BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

IN THE MATTER OF:

)

)

PROPOSED NEW 35 ILL. ADM. CODE )

PART 223 STANDARDS AND

)

R08 - 017

LIMITATIONS FOR ORGANIC

)

(Rulemaking – Air)

MATERIAL EMISSIONS FOR AREA )

SOURCES

)

)

NOTICE

TO:

John Therriault, Assistant Clerk

Illinois Pollution Control Board

State of Illinois Center

100 West Randolph, Suite 11-500

Chicago, Illinois 60601

SEE ATTACHED SERVICE LIST

PLEASE TAKE NOTICE that I have today filed with the Office of the Pollution Control

Board the ILLINOIS ENVIRONMENTAL PROTECTION AGENCY’S THIRD ERRATA

SHEET TO ITS PROPOSAL FOR THE ADDITION OF 35 ILL. ADM. CODE 223 and the

ILLINOIS ENVIRONMENTAL PROTECTION AGENCY’S POST-HEARING COMMENTS

TO THE JUNE 4, 2008 HEARING ON THE PROPOSAL FOR THE ADDITION OF 35 ILL.

ADM. CODE 223 a copy of which is herewith served upon you.

ILLINOIS ENVIRONMENTAL

PROTECTION AGENCY

By: ______________________

Charles E. Matoesian

Assistant Counsel

Division of Legal Counsel

DATED: July 10, 2008

1021 North Grand Avenue East

Springfield, Illinois 62794-9276

217.782.5544

217.782.9143 (TDD)

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

IN THE MATTER OF:

)

)

PROPOSED NEW 35 ILL. ADM. CODE )

PART 223 STANDARDS AND

)

R08 - 017

LIMITATIONS FOR ORGANIC

)

(Rulemaking – Air)

MATERIAL EMISSIONS FOR AREA )

SOURCES

)

)

ILLINOIS ENVIRONMENTAL PROTECTION AGENCY’S THIRD ERRATA

SHEET TO ITS PROPOSAL FOR THE ADDITION OF 35 ILL. ADM. CODE 223

NOW COMES the Illinois Environmental Protection Agency (“Illinois EPA”), by

and through its attorney Charles E. Matoesian, and submits this Third Errata Sheet to its

proposal for the addition of 35 Ill. Adm. Code 223. The Illinois EPA proposes the

following amendments to the text of the rules submitted in its proposal to the Board dated

January 2, 2008:

1. Amend Section 223.105 to clarify the abbreviations and acronyms. Several are no

longer necessary as Subpart D is being withdrawn.

Section 223.105

Abbreviations and Acronyms

Unless otherwise specified within this Part, the abbreviations used in this Part shall be the

same as those found in 35 Ill. Adm. Code 211. The following abbreviations and

acronyms are used in this Part:

ACP

Alternative Control Plan

Act

Environmental Protection Act [415 ILCS 5/1 et seq .]

Agency

Illinois Environmental Protection Agency

ASTM

American Society for Testing and Materials

BAAQMD

Bay Area Air Quality Management District

CARB

California Air Resources Board

o

C

Degrees Celsius

CFCs

Chlorofluorocarbons

CO

2

Carbon Dioxide

o

F

Degrees Fahrenheit

FDA

United States Food and Drug Administration

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

FIFRA

Federal Insecticide, Fungicide, and Rodenticide Act, 7 U.S.C. §§136

through 136y

FRP

Fiberglass reinforced plastic

HVOM

High Volatility Organic Material

HCFCs

Hydrochlorofluorocarbons

HFCs

Hydrofluorocarbons

LVP-VOM

Low Vapor Pressure – Volatile Organic Material

MIR

Maximum Incremental Reactivity

MVOM

Medium Volatility Organic Material

N

2

Nitrogen

N

2

O

Nitrous Oxide

OER

Original Equipment Manufacturer

PCBTF

Parachlorobenzotrifluoride

PWMIR

Product-Weighted Maximum Incremental Reactivity

ROC

Reactive Organic Compound

ROG

Reactive Organic Gas

SCAQMD

South Coast Air Quality Management District

USEPA

United States Environmental Protection Agency

ULKR

Upper-Limit Kinetic Reactivity

ULMIR

Upper-Limit Maximum Incremental Reactivity

ULMR

Upper-Limit Mechanistic Reactivity

VOM

Volatile Organic Material

2. Amend Section 223.120 to clarify the incorporations by reference. Several

inconsistencies were inadvertently included in the proposed rule.

Section 223.120

Incorporations by Reference

The following materials are incorporated by reference. These incorporations do not

include any later amendments or editions.

a)

40 CFR 59, Subpart D, Appendix A, Determination of Volatile Matter

Content of Methacrylate Multicomponent Coatings Used as Traffic

Marking Coatings, 64 Fed. Reg. 35002 (June 30, 1999).

b)

40 CFR 59, Subpart C, National Volatile Organic Compound Emission

Standards for Consumer Products, 69 Fed. Reg. 18803 (April 4, 2004).

c)

40 CFR 60, Appendix A, Method 24, Determination of Volatile Matter

Content, Water Content, Density, Volume Solids, and Weight Solids of

Surface Coatings, 36 Fed. Reg. 24877 (December 23, 1971).

d)

40 CFR 82, Subpart A, Appendix A, Class I Controlled Substances, 68

Fed. Reg. 42892 (July 18, 2003) and Appendix B, Class II Controlled

Substances, 68 Fed. Reg. 2859 (January 21, 2003).

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

e)

29 CFR 1910.1200(d)(4), Hazard Communication, 61 Fed. Reg. 9245,

(March 7, 1996).

f)

ASTM International, 100 Barr Harbor Drive, PO Box C700, West

Conshohocken, PA, 19428-2959 American Society for Testing and

Materials (ASTM), 1916 Race Street, Philadelphia, PA, 19103.

1)

ASTM E119-05a, Standard Test Methods for Fire Tests of Building

Construction and Materials, approved November 1, 2005.

2)

ASTM Designation D523-89(1999), Standard Test Method for

Specular Gloss, reapproved May 10, 1999.

3)

ASTM D 1640-03, Standard Test Methods for Drying, Curing, or

Film Formation of Organic Coatings at Room Temperature,

approved December 1, 2003.

4)

ASTM Method D 3912-95(2001), Test Method for Chemical

Resistance of Coating Used in Light-Water Nuclear Power Plants,

reapproved 2001.

5)

ASTM Method D 4082-02, Test Method for Effects of Radiation on

Coatings Used in Light-Water Nuclear Power Plants, approved

2002.

6)

ASTM Designation D4214-98, Standard Test Methods for

Evaluating the Degree of Chalking of Exterior Paint Films,

approved August 10, 1998.

7)

ASTM D1613-03, Standard Test Method for Acidity in Volatile

Solvents and Chemical Intermediates Used in Paint, Varnish,

Lacquer, and Related Products, approved October 1, 2003.

8)

ASTM E84-07, Standard Test Method for Surface Burning

Characteristics of Building Materials, approved 2007.

9)

ASTM D4359-90(2006), Standard Test Method for Determining

Whether a Material is a Liquid or a Solid, reapproved

2006.

10)

ASTM E260-96(2006), Standard Practice for Packed Column Gas

Chromatography, reapproved 2006.

11)

ASTM D5043-04, Standard Test Methods for Field Identification of

Coatings, approved 2004.

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

11)12) ASTM E2167-01, “Standard Guide for Selection and Use of Stone

Consolidants” (see section 4, Stone Consolidant), approved 2001.

12)13)

ASTM C836-06, Specification for High Solids Content, Cold

Liquid-Applied Elastomeric Waterproofing Membrane for Use with

Separate Wearing Course, approved 2006.

13)

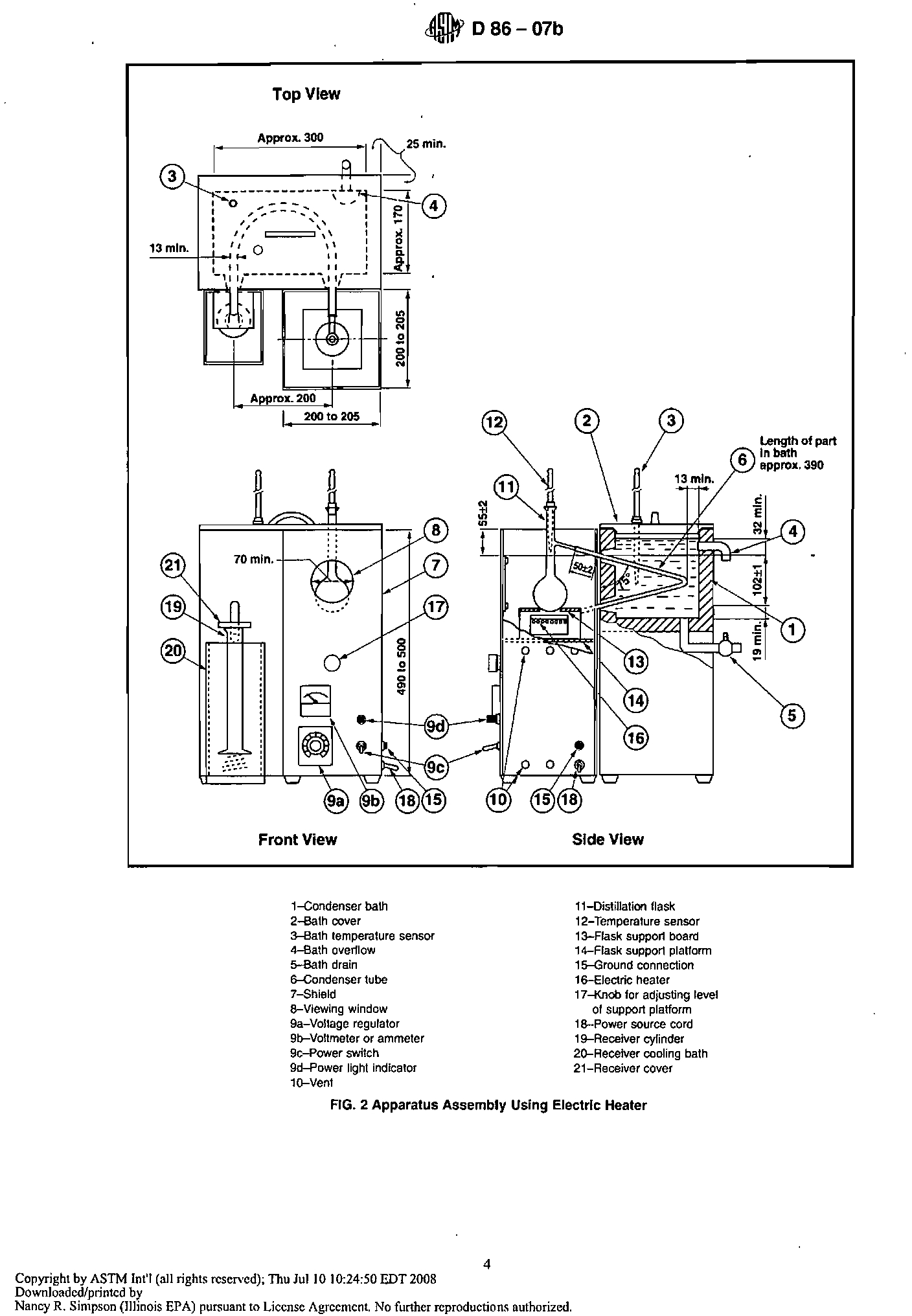

ASTM D86-07b

,

Standard Test Method for Distillation of

Petroleum Products at Atmospheric Pressure, approved 2007

g)

South Coast Air Quality Management District

,

21865 Copley Dr., Diamond

Bar CA 91765.

1)

South Coast Air Quality Management District (SCAQMD) Method

304-91, Determination of Volatile Organic Compounds in Various

Materials, revised February 1996.

h)

2)

SCAQMD Method 303-91, Determination of Exempt Compounds,

revised February 1993.

i)

3)

SCAQMD Method 318-95, Determination of Weight Percent

Elemental Metal in Coatings by X-Ray Diffraction, approved

August 10, 1998.

j)

h)

Bay Area Air Quality Management, District Office, 939 Ellis Street, San

Francisco, CA 94109.

1)

Bay Area Air Quality Management District (BAAQMD) Method

43, Determination of Volatile Methylsiloxanes in Solvent-Based

Coatings, Inks, and Related Materials, amended May 18, 2005.

k)

2)

BAAQMD Method 41, Determination of Volatile Organic

Compounds in Solvent-Based Coatings and Related Materials

Containing Parachlorobenzotrifluoride, amended May 18, 2005.

i)l)

California Air Resources Board (CARB) Method 310, Determination of

Volatile Organic Compounds in Consumer Products and Reactive Organic

Compounds in Aerosol Coating Products, amended May 5, 2005.

California Air Resources Board

,

1001 I Street, P.O. Box 2815, Sacramento,

CA 95812

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

j)m)

SCAQMD Rule 1174, Ignition Method Compliance Certification Protocol

(February 27, 1991).

k)n)

Cal. Admin. Code title 17 § 94509(h), Standards for Consumer Products

(2005).

l)o)

California Code, Health and Safety Code, § 41712(h)(2) (2005).

m)p)

Cal. Admin. Code title 17, Article 4, Alternate Control Plan §§ 94540-

94555, (1996).

n)q)

Cal. Admin. Code title 17 § 94511, Innovative Products (1997).

o)r)

Cal. Admin. Code title 17 § 94503.5, Innovative Products (1996).

p)s)

7 USC 136 to 136y, FIFRA, Environmental Pesticide Control, published

January 19, 2004, in Supplement III of the 2000 Edition of the United

States Code.

q)t)

Federal Specification MMM-A-181D, Adhesives, Phenol, Resorcinol, or

Melamine Base (1980).

3. Amend Section 223.203 to clarify the definitions of certain words. Several

clarifications need to be made.

“Colorant” means for purposes of this Subpart Subpart B, any pigment or coloring

material used in a consumer product for an aesthetic effect, or to dramatize an

ingredient. For purposes of Subpart C, “Colorant” means a concentrated pigment

dispersion in water, solvent, and/or binder that is added to an architectural coating

after packaging in sale units to produce the desired color.

“Lacquer” means for purposes of Subparts B and C of

this Subpart, a clear or

opaque wood coating, including clear lacquer sanding sealers, formulated with

cellulosic or synthetic resins to dry by evaporation without chemical reaction and

to provide a solid, protective film. For purposes of Subpart D of this Part,

“Lacquer” means a thermoplastic film-forming material dissolved in organic

solvent, which dries primarily by solvent evaporation, and is resoluble in its

original solvent.

“Liquid” means a substance or mixture of substances which is capable of a visually

detectable flow as determined under ASTM D-4359-90

ASTM

D-4359-90(2000)e1, including any subsequent amendments or an equivalent

method approved by the California Air Resources Board. This does not include

powders or other materials that are composed entirely of solid particles.

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

“Solid” means a substance or mixture of substances which, either whole or

subdivided (such as the particles comprising a powder), is not capable of visually

detectable flow as determined under ASTM D-4359-90(2000)e1, or an equivalent

method approved by the California Air Resources Board.

“Special Purpose Spray Adhesive” means an aerosol adhesive that meets any of the

following definitions:

“Mounting Adhesive” means an aerosol adhesive designed to permanently

mount photographs, artwork, and any other drawn or printed media to a

backing (paper, board, cloth, etc.) without causing discoloration to the

artwork.

“Flexible vinyl adhesive” means an aerosol adhesive designed to bond

flexible vinyl to substrates. Flexible vinyl means a nonrigid polyvinyl

chloride plastic with at least five percent, by weight, of plasticizer content.

A plasticizer is a material, such as a high boiling point organic solvent, that

is incorporated into a plastic to increase its flexibility, workability, or

distensibility, and may be determined using ASTM Method E260-96

ASTM Method E260-91, or from product formulation data or an equivalent

method approved by the CARB.

“Polystyrene Foam Adhesive” means an aerosol adhesive designed to bond

polystyrene foam to substrates.

“Automobile Headliner Adhesive” means an aerosol adhesive designed to

bond together layers in motor vehicle headliners.

“Polyolefin Adhesive” means an aerosol adhesive designed to bond

polyolefins to substrates.

“Laminate Repair/Edgebanding Adhesive” means an aerosol adhesive

designed for:

The touch-up or repair of items laminated with high pressure

laminates (e.g., lifted edges, delaminates, etc.); or

The touch-up, repair, or attachment of edgebanding materials,

including but not limited to, other laminates, synthetic marble,

veneers, wood molding, and decorative metals.

For the purposes of this definition “high pressure laminate” means

sheet materials which consist of paper, fabric, or other core material

that have been laminated at temperatures exceeding 265 degrees F,

and at pressures between 1,000 and 1,400 psi.

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

“Automotive Engine Compartment Adhesive” means an aerosol adhesive

designed for use in motor vehicle under-the-hood applications which

require oil and plasticizer resistance, as well as high shear strength, at

temperatures of 200 - 275 degrees F.

“VOM Content” means, for purposes of Subpart B of this Subpart, except for

charcoal lighter products, the total weight of VOM in a product expressed as a

percentage of the product weight (exclusive of the container or packaging), as

determined pursuant to Section 223.285(a) and (b).

4. Amend Section 223.208 to strike the second reference to Section 223.207. The citation

was inadvertently repeated in the proposed rule.

Section 223.208

Requirements for Aerosol Adhesives

a)

As specified in California Code section 41712(h)(2), incorporated by

reference in Section 223.120, the standards for aerosol adhesives apply to

all uses of aerosol adhesives, including consumer, industrial, and

commercial uses. Except as otherwise provided in Sections 223.207,

223.230, 223.240, 223.245, and 223.207, no person shall sell, supply, offer

for sale, use or manufacture for sale in Illinois any aerosol adhesive which,

at the time of sale, use, or manufacture, contains VOMs in excess of the

specified standard.

5. Amend Section 223.250 to clarify the Product Dating requirements. The requirement

that the date code be displayed 12 months prior to the effective date of the rule was

inadvertently left in the proposed rule.

Section 223.250

Product Dating

a)

Each manufacturer of a consumer product subject to Section 223.205(a)

shall clearly display on each consumer product container or package, the

day, month, and year on which the product was manufactured, or a code

indicating such date.

b)

A manufacturer who uses the following code to indicate the date of

manufacture shall not be subject to the requirements of Section 223.255(a),

if the code is represented separately from other codes on the product

container so that it is easily recognizable:

YY DDD = year year day day day

Where:

YY = Two digits representing the year in which the product was

manufactured,

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

DDD = Three digits representing the day of the year on which the product

was manufactured, with “001” representing the first day of the year,

“002” representing the second day of the year, and so forth (i.e., the

“Julian date”)

c)

This date or code shall be displayed on each consumer product container or

package no later than twelve months prior to the effective date of the

applicable standard specified in Section 223.205(a).

d)

The date or datecode information shall be located on the container or inside

the cover/cap so that it is readily observable or obtainable by simply

removing the cap/cover without irreversibly disassembling any part of the

container or packaging. For the purposes of this subsection, information

may be displayed on the bottom of a container as long as it is clearly legible

without removing any product packaging.

e)

The requirements of this Section 223.250 shall not apply to products

containing no VOMs (as defined in Section 223.203), or containing VOMs

at 0.10% by weight or less.

6. Amend Section 223.255 to clarify the Product Dating requirements. The requirement

that the date code be displayed 12 months prior to the effective date of the rule was

inadvertently left in the proposed rule.

Section 223.255

Additional Product Dating Requirements

a)

If a manufacturer uses a code other than specified in 223.250(b) indicating

the date of manufacture for any consumer product subject to Section

223.205(a), an explanation of the date portion of the code must be filed

with the Agency no later than 12 months prior to the effective date of the

applicable standard specified in Section 223.205.

b)

If a manufacturer changes any code indicating the date of manufacture for

any consumer product subject to Section 223.255(a), an explanation of the

modified code must be submitted to the Agency before any products

displaying the modified code are sold, supplied, or offered for sale in

Illinois.

ac)

No person shall erase, alter, deface, or otherwise remove or make illegible

any date or code indicating the date of manufacture from any regulated

product container without the express authorization of the manufacturer.

No manufacturer shall affix a date-code that is not true for the date the item

was manufactured.

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

bd)

Date code explanations for codes indicating the date of manufacture are

public information and may not be claimed as confidential.

7. Amend Section 223.285 (c) and (e) to correct the citation to the ASTM and reconcile it

with the version which was incorporated by reference.

c) Testing to determine whether a product is a liquid or solid shall be performed using

ASTM D4359-90 (2000)e1

, which is incorporated by reference in Section 223.120

or an equivalent method approved by the CARB.

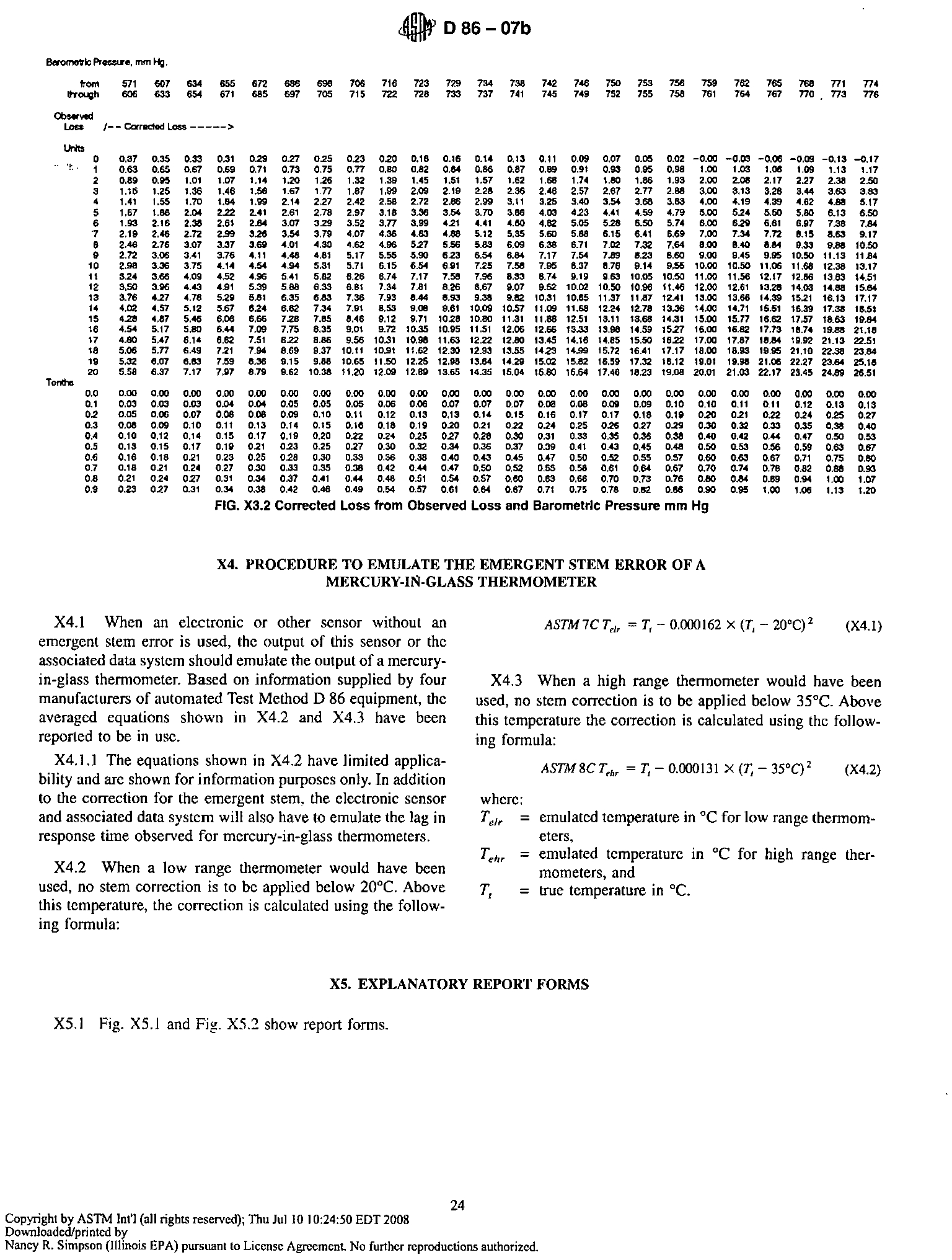

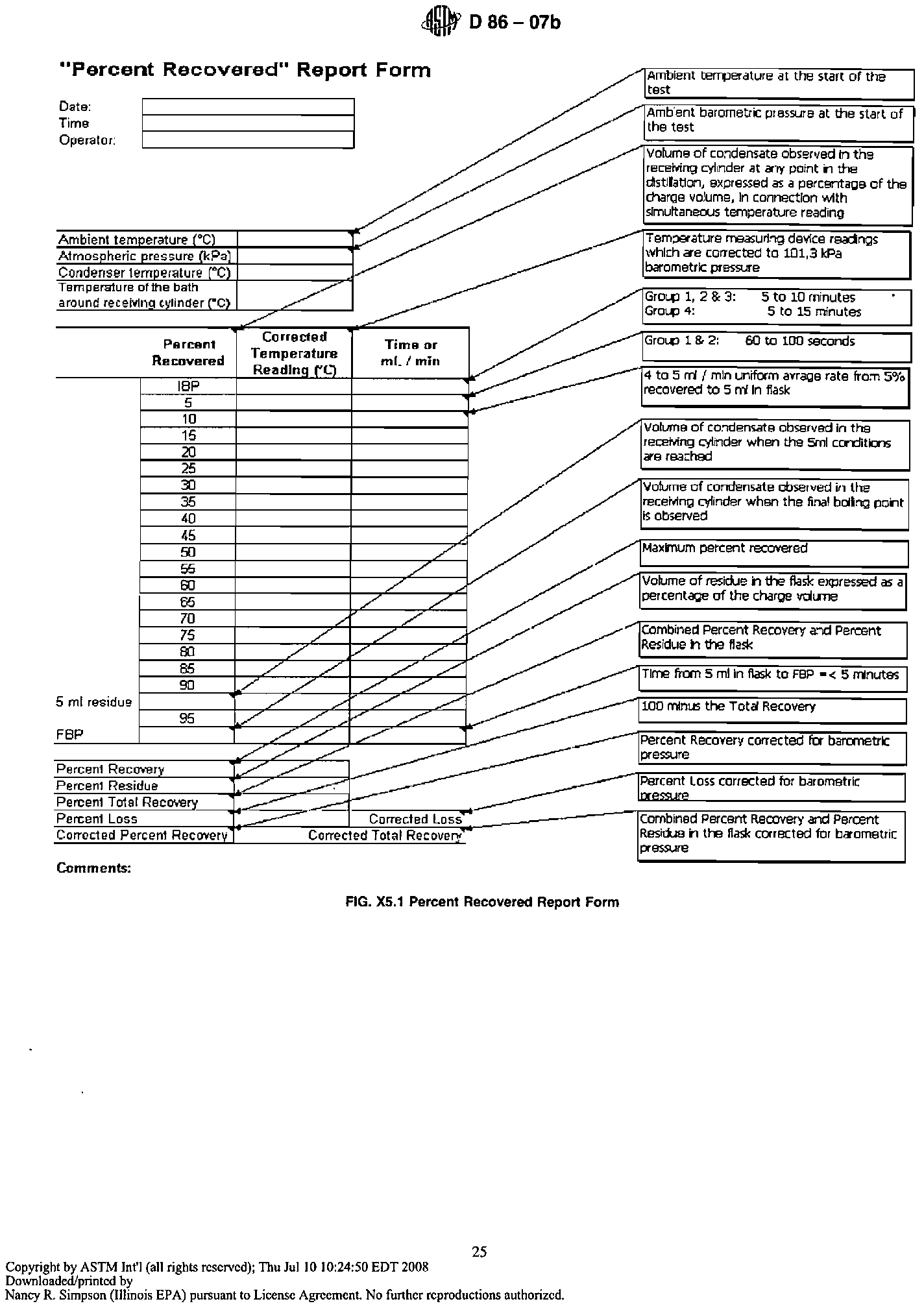

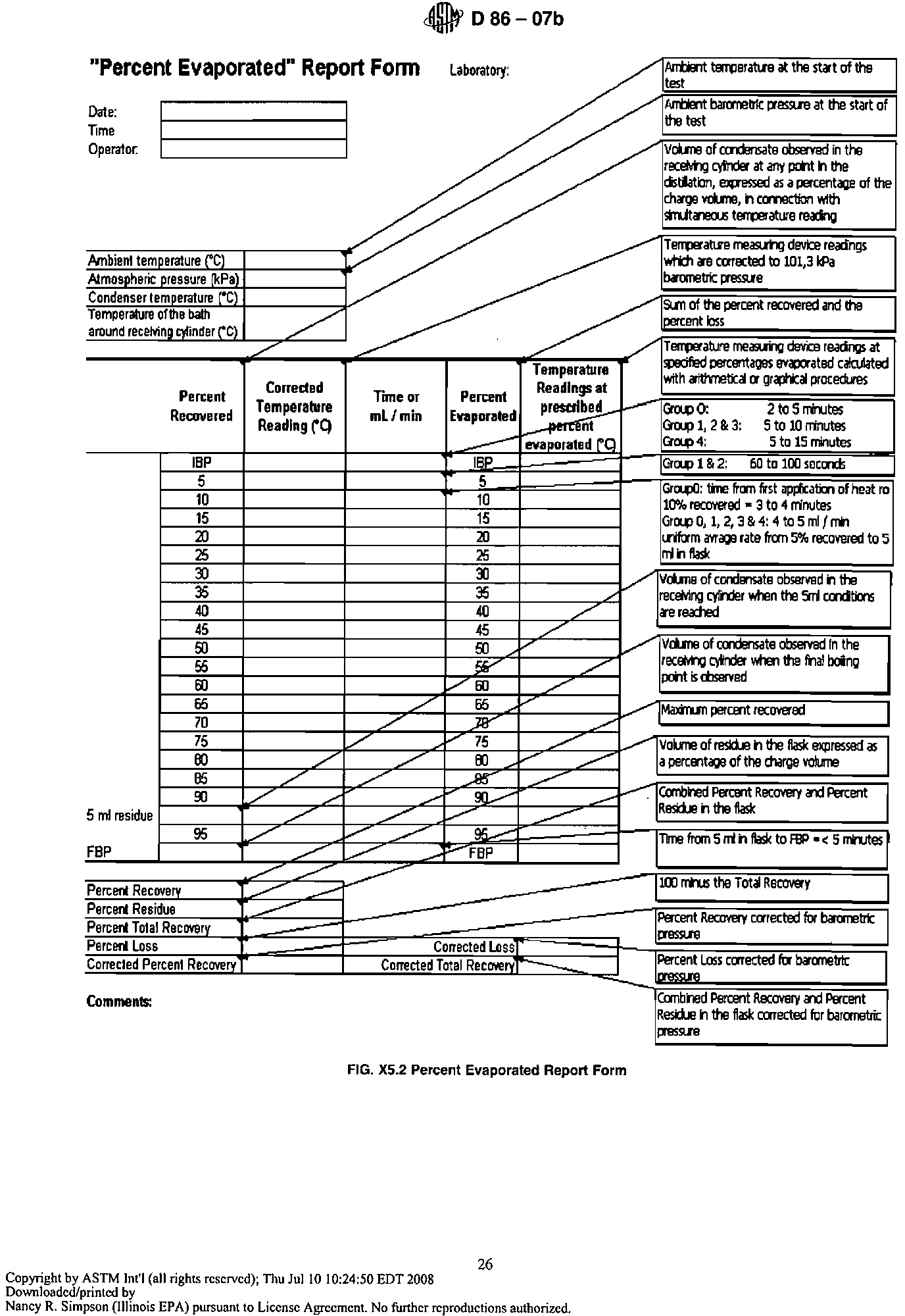

e) Testing to determine distillation points of petroleum distillate-based charcoal

lighter materials shall be performed using ASTM D86-07b, 2007

, ASTM D86-04b,

2004 edition, which is incorporated by reference in Section 223.120 or an

equivalent method approved by the CARB.

8. Amend Section 223.307 to correct certain misspellings in definitions and ASTM

references. These errors were inadvertently left in the rule. An “s” was inadvertently

added to the word “born” in the definition of “Calcamine Recoaters.”

“Calcamine Recoaters” means a flat solvent borns

coatings formulated and

recommended specifically for recoating calcamine-painted ceilings and other

calcamine-painted substrates.

“Fire-Retardant Coating” means a coating labeled and formulated to retard ignition

and flame spread, that has been fire tested and rated by a testing agency approved

by building code officials for use in bringing building and construction materials

into compliance with federal, state, and local building code requirements. The

fire-retardant coating and the testing agency must be approved by building code

officials. The fire-retardant coating shall be tested in accordance with ASTM

Designation E 84-07

84-99, incorporate by reference in Section 223.120.

“Nuclear Coating” means a protective coating formulated and recommended to seal

porous surfaces such as steel (or concrete) that otherwise would be subject to

intrusions by radioactive materials. These coatings must be resistant to long-term

(service life) cumulative radiation exposure [ASTM Method D 4082-02 4082-89],

relatively easy to decontaminate, and resistant to various chemicals to which the

coatings are likely to be exposed [ASTM Method D 3912-95

3912-80].

“VOM Content” means the weight of VOM per volume of coating, calculated

according to the procedures specified in subsection 223.340(a)

223.400(a).

“Varnish” means a clear or semi-transparent wood coating, excluding lacquers and

shellacs, formulated to dry by chemical reaction on exposure to air. Varnishes may

contain small amounts of pigment to color a surface, or to control the final

fetal

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

sheen or gloss of the finish.

9. Amend Section 223.307 to add the definitions of certain words. Several clarifications

need to be made.

“Colorant” means for purposes of this Subpart, “Colorant” means a concentrated

pigment dispersion in water, solvent, and/or binder that is added to an architectural

coating after packaging in sale units to produce the desired color.

“Lacquer” means for purposes of this Subpart, a clear or opaque wood coating,

including clear lacquer sanding sealers, formulated with cellulosic or synthetic

resins to dry by evaporation without chemical reaction and to provide a solid,

protective film.

“Concrete surface retarder” means a mixture of retarding ingredients such as

extender pigments, primary pigments, resin, and solvent that interact chemically

with the cement to prevent hardening on the surface where the retarder is applied,

allowing the retarded mix of cement and sand at the surface to be washed away to

create an exposed aggregate finish."

10.

Amend Section 310(a) to include “Concrete Surface Retarder” under the most

restrictive limit subsection of the rule at the appropriate place. This was

inadvertently omitted from the proposal.

11a.

Concrete Surface Retarder

780g/l

(6.5)

11.

Amend Section 310(c) to include “Concrete Surface Retarder” under the most

restrictive limit subsection of the rule at the appropriate place. This was

inadvertently omitted from the proposal.

21.

Concrete Surface Retarder

12. Amend Section 223.370 to clarify that the various test methods specified were

incorporated by reference. The notation was inadvertently omitted from the proposed

rule.

a)

Flame Spread Index. The flame spread index of a fire-retardant coating

shall be determined by the ASTM Designation E 84-07 84-99, “Standard

Test Method for Surface Burning Characteristics of Building Materials,”

(see Section 223.307, Fire-Retardant Coating) or an equivalent method

approved by the CARB.

e)

Acid Content of Coatings. The acid content of a coating shall be

determined by ASTM Designation D 1613-03

1613-96, “Standard Test

Method for Acidity in Volatile Solvents and Chemical Intermediates Used

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

in Paint, Varnish, Lacquer and Related Products,” as incorporated by

reference in Section 223.120, (see Section 223.307, Pre-Treatment Wash

Primer) or an equivalent method approved by the CARB.

f)

Drying Times. The set-to-touch, dry-hard, dry-to-touch and dry-to-recoat

times of a coating shall be determined by ASTM Designation D 1640-03

1640-95, “Standard Methods for Drying, Curing, or Film Formation of

Organic Coatings at Room Temperature,” as incorporated by reference in

Section 223.120, (see Section 223.307, QuickDry Enamel and Quick-Dry

Primer, Sealer, and Undercoater). The tack free time of a quick-dry enamel

coating shall be determined by the Mechanical Test Method of ASTM

Designation D 1640-03 1640-95 or an equivalent method approved by the

CARB.

h)

Exempt Compounds – Siloxanes. Exempt compounds that are cyclic,

branched, or linear, completely methylated siloxanes, shall be analyzed as

exempt compounds for compliance with Section 223.340 by BAAQMD

Method 43, “Determination of Volatile Methylsiloxanes in Solvent-Based

Coatings, Inks, and Related Materials,” BAAQMD Manual of Procedures,

Volume III, adopted May18, 2005 November 6, 1996, as incorporated by

reference in Section 223.120, (see Section 223.307, VOM content Volatile

Organic Material, and subsection 223.340(b)).

i)

Exempt Compounds - Parachlorobenzotrifluoride (PCBTF). The exempt

compound parachlorobenzotrifluoride, shall be analyzed as an exempt

compound for compliance with Section 223.400 by BAAQMD Method 41,

“Determination of Volatile Organic Compounds in Solvent-Based Coatings

and Related Materials Containing Parachlorobenzotrifluoride,” BAAQMD

Manual of Procedures, Volume III, adopted May 18, 2005 December 20,

1995, as incorporated by reference in Section 223.120, (see Section

223.307, VOM content

Volatile Organic Material, and subsection

223.340(b)).

m)

Methacrylate Traffic Marking Coatings. The VOM content of methacrylate

muticomponent coatings used as traffic marking coatings shall be analyzed

by the procedures in 40 CFR part 59, subpart D, appendix A,

“Determination of Volatile Matter Content of Methacrylate

Multicomponent Coatings Used as Traffic Marking Coatings,” (June 30,

1999 September 11, 1998), as incorporated by reference in Section 223.120,

(see subsection 223.360) or an equivalent method approved by the CARB.

13.

Strike the whole of Subpart D from the rule, including references in the index to the

rule. The USEPA has promulgated an identical rule concerning “Aerosol Coatings”

thus mooting the proposed Subpart D.

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

SUBPART D: AEROSOL COATINGS

Section

223.400

Purpose

223.405

Applicability

223.407

Definitions for Subpart D

223.410

Limits and Requirements for Aerosol Coating Products

223.420

Exemptions

223.430

Most Restrictive Limit

223.440

Labeling Requirements

223.450

Reporting Requirements

223.460

Test Methods

***

SUBPART D: AEROSOL COATINGS

Section 223.400

Purpose

The purpose of this Subpart is to limit emissions of volatile organic materials (VOMs) by

requiring reductions in the VOM content of Aerosol Coating products.

Section 223.405

Applicability

This Subpart shall apply to any person who sells, supplies, offers for sale, applies, or

manufactures aerosol coating products for use in the state of Illinois, except as provided in

Section 223.420.

Section 223.407 Definitions for Subpart D

The definitions

contained in this Section apply only to the provisions of this Subpart.

Unless otherwise defined herein, the definitions of terms used in this Subpart shall have

the meanings specified for those terms in 35 Ill. Adm. Code Part 211.

“Adhesive” means a product used to bond one surface to another.

“Aerosol Coating Product” means a pressurized coating product containing

pigments or resins that dispenses product ingredients by means of a propellant, and

is packaged in a disposable can for hand-held application or for use in specialized

equipment for ground traffic/marking applications.

“Anti-Static

Spray” means a product used to prevent or inhibit the accumulation of

static electricity.

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

“Art Fixative or Sealant” means a clear coating, including art varnish, workable art

fixative, and ceramic coating, which is designed and labeled exclusively for

application to paintings, pencil, chalk, or pastel drawings, ceramic art pieces, or

other closely related art uses, in order to provide a final protective coating or to fix

preliminary stages of artwork while providing a workable surface for subsequent

revisions.

“Auto Body Primer” means an automotive primer or primer surfacer coating

designed and labeled exclusively to be applied to a vehicle body substrate for the

purposes of corrosion resistance and building a repair area to a condition in which,

after drying, it can be sanded to a smooth surface.

“Automotive Bumper and Trim Product” means a product, including adhesion

promoters and chip sealants, designed and labeled exclusively to repair and refinish

automotive bumpers and plastic trim parts.

“Automotive Underbody Coating” means a flexible coating which contains asphalt

or rubber and is designed and labeled exclusively for use on the underbody of

motor vehicles to resist rust, abrasion and vibration, and to deaden sound.

“

Aviation Propeller Coating” means a coating designed and labeled exclusively to

provide abrasion resistance and corrosion protection for aircraft propellers.

“Aviation or Marine Primer” means a coating designed and labeled exclusively to

meet federal specification TT-P-1757.

“Base Reactive Organic Gas Mixture” (Base ROG Mixture) means the mixture of

reactive organic gases utilized in deriving the MIR scale.

“Belt Dressing” means a product applied on auto fan belts, water pump belting,

power transmission belting, and industrial and farm machinery belting to prevent

slipping, and to extend belt life.

“Cleaner” means a product designed and labeled primarily to remove soil or other

contaminants from surfaces.

“Clear Coating” means a coating which is colorless, containing resins but no

pigments except flatting agents, and is designed and labeled to form a transparent

or translucent solid film.

“Coating Solids” means the nonvolatile portion of an aerosol coating product,

consisting of the film forming ingredients, including pigments and resins.

“Commercial Application” means the use of aerosol coating products in the

production of goods, or the providing of services for profit, including touch-up and

repair.

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

“Corrosion Resistant Brass, Bronze, or Copper Coating” means a clear coating

designed and labeled exclusively to prevent tarnish and corrosion of uncoated

brass, bronze, or copper metal surfaces.

“Distributor” means any person to whom a consumer

product is sold or supplied

for the purposes of resale or distribution in commerce, except that manufacturers,

retailers, and consumers are not distributors.

“Dye” means a product containing no resins which is used to color a surface or

object without building a film.

“Electrical Coating” means a coating designed and labeled exclusively as such,

which is used exclusively to coat electrical components such as wire windings on

electric motors to provide insulation and protection from corrosion.

“Enamel” means a coating which cures by chemical cross-linking of its base resin

and is not resoluble in its original solvent.

“Engine Paint” means a coating designed and labeled exclusively to coat engines

and their components.

“Exact Match Finish, Engine Paint” means a coating which meets all of the

following criteria:

The product is designed and labeled exclusively to exactly match the

color of an original, factory-applied engine paint;

The product is labeled with the manufacturer's name for which they

were formulated; and

The product is labeled with one of the following:

The original equipment manufacturer's (O.E.M.) color code

number;

The color name; or

Other designation identifying the specific O.E.M. color to the

purchaser.

“Exact Match Finish, Automotive” means a topcoat which meets all of the

following

criteria:

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

The product is designed and labeled exclusively to exactly match the

color of an original, factory-applied automotive coating during the

touch-up of automobile finishes;

The product is labeled with the manufacturer's name for which they

were formulated; and

The product is labeled with one of the following:

The original equipment manufacturer's (O.E.M.) color code

number;

The color name; or

Other designation identifying the specific O.E.M. color to the

purchaser. Not withstanding the foregoing, automotive clear

coatings designed and labeled exclusively for use over

automotive exact match finishes to replicate the

original

factory applied finish shall be

considered to be automotive

exact match finishes.

“Exact Match Finish, Industrial” means a coating which meets all of the following

criteria:

The product is designed and labeled exclusively to exactly match the color

of an original, factory-applied industrial coating during the touch-up of

manufactured products;

The product is labeled with the manufacturer's name for which they

were formulated; and

The product is labeled with one of the following:

The original equipment manufacturer's (O.E.M.) color code

number;

The color name; or

Other designation identifying the specific O.E.M. color to the

purchaser.

“Flat Paint Products” means a coating which,

when fully dry, registers specular

gloss less than or equal to 15 on an 85

o

gloss meter, or less than or equal to five on

a 60

o

gloss meter, or which is labeled as a flat coating.

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

“Flatting Agent” means a compound added to a coating to reduce the gloss of the

coating without adding color to the coating.

“Floral Spray” means a coating designed and labeled exclusively for use on fresh

flowers, dried flowers, or other items in a floral arrangement for the purposes of

coloring, preserving or protecting their appearance.

“Fluorescent Coating” means a coating labeled as such, which converts absorbed

incident light energy into emitted light of a different hue.

“Glass Coating” means a coating designed and labeled exclusively for use on glass

or other transparent material to create a soft, translucent light effect, or to create a

tinted or darkened color while retaining transparency.

“Ground Traffic/Marking Coating” means a coating designed and labeled

exclusively to be applied to dirt, gravel, grass, concrete, asphalt, warehouse floors,

or parking lots. Such coatings must be in a container equipped with a valve and

sprayhead designed to direct the spray toward the surface when the can is held in

an inverted vertical position.

“High-Temperature Coating” means a high performance coating, excluding engine

paint, labeled and formulated for application to substrates exposed continuously or

intermittently to temperatures above 204°C (400°F).

“Hobby/Model/Craft Coating” means a coating which is designed and labeled

exclusively for hobby applications and is sold in aerosol containers of six ounces

by weight or less.

“Ingredient” means a component of an aerosol coating product.

“Ink” means a fluid or viscous substance used in the printing industry to produce

letters, symbols or illustrations, but not to coat an entire surface.

“Lacquer” means a thermoplastic film-forming material dissolved in organic

solvent, which dries primarily by solvent evaporation, and is resoluble in its

original solvent.

“Layout Fluid” (or toolmaker's

ink) means a coating designed and labeled

exclusively to be sprayed on metal, glass or plastic, to provide a glare-free surface

on which to scribe designs, patterns or engineering guide lines prior to shaping the

piece.

“Leather preservative or

cleaner” means a leather treatment material applied

exclusively to clean or preserve leather.

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

“Lubricant” means a substance such as oil, petroleum distillates, grease, graphite,

silicone, lithium, etc. that is used to reduce friction, heat, or wear when applied

between surfaces.

“Manufacturer” means any person who imports, manufactures, assembles,

produces, packages, repackages, or relabels a consumer product.

“Marine Spar Varnish” means a coating designed and labeled exclusively to

provide a protective sealant for marine wood products.

“Maskant” means a coating applied directly to a component to protect surface areas

when chemical milling, anodizing, aging, bonding, plating, etching, or performing

other chemical operations on the surface of the component.

“Maximum Incremental Reactivity” (MIR) means the maximum change in weight

of ozone formed by adding a compound to the “Base ROG Mixture” per weight of

compound added, expressed to hundredths of a gram (g O

3

/g ROC). MIR values

for individual compounds and hydrocarbon solvents are specified in Appendices A

and B to this Part.

“Metallic Coating” means a topcoat which contains at least 0.5 percent by weight

elemental metallic pigment in the formulation, including propellant, and is labeled

as “metallic”, or with the name of a specific metallic finish such as “gold,”

“silver,” or “bronze.”

“Mold Release” means a coating applied to molds to prevent products from

sticking to the surfaces of the mold.

“Multi-Component Kit” means an aerosol spray paint system which requires the

application of more than one component (e.g. foundation coat and top coat), where

both components are sold together in one package.

“Nonflat Paint Product” means a coating which, when fully dry, registers a

specular gloss greater than 15 on an 85

o

gloss meter or greater than five on a 60

o

gloss meter.

“Ozone” means a colorless gas with a pungent odor, having the molecular form O

3

.

“Percent VOM By Weight” means the ratio of the weight of VOM to the total

weight of the product contents expressed as follows:

Percent VOM By Weight = (W

VOM

/ W

total

) x 100

Where:

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

For products containing no water and no volatile compounds exempt

from the definition of VOM: W

VOM

= the weight of volatile

materials;

For products containing water or exempt compounds: W

VOM

= the

weight of volatile compounds, less water, and less compounds

exempt

from the VOM definition in Section 223.407; and

W

total

= the total weight of the product contents.

“Photograph Coating” means a coating designed

and labeled exclusively to be

applied to finished photographs to allow corrective retouching, protection of the

image, changes in gloss level, or to cover fingerprints.

“Pleasure Craft” means privately owned vessels used for noncommercial purposes.

“Pleasure Craft Finish Primer/Surfacer/Undercoater” means a coating designed and

labeled exclusively to be applied prior to the application of a pleasure craft topcoat

for the purpose of corrosion resistance and adhesion of the topcoat, and which

promotes a uniform surface by filling in surface imperfections.

“Pleasure Craft Topcoat” means a coating designed and labeled exclusively to be

applied to a pleasure craft as a final coat above the waterline and below the

waterline when stored out of water. This category does not include clear coatings.

“Polyolefin Adhesion Promoter” means a coating designed and labeled exclusively

to be applied to a polyolefin or polyolefin copolymer surface of automotive body

parts, bumpers, or trim parts to provide a bond between the surface and subsequent

coats.

“Primer” means for purposes of this Part, a coating labeled and formulated for

application to a substrate to provide a firm bind between the substrate and

subsequent coats.

“Product-Weighted

MIR” (PWMIR) means the sum of all weighted-MIR for all

ingredients in a product subject to this article. The PWMIR is the total product

reactivity expressed to hundredths of a gram of ozone formed per gram of product

(excluding container and packaging) and calculated according to the following

equations:

Weighted MIR (Wtd-MIR) ingredient = MIR x Weight fraction

ingredient,

and,

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

Product Weighted MIR = (Wtd-MIR)

1

+ (Wtd-MIR)

2

+…+ (Wtd-

MIR)

n

Where,

MIR = ingredient MIR, as specified in Section 223.410(m);

Wtd-MIR = MIR of each ingredient in a product multiplied by the

weight fraction of that ingredient, as shown in (a);

1,2,3,...,n = each ingredient in the product up to the total n ingredients

in the product.

“Propellant” means a liquefied or compressed

gas that is used in whole or in part to

expel a liquid or any other material from the same self-pressurized container or

from a separate container.

“Reactivity Limit” means the maximum “Product-Weighted MIR” allowed in an

aerosol coating product that is subject to the limits specified in Section 223.410(c)

for a specific category, expressed as g O

3

/g product.

“Reactive Organic Compound (ROC)” means any compound that has the potential,

once emitted, to contribute to ozone formation in the troposphere.

“Responsible Party” means the company, firm or establishment which is listed on

the product's label. If the label lists two companies, firms or establishments, the

responsible party is the party which the product was “manufactured for” or

“distributed by,” as noted on the label.

“Retailer” means any person who sells, supplies, or offers consumer products for

sale directly to consumers.

“Retail Outlet” means for purposes of this Part, any establishment at which

consumer products are sold, supplied, or offered for sale directly to consumers.

“Rust Converter” means a product designed and labeled exclusively to convert rust

to an inert material and which contains a minimum acid content of 0.5 percent by

weight, and a maximum coating solids content of 0.5 percent by weight.

“Shellac Sealer” means a clear or pigmented coating formulated solely with the

resinous secretion of the lac beetle (Laccifer lacca), thinned with alcohol, and

formulated to dry by evaporation without a chemical reaction.

“Slip-Resistant

Coating” means a coating designed and labeled exclusively as such,

which is formulated with synthetic grit and used as a safety coating.

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

“Spatter Coating/Multicolor Coating” means a coating labeled exclusively as such

wherein spots, globules, or spatters of contrasting colors appear on or within the

surface of a contrasting or similar background.

“Stain” means a clear, semi-transparent, or opaque coating labeled and formulated

to change the color of a surface, but not conceal the grain pattern or texture.

“Upper-Limit Kinetic Reactivity” (ULKR) means the maximum percentage of the

emitted ROC which has reacted. For Subpart D, the ULKR is one hundred percent

and is used to calculate the ULMIR.

“Upper-Limit Mechanistic Reactivity” (ULMR) means the maximum gram(s) of

ozone formed per gram of reactive organic compound (ROC) reacting. The ULMR

is used to calculate the ULMIR.

“Upper-Limit

MIR” (ULMIR) means the upper-limit kinetic reactivity (ULKR)

multiplied by the upper-limit mechanistic reactivity (ULMR), as calculated using

the following equation:

ULMIR = Upper Limit KR x Upper Limit MR.

The units for ULMIR are g O

3

/g ROC.

“Vinyl/Fabric/Leather/Polycarbonate Coating” means a coating designed and

labeled exclusively to coat vinyl, fabric, leather, or polycarbonate substrates.

“Webbing/Veiling Coating” means a coating designed and labeled exclusively to

provide a stranded to spider webbed appearance when applied.

“Weight Fraction” means the weight of an ingredient divided by the total net

weight of the product, expressed to thousandths of a gram of ingredient per gram of

product (excluding container and packaging). The weight fraction is calculated

according to the following equation:

Weight Fraction =

Weight of the Ingredient

_______________________

Total Product Net Weight

(excluding container and packaging).

“Weld-Through

Primer” means a coating designed and labeled exclusively to

provide a bridging or conducting effect for corrosion protection following welding.

“Wood Stain” means a coating which is formulated to change the color of a wood

surface but not conceal the surface.

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

“Wood Touch-Up/Repair/Restoration” means a coating designed and labeled

exclusively to provide an exact color or sheen match on finished wood products.

“Working Day” means any day between Monday through Friday, inclusive, except

for days that are federal holidays.

Section 223.410

Limits and Requirements for Aerosol Coating Products

a)

Compliance with Limits. Aerosol coating products manufactured

beginning January 1, 2009, shall comply with the reactivity requirements

specified in Section 223.410(b).

b)

Reactivity Limits for Aerosol Coating Products.

Except as provided in Sections 223.410(a) and 223.420, no person shall

sell, supply, offer for sale, apply, or manufacture for use in Illinois, any

aerosol coating product which, at the time of sale, use, or manufacture,

contains reactive organic compounds that have a PWMIR in excess of the

limits specified below after January 1, 2009.

Aerosol Coating Category

Product-Weighted

MIR in

Grams Ozone per

Gram Product (gO

3

/g

product)

1) General Coatings

A) Clear Coatings

1.50

B) Flat Paint Products

1.20

C) Fluorescent Coatings

1.75

D) Metallic Coatings

1.90

E) Nonflat Paint Products

1.40

F) Primers

1.20

2) Specialty Coatings

A) Art Fixatives or Sealants

1.80

B) Auto Body Primers

1.55

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

C) Automotive Bumper

1.75

and Trim Products

D) Aviation or Marine Primers

2.00

E) Aviation Propeller Coatings

2.50

F) Corrosion Resistant Brass,

1.80

Bronze, or Copper Coatings

G) Exact Match Finishes:

1) Engine Enamel

1.70

2) Automotive

1.50

3) Industrial

2.05

H) Floral Sprays

1.70

I) Glass Coatings

1.40

J) Ground Traffic/Marking Coatings

1.20

K) High Temperature Coatings

1.85

L) Hobby/Model/Craft Coatings:

1) Enamel

1.45

2) Lacquer

2.70

3) Clear or Metallic

1.60

M) Marine Spar Varnishes

0.90

N) Photograph Coatings

1.00

O) Pleasure Craft Finish Primers,

1.05

Surfacers or Undercoaters

P) Pleasure Craft Topcoats

0.60

Q) Polyolefin Adhesion Promoters

2.50

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

R) Shellac Sealers:

1) Clear

1.00

2) Pigmented

0.95

S) Slip-Resistant Coatings

2.45

T) Spatter/Multicolor Coatings

1.05

U) Vinyl/Fabric/Leather/Polycarbonate Coatings

1.55

V) Webbing/Veil Coatings

0.85

W) Weld-Through Primers

1.00

X) Wood Stains

1.40

Y) Wood Touch-Up, Repair

1.50

or Restoration Coatings

c)

If an aerosol coating product is subject to both a general coating limit and a

specialty coating limit, as listed in subsection 223.410(b), and the product

meets all the criteria of the applicable specialty coating category as defined

in Section 223.407, then the specialty coating limit shall apply instead of

the general coating limit.

d)

Notwithstanding the provisions of Sections 223.410(c) and 223.430, high

temperature coatings that contain at least 0.5 percent by weight of an

elemental metallic pigment in the formulation, including propellant, shall

be subject to the limit specified for metallic coatings.

e)

Notwithstanding the provisions of Section 223.410(a) and (b), an aerosol

coating product manufactured prior to each of the effective dates specified

for that product in Section 223.410(b) may be sold, supplied, offered for

sale, or applied for up to January 1, 2012. This subsection (f) does not

apply to any product which does not display on the product container or

package the date on which the product was manufactured, or a code

indicating such date.

f)

Products Containing Methylene Chloride or Trichloroethylene.

1)

For any aerosol coating product subject to the reactivity limits

specified in Section 223.410(b), no person shall sell, supply, offer

for sale, apply, or manufacture for use in Illinois any aerosol coating

product which contains methylene chloride or trichloroethylene.

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

2)

The requirements of this Section shall not apply to any aerosol

coating product containing methylene chloride or trichloroethylene

that is present as an impurity in a combined amount equal to or less

than 0.01% by weight of the product.

g)

Products Containing Perchloroethylene or Ozone Depleting Substances.

1)

For any aerosol coating product subject to the reactivity limits

specified in Section 223.410(b), no person shall sell, supply, offer

for sale, apply, or manufacture for use in Illinois any aerosol coating

product which contains perchloroethylene.

2)

For any aerosol coating product subject to the reactivity limits

specified in Section 223.410(b), no person shall sell, supply, offer

for sale, apply, or manufacture for use in Illinois any aerosol coating

product which contains an ozone depleting substance identified by

the USEPA in the Code of Federal Regulations, 40 CFR Part 82,

Subpart A, under Appendices A and B, July 1, 1998.

3)

The requirements of Section 223.410(g)(1) and (g)(2) shall not

apply to any aerosol coating product containing perchloroethylene,

or an ozone depleting substance as identified in Section

223.410(g)(1) or (g)(2), that are present as impurities in a combined

amount equal to or less than 0.01% by weight of the product.

h)

Multicomponent Kits.

1)

No person shall sell, supply, offer for sale, apply, or manufacture for

use in Illinois any multi-component kit, as defined in Section

223.407, in which the total weight of VOM and methylene chloride

contained in the multi-component kit (Total VOM + MC)

actual

is

greater than the total weight of VOM and methylene chloride that

would be allowed in the multi-component kit if each component

product in the kit had separately met the applicable VOM standards

(Total VOM+ MC)

standard

as calculated below:

(Total VOM + MC)

actual

= (VOM

1

x W

1

) + (MC

1

x W

1

) + (VOM

2

x

W

2

) + (MC

2

x W

2

) + (VOM

n

x W

n

) + (MC

n

x W

n

)

(Total VOM + MC )

standard

= (STD

1

x W

1

) + (STD

2

x W

2

) + (STD

n

x

W

n

)

Where:

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

VOM =

the percent by weight VOM of the

component product

MC

=

the percent by weight methylene chloride of

the Component product

STD

=

the VOM standard specified in Section

223.410(a) which applies to the component

product

W

=

the weight of the product contents

(excluding container)

Subscript 1 denotes the first component product in the

kit

Subscript 2 denotes the second component product in the kit

Subscript n denotes any additional component product

2)

No person shall sell, supply, offer for sale, apply, or manufacture for

use in Illinois any multi-component kit, as defined in Section

223.407, in which the Kit PWMIR is greater than the Total

Reactivity Limit. The Total Reactivity Limit represents the limit

that would be allowed in the multi-component kit if each component

product in the kit had separately met the applicable Reactivity

Limit. The Kit PWMIR and Total Reactivity Limit are calculated as

in equations (A), (B) and (C) below:

A)

Kit PWMIR = (PWMIR

(1)

x W

1

) + (PWMIR

(2)

x W

2

) +…+

(PWMIR

(n)

x W

n

)

B)

Total Reactivity Limit = (RL

1

x W

1

) + (RL

2

x W

2

) +…+ (RL

n

x

W

n

)

C)

Kit PWMIR

≤

Total Reactivity Limit

Where:

W

=

the weight of the product contents (excluding

container)

RL

=

the Reactivity Limit specified in Section 223.410(b)

Subscript 1 denotes the first component product in the kit

Subscript 2 denotes the second component

product in the kit

Subscript n denotes any additional component product

i)

No person shall sell, supply, offer for sale, apply, or manufacture for use in

the state of Illinois any aerosol coating product assembled by adding bulk

paint to aerosol containers of propellant, unless such products comply with

the reactivity limits specified in Section 223.410(b) for products subject to

those limits.

j)

Assignment of Maximum Incremental Reactivity (MIR) Values.

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

1)

In order to calculate the PWMIR of aerosol coating products as

specified in Section 223.407, the MIR values of product ingredients

are assigned as follows:

A)

Any ingredient which does not contain carbon is assigned a

MIR value of 0.0.

B)

Any aerosol coating solid, including but not limited to

resins, pigments, fillers, plasticizers, and extenders is

assigned a MIR value of 0.0.

C)

For any ROC not covered under subparagraphs (A) and (B)

of this paragraph (1), each ROC is assigned the MIR value

set forth in Appendices A and B to this Part.

D)

Except as provided in paragraph (3) of this subsection, only

ROCs listed in Appendices A and B to this Part, can be used

to comply with the reactivity limits specified in Section

223.410(b).

E)

All individual compounds in an amount equal to or

exceeding 0.1 percent shall be considered ingredients in

calculating the PWMIR. Such individual compounds shall

be considered ingredients whether or not they are reported

by the manufacturer pursuant to Appendix A and B.

2)

Calculating PWMIR Values.

A)

The MIR values dated January 1, 2009, shall be used to

calculate the PWMIR for aerosol coating products.

B)

If a new ROC is added to Appendices A and B to this

regulation, then the new ROC may be used in aerosol

coating products, and the MIR value for the new ROC shall

be used to calculate the PWMIR after the effective date of

the MIR value.

3)

The MIR value for any aromatic hydrocarbon solvent with a boiling

range different from the ranges specified in subsection (b) of

Appendix B of this Part shall be assigned as follows:

A)

If the solvent dry point is lower than or equal to 420 degrees

F, the MIR value specified in subsection (b) of Appendix B

of this Part for Bin 23 shall be used.

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

B)

If the solvent initial boiling point is higher than 420 degrees

F, the MIR value specified in subsection (b) of Appendix B

of this Part for Bin 24 shall be used.

Section 223.420

Exemptions

a)

This Subpart shall not apply to aerosol lubricants, mold releases,

automotive underbody coatings, electrical coatings, cleaners, belt dressings,

anti-static sprays, layout fluids and removers, adhesives, maskants, rust

converters, dyes, inks, and leather preservatives or cleaners.

b)

This Subpart shall not apply to any aerosol coating product manufactured in

Illinois for shipment and use outside of Illinois.

c)

The provisions of this Subpart shall not apply to a manufacturer, distributor,

or responsible party who sells, supplies, or offers for sale in Illinois an

aerosol coating product that does not comply with the limits specified in

subsection 223.410(b), as long as the manufacturer, distributor, or

responsible party can demonstrate both that the aerosol coating product is

intended for shipment and use outside of Illinois, and that the manufacturer,

distributor, or responsible party has taken reasonable prudent precautions to

assure that the aerosol coating product is not distributed to Illinois. This

subsection (c) does not apply to aerosol coating products that are sold,

supplied, or offered for sale by any person to retail outlets in Illinois.

d)

The requirements in subsection 223.410(b) prohibiting the application of

aerosol coating products that exceed the limits specified in the subsection

223.410(b) shall apply only to commercial application of aerosol coating

products.

Section 223.430

Most Restrictive Limit

Except as otherwise provided in Section 223.410(c), if anywhere on the container of any

aerosol coating product subject to the specified limits in subsection 223.410(b), or on any

sticker or label affixed thereto, or in any sales or advertising literature, any representation

is made that the product may be used as, or is suitable for use as a product for which a

lower limit is specified, then the lowest applicable limit shall apply.

Section 223.440

Labeling Requirements

a)

Both the manufacturer and responsible party for each aerosol coating

product subject to this Subpart shall ensure that all products clearly display

the following information on each product container which is manufactured

90 days or later after the effective date of this Subpart.

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

1)

The applicable reactivity limit for the product that is specified in

Section 223.410(b);

2)

The aerosol coating category as defined in Section 223.407, or an

abbreviation of the coating category; and

3)

The day, month, and year on which the product was manufactured,

or a code indicating such date.

b)

The information required in Section 223.440(a), shall be displayed on the

product container such that it is readily observable without removing or

disassembling any portion of the product container or packaging. For the

purposes of this subsection, information may be displayed on the bottom of

a container as long as it is clearly legible without removing any product

packaging.

c)

No person shall remove, alter, conceal, or deface the information required

in Section 223.440(a) prior to final sale of the product.

d)

For any aerosol coating product subject to Section 223.410(a), if the

manufacturer or responsible party uses a code indicating the date of

manufacture or an abbreviation of the coating category as defined in

Section 223.407, an explanation of the code or abbreviation must be filed

with the Agency prior to the use of the code or abbreviation.

Section 223.450

Reporting Requirements

a)

Any responsible party for an aerosol coating product subject to this article

which is sold, supplied, or offered for sale in Illinois, must supply the

Agency, upon request, with the following information within 30 days of the

effective date of this Subpart: the company name, mail address, contact

person, and the telephone number of the contact person. For responsible

parties who do not manufacture their own aerosol coating products, the

responsible party shall also supply the information specified in this

subsection (a) for those manufacturers which produce products for the

responsible party. The responsible party shall also notify the Agency

within 30 days of any change in the information supplied to the Agency

pursuant to this subsection (a).

b)

Upon 30 days written notice, each manufacturer or responsible party

subject to this Subpart shall submit to the Agency a written report with all

of the following information for each product they manufacture under their

name or another company's name:

1)

The brand name of the product;

2)

Upon request, a copy of the product label;

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

3)

The owner of the trademark or brand names;

4)

The product category as defined in Section 223.407;

5)

The annual Illinois sales in pounds per year and the method

used to calculate Illinois annual sales;

6)

Product formulation data:For products subject to the reactivity limits

specified in Section 223.410(c), the WMIR and the weight fraction

of all ingredients including: water, solids, each ROC, and any

compounds assigned a MIR value of zero as specified in Section

223.410(j), and Appendices A or B to this Part. Each ROC must be

reported as an ingredient if it is present in an amount greater than or

equal to 0.1% by weight of the final aerosol coatings formulation. If

an individual ROC is present in an amount less than 0.1% by

weight, then it does not need to be reported as an ingredient. In

addition, an impurity that meets the following definition does not

need to be reported as an ingredient.

For the purpose of this section, an “impurity” means an individual

chemical compound present in a raw material which is incorporated

into the final aerosol coatings formulation, if the compound is

present below the following amounts in the raw material:

A)

For individual compounds that are carcinogens, as

defined in 29 CFR section 1910.1200(d)(4), each

compound must be present in an amount less than

0.1% by weight in order to be considered an

“impurity.”

B)

For all other compounds present in a raw material,

a compound must be present in an amount less

than one percent by weight in order to be considered

an “impurity”;

7)

An identification of each product brand name as a “household,”

“industrial,” or “both” product; and

8)

Any other information necessary to determine the emissions or the

product-weighted MIR from aerosol coating products. The

information requested in this Subsection 223.450(b) may be

supplied as an average for a group of aerosol coating products

within the same coating category when the products do not vary in

VOM content by more than two percent (by weight), and the

coatings are based on the same resin type, or the products are color

variations of the same product (even if the coatings vary by more

than two percent in VOM content).

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

c)

Upon written request, the responsible party for aerosol coating products subject

to this Subpart shall supply the Agency with a list of all exempt compounds

contained in any aerosol coating product within 15 working days.

Section 223.460

Test Methods

Compliance with the requirements of this Subpart shall be determined by using the

following test methods, which are incorporated by reference herein. Alternative test

methods which are shown to accurately determine the VOM content, ingredient name and

weight percent of each ingredient, exempt compound content, metal content, specular

gloss, or acid content may also be used after approval in writing by the Agency:

a)

The VOM content of all aerosol coating products subject to the provisions

of this Subpart shall be determined by the procedures set forth in “Air

Resources Board Method 310, Determination of Volatile Organic

Compounds (VOM) in Consumer Products and Reactive Organic

Compounds in Aerosol Coating Products,” adopted September 25, 1997,

and as last amended on May 5, 2005.

b)

Testing for Products Subject to the Reactivity Limits Specified in Section

223.410(b).

1)

The ingredients and the amount of each ingredient of all aerosol

coating products subject to the provisions of this Subpart shall be

determined by the procedures set forth in “Air Resources Board

Method 310, Determination of Volatile Organic Compounds (VOM)

in Consumer Products,” adopted September 25, 1997 and as last

amended on May 5, 2005.

2)

Upon written notification from the Agency, the aerosol coating

manufacturer shall have 10 working days to provide to the Agency

the following information for products selected for testing:

A)

The product category as defined in Section 223.407;

B)

The PWMIR;

C)

The weight fraction of all ingredients including: water,

solids, each ROC, and any compounds assigned a MIR value

of zero as specified in sections 223.410(j), and Appendices

A and B to this Part. Each ROC must be reported as an

ingredient if it is present in an amount greater than or equal

to 0.1% by weight of the final aerosol coatings formulation.

If an individual ROC is present in an amount less than 0.1%

by weight, then it does not need to be reported as an

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

ingredient. In addition, an impurity that meets the following

definition does not need to be reported as an ingredient.

For the purpose of this section, an “impurity”

means an

individual chemical compound present in a raw material

which is incorporated into the final aerosol coatings

formulation, if the compound is present below the following

amounts in the raw material:

i)

For individual compounds that are carcinogens, as

defined in 29 CFR Section 1910.1200(d)(4), each

compound must be present in an amount less than

0.1% by weight in order to be considered an

“impurity.”

ii)

For all other compounds present in a raw material, a

compound must be present in an amount less than

one percent by weight in order to be considered an

“impurity”;

D)

Any other information necessary to determine the PWMIR

of the aerosol coating products to be tested.

3)

Final determination of the PWMIR of the aerosol coatings shall be

determined using the information obtained from Appendix A and B.

c)

Metal Content. The metal content of metallic aerosol coating products shall

be determined by SCAQMD Test Method 318-95 “Determination of

Weight Percent Elemental Metal in Coatings by X-ray Diffraction” July

1996, which is incorporated by reference in Section 223.120.

d)

Specular Gloss. Specular gloss of flat and nonflat coatings shall be

determined by ASTM Method D-523-89, March 31, 1989, which is

incorporated by reference in Section 223.120.

e)

Acid Content. The acid content of rust converters shall be determined by

ASTM Method D-1613-96, “Standard Test Method for Acidity in Volatile

Solvents and Chemical Intermediates Used in Paint, Varnish. Lacquer, and

Related Products, May 10, 1996, which is incorporated by reference in

Section 223.120.

f)

Lacquers. Lacquer aerosol coating products shall be identified according to

the procedures specified in ASTM Method D-5043-90, “Standard Test

Methods for Field Identification of Coatings,” April 27, 1990, which is

incorporated by reference in Section 223.120.

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

14.

Strike the whole of Appendix A from the rule, including references in the index to the

Appendix. The USEPA has promulgated an identical rule concerning “Aerosol

Coatings” thus mooting the proposed Subpart D and related appendices.

APPENDIX A

MAXIMUM INCREMENTAL REACTIVITY

***

APPENDIX A

MAXIMUM INCREMENTAL REACTIVITY

Tables of Maximum Incremental Reactivity (MIR) Values

MIR Values for Compounds.

Organic Compound

MIR Value

1.

Carbon Monoxide

0.06

2.

Methane

0.01

3.

Ethane

0.31

4.

Propane

0.56

5.

n-Butane

1.33

6.

n-Pentane

1.54

7.

n-Hexane

1.45

8.

n-Heptane

1.28

9.

n-Octane

1.11

10. n-Nonane

0.95

11. n-Decane

0.83

12. n-Undecane

0.74

13. n-Dodecane

0.66

14.

n-Tridecane

0.62

15. n-Tetradecane

0.58

16.

n-Pentadecane

0.53

17.

n-C16

0.52

18. n-C17

0.49

19. n-C18

0.44

20.

n-C19

0.44

21. n-C20

0.42

22.

n-C21

0.40

23. n-C22

0.38

24. Isobutane

1.35

25.

Isopentane

1.68

26. Neopentane

0.69

27.

Branched C5 Alkanes

1.68

28.

2,2-Dimethyl Butane

1.33

29.

2,3-Dimethyl Butane

1.14

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

30. 2-Methyl Pentane (Isohexane)

1.80

31. 3-Methyl Pentane

2.07

32. Branched C6 Alkanes

1.53

33.

2,2,3-Trimethyl Butane

1.32

34.

2,2-Dimethyl Pentane

1.22

35. 2,3-Dimethyl Pentane

1.55

36. 2,4-Dimethyl Pentane

1.65

37. 2-Methyl Hexane

1.37

38.

3,3-Dimethyl Pentane

1.32

39.

3-Methyl Hexane

1.86

40. Branched C7 Alkanes

1.63

41. 2,2,3,3-Tetramethyl Butane

0.44

42. 2,2,4-Trimethyl Pentane (Isooctane)

1.44

43.

2,2-Dimethyl Hexane

1.13

44.

2,3,4-Trimethyl Pentane

1.23

45. 2,3-Dimethyl Hexane

1.34

46. 2,4-Dimethyl Hexane

1.80

47. 2,5-Dimethyl Hexane

1.68

48. 2-Methyl Heptane

1.20

49. 3-Methyl Heptane

1.35

50. 4-Methyl Heptane

1.48

51. Branched C8 Alkanes

1.57

52. 2,2,5-Trimethyl Hexane

1.33

53. 2,3,5-Trimethyl Hexane

1.33

54. 2,4-Dimethyl Heptane

1.48

55. 2-Methyl Octane

0.96

56. 3,3-Diethyl Pentane

1.35

57. 3,5-Dimethyl Heptane

1.63

58. 4-Ethyl Heptane

1.44

59. 4-Methyl Octane

1.08

60.

Branched C9 Alkanes

1.25

61. 2,4-Dimethyl Octane

1.09

62.

2,6-Dimethyl Octane

1.27

63.

2-Methyl Nonane

0.86

64. 3,4-Diethyl Hexane

1.20

65. 3-Methyl Nonane

0.89

66.

4-Methyl Nonane

0.99

67. 4-Propyl Heptane

1.24

68.

Branched C10 Alkanes

1.09

69. 2,6-Dimethyl Nonane

0.95

70. 3,5-Diethyl Heptane

1.21

71.

3-Methyl Decane

0.77

72. 4-Methyl Decane

0.80

73.

Branched C11 Alkanes

0.87

74.

2,3,4,6-Tetramethyl Heptane

1.26

75.

2,6-Diethyl Octane

1.09

Electronic Filing - Received, Clerk's Office, July 10, 2008

* * * * * * * Errata Sheet and PC #3 * * * * *

76. 3,6-Dimethyl Decane

0.88

77. 3-Methyl Undecane

0.70

78. 5-Methyl Undecane

0.72

79.

Branched C12 Alkanes

0.80

80.

2,3,5,7-Tetramethyl Octane

1.06

81. 3,6-Dimethyl Undecane

0.82

82. 3,7-Diethyl Nonane

1.08

83. 3-Methyl Dodecane

0.64

84.

5-Methyl Dodecane

0.64

85.

Branched C13 Alkanes

0.73

86. 2,4,6,8-Tetramethyl Nonane

0.94

87. 2,3,6-Trimethyl 4-Isopropyl Heptane

1.24

88. 3,7-Dimethyl Dodecane

0.74

89.

3,8-Diethyl Decane

0.68

90.

3-Methyl Tridecane

0.57

91. 6-Methyl Tridecane

0.62

92. Branched C14 Alkanes

0.67

93. 2,4,5,6,8-Pentamethyl Nonane

1.11

94. 2-Methyl 3,5-Diisopropyl Heptane

0.78

95. 3,7-Dimethyl Tridecane

0.64

96. 3,9-Diethyl Undecane

0.62

97. 3-Methyl Tetradecane

0.53

98. 6-Methyl Tetradecane

0.57

99. Branched C15 Alkanes

0.60

100. 2,6,8-Trimethyl 4-Isopropyl Nonane

0.76

101. 3-Methyl Pentadecane

0.50

102. 4,8-Dimethyl Tetradecane

0.55

103. 7-Methyl Pentadecane

0.51

104. Branched C16 Alkanes

0.54

105. 2,7-Dimethyl 3,5-Diisopropyl Heptane

0.69

106.

Branched C17 Alkanes

0.51

107. Branched C18 Alkanes

0.48

108.

Cyclopropane

0.10

109.

Cyclobutane

1.05

110. Cyclopentane

2.69

111. Cyclohexane

1.46

112.

Isopropyl Cyclopropane

1.52

113. Methylcyclopentane

2.42

114.

C6 Cycloalkanes

1.46

115. 1,3-Dimethyl Cyclopentane

2.15

116. Cycloheptane

2.26

117.

Ethyl Cyclopentane

2.27

118. Methylcyclohexane

1.99