THIS FILING SUBMITTED ON RECYCLED PAPER

BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

VESUVIUS USA CORPORATION,

)

)

Petitioner,

)

)

v.

)

PCB 08-____

)

(Air Permit Appeal)

ILLINOIS ENVIRONMENTAL

)

PROTECTION AGENCY,

)

)

Respondent.

)

NOTICE OF FILING

TO:

Mr. John Therriault

Division of Legal Counsel

Assistant Clerk of the Board

Illinois Environmental Protection Agency

Illinois Pollution Control Board

1021 North Grand Avenue East

100 West Randolph Street

Post Office box 19276

Suite 11-500

Springfield, Illinois 67294-9276

Chicago, Illinois 60601

(VIA ELECTRONIC MAIL)

(VIA U.S. MAIL)

(PERSONS ON ATTACHED SERVICE LIST)

PLEASE TAKE NOTICE that I have today filed with the Office of the Clerk of

the Illinois Pollution Control Board the

ENTRY OF APPEARANCE OF

KATHERINE D. HODGE, ENTRY OF APPEARANCE OF THOMAS G.

SAFLEY,

and

PETITION FOR REVIEW

on behalf of VESUVIUS USA

CORPORATION, copies of which are herewith served upon you.

Respectfully submitted,

By:

/s/ Katherine D. Hodge

Katherine D. Hodge

Dated: March 3, 2008

Katherine D. Hodge

Thomas G. Safley

HODGE DWYER ZEMAN

3150 Roland Avenue

Post Office Box 5776

Springfield, Illinois 62705-5776

(217) 523-4900

Electronic Filing - Received, Clerk's Office, March 3, 2008

* * * * * PCB 2008-048 * * * * *

CERTIFICATE OF SERVICE

I, Katherine D. Hodge, the undersigned, hereby certify that I have served the

ENTRY OF APPEARANCE OF KATHERINE D. HODGE, ENTRY OF

APPEARANCE OF THOMAS G. SAFLEY, and PETITION FOR REVIEW upon:

Mr. John Therriault

Assistant Clerk of the Board

Illinois Pollution Control Board

100 West Randolph Street

Suite 11-500

Chicago, Illinois 60601

via electronic mail on March 3, 2008; and upon:

Division of Legal Counsel

Illinois Environmental Protection Agency

1021 North Grand Avenue East

Post Office Box 19276

Springfield, Illinois 62794-9276

by depositing said documents in the United States Mail, postage prepaid, in Springfield,

Illinois on March 3, 2008.

/s/ Katherine D. Hodge

Katherine D. Hodge

VESU:003/Fil/EOAs – KDH, TGS, Petition

Electronic Filing - Received, Clerk's Office, March 3, 2008

* * * * * PCB 2008-048 * * * * *

BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

VESUVIUS USA CORPORATION,

)

)

Petitioner,

)

)

v.

)

PCB 08-____

)

(Air Permit Appeal)

ILLINOIS ENVIRONMENTAL

)

PROTECTION AGENCY,

)

)

Respondent.

)

ENTRY OF APPEARANCE OF KATHERINE D. HODGE

NOW COMES Katherine D. Hodge, of the law firm HODGE DWYER ZEMAN,

and hereby enters her appearance in this matter on behalf of Vesuvius USA Corporation.

Respectfully submitted,

By: /s/ Katherine D. Hodge

Katherine D. Hodge

Dated: March 3, 2008

Katherine D. Hodge

HODGE DWYER ZEMAN

3150 Roland Avenue

Post Office Box 5776

Springfield, Illinois 62705-5776

(217) 523-4900

VESU:003/Fil/EOA – KDH

Electronic Filing - Received, Clerk's Office, March 3, 2008

* * * * * PCB 2008-048 * * * * *

BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

VESUVIUS USA CORPORATION,

)

)

Petitioner,

)

)

v.

)

PCB 08-____

)

(Air Permit Appeal)

ILLINOIS ENVIRONMENTAL

)

PROTECTION AGENCY,

)

)

Respondent.

)

ENTRY OF APPEARANCE OF THOMAS G. SAFLEY

NOW COMES Thomas G. Safley, of the law firm HODGE DWYER ZEMAN,

and hereby enters his appearance in this matter on behalf of Vesuvius USA Corporation.

Respectfully submitted,

By: /s/ Thomas G. Safley

Thomas G. Safley

Dated: March 3, 2008

Thomas G. Safley

HODGE DWYER ZEMAN

3150 Roland Avenue

Post Office Box 5776

Springfield, Illinois 62705-5776

(217) 523-4900

VESU:003/Fil/EOA – TGS

Electronic Filing - Received, Clerk's Office, March 3, 2008

* * * * * PCB 2008-048 * * * * *

BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

VESUVIUS USA CORPORATION,

)

)

Petitioner,

)

)

v.

)

PCB 08-____

)

(Air Permit Appeal)

ILLINOIS ENVIRONMENTAL

)

PROTECTION AGENCY,

)

)

Respondent.

)

PETITION FOR REVIEW

NOW COMES Petitioner, VESUVIUS USA CORPORATION, an Illinois

Corporation (“Vesuvius”), by and through its attorneys, HODGE DWYER ZEMAN,

pursuant to Section 40.2 of the Illinois Environmental Protection Act (415 ILCS 5/40.2)

(“Act”) and 35 Ill. Admin. Code § 105.Subpart C, and petitions the Illinois Pollution

Control Board (“Board”) for review of the Federally Enforceable State Operating Permit

(“FESOP”) issued to Vesuvius by the Illinois Environmental Protection Agency (“Illinois

EPA”) pursuant to Section 39.5 of the Act on January 28, 2008.

In support thereof, Vesuvius states as follows:

1.

Vesuvius owns and operates a ceramic manufacturing facility in

Charleston, Illinois, which operates pursuant to a FESOP.

2.

Pursuant to Section 39.5 of the Act, on December 7, 2006, Vesuvius

submitted an application to Illinois EPA to renew the FESOP for its Charleston, Illinois

facility.

3.

Thereafter, Vesuvius received a preliminary draft FESOP from Illinois

EPA for review.

Electronic Filing - Received, Clerk's Office, March 3, 2008

* * * * * PCB 2008-048 * * * * *

2

4.

On October 22, 2007, Vesuvius asked Illinois EPA to make changes to the

preliminary draft FESOP. Among other requests, Vesuvius asked that Illinois EPA add

language to section 5b of the draft permit requiring the seven fume incinerator

combustion chambers to operate at one of the following temperatures: (1) the

manufacturer’s recommended temperature; (2) at least 1400°F in the absence of

compliance testing; or (3) if compliance testing has been performed, at a temperature to

meet the emissions conditions of permit Section 4b. Vesuvius proposed to add this

operating temperature language to replace the combustion chamber preheating

requirements in Section 5b of the draft FESOP. That request was made in a letter sent to

Illinois EPA dated October 22, 2007. That letter is attached to this Petition as Exhibit A.

5.

On January 28, 2008, Illinois EPA issued a final FESOP for Vesuvius’s

Charleston facility. This permit is attached as Exhibit B. Section 5b of the final permit

does not contain the language requested by Vesuvius, but instead requires Vesuvius to

preheat the fume incinerator’s combustion chambers to “at least the manufacturer’s

recommended temperature but not less than the temperature at which compliance was

demonstrated in the most recent compliance test or 1400°F in the absence of a

compliance test.”

6.

Vesuvius believes that it can comply with the emissions limitations in

Section 4b without preheating the combustion chambers and therefore should not be

subject to the preheating requirements of Section 5b of the final permit.

7.

As set forth above, Illinois EPA included conditions in the FESOP that are

not required by the Act or regulations promulgated thereunder, and are not necessary to

Electronic Filing - Received, Clerk's Office, March 3, 2008

* * * * * PCB 2008-048 * * * * *

3

correct, detect, or prevent noncompliance with, or to accomplish the purpose of, the Act

or regulations promulgated thereunder.

WHEREFORE, Petitioner VESUVIUS USA CORPORATION petitions the

Illinois Pollution Control Board for a hearing on the Illinois Environmental Protection

Agency’s action to issue this FESOP permit with this requirement.

Respectfully submitted,

VESUVIUS USA CORPORATION

Petitioner,

By:/s/ Katherine D. Hodge

One of Its Attorneys

Dated: March 3, 2008

Katherine D. Hodge

Thomas G. Safley

HODGE DWYER ZEMAN

3150 Roland Avenue

Post Office Box 5776

Springfield, Illinois 62705-5776

(217) 523-4900

VESU:003/Fil/Petition for Review

Electronic Filing - Received, Clerk's Office, March 3, 2008

* * * * * PCB 2008-048 * * * * *

SENDER:

COMPLETE TH1S SECTION

ý COMPLETE THIS SECTfON ON DELIVERY

" Complete

items

1, 2, and 3. Also complete

item 4 if Restricted-

eAy is desired.

" Print your name and address on the reverse

so that we can return the card to you.

IIIIIII Attach this card to the back of the mailpiece,

Octobl

or on the front if space permits.

Edwin

Acting

Divisic

Illinois

1021 r

PO Bc

Spring

Re: P

ID No:

Applia

1 . Article Addressed to:

ý ýýýlowsx,,

126 r

r 9sý

5fý r

IN

7 ,e i<l

l

L

2 . Article Number

(Transfer from service lat

Dear c PS

Form 3811, August 2001

A . Signature

X

B . Received by (Printed Name)

Illinois Environmental

Proi

0 Agent

I

0 Addressee

C. Date

of Delivery

c tion An iza

D . Is delivery a

eV-ti* ite`f ,.

I`Yes

If YES, entgS4delivery address below

.:

,St o

OCT 2,5

2007

3 . Service Type

Certified Mail

0 Registered

0 Insured Mail

0

d Al

Express Ma I

Return Receipt for Merchandise

0 C.O.D.

'

i

4. Restricted Delivery? (Extra Fee)

7002 2030 0005

3853 1641

0 Yes

D omestic Return Receipt

ný.ý Fýý p

102595-02-M-1035

Vesuvius USA

respectfully requests the following

changes in the Preliminary Draft FESOP.

Page 1--change Attn: John Herring

to Attn: Joe Woodall

Page 1--change 4 Fume

Incinerators (FI-3-6) to 3 Fume Incinerators (FI-4-6) (The Brule

incinerator

(FI-3) was removed in 1999

when incinerator FI-6 was installed for the New Mix

Plant (TD-3) and the Old Mix Plant

(TD-2).)

Page 1--change Tube Dryer (TD-2)

... (FI-3) to Tube Dryer (TD-2) ... (FI-6)

Page 3 section 5a--Change the

6 to a 7 and remove "at all times" (the facility has 7 fume

incinerators/afterburners)

Page

3 section 5b--Remove the first sentence

"Fume incinerator (FI-3)..."

Page 3 section 5b--Replace the second

sentence "The other 5 Fume incinerators..." with

the following:

"The 7 fume incinerator combustion

chambers shall be operated at one of the

following temperatures:

1) the manufacturers recommended

temperature,

2) In the absence of a compliance

test, at least 1400 degrees F, or

3) if compliance testing has been

done, at a temperature to meet the conditions

of

section

4b."

Page 7 section 9a--Change 6 to 7

Page 7 section 9b--Change 6 to 7

Page 8 section 12.a.ii--Remove

the words "each day" from the sentence.

Page 8 section 12.a.ii.A--Change the

sentence to read "Daily monitoring data

of the

Incinerator/Afterburner combustion

chamber temperature."

Page 8 section 12.a.ii.B--Change

the sentence to read "A monthly log of

operating time..."

A marked up copy of the Preliminary draft

FESOP is

attached.

If You have any questions,

please contact

me at 217-345-7095 extension

277.

S incerely yours,

Jffsepph D. Woodall

Facilities Manager

Cc:

Randy Swank

David E. Haney

Electronic Filing - Received, Clerk's Office, March 3, 2008

* * * * * PCB 2008-048 * * * * *

I , Xoq

SNI

UI

jT+diL

Nu°

o 6-J

'ON 1l

a

a?d

O ctober 22,2007

19A

NI

North 5.S treet

Charleston, Illinois 61920

217-345-7095

Edwin C.

Bakowski, P.E.

Acting Manager, Permit Section

Division

of Air Pollution Control

Illinois Environmental Protection

Agency

1021

North Grand Avenue East

PO Box 19506

Springfield,

Illinois 62794-9506

Re:

Preliminary Draft FESOP

ID No: 029010AAE

Application

No: 95120117

Dear

Sir.

Vesuvius USA respectfully

requests the following changes in the Preliminary Draft FESOP.

Page 1--change Attn: John Herring to Attn: Joe Woodall

Page 1--change 4 Fume Incinerators (FI-3-6) to 3 Fume Incinerators (FI-4-6) (The

Brule

incinerator (FI-3) was removed

in 1999

when

incinerator FI-6 was installed for the New Mix

Plant (TD-3) and the Old Mix Plant (TD-2).)

Page 1--change Tube Dryer (TD-2) ... (FI-3) to Tube Dryer

(TD-2)... (FI-6)

Page 3 section 5a--Change the 6 to a 7 and remove "at all times" (the

facility has 7 fume

incinerators/afterburners)

Page 3 section 5b--Remove

the first sentence "Fume incinerator (FI-3)..."

Page 3 section 5b--Replace the second

sentence

"The other

5 Fume incinerators..." with

the following:

"The 7 fume incinerator combustion

chambers

shall

be operated at one of the

following temperatures:

1) the manufacturers recommended temperature,

2) In the absence of a compliance test, at least 1400

degrees F, or

3) if compliance testing has been done,

at a

temperature to

meet

the

conditions of

section 4b."

Page 7 section 9a--Change 6 to

7

Page 7 section 9b--Change 6 to 7

Page 8 section 12.a.ii--Remove the words "each day" from the sentence.

Page 8 section 12.a.ii.A--Change the sentence to read "Daily monitoring data of

the

Incinerator/Afterbunner combustion chamber temperature."

Page 8 section 12.a.ii.B--Change the sentence to read "A monthly log of operating time..."

A marked up copy of the Preliminary draft FESOP is attached. If You have any questions, please contact

me at 217-345-7095 extension 277.

S incerely yours,

0.

1ýarZY

J sepph D. Woodall

Facilities Manager

Cc: Randy Swank

David

F. Nancy

Electronic Filing - Received, Clerk's Office, March 3, 2008

* * * * * PCB 2008-048 * * * * *

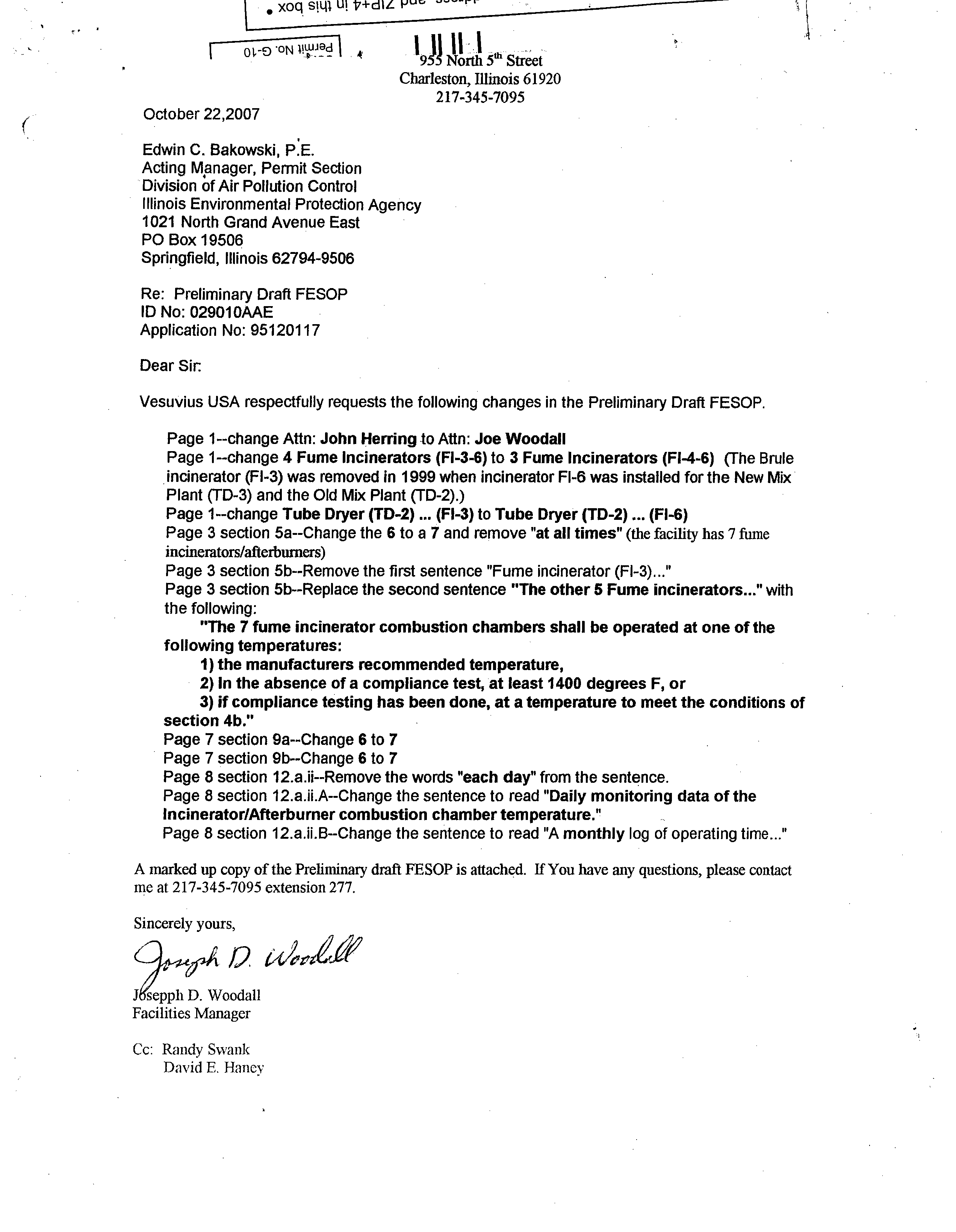

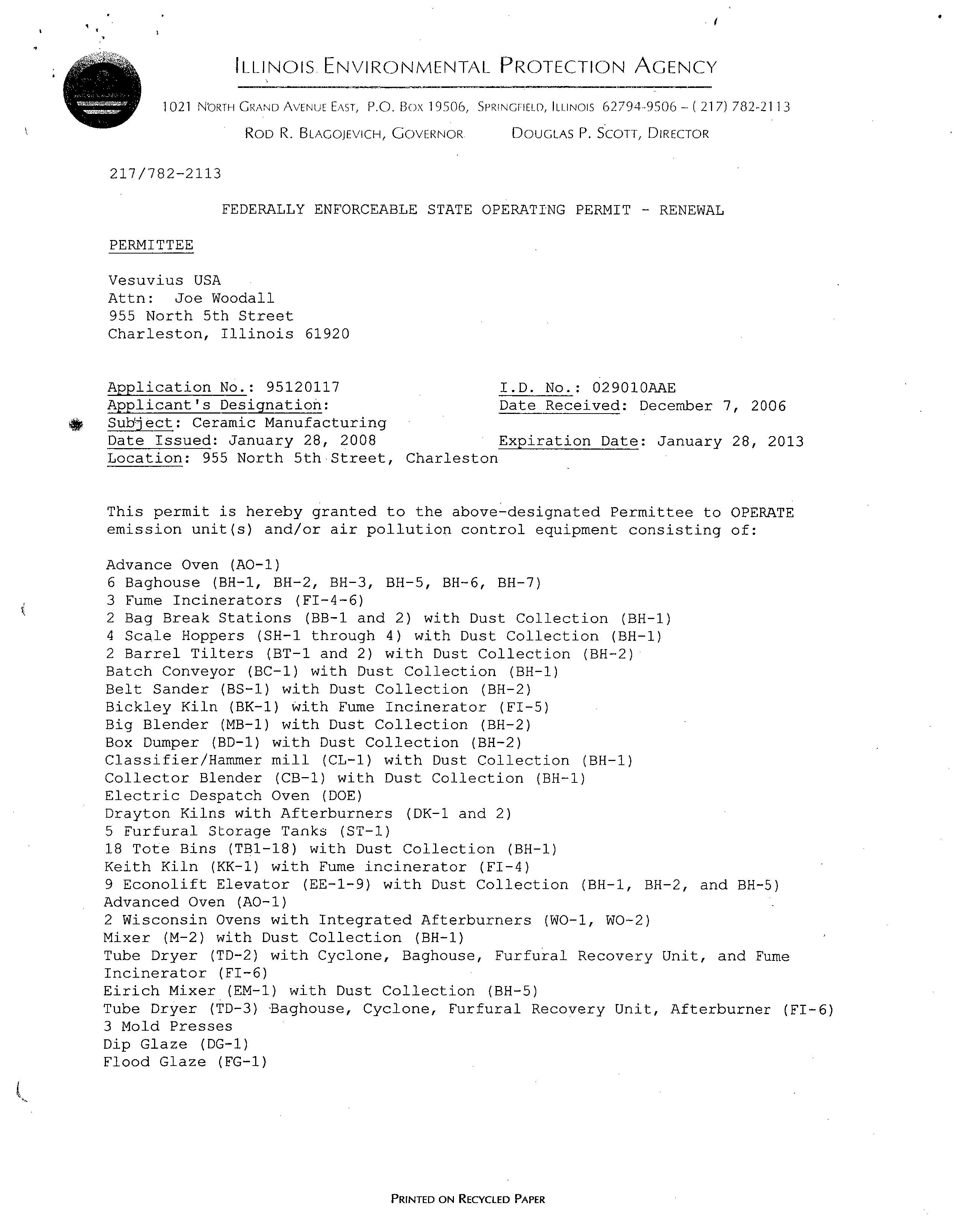

ILLINOIS ENVIRONMENTAL PROTECTION AGENCY

1 021 NORTH GRAND AVENUE EAST, P.O. BOX 19506, SPRINGFIELD, ILLINOIS 62794-9506

- ( 217) 782-2113

ROD R.

BLAGOIEVICH,

GOVERNOR

DOUGLAS P. SCOTT, DIRECTOR

2 17/782-2113

FEDERALLY ENFORCEABLE STATE OPERATING PERMIT -- RENEWAL

PERMITTEE

Vesuvius

USA

A ttn: John Herring

__"C?

Lý7 ýýGýýý- L L

955 North 5th Street

Charleston, Illinois 61920

Application No.: 95120117

I.D. No.: 029010AAE

Applicant's Designation:

Date Received: December 7, 2006

Subject: Ceramic Manufacturing

Date Issued:

Expiration Date:

Location: 955

North 5th Street, Charleston

This permit is hereby granted to the above-designated Permittee to OPERATE

emission unit(s) and/or air pollution control equipment consisting of:

Advance Oven (AO-1) '

6

Baghouse

(BH-1,

BH-2,

ýBH-3,

BH-5, BH-6, BH-7)

4 Fume Incinerators (FI-a-6)

2 Bag Break Stations (BB-1 and 2) with Dust Collection (BH-1)

4 Scale Hoppers (SH-1

through 4) with Dust Collection (BH-1)

2 Barrel Tilters (BT-1 and 2) with Dust Collection (BH-2)

Batch Conveyor (BC-1)

with Dust Collection (BH-1)

Belt Sander (BS-1) with Dust Collection (BH-2)

Bickley Kiln (BK-1) with Fume Incinerator (FI-5)

Big

Blender

(MB-1)

with Dust Collection (BH-2)

Box Dumper (BD-1) with Dust Collection (BH-2)

Classifier/Hammer mill (CL-1) with Dust Collection (BH-1)

Collector Blender (CB-1) with Dust Collection (BH-1)

Electric Despatch Oven (DOE)

D rayton Kilns with Afterburners (DK-1 and 2)

5 Furfural Storage Tanks (ST-1)

1 8 Tote Bins (TB1-18) with Dust Collection (BH-1)

Keith Kiln (KK-1) with Fume

incinerator

(FI-4)

9 Econolift Elevator (EE-1-9) with Dust Collection (BH-1, BH-2, and BH-5)

Advanced Oven

(AO-1)

2 Wisconsin Ovens with Integrated Afterburners (WO-1,

WO-2)

Mixer (M-2) with

Dust

Collection (BH-1)

T ube Dryer (TD-2) with Cyclone, Baghouse, Furfural

Recovery Unit, and

Fume

Incinerator {-F-I j- F',.1.

- 6

Eirich Mixer (EM-1)

with

Dust

Collection (BH-5)

Tube Dryer (TD-3) Baghouse, Cyclone, Furfural Recovery Unit,

Afterburner

(FI-6)

3 Mold Presses

Dip Glaze (DG-1)

Flood Glaze (FG-1)

5 Grinding Stations (GR-1-5) with

Dust

Collection

(BB-3)

Holding Bin (HB-1) with Dust Collection (BH-1)

8 Holding

Hoppers

(HH-1-8) with Dust Collection (BH-2)

Small Weighment Filling Station (SWFS) with

Dust Collection

(BH-7)

P RIN1- ED

ON

R EC

Y CLED PAPER

Electronic Filing - Received, Clerk's Office, March 3, 2008

* * * * * PCB 2008-048 * * * * *

Page 2

Small Blender (SB-1)

with Dust Collection (BH-2)

5 Bulk Bag Stations (BB-1-5),with Dust Collection

(BH-7)

Pneumatic Transporter (PT-1)

with Dust Collection (BH-7)

Feedback Station (FS-1) with

Dust

Collection

(BH-6)

1 5 Bulk Bagging Stations

(BB-6-20) with Dust Collection (BH-6)

Traveling Skip (TSK-1) with Dust Collection

(BH-6)

Carrier Conveyor (CC-1)

with Dust Collection (BH-6)

Classifier (CL-3) with Dust Collection (BH-5)

2 Hammermills (HM-1-2)

with Dust Collection (BH-5)

1 Glaze Mixer with Dust

Collector

1 Makino Milling machine with

dust collector

1 Antares

Milling Machine with Dust Collector

pursuant to the above-referenced

application. This Permit is subject to

standard conditions

attached hereto and the

following special condition(s):

la. This

federally enforceable state operating

permit is issued to limit the

emissions of air pollutants

from the source to less than

major source

thresholds

(i.e., VOM to less than

100 tons/year, 10 tons/year for a

single HAP and 25 tons/year

of any combination of such HAPs).

As a result

the

source is excluded from the requirement

to obtain a Clean Air Act

Permit Program (CAAPP)

permit. The maximum emissions

of this source, as

limited by the conditions

of this permit, are described

in Attachment A.

b. Prior to issuance,

a draft of this permit has undergone

a public notice

and comment period.

c. This permit supersedes

all operating permits issued for this

location.

2a.

No person shall cause or

allow the emission of smoke or other

particulate

matter, with an opacity greater

than 30 percent, into the

atmosphere from any

emission unit other than those

emission units

subject to the requirements of

35 Ill. Adm. Code 212.122, pursuant to

35 Ill.

Adm. Code 212.123(a), except as

allowed by 35 Ill. Adm. Code

212.123(b) and

212.124.

b. No person

shall cause or allow any visible

emissions of fugitive

particulate matter

from any process, including any

material handling or

storage activity beyond

the property line of the emission source

unless

the wind speed

is greater than 40.2 kilometers

per hour (25 miles per

hour), pursuant to 35

Ill. Adm. Code 212.301 and

212.314.

c. Pursuant to 35

Ill. Adm. Code 212.321(a), no person

shall cause or

allow the emission of particulate

matter into the atmosphere

in any one

hour period

from any new process emission unit

which, either alone or

in combination with the

emission of particulate matter from all other

similar process

emission units for which construction

or modification

commenced on or after

April 14, 1972, at a source or premises,

exceeds

the

allowable emission rates specified

in subsection (c) of 35 Ill.

Adm. Code 212.321.

3.

Pursuant to 35 Ill. Adm. Code 214.301,

no person shall cause or allow

the emission of sulfur

dioxide into the atmosphere from

any process

emission source to excess 2000 ppm.

Electronic Filing - Received, Clerk's Office, March 3, 2008

* * * * * PCB 2008-048 * * * * *

Page 3

4a. Pursuant

to 35 Ill. Adm. Code 215.301,

no person shall cause

or allow the

discharge of more than

3.,6 kg/hour (8

lbs/hour) of organic material

into

the atmosphere from any emission

unit, except as provided

in 35 Ill. Adm.

Code 215.302,

215.303, and 215.304

and the following exception:

If no

odor nuisance exists

the limitation of 35

Ill. Adm. Code 215 Subpart

K.

shall

apply only to photochemically

reactive material.

b.

Pursuant to 35 Ill.

Adm. Code 215.302, emissions

of organic material in

excess of

those permitted by 35

Ill. Adm. Code 215.301 are allowable

if

such emissions are

controlled by one of the following

methods:

i.

Flame, thermal

or catalytic incineration

so as either to reduce

such

emissions to 10 ppm

equivalent methane (molecular

weight 16)

or less, or to

convert 85 percent

of the hydrocarbons to carbon

dioxide

and water; or

5a.

K

ii.

Any other air pollution

control equipment

approved by the Illinois

EPA

capable of reducing by

85 percent or more the

uncontrolled

organic

material that would be otherwise

emitted to the atmosphere.

7

The,ki'Fume Incinerators/Afterburners,

6 Baghouses, and 2 Furfural

Recovery units shall be

in operation

, when the associated

emission

units are in operation

and emitting air contaminants.

b .

b'?**,

?

c

i n P r a t r, r ( E T - 3 .;_..r-emb tý.catý-c--ha

be-prý'1°tez -ed- -o--a

t

F

l -

[

o

"r s

ýý, a-ý t ,

i- h a mdSýllfý r t , i

r c

ý ý =ý

GBIF1mýI}ý-ýd-ýeFtlpý-rý-ý-13

'2--ý3ý-Tv -

1 °-ýý.zd-A

,lý L

i!'7

Z' rf

-

2.9-9-°-E-as--demo-rý-s to at-ed-i-fr-

lie-mom-t- -eee-x-t--eompýi-any-t-eý

ng .

e--

f

rV

i el- el `I

7

1 -GýBý--`ciie--c.,u-A'ýýf-t17rPrý-c

ro_

=OIRIAýIdd6G1--ýP>ýC1ýJ.Pýd-t-lý-ý2-ý3k3ý-.,-,n-=oz.r°aS-ý1a-fl

14OtT°-E'-i`ný-h-e--ýa-ýcPn

e of

a complianee--týý.

ýýWkCTl4%'/ý.

F ý

c .

The Permittee shall follow

good operating practices

for all air

pollution

control equipment covered

by this permit,

including periodic

inspection, routine

maintenance and prompt

repair of defects.

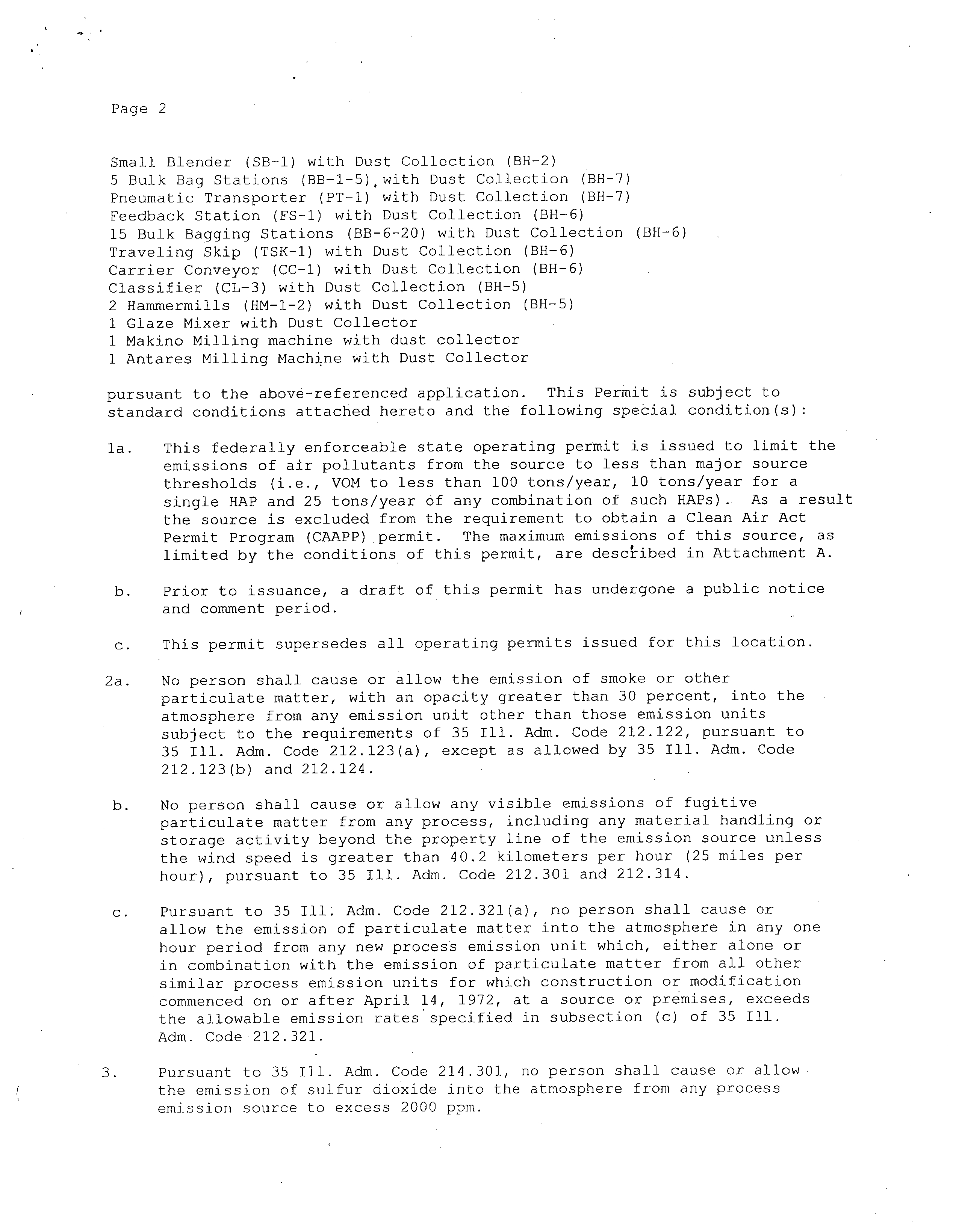

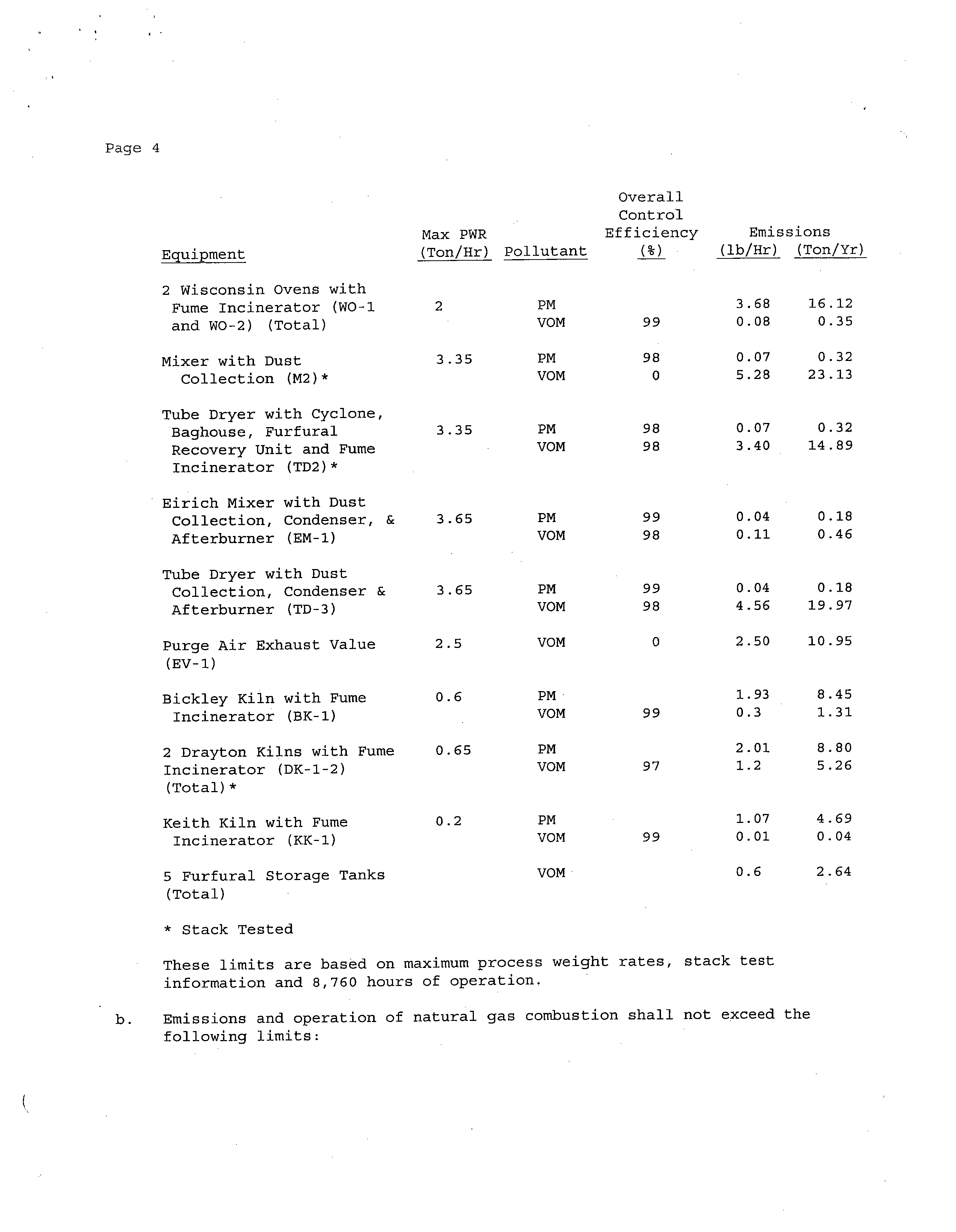

6a. Emissions and

operation of ceramic

manufacturing process

shall not

exceed

the following

limits:

Overall

Control

Max PWR

Efficiency

Emissions

Equipment

(Ton/Hr)

Pollutant

(°s)

(Lb/Hr) (Ton/Yr)

2 Wisconsin Ovens

with

Fume Incinerator (WO-1

2.00

PM

3.68

16.12

and WO-2)

(Total)

VOM

99

0.08

0.35

M ixer with Dust

3.35

PM

98

0.07

0.32

Collection

(M2)*

VOM

0

5.28 23.13

Tube

Dryer with Cyclone,

B aghouse, Furfural

3.35

PM

98

0.07

0.32

Recovery

Unit and Fume

VOM

98

3.40 14.89

Electronic Filing - Received, Clerk's Office, March 3, 2008

* * * * * PCB 2008-048 * * * * *

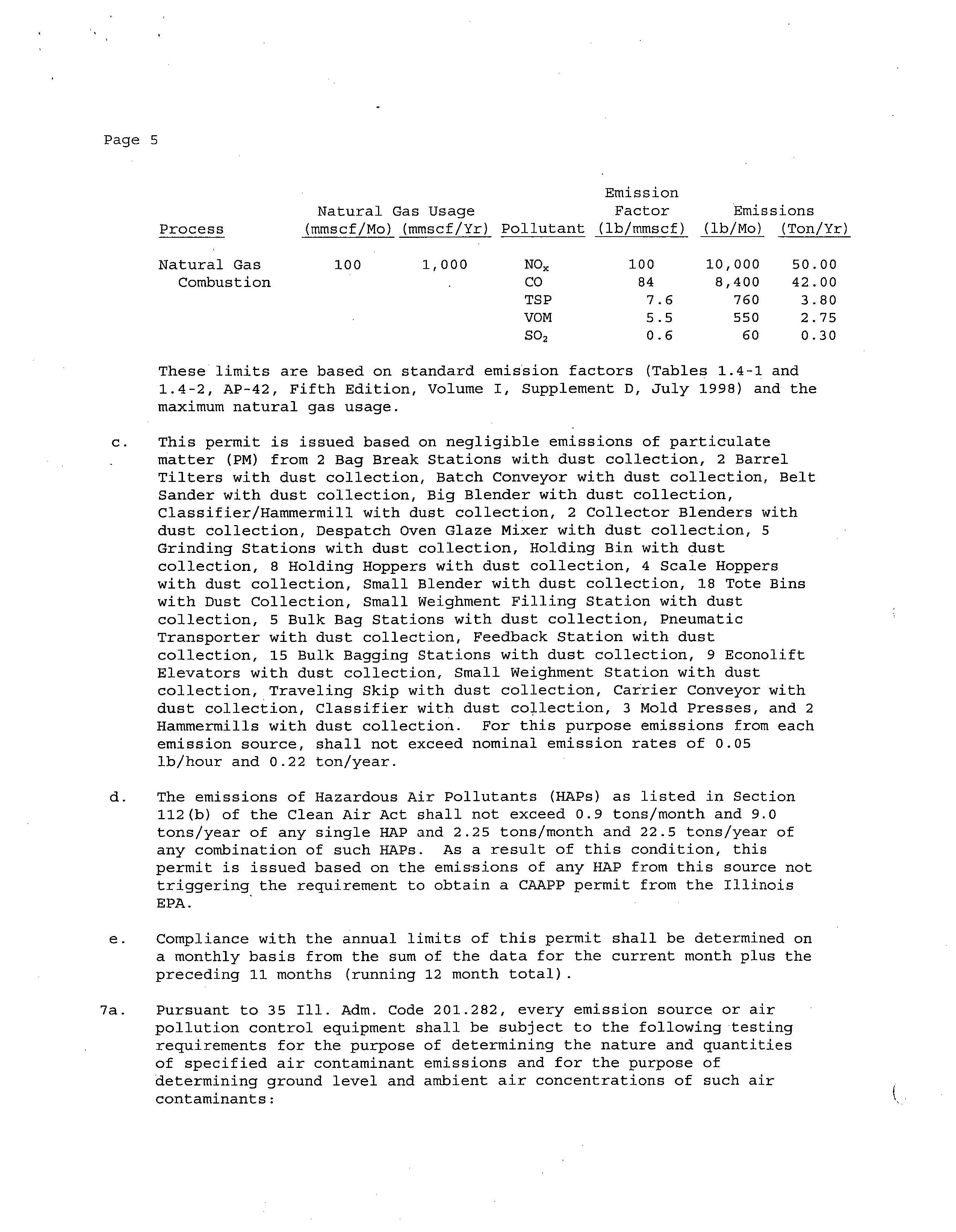

Page 4

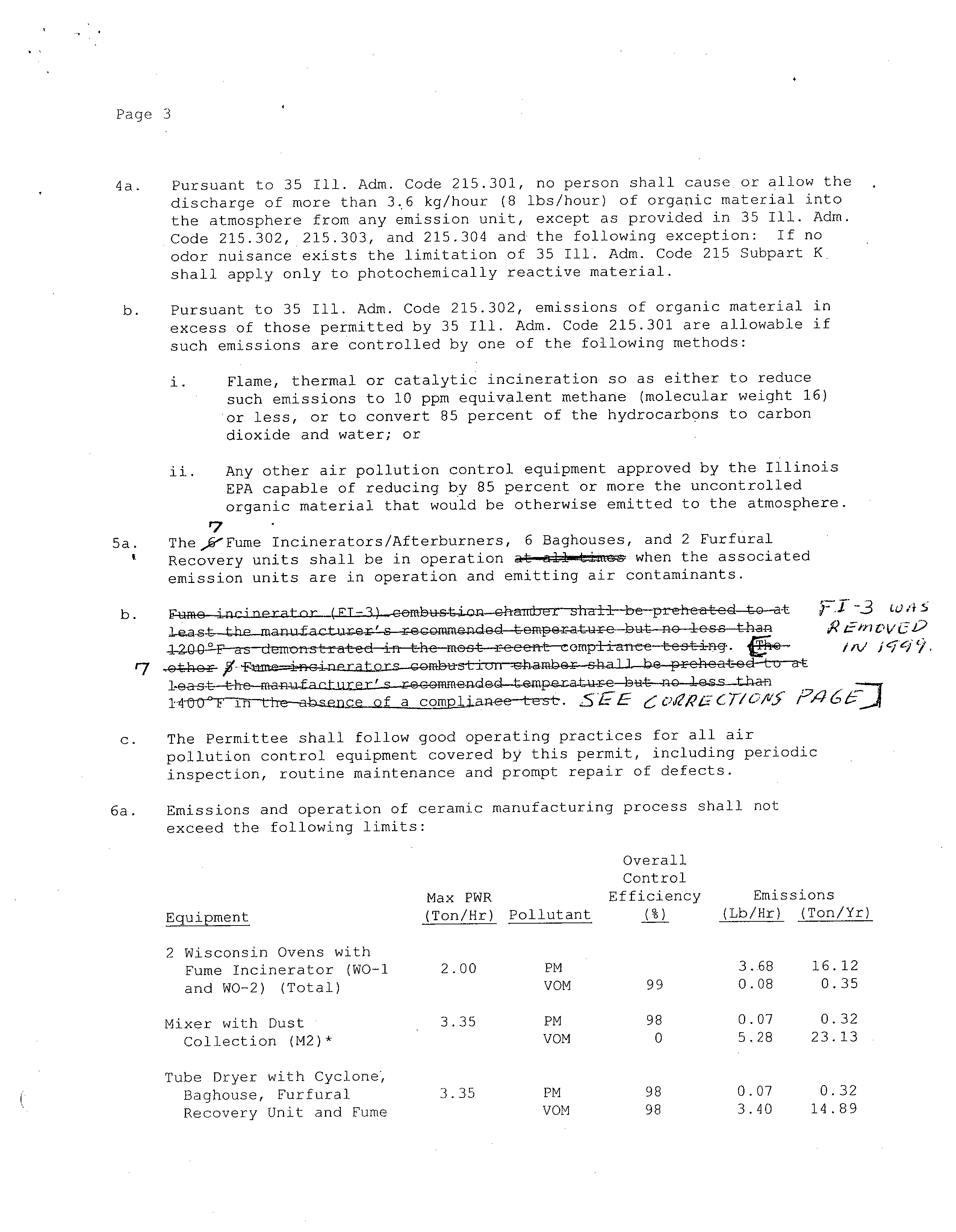

Overall

Control

Max

PWR

Efficiency

Emissions

Equipment

(Ton/Hr) Pollutant

(%)

(Lb/Hr) (Ton/Yr)

Incinerator (TD2)*

Eirich Mixer

with Dust

C ollection, Condenser, &

3.65

PM

99

0.04

0.18

Afterburner (EM-1)

VOM

98

0.11

0.46

Tube Dryer with Dust

C ollection, Condenser

&

3.65

PM

99

0.04

0.18

Afterburner (TD-3)

VOM

98

4.56 19.97

Purge Air Exhaust

Value

2.50

VOM

0

2.50

10.95

(EV-1)

Bickley Kiln with Fume

0.60

PM

1.93

8.45

Incinerator (BK-1)

VOM

99

0.3

1.31

2 Drayton Kilns

with Fume

0.65

PM

2.01

8.80

Incinerator (DK-1-2)

1

,

VOM

97

1.2

5.26

(Total)*

Keith

Kiln with Fume

0.20

PM

1.07

4.69

Incinerator (KK-1)

VOM

99

0.01

0.04

5 Furfural Storage Tanks

VOM

0.6

2.64

(Total)

* Stack

Tested

T hese

limits are based on maximum process

weight rates, stack test

information and

8,760 hours of operation.

b . Emissions

and operation of natural gas combustion

shall not exceed the

following limits:

Emission

Natural Gas Usage

Factor

Emissions

P rocess

(mmscf/Mo) (mmscf/Yr) Pollutant

(Lb/mmscf)- (Lb/Mo) (Ton/Yr)

Natural Gas

100

1,000

NOX

100

10,000 50.00

Combustion

CO

84

8,400 42.00

TSP

7.6

760

3.80

VOM

5.5

550 2.75

S02

0.6

60

0.30

These limits are based

on standard emission factors (Tables 1.4-1 and

1.4-2, AP-42, Fifth Edition,

Volume I, Supplement D, July 1998) and the

maximum natural

gas usage.

Electronic Filing - Received, Clerk's Office, March 3, 2008

* * * * * PCB 2008-048 * * * * *

Page 5

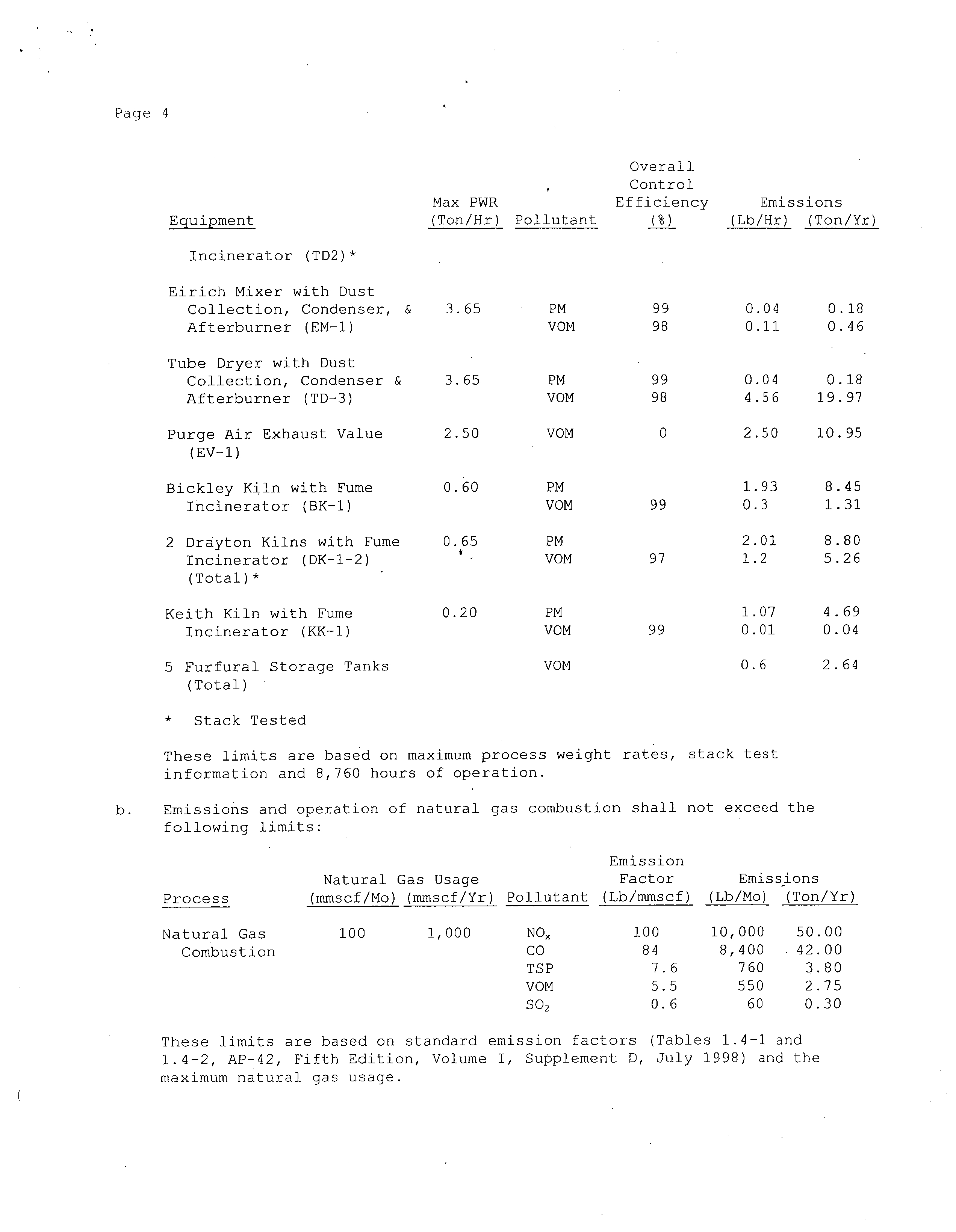

c .

This permit is issued

based on negligible emissions

of particulate

matte,r (PM)

from 2 Bag Break Stations

with dust collection,

2 Barrel

Tilters with dust collection,

Batch Conveyor

with dust collection, Belt

Sander

with dust collection,

Big Blender with

dust collection,

Classifier/Hammermill

with dust collection,

2 Collector Blenders

with

dust collection,

Despatch Oven Glaze Mixer

with dust collection, 5

Grinding

Stations with dust collection,

Holding Bin

with dust

collection, 8 Holding

Hoppers with dust

collection, 4 Scale Hoppers

with dust

collection, Small

Blender with dust collection,

18 Tote Bins

with Dust Collection,

Small Weighment

Filling Station with dust

collection,

5 Bulk Bag Stations

with dust collection,

Pneumatic

Transporter with

dust collection,

Feedback Station with dust

collection, 15 Bulk

Bagging Stations

with dust collection, 9 Econolift

Elevators

with dust collection,

Small Weighment

Station with dust

collection, Traveling

Skip with dust

collection, Carrier Conveyor

with

dust

collection, Classifier

with dust collection,

3 Mold Presses, and

2

Hammermills

with dust collection.

For this purpose emissions

from each

emission source, shall

not exceed nominal

emission rates of 0.05

lb/hour

and 0.22 ton/year.

d. The

emissions of Hazardous

Air Pollutants

(HAPs) as listed in

Section

112(b) of the

Clean Air Act shall

not exceed 0.9

tons/month and 9.0

tons/year of any single

HAP and 2.25

tons/month and 22.5 tons/year

of

any combination

of such HAPs.

As a result of

this condition, this

permit is issued

based on the emissions

of any HAP from this

source not

triggering

the requirement

to obtain a CAAPP permit

from the Illinois

EPA.

e. Compliance

with the annual limits

of this permit

shall be determined

on

a

monthly basis from

the sum of the data

for the current

month plus the

preceding 11

months (running

12 month total).

7a. Pursuant

to 35 Ill. Adm.

Code 201.282,

every emission source

or air

pollution control

.equipment shall

be subject to

the following testing

requirements for the

purpose of determining

the nature and quantities

of specified

air contaminant

emissions and for

the purpose of

determining ground

level and ambient

air concentrations

of such air

contaminants:

i.

Testing by Owner

or operator.

The Illinois EPA

may require the

owner

or operator of

the emission

source or air pollution control

equipment

to conduct such tests

in accordance

with procedures

adopted by the

Illinois EPA, at

such reasonable

times as may be

specified

by the Illinois

EPA and at

the expense of the owner or

operator

of the emission source

or air pollution

control

equipment.

The Illinois EPA may adopt

procedures detailing

methods

of testing and formats

for reporting

results of testing.

Such procedures

and revisions thereto,

shall not become

effective

until

filed with the Secretary

of State,

as required by the APA

Act. All such

tests shall be made

by or under the

direction of a

person qualified by

training and/or

experience in the field of

air pollution

testing. The Illinois

EPA shall

have the right to

observe all aspects

of such tests.

Electronic Filing - Received, Clerk's Office, March 3, 2008

* * * * * PCB 2008-048 * * * * *

Page 6

i i. Testing by the Illinois EPA. The Illinois EPA shall have the

right

to

conduct such

tests

at

any time

at

its own

expense. Upon

request of the Illinois EPA, the owner or operator of the

emission source or air pollution control equipment shall provide,

without charge to the Illinois EPA, necessary holes in stacks or

ducts and other safe and proper testing facilities, including

scaffolding, but excluding

instruments and sensing devices,

as

may be necessary.

b. Testing required by Condition 8 shall be performed upon a

written

request from the Illinois EPA by a qualified independent testing

service.

8a

Pursuant to 35 Ill. Adm. Code 212.107, for both fugitive and

nonfugitive particulate matter emissions, a determination as to the

presence or absence of visible emissions from emission units shall be

conducted in accordance with Method 22, 40 CFR part 60, Appendix A,

except

that the length of the observing period shall be at the

discretion of the observer, but

not less

than

one minute.

This

Condition shall not apply to 35 Ill. Adm. Code 212.301.

b. Pursuant to 35 Ill. Adm. Code 212.109, except as otherwise provided in

35 Ill. Adm. bode Part 212, and except for the methods of data

reduction when applied to 35

Ill. Adm. Code 212.122 and 212.123,

measurements of opacity shall be conducted in accordance with Method 9,

40 CFR

Part 60, Appendix A, and the procedures in 40 CFR 60.675(c) and

(d), if applicable, except that for roadways and parking

areas

the

number of readings required for each vehicle pass will be three taken

at 5-second

intervals. The first reading shall be at the point of

maximum opacity and second and third readings shall be made at the same

point, the observer standing at right angles to the plume at least 15

feet away from the plume and observing 4

feet above the surface of the

roadway or parking area. After four vehicles have passed, the 12

readings

will be averaged.

c. Pursuant to

35

Ill.

Adm. Code 212.110(a), measurement of particulate

matter emissions from stationary emission units subject to 35

Ill.

Adm.

Code Part 212 shall be conducted in accordance with 40 CFR part 60,

Appendix

A, Methods 5, 5A, 5D, or 5E.

d.

Pursuant to 35 Ill. Adm. Code 212.110(b), the volumetric flow rate and

gas velocity shall be determined in accordance with

40

CFR

part 60,

Appendix A, Methods 1, 1A, 2, 2A, 2C, 2D, 3, and 4.

e. Pursuant to 35 Ill. Adm. Code 212.110(c), upon a written notification

by the Illinois

EPA, the owner or operator of a particulate matter

emission unit subject to 35 Ill. Adm.

Code

Part 212 shall

conduct the

applicable testing for particulate matter emissions, opacity, or

visible emissions at such person's own expense, to demonstrate

compliance. Such test results shall be submitted to the

Illinois

EPA

within thirty (30) days after conducting the test unless an alternative

time

for submittal

is

agreed to by the Illinois EPA.

Electronic Filing - Received, Clerk's Office, March 3, 2008

* * * * * PCB 2008-048 * * * * *

Page 7

rJ

9a. The,fo" Fume Incinerators/Afterburners shall be equipped with a

continuous monitoring device, which is installed, calibrated,

maintained and operated according to vendor's specifications at all

times the incinerators/afterburners are in use.

This device

shall

monitor the afterburner combustion chamber temperature.

r

b.

The,.F1 fume incinerators/afterburners shall be

equipped

with

a

continuous temperature indicator and strip chart recorder or disk

storage for the,, fume incinerators/afterburners combustion chamber

temperature. 7

10. Pursuant to 40 CFR 63.10(b)(3), if an owner or operator determines that

his or her stationary source that emits (or has the potential to emit,

without considering controls) one or more hazardous air pollutants

regulated by any standard established pursuant to section 112(d) or (f)

of the Clean Air Act, and that stationary source is in the source

category regulated by the relevant standard,

but

that source is not

subject to the relevant standard (or other requirement established

under

40 CFR

Part 63)

because

of limitations on the source's potential

to emit or an exclusion, the owner or operator must

keep

a record of

the applicability determination on site at the source for a period of 5

years after the determination, or until the source changes its

operations to become an

affected

source,

whichever comes first. The

record of the applicability determination

must

be signed by the

person

making the

determination and include an analysis (or other information)

that demonstrates why the owner or operator believes the source

is

unaffected (e.g., because the source is an area source). The analysis

(or other information) must be sufficiently detailed to allow the USEPA

and/or Illinois EPA to make a finding

about the source's applicability

status with regard to the relevant standard or other requirement.

If

relevant, the analysis must be performed in accordance with

requirements established in relevant subparts of

40 CFR Part 63 for

this purpose for particular categories of stationary sources.

If

relevant, the analysis should be performed in accordance with USEPA

guidance materials published to assist

sources in making applicability

determinations under Section 112 of the Clean Air Act, if any. The

requirements to determine applicability

of a standard under 40 CFR

63.1(b)(3) and to record the results of that determination

under 40 CFR

63.10(b)(3) shall not by themselves create an obligation for the owner

or operator to obtain a Title V permit.

11. Pursuant to 35 Ill. Adm. Code 212.110(e),

the owner or

operator-of

an

emission unit subject to 35 Ill. Adm. Code Part

212 shall retain

records of all tests which are performed. These records shall be

retained for at least three (3) years

after the date a test is

performed.

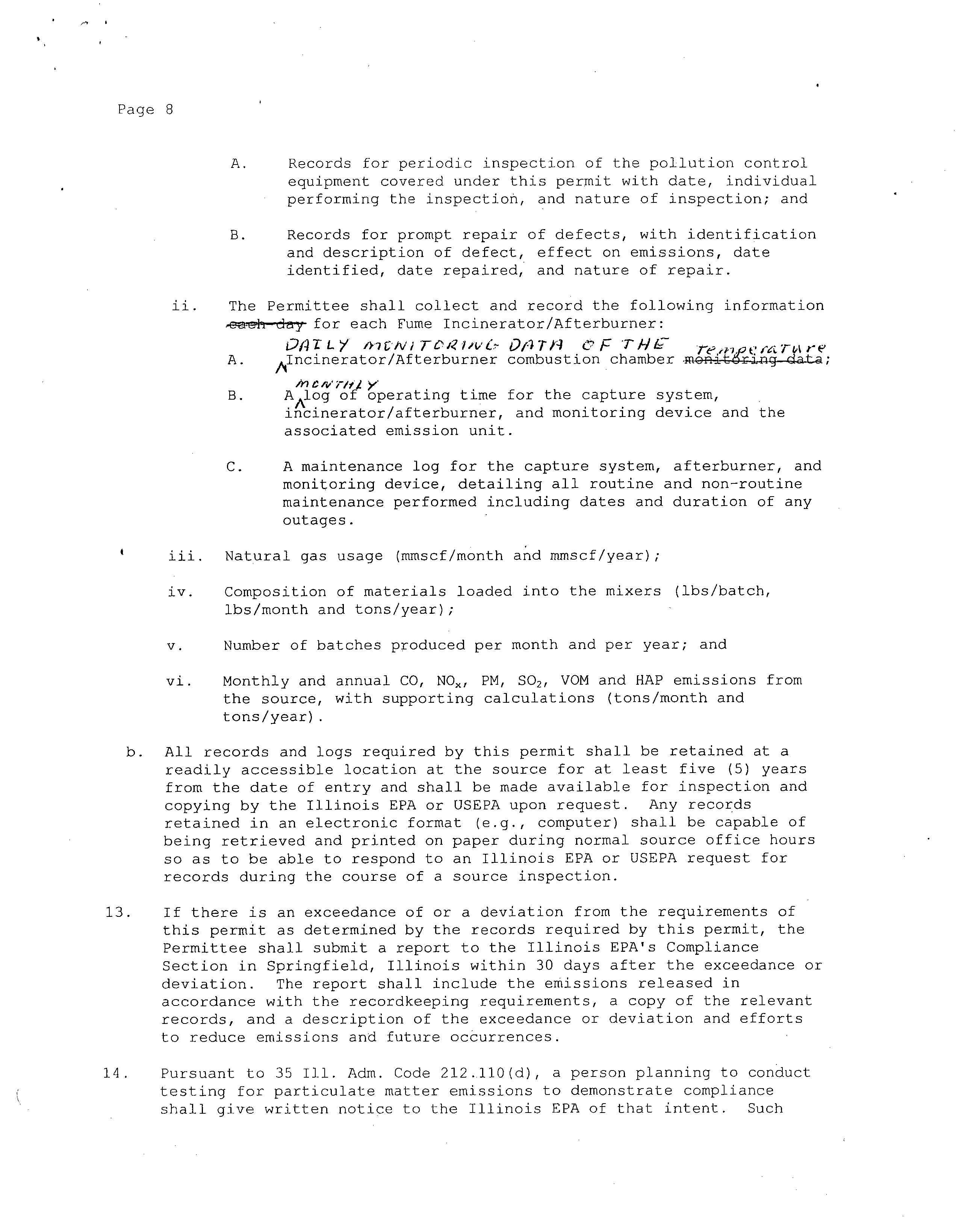

12a. Permittee shall maintain records of the following items

so as to

demonstrate compliance

with the conditions of this permit:

Records addressing use of good operating practices for the

pollution control equipment covered under

this permit:

Electronic Filing - Received, Clerk's Office, March 3, 2008

* * * * * PCB 2008-048 * * * * *

Page 8

A.

Records for periodic inspection

of the pollution control

equipment covered under this permit with date, individual

performing

the inspection, and nature of inspection; and

B.

Records for prompt repair of defects, with identification

and description

of defect, effect on emissions, date

identified, date repaired, and nature of repair.

ii. The Permittee shall collect and record

the following information

for each Fume Incinerator/Afterburner:

i7AT

L. y nýGw1

T

L'rZ,yr

v Lý

L7/IT

M

(27F

'Tf/L

A .

AIncinerator/Afterburner

combustion chamber .M.ernýy-t- r-ý.- a-tom ;

in e rv r

/>

y-

B .

A^log of ý

'yoperating

time

for the capture system,

incinerator/afterburner, and monitoring device and the

associated

emission unit.

C. A maintenance log for the capture system, afterburner, and

monitoring device, detailing

all routine and non-routine

maintenance performed including dates and duration of any

outages.

i ii.

Natural gas usage (mmscf/month and mmscf/year);

i v. Composition of materials loaded into the mixers (lbs/batch,

lbs/month and

tons/year);

v .

Number

of batches produced per month and per year; and

vi.

Monthly and

annual CO, NO., PM, S02, VOM and HAP emissions from

the source,

with

supporting

calculations (tons/month and

tons/year).

b. All records and logs

required by this permit shall be retained at a

readily accessible location at the source for at

least five (5) years

from the date of entry and shall be made available for inspection and

copying by the Illinois

EPA

or

USEPA upon request. Any records

retained in an electronic format (e.g., computer) shall be capable

of

being retrieved and

printed on paper during normal source office hours

so as to be able to respond to an Illinois EPA or

USEPA request for

records

during

the course of a source inspection.

13. If there is an exceedance of or a deviation from the requirements of

this permit as

determined by the records required by this permit, the

Permittee shall submit a report to the

Illinois EPA's Compliance

Section in Springfield, Illinois within 30 days after the exceedance or

deviation. The report shall include

the emissions released in

accordance with the recordkeeping requirements, a copy of the relevant

records, and a description

of the exceedance or deviation and efforts

to reduce emissions and future occurrences.

14. Pursuant to 35 Ill. Adm. Code 212.110(d),

a person

planning

to conduct

testing for

particulate matter emissions to demonstrate compliance

shall give written notice to the

Illinois EPA of that intent. Such

Electronic Filing - Received, Clerk's Office, March 3, 2008

* * * * * PCB 2008-048 * * * * *

Page

9

notification shall be given at least thirty (30) days prior to the

initiation of the test unless a shorter period is agreed to by the

Illinois EPA. Such notification shall state the specific test methods

from 35 Ill. Adm. Code 212.110 that will be used.

15. Two (2) copies of required reports and notifications shall be sent to:

Illinois Environmental Protection Agency

Division of Air Pollution Control

Compliance Section (#40)

P .O. Box 19276

S pringfield, Illinois 62794-9276

_and

one (1) copy shall be

sent

to

the Illinois EPA's regional office at

the following address unless otherwise indicated

I llinois Environmental Protection

Agency

Division of Air Pollution Control

2009 Mall

Street

Collinsville, Illinois 62234

If you have any questions on this, please

call German Barria at 217/782-2113.

E dwin C. Bakowski, P.E.

Date Signed:

Acting Manager,

Permit Section

D ivision of Air Pollution Control

ECB:GB:psj

cc: Illinois EPA, FOS Region

3

Lotus Notes

Electronic Filing - Received, Clerk's Office, March 3, 2008

* * * * * PCB 2008-048 * * * * *

Attachment A - Emission Summary

This attachment provides a summary of the maximum emissions from ceramic

manufacturing

operating in

compliance with the requirements of this federally

enforceable permit. In preparing this summary,

the Illinois EPA used the

annual operating scenario which results in maximum emissions from such a

plant. The resulting maximum emissions are below

the levels (e.g., 100 tons

per year of Volatile Organic Material (VOM) 10 tons per year for a single

HAP, and 25 tons per year for totaled HAP) at

which this source would be

considered a major source for purposes of the Clean Air Act Permit Program.

Actual emissions from this source will be less

than predicted in this summary

to the extent that less material is handled, and control measures are more

effective

than required in

this

permit.

E M I S S 1 0 N S (Tons/Year)

S ingle Total

Emission Unit

CO

NOX

PM

so,

VOM

HAP

HAPs

2 Wisconsin Ovens

(WO-1 and

WO-2)

16.12

0.35

Mixer (M2)

0.32

23.13

Tube Dryer (TD2)*

0.32

14.89.

Eirich Mixer (EM-1)

0.18

0.46

Tube Dryer (TD-3)

0.18

19.97

Purge Air Exhaust

Value (EV-1)

10.95

Bickley Kiln (BK-1)

8.45

1.31

2 Drayton Kilns (DK-1

and DK-2)

8.80

5.26

Keith Kiln (KK-1)

4.69

0.04

5 Furfural Storage

Tanks

2.64

2

Bag

Break

Stations

0.44

2 Barrel Tilters

0.44

Batch Conveyor

0.22

Belt Sander

0.22

Big Blender

0.22

Classifier/Hammermill

0.22

2 Collector Blenders

0.44

Despatch Oven Glaze

Mixer

0.22

5 Grinding Stations

1.10

Holding Bin

0.22

8 Holding Hoppers

1.76

4 Scale Hoppers

0.88

Small Blender

0.22

18 Tote Bins

3.96

Small Weighment

F illing Station

0.22

5 Bulk Bag Stations

1.10

Pneumatic

Transporter

0.22

Feedback Station

0.22

15 Bulk Bagging

S

tations

3.30

9 Econolift Elevators

1.98

Electronic Filing - Received, Clerk's Office, March 3, 2008

* * * * * PCB 2008-048 * * * * *

E M I S S

I O N S (Tons/Year)

Single

Total

Emission Unit

CO

No.

PM

so,

VOM

HAP

HAPs

S mall Weighment

Station

0.22

Traveling Skip

0.22

Carrier Conveyor

0.22

Classifier

0.22

3 Mold Presses

0.66

2 Hammermills

0.44

Fuel Combustion

42.00 50.00 3.80 0.30

2.75

Totals 42.00 50.00

62.44 0.30 81.75

9.0

22.5

GB:

psj

Electronic Filing - Received, Clerk's Office, March 3, 2008

* * * * * PCB 2008-048 * * * * *

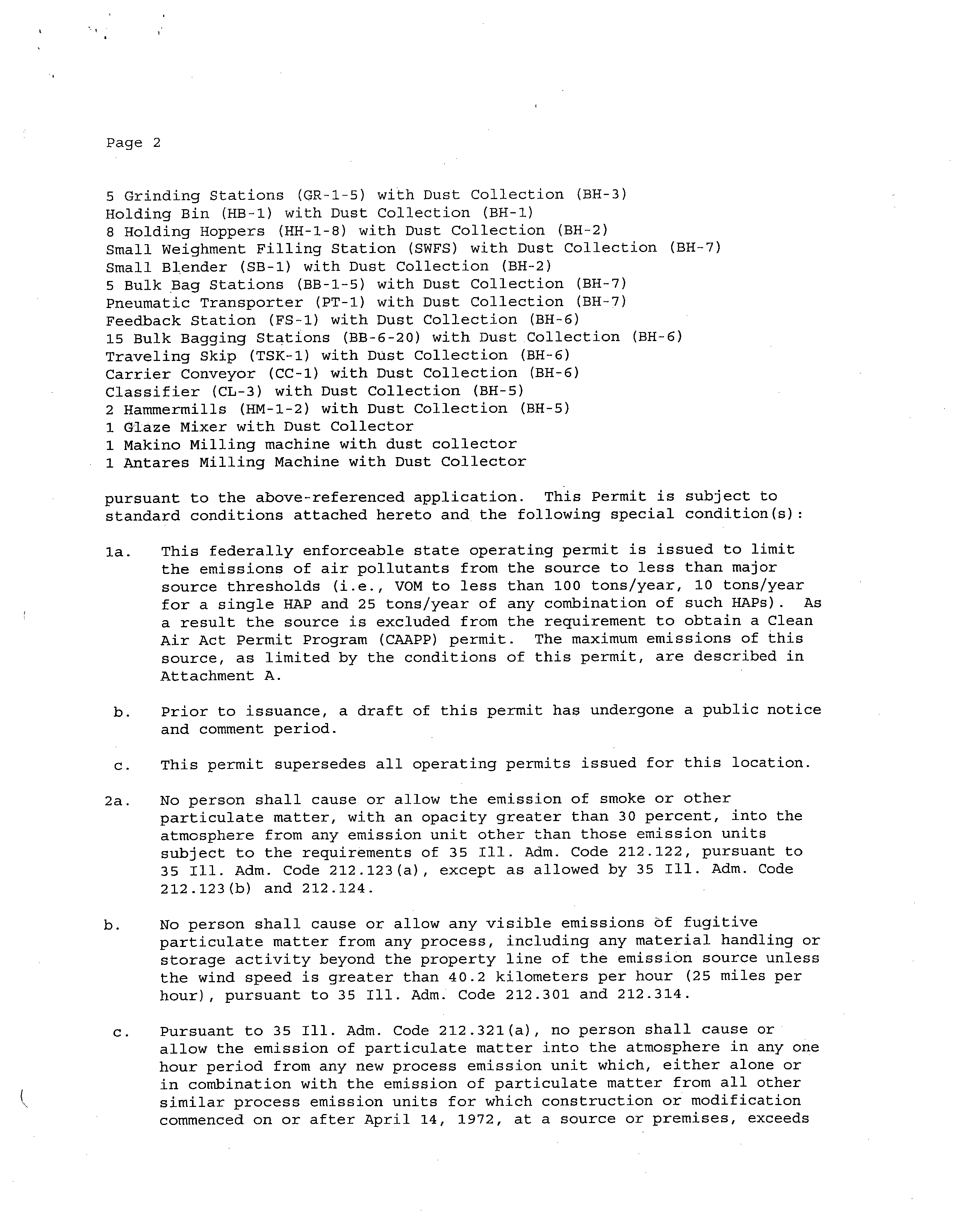

ILLINOIS ENVIRONMENTAL PROTECTION AGENCY

1 021

N'ORTFI GRAND A VENUE EAST, P .O. Box 19506, S PRINGFIELD, ILLIN01s 62794-9506

- (

217)

782-2113

R OD R. BLAGOJEVICi I, GOVERNOR

DOUGLAS P.

SCOTT,

DIRECTOR

2 17/782-2113

FEDERALLY ENFORCEABLE STATE OPERATING PERMIT - RENEWAL

PERMITTEE

Vesuvius USA

Attn: Joe Woodall

955 North 5th Street

Charleston,

Illinois

61920

Application No.: 95120117

I.D. No.: 029010AAE

Applicant's Designation:

_Date ReReceived:

December

7, 2006

Subject: Ceramic Manufacturing

Date

Issued: January 28, 2008

Expiration Date: January 28, 2013

Location: 955 North 5th Street, Charleston

This permit is hereby granted to the above-designated Permittee

to OPERATE

emission unit(s) and/or air pollution

control equipment consisting of:

Advance Oven (AO-1)

6 Baghouse (BH-1, BH-2, BH-3, BH-5, BH-6, BH-7)

3 Fume Incinerators (FI-4-6)

2 Bag Break Stations (BB-1 and 2) with Dust Collection (BH-1)

4 Scale Hoppers (SH-1 through 4) with Dust

Collection (BH-1)

2 Barrel Tilters (BT-1 and 2) with Dust Collection (BH-2)

Batch Conveyor (BC-1) with Dust Collection (BH-1)

Belt Sander (BS-1)

with Dust

Collection (BH-2)

Bickley Kiln (BK-1) With Fume Incinerator (FI-5)

Big Blender (MB-1) with Dust Collection (BH-2)

Box Dumper

(BD-1) with Dust

Collection (BH-2)

Classifier/Hammer mill (CL-1) with Dust Collection (BH-1)

Collector Blender (CB-1) with Dust Collection (BH-1)

Electric Despatch Oven (DOE)

Drayton Kilns with Afterburners (DK-1 and 2)

5

Furfural Storage Tanks (ST-1)

1 8 Tote Bins (TB1-18)

with

Dust Collection (BH-1)

Keith Kiln (KK-1) with Fume incinerator (FI-4)

9 Econolift Elevator (EE-1-9) with Dust Collection (BH-1,

BH-2, and BH-5)

Advanced

Oven (AO-1)

2 Wisconsin Ovens with Integrated Afterburners (WO-1, WO-2)

Mixer (M-2) with Dust Collection (BH-1)

'

Tube Dryer (TD-2) with Cyclone, Baghouse, Furfural Recovery Unit, and Fume

Incinerator (FI-6)

Eirich Mixer (EM-1) with Dust Collection (BH-5)

T ube Dryer (TD-3) Baghouse, Cyclone, Furfural Recovery Unit, Afterburner

(FT-6)

3 Mold Presses

Dip Glaze (DG-1)

Flood Glaze (FG-1)

PRINTED ON RECYCLED PAPER

Electronic Filing - Received, Clerk's Office, March 3, 2008

* * * * * PCB 2008-048 * * * * *

Page 2

5

Grinding Stations (GR-1-5) with Dust

Collection (BH-3)

Holding Bin (HB-1)

with Dust Collection (BH-1)

8 Holding Hoppers (HH-1-8) with Dust Collection

(BH-2)

Small Weighment

Filling Station (SWFS) with Dust Collection

(BH-7)

Small Blender (SB-1) with Dust Collection

(BH-2)

5 Bulk

Bag Stations (BB-1-5) with Dust Collection

(BH-7)

Pneumatic Transporter

(PT-1) with Dust Collection (BH-7)

Feedback Station (FS-1)

with

Dust

Collection (BH-6)

15 Bulk

Bagging Stations (BB-6-20) with Dust Collection

(BH-6)

Traveling Skip (TSK-1)

with Dust Collection (BH-6)

Carrier Conveyor (CC-1)

with Dust Collection (BH-6)

Classifier

(CL-3) with Dust Collection (BH-5)

2 Hammermills (HM-1-2)

with Dust Collection (BH-5)

1

Glaze Mixer with Dust Collector

1 Makino Milling

machine with dust collector

1 Antares Milling

Machine with Dust Collector

pursuant

to the above-referenced application. This

Permit is subject to

standard conditions

attached hereto and the following special

condition(s):

la.

This federally enforceable state operating permit

is issued to limit

the emissions of air pollutants

from the source to less than major

source

thresholds (i.e., VOM to less than

100 tons/year, 10 tons/year

for a single

HAP and 25 tons/year of any combination

of such HAPs). As

a result the source is excluded

from the requirement to obtain a Clean

Air

Act Permit Program (CAAPP) permit. The

maximum emissions of this

source, as limited

by the conditions of this permit, are

described in

Attachment A.

b. Prior to issuance,

a draft of this permit has undergone a public notice

and comment period.

c. This permit supersedes

all operating permits issued for this

location.

2a. No person

shall cause or allow the emission of

smoke or other

particulate

matter, with an opacity greater than 30 percent,

into the

atmosphere from any emission unit

other than those emission units

subject

to the requirements of 35 Ill.

Adm. Code 212.122, pursuant to

35 Ill.

Adm. Code 212.123(a), except as allowed by 35

Ill. Adm. Code

212.123(b) and 212.124.

b. No person shall cause or allow

any visible emissions of fugitive

particulate matter from any process, including

any material handling or

storage

activity beyond the property line of the

emission source unless

the wind speed is greater than

40.2 kilometers per hour (25

miles

per

hour),

pursuant to 35 Ill. Adm. Code 212.301

and 212.314.

c.

Pursuant to 35 Ill. Adm. Code 212.321(a),

no person shall cause or

allow

the emission of particulate matter into the

atmosphere in any one

hour period from any new

process emission unit which, either

alone

or

in combination with the emission of particulate

matter from all other

similar process

emission units for which construction

or modification

commenced on or after

April 14, 1972, at a source or premises, exceeds

Electronic Filing - Received, Clerk's Office, March 3, 2008

* * * * * PCB 2008-048 * * * * *

Page 3

the allowable emission rates

specified

in subsection (c) of

35 Ill.

Adm. Code 212."321.

3. Pursuant to 35 Ill. Adm.

Code 214.301, no person shall cause or allow

the emission of

sulfur dioxide into the atmosphere from any process

emission source to excess 2000 ppm.

4a.

Pursuant to 35 Ill. Adm. Code 215.301, no person shall cause or allow

the discharge of more than 3.6 kg/hour (8 lbs/hour) of

organic material

into the atmosphere

from any emission unit, except as provided in 35

Ill.

Adm. Code 215.302, 215.303, and 215.304 and the following

exception: If no odor nuisance

exists the

limitation

of 35 Ill. Adm.

Code 215 Subpart K

shall apply only to photochemically reactive

material.

b. Pursuant to 35 Ill. Adm. Code 215.302,

emissions of organic material in

excess

of those permitted by 35 Ill. Adm. Code 215.301 are allowable if

such emissions are controlled by one of the following methods:

i.

Flame,

thermal or catalytic incineration so as either to reduce

such emissions to 10 ppm equivalent methane (molecular weight

16)

or less, or

to convert 85 percent of the hydrocarbons to carbon

dioxide

and water; or

ii. Any other air pollution

control equipment approved by the

Illinois EPA capable of reducing by 85 percent or more the

uncontrolled organic

material that would be otherwise emitted to

the atmosphere.

5a. The fume incinerators/afterburners,

baghouses,

and furfural

recovery

units shall be in

operation at all times when the associated emission

units are in operation and emitting air contaminants.

b. The fume incinerators

combustion chamber shall be preheated to at least

the manufacturer's recommended temperature but not less than the

temperature at which compliance was

demonstrated

in the most

recent

compliance test or 1400°F

in the absence of a compliance test. This

temperature

shall be maintained during operation of the emission units

associated with the fume incinerators.

c. The Permittee

shall follow good operating practices for all air

pollution control equipment covered by this permit, including periodic

inspection, routine maintenance

and prompt

repair

of defects.

6a. Emissions and operation

of ceramic manufacturing

process

shall not

exceed the following

limits:

Electronic Filing - Received, Clerk's Office, March 3, 2008

* * * * * PCB 2008-048 * * * * *

Page

4

O verall

Control

Max PWR

Efficiency

Emissions

Equipment

(Ton/Hr)

Pollutant

(%)

(lb/Hr) (Ton/Yr)

2 Wisconsin

ovens with

Fume Incinerator

(WO-1

2

PM

3.68 16.12

and WO-2) (Total)

VOM

99

0.08

0.35

Mixer with Dust

3.35

PM

98

0.07

0.32

Collection

(M2)*

VOM

0

5.28

23.13

Tube Dryer with Cyclone,

Baghouse, Furfural

3.35

PM

98

0.07

0.32

Recovery Unit

and Fume

VOM

98

3.40 14.89

Incinerator (TD2)*

Eirich Mixer

with Dust

Collection, Condenser,

&

3.65

PM

99

0.04

0.18

Afterburner

(EM-1)

VOM

98

0.11

0.46

Tube Dryer with Dust

Collection,

Condenser &

3.65

PM

99

0.04

0.18

Afterburner (TD-3)

VOM

98

4.56 19.97

Purge Air

Exhaust Value

2.5

VOM

0

2.50 10.95

(EV-1)

Bickley Kiln

with Fume

0.6

PM

1.93

8.45

Incinerator (BK-1)

VOM

99

0.3

1.31

2 Drayton Kilns

with Fume 0.65

PM

2.01

8.80

Incinerator (DK-1-2)

VOM

97

1.2

5.26

(Total)

Keith Kiln with Fume

0.2

PM

1.07

4.69

Incinerator

(KK-1)

VOM

99

0.01

0.04

5 Furfural Storage

Tanks

VOM

0.6

2.64

(Total)

* Stack Tested

These limits

are based on maximum process

weight rates,

stack test

information and 8,760 hours

of operation.

b.

Emissions and operation

of natural gas

combustion shall

not exceed the

following

limits:

Electronic Filing - Received, Clerk's Office, March 3, 2008

* * * * * PCB 2008-048 * * * * *

Page 5

Emission

Natural Gas Usage

Factor

Emissions

P rocess

(mmscf/Mo) (mmscf/Yr)

Pollutant (lb/mmscf) (lb/Mo) (Ton/Yr)

Natural Gas

100

1,000

NO,,

100

10,000 50.00

Combustion

CO

84

8,400 42.00

TSP

7.6

760

3.80

VOM

5.5

550

2.75

S02

0.6

60

0.30

These

limits

are based on standard

emission factors (Tables 1.4-1 and

1.4-2, AP-42, Fifth Edition, Volume I, Supplement D, July 1998)

and

the

maximum natural gas usage.

c. This permit is issued based on

negligible emissions of particulate

matter (PM) from 2 Bag Break Stations with dust collection,

2

Barrel

Tilters with dust collection, Batch Conveyor with dust collection, Belt

Sander

with

dust collection,

Big Blender with dust collection,

Classifier/Hammermill with dust collection, 2 Collector Blenders with

dust collection, Despatch Oven Glaze Mixer with dust collection, 5

Grinding Stations with dust collection,

Holding Bin with dust

collection, 8 Holding Hoppers with dust collection, 4 Scale Hoppers

with dust collection, Small Blender with dust collection, 18 Tote Bins

with Dust Collection, Small Weighment

Filling Station with dust

collection, 5 Bulk Bag Stations with dust collection, Pneumatic

Transporter with dust collection, Feedback Station with dust

collection, 15 Bulk Bagging Stations

with dust collection, 9 Econolift

Elevators with dust collection, Small Weighment Station with dust

collection, Traveling Skip

with dust collection, Carrier Conveyor with

dust collection, Classifier with dust collection, 3 Mold Presses, and 2

Hammermills with dust collection. For this purpose emissions from each

emission source, shall not exceed

nominal emission rates of 0.05

lb/hour and 0.22 ton/year.

d. The emissions

of

Hazardous Air Pollutants (HAPs) as listed in Section

112(b) of the Clean Air Act shall

not exceed 0.9 tons/month and 9.0

tons/year of any single HAP and 2.25 tons/month and 22.5 tons/year of

any combination of such HAPs. As a result of this condition, this

permit is issued based on the emissions

of any HAP from this source not

triggering the requirement to obtain a CAAPP permit from the Illinois

EPA.

e. Compliance with the annual limits of this permit shall be determined on

a monthly basis from the sum of the data for the current month plus the

preceding 11 months (running 12

month total).

7 a.

requirements for the purpose

of specified air contaminant

determining ground level and

contaminants:

air

pollution control equipment shall be subject to the following testing

Pursuant to 35 Ill. Adm. Code 201.282,

every emission source, or

of determining the nature and quantities

emissions

and for the purpose of

ambient air

concentrations

of such

air

Electronic Filing - Received, Clerk's Office, March 3, 2008

* * * * * PCB 2008-048 * * * * *

Page 6

i . Testing by Owner or Operator.

The Illinois EPA may require the

owner or operator of the emission source or air pollution control

equipment

to conduct such tests in accordance with procedures

adopted by the Illinois EPA, at such reasonable times

as may be

specified

by the Illinois EPA and at the expense of the owner or

operator of the emission source or air pollution control

equipment.

The Illinois EPA may adopt procedures detailing

methods of.testing

and formats for reporting results of testing.

Such procedures and revisions thereto, shall not become

effective

until filed with the Secretary of State, as required by the APA

Act.

All

such

tests shall be made by or under the direction of a

person qualified by training and/or experience in the field

of

air pollution testing. The Illinois EPA shall have the right to

observe

all aspects of such tests.

ii.

Testing by the Illinois EPA. The Illinois EPA shall have the

right to conduct such tests at

any

time

at its own expense. Upon

request of the Illinois EPA, the owner or operator of

the

emission source or air pollution control equipment shall provide,

without charge

to the Illinois EPA, necessary holes in stacks or

ducts and other safe and proper testing facilities,

including

scaffolding,

but excluding instruments and sensing devices, as

may be necessary.

b. Testing required by Condition

8

shall

be performed upon a written

request from the Illinois EPA by a qualified independent

testing

service.

8a Pursuant to 35 Ill. Adm. Code 212.107, for both fugitive

and

nonfugitive

particulate matter emissions, a determination as to the

presence or absence

of visible

emissions

from emission units shall be

conducted in accordance with Method 22, 40 CFR part 60,

Appendix A,

except

that the length of the observing period shall be at the

discretion of the observer, but not less than one

minute. This

Condition

shall not apply to 35 Ill. Adm. Code 212.301.

b. Pursuant to 35

Ill. Adm.

Code 212.109, except

as otherwise provided in

35 Ill. Adm. Code Part 212, and except for the methods

of data

reduction when applied to 35 Ill. Adm. Code 212.122 and 212.123,

measurements of opacity

shall

be

conducted in accordance with method 9,

40 CFR Part 60, Appendix A, and the procedures in

40 CFR 60.675(c) and

(d),

if applicable, except that for roadways and parking areas the

number of readings required for each vehicle pass

will be three taken

at 5-second

intervals. The first reading shall be at the point of

maximum opacity and second

and

third

readings shall be made at the same

point, the observer standing at right angles to the plume

at least 15

feet away

from the plume and observing 4 feet above the surface of the

roadway or parking area.

After

four

vehicles have passed, the 12

readings will be averaged.

c. Pursuant to 35

Ill. Adm.

Code

212.110(a), measurement of particulate

matter emissions from stationary emission units subject to 35 Ill. Adm.

Electronic Filing - Received, Clerk's Office, March 3, 2008

* * * * * PCB 2008-048 * * * * *

Page 7

Code Part 212 shall be conducted in accordance with 40 CFR part

60,

Appendix A, Methods 5,

5A,

5D, or 5E.

d. Pursuant to

35 Ill. Adm. Code 212.110(b), the volumetric flow rate and

gas velocity shall be determined in accordance

with 40 CFR part 60,

Appendix A, Methods 1, 1A, 2, 2A, 2C, 2D, 3, and 4.

e. Pursuant to 35 Ill. Adm. Code 212.110(c),

upon a written notification

by the Illinois EPA, the owner or operator of a particulate

matter

emission unit

subject to 35 Ill. Adm. Code Part 212 shall conduct the

applicable testing for particulate matter emissions, opacity,

or

visible emissions

at such person's own expense, to demonstrate

compliance. Such

test results shall be submitted to the Illinois EPA

within thirty (30) days

after

conducting the

test unless an alternative

time for submittal is agreed to by the Illinois EPA.

9a. The fume incinerators/afterburners shall

be equipped with a continuous

monitoring device, which is installed, calibrated,

maintained and

operated

according to vendor's specifications at all times the

incinerators/afterburners are in use. This device

shall monitor the

afterburner combustion chamber temperature.

b. The fume incinerators/afterburners shall be equipped

with a continuous

temperature

indicator and strip chart recorder or disk

storage for the

fume incinerators/afterburners

combustion chamber temperature.

10. Pursuant

to 40 CFR 63.10(b)(3), if an owner or operator

determines that

his or her stationary

source that emits (or has the potential to emit,

without considering controls) one or more hazardous

air pollutants

regulated

by any standard established pursuant to section 112(d) or (f)

of the Clean Air

Act, and that

stationary

source is in the source

category regulated by the relevant standard, but

that source is not

subject

to the relevant standard (or other requirement

established

under 40 CFR

Part 63) because of limitations on the source's potential

to emit or an exclusion, the owner or operator

must keep a record of

the applicability determination on site at the source

for a period of 5

years after

the determination, or until the source changes its

operations to become an affected source,

whichever comes first. The

record of the applicability determination must be

signed by the person

making the determination

and include an analysis (or other

information)

that demonstrates why the

owner

or operator

believes the source is

unaffected

(e.g., because the source is an area source).

The analysis

(or other

information) must be sufficiently detailed to

allow the

USEPA

and/or Illinois EPA to

make

a finding about

the source's applicability

status

with regard to the relevant standard or other

requirement. If

relevant, the

analysis must be performed in accordance with

requirements established in relevant subparts of

40 CFR Part 63 for

this purpose

for particular categories of stationary sources.

If

relevant, the analysis

should

be performed

in accordance with USEPA

guidance materials published to assist sources in

making applicability

determinations

under Section 112 of the Clean Air Act,

if any. The

requirements to determine

applicability

of

a standard under 40 CFR

63.1(b)(3) and to record the results of that determination

under 40 CFR

Electronic Filing - Received, Clerk's Office, March 3, 2008

* * * * * PCB 2008-048 * * * * *

Page 8

63.10(b)(3) shall not

by themselves create an obligation

for the owner

or operator

to obtain a Title V permit.

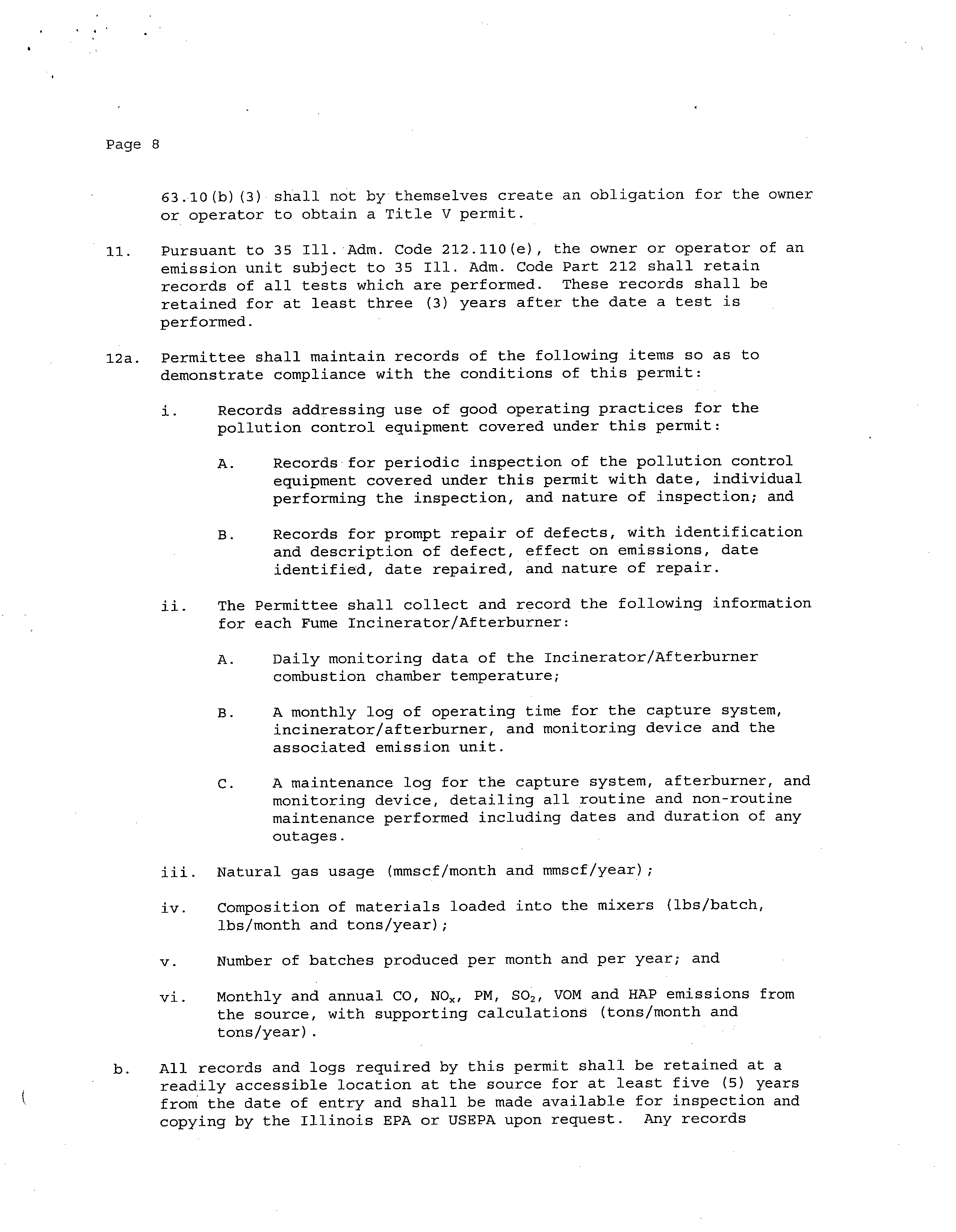

11. Pursuant

to 35 Ill. Adm. Code 212.110

(e), the owner or operator of

an

emission unit subject

to 35 Ill. Adm. Code Part

212 shall retain

records

of all tests which

are performed. These records shall

be

retained

for at least three (3) years after

the date a test is

performed.

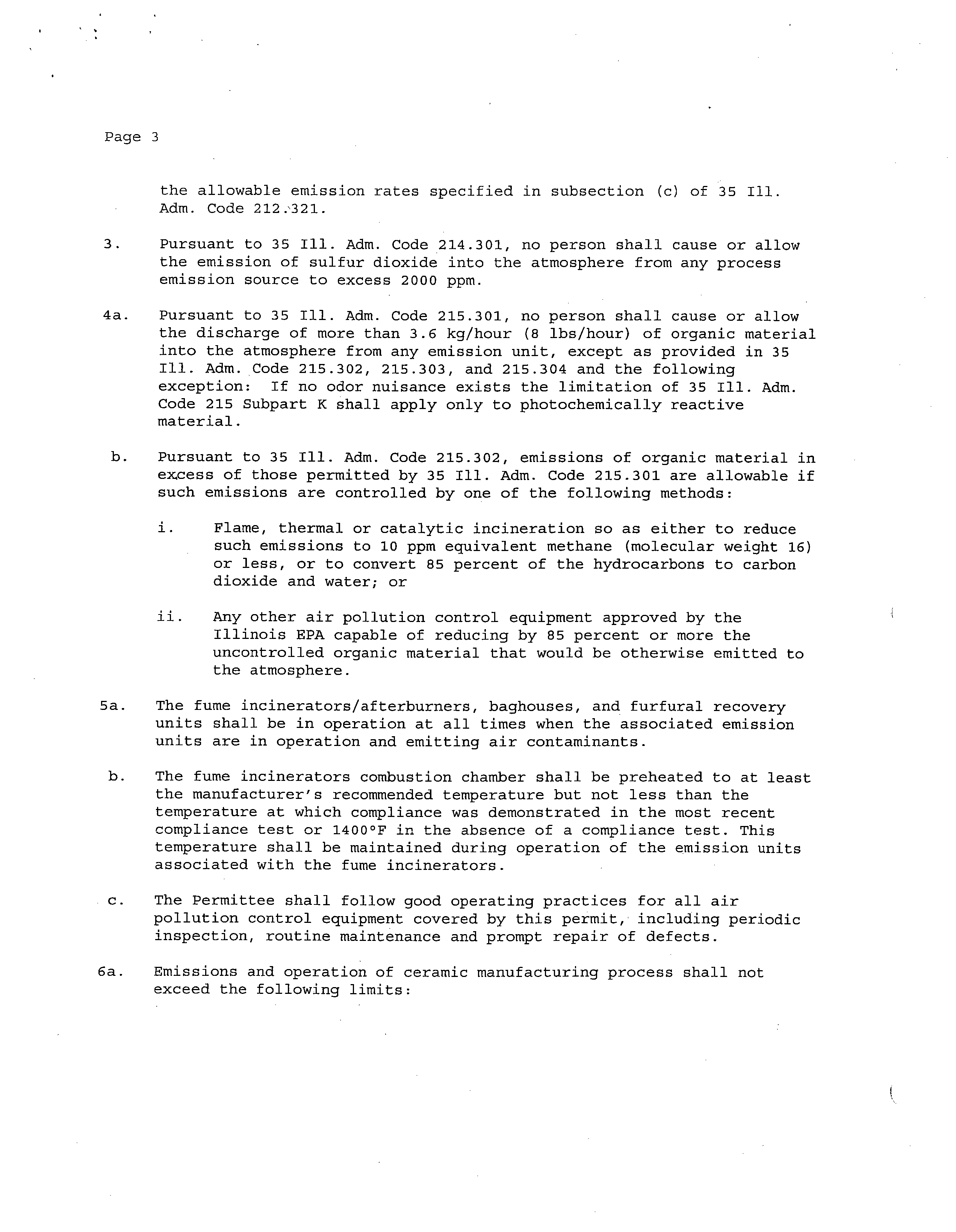

12a. Permittee

shall maintain records of the

following items so as to

demonstrate compliance

with the conditions of this

permit:

i.

Records addressing use of good operating

practices for the

pollution control

equipment covered under

this permit:

A.

Records for periodic inspection

of the pollution control

equipment

covered under this permit

with date, individual

performing the inspection,

and nature of

inspection; and

B. Records

for prompt repair of defects,

with identification

and description of

defect, effect on emissions, date

identified, date repaired, and nature

of repair.

ii.

The Permittee shall collect and

record the following information

for each

Fume Incinerator/Afterburner:

A.

Daily monitoring data of the

Incinerator/Afterburner

combustion

chamber temperature;

B.

A monthly log of operating time

for the capture system,

incinerator/afterburner,

and monitoring

device and the

associated emission unit.

C. A maintenance

log for the capture system,

afterburner, and

monitoring device, detailing

all routine

and non-routine

maintenance performed including

dates and duration of any

outages.

iii.

Natural gas usage (mmscf/month

and mmscf/year);

iv. Composition of materials

loaded into the mixers (lbs/batch,

lbs/month

and tons/year);

v.

Number of batches produced per

month and per year;

and

vi.

Monthly and annual CO,

NO., PM, SO,, VOM and

HAP emissions from

the

source, with supporting calculations

(tons/month and

tons/year).

b. All records

and logs required by this permit

shall be retained at a

readily accessible location

at the source for at

least five (5) years

from the

date of entry and shall be

made available for inspection and

copying by the

Illinois EPA or USEPA upon

request. Any records

Electronic Filing - Received, Clerk's Office, March 3, 2008

* * * * * PCB 2008-048 * * * * *

Page 9

r etained in an electronic format (e.g.,

computer) shall be capable of

being retrieved

and printed on paper during normal

source office hours

so as to be able to respond to

an Illinois EPA or USEPA request for

records during the course of a source

inspection.

13. If there is an exceedance of or a deviation

from the requirements of

this permit as determined

by the records required by

this permit, the

Permittee shall submit a report

to the Illinois EPA's Compliance

Section in Springfield, Illinois within

30 days after the exceedance or

deviation.

The report shall include the emissions

released in

accordance with the recordkeeping

requirements, a copy

of

the

relevant

records, and a description of the exceedance

or deviation and efforts

to

reduce emissions and future occurrences.

14. Pursuant to 35 Ill. Adm. Code 212.110(d),

a person planning to conduct

testing for particulate matter emissions

to demonstrate compliance

shall give written notice to

the Illinois EPA of that

intent. Such

notification shall be given at least

thirty (30) days prior to the

initiation of the test unless a shorter

period is agreed to by the

Illinois EPA. Such

notification shall state the specific

test methods

from 35 Ill. Adm. Code 212.110 that

will be used.

15. Two (2) copies of

required reports and notifications shall be sent to:

Illinois

Environmental Protection Agency

Division of Air Pollution

Control

Compliance Section (##40)

P .O. Box 19276

Springfield, Illinois 62794-9276

and

one (1) copy shall be sent to the Illinois

EPA's regional office at

the following address unless

otherwise indicated:

Illinois Environmental Protection

Agency

Division of Air Pollution

Control

2009 Mall Street

Collinsville, Illinois 62234

If you have any questions on this, please

call German

Barria at 217/782-2113.

Edwin C. Bakowski, P.E.

Acting Manager, Permit Section

Division of

Air Pollution Control

ECB:GB:jws

Date Signed:

0;ý"

CC: Illinois EPA, FOS Region 3

Lotus Notes

Electronic Filing - Received, Clerk's Office, March 3, 2008

* * * * * PCB 2008-048 * * * * *

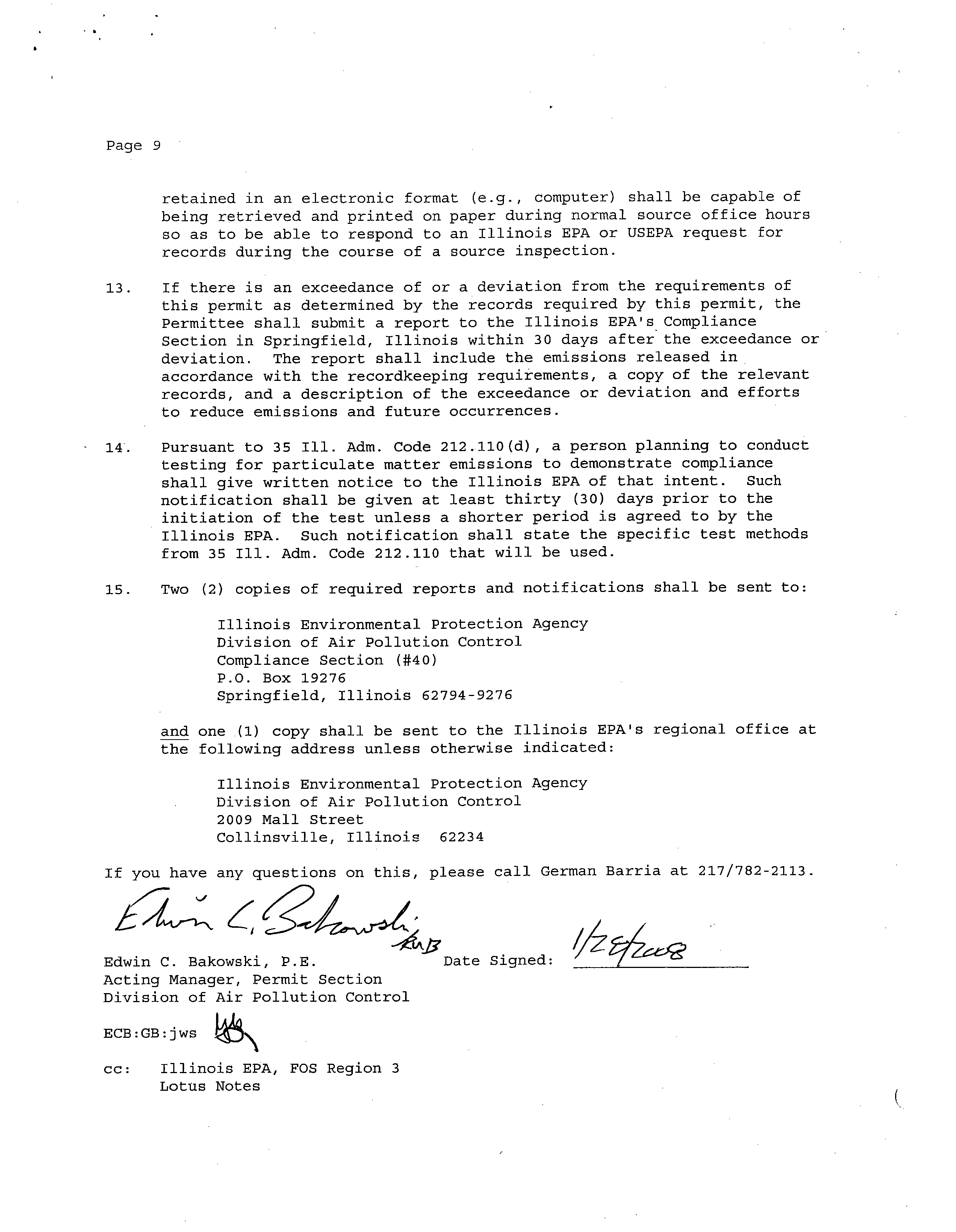

Attachment A - Emission Summary

This attachment provides a summary of the maximum emissions from ceramic

manufacturing operating

in compliance with

the requirements of this federally

enforceable permit. In preparing this summary, the Illinois EPA used the

annual operating scenario which results in maximum emissions from

such

a

plant. The resulting maximum emissions are well below the levels (e.g., 100

tons per year of Volatile Organic Material (VOM) 10 tons per year for a

single HAP, and 25 tons per

year for totaled HAP)

at which this source would

be considered a major source for

purposes

of the Clean Air Act Permit

Program. Actual emissions from this source will be less than predicted in

this summary to the

extent that less material

is handled, and control

measures are more effective

than required

in this permit.

E M I S S I O N S (Tons/Year)

S ingle Total

Emission Unit

CO

NO,,

PM

S02

VOM

HAP

HAPs

2 Wisconsin Ovens

(WO-1 and WO-2)

16.12

0.35

Mixer (M2)

0.32

23.13

Tube Dryer (TD2)*

0.32

14.89

Eirich Mixer (EM-1)

0.18

0.46

Tube Dryer (TD-3)

0.18

19.97

Purge Air Exhaust

Value (EV-1)

10.95

Bickley Kiln (BK-1)

8.45

1.31

2 Drayton Kilns (DK-1

& DK-2)

8.80

5.26

Keith Kiln (KK-1)

4.69

0.04

5 Furfural Storage

Tanks

2.64

2 Bag Break Stations

0.44

2 Barrel Tilters

0.44

Batch Conveyor

0.22

Belt Sander

0.22

Big Blender

0.22

Classifier/Hammermill

0.22

2 Collector Blenders

0.44

Despatch Oven Glaze

Mixer

0.22 '

5 Grinding Stations

1.10

Holding Bin

0.22

8 Holding Hoppers

1.76

4 Scale Hoppers

0.88

Small

Blender

0.22

18 Tote Bins

3.96

Small Weighment

F illing Station

0.22

5 Bulk Bag Stations

1.10

Pneumatic Transporter

0.22

Feedback Station

0.22

Electronic Filing - Received, Clerk's Office, March 3, 2008

* * * * * PCB 2008-048 * * * * *

E M I S S I O N S (Tons/Year)

S ingle

Total

Emission Unit

CO

N_Ox

_PM

_so,

VOM

HAP

HAPs

15 Bulk

Bagging

S tations

3.30

9 Econolift Elevators

1.98

Small

Weighment

Station

0.22

Traveling Skip

0.22

Carrier Conveyor

0.22

Classifier

0.22

3

Mold Presses

0.66

2 Hammermills

0.44

Fuel Combustion

42.00 50.00

3.80 0.30

2.75

_----

Totals

42.00 50.00 62.44 0.30

81.75

9.0

22.5

GB: jws

Electronic Filing - Received, Clerk's Office, March 3, 2008

* * * * * PCB 2008-048 * * * * *

STATE OF ILLINOIS

ENVIRONMENTAL PROTECTION AGENCY

DIVISION

OF AIR POLLUTION CONTROL

P.O. BOX 19506

SPRINGFIELD, ILLINOIS 62794-9506

S TANDARD CONDITIONS

FOR

OPERATING PERMITS

May, 1993

The Illinois Environmental Protection Act (Illinois Revised Statutes, Chapter 111-1/2,

Section

1039) grants the Environmental Protection Agency authority to impose conditions on permits

which it

issues.

The following

conditions

are

applicable

unless superseded

by special permit conditions(s).

1. The issuance of this permit does not release the Permittee from

compliance with state

federal regulations which are part of the Illinois State Implementation

Plan, as well as

other applicable statues and regulations of the United States

or the State of Illinois or

applicable local laws, ordinances and regulations.

2.

and

with

with

The Illinois EPA has issued this permit based upon the information

submitted by the Permittee