3.3 Relative Accuracy

3.3.1 Relative Accuracy for CO2 and O2 Monitors

The relative accuracy for CO2 and O2 monitors must not exceed 10.0 percent. The relative accuracy test results are also acceptable if the difference between the mean value of the CO2 or O2 monitor measurements and the corresponding reference method measurement mean value, calculated using equation A-7 of this Exhibit, does not exceed +- 1.0 percent CO2 or O2.

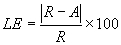

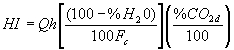

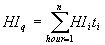

(Equation A-7)

(Equation A-7)

where,

n = Number of data points.

di = The difference between a reference method value and the corresponding continuous emission monitoring system value (RMi–CEMi) at a given point in time i.

3.3.2 Relative Accuracy for Flow Monitors

| (a)

| The relative accuracy of flow monitors must not exceed 10.0 percent at any load (or operating) level at which a RATA is performed (i.e., the low, mid, or high level, as defined in Section 6.5.2.1 of this Exhibit). |

| |

| (b)

| For affected units where the average of the flow reference method measurements of gas velocity at a particular load (or operating) level of the relative accuracy test audit is less than or equal to 10.0 fps, the difference between the mean value of the flow monitor velocity measurements and the reference method mean value in fps at that level must not exceed +- 2.0 fps, wherever the 10.0 percent relative accuracy specification is not achieved. |

| |

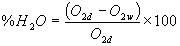

3.3.3 Relative Accuracy for Moisture Monitoring Systems

The relative accuracy of a moisture monitoring system must not exceed 10.0 percent. The relative accuracy test results are also acceptable if the difference between the mean value of the reference method measurements (in percent H2O) and the corresponding mean value of the moisture monitoring system measurements (in percent H2O), calculated using Equation A-7 of this Exhibit does not exceed +- 1.5 percent H2O.

3.3.4 Relative Accuracy for Mercury Monitoring Systems

The relative accuracy of a mercury concentration monitoring system or a sorbent trap monitoring system must not exceed 20.0 percent. Alternatively, for affected units where the average of the reference method measurements of mercury concentration during the relative accuracy test audit is less than 5.0 µg/scm, the test results are acceptable if the difference between the mean value of the monitor measurements and the reference method mean value does not exceed 1.0 µg/scm, in cases where the relative accuracy specification of 20.0 percent is not achieved.

3.4 Bias

3.4.1 Flow Monitors

Flow monitors must not be biased low as determined by the test procedure in Section 7.4 of this Exhibit. The bias specification applies to all flow monitors including those measuring an average gas velocity of 10.0 fps or less.

3.4.2 Mercury Monitoring Systems

Mercury concentration monitoring systems and sorbent trap monitoring systems must not be biased low as determined by the test procedure in Section 7.4 of this Exhibit.

The cycle time for mercury concentration monitors, oxygen monitors used to determine percent moisture, and any other monitoring component of a continuous emission monitoring system that is required to perform a cycle time test must not exceed 15 minutes.

4. Data Acquisition and Handling Systems

Automated data acquisition and handling systems must read and record the full range of pollutant concentrations and volumetric flow from zero through span and provide a continuous, permanent record of all measurements and required information as an ASCII flat file capable of transmission both by direct computer-to-computer electronic transfer via modem and EPA-provided software and by an IBM-compatible personal computer diskette. These systems also must have the capability of interpreting and converting the individual output signals from a flow monitor, a CO2 monitor, an O2 monitor, a moisture monitoring system, a mercury concentration monitoring system, and a sorbent trap monitoring system, to produce a continuous readout of pollutant emission rates or pollutant mass emissions (as applicable) in the appropriate units (e.g., lb/hr, lb/MMBtu, ounces/hr, tons/hr). These systems also must have the capability of interpreting and converting the individual output signals from a flow monitor to produce a continuous readout of pollutant mass emission rates in the units of the standard. Where CO2 emissions are measured with a continuous emission monitoring system, the data acquisition and handling system must also produce a readout of CO2 mass emissions in tons.

Data acquisition and handling systems must also compute and record monitor calibration error; any bias adjustments to mercury pollutant concentration data, flow rate data, or mercury emission rate data.

5. Calibration Gas

5.1 Reference Gases

For the purposes of this Appendix, calibration gases include the following:

5.1.1 Standard Reference Materials (SRM)

These calibration gases may be obtained from the National Institute of Standards and Technology (NIST) at the following address: Quince Orchard and Cloppers Road, Gaithersburg, MD 20899-0001.

5.1.2 SRM-Equivalent Compressed Gas Primary Reference Material (PRM)

Contact the Gas Metrology Team, Analytical Chemistry Division, Chemical Science and Technology Laboratory of NIST, at the address in Section 5.1.1, for a list of vendors and cylinder gases.

5.1.3 NIST Traceable Reference Materials

Contact the Gas Metrology Team, Analytical Chemistry Division, Chemical Science and Technology Laboratory of NIST, at the address in Section 5.1.1, for a list of vendors and cylinder gases that meet the definition for a NIST Traceable Reference Material (NTRM) provided in 40 CFR 72.2

, incorporated by reference in Section 225.140.

5.1.4 EPA Protocol Gases

| (a)

| An EPA Protocol Gas is a calibration gas mixture prepared and analyzed according to Section 2 of the "EPA Traceability Protocol for Assay and Certification of Gaseous Calibration Standards," September 1997, EPA-600/R-97/121 or such revised procedure as approved by the Administrator (EPA Traceability Protocol). |

| |

| (b)

| An EPA Protocol Gas must have a specialty gas producer-certified uncertainty (95-percent confidence interval) that must not be greater than 2.0 percent of the certified concentration (tag value) of the gas mixture. The uncertainty must be calculated using the statistical procedures (or equivalent statistical techniques) that are listed in Section 2.1.8 of the EPA Traceability Protocol. |

| |

| (c)

| A copy of EPA-600/R-97/121 is available from the National Technical Information Service, 5285 Port Royal Road, Springfield, VA, 703-605-6585 or http://www.ntis.gov

, and from http://www.epa.gov/ttn/emc/news.html

or http:// www.epa.gov/appcdwww/tsb/index.html

. |

| |

5.1.5 Research Gas Mixtures

Research gas mixtures must be vendor-certified to be within 2.0 percent of the concentration specified on the cylinder label (tag value), using the uncertainty calculation procedure in Section 2.1.8 of the "EPA Traceability Protocol for Assay and Certification of Gaseous Calibration Standards," September 1997, EPA-600/R-97/121. Inquiries about the RGM program should be directed to: National Institute of Standards and Technology, Analytical Chemistry Division, Chemical Science and Technology Laboratory, B-324 Chemistry, Gaithersburg, MD 20899.

5.1.6 Zero Air Material

Zero air material is defined in 40 CFR 72.2

, incorporated by reference in Section 225.140.

5.1.7 NIST/EPA-Approved Certified Reference Materials

Existing certified reference materials (CRMs) that are still within their certification period may be used as calibration gas.

5.1.8 Gas Manufacturer's Intermediate Standards

Gas manufacturer's intermediate standards is defined in 40 CFR 72.2

, incorporated by reference in Section 225.140.

5.1.9 Mercury Standards

For 7-day calibration error tests of mercury concentration monitors and for daily calibration error tests of mercury monitors, either NIST-traceable elemental mercury standards (as defined in Section 225.130) or a NIST-traceable source of oxidized mercury (as defined in Section 225.130) may be used. For linearity checks, NIST-traceable elemental mercury standards must be used. For 3- level and single-point system integrity checks under Section

1.4(c)(1)(E) of this Appendix, Sections 6.2(g) and 6.3.1 of this Exhibit, and Sections 2.1.1, 2.2.1 and 2.6 of Exhibit B to this Appendix, a NIST-traceable source of oxidized mercury must be used. Alternatively, other NIST-traceable standards may be used for the required checks, subject to the approval of the Agency. Notwithstanding these requirements, mercury calibration standards that are not NIST-traceable may be used for the tests described in this Section until December 31, 2009. However, on and after January 1, 2010, only NIST-traceable calibration standards must be used for these tests.

5.2 Concentrations

Four concentration levels are required as follows.

5.2.1 Zero-level Concentration

0.0 to 20.0 percent of span, including span for high-scale or both low- and high-scale for CO2 and O2 monitors, as appropriate.

5.2.2 Low-level Concentration

20.0 to 30.0 percent of span, including span for high-scale or both low- and high-scale for CO2 and O2 monitors, as appropriate.

5.2.3 Mid-level Concentration

50.0 to 60.0 percent of span, including span for high-scale or both low- and high-scale for CO2 and O2 monitors, as appropriate.

5.2.4 High-level Concentration

80.0 to 100.0 percent of span, including span for high-scale or both low-and high-scale for CO2 and O2 monitors, as appropriate.

6. Certification Tests and Procedures

6.1 General Requirements

6.1.1 Pretest Preparation

Install the components of the continuous emission monitoring system (i.e., pollutant concentration monitors, CO2 or O2 monitor, and flow monitor) as specified in Sections 1

, 2

, and 3

of this Exhibit, and prepare each system component and the combined system for operation in accordance with the manufacturer's written instructions. Operate the unit(s) during each period when measurements are made. Units may be tested on non-consecutive days. To the extent practicable, test the DAHS software prior to testing the monitoring hardware.

6.1.2 Requirements for Air Emission Testing Bodies

| (a)

| On and after January 1, 2009, any Air Emission Testing Body (AETB) conducting relative accuracy test audits of CEMS and sorbent trap monitoring systems under Part 225, Subpart B, must conform to the requirements of ASTM D7036-04 (incorporated by reference under Section 225.140). This Section is not applicable to daily operation, daily calibration error checks, daily flow interference checks, quarterly linearity checks or routine maintenance of CEMS. |

| |

| (b)

| The AETB must provide to the affected source(s) certification that the AETB operates in conformance with, and that data submitted to the Agency has been collected in accordance with, the requirements of ASTM D7036-04 (incorporated by reference under Section 225.140). This certification may be provided in the form of: |

| |

| (1)

| A certificate of accreditation of relevant scope issued by a recognized, national accreditation body; or |

| |

| (2)

| A letter of certification signed by a member of the senior management staff of the AETB. |

| |

| (c)

| The AETB must either provide a Qualified Individual on-site to conduct or must oversee all relative accuracy testing carried out by the AETB as required in ASTM D7036-04 (incorporated by reference under Section 225.140). The Qualified Individual must provide the affected source(s) with copies of the qualification credentials relevant to the scope of the testing conducted. |

| |

6.2 Linearity Check (General Procedures)

Check the linearity of each CO2, Hg, and O2 monitor while the unit, or group of units for a common stack, is combusting fuel at conditions of typical stack temperature and pressure; it is not necessary for the unit to be generating electricity during this test. For units with two measurement ranges (high and low) for a particular parameter, perform a linearity check on both the low scale and the high scale. For on-going quality assurance of the CEMS, perform linearity checks, using the procedures in this Section, on the range(s) and at the frequency specified in Section 2.2.1 of Exhibit B to this Appendix. Challenge each monitor with calibration gas, as defined in Section 5.1 of this Exhibit, at the low-, mid-, and high-range concentrations specified in Section 5.2 of this Exhibit. Introduce the calibration gas at the gas injection port, as specified in Section 2.2.1 of this Exhibit. Operate each monitor at its normal operating temperature and conditions. For extractive and dilution type monitors, pass the calibration gas through all filters, scrubbers, conditioners, and other monitor components used during normal sampling and through as much of the sampling probe as is practical. For in-situ type monitors, perform calibration checking all active electronic and optical components, including the transmitter, receiver, and analyzer. Challenge the monitor three times with each reference gas (see example data sheet in Figure 1). Do not use the same gas twice in succession. To the extent practicable, the duration of each linearity test, from the hour of the first injection to the hour of the last injection, must not exceed 24 unit operating hours. Record the monitor response from the data acquisition and handling system. For each concentration, use the average of the responses to determine the error in linearity using Equation A-4 in this Exhibit. Linearity checks are acceptable for monitor or monitoring system certification, recertification, or quality assurance if none of the test results exceed the applicable performance specifications in Section 3.2

of this Exhibit. The status of emission data from a CEMS prior to and during a linearity test period must be determined as follows:

| (a)

| For the initial certification of a CEMS, data from the monitoring system are considered invalid until all certification tests, including the linearity test, have been successfully completed, unless the conditional data validation procedures in Section

1.4(b)(3) of this Appendix are used. When the procedures in Section

1.4(b)(3) of this Appendix are followed, the words "initial certification" apply instead of "recertification," and complete all of the initial certification tests by January 1, 2009, rather than within the time periods specified in Section 1.4(b)(3)(D) of this Appendix for the individual tests. |

| |

| (b)

| For the routine quality assurance linearity checks required by Section 2.2.1 of Exhibit B to this Appendix, use the data validation procedures in Section 2.2.3 of Exhibit B to this Appendix. |

| |

| (c)

| When a linearity test is required as a diagnostic test or for recertification, use the data validation procedures in Section

1.4 (b)(3) of this Appendix. |

| |

| (d)

| For linearity tests of non-redundant backup monitoring systems, use the data validation procedures in Section

1.4(d)(2)(C) of this Appendix. |

| |

| (e)

| For linearity tests performed during a grace period and after the expiration of a grace period, use the data validation procedures in Sections 2.2.3 and 2.2.4, respectively, of Exhibit B to this Appendix. |

| |

| (f)

| For all other linearity checks, use the data validation procedures in Section 2.2.3 of Exhibit B to this Appendix. |

| |

| (g)

| For mercury monitors, follow the guidelines in Section 2.2.3 of this Exhibit in addition to the applicable procedures in Section 6.2 when performing the system integrity checks described in Section

1.4(c)(1)(E) and in Sections 2.1.1, 2.2.1, and 2.6 of Exhibit B to this Appendix. |

| |

| (h)

| For mercury concentration monitors, if moisture is added to the calibration gas during the required linearity checks or system integrity checks, the moisture content of the calibration gas must be accounted for. Under these circumstances, the dry basis concentration of the calibration gas must be used to calculate the linearity error or measurement error (as applicable). |

| |

6.3 7-Day Calibration Error Test

6.3.1 Gas Monitor 7-day Calibration Error Test

Measure the calibration error of each mercury concentration monitor, and each CO2 or O2 monitor while the unit is combusting fuel (but not necessarily generating electricity) once each day for 7 consecutive operating days according to the following procedures. For mercury monitors, you may perform this test using either elemental mercury standards or a NIST-traceable source of oxidized mercury. Also for mercury monitors, if moisture is added to the calibration gas, the added moisture must be accounted for and the dry-basis concentration of the calibration gas must be used to calculate the calibration error. (In the event that unit outages occur after the commencement of the test, the 7 consecutive unit operating days need not be 7 consecutive calendar days.) Units using dual span monitors must perform the calibration error test on both high- and low-scales of the pollutant concentration monitor. The calibration error test procedures in this Section and in Section 6.3.2 of this Exhibit must also be used to perform the daily assessments and additional calibration error tests required under Sections 2.1.1 and 2.1.3 of Exhibit B to this Appendix. Do not make manual or automatic adjustments to the monitor settings until after taking measurements at both zero and high concentration levels for that day during the 7-day test. If automatic adjustments are made following both injections, conduct the calibration error test such that the magnitude of the adjustments can be determined and recorded. Record and report test results for each day using the unadjusted concentration measured in the calibration error test prior to making any manual or automatic adjustments (i.e., resetting the calibration). The calibration error tests should be approximately 24 hours apart, (unless the 7- day test is performed over non-consecutive days). Perform calibration error tests at both the zero-level concentration and high-level concentration, as specified in Section 5.2 of this Exhibit. Alternatively, a mid-level concentration gas (50.0 to 60.0 percent of the span value) may be used in lieu of the high-level gas, provided that the mid-level gas is more representative of the actual stack gas concentrations. Use only calibration gas, as specified in Section 5.1 of this Exhibit. Introduce the calibration gas at the gas injection port, as specified in Section 2.2.1 of this Exhibit. Operate each monitor in its normal sampling mode. For extractive and dilution type monitors, pass the calibration gas through all filters, scrubbers, conditioners, and other monitor components used during normal sampling and through as much of the sampling probe as is practical. For in-situ type monitors, perform calibration, checking all active electronic and optical components, including the transmitter, receiver, and analyzer. Challenge the pollutant concentration monitors and CO2 or O2 monitors once with each calibration gas. Record the monitor response from the data acquisition and handling system. Using Equation A-5 of this Exhibit, determine the calibration error at each concentration once each day (at approximately 24-hour intervals) for 7 consecutive days according to the procedures given in this Section. The results of a 7-day calibration error test are acceptable for monitor or monitoring system certification, recertification or diagnostic testing if none of these daily calibration error test results exceed the applicable performance specifications in Section 3.1

of this Exhibit. The status of emission data from a gas monitor prior to and during a 7-day calibration error test period must be determined as follows:

| (a)

| For initial certification, data from the monitor are considered invalid until all certification tests, including the 7-day calibration error test, have been successfully completed, unless the conditional data validation procedures in Section

1.4(b)(3) of this Appendix are used. When the procedures in Section

1.4(b)(3) of this Appendix are followed, the words "initial certification" apply instead of "recertification," and complete all of the initial certification tests by January 1, 2009, rather than within the time periods specified in Section

1.4(b)(3)(D) of this Appendix for the individual tests. |

| |

| (b)

| When a 7-day calibration error test is required as a diagnostic test or for recertification, use the data validation procedures in Section

1.4(b)(3) of this Appendix. |

| |

6.3.2 Flow Monitor 7-day Calibration Error Test

Flow monitors installed on peaking units (as defined in 40 CFR 72.2

, incorporated by reference in Section 225.140) are exempted from the 7-day calibration error test requirements of this part. In all other cases, perform the 7-day calibration error test of a flow monitor, when required for certification, recertification or diagnostic testing, according to the following procedures. Introduce the reference signal corresponding to the values specified in Section 2.2.2.1 of this Exhibit to the probe tip (or equivalent), or to the transducer. During the 7-day certification test period, conduct the calibration error test while the unit is operating once each unit operating day (as close to 24-hour intervals as practicable). In the event that unit outages occur after the commencement of the test, the 7 consecutive operating days need not be 7 consecutive calendar days. Record the flow monitor responses by means of the data acquisition and handling system. Calculate the calibration error using Equation A-6 of this Exhibit. Do not perform any corrective maintenance, repair, or replacement upon the flow monitor during the 7-day test period other than that required in the quality assurance/quality control plan required by Exhibit B to this Appendix. Do not make adjustments between the zero and high reference level measurements on any day during the 7-day test. If the flow monitor operates within the calibration error performance specification (i.e., less than or equal to 3.0 percent error each day and requiring no corrective maintenance, repair, or replacement during the 7-day test period), the flow monitor passes the calibration error test. Record all maintenance activities and the magnitude of any adjustments. Record output readings from the data acquisition and handling system before and after all adjustments. Record and report all calibration error test results using the unadjusted flow rate measured in the calibration error test prior to resetting the calibration. Record all adjustments made during the 7-day period at the time the adjustment is made, and report them in the certification or recertification application. The status of emissions data from a flow monitor prior to and during a 7-day calibration error test period must be determined as follows:

| (a)

| For initial certification, data from the monitor are considered invalid until all certification tests, including the 7-day calibration error test, have been successfully completed, unless the conditional data validation procedures in Section

1.4(b)(3) of this Appendix are used. When the procedures in Section

1.4(b)(3) of this Appendix are followed, the words "initial certification" apply instead of "recertification," and complete all of the initial certification tests by January 1, 2009, rather than within the time periods specified in Section

1.4(b)(3)(D) of this Appendix for the individual tests. |

| |

| (b)

| When a 7-day calibration error test is required as a diagnostic test or for recertification, use the data validation procedures in Section

1.4(b)(3). |

| |

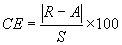

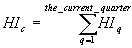

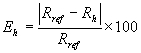

(Equation A-6)

(Equation A-6)

where:

CE = Calibration error as a percentage of span.

R = Low or high level reference value specified in Section 2.2.2.1 of this Exhibit.

A = Actual flow monitor response to the reference value.

S = Flow monitor calibration span value as determined under Section 2.1.2.2 of this Exhibit.

6.3.3

For gas or flow monitors installed on peaking units, the exemption from performing the 7-day calibration error test applies as long as the unit continues to meet the definition of a peaking unit in 40 CFR 72.2

, incorporated by reference in Section 225.140. However, if at the end of a particular calendar year or ozone season, it is determined that peaking unit status has been lost, the owner or operator must perform a diagnostic 7-day calibration error test of each monitor installed on the unit, by no later than December 31 of the following calendar year.

6.4 Cycle Time Test

Perform cycle time tests for each pollutant concentration monitor and continuous emission monitoring system while the unit is operating, according to the following procedures. Use a zero-level and a high-level calibration gas (as defined in Section 5.2 of this Exhibit) alternately. For mercury monitors, the calibration gas used for this test may either be the elemental or oxidized form of mercury. To determine the downscale cycle time, measure the concentration of the flue gas emissions until the response stabilizes. Record the stable emissions value. Inject a zero-level concentration calibration gas into the probe tip (or injection port leading to the calibration cell, for in situ systems with no probe). Record the time of the zero gas injection, using the data acquisition and handling system (DAHS). Next, allow the monitor to measure the concentration of the zero gas until the response stabilizes. Record the stable ending calibration gas reading. Determine the downscale cycle time as the time it takes for 95.0 percent of the step change to be achieved between the stable stack emissions value and the stable ending zero gas reading. Then repeat the procedure, starting with stable stack emissions and injecting the high-level gas, to determine the upscale cycle time, which is the time it takes for 95.0 percent of the step change to be achieved between the stable stack emissions value and the stable ending high-level gas reading. Use the following criteria to assess when a stable reading of stack emissions or calibration gas concentration has been attained. A stable value is equivalent to a reading with a change of less than 2.0 percent of the span value for 2 minutes, or a reading with a change of less than 6.0 percent from the measured average concentration over 6 minutes. Alternatively, the reading is considered stable if it changes by no more than 0.5 ppm, 0.5 µg/m3 (for mercury) for two minutes. (Owners or operators of systems which do not record data in 1-minute or 3-minute intervals may petition the Agency for alternative stabilization criteria). For monitors or monitoring systems that perform a series of operations (such as purge, sample, and analyze), time the injections of the calibration gases so they will produce the longest possible cycle time. Refer to Figures 6a and 6b in this Exhibit for example calculations of upscale and downscale cycle times. Report the slower of the two cycle times (upscale or downscale) as the cycle time for the analyzer. On and after January 1, 2009, record the cycle time for each component analyzer separately. For time-shared systems, perform the cycle time tests at each probe locations that will be polled within the same 15-minute period during monitoring system operations. To determine the cycle time for time-shared systems, at each monitoring location, report the sum of the cycle time observed at that monitoring location plus the sum of the time required for all purge cycles (as determined by the continuous emission monitoring system manufacturer) at each of the probe locations of the time-shared systems. For monitors with dual ranges, report the test results for each range separately. Cycle time test results are acceptable for monitor or monitoring system certification, recertification or diagnostic testing if none of the cycle times exceed 15 minutes. The status of emissions data from a monitor prior to and during a cycle time test period must be determined as follows:

| (a)

| For initial certification, data from the monitor are considered invalid until all certification tests, including the cycle time test, have been successfully completed, unless the conditional data validation procedures in Section

1.4(b)(3) of this Appendix are used. When the procedures in Section

1.4(b)(3) of this Appendix are followed, the words "initial certification" apply instead of "recertification," and complete all of the initial certification tests by January 1, 2009, rather than within the time periods specified in Section

1.4(b)(3)(D) of this Appendix for the individual tests. |

| |

| (b)

| When a cycle time test is required as a diagnostic test or for recertification, use the data validation procedures in Section

1.4(b)(3) of this Appendix. |

| |

6.5 Relative Accuracy and Bias Tests (General Procedures)

Perform the required relative accuracy test audits (RATAs) as follows for each flow monitor, each O2 or CO2 diluent monitor used to calculate heat input, each mercury concentration monitoring system, each sorbent trap monitoring system, and each moisture monitoring system:

| (a)

| Except as otherwise provided in this paragraph, perform each RATA while the unit (or units, if more than one unit exhausts into the flue) is combusting the fuel that is a normal primary or backup fuel for that unit (for some units, more than one type of fuel may be considered normal, e.g., a unit that combusts gas or oil on a seasonal basis). For units that co-fire fuels as the predominant mode of operation, perform the RATAs while co-firing. For mercury monitoring systems, perform the RATAs while the unit is combusting coal. When relative accuracy test audits are performed on CEMS installed on bypass stacks/ducts, use the fuel normally combusted by the unit (or units, if more than one unit exhausts into the flue) when emissions exhaust through the bypass stack/ducts. |

| |

| (b)

| Perform each RATA at the load (or operating) level(s) specified in Section 6.5.1 or 6.5.2 of this Exhibit or in Section 2.3.1.3 of Exhibit B to this Appendix, as applicable. |

| |

| (c)

| For monitoring systems with dual ranges, perform the relative accuracy test on the range normally used for measuring emissions. For units with add-on mercury controls that operate continuously rather than seasonally, or for units that need a dual range to record high concentration "spikes" during startup conditions, the low range is considered normal. However, for some dual span units (e.g., for units that use fuel switching or for which the emission controls are operated seasonally), provided that both monitor ranges are connected to a common probe and sample interface, either of the two measurement ranges may be considered normal; in such cases, perform the RATA on the range that is in use at the time of the scheduled test. If the low and high measurement ranges are connected to separate sample probes and interfaces, RATA testing on both ranges is required. |

| |

| (d)

| Record monitor or monitoring system output from the data acquisition and handling system. |

| |

| (e)

| Complete each single-load relative accuracy test audit within a period of 168 consecutive unit operating hours, as defined in 40 CFR 72.2

, incorporated by reference in Section 225.140 (or, for CEMS installed on common stacks or bypass stacks, 168 consecutive stack operating hours, as defined in 40 CFR 72.2

, incorporated by reference in Section 225.140). Notwithstanding this requirement, up to 336 consecutive unit or stack operating hours may be taken to complete the RATA of a mercury monitoring system, when ASTM 6784-02 (incorporated by reference under Section 225.140) or Method 29 in appendix A-8 to 40 CFR 60, incorporated by reference in Section 225.140, is used as the reference method. For 2-level and 3-level flow monitor RATAs, complete all of the RATAs at all levels, to the extent practicable, within a period of 168 consecutive unit (or stack) operating hours; however, if this is not possible, up to 720 consecutive unit (or stack) operating hours may be taken to complete a multiple-load flow RATA. |

| |

| (f)

| The status of emission data from the CEMS prior to and during the RATA test period must be determined as follows: |

| |

| (1)

| For the initial certification of a CEMS, data from the monitoring system are considered invalid until all certification tests, including the RATA, have been successfully completed, unless the conditional data validation procedures in Section

1.4(b)(3) of this Appendix are used. When the procedures in Section

1.4(b)(3) of this Appendix are followed, the words "initial certification" apply instead of "recertification," and complete all of the initial certification tests by January 1, 2009, rather than within the time periods specified in Section

1.4(b)(3)(D) of this Appendix for the individual tests. |

| |

| (2)

| For the routine quality assurance RATAs required by Section 2.3.1 of Exhibit B to this Appendix, use the data validation procedures in Section 2.3.2 of Exhibit B to this Appendix. |

| |

| (3)

| For recertification RATAs, use the data validation procedures in Section

1.4(b)(3). |

| |

| (4)

| For quality assurance RATAs of non-redundant backup monitoring systems, use the data validation procedures in Sections

1.4(d)(2)(D) and (E) of this Appendix. |

| |

| (5)

| For RATAs performed during and after the expiration of a grace period, use the data validation procedures in Sections 2.3.2 and 2.3.3, respectively, of Exhibit B to this Appendix. |

| |

| (6)

| For all other RATAs, use the data validation procedures in Section 2.3.2 of Exhibit B to this Appendix. |

| |

| (g)

| For each flow monitor, each CO2 or O2 diluent monitor used to determine heat input, each moisture monitoring system, each mercury concentration monitoring system, and each sorbent trap monitoring system, calculate the relative accuracy, in accordance with Section 7.3 of this Exhibit, as applicable. |

| |

6.5.1 Gas and Mercury Monitoring System RATAs (Special Considerations)

| (a)

| Perform the required relative accuracy test audits for each CO2 or O2 diluent monitor used to determine heat input, each mercury concentration monitoring system, and each sorbent trap monitoring system at the normal load level or normal operating level for the unit (or combined units, if common stack), as defined in Section 6.5.2.1 of this Exhibit. If two load levels or operating levels have been designated as normal, the RATAs may be done at either load level. |

| |

| (b)

| For the initial certification of a gas or mercury monitoring system and for recertifications in which, in addition to a RATA, one or more other tests are required (i.e., a linearity test, cycle time test, or 7-day calibration error test), the Agency recommends that the RATA not be commenced until the other required tests of the CEMS have been passed. |

| |

6.5.2 Flow Monitor RATAs (Special Considerations)

| (a)

| Except as otherwise provided in paragraph (b) or (e) of this Section, perform relative accuracy test audits for the initial certification of each flow monitor at three different exhaust gas velocities (low, mid, and high), corresponding to three different load levels or operating levels within the range of operation, as defined in Section 6.5.2.1 of this Exhibit. For a common stack/duct, the three different exhaust gas velocities may be obtained from frequently used unit/load or operating level combinations for the units exhausting to the common stack. Select the three exhaust gas velocities such that the audit points at adjacent load or operating levels (i.e., low and mid or mid and high), in megawatts (or in thousands of lb/hr of steam production or in ft/sec, as applicable), are separated by no less than 25.0 percent of the range of operation, as defined in Section 6.5.2.1 of this Exhibit. |

| |

| (b)

| For flow monitors on bypass stacks/ducts and peaking units, the flow monitor relative accuracy test audits for initial certification and recertification must be single-load tests, performed at the normal load, as defined in Section 6.5.2.1(d) of this Exhibit. |

| |

| (c)

| Flow monitor recertification RATAs must be done at three load level(s) (or three operating levels), unless otherwise specified in paragraph (b) or (e) of this Section or unless otherwise specified or approved by the Agency. |

| |

| (d)

| The semiannual and annual quality assurance flow monitor RATAs required under Exhibit B to this Appendix must be done at the load level(s) (or operating levels) specified in Section 2.3.1.3 of Exhibit B to this Appendix. |

| |

| (e)

| For flow monitors installed on units that do not produce electrical or thermal output, the flow RATAs for initial certification or recertification may be done at fewer than three operating levels, if: |

| |

| (1)

| The owner or operator provides a technical justification in the hardcopy portion of the monitoring plan for the unit required under 40 CFR 75.53

(e)(2), incorporated by reference in Section 225.140, demonstrating that the unit operates at only one level or two levels during normal operation (excluding unit startup and shutdown). Appropriate documentation and data must be provided to support the claim of single-level or two-level operation; and |

| |

| (2)

| The justification provided in paragraph (e)(1) of this Section is deemed to be acceptable by the permitting authority. |

| |

6.5.2.1 Range of Operation and Normal Load (or Operating) Level(s)

| (a)

| The owner or operator must determine the upper and lower boundaries of the "range of operation" as follows for each unit (or combination of units, for common stack configurations): |

| |

| (1)

| For affected units that produce electrical output (in megawatts) or thermal output (in klb/hr of steam production or mmBtu/hr), the lower boundary of the range of operation of a unit must be the minimum safe, stable loads for any of the units discharging through the stack. Alternatively, for a group of frequently-operated units that serve a common stack, the sum of the minimum safe, stable loads for the individual units may be used as the lower boundary of the range of operation. The upper boundary of the range of operation of a unit must be the maximum sustainable load. The "maximum sustainable load" is the higher of either: the nameplate or rated capacity of the unit, less any physical or regulatory limitations or other deratings; or the highest sustainable load, based on at least four quarters of representative historical operating data. For common stacks, the maximum sustainable load is the sum of all of the maximum sustainable loads of the individual units discharging through the stack, unless this load is unattainable in practice, in which case use the highest sustainable combined load for the units that discharge through the stack. Based on at least four quarters of representative historical operating data. The load values for the unit(s) must be expressed either in units of megawatts of thousands of lb/hr of steam load or mmBtu/hr of thermal output; or |

| |

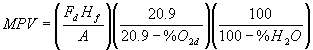

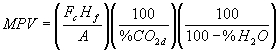

| (2)

| For affected units that do not produce electrical or thermal output, the lower boundary of the range of operation must be the minimum expected flue gas velocity (in ft/sec) during normal, stable operation of the unit. The upper boundary of the range of operation must be the maximum potential flue gas velocity (in ft/sec) as defined in Section 2.1.2.1 of this Exhibit. The minimum expected and maximum potential velocities may be derived from the results of reference method testing or by using Equation A-3a or A-3b (as applicable) in Section 2.1.2.1 of this Exhibit. If Equation A-3a or A-3b is used to determine the minimum expected velocity, replace the word "maximum" with the word "minimum" in the definitions of "MPV," "Hf," " ," and ," and  ," and replace the word "minimum" with the word "maximum" in the definition of "CO2d." Alternatively, 0.0 ft/sec may be used as the lower boundary of the range of operation. ," and replace the word "minimum" with the word "maximum" in the definition of "CO2d." Alternatively, 0.0 ft/sec may be used as the lower boundary of the range of operation. |

| |

| (b)

| The operating levels for relative accuracy test audits will, except for peaking units, be defined as follows: the "low" operating level will be the first 30.0 percent of the range of operation; the "mid" operating level will be the middle portion (>30.0 percent, but <=60.0 percent) of the range of operation; and the "high" operating level will be the upper end (>60.0 percent) of the range of operation. For example, if the upper and lower boundaries of the range of operation are 100 and 1100 megawatts, respectively, then the low, mid, and high operating levels would be 100 to 400 megawatts, 400 to 700 megawatts, and 700 to 1100 megawatts, respectively. |

| |

| (c)

| Units that do not produce electrical or thermal output are exempted from the requirements of this paragraph, (c). The owner or operator must identify, for each affected unit or common stack, the "normal" load level or levels (low, mid or high), based on the operating history of the unit(s). To identify the normal load level(s), the owner or operator must, at a minimum, determine the relative number of operating hours at each of the three load levels, low, mid and high over the past four representative operating quarters. The owner or operator must determine, to the nearest 0.1 percent, the percentage of the time that each load level (low, mid, high) has been used during that time period. A summary of the data used for this determination and the calculated results must be kept on-site in a format suitable for inspection. For new units or newly-affected units, the data analysis in this paragraph may be based on fewer than four quarters of data if fewer than four representative quarters of historical load data are available. Or, if no historical load data are available, the owner or operator may designate the normal load based on the expected or projected manner of operating the unit. However, in either case, once four quarters of representative data become available, the historical load analysis must be repeated. |

| |

| (d)

| Determination of normal load (or operating level) |

| |

| (1)

| Based on the analysis of the historical load data described in paragraph (c) of this Section, the owner or operator must, for units that produce electrical or thermal output, designate the most frequently used load level as the normal load level for the unit (or combination of units, for common stacks). The owner or operator may also designate the second most frequently used load level as an additional normal load level for the unit or stack. If the manner of operation of the unit changes significantly, such that the designated normal load(s) or the two most frequently used load levels change, the owner or operator must repeat the historical load analysis and must redesignate the normal load(s) and the two most frequently used load levels, as appropriate. A minimum of two representative quarters of historical load data are required to document that a change in the manner of unit operation has occurred. Update the electronic monitoring plan whenever the normal load level(s) and the two most frequently-used load levels are redesignated. |

| |

| (2)

| For units that do not produce electrical or thermal output, the normal operating level(s) must be determined using sound engineering judgment, based on knowledge of the unit and operating experience with the industrial process. |

| |

| (e)

| The owner or operator must report the upper and lower boundaries of the range of operation for each unit (or combination of units, for common stacks), in units of megawatts or thousands of lb/hr or mmBtu/hr of steam production or ft/sec (as applicable), in the electronic monitoring plan required under Section

1.10 of this Appendix. |

| |

6.5.2.2 Multi-Load (or Multi-Level) Flow RATA Results

For each multi-load (or multi-level) flow RATA, calculate the flow monitor relative accuracy at each operating level. If a flow monitor relative accuracy test is failed or aborted due to a problem with the monitor on any level of a 2-level (or 3-level) relative accuracy test audit, the RATA must be repeated at that load (or operating) level. However, the entire 2-level (or 3-level) relative accuracy test audit does not have to be repeated unless the flow monitor polynomial coefficients or K-factor(s) are changed, in which case a 3- level RATA is required (or, a 2-level RATA, for units demonstrated to operate at only two levels, under Section 6.5.2(e) of this Exhibit).

6.5.3 Calculations

Using the data from the relative accuracy test audits, calculate relative accuracy and bias in accordance with the procedures and equations specified in Section 7

of this Exhibit.

6.5.4 Reference Method Measurement Location

Select a location for reference method measurements that is (1) accessible; (2) in the same proximity as the monitor or monitoring system location; and (3) meets the requirements of Performance Specification 3 in appendix B of 40 CFR 60, incorporated by reference in Section 225.140, for CO2 or O2 monitors, or Method 1 (or 1A) in appendix A of 40 CFR 60, incorporated by reference in Section 225.140, for volumetric flow, except as otherwise indicated in this Section or as approved by the Agency.

6.5.5 Reference Method Traverse Point Selection

Select traverse points that ensure acquisition of representative samples of pollutant and diluent concentrations, moisture content, temperature, and flue gas flow rate over the flue cross Section. To achieve this, the reference method traverse points must meet the requirements of Section 8.1.3 of Performance Specification 2 ("PS No. 2") in appendix B to 40 CFR 60, incorporated by reference in Section 225.140 (for moisture monitoring system RATAs), Performance Specification 3 in appendix B to 40 CFR 60, incorporated by reference in Section 225.140 (for O2 and CO2 monitor RATAs), Method 1 (or 1A) (for volumetric flow rate monitor RATAs), Method 3 (for molecular weight), and Method 4 (for moisture determination) in appendix A to 40 CFR 60, incorporated by reference in Section 225.140. The following alternative reference method traverse point locations are permitted for moisture and gas monitor RATAs:

| (a)

| For moisture determinations where the moisture data are used only to determine stack gas molecular weight, a single reference method point, located at least 1.0 meter from the stack wall, may be used. For moisture monitoring system RATAs and for gas monitor RATAs in which moisture data are used to correct pollutant or diluent concentrations from a dry basis to a wet basis (or vice-versa), single-point moisture sampling may only be used if the 12-point stratification test described in Section 6.5.5.1 of this Exhibit is performed prior to the RATA for at least one pollutant or diluent gas, and if the test is passed according to the acceptance criteria in Section 6.5.5.3(b) of this Exhibit. |

| |

| (b)

| For gas monitoring system RATAs, the owner or operator may use any of the following options: |

| |

| (1)

| At any location (including locations where stratification is expected), use a minimum of six traverse points along a diameter, in the direction of any expected stratification. The points must be located in accordance with Method 1 in appendix A to 40 CFR 60, incorporated by reference in Section 225.140. |

| |

| (2)

| At locations where Section 8.1.3 of PS No. 2 allows the use of a short reference method measurement line (with three points located at 0.4, 1.2, and 2.0 meters from the stack wall), the owner or operator may use an alternative 3-point measurement line, locating the three points at 4.4, 14.6, and 29.6 percent of the way across the stack, in accordance with Method 1 in appendix A to 40 CFR 60, incorporated by reference in Section 225.140. |

| |

| (3)

| At locations where stratification is likely to occur (e.g., following a wet scrubber or when dissimilar gas streams are combined), the short measurement line from Section 8.1.3 of PS No. 2 (or the alternative line described in paragraph (b)(2) of this Section) may be used in lieu of the prescribed "long" measurement line in Section 8.1.3 of PS No. 2, provided that the 12-point stratification test described in Section 6.5.5.1 of this Exhibit is performed and passed one time at the location (according to the acceptance criteria of Section 6.5.5.3(a) of this Exhibit) and provided that either the 12-point stratification test or the alternative (abbreviated) stratification test in Section 6.5.5.2 of this Exhibit is performed and passed prior to each subsequent RATA at the location (according to the acceptance criteria of Section 6.5.5.3(a) of this Exhibit). |

| |

| (4)

| A single reference method measurement point, located no less than 1.0 meter from the stack wall and situated along one of the measurement lines used for the stratification test, may be used at any sampling location if the 12-point stratification test described in Section 6.5.5.1 of this Exhibit is performed and passed prior to each RATA at the location (according to the acceptance criteria of Section 6.5.5.3(b) of this Exhibit). |

| |

| (c)

| For mercury monitoring systems, use the same basic approach for traverse point selection that is used for the other gas monitoring system RATAs, except that the stratification test provisions in Sections 8.1.3 through 8.1.3.5 of Method 30A must apply, rather than the provisions of Sections 6.5.5.1 through 6.5.5.3 of this Exhibit. |

| |

6.5.5.1 Stratification Test

| (a)

| With the unit(s) operating under steady-state conditions at the normal load level (or normal operating level), as defined in Section 6.5.2.1 of this Exhibit, use a traversing gas sampling probe to measure diluent (CO2 or O2) concentrations at a minimum of twelve (12) points, located according to Method 1 in appendix A to 40 CFR 60, incorporated by reference in Section 225.140. |

| |

| (b)

| Use Method 3A in appendix A to 40 CFR 60, incorporated by reference in Section 225.140, to make the measurements. Data from the reference method analyzers must be quality assured by performing analyzer calibration error and system bias checks before the series of measurements and by conducting system bias and calibration drift checks after the measurements, in accordance with the procedures of Method 3A. |

| |

| (c)

| Measure for a minimum of 2 minutes at each traverse point. To the extent practicable, complete the traverse within a 2-hour period. |

| |

| (d)

| If the load has remained constant (+-3.0 percent) during the traverse and if the reference method analyzers have passed all of the required quality assurance checks, proceed with the data analysis. |

| |

| (e)

| Calculate the average CO2 (or O2) concentrations at each of the individual traverse points. Then, calculate the arithmetic average CO2 (or O2) concentrations for all traverse points. |

| |

6.5.5.2 Alternative (Abbreviated) Stratification Test

| (a)

| With the unit(s) operating under steady-state conditions at the normal load level (or normal operating level), as defined in Section 6.5.2.1 of this Exhibit, use a traversing gas sampling probe to measure the diluent (CO2 or O2) concentrations at three points. The points must be located according to the specifications for the long measurement line in Section 8.1.3 of PS No. 2 (i.e., locate the points 16.7 percent, 50.0 percent, and 83.3 percent of the way across the stack). Alternatively, the concentration measurements may be made at six traverse points along a diameter. The six points must be located in accordance with Method 1 in appendix A to 40 CFR 60, incorporated by reference in Section 225.140. |

| |

| (b)

| Use Method 3A in appendix A to 40 CFR 60, incorporated by reference in Section 225.140, to make the measurements. Data from the reference method analyzers must be quality assured by performing analyzer calibration error and system bias checks before the series of measurements and by conducting system bias and calibration drift checks after the measurements, in accordance with the procedures of Method 3A. |

| |

| (c)

| Measure for a minimum of 2 minutes at each traverse point. To the extent practicable, complete the traverse within a 1-hour period. |

| |

| (d)

| If the load has remained constant (+-3.0 percent) during the traverse and if the reference method analyzers have passed all of the required quality assurance checks, proceed with the data analysis. |

| |

| (e)

| Calculate the average CO2 (or O2) concentrations at each of the individual traverse points. Then, calculate the arithmetic average CO2 (or O2) concentrations for all traverse points. |

| |

6.5.5.3 Stratification Test Results and Acceptance Criteria

| (a)

| For each diluent gas, the short reference method measurement line described in Section 8.1.3 of PS No. 2 may be used in lieu of the long measurement line prescribed in Section 8.1.3 of PS No. 2 if the results of a stratification test, conducted in accordance with Section 6.5.5.1 or 6.5.5.2 of this Exhibit (as appropriate; see Section 6.5.5(b)(3) of this Exhibit), show that the concentration at each individual traverse point differs by no more than +-10.0 percent from the arithmetic average concentration for all traverse points. The results are also acceptable if the concentration at each individual traverse point differs by no more than +-5ppm or +-0.5 percent CO2 (or O2) from the arithmetic average concentration for all traverse points. |

| |

| (b)

| For each diluent gas, a single reference method measurement point, located at least 1.0 meter from the stack wall and situated along one of the measurement lines used for the stratification test, may be used for that diluent gas if the results of a stratification test, conducted in accordance with Section 6.5.5.1 of this Exhibit, show that the concentration at each individual traverse point differs by no more than +-5.0 percent from the arithmetic average concentration for all traverse points. The results are also acceptable if the concentration at each individual traverse point differs by no more than +-3 ppm or +-0.3 percent CO2 (or O2) from the arithmetic average concentration for all traverse points. |

| |

| (c)

| The owner or operator must keep the results of all stratification tests on-site, in a format suitable for inspection, as part of the supplementary RATA records required under Section 1.13(a)

(7) of this Appendix. |

| |

6.5.6 Sampling Strategy

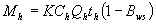

| (a)

| Conduct the reference method tests so they will yield results representative of the pollutant concentration, emission rate, moisture, temperature, and flue gas flow rate from the unit and can be correlated with the pollutant concentration monitor, CO2 or O2 monitor, flow monitor, and mercury CEMS measurements. The minimum acceptable time for a gas monitoring system RATA run or for a moisture monitoring system RATA run is 21 minutes. For each run of a gas monitoring system RATA, all necessary pollutant concentration measurements, diluent concentration measurements, and moisture measurements (if applicable) must, to the extent practicable, be made within a 60-minute period. For flow monitor RATAs, the minimum time per run must be 5 minutes. Flow rate reference method measurements may be made either sequentially from port to port or simultaneously at two or more sample ports. The velocity measurement probe may be moved from traverse point to traverse point either manually or automatically. If, during a flow RATA, significant pulsations in the reference method readings are observed, be sure to allow enough measurement time at each traverse point to obtain an accurate average reading when a manual readout method is used (e.g., a "sight-weighted" average from a manometer). Also, allow sufficient measurement time to ensure that stable temperature readings are obtained at each traverse point, particularly at the first measurement point at each sample port, when a probe is moved sequentially from port-to-port. A minimum of one set of auxiliary measurements for stack gas molecular weight determination (i.e., diluent gas data and moisture data) is required for every clock hour of a flow RATA or for every three test runs (whichever is less restrictive). Alternatively, moisture measurements for molecular weight determination may be performed before and after a series of flow RATA runs at a particular load level (low, mid, or high), provided that the time interval between the two moisture measurements does not exceed three hours. If this option is selected, the results of the two moisture determinations must be averaged arithmetically and applied to all RATA runs in the series. Successive flow RATA runs may be performed without waiting in-between runs. If an O2-diluent monitor is used as a CO2 continuous emission monitoring system, perform a CO2 system RATA (i.e., measure CO2, rather than O2, with the reference method). For moisture monitoring systems, an appropriate coefficient, "K" factor or other suitable mathematical algorithm may be developed prior to the RATA, to adjust the monitoring system readings with respect to the reference method. If such a coefficient, K-factor or algorithm is developed, it must be applied to the CEMS readings during the RATA and (if the RATA is passed), to the subsequent CEMS data, by means of the automated data acquisition and handling system. The owner or operator must keep records of the current coefficient, K factor or algorithm, as specified in Section 1.13(a)

(5)(F) of this Appendix. Whenever the coefficient, K factor or algorithm is changed, a RATA of the moisture monitoring system is required. For the RATA of a mercury CEMS using the Ontario Hydro Method, or for the RATA of a sorbent trap system (irrespective of the reference method used), the time per run must be long enough to collect a sufficient mass of mercury to analyze. For the RATA of a sorbent trap monitoring system, the type of sorbent material used by the traps must be the same as for daily operation of the monitoring system; however, the size of the traps used for the RATA may be smaller than the traps used for daily operation of the system. Spike the third section of each sorbent trap with elemental mercury, as described in Section 7.1.2 of Exhibit D to this Appendix. Install a new pair of sorbent traps prior to each test run. For each run, the sorbent trap data must be validated according to the quality assurance criteria in Section 8

of Exhibit D to this Appendix. |

| |

| (b)

| To properly correlate individual mercury CEMS data (in lb/MMBtu) and volumetric flow rate data with the reference method data, annotate the beginning and end of each reference method test run (including the exact time of day) on the individual chart recorder(s) or other permanent recording device(s). |

| |

6.5.7 Correlation of Reference Method and Continuous Emission Monitoring System

Confirm that the monitor or monitoring system and reference method test results are on consistent moisture, pressure, temperature, and diluent concentration basis (e.g., since the flow monitor measures flow rate on a wet basis, Method 2 test results must also be on a wet basis). Compare flow-monitor and reference method results on a scfh basis. Also, consider the response times of the pollutant concentration monitor, the continuous emission monitoring system, and the flow monitoring system to ensure comparison of simultaneous measurements.

For each relative accuracy test audit run, compare the measurements obtained from the monitor or continuous emission monitoring system (in ppm, percent CO2, lb/mmBtu, or other units) against the corresponding reference method values. Tabulate the paired data in a table such as the one shown in Figure 2.

6.5.8 Number of Reference Method Tests

Perform a minimum of nine sets of paired monitor (or monitoring system) and reference method test data for every required (i.e., certification, recertification, diagnostic, semiannual, or annual) relative accuracy test audit. For 2-level and 3-level relative accuracy test audits of flow monitors, perform a minimum of nine sets at each of the operating levels.

6.5.9 Reference Methods

The following methods are from appendix A to 40 CFR 60, incorporated by reference in Section 225.140, or have been published by ASTM, and are the reference methods for performing relative accuracy test audits under this part: Method 1 or 1A in appendix A-1 to 40 CFR 60 for siting; Method 2 in appendices A-1 and A-2 to 40 CFR 60 or its allowable alternatives in appendix A to 40 CFR 60 (except for Methods 2B and 2E in appendix A-1 to 40 CFR 60) for stack gas velocity and volumetric flow rate; Methods 3, 3A or 3B in appendix A-2 to 40 CFR 60 for O2 and CO2; Method 4 in appendix A-3 to 40 CFR 60 for moisture; and for mercury, either ASTM D6784-02 (the Ontario Hydro Method) (incorporated by reference under Section 225.140), Method 29 in appendix A-8 to 40 CFR 60, Method 30A, or Method 30B.

7. Calculations

7.1 Linearity Check

Analyze the linearity data for pollutant concentration monitors as follows. Calculate the percentage error in linearity based upon the reference value at the low-level, mid-level, and high-level concentrations specified in Section 6.2 of this Exhibit. Perform this calculation once during the certification test. Use the following equation to calculate the error in linearity for each reference value.

| (Equation A-4) |

| |

| where,

|

| |

| LE=Percentage Linearity error, based upon the reference value.

|

| |

| R=Reference value of Low-, mid-, or high-level calibration gas introduced into the monitoring system.

|

| |

| A=Average of the monitoring system responses.

|

| |

7.2 Calibration Error

7.2.1 Pollutant Concentration and Diluent Monitors

For each reference value, calculate the percentage calibration error based upon instrument span for daily calibration error tests using the following equation:

(Equation A-5)

(Equation A-5)

where,

CE = Calibration error as a percentage of the span of the instrument.

R = Reference value of zero or upscale (high-level or mid-level, as applicable) calibration gas introduced into the monitoring system.

A = Actual monitoring system response to the calibration gas.

S = Span of the instrument, as specified in Section 2 of this Exhibit.

7.2.2 Flow Monitor Calibration Error

For each reference value, calculate the percentage calibration error based upon span using the following equation:

(Equation A-6)

(Equation A-6)

where,

CE = Calibration error as a percentage of span.

R = Low or high level reference value specified in Section 2.2.2.1 of this Exhibit.

A = Actual flow monitor response to the reference value.

S = Flow monitor calibration span value as determined under Section 2.1.2.2 of this Exhibit.

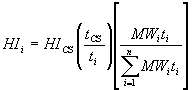

7.3 Relative Accuracy for O2 Monitors, Mercury Monitoring Systems,

and Flow Monitors

Analyze the relative accuracy test audit data from the reference method tests for CO2 or O2 monitors used only for heat input rate determination, mercury monitoring systems used to determine mercury mass emissions under Sections 1.14 through 1.18 of Appendix B, and flow monitors using the following procedures. Summarize the results on a data sheet. An example is shown in Figure 2. Calculate the mean of the monitor or monitoring system measurement values. Calculate the mean of the reference method values. Using data from the automated data acquisition and handling system, calculate the arithmetic differences between the reference method and monitor measurement data sets. Then calculate the arithmetic mean of the difference, the standard deviation, the confidence coefficient, and the monitor or monitoring system relative accuracy using the following procedures and equations.

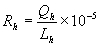

7.3.1 Arithmetic Mean

Calculate the arithmetic mean of the differences, d, of a data set as follows.

(Equation A-7)

(Equation A-7)

where,

n = Number of data points.

di = The difference between a reference method value and the corresponding continuous emission monitoring system value (RMi–CEMi) at a given point in time i.

7.3.2 Standard Deviation

Calculate the standard deviation, Sd, of a data set as follows:

(Equation A-8)

(Equation A-8)

where,

n = Number of data points.

di = The difference between a reference method value and the corresponding continuous emission monitoring system value (RMi–CEMi) at a given point in time i.

7.3.3 Confidence Coefficient

Calculate the confidence coefficient (one-tailed), cc, of a data set as follows:

(Equation A-9)

(Equation A-9)

where,

t0.025=t value (see Table 7-1).

Table 7-1 t-Values

----------------------------------------------

n-1 t0.025 n-1 t0.025 n-1 t0. 025

----------------------------------------------

1 ...... 12.706 12 2.179 23 2.069

2 ....... 4.303 13 2.160 24 2.064

3 ....... 3.182 14 2.145 25 2.060

4 ....... 2.776 15 2.131 26 2.056

5 ....... 2.571 16 2.120 27 2.052

6 ....... 2.447 17 2.110 28 2.048

7 ....... 2.365 18 2.101 29 2.045

8 ....... 2.306 19 2.093 30 2.042

9 ....... 2.262 20 2.086 40 2.021

10 ...... 2.228 21 2.080 60 2.000

11 ...... 2.201 22 2.074 >60 1.960

----------------------------------------------

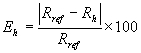

7.3.4 Relative Accuracy

Calculate the relative accuracy of a data set using the following equation.

(Equation A-10)

(Equation A-10)

where,

= Arithmetic mean of the reference method values.

= Arithmetic mean of the reference method values.

= The absolute value of the mean difference between the reference method values and the corresponding continuous emission monitoring system values.

= The absolute value of the mean difference between the reference method values and the corresponding continuous emission monitoring system values.

= The absolute value of the confidence coefficient.

= The absolute value of the confidence coefficient.

7.4 Bias Test

Test the following relative accuracy test audit data sets for bias: flow monitors; mercury concentration monitoring systems, and sorbent trap monitoring systems, using the procedures outlined in Sections 7.4.1 through 7.4.4 of this Exhibit. For multiple-load flow RATAs, perform a bias test at each load level designated as normal under Section 6.5.2.1 of this Exhibit.

7.4.1 Arithmetic Mean

Calculate the arithmetic mean of the difference, "d", of the data set using Equation A-7 of this Exhibit. To calculate bias for a flow monitor, "d" is, for each paired data point, the difference between the flow rate values (in scfh) obtained from the reference method and the monitor. To calculate bias for a mercury monitoring system when using the Ontario Hydro Method or Method 29 in appendix A-8 to 40 CFR 60, incorporated by reference in Section 225.140, "d" is, for each data point, the difference between the average mercury concentration value (in µg/m3) from the paired Ontario Hydro or Method 29 in appendix A-8 to 40 CFR 60 sampling trains and the concentration measured by the monitoring system. For sorbent trap monitoring systems, use the average mercury concentration measured by the paired traps in the calculation of "d".

7.4.2 Standard Deviation

Calculate the standard deviation, Sd, of the data set using Equation A-8.

7.4.3 Confidence Coefficient

Calculate the confidence coefficient, cc, of the data set using Equation A-9.

7.4.4 Bias Test

If, for the relative accuracy test audit data set being tested, the mean difference, d, is less than or equal to the absolute value of the confidence coefficient,  , the monitor or monitoring system has passed the bias test. If the mean difference, d, is greater than the absolute value of the confidence coefficient,

, the monitor or monitoring system has passed the bias test. If the mean difference, d, is greater than the absolute value of the confidence coefficient,  , the monitor or monitoring system has failed to meet the bias test requirement.

, the monitor or monitoring system has failed to meet the bias test requirement.

7.5 Reference Flow-to-Load Ratio or Gross Heat Rate

| (a)

| Except as provided in Section 7.6 of this Exhibit, the owner or operator must determine  , the reference value of the ratio of flow rate to unit load, each time that a passing flow RATA is performed at a load level designated as normal in Section 6.5.2.1 of this Exhibit. The owner or operator must report the current value of , the reference value of the ratio of flow rate to unit load, each time that a passing flow RATA is performed at a load level designated as normal in Section 6.5.2.1 of this Exhibit. The owner or operator must report the current value of  in the electronic quarterly report required under 40 CFR 75.64

, incorporated by reference in Section 225.140, and must also report the completion date of the associated RATA. If two load levels have been designated as normal under Section 6.5.2.1 of this Exhibit, the owner or operator must determine a separate in the electronic quarterly report required under 40 CFR 75.64

, incorporated by reference in Section 225.140, and must also report the completion date of the associated RATA. If two load levels have been designated as normal under Section 6.5.2.1 of this Exhibit, the owner or operator must determine a separate  value for each of the normal load levels. The reference flow-to-load ratio must be calculated as follows: value for each of the normal load levels. The reference flow-to-load ratio must be calculated as follows: |

| |

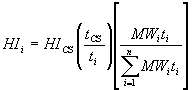

(Equation A-13)

(Equation A-13)

where,

= Reference value of the flow-to-load ratio, from the most recent normal-load flow RATA, scfh/megawatts, scfh/1000 lb/hr of steam, or scfh/ (mmBtu/hr of steam output).

= Reference value of the flow-to-load ratio, from the most recent normal-load flow RATA, scfh/megawatts, scfh/1000 lb/hr of steam, or scfh/ (mmBtu/hr of steam output).

= Average stack gas volumetric flow rate measured by the reference method during the normal-load RATA, scfh.

= Average stack gas volumetric flow rate measured by the reference method during the normal-load RATA, scfh.

= Average unit load during the normal-load flow RATA, megawatts, 1000 lb/hr of steam, or mmBtu/hr of thermal output.

= Average unit load during the normal-load flow RATA, megawatts, 1000 lb/hr of steam, or mmBtu/hr of thermal output.

| (b)

| In Equation A-13, for a common stack, determine  by summing, for each RATA run, the operating loads of all units discharging through the common stack, and then taking the arithmetic average of the summed loads. For a unit that discharges its emissions through multiple stacks, either determine a single value of by summing, for each RATA run, the operating loads of all units discharging through the common stack, and then taking the arithmetic average of the summed loads. For a unit that discharges its emissions through multiple stacks, either determine a single value of  for the unit or a separate value of for the unit or a separate value of  for each stack. In the former case, calculate for each stack. In the former case, calculate  by summing, for each RATA run, the volumetric flow rates through the individual stacks and then taking the arithmetic average of the summed RATA run flow rates. In the latter case, calculate the value of by summing, for each RATA run, the volumetric flow rates through the individual stacks and then taking the arithmetic average of the summed RATA run flow rates. In the latter case, calculate the value of  for each stack by taking the arithmetic average, for all RATA runs, of the flow rates through the stack. For a unit with a multiple stack discharge configuration consisting of a main stack and a bypass stack (e.g., a unit with a wet SO2 scrubber), determine for each stack by taking the arithmetic average, for all RATA runs, of the flow rates through the stack. For a unit with a multiple stack discharge configuration consisting of a main stack and a bypass stack (e.g., a unit with a wet SO2 scrubber), determine  separately for each stack at the time of the normal load flow RATA. Round off the value of separately for each stack at the time of the normal load flow RATA. Round off the value of  to two decimal places. to two decimal places. |

| |

| (c)

| In addition to determining  or as an alternative to determine or as an alternative to determine  , a reference value of the gross heat rate (GHR) may be determined. In order to use this option, quality assured diluent gas (CO2 or O2) must be available for each hour of the most recent normal-load flow RATA. The reference value of the GHR must be determined as follows: , a reference value of the gross heat rate (GHR) may be determined. In order to use this option, quality assured diluent gas (CO2 or O2) must be available for each hour of the most recent normal-load flow RATA. The reference value of the GHR must be determined as follows: |

| |

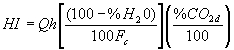

(Equation A-13a)

(Equation A-13a)

where,

= Reference value of the gross heat rate at the time of the most recent normal-load flow RATA, Btu/kwh, Btu/lb steam load, or Btu heat input/mmBtu steam output.

= Reference value of the gross heat rate at the time of the most recent normal-load flow RATA, Btu/kwh, Btu/lb steam load, or Btu heat input/mmBtu steam output.

= Average hourly heat input during the normal-load flow RATA, as determined using the applicable equation in Exhibit C to this Appendix, mmBtu/hr. For multiple stack configurations, if the reference GHR value is determined separately for each stack, use the hourly heat input measured at each stack. If the reference GHR is determined at the unit level, sum the hourly heat inputs measured at the individual stacks.

= Average hourly heat input during the normal-load flow RATA, as determined using the applicable equation in Exhibit C to this Appendix, mmBtu/hr. For multiple stack configurations, if the reference GHR value is determined separately for each stack, use the hourly heat input measured at each stack. If the reference GHR is determined at the unit level, sum the hourly heat inputs measured at the individual stacks.

= Average unit load during the normal-load flow RATA, megawatts, 1000 lb/hr of steam, or mmBtu/hr thermal output.

= Average unit load during the normal-load flow RATA, megawatts, 1000 lb/hr of steam, or mmBtu/hr thermal output.

| (d)

| In the calculation of  , use , use  , the average volumetric flow rate measured by the reference method during the RATA, and use the average diluent gas concentration measured during the flow RATA (i.e., the arithmetic average of the diluent gas concentrations for all clock hours in which a RATA run was performed). , the average volumetric flow rate measured by the reference method during the RATA, and use the average diluent gas concentration measured during the flow RATA (i.e., the arithmetic average of the diluent gas concentrations for all clock hours in which a RATA run was performed). |

| |

7.6 Flow-to-Load Test Exemptions

| (a)

| For complex stack configurations (e.g., when the effluent from a unit is divided and discharges through multiple stacks in such a manner that the flow rate in the individual stacks cannot be correlated with unit load), the owner or operator may petition the USEPA under 40 CFR 75.66

, incorporated by reference in Section 225.140, for an exemption from the requirements of Section 7.7 to Appendix A to 40 CFR Part 75 and Section 2.2.5 of Exhibit B to Appendix B. The petition must include sufficient information and data to demonstrate that a flow-to-load or gross heat rate evaluation is infeasible for the complex stack configuration. |

| |

| (b)

| Units that do not produce electrical output (in megawatts) or thermal output (in klb of steam per hour) are exempted from the flow-to-load ratio test requirements of Section 7.5 of this Exhibit and Section 2.2.5 of Exhibit B to Appendix B. |

| |

Figures for Exhibit A to Appendix B

Figure 1.--Linearity Error Determination

-------------------------------------------------------------------------------

Day Date and Reference Monitor Difference Percent of

time value value reference

value

-------------------------------------------------------------------------------

Low-level:

-------------------------------------------------------------------------------

-------------------------------------------------------------------------------

-------------------------------------------------------------------------------

-------------------------------------------------------------------------------

-------------------------------------------------------------------------------

-------------------------------------------------------------------------------

-------------------------------------------------------------------------------

Mid-level:

-------------------------------------------------------------------------------