'FORE'

POSED S

RULE FO

ILL

TIE

OF:

UTI

SECTION 302.208(g)

NOTICE OF FIL

TO: Mr. John Therriault

Assistant

Clerk of the Board

ago, Illinois 60601

n

trot Board

1

00

West Randolph Street

Suite

11-500

Marie

°i

ecific .Rulernaking - Water)

Pollution Control

Board

James R. Thompson Center

100

West Randolph.

Suite I

Chicago, Illinois 60601

S.

ith the Office

of the Clerk of the

SITI

SN CIFIC

1-'«1>i

)',1

r)

SITE

1 T Cth 1 G 1a PRC)

'I I .--l 1 `40NY

OF GREGG F

RF,-!-ILLD TFSTIMONY OF

FIC

RULE; PRE-FILED TES

LUTION

C

}

R09-S

it

I '1'.I'-FILED TI

1_C,11 f C RULE,

I.'

c;1)I-Vtfully subiruteed,

INGFIELD, ILLINOIS,

OFFICE

OF PU

and

DISTRICT

Date: October 20. 2008

By: lsl Christine G. Zcinuw

One of Their Attor

LED PAPER

Electronic Filing - Received, Clerk's Office, October 20, 2008

BEFOR

THE MATTER

OF:

SPECIFIC

RULE FOR

CITY OF S

ND SP

ILLINOIS, OFFICE

OF PUBLIC

S, CITY WATER,

LIG

Specific Rule - Watei°)

ETRO

SANITAR

Public Uti

ingfield, Illinois

("

Light and Power ("CWLP")

and Springfield Metro

Sani

("SMSD") (collectively

08, su

Pre-

h .

r

,-,

k

: ncnced

matter.

My name is Dave Farr

oners"),

by and through their

attorneys, HODGE

CW

P as the Environmental

Healt

have aver thirty years

of experience in the area of

environni

emphasis ii

. I hold a Bachelor

of Science in

eld), a

nal Safety from Illinois

State University, a Master

of Business

11

Sangamon

State University (which is now

known as the University

Electronic Filing - Received, Clerk's Office, October 20, 2008

My testimony

today concerns

a description of

CWLP's facility,

CWLP's National

Pollutant

Discharge Elimination

System ("NPDES")

permit

and the limits therein; an

overview of

s boron mitigation

efforts; and an overview

of CWLP's

consideration

of

alternatives and alternative

technologies.

CWLP owns

and operates two power

stations, referred

to as the V.Y. Dallman

"Dallman") and

the Lakeside Power

Station ("Lakeside"),

and a potable

water treatment plant

at 3 100 Stevenson Drive,

Springfield,

Sangamon County, Illinois.

These

plants generate electricity for

the residents and bus

ding communities.

Approximately 186

r treatment

plant. T

ed at Dallman and

Dallman has an

8, 1972, and

atin

r c,,l3cetively.

Units 3.1. and 32 are identica

rived

megawatts of generating capacity.

1,250 psig an

boilers

in Units 31 and 32

operate at

nit 33 includes a

tangentially fired boiler and

has a generatin

it 33 operates at 2,400

psig and 1,000°F. Each of

the

man units

is equipped with a flue gas

desulfurization system ("FGDS")

that

,er 90 percent of the

sulfur dioxide from the unit's flue

gases. Selective

Catalytic Reduction ("S

R") air- polluti

removal

were added to all three Dallman Units

in 2003. CWLP currently

operates the

wring the ozone season (May

1 through September

30) to remove approximately

Electronic Filing - Received, Clerk's Office, October 20, 2008

90 percent of ISO,; from its air emissions at the Dallman units. The

SCRs

will begin year-

round operations in July 2009, to assist in control

of the mercury em

began

opera

turbine generators

Originally, there were ei

Only two boilers and two

turbine generators are still in

7 and 8 are

identical

33-megawatt cyclone coal-fired units. Boiler 7-

Turbine 6 went into operation in 1959, and Boiler 8-Turbine 7 began operation

4.

900°F. Lakeside

will be retired in the near future.

Total coal consumption at the CW

l

s atCW P are typical for a coal-fir

Bottom ash

ds. The raw lake water used for

ed frnm the once-through c

c,_ýiiJ,-i l 's.

Tin,, ý:

__ (.i),1+,1i1,.

Dal loran Unit 33, and -

illion tons per year.

ýzý n-- serve Dallnan Units 31 and 32,

,,I Id

bottom,

1

lant sludge and

leachate

collected

ash

scrubber

sludge landfill

adjacent

to the ash ponds.

The south

dividin

1

normally

discharged to

The east portion of the pond, re

s treams

v ary, but

depend

receives lime sludge from the filter plant and miscellaneous

water

an, including the F GDS e

ally upon the generating units in service.

3

Electronic Filing - Received, Clerk's Office, October 20, 2008

A new electric

generating un

about 2,440

rred to as Dallrnan

Unit 4, is currently

un

The Dallman Unit 4

will include a coal-fired

boiler wi rated capacity

250 megawatts.

The new boiler will be

equipped with low-NO,

combustion technol

owing air pollution

control systems: SCR, a fabric

filter, wet flue gas

tan

itator.

Dallman Unit 4 will utilize

a dry ash

able water treatment plant. has a

capacity o

day. A

conventional lime-softening/filtration/disinfection

process is

employed to

produce potable water. Five clarifers

and

late

matter from

Spaulding

em.

1

,.v.

; i

/hour

and a steam turbine-generator

with a nominal

capacity of

v+ titer from

the filters is disciýaý-,._ý ý_I to ash ponds

located north of

c _[ backwash

water discharged to the ash pond

and herbicides. The PAC

also

he clarifers

and disposed

in the ash ponds.

Lake S gfield, a 4,224-acre

rese

ucted in 1934

by

impoundment

o

oling water for the CWLP complex,

for the City of Springfield

and

ms flowing into

Lake Springfield are

and ick Creek, which drain i

Electronic Filing - Received, Clerk's Office, October 20, 2008

se of lake

water for the C

for 3.9 million gallons

of lake water usage

ive a variety of n

Dallman and Lakeside

and the

which

also provi

under a

ter, flows into a clarification

pond,

on, before it discharges

into Sugar Creek

renewal t

on discharges from

is Pollut

Board's water qu

Lied by the Illinois Environmental

Protection Agency

rnatant from

the two ash ponds,

lading miscellaneous

water streams from

ES permit

issued in 1991, IEPA placed

a boron

the clarification pond. On May 4, 1994,

CWLP filed a petition

Control Board ("Board")

seeking an adjusted

standard from

on that was, at that time, found

at 35 111. Adm,

Code 302.208(e).

On

December

1,

m gll

reek (Outfalls

00

compliance was reached

the Board grant

`..tC \i it Cr d

T he aajr!

!:.

uality standard for

boron at the point of discharge frog

downstream of t

alternative water qu

tandard for boron al

ns of

waters

at issue in this matter.

From 1994, when the

adjusted standard was granted, until May 20

neral compliance of its NPDES Permit IL0024767,

However,

("Spr

ant") (Outfall

007) to

on River

with Spring Creek. Thus,

an

inting

11.0

Electronic Filing - Received, Clerk's Office, October 20, 2008

mg/

at Gutfall 004, co iding

wi

systems.

Subsequent

to a meeting with IEPA

in July 2003, CWLP

committed to a further

of the process

chemistry and interaction

o

s treams;

It Il1ve

w astewater streams with high

boron content. CWLP used both internal

resources and

those of

investigation

demonstrated that the FGDS

blowdown, or the scrubber

return wa

tering

the scrubber solids (gypsum),

was a primary culprit ii

nson Professional

Services Inc. (" Hanson")

to conduct this investigation.

The

h boron levels in the

h the testing and start

of SCR air pollution control

reams of C7utfall 004,

to identify the

d.

Levels above 500 mg/L were identified

i

afc"riril

i`;

rcncrated by

dewatering the scrubber

-+rc,,Amately

200,000 gal

IEPA concerning the

On November 25, 2003,

response,

1 and its

progress in identifying

LP received a violation notice

("VN") from IEPA

00471). CWLP responded to the VN

ry 12, 2004. In its wri

LP exp

wastewater streams of CJutfall 004 wi

retained Hanson to investigate the

causes of the

s m o

o

n

to characterize the

ration, and after they had

beer

shut down following the

ozone season. On February 11, 2004, IEPA

accepted CWL

2004, w

Electronic Filing - Received, Clerk's Office, October 20, 2008

e

date of May 2005 was proposed. In the interim, for the remainder of

ampl

confirmed that a highly significant contributor of boron to Outfall

004 was

the PGDS

blowdown wastewater stream, or scrubber return water from

the gypsum de-watering

system.

On

July 28, 2004,

CWLP proposed to IEPA a three-prong approach to solving

the boron exceedance issue, including a proposal to engineer and design a temporary

for the

2004 ozone season,

nd would be included in the construction of the new Dallman Unit 4. A

hich discharge into the ash ponds and

for

ream was unfruitful

()

s

Oh, CWLP met with IEPA to

ion project. CWLP requested to amend the project implementation

schedule as the application o

r ns>,

s

ibility

of

permanent wastewater treatment options. The

outcome of

IE

ile a permanent

facility was

rovided recommendations to CWLP to pursue a brine concentrator and spray

rber. I

ional inve

continuously operate the Lakeside sluice

r earnaj

i>r,ý<<_j,

o logy was very unique and the consulting

ndor encountered

issues

that

required

significant changes in the project on

as now determined to generate order of magnitudes

e cost had expanded many times the

original

$13 million price

7

Electronic Filing - Received, Clerk's Office, October 20, 2008

ed six months, or

until April 9, 2007,

to fully evaluate

all alternatives.

The

feasibility and cost assumptions

for the

brine concentrator are

no longer valid.

2007,

C

m et with

IEPA and proposed

to construct a pretreatment

system

for the FGDS blowdown

consisting

of a ClariConeTM/clarifies- and

the addition of

force ma

WLP requested

a 90-day period,

or until July 9, 2007,

to pursue

stream

would be sent via

this strategy and submit

to the Agency design

and schedule information.

CWLP would

also

have to consider the need to work

with S

In May 2007, at

the request of the Agency,

electrocoa

r unt im

a nd

a bench top test was conducted

utilizing this waste

stream. The data generated from

coagulation would

be prone to failure

tewater

stream to the MSD

Srrrin;- Cn.vi

ith the SMSD Spring

Creek Plant for boron.

revised

CCA and granted an

extension to attain compliance with

the 2

chic

notice by August 2009.

Documents relevant to my testimony

related to the

VIN1 and

n the record

of this proceeding as Group Exhibit

A attached to

/new.

Respectfully su

8

Electronic Filing - Received, Clerk's Office, October 20, 2008

ILLI

OFFICE OF PUBLIC

UTILITI

CITY WATER,

and

Date: October 20, 200

I-Iodge

Christine G. Zen

IIODGE DW

P.O. Box 5776

field, Illinois

62705

-4900

Electronic Filing - Received, Clerk's Office, October 20, 2008

RESUME

a SURRY PLAC

GFIELD, ILLINOIS 6271-1

787-9091 (Home)

7) 757-8610 (Work)

'RIENCE

2 -

AFETY

City Water, Light and Power, Springfield, Illinois

Responsible for management

of Environmental Health and Safety staff of 10

for environmental compliance efforts in the areas of air, land,

3-

Southern Illinois University,

Carbondale,

Illinois

id Safety and Managerial

Supervision

Jamiar

D ccc-aber

I ND

nd industrial. hygiene programs of

the

Missouri Campus

h -Aion

of

S al,

1y

P rograms

I icne

J anuary 1983 -

February 1992

Light

and Power, Springfield,

Illinois

anti organizing tfhe industrial 11ygie ne

afety & Industrial

safety programs.

City Water, Light and Power, Springfield, Illinois

isk management prograrn

of the Insurance and Safety 0

e ongoing occupational

ources of loss. Devel

es to reduce dependence on

Electronic Filing - Received, Clerk's Office, October 20, 2008

January

1980 -

March

1987

City Water, Light and Power,

Sprin eld, Illinois

Completely

restructured the existing

safety program.

Responsibilities included

all

aspects

of employee safety, accident

prevention,

fire safety, industrial

hygiene, and

workers' compensation.

Responsible for direct supervision

of professional

employees in the Safety

Office.

1978

-

ry 1980

TOR

Western Illinois

University, Macomb,

Illinois

ongoing

safety program

which included fire

safety and employee

health and safety.

LOSS

CONTROL REPRESENTATIVE

Crum and Forster Insurance,

St. Louis, Missouri

Responsible

for inspection and

evaluation of risks from

a fire safety, workers'

d liability

standpoint.

r 1985

Rnsiuess

Administration (M

S1.1tý-

_

;ti:t_fc, t

y

I llinois

State

PROFESSIONAL

AFFILIATIONS, CERTIFICATIONS

AND LICENSES

C ertified

Safety Professional

Safety Professionals

Certified

in Comprehensive Prac

Agency

American

Elygiene Associa

Licensed

Industrial Hygienist

Exami

t. Louis

Local Section

American Industrial

Hygiene Association: Fundamentals

of

Industrial

Electronic Filing - Received, Clerk's Office, October 20, 2008

E ILLINOIS POLLUTION

CONTR

?IC

FOR

CITY OF SPRINGFIELD,

OIS, OFFICE

OF

PUBLIC

ITIES, CITY WATER,

METRO

SA

R 0 9 - 8

u le -- Water)

FROM 35 ILL.

E-FILED TESTIMON

Illinois, Office

of Public

t and Power

("CWLP") anti Springfield

Metro Sanitarv Di

("SMSD") (collectively "Petitioners"),

by and through

their attorneys, HODG

.424 and the hearing

ed in the aboti rui. rýý

igan.

Since 2004, I have been employed

at CWLP as 11-

S uperintendent of Production. In

this position, I am responsible

for operations of and

personnel for

the five electric generating units

at the Dallman Power Station

and the Lakeside Power- Station,

the combustion turbine at the Interstate

site, and all

environmental

control systems at Dallman. Previously,

I was the Chemical

P, from 1988 to 2004. I holed Bachelor

of Science degrees in

Bi

Oho 302208(g)

)

University in Decatur, Illinois. My

current resume

Electronic Filing - Received, Clerk's Office, October 20, 2008

ony today concerns CWLP's power plant

operations and CWLP's

alternative technologies

as it relates to the chemistry at

Boron is an element that is widespread in

the

environment taut

occurs

sually

as

borax, colemanite, boronatroca

Boron

rural se

s borosilicates, which are

considered biologically

ically released to

the environment slowly an

ering processes. Most of the natural. boron

compounds usually degrade or

are transformed by natural weathering of rocks

to borates or boric acid, which are the

-on compounds of ecological significance. Boron is present in coal ash as

various compounds. The boron compounds are captured in the sl

iDS") blowdown, and because boron i

ocess ),,

1'ý "-?

1

ds.

t ro'

T..?

?

;r

for boron

that was, at that time, found at 35 111. Adm. Code 302.205(e). On December 1,

003 and 004) with downstream decreases in the receiving

n adjusted standard for boron of 11.0 mg/L, for process discharges

waterways until compliance was reached with the general water quality

standard of 1.0

adjusted standard included an alternative water quality standard for boron at

of

C}utfall

Spring Cr,

ý,1ý

Sanitary

Treatment

Plant (

confluence of the

Electronic Filing - Received, Clerk's Office, October 20, 2008

to portions o

s matter.

able

to operate while meeting

the adjusted boron

standard in Sugar

Creek. However, since Selective

Catalytic Reduction

("SCR") air

pollution control

systems for removal

of nitrogen oxides were

added to Dallman's three

an alternative water quality standard

for boron already

app

coal-fired uni

for boron

through

Se

ification pond. The

increased boron levels

from the Dallman

ash

pond are below the adjusted

standard, but when the boron

content o

FGDS

lan d i 4 ; i c i ()n

the boron concentration at

Outfall 004

are als-

F,,

be quanti

,.

o,

,

Conversion to a dry fly ash system will

n.y other

owdown stream,

h boron

ons

anon in the

since it is generated

by the air pollution control equipment

(FGDS treats the flue

gas

roduct

of burning coal) and is not associated

with the fly ash disposal

system.

As Superintendent

of Production and Chemical

Supervisor, l have been

its to investigate

the effect of operation

of the

0. Apparently,

trace ammonia concentrations

from SCR oper

Creek. The SCRs operate

during the ozone season,

from May l

2003,

CWLP has had difficulty

complying with the adjusted

standard

reased

boron solubility

boron concentratio

Electronic Filing - Received, Clerk's Office, October 20, 2008

was involved

i

the Dall

ash pond and

Ctutfall 004 to Spring Creek.

d boron

concentrations at

Prior to April

of

2003,

Outfall 004 showed minimal

excursions beyond the

adjusted

standard of 11.0 mgll boron limitation.

In April 2003,

CWLP

that

time,

systems for nitrogen

oxide removal at Dallman (on

units 31, 32, and 33). At

he Chemical Supervisor

at CWLP, and was in charge of process

analysis

and chemistry control of the new

systems. Laboratory personnel

were monitoring the

in the ash systems

and in the Dallman ash pond

as part of the process control for the

SCRs. In addition, the chemistry

staff had

responsibility for tl

charge Elimination

System monthly

nthly

samples for boron. analysis

Analytiý . .,1.

itation.

last SCR went

boron levels was

a

startup of eac

chemically stable arnmoi

chec

limitation, at about

ided wi

e did some research

on boron solubility and found

a direct

ammonia having

an affinity for boron. compounds, forming

more

d September of 2003,

we began investigating the cause

of the boron

wastewater streams, as well as the incoming streams

to these bodies to determine

the

4

Electronic Filing - Received, Clerk's Office, October 20, 2008

of the increased

boron concentration.

This study was

done in conjunction

with

Engineering, which

is now known as Hanson

Professional

Services I

this extensive study

of all of the wastewater

streams

not to the levels that would

have exceeded the

we were

able to ident

into Outfall 004 to

Sugar

allman ash pond had increased,

but

fisted standard

of 11..0 mg/l. However,

FGDS blowdown effluent

stream contained excessive

amounts of boron, from

16.4 to 837 mg/l. This

effluent was found

to be 250,000

0 gallons per day being sent to the

filter plant sludge ponds,

which subsequently

discharge supernatant to

the Clarification pond, which

flows to Outfall 004,

present

prior to the operation

of the SCR

sed boron concentrati

4, resultil

ich is the major

of the

SCRs and the ammonia

effect on boron solubility, increased

the boron level to the

wdoa,Ni n =, rý,:;; ii

l boron

f,_

( ,. ould not:

'be

oposal will not eliminate

CWLP's need for the adjusted

standard; it is the

most

reasonable approach

for CW Ptome

I will be happy to answer any que!

Respectfully

submitted,

CITY O

OFFICE

OF P

and

Electronic Filing - Received, Clerk's Office, October 20, 2008

Date:

October 20, 2008

By:

Katherine D. Hodge

Christine

TRO SANITARY

istine

G. Zeman

_

One of Their

Attorneys

3150 Roland Avenue

1'.O. Box 5776

llinois 62705

(217) 523-4900

C'WLP:002/Fil/Pre-Filed

Testimony of Finigan

Electronic Filing - Received, Clerk's Office, October 20, 2008

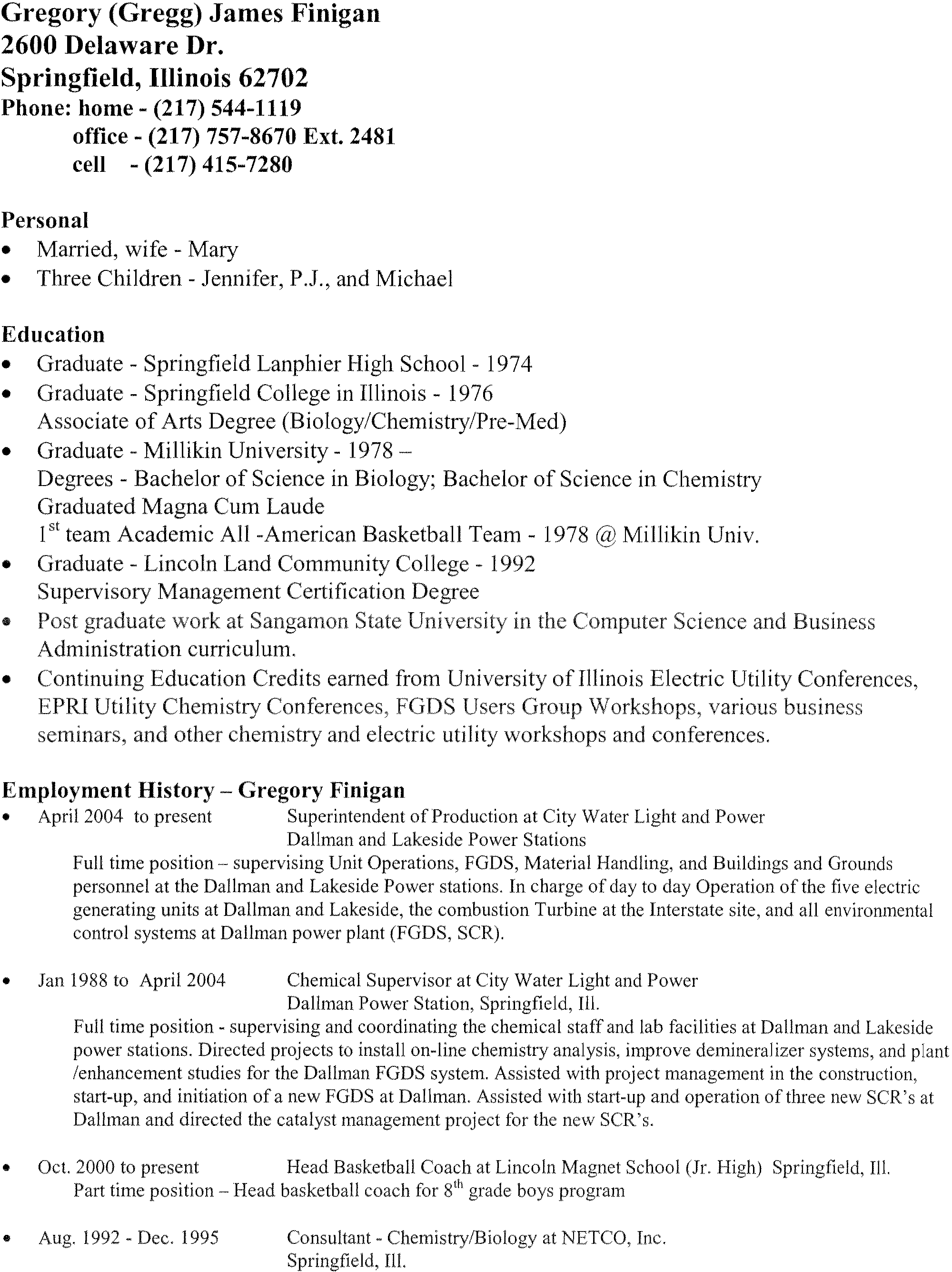

Gregory (Gregg) James Finigan

elaware

Dr.

e d, wife -

Mary

hone: home - (217)

544-111.9

office - (217)

757-8670

Ext. 248

cell - (217) 415-7280

Personal

hree Children - Jennifer, P.J.,

Education

" Graduate - Springfield Lanp

oc

Graduate - Springfield College in Illinois - 1976

Graduate -

I llinois 62702

i ology/Chemistry/Pre-Med)

- 1978

Degrees - Bachelor o

Graduated Magna Cum

1

sc

team Academic All -Amertc

Graduate -

i,-m curriculum.

1 duý-;ition Credits earned from

r C

I

v:. rnistrv Conferences. FGTR

Employment History - Gregory Finigan

" April 2004 to present

Superintendent of Production at City Water Light an.

Iman and Lakeside Po

nits at Dallman and Lakeside, the combos

llman power

ies for the Dallman FGDS syst

improve deminera

ted with project management in the

construction,

start-up, and initiation of a new FGDS at Dallman. Assisted with start-up and operation of three new

SCR.'s at.

Dallman and directed the catalyst management project for the new SCR's.

Dallman Power

H igh Schoo

B ology; Bachelor of Science in Chemistry

i i t_e,_<<<1. Business

,k

1?

11

d ay Operation of the five electric

bine at the Interstate site, and all environment

Chemical Sup

at City Water Light and Power

Springfield, 111.

r Stations

tion - supervising and coordina

chemical staff and lab facili

. Directed projects to

install

on-line

to present

Head Basketball Coach at Lincoln Magnet School (Jr. .High) Spr

ime position - Head

basketball

coach for

8

5

Consultant - Chernistry/Biology at NLTCO, Inc.

Springfield, Ill.

Electronic Filing - Received, Clerk's Office, October 20, 2008

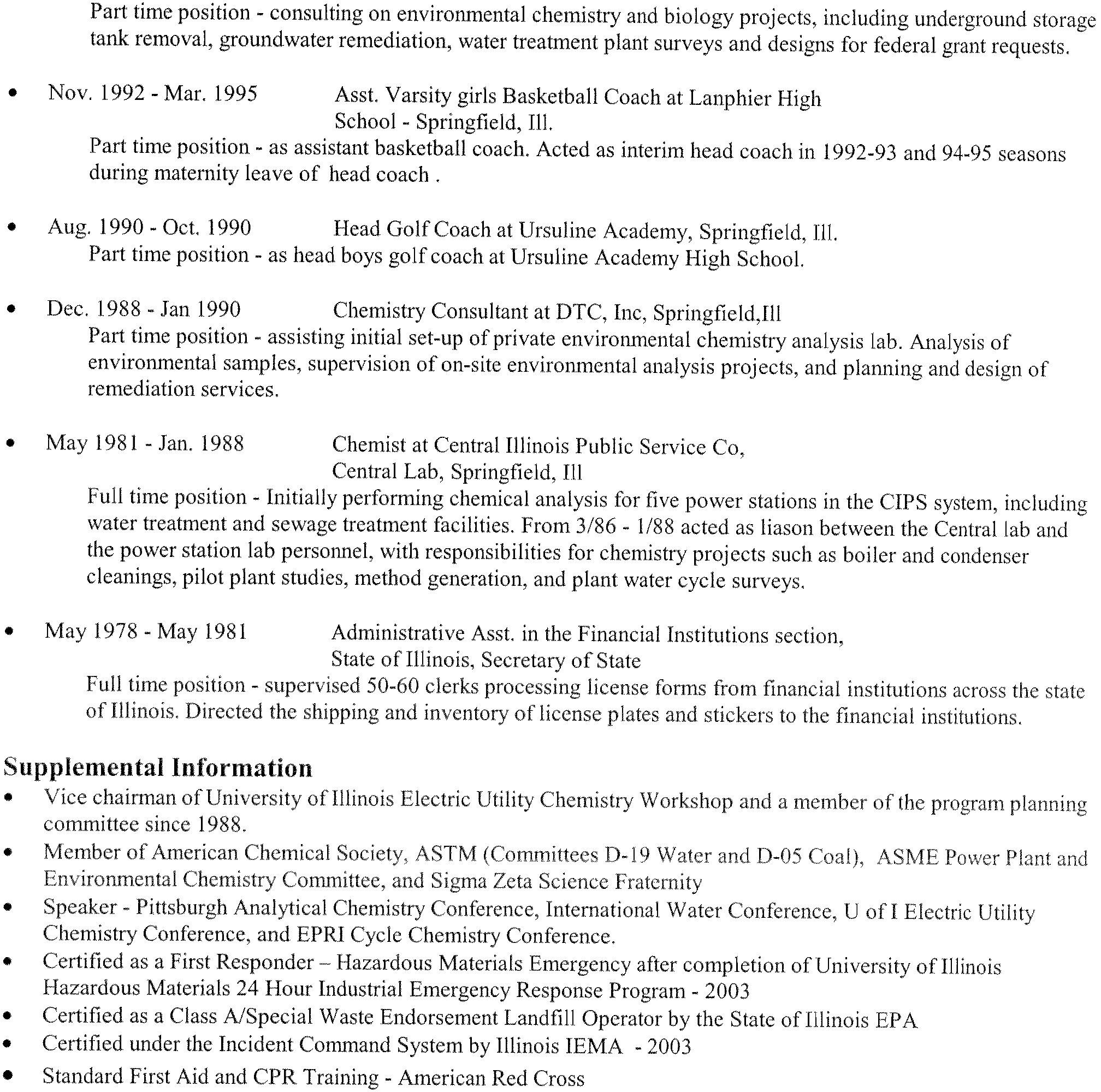

Part time position - consulting

on environmental

chernis

tank removal, groundwater remediation,

water treatmen

" Nov.

1992 - Mar. I

during maternity leave of head

coach .

tion - as

assistant basketball coach.

Acted as interim head coach

in 1992-93 and 94-95

seasons

" Aug.

1990 - Oct. 1990

Head

Golf Coach at Ursuline Academy,

Springfield, III.

Part time

position - as head boys golf

coach at Ursu

" Dec.

1988 - Jan 1990

environmental samples,

superv

o1,

f private

environmental chemistry

analysis lab. Analysis

of

site environmental

analysis projects, and

planning and design of

nd biology projects,

including underground

storage

" May 1981 - Jan. 1988

Chemist at

Central Illinois Public Service

Co,

gfield,

III

Consultant at D"

cleanings,

pilot plant studies, method generation,

and

Full time position -

Initially performing chemical analysis for

five power stations in the

LIPS system, including

water treatment and sewage treatment

facilities. From 3/86 - 1/88 acted

as liason between the

Central lab and

the power station lab personnel, with responsibilities

for chemistry projects

such as boiler and condenser

0

tions sec

processing license forms

from financial institutions across the

state

cc

chairman of U

utitiný:e

°,rný

ri(;;n C

L,, rni, :it

So, 4

'i

ASTM (Con,rr,rr,.-

-.

h-19

Water

and L1-0 G)al),

i

C,Il

r:_ Il

_

.;lid Sigma Zet.ý

i;ýý I ,.ýi

veys and designs

for federal grant requests.

t. Varsity girls Basketball

Coach at Lanphier High

ool

-

Springfield, 111,

o f licem t

p, ;t,.

.And stickers

to the ftnanei

lin,,i! Il_ýtricUtility

Chrnri>,Irý

" Spy ýký._r -PitL,hu

,'h

Aý1,11ý

ticýi.l

Clr.-niiýaty

Conferen;_

Water COnf ýýiý<<ý,:,

U of I Electric Utility

Chemistry

Confcrc

nt

e, and EPRI Cycle Chemistry Cool, i t ii;-c

" Certified as a First Responder -- Hazardous Materials Emergency

after completion of Universit

Hazardous Materials 24

Hour Industrial Emergency Response Program -

2003

" Certified as

a Class A/Special Waste Endorsement Landfill

Operator by the State

" Certified cinder the Incident Command System

by

Illinois

IEMA - 2003

Standard First Aid and CPR. Trait

Electronic Filing - Received, Clerk's Office, October 20, 2008

POLLUTION

CONTROL BO

PROPOSED SITE SPECIFIC

RULE FO

CITY WATER, LIGHT

SPRINGFIELD

)

(Site

Specific Rule - Water)

DISTRICT

l

SECTION 302.208(g)

MONY OF DOUG BROWN,

T OF PROPOSED

SITE S

the Petitioners, City of Springfield, Illinois, Office of Public

ies, City Water, Light and Power (" WLP") and

Springfield Metro Sanitary District

") (collectively "Petitioners"),

by

and through

their attorneys,

I rý .xilig Officer

Order,

almo(ly

o f Doug

a ber 3, 2008 hearing s

m atter.

e cts Director. I

fourteen years of experience

in

the

field

of electrical engineering and as an engineer

or of Sci

at Urbana-Ch

from th

ree in Electrical Engineering from

the

ntly

obtaining my Master of

and engineering technicians

to

INOIS, OFFICE

OF

PUBLIC

l requirements, budgets,

Electronic Filing - Received, Clerk's Office, October 20, 2008

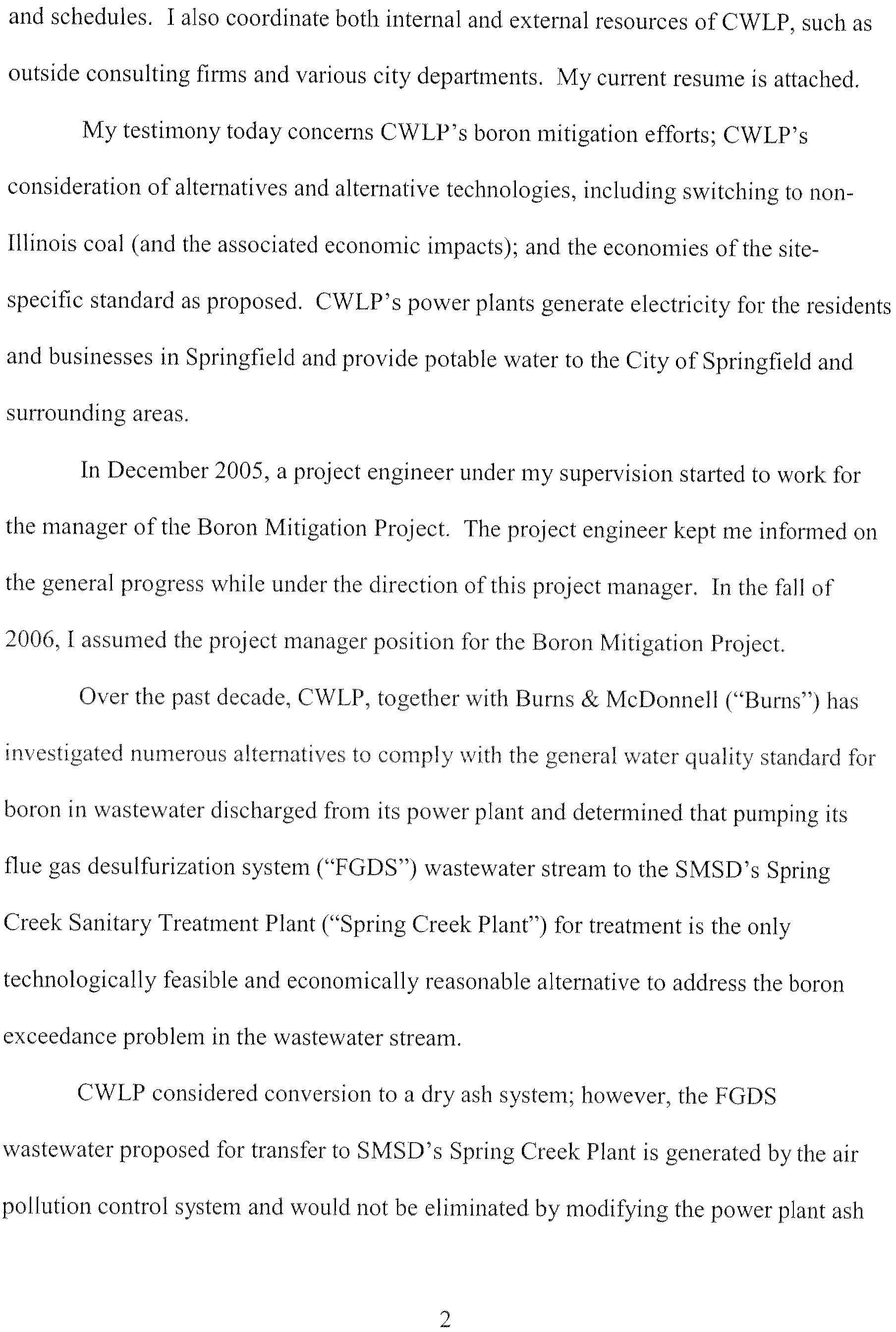

and schedules. I

also coordinate froth internal

and external resources

of CWLP, such as

ulting fines and various

city departments.

My testimony today

concerns C

on igation efforts;

CWLP's

consideration

of alternatives and alternative

technologies,

r the residents

potable water to

the City of Springfield

and

surrounding areas.

OS, a project

the manager of the Boron

the general progress

while under

,in:A

lfT,.;

proje,, i w.iii;

the

on

roe Mitigation

Proj

-oject manager.

In the fall of

1

1!, J

!`Iulncrous alternýýAei

its power plant any determined

that p

flue gas desulfurization

system ("FGDS") wastewate

tary Treatment Plant ("

-ns") has

in totheS

technologically

feasible and economically reasonable

alternative to address the

boron

exceedance problem i

considered

conversion t

Creek Plant

er my supervision

started to wo

llution control

system and would not be eliminated by modifying

the power plant ash

Electronic Filing - Received, Clerk's Office, October 20, 2008

handling system,

although CW

bottom ash han

In 2005,

Dallman

ost to convert all of

0.2 million. With added

itional equipment and operations, along with

collected ash

disposal,

Burns

calculated the

2005 net

present value of conversion to dry fly ash as

ion, with a 2008 net present value of $24.5 million, for a cost of $368 per

conversion to

dry

fly

ash would not address the

boron generated by the air pollution control systems

Burns also found that convers

feasible, due ,-, " IC"?

allman

it 4 will include dry fly ash and

s

Units

31 and

32

to a dry bottom ash

wash :ý ýitci, which contains high concentrations of dissoly

that less-cxpen

1

million to $9.2

costs and from $0.80 million per year to $14 million per

year

- Iids, such

ual operating and

es range from

$22 million to $254 million.

1

Such

technology

otherwi

arate and recover water

from the wastewater solution. The most commonly used BC's use

a

vapor compressor to

Electronic Filing - Received, Clerk's Office, October 20, 2008

provide a self-sufficient

supply of steam to heat

up

t ewate

wastewater evaporates and

generates steam that is compressed

and used for reheating

the

wastewater slurry,

which is then recirculated in

a vertically mounted tube

bundle. Due to

n

he tubes from titanium, and

are very expensive. In

addition, the

come in contact with

these higher concentrates are normally

made from higl

lie slurry recirculation pumps consume

a significant amount

of

into a spray dryer, where

it would

ly dried to a solid form

for

combusted n

gas

would

ved solids ("TDS") and chlorides,

the materials t

wining

ed, leaving behind

the solids.

^cc«mirio¬fi ýiý.° l,rriodic

maintenance, and possible

ie maximum

c apacity re

t,-1

', i

ý <

<

l

train spray

w

I i, i.d

a

CWLP also considered reverse

osmosis ("RC?") followed by crystallizer

and a

spray dryer. The

RC) process was considered as an alternative

to the first stage treatment,

hanical

the high concentrations

of ssolved constituents in the

ible dine to the osmotic pressure and the pressur

available

nes. Burns concluded that, because

of the

wn, including high suspended

solids, pretreatment

uld be treated by an RCS system.

Electronic Filing - Received, Clerk's Office, October 20, 2008

To address the problems

caused by these consti

example, that whey

ed in the RO

system at neutral or acid pH,

sil

for

trations

may exceed its so

and that

boro

could also foul

up the

y and cause a scaling problem

on the RO

ystallize to form

boric acid, a waxy substance

that

O membranes. Thus,

following the lime

soda softener, Burns

considered a HERO system (a patented

high efficiency RO

system design

covery is limited

by the osmotic

Due

to the limitation of the recovery

of the HERO, the size

much larger a

B ut,

the cost

of the HERO is generally less than

that of a BC and consumes

less electrici

also has some disadvanvv,c ;,

The BC option is more favorable than

the HERO

HERO systems had a capi

the 1

Finally,

a

so

0,000 and an annua

followed by dua

ýtit'

ý__

T

hese values represent 2005 dollars,

In December 2005,

based upon Burns' recommendation, CWLP entered

into a

contract with Aquatech

to provide a Zero Liquid Discharge ("ZLD")

plant for the

treatment of FGDS wastewater, consisting of two IBCs

followed by spray dryers,

to

trý...it

the blowdown from the FGDS

system at CWLI''s plant. The process

energy would be

oped

by four vapor compressors that would consume

550 horsepower each. The

concentrated saltwater would be sent

to

, -ý

ýý ;-fired spray dryer that would

convert the

Electronic Filing - Received, Clerk's Office, October 20, 2008

nto a powdered

salt, The solid

salt would not be included

with the Aquatech

system, but instead would

be taken to a landfill. Ninety

percent of the evaporated

water

would be condensed

and could be recycled in

various plant processes.

In

ystern to remove suspended

solids from. the

system, to prevent scale

engineering, it was discovered

that the Aquatech

system would have to

be sup

front forming in the evaporators

and preheaters. This led

to the design of a pretreatment

The pretreatment

systern would be used

to separate t

r eturn

i1. e:ý ?

r i

!'or the boron remov;;

to treat the

that req

gan working

with Aquatech on the

jeer, CWLP retained

siderable expense,

rience in this application

translated into design

app

f the system progressed. Burns

and Aquatech encountered

ificant changes

in the project on a fairly regular

basis, because

as unproven, ai

stream. There was relatively little expertise

in this area, such that the design

changed as

and the project

was considered a pilot project,

For example, the

equipment,

typically used for co

6

Electronic Filing - Received, Clerk's Office, October 20, 2008

cations, was a much

different application

due to the heavier dissolved

prese

ally investigated processing

one to two bags an hour

to d

soon learned

that the material

re

such that the number of bags to

unload increased to 20 bags

every 10

utes. CWLP then considered a

conveyor and truck trailer removal

arrangement,

g excessive costs in trucking and landfill fees,

due to the increase in volume

of

according to chemica

over,

the byproduct would be considered

a

special

waste

1

environment,

turning

1

lance, posing

1 scope of work

and the a

ystem. At

ost had risen

and maintenance

cost had risen to $3.7 million. It was

nual operating

the

original Burns

the BC option,

s

s ystem

was never resolved.

e

rmed of the proble

In September 2006, CWLP decided to pursue

alternate

ses and the

design and operating issues

onds in

Electronic Filing - Received, Clerk's Office, October 20, 2008

conjunction with the BC

option, or without them.

The study indicated

that it was not

feasible to use

this method without forced

evaporation methods,

which would be too

costly in

conjunction with the costs

to build the ponds. In

December 2006,

CMT

provided

CWLP with a preliminary study

on using the SM

alternate

option,

onse to a request

from the Illinois Environmental

Protection Agency

in t

g

of 2007, CWLP evaluated boron removal

using electrocoagulation

(`

method

of treating wastewater

destabilized and

ates separately

by thin

olves

the electrodes. The dissolved metal

ions react with

ates of

/precipitation

and ads

and are

removed along wit

flocculants

ported to be only 20 percent of available

boron, when ads

other contain

such as chlorides

and sulfates, both of which

exist in

Targeting

boron specifically for removal by EC

in the

astewater

is

d ifficult because boron is known

to

exist in

at least six pl-I dependent species

in water,

such that 50 to

of the boron will be in the

boric acid form, which is

difficult to

remove

by most available technolo

wastewater cons

ons from

other FGDS

;ally lower

8

al.

Electronic Filing - Received, Clerk's Office, October 20, 2008

CWLP to produce a letter

of recommendation on the EC

option.

CWLP supported the efforts with

a sinall scale test on-site

with a local supplier

oval of boron in FGDS

wastewater would

require a capital cost of $9,207,000

and annual operating

costs of $14,074,000,

concluding

that economically, EC is not recommended

for FGDS

wastewater due to high

sts relative to low boron removal

efficiencies, based on

from studies performed

on wastewater much

different from the

removal

efficiency cannot be predicted

due to lac

verified boron removal

efficiencies in high boron and

high TDS wastewater,

creased from

theoretical

estimates due to compe

process. The

on-site tests

at

1 6

wastewater.

Compliance k tudy Report,

dated

October

19 8, switching the

CWLP coal

s evaluated. PRB coal,

d eliv

T llinoi

he

western United States, is low-sulfur, low-boron

coal, as compared

to coal

al to the plant, and the plant site is not large

enough for unit train coal

major modifications

would be required to enable limited rail unloading

of

livery were identified

by CWLP during

this

facility and t

Electronic Filing - Received, Clerk's Office, October 20, 2008

difcations would include retrofitting

existing hammer

coal, and installation of dust control systems,

including enclosures of

operations to reduce dust emissions

during unloading operations. Test burns

revealed that installation

of a limestone storage silo and feed system would

also be

concern for operation

of existing

and systems to burn Ply oal,

ity of the forced draft

he coal feeder, the bowl mill and the

exhauster, poten

yclone slag flex

agents, as well as

to the ash han

noted that certa

n, such as

bottom ash split

ke it impossible for

conditions

burning P

1 ,ýzsc

D allinan

port of this

1, 2) economic benefits for Springfield

creating over $10 million

related

jobs; 3;

1 9 years; 4)

G

oal sales, and treat

has successfully operat

had

budgeted

$12.5 million

I

ne related

jobs,

0 constrtictioii

on Unit 33 for

10

Electronic Filing - Received, Clerk's Office, October 20, 2008

lowing disadvantages

of using PR13 coal: 1) over

tions; and 6) concerns about explo

illmois annually;

2) shipping delays; 3) major

to butte lllii

ors, according to

7.5

in the wastewater can be removed w

to accep

cost to CWLP of

X5100,000 per month, provided that

plant

operations.

t 22 hours of holding time for the wastewater

solids

removal prior to pumping

the

oratory

ý I ý ý

-r to

ion tons, of the coal used by Illino

t

CWLP proposes coil

holding tank. This

allons per minute

cent holding tank

will be

fed

to a ClariCone

will

provi

oal, only 13.5

utilities

and industrial users in 2005 was

ce of Coal Development.

is atypical o

i s acce

n ot upset normal

e FGDS waste stream with conventional

centrations it

the FGDS waste stream in

a

250,000

gallon influent

to be approxima

with

a. 240 gpm capacity.

`lariConeTm has been demonstrated at

over 300

ationwide. Mixinv,

tapered flocculation and sedimentation al

e

Electronic Filing - Received, Clerk's Office, October 20, 2008

suspended, rotating slurry blanket

that provides solids contact,

accelerated floc formation

apture. The conically shaped concentrator

maximizes the slurry discharge

concentration

and allows plant personnel

to visually monitor slurry

discharge. The large

mass of retained slurry and

unique helical flow pattern in

the ClariConeTM prevent

s

and resists process upsets.

As part of this

project,

a pumping

station would be constructed

near the Scrubber

at the CWLP plant. All sump and pump materials

will be corrosion resistant. A

am would be constructed from the pumping

station to a sani

1

Standard sewe

ub-area,

generally southwest of Bergen Park in

S

Lion will be

used,

to four air

release

valves

will be required. Sealed

and

manhole and sewer is antic J 1): 11

'"tesor

i,ii

corrosion,

il

a ntly lower than options investigated by

CWLP. The

a

pretreated

FCDS wastewater and chemical

$15.5 million. T

stem,

he

m(s) to control odor

to the plant, is

cost of such treatment,

other treatment options. While some costs may remain fixed, other

C) & M costs will

likely escalate. Using a $10,0100

per

year

escalation factor, a pretreatment life of 30

Electronic Filing - Received, Clerk's Office, October 20, 2008

years, and an interest

completion date of March 2009. The engineering design of the S -

present value per electric service of $544. In addition, the pun

ly less space than other alternative

technologies and no special o

waste would be generated.

III occupy

e ClariConerTNI and pumping station is

currently

in

progress

forcemain is currently being performed by CMT and is estimated to be complete in

December 2008.

Construction

is estimated to start in

April

2009

and end by August

2 00 9 .

for the si

al of this p

red ý,ciýý.iring station is being constru, <<_ý1,

a s a in

1d have estimated the flow of the Dallman Unit 4

FGDS

blowdown to

present value of $36,100,000, a

average.

to

an:,

\,, c r any

clue

bznitted,

and

13

Electronic Filing - Received, Clerk's Office, October 20, 2008

DISTRICT,

Date: October 20, 2008

By: /s/ Christine G. Zeman

One of Their Attorneys

herine D. Hodge

. Zeman

ZEMAN

d

Avenue

P.O. Box 5776

Springfield, Illinois 62705

(217) 523-4900

CWI-F':002/Fil/Pre-Filed

Testinlonv of D. Brown

Electronic Filing - Received, Clerk's Office, October 20, 2008

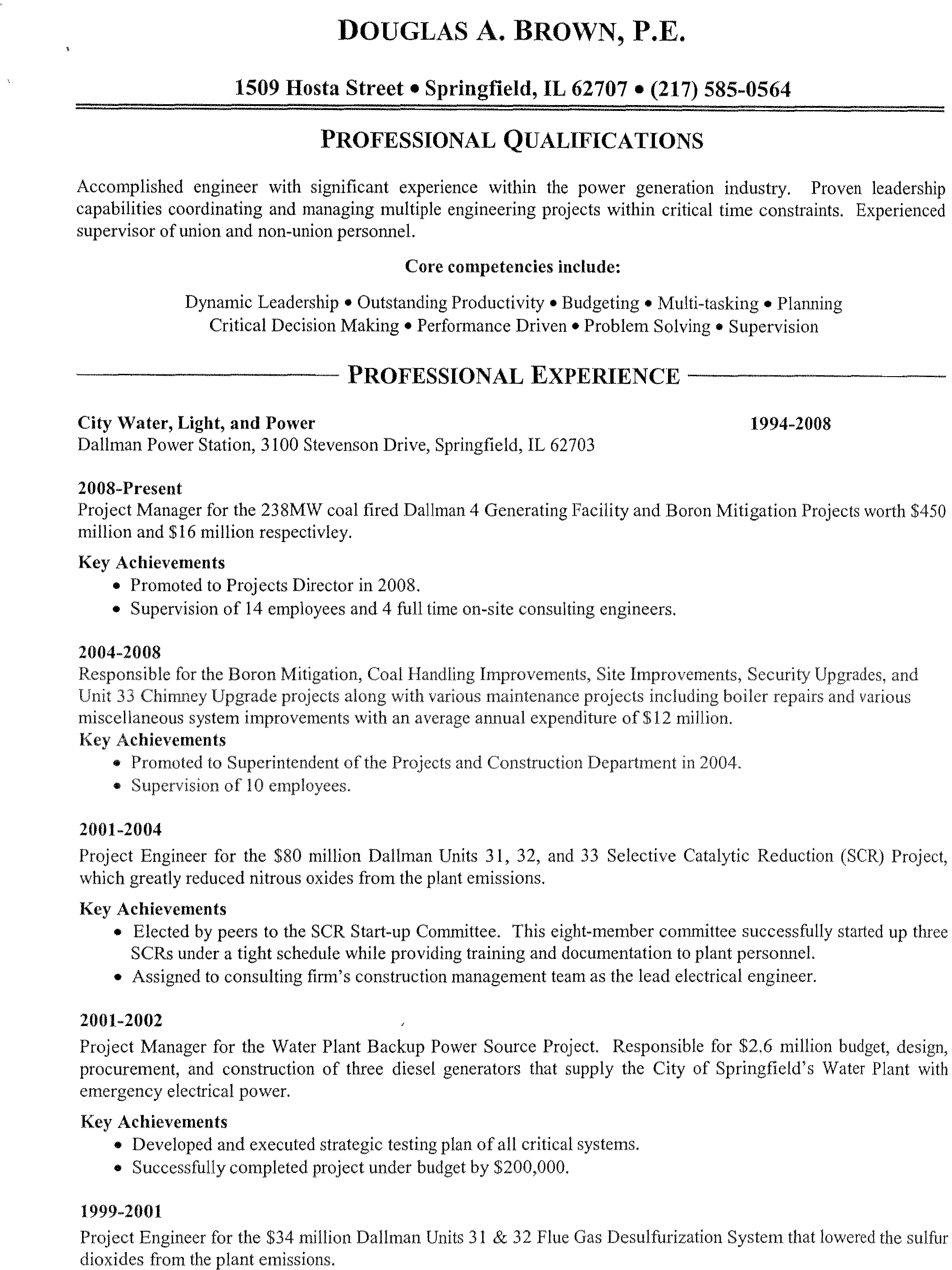

ROWN

1 509 HOsta Street

9

Springfield, IL 62707

" (217) 585-0564

A

ccomplished engineer with significant experience within the power generation

industry.

Proven

leadership

capabilities

coordinating and

managing

multiple engineering projects within critical time constraints. Experienced

or of union and non-union

Critical Decision Making " Performance Driven *Problem Solv

Dynamic Leadership " Outstanding

Productivity

"

Budge

City Water, Light,

and Power

Dallman Power Station, 3 100 Stevenson Drive, Springfield, IL 62703

2008-Present

rrtJ'i

nvr-rnpnj

K ey Achievements

" Promoted to

for the 238MW coal fired Dallman 4 Generating Facility and Boron Mitigation Projects worth

$450

million respectivley.

2604 -200R

1:._- 1,; n if ]e f

U1:.,

, ;iI

,,,

Key Achievements

008

it ý Upgrades,

and

11

11,.

;n:,1 expendii1!of

$12 mil

ng

*

Supervision

2001-2004

Key AchicN cments

.

Elcý_ tý (I by peers to the SCR Start-up Committee.

action (SCR) Project,

SCRs under a tight schedule

while

providing training and documentation to

plant

personnel.

tang firm's construction management team as the lead electrical eng

2001-2002

Plant

Backup

Power

Source

Project. Responsible for $2.6 million

d iesel generators that su

Key Achievements

Developed and executed

strategic

testing plan of all

fully completed project under budget by $200,000.

Electronic Filing - Received, Clerk's Office, October 20, 2008

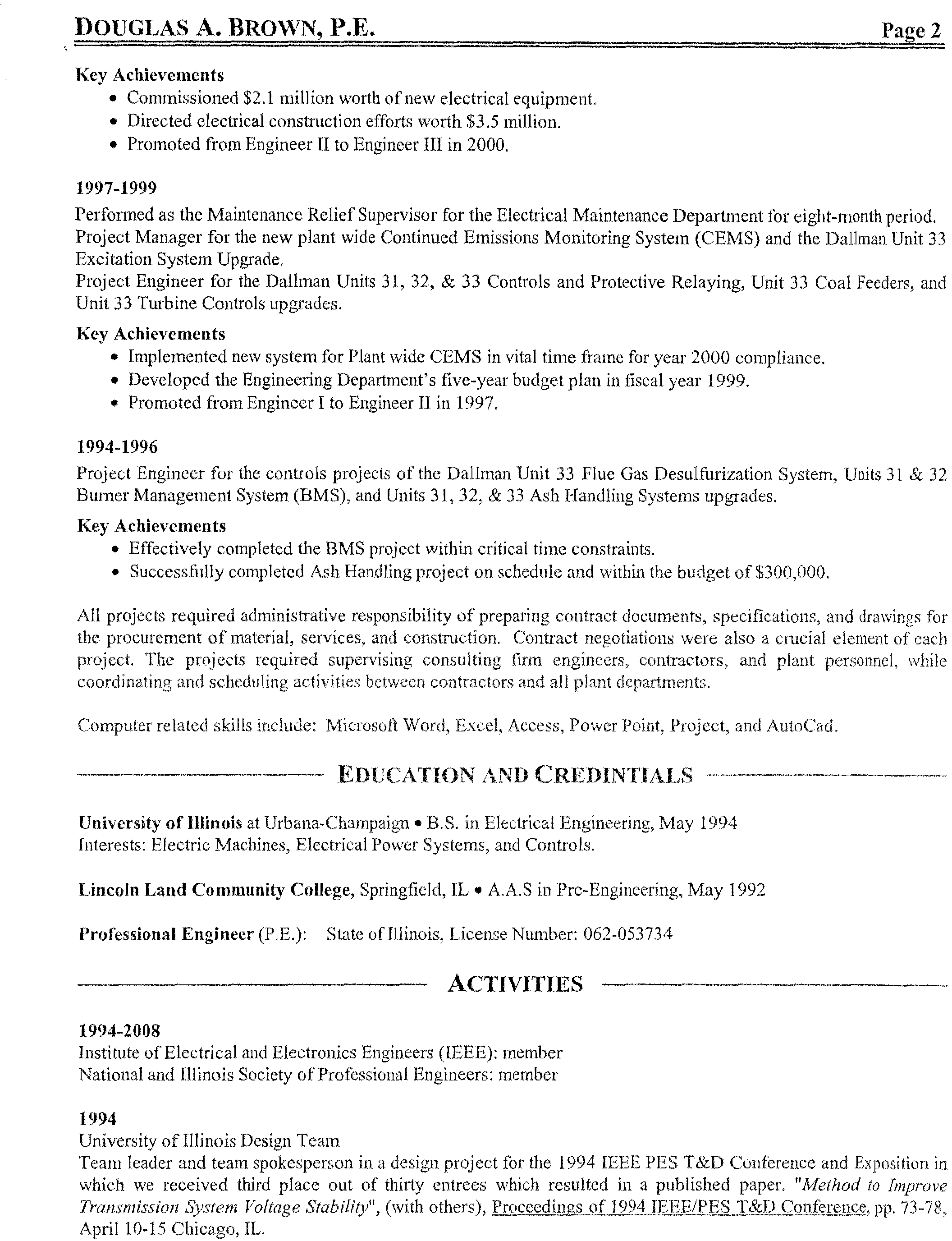

DOUGLAS A. BROWN. P.

K ey Achievements

" Commissioned

$2,1 million worth of new electrical equipment.

" Directed electrical construction efforts worth $3.5 million.

ted from Engineer II to Engineer III

in

2000,

Page 2

1

997-1999

nce Relief Supervisor for the Electrical Maintenance Department

for eight-month period,

eager for the new plant wide Continued Emissions Monitoring System (GEMS) and the

Dalllnan Unit 33

System Upgrade,

t Engineer for the Dallman Units 31, 32, & 33 Controls

and

Protective

Relaying, Unit

.

`ý

des,

Key Achievements

" Implemented new system for Plant wide GEMS in vital time frame for

year

2000

compl

" Developed the Engineering

Department's five-year budget plan in fiscal year 1999.

" Promoted from Engineer I to Engineer II in 1997.

1 994-1996

Project Engineer for the

controls

projects

of

the

Dallman Unit 33 Flue Gas Desu

B urner Management System (BMS), and Units 31, 32, & 33 Ash Handling Systems upgra

Key Achievements

completed the BMS project within critical time constraints.

completed Ash

Handling

project on schedule and within the budget of $300,000.

32

ement of material, services, and construction. Contr::et n ý^al',,t

I p rojects r equired supervising cor -(t l

l l

w ý b

i rn E I `t i _ ý' 1 ".,

s cheduling activities between contr -- irs and all

1

,

deo

111, iors,

and plant personnel, while

O ver ,,

1.',,!,d

AutoCad.

t>:. I-ýoctric

Machines,

Lincoln Land Community College, Snrin2field. IL

"

A.A.S in

4

1994-2008

Institute

of Electrical

and

Electronics

National and Illinois Societv of Professional Engineers: member

1 994

o f Illinois Design Team

spokesperson in a design project .for the 1994 IEEE PES T&D Co)

l : ice

anal Exposition

i

f° thirty entrees which resulted in a published paper, "Method to Improve

roc'i'i

rýtn::ý';

of

1994I.EEE/PES T&D Conf -e:

Electronic Filing - Received, Clerk's Office, October 20, 2008

I have been a Utility Engineer

Projects Manager for 4 years with projects such as the Site Improvements for $2.Smil

(roads and parking lot),

Security

Upgrades for

various CWLP sites, Unit 33 Chimney Improvements worth $2.6mil,

Boron Mitigation worth $16mil down from

$40mil,

others

item were maintenance contracting such as scaffolding,

industrial cleaning services for the boilers and scrubbers, and boiler repairs.

Electronic Filing - Received, Clerk's Office, October 20, 2008