BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

IN THE MATTER OF:

PETITION OF AMEREN ENERGY

GENERATING COMPANY FOR ADJUSTED

STANDARDS FROM 35 ILL. ADM. CODE

PARTS 811, 814, AND 815

)

)

)

)

)

)

AS 09-

---

(Adjusted Standard Land)

To:

John Therriault, Acting Clerk

Pollution Control Board

100 West Randolph St.

Suite 11-500

Chicago, Illinois 60601

NOTICE OF FILING

William Ingersoll

Illinois Environmental Protection Agency

1021 North Grand Avenue East

P.O. Box 19267

Springfield, IL 62795-9276

Kyle Davis

Illinois Environmental Protection Agency

1021 North Grand Avenue East

P.O. Box 19267

Springfield, IL 62795-9276

Please take notice that on August

11,

2008, we filed electronically with the Office of the Clerk of

the Illinois Pollution Control Board, the attached Petition of Ameren Energy Generating

Company for Adjusted Standards from 35 Ill. Adm. Code, Parts 811, 814, and 815, Certificate of

Service, and Appearance, copies of which are served upon you.

Ameren Energy Generating Company

August

11,

2008

Amy Antoniolli

Schiff Hardin LLP

6600 Sears Tower

233 South Wacker Drive

Chicago, IL 60606

Telephone: 312-258-5550

Email: aantoniolli0>schiffhardin.com

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

CERTIFICATE OF SERVICE

I, the undersigned attorney, certify that I have filed the documents described above electronically

with the Illinois Pollution Control Board and served the Illinois Environmental Protection

Agency with the same documents by First Class Mail, postage prepaid, on August 11, 2008.

August 11, 2008

Amy Antoniolli

Schiff Hardin LLP

6600 Sears Tower

233 South Wacker Drive

Chicago,

IL 60606

Telephone: 312-258-5550

EmaIl: aantoniolli@schifthardin.com

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

IN THE MATTER OF:

PETITION OF AMEREN ENERGY

GENERATING COMPANY FOR ADJUSTED

STANDARDS FROM 35 ILL. ADM. CODE

PARTS 811, 814, AND 815

)

)

)

)

)

)

AS 09-__

(Adjusted Standard - Land)

APPEARANCE

Schiff Hardin LLP,

by its attorneys, Amy Antoniolli and Joshua More, files its

appearance on behalf

of Ameren Energy Generating Company.

Amy

a~~~t4~

An 101h

Amy Antoniolli

Telephone: 312-258-5550

Email: aantoniolli(cl)schiffhardin.com

Joshua More

Telephone: 312-258-5769

Email: jmore@schiffhardin.com

Schiff Hardin LLP

6600 Sears Tower

233 South Wacker Drive

Chicago, Illinois 60606

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

BEFORE THE

ILLINOIS POLLUTION CONTROL BOARD

IN THE MATTER OF:

)

)

PETITION OF AMEREN ENERGY

)

GENERATING COMPANY FOR ADJUSTED

)

STANDARDS FROM 35 ILL. ADM. CODE

)

PARTS 811, 814, AND 815

)

AS 09-

---

(Adjusted Standard Land)

PETITION FOR ADJUSTED STANDARDS FROM

CERTAIN REGULATIONS GOVERNING EXISTING LANDFILLS

Submitted on behalf of

Ameren Energy Generating Company

St. Louis, Missouri

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

IN THE MATTER OF:

PETITION OF AMEREN ENERGY

GENERATING COMPANY FOR ADJUSTED

STANDARDS FROM 35 ILL. ADM. CODE

PARTS 811, 814, AND 815

)

)

)

)

)

)

AS 09-

----

(Adjusted Standard - Land)

PETITION FOR ADJUSTED STANDARDS

Ameren Energy Generating Company ("Ameren" or "the Company"),

by and through its

attorneys, Schiff Hardin, LLP, and pursuant to Section 28.1

of the Environmental Protection Act,

415 ILSC 5/28.1 (the "Act"), and

35 Ill. Adm. Code 104, requests that the Illinois Pollution

Control Board (the "Board") adopt adjusted standards from certain solid waste landfill standards

set forth in 35 Ill. Adm. Code Parts 811,814, and 815 as those Parts apply to closure

ofa former

ash impoundment located at

the.. Hutsonville Power Station (the "Facility" or "Station").

I.

INTRODUCTION

The Station contains a coal-fired electrical generating plant and a wastewater disposal

system for management

of coal-combustion wastes, including fly ash. The wastewater disposal

system consists of five surface impoundments, denominated Pond A, Pond B, Pond C, Pond D,

and the bottom ash pond. Pond D, the subject

of this petition, was constructed as a surface

impoundment in 1968, and was operated and permitted

as such.

Ameren seeks this relief in order to complete the closure

of Pond D. The pond is no

longer receiving coal combustion wastes and has been dewatered. According to the Illinois

Environmental Protection Agency (the "Agency"), the pond must now be closed consistent with

the landfill regulations contained in

35

Ill.

Adm. Code Parts 811 through 815, as they apply to

the closure

of Pond D. Because Pond D was created, operated, and managed throughout its

operating life as a surface impoundment, no landfill permit was required pursuant to Section

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

2l(d) of the Act. 415 ILCS

5121

(d) (2006); 35 Ill. Adm. Code 810.103;

see

In re: Conversion

Systems, Inc., PCB AS 93-4, slip op. at

1, fn. 3 (Aug. 26, 1993), ("the definition oflandfill in the

Board's landfill regulations presently does not include the surface impoundments commonly

used

by utilities for disposal").

Upon final disposition

of this petition, Ameren will initiate closure of Pond D. Ameren

considers Pond D at closure

as an "existing" facility under the applicable landfill regulations

because it accepted wastes prior to September 18, 1990, the effective date

of the landfill

regulations. 415 ILCS

5/810.103

(2006); Development, Operating and Reporting Requirements

for Non-Hazardous Waste Landfills, R88-7 (Aug. 17, 1990). Because Ameren operated Pond D

as a water pollution treatment facility and Pond D has received only wastes generated

by Ameren

within the Site, no landfill permit is required pursuant to Section

21 (d) of the Act at closure. 35

Ill. Adm. Code 810.103. As an existing facility exempt from permitting requirements under

Section 21(d)(1)(i)

of the Act (415 ILCS

5/21

(d)(1)(i», Pond D is subject to 35 Ill. Adm. Code

8l4.302(a) and (b), as well as the applicable Part 811 and Part 815 requirements, at closure.

Because these regulations were drafted to manage solid waste landfills, many

of the

landfill regulations are not applicable to a previously operated surface impoundment, permitted

as a water pollution control facility. Plainly, the circumstances applicable to this ash pond are

very different from those contemplated

by the Board in adopting Parts 811 through 815.\

As discussed below, granting the proposed

relief will not result in any environmental or

health effects substantially or significantly more adverse than the effect considered by the Board

The need for regulatory relief for the closure of ash ponds is not unique to Ameren's Hutsonville Power

Station. Many more coal combustion electric generating facilities throughout Illinois will face a similar

need for relief as their on-site ash ponds reach capacity and are taken out of operation.

2

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

in adopting the landfill regulations. For the reasons discussed in this Petition, Ameren

respectfully requests that the Board grant this relief.

II.

REGULATIONS FROM WHICH

ADJUSTED STANDARDS ARE SOUGHT

(35 Ill. Adm. Code 104.406(a»

Ameren requests adjustments to the following sections

of 35

Ill.

Adm. Code Parts 811

2

,

814, and 815:

(1)

Final cover requirements (35 Ill. Admin Code 811.314(b)(3);

(2)

Standards prescribing a leachate collection and management system (35

Ill.

Adm.

Code 814.302(b» and 811.309;

(3)

Groundwater impact assessment requirements (35

Ill.

Adm. Code 811.317 and

319(c»;

(4)

Maximum allowable predicted concentration ("MAPC") requirements (35 Ill.

Adm. Code 811.318 and 811.319);

(5)

Groundwater quality standards as applied to boron, sulfate, manganese, pH and

total dissolved solids ("TDS") and the groundwater quality standards as they

define the zone

of attenuation (35 Ill. Adm. Code 811.320);

(6)

Groundwater monitoring requirements for selected inorganic and all organic

constituents (35

Ill.

Adm. Code 811.319);

(7)

Monitoring well location requirements(35

Ill. Adm. Code 811.318(b»;

(8)

The following operating conditions do not apply:

35 Ill. Adm. Code 811.105 - compaction of waste

35 Ill. Adm. Code 811.106 - daily cover

35 Ill. Adm. Code 811.1 07(a) - phasing of operations

35

Ill.

Adm. Code 811.1 07(b) - working face

35 Ill. Adm. Code 811.1 07(i) - vector control

35

Ill.

Adm. Code 811.310, 811.311, 811.312 - landfill gas monitoring and

management

35 Ill. Adm. Code 811.313 - intermediate cover

As amended by Proposed Amendments to Solid Waste Landfill Rules, 35 Ill. Adm. Code 811 and 814,

R07-8 (Nov.

15,2007) (eff. Dec. 7, 2007, 31

Ill.

Reg. 49,16167,16172).

3

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

35 Ill. Adm. Code 811.321 - waste placement

35 Ill. Adm. Code 811.322 - final slopes and stabilization

35 Ill. Adm. Code 8l5.202(a) - Initial facility report filing deadline

35 Ill. Adm. Code 8l5.302(b) - Permit information requirements

35 Ill. Adm. Code 8l5.303(a) - Annual report information requirements

II.

THE REGULATIONS OF GENERAL APPLICABILITY

DO NOT IMPLICATE STATE IMPLEMENTATION

OF FEDERAL PROGRAMS

(35

Ill. Adm. Code 104.406(b))

The regulations described above do not implement the requirements of the Clean Water

Act, the Safe Drinking Water Act, the Comprehensive Environmental Response Compensation

and Liability Act or the state Resources Conservation and Recovery Act ("RCRA"),

Underground Injection Control ("UIC"), or National Pollutant Discharge Elimination System

("NPDES") programs.

See

415 ILCS 5/28.1 (2006).

III.

THE LEVEL OF JUSTIFICATION REQUIRED

FOR THESE ADJUSTED STANDARDS

(35

Ill. Adm. Code l04.406(c»

The regulations from which Ameren seeks the adjusted standards do not specify a level of

justification. Therefore, the level ofjustification specified by Section 28.1 of the Act applies:

(1)

factors relating

to that petitioner are substantially and significantly different from

the factors relied upon

by the Board in adopting the general regulation applicable

to that petitioner;

(2)

the existence

of those factors justifies an adjusted standard;

(3)

the requested standard will not result in environmental or health effects

substantially and significantly more adverse than the effects considered

by the

Board in adopting the rule

of general applicability; and

(4)

The adjusted standard is consistent with any applicable federal law.

4l5ILCS

5/28.l(c) (2006).

4

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

Ameren must also justify all of the requested adjustments consistent with Section 27(a) of

the Act. 415 ILCS 5/28.1 (a) (2006). Section 27(a) of the Act requires the Board to consider the

following factors in promulgating regulations:

[T]he Board shall take into account the existing physical

conditions, the character

of the area involved, including the

character

of surrounding land uses, zoning classifications, the

nature

of the existing air quality, or receiving body of water, as the

case may be, and the technical feasibility and economic

reasonableness

of measuring or reducing the particular type of

pollution. 415 ILCS 5/27(a) (2006).

V.

DESCRIPTION OF THE NATURE

OF PETITIONER'S ACTIVITIES

(35 Ill. Adm. Code l04.406(d))

For more than sixty years, Ameren or its corporate predecessor

3

has generated electricity

at a power plant known as the Hutsonville Power Station ("the facility" or "the Station"). The

Station is located in Crawford County, near Hutsonville, Illinois, on approximately 205 acres

(the "Site"). The Wabash River forms its eastern border while farmland comprises the southern

and western borders. The northern border is undeveloped, wooded land. The closest residence

is

approximately one-half mile from the Station.

(See

Site Map, attached hereto and incorporated

herein

as Exhibit 1). Fifty-eight employees work at the Station which is staffed twenty-four

hours per day, seven days per week. The Station

is part of Ameren's generation system which

provides electricity to residential and commercial customers in Illinois.

Principal equipment at the Station includes coal-fired boilers for steam production and

steam driven turbine generators. The facility draws water from the Wabash River through a

On May I, 2000, as required by and pursuant to the terms of a sale transfer agreement, Central Illinois

Public Service Company d/b/a AmerenCIPS transferred its generating assets, including the Hutsonville

Power Station, to Ameren Energy Generating Company. Both AmerenCIPS and Ameren Generating

Company are subsidiaries

of Ameren Corporation.

5

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

circulating water system that is used in the boiler and turbine equipment systems. Ash, a by-

product

of coal combustion, is removed from the boilers and sluiced to an ash impoundment

system via pipelines. This current impoundment system is comprised

of a series of Ponds (Ponds

A-C) and the bottom ash pond in which solids settle and sluicewater decants from pond to pond

before discharging to the Wabash River via

an NPDES permitted outfall. The ash ponds accept

only coal combustion waste (fly ash and bottom ash) and low-volume waste from the Hutsonville

facility. A diagram depicting the various site features is appended hereto as Exhibit

2.

The subject of this petition, the unlined ash impoundment ("Pond D"), is located in the

center

of the S 1/2 of Section 17, Township 8N, Range llW, Crawford County, Illinois, on the

west bank

of the Wabash River, and is as close as one hundred (100) feet to the river.

It

covers

an area

of approximately twenty-two (22) acres. Pond D was constructed from indigenous

earthen materials in 1968 and operated

as the Station'swastewater treatment unit (receiving

bottom and fly ash transport water and miscellaneous low-volume wastes) until the construction

of a synthetically-lined pond ("Pond A") in 1986. In 2000, Ameren excavated all coal ash from

the former laydown area and constructed two lined ponds ("Ponds

Band C") to supplement the

ash management capabilities and to improve surface water management at the property. Upon

completion

of Ponds Band C, Pond D was removed from service and allowed to dewater.

Because Ameren intends to leave the ash in Pond D it intends to close Pond D in accordance

with applicable landfill regulations

as set forth more fully in this Petition. Ameren estimates that

during its 30- years

of active operation, Pond D accumulated approximately 750,000 cubic yards

of ash and approximately one-third of this volume (280,000 cubic yards) lies below the water

table.

4

An additional 200,000 cubic yards of ash were added to Pond D since it was taken out of

4

See

Exhibit 3, Table 3-2.

6

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

service (with Illinois Environmental Protection Agency approval) to establish an acceptable

grade in anticipation

of constructing the proposed cap at closure.

VI.

DESCRIPTION

OF THE IMPACT OF PETITIONER'S

ACTIVITIES ON

THE ENVIRONMENT

(35 Ill.

Adm. Code l04.406(g»

The following discussion summarizes relevant technical details concerning site geology

and groundwater quality and the environmental impacts of Pond D. More comprehensive

descriptions

of geology and groundwater conditions are provided in the August 1999

Hydrogeologic Assessment Report attached and incorporated as Exhibit 4, the January 2000

Groundwater Model Evaluation Report of Impoundment Closure Options attached and

incorporated as Exhibit 5, the 2005 Alternative Analysis Report, Section 2 (Exhibit 3), and the

proposed groundwater monitoring plan (Exhibit 11).

A.

SITE GEOLOGY

Site geology consists of four hydrostratigraphic units: (1) unlithified sand overlying

lithified Pennsylvanian-age sandstone, present in upland areas, with a combined thickness that is

typically between

15 and 35 feet; (2) unlithified fine-grained alluvial sediments within the

Wabash River bedrock valley that are approximately 20 feet thick; (3) coarse-grained alluvial

sediments within the Wabash River bedrock valley that are as much as 70 or more feet thick; and

(4) Pennsylvanian-age shale that underlies the sandstone in the upland areas and the coarse-

grained alluvium in the bedrock valley. The western portion

of Pond D overlies the upland sand.

The eastern portion of Pond D overlies the fine-grained alluvium in the Wabash River Valley.

The upland sand and underlying sandstone beneath the western portion

of Pond D and thin sand

lenses within the fine-grained alluvium that lies under the eastern portion

of Pond Dare

collectively referred to as the "upper migration zone." The coarse-grained alluvial deposits at

7

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

depth in the Wabash River bedrock valley are referred to as the "deep alluvial aquifer." Included

in Exhibit

11 are cross-section diagrams that illustrate the stratigraphic relationships of these

formations.

The fine-grained alluvial deposits overlying the deep alluvial aquifer occur over an

elevation range that overlaps the upland shale

(see

Exhibit 11, Figure 2), combining to form a

confining layer that restricts vertical migration

of groundwater between the upper migration zone

and deep alluvial aquifer. As a result, the uppermost aquifer at the Site is the upper migration

zone. The efficacy

of the confining layer is supported by the concentration data because, as

explained below, the only ash leachate impacts observed in the deep alluvial aquifer are highly

localized, and at concentrations lower than Class I standards and much lower than in the upper

migration zone, despite the fact that Pond D was fist placed in service more than 40 years ago.

Groundwater flow direction in both the upper migration zone and the deep alluvial

aquifer is eastward, toward the Wabash River. Maps depicting groundwater flow in these units

over four consecutive quarterly measurements are provided in Exhibit

11.

The upper migration zone is not used for water supply at or downgradient of the Site,

because this zone is not sufficient for power plant operational uses, agricultural irrigation

purposes or domestic uses.

5

Only the deep alluvial aquifer at depth in the Wabash River bedrock

valley has sufficient thickness and hydraulic conductivity to yield adequate groundwater supplies

for power plant and agricultural irrigation purposes.

Shallow sandstone provides limited groundwater yield adequate for domestic uses in other parts of the

county, but there are no such wells at or downgradient

of Pond D, and deep formations are saline (see the

ISWS State Aquifer Map, a copy

of which is attached and incorporated here as Exhibit 7).

8

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

B.

GROUNDWATER QUALITY

1.

Parameters of Concern

Coal ash is comprised of non-combustible inorganic materials (aluminum, clay, iron,

limestone, silica sand and trace quantities

of oxidized naturally occurring elements

6

)

that are

impurities within the coal. Since 1984, and

as a condition of its State Operating Permit

(currently Permit #

2005-EO-3689\ Ameren's permit requires monitoring for the following

constituents around Pond

A: boron, sulfate, manganese, pH, and TDS.

8

All of these constituents

occur naturally in Illinois groundwater to varying degrees. Boron and sulfate are considered

primary indicators

of coal ash leachate due to their consistently high concentrations in coal ash

leachate, persistence in the environment, and mobility in groundwater.

9

As set forth more fully

below, groundwater samples reflect elevated levels

ofboron and sulfate at discrete locations at

the Site.

2.

Groundwater Monitoring Network

The Company has monitored groundwater quality at the Site, via a monitoring well

network, since 1984 to define groundwater flow direction, monitor groundwater quality, and to

characterize hydrogeologic conditions. In addition to the well network, Ameren collected

direct-push (GeoProbe) samples near the ash impoundments and at off-site locations and

collected soil, leachate, and groundwater samples. Exhibit 2 depicts the well and direct-push

locations. As a result

of these activities, the Company is able to fully characterize and delineate

American Coal Ash Association, 2003, "ACAA Glossary of Terms," found at the following address:

http://acaa.affiniscape.com/displaycommon.cfm?an=8.

7

9

NPDES Permit

#

2005-EO-3689, effective June 14,2005.

Groundwater monitoring commenced prior

to initiation of ash management operations in Pond A.

Environmental Performance ofCCPs, Murarka, 2002, http://www.mcrcc.osmre.govIPDF/Forums/CCB3/4-

6.pdf

9

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

hydraulic properties, groundwater flow, and the extent of groundwater impacts associated with

Pond D at the Site.

(See

Exhibits 3 and 4).

3.

Localization of Upper Migration Zone Impacts

Groundwater within the upper migration zone immediately surrounding and adjacent to

Pond D shows evidence

of ash leachate impacts. 10 Monitoring well data from the upper

migration zone along the southern property line suggest the potential for off-site migration.

Ameren investigated the extent

of off-site impact by obtaining direct-push samples as close to

Pond D as possible (approximately 1,300 feet) in the actively farmed agricultural field

immediately south

of the property line and determined that the upper migration zone was not

impacted at these locations because the concentrations

of boron and sulfate reflected expected

background concentrations. (Exhibit 4, Table 6). Because access to the neighboring property

was limited, Ameren, used a calibrated groundwater flow and transport model to estimate the

extent

of off-site contamination in the upper migration zone. The modeling results suggest that

the extent

of off-site impacts in the upper migration zone extends approximately 500 feet from

the southern property line downgradient

of Pond D. (Exhibit 5, Figure 7) As set forth more fully

in this petition, the past dewatering together with the future capping

of the unlined pond will

result in a dramatic improvement

of groundwater quality south of Pond D: meeting Class I

groundwater standards.

4.

Description of Deep Alluvial Aquifer Impacts

Groundwater in the deep alluvial aquifer of the Wabash River valley has been minimally

impacted from Pond

D. Sulfate and boron concentrations at MW-14 are higher than background

10

In particular, boron and sulfate concentrations exceed 35 Ill. Adm. Code Part 620 groundwater quality

standards.

See

Exhibit 4, Figure

10.

10

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

concentrations calculated for the deep alluvial aquifer

(see

Exhibit 11 for the background

calculation), yet lower than their respective Class I standards. Because sulfate is a mobile

indicator parameter for coal ash impacts, the elevated concentrations at MW-14 suggest localized

impact from Pond D. No other well screened in the deep alluvial aquifer shows evidence

of

impacts from coal ash operations. Accordingly, groundwater quality impacts to the deep alluvial

aquifer are minimal and localized to an area near MW-14 (immediately southeast

of Pond D).

Groundwater data from the deep alluvial aquifer reveal elevated concentrations

of

manganese. These concentrations are consistent throughout the deep alluvial aquifer and are

attributable to natural geochemical conditions, which cause a release

of manganese from the

aquifer soils.

II

C.

IMPACTS TO THE WABASH RIVER

Ameren has determined potential impacts of groundwater discharge to the Wabash River

by two different methods and determined that it is unlikely to result in a measurable change in

river water quality. First, the Company used a calibrated groundwater flow and transport model

to calculate the boron loading rate to the Wabash River, which is the regional destination for

groundwater flow in the basin. The model calculations determined that when in service (prior to

2000), Pond D discharged twenty-five (25) pounds

of boron daily into the Wabash River.

(Exhibit

5, Figure 14) The model calculation further indicated that dewatering of Pond D, would

decrease the boron loading rate to the Wabash River

by approximately eighty-five percent (85%)

(Exhibit

5, p. 17) reducing the estimated daily loading rate for boron from twenty-five (25)

pounds to less than five (5) pounds. These loading rates were used to conservatively estimate the

II

See Table 2 for a comparison of background concentrations of contaminants in the deep alluvial aquifer to

Class I standards.

11

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

effect of groundwater discharge on river water concentrations under worst case, low flow,

conditions.

The results

of this calculation indicate that the boron loading rate both before and after

dewatering was not sufficient to significantly increase the boron concentration in river water

(Ameren prepared a spreadsheet showing concentration change at low flow, a copy

of which is

attached and incorporated as Exhibit

8).

Second, river water quality data obtained from the USEPA STORET database for the

closest downstream monitoring station (at Hutsonville, one-mile south

of the impoundment)

confirm the model calculation. The STORET data indicate boron concentrations lower than

median concentrations in the upper migration zone upgradient

of Pond D, suggesting little or no

impacts to the river (Ameren attaches and incorporates a copy of a memo regarding this finding

as Exhibit

9).

D.

GROUNDWATER USAGE

Groundwater usage near the Station is limited. A review of Illinois State Geological

Survey water well records within one-mile

of Pond

D

identified 20 water well logs pumping

groundwater from depths

of 14 to 105 feet

(see

Exhibit 4, Appendix

D).

A follow-up search was

performed using the Illinois State Geological Survey ILWATER database, which identified six

wells within

12 mile of Pond D. Two of these wells are the plant production wells, and the other

four are irrigation wells

(see

Well Survey Report, attached and incorporated herein as Exhibit

7).12 All six wells pump from the deep alluvial aquifer, which as discussed above, shows only

minimal and highly localized impacts from Pond

D

(at MW-14). In addition, the City of

12

Exhibit 8 was created in 2005. The database was rechecked on February 26,2008 and no changes were

noted.

12

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

Hutsonville'spublic water supply wells draw groundwater from the deep alluvial aquifer

approximately one mile south

of Pond D. However, considering the relatively large distance to

these wells, the observed easterly groundwater flow direction in the deep alluvial aquifer at the

Site, and the fact that only one monitoring well in this aquifer has experienced ash leachate

impacts, and those impacts have been low-level after 40 years

of operation, it seems unlikely that

the Hutsonville wells could ever be impacted

by ash leachate from Pond D.

There are no wells drawing groundwater from the upper migration zone downgradient or

sidegradient

of the Site. The Station'snearest residential neighbor to the south, who owns the

field above the area

of impacted groundwater, is connected to the City of Hutsonville'spublic

water supply system.

VII.

DESCRIPTION OF EFFORTS TO COMPLY

(35 Ill. Adm. Code 104.406(e))

The Board regulations require Ameren to describe the efforts necessary to comply with

the regulations

of general applicability. Ameren discusses various compliance alternatives

below. Costs corresponding to the cover system and leachate management alternatives are

discussed and set forth in more detail in Exhibit 3.

A.

THE COMPANY'S CLOSURE PLANS AND COVER SYSTEMS

35 Ill. Adm. Code 811.314

Section 811.314 prescribes a process of final cover. Acceptable technologies include

compacted earth, geomembranes, or similarly performing material. 35

Ill.

Adm. Code Part

811.314(b)(3)(A)(iii) allows Ameren to use alternative low permeability layer construction

techniques or materials, provided that they provide equivalent or superior performance to the

Section 811.314 requirements. Part 816 (Alternative Standards for Coal Combustion Power

Generating Facilities Waste Landfills) contains alternative standards for coal combustion power

13

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

generating facility waste landfill. In promulgating 35 Ill. Adm. Code Part 816, the Board

approved a proprietary process called Poz-O-Tec as an alternative means for satisfying liner and

cap requirements for coal ash monofills, such as Pond D upon closure. Part 816 allows coal

combustion waste landfills to utilize a pozzolanic cap instead

of those required by Section

811.314. Under Part 816, flue gas desulfurization (FGD) sludge and coal combustion waste may

be used for cap construction

to meet Section 811.314 requirements. 35 Ill. Adm. Code 816.510.

Ameren proposes to use an alternative low permeability layer construction material and

seeks an adjusted standard to 811.314(b)(3)(A)(iii) to construct a pozzolanic cap that

substantially complies with the strength and permeability standards set forth in

35 Ill. Adm. Code

Part 816.

Ameren'sproposed cap is a variation

ofthe conceptual process endorsed by the Board in

Part 816. Under Ameren's approach, ash from Pond A is mixed with stabilizing reagents to form

a material that can

be used to construct a final cover for Pond D. As documented in Exhibit 10,

Ameren performed extensive laboratory research to evaluate cap performance for coal ash from

Pond A when mixed with different stabilizing reagents: Portland cement; Class C fly ash;

fluidized bed residue; quicklime; FGD scrubber sludge; and native soils. The various mixes

were cured for eighty-four (84) days and evaluated for unconfined compressive strength,

hydraulic conductivity, economics and constructability issues. Four (4) optimal mixes were then

tested for leachate characteristics using the TCLP leaching procedure.

Results

of this research indicated that hydraulic performance of the mixes varied

considerably; while leaching performance, as determined using the TCLP procedure, resulted in

low or non-detectable metals concentrations for all mixes (Exhibit 10, Table 4). Based on these

results, Ameren has determined that a mix containing at least five percent (5%) Portland cement

14

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

best meets perfonnance, workability, and economic criteria. Perfonnance characteristics of the

selected mix (Mix 2 in Exhibit 10) include an 84-day laboratory hydraulic conductivity value

of

4.7 x

10-

6

centimeters per second (cm/s) and a compressive strength of 165 pounds per square

inch (psi).

Part 811.314(b)(3)(A)(iii) allows for alternative specifications provided that the

perfonnance

of the low penneability layer is equal to or superior to the perfonnance of a three-

foot

(3 ft) thick cap with hydraulic conductivity of 1.0 x 10-

7

cm/s based upon a geometric

average

of penneability testing results. Part 816.51 O(g) requires that a Poz-O-Tec cap be at least

three feet thick. 35

IlL Adm. Code 816.510(g). Ameren proposes to construct a cap with a low

penneability pozzolanic layer at least three feet thick. The hydraulic conductivity

of this

pozzolanic layer, as constructed in the field, will be lower than 5.0 x

10-

6

cm/s. While this value

is greater than 1.0 x

lO-

7

cm/s, it will provide equivalent protection as discussed below and as

documented in Exhibit 3.

Ameren perfonned groundwater transport modeling using hydraulic conductivity values

ranging from

of 1.0 x lO-

5

to 1.0 x 10-

7

cm/s for the pozzolanic layer

(see

Exhibit 3, Appendix D,

Figures D-4a and D-4b, graph lines CO-3a, CO-3b, and CO-3c). While there were differences in

cap percolation predicted for this range

of hydraulic conductivity values, there was no significant

difference in predicted concentrations for groundwater downgradient

of Pond D. The similar

perfonnance

of the modeled cap scenarios under a range of cap hydraulic conductivity values

reflect the following facts: (1) the volume

of water percolating through the cap, regardless of its

modeled hydraulic conductivity value, is less than five percent (5%)

of the volume of water that

15

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

percolated through Pond D when it was active and receiving sluicewater; 13 and (2) the dominant

mechanism for leachate generation, since dewatering

of Pond D in 2000, is groundwater seepage

through saturated coal ash (i.e., ash below the water table), rather than percolation

of surface

water (precipitation, snow melt) through the cap.

Once a cap is installed, the relatively minor changes in cap percolation will have little

effect

on the volume of leachate generated in Pond D, and subsequently, little effect on

downgradient concentrations in groundwater. Moreover, because Pond

D

has no underlying

barrier liner, and the hydraulic conductivity

of the coal ash contained in Pond

D

is estimated to

be greater than 5.0 x

10-

6

crn/s, the proposed cap will not result in accumulation of water

(i.e.,

"bathtub effect") within Pond D. In summary, the cap constructed over Pond D will not

influence the primary mechanism

of leachate generation: groundwater seepage through saturated

ash. Accordingly, the hydraulic characteristics

of the cap will have minimal effect on

downgradient groundwater quality.

Finally, Ameren recognizes that the hydraulic conductivity values

of the test mixes are

laboratory derived, and a field-derived value may be higher. Ameren, therefore, seeks an

adjusted standard from

8l1.314(b)(3)(A)(iii) to construct a pozzolanic cap that will meet a

performance standard hydraulic conductivity

of 5.0 x

10-

6

cm/s. This hydraulic conductivity is

based upon a geometric average

of permeability testing results and a performance standard of

150 psi based upon an arithmetic average of the strength testing results as determined during

construction

of a test pad using a testing methodology substantially equivalent to that outlined in

Part 816. If the five percent (5%) cement mix does not achieve the performance standard, then

13

Percolation for the active, ponded Pond D was estimated at 360 inches per year (Exhibit 4, Table 3), while

percolation for the Pond D with a pozzolanic cap is estimated at less than

10 inches per year (Exhibit 11,

Table D-2).

16

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

up to 10% cement will be added to the mixture to achieve a 5.0 x 10-

6

cmls

hydraulic

conductivity.

For final cover, Section 816.51

O(g) defers to the low permeability layer requirement of

Section 811.314. Accordingly, the cap will be covered with three feet of soil to support

vegetative growth and function as a final protective layer as required by 35 Ill. Adm. Code

811.314(c). Exhibit 10 (a report prepared

by VFL regarding the construction of the cap is

attached and incorporated here) includes a diagram of a representative cross-section of Pond

D

and depicting the top soil cover, granular drainage layer

l4

and pozzolanic cap. (Exhibit 10,

Figure 1.)

Overall capital costs as well as the annualized capital and operating costs of the closure

alternatives investigated for Pond D are set forth in Exhibit 3, Table 5-1.

B.

LEACHATE MONITORING AND MANAGEMENT

SYSTEMS

35 Ill. Adm. Code Parts 814.302(b) and 811.309

Section 814.302(b) requires a "system which will effectively drain and collect leachate

and transport it to a leachate management system." 35 Ill. Adm. Code 814.302(b). Section

811.309 establishes the standards generally applicable to the leachate management system. The

landfill regulations define leachate as any "liquid that has been or in direct contact with a solid

waste."

35 Ill. Adm. Code 810.103.

Because Pond D has been operated

as a surface impoundment, rather than as a landfill,

Pond D has not been subject to the leachate standards of the landfill regulations. Accordingly,

no leachate control, transport or management system currently exists at Pond D. As described in

14

The granular drainage layer was not considered in the modeling of pozzolonic cap performance

documented in Exhibit

3. This was a conservative assumption because a drainage layer would reduce the

volume

of water percolating through the cap.

17

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

more detail below, the implementation of new leachate control, transport and management

system at Pond D at closure is unnecessary and prohibitively expensive. Accordingly, Ameren

asks the Board to find that compliance with the leachate standards

of 35 Ill. Adm. Code 811.309

and 8l4.302(b) is not required for Pond D at closure.

1.

Leachate Monitoring

The regulations require leachate monitoring to '''helpdetermine the degree to which a

landfill poses a threat to the groundwater by ascertaining what types

of contaminants are

leaching out

of the wastes that have been disposed in the landfill and in what concentrations. '"

Proposed Amendments to Solid Waste Landfill Rules, 35 Ill. Adm. Code 810 and 811, R07-8,

slip op. at 3 (Oct. 4, 2007). Leachate monitoring requirements address monitoring parameters,

locations, and frequency. The materials disposed in Pond D are exclusively coal-combustion

waste material, the contaminants from which have been documented. Further, because Pond

D

is

unlined, there is no separation between the coal ash leachate and groundwater at the Site. As

discussed in more detail below, Ameren has a network

of wells in place at the Site to monitor

groundwater quality. For these reasons, Ameren requests that the proposed groundwater quality

monitoring plan apply in lieu

of the leachate monitoring requirements of Section 811.309.

2.

Leachate Management

In promulgating its leachate drainage, collection, and management standards, the Board

did not prescribe a specific system that must be used to collect and manage leachate at an

existing landfill.

IS Rather, the Board'srules are premised upon the goal of "preventing a

discharge to groundwater by using the best economically available containment and leachate

removal technology."

See

Recommendations For a Non-Hazardous Waste Disposal Program in

15

Leachate is defined as "liquid that has been or is in direct contact with solid waste."

18

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

Illinois and Back Ground Report. Scientific/ Technical Section (STS Recommendations), R84-17

Docket D, slip

op. at 8 (Mar. 7, 1988). At the time the Board issued its regulations, the best

available containment and leachate removal technology was the installation

of a "compacted

earth liner three feet thick with a leachate drainage layer and collection system."

!d.

With such a

design, leachate

is contained by the bottom liner, directed through a system of drains to a

collection system from which it could be routed to a treatment system. Such a design is

inapplicable to Pond D at closure.

The Board recognized that, due

to the technical impracticability, existing units are not

required to comply with the requirements set forth in Sections 811.306, 811.307 and 811.308.

See

35 Ill. Adm. Code 814.302(a)(1);

see also

STS Recommendations, (Mar. 7, 1988). As the

Scientific/ Technical Section

of the Board noted: "[a]n existing facility cannot retrofit a

foundation or liner."

!d.

at p.

110.

Part 814 does not prescribe specific standards for leachate

management systems. Rather, existing facilities must implement a system that will "effectively

drain and collect leachate and transport it to a leachate management system." 35 Ill. Adm. Code

814.302(b)(1). A leachate management system can consist

of any combination of storage,

treatment, pretreatment and disposal options. Treatment

of leachate is not necessary if the

leachate constituents do not exceed wastewater effluent standards. 35 Ill. Adm. Code

811.309(h)(2).

Approximately 280,000 cubic yards

of coal ash in Pond D are in continual contact and

saturated

by groundwater. As described more fully herein, it is not possible to "effectively drain

and collect leachate" from Pond D at closure. Dewatering the impoundment reduced the volume

of leachate discharged to the Wabash River by more than 80 percent, and capping will further

19

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

reduce this volume, although to a much lesser extent than dewatering. Exhibit 3, Appendix D,

Figure D-3.

For the reasons set forth below, Ameren seeks an adjusted standard from the leachate

management and disposal requirements

of Section 811.309 because they are technically

impracticable and unwarranted at the Site.

a.

Leachate At The Site Complies With Wastewater Effluent Standards

As a preliminary matter, and given the various closure and monitoring activities proposed

in the Company's Petition, it is simply unnecessary to treat leachate associated with Pond

D. All

point source discharges from the Site must comply with effluent standards set forth in the

Station'sNPDES permit and 35 Ill. Adm. Code 304.124,304.125 and 304.126. The Company

has analyzed groundwater that would be extracted near Pond D

as part of an extemalleachate

collection system and determined that it would not cause exceedences

of effluent standards at the

NPDES discharge. Accordingly, assuming that the leachate could be collected and managed at

the Site, it could be discharged without treatment and meet effluent standards.

Moreover, given the relatively low toxicity associated with Petitioner's coal combustion

waste,16 the collection and management

of any incremental amount of leachate generated below

the water table would result in little, if any, discemable environmental benefit. In effect, the

leachate would be collected from groundwater flowing toward the Wabash River, channeled

through the existing ash pond wastewater management system, and discharged into the Wabash

River, along with the Station's sluice waters, via the NPDES outfall. As the Board'stechnical

section noted:

"[I]f leachate is approximately the same as any other treated effluent, then there is

16

Relevant portions of the USEPA's detennination that coal ash is not a hazardous waste is attached as

Exhibit

12. Final Regulatory Detennination on Four Large-Volume Wastes from the Combustion of Coal

by Electric Utility Power Plants,

58 FR 42466 (Aug. 9, 1993).

20

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

no logical reason to pump it out of the ground, only to discharge it directly to a surface water

body." STS Recommendations, at

p. 45.

b.

Traditional Leachate Drainage and Collection Technologies Will Not

Work At the Site

In attempting to comply with Section 814.302(b)(1) requirements, Ameren examined the

following technologies and/or strategies: ash removal (both on-site redeposition and off-site

disposal), perimeter trenching, and barrier wall containment. These compliance alternatives

were rejected for the reasons set forth below.

(i)

Ash Removal And On vs. Off-Site Disposal

As part

of its analysis, Ameren considered the traditional leachate drainage and collection

technologies, including ash removal. Two strategies

of ash removal were reviewed: temporary

ash removal and installation

of an underdrainage system17, and ash removal with off-site

disposal. Both strategies require removal

of the saturated ash and the result would be a reduction

in leachate and an improvement in groundwater quality. The alternative requiring ash removal

and off-site disposal would eliminate the need to comply with the landfill requirements at Pond

D. However, an analysis of alternatives by NRT concluded that ash removal, regardless of its

end use, is neither technically feasible nor economically reasonable. Exhibit 3, Table 3-1.

Whether considering on-site redeposition after drainage system installation or off-site

disposal, removal

of the approximately 750,000

18

cubic yards of ash from the unlined pond

creates significant logistical hurdles. The saturated ash alone would require unconventional

17

18

Installing an underdrainage system above the ash waste would not effectively address leachate escaping

from waste already placed in the impoundment. Groundwater would continue to generate leachate from the

saturated ash. Thus, such an underdrainage system would have no impact on leachate generated at the Site.

An

additional 200,000 cubic yards of ash have been added to Pond D since the pond was dewatered per

Illinois Environmental Protection Agency approval.

21

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

excavation techniques such as dredging, or mechanical sluicing

(i.e.,

mudcat auger excavation).

The physical configuration of the Site and the narrow access around the impoundment

significantly limit implementation

of these unconventional excavation techniques. Such

techniques would

be ineffective in removing the ash. The on-site disposal alternative poses an

additional technical feasibility challenge because there is insufficient land on the Site to

construct dewatering and storage facilities large enough to handle the ash. Use

of the lined pond

(Pond A) is not feasible because it would completely fill Pond A causing Hutsonville to cease

burning coal, and generating electricity.

Also importantly, ash removal is not economically reasonably for Ameren. The cost

of

excavation and off-site disposal of the total volume of ash is estimated to cost approximately $34

million. Exhibit 3, Appendix B. Further, the replacement

of excavated ash on top of clean fill is

estimated at approximately $22 million.

Id.

The latter estimate does not even include the cost of

installing an underdrainage system which could cost well over $1 million, nor does it include the

cost

of temporary storage of ash at some location because on-site temporary storage is not

feasible. Further, the cost analysis was completed in 2005 and noted that

if general fill or ash

disposal costs increase, the capital costs for these alternatives could double. Exhibit 3, Table 3-

1. Thus, although considered, ash removal does not present a viable strategy for closure of Pond

D.

(ii)

Perimeter Leachate Collection Trench

or Recovery Wells

Under appropriate circumstances, a perimeter collection trench

or recovery wells (Exhibit

3, p. 3-3) could

be used to collect leachate from a landfill to reduce the off-site migration of

contaminants. Such a trench is typically constructed by excavating downgradient of a

contamination source, and installing a drainage pipe surrounded

by permeable granular soil

backfill. Ameren considered the construction

of a trench system along the southern border of

22

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

Pond D to mitigate off-site impacts to the neighboring property to the south, and performed

groundwater transport modeling

to evaluate its effectiveness. Exhibit 3, Section 4, Table 4-2,

and Appendix D of Exhibit 3. A leachate collection trench, however, is not economically viable

or environmentally justified because it would not remove the contaminants from the

environment. Rather, such a system would simply divert groundwater, which currently slowly

discharges to the Wabash River, immediately and directly

to the river via the NPDES outfall.

Ameren has concluded this alternative is not economically reasonable given the lack

of

environmental benefit of pumping water out of the ground only to discharge it directly to the

Wabash River. Further, Ameren expects groundwater offsite will meet Class I standards within

16 years

of dewatering and installing the proposed cover system (Exhibit 3, Table 4-2).

(iii)

Containment Using a Barrier Wall

Ameren also evaluated the alternative

of constructing a low-permeability barrier wall

around the impoundment to prevent lateral migration

of ash leachate. Construction of a vertical

barrier or "slurry wall" is dependent upon keying into a geologic formation with low hydraulic

conductivity such as shale bedrock or clay that would prevent vertical migration

of contaminants.

As the Board'stechnical staff noted: "[t]he slurry wall must extend into the lower confining

layer to a depth necessary to maintain a continuous hydraulic barrier and prevent seepage." STS

Response to Comments, p. 37. The sandstone bedrock beneath the western portion

of Pond D

does not provide a sufficient key-in layer for an impermeable barrier wall. Without a low

permeability formation in which to key the barrier wall, proper containment cannot be achieved.

(See

Exhibit 3, pp. 3-5). This alternative is, therefore, technically infeasible.

23

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

c.

Description of Ameren's Proposed Leachate Management System

Alternative

Ameren has designed a final cover and surface water management system that will limit

the amount

of leachate generated from Pond D. The percolating effect of precipitation will be

reduced

by designing and constructing a final cover system for Pond D with low hydraulic

conductivity to limit vertical infiltration, and with a slope sufficient to divert runoff from the

final cover surface. Such a system should divert the vast majority

of controllable water from the

closed impoundment and reduce the amount

of leachate generated at the Site.

Under these circumstances, the proposed surface water collection system and pozzolonic

cap will effectively drain and control precipitation into Pond D and thus reduce leachate volume.

The incremental costs and technical hurdles associated with installing a leachate collection

system far outweigh any discernable environmental benefit. Accordingly, Ameren requests that

the Board issue an adjusted standard that allows the closure

of Pond D through the construction

of a pozzolanic cap to divert surface flow without the construction of a leachate collection

system,

as outlined more fully herein.

C.

GROUNDWATER IMPACT ASSESSMENT

&

PREDICTIVE CONTAMINANT

TRANSPORT MODEL - Section 811.317

The regulations envision that before designing and constructing a landfill, "an integrated

evaluation

of the entire landfill site and design be performed using site-specific data, a

contaminant transport model, and reasonable operational assumptions. A point

of compliance

some distance away from the edge

of a unit is specified, as are maximum contaminant levels

acceptable at the compliance point." STS Recommendations,

p. 60. If the assessment shows

that the design and performance standards in Part

811 are inadequate to prevent contamination of

the groundwater outside the zone of attenuation ("ZOA"), then additional protection can be

24

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

considered such as multiple collection or liner systems or even relocation to a more suitable site.

Id.,

at 61.

Section 811.317 requires a person seeking a landfill permit to predict the potential

impacts caused

by leachate seepage from the landfill. The regulation requires a groundwater

impact assessment using a groundwater contaminant model incorporating site-specific

hydrogeologic information, and landfill design standards (liners, leachate collection system, final

cover, etc.) to demonstrate that concentrations

of all constituents in groundwater outside the

ZOA will be less than the groundwater quality standards

of35

Ill.

Adm. Code 811.320. Based

on this model, the permittee determines the leachate amount, the constituent concentrations in

the leachate, and the constituent concentrations over time.

This regulation is inapplicable here because the groundwater impact assessment is

intended as a tool to aid in conceptual design

of a new landfill, rather than closure of an existing

site. Furthermore, impacts to the groundwater and the migration

of contaminants from Pond

D

have already occurred, and as a result a groundwater impact assessment, as prescribed by the

landfill regulations, cannot be performed. The pond was constructed long before the regulations

were in place and Ameren has conducted sampling to characterize groundwater adjacent to Pond

D

as a result ofthose operations

(see

Exhibits 3 and4). Further, Ameren has performed

modeling, calibrated using this sampling, to predict the movement

of the plume under different

closure scenarios. Thus, Ameren has performed modeling consistent with the technical

requirements

of Section 811.317 but with the purpose of identifying closure scenarios rather than

developing maximum allowable predicted concentrations ("MAPCs") which would not be

relevant to the Site's current conditions.

25

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

Ameren has determined the impacts of leachate seepage from Pond D following

implementation

of final cover and slope configuration by using techniques different than those

specified in Section 811.317

(see

Exhibit 3). Ameren has also analyzed leachate from Pond D

and determined the constituents found within that leachate

(see

Exhibit 4, Table 6).

See

35 Ill.

Adm. Code 811.317(a)(2). Ameren must seek relief from Section 811.317 because that section

requires the operator to predict contaminant concentrations in leachate when no release has yet

occurred in order

to derive MAPCs.

The purpose

of the groundwater contaminant transport model ("GTM") is to predict

whether leachate from the landfill will result in a statistically significant increase over

background concentrations beyond the ZOA for 100 years after the close

of the landfill. 35 Ill.

Adm. Code 811.3l7(b). In adopting the groundwater impact assessment and predictive

modeling requirements, the Board clearly intended the groundwater impact assessment be

performed prior to the placement

of waste in a landfill unit. Petition of Carns Chemical Co.for

an Adjusted Standard from 35 Ill. Adm. Code 814, Subpart D, AS 98-1, slip op. at

12 (Sept. 19

1997). "In this regard, the Board noted that it would be inappropriate to assess the potential for

contamination

of landfill design after the landfill is placed into operation and contamination

occurs."

!d.;

see also,

In the Matter of: Development, Operation and Reporting Requirements

for Non-Hazardous Waste Landfills, R88-7, Appendix A-I at

65 (Aug. 17, 1990)

("It

would be

inappropriate to assess the potential for contamination

of a design after the landfill is placed in

operation and the contamination occurs. The opinion should show that the facility is unlikely

to

cause groundwater contamination before a permit is issued, not after contamination has

occurred.").

26

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

Predictive modeling is unnecessary where the conditions sought to be predicted have

occurred and actual data are available. Ameren has performed modeling to evaluate the

reduction in leachate volume, and its migration in groundwater under different closure scenarios

and proposed monitoring to demonstrate that the closure scenario approved here will conform to

the modeling predictions. Rather than predictive modeling, Ameren proposes to use a

monitoring network to assess constituent data and transport from Pond

D. Ameren proposes that

in lieu

of the specific requirements set forth in Section 811.317, the Company will continue to

gather actual groundwater data from the monitoring network proposed in this petition to measure

the impact to groundwater.

D.

DESIGN, CONSTRUCTION AND OPERATION OF GROUNDWATER

MONITORING SYSTEMS - SECTIONS 811.318 and 811.319

The regulations envision that in selecting a new site a landfill operator will develop a

groundwater monitoring program that identifies and compares upgradient (background) water

quality to downgradient water quality. Monitoring wells are to be established both within and

outside the ZOA. The specific requirements

of these regulations are not necessary at a surface

impoundment in existence prior to the time the regulations were adopted and in operation for

many years before those regulations became applicable. Ameren has already characterized the

groundwater contamination from Pond D and proposes to implement the groundwater

monitoring program described below.

Ameren has maintained a monitoring well network on Site and has sampled wells

periodically over many years. As described above and in Exhibits 3, 4, and

13 this sampling has

allowed Ameren to characterize the extent

of the plume. Ameren has also performed modeling

to identify the impacts

of various closure scenarios. Ameren has dewatered Pond D, thus

removing the hydraulic head causing mounding and subsequent migration

of constituents to the

27

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

south of Pond D. Finally as described below, Ameren proposed a groundwater monitoring

program to document the diminished plume over time. While this plan generally complies with

the requirements

of Sections 811.318, Ameren requests relief from parts of that Section.

1.

Monitoring Well Locations

Set forth in Exhibit

11

is a groundwater monitoring plan for Pond D which Ameren

believes substantially complies with Section 811.318 monitoring requirements. Ameren requests

adjusted standards from Sections 811.318(b)(3) to allow the continued use

of the current

monitoring well network:

Section 811.318(b)(3) requires that

***

Monitoring wells shall be established as close to the potential

source

of discharge as possible without interfering with the waste

disposal operations, and within

half the distance from the edge of

the potential source of discharge to the edge of the zone of

attenuation downgradient, with respect to groundwater flow, from

the source.

The physical configuration

ofthe Site precludes compliance with this particular location

requirement because

ofburied utilities and access necessary for plant operations.

Additional monitoring wells outside the current coverage area is also not feasible because

areas east

of the current monitoring system are in the flood plain of the Wabash River where

monitoring wells are subject to flooding and damage

by flotsam during flood period, and the area

south

of the impoundment is an actively farmed agricultural field for which the land owner has

refused to allow Ameren to install permanent monitoring wells on their property.

2.

Maximum Allowable Predicted Concentrations - Section 811.318(c)

Under the typical landfill setting envisioned by the Design, Construction and Operation

of Groundwater Monitoring Requirements, groundwater monitoring wells are to be installed at

28

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

various downgradient locations within a ZOA, to identify the migration of contaminants

approaching the edge

of the ZOA. 35 Ill. Adm. Code 811.318(b). The landfill operator must

then calculate MAPCs for each monitoring point.

Id.

at 811.318(c); STS Recommendations, at

70. MAPCs may be thought

of as breakthrough points - concentrations below which there will

be no groundwater quality violations at the ZOA's edge.

Id.

"The maximum allowable

concentration at any monitoring point is established

by predicting the concentrations at that point

and time with a groundwater containment model."

Id.

As for the groundwater impact assessment, MAPCs are factually inapplicable because

Site conditions defeat the purpose

of MAPCs. Section 811.318(c) requires that MAPCs be based

on the "same methods, data, and assumptions as used in the groundwater impact assessment." 35

Ill. Adm. Code 811.318(c). An MAPC is a trigger point, above which assessment monitoring

must be implemented. The goal

of MAPCs is to predict groundwater exceedences outside the

ZOA. STS Recommendations, at 70. Because Pond D is only becoming regulated as a landfill

at the closure stage, there is nothing to predict. Ameren already possesses actual monitoring

data. Establishing MAPCs would not serve the predictive function envisioned by the Board in

adopting Section 811. Accordingly, Ameren requests relief from Section 811.318(c).

Instead,

the Company proposes to implement the monitoring plan set forth in Exhibit

11,

extend the ZOA

eastward to the Wabash River and eastern property boundary, and request adjusted standards for

boron and other constituents that do not meet applicable groundwater quality standards at

specified wells.

The MAPC-related requirements

of Section 811.319 are equally inapplicable. Instead,

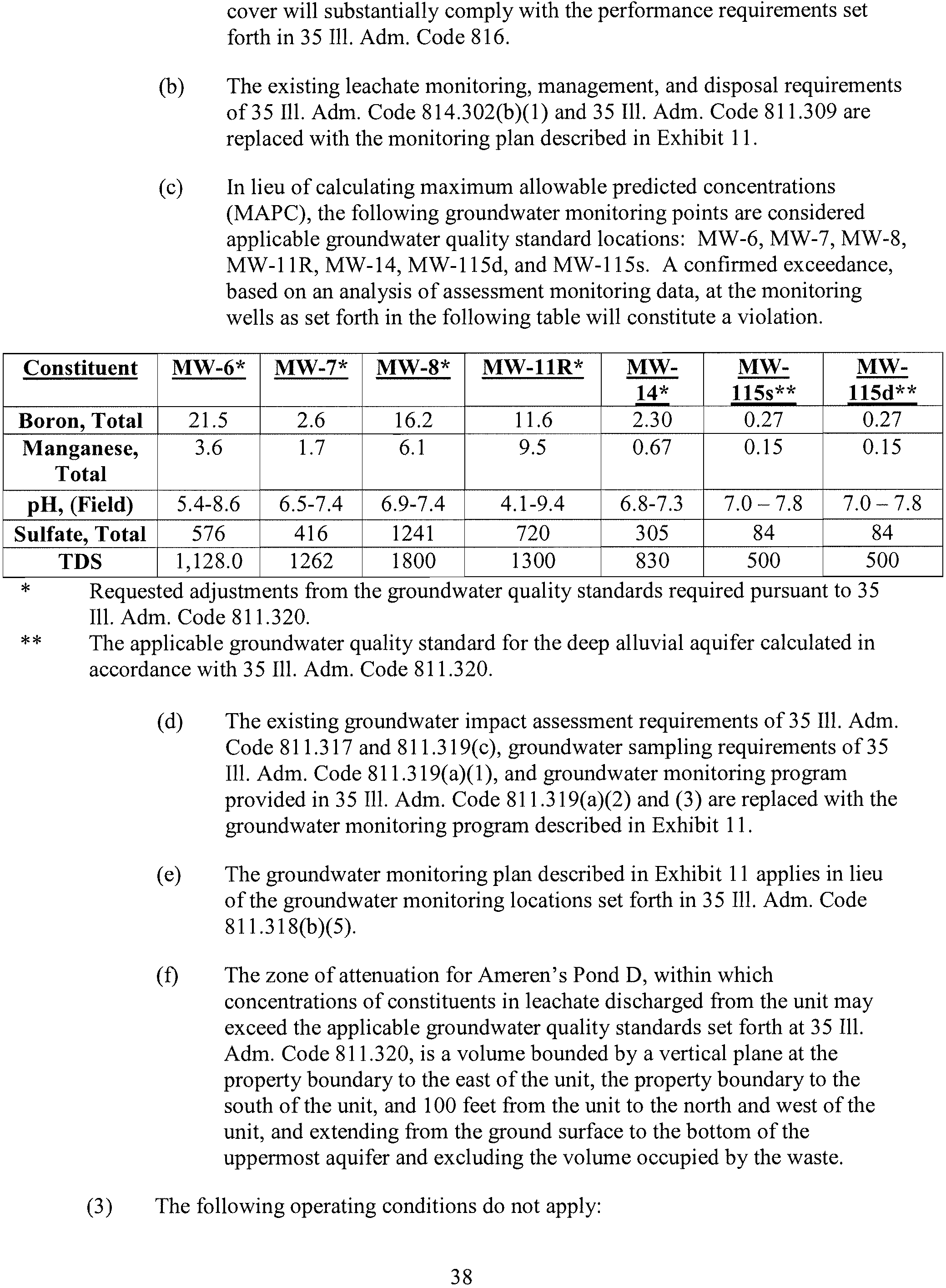

Ameren proposes that monitoring wells MW-6, MW-7, MW-8,

MW-llR, MW-14, MW-1l5s,

29

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

and MW-115d serve as points for determining compliance with the applicable groundwater

quality standard ("AGQS")

as required by 811.318(b)(5)

(see

Exhibit 2 for well locations).

3.

Constituent Monitoring

Section 811.319 of the generally applicable landfill standards requires Ameren to monitor

the Site groundwater for:

(1)

Constituents that appear in, or are expected

to be in, the leachate (35 Ill. Adm.

Code 811.319(a)(2)(A)(i));

(2)

A list

of 14 indicator contaminants (35 Ill. Adm. Code 811.319(a)(2)(A)(ii));

(3)

For facilities collecting more than 50%

by volume non-municipal waste,

additional indicator parameters based upon leachate characteristic and waste

content (35 Ill. Adm. Code 811.319(a)(2)(A)(iv));

(4)

Fifty-one (51) organic chemicals in drinking water described at 40 C.F.R. 141.40

(1988) and 40 C.F.R. 258.Appendix I (2006),

as incorporated by 35 Ill. Adm.

Code 810.104 (35 Ill. Adm. Code 811.319(a)(3)(A)(i)); and

(5)

A specific list

of organic chemicals for which groundwater must be monitored (35

Ill. Adm. Code 811.319(a)(3)(A)(i)). 35 Ill. Adm. Code 811.319.

The Board'sgroundwater monitoring program

is intended to ensure that constituents

from waste deposited in a landfill

do not migrate into and degrade groundwater. The Board's

regulations require broad-based organic and inorganic constituent monitoring. While such

an

approach is appropriate for municipal landfills where wastes originate from a variety of sources,

it is unnecessary at monofill facilities such

as Hutsonville's Pond D, where there has only been

one generator and the waste constituents have been characterized.

In lieu of broad-based

monitoring, one or more indicator constituents that are representative ofleachate transport may

be chosen for monitoring.

35 Ill. Adm. Code 811.319(a)(2)(B). Ameren proposes that boron and

sulfate be utilized as the primary indicators for coal ash leachate due

to their consistently high

concentration in coal ash leachate and due

to their persistence and high mobility in groundwater.

30

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

Based upon the ash and groundwater sampling results, Ameren seeks an adjusted

standard from Section 811.319(

a) and proposes that it sample only those constituents identified

in its groundwater monitoring plan described below. Ameren asserts that there is no need to

sample for organic constituents since the combustion process destroys volatile organic

compounds that exist in the coal before burning (Exhibit 11). Ameren believes that the

homogenous nature

ofthe ash disposed in the impoundment supports this request for reduced

monitoring. Similarly, Ameren asserts that sampling for boron and sulfate is sufficient to

document the extent

of the plume for all other inorganic constituents. Since these constituents

are the most mobile

ofthe constituents expected to be associated with coal ash combustion

leachate, Ameren believes that they serve

as valid indicators. As described more fully in Exhibit

11, Ameren proposes to monitor for the constituents required in the Facility's State Operating

and NPDES Permits (pH, temperature, specific conductance, groundwater depth, boron, sulfate,

manganese, and TDS) at the following monitoring well locations: MV/-1, MW-6, MW-7, MW-8,

MW-10, MW-11R, MW-7D, MW-14, MW-115s, MW-115d, MW-121.

The cost for the full monitoring required

by the Board'srule is expected to be

approximately $29,000 per year. The cost for Ameren's proposed monitoring is $4,300.

Ameren believes the monitoring program required by Section 811.319 is not economically

reasonable given the known content

of the ash in Pond D.

E.

GROUNDWATER QUALITY

STANDARDS

- SECTION 811.320

Landfills regulated under 35 Ill. Adm. Code Part 811 are subject to the applicable

groundwater quality standard.

35 Ill. Adm. Code Part 811.320(a). The AGQS has been

interpreted to mean "the ambient concentration determined by a statistical analysis

of the

existing groundwater quality." Solid Waste Landfill Rules, R07-8, slip op. at 6 (Nov. 15,2007).

Further, the AGQS applies

"'atthe edge of the zone of attenuation or compliance boundary (l00

31

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

feet from the edge of the waste or the property boundary, if closer).' If natural background

concentrations are lower that those allowed

by any standard, then the landfill must meet the

lower concentration.,,19

Id.

1.

Zone of Attenuation Around Pond D

Groundwater within the ZOA is Class IV groundwater that must meet Class II

groundwater quality standards "except for concentrations of contaminants within leachate

released from a permitted unit." 35 Ill. Adm. Code 811.320; 35 Ill. Adm. Code 620.440. Pond

D

qualifies as a "permitted unit" because it was permitted under a water pollution control permit

until dewatering in 2000. Furthermore, Section 811.320(c) confirms that leachate within the

ZOA may exceed the AGQS:

The zone

of attenuation, within which concentrations of constituents in leachate

discharged from the unit

may exceed the applicable groundwater quality standard

of this Section, is a volume bounded by a vertical plane at the property boundary

or 100 feet from the edge

of the unit, whichever is less, extending from the

ground surface to the bottom

of the uppermost aquifer and excluding the volume

occupied

by the waste. 35 Ill. Adm. Code 811.320(c).

Any other reading

of the landfill regulations and Part 620.440 would contravene the

intent

of the ZOA: "to provide a buffer area between the source of the discharge and the point at

which the applicable groundwater standards are enforced.,,2o STS Recommendations, at 76.

19

20

In conflict with this testimony, however, Appendix C to the Illinois Environmental Protection Agency's

Landfill Development Permit Application form (LPC-PA2) states:

"If the background concentration for a

groundwater constituent exceeds a 'Boardestablished standard' as defined in 8l1.320(a)(3)(B) an adjusted

groundwater quality standard is not required. The background concentration

is the applicable standard."

LPC-PA2, Appendix C at C-5.

If the approach set forth in the landfill application form applies, then

Ameren would need less relief from the groundwater quality standards.

In the event that the Board determines that groundwater within the ZOA must meet Class II groundwater

quality standards, Ameren also requests that the constituent concentrations at the monitoring wells as

identified in Table 3 apply in lieu

of the AGQS.

32

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

Ameren seeks to extend the ZOA eastward to the property boundary along the Wabash

River. Pond D was constructed in 1968, prior to promulgation

of modern landfill and

impoundment design standards, and as a result leachate has been released from the unit.

However, attenuation is occurring within the ZOA, as demonstrated

by boron and sulfate

concentrations in MW-7 that are a factor

of two or more lower than in downgradient monitoring

wells closer to the facility

(see

Figures 5a and 5b, Exhibit 11). Extending the ZOA eastward to

the Wabash river will allow for continued attenuation. Finally, the proposed AGQS wells would

then lie near, at, or beyond the proposed boundaries

of the ZOA in appropriate locations for

determining compliance.

2.

Background Concentrations of Constituents

Groundwater outside of the ZOA must be maintained at each constituent's background

concentration or the applicable groundwater quality standard set forth in Part 620, whichever is

lower?'

See

STS Response to Comments on Proposed Parts 807 Through 815, R88-7, slip op. at

160-61 (Mar.

1, 1990). Alternatively, the applicable standard could be a Board adjusted

standard.

Id.

In promulgating the landfill regulations, the Board has highlighted the importance of

establishing background concentrations of contaminants: "[b]ecause a non-degradation

groundwater standard is applied at the compliance point it is in the operator'sbest interest to

establish, beyond all reasonable doubt, the background water quality. All groundwater down to

the uppermost aquifer should be evaluated to determine stratigraphic variations." STS

Recommendations, at 90. Accordingly, Ameren has calculated background for both the upper

migration zone and deep alluvial aquifer. The background concentrations

of constituents, Class I

21

See, however, footnote 19 above for a conflicting Illinois Environmental Protection Agency interpretation.

33

Electronic Filing - Received, Clerk's Office, August 11, 2008

* * * * * AS 2009-001 * * * * *

standards, and AGQS22 outside of the ZOA for each constituent as required by Section 811.320

are set forth in the following tables.

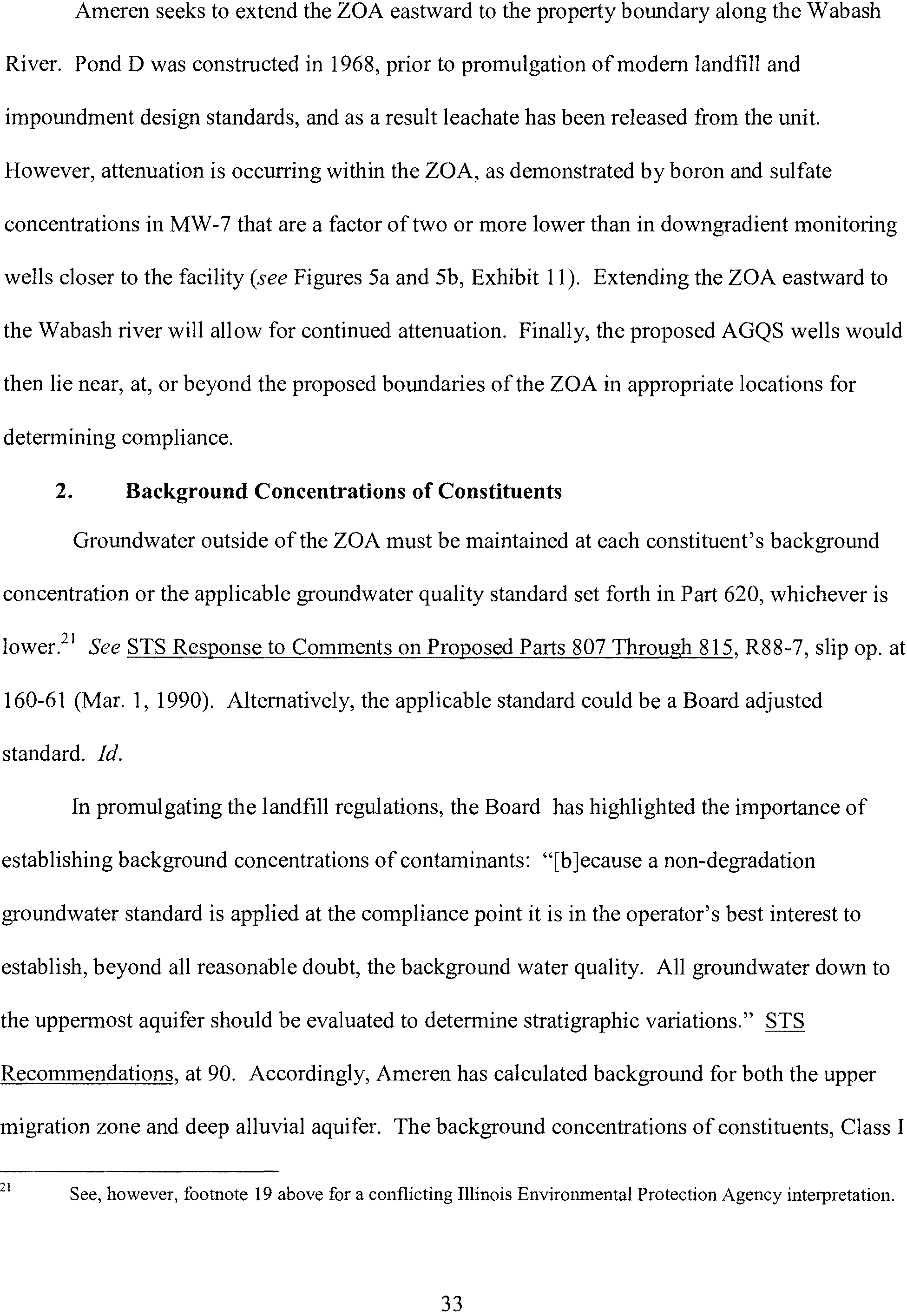

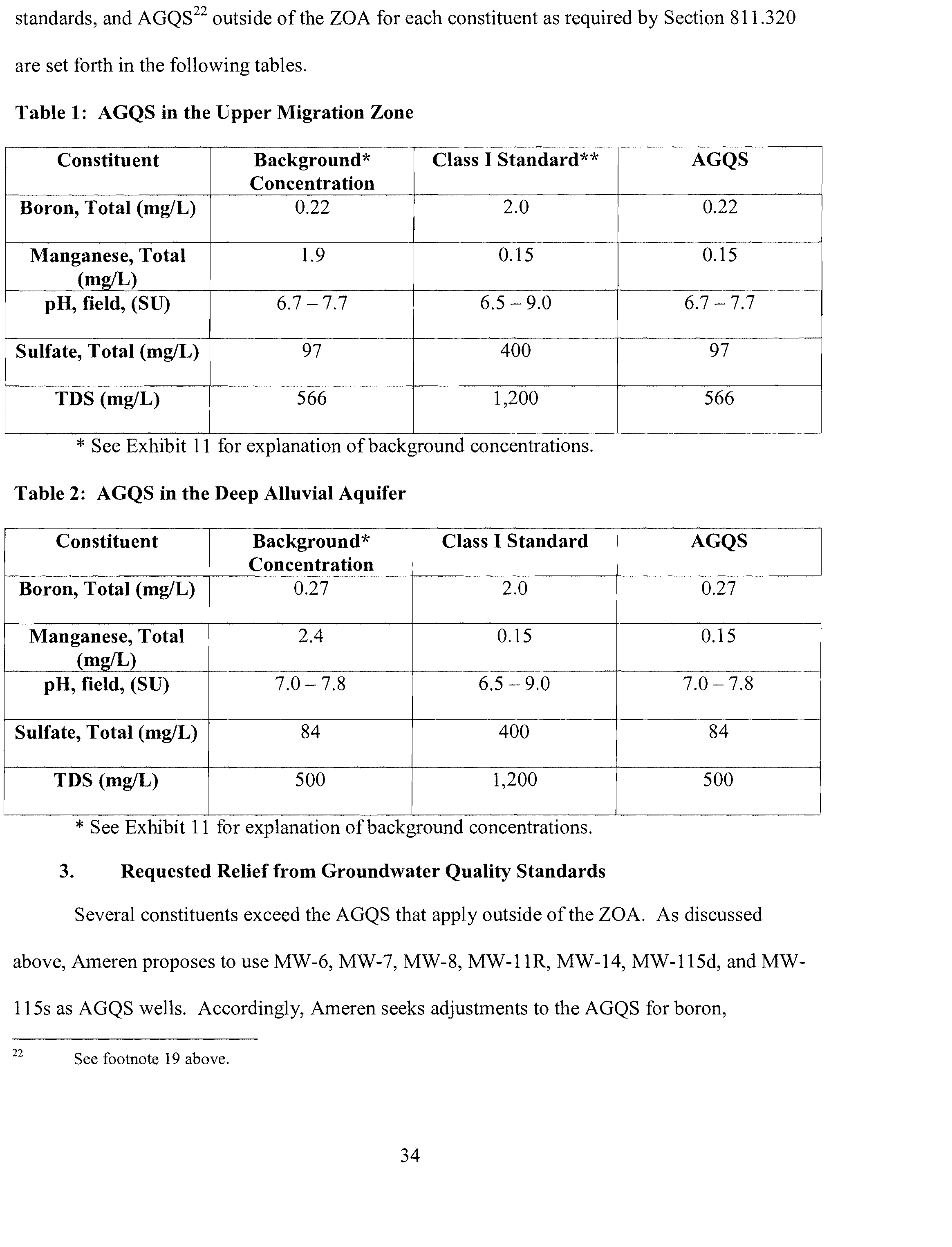

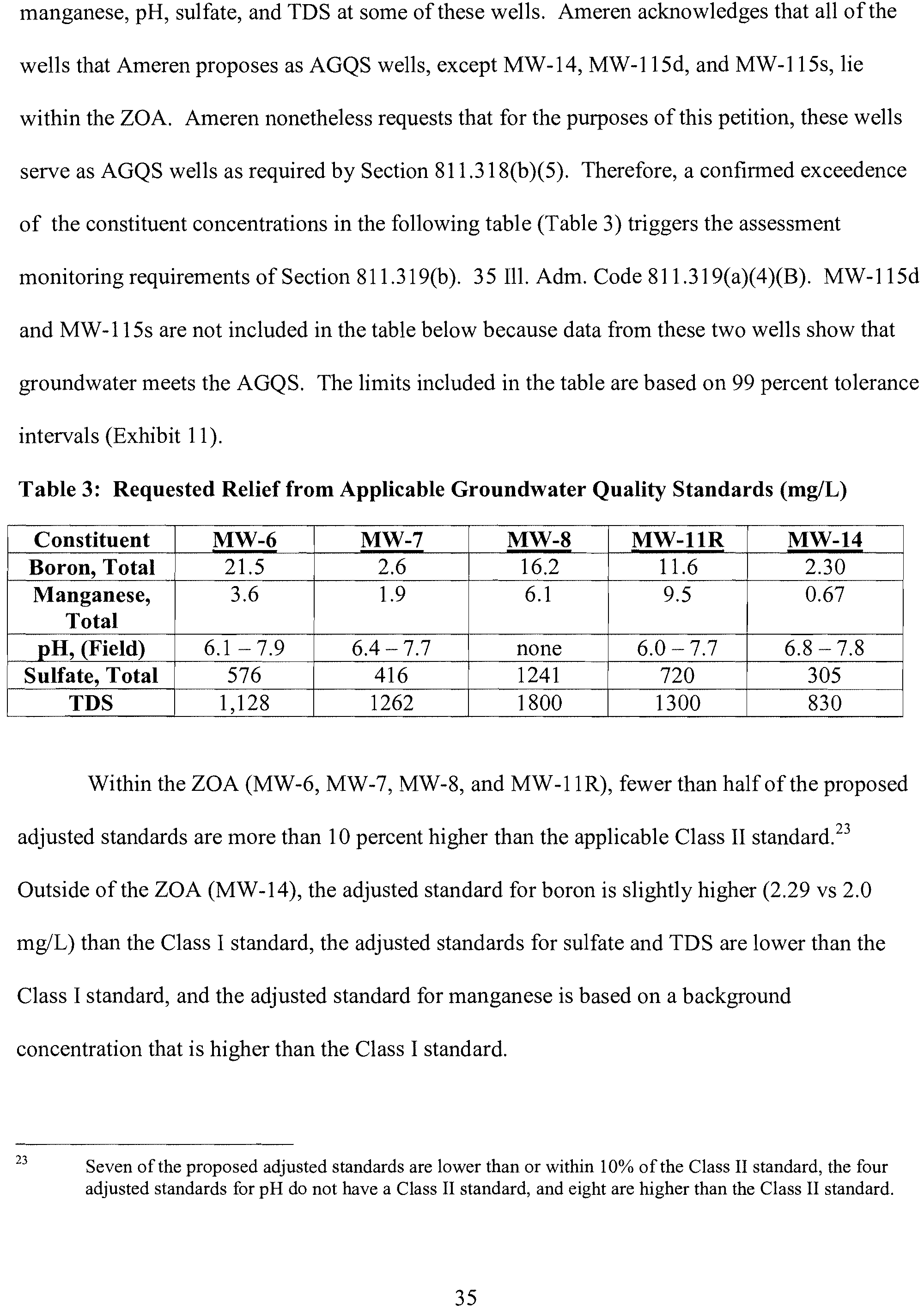

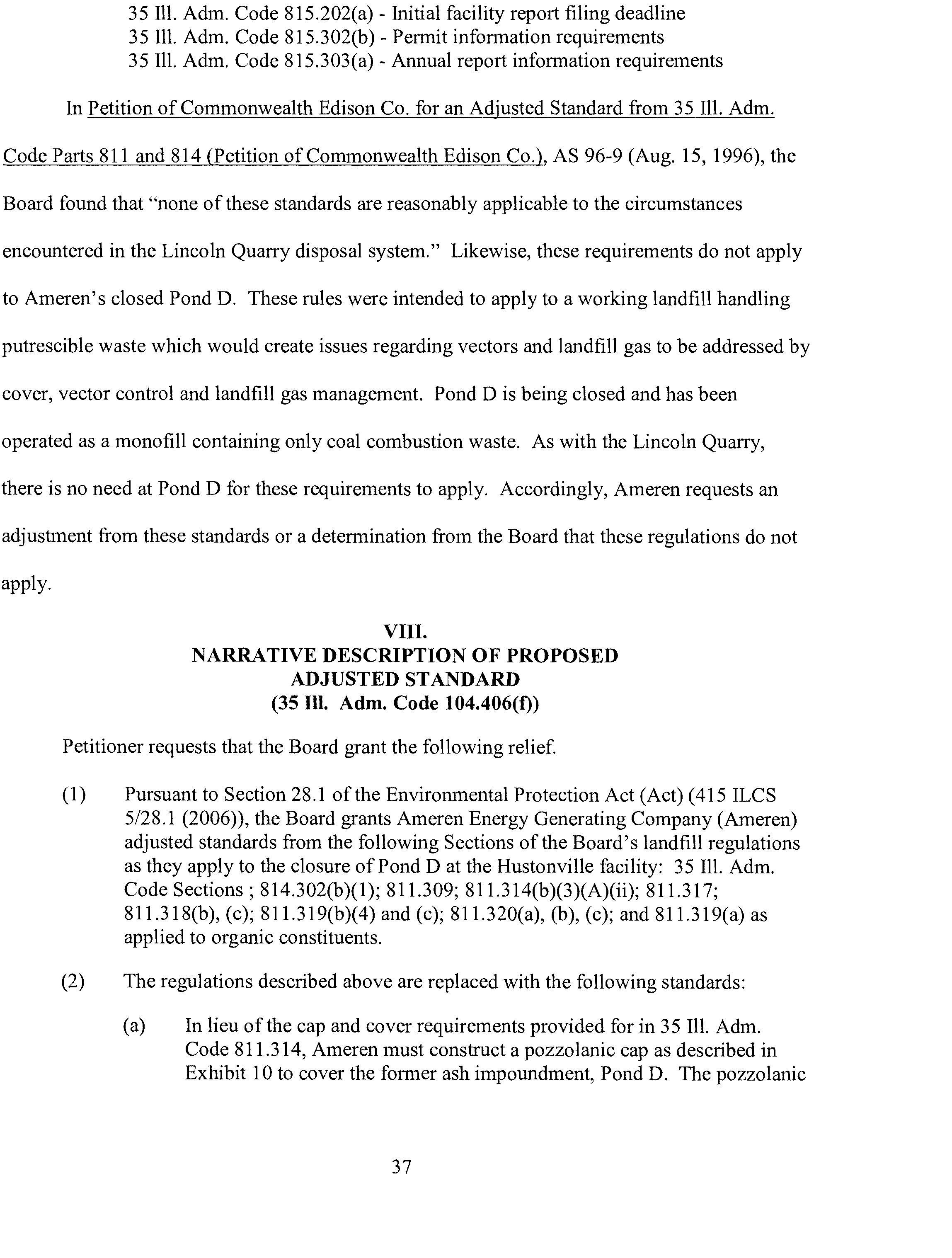

Table 1: AGQS in the Upper Migration Zone

Constituent

Background*

Class

I

Standard**

AGQS