AS

0B-2

Oetober 28.

tr999.

Hearing

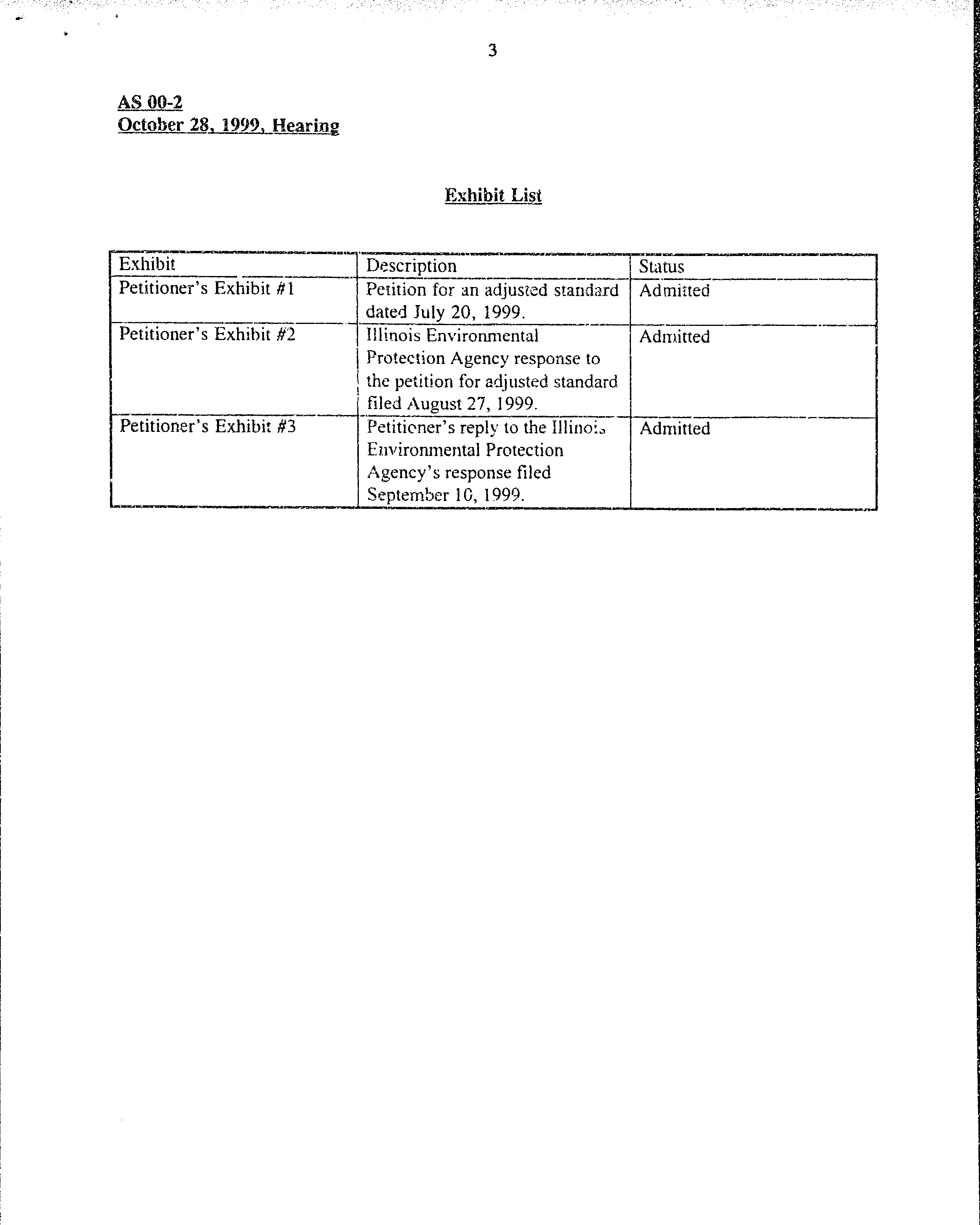

Exhibit

Petitioner's

Exhibit #1

Petitioner's

Petitioner's

Exhibit Lisl

Descriotion

Petition

for en

adjr:sted

stanciard

dated

July 20, 7999.

I

ilinoi

s

Environmental

Protection

Agency response

to

the

petition

for adjusted standard

filed

r\

27, 1999.

Fetitiener's

reply

to

the Illilroi,

Elrvironmental

Protection

/rgency's

response

fi led

September

I C,

1999.

Jr")

#3

j'::

--

-

.':l':::,'1':

.:1

"

4

CERTIFICATION OF SERVICE

it is hereby certified thiat true copies cf the tbregoing order

were

each of

t'e

rollouring

on Ncvember i6. 1999:

first class,

ttr

Paul E.

Gutermann

John N. N'loore

Akin, Gump,

Strauss-

Hauer

&

Feld Larv Offices

cf John

N.

lvloore

i333 New

Hrmpshire Ave,

N,\H.

200

North LaSaile

Street

V/ashington.

IDC 20036

Suite 2200

Chicago,

IL

60601-1095

Peter E. Orlinsky,

Assistant Counsel

Robert T. Lawley,

Chief kgal Counsel

IEPA, Division

of Legal Counsel

lllinois Department

of

Natural Resources

1701

Sourir First Avenue

Suite 600

N{avrvood. iL 60153

524 South Siecond

Street

Room 400

Springfield, n- 62701-11

87

it

is herebv certified

that a

true

cc.p)'

of the

foregoing

order

was hand deiivered to the

follorving on lJovember

16, 1999:

Dorothy Iu{.

Gunn

lilinois

Pollution Control Board

James

R.

'Ihompson

Center

100

W. Randolyrh

St., Ste.

11-500

Chica-eo.

l.llinois

60601

.,,"

/

,,///

.' /

,/

.., L/

\

y'<5lur

Kninle

/

Hearrng Officer

'

Illinois Pollution

Control Board

Janies R. Thompson

Center,

Suite

11-500

100 West Randolph

Street

Chicago, Illinois 60601

312.814.3473

/

."2

PI,.A!NTIFF'S

s .

EXHtBt'r

itr

-,

r

\--

H'-i-

11

'

J

fi=:--J-----

v

;.ii1i

il6TE:

$

R;EL'

x'

iiiJh'-iff

Ex

H

le'ejsrss

PETITIOI{

FOR

AN

ADJUSTE'D

STANDARD

Submitted

to

ihe

ILLINOIS

POLI-T-]TION

CONTROL

BOARD

By

FIORSEI{EADRESOUR'CEDEvELoPh,IENTCotsIPAN\',INC.

Date:

JulY

20,

1999

---

=1:=;

-l

t

I

I

I

;

3

n

g

&

E

E

tE

ln

Ia

Adiusted

Standard

No'

99-

(R.cRA)

$

€

#

ffi

&

&

&

g

w

I

E

fr

E

E

#

fi

fi

g

a

'5^r,+it'v+,+v.+.t

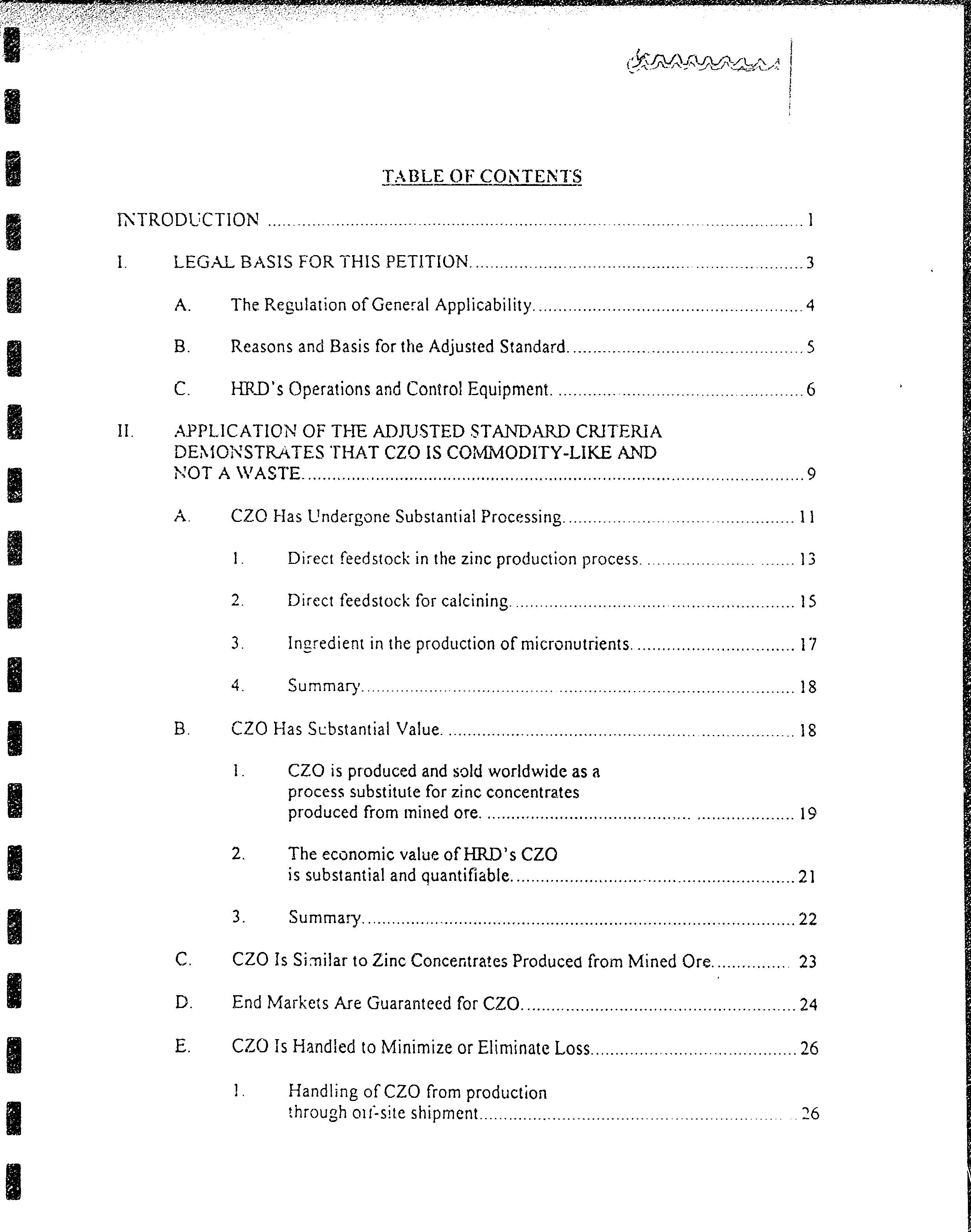

JABLE

OF CO_r\TE_NT'$

NiTRODUCTION

LEGAL BASIS

FOR THIS PETITION

3

A.

The Regulation of Ceneral Applicability.

B.

Reasons and Basis

lor

the Adjusted

Standard.

...........5

C.

F{RJ's

Operations

and

Control

Equipment.

....... ......

......6

II

APPLICATIO}.I

OF THE ADruSTED

STANDARD CNTERIi\

DETIONSTRATES'THAT

CZO

IS COMMODITY-LIKE A}ID

,\joT A

\\'ASTE.

............9

A.

CZO Has

Undergone

SubstantialProcessing.

............... I I

L

Direct feedstock in

the zinc

protluction

process.

.

. ..

.

l3

2.

Dircct

feedstock

for calcining

....... 15

3.

Ineredient in

the

production

of

mieronutrients..............

.

................ l7

4.

Summar\,.

................

l8

B.

CZO

Has

Sr:bstantial

Value.

..... ..........

.l8

L

CZQ

is

produced

and

scld

worldwide

as

a

process

substitute for

zinc

concentrates

produced

from rnined

ore............

.................... l9

2.

The economic value

of HRD's

CZO

is

substantial

and

quantifiable

......................21

3.

Summary.

...............22

C.

CZOIs

Si:nilar

toZincConcentratesProduceo

fromMined

Ore............... 23

D.

End Markets

Are Guaranteed

for

CZO.

...................24

E.

CZO

is

Handied

to Minimize

or Eliminate

Loss........

.................2d

l.

Handling

of

CZO from

production

through

ort'-site

shipment....

16

HE

HE

HI

H!

g1

m

ts

2.

l.

i

2.

Handling

during

processing

into

ziric

metal'

.27

3.Handlingduringprocessingintronticiorrutrientingredient......,.'...21

Other

Relevant

Factors

"""""2E

i.

The

Big

Rivcr

Zirrc

adjusted

standard

for

crude

zinc

oxide'

ta

Other

variances

from

the

definition

af

solid

waste'

""""

30

An

adjusted

standard

support's

statutory

resource

recL)very-

and

waste

mininlization

mandates "'-

""""

31

.

.33

CO*-CLUSION

Eu-lsug

I.

Facilin'

Process

florv

diagram'

3

HT\{R

Feedstock

1998

monthiy

composites'

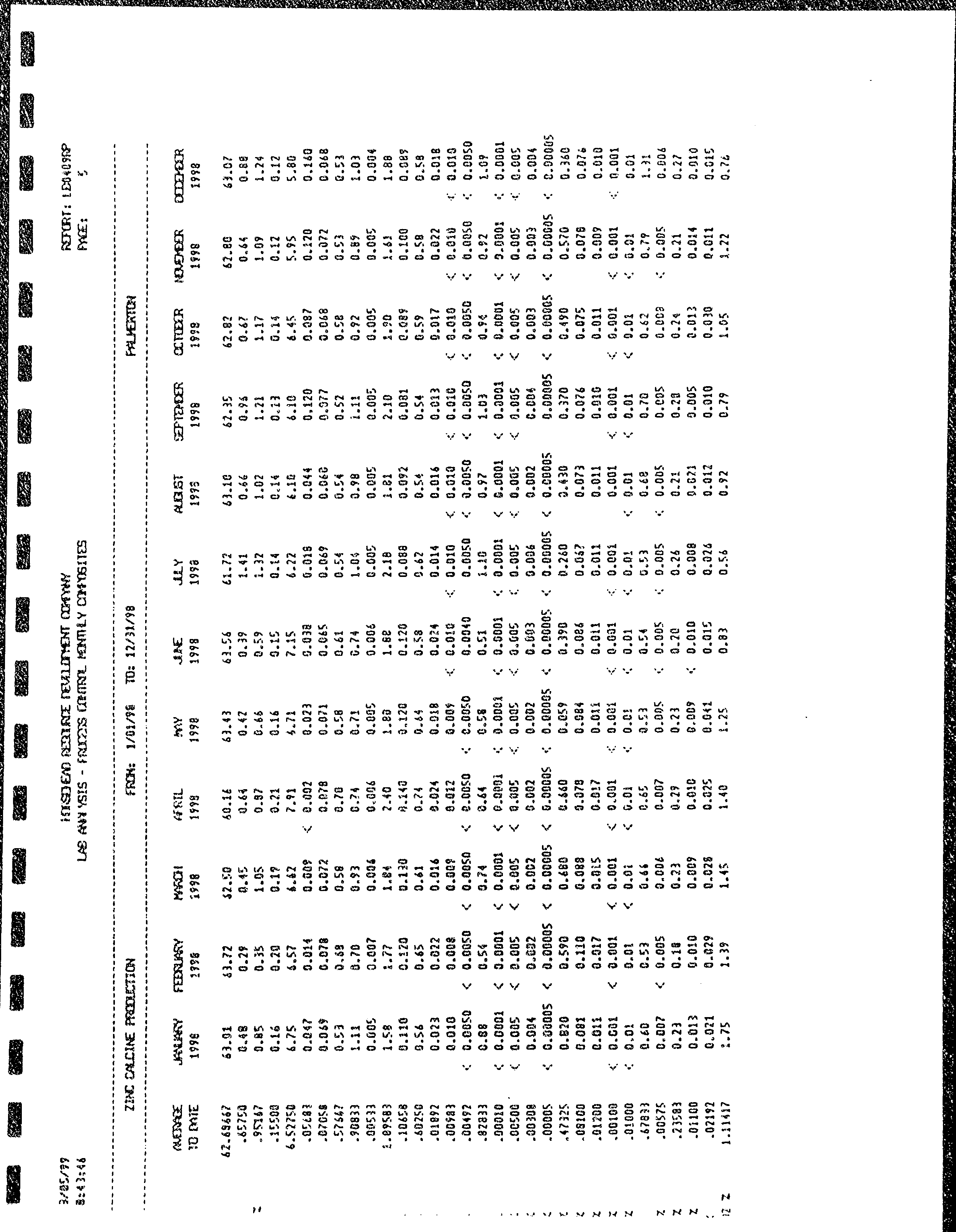

i CZO

1998

monthlS'comPosites'

,1

ZCrl,',\lonaca,

Pennsylvania

process

florv

diagram'

5.

Excerpr

from

Pehlke,

unit

Praqtiqes

oGx3lac-tiye

Melalluigy'

5

Zinc

Calcine

1998

monthly

composites'

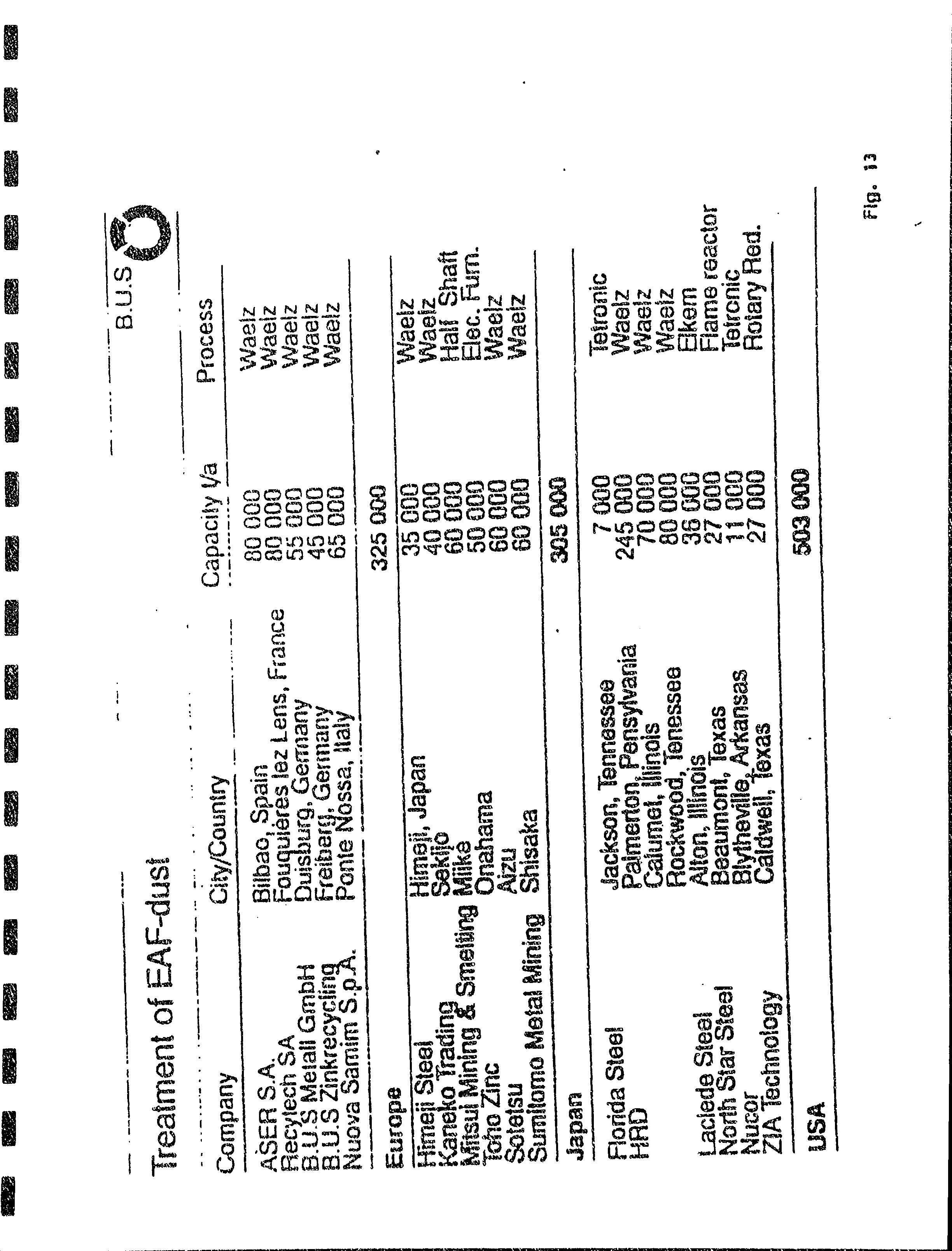

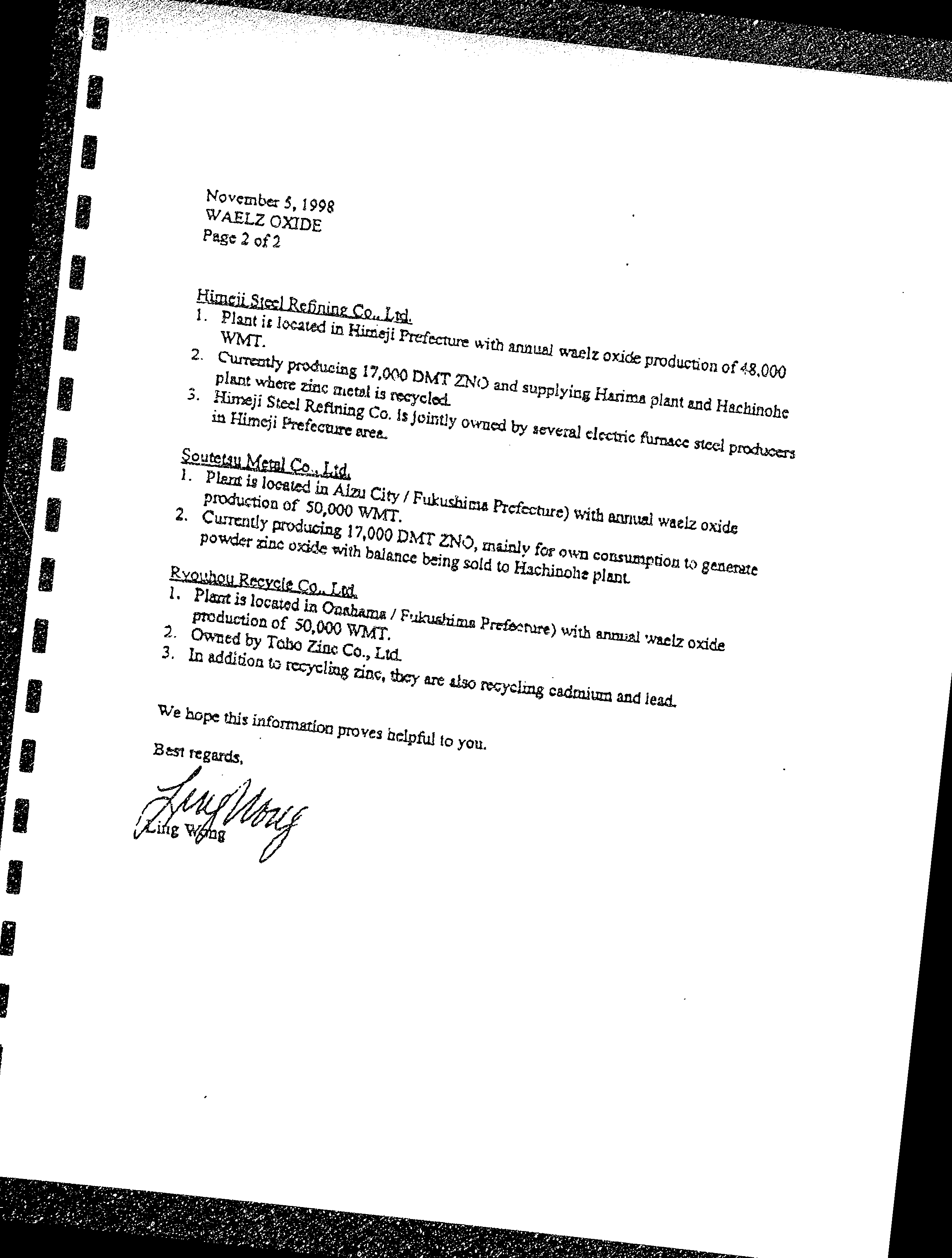

7.(a)SummaqyofEAFdustprocessin-gcapac.itiesinEurope,Japar,,,aridtheUnitedStates,and

iui

r-*n.r

frbm

Ling

Wcng

lo

Tom

Theobaid'

8. HRD

1998

invoices

to

Zinc

i'lacional

for

sales

of

CZO'

g.

F{RD

1998

invoices

to

zinc

corporation

of

Anrerica

for

sales

of

cZo'

10.

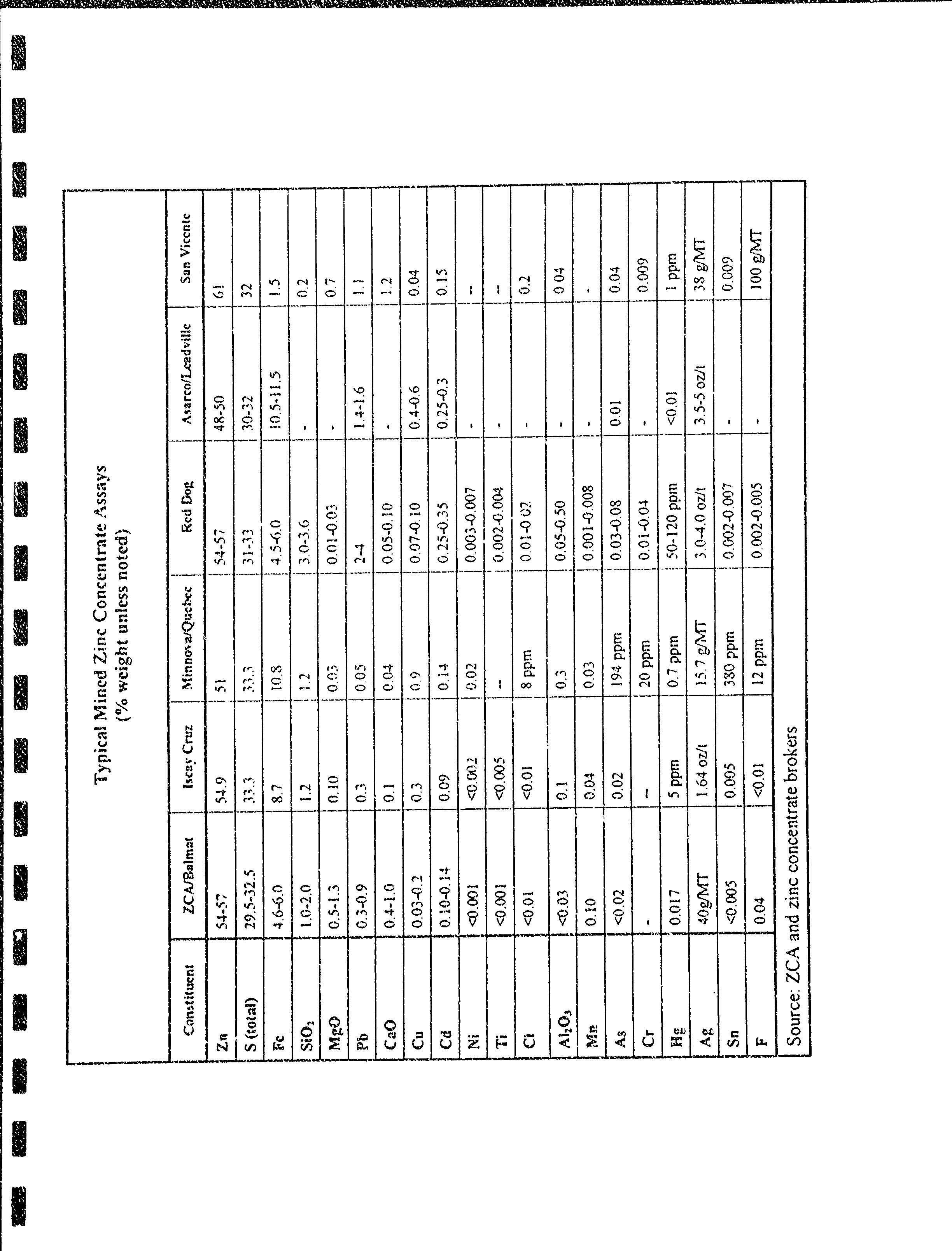

Typical

Mined

Zinc

ConceRtrate

Assays'

H

ffi

B

ffi

n

ffi

I I

. Opinions

an<J

Orders

of

the

lllinois

Pollution

Control

Board

in

In

re

Petjtiori

of

Big

-Ri"'gt

Zinc

Corpcrati0I

1999,

amended

MaY

5,

1999),

AS

99-3'

a

A

il

Tertnessee

Depanntcrtt

oiErtvirorirttent and

Consen'ation decision

granting

rariance

from

ciassificaiion

as a solid

\\aste

to AlteriS,eel Dust

Processing

Di',ision

lor

cn-rde

zinc

oxide

ffi

(Sept

I l.

lees)

l3 Ercerpts

front

"A

Pocket

Guide

to Zinc" and

related

irrforrnation

provided

by

the

ffi

lniernarionai Zinc

Associarion.

a

B

g

fr

F

n

g

F

a

a

n

a

a

il

w

*

n

a

E

&

fr

ffi

a

fi

fr

a

I

fr

w

a

n

n

n

BEFORE THE

ILLINOIS

POLLI.''TION

CO.\TROL

BOARD

Ni THE

}l.{TTER

OF:

PETITIOn*

CF I{CIRSEI{EAp

RESOURCE

DEITELOPIIENT

COTTFANY,

IHC.

FOR AN

ADJUSTtrD

STANDA,RD

UT,{DER, 35 II,L.

ADlt.

CODE

720,131(c)

AS 99-_.__

{Adjusted

StanCard

-

RCRA)

PE'TITION

FOR

4_N

ADJUSTE]|}

SJANDARD

lNlRSDllCrrOry

Horsehead

Resource

Development

Company, Inc.

("[{RD")

herebl,petitions

rhe Illinois

Pollution

Control Board

("Board")

foran

adjusted

standarci

under

35

lll. Adm.

Code

720.131(c)

for

crude

zinc

oxide

C'CZO")

produced

by HRD

at

its

Chicago

facilitv

(hereinafter

referred

ro as

the

"Facility.'')

SectionT?0.131(c)

authorizes parties

lo

petition

for

a derermination

rhar

"[m]aterials

that

have

been reclaimed

but

must

be

reclaimed

lurther

before

recoverv

is

comalered

are not solid

r'.'astes

if, after

initial reclamation,

tbe

resulting

material

is

coarmodity-tike."

I-[tD's

CZO,

like

C7O produced

elsewhere in

ihe Unite<i

States and in

orher countries,

has

substantial economic value

and

is

sold

for valuable

ccnsirJeration

in

lnarkets rvorldrvide.

it is

used

to

p:'oduce

zirrc

and

other

nretal

products,

often as a direct

process

subsritute

for

zinc

concentrates

pioduced

from

mined

ore. HRD

produces

CZO

from

the recycling

of

electric

arc

furnace

("E41=";

riust,

a hazardous

waste,

along with

significantly

srna!ler

quantiries

of

other

metal

bearing

feedstocks,

in

FIRD's

high

temperature

metal

recovery ("HTMR") process.

Recyciing EA-p

dust

results

in

multiple

environmental

benefits, inclucling

a

reduition

in

the

volume

of EAF dust

that

cthenvise

rvould

be

rvastefully

disposecl

of in landfitls,

consen.arion

of

non-rene\\'able

natural

resources

(e.g.,

zinc

clre), and

saving

energy

by'reducing tlre rieed

tor

:ffi,ffi:

;tocks,

orzi'c

including

ores

cZo

virgin

rhererore

zinc

ores,

is

preferabre

and

irs

r

ro

rnany

other

primary

and

dergf

gpnlgnl.

-'

LJ'

3rr'

tts

use

promotes

susrainable

::-#::;ffi

,:::,1;:'d

sran'ljaid

roiEAF

dusr

zinc

oxide

p:-ocesseci

by

Bis

lee

in

re

Periri^.

^F"'-.- ^,

;,;J:"1;

,Code

720

ti

lic.)

(Aprit

lS,

t

999,

n&end€d

hfay

6,

I

999)"

AS

ard

l-jnder-

35

Ilr

Adn

;::,lllll;s;f

sanaar.,

rfrL^

-

laeilities'

functicn

to

contain

rhe

EAF

similar

dusr

concr:ntrations

zirrc

oxide

processed

by

BRe.

Bosh

;,:

nrareriars

;:.;::"":::naure

are

produced

by

Hrj\{R

zinc

and

other

p;'oducts

Moreo

ver'

czomeets

of

zinc

and

rhe

se*ion

other

constituents,

72o.r3r(c)

ancr

adju.sted

are

used

to

produce

lor

s!n'lilar

reasons

as

the

EAF

zinc

oxide.

Therefore,

rhe

BRZ

adjusred

standard

"randar',

prc'ides

cnteria

a

unguestionably

As

con:pelling

explained

precedential

in

detaii

in

this

basis

Perition,

for

the

Board

czc,

ro

rikethe

granr

EA.r'dust

rhis

Ferition.

zinc

see

oxide

pan

processed

II.F.

r.

of

by

rhis

Bi€,

peririon.

commodity-liI,e

meets

material

the

for

criteria

the

following

in

section

reasons:

720-r3r(c)

for

an

adjusred

srandard

for

a

l.

CZA

is

subsraii

,

o

a ;,

;

" ",i

p,Jj

x,i

i

:r,

i:

"xH

:i

[T

i

ffii:

TJ,1,;;,,T

:

;

l;1

fi

:,

_.,

2.

CZO

has

a

docr

averagemarket

lmented

hislory

of

su'

o"'.it..,

jt,:*::l*f

*,*t'i[T';lffi

';.':ffJ:ilill:,ilJ,ilf;

l,n

3

CZA

issimilar

ifi

comnn.;r;^_ _

co

n

ce

n

r ra

r

e;

;;;il;1,il?:j

;|ff

:

j

eq

u

i'a

t

e

n

t i

n p

r-o

c

es

s

s

u

i

r

a

b

i

r

i

i

l,

r

o

zi

n

c

4

CZO

has

guaranr.eed

erd

markers,

and

all

CZO

produced

b

snrpped

off-site,

inro

rhe

rtr;;;;';'f

.;;'1n'erce,

;",","air,*ri:.xyrj:j:lijl,

r<::

Seo

ts

Periri

etrtiOn

I

T

E

fi

ffi

ffi

ffi

$

tr

ff

I

u

g

ffi

w

E

ffi

a

H

ffi

g

E

F

F

g

H

B

g

a

n

5.

CZO

is

ntanaged

in an environntentally

protecti!'e manner.

6. An adjusted

starrdard

for

CZO

is consistent

rvith

variances for

commodity-like

rnaterials

issueel by the Board

and other

regulatory

agencies, and

supports

the

nrandates

of Illinois and

federal

law

prioritizing

recycling over disposal.

Part i of

this Perition,

rvhich

sets

forth the

legal

basis

for ihis Petition

for an adjusted

standard,

ciescribes the

regulaticn

of

generai

applicability,

states the

reasons and

basis

for

the

adjusred

srandard, and summarizes

HRD's operations

and control

equipment. Part

il of the

Perition

cjemonsrrates that

F{RD's CZC

meets all of

the criteria

in

Section

i20.l3l(c)

t-or

determining

rvhen

a material

is

"commodity-like"

and not a solid

waste. Based

on the

information

conrained

in

this

Petition,

HRD respectfi.rlly

requests

that the

Boai-d

grar:t

HRD an

arJjusted

srandard

froi-n the

definition

of solid

waste for

CZO

produced by

HRD

at

the Facility

T.

LEGAL

BASIS FOR

THIS PETITION.

Section

28.1

of

rhe

IllincisEnvironmental

Protection Act

("Act")

authorizes the Board to

granr an

adjusred standard

frcm a

regulation

of

general

applicability upon

request

of

persons',rho

can

justifl'rhe

adjustecl standard.

4l5ILCS 5/28.1(a).

The regulation

of

general

applicabiliti'

from

n'hich

FIRD seeks

an

adjusted

standard

is 35lll.

Adm.

CoCe

721.102

(definition

of solid

rvaste). .4s explained

in Part

II

of this

Petition, the criteria

to be

used in

justifoing

the adjusted

standard

are established by

Board

regulation.

Secrion

28.1(d)

of

the

Act sets forth tlie basic

procedural

requirements

ior an

adjusted

standard,

and

the

Boaid's

implementing regulations

include more

specific

requirements

applicable

to

RCI(A adjusted standards in

particular. Seg 35lll.

Adm.

Code

106.410

et seq.

Those

regulations

require

the

following

information

to be

provided.

(,a)

Identification of

the regulation of

gerreral

appii:abiiir;'for

which

FIRD

seeks an adiusted standard.

A

*ritten

statenlent

outlining

the scope of the

"evaluation,"

the

nature of,

the

reasons

for and the basis

of tbe

adjusted standard,

consistent

rvith

tlie level

ofjustihcation

contained

in

the

reguiation

cf

general applicability;

The

nature of

i{RD's

opeiations

and control

equipment;

and

Any

additional

information

which

nray be

required

in the

regulation

of

general

applicabil

ity.

5eS

35

lll. Adm. Code

106.413.

HRD addresses

the first three

lactors below.

The fourth

iactcr

isnorapplicablehere,sincethe"regulationcfgeneral

applicability"(35

Ill.Adrn

Code721

102)

does

not require

any such

aclditional

information.

A.

The

Regula(ion

of General

Applicability.

lllinois larv,

like federal

lau,,

classifies

non-prcduct

materials

derived

from

the

reclamarion

or

other

treatment

of

"listed"

hazardous

wastes

as soiid

and hazardous

*'astes.I

Neither

Illinois

larv nor federal

larv, horvever,

regulates as

solid or

hazardous

\\'aste

all

rnaterial

produced

from the reclarnation

of haz,ardotis

waste. Products,

refined

materials,

and other

non'

\\'astes

produced

fiom

the reclamation

oiiisted

hazardous

waste

and that

are

used beneficially'

are

not

solid

or

hazardous

wastes:

"l'{aterials

that

ate

reclairned

lrom solid

wastes

and

that are

used

beneficial!y

are

nolsolid-ivaslg5

and

hence

are not

lrazgtd-Q.us

wastes

ttnder

this

provision

unless

the

reclaimed

material

is

burned

for energy

recovery

or used

in a manner

constituting

disposal."

35lll. ACm. Code

$

721,103(eXl)

(emphasis added)

When

the Ui:ited

Siates

Environmental

Protec{ion

Agency

("U.S,

EP/r")

promulgated the

identical federal equivalcnt of

rhis

rule in 1985,

u.S. EPA explained that

its

purpose

was to

make clear that

fully

reclairned

i

See35lll.Adm.Code72l.l02(c)(3)(cross-referencingcolumnioftlietableirr.\ppendirZ)

and72l

l03(eXl)(lliinois

larv);

ses also

40

C

F

R

S

261

?(c)(3) and

$

?61

3(cX:)(i)

(fedc'rrl

Ia*').

(b)

g

ffi

ffi

ffi

ffi

ffi

E

F

E

E

ffi

ffi

ffi

ffi

H

g

(c)

(d)

w

H

ffi

'#

&

8

&

products

arc

,lot

\\asres,

eyen

if

lhe

produ

conrntercial

vaiue:

..

..."

yruuucis

subsequently

are

r"eflned

to

jncrease

their

fr

ffi

IC]onrnrercial

pr_odu

\\.asres,

ano

so;;;;::t:':clairned

rronr

h

regenera:ed

,u,"*n,r'jlU.;..t

ro

i,iii

i'ltidous

lvastes

are producrs,

nor

*fft*.',ffi/'ffi

lc,

are

not

g

fi

50

Fed.

Reg.

6

14.

634

(lan.

4,t985)

(emphasis

adcled).

B.

Reasons

and

Basis

for

the

Adjuster!

Standard.

As

esplaineel

in

cetail

iater

in

thi's

Fetirion,

lxRD

fundarnentaf,y

transforns

a

lo.,v-zinc.

high-iron

hazardous

ivasre

feedstock

into

a

high-zlnc,

row-ir

on

czoproduct.

cZo

and

other

crude

zinc

oxides;lre

commodities

thar

are

used

and

sord

thror,:ghout

the

rvorld.

As

a

resuir,

FIR'D

has

alr'ays

unciei'stood

that

irs

Cza

isa

fi-r,y

reclaimed

product

and

is

nor

a

nr:nirnary,

pt'ocessed

or

partially

:'claimed

material'

The

Itincis

Environmentaiprotecrion

Agency

("lllinois

EPA"')

has

talien

the

position

r'at

cZo

may

not

be

a

fury

recraimed

produci

and,

therefore,

rvouid

be

subjecr

ro

regulation

as

a

solid

and

hazardous

rvas(e.

Illinois

larv

provides,

hoi'r'e'er'

that

even

a

parriailv

reclaimed

materiar

can

be

excli.rded

from

reguration

as

a

sorid

r*aste

if

ir

is "conmcdity-!ikc."

35

Ir.

Adrn.

code

72o.r3r(c).

Therefore,

to

resor'e

any

question

that

may

exist

regarciing

cZo's

reguratory

status,

FlrD

is

firing

rhis

petition

for

an

adjusted

srandard'3

An

adjusted

-ctandard

for

czowirr

resorve

any

porenrial

regurarory

issue

rhar

nay

exist'

and

it

wi'further

€ncoufage

recyclingof

renervable

natural

resources.

EAF

dusr

v.

r_/rr

oust

and

reduce

deplef

ion

of

non-

fr

g

fr

#

n

r

t

t

I

I

oi

'

The

at

anyrime

filing

of

has

rhis

or:j":l

I

should

not

be

en,

a

soiiJrr;;;;".ue

coDSrflrBd

as

an

adntission

of

lau,or

iacr

rl*r

CZO

is.

,aa

_:

.:.:'

-1

-.

'.-:,:.:'.'

I

.

'

:

1

:

:r:;

.:-T;:::-ili::--..llT::T:::"T::-T-:r-::---:iTTTTT

C.

HRD's

Operations nnd

Control Equipment.

I-IR,D is ihe largest

cperalorof

HTNfi,

faciiities

in

the

Unired

Srares,

and is

the

largesr

recvcler

of

inorganie

hazardous \vastes.

Historically,

foraimost

sixty

years,

the

priorowners

of

ffiD's

"\\'irelz"

rotary

kilns

in Palrnerlon.

Pennsylvania,

operated

the kiins

to produce

zinc-

based products

from

oxidized zinc

oies

and

similal

zinc-bearing

secondar-y

r:rateriais.l

irr

the

nrid'1970s,

as

mirte

reserves

\\'ere

being

depteted,

the

operarcrs

of the Wae!z

kilns

explcred

other

t"aw

mate!-ial

sources

of zinc

for

the

\-Vaelz

kilns,

and

iound

that steelmaking

dusts,

including

E.A.F

dust,

coulci

serve

as an

effective

aiternativc

to the

oxidized zinc

ores.

Zinc

is

an

abundant

cons:ituent

in EAF dust;

its

concentration

ranges

from

five to

forty-trvo p€rcent,

or up

to

eight

times

more

zinc than

in

rarv

ore. Lead

and

cadmiunr

also

are

present

in recoverable

quanlities

in

EAF

dust.

EAF

dust

was processed

lor netal

recovery

in

Palmerlon

before

U.S.

EpA

lisred

rhe

materiai

as K06l in

1980,

and EAf

dust

resource

recovery

efforrs

accelerared

thereafter.

The

reci'cling

of

EAF

dust

in

\\tae!z

kilns

has

served

as a nationat

model

of resource

recovery

and

tvaste

minimization.

Significantiy, lJ.S.

EPA relied

on rhe proven performance

of

HTlr{R

technologies

wherr

it

designated

I-lTlvIR

as

ihe

Best

Demoiisrrared

Available

Technotogy

("BDAT")

for K06l

under

the

Resource

Conservation

and R-ecovery

Act's

("RCRA")

land

disposal

restrictions program.

U.S.

EPA

concluded

that rhc

H';MR piocess

ccnsen,es

natural

resoutces

by recycling

zinc

and

other

metals

recovered

from

the EA.F

dust

that

otherrvise

*'ould

be m!ned,

and recycles

the

K06t

into

non-rvasre

procluas.

53 Fed.

Reg.

31138,

Jl162

(AuE.

lg,

I

rhe

\\'aelzing

process

deri'es

its

name

lrom

the Gernran r.erb.,rr.aelzen

tr'rndle

or roll, aptly

describing

the rolling

movenrent

of rhe feed nraterial

of

the kiln

,"

rrhicir

nlesns

ic

along

the insidr-

slcpe

.a.:-a.:-

ffi

ffi

ffi

ffi

H

H

g

H

fr

ffi

H

H

ffi

H

w

B

ffi

H

w

lgSS).!

EPA

alsg

has

designated

Hfit{R as

the BDAT for othei

metal-bearing

rvastes. Seg l'7

Fed

Reg.37l9.1.312A7

(Aug 18, 1992)(F006);

63Fed Reg

28556

2856C1

(May26,1998)

(rogerhe;rr.ithsrabilization,fornon-lisredrvastes).

LIRD'SFaciliryislocated

at27Ol

ll46St:eet

in

Chicago,

anci

rvas

first

peri''iitiedby the lllinois

EPA

Division

of

Land

to

operate

a solid

tf'a.ite

rnanagernent

faciliry

in 198'9

'l

lre Facility

emptoys

trvs

Waelz kiln

HTlr{R unitst

and accepts

for recy,cling

K061 and smailer

quantities oicther

hazardous

and non-hazardous

z!nc-bearing

feedstocl:s.

h{ore

than

ninety

percent

of

the feedstock

consists

of

EAF dust.

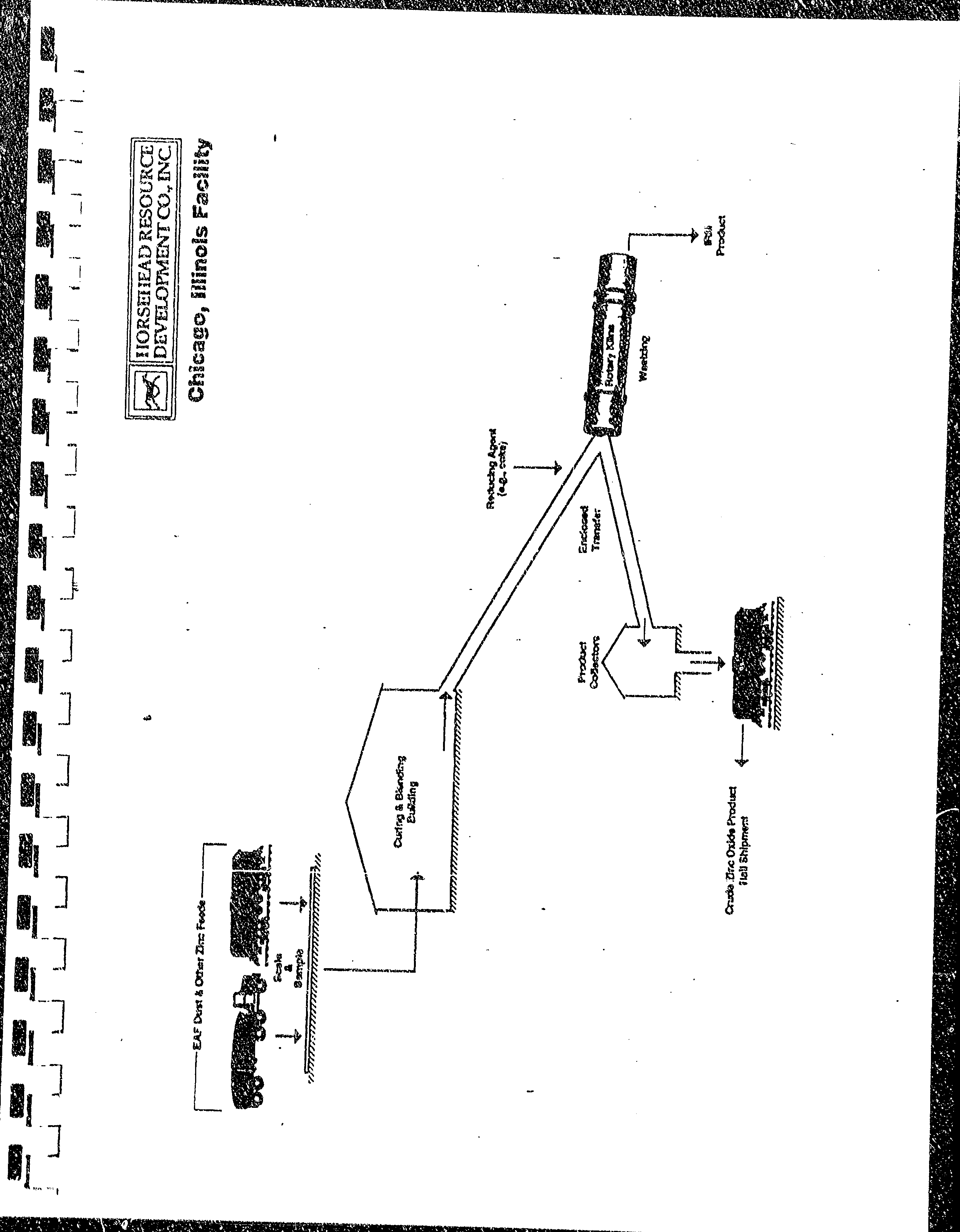

A

process

florv

diagranr

of rhe

Faciliry

is

included as

trrhibit /. Notably,

all

phases

of

I-[RD's feedstock

management

occur

in an enclosed,

negative

pressure

environment,

anC all

nraterial

lransfer

points

are

equipped

rvith

collcction equipment

and

baghouses

to

prevent material

loss and

to

recl'cle the

collect*rJ

maierial.

HRD

receires

EAF dust

arrd

other

zinc-bearing

feedstocks

frorn of'!'-site

by

enclosed

railcar

and

rr.rck.

Up,tn

arrivai at the

faciiity,

tlre

tbedstocks

unclergo

confirmatory

testing

Bnd

sampling.

This

:;ampling and resting consists

of

visual

inspection

for

nonconforming

material,

tests

for radioacrivity

and the collection

of

generator-specific

samplss

for metal

content

analy'sis

The

feeclstocks

are then

untoarled for direct

introduction

into

the recycling

process,

rvithout

J

U.S.

EPA

origina!ly drrsignated

HTMR

as

BDAT

in

the

so-called

"First

Third" rulemaking,

in

which U.S.

EPA also establishcd

rccycling

as the

required

treatment

method

fbr K051.

5i

Fed

Reg.3il38,3ll63(Aug.

17, 1988). Althoughthe{J.S.CourtofAppealsfortheD.C.Circuit

subsequentty

vacated

and

remarrded the

treatment

method

dctermination;API-YJ,SI:PA

906

F.Zd

'l'29

(D.C.

Cir.

1990), the BDAT designation

*,as

not challenged

and, therefore,

was

not an

issue

in the

litigation.

Nelther the rulemaking

follorving

the

remand,

56 Fed.

Reg.

4l161

(Aug

19.

l99i),

nor

the decision

uphotd,ing

the rule,

SMA

V.

U.S.

EPA

2,7

F.3d

642'

(D

C Cir.

199{),

affected

the

BDAT Cesignarion fc,r

K061.

Although

the Li.S.

EPA nrore

recently

also

has

designated

sraL,ilization

as a

BDAT

(along rvith

FITh{R)

for metal-bearing

\\'astes in

general,

the

agency's

findings

regarding l{Tlv'lR's resource

recoveD'benefits

remain tnte

todal'

storagei in tiie

Curing

and

Blending

("C&8")

Bu,:ding

(illinois EPA

approved

rhe

design

o!'ihs

f

ft'B Bu$Snr>

DDlr>aDt

lD l

DEDDi')

)EliliDrr $atE$

Ouaber 1$. t99'r

)

lnn$i>reip

ipa>

unloading

in the

C&B

Bu.lding. feedstocks

sre conoitioned rvith water

to achieve

a moisrure

conient

of approximatelS' l0

percen:,

iareC,

and

blended

before:ransfer

to a

fced hopper

for

transport

to

the HTI'{R

prccessing

area.

These

prepdratoq/

steps achieve

a unifc,rm

feed

composition ficr processing

i,,

rhe HTIvffi.

rrrrits

to achieve

optimal efTiciency.

The

C&B

Bui(ding is "enlcd acd cquip2ed with

collestion

equiprnent

antl a baghoute

to

prevenl

natcr:al

ioss

and lo recycle

the

collected mate:ial.

'the

C&B Building

is operaled

undei-

negarive

pressure

to

pi:event

fugitive

emissions.

The blencieri

zinc-bearing

feedstock is conveyed

l-''y fully enclosed

belt

cunve,r'ors lrom

r.he

C&'$

Builciing

to Ged

bins

that suppii' the

\i/aclz

l:iln

HT,\{R

units.

From

the feed

bins, rhe

feedstock

is metered

in

proper proportion

rvith

a carbon

source, for

example, coke

(added

as

a

reducing agent)

CIilc a eorrtpiereiy eneloted

eoh\re\l6i hnd tianifciied

to

lhe HT\R

untr,

ln rhe

liTN,'{R

reci'cling

process,

a complex

series

of chemical

o;tidation

and reduction

reacrions

concenlrare

the

non-ferrous

metals

of the feedstocks

into

CZO.

The

leedstocks

are

first heated

ro

a

temperature

high enough

(approximately

1200u

C)

to chenrically

reduce

nanferrous

merals

Then,

these constituenls are

reoxidized

in a

countercurrent air srream,

ar,d the resulting

product

is

ccoled and

collected

as

CZO. The HTtvfR

process

also

produces

rhe

lron-Rich

Material ("tIL\f')

prorJuct,

which

is

a

coarse aggregate

The IT{M

is

sold as an asphalt aggregate,

an

iron

source lbr

cement production,

or

as

an

aggregate

for

conltruction

use. The

process produces

no

rvasres

and

no

water

dischargt:s

:

q'O emptoys

t\\'o t)'pes

of I{T}rO(

units:

a) rotaiy

\\'aelz

kilrrs in

Palnrcrrcn.

Pcnnsr.lr.ania,

Chicago,

Illinois,

and

Rockrvood,

Tenrressee,

anC

b) a

flanre

ref,clor

in Bear,rnronr.

Tcras

Ssc

also

40

C.F.R.

0

261 3

(idenrif5'ing

r1,pes

of

HTN,TR

units).

ffi

H

g

H

H

$

6

H

g

B

H

F

H

B

w

ffi

a

B

w

',-12t:,

H:,

fi

a

n

&

a

g

w

a

n

lfr

la

lE

iu

lH

lF

ln

la

IE

CZO

produced

fronr rhe

HTil{R

recl'cling

process is

collected

coniinuously in

product

coliecrors

and

rail car

loading

tanks.

The

eollected

CZO

is

then

transferred

by encioseci

screw

eon\'e),or

to

fi-rlly,-enclosed

pressure

differer:tial

rail cars

for shiprnerlt <1ff-site

U.

APPI-ICATIOiV

GF

HE .ADJUSTED

STANDAR.D

CRITERIA

DEh1OiiSTRATES'THAT

CZO

IS CONN{ODITY-LU<E

AND

NOT A

\\'ASI'E.

Section

720.13!(c)

authorizes

a

delermination

that a

ntaterial

is not

a soiid

rvaste

if the

rnarerial,

aF.er

initial reciamation,

is commodiry-!ike.

Section

720.131(c)

provides

in

full thar:

"l'he

Board

will

determine

that those

materials

that have been

rec!aimed

bur

rnus!

be

reclaimed

further befbre

rccavcry is

completed are

not

solid

\\'aste5

if, after initial

reclanration,

the

resulting material

is

commodity-like

{even

though

it is not

yet

a

commercial

product,

and

has

to

be reclaimed

firrther).

This determination

is based

on

the follorving criteria:

l)

The degree of

processing the

material

has undergone

and the

degree of

further

processing

that

is required,

2)

The

valuc

of the

material

after

it

has been

reclaimed;

3)

The degree

to

r.vhich'.he

reciaimed

material

is like an

arialogous

raw material;

4) J'he extent to

which

an end

marhet

for

the

reclaimed material

is

guaranteeci;

5)

The extent

to

rvhich

the

reclaimed

material

is

handled

to

minimize

loss; arrd

5) Other

relevant

factors."

35 Ill.

Adm. Code

720.131(c);ge

als! id.

720.1,30,720.133

(procedures

for determinations).

(.These

criteria

are identical to

the federal

criteria

for

a

commoclity-like

variance.

Sqe

a0

C.F.R.

$

260.31(c)).

As

ciiscussed in detail

belorv, CZO

unquestionably

meets the

criteria

for

an

acljusred r-tandard

for a commodity-like material

because

CZO:

(i)

is

substantiall;'

reclainred

fronr

hazardous

\\'aste;

(ii)

has

substantial

value,

(iii)

is

a substituie

for

zinc conccntrales

produced

from

mined o:'e;

(iv)

tras

guaranteed

end markets; and

(v)

is

LranCleci

to

elinrinate

or

ntinintize

proCucl

lo s. Orher

relevant

faitors also support an

adjusteri

standard.

One

r,uch

factor

is

the

Board's recentl)'-pronruigated

adjusted

standard for

EAf

zinc

oxiCe

processed

by BRZ. The

BRZ

adjusted stanciard

is conp:lling and favcrable

precedent

because it confirn,s

the

commodit5'-like nature

of CZO.

HRf) dernonstrates

in

this

Petition that

CZO rneets

the

adjusted

standard criieria for substantially

the

same

reasons as the EAF zinc oxide

in

ihe BPJ adjusted

standard.

A

related

factor

is

consistency

with variances

frorn

the definition

of solid

u,aste

promutgated

by other

regulatcry agencies

(including

a

variance issued

b-v

Tennessee

tbr

the

sane

EAF dust

zinc

cxide

inaterialthat

rvas

the basis for the

BRZ

adjusted standard).

/tnother facior

is

encouraging

recycling oflEAF

dust

and the conservation ofncn-renervable resources, thereby

prcmoting

sustainable

developnrerrt.

!

HILD

thereiore

respectfulll' requests that an

adjusted

staniiard

lronr the deflnition

cf solid

waste

for HRD'.s CZO

be

granted.?

Irr the remainder of

this

Petition, HRLr apl

lies

each criterion

for

a.n adjusted

standard

fcr

e comrnodit5,-iike

material to

CZO to

denronstrate that

CZO

is

commodity-like

and noi

a

solid

\i'asre

The

adjr.rsted starrdard regtiiations are substanlively

identical

tc the

federa!

regulations ar

10

C.F.R.

$5

260 30-26C.33.

U.S.

EPA

precedent

therefore

is relevant

to

interpreting

and

appii'ing

the

commodity-like

adjusted

standard criteria,

and HRD

addresses

U.S.

EPA

precedenr

in this Petition

where

appropriate

$ee

Rec:els_teEhnalag,re.9, AS 9?-9,

siip.

op.

at 6

("[T]he

Board

has

referred to

USEPA

preamble

langrr6gg

interpreting

the

federa! counierpart

to

the

E

U.S.

E?A first

promulgated

tlre

grrovisions

on

rvhich

the

Board's

adjus'red standard authority is

based

in

the context

of the redefinition

of solid

wastc. 50 Fcd. Reg 614

(Jan.4,

1985).

One

of

the

principa.l

purpcses

underlying

these

regulations

was promoting

appropriate

rec5'cling,

therebl'

rendering

this factor

"re'levant"

to FIRD's Peiition

for

an

adjusted srandard.

2

in

addition

to

the

BPJ

adjusted

standarrl, rhe

[Joard

has decided trr'<l adjusted stancla;d

petitions

under 9ection

'120.131(c):.ln

re

Pedtiouof Rec],clc'fechnoiogies.

lnc

for

f

djus!_ed

Standard

Under

35

lll

Ari_ln

Code

120

l3l(c)

(Sepr

3, 1998),

AS

97-9;!n

re Petirion

of

ffi

H

H

$

H

H

ffi

ffi

fr

ffi

H

H

H

B

m

tr

ffi

w

ffi

l0

n

E

n

v

a

a

u

n

fr

g

&

g

a

fr

8

fr

F

H

il

Board regulations at

issue.").

U.S. EPr\ clearly' inlended

that the

criteria be applied

te

individua!

nraterials in a conrnron-sense

n'rilnner.

"The

Regional

Administrator

(or

an

authorized

slate)

ma,v

rveigh

these factors as slre sees fit, and

may

rely on any or

alloithem ro

reach

a decision." 50

Fed.

Reg. al655. Even though

not

ail the criteria

nnust

be

relied

on

in

making

a decision, IIRD

demonstrates

that

CZO

rneets each and

every criterion

for

an

adjusted

standard

for a commodity-

iike material.

A.

CZO

IIas

Undergone

Substantial Processing.

The

tlrst

factor to

be

considered is the

degree of

processing

that the material

has

undergone

and

the

degree

of further

processing

that is required. According to the

Board,

the

"more

substantial

the initial

processing,

the

nroie likely the resulting materiai is

to be

commcrdity-like

"

.&cgi:gle-kgb!91ag,ies,

AS 97-9,

slip o?.

ar7

(quoting

50

Fed. Reg ar

655)

HRD

recycles EAF dust

and other rnetal-bearing

feedstocks

in its I{TiMR process

to

produce

CZO

in

a complex

series of chenrical reduction

and oxidation reactions. These reactiorrs

iundamcntally

transforrn relatively

locv-zinc,

high-iron

wastes

that are

incapable

of

being

processed

at a zinc re fineryE

intc

the high-zinc, iow-iron

CZO

product

ihat requires

only'

minimal

additional

processirrg.

The

HTMR

process

also

prodirces

the high-iron

product

iRlr{. The

HT\{R

process

results

in

substantial

processing

for

the

follorvirrg reasons:

l.

Zinc is

concentrated in

the

CZO,

quadruplin;

in

content

fronr approximately

l5

percent

in

the

blended HTMR feedstock

to approximately 60

perceirt

in

the

CZO

produA.

Chemetco.

Inc f'ut&iu:!sd-Standard

from 35lllldrn-.]eoc!e:2Ol3l(a) and

iS)

ft{arch

19,

1998), AS

97

-2.

s

Zinc

t'efineries are

incapable

of

recy,cling

EAF

tiust

and sinrilar loi','-zinc

\\'astes

becruse tlre

refinery equipment is neither

designed nor

built

ro

remove

thc si.gnificant

levels of ncn-zinc

constituents

(e.9,

iron)

in

steel inCustry

\\'aste

feedstocks.

Sgg

pages

l3-15 belorr for a dc'tailed

description af

zinc

refinerl'equipmenr

used lo

process

CZO.

l!

?

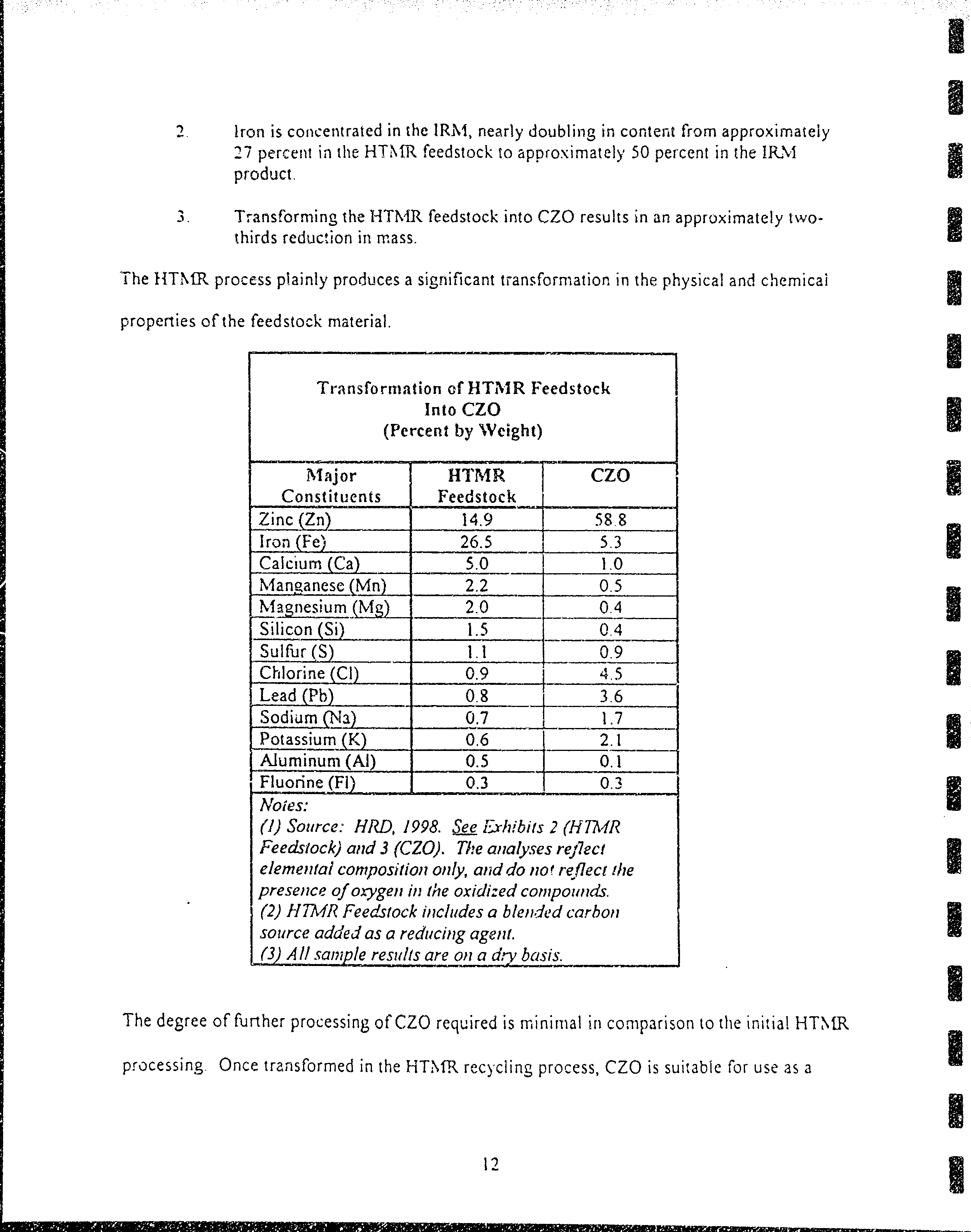

lron is

concentrated

in the lRtr{,

nearly

doubling in conterrt from approximately

27

percerrt

in

the HTI\{R

feedstock

to aporoximately

50

percent

in the IR\I

produet.

3.

Transforming the

I-ITN'{R feedstock

into

CZO

results in an

approximately two-

thirds reduction in mass.

The

t{Tlt{R process plainly produces

a significant

transfornration in the

physical

and chemicai

properties

of the feedstock

material.

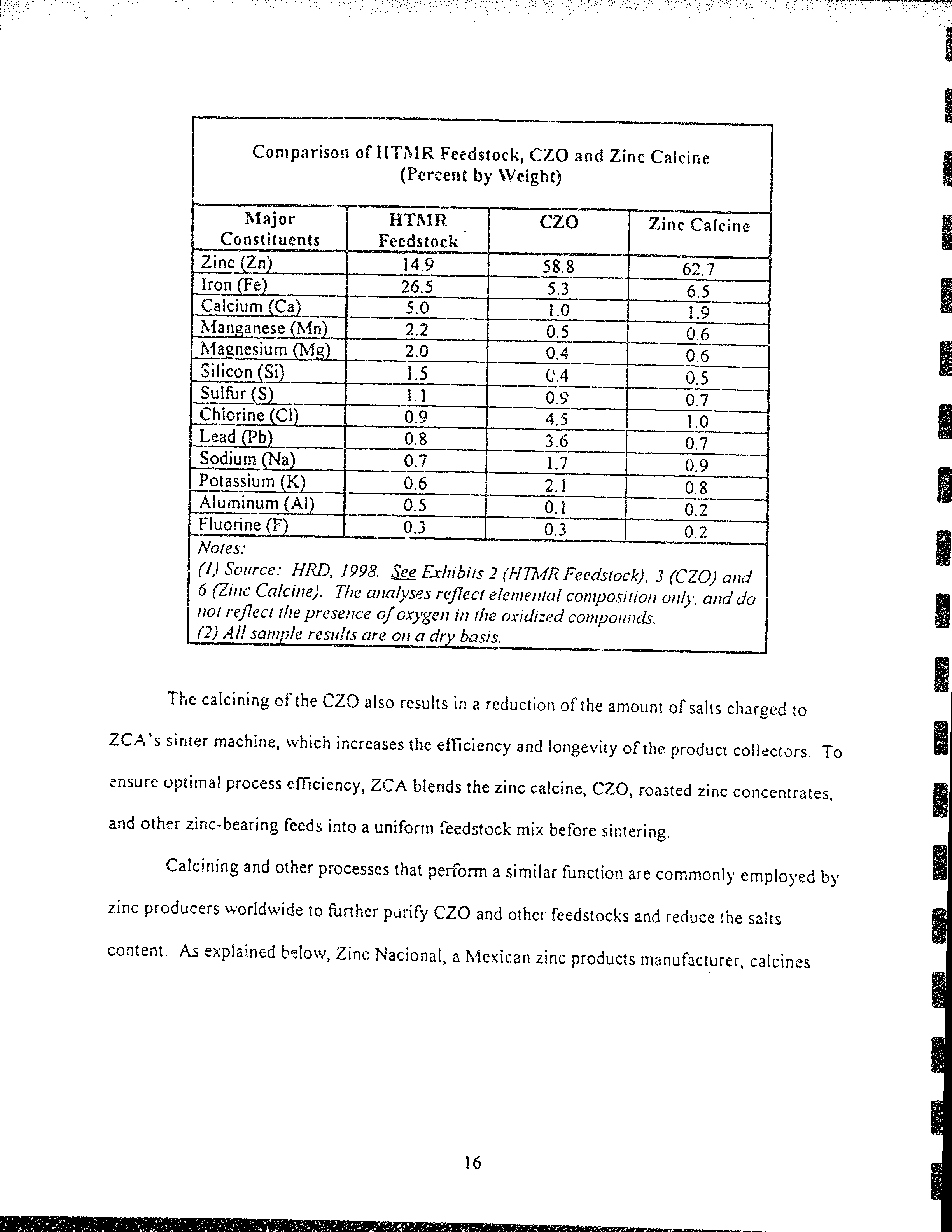

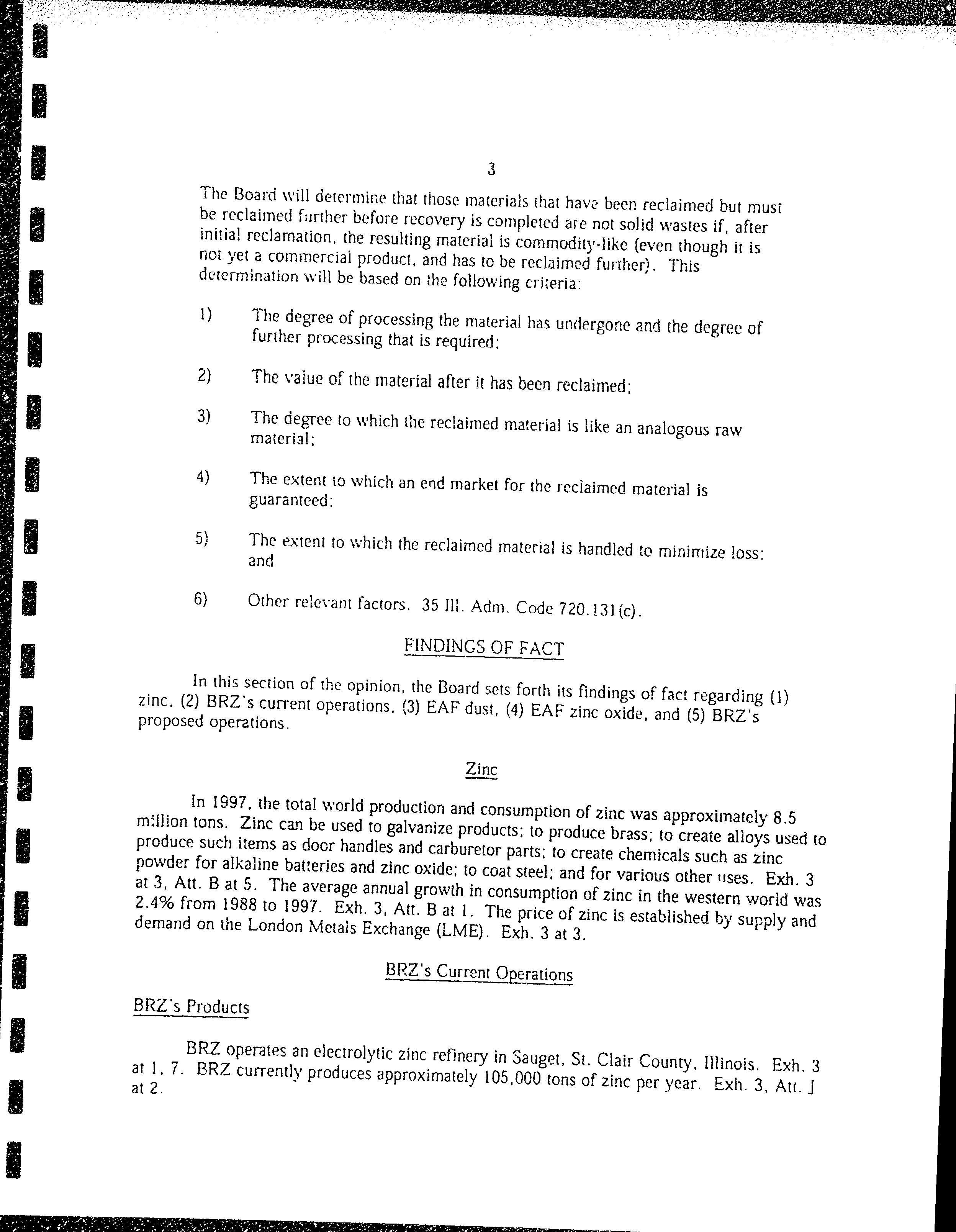

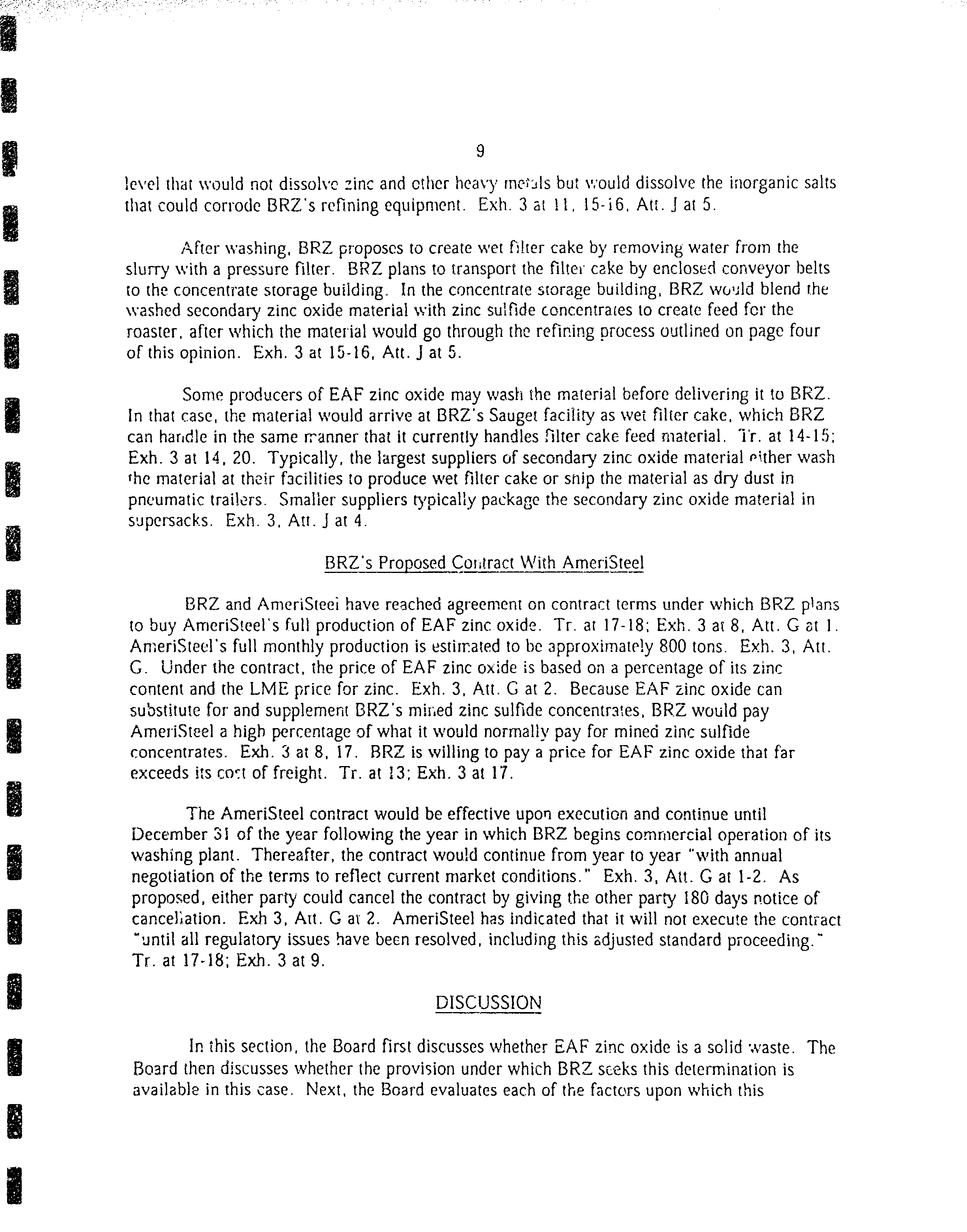

Tra nsfo

rmation of HTilt R F'eedstock

Into

CZO

(Percent

by

Weight)

ilIajor

Constit uents

HTMR

Feedstock

CZO

Zinc

(Zn\

14.9

588

Iron

(Fe)

26.5

53

Calcium

(Ca)

5.0

I.0

N'lanqancse

(Mn)

2.2

0.5

l"{€l..tu11(Mg)

2.0

04

Sr!,c,oq(!i)

1.5

0.4

Sulfur

(S)

l.l

09

Chlorine

(Cl)

0.9

4..5

Lead

(Pb)

0.8

36

Sodium

fNs)

0.7

1.7

Potassium

(K)

0.6

2.1

Aluminum

(Al)

0.5

0.1

Fluorine

(Fl)

0.3

0.-1

Noies:

(l)

Source:

HRD, 1998. See ishibits

2

(HTMR

Feedstock)

and

3

(CZO).

The analy.ses relilecr

elemenlal

compositiotr

only, and do not re{lect

the

presetrce

of

orygen

in

the

oxidized

compounds.

(2)

hITMR

Feedstock includes a blen,Ted

carbon

source

adde,J

as

a reducing ageilt.

(3)

All

sample

remlts

are

on

a dry

basis.

The

degree of

further

processing

of CZO required

is

minirnal

in conrparison

to rhe inirial

HT\1R

processing

Once transformed

in

the HTi\fB. rec5'ciing

process,

CZO

is

suirabie

for use

as a

H

6

ffi

B

B

E

ffi

ffi

H

g

ffi

g

fr

fr

B

H

$

ffi

w

t2

t3

'f'"t

""

&

n

&

&

&

ffi

u

fr

a

n

fr

a

w

n

fr

&

a

E

direct

fleedstocl.:

in

zinc production,

a"

a direc't

feedstock

for

calcining,

or

as an

ingreclienr

in

the

production

of nricrcnutrients.

(CZO

is not

used for

lerrilizer.)

Each

use

is

desci'ibed

in

furiher

detail

beiorr'.

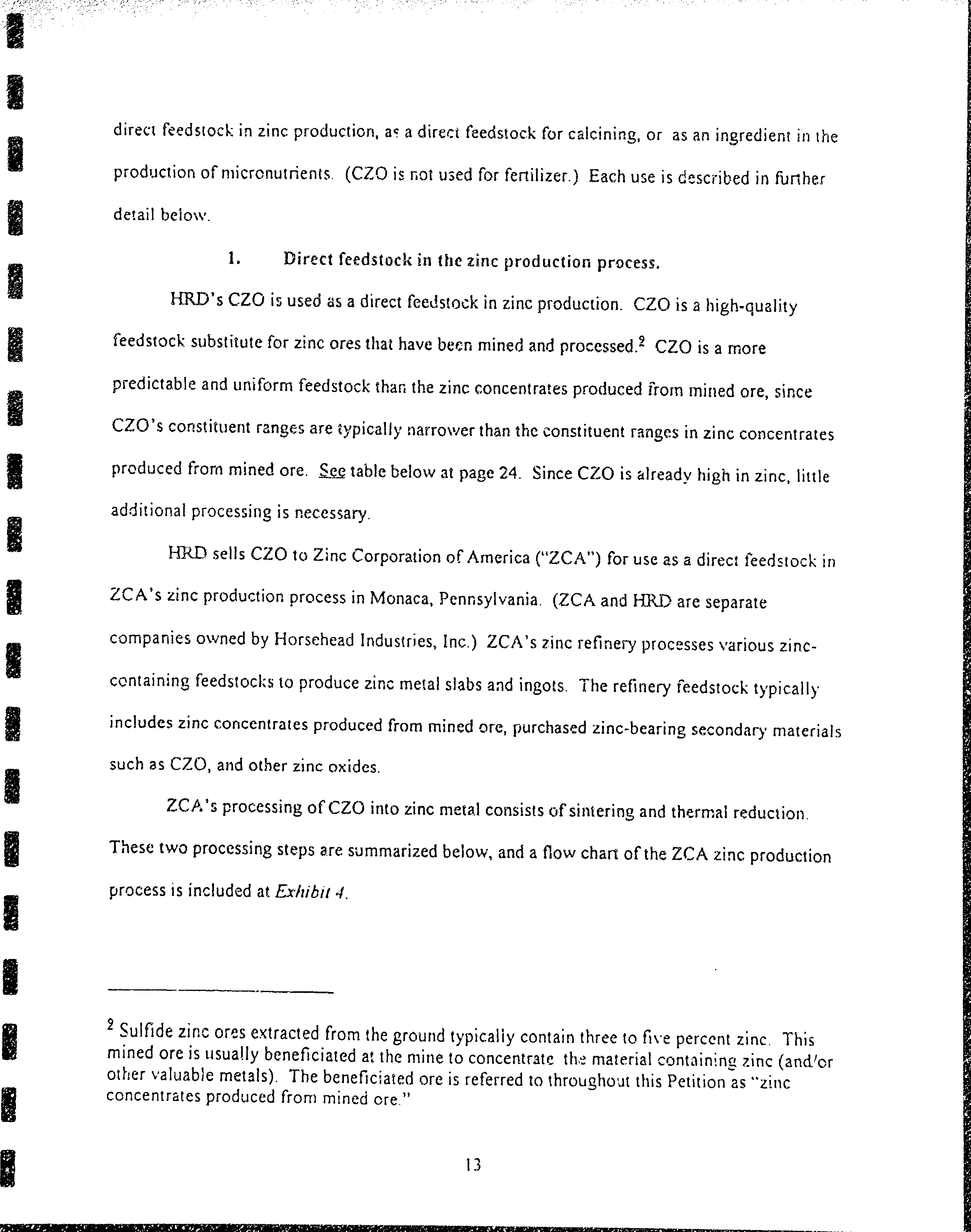

l.

Direct

feedstock

in

the zinc productiarr

process.

FRD's

CZO

is

used

as a direct

feedstock

in

zinc

production.

CZO

is

a

high-quality

feedstock

substitute

for

zinc

oresthat

have

been

mined

and

processed.z

CZA

is

a

more

predictable

and

uniform

feedstock

than

the

zinc

concentrates

produceC

irorn

miled

ore,

since

CZO's

constituent

ranges

are

typically

narro\t/erthan

the

constituent

ranges

in

zinc

concentrates

produced

f?orn

mined

ore.

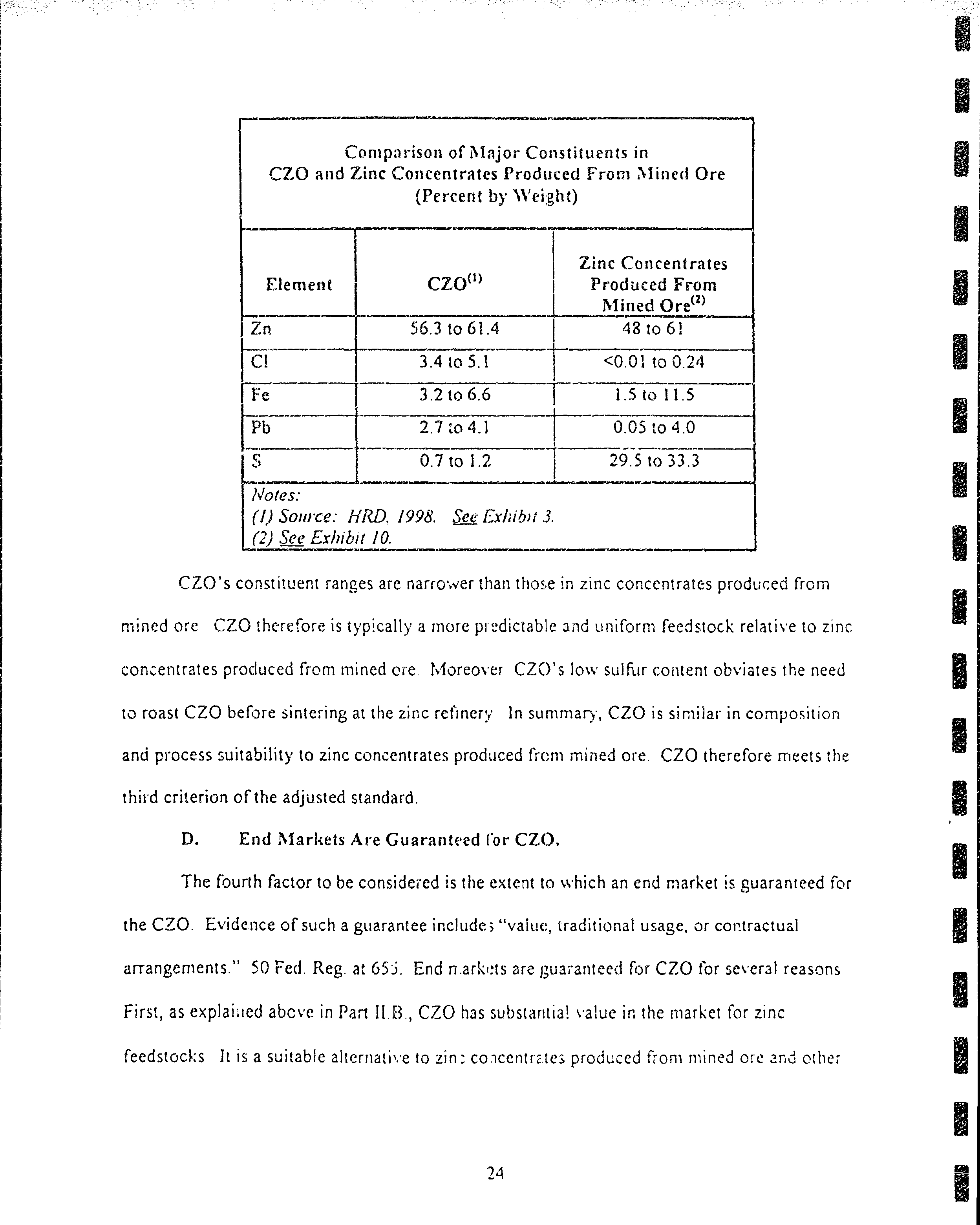

See table

belorv

at

page

24.

Since

CZO is

already

high

in

zinc, litrle

additional

processing

is necessary.

HRD

sells

CZO

to Zinc

Corporation

of America

("2C.4")

for use

as a

direcr

tterjsrock

in

ZCA's

zinc

production

orocess

in

Monaca,

Pcnnsylvania. (ZCAand

HRD

are

separate

companies

orvned

by

Horsehead

Industries,

Inc.)

ZCA's

zinc

refinery processes.r,arious

zinc-

ccntaining feedstocl<s

to

produce

zinc

metal

slabs

and ingots.

The refinery

ieedstock

ty,picalll,

includes

zinc

concentrates

produced

from

mined

ore,

purchased

zinc-bearing

secondar;,materials

such

as

CZO,

and other

zinc

oxides.

ZCA's

processing

of

CZO into

zinc

meta.l

consists

af sintering

and

thernlal

reducrion.

These two

processing

steps

are

summarized

below,

ancl a

flowchart

of the

ZCAzincproduction

process

rs

included

at

Ex-hibit

4.

2

Sulfide

zinc

ores

extracted

from

the ground

typicaliy

contain

three

ro

fir.e percenr

zinc.

This

mined

ore is usually

beneficiateci

at

the

mine

to concintrete

ihe marerial

containing

zinc

(and./or

other

valuabie

metals).

The

beneficiated

ore is referred

ro

throughout

rhis

petirion

as.'zirrc

ccncentrates

produced

from

minecj

cre."

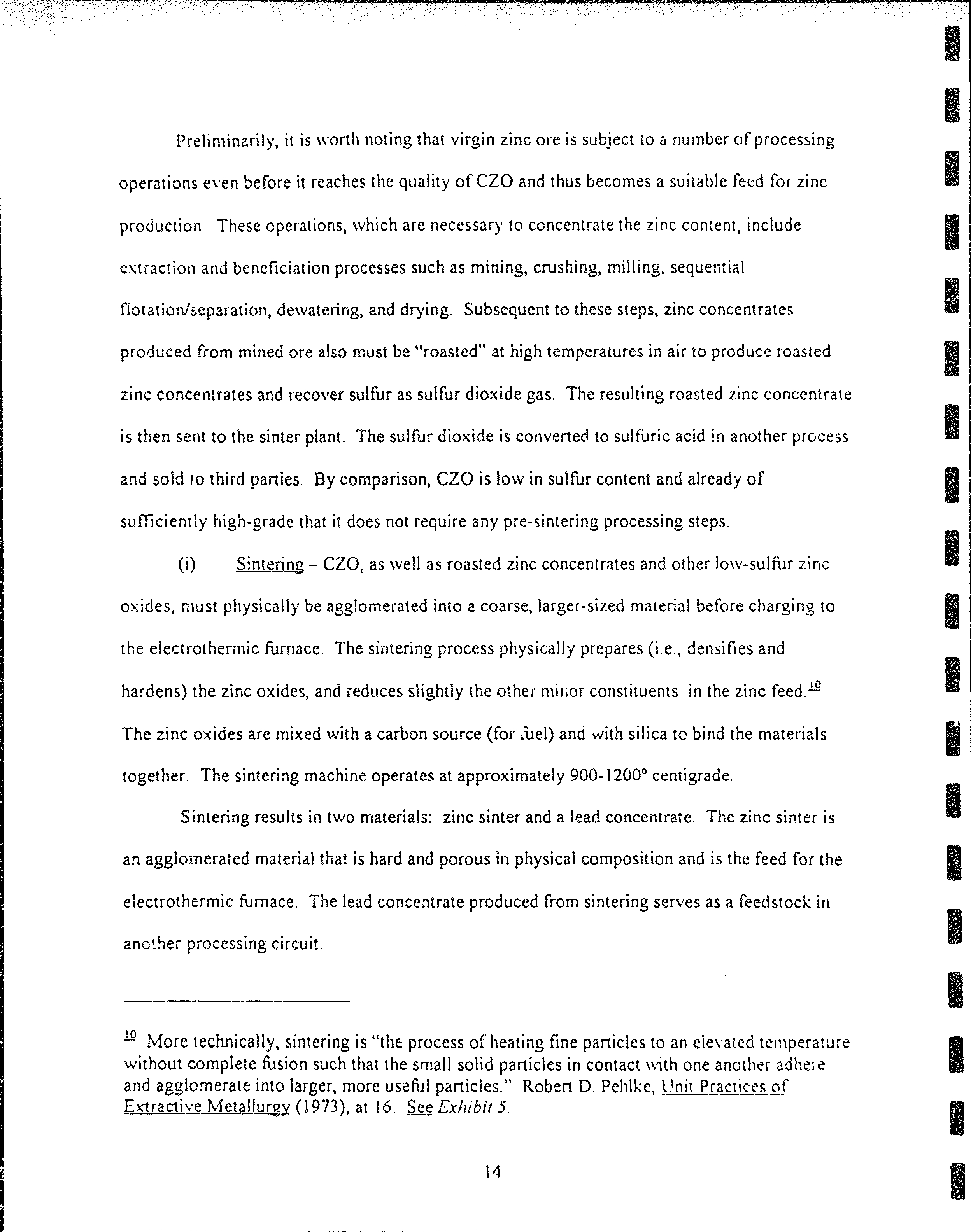

Prelinrinarily,

it

is

rvorth noting that

virgin

zinc

ore

is subject to a

number

of

processing

operations e"'en

before

it reaches

the

quality

of CZO and

thus

becomes

a

suitatrle

feed

for zinc

procluction.

These

cperations,

rvhich

are

necessar)' to

concent!'ate the

zinc

content, include

extraction

and

beneficiation

processes

such

as

mining,

crushing,

milling,

sequenlial

fiotatioa/separation,

dervatering,

and drying. Subsequent to these steps,

zinc concentrates

produced

from mineci cre

also must be

"roasted"

at high

temperatures

in air

to

produce

roasted

zinc

concentretes and recover sulfur

as sulfur dioxide

gas.

The resulting

roasted

zinc concentrate

is

then

sent

to the

sinter

plant. The

sulfur

dioxide

is

converted to sulfuric

acld !n

another

process

and

soid

to

third

parties.

By comparison, CZO

is

lorv

in sulfur

content

and already

of

sufliciently

high-grade

that

it

dces

not require any

pre-sintering

processing

steps.

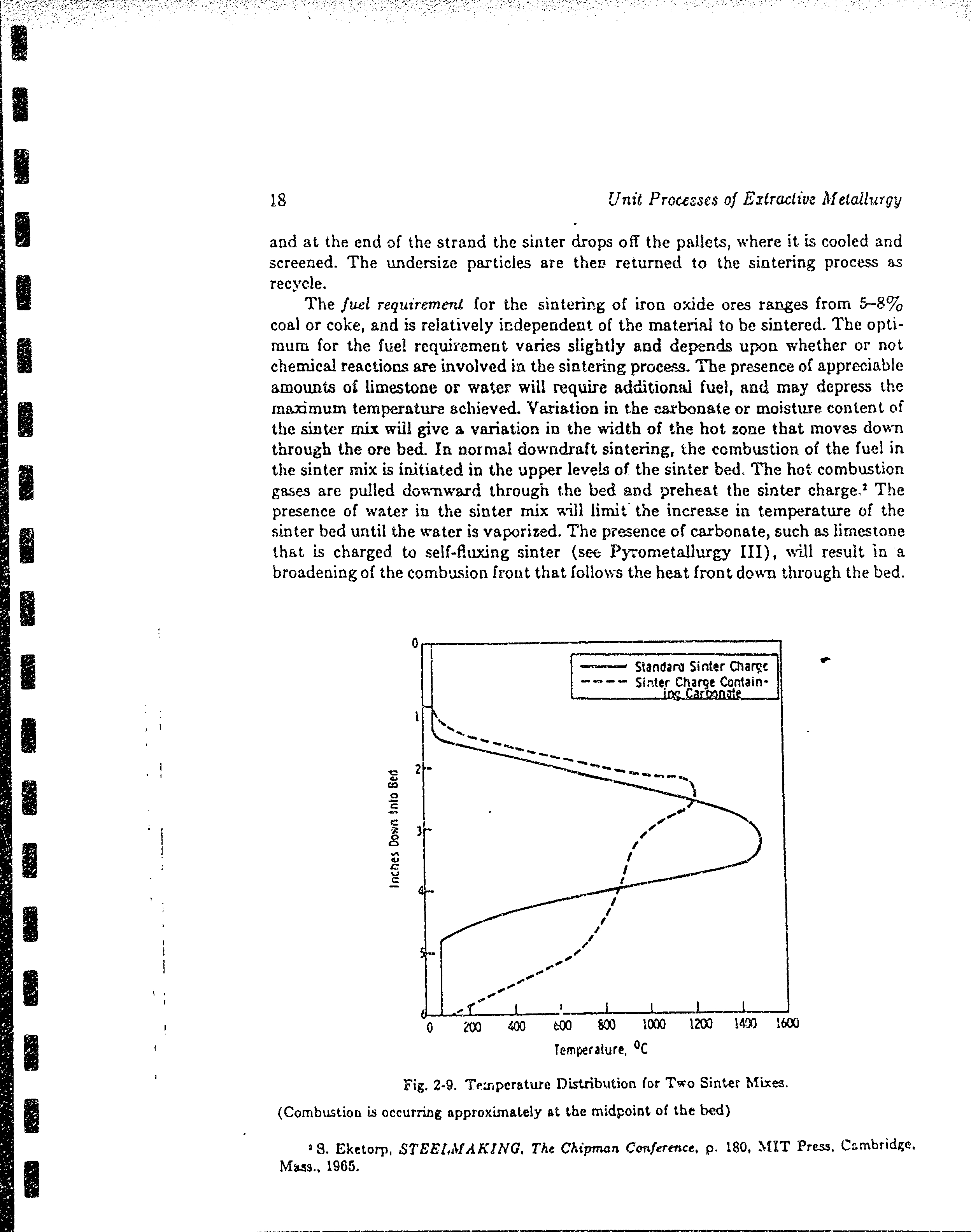

(i)

Sintering

-CZA,

as

rveil

as

roasted zinc conceritrates and other

lorv-sulfur zinc

oxides,

must

physically

be

agglomerated into a

coarse,

larger-sized

materiai

before charging to

the electrothermic fi;rnace

.

l'he

sintering

process physically

prepares (i.e.,

densifies

and

hardens) the zinc oxides, and

reduces

siightiy the

rrther

mil;or

constituents in the

zinc feed.E

The zinc

oxides are mixed

with

a

carbon source

(for:i.rel)

anci

with

silica ta

bind

the materials

rogether

The

sintering machine

operates at approximately

900-1200o

centigrade.

Sinterirrg

results in two

materials: zinc

sinter and a

lead

concentraie.

The

zinc

sinter

is

an agglomerated

material that is hard and

porous

in

physical

composition and

is the

feed for

the

electrothermic

furnace.

The

lead

concentrate

produced

from sintering senes as a feedstock

in

anolhei

processing

circuit.

&

More

technically,

sintering is

"the

process

o{'heating

fine

particles

to an

eievated

tenrperature

ivithout

complete

fusion such that the

small

solid

particles

in contact

ri'ith

one

anorher

adhe

re

and agglcmerate

into

larger,

more useful

particles."

Robert D. Pehlke, Unit Pracriges

gf

Ertraaive

lr{etal.Iurgy

(1973),

at

16.

See

Exhibit

5.

ffi

ffi

ffi

ffi

ffi

ffi

ffi

ffi

H

ffi

ffi

&

ffi

H

ffi

ffi

&

g

ffi

l4

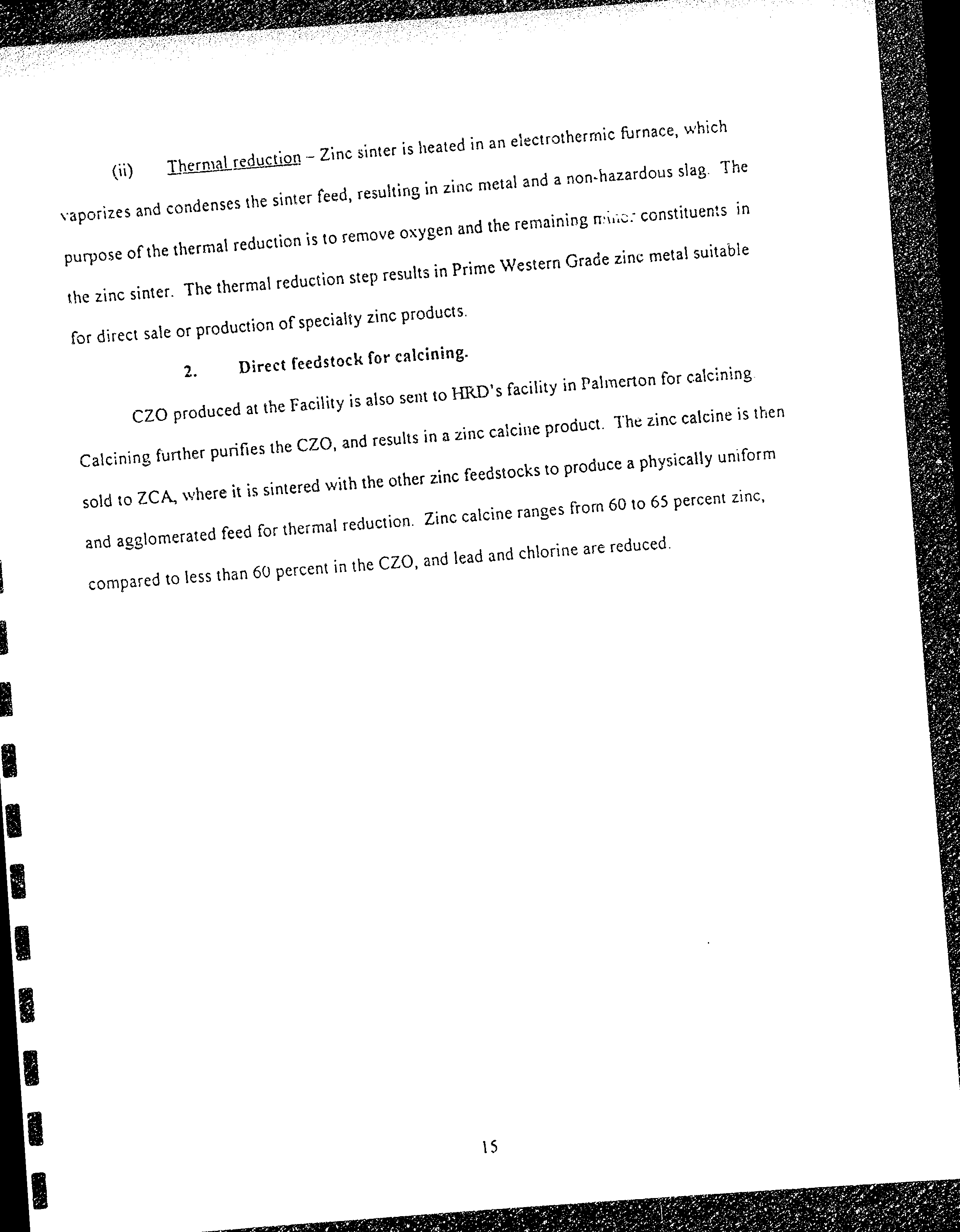

(ii).lhgll]]a!-reduction.-Z\ncsinterislreatedinanelectrorherrnicfurnace,r.r,hich

r.aporizes

and

condenses

rhe

sinrer

feed,

resurting

in

zi.c

metar

and

a

non'hazardous

siag'

The

purpose

of

the

thermar

reduction

is

to

remove

oxygen

and

the

remaining

n:iri!"

constituents

in

rhe

zinc

sinter.

The

thermar

reduetion

step

resurts

in

prime \{esterrr

Grade

zinc

metal

suitable

for

direct

sale

or

production

of

specialty

zinc

products'

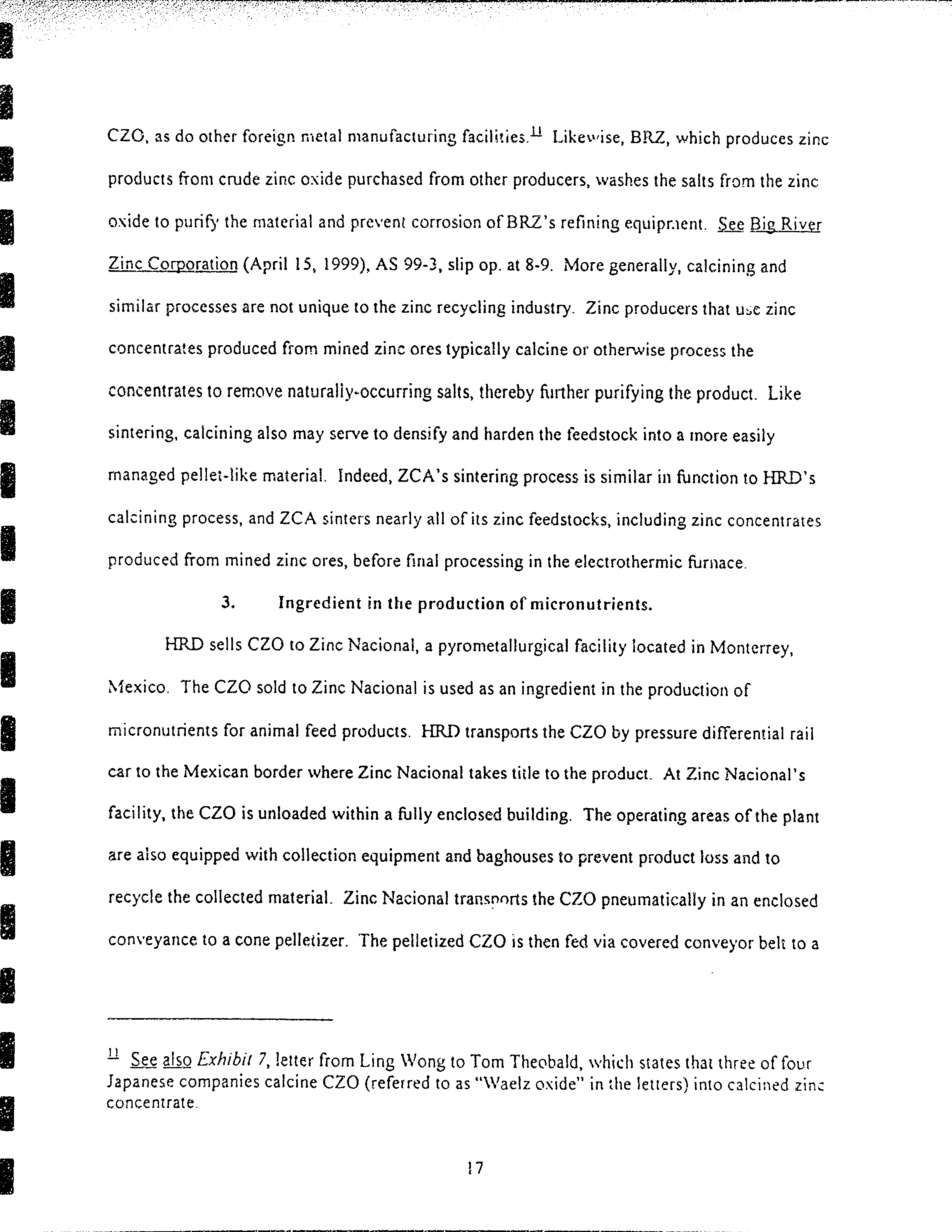

2'

Direct

feedstock

for

calcining'

cZO

produced

ar

the

Faciriry

is

also

sert

to

IIRD,s

fac*ity

in

Farrnerron

for

c.alcining

carcining

furrher

purifies

the

cZo,

and

resurts

in

a

zinc

calci*e

product'

"l'hc

zinc

calcine

is

then

soldtoT]f[r,,:hereitissinteredrviththeotherzincfeedstockstoproduceaphysicallyuniform

and

agglomerared

feed

for

thermar

reduction.

zinc

calcine

ranges

from

60

ro

65

percent

zinc'

compared

to

less

than

60

percent

in

the

CZO'

and

lead

and

chlorine

are

reduced'

n

B

I

rg

r5

E

g

E

*

ff

tr

tr

ffi

g

&

g

The

calcining

of

the

CZC

also

results

in

a

reduction

of

the

amounr

of sahs

charged

to

ZCA's

sirrter

machine,

rvhich

increases

the

efTiciency

and iongevity

of the

producr

collecrors

To

ensure tlplimal process

efTiciency,

ZCA

blends

the

zinc

calcine,

CZo,

roasted

zinc

concenrrates,

and othar

zirrc-bearing

feeds

into

a

unilorrn

feedstock

mix

belore

sintering.

Calctning

and

other

pfocesses

that

perform

a

similar

function

are

commonly,

emplol,ed

by,

zinc

producers

worldwide

to

funher

p,irify

CZO

and

other

feedstocks

and

recluce

:he

salts

content'

As explained

t'elorv'

Zinc

Nacional,

a N{exican

zinc

products

manufacturer,

calcines

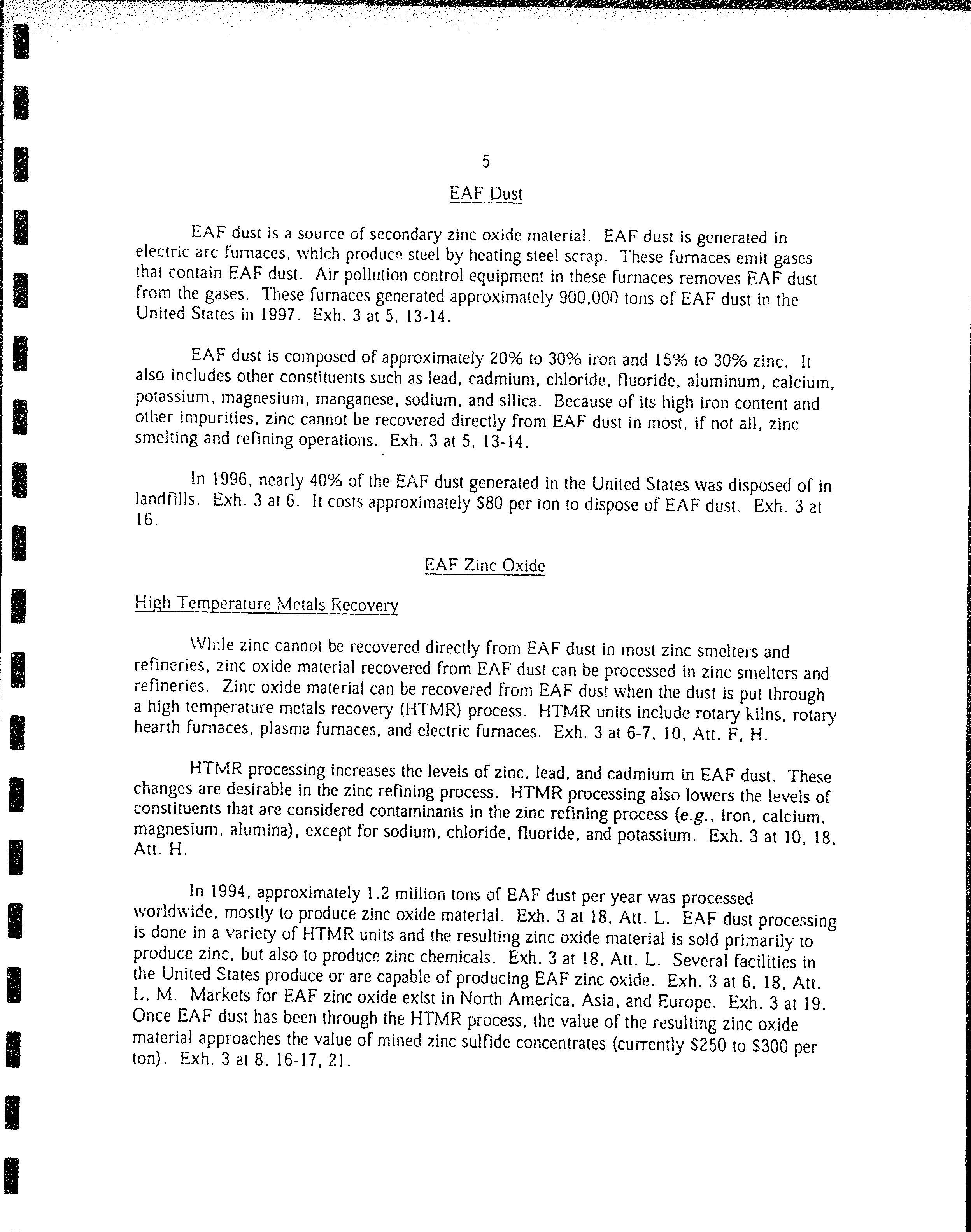

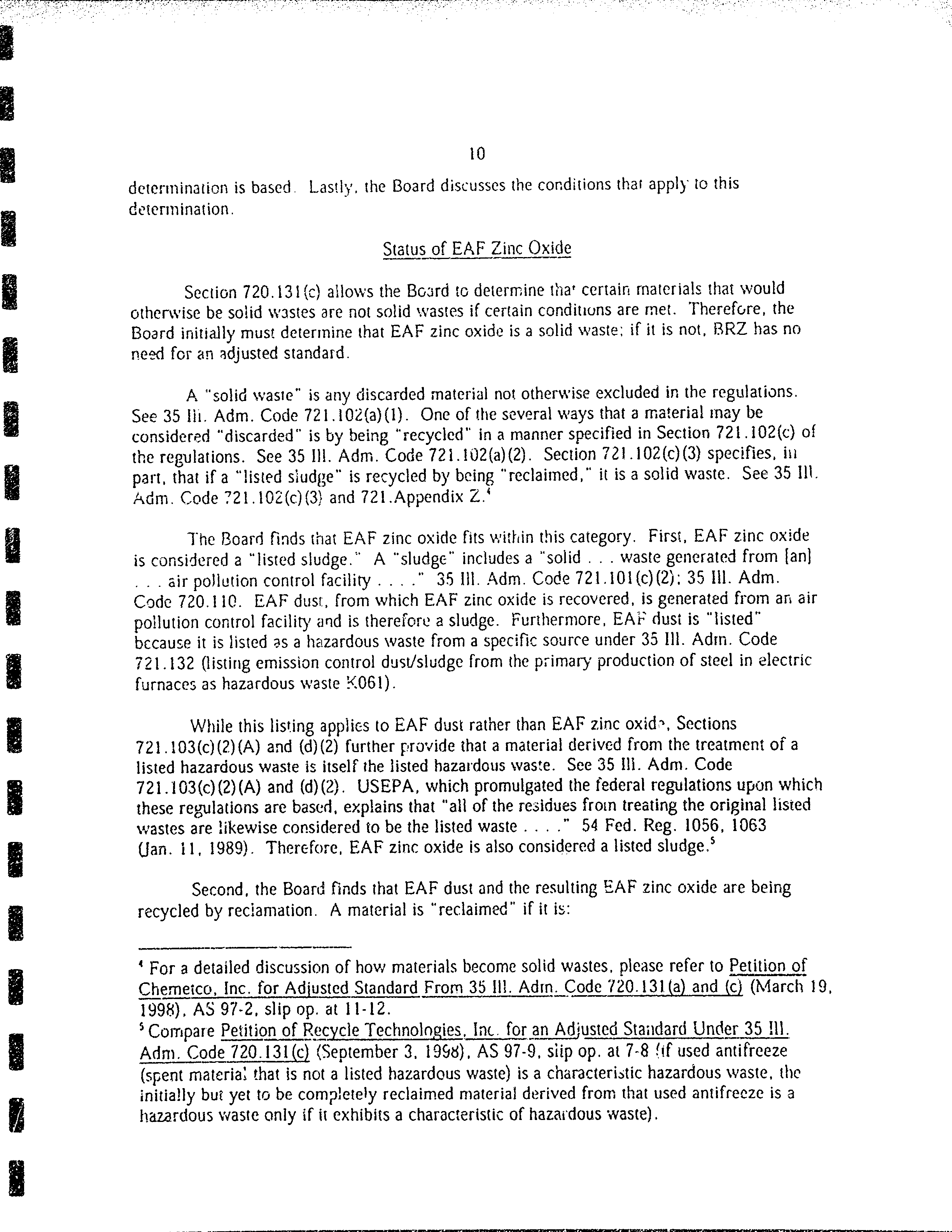

Conrpariso:: of

l{TfrtR

Feedsiock,

CZO

ancl

Zinc

Calcine

(percent

by

tVeighr)

Stajor

Cons(ituents

HTfr{R

Feedstoek

czo

Zinc

Cale ine

4nc

(Zn)

t49

s8.8

62'l

Iron

[Fe)

26.5

5.3

6.5

Calcium

(Ca)

5.0

t.0

t.9

lr{aneanese

{i\,{n)

2.2

0.5

0.6

l'{aenesium

ffo{s)

2.A

0.4

0.6

Silicon

(Si)

1.5

C4

0.5

Sultur

(S)

t.t

0.e'

0.7

Chlorine

(Cl)

0.9

4.5

t.0

Lead

fPb)

0.8

3.6

07

Sodium

[Na)

0.7

t.7

0.9

Potassium

(K)

0.6

2.1

08

Aluminum

(Al)

0.5

0.i

o?,

Fluorine

(F)

0.3

0.3

02

Nales:

$)

source:

HRD.

1993.

see Frhibirs

2

(HTMI?

Feeclstock),

3

(CZo)

artd

6

Q.inc

Calcine).

Thc

analyses

refiect

elernetttal

contpositiott

ottl1,,

atvl

do

ttot

reflect

the

presence

of

ox\'gen

i,

rhe

oxidircd

conipo,ttris.

(2)

All

y11ple results

dre

on

a dry

basis.

CZO, as

do

other foreign

nietal nranuiacturing

facilities.!

l-iker,,ise,

BRZ, which

produces

zinc

products

front

crude zinc oside

purchased

from

other

producers,

rvashes

the

salts frcm

the

zinc

oxide

to

purif1'the

material and

prevent

corrosion

of BM's refiningequipnrent.

,Sge B_rS.Rty,sr

ZincJCgrp.orati-on

(April

I

5, 1999).

AS

99-3,

slip

op. at 8-9.

More

generally,

catcining

and

similarprocessesarenotuniquetothezincrecyclingindustry.

Zincproducersthatusczinc

concentrales

produced

fiom mined

zinc ores typically

calcine

or otherwise process

the

cOncentrates

lo

rernove

naturaliy-occurring

salts,

thereby frrrrher

purifying

the

product.

Like

sintering, calcining

also

may serve

to

densily

and

harden

the

feedstock into

a

lnore

easily

rnanaged pellet-like

material.

Indeed, ZCA's

sintering

process

is similar

in

function

to HRD's

calcining process,

andZCA

-q.inters

nearly

all

of

its

zinc feedstocks,

including

zinc

concentrates

produced

from mined

zinc

ores, before

final

processing

in

the electrothermic

firrnace.

3.

Ingredient

in ttre

production

of micronutrients.

HRD sells CZA

to Zinc

Nacional,

a

pyronretallurgical

facility

located

in

Monrerrey,

N{exico. The

CZO sold

to Zinc Nacional

is

used as

an

ingredient

in

the

producriorr

of

micronutrients

for

animal

feed

products.

HRD

transports

the

CZO by

pressure

differenrial

rail

car to the Mexican

border rvhere

Zinc Nacional

takes tiile

to the

proCuct.

At

Zinc

Nacionat's

facility,

the

CZO

is unloaded

within

a fully enclosed

building. The

operating areas

of the

plant

are

aiso

equipped

with

collection

equipment

and baghouses

to

prevent product

loss

and

to

recycle the collected

material.

Zinc Nacional

transnorts

the

CZO

pneumatically

in

an

enclosed

conveyance to a

cone

pelletizer.

The pelletized

CZO

is

then fed

via

covered

conve!'or

belt to a

"

S.J

alsg

Exhibit

T,tetter

from

Ling

Wong

to

Tom

Theobald, s,hich

srares

rhar

three

of four

Japanese companies calcine

CZO

(referred

to as

"\\,aelz

oxide" in ihe

letters)

into

calcirred

zinc

concentrate.

lr7

t\\'o-staqe

calcine

process

tlrat

volatilizes

certain

nretal

compounds, ren'roves

salts,

and

prcduces

a

zinc

oside,

',r'hich

is sold

to the agriculture

industry

as

a rnicronutrient

for

animal

feed

prorjucts

4.

Summary.

F{RD's

t'lTi\{R

process

substantially transforms

the hazarCous

waste

feedsiock

from a

lou'-zinc,

high-iron luasle

mixture

to the

high-zinc,

!ow-iron

CZO

product

suitable

for

direct use

in

the zinc

production

process,

for calcining

in

HRD's

calcining

kilns,

and

as an

ingredient

in rhe

Production

of

micronutrients.

The

CZO

results

from

substantial processing

of the feecJstock

and

i'equires

oniy minimal

additional processing

to

produce

zinc

products.

CZO therefore

meers

the

first

criterion

cf

rhe adjusted

standard fbr

commodity-liiie

products.

B.

CZO Has

Substantial

Value.

The

second

criterion

to

be considered

is

thevalue

oithe

material

after it

has

been

reclaimed.

According

to

the

U.S. EPA

guidance, "[o]bviously,

the

more

valuable

a mater-ial

is

after initial processing,

the more

likely

ir is to

be commodity-tike."

50

Fed. Reg.

at 655.

The

HTN{R process

transforms

material

rvith

negative

eeonomic

value

into

a material

rvith

sr.:bstanrial

positive

economic value.

More

specifically,

the hazardous

wastes

used

to

produce

CZO

haye

ne.gative

economic'value

because

generators

rnust

pay

lor

the rnaterial

to

be

either

Cisposed

of

or

reeycled.

indeed,

EAF

dust's

high iron

content

and

relatively

lorv zinc

content

prevent

zinc

produaion

facilities

from

using

EAF dust

directly as a feedstock.

The processing

of EAF

dusr

and other feedstocks

in

HRD's

HTMR

process

produces

the comnrodity-!ike

product

CZO,

u'hich"

along

u'ith

other zinc

concentraies,

is

part

of

the

rvorldrvide

market

in zinc

commodities.

CZO

is

a

valuable

product

because

it is

high

in

ziric and lorv in

consiituenrs

like

iron that

cannor

be

processed

at

zinc

production

lacilities

Zinc'sprice

is esrablished

bl,suppl;.an,J

dc'nrand

on

the London

\fetal Exchange

("LME")

The

long

rernr

average

Lj\{E

price

for

z_inc is

ffi

ffi

ffi

ffi

ffi

g

H

ffi

ffi

H

ffi

ffi

ffi

ffi

I

ffi

w

ffi

ffi

IB

t9

;3

Fs

Es

f;m

lm

ilE

l€

ls

rg

€

g

F

fr

g

t

a

n

approlin]rteii'5s

cents/pcund,

but

in

the past

ten

),ears

the

LN{E

zine price

has uaried

from

a

lo$'of

39'7

cents/pound

in

seprenrber

l99i

ro

a high

of

g3.7

ccnrs/pound

in

h{arch

lggg.

The value

of ntost

zinc-bearing

mate:"ials,

including

czo,isbased

on

a tbrmula

that

is

generalll'

accepted

in

the

rvorldrvide

indusrry.

The generic

iormula

is

lypically

to

pay

rhe

LI,IE

orice for

a

fixed

percentage

of

the

zinc

contained

in

rhe

marerial.

The

buyer

(e.g.,

a

zinc

refiner),

mdi'3!so

re'ise

the

fc;^mula

to

inclucie

and

deduct

a

"processing"

charge

from

rhe

zinc paymenr,

r'hich

represents

an

approximate

overall

cost

to

process

the

material

in

the

zinr:

producrion

proeess.

The

processing

charge

rvi!l

increase

or

decrease

with

the price

of

zinc,

so

that

the

mine

and

the

zinc

producer

share

in

the

risk

associated

rvirh

fiuctuations

in

the

zinc price

Finat!y,

credits

and

debits

may

be paid

by

the

buyer

(or

applied

to

rhe

selter-)

lor

cerrain

non-zinc

:onstiiuents

in

the

zinc-bearing

material.

As

explained

below,

CZo

is

produced

and

sotd rvorldrvide

as

a process

subsrirure

for

zinc

concentrates

produced

from

nined

ore.

h{oreover,

the

economic

value

of

HRD,s

CZo,

lii:e

oiher

cZo

end

z1'nc

concenlrates

produced

from

mined

ore,

is

substantial

and

quantilrable

czo

iherefore

meets

lhe

"\'alue"

criterion

of

an

adjusted

standard

for

commodity-like

producrs.

I'

concentrates

CZo

is

produced

produced

and

sc,ld

frorn

worldrvide

mined

ore.

es

a

process

substitute

for

zinc

Hundreds

of

thousands

of tons

of

cza

and

sinrilar

zinc

feedsrocks

are

sold

*.orldr'ide

as

a

process

substitute

lbr

zinc

ccncentrates

produced

from

mined

ore

because

they

contain

higlr

zinc

content

and

are

suitable

forprocessing

at

zinc

manufacturing

facilities.

CZo,s

economic

value'

like

any

other

valuable

zinc-bearing

marerial,

depends

rargely

on

its

zinc

contenr

and

ihe

LN{E

price

for

zinc.

The

same

is

true

for

other

zinc

concentrates

or

secondan,

materiars

pr.r;'chased

by ZCA

and

other

zinc

producers

i

I

t

I

I

I

I

I

I

I

I

]

!

a

I

E

E

E

g

H

I

I

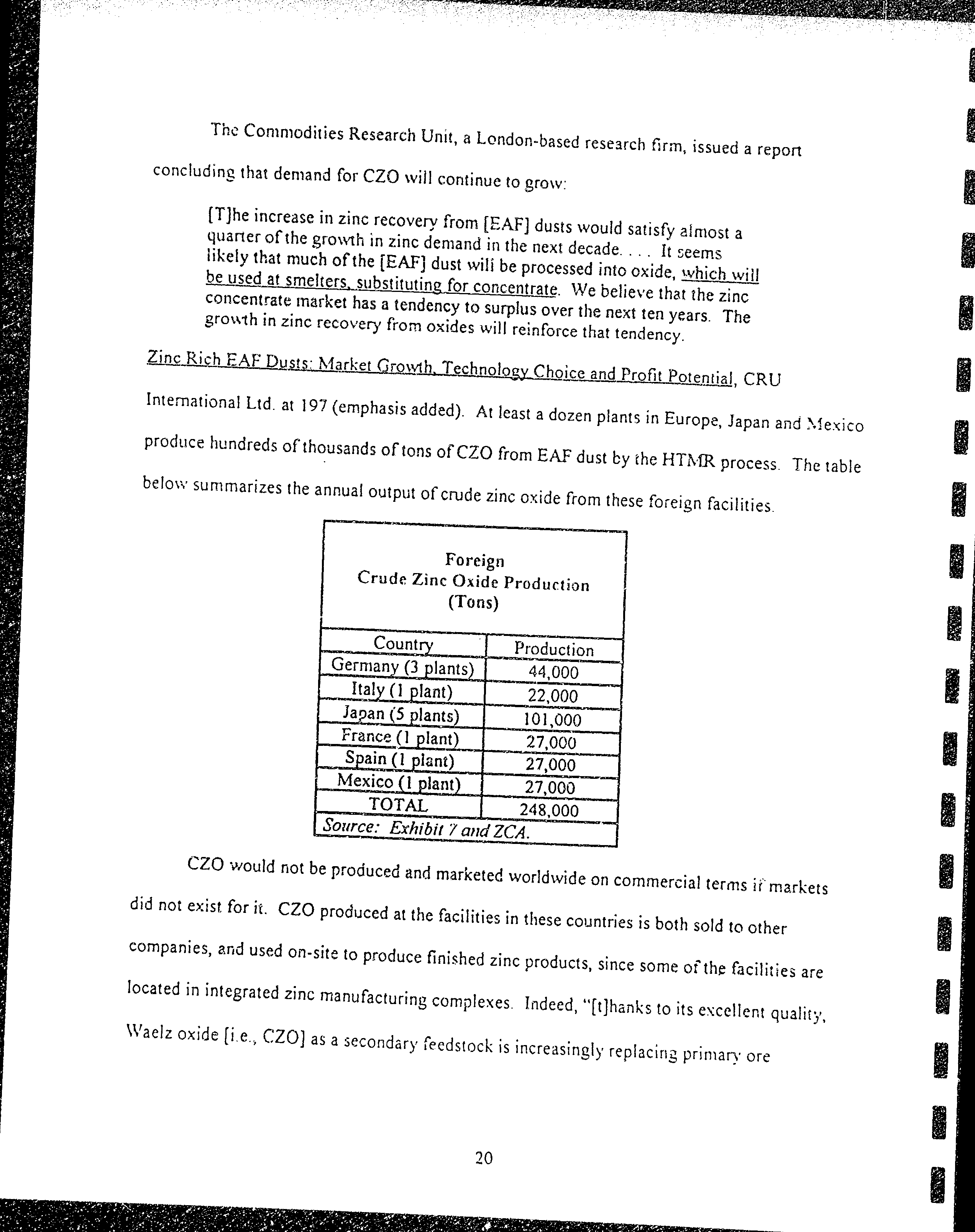

Thc

conrnrodities

Research

unit,

a

Loncon-based

research

f;rm,

issueci

a

repon

concluding

rhat

denrand

for

CZO

rvilt

continue

to

gro\v:

gror*rh

concentrate

U"r

iikely

quafler

[TJhe

that

increase

in

of

zinc

the

muc-h

market

gro*,rh

recovery

in

of

zinc.recovery

the

has

in

tEAFi

a_tendency

fronr

zinc

d-en:andln

oxides

dust

from.

to

wiri

wirr

TEAFJ

surpru,

u.

trr.

relnforce

pro..rr.J'iito

n*^ia*.uae

dusts

**,

.

We

rvourd

tlre

that

belie'e

next

tendencv.

satisfy

.

o*id.,

.

ren

rhar

Ir

years.

seems

arrnost

rvhic_h

the

zincThervitf

a

$

tr

ffi

tr

ffi

g

ffi

ffi

rv,,,,

v'

vvurJ

\. rlg

I

cg

a

n

o

l,ro

I

[_

pot

e

n

t i

a

l,

CR

U

International

Lrd'

at

I9? (emphasis

added).

Ar

teast

a

dozen

prants

in

Europe,

Japan

anc

),1exico

produce

hundreds

of

rhousands

of

tcns

of

CZo

from

EA*F

dust

by

rhe

HTi\.{R

process.

The

rable

belori'summarizes

the

annual

output

of

crude

zinc

oxide

from

these

foieign

facilities

cZo

'"rould

not

be

prociuced

ancl

marketec

worldwide

on

commerciar

terms

ii.rnarkets

did

not

exist

for

it'

cza

produced

at

the

facilities

in

these

counrries

is

both

sold

ro

other

companies'

and

used

on-site

to

procluce

finished

zinc

products,

since

some

of

the

facirities

ar-e

Iocated

in

integrate

d

zinc

manulacturing

complexes.

Indeed,

"[t]hanks

to its

excelrent

quarit1,,

\\/aelz

oxide

Ii

e.,

czo)as

a

secondarS,feedsrock

is

increasingry,repracing

prinran,ore

ffit

I

ffil

ff$

Foreign

Crude

Zinc

Oxid-e

production

(Tons)

Prcduction

France

(l

fur*t

tAW,

f

"rd

ZCA.

lF

a

fi

g

8

t

faciliries

con!'entrlles

or

used

in

tlte

on-sire

European

b1'zinc

zinc

ntanufacturers,

and

lead

snrerrers."r

it

is

an

econonricaily

11,;-,.,

her

czeis

and

environmentaril,

sord

ro

zir;cprodu*ron

desirabre

subsrirute

fbi'zinc

concentrates

pioduced

from

mined

ore.

z.

The

econonric

varue

of

HRD,s

CZO

is

substanr:at

and

guantifiabre.

CZO's

economic

value

is

c,rant!fied

by

its

transaction

price.

The

commercial

the

summarized

transactions

esrablishea.econonric

belo*''

for

czQ

The

sold

transacrion

by

FIRD'

as

price

rvel!

of

as

at

for

least

rransacrions

srio

per

ton

for-

for

other

cZo

zinc

ctearry

oxide

demonsrrates

products,

are

value

of

CZO.

E2l

ffiffi

mfi ** ..

;i;tltU!:JL"Jfj,"*,?:;:lllljJl;j".*

of

B

U

s

,

Ber.zirius

Un,*eir.sen

ice

AG

llu":t:r:tr ,t!e!