NATURAL

RESOU

RCE

TECHNOLOGY

WAmorefi

Leachate

Management

and Final Cover

Alternatives

Analysis Report

Hutsonville

Power

Station

Unlined Ash

Impoundment Pond

Closure

Hutsonville

IL

July

19

2005

Electronic Filing - Received, Clerks' Office, August 11, 2008--AS 09-1, Exhibit 3

NATURAL

RESOURCE

TECHNOLOGY

AMEREN

SERVICES

LEACHATE MANAGEMENT

AND FINAL COVER

ALTERNATIVES ANALYSIS REPORT

HUTSONVILLE POWER STATION

UNLINED ASH IMPOUNDMENT

POND

CLOSURE

HUTSONVILLE

IL

Project

No 1375

Prepared

For

Anieren Services

One Anieren Plaza

1901 Chouteau

Avenue

St

Louis

NIissouri

Prepared By

Natural Resource

Technology

Inc

23713

Paul

Road

Suite

Pewaukee

WI 53072

Final

Report

July

19

2005

Christopher

Robb

PE

i4ice

Hensel

PG

Project

Engineer

Senior

Hydrogeologis

23713

Paul

Rd

Ste

Pewaukee

WI 53072

Phone 262.523.9000

Fax 262.523.9001

www.naturalrt.com

Pewaukee

Madison

Electronic Filing - Received, Clerks' Office, August 11, 2008--AS 09-1, Exhibit 3

EXECUTIVE SUMMARY

The Hutsonville Power Station in Crawford

County

Illinois is located on the west bank of the Wabash

River

approximately

mile north of

Hutsonville

Illinois

Fly

ash from this coal-fired

power plant

is

collected

by

an electrostatic

precipitator

and has been sluiced

to two

ash

impoundments

Groundwater

quality

has been monitored

at this

facility

since 1984 Concentrations of boron and

sulfate

indicator

parameters

of coal ash

leachate

exceed the Section 811.320

applicable

background

concentrations and Illinois Class Groundwater

Quality

Standards at several shallow

monitoring

wells

near an unlined

impoundment

Pond

which is

no

longer

in service

Impacted groundwater

is

migrating

east towards the Wabash River

through

shallow

sediments

which

are

not utilized

as

source

of

groundwater

supply

Elevated

concentrations

were

also

noted in shallow

monitoring

wells

along

the

south

property

boundary suggesting potential

for off-site

migration

however

impacts

have not been

noted in

water

samples

collected south

of the

impoundment

There are five

groundwater

supply

wells within

mile of the

site

all finished in

deep

alluvial sand

and

gravel

in the Wabash River

valley

Two

wells

directly

east of the unlined

impoundment

are

used for

potable

and

process plant

water

and

one

well southwest and

two

wells

southeast

of the

impoundment

are

used

for

irrigation

water Concentrations of boron and sulfate in

samples

collected from

one on-site

monitoring

well

were

higher

than

811.320

background

concentrations

but lower

than Class

groundwater

quality

standards Six other

monitoring

wells screened in the

deep

alluvial

aquifer

on the Illinois side of

the river show

no

evidence of

impacts

The

primary objective

of this alternatives

analysis

was

to evaluate

and make

recommendations

on

leachate

management deep

alluvial

aquifer

containment

and final cover alternatives

for closure of the

unlined

ash

impoundment Pond

based on technical and

cost

considerations

Alternatives

analysis

objectives

herein referenced

as

Closure

Objectives

were identified to

protect

human health and the

environment for both the

parameters

of concern

POCs

identified in the

Hydrogeologic Assessment

and

to limit

exposure

pathways

in

accordance with

applicable

environmental standards

Site-specific

considerations

for

establishing

appropriate

Closure

Objectives

for Pond

include

proximity

of

the

Wabash

River to Pond

hydrogeology

and

groundwater

quality

in the

vicinity

of

Pond

and the

presence

or

absence of

exposure

pathways

for identified POCs

groundwater

soil

and surface

water

Based on review of the

regulations

promulgated

in 35 Illinois

Administrative Code

IAC

Part 811 and

814 and

site-specific

considerations

identified

above

the

following

Closure

Objectives

were

developed

Manage

groundwater

quality

to meet

the

requirements

of Section 811.320 and

Construct

final

cover

system

that meets the

requirements

of Part 811

or an

adjusted

standard

approved by

the Illinois Pollution

Control Board

PCB

Specific

parameters

for

performing

the alternatives

analysis

were

developed

on the basis of

the results

of the 1999

Hydro geologic Assessment

the Groundwater Model Evaluation

of Impoundment

Closure

Options

dated

January

2000

and

two

supplemental

investigations

performed

for this

analysis

groundwater

flow and

transport modeling

for selected

alternatives

and

considerations

for

pursuing

adjusted

standards

through

the Illinois PCB Four final

cover

alternatives

and four

combinations of final

cover and leachate

management

alternatives

were carried

through

the

groundwater

transport modeling

evaluation

Subsequent

to the model

analysis

four alternatives

were

selected for

detailed

analysis

1375 Alternatives

Analysis Report-Final

NATURAL

ES-i

RESOURCE

TECHNOLOGY

Electronic Filing - Received, Clerks' Office, August 11, 2008--AS 09-1, Exhibit 3

EXECUTIVE SUMMARY

Closure Alternative

No

Geosynthetic

Final Cover with East and South

Interceptor

DrainiTrench and Groundwater

Extraction from the

Deep

Alluvial

Aquifer

This closure

alternative

adheres

to

the Section

811.314

requirements

for

final

cover

system

and

implements

leachate

collection

along

the

east

and south

boundaries of Pond

and

groundwater

extraction

in

the

deep

alluvial

aquifer

to meet the

requirements

for

meeting

applicable

groundwater

quality

standards

at

the

edge

of the

zone of attenuation

as

defined in

Section

811.320c

Closure Alternative

No

Earthen Final Cover with South

Interceptor

DrainlFrench

This

closure alternative

balances lower cost with leachate

collection

and is

designed

to

prevent

off-site

migration

of

groundwater

to the south

Adjusted

standards

would be

required

to

implement

this closure alternative

Closure Alternative

No

Earthen Final

Cover This closure alternative

represents

the

lowest

cost alternative

for closure of Pond

and would

require

adjusted

standards

to

seek relief from several sections of

Part 811 and Part 81

4.302b

Closure Alternative

No

Pozzolanic

Fly

Ash Final Cover This closure alternative

provides equivalent

effectiveness

to

Closure

Alternative

No

and has the added benefit

of

providing

renewed

capacity

for the active

Pond

fly

ash

impoundment

This

alternative

would

require adjusted

standards to seek relief from several sections of Part

811 and Part

814.302b1

utilizing technology

and

construction

techniques substantially

similar

to those

promulgated

in 35 IAC Part 816

Alternative

Standards for Coal

Combustion Power

Generating

Facilities Waste

Landfills

Surface water

management

was

considered

for each of the selected alternatives

The

optimal

alternative

routes surface water east toward the Wabash River and

west

toward

drainage

collection

pond

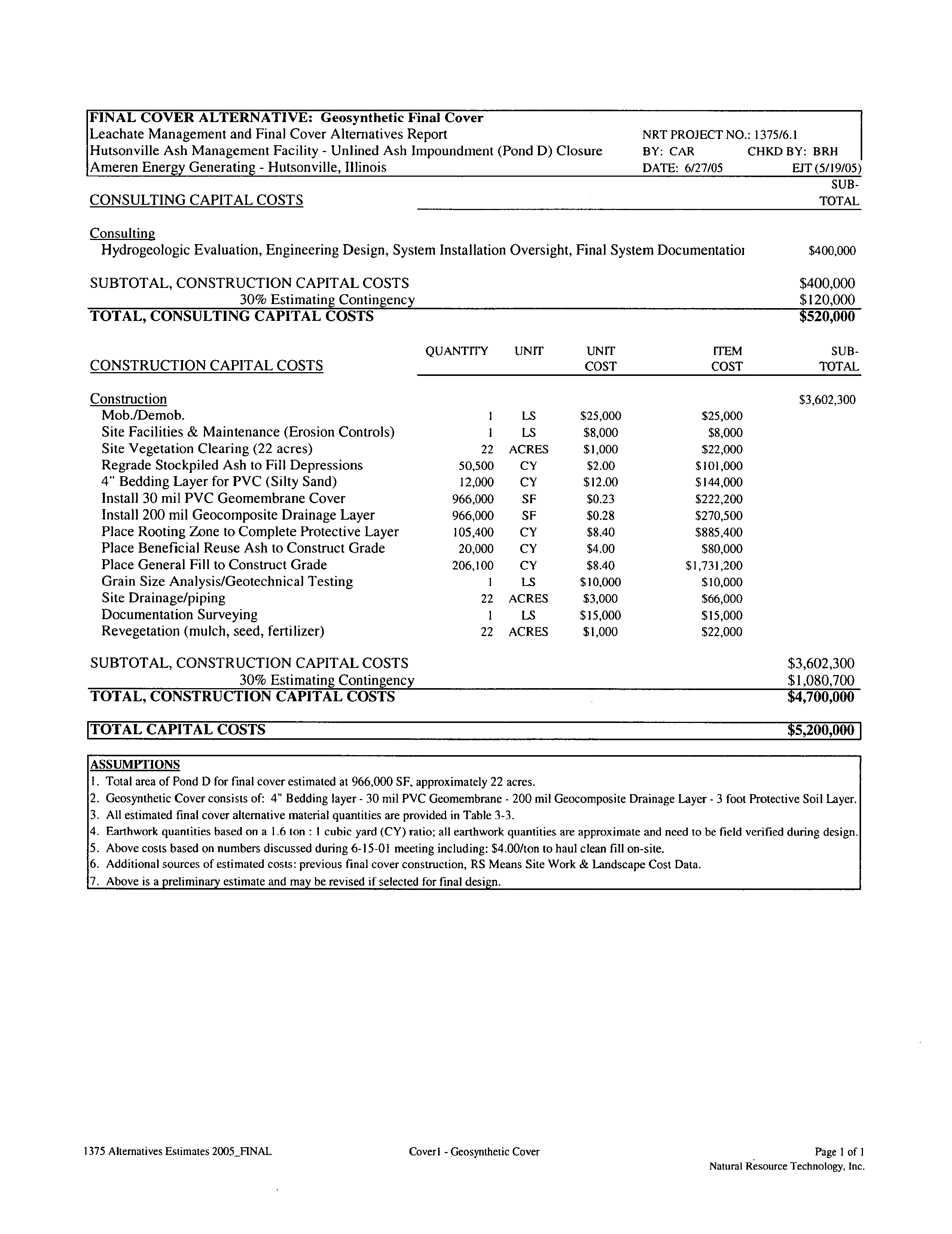

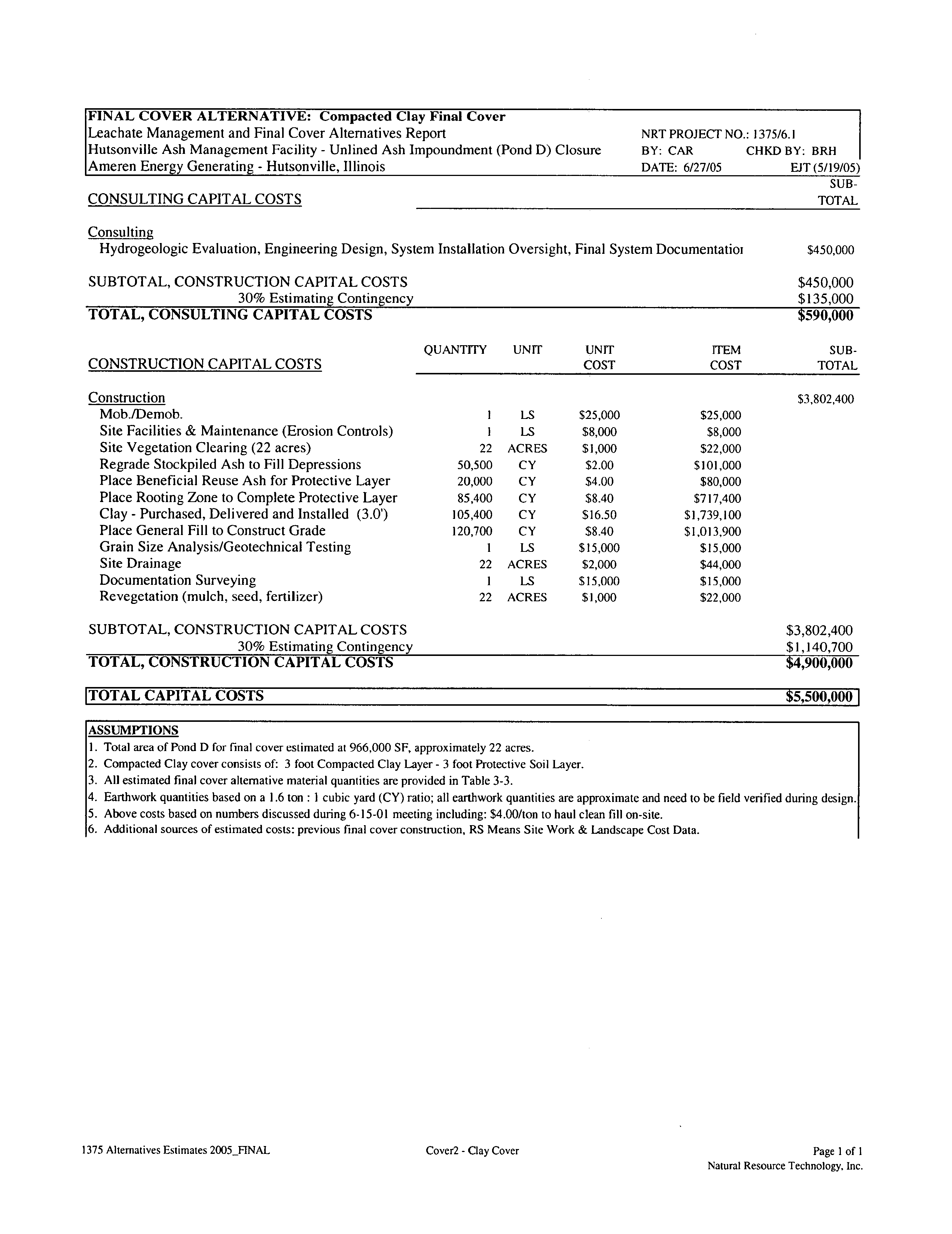

Costs for each of the closure alternatives

and the alternate final

cover are summarized

below

Closure Alternative

No

has the

highest

initial

capital

cost

$6.8

million

and

highest

operating

and maintenance

cost $3.1

million

over 30

years

based on 2003 dollars Ease

of

implementation

and

performance

are not

concerns as

the remedial

components

consisting

of

geosynthetic cover

leachate

collection

via an

interceptor

drain/trench

and

groundwater

extraction

in the

deep

alluvial

aquifer

are demonstrated

technologies

that are

widely

available

Closure Alternative

No

provides significant cost

savings

versus Alternative

No

in

up-front

capital

cost $4.7

million

and

lower

operating

and maintenance

cost

$1.1

million over 30

years

Predicted

performance

effectiveness

and

reliability

along

the

south

impoundment boundary

are

nearly equivalent

to Closure

Alternative

No

Closure Alternative

No

represents

the lowest cost alternative

with

significant savings

in

up-front

capital

$4.2

million

and low

operating

and maintenance cost

$0.2

million

over

30

years

Groundwater

transport

modeling suggests

that

an earthen cover

may

provide performance

and

long

term

effectiveness

along

the south

property boundary

similar to Closure Alternatives

No

and

Closure Alternative

No

provides performance

reliability

and effectiveness

equivalent

to the final covers

proposed

for each alternative

at

mid-range

capital

cost for final cover

1375 Alternatives

Analysis

Report-Final

NATURAL

ES-2

RESOURCE

TECHNOLOGY

Electronic Filing - Received, Clerks' Office, August 11, 2008--AS 09-1, Exhibit 3

EXECUTIVE SUMMARY

$4.5 million

and with low

long

term

operating

and maintenance

costs

$0.2

million over

30

years

An

adjusted

standard would

be

required

to

gain regulatory

acceptance

for the

technology

for construction

of

pozzolanic fly

ash

cover

however

regulatory

precedent

exists for similar

construction

of

final

covers

35

IAC Part

816

Each of the four alternatives

is

potentially appropriate

for the site with similar

performance

and

effectiveness

and reflects

range

of

approaches contingent

on

capital expenditure

and

varying approval

of

adjusted

standards

with the Illinois PCB

However

Closure Alternative

No

the Pozzolanic

Fly

Ash

Cover

provides

the best

balance of

capital expenditure

and

pursuit

of

adjusted

standards

for the

following

reasons

Groundwater

transport modeling

indicates

that

pozzolanic fly

ash final cover

system

will have similar

performance

and effectiveness

as

cover

system

that meets the

requirements

of Section 811.314

e.g geosynthetic

final

cover

Groundwater

transport modeling

indicates that the

pozzolanic fly

ash final cover will

achieve the Class Groundwater

Quality

Standards

along

the south

property boundary

MW-I IR

within

approximately

16

years

which

compares

favorably

to the

ten-year

period predicted

for Alternative

No

This alternative should

satisfy long-term

regulatory

concerns with off-site

migration

No leachate

management

is

proposed along

the east

impoundment boundary

However

groundwater

impacted by

ash

leachate

discharges

to the Wabash River and does

not

threaten

any downgradient groundwater

receptors

Based

on

this

discussion

pursuit

of an

adjusted

standard for the

applicable

groundwater

quality

standards

along

the east

edge

of

the zone of attenuation is warranted

Regulatory precedent

exists

35

JAC

816

for construction

of

pozzolanic

fly

ash final

cover

system

using

substantially

similar

technology

and

construction

techniques

Significant

cost

savings

may

be realized

through

construction

of

pozzolanic fly

ash

final cover

by providing

additional

capacity

for

fly

ash in

Pond

Based

on this

discussion

pursuit

of

an

adjusted

standard

for construction

of

pozzolanic fly

ash final

cover is warranted

1375 Alternatives

Analysis Report-Final

NATURAL

ES-3

RESOURCE

TECHNOLOGY

Electronic Filing - Received, Clerks' Office, August 11, 2008--AS 09-1, Exhibit 3

TABLE OF CONTENTS

INTRODUCTION

1-1

1.1

Background

1-1

1.2

Investigation

Time Line

1-2

1.3

Alternatives

Analysis

Objectives

and

Approach

1-3

SUMMARY OF SITE CONDITIONS

2-1

2.1

Supplemental

On-Site

Investigation

October 2001

2-1

2.1.1

Advancement of Soil

Borings

2-1

2.1.2

Installation

Abandonment of

Monitoring

Wells

2-2

2.1.3

Hydraulic Testing

2-3

2.2

Supplemental

Off-Site

Investigation

April

and

May

2004

2-3

2.2.1

Installation of

Monitoring

Wells

2-3

2.2.2

Hydraulic Testing

2-5

2.3

Groundwater

Sampling

and

Analysis

2-5

2.4

Summary

of

Hydrogeology

and Groundwater

Quality

2-6

2.4.1

Distribution

of Coal Ash Fill

2-6

2.4.2

Hydrogeology

2-6

2.4.3

Evaluation of

Daily

Groundwater and River Elevation Data

2-7

2.4.4

Groundwater

Quality

and Parameters of Concern

2-7

2.4.5

Background

Concentrations

2-7

2.4.6

Groundwater

Quality

2-9

2.5

Exposure Pathways Groundwater Soil

Surface

Water

2-10

IDENTIFICATION OF LEACHATE MANAGEMENT AND FINAL COVER ALTERNATIVES3-1

3.1

Identification

of

Alternatives Overview

3-1

3.2

Leachate

Management

and

Deep

Alluvial

Aquifer

Source Control Alternatives

3-2

3.2.1

Selection of Alternatives for Initial

Screening

3-2

3.2.2

Site

Monitoring

with No Leachate

Collection

3-2

3.2.3

Groundwater Extraction

Leachate Collection Alternatives

3-3

3.2.4

Source Control of

the

Deep

Alluvial

Aquifer

3-3

3.2.5

Ash Stabilization

3-4

3.2.6

Ash Removal and

Disposal Recycling

at an Off-Site

Facility

or

Beneficial

Reuse

3.4

3.2.7

Ash

Impoundment

Reconstruction

3-5

3.2.8

Containment

Using

Low-Permeability

Barrier Wall

3-5

3.3

Final Cover Alternatives

3-6

3.4

Surface Water

Management

Alternatives

3-7

3.5

Initial

Screening

Criteria and Results

3-8

1375 Alternatives

Analysis Report-Final

NATURAL

RESOURCE

TECHNOLOGY

Electronic Filing - Received, Clerks' Office, August 11, 2008--AS 09-1, Exhibit 3

TABLE

OF CONTENTS

3.6

Treatability Study

for

Pozzolanic

Fly

Ash Final Cover

3-10

MODELING

AND

EVALUATION OF SELECTED ALTERNATIVES

4-1

4.1

Purpose

4-1

4.2

Model

Approach

4-2

4.2.1

HELP

Modeling

4-2

4.2.2

MODFLOW/MT3DMS

4-3

4.2.3

Criteria for Evaluation of

Modeling

Results

4-3

4.2.4

Simulation of Final Cover and Leachate

Management

Alternatives

4-3

4.2.5

Simulation of

Deep

Alluvial

Aquifer

Source Control Alternative

4-4

4.3

Modeling

Results and Recommendations for Alternative

Assembly

4-4

4.3.1

Modeling

Results Final Cover Alternatives

4-5

4.3.2

Modeling

Results Final Cover Alternatives

Combined with Leachate

Management

Alternatives

4-5

4.3.3

Recommendations for

Alternatives

Assembly

4-6

ASSEMBLY AND DETAILED

ANALYSIS OF CLOSURE ALTERNATIVES

5-1

5.1

Assembly

and Selection Rationale

5-1

5.2

Detailed

Analysis

of Closure Alternatives

5-2

5.3

Recommended

Closure

Strategy

5-3

5.4

Recommended

Pre-Design

Evaluation and Field

Testing

5-4

REFERENCES

6-1

FIGURES

Figure

1-1

Site Location

Map 1375-A03

Figure

1-2

Site Plan

1375-61-B30

Figure

2-1

Geologic

Cross

Sections

1375-61-BOl

Figure

2-2

Groundwater

Elevation

Contours

September

14

2004

1375-61-A04

Figure

2-3

Groundwater Elevation

Contours

October

26

2004

1375-61-A03

Figure

2-4

Groundwater

Elevation

Contours

November

16

2004

1375-61-A02

Figure

2-5

Comparison

of Groundwater

Elevation Data to Well

Pumpage

September-

November 2004

Figure

2-6

Boron Concentration

in

Background

Wells

Figure

2-7

Sulfate Concentration

in

Background

Wells

Figure

5-1

Alternative No

PVC Final Cover With East

and South

Interceptor

Drain/Trench

and

Deep

Groundwater Extraction

System 1375-61-BO3C

Figure

5-2

Alternative No

Earthen Final Cover With

South

Interceptor

Drain/Trench

1375-61 -BO4C

Figure

5-3

Alternative No

Earthen Final Cover or Pozzolanic

Fly

Ash

Final Cover

1375-61

-BO5C

1375

Alternatives

Analysis Report-Final

NA11JRAL

ii

RESOURCE

TECHNOLOGY

Electronic Filing - Received, Clerks' Office, August 11, 2008--AS 09-1, Exhibit 3

TABLE OF CONTENTS

APPENDICES

Soil

Boring

and Discrete Groundwater

Sampling

Data

Monitoring

Well

Locations Elevations

Depth

to

Bedrock

and Screened

Formation

Monitoring

Well

Completion

Details

Monitoring

Well

Slug

Test Results

Background

Statistical

Summary

Groundwater

Concentration

Results from

Monitoring

Wells

Initial

Screening

of Leachate

Management

and Final Cover Alternatives

Areal Extent and Volumes of

Unsaturated and Saturated Ash in Pond

Final Cover Alternatives Material Balance

Analysis

Comparison

of Recommended

Mix

Designs

to Performance Goals and Cost

Sensitivity Analysis

Selected Alternatives for Groundwater Flow and

Transport

Modeling

Groundwater Flow

and

Transport

Model

Results

Closure Alternatives Cost

Summary

Detailed

Analysis

of Closure

Alternatives

Appendix

Appendix

Appendix

Appendix

Appendix

Appendix

Supplemental

Site

Investigation Appendices

A-i

Soil

Boring Logs

A-2

Monitoring

Well

Completion Reports

and Abandonment

Log

A-3

Slug

Test

Data

A-4

Groundwater

Sampling

SOP

AEG

Alternative Cost

Summary

Sheets

Treatability

Study

for

Pozzolanic Final

Cover

System

C-i

Conceptual Development

of Pozzolanic

Cap

for Closure of Basin

at

The

Hutsonville Power Station

C-2

VFL Cost Data

Groundwater

Transport Modeling

Results and

Supporting

Documentation

Statistical Calculations

Groundwater

Velocity

Calculation

1375 Alternatives

Analysis

Report-Final

111

NATuRAL

RESOURCE

TECHNOLOGY

TABLES

Table 2-1

Table 2-2

Table 2-3

Table 2-4

Table 2-5

Table 2-6

Table 3-1

Table 3-2

Table 3-3

Table 3-4

Table 4-1

Table 4-2

Table 5-1

Table 5-2

Electronic Filing - Received, Clerks' Office, August 11, 2008--AS 09-1, Exhibit 3

INTRODUCTION

1.1

Background

Ameren

Energy Generating operates

the Hutsonville Power

Station

in

Crawford

County

Illinois

Figure 1-1

The

power

station is located

on

the

west

bank

of the Wabash River

mile north of the

city

of Hutsonville SW

Section

17

Township

8N Range 11W

The coal fired

power plant

has been in

operation

since the

1940s There are

currently

two units

operating

at the

plant completed

in 1953

unit

and 1954

unit

with combined

generating capacity

of 164 MW

Fly

ash from the

operating

units

is collected

by

an

electrostatic

precipitator

and sluiced

to

12-acre lined ash

impoundment Pond

Figure

1-2

which

was

constructed in 1984 Bottom ash is

sluiced to

separate pond

and

eventually

recycled

Sluice

water

from

Pond

is routed

through

4.2-acre lined interim

pond Pond

constructed

in

2000

before

discharge

to the Wabash River via NPDES

permitted

outfall

002

IL0000 175

Sluice

water from the bottom ash

pond

is routed

through

1.7-acre

drainage

collection

pond Pond

constructed in

2000

and Pond

before

discharge

to the Wabash River via the

same

outfall

The site also has

22-acre unlined ash

impoundment Pond

which was constructed in 1968 This

impoundment

was the

primary

ash

management

unit

prior

to

construction

of Pond

in

1984

and was

used as

secondary settling pond

from 1984

through

construction

of Pond

in 2000

It has been inactive

since 2000

although precipitation

and flood backwater have accumulated

in the

impoundment

at

times

resulting

in

ponded

conditions

Groundwater

quality

has been monitored at this

facility

since 1984 Concentrations of boron and sulfate

at several

monitoring

wells exceed the 35 Illinois

Administrative Code

IAC

811.320

groundwater

quality

standards

Section

811.320

applicable

background

concentrations

and the Illinois Class

groundwater

quality

standards Boron and sulfate

are indicator

parameters

for coal ash leachate In

response

to

these

findings

Ameren Services contracted

Science

Technology

Management

Inc

STMI

and Natural Resource

Technology

Inc

NRT

to

perform

Hydrogeologic

Assessment that

was

completed

in

August

1999

The

Hydrogeologic

Assessment identified

correlation

between shallow

groundwater

quality

elevated

boron and sulfate concentrations

in

groundwater

and

potential

leachate

sources

namely

the former ash

laydown

area which was

excavated

prior

to

construction

of

Ponds

and

and the unlined ash

1375 Alternatives

Analysis Report-Final

NATURAL

1-1

RESOURCE

TECHNOLOGY

Electronic Filing - Received, Clerks' Office, August 11, 2008--AS 09-1, Exhibit 3

INTRODUCTION

impoundment Pond

Boron and sulfate are

migrating

east

towards the

Wabash River

however

there

are no

groundwater

supply

wells in the shallow sediments between the unlined ash

impoundment

and the

Wabash River

There are four

groundwater

supply

wells within

mile of the

site

all

finished in

deep

alluvial sand and

gravel aquifer

in the Wabash River

valley

Two wells

are

directly

east

of the unlined

impoundment

and

are

used for

plant water

and two wells are southeast

of the

impoundment

and used for

irrigation

water

Groundwater

quality

data from

monitoring

well

MW-14

which is

directly

southeast

of the unlined ash

impoundment

and is screened in the

deep

alluvial sand and

gravel

indicates evidence of ash

impoundment impacts

in that

aquifer

based

on

comparison

to Section 811.320

applicable background

concentrations

However

concentrations

are

lower than

the Illinois Class

groundwater

quality

standards

1.2

Investigation

Time Line

NATURAL

RESOURCE

TECHNOLOGY

1999

The

Hydrogeologic

Assessment

report

characterizes

hydrogeology

at the site and identifies

Pond

and an ash

laydown

area as the sources

of shallow

groundwater

quality impacts

at the

site No evidence of

groundwater

impacts

are found in the

deep

alluvial

aquifer

2000

Groundwater

Model Evaluation

of

Impoundment

Closure

Options

concludes that

dewatering

of Pond

will reduce leachate

loading

to the Wabash river

by

more

than

80

percent

however no

capping option

will result in

attainment of Class

groundwater

quality

standards

due to

continuing groundwater

flow

through

ash

deposited

below the water

table

2000

Ash in the former ash

laydown

area is

removed

Ponds

and

are constructed

and

Pond

is

permanently

removed from service

2001

supplemental

site

investigation

is

performed

for this

alternatives

assessment

Additional

monitoring

wells are installed in the

deep

alluvial

aquifer

There is

no evidence of ash

impacts

in the

deep

alluvial

aquifer

2002

Research is

performed

for

an

innovative

approach

to

capping

Pond

2003

The first draft of this

Alternatives

Assessment

report

and

petition

for

adjusted

standards

is

completed

After

meeting

and discussion of

preliminary

results

IEPA determines that

Groundwater

Impact

Assessment is

required

for the

deep

alluvial

aquifer

Spring

After

delays

in

obtaining

site access on off-site

private

property

an

investigation

is

performed

2004

to characterize

hydrogeology

in the

deep

alluvial

aquifer

2005

During

data

review it is determined that MW-14 has elevated boron and

sulfate

concentrations

In

response

to this

finding

it is determined that the Groundwater

Impact

Assessment is no

longer necessary

and

plan

is

developed

to

sample

the off-site wells to

determine

whether or not

groundwater

impacts

in the

deep

alluvial

aquifer

extend to the

south

however

flood conditions

on

the

Wabash river

delay

data collection Work

commences on

completion

of this Alternatives

Analysis

1375 Alternatives

Analysis Report-Final

1-2

Electronic Filing - Received, Clerks' Office, August 11, 2008--AS 09-1, Exhibit 3

INTRODUCTiON

1.3 Alternatives

Analysis Objectives

and

Approach

The

primary objective

of the alternatives

analysis

is to evaluate

and make recommendations

on

leachate

management

and

final

cover alternatives

for closure of the unlined ash

impoundment

Pond

based

on

technical and

cost

considerations

Alternatives

analysis objectives

herein referenced

as

Closure

Objectives

were

identified for

protecting

human

health and the environment for both the

parameters

of

concern POCs

identified in the

Hydrogeologic Assessment

and

exposure

pathways

in accordance with

applicable

environmental standards

Site-specific

considerations

for

establishing

appropriate

Closure

Objectives

for Pond

include

proximity

of

the Wabash River

to

Pond

hydrogeology

and

groundwater

quality

in the

vicinity

of Pond

and the

presence

or

absence

of

exposure pathways

for identified POCs

groundwater

soil

and surface

water

Standards are

promulgated

for the

design

and

operation

of solid

waste landfills under 35 Illinois

Administrative Code

IAC

Parts 810

to

816 Based

on

review of

these

regulations

and on

site-specific

considerations

the

following

Closure

Objectives

were

developed

Manage groundwater

quality

to meet the

requirements

of Section

811.320 and

Construct

final

cover

system

that

meets

the

requirements

of Part 811 or an

adjusted

standard

approved by

the Illinois Pollution Control Board

PCB

Specific

parameters

for

performing

the alternatives

analysis

were

developed

on

the basis of

the results

of the 1999

Hydrogeologic

Assessment the Groundwater Model Evaluation

of impoundment

Closure

Options

dated

January 2000

and

supplemental investigations

performed

for this

analysis Section

additional

groundwater

flow

and

transport modeling

of alternatives

Section

and

considerations

for

pursuing adjusted

standards

through

the Illinois PCB The

range

of

technological

applications

considered

included conventional and innovative

alternatives

Tables

3-1 3-2 3-3 4-1 4-2 5-1

and 5-2 summarize the

findings

of this alternatives

analysis

which are

described in Sections

and

This alternatives

analysis

process

was

developed

to meet the

substantive

regulatory

requirements

of 35 IAC Part 811 and is divided into four

major

stages

as follows

Initial

Screening

This

stage

consisted of

three

steps

First site

specific

Closure

Objectives

were established

to address

parameters

of

concern

and

exposure pathways

Section

3.1

Second closure alternatives

to meet these

objectives

were

divided into

three

categories

leachate

management

alternatives

final

cover

alternatives

and

surface

water

management

alternatives

Third

these alternatives

were

initially

screened

on

the basis of construction

implementation feasibility effectiveness

and cost

Table

1375

Alternatives

Analysis Report-Final

NATURAL

1-3

RESOURCE

TECHNOLOGY

Electronic Filing - Received, Clerks' Office, August 11, 2008--AS 09-1, Exhibit 3

INTRODUCTION

3-1

Alternative

specific rough

cost estimates were

developed

at this

stage Appendix

Groundwater

Transport Modeling

and Secondary Effectiveness

Evaluation The closure

alternatives

that met the initial

screening

criteria

were combined into model scenarios for

prediction

of their effects

on

groundwater

quality using

calibrated

groundwater

flow

and

transport

model

Table

4-1

These results

were

used

to reduce the number of

alternatives

that

would be

subject

to the next

step

of detailed

analysis

Table 4-2

Assemble

Alternatives

for Detailed

Analysis Specific

closure alternatives

that

met

the

secondary

effectiveness

screening

criteria

were

evaluated with

respect

to

meeting

the

Closure

Objectives

regulatory

acceptance

and relative cost

Section 5.1

From these

alternatives

four

were

selected that

represented

range

of

closure alternatives

on the

basis of the

following

criteria

an alternative

that

meets

the

requirements

of 35

IAC

Parts 811 and

814

an

alternative

that

meets

the

effectiveness criteria

Section 4.2.3

with

adjusted

standards

and includes leachate

collection

an alternative

that

represents

the lowest cost alternative and meets the effectiveness criteria

Section 4.2.3

with

adjusted

standards

and

no

leachate

collection and

an alternative

that meets the

effectiveness

criteria

Section 4.2.3

with

adjusted

standards

and

meets

the intent of

35 JAC Part 811 and 814

through

utilization

of

technology

and construction

techniques

substantially

similar to those

promulgated

in 35 IAC Part 816

Alternative

Standards for

Coal Combustion Power

Generating

Facilities Waste

Landfills

Detailed Analysis The four final closure alternatives

were

further evaluated in

terms of

total

cost Table

5-1

and in

general

accordance with the criteria listed in Table 5-2 to

develop

final recommendation

for the site These criteria include

the

degree

to which

the

proposed remedy

is

protective

of

human health and the

environment

short and

long

term

effectiveness

ease of

implementation

performance

reliability potential impacts

time-frame for

completion

cost

and

institutional

requirements

required

for

regulatory

acceptance

1375 Alternatives

Analysis Report-Final

NATURAL

1-4

RESOURCE

TECHNOLOGY

Electronic Filing - Received, Clerks' Office, August 11, 2008--AS 09-1, Exhibit 3

SUMMARY OF SITE CONDITIONS

Hydrogeology

and

groundwater

quality

were

thoroughly

characterized

in the

Hydrogeologic

Assessment

report

Additional

field

investigation

was

performed

for this

project

to

upgrade

the

monitoring

well

system surrounding

Pond

characterize

the

deep

alluvial

aquifer

and

to

collect detailed

information

specific

to

the alternatives

assessment

2.1

Supplemental

On-Site

Investigation

October 2001

The first

supplemental

site

investigation

was

performed

from

October

to

2001 The

scope

of work

included

advancement of

six soil

borings SB-101

through

SB-106

installation of

one additional

monitoring

well

MW-14

and one

temporary monitoring

well

TW

and

abandonment of

monitoring

well MW-Il and

replacement

with MW-I 1R In

addition hydraulic

conductivity

tests

were

performed

on

selected

new

and

existing monitoring

wells

2.1.1 Advancement of Soil

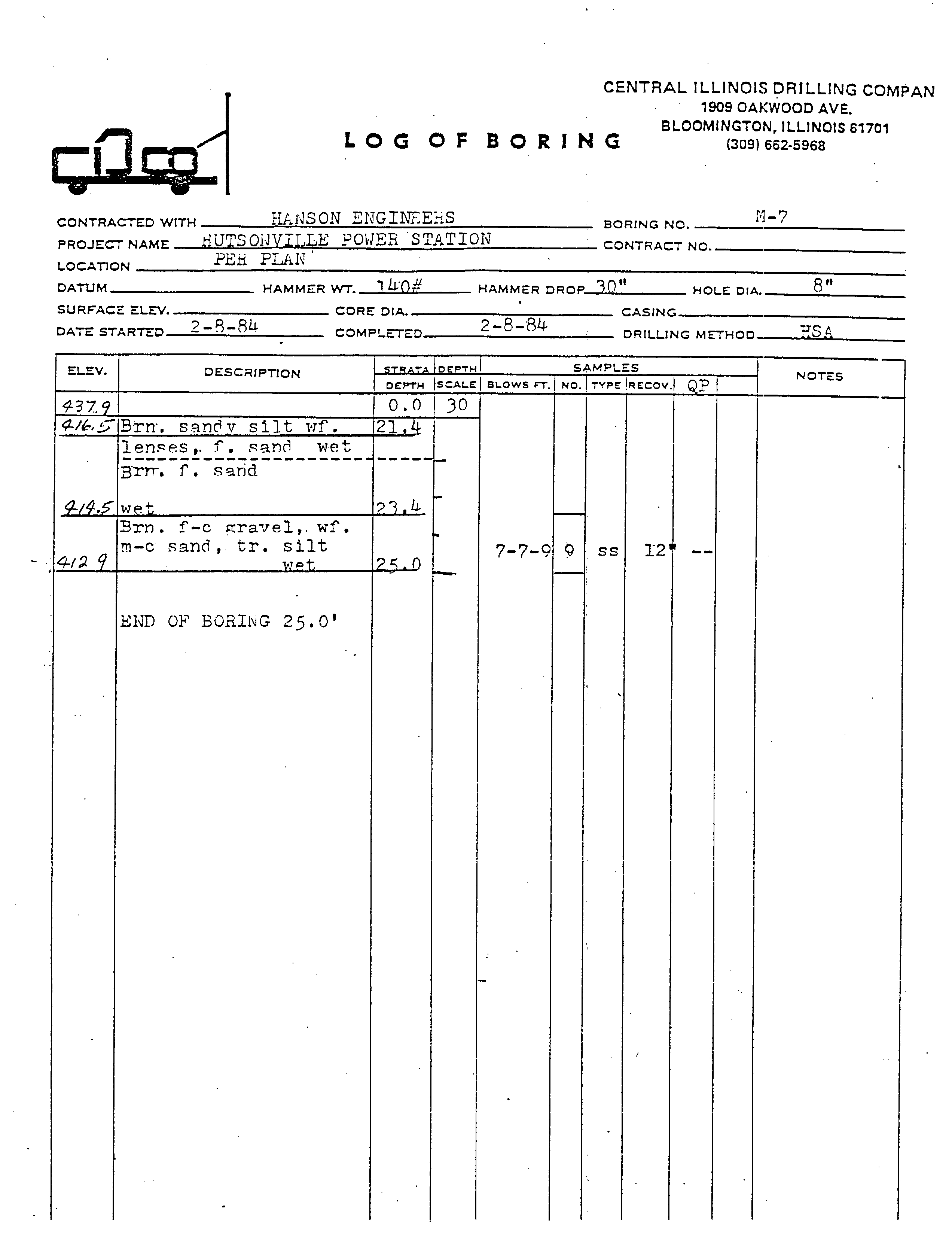

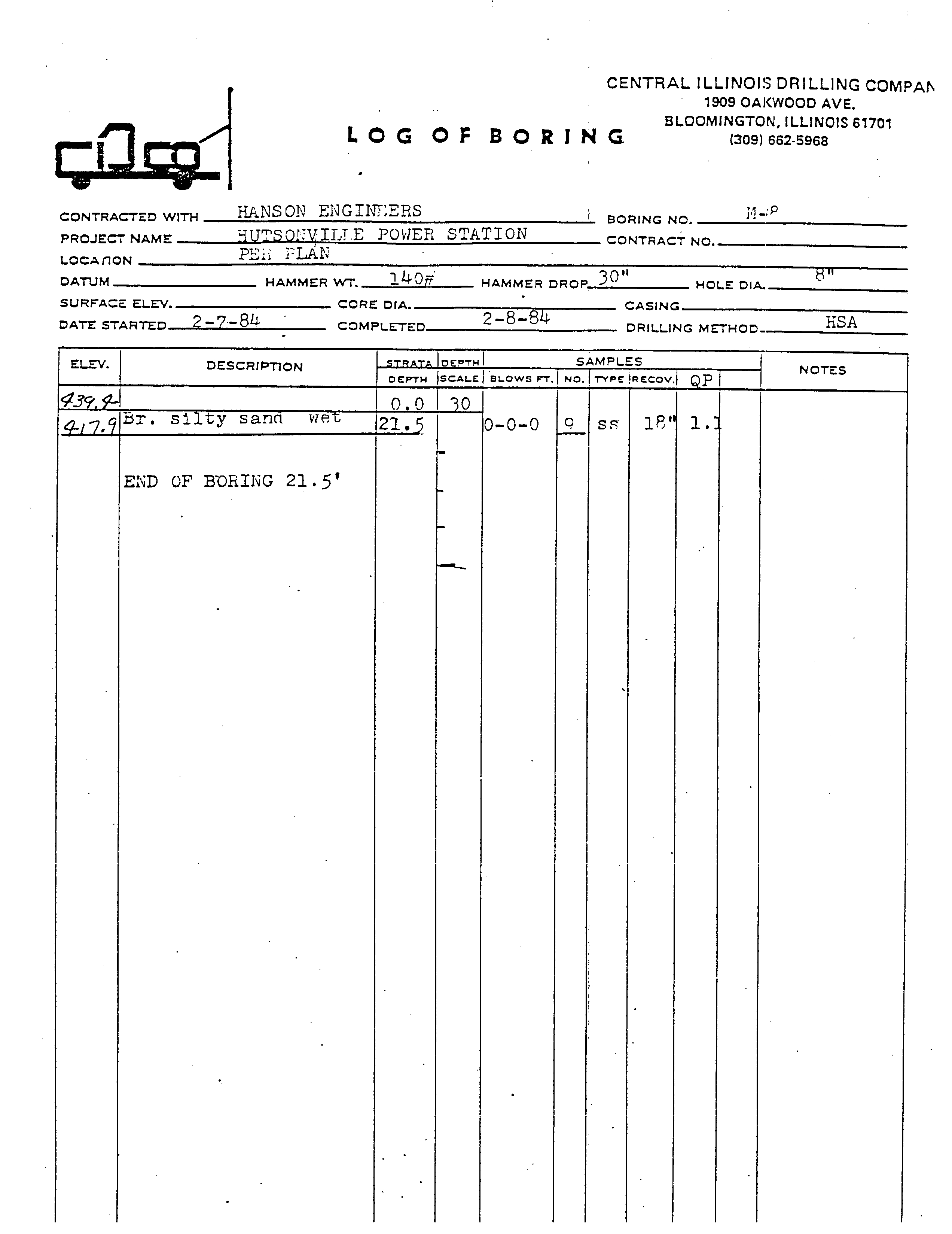

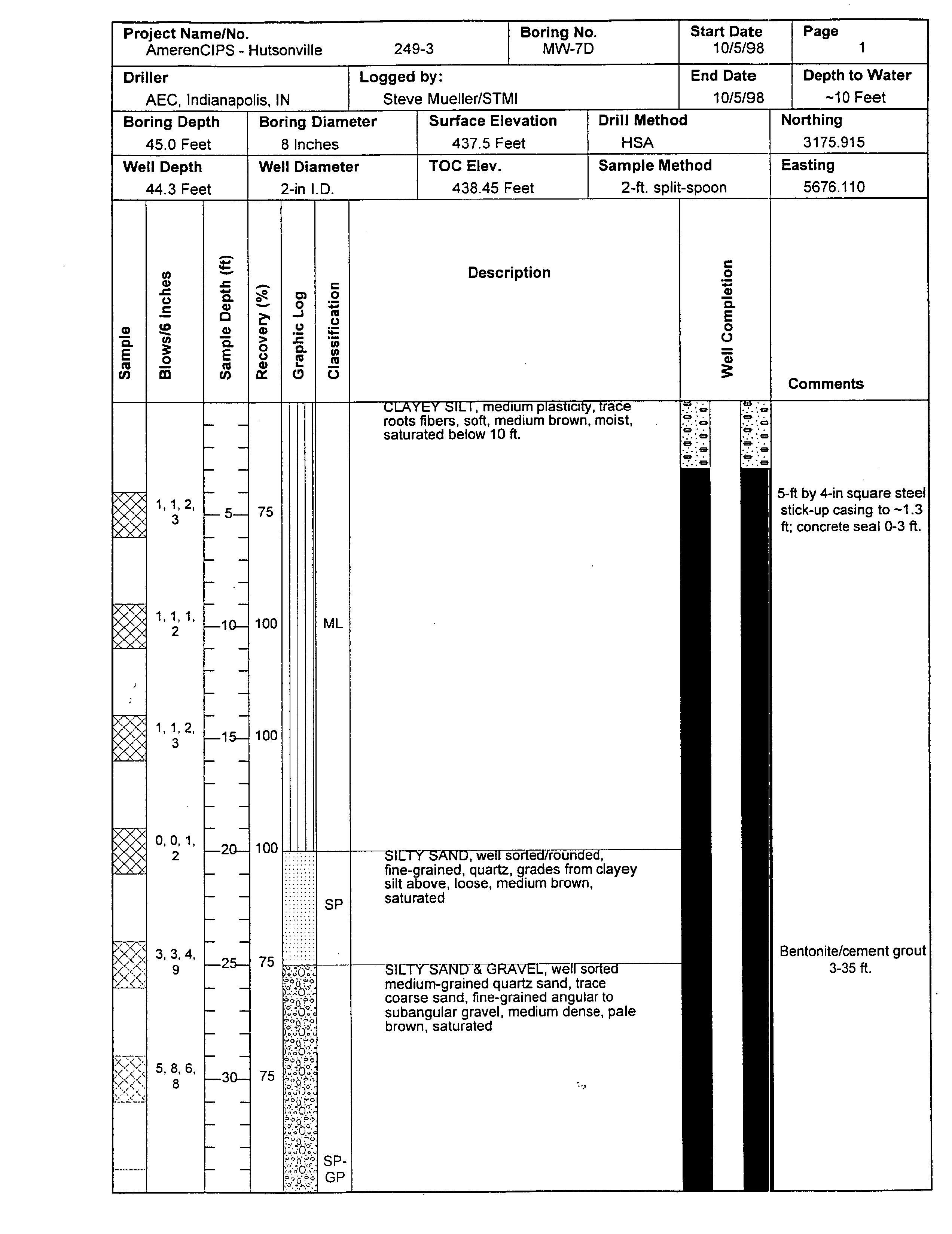

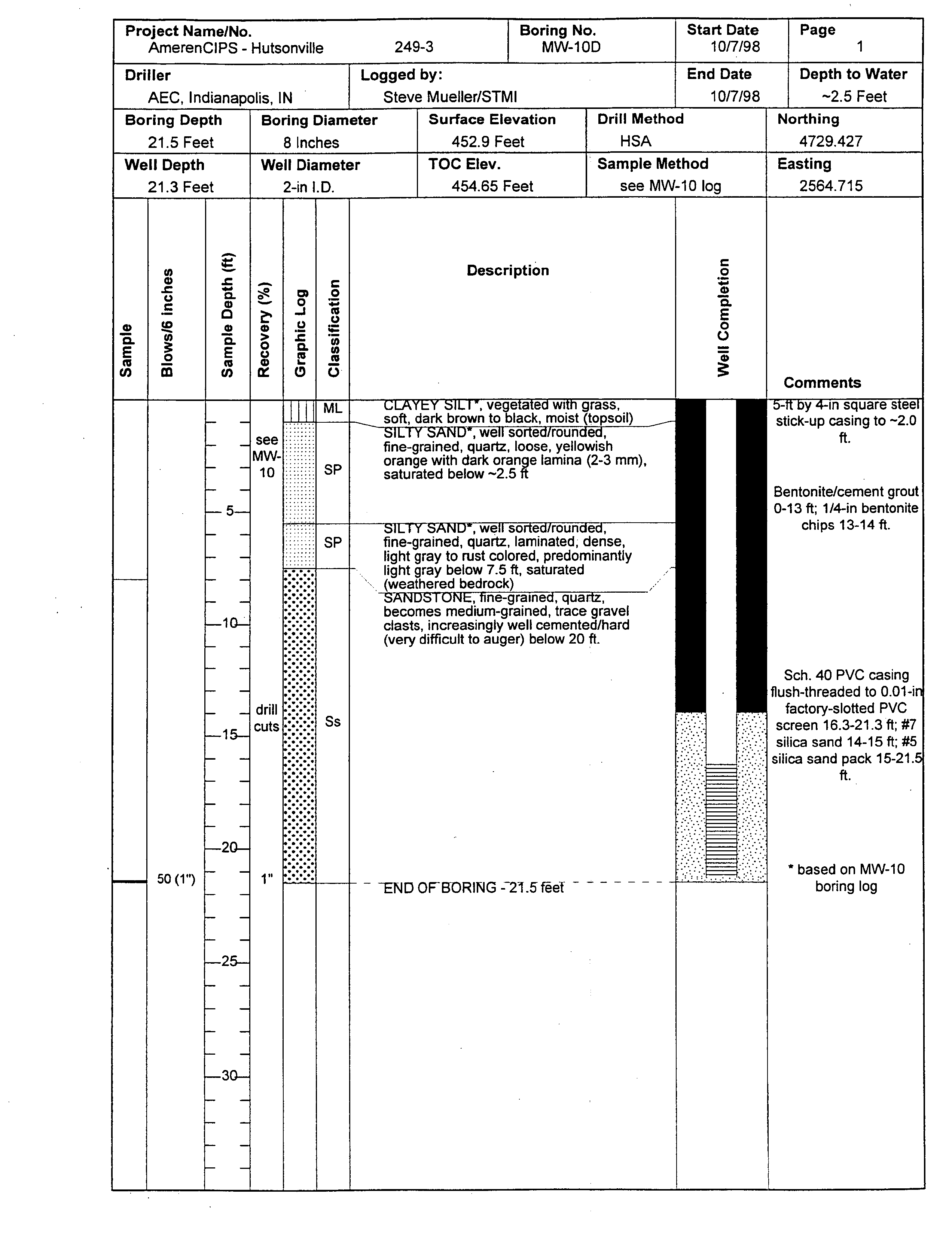

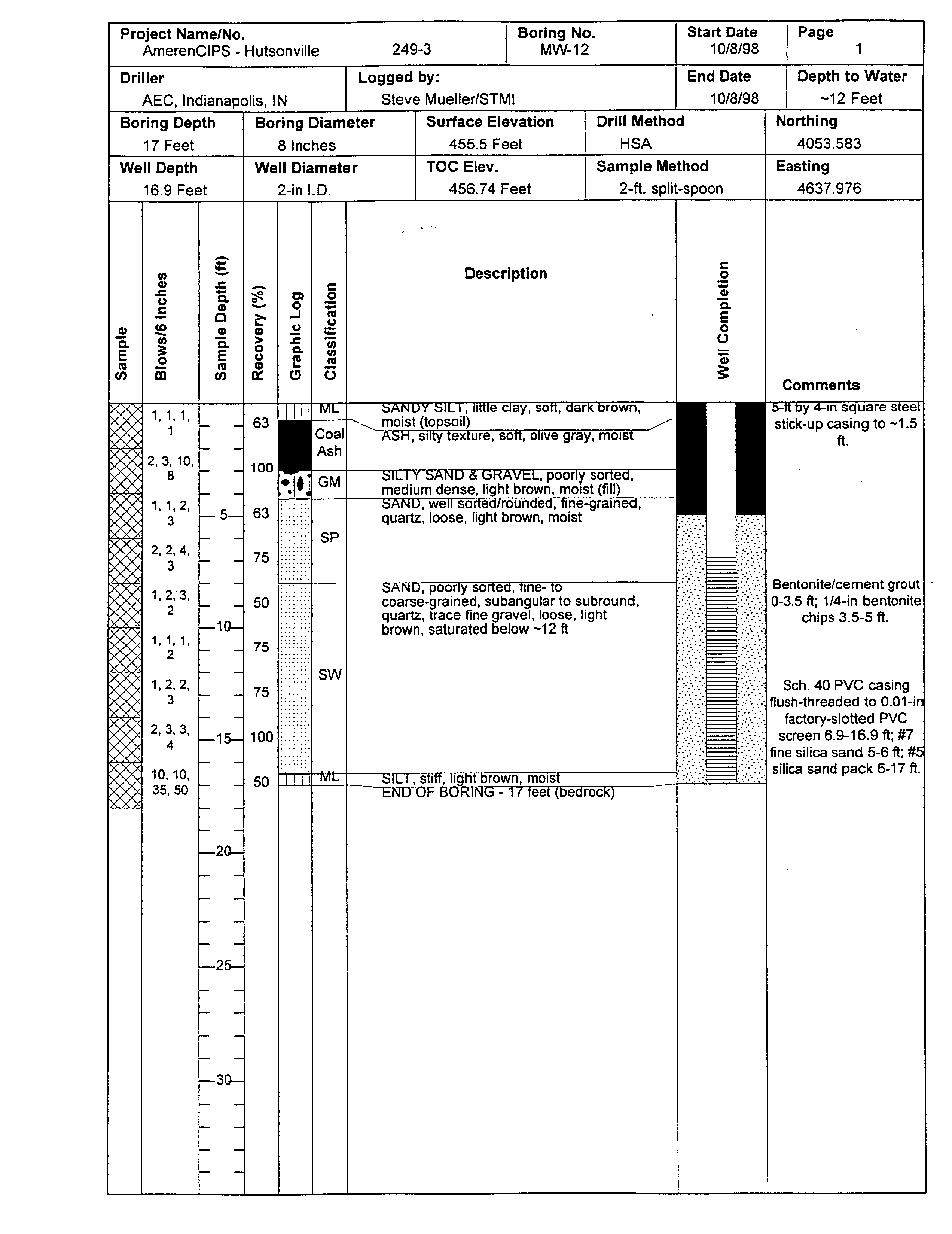

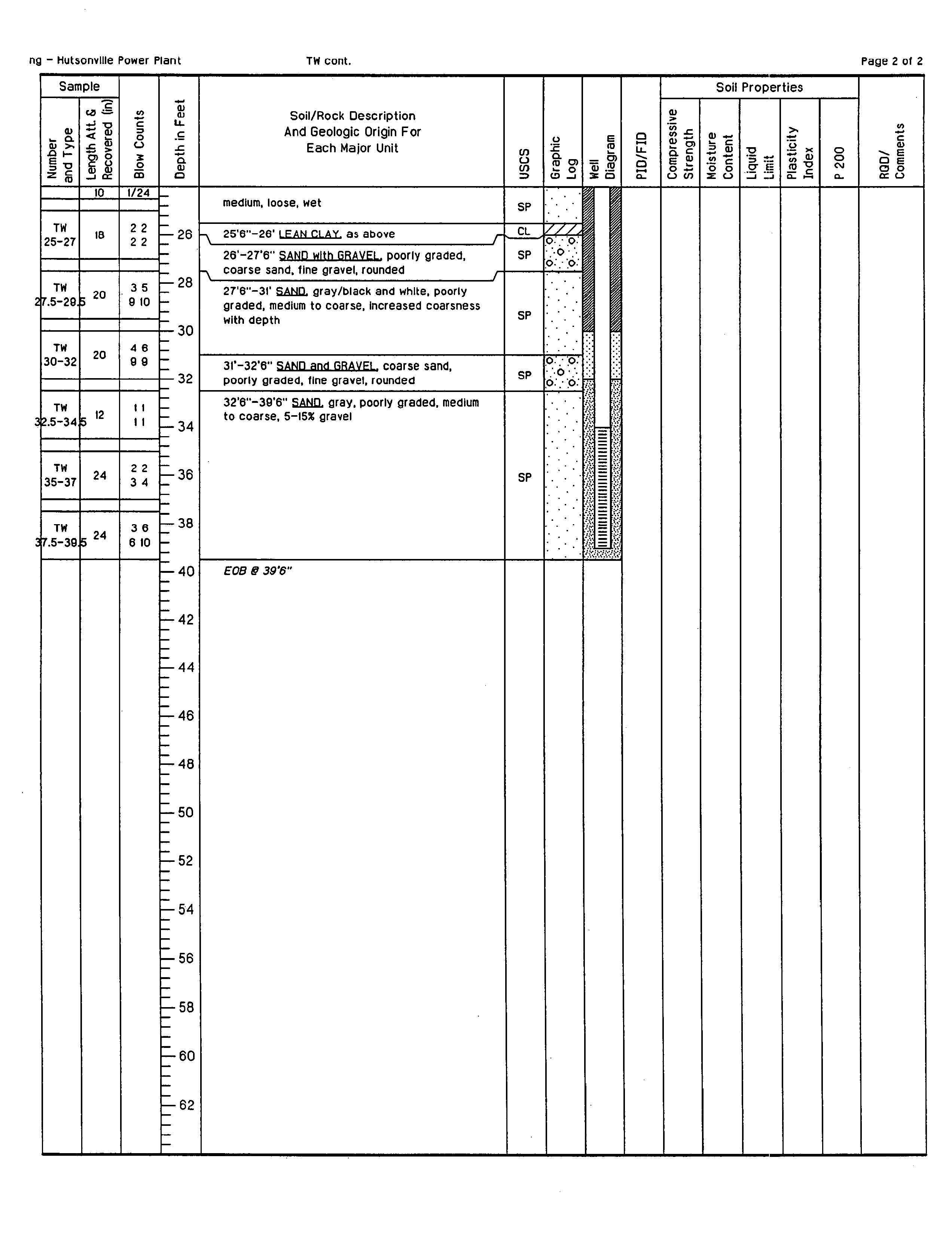

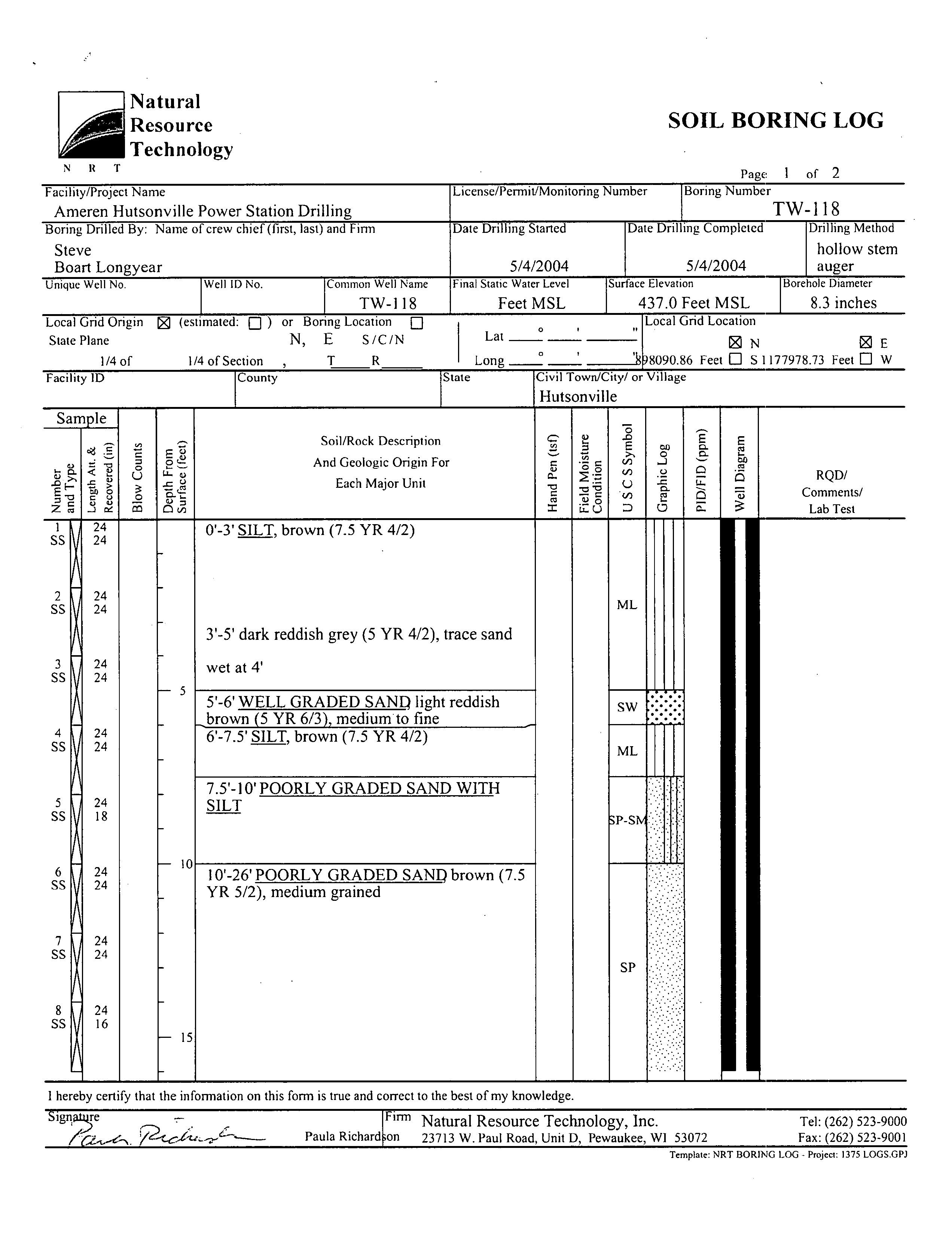

Borings

An all-terrain drill

rig equipped

with

-inch

hollow-stem

augers

was

used to

perform

all soil

borings

direct

push sampling

and

monitoring

well installations

at

the

site

total of nine soil

borings

were

advanced

at the

site

two of which

were

converted into

permanent monitoring

wells

MW-I

1R and

MW-14

and one that was converted into

temporary monitoring

well

TW

Soil

borings

SB-I01

through

SB-103 were advanced

to better characterize

the

type

and

extent

of

geologic

materials

surrounding

Pond

Soil

borings

SB-104

through

SB-106 were advanced

north of the

ash

impoundment

to find

suitable location for

background

monitoring

well within the

deep

alluvial sand and

gravel

The

latter

borings

were drilled in the

only

accessible locations that

were not

downgradient

of the ash

impoundments

However

shallow bedrock

was encountered at all three

locations

and

natural coal

seam was encountered

at

SB-106

indicating

that

the Wabash River was over the west side of the

valley

in

this area As

result an

upgradient

well could

not be installed within the

deep

sand and

gravel

of the

valley

Geologic

materials at all soil

borings were

logged every

feet

using

2-inch diameter

by

2-foot

long

split-barrel sampler

The soil

borings

were advanced

to

bedrock to

design depth

or

adjusted

in the field

as

necessary

ranging

from

feet to 39

feet below

ground

surface

Table

2-1 Upon completion

of

1375 Alternatives

Analysis

Report-Final

NATURAL

2-I

RESOURCE

TECHNOLOGY

Electronic Filing - Received, Clerks' Office, August 11, 2008--AS 09-1, Exhibit 3

SUMMARY OF SITE CONDITIONS

sampling

all soil

borings

were

backfilled

with

bentonite

chips

and

hydrated or

converted into

monitoring

wells

Appendix

A-I

During

advancement

of soil

borings

SB-102

MW-I

and

TW

hydro-punch

discrete water

sampler

was

used to collect

groundwater

samples

at

targeted depths Table 2-1

The

purpose

of the discrete water

sampling

was to determine the

geologic

formations

where ash leachate

was most

prevalent

and better

assess

the

feasibility

of

leachate

collection

surrounding

Pond

Discrete

samples

were

designed

to

target

groundwater

in the shallow

silty

alluvial sediments

immediately

below the silt interface

at

the

top

of

the

deep

alluvial

sand

and

at

depth

in the

deep

alluvial sand

minimum of

10 feet below the

silty

alluvium

This

analysis

showed

decreasing

concentrations

with

depth

however

interpretation

of results

was

uncertain due

to

potential

vertical

migration

within the borehole

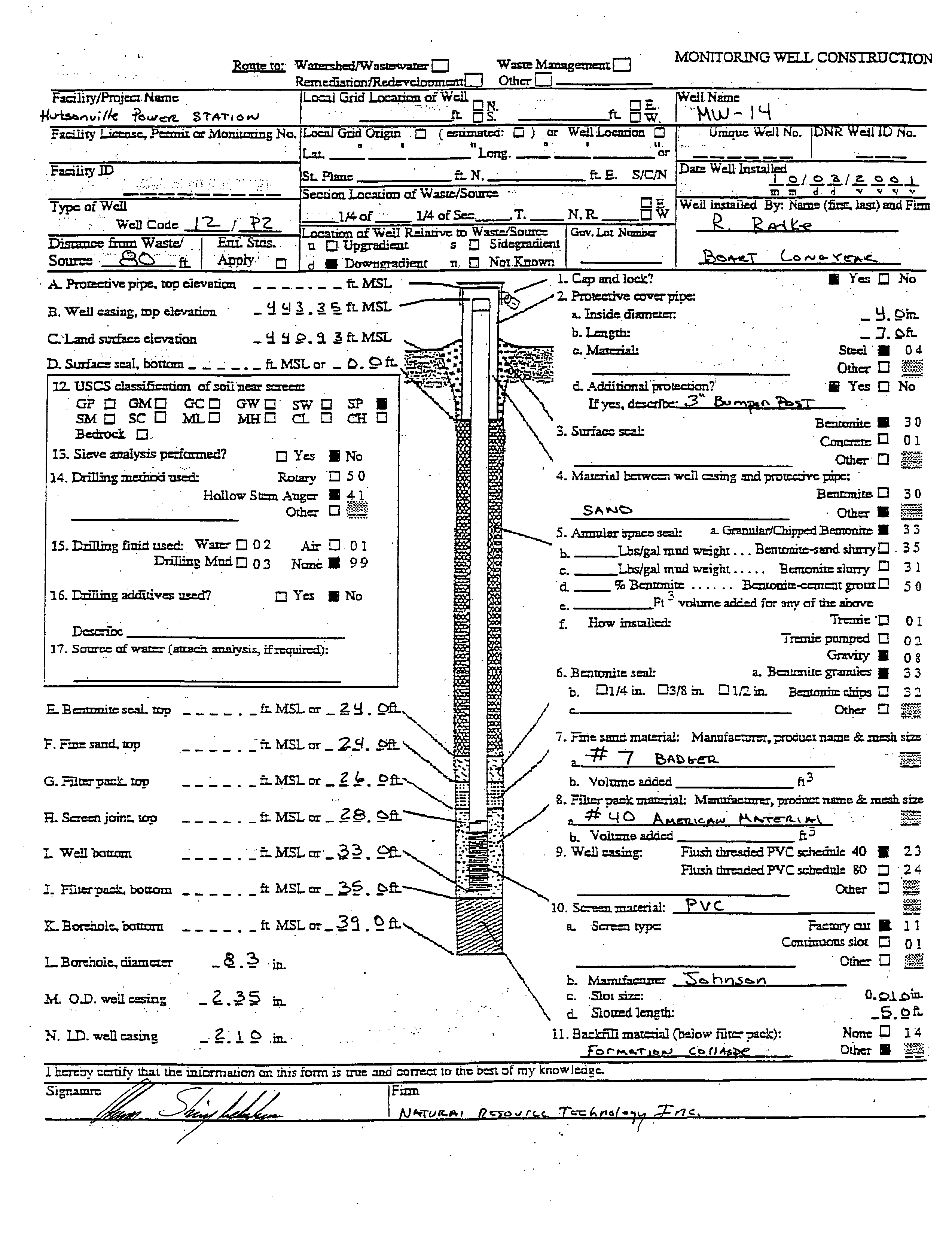

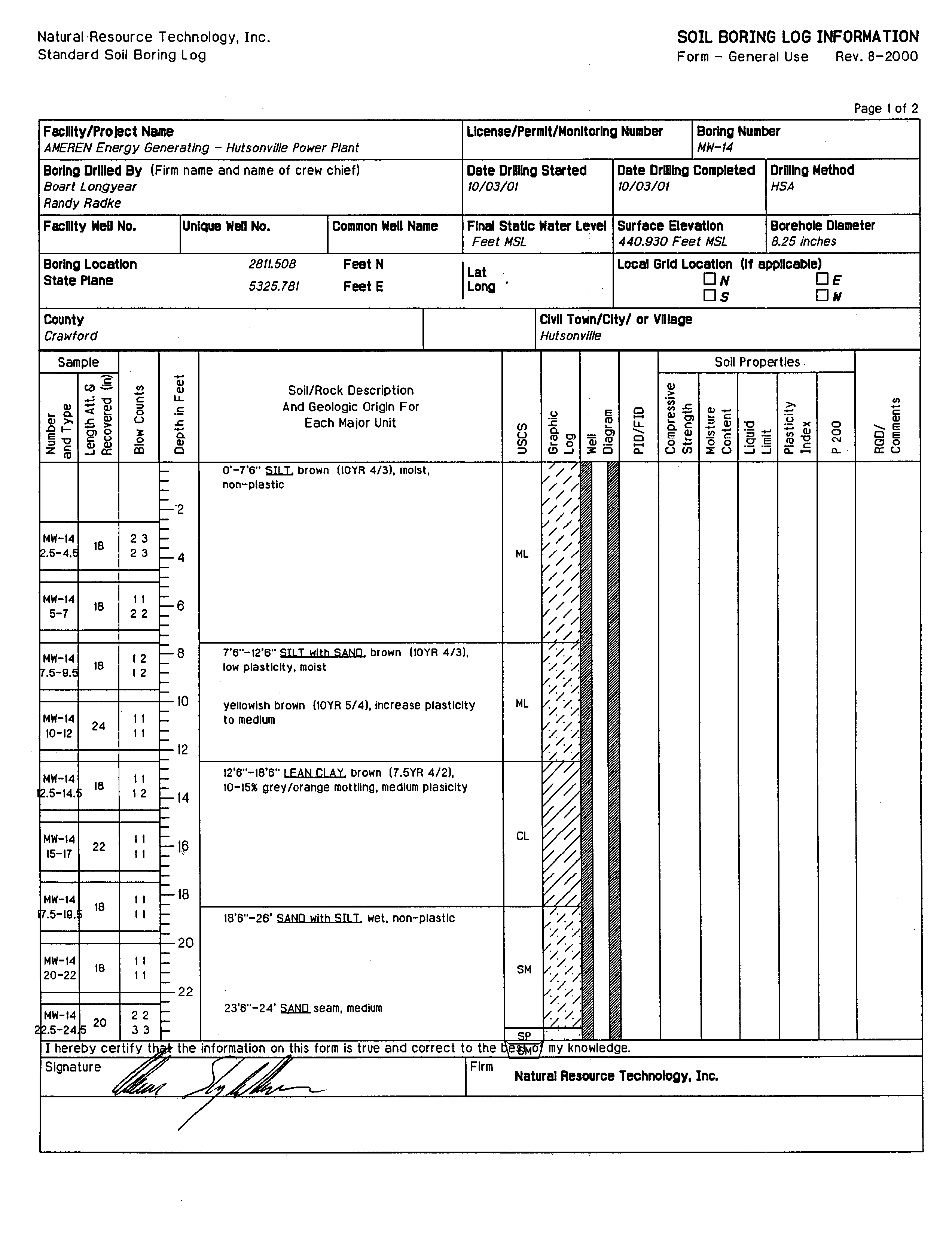

2.1.2 Installation

Abandonment of

Monitoring

Wells

Monitoring

well MW-14

was

installed

to

support

the

creation of

groundwater

monitoring

network

surrounding

Pond

The

screen

of MW-14 is

designed

to monitor the

deep

alluvial sand and

gravel

aquifer immediately underlying

the shallow alluvial silt and

clay

unit The

temporary monitoring

well

TW

was installed to

provide

additional

data for characterization

of the

deep

alluvial

aquifer

The screen

of TW monitors the

deep

sand and

gravel aquifer

at

depth

of nine feet below

the silt and

clay

unit

Monitoring

well MW-hR

was

installed

to

replace monitoring

well

MW-Il

which was

yielding

anomalous results

Monitoring

well MW-I 1R

was

screened in

unlithified materials

atop

shallow

bedrock

All

of the wells were constructed with 2-inch inner diameter

I.D

schedule 40 Pvc

pipe

flush-threaded

to

foot

MW-

14 and

TW or

10 foot

MW-Il

long

section of

0.010-inch factory

slotted PVC well

screen

Tables

2-2 and

2-3

From bottom to

top

the

monitoring

wells

were

completed

with

filter

pack

consisting

of uniform

silica

sand to at least one foot above the well

screen

one-half to two feet of

fine

sand

and

minimum of

two feet of

hydrated

bentonite

chips

to

near

ground

surface

Appendix

A-2

All of the

monitoring

wells were finished with

stick-up style locking

steel

well

protective casings

surrounded

by

set of steel

bumper posts

Following

well

completion

all

wells were

developed

to

remove

sediment and

restore

groundwater

flow

surrounding

the well

1375 Alternatives

Analysis Report-Final

NATURAL

2-2

RESOuRCE

TECHNOLOGY

Electronic Filing - Received, Clerks' Office, August 11, 2008--AS 09-1, Exhibit 3

SUMMARY

OF SITE CONDITIONS

2.1.3

Hydraulic Testing

Single

well

recovery

tests were

performed

on

newly

installed wells and wells that

were not

previously

tested Wells

MW-I MW-14

MW-hR

and TW were tested Well MW-8 could

not be tested due to

slow

recovery

after

groundwater

sampling

Data

were

collected

using

an in-Situ HermitlM

datalogger

and

pressure

transducers

Pressure transducers and

disposable

bailers were

placed

in the

wells

and time

was

allowed for

groundwater

to reach

equilibrium

After

groundwater

had returned

to static water

level

the

transducers

were linked to the

datalogger

and set to

begin

slug

of

water was removed

using

disposable

bailer with

approximately

0.037

ft3

of

displacement

for wells MW-I

and MW-IIR

Two

disposable

bailers

0.074

ft3

of

displacement

were

joined

together

and used to

remove

the

slug

at

well

MW-I

and three bailers

0.11

ft3 of

displacement

were used at TW due to the static head of the

water

table and the screened formation

Test duration was about 25

minutes or

until water had returned

to

static level

Upon

test

completion

the data

were

downloaded

and

processed using

the

Aqtesolv

software

Data were

interpreted using

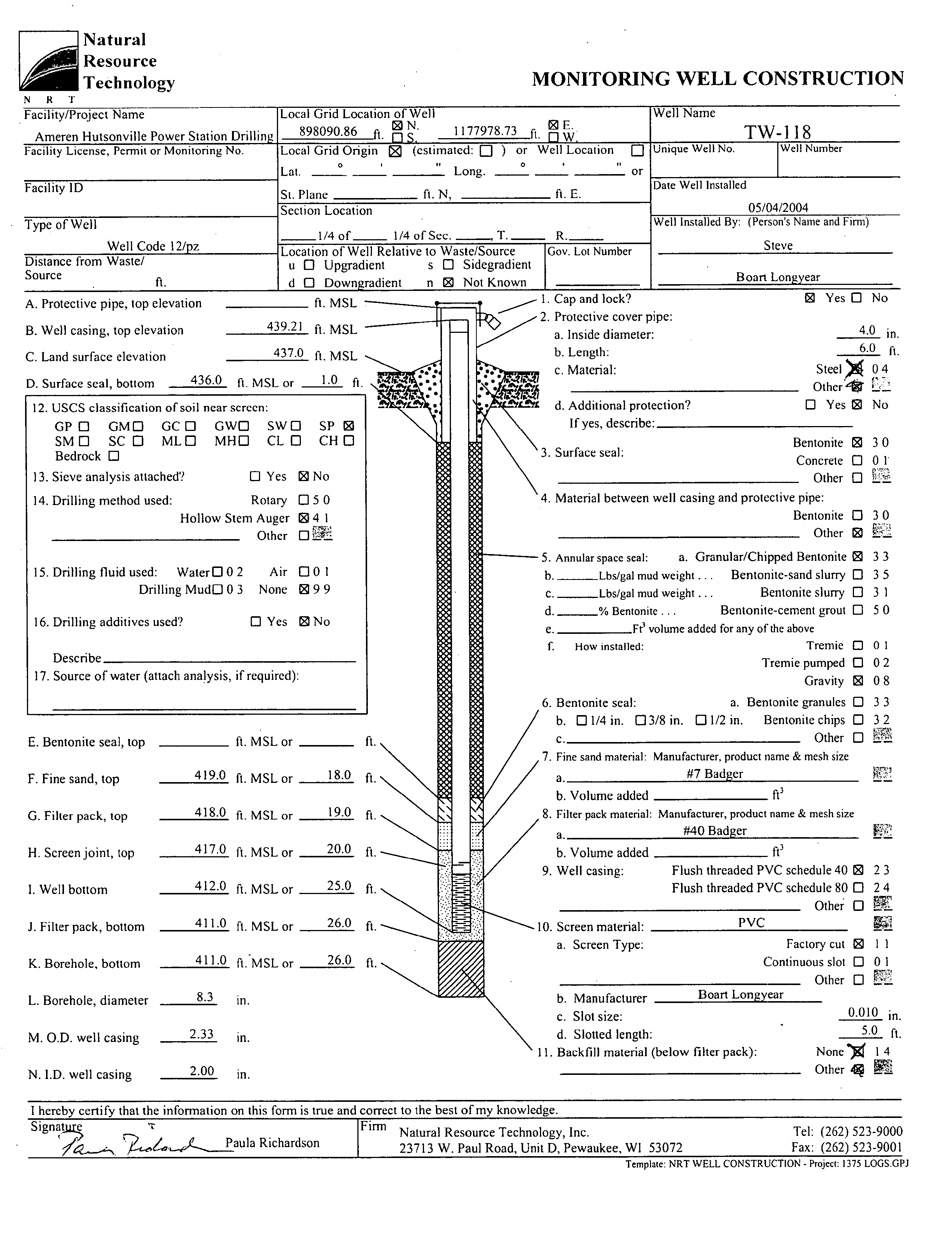

the Bower-Rice

1976

method

Table 2-4

Appendix A-3 Slug

test results

from

wells

MW-14

and MW-I JR could not be

interpreted

due to

an

equipment

malfunction

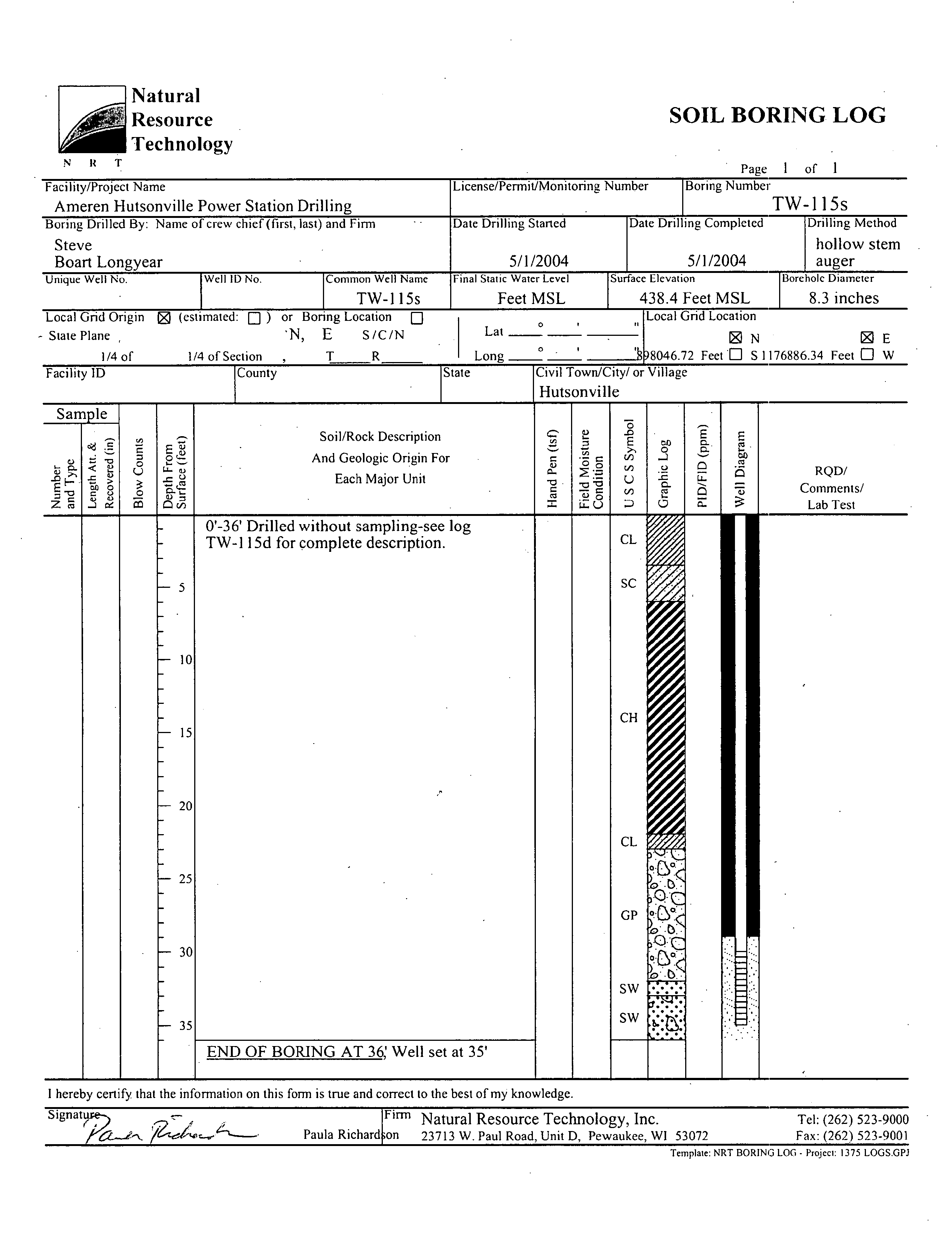

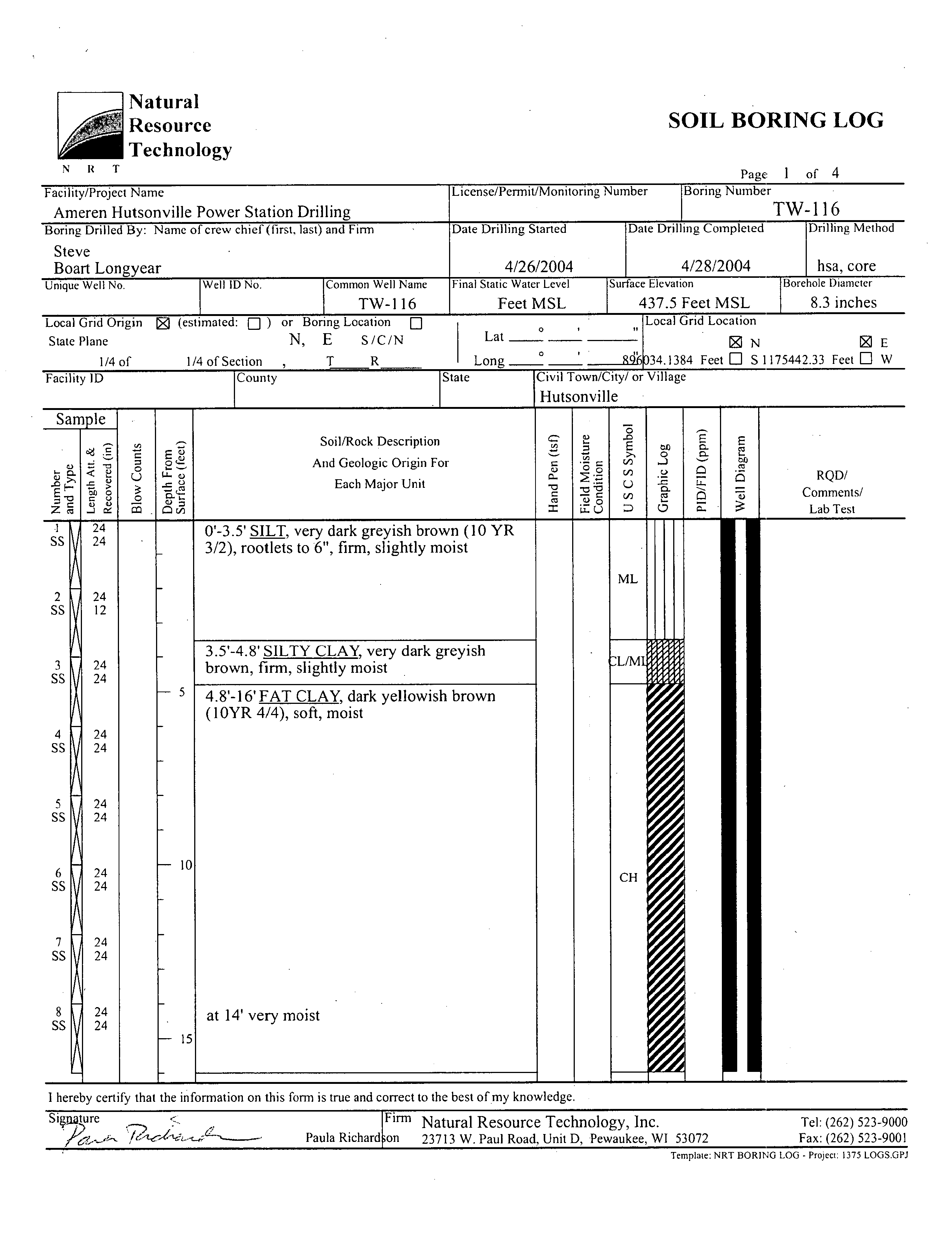

2.2

Supplemental

Off-Site

Investigation April

and

May

2004

The

supplemental

off-site

investigation

was

performed

from

April

26 to

May

13

2004

The

scope

of

work included

installation of seven

temporary monitoring

wells

TW-1

15S

through TW-120

deployment

of downhole

datahoggers

for continuous

groundwater

elevation

observations in TW-1

15S

TW- 11

SD

and TW-

118

performance

of

single

well

recovery slug

tests on new wells to characterize

aquifer

characteristics

near the

monitoring points

survey

of all

new wells

and

collection

of

groundwater

elevation data

at

all

new and

existing

wells In

addition

pumpage

data for the

two

plant

water wells

was

collected and

analyzed

to determine the effect of

pumpage

on

the

nearby monitoring

wells

TW-1

15S and TW-I

15D

2.2.1

Installation of

Monitoring

Wells

An all-terrain drill

rig

equipped

with -inch hollow-stem

augers

was used to

perform

all

monitoring

well installations

during

the 2004

supplemental investigation

Geologic

materials at all well locations

were

logged

continuously

to the extent

practicable

using

2-inch

diameter

by

2-foot

long split-barrel

sampler

Rock cores were collected from

borings

TW-115D

TW-1

16 and TW-1 19

utilizing

diamond

tipped

rock core barrel Each of the wells

was

constructed

with 2-inch inner diameter

I.D

schedule 40

1375 Alternatives

Analysis Report-Final

NATURAL

2-3

REsOURCE

TECHNOLOGY

Electronic Filing - Received, Clerks' Office, August 11, 2008--AS 09-1, Exhibit 3

SUMMARY OF SITE CONDITIONS

PVC

pipe

flush-threaded

to

5-foot

long

section of 0.0

10-inch

factory

slotted PVC well screen

Tables

2-2

and

2-3

From bottom to

top

the

monitoring

wells

were

completed

with

filter

pack consisting

of

uniform silica

40

sand to at least

foot above the well

screen

foot of fine

sand and

minimumof feet of

hydrated

bentonite

chips

to near

ground

surface

Appendix A-2

All of the

monitoring

wells

were

finished with

stick-up style locking

steel

protective

casings

TW-1 15S and TW1I5D

were

drilled

directly

north of

EW2 as close to the river as

possible Figure

2-1

to be used in

conjunction

with

existing

well MW-7D and

pumpage

records from EWI and EW2 to

determine the effects of

plant

pumpage

on

groundwater

flow within the

deep

alluvial

aquifer

TW-l 15D

was

drilled

to

bedrock and

cored 15 feet into the

shale

to

total

depth

of 105 feet below

ground

surface

bgs

The borehole

was

then backfilled

with

bentonite to

approximately

88 feet

bgs

and the well

was

screened near the base of the

deep

alluvial

aquifer

to characterize

the vertical flow within the

aquifer

TW-l l5S was blind drilled to 36 feet and screened

near

the

top

of the

aquifer

TW-1

16 and TW-1 17 were drilled

approximately

one-half mile

south/southeast

of the

impoundment

on

the west side of the river

TW-116

farther from the

river was

drilled

to

depth

of 79.2 feet

bgs

cored

19 feet into

shale

backfilled

with bentonite

to 55 feet

bgs approximately

five

feet above the

bedrock

and then the

augers

were rotated backwards

out of the hole to allow the sand and

gravel

to

collapse

The

well screen

was

set at 30 feet

bgs

in

clayey

sand

to

gravel

at what was assumed to be the

top

of the

deep

alluvial

aquifer Subsequent

review of the

lithology

determined that TW- 116 is

actually

screened in the

fine-grained

alluvium above the

deep

alluvial

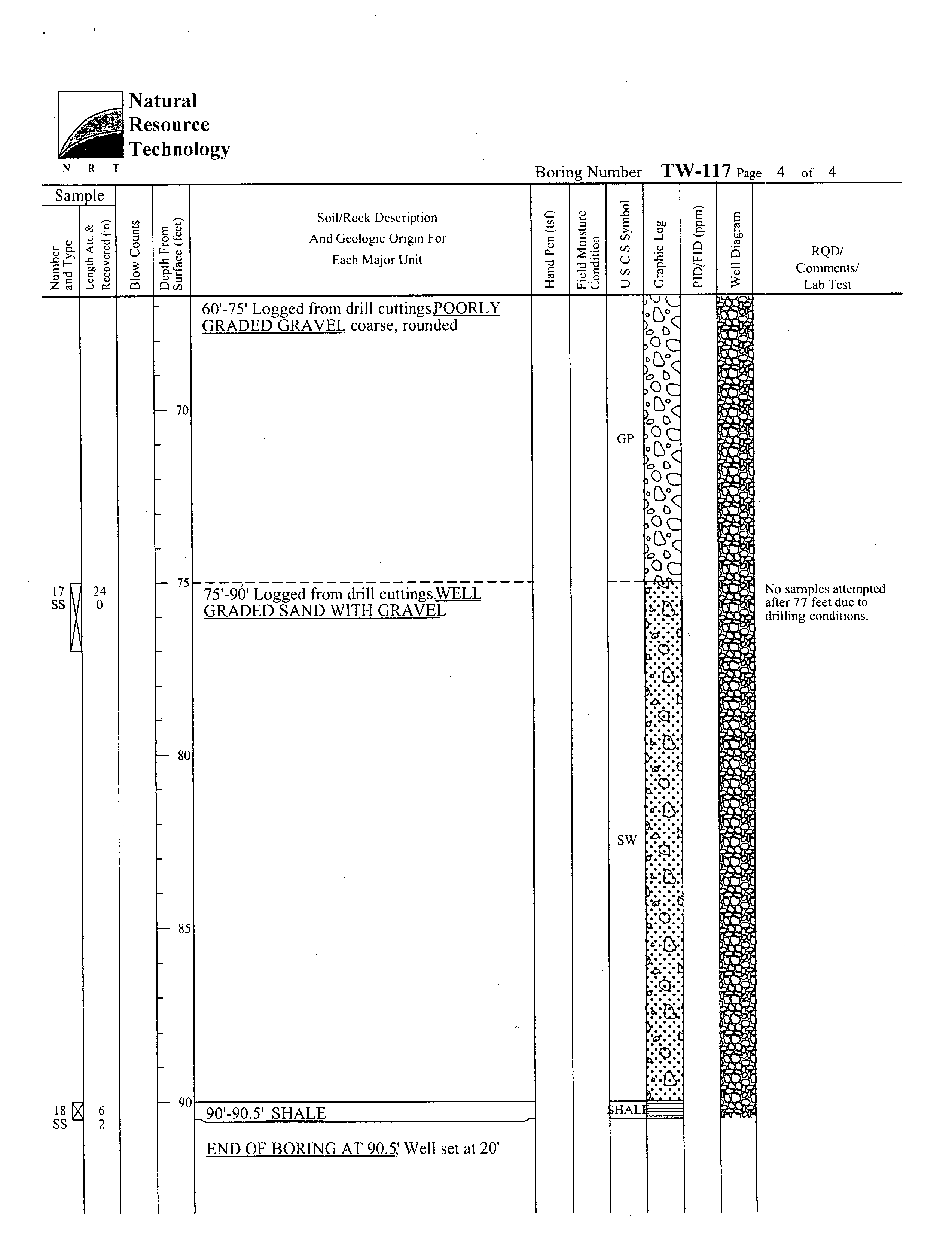

aquifer TW-117

closer

to

the

river was drilled to

total

depth

of 90.5 feet

bgs six

inches into

shale

the

augers

were

then rotated

backwards out of the borehole

and the borehole

was

allowed

to

collapse

to

depth

of 21 feet

bgs

The well

screen was set at

20

feet at

the same

approximate

elevation

as

TW-1 16

to allow the two wells to

serve as

downgradient groundwater

elevation

calibration

points

and

as

lithologic

controls

on

the

configuration

of the bedrock

valley

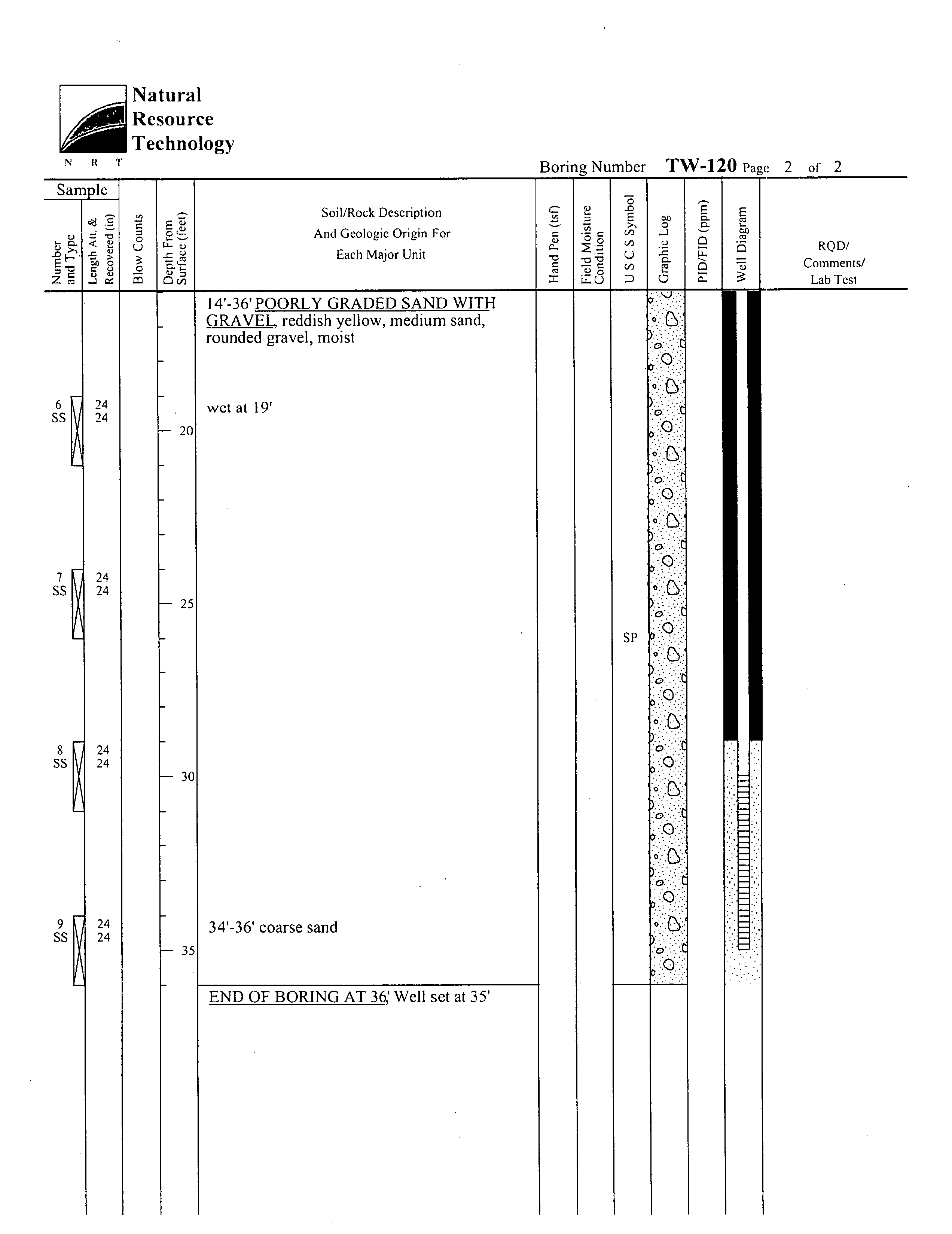

TW-118 TW-119 and TW-120 were drilled east of the river

Only

TW-119 was drilled to

bedrock as

bedrock

depth

at TW-118 was assumed to be similar

to

TW-115D

and TW-120 was assumed to be similar

to TW-119

TW-l 19 was cored 20 feet into

shale

to

total

depth

of 100 feet

bgs

The borehole

was

sealed with bentonite

to 75 feet

bgs

approximately

five feet above

bedrock The hole was then allowed to

collapse

as the

augers

were rotated out to

depth

of 21 feet

bgs

All three wells

were screened near the

top

of the

aquifer

1375 Alternatives

Analysis Report-Final

NATURAL

2-4

RESOURCE

TECHNOLOGY

Electronic Filing - Received, Clerks' Office, August 11, 2008--AS 09-1, Exhibit 3

SUMMARY OF SITE CONDITIONS

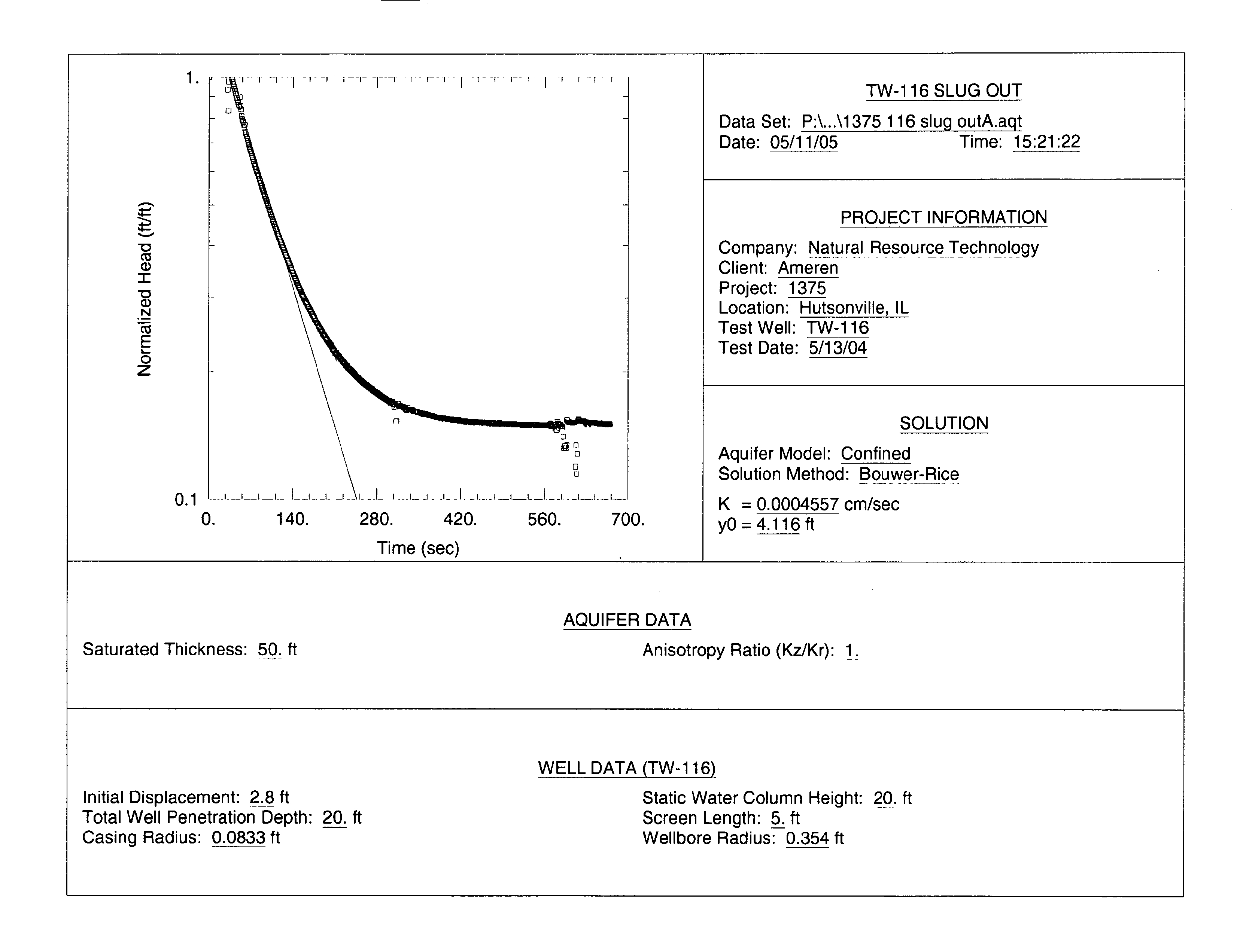

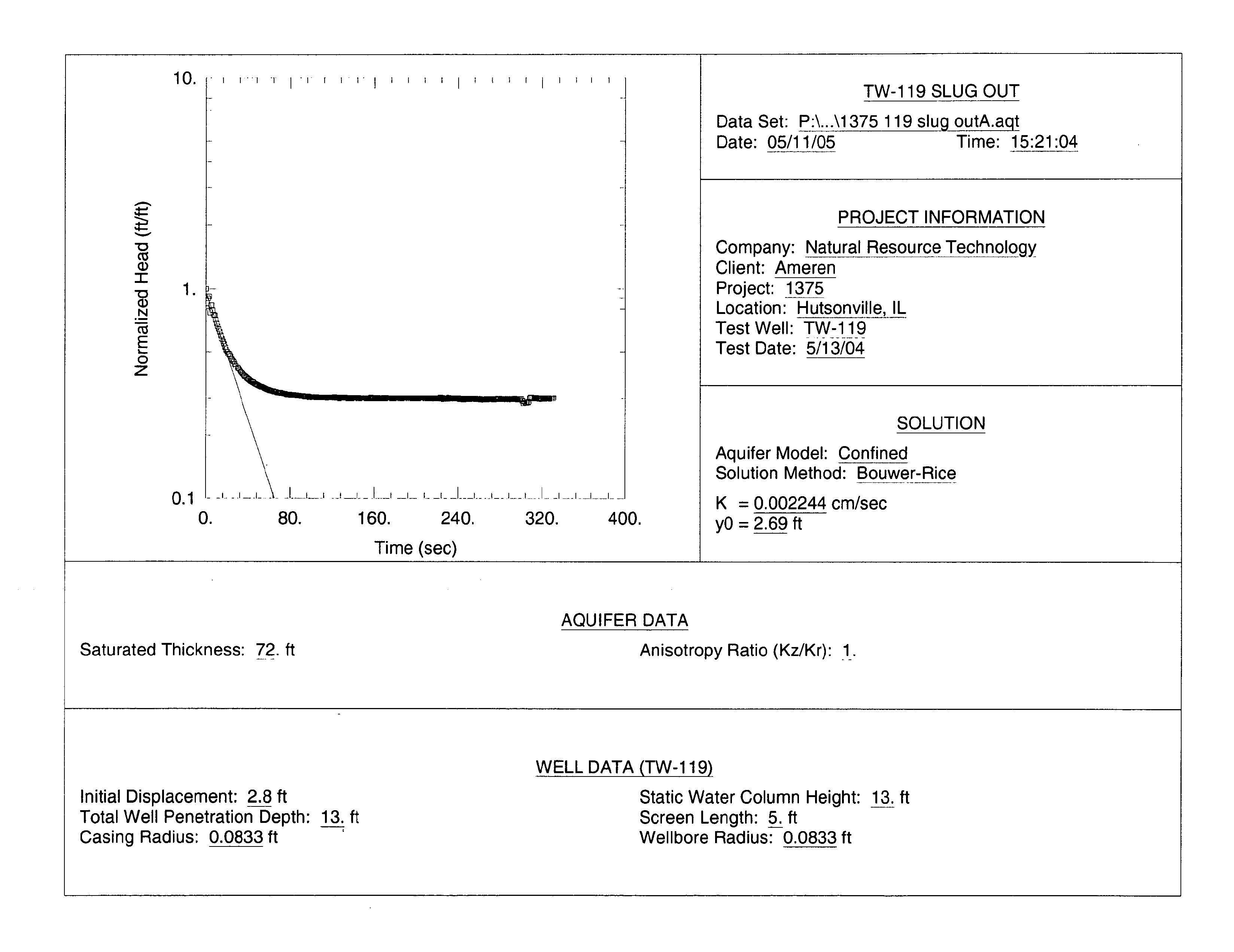

2.2.2

Hydraulic Testing

Single

well

recovery

tests were

performed

on

newly

installed wells Well

TW-120 could not be tested

because

the

depth

to

groundwater

was

greater

than the

length

of the

pressure

transducer

cord Data were

collected

using

laptop

and MiniTrollTM

pressure

transducers

Pressure transducers

were

placed

in

the

wells and the

tests started

0.061

ft3

steel

slug

was inserted

and time

was

allowed for

groundwater

to

reach

equilibrium slug-in

test

After

groundwater

had returned

to

static

water

level

the

slug

was

removed and the water column left to

equilibrate again slug-out test

Test duration was

to 10 minutes

Upon

test

completion

the data were downloaded and

interpreted

using

the Bower-Rice

1976

method as

coded

in

the

Aqtesolv software

with the

exception

of TW-1 15S and TW-1

18

which

were

interpreted

using

the Butler

1998

analysis

method

Table 2-4 Appendix

A-3

The MiniTrollTM

dataloggers

were

then

deployed

in

wells

TW-l

15S

TW-1

15D

and TW-1 18 for

continuous

groundwater

elevation observations

The

dataloggers

were set to take

pressure

head

readings

of the

height

of the water column above the transducers

every

hour

for six months

2.3 Groundwater

Sampling

and

Analysis

Groundwater

sampling

was

performed by

AEG

according

to their standard

operating

procedure

Appendix A-4 Analysis was

performed by

PDC laboratories

Analytical

methods are listed below

Analyte

Method

Alkalinity

Tot

SM

18

2320B

Boron

Tot

SW-846 6020B R0.0

Calcium

Tot

EPA 7140

prior

to

2002

SW-846 6020B

R0.0

since 2002

Hardness

total

SM

18

2340C

Manganese

Tot

243.1

prior to

2002

SW-846 6020B RO.O

since 2002

Sulfate

Tot

375.4

prior

to

2002

EPA 300.0 R2.1

since

2002

TDS

160.1

prior

to

2002

SM

18

2540C

since 2002

Only

one

of the

two in or

out

tests

is

reported

if the other test

yielded

non-linear

recovery

curve

1375 Alternatives

Analysis Report-Final

NAI1.JRAL

2-5

RESOURCE

TECHNOLOGY

Electronic Filing - Received, Clerks' Office, August 11, 2008--AS 09-1, Exhibit 3

SUMMARY OF SITE CONDITIONS

2.4

Summary

of

Hydrogeology

and

Groundwater

Quality

2.4.1 Distribution of Coal Ash Fill

Ash

at

the Hutsonville

Power Station has been

managed

in Ponds

and

In

addition

ash

was

placed

in

laydown

area between the southern

portions

of Ponds

and

The ash

laydown

area was

roughly

triangular

in

shape

and covered

an area

of about

acres

In

2000 all ash in the

laydown

area was

excavated

and the interim

pond Pond

and

drainage

collection

pond

Pond

were

constructed in that

general

location

Four

direct-push

probe

holes

GP-20 through GP-23

advanced

through

Pond

during

the 1999

Hydrogeologic

Assessment

indicated ash thickness

ranging

from

about 12 feet at the north end of the

impoundment

to 31 feet in the central

portion

of the

impoundment Section C-C

Figure

in the

Hydrogeologic

Assessment

report

Ash in the central and

southern

portions

of Pond

extended

as

much

as 16 feet below the normal water table elevation

2.4.2

Hydrogeology

The

upland portion

of the site is underlain

by

thin

less

than 20 feet

thick layer

of sand-rich

soil

which

is

underlain

by Pennsylvanian-age

sandstone

The lowland

portion

of the Site is in the

Wabash River

valley

and is underlain

by

90 feet of

alluvium

that coarsens downward The

upper

alluvium consists of

silt and

clay

with

thickness of

to

30 feet

Figure 2-1

The lower alluvium is sand and

gravel

which

extends to

Pennsylvanian-age

shale

at

60

to

90 feet

bgs

The water table

throughout

most of the

upland

area occurs within the surficial sand unit Groundwater

flow in this unit is

east

toward

the Wabash River

see Figures

and

in the 1999

Hydrogeologic

Assessment

report

Flow

velocity

in the

upper

sand

varies with

hydraulic

gradient

and

hydraulic

conductivity

and was

previously reported

at 150 to 240 feet

per year

The

water

table within the

Wabash River

valley

occurs in the surficial silt and

clay deposits

therefore

the

deep

alluvial

aquifer

is confined

Groundwater

flow in the

deep

alluvial

aquifer

on

the

Illinois side of the

river is east to

northeast

toward

the Wabash

River

Figures

2-2 2-3

and

2-4

typical

horizontal

gradient

in the

deep

alluvial

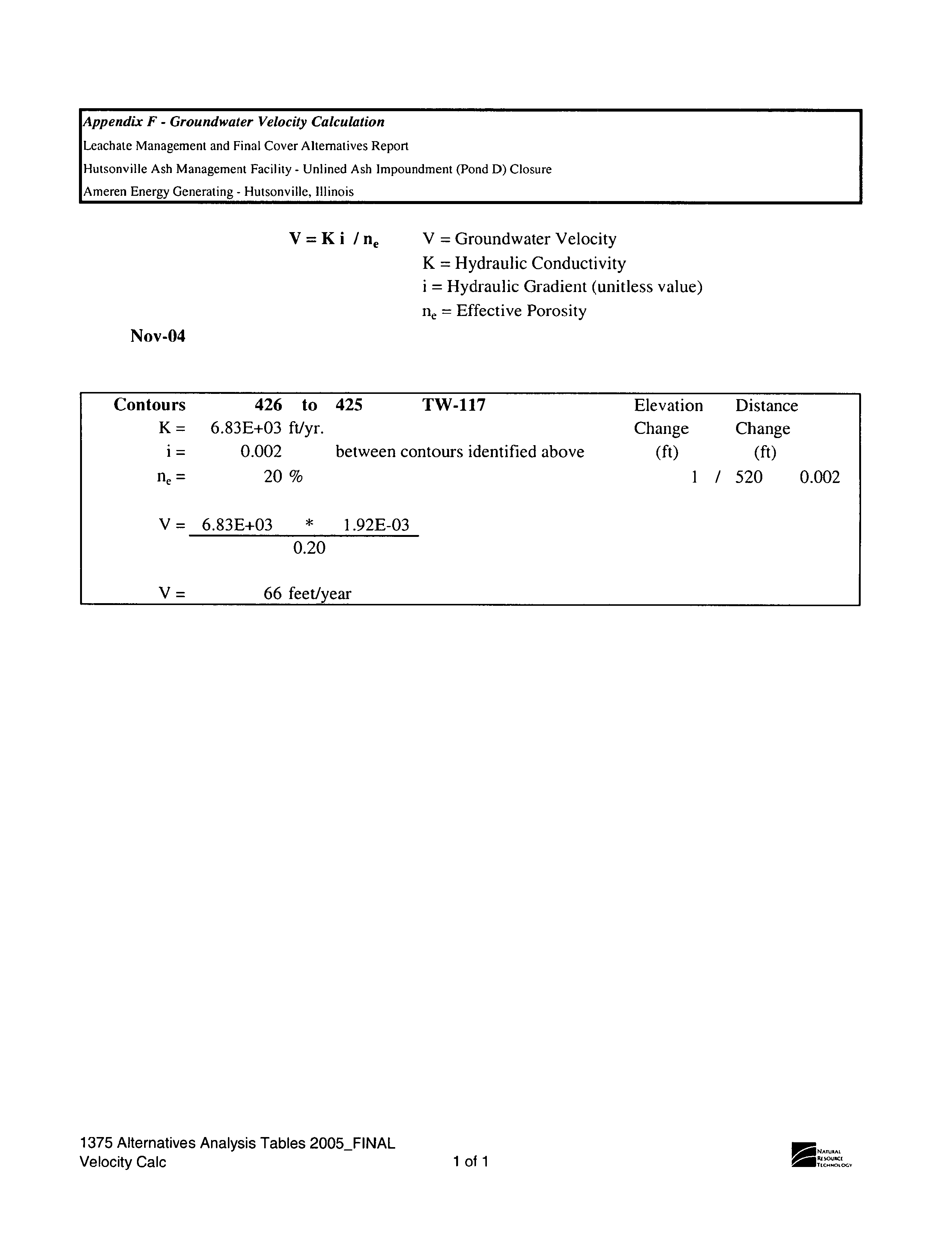

aquifer

south of the site

was

0.002 ft/ft

Appendix

Horizontal

groundwater

flow

velocity

was estimated to be

approximately

66

ft/yr

in the

deep

alluvial

aquifer

Appendix

The

relatively

low

velocity

is function of the fiat

gradients

in this formation

The

high

1375 Alternatives

Analysis

Report-Final

NATURAL

2-6

RESOURCE

TECHNOLOGY

Electronic Filing - Received, Clerks' Office, August 11, 2008--AS 09-1, Exhibit 3

SUMMARY OF SITE CONDITIONS

hydraulic conductivity

of

this formation

2.2

1O

to

1.6

10

cmls

combined with its thickness

indicates

highly

transmissive

formation

2.4.3

Evaluation of

Daily

Groundwater and River Elevation Data

Groundwater

elevation

in TW-l

5D

TW-1

15S and TW-1 18 were

continuously

measured2

and the

results

compared

to determine whether

or

not

power plant

pumpage

has

noticeable

effects on

groundwater

elevation in the

deep

alluvial

aquifer

There

was no

apparent relationship

between

plant

pumpage

and

groundwater

elevation

Figure

2-6

This

indicates that the

cone

of

depression

associated

with the

plant

wells is

small

as

might

be

expected given

the

high transmissivity

of the

deep

alluvial

aquifer

2.4.4 Groundwater

Quality

and Parameters of Concern

The

1999

Hydrogeologic

Assessment identified

boron sulfate

manganese

and TDS

as

parameters

of

concern

POCs

because their concentrations

in

groundwater

near Pond

exceeded Illinois Class

groundwater

quality standards

which were the

applicable

standards

for

this site at the time Boron and

sulfate are indicator

parameters

of coal ash

leachate

and

are

the

primary

POCs

Manganese

is

ubiquitous

in

soils

may

have

higher

concentrations

in soil than in coal

ash

and is

highly

sensitive

to

redox

conditions therefore

it is

not

reliable

indicator of coal ash leachate

High

TDS

may

be observed

at

sites where coal ash leachate

migration occurs

because

high

TDS concentrations

reflect elevated

concentrations of soluble ash constituents

such

as

calcium potassium sodium

and

sulfate however

other natural and

anthropogenic

sources

can cause

high

TDS concentrations

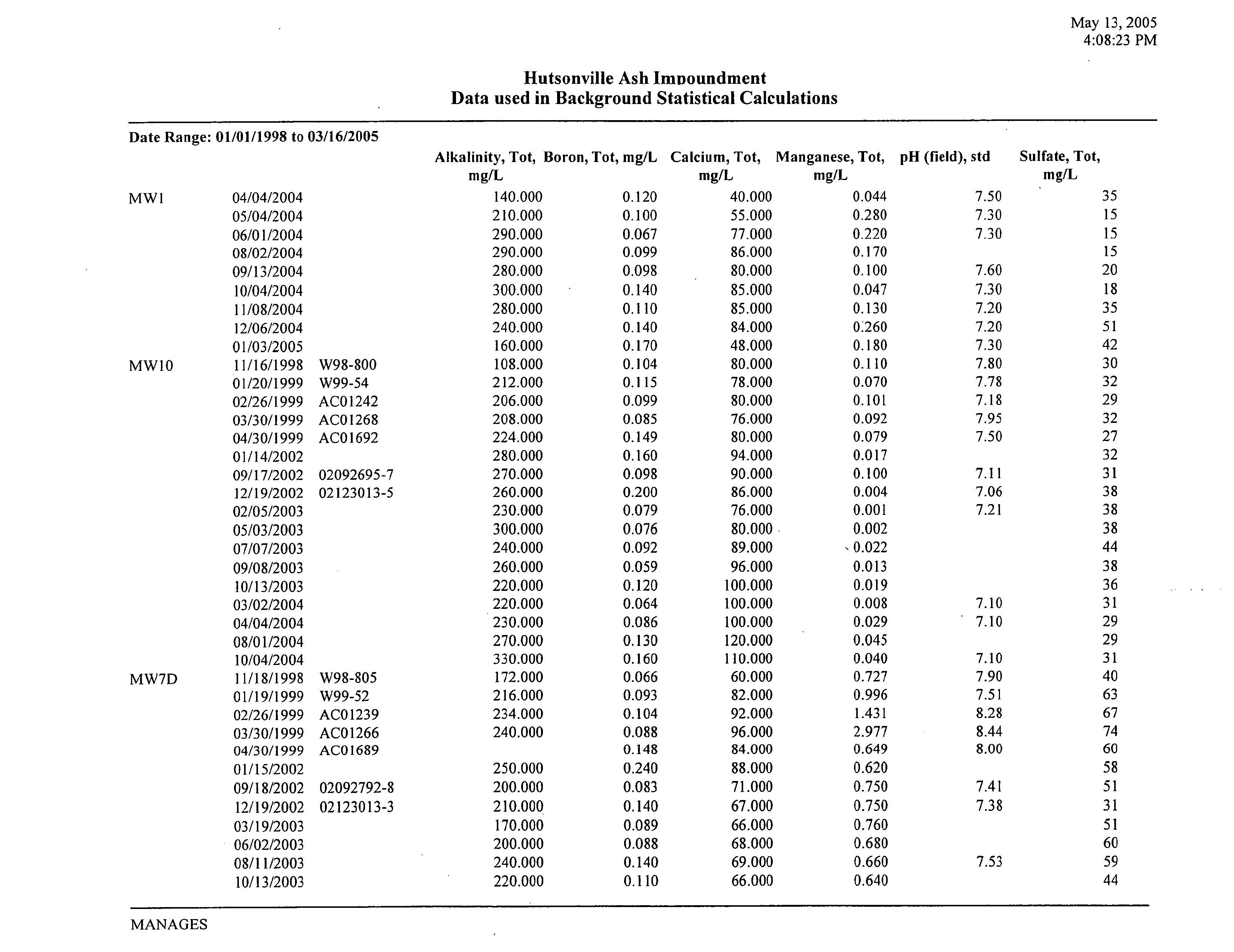

2.4.5

Background

Concentrations

Background

groundwater

quality

values

were calculated

in

anticipation

of site closure under Section 811

These calculations

were

performed using

data from

background

wells MW-I and

MW-b.3

Data

at these

wells

were

collected

beginning

in 1984

However review of these data found

anomalously high

results

for Boron in MW-

which

appear

to decrease over time

Figure 2-7

Sulfate concentrations

show

no

Due to an

equipment malfunction

continuous

data

were

only

available

for TW-1 15S after

September

2004

MW-10D

was not used because

it is finished in sandstone

1375 Alternatives

Analysis Report-Final

NATURAL

2-7

RESOURCE

TECHNOLOGY

Electronic Filing - Received, Clerks' Office, August 11, 2008--AS 09-1, Exhibit 3

SUMMARY OF SITE CONDITIONS

such

anomaly

and have

no

trend

Figure 2-8

As noted

previously

sulfate is also

an

indicator

parameter

for coal ash

leachate

and the absence of sulfate

suggests

that

the elevated

boron concentrations in MW-I

were not due to

migration

from the ash

ponds

Rather

these results

may

reflect

changes

in

agricultural

activity

in the

area.4

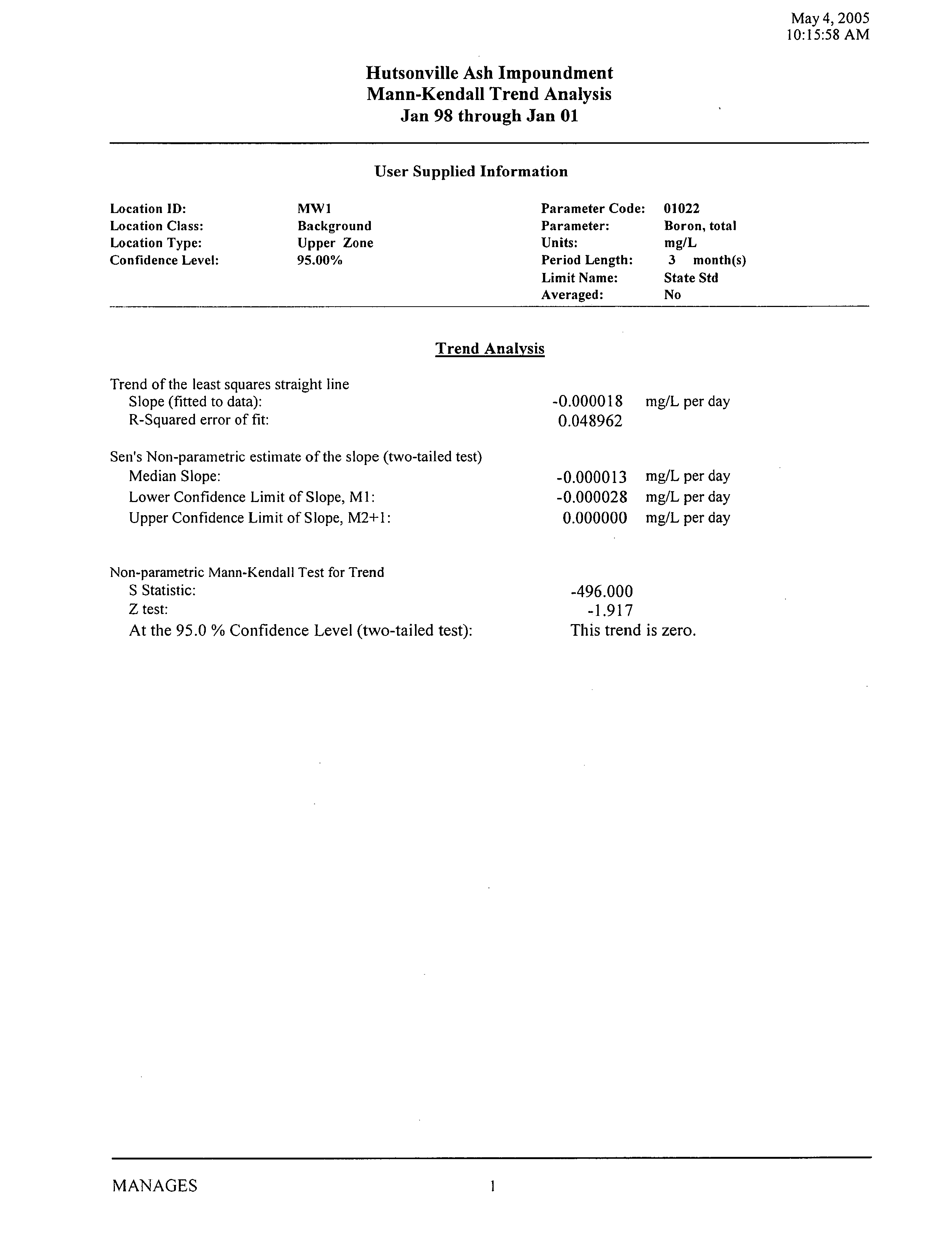

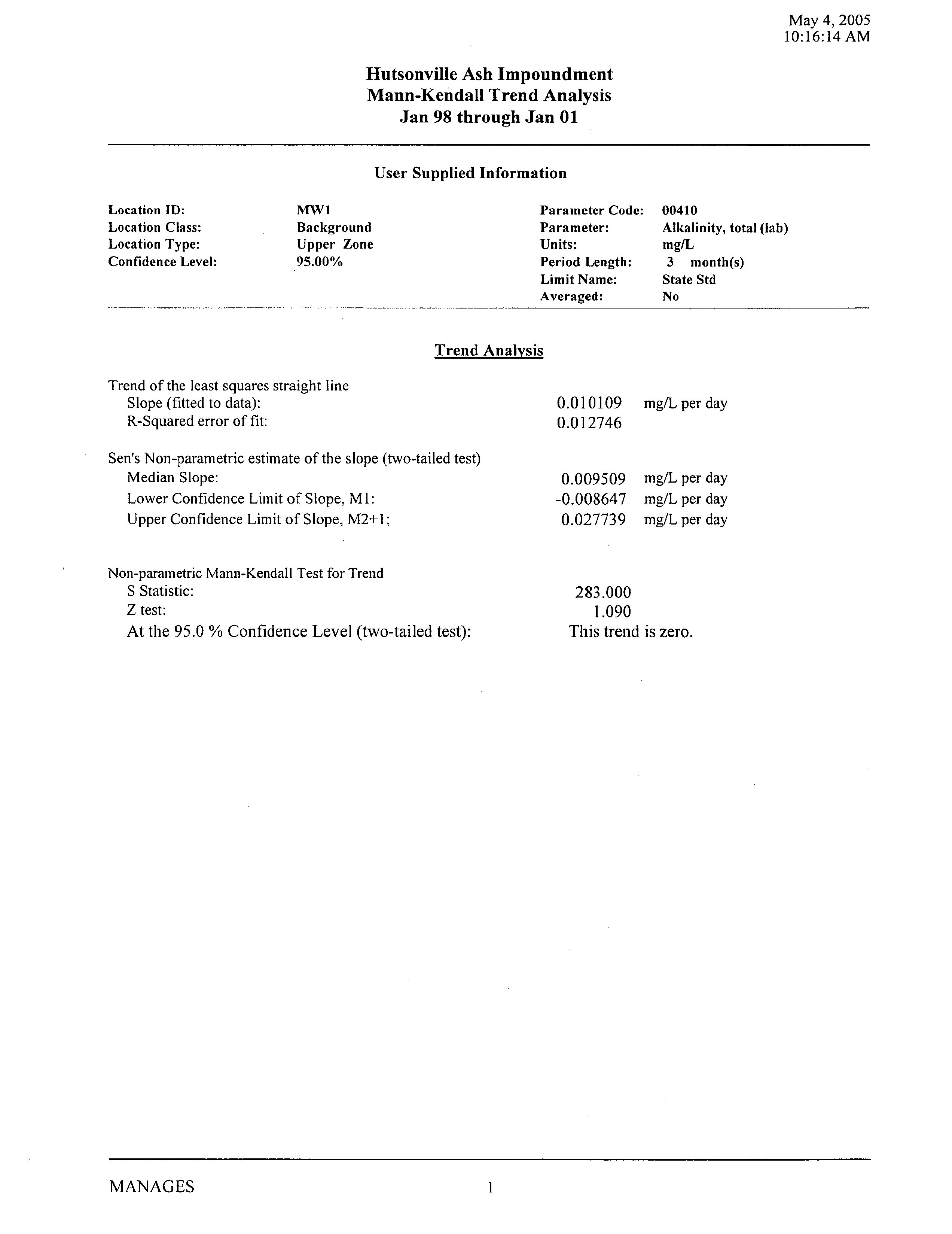

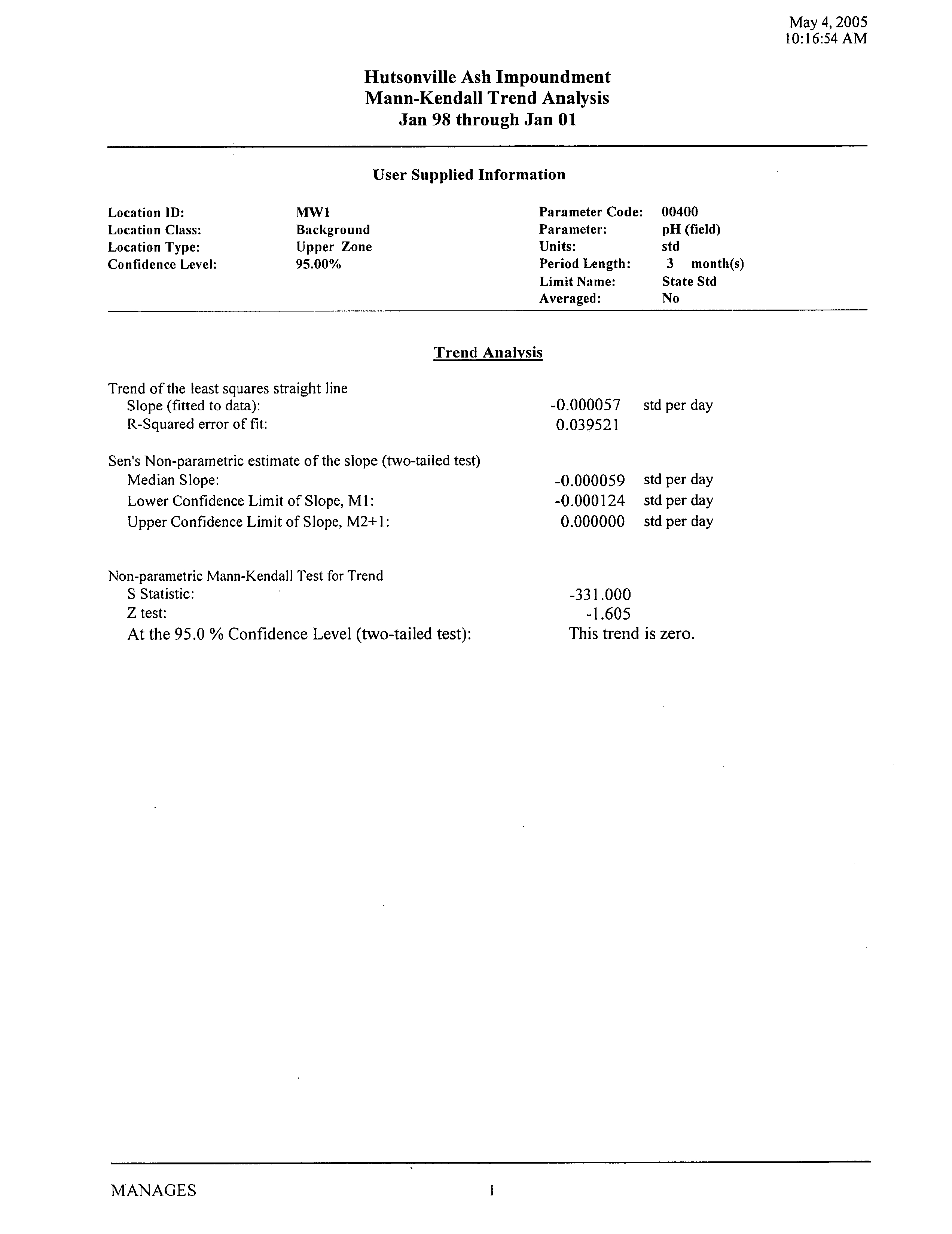

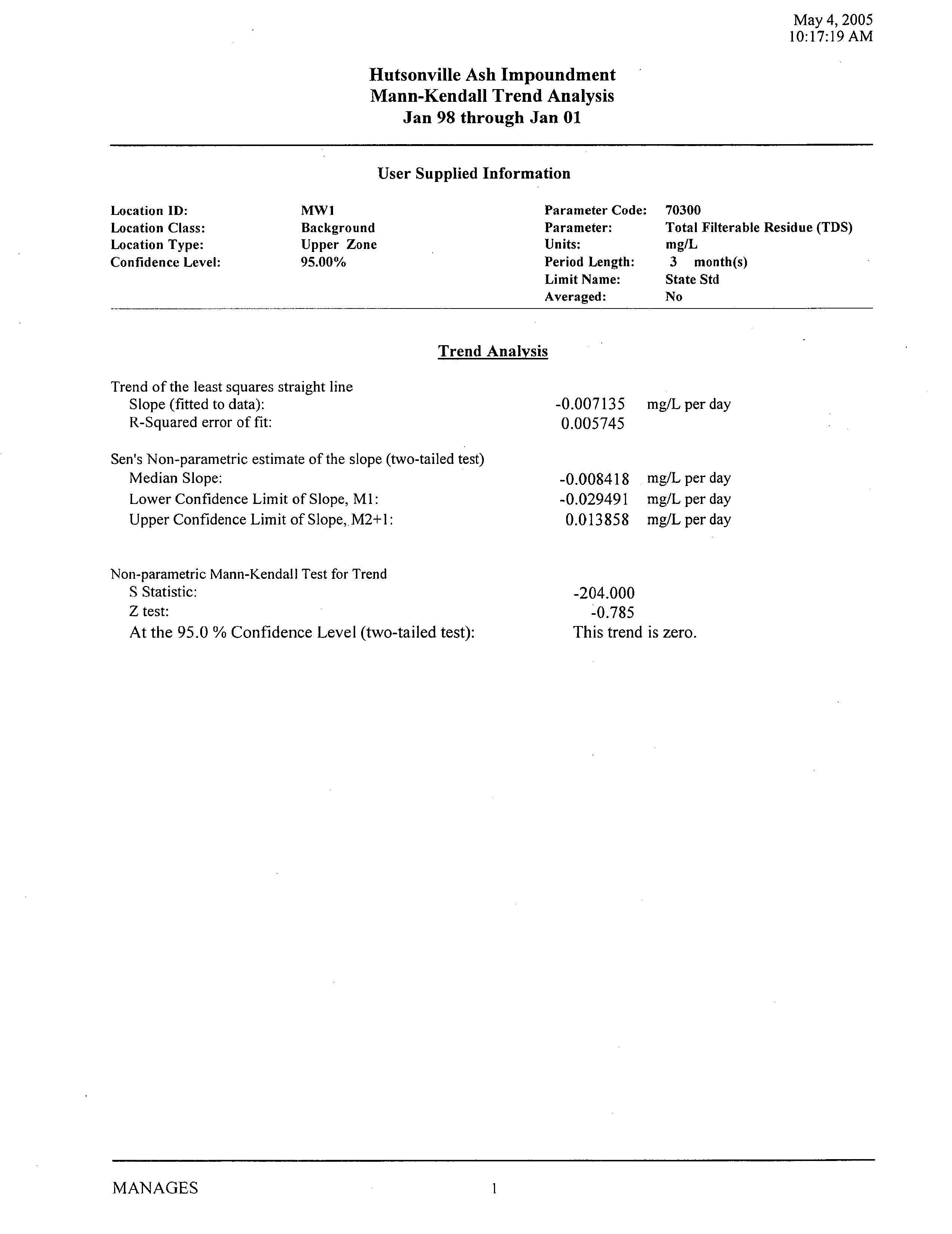

Trend

analysis

was

repeatedly performed using

the

Shapiro-Wilk test

retroactively

from 2005

i.e

based

on 2000 to 2005

data

then

based

on

data from 1999

to 2005 then based on 1998 to

2005 etc

This

analysis

indicated that there is

no

statistical

trend in boron

concentrations

in either

background

well since

1998

Appendix

Therefore

all

background

statistics for the

upper

aquifer

are calculated

using

data

collected after

January

1998

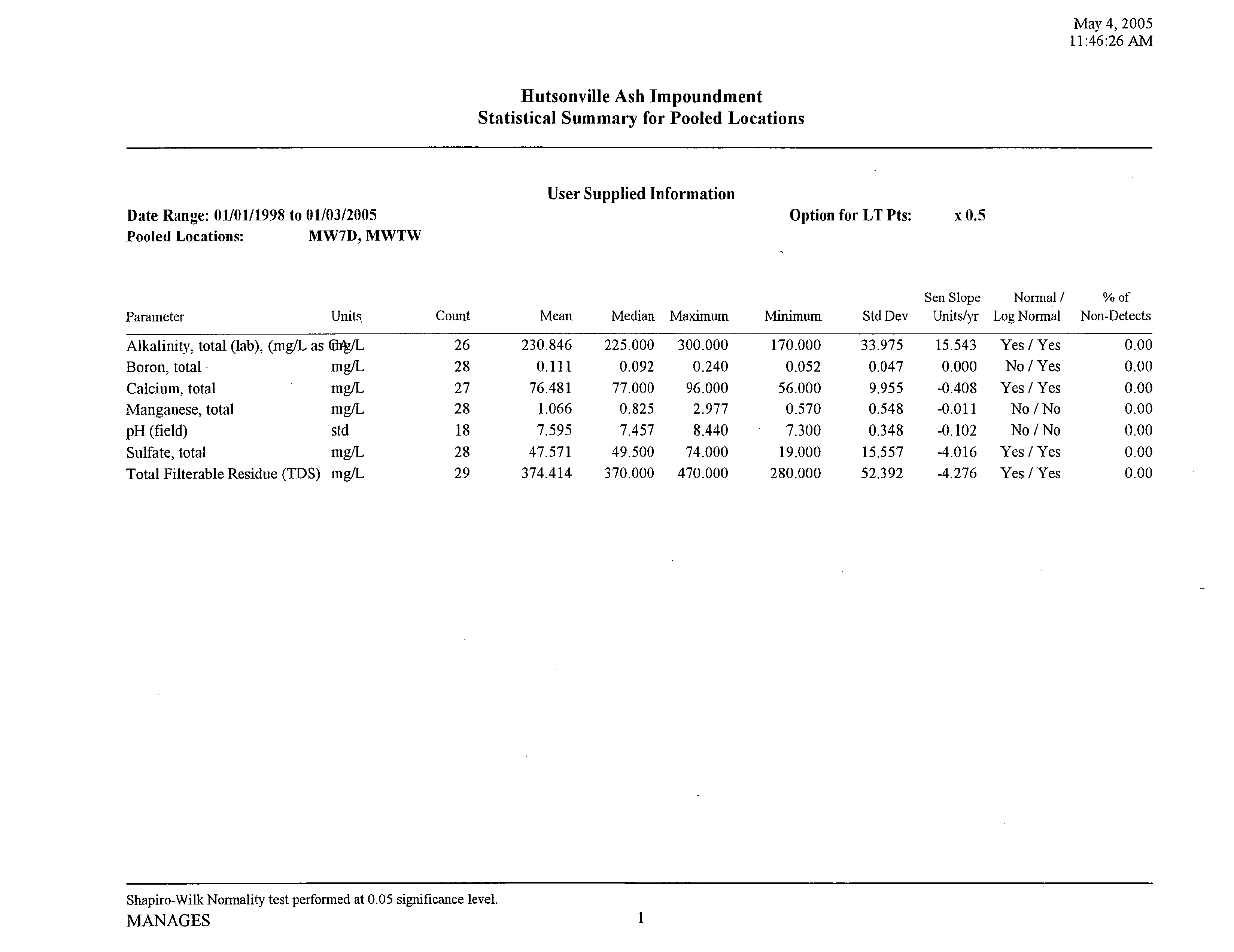

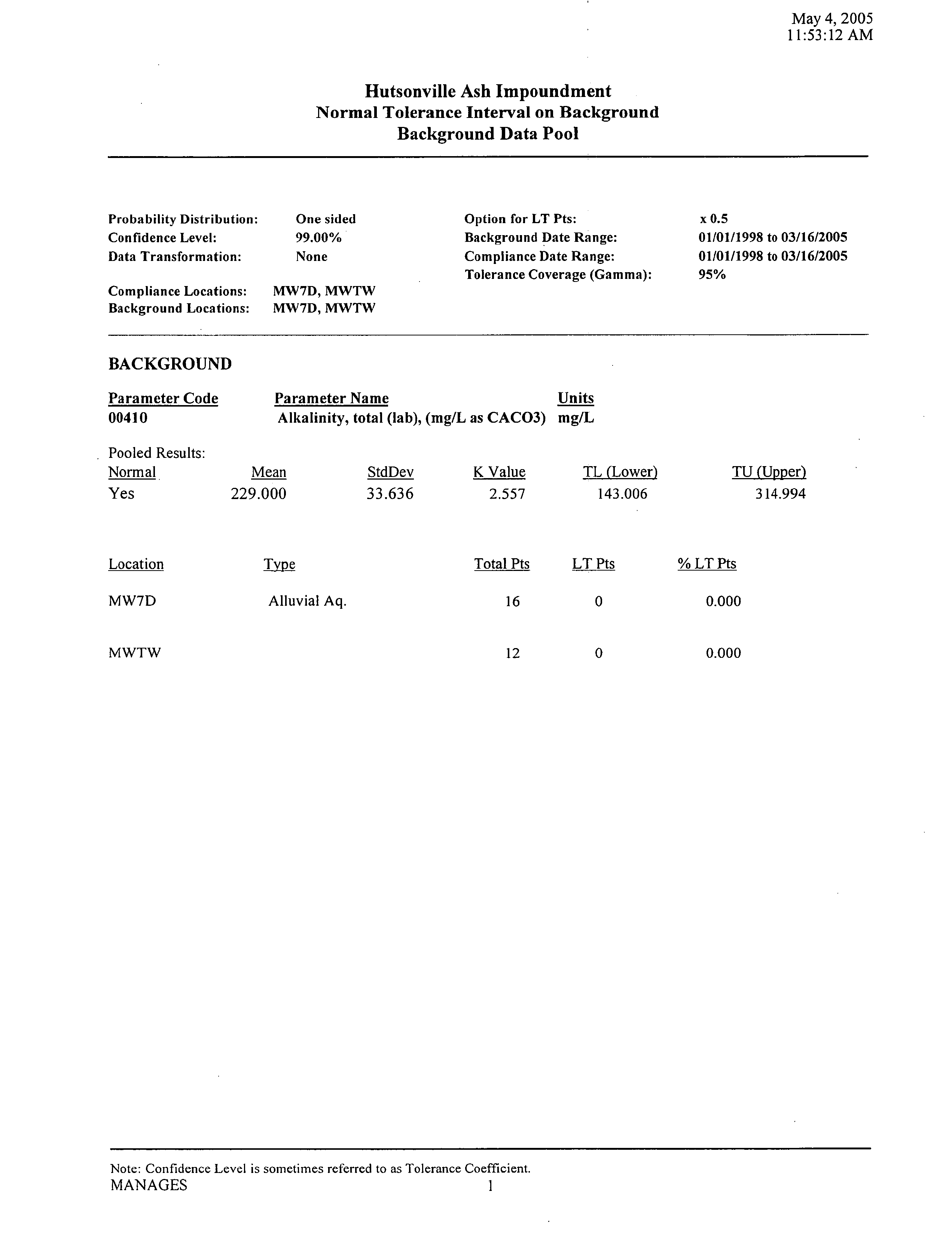

All statistical

calculations

were

performed using

the MANAGES software

EPRI 2002

Analyses

were

performed

for the

parameters currently

monitored

at Ponds

and

The data were first tested for

normality

and detection

frequency

There

were

few non-detects

in the

database

and

normality

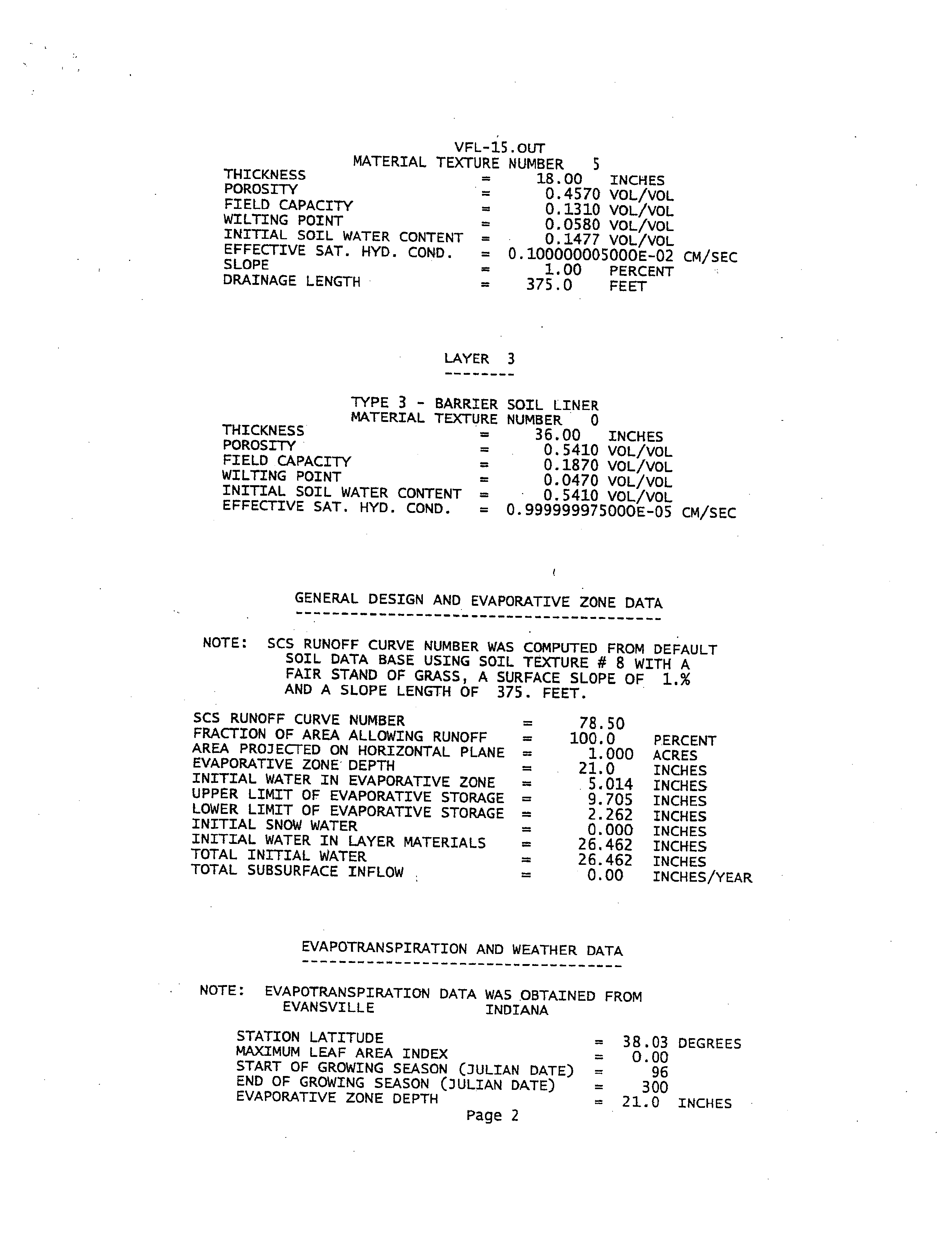

varied

by

parameter

Based

on the

normality results

the

following background

tests were

performed

Tolerance interval at 99

percent

confidence

and 95

percent

coverage

for data with

normal distribution

TDS

Tolerance interval at 99

percent

confidence

and

95

percent

coverage

for data with

log-

normal distribution

boron

and

manganese

Non-parametric

tolerance interval

maximum concentration

for data that had

neither

normal

or log-normal

distribution

Background

statistical

analysis

results are summarized in Table

2-5

and the

adjusted

811.320

background

standards

are

compared

to

analytical

results in Table 2-6a

Background

data and statistical

print-outs

are

included in

Appendix

There are no locations

on

the

power

plant

property

where an

upgradient monitoring

well could be

screened in the

deep

alluvial

aquifer

The river

abuts the west side of the

valley

north of Pond

the

aquifer

does not extend west of Pond

and

Pond

extends to the southern

property boundary

As

discussed in Section

2.4

groundwater

flow in

this formation is

primarily

eastward toward the Wabash

River

Boron is

common constituent in

agricultural

fertilizers and

pesticides

which account for

percent

of the boron

consumed

in the United

States

Source USGS 2003

httpllminerals.usgs.gov/minerals/pubs/commodityIboronlboronmybo3

.pdf

1375 Alternatives

Analysis Report-Final

NATURAL

2-8

RESOURCE

TECHNOLOGY

Electronic Filing - Received, Clerks' Office, August 11, 2008--AS 09-1, Exhibit 3

SUMMARY OF SITE

CONDITIONS

Nine

monitoring

wells

were

installed in the

deep

alluvial

aquifer

five on the

plant property

near Pond

MW-7D

MW-

14 TW

TW- 11

5S

and TW- 11

5D

one5

south of the

plant property

TW-

117

and three

east

of the

Wabash River

TW-118

TW-1 19 and

TW-120

Six

of these wells have been in

place

since

2004

TW-100

series

and do not have sufficient data for

statistical

analysis

and one

MW-14

shows

elevated

boron and

sulfate

concentrations

indicative

of ash

pond impacts

As

result

background

concentrations were calculated

using

two of the older

wells

MW-7D and

TW which are

hydraulically

downgradient

of the

impoundment

but

are not

impacted

by

power plant

activities

The

background

calculations

were

performed

using

the

same

approach

as for the shallow sand

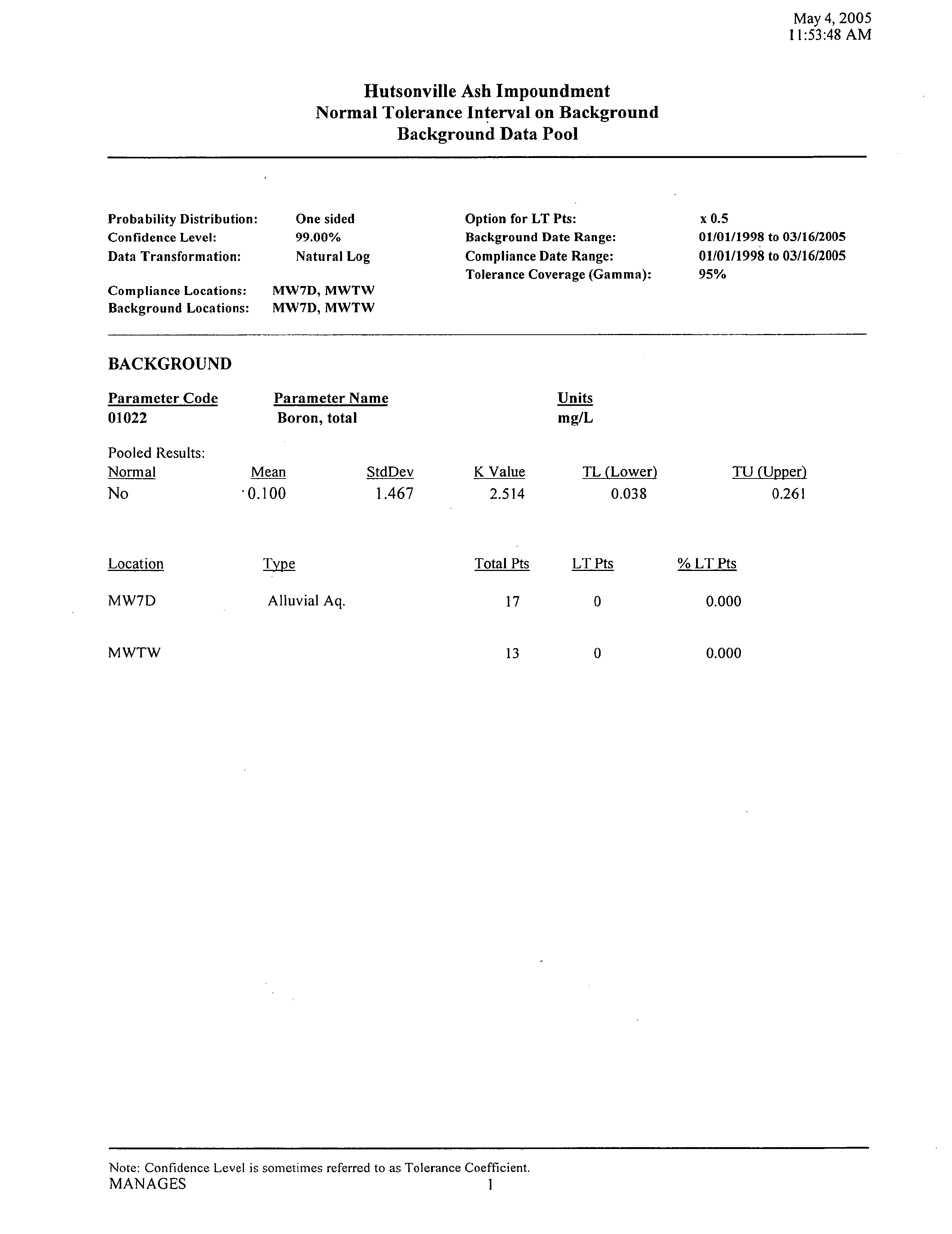

Tolerance interval at 99

percent

confidence and

95

percent coverage

for data with

normal distribution

alkalinity

calcium

sulfate TDS

Tolerance interval at 99

percent

confidence

and 95

percent

coverage

for data with

log-

normal distribution

boron

Non-parametric

tolerance interval

maximum concentration

for data that had neither

normal

or

log-normal

distribution

Deep

alluvial

aquifer

background

statistical

analysis

results are summarized in Table

2-5

and

the

adjusted

811.320

background

standards

are

compared

to

analytical

results in Table 2-6b The

resulting

background

concentrations

were similar to those calculated for the

upper

sand

with the

exception

of

sulfate

which

was

considerably

lower

Table 2-5 Background

data and

statistical

print-outs

are

included in

Appendix

2.4.6 Groundwater

Quality

Boron concentrations

exceeded the

Section 811.320

applicable background

concentrations

and Class

groundwater

quality

standards

at

monitoring

wells

MW-6 MW-7 MW-8

and

MW-I

lR

which are

downgradient

of Pond

Table 2-6a

The

highest

boron concentrations

were

observed

along

the south

perimeter

of

Pond

MW-6

and

MW-1IR

and in the

shallow silt unit

downgradient

of Pond

MW-8

Sulfate concentrations exceeded the

applicable background

concentrations and Class

groundwater

quality

standards

at the same four wells

TW-1 16 is screened in

fine-grained

alluvium

just

above the

deep

alluvial

aquifer note

the

relatively

low

hydraulic

conductivity

value listed in Table

2-4

The sand

pack

for this

well extends into the

deep

alluvial

aquifer

and

it

is

valid

point

for

measuring groundwater

elevation in that

formation however

it will

not

yield samples

representative

of

groundwater

in the

deep

alluvial

aquifer

1375 Alternatives

Analysis Report-Final

NATURAL

2-9

RESOURCE

TECHNOLOGY

Electronic Filing - Received, Clerks' Office, August 11, 2008--AS 09-1, Exhibit 3

SUMMARY OF SITE CONDITIONS

Since

2002

sulfate and boron

were

detected

at concentrations

higher

than the 811.320

applicable

background

concentrations

at

monitoring

well MW-14

Table 2-6b

that is screened in the

deep

alluvial

aquifer although

these concentrations

are

lower than

Class

groundwater

quality

standards Ash

impacts