BEFORE THE POLLUTION CONTROL BOARD

OF THE STATE OF ILLINOIS

IN THE MATTER OF:

PROPOSED ADJUSTED STANDARD FOR

AMMONIA NITROGEN DISCHARGE LEVELS

APPLICABLE TO CITGO PETROLEUM

CORPORATION AND PDV MIDWEST

REFINING, L.L.C., PETITIONERS

)

)

)

) AS 08-

_

) (Adjusted Standard - Water)

)

)

NOTICE OF FILING

To:

Dorothy Gunn

Clerk of the Board

Illinois Pollution Control Board

100 West Randolph Street - Suite 11-500

Chicago, IL 60601

Illinois EPA

1021 N. Grand Ave. East

P.O. Box 19276

Springfield, IL 62794

Illinois Department

ofNatural Resources

100 West Randolph

Suite 4-300

Chicago,

IL 60601

Illinois Attorney General

188 West Randolph

Suite 2001

Chicago, IL 60601

Connie Tonsor/Sanjay Sofat

Illinois EPA

1021 N. Grand Ave. East

Springfield, IL 62794

Please take notice that on March 18,2008, we filed electronically with the Office

of the

Clerk

of the Illinois Pollution Control Board the attached Petition for an Adjusted Standard, a

copy

of which is served upon you.

By:

---->.,--'1'-1't=1'--Jhhr-----7"-~

CITGO PETROLEUM CORPORATION, and

PDV MIDW

,LL, Petitioners

(

Jeffrey C. Fort

Ariel J. Tesher

Sonnenschein Nath

&

Rosenthal LLP

7800 Sears Tower

233

S. Wacker Drive

Chicago, IL 60606-6404

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

BEFORE THE POLLUTION CONTROL BOARD

OF THE STATE OF ILLINOIS

IN THE MATTER OF:

PROPOSED ADJUSTED STANDARD FOR

AMMONIA NITROGEN DISCHARGE LEVELS

APPLICABLE TO CITGO PETROLEUM

CORPORATION AND PDV MIDWEST

REFINING, L.L.C., PETITIONERS

)

)

)

) AS 08-

_

) (Adjusted Standard - Water)

)

)

PETITION FOR AN ADJUSTED STANDARD

CITGO Petroleum Corporation and PDV Midwest Refining, LLC ("CITGO" or

"Petitioner") petition the Illinois Pollution Control Board ("Board") for an Adjusted Standard

applicable to its Lemont Refinery. This rule change would reduce the allowable levels

of

ammonia nitrogen in the wastewater discharges from a refinery located in Lemont, Will County,

Illinois. ("Refinery") CITGO is the operator

of the Refinery and PDV Midwest Refining, LLC is

the owner

of the Refinery. For the reasons stated below, Petitioner requests an Adjusted

Standard from Section 304. 122(b)

of Subpart B of Part 304 of Title 35 ofthe Illinois

Administrative Code. Petitioner's existing site-specific regulation pertaining to ammonia

nitrogen, 35 Ill. Admin. Code § 304.213, will expire on December 31, 2008. This Petition for an

Adjusted Standard ("Petition") is brought pursuant to Section 28.1

of the Act, 415 ILCS 5/28.1,

and Part 104

of Chapter 35 of the Illinois Administrative Code, 35 Ill. Admin. Code § 104.400 et

seq. In support of this Petition, CITGO states as follows:

STATEMENT OF REASONS

1.

PDV Midwest Refining, L.L.C. ("The Refinery") owns a petroleum refinery

located on an 860-acre tract in Will County near Lemont, Illinois. The Refinery was formerly

owned and operated by the Union Oil Company

of California ("Union") and then operated by the

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

UNO-VEN Company. On May 1,1997, PDV became the owner of the Refinery and CITGO

was contracted to operate the Refinery.

2.

Despite extensive improvements and other efforts, the Refinery is not able to

consistently meet the ammonia nitrogen effluent limits contained in Section 304. 122(b) of

Subpart B of Part 304 of Title 35 of the Illinois Administrative Code (ammonia nitrogen rule).

The general ammonia nitrogen discharge rule would apply to the Refinery, but for site specific

rule changes granted in 1987, 1993 and 1998. Despite steady improvements during the last

twenty years, Petitioner and its predecessors have been unable to consistently achieve the

effluent limits of the ammonia nitrogen rule. The Refinery has been successful in lowering the

ammonia nitrogen concentration in its effluent and has achieved this success even though the

plant throughput has increased and wastewater usage has decreased. The Refinery is prepared to

continue efforts to reduce its ammonia nitrogen discharge, but it cannot commit to meet the

general effluent limit in

35 Ill. Admin. Code 304.122(b).

3.

The Refinery currently discharges to the Chicago Sanitary and Ship Canal

("Canal") which is a tributary of the Illinois River. The discharge is quickly dispersed in the

Canal and assimilated by the receiving stream. The dilution pattern of the effluent is rapid and

immediate under the criteria of 35 Ill. Admin. Code Subtitle C, Chapter I, Section 302.102.

4.

Petitioner proposes the following adjusted standard be adopted by the Board:

a)

This standard applies to discharges from PDV Midwest Refining, L.L.C.

Refinery ("The Refinery"), located in Lemont into the Chicago Sanitary and Ship

Canal;

b)

The requirements

of Section 304. 122(b) shall not apply to the discharge.

The Refinery shall meet applicable Best Available Technology Economically

Achievable (BAT) limitations pursuant to 40 CFR 419.23 (2003), incorporated by

reference in subsection (d);

2

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

c)

The Refinery shall also meet a monthly average limitation for ammonia

nitrogen of 6.93 mg/1 whenever the monthly average discharge exceeds 100 lbs

per day and 10.61 mg/1 whenever the daily discharge exceeds 200 pounds

of

ammoma;

d)

The Board incorporates by reference 40 CFR 419.23 (2003) only as it

relates to ammonia nitrogen as N. This incorporation includes no subsequent

amendments or editions;

e)

The Refinery shall continue its efforts to reduce the concentration

of

ammonia nitrogen in its wastewaters;

f)

The Refinery shall monitor the nitrogen concentration of its oil feedstocks

and report on an annual basis such concentrations to the Agency;

g)

The Refinery shall continue its efforts to control and manage solids from

its crude oil supply with respect to its wastewater treatment system;

h)

The Refinery shall submit the reports described in subsection

"f'

no later

than 60 days after the end of a calendar year; and

i)

The provisions

of this Section with respect to Ammonia Nitrogen shall

terminate on December 31, 2013.

5.

The limits for ammonia nitrogen proposed here are based on a statistical analysis

using the 95th percentile

ofthe standard deviation over historical and representative time periods

to calculate the effluent limits. The daily and monthly limit is based on the 95th percentile based

on the last five years

of effluent data. The limits proposed demonstrate the commitment to

improvement in nitrification, a reduction in the daily limit

of 59 percent and in the monthly limit

of27 percent.

6.

Over the last several years, Lemont Refinery has been processing an increased

percentage

of heavy crudes and can expect the trend in feedstocks over the course of this petition

to continue. The uncertainty associated with this issue justifies the Board choosing to set daily

and monthly limits that take into account this uncertainty. Moreover, this analysis indicates that

the proposed limits represent a continued emphasis

on improvement in wastewater controls and

achieving nitrification in the wastewater treatment plant even with more difficult wastewater

3

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

streams to be treated. Over the last 5 years, on a net basis, the Refinery has exceeded 100

pounds on a monthly daily average for ammonia only

33 percent of the time, and exceeded 200

pounds per day for ammonia only

17 percent of the time.

GENERAL INFORMATION

7.

The water quality conditions in the receiving stream do not require further

treatment

of the Refinery discharge to meet applicable water quality standards. The un-ionized

ammonia levels in the receiving streams currently meet the applicable water quality standard

(0.1 mg/l). Further reductions in the ammonia discharged are expected during the course of this

proposed adjusted standard

8.

At this point, Petitioner and its predecessors have expended significant resources

in improving the wastewater treatment system at the Refinery. Petitioner and its predecessors

have spent nearly $75,000,000 to upgrade and improve the wastewater treatment facilities at the

Refinery; approximately $45,000,000

of that was spent just in the last 10 years.

9.

While there has been success in reducing the effluent ammonia nitrogen

concentration, the Refinery is unaware of proven means to comply with the ammonia nitrogen

rule on a continuous basis. The options available to Lemont are two orders of magnitude more

expensive, on a unit cost basis, than other available alternatives for ammonia removal.

Therefore, it is possible to spend millions

of dollars in an attempt to implement unproven

strategies for potential ammonia nitrogen reduction even though: (a) the present level

of

wastewater treatment at the Refinery is better than the United States Environmental Protection

Agency's ("U.S. EPA") effluent guideline

of best available technology ("BAT") economically

4

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

achievable; and (b) the ammonia nitrogen discharge for the Refinery has no discemable water

quality impact on the receiving stream.

10.

The requested amendment will allow Lemont Refinery to continue to operate

without spending millions

of dollars on unproven technology in an attempt to accomplish further

ammonia nitrogen reductions with little or no environmental benefit. The Refinery will continue

to optimize its treatment facilities, regardless

of the outcome of this Petition. Indeed, the daily

limit requested here represents a 59 percent reduction, substantially below the level authorized in

1998.

11.

The following paragraphs and exhibits address the remaining requirements of

35 Ill. Admin. Code § 104.406 with respect to adjusted standards. With respect to ammonia

nitrogen, the other major sources are the same

as in the previous proceedings: the three major

plants

of the Metropolitan Water Reclamation District of Greater Chicago (MWRDGC).

12.

Petitioner has consulted with the Agency regarding this petition for an adjusted

standard; the Agency, however, has not yet determined its position on this request.

REFINERY INFORMATION

13.

The Refinery was constructed during the period 1967 through 1970.

It

became

operational in late fall

of 1969. Currently, the maximum daily production is approximately

168,000 barrels per day. The Refinery employs approximately 530 people.

14.

Approximately twenty-five different products are produced at the Refinery,

including gasolines, turbine fuels, diesel fuels, furnace oils, petroleum coke and various specialty

naphthas which can be manufactured into many intermediate products, including antifreeze,

5

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

dacron, detergent, industrial alcohols, plastics and synthetic rubber. Ninety percent of the

Refinery's output goes into making gasolines, diesel fuels, home heating oils and turbine fuels

for use in Illinois and throughout the Midwest.

15.

The Refinery draws from and discharges to the Canal. The Refinery takes

approximately 5.0 million gallons

of water daily from the Canal, and discharges approximately

4.5 million gallons to the Canal, the difference being cooling tower evaporation and steam

losses. The wastewater effluent contains ammonia as nitrogen derived from compounds present

in crude oil that are removed from the crude by various Refinery operations, as well as the

ammonia already present in the intake water from the Canal.

16.

The Refinery operates under a National Pollutant Discharge Elimination System

("NPDES") permit (No. IL 0001589), issued by the Illinois Environmental Protection Agency

("IEPA," or "the Agency"). The most recent NPDES permit was issued as modified June 22,

2007 and expires July 31, 2011. The NPDES permit includes outfall 001 at the Refinery at river

mile 296.5 on the Canal (Latitude 41 °38'58", Longitude 88°03 '31"). The current NPDES permit

includes ammonia nitrogen limits in the existing

35 lAC 304.213.

EXISTING

WATER QUALITY

17.

The requested adjusted standard will not result in environmental or health effects

substantially and significantly more adverse than the effects considered by the Board in adopting

the rules of general applicability for ammonia nitrogen. No adverse environmental impact,

including harm to aquatic life, will result from the granting of the requested adjusted standard.

At 3 mg/l, the allowable discharge of ammonia nitrogen from the Refinery is 145 pounds at the

design average flow. The annual average discharge loading to the Canal over the last 5 years

6

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

has been an average of 102.4 pounds per day, with a net ammonia discharge of 76.2 pounds per

day; 26.2 pounds per day are estimated to be in the intake water from the Canal, on an average

day. Thus, about 25 percent

of the ammonia nitrogen currently discharged is due to background

conditions in the Canal.

18.

The Refinery discharges into the Canal, upstream

of the Lockport Lock

&

Dam.

Below the dam, the Canal merges with the Des Plaines River, passes through Joliet and

11 miles

downstream

of Joliet passes beneath the I-55 Bridge. Until the I-55 Bridge, the receiving waters

are designated as Secondary Contact waters; below the I-55 Bridge, the Des Plaines River is

designated as General Use Water. The General Use Waters begin 18.5 miles below the

Refinery's outfall.

AMMONIA NITROGEN WATER QUALITY

19.

In 1992, UNO-VEN engaged Huff

&

Huff, Inc. to investigate and report on the

environmental effects

of its ammonia nitrogen discharge on the Canal. The consequent report,

entitled "Environmental Assessment of Ammonia Concentration in the Wastewater Discharge of

the UNO-VEN Refinery, Lemont, Illinois" (the 1992 Huff

&

Huff report), contained a detailed

assessment

of the discharge on the receiving waters. The 1992 Huff

&

Huff report was included

in UNO-VEN's 1993 Petition for a site specific rule change.

20.

The 1992

Huff & Huff report concluded that the Refinery's discharge results in a

10: 1 dilution plume in an area 15 feet long by 8 feet wide. The effluent is dispersed to a 10: 1

dilution in approximately 7 seconds which is considered "rapid" and "immediate" under Board

regulations. Effluent conditions and low flow conditions in the Ship Canal have not changed

materially,

so this Zone ofInitial Dilution analysis remains valid today. The overall mixing zone

7

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

was determined to provide a dilution ratio of 40: 1 during this same 1992 study. Again,

conditions are similar today, except that the 7-day 10-year low flow in the Ship Canal has been

reduced from 1,100 MOD to 850 MOD due to the loss

of discretionary diversion of Lake

Michigan water. The result is a current mixing zone dilution ratio

of 36.1: 1 at the design average

flow for the Lemont Refinery.

21.

In order to further evaluate the water quality and the effect

of the Refinery's

discharge,

Huff

&

Huff conducted benthic macroinvertebrate sampling of the Canal. The

sampling retrieved 1,967 specimens representing

14 different species. A comparison of samples

taken upstream and downstream of the Refinery outfall showed no significant variation in the

type and number

of species retrieved. No measurable impact from the Refinery's discharge on

the benthic organisms in the Canal was discerned. Furthermore, the 1992

Huff

&

Huff study

showed a dramatic improvement in the benthic community between 1983 and 1992. These

results were corroborated by a June

1991 study conducted by the MWRDOC.

22.

In 1997, the Refinery contracted

Huff

&

Huff for another assessment of the

environmental impact of the ammonia in the Refinery'swastewater effluent on the receiving

stream.

Huff

&

Huff produced another report, entitled "Environmental Assessment

&

Effluent

Limit Derivation Report

of The Lemont Refinery Wastewater Discharge" (the 1997 Huff

&

Huff

report).

23.

The 1997

Huff

&

Huffreport reviews the water quality data for the Canal. For

each year from 1992 to 1997 (except 1993), the total ammonia levels downstream

of the

Refinery were less than the upstream values. This reduction in ammonia suggests that active

nitrification is being achieved in this portion

of the Canal. The 1997 Huff

&

Huff report notes a

8

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

5 percent reduction in total ammonia in the 5.3 miles of Canal upstream of the Refinery and a

56 percent reduction in the 5.5 miles downstream

of the Refinery. This ammonia reduction

downstream indicates that the Refinery effluent does not have a negative impact

on nitrification

in the Canal.

24.

The Refinery has again requested

Huff and Huff to summarize more recent water

quality information. That report, entitled "Environmental Assessment

&

Effluent Limit

Derivation Report for the Ammonia Discharge from the CITGO Lemont Refinery" ("2007

Huff

&

Huff Report,") is attached as Exhibit

A.

This report analyzes the existing water quality data in

the Ship Canal and projects the impact

ofthe proposed monthly limitation: among the

conclusions are that the ammonia levels in the Ship Canal, at the edge

of the mixing zone, would

be 0.805 mg/l. Since the Refinery usually is able to nitrify the typical levels in the Canal after

mixing would be lower. Moreover, the maximum unionized ammonia level recently collected in

the Canal [downstream at Lockport] was 0.079 mg!l - which includes the discharge

of the

Refinery. Thus, the ammonia levels in the Canal today are well within established water quality

standards.

THERE ARE NO REGULATORY CONSTRAINTS THAT PROHIBIT THIS

RELIEF

25.

Section 303(d) of the Clean Water Act requires states to identify impaired

waterways and the causes

of impairment and then develop what is essentially a waste load

allocation for addressing the impairment. Illinois prepared its list

of impaired waterways in

1998; 738 segments were identified. Illinois also developed a priority list for addressing these

738 segments. According to the Agency's

Illinois Water Quality Report 2006,

the Chicago

9

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

Sanitary and Ship Canal is listed as an impaired waterway, for a variety of reasons. However,

none

of the reasons listed are for Ammonia Nitrogen.

26.

Effluent Limits - With respect to Ammonia Nitrogen, the applicable effluent

limits for the Refinery have been those set in the site specific rules for the Refinery, as adjusted

over time.

27.

Mixing Zone - Under Illinois regulations, the maximum allowable mixing zone is

25 percent of the stream flow. Water quality standards must be achieved at the edge of the

mixing zone. Using the requested monthly average concentration

of6.9 mg/l as the projected

discharge and only

25 percent of the Canal's low flow yields an incremental change of 0.17 mg/l

at the edge

of the mixing zone.

28.

Categorical Limits - U.S. EPA has promulgated categorical limits on various

industries, including the petroleum refining industry. While these regulations, found in 40 CFR

419, do specify limits for ammonia nitrogen, these are less stringent than the limits in the

existing site-specific rule. The Board has previously found that the wastewater treatment system

goes beyond Best Available Technology ("BAT") requirements.

29.

The U.S. EPA has established effluent guidelines for wastewater discharges by

industry category. The petroleum refining industry is divided into five subcategories based on

the processes utilized and the products produced. The Refinery is classified as a Subcategory-B

cracking refinery under the federal regulations. Effluent limits under the federal regulations are

based on production, and are computed on a pounds per day basis.

30.

The Board has adopted Title 35, Section 304.122

to control ammonia discharges

to the Illinois River System, originally Rule 406, adopted Jan 6,1972. Rule 304. 122(b) limits

10

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

larger industrial discharges (greater than 100 lbs!day ammonia) to an effluent discharge

concentration

of 3.0 mg!l NH

3

-N. Historically, the refinery has achieved compliance with the

federal effluent regulations; however, the 3.0 mg!l effluent limit has not been attainable on a

consistent basis.

31.

From 1977 through 1984, Union operated the Refinery under several variances

from the Board for the ammonia nitrogen discharge. In 1982, the Board granted Union a

variance, contingent that by

May of 1984, Union would submit a program to ensure compliance

with Rule 304.122 or prepare a proposal for a site specific rule change.

In December of 1984,

Union petitioned the Board for a site specific rule change. The Board granted Union site specific

effluent limits set at the U.S.

EPA's best available technology (BAT) pursuant to 40 CFR 419.23

(1985). This site specific rule change terminated

on December 31, 1993. In 1993, UNO-VEN

petitioned the Board for a site specific rule change. The Board granted

UNO-VEN's request and

set effluent limits for ammonia nitrogen

of9.4 mg!l monthly average and 26.0 mg!l daily

maximum.

By final order dated December 17, 1998, the Board made only two changes to the

rule as adopted in 1993: a change

of the name to reflect the sale to PDV Midwest Refining,

LLC, and an extension

of the termination date by 9 years to December 31,2008.

32.

Based on the foregoing, the Lemont Refinery submits that the relief here

requested is not inconsistent with the effluent standards and area-wide planning criteria under the

Clean Water Act.

OTHER FACTORS JUSTIFYING THE SITE-SPECIFIC STANDARD

33.

The Refinery utilizes a physical/chemical and biological wastewater treatment

plant. The treatment plant performs primary, secondary and tertiary treatment on the generated

11

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

wastewater before it is discharged into the Canal. The original wastewater treatment plant,

which began operation in 1969, included two oil/water separators, a flow equalization tank, a

primary clarifier, an activated sludge system and a polishing pond. Several wastewater treatment

plant modifications have been made since the original installation. Major changes to the system

include new oil/water separators, process water storage tanks, a new aeration basin, a high

efficiency aeration system, a second final clarifier, an induced gas flotation system, additional

strippers in the sour water system, upgrades to the diffused aerators, and addition

of a purge

treatment unit, associated with operating the WGS.

34.

The primary treatment portion

ofthe current plant consists of four sour water

strippers for ammonia and sulfide removal, oil/water separators for free oil removal, stormwater

impoundment, equalization, and emulsified oil removal using organic polymers.

35.

The effluent from the primary clarifier flows to the Induced Gas Flotation ("IGF")

vessel and then to the secondary treatment portion

of the wastewater plant which consists of a

single stage activated sludge treatment system. The system includes three aeration basins

operated in parallel with a total aeration basin volume

of a 1.92 million gallons. Aeration is

provided by a fine-bubble diffused aeration system. Activated sludge is settled in two 1

DO-ft.

diameter secondary clarifiers. Within the aeration basin, phosphorous is added as a nutrient for

biological organisms. During the winter, steam is injected to the equalization tank to maintain

operating temperatures at a minimum

of 70°F in the aeration basin effluent.

36.

The tertiary system consists

of a 16 million gallon polishing lagoon. The purpose

of the lagoon is to remove any carryover solids from the secondary clarifier. The lagoon also

serves as a water supply for fire protection.

12

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

37.

Under the site specific rule change granted in 1987, the Refinery was required to

continue its efforts to reduce the concentration

of ammonia nitrogen in its wastewaters. The

Refinery met this requirement through continuous upgrades to the wastewater treatment plant.

After petitioning for the 1987 site specific rule change, the Refinery:

•

Added a third aeration basin, increasing the total aeration volume from 1.38

million gallons to 1.92 million gallons;

•

Upgraded the aeration system by replacing the existing mechanical surface

aerators with a fine-bubble diffused aeration system; and

•

Added the second 1

DO-ft. diameter secondary clarifier, doubling the secondary

clarifier capacity.

These improvements were designed to increase ammonia oxidation, increase available dissolved

oxygen and increase hydraulic throughput.

38.

While the site specific rule change was granted

in 1993, the Refinery continued its

efforts to reduce the concentration

of ammonia nitrogen in its wastewaters. From 1992 until

1998, the Refinery:

•

Installed a new chemical feed facility at the WWTP;

•

Eliminated discharge

of process wastewater to the stormwater basin and provided

tankage for equalization/oil separation

of process wastewater;

•

Converted the WWTP control system to new DCS control;

•

Modified the sour water stripper charge tanks inlet line for better oil/water

separation;

•

Performed a clean closure

of the stormwater basin; and

•

Utilized Nalco dried bacteria and conducted nitrifier inhibition testing.

39.

Since 1998, the Refinery has continued to make improvements to its wastewater

treatment system. Those measures have included:

13

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

•

In 2000, installed induced gas flotation system with polymer addition;

•

In 2003, added additional strippers in the sour water system for ammonia

removal;

•

Also in 2003, upgraded diffused aerators to improve oxygen transfer;

•

In 2006, upgraded phosphoric acid feed system and the aerators to improve

oxygen transfer;

•

In 2007, installed purge treatment unit to treat the discharge from the FCC

scrubber; and

•

Also in 2007, upgraded diffused aerators to improve oxygen transfer.

The total cost

of these improvements was approximately $45,000,000.

40.

Despite the improvements in its treatment plant, the Refinery has been unable to

continuously meet the Illinois standard for ammonia concentration in treated wastewater effluent.

As a result, the Refinery contracted with AWARE Environmental, Inc. ("AWARE") to evaluate

current conditions at the Refinery. AWARE was also asked to evaluate the treatment system

operations and to evaluate alternative ammonia removal technologies. AWARE reported its

findings in "Technical Review

of Ammonia Treatment At The Wastewater Treatment Plant-

CITGO Petroleum Corporation, Lemont Refinery" (the 2007 AWARE report). The 2007

AWARE report is attached hereto as Exhibit

B.

41.

The 2007 AWARE report concludes that the Refinery is a BAT plant that

employs the best available treatment technology currently required of refineries in the U.S. The

report also concludes that the current plant is unable to continuously attain the limits set by the

State

of Illinois for effluent ammonia nitrogen. While the Refinery and its predecessors have

made progress toward meeting the Illinois limits, the Refinery is still unable to meet these limits

on a continuous basis.

14

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

42.

The Refinery has improved its performance of ammonia removal despite higher

crude throughput and a decrease in wastewater volume. Wastewater volumes have decreased

since 1984 through the exercise

of sound water management practices. Despite these factors that

would tend to increase ammonia concentration, the Refinery has maintained/improved its

performance in ammonia removal.

43.

At this point in time, the total ammonia discharge from the Refinery, on an

average basis over the last 5 years, is less than the allowable discharge

of 3 mg/l, even when

about

25 percent of that discharge is due to the ammonia nitrogen levels already in the Canal.

[See paragraph

17 above.] Nevertheless, the Refinery will continue to look to improve its

treatment for ammonia nitrogen.

44.

The 2007 AWARE report reviewed the continued improvements made by the

Refinery in its wastewater treatment. Since 1997, the average removal

of ammonia from the

strippers has increased to 96.8 percent. The report also demonstrates that the Refinery has

excellent control over the key parameters which control nitrification: the food-to-microorganism

[F/M] ratio show lower BOD levels than in prior years; sludge age indicates good wastewater

treatment plant operation and does not appear to be a limiting factor; the aeration system is

operated to provide adequate D.O. levels; the alkalinity pH is maintained in an adequate range;

and the system is operated at an appropriate temperature to provide for nitrification. Yet the

Refinery cannot continuously meet the 3 mg/llimitation.

45.

The 2007 AWARE report evaluated several alternatives

to the current treatment

process. AWARE qualifies its analysis

of these alternatives with the assumptions that each

alternative will be effective and reliable. The report stated that the choices are design

15

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

alternatives and that there are no data to show that even with these alternatives the Refinery can

continuously comply with the 3.0 mg/l ammonia nitrogen limit. The report concluded that of the

technologies available, the following have the greatest potential for meeting the Illinois standard:

•

Activated sludge with powdered activated carbon treatment,

•

Activated sludge with a fixed media system;

•

Membrane bioreactor activated sludge; and

•

Activated sludge with breakpoint chlorination and dechlorination.

Even with the uncertainty associated with these technologies, the costs

of implementing the

alternatives ranged from a low capital cost

of $1 ,400,000 for activated sludge with breakpoint

chlorination/dechlorination to a high

of $54,700,000 for the membrane bioreactor activated

sludge process. Operation and Maintenance (O&M) costs ranged from a low of $220,000 per

year for activated sludge with a fixed media system to a high of $3,280,000 per year for activated

sludge with membrane bioreactor. The lowest equivalent annual cost ($3,220,000) was for the

activated sludge plant with a fixed media system.

46.

The 2007 AWARE report does not recommend that the Refinery pursue any

of

these alternatives and concludes that implementing the alternative technologies is not justified.

None

of these technologies have been demonstrated as technically feasible or as able to provide

better control

of the ammonia nitrogen discharge than currently achieved by the Refinery.

Continued optimization

of the treatment system and continued efforts to improve handling of the

solids from the heavy crude oil supply is the most appropriate approach to the Refinery's

ongoing efforts to control the ammonia nitrogen in its wastewater.

16

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

47.

The least expensive option available to the Refinery which might meet the

ammonia nitrogen rule is activated sludge with the fixed media system. This option, and the

others studied by AWARE, should not be considered only in terms

of overall cost. Rather, with

respect to cost, they should be evaluated in terms of a unit cost of dollars-per-pound of ammonia

removed from the Canal. The results of that analysis should be compared with other measures

available to improve the water quality in the Canal.

48.

The fixed media option costs $13.5 million in capital and $1.2 million in annual

O&M. These figures translate into a total annual cost

of $3.2 million.) Using effluent data

available from June 2002 through July 2007, and assuming the fixed media system would yield

an effluent

of 0.5 mg/l, an additional 28,250 pounds of ammonia would be removed from the

Canal per year. The unit cost for this removal would be $113.30 per pound of ammonia

removed. By comparison, a 1983 analysis showed that the Calumet Water Reclamation Plant

removes ammonia at a cost of $1.40 per pound. See "Environmental Assessment of Ammonia

Concentrations in the Wastewater Discharge of Union Oil Company, Chicago Refinery" (by

L.L.

Huff and J.E. Huff, 1983). Allowing for inflation, the latter figure is currently closer to $3.00

per pound. But even when adjusted for inflation, the Calumet Water Reclamation Plant unit cost

is 37 times smaller than the cost facing the Refinery to meet the ammonia nitrogen rule.

49.

The costs

of reducing ammonia in the Refinery effluent are similarly prohibitive

when compared with other programs for addressing water quality in the Canal. The MWRDGC

has installed five side-stream aeration facilities on the Chicago Waterway. These facilities

address the same problem as limits on ammonia concentration in effluent -- they increase the

I

Capital cost annualized over 10 years at 9% interest.

17

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

dissolved oxygen ("DO") concentration in the Chicago Waterway. The MWRDGC spent

$39 million for these side-stream aerations which have the potential for adding enough DO to

compensate for 720,000 pounds of ammonia per year. These figures translate into a unit cost of

$6.94 per pound of ammonia oxidized. Again, this unit cost is nearly twenty fold smaller than

the least expensive alternative available to the Refinery.

50.

The Lemont Refinery has investigated the available information on the

performance

of other refineries in Illinois to provide nitrification. The conclusions of that

investigation are in the 2007 Aware report, but can be summarized as follows: (a) the other

refineries were using similar technological approaches as used by the Lemont refinery design,

and none

of them were using the technologies investigated by Aware as possible additions to the

Lemont Refinery; (b) there are site specific variations in how the wastewater treatment systems

are designed and operated, as well as some differences in the crude supply; and (c) there are

some differences in these design specifics which may be worth exploring for potential use and

modifications at the Lemont Refinery to further enhance its nitrification capabilities.

51.

Based on evaluations and reports that accompany this Petition, the Refinery will

continue to investigate improvements to its existing wastewater treatment system.

It

is believed

that focusing on better solids handling from the desalter holds the greatest promise for achieving

improved wastewater treatment performance on a consistent basis. The options that will be

investigated include: an in situ solid removal system, increased tankage to allow brine

segregation; amine management; and adjusting chemical usage to reduce emulsification in the

primary treatment units.

18

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

DIFFERENT FACTORS EXIST HERE THAN THOSE CONSIDERED BY THE

BOARD IN ADOPTING THE EXISTING AMMONIA NITROGEN EFFLUENT

LIMITATION

52.

Several factors relating to this matter are substantially and significantly different

from the factors relied on by the Board in adopting the water quality standards cited here.

a) The Board has already found the situation for ammonia nitrogen

treatment at the Refinery to be unique and site specific relief

justified.

See e.g., In the Matter

ofPetition ofPD V Midwest

Refining,

L.L.c.,

R98-14

,

Opinion

and Order ofthe Board

(December

17,1998);

In the Matter ofPetition ofUno-ven, R93-8,

Opinion

and Order ofthe Board (December

16, 1993)

b) In 1972, the Lemont Refinery was just coming on line and was

clearly not known as a source of discharge into the Des Plaines

River of ammonia. The Board did not then consider the costs of

treatment for ammonia in a refinery wastewater discharge and

certainly did not anticipate that treatment would require the kind of

massive investment that would be required to meet the ammonia

nitrogen rule.

c) The discharge from the Refinery that will occur does not pose

any threat to human health

or the environment and is not

significantly greater than the environmental impact that the Board

was trying to control when it adopted the ammonia nitrogen rule.

Indeed, the recent discharge, in terms

of mass, is less than the

"allowable" discharge were the Refinery discharging at its design

flow.

d)

It

appears that there are no treatment technology differences

between the Refinery and other refineries in Illinois, but there are

differences in specific design details. While CITOO is able to

achieve nitrification, it cannot do so

on a consistent basis.

However, the Refinery continues to undertake investigations and

studies to determine how to be able to consistently provide

nitrification.

For each and all

of the preceding reasons, the situation relating to the Lemont Refinery is

fundamentally different than those considered by the Board in adopting the ammonia nitrogen

rule.

19

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

CONCLUSION

This Petition satisfies the requirements

of the Act and of the Board'sProcedural Rules for

Adjusted Standards as shown in the Appendix. The situation here represents conditions which

are substantially and significantly different from the factors relied on by the Board in adopting

the ammonia nitrogen effluent rule. Those factors necessitate the relief here sought. The

requested standard will not result in environmental and health effects more adverse than the

effects considered by the Board (see

~~

17-24); and the requested standard is consistent with

applicable federal law (see

~~

7,25,28-29). The regulation of general applicability from which

Petitioners seek an adjusted standard does not specify a level

ofjustification or other

requirements. As such, 415 ILCS 5/28.1 (c) applies. For proof satisfying that section, please see

~~9,

17-30, 32, and 52.

53.

Pursuant to 35 Ill. Admin. Code

§104.4060), Petitioners request a hearing on this

Petition. The Petitioner has discussed this request with the Agency; the Agency has stated that it

does not have a position on the Petition at this time.

WHEREFORE, Petitioner requests that the Board grant this adjusted standard.

CITGO PETROLEUM CORPORATION, and

PDV MIDWEST REFINING,

L.L.c.,

Petitioners

One

of Its Attorneys

Jeffrey

C.

Fort

Ariel 1. Tesher

Sonnenschein Nath

&

Rosenthal LLP

7800 Sears Tower

233 South Wacker Drive

Chicago, IL 60606-6404

12369067

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

CERTIFICATE OF SERVICE

The undersigned, an attorney, certifies that I have served upon the individuals named on

the attached Notice

of Filing true and correct copies of the Petition for an Adjusted Standard by

First Class Mail, postage prepaid, on March 18, 2008

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

APPENDIX

The table below sets out those paragraphs that correspond to the subsections of 35

Ill.

Admin. Code §l04.406:

a) A statement describing the standard from which an Preamble paragraph and

~2.

adjusted standard is sought. This must include the

I1Iinois Administrative Code citation to the regulation of

general applicability imposing the standard as well as

the effective date

of that regulation;

b) A statement that indicates whether the regulation

of

~~25,

28-30, and 32

general applicability was promulgated to implement,

in

whole or in part, the requirements of the CWA

0,

Safe

Drinking Water Act ((f) et seq.), Comprehensive

Environmental Response, Compensation and Liability

Act (42 USC 9601 et seq.),

CAA

(42 USC 7401 et seq.),

or the State programs concerning RCRA, UIC, or

NPDES [415 ILCS 5/28.1];

c) The level of justification as well as other information

~~9,

17-30,32, and 52

or requirements necessary for

an adjusted standard as

specified by the regulation

of general applicability or a

statement that the regulation

of general applicability

does not specify a level

of justification or other

requirements [415 ILCS 5/28.1] (See Section 104.426);

d) A description

of the nature of the petitioner's activity

~~7

-10, 13-16, 18-24, and 33-45

that

is the subject of the proposed adjusted standard. The

description must include the location of, and area

affected by, the petitioner's activity. This description

must also include the number

of persons employed by

the petitioner's facility at issue, age

of that facility,

relevant pollution control equipment already

in use, and

the qualitative and quantitative description

of the nature

of emissions, discharges or releases currently generated

by the petitioner's activity;

e) A description

of the efforts that would be necessary if

~~45-50

the petitioner was to comply with the regulation of

general applicability. All compliance alternatives, with

the corresponding costs for each alternative, must be

discussed. The discussion of costs must include the

overall capital costs

as well as the annualized capital and

operating costs;

f) A narrative description of the proposed adjusted

~~4-6

standard as well as proposed language for a Board order

that would impose the standard. Efforts necessary to

achieve this proposed standard and the corresponding

costs must also be presented;

g) The quantitative and qualitative description

of the

~~17-24,

30

impact

of the petitioner's activity on the environment if

the petitioner were to comply with the regulation

of

general applicability as compared to the quantitative and

qualitative impact on the environment

if the petitioner

were to comply only with the proposed adjusted

standard. To the extent applicable, cross-media impacts

must be discussed. Also, the petitioner must compare the

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

qualitative and quantitative nature

of

emissions,

discharges or releases that would be expected from

compliance with the regulation

of general applicability

as opposed to that which would be expected from

compliance with the proposed adjusted standard;

h) A statement which explains how the petitioner seeks

~~9,

17-30, 32, and 52

to justify,

pursuant

to the applicable

level

of

justification, the proposed adiusted standard;

i) A statement with supporting reasons that the Board

~~25,

28-30, and 32

may grant the proposed adjusted standard consistent

with federal law. The petitioner must also infonn the

Board

of all procedural requirements applicable to the

Board's decision

on the petition that are imposed by

federal law and not required by this Subpart. Relevant

regulatory and statutory authorities must be cited;

j) A statement requesting or waiving a hearing on the

~~53

petition (pursuant to Section 104.422(a)(4) of this Part a

hearing will be

held

on all petitions

for adjusted

standards filed pursuant to 35

III.

Adm. Code 212.126

(CAA»;

k) The petition must cite to supporting documents or The Petition cites

to such support throughout its text.

legal authorities whenever they are used

as a basis for See, e.g.,

~~2,

3, 19,25,49, and 52.

the

petitioner's proof. Relevant portions

of the

documents

and legal authorities

other

than Board

decisions, State regulations, statutes, and reported cases

must be appended to the petition;

I) Any additional infonnation which may be required in Nothing required.

the regulation

of general applicability.

2

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

TECHNICAL REVIEW OF AMMONIA

TREATMENT AT THE WASTEWATER

TREATMENT PLANT – CITGO PETROLEUM

CORPORATION, LEMONT REFINERY

Prepared for:

CITGO Petroleum Corporation

Lemont Refinery

Lemont, Illinois

Prepared by:

AWARE Environmental Inc.

9305-J Monroe Road

Charlotte, NC 28270-1490

AEI Job No. N356-06

AEI Document No. 35606r004

February 2008

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

i

EXECUTIVE SUMMARY

CITGO Petroleum Corporation operates a petroleum refinery (Lemont Refinery) in Lemont, Illinois.

The process wastewater and stormwater from the refinery are treated in the refinery’s wastewater

treatment facility and are discharged into the Chicago Sanitary and Ship Canal under a National

Pollutant Discharge Elimination System (NPDES) permit issued by the State of Illinois. The

wastewater treatment facility utilized by Lemont Refinery surpasses the criteria for Best Available

Technology Economically Achievable (BAT) for treatment of refinery wastewaters as define by the

U.S. EPA. Specifically, the refinery treatment system includes sour water strippers which provide

greater than 95 percent ammonia removal, oil and solids removal, flow equalization, clarification,

single-stage activated sludge treatment and final polishing.

The U.S. EPA effluent limitations guidelines provide mass based limits for ammonia nitrogen (and

other parameters) based on refinery production, with the use of BAT treatment technology. The

Illinois regulations contain ammonia discharge standards which are much more stringent than the U.S.

EPA limitations. The Illinois standards would require Lemont Refinery to meet a

3.0 mg/l ammonia nitrogen discharge standard. Lemont Refinery has been unable to consistently

comply with the 3.0 mg/l limit. The Illinois Pollution Control Board granted the refinery a site

specific rule change effective through December 31, 2008. The refinery has consistently achieved

compliance with these regulations and typically provides an effluent quality significantly better than

the regulatory criteria.

Lemont Refinery is in the process of preparing a request for an adjusted standard for its discharge of

ammonia. AWARE Environmental Inc. (AEI) was retained to conduct a technical review of the

ammonia removal capacities of the wastewater treatment system. The primary objectives of this

review are to:

1. Determine if the present wastewater treatment system is consistent with the U.S. EPA BAT

criteria;

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

ii

2. Determine if the wastewater treatment system operating conditions are conducive to biological

nitrification; and

3. Evaluate alternative ammonia removal technologies and the cost of those technologies to

determine if changes in the present wastewater treatment system are warranted as part of a

program to achieve compliance with the 3 mg/l ammonia nitrogen criteria.

The results of this evaluation indicate that Lemont Refinery has a wastewater treatment system which

exceeds BAT criteria and which allows the facility to comply with U.S. EPA refinery discharge

regulations. The long term performance data has demonstrated that the refinery wastewater treatment

facility has achieved compliance with the current mass based limitations for ammonia nitrogen

contained in the NPDES permit, but that the refinery has not been able to consistently meet a 3.0 mg/l

ammonia nitrogen limit as per the Illinois regulations.

A review of the wastewater treatment technologies employed at the other Illinois Refineries was

conducted. These refineries were Conoco-Phillips, Roxana, IL; Exxon-Mobil, Joliet, IL; and

Marathon, Robinson, IL. The wastewater treatment processes employed by these Refineries are very

similar to those utilized at the Lemont Refinery.

A review of the activated sludge treatment plant was performed with regard to factors which control

the ability of a biological treatment facility to achieve nitrification. These factors include food to

microorganism ratio (F/M), sludge age, dissolved oxygen concentration, temperature, pH, and

alkalinity. The review indicates that these parameters have been maintained in the ranges favorable

to nitrification. However, in spite of this, the refinery treatment facility has been unable to meet the

3.0 mg/l ammonia nitrogen standard on a consistent basis.

Lemont Refinery has maintained an ongoing optimization program which has resulted in improved

ammonia nitrogen removal. The program has been expanded to address changes in the petroleum

refinery industry. The refinery has spent over $45,000,000 over the last ten years on capital projects

related to ammonia control and reduction.

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

iii

As a result of changes in crude quality, Lemont refinery has experienced a five-fold increase in

wastewater treatment chemical addition costs over the last 4 years. Lemont refinery has and is

continuing to conduct research which addresses the environmental impacts caused by crude quality

fluctuations. Crude quality fluctuations confirm AEI’s previous analysis which indicated that the

capability of the wastewater treatment system is limited, in large part, due to the inherent variability

of refinery wastewater.

Potential alternative technologies were evaluated for upgrading the wastewater treatment facility with

additional nitrogen removal technologies which would increase the likelihood of consistently meeting

the 3.0 mg/l ammonia nitrogen standard. Several alternatives were screened and preliminary process

designs and budget cost estimates were developed for the four most viable alternatives. These four

alternatives include powdered activated carbon addition (PACT), fixed media biological treatment,

membrane bioreactors, and breakpoint chlorination. Addition of a fixed media biological reactor

would be the most cost-effective alternative. The fixed media system would utilize a rotating

biological contractor (RBC) and would have an estimated capital cost of $13,500,000 and an

estimated annual operating cost of $1,220,000. The estimated total annualized cost for the addition of

the fixed media reactor system over a ten (10) year period at 8 percent interest is $3,220,000/year.

Even with the ammonia removal upgrades, the ability of the treatment system to consistently meet the

3.0 mg/l ammonia nitrogen standard is uncertain. Based on the significant cost of upgrading the

system, and the uncertainty that the upgraded system would achieve consistent compliance with the

3.0 mg/l ammonia nitrogen standard, upgrading the treatment system with additional treatment

technologies for ammonia removal is not justified.

We recommend that Lemont Refinery continue its ongoing research studies and projects designed to

optimize the existing wastewater treatment system. These efforts should be directed toward obtaining

the maximum possible ammonia removal on a consistent basis. Continued development of

operational data under the varying conditions inherent with refinery wastes will help to improve the

performance of the system, and will allow the maximum ammonia removal capability of the system to

be achieved.

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

iv

TABLE OF CONTENTS

Section No.

Description

Page No.

EXECUTIVE SUMMARY ......................................................................... i

TABLE OF CONTENTS........................................................................... iv

LIST OF TABLES.......................................................................................v

LIST OF FIGURES ................................................................................... vi

LIST OF APPENDICES............................................................................ vi

1.0

INTRODUCTION .......................................................................................1

2.0

REGULATORY REVIEW..........................................................................3

2.1

U.S. EPA Effluent Limitations Guidelines ............................................3

2.2

Illinois Water Pollution Regulations......................................................5

3.0

ANALYSIS OF EXISTING FACILITY

WITH RESPECT TO BAT AND

NITRIFICATION ........................................................................................7

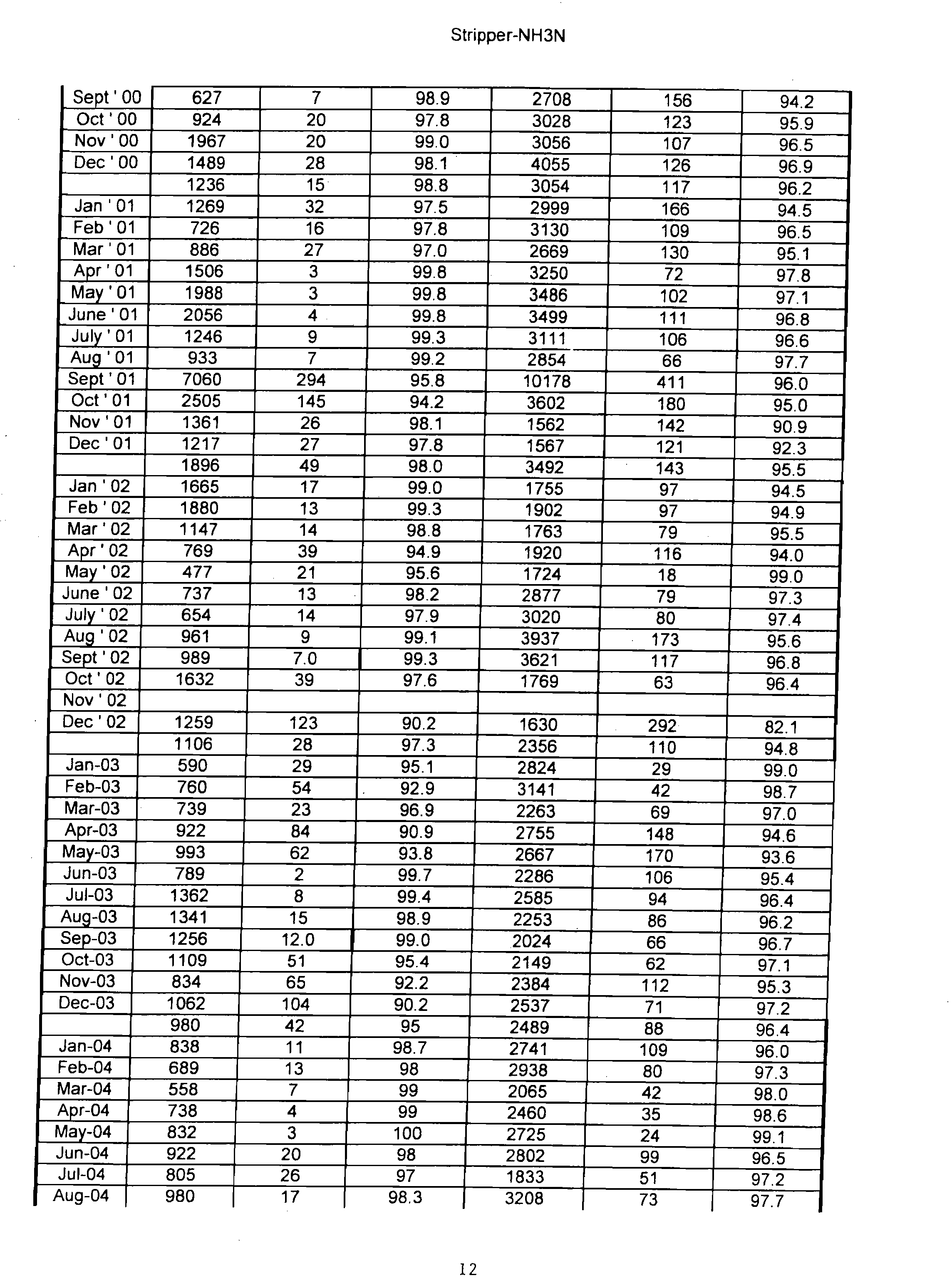

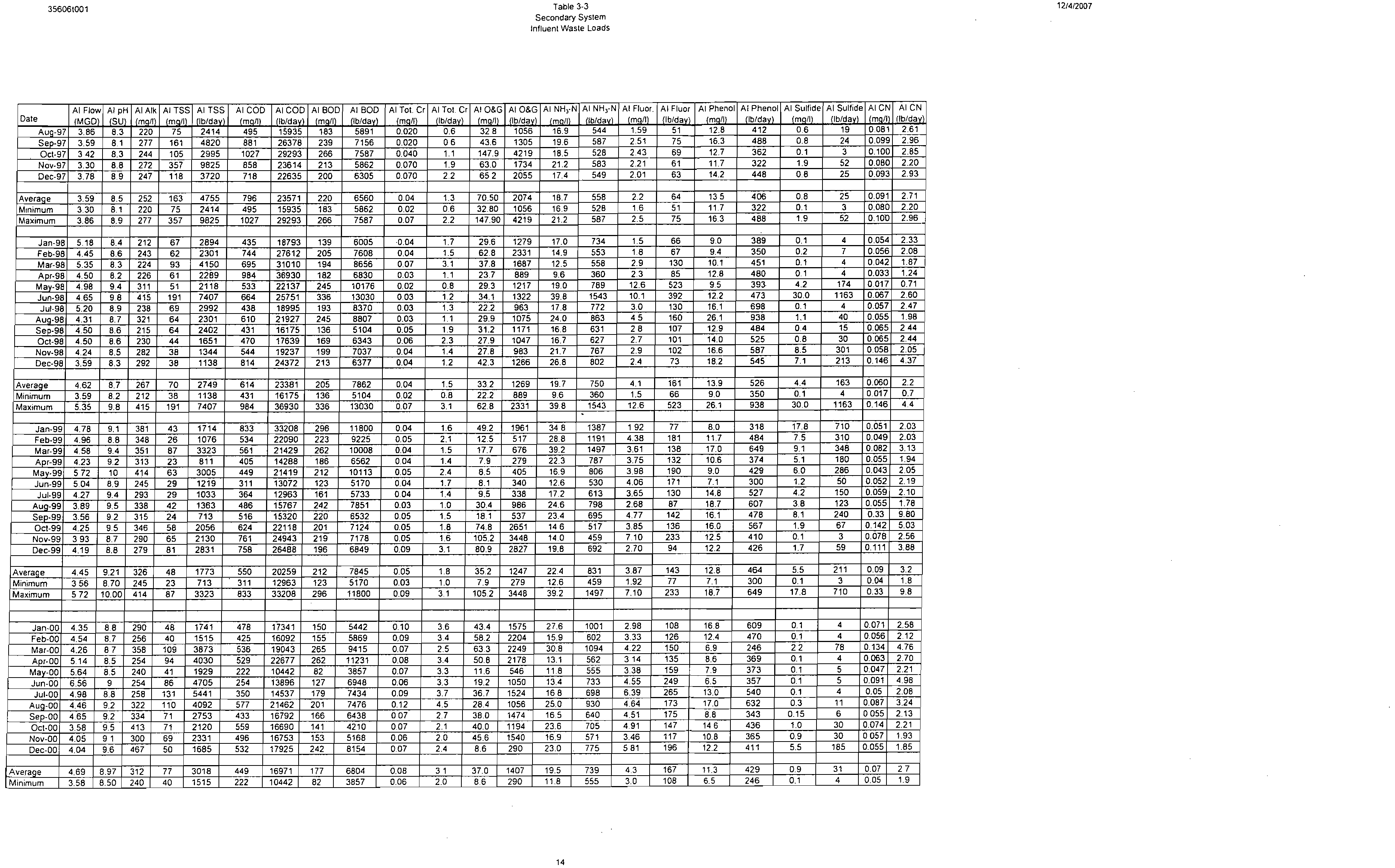

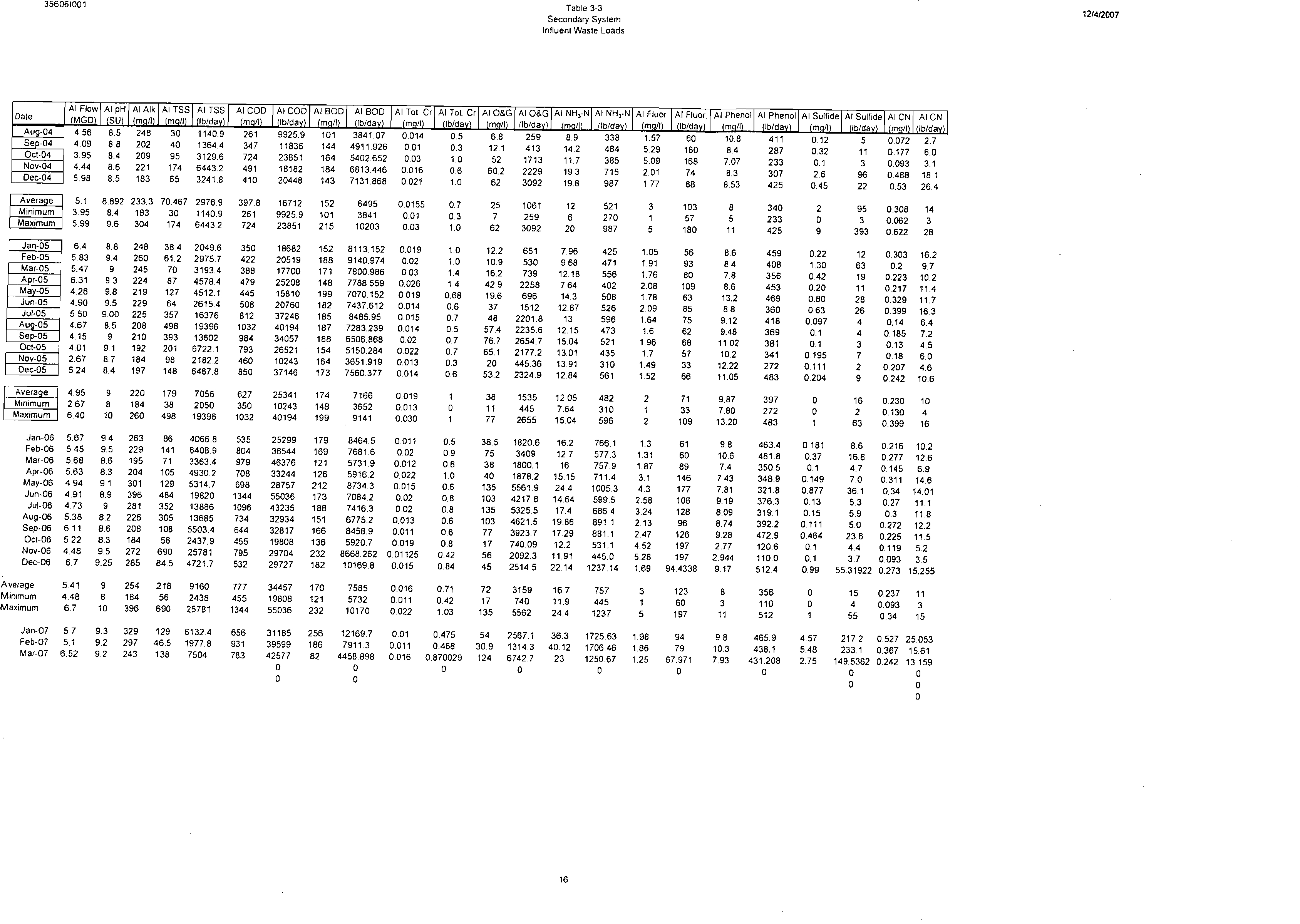

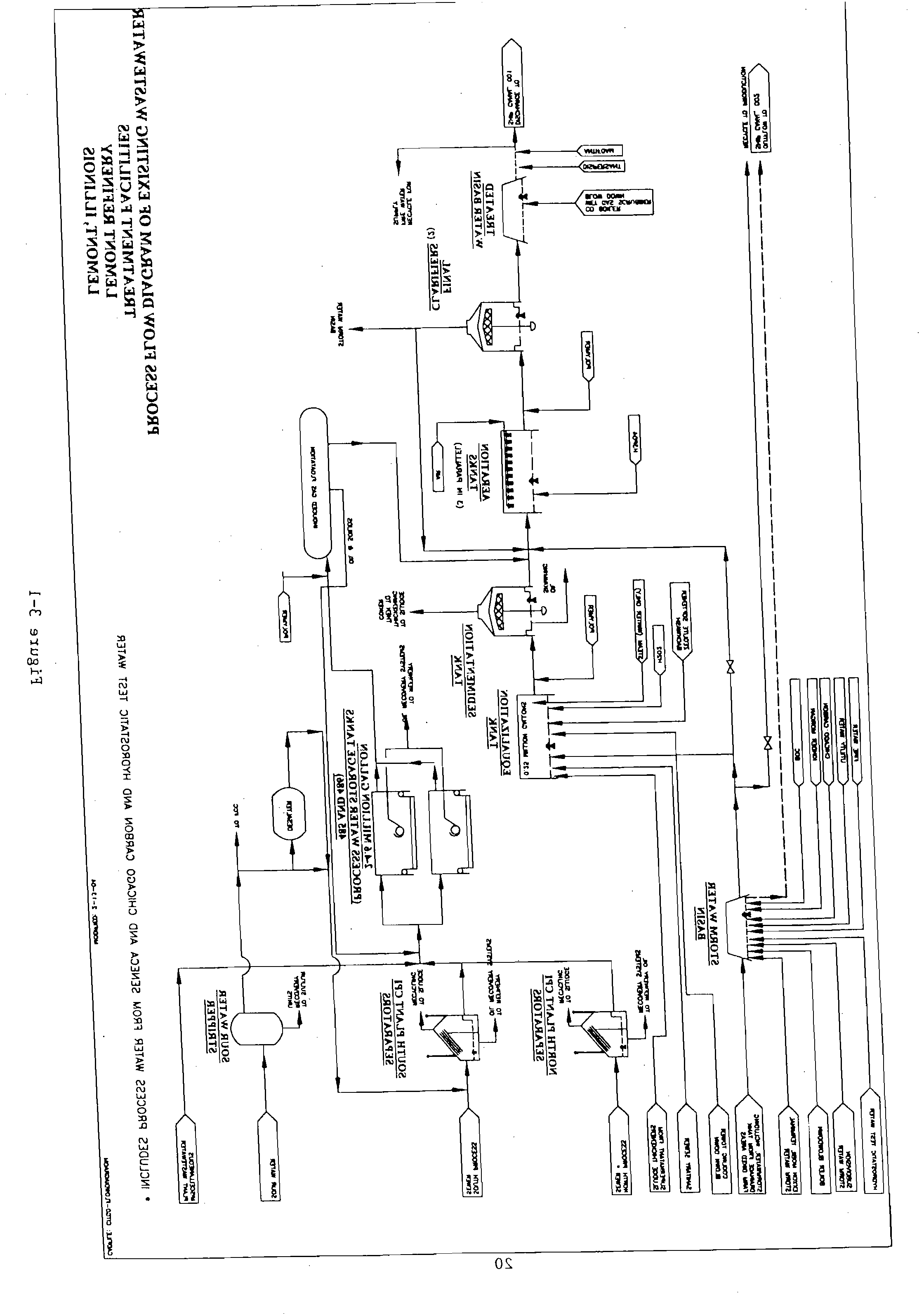

3.1

Analysis of Refinery Wasteloads.........................................................10

3.2

Current Wastewater Collection and Treatment System.......................19

3.3

Comparison of Lemont Refinery’s Wastewater Treatment ...................

Performance with BAT ........................................................................24

3.4

Review of Long Term Ammonia Removal Performance ....................30

3.5

Parameters Which Control Nitrification ..............................................35

3.6

Summary ..............................................................................................38

4.0

ANALYSIS OF ALTERNATIVES...........................................................40

4.1

Selected Technologies for Evaluation .................................................40

4.2

Activated Sludge with Powdered Activated Carbon Addition ............43

4.3

Activated Sludge with A Fixed Media System....................................46

4.4

Activated Sludge with Membrane Bioreactor......................................47

4.5

Activated Sludge with Breakpoint Chlorination/ Dechlorination........53

4.6

Analysis of Technologies Utilized at Illinois Refineries .....................57

4.7

Conclusions..........................................................................................57

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

v

LIST OF TABLES

Table No.

Description

Page No.

2-1

U.S. EPA Refinery Subcategories

4

3-1

Observed Maximum Monthly Production Rates

8

3-2

Sour Water Stripper – Ammonia Removal

11

3-3

Secondary System Influent Waste Loads

14

3-4

Summary of Design Wastewater Loadings

18

3-5

Process Design Summary Existing Wastewater

Treatment Plant

21

3-6

Comparison of BAT Guidelines with Lemont Refinery’s

Wastewater Treatment System

25

3-7

Summary of Waste Treatment Modifications/Upgrades

26

3-8

Secondary System Operating History

27

3-9

BPT & BAT Limitations and IEPA/NPDES Limitations

31

3-10

Typical Operating Ranges for Nitrification

32

3-11

Typical Operating Ranges For Nitrification

36

4-1

Summary of Potential Technologies

42

4-2

Process Design Summary for Activated Sludge with PAC 44

4-3

Process Design Summary for Activated Sludge with a

Fixed Media System

48

4-4

Process Design for Membrane Bioreactor Activated Sludge 51

4-5

Process Design Summary for Activated Sludge with

Breakpoint Chlorination and Dechlorination

54

4-6

Summary of Project Cost Estimate

58

4-7

Comparison Of Wastewater Treatment at

Illinois Refineries

60

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

vi

LIST OF FIGURES

Figure No.

Description

Page No.

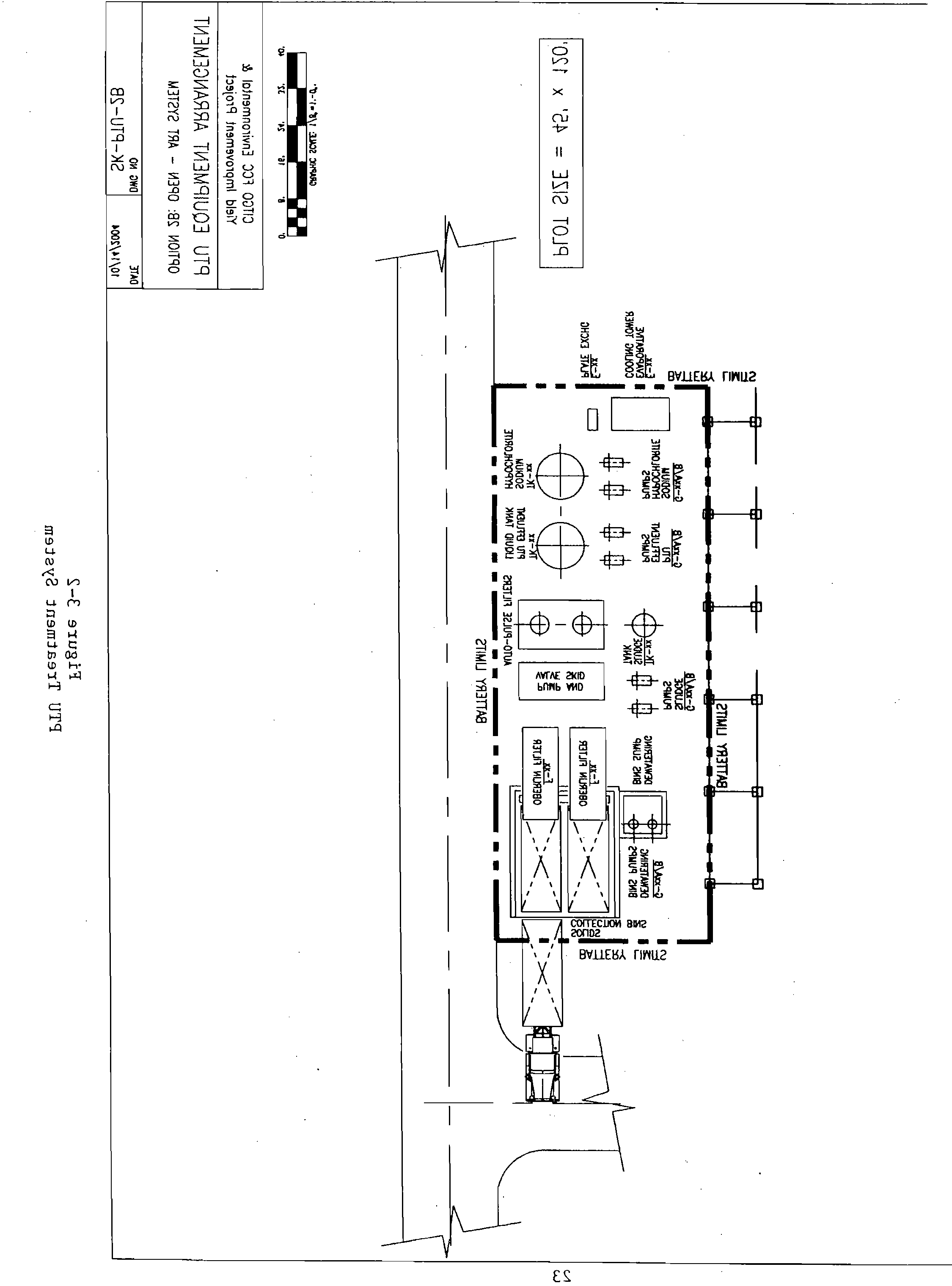

3-1

Process Flow Diagram of Existing Wastewater

Treatment Facilities

20

3-2

PTU Equipment Arrangement

23

3-3

Variability of Effluent Ammonia Nitrogen as Compared

to Proposed 3.0 mg/l Limitation

34

4-1

Activated Sludge with PAC Addition

45

4-2

Activated Sludge with a Fixed Media System

49

4-3

Membrane Bioreactor Activated Sludge

52

4-4

Activated Sludge with Breakpoint

Chlorination-Dechlorination

55

LIST OF APPENDICES

A

Calculation of Effluent Criteria

B

Statistical Data Analysis

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

1

SECTION 1.0

INTRODUCTION

CITGO Petroleum Corporation (CITGO) operates a petroleum refinery (Lemont Refinery) in

Lemont, Illinois. The refinery produces gasoline, a variety of other fuels, coke, and solvents

from crude oil. Lemont Refinery was formerly owned and operated by the UNO-VEN

Company, and had previously been operated as the Union Oil Refinery. On May 1, 1997 PDV

Midwest Refining, L.L.C. purchased the Lemont Refinery and contracted with CITGO to operate

the refinery.

The process wastewater generated by the refinery and the contaminated stormwater runoff from

the facility are treated in a single stage activated sludge wastewater treatment plant. The treated

wastewater is discharged to the Chicago Sanitary and Ship Canal under a National Pollutant

Discharge Elimination System (NPDES) permit. The current permit (No. IL0001589) was

issued by the Illinois Environmental Protection Agency (IEPA) on July 28, 2006, became

effective August 1, 2006 and was modified on June 22, 2007. The permit expires on July 31,

2011.

The State of Illinois has ammonia nitrogen discharge standards for sources which discharge

greater than 100 lb/day of ammonia nitrogen, such as the Lemont Refinery. These criteria are

contained in the State of Illinois Rules and Regulations under Title 35: Environmental

Protection, Subtitle C: Water Pollution, Chapter I: Pollution Control Board. Section 304.122

(b) of this regulation sets monthly average discharge standards at 3.0 mg/l of ammonia nitrogen.

Lemont Refinery has been unable to consistently meet the 3.0 mg/l ammonia concentration

standard. As a result, the Illinois Pollution Control Board (IPCB) granted the refinery a site

specific rule change for ammonia under Section 304.213 of the Illinois regulations. The current

site specific rule was adopted in 1998, as an extension of a previous rule change, and is effective

through December 31, 2008. This site specific rule change exempts the facility from the

ammonia limits under Section 304.122(b) of the Illinois regulations and requires that the facility

meet the U.S. EPA Best Available Technology Economically Achievable (BAT) limitations for

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

2

ammonia pursuant to 40 CFR 419.23 (1992). Under the site specific rule, the facility is required

to meet a monthly average ammonia limit of 9.4 mg/l, a daily maximum ammonia limit of 26.0

mg/l, to continue its efforts to reduce ammonia discharges and to monitor and report nitrogen

concentrations of its oil feedstocks.

Lemont Refinery has retained AWARE Environmental Inc. (AEI) of Charlotte, North Carolina to

evaluate current conditions, to evaluate potential alternatives for upgrading the treatment system

to meet a 3.0 mg/l limit, and to evaluate the need to re-apply for a site specific rule change. AEI

conducted a conceptual evaluation of Lemont Refinery wastewater treatment system, and the

available alternatives to achieve ammonia removal from a refinery wastewater. The primary

objectives of this program were to:

1. Determine if the present wastewater treatment system is consistent with the U.S. EPA

BAT criteria;

2. Determine if the wastewater treatment system operating conditions are conducive to

biological nitrification; and

3. Evaluate alternative ammonia removal technologies, and the cost of those technologies to

determine if changes in the present wastewater treatment system are warranted as part of

a program to achieve compliance with the 3.0 mg/l ammonia nitrogen criteria.

This report presents the AEI findings.

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

3

SECTION 2.0

REGULATORY REVIEW

There are a wide range of regulations which control the wastewater discharges from petroleum

refineries. The primary regulatory drivers for determining the ammonia discharge limitations

from Lemont Refinery are the U.S. EPA effluent limitations guidelines and the State of Illinois

water pollution regulations. As a part of the development of this report, current regulations and

potential pending changes in regulations which may impact Lemont Refinery wastewater

treatment operations and/or ammonia discharge were reviewed.

2.1

U.S. EPA EFFLUENT LIMITATIONS GUIDELINES

The U.S. EPA has developed effluent limitations guidelines for the petroleum refining industry

which are included in 40 CFR 419. The basis for these guidelines are included in the 1982

Development Document for Effluent Limitations Guidelines, New Source Performance Standards

and Pretreatment Standards for the Petroleum Refining Industry

(EPA 440/1-82/014). These

guidelines provide effluent load-based limitations for conventional pollutants based on the Best

Practicable Control Technology Currently Available (BPT) (40 CFR 419.22) and for non-

conventional pollutants based on Best Available Technology Economically Achievable (BAT)

(40 CFR 419.23). Conventional pollutants include BOD

5

, TSS, oil and grease, and pH. Non-

conventional pollutants include COD, ammonia nitrogen, sulfide, phenolic compounds, total

chromium, and hexavalent chromium. The effluent limitations guidelines are based on actual

effluent flows and pollutant concentrations obtained by refineries employing BAT and BPT

treatment technologies.

EPA guidelines define five (5) general subcategories of refineries based on the production

processes employed. These categories are summarized in Table 2-1. Lemont Refinery is

classified as Subcategory B – Cracking Refinery. Under the guidelines, effluent limitations are

calculated for each individual facility based on the refining subcategory, the maximum feedstock

processing rate and the process configuration.

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

4

TABLE 2-1

U.S. EPA REFINERY SUBCATEGORIES

Subcategory

Basic Refinery Operations Included

A - Topping

Topping and catalytic reforming whether or not the

facility includes any other process in addition to topping

and catalytic reforming.

This subcategory is not applicable to facilities which

include thermal processes (coking, visbreaking, etc.) or

catalytic cracking.

B – Cracking

Topping and cracking, whether or not the facility

includes any processes in addition to topping and

cracking, unless specified in one of the subcategories

listed below.

C – Petrochemical

Topping, cracking and petrochemical operations

whether or not the facility includes any process in

addition to topping, cracking and petrochemical

operations’, except lube oil manufacturing operations.

D – Lube

Topping, cracking and lube oil manufacturing processes,

whether or not the facility include any process in

addition to topping, cracking and lube oil manufacturing

processes, except petrochemical operations’.

E – Integrated

Topping, cracking, lube oil manufacturing processes and

petrochemical operations, whether or not the facility

includes any processes in addition to topping, cracking

and lube oil manufacturing processes and petrochemical

operations’.

The term “petrochemical operations” shall mean the production of second generation

petrochemicals (i.e. alcohols, ketones, cumene, styrene, etc.) or first generation petrochemicals

and isomerization products (i.e. BTX, olefins, cyclohexane, etc.) when 15% or more of the

refinery production is as first generation petrochemicals and isomerization products.

Source: Development Document for Effluent Limitations Guidelines and Standards for the

Petroleum Refining Point Source Category, EPA 440/1-82-014, October 1982, 64-65.

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

5

The U.S. EPA BAT guidelines are based on the implementation of in-plant water

reuse/conservation measures to minimize the volume of wastewater discharge, and the use of

sour water strippers to reduce ammonia and sulfide loads in the process wastewater. These in-

refinery controls should be followed by end-of-pipe treatment technologies. The U.S. EPA BAT

model, as found in the 1982 “Development Document”, is based on a wastewater treatment plant

(WWTP) that includes the following treatment processes:

1. Flow equalization;

2. Initial oil and solids removal (API separator or baffle plate separator);

3. Additional oil/solids removal (clarifiers or dissolved air flotation);

4. Biological treatment; and

5. Filtration or other final polishing steps.

As a part of this report preparation, contacts were made with the U.S. EPA personnel responsible

for developing guidelines for the Petroleum Refinery subcategory to determine if modifications

to the effluent guidelines for petroleum refinery are anticipated. According to U.S. EPA

personnel, U.S. EPA has no immediate plans to revise the effluent guidelines. The 304 (m)

process involves substantial public input and generally, leads to lengthy studies before any type

of rule making is identified. Presently, petroleum refineries are not being considered for updated

guidelines.

2.2

ILLINOIS WATER POLLUTION REGULATIONS

Under the current Illinois water pollution regulations, as amended through November 21, 2005,

the State of Illinois has established ammonia nitrogen limitations for discharges into the Illinois

River system. Under Section 304.122 (b) of the regulations, ammonia nitrogen discharges of

greater than 100 lb/day are required to meet a 3.0 mg/l monthly average effluent ammonia

nitrogen limit. This limitation is significantly more stringent than the ammonia nitrogen

standards in the U.S. EPA effluent limitations guidelines.

Lemont Refinery discharges treated wastewater into the Chicago Sanitary and Ship Canal, a

secondary contact waterway, and periodically discharges more than 100 lb/day of ammonia

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

6

nitrogen. Therefore, Lemont Refinery discharge is regulated by the 3.0 mg/l ammonia nitrogen

discharge rule.

The refinery has not been able to consistently meet the 3.0 mg/l ammonia limit under the Illinois

regulations. Based on the results of previous evaluations performed in conjunction with the

petitions for the site specific rule changes, no economically feasible treatment methods were

identified which could ensure consistent compliance with a 3.0 mg/l ammonia nitrogen limit. As

discussed above, site specific rule changes were granted by the IPCB to the refinery under

Section 304.213 of the Illinois water pollution regulations. The site specific rule change exempts

the refinery from the ammonia limits under Section 304.122 of the Illinois regulations and

requires the refinery to meet the U.S. EPA BAT limitations for ammonia nitrogen pursuant to 40

CFR 419.23 (1992). The facility is also required to comply with a monthly average ammonia

nitrogen limit of 9.4 mg/l and a daily maximum ammonia nitrogen limit of 26.0 mg/l. In

addition, as part of the site specific rule change, the refinery is required to continue its efforts to

reduce ammonia discharge and to monitor and report nitrogen concentrations of its oil

feedstocks.

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

7

SECTION 3.0

ANALYSIS OF EXISTING FACILITY

WITH RESPECT TO BAT AND NITRIFICATION

A detailed analysis of the wastewater treatment program was conducted in order to determine if

the refinery continues to be a BAT facility. Included in this analysis were evaluations of the

refinery wasteloads and the current wastewater treatment program. These were conducted with

regard to the ability of the system to provide consistent biological nitrification. The objects of

this analysis were to:

1. Determine if the waste loadings, and the hydraulic and ammonia loads in particular, are

consistent with BAT criteria;

2. Determine if the BAT effluent limitations guidelines and discharge permit criteria are

being met;

3. Determine if the physical facility is consistent with the EPA BAT technology model; and

4. Evaluate the present treatment program to determine if it is consistent with the refinery’s

objective of improving ammonia removal, and if additional changes in the program are

warranted.

The results of this analysis are presented in this section.

Currently, the refinery does not have long term crude supply agreements or super tanker

unloading facilities which could provide a fairly consistent grade of crude to the refinery.

Therefore, crude quality will vary significantly. In addition, the refinery is processing heavier

crudes. These factors affect the feed stock. There are frequent feed stock fluctuations which

result in chemical and operating changes throughout the day. These fluctuations affect the water

quality discharged to the wastewater treatment plant.

The maximum monthly production rate for Lemont refinery observed during the period of 1997

to present was 170,341 barrels per day which occurred in September 2005. The maximum

production of each individual process is presented in Table 3-1. The United States

Environmental Protection Agency uses these process capacities as the basis for defining effluent

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

8

TABLE 3-1

OBSERVED MAXIMUM MONTHLY PRODUCTION RATES

(1)

Process

Max Production

Rate

(bbl/day)

Crude Processes

Desalting

Atmospheric Distillation

Vacuum Distillation

168,626

168,626

82,807

Cracking Processes

Fluid Catalytic Cracking

Delay Coking

Needle Coking

69,098

40,326

6,413

Asphalt Production

Asphalt Production

Asphalt Oxidation

4,329

10,935

(1)

This is based on the monthly average production rates for the period used

to develop the current NPDES permit. Note that the maximum monthly

production rate reached 170,341 in September 2005. (This was after the

time period utilized for NPDES development).

Electronic Filing - Received, Clerk's Office, March 18, 2008

* * * * * AS 2008-008 * * * * *

9

criteria. The specific calculations to define the present design criteria are presented in Appendix

A.

The waste load to the refinery treatment system has become more variable. Several of the

factors which affect the waste loads are:

1. Operate consistently at design thru put rates;

2. Changes in the quality of crude; and

3. Feedstocks with a higher percentage of heavy crude.

Specifically, these problems are as follows:

1. Because of increased gasoline demand, refineries are operating at design capacities and

there is very little production variability on a month to month basis. This provides less

time for turnarounds and the potentials for malfunctions or upsets to occur is increased at

higher production levels.