SIERRA

CLUB

n

p

Ficru

cic

r

E

s

FvFl

E

ce

ti

1-; (

?

L

FOUNDED 1893

MAY 0 7 2008

Heart of Illinois Group

P.O. Box 3593, Peoria, 1L 61614

STATE OF

IL

2419 E. Reservoir

Pollution

Control

L INOIS

Board

Peoria, IL 61614-8029

May 7, 2008

Illinois

Pollution Control Board

RE: PCB 08-42

100 W. Randolph St., Suitell-500

Chicago, IL 60601

To the Illinois Pollution Control Board Regarding Case PCB 08-42:

This letter is being sent on behalf of Heart of Illinois Group Sierra Club (HOD, which has nearly

900 members in central Illinois and approximately 600 members in the Peoria metropolitan

area. Our members drink Peoria water and breathe Peoria air. We want a safe environment for our

families and for our future, and we contend that the currently issued IEPA Operating Permit for PDC is

lacking in critical factors to protect the public health and safety and that the issue of this landfill

capacity must be reviewed.

On behalf of HOL I supplied comments and questions at the IEPA Public Hearing, February 28, 2007,

in

Peoria,

as

did other HOI members who spoke regarding the Operating Permit for Peoria Disposal

Company Hazardous Waste Landfill. HOE has concerns related to petitioner Tom Edward's issues

regarding this hazardous waste landfill and the currently issued operating permit.

We ask the Illinois Pollution Control Board to review the following:

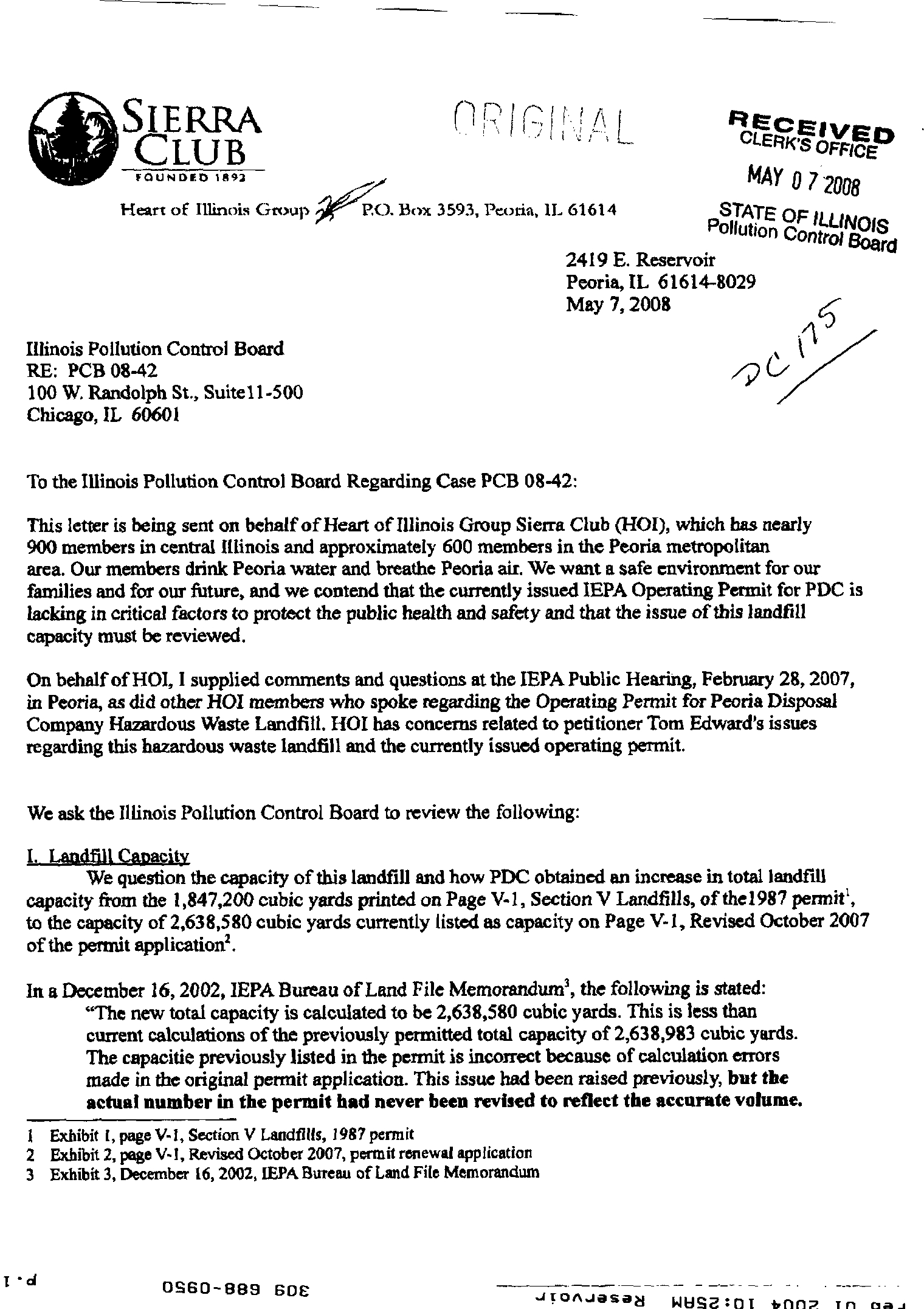

I. Landfill Canacity

We question the capacity of

this

landfill and how PDC obtained an increase in total landfill

capacity from the 1,847,200 cubic yards printed on Page V-1, Section V Landfills, of the1987 permit',

to the capacity of 2,638,580 cubic yards currently listed as capacity on Page V-1, Revised October 2007

of the permit application.

In a December 16, 2002, IEPA Bureau of Land File Memorandum', the following is stated:

"The new total capacity is calculated to be 2,638,580 cubic yards. This is less than

current calculations of the previously permitted total capacity of 2,638,983 cubic yards.

The capacitie previously listed in the permit is incorrect because of calculation errors

made in the original permit application. This issue had been raised previously,

but the

actual number in the permit had never been revised to reflect the accurate volume.

I Exhibit I, page V-1, Section V Landfills, 1987 permit

2 Exhibit 2, page

V- I, Revised October 2007, permit renewal application

3 Exhibit 3, December 16, 2002, IEPA Bureau of Land File Memorandum

I 'd

?

0660-8139 60E

?

JIOAJOSaa

WUS2:01

bon?

in

Page 2

[bold added/ROI] This error has been corrected in the modified permit. The

submittal does not contain a breakdown of the new capacities of Cells C-1

through C-4. I have contacted Ron Welk of PLC to obtain these values,

which will be included in the modified permit."

The modified permit being referred to is the Class 2 Permit Modification Dated December 18, 2002.

We specifically ask the IPCB to look at the Agency (IEPA) public notice regarding this specific year

2002 permit modification', which gives this Description of Project':

"1. Use municipal wastewater treatment plant sludge as part of the final cover

topsoil component.

2. Reconfigure landfill units

with no increase in capacity."

[bold added/H01]

Without significant investigation studying the permits, the public could not know that in this permit

modification the Agency changed the printed permitted capacity of the PDC Hazardous Waste Landfill

from 1,847,200 cubic yards to 2,638,580 cubic yards (in the year 2002 permit modification). This

change should have at least merited an accurate mention in the public notice wording. We question if

this should not also have required a public hearing.

Please also note the comment from above that "The submittal does not contain a breakdown of the new

capacities of Cells C-1 through C-4,"' yet the recalculation of permitted cubic yards in total is accepted.

The recalculation, "... is done by adjusting final contours of Cells C-1 through C-4. Calculations

showing that the units will be able to support the additional loading are included in the appendicies of

the application."'

HOI asks the IPCB to review the "calculated redesign" of the landfill height, weight, and slopes over

Cell CI in particular, and over Cells C2-C4 to verify that the additional load and increased slopes are

protective of the public health and safety The steepest slopes with 4 to 1 raise are at the south edge of

the landfill closest to Pottstown, and in proximity above the Peoria Dog Obedience Training Club on

Southport Road.

The capacity of the C Cells show huge increases from the originally permitted levels:

From Page V-1, ILD000805812, Section V Landfills (1987 permit) 1:

Surface Area

Approximate

?

Dimensions of

Landfill Cell

?

Total

?

Landfill Cell

Designation

?

Capacity (c.Y.1

?

(Acres)

Trench C-1

?303,700

?

7.9

Trench C-2?

252,700

?

6.8

Trench C-3?

346,700

?

7.7

Trench C-4

?

409,500?

11.8

Trench C-5?

303,100

?

7.9

4 Exhibit 4, "Notice of Application for Permit to Manage Waste (LPC-PA16)

a •

d

?

OGG0-8139 SOC

?

JiciAJased WEIG2

r

OT 4002 TO clad

Page 3

From Page V-1, ILD00085812, Section V Landfills Revised: October 2007':

Surface Area

Approximate

Dimensions of

Landfill Cell

Total

Landfill Cell

Dgnation

?

Capacity (c.v.)

(Acres)

Trench C-1

425,929

7.3

Trench C-2

453,846

6.4

Trench C-3

775,939

7.3

Trench C-4

982,865

11.0

The changing capacity figures are one reason HOI views the capacity of this site with complete

discomfiture. The wording of the Agency public notice for the Class 2 Permit Modification of 2002,

stated "no increase in capacity" yet the capacity change of total cubic yards from 1.8 million to 2.6

million was in this document. This is another reason we sincerely request the IPCB review capacity

issues with this site.

We question if this landfill should not already be considered at capacity, and we request that a date

certain for closure of March, 2009, be required in the Operating Permit

While we respect that the Agency has a great many important duties and demands, the fact that this

operating permit was for ten years from 1987 to 1997, and the ten year renewal was actually issued by

the Agency in 2007, ten years after the renewal date, does not help in the public perception of the

priority, level of attention, and scrutiny being given to this hazardous waste landfill. It also seems to

indicate that perhaps due to lack of staff, or other issues, that timely evaluation and issuing of this

RCRA operating permit was delayed ten years, which gives those of us in Peoria great cause for

concerns with the Agency ability to give adequate oversight to the huge details of this facility.

Monitorin g

Should Not

Be

Reduced

On Page VI-5, Revised October 2007 of the RCRA Part B Permit, letter E, Monitoring

Parameters,' the newly issued operating permit allows a change to semi-annual detection monitoring of

up-gradient and point of compliance wells. This is not protective of public health and safety. We ask

that monitoring be required quarterly, as in the previous operating permit.

Page 3

Aquifer level sands below the PDC waste site link to the Sankoty aquifer, which supplies water

for Peoria and outlying communities. It is well documented that sand lenses occur on the east side of

the landfill.', and that two large sand lenses were encountered in the excavation of Cell C-1.7

The change to semi-annual monitoring is particularly of concern because of the time it would

then take for any constituent detected which exhibits a progressive increase over four consecutive

sampling events. Those must be identified (in letter b. below F. Detection Monitoring on page VI – 9 of

5 Exhibit 5,

page

VI- 5,

Revised: October

2007, MD000805812

6

Exhibit 6, Herzog et all, Evaluation of Groundwater Monitoring Programs at Hazardous Waste Disposal Facilities in

Illinois (1988),

Figure

25,

"Cross-section

B-B'

along east side

of

Peoria Disposal Company site"

7

Exhibit

7,

Trench

C-1,

"Sand Scam Overexcavated ..." trench drawing

' al

?

0960-6139 606

?

JI"JaSad

14892:01 4002

to

clad

Page 4

the pennitt and it appears to indicate that two years would elapse before a progressive increase would

be given critical consideration, and that is only if there were four consecutive increases.

There are known problems with the Cell C liners. In his letter to the Peoria County Board, dated

March 27, 2006 , Charles Norris, Geo-Hydro, Inc., has an entire section regarding "Leaking from the

Liner Systems Under Section C,"" where he states:

"The operating record and the monitoring data for leachate production from

Section C demonstrates that the primary basal liners of trenches Cl through

C4 leak, and that the primary basal liner of trench C-1 shows the worst

leakage. Further, the data from trench CI shows that the secondary liner

also leaks."

Mr. Norris goes on to provide supporting details for his conclusion, including the following:

"By 1988 it was recognized that the integrity of the basal liner for trench Cl

was compromised. The leak detection system was producing fluid far in excess

of what could be expected from an intact liner and the chemistry of the fluid

was similar to the leachate from trench Cl with respect to the constituents

present and their relative concentrations. Effective 21-Sep-88, a new permit

condition required PDC to document production rates from the leak

detection system daily, analyze the composition of the fluid from the leak

detection system twice monthly, and report that documentation toe IEPA

monthly (reduced to annual reporting in 1993)."

Mr. Norris goes on with his discussion that there is thready contamination under the PDC waste

disposal complex.'

"It is undisputed that the water under and adjacent to the PDC waste disposal

complex is contaminated with synthetic chemicals. It is undisputed that inorganic

contaminants such as chloride are anomalously high and, in many cases, are known to

have risen above original base line levels. PDC's consultants hold that none of the

contamination that is found under the site is from the PDC waste disposal complex or

the result of PDC operations. In every case, the water beneath the PDC waste

disposal complex has been the victim of migration from some off-site source

or migration upward from the earth beneath the site. Unknown, unproven, and

speculative off-site sources are rationalized as the cause of all on-site contamination.

Simple, downward migration front historic and current waste disposal units and

operations are rejected as possible causes."

A specific example of contamination that HOI asks the IPCB to review, is the nickel

exceedances in five monitoring wells, allowed by the Agency to be due to leaching of nickel from the

monitoring well stainless steel screens. In October, 1993, the Agency accepted PDC 's April, 1993,

explanation of nickel exceedances in wells R121, Al26, R128, R129, and G136 to leaching of nickel in

the stainless steel screens in the monitoring wells.

w

This exemption appears to be continued in the

newly issued operating permit. HOI asks the IPCB to consider our dismay that since 1993, five

monitoring wells have been exempted from nickel exceedances and that there is no evidence that the

Agency has required new monitoring wells for these locations, PVC, or other corrections to the existing

S

Exhibit 8, page V1-9, Revised:

October

2007, ILD000805812

9 Exhibit 9,

Norris,

Charles, March 27, 2006, letter to the Peoria

County

Board

Siting

Committee,

page s 14

10 Exhibit 10, Vol. 14, Section 3, Page 6, 1997 permit

application

draft

0980-889 SCE

--•

JICIAJOSaS

141:1S2:01 b002

to

clad

Page 5

wells to insure that adequate and responsible monitoring for nickel, as required and regulated, is being

done. This is not in the interests of public health and safety and what would appear to be the

requirements of the regulations.

III. Testing for Mercury Should Be Required

HOI asks specifically, as Mr. Edwards does, that monitoring and testing for mercury pollution

be required. The current Operating Permit states in several locations" that wastes cannot be accepted

with over 2% of mercury by weight, yet there is no monitoring well testing for mercury. Considering

that up to 2% of weight of wastes can be mercury, testing should be required. The lack of mercury

testing seems to be a distinct disconnect between hazardous waste going into the landfill, and adequate

monitoring to protect the public health and safety.

IV.

Additional Down-

Gradient Monitoring Wells Should be Re

q

uired for Older Parts of,Land^l

While five upgradient monitoring wells exist for the Barrel Trench Area, and older parts

of the landfill outside the C-Cells, there are not adequate downgradient monitoring wells for

for the older parts of the landfill. HOI is concerned that the Agency has not required as many

downgradient monitoring wells for the older sections as up gradient monitoring wells.

Additional downgradient test wells should be required to monitor the Barrel Trench, Part A, Part B,

and the additional pre-regulation waste area on the west side of the site.

V.

Air Monitoring for this Site Is Not Adequate and Permit Provisions Me Not Monitored

Page V– 5 of the RCRA Permit Revised October 2007 states at #18

12

that:

"No person shall cause or allow operation of the landfill so as to cause or

threaten or allow discharge or emission of any contaminant into the

environment in any state so as to cause or tend to cause air pollution in

Illinois, either done or in combination with contaminants from other

sources, or so violate regulations or standards adopted by the Board

under the Act."

In spite of this permit directive, there is no air monitoring for this hazardous waste landfill except

for the Waste Stabilization Plant baghouse processes. This landfill permit does not have restrictions on

landfill operations regarding wind speeds or direction. The landfill is upwind of the preponderance of

the city of Peoria, with residences within less than 300 feet from the landfill boundary. Prevailing south

westerly winds go over the landfill to the city of Peoria, with over 53,000 people within 3 miles of the

landfill site. Fine particulates, P.M. 2.5 can travel miles. About 113,000 people live in Peoria, and

having an active hazardous waste landfill immediately next to a large city population without ambient

air monitoring at the perimeter of the landfill and in adjacent neighborhoods is not protective of the

public health and safety. Low-income housing, senior citizen residences, private homes, and children's

playgrounds are all within close proximity to the landfill and are subject to prevailing winds. The fact

that the landfill has been granted a reconfiguration of the site, adding height over the previous plans,

adds to our concerns regarding wind carrying pollutants to adjacent residential areas. Some parts

11 Exhibit 11 #1: Letter B. Waste Identification, #4., Page III-1, Section III Containment Building, Revised: October 2007,

ILD000805812, Hazardous Waste Management RCRA Permit Pan B (effective January 1, 2008);

#2: Letter Letter E: Stabilization Facility, #1., Page X-3, Section X Additional Special Conditions, Revised:

October 2007, ILD000805812, Hazardous Waste

Management

RCRA Permit Part B (effective January 1, 2008)

12 Exhibit 12, Page V-5, C. Design and operating requirements, #18, Revised: October 2007, ILD000805812, Hazardous

Waste Management RCRA Pennit Part B (effective January I, 2008)

s

ci

?

0S60-889 60E

JT0AJesa8

WEI92

: 01

.

000E TO

(BA

Page 6

of the landfill will be an additional ten to twenty feet higher for the open landfill face, than in the

original permit.

HOI requests, as does Mr. Edwards, that the IPCB direct the Agency to require additional air

monitoring. We ask that air monitoring be done at the perimeter of the landfill, and in adjacent

neighborhoods. We would like to see regular reporting, and constant monitoring during winds. We ask

that restrictions on dumping during high wind conditions be added. Without additional air monitoring

beyond the baghouse testing, the provision of the current permit quoted above has no means of being

adequately monitored and is actually not being monitored.

VI. Hazardous

inith=mLargeldnniejpalityangCharAgnifer

The 2002 Permit Revisions for this landfill stated that the expected date for landfill closure was

in 2005". The current permit states that the anticipated landfill closure is to be in March, 2009.

The current permit application has a table with closure plans and post-closure plans (Section I,

"Closure Plans, Post-Closure Plans and Financial Requirements," Table I-1, in Application Volume 17,

Revised November 2006)" for other units of the landfill, including the Waste Stabilization Building

and Waste Storage Silos and Tanks, however, there is nothing required by the Agency that appears to

trigger closure of the Waste Stabilization Plant and related waste silos and storage areas. PDC owns

numerous municipal waste landfills and trucking, and has been sending lead and PCB wastes to their

Indian Creek Municipal Waste Landfill near Hopedale, in Tazewell County, since 2007 (that we know

of). The citizens of Peoria are faced with the continued trucking of toxic wastes into PDC #1 with the

processing and handling of the wastes upwind of family residences, senior citizen homes, playgrounds,

and public streets.

We ask the Illinois Pollution Control Board's consideration for stronger protections for our

community and our aquifer, and that the Agency be required to set a date certain for closure of the

Waste Stabilization Plant, waste storage silos, and other temporary storage areas, within two years after

the final landfill waste cell closure.

The current permit has sections allowing the construction of a solids storage building with nine

hazardous waste storage tanks, construction of two proposed storage silos and concrete vault, and the

option for storing up to ten roll-off containers in the container storage/staging area (page iv, of the

permit and I-1) remain in the permit. Since this landfill is expected and requested to close in March,

2009, there is no need for these additional features to be in the newly issued Operating Permit and we

ask that the Agency be directed to remove permission for any additional facilities not currently in

operation. It is obviously our concern that these facilities will be added to expand the Waste

Stabilization Plant operations, which could mean more hazardous waste trucks traveling in and out of

the site and over our county roadways and highways. We think it is essential that the permit be clarified

that the Waste Stabilization Plant is part of the RCRA landfill, and that it must close in connection to

the closure of the landfill.

Closing

Comment;

PDC attempted a site expansion, which was soundly turned down by the Peoria County Board

vote of 12 to 6, in May, 2006. In 2007, the Agency denied PDC's attempt for a Class 3 Operating

Permit expansion. Both of these denials were affirmed by the Illinois Pollution Control Board .

While the explanation is given that the capacity is not yet at the allowable limit, and the

maximum height limit is still met by the "landfill reconfiguration", HOI

asks the

IPCB:

13 Page V-I, Section V Landfills, Part A Summary, Revised: December, 2002, ILD000805812, Permit Modification

14 Page V-1, Section V Landfills, Part A Summary, Revised: October, 2007, 11.D 000805812, Hazardous Waste

Management RCRA Permit Part

B

(effective January

1, 2008)

9•d

?

0960-089 606

?

JI0A-JasaN WEI92

: 01

t

.

002 TO clai

Page 7

How much hazardous waste should be allowed to be squeezed in effect, on the existing cells? The

additional height will be added over cells with compromised liners. The waste will be added at higher

levels, putting the adjacent neighborhoods at greater risk from air-born particulates that are transported

by the prevailing winds from the southwest going over the landfill toward residential areas. The

working areas of the landfill are not covered during the day when work is underway. The landfill is in

operation on days with strong winds. Children play outside in neighborhood playgrounds within easy

view of the landfill. There is a popular dog obedience training school below the edge of the landfill

property at Pottstown on Southport Road, and their facility and parking lot is in easy view of a raw dirt

edge looming above in close proximity. There is no air monitoring at the perimeter or in the adjacent

neighborhoods. There are known sand lenses, in particular on the east side of the landfill, where Cell

C-1 is located.

We are concerned that the continued operation of this landfill further compromises the functional

capabilities of the C — Cells and means greater pollution risks for our community and the Sankoty

Aquifer. We do not want Peoria and the people of our community treated as a sacrifice zone for the

continued operations of this privately owned and for-profit hazardous waste landfill.

We question how the capacity limit of 2,638,586 cubic yards was determined by PDC, and how

the 1987 originally permitted capacity was changed. PDC has made it clear that they will push the

limits in their every attempt to expand their landfill. We believe they are pushing the limits of the

existing site, and that a date certain for closure of March, 2009, must be required.

On Page VIII —I of the Permit, the statement #1. Effect of Permit reads":

Issuance of this permit does not authorize any injury to persons or property or

invasion of other private rights, or infringement of state or local law or

regulations.

HOI contends that the Peoria community and Peoria County has had enough toxic

waste

on

behalf of Illinois and thel 5 outside states with locations sending hazardous waste to this site.

The continued operations of this site affect the the public health and safety of our community and for

many individuals, our private rights to peace of mind have been invaded by this hazardous waste

landfill.

Sincerely,

yce Blumenshine

volunteer Heart of IL Group Sierra Club

I5 Page

V111-1, ILD 000805812, Hazardous

Waste Management RCRA Permit Part B (effective

January 1, 2008)

Z. • d

?

OSGO-889 GOE

?

JIOAJOSad

W8t2:Ot

bona

TO

gad

ILLINOIS ENVIRONMENTAL PROTECTION AGENCY

1021 NORTH GRAND AVENUE EAST, P.O. Box 19276, SPRINGFIELD, ILLINOIS 62794-9276 - ( 217) 782-3397

JAWS R. THOMPSON CENTER, 100 WEST RANDOLPH, SUITE 11 -3 00, CHICAGO, IL 60601 - (312) 814 -6026

ROD R. BLAGOIEVICN, GOVERNOR?DOUGLAS P. SCOTT,

DIRECTOR

April 28, 2008

Heart of

IL Group Sierra Club

Attn: Ms. Joyce Blumenshine

2419 E Reservoir

Peoria, IL 61614-8029

Re: Freedom of Information Act

Dear Ms. Blumenshine:

Phone: 217/782-9878

Fax: 217/782-9290

www.epa.state.il.us/foia

The FOIA Sector, Bureau of Land, has processed your request dated April 17, 2008 and

received on April 17, 2008 for public records pursuant to the Freedom of Information Act

(FOIA) (5 ILCS 140/1 et. seq.). The information you requested from the below listed

Site is enclosed.

Bureau of Laud Site?

bunged Documents No. of Images

?

Inches

of

Paper?

Pages

of

Microfiche

1431120003 PEORIA DISPOSAL CO INC

4349 504.:7HPOrr RD, PEORIA?

0?

0

?

0.10?

0

Total imsgursge

Cowles:?

0

?

0

?

3

? 0

In order to obtain more detailed information, you would need to review the permit application at

our office here in Springfield. Please contact me by telephone at 217/557-2482 or by email at

Jan.Oaderi@illinois.gov

to schedule a file review if you are interested.

Sincerely,

Jan Ogden, FOIA Coordinator

Records Management Unit

Bureau of Land

53067

ROCICEORD-

4302

North

Main Street, Rockford, IL 61103 -

(815) 987-7760 • DES

PLAINS - 9511 W.

Harrison SI., Des Plaines, IL

60016- (847) 294-4000

ELGIN -595 South State,

Elgin,

IL 60121 - (847) 608-31

31 • PEORIA - 5415 N.

University St.,

Peoria, IL

61 614 -

1309) 693-5463

BVREAU Of LAND - PEORIA - 7620

N. University St., Peoria,

IL 61614 -1309) 693-5462 • CHAMPAIGN -

2125 Soulh First

Street. Champaign,

8.61820 -

(2171 278-5800

SPRINGFIELD- 45005.

Shah Street

Rd.,

Springfield,

IL 62706 - (217) 786-6892 • Cotur8V4.1.E - 2009

Mall Street, Collinsville,

11. 62234-

(618) 346-5120

MARION - 2309 W. Main St., Suite

116, Marion, IL

62959 - I6181993-7100

PRINTED ON RECYCLED PAPER

a

• d

0960-889 606

JIDAJ

asea

waaa:ot vooa

TO clad

•

ILD000805812

Page V-1

Section V LANDFILLS

A.

SUMMARY

Peoria Disposal Company operates a ninety (90) acre facility, seventy-four

(74) of which are approved for disposal units. The total waste capacity

is approximatel 1,847,200 cubic yards. Industries served by the site

c u•e earthmov ng an ag?equ pment manufacturers, chemical and

steel companies, and breweries. Some wastes are to be treated at the

Stabilization Unit at the facility prior to disposal in a landfill cell.

The landfill is to be operated so as one landfill unit is nearing final

capacity and closure, the next unit is prepared for disposal activity.

The final landfill unit is scheduled to close in the year 2005.

This section presents permit conditions for the landfill according to the

regulatory requirements of 35 IAC 724 Subparts N (Landfills) and G

(Closure).

B.

HASTE IDENTIFICATION

1. The landfill disposal units are, or are to be, located as shown in

Attachment F to this permit.

2. The Permittee may dispose the following wastes in landfill cells,

subject to the terms of this permit:

Landfill?

Cell

Desi

g nation

Capacity (c.y.)

Surface Area

Dimensions of

Landfill Cell

Description

of

?Hazardous

Waste?

Waste No.

Barrel Trench

Area

35,000

14

See Attachment C

for Waste List and

Section A

6,500

8

Hazardous Waste Mos.

Section 8

190,000

10

and

Trench C-1

303,700

7.9

Non-hazardous

Trench C-2

252,700

6.8

waste approved

Trench C-3

346,700

7.7

by IEPA

Trench C-4

409,500

11.8

special waste

Trench C-5

303,100

7.9

stream permit

3.

The Permittee is prohibited from disposing any waste 1n the permitted

units not included in Condition 8. 2. of this Section.

6•d

0960-869 60C

JI0AJ

ased

w882:01 tro

p

e

ID

ciaA

•

TOPSOIL

FETES

—

CILTE11 IAATENIAL

con*

TEL

sonnvious pi.

&IV/ / 7,0

ORAN NOT

z

N

I

O

SRA

IA

POITITHYLENE PIPS.

FILLED WITH

TinterTiON STONE

API.

• IONA

FILTER !Age

11116LWI26"11.11111

leftet SEAL (WIN 010.

GOVI101 DIAL

WIN mATIINIL

RANDOM FILL.

IYAMMA

cle11111111141------

is eithill/m

OAS SENT 010014

• AC•IIILLID WITH •. • •

D

RAIN MATN11/4„

•

,

WASTE

•

•

•

?

• MATERIAL

.?

.?

•?

-Thp•

,

COVER SYSTEM TYPICAL SECTION

SON! 0

I

MT

LA-1J

10.000

L.A

I

T I

•

•

500

11LS

NI.1111FINING

▪

ONASSCOVIIII

..--11A10011

ea

S.

II

74100

,

100

Nk

pIRM

/DO-

00)

EANOt OP I II

NCK

FINAL COVER GEOMETRY

2011/

efassi nu

Lemma

2E1

11.111

12.1/1

120

202

10.110

12.175

NS

I.411

11.A55

NO

704

10.1N

MO

'OS

10.454

10.174

?

NO

TN

111.04

11.015

NS

20?

10.n?

11.441

PIO

204

11.143

11.1

510

Nil

11.141

12.111

NO

71F

10.510

11.450

151

711

10.411

11.410

547

712

211

1

0

11

.4111

M

1I

11.4211

541

11.111

214

10.545

11.M

147

215

10.10

11.110

5E7

LEGEND:

•

OAS VINT

00.

•••••

OAS TINT

DITCH

!AGITATION

woe

nu

?

COVVI CONTOURS

CLITNLE ANINOSIANS

(Fla)

DAMN

NIT

FILM Pete

NANNOLS Gee

NOTES:

I. TOPOCIIIAPNV TARN. FROM MAPPING PII►UMO POE mall.

emoomemoNo

CO_ NG. ET aniDeTtioG ENINNEERINO NG.

DATE OP FOIDORAINT: 5450151.

S. 1.1111AL NONIOANIES.STFRIGNINES.

IMO

ALL ExPLONATION 10Th

NITA". AND

•11101112

THE LISTS M 1NiS omen An reek

11114e0 MIMI

It.

S. 0014

FERIMITIE

GOONONATtil• Ueda DETAILS, AND

MANHOLE

DETAILS

NI

INIANTel 151n1 05.

IIIrti

04,

AND 151711 OA

PIESPEGTIVIl•

4. VENT INTENIS 040%/7 NOT

DI

MIT

CLOSSA THAN It TO

TIC

TOP

Of

Till ay

. SLOPS AEON TN

43412485

SOILS 0

100

TOO FILET

1110117 AS NOTED

PEORIA DISPOSAL COMPANY

PEON,

ILLINOIS

DEVELOPMENT PERMIT APPLICATION' AREA C

01110014 FILL

NOM SMITE MI

•

•

•

•

•

WAITS.

•

IINTENAL

SECTION A-A (TYP)

NOT

TO KALI

DOAN MAMMAL

DACE

IN I'

Him

OAS

cousenow

EXCAVATION

24:

MA.

•flett •••i

Ava

See

TO 15MM OA

AM

FINAL COVER

PLAN

RZA ENVIRO

?

VICES. INC.

00110,110

One0.11.0001

C

i

?

161714 06

V

tt

NIt

AMARA of NIHON%

?

ST

Owe Alto

OT 'd

OcBO-899 60€

JI0A-lasam

wuez:ot frocia

TO

qaj

Revised: October 2007

IL D000805812

Page V-1

Section V LANDFILLS

A. SUMMARY

Peoria Disposal Company operates a ninety (90) acre facility, seventy-four (74) of which

are approved for disposal units. The total waste capacity is approximate 2,638,580 cubicLe.

yards. Industries served by the site include earthmoving and agricultural equipment

manufacturers, chemical and steel companies, and breweries. Some wastes are to be treated

at the Stabilization Unit at the facility prior to disposal in a landfill cell. The final landfill

unit is scheduled to close in the year 2009.

This section presents permit conditions for the landfill according to the regulatory

requirements of 35?

Adm. Code 724 Subparts N (Landfills) and G (Closure).

B.

WASTE IDENTIFICATION

1.

The landfill disposal units are located as shown on the site topographic map contained

n Appendix B-2 of the approved permit application.

2.

The Permittee may dispose the following wastes in landfill cells, subject to the terms

of this permit:

Landfill Cell

Designation

Approximate

Total

Capacity (c.v.)

Surface Area

Dimensions of

Landfill Cell

(Acres)

Description

of

Hazardous

Waste

Barrel Trench

Area

35,000

14

See Attachment C

for Waste List and

Section A

6,500

8

Hazardous Waste Nos.

Section B

190,000

10

and

Trench C-1

425,929

7.3

Non-hazardous

Trench C-2

453,846

6.4

wastes identified

Trench C-3

775,939

7.3

in Condition X.H.2

Trench C-4

982,865

11.0

3. The Permittee is prohibited from disposing any waste in the permitted units not

included in Condition B. 2. of this Section.

•

cl

?

OS60-13139 608

?

JP3AJasaa WEI62

: 0T

4002

TO clad

MEMORANDUM

Date: December 16, 2002

To: BOL File

Aft

From:

Mark

Mark

L. Critei, RCRA Permits

Re:

Class 2 Permit Modification - Reconfiguration of Landfill Cells

1438120003 -

Peoria County

ILD000805812

Log No. 13-24-M-56

Discussion

In this submittal,

2

modifications are requested to the Part B Permit for the above -

referenced facility. These modifications are discussed below:

1.

Allow the use of municipal wastewater treatment plant sludge as a soil amendment in

final cover soils.

According to Inuan Sayed, of the Solid Waste unit, this is currently done in solid waste

landfill permits. The main concern is that the sludge be applied at agronomic rates (20

tons per acre per year) so

that a state permit is not required. I have incorporated language

used by the Solid Waste unit in permits where MWTPS is used as a soil amendment. The

specific language I have used is drawn crom the permit for Harbor View landfill (Permit

No. 1995-0600LFM). A copy of the page containing the applicable condition is attached.

2.

Reconfigure the existing landfill units to eliminate the proposed Cell C-5, and increase

capacity in cells C-1 through C-4 without increasing overall capacity, or final permitted

elevations.

This is done by adjusting final contours of Cells C-1 through C-4. Calculations showing

s-?

t at the units will be able to support the additional loading are inclunsthespendicie,i

f the application. The new total capacity is calculated to be 2,638,

?

cu is yards!

1?

This is less than current calculations of the previously permitted total capacity of

2,638,983

cubic yards. The capacitie previously listed in the permit is incorrect because

of calculation errors made in the original permit application. This issue had been raised

previously, but the actual number in the permit had never been revised to reflect the

accurate volume. This error has been corrected in the modified permit. The submittal

— does not contain a breakdown of the new capacities of Cells C-1 through C-4. I have

contacted Ron Welk of PDC to obtain these values, which will be included in the

modified permit.

2 • d

O

S60-889

60E

?

JIOAJOSO8

W1162

:

0I

booa

To

gad

ILLINOIS ENVIRONMENTAL PROTECTION AGENCY

1021

NORTH GRAND AVENUE EAST,

P.O. Box 19276,

SPRINGFIELD, ILLINOIS

62794.9276

THOMAS

.

V. SKINNER, DIRECTOR

NOTICE OF APPLICATION FOR PERMIT TO MANAGE WASTE (LPC-PA16)

Dale

August 13, 2002

To Elected Officiah and Concerned Citizens:

The prima of dal

DoSesSmintem

you

that a palit applation has been

euhmitied

to the IEPA, Bureau orLand, fora solid waste project described

below.

You are not obligated to respond bs this notice, hoverer, if you have any

COMM%

please

submit them In writing to the address below, or call the Parrs*

Section at 217/5243300, within twenty-one

(21) days.

Peoria Journal Star

Illinois Environment& Protection

Agency

News Room

?

B

aran ottand, 'emit Section (133)

1 News Plaza

1021 North

Spfingfield,

Orand Avenue

Illinois

Rest,

62794-9276

Post

Office Box

19276

Peoria, IL 61643

The

permit application, Mitch is identified below, is for a prefect described at the bottom of this page.

SITE IDENTIFICATION

Site Name,

IMOr ia Disposal Company

Address:

4349 Southport' Road

City.

Peoria

r

YPT. PERMIT

suawassiort

?

TYPE FACITITY;

New Landfill

Landfill •

LandfillExpansion

Land Treatment

First Sipsificent

Modikadon

Transfer Station'

Significant Modifieafion

to OperateTreatmet&Faciity

Other SigniGoint

Modification

Stomp

Renewal of Landfill

Incinerator

Development

Composting

Operating

Recyclinp/Rcelamation

Supplemental

Other

Transfer

•

Name Change

amic

f

G

liltA Part B

?

S_-

DESCRIPTION OF

PROthler

•■■••••■■

zoo (awn

14 3 8 12 0003

County:

Peoria

TYPE

WASTE;

General Municipal Refuse

SPerial

(Non-lirmitrdous)

Chemical

Only (exec. putrescibk)

Inert Only Oman &tern. do putrcsoibk)

Used

01

Solvents

Icandscape/Yard Waste

Other (Specify

I. Use municipal wastewater treatment plant sludge as part of the final cover

tzz

k7

topsoil component.

2. Reconfigure landfill units with no increase in capacity.

RECEIVED

Ail6

2 0_2002

Please retain copy for your

own use.

PEKR/T SECTION

I

151,532A0R3441av

CI-d

0560-089 608

Ann-C10

JTOAJOSed

WUOC:OT 4002 TO gad

Revised: October 2007

ILD000805812

Page VI-5

4.

Should any well become consistently dry or unserviceable; a replacement well

shall be provided within ten (10) feet of the existing well. This well shall monitor

the same geologic zone as the existing well and be constructed in accordance with

the current Illinois EPA groundwater monitoring well construction standards at

the time that the well is replaced. A replacement well which is more than ten (10)

feet from the existing well or does not monitor the same geologic zone

must be

approved by the Illinois EPA and designated as a new well.

6

5.

The Permittee shall submit boring logs, construction diagrams and data sheets

from installation and development of a new or replacement well

to

the Illinois

EPA at the address below with thirty (30) days of the date that installation of the

well is completed. In addition, the Permittee shall submit certification that

plugging and abandonment of

a

well was carried out in accordance with the

approved procedures to the Illinois EPA at the address below within thirty (30)

days of the date that the well is plugged and abandoned. All information should

be submitted to the appropriate State Agencies.

Illinois Environmental Protection Agency

Bureau of Land - #33

Permit Section

1021 North Grand Avenue East

Post Office Box 19276.

Springfield, Illinois 62794-9276

6.

All wells/piezometers shall be equipped with protective caps and locks.

Monitoring wells or piezometers located in high traffic areas must protected with

bumper guards.

7.

All groundwater monitoring wells and piezometers not utilized in the groundwater

monitoring system, but retained by the facility, must be constructed and

maintained in accordance wit

dm. Code 920 regulations. Monitoring

wells

and piezometers thrare improper constructed

must be abandoned in

accordance with Conditions VI.D.3.

E. MONITORING PARAMETERS •

1.

The Permittee shall determine groundwate

l

r quality at groundwater monitoring

ells identified in Condition IV.D.1, arboth the upgradient and point of

ompliance locations, semi-annuallyduring the active life (including closure and

ost-closure care period) of the„Ifindfill. Samples collected during the semi-

--.

/2

OSGO-889 BOE

?

JTonaasaH WUOE

:

OT

frooa

TO clad

gs-

ae.2-

Revised: October 2007

1LD0008058 12

Page VI-6

annual events of each year shall be analyzed for the field parameters and

hazardous waste constituents below.

List 01 – Semi-Annual_Groundwater Sampling

Storet

?

Reporting

Field Parameters

?

Number

?

Units

a

?

8

pH?

00400

Specific Conductance

?

00094

?

micromos/cm

Temperature of Water Sample

?

00011

?

(°F)

Turbidity

?

45626

?

Ntus

Depth to Water (below land surface)?

72019

?

Feet

Depth to Water (below measuring

point)?

72109

?

Feet

Elevation of Bottom of Went,

?

72020

?

Ft-MSL

Elevation of Groundwater Surface

?

71993

?

Ft-MSL

Elevation of Measuring Point (top of casing)#N

?

72110

?

Ft-MSL

Shall be determined during the second sampling event each year.

##?

Shall be surveyed once every five (5) years, or at the request of the 111inois EPA, or

whenever the elevation changes

as

required by Condition VI.G 2.

Storet?

Reporting

Hazardous Waste Constituents

?

Number?

_ nits

Inorganics

Barium, Ba (dissolved)

?

01005

?

ug/l

Cadmium, Cd (dissolved)

?

01025

?

ugh

Chromium (dissolved)

?

01030?

ug/1

Iron, Fe (dissolved)

?

01046?

ug/I

Lead, Pb (dissolved)

?

01049?

ugh

Manganese, Mn (dissolved)

?

01056?

ug/1

Nickel, Ni (dissolved)

?

01065

?

ug/1

Zinc, Zn (dissolved)

?

01090

?

ugh

Calcium, Ca (dissolved)

?

00915?

mg/1

Chloride, CI (dissolved)

?

00941

?

mg/I

Cyanide, CN (total)

?

00720?

ugh

Sodium, Na (dissolved)

?

00930?

mg/1

Sulfate, SO4

(dissolved)

?

00946

?

mg/1

S I • cl

0960-889 606

•?

•-

-

1I0A

-

Ja

seN

WUTE

:

OT 1,002 TO clad

Feb 01 2004 10:31RM Reservoir

?

309 688-0950?p.16

awe

70001030 3LV1S MOWN

saamoSsij titioN P

us

MAW W Os848,080

Bet SALON AS01030

laN311,44013AN3

uee

t

ele? ma

gg

i Pee laiteirld Leer

lawmen papa

t

aeuern imam( tavern Marne

SIONITII NI 63111-110Vd

1V8OdSICI 3ISVA1 snoauvzvm IV SOVVIMOISci

ON11101INOW 1:131VMONnOlie NOUVIIIVA3

M03

goviitaio

1194RBOWb

Feb 01 2004 10:31AM Reservoir

?

309 688-0950

?p.17

„air ac----tensa

m

i

r°

i

MParmiallaanni

4

, 1

*

0

IIPLW

4

t

I

?

,

?

a

4

r

PAili

ria

-a

CO

Revised: October 2007

ILD0008058I 2

Page VI-9

b.?

In developing the data base used to determine a background value for each

parameter or constituent, the Permittee shall take a minimum of four

replicate

samples

from each upgradient well during each of the

four

quarterly background sampling events. An equal number of replicate

samples will be taken from each upgradient well to ensure equal

weightings in statistics,

0?

For those monitoring parameters or constituents not detected above the

practical quantitation limit (PQL) duringebackground gathering, the PQL

shall be the established background value.

DETECTION MONITORING PROGRAM

1.

The Permittee shall determine groundwater quality at each monitoring well at the

compliance point identified in Condition VID.1 semi-annually during the active

life of the regulated unit (including the closure and post-closure care periods).

The Permittee shall express the groundwater quality at each monitoring well in a

form necessary for the determination of statistically significant changes (i.e.

means, variances,

etc.).

2.

The Permitted shall determine the groundwater flow rate and direction in the

uppermost aquifer semi-annually and reported to the Illinois EPA, at least

ally, from monitoring wells identified in Condition IV.D. I

The rmittee shall evaluate the results of the analysis required by Condition

VI. I above and identify:

The concentration of any constituent detected which was not detected in

the previous s. ,

?

-

The concentration of any constituent detected which exhibits a progressive

increase over four (4) consecutive sampling events.

4.?

The Permittee shalt determine whether there

is

a statistically significant increase,

(or decrease in the case of pH) over the background values established for each

parameter identified in Condition VI.E.1 each time groundwater quality is

determined at the point of compliance. In determining whether such a change has

occurred, the Permittee must compare the groundwater quality at each monitoring

well identified

in Condition

IV.D.1 to the background value derived in

accordance with the statistical procedures specified in Section E of the approved

Permit Renewal Application.

ST •

d

?

OS60-9139 SUE

?

-IT

°

mas

a?' Widt

•

E

:

OT 4002 TO clad

Charles H. Norris

Geo-Hydro, Inc.

1928

East

1.4

m

Avenue

Denver

CO 80206

(303) 322-3171

cnorris@geo-hvdro.com

March 27, 2006

Peoria County Board, Siting Committee

324 Main Street

Peoria IL 614

Dear Board Members:

I would like to thank you for the opportunity to participate in your decision regarding the

possible expansion of the PDC hazardous waste disposal facility and for your attention during

my testimony at the hearings. I admire your determination to understand. You have a difficult

task – determining what is, in final analysis, most protective of the citizens of Peoria County.

This final analysis, the Board's analysis, properly includes every site technical issue one can

imagine; traffic patterns and truck counts of hazardous waste entering the facility, statistics and

opinions on real estate values, computer-generated "pictures" of the final landform and opinions

on its compatibility, detailed (and often conflicting) interpretations of the geology and

hydrogeology data, complex engineering designs and operations, differences between historic

and anticipated waste streams and characteristics of the wastes, decades of monitoring data, and

computer model projections of conditions 100s of years in the future.

The Board's analysis also properly includes subjective issues beyond the site's technical issues.

It includes social, psychological, Justice, and economical issues – those elements of public

welfare that lie beyond the equations of ground water flow, regulatory language of the permit,

applicable ground water quality standards, statistically significant increases, and various

performance criteria. Collectively these constitute what some call the "quality of life" issues.

The Board's analysis is final in two other, important ways. The analysis by Peoria County is the

final, indeed the only, analysis that will consider any of these issues, including the subjective

issues, with respect to the suitability of the site. There is no backup process, no over-writing

authority that will confirm, double-check, or revise your decision of site suitability.

The Board's analysis is also the final opportunity for someone to link all of the disposal areas

(closed, existing and proposed) and consider the site as a single entity that, as an entity, impacts

the public health, safety, and welfare of the citizens of Peoria County. The Illinois

Environmental Protection Agency will issue a permit for the expanded facility; perhaps without

or perhaps with modifications to the application you are reviewing. But, it will eventually issue

Page 1 of 14

02 •cl

0960-889 SOE

JTotwasad WIrlt

r

E

:

OT 4

.

002

16

clad

a permit if you find the site suitable for hazardous waste disposal. That permit will consider the

proposed expansion as a facility that is independent of the existing closed units at the PDC waste

disposal complex. There will be no integration or linkage of the proposed expansion to the

remediation of, or risk reduction from, the barrel trench, Section A, Section B, or the old

municipal solid waste unit. That linkage can only come from Peoria County.

Your task is unquestionably made more difficult by the narrow circle of experts upon whom you

must rely. Landfill design and siting hearings almost constitute a cottage industry. At one

proposed site, Company A designs the landfill for an applicant and Company B reviews the

design on behalf of the siting authority. Company B's fees may be paid by Company A. At

another proposed site, Company B designs the landfill for the applicant and Company A reviews

the design on behalf of the siting authority. Lawyer X may represent intervenors in some cases,

but Corporation Z for its applications. Lawyer X may also represent the siting authority in other

cases and serve as the hearing officer in yet others. Consultant R may work only for intervenors,

but in doing so may be working with or opposing the nine limited set of lawyers and

consultants. Consultant S, representing an applicant, may have previously been the Regulator

passing judgement on that same applicant's facilities. In this musical chairs of consultants,

corporations, lawyers, and roles, it is difficult to avoid a vague feeling of something between

potential conflicts of interest and outright chicanery.

The above observations and comments are made personally, as a citizen who has observed and

participated in many of these siting hearings. They are non-expert in nature and are offered

without reliance on any professional or scientific training or expertise 1 may hold.

Below are a number of observations that I offer to supplement my expert testimony. They are

technical and scientific in nature and do rely on my professional expertise. To the extent that

these comments fall within the rubric and scope of the Illinois professional practices statutes and

regulations, I mention that I hold a license in Illinois as a Professional Geologist. My license

number is 196-001082 and it will expire March 31, 2007. I personally developed these

comments and interpretations, they are made, as the lawyers would say, "to a reasonable degree

of scientific certainty", and I

impress my seal

upon them.

Copies of figures

shown during testimony

Attachment 1 to this letter contains 4 figures which I showed and discussed during my

testimony.

Leaking from

the

liner systems under Section

C

In the four weeks since I testified, I have continued to review the materials filed by PDC with the

County, specifically the scanned data from the 43 boxes that represent the operating record,

Exhibit A. As a result of that continued review, I must modify the opinions I expressed in

Page 2 of 14

T2 •d

?

OS60-889 60E

?

JtoAJasaa

WUfre

:

OT

frooz

TO clad

testimony.

I am no longer confident that wastes disposed in Section C are significantly more isolated by

virtue of the double liner technology than the wastes in the older disposal areas. The further

review of the operating system shows that at least the primary basal liners in Section C leak.

The review also shows that the secondary basal liner of trench CI also leaks. The evidence for

the leaking, and its implications for ability of the most modern units to isolate the wastes in

Section C, are discussed below.

In my testimony, I stated that the continuing and most immediate threat to the aquifer under the

site comes from the older disposal facilities at the site; the municipal solid waste unit, the barrel

trench disposal area, Section A and Section B. I expressed the opinion that wastes disposed in

the various Section C units, due to the modem technology and construction techniques for these

areas, would likely be isolated effectively for some time to come. I testified that wastes in the

older units, without the benefit of the double composite liners were more likely to leak in the

near future and more likely to contaminate the underlying aquifer. I further testified that

contamination of the aquifer with chlorinated organic compounds,

Le.,

man-made compounds,

had already occurred and was ongoing. When I testified, I considered the likeliest source for this

contamination to be the older facilities and operations at the site, even though some of the

contamination was observed adjacent to parts of Section C. I no longer believe that solely to be

the case.

The operating record and the monitoring data for leachate production from Section C

demonstrates that the primary basal liners of trenches Cl through C4 leak, and that the primary

basal liner of trench C-1 shows the worst leakage. Further, the data from trench Cl shows that

the secondary liner also leaks. It is unclear why this information was not specifically discussed

and made explicitly clear to the Board by PDC when the double composite liner systems were

being discussed in testimony.

As discussed in testimony on behalf of PDC, the primary basal liner system is designed to

contain the leachate that is or may be produced from waste disposed in a particular cell.

Leachate that forms sinks to the primary basal liner and flows along that liner to a sump, where it

is

pumped from the landfill cell to keep it from building up. Unlike a municipal landfill in

Illinois, the PDC hazardous waste landfill has a second composite basal liner, as a back-up to the

first. Between the two liners is a permeable layer that flows to its own sumps, a leak detection

layer. If the primary liner is built to the level of integrity specified in this application, the leak

detection system remains virtually dry.

(The qualifier "virtually" is necessary because there are times and conditions under which some

fluid that is not related to leaking leachate may be produced and some leaking is expected.

These production rates are small and dominantly occur early in the history of a cell. For this

facility, built in unsaturated sediments, the principle non-leachate source of water is

consolidation water that is pressed out of the clay liner during and shortly after disposal, as the

weight of waste is added on the liner. Once the liner has fully compacted, discharge from

Page 3 of 14

0S60-889 60E

?

-non-lases

WUSE:OT

bona

TO

qsj

a

• cl

consolidation stops. In addition, some leachate leakage is expected. It is recognized that a

perfect liner is not possible, and there is a rate leachate leaking that is accepted into the design.

According to documents developed by PDC consultants that are in the operating record (Exhibit

A), the production rate for consolidation water from a young clay liner would be around 3-6

gallons per acre per day (gpad), and the expected rate of leachate leaking from a properly

constructed liner would be up to I gpad. For a landfill cell of 5 acres, roughly comparable to

trench CI, this represents an initial rate of production from the leak detection system of 20 to 35

gallons per day (gpd), and an eventual rate of 5 gpd, so long as leachate is produced from the

overlying waste. More details can be reviewed by going to the operating record and reading

"Response Action Plan for Landfill Trenches C-3, C-4, and C-5" developed by GeoSyntec. It

can be found beginning on page 513 of file

B

15 PERMIT MODIFICATIONS-CLASS I ('90-1996) PEORIA DISOSA.pdf

of scanned the documents from the operating record found on the disk oi

•

in the directory

412 05 0044 Box 2 of 3.)

A quantity of the fluid from the leak detection system that exceeds what is expected by liner

consolidation and design-accepted leaking suggests that the integrity of the.primary basal liner

system has been compromised. A quality of the fluid from the leak detection system that is

similar to, or characteristic of, the leachate of the overlying cell similarly suggests that the

integrity of the primary basal liner system has been compromised.

By 1988 it was recognized that the integrity of the basal liner for trench CI was compromised.

The leak detection system was producing fluid far in excess of what could be expected from an

intact liner and the chemistry of that fluid was similar to the leachate from trench CI with

respect to the constituents present and their relative concentrations. Effective 21-Sep-88, a new

permit condition required PDC to document production rates from the leak detection system

daily, analyze the corimosition of the fluid from the leak detection system twice monthly, and

report that documentation to 1EPA monthly (reduced to annual reporting in 1993). Many of the

reports from 1991-93 are contained in

B 12 SECIX-CONDITION E RESPONSES "91) PEORIA DISPOSAL COM.pdf

found in

412 05 0044

Box

2 of 3.

These reports provide Board members an opportunity to review directly the quantity and quality

of the fluid from the leak detection system.

During the early 1990s, before the top liner was installed, over 40,000 gallons of leachate was

pumped some months from the leak detection system for trench C I. In May and June, 1991,

84,648 gallons were reported to have been pulled from the leak detection system. Some of this

pumpage, 40,250 gallons, was taken from accumulated storage in the leak detection layer. The

total net leakage during these months was 44,398 gallons or 728 gpd, a rate that is more than 145

times the design-excepted leak rate. It is important to note that this is a net rate of leaking. That

is, it

represents the rate of leachate leaking through the primary liner minus leachate leaking

through the secondary liner.

Page 4 of 14

E2'

4

?0660-889 60E

?

JTOAJ8SaN

WH9E

: OT

frond

TO clad

There is no direct way to measure the rate of leachate leakage through the lower liner, since there

is no leak detection system below it to intercept it. However, one can investigate the integrity of

the lower liner qualitatively by considering the rates withdrawn from the leak detection system

under the variety of conditions that are observed over the years of record. For example, during

the May and June,1991, the period above, when there was declining storage (and declining heads

across the bottom liner) in the leak detection system, the net production rate for that system

(pumped leachate less leachate withdrawn from storage) was 728 gpd. During the previous five

months (December, 1990, through April, 1991), with a higher level of storage in the leak

detection layer (and, therefore, a higher head across the bottom liner), the average daily net

production from the leak detection layer was 614 gpd. The difference of 114 gpd represents an

increase in (but, not total of) leaking across the lower liner due

to

leachate build-up within the

leak collection layer.

During a 71 day period within the December, 1990, through April, 1991, interval, when there

was a higher and constant storage volume of leachate of 50,000 gallons within the leak detection

system, the net production rate was only 325 gpd, with the balance of 403 gpd leaking through

the secondary liner system. Further, for periods with no extraction from the leak detection layer,

there was no increase in storage, indicating that everything leaking through the upper liner into

the leak detection system was also leaking from the leak detection system through the lower liner

and into the subsurface environment. The data indicate that, unless leachate is continually

pumped from the landfill and from the leak detection system, the integrity of the lower liner is no

better than that of the upper liner once 50,000 gallons or more of leachate is allowed to build up

in the leak detection system. 1.

e.,

everything leaking through the primary liner is also leaking

past

the secondary liner.

The quantity of water produced from the leak detection system for CI has declined substantially

from the rates that were produced during the early 1990s, but the quality still reflects leaking

leachate from the cell above. The reduced flow does not represent "healing" of the compromised

liners. Rather, it represents a reduction in the rate of leachate produced from the waste in the cell

as a result of the installation of the top liner closing the cell and preventing new water from

entering the cell. During 1995, after installation of the top liner, the average daily amount

pumped from the leak detection system had declined to 19 gpd, only about 4 times the design-

accepted rate for a leaking liner. Lower current rates of leachate production generate lower

current rates of leaking leachate. The trend of the downgradient wells toward lower chloride

contamination probably reflects the current reduced leachate production. As the top liners

degrade, or are removed as part of the expansion, the leaking of leachate, and associated

contamination, can be expected to increase again.

The leaking that is documented through the primary bottom liners for trenches C2, C3, and C4 is

very convincing from a standpoint of the water quality pumped from the leak detection systems;

in each case there is a match even to minor constituents with the composition of the leachate of

that cell. The data that have been reviewed to date shed less information on the quantity of the

leachate that is leaking, however. In 1995, after at least partial installation of the top liner, the

average fluid removed from the leak detection system for C2 was about 8 gpd, and for C3 was

Page 5 of 14

fra

OS60-8139 60E

?

JT0A-Jasa8 WU

jE

:

OT *002 TO clad

about 5 gpd. These rates could represent consolidation water from the clay liner. However, for

each of

the

cells, there is a strong correlation between the leachate water quality from the

leachate collection system and the fluid pumped from the respective leak collection systems.

Sufficient data have been reviewed for trenches C2 and C3 to suggest that the potential

magnitude of leaking through the C2 and C3 primary bottom liners are probably less than that of

the CI primary bottom liner. In none of the other cases have the necessary data been identified

to evaluate leakage through the secondary bottom liners.

Contamination Under the PDC Waste

Disposal Complex

It is undisputed that the water under and adjacent to the PDC waste disposal complex is

contaminated with synthetic chemicals. It is undisputed that inorganic contaminants such as

chloride are anomalously high and, in many cases, are known to have risen above original base

line levels. PDC's consultants hold that none of the contamination that is found under the site is

from the PDC waste disposal complex or the result of PDC operations. In every case, the water

beneath the PDC waste disposal complex has been the victim of migration from some off-site

source or migration upward from the earth beneath the site. Unknown, unproven, and

speculative off-site sources are rationalized as the cause of all on-site contamination. Simple,

downward migration from historic and current waste disposal units and operations are rejected as

possible causes.

Ockham's Razor is a scientific premise that states the explanation of a phenomenon should make

as few assumptions as possible. The multitude of assumptions that are necessary to explain

away all of the contamination under the PDC waste disposal complex definitely does not

conform with that maxim. The presence of some contaminants are speculated as being the result

of vapor-phase transport front unknown sources. Other contaminants are speculated as the result

of surface water flows from unknown sources to topographically low areas where the aquifer is

near the surface of the land, infiltration into the aquifer, and lateral migration in the aquifer to a

location beneath the facilities. A given contaminant may need multiple sources to rationalize its

distribution across the site. Such hypothetical complexities are not consistent with Ockham's

Razor.

Chloride

Chloride is a contaminant that has received considerable discussion by PDC consultants in an

attempt to conclude that the PDC waste disposal complex is not responsible for the increases and

variations in chloride concentrations under the site. Off-site sources are postulated as a result of

apparent inconsistencies within monitoring data that are perceived as precluding site sources.

The chloride increases and variations are independent of sulfate concentrations, precluding

leachate as a source since it contains both chloride and sulfate. Road salt contamination was one

speculation Migration upward from the underlying shale bedrock was another speculation.

Each of these speculative off-site sources can be easily eliminated, and there is no inconsistency

between chloride and sulfate patterns with respect to a leachate source.

Page 6 of 14

sa •

d

?

0960-8139 60E

?

JI0A-Jasad WULE Ot

frooa

TO clai

Road salt began being generally used in Illinois around 1960 (PDC (Liss) 22-Mar-06 submittal

reference: Panno,

et at.,

Ground Water, 2005.). The application indicates that the physical

migration rate of water under the site, generally from northwest to southeast, is approximately 8

feet per day. Significant chloride contamination occurred in some wells as early as 1990. At the

migration rate specified in the application, road salt, once it got into the aquifer, could have

moved only 240 feet (30 years x 8 feet/year). There simply are no off-site sources of road salt

that exist within 240 feet northwest of the each of the impacted wells. For the chloride-impacted

wells along the east side of the PDC waste disposal complex, however, migration from 240 feet

northwest of the wells does imply source locations in Sections A, B, and C. Further, as

acknowledged by Liss in his testimony, there is a lack of similarity between sodium

concentrations and variations and chloride concentrations and variations. Such similarity would

be expected if road salt, predominantly sodium chloride, were the contamination source.

The bedrock underlying the site aquifer is Pennsylvanian-aged shale. This unit is described in

the application as an aquitard, a unit that does not readily transmit water. In the site model, it is

numerically considered a no-flow bottom to the aquifer. Although wells completed in sands or

coals in the shale do have higher chloride, sodium, sulfate, and iron concentrations typically than

do glacial sediments, the site description says that in the area of the PDC facility, there are no

aquifers in the shale. If one accepts the contamination premise of upward flow froth the

underlying shale instead of the modeling premise of no-flow from the shale, one finds that the

chloride contamination cannot be explained with that premise. As with dissolved road salt, such

flow contains relatively high concentrations of sodium, yet sodium does not rise or vary with the

chloride concentration. The speculation of water from shale as a source would also have to

explain why such flow has increased over the last two decades, why such flow has varied greatly

from season to season, year to year, and location to location, and why, at some wells, such flow

has seemingly decreased in recent years. Finally, were the chloride contamination due to water

from the shale, there would be corresponding increases and variations in sulfate as in chloride.

The lack of these corresponding changes is the argument used by PDC for chloride not coming

from leachate leaks. Although the argument is invalid for the issue of a leachate source, as

discussed below, it is an appropriate argument against flow from the shale as a source of the

chloride.

The dismissal of leachate as a possible source of chloride contamination on the basis of the lack

of correspondence between sulfate and chloride, both of which are in the leachate of at least the

C-area trenches, is inappropriate. First, with respect to wells east of Sections B and C

(e. g.,

wells G,R125, 6,R,Al26, G,R138) the chloride Increases begin during the period when areas B

and C were not yet capped and at least C-1 was known to be leaking. Subsequent to capping of

these

areas,

the chloride levels in these down gradient wells stabilized and/or declined.

Second, for many of the wells, including "upgradient" wells, the chloride levels dropped to near

nothing during the drought of 1989-90. Were the chloride from some off-site source at distance

from the wells, there would not be a decline in chloride contamination contemporaneous with a

dramatic drop in current precipitation and infiltration; the chloride at the wells would have been

introduced to the aquifer years prior to the drought. The coincident drop in multiple wells at

Page 7 of 14

92'

d

?0S80-889 GOE

?

JTOAJaSaa

WEIBE

: 0I-

4002 TO iieJ

widely varying locations reflects an event that is contemporaneous with on-site conditions.

Chloride/Bromide Ratios

PDC provided in 22-Mar-06 supplemental public comments a discussion of a "special" one-time

sampling event to determine chloride/bromide ratios, in a attempt to further identify or eliminate

potential sources of chloride contamination. Data were reported for the leachate collection

system and the leak detection system of trench C-1 and for 8 of the monitoring wells. It was not

reported whether these 8 wells and single source of leachate constituted the entirety of the

"special" sampling event, or a subset. The underlying laboratory data and chains of custody

were also not provided, so it is unknown when the sampling occurred, when the samples were

analyzed, by whom the data were analyzed, or whether other analyses were performed that were

not reported.

The chloride/bromide ratios at the level of the aquifer were largely similar across the site and had

a ratio that the referenced literature indicates is within the range that is typical of municipal

landfill leachates. The ratio that was measured for the CI leachate was dissimilar from the ratios

observed in the aquifer and showed a much higher bromide component than would be

characteristic of a typical municipal landfill.

One reasonably-drawn conclusion from this data is that, in a 2006 (perhaps late 2005) sampling

of water from the site aquifer, there is not evidence of a significant component of leachate from

trench CI . This is to be expected since leaking from this trench has, for now, largely been

controlled with the installation of the top liner a dozen years ago. The "special" sampling event

provides no insight with respect to the chloride/bromide ratios that would have existed when

trench Cl was actively leaking.

Mother reasonably-drawn conclusion from this data is that the municipal solid waste unit, the

original disposal area of the PDC waste disposal complex, is a likely source of much of the

chloride contamination across the site. The chloride/bromide concentrations are consistent with

leachates from a municipal landfill and the waste disposed in oldest unit on site probably is the

closest to a traditional municipal solid waste landfill. Analyses of the leachate from several

areas of this old unit would allow testing of this conclusion and could shed considerable light on

other contaminant concentrations and distributions related to the PDC waste disposal complex as

a whole.

Of the wells for which analyses are reported, well R129 has the lowest chloride/bromide

concentration and one of the lower increases in chloride concentration. This is consistent with

its being the closest to pristine conditions of the wells reported in the chloride/bromide study.

Well RI29 is also positioned off the south end of the municipal solid waste unit geographically

and with respect to potentiometic map on Sheet 1 of the 22-Mar-06 supplemental comments. It

is also the furthest removed from older disposal units Area 1, Sections A and B, and trench Cl.

Tritium Data

Page 8 of 14

a2-01

?

OS60-889 60C?

JICIAJaSaN

WIAGC : OT 4002 TO clad

6i21#/31

bromine, or iodine) associated with dissolved organic substances. TOX does not measure

specific compounds, and water quality standards have not been established for TOX. False

positive TOX results are possible if the sample contains sediment, chloride, or inorganic halides

such

as

common laboratory and industrial solvents. ASTM

Method D 4744,

Standard Test

Method for Organic Halides in Water by Carbon Adsorption-Microcoulometric Detection,

notes

the possibility of interference with the chloride ion during the TOX analysis. If the inorganic

halide concentration is greater than 20,000 times the concentration of organic halides, the TOX

result may be affected significantly. The monitoring results of the facility groundwater program

over the permitted life of the facility reflect these variations.

Several facility groundwater monitoring wells have been analyzed for the Appendix IX

parameters in the past as a result of TOX results. No non-naturally occurring organic