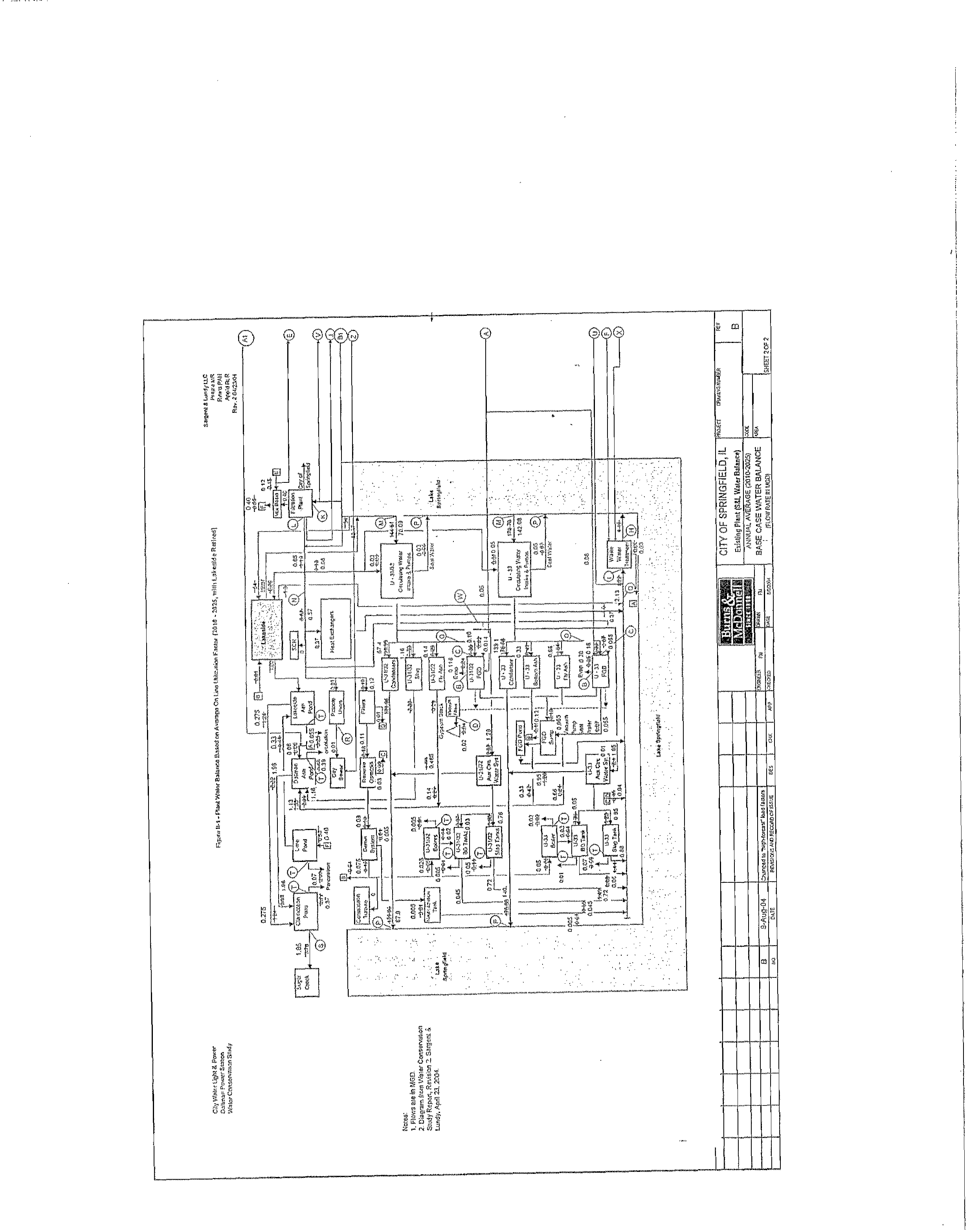

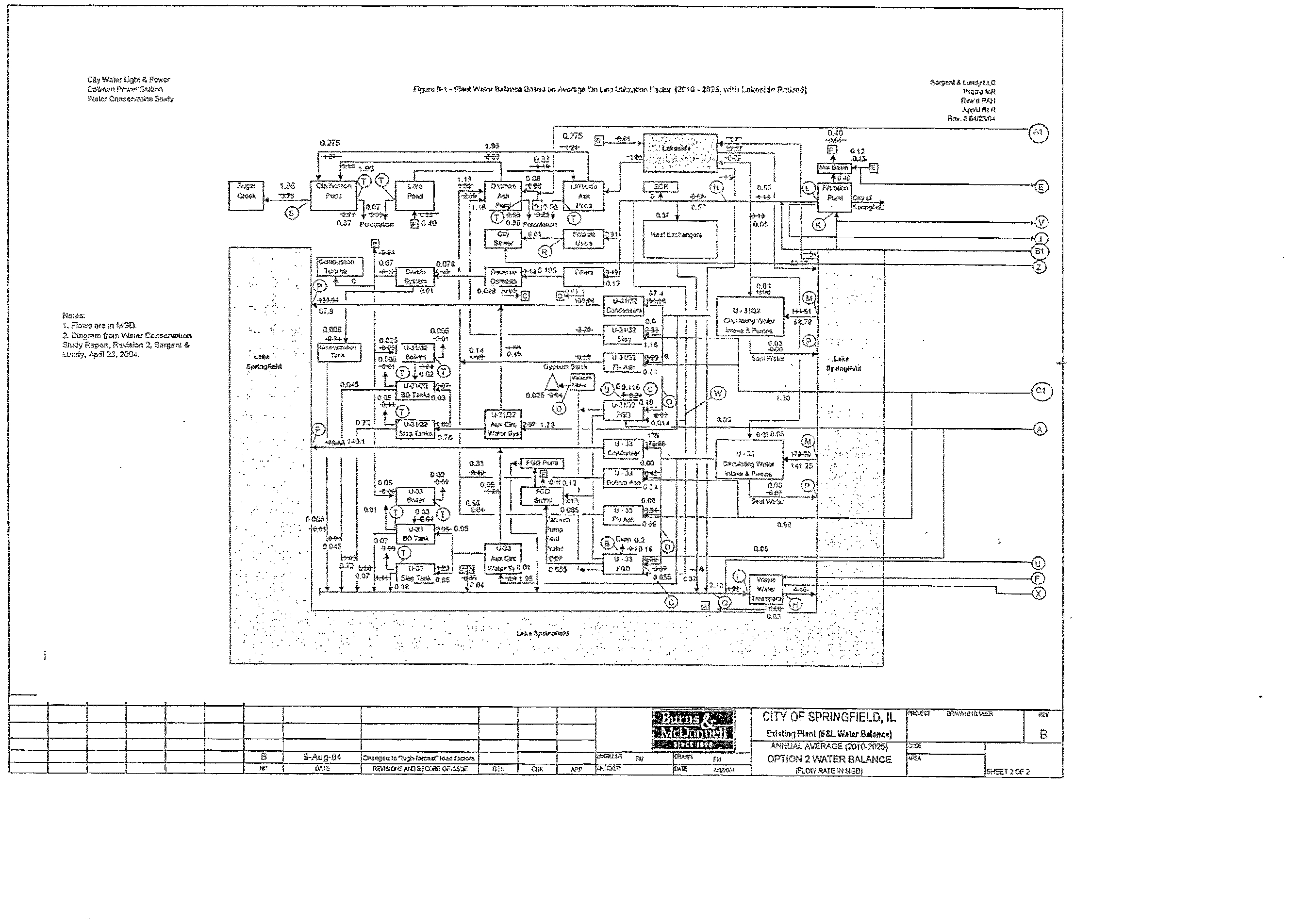

O ption 1, Using Lake Wýjtc-a with No Water Conservation Options,

Maximum Flow

Option

1, Using Lake Water with No Water Conservation Options,

Annual Average Flow

Option

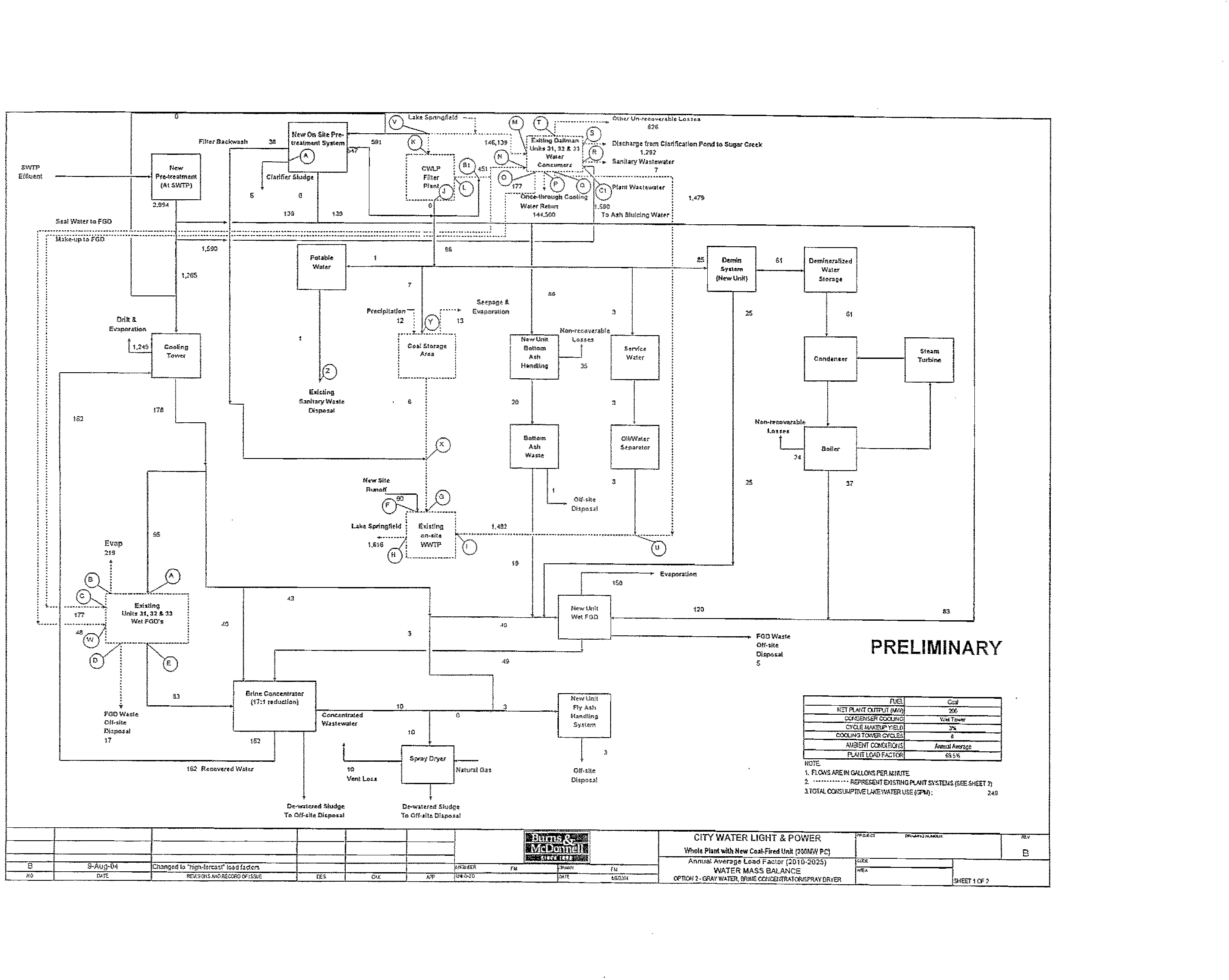

2, Using Cray Water, Annual Average Flow, Annual Average

Flow

Option

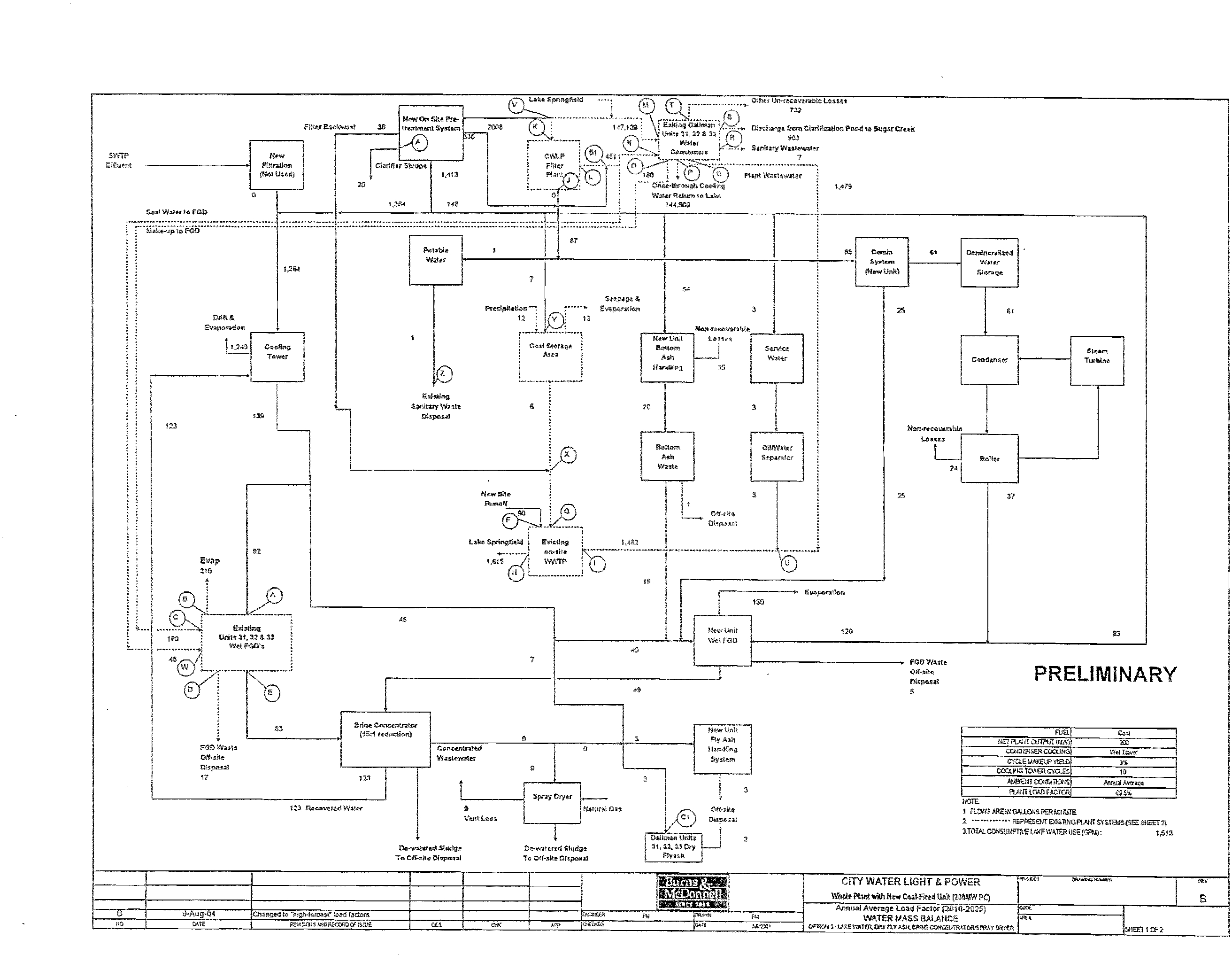

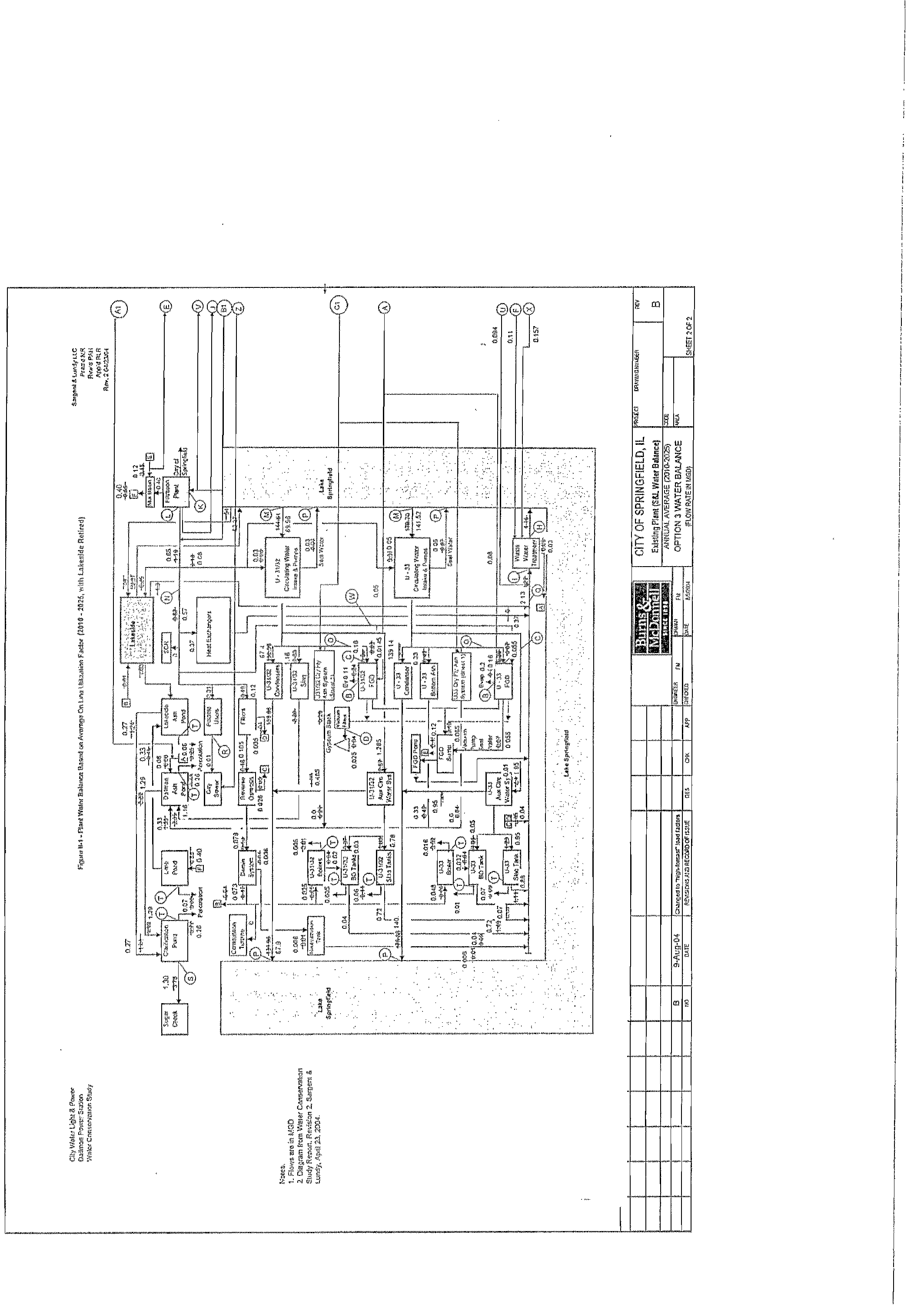

3, Using Lake Water with Dry Fly Ash, Annual Average Flaw

4 Option 4, Using Lake Water with Closed-loop Bottom Ash System,

Annual Average Flaw

Option

5, Using Lake Water with Recycling Ash Pond Effluent, Annual

Average

Flow

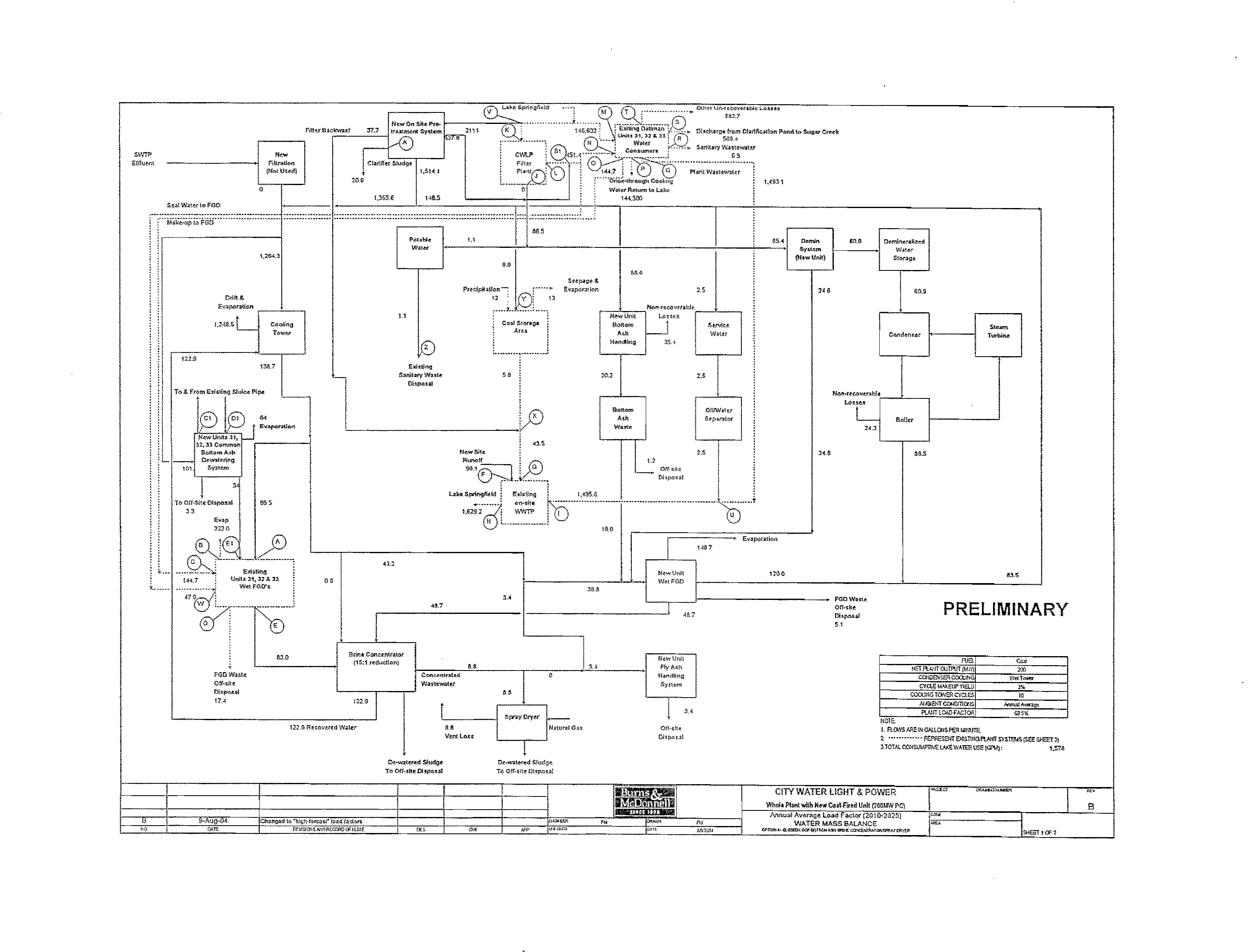

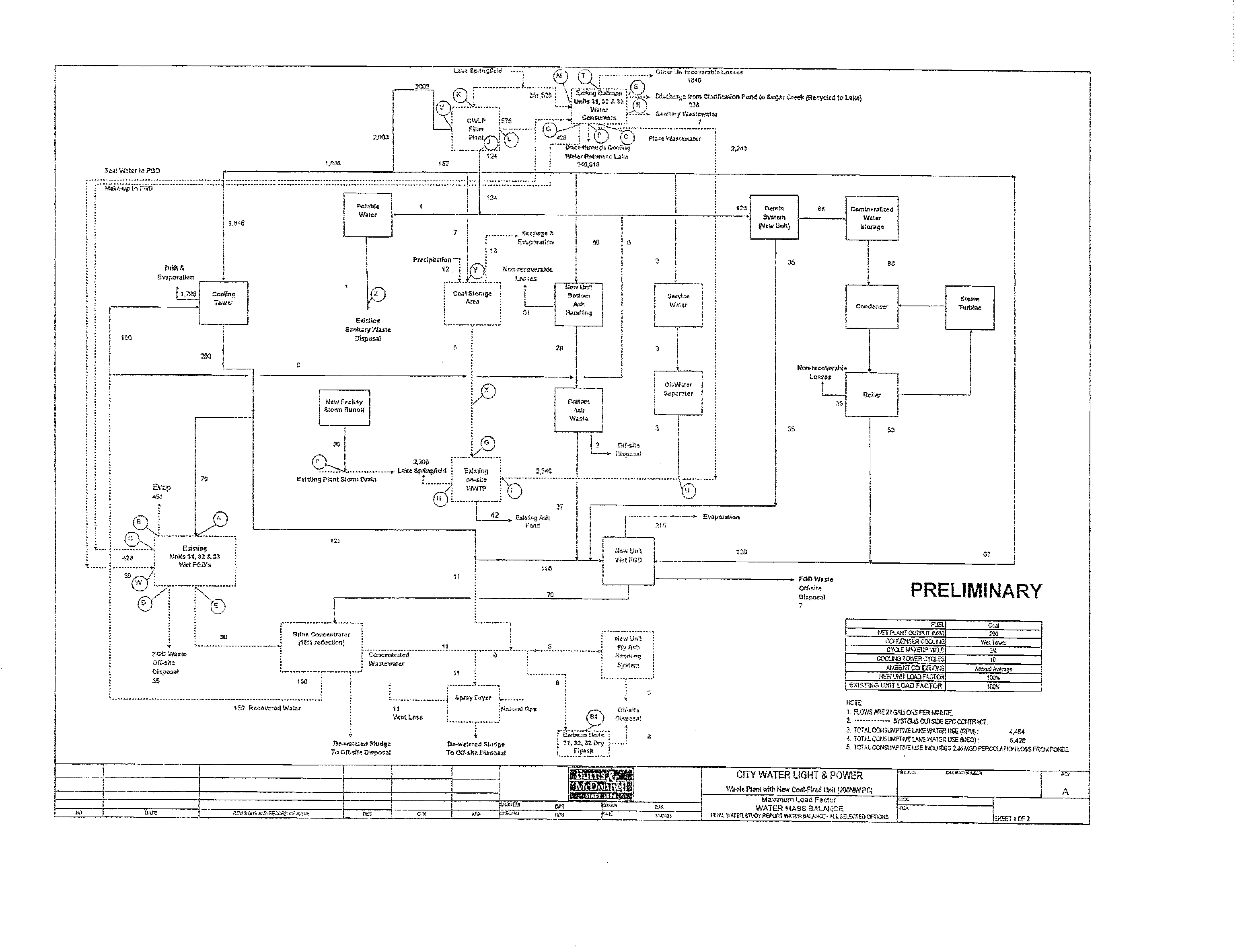

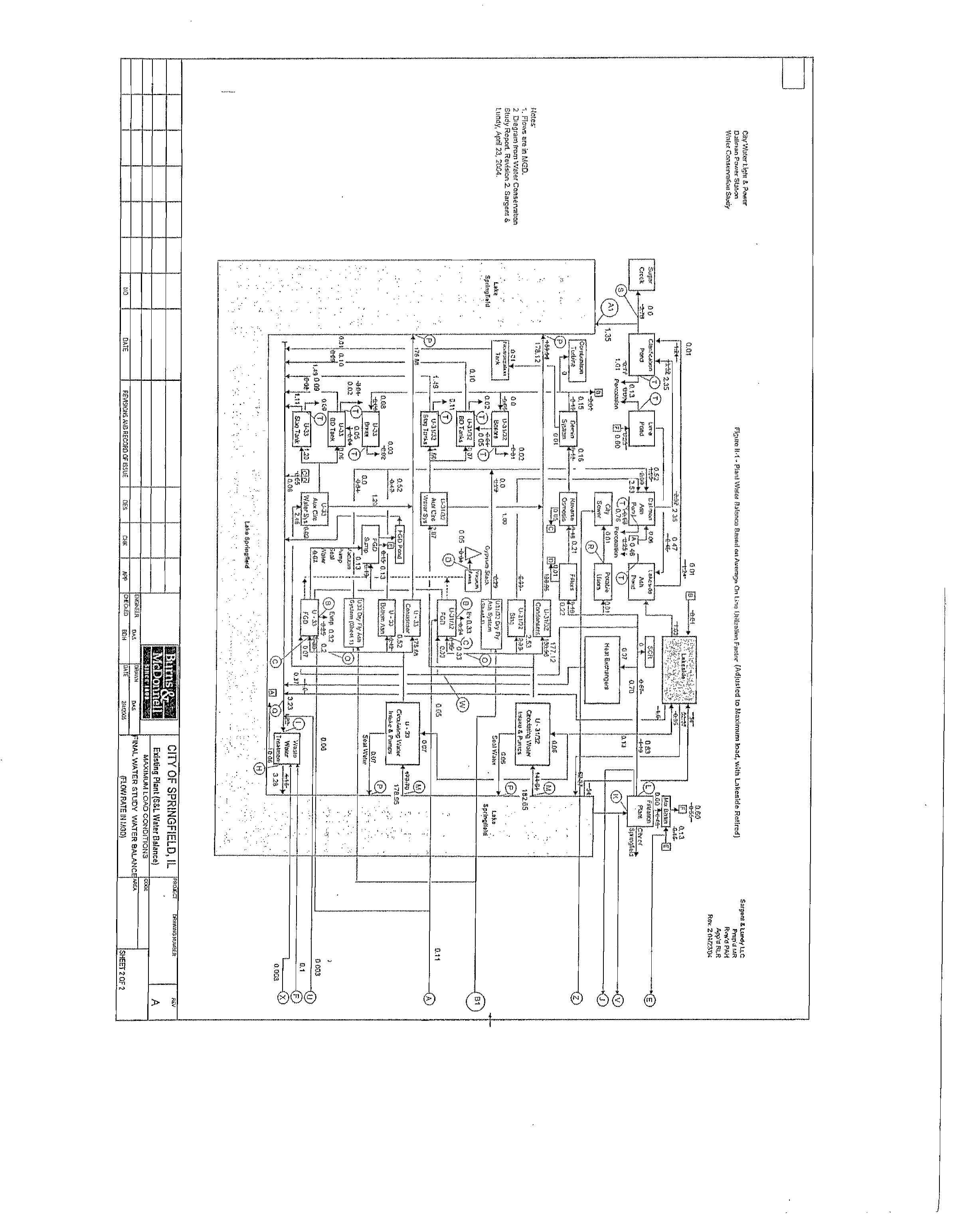

F inal Water Study Water Balance - All Selected Options

Final

Water

Study

Water

Balance --All Selected Options (Maximum

Load)

PFD1 - Typical Brine Concentrator/Spray Dryer Process Flow Diagram

(Sheet 1 and Sheet 2)

PFD2

-

Typical HERO System Process Flow Diagram

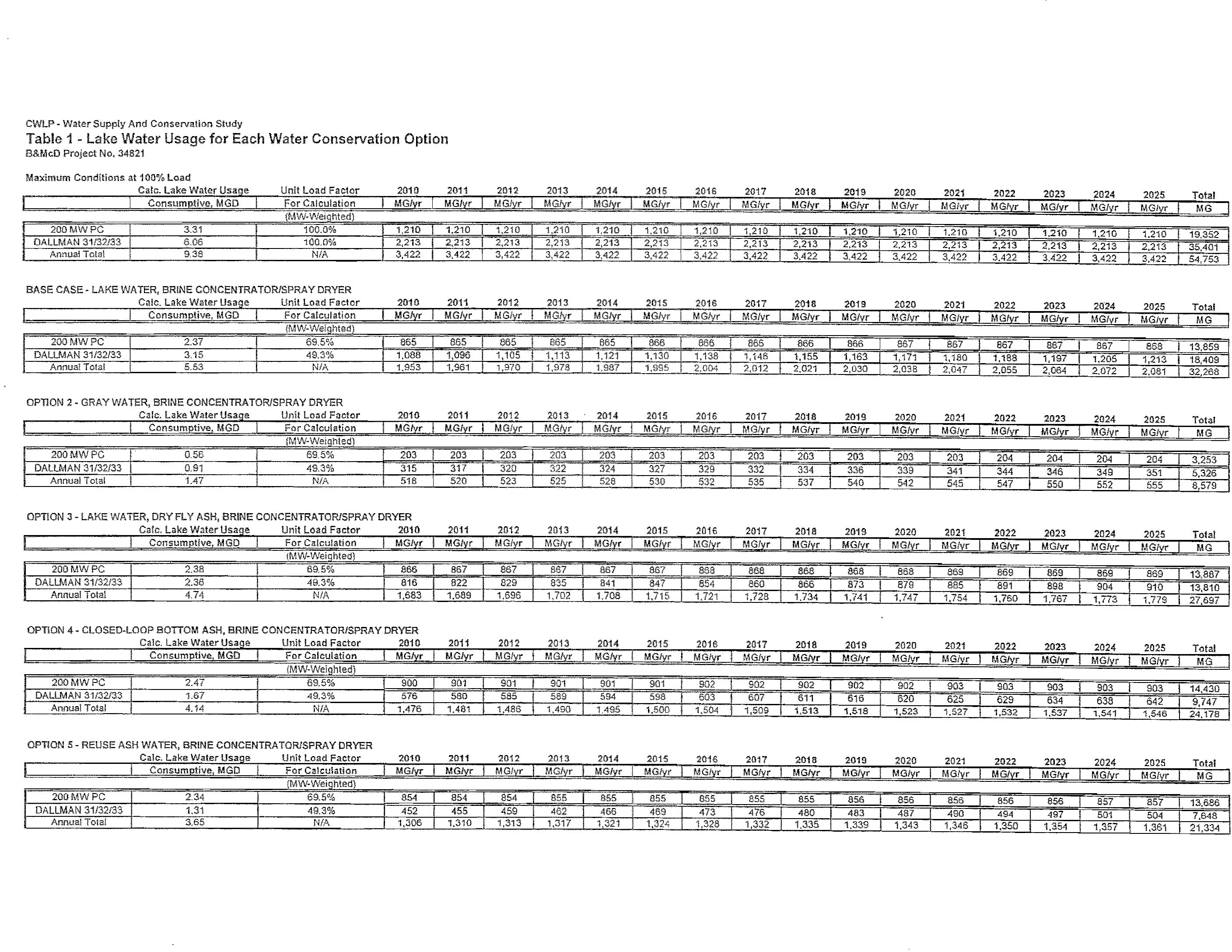

Table 1 - Water Usage Projection for 2010-2050

C ity Water Light & Power, Springfield, Illinois

TOC-2

B urns & McDonnell Engineering Co.

Project 3482?, REV. 1, February 2005

Kansas City, Missouri

CWLP Water Study Feb 2005.doc

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Water Study

Executive Summary

1 .0 EXECUTIVE SUMMARY

treatment system options

tewater

production rates.

to study water conservation

o

t the Ntevenson Drive generating

porate the results

of

the pr

loped that

sis of var

t water source is treated

economics may change which may

i1:j''. e

ý 'o ns to implement to aid in

finalized.

discharged from the plant. Because o

ise the exiting city fihc. c

plant

has suffic

new generation facilities'

up w¬aý:r cteýzl, ýýid.

Thus city water treatment plant treated

water is the recommended water source.

us boron mitigation studies indicated that the major source

of boron

exiti

liquid blowdown from the Dallman 31, 3'2 and 33 FGU systems. Alternatives for

treatment

of this water stream were investigated during the

water study. The preferred

ndary option

ystems from

r Light &

821,

REV.

1,

E

®1

r Study Feb

B ums & McDonnell E-!7in,-nf

-7

Kansas City, (:ii:soud

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

wet to dry handling to

ree of boron that i

it

reek, In

p ond water for makeup to the

new uni

lowdown treatment

equipment

oundwater contamination and ash pond life expectancies

ash

from

the ash ponds.

The

would need to be conducted to determine if this option is feasible. Additionally,

a study

should be conducted on the effect of the existing fly ash content of the ash ponds, as well

l

andfill

leachate, on the ash pond and ground

B esides the recommending boron removal and/or water conservation options, urgent R

ded recycling the FGD vacuum pump seal water. This

being

made by

eludes

a zero

discharge FGD

followed by two

Unii,, i o dry fly ash

Ice-up be

recotr

Tit,-

i

I

c,-, i j

Awntr _ttors and

In the c-,rent

that

the

Ash Pond water quality is

not suitable for

direct

discharge

to Lake

Sprirzi_ iiuld_ a wastewater treatment system could be added to allow recovery of the Ash

Pond eftlucat as makeup to the new unit cooling tower for water conservation.

B urns &

Mchonneýi Ei7gine

r,-nq

C;o.

h=r. -

s

;'Y. Výscluri

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

2.0 INTRODUCTION

&McD) to p

new generation facilities at the Dallman Station. The study investigated the availabil

and :Feasibility of water supply sources required for the planned

new coal-fired unit (200

followin

wastewater treatment concerns;

2004 report.

r

,-:ý

o

,'the

r C f ý.

Iti",Jtl'

b

Tn `1:

,(1'tiri the c ;J:t't)glfiiii", e'1-, ,1-thybent,ti I

d y,

Report L-008254, Sargent & Lundy, April 23,

v,irious

p1

ý!I < ýý ?ýh water

streams,

u,1

provided sevei A recommendations to CM'[,P to

reduce boron concentrations in thei

installed SCR

equ

Potentially feasible boron removal. options were identified and evaluated

and three

potentially viable options were selected. The net present value of each o

calculated

based on estimated installed equipment cost,

and annual operation and

Based on the net present value analysis, and other factors, a pre

cted

as the base-case option. This base-case opti

t l on o

r Light

Project 34829, REV. 1,

C WLP Water St udy

Feb

2(705.

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Water

Study

Introduction

Additional methods for conserving take water were reviewed. Three possible water

tliods were selected

for

further study.

These options, combined with two water supply options (Lake Springfield and the gray

water), formed the five options studied to provide far the plant water supply and water

. A. water balance was prepared for each of these live options, and water

as calculated. `eater conservation options were then evaluated u

these

op

lesions and Recommendations) of this

report.

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Water Study

Water Supply

3 .0 WATER SUPPLY

W ith the addition of a new unit at the Stevenson Drive plant site, the water source to

this

operation

must be

chosen.

This section of

the

Water Study report discusses

.'I Lake Springfield

Lakeside

and Dallman Units. It

The

consumptive loss of the lake water far condenser cooling.

of the lake water far the existing units is

a i-111 rn[W : .iur. a ''Cli.. L'lIII

w

ater.

V

L ite DC VV

u-

ump

lant use without requir

. S anitary Wastewater

T

reatment

E

ffluent

(Gray

Water)

The use of gray water as make-up water to power plants is b: corning a mor, widely used

method to conserve ri-esh

water. Although

this type

of

ý:Ii. <,.1

ýn has

w .,.I

problems at some f 'shies, there are several successful cG ses of gray er reuse. The

use of gray water

Lt: ý UpWciat

concerns in the operations and maintenance of power plant

which is the fresh water supply

snore valuable due to growth in demand,

ling

and corrosion within

n ,-"is to be rc:,,,oved by bleu,- town.

ad:";ti, r,:.,1 treatment

if

ant

ýe r vice

water arid

ities exist to provide the lake water to

r plant, Water from the city high

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Wafer Study

Wafer

Supply

t is important to mi

is

located about 3 miles away

ruction of a pipeline to bring the gray water to the site would be

is would be costly and thus is a disadvantage

compared to using the lake

water as make-up water to the new

unit. However, the use of gray water provides

ianificant

reduction of consumptive use of the lake water.

nificant total organic content

and solids content still remain that could cause problems

with reusing gray water result from

h igh potential

for biological

deposit or microbiologically

content

(d

p roblems

associated

i

Light E Power, Springfield, Illinois

3 -2

Burns ? McDonnell E

ngin

1 , REV. 1, February 2005

Kansas

City, Missouri

s t of the suspended solids and organics in the incoming

water are removed,

b 2005.doc

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Water Study

Wastewater

Treatment

4.0 WASTEWATER TREATMENT

T

here

are

several types of

wastewater

streams

generated

from

various plant systems.

they

fall in three

consists

of

wastewater

streams

that can

be

. The

third type

will be

a

ess than the FGD blowdown and can continue to be treated

nd currently the FGD system blowdown. This

S ugar Creek. The boron content of the ash

ily the FGD system blowdown. This

of

boron and

cannot be discharged. This

4.1 On-Site Wastewater Treatment Plant

Dallman and Lakeside Units share a common on-site wastewater clarifier

wastewater streams from the site, processes them

afer to Lake Spr'- ;,field. Th_ ti f:,tment syst-,i-, k

ponds using lake

not

rerno;-e any signifc

.

',;mount of dissolved

:-r-ttd t

r (ý,

arm , Sttch ^s th- FCT3

n 1,1owdown, are n, ,t ,a[:

water supply. The second

6

1r _S would

cause.

i

s uspend,

systems.

The treatmer (pt , o t provi

lake

water or the mitigation of boron dischn)

h plant service water drains, should be able

to

share the common wastewater

clarifer treatment

facility.

However, modification

of

lant N

streams e:_uld be discharge through the existing wastewater clarifier treatment facility.

The disch<ti Ye from the wastewater clarifer plant is directed to Lake Springfield, which is

the rev, ,,: ttcr -supply source to the plant. Thus the wastewater streams treated by

the

wastewater treatment plant are not considered consumptive losses froze lake water.

4 . Ash Pond Discharge

. {ail, float

fication pond.

At

this

stage,

chemi,.i 1

Its in settling; and separation of mos`

ifed water overflows to Sugar Creek (via autfall #004).

ischarge has periodically

exceeded the discharge

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Water Study

Wastewater Treatment

occurred when the plant SCR system is in service (average concentrate

Hanson's study report). The higlh,:st concentrations of

boron

are prom

the

blowdown streams (2010-400 ppm). However, ev

levels have app

ro«,ýftad

the discharge

s ource of boron contamination (40-50 ppm).

d analysis, that eliminating the fly ash sluicing

eters,

t he

baron

discharge problem. Because the p'GD blowdown has much hi

than any other wastewater streams contributing to the ash pon

CWLP personnel have expressed concerns th

ý,:

'ally dur

,e boron are

ru

r<<oni,i Maya

a.;1-1,-nciI in;rt a. dry

system.sexper

indicates that the fly ash

sluicing water

the largest

treatment options for

which boron, as

likely and reliable o

indiscriminately removed (separated) from the water.

in

dissolved

solids,

and may

be

reused as make-up water with

mnf."Alp

r.t :;icw,.ýter

(e.g.,

prcr=: t_,ss.

of th i

Common

zero-discharge processes

i

f ed) must be further treated in a

brine concerti It

it bi,A

to a sol

i: ý n n ý r f- ,!turers have suL

'roject 3 4¬321, REV. 1,

C WLP Water Study Feb 2005.dcac

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Water Study

Wastewater Treatment

allizers may not be able to completely convert the wastewater to a

solid waste.

ever, if an RC} system is used, the proper treatment of the RQ waste brine

crystallizer due to cost as well as the difference

it

the

water

chemistry

after an RO

system.

in this report.

The

high for these systems. The disposal of the solids

from the zero-discharge treatment equipment could be costly, too,

s idered hazardous. This is not typical but high levels of

a

hazardous

material

classification

which would cause the

al expense to go up significantly. Potential constituents of concern

and

boron. Thus, zero-discharge options are normally not economical options far

water conservation, but necessary means to meet discharge limits - in this case, the

boron

discharge limit.

C tfy Wate7ight &

Project 34821, REV. 9, FeLru-,

i,,

ý

,1

cnginee

C ity,

C WLP Water Study Feb 2005.doc

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

5.0

OPTIONS

for w ater c onservation a nd boron m itigation involved t he review of

i

dentified options. New options were also considered and evaluated if

they were considered feasible.

5 .1 Previous Study Options

5.1.1 Water Conservat

In the &L study; several potential water

conservation op

as follows:

a sh handling systems

(3)

Dry

(4) Sanitary wastewater

trc-;ýtment effluent as additional water source

(S) Recycle of ash pond e I

i

luent to Lake Springfield

(6)

FGD vacuum pump seal water and routing

of

FGD sump pit effluent

(7)

Ash handlin__

water managem en t

T

(8) Pleat ex. l,

ý,;

me of FGD

blo down from the

of lake wat: r° because city water also origin -.tes

')tal

,r

for the recovery o

s currently being pursued

by

CAILR

ns

i .;r to lab

requires a relatively small cap

its, which will help re

Iso small. Amore

. br

ption

discussed

b3

' < <

gray water to

"

'b

e

-C,-;

nd spray dryers). This op

ply turning them

lips,

w ould be

rr^ c inversion to using lake water as

the

coo

water.

led ash p f"

lake water (clad

e

r

pf-r

water,

it is more econorri'''?l

1ý ý

Uý7- treated

ir; ;b.! crfpotable water, for lxý,ýt ý.:.c h +i -rý°s

:

cad

some otl

i,-,r 11:

;. r

of pot

However, many users offýc.ýý-'ýh

,,;J,

r :;r

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Water Study

Options

currently connected

to the same headers, such as

safety

showers, eye wa

washroom facilities, which require true potable-quality water. The modifications

5 .1.2 Boron Mitigation Options

o r, crystallizer, spray dryer, etc.).

if

feasible, could be significantly less costly, but it is not recommended based

on

the lack

of

successful commercial operations of these types of systems for FGD blowdown treatment

lications. In contrast, mechanical evaporation and/or R4

systems

are

considered

more proven technologies for this applic:tf

i,:)n.

Therefore,

for selective

boron removým1 pr-)cesse.;, erh.. cin?.ly the

ion

exchange

res

wid

in

anu

ý 7-, ý turing),

W ithout s ufficient iniora

l

r

ed-,.) ý. f 'cuses on more,

to

s pray dryer,,- .ý uld be require

re i x;,,.,

ý1

options concentrates c

5 . Additional Options

Besides the opt

the true

potable

water users anti the outer potable water users may

recommends that the following o

,posting a spray

wet to dry h; f

i

t, i lit

is report.

o ption

by activated carbon, ion exchange resin or chemical

l fýý-;s

for this

i ;,

j

ided to CWLI', B&McD also

l

aloe-up to the new un

and boron removal

is using

e concentrator bleed. Dry fly ash unloading (to

off-

quire water for dust control. If brine concentrator bleed

t o mix

d isposa

could be used for

th

if

doing

so meets fly ash disposal quali

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Water Study

Options

One idea considered by B&McD was

to

r

lowdown flow rate

construction are compatible with the higher chloride concentrations. Lower FGD

blowdown flow rates will make the brine concentrators/spray dryers smaller. Based on

the scrubber design at the

Dallman Units, the chloride concentration is maintained below

10,000 ppm for corrosion prevention. Any reduction in the FGD blowdown rate to

conserve water would result

in an

W hile smaller

equipment means lower capital and O&M costs, the

concentration in the scrubber and gypsum may cause the gypsum

ich must meet certain quality specifications,

its disposal will also

ant operating expense. This

option only slightly reduces the boron-

oenetit is not signiticant, t)ut the prowern it orings coma oe

C ity Water Light &

Power, Springfield, fftin

B urns & McDonnell Engineering

Co.

P roject 34821, REV. 1, February 2005

Kansas City, Missouri

CWL,P Water Study Feb 2005.doc

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Water Study

Evaluation of Options

D and 1.0 M

6.1.1 Plant Wastewater Discharges

A ccording to the S &L water balance

w astewater discharge to the on-s

6.0 EVALUATION OF OPTIONS

cost and

benefit

evaluation was performed for the

boron

treatment

4.22 MGD, respectively. The m

orm water flow

which

will still c-gist after

ired.

After the Lakeside Units are retired in 2009, wý_rcwater

ite wastewater clarificr treatment should decrease by appro:ý: i i, i <i i

"the waste water clarif <<-r plant is about 7 MGD

a

ý1. -to

t~'.,rLlý'

al

I'

I.,

f

n'h.

:

pl

i,; for'i.:.:t:rclii-

1 1

1.1!

l

1 !1i1 llll

:

110ý 1 ! h- 11 ý7 , 'IaaL'1ý 0.

a ll Dalhrlan

Uilit' 1 (il'ýs . tFlt: on ,ite wastewaicrý ýý[:irifier treatment

p lant.

e d to the existing wastewater c

plant area

st

C 1 c.,n

t

and the new unit wastewater.

e xisting wastewater treatment

6 .1.2 Ash Pond Discharges and Boron Removal Approach

n <,

the Ranson study, as well as information

from

CWLP's staff, B&McD believes that

refi loving the FGD blowdown stream(s) from

the plant discharge to Sugar Creek may provide sufficient reduction of boron in the final

wastewater discharge to meet the current 10 pl,m limit. Once removed from the Sugar

the FGD blowdown stream

r1 gust

be

treated to removal boron

ihcations will be requi

c,

(i

a w.{i.ste for off-site disposal.

D ; t 1 h

.

_n

l

GD system blowdown

u :

104

1-ýu}ýi.

The

r Light& Power, Spry

, REV. 9, January

Feb 2005.doc

Burns

& McDonnell Engineering Co.

Kansas City, Missouri

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Water Study

Evaluation of Options

wastewater from plant

Outfall #004 would likely reduce boron concentration

in Outfall #404 to below the

current discharge limit. More importantly, if the FGD blowdown streams (including the

new unit) are allowed to be discharged

to the ash

ponds

in future, Outfall #004 would

a lmost certainly exceed the boron discharge limit after the new unit is in servi

combined FGD wastewater is about 201 ppm

of the discharge to Sugar Creep is about 3.78 MGD w

of 17.9 ppm during times when the SCR is in

operation. Removing the FGD wastewater

blowdown from the ash ponds is estimated to reduce the concentration

of

boron

in the

e lc down to about 10 ppm of boron, which is lower than the

of 11 ppm, although the margin is not

large.

vc F,,

I

-n reported. Thu ;, not removing t

I

I t :,te ý-,

,

potenti:-,t '1

c

I 'n- the

The results

ý," (I

stt:;t11-3

rý-iit

Cb,, a'.11

indicated that,

h ponds,

1n-a Dallman

to Sugar Creek from the above 10 ppm to about 5

ry handling alone would further reduce boron

1 ppm

additional reduction

A lt o

s h systems to dry

c

oncentrations) of various

ion of the current

of 0.15 MGD.

The total flow

ac-

is

root

Miclenttocý'!ý.ply

ing, the boron

ischarge to Sugar Creels.

nly,

These were

reviewed

in more detail, and manufacturers that special

h

concentrati, w {-efdissolved

R EV, 1, a' :rt!ý:.ry2008

Kansas City; Missouri

ight & Power; i ,,gf,,,d Illinois

6-2

r, car Mh.Oonnell Engineering Co.

Feb 2005, doe

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Water Study

Evaluation of Options

to remove boron. For example, materials of construction need to be

corrosion

resistant;

ch as reverse osmosis (.RC7) will not have high recovery due to the

limitation

on osmotic pressure, and the high suspended solids content requires pre-

treatment.

T

he Hanson study evaluated several options including selective boron removal, as well as

general dissolved solids remove such as RC) and mechanical evaporation, However,

B &McD's investigation

change resin or a

indicated

that, due to

the application of selective

Id not be realistic (frequent

ion

or media change-out will be required). On

the

other

hand, chemical

ected to be effective, but in this case,

concentra

al methods, such as RC) and mechanical evaporation, are the only

plication

at

CWLP. When

iLccl -,,,-c,`cr normally becomes a

I:igh-qur

brine

cancel'fr.'.1-,I

small,

r <<i I It 1ý

I

1l,

"tý

6.1.3.1

Option

1-1

- Brine Concentrator Followed by Spray Dryer (Singli Train)

, nc Cl:ariic:.4 tporators that separate and recovs

r

hater from the

is high-quality, and may be reused in many

power

plant applications. The roar, [EiraLCd solution left behind is of much smaller

volume, but still in a liquid (slurry) form. The most

commonly

used brine

concentrators

are called

falling film seeded slurry brine concentrators, and most of these use a vapor

compressor

to provide self-sufficient supply of steam to heat up the wastewater slurry,

The heated wastewater evaporate rnd generates steam that

r slurry in. The slurry

is recirculated in a vertica

.:cl-l.tager), with the steam on the shell side. Due to the

chlorides,

the

wetted materials are

normally

made from

d the tubes from titanium. These types of brine

ressor

and the

o usly bled from the system

the system sea

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Options

as 30:1 of

the

wastewater

is achievable. However, to be conservative, in the water

balances for this study, a 15:1 reduction was assumed. The water balances are attached

ices of this report.

The concentrated bleed would be taken to a spray dryer where it is

completely dried

to a

solid

form for disposal. The spray

dryer is designed based on 20:1 wastewater volume

reduction at maximum design flow rate. The above 15:1 reduction is for average

itions which have

flow rates much lower than the maximum design

under the average operating conditions

tle on the bottom of the drying; chamber, or are carried by the hot air to

dowr; .t: i i lids-removal equipment, such as bag houses or

cyclones.

The rema

n, these systems are then comp. cted by an "agglornerizer" to increase

iiý - ,iids.

This is important,*!'

f 1

*; posal cost of the solids is

of total ,

ý. ; I

h Lire base (

be treated by the spray dryer than its

the power plant. No liquid

once,

such

as

that

the incoming

T

he opt

at trains of the br

w unit

a lso

dryer units, each designed for

50°% of the maximum capacity required.

by two 50% spray dryer instead of one 10

cost of this option

will

be

higher due to the more pi

ill serve all

1 1,1-)st

of the other TD) from th-

ine concentrator of the dual un

Power, Springfield, Illinois

6-4

Sums & McDonnell Engineering Co.

>, January 2005

Kansas City,

Missouri

dy Feb 2Q05.doc

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Water Study

Evaluation of options

r ay D ryer

A

n

altern

process to recov

ical evaporation is to use a RO

volume). However,

water

(to reduce

dissolved constituents in the FGD

blowdown streams, very high reco

pressure

and the pressure limitati

system is impossible due to the osmoti

ially available RO membranes,

about 75% (the RO reject is about 25%

most of the dissolved solids end up in the RO reject, this 25

flow would also

contain

about 4 times the concentrations of dis

solves

this problem

1,`.'i;

; alts

1 ,'i

A fter the liiý,.e/soda softener, water would contain relatively low hardness, but si

conc(iJti ;,11 ý- J E is not affected

by lime/soda softener as much as hardness. When

lower solubility.

could

foul

up the RO

membranes. A hi

by operating the RO system at elevated pH (l I or higher

b oron stay in their soluble form and will not cause scaling probloms.

s ilica and

lime/soda

softener, a HERO system (a patented high-pH RO,: y,-,tcm design) is use

ERO is still an RO system, so its recovery is limited by tltC w.; ýzýutic pressure.

Cil

,.

I-ILRO. the size of the crvstalli

! i,

rr

y dryer afr -! the

Cite cost of the HERO is generall

ch

less

electricity.

i

ýYiii

8. ;, REV,

:udy Feb 2QQ5,doo

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Water Study

Evaluation of C?pti

Compared to the brine concentrator/spray dryer design, the HERO

disadvantages. From a simplicity

point of

view, the brine concentrator option is more

favorable because it involves fewer components to operate. In contrast, the HERO

f the lime/soda softener

(chemical.

feed, solids removal and disposal),

p re-treatment of the HERO system, and the HERO itself. Typically, the pre-treatment

includes a polishing ion exchange resin

softener, such as a weak acid cation (WAC) resin

i

re concentrator unit. A typical process flow

6.1.3.4 Option 3 -- Spray

Dryer versus

Fly Ash Mixing

&J,

_1

information,

projected

avera

°fa moisture content

ing only

3

.,

4

for bleed for wet

a verage operating conditions and plant load factors).

Thus for this option to be used,

Dallman Unit 33 trust be

converted to dry fly ash system. This study assumed that

Dallman Unit 33 would be converted to dry fly ash handling for this purpose.

0

S. This will require about 3 gpm

fly

ash system, there would be sufficient fly ash (in addition to the fly ash

from the new unit) for the brine concentrator bleed to

mix with. "Ibis will eliminate the

need for dual trains

of

spray

dyers. A single train of spray dryer is still recommended as

nit

33 is offline (not providing the required additional fly ash).

anct

a pt1 adjustment prior

solids removal (for

Lion

of the

igher

compared to the spray dryer following the brine

concentrator,

ich

is a trade-off with the

cost

savings on

energy consu

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

the converted dry fly ash system is expected to be much less than

that of the spray dryer.

Thus the overall

economics

of

this option may be more rat. o;-:J-,1e.

ent. In this case

this option becomes invalid, unless the customers consider

w ith brine concentrator bleed, this could add significant expenses to

the total (3&M cost

of

this

option. Another concern with this option is that many potential customers for the

fly ash fxom CWLP prefer pneumatically transferred fly ash, which does

not need any

tied fly ash.

6.1.3.5 Other Option

,

gr-selective

(1)

ic y: t:,ý ý+. tj

sale, and must be taken

c ost

is higher than regular landfill because of the in

ed in the Hanson study, were also reviewed,

These opti

f f,h

i

63. According

f

,1)

,100 cu.ft.

of resin would hi :

Acid and caustic are normally to-.:for

S-108, the total regeneration

if the capacity of resin is at 2 ounces/f . If

imately 550 cubic feet of S-108 will last about 4 hours

wastewater. As an example, for total treatment flow

rate of 1'74 gpm with 200

The operating cost of the system depends on the concentrat

,,

Jvutent in lieu of a brine concentrator, but some of tf,ý

it lust be provided to treat the

r-_.d to the brine concentrator/spray dryer

option,

11 ion exchange

be

C ity Water L rqjd

P roject

348- 1, REV. 1,

CWLP Water Study Feb 2005. doc

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Water Study

Evaluation of Options

to

the

spray

dryer. The O&M. cost of the ion exchange resin systems is much cheaper than

that of the brine concentrator. But the crystallizer O&M cost may be much higher

than

that of the spray dryer following the brine concentrator.

FGD blowdown for the resin to achieve its typical performance for boron

removal.

Pilot testing would be recommended before this option could be more

FGD blowdown. For examp

applications. This type of resin may not perform well with the water chew

applications are for lower concentrations of boron, and for

water purifica

FGD blowdown treatment application. Most of ion exchange boron removal

The biggest concern of selecting this op

converted

to dry systems,

s with

l; r:

, i

ly considered.

i :M n their

n

aii-,-,icon

, :

r1ie

c u".

(2) A tr;carbon for boron removal.

This

option

v: ;

discussed

briefly

by

( 3)

°'s capabilities by B&McD has not provided any

i11

Engineers; but there was not sufficient inf,rrrn-i

I, )i

L

to determine the

b ility of activated carbon for boron removal. Re, earch into activated

1 by activated carbon. Thus,

thi

i

:',:(ýrn:.e

lim

it because the product failed to perform. Thus th

agent indicated that the company that prcctýjc

more applicable at higher boron

conc:uýlirý IT

o f the high solubility

of

ould remove a sufficient amount of boron from the

be

discharged with other wastewater in the ash

C ity Water

Light

& Power,

Springfield, Illinois

5-8

Bums & Mono

nrneerlng Co.

Project 34821, REV 1, January 20175

K4, v _y, Missouri

CWLP Water Study Feb 2005.doc

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Water Study

Evaluation of Options

6 .2 Water Supply and Conservation Options

Two water supply sources were evaluated for use as make-cap water to bath the existing

unit, Lake

Springfield

and the sanitary

wastewater treatment plant

Lake Springfield is the raw water source to the existing units and

plant ýt, titer Plant) located on the plant site, and it

fly second water source is the

ater supply source as make-up

i

Springfield. The water is the treated, clarifier and filtered before being stored in

large

underground storage basins. The treated water is pump from the basins through a several

fl. =,V

cy and close proximity of the lake,

be installed to extract water from the once-through

through

system operates at a low pressure.

'pl'r--imately

3-mile

p

forv.-arding pumps, won

rce and

cause

severe operational problems in coolin

s ystems, which take cooling tower blowdown as make-up water.

ontent and high bio-activity could

cause

fouling and fouling-induced corrosi

in plant equipment such as coo

cont; l w iw:,rts in the

trcatr<<,r,t, (-spec

c hew

;..ýal

treats

ing station at

the

SWTP, an

ility is recommen

?Isc 1_,jrfij-mentproblems,

W ater Light& Power, Springfield, Illinois

6-g

igher than if lake water is used.

t 34621, REV. fi, January 2005

Kansas c f,,, Missouri

later Study Feb 2005, doc

Id

s tora.,,:.- w uld be requir

c

flýcuive,

some

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Water Study

Evaluation of

Captions

a nd some commercial and

r esidential properties that are not owned by CWL,P. Obtaining casements across other

properties

could be time-consuming and costly. These costs are not included in the cost

estimate for this option,

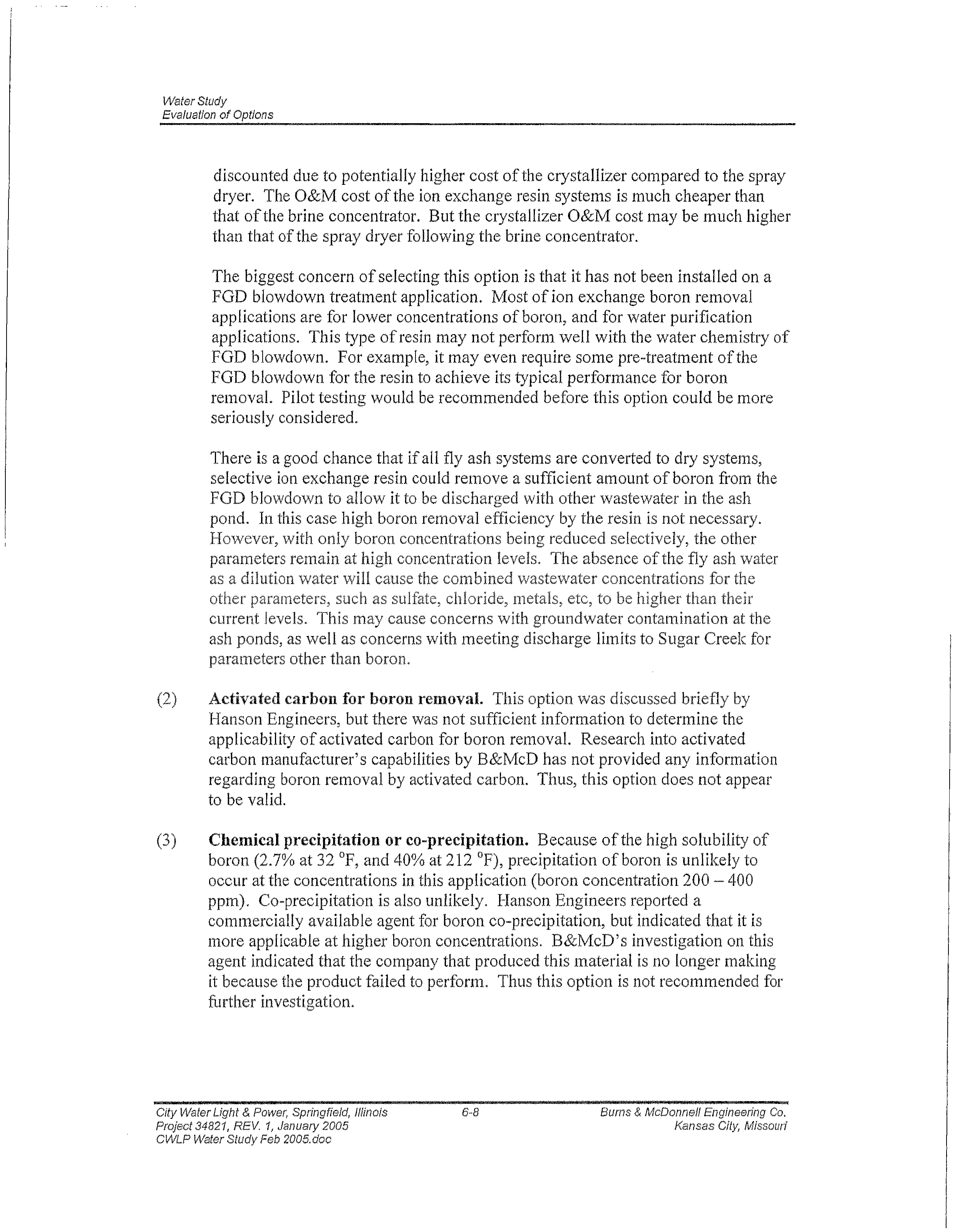

more costly to use gray water than lake water, as make-up water to the

ay Water as Make-up tea New Urea:

Comparison Items --

Lake Spririgý eld

S WTP Gray Water ---- --

Capital Cost

_

$150,0 00

$ 3.7M'

Pumps., pipeline, and tanks

Pumping Cost

$ 0 .0 013911,000-gal

2

40

hp, continuous

($0 .0211,000- gat if

e

lectricity co t<

hr)

Pu..-i aýý 17

$6

l.

,

It I

- 0 t-}`,

, hs (acid,

-75 hp

,

c,,.

i.

i.s

(acid,

c £,

c y

14

iIif

'

ar°

.

l

ired.

N lýi:::1M!I!n Cycles of

> 10

<8

t -

n r _ i

Co(`

i I TI .'vý'r 1

91

I

,

I I : "`, ird H igh-,iý. I-?; .fill maybe Low-Foul fill may be

Con: i i ! ý'Aion

used for lakrý water due to

required for gray water.

lower potential

of fouling. Cost is about $400,000

higher than the high-

_

effr_cienc_y_fiill..

Additional Cooling Tower

_

NIA.

-

_

More-frequent biocide

Chemical Cost

treatment and higher

concentrations, or more

expensive types, of scale

and corrosion inhibitor

treatment are expected.

Possibly

more chemical

waste

(in blowdown)

due to

lower cycles of

concentration.

__

OtherC t'I.<.i`

- Allinstallation and

-Offsi cr'r,ý`!-Action of

e quipment modifications pipeline, ;ind writing with

are on-site.

outside orb', i izations, could

b e costly.

ingfield, Illinois

6-90

Burns & McDonnell Engineering Co.

Kansas City;

Missouri

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Notes

1. B&McD internal

est

tables).

2 .

3 .

ided by CWLP letter 2/1112044.

o st analysis

ith using gray water

iced that the use

o f gray water

will not

be pursued at this time as part of this project.

They may

consider

future use of gray water if it becomes less expensive than other make-up supply sources.

6 ,2.2

Water C onservation O

ptions

limited

and potentially

very costly. . S&L provided some recoiniriendations in their study for conserving lake

water,

mostly by modifying the plant s= ;f°rns, but also by reviewing and improvi

ional procedures and water rn )

A i

aher

of

i

Thi

1-1 ý

s u-PL. i

solid-,

water to remove ash fines,

rem(,, c, but it prori las signi

ition,

t he

five options

ort. The water balances are

2 010-2025.

it load factors for

o

r-can

lower flows in Sugar Creek which is

currently

where the ash sluiicin-

d isch, a .Ied from the clarification pond. In some small streams reduced flow in cý;o ý ýi ix

drou dhf times of a year could be of concern to plants or animals living in or around

the

streziiný

Try

this study, we have assumed that

the effect on the hydrology and the ecology

o f Sugaý-1

" i .iot significant as a result of the water conservation options di

below.

L ight & Power, Springfield, Illinois

REV.

1, January

2005

udyFeb 2005,doc

6-T1

B urns & McDonnell Engineering Co.

Kansas City, Missouri

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

6.2.2.1 Option 1 (Base

Case)

- Use Lake Water for Make-up with

Pre-treatment

acted from

the

existing

Dallman Units' cooling water

e-treatment system on site. This option has no reduction on take

w ill have the minimum cost among

in this report, due to some impurities in

handling

systern

make-up water.

ids, it requires pre-treatment before it could be used as a

some

of the problems caused

condenser tubes

which has been known to cause corros

alloys,

higher-grade

stainless

steel

is an alternative to pre-treatment of the make-up water.

This alternative could save some money on capita-t cost, as well as operating and

of

the make-up water. However, it i, a

r ,-ative approach to remove the problc i a

r , ,r,-i

the source rather than deal try

:

r ; ,

i

di it

not save any

lake eater, but requires the least amount o

6.2.2.2 Option 2 - Use Gray Water for Make-up with Pre-treatment. Use Lake

Water

as Backup

In

this

option, gray water from

the city's San

pre-treated and transferred to CWLP's plant site for make-up to the new unit,

the cooling tuwers. S&L recommended

using

gray

water as ash sluicing water. In

uld be used as make-up water to the FGD

for the new unit. Water used for service

water and

D ue to reliability issues associated with a 3 mile

pil',either

a large storage tank or a

backup water source would be required. Because

lc l c, water is available and less costly

than a

large storage

tank,

it

i

recommended th; ý `. ( e water be used as an ý: azergency

backup for cooling tov,-"r r,i:,'::e-up in case gray w ii,.r supply is interruftc-`.

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Wafer Study

Evaluation of Options

A s discussed earlier, gray water is mare expensiv

a f ltration.

chlorination is also incl

ich is clarification

in

a

clarifier

to remove suspended solids and some organic matters. Other treatment

technologies,

such as microfiltration or ultrafiltration,

may be used in this application, but

the

clarifier

equipment and O&M costs are expected to be less expens

for cooling tower make-up, F'GD

or ash sluicing

water (for the Dallman

sluicing water, it would eventually be discharged to Sugar

line and pumps must be i

to the Dallman

Station. Gray water contains

o blems such as fouling and corrosion, and thus pre.-

this

study,

the pre-treatment

method is assumed to be the

ical growth in the transfer pipeline from

the SW

ischarges its treated

effluent,

thus

the

impact on the

be an

is ,.

i,c.

However, the 1

in the ash pr

,;rd

, -ill

vr .,

,, ,tc_i.

itneeds ý

3rminedif Výi,

is

; r

P..

Yvater on site couto c:_<<

o r dem

) ý_ CIr,ýin::1

as good as the take water in terms of water qua

p owc 1. Plant maybe

limited. The use of gray water is not recommen

ý i i 1: ý t.+;11'5,

b le.

l .`

?a, 1(} cycles of cone c

a was

assumed

in the cooling towers

when

Ice

water is the make-up v; ater, but for this option only cycles is

recommended. This

results in higher quantities of blowdown. Cooling tower blowdown

the FGD system as part of the total make-up water, but suffici

ided for the F GD m ist eliminator because c ooling t ower b 1

acceptable for this app

C ity Water Light & Rower, Springfield, Illinois

8-93

Burns & McDvnr fncýiru ng co,

Project 34829,

REV.

1,

January 2005

K r

%r- ; r9

CWLP Wafer Study Feb 2005.doc

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Water Study

Evaluation of Options

t

t o the bri

water is still of similar quality to that

in

Caption 1.

T

his

design

increases

the quantity

of wastewater to be treated by the brine concentrator

and the spray dryer, which in turn increases the operating and maintenance cost of the

plant.

However,

increasing the

maximum design

capacity

(currently

at 200 gpm) of the

brine concentrator

is not necessary because of this additional wastewater.

This

is because

the average wastewater flow rate (15 l. gpm) for this option is below the maximum design

I thkt it also re

for the short

time durations.

However, the

chance

for all un

extended time

un at higher load

ling tower bl-:o="dov.,n

6.2.2.3 Option 3 - Dry Fly Ash Systems for All Existing D llman Units

between

ammonia r ad

boron

in fly ash wi

Unit

33 generates the most fly h due to its IBC ftirnace (as opposed to cyclones

for Units

31/32),

and its projected lc:.ýd i_LJCT is much higher than Units 31/32. In addition, Unit

33

could utilize a shared silo v iih the new

unit, which will be installed

regardless

of the

fly ash transfer method of Unit 33. Converting only Unit 33 to dry fly ash is the most

is pre-determined

based on

the system

ler

converting

all Dallman Units

to

dry fly ash and converting only Uni

concern with not converting Units 31/32 to dry systems is that there is still a potential

if all fly ash is not removed.

ing any fly ash to the pond is that during times when the SCR is in

ipped from the SCR could be adsorbed by the fly ash, and then

Therefore,

3 is also an option to in iti

discharge limit of

c ost analysis included

later in this report,

e detail. The comparison between

t int

Cr

i n,, a po:

t he bor,_-n

,ii wlic

the ash ponds,

r

(lie ash ponds could be analyzed as follov ;

load factors, more cooling tourer blowdown to the FGD

means

less fresh

. This makes the

combined

water quality worse than that of Option 1.

McDonnell

Kansas

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Lions

The total existing fly ash water to the ash ponds, according

to

the

S&L water

balance, is about 1.13 1VIGD based on the average water balance for the

concentrations

of Dallman Units' fly ash slui

Dallman Units. According to the Hanson study report,

the avera.

ppm, and

41.1 ppm, re

ed on the S&L and

is in operation.

uming an average of the three boron concentr

about

6 ppm, which is

well below

the discharge limit

of I I ppm.

pond would reduce the boron concentratio

about 46 ppm, removin

o nly the Dallman FGD blowdown wastewater be

w unit is in service, the FGD wastewater

from

the

new

unit

f boron), combined with that from

ould potentially cause

vio

%ithout fly ash slu

ash wi

:, not so

?bined with a zero-di: :h_

I:i}rnace

design. Thus converting Unit 33 to dry fly ash

eliminates

t is current being sent to the ash ponds. It is also possible to share

t

he

ash

silo of

the

new unit

with

Unit 33 which makes converting Unit 33 to

dry

fly ash

more economical. However, a concern with not converting Units 31/32 to dry systems is

o n Closed-Loop Bottom Ash System (with mechanical

istina ®allman Uni

involves conve

chanical dew

bins, settlers or thi(';_ rrs). The supernate from th,._

ciý: ,,Aý_iing

equipment is rech

as ash sluicing water in!' :ad of using the lake water. Th,:: system has unrecoverable

Illinois

6-95

Burns & McDonnell E

t 31/32

Kansas C

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Wafer Study

Evaluation

of

Options

as chlorides and sulfates could also cause corrosion

at elevated concentrations. Thus a

blowdown would be required from the system, similar to

the operati

tower.

Besides blowdown,

water is also lost froth hopper seal water over

blowdown from this closed-loop bottom ash system could typ

ommon system.

bins, where most

of the

a ter. The supernate overflows to the

L ion.

The final

clarified

water is collected in

option. Both S&L and Hanson stated

that the

r emoval of bottom ash water

from the ash pond discharge could cause the boron

C urrent

U,:

ý: 33 bottom ash is a ;

sý_

['--<ttuly. Due to the lack ,

th

remai

: irrent

available

pond

stoat

According to CWLP a hi

in Springfield potentially

would be able

to

use about 50% of the ash

t his does not happen, CWLP may also dredge the pond and dispose of

the ash in a landfill. Thus it is assumed for this

study that the

ponds

will have sufficient

service life in future.

6.2.2.5 Option 5

..

Recycle of Ash Water Clarification Pond Effluent a Make-up to

the New Unit

lake water for the operations of the

Dallman Units.

1 icill : ý r c

Lý

pt

when

the

new uni

gent t- i1 i> l~ GD systems as make-

_.;r.__(,

Lni_rator. Normally the

to the new unit,

li .1 quantity c -ake water is sa.v

unit, rd

ljhtr.

.gyp 101

- ;;321,;73'.

-:

1, ý_: ruary X 005

r ter Study Fed 2005. doe

This is because the

bottom

ash

sluicin : water with

ilution water to other w< t,

blowdown.

rind is thus a consumptive

loss of

aloe-up water

of

the

new

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Water Study

Evacuation of Options

Compared to gray water, ash sluicing water

(using

lake water)

is

However, pre-treatment would still be recommended due to the potentially

ntly discontinued, and the plant becomes a

and suspended solids, as well as some metals

content, in

the recycled ash water. Most of

the

recovered water from the clarification pond is from the Dallman unit's ash sluicing

water.

Thus Options 3 and 4 above, which

will

reduce ash sluicing water to the ash

ponds,

will in turn reduce the quantity of ash water that is available for recovery from the

clarification pond. If neither of Options 3 & 4 are selected for actual implementation (all

Dallman Units will still sluice

both

their fly ash and bottom ash to the ash ponds), the

larification pond effluent water available for recovery

,ible way to achieve this is to ree

on the water balance. The average

total raw water requirement

is

about

3 MG

The pre-treatment of the lake water and the recovered ash water is very

id be reused for other applications at the

plant,

then

S uspended solids and certain metals are the primary concern. Thus, there only needs to

bt one pre-treatment system that is shared between the lake water quad the recovered ash

-ýn

. In Of, 1,i

.

1, a clari er system was assumed as the pre-

eýi.dlm}rrýtv,-ýu1d

be

able

to

pre

tr

he

Dallman

Units

only when

nt equipment. This

1. Thus the pre-

ii-

means of tempor,

Creek

is i

age while the Dallman Units

are

still

in

service.

1. The

make-up

to the new unit. The lerz _ c1; f ti

i ý_ý

V,ud

to

be a base

. In this mode of operation, for short periods the ash p,-, .d water quality could

become worse due to the closed-loop content

of the ti

. Thus some lake water must still be consumed.

a n e is possible, it aii

ash

ay

still cause boron.

ystems.

As discuss

pringfield, liiinois

uary 2005

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Water Study

Evaluation of Options

ash pond may not resolve the boron discha

ion

because the discharge of boron to Sugar Creep

is

permanently

to dry systems, the boron level would

be further reduced. This is assuming that there

[ , :,i j

c-n-,

nrr t,_,i -

Yin.ation. Accordingto

e several vround water

still be

discharge

to Sugar Creels from the ash ponds. If all ash pond effluent is recycled,

then the

cost of converting

to dry

fly

ash systems

e liminated.

I n this option; and other water

conservation o

flow in

Sugar Creels will have no adverse

luent) for

Existinq Daliman units

supernate

o f 6

s hould be further

investirated

shou

-Loop Ash Water

Systems

(Recirculatinc Ash Water Clarification

n

4 ab._, re. However, the cost

llman Units

According

to S&L,, only L)allman Unit 33 is suitable for

conversion to dry botto

sting equipment and space limitations. However,

the cost-benefit ratio of this

be unfavorable (bottom ash is only a small por

of

this type

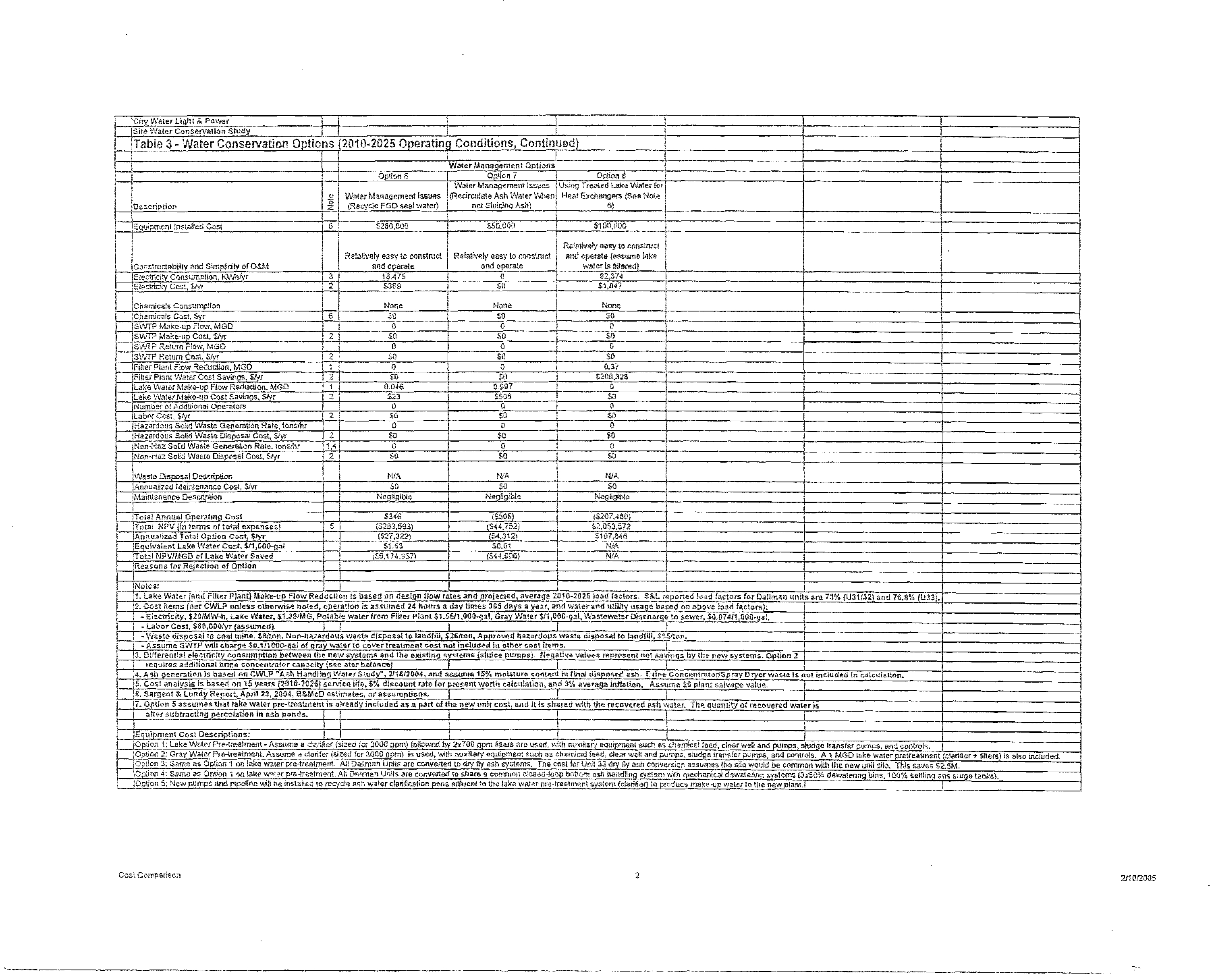

6.2.2.8 Water Mnnageanient Options

gn

( eject 54829,

a list- Y'arious options

to reduce lake

rocedures

of certain systems and equ

C

WLP

Water

Study Feb 2005,

ý in.-to

i s ili;ts Pwmp

c ,tiiý-;ýiýcý1t

to-18

Sums

&

McDonnell

Engineer,

K ansas City, M issou

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Water Study

Evaluation of Options

(1)

recycle of

collected

and pump

o w

for

being dis

(in future). This

ificant amount of water (only

about 0.06 MGD based on the

ater. In this op

Units).

wastewater discharged to the brine concentrator

will

snake

the

much smaller, and thus less costly to install and operate. The equ

mmendations

on

nds. S&L agreed that

a

ly flowing to the ash

ion

node far

11

i

nd the scope

of

thi:, rL i ý-rt. However, eliminating continuous sluice water flow to the ash ponds has

implemeated to both conserve water and reduce power usage in ash slid

shout

significant capital expenditure. Factors such as system water

(3) Use Lake Water fur Heat Exchangers. Currently many plant process equipment

lading building HVAC) are cooled by potable water

years.

to lake water. However, some potable water users (users that require

I

c,: ý'

b

:

%,* r)

are

connected

to

the

same headers as the heat

exchangers.

The separatic u (f f I I «- , e

potable water users from the rest of the system could be costly. Additionally, tube

6_19

B urn: & McDonnell Engi

Kansas City,

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Water Study

Evaluation of Options

s ystem

was

used. Also, the

Ill inch, unless an

o cal pre-chlorination a nd possible de-c hlorination ( required

to meet

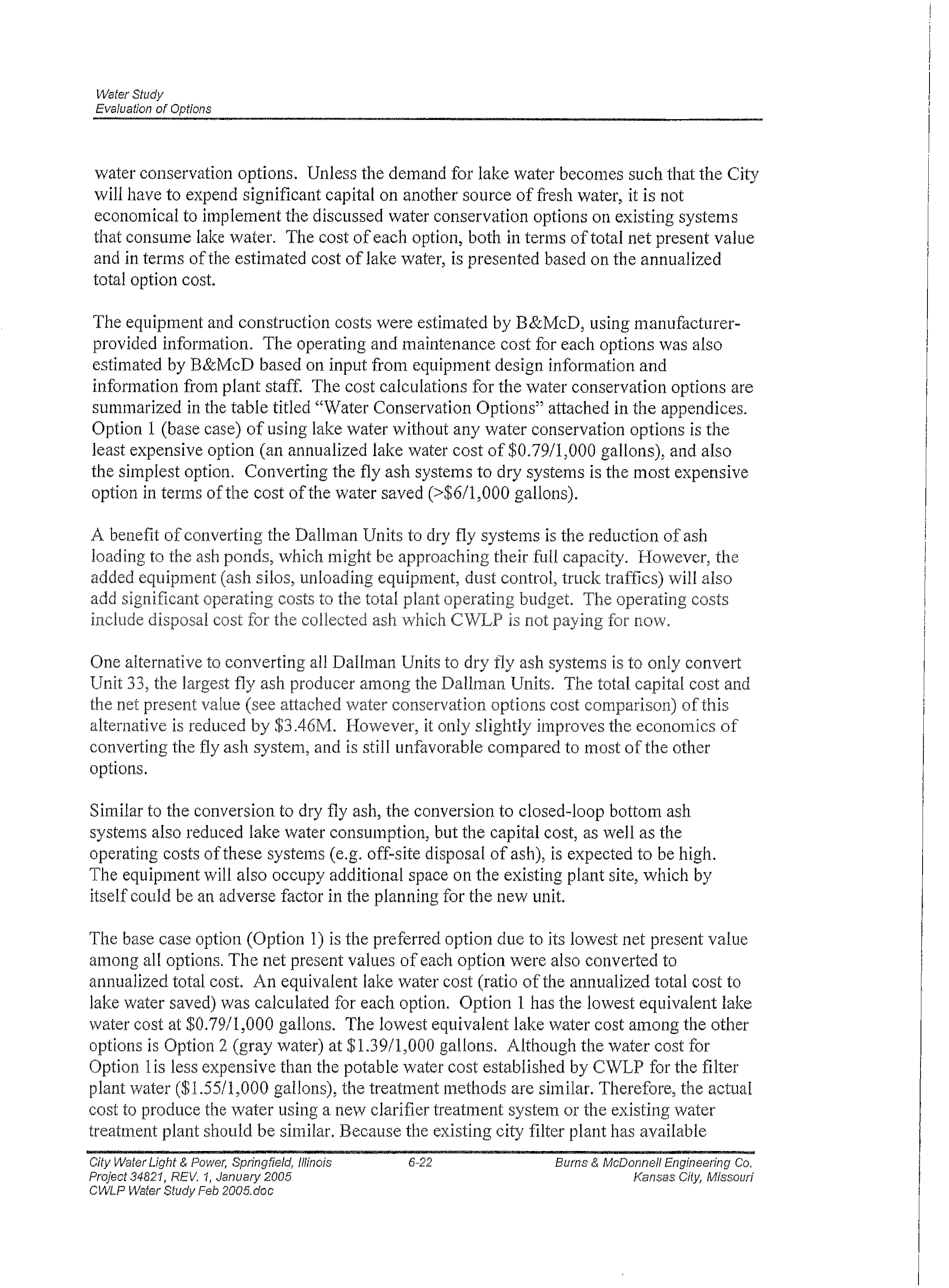

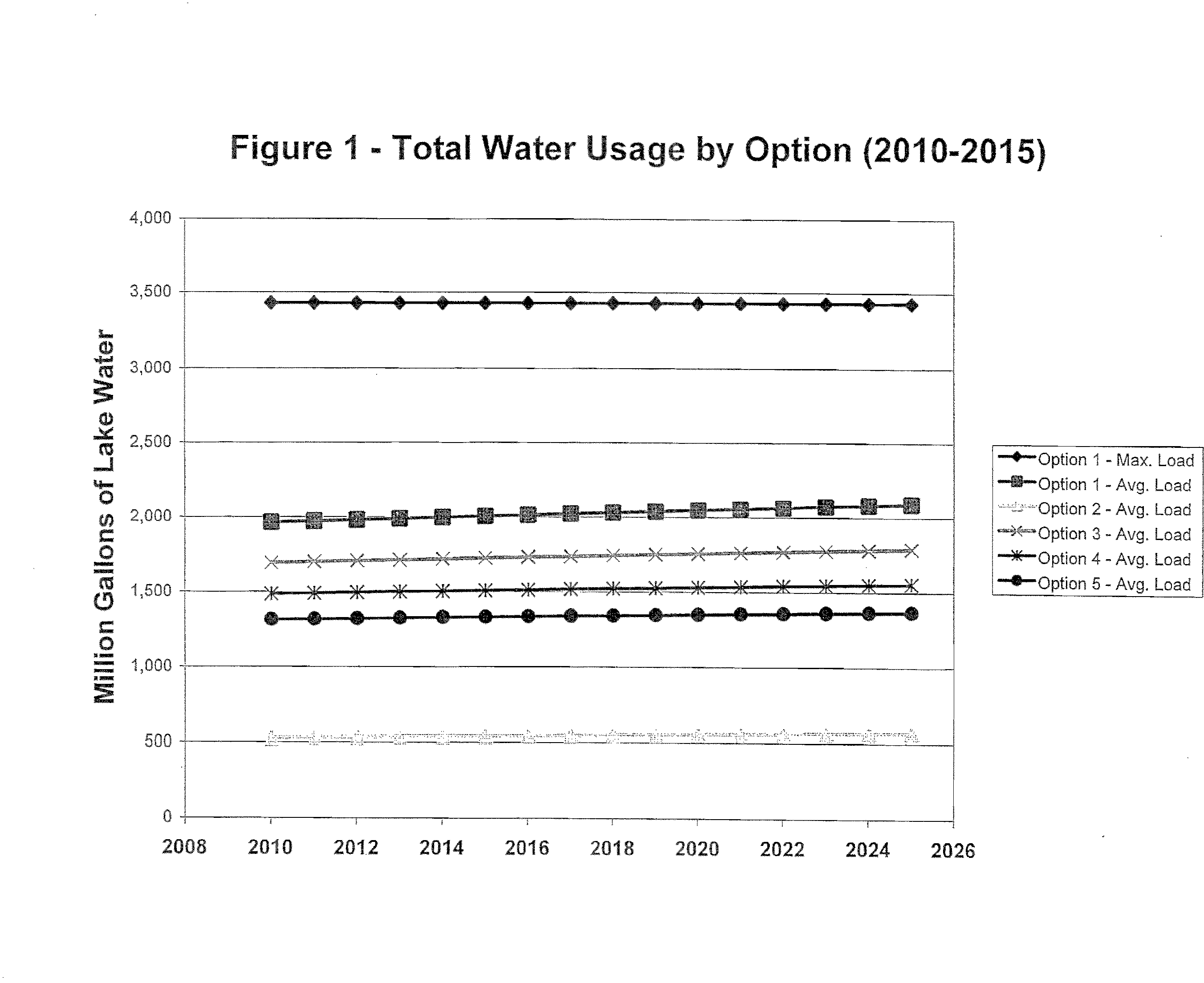

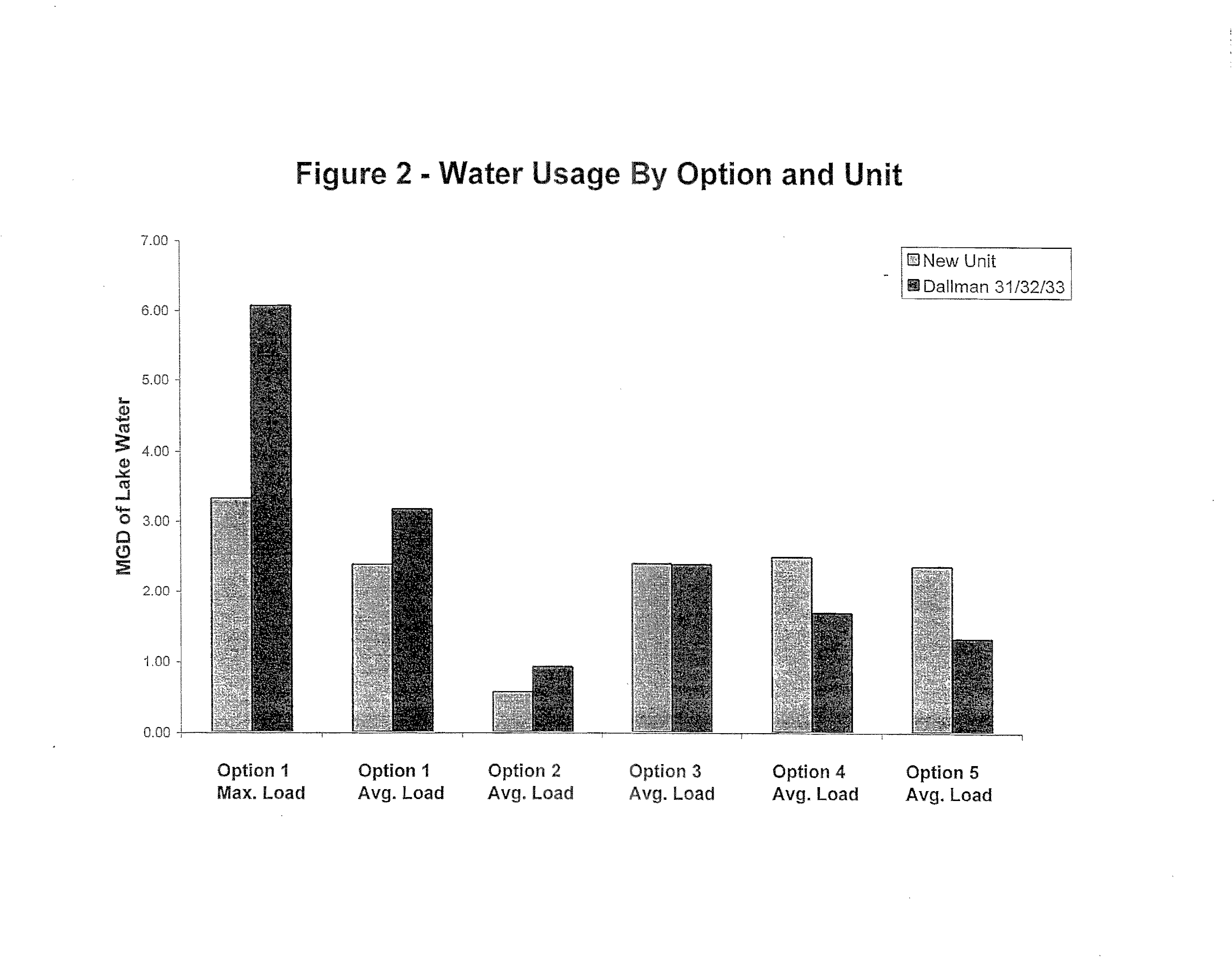

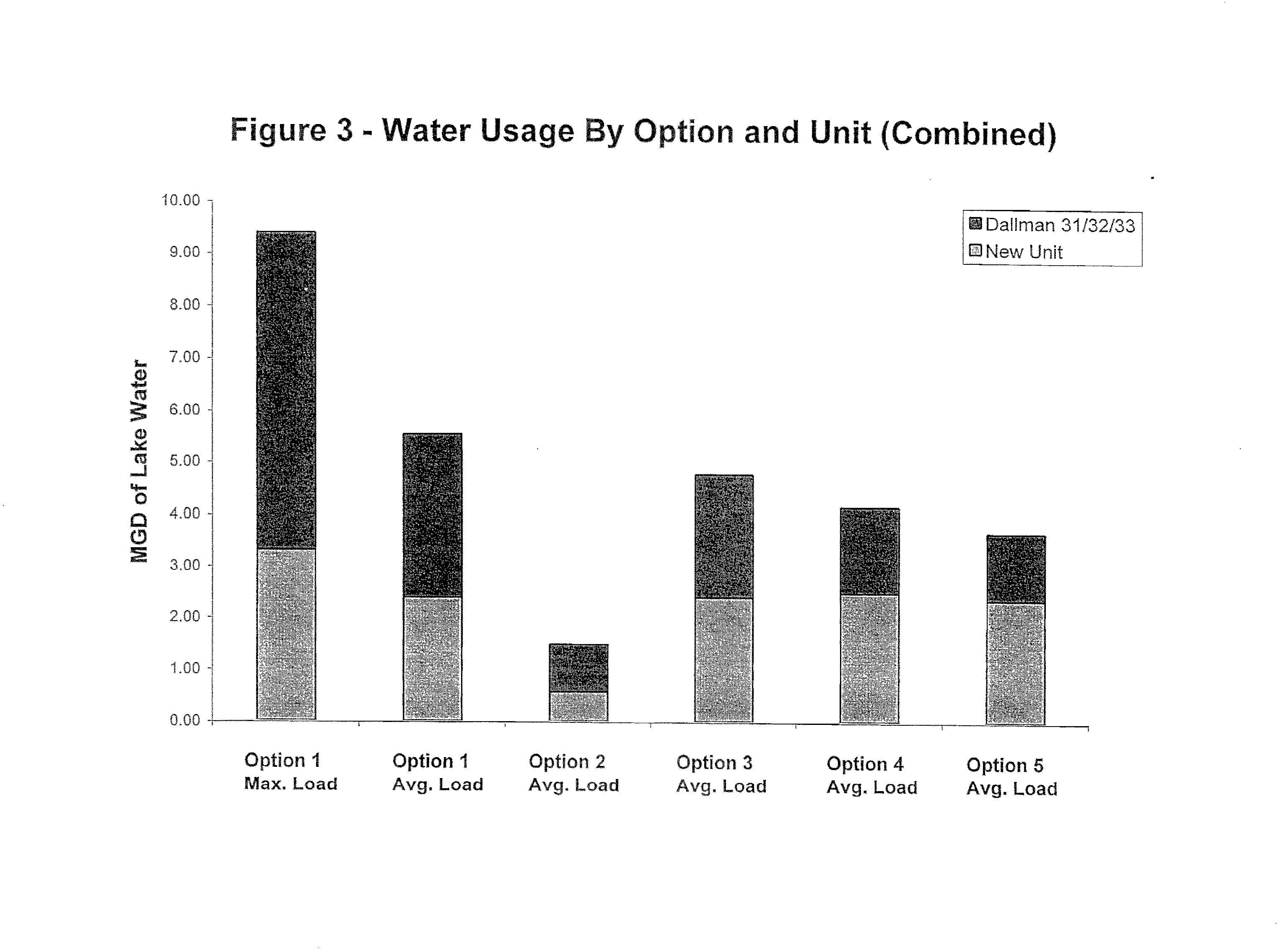

6 .2.3 Water Usage

average water balance flow r

ch

year

from 2010 to 2025 were

coons

for each unit

r total water usa

the

five water conservation

rptions

discussed in the section above. The table

titled

"Table 1 - Lake Water Us<<:rc l')r Each Water Conservation Option (2010-2025)"

,ti

tched table in the appendices). The result ofthe

in Section 7.

Lake

water usage for makeup water obtained

on

1, because

the water

stays the same independent 0- the options.

r

,

hake-ul -w,

r

ýýc

because no lake

moval equipment options, the installed equipment cost was either

project

was

the net prr,, nt value of the various options was

calculated

for

2010 - 2025

The most

v iable., op!

L ight & Flower Springfield, Illinois

R EV. t, January 2005

<, ".i um ;

-i1-

ngineering C

K insas City; Missouri

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Water

E valuation or" Options

n d water or surface

water (ash is impounded at Turris, but the impoundment

ost economical

s . Thus the

B&McD estimates were used in this cost

calculations of the boron removal options and

the water

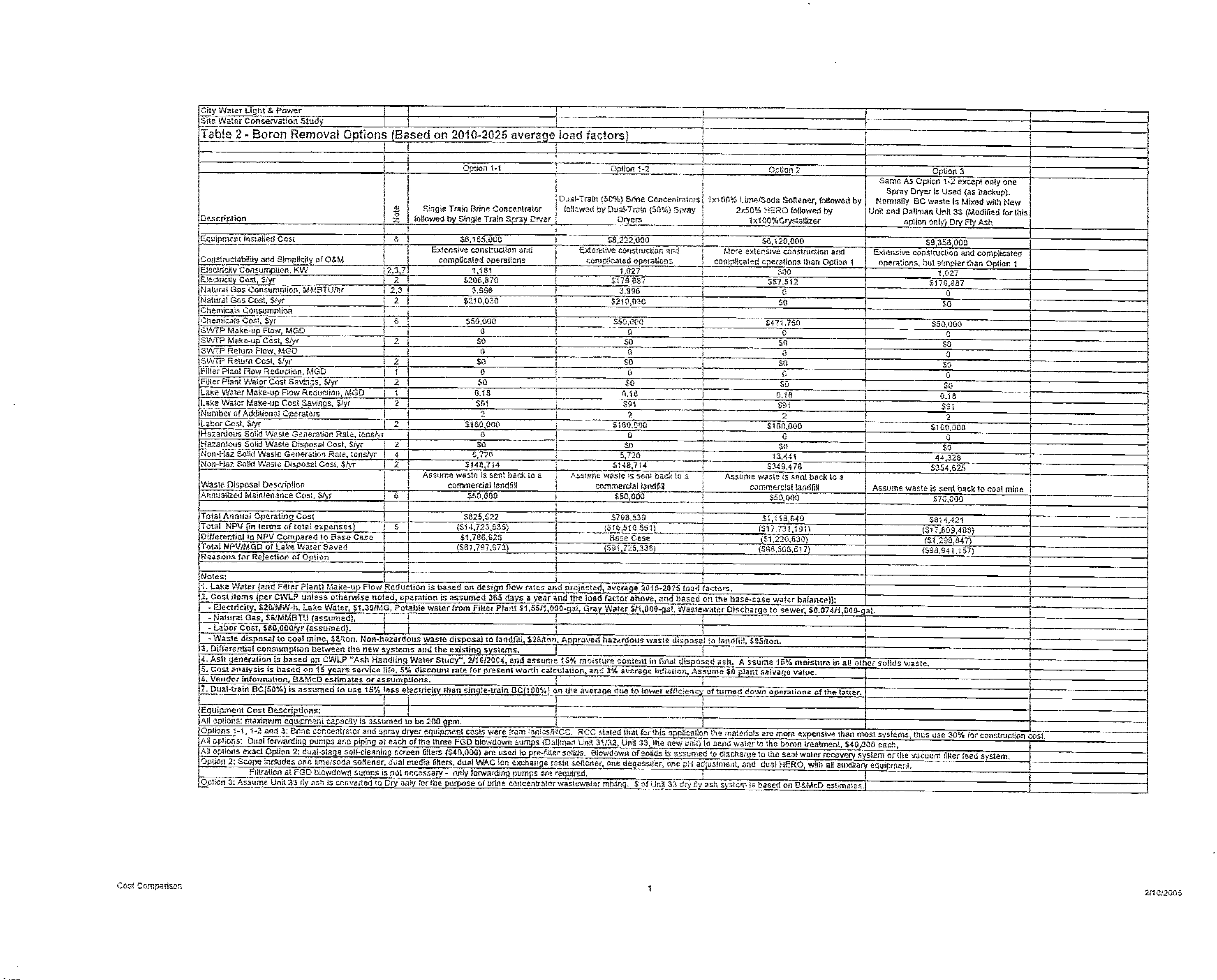

the tables (Table 2 and Table 3) in the

6.3.1 Boron-Removal

Options Summary

Among the options studied, O

a nd reliability. This option

s pray dryers. Compared to Opti

concentrator/spray

dryer), but O

tlic redundant equipment design,

r v

nit

(a total

olid.

waste gea, -r ..;:_ ' from

0% brine concentrators followed

by t, :o

' -1 is less costly ( 100' `

li

in option t, option, t' , ti i,..

1-2 is the preferred

vý:it: . ;;t certain

options

may be ditterent,

or

i - c(

,nmercial landfills, where

the solids waste may

J

r?sive.

may not be acceptable as a construction

mater

by I3&McD. S&L's

report

n I i trough the lowest

cost option

based on the net press j ýý

_i

I,ýd to finalize the

df Il or back to Tunis Mine, there could also be concerns of leaching

au, t-dringfie(d,

1G`inots

J anuei y 2005

?> 705.doc

dfor O&M costs to implement

6-21

Burns & McD gar:

1-,r,-5;1

Ue 11111ch more

tsa,w

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Water Study

Evaluation of Options

ions. Unless the demand for lake water becomes such that the City

ificant

capital on another source of fresh water, it is not

i

I

i lie Dallrit,-Ia

Units

to dry

fly systems is t1 -e,luction of aýh

The e

provided

estimated

i

nfo

1 iy

l'Lýý

C i{ýi

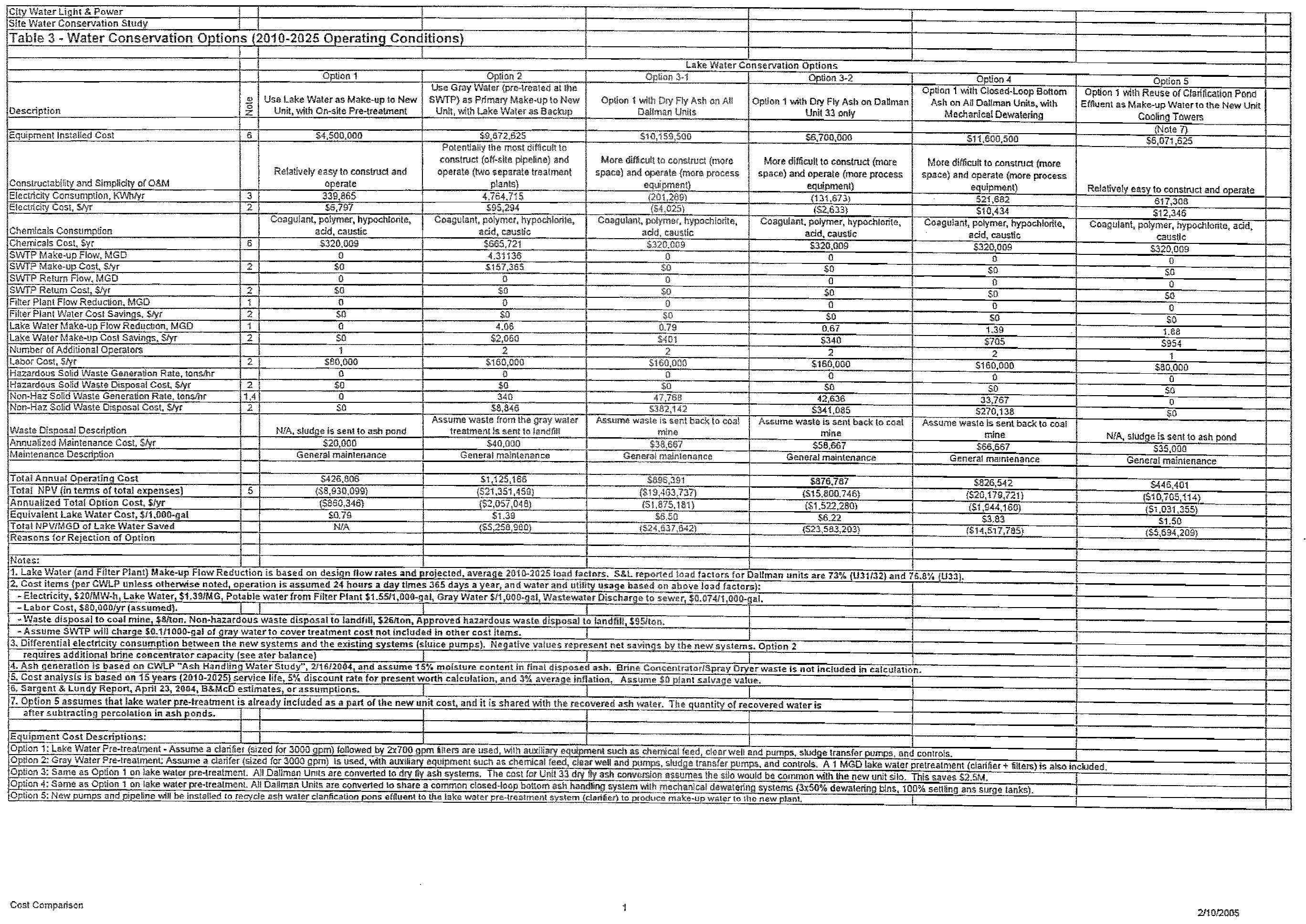

iscussed water conservation options

on existing systems

cost

of each option, both in terms of total net present value

"Water Conservation Options"

attached in the appendic(

lake

water without any water conservation options is the

realized lake

water

cost

of $0.79/1,000 gallons). and also

ý.ý. 1:

lý

r'h b ; ýrc F

.

it

fill

ý-

water,

is

presented

based on the annualized

11

D

.'1n1nii

Ur;<i,

anufacturer-

ons was also

d

` ill un.`'.

conversion to dry fly ash, the conv

reduced

lake

a r::i

'

t o most 01 0 1

y additional space on the existing

lannin2 for the new unit.

p resent

values

of

each

option

were also converted to

ivalent lake water cost (ratio of the annualized total cost to

lake water

saved)

was calculated for each

option.

Option 1

has the lowest

equ

water cost at $0.79/1,000 gallons. The lowest equivalent lake water cost among the other

options

is Option 2 (gray water) at $1.39/1,000 gallons. Although the water cost for

Option l. is less expensive than the potable water cost established

by CWLP for the filter

plant water ($1.5511,000 gallons); the treatment ir<<Allods r ,a similar. Therefore, the actual

cost

to produce the water using a new clari

plant should 1 sirnilar. Because

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

water treatment capacity

new unit's makeup demand, additional capital

expenditure for

d maintenance expense.

ater treatment plant would also add

The costs of the S&L propo

calculated in the table. These op

ings. It is recommended that a separate study be conducted

after

a final

to optimize

the operation of this system.

ifying operatin

i i _-r:, instead

of

pots

demand, (

01ý-

mater

and loc-:' iiýýrinat

,f,-f:

tj`

e

i

rlnafiej,i

ry 2(3( --

F eb 2005,doc

6-23

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Water Study

Conclusions and Recommendations

7 .0 CONCLUSIONS AND RECOMMENDATIONS

Boron lVlitigation at Ash Pond Discharge

h andling water usage and water

conservation

by Hanson

Engineers,

C WI,P,

and

Sargent & Lundy were reviewed and

analyzed. The study results indicated that the most significant source for baron

was FGD

wastewater, but fly ash also contributed a significant amount of boron to the plant

discharge.

Bottom ash boron contribution was determined to be limi

two above. Therefore, the most effective option to resolve the boron d

at the ash water ponds is to prevent the FGD wastewater from being discharged to

the

ponds.

irte

SO°%

spray dryers, is the

preferred

boron mitigation option.

this treatment option by itself would only reduce boron concentration in

the

discharge

to Sugar Creek to less than the disch lr.ý:1 limit by a small margin, and the

,re base

ý;,

avý.iý'_

l?,i

c i,

. ý,j

,;",ýf ,:!.ins

of < `i(a;i

,.

dnurnlaer

of s,u

cL,i.,r

tl.;

=

f1(*,,:;

option

by it,--elf

i-

net suiocient to mitigate

)6lems, then

in the second phase, conversion of the fly ash to dry

sion of only Unit 33 to dry fly ash is preferred

design,

provided that fly

ds. In addition, Unit

this modification more

Lion pond could be recycled back to the plant at all times,

is not necessary for the purpose of more certain boron

actually

a

more

economical solution

than

converting

to dry fly

s that this option might involve closed-loop

ash

of time

when the new unit is in an outage. This

possi

grc,ttnd water quality, to become worse during these frees. Also, c,

ý;ý ,

<<ing to send fl4

ash

try

the ash ponds may also be

a

concern for boron contamination "1 gi'ound water.

these issues

can be resolved, this option is not considered a vial: le option.

,

ight & Power, Springfield, Illinois

7-1

Burns & McDonnell Lili?7 ,,,y L:o,

2

1,

REV,

1, January 2005

Kansas city, Missouri

Study Feb 2005.doc

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Water

Study

Conclusions and Recommendations

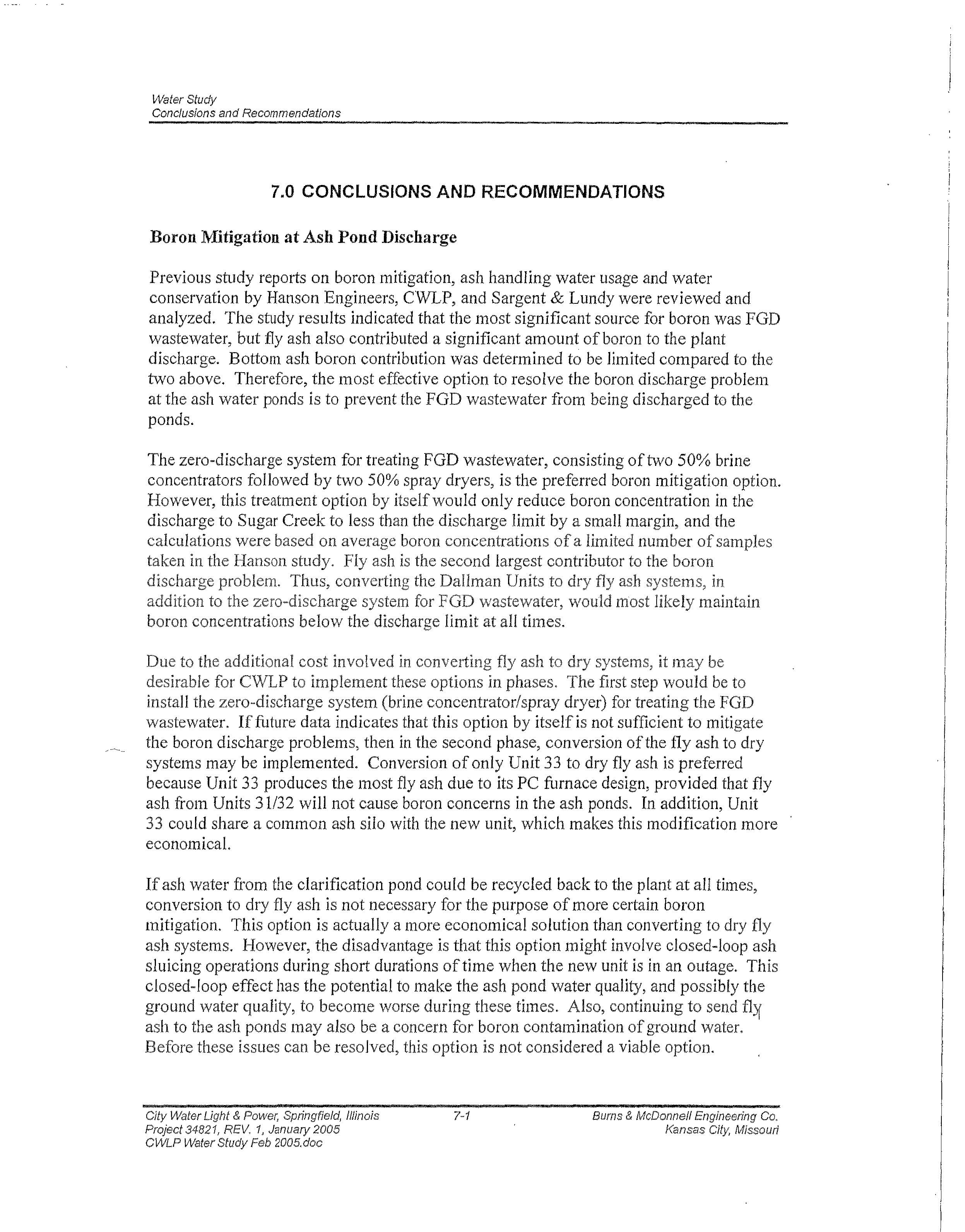

of economical to implement

any

lake water conserva

ors, such as tine additional boron-removal

1

or recycling

of clarification pond

s in lake water conservation.

This study has

assumed

that the water conservation options, which would

result in reduced Su

flow, will have no impact

on

the ecology in or around the creek.

The ash ponds are believed to be

approaching their useful life. However, currently

there

fficient information to determine if this is the case (CNVLP

stated that there is a

that the ash could

be

dredged

and used

for a highway project). Additionally,

isposing of the dredged ash off

site is always an option.

Therefore the current recommendation to

CVvLP is to keep at least the bottom ash

its unchanged until an important

factor has changed in future,

toLI ccA of t1., diG ., `,`later conservation

op ti

4

.o .r

;;.ii

I

wt

t',

III

S

;,Ilir

I

'I

i,1

_

ater

A erafe

t J:

r

:,',,^,

( A Tt'

;

T

?i

;e

x

". i I' i,

r'

4.on t

k

-

fs

Lake

1`.

I'

3 D

5 .53 MG0

1 .,(

ii'

rv

($0.79;

t,001=i-gal)

, .

L` A,. re-Ft.)

,

1.-.,

r

r ,

i :

421,315,459

1.47 MGD

`, iI,

J f ::-:L_- iýla

($1.39/1,000-gal)

(26,'-,28 Acre-Ft.)

0 , Itlon 3, Dry

Fly -$19,463,737

27,697 MG

4.74 MGD

Ash

($6.50/1,000-gal)

(

84,998 Acre-Ft.)

Option 4, Closed- -$20,179,721

24,178

MG

4.14 MGD

L oop Bottom Ash

($3.83/1,000-gal)

(74,199

Acre-Ft.)

O ption 5, Recycling

-$10,705,1.14

21,334 MG

3.65

MGD

Clarification Pond ($1.50/1,000-gal)

(65,473

Acre-Ft.)

ýororrical option.

Again, this conclusion

is based on the

.,rý.1,

(11.39/Million Gallons). Unle " this cost of lake,

nc_ ý:A to expand or construct ono [ I L (J° I i : ý,i

water

lake,

or

stiff the cost for any

of

thu

w4o,,)

--nsý_:rvation

options.

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

and

Recommendations

filter plant effluent, CWLP has indicated the existing filter

plant has excess capacity and

can

produce

water mare

economically than a new water treatment plant designed to serve

just the makeup requirements for the new plant.

provided from

the CWLP Filtration Plant be used as the pr

ter. A final water balance is provided in the appendices of this rep

following recommended moth

1

concentrators and spray dryers.

that

the Ash Pond water qual

stem crould be added to allow recov,ýiT

ur"it

cn, ý l i n e tower. if the

value of ww

r conservation

ýn` ý"A associated added or,

i;and

ringfield, Illinois

='

Burn

2005

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

APPENDICES

f or/Spray Dryer F

Flow Diagram

0

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Bil

l

1 11

e

m

I IV

-L_

'

U411

Z

a

o ý

U

R 1

1.1

0

-HE

e

3'I

m

e

a

fl

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

asz

£va p

215

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

cywa.Opapapa

drpma-ruc

aaaroe peearSbWi

NO:n

IFt.MeYtIUlagKa uxppnlWVysOrLgIhiyYenFabar

(t610.7D15,MIh InkeeNe Nafndl

MFa?R

9W4vORgF ialwEmba

A-PNI

puaica

11r.3MSt.

x 75

N oes

LPoneanicMGQ

2 awg-danvmaCý

W*.A

ApA

pa2R21

0i

wn2,5agenG

tuMy.

170x.

, .N

I

I

1

I

I

I - ý -I -s-nugasýa.venTaý.ru+.um.

ý

1 - -I

w

arE

ýnrunwaeearoffýrE

aes

p -- m- -F-- -M

as

rip

w

eaaw

CITY OF SPRINGFIELD, IL

E7NIYpPW,t(6i1.WatarB,leneel-

A

MwLAE-

14102.)

OPTION 2 WATER BALANCE

FLOW M1E W Y001

ua

r B

9 ff770F1

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

SW7P

Mr.-

7 ,479

Sez7 Waxe7ta Fan

t ry

ý

ý &7

Fan W. 1t

0 0ý0e

kekpexxt

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

§1n

V ill

I

x

) if

p

0

m

8

BB i ll

,

IN

n

2

0

4

9

I

lg

R

0 319

I IT-II

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Se4 WMSrtaFa}

Rd'§cu

._..__.........__.._

pzaFG:

_-___-__....

..ý

i

ck......

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

3

S

a

a

S

S

i

e

m

J

v

s

a

a I

I

m

I

0

H

H

0

b

i

S

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

All

a s

aý.g

d35

1X12 Rc cs`nr

t1Nattr

Rmw.

To .1 ,

a6

Yaa1LCax

o t.wsMrtG SiaCgs

7o- GTýattt SF}apaaxi

Fm Want

o1t.nt

c;aýsaa

a¢

B a

9

P RELI'c"AVIARY

h

.'!i

l

I

CITY WATER LIGHT a I'OWC7

z:

I

YV

1 '-

1 ý1

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

P-

FpnrrY.,.IýYfwrlWrmt4vldýnixe,MOnL'nUYta Farb(20fý-20Mýw1h4aircttJaANhMI

a 1jF-m

WýCýwA?

R-

PM'

"ftft

iwr.a"1141

Nxp:

1.IM-

ft-

Wa1r

2 DIM-

on

Sw*R

2Mm

I S.F.

5,vp,rta

LuiMy"RWNpd1 23.2327W.

9

I

X0.04

w r,wwn

w F- m

C RY OF

SPRINGFIELD, IL

E,4f2PImtISLLWMCOdwce)

AW,UALAVEItAb (Nfa7Wý

°ý

OPf10N 3 WATER BALNICE / +

Fwxwrenumý

m

1"IX

M+sanuowmoasns R9 PK

0 W2OF2

Y!

ZRW

0

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

1.443

1 1ý.

!,4M

PRELIMINARY

--------------

-

-a W?w

N

-toas

Ycm Lasx

}

..v.

1

°c

U.....

-

3297

-iouým+Xdpwp9

CITY WATER LIGHT .

d+4i-1eiNxAwAAH-Ceatr'"-

Ann" A-ge L--

;MATER 311 B-1

w'ýrsrvr41c9xuun

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

all

K

i

rc

y

I

Q

t

J Q

W

H

U

8

I

iv

0I

0

I

H

I

0

9

b

i

0

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

2M

r

ao9

9,d46

NawPxcpup

Src.-rn Rxnal(

PAC to Sugar Cit0 (R.yded to ukej

2,241

1 21

E 110mg

SanazgW.-

Fsposil

t^.!

WTE

1, RC'

,

2.

....._.-..-

"a. TOTAI"n

S. TOTPi.:

5. TOT-

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

'rl1

xa

a

i

Il

I

I

i

l

0

T

N

L

g

O

r

a

0

Mý4

I

Q

w

S

s

u

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

PFD1- Example Brine Concentrator Flow Diagram - For Reference

Only (Sheet 112)

W IRIATE P UMP

7D SPRAY ORM

MFR

7 D MIST

EWKAT0R RASH

F® TMK

F ® PUMP

N EAT DMANOEN (2)

m nK w

I LI

i

R

u

6

7

I

FEýt

I

w

1-1- 1"

6

1--Q

1

11 7

11

1 1 11

1

1

i

1

...

SEED PUMP

01S161A7E

TANK

ANi1FOAM

ANTFOAY

PUMP (2)

SUPPLY

7 0 SPRAY DRWR

FFfD TANT

SEED

TANK

STEAL

(STARr

C AUS710 SUPPLY

A .II)

0

C

s

A

1

4

R ESOURCES CONSERVATION

COMPANY

3ý

2

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

PFD1- Example Spray