225

.APPENDTX

B

Continuous

Emission

Monitoring

Systems

for

Mercury

Section

1.1

Applicability

The

provisions

of

this

Appendix

apply

to

sources

subject

to 35

III

Admin.

Code

Part

225

mercury

(Hg)

mass

emission

reduction

program.

Section

1.2

General

operating

requirements

a)

Primary

Equipment

Performance

Requirements.

The

owner

or

operator

must

ensure

that

each

continuous

mercury

emission

monitoring

system

required

by

this

Appendix

meets

the

equipment,

installation,

and

performance

specifications

in Exhibit

A to

this

Appendix

and

is maintained

according

to the

quality

assurance

and

quality

control

procedures

in

Exhibit

B

to this

Appendix.

b)

Heat

Input

Rate

Measurement

Requirement.

The

owner

or operator

must

determine

and

record

the heat

input

rate,

in

units

of

mmBtu!hr,

to

each

affected

unit

for

every

hour

or

part

of

an

hour

any

fuel

is combusted

following

the procedures

in

Exhibit

C

to

this

Appendix.

c)

Primary

equipment

hourly

operating

requirements.

The

owner

or

operator

must

ensure

that

all

continuous

mercury

emission

monitoring

systems

required

by

this

Appendix

are

in

operation

and

monitoring

unit

emissions.

at

all

times

that

the

affected

unit

combusts

any

fuel

except

during

periods

of calibration,

quality

assurance,

or preventive

maintenance,

performed

pursuant

to

Section

1.5

of

this

Appendix

and

Exhibit

B

to this

Appendix,

periods

of

repair,

periods ofbackups

of

data

from

the data

acquisition

and

handling

system,

or

recertification

performed

pursuant

to

Section

l.4.of

this

Appendix.

1)

The

owner

or

operator

must

ensure

that

each

continuous

emission

monitoring

system

is

capable

of

completing

a minimum

of

one

cycle

of operation

(sampling,

analyzing,

and

data

recording)

for

each

successive

15-minute

interval.

The

owner

or

operator

must

reduce

all

volumetric

flow,

CO

2

concentration,

02

concentration,

and

mercury

concentration

data

collected

by

the

monitors

to

hourly

averages.

Hourly averages

must

be

computed

using

at

least

one

data

point

in

each

fifteen

minute

quadrant

of an

hour,

where

the

unit

combusted

fuel

during

that

quadrant

of

an

hour.

Notwithstanding

this

requirement,

an

hourly

average

may

be

computed

from

at

least

two

data

points

separated

by

a minimum

of

15

minutes

(where

the

unit

operates

for

more

than

one

quadrant

of

an

hour)

if

data

are

unavailable

as

a

result

of

the

performance

of

calibration,

quality

assurance,

or

preventive

1

maintenance;activities’pursuantto

Sectiôn’L5of

this

Appendix

and

Exhibit

B

to

this

Appendix,

or

backups

of

data

from the

data

acquisition

and

handling

system,

or

recertification,

pursuantto

Section 1.4

to

thisAppendix

The

owner

or

operator

must

use

all

valid

measurements

or

data

points

collected

during an

hour

to

calculate

the

hourly

averages.

All

data

points

collected

during an

hour

must

be,

to

the

extent

practicable,

evenly

spaced

over the

hour.

2)

Failure

of a

CO

2

oLQ2

emissions

concentration

monitor,

mercury

concentration

monitor,

flow

monitor,

or

a

moisture

monitor

to

acquire

the

minimum

number

of

data

points

for

calculation

of

an

hourly

average

in paragraph

(c)(

1)

of

this

Section

must

result

in the

failure

to

obtain

a

valid

hour

of

data

and

the

loss

of

such

component

data for

the

entire

hour.

For

a

moisture

monitoring

system

consisting

of

one

or

more

oxygen

analyzers

capable

of

measuringQ

2

on

a

wet-basis

and

a

dry-basis,

an

hourly

average

percent

moisture

value

is

valid

only

if

the

minimum

number

of

data

points

is acquired

for

both

the

wet-and

dry-basis

measurements.

d)

Optional

backup

monitor

requirements.

If

the

owner

or

orator

chooses

to

use

two

or

more

continuous

mercury

emission

monitoring

systems,

each

of

which

is

capable

of

monitoring

the

same

stack or

duct

at

a

specific

affected

unit,

or

group

of

units

using

a

common

stack,

then

the

owner

or

operator

must

designate

one

monitoring

system

as

the

primary

monitoring

system,

and

must

record

this

information

in

the

monitoring

plan, as

provided

for

in

Section

1.10

of

this

Appendix.

The

owner

or

operator must

designate

the

other

monitoring

system(s)

as

backup

monitoring

system(s)

in

the

monitoring

plan.

The

bàcku

monitoring

system(s)

must

be

designated

as

redundant

backup monitoring

system(s),

non-redundant

backup

monitoring

system(s),

or

reference method

backup

system(s),

as

described

in

Section

1.4(d)

of

this

Appendix.

When

the

certified

primary

monitoring

system

is

operating

and

not

out-of-control

as

defined

in

Section

1.7

of

this

Appendix,

only

data

from

the

certified primary

monitoring

system

must

be

reported

as

valid,

quality-assured

data.

Thus,

data

from

the

backup

monitoring

system

may

be

reported

as

valid,

quality-assured

data

only

when

the

backup

is

operating

and

not

out-of-

control

as

defined in

Section

1.7

of

this

Appendix

(or

in the

applicable

reference

method

in

appendix

A

of 40

CFR60,

incorporated

by

reference

in

Section

225.140)

and

when

the

certified

primary

monitoring

system is

not

operating

(or

is

operating

but

out-of-control).

A

particular

monitor

may

be

designated

both

as

a certified

primary

monitor

for

one

unit

and

as

a

certified

redundant

backup

monitor

for

another

unit.

e)

Minimum

measurement

capability

requirement.

The

owner

or

operator

must

ensure

that

each

continuous

emission

monitoring

system

is

capable

of

accurately

measuring,

recording,

and

reporting

data,

and

must

not

incur

an exceedance

of

the

full

scale

range,

except

as

provided

in

Section

2.1.2.3

of

Exhibit

A to

this

Appendix.

2

f).

Operator must

record

and

the

designated

representative

must

report

the.

hourly,

daily,

quarterly,

and

annual

information

collected

under

the

requirements

as

specified

in

subpart

G

of 40

CFR

75,

incorporated

byreference,in

Section

225.140,

and

Section

1

.1 F

through 1.13

of

this

Appendix.

Section

1.3

Special

provisions

for

measuring

mercury

mass

emissions

using

the

excepted

sorbent

trap

monitoring

methodology

For

an

affected

coal-fired

unit

under

.35.111

Admin.

Code.

Part

225

if

the.

owner

or

operator elects

to

use

sorbent

trap

monitoring

systems

(as

defined

in

Section

225.130) to

quantify

mass

emissions,

the

guidelines

in

paragraphs

(a)

through

(1)

of this

Section

must

be

followed

for

this

excepted

monitoring

methodology:

a)

For

each

sorbent

trap

monitoring

system

(whether

primary

or

redundant

backup),

the

use

of

paired

sorbent

traps,

as

described

in Exhibit

D

to this

Appendix,

is

required:

b’)

Each

sorbent

trap

must

have

a

main

section,

a backup

section,

and

a

third

section

to

allow

spiking

with

a calibration

gas of

known mercury

concentration,

as

described

in

Exhibit

D to

this

Appendix:

c)

A

certified

flow

monitoring

system

is

required;

d)

Correction

for

stack

gas

moisture

content

is

required,

and

in some

cases,

a

certified

O2or

Q2

monitoring

system

is

required

(see

Section

1.1

5(a)(4));

e)

Each

sorbent trap

monitoring

system

must

be

installed

and

operated

in

accordance

with

Exhibit

D

to

this

Appendix.

The

automated

data.acguisition

and

handling

system

must

ensure

that

the

sampling

rate

is

proportional

to

the

stack

gas

volumetric

flow

rate.

f)

At

the

beginning

and

end

of

each

sample

collection

period,

and

at

least

once

in

each

unit

operating

hour

during

the

collection

period,

the

gas

flow

meter

reading

must

be

recorded.

g)

After

each

sample

collection

period,

the

mass

of

mercury

adsorbed

in

each

sorbent

trap

(jn

all

three

sections)

must

be

determined

according

to the

applicable

procedures

in

Exhibit

D

to

this

Appendix.

h)

The

hourly

mercury

mass

emissions

for

each

collection

period

are

determined

using

the

results

of

the

analyses

in

conjunction with

contemporaneous

hourly

data

recorded

by

a

certified

stack

flow

monitor,

corrected

for

the

stack

gas

moisture

content.

For

each

pair

of

sorbent

traps

analyzed,

the

average

of

the

two

mercury

concentrations

must

be

used

for

reporting

purposes

under

Section

1.18(f)

to

this

Appendix.

Notwithstanding

tlils

3

requirement,

if,

due

to

circumstances

beyond

the

control

of the

owner

or

operator,

one

of.

the

paired

traps.is

accidentally

lost,

damaged,

or

broken

and

cannot.

be

analyzed, the..

results

of

the analysis

of

the

other

trap

may

be

used

fr

reporting

purposes,

provided

that

the

other

trap

has

met

all

of the

applicable

quality-assurance

requirements

of

this

part.

i)

All

unit

operating

hours

for

which valid

mercury

concentration

data

are

obtained

with

the

primary

sorbent

trap

monitoring

system

(as

verified

using

the

quality

assurance

procedures

in

Exhibit

D

to this

Appendix)

must

be

reported

in

the electronic

quarterly

report

under

Section

1.18(f) .to this

Appendix.

For.hours

in

which

data

from

the

primary

monitoring

system

are

invalid,

the

owner

or

operator

may,

in

accordance

with

Section

1.4(d)

to this

Appendix,

report

valid

mercury

concentration

data

from:

A

certified

redundant

backup

CEMS

or sorbent

trap

monitoring

system;

a certified

non-redundant

backup

CEMS

or

sorbent

trap

monitoring

system;

or

an applicable

reference

method

under

Section

1.6

to

this

Appendix.

j)

Initial

certification

requirements

and

additional

quality-assurance

requirements

for

the

sorbent.trap.monitoring

systems

are

found

in

Section

L4(c)(7),

in

Section

6.5.6

of

Exhibit

A

to

this

Appendix,

in

Sections

1.3

and

2.3

of Exhibit

B

to this

Appendix,

and

in

Exhibit

D

to

this

Appendix.

k)

During

each

RATA

of a

sorbent

trap

monitoring

system,

the

type

of sorb

ent

material

used

by

the

traps

must

be

the

same

as

for

daily

operation

of

the

monitoring

system.

A

new

pair

of

traps

must

be

used

for

each

RATA

run.

However,

the

size

of

the

traps

used

for

the

RATA

may

be

smaller

than

the

traps

used

for

daily

operation

of

the

system.

1)

. Whenever

the

type

of

sorbent

material

used

bythetraps

is changed,.

the

owner

orroperator

must

conduct

a

diagnostic

RATA

of the

modified

sorbent

trap

monitoring

system

within

720

unit

or

stack

operating

hours

after

the.

date

and

hour

when

the

new

sorbent

material

is

first

used.

If

the

diagnostic

RATA

is

passed,

data

from

the

modified

system

maybe

reported

asquality-assured.

back

to the

date

andhour

when.

the

new

sorbent

material

was

first

used.

If

the

RATA

is

failed,

all

data

from

the

modified

system

must

be

invalidated,

back

to

the

date

and

hour

when

the

new

sorbent

material

was

first

used,

and

data

from

the

system

must

remain invalid

until

a

subsequent

RATA

is

passed.

If

the

required

RATA

is

not

completed

within

720

unit

or

stack

operating

hours,

but

is passed

on

the

first

attempt,

data

from

the

modified

system

must

be

invalidated

beginning

with

the

first

operating

hour

after

the

720

unit

or stack

operating

hour

window

expires

and

data

from

the

system

must

remain

invalid

until

the

date

and

hour

of

completion

of

the

successful

RATA.

Section

1.4

Initial

certification

and

recertification

procedures

a)

Initial

certification

approval

process.

The

owner

or

operator

must

ensure

that

each

continuous

mercury

emission

monitoring

system

required

by

this

Appendix

meets

4

the

iitiaI c&ifiation•requirementsof

this

SeôtiOn;

In

addition,

whenever’the

owner

or

operator

installs

a

continuous

mercury

emission

monitoring

system

in

order

to

meet

the

reqriirmentsof

Sections

1.3

of

this

Appendix

and

40

CFR

Sections

75.11

through

75.14

and

75

.16

through

75.18,

incorporatedby

reference

in

Section

225.140,

where

no

continuous

emission

monitoring

system

was.

previously

installed,

initial

certification

is

required.

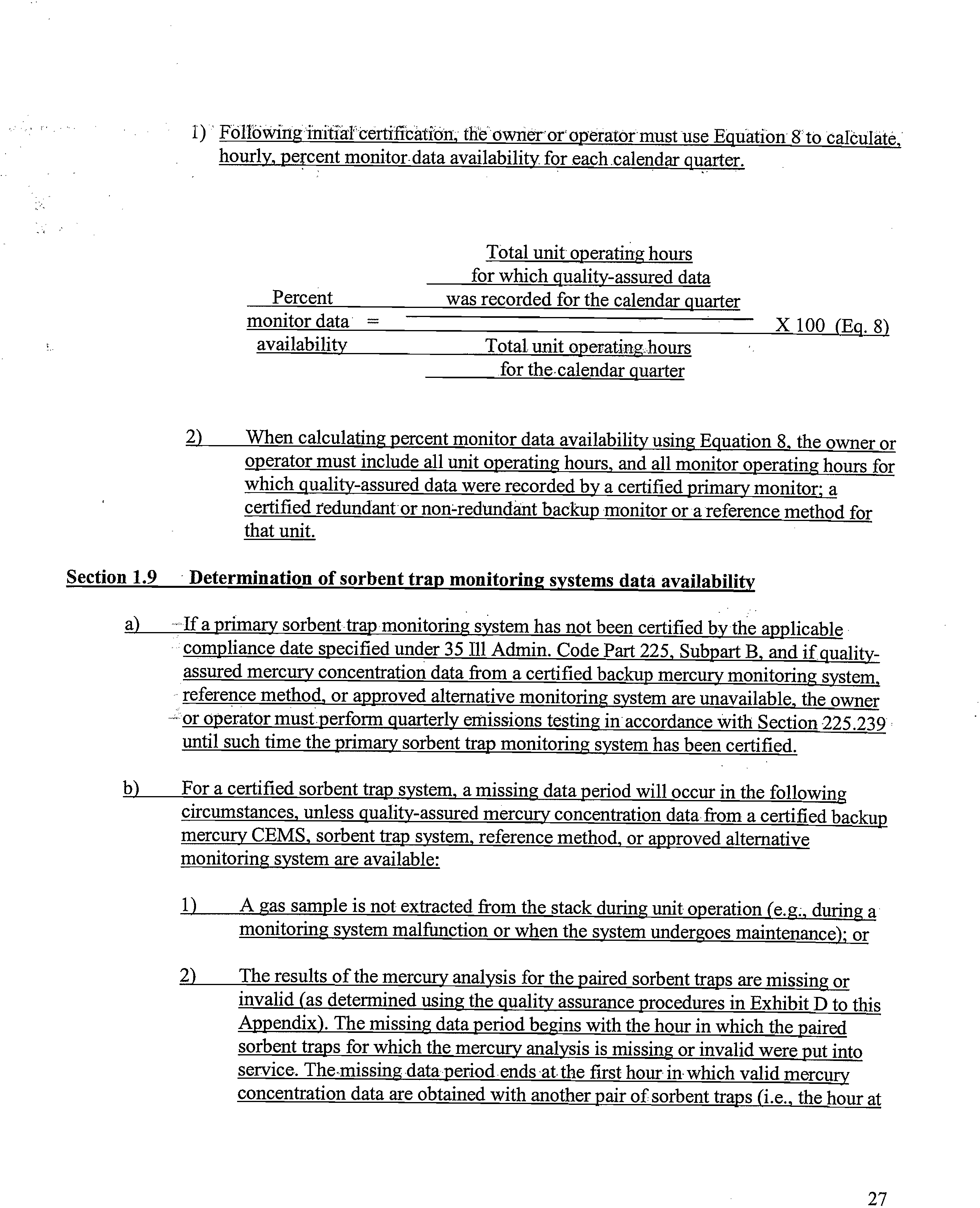

1)

Notification

of

initial

certification

test

dates.

The

owner

or

operator

or

designated

representative

must

submit

a

written

notice

of

the

dates

of

initial

certification

testing at

the

unit

as

specified.

in

40

CFR

75.61

(a)(

1),

incorporated

by

reference

in

Section

225.140..

2)

Certification

application.

The

owner

or

operator

must

apply

for

certification

of

each continuous

mercury

emission

monitoring

system.

The

owner

or

operator

must

submit

the

certification

application

in

accordance

with

40

CFR

75.60,

incorporated

by

reference

in

Section

225.140,

and

each

complete

certification

application

must

inolude

the

information

specified

in

40

CFR

75.63,

inCorporated

by

reference

in

Section

225.140.

3)

Provisional

approval

of

certification

(or

recertification)

applications.

Upon

the

successful

completion

of

the

required

certification

(or

recertification)

procedures

of

this

Section,

each

continuous

mercury

emission

monitoring

system

must

be

deemed

provisiànally

certified

(or

recertified)

for

use

for

a period

not

to

exceed

120

days following

receipt

by

the

Agency

of

the

complete

certification

(or

recertification)

application

under paragraph

(a)(4) of

this

Section.

Data

measured

and

recorded

by

aprovisionally

certified

(or

recertified)

continuous

emission

monitoring

system,

operated

in

accordance

with

the

requirements

of

Exhibit

B

to

this

Appendix,

will

be

considered

valid

quality-assured

data

(retroactive

to

the

date

and

time

of

provisional

certification

or

recertification),

provided

that

the

Agency

does

not

invalidate

the

provisional

certification

(or

recertification)

by

issuing

a

notice

of

disapproval

within

120

days

of

receipt

by

the

Agency

of

the

complete

certification

(or

recertification)

application.

Note

that

when

the

conditional

data

validation

procedures

of

paragraph

(b)(3)

of

this

Section

are

used

for

the

initial certification

(or

recertification)

of

a

continuous

emissions

monitoring

system,

the

date

and

time

of

provisional

certification

(or

recertification)

of

the

CEMS

may

be

earlier

than

the

date and

time

of

completion

of

the

required

certification

(or

recertification)

tests.

4)

Certification

(or

recertification)

application

formal

approval

process.

The

Agency

will

issue

a

notice

of

approval

or

disapproval

of

the

certification

(or

recertification)

application to

the

owner or

operator

within

120

days

of

receipt

of

the

complete

certification

(or

recertification)

application. In

the

event

the

Agency

5

does

not

issue

such

a

notice

within

120

days

of

receipt,

each

continuous

emission

monitoring

system

which

meets the

performance

requirements

of

this

part

and

is

included

in

the

certification

(or

recertification)

applicationwill

be

deemed

certified

(or

recertified) for

use

under

35

IliAdmin.

Code

Part

225.

A)

Approval

notice.

If

the

certification

(or

recertification)

application

is

complete

and

shows

that

each

continuous

emission

monitoring

system

meets

the performance

requirements

of

this

part,

then

the

Agency

will

issue

a

notice

of

approval

of

the

certification

(or

recertification)

application

within

120

days

of

receipt.

B)

Incomplete

application

notice.

A

certification

(or

recertification)

application

will

be

considered

complete

when

all

of

the

applicable

information

required

to

be

submitted

in

40

CFR

75.63,

incorporated

by

reference

in

Section

225.140,

has

been received

by

the

Agency.

If

the

certification

(or

recertification)

application

is

not

complete,

then

the

Agency

will

issue

a notice

of

incompleteness

that

provides

a

reasonable•

timeframe

for

the

designated

representative

to

submit

the

additional

information

required

to

complete

the

certification

(or

recertification)

application.

If

the

designated

representative

has

not

complied

with

the

notice

of

incompleteness

by

a

specified

due

date,

then

the

Agency

may

issue

a

notice

of

disapproval

specified

üñder

paragraph

(a)(4)(C)

of

this

Section.

The

120-day

review

period

will

not

begin

prior

to

receipt

of

a

complete

application.

C)

Disapproval

notice.

If

the

certification

(or

recertification)

application

shows

that

any

continuous

emission

monitoring

system

does

not

meet

the

performance

requirements

of

this

part, or

if

the

certification

(or

recertification)

application

is

incomplete

and

the

requirement

for

disapproval

under

paragraph

(a)(4)(B)

of

this

Section

has

been

met,

the

Agency

must issue

a

written

notice

of

disapproval

of

the

certification

(or

recertification)

application

within

120

days

of

receipt.

By issuing

the

notice

of

disapproval,

the

provisional

certification

(or

recertification)

is

invalidated

by

the

Agency,

and

the

data

measured

and

recorded

by

each

uncertified

continuous

emission

or

opacity

monitoring

system

must

not

be

considered

valid

quality-assured

data

as

follows:

from the

hour

of

the

probationary

calibration

error

test

that

began

the

initial

certification

(or

recertification)

test

period

(if

the

conditional

data validation

procedures

of

paragraph

(b)(3)

of

this

Section

were

used

to

retrospectively

validate

data)

or

from

the

date

and

time

of

completion

of

the

invalid

certification

or

recertification

tests

(if

the

conditional

data

validation

procedures

of

paragraph

(b)(3)

of

this

Section

were

not

used).

The

owner

or

operator

6

must

follow

the

procedures

forioss

of

initial

certification

in

paragraph

(a)(5)

of

this

Section

for

each

continuous

emission

or

opacity

monitoring

sytetii

which

is

disapproved

for

initial

certification.

For

each

disapproved

recertification,

the

owner

or

operator

must

follow

the

procedures

of

paragraph

(b)(5)

of

this

Section.

5)

Procedures

for

loss

of

certification.

When

the

Agency

issues

a notice

of

disapproval

of a

certification

application

or

a notice

of

disapproval

of

certification

status

(as

specified

in

paragraph

(a)(4)

of

this

Section),

then:

A)

Until

such

time,

date,

and

hour

as

the

continuous

mercury emission

monitoring

system

can

be

adjusted,

repaired,

or replaced

and

certification

tests

successfully

completed

(or,

if the

conditional

data

validation

procedures

in

paragraphs

(b)(3)(B)

through

(b)(3)(I)

of

this

Section

are

used,

until

a

probationary

calibration

error

test

is passed following

corrective

actions

in

accordance

with

paragraph

(b)(3)(B)

of

this

Section),

the

owner

oroperator

must

perform

emissions

testing

pursuant to

Section

225.239.

B)

The

designated

representative

must

submit

a

notification

of

certification

retest

dates as

specified

in

Section

225.250(a)(3)(A) and

a

new

certification

application

according

to

theprocedures

in

Section

225.250(a)(3)(B);

and

C)

The

owner

or

operator

must

repeat

all

certification

tests

or other

requirements

that

were

failed

by

the

continuous

mercury

emission

monitoring

system,

as

indicated

in

the

Agency’s

notice

of

disapproval,

no

later

than

30

unit

operating

days

after

the

date

of

issuance

of

the

notice

of

disapproval.

b)

Recertification

approval

process.

Whenever

the

owner

or

operator

makes

a

replacement,

modification,

or

change

in

a

certified

continuous

mercury

emission

monitoring

system

that

may

significantly

affect

the

ability

of

the

system

to

accurately

measure

or

record

the

gas

volumetric

flow

rate,.mercury

concentration,

percent

moisture,

or

to

meet

the

requirements

of

Section

1.5

of this

Appendix

or Exhibit

B

to

this

Appendix,

the

owner

or

operator

must

recertify

the

continuous

mercury

emission

monitoring

system,

according

to

the

procedures

in

this

paragraph.

Examples

of changes

which

require

recertification

include: replacement

of

the

analyzer;

change

in location

or

orientation

of

the

sampling

probe

or site;

and

complete

replacement

of

an

existing

continuous

mercury

emission

monitoring

system.

The

owner

or

operator

must

also

recertify

the

continuous

emission

monitoring

systems for

a unit

that

has

recommenced

commercial

operation

fo1lowing

period

of

long-term

cold storage

as

defined

in

Section

225.130.

Any

change

to

a

flow

7

monitor

or

gas

monitoring

system

for

which

a

RATA

is

not

necessary

will

not

be

considered

a

recertification

event.

In addition,

changipg

the

polynomial

coefficients

or

K

factor(s)

of a

flow

monitor

will

require

a

3-1badRATA,

but

is

not

considered

to

be a

recertification

event;

however,

records

of

the

polynomial

coefficients

or

K

factor(s)

currently

in

use

must

be

maintained

on-site

in

a

format

suitable

for

inspection.

Changing

the

coefficient

or

K

factor(s)

of amoisture

monitoring

system

will

require

a RATA,

but

is

not

considered

to

be

a

recertification

event;

however, records

of

the

coefficient

or

K

factor(s)

currently

in use

by

the

moisture

monitoring

system

must

be maintained

on-site

in

a format

suitable

for

inspection.

In

such

cases,

any

other

tests

that

are

necessary

to

ensure

continued

proper operation

of

the

monitoring

system

(e.g.,

3-load

flow

RATAs

following

changes

to flow

monitor polynomial

coefficients,

linearity

checks,

calibration

error

tests,

DAHS

verifications,

etc.)

must

be

performed

as

diagnostic

tests,

rather

than

as

recertification

tests.

The

data

validation

procedures

in paragraph

(b)(3)

of

this

Section

must

be

applied

to

RATAs

associated

with

changes

to

flow

or

moisture

monitor

coefficients,

and

to

linearity

checks,

7-day

calibration

error

tests,

and

cycle

time

tests,

when

these

are

required

as

diagnostic

tests.

When

the

data

validation

procedures

of

paragraph

(b)(3)

ofthis

Section

are

applied

in

this

manner,

replace

the.word

“recertification”

with

the word

“diagnostic.”

1)

Tests

required.

For

all

recertification

testing,

the

owner

or

operator

must

complete

all

initial

certification

tests

in paragraph

(c)

of

this

Section

that

are

applicable

to

the

monitoring

system,

except

as Otherwise

approved

by

the

Agency.

For

diagnostic

testing

after

changing

the

flow

rate

monitor

polynomial

coefficients,

the

owner

or

operator

must

complete

a 3-level

RATA.

For

diagnostic

testing

after

changing

the

K factor

or mathematical

algorithm

of

a moisture

monitoring

system,

the

owner

or operator

must

complete

a RATA.

2)

Notification

of recertification

test

dates.

The

owner,

operator,

or

designated.

representative

must

submit

notice

of

testing

dates

for

recertification

under

this

paragraph

as

specified

in

40

CFR

75.61

(a)(

1

)(ii),

incorporated

by

reference

in

Section

225.140,

unless

all

of

the tests

in paragraph

(c)

of

this

Section

are

required

for

recertification,

in

which

case

the

owner

or

operator

must

provide notice

in

accordance

with

the

notice

provisions

for

initial

certification

testing

in

40

CFR

75.61(a)(1)(i),

incorporated

by

reference

in

Section

225.140.

3)

Recertification

test

period

requirements

and

data

validation.

The

data

validation

provisions

in

paragraphs

(b)(3)(A) through

(b)(3)(I)

of

this

Section

will

apply

to

all

mercury

CEMS

recertifications

and

diagnostic

testing.

The

provisions

in

paragraphs

(b)(3)(B)

through

(b)(3)(I)

of

this

Section

may

also

be applied

to

initial

certifications

(see

Sections

6.2(a).

6.3.1(a),

6.3.2(a),

6.4(a)

and

6.5(f)

of

Exhibit

A

to

this

Appendix)

and

may

be

used

to

supplement

the

linearity

check

and

RATA

8

data

validatiónprocedures

in

Sèctions2.2.3(b)

and

2.3.2(b)

of

Exhibit

B

to

this

Appendix.

A)

The

owner

or

operator

must

report

emission

data

using

a reference

method

or

another

monitoring

system

that

has

been

certified

or

approved

for

use

under

this

part,

in the

period

extending

from

the hour

of

the

replacement,

modification,

or

change

made

to

a

monitoring

system

that

triggers

the

need

to

perform

recertification

testing,

until

either:

the

hour

of

successful

completion

of

all

of the

required

recertification

tests;

or

the

hour

in

which

a probationary

calibration

error

test

(according

to

paragraph

(b)(3)(B)

of

this

Section)

is performed

and

passed,

following

all

necessary

repairs,

adjustments,

or

reprogramming

of the

monitoring

system.

The

first

hour

of

quality-assured

data

for the

recertified

monitoring

system

must

either

be

the

hour

after

all

recertification

tests

have

been

completed

or,

if

conditional

data

validation

is

used,

the

first

quality-assured

hour

must

be

determined

in

accordance

with

paragraphs

(b)(3)(B)

through

(b)(3)(I)

of

thisSection.

Notwithstanding

theserequirements,

if the

replacement,

modification,

or

change

requiring

recertification

of

the

CEMS

is

such

that

the

historical

data

stream

is

no

longer

representative

(e.g.,

where

the

mercury

concentration

and

stack

flow

rate

change

significantly

after

installation

of a

wet

scrubber),

the

owner

or operator

must

estimate

the

mercury

emissions

over

that

timeperiod

and

notify

the

Agency

within

15

days

of

the

replacement,

modification,

or

change

requiring

recertification

of the

CEMS.

B)

Once

the

modification

or changeto

the

CEMS

has been

completed

and

all

of

the associated

repairs,

component

replacements,

adjustments,

linearization,

and

reprogramming

of the

CEMS

have

been

completed;

a

probationary

calibration

error

test

is

required

to

establish

the

beginning

point

of

the.recertification

test

period.

In

this

instance,

the

first

successful

calibration

error

test

of the

monitoring

system

following

completion

of

all

necessary

repairs,

component

replacements,

adjustments,

linearization

and

reprogramming

must

be

the probationary

calibration

error

test.

The

probationary

calibration

error

test

must

be

passed

before

any

of

the

required

recertification

tests

are

commenced.

C)

Beginning

with

the

hour

of commencement

of

a

recertification

test

period,

emission

data

recorded

by

the

mercury

CEMS

are

considered

to

be

conditionally

valid,

contingent

upon

the

results

of

the

subsequent

recertification

tests.

9

D)

Each

required

recertification

test’

must

be completed

no

later

than

the

following

number

of

unit

operating

hours

(or

unit

operating

days)

after

the

probationary

calibratkrn

error

testthat

initiates

the test

period:

i)

For

a

linearity

check

and/or

cycle

time

test,

168

consecutive

unit

operating

hours,

as

defined

in

40

CFR

72.2,

incorporated

by

reference

in Section

225.140,

or,

for

CEMS

installed

on

common

stacks

or

bypass

stacks,

168

consecutive

stack

operating

hours,

as

defined

in

40CFR

72.2:

ii)

For

a

RATA

(whether

nonnal-load

or multiple-load),

720

consecutive

unit

operating

hours,

as defined

in

40

CFR

72.2,

incorporated

by

reference

in Section 225.140,

or,

for

CEMS

installed

on

common

stacks

or bypass stacks,

720

consecutive

stack

operating

hours,

as defined

in

40

CFR

72.2;

and

iii)

For a

7-day

calibration

error

test,

21 consecutive

unit

operating

days,

as

defined

in

40

CFR

72.2,

incorporated

by

reference

in

Section

225.140.

E)

All recertification

tests

must

be performed

hands-off.

No

adjustments

to

the

calibration

of

the

mercury

CEMS,

other

than

the

routine

calibration

adjustments

following

daily

calibration

error

tests

as

described

in

Section

2.1.3

of

Exhibit

B to

this

Appendix,

are

permitted

during

the

recertification

test

period.

Routine

daily

calibration

error

tests

must

be

performed

throughout

the

recertification

test

period,

in

accordance.with

Section 2.1.1

of Exhibit

B

to this

Appendix.

The

additional

calibration

error

test

requirements

in

Section

2.1.3

of

Exhibit

B to

this

Appendix,

must

also

apply

during

the

recertification

test

period.

F)

If all

of

the required

recertification

tests

and

required

daily

calibration

error

tests

are

successfully

completed

in

succession

with

no

failures,

and

if

each

recertification

test

is

completed

within

the

time

period

specified

in

paragraph

(b)(3)(D)(i),

(ii),

or

(iii)

of

this

Section, then

all

of the

conditionally

valid

emission

data

recorded

by

the mercury

CEMS

will

be

considered

quality

assured,

from

the

hour

of commencement

of

the

recertification

test

period

until

the hour

of

completion of

the

required

test(s).

G)

If

a

required

recertification

test

is

failed

or

aborted

due

to

a

problem

with

the

mercury

CEMS,

or

if

a

daily

calibration

error

test

is

failed

during

a

recertification

test

period,

data

validation

must

be

done

as follows:

10

i)

If

any

required

recertification

test

is failed,

it must

be

repeated,.

If

any

recertification

test

other

than

a 7-day

calibration

error

test

is

failed

or

aborted

due

to

a problem

with

the mercury

CEMS,

the

original

recertification

test period

is ended,

and

a new

recertification

test period

must

be

commenced

with

a

probationary

calibration

error

test.

The

tests

that

are

required

in the

new

recertification

test

period

will

include

any tests

that

were

required

for

the

initial

recertification

event

which

were

not•

successfully

completed

and

any recertification

or diagnostic

tests

that

are

required

as

a

result

of changes

made

to

the monitoring

system

to

correct

the

problems

that

caused

the

failure

of

the

recertification

test.

For

a 2-

or 3-load

flow

RATA,

if

the relative

accuracy

test

is

passed

at one

or

more

load

levels,

but

is

failed

at

a

subsequent

load

level,

provided

that

the

problem

that

caused

the

RATA

failure

is

corrected

without

re-linearizing

the

instrument,

the

length

of the

new

recertification

test

period

must

be

equal

to

the

number

of unit

operating

hours

remaining

in

the

original

recertification

test

period,

as

of

the hour

of failure

of the

RATA.

However,

if

re-linearization

of the

flow

monitor

is

required

after

a flow

RATA

is

failed

at

a

particular

load

level,

then

a

subsequent

3-load

RATA

is

required,

and

the

new

recertification

test

period

must

be

720

consecutive

unit

(or

stack)

operating

hours.

The new

recertification

test

sequence

must

not

be

commenced

until

all

necessary

maintenance

activities,

adjustments,

linearizations,

and

reprogramming

of

the

CEMS

have

been

cornpleted

ii)

Ifa

linearity

check,

RATA,

or

cycle

time

test is

failed

or

aborted

due

to a

problem

with

the

mercury

CEMS,

all

conditionally

valid

emission

data

recorded

by

the

CEMS

are

invalidated,

from

the

hour

of

commencement

of the

recertification

test

period

to

the

hour

in

which

the test

is

failed

or aborted,

except

for the

case

in

which

a

multiple-load

flow

RATA

is

passed

at one

or

more

load

levels,

failed

at

a subsequent

load

level,

and

the

problem

that

caused

the

RATA

failure

is corrected

without

re-linearizing

the

instrument.

In

that

case,

data invalidation

will

be

prospective,

from

the

hour

of

failure

of the

RATA

until

the commencement

of

the

new

recertification

test

period.

Data

from

the CEMS

remain

invalid

until

the

hour

in which

a new

recertification

test

period

is

commenced,

following

corrective

action,

and

a

probationary

calibration

error

test

is

passed,

at

which

time

the

conditionally

valid

status

of

emission

data

from

the

CEMS

begins

again;

11

iii)

If

a

7-day

calibration error

test

is

failed

within

the

recertification

test

period,

previously-recorded

conditionally

valid

émissión

data

from

the mercury

CEMS

are not

invalidated.

The

conditionally

valid

data

status

is

unaffected,

unless

the calibration

error

on

the

day

of

the failed

7-day

calibration

error

test

exceeds

twice

the

performance

specification

in

Section

3

of Exhibit

A

to

this

Appendix,

as described

in

paragraph

(b)(3)(G)(iv) of this

Section.

iv)

If a

daily

calibration

error

test

is

failed

during

a

recertification

test

period

(i.e.,

the

results

of

the

test

exceed

twice

the

performance

specification

in

Section

3 of

Exhibit

A

to this

Appendix),

the

CEMS

is

out-of-control

as

of

the

hour

in

which

the

calibration

error

test

is

failed.

Emission

data

from

the

CEMS

will

be

invalidated

prospectively

from

the

hour

of the

failed

calibration

error

test

until

the

hour

of

completion

of

a

subsequent

successful

calibration

error

test

following

corrective

action,

at which

time

the

conditionally

valid

status

of data

from

the

monitoring

system

resumes.

Failure

to perform

a

required

daily

calibration

error

test

during

a

recertification

test

period

will

also

cause

data

from

the

CEMS

to

be

invalidated prospectively,

from

the hour

in which

the

calibration

error

test

was

due

until

the

hour

of

completion

of a

subsequent

successful

calibration

error

test.

Whenever

a

calibration

error

test

is

failed

or

missed

during

a recertification

test

period,

no

further

recertification

tests

must

be

performed

until

the

required

subsequent

-calibration

error

test

has

been

passed,

re-establishing

the

conditionally

valid

status

of

data

from

the monitoring

system.

If

a

calibration

error

test

failure-

occurs

while

a

linearity

check-or

RATA

is

still

in

progress,

the

linearity

check

or RATA

must

be

re

started.

v)

Trial

gas

injections

and

trial RATA

runs

are permissible

during

the

recertification

test

period,

prior

to commencing

a linearity

check

or

RATA,

for

the purpose

of optimizing

the

performance

of

the

CEMS.

The

results

of

such gas

injections

and

trial

runs

will

not

affect

the

status

of

previously-recorded

conditionally

valid

data

or

result

in

termination

of

the

recertification

test period,

provided

that

they meet

the

following

specifications

and

cOnditions:

for

gas

injections,

the

stable,

ending

monitor

response

is

within

+-5

percent

or

within

5

ppm

of the

tag

value

of

the

reference

gas;

for

RATA

trial

runs,

the

average

reference

method

reading

and

the

average

CEMS

reading

for

the

run

differ

by

no

more

than +-lO%

of

12

the

average

referencemethod

value

or

+-15

ppm,

or

+-1.5%

HQ

or

+-O.02

lb/mmBtu

from

the

average

reference

method

value,

as

applicable;

no

adjustments

to

the calibration

f

the

CEMS

are

made

following

the

trial

injection(s) or

run(s),

other

than

the

adjustments permitted

under

Section

2.1.3

of

Exhibit

B to

this

Appendix

and

the

CEMS

is

not

repaired,

re-linearized

or

reprogrammed

(e.g.,

changing

flow

monitor

polynomial

coefficients,

linearity

constants,

or

K-factors)

after

the

trial

injection(s)

or

run(s).

vi)

If the

results

of

any trial

gas

injection(s)

or

RATA

run(s)

are

outside

the limits

in paragraphs

(b)(3)(G)(v) of

this

Section

or

if

the CEMS

is

repaired,

re-linearized,

or

reprogrammed

after

the

trial

injection(s)

or

run(s),

the

trial

injection(s)

or

run(s)

will

be

counted

as

a

failed

linearity

check

or

RATA

attempt.

If this

occurs,

follow

the procedures

pertaining

to failed

and

aborted

recertification

tests

in paragraphs

(b)(3)(G)(i)

and

(b)(3)(G)(ii)

of

this

Section.

H)

If

any

required

recertification

test is

not completed

within

its

allotted

time

period,

data

validation

must

be done

as follows.

For

a

late

linearity

test,

RATA,

or cycle

time

test

that

is

passed

on

the

first

attempt,

data

from

the

monitoring

system

will

be

invalidated

from

the

hour

of

expiration

of

the

recertification

test

period

until the

hour

of

completion

of the

late

test. For

a

late

7-day

calibration

error

test,

whether

or

not it

is passed

on

the

first

attempt,

data

from

the

monitoring

system

will

also

be invalidated

from

the

hour

of

expiration

of

the

recertification

test

period

until

the

hour

of

completion

of the

late

test.

For a

late linearity

test,

RATA,

or cycle

time

test

that

is failed

on

the

first

attempt

or

aborted

on

the

first

attempt

due to

a

problem

with

the

monitor,

all conditionally

valid

data

from

the

monitoring

system

will

be considered

invalid

back

to

the

hour

of

the

first

probationary

calibration

error

test

which

initiated

the

recertification test

period.

Data

from

the

monitoring

system

will

remain

invalid

until

the hour

of

successful

completion

of the

late

recertification

test

and

any

additional

recertification

or diagnostic

tests

that are

required

as a

result

of

changes

made

to the

monitoring

system

to correct

problems

that caused

failure

of

the

late

recertification

test.

I)

If

any required

recertification

test

of

a

monitoring

system

has

not

been

completed

by

the end

of

a

calendar

quarter

and

if data

contained

in

the

quarterly

report

are.

conditionally

valid

pending

the results

of

test(s)

to

be

completed

in a

subsequent quarter,

the

owner

or operator

must

indicate

13

this

by

meansofasuitableconditionailyvaliddataflag

in

the

electronic

quarterly

report,

and

notification

within

the

quarterly

report

pursuant

to

225;29Ob)(

l)(),

for

that

quarter.

The

owner

or operator

must

resubmit

the

report

for

that

quarter

if

the

required

recertification

test

is

subsequently

failed.

If

any

required

recertification

test

is

not

completed

by

the

end

of

a

particular

calendar

quarter

but

is

completed

no

later

than

30

days

after

the

end

of

that

quarter

(i.e.,

prior

to

the

deadline

for

submitting

the

quarterly

report

under

40

CFR

75.64,

incorporated

by

reference

in Section

225.140),

the

test

data

and

results

may

be

submitted

with

the

earlier

quarterly

report

even

though

the

test

date(s)

are

from

the

next

calendar

quarter.

In

such

instances,

if

the

recertification

test(s)

are

passed

in

accordance

with

the

provisions

ofparagraph

(b)(3)

of

this

Section,

conditionally

valid

data

may

be reported

as

quality-assured,

in

lieu

of

reporting

a

conditional

data

flag.

In

addition,

if

the

owner

or

operator

uses

a conditionally

valid

data

flag

in

any

of

the

four

quarterly

reports

for

a

given

year,

the

owner

or

operator

must

indicate

the

final

status

of

the

conditionally

valid

data

(i.e.,

resolved

or

unresolved) in

the

annual

compliance

certification

report

required

under

40

CFR

72.90

for that

year.

The

Agency

may

invalidate

any

conditionfly

valid

data

that

remains

unresolved

at the

end

of

a particular

calendar

year.

4)

Recertification

application.

The

designated

representative

must

apply

for

recertification

of each

contihuous

mercury

emission

monitoring

system.

The

owner

or

operator

must

submit

the

recertification

application

in

accordance

with

40

CFR

75.60,

incorporated

by

reference

in

Section

225.140,

and

each

complete

recertification

application

must

include

the

information

specified

in

40

CFR

75.63, incorporated

by

reference

in

Section

225.140.

5)

Approval

or

disapproval

of

request

for

recertification.

The

procedures

for

provisional

certification

in

paragraph

(a)(3)

of

this

Section

apply

to

recertification

applications.

The

Agency

will

issue

a

notice

of

approval,

disapproval,

or

incompleteness

according

to the

procedures

in

paragraph

(a)(4)

of

this

Section.

Data

from

the

monitoring

system remain

invalid

until

all

required

recertification

tests

have

been

passed

or

until

a

subsequent

probationary

calibration

effor

test

is

passed,

beginning

a new

recertification

test

period.

The

owner

or

operator

must

repeat

all

recertification

tests

or

other

requirements,

as indicated

in the

Agency’s

notice

of disapproval,

no

later

than

30

unit

operating

days

after

the

date

of

issuance

of

the

notice

of

disapproval.

The

designated

representative

must

submit

a

notification

of the

recertification

retest

dates,

as

specified

in

40

CFR

75.61(a)(l)(ii),

incorporated

by

reference

in

Section

225.140,

and

must

submit

a

new

recertification

application

according

to

the procedures

in

paragraph

(b)(4)

of

this

Section.

14

c)

Initial certification

and

recertification

procedures.

Prior

to

the

applicable

deadline

in

35

Ill

Admin.

Code

225.240(b),

the

owner

or.

operator

must

conduct

initial certification

tests

and

in

accordance

with

40CFR75.63,

incorporated

by

reference

in

Section

225.140.

the

designated

representative

must

submit an

application

to

demonstrate

that

the

continuous

emission

monitoring

system

and

components

thereof

meet

the

specifications

in

Exhibit

A

to

this

Appendix.

The

owner

or

operator

must

compare

reference

method

values

with

output

from

the

automated

data

acquisition

and

handling

system

that

is

part

of

the

continuous

mercury

emission

monitoring

system

being

tested.

Except

as

otherwise

specified

in

paragraphs

(b)(1),

(d),

and

(e)

of

this

Section,

and

in

Sections

6.3.1

and

6.3.2

pfxhibit

A

to this

Appendix,

the

owner

or

operator

must

perform

the

following

tests

for

initial

certification

or.recertification

of

continuous

emissionmonitoring

systems

or

components

according

to the

requirements

of

Exhibit

B

to

this

Appendix:

1)

For

each

mercury

concentration

monitoring

system:

A)

A

7-day

calibration

error test;

B)

A

linearity check,

for

mercury

monitors,

perform

this

check

with

elemental

mercury

standards;

C)

A

relative

accuracy

test

audit

must

be

done

on a

jig/scm

basis;

D)

A bias

test;

B)

A

cycle

time

test;

F)

For

mercury

monitors

a

3-level

system

integrity

check,

using

a

NIST

traceable

sourceof

oxidized mercury,

as

described

in Section

6.2

of

Exhibit

A

to this

Appendix.

This

test

is

not

required

for

a

mercury

monitor

that

does

not

have

a converter.

2

For

each

flow

monitor:

A)

A

7-day

calibration

error

test;

B)

Relative

accuracy

test

audits,

as

follows:

i)

A

single-load

(or

single-level)

RATA

at

the

normal

load

(or

levefl,

as

defined

in

Section

6.5.2.1(d) of

Exhibit

A

to

this

Appendix,

for

a

flow

monitor

installed

on

a

peaking

unit

or

bypass

stack,

or

for

a

flow

monitor

exempted

from multiple-level

RATA

testing

under

Section

6.5.2(e)

of

Exhibit

A

to this

Appendix;

15

ii)

For

all

other

flow

monitors,

a

RATA

at

each of

the

three

load

lvels

(or

perating

levels)

corrsponding

to

the

three

flue gas

velocities

described

in

Section

6.5.2(a)

of

Exhibit

A

to

this

Appendix;

C)

A

bias

test

for

the

single-load

(or

single-level)

flow

RATA

described

in

paragraph

(c)(2)(B)(i)

of

this

Section:

and

D)

A

bias

test

(or

bias

tests)

for

the

3-level

flow

RATA

described

in

paragraph

(c)(2)(B)(ii) of this

Section,

at

the

following

load

or

operational

level(s):

i)

At

each

load

level

designated

as

normal

under

Section

6.5.2.1(d)

of

Exhibit

A

to this

Appendix,

for

units

that

produce

electrical

or

thermal

output,

or

ii)

At

the

operational

level

identified

as

normal

in

Section

6.5.2.1(d)

of

Exhibit

A

to this