Page

1 of2

John

Therriault

- Fwd: PCB

07-95 People

v. AET Environmental

Inc.

and

EOR

Energy

LLC

From:

Carol Webb

Date:

To:

Therriault,

10/20/2008

John

1:30PM

CLERK’S

E

c

E

OFFICE

VE

D

Subject: Fwd: PCB 07-95

People v. AET

Environmental

Inc. and

EOR Energy

LLC

OCT

Joim

STATE

OF

ILLINOIS

Please docket this

email into COOL.

PolIuton

Control

Board

Thanks,

Carol

>>>

“ART”

<arthurcIark@aetenvironmental.com>

10/20/2008

1:07

PM>>>

Ms. Webb.

Lori DeVito the President

of AET is

out of town this week

and therefore

not available

for the conference

call. We

have had a hard time

getting an attorney

due to certain actions

by the

AG.

Our attorney Mr.

Oneill is reluctant

and suggests

that we petition the

board for waiver

of the rule

requiring

attorney

representation for a

corporation.

I have attached our

previous settlement

offer and

have

never received

any comment or counter

offer. Also

attached

is a previous email which

shows that

a settlement was

requested

by

the AG

(and an amount

of

something more

than our offer was

implied, we

expected

a counter offer).

At this point

we feel that

the

AG

is

simply

trying to extort monies

from

us, since

we broke no law,

caused no environmental

damage,

and

if

anything,

the AG should have

gone after Rick and

Charlie, if they did

what

they said.

So

why the

immunity,

and

total lack of

interest in them, and the

lost interest in

Kincaid P&P, USA

Coal etc.? Are we

an easier

target?

In any case

our attorney, Oneill,

believes that we should

be

able to listen

to

the

conference

call even

without

and

attorney present.

This case is simply

the vindictive attack

by

Mike

Cook,

(he was the lead

field investigator in

prosecution

of

Luxury

Wheels

the owner

of the acid, for alleged

improper

discharge of poorly treated

water)

since

he

could not

get the US EPA

or US Attorney to file

charges, since

there was nothing wrong,

different

from the norm

but

innovative

and

in

the spirit

of

the three R’s

of reduce, reuse,

and recycle as encouraged

by the

IL EPA

at its

web

site, and

by the US EPA. Additionally

the EPA

does not regulate the

methods

used

in oil and gas production.

It is of

interest that the

US

EPA

concluded

that the acid was

used in the production

of oil and

gas therefore

okay.

And amazingly after this

conclusion, Mike

Cook conveniently

got Rick

and Charlie

to admit”

to

putting

the acid

down

the salt

water disposal well

(this was impossible,

see attachment),

rather than

the production

wells,

but failed to prosecute

them. Why? And note

they

never

said that they were

instructed to do this

by AET,

or EOR.

There

is a

complete

lack of knowledge

on the use

of acids in the production

of oil and gas,

by

the

AG,

as

well as

the IL EPA. Additionally

when Lori and I

met with the IL

EPA several years

ago, their attorney

said

“somebody

did something

wrong somewhere”,

and when

ask who, what, where,

the answer was

“I do not

know

but

someone”.

This material was unused,

direct substitution,

and used and

stored as a material. It

was

not dumped,

rather

taking

months

to

be used in a judicious

manner, like

a product, not a waste.

The owner,

generator,

offered

if for

reuse or continued

use. It simply was a

product. This

entire case came from

Mike

Cook after

meetings

with

the

US

Assistant

AG and AET, where

he was shown

to be wrong (embarrassed)

and then

proceeded

to intimidate

Rick and Charlie

to lie, and

pushed

the

IL EPA to act incorrectly.

He was

moved

out of

US EPA.

Please

let me know what you think

and as we stated nearly

a year ago,

the

actions

of our contractors was

their

choice if true,

not by our

direction. And keep

in

mind that this

action

is from

a reuse (continued

use) six

years

ago.

This material was a pure

reuse or more correctly

a continued

use of an

acidic

material, not a waste.

.-...,i

mL...:.-.T’,r .-..,i C 4:m\’

flnnrri TTK

Page 2

of 2

Thank

you for your time.

Arthur

Clark

No virus

found in this outgoing message.

Checked

by AVG.

Version:

7.5.549 / Virus Database:

270.8. 1/1732

- Release Date: 10/18/2008

6:01 PM

Q

o.-÷+

\m

\rinnnnnni Tzrm,r

1nI’,r/’,nro

Settlement

Proposal

AET

andEOR

071106

—

A—%%.#

%d’%.

-

.%.

I

iL

Jjwironmentai

14 Lakeside Ln,

Denver, CO 80212

303-333-8521

Environmental

Ser,ices-Hzardous

Waste Management-

Bird-Aircraft Strike

Hazard Management

L.

oc&

lie

A:Liily

Environmental

Bureau

‘_

./

)

500 South

Second

Street

Springfield,

IL

62706

November

5

2007

D”.

hi Pfl

fl7Qc

T”’

Dear

Sir:

AET

Environmental

and EOR

Energy would

like

to propose

a settlement for the above

complaints.

Complaint

Regardhlg

AET Environm

tal Source

Environmental,

Inc.

AETISource

Th

f flwhw

Elernnnstrah)e

facts

and information are

offered

in support

of

settling

the

nmnJaint

acainst

AET/Source.

1.

AET/Source

did

not ship

into

Illinois,

transport into Illinois,

store in Illinois, or

in

any

way

handle hazardous material in Illinois. AET/Source does

not appear on any

document

showing involvement

in IHinois.

2.

The

shipper was Luxury Wheels

of

Colorado,

the

recipient

was Kincaid P&P, and

USA

Coal of

Illinois.

Ir

rdrtio.

o

the

therefnre,

AET reqnects

the

dismissal

of the

complaint

against

h it

pntirtv.

i.e. to

he

released

entirely

from the

above

referenced complaint.

Complaint

Regarding MJK nergy

Th

f*

ni1

information

are offered

in

supvort of

settliiig

the

complaint against

EOR

Energy.

1.

EOR.

intended to utilize

the subject material,

an

excellent acid

with many

characteristics

of an acid

that works extremely well in

the

cleaning

of its wells, in

its oil

producing wells to increase

oil

production,

2.

EOR

tested the acid

for

reaction,

on

the

metals of consthiction that

were used inthe

wells.

The acid cleaned

the metals

and did not

damage

them.

Therefore, it was

SettInwnf

Prnnnsal

2

APT

and F,flR

07fl06

detennined

that

the acid

would

not

damage

the well casing,

well tubing,

well

rods, or the

down

hole

pump.

3.

EOP

had

.ire1

two

ontractnrs

who

were experienced

in oil and

gas production

techniques,

including

acid cleaning

techniques,

to perform

the work required to

accomnhsh

the above

activity,

i.e. acid

cleaning of the

production

wells. These

c’cmIrartcn

s

Ii

d

done ‘ork

loi LOR br the

nnor

t’Ao yeats

being paid upon receipt

ol

in1rnie

for

niaintainiiw

and oiieratiiw

the

EOR

oil fields.

4.

EOR

understood

from numerous

telephone

conversations

that the two

contractors

were

nsim

the acid at

n

moderate

nace.

nlacin

it down

the

casings

of wells.

following

it

with

300 gallons

water, then circulating

the

acid up the

tubing and back down

the casing

for

several hours. The

hoses

and fittings

in

photographs

taken

at

the

site

are fittings fr

of

t”

oA it-fo

fh

casiug,

nf

tlw

tii’e

nereccarv

for

introduction

of

the

acid

into

the

liihuw

Additionally

as they

knew

and in fact stated

the

tubing

has

a

cheek

on the

ntimn

1

mevent

n

the

mu

oduction

of acid

into

the well via

the

tubing a

physical impossibility.

iw

saw an

increace in nil

production

after the use of

the

acid.

Thus,

EOR

h1pu,r1

that

fh’

trpatrnp,nt

wac

wnvfrmna,

6.

EOR

also understands that

the two contractors

told

EPA something

different,

that

the’,’ had poured

some

of the acid

down

the

brine

weli., This

statement

is

demonstrably

Thlce in

that

the

brine

wells

in question

at

that

time. Galloway

and Rink,

were under

750

nci .nci

6 nsi

pis

rires’ure

resnectreEv

dining that time

1

he

gas

oressure was

on

the

tiihjn

of the

weB

and

the

casing

was fill to

the

top,

which

was necessary

for

the

MIT

test. For the acid to be

added to

those

wells, the contractors

would

have had to

overcome

750 psi,

which was enough

pressure to

blow

acid all

over

themselves.

The pressure

would

have

never

allowed

them to place

any of the acid

in those

wells.

In

addition

to

the

physical impossibility,

they

themselves

would

simply

never

have done

it.

7

EO ur.

derstands

that the

contractors

lied, but does

not know

why

they

lied.

There does

not

seem to

be any good reason.

for them to admit

to

doing something

other

thai, what

they were

mid In do

FOR

slisnecis

that

FPA

Region 8

(ID

agent

Cook

who

may

have

been

upset that

his research

was leading to

naught, convinced

them

to

make

these

statements.

Most likely

Agent

Cook

did not realize

that the

wells

were

pressurized

and

could

never

have

received

any

liquid

into

them.

8.

EOR

understands

that

Agent

Cook was

moved to Homeland

Security

shortly

after

Abi

L;oiflaifl1ii

caiü.

CL[fLJ1s.

0

EO1 further

underctands

that

some of

the concern

reaanii.ni

its

use

of the acid

sr’oi,mds the

fact

of whether or

not the

acid was

such

a

horrible

threatening

hazardous

chemical

that

no

treatment

storage

and disposal

facility

would

dare to

handle it.

See the

attachment

for

information

that

addresses

this concern.

10.

Furthermore,

the Tllinnjs

EPA

sponsors

aweh

site

IMES,

(Industrial

Materials

FxchanQe Svsteni

htti, //www

ena state

ii

usilandlirnesnmes-listing

pdf),

which

lists

a

Settwnt

Pronn’a1

3

AET

and

EOR

071106

similar

acid,

(JM:A01/81

10),

as an

industrial

material, not a

waste

materiaL

The

listing

is

for

a

previously

used

acid,

composition

50%

nitric

acid, 25%

suiffiric

(vs. phosphoric),

mmnmuni hifhiotide

and

pie’iousl

used

loi

c1eaiing

aluminum

parts

n

..oiitjast

the

‘i

flP

UQM

w

not

!wevous1v

used.

rather

simnly

tested

for

usefulness,

and

stored.

ii.

When

one

examines

the

TMES

Qittp://www.epa.state.iLus/iandJirnes/imes

listing.pdf) site,

there

are

many

hazardous

materials

available

for use,

rather

than

disposal,

-fh;1

won1i

hi

P

flPA

rv

terictic

nd

therefore

hazardous

waste

if

disposed,

but

not

soif

used.

1 2

Why

does

tie

TEPA

o’i the

one

band

spnnsor

the

rei.se

of

used

hazardous

materials

partc1ar1y a

nitric

snifiric. fluoride,

aluminum

cleaning

acid.

and

in this

case

persecute

the

use

of

unused

nearly

identical

acid?

In

consideration of

the

above,

and

the

information contained

in

the

attachrnents

EOR

suggests

the

following

ientcnu

FOl

nii

nih1itv

for

the

acth-mc

of

the

two

contract

workers.

Both

were

well

hi *hp

nrn1m’tnn

tehniom

of

those

fields

and

had

worked

for

several

years

inthose

nrinr

tn

fhi

ed

treatment.

and

had

nerformed

well cleaning

with

acid

nreviously.

If

they

performed any

illegal

activity,

it

was

not

with

the

knowledge

or

at the

behest

of

EOR.

EOR

will

accept

some

responsibility

for

hiring

contractors

who

clearly

do

not tell

the

truth,

who

are

less

than

reliable

and

possibly

wrongly

frightened

by

the

authority

figure

of

an EPA

qen.

t.

Any

uce

of

the neid

other

thn

the

treatment

of

oil

production

wells,

they

did

on their

Since

there

wa

no

envwoxrrnentai

harm

none,

the

matenal

was

cieariy

uou-RCRA,

the

acid

w

in

nrlpgi

tn

Ii

ud

enrrectlv.

anti

since

there

ic

a need

for trained

workers

in the

oil

oa

industry..

EOR

will

donate

S2.,500

to a fund

to

better

educate

and

train

employees

in

the

secondary

recovery

oil

and gas

wells

of

IllinoIs, a fund

designated

by the

Illinois

EPA.

JTnnn

thi

monetary

contrihuhirn

the comolaint

aaaanct

EOR

will

he

dismissed

and the

EPA

an!

FOP

viil

agree

that

there

will

he no

further

action

by

either

party.

Smr.ereiy,

Lori

DêVito

lm

Hamilton,

UIIiI

‘

Settlement

Proposal

4

AET

and

EUR 071106

Attac.ment A

First, wiie a

materi& s

“isd

re eds

ffeitive snhsfitiite

for

a

commercially available

tlw

nitpi-ial

is

no?

a

waste when used as

one would use the

commercial material

n r’ip i

(W

Th.r+nv

t1

n,atpriaj in

nuectinri was

not

a waste srnce it

was an

“effective

substitute” for

the

15-25%

hydrochloric acid

injected into oil wells and

as

a

prniiuctinn technique

to clean or

acidize oil wells. Remember

that

a vet-v

large

twi-eentae of

nil

wells

u-i this tvne of limestone formation are imtially

acidized with

1500

+.,

çfl(’fl aqllnii of

ann in nrier to onen

un

the nul heannp

tormatiori

And of the 40

000

plus

oil wells

in

Illinois, many are “acid fraced” and acid treated many

times in order to

stimulate

productioi..

Acid

treatmeit

of oil

wells

is common.

Sennk

the

wi-

1material

innsei1

nf

would not carry

a D003. in

order for

a waste to

carry a

D003

it MUST

fit the definition

as

stated

in 40 CFR 261.23. The statement that the

materia! wis “reactinc”

is

rot

fern. used

i”

R PA

since even iron

metal

is

“reacting” ic.

rting.

-ecfinq with

ovvge’

The term

is

‘R1EACTIVF:”

and

is

defined.

in

4fl flFR

261.23.

Thic

wg \Tfll

(1

nnrrnl1v

iinctahle’

flTfl

Nfl

j’)’

react

violently with

water...”,

(in fact was simply diluted with

water), DiD NOT (3) “form

potentially

r mi’y+n*-

(iii

font nuite

the nnno,te’

flTfl NflT

(4

“when

mixet-l with water”

gives

off

toxic

gases.... WAS

NOT (5) “a cyanide of

sulfide

containing

“, WAS NOT

(6)

“canahie of detonation

“. WAS

NOT

(7) “readily

caabie

of detonation

at

standard

temperature and pressure”,

AND WAS NOT (8) “a

forbidden explosive

any

other

explosive).

In fact the

material was described in patent #

5,669,980, and

the

manufacturer’s

technical data sheet

as “inherently

stable”.

The technical

data sheet

mentions

that

when treating large metal

pieces at

elevated

temperatures, excessive

gases

may be

produced,

and

if so, remove

the metal and

cool or add

water to

quench the reaction.

Simply

put the

nv..terial would not

he 1)003 if it

were

disposed. The

statement in

the

nomni

ailit

that

totes

were

meltm

is irresnorisihjv

false

and the simniest

lnvestwation

would

have hown it

so

To

imnlv

that the material

was exheme1v

dangerous,

to the

poi’ nt

of

not being

able to he

handled is incorrect.

This

concern has no basis

in reality

or truth

uid

is

r.espotwible.

See

the

attachment for flirtl-i.er

information.

Third +he n,qfe,-ial

was

not

a waste hut

there has

been

disciiscioti

about

the

lOnnm

chromium

thus.

some discussion

about

that

chromium

is

necessary.

Chrome is

used as

a

corrosion

inhibitor

in the oil and

as

industry.

esneciallv

in oil well

treatments. See

for

examnie

patent #

5,690,174, #5,836,392

where

chromium

is a

corrosion

inhibitor,

or across linker,

naterit

6

‘9

Bi

where

chromium

ion is

used as

a corrosion

inhibitor with

glvcol

ether solvents, # 3,986,964 where chrOmium sulfate

is used in

drilling

mud, and

#

A o,c7

R

xihiinh

teanhes

the

use

of”cirepn

nhoqnhnric’

arid”

technical

grade

which

is

neutralized to make potassium

phosphate solution and

contulns “at

least

10 ppm

(ranging

Settlement

Proposal

AET

and EOR

071106

to

e’er

2fl

rnm’

‘hromium

heiavalent”

to he

effective

as a

corrosion

inhibitor.

This

is

nn!v

a minute

exaumle

of

the

use

of

chrome

in the

oil

and gas

industry

as

a

corrosion

inhibitor

especially

in

acid

treatments.

Therefore

the

presence

of Ioppm

chromium

in

the

nbocphnrir

mtrw

acid solution

would

be an

advantage

The

presence

of chromium

would

not

comprornis

the

acid

mixture

for use

as an

oil

well

cleaning

solution.

Further,

if the

chromium

came

from

a RCRA

empty

tank,

in

2002,

that

material

was not

RCRA

+,-f-

1-

yiiii’

with

the

ritl riliitin

wn-iil(-l

iint

he

mixing

a

RCRA

,if1

fhc

qr,cl

1 he

mtpriai

hi

never

been

used

in

any

oroduction

and

so

the

ohrome

‘.°u1d

i,ni- kie

‘cm’

frit

any nIatin

cmeratinn.

The

chrome

may

have been

a

part

of

the

phosphoric

acid

Simply,

the

origin

of

the chromium

is not

known,

but

its

presence

does

not

make

the acid

a waste

and

therefGre

not

a .RCRA

waste,

it

was

a

product

10

oe

Useu

iU

rca

ii

Fourth,

glycolic

acid

is

widely

sold

by

DOW

chemical

Company

as

an oil

well treatment

hcmicaL

This

‘-“os

w’

o

t’e

!fl

FPA

an1

Oil

and

(as

Division.

The

mixture

contame

some

givcc

lie acid.

Fifth,

illinois

EPA

sanctions

.promotes

and.

sponsors

the

(re)u.se

of

haarckus

materials,

previously

used,

or off

spec

hazardous

materials,

including

an

acid

closely

analogous

to

the

materiiJ

used

and

suhiect.

to

this actioit

In

fact the

acid

that the

IMES

(http://www.ena.state.iLus/landJunes/irnes4isting.pdf,

lists asIM:.A01/8i

10

is

remarkably

similar

in

composition

and

use,

and seems

to

be

fine with.

IEPA

as

a product.

5ivth

.

It

.j

pot

tnie

th

at

this

material

was

so dangerous

that

no TSDF

would

take

it

for

disposal.

When

the

i-ernaisiim.

totes

of

the

material

were

sent

for

disposal

in

2005.

it

was

approved

for

disposal

at

Waste

Management

of

Ohio.

Pollution

Control

Industries

.of.Indiana,

and

SET

of

Texas

where

it

was

finally sent.

Additionally

the

mixture,

prior

to shipment

to Illinois,

was tested

and

shown

to

not corrode

the

materials

of construction

of the

oil

wells

in

Illinois,

and

in

fact it

was

a

very

good material,

the

phsphoric

aiM

has

been

shown

fri

he

better

than

hydrochloric

by

the

US

DOE.

the

mtr

add

had the

iotentjal

to

loosen

the

oil

densits

as.ha

been

shown

to take nl.ace

patent#

3,292,192

which teaches

the

use

of the

anhydrous

nitric

acid:,

theorange

gas,

and

4,

g1 fviW

‘itl

i

xyi,lgly

iiqp

tri

itlOsre r’1e

rlnnitç

.

the

material

xras

pota

wate

when

shined

to storedor

used

in Illinois.

The

material

was

to

be

.as

a

cleaner

nf

nil

nrndiictinn

wpil

which

was

a

legitimate

use

of the

material.

FO

believes

that

the

testimony

of

two

itirlependent

contractors,

hired

to

treat

the

oil wólls,

that

the”

dmir’et1

the

dd

into

inectinn

wells

is

false.

Firstly.

and

demonstrably

true

is that

the

Gl

1

°wa

w11

hail

7Sflnsi

ous

nreqsnre

nnnthing

of

the well

at the

time

they

said they

added

acid

to

the

well,

and

the

casing

was

full.

to

the

top.

with

water,

necessary

for

the

MIT test.

So

for

the acid

to be

added

to the

well

the

contractors

would

have had

to

overcome

750

psi,

enough

pressure

to blow

acid

.ailover

the

place

and the

contractors

andnever.get

any

in the

well,

much less

a tote

of275

gallons.

They lied,

but

why?

Industrial

Material

Exchange

Service

Page

1

of

Industrial

Material

Exchange

Service

A

Free

C

fivIøntiI

Mril

Fwhnrui

Drririrni

.‘I4

r

Rod

R.

Blagojevich,

Eggshè

Its

are

used

for

tile

pigment..

dryer

lint

is

used

as

casket

stuffing...fish

waste

is

used

for

asphaft

blendinq..

.and

horror

movie

sets

are

used

as

a

Haunted

House

for

Halloween...

What

do

eggshells,

fish

waste,

lint

and

creaking

doors

have

in

common?

All

have

been

reused

or

rprvrled

for

new

uses

thrniirih

uruicwI

TIJjlç

FPA

inHiitrv

oriented

prociram.

The

creative

reuse

of

these

materials

demonstrates

the

basic

premise

of

the

Tilinos

Industrial

Material

Exchange

Service

(IMES),

that

on

cornpanyrs

waste

can

be

a

valuabie

resource

mater,alto

another

Acting

as

an

information

clearinghouse,

di?èctcry,

a

for

reusable

ihdustrial

materials,

IMES

deals

with

waste

by-products,

off-spec

items,

hazardous

and

nonhazardous

materials,

overstock,

and

damaged

or

unwanted

materials.

IMES

Documents

-

IMES

Directory

IMES

Listing

Form

I

TM

‘r,’n

New

listings

available:

These

listings

are

in

addition

to

those

found

in

the

current

IMES

Directory.

-

IMES

New

Listings

A

survey

of

TMFc

dients

shows

that

th

nrnnrm

h

dirørtiv

frnd

nte

trr.cctions

bet’’n

‘np’’-

that

generated

more

than

$204.4

million

in

cost

savings.

More

than

2494

million

gallons

or

gallon

equivalents

of

material

have

been

diverted

from

landfill

disposal

in

th

nrness

IfrIES

can

help

manage

an

industry’s

waste

streams

when

other

source

reductiOn

or

pollution

prevention

applications

are

not

possible

or

practical,

when

on-site

treatment

or

disposal

is

too

expensive,

or

when

no

in-house

expertise

is

available

for

on-site

waste

treatment.

The

process

can

work

both

when

waste

is

routinely

generated

with

properties

and

volumes

that

are

predictable,

or

when

waste

is

generated

on

a

one-time

only

basis.

How

Does

IMES

Work’

IMES

publishes

a

semi-annual

directory

that

goes

to

14,000

subscribers

nationwide.

It

lists

both

materials

that

are

availableand

materials

industries

are

seeking.

Request

forms

are

included

in

the

front

of

each

directory.

To

respond,

or

to

list

a

material,

firms

can

send

phone

or

fax

requests

to

the

IMES

office.

Copies

of

the

most

recent

IMES

directory

can

be

obtained,

or

firms

can

be

added

to

the

mailing

list,

by

calling

217782-045o.

After

a

firm

responds

to

a

listing,

IMES

puts

the

potential

user

in

contact

with

the

generator,

with

the

final

transaction

and

transoortation

of

materials

left

to

the

cnmphiec

invnlvert:

Materials

listinos

sty

the

rllrectry

fcr

a

minimum

o

one

year

unless

the

hct4no

s

withdrawn

Tf

firm

rrfr

M

their

mteriafs

r1er’t

TMC

II

not

release

a

cnmpny

name

or

hnne

rnmher

withoif-

rermiccior.

Focus

of

the

IMES

program

is

on

services

to

industrial

clients,

so

the

program.

does

not

have

direct

involvement

with

regulatory

bureaus

or

the

Illinois

EPA

1

s

comoliance

nrncrams.

and

does

not

allow

acres

to

its

files,

or

discuss

cIiet

companies

4

needs

with

Agency

bureaus.

TMF

Tc

Prllhs

Awcckii

Bureau

of

Land

http://www.epa.state.il.us/land/imes/

11

/9/20O

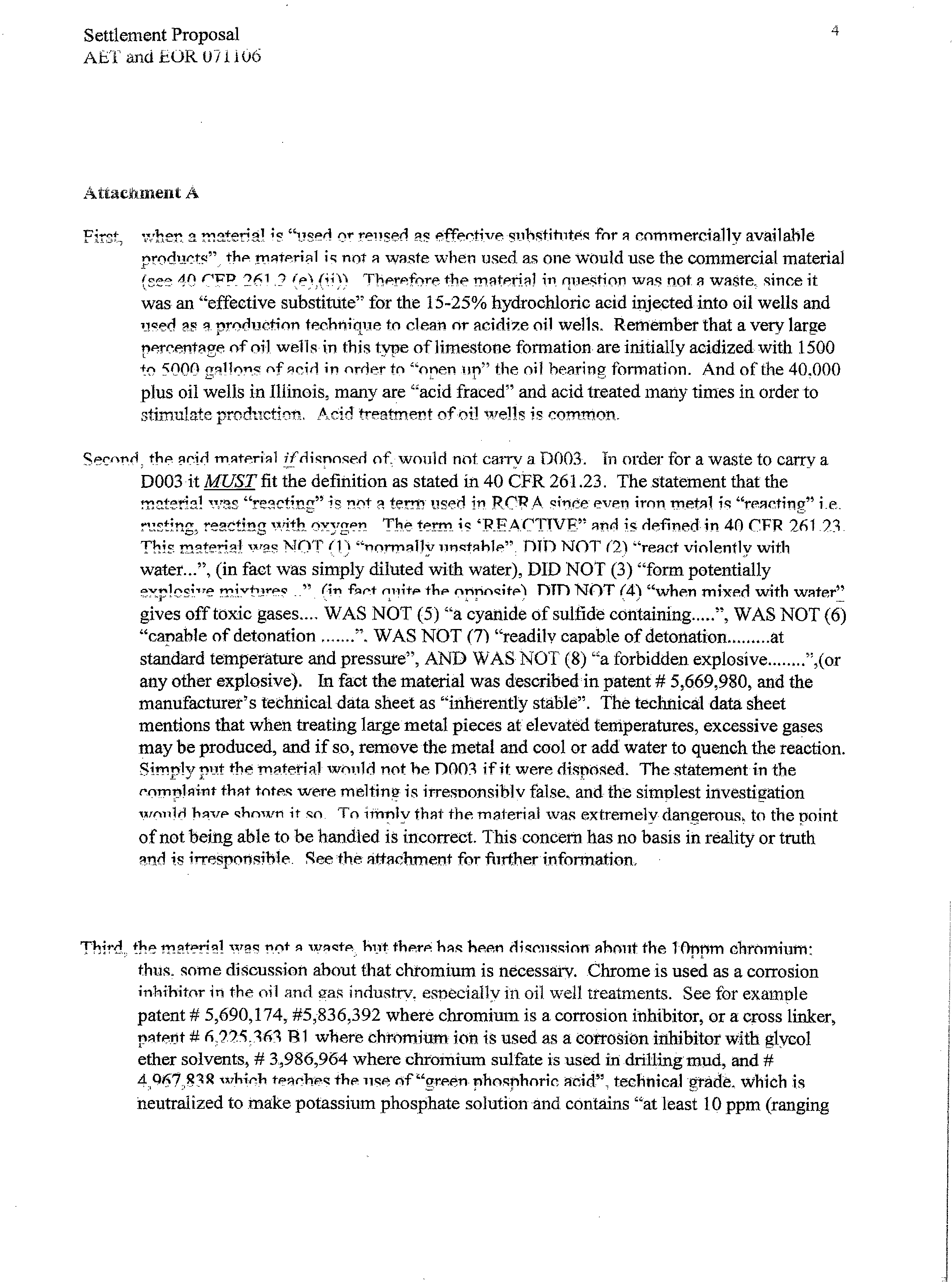

FIeedsI.

Acids

Acetic

Acid

IM:AO1/9229

99.5%

acetic

acid,

APHA

color

20-30,

three-tank

truck

loads

per

month,

minimum

one

tank

load,

sample,

lab

analysis

and

MSOS

on

request

Confidential

List/na

Acetic

Acid

IM:AO1/9230

85-92%

acetic

acid.

water.

acrviic

acid

solution,

three

tank

truck

loads

now,

bulk,

15,000

gallons

per

month,

minimum

one

tank

tritck

load,

sample,

lab

analysis

and

MSDS

on

renuest.

Confidential

List/na

Acetic

Acid

Solution

lM:AO’t

/0265

Obsolete

material,

approximately

six

years

old,

60-70%

lariaI

aetiO

eid.

30-40%

water.

2.500

oallnns

available

one

time

only.

sample

and

MSDS

on

request.

confidential

Listina

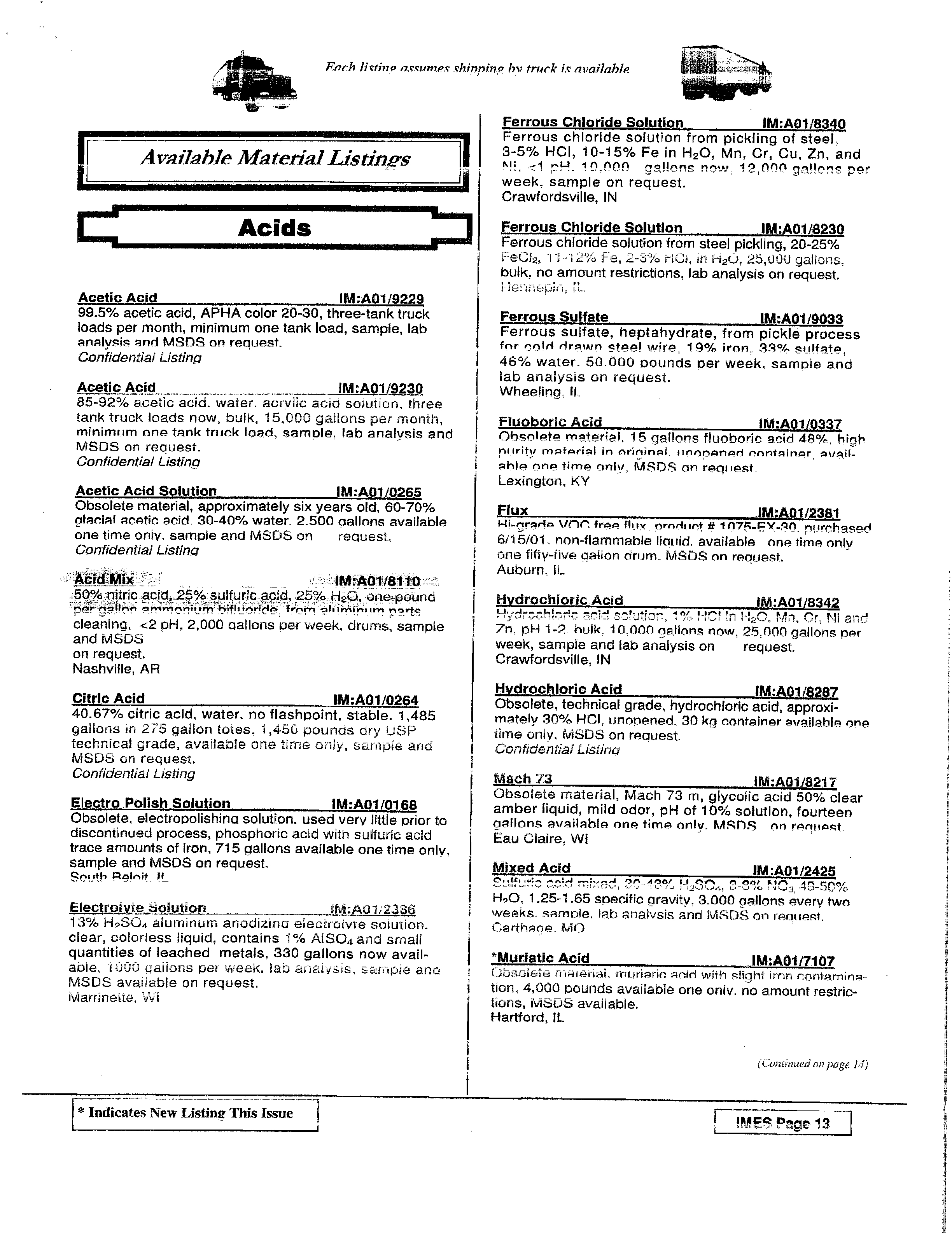

A

1M1x

:.

IMAOI/S1W

5O%nitric

acid,

25%suIfuric.ad,

25%.

HO.

one

pound

hf1

nn

cleanino.

<2

oH.

2.000

eallons

per

week,

drums,

sample

and

MSDS

on

request.

Nashville,

AR

Citric

Acid

lM:A01/0264

40.67%

citric

acid,

water,

no

flashpoint.

stable.

1,485

gallons

tO

2Y5

gallon

totes,

1,450

pounc

cry

LiSP

technical

grade,

available

aria

trne

only,

sample

and

MSDS

on

request.

Con

uideniial

Listing

Electro

Polish

Solution

lM:A0110168

Obsolete,

electropolishinq

solution,

used

very

little

prior

to

discontinued

process,

phosphoric

acid

with

sulfuric

acid

trace

amounts

of

iron,

715

aallorts

available

one

time

only.

sample

and

l’vISDS

on

request.

.fh

PIoi*

çtj,jL

e

sitori

13%

H

9

S0

4

aluminum

anodizino

electroiwe

sonnion.

clear,

colcriess

liquid,

contains

1%

AlSO

4

and

small

quantities

of

leached

metals,

330

gallons

now

avail

aole.

uUU

qailons

pet

weeK.

lao

anrnvsls.

s1i-p,&

aflu

MSDS

available

on

request.

Marrinette,

Ji

Ferrous

Chloride

Solution

IM;A0118340

Ferrous

chloride

solution

from

pickling

of

steel,

3-5%

HCI,

10-15%

Fe

in

H

2

0,

Mn,

Cr,

Cu,

Zn,

and

M

‘t

....L.I

10

000

tt,’r

10,000

Ire

week,

sample

on

request.

Crawfordsville,

IN

Ferrous

Chloride

SolutIon

IM:A0118230

Ferrous

chloride

solution

from

steel

pickling,

20-25%

i1-i

i-c,

.-a

%

MLii,

H

2

u,

25,01J0

gallons.

bulk,

no

amount

restrictions,

lab

analysis

on

request.

Ferrous

Sulfate

IM;AO1/9033

Ferrous

sulfate,

heptahydrate,

from

pickle

process

fr

rnIrl

r1rwn

tø!

wire.

1%

irnn

3°/.

ulfte.

46%

water.

50.000

oounds

ocr

week.

samole

and

lab

analysis

on

request.

Wheelino.

II.

Fluoboric

Acid

lM:AO1/0337

Ohsrilete

msteril

15

qllnns

fluoboric

cd

S%,

hiqb

01

ritu

fôrl

in

orirtinal

a

innønd

onntiner

,il

able

one

time

nnI,.

MSDS

on

rent

est

Lexington,

KY

Flux

lMAO1l236i

WicrrI

Vflfl

fr

fiw

1n75EY-’fl

,rcbsse

6/15/01.

non-flamniable

liould,

available

onetime

only

one

fifty-five

calion

dram.

MSDS

on

renuest.

Auburn,

iL

Hydrochloric

Acid

IM:A01/8342

LI

N

&

!-i’t

‘-‘

M,

r,

Ni

an

7n,

oH

1-2

hulk.

10.000

nallons

now.

25000

nalloos

per

week,

sample

and

lab

analysis

on

request.

Crawfordsville,

IN

Hydrochloric

Acid

IM:A01/8287

Obsolete,

technical

grade,

hydrochloric

acid,

approxi

matelv

30%

HOL

aannnened.

30

kq

container

availbla

°e

time

only.

MSDS

on

request.

Confident/al

Listina

Mach

73

,IM:AO1/8217

Obsolete

material,

Mach

73

m,

glycoiic

acid

50%

clear

amber

liquid,

mild

odor.

pH

of

10%

solution,

fourteen

cjallrns

vailahle

one

time

only

MSflS

on

rrtaaqt

Eau

Ciaire,

WI

MIxed

Acid

IM:A01/2425

,.l

-

1

HO.

1.25-1.65

soenific

qravitv.

3.000

nallons

varv

two

weeks.

samnie,

lab

analysis

and

MSOS

on

ran

jest.

(arthaoe

Mfl

*Murlatic

Acid

JM:A01

17107

Uhsciiete

n

i4ni.

rnurianc

id

with

slinhi

mn

cnntamin.

don,

4,000

pounds

available

one

only,

no

amount

restric

tions,

MSOS

available.

Hartford,

IL

(inued

an

page

11)

*

Jndicates

New

Listing

This

Issue

J,

r1M13

I

F,y,’I,

)icti;;e

n.c.cumpc

chjr,r,inc,

Ire

truck

Lv

.lvnhlahh?

Page

1

of

1

ART

From:

Mankowski,

Michael

Emmankowski@atg.state.iI.us}

Sent:

Friday,

October

26,

2007

10:02

AM

To:

ART

Subject:

RE:

AET

EQR

Art,

I

just

got

the

copies

of

the

filed

answers

and

Dave’s

appearance,

so

the

PCB

part

looks

good

for

now.

If

we

can

work

Out

a

settlement

than

that

is

all

that

you

should

have

to

do

on

the

PCB

end.

Since

that

end

of

it

is

now

in

order,

I

would

encourage

you

to

write

a

letter

with

a

counter

offer.

My

management

is

open

to

the

idea

and

I

hope

that

we

can

come

to

an

agreeable

settlement.

Thanks,

Michael

D.

Mankowski,

AAG

Environmental

Bureau

This

message

and

any

attachments

may

contain

confdarttiaVphvilegèd

information

protected

by

the

attomey-okent

or

attorney

work

product

privilege,

If

you

are

not

the

intended

recipient,

please

notiFy

the

sender

immediately

and

d&ete

the

original

message

and

aoy

attachments.

Thank

you.

From:

ART

n,ailto:arthirdark@aetenvironmentaicorn]

nt;

itlday,

October

2,

2001

10:57

AM

TO:

Maflkowski,

Michael

Subject:

AEr

EOR

Should

I

prepare

an

offer

to

settle

based

on

our

conversation?

IS

there

something

I

still

need

to

do

for

the

PC

board?

Thanks

fàryour

professional

attitude

in

this

matter.

M

No

vinis

found

in

this

outgoing

message.

Checknd

by

AVG

Free

Edition.

Version:

7.5.503

/

Vhs

Database:

269.15.11/1093

Release

Date:

10125/2007

51E

PM

No

vhs

found

in

this

incoming

message.

Checked

by

AVG

Free

Edition.

Version:

7.5.503

/

Virus

Database:

269.15.11/1093

-

Release

Date:

10125/2007

5:38

PM

7/29/2008