BEFORE THE ILLINOIS

POLLUTION CONTROL BOARD

O F:

ABBOTT LABORATORIES'

PROPOSED

-SPECIFIC AMENDMEN

PLICABILITY

SECTION OF ORGANIC

TERIAL EMISSION

STANDARDS AND )

LIMITATIONS FOR THE CHICAGO AREA; )

SUBPART T:

218.480(b))

Kathleen

M. Crowley

Hearing

Officer

Illinois Pollution Control Board

100 West Randolph Street

NOTICE OF FILING

TO: Mr. John Therriault

Assistant Clerk of the Board

ois Pollution Control Board

100

West

Randolph Street

-500

g o, Illinois 60601

ELECTRONIC MAIL)

e 11-500

R08-8

(Rulemaking - Air)

Illinois

60601

(VIA U.S. MAIL)

ACHED SERVICE L

ICE that

linois Pollution Control Board MOTION

is herewith served upon you.

Respectfully submitted,

By:

Dated: April 7, 2008

ine D. Hodge

Lauren C. Lurkins

HODGE DWYER 2E

3150 Roland Avenue

Post Office Box 5776

62705-5776

THIS TILING SUBMITTED ON RECYCLED PAPER

Electronic Filing - Received, Clerk's Office, April 7, 2008

CERTIFIC OF SERVICE

I, Katherine

D. Hodge, the undersigned, hereby certify

that I have served

MOTION TO CORRECT TRANSCRIPT

upon:

Assistant

Clerk of the Board

Illinois Pollution Control Board

100 West Randolph Street

Suite

I1-500

ago, Illinois 60601

via electronic mail on April 7, 2005; and upon:

Kathleen M. Crowley

Matthew J. Dunn, Chief

Hearing Officer

Environmental

Bureau North

ois Pollution Control Board

Office of the Attorney

General

'hompson Center

69 West Washington Street, Suite 1800

100 West Randolph Street, Suite 11-500

Chicago, Illinois

60602

Chicago, Illinois 60601

ion Agency

ue East

Post Office Box 19276

62794-9276

Resources

linois 62702-1271

ument in the United States Mail, postage pre

on April 7, 2008.

/s/ Katherine D.

A BOT:003/FilingsiNOF & COS, Mtn to Correct Transc

Electronic Filing - Received, Clerk's Office, April 7, 2008

BEFORE THE ILLINOIS POLLU'.

OF:

BOTT LABORATORIES' PROPOSED

SITE-SPECIFIC AMEND

APPLICABILITY SECTION OF ORGANIC )

MATERIAL EMISSION STANDARDS AND )

LIMITATIONS

FOR THE CHICAGO AREA; )

SUBPART

T: PHARMACEUTICAL

)

MANUFACTURING

(35

ILL. ADM. CODE )

218.480(b))

R08-8

aking -Air)

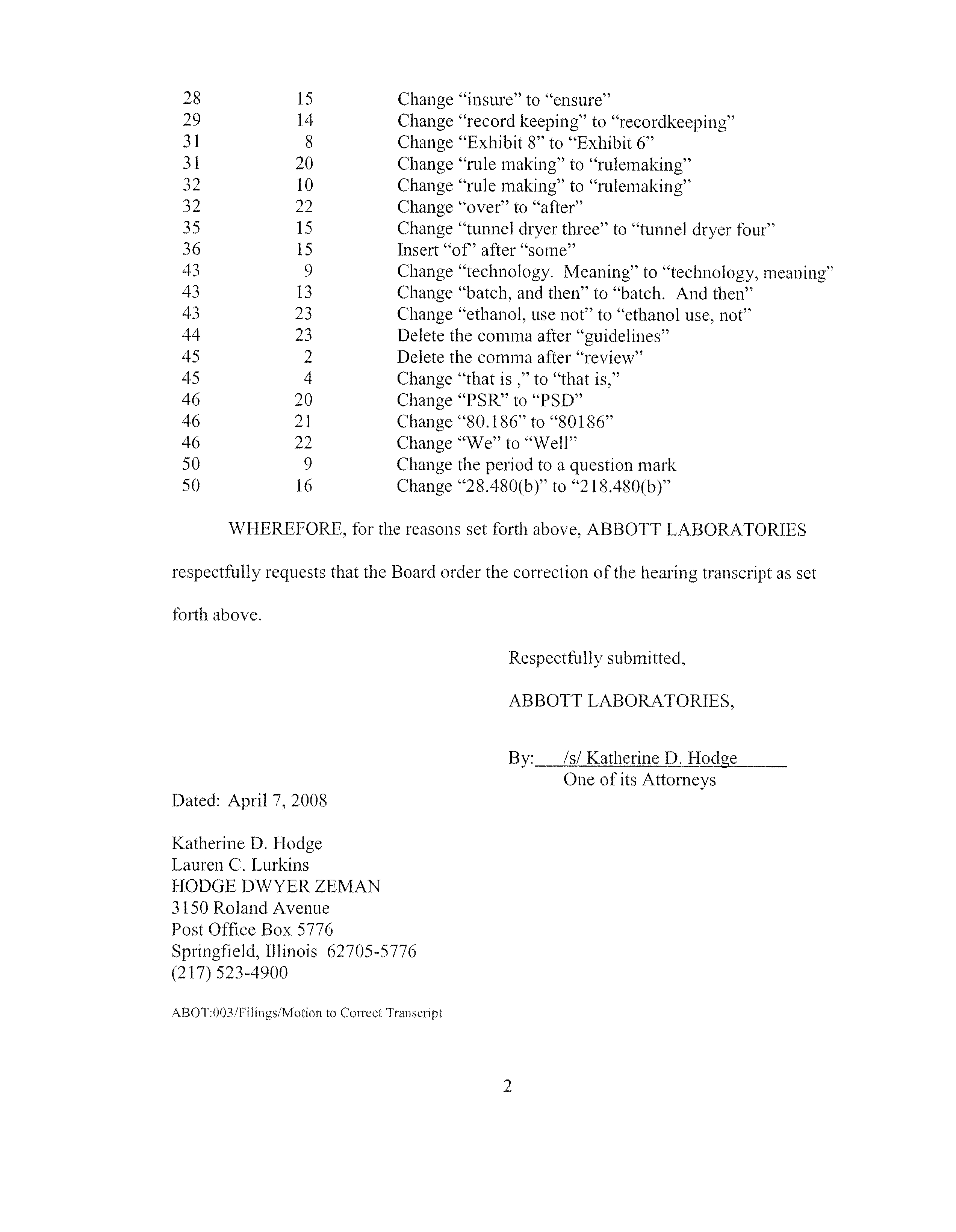

MOTION TO CORRECT

ES AB

RAN SCRIPT

OTT LABORATORIES, by and through its attorneys,

HODGE DWYER ZEMAN, and pursuant to 35 Ill. Admin. Code

§

1

3

3

Pollution Control Board ("Board") order the correction

his matter held on March 7, 2008. as .follows:

17

4

3

10

4

12

6

9

6

13

9

14

11

4

11

22

13

5

10

18

9

19

1

21

11

23

12

25

5

2

26

9

26

11

27

11

ION CONTROL BOARD

01..604, requests that

Laboratories" to "Abbott Laboratories"'

Insert "Area" after "Chicago"

Change "218.408(b)" to "218.480(b)"

Change "rule making" to "rulemaking"

Change "Zeeman" to "Zeman"

Change "hearing" to

Change

"apply" to "applies"

Change "effected" to "affected"

Change "Program" to "Programs"

Change

"EIP's" to "ElPs"

Change "EPA-452/R-01-001" to "EPA-452/R_01-001"

Change "Granulation Process Fluid Bed Drawi

"Granulation Process - Fluid Bed Drying"

Change "air" to "bed"

rt "and" after "months"

Change "results" to "result"

Change`

Change "effected" to "affected"

Change "One be

to

"One would be to"

Electronic Filing - Received, Clerk's Office, April 7, 2008

28

15

Change "insure" to "ensure"

29

14

Change "record keeping"

to "recordkeeping"

31

8

Change "Exhibit 8" to "Exhibit

6"

31

20

Change "rule making" to "rulemaking"

32

10

Change "rule making" to "rulemaking"

32

22

Change "over"

to "after"

35

15

Change "tunnel dryer three"

to "tunnel dryer four"

36

15

Insert "of' after "some"

43

9

Change "tectmology.

Meaning" to "tect-mology, meaning

43

13

Change "batch, and then"

to "batch. And then"

43

23

Change "ethanol, use not" to "ethanol use, not"

44

23

Delete the

comma after

45

2

Delete the comma

after

45

4

Change "that is ," to

46

20

Change "PSR" to "PSD"

46

21

Change "80.186" to "80186"

46

22

Change "We" to "Well"

50

9

Change the period to a question mark

50

16

Change "28.480(b)" to "218.480(b)"

WHEREFORE, for

ons set forth above,

0

hearing transcript as set

forth above.

Respectfully

submitted,

DRIES,

By: /s/ Katherine D. Hoc

One of its Attorneys

Dated: April 7, 2008

erine D. Hodge

Lauren C. Lurkins

HODGE

DWYER ZEMAN

3150 Roland Avenue

Post Office Box 5776

I

217)

523-4900

s 62705-5776

ABOT:003/Filings/Motion to Correct Transcript

Electronic Filing - Received, Clerk's Office, April 7, 2008

1

1

BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

2

3 IN THE MATTER OF:

)

4

)

5 ABBOTT LABORATORIES'

)

6 PROPOSED SITE-SPECIFIC

)

7 AMENDMENT TO APPLICABILITY

)

8 SECTION OF ORGANIC MATERIAL ) NO. R08-8

9 EMISSION STANDARDS AND

) (Rulemaking-Air)

10 LIMITATIONS FOR THE CHICAGO )

11 AREA; SUBPART T:PHARMACEUTICAL )

12 MANUFACTURING (35 ILL.ADM.CODE )

13 218.480(b)

)

14

15

16

REPORT OF PROCEEDINGS had before the

17 ILLINOIS POLLUTION CONTROL BOARD held on March 8,

18 2008, at 1:00 o'clock p.m. at the Libertyville

19 Village Hall, 118 Cook Road, Libertyville, Illinois.

20

21

22

23

24

2

1 A P P E A R A N C E S:

2

MEMBERS PRESENT:

3

4 ANAD RAO, CHAIRMAN

THOMAS E. JOHNSON, MEMBER

5 NICHOLAS J. MELAS, MEMBER

6

7 CHARLES MATOESIAN

8 Illinois Environmental Protection Agency

9

HODGE DWYER ZEMAN

10 BY: MS. KATHERINE D. HODGE

3150 Roland Avenue

11 Post Office Box 5776

Springfield, Illinois 62705-5776

12 (217) 523-4900

13

On behalf of Abbott Laboratories;

14

15

16

17

18

19

20

21

22

23

24

3

1

MS. CROWLEY: Good afternoon. This is

2

a hearing being conducted by the Illinois

3

Pollution Control Board in a matter of

4

our docket number R08-8 Abbott Laboratories

5

proposed site specific amendment to

6

applicability section of organic material

7

emission standards and limitations for the

8

Chicago, Subpart-T, Pharmaceutical

9

manufacturing at 35 Illinois Administrative

10

Code 218.408(b).

11

The Board opened this docket

12

October 4th to consider Abbott's proposal for

13

site specific rulemaking. In addition to

14

myself, present from the Board today are

15

seated to my immediate right, Board member

16

Nicholas J. Melas, who is the lead Board

17

member for this rulemaking. Seated to my

18

immediate left is Anad Rao, an environmental

19

engineer on the board's technical staff, and

20

seated to Mr. Rae's left is Board member

21

Thomas E. Johnson.

22

Board member Andrea Moore asked me

23

to remind you that she is abstaining from any

24

participation in the hearing or decision

4

1

making in this rulemaking as she owns a small

2

amount of stock in Abbott and also has close

3

family members who are employed by Abbott.

4

Would you like to make any remarks at this

5

point, Mr. Melas?

6

MEMBER MELAS: Nothing else but to

7

welcome you all here. It will be a pleasure

8

listening to the answers to the pre-filed

9

questions.

10

MS. CROWLEY: Today we're holding the

11

first and only hearing currently scheduled in

12

this rule making. I see that there are no

13

members of the public present so I will cut

14

short the introductory remarks that we

15

usually make a little bit.

16

The proceeding is governed by the

17

Board's procedural rules. All information

18

that is relevant and not repetitious is

19

admitted into the record. The Board makes

20

its rulings on the basis of its sworn and

21

transcribed records. So the hearing officer

22

will be asked to swear in the witnesses. I

23

also want to remind you that any questions

24

that may be posed today by any member of the

5

1

Board or staff are intended solely to develop

2

a complete and clear record for the Board and

3

are not intended to reflect any prejudgment

4

of the proposal.

5

The hearing today will consider

6

both the technical justification of the

7

proposal, as well as any economic impact of

8

the proposed rules as required by Section

9

27-B of the Environmental Protection Act. On

10

October 18, 2007 the Board requested The

11

Department of Commerce and Economic

12

Opportunity to conduct an economic impact

13

study. That department has not responded to

14

this request or pre-filed a study within the

15

45-day period the Act provides, so the Board

16

will be basing its decision on the economic

17

information that is provided today and in any

18

post-hearing comments. The Board has

19

received pre-filed testimony in this

20

proceeding only from the two witnesses from

21

Abbott. We also have some pre-filed

22

questions that were developed by the Board

23

and given to the parties on March 4, 2008.

24

So we will begin, I think, by asking the

6

1

attorneys to introduce themselves and then we

2

will turn the proceedings over to Ms. Hodge

3

for Abbott.

4

MS. HODGE: Thank you very much. Good

5

afternoon, everyone. Thank you for allowing

6

us to come here today to present support for

7

our proposal. My name is Katherine Hodge,

8

H-O-D-G-E, and I'm with the Hodge Dwyer

9

Zeeman here today representing Abbott

10

Laboratories.

11

MR. MATOESIAN: Good afternoon. I'm

12

Charlie Matoesian. I'm with the Illinois

13

Environmental Protection agency. I'm hearing

14

appearing for the agency, although we are not

15

part of the filing per se.

16

MS. HODGE: Also present with me today

17

on behalf of Abbott Labs is Mr. Steve

18

Ziesmann, right here. He is the senior

19

counsel for legal and regulatory compliance

20

for Abbott. Diane Beno, to my immediate

21

left. She is the manager of Abbott's

22

operations in building AB16, some of which

23

are the topic for this proceeding. Mr. Bob

24

Wells to her left, and Bob is the air manager

7

1

for environmental support in Abbott's global

2

environmental health and safety department

3

and then Mr. Keith Marhafka, and he is the

4

environmental health and safety manager for

5

building AB16.

6

MS. CROWLEY: I'm sorry, I didn't

7

catch the first and last names, if we could

8

say them again.

9

MS. HODGE: Steven Ziesmann,

10

Z-I-E-S-M-A-N-N. Diane Beno. Robert Wells.

11

You have that, and Mr. Keith Marhafka, M-A-R-

12

H-A-F-K-A.

13

MS. CROWLEY: Thank you.

14

MS. HODGE: And I have just a short

15

opening statement to make, and then we'll

16

move on to our two witnesses for today.

17

Abbott owns a pharmaceutical

18

manufacturing building located at 100 Abbott

19

Park Road in Unincorporated Lake County in

20

Libertyville Township, Illinois. Abbott

21

produces a number of pharmaceutical products

22

at this facility. And these operations are

23

subject to 35 Illinois Administrative Code,

24

Subpart-T, Pharmaceutical Manufacturing. As

8

1

it is currently written, Subpart-T, and in

2

particular section 218.480(b) contains

3

certain exemptions that are applicable to

4

Abbott's air suspension of coater dryers,

5

fluid bed dryers, tunnel dryers, and

6

accelacotas, a-c-c-e-l-a-c-o-t-a-s, located

7

in building AB16 of the facility.

8

Today through our testimony and in

9

response to questions, we intend to

10

demonstrate that Abbott's proposal to amend

11

these site specific exceptions will, one,

12

allow Abbott to use the combined actual

13

emissions from its effective tunnel bed

14

dryers and fluid bed dryers to determine the

15

applicability of Subpart-T to these units;

16

and, two, decrease the overall VOM emissions

17

that would be allowed below the level of

18

historical actual emissions from the tunnel

19

dryers and fluid bed dryers as a group

20

relating to the 35 Illinois Administrative

21

Code, Section 218.480(b), the VOM exemption,

22

while at the same time increasing operational

23

flexibility by allowing preferential use of

24

the more efficient dryer or dryers for a

9

1

particular manufacturing campaign.

2

The proposed amendment also will

3

not impose any new control requirements on

4

any other source other than Abbott's

5

facility. The proposed amendment will not

6

result in any increase in emissions. First

7

before offering testimony in support of our

8

proposal, I would like to address a matter

9

raised in the hearing officer order dated

10

January 31, 2008. As you know, Ms. Crowley

11

requested Abbott to address economic and

12

budgetary effects, issues associated with our

13

proposal. In that regard, the proposed rule

14

if adopted by the Board apply only to

15

specific emission units within Abbott's

16

facility, and again the proposed rule will

17

allow for increased operational flexibility

18

at Abbott's facility which in turn will

19

result in more efficient and cost effective

20

production of pharmaceutical products.

21

Moreover the proposal will not impose any new

22

requirements upon the Illinois EPA, so there

23

will be no budgetary effect. In light of the

24

limited and site specific nature of the

10

1

proceeding and the information set forth in

2

Abbott's proposal and the testimony to be

3

presented today in answers to questions,

4

Abbott believes there's sufficient

5

information in this record for the Board to

6

make an analysis of the economic and

7

budgetary effects of the proposal. However,

8

Abbott would be happy to answer any questions

9

the Board may have on this topic.

10

Abbott will present two witnesses

11

today, and first Ms. Diane Beno. She is the

12

plant manager of the portion of the Abbott

13

facility internally known as Building AB16.

14

Ms. Beno will provide information about the

15

processes carried out in Building AB16 and

16

the products manufactured at that location.

17

Mr. Robert Wells is the air manager for

18

environmental support in Abbott's Global and

19

Environmental Health and Safety Department,

20

and he will testify as to the technical

21

description of the process and dryers at

22

issue in this rulemaking. He will also

23

discuss the current rule and explain how it

24

causes inefficiencies in the operations, and

11

1

then he will discuss the methods Abbott has

2

utilized in an attempt to alleviate those

3

inefficiencies. Finally, Mr. Wells will

4

discuss the emissions from the effected

5

dryers from both a historical and prospective

6

perspective. The testimony of these two

7

witnesses also will demonstrate that Abbott

8

has worked closely with the Illinois EPA and

9

the US EPA on this issue over the course of

10

several years. We thank both the Illinois

11

EPA and the US EPA for working with us in

12

trying to resolve this issue and we

13

appreciate Illinois EPA's participation here

14

today.

15

As set forth in Abbott's proposal

16

that was filed with the Board on September 4,

17

2007, Abbott's testimony today will focus on

18

the concept called the "Source Specific

19

Emissions Cap EIP." Abbott included a full

20

copy of the US EPA guidance document entitled

21

"Improving Air Quality With Economic

22

Incentives Program," and that was included as

23

Exhibit 2 to our initial proposal. The EIP

24

guidance provides direction on a number of

12

1

types of EIPs, including the source specific

2

emission caps. The EIP guidance provides

3

that there are fundamental principles that

4

must be included in every EIP; number one,

5

integrity; number two, equity; and three,

6

environmental benefit. All EIP's must

7

contain four elements that compose the

8

integrity principle: Surplus, quantifiable,

9

enforceable and permanent. Second, with

10

regard to the equity principle, all EIP's

11

must contain an element of general equity.

12

Finally as noted, all EIP's must demonstrate

13

environmental benefit.

14

A source specific emissions cap

15

EIP allows a specified stationary source or a

16

limited group of sources that are subject to

17

a rate based emission limit to meet that

18

requirement by accepting a mass based

19

emission limit or cap rather than complying

20

directly with the rate based limit. The US

21

EPA's stated goal for this type of EIP is

22

compliance flexibility. Abbott in

23

consultation with both the Illinois EPA and

24

the US EPA relied upon and followed this

13

1

federal guidance in formulating its proposal.

2

Mr. Wells will provide additional detail in

3

how Abbott's proposal is consistent with the

4

Federal guidance for source specific

5

emissions cap EIP's.

6

With that, if there are no

7

questions, I would like to move ahead with

8

the testimony of Ms. Diane Beno and Mr. Bob

9

Wells. And Ms. Beno is going to, her

10

testimony is short and she would like to go

11

ahead and read that into the record. Bob's

12

testimony, we're happy to enter into the

13

record as if read, but he would like to offer

14

a summary, and we'll be happy to move to

15

Board questions or, you know, to agency

16

questions as appropriate.

17

MS. CROWLEY: Can we go off the record

18

for a one moment.

19

(Discussion off the record, after

20

which the following proceedings

21

were had:)

22

MS. CROWLEY: Go back on the record.

23

We discussed briefly entering some of the

24

exhibits to the original proposal as hearing

14

1

exhibits just to keep the record tidy. So

2

the first Exhibit will be Exhibit 1, which is

3

an aerial photograph of Abbott Park and

4

vicinity in Libertyville Township and is so

5

labeled. The second will be the US EPA

6

document that is entitled "Improving Air

7

Quality With Economic Incentive Programs"

8

prepared by the United States Environmental

9

Protection Agency, dated January 2001, and

10

that is EPA document number EPA-452/R-01-001.

11

And then finally, the third exhibit is

12

Exhibit 3 entitled "Revised Exhibit 3," dated

13

2-29-08 entitled "Historical VOM Air

14

Emissions From Tunnel Dryers And Fluid Bed

15

Dryers At The Abbott Park Facility." For the

16

record this is slightly revised from the copy

17

that was attached as Exhibit 3 to Abbott's

18

original September 4th proposal. So those

19

are marked and entered into the record as

20

exhibits.

21

Now you may proceed.

22

MS. HODGE: Thank you. I do have

23

extra copies of this pre-filed testimony here

24

today, but I'm assuming everyone has a copy.

15

1

With that, I think we're ready to move ahead

2

with Ms. Beno. And I'm not sure how you want

3

to handle the --

4

MS. CROWLEY: I'm sorry, I didn't

5

quite hear that.

6

MS. HODGE: I think we're ready to

7

move forward.

8

MS. CROWLEY: Yes, go ahead.

9

(WITNESSES SWORN.)

10

DIANE BENO

11 Having been first duly sworn, was examined and

12 testified as follows:

13 BY MS. BENO:

14

Thank you for the opportunity to

15 speak here today. My name is Diane Beno. I am the

16 plant manager of the portion of the Abbott

17 Laboratories facility internally known as AB16. The

18 operations contained in AB16 produce intermediate

19 and final product formulations including liquids,

20 tablets, capsules packaged in bottles and blister

21 formats. The general process flow includes receipt

22 of raw materials, weighing of ingredients, massing

23 and granulation of ingredients, coating tablets or

24 particles, printing symbols onto tablets and

16

1 packaging finished products for distribution.

2

Over the course of a year we

3 produce many different products in building AB16.

4 For example, we produce products that treat diseases

5 in the field of neuroscience such as epilepsy and

6 bipolar disorder. We make anti-viral products for

7 the treatment of AIDS. We manufacture products to

8 fight infection. We package products that help

9 patients achieve healthy cholesterol levels and

10 products that improve the lives of people with

11 rheumatory arthritis, psoriasis and Crohn's disease.

12 We manufacture our products using batch production

13 processes. In batch production all of the

14 processing equipment in a process train, including

15 the dryers, manufactures one product at a time.

16 Each batch is completed before the manufacture of

17 the next batch begins. In a typical process, the

18 active and inactive ingredients are combined with

19 the liquid in a process called massing. The massing

20 process forms uniform granules. The wet granules

21 are dried in tunnel dryers or in fluid bed dryers

22 and then further processed into tablets or capsules.

23 The massing fluid which is typically either water or

24 ethanol is evaporated from the solid material in the

17

1 drying step. If an organic solvent is volatilized

2 from the dryer, it is emitted to the ambient air as

3 VOM or VOC. The quantity of VOM emissions will vary

4 for different products and is calculated from the

5 quantity of VOM added to the mixture and loss

6 factors defined for the dryers and specified in the

7 Clean Air Act Permitting Program permit for the

8 facility. It's also important to note that the

9 organic solvent currently used in granulation and

10 dried from the granulated mixtures in building AB16

11 is ethanol. Ethanol is a VOM, but it's not

12 considered a Hazardous Air Pollutant or HAP. The

13 proposed site specific amendment will have no impact

14 on HAP emissions.

15

Abbott's proposed site specific

16 amendment for building AB16 covers four tunnel

17 dryers and three fluid bed dryers. One additional

18 fluid bed dryer located in building AB16 is used

19 exclusively for research and development and is not

20 involved in the normal operating processes in

21 building AB16; therefore our proposed amendment does

22 not include that dryer. The tunnel dryers and fluid

23 bed dryers operate on different principles. We have

24 some diagrams here to help explain this point, so

18

1 I'll go ahead and pass these out. I think this will

2 help us make a point. I think this will be helpful

3 as we get into the pre-filed questions later on. So

4 as I stated --

5

MS. CROWLEY: Just one moment. I'd

6

like to mark this as Exhibit 4, if you have

7

no objection, and it's a single-page document

8

with a heading "Granulation Process Fluid Bed

9

Drawing." Thank you. Go ahead.

10

MS. BENO: The tunnel dryers and fluid

11

bed dryers operator on different principles.

12

In the use of tunnel dryers depicted on the

13

lower half of the exhibit, materials are

14

spread on trays and placed in a warming

15

chamber or tunnel that circulates warm air

16

over and under the trays. As shown in the

17

upper portion of the diagram, a fluid bed

18

dryer is a large vertical cylindrical shaped

19

vessel with a diffuser that blows warm air up

20

from the bottom of the vessel. The wet

21

intermediate granules are loaded into the

22

dryer, and flow upward suspended in a warm

23

air stream.

24

Abbott has increased its use of

19

1

fluid air dryers for recently developed

2

products because they are more efficient and

3

produce a more uniform product than the

4

tunnel dryers. Abbott anticipates increased

5

use of water for massing fluid in future

6

products, and Abbott expects that this

7

preferential use of fluid bed dryers and

8

water based products will continue. That is,

9

many new products are expected to use fluid

10

bed dryers and water based formulations,

11

while older products continue to be

12

manufactured using tunnel dryers.

13

Batches of specific products are

14

typically manufactured using either one or

15

more tunnel dryers or one or more fluid bed

16

dryers, but not both because the technologies

17

are not interchangeable. Individual dryers

18

of the same type can typically be used in

19

combination or interchangeably in many cases,

20

but specific dryers are preferable for

21

combining with other equipment in a process

22

train to manufacture certain products from an

23

operational efficiency standpoint.

24

Abbott manufactures its batch

20

1

processes whereby each manufacturing process

2

train and its associated equipment, including

3

the dryers, produces one product at a time in

4

fixed batch sizes. Process trains are

5

designed to accommodate batches of different

6

scales with some for large batches and some

7

for small batches. Therefore, the scale of a

8

given batch plays an important role in

9

determining which of the dryers will be most

10

efficient. Additionally, in accordance with

11

the U.S. Food and Drug Administration current

12

good manufacturing processes, extensive

13

equipment cleaning is required between

14

batches of different products, resulting in

15

up to three days of lost production time.

16

Therefore Abbott uses a campaign strategy to

17

continue running batches of the same product

18

consecutively in the process train to

19

minimize this cleaning time.

20

As currently written 218.480(b)

21

effectively defines a 12 month total VOM

22

limit on each individual dryer. This can

23

limit Abbott's ability to schedule the

24

campaigns of certain products to maximize the

21

1

efficiency of the processes. In other words,

2

to insure compliance with the current 12

3

month VOM limit on each dryer for a

4

particular batch, Abbott may be required to

5

utilize a dryer with a low VOM emissions

6

during the last 12 months, instead of using

7

the dryer that is most efficient from a

8

production scale standpoint. Such selection

9

of dryers is based only on the amount of VOM

10

that has been emitted from an individual

11

dryer during the preceding 12 months is an

12

inefficient approach to the scheduling of

13

Abbott's equipment and resources.

14

Additionally, the dryer selected for a given

15

campaign also depends on dryer availability

16

and other factors. For example, one dryer

17

may be temporarily out of use to allow for

18

cleaning or for unscheduled maintenance

19

requirements; therefore the standards as

20

currently defined can result in wasted

21

resources by requiring Abbott to dry a small

22

batch of our product in our large scale

23

process train to maintain our equipment

24

specific VOM limits. Total annual emissions

22

1

from a dryer result in a quantity of organic

2

solvent removed from the different products

3

processed in a dryer over a 12-month rolling

4

period. The material is processed in a

5

number of individual campaigns for particular

6

products each consisting of multiple

7

individual batches. The assignment of a

8

campaign of a particular product to one or

9

more dryers involves a number of operating

10

factors, such as the scale and equipment

11

availability that contribute to the

12

efficiency of manufacturing. The VOM

13

emission threshold effectively acts as an

14

overriding factor that can force a particular

15

production campaign with VOM emissions to be

16

scheduled using equipment that has low enough

17

recent emissions to avoid exceeding a dryer's

18

threshold, but that may not otherwise be the

19

optimal or most efficient equipment for the

20

campaign. This scheduling shift increases

21

the operational cost, but results in no

22

environmental benefit because the actual

23

emissions will be the same as if the campaign

24

would have used the optimal equipment.

23

1

In order to assure Abbott's Lake

2

County manufacturing facilities remain

3

competitive with our national and global

4

competitors Abbott must continually seek ways

5

of making our manufacturing operations more

6

efficient. The scheduling inefficiency

7

created by Subpart-T was identified as one

8

area where improvements in efficiency could

9

be made and is the basis for the proposed

10

amendment. This seems particularly

11

appropriate as the business costs created by

12

this efficiency results in no environmental

13

benefit. The most efficient method to

14

manufacture Abbott's products in AB16 would

15

be to use the dryer that is best suited to

16

the requirements of the production schedule

17

and scale, regardless of the amount of VOM

18

that has been emitted from that dryer in the

19

past 12 months. Provided that the combined

20

VOM emissions from all of the dryers are less

21

than the combined amount allowed under

22

section 218.480(b), this method of operation

23

would not require an increase in allowable

24

VOM emissions from the facility. In fact,

24

1

the proposed amendment would provide Abbott

2

improved production flexibility to utilize

3

the most efficient dryers for a given product

4

while significantly lowering the total

5

allowed VOM emissions for all of the dryers

6

combined.

7

Thank you. I'll be happy to

8

answer any questions.

9

MS. HODGE: Shall we move on to Bob.

10

Why don't you go through a summary of your

11

testimony, and then we'll be happy to turn to

12

the Board's questions well.

13

MS. CROWLEY: That's certainly

14

acceptable.

15

MR. WELLS: I am going to attempt to

16

summarize my testimony in a shorter summary

17

than the actual testimony. My name is a

18

Robert Wells. I'm air manager for

19

Environmental Support in Abbott's Global EHS

20

Department. I've been assisting the EHS

21

staff with regulatory statutes with our

22

proposal, and I'm going to touch on some of

23

the technical points that relate to why we

24

proposed what we did and where we see that

25

1

we're consistent with the approaches that

2

we've proposed.

3

The concern today is for

4

provisions applicable to seven of the Abbott

5

parking units, four tunnel dryers and three

6

fluid bed dryers. Subpart-T requires VOM

7

controls for tunnel dryers and fluid bed

8

dryers if their annual emissions exceed

9

seven-and-a-half tons per year for an

10

individual tunnel dryer and five tons per

11

year for individual fluid bed dryers. The

12

seven units therefore have a total potential

13

emissions without control of 45 tons per

14

year. Because of the cost associated with

15

VOM control for this type of equipment, it is

16

impractical to add control. So effectively

17

the limits before control is required act as

18

upper limits on the air emissions from the

19

seven units. The actual emissions from these

20

units vary year to year based on the quantity

21

of production and based on the different

22

materials produced. In recent years the

23

tunnel dryer emissions have varied from

24

six-tenths of a ton to 5.6 per year, each

26

1

year. Fluid bed dryer emissions have varied

2

from .1 tons to 3.9 tons per year each where

3

the units have been operating. And you can

4

see from Exhibit 3 that's where those numbers

5

came from, although they were not in my

6

pre-filed testimony.

7

Abbott sought solutions to

8

eliminate manufacturing constraints that

9

effected the efficiency of the overall

10

operation, and two options were initially

11

considered. One be would be to request an

12

increase in the threshold that would have to

13

be exceeded before control were required, and

14

the second would be to refine Subpart-T so

15

that the individual unit control would be

16

applied as a group to the combined emissions

17

of the combined allowed emissions of the

18

seven dryers. We evaluated the alternatives,

19

and we did some analysis that demonstrated to

20

us that it would be justifiable to increase

21

the limit for each dryer, that the cost of

22

control was such that at the levels that the

23

threshold of requiring control and at higher

24

levels, that the cost would be beyond

27

1

reasonably available control technology or

2

RACT.

3

Considering the combined emission

4

controlled threshold, we determined that the

5

flexibility that we were looking for would

6

fit well within that so that there was -- we

7

could go forward with that program without

8

increasing the allowable emissions from the

9

units. We discussed these alternatives with

10

Illinois EPA and later with both IEPA and US

11

EPA through our attorneys Hodge Dwyer Zeeman.

12

And IEPA and US EPA identified a third

13

alternative that was preferable to them and

14

that was a source specific emission cap,

15

SSEC, under US EPA's economic incentive

16

program or EIP. The source specific emission

17

cap would allow us to combine our future

18

emission limits for all the dryers but set to

19

a limit below the historical actual emissions

20

rather than the previously allowable

21

emissions or emissions allowable without

22

control. The historical emissions could be

23

based on a concept called baseline actual

24

emissions defined as the highest two year

28

1

period in the last ten years. I know there

2

was some confusion about that following my

3

filing of the pre-filed testimony and we're

4

prepared to answer that question in detail

5

when we go through the prepared questions.

6

This is a change from the original definition

7

of historical actual emissions that the US

8

EPA included in their 2001 guidance. Abbott

9

reviewed the actual emissions that we've had

10

from the dryers in the most recent ten years,

11

and we identified the maximum two-year period

12

with emissions of 22.9 tons per year in 1999

13

and 2000. As I'll discuss later, a reduction

14

of ten percent of that level is applied to

15

insure environmental benefit and that results

16

in an emission limit for the seven units of

17

20.6 tons per year. This restriction would

18

be less than half of the 45 ton per year

19

effective limit that now applies to the seven

20

units taken together. This significantly

21

lower allowable limit though is acceptable to

22

Abbott's anticipated business and meets our

23

needs for flexibility.

24

Abbott considered the requirements

29

1

of the EIP program in going forward with this

2

in order to define our conformance with the

3

three general principles for an EIP,

4

integrity, equity and environmental benefit.

5

Integrity, the integrity principle focuses on

6

the emission reductions themselves and

7

requires them to be surplus, bonafiable,

8

enforceable and permanent. This proposal

9

satisfies those conditions. The emissions

10

are surplus because our future allowable

11

emissions will be below past baseline

12

emissions for the dryers. Our emissions are

13

quantifiable because the VOM emissions can be

14

readily calculated from process record

15

keeping as established in the facility's

16

title five permit. The limits are

17

enforceable because they will be included in

18

Illinois's state implementation plan and also

19

in our Title V permit for Abbott Park and

20

they are permanent for the same reason. They

21

will be established as continuing limits on

22

our operations.

23

The proposed program satisfies the

24

equity principle because it involves only

30

1

emissions at one facility. There is no

2

instance of relative increases and decreases

3

that must be balanced against one another.

4

The program satisfies the environmental

5

benefit principle because future emissions

6

will be reduced by ten percent below our

7

baseline actual emissions.

8

So in summary, the proposal limits

9

our maximum future allowable emissions to a

10

level below what we historically had really

11

in the course of the variations in our

12

manufacturing, but it will give us the

13

flexibility to operate more efficiently.

14

Thank you. I'll be happy to

15

answer any further questions.

16

MS. HODGE: Thank you very much.

17

We're ready to move on to the Board's

18

questions unless counsel for Illinois EPA has

19

anything now?

20

MS. CROWLEY: If we could first mark

21

as Exhibit No. 5, the pre-filed testimony

22

submitted by Mr. Wells on February 22nd, as

23

I'm sure he would like the complete testimony

24

included in this record.

31

1

MS. HODGE: Yes, he would.

2

MS. CROWLEY: We will do that.

3

MS. HODGE: Now, we'll turn to the

4

questions of the Board that were included in

5

the hearing officer order dated March 4,

6

2008.

7

MS. CROWLEY: And let's mark that as

8

Exhibit 8.

9

MS. HODGE: And we're not going to

10

read the questions. We'll just go straight

11

to the answers, if that's acceptable.

12

MS. CROWLEY: Unless you are more

13

comfortable having us read the questions, we

14

can dispense with that.

15

MS. HODGE: Okay. Then we'll probably

16

answer the questions certainly in order. And

17

No. 1, we'll start with --

18

MR. WELLS: Question 1-A refers to

19

whether the economic feasability for the

20

original rule making still applies? The

21

answer to that is yes. As a part of this

22

process we analyzed the cost of control using

23

a methodology developed by the United States

24

EPA for what's referred to as BACT analysis,

32

1

Best Available Controlled Technology, and

2

using this analysis we found that the cost of

3

control was continued to be significantly in

4

excess of what's normally considered

5

reasonably available control technology. So

6

essentially the economics have not changed.

7

And as to question 1-B, there have been no

8

fundamental changes in emission control

9

technology that would be applicable to the

10

facility since that original rule making. So

11

what we were looking at were the same control

12

technologies that were considered at that

13

time.

14

MEMBER RAO: We're fine with that.

15

MS. HODGE: Thank you. And let's move

16

on to the Board's question No. 2 dealing with

17

emission trends.

18

MS. BENO: Okay. 2-A is in regard to

19

the lower actual emissions since 2000.

20

That's due to many factors. For example,

21

pharmaceutical manufacturing business

22

activity is highly variable year over year.

23

The types of products that we produce in a

24

given year can vary based on a number of

33

1

market factors and patient demand. So

2

therefore, as I stated in the testimony,

3

different products emit different levels of

4

VOM. So product mix is a primary factor in

5

regard to the variability of our emissions.

6

MEMBER RAO: Has there been any change

7

in terms of production itself because when we

8

look at this, we see some variation but there

9

is also a significant, you know, reduction in

10

VOM emissions since 2000?

11

MS. BENO: As stated in the testimony

12

many new products where possible utilize

13

water based massing fluid, and so we make an

14

attempt using water instead of ethanol or

15

other VOM. So therefore the new products

16

that have been introduced to the facility

17

typically have used water based solvents.

18

MEMBER JOHNSON: And there's no VOM

19

produced when you use water as a fluid?

20

MS. BENO: No, no.

21

MEMBER RAO: Do you anticipate VOM

22

emissions to increase over time?

23

MS. BENO: We don't anticipate them to

24

increase over time.

34

1

MEMBER MELAS: I have a question. You

2

stated earlier that the fluid bed drying is a

3

more efficient way of doing it. Do you

4

contemplate over the course of time now that

5

you will be phasing out the tunnel drying

6

equipment and concentrate on buying or

7

purchasing new fluid drying equipment?

8

MS. BENO: No, that's not currently

9

the plan. In fact, the products that we

10

manufacture in the tunnel dryers, we will

11

continue to manufacture those in the tunnel

12

dryers. To switch between the technologies

13

can have an impact on the safety or efficacy

14

of the drug product. So it would require a

15

lengthy amount of process development and

16

studies potentially, even clinical trials, so

17

that is the lengthy FDA process I referred

18

to.

19

MEMBER MELAS: You say there is a

20

one-on-one relationship to the type of

21

product to the type of dryer?

22

MS. BENO: Yes, absolutely.

23

MEMBER JOHNSON: Let me ask then.

24

There is then in your mind a potential any

35

1

way that your company will begin some time in

2

the future to manufacture products that

3

either can't use the water as a massing fluid

4

and have to use ethanol; there is a potential

5

that you'll get back up to VOM rates

6

comparable to what they were in '99 and 2000?

7

MS. BENO: I wouldn't rule it out. It

8

certainly wouldn't be our intent, but I

9

wouldn't rule out the possibility.

10

I'll move on to B?

11

MS. HODGE: Yes.

12

MS. BENO: B is in regard to tunnel

13

dryer number four specifically, and in

14

Exhibit 3 it was noted that there was no VOM

15

from tunnel dryer three since 2005, and based

16

on Abbott's production needs, tunnel dryer

17

No. 4 has not been in use since 2005.

18

However, it remains fully validated and

19

maintained and available for use should

20

production needs demand. So it serves us as

21

a back up in the event that one of the other

22

tunnel dryers would become unavailable for

23

use.

24

MEMBER RAO: Since the emissions for

36

1

all these dryers that you have listed in

2

revised Exhibit 3 are significantly lower

3

than the applicable limits, does Abbott have

4

enough flexibility under the current rule

5

itself or do you need to have the combined

6

limit to provide you that flexibility?

7

MS. BENO: We believe we need the

8

combined limit to provide flexibility.

9

MEMBER RAO: Can you explain a little

10

more why, if you don't have enough

11

flexibility under the current rule?

12

MS. BENO: It's based on the highly

13

variable nature of the product mix in the

14

facility. So in the event we were to run

15

more or some the products that have an

16

ethanol based mass in fluid, it would prevent

17

us from using the most effective and

18

efficient equipment.

19

MEMBER RAO: Have you had that kind of

20

situation in the past?

21

MS. BENO: What specific situation?

22

MEMBER RAO: Where you were not able

23

to use whatever dryer you wanted to under the

24

current rules.

37

1

MS. BENO: It's become very close.

2

MEMBER RAO: Looking at this data that

3

you have provided, fluid bed dryer 3

4

obviously could be the one which is kind of

5

closer to its limit?

6

MS. BENO: Right.

7

MEMBER RAO: Is that a situation where

8

you see and you'd need to use another dryer

9

similar to that again?

10

MS. BENO: Yes, absolutely. Fluid bed

11

dryer 3 in Exhibit 3, as you noted, has

12

reached 3.9 in recent years which approaches

13

our current limit.

14

MEMBER RAO: Thank you.

15

MS. HODGE: Let's move on to the

16

questions in the Board's order relating to

17

the pre-filed testimony of Ms. Beno, and

18

question No. 1.

19

MS. BENO: This is in regard to the

20

type of organic massing fluid that we

21

currently use, and ethanol has been the only

22

organic massing fluid that we've used in

23

building AB16 during the ten-year period

24

under review for this proposal. I do want to

38

1

note that prior to late 2002 the type of

2

ethanol used was denatured ethanol which

3

contains a small percentage of methanol as

4

the denaturant, but since late 2002 we've

5

converted to all beverage grade ethanol which

6

does not contain methanol as the denaturant.

7

MS. HODGE: Question number two?

8

MS. BENO: Again, number two is in

9

regards for the basis for choosing the

10

massing fluid, and the choice of massing

11

fluid is dependent on the particular

12

properties of a product. For example, the

13

relative solubility of the product in either

14

water or ethanol plays a key role in

15

determining which solvent will be required

16

for the massing fluid. So it's really

17

related to the various properties of the

18

product we're intending to manufacture

19

whether or not water is an option for us or

20

not.

21

MEMBER RAO: So it's got nothing to do

22

with the type of dryer you are using; it's

23

all the product you are manufacturing?

24

MS. BENO: No, either can be used in

39

1

either dryer. Water or ethanol can be used

2

in either drying technology.

3

MS. HODGE: Question number three?

4

MS. BENO: No. 3, this is in regard to

5

increased use of fluid bed dryers and water

6

for massing fluid. Abbott does in fact

7

expect there will be an increased mass for

8

water in new products as I indicated. It's

9

not practical to change the ethanol based

10

processes to a water based process because of

11

the FDA considerations that I indicated

12

before had the opportunity to influence the

13

safety and efficacy of the product. But we

14

do consider the type of massing fluid as we

15

developed new products with a preference to

16

using water. So accordingly we expect there

17

will be an increased use of water for the

18

massing fluid for new products. Questions

19

there?

20

B, this is in regard to the use of

21

water to avoid VOM emissions. And in fact

22

VOM emission avoidance is one of several

23

factors that we consider as one of the

24

benefits resulting from increased use of

40

1

water for the massing fluid. Other benefits

2

include increased raw material costs, reduced

3

worker exposure to organic materials in the

4

work place and improved safety due to

5

reduction of flammable solvents.

6

In regard to C, water based

7

products are preferable for a number of

8

reasons. As described previously, they are

9

preferable because they don't contribute to

10

VOM emissions, reduced raw material costs,

11

reduced worker exposure and improve overall

12

safety to the facility. Those were similar

13

questions.

14

In regard to the fluid bed dryers

15

being more efficient, it's mainly related to

16

the way they operate. If you refer to the

17

diagram, you can see in a fluid bed dryer,

18

individual granules, very small pieces of the

19

product are airborne in the warm air stream

20

and the air moves around freely on all

21

surfaces of the particle or granule drying

22

the drying process. This results in a much

23

more even drying process and higher quality

24

end product because of the evenness of the

41

1

drying. Tunnel dryers on the other hand are

2

like cookie sheets in an oven. You hand-load

3

the material onto the cookie sheet, onto the

4

big rack, push the rack into the tunnel dryer

5

and it's exposed to air movement in the

6

tunnel. What can happen in a tunnel dryer

7

similar to in baking, you could have parts of

8

the cookie that are more done than other

9

parts of the cookie. Whereas in the fluid

10

bed drying technology, a smaller portion of

11

the product is exposed to the warm air across

12

the entire surface. So it makes for a much

13

more uniform drying process which makes the

14

downstream processing much easier.

15

MEMBER RAO: I think you answered 4B

16

already.

17

MS. BENO: Yes, yes. Thank you.

18

MS. HODGE: Number five?

19

MS. BENO: Selection of the dryers.

20

One example of the inefficiencies created by

21

the current rule is that the most

22

appropriately sized equipment may not be

23

chosen. As I mentioned in the testimony, we

24

have small scale process trains and large

42

1

scale process trains. Now, in the event that

2

the small scale process train would be

3

approaching its limit, we may be forced to

4

use the large scale process train to process

5

smaller batches than would normally be

6

processed in that particular process train.

7

So that is the main consideration in regards

8

to inefficiency of the scheduling that could

9

be influenced by the current rule. It's much

10

like flying a plane half full or running a

11

dishwasher half full, you are not utilizing

12

the full capacity of the equipment in that

13

particular area.

14

MR. RAO: In this regard, I didn't see

15

any information about the drying capacity of

16

these dryers. Are they all about the same or

17

each dryer is different.

18

MS. BENO: It has to do with the

19

processing suits that they are in. We have

20

one dryer in one processing suit, and we have

21

two dryers in another processing suit.

22

That's our large scale processing train

23

versus our small scale processing train. As

24

I mentioned, you can only run one product in

43

1

a process train at any given time.

2

MEMBER RAO: Thank you.

3

MS. BENO: So there was one final

4

question regarding how we select which dryer

5

to use for a given campaign. And the

6

selection of dryers is mainly based on the

7

technology first. As I mentioned there is a

8

one to one relationship of which product goes

9

in which type of technology. Meaning a

10

tunnel dryer or a fluid bed dryer. The

11

second consideration would be the scale,

12

whether it's a large scale batch or a small

13

scale batch, and then the third consideration

14

is general availability; do we have more

15

products running in one size suit than the

16

other or is one of the suits down for

17

maintenance or cleaning. So those are the

18

critical factors that we consider when

19

scheduling the production in the dryers.

20

MEMBER RAO: Thank you.

21

MEMBER JOHNSON: The amount of VOM

22

produced is dependent upon the amount of

23

ethanol, use not on your choice of which

24

drying --

44

1

MS. BENO: Absolutely because we're

2

going to be drying to the specification of

3

the product so we'll always be drying off the

4

same amount of VOM for a given product for a

5

given batch.

6

MS. HODGE: Thank you. Anything else?

7

MS. CROWLEY: Mr. Matoesian, have you

8

had any questions?

9

MR. MATOESIAN: No, not so far.

10

MS. CROWLEY: I've been keeping an eye

11

on you, but I just wanted to state it for the

12

record.

13

MS. HODGE: Let's move on to the

14

questions of the pre-filed testimony of

15

Mr. Wells.

16

MR. WELLS: I talked briefly earlier

17

about the two-year period. What has happened

18

is that there has been a change in philosophy

19

on the conceptual level in US EPA's

20

application of historical emissions.

21

The definition of historical

22

actual emissions that appears in the 2001

23

guidelines, the US EPA developed is the same

24

as the concept in prevention of significant

45

1

deterioration, PSD, or non-attainment new

2

source review, netting that US EPA has

3

previously used and what was in place at the

4

time; that is , the two years immediately

5

preceding the action or another two year

6

period, if it's determined to be more

7

representative. There's been a lot of

8

problems historically in the determination of

9

whether a particular period is

10

representative, and the US EPA in 2002

11

changed the definition of actual emissions.

12

They defined a term "baseline actual

13

emissions" for the PSD and the non-attainment

14

new source review program. And what they

15

said was that you can use any 24-month period

16

in the preceding ten years. That assures

17

that you can look back far enough to see a

18

representative business cycle so that you can

19

see the periods when your normal fluctuation

20

of business would result in relatively higher

21

emissions. But at the same time it gives a

22

simple concrete basis to make that decision.

23

That was originally suggested to us in the

24

conversations that our attorneys had with

46

1

IEPA and with US EPA. That was the

2

recommended interpretation at the time, and

3

as we understand it, US EPA guidance is now,

4

their guideline on the EIP process, which is

5

not a regulation. It is guidance, is being

6

interpreted differently to allow the use of

7

that two-year period as far back as ten

8

years. I'll also point you to the revised

9

Exhibit 3. If you notice, 1999 and 2000 were

10

the highest years. 1998 was actually lower

11

than the emissions in either 1999 or 2000.

12

So it is in fact a peak that we are talking

13

about rather than just a continuing decline.

14

MEMBER RAO: And, Mr. Wells, do you

15

have any specific US EPA publication or

16

memorandum that talks about this change in

17

their policy?

18

MR. WELLS: Well, the baseline actual

19

emissions were established in a federal

20

register notice amending the PSR rules at 67

21

Federal Register 80.186.

22

MEMBER JOHNSON: We, as good corporate

23

citizens, it's to your benefit to keep your

24

VOM emissions as low as possible, but what

47

1

you want to be able to do, at least I take it

2

is, that the demand for whatever product you

3

are producing in 1999 and 2000 were to return

4

and you had to use the same drying system or

5

use the ethanol rather than water on that to

6

develop that or make that particular product,

7

you want to be covered so that you can do

8

that and fulfill the demand. And that's why

9

even though these VOM emissions are at least

10

twice as much as the next five years, that's

11

why you want to have that set as your

12

baseline?

13

MR. WELLS: Exactly.

14

MS. HODGE: And, again, just to note

15

for the record, that historical baseline is

16

being reduced by ten percent, you know, in

17

the limit that we're requesting.

18

MEMBER JOHNSON: And in fact, the

19

reduction from what it is now is

20

significantly more than that. If you ran all

21

of your dryers at capacity, you would produce

22

45 tons, and this site specific rule as

23

proposed reduces that by over 30 tons, right?

24

MEMBER RAO: Half.

48

1

MR. WELLS: Over half, a little over

2

half.

3

MEMBER RAO: Thank you.

4

MR. WELLS: Question two, I think it

5

kind of follows question one.

6

MS. HODGE: We're good there. Shall

7

we move on the economic incentive program

8

guidance? Question No. 1. And this is

9

something that we thought might be more

10

properly addressed to the Illinois EPA.

11

MR. MATOESIAN: That's fine. Charles

12

Matoesian speaking. With me today I have

13

Mr. Yoginder Mohajan (Phonetic), who is an

14

engineer with the Illinois Environmental

15

Protection Agency, he is here to answer some

16

questions from the board. He is currently in

17

the air quality planning section of the

18

Bureau of Air and has prepared some answers

19

for these questions.

20

MS. CROWLEY: Would you swear him in?

21

YOGINDER MAHAJAN

22 having been first duly sworn, was examined and

23 testified as follows:

24

Question No. 1 on page three, the

49

1

guidance states that the guidance applies if

2

state applies --

3

MS. CROWLEY: Off the record.

4

(Discussion off the record.)

5

MS. CROWLEY: Go back on the record.

6

MR. MAHAJAN: The answer to the

7

question, I spoke with the US EPA, Mr. Steve

8

Rosenthal. He told me that the option of the

9

EIP is not required. It is recommended. It

10

is nice if you have it adopted, but it's not

11

required and the agency's intention is not to

12

adopt it. It will deal with it on a case by

13

case basis.

14

Question No. 2, yes, the agency

15

has discussed this with the US EPA and

16

confirmed that this amendment is consistent

17

with the EIP guidelines.

18

No. 3, yes. And question No. 3B

19

is also no. Regarding emissions being

20

surplus is there any concern? No we don't

21

have any concern. It's discussed with the US

22

EPA, and they said that it is consistent with

23

the EIP guidelines.

24

MEMBER RAO: Thank you.

50

1

MS. HODGE: Do you have any other

2

questions?

3

MEMBER RAO: There was one question

4

about the proposed amendment.

5

MS. HODGE: We're ready to move to

6

that.

7

MEMBER RAO: No follow-ups.

8

MS. CROWLEY: Do you have any

9

follow-ups for this.

10

MS. HODGE: No. So we'll move on to

11

the question on the proposed amendments,

12

question No. 1.

13

MR. WELLS: Yes. The only concern

14

that we had with the specification of the

15

equipment was that we not specify that --

16

28.480(b) now covers the entire facility,

17

more than just building AB16. We would not

18

have a problem if the specification were made

19

on the SSEC that we've been discussing today.

20

As far as specifically 218.480(b)(4), as far

21

as the general applicability of 218.480(b),

22

it's our understanding that still applies to

23

the facility, and it is possible that we

24

might find the need to install a fluid bed

51

1

dryer in another building for a totally

2

unrelated manufacturing process.

3

MEMBER RAO: You are comfortable with

4

the way the rule is proposed now?

5

MR. WELLS: That's correct.

6

MEMBER RAO: I think that question was

7

triggered because the way 218.480(b) is now

8

currently written, Abbott's name is not

9

mentioned in that section at all. And I know

10

it's highly unlikely that somebody else would

11

set up shop with four dryers and give them

12

names and take advantage of this rule, but in

13

most of our site specific rules we have the

14

name of the company involved in it. So I

15

just wanted to know what your thoughts were

16

on it.

17

MR. WELLS: In terms of identifying

18

the company, I don't think we have any

19

objection to it. The drafting of the

20

original rule was before my time. I'm not

21

sure where the language came from, but that

22

wouldn't be a problem. Again, the only thing

23

we wanted to be sure was that it wasn't

24

defined specifically to cover building AB16,

52

1

just to allow us the same flexibility in the

2

future.

3

MEMBER RAO: Okay.

4

MEMBER JOHNSON: The road is named

5

after you so --

6

MEMBER RAO: Thank you very much.

7

MS. HODGE: Thank you.

8

We have one more issue that we'd

9

like to address, and this deals with a

10

request that has been made by US EPA through

11

the Illinois EPA, and they had asked if we

12

could submit to them some of the supporting

13

emission calculations for the baseline years,

14

1999 and 2000. We've talked with IEPA about

15

how the emissions are calculated and US EPA

16

wants a little bit more information. We are

17

currently preparing that, and we will submit

18

additional information in response to that

19

request subject to CBI, confidential business

20

information requirements on that. So that

21

will be forthcoming, and I understand from

22

talking with counsel for IEPA, that you would

23

like to have some of that in this board's

24

record, that IEPA would like to have some of

53

1

that in the Board's record.

2

MS. CROWLEY: I understand that.

3

Please if any of it is confidential business

4

information or trade secrets, that when it is

5

submitted that it is properly submitted with

6

a redacted copy, as well as the copy that you

7

would like to have protected so that there

8

isn't any problem with that.

9

MS. HODGE: We can do that, and we

10

will work with IEPA and Mr. Steve Rosenthal

11

at US EPA to make sure that everyone is

12

comfortable with what we submit.

13

With that, I don't have anything

14

else.

15

MR. MATOESIAN: We have nothing.

16

MS. CROWLEY: One little left over bit

17

was the motion to file the amendment, Exhibit

18

3, and the motion to amend the proposal

19

specifically as it regards proposed

20

218.480(b)(4) to reflect the change to the 90

21

percent baseline calculations. Do you have

22

any objection to that?

23

MR. MATOESIAN: No.

24

MS. CROWLEY: Thank you. That motion

54

1

then is granted. Let's go off the record for

2

a moment.

3

(Discussion off the record.)

4

MS. CROWLEY: Back on the record. We

5

have had a brief discussion about what would

6

be a reasonable post-hearing comment period.

7

We have chosen May 1st as the close comment

8

period date subject to an extension if

9

necessary to allow completion of data

10

gathering for US EPA or if any other person

11

needs additional time. We specifically do

12

request that the agency file, even if short,

13

some comment on this record indicating their

14

view of whether this rule should or should

15

not be granted. If there is nothing else --

16

MR. MATOESIAN: We can say, the Agency

17

can state that it supports the petition.

18

MS. CROWLEY: Okay, fine. If there's

19

nothing else then, I thank you all for your

20

participation. The Board again thanks Abbott

21

for its patience in bearing with our

22

scheduling problems. We will try to render a

23

decision in an expedited fashion once the

24

record is closed. Again, thank you all very

55

1

much.

2 STATE OF ILLINOIS )

) SS.

3 COUNTY OF COOK )

4

5

I, DENISE ANDRAS, being a Certified

6 Shorthand Reporter doing business in the City of Des

7 Plaines, Illinois, County of Cook, certify that I

8 reported in shorthand the proceedings had at the

9 foregoing hearing of the above-entitled cause. And

10 I certify that the foregoing is a true and correct

11 transcript of all my shorthand notes so taken as

12 aforesaid and contains all the proceedings had at

13 the said meeting of the above-entitled cause.

14

15

16

___________________________

17

DENISE Andras, CSR

CSR NO. 084-003437

18

19

20

21

22

23

24