| | - BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

- NOTICE OF FILING

- METROPOLITAN WATER RECLAMATION DISTRICT OF GREATER CHICAGO

- PROOF OF SERVICE

- SERVICE LIST R08-9 (Rulemaking - Water)

- UV DISINFECTION COST STUDY

- Cost Study Report

- METROPOLITAN WATER RECLAMATION

- DISTRICT OF GREATER CHICAGO

- VOLUME 1 OF 2

- STICKNEY WATER RECLAMATION PLANT

- September 9, 2008

- 303 EAST WACKER DRIVE, SUITE 600

- CHICAGO, ILLINOIS 60601

- TABLE OF CONTENTS

- Volume 1 – Report and Appendices

- LIST OF TABLES

- LIST OF FIGURES

- LIST OF APPENDICES

- Volume 2 – Conceptual Design Drawings

- EXECUTIVE SUMMARY

- Introduction

- Objectives

- Proposed Facilities

- Hydraulics

- Site Layout

- Figure ES 1 - Proposed UV Facilities Flow Diagram

- Preliminary Cost Opinion

- Table ES-1 – SWRP UV Disinfection Facilities Preliminary OPCC and M&O Costs

- Capital Cost Estimates

- Total Capital Cost $260,530,000

- Maintenance & Operations Cost Estimates

- Total Present Worth $542,930,000

- 1.0 INTRODUCTION

- 2.0 HYDRAULICS

- 2.1 Hydraulic Analysis of the UV Disinfection Facilities

- 3.0 SWRP DISINFECTION PROCESS

- 3.2 UV Disinfection System

- 3.2.3 Process Control

- 3.2.4 Safety

- 3.2.5 Proposed Design Criteria for UV Disinfection Equipment

- Table 3.2-1 – Design Parameters for UV Disinfection Unit at SWRP

- Parameter Design Value

- Table 3.3-1 – Low Lift Pump Station Basis of Design

- 3.3.2 Pump Type

- 3.3.3 Proposed Operational Description

- Table 3.3-2 – Examples of Pump Operation

- Flow, MGD Pump Drive

- PumpFlow, gpm

- TDH, ft Pump Eff. Power Demand,

- 3.3.4 Proposed Layout

- Figure 3.3-1 - Proposed UV Disinfection Flow Diagram

- 4.1.5 Geotechnical Information

- 5.0 SWRP STRUCTURAL AND ARCHITECTURAL

- 5.1.1 Codes and Specifications

- 5.1.2 Loads

- 5.1.3 Design Stresses

- 5.1.4 General Design

- 6.0 SWRP ELECTRICAL

- Table 6.2-1 – Existing and Proposed SWRP Electrical Loads

- Item Value

- 6.9.1 Medium Voltage Switchgear

- Table 6.9.1-1 – Medium Voltage Switchgear Criteria

- Table 6.9.1-2 – Circuit Breaker Ratings and Features Criteria

- Item Criteria

- Table 6.9.1-3 – Circuit Breaker Battery Criteria

- Item Criteria

- 6.9.2 Secondary Unit Substation

- Table 6.9.2-1 – Secondary Unit Substation

- Item Criteria

- Table 6.9.3-1 – Motor Control Center Criteria

- Item Criteria

- Item Criteria

- 8.0 SWRP MECHANICAL AND PLUMBING

- 8.2.1 Ventilation Rates

- Table 10.0-1 – SWRP UV Disinfection Facilities Preliminary OPCC and M&O Costs

- Capital Cost Estimates

- Total Present Worth $542,930,000

- Table 10.2-1 – M&O Labor Requirements

- Activity Labor Type Number Hours per Week

- per Worker

- Low Lift Pump Station

- Table 10.4-1 – OPCC Selected Line Item Description

- APPENDIX A

- HYDRAULIC TECHNICAL MEMORANDUM

- DISINFECTION?COST?STUDY

- HYDRAULIC?EVALUATION

- METROPOLITAN?WATER?RECLAMATION

- DISTRICT?OF?GREATER?CHICAGO

- STICKNEY?WATER?RECLAMATION?PLANT

- TECHNICAL?MEMORANDUM

- June?2,?2008

- 303?EAST?WACKER?DRIVE,?SUITE?600

- CHICAGO,?ILLINOIS?60601

- MWRDGC?Project?No.?07-026-2P

- CTE?Project?No.?60040695

- TABLE?OF?CONTENTS

- LIST?OF?TABLES

- LIST?OF?FIGURES

- LIST?OF?APPENDICES

- 1 INTRODUCTION

- 1.1?? Objective

- 2 PROPOSED?FACILITIES

- 2.1.1?Site?Constraints

- Conditions

- 3 HYDRAULIC?ANALYSIS?OF?THE?UV?DISINFECTION?FACILITIES

- 4 UV?DISINFECTION?FACILITIES

- Table?3?–?Design?Parameters?for?UV?Disinfection?Unit?at?NSWRP

- Parameter Design?Value

- 5 LOW?LIFT?PUMP?STATION

- Table?4?-?Low?Lift?Pump?Station?Basis?of?Design

- Pumps

- Table?5?-?Summary?of?Pump?Operation

- Flow,?MGD Pump?Drive?Type Pump?Flow,?gpm

- APPENDIX?A

- Site?Plan?from?the?SWRP?Master?Plan

- APPENDIX?B

- Selected?Pages?from?USACE?CUP?DDR

- APPENDIX?CLLPS?Proposed?Layout

- APPENDIX B

- NORTH SIDE WRP UV TECHNOLOGY

- TECHNICAL MEMORANDUM

- DISINFECTION?COST?STUDYULTRAVIOLET?DISINFECTION?TECHNOLOGY

- EVALUATION

- METROPOLITAN?WATER?RECLAMATION

- DISTRICT?OF?GREATER?CHICAGO

- NORTH?SIDE?WATER?RECLAMATION?PLANT

- TECHNICAL?MEMORANDUM

- OCTOBER?23,?2007

- TABLE?OF?CONTENTS

- LIST?OF?TABLES

- LIST?OF?FIGURES

- LIST?OF?APPENDICES

- Appendix Content

- INTRODUCTION

- Background

- Objective

- AVAILABLE?UV?DISINFECTION?TECHNOLOGIES

- Figure?1?–?Categories?of?Currently?Available?UV?Disinfection?Systems?(Hunter,?et

- al.,?2006b)

- Low?Pressure?–?Low?Intensity?(LP-LI)

- Open?ChannelHorizontal

- Lamps?parallel?to?flow

- Closed?Channel

- Horizontal

- Lamps

- perpendicular?to

- HorizontalLamps?parallel?to?flow

- Vertical

- Horizontal Vertical

- Table?1?–?Typical?UV?Technology?Categories?(Bazzazieh,?2005)

- UV?System Low?Pressure,

- Low?Intensity

- Low?Pressure,High?Intensity

- Medium?Pressure,High?Intensity

- Low?Pressure?–?High?Intensity?(LP-HI)

- Medium?Pressure?–?High?Intensity?(MP-HI)

- LITERATURE?REVIEW?OF?SELECTED?MP-HI?UV?TECHNOLOGY

- Typical?MP-HI?System?Configuration

- Influent?Characteristics

- Reactor?Configuration?and?Hydraulics

- Lamps?and?UV?Intensity?Control

- Lamp?Fouling?and?Cleaning

- Process?Control

- Safety

- REVIEW?OF?AVAILABLE?TECHNOLOGIES?FROM?MANUFACTURERS

- Trojan?Technologies?–?Trojan?UV4000™Plus

- Figure?2?–?UV4000+?System(Courtesy?of?Trojan?Technologies)

- Aquionics?–?InLine50,000+

- Figure?3?–?InLine50,000+?System

- (Courtesy?of?Aquionics)

- Calgon?Carbon?–?C

- 3500™

- Figure?4?–?TAK25?System

- (Courtesy?of?ITT/Wedeco)

- Severn?Trent?Services?(STS)/Quay?–?MicroDynamics™

- Figure?5?–?MicroDynamics?System

- (Courtesy?of?STS/Quay)

- Table?2.?Summary?of?Manufacturer-recommended?UV?Technologies?for?NSWRP

- Troanj

- Technologies

- Aquionics Calgon?Carbon? STS/Quay

- REFERENCE?INFORMATION?FROM?OTHER?OPERATING?FACILITIES

- Table?3.?Basis?of?Design?–?Clayton?WRC

- Telephone?Survey?of?Experience?at?Other?Facilities

- Facility Racine?WWTP R.L.Sutton?WRF Grand?Rapids

- Jacksonville?WWTP? Valley?Creek?WWTP

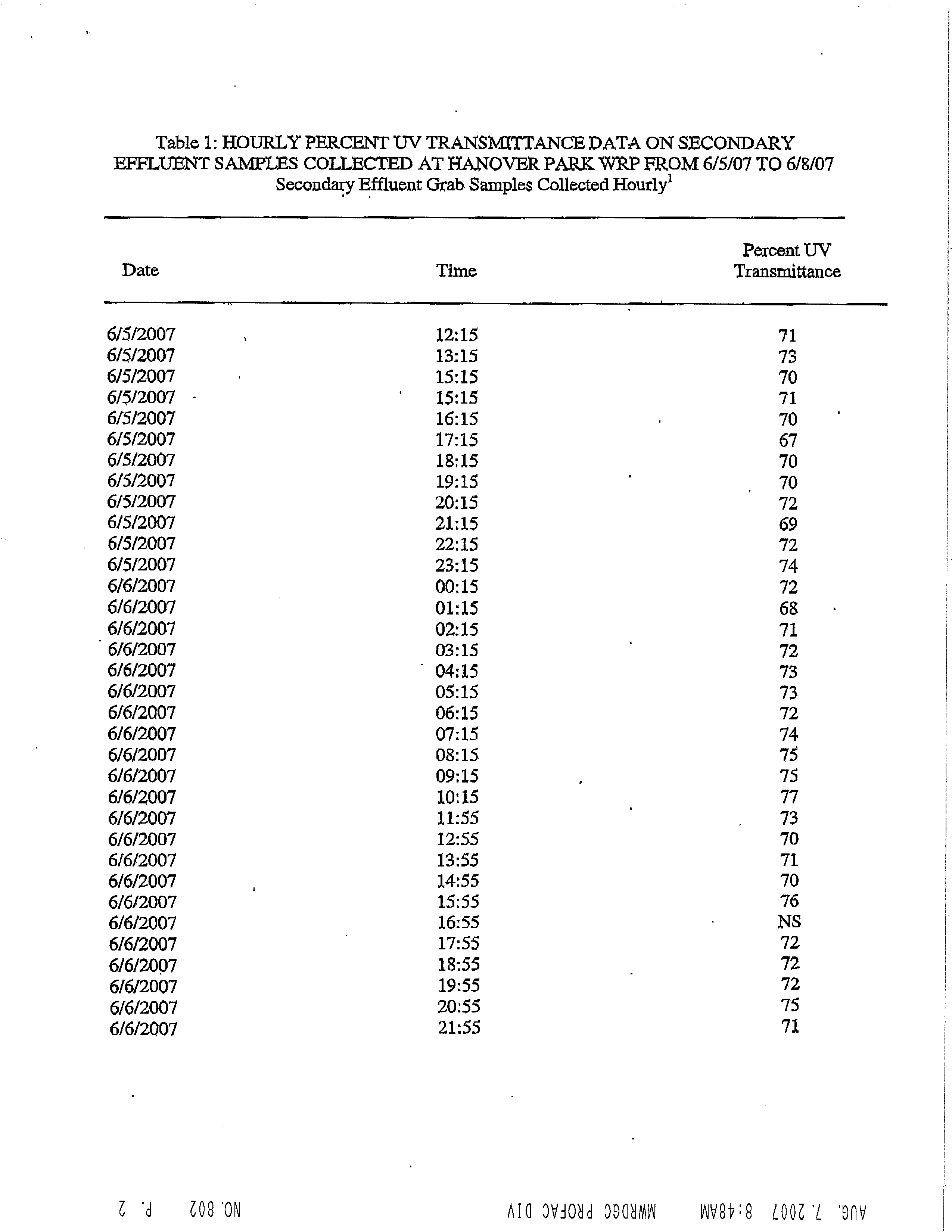

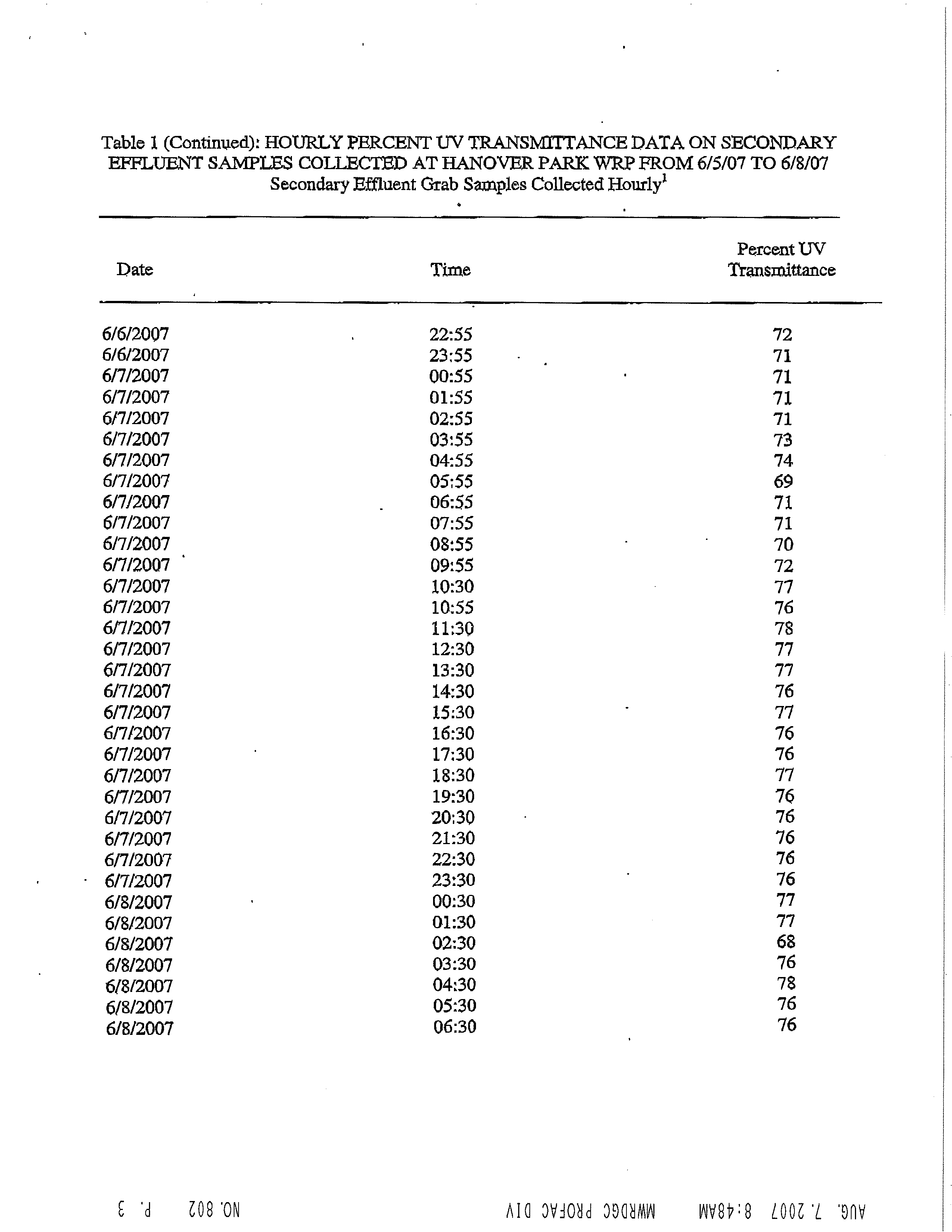

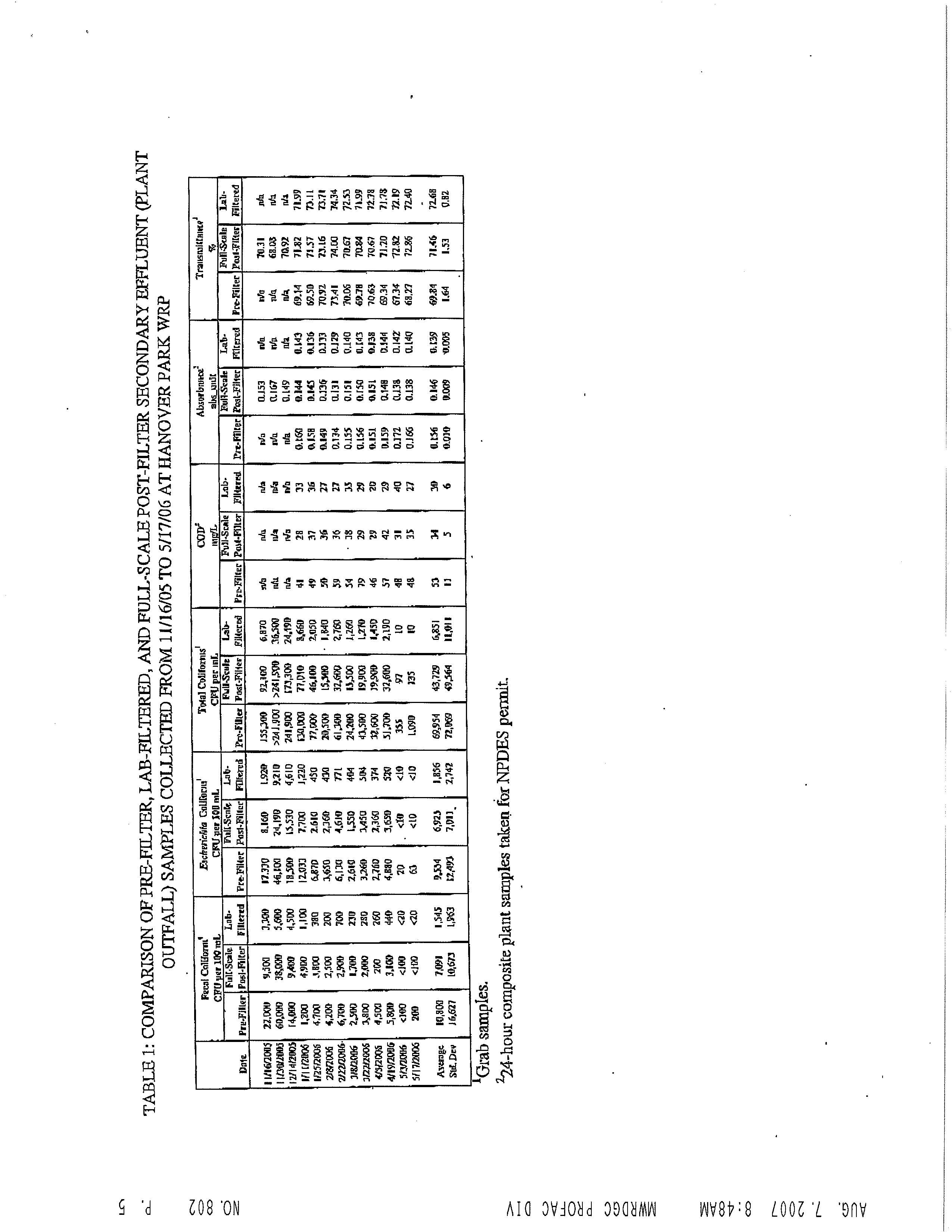

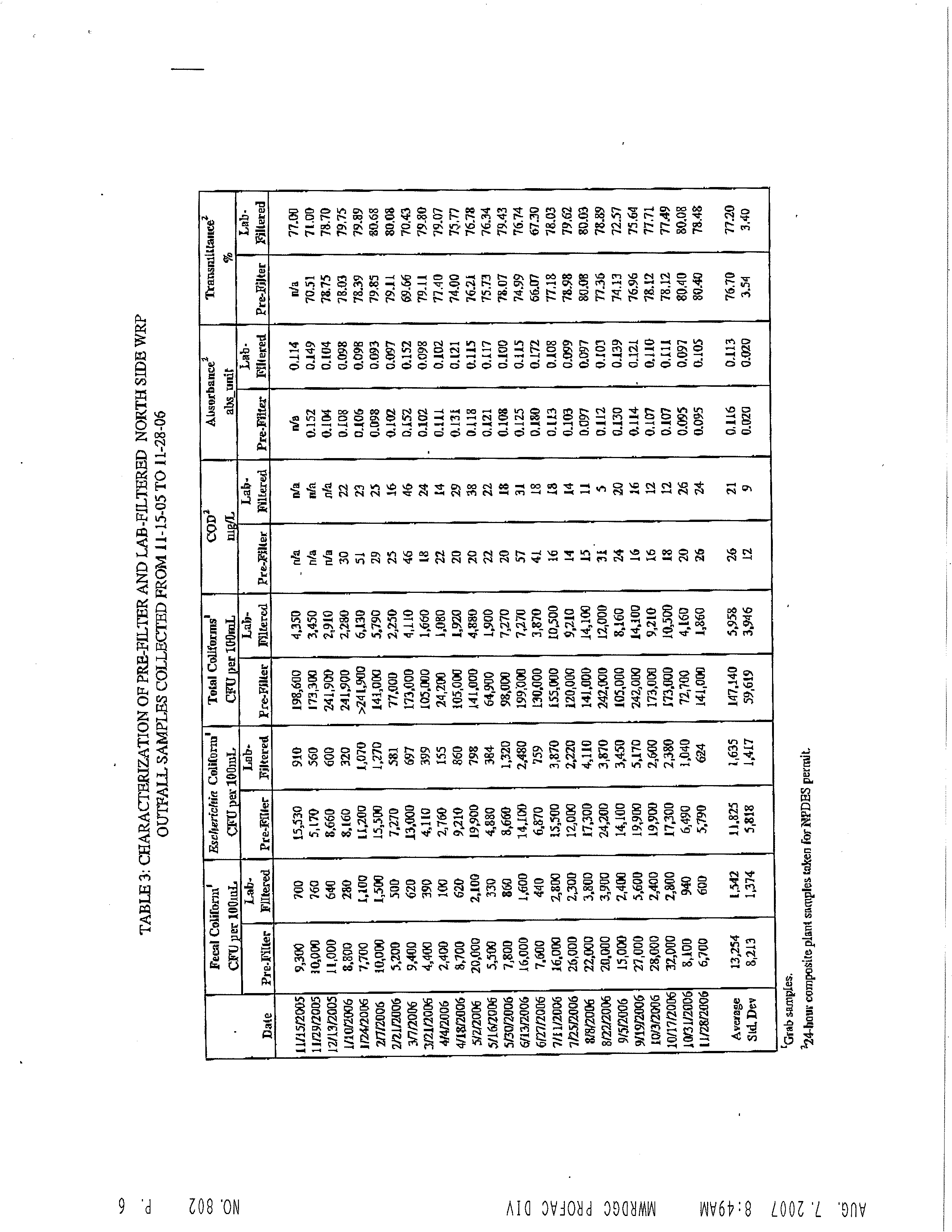

- Table?6.?Summary?of?2006/2007?Water?Quality?Testing

- Fecal

- 1E.ColiTotalColiformCODUV

- Site Transmittance

- NSWRP

- Need?for?Pilot?Testing

- BASIS?OF?DESIGN?OF?UV?SYSTEM?FOR?NORTH?SIDE?WRP

- Table?7.?Design?Parameters?for?UV?Disinfection?Unit?at?NSWRP

- Parameter Design?Value

- REFERENCES

- APPENDIX?A

- 2006?UV?TRIAL?WATER?QUALITY?DATA

- NSWRP,?CWRP,?AND?HPWRP

- APPENDIX C

- UV EQUIPMENT TECHNICAL INFORMATION

- www.trojanuv.com

- APPENDIX D

- PUMP TECHNICAL INFORMATION

- Pump Performance

- Pump Performance

- Pump Performance

- Pump Performance

- Pump Performance

- Pump Performance

- APPENDIX E

- DRAFT GEOTECHNICAL DESIGN REPORT

- FOR NEW PRELIMINARY TREATMENT FACILITIES AT STICKNEY

- AND CALUMET WRPS

- Draft Geotechnical Design Report for Stickney WRP Phase I & IA

- New Preliminary Treatment Facilities

- at Stickney and Calumet WRPs

- Contract No. 04-823-3P

- 1.0 GENERAL

- 2.0 PROJECT DESCRIPTION

- 3.0 PROJECT DATUM

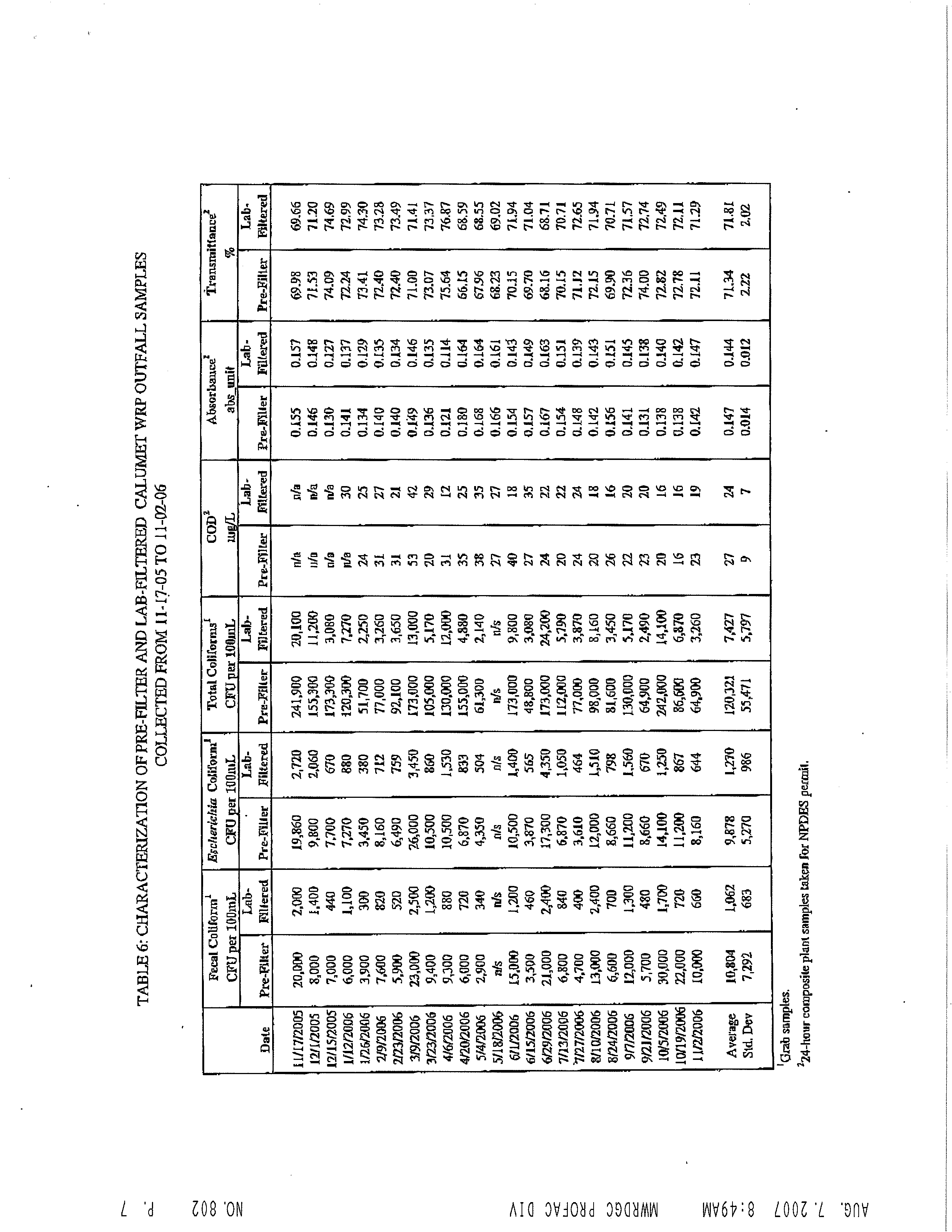

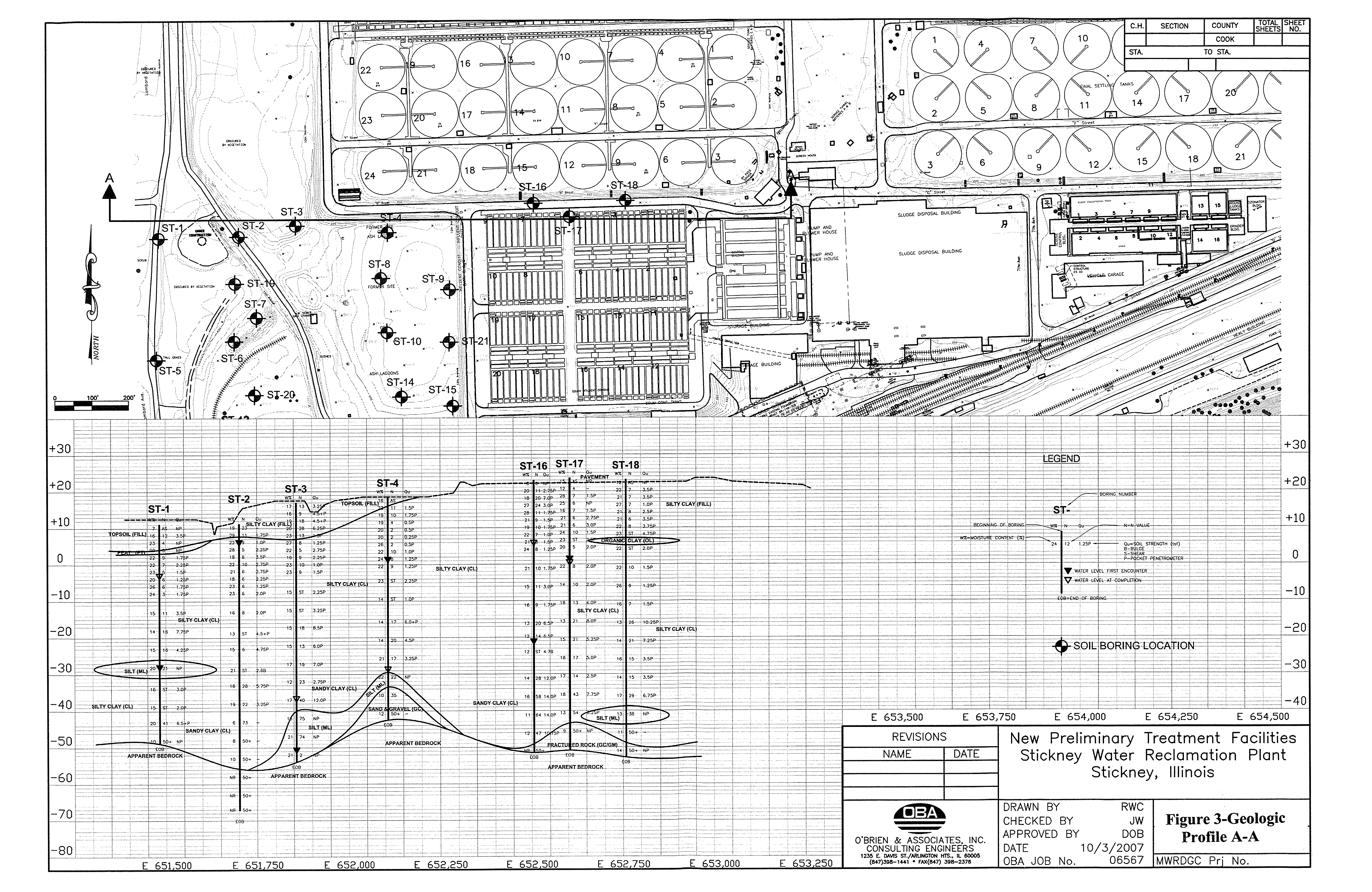

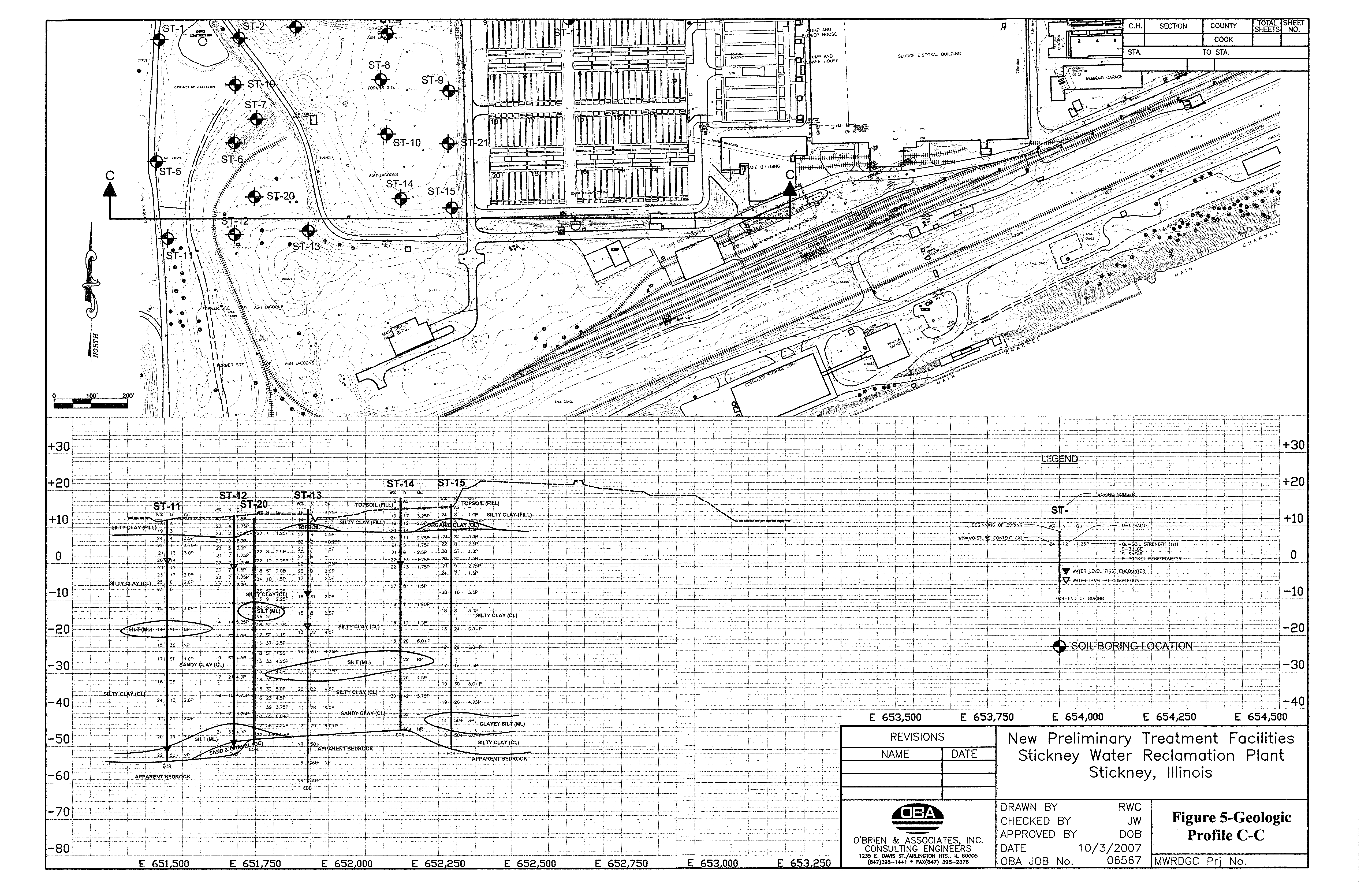

- 4.0 SITE INVESTIGATION

- Boring

- GroundSurfaceElevation

- Depth ofBoring(ft)

- Depth toGroundwater

- GroundwaterElevation

- Top of

- BedrockElevation

- 5.0 SITE CONDITIONS

- 6.0 REGIONAL GEOLOGY

- 7.0 SUBSURFACE CONDITIONS

- 8.0 GROUNDWATER EVALUATION

- Groundwater Elevation

- Date of Reading

- Adjacent to ST-1Ground EL +11.6

- Obs. Well W-2Adjacent to ST-12Ground EL 13.8

- Obs. Well W-3Adjacent to ST-

- Ground EL 18.5

- 9.0 TESTING

- 10.0 ENVIRONMENTAL ASSESSMENT OF ASH LAGOONS

- 11.0 GEOTECHNICAL DESIGN PARAMETERS

- 12.0 PROPOSED FACILITY FOUNDATION INFORMATION

- 13.0 FOUNDATION TYPE OF EXISTING FACILITY STRUCTURES

- 14.0 PRELIMINARY GEOTECHNICAL RECOMMENDATIONS

- 15.0 CONSTRUCTION CONSIDERATIONS

- 16.0 PROPOSED PHASE II INVESTIGATIONS

- 17.0 LIMITATIONS

- 18.0 REFERENCES

- APPENDIX F

- COST ESTIMATE BREAKDOWN TABLES

- APPENDIX G

- ELECTRICAL EVALUATION TECHNICAL MEMORANDUM

- DISINFECTION COST STUDY

- ELECTRICAL EVALUATION

- METROPOLITAN WATER RECLAMATION

- DISTRICT OF GREATER CHICAGO

- STICKNEY WATER RECLAMATION PLANT

- TECHNICAL MEMORANDUM

- August 1, 2008

- 303 EAST WACKER DRIVE, SUITE 600

- CHICAGO, ILLINOIS 60601

- MWRDGC Project No. 07-026-2P

- CTE Project No. 60040695

- TABLE OF CONTENTS

- LIST OF TABLES

- APPENDICES

- 2.0 OBJECTIVE

- 4.0 ELECTRICAL BASIS OF DESIGN

- 4.1 Electric Service

- Table 1 Existing and Proposed SWRP Electrical Loads

- Item Value

- 4.2 System Grounding

- 4.3 Conduit

- 4.7 Lightning Protection

- 4.8 Specific Electrical Equipment

- Table 2 Medium Voltage Switchgear Criteria

- Item Criteria

- Criteria

- Table 3 Circuit Breaker Ratings and Features Criteria

- Item Criteria

- Table 4 Circuit Breaker Battery Criteria

- Item Criteria

- Table 6 Motor Control Center Criteria

- Item Criteria

|

BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

IN THE MATTER OF:

WATER QUALITY STANDARDS AND

EFFLUENT LIMITATIONS FOR THE

CHICAGO AREA WATERWAY SYSTEM

AND THE LOWER DES PLAINES RIVER:

PROPOSED AMENDMENTS TO 35 Ill.

Adm. Code Parts 301, 302, 303 and 304

)

)

)

)

)

)

)

)

R08-9

(Rulemaking - Water)

NOTICE OF FILING

To:

ALL COUNSEL OF RECORD

(Service List Attached)

PLEASE TAKE NOTICE

that on the 20th day of October, 2008, I electronically filed

with the Office of the Clerk of the Illinois Pollution Control Board the following documents on

behalf of the Metropolitan Water Reclamation District of Greater Chicago:

1.

UV Disinfection Cost Study (Stickney Water Reclamation Plant) Volume I

2.

UV Disinfection Cost Study (Stickney Water Reclamation Plant) Volume II

3.

UV Disinfection Cost Study (North Side Water Reclamation Plant) Volume I

(also discussing Calumet Water Reclamation Plant)

4.

UV Disinfection Cost Study (North Side Water Reclamation Plant) Volume II

(also discussing Calumet Water Reclamation Plant)

5.

Hydraulic Technical Memorandum - Appendix A for North Side Water

Reclamation Plan UV Disinfection Cost Study

6.

UV Technology Technical Memorandum - Appendix B for North Side Water

Reclamation Plan UV Disinfection Cost Study

7.

UV Equipment Technical Information - Appendix C for North Side Water

Reclamation Plan UV Disinfection Cost Study

8.

Pump Technical Information - Appendix D for North Side Water Reclamation

Plan UV Disinfection Cost Study

Electronic Filing - Received, Clerk's Office, Octobr 20, 2008

[This filing submitted on recycled paper as defined in 35 Ill. Adm. Code 101.202]

2

9.

Historic Soil Boring Information - Appendix E for North Side Water Reclamation

Plan UV Disinfection Cost Study

10.

Cost Estimate Breakdown Tables - Appendix F for North Side Water Reclamation

Plan UV Disinfection Cost Study

11.

Disinfection Cost Study Hydraulic Evaluation - Technical Memorandum

(Stickney Water Reclamation Plant)

Dated: October 20, 2008

METROPOLITAN WATER RECLAMATION

DISTRICT OF GREATER CHICAGO

By:

/s/ David T. Ballard

One of Its Attorneys

Fredric P. Andes

David T. Ballard

BARNES & THORNBURG LLP

Suite 4400

One North Wacker Drive

Chicago, Illinois 60606

(312) 357-1313

Electronic Filing - Received, Clerk's Office, Octobr 20, 2008

[This filing submitted on recycled paper as defined in 35 Ill. Adm. Code 101.202]

3

PROOF OF SERVICE

The undersigned, a non-attorney, certifies, under penalties of perjury pursuant to 735

ILCS 5/1-109, that I caused a copy of the forgoing, Notice of Filing, to be served via First Class

Mail, postage prepaid, from One North Wacker Drive, Chicago, Illinois, on the 20th day of

October, 2008, upon the attorneys of record on the attached Service List.

/s/ Barbara E. Szynalik

Barbara E. Szynalik

Electronic Filing - Received, Clerk's Office, Octobr 20, 2008

[This filing submitted on recycled paper as defined in 35 Ill. Adm. Code 101.202]

4

SERVICE LIST

R08-9 (Rulemaking - Water)

Richard J. Kissel

Roy M. Harsch

Drinker, Biddle, Gardner, Carton

Suite 3700

191 N. Wacker Drive

Chicago, IL 60606-1698

Claire A. Manning

Brown, Hay & Stephens LLP

700 First Mercantile Bank Building

205 South Fifth St., P.O. Box 2459

Springfield, IL 62705-2459

Deborah J. Williams, Assistant Counsel

Stefanie N. Diers, Assistant Counsel

IEPA

Division of Legal Counsel

1021 North Grand Avenue East

P.O. Box 19276

Springfield, IL 62794-9276

Katherine D. Hodge

Monica T. Rios

Matthew C. Read

Hodge Dwyer Zeman

3150 Roland Avenue

P.O. Box 5776

Springfield, IL 62705-5776

Kevin G. Desharnais

Thomas W. Dimond

Thomas V. Skinner

Mayer, Brown LLP

71 South Wacker Drive

Chicago, IL 60606-4637

Charles W. Wesselhoft

James T. Harrington

McGuireWoods LLP

Suite 4100

77 West Wacker Drive

Chicago, IL 60601-1818

Robert VanGyseghem

City of Geneva

1800 South Street

Geneva, IL 60134-2203

Jerry Paulsen

Cindy Skrukrud

McHenry County Defenders

132 Cass Street

Woodstock, IL 60098

Matthew J. Dunn, Chief

Office of the Attorney General

Environmental Bureau North

Suite 1800

69 West Washington Street

Chicago, IL 60602

Kevin B. Hynes

O’Keefe Lyons & Hynes, LLC

Suite 4100

30 North LaSalle Street

Chicago, Illinois 60602

Bernard Sawyer

Thomas Granto

Metropolitan Water Reclamation District

6001 W. Pershing Road

Cicero, IL 60804

Lisa Frede

Chemical Industry Council of Illinois

Suite 239

2250 East Devon Avenue

Des Plaines, IL 60018-4509

James L. Daugherty, District Manager

Sharon Neal

Electronic Filing - Received, Clerk's Office, Octobr 20, 2008

[This filing submitted on recycled paper as defined in 35 Ill. Adm. Code 101.202]

5

Thorn Creek Basin Sanitary District

700 West End Avenue

Chicago Heights, IL 60411

Commonwealth Edison Company

125 South Clark Street

Chicago, IL 60603

Tracy Elzemeyer, General Counsel

American Water Company Central Region

727 Craig Road

St. Louis, MO 63141

Margaret P. Howard

Hedinger Law Office

2601 South Fifth Street

Springfield, IL 62703

Keith I. Harley

Elizabeth Schenkier

Chicago Legal Clinic, Inc.

4

th

Floor

205 West Monroe Street

Chicago, IL 60606

Frederick D. Keady, P.E., President

Vermilion Coal Company

1979 Johns Drive

Glenview, IL 60025

Roy G. Wilcox

Attorney at Law

16 West Madison

P.O. Box 12

Danville, IL 61834

Georgia Vlahos

Naval Training Center

2601A Paul Jones Street

Great Lakes, IL 60088-2845

W.C. Blanton

Blackwell Sanders LLP

Suite 1000

4801 Main Street

Kansas City, MO 64112

Dennis L. Duffield

Director of Public Works & Utilities

City of Joliet, Department of Public

Works & Utilities

921 E. Washington Street

Joliet, IL 60431

Traci Barkley

Prarie Rivers Networks

Suite 6

1902 Fox Drive

Champaign, IL 61820

Ann Alexander, Sr. Attorney

Natural Resources Defense Council

Suite 609

101 North Wacker Drive

Chicago, IL 60606

James Huff, Vice President

Huff & Huff, Inc.

Suite 3300

915 Harger Road

Oak Brook, IL 60523

Beth Steinhorn

2021 Timberbrook

Springfield, IL 62702

Electronic Filing - Received, Clerk's Office, Octobr 20, 2008

[This filing submitted on recycled paper as defined in 35 Ill. Adm. Code 101.202]

6

Cathy Hudzik

City of Chicago - Mayor's Office of

Intergovernmental Affairs

City Hall - Room 406

121 N. LaSalle Street

Chicago, IL 60602

Dr. Thomas J. Murphy

DePaul University

2325 N. Clifton Street

Chicago, IL 60614

Irwin Polls

Ecological Monitoring and Assessment

3206 Maple Leaf Drive

Glenview, IL 60025

Susan M. Franzetti

Franzetti Law Firm P.C.

Suite 3600

10 S. LaSalle Street

Chicago, IL 60603

Marc Miller, Senior Policy Advisor

Jamie S. Caston, Policy Advisor

Office of Lt. Governor Pat Quinn

Room 414 State House

Springfield, IL 62706

Vicky McKinley

Evanston Environment Board

223 Grey Avenue

Evanston, IL 60202

Albert Ettinger, Senior Staff Attorney

Jessica Dexter

Environmental Law & Policy Center

Suite 1300

35 E. Wacker Drive

Chicago, IL 60601

Kenneth W. Liss

Andrews Environmental Engineering

3300 Ginger Creek Drive

Springfield, IL 62711

Tom Muth

Fox Metro Water Reclamation District

682 State Route 31

Oswego, IL 60543

Bob Carter

Bloomington Normal Water

Reclamation District

P.O. Box 3307

Bloomington, IL 61702-3307

Jack Darin

Sierra Club

Illinois Chapter

Suite 1500

70 E. Lake Street

Chicago, IL 60601-7447

Kay Anderson

American Bottoms RWTF

One American Bottoms Road

Sauget, IL 62201

Electronic Filing - Received, Clerk's Office, Octobr 20, 2008

[This filing submitted on recycled paper as defined in 35 Ill. Adm. Code 101.202]

7

Marie Tipsord, Hearing Officer

John Therriault, Assistant Clerk

Illinois Pollution Control Board

100 W. Randolph Street

Suite 11-500

Chicago, IL 60601

Kristy A. N. Bulleit

Brent Fewell

Hunton & Williams LLC

1900 K Street, NW

Washington, DC 20006

Stacy Meyers-Glen

Openlands

Suite 1650

25 East Washington

Chicago, Illinois 60602

Jeffrey C. Fort

Ariel J. Tesher

Sonnenschein Nath & Rosenthal LLP

7800 Sears Tower

233 S. Wacker Drive

Chicago, IL 60606-6404

Susan Hedman

Andrew Armstrong

Environmental Counsel Environmental Bureau

Suite 1800

69 West Washington Street

Chicago, IL 60602

Ronald M. Hill

Margaret T. Conway

Metropolitan Water Reclamation District of

Greater Chicago

100 E. Erie Street, Room 301

Chicago, Illinois 60611

Alec M. Davis

General Counsel

Illinois Environmental Regulatory Group

215 East Adams Street

Springfield, IL 62701

503739

Electronic Filing - Received, Clerk's Office, Octobr 20, 2008

UV DISINFECTION COST STUDY

Cost Study Report

FOR

METROPOLITAN WATER RECLAMATION

DISTRICT OF GREATER CHICAGO

VOLUME 1 OF 2

STICKNEY WATER RECLAMATION PLANT

September 9, 2008

Prepared By

303 EAST WACKER DRIVE, SUITE 600

CHICAGO, ILLINOIS 60601

MWRDGC Project No. 07-026-2P

CTE Project No. 60026610

Electronic Filing - Received, Clerk's Office, Octobr 20, 2008

i

TABLE OF CONTENTS

Volume 1 – Report and Appendices

EXECUTIVE SUMMARY ............................................................................................................. 1

Introduction .............................................................................................................................1

Objectives ...............................................................................................................................1

Proposed Facilities ..................................................................................................................1

Hydraulics ...............................................................................................................................2

Disinfection Technology...........................................................................................................2

Site Layout ..............................................................................................................................2

Preliminary Cost Opinion .........................................................................................................3

1.0

INTRODUCTION ............................................................................................................ 5

1.1

Background ................................................................................................................5

1.2

Objective ....................................................................................................................5

1.3

General Design Standards..........................................................................................5

1.4

Organization of this Report .........................................................................................6

2.0

HYDRAULICS ................................................................................................................ 6

2.1

Hydraulic Analysis of the UV Disinfection Facilities .....................................................6

2.2.1

Objectives ..............................................................................................................6

2.2.2

Overview ................................................................................................................6

2.3

Assumptions...............................................................................................................7

2.4

Results .......................................................................................................................8

2.5

Conclusion .................................................................................................................8

3.0

SWRP DISINFECTION PROCESS ............................................................................... 10

3.1

Introduction .............................................................................................................. 10

3.2

UV Disinfection System ............................................................................................ 10

3.2.1

Background .......................................................................................................... 10

3.2.2

Basis of Design .................................................................................................... 11

3.2.3

Process Control .................................................................................................... 12

3.2.4

Safety................................................................................................................... 13

3.2.5

Proposed Design Criteria for UV Disinfection Equipment ...................................... 13

3.3

Low Lift Pump Station............................................................................................... 15

3.3.1

Basis of Design .................................................................................................... 15

3.3.2

Pump Type........................................................................................................... 15

3.3.3

Proposed Operational Description ........................................................................ 16

3.3.4

Proposed Layout .................................................................................................. 16

4.0

SWRP CIVIL................................................................................................................. 17

4.1

Basis of Design......................................................................................................... 18

4.1.1

Roadways and Other Site Improvements .............................................................. 18

4.1.2

Junction Chamber/Effluent Conduits ..................................................................... 18

4.1.3

Site Utilities .......................................................................................................... 19

4.1.5

Geotechnical Information...................................................................................... 19

5.0

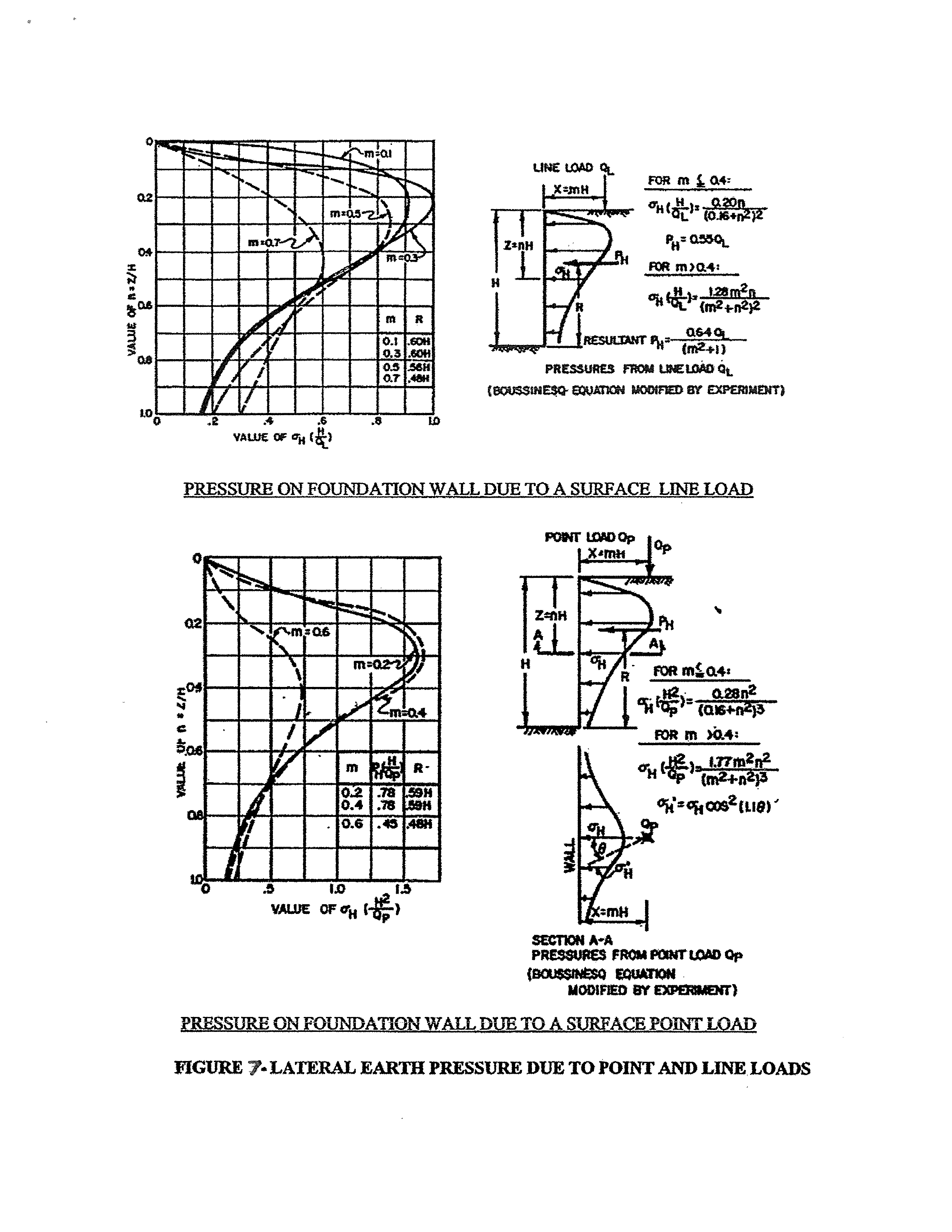

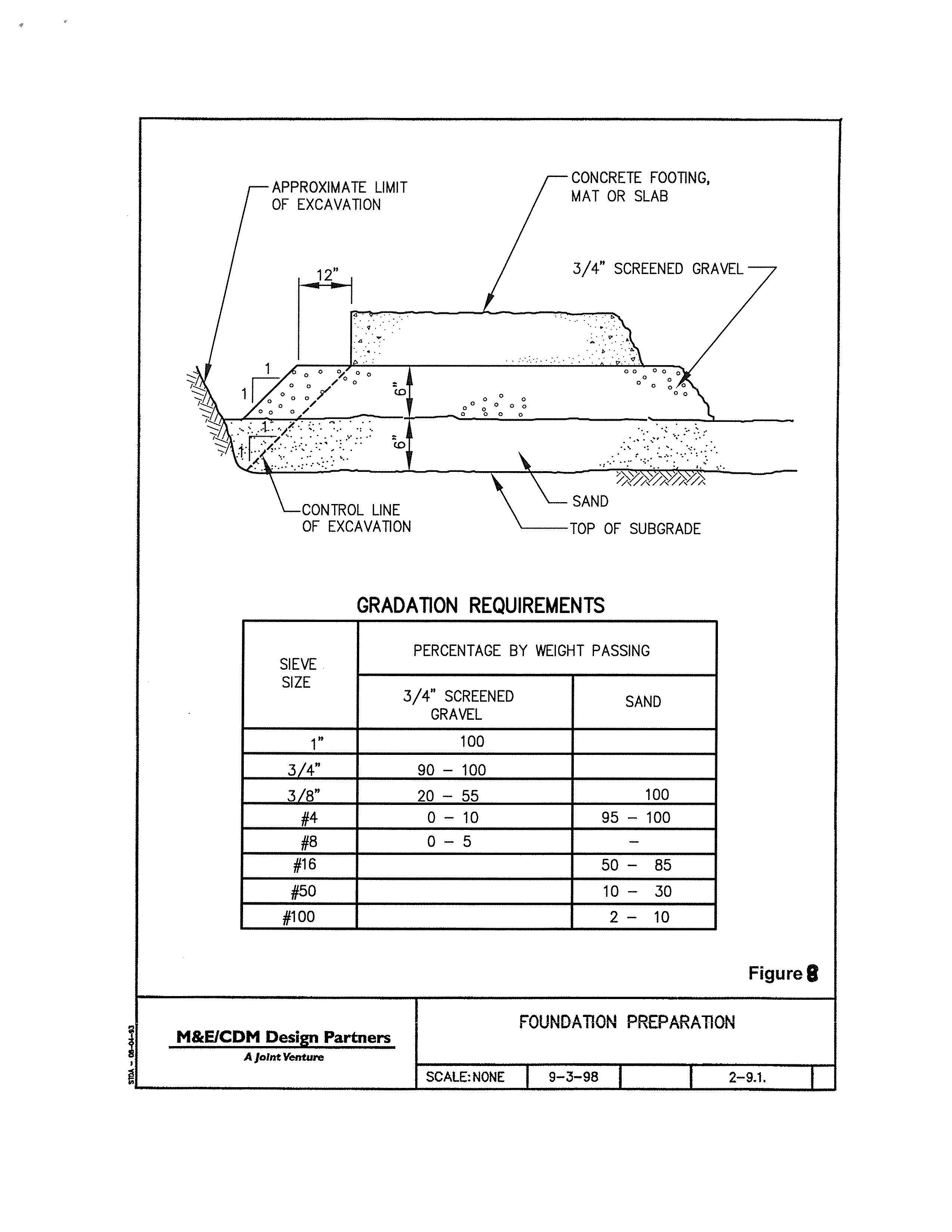

SWRP STRUCTURAL AND ARCHITECTURAL............................................................ 20

5.1

Introduction .............................................................................................................. 20

5.1.1

Codes and Specifications ..................................................................................... 20

5.1.2

Loads ................................................................................................................... 21

5.1.3

Design Stresses ................................................................................................... 22

5.1.4

General Design .................................................................................................... 23

5.1.5

Foundation Design ............................................................................................... 23

5.2

SWRP UV Facility..................................................................................................... 23

5.3

Low Lift Pump Station............................................................................................... 24

6.0

SWRP ELECTRICAL .................................................................................................... 24

6.1

Codes/Standards ...................................................................................................... 24

6.2

Electric Service......................................................................................................... 25

Electronic Filing - Received, Clerk's Office, Octobr 20, 2008

ii

6.3

System Grounding.................................................................................................... 25

6.4

Conduit..................................................................................................................... 25

6.5

Wire ......................................................................................................................... 25

6.6

Motors (Except Low Lift Pump Motors)...................................................................... 26

6.7

Emergency Systems................................................................................................. 26

6.8

Lightning Protection .................................................................................................. 26

6.9

Specific Electrical Equipment .................................................................................... 26

6.9.1

Medium Voltage Switchgear ................................................................................. 26

6.9.2

Secondary Unit Substation ................................................................................... 28

6.9.3

Motor Control Centers .......................................................................................... 28

7.0

SWRP INSTRUMENTATION SYSTEM......................................................................... 29

7.1

Applicable Codes and Standards .............................................................................. 29

8.0

SWRP MECHANICAL AND PLUMBING ....................................................................... 30

8.1.

Mechanical Codes .................................................................................................... 30

8.2

Basis of Design......................................................................................................... 30

8.2.1

Ventilation Rates .................................................................................................. 30

8.2.2

Design Temperatures ........................................................................................... 30

8.2.3

Plumbing .............................................................................................................. 30

8.3

Proposed Mechanical and Plumbing System............................................................. 31

8.3.1

UV Disinfection Facility ......................................................................................... 31

8.3.2

Low Lift Pump Station........................................................................................... 31

9.0

SWRP AREAS REQUIRING FURTHER ANALYSIS...................................................... 32

10.0

SWRP PRELIMINARY COST OPINION........................................................................ 32

10.1

Basis of Opinion of Capital Cost................................................................................ 33

10.2

Basis of Operation and Maintenance Costs............................................................... 34

10.3

Basis of Net Present Value Calculation ..................................................................... 34

10.4

Discussion of Cost Estimate Line Items .................................................................... 35

LIST OF TABLES

Table ES-1 – SWRP UV Disinfection Facilities Preliminary OPCC and M&O Costs......................3

Table 2.4-1 – Summary of Proposed WSE including UV Disinfection Facilities.............................8

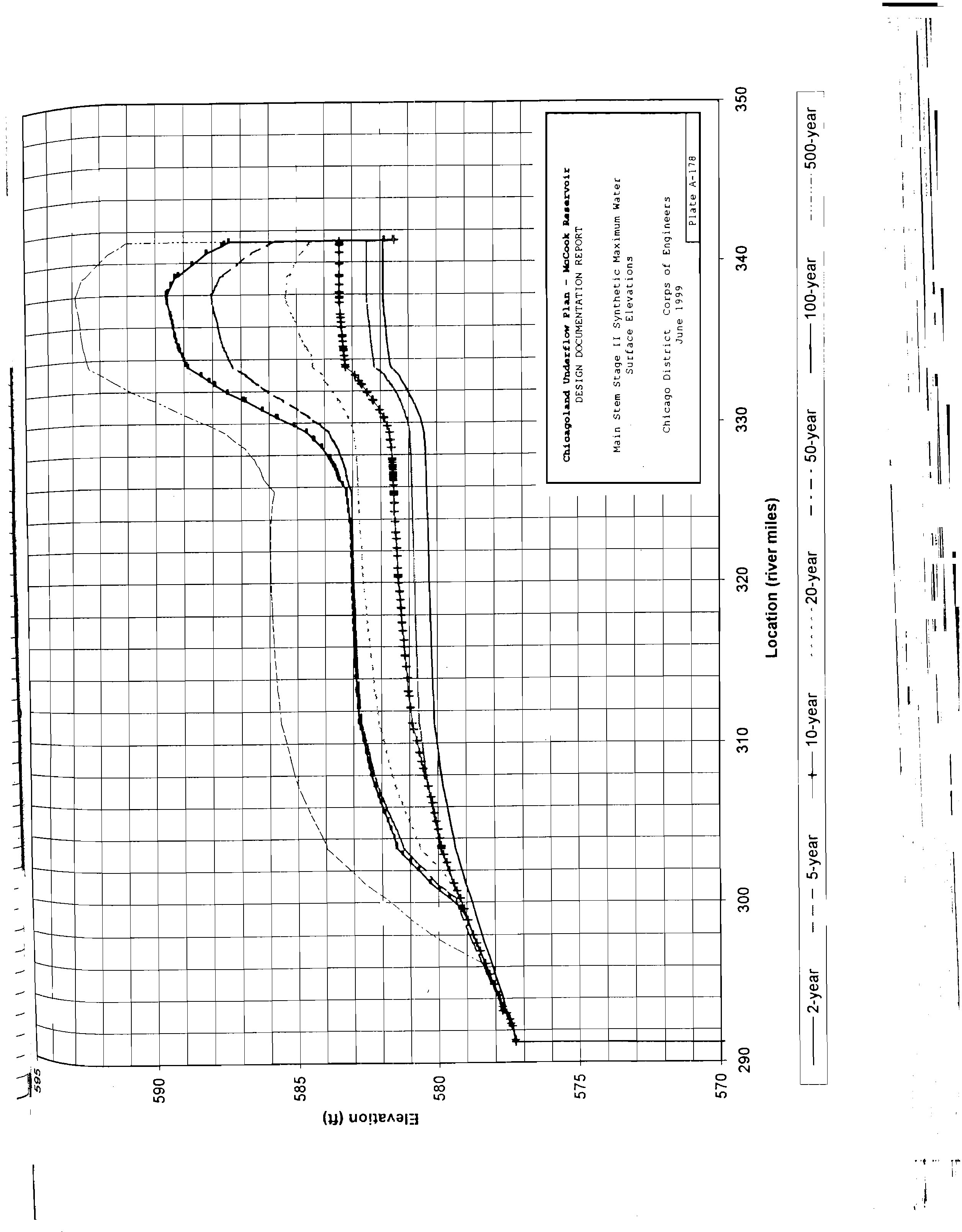

Figure 2.4-2 - Hydraulic Profile for Disinfection Cost Study ..........................................................9

Table 3.2-1 – Design Parameters for UV Disinfection Unit at SWRP .......................................... 13

Table 3.3-1 – Low Lift Pump Station Basis of Design ................................................................. 15

Table 3.3-2 – Examples of Pump Operation............................................................................... 16

Figure 3.3-1 - Proposed UV Disinfection Flow Diagram.............................................................. 17

Table 6.9.1-1 – Medium Voltage Switchgear Criteria.................................................................. 26

Table 6.9.1-2 – Circuit Breaker Ratings and Features Criteria.................................................... 27

Table 6.9.1-3 – Circuit Breaker Battery Criteria.......................................................................... 27

Table 6.9.2-1 – Secondary Unit Substation................................................................................ 28

Table 6.9.3-1 – Motor Control Center Criteria ............................................................................ 28

Table 10.0-1 – SWRP UV Disinfection Facilities Preliminary OPCC and M&O Costs.................. 33

Table 10.2-1 – M&O Labor Requirements.................................................................................. 34

Table 10.4-1 – OPCC Selected Line Item Description................................................................ 35

Electronic Filing - Received, Clerk's Office, Octobr 20, 2008

iii

LIST OF FIGURES

Figure ES 1- Proposed UV Facilities Flow Diagram .....................................................................3

Figure ES 2 - SWRP Proposed Site Plan.....................................................................................4

Figure 2.4-1 - Hydraulic Profile for Disinfection Cost Study ..........................................................9

Figure 3.3-1 - Proposed UV Disinfection Flow Diagram.............................................................. 17

LIST OF APPENDICES

Appendix A

Hydraulic Technical Memorandum

Appendix B

North Side WRP UV Technology Technical Memorandum

Appendix C

UV Equipment Technical Information

Appendix D

Pump Technical Information

Appendix E

Draft Geotechnical Design Report for New Preliminary Treatment Facilities at

Stickney and Calumet WRPs

Appendix F

Cost Estimate Breakdown Tables

Appendix G

Electrical Evaluation Technical Memorandum

Volume 2 – Conceptual Design Drawings

Electronic Filing - Received, Clerk's Office, Octobr 20, 2008

1

\\Uschg1fp207\p60040695\P60040695\500_Submittals\503_Cost

Study Report\503.1_Draft Report\Final_Cost_Study_Report_091008.doc

EXECUTIVE SUMMARY

Introduction

The Technical Memorandum 1WQ Disinfection Evaluation (TM1-WQ) was completed in August

2005 for the Metropolitan Water Reclamation District of Greater Chicago (MWRDGC or District)

as part a Water Quality (WQ) Strategy for affected Chicago Area Waterways. TM1-WQ reviewed

the alternative disinfection technologies available for use at the District’s North Side (NSWRP),

Calumet (CWRP) and Stickney Water Reclamation Plants (SWRP) and provided an initial

estimate of construction cost for the facilities. On the basis of that report, the District requested

further investigation into UV disinfection. The findings of the Preliminary Cost Opinion for

Ultraviolet (UV) Disinfection Facilities Study at the Stickney Water Reclamation Plant are

presented in this Report.

Objectives

This evaluation is based upon the TM1-WQ, the comments received from the USEPA as part of

the Use Attainability Analysis (UAA) evaluations, and new information obtained since the previous

work. The primary objectives of the evaluation presented in this report are:

x

To describe the conceptual facilities developed as part of this study including their basis of

design and the assumptions used for their development.

x

To develop a Level 3 Preliminary Opinion of Probable Construction Cost per the Association

for the Advancement of Cost Engineering recommended practices for the proposed facilities

at the SWRP, which represents an expectation that actual cost will deviate from the

estimated cost by -15% to 30%.

x

To develop annual maintenance and operations (M&O) costs for the conceptual facilities.

Proposed Facilities

This study reviewed the proposed facilities for the UV Disinfection Alternative in TM-1WQ

including the four primary components: Site work, a low lift pump station, tertiary filters and UV

disinfection. Through that review, it was determined that the low lift pump station and the tertiary

filters required re-evaluation.

At the time TM-1WQ was developed, very little information was available regarding the water

quality of the plant effluent as it related to ultraviolet light transmissivity, and the that data which

was available indicated low transmissivity levels. In TM-1WQ, tertiary filters were included in the

initial proposed facilities in order to improve disinfection effectiveness by removing components

that would inhibit the disinfection process. Since that time, additional water quality data was

collected for the NSWRP by the District during the North Side UV Disinfection Cost Study Report.

A review of that data indicated that the UV transmissivity is within the minimum range necessary

for UV disinfection without filtration. As a result, tertiary filters were not included in the North Side

Cost Study and are not included in the proposed disinfection facilities presented in this report.

However, the exclusion of tertiary filters from this report should not suggest that tertiary filters

may not be required in the future to meet stricter suspended solids or total phosphorous limits, or

that tertiary filters would not improve the effectiveness of a UV disinfection process. As

concluded in the SWRP Master Plan, space would be reserved on the site for future tertiary filter

faciilties.

As tertiary filters would not be required as part of the implementation of UV disinfection, the need

for a low lift pump station was questioned. Additional pumping would be required only if the head

loss added by the new UV Disinfection Facilities and associated flow conduits and flow splitting

structures exceeds the available head at the plant. To determine the required head through the

UV Disinfection facilities, a hydraulics evaluation was performed.

Electronic Filing - Received, Clerk's Office, Octobr 20, 2008

2

\\Uschg1fp207\p60040695\P60040695\500_Submittals\503_Cost

Study Report\503.1_Draft Report\Final_Cost_Study_Report_091008.doc

Hydraulics

Hydraulic modeling was not included as part of the Master Plan for Stickney WRP and so a

hydraulic model was developed for this report based on existing plant water levels as

documented in previous design projects as well as projected water levels in the Ship and Sanitary

Canal for a 100-year flood event based on the USACE’s CUP Report. This model was modified

to include the additional effluent conduits, gate structures, and UV channels/reactors required for

the new facilities. The model was used to determine the required head following implementation

of the new UV Disinfection Facilities.

The results of this evaluation showed that the projected head required through the proposed UV

facilities exceeds the head available at the plant by over 8.7-ft and confirms the need for a Low

Lift Pump Station (LLPS) in order to convey the peak flow of 1,440 MGD through the UV facilities

at the 100-year flood elevation.

Disinfection Technology

The Trojan UV4000™Plus system, which utilizes medium pressure, high intensity type UV lamps,

was used to develop the basis of design for the UV disinfection system at the SWRP. This type of

UV system was selected due to the lower number of lamps required compared to other systems

and based upon the recommendations of a team of disinfection experts that evaluated the

available disinfection technologies during the Master Plan effort.

During the NSWRP UV Disinfection Cost Study, the details of the implementation of this UV

technology were updated by consultation with the manufacturer and incorporated into the basis of

design. In addition, a phone survey of other facilities of similar size and source water quality was

conducted. This survey revealed several important conclusions including the following:

x

When using ferric salt addition for improved settleability of solids or phosphorus removal

in the treatment process upstream of UV disinfection, an increase in the fouling rate was

experienced.

x

The level of maintenance and operations efforts was highly variable and site specific,

even with plants using the same technology and source water.

x

The most effective method of power control for the UV system is highly site specific and

has a great impact on the disinfection effectiveness and the energy effectiveness of the

system.

Due to the size of the proposed SWRP UV Disinfection Facilities, which would be among the

largest continually-operating UV disinfection systems in the world, CTE recommends the District

undertake an extensive program which includes review of system specific independent validation

studies, collimated beam testing, UV transmittance testing and a reasonably sized pilot facility.

This program would determine, among other factors, the following information in-situ:

x

Appropriate control sequences and optimization for the UV disinfection equipment,

including appropriate sensing equipment to allow advanced power management.

x

In-situ disinfection performance including fouling rates or the lamps with and without ferric

salt addition.

x

Actual M&O requirements in terms of labor and consumables as well as space

requirements to complete required maintenance activities.

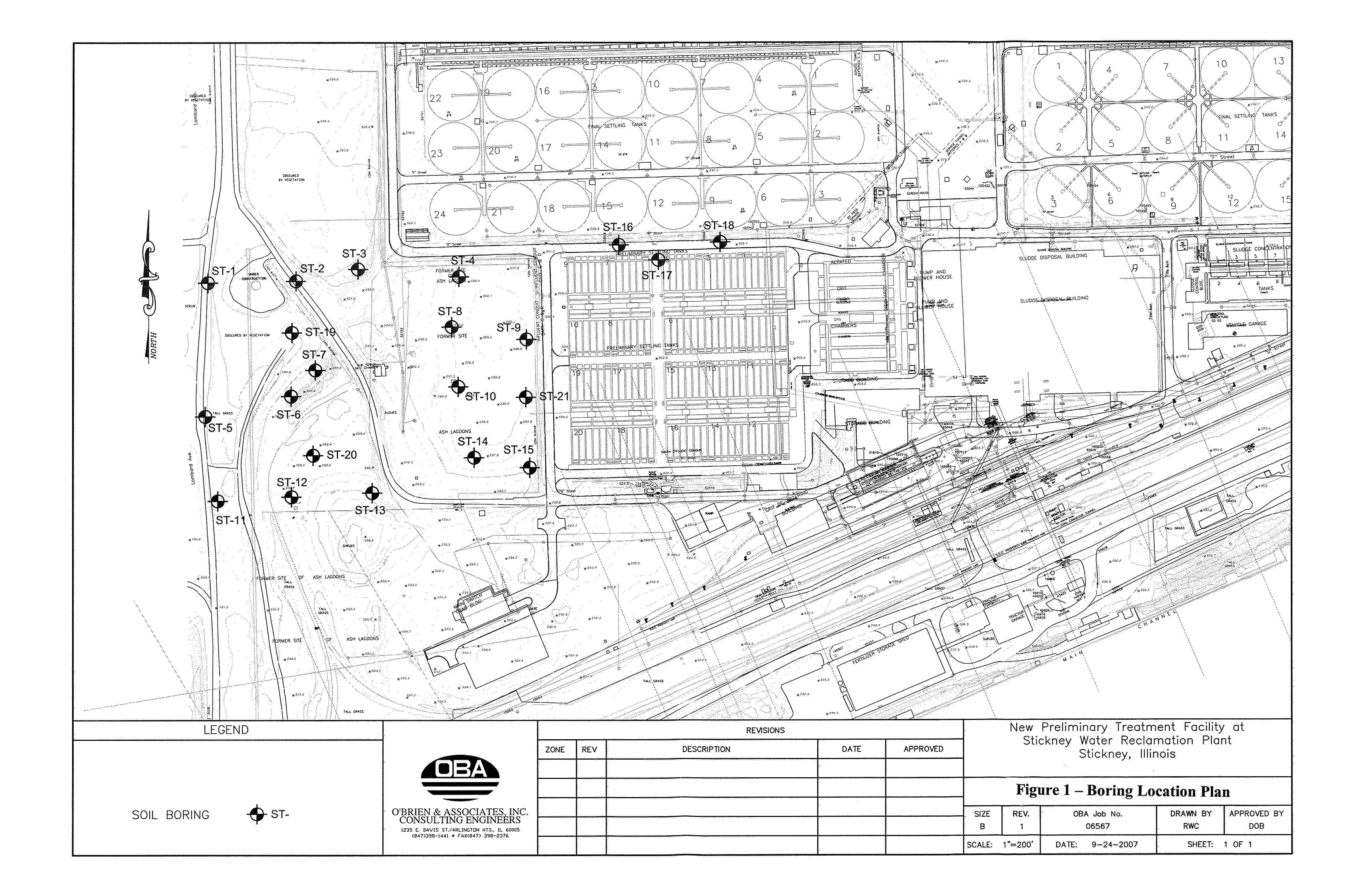

Site Layout

As part of the study, a proposed layout of the disinfection facilities at the SWRP was developed

including the Low Lift Pump Station, UV Disinfection Facilities, related gate structures/effluent

conduits and space reserved for future tertiary filters.

Figure ES-2

and Volume 2 of this report

show the proposed site layout while

Figure ES-1

shows the proposed flow diagram for the new

UV Disinfection Facilities.

Electronic Filing - Received, Clerk's Office, Octobr 20, 2008

3

\\Uschg1fp207\p60040695\P60040695\500_Submittals\503_Cost

Study Report\503.1_Draft Report\Final_Cost_Study_Report_091008.doc

Figure ES 1 - Proposed UV Facilities Flow Diagram

Due to the limited space available upstream of the existing outfall, flow would be directed

approximately 1,800-ft to the new facilities located to the southwest of the site. As a result of the

location of the new facilities, it is recommended that a new plant outfall to the Ship and Sanitary

Canal be constructed directly south of the new facilities (and west of the existing outfall) in lieu of

installing an extensive return conduit back to the existing outfall. It should be noted that the new

outfall would require permitting through the United States Army Corps of Engineers (USACE) and

others. The cost of this new outfall is included in the cost opinion.

Preliminary Cost Opinion

The preliminary opinion of probable construction cost (OPCC) for SWRP UV Disinfection

Fac ilities is shown

Tab

in

le ES-1

below. As shown, the projected construction cost for the SWRP

UV Disinfection facilities is $542.9 million. The details of the basis of design for the proposed

facilities and the methods of developing the OPCC are presented in the body of this report.

Table ES-1 – SWRP UV Disinfection Facilities Preliminary OPCC and M&O Costs

Capital Cost Estimates

A. General Sitework

$61,890,000

B. Low Lift Pump Station

$86,220,000

C. Disinfection System

$112,420,000

Total Capital Cost

$260,530,000

Maintenance & Operations Cost Estimates

A. General Sitework

$90,000/yr

B. Low Lift Pump Station

$2,540,000/yr

C. Disinfection System

$9,560,000/yr

Total Annual M&O Cost

$12,190,000/yr

Total Present Worth M&O Cost

$282,400,000

Total Present Worth

$542,930,000

All costs in 2007 dollars.

E x isting

Plant

LLPS

UV

Facilities

Future

Tertiary

Filters

New

Outfall

E x isting

Outfall

Q=1,440

MGD

(Winter Operation)

Junction

Chamber

Electronic Filing - Received, Clerk's Office, Octobr 20, 2008

N

NOT FOR CONSTRUCTION

Electronic Filing - Received, Clerk's Office, Octobr 20, 2008

5

\\Uschg1fp207\p60040695\P60040695\500_Submittals\503_Cost

Study Report\503.1_Draft Report\Final_Cost_Study_Report_091008.doc

1.0

INTRODUCTION

1.1

Background

This report has been developed to present the findings of the Preliminary Cost Opinion for

Ultraviolet (UV) Disinfection Facilities Study at the Metropolitan Water Reclamation District of

Greater Chicago’s (MWRDGC, or District) Stickney Water Reclamation Plant (SWRP) in

Stickney, Illinois. This report continues the work began in TM1-WQ, which was developed

previously as part of the comprehensive Infrastructure and Process Needs Feasibility Study

(Master Plan) for the SWRP and a Water Quality (WQ) Strategy for affected Chicago Area

Waterways.

The TM1-WQ documented the results of a CTE study of effluent disinfection alternatives for the

District’s North Side, Calumet and Stickney WRPs. In that study, a task force of national experts

(referred to as the Blue Ribbon Panel) reviewed available disinfection technologies and their

range of pathogen destruction efficiency, disinfection byproducts and impacts upon aquatic life

and human health. Their investigation also included an examination of the environmental and

human health impacts of the energy required for the operation of the facility and for the

processing and production of process chemicals. Based on economic and non-economic

evaluation of alternatives, ozone disinfection and UV disinfection were selected and preliminary

design and cost estimates were developed. Based on the results of that subsequent evaluation,

the District determined that UV disinfection is the most cost-effective alternative.

1.2

Objective

The District has requested further evaluation of the UV disinfection technology. This additional

evaluation is based on the TM-1WQ, the comments received from the United States

Environmental Protection Agency (USEPA) as part of the Illinois Environmental Protection

Agency’s (IEPA) Use Attainability Analysis (UAA) evaluations, and new information obtained

since the previous work. The primary objectives of the evaluation presented in this report are:

x

To describe the conceptual facilities developed as part of this study including their basis

of design and the assumptions used for their development

x

To develop a Level 3 (per the Association for the Advancement of Cost Engineering)

Preliminary Opinion of Probable Construction Cost for the proposed facilities at SWRP,

which represents a conceptual estimate with an expected deviation range from actual

cost of -15% to +30%.

x

To develop annual maintenance and operations (M&O) costs for the facilities

1.3

General Design Standards

Where applicable, the latest version of the codes and standards from the following

institutions/organizations would govern the design:

State of Illinois, Illinois Recommended Standards for Sewage Works, Title 35.C.II.370.

Great Lakes – Upper Mississippi River Board of State and Provincial Public Health and

Environmental Managers, Recommended Standards for Wastewater Facilities (Ten States

Standards).

National Fire Protection Association Standard 820 – Standard for Fire Protection in Wastewater

Treatment and Collection Facilities.

International Building Code, 2003.

Metropolitan Water Reclamation District of Greater Chicago Standard Specifications.

Electronic Filing - Received, Clerk's Office, Octobr 20, 2008

6

\\Uschg1fp207\p60040695\P60040695\500_Submittals\503_Cost

Study Report\503.1_Draft Report\Final_Cost_Study_Report_091008.doc

1.4

Organization of this Report

The Cost Study Report is divided into two volumes. Volume 1 is the text and backup materials

presenting the findings of the additional evaluation of the cost of implementation of UV

disinfection at the SWRP. Volume 2 is the conceptual level drawings presenting the preliminary

layouts and some details of the proposed facilities from which the preliminary opinion of

construction cost was developed.

The basis of this evaluation is the proposed facilities necessary for UV Disinfection Facilities and

related ancillary improvements at the SWRP. The sections of Volume 1 are organized as follows:

Section 2 – Discussion of the hydraulic analysis that was performed that forms the basis of

decisions regarding the need for a low lift pump station and the general layout of the facilities.

Sections 3 through 8 – Discussion of the basis of design for the proposed facilities by design

discipline and the assumptions necessary for development of the conceptual design presented in

Volume 2.

Section 9 – Discussion of areas that require further analysis during the preliminary design of the

proposed facilities due either to their critical nature regarding design decisions or their large

impact on potential construction or operating costs.

Section 10 - Summary of the Preliminary Opinion of Probable Construction Cost (OPCC) and

annual operating costs as well as discussion of the assumptions used to develop those costs.

2.0

HYDRAULICS

2.1

Hydraulic Analysis of the UV Disinfection Facilities

2.2.1 Objectives

Hydraulic analyses of the SWRP had not been performed as part of the SWRP Master Plan. For

this study, a preliminary hydraulic model was created to evaluate the existing plant hydraulics

which would be affected by the UV Disinfection Facilities. This model was then modified to

include the effluent conduits, gate structures, UV channels and reactors and Low Lift Pump

Station in order to provide a more comprehensive hydraulic evaluation of the UV disinfection

faciilties.

2.2.2 Overview

The hydraulic analysis was completed using a spreadsheet utilizing standard open channel and

closed conduit flow equations. The hydraulics evaluated were for the Year 2040 conditions,

including both infrastructure and permit-related improvements related to disinfection at a peak

flow of 1,440 MGD. Flow in excess of 1,440 MGD is assumed to be diverted to the TARP

system.

The flow path was modeled from the effluent aerator weir downstream of Battery B to the Sanitary

and Ship Canal outfall. Due to site constraints, the new UV disinfection facilities were located to

the southwest of the plant. Flow would be diverted via a new gate chamber downstream of the

Pump and Blower Building, located approximately 800 ft upstream of the existing plant outfall. At

this location, secondary effluent from all Aeration Batteries (A, B, C & D) could be diverted to the

new disinfection facilities. Additionally, a new plant outfall was assumed to be provided rather

than conveying the disinfected flow back to the original outfall.

Electronic Filing - Received, Clerk's Office, Octobr 20, 2008

7

\\Uschg1fp207\p60040695\P60040695\500_Submittals\503_Cost

Study Report\503.1_Draft Report\Final_Cost_Study_Report_091008.doc

The existing plant hydraulics were evaluated using a water surface elevation (WSE) in the

Sanitary and Ship Canal of +3.5 CCD. This was based upon the hydraulic profile from the

Contract 78-102-EP, West-Southwest Treatment Works, February, 1985

1

; however this is

considered the typical annual high water level in the canal and not the 100-yr flood elevation.

For the conceptual design of the new UV facilities the water surface elevation of +9.0 CCD will be

utilized in order to ensure the new facilities can operate during the 100-year flood. The 100-year

flood elevation for the Sanitary and Ship Canal has been calculated using the USACE’s Chicago

Underflow Plan (CUP) Design Report. The CUP report used observed high water levels to model

the predicted high water levels throughout the Chicago Area Waterways at each of the

construction phases. Appendix A provides select pages from this report.

2.3

Assumptions

Due to the preliminary nature of the selected site plan, assumptions were made in the

development of the hydraulic model. These assumptions are as follows:

1.

SWRP drawings obtained from MWRDGC are on the Chicago City Datum (CCD) or

the National Geodetic Vertical Datum (NGVD). All elevations were converted to CCD

using conversion CCD = NGVD – 579.48.

2.

The CCD has not changed since the plant was originally constructed in the 1920’s.

3.

UV Facilities should be operable at the 100 yr flood event. The estimated 100-yr flood

elevation is +9.00 CCD, as calculated in the Chicago Canal System Model, UNET.

Appendix A provides selected pages from the USACE’s Chicago Underflow Plan

(CUP) Design Report presenting these results. Pre-Stage 1 (Stage 1 of the McCook

Reservoir Construction) values are used since the USACE’s current estimate for

completion of Stage 1 construction in 2020 or later. It should be noted that higher

levels of +10.1 CCD have been predicted for storms greater than the 100-yr storm.

At water levels rise higher than +9.00 CCD (100-yr flood) then flow bypassing would

be necessary to avoid flooding the UV and other facilities.

4.

Post Aeration hydraulics and space planning are not included in this study.

5.

A new plant outfall will be provided to convey disinfected effluent to the Ship and

Sanitary Canal.

6.

Velocity in Disinfection Influent and Effluent Distribution Chambers is zero to allow

adequate flow distribution.

7.

Flow is divided equally between the Batteries A, B, C and D, with each receiving 360

MGD.

8.

Batteries A, B, C and D are all at the same elevation.

9.

The UV process requires approximately 6 ft of submergence, thus the disinfection

channel effluent weir is assumed to be 5.5 ft above invert to ensure a submerged

weir at low flow conditions.

10.

The following modeling equations were used:

a. Pressure Flow – Hazen Williams Equation

b. Open-Channel Flow – Manning’s Equation

c. Flow junctions – Pressure Momentum Analysis.

1

El +3.5 is listed as the maximum water level in the Sanitary and Ship Canal to which the plant would not

flood, based on a maximum design flow rate of 2,000 MGD. This profile appears to be the last official

hydraulic profile conducted for the SWRP.

Electronic Filing - Received, Clerk's Office, Octobr 20, 2008

8

\\Uschg1fp207\p60040695\P60040695\500_Submittals\503_Cost

Study Report\503.1_Draft Report\Final_Cost_Study_Report_091008.doc

11.

Hydraulic coefficients used in developing this model include:

a. Hazen Williams – 110 (concrete)

b. Manning’s

i.

Regular channel – 0.013

ii.

Aerated channel – 0.035

2.4

Results

Table 2.4-1

presents the final water surface elevations (WSE’s) through the plant, including the

Low Lift Pump Station (LLPS) and UV Disinfection Building. The hydraulic profiles show the

estimated WSE’s at the maximum flow of 1,440 MGD. Flow that exceeds 1,440 MGD is diverted

into the TARP system.

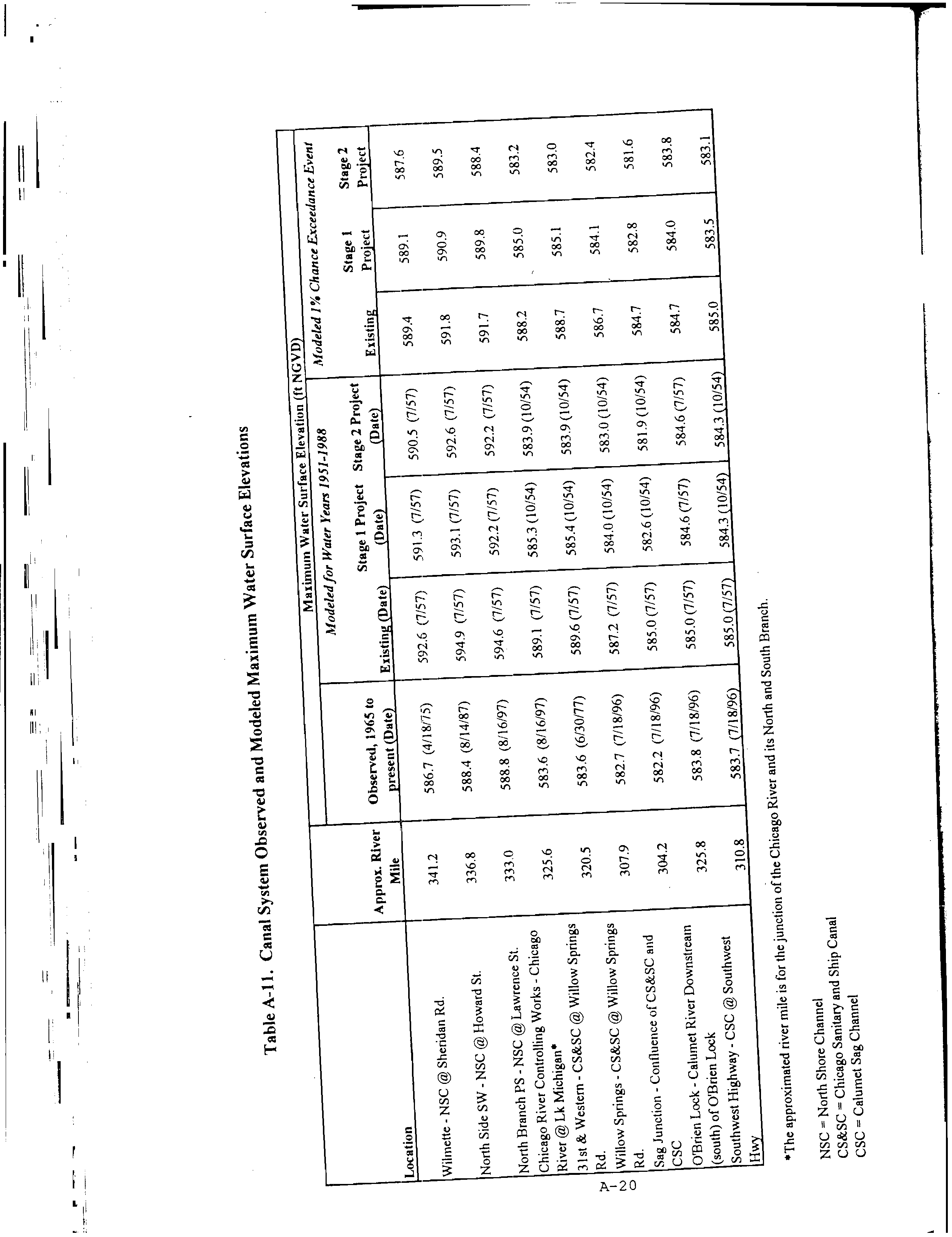

Table 2.4-1 – Summary of Proposed WSE including UV Disinfection Facilities

Location

WSE

WSE in Effluent Aerator

10.37

WSE just d/s of Pump Discharge Chamber

5.50

WSE at New Gate Chamber

4.06

WSE in LLPS Influent Conduit

-0.75

WSE in LLPS Wet Well just u/s of curtain wall

-3.25

WSE just D/S of Low Lift PS

13.70

WSE just U/S of Influent gate

13.00

WSE just U/S UV Reactor

12.65

WSE just U/S of Weir Gate

11.89

WSE just D/S of Weir gate

11.42

WSE @ D/S Disinfection Effluent Chamber

9.73

WSE in Sanitary and Ship Canal, Approximate 100 yr flood elevation

9.00

Notes:

All WSE in CCD.

WSE – Water Surface Elevation

D/S – Downstream

U/S – Upstream

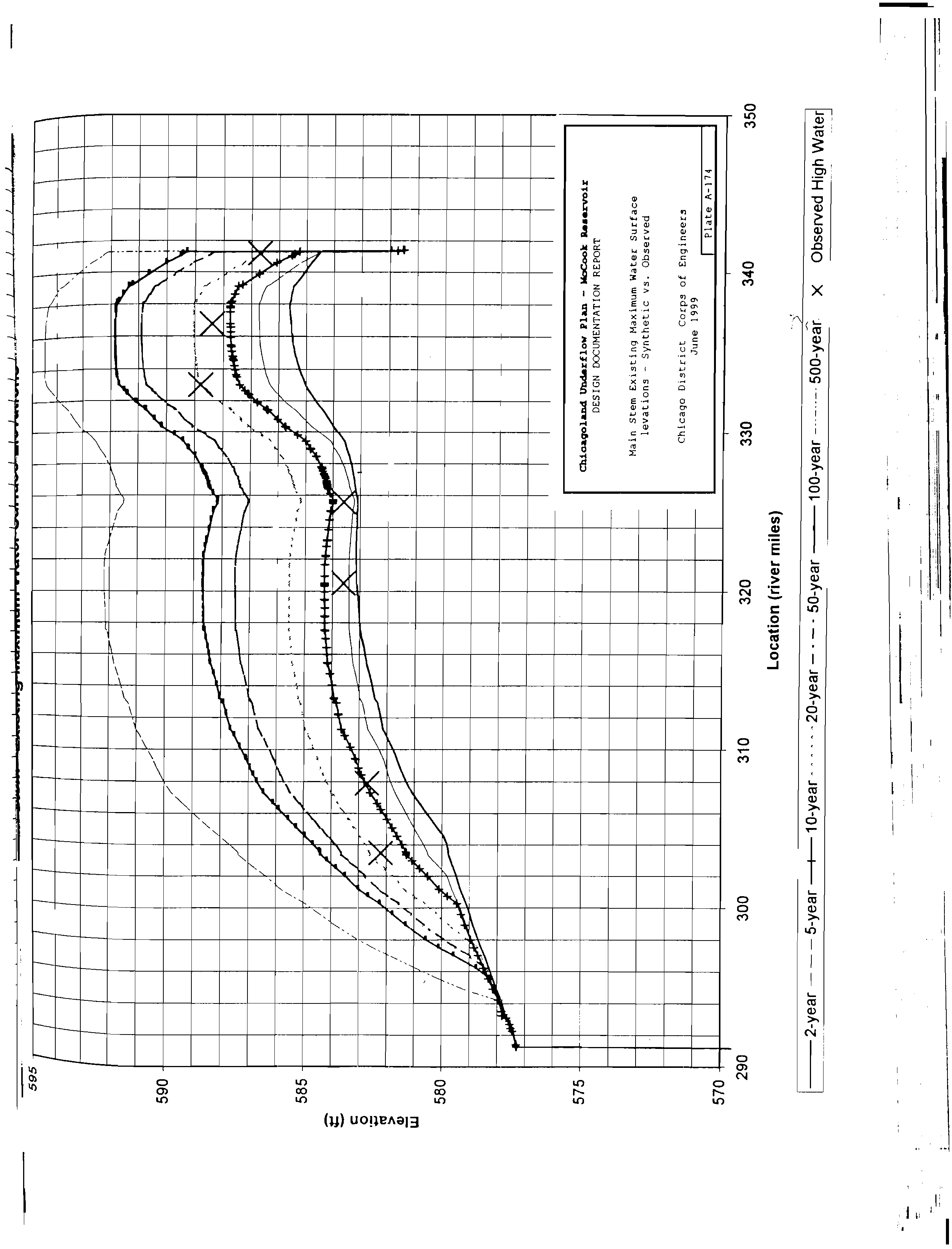

Figure 2.4-1

contains the hydraulic profile of the flow path from the new outfall in the Sanitary

and Ship Canal through the new UV disinfection facilities and the available freeboard at the

locations where water surface elevations (WSE’s) were calculated at the peak day flow starting at

the 100-year flood elevation.

2.5

Conclusion

Based on the preliminary hydraulic analysis performed as part of this study, the estimated total

head required to convey flow through the new UV Disinfection facilities and associated structures

is 8.7-ft. The available head downstream of the Pump and Blower Building is 1.95 ft. In order to

maintain flow at the 100-yr flood, a new Low Lift Pump Station is required to lift flow 16.95-ft to

convey flow via gravity through the new UV facilities to the new outfall in the Sanitary and Ship

Canal.

Electronic Filing - Received, Clerk's Office, Octobr 20, 2008

N

Electronic Filing - Received, Clerk's Office, Octobr 20, 2008

10

\\Uschg1fp207\p60040695\P60040695\500_Submittals\503_Cost

Study Report\503.1_Draft Report\Final_Cost_Study_Report_091008.doc

3.0

SWRP DISINFECTION PROCESS

3.1

Introduction

The District has preliminarily selected the medium-pressure high-intensity (MP-HI) UV disinfection

technology for disinfection of final effluent at the SWRP. This section presents the results of

further evaluation of the MP-HI UV disinfection technology per the District’s requirement. In the

following discussion, the basis of design of the MP-HI UV system is presented and a preliminary

basis of design of the UV system to be used at the SWRP is provided. The low-lift pump station’s

basis of design, operation and layout are provided later in this section.

3.2

UV Disinfection System

3.2.1 Background

The Technical Memorandum on the UV Disinfection Technology performed as part of the North

Side Disinfection Cost Study, included in Appendix B, incorporates the following:

x

Information from literature including technical proceedings from the Water Environment

Federation (WEF), Water Environment Research Foundation (WERF), proceedings from

the latest Disinfection conference series undertaken by WEF, American Water Works

Association (AWWA), and International Water Association (IWA). This information

provided the latest updates in the UV disinfection technology.

x

Updated recommendations on the UV system from four manufacturers – Trojan

Technologies, Aquionics, Calgon Carbon, and Severn Trent Services (STS)/Quay.

x

Reference information on experience of UV disinfection at five selected facilities – Racine

WWTP (Racine, WI), R.L. Sutton WRF (Cobb County, GA), Grand Rapids WWTP (Grand

Rapids, MI), Jacksonville WWTP (Buckman, FL), and Valley Creek WWTP (Valley Creek,

AL). A summary of the information collected through the phone survey is provided in

Appendix B, and important inferences from the phone survey are as follows.

1. Fouling due to iron in the effluent has been a problem at the Racine, Sutton, and

Grand Rapids facilities.

Fouling results in lower then expected disinfection

performance, higher operating costs, and higher M&O efforts. The iron in the effluent

at all three plants was primarily from the chemical phosphorus removal using Ferric

Chloride. At Grand Rapids WWTP, the chemical addition is upstream of the

secondary treatment process; staining of sleeves was found only when the chemical

addition was in the secondary clarifiers. At the Sutton WRF, fouling of lamps due to

iron is observed although chemical addition is upstream of secondary process and

sand filters are used upstream of the UV disinfection system. At the Racine WWTP,

fouling may be due to ferric chloride addition and/or due to the additional iron brought

by the ferric sludge from another water treatment plant, although operational controls

are used to prevent both sources from occurring simultaneously.

2. Calcium fouling due to hardness in the source water is not a significant problem

because of the automatic mechanical/chemical cleaning system that dissolves and

wipes away any scales. The lack of calcium hardness was observed in all five plants

including the Racine and Grand Rapids utilities which have Lake Michigan source

water and is attributed to the automatic cleaning system performance.

3. The frequency of cleaning and changing of the cleaning solution is specific to the

utility and would have to be determined only by experience.

4. Labor requirements varied amongst facilities, with some facilities requiring more labor

to handle the fouling caused by iron salt addition.

Electronic Filing - Received, Clerk's Office, Octobr 20, 2008

11

\\Uschg1fp207\p60040695\P60040695\500_Submittals\503_Cost

Study Report\503.1_Draft Report\Final_Cost_Study_Report_091008.doc

5. As long as other processes in the plant are performing as desired, all five facilities

were satisfied with the UV disinfection system because it met their disinfection goals.

In conclusion, the phone survey had revealed that fouling of the quartz sleeves is a concern for

this application, particularly if iron salts are added for phosphorous removal in the future. In

addition, the phone survey results suggest that the manufacturer’s recommended labor

assumptions for routine maintenance including cleaning and inspection of the lamps is too low for

this application. As transmissivity is directly related to lamp fouling, additional lamps and/or more

frequent cleaning may be required in future if iron salts are to be utilized upstream of this

technology.

Using this information and the updated information available from manufacturers, a preliminary

basis of design of the MP-HI UV disinfection system has been developed for disinfection of the

final effluent at the SWRP.

3.2.2

Basis of Design

The MP-HI system involves sending the secondary or tertiary effluent through channels

containing banks of MP-HI UV lamps. Refer to the process drawings included in Volume 2 of this

report. The Trojan UV4000™Plus system is used here to develop the basis of design for the UV

disinfection system. The system consists of a power supply, an electrical system, a reactor, MP-

HI lamps, a mechanical and chemical cleaning system, and a control system. The MP-HI UV

lamps are enclosed in individual quartz sleeves for protection against dirt and breakage. Reactor

chambers (open channels) hold the lamps in a horizontal configuration. The effluent weirs and

level sensors are used to keep the lamps submerged under the effluent water.

This

submergence ensures that the lamps do not overheat, thereby preventing lamp life reduction or

burnout.

The UV system is assumed to operate from March to November each year. During the winter

months, the equipment would sit idle as the flow is bypassed around the LLPS and UV

Disinfection Building. However, due to the size of the facility including twelve reactors and over

4000 lamps, maintenance activities would be conducted every working day from March to

November and periodically during the winter months. It is reasonable to expect that the area

would continue to experience normal weather patterns for the Chicago area including extreme

weather during all four seasons. In order to protect the safety of the M&O staff, ensure

operational and maintenance-related productivity, and protect the UV equipment from adverse

weather common to the Chicago area including high winds, rain, lightning, snow, and extreme

temperatures, the UV system would be enclosed in a building.

3.2.2.1 Influent Characteristics

The water quality characteristics that affect UV transmittance include iron, hardness, suspended

solids, humic materials and organic dyes. These effluent constituents have a tendency to absorb

UV light and thus impact the disinfection process. The UV transmittance generally needs to be

above 65% for effective disinfection. The water quality testing done at the North Side WRP and

Calumet WRP as part of the UV disinfection technology trials conducted by the District during

2006-2007 showed an average transmittance above this minimum value. Although testing was

not done at Stickney WRP the characteristics are likely to be very similar. Refer to Appendix B

for more information regarding the influent characteristic testing. The total suspended solids limit

is projected to be 15 mg/L for the purposes of sizing the UV system.

3.2.2.2 Reactor Configuration and Hydraulics

An open channel is used as a reactor. Each channel has one reactor with two banks each. Each

bank includes stainless steel UV modules with the MP-HI lamps mounted on them and arranged

in a linear configuration to increase intensity along the linear axis by avoiding UV emission losses

due to self absorption, reflection or refraction that can occur if a UV lamp were twisted into loops

or spirals. The lamps are positioned horizontally and parallel to the flow.

Electronic Filing - Received, Clerk's Office, Octobr 20, 2008

12

\\Uschg1fp207\p60040695\P60040695\500_Submittals\503_Cost

Study Report\503.1_Draft Report\Final_Cost_Study_Report_091008.doc

The optimum hydraulic scenario for this system involves turbulent flow with mixing while

minimizing head loss. Reactor design, including inlet and outlet flow distribution is done so that

the unit operates close to a plug flow. Inlet conditions are designed to distribute the flow and

equalize velocities. Sufficient length is provided in the channel upstream of the reactor to allow

equalization of the flow. A motorized weir gate is provided downstream of each reactor to control

the water level at a constant level with little fluctuation within the UV disinfection reactor.

3.2.2.3 Lamps and UV Intensity Control

The MP-HI lamps produce polychromatic radiation, which is concentrated at select peaks

throughout the germicidal wavelength region. The IEPA requires a minimum UV dose of 40 mW-

s/cm

2

which was considered during the design of the UV system. It may be possible to document

a lower required dose to the regulating body (IEPA) during design development, but lacking such

data, this study does not deviate from the required minimum dose.

Each lamp is enclosed in a quartz sleeve because quartz effectively protects the lamps while

minimizing any UV transmission losses. Electronic ballast for each lamp is used to control the

power to the lamp. If the UV dose is to be reduced, the variable output electronic ballast

regulates the power to the lamp from 100% to 30%. Entire banks can also be turned off if there is

no flow. This allows dose-pacing based on the secondary or tertiary effluent flow and quality,

which helps save power and lamp life and hence reduce costs.

3.2.2.4 Lamp Fouling and Cleaning

The MP-HI lamps operate at a temperature range of 600 to 900 degree C. These warm

temperatures promote fouling on the surface of the quartz sleeves when the lamps are placed

directly within the wastewater stream. Iron is the most abundant metal in these scales along with

other mineral salts and oil, grease, suspended solids deposits, and biofilms. If no tertiary

treatment is provided, physical debris may contribute to fouling as well.

Since lamp fouling significantly reduces the effectiveness of UV disinfection by blocking the UV

rays, calculation of the UV dose incorporates a term called the “fouling factor”, which allows the

designer to estimate the effects of fouling on performance of the disinfection process. To combat

fouling, a chemical and mechanical cleaning system is proposed for the MP-HI UV disinfection

system. The latest technology uses a system of mechanical wipers and sleeves containing

cleaning chemicals surrounding the lamp. The cleaning solution contains some acidic solution

that prevents fouling. This cleaning system can be programmed to clean at a set frequency

without the need for disrupting the disinfection process. The cleaning solution needs to be

replaced periodically depending on the type of solution used and characteristics of the effluent

water quality. Similar facilities using Lake Michigan as source water have found that changing

the cleaning solution on a monthly basis is required for adequate performance.

Due to the mechanical and chemical features of the Trojan automatic cleaning system, the IEPA

accepts the default value of 100% for the fouling factor in the UV

dis

software package (dosage

modeling software) for sizing the equipment. Based on the phone survey results that indicated a

higher potential for fouling in the event of Lake Michigan source water with ferric salt addition, the

District has elected to incorporate a safety factor of 10% by using a fouling factor of 90%.

3.2.3 Process Control

An automated process control must be provided to facilitate online pacing of the UV dose to

prevent overdosing that wastes electricity and to avoid under-dosing that would not meet the

disinfection regulatory requirements and goals. The process control should also allow the dose-

pacing to be interfaced with the plant’s overall supervisory control and data acquisition (SCADA)

system. The flow, lamp output, and water conditions are measured in pacing of the dose, and an

algorithm is developed based on long-term measurements to predict necessary system

adjustments, maintenance, and component replacements.

Electronic Filing - Received, Clerk's Office, Octobr 20, 2008

13

\\Uschg1fp207\p60040695\P60040695\500_Submittals\503_Cost

Study Report\503.1_Draft Report\Final_Cost_Study_Report_091008.doc

Programmable logic control (PLC) technology must be used for dose pacing in the MP-HI UV

disinfection system. The PLC interacts with the ballasts, sensors, and online monitoring

technology for each disinfection unit. The PLC then interacts with the plant’s overall control

system to allow remote monitoring and adjustment of the system. The PLC should be supplied

by the manufacturer of the unit.

3.2.4 Safety

The high voltage power supplies for the MP-HI UV disinfection system may pose an issue as the

lamps are submerged in the water most of the time and compliance with electrical safety codes is

required. In addition, UV light poses a risk to personnel and can cause damage to skin or eyes

upon exposure. Submerging a lamp in water, even if it is just a few inches below the surface,

greatly reduces the intensity. During operation the system should be covered by hatches and

should be designed to ensure constant water levels to minimize the risk of UV exposure.

3.2.5 Proposed Design Criteria for UV Disinfection Equipment

Based on a review of the information provided by the UV equipment manufacturers and the

experience of five other facilities (Appendix B), it is observed that Trojan Technologies provides a

widely-used low-maintenance solution for final effluent disinfection. The design of the MP-HI UV

disinfection system for the Stickney WRP is based on the Trojan UV4000™Plus equipment

provided by Trojan Technologies. The basis of design is given in

Table 3.2-1

.

Table 3.2-1 – Design Parameters for UV Disinfection Unit at SWRP

Parameter

Design Value

Capacity and Water Quality

Design flow, MGD

1,440

Average flow, MGD

1,250

Maximum TSS

a

, mg/L

15

Pre-Disinfection Effluent Fecal Coliform Count

b

, cfu/100 mL,

maximum (Assumed)

25,000

Post-Disinfection Effluent Fecal Coliform Count Target

c

, cfu/100 mL

400

Effluent Hardness

d

, mg/L as CaCO

3

270

Dosage

UV transmittance, minimum, %

65

UV intensity

e

, W/lamp

4,000

Lamp Life, hours

5,000

Fouling factor, %

90

Lamp aging factor, %

89

UV dose, mW-s/cm

2

40

Physical Characteristics

Channel dimensions, WxD

106” x 172”

Number of channels

12 (11 plus 1 standby)

Number of reactors per channel

1

Number of banks per reactor

2

Number of modules per bank

7

Number of lamps per module

24

Total number of lamps

4,032

Total power requirement, kW

11,827

Average power requirement, kW

9,225

Hydraulics

Headloss, UV reactor only

9”

Velocity in each channel, V, ft/s

1.87

Liqui

a

b

d

AMonth

l

nn

ev

u

e

al

l

l

cont

y

avpereragmit

ro

e

l

li

in

mit

channel

12 mg/L

c

d

FuturMean e

valrequuire

ement (monthly geom

e

100et%

ric

intavenseragity

e)at

100

Mot

hours

ori

o

zed

f lam

W

p us

eir

e

Gate

Electronic Filing - Received, Clerk's Office, Octobr 20, 2008

14

\\Uschg1fp207\p60040695\P60040695\500_Submittals\503_Cost

Study Report\503.1_Draft Report\Final_Cost_Study_Report_091008.doc

The above design criteria are assumed based on available information and the current state of

ultraviolet disinfection technology. A more extensive technology evaluation should be conducted

prior to final design of the facility. Due to the extraordinary scale of this facility, CTE recommends

the District undertake the following design process for selection and design of the UV disinfection

equipment if final design is initiated:

1. Request and evaluate independent, full-scale validation data (also known as

biodosimetry data) from manufacturers of candidate disinfection systems for similarly

sized units or the largest size for which the manufacturer has data available. This

evaluation would provide an initial level-of-confidence that the candidate systems can

achieve the target disinfection levels. Data should be from systems using the same bulb,

ballast, and control technology as proposed for the full-scale system. Candidate systems

should include both medium pressure, high intensity as well as appropriate low pressure,

high intensity systems,

2. Conduct a collimated beam testing program. This program would use site specific

effluent and bacteria to determine the sensitivity of the site specific bacteria and

pathogens to UV disinfection. The data would be used to size the UV lamps and

reactors.

3. Increase frequency of UV transmittance testing at each plant to at least once per day for

a period of one year or more to collect data on seasonal variability, daily variability,

diurnal variability, and to capture the frequency of events that might reduce transmissivity

such as wet weather and infrequent industrial discharges.

4. Conduct a more detailed life cycle cost analysis of the candidate disinfection systems

based on the data collected during steps 1 through 3 above.

5. Construct a pilot testing facility (approximately 20 MGD, subject to change) designed to

match lamp spacing, velocity profile and other design parameters of the proposed full

scale units. The pilot testing facility would be used to determine:

a. Appropriate control sequences and optimization for the UV disinfection equipment,

including appropriate sensing equipment to allow advanced power management.

b. In-situ disinfection performance including fouling rates of the lamps with and without

ferric salt addition.

c. Design life of lamps and other UV system parts.

d. Actual M&O requirements in terms of labor and consumables as well as space

requirements to complete required maintenance activities.

e. Performance of alternate equipment manufacturers, if alternates are available at the

time of piloting.

f. Accuracy of life cycle cost analysis prior to final design of the full-scale system.

6. Conduct post-construction full-scale validation testing (biodosimetry testing) to confirm

performance and determine operating parameters.

Using a program as described above, it may be possible to demonstrate the effective UV

dosages to the regulators and optimize the equipment sizing criteria. For this study, reduction in

the Illinois requirements for UV system sizing is not assumed based on the lack of data similar to

that described above.

Electronic Filing - Received, Clerk's Office, Octobr 20, 2008

15