Worldwide Engineering , Environmental , Construction , and IT Services

Revision 1

Certain figures in this Report contain sensitive, security-

related information protected from public disclosure by

Federal and State law. This Report is suitable for

public disclosure only after these figures are removed.

HYDROGEOLOGIC INVESTIGATION REPORT

FLEETWIDE ASSESSMENT

ZION STATION

ZION, ILLINOIS

Prepared For:

Exelon Generation Company, LLC

DISCLAIMER:

SOME FORMATTING CHANGES MAY HAVE OCCURRED WHEN

THE ORIGINAL DOCUMENT WAS PRINTED TO PDF; HOWEVER,

THE ORIGINAL CONTENT REMAINS UNCHANGED.

SEPTEMBER 2006

R

EF. NO. 045136 (22)

Prepared by:

Conestoga-Rovers

& Associates

651 Colby Drive

Waterloo, Ontario

Canada N2V 1C2

Office: (519) 884-0510

Fax:

(519) 884-0525

web: http:\\www.CRAworld.com

Revision 1

TABLE OF CONTENTS

Page

EXECUTIVE SUMMARY.................................................................................................................... i

1.0

INTRODUCTION ...................................................................................................................1

2.0

STATION DESCRIPTION .....................................................................................................2

2.1

STATION LOCATION .......................................................................................2

2.2

OVERVIEW OF COOLING WATER OPERATIONS.....................................2

2.3

SURROUNDING LAND USE ...........................................................................4

2.4

STATION SETTING............................................................................................5

2.4.1

TOPOGRAPHY AND SURFACE WATER FEATURES.................................5

2.4.2

GEOLOGY............................................................................................................6

2.4.3

HYDROGEOLOGY .............................................................................................7

2.5

AREA GROUNDWATER USE..........................................................................8

3.0

AREAS FOR FURTHER EVALUATION.............................................................................9

3.1

SYSTEMS EVALUATIONS................................................................................9

3.2

HISTORICAL RELEASES ................................................................................12

3.3

STATION INVESTIGATIONS.........................................................................12

3.3.1

PRE-OPERATIONAL RADIOLOGICAL

ENVIRONMENTAL MONITORING PROGRAM .......................................12

3.3.2

RADIOLOGICAL ENVIRONMENTAL MONITORING PROGRAM ......13

3.3.3

DEFUELED SAFETY ANALYSIS REPORT...................................................14

3.3.4

WISCONSIN DEPARTMENT OF HEALTH AND

FAMILY SERVICES MONITORING ..............................................................15

3.4

IDENTIFIED AREAS FOR FURTHER EVALUATION ...............................15

4.0

FIELD METHODS.................................................................................................................18

4.1

STAFF GAUGE INSTALLATION...................................................................18

4.2

GROUNDWATER MONITORING WELL INSTALLATION.....................18

4.3

GROUNDWATER MONITORING WELL DEVELOPMENT ....................20

4.4

SURVEY ..............................................................................................................21

4.5

GROUNDWATER AND SURFACE WATER

ELEVATION MEASUREMENTS....................................................................21

4.6

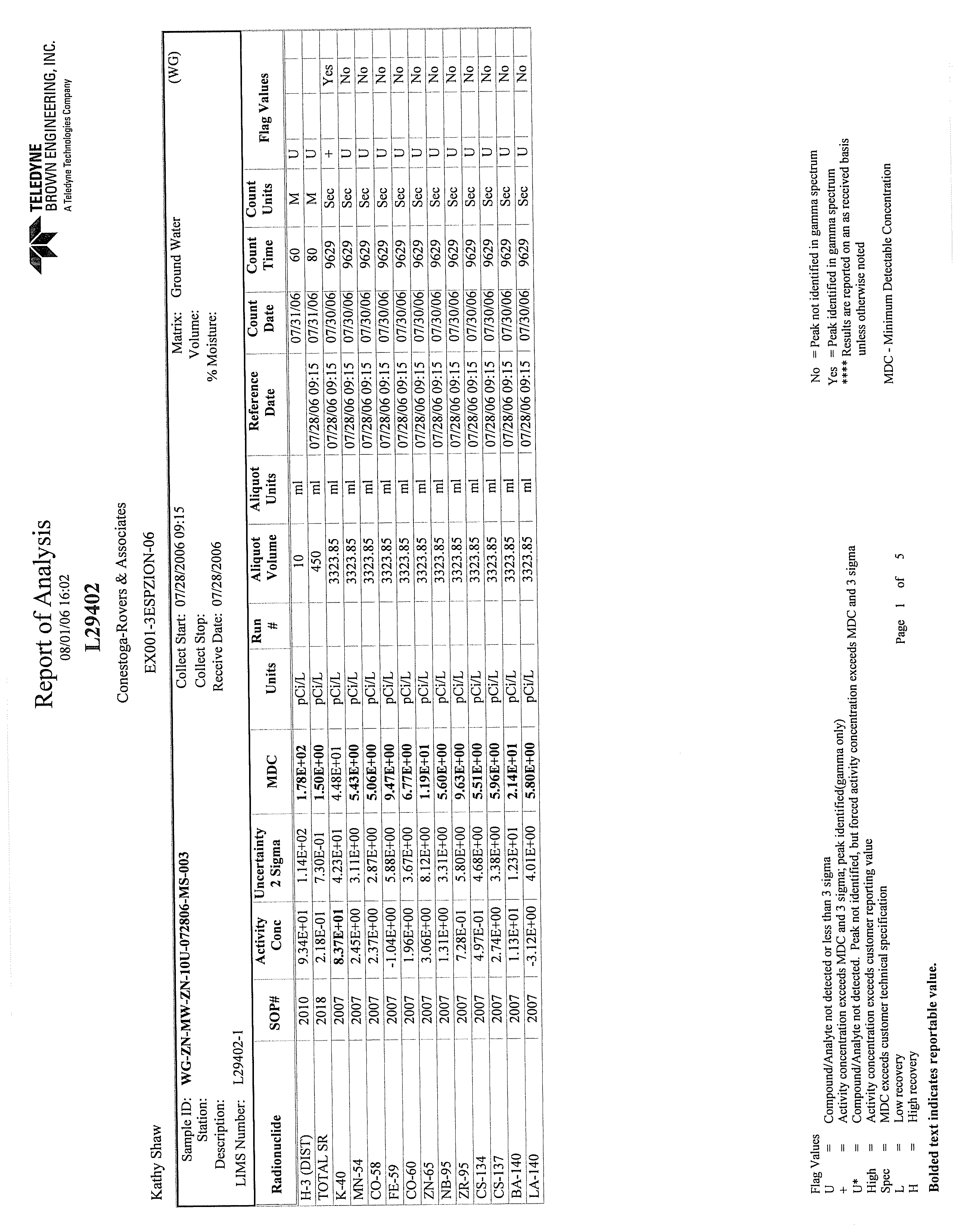

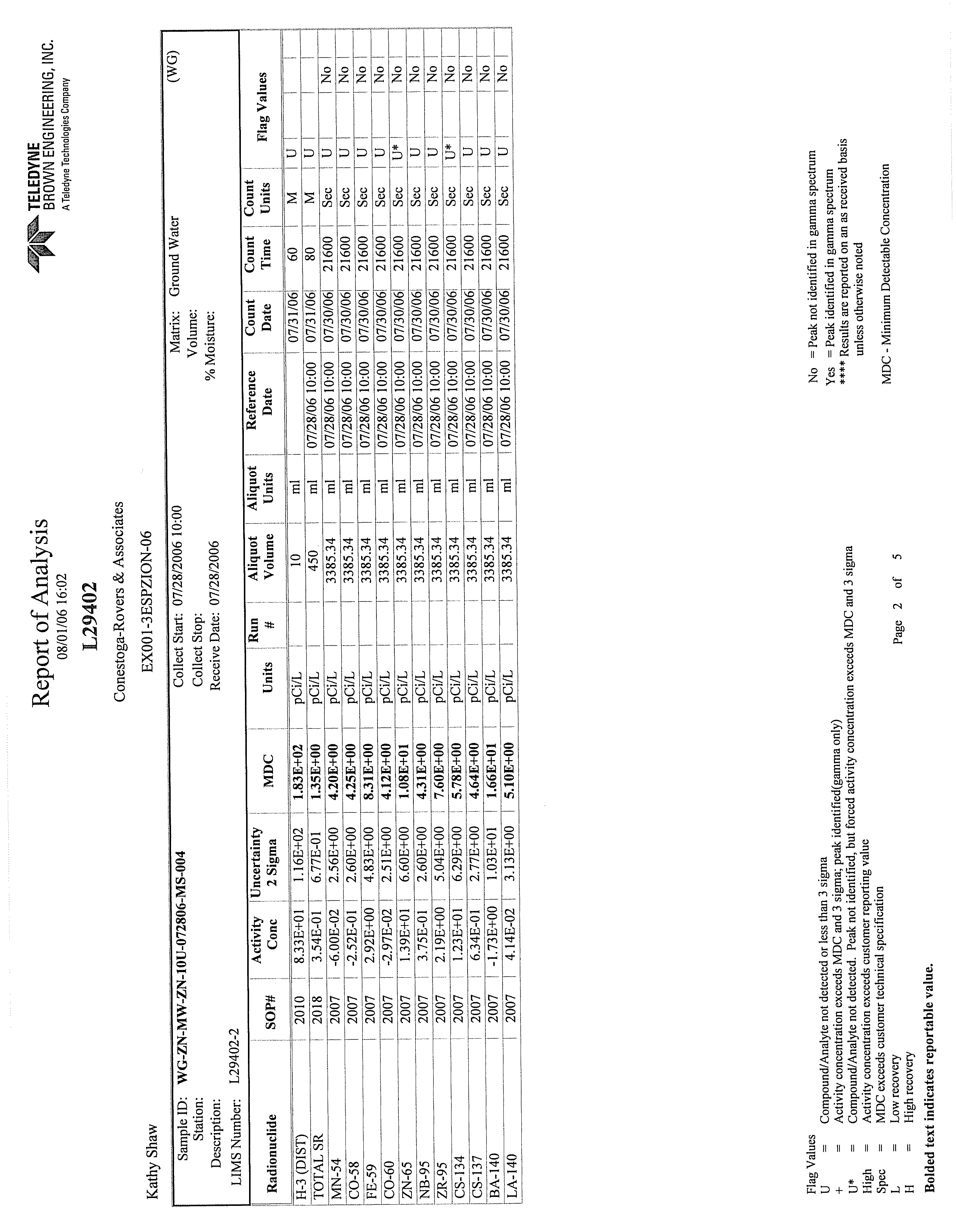

GROUNDWATER AND SURFACE WATER SAMPLE COLLECTION...22

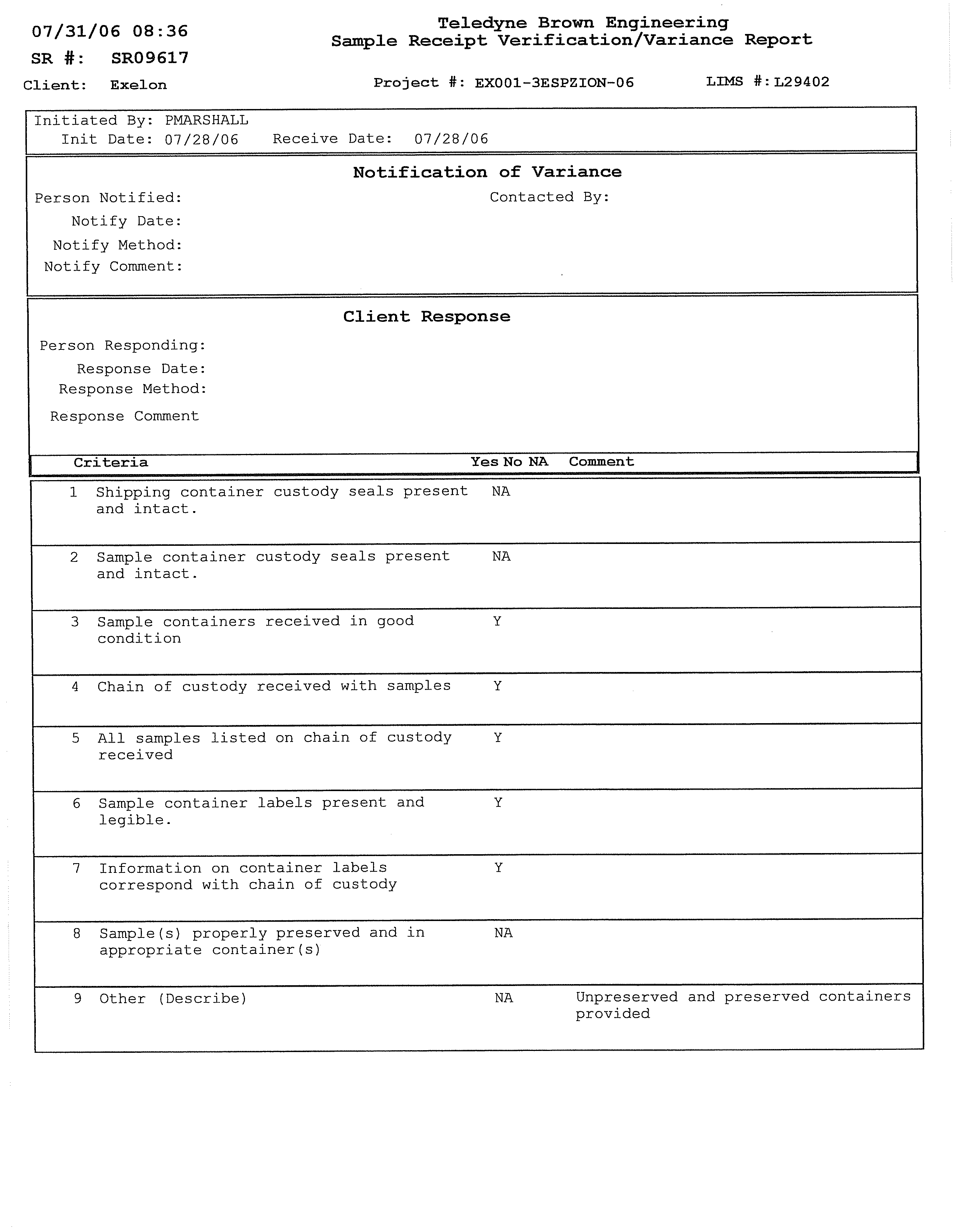

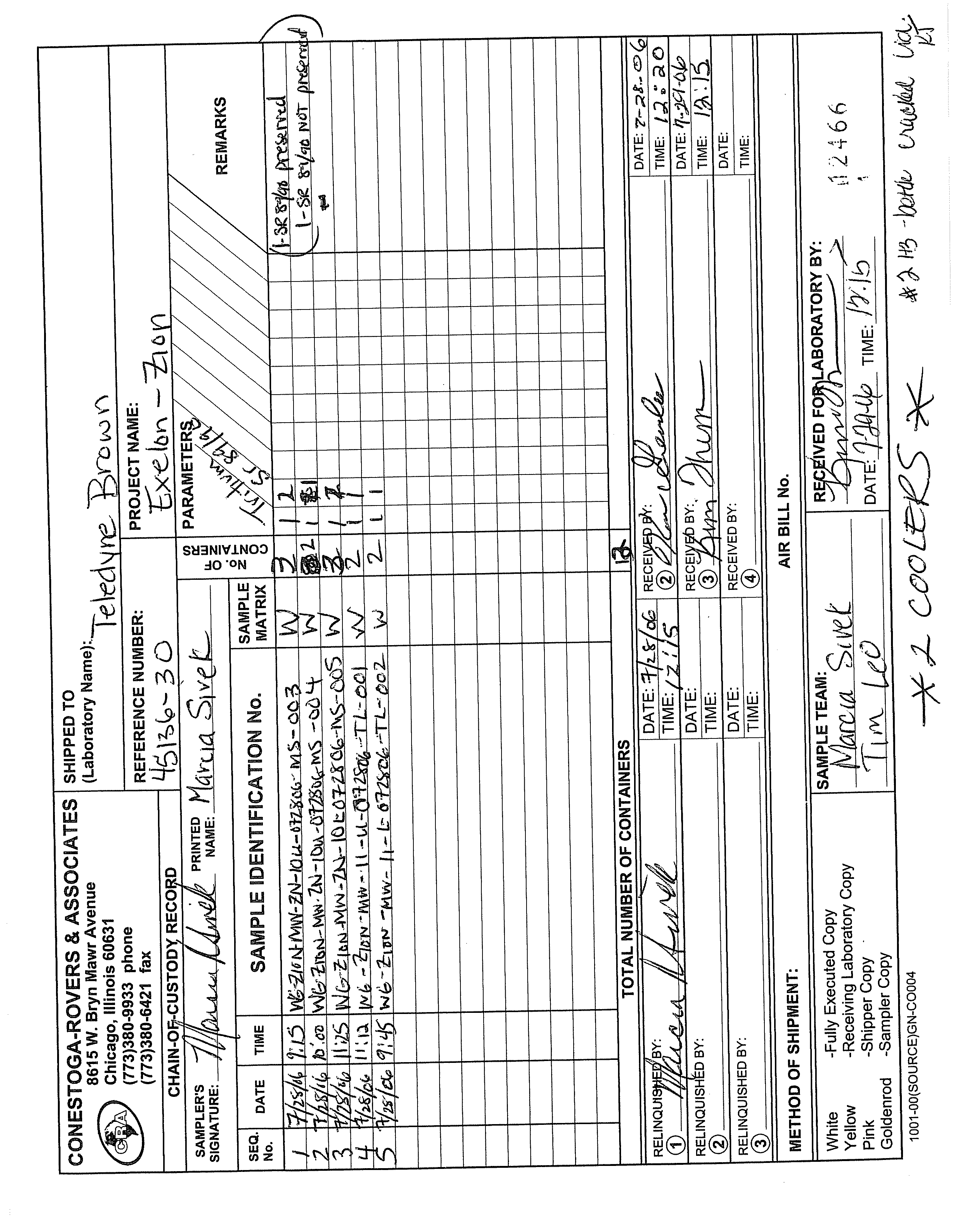

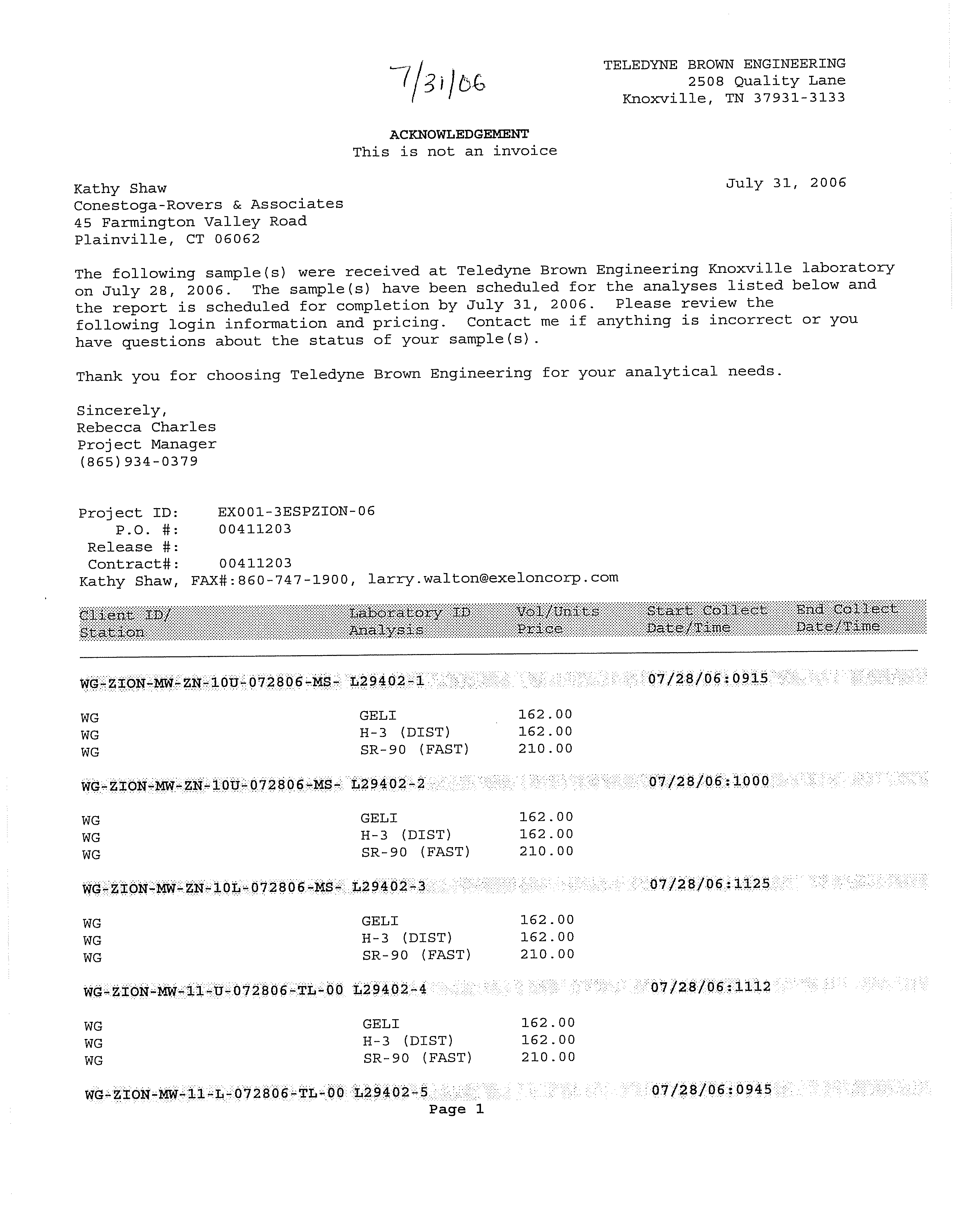

4.7

DATA QUALITY OBJECTIVES.......................................................................24

4.8

SAMPLE IDENTIFICATION...........................................................................25

4.9

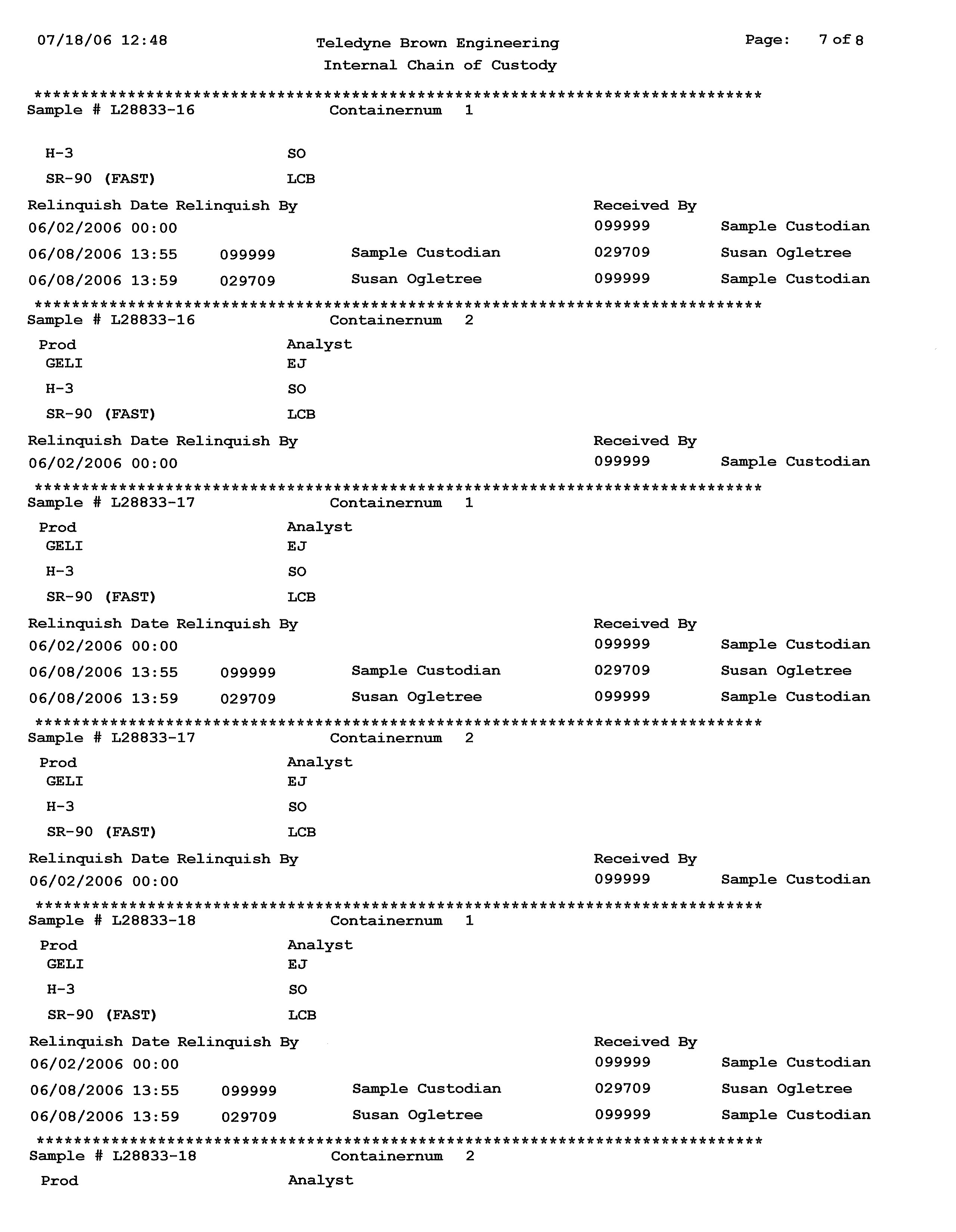

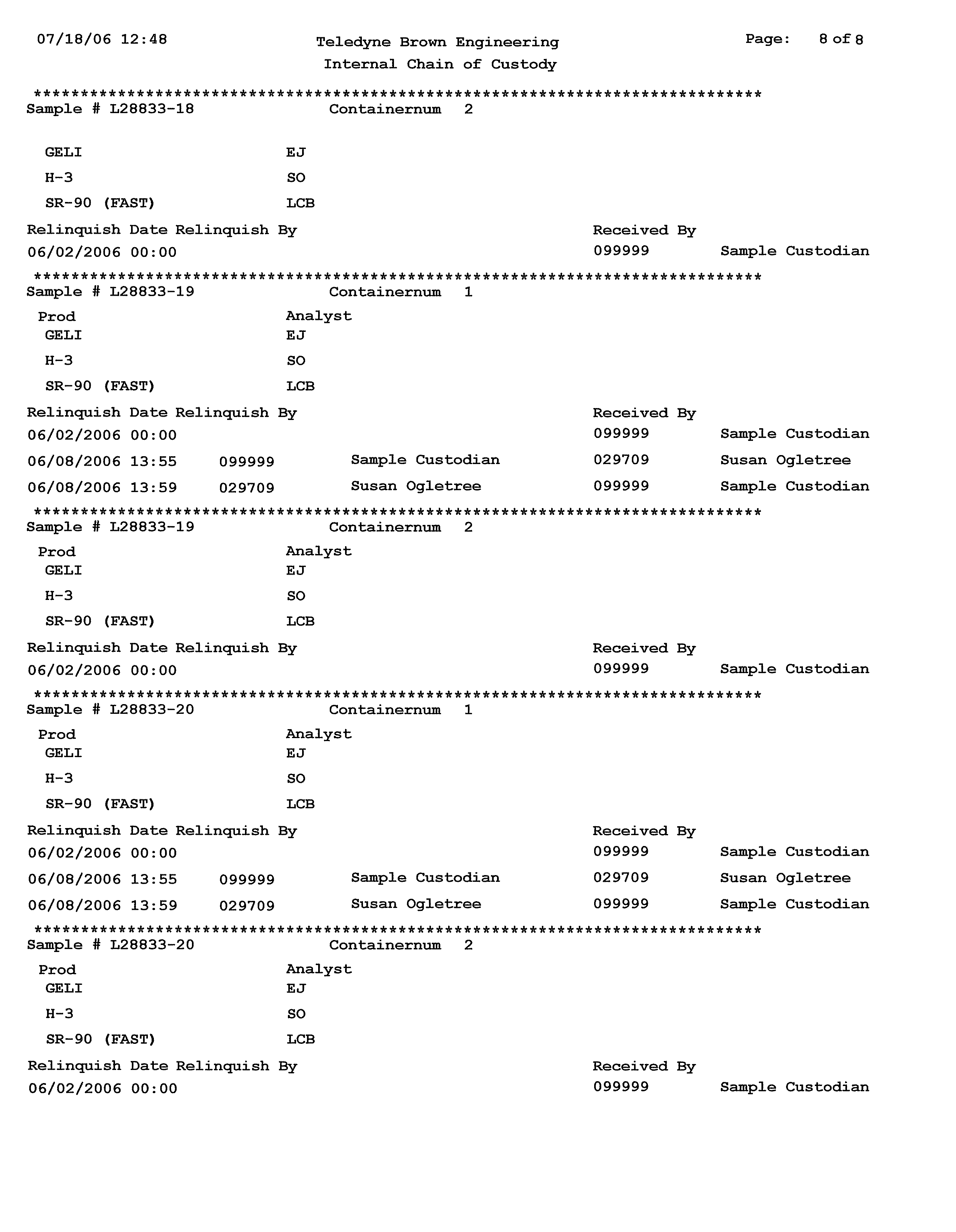

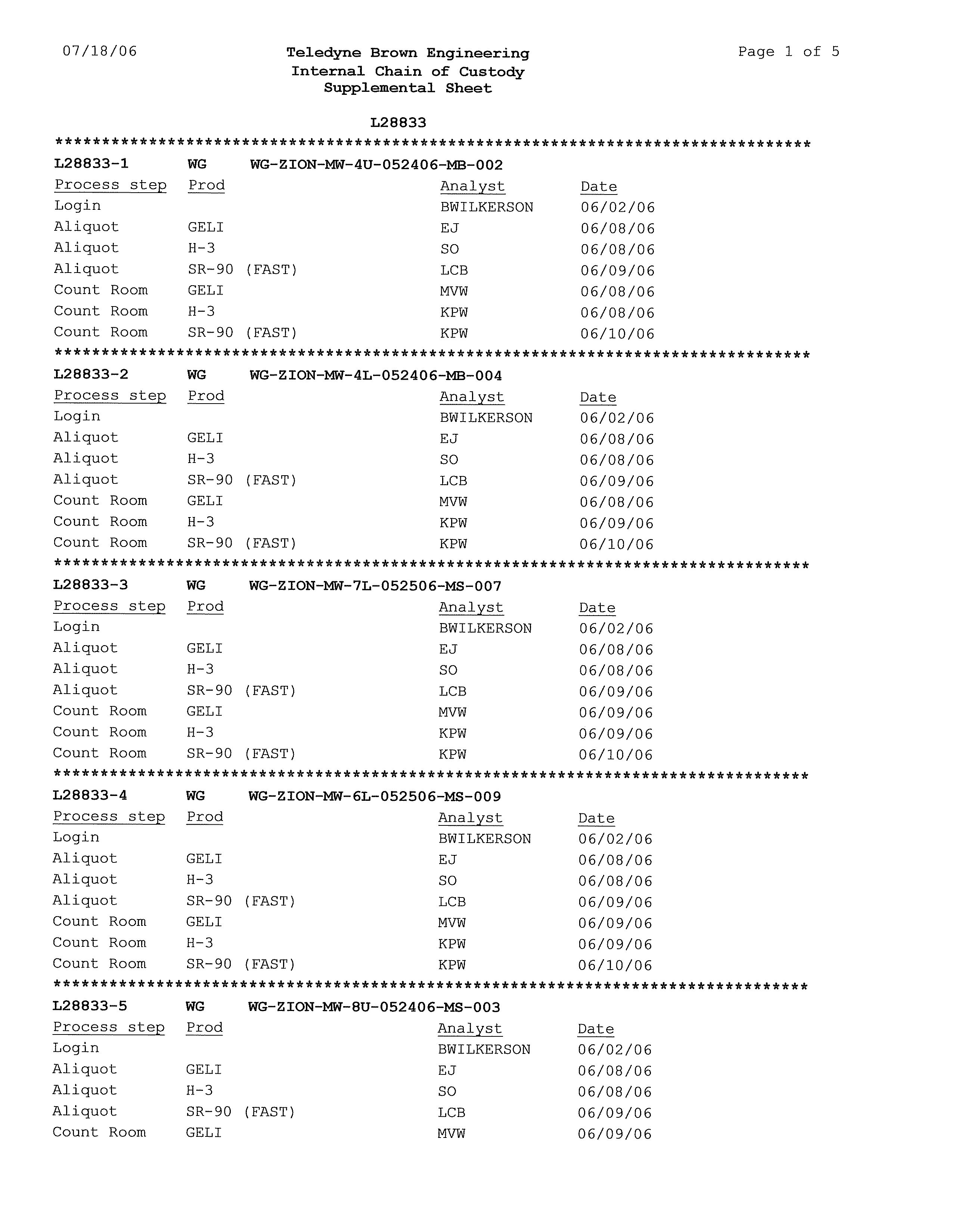

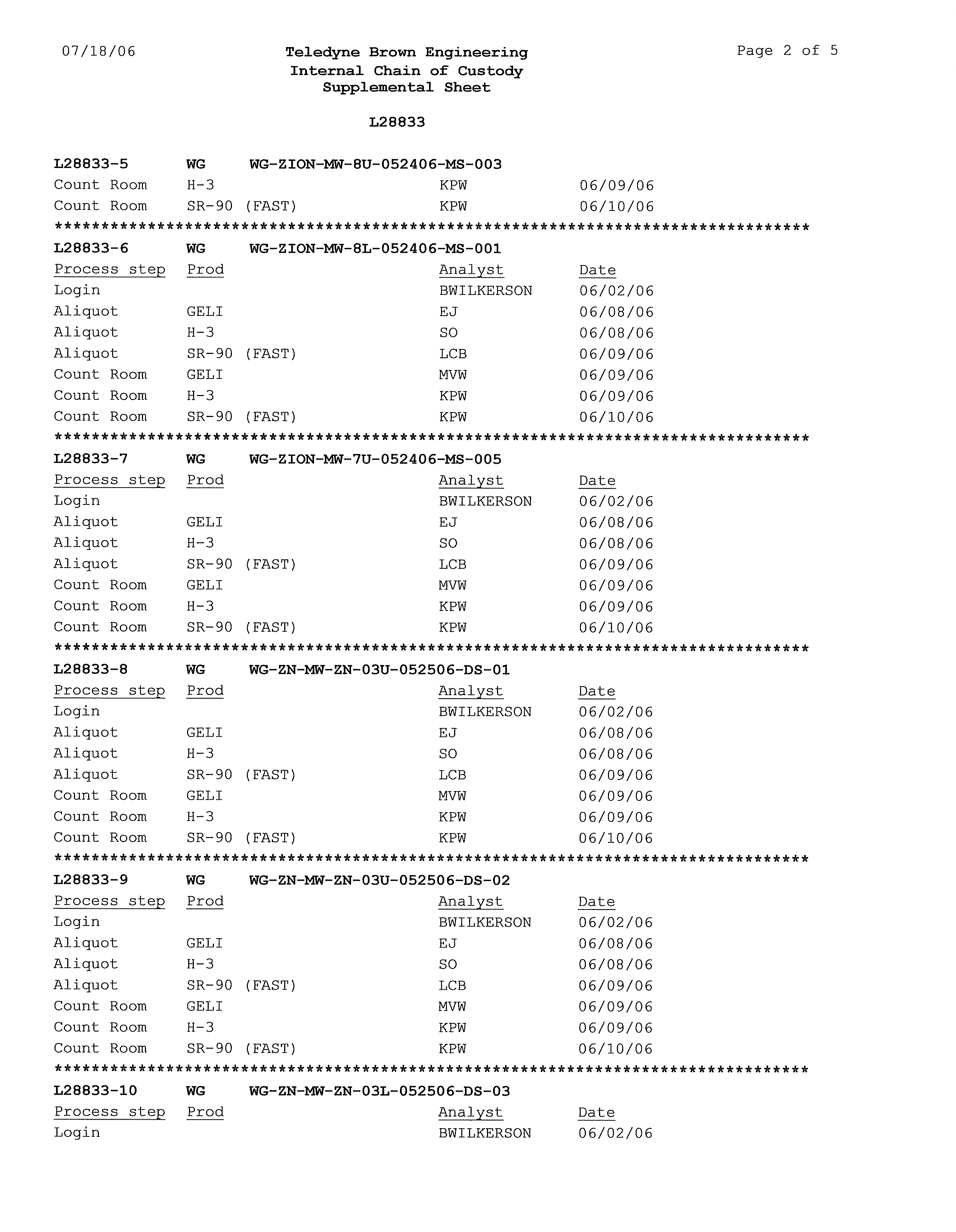

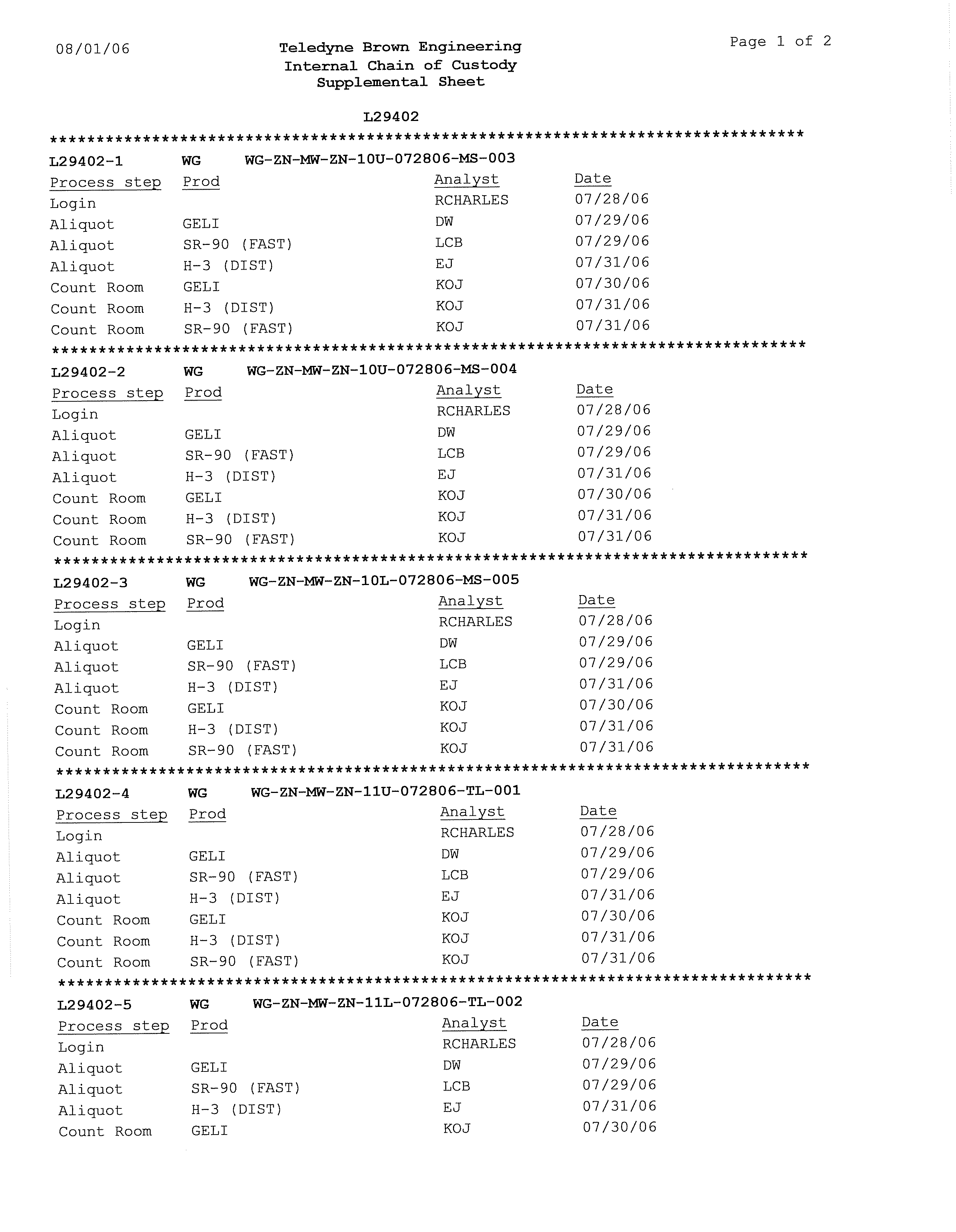

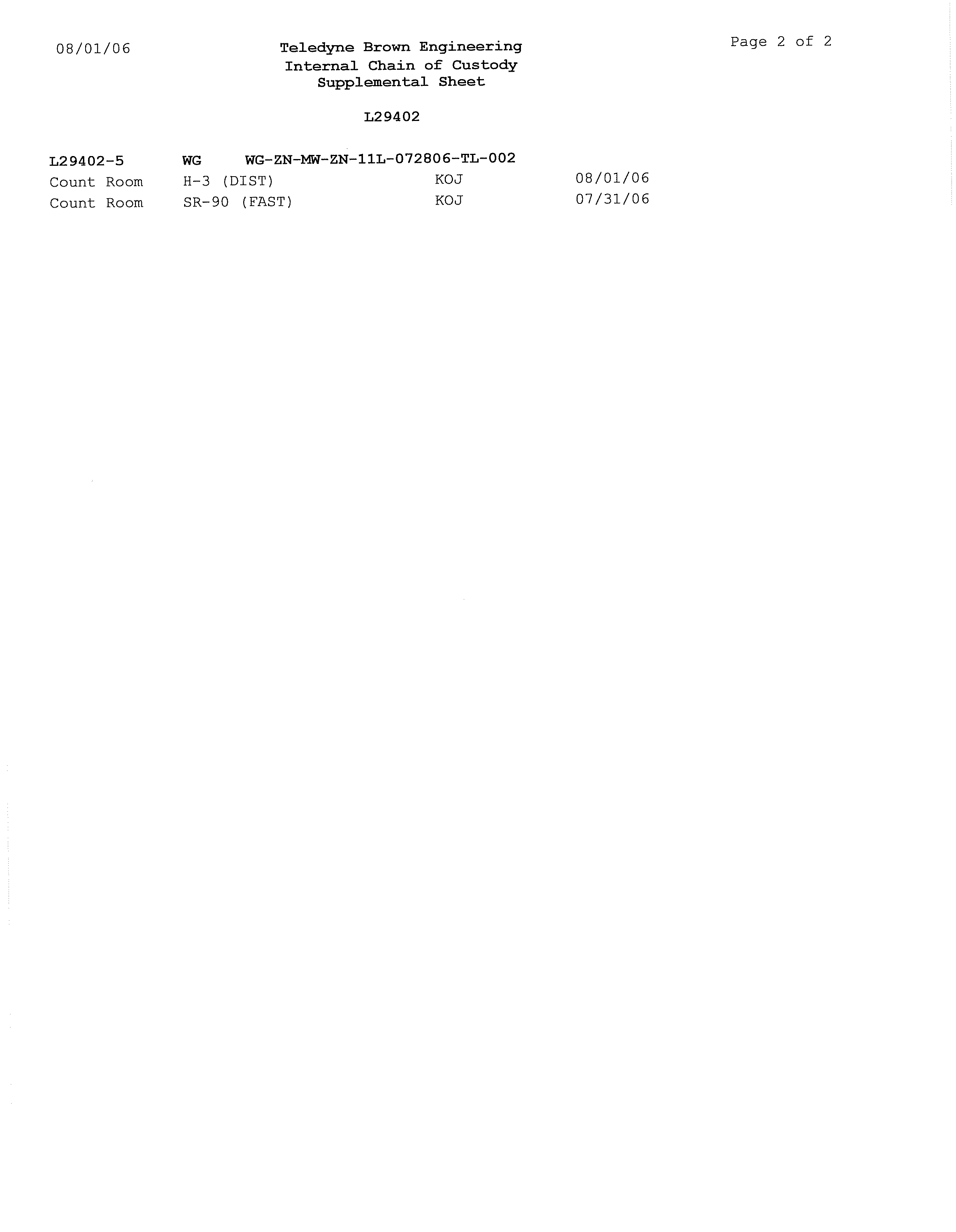

CHAIN-OF-CUSTODY RECORD...................................................................25

4.10

QUALITY CONTROL SAMPLES ...................................................................26

4.11

ANALYSES.........................................................................................................26

045136 (22) Zion Station

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

TABLE OF CONTENTS

Page

5.0

RESULTS SUMMARY..........................................................................................................27

5.1

STATION GEOLOGY .......................................................................................27

5.2

STATION HYDROGEOLOGY ........................................................................29

5.2.1

GROUNDWATER FLOW DIRECTIONS ......................................................29

5.2.2

MAN-MADE INFLUENCES ON GROUNDWATER FLOW .....................29

5.2.3

VERTICAL HYDRAULIC GRADIENTS........................................................30

5.2.4

LATERAL GROUNDWATER FLOW AND VELOCITY.............................30

5.3

GROUNDWATER QUALITY..........................................................................31

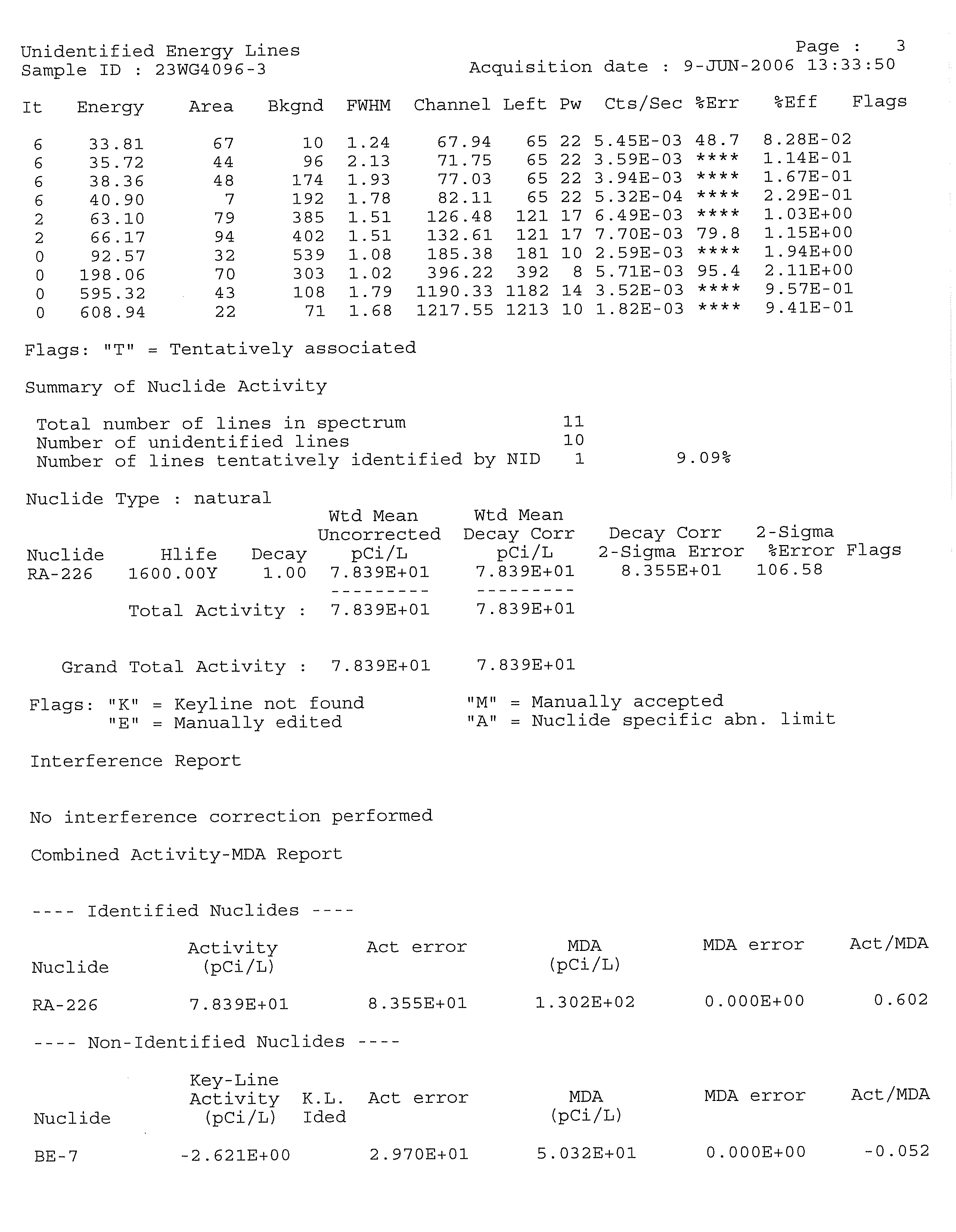

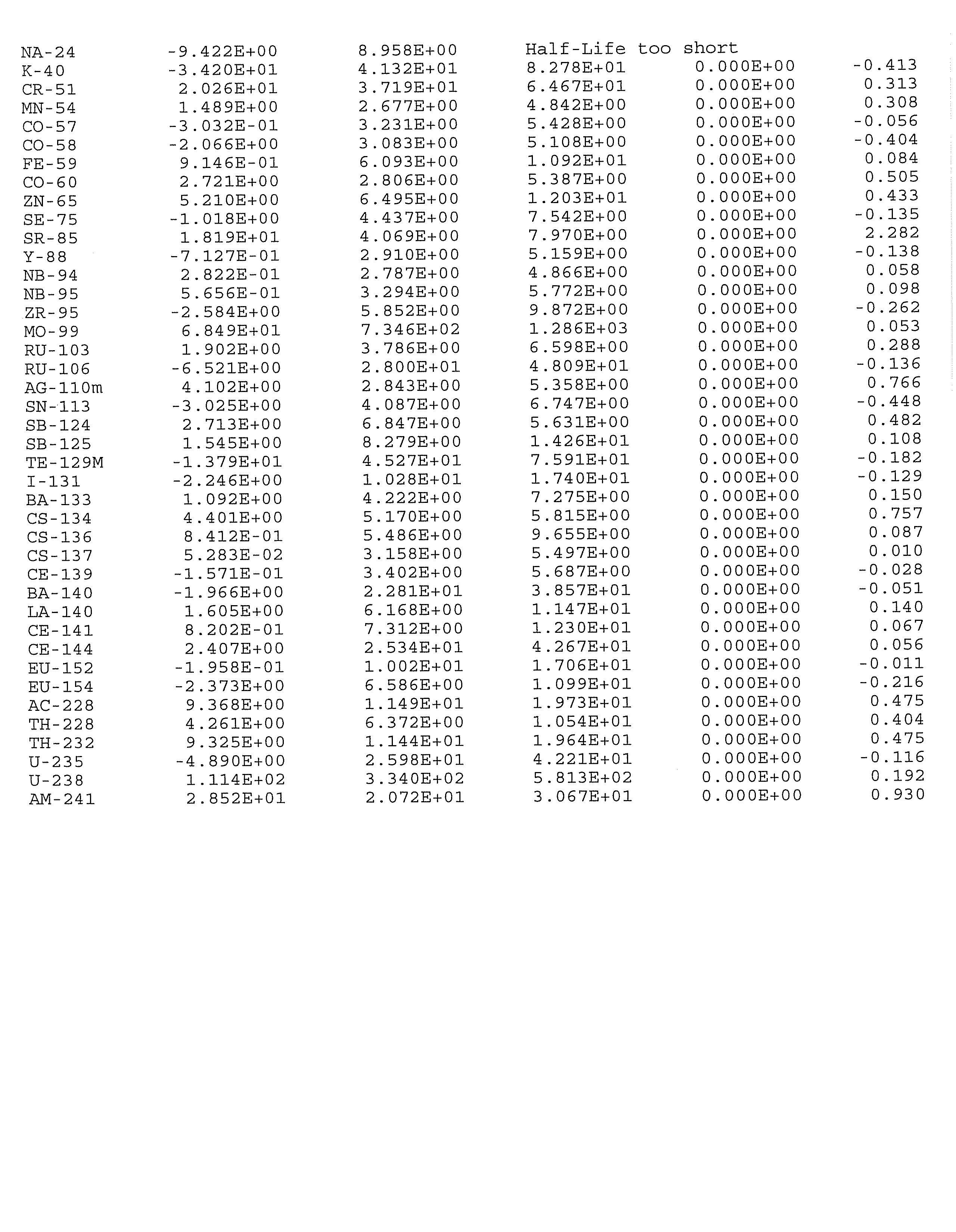

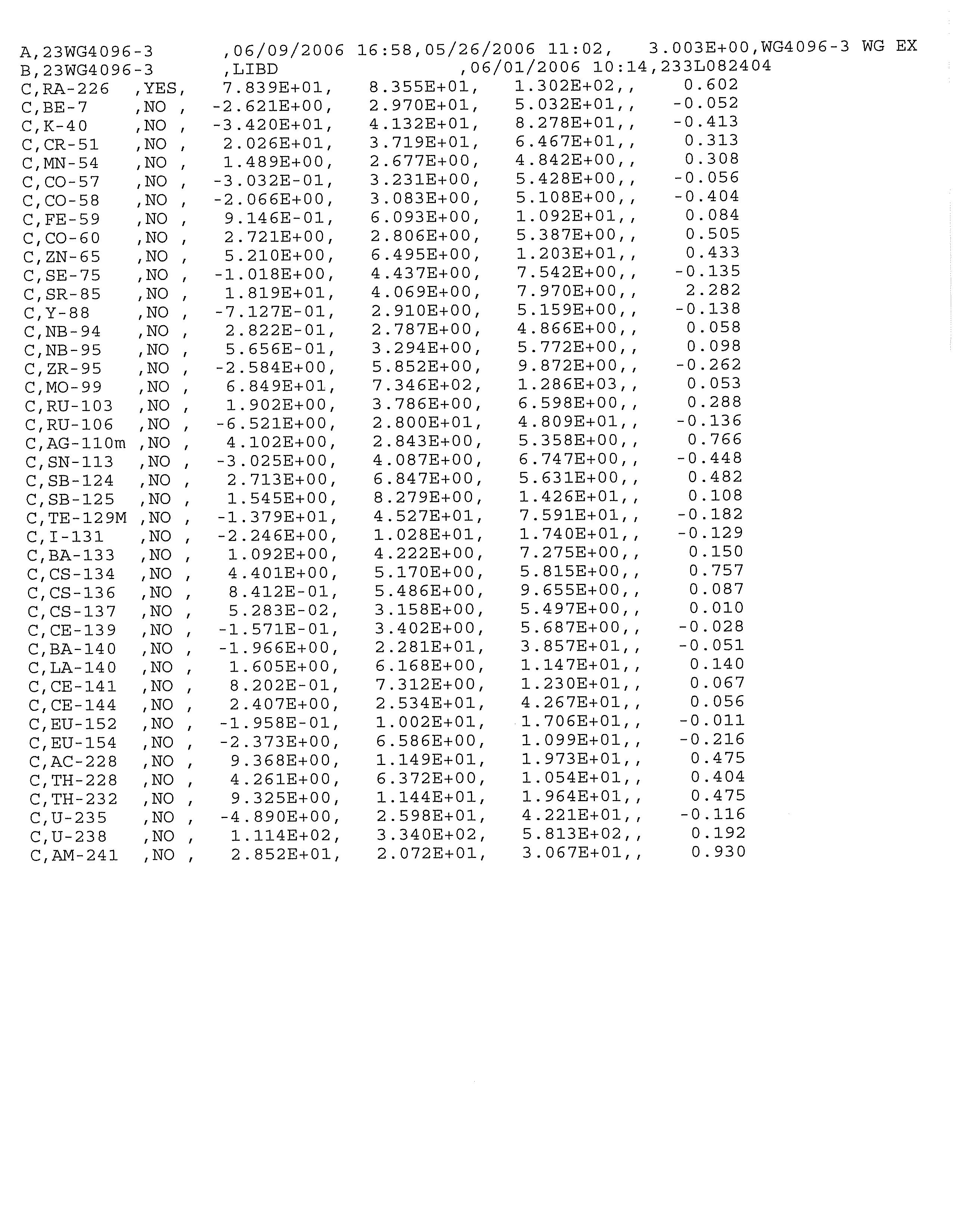

5.3.1

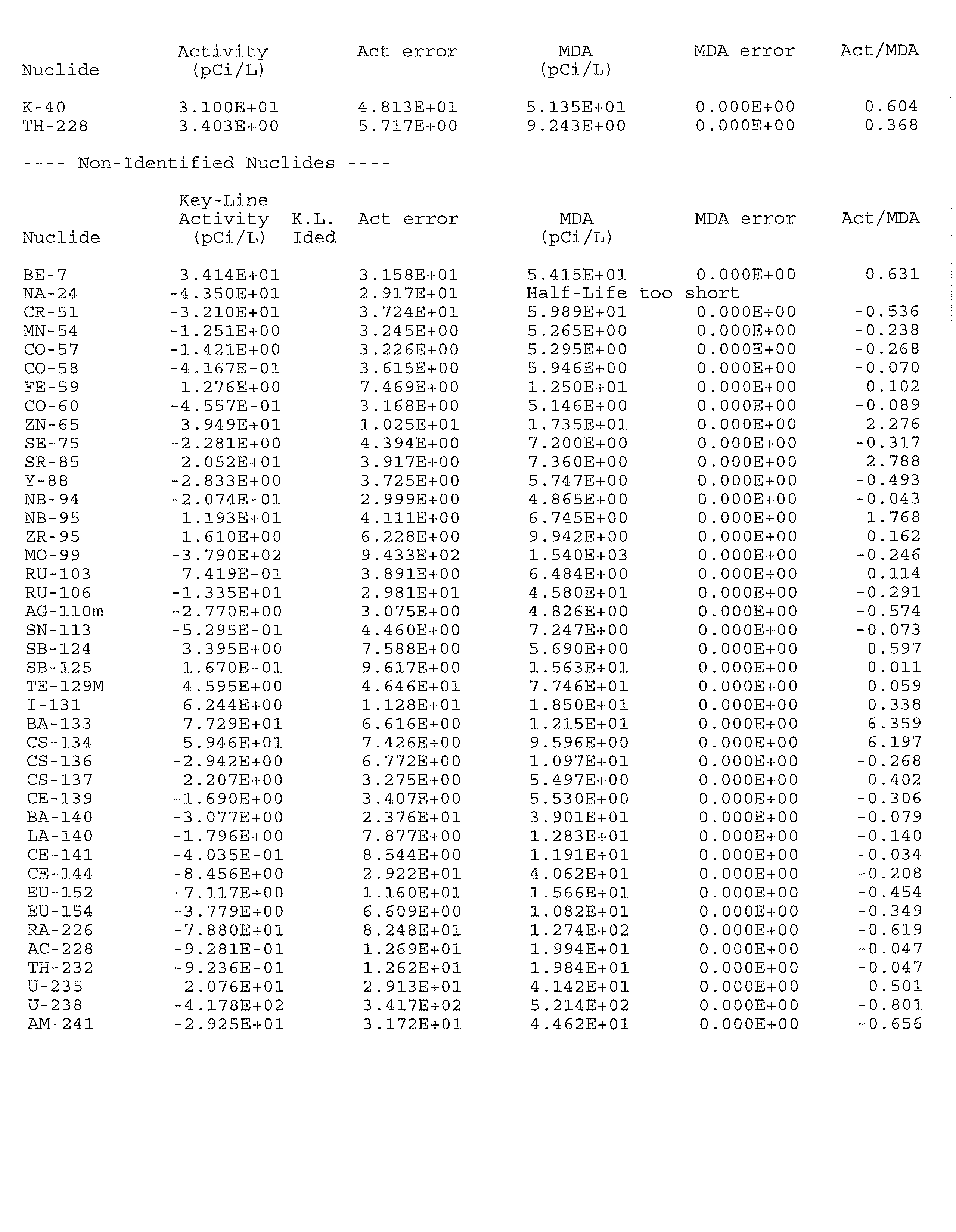

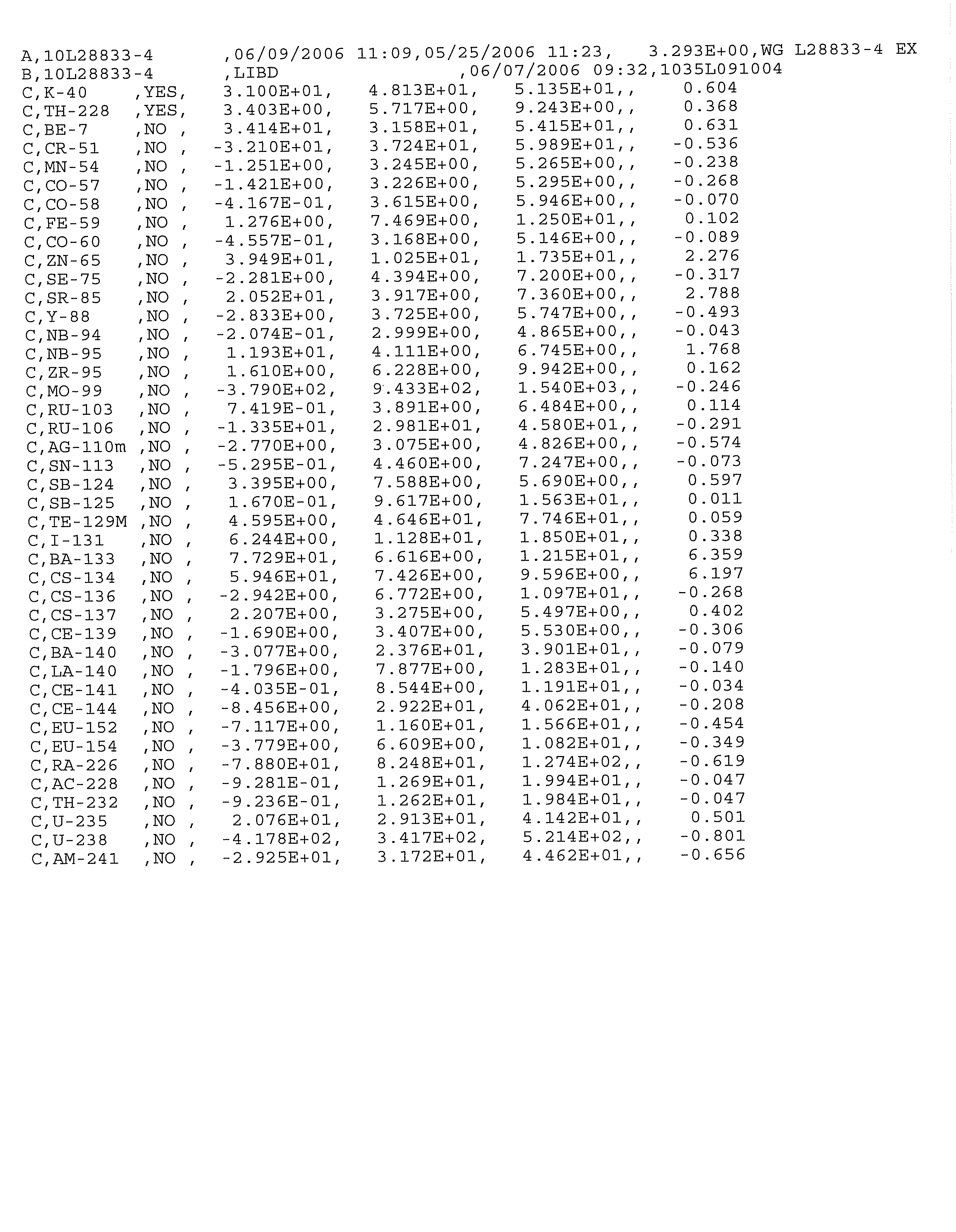

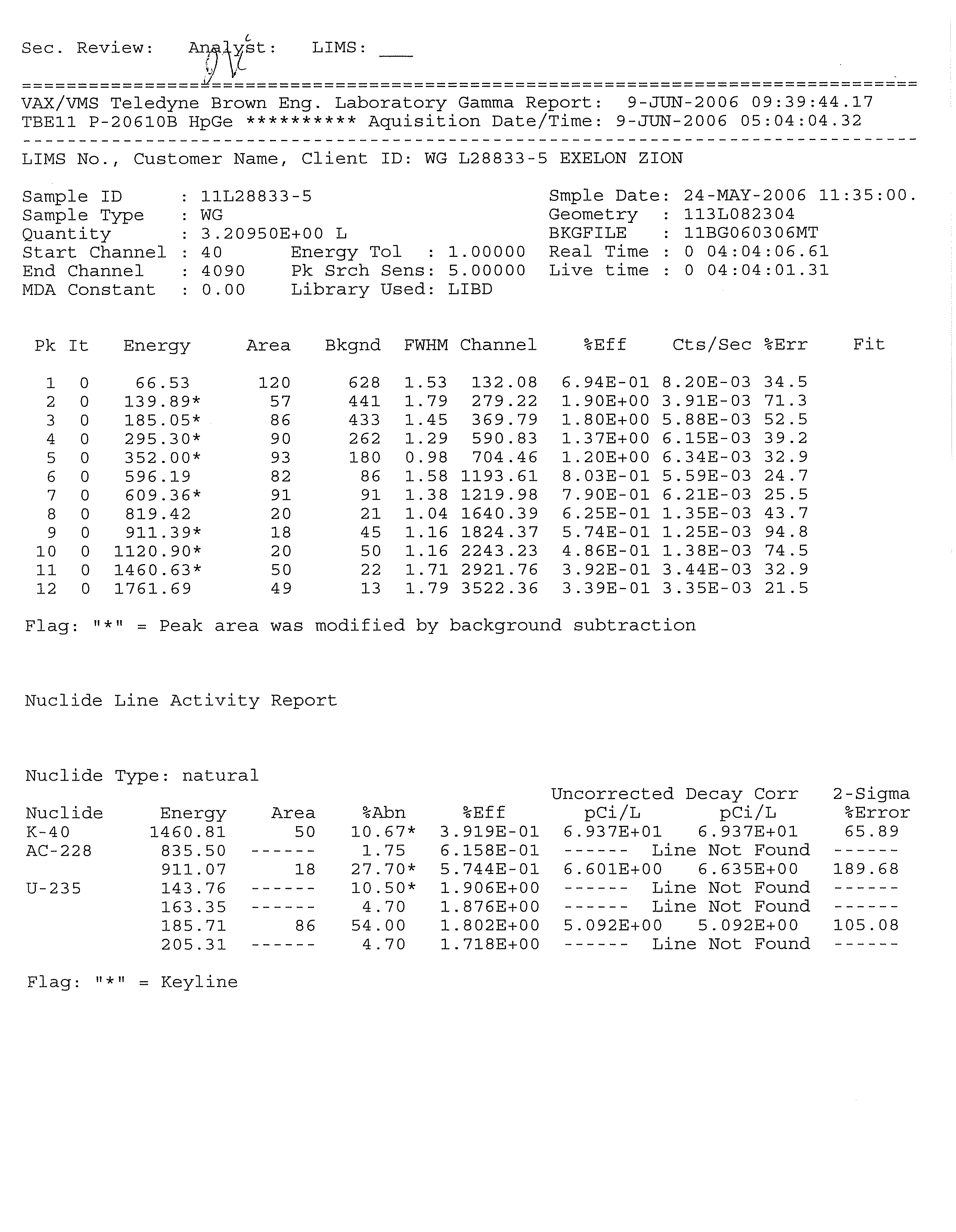

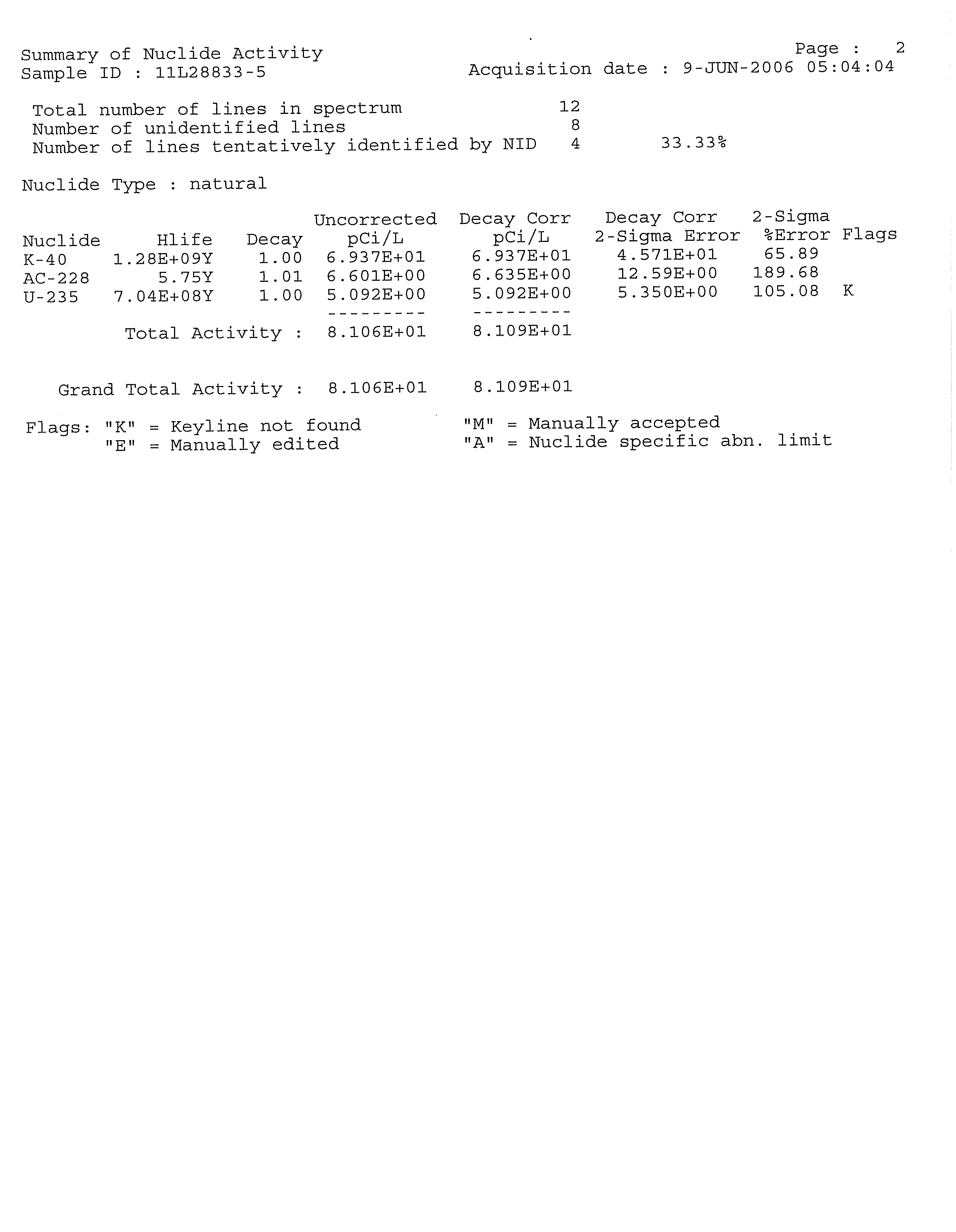

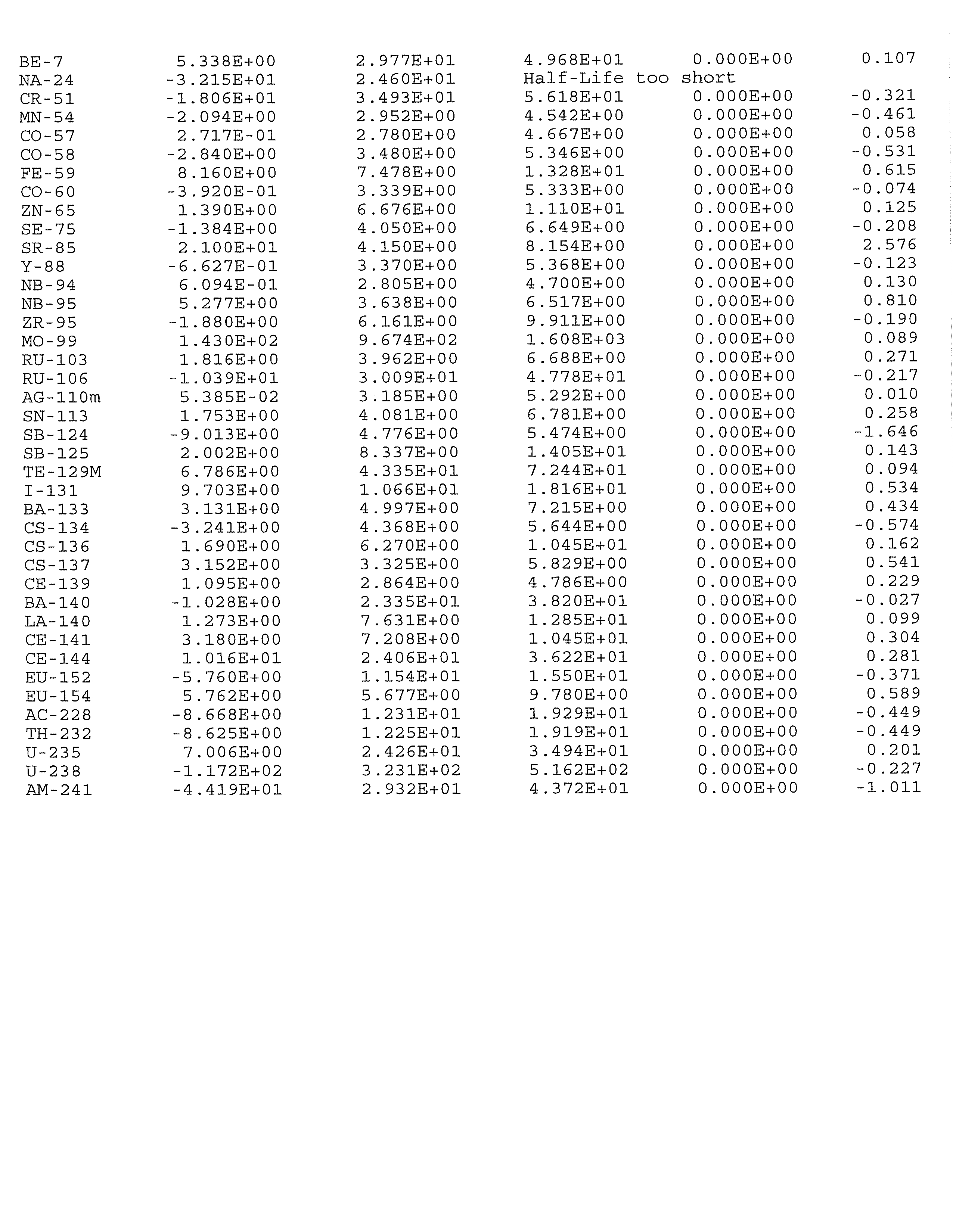

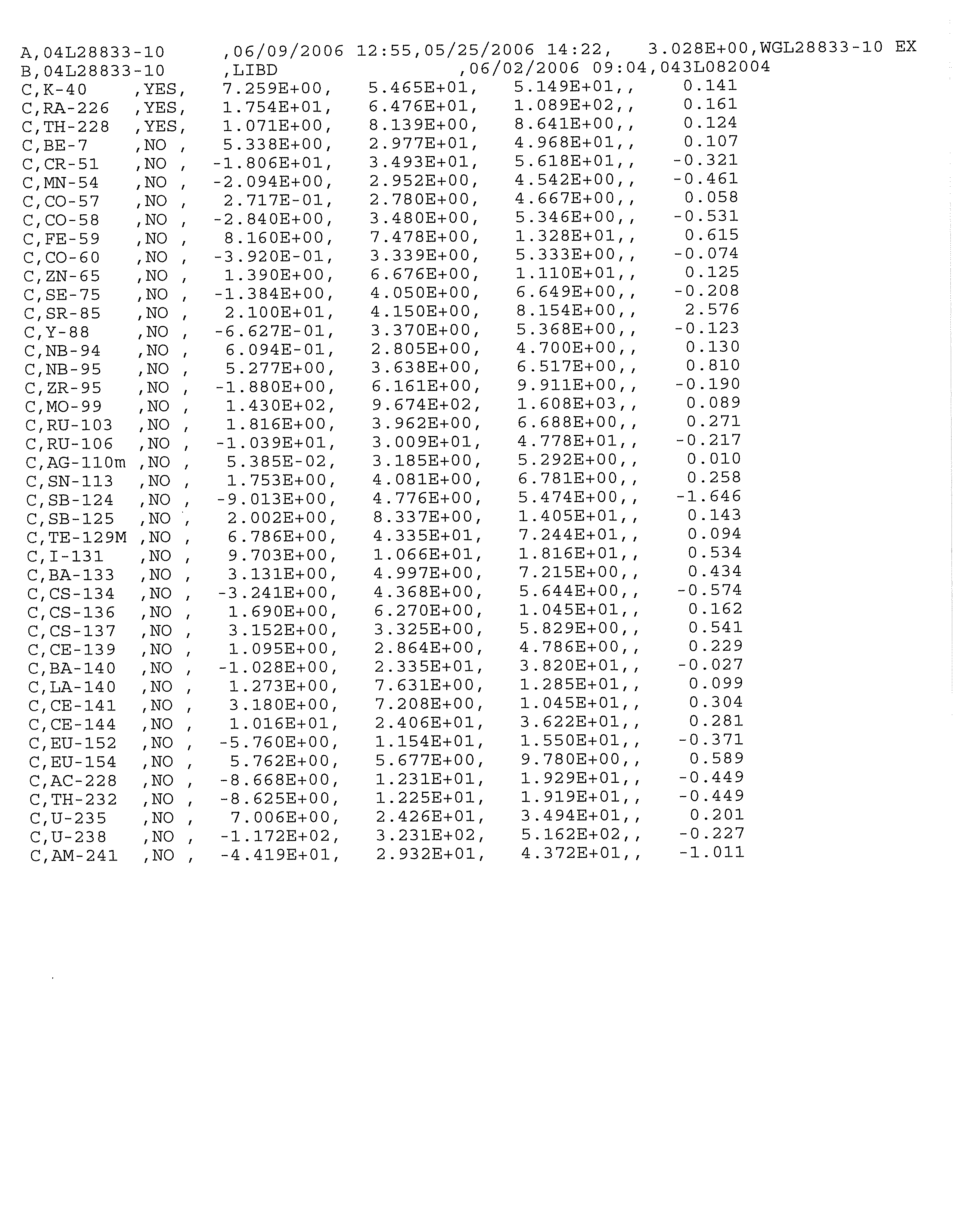

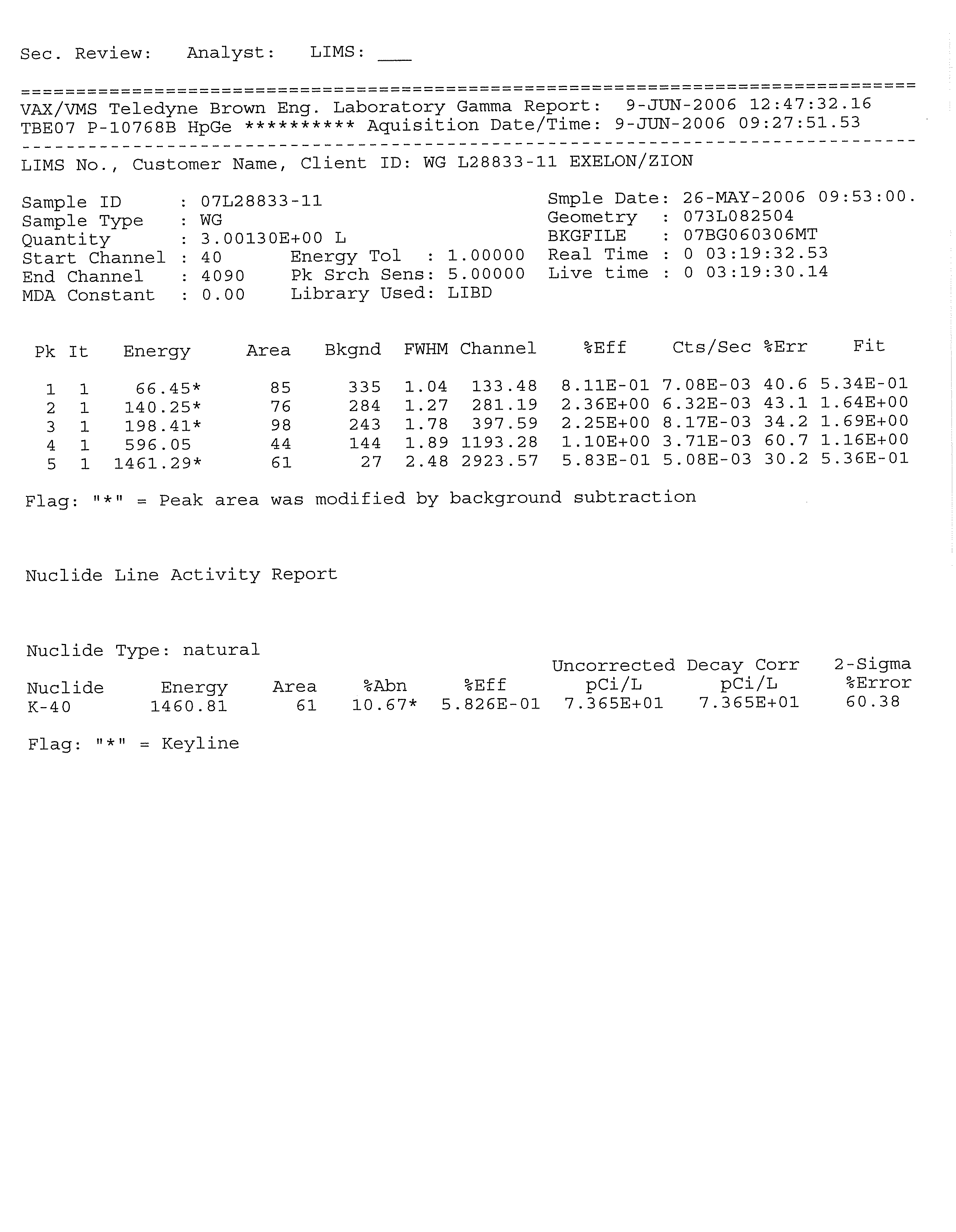

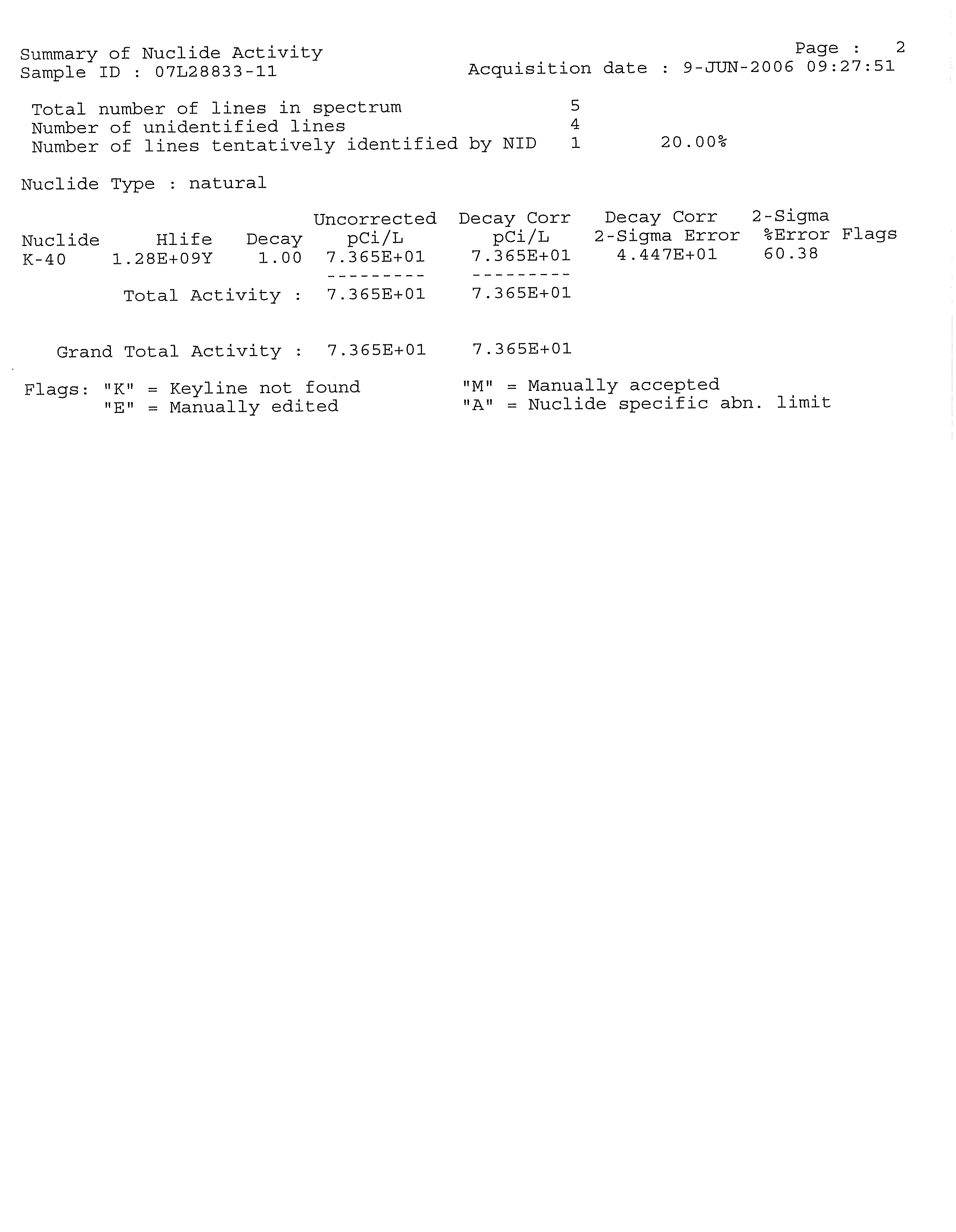

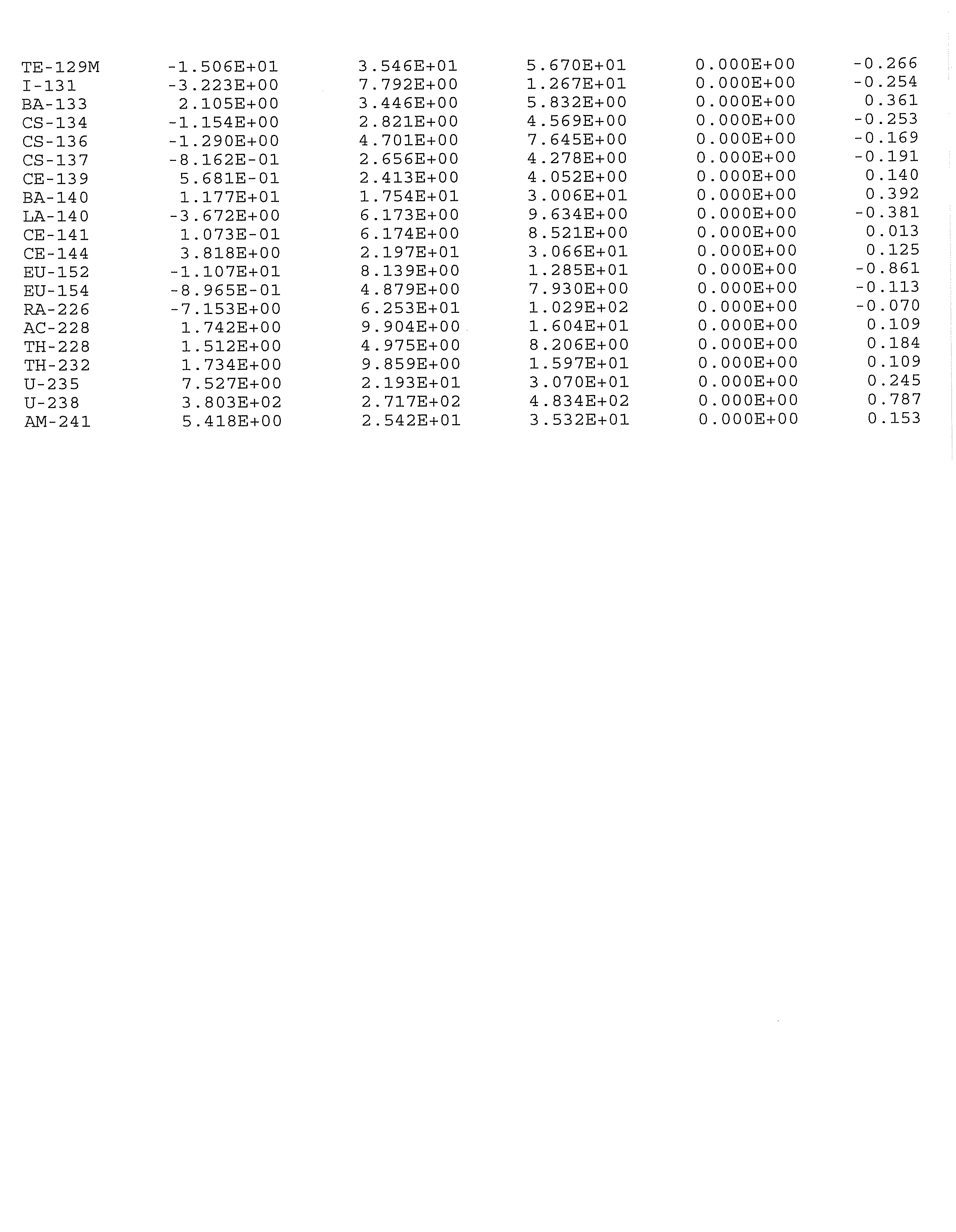

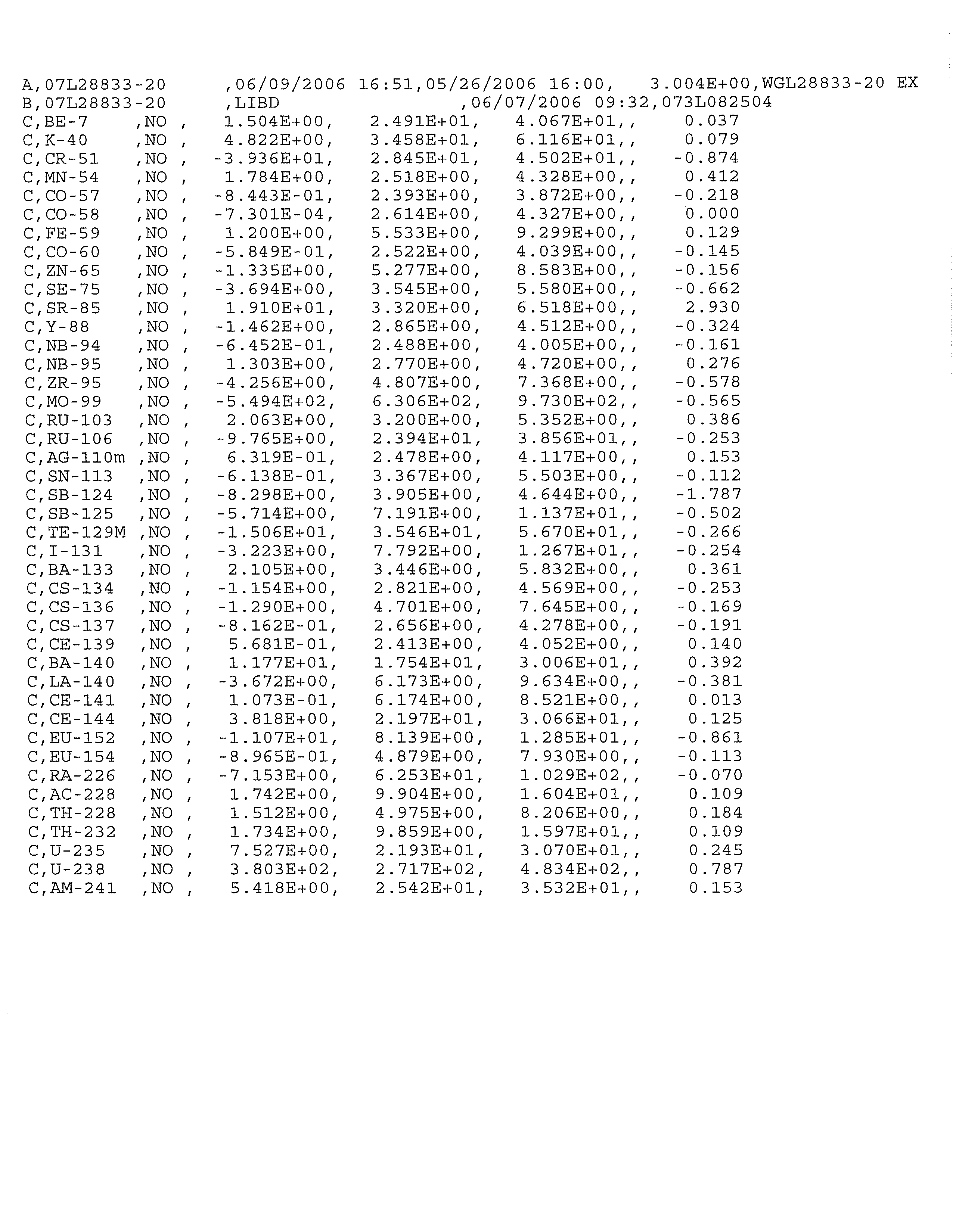

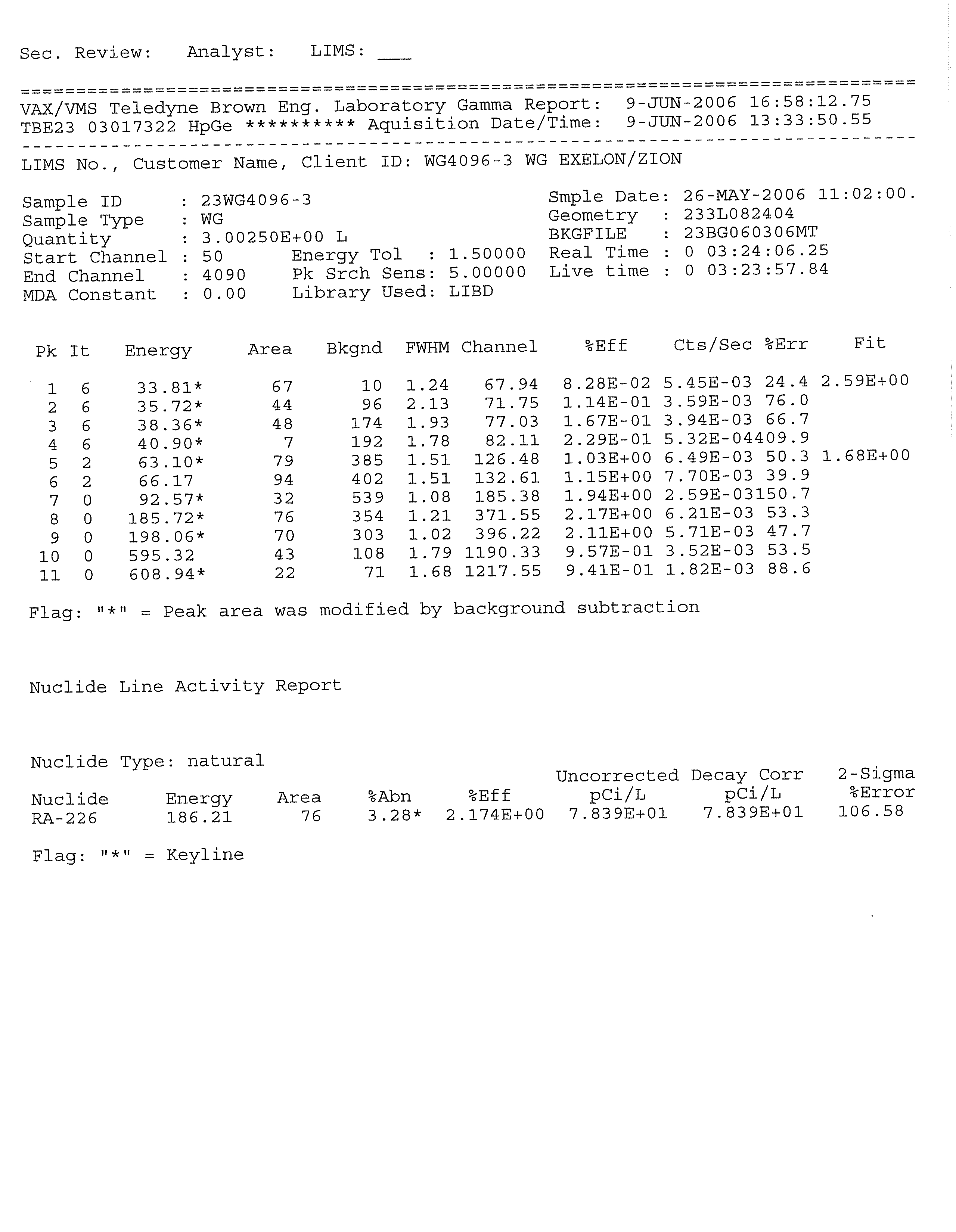

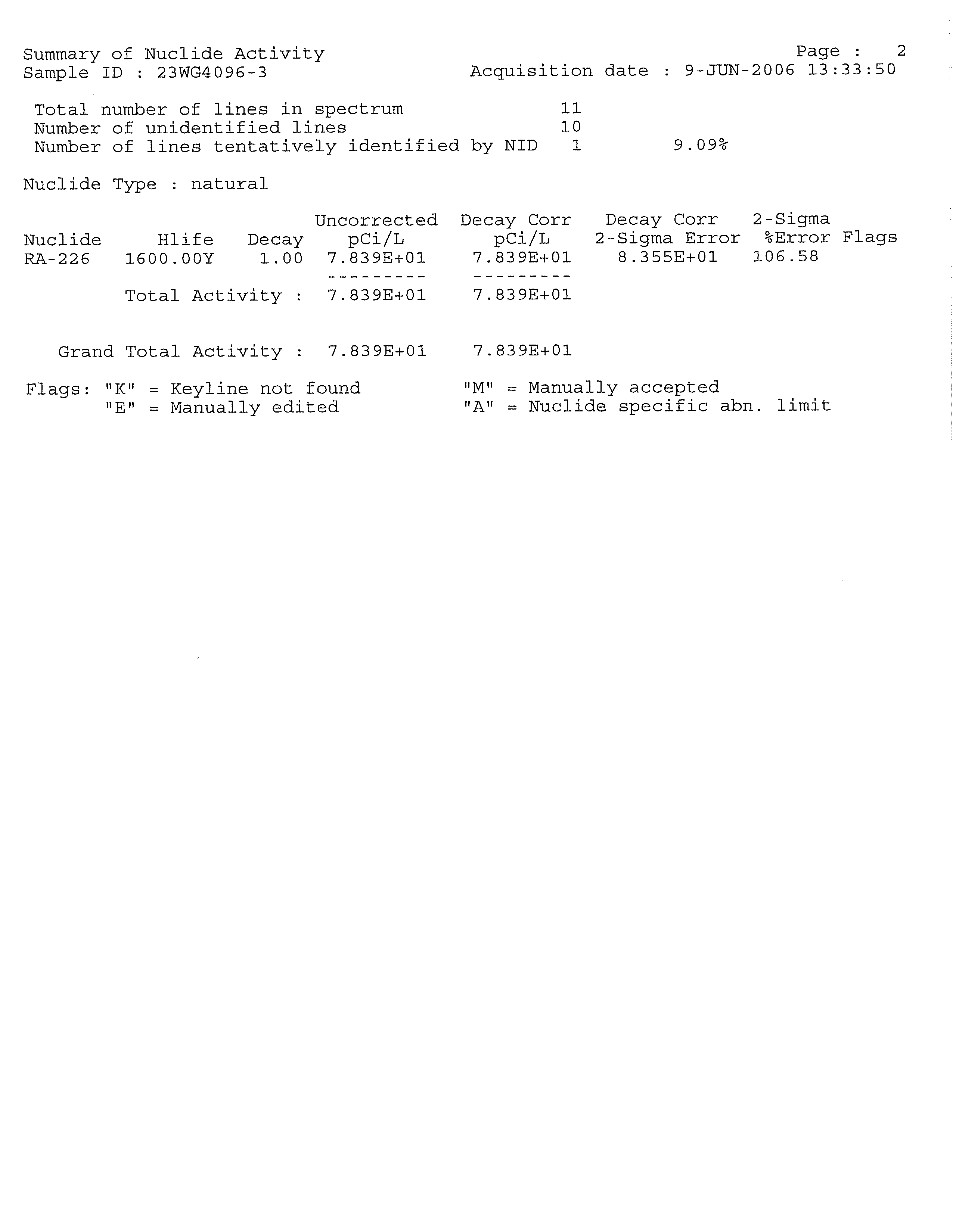

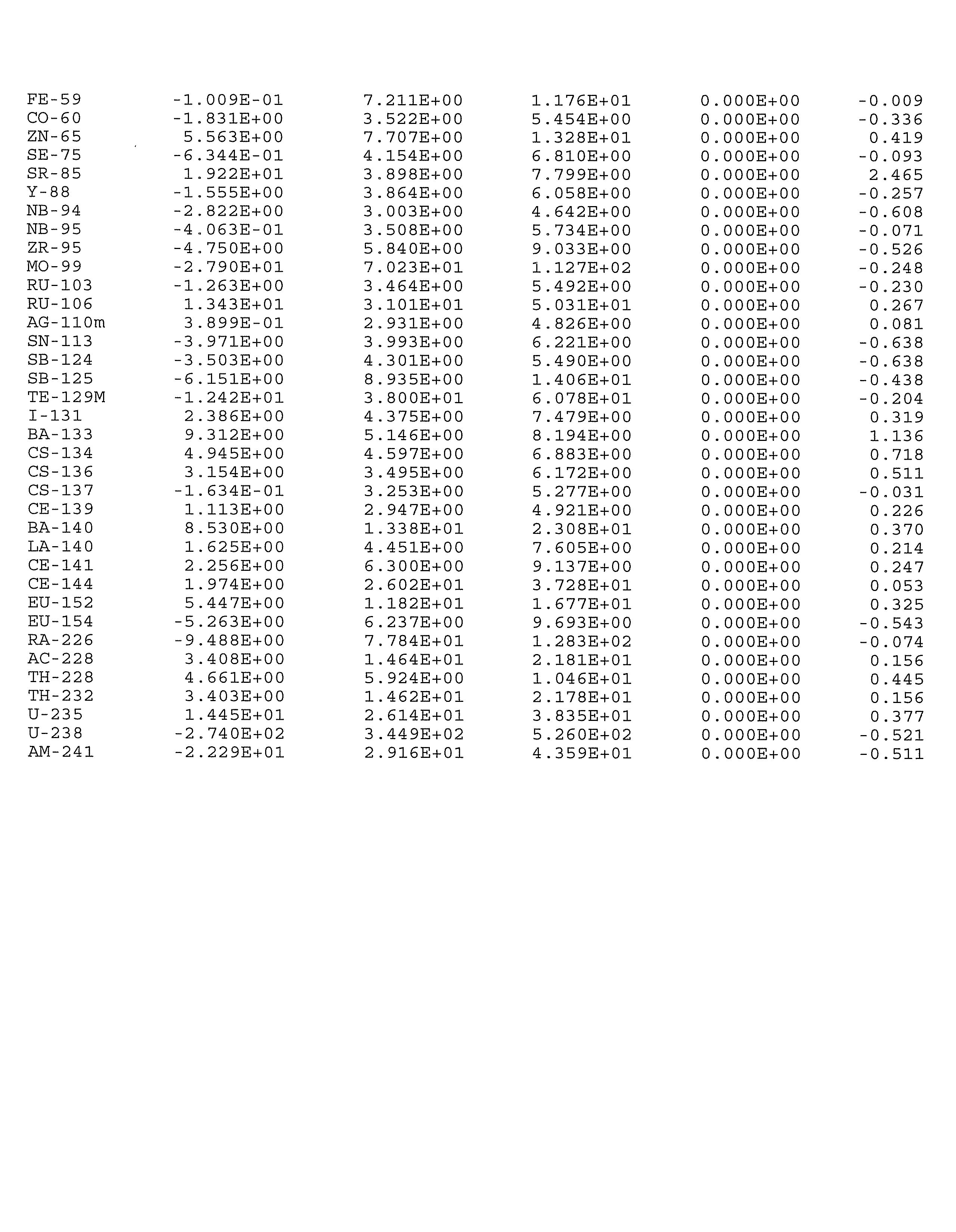

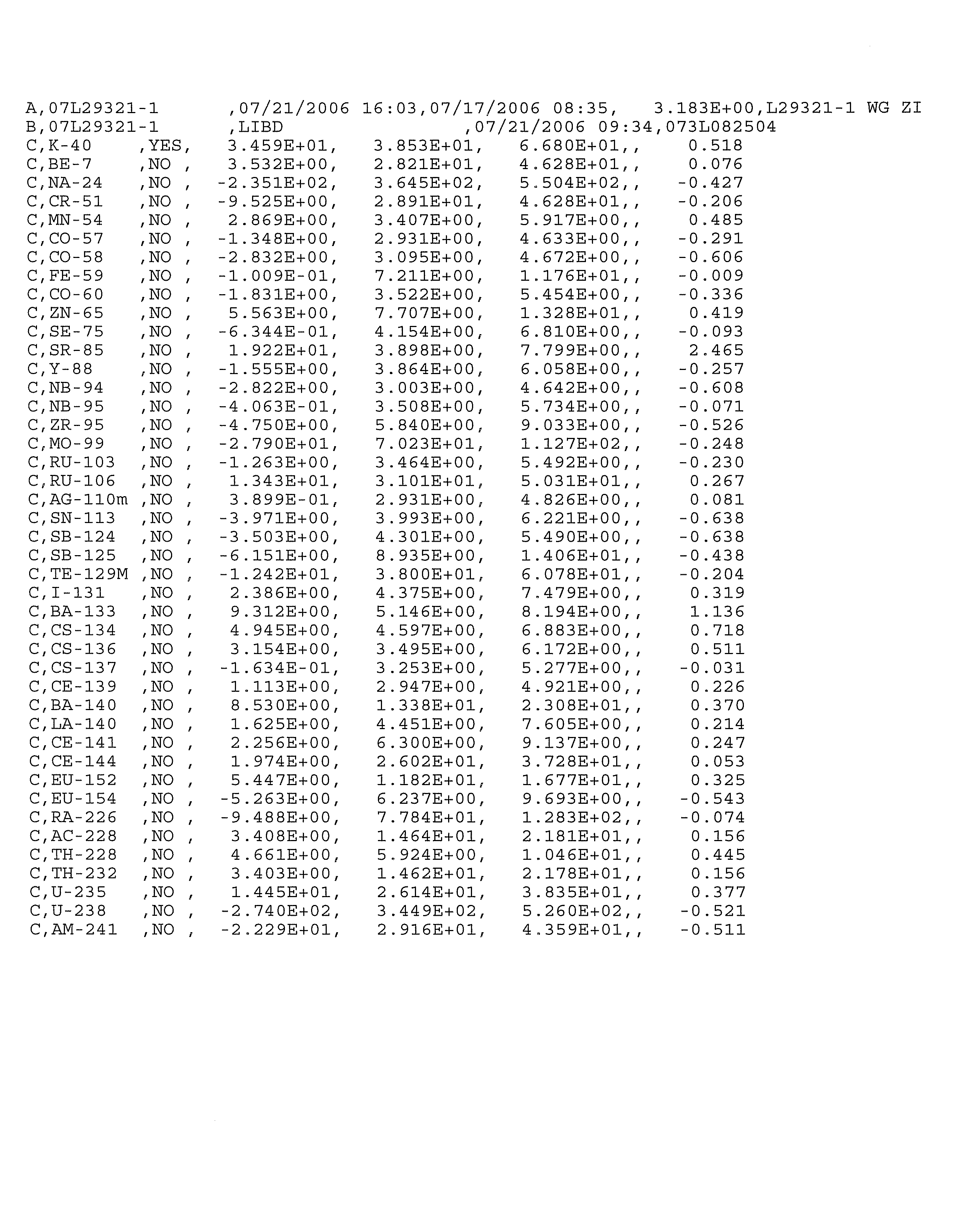

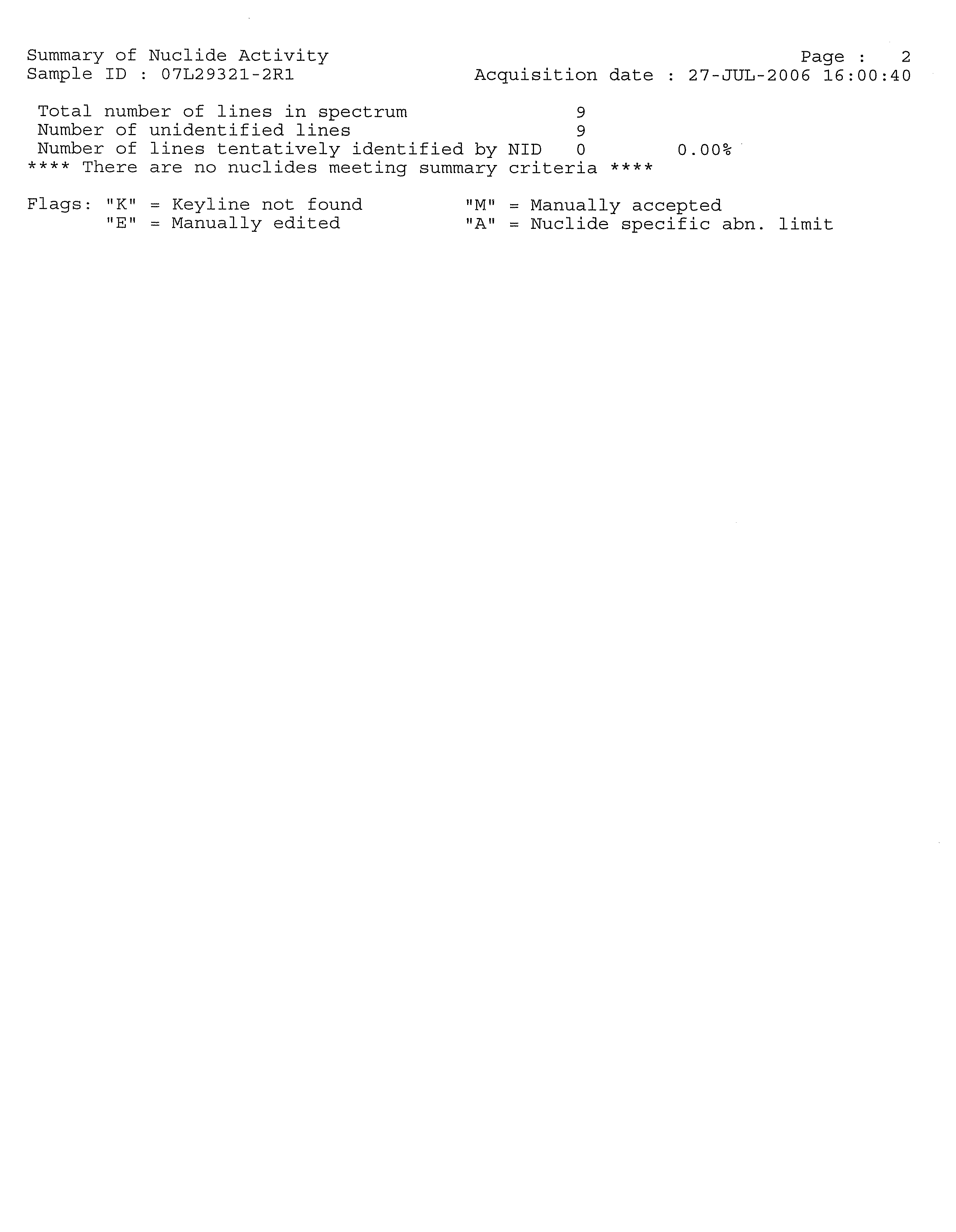

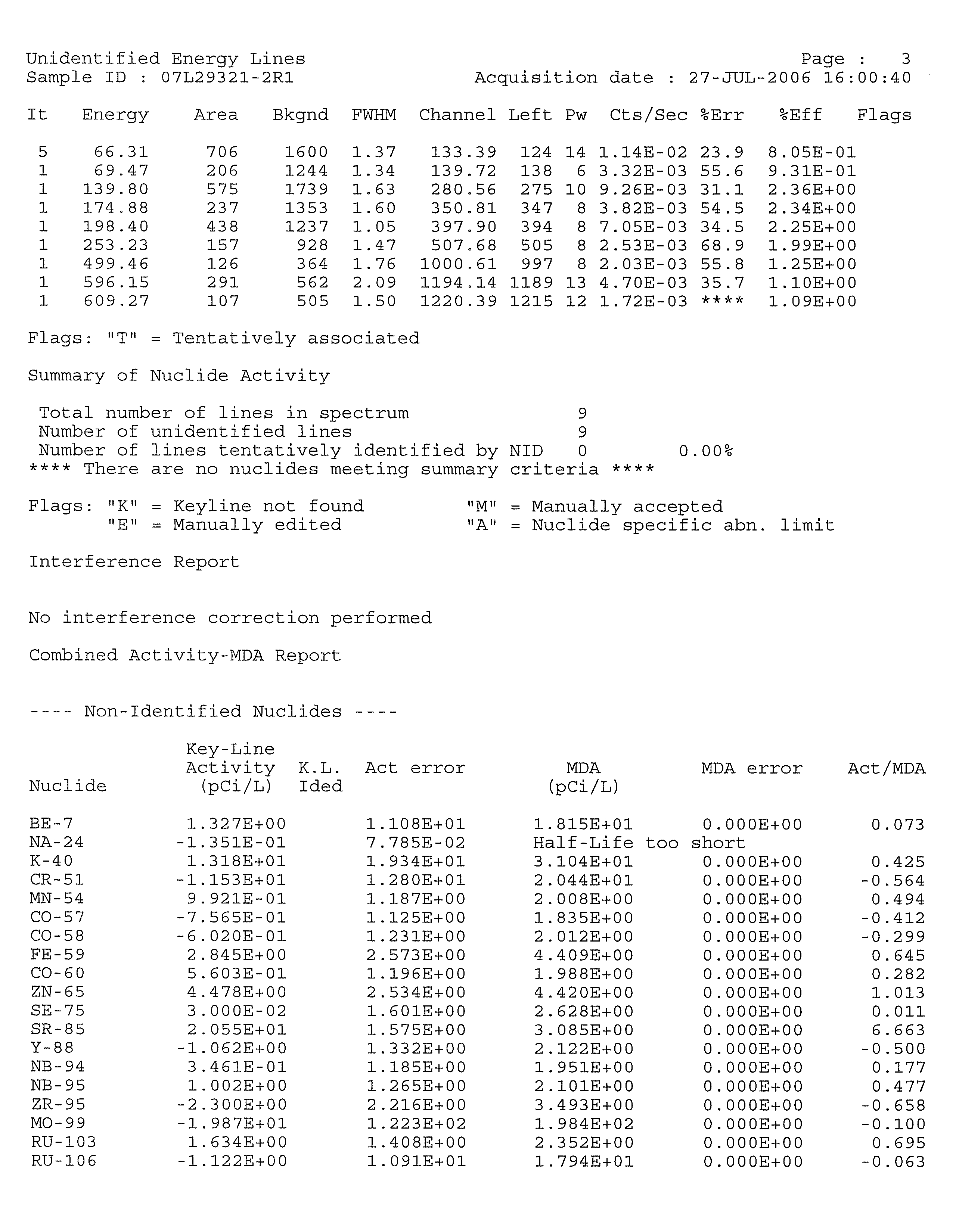

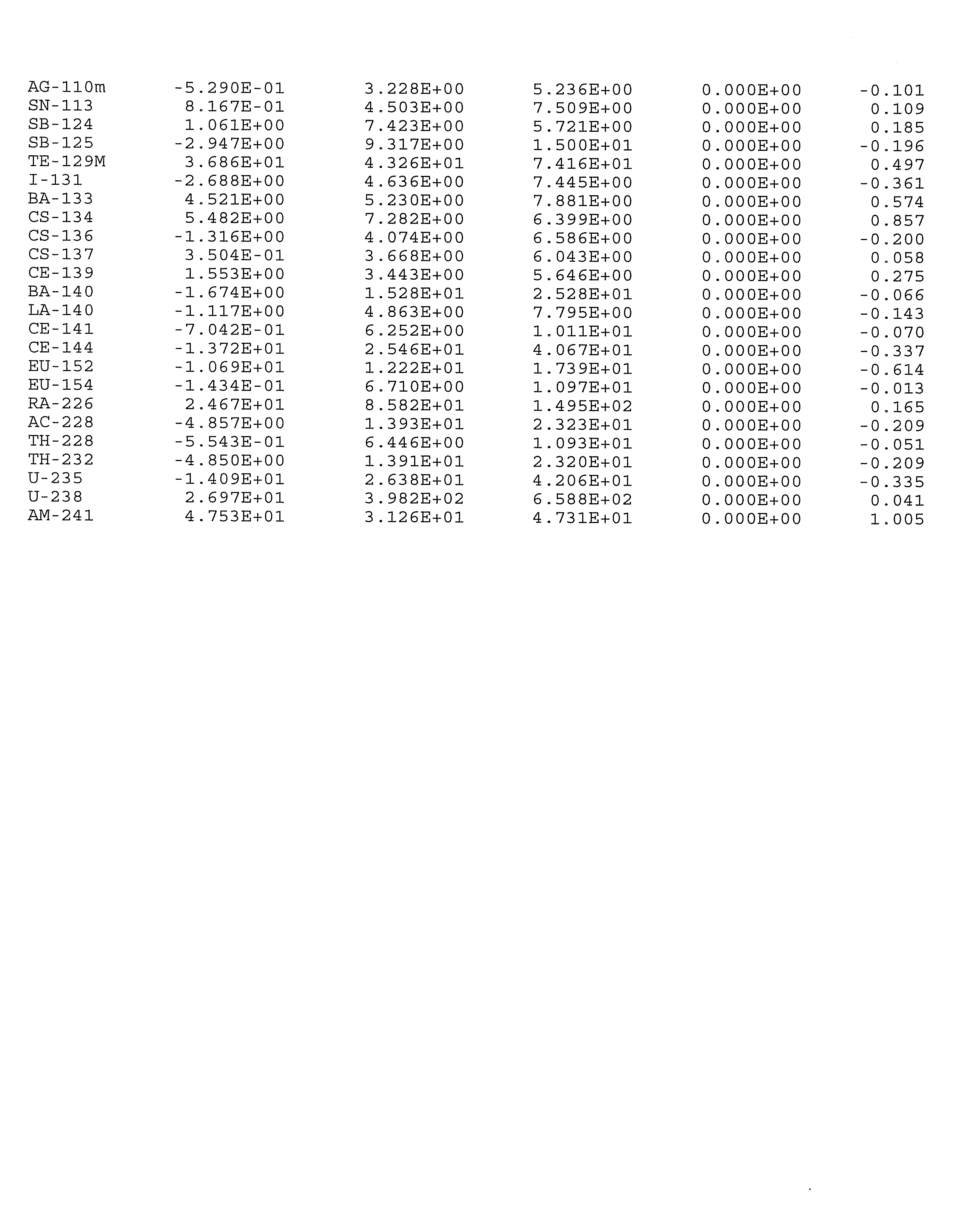

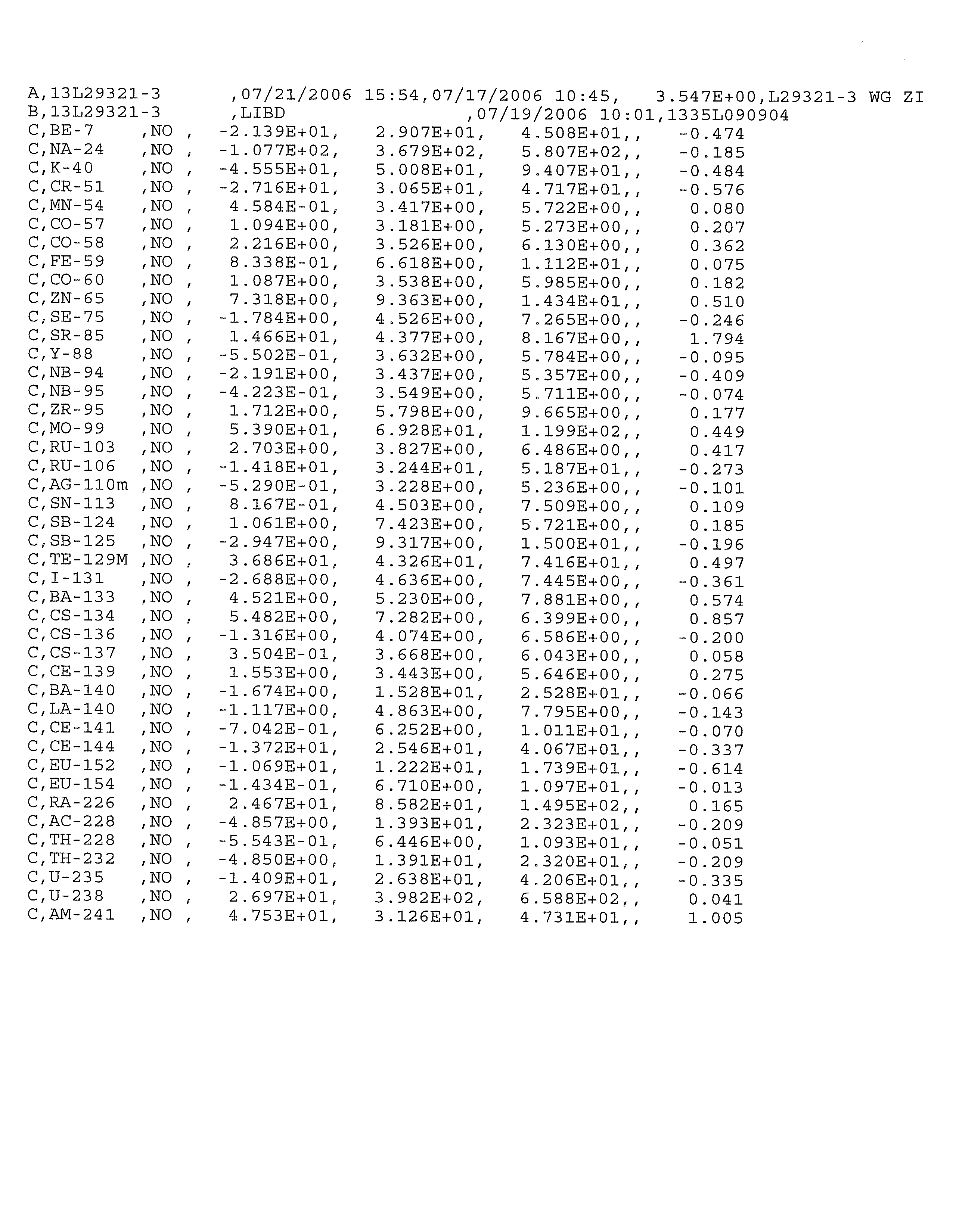

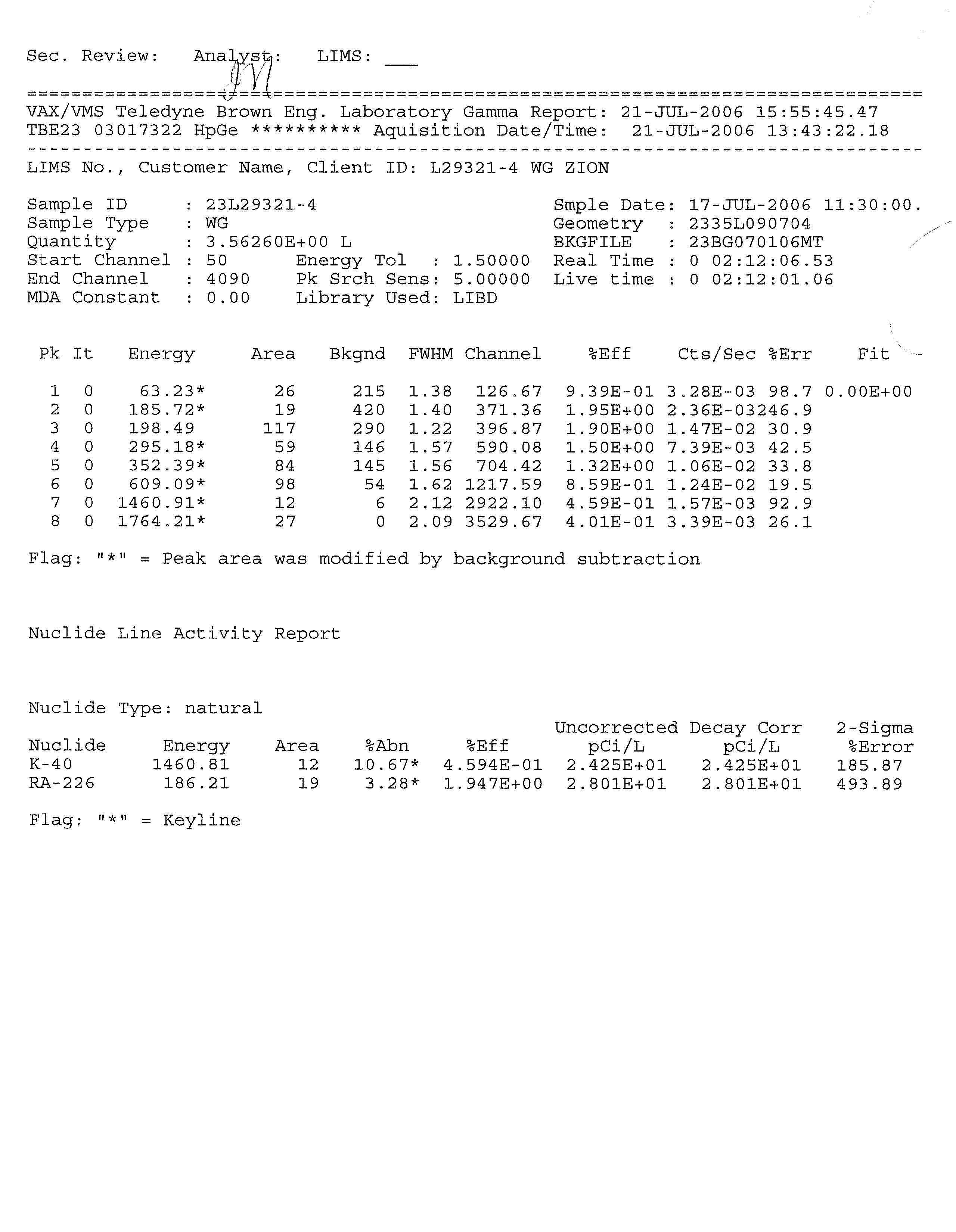

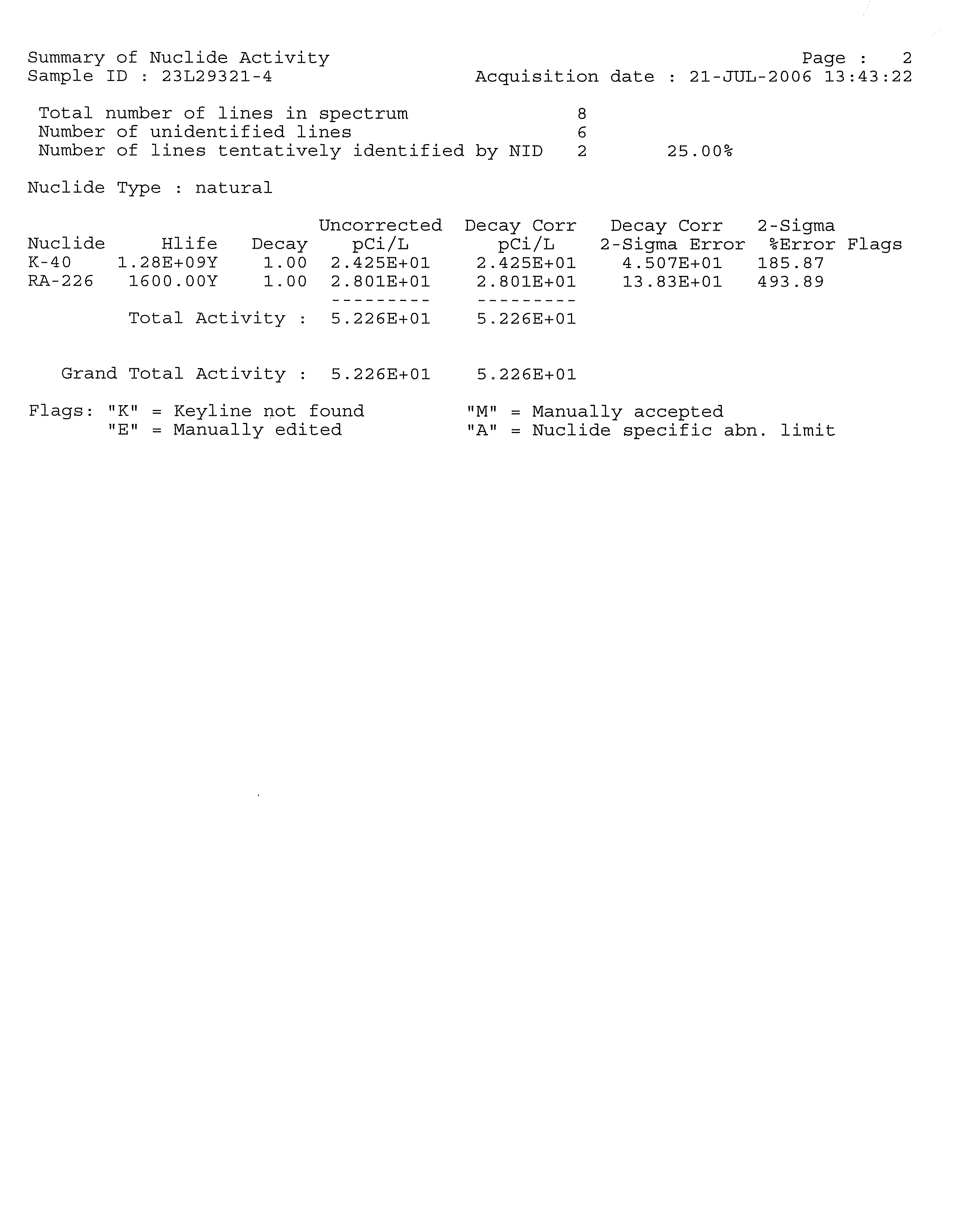

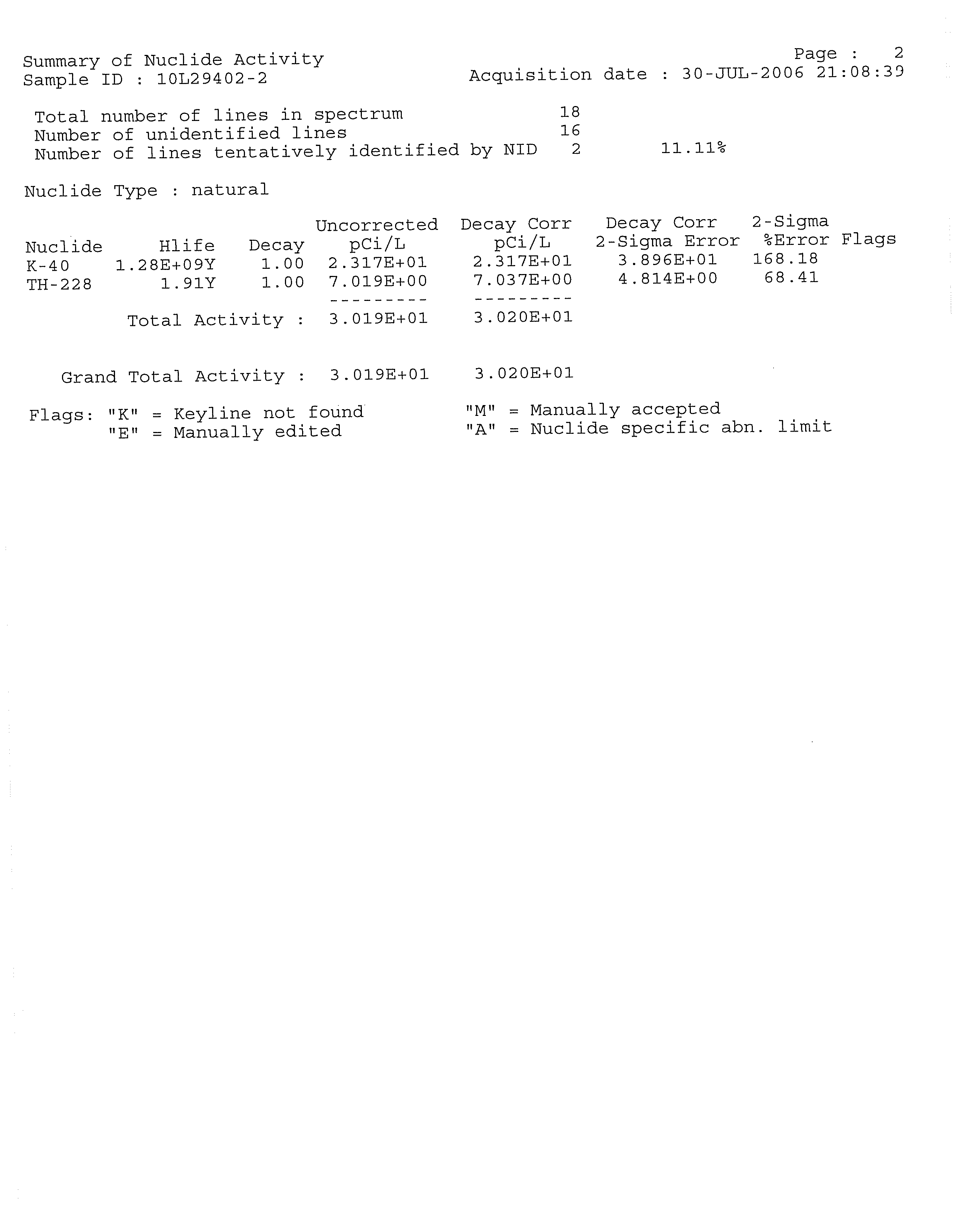

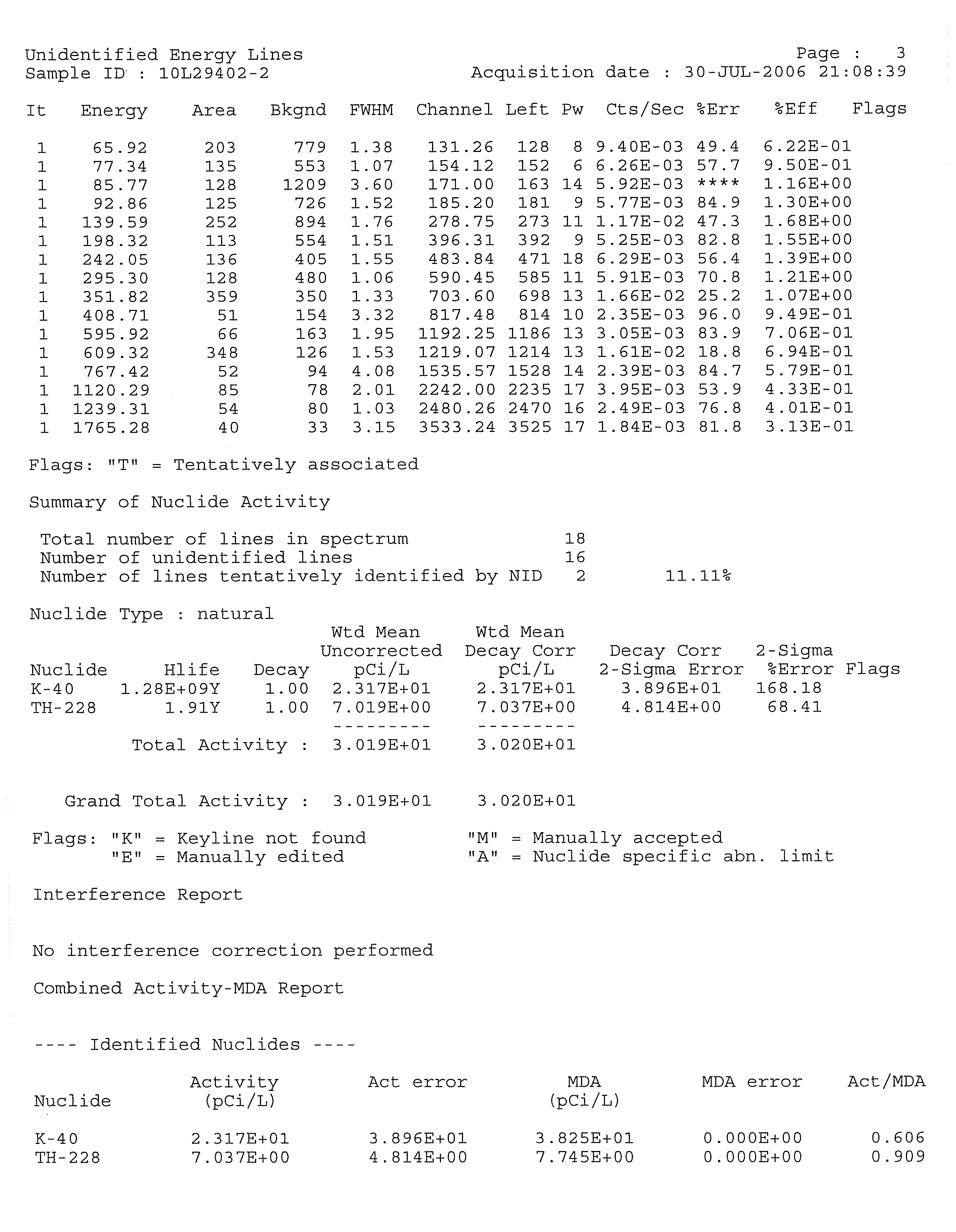

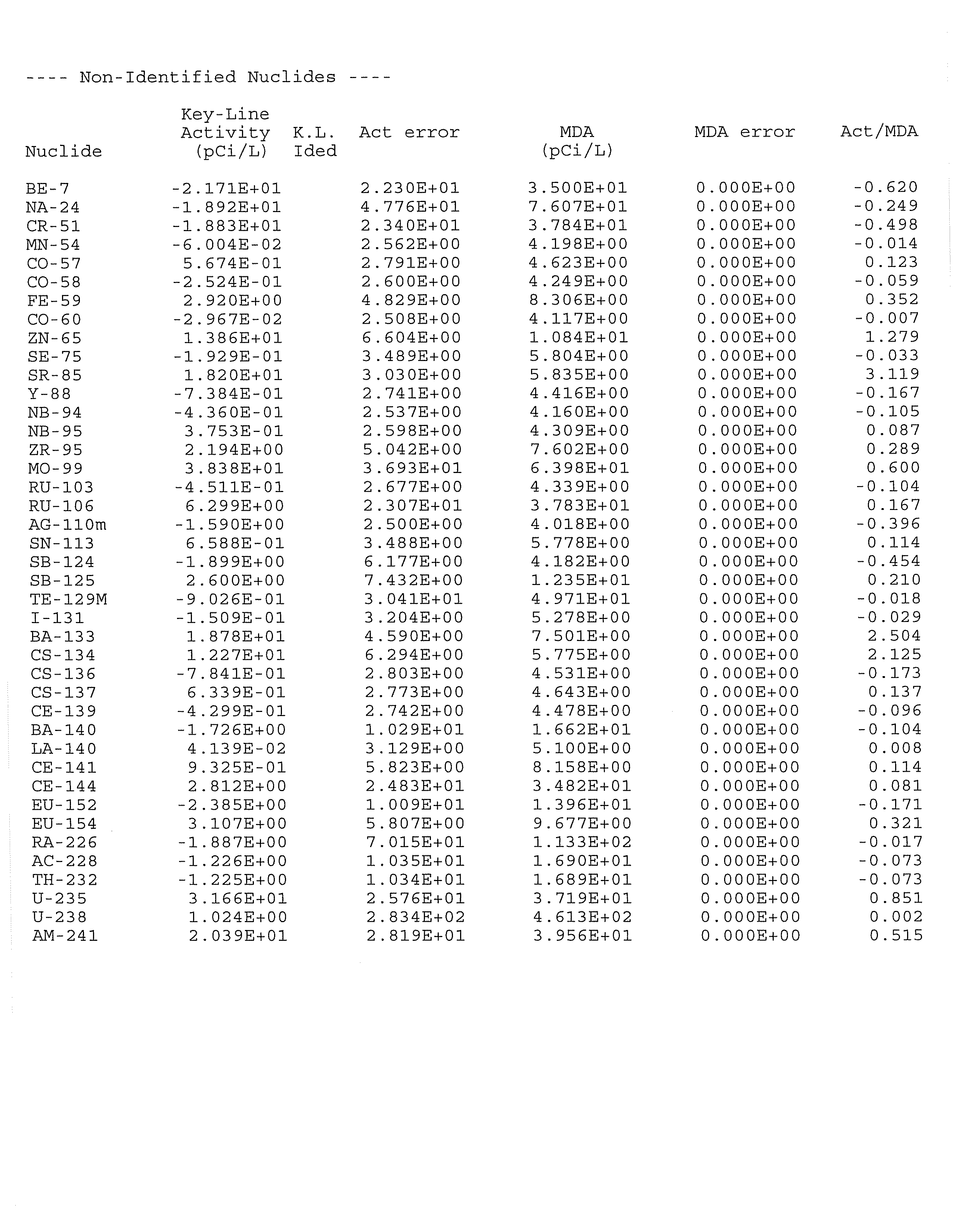

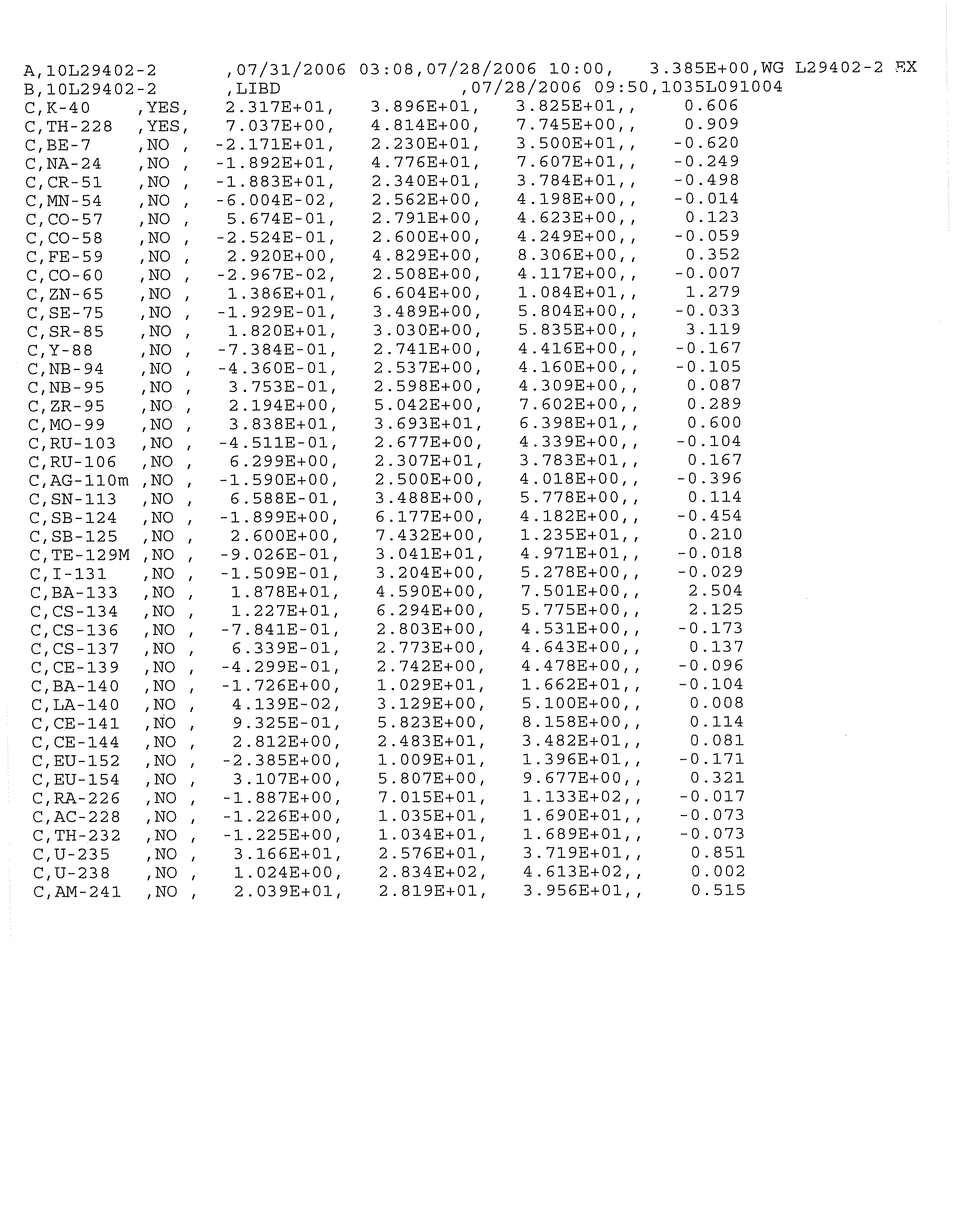

SUMMARY OF BETA-EMITTING RADIONUCLIDES

ANALYTICAL RESULTS.................................................................................31

5.3.2

SUMMARY OF GAMMA-EMITTING RADIONUCLIDES

ANALYTICAL RESULTS.................................................................................32

5.3.3

SUMMARY OF FIELD MEASUREMENTS ...................................................32

5.4

SURFACE WATER QUALITY.........................................................................33

5.4.1

SUMMARY OF BETA-EMITTING RADIONUCLIDE

ANALYTICAL RESULTS.................................................................................33

5.4.2

SUMMARY OF GAMMA-EMITTING RADIONUCLIDES

ANALYTICAL RESULTS.................................................................................33

6.0

RADIONUCLIDES OF CONCERN AND SOURCE AREAS .........................................35

6.1

GAMMA-EMITTING RADIONUCLIDES.....................................................35

6.2

BETA-EMITTING RADIONUCLIDES ...........................................................35

6.3

TRITIUM.............................................................................................................35

6.3.1

GENERAL CHARACTERISTICS....................................................................35

6.3.2

DISTRIBUTION IN STATION GROUNDWATER.......................................36

6.3.3

CONCEPTUAL MODEL OF TRITIUM

RELEASE AND MIGRATION.........................................................................37

6.3.4

ATTENUATION OF TRITIUM WITHIN THE SHALLOW

GROUNDWATER SYSTEM ............................................................................37

7.0

EXPOSURE PATHWAY ASSESSMENT............................................................................39

7.1

HEALTH EFFECTS OF TRITIUM...................................................................39

7.2

BACKGROUND CONCENTRATIONS OF TRITIUM ................................40

7.2.1

GROUNDWATER.............................................................................................40

7.2.2

PRECIPITATION DATA..................................................................................40

7.2.3

SURFACE WATER DATA ...............................................................................41

7.2.4

DRINKING WATER DATA ............................................................................42

7.2.5

EXPECTED TRITIUM BACKGROUND FOR THE STATION ...................42

7.3

IDENTIFICATION OF POTENTIAL EXPOSURE

PATHWAYS AND POTENTIAL RECEPTORS ............................................43

7.3.1

POTENTIAL GROUNDWATER MIGRATION TO DRINKING

WATER USERS OFF THE STATION PROPERTY .......................................43

045136 (22) Zion Station

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

TABLE OF CONTENTS

Page

7.3.2

POTENTIAL GROUNDWATER MIGRATION TO

SURFACE WATER USERS ..............................................................................44

7.4

SUMMARY OF POTENTIAL TRITIUM EXPOSURE PATHWAYS ..........44

7.5

OTHER RADIONUCLIDES.............................................................................45

8.0

CONCLUSIONS....................................................................................................................46

9.0

RECOMMENDATIONS.......................................................................................................49

9.1

DATA GAPS ......................................................................................................49

9.2

GROUNDWATER MONITORING ................................................................49

10.0

REFERENCES........................................................................................................................50

045136 (22) Zion Station

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

LIST OF FIGURES

(Following Text)

FIGURE 1.1

STATION LOCATION MAP

FIGURE 1.2

STATION BOUNDARIES AND FEATURES

FIGURE 2.1

STATION SURFACE WATER FEATURES

FIGURE 2.2

REGIONAL STRATIGRAPHIC CROSS-SECTION

FIGURE 2.3

CROSS-SECTION OF THE ZION BEACH-RIDGE PLAIN

FIGURE 2.4

PRIVATE/PUBLIC WATER SUPPLY WELL LOCATIONS

FIGURE 3.1

AREAS FOR FURTHER EVALUATION

FIGURE 4.1

GROUNDWATER AND SURFACE WATER MONITORING LOCATIONS

FIGURE 5.1

STATION GEOLOGIC CROSS–SECTION LOCATION MAP

FIGURE 5.2

GEOLOGIC CROSS–SECTION A-A'

FIGURE 5.3

GEOLOGIC CROSS–SECTION B-B'

FIGURE 5.4

POTENTIOMETRIC SURFACE CONTOURS - MAY 2006 -

SHALLOW GROUNDWATER ZONE

FIGURE 5.5

POTENTIOMETRIC SURFACE CONTOURS - JULY 2006 -

SHALLOW GROUNDWATER ZONE

FIGURE 5.6

TRITIUM CONCENTRATIONS - GROUNDWATER AND

SURFACE WATER

FIGURE 5.7

RADIONUCLIDE CONCENTRATIONS - GROUNDWATER

AND SURFACE WATER

045136 (22) Zion Station

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

LIST OF TABLES

(Following Text)

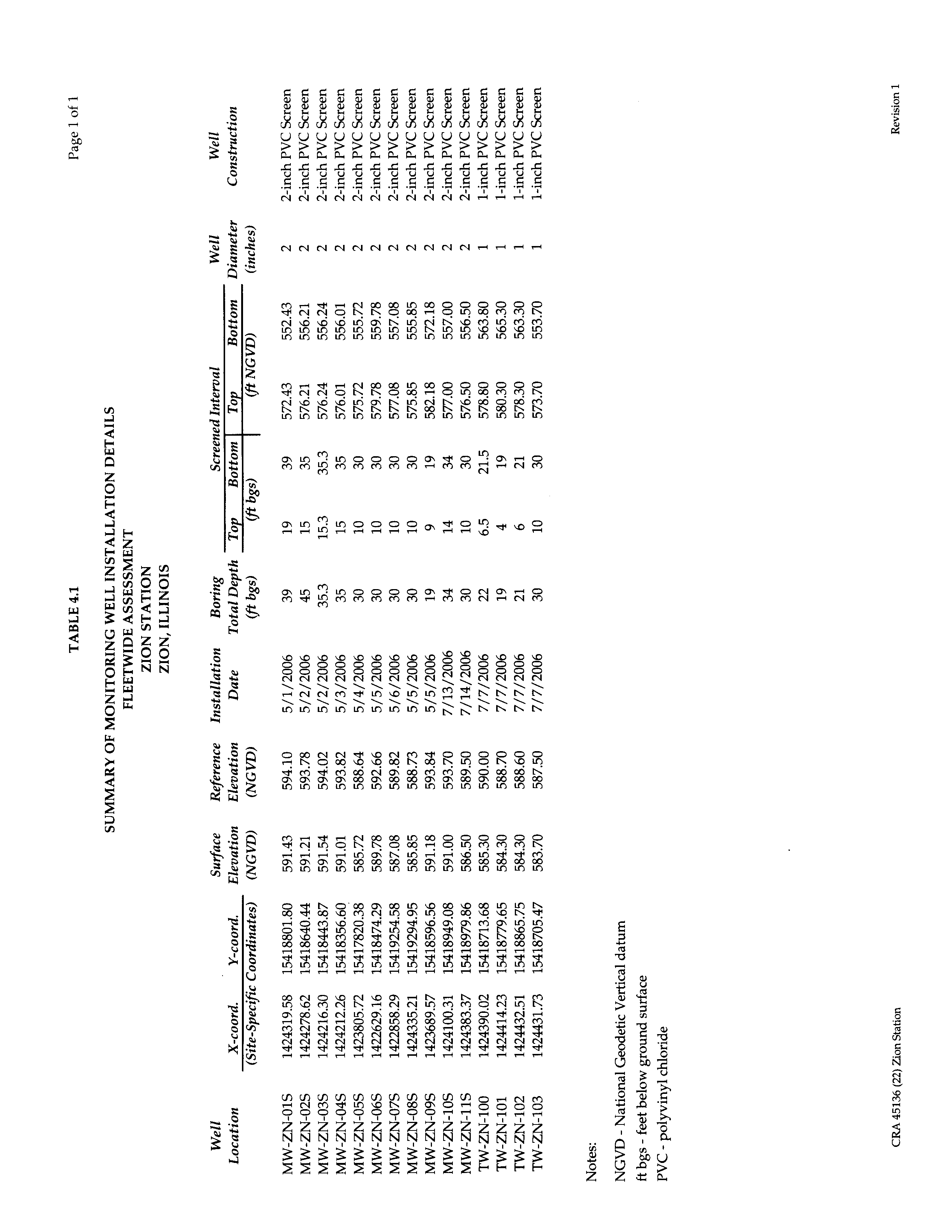

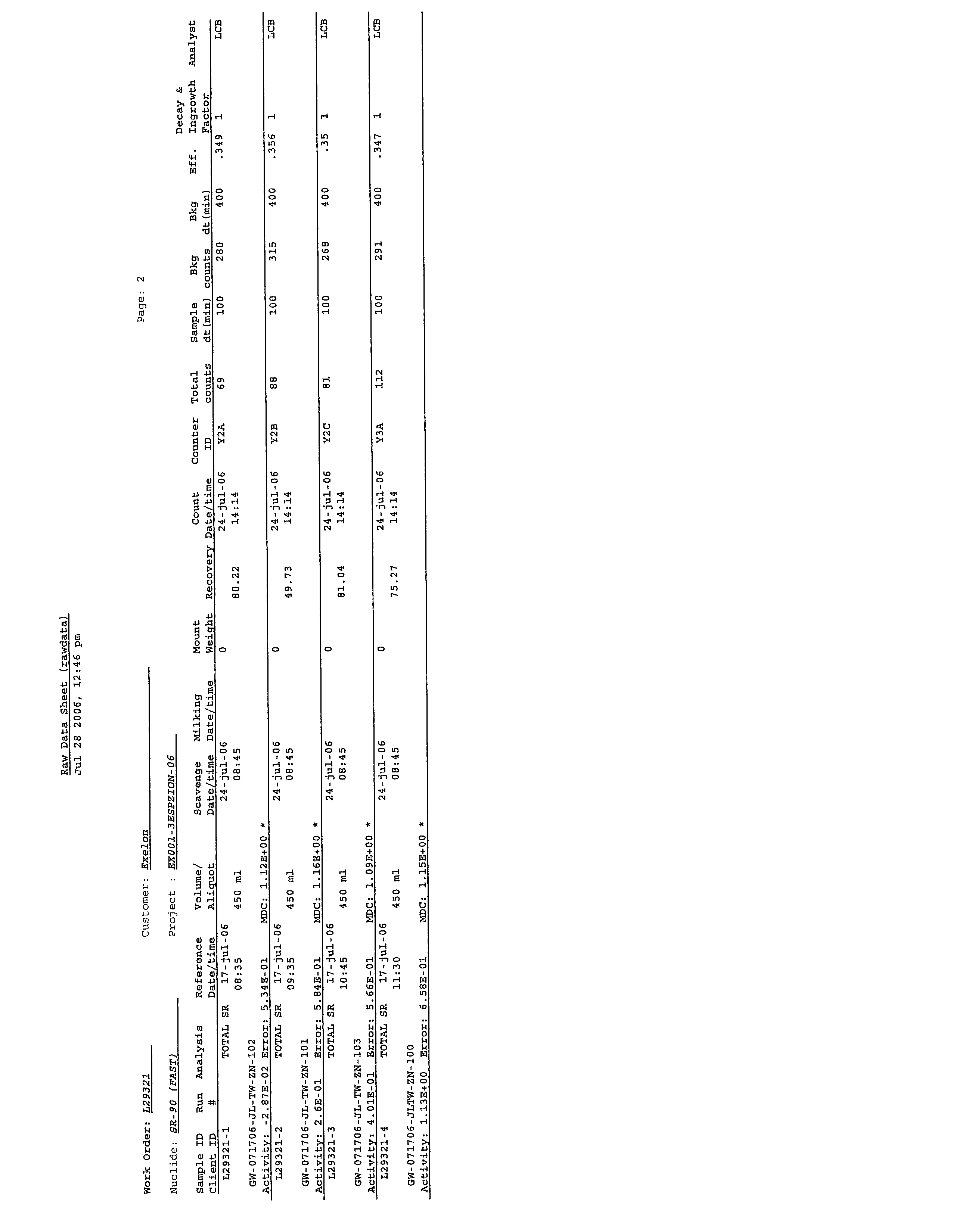

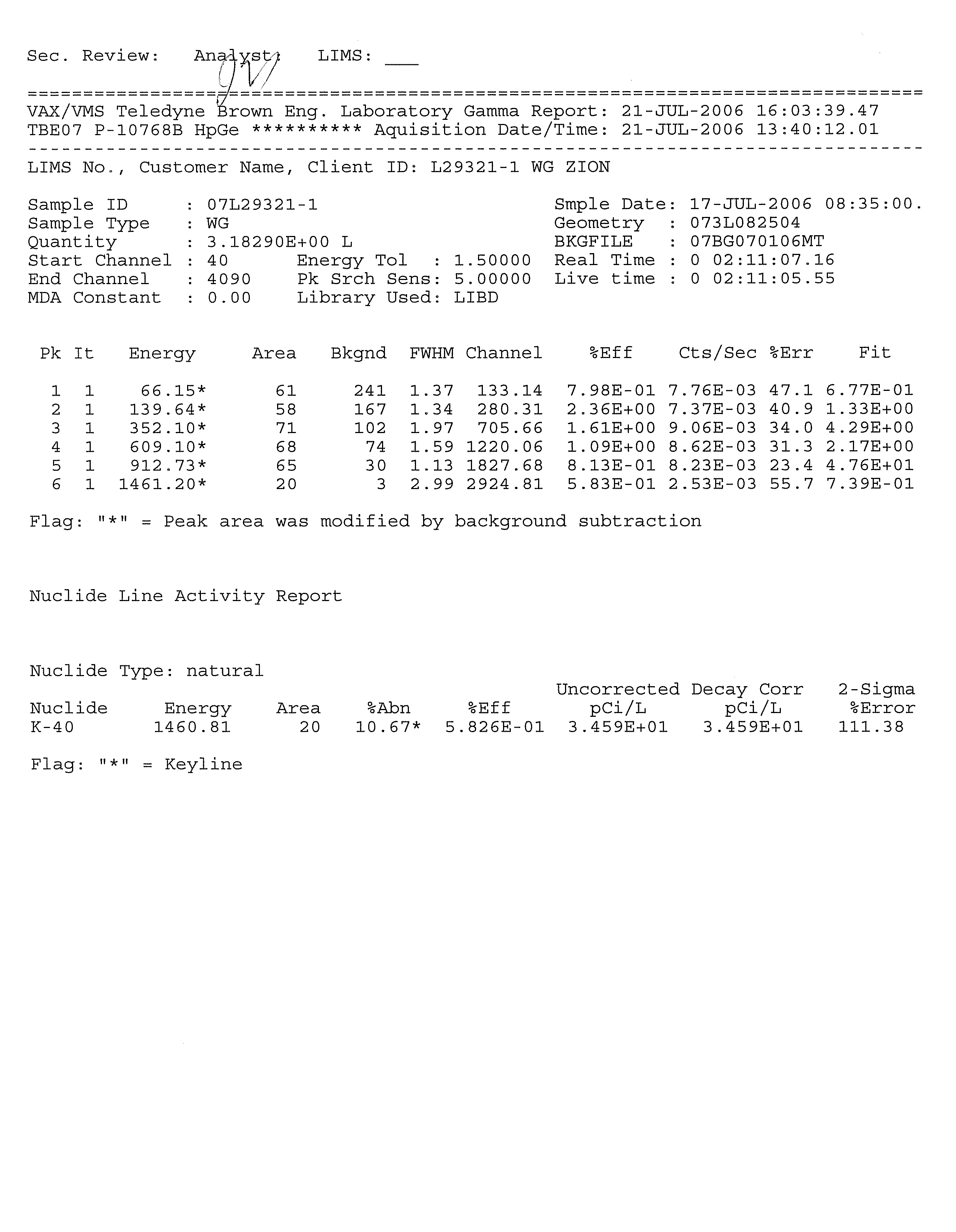

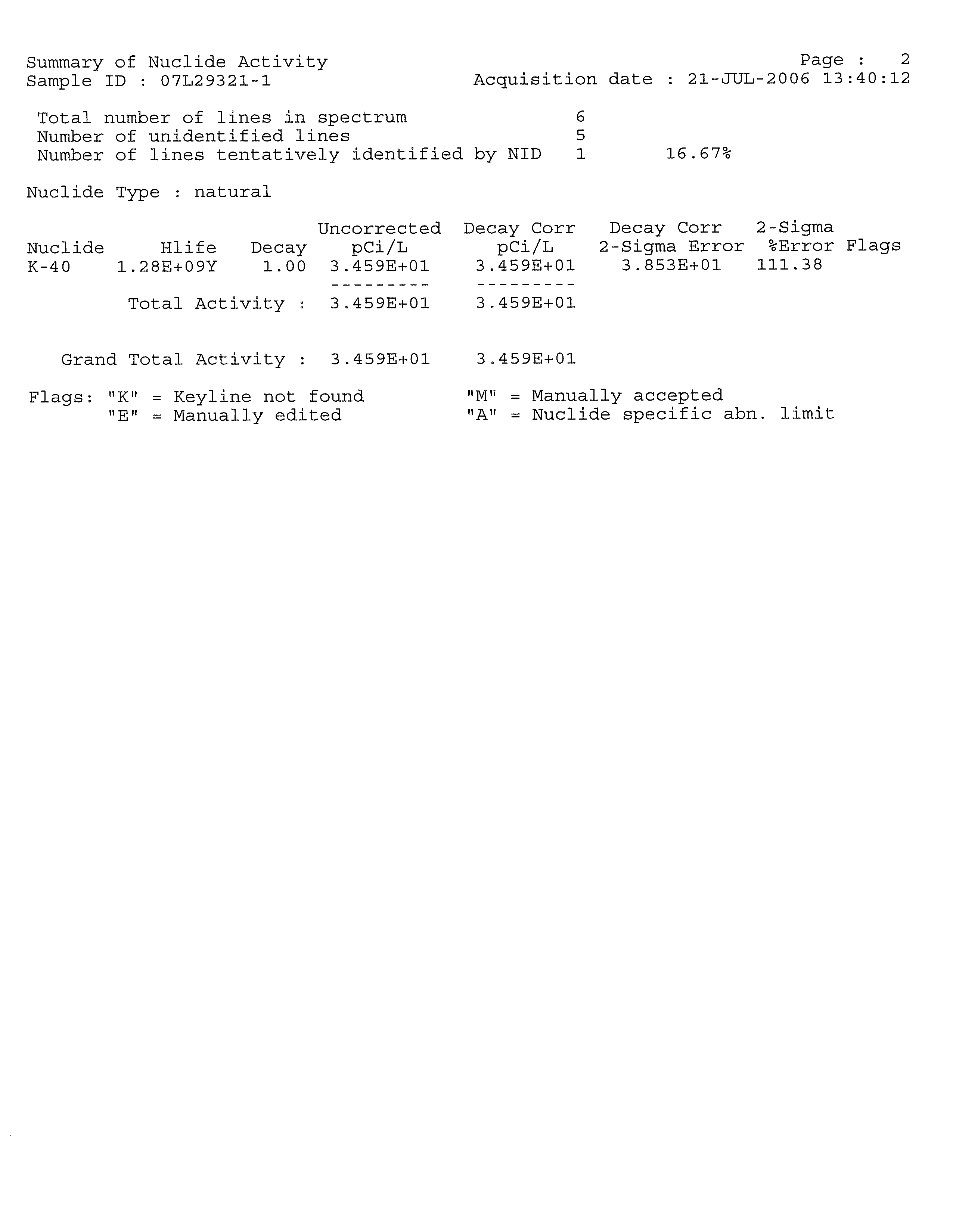

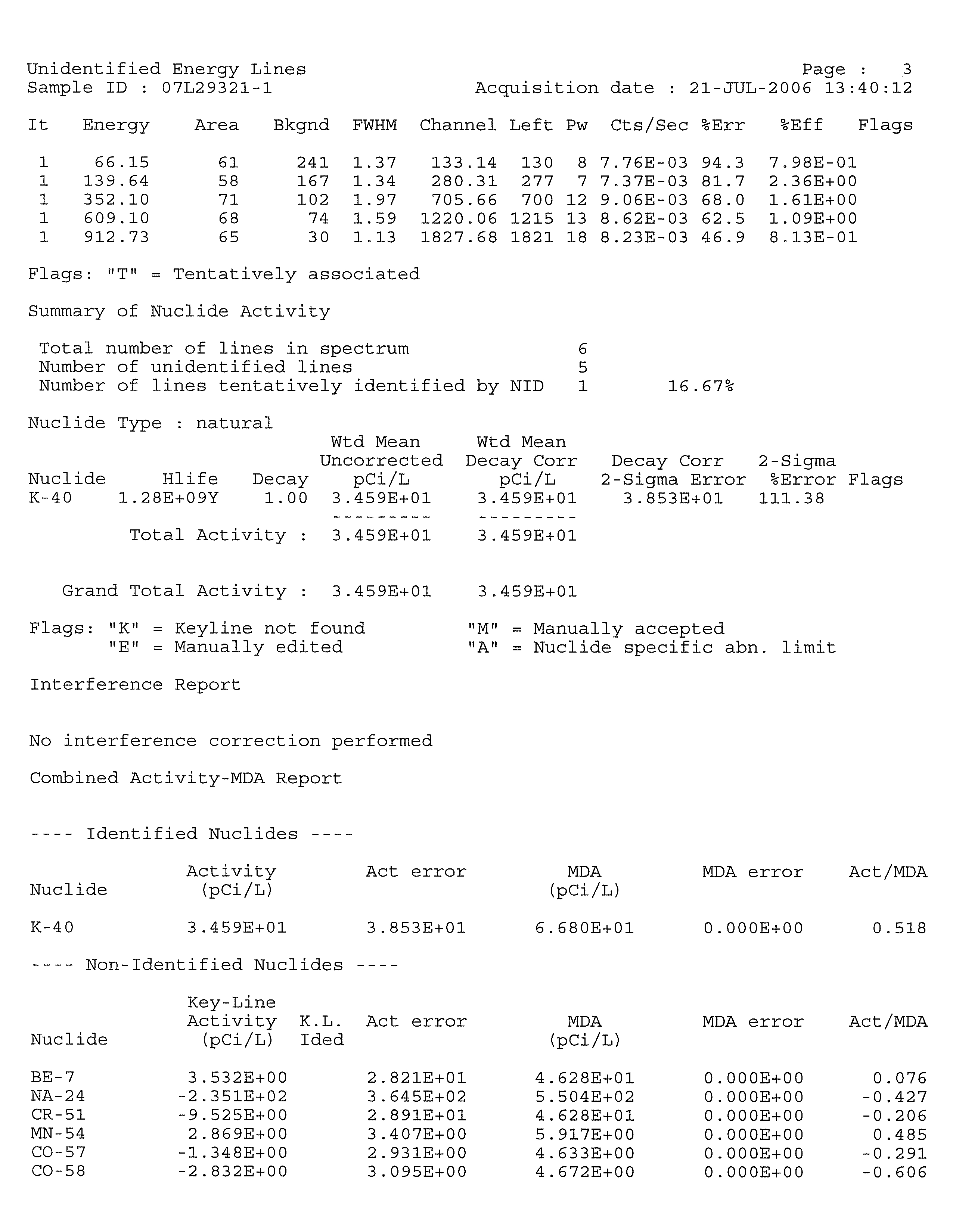

TABLE 4.1

SUMMARY OF MONITORING WELL INSTALLATION DETAILS

TABLE 4.2

SUMMARY OF MONITORING WELL DEVELOPMENT PARAMETERS

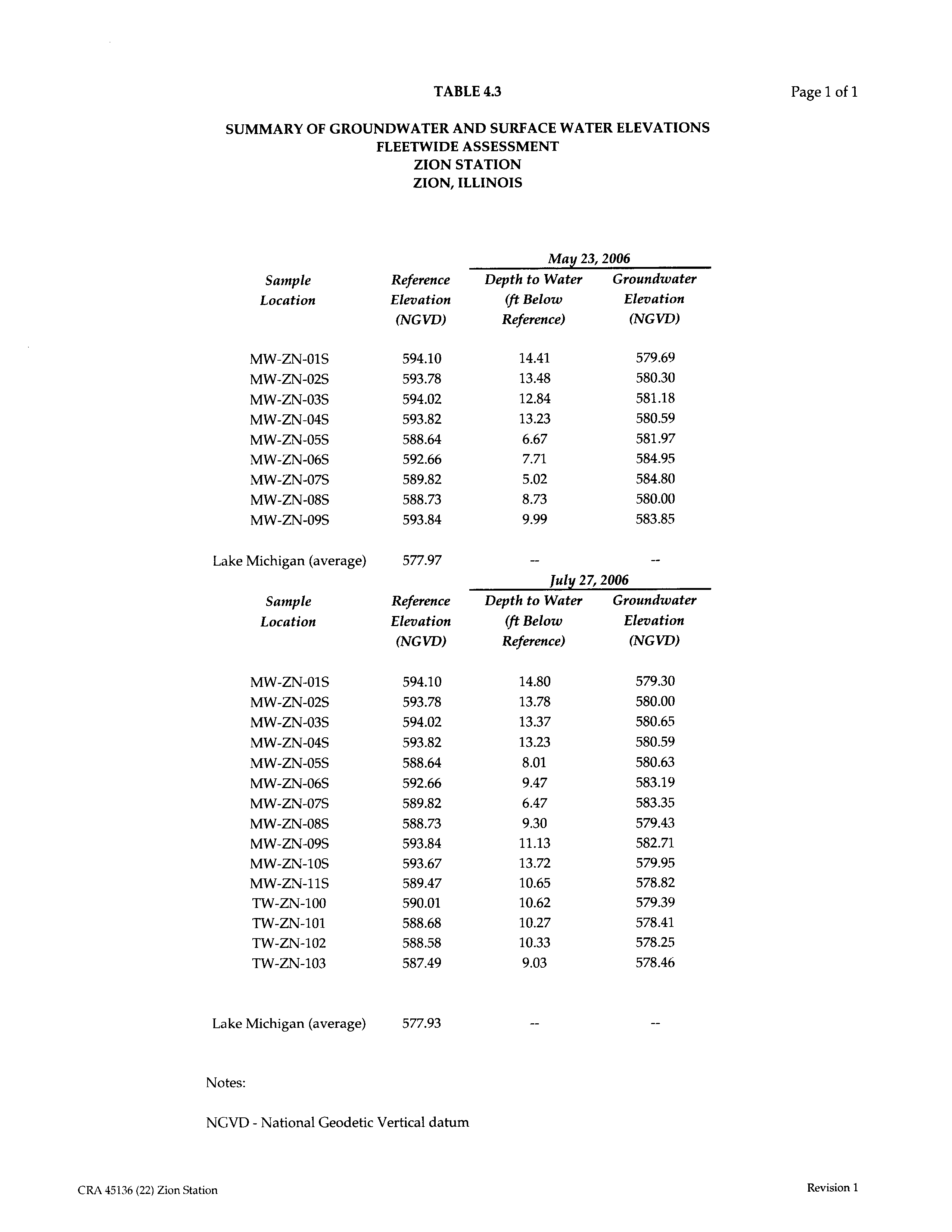

TABLE 4.3

SUMMARY OF GROUNDWATER AND SURFACE WATER ELEVATIONS

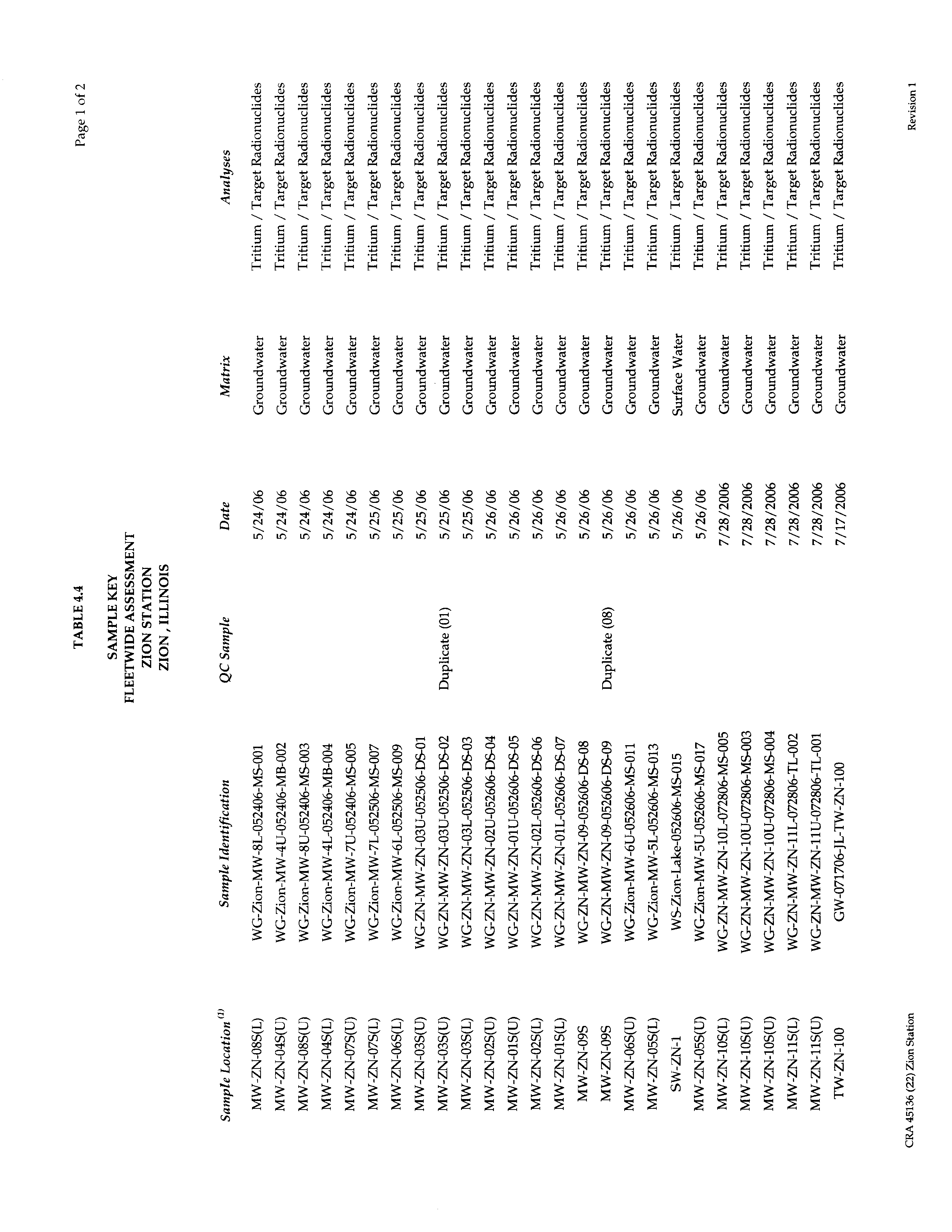

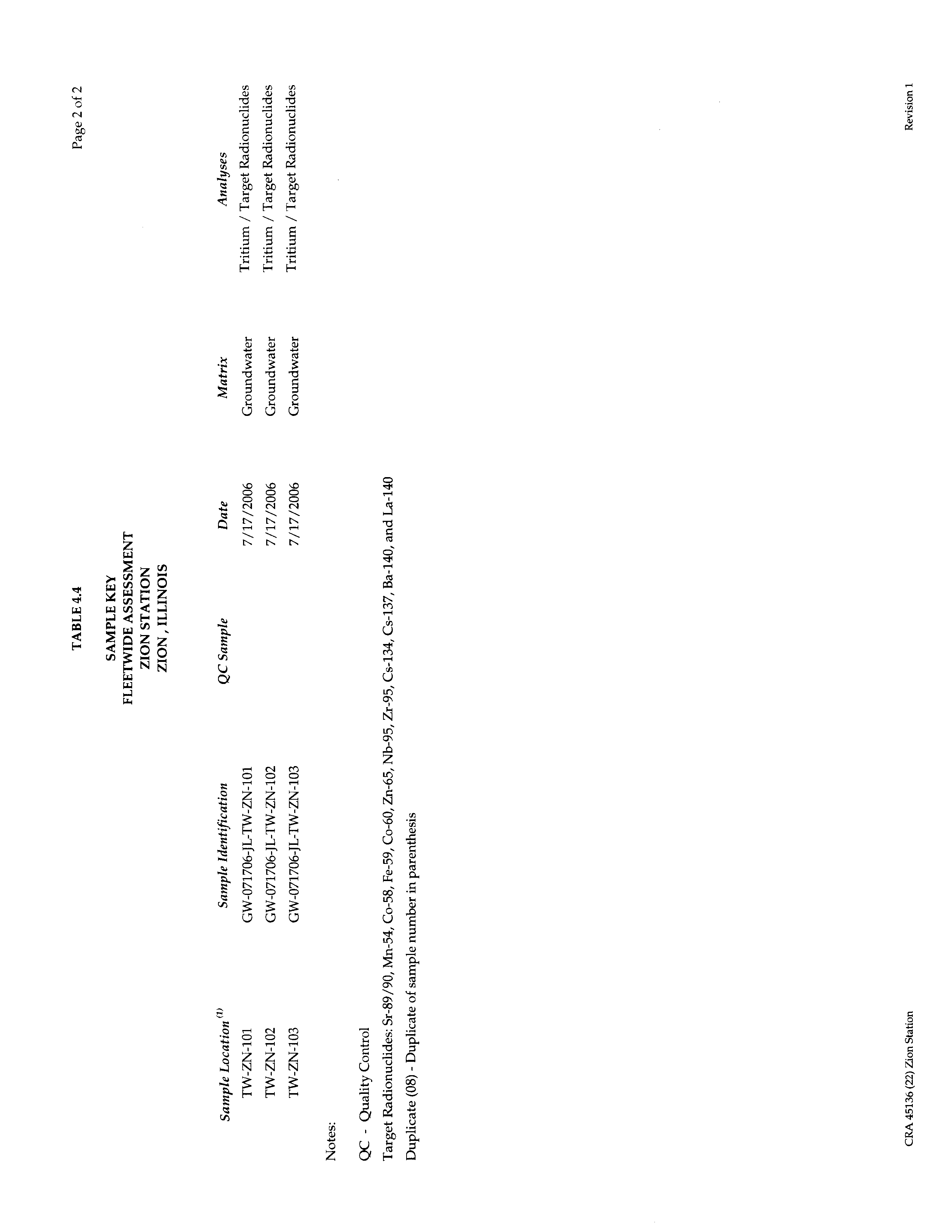

TABLE 4.4

SAMPLE KEY

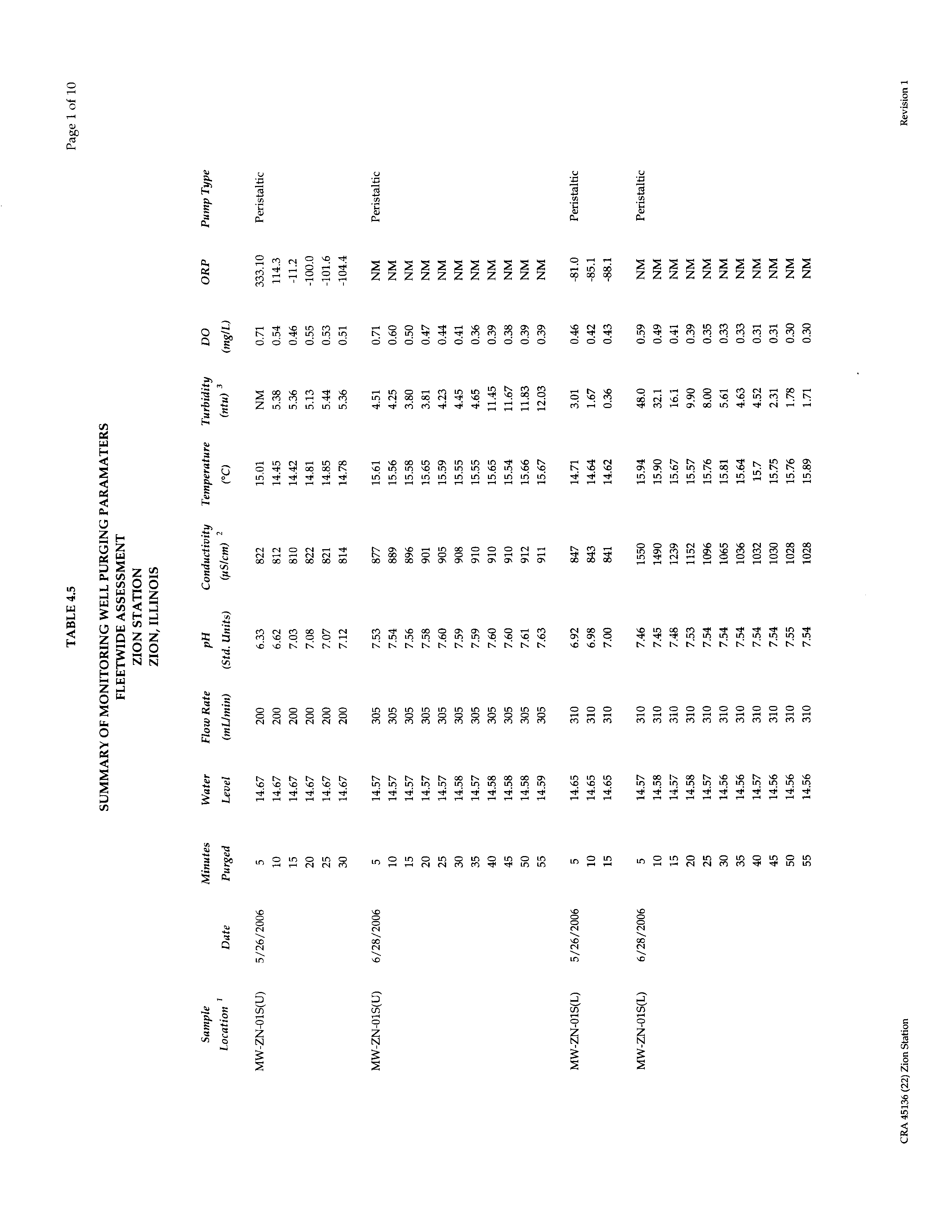

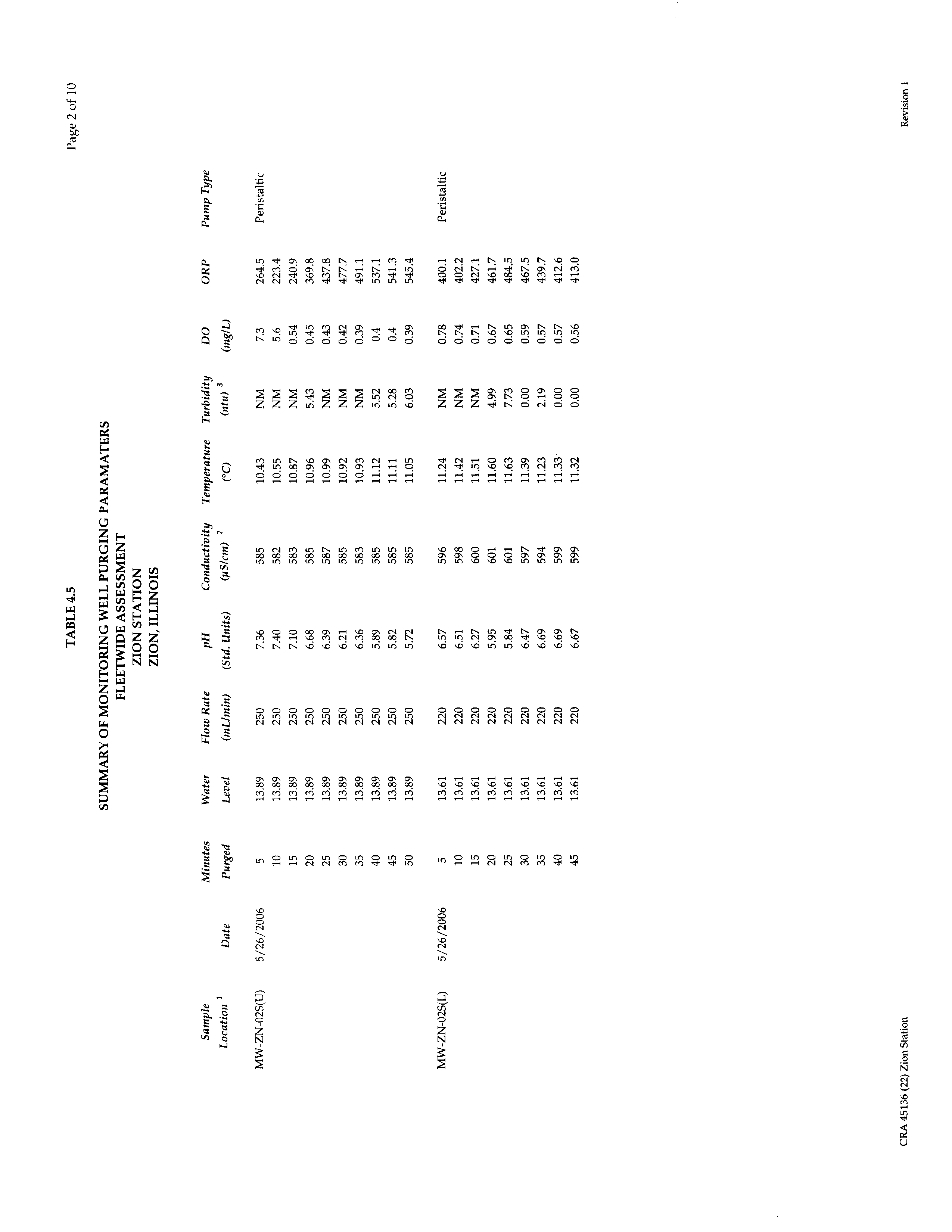

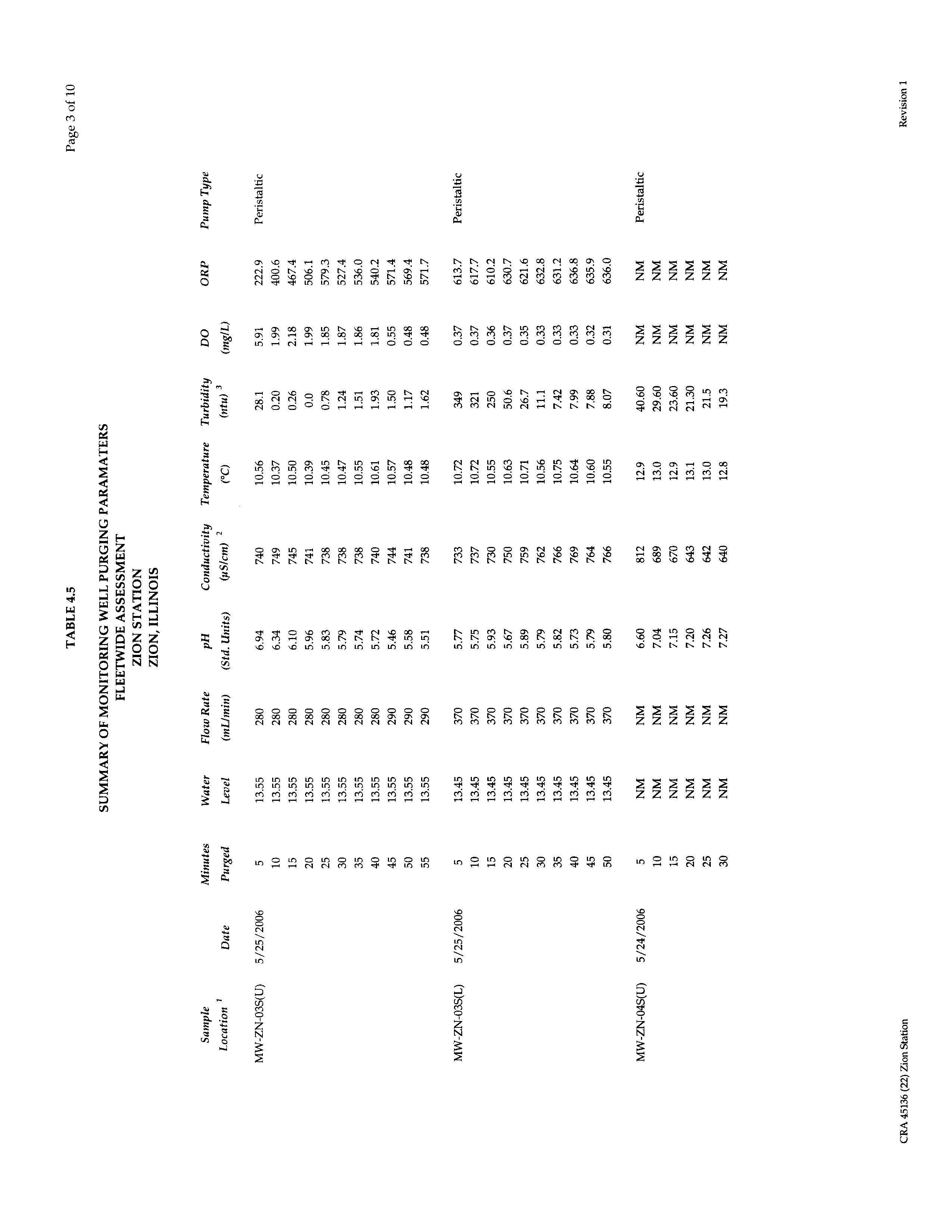

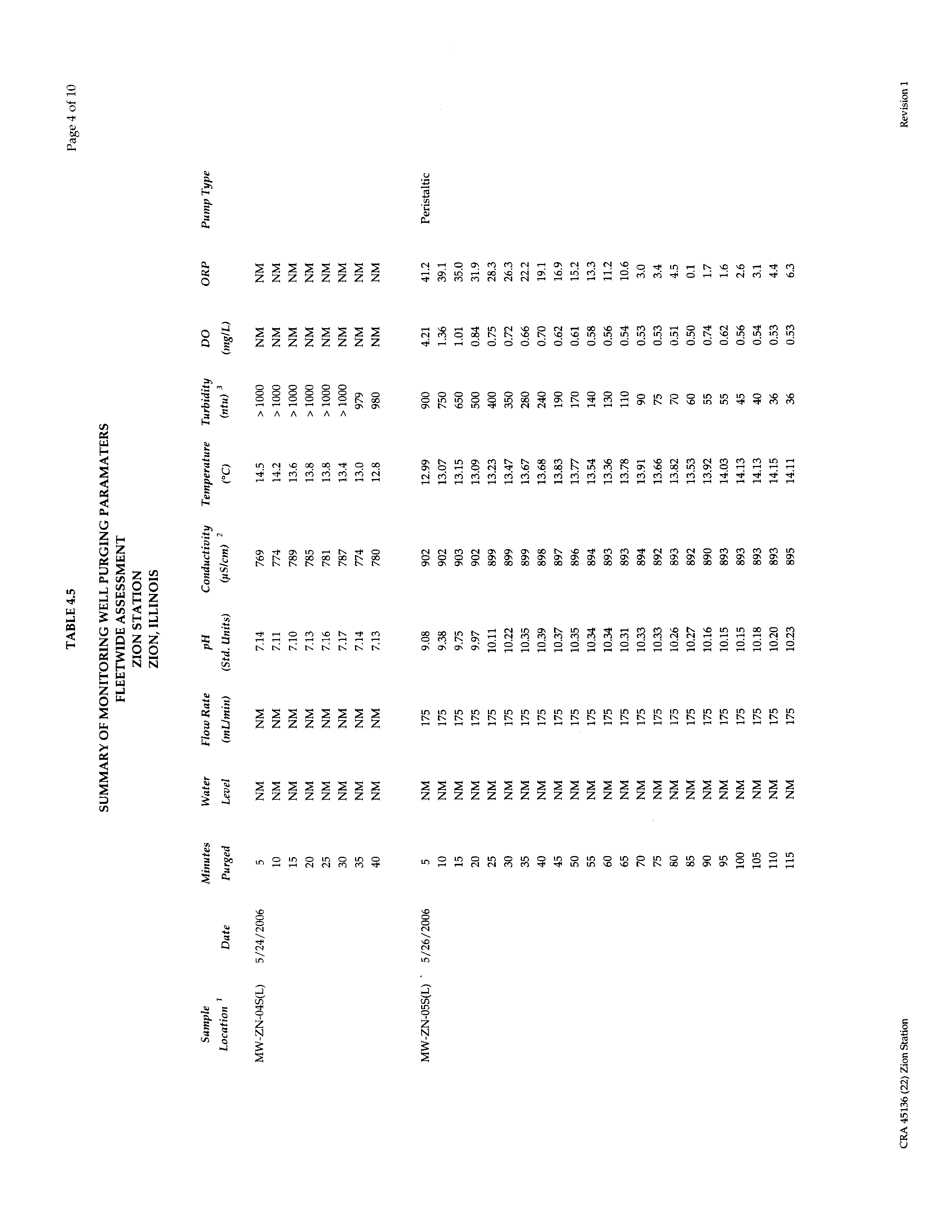

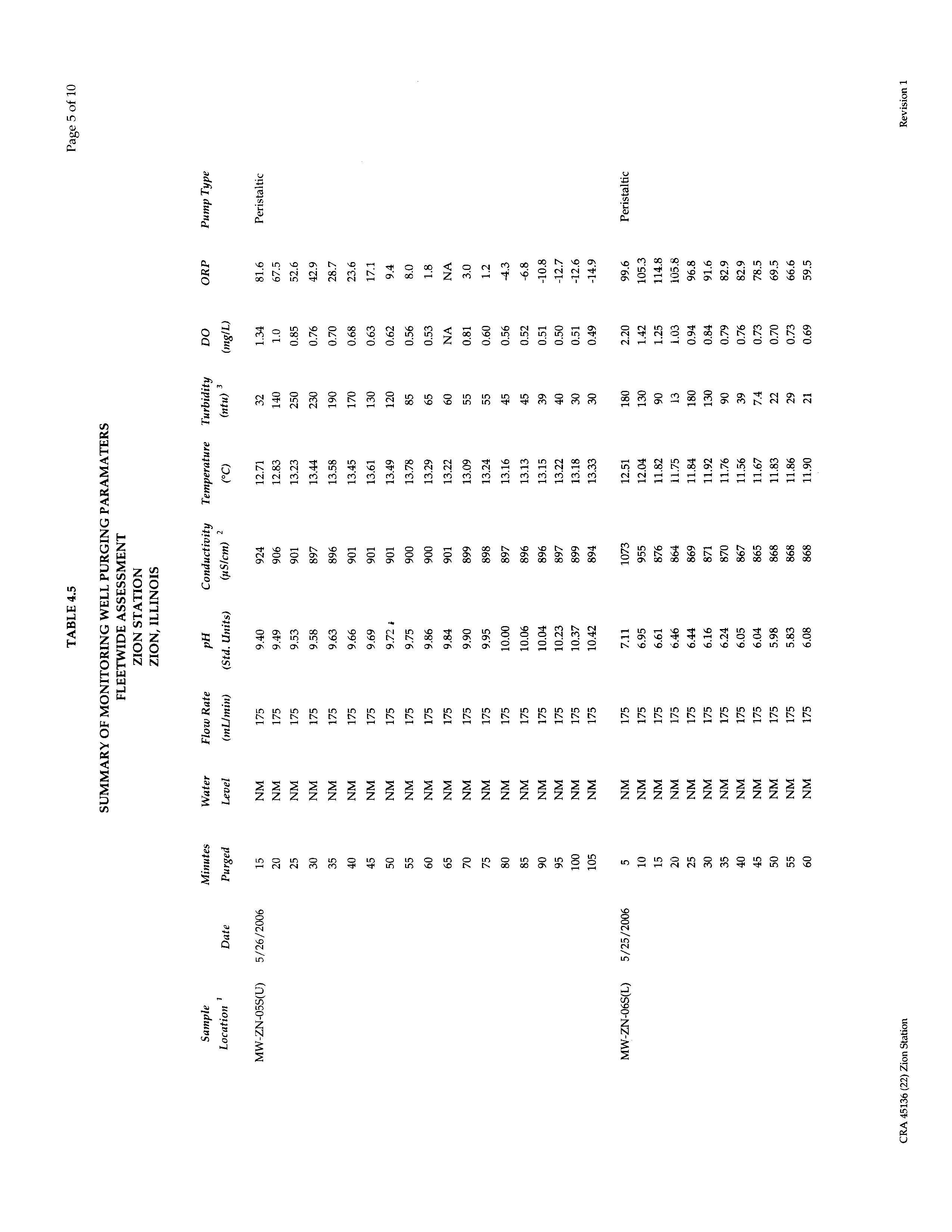

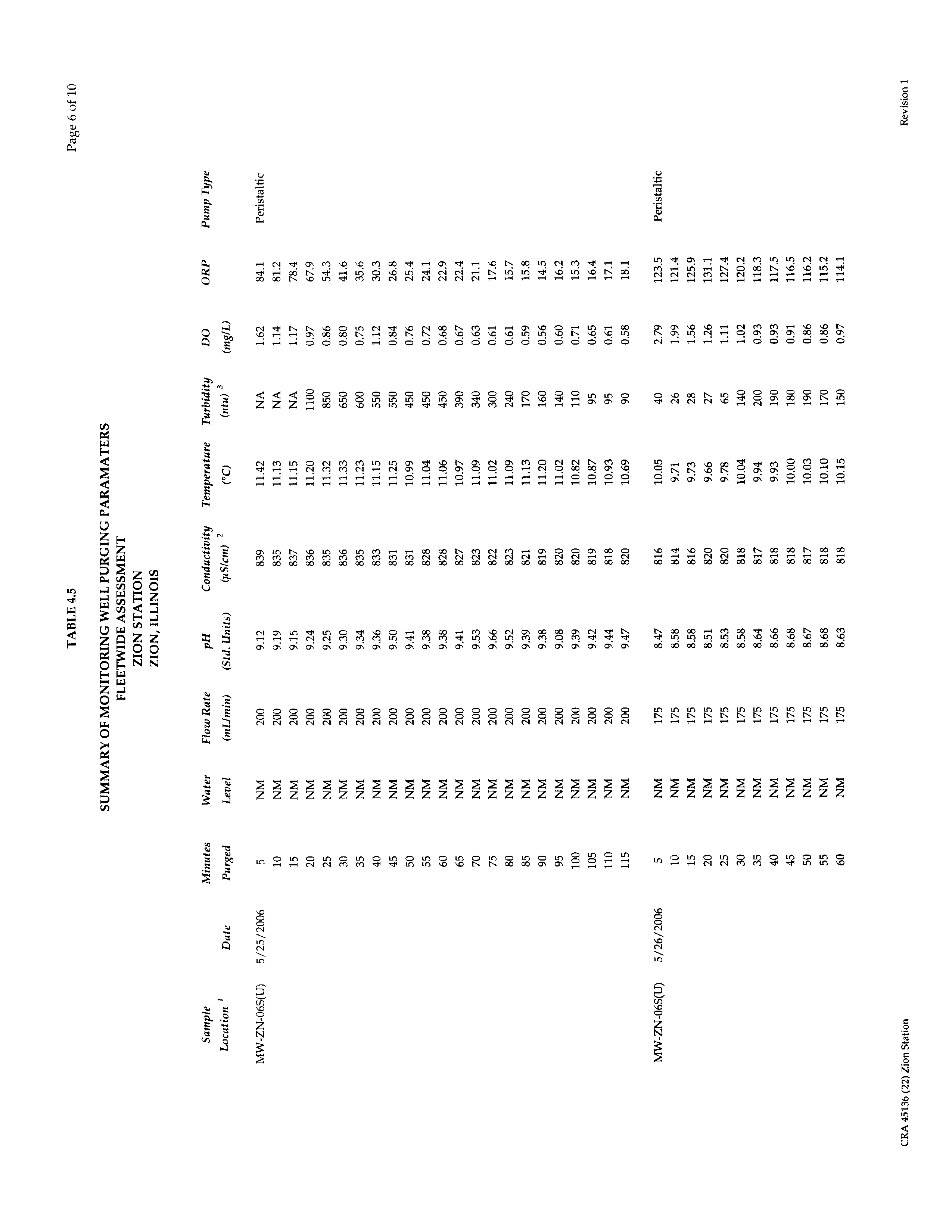

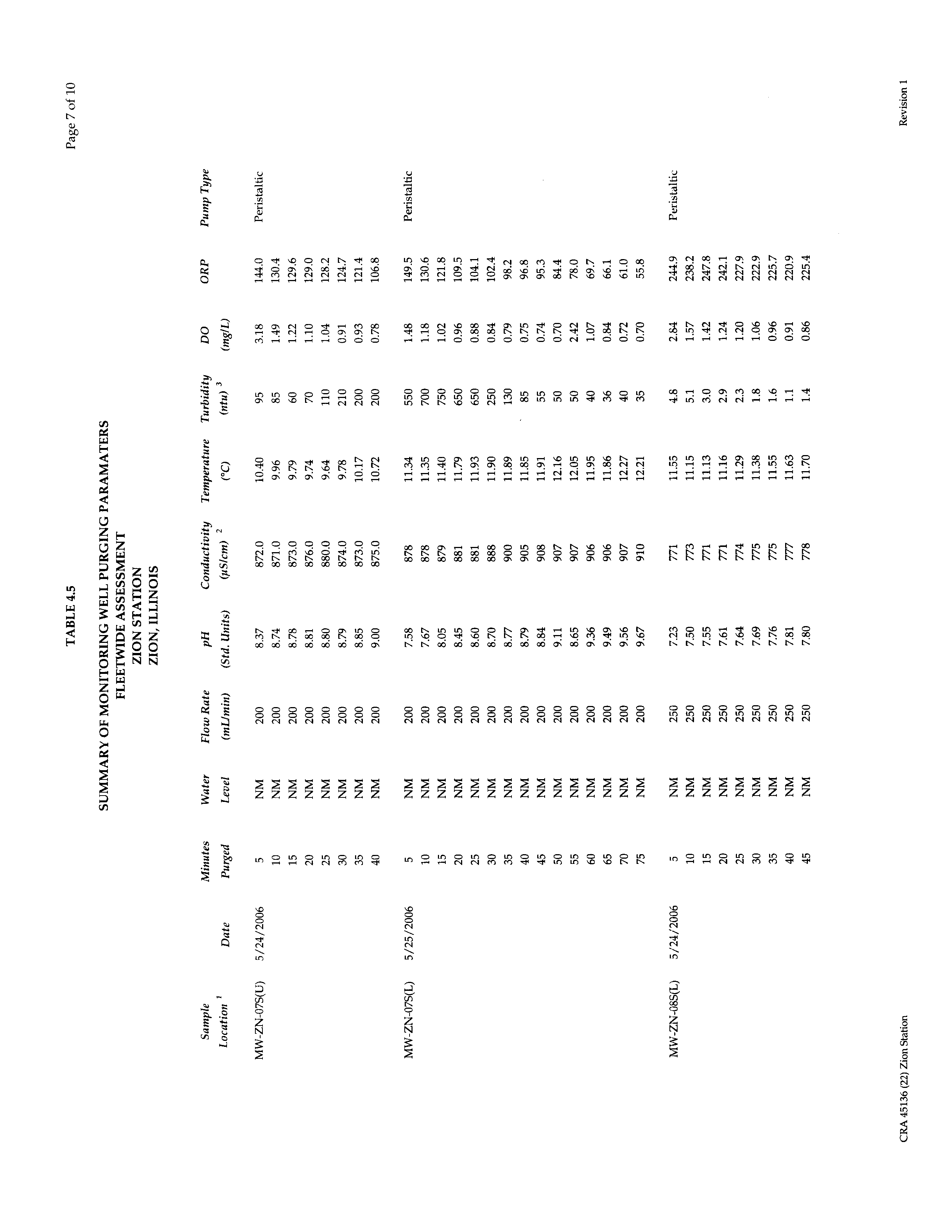

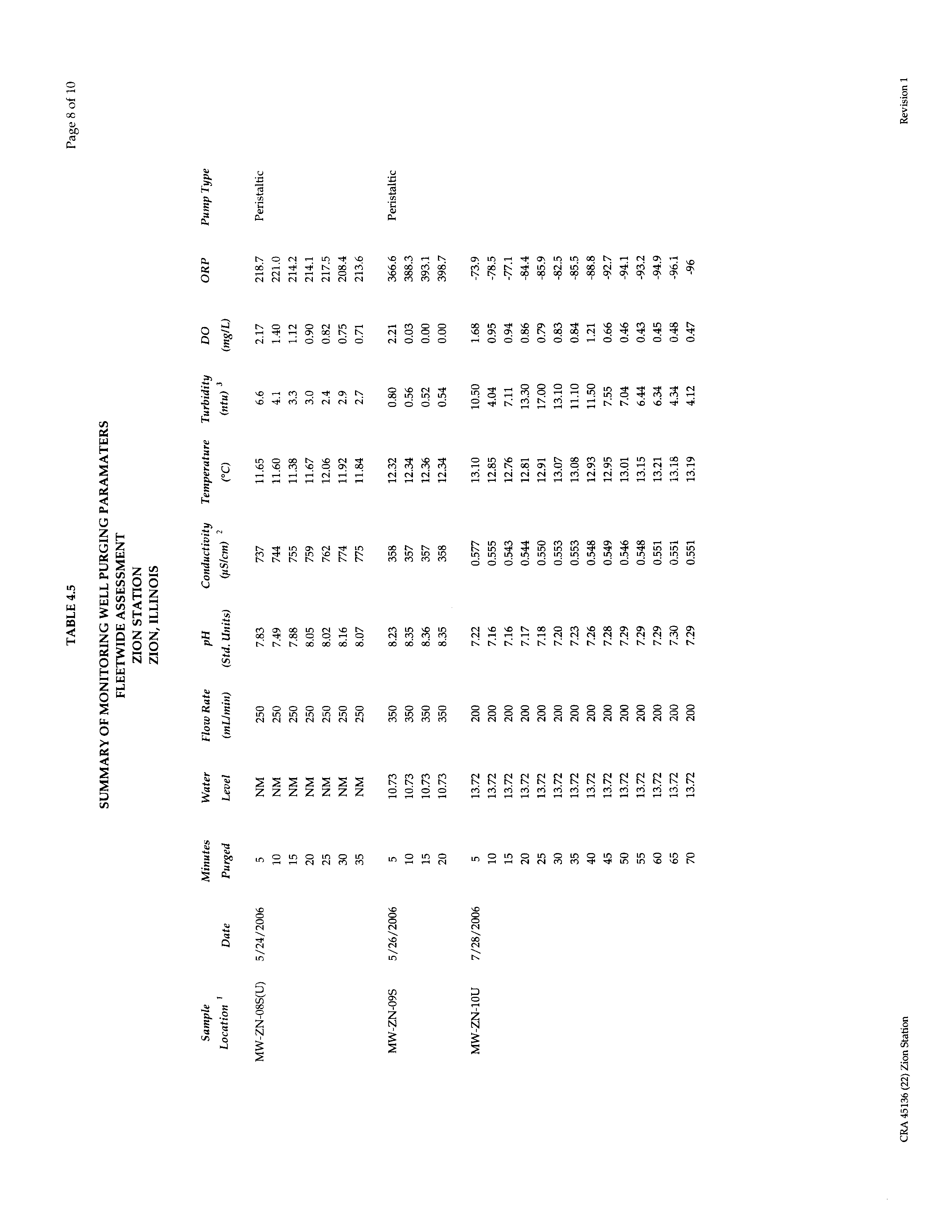

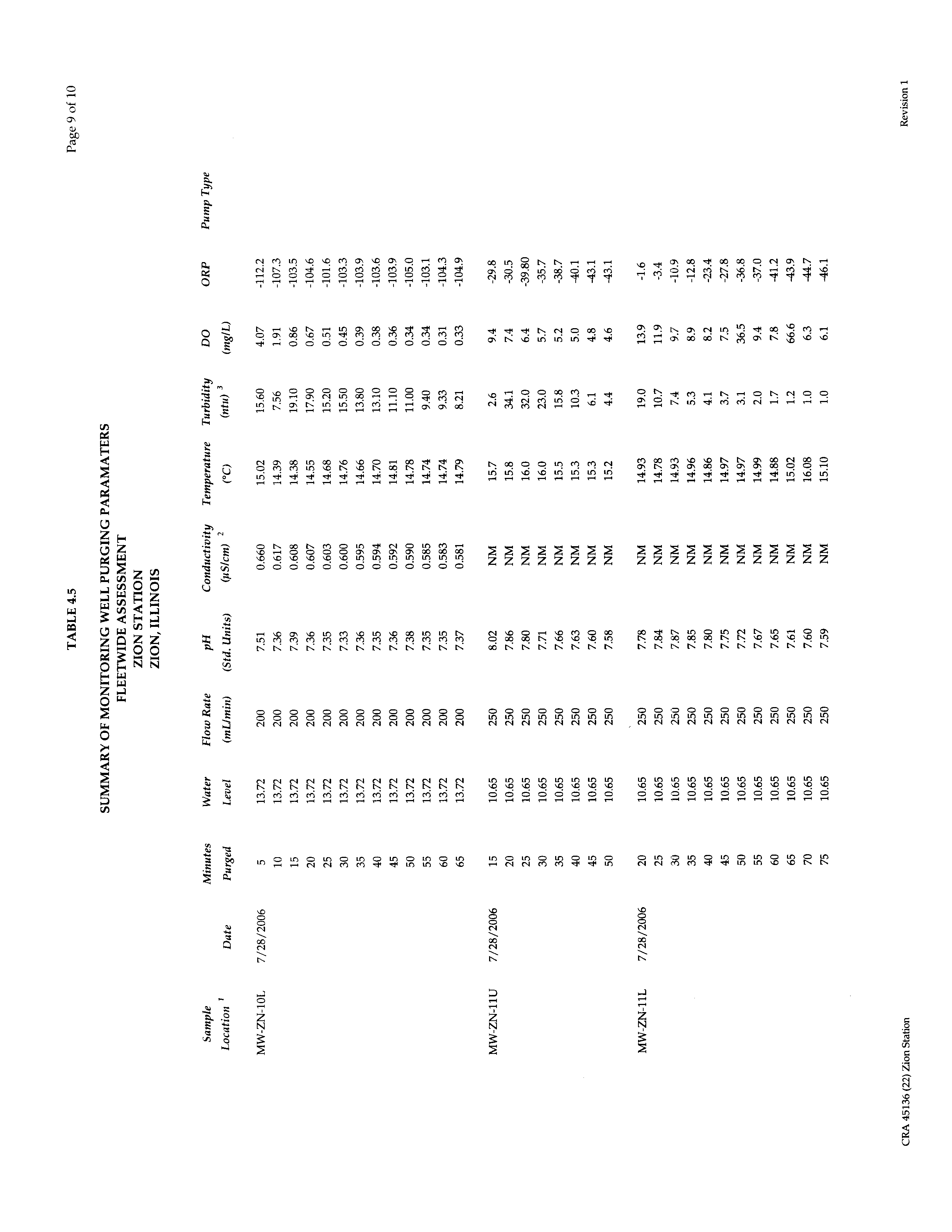

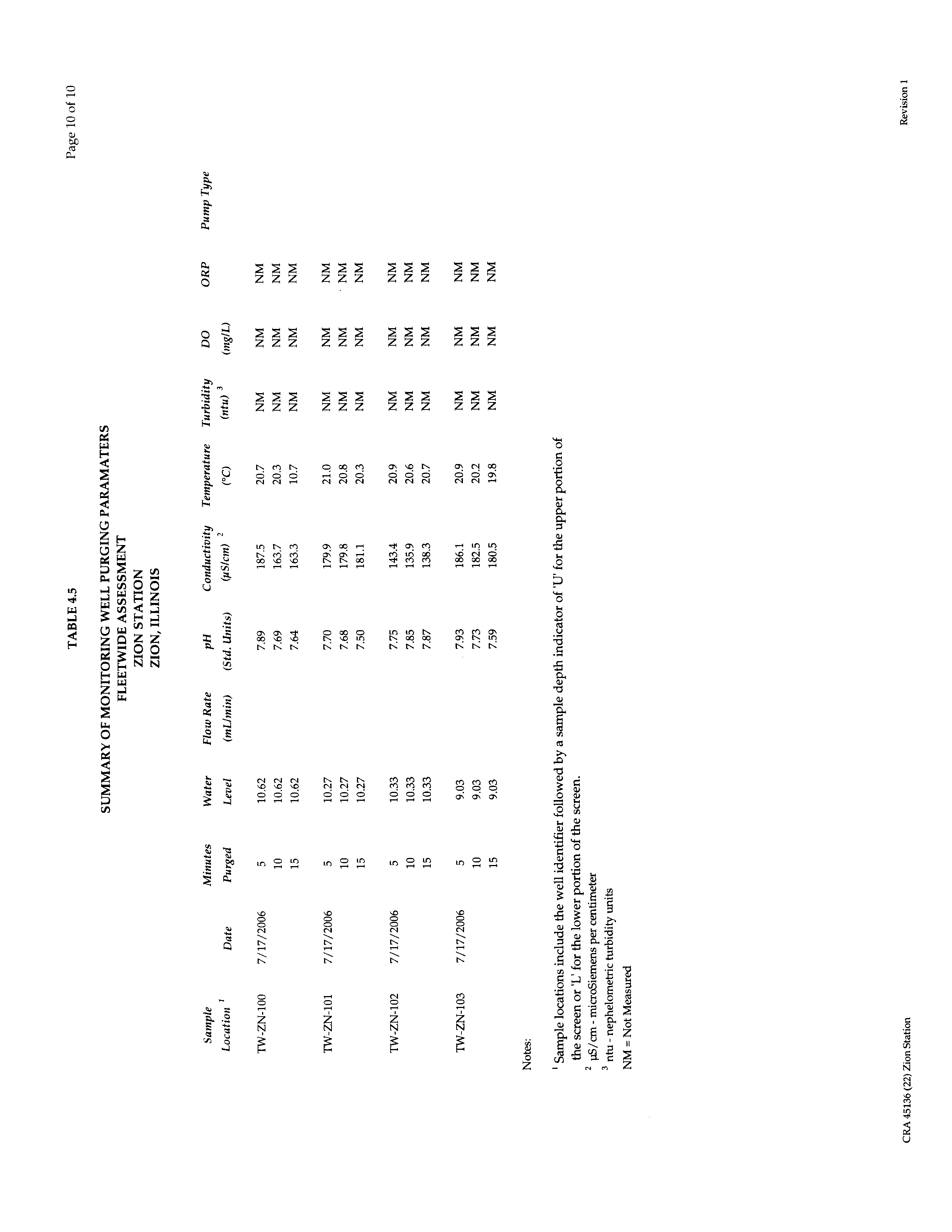

TABLE 4.5

SUMMARY OF MONITORING WELL PURGING PARAMETERS

TABLE 5.1

ANALYTICAL RESULTS SUMMARY – TRITIUM IN GROUNDWATER

AND SURFACE WATER

TABLE 5.2

ANALYTICAL RESULTS SUMMARY – RADIONUCLIDES IN

GROUNDWATER AND SURFACE WATER

045136 (22) Zion Station

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

LIST OF APPENDICES

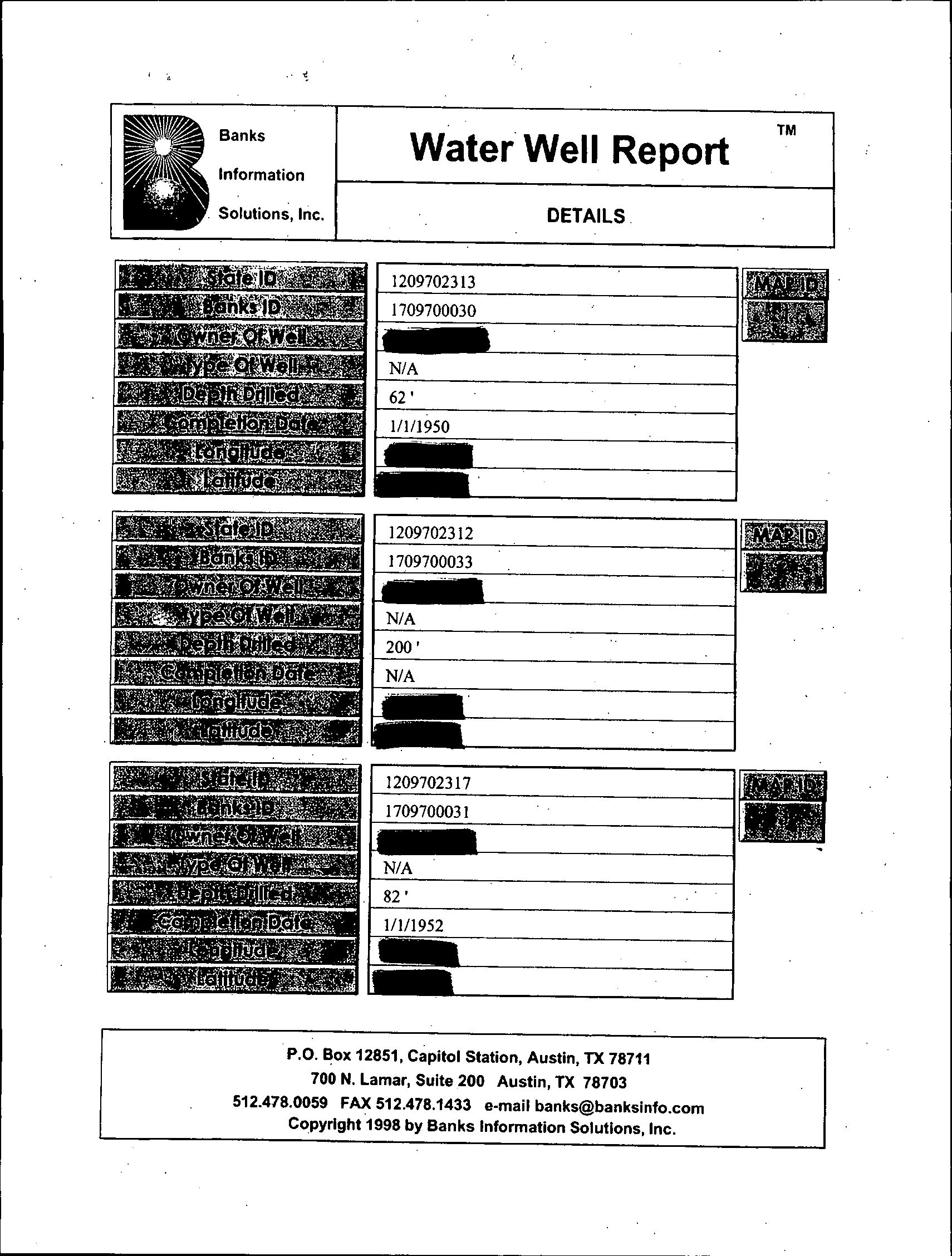

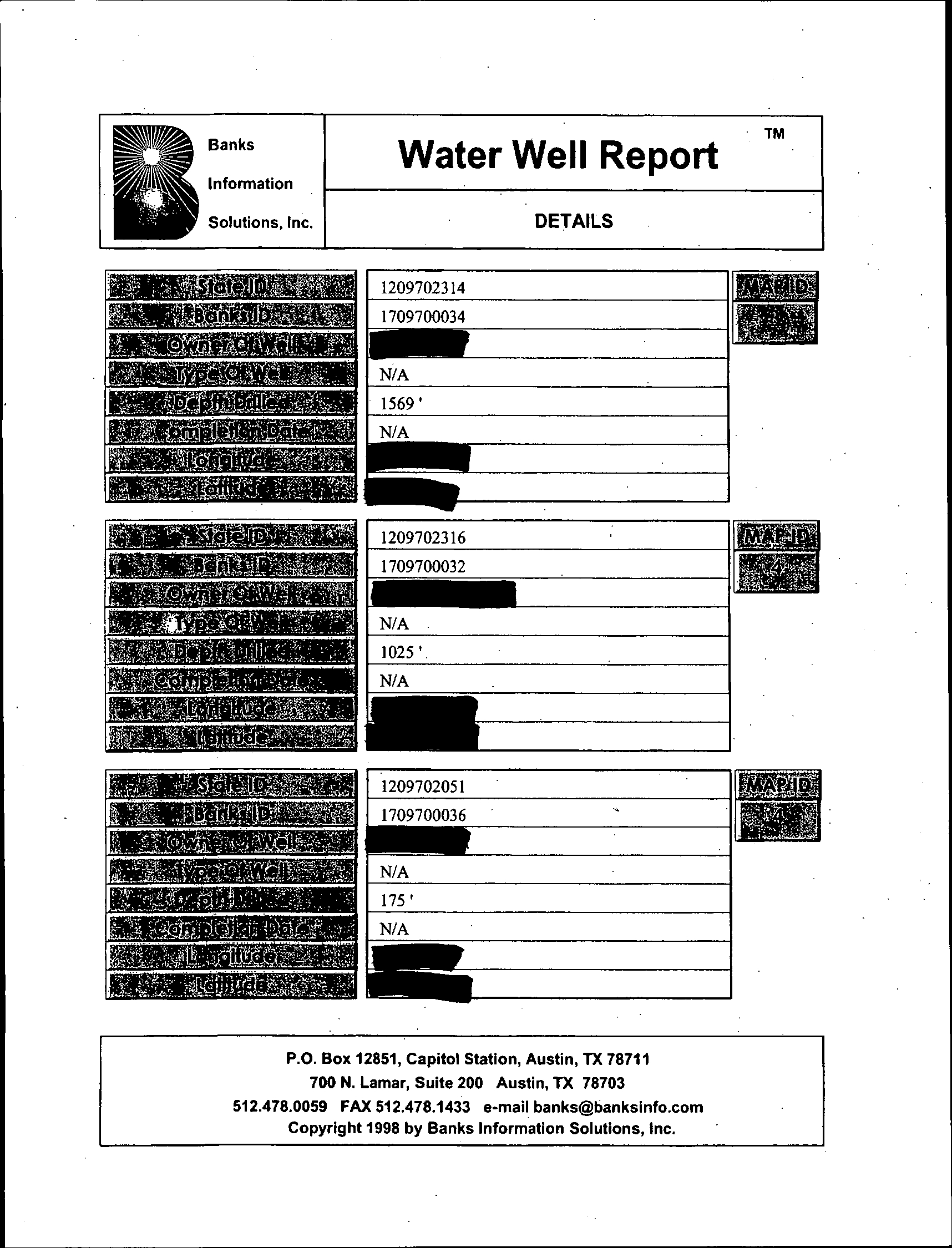

APPENDIX A

WATER WELL INVENTORY RECORDS

A.1

BANKS 2006 WATER WELL REPORT

A.2

ISWS LOGS

APPENDIX B

BORING LOGS

B.1

2006 STRATIGRAPHIC AND INSTRUMENTATION LOGS

B.2

HISTORIC GEOTECHNICAL LOGS

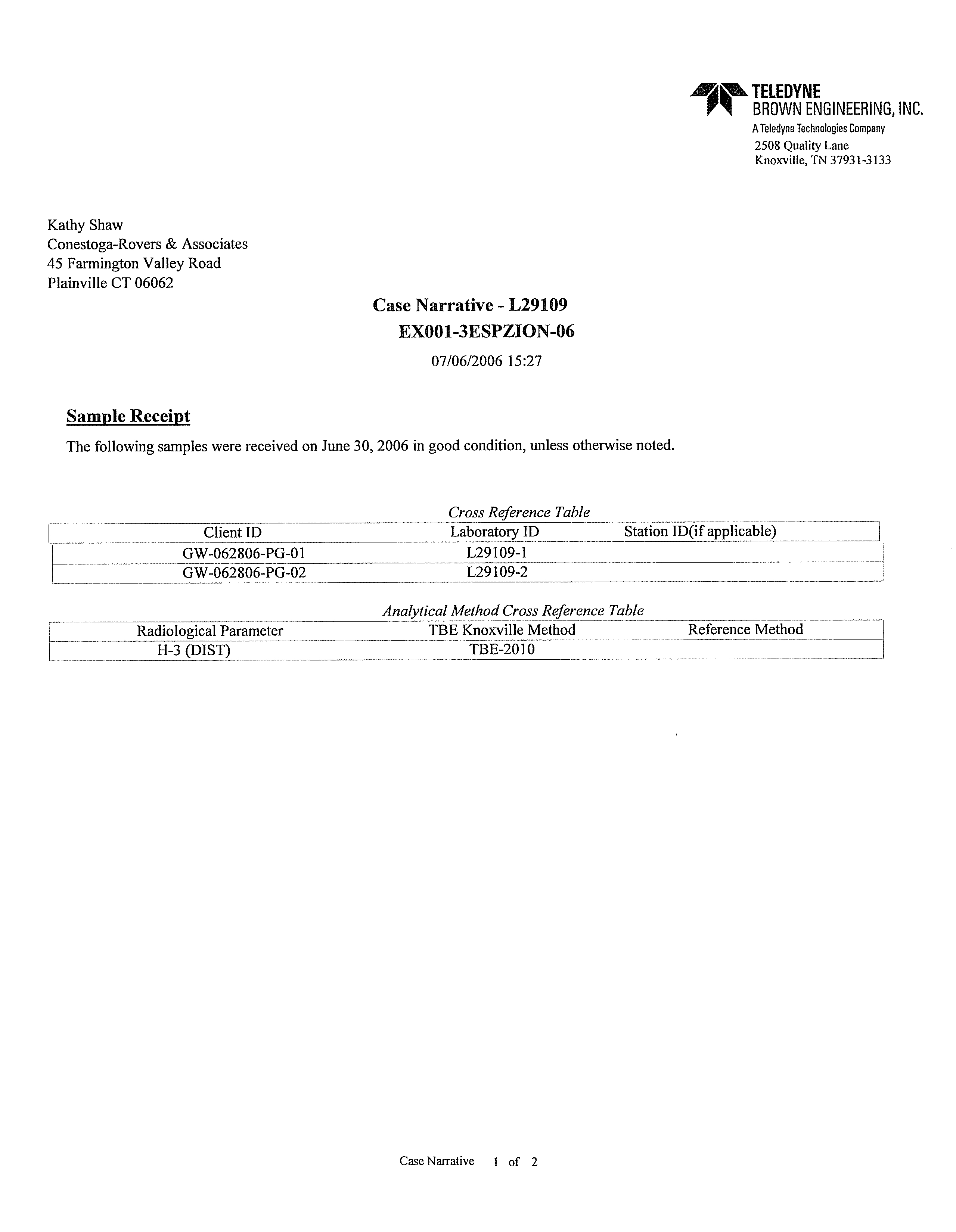

APPENDIX C

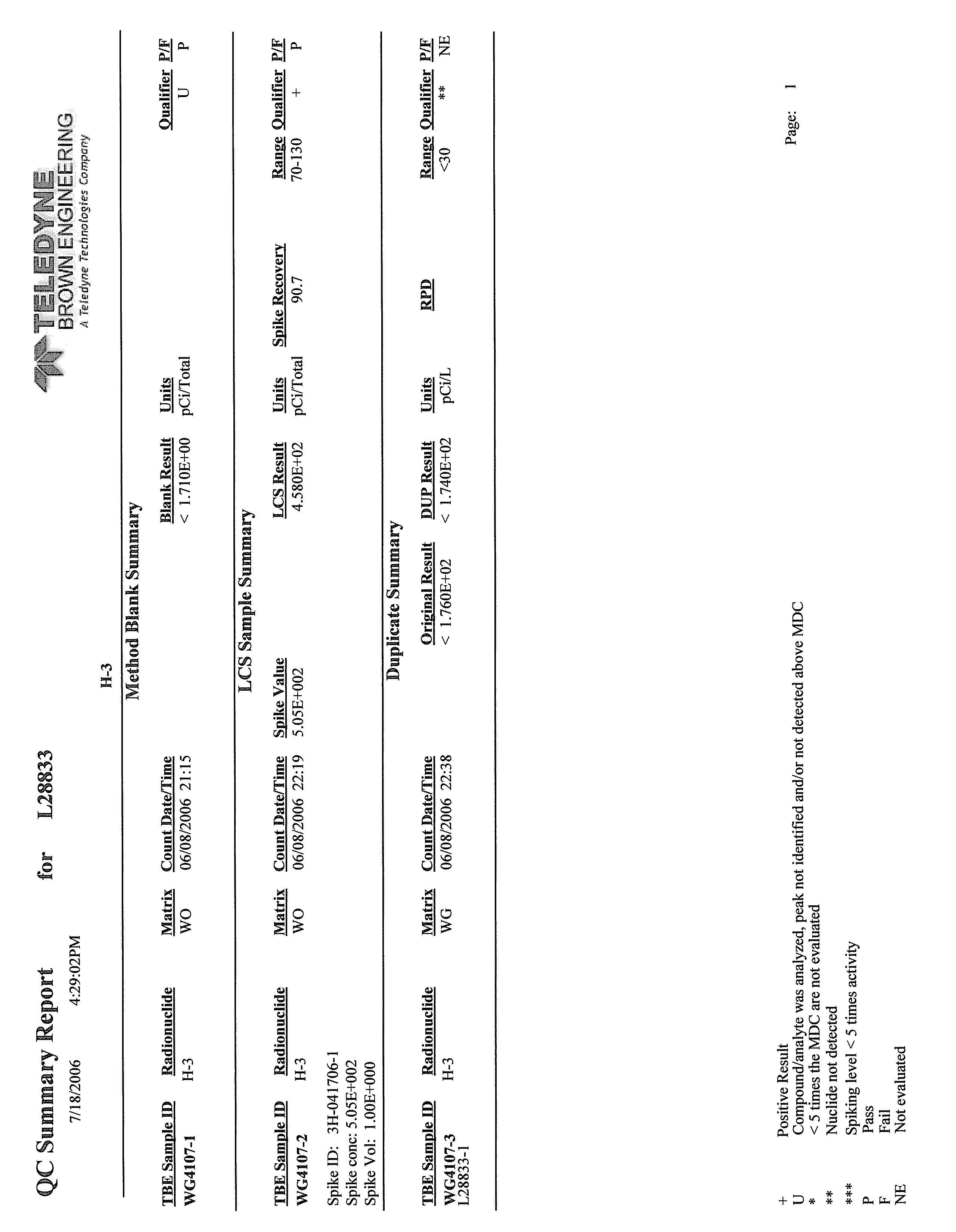

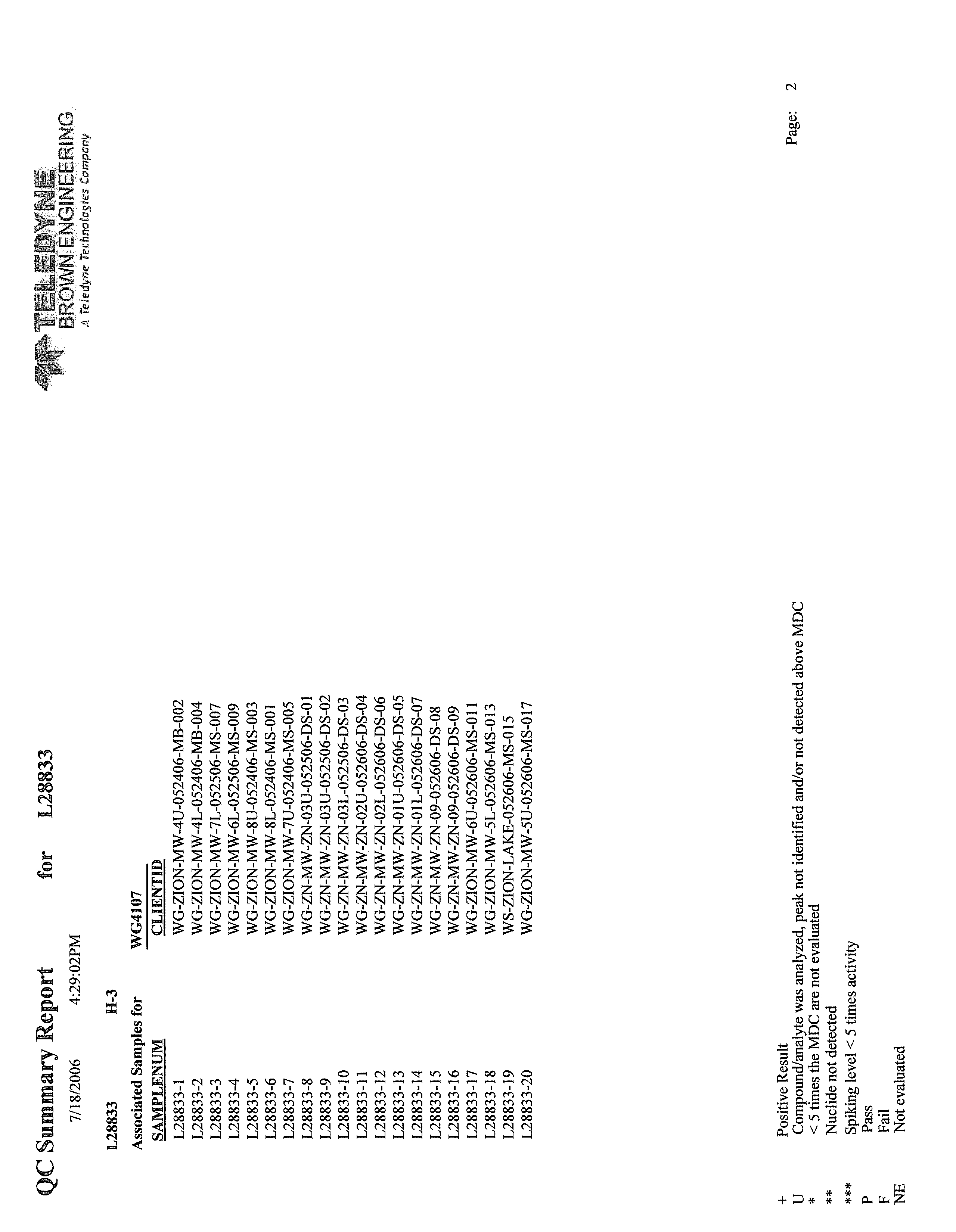

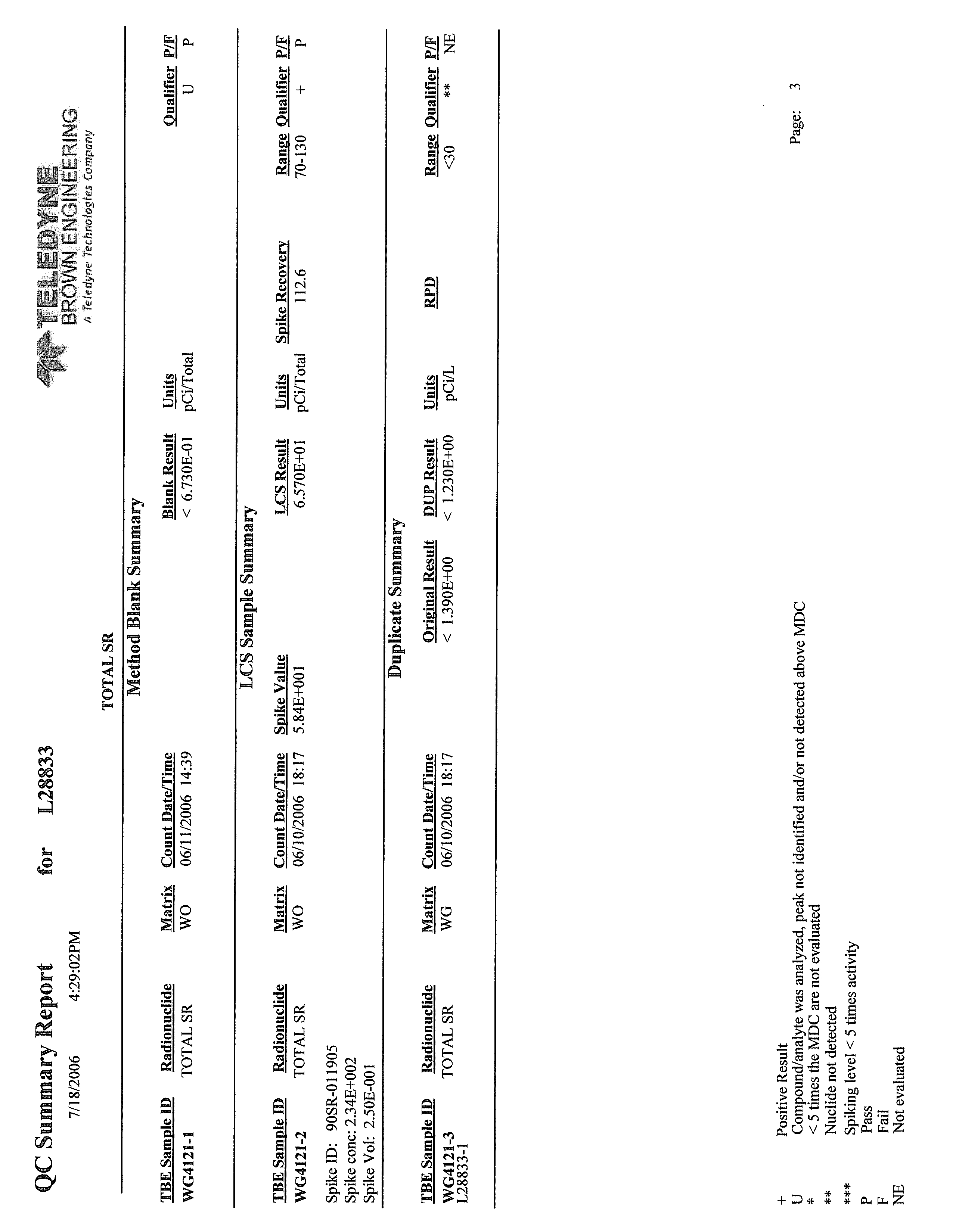

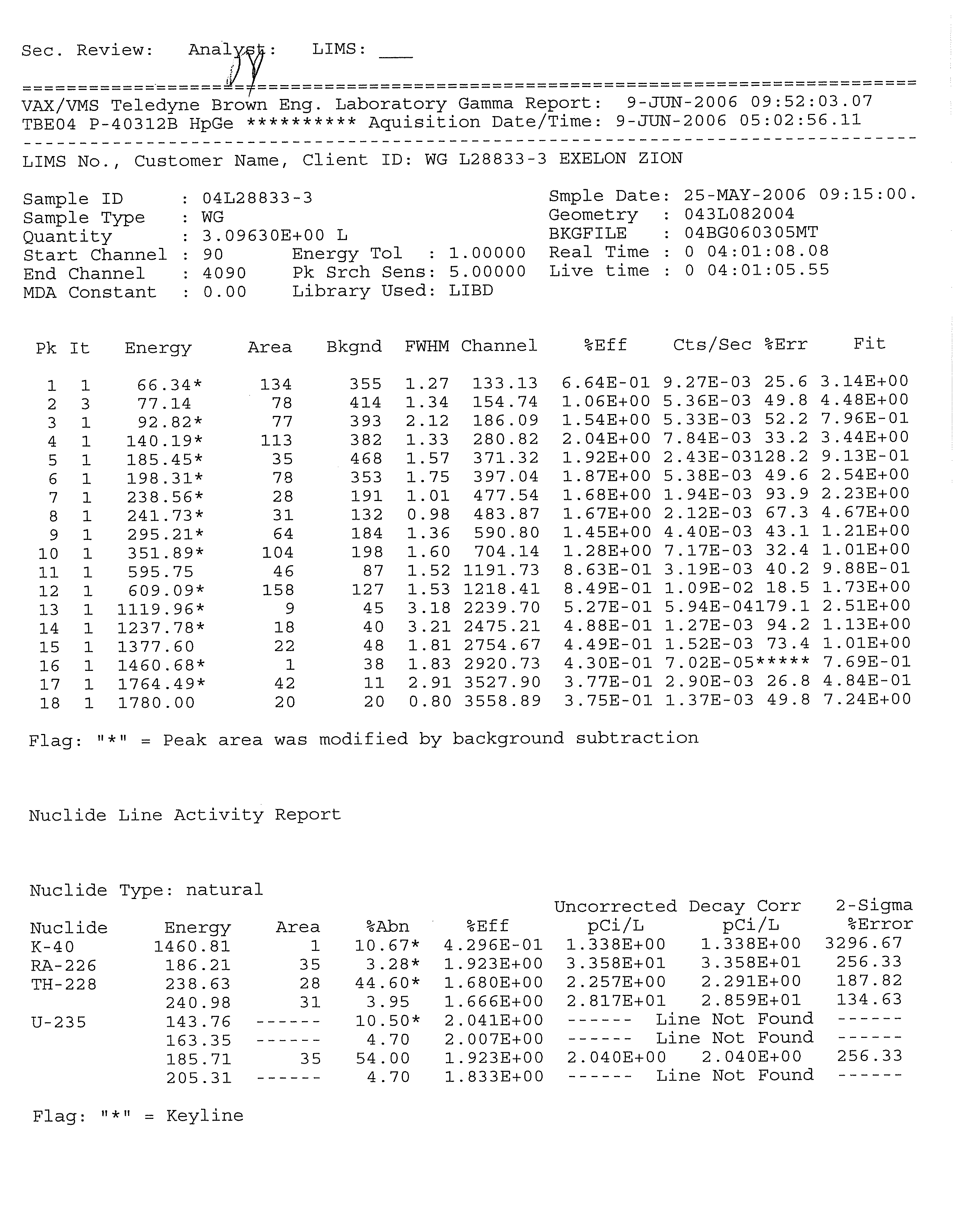

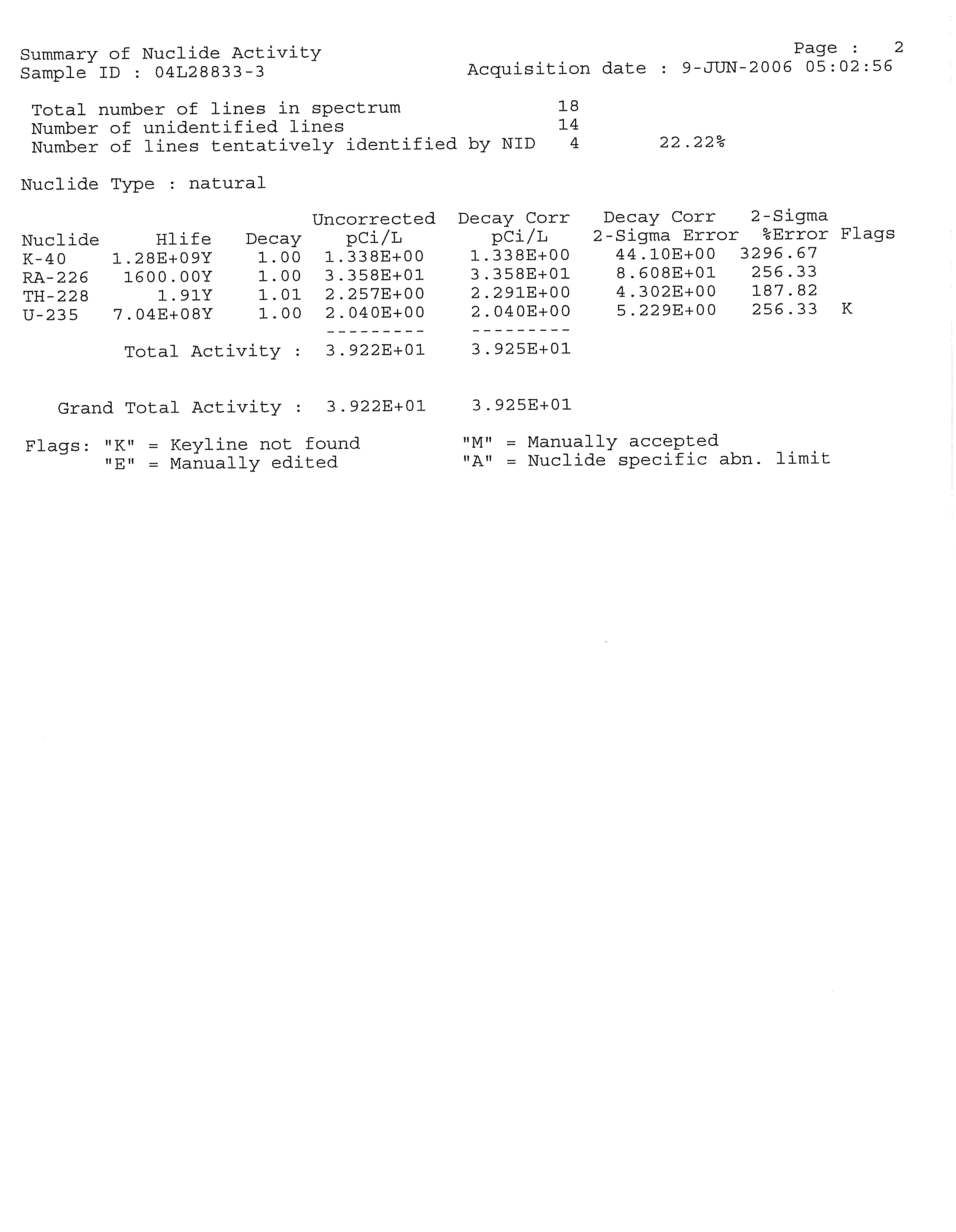

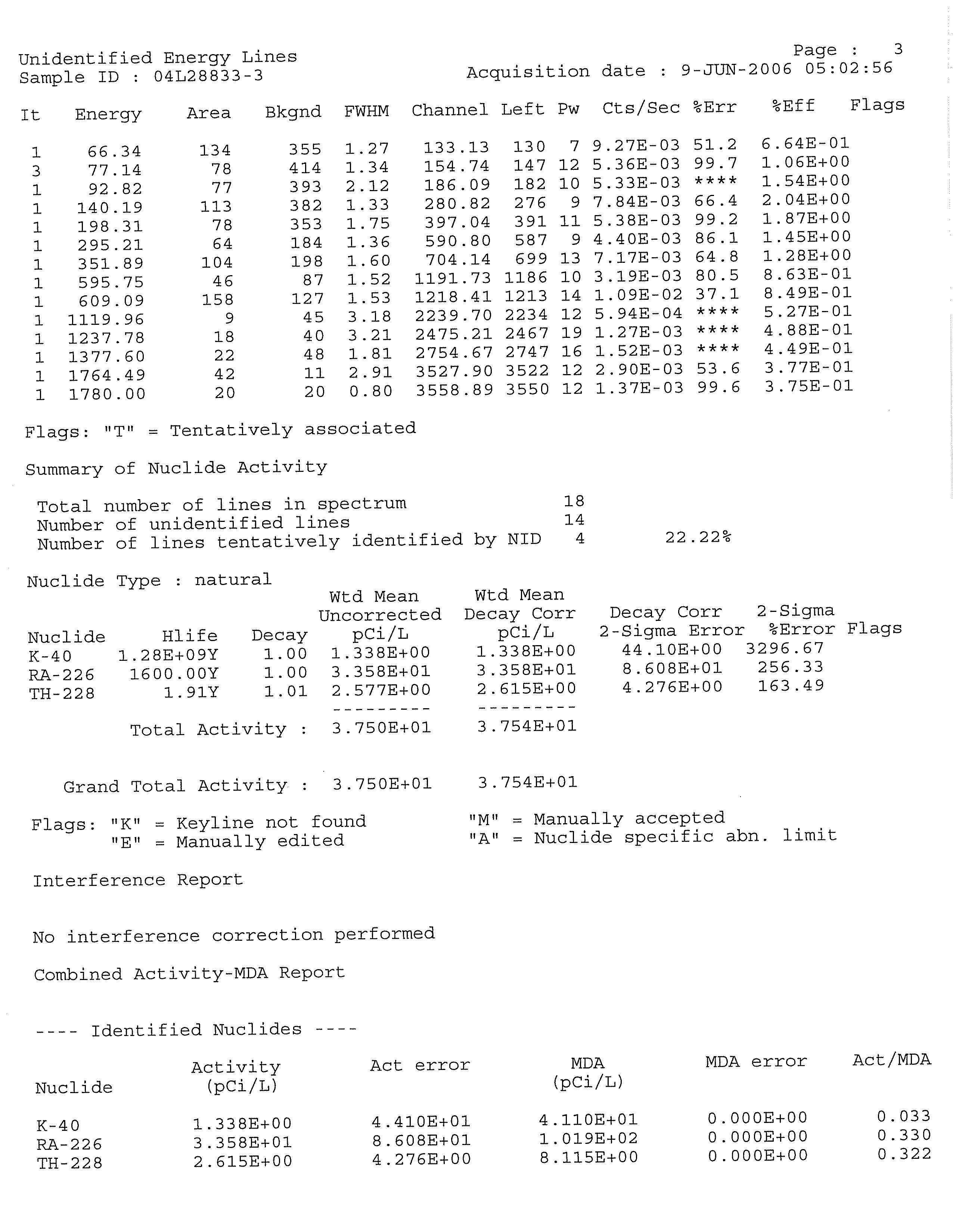

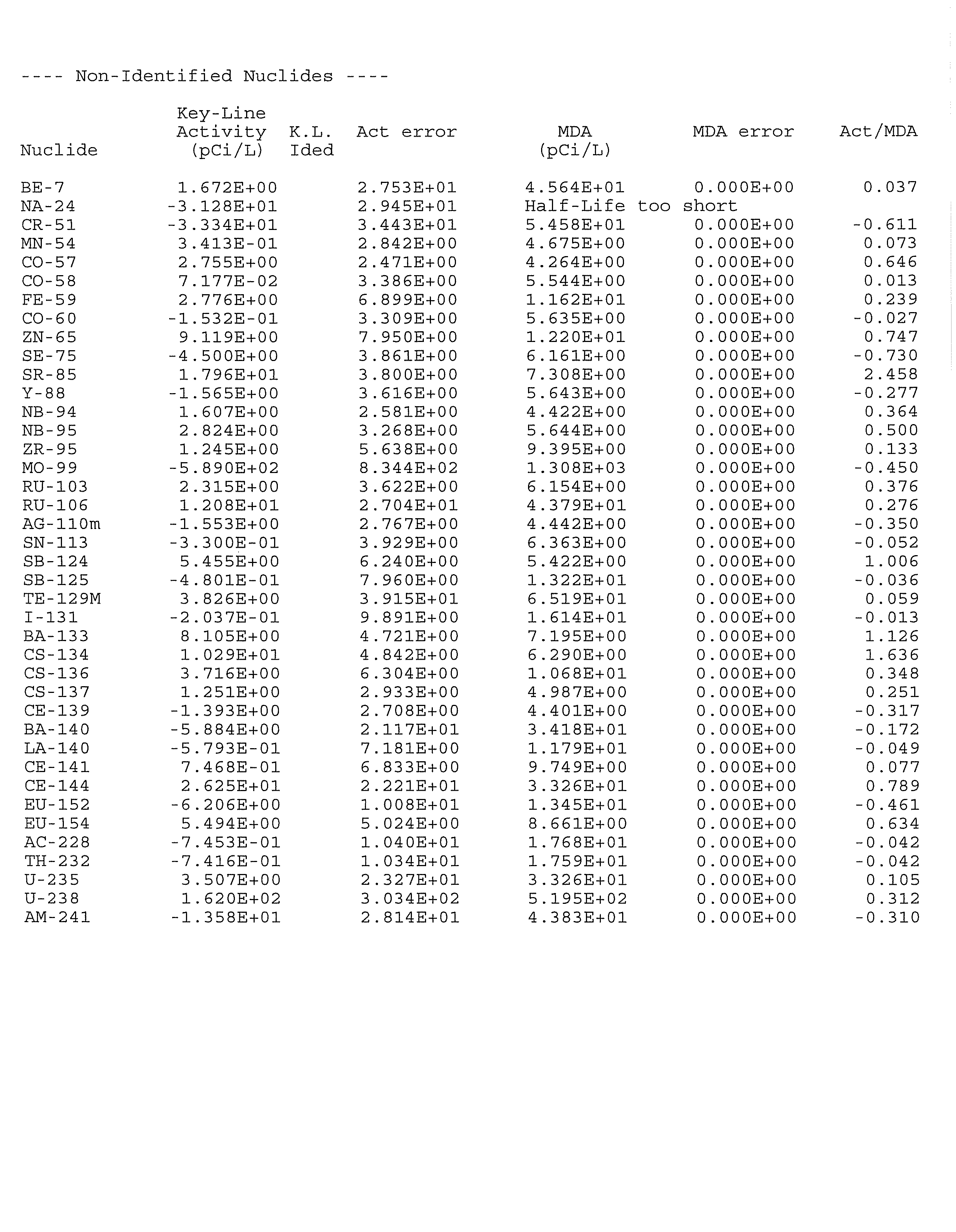

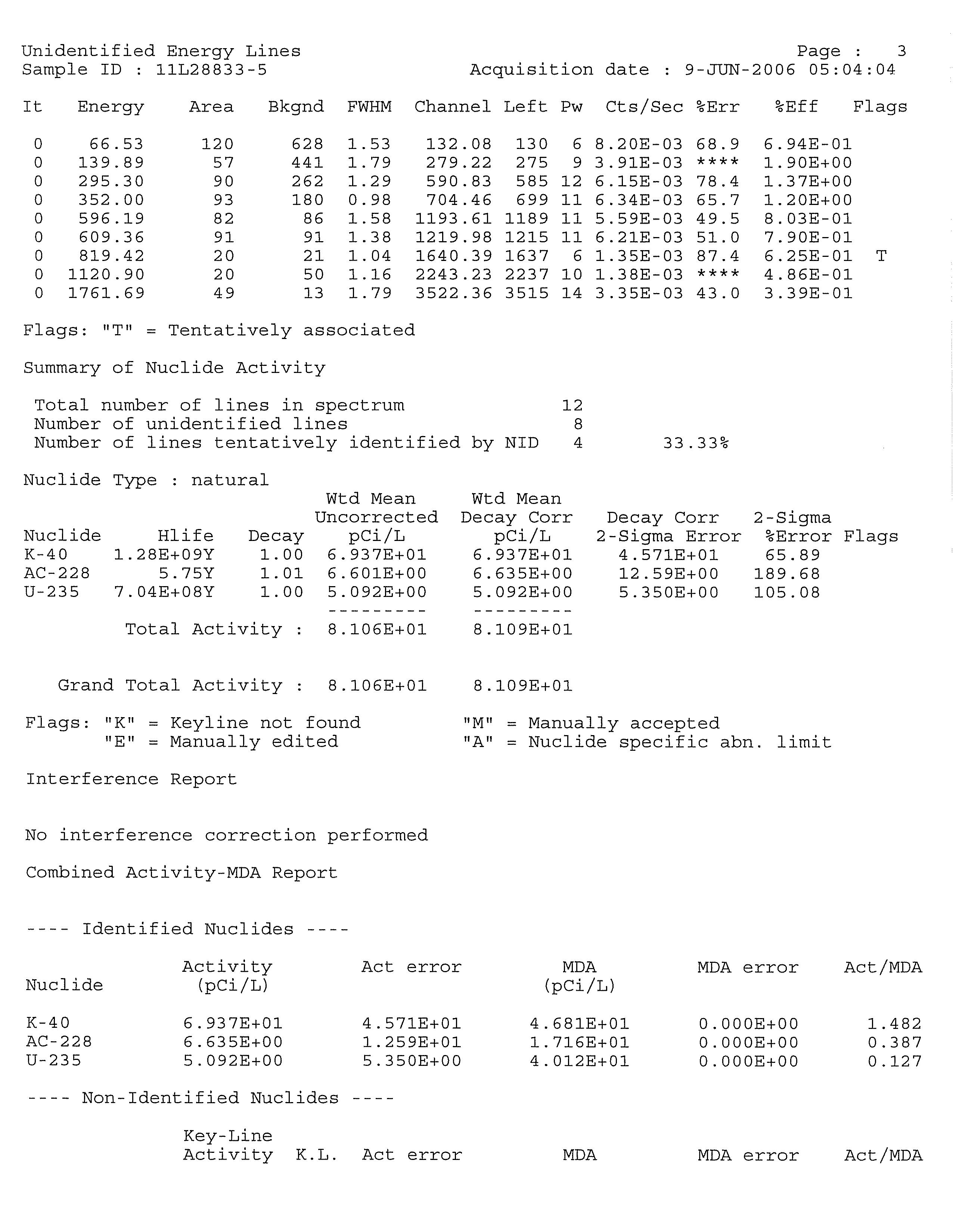

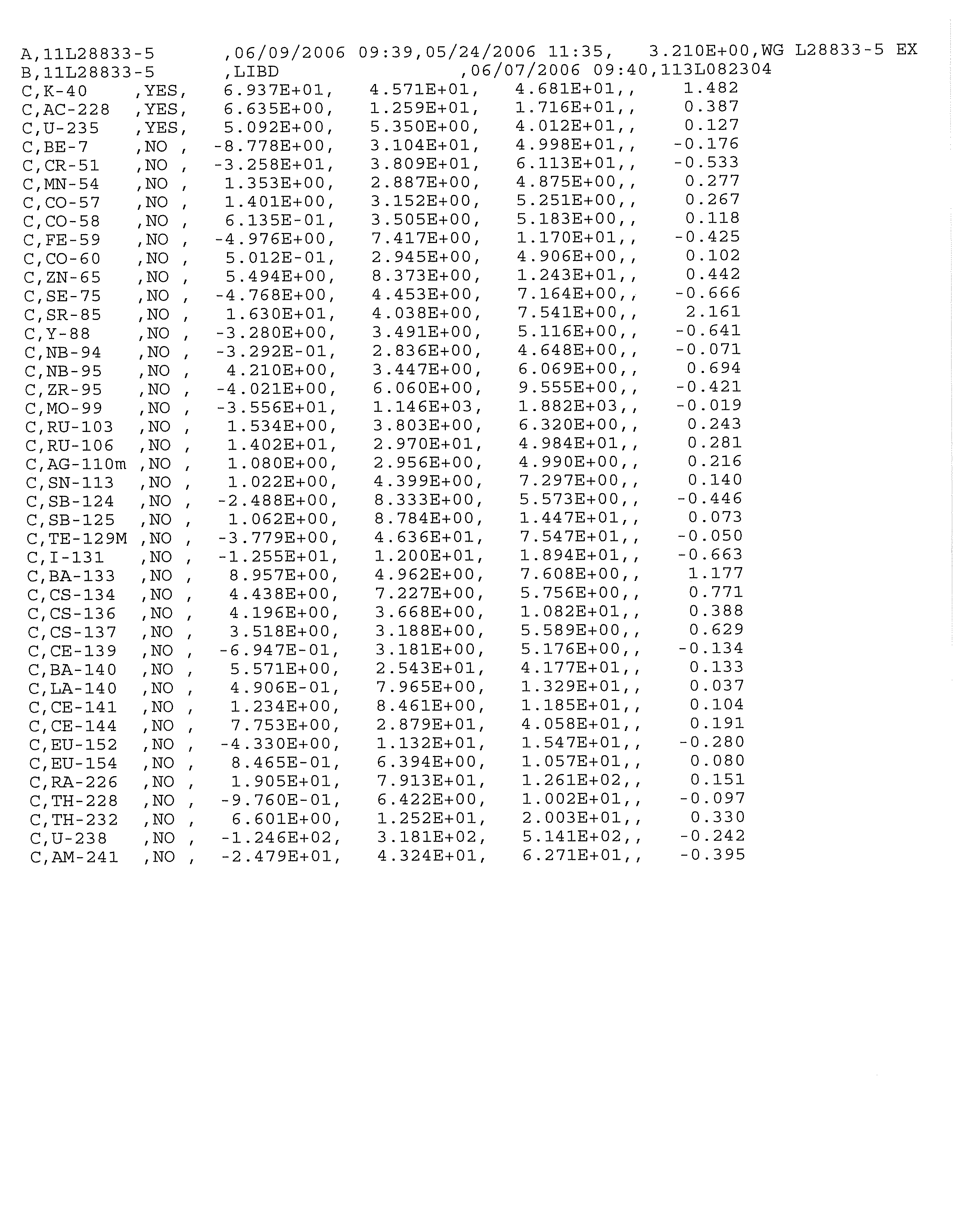

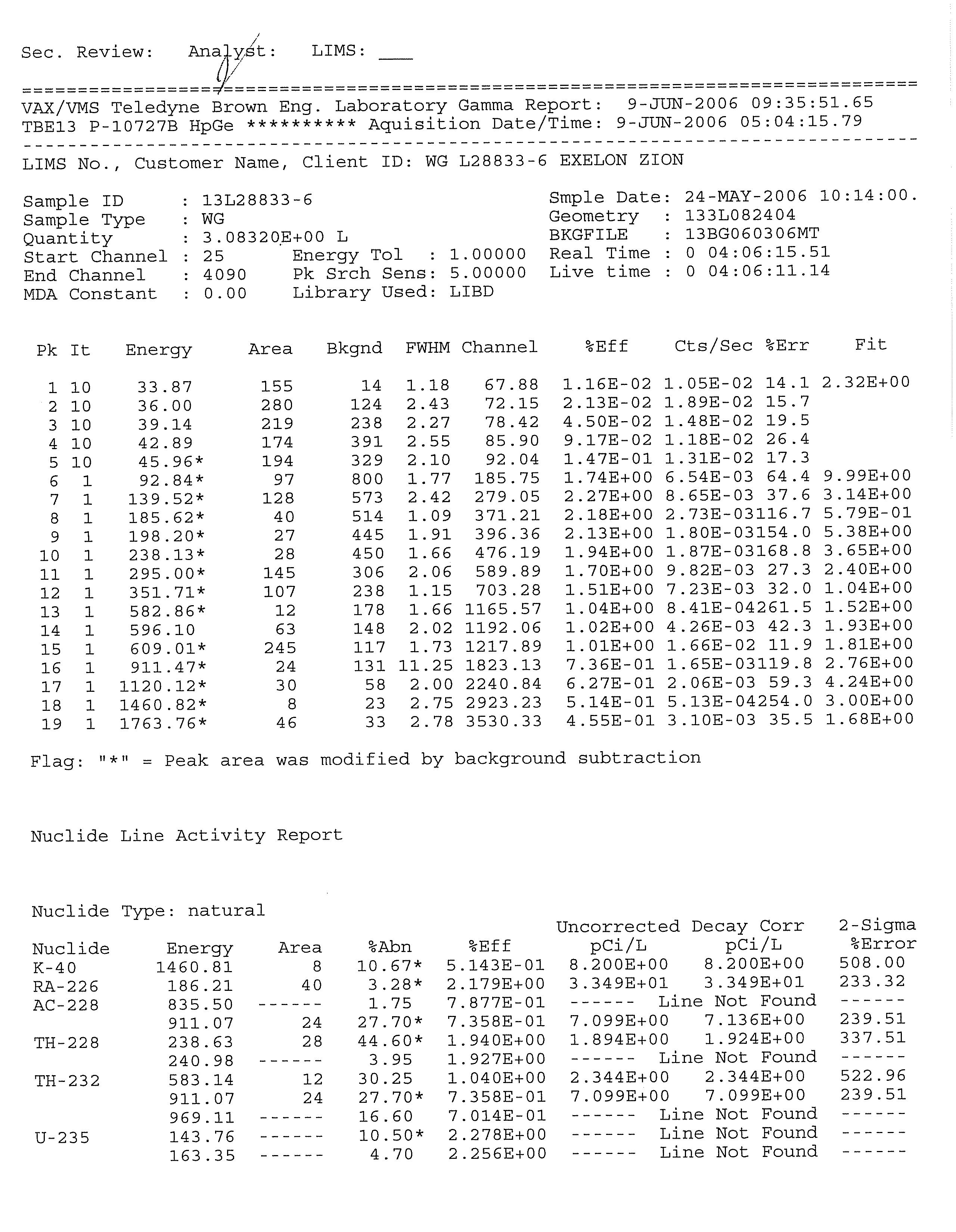

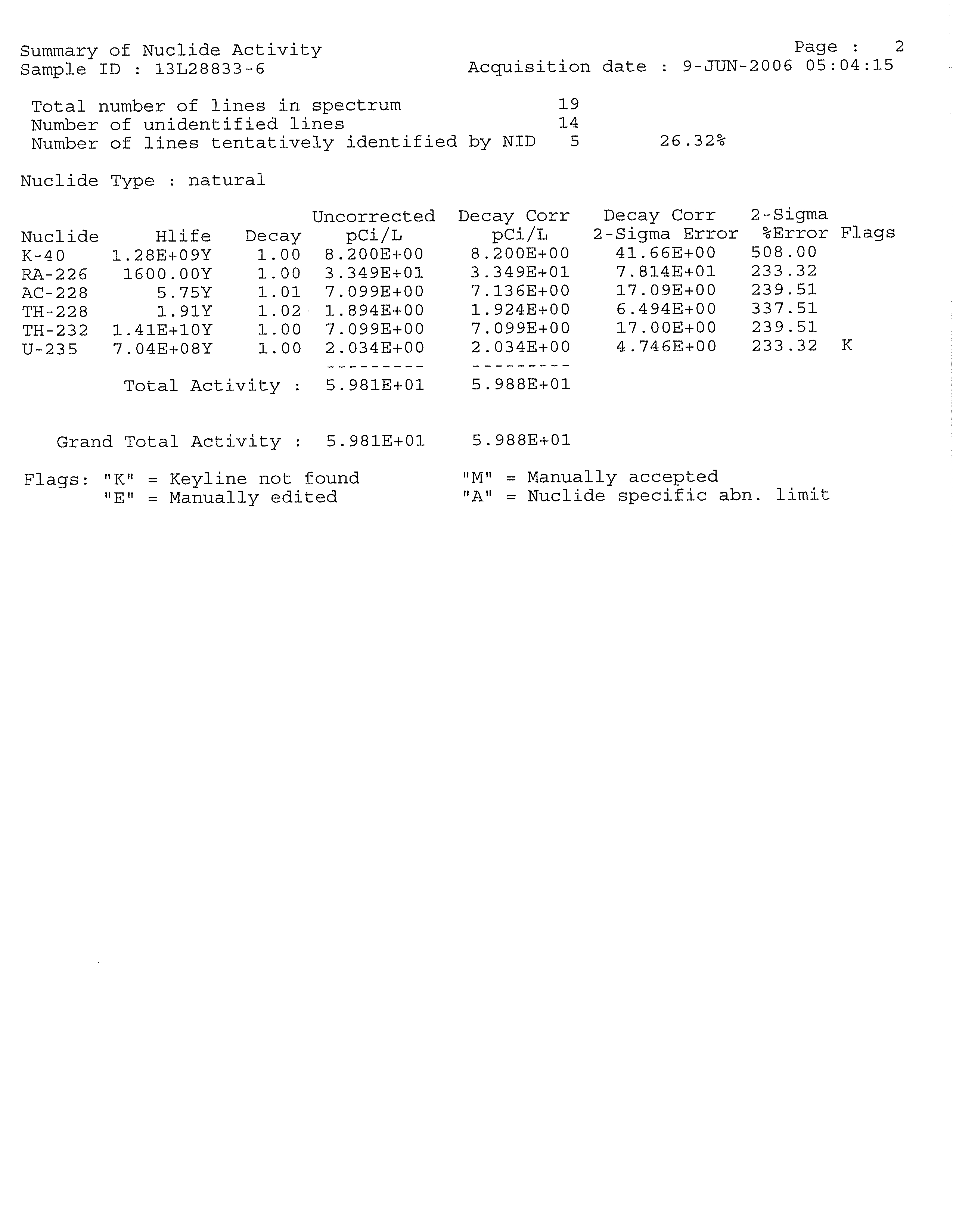

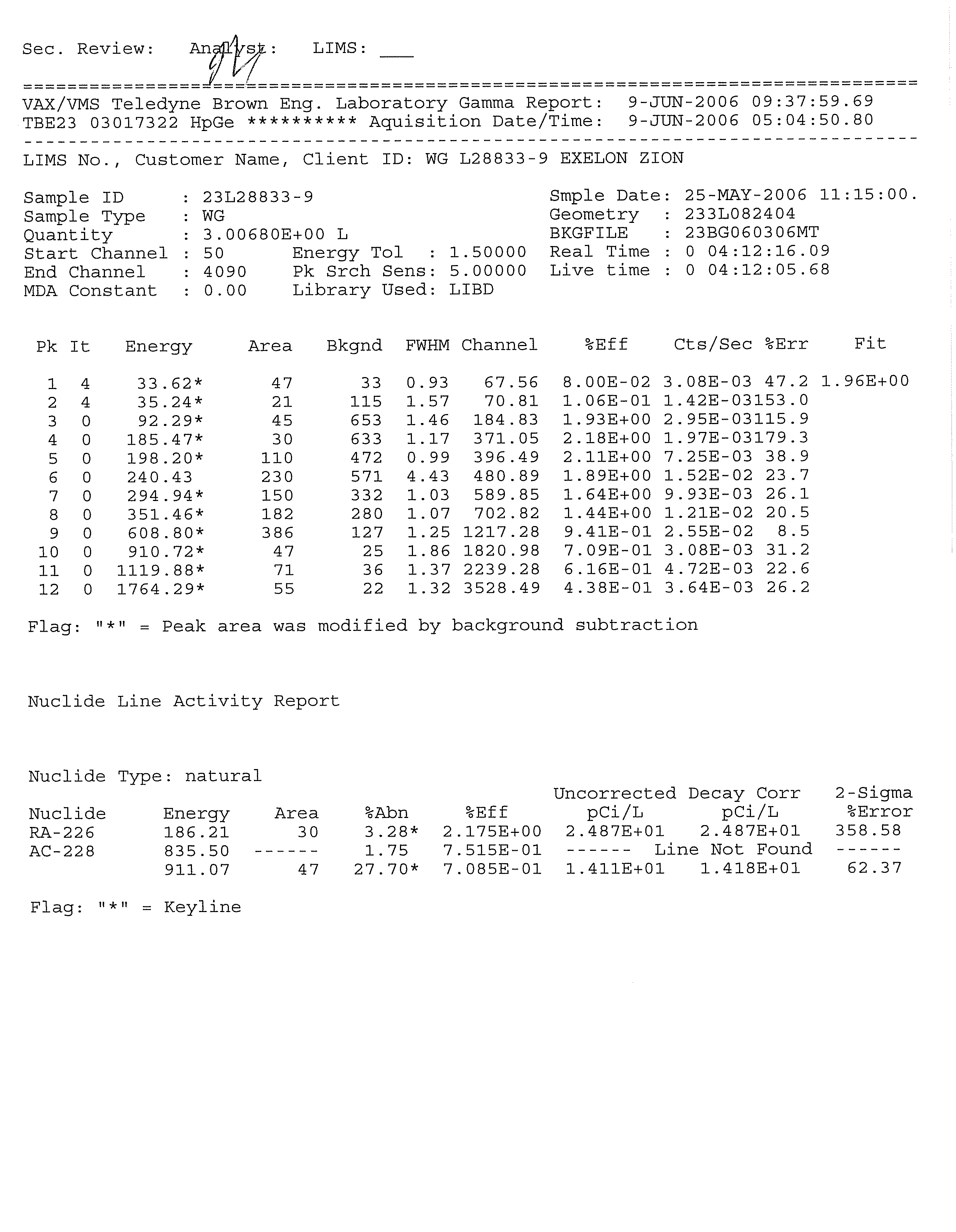

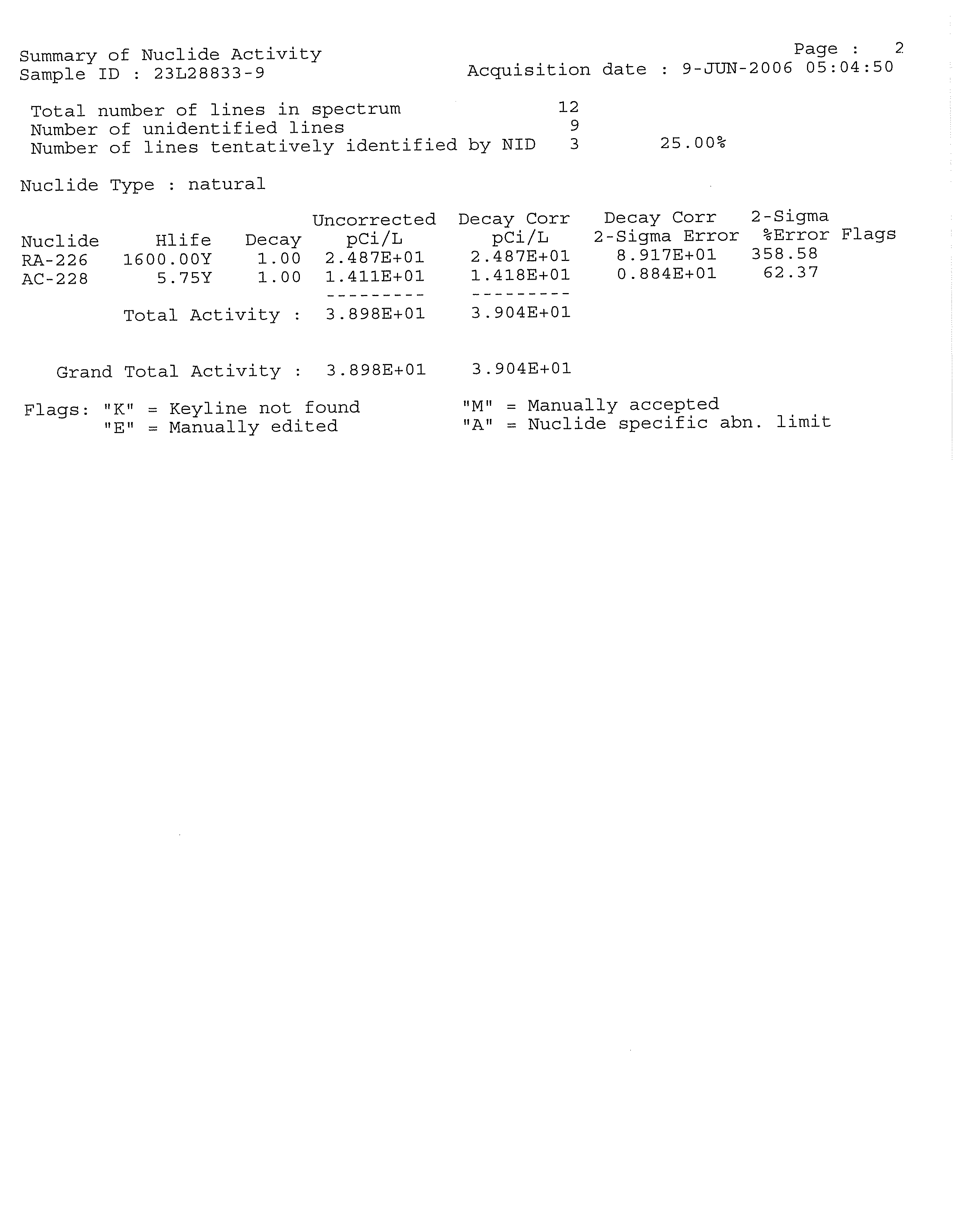

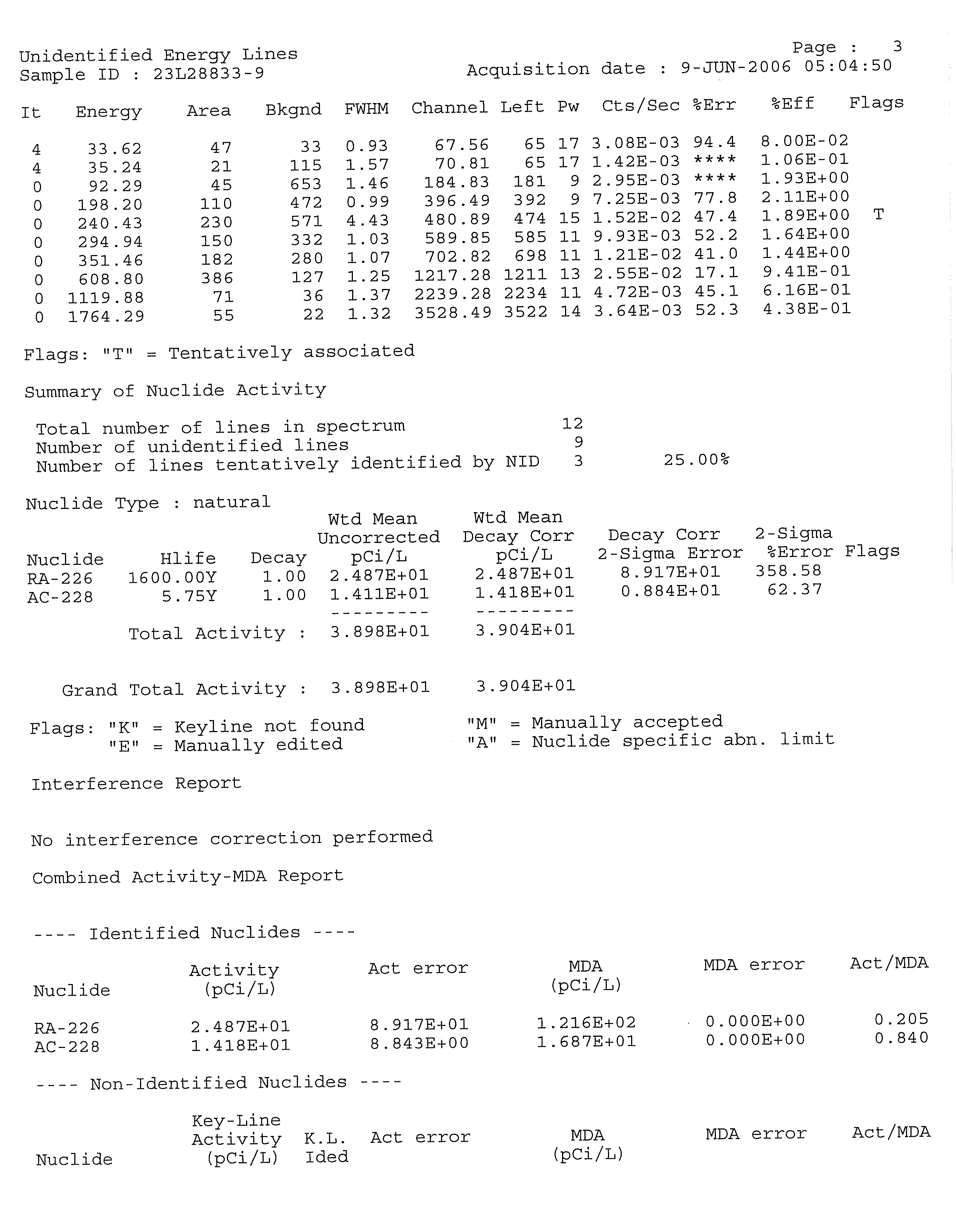

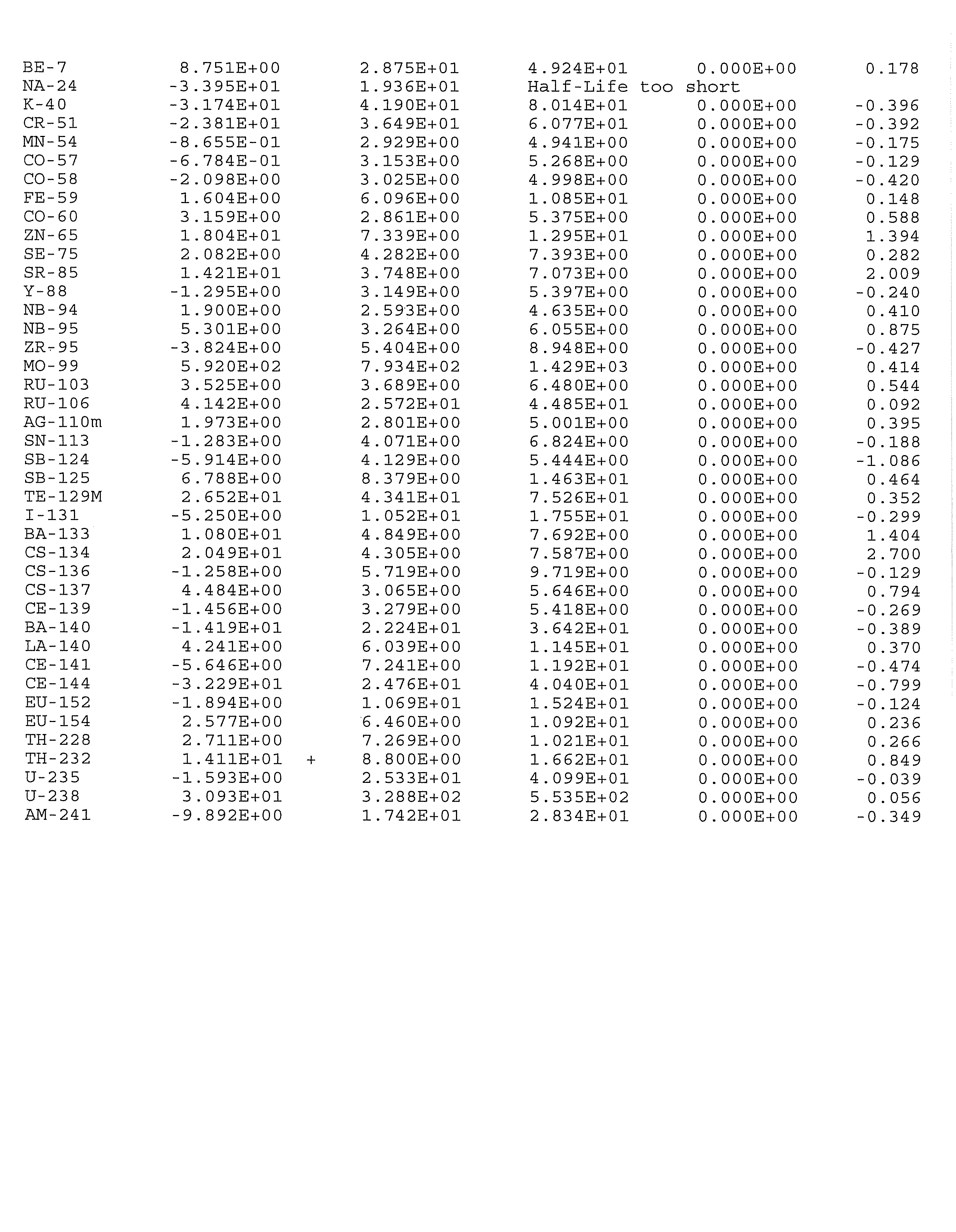

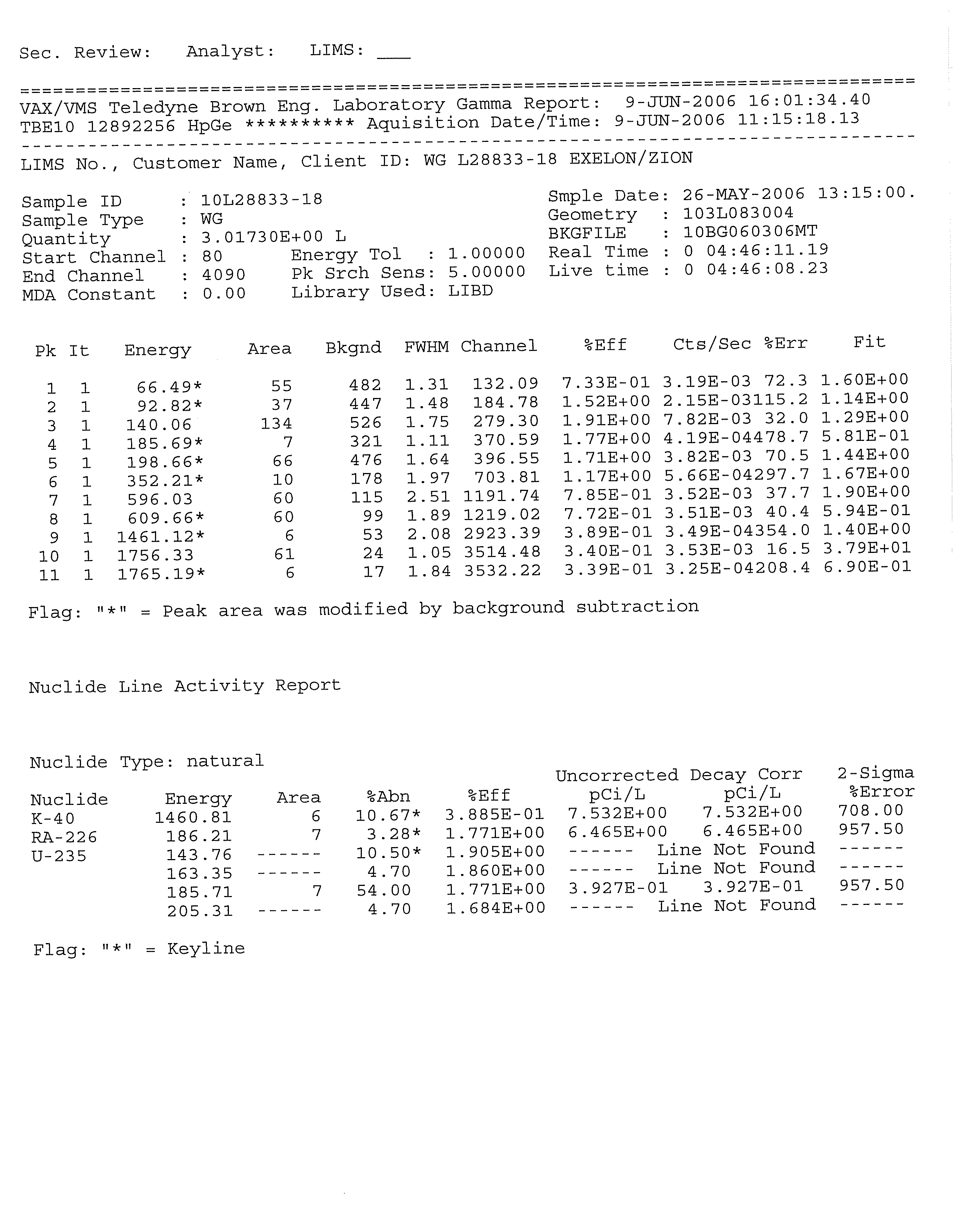

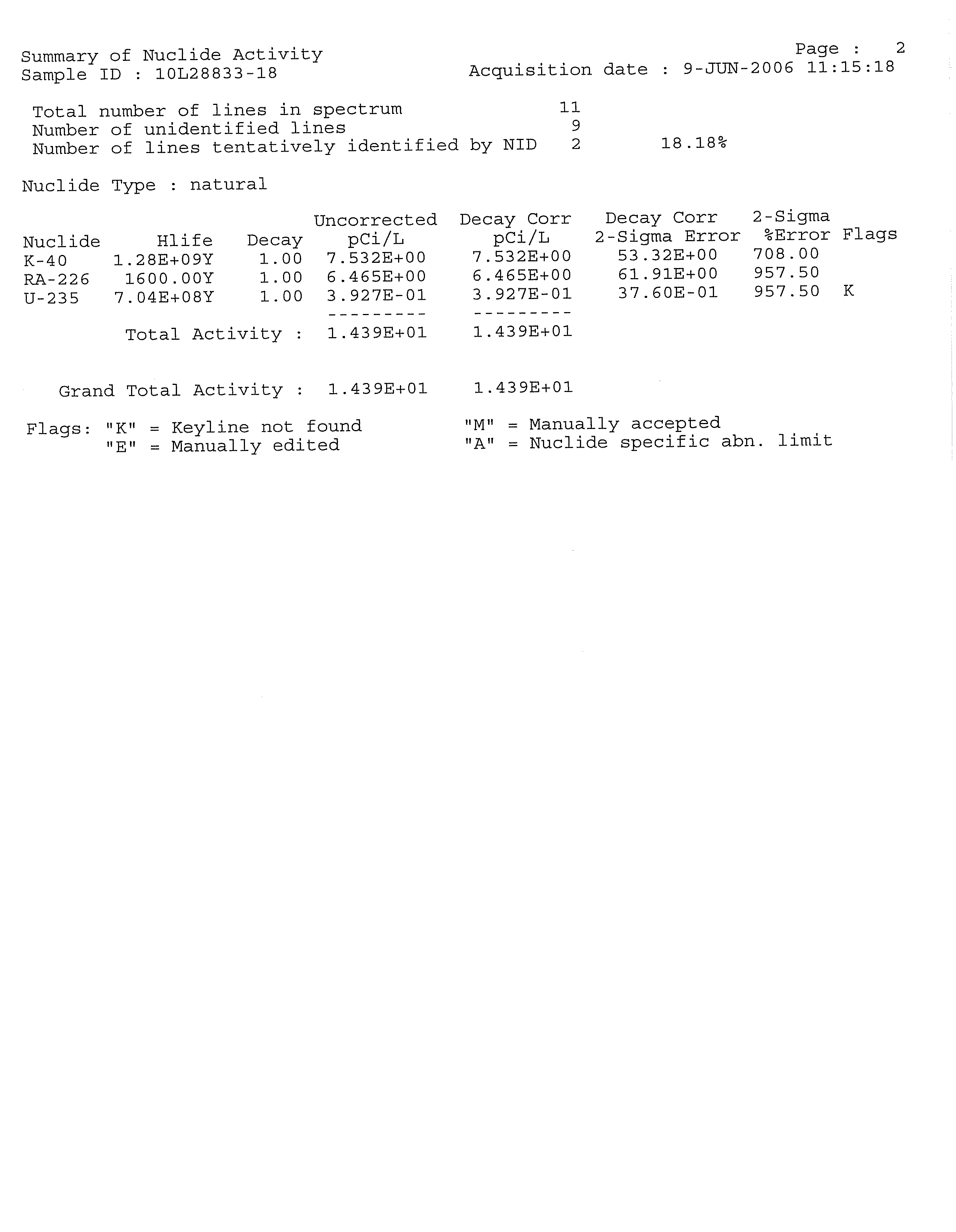

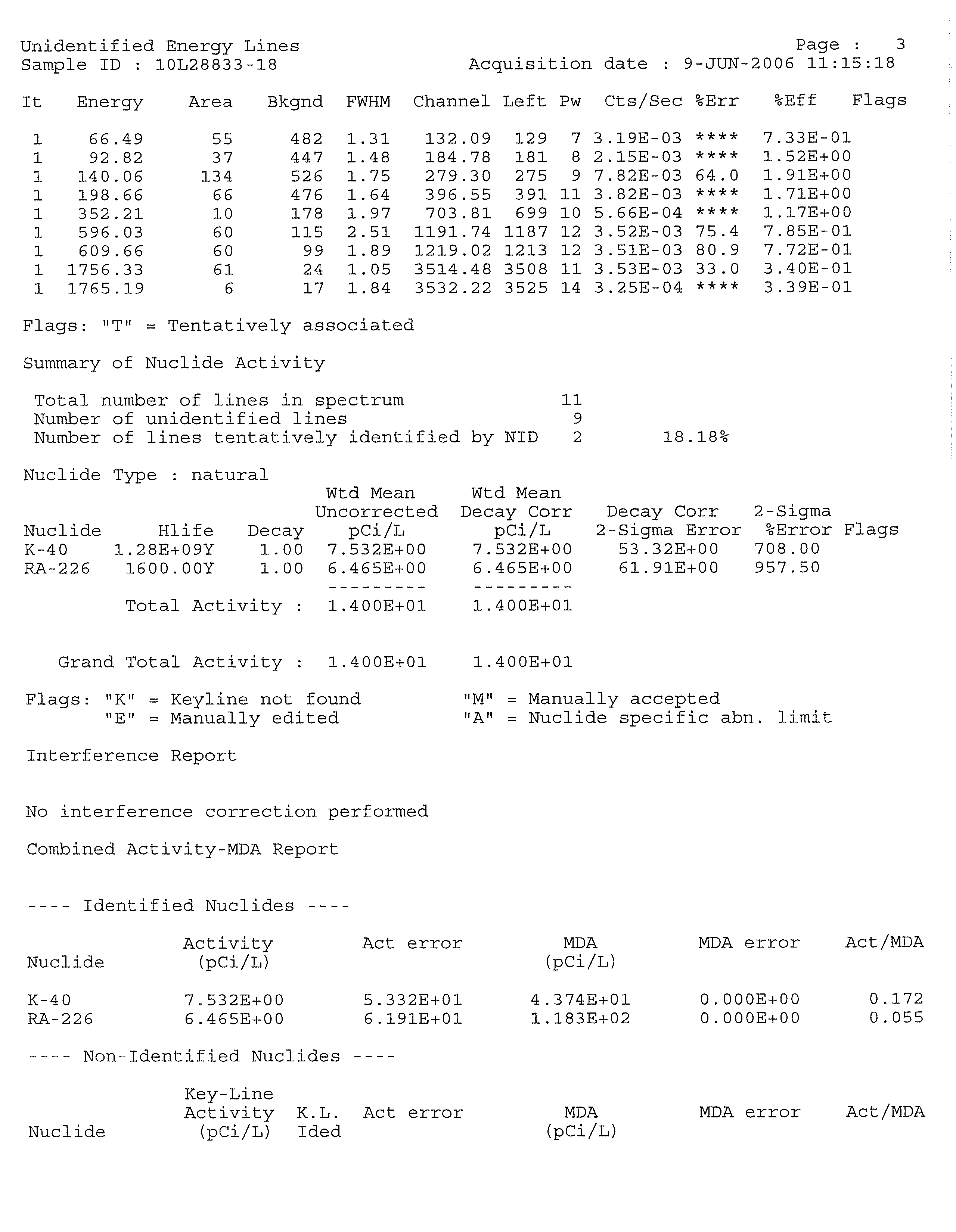

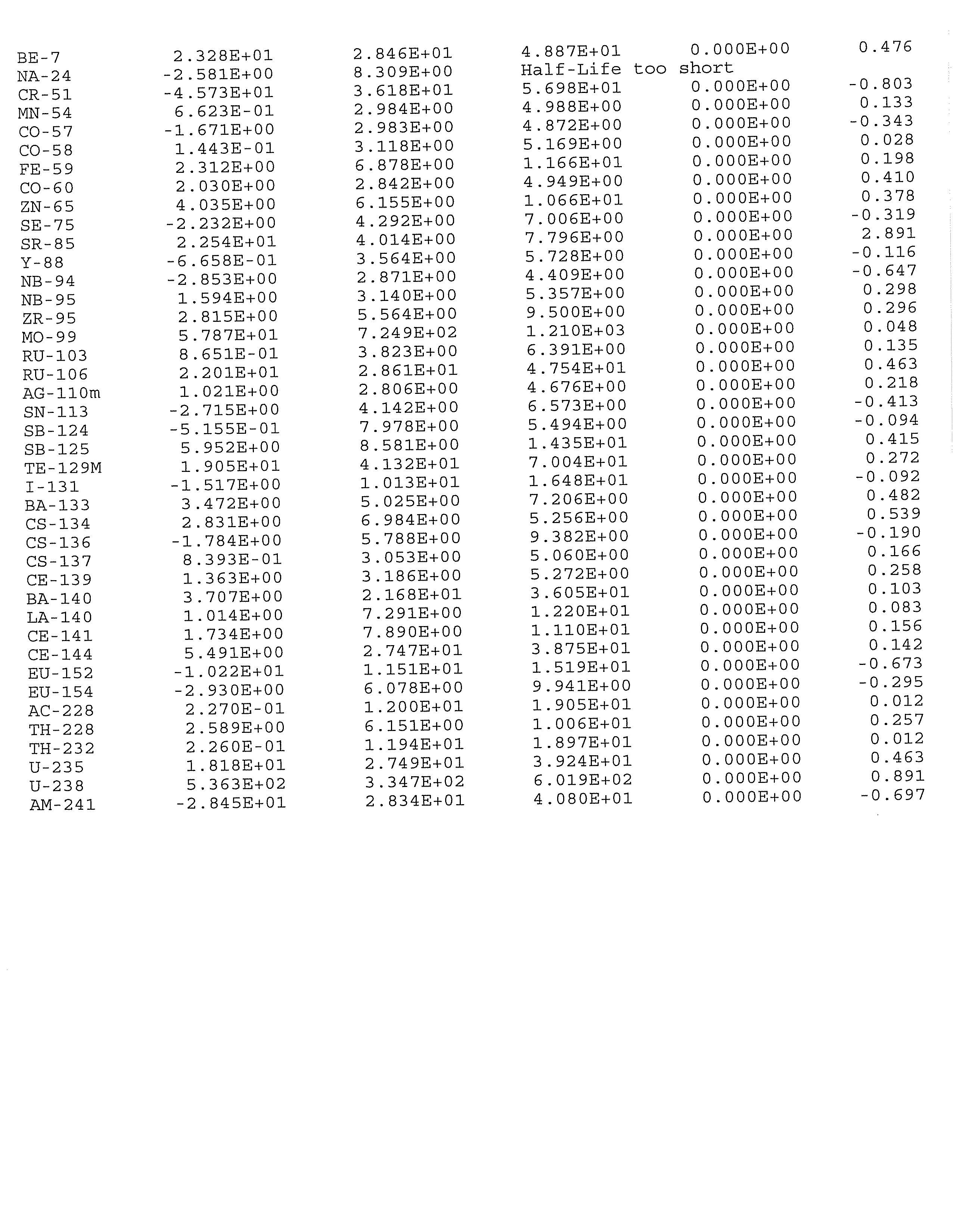

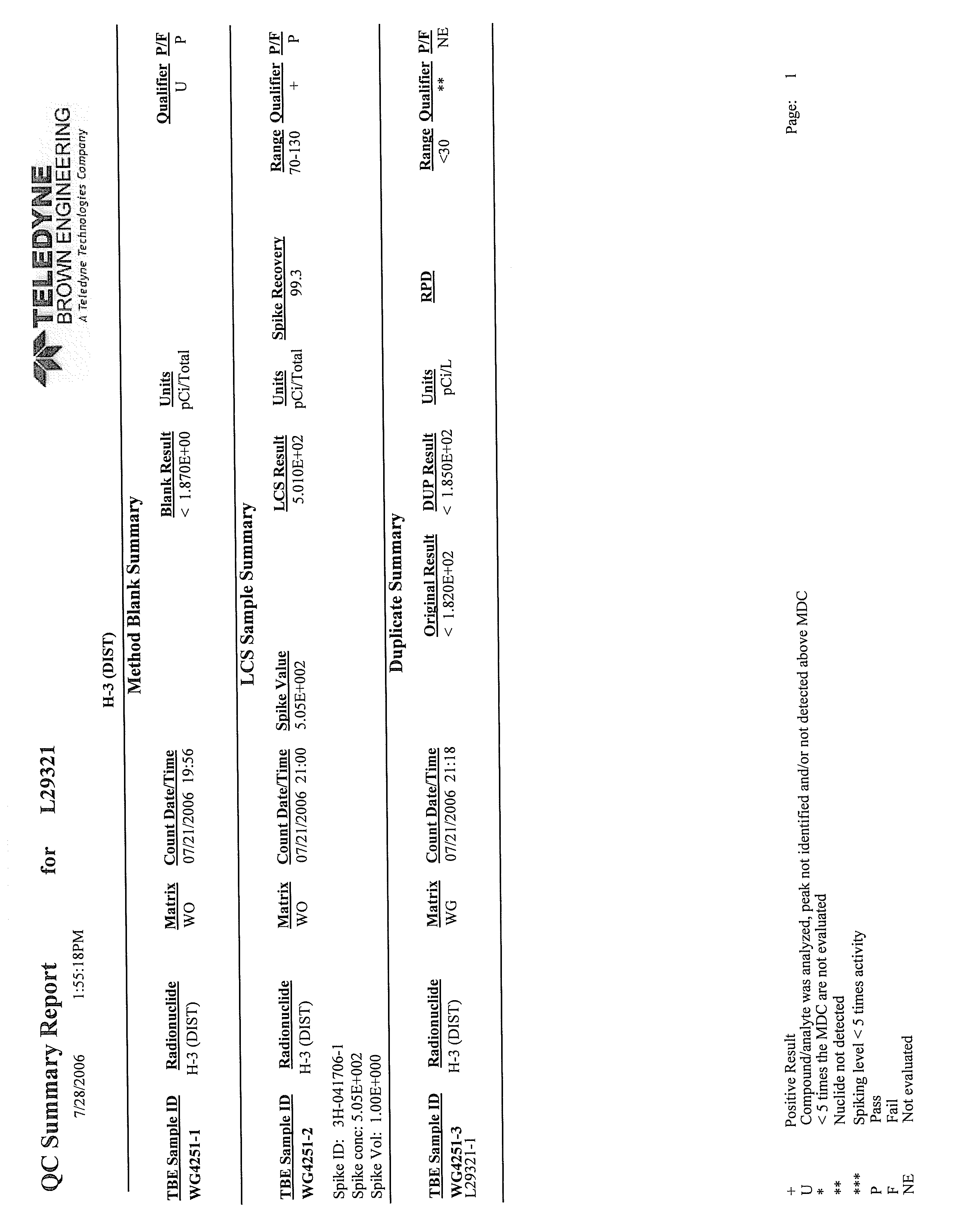

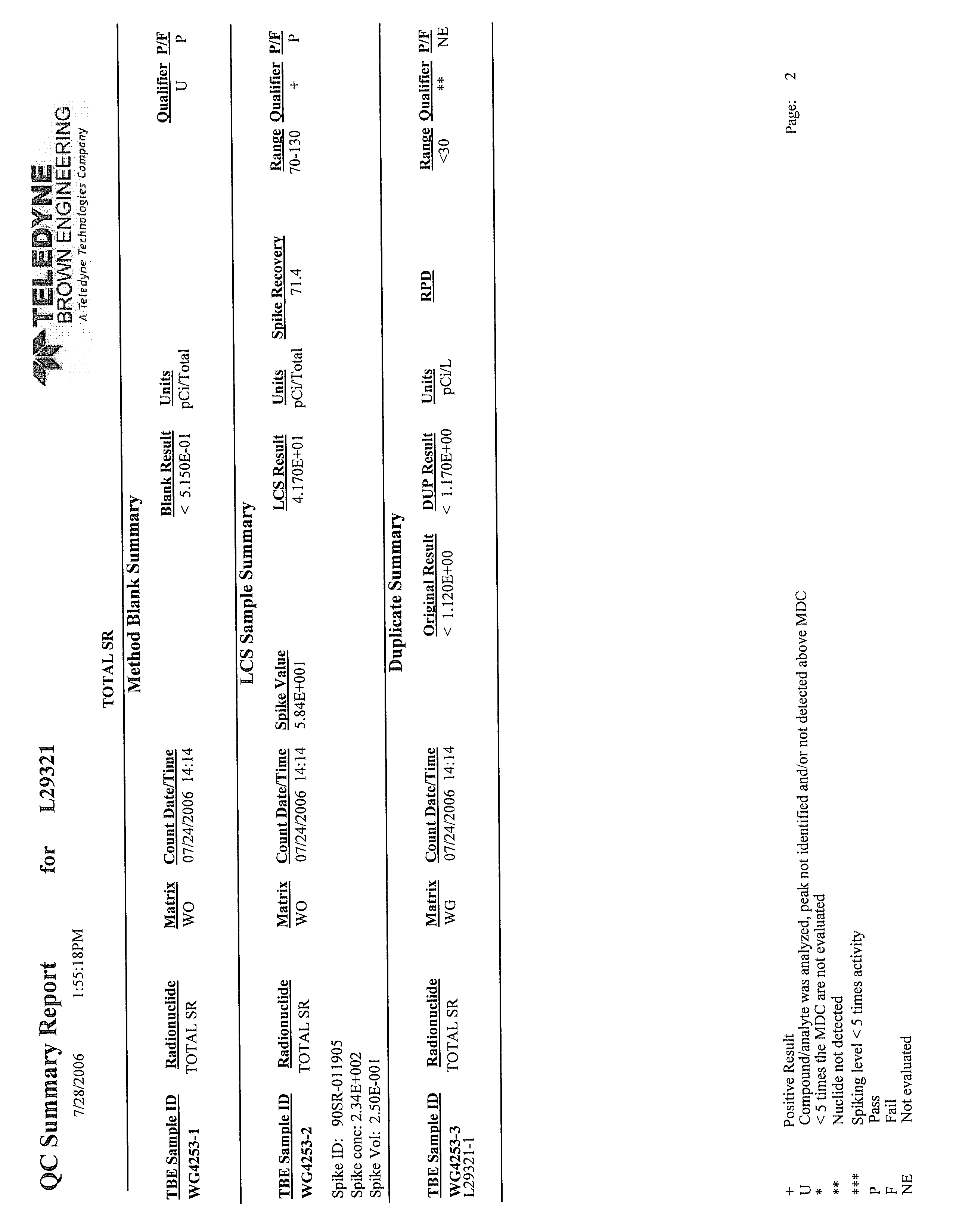

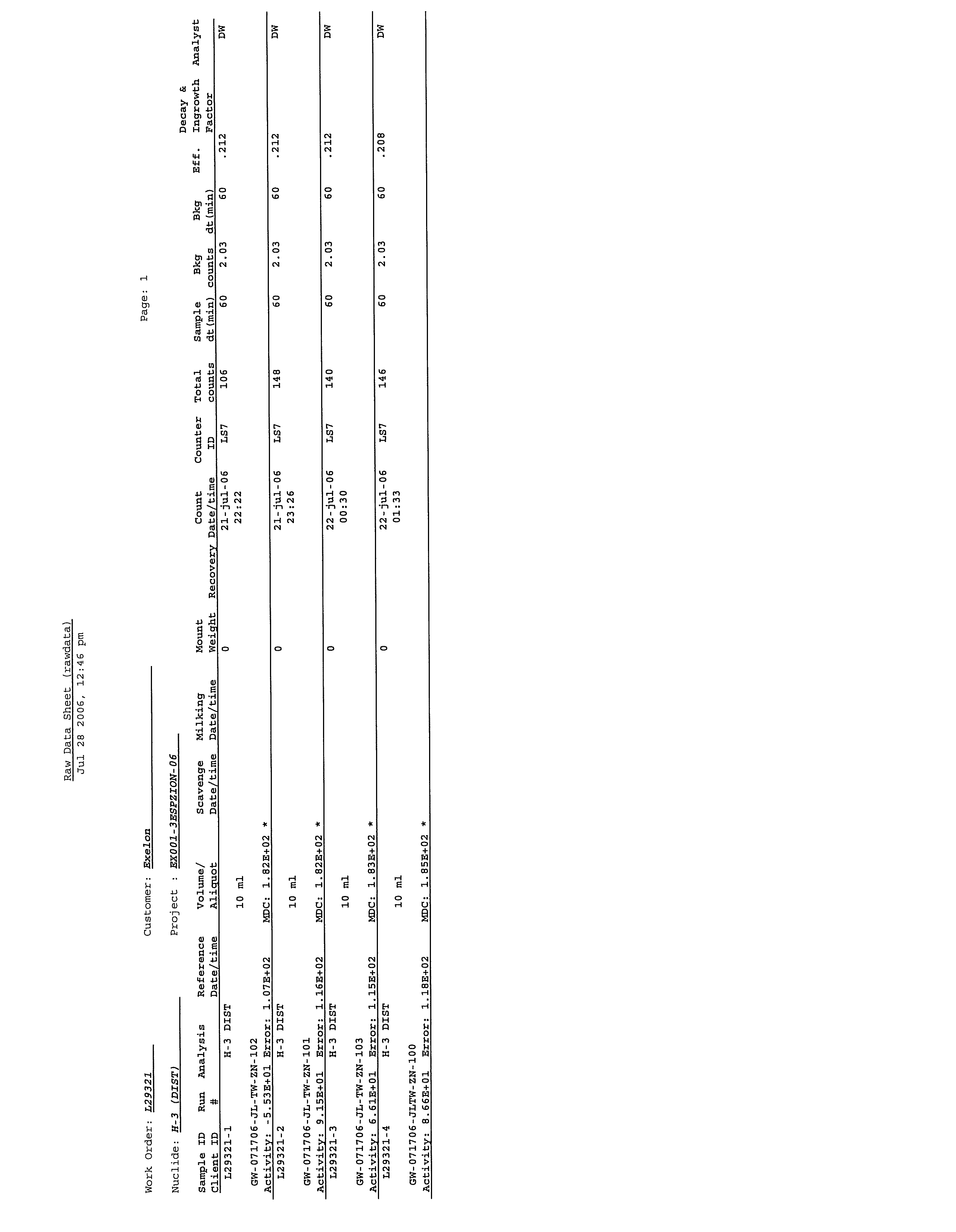

QUALITY ASSURANCE PROGRAM - TELEDYNE BROWN

ENGINEERING, INC.

APPENDIX D

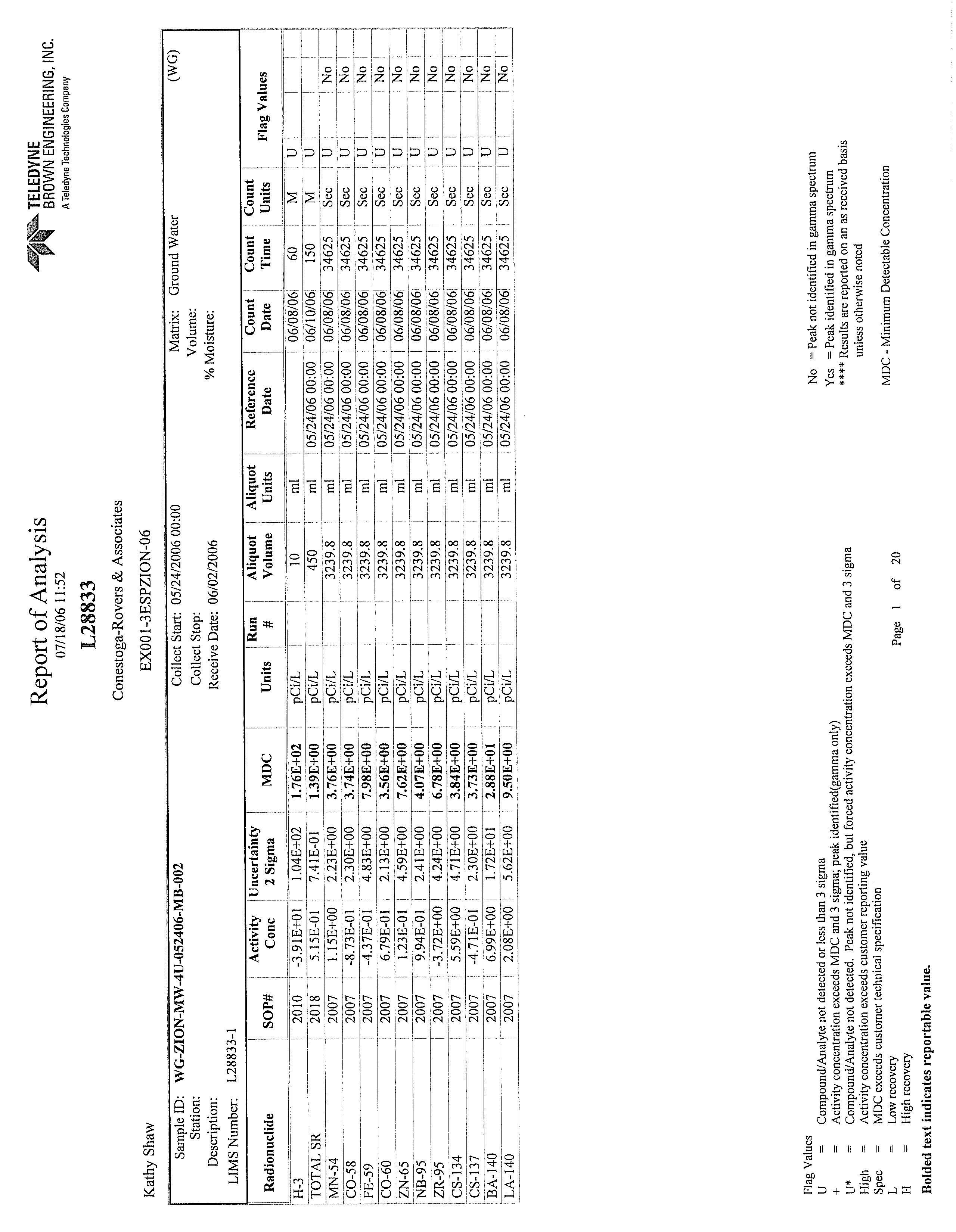

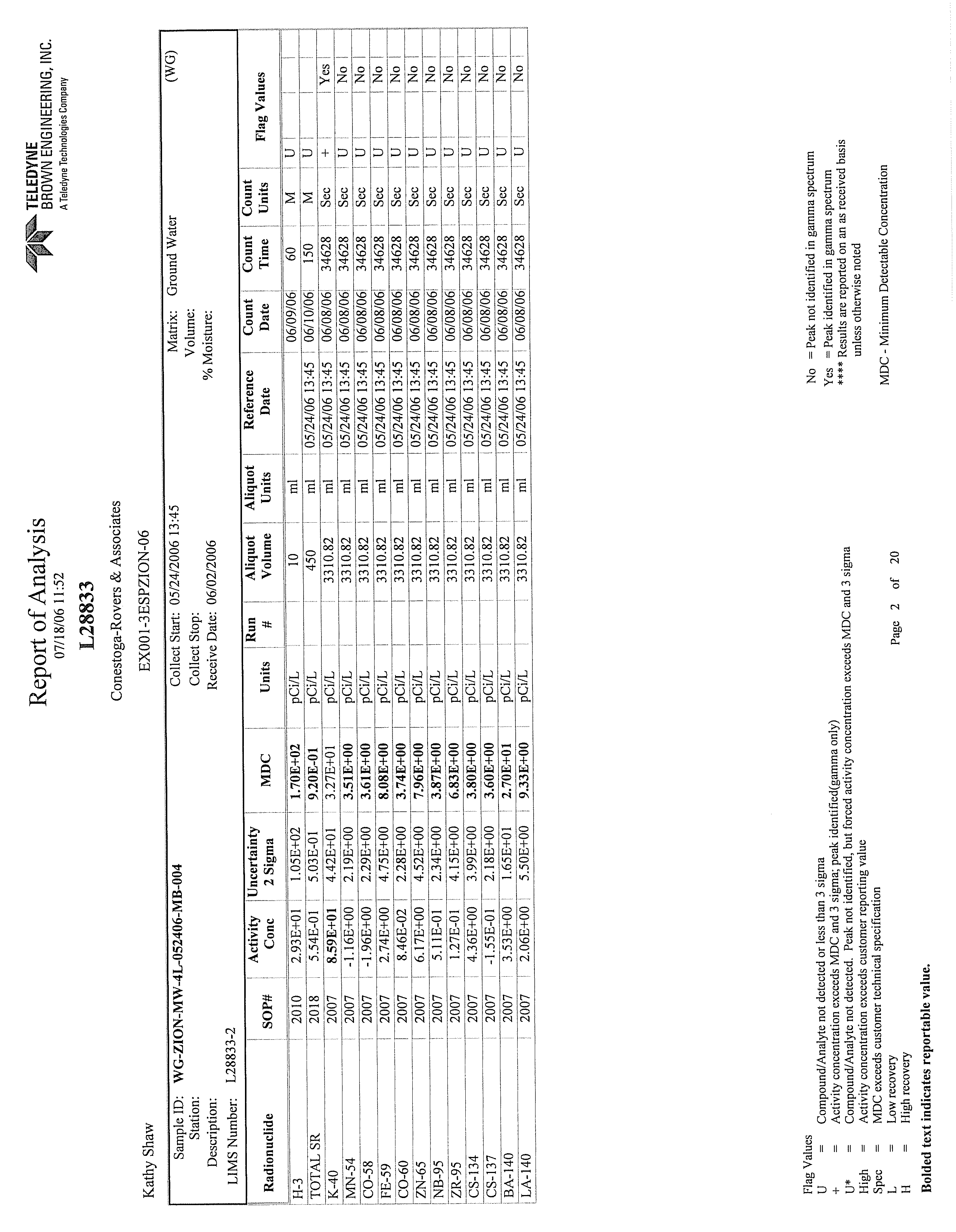

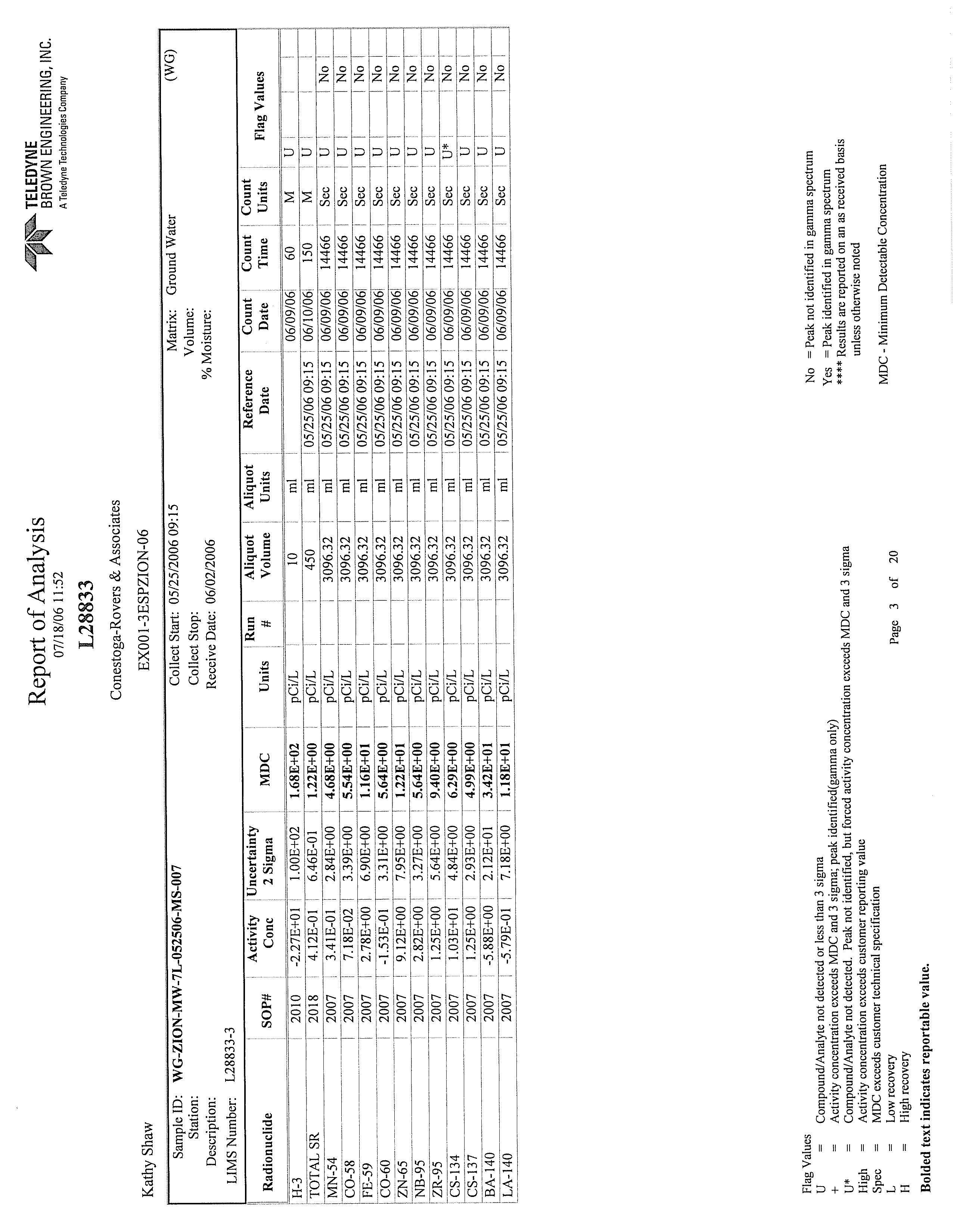

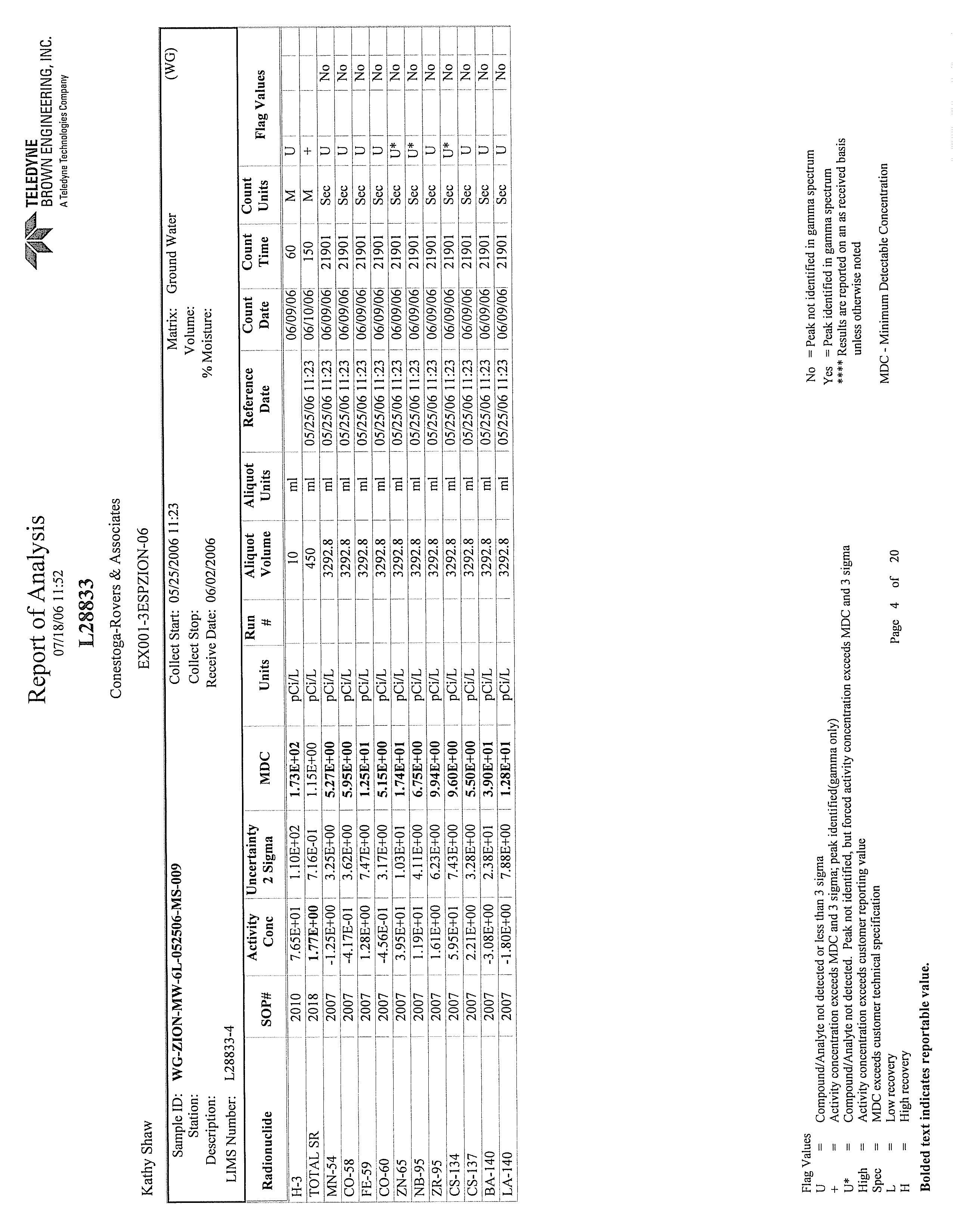

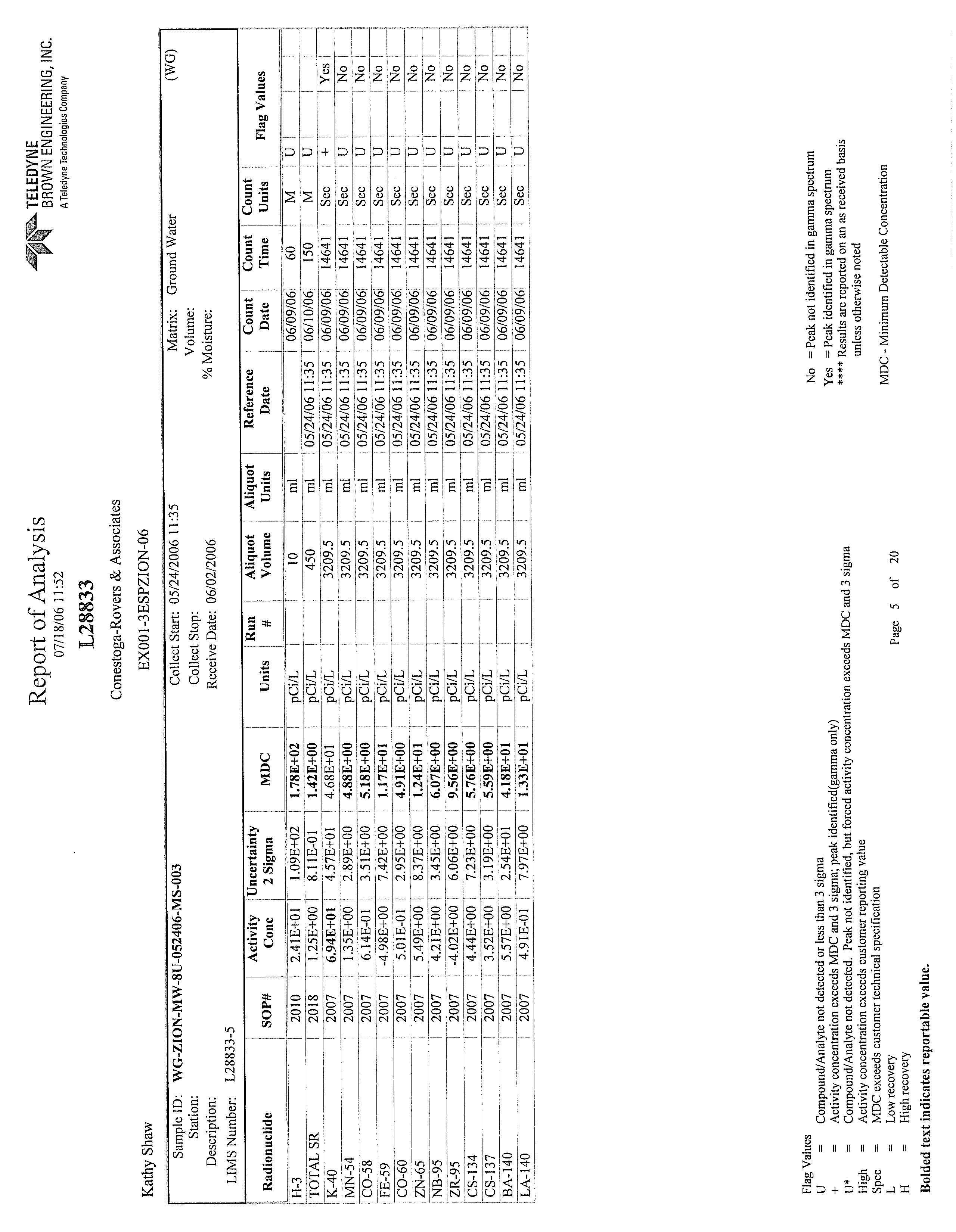

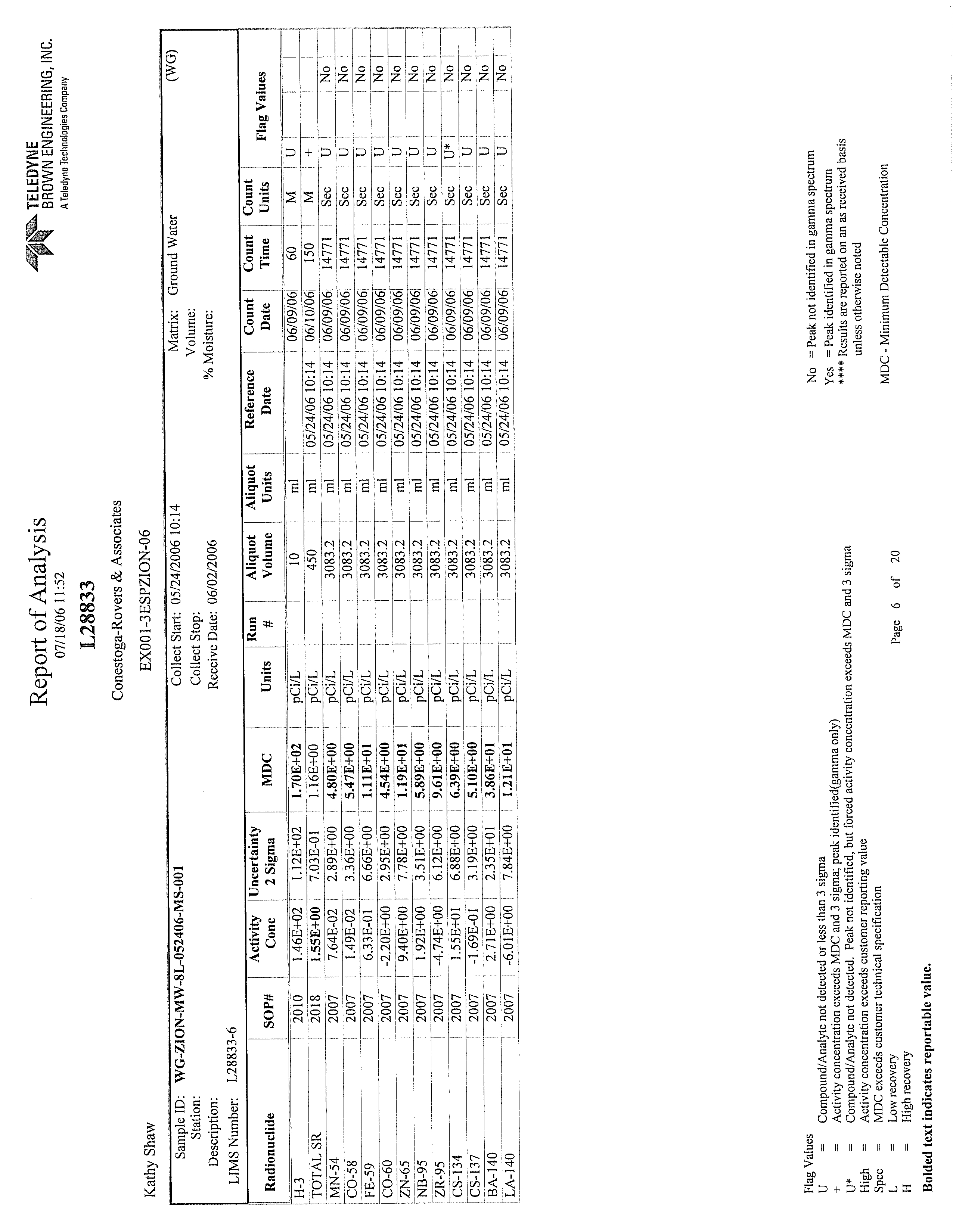

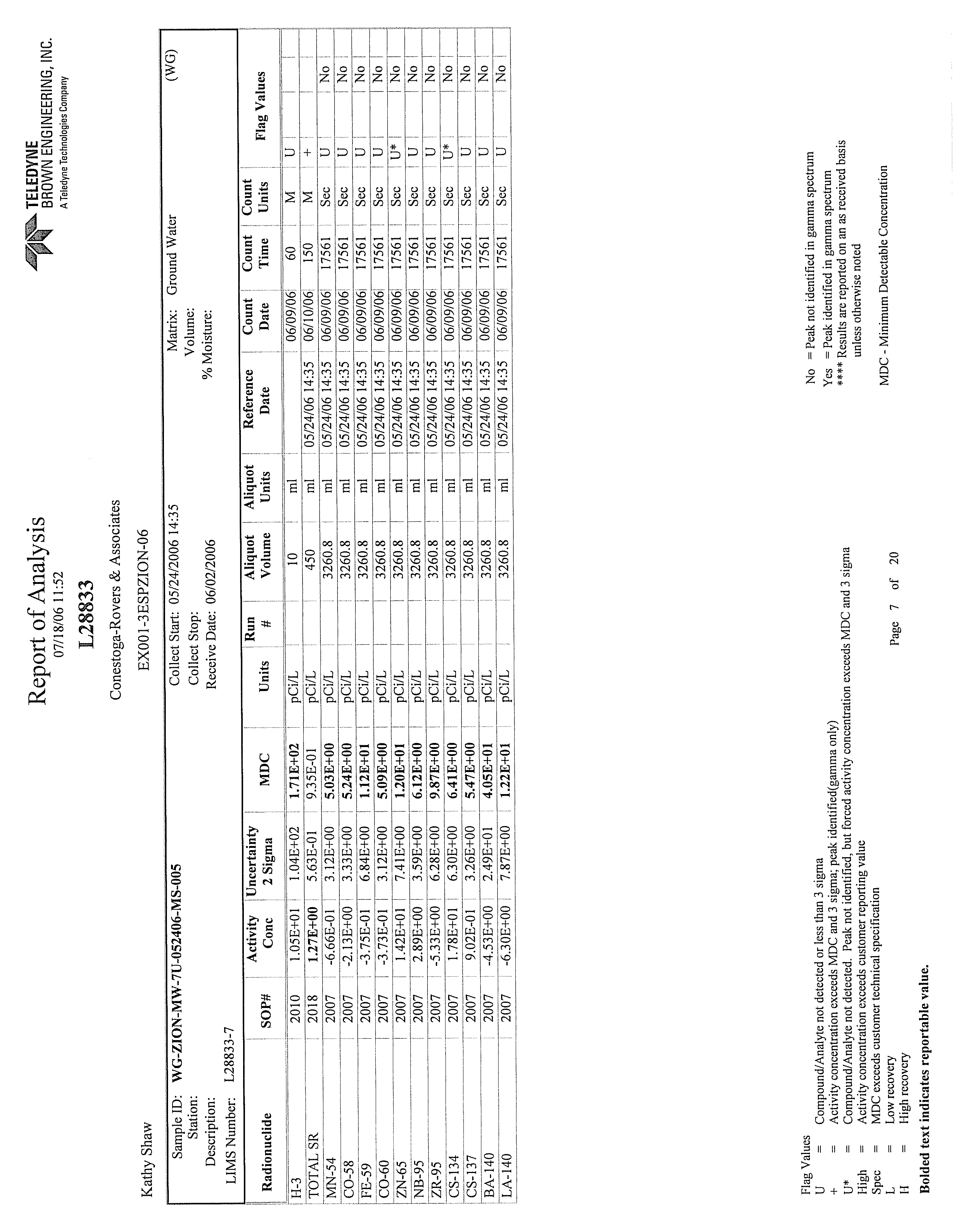

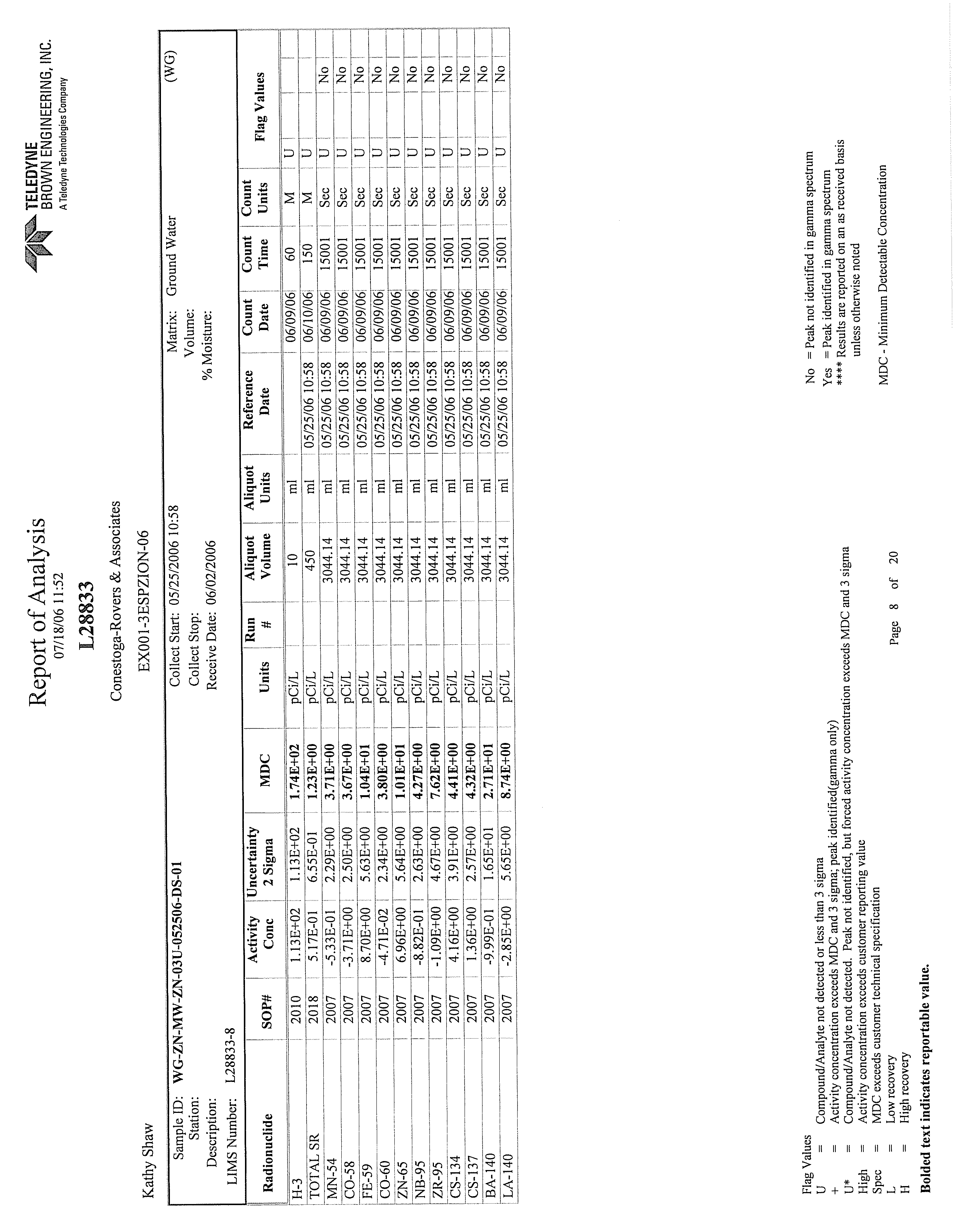

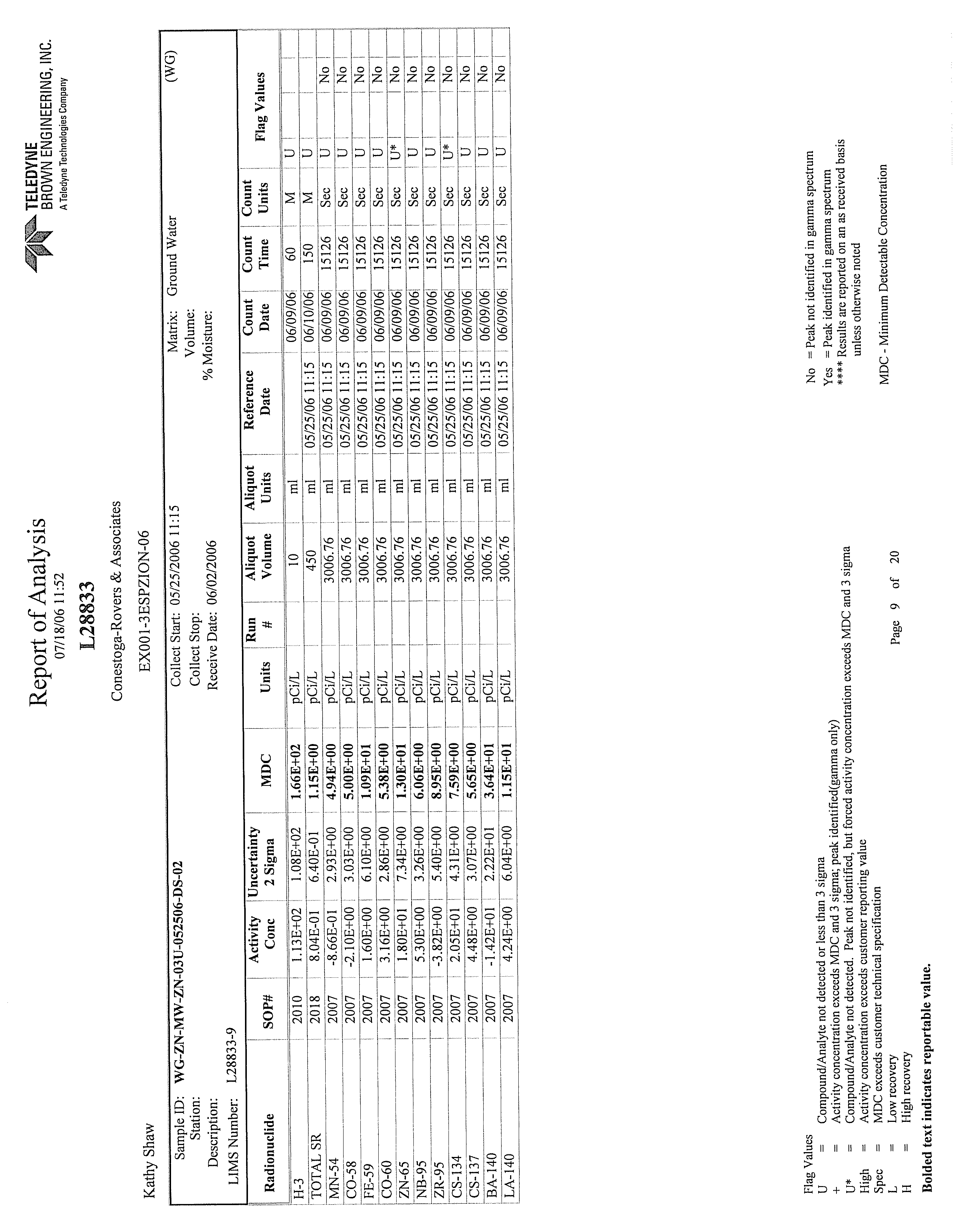

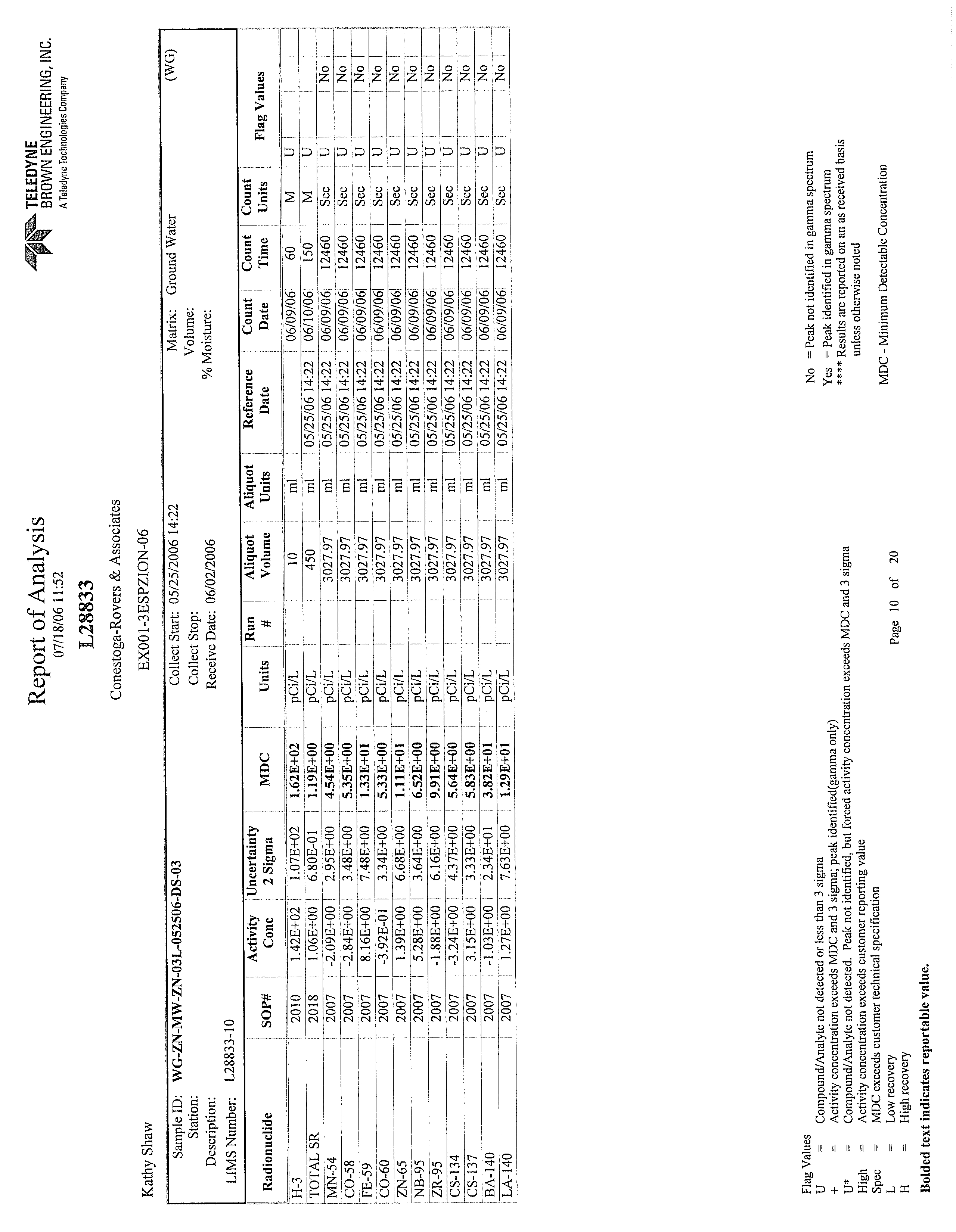

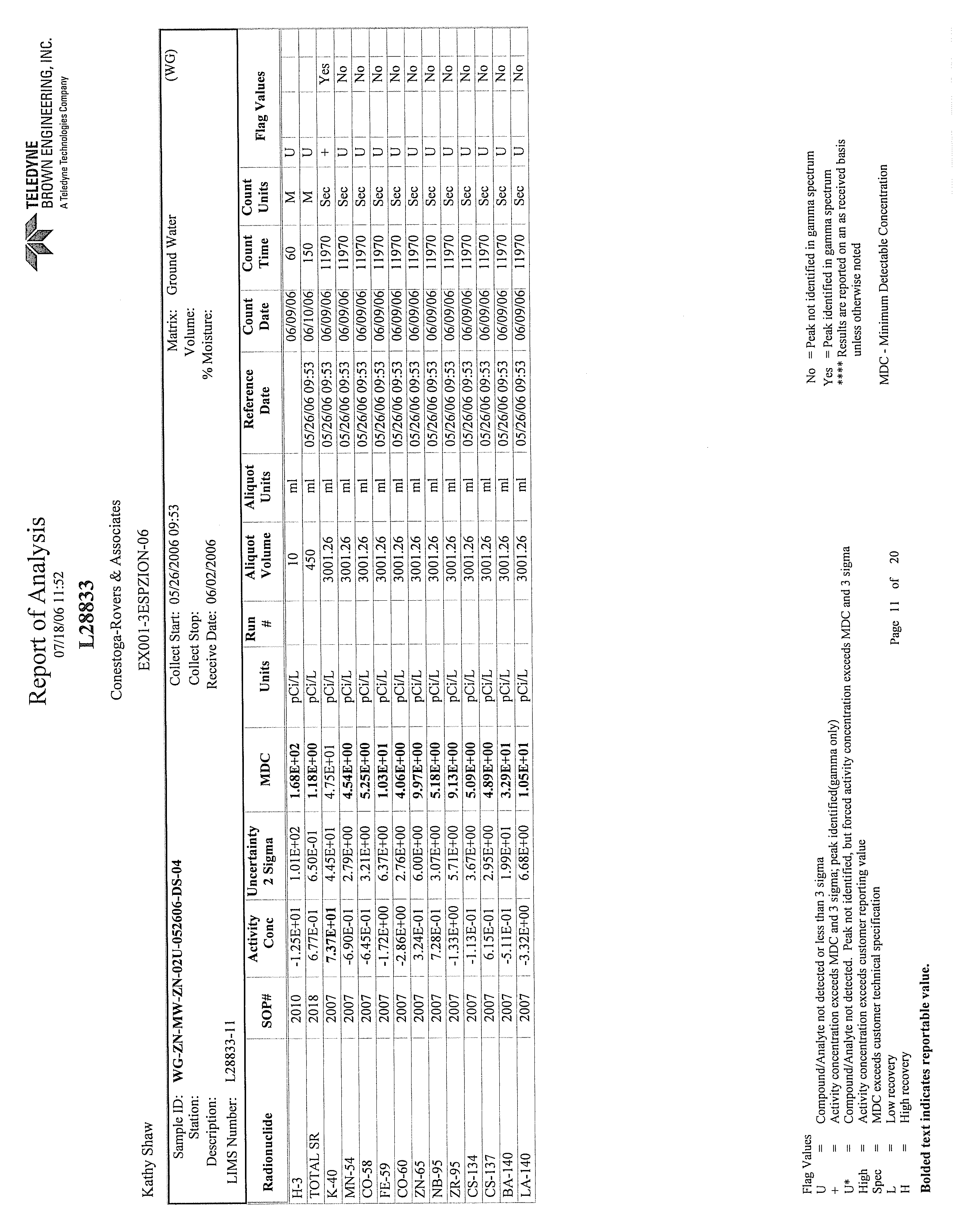

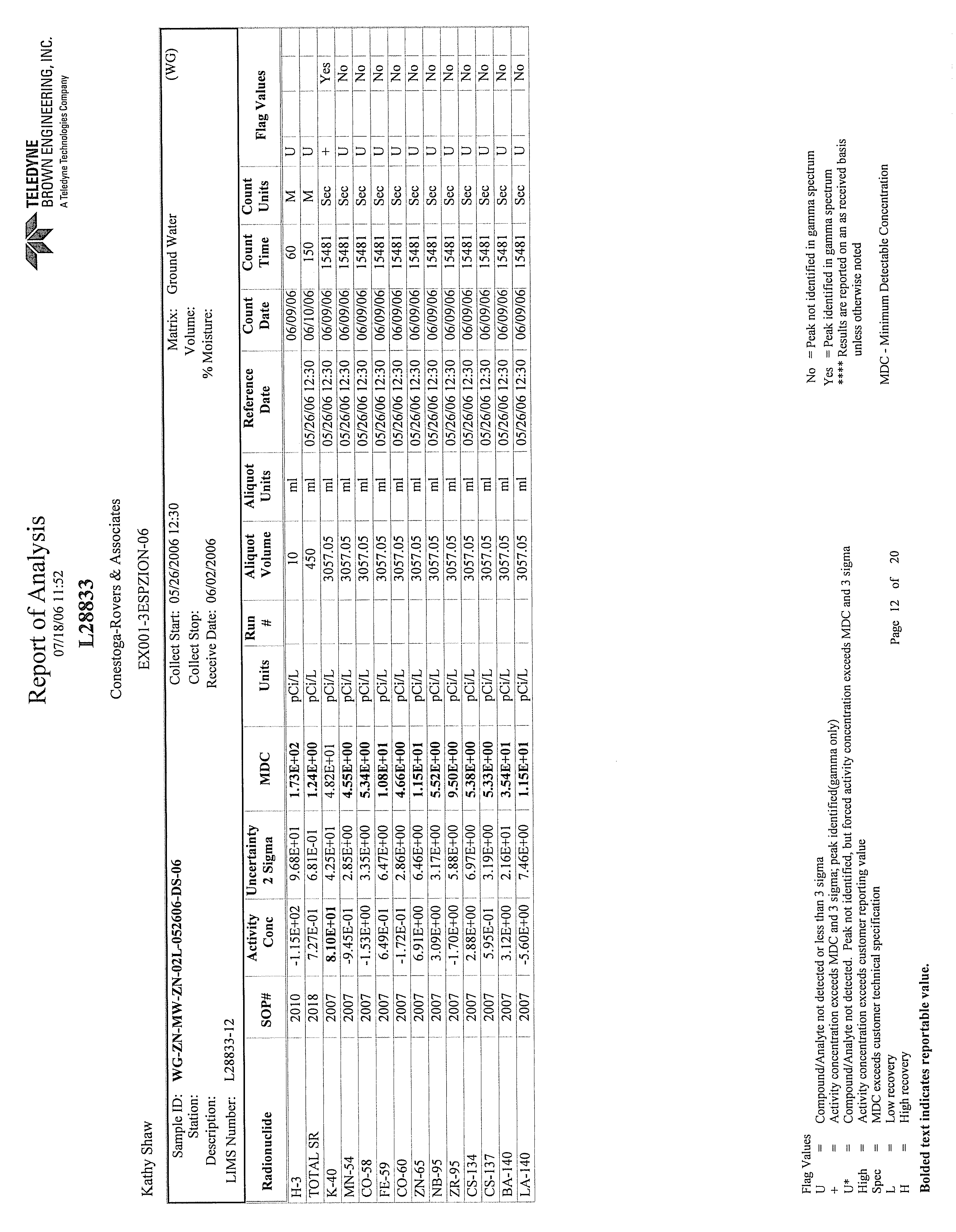

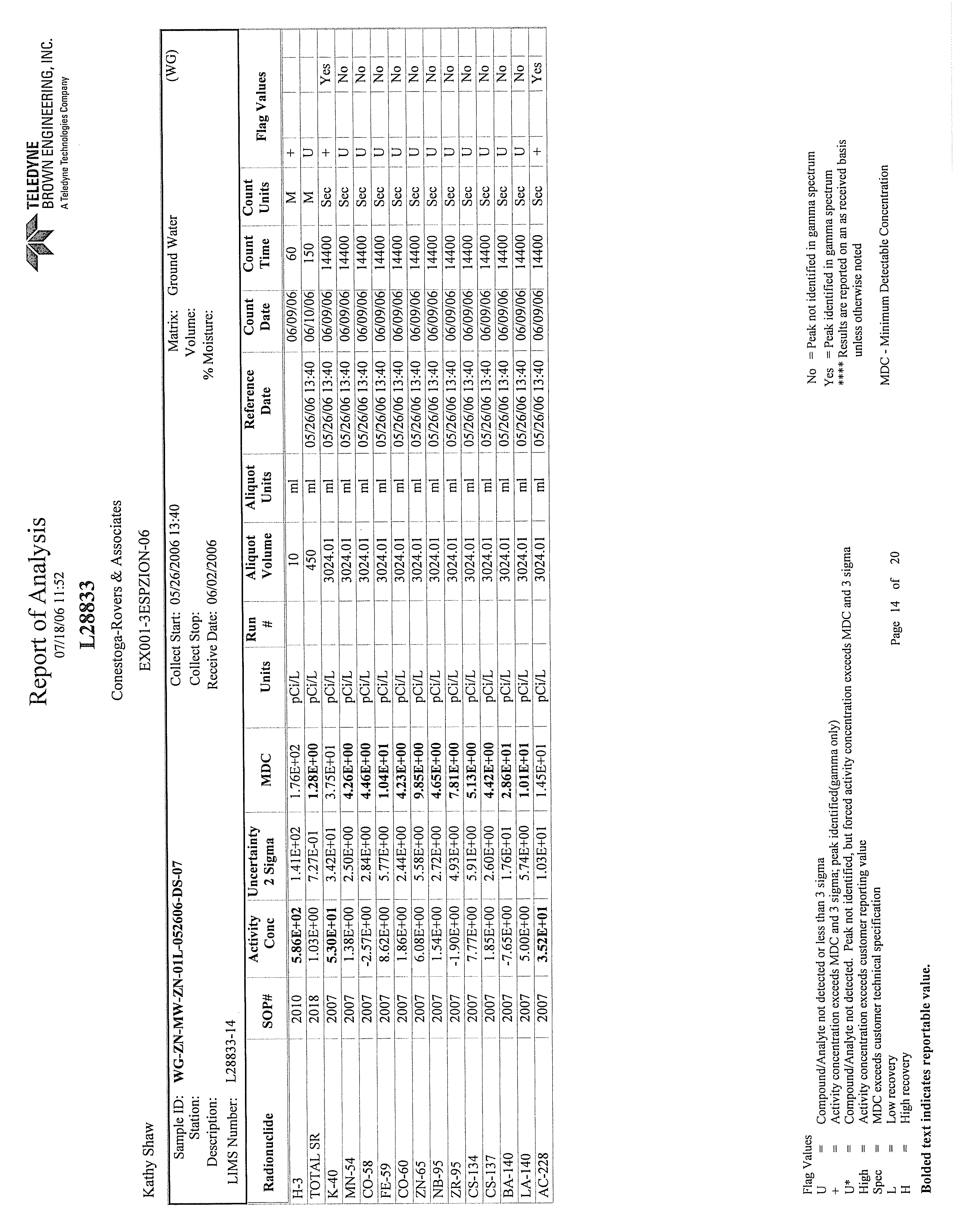

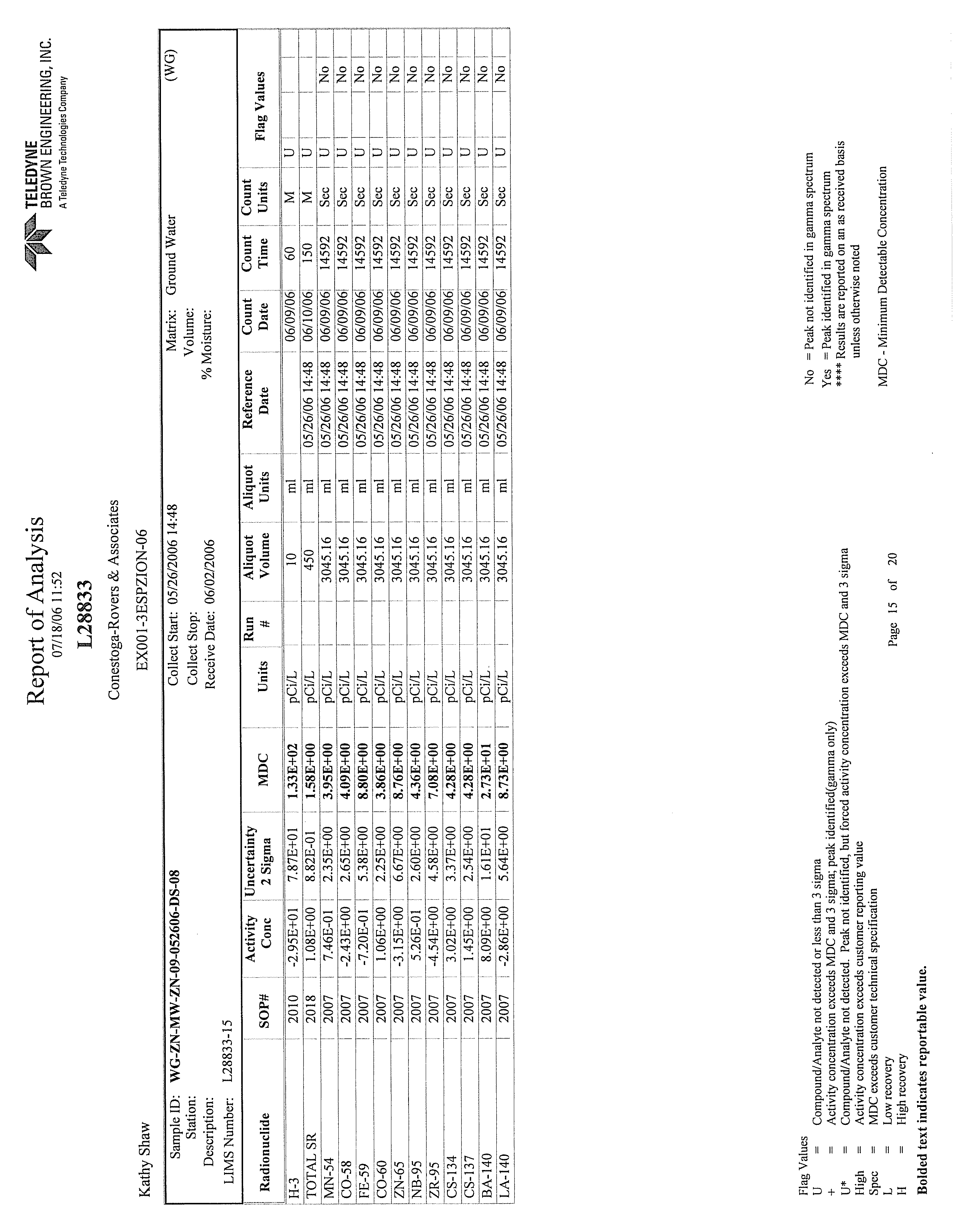

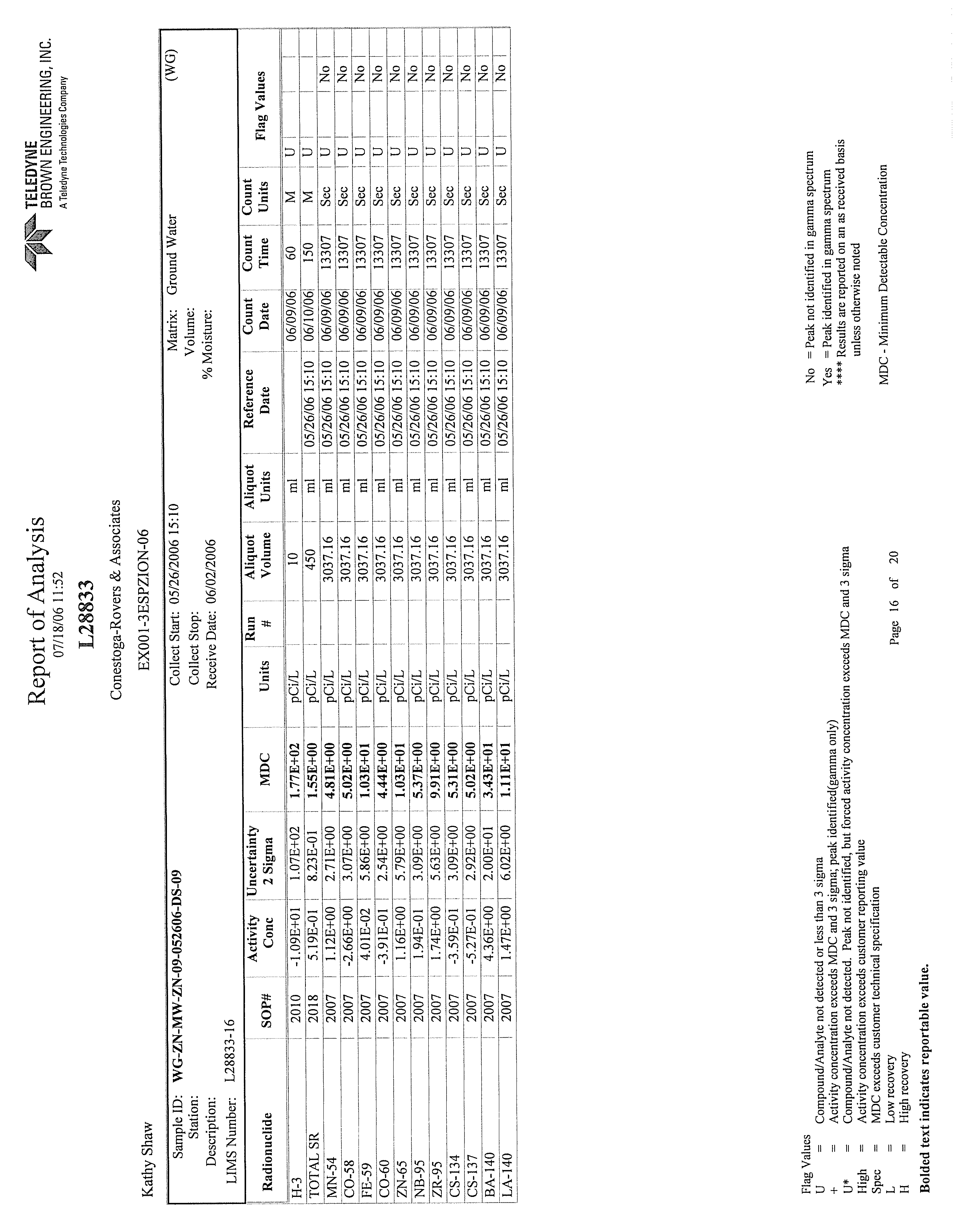

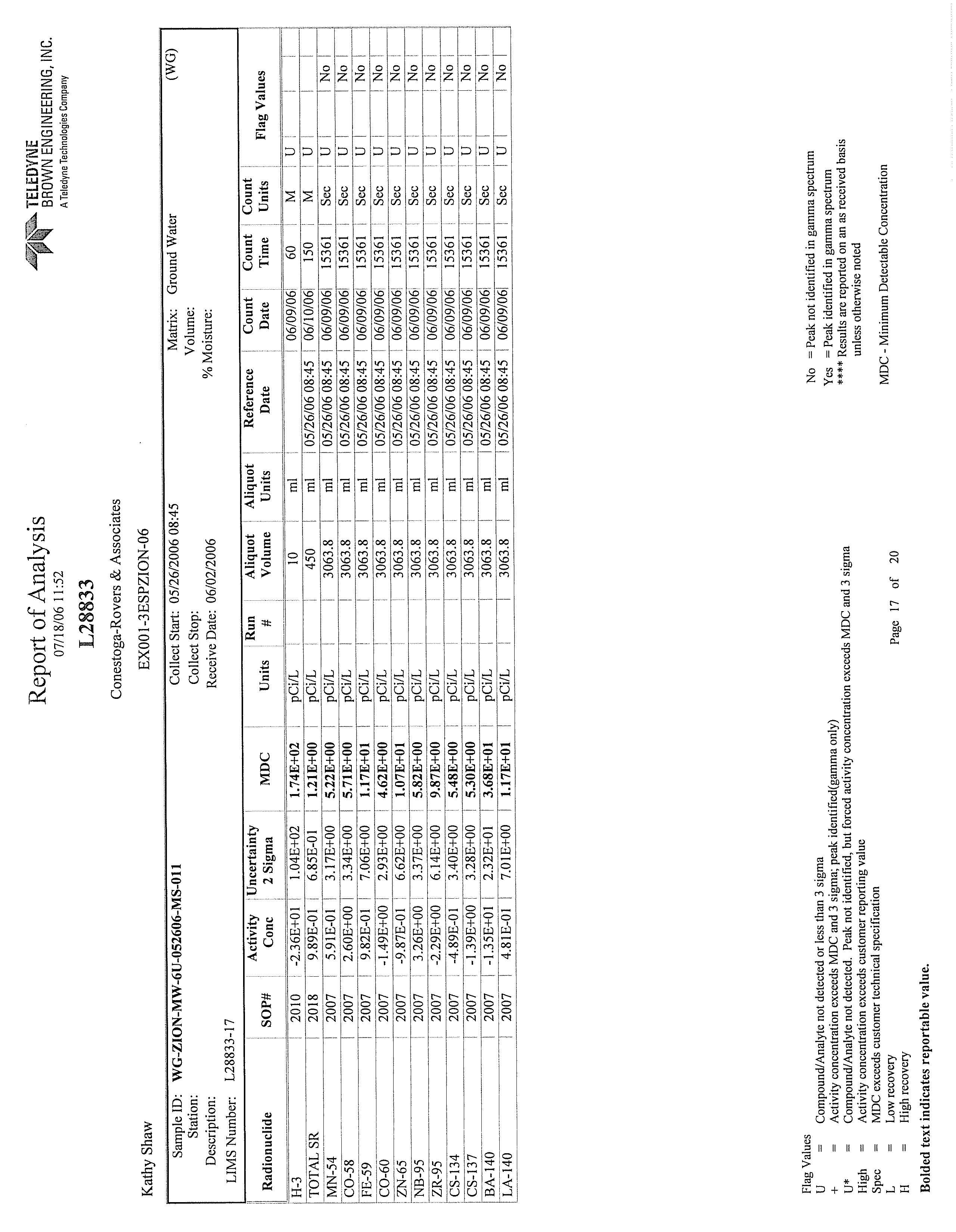

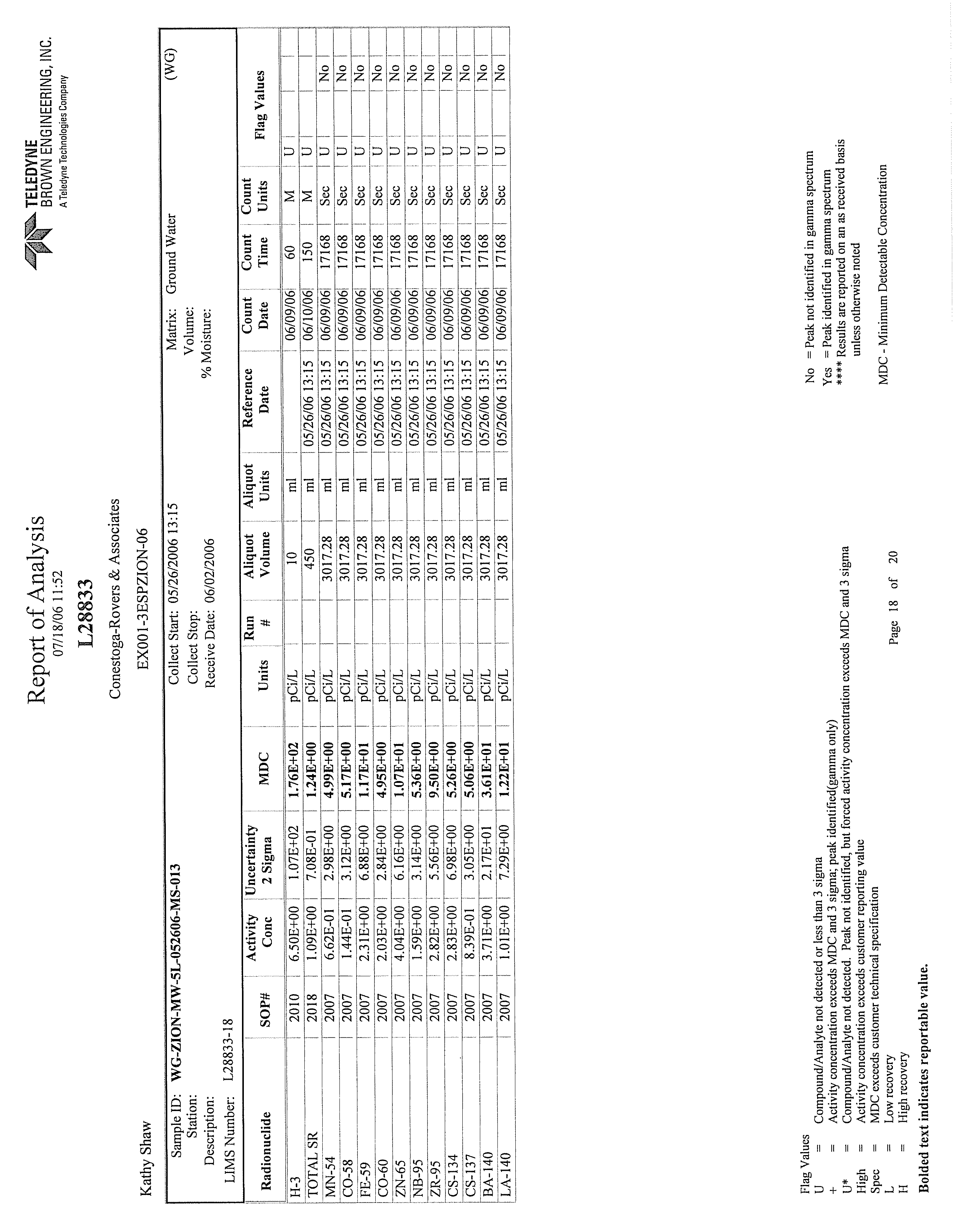

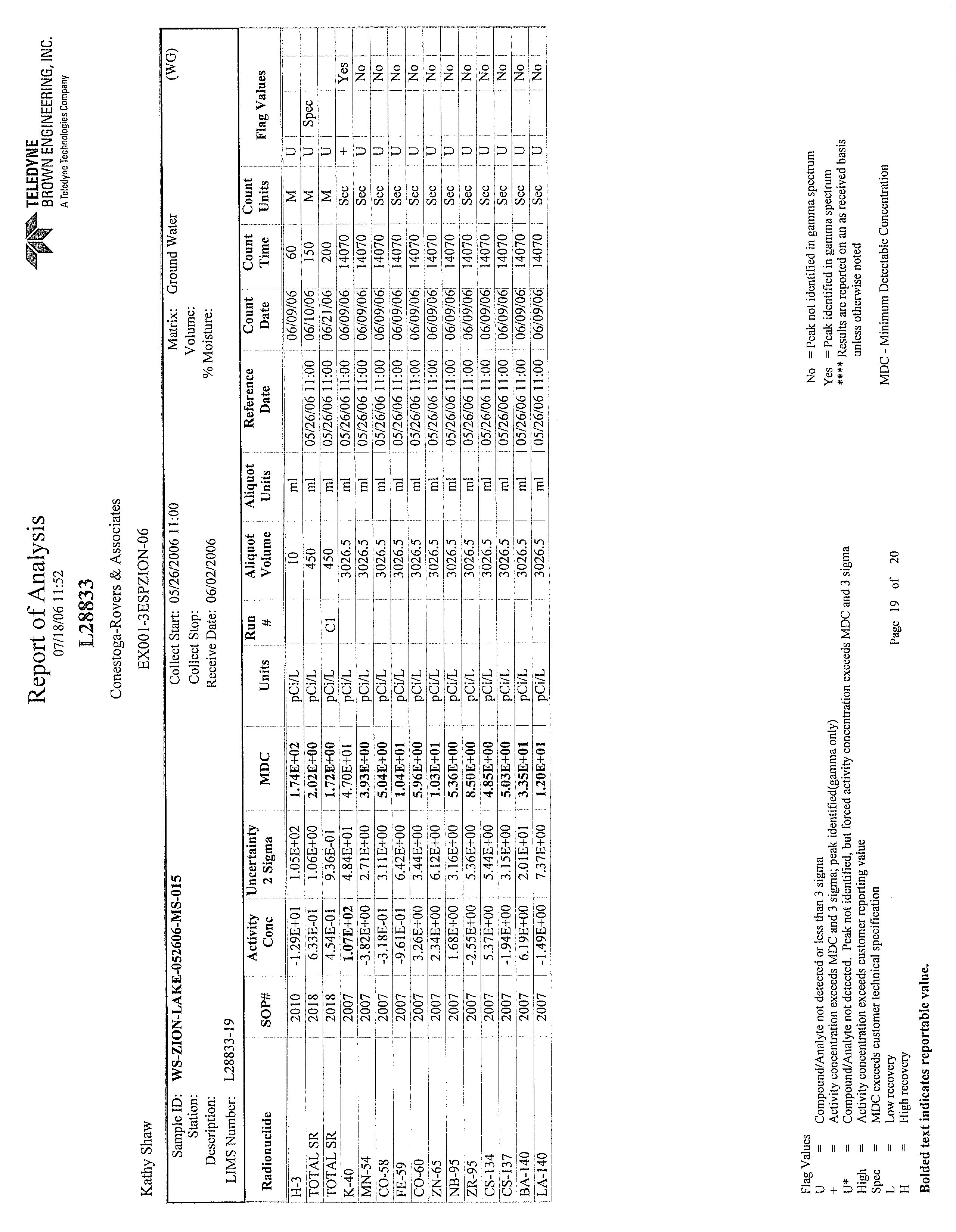

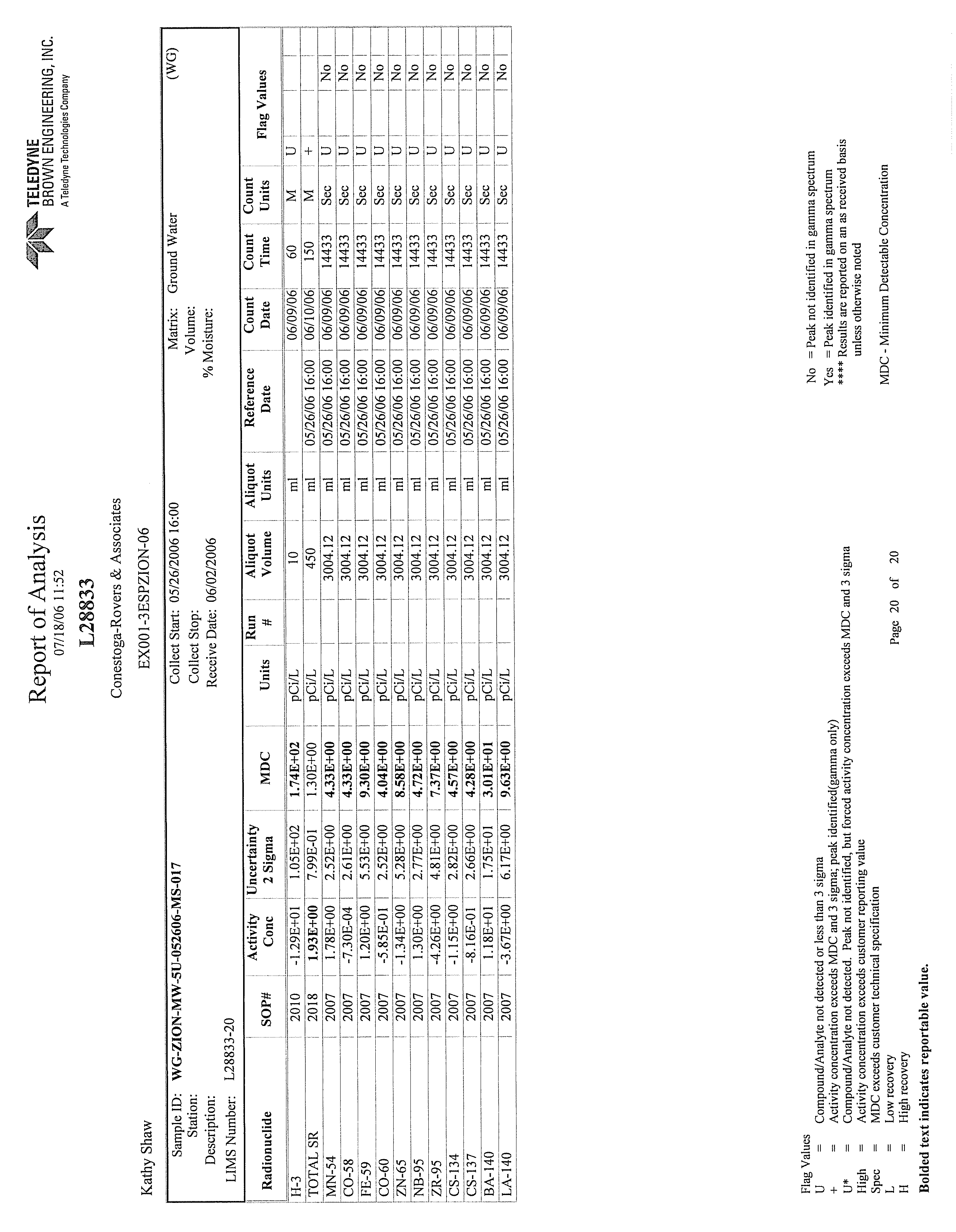

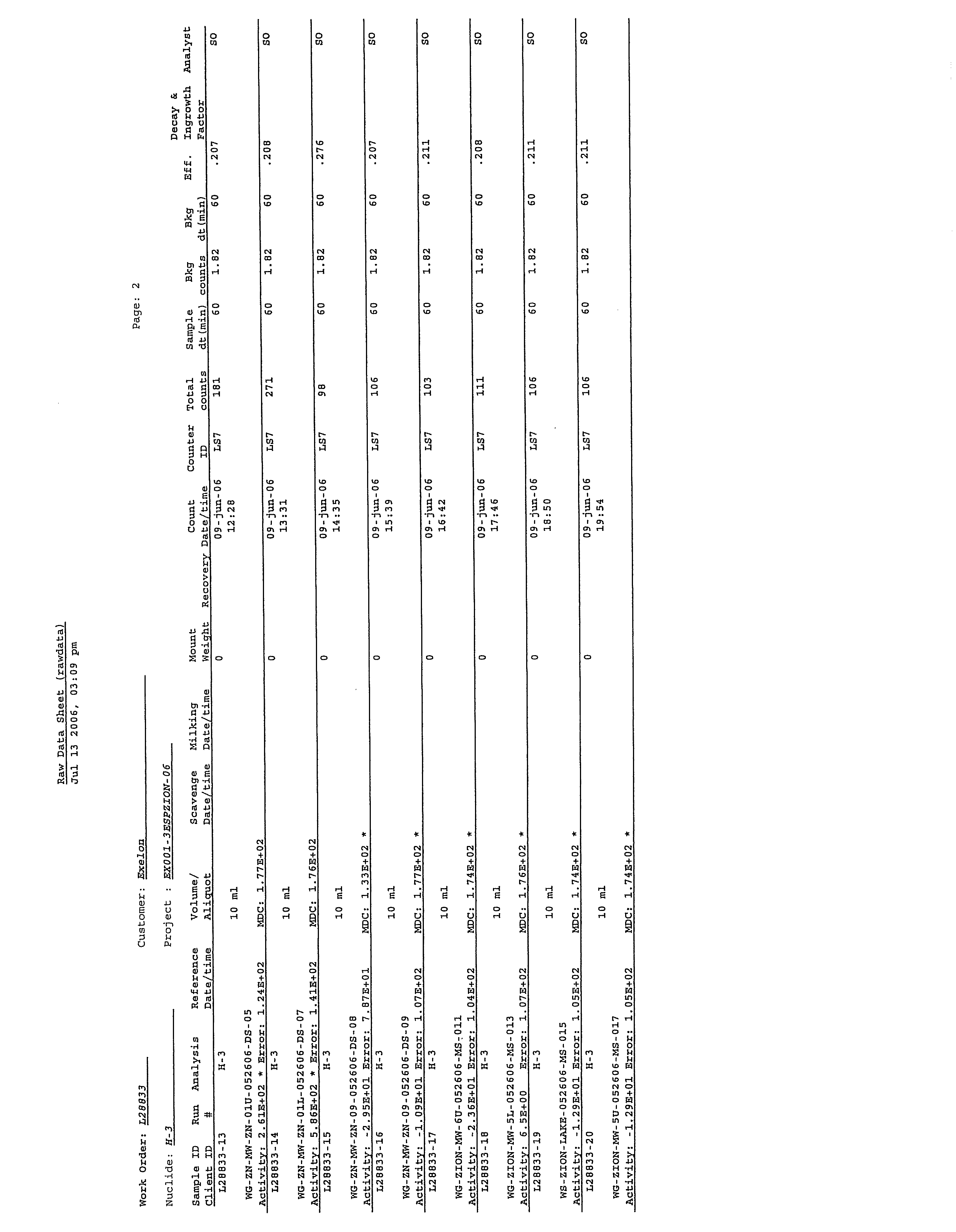

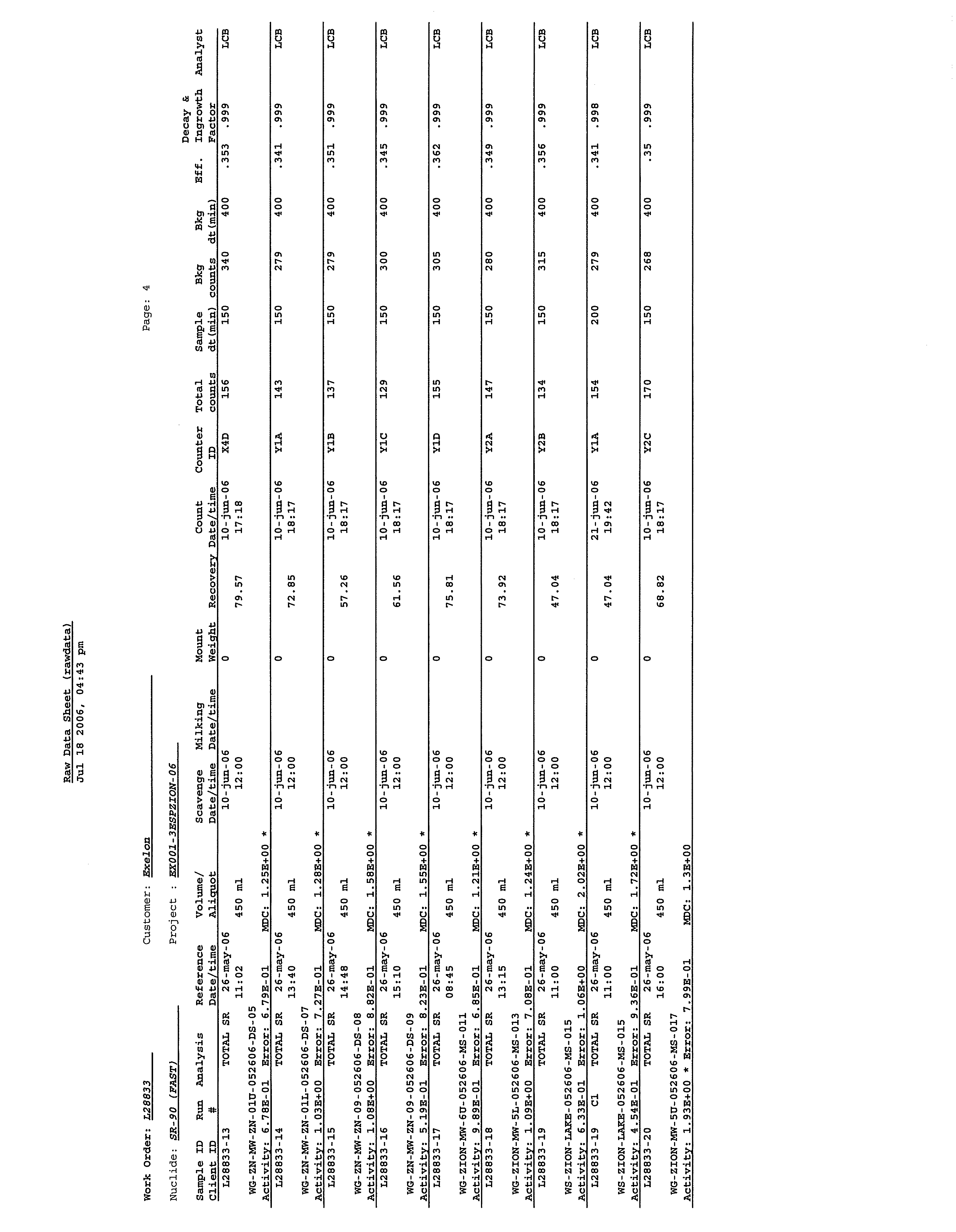

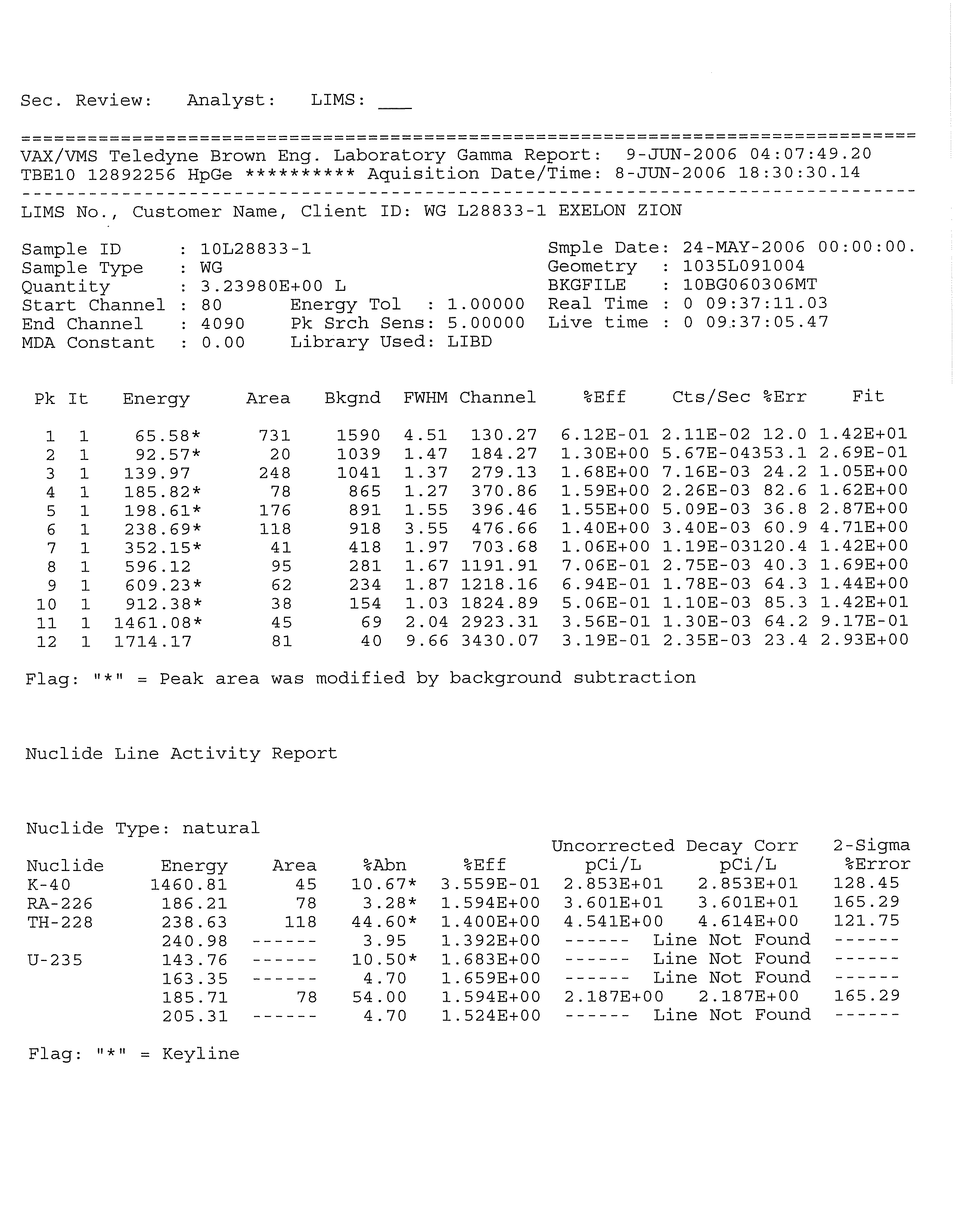

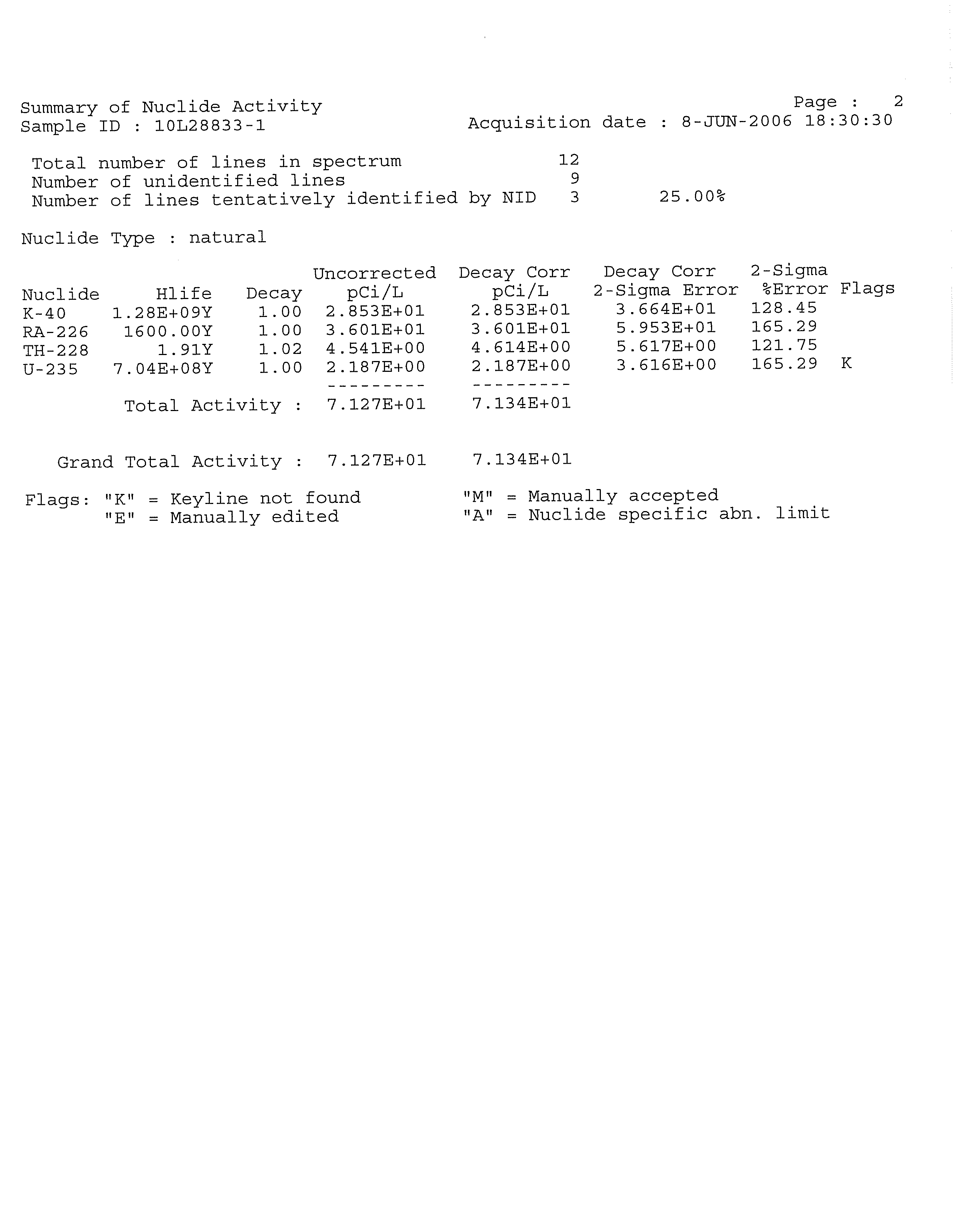

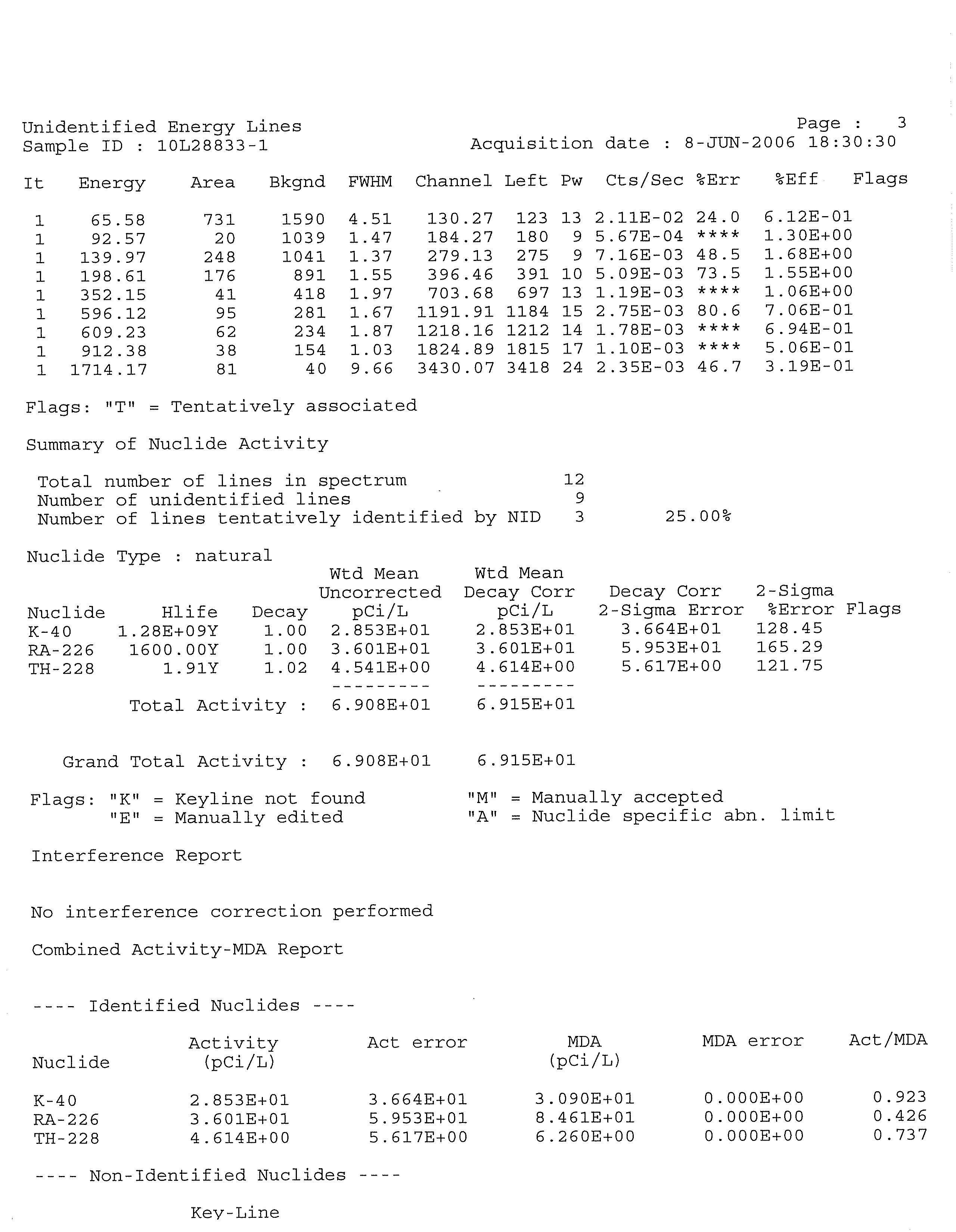

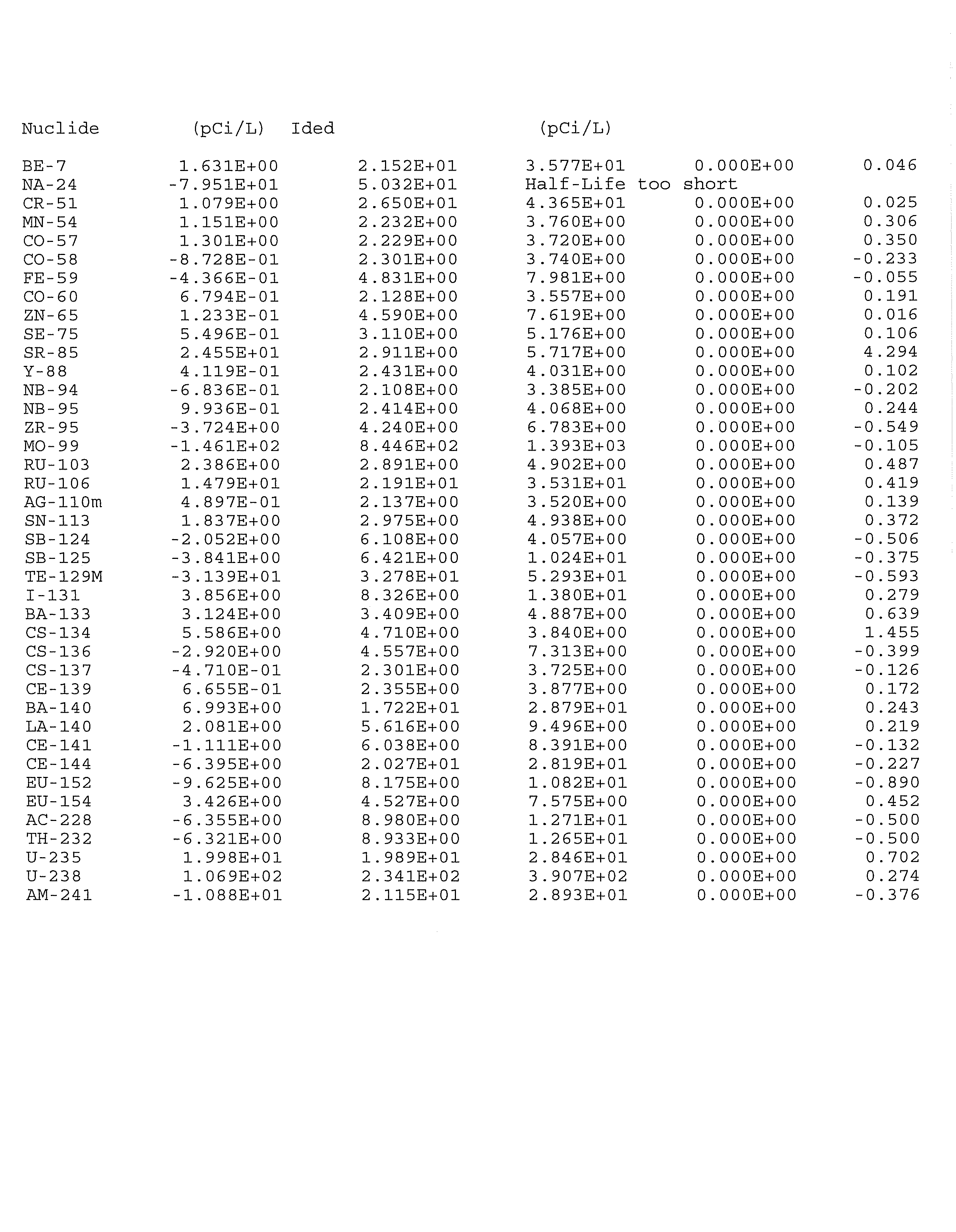

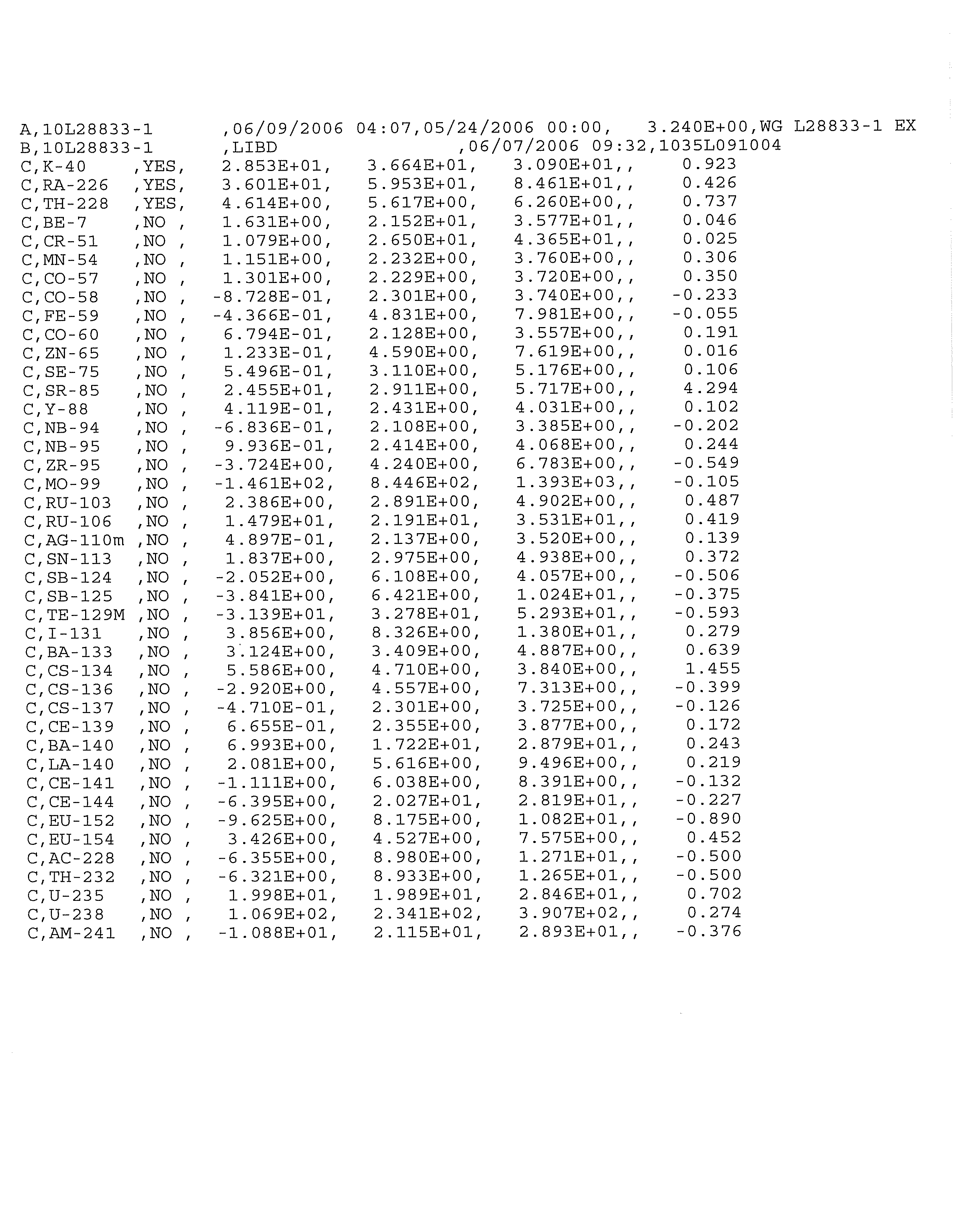

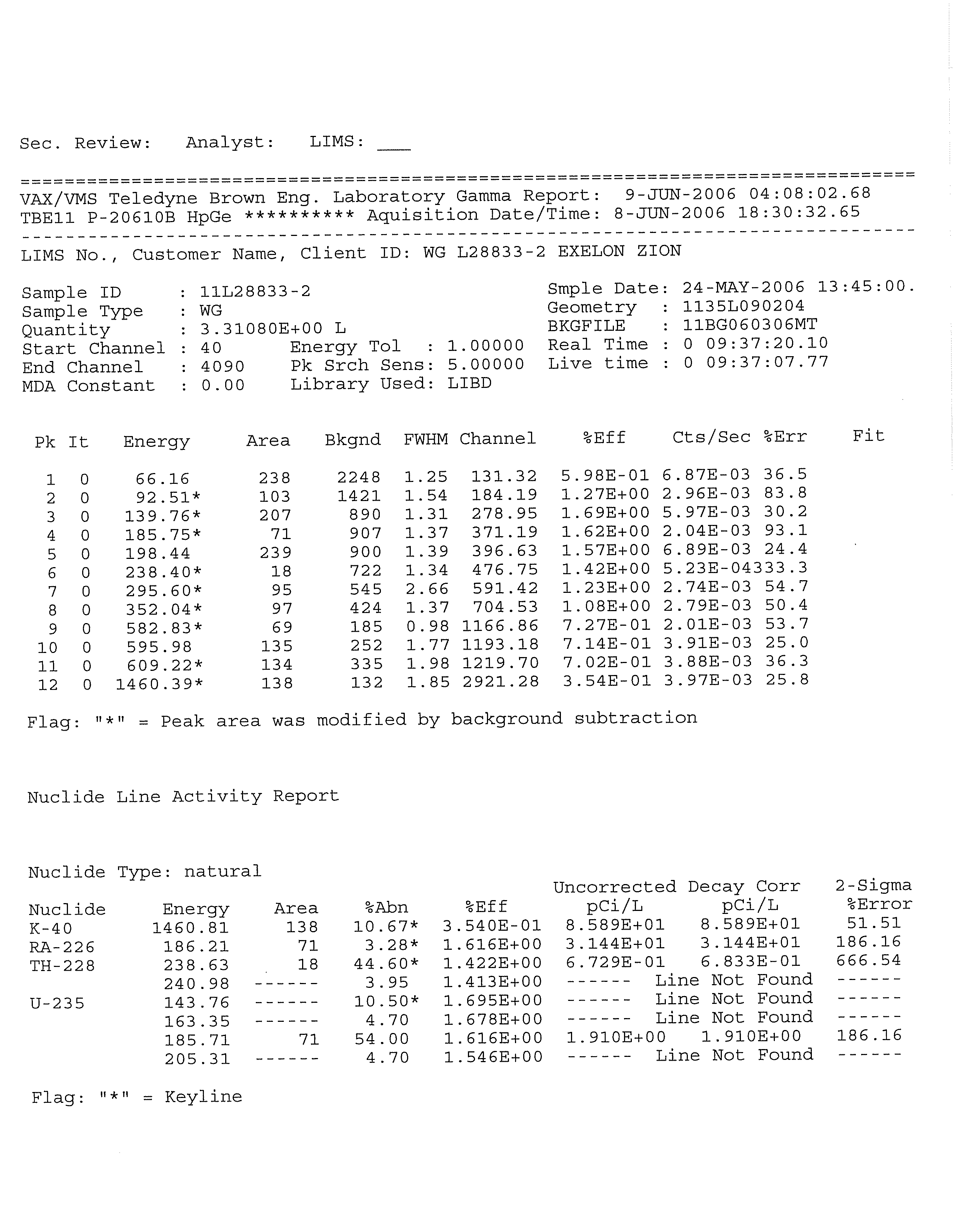

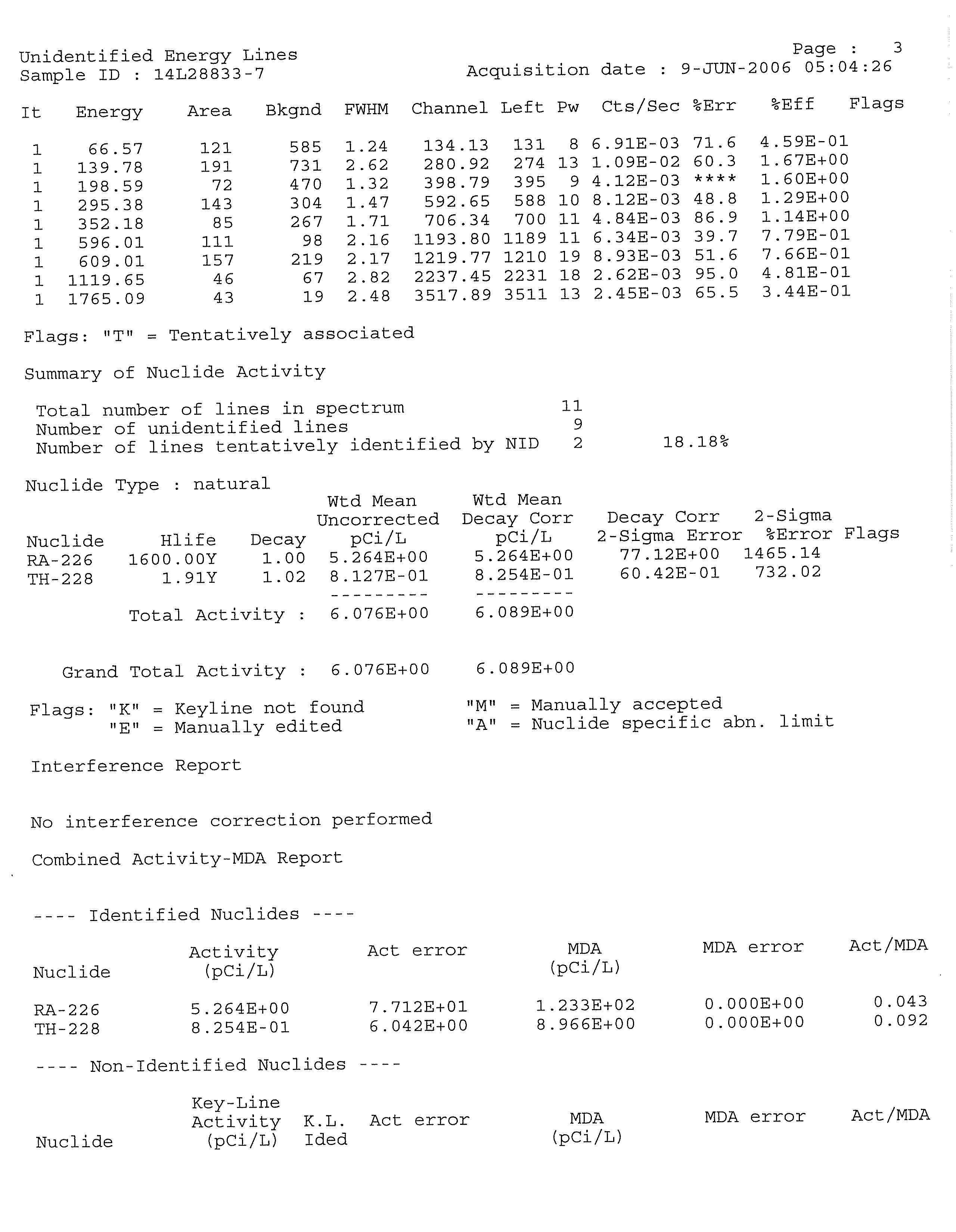

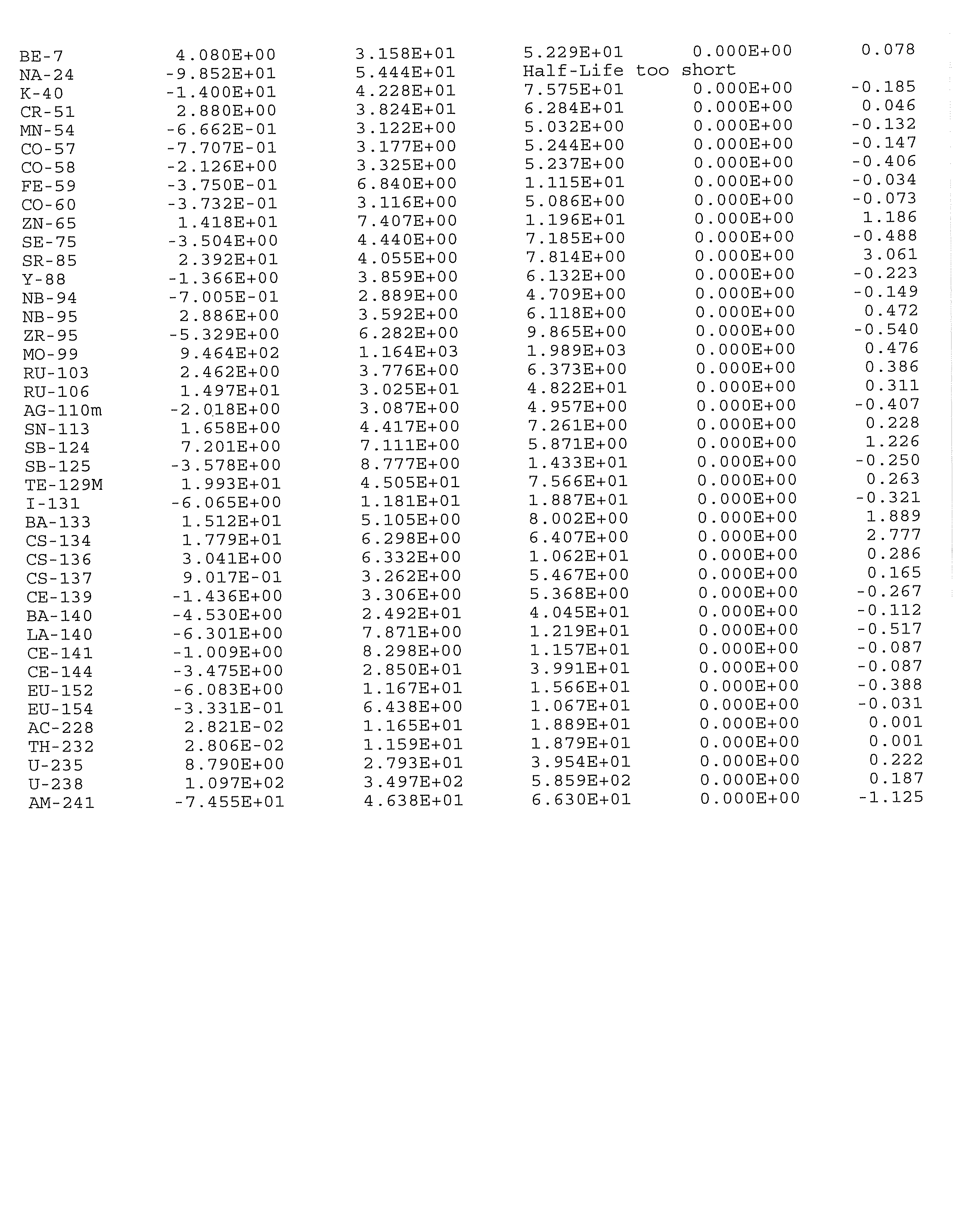

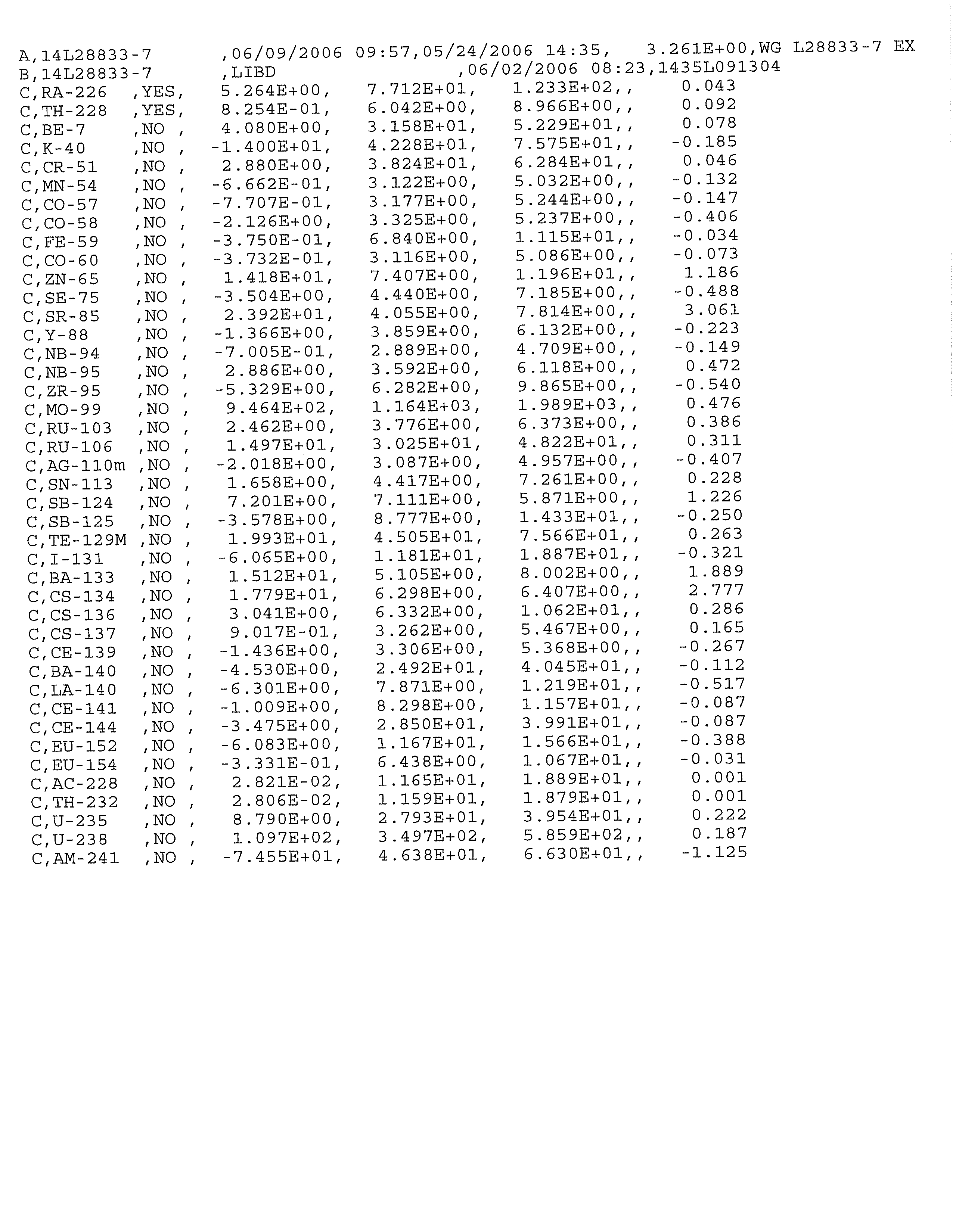

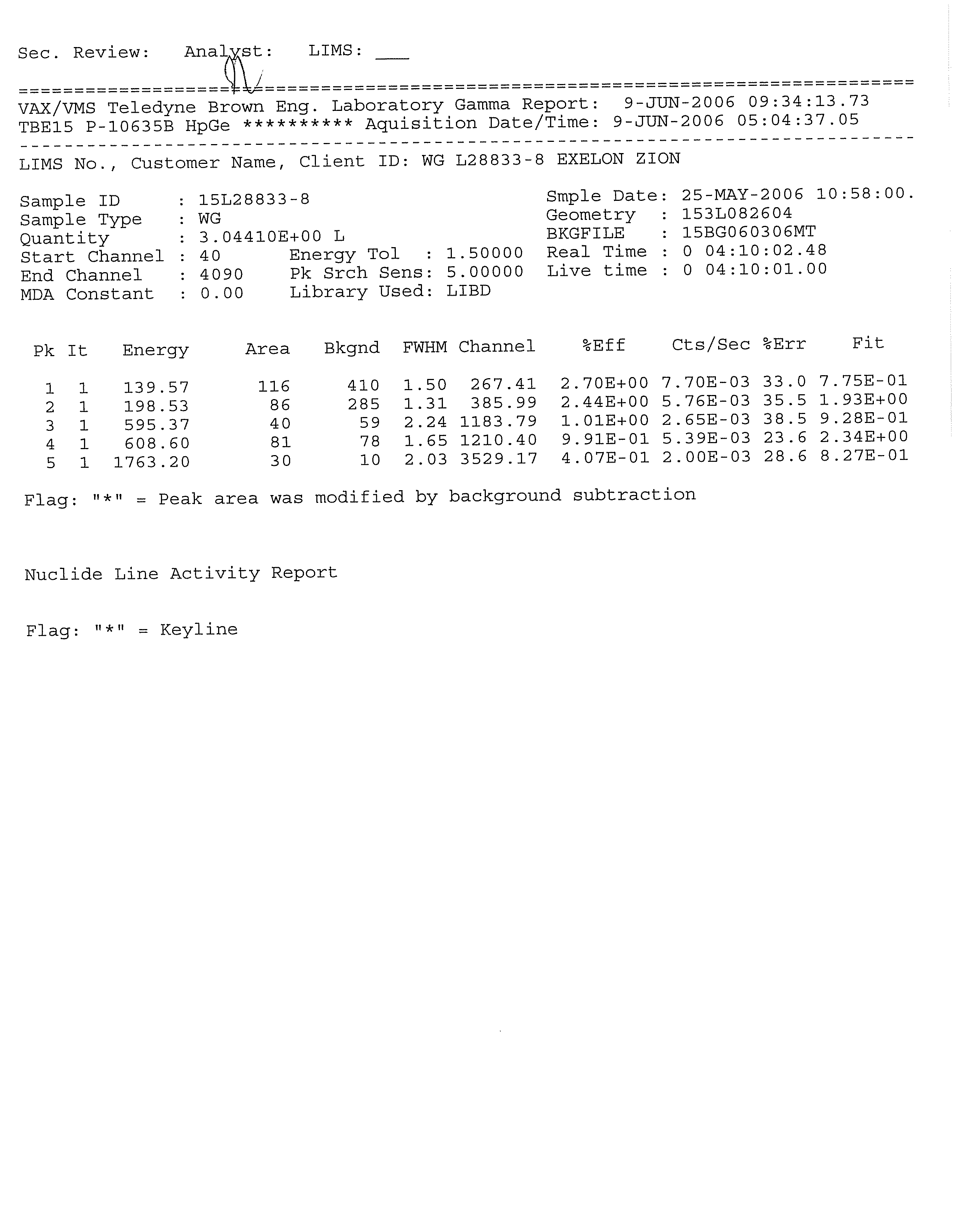

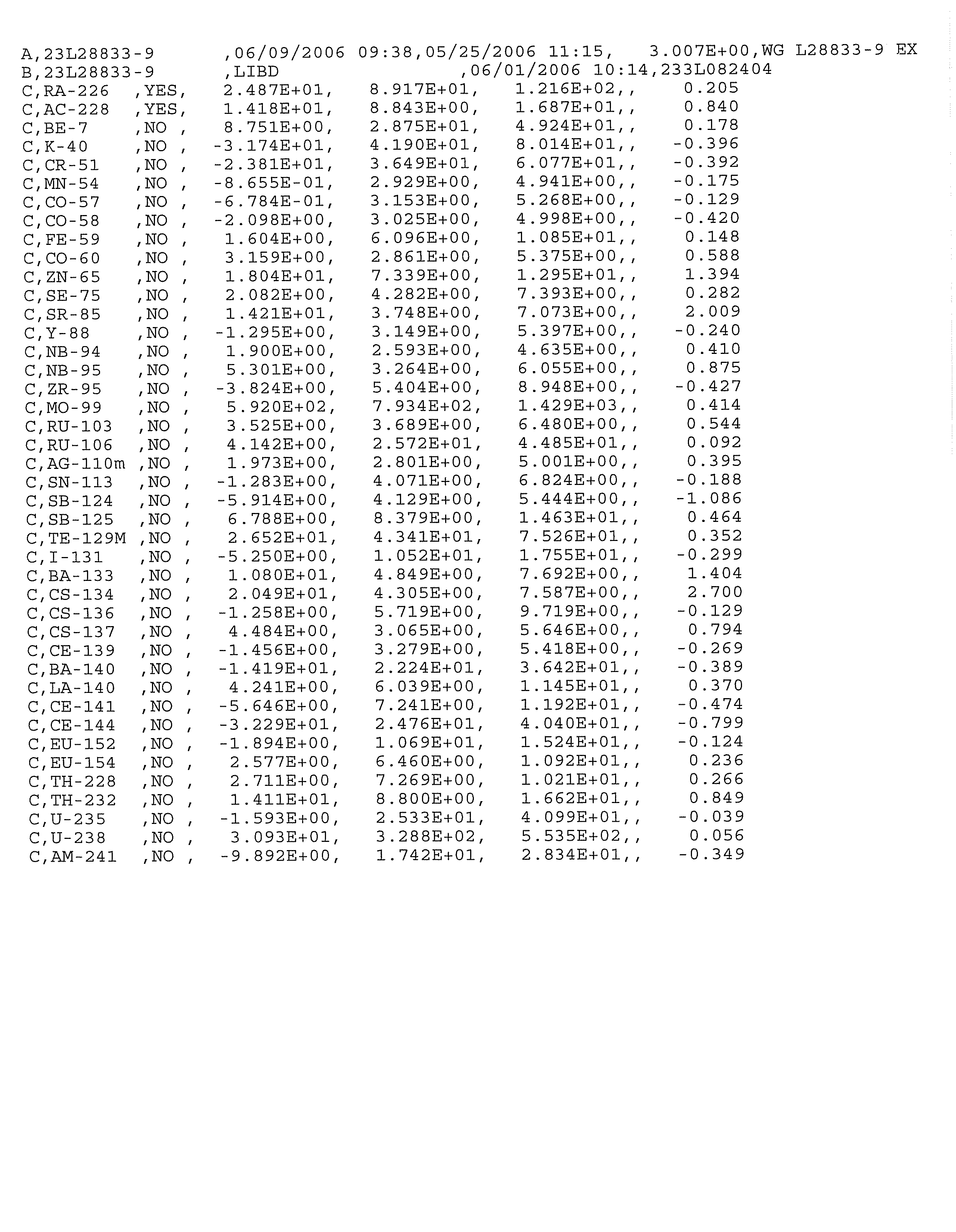

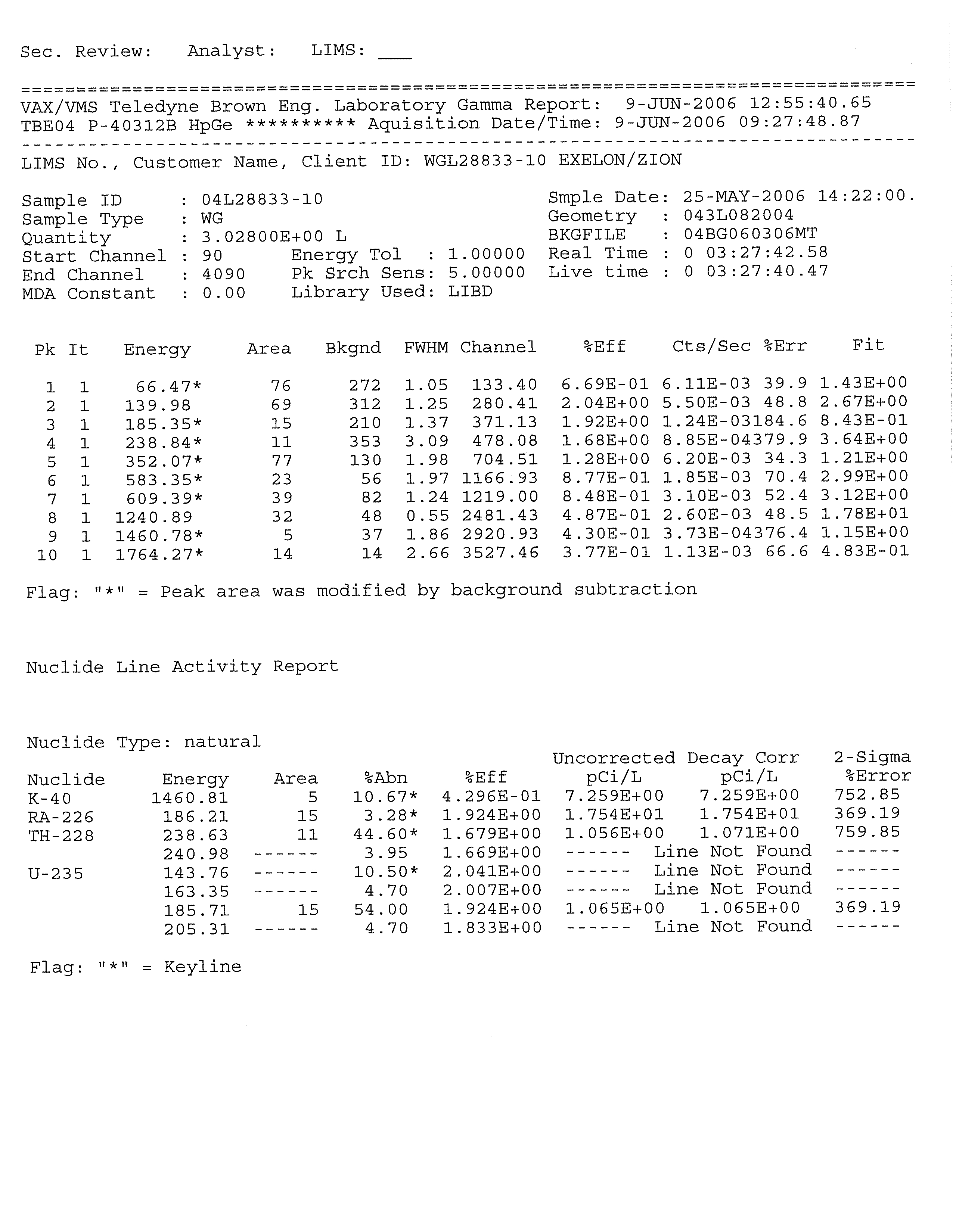

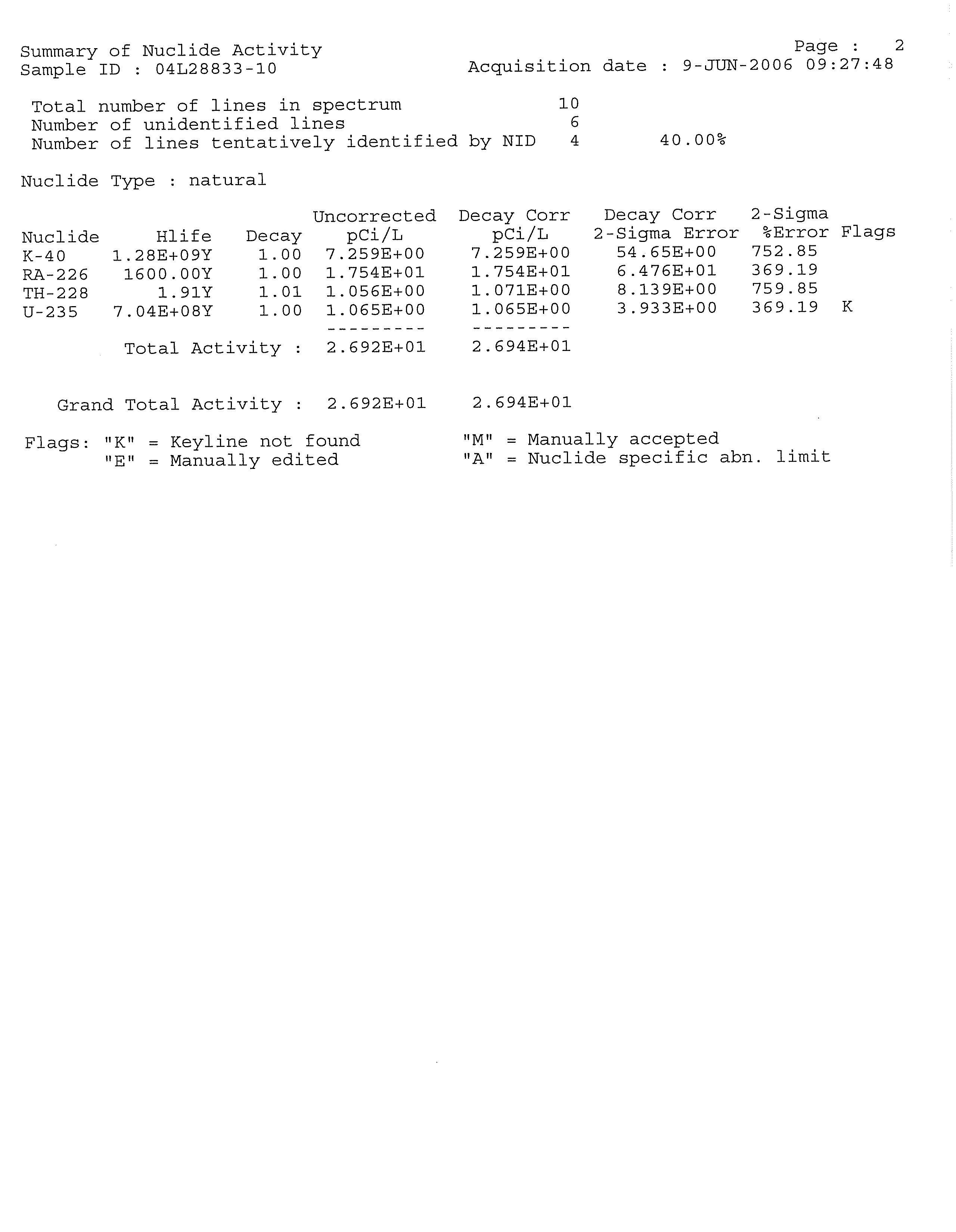

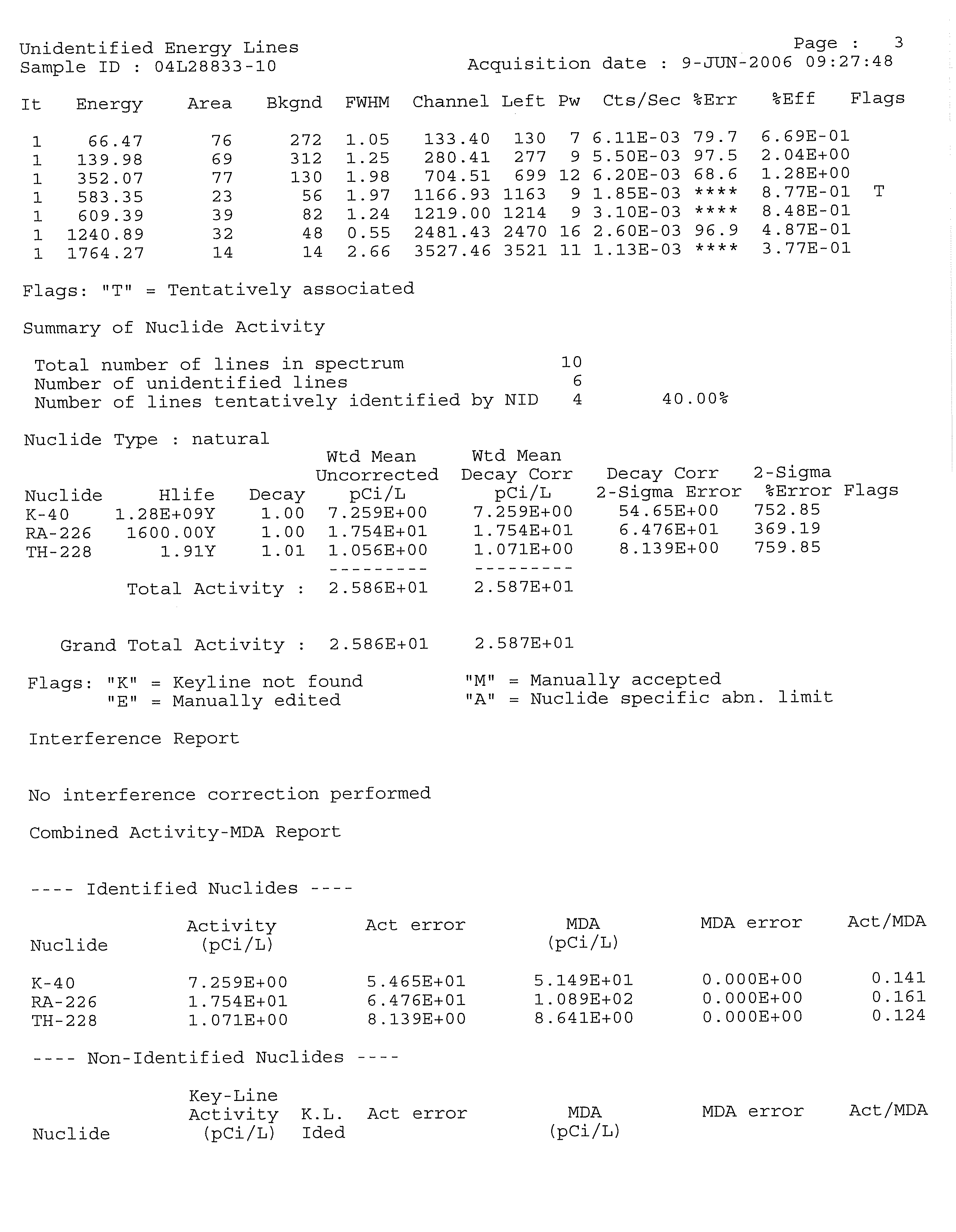

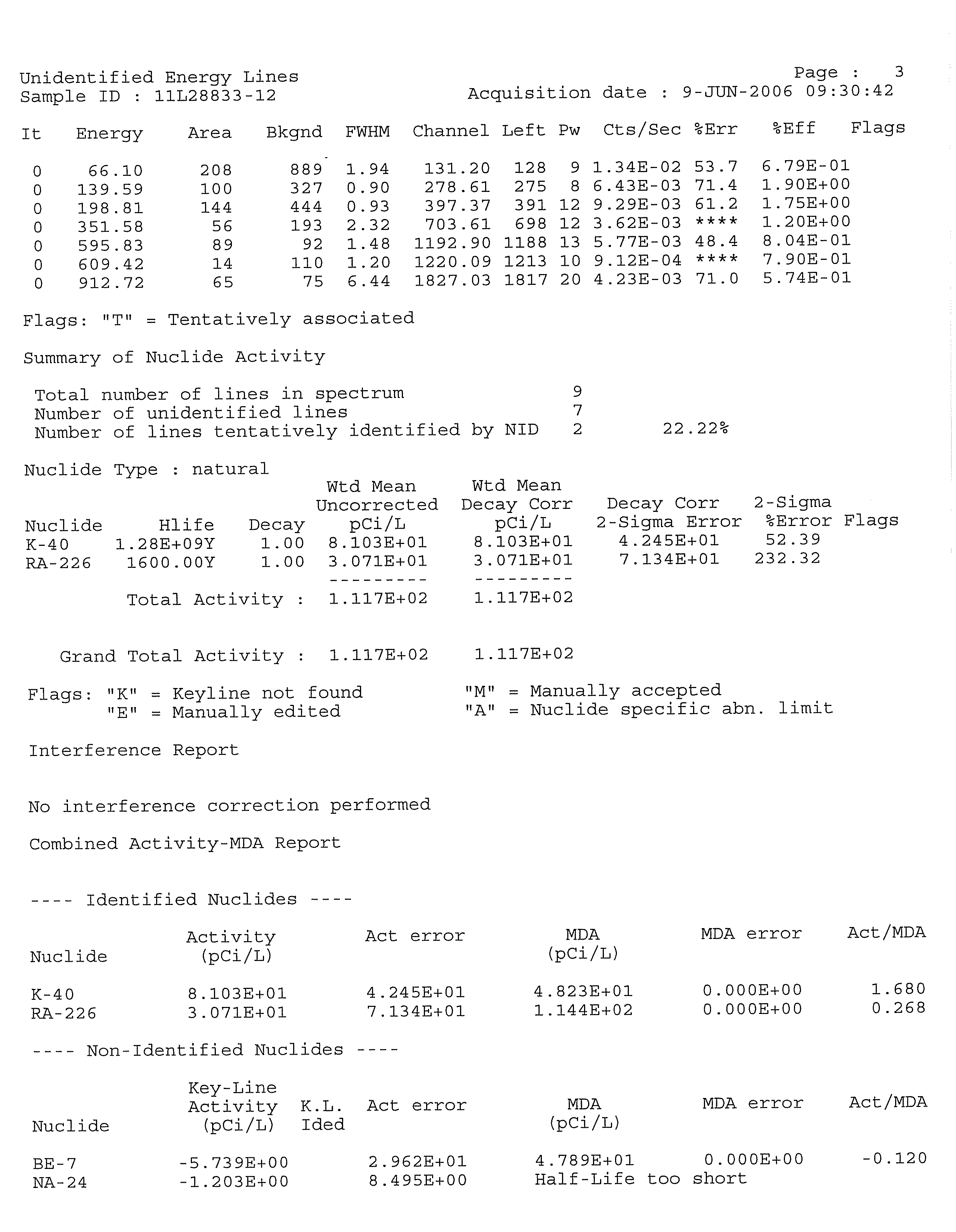

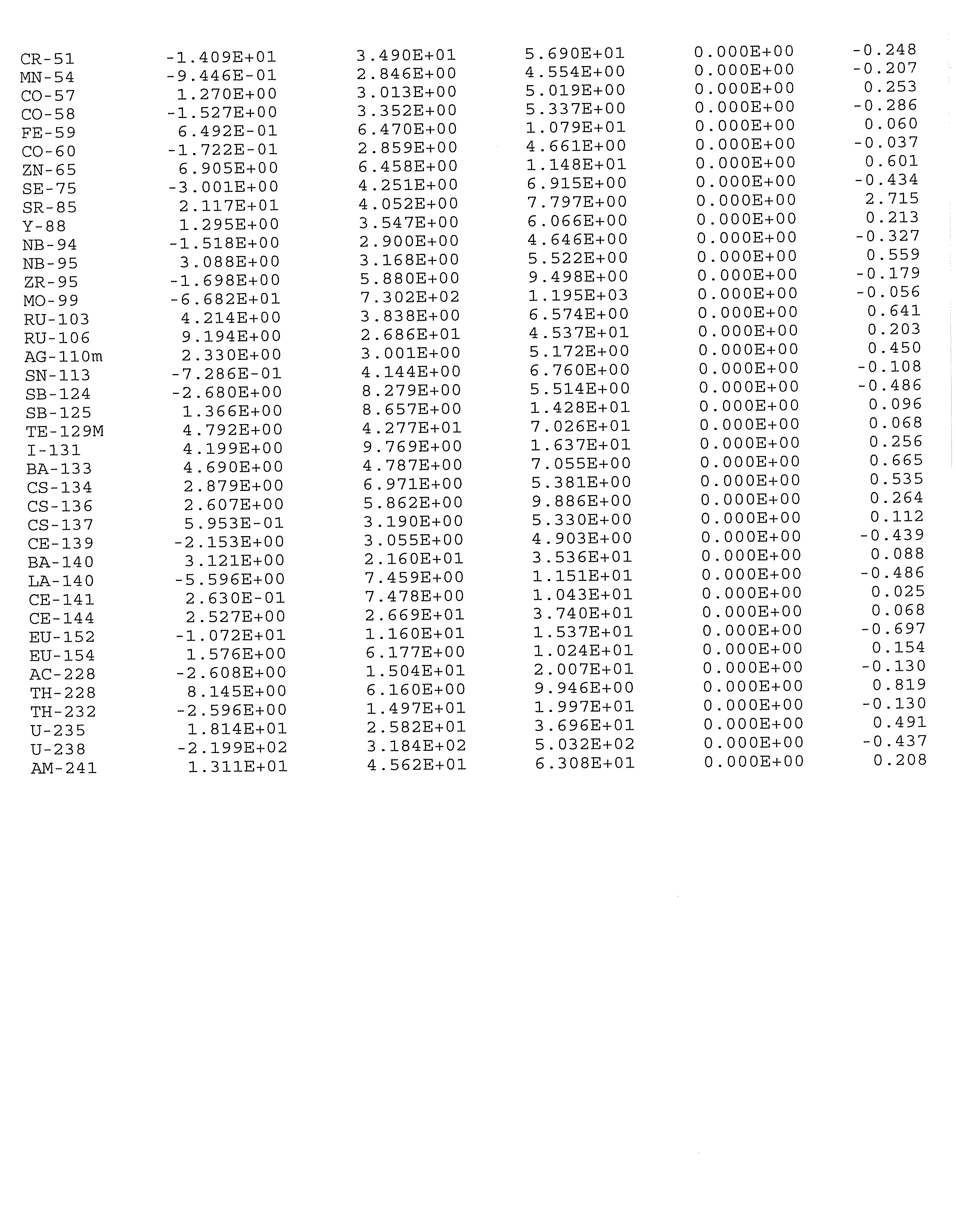

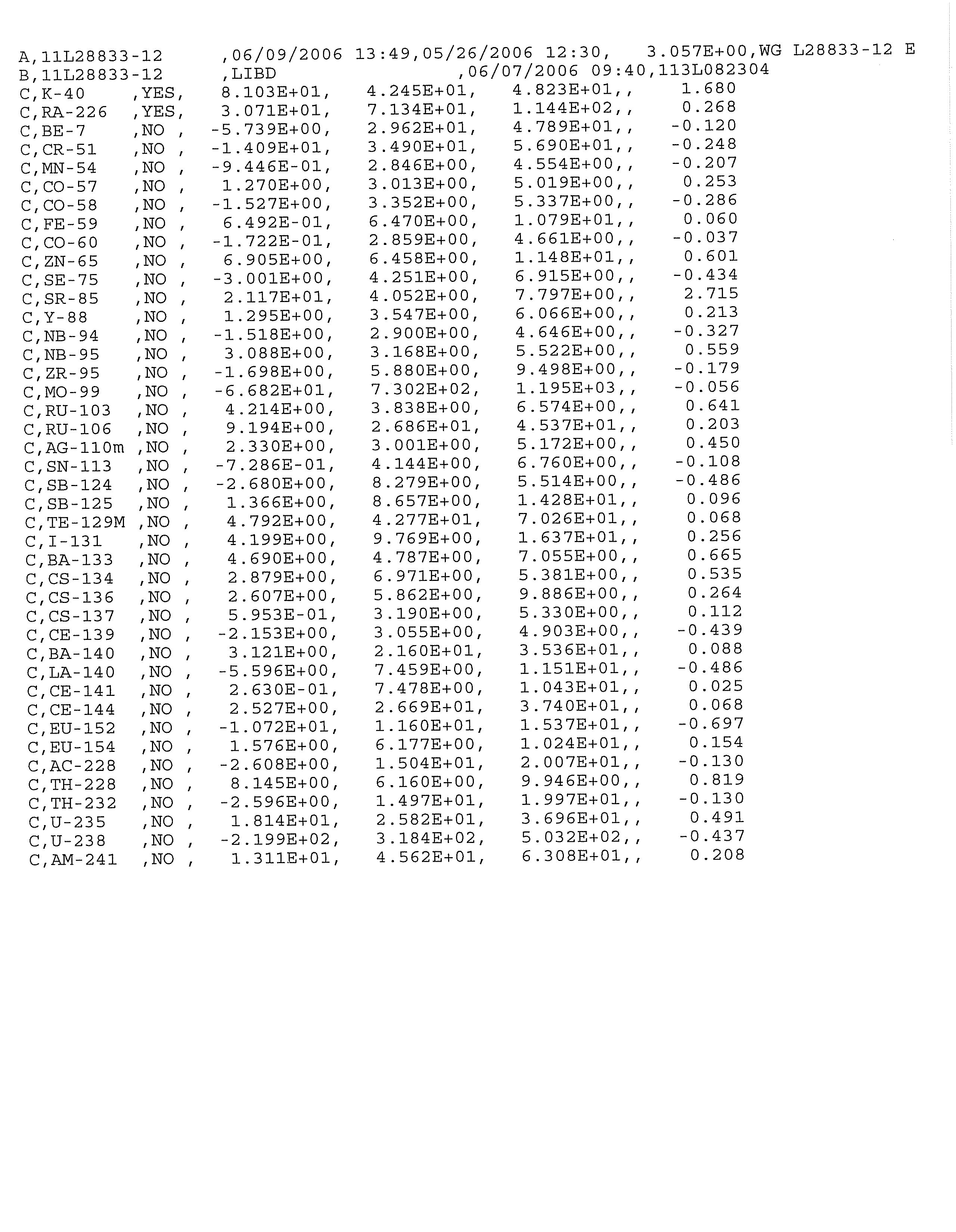

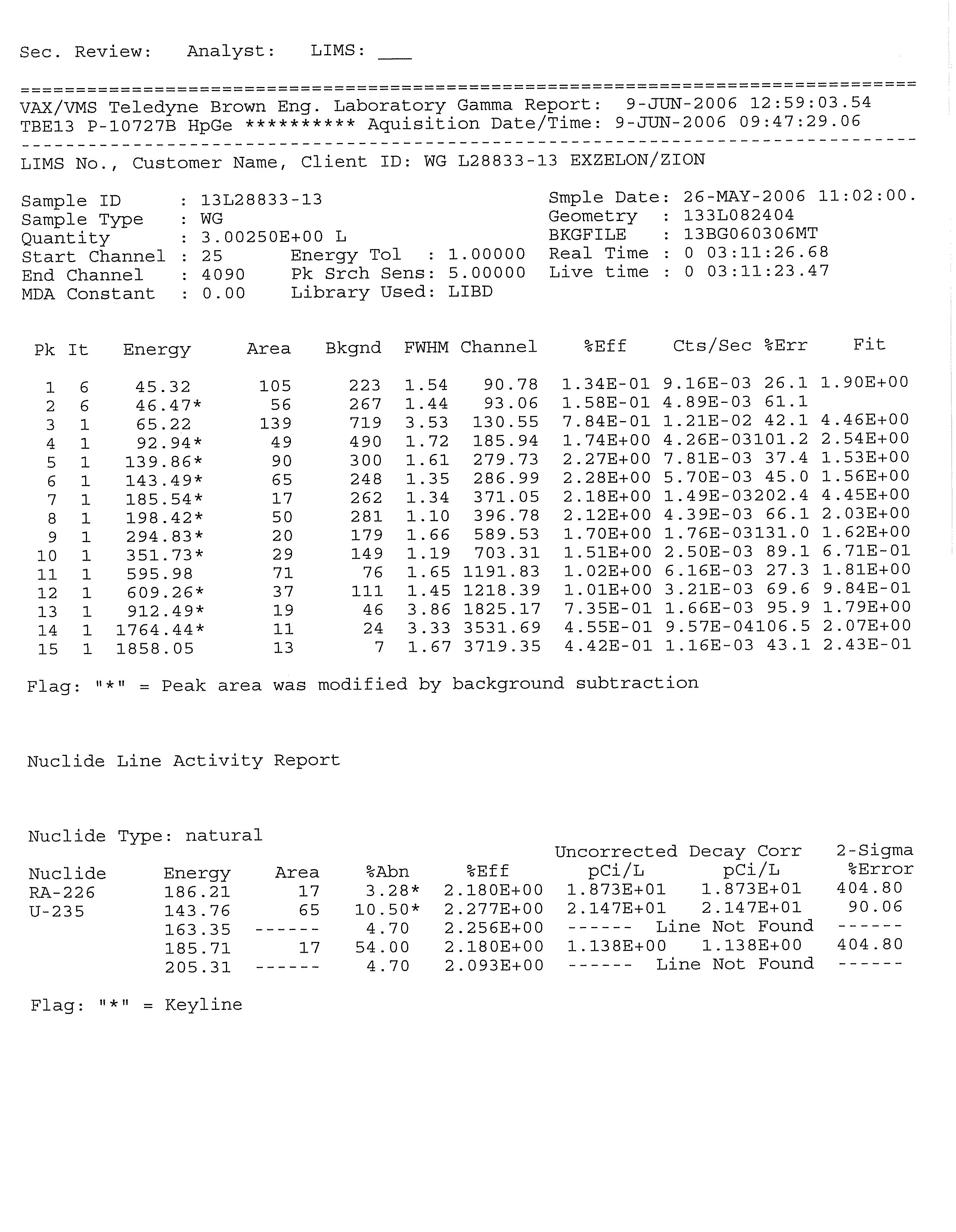

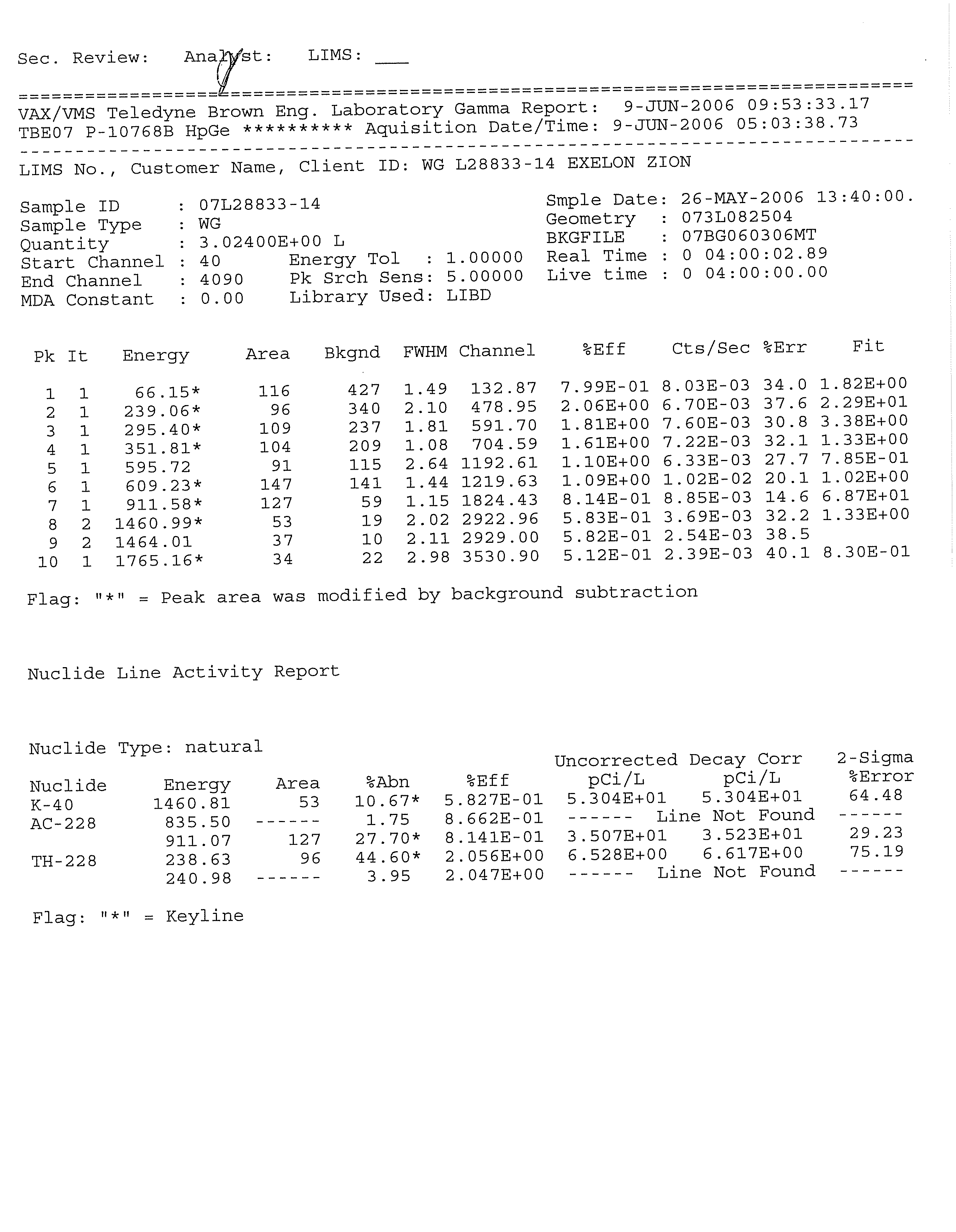

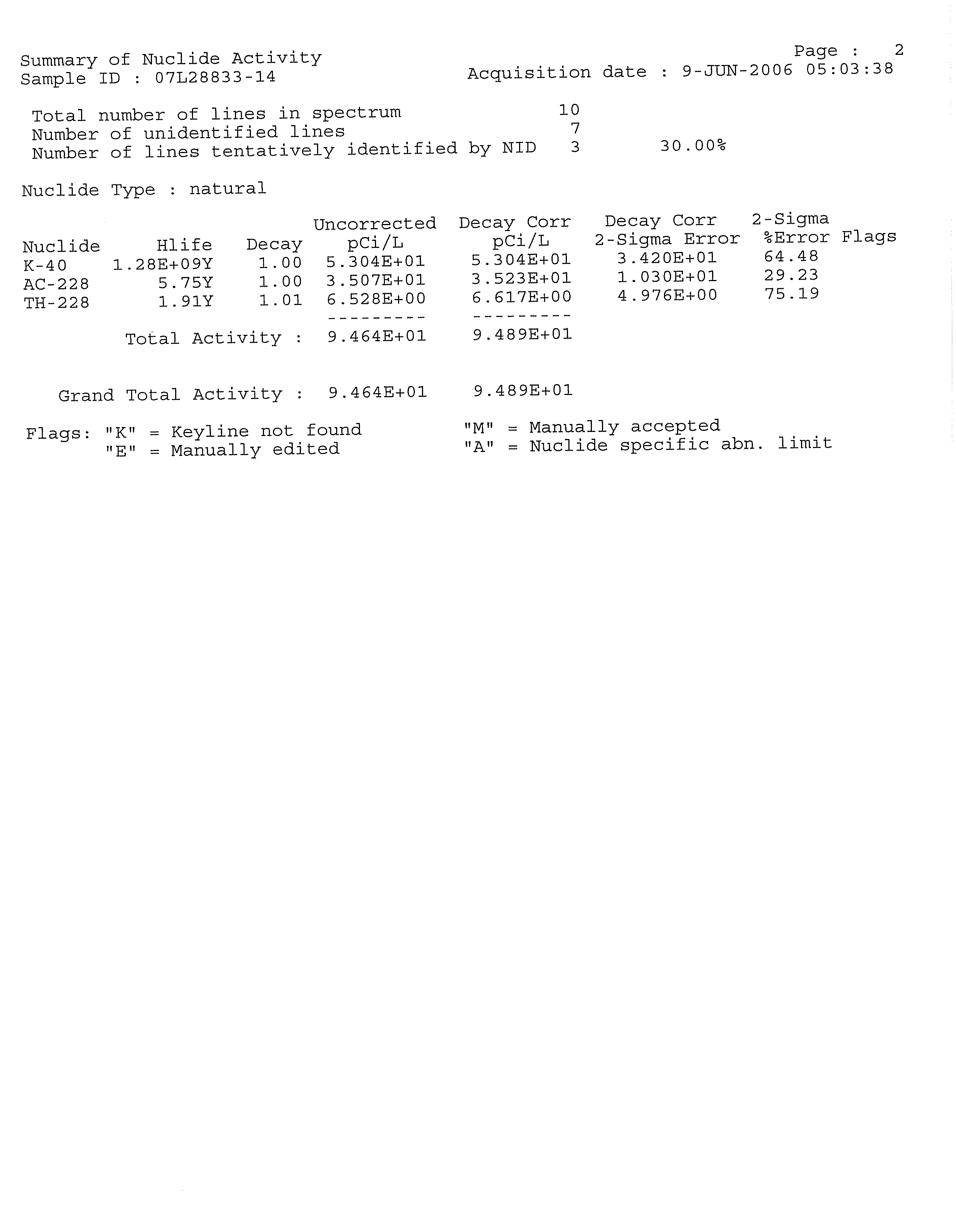

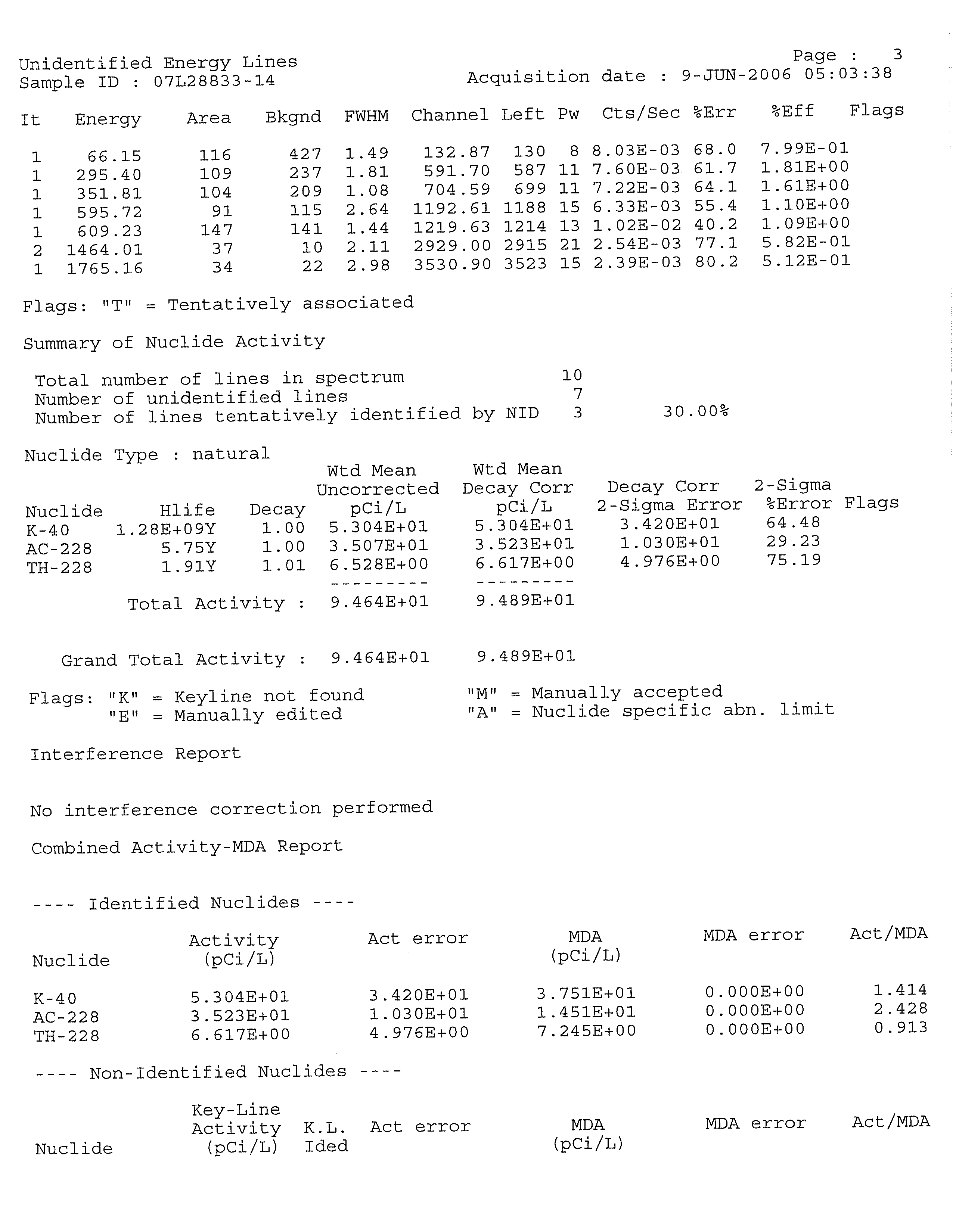

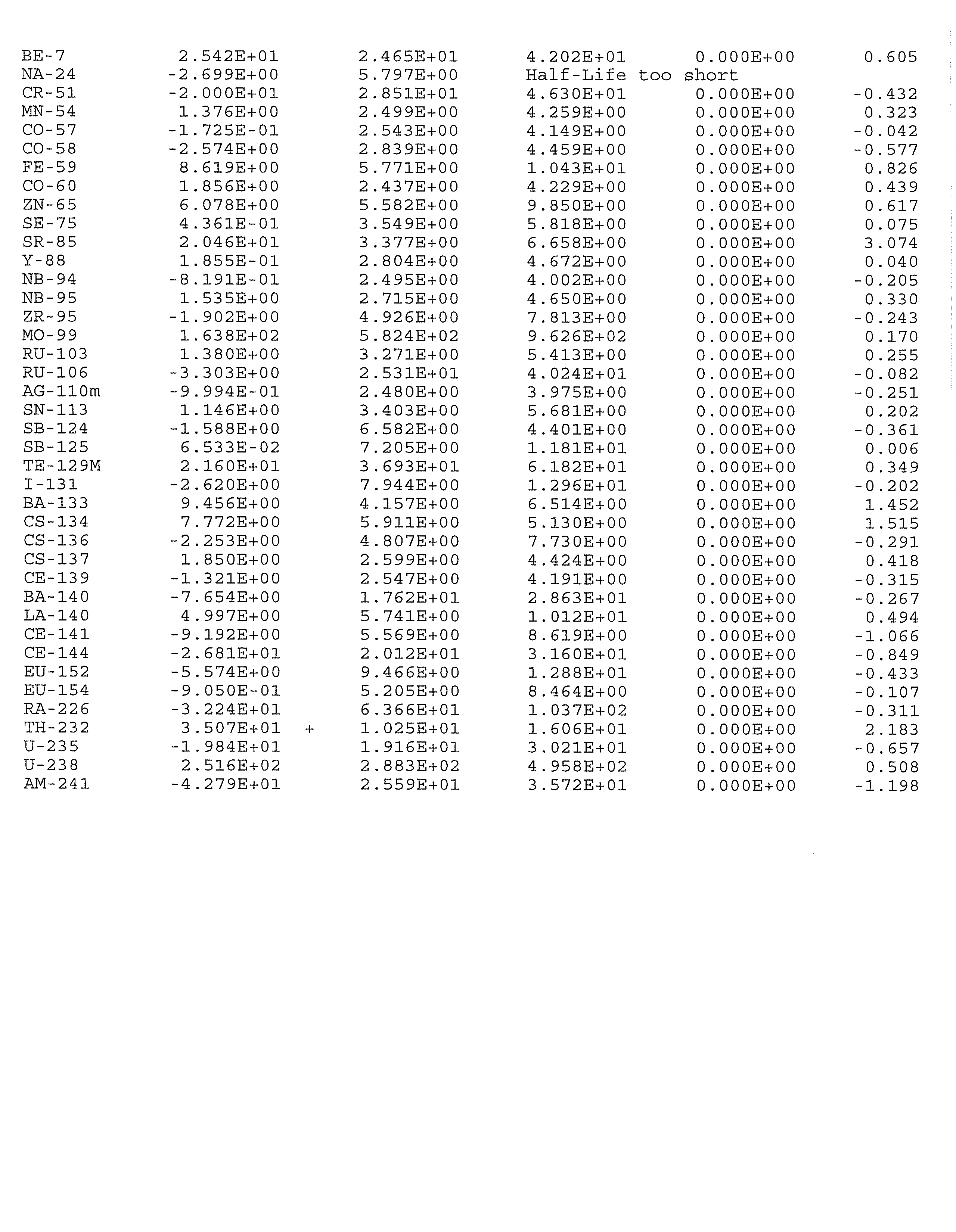

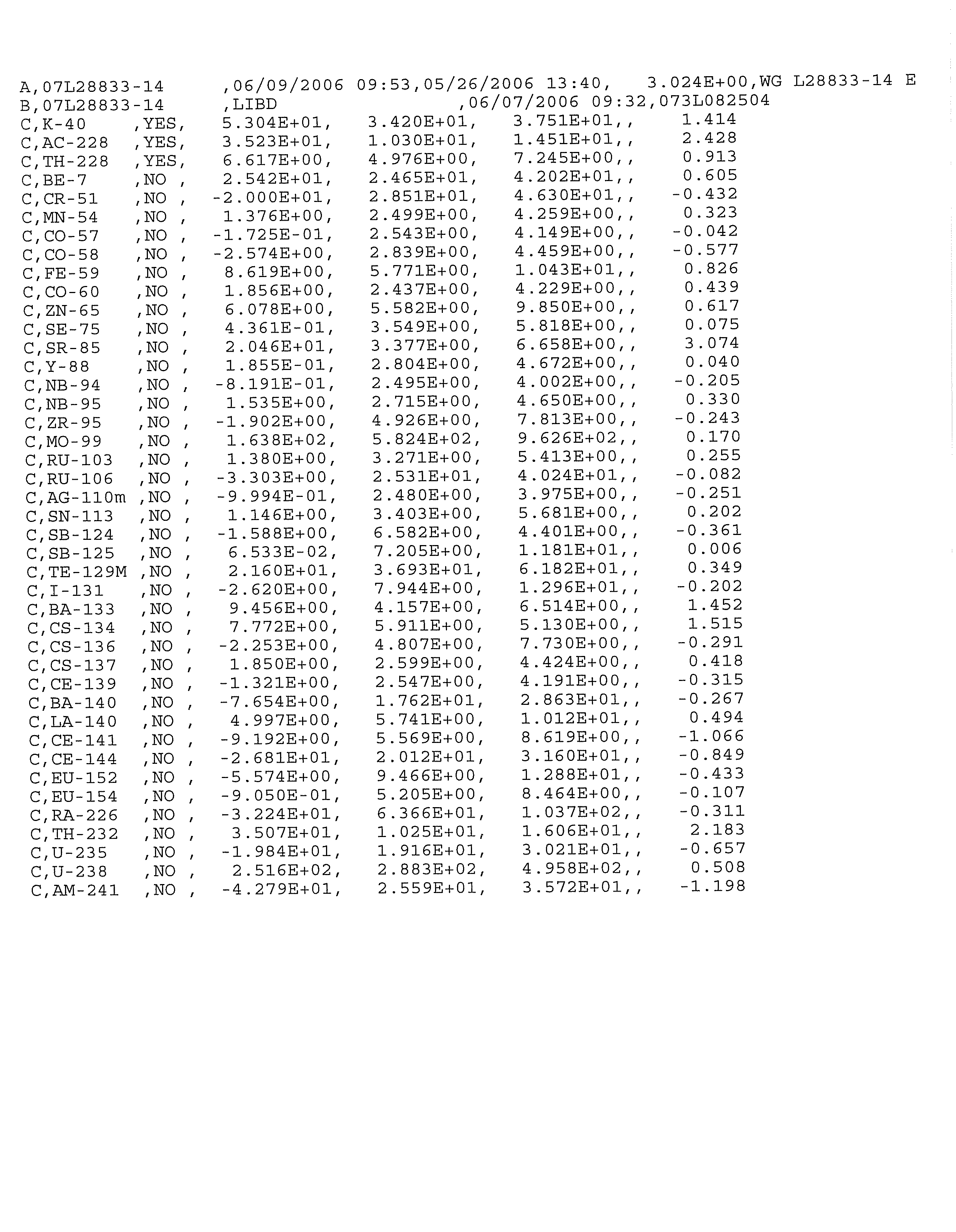

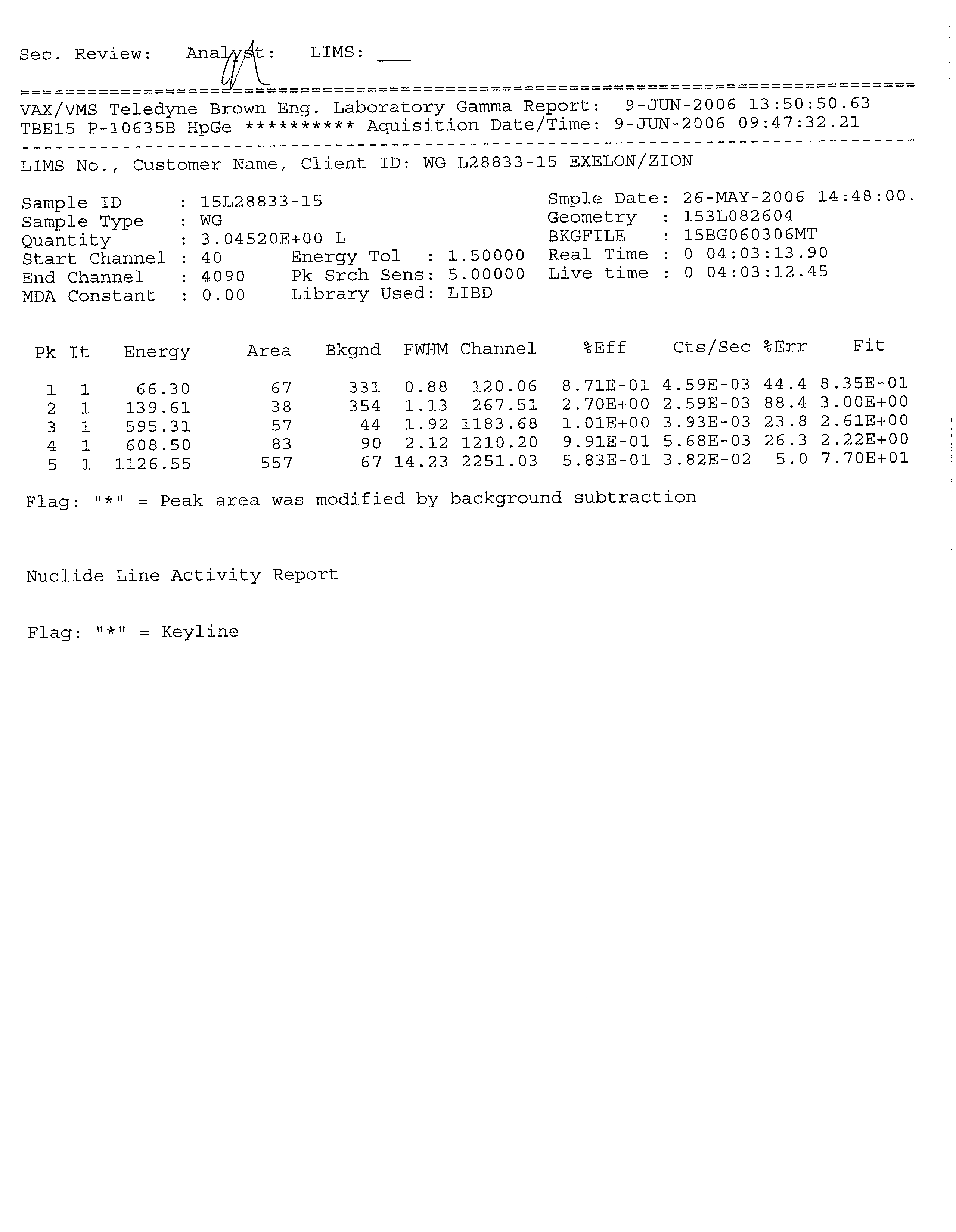

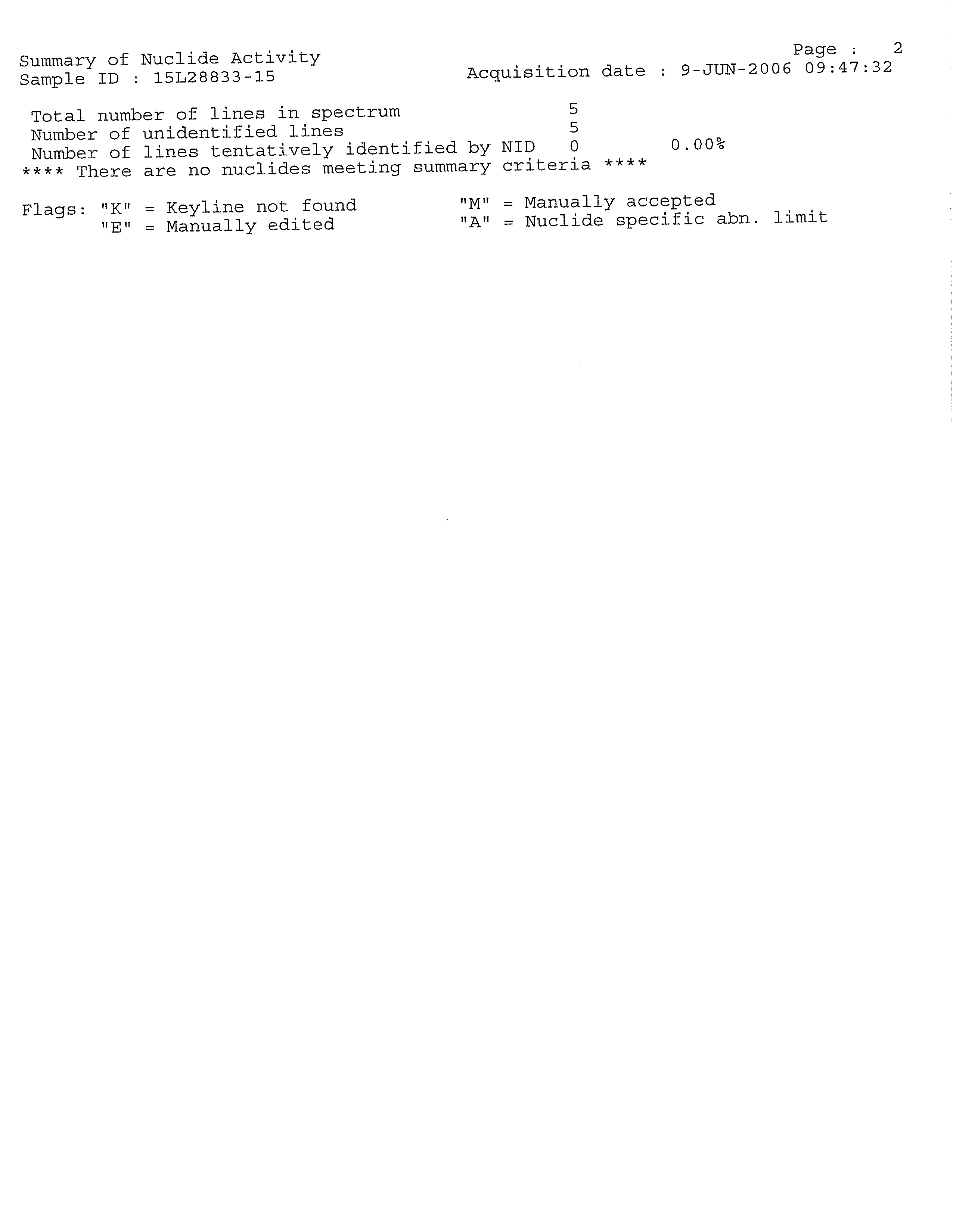

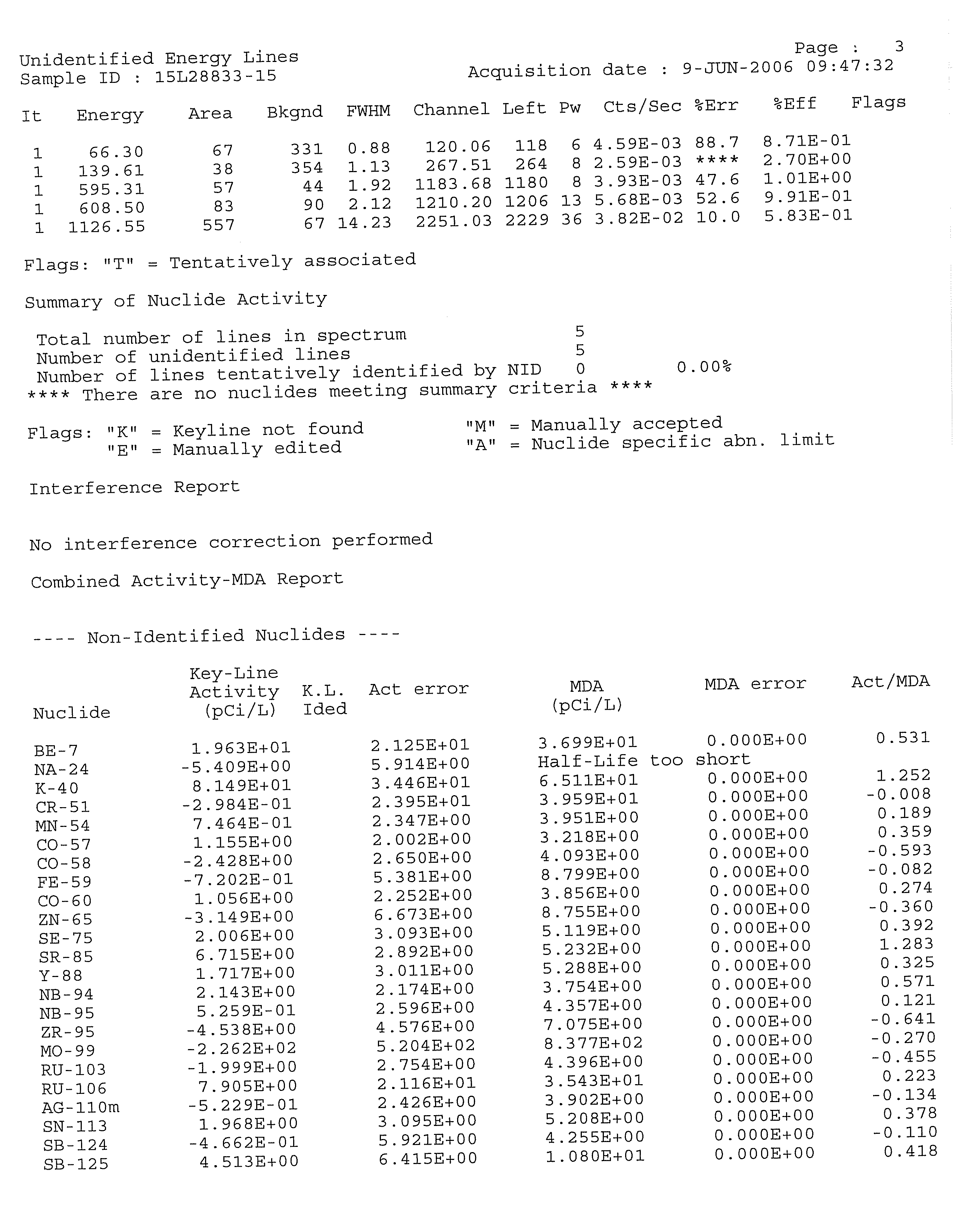

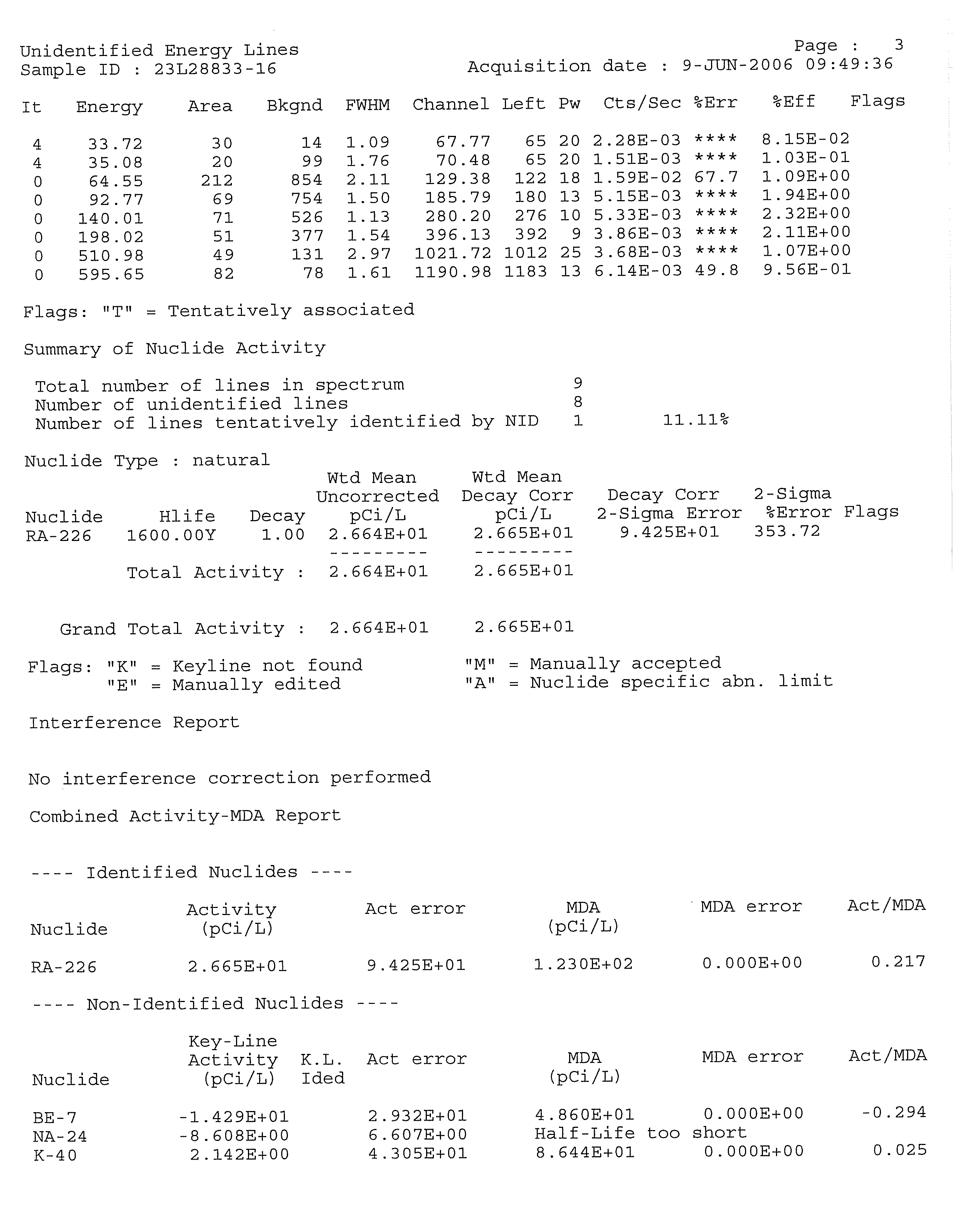

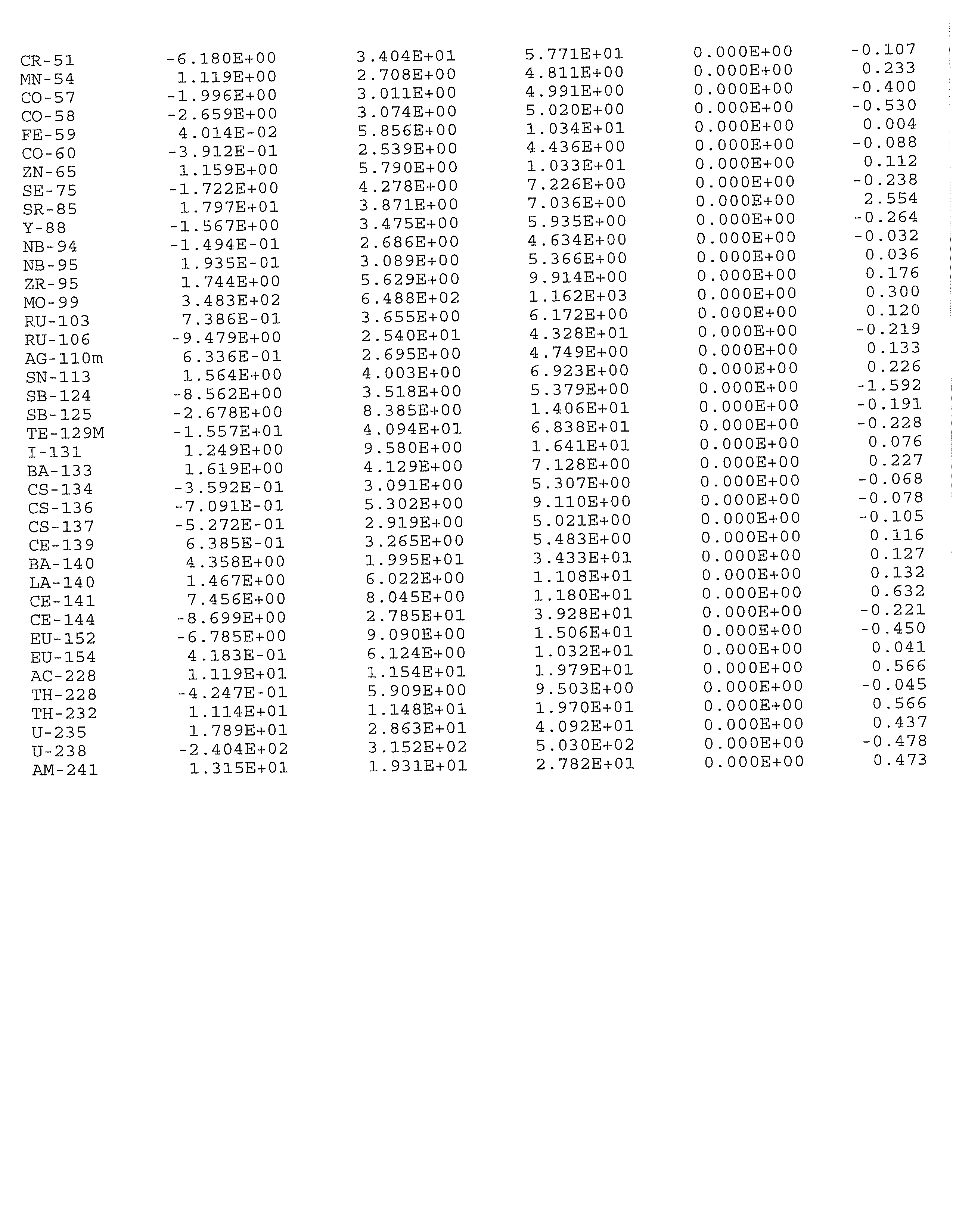

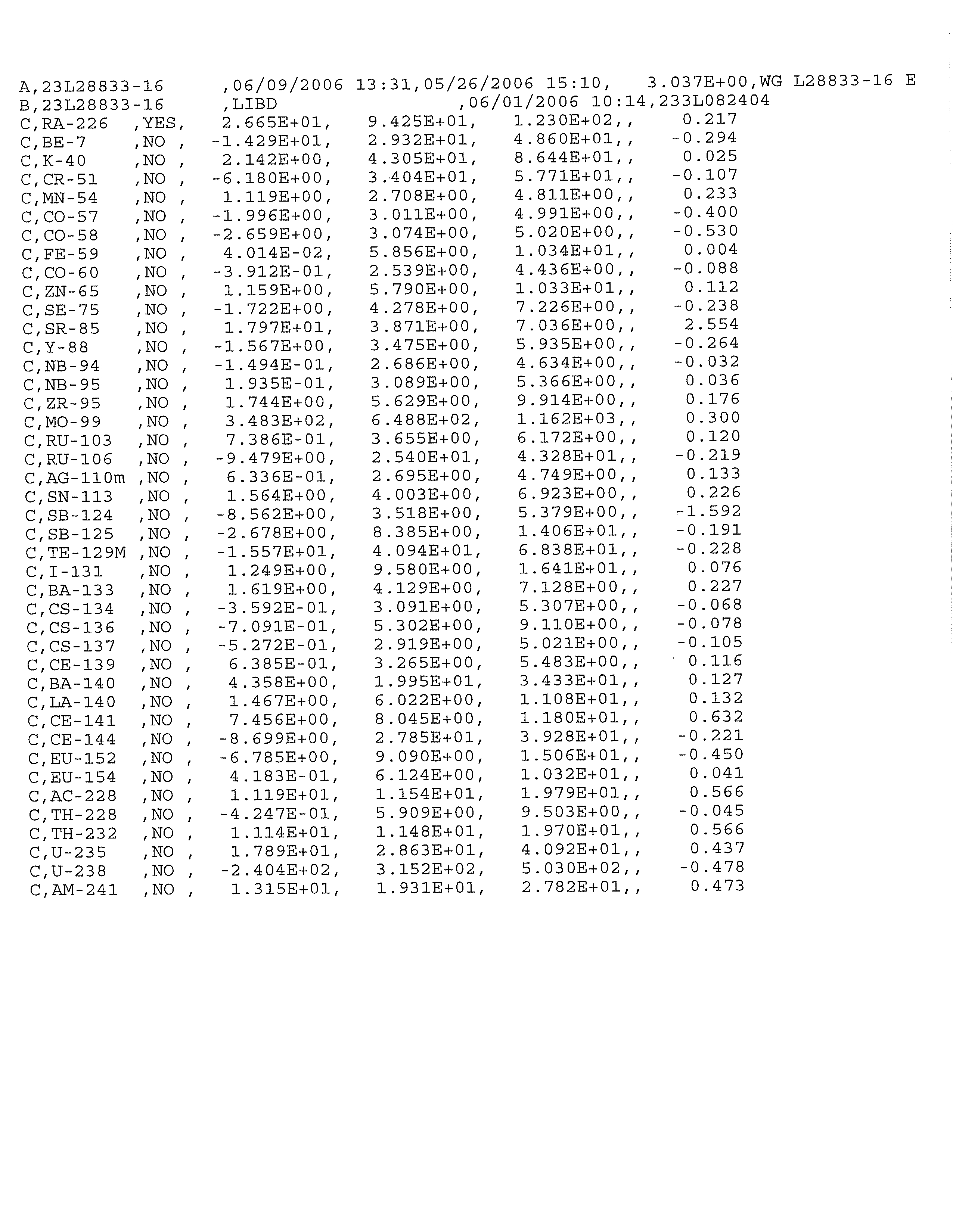

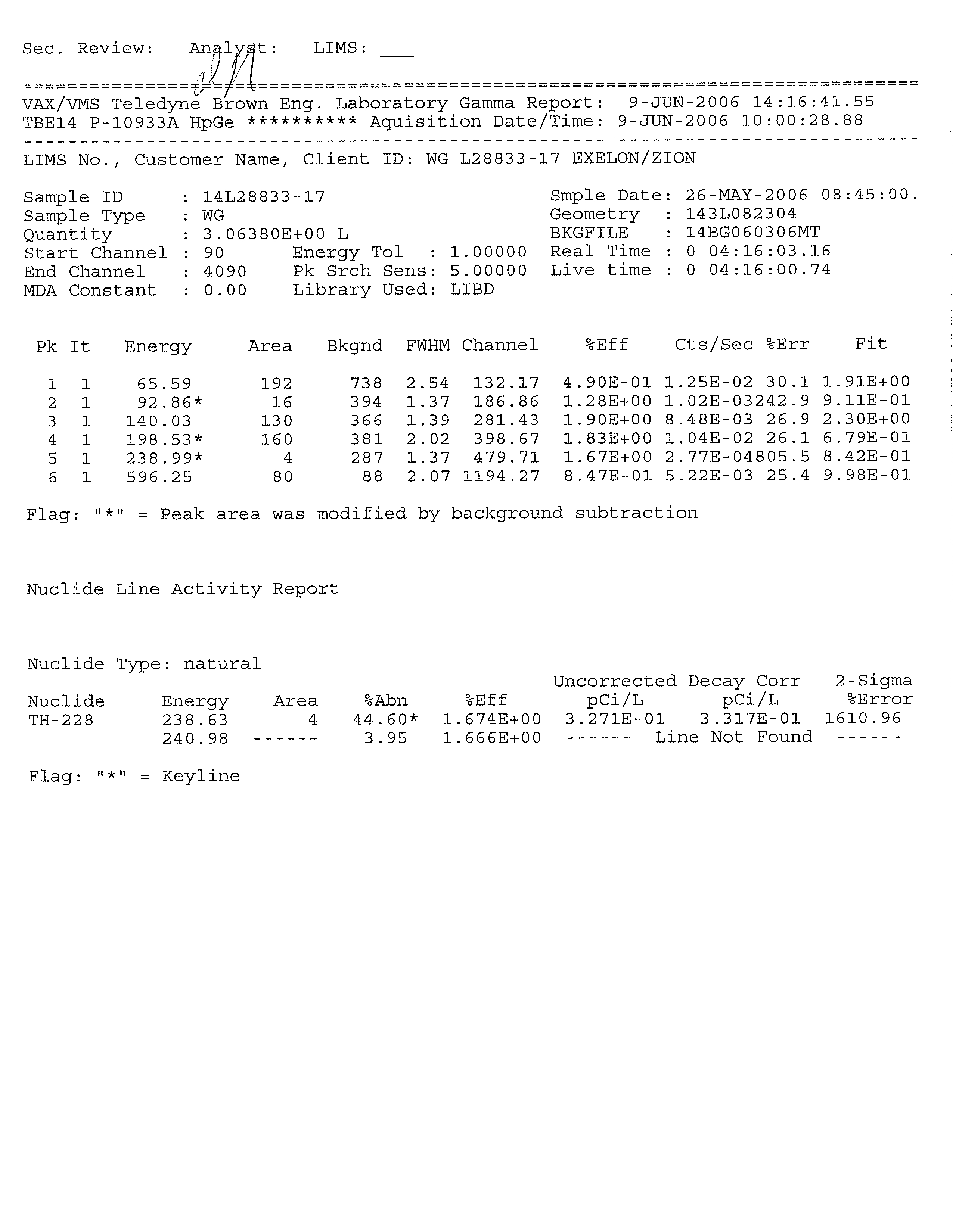

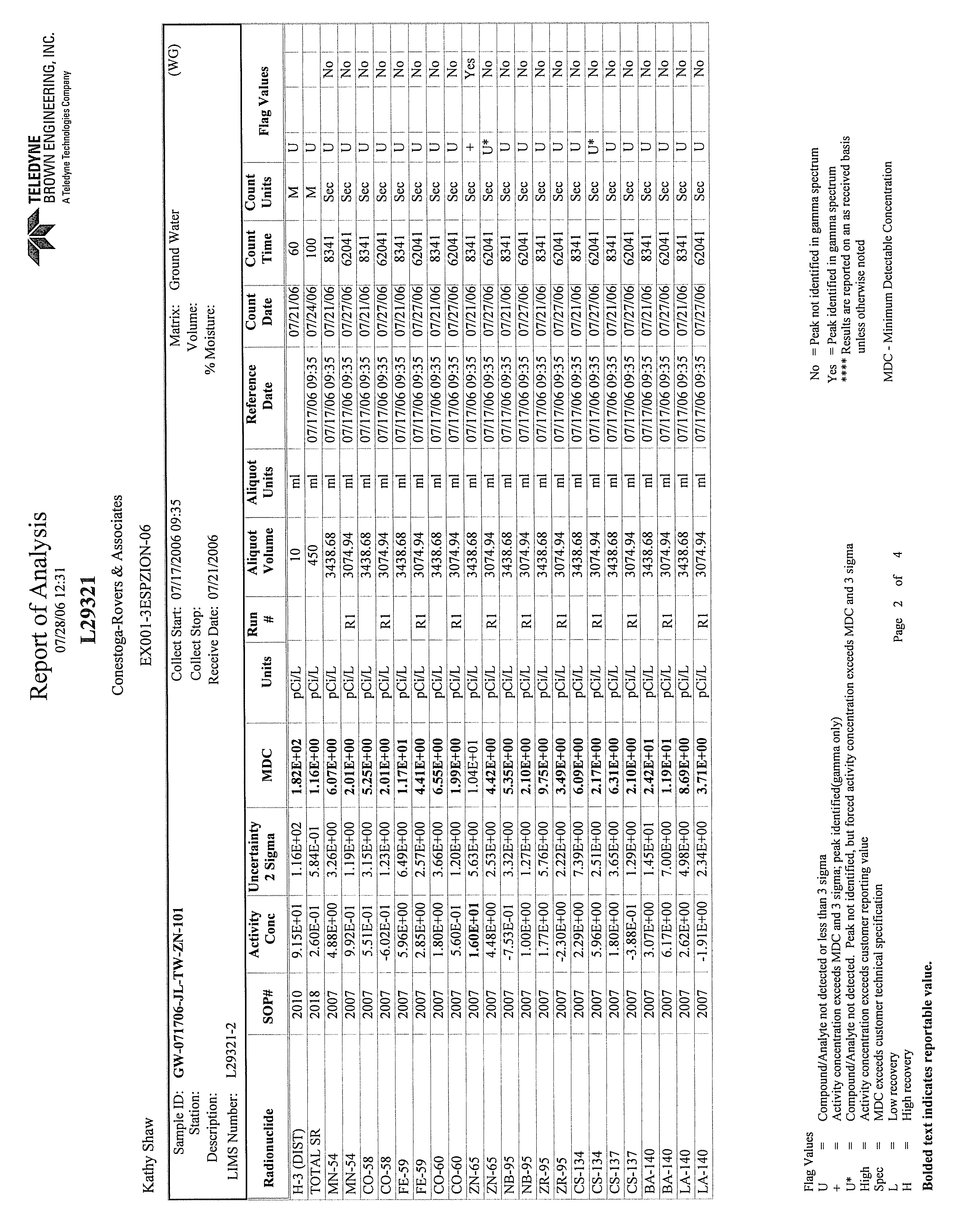

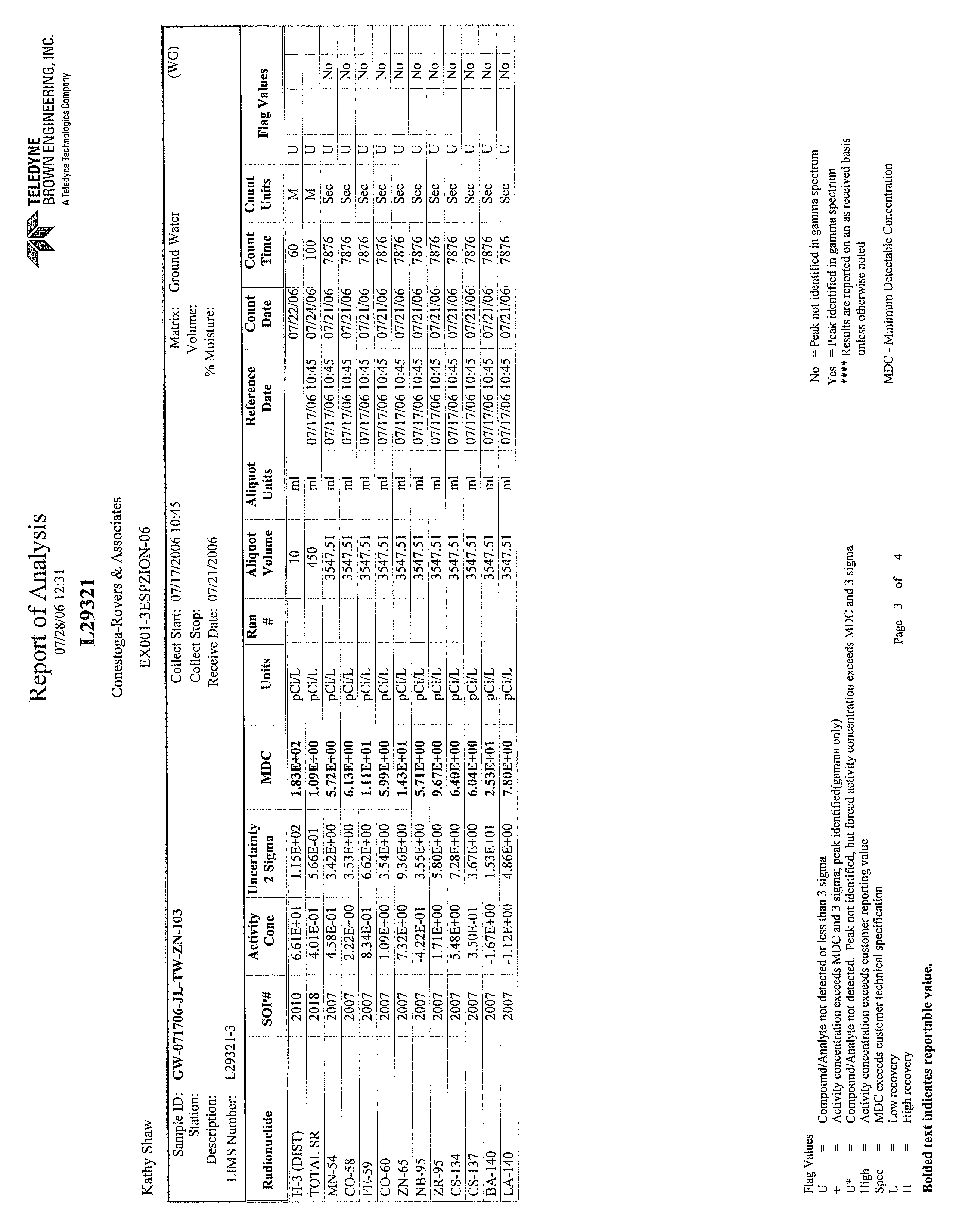

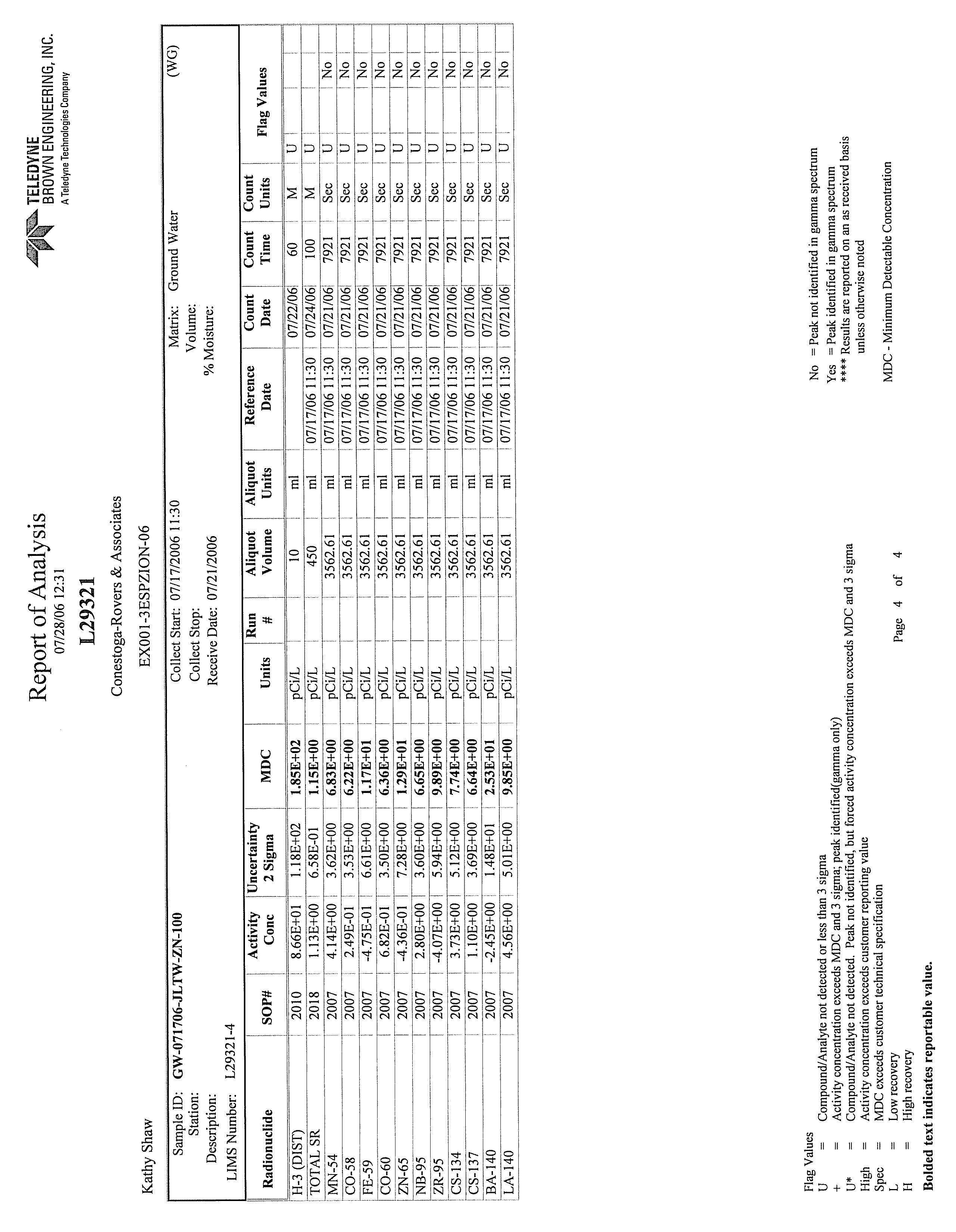

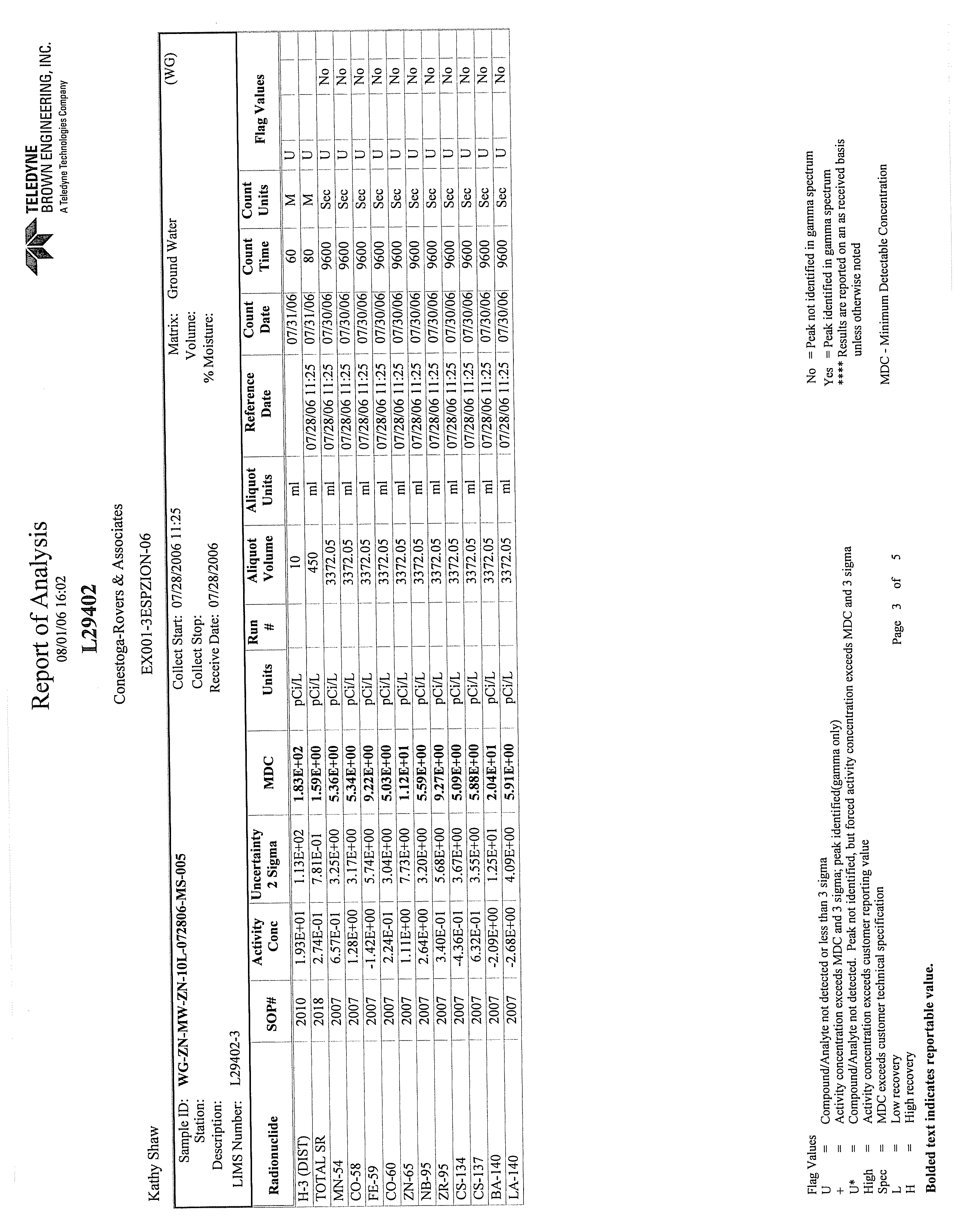

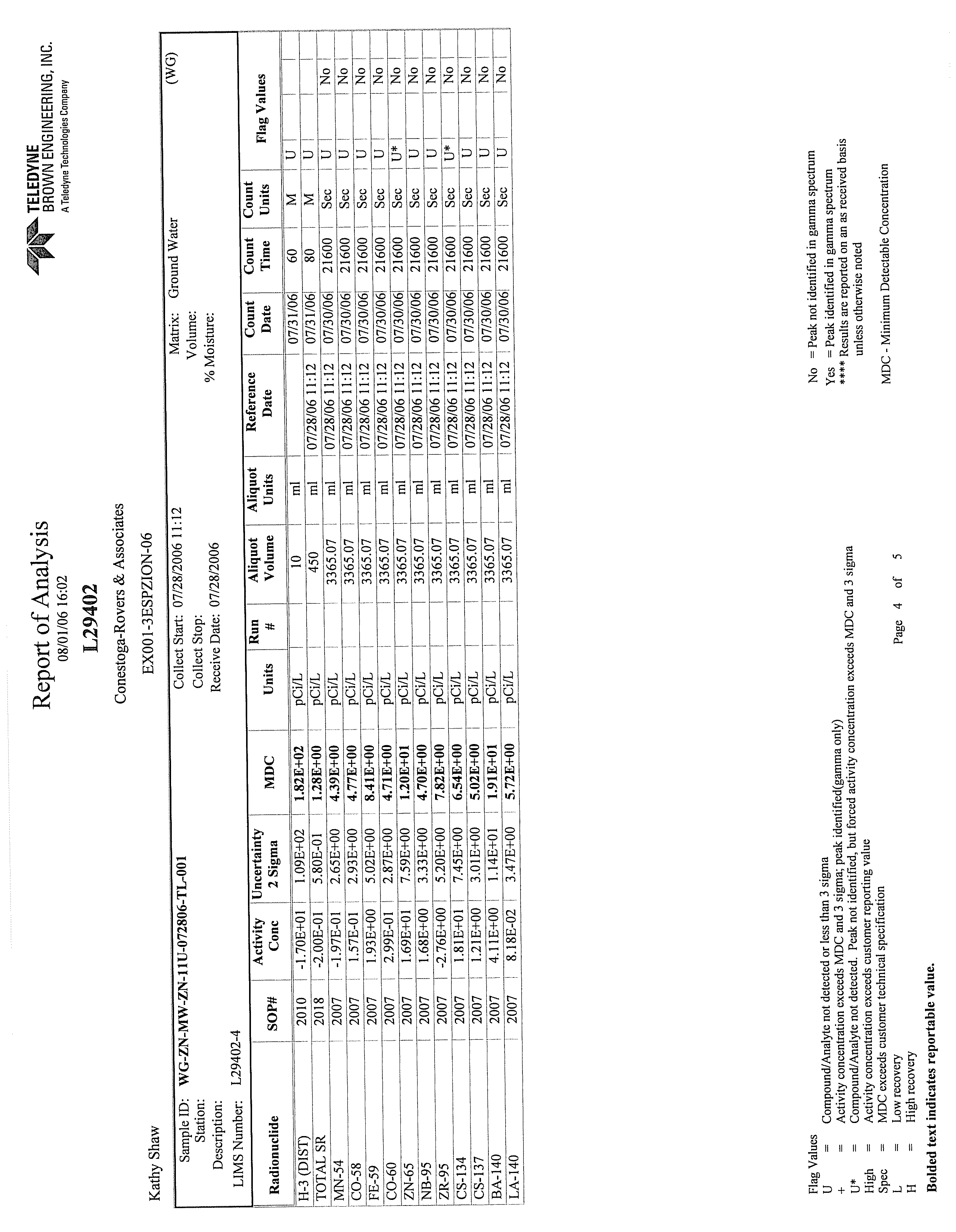

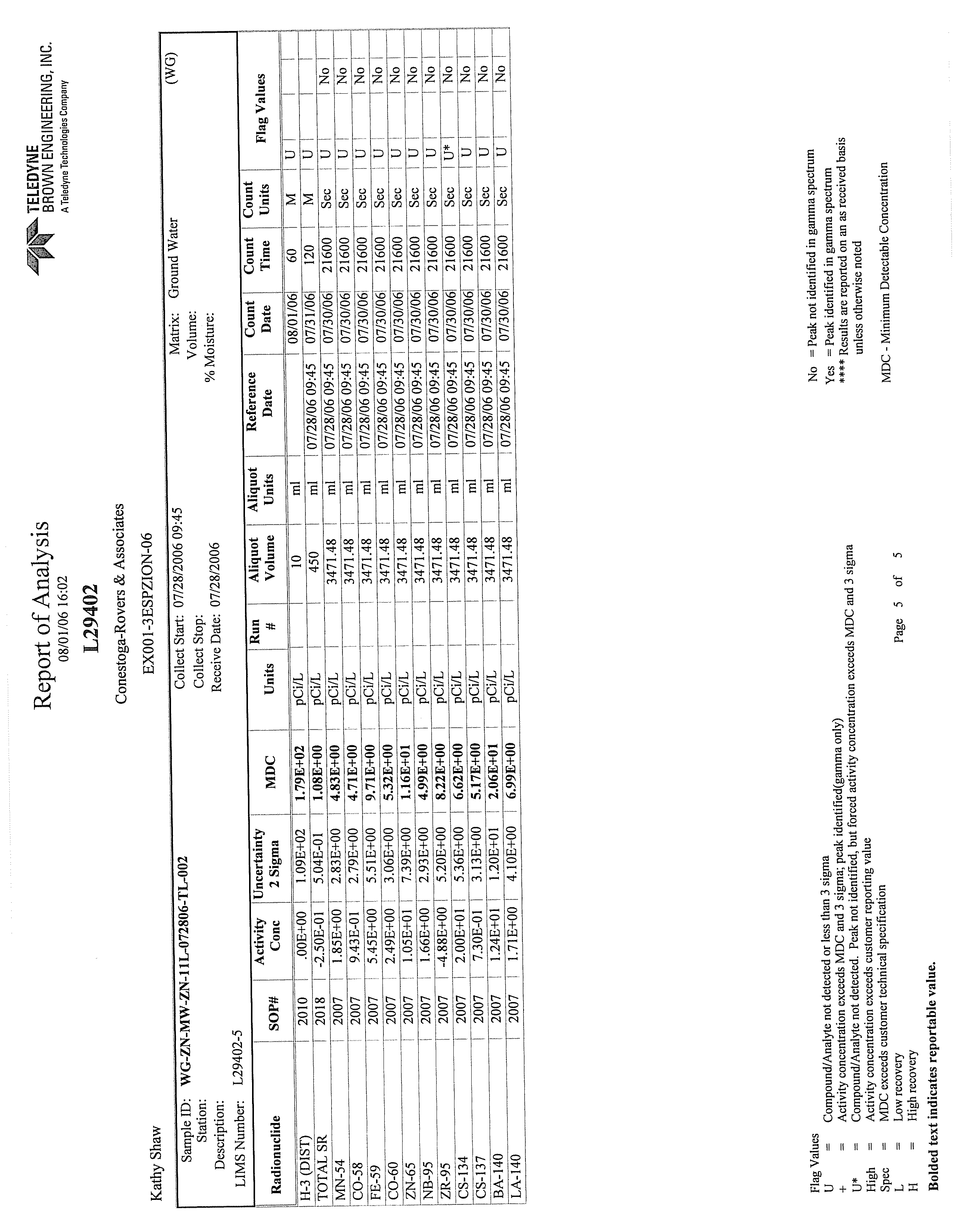

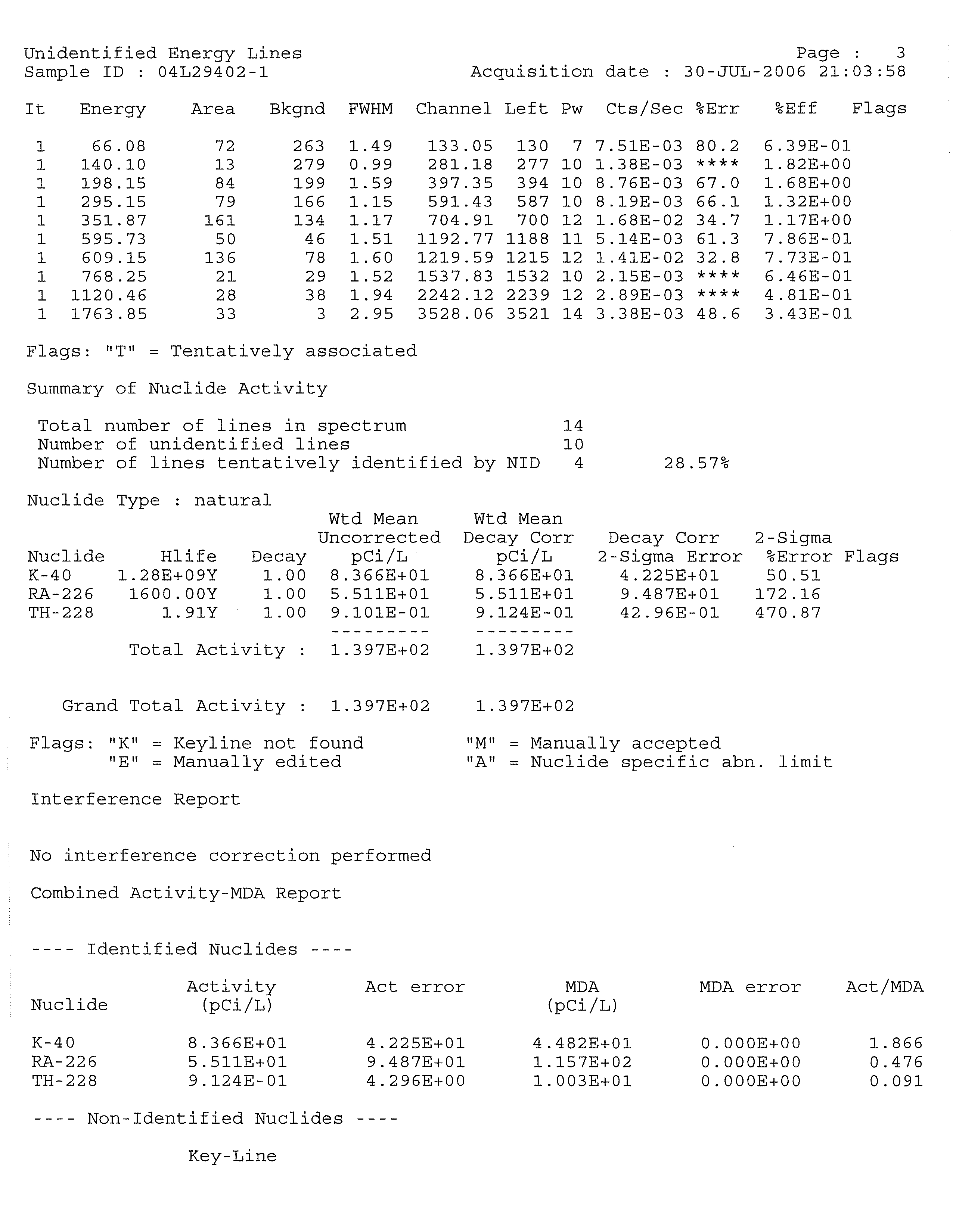

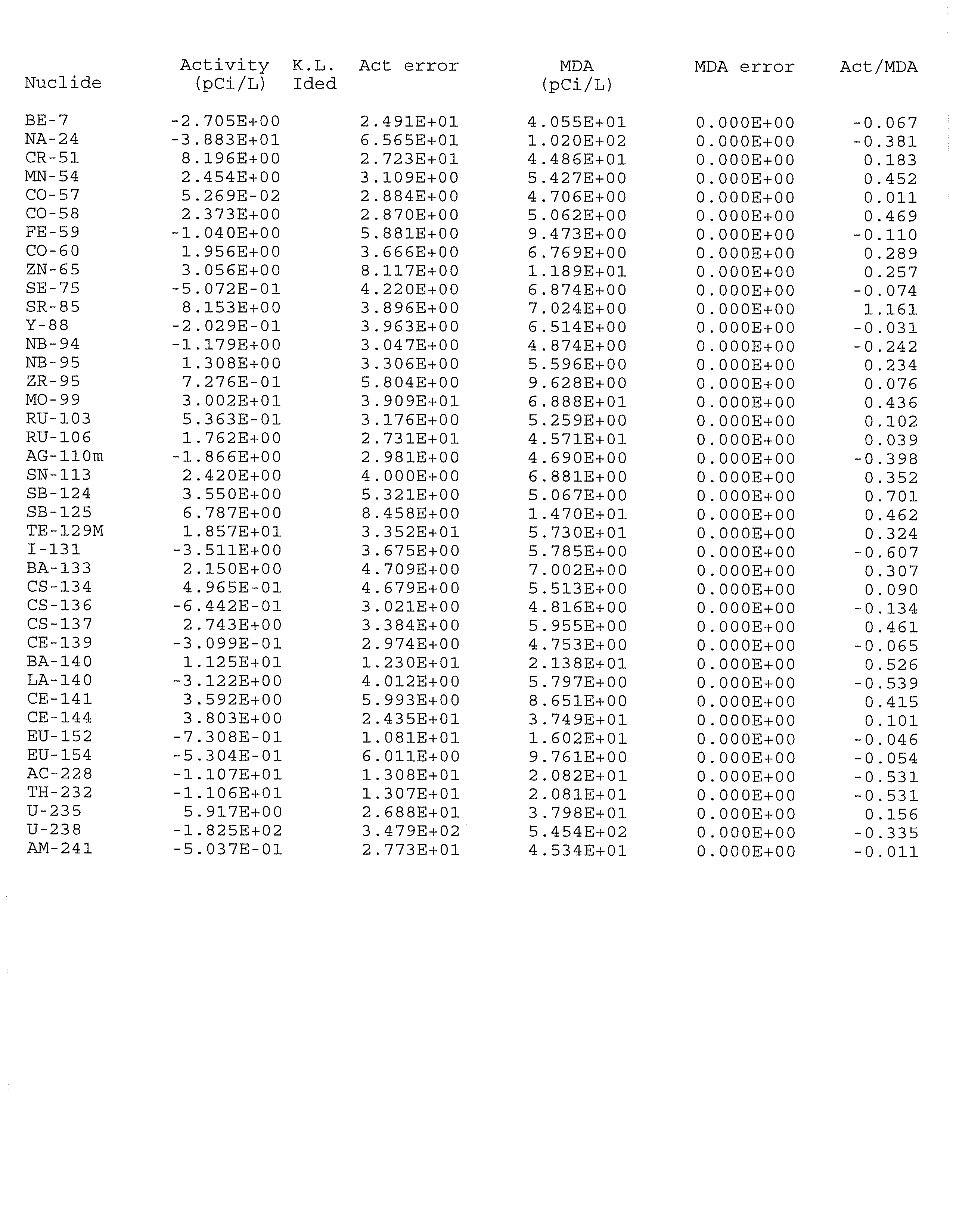

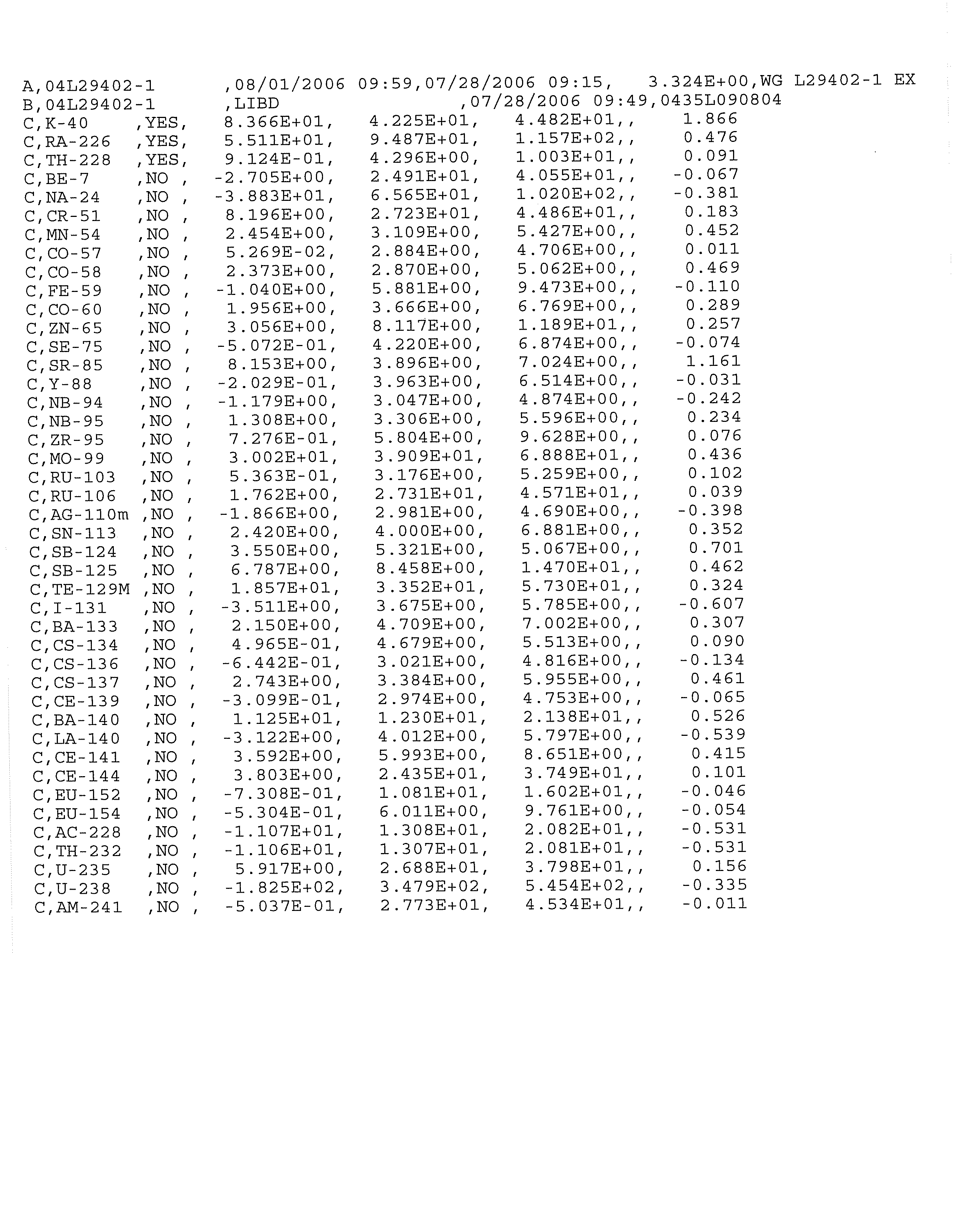

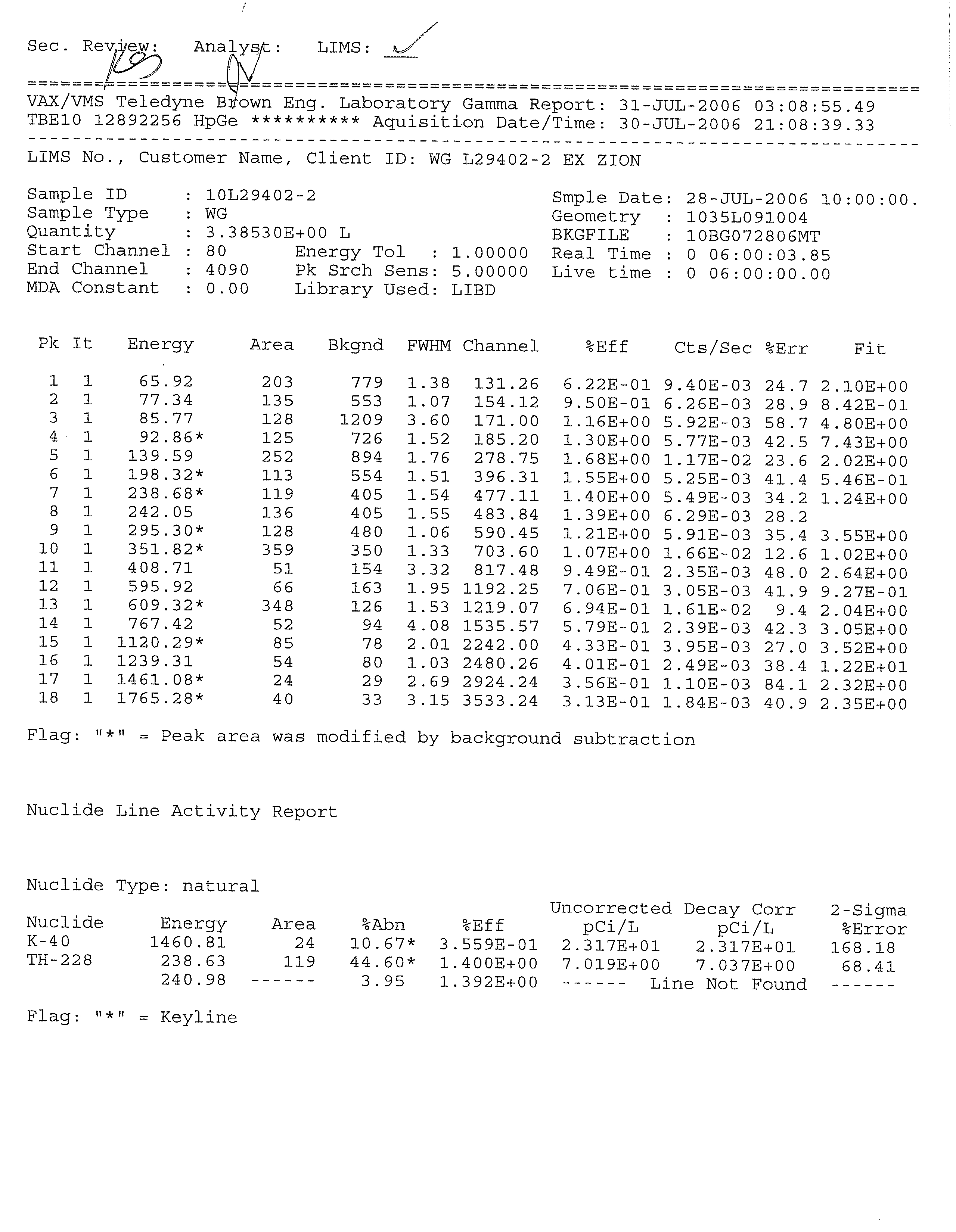

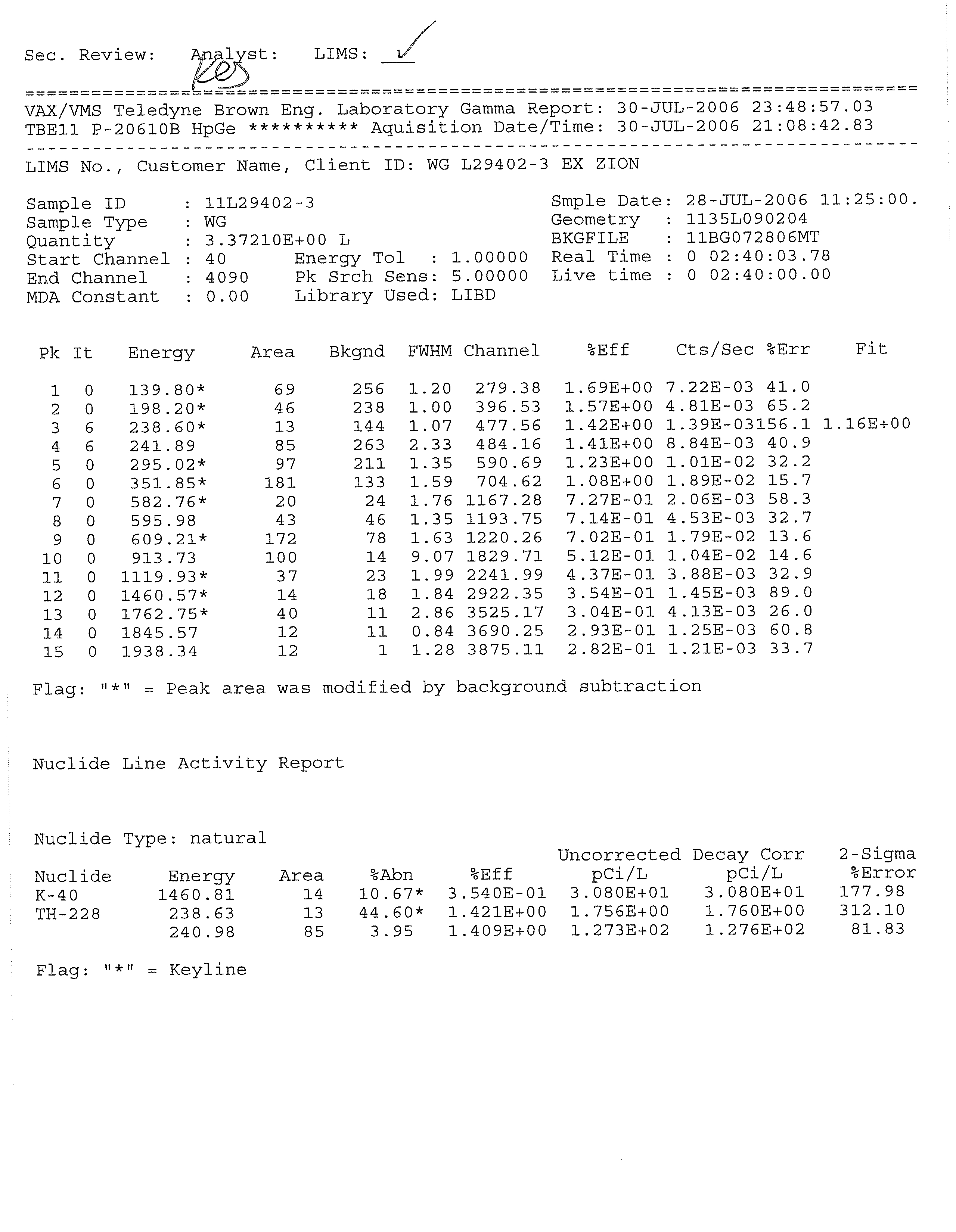

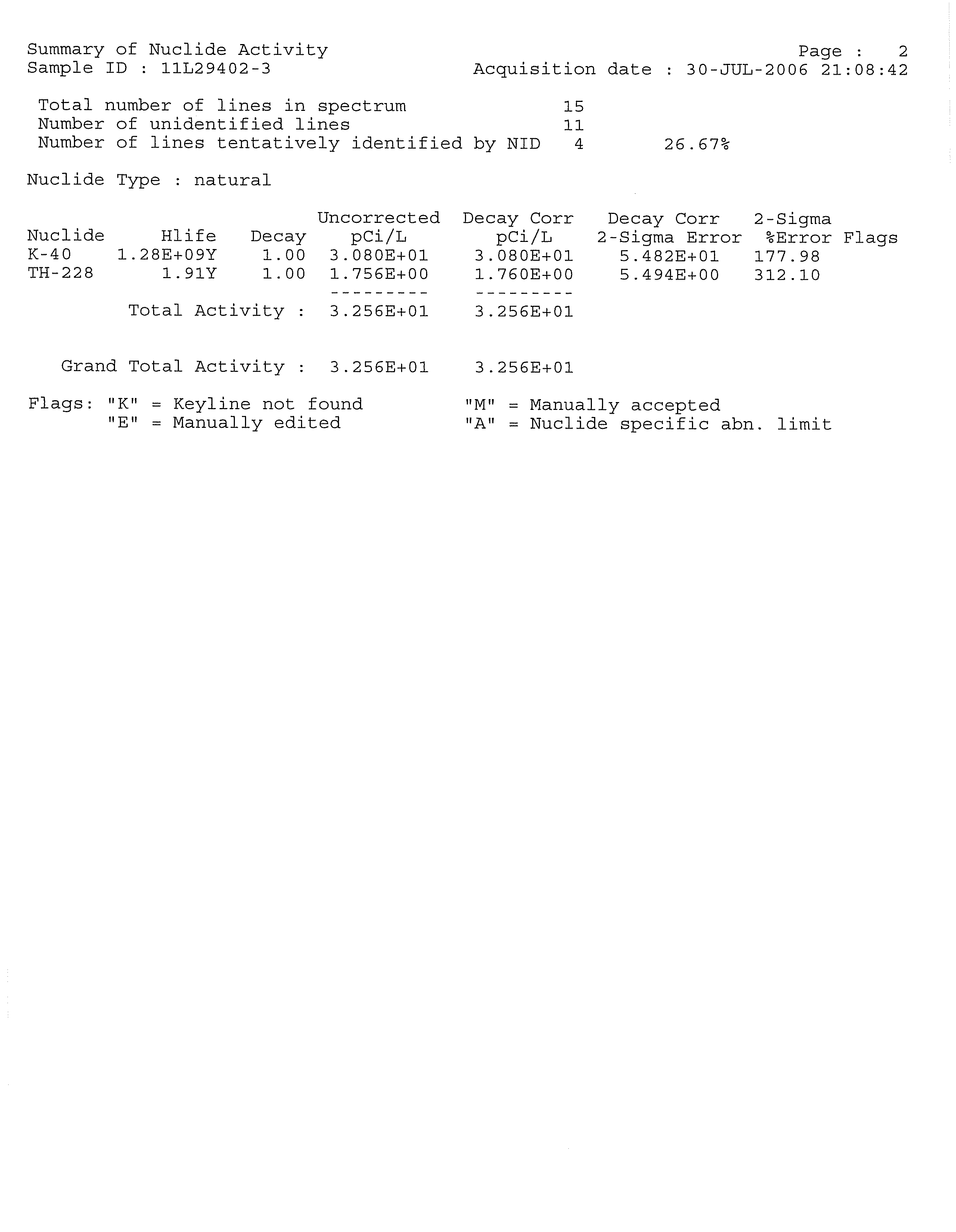

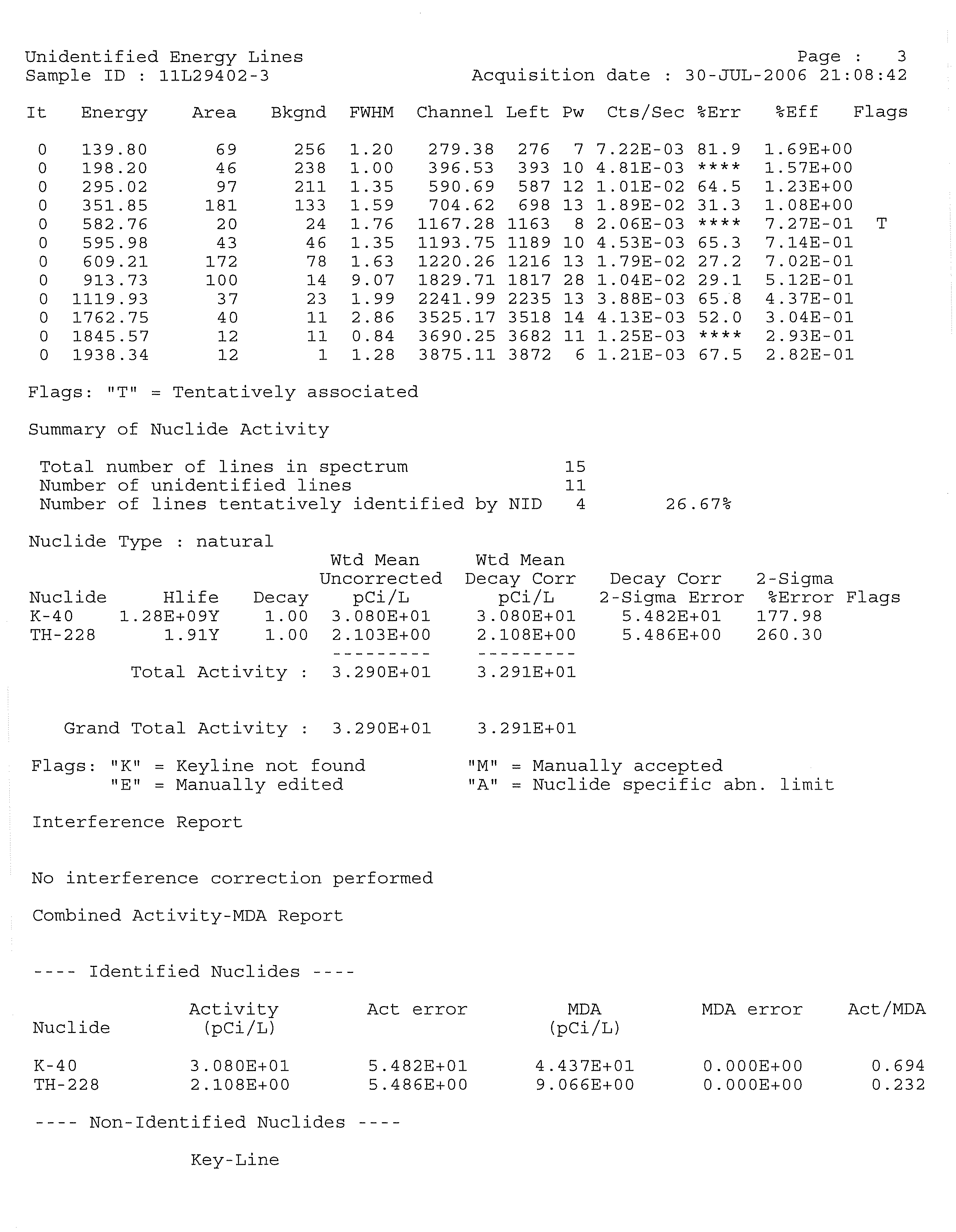

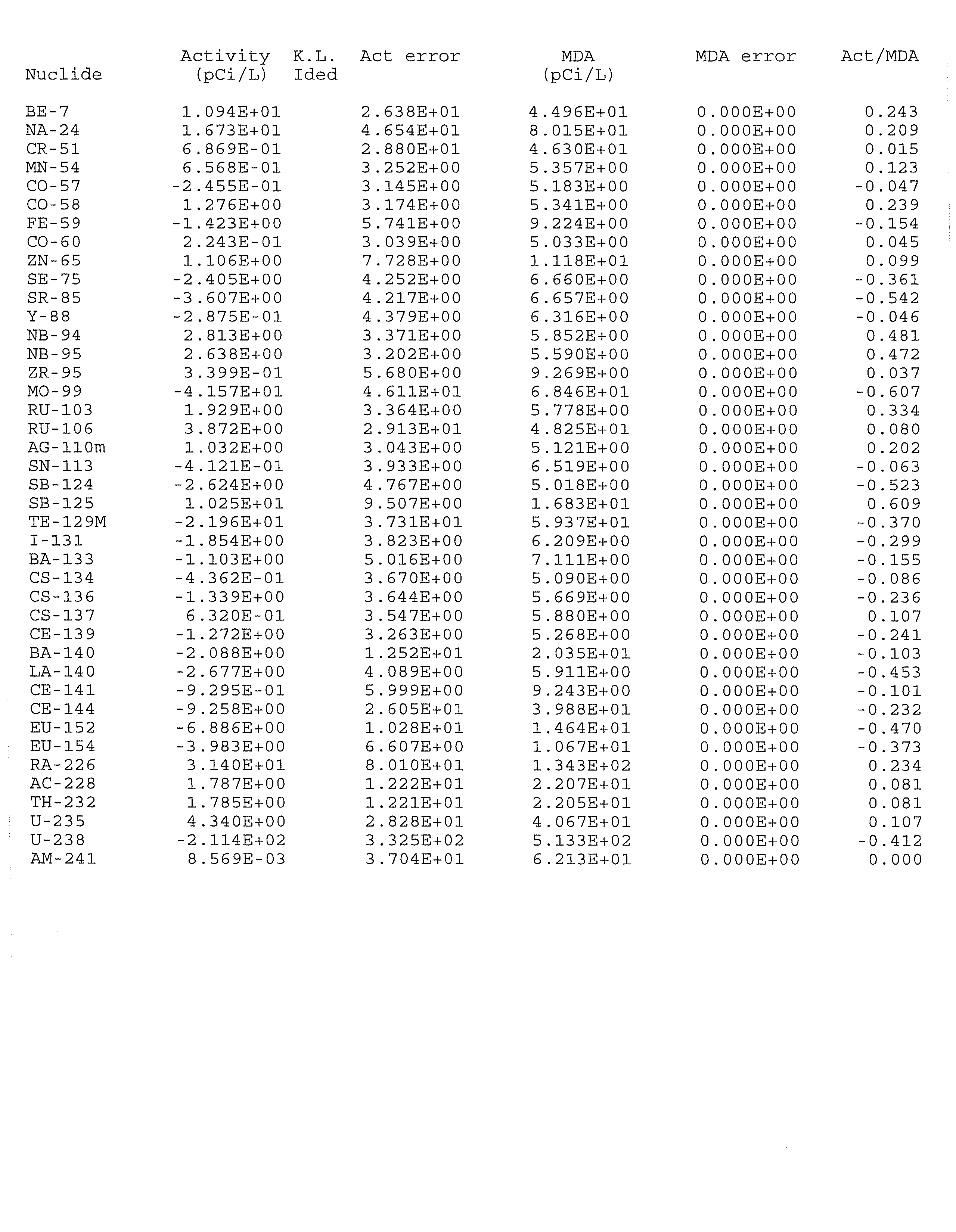

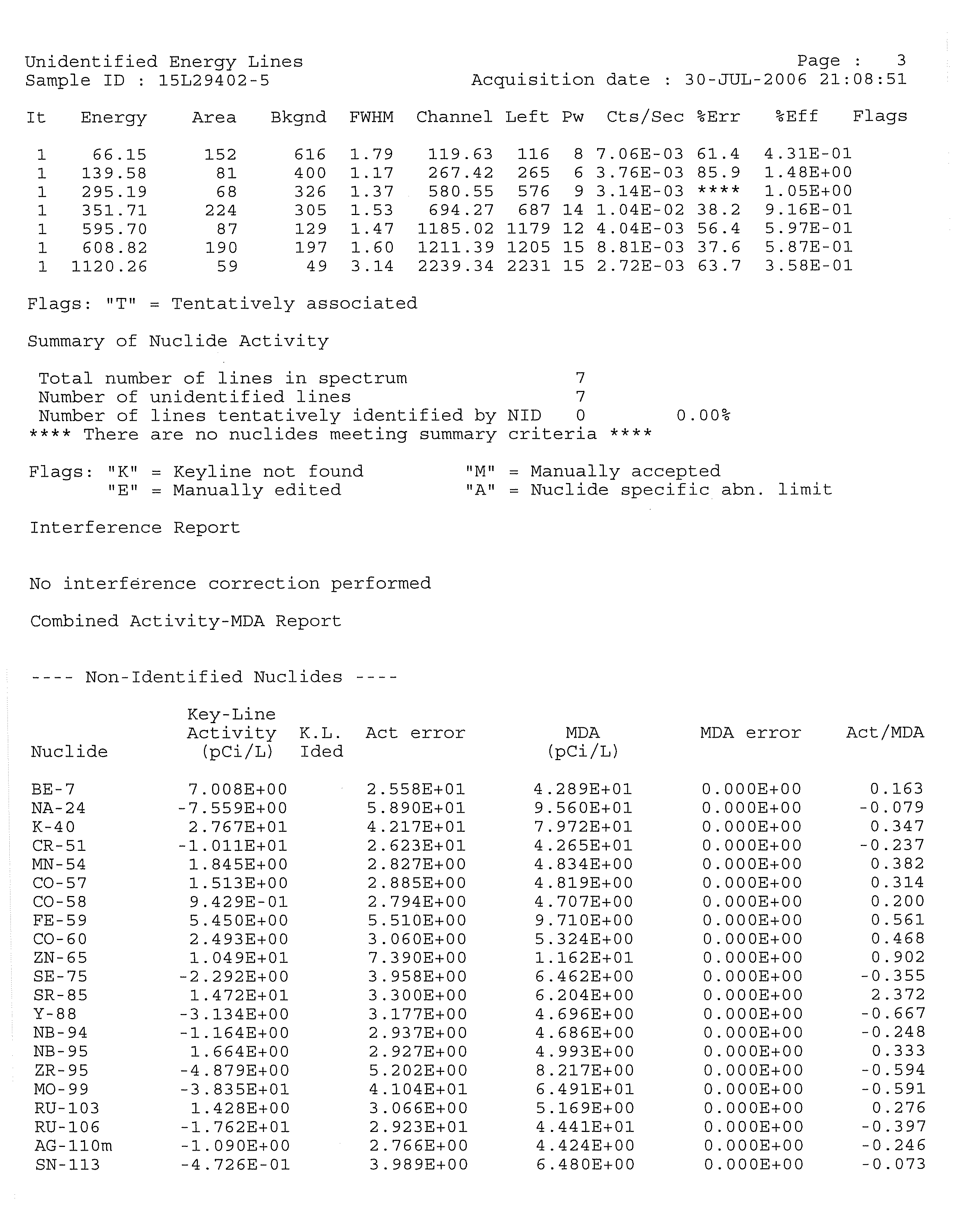

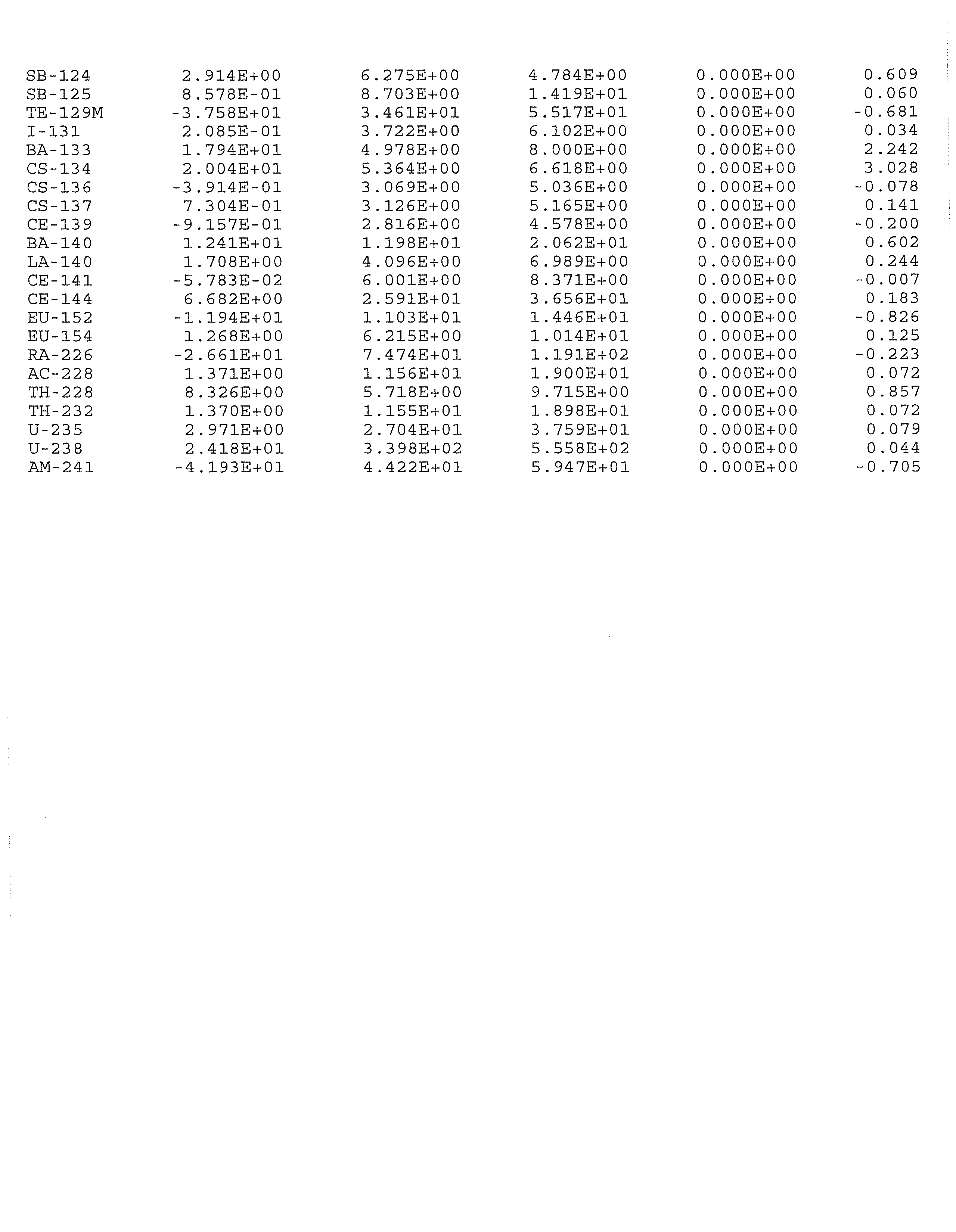

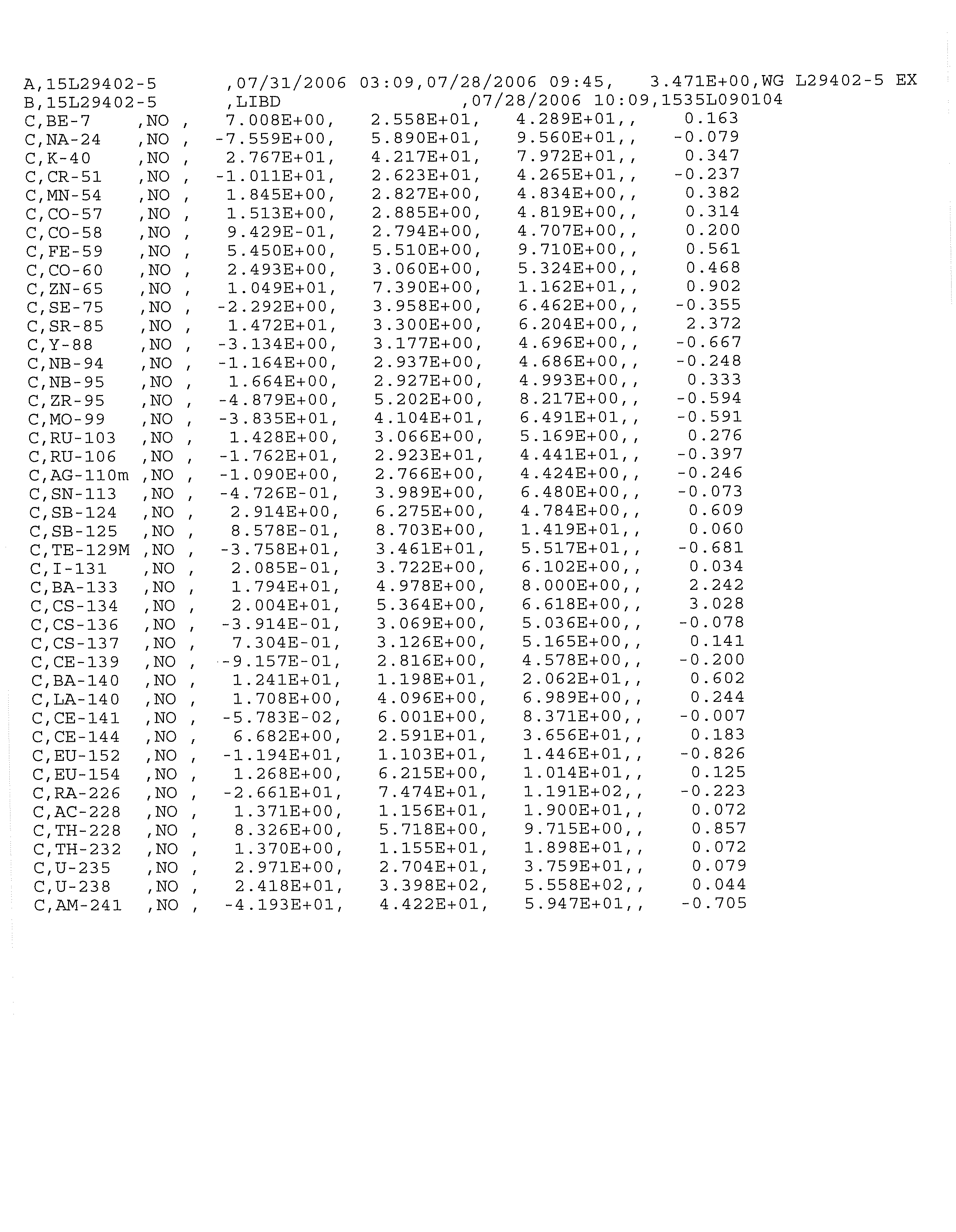

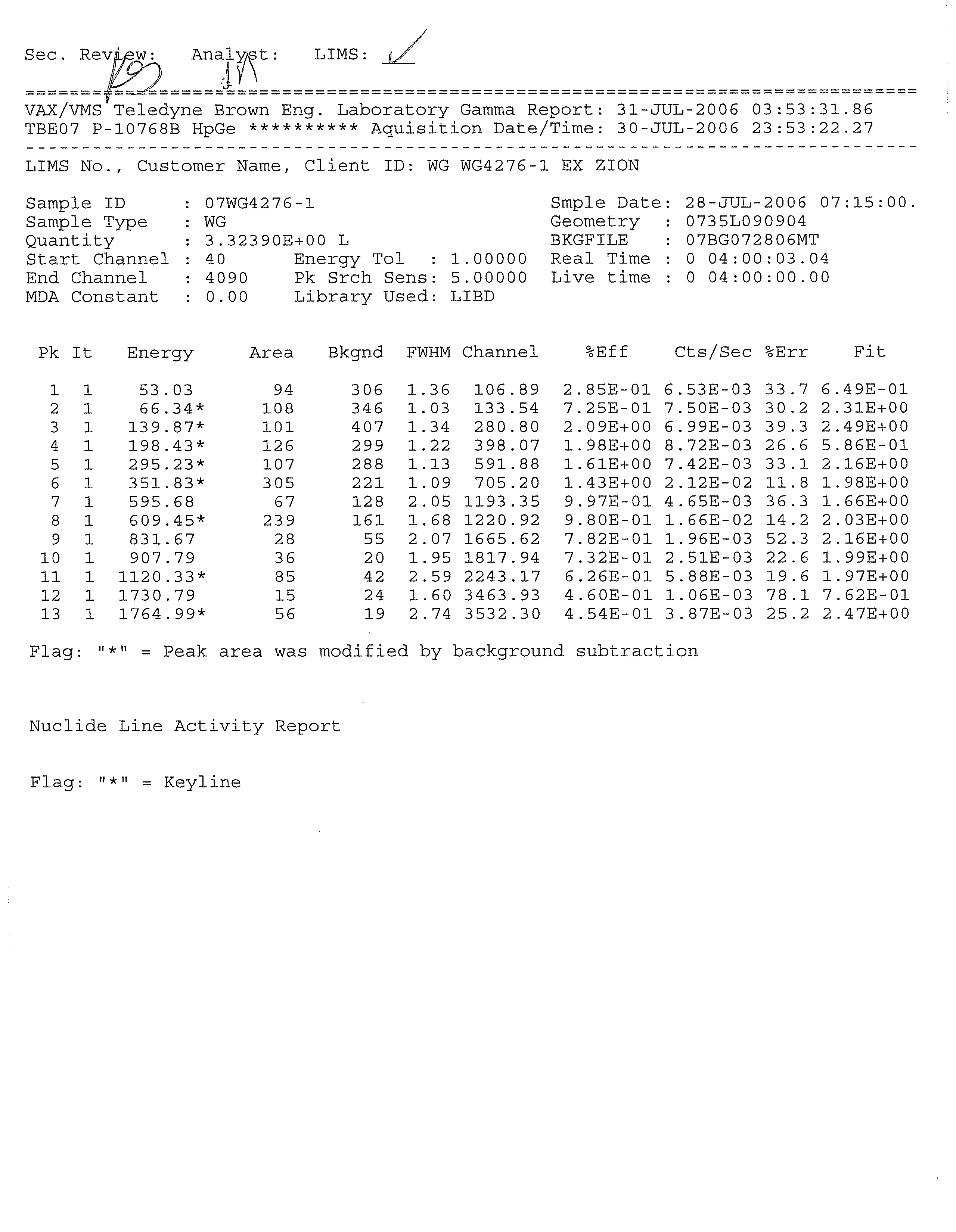

LABORATORY ANALYTICAL REPORTS

APPENDIX E

DATA VALIDATION MEMORANDUM

045136 (22) Zion Station

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

EXECUTIVE SUMMARY

This Hydrogeologic Investigation Report (HIR) documents the results of

Conestoga-Rovers & Associates' (CRA's) May to July 2006 hydrogeologic investigation

pertaining to the Zion Station (Station). CRA prepared this HIR for Exelon as part of its

Fleetwide Program to determine whether groundwater at and in the vicinity of its

nuclear power generating facilities has been adversely impacted by any releases of

radionuclides.

CRA collected and analyzed information on any historical releases, the structures,

components, and areas of the Station that have the potential to release tritium or other

radioactive liquids to the environment and past hydrogeologic investigations at the

Station. CRA used this information, combined with its understanding of groundwater

flow at the Station to identify the Areas for Further Evaluation (AFEs) for the Station.

Fifteen new monitoring wells were installed, including 11 permanent and 4 temporary

monitoring wells. CRA also collected two rounds of water levels from the newly

installed wells and the surface water staff gauge. All groundwater and surface water

samples were analyzed for tritium, strontium-89/90, and gamma-emitting

radionuclides. Field activities were completed between May and July 2006.

The results of the hydrogeologic investigation are:

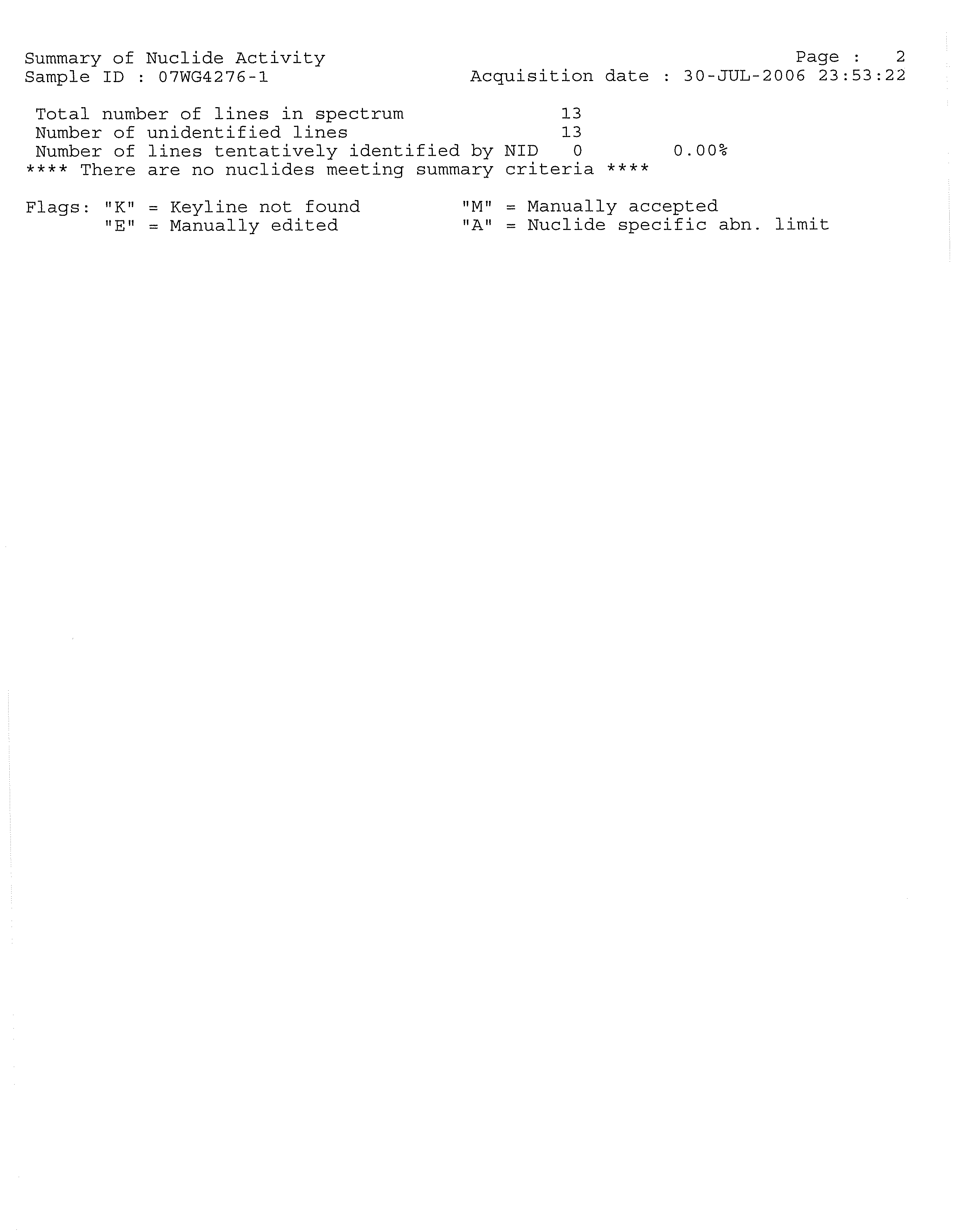

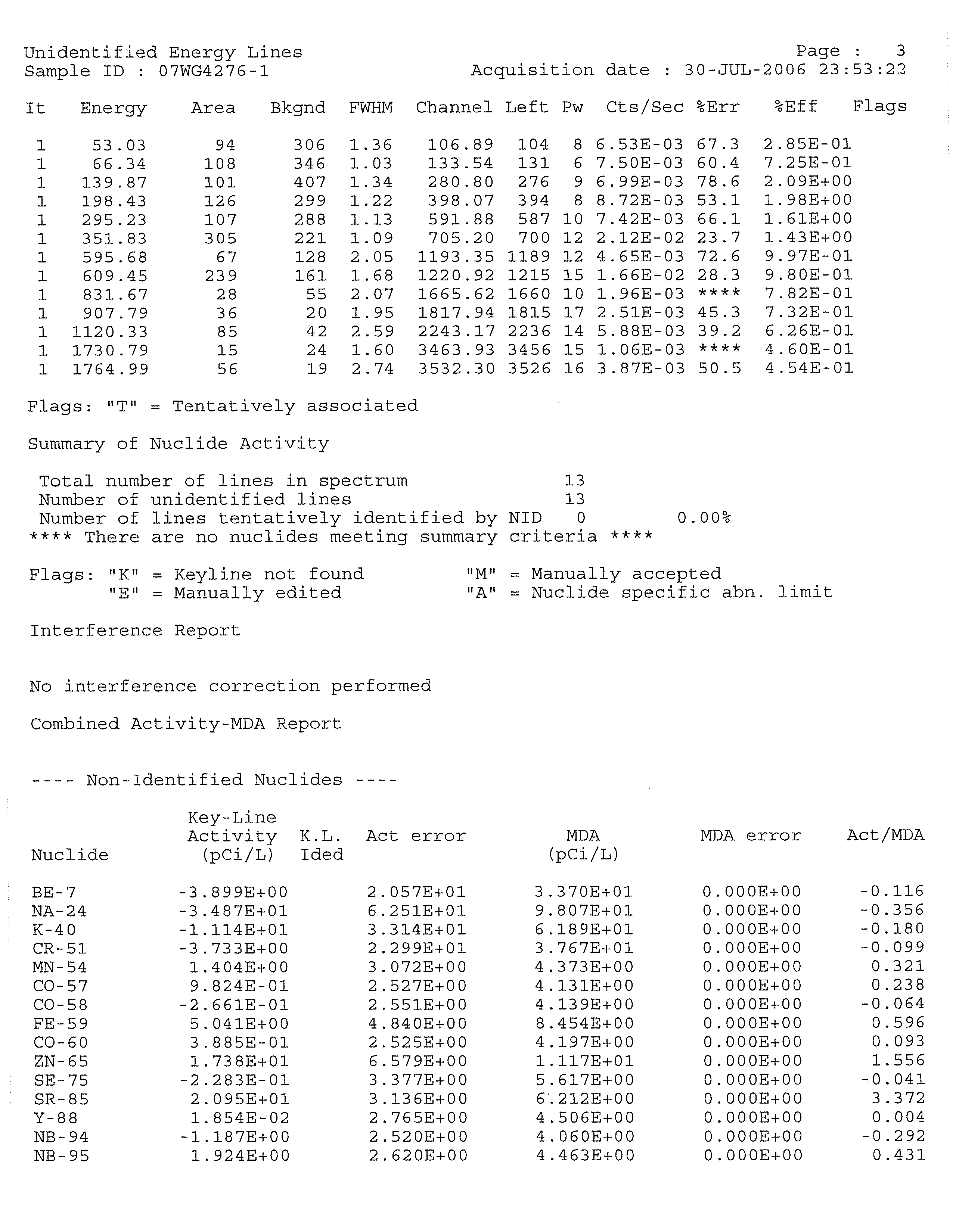

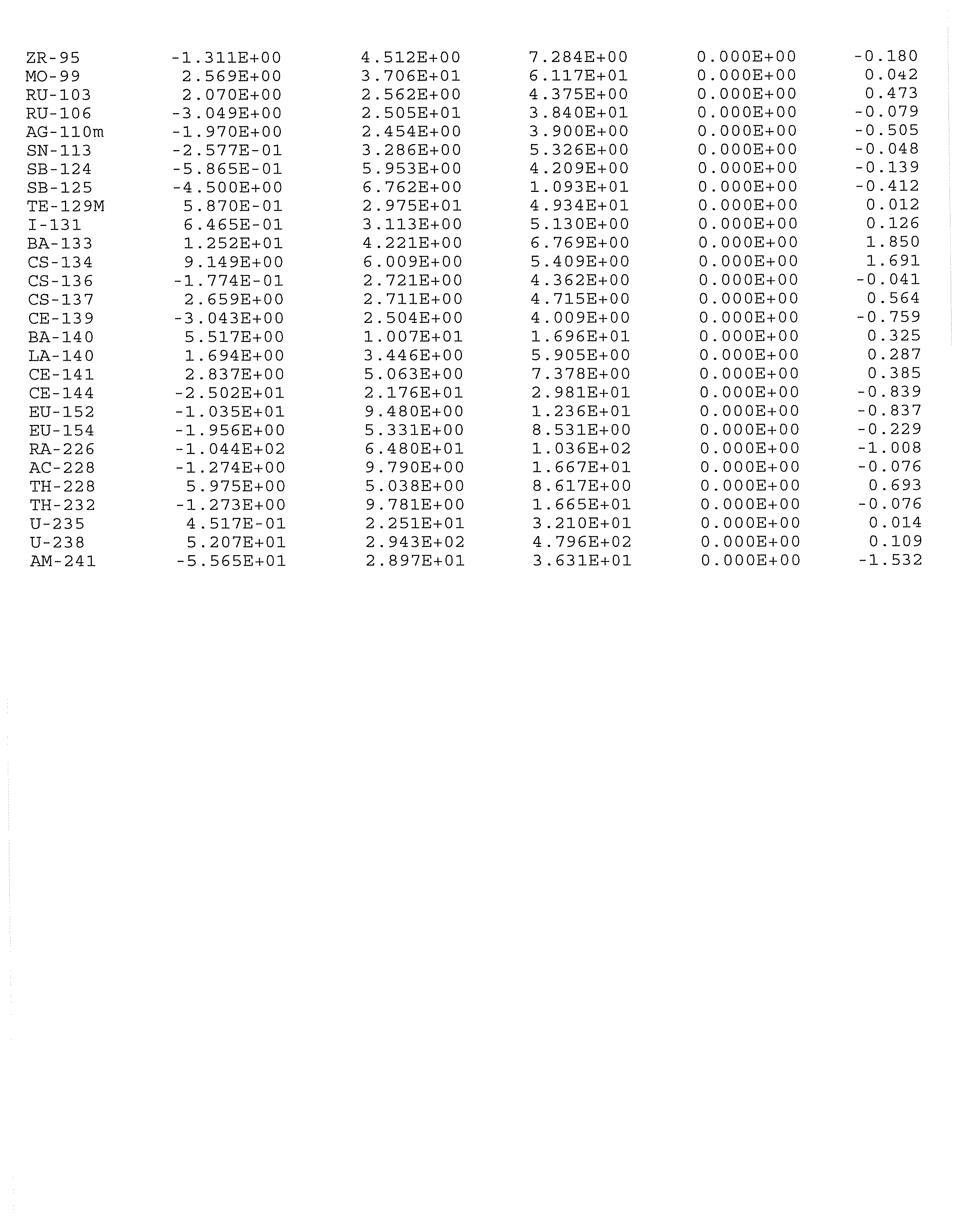

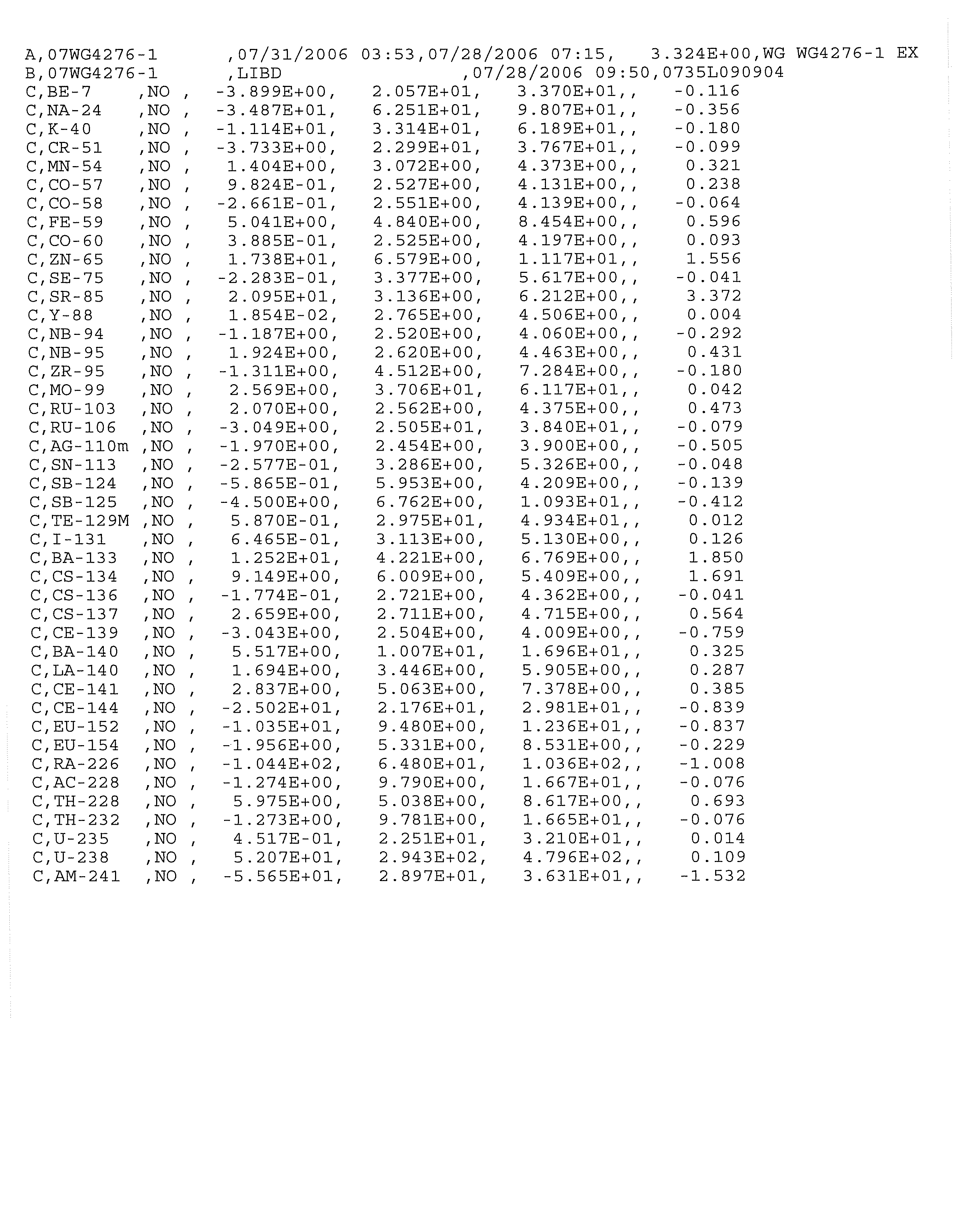

•

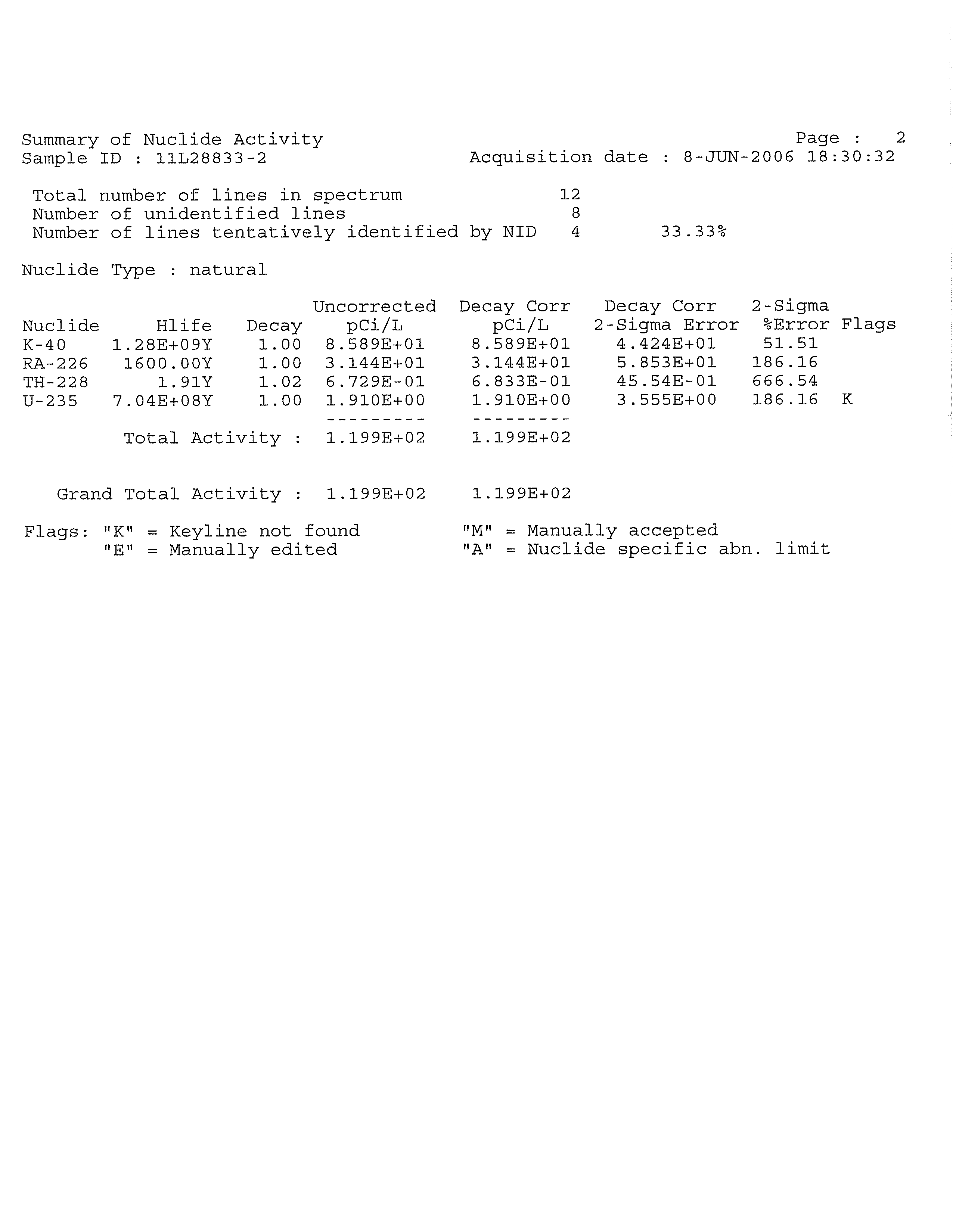

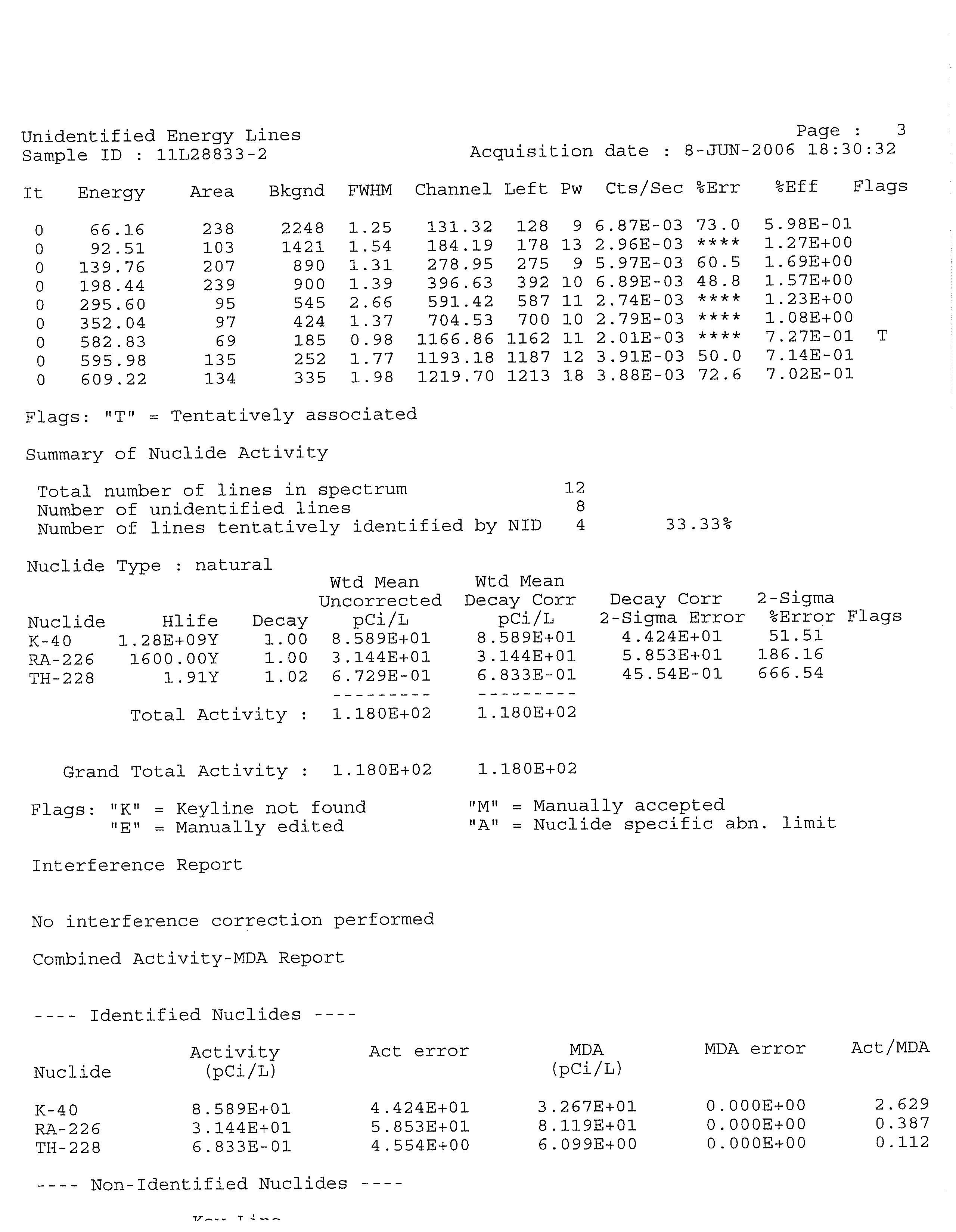

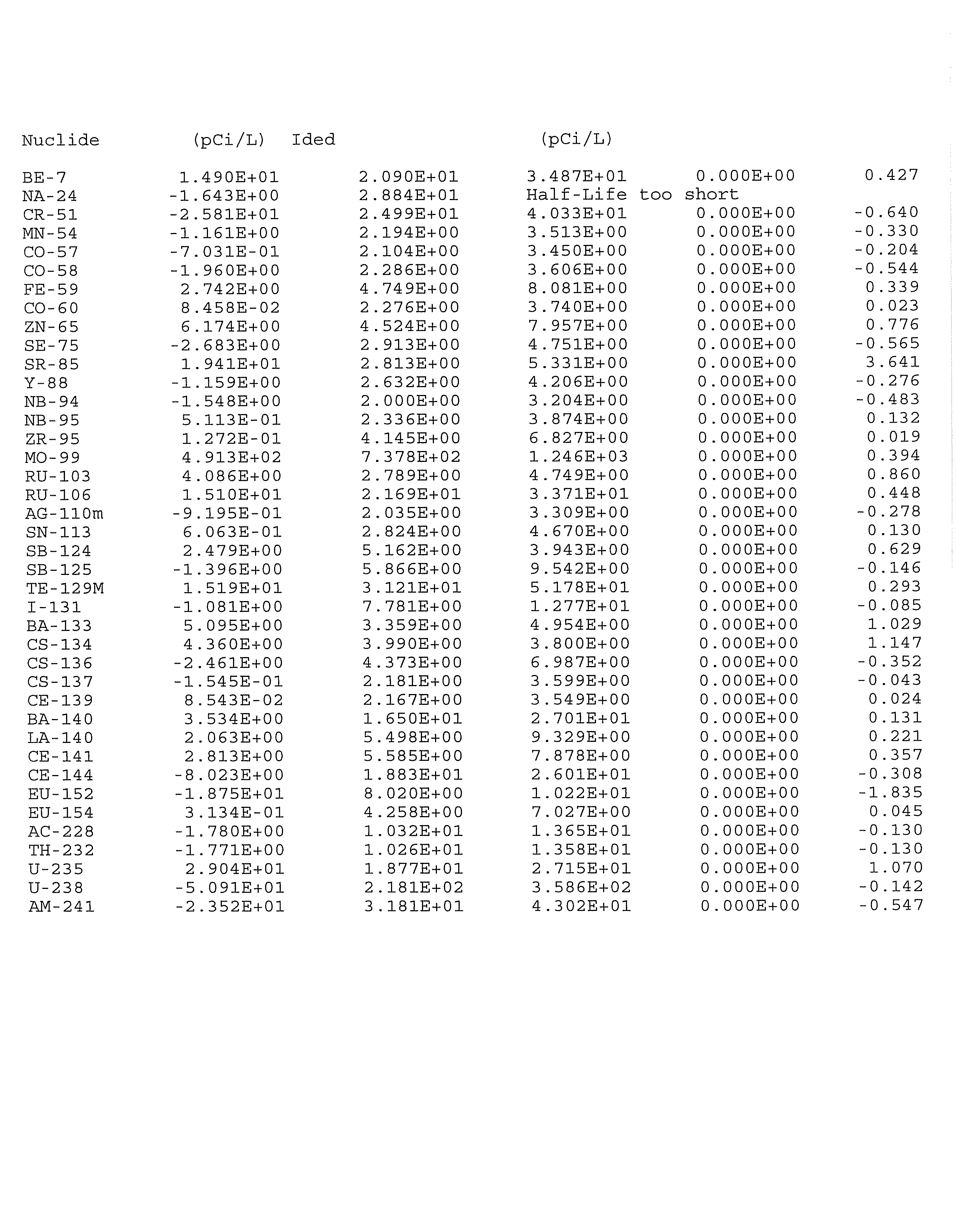

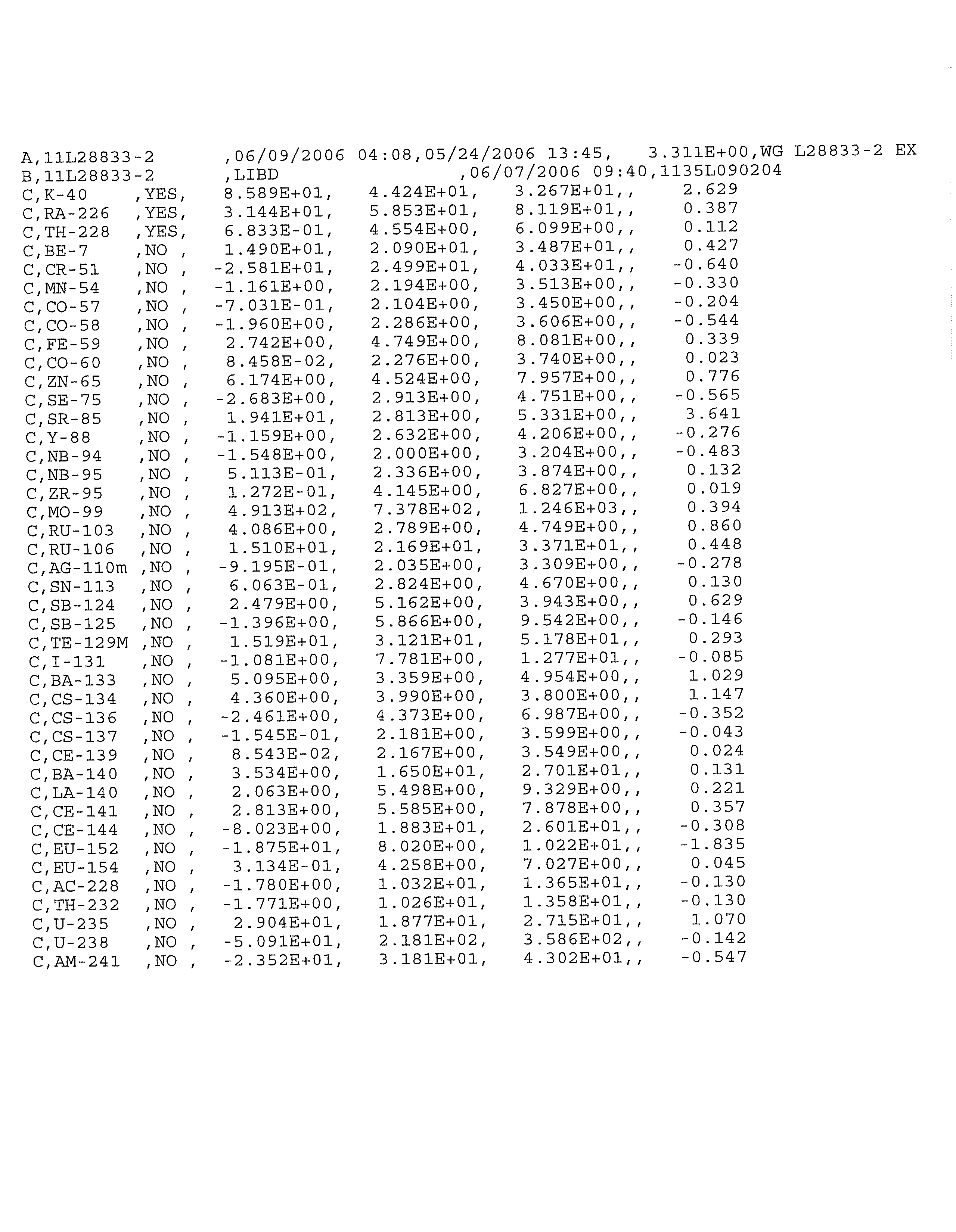

Gamma-emitting radionuclides associated with licensed plant operations were not

detected at concentrations greater than their respective Lower Limits of Detection

(LLDs) in any of the groundwater or surface water samples obtained and analyzed

during the course of this investigation;

•

Strontium-89/90 was not detected at a concentration greater than the LLD of

2.0 picoCuries per liter (pCi/L) in any of the groundwater or surface water samples

obtained and analyzed during the course of this investigation;

•

Tritium was not detected within any area in or adjacent to the Station at levels above

the United States Environmental Protection Agency drinking water standard of

20,000 pCi/L in any of the groundwater or surface water samples obtained and

analyzed during the course of this investigation;

•

Low levels of tritium were detected at concentrations greater than the LLD of

200 pCi/L, which is considered background;

•

Tritium was detected in groundwater samples collected from monitoring well

MW-ZN-01S. These concentrations ranged from less than LLD (most recently) to

586 ± 141 pCi/L (lower interval) and 220 ± 123 pCi/L to 261 ± 124 pCi/L (upper

045136 (22) Zion Station

i

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

interval). The detected concentrations are significantly less than applicable drinking

water standard. The source of tritium in this location is likely attributable to

historical releases in this area. However, the most recent sample results are within

the range of background concentrations;

•

Based on the results of this investigation, tritium is not migrating off the Station

property at detectable concentrations;

•

Based on the results of this investigation, there is no current risk from exposure to

radionuclides associated with licensed plant operations through any of the identified

potential exposure pathways; and

•

Based on the results of this investigation, there are no known active releases into the

groundwater at the Station.

Based upon the information collected to date, CRA recommends that Exelon conduct

periodic monitoring of selected sample locations.

045136 (22) Zion Station

ii

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

1.0

INTRODUCTION

Conestoga-Rovers & Associates (CRA) has prepared this Hydrogeologic Investigation

Report (HIR) for Exelon Generation Company, LLC (Exelon) as part of its fleetwide

program to determine whether groundwater at and near its nuclear power generating

facilities has been adversely impacted by any releases of radionuclides. This report

documents the results of CRA's May 2006 Hydrogeologic Investigation Work Plan

(Work Plan), as well as several other investigative tasks recommended by CRA during

the course of the investigation. These investigations pertain to Exelon's Zion Station

(Station) in Zion, Illinois (see Figure 1.1). The Station is defined as all property,

structures, systems, and components owned and operated by Exelon LLC and located at

101 Shiloh Boulevard, Zion, Lake County, Illinois.

The approximate property

boundaries are depicted on Figure 1.2.

Pursuant to the Work Plan, CRA assessed groundwater quality at the Station in

locations designated as areas for further evaluation (AFEs). The process by which CRA

identified AFEs is discussed in Section 3.0 of this report.

The objectives of the Work Plan were to:

•

characterize the geologic and hydrogeologic conditions at the Station including

subsurface soil types, the presence or absence of confining layers, and the direction

and rate of groundwater flow;

•

characterize the groundwater/surface water interaction at the Station, including a

determination of the surface water flow regime;

•

evaluate groundwater quality at the Station including the vertical and horizontal

extent, quantity, concentrations, and potential sources of tritium and other

radionuclides in the groundwater, if any;

•

define the probable sources of any radionuclides released at the Station;

•

evaluate potential human, ecological, or environmental receptors of any

radionuclides that might have been released to the groundwater; and

•

evaluate whether interim response activities are warranted.

045136 (22) Zion Station

1

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

2.0

STATION DESCRIPTION

The following section presents a general summary of the Station location and definition,

overview of Station operations, surrounding land use, and an overview of both regional

and Station-specific topography, surface water features, geology, hydrogeology, and

groundwater flow conditions. This section also presents an overview of groundwater

use in the area.

2.1

STATION LOCATION

The Station is a former nuclear power generating facility that, in the early spring of 1998,

converted both units' generators to synchronous condensers that provide voltage

stability to the northeast Illinois power grid. The Station encompasses approximately

250 acres (Exelon, 2004). Figure 1.2 presents a Station Boundaries and Features plan.

The Station is located on the eastern edge of Zion between 23rd and 29th Streets, from

the Chicago and Northwestern Railroad tracks to Lake Michigan.

The Station is being maintained and monitored under the "SAFSTOR" (safe storage of

components of the nuclear power plant) phase of decommissioning, as is discussed

below.

2.2

OVERVIEW OF COOLING WATER OPERATIONS

Former Operations

In the mid-1950s, Commonwealth Edison Company (ComEd) purchased about 250 acres

on the eastern edge of Zion. The Station operated as a dual unit pressurized water

reactor plant. A construction permit was issued in December 1968. An operating license

was issued October 19, 1973 for Unit 1 and November 14, 1973 for Unit 2. Commercial

operations commenced in December 1973 for Unit 1 and September 1974 for Unit 2.

Unit 1 operations ended on February 21, 1997 and Unit 2 operations ended on

September 19, 1996. All fuel was removed from the reactor and placed in the spent fuel

pool on April 27, 1997 for Unit 1 and on February 25, 1998 for Unit 2. Commercial

operation of the plant ended on January 14, 1998 when the Unicom Corporation and

ComEd Boards of Directors authorized the permanent cessation of operations at the

Station. Exelon submitted the certification of fuel transfer on March 9, 1998. In addition

045136 (22) Zion Station

2

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

to maintaining the synchronous condensers, the Station's employees also monitor the

safe storage of spent fuel.

Discharges from the Station are subject to the requirements of Nuclear Regulatory

Commission (NRC) Operating Licenses DPR-39 and DPR-48. Discharges from the

Station are also subject to regulation under the Illinois Environmental Protection Agency

(EPA) National Pollutant Discharge Elimination System (NPDES) Permit IL0002763.

The NPDES permit provides limits on parameters such as pH, total suspended solids,

and oil and grease.

Cooling Water Operations 1973-1997

The Station is comprised of two nearly identical pressurized water reactors with

supporting facilities.

Both primary reactor coolant systems were designed by

Westinghouse Corporation and each is comprised of a reactor vessel and four heat

transfer loops. Each loop contains a reactor coolant pump, steam generator, and

associated piping and valves. In addition, each system includes a pressurizer, a

pressurizer relief tank, interconnecting piping, and the instrumentation necessary for

operational control.

Each Containment Building is cylindrical with a shallow dome roof and has a flat slab

foundation. The entire structure is internally lined with a welded steel plate and

completely encloses the primary coolant system, steam generators, reactor coolant loops,

and portions of the auxiliary and engineered safety feature systems.

Heat produced in the reactor was converted to electrical energy by the power conversion

system between 1973 and 1997. A turbine generator converted the thermal energy of

steam produced in the steam generators into mechanical shaft power and then into

electrical energy.

The exhaust steam from the turbine was condensed and deaerated in the main

condenser. The waste heat in the main condenser was removed by the circulating water

system. Circulating water was withdrawn from Lake Michigan, approximately 450 feet

east of the condensate storage tank, via an intake pipe connected to the circulating water

pumps. After circulating through the plant condensers, the cooling water was routed

back to the lake via discharge lines (ComEd, 1999).

045136 (22) Zion Station

3

CONESTOGA-ROVERS & ASSOCIATES

Primary coolant was treated to remove impurities and recirculated through the primary

water (PW) system. Primary coolant was stored in two above ground storage tanks

(ASTs) located on the east side of the Turbine Building.

Revision 1

Secondary cooling water (condensate cooling water) was treated to remove impurities

and recirculated through the condensate (CD/SC) system. Secondary cooling water is

stored in ASTs located on the east side of the Turbine Building.

Circulating water is drawn from Lake Michigan by way of an intake pipe that extends

approximately a half mile into the Lake. Circulating water is returned to Lake Michigan

by way of two discharge pipes that extend approximately a quarter mile into the lake.

Liquid wastes have been discharged under the NRC permit through the blowdown line,

which is piped to the circulating water discharge pipe located east of the Turbine

Building.

Voltage Stabilization and SAFSTOR

The Station is being decommissioned under the NRC regulatory process. The Station is

currently in the "SAFSTOR" phase of the decommissioning process where the Station is

maintained in a condition that allows it to be safely stored and subsequently

decontaminated to levels that permit its release for unrestricted use.

2.3

SURROUNDING LAND USE

The Station is located on the shore of Lake Michigan, in the eastern portion of the City of

Zion, and adjacent to the Illinois Beach State Park.

The Illinois Beach State Park is located along the Lake Michigan shoreline and is divided

into a northern unit and a southern unit, with the Station situated between the two units.

The Illinois Beach State Park encompasses 4,160 acres and received approximately

2.75 million visitors in 1998. The Park is considered a natural resource (ATSDR, 2000).

The land located to the west of the Station is generally undeveloped with a limited

number of industrial/commercial facilities present along Deborah Avenue. Residential

areas and the City of Zion downtown are located west of the Chicago & Northwestern

Railroad, which is west of the Station. Lake Michigan borders the Station to the east.

045136 (22) Zion Station

4

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

2.4

STATION SETTING

The following sections present a summary of the topography, surface water features,

geology, hydrogeology, and groundwater flow conditions in the region surrounding the

Station. The information was primarily gathered from Sections 2.1 and 2.3 of the Zion

Defueled Safety Analysis Report (DSAR) last revision dated October 2004 (Exelon, 2004).

The main references the DSAR relies upon are listed in Section 10.0 of this HIR. CRA

checked and verified all DSAR references that apply to this HIR.

2.4.1

TOPOGRAPHY AND SURFACE WATER FEATURES

Lake County consists of moraines, outwash plains, lake plains, kames, stream terraces,

flood plains, beaches, and bogs. The county is in the Wheaton Morainal country of the

Great Lakes section of the Central Lowland province. Relief in Lake County was caused

by differences in the thickness of deposits left by the most recent glacier. The land

surface gradually slopes to the south or southeast. The highest point in the county,

957 feet above mean sea level (AMSL), is located on Gander Mountain in the northwest

corner of the county. The lowest point is at the Lake Michigan shore near Waukegan.

Several moraines run through the county. From east to west, they are the Lake Border

Morainic System, the Tinley Moraine, the Valparaiso Morainic System, and the Fox Lake

Moraine. In general, Lake County has a poorly defined drainage pattern. Many

drainage ways terminate in depressions and marshes. The land area falls into four

major watersheds and 26 drainage basins. The Chicago River, Des Plaines River, Fox

River, and Lake Michigan watersheds are all shared with neighboring counties in Illinois

and Wisconsin (NRCS, 2005).

The Lake Michigan shoreline between North Chicago, Illinois and Kenosha, Wisconsin

comprises the Zion beach-ridge plain. The Zion beach-ridge plain consists of linear,

generally coast-parallel mounds of sand and gravel that have been built up by wave

action to extend the coast outward into Lake Michigan. The Zion beach-ridge plain has

a maximum width of approximately 1 mile near the City of Zion (Chrzastowski and

Frankie, 2000). The older dunes become root-bound by vegetation resulting in long lines

of sandy ridges separated by linear marshes.

The main portion of the Station is located on a sand ridge that runs parallel to the Lake

Michigan shoreline as shown on Figure 1.2. The area in the immediate vicinity of the

Station has been leveled and is paved. The ground elevation at the main complex is

591 feet AMSL. The average lake level is 577 feet AMSL. The eastern portion of the

045136 (22) Zion Station

5

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

Station is a beach gently sloping to the Lake Michigan shoreline. The area to the west of

the Station is a low-lying wet area.

Lake Michigan has a surface area of 22,300 square miles, with a mean depth of 276 feet

and a volume of 1,170 cubic miles. Lake Michigan has a natural outlet through the

Straits of Mackinac on the north end of the lake and a second outlet through the Illinois

Waterway near Chicago (USEPA, 1995).

The average surface elevation of Lake Michigan is 577 feet AMSL. The surface elevation

of Lake Michigan varies daily and annually, and is affected by hydrologic and

atmospheric conditions and flow through the two outlets. Water levels in Lake

Michigan typically vary about 1 foot in elevation between annual low and high

measurements.

Generally, the lowest levels occur in winter when much of the

precipitation is locked up in ice and snow on land, and dry winter air masses pass over

the lakes enhancing evaporation. Levels are highest in summer after the spring thaw

when runoff increases (USEPA, 1995).

The low-lying wet area on the western portion of the Station is in the watershed of the

Dead River, which flows through the marshy swales located to the west of the

longitudinal sand dunes that follow the Lake Michigan shoreline. The Dead River

passes through the Illinois Beach State Park as shown on Figure 1.1. The Dead River

flows into Lake Michigan at a point approximately 2.3 miles south of the Station. The

Dead River was so named because the mouth is periodically blocked by shifting

sandbars on the Lake Michigan shoreline.

Storm water runoff from the switchyard is captured by the perimeter ditch, which is a

drainage channel that follows the Station's outer fence. The perimeter ditch connects to

Lake Michigan to the north and south of the Protected Area (PA). Figure 2.1 presents a

depiction of the perimeter ditch and the stormwater drainage ditches that control

surface water at the Station. On the western portion of the Station property some of

these drainage systems intercept the shallow groundwater. This is not the case on the

eastern portion of the Station property where the stormwater drainage system is located

above the water table as it drops towards Lake Michigan.

2.4.2

GEOLOGY

This section presents an overview of Station geology based upon the 1967 Foundation

Investigation (Dames and Moore, 1967) and other geologic publications. The Station is

underlain by overburden deposits and a regionally extensive sequence of consolidated

045136 (22) Zion Station

6

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

sedimentary deposits. The major stratigraphic features can be divided into Paleozoic

aged bedrock and Quaternary Period overburden deposits. Figure 2.2 presents a

stratigraphic cross-section representative of bedrock units in Lake County, Illinois.

Figure 2.3 presents a cross-section of the overburden deposits associated with the Zion

beach-ridge plain.

Rocks of the Cambrian through Silurian Periods are marine in origin and were deposited

in a sea that covered all of Illinois (Willman, 1971). The rocks consist of sandstones,

shales, and carbonates for a combined thickness of approximately 2,500 feet. Southerly

long shore currents have eroded the Root River delta and transported the sediments

along the western shore of Lake Michigan to form the Zion beach-ridge plain

(Chrzastowski and Frankie, 2000).

2.4.3

HYDROGEOLOGY

Groundwater in the region occurs in shallow glacial, alluvial, and lacustrine deposits.

The shallow water-bearing zone is isolated from the underlying regional bedrock

aquifers by a significant thickness of glacial or lacustrine silts and clays.

Bedrock units form three major aquifer systems in northeastern Illinois. The uppermost

bedrock aquifer consists of the Silurian dolomites. The underlying Maquoketa Group

shales hydraulically separate the Silurian aquifer from deeper units.

The deeper aquifer systems include the Cambrian-Ordovician aquifer group, which

includes the St. Peter and Ironton-Galesville sandstones. The underlying Eau Claire

Formation hydraulically separates the Cambrian-Ordovician aquifer group from the

deeper Mt. Simon Aquifer (Visocky et al., 1985).

The sandstones of the Mt. Simon Formation are not typically used for potable water

because of undesirable characteristics including high concentrations of total dissolved

solids and natural radioactivity. Crystalline basement rock underlies the Mt. Simon

Formation (Visocky et al., 1985).

Lake Michigan acts as a major regional discharge zone for groundwater.

The

groundwater flow in both unconsolidated deposits and bedrock units in the region is

generally toward the lake; however, localized pumping induces variations in flow

directions in the bedrock aquifers.

045136 (22) Zion Station

7

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

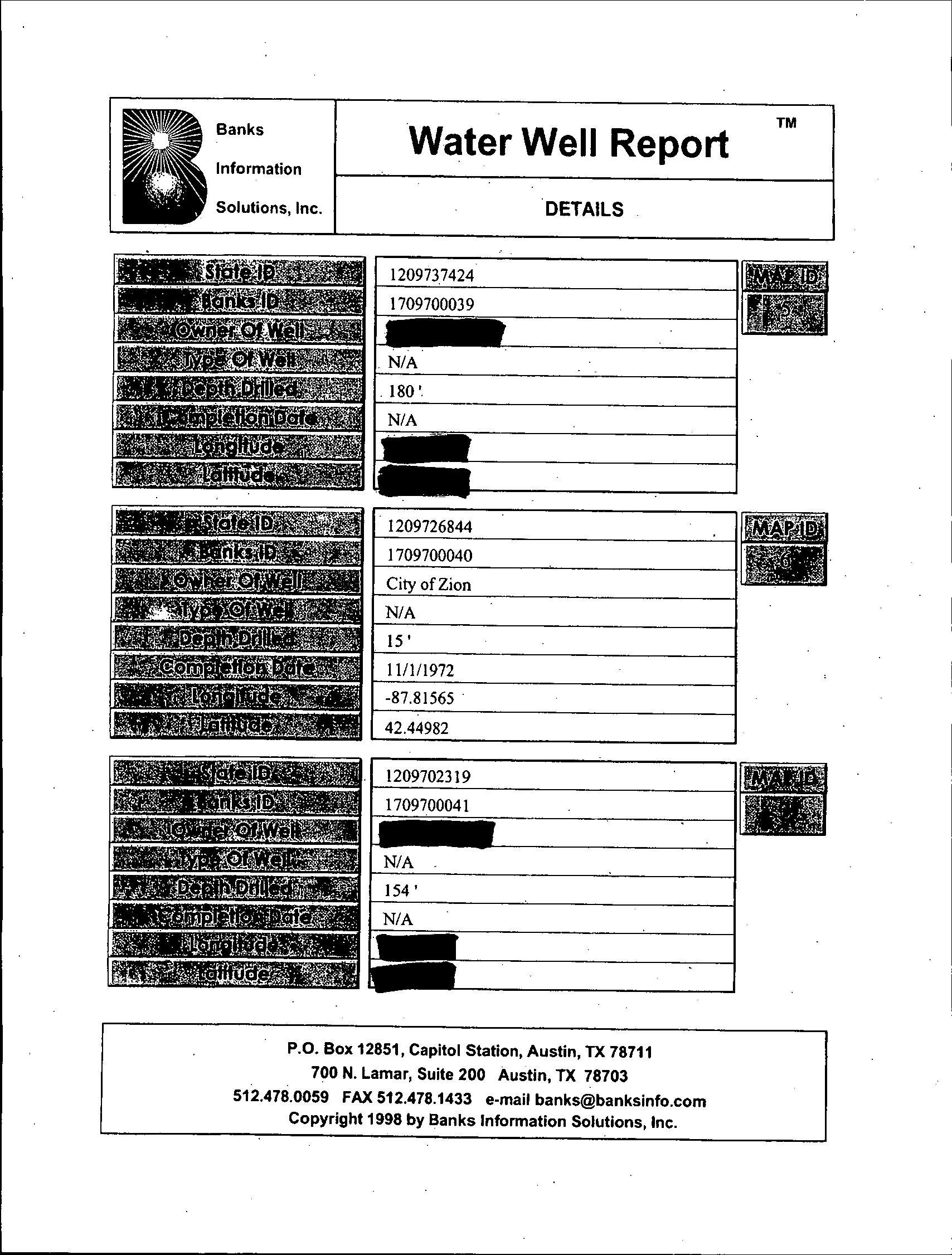

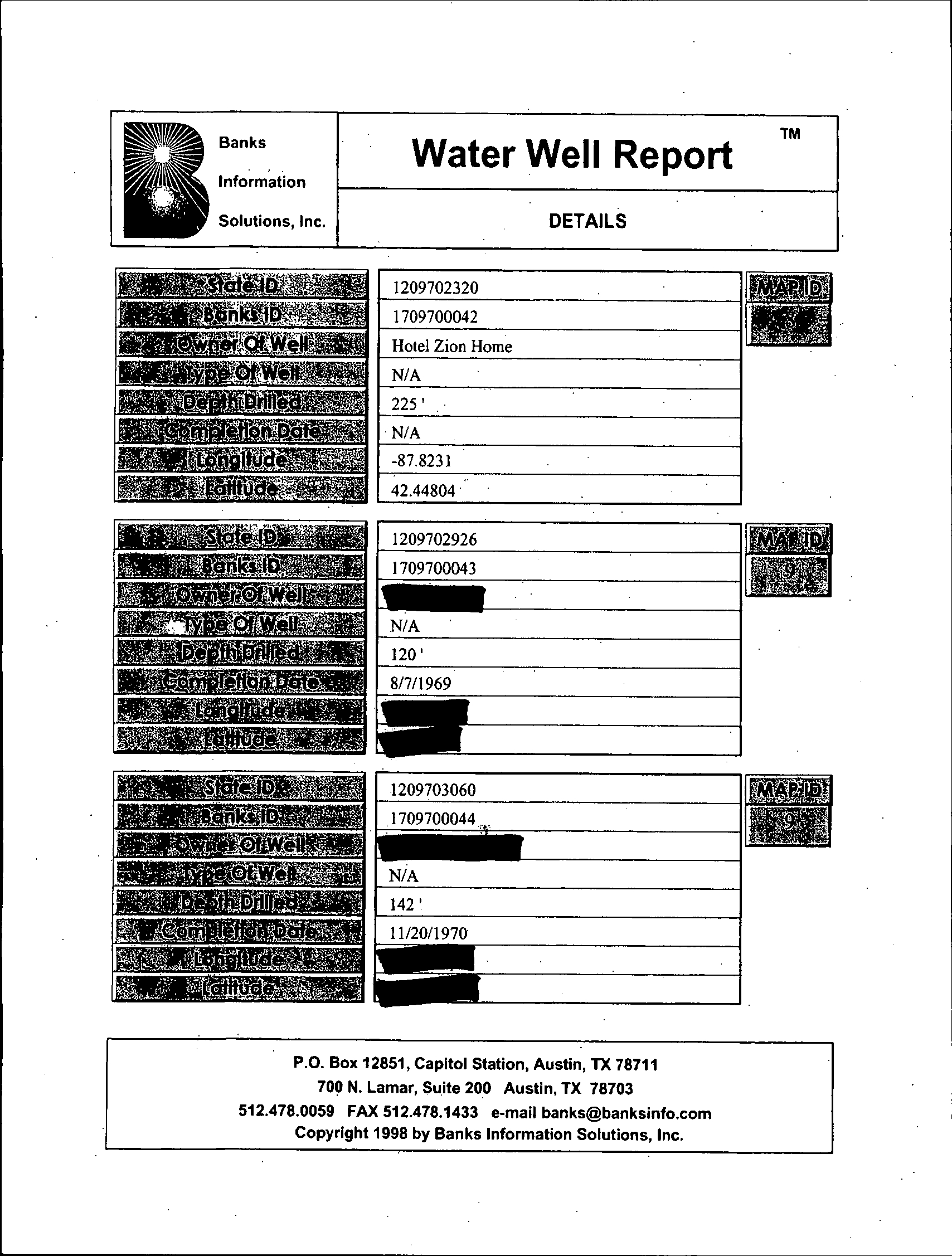

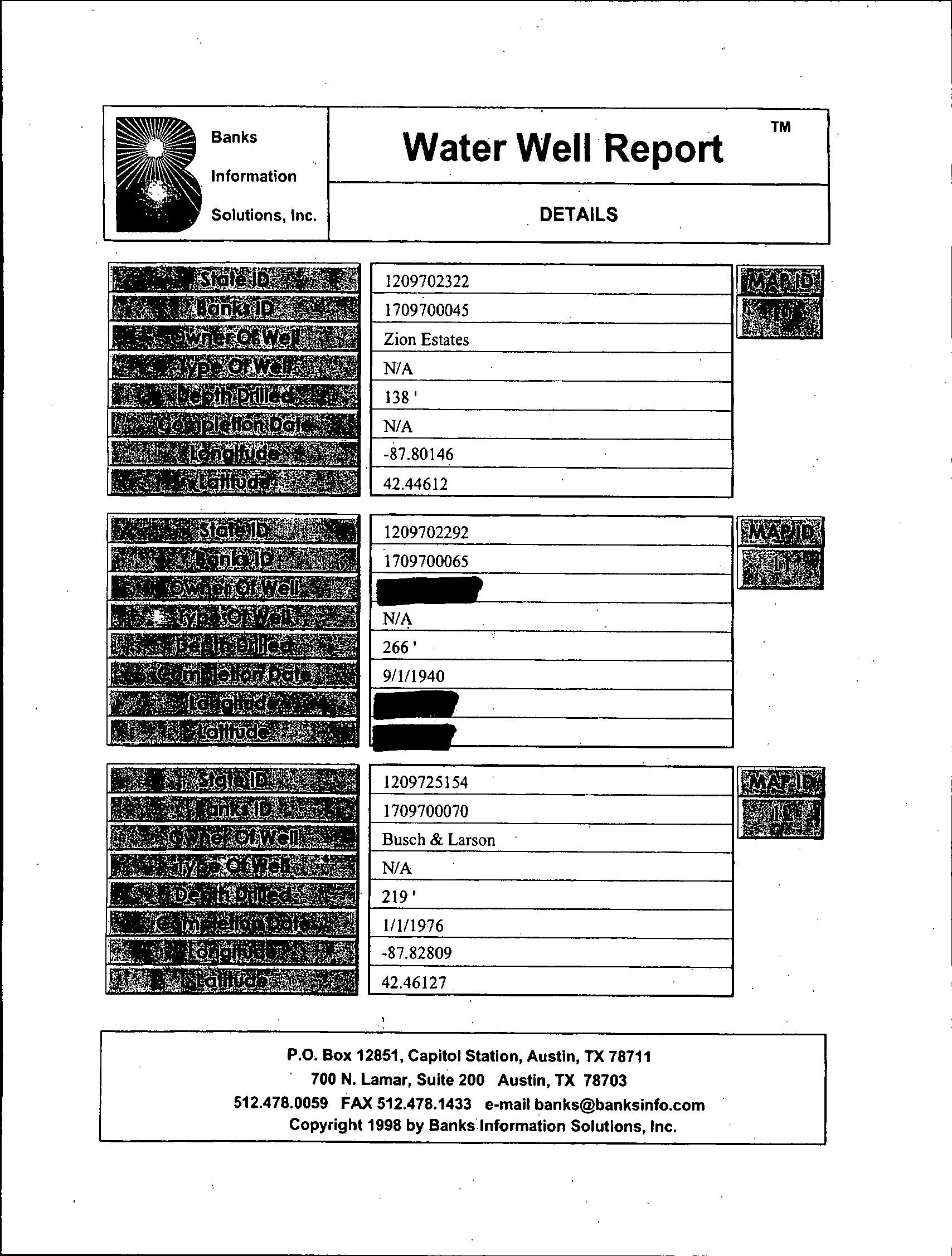

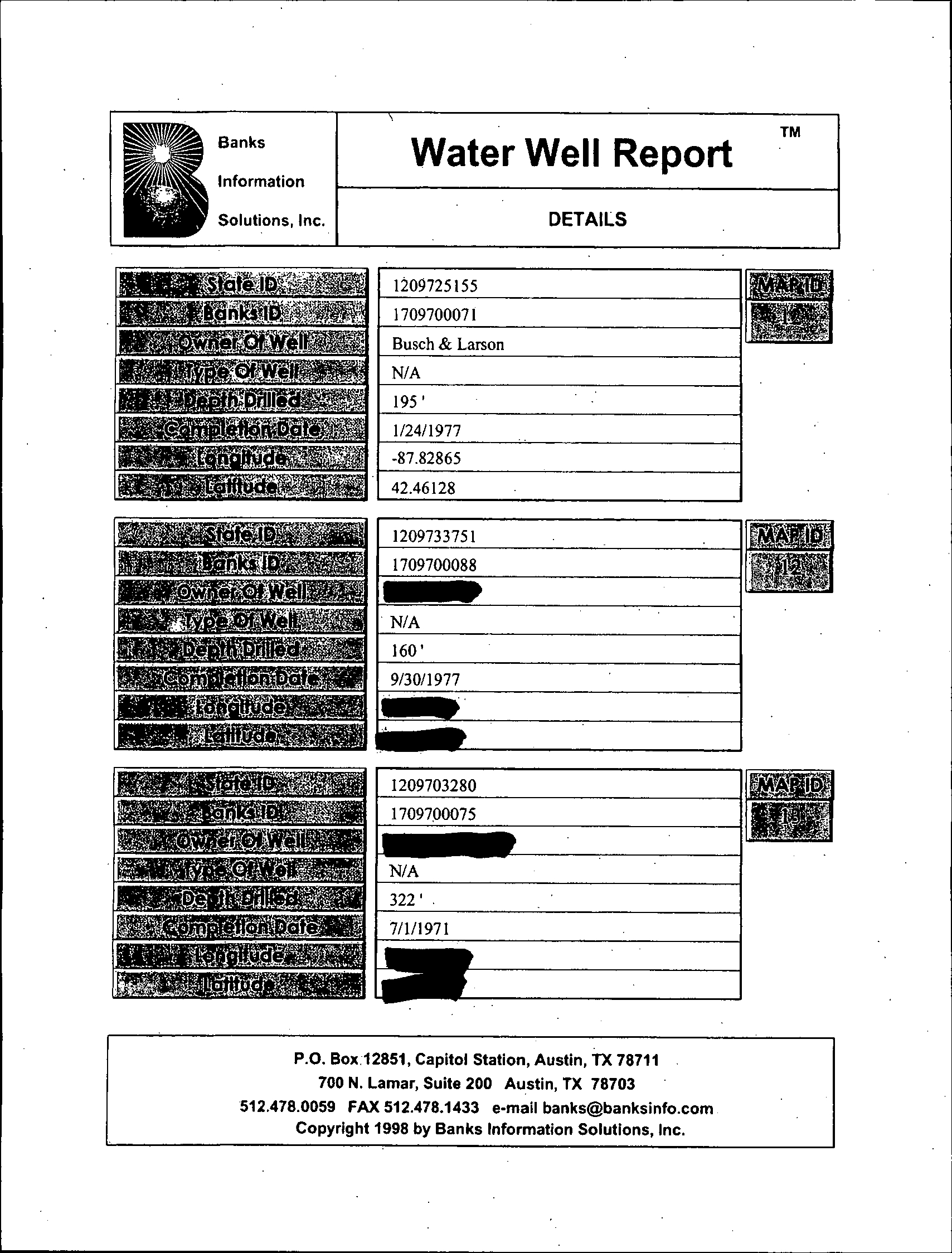

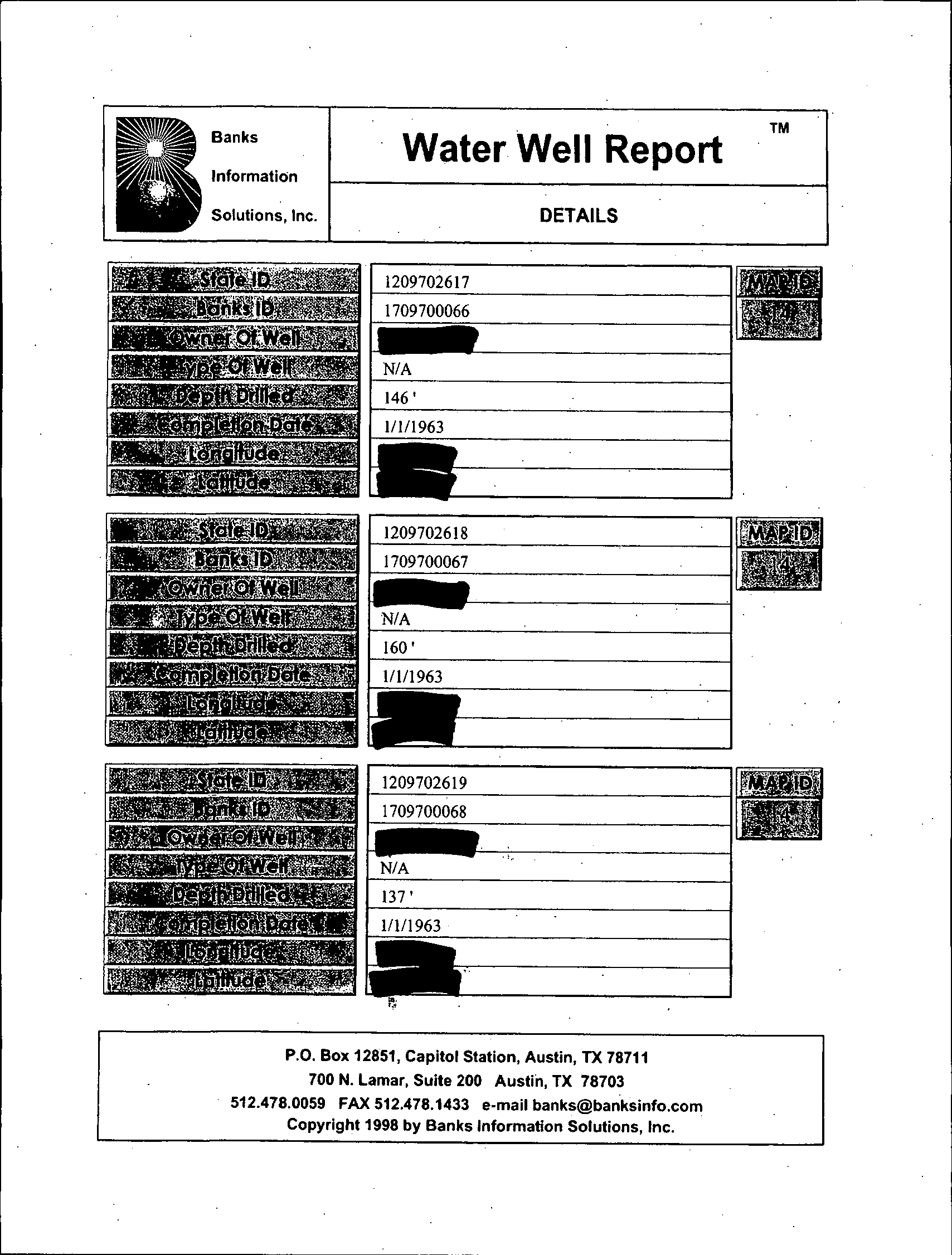

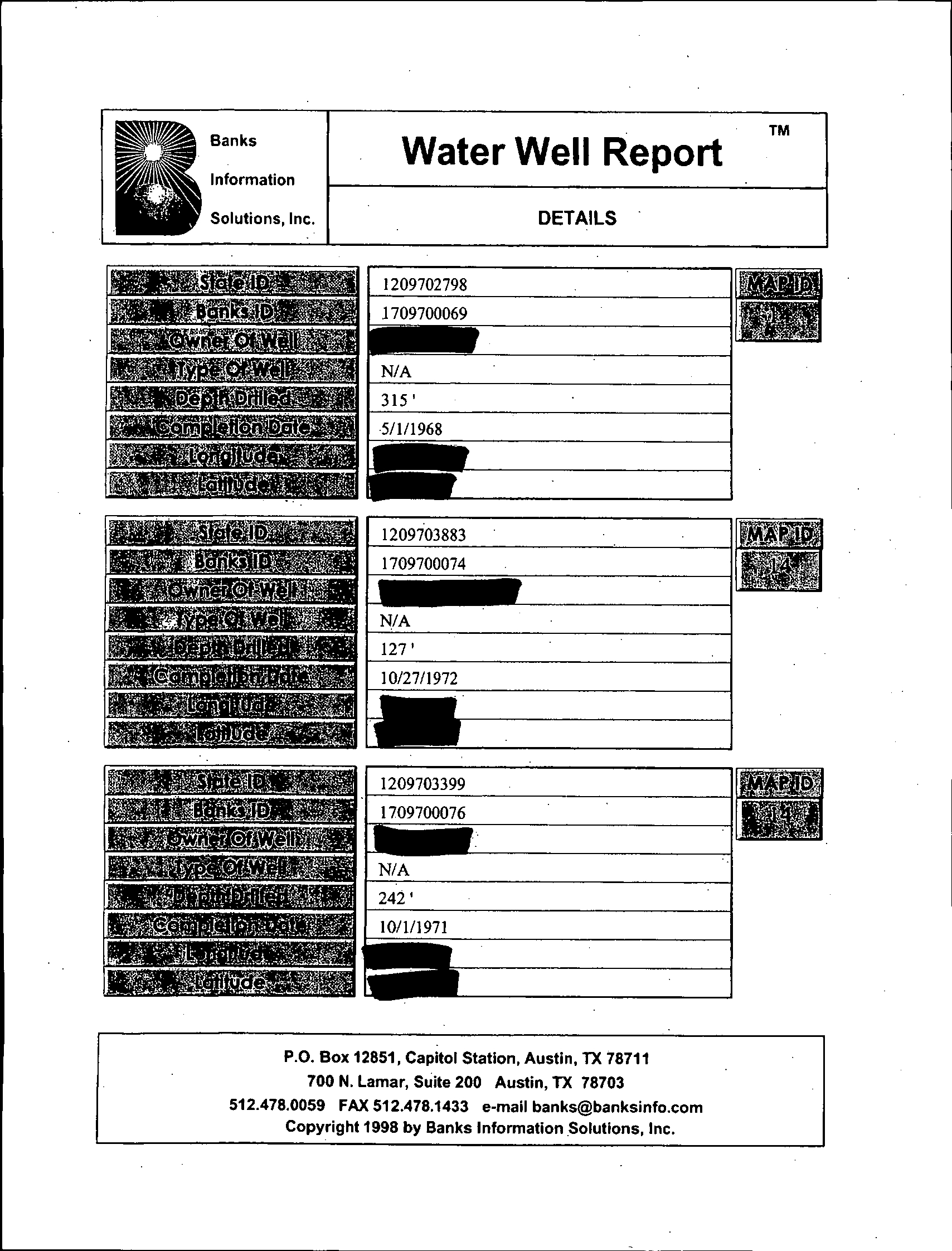

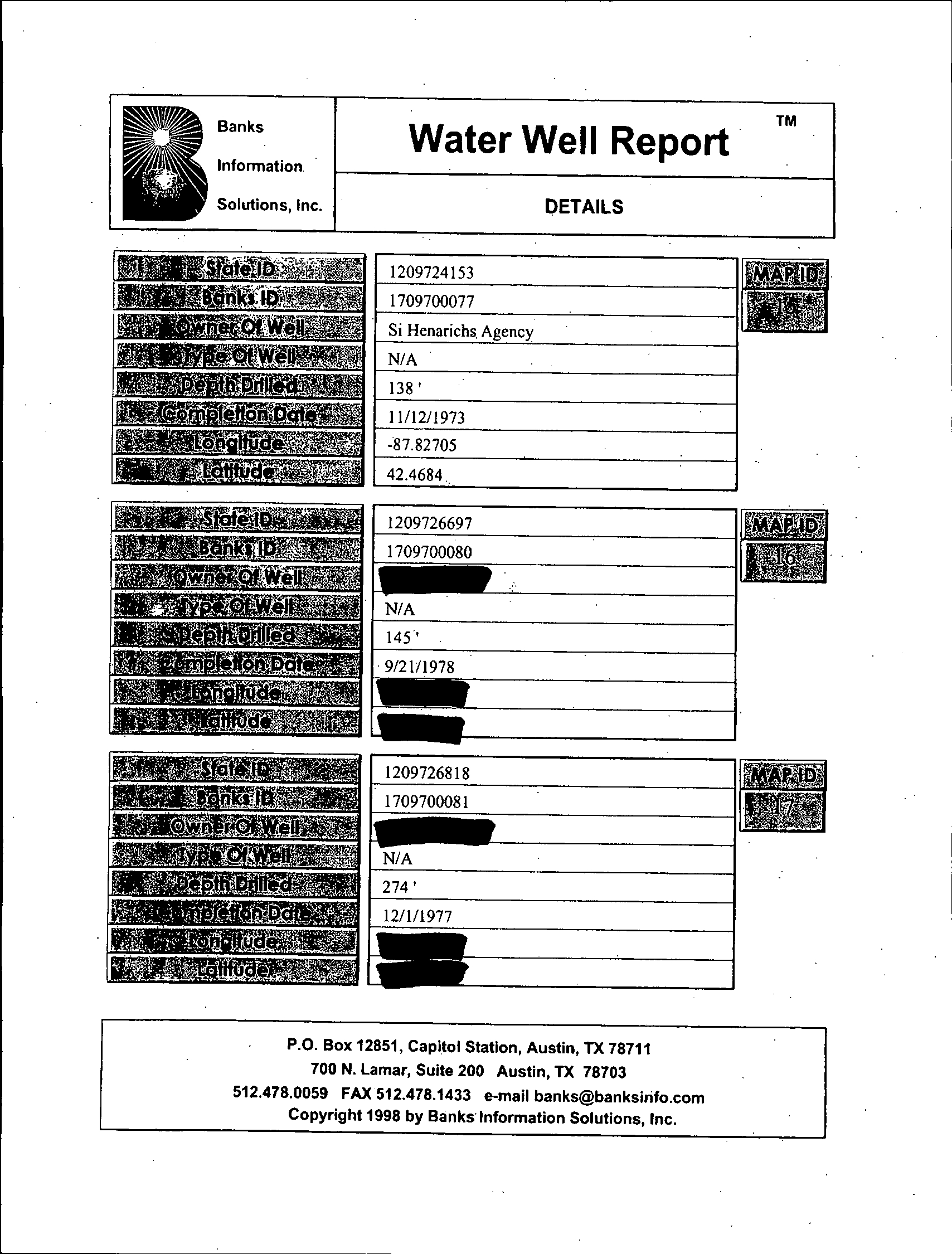

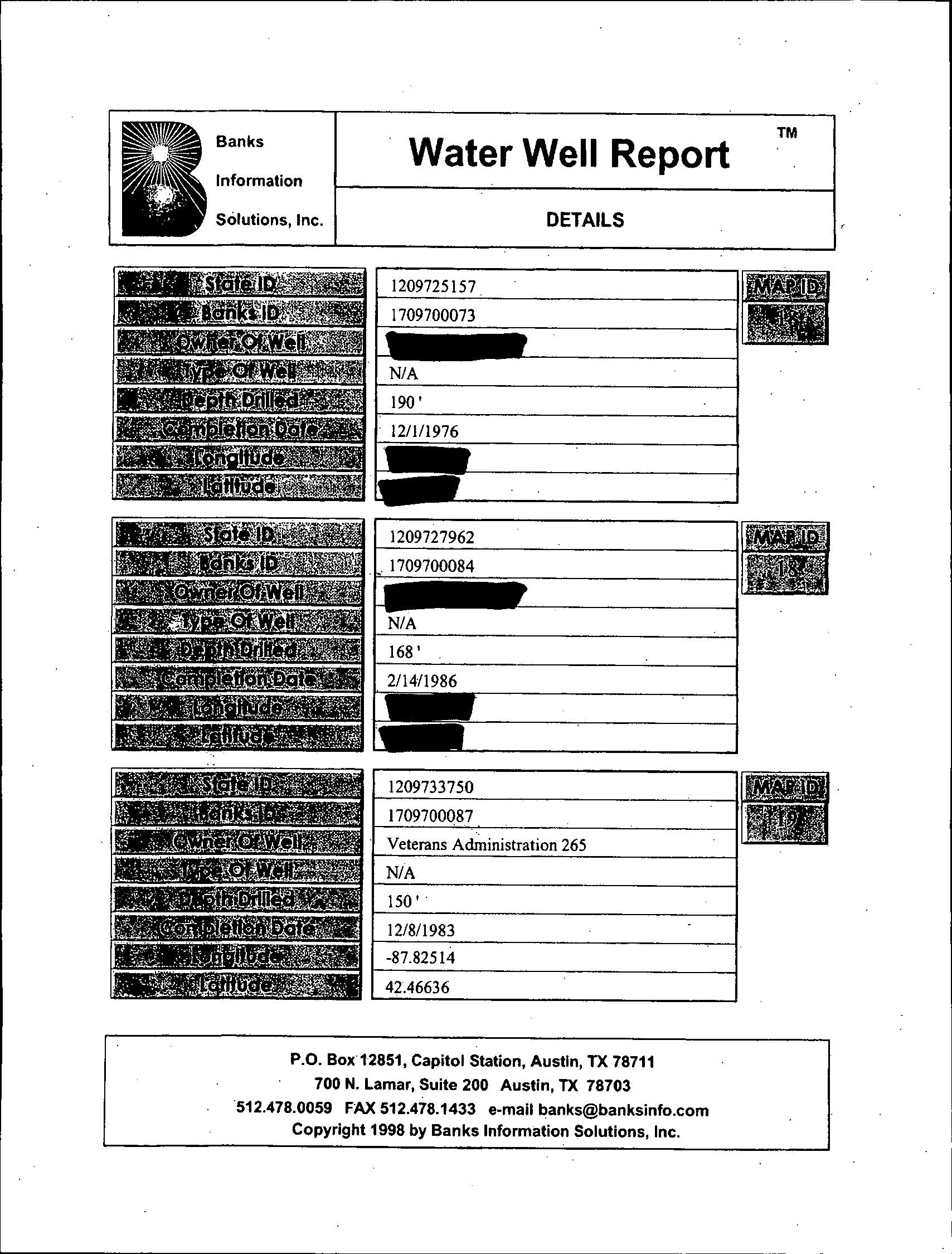

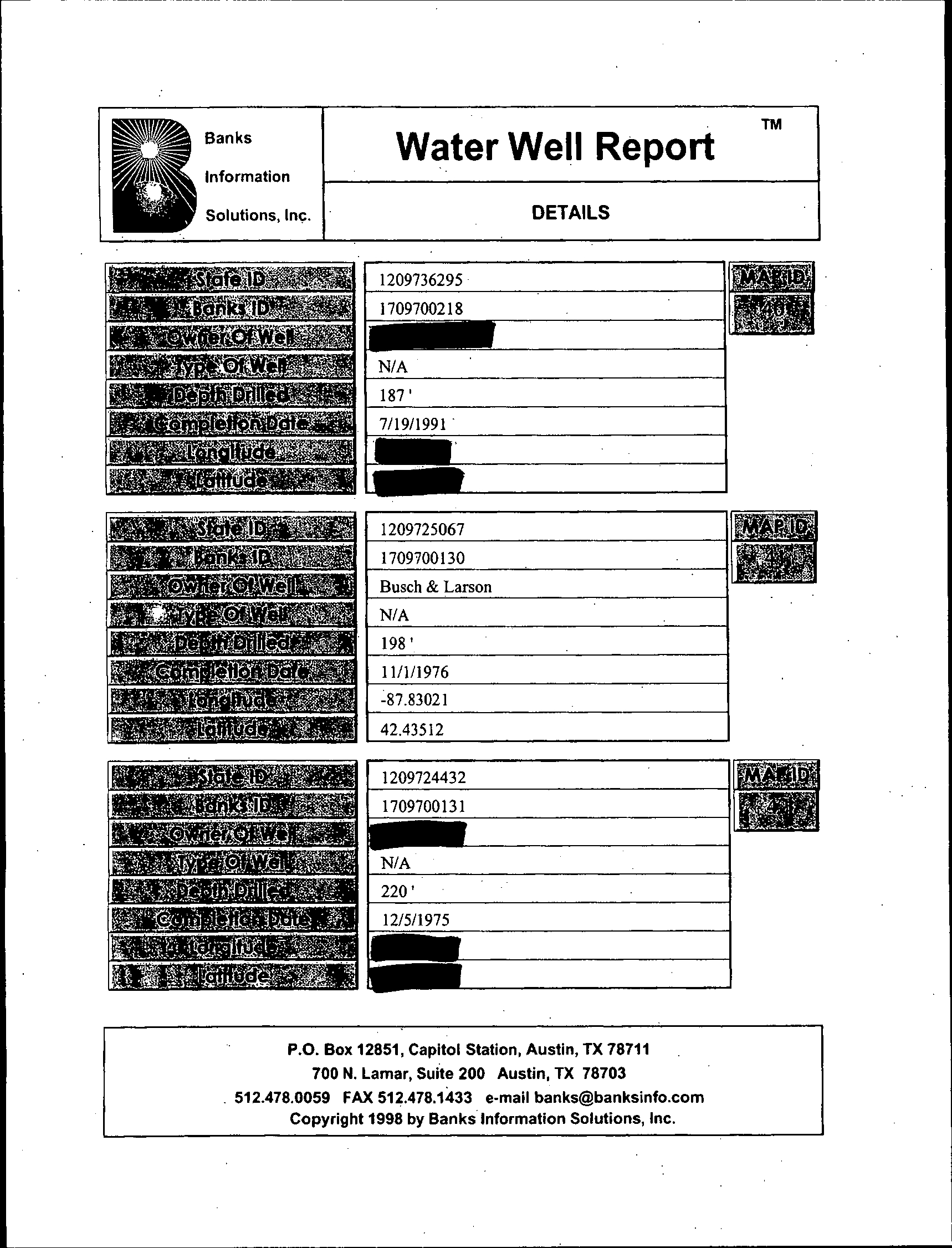

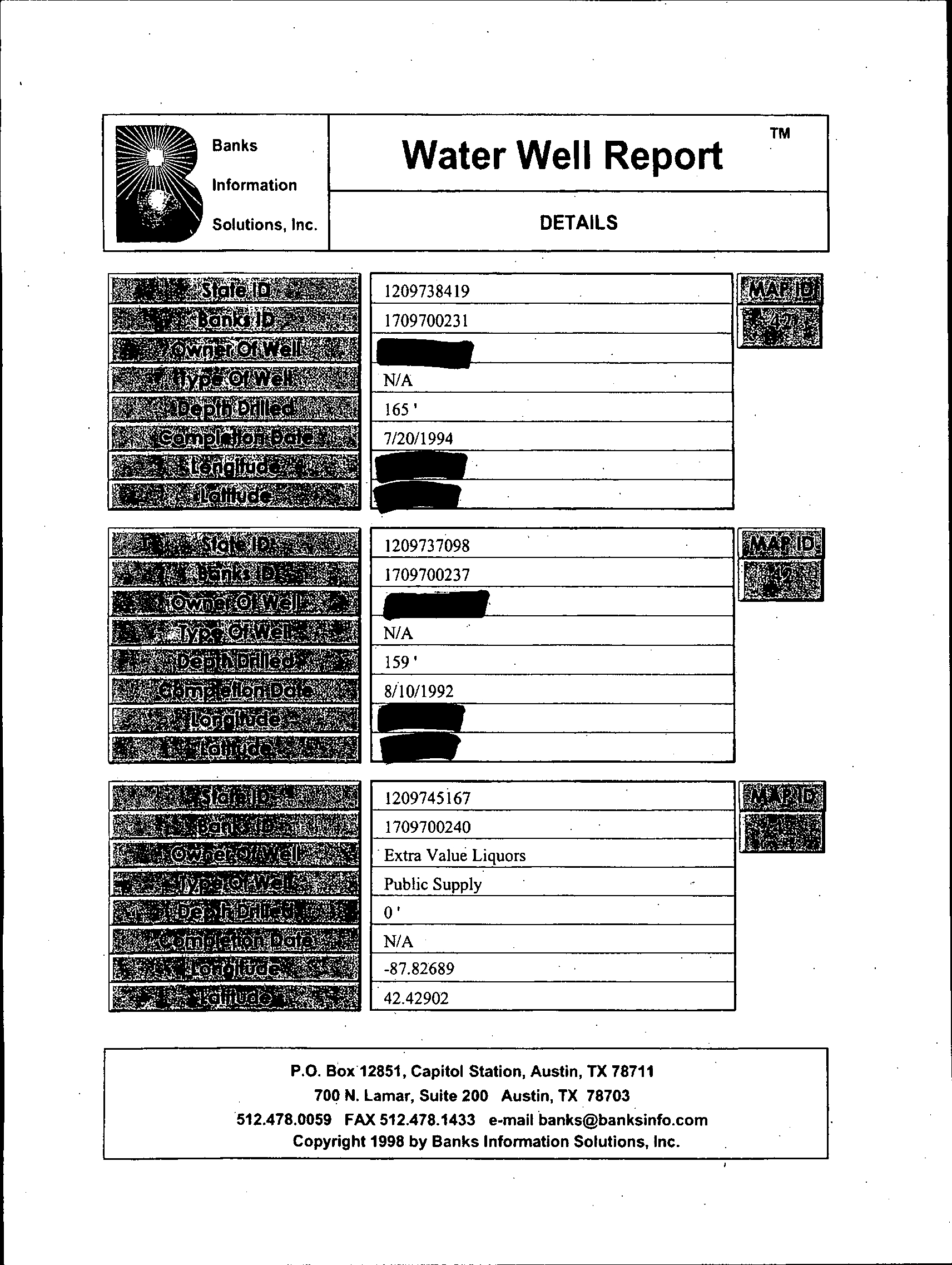

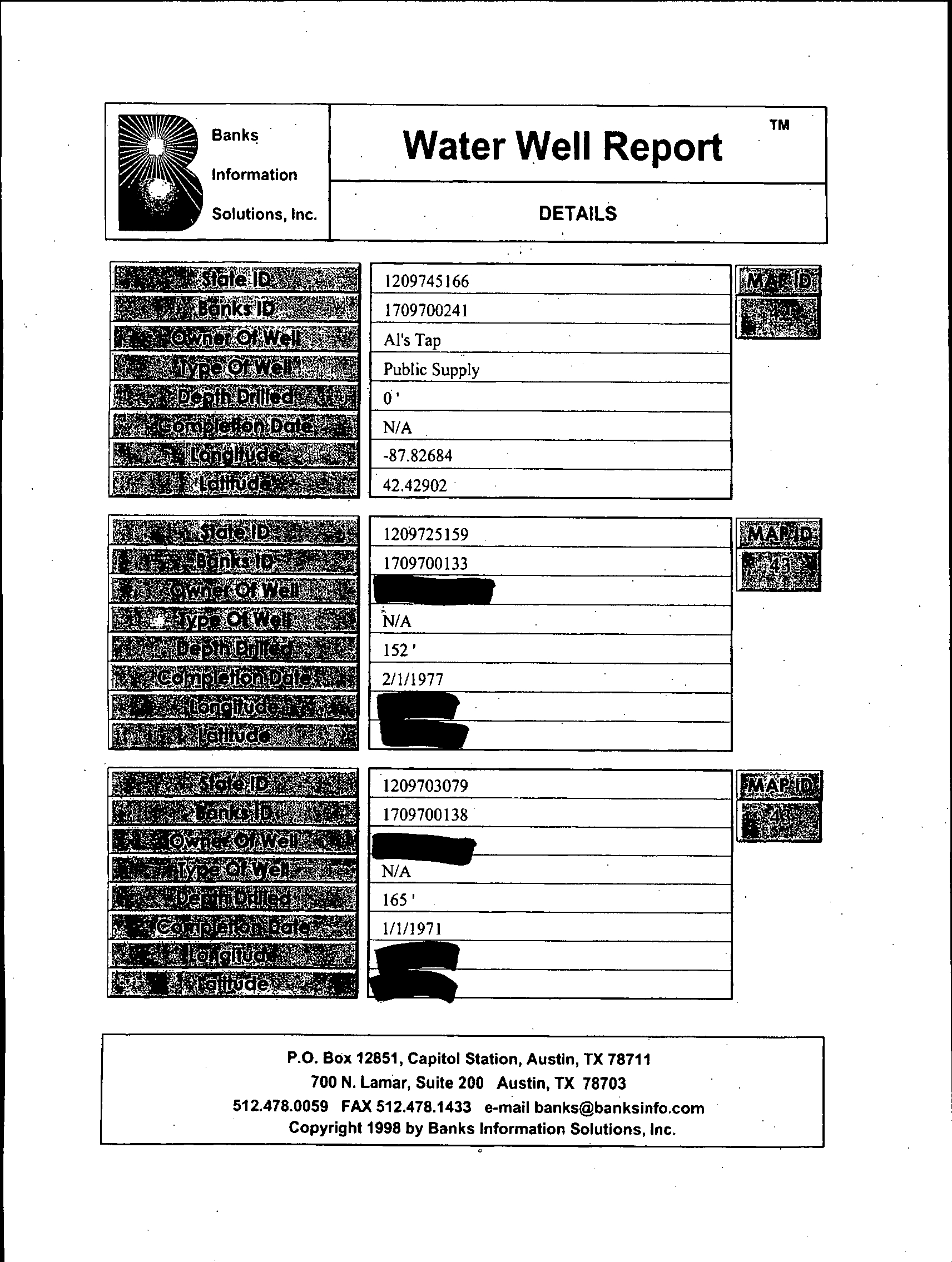

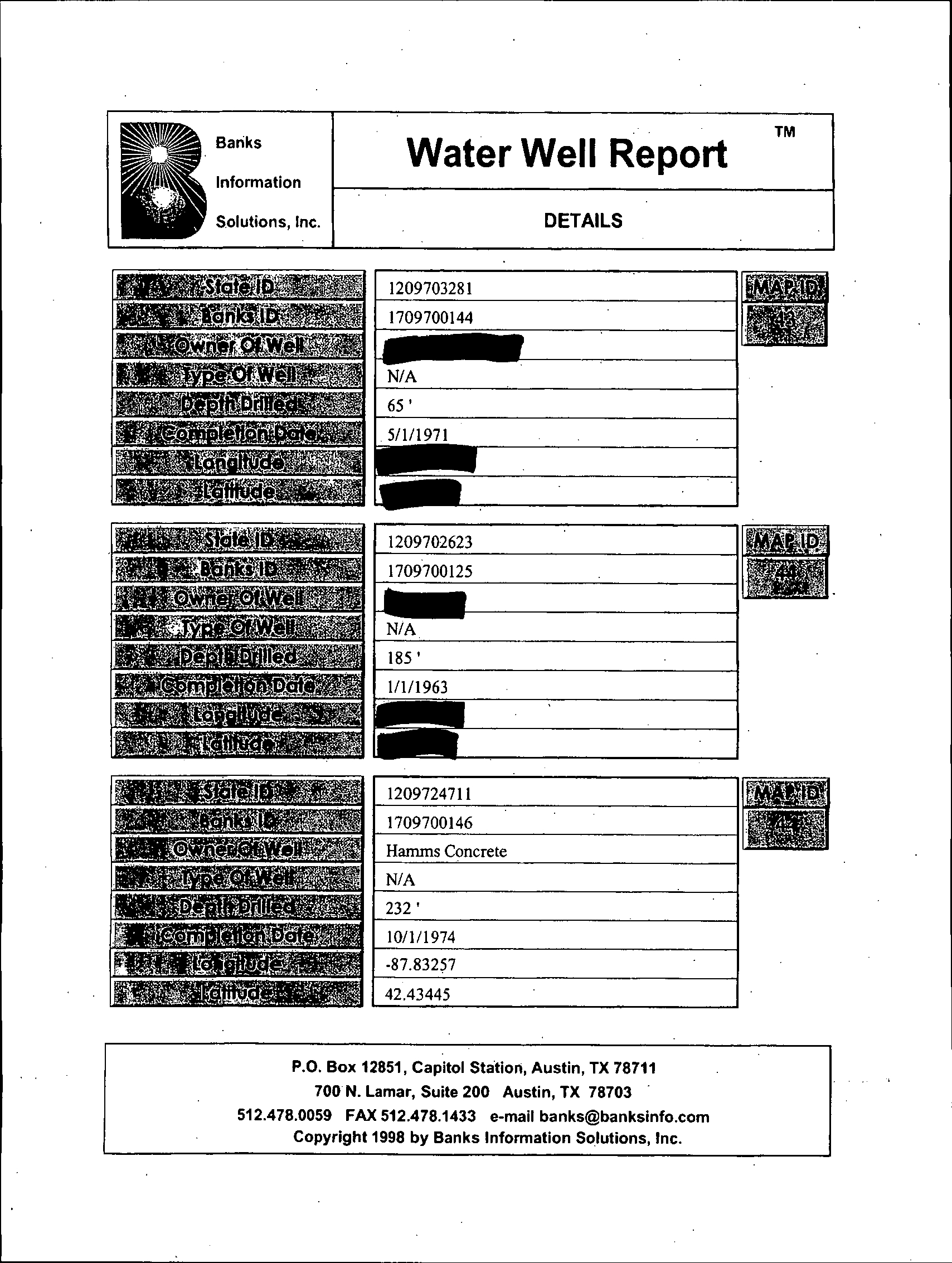

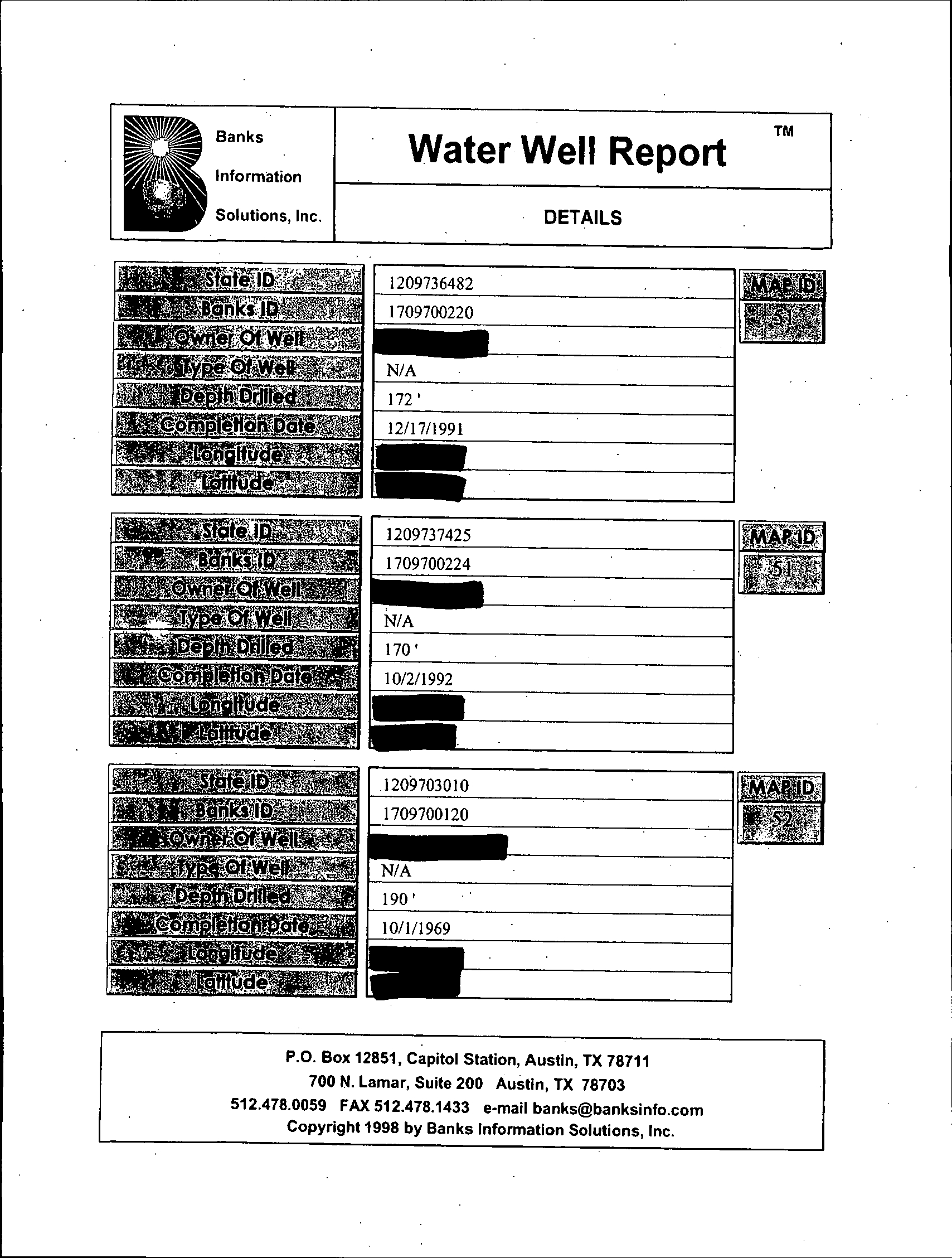

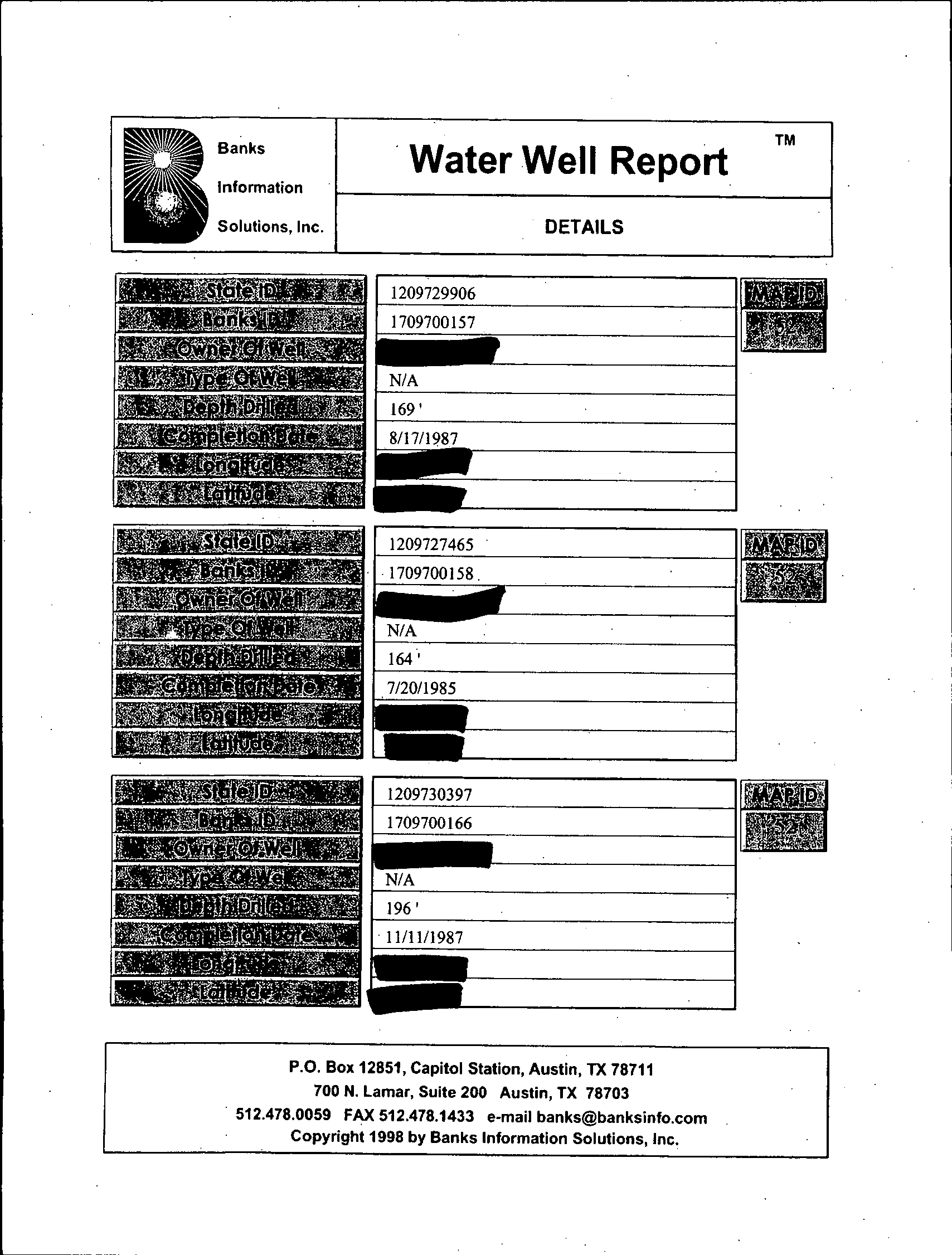

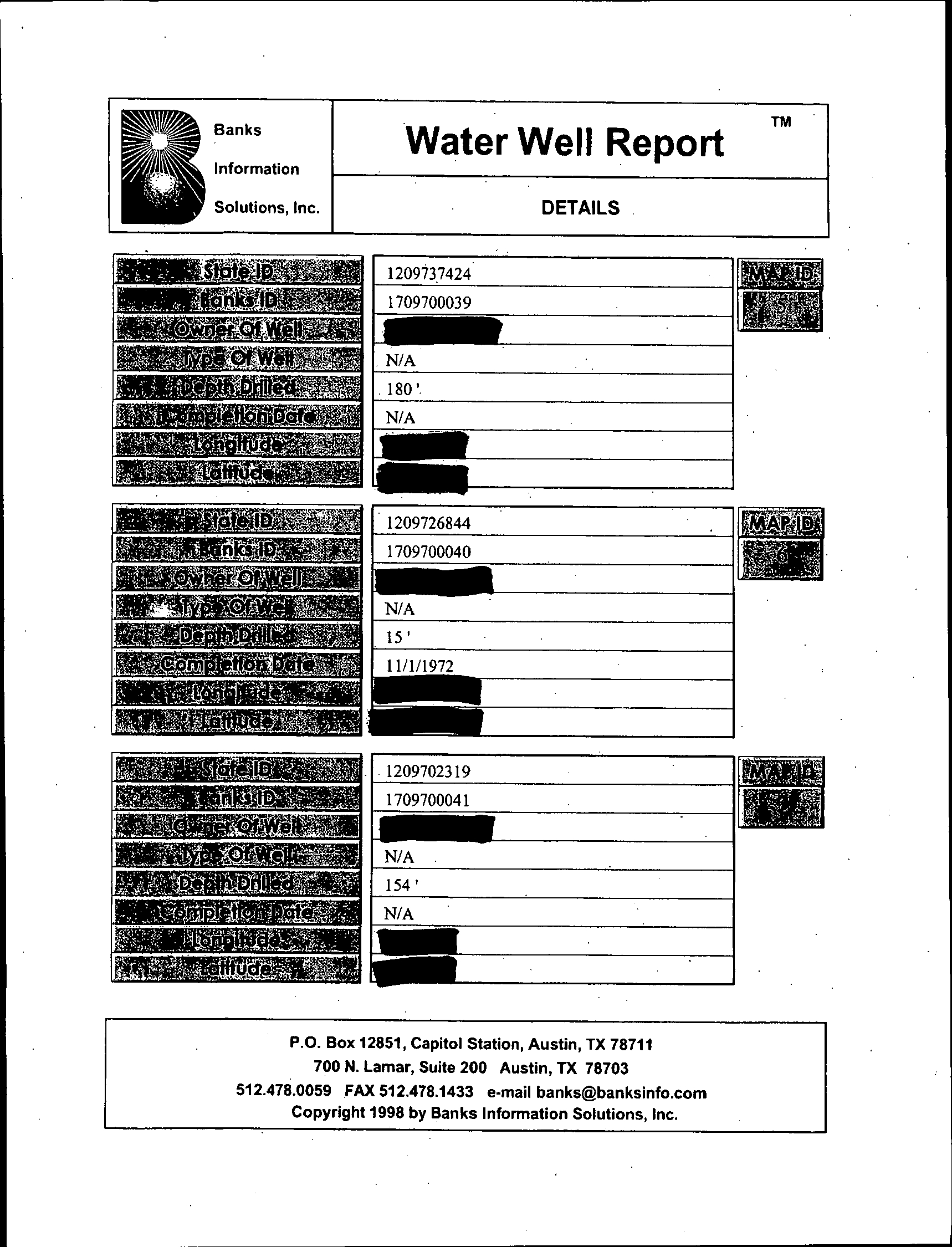

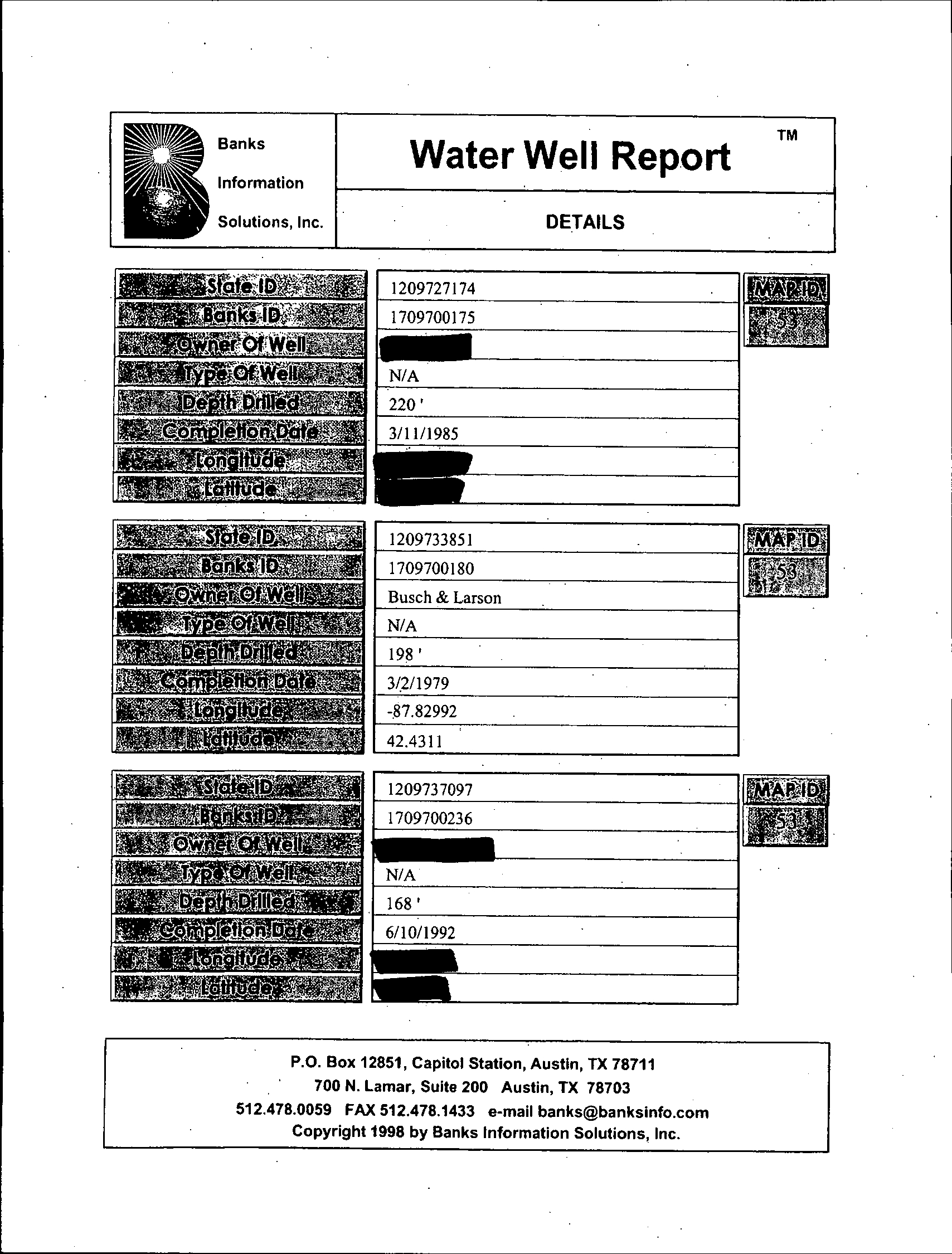

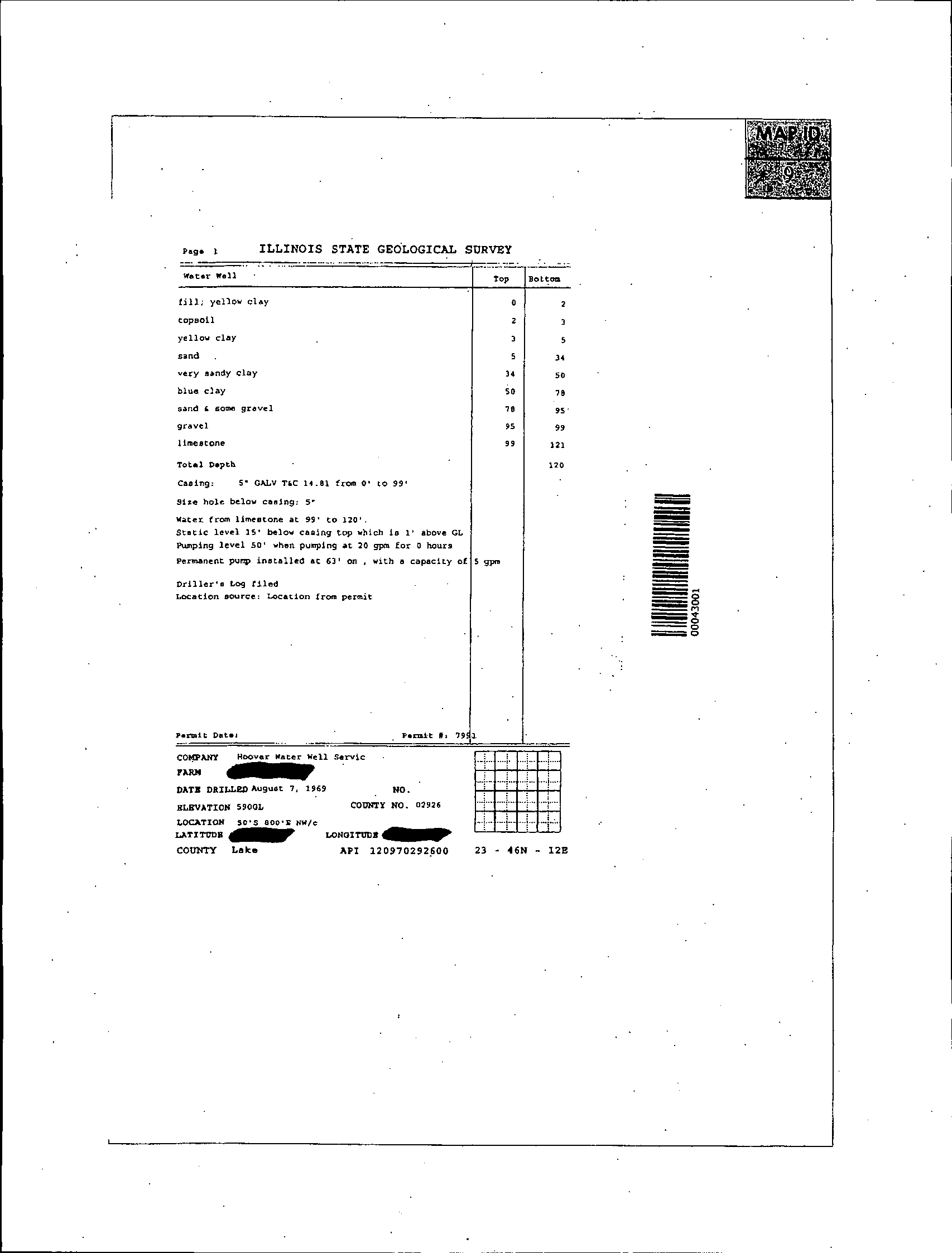

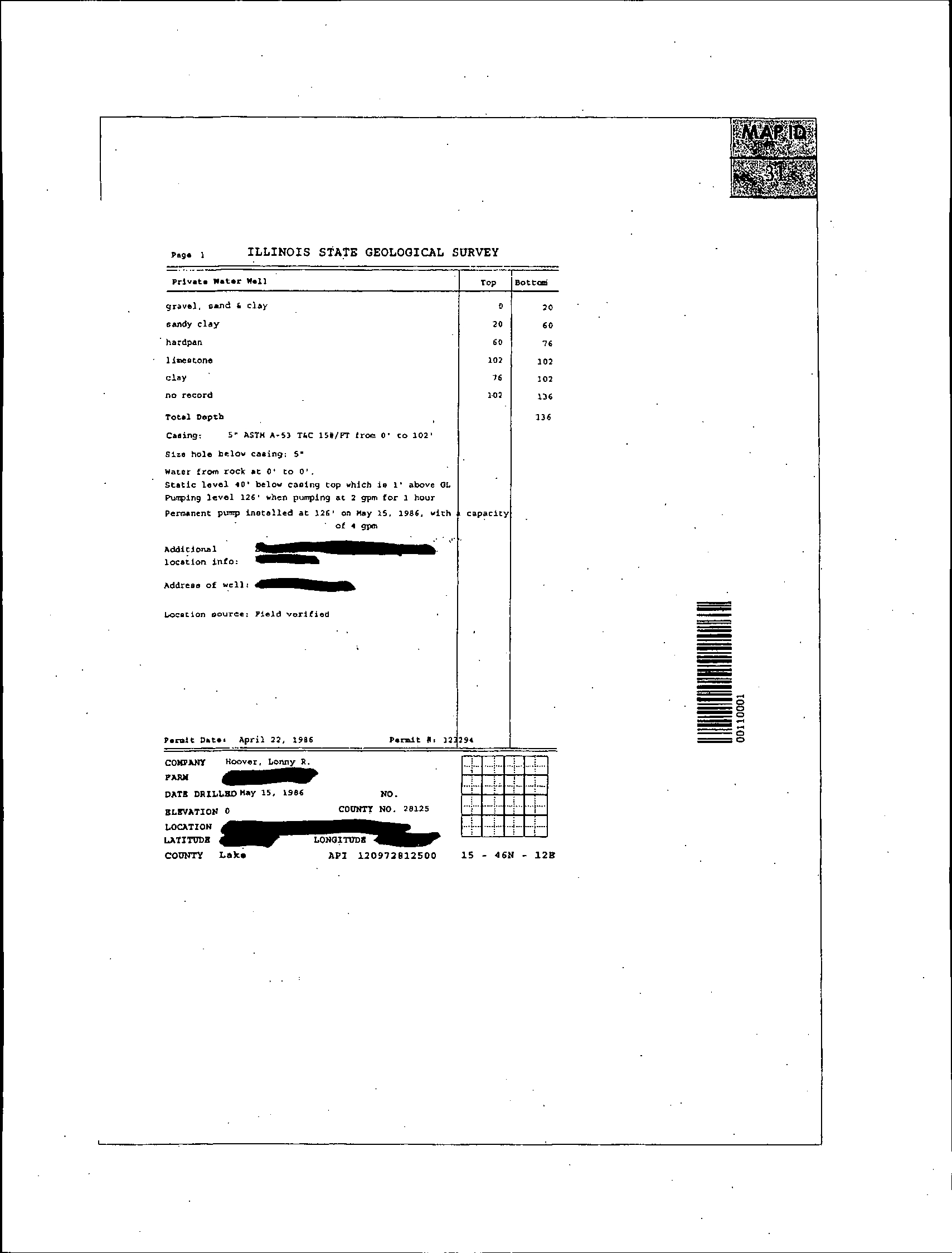

2.5

AREA GROUNDWATER USE

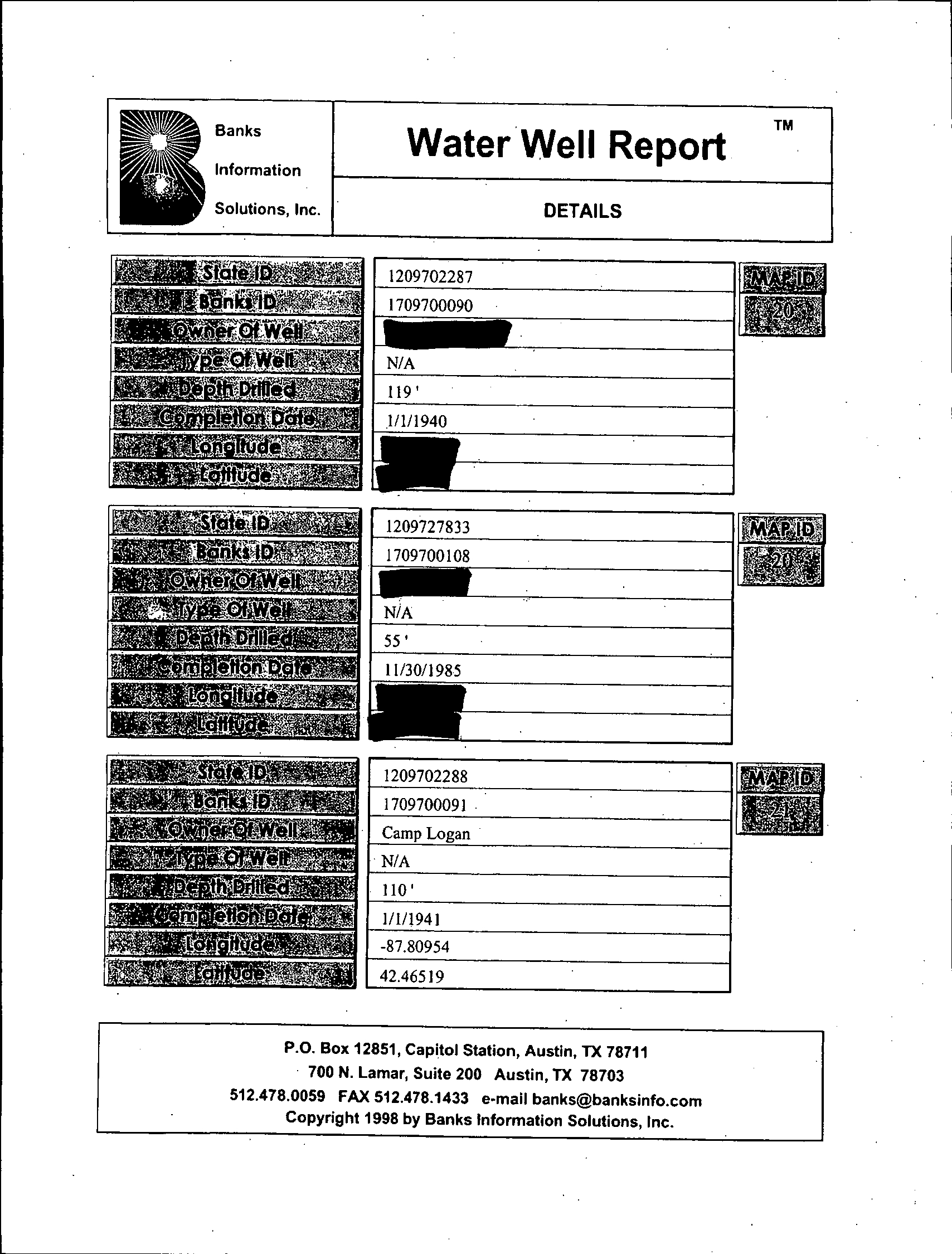

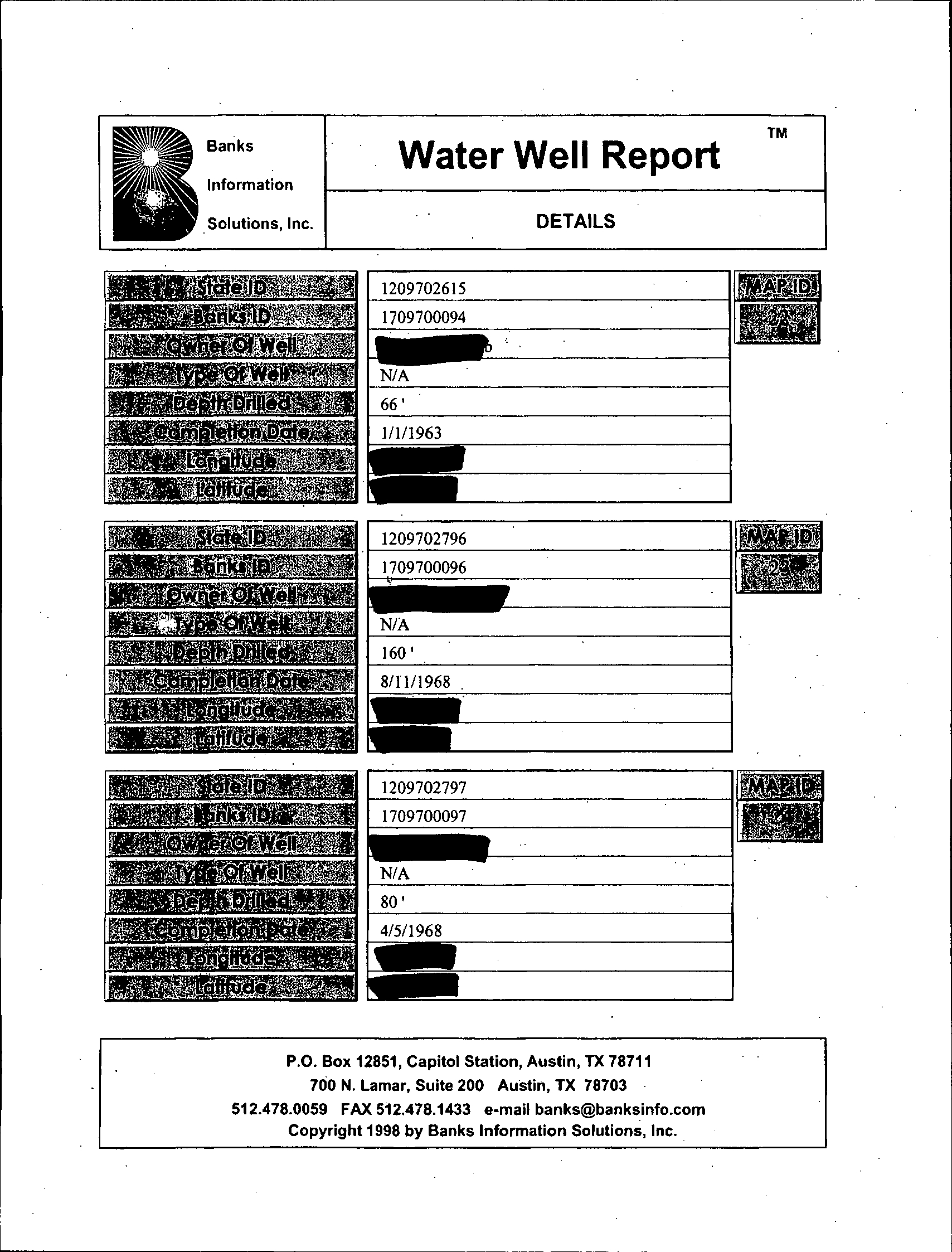

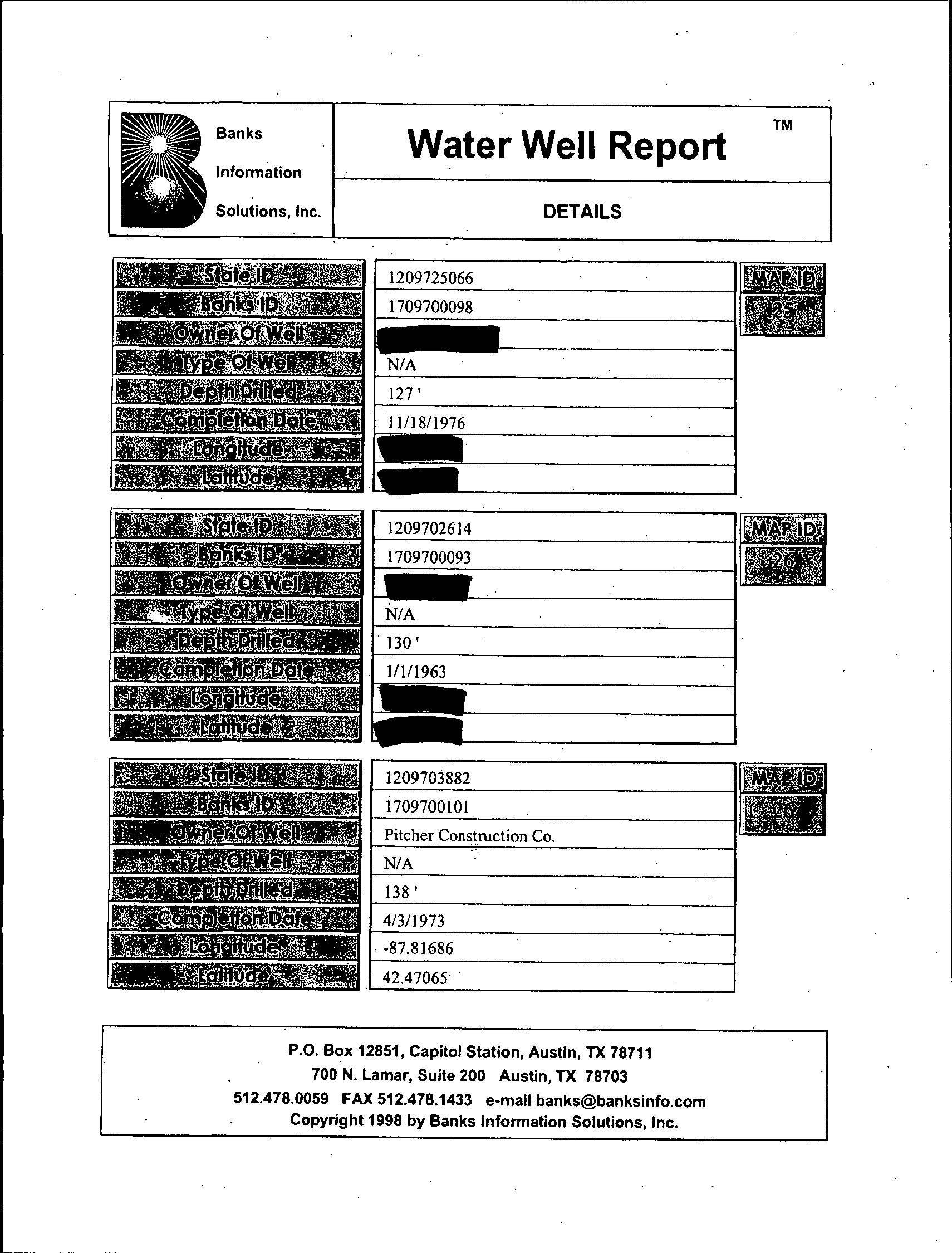

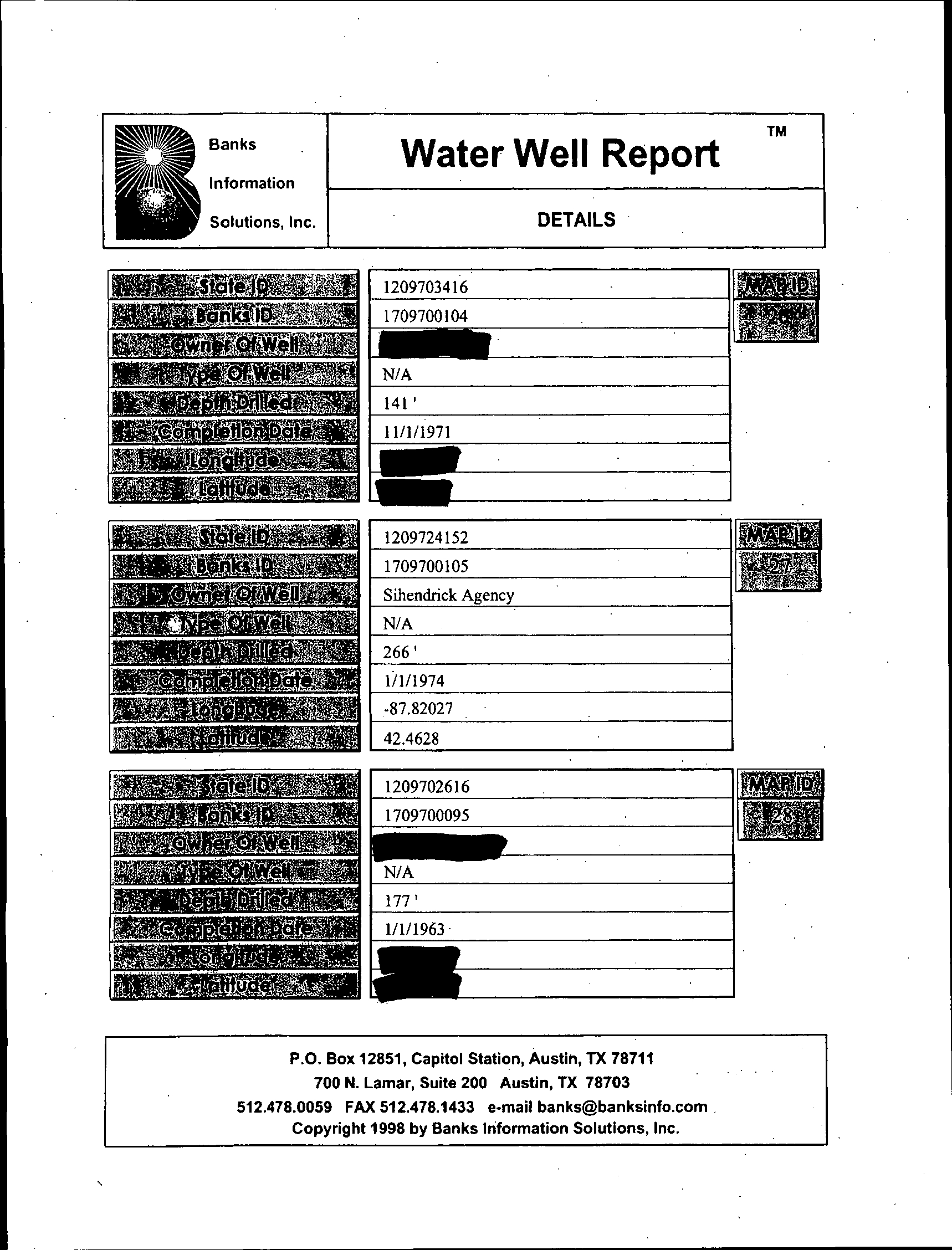

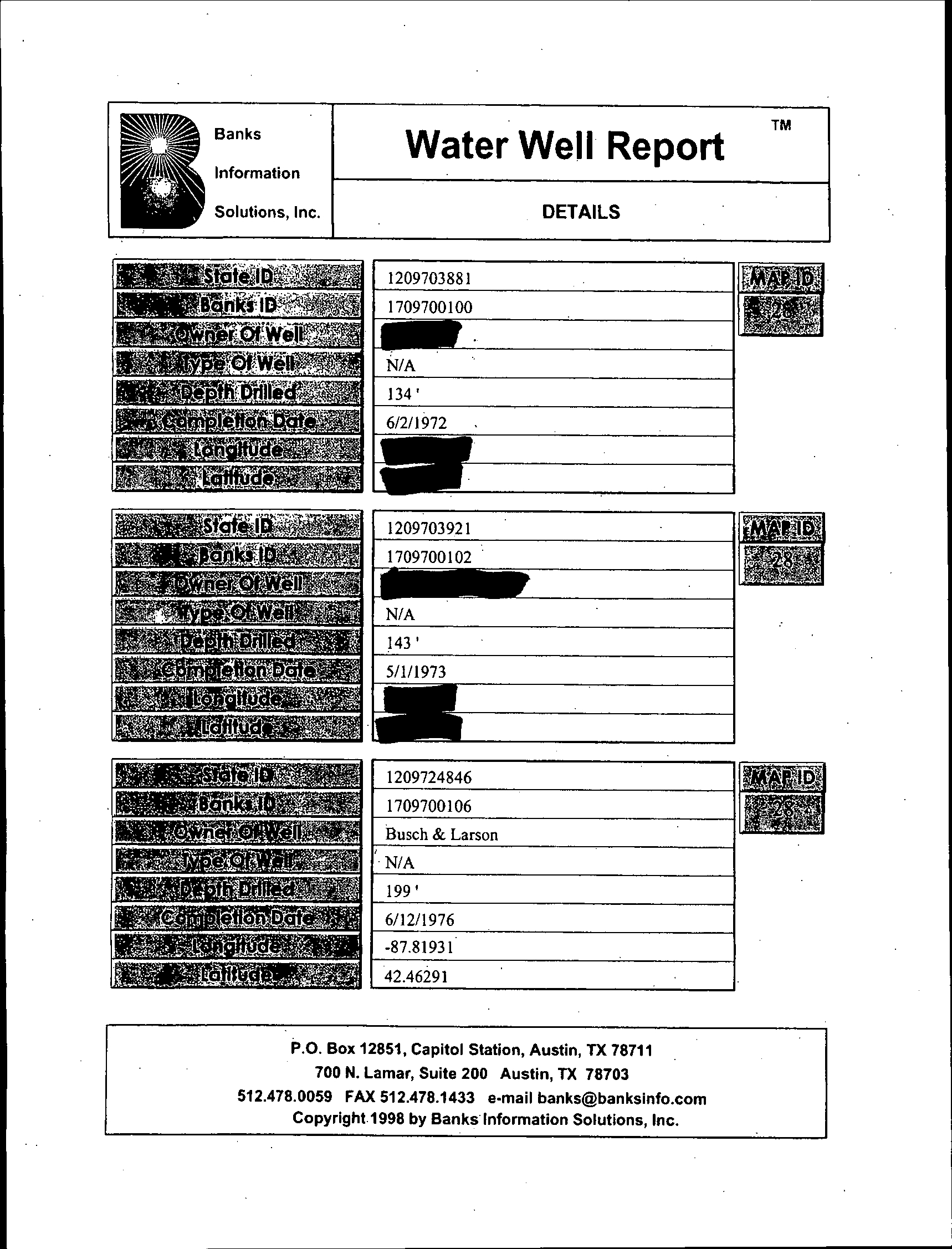

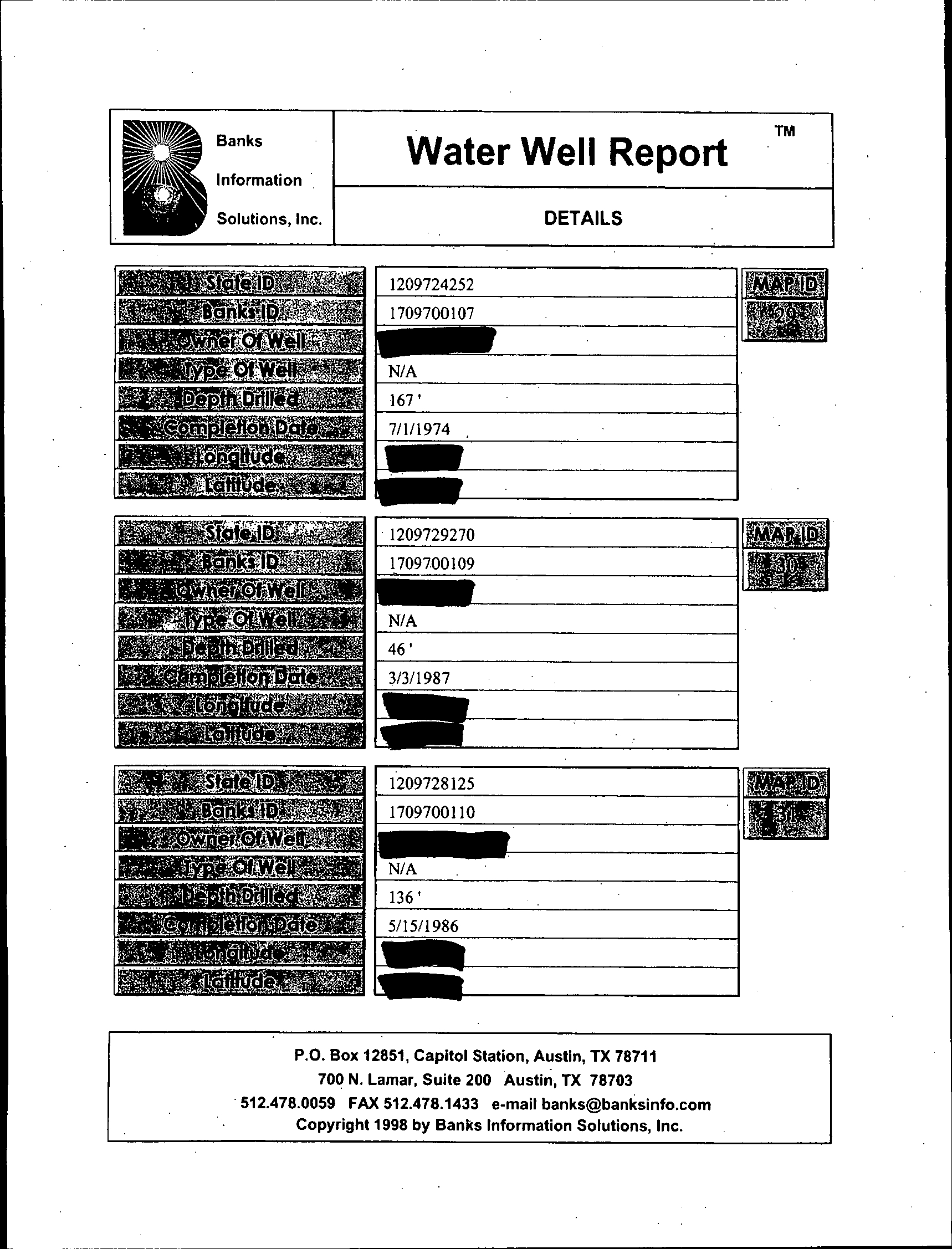

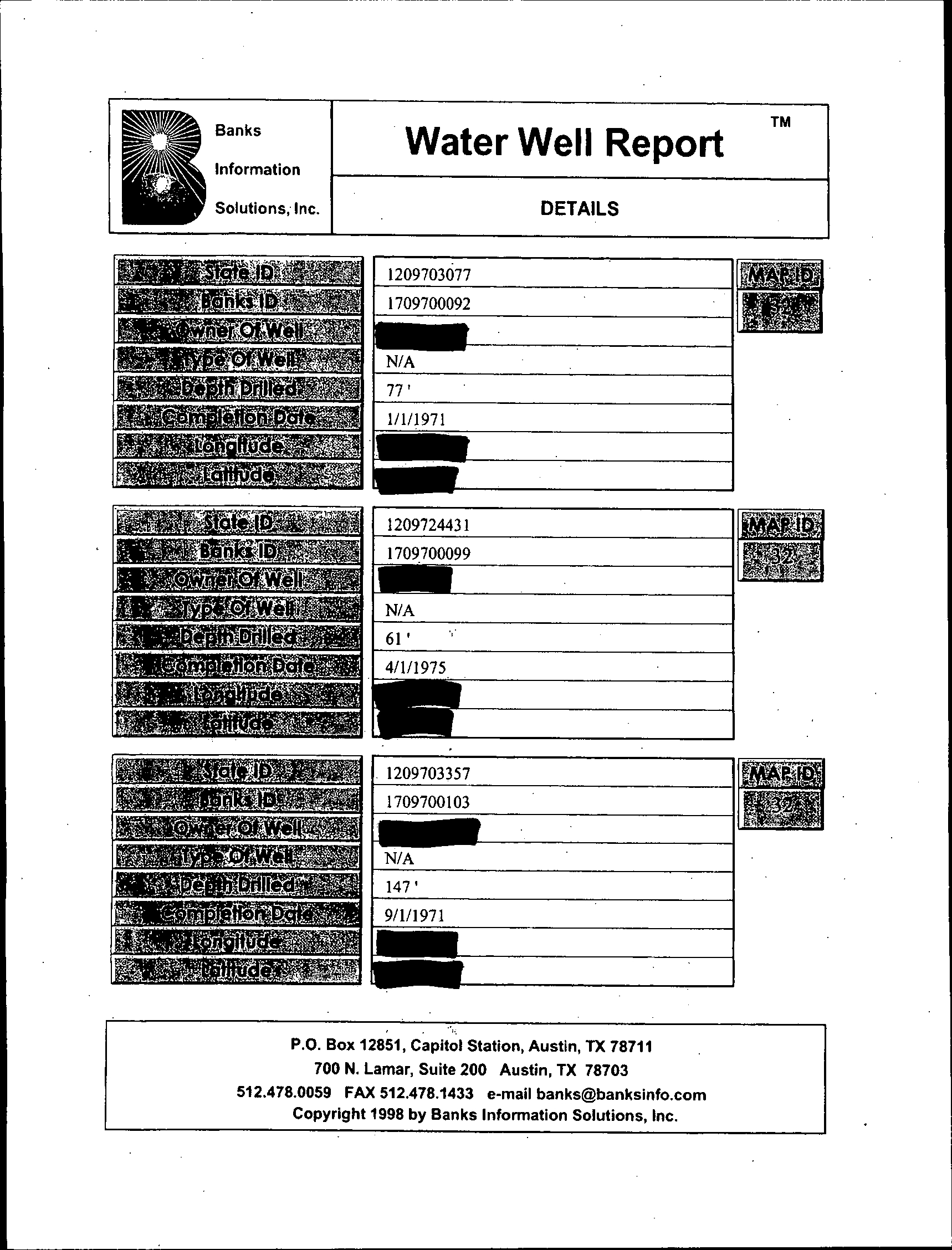

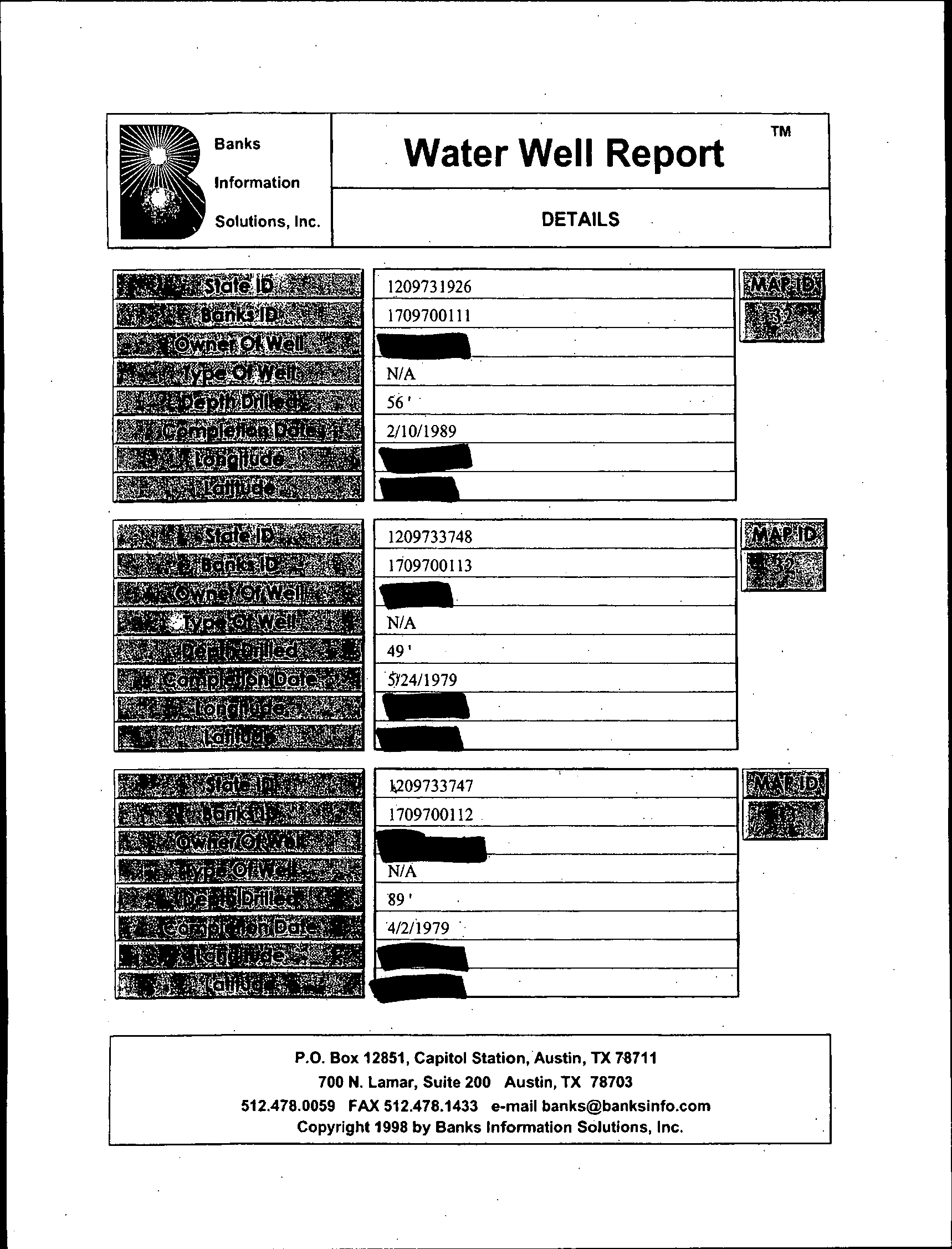

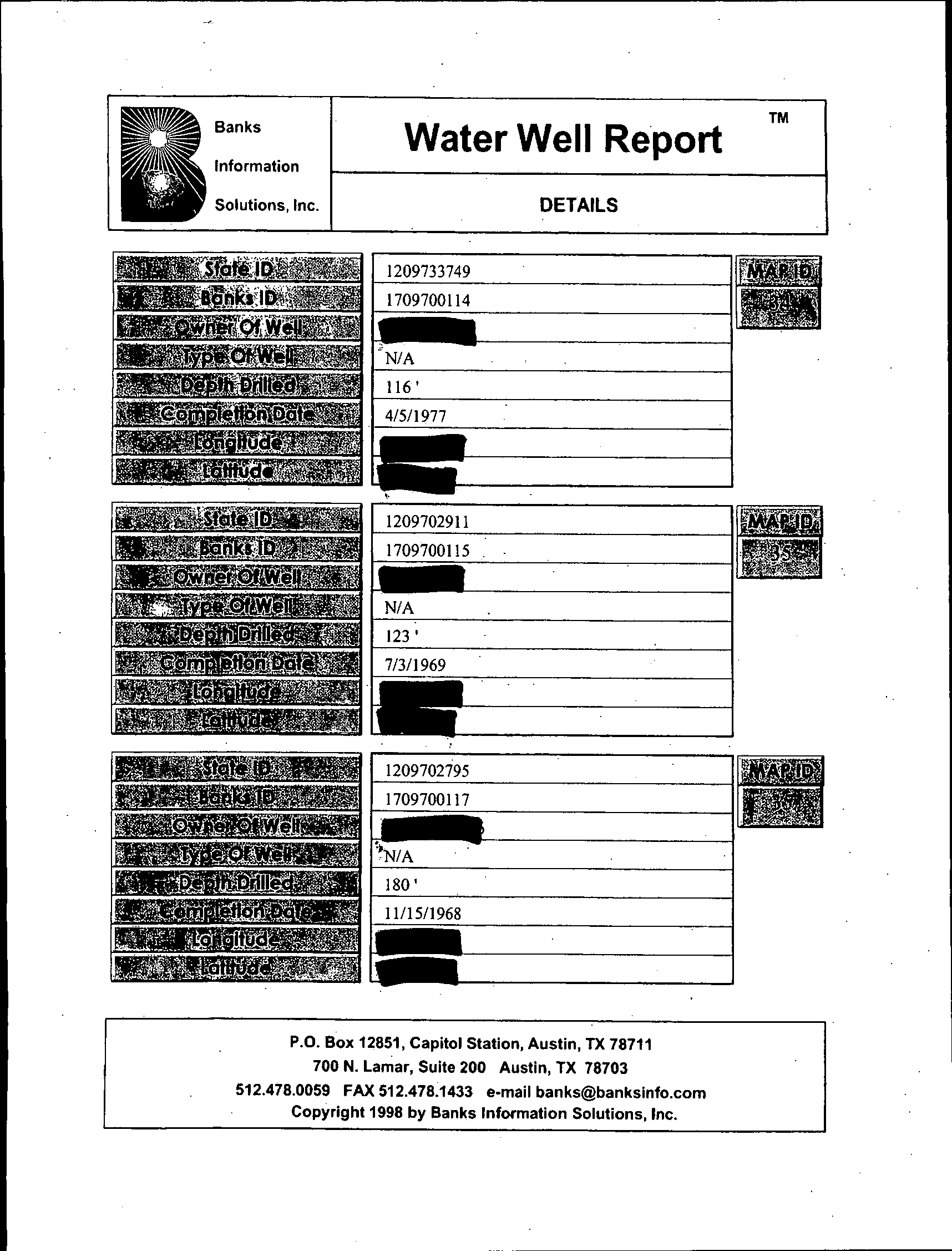

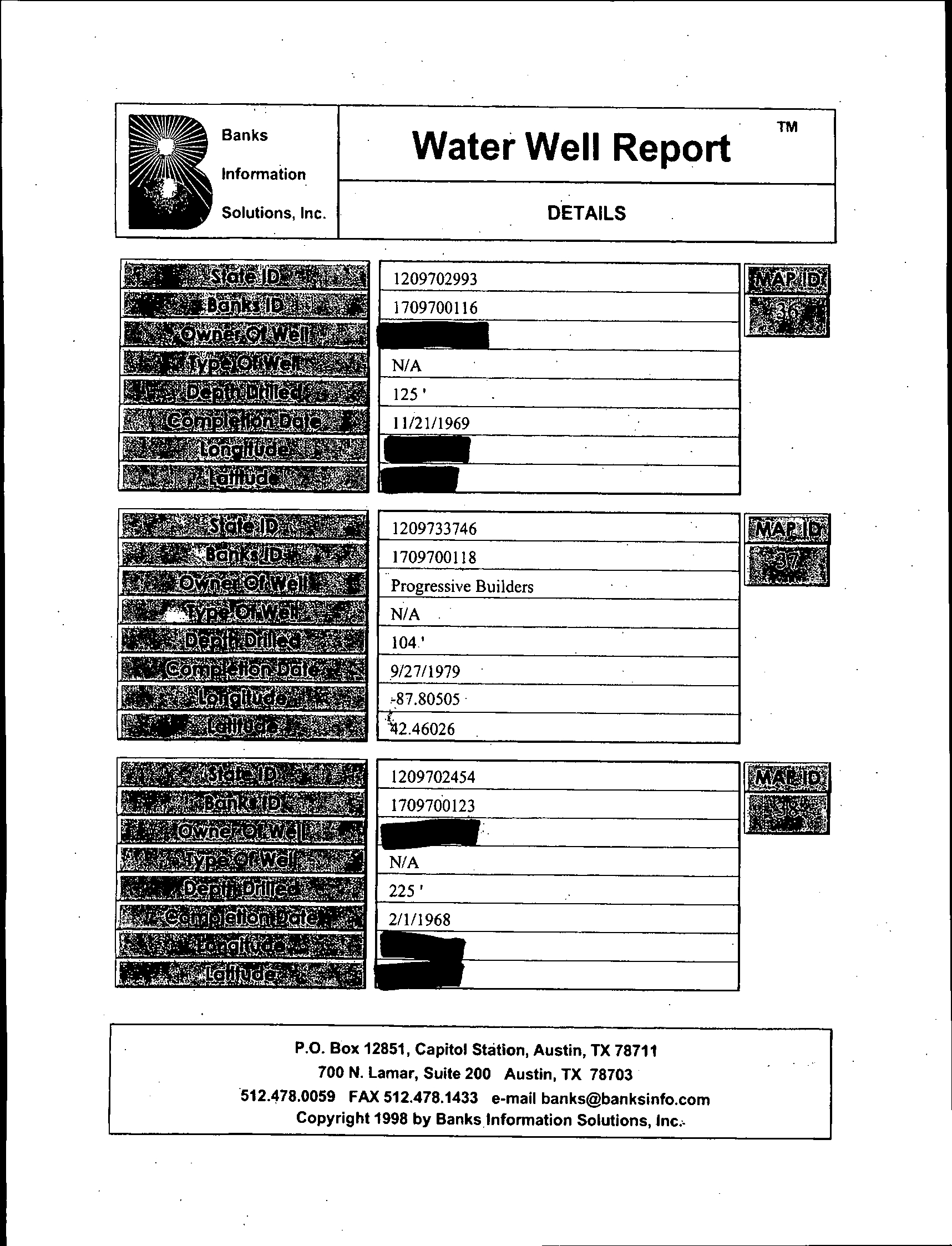

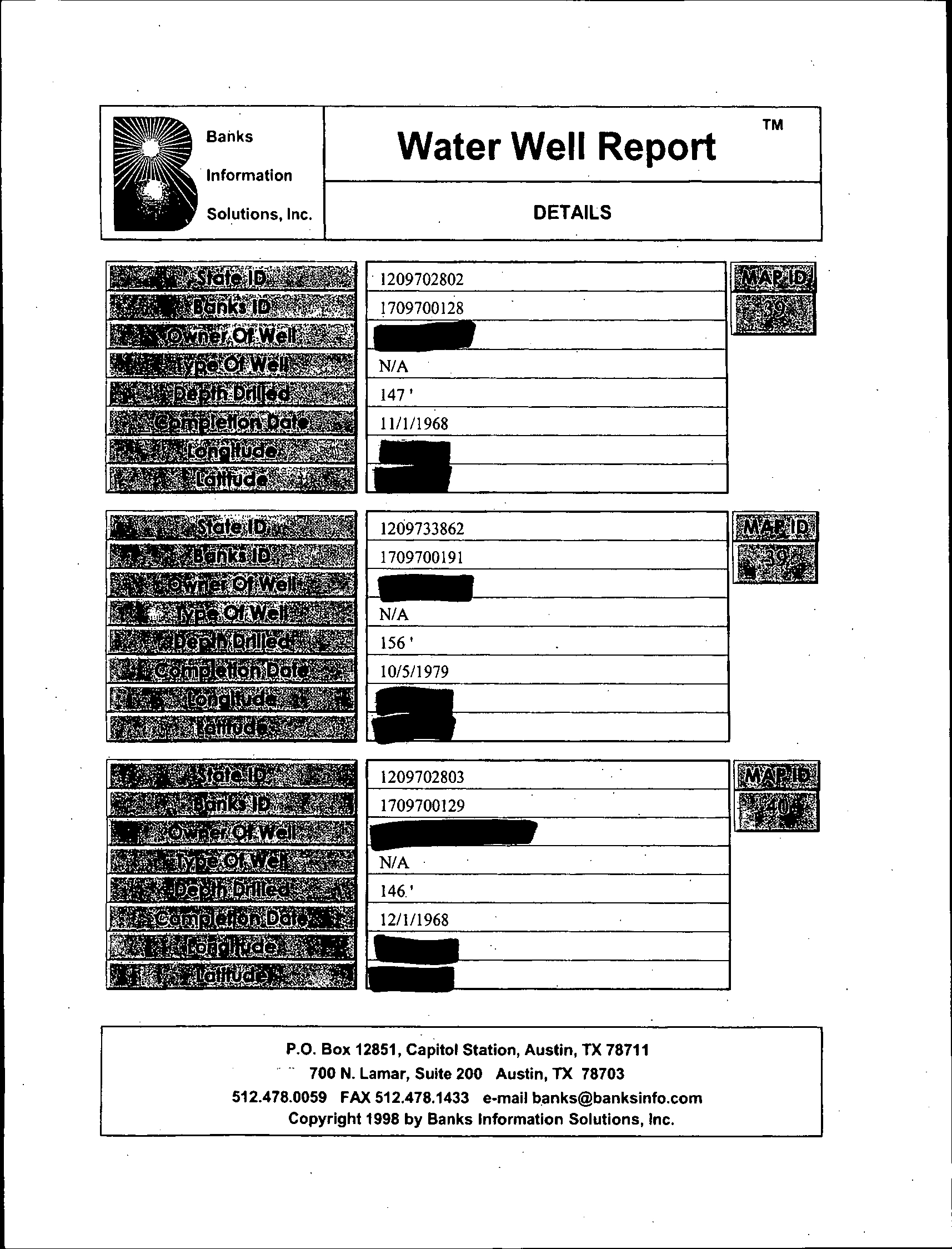

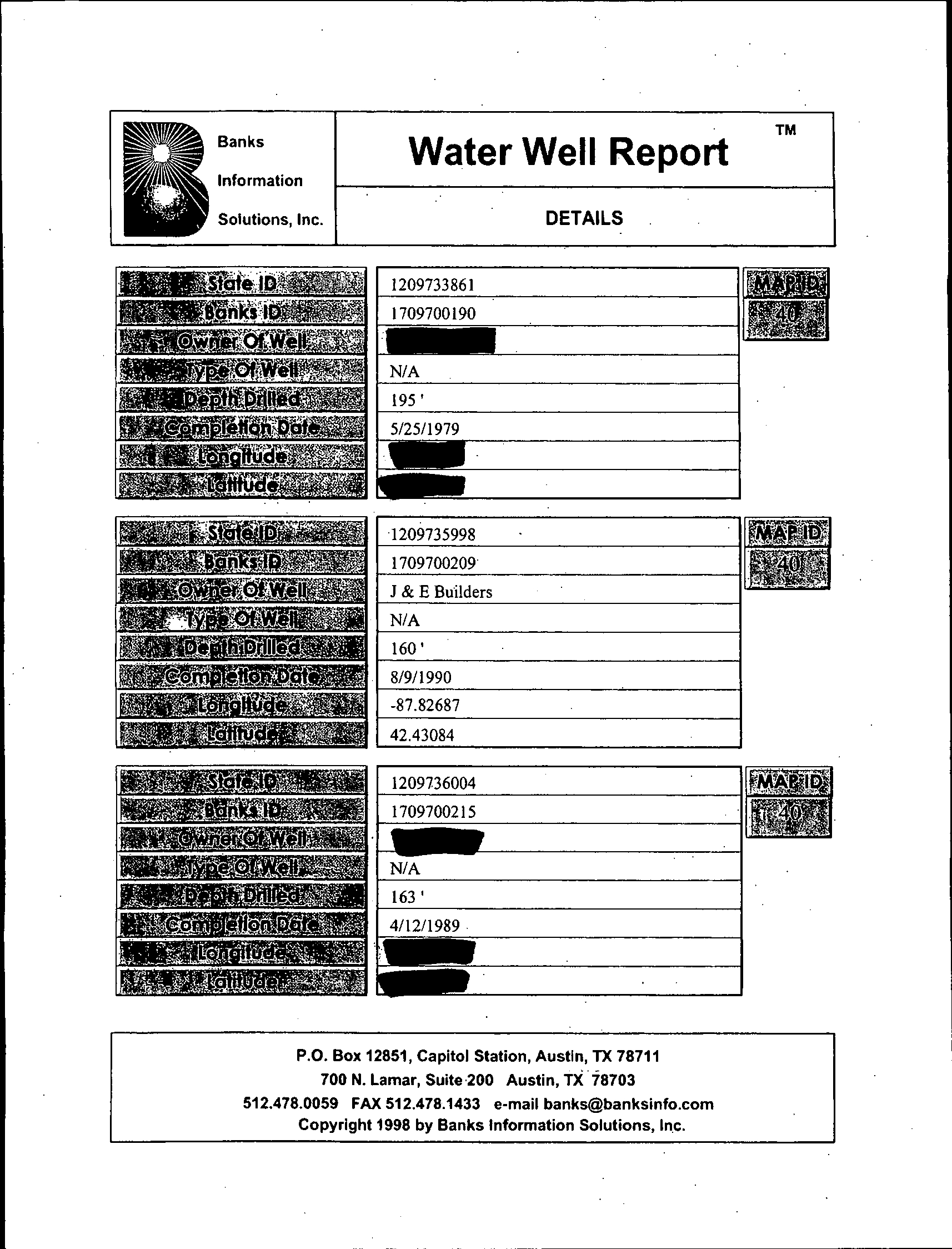

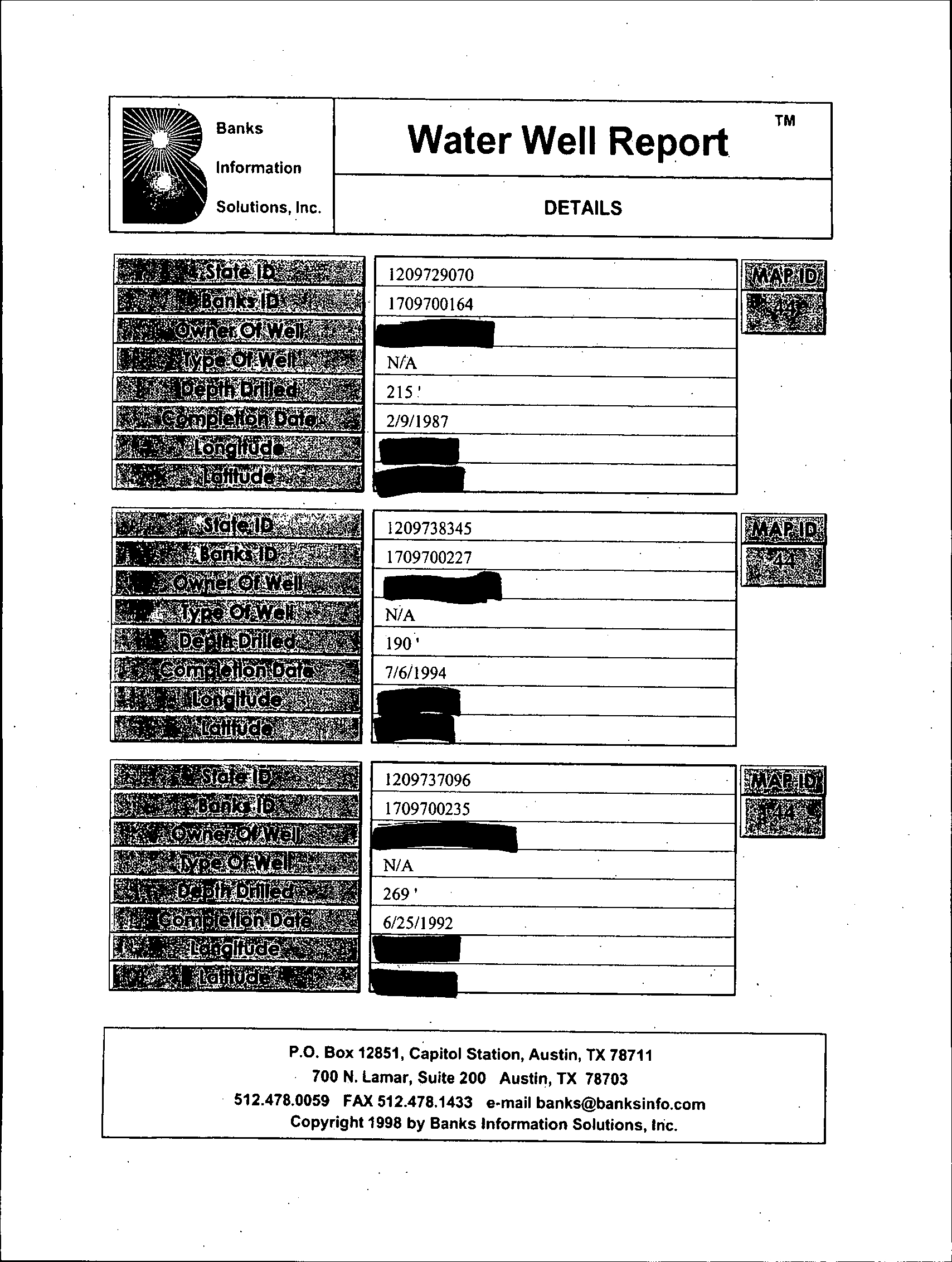

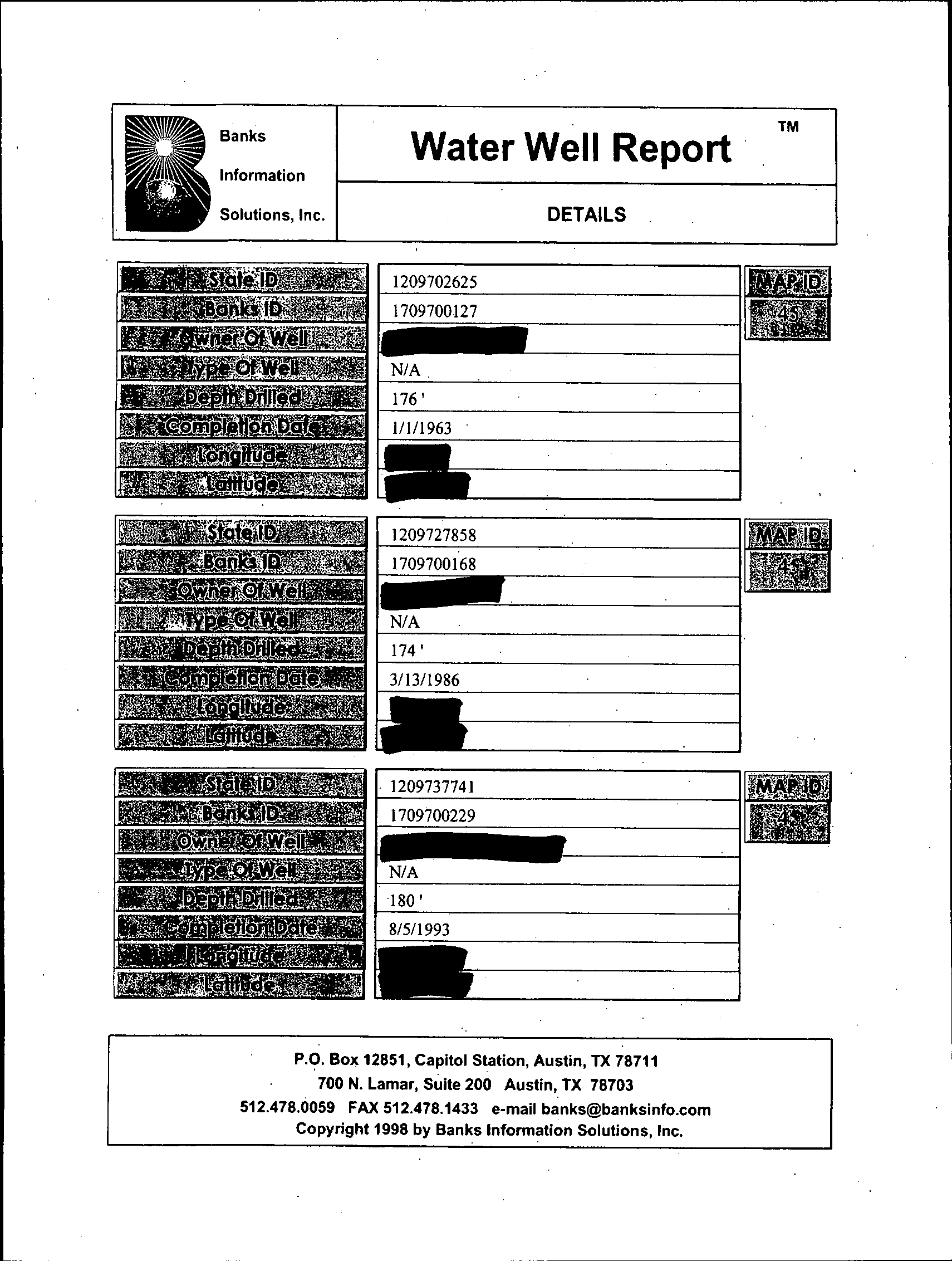

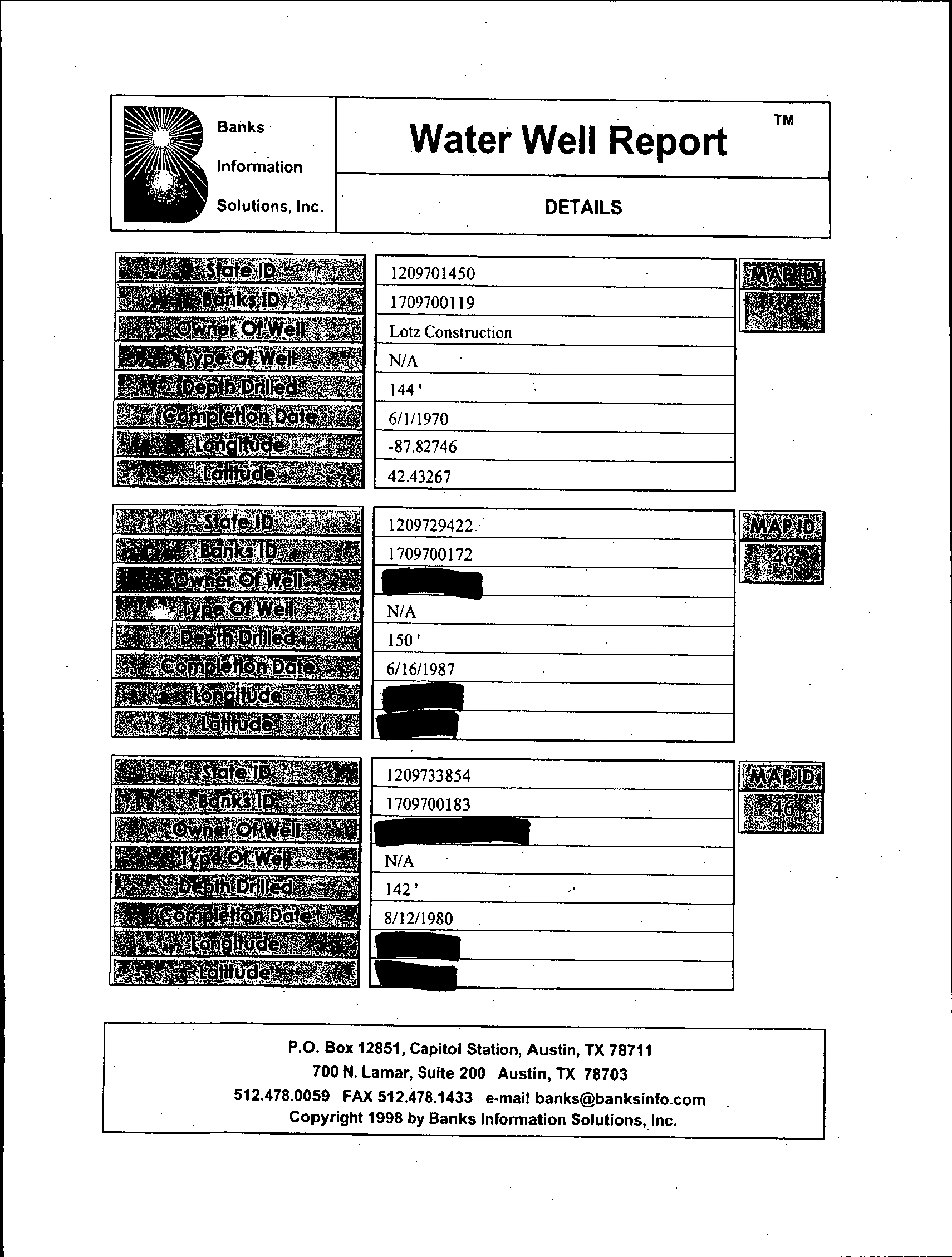

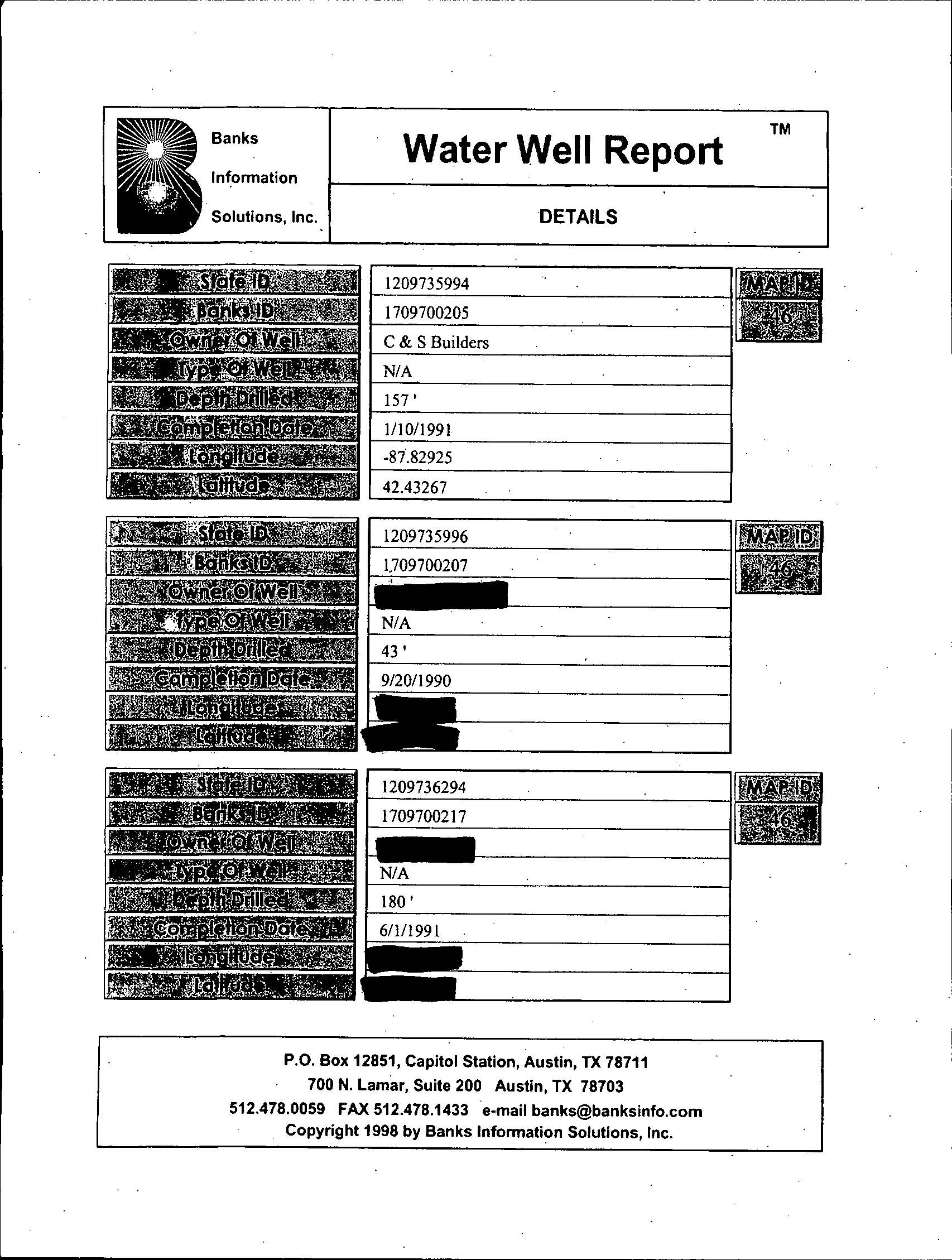

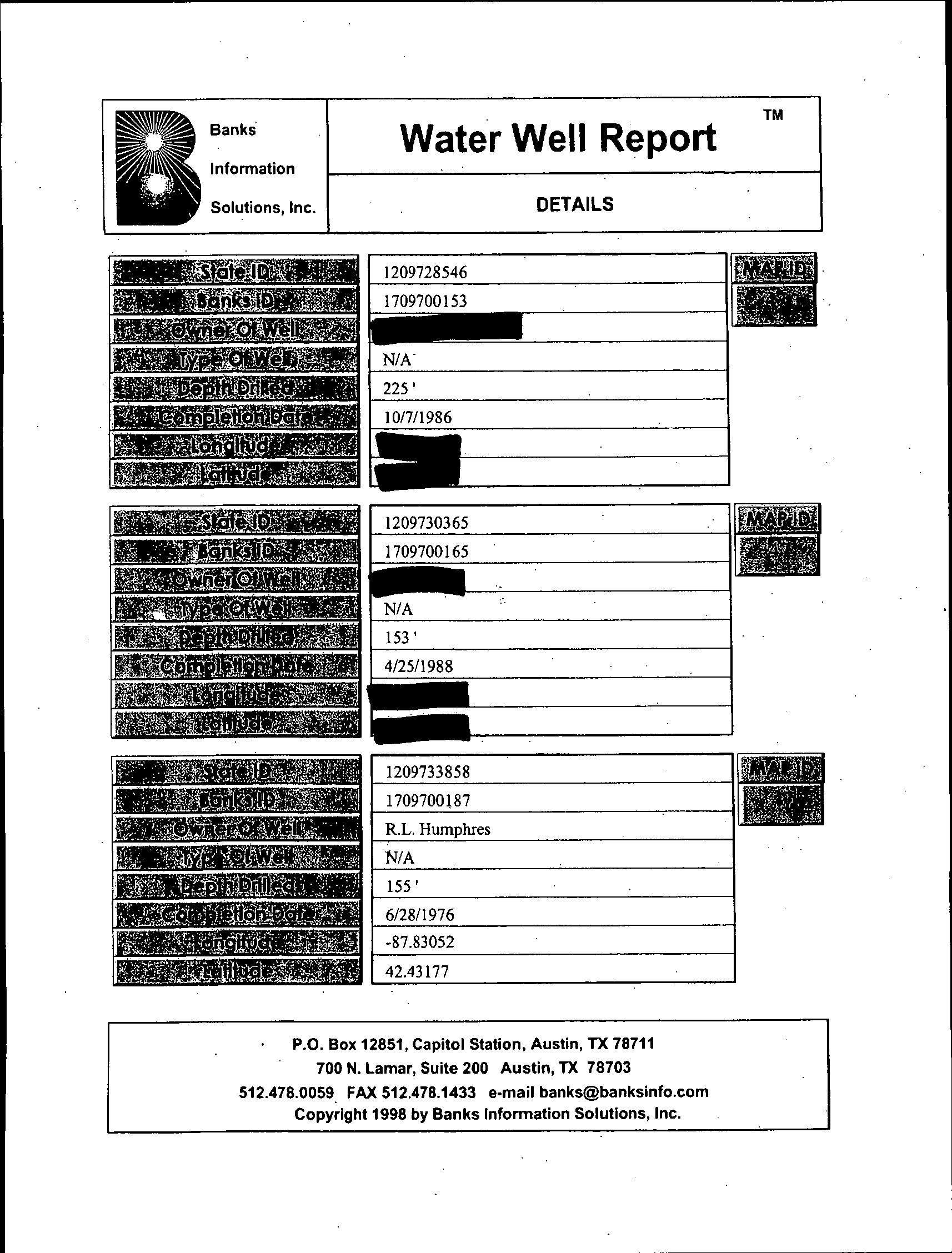

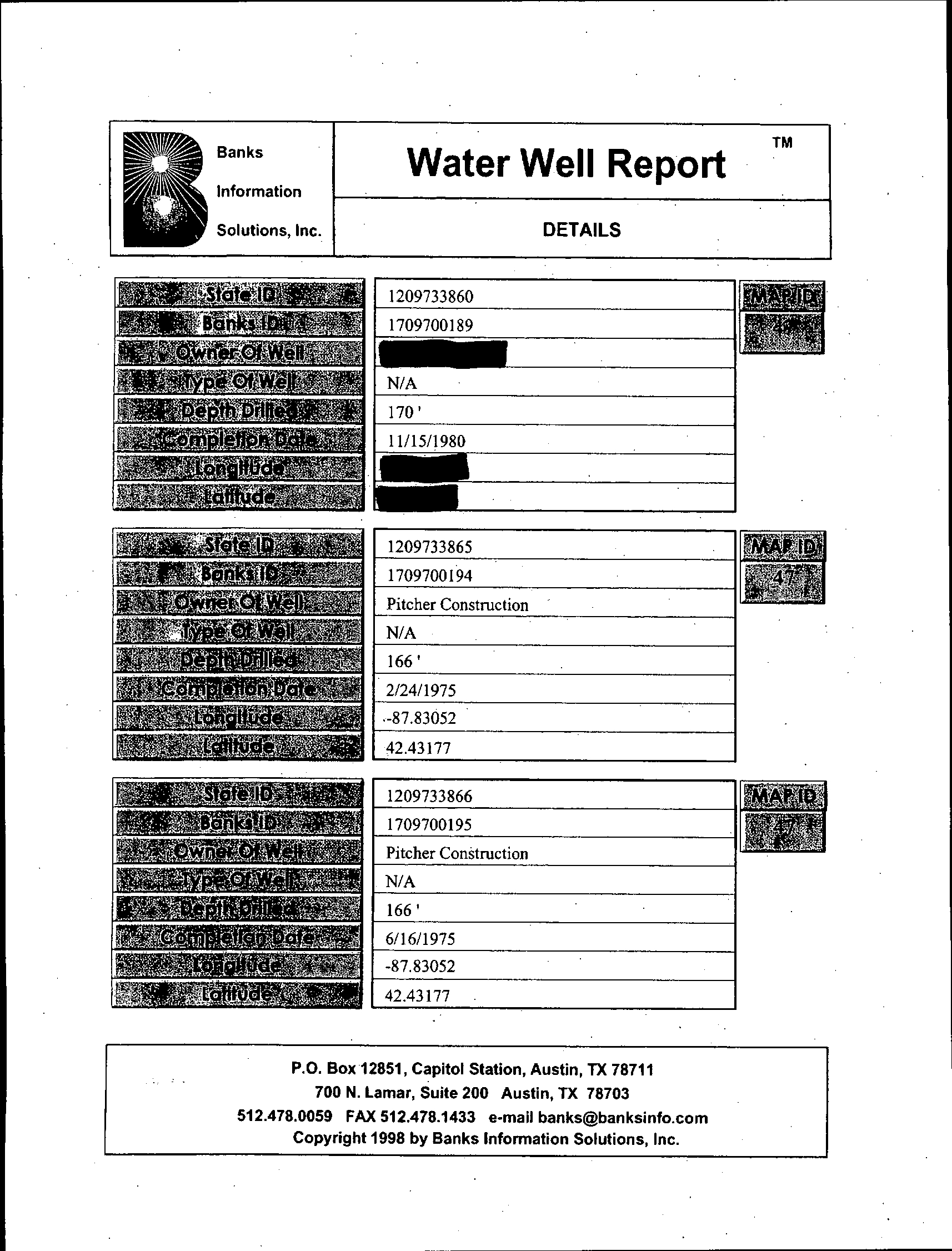

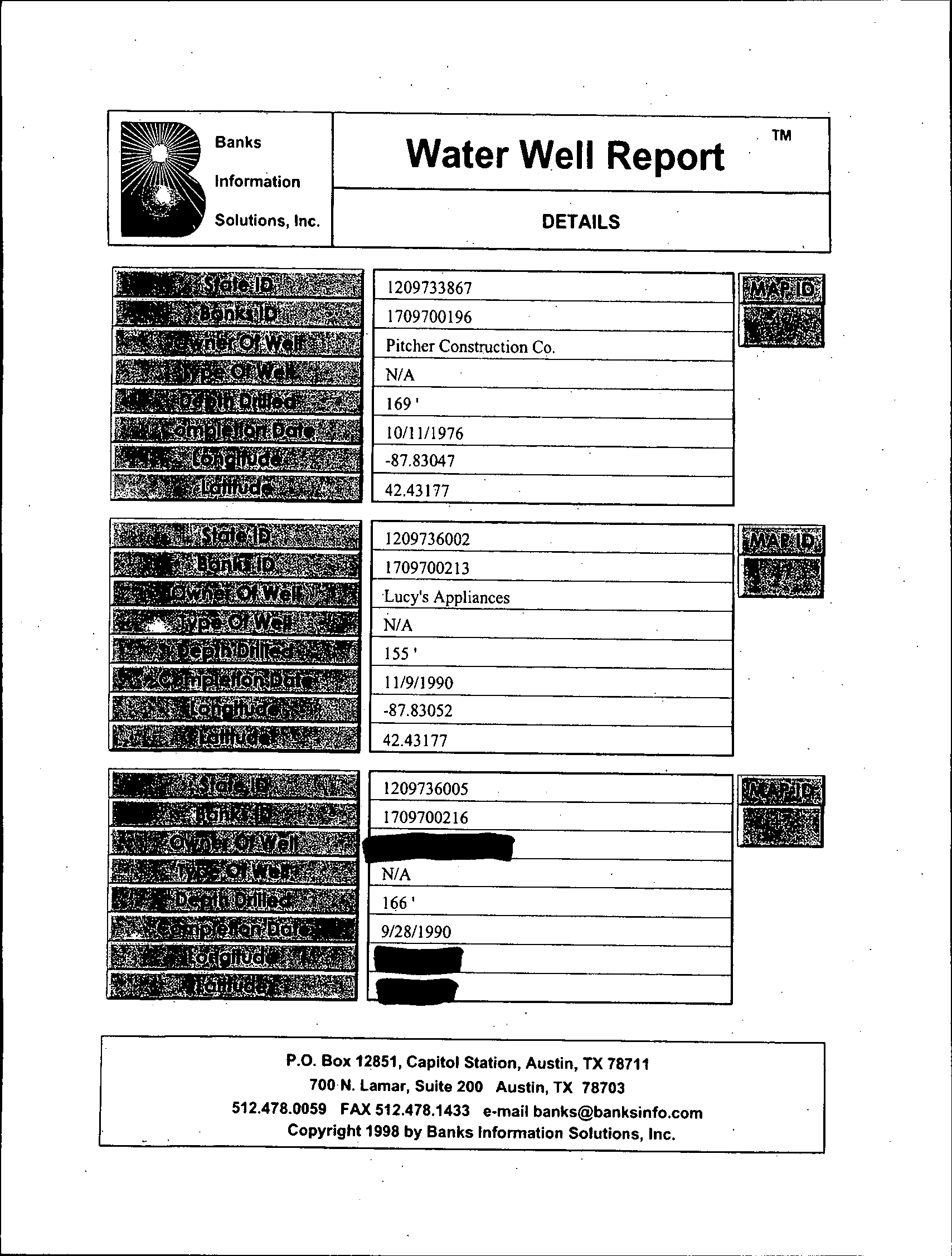

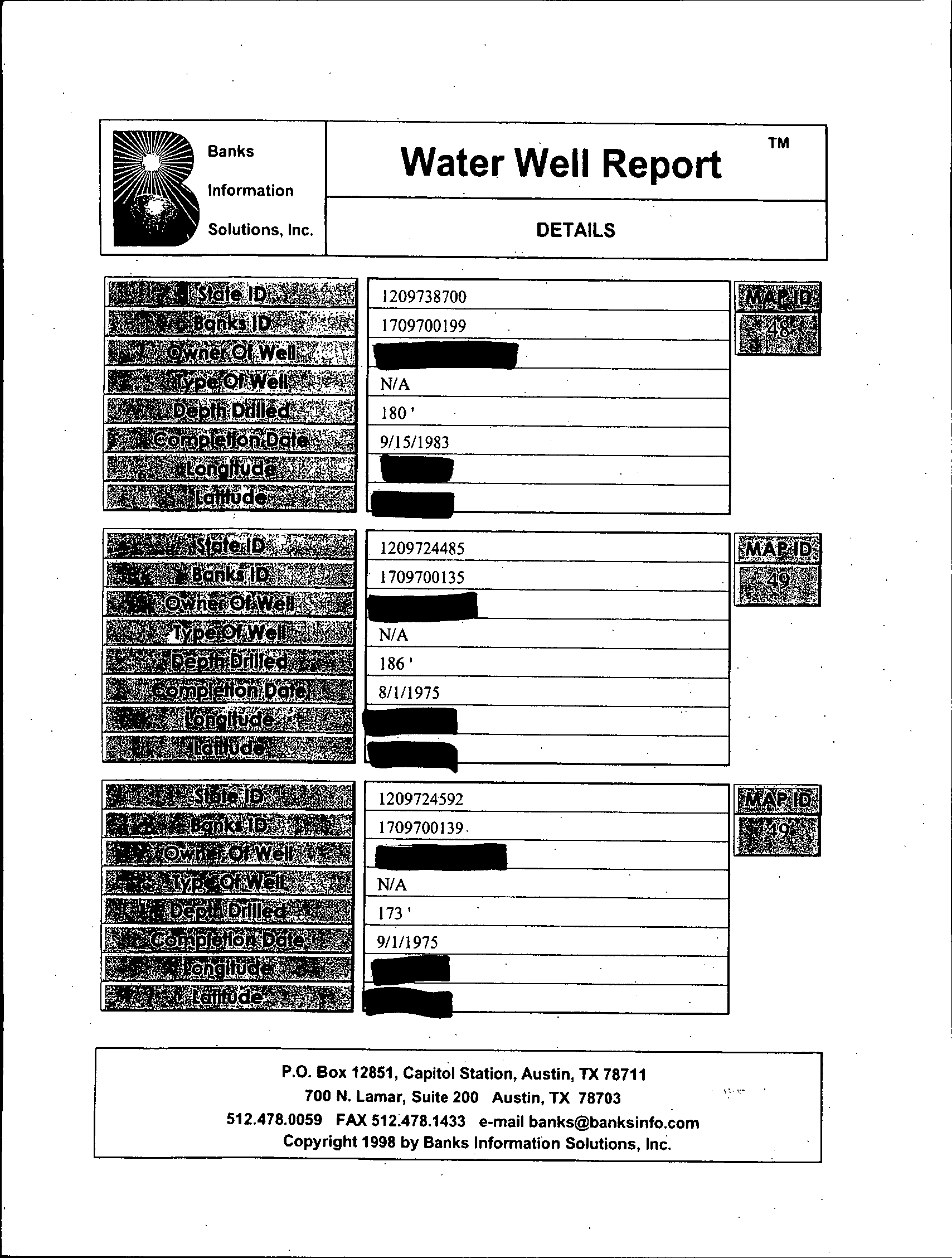

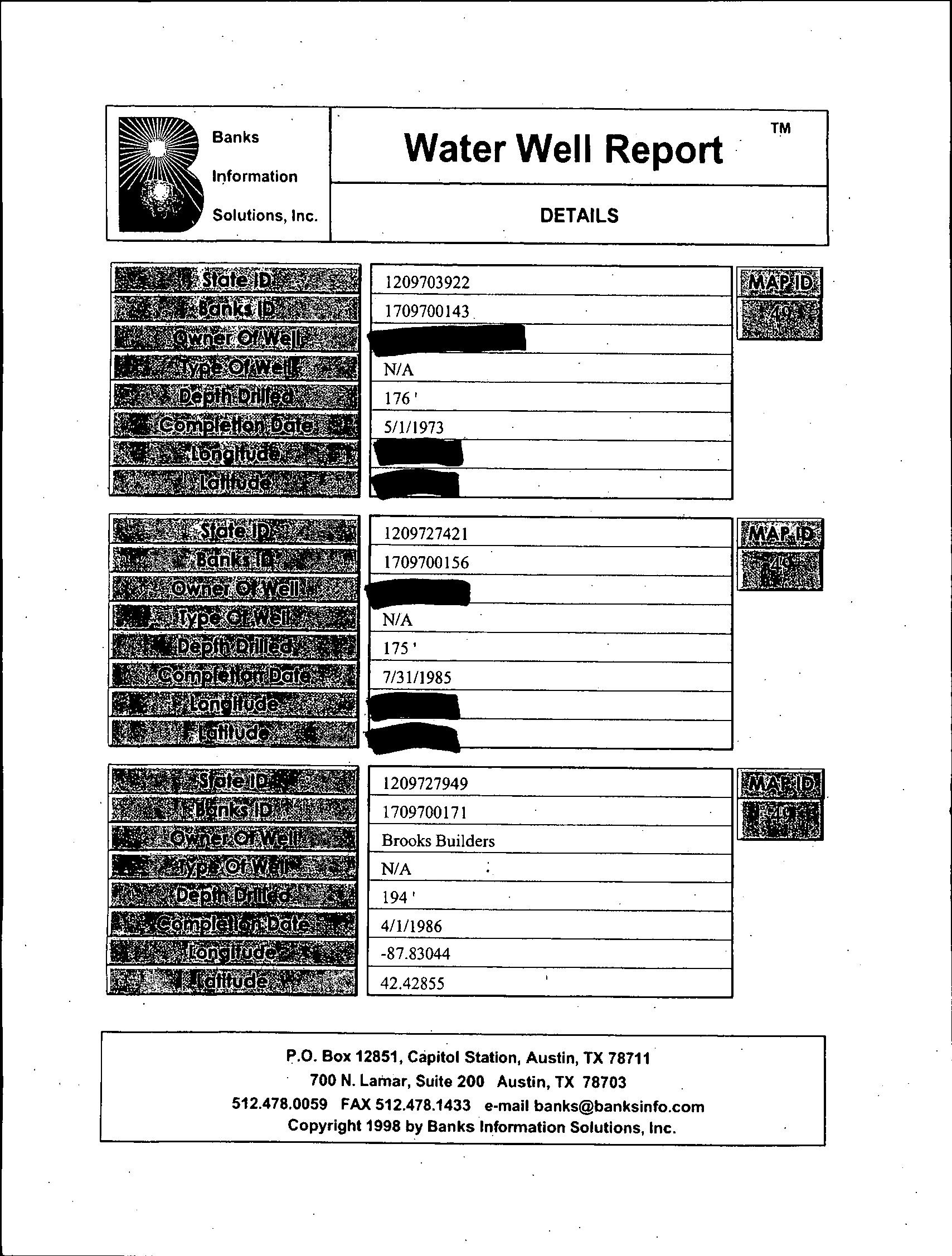

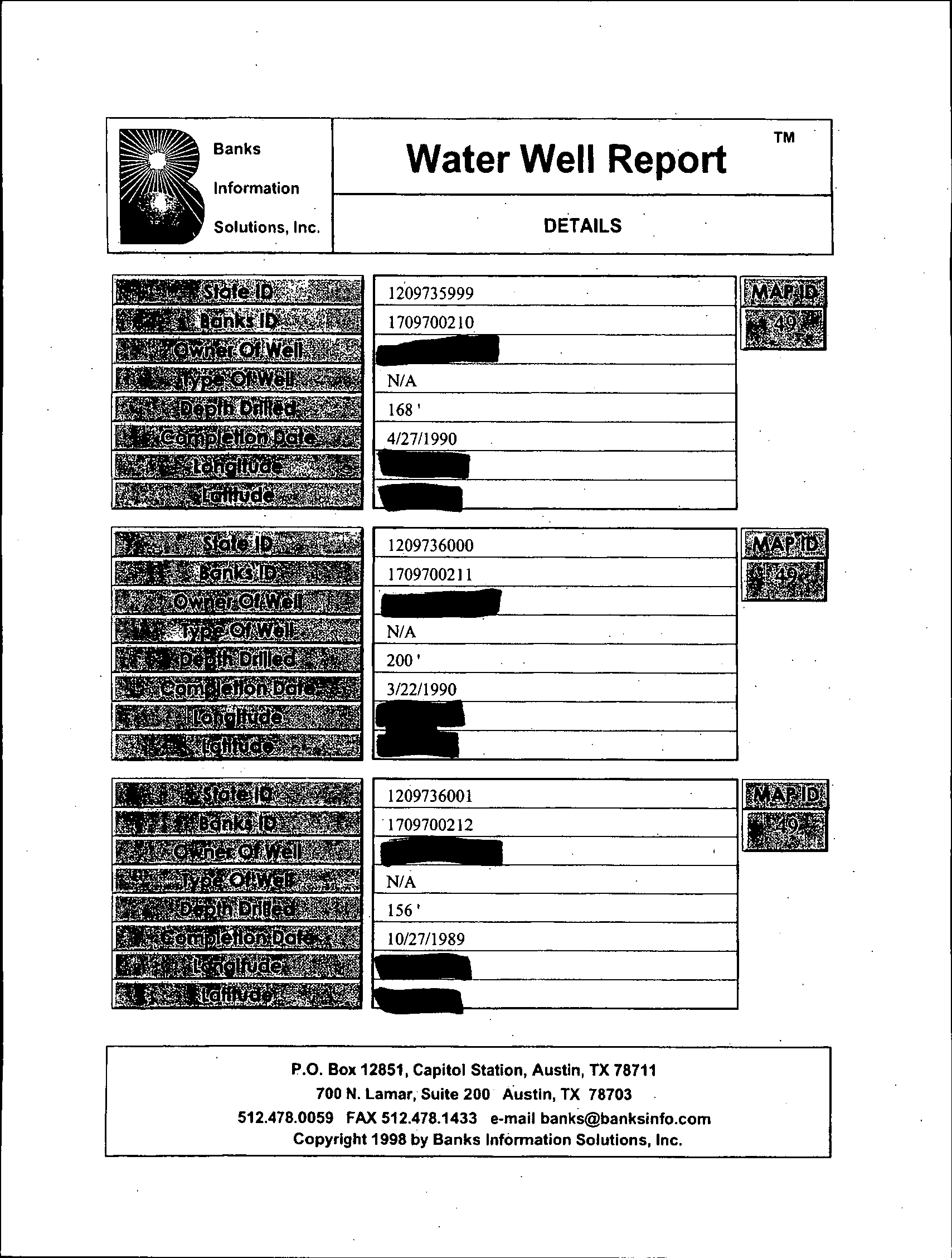

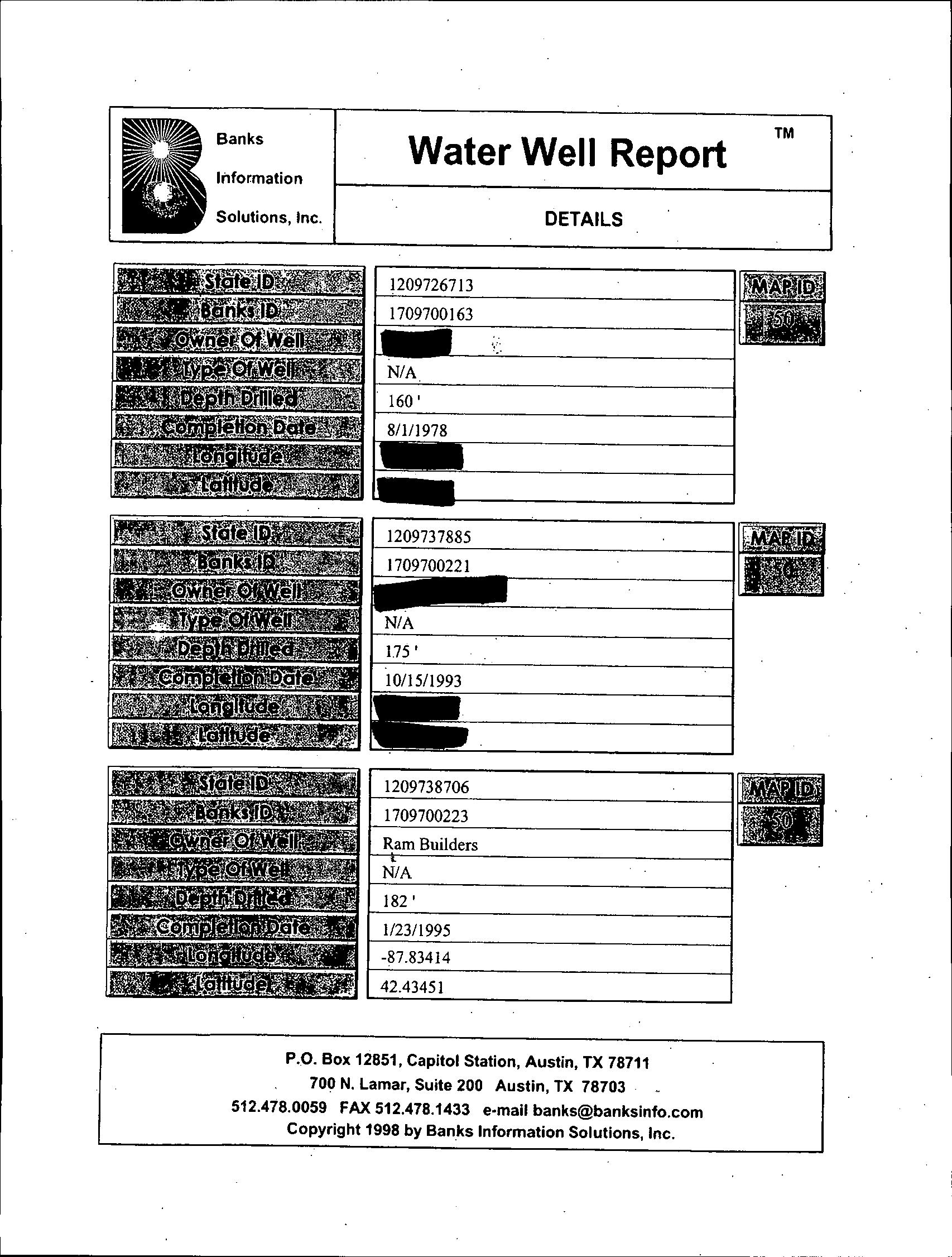

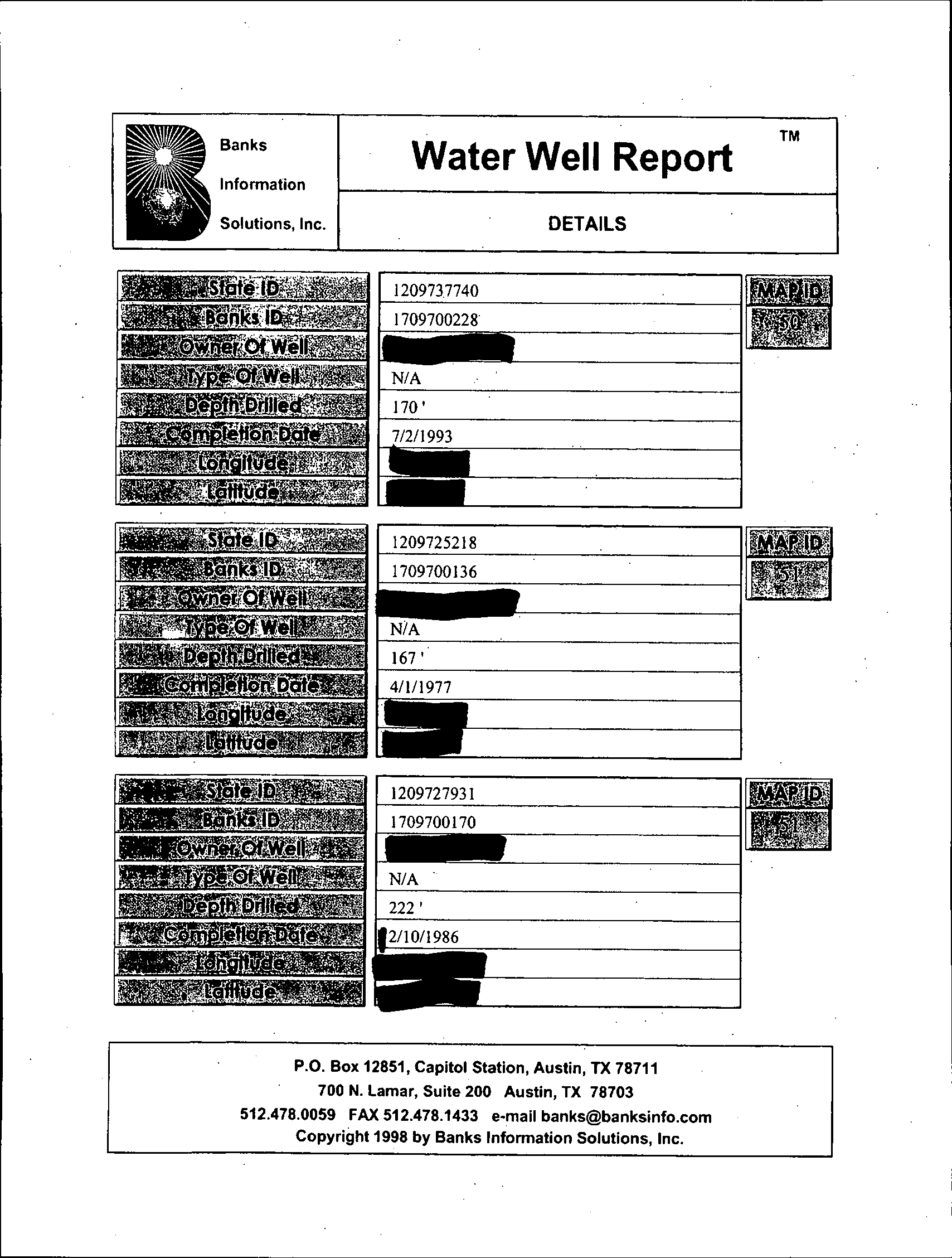

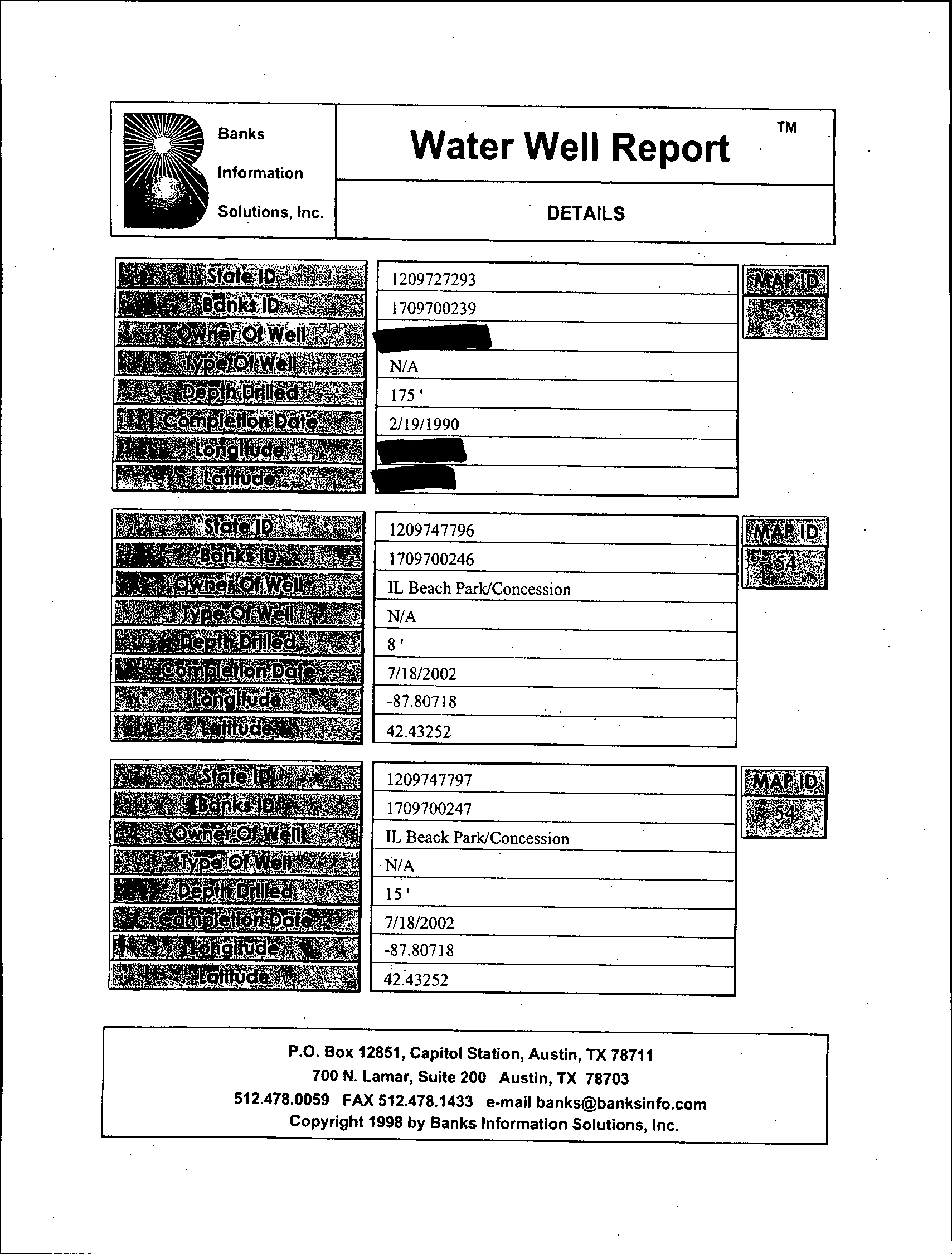

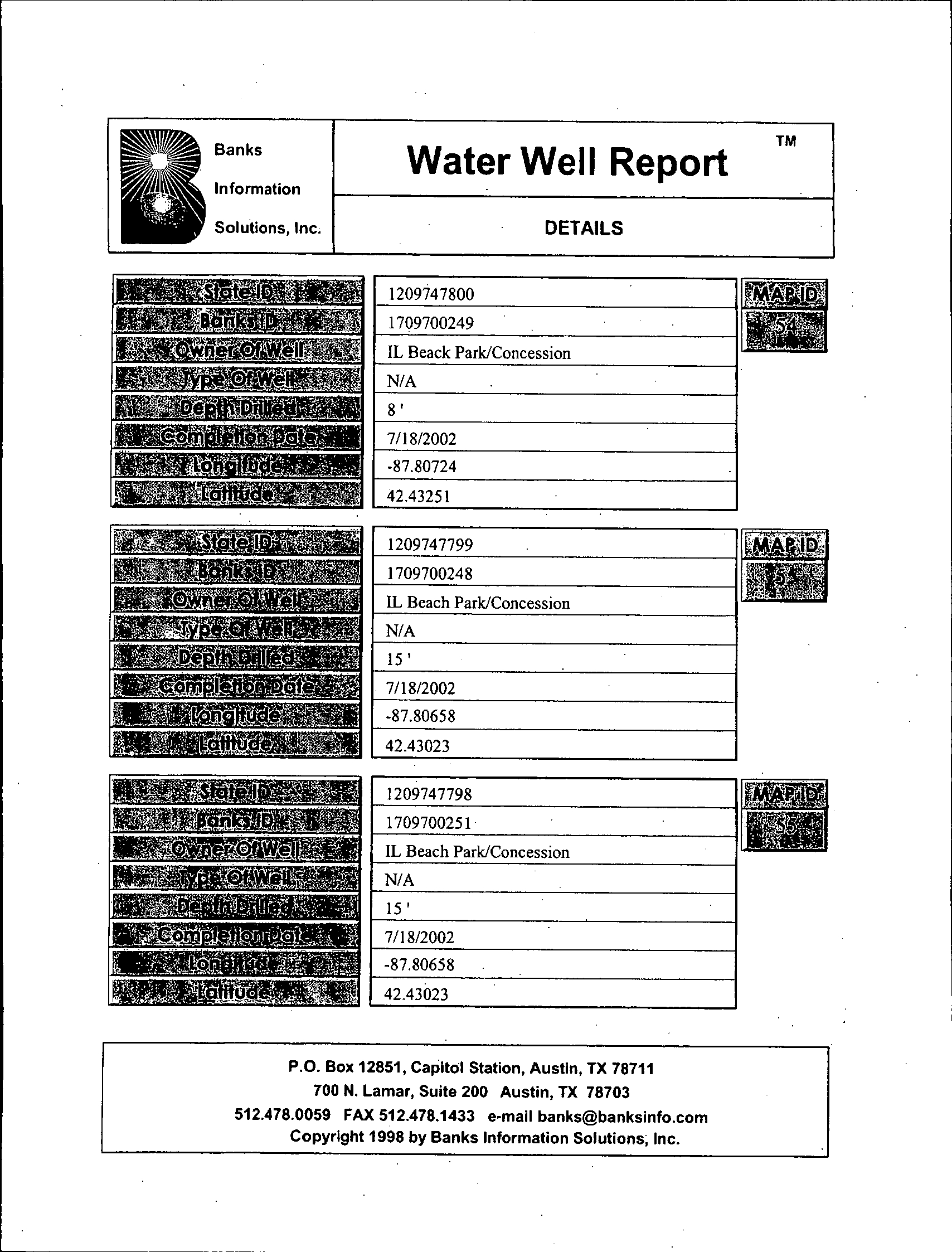

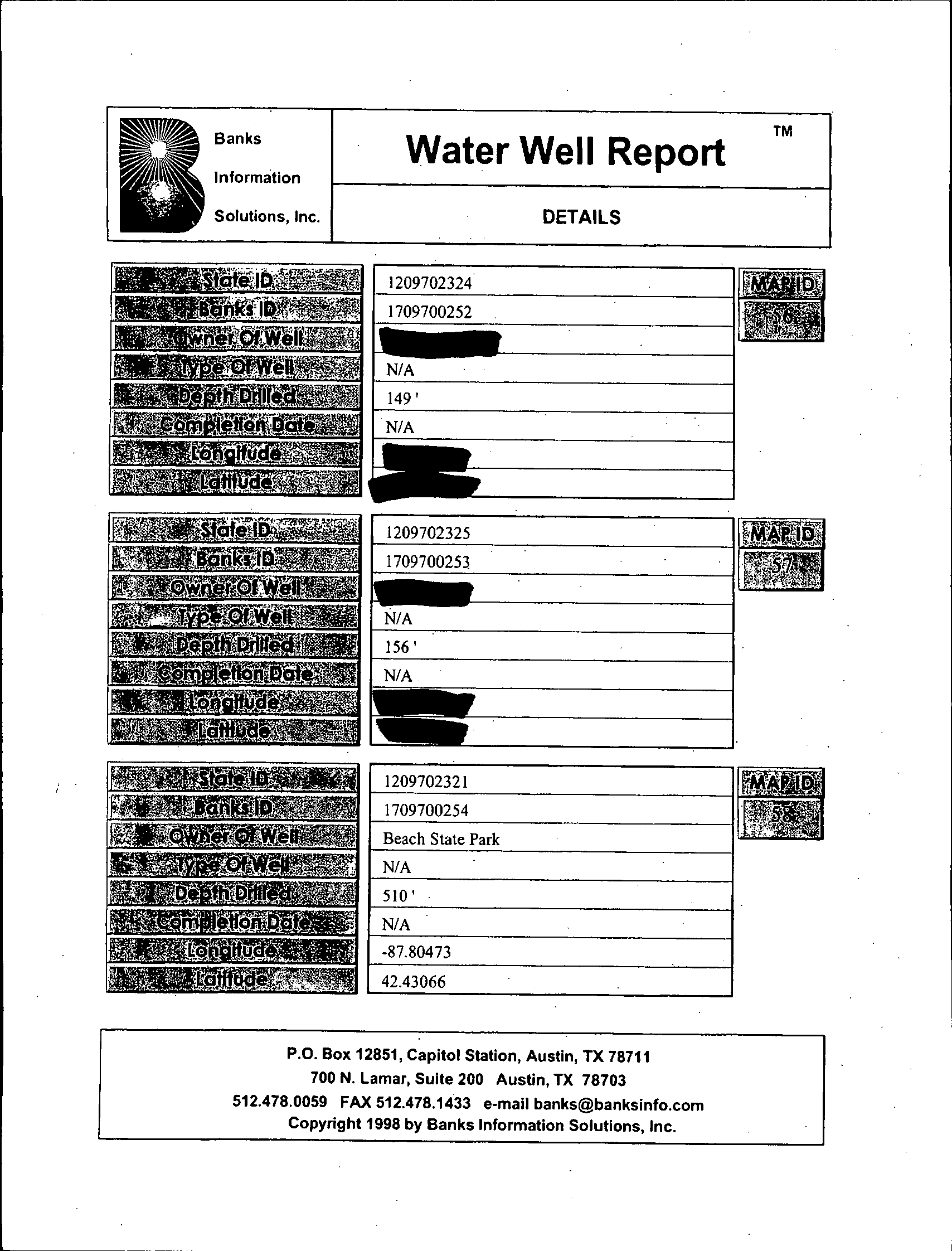

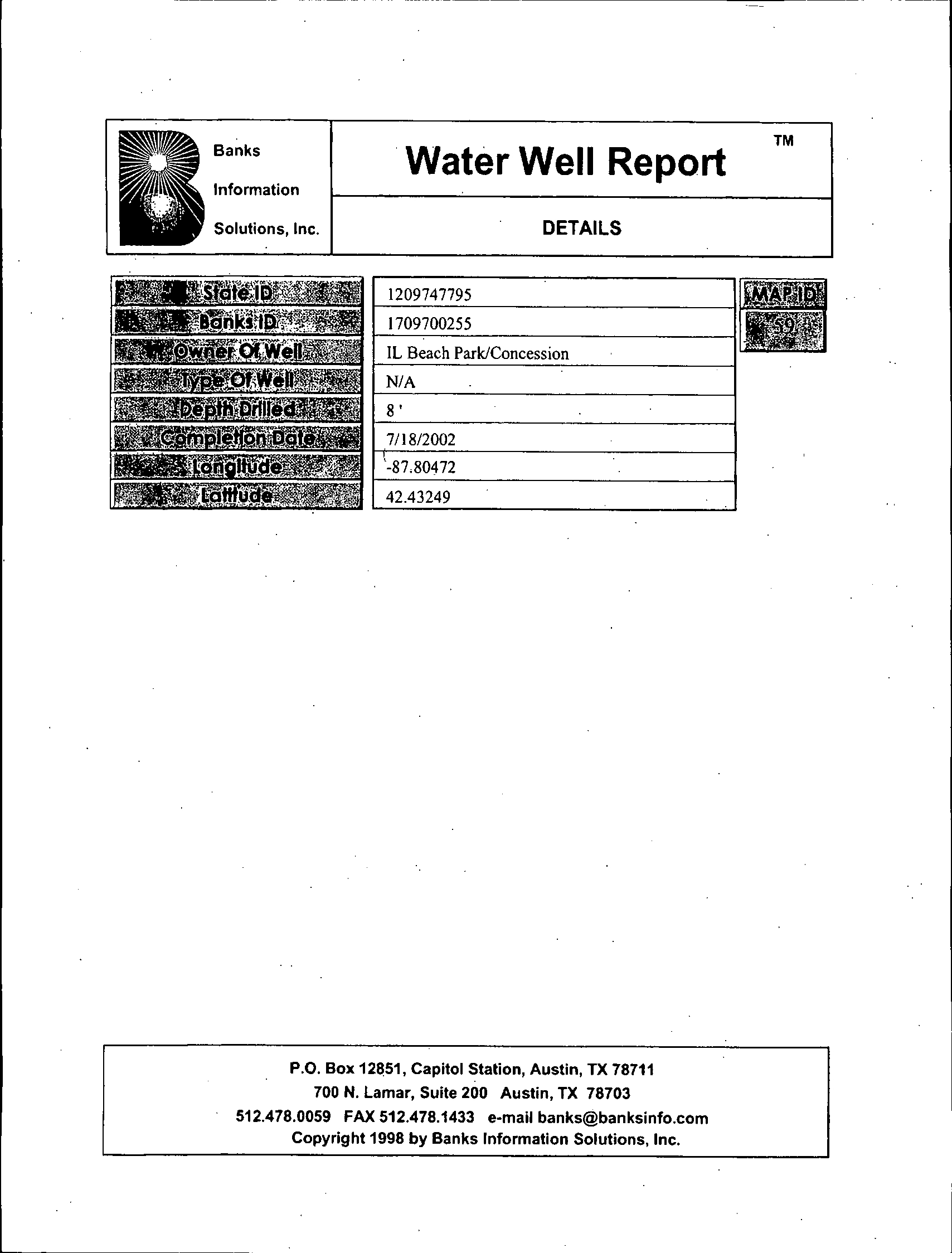

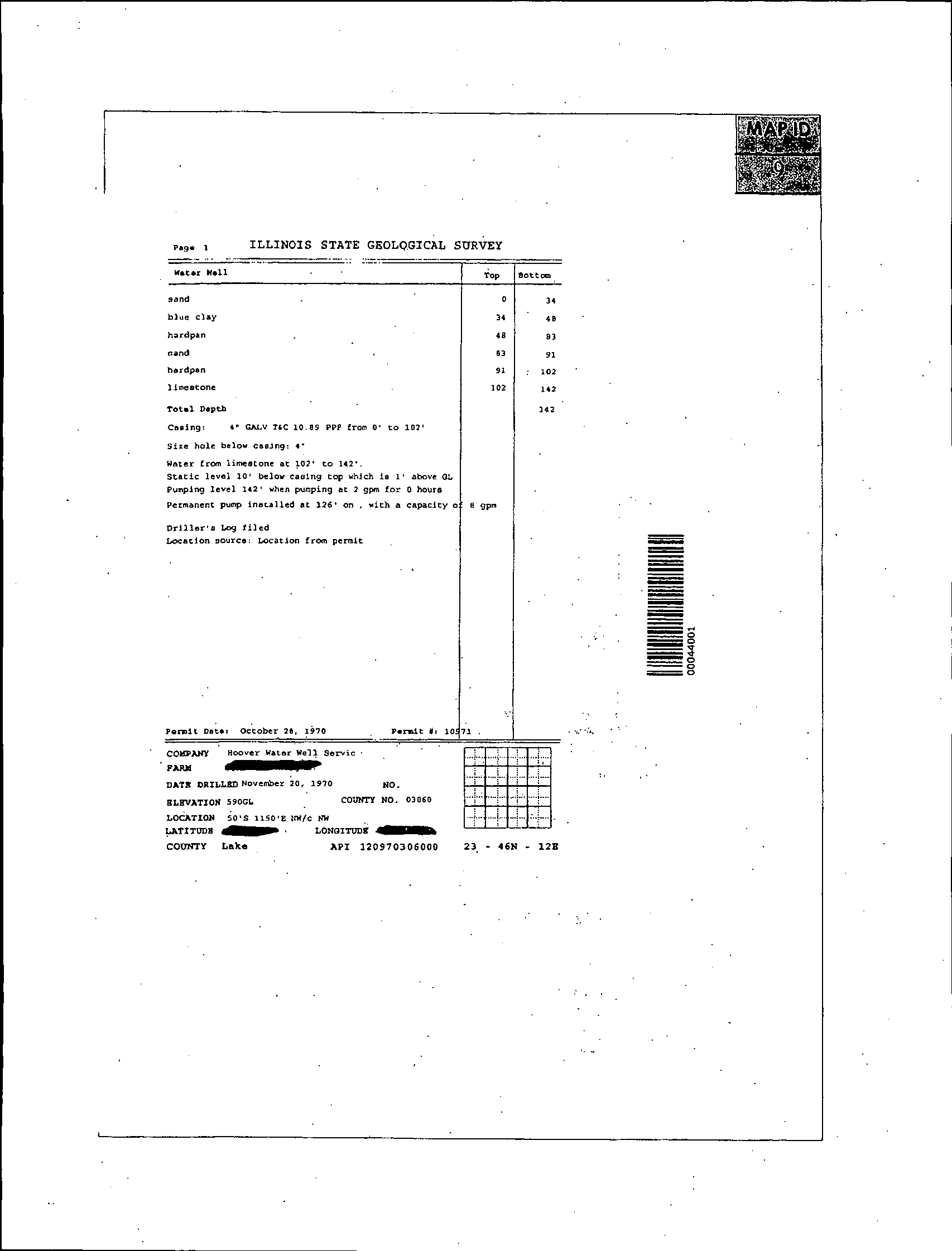

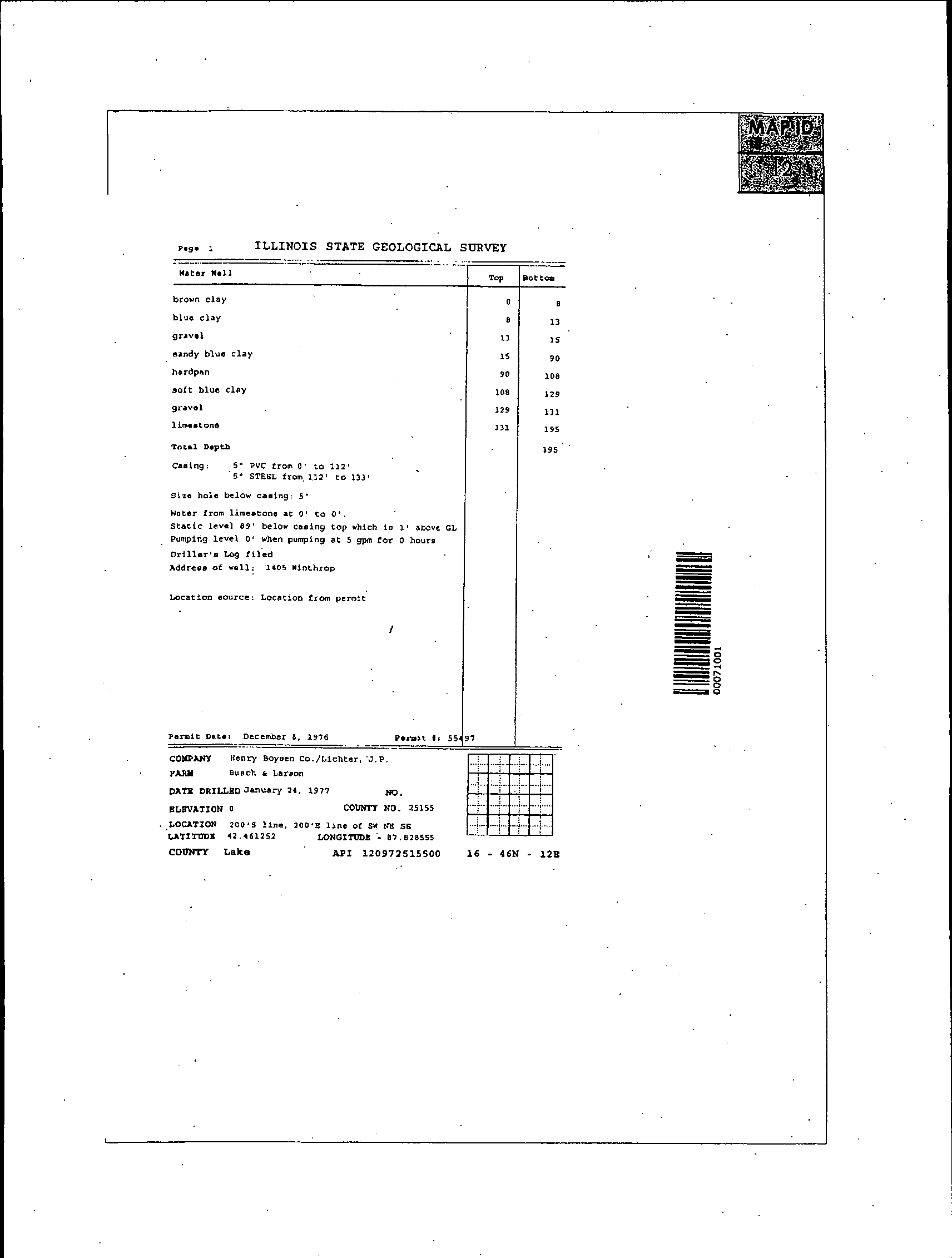

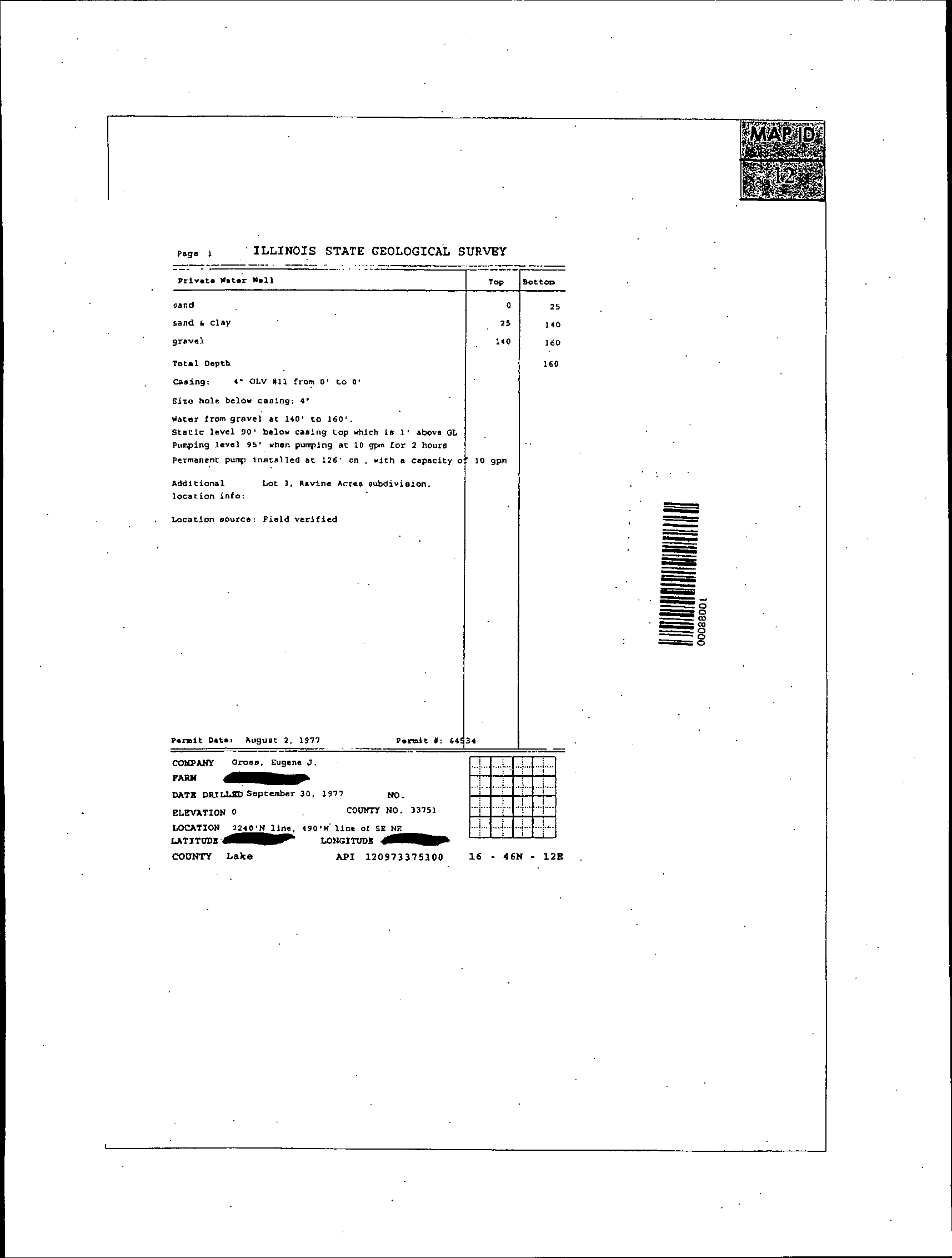

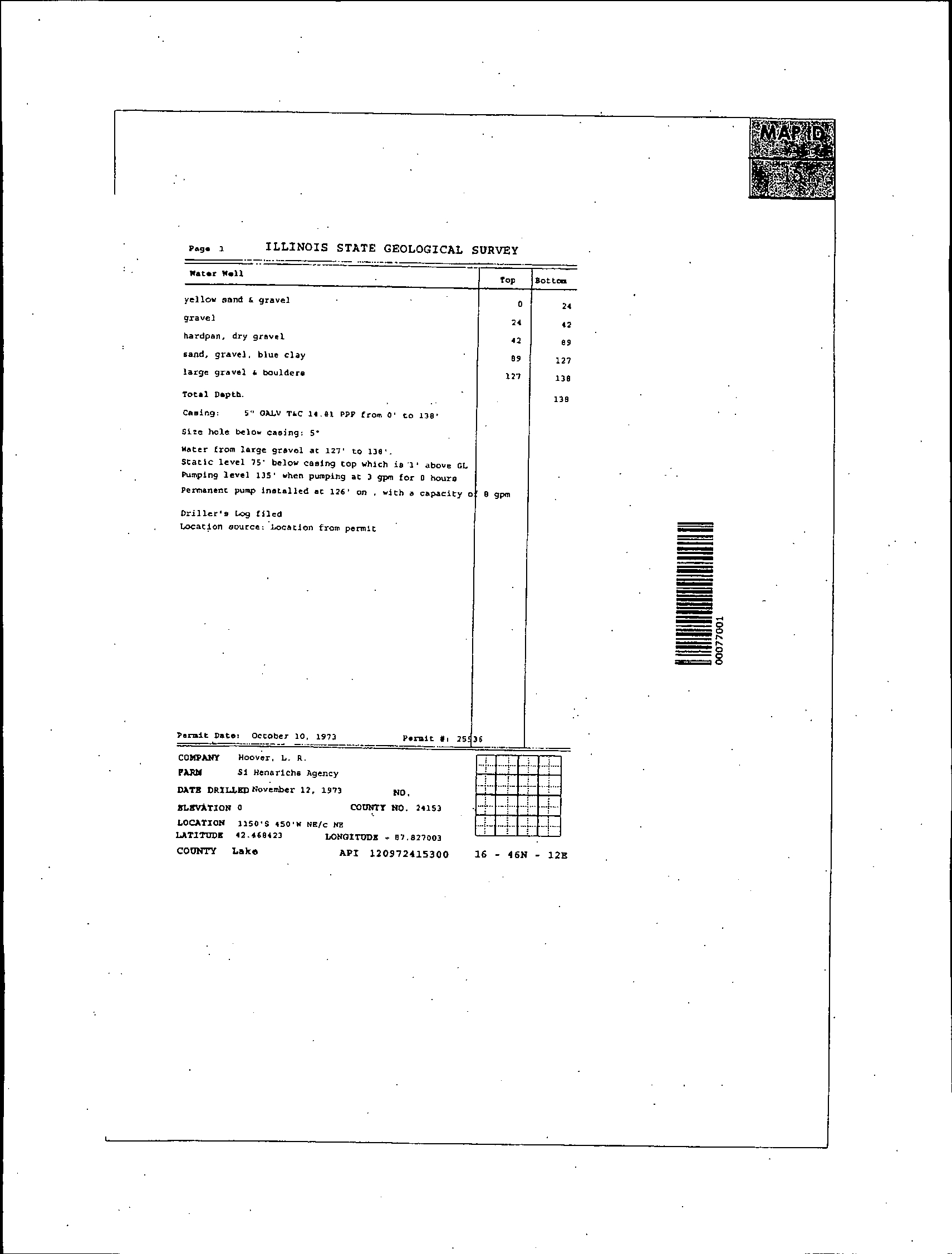

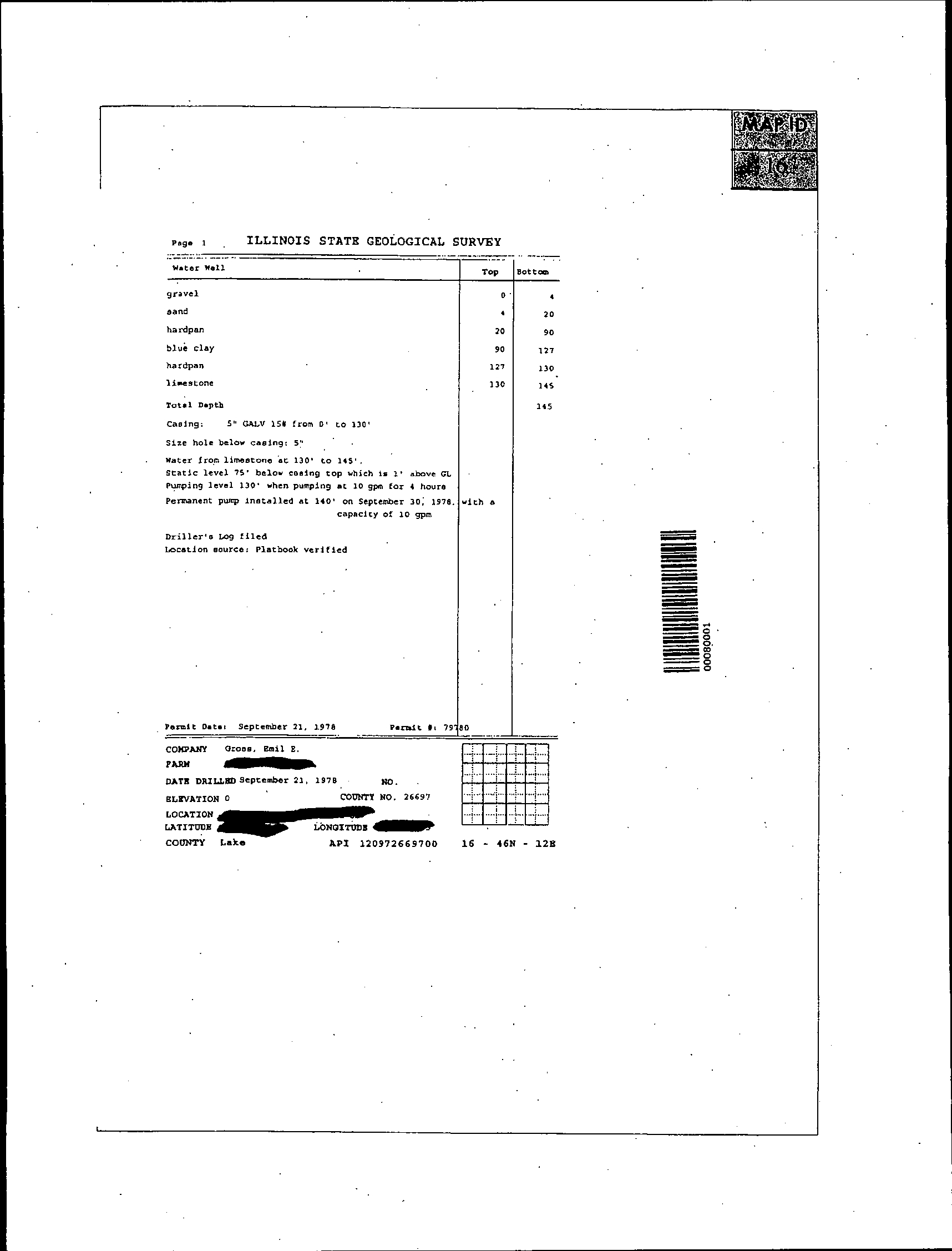

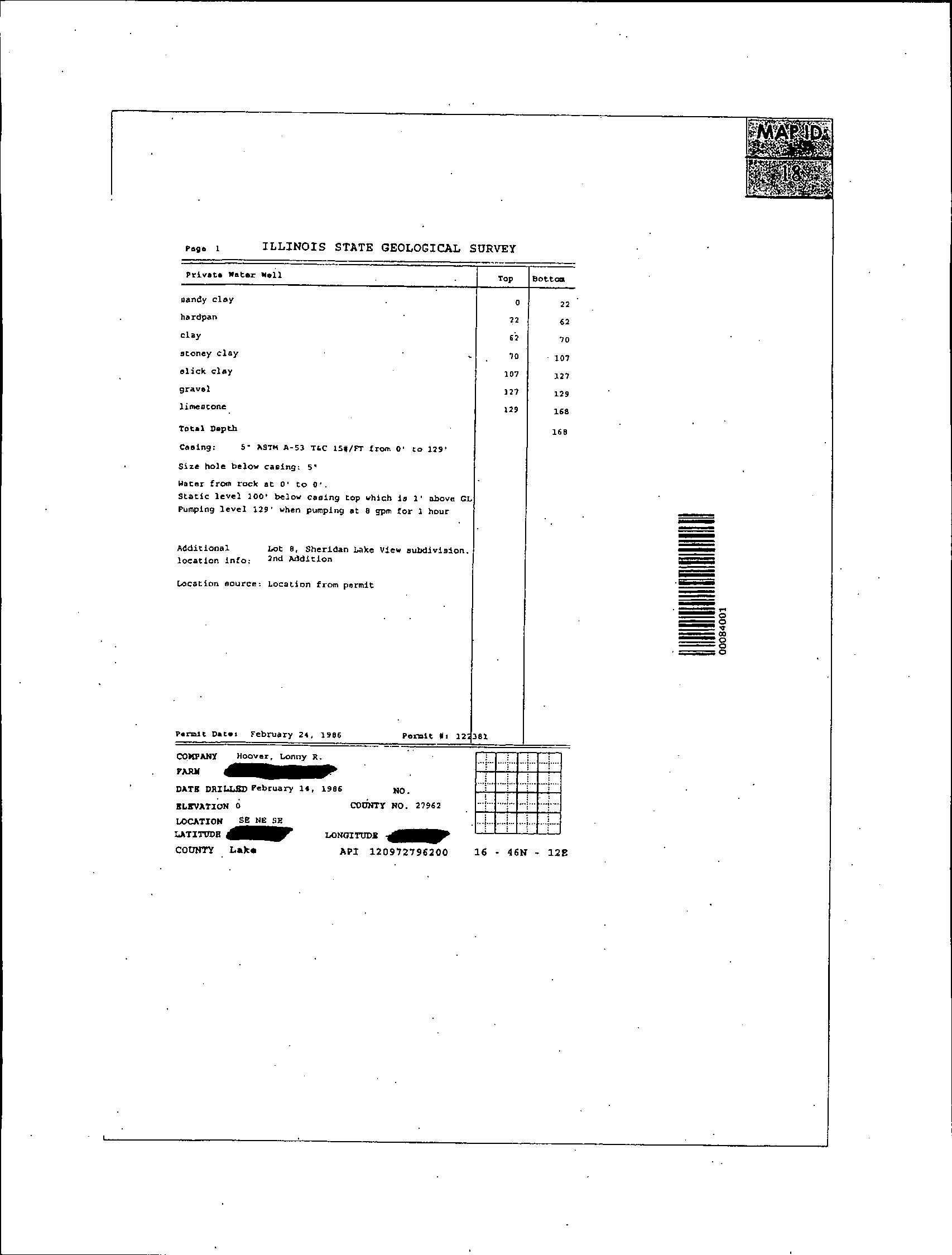

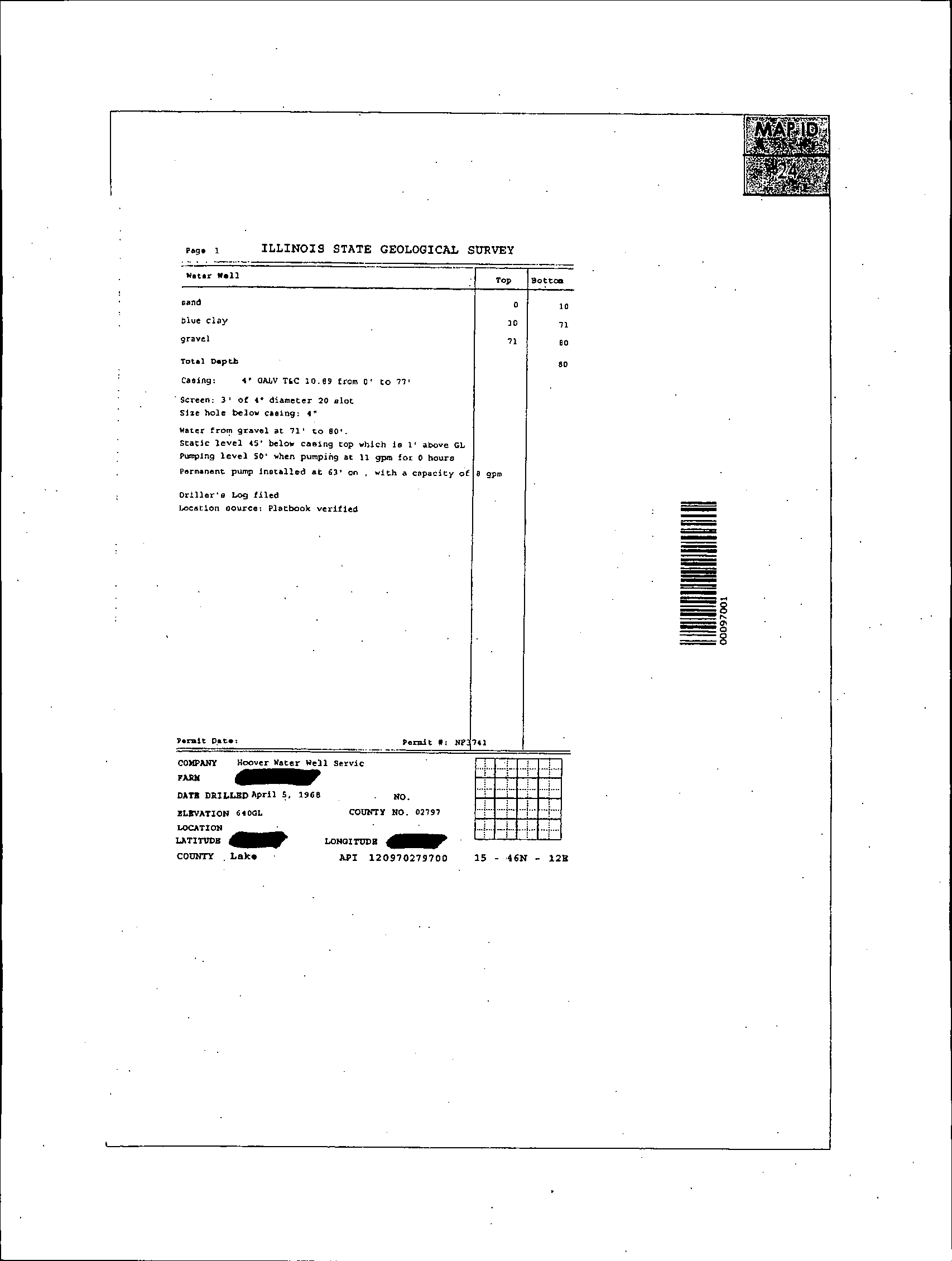

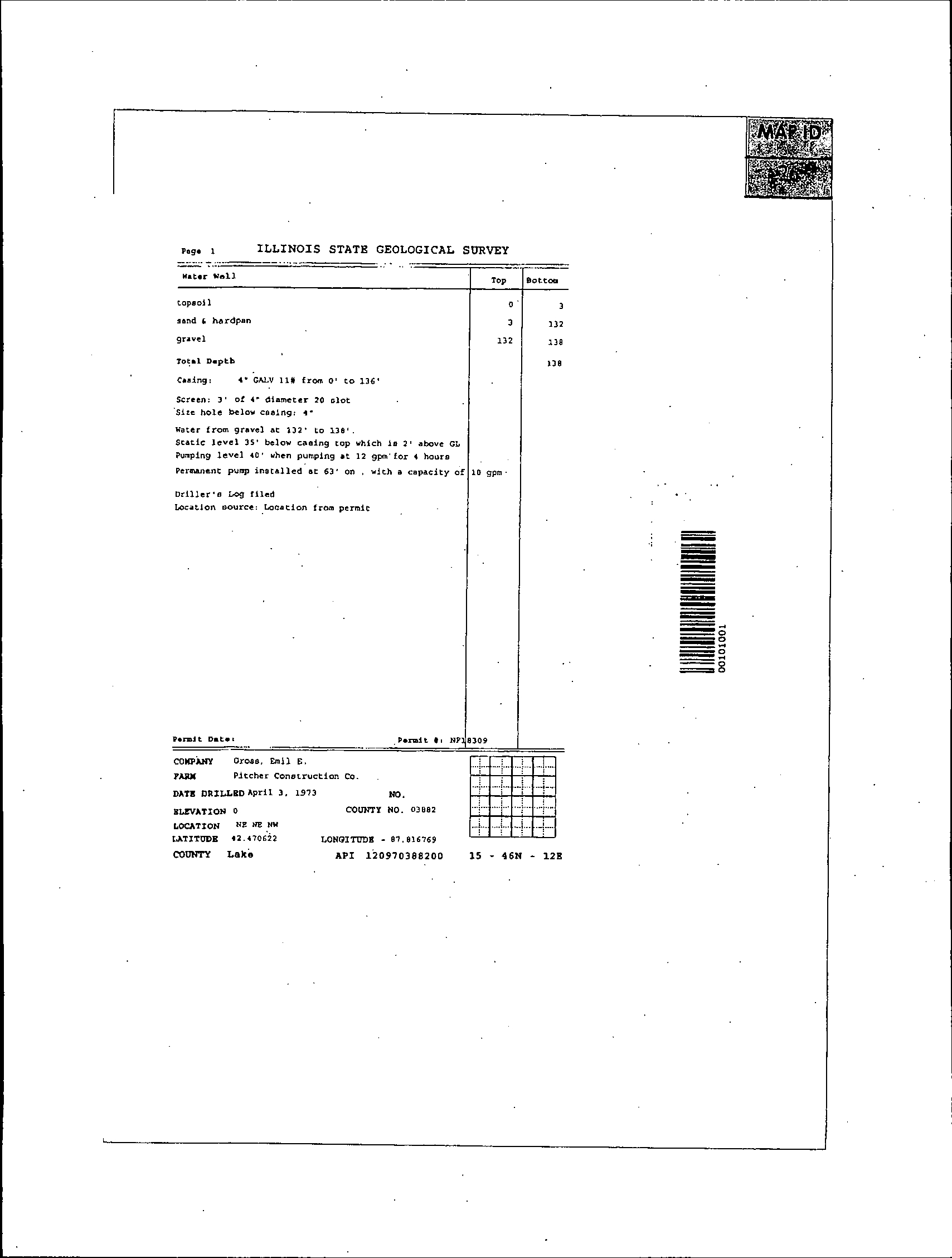

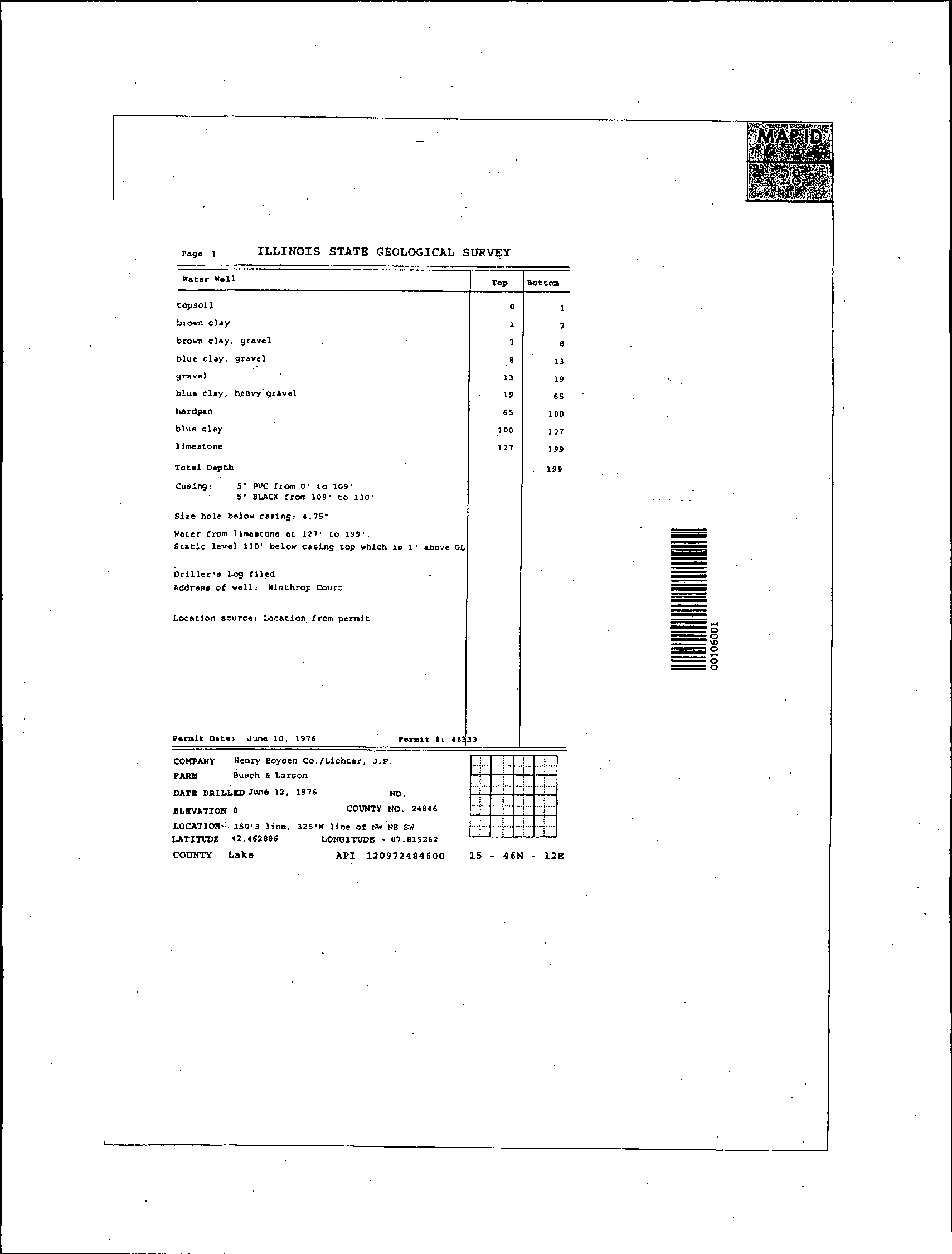

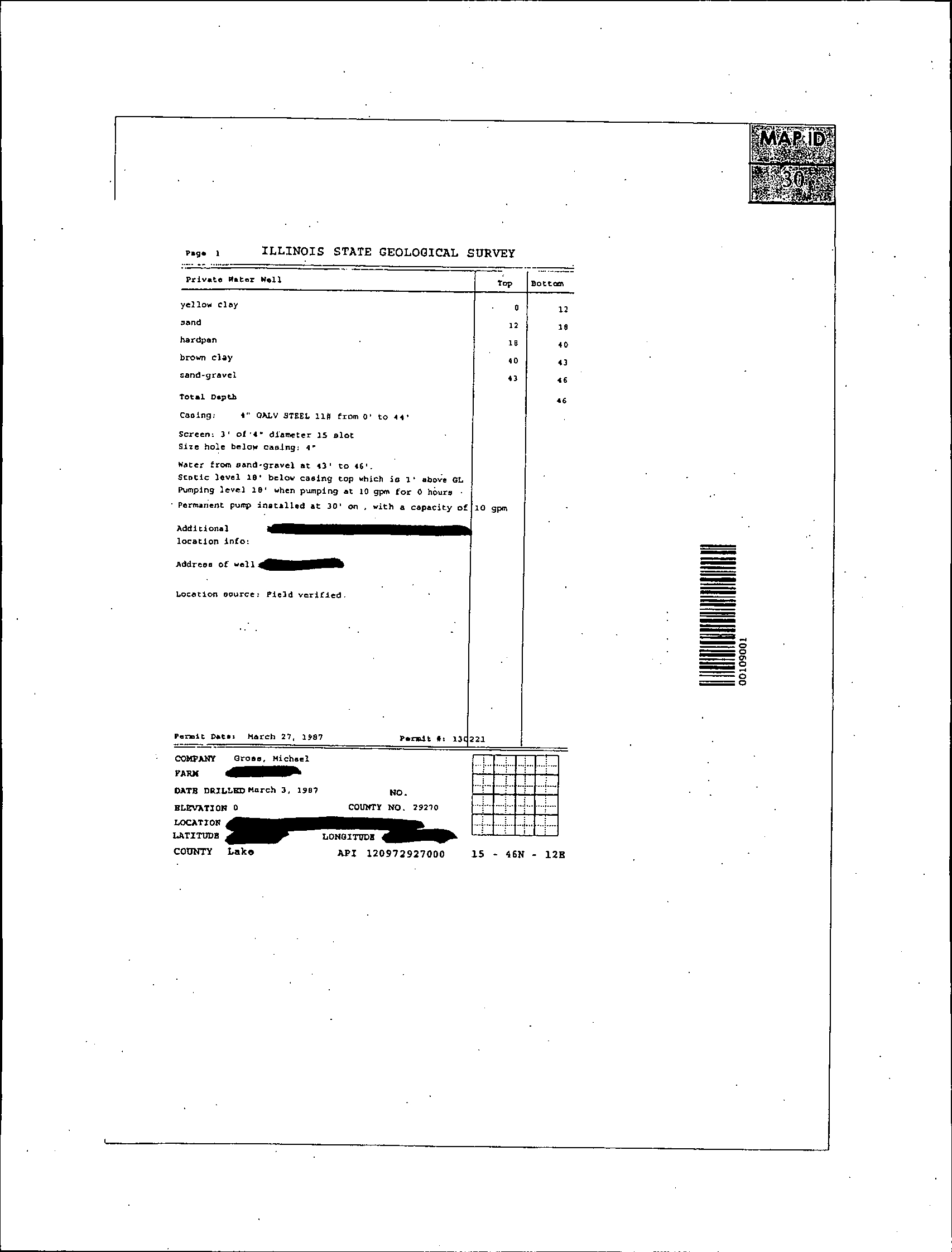

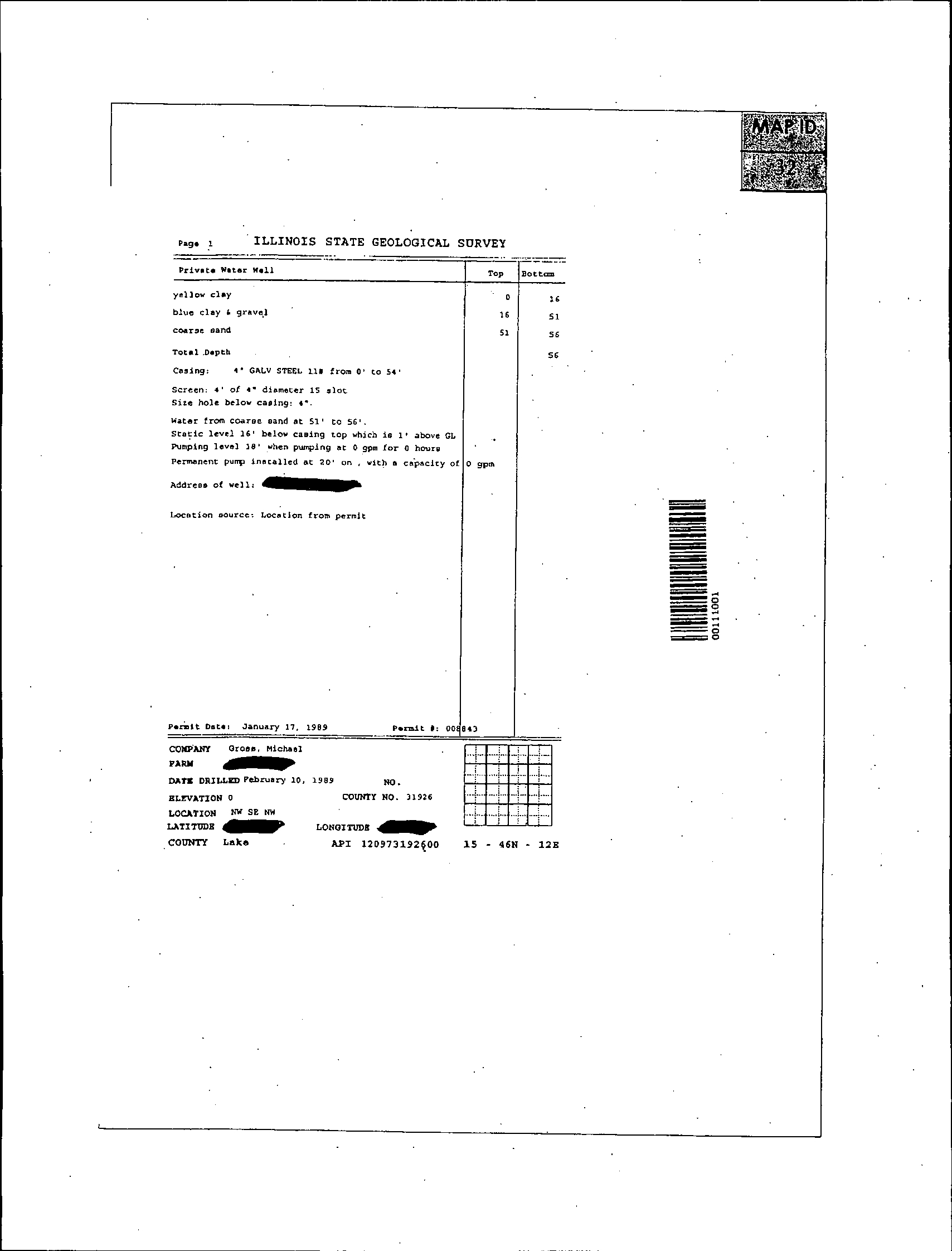

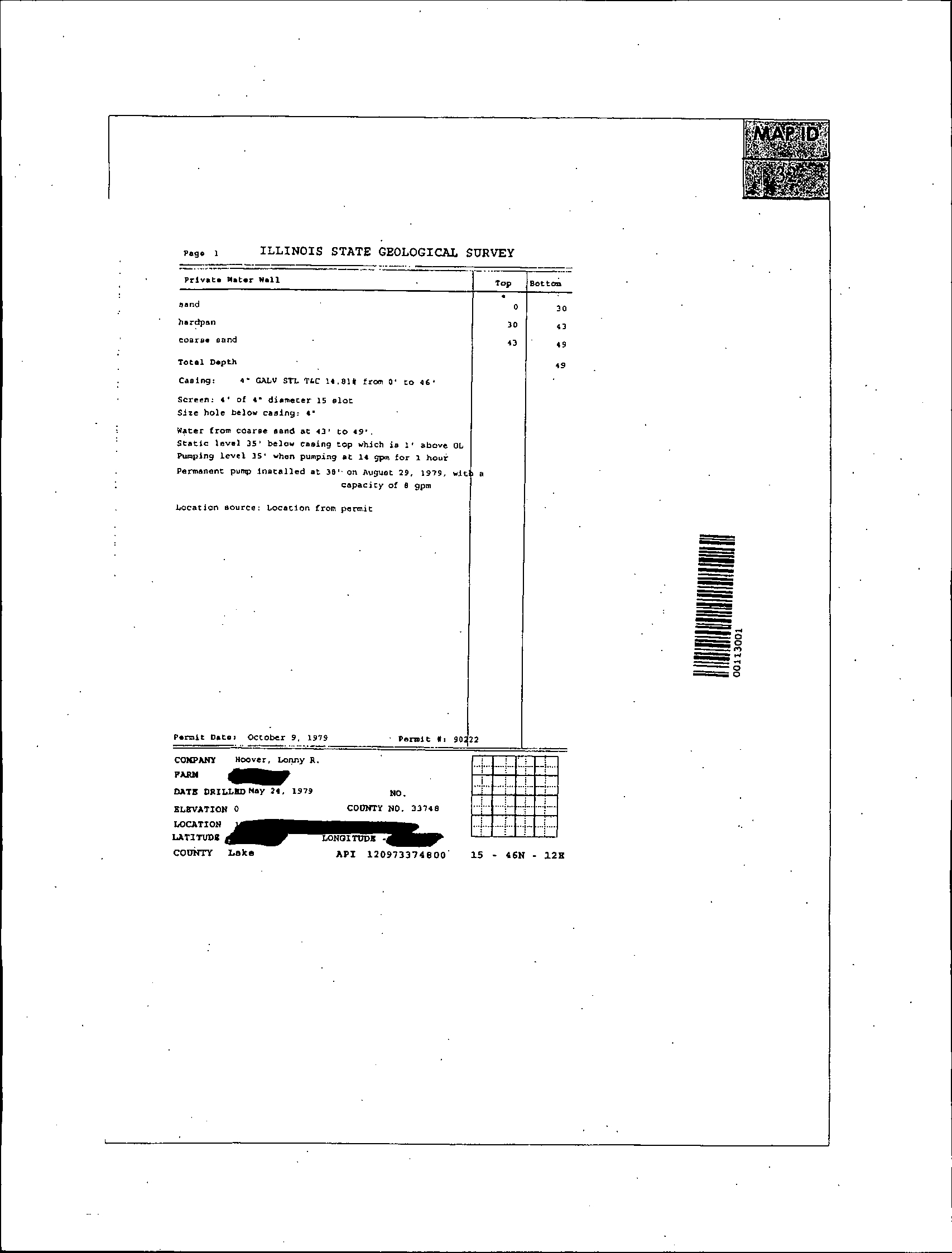

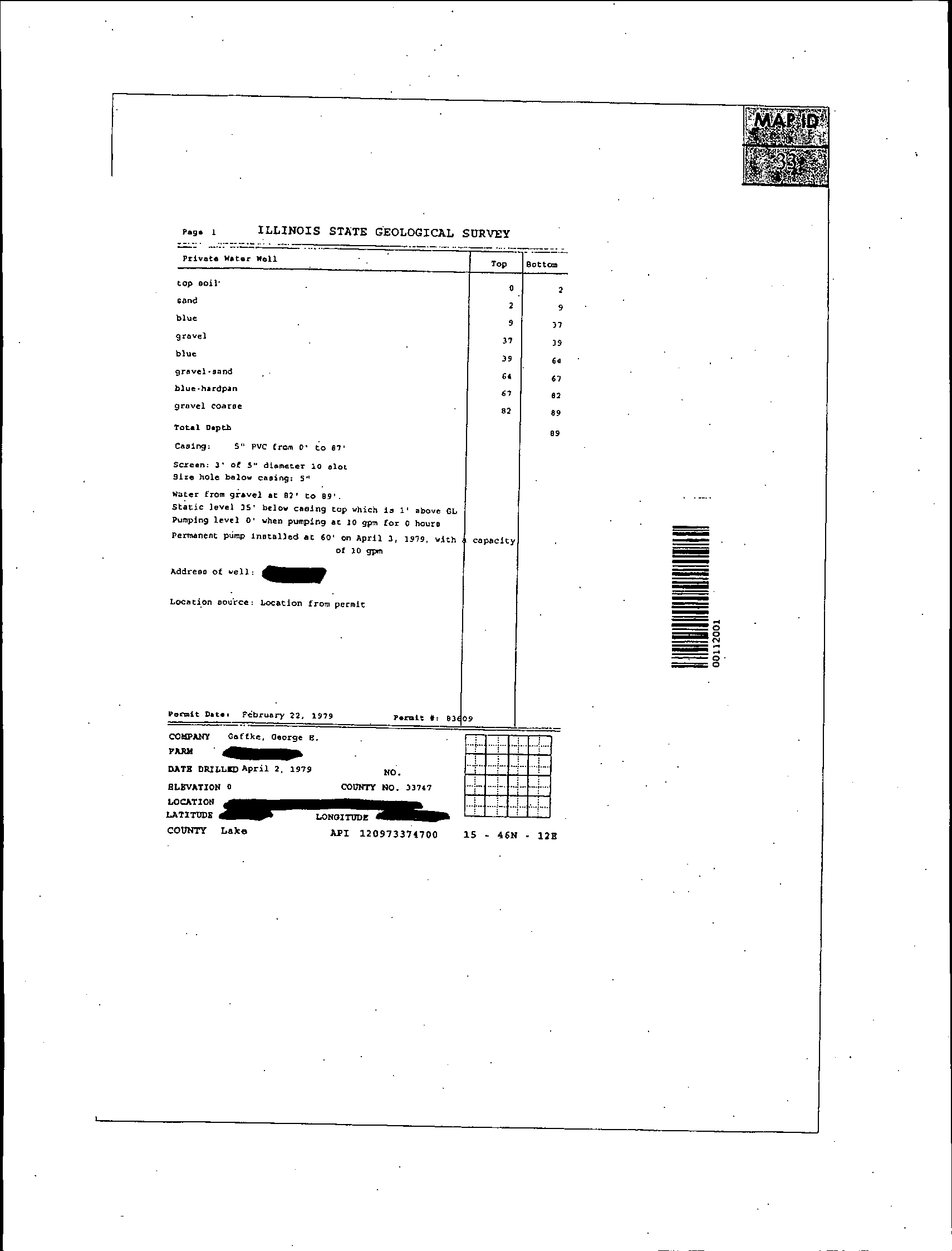

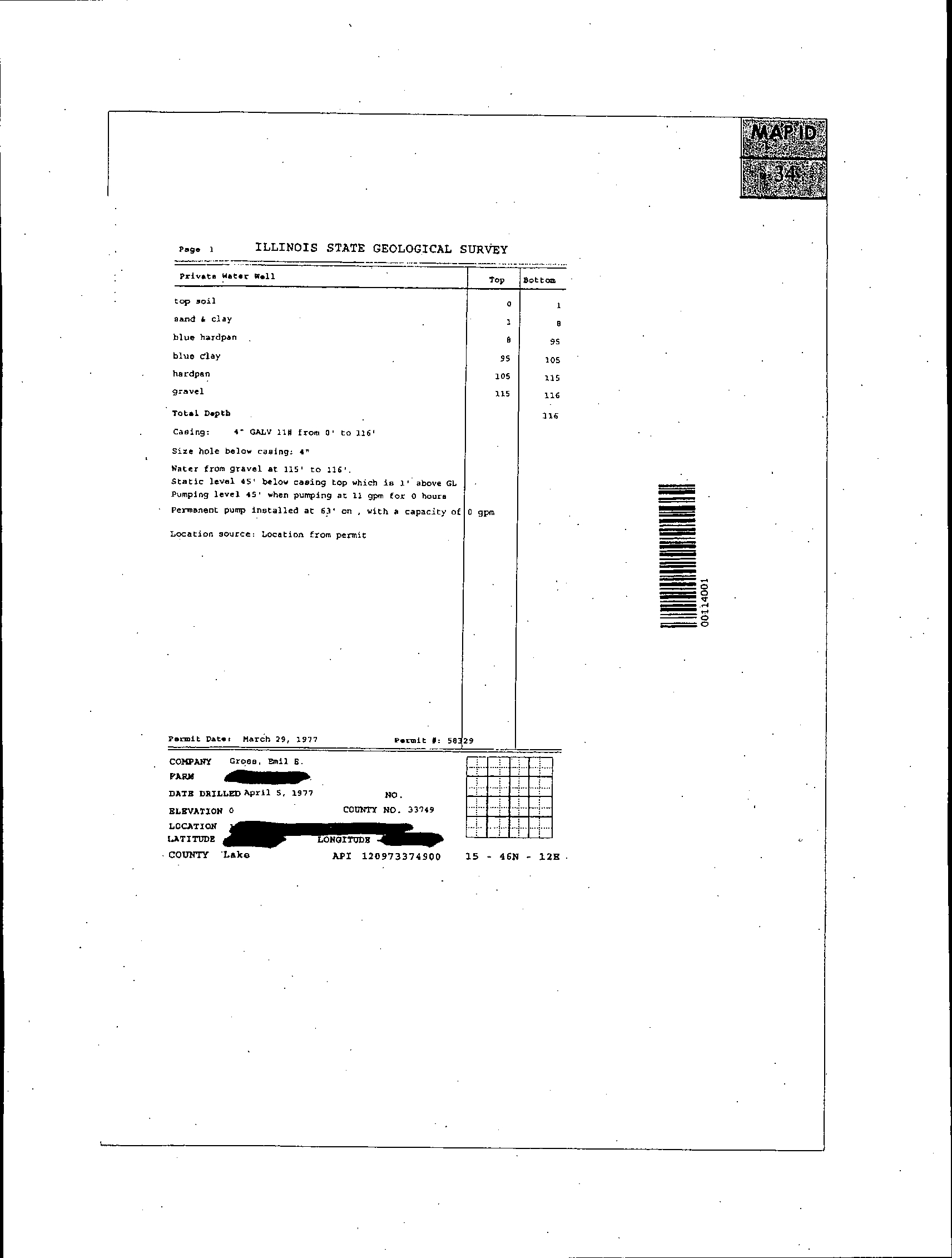

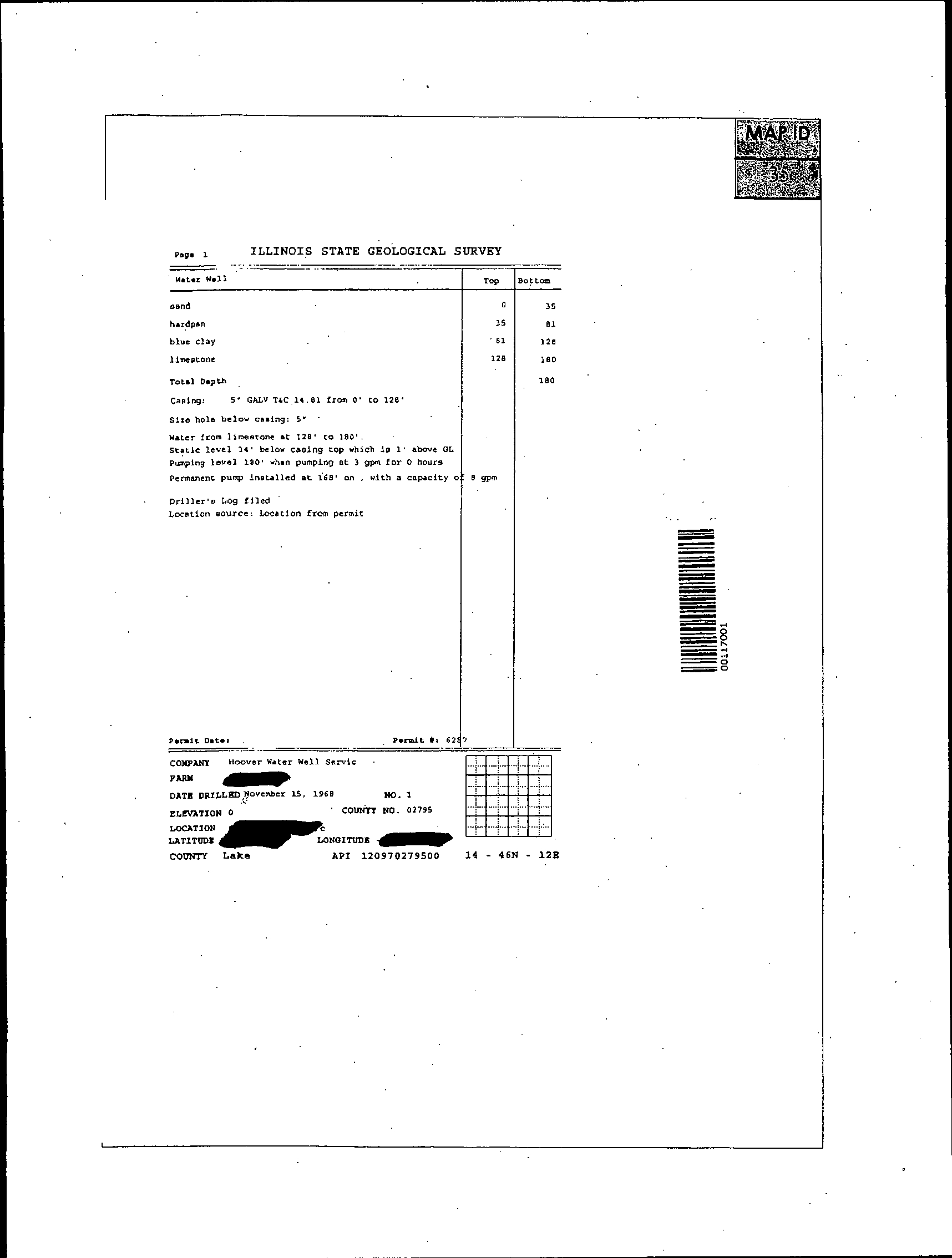

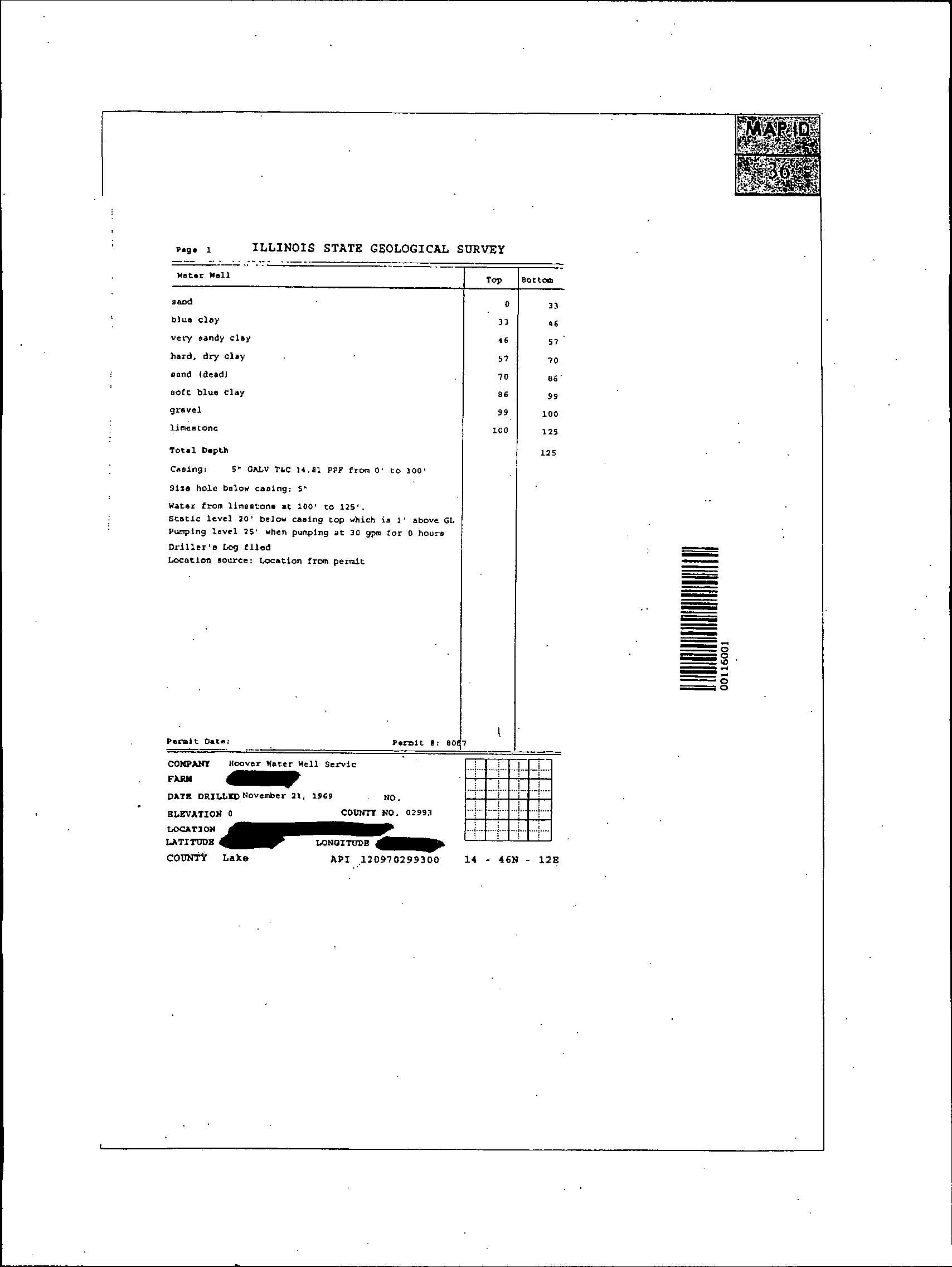

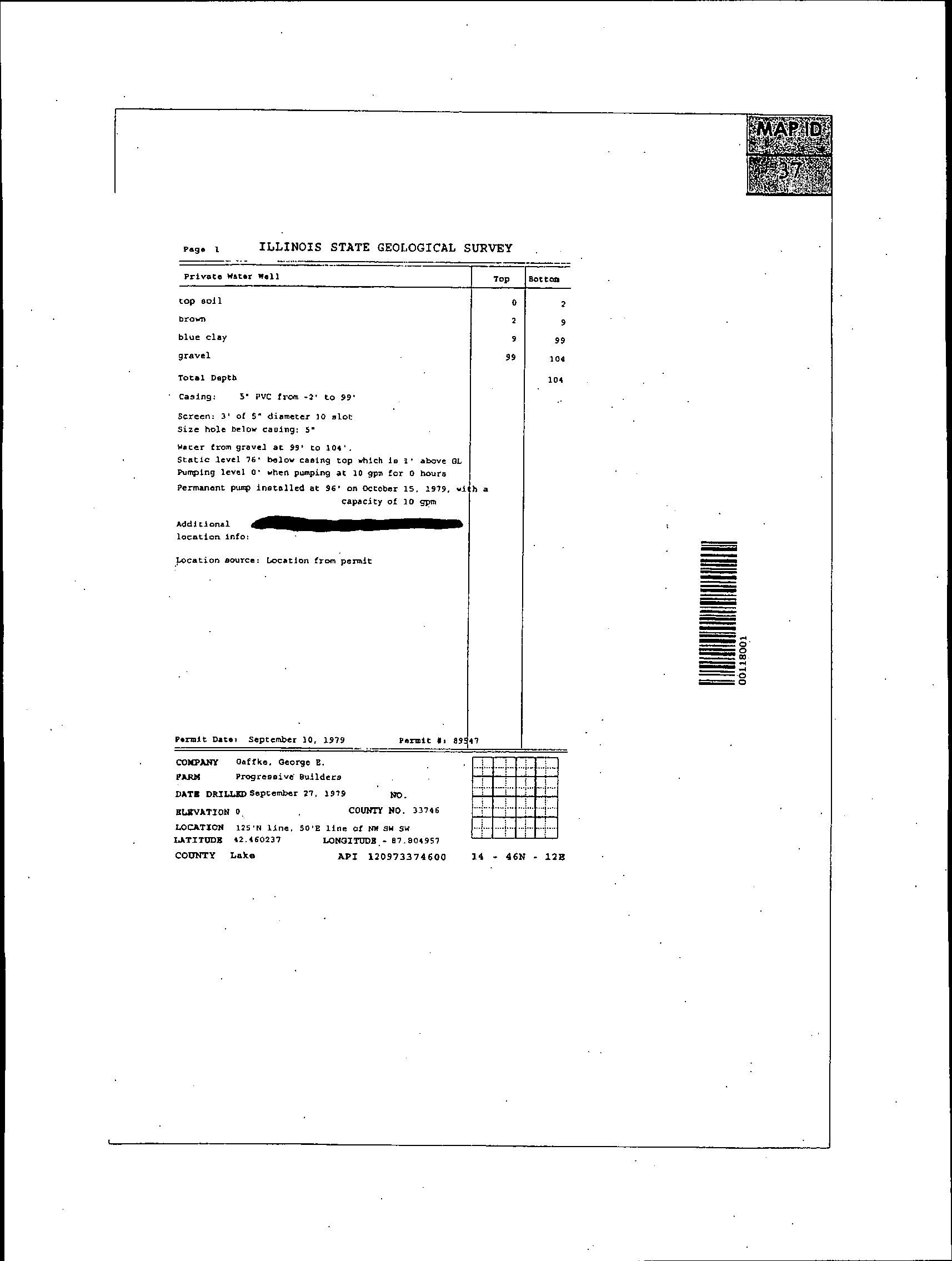

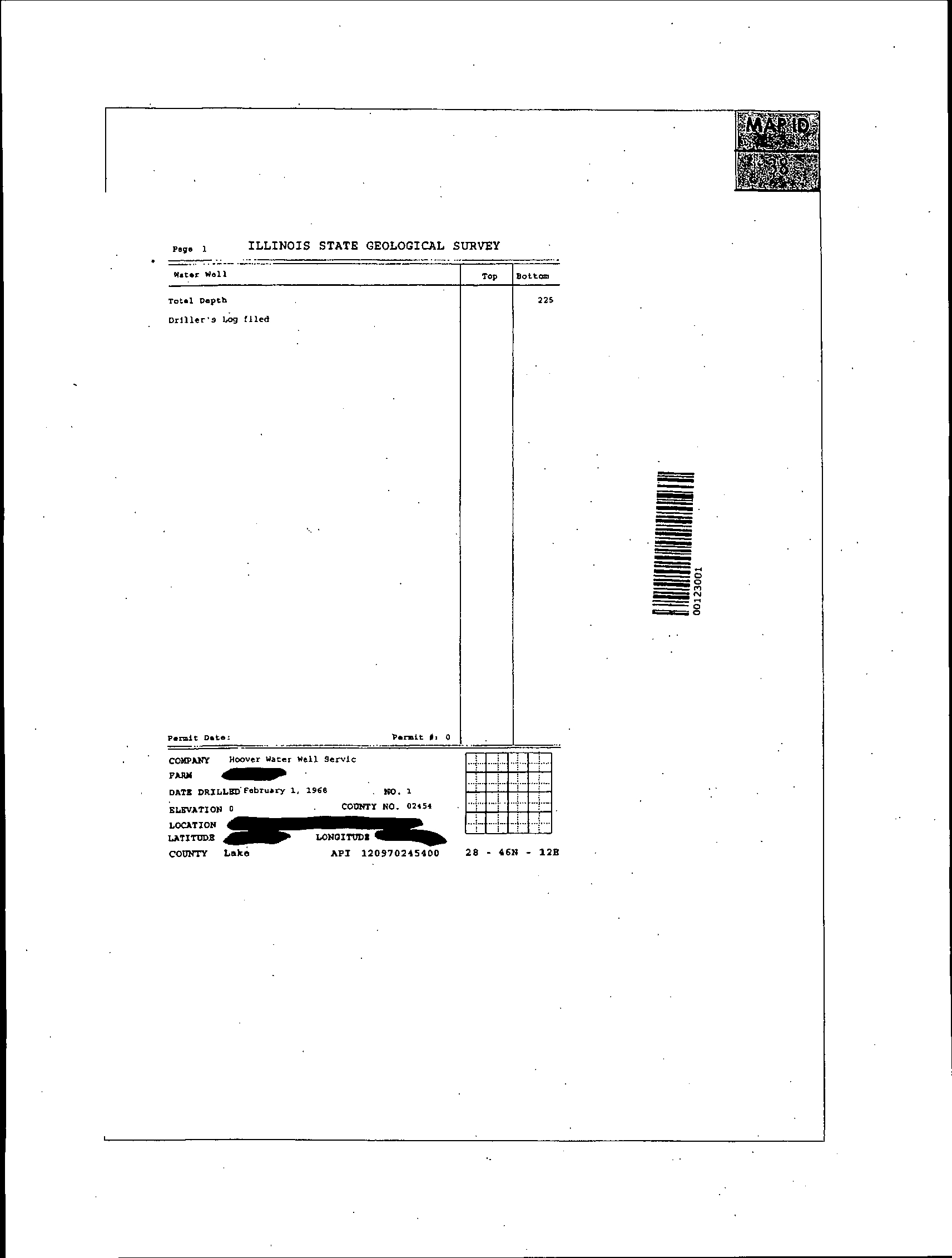

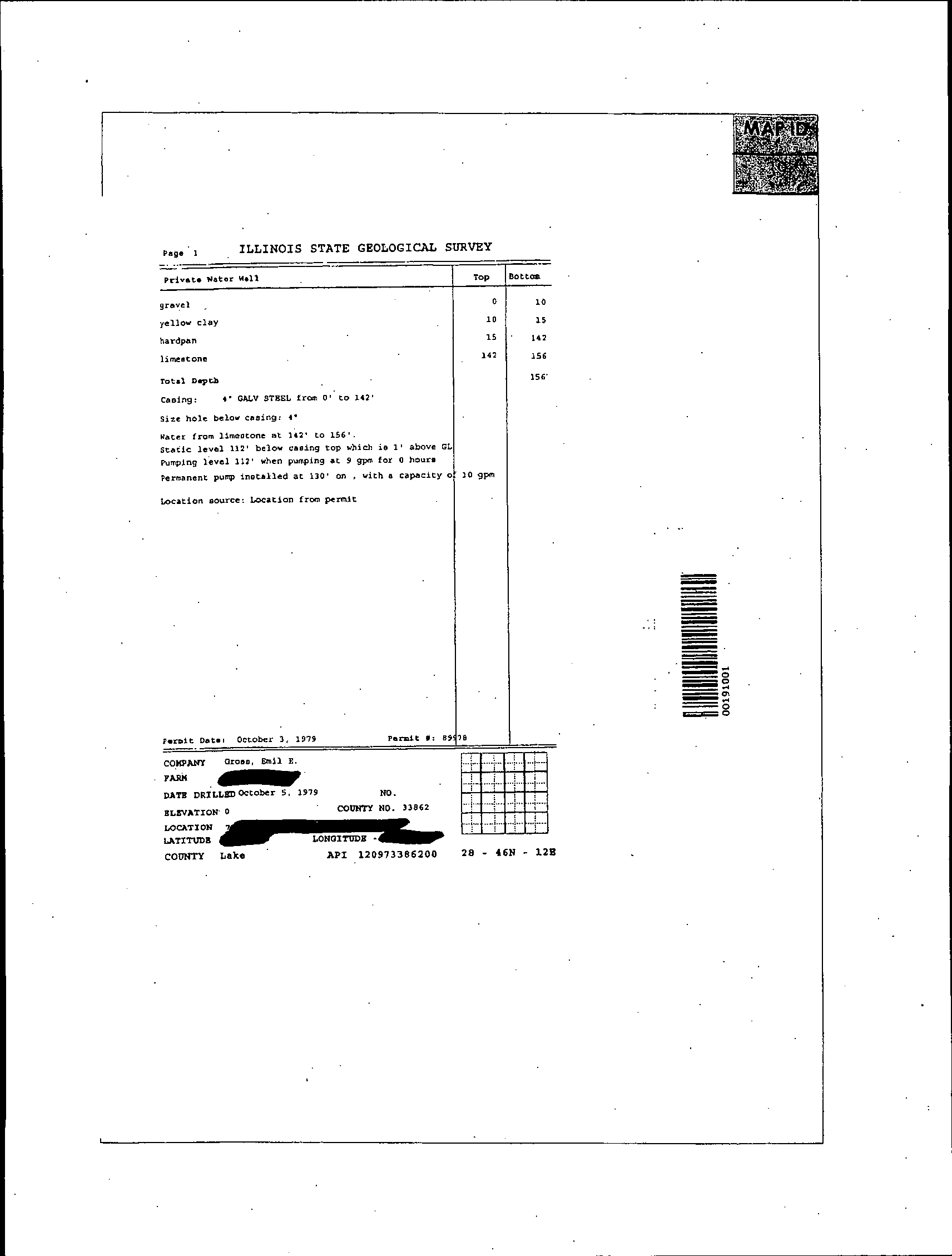

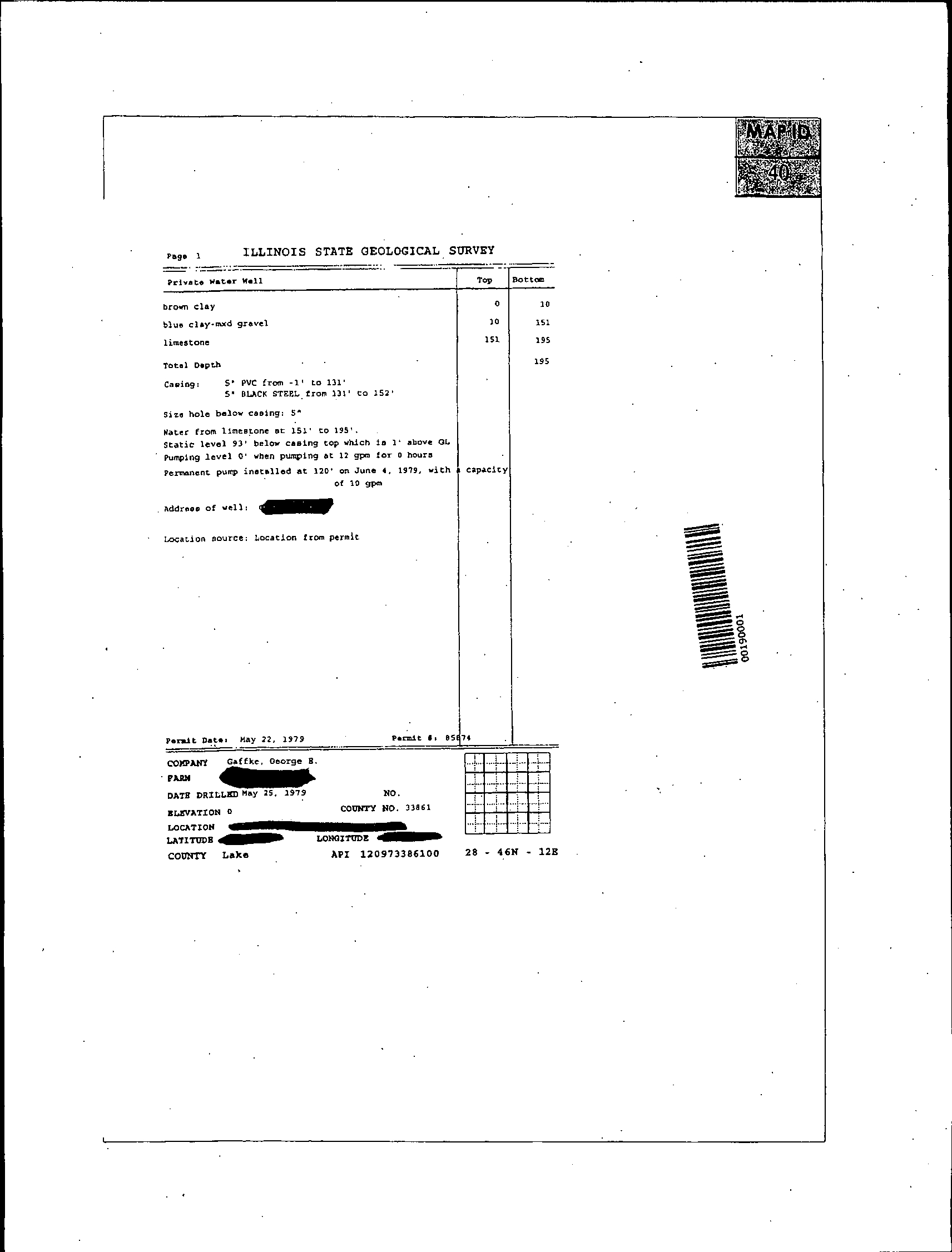

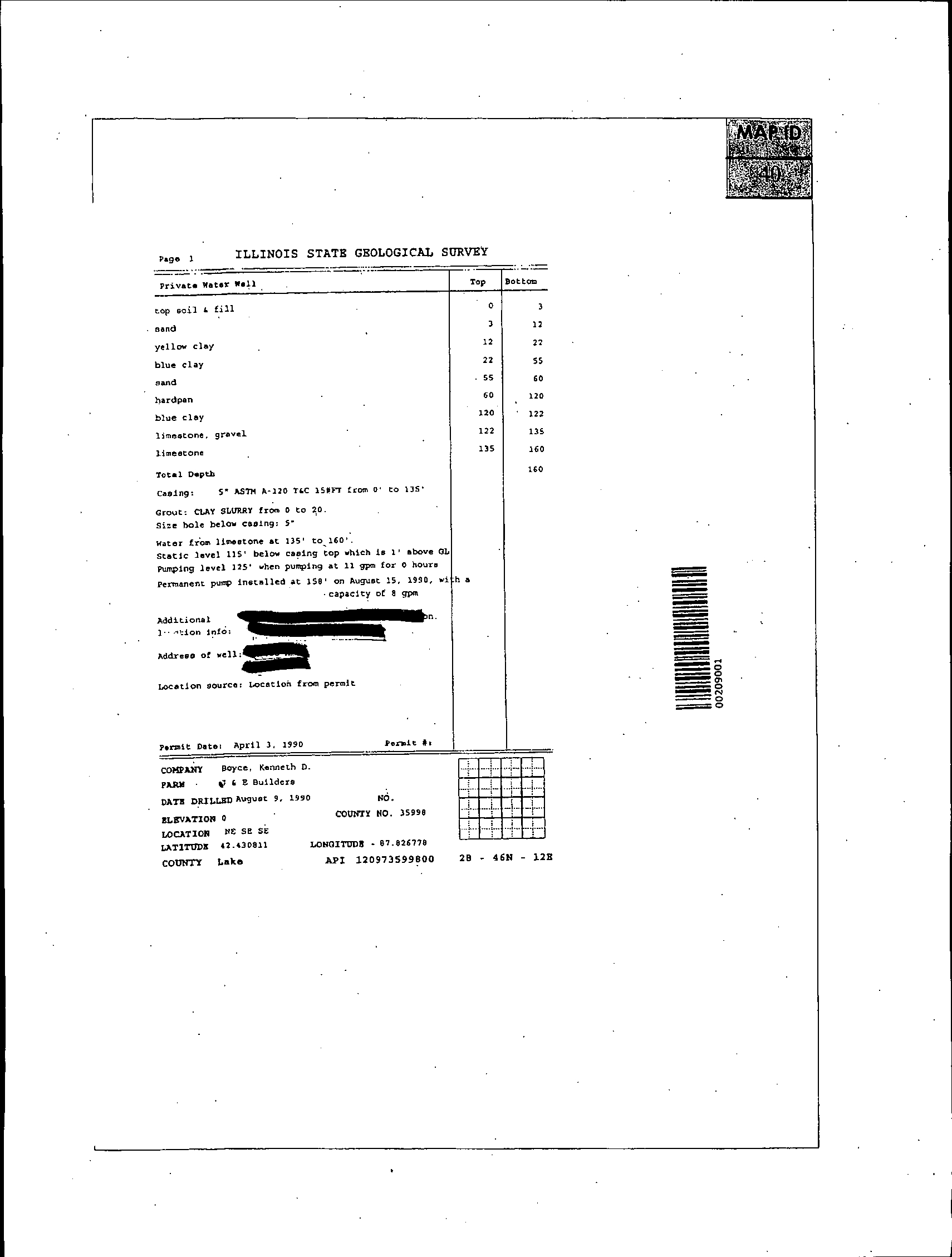

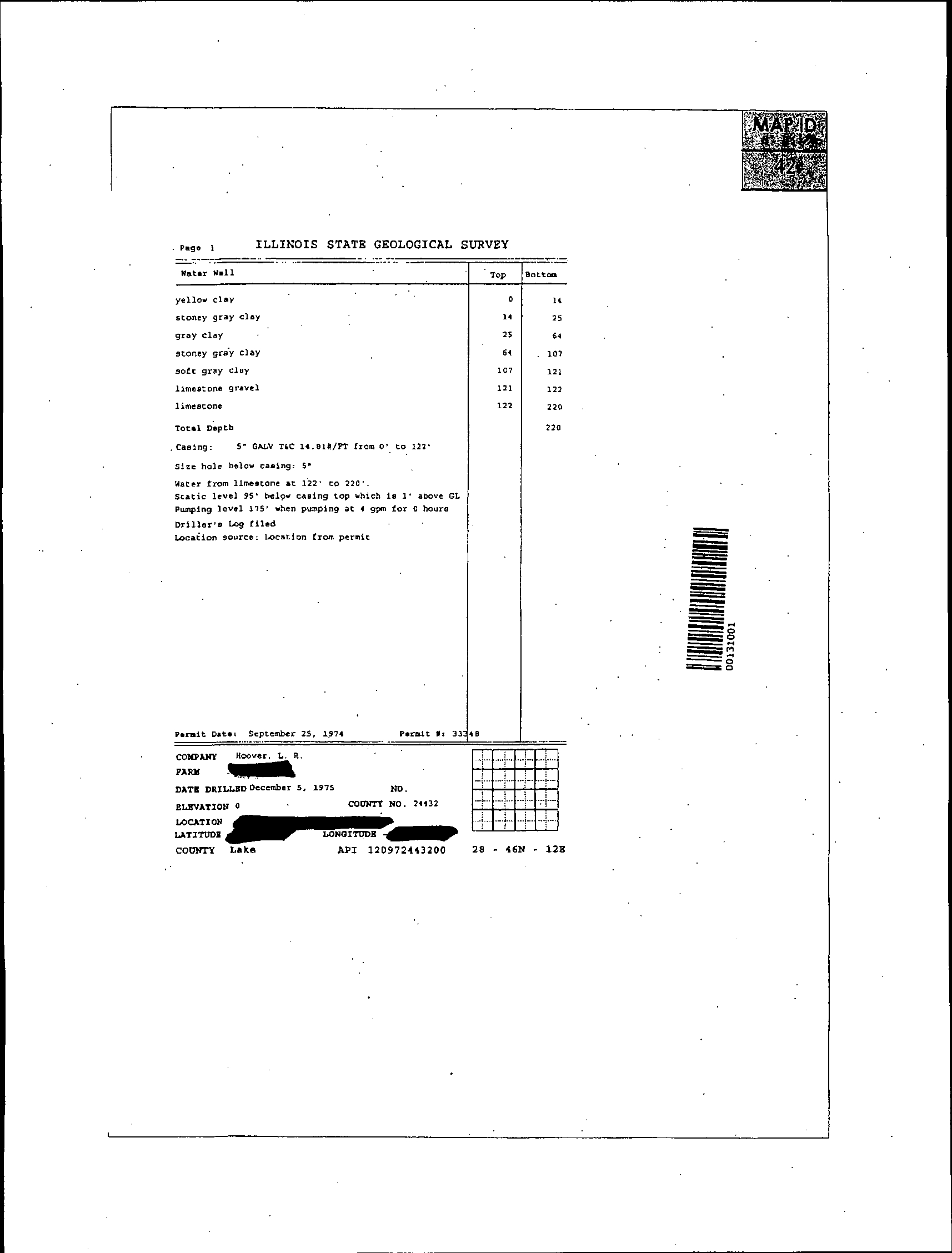

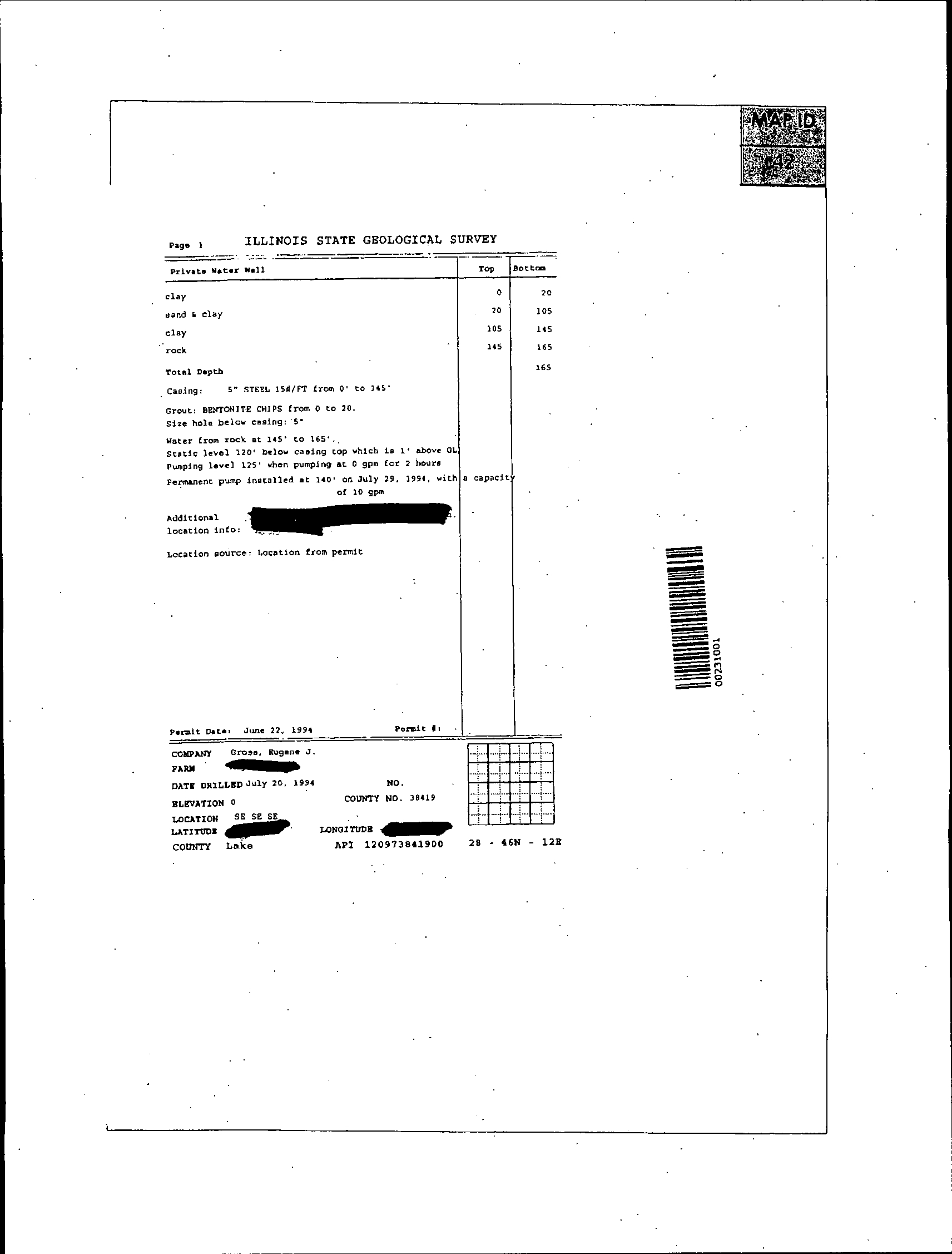

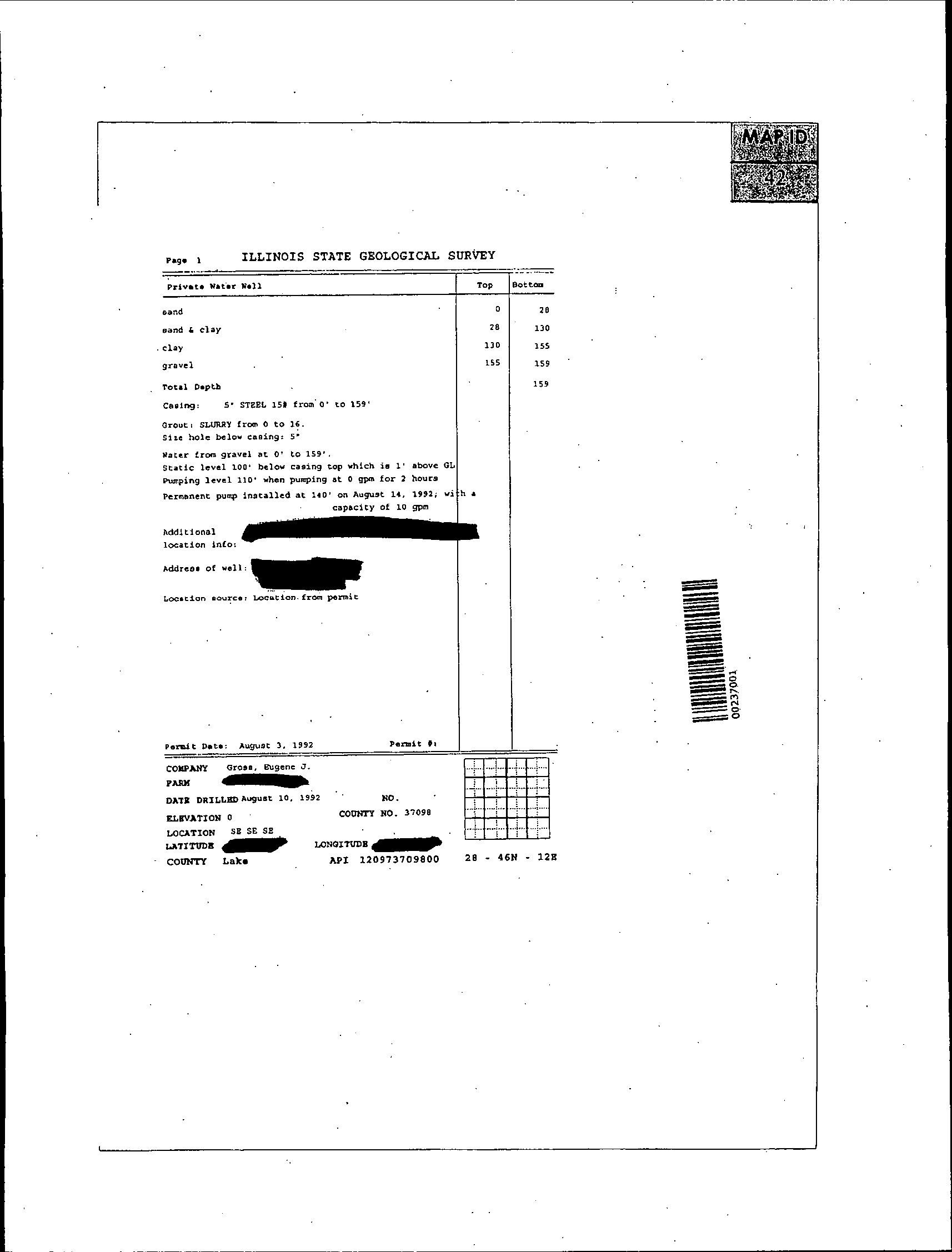

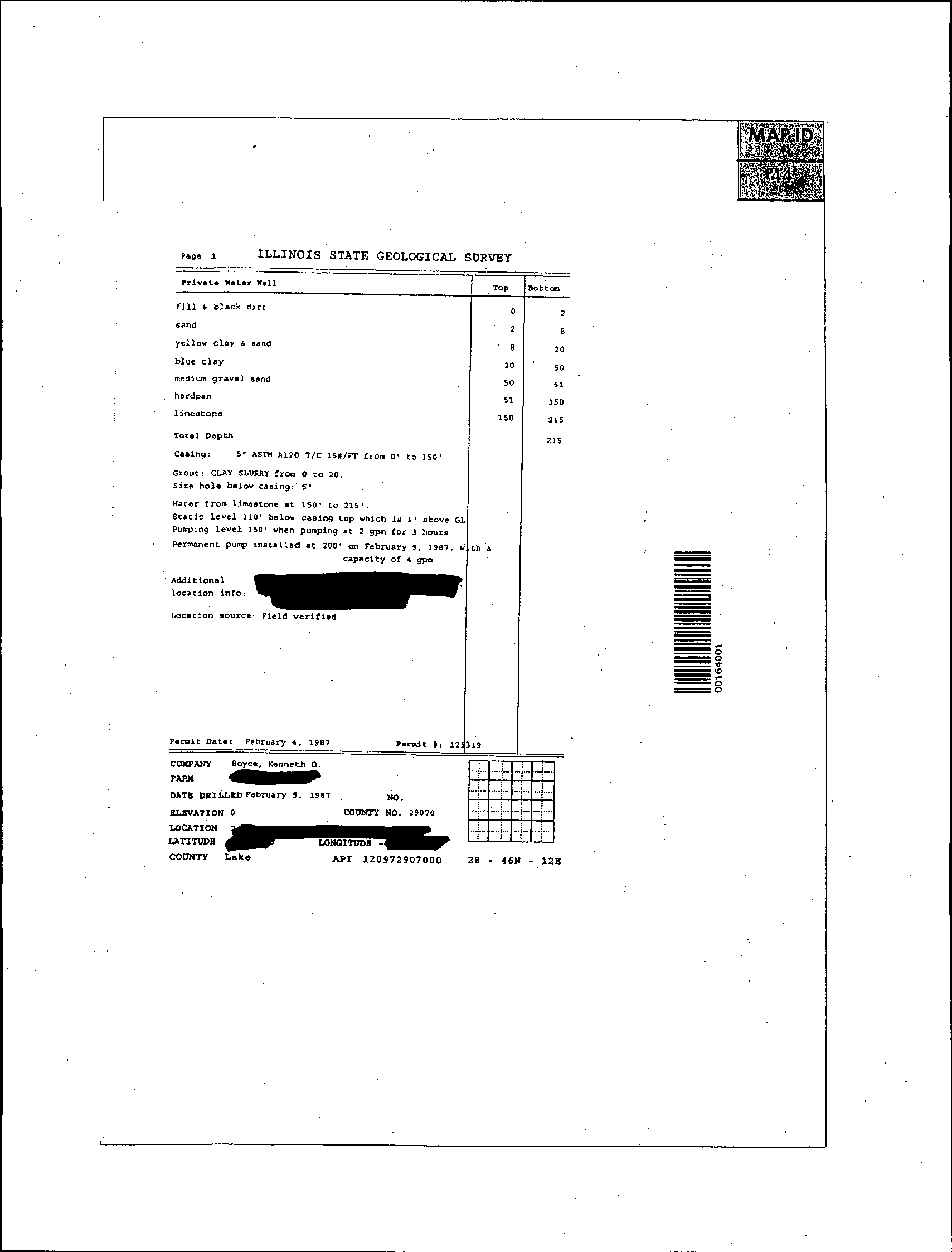

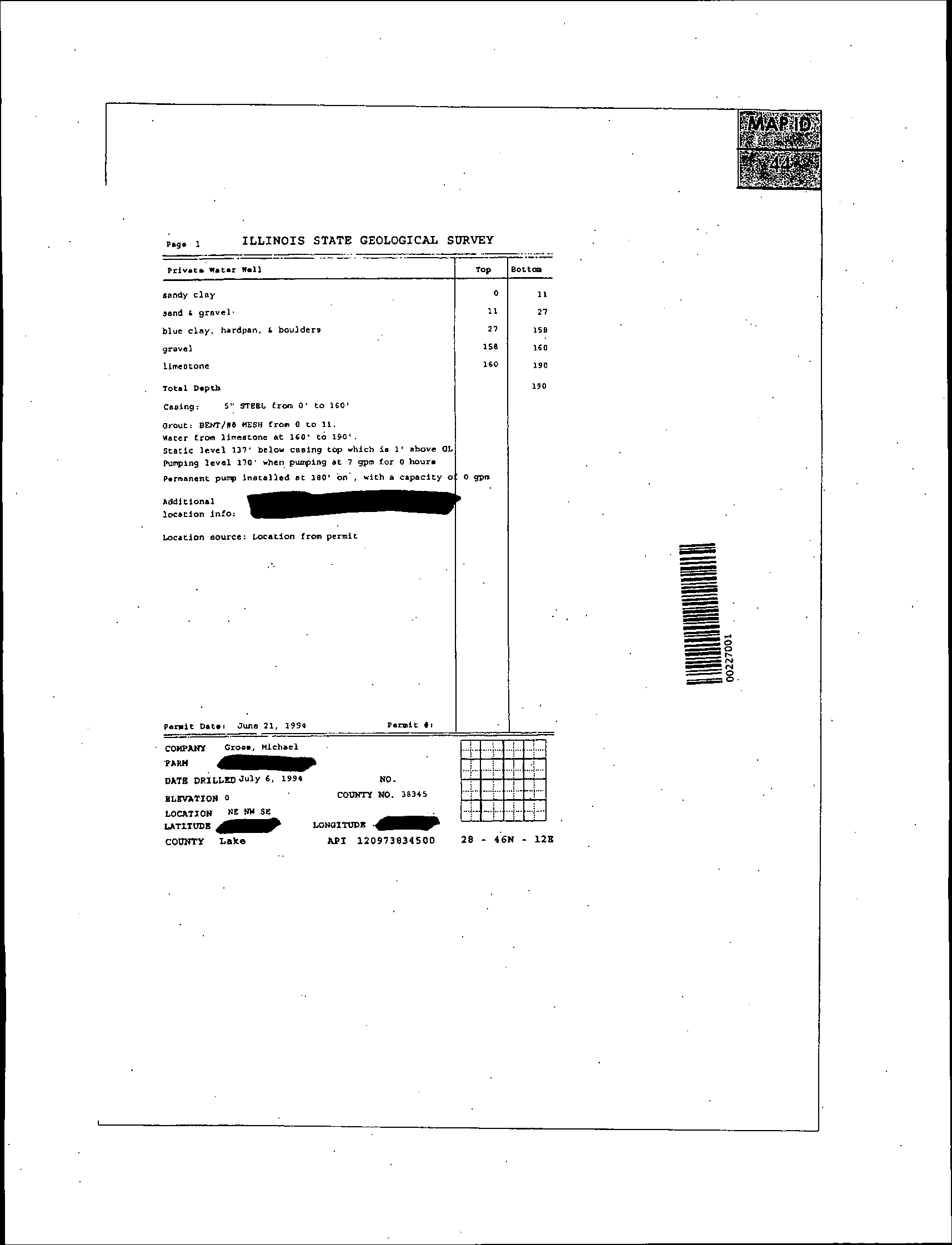

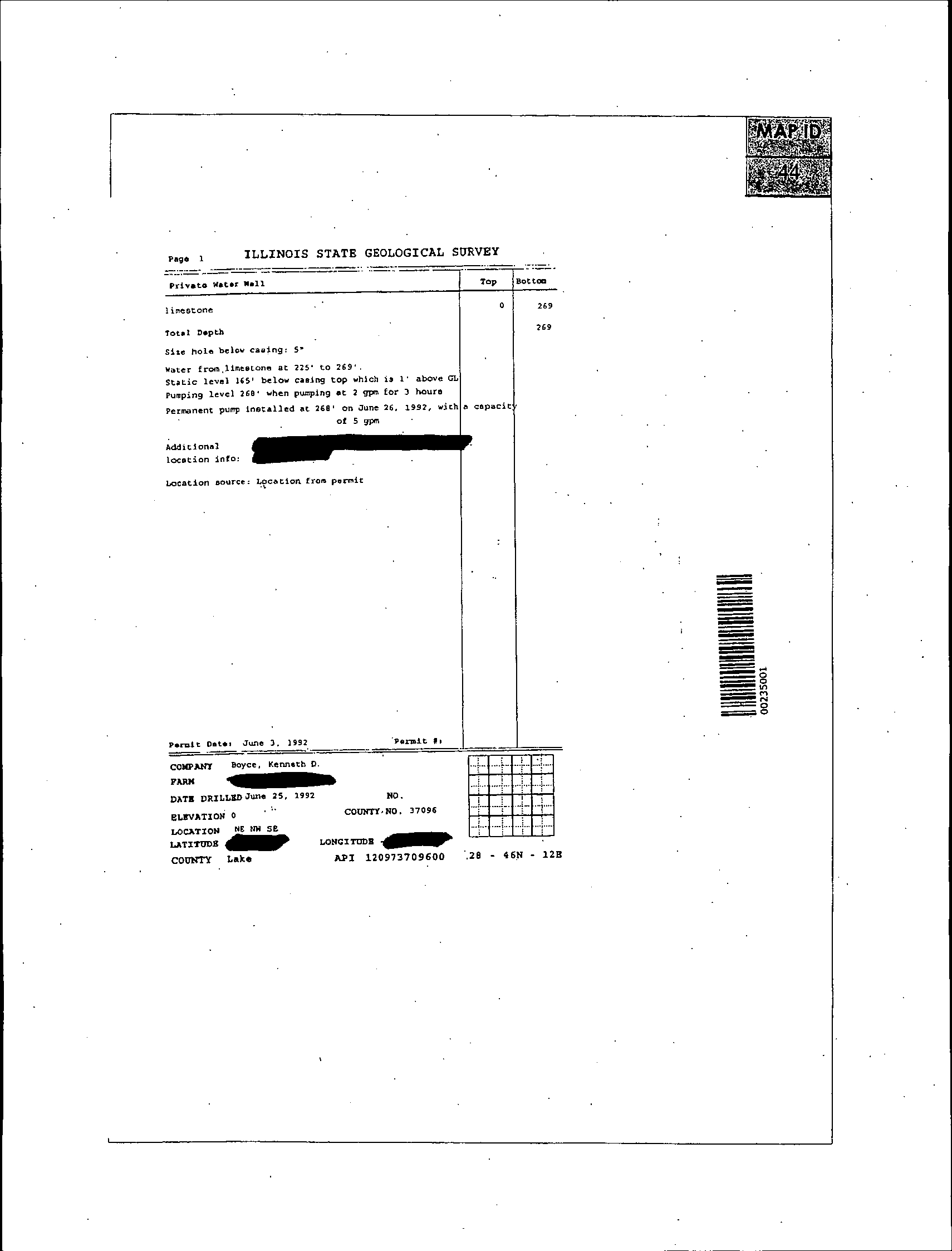

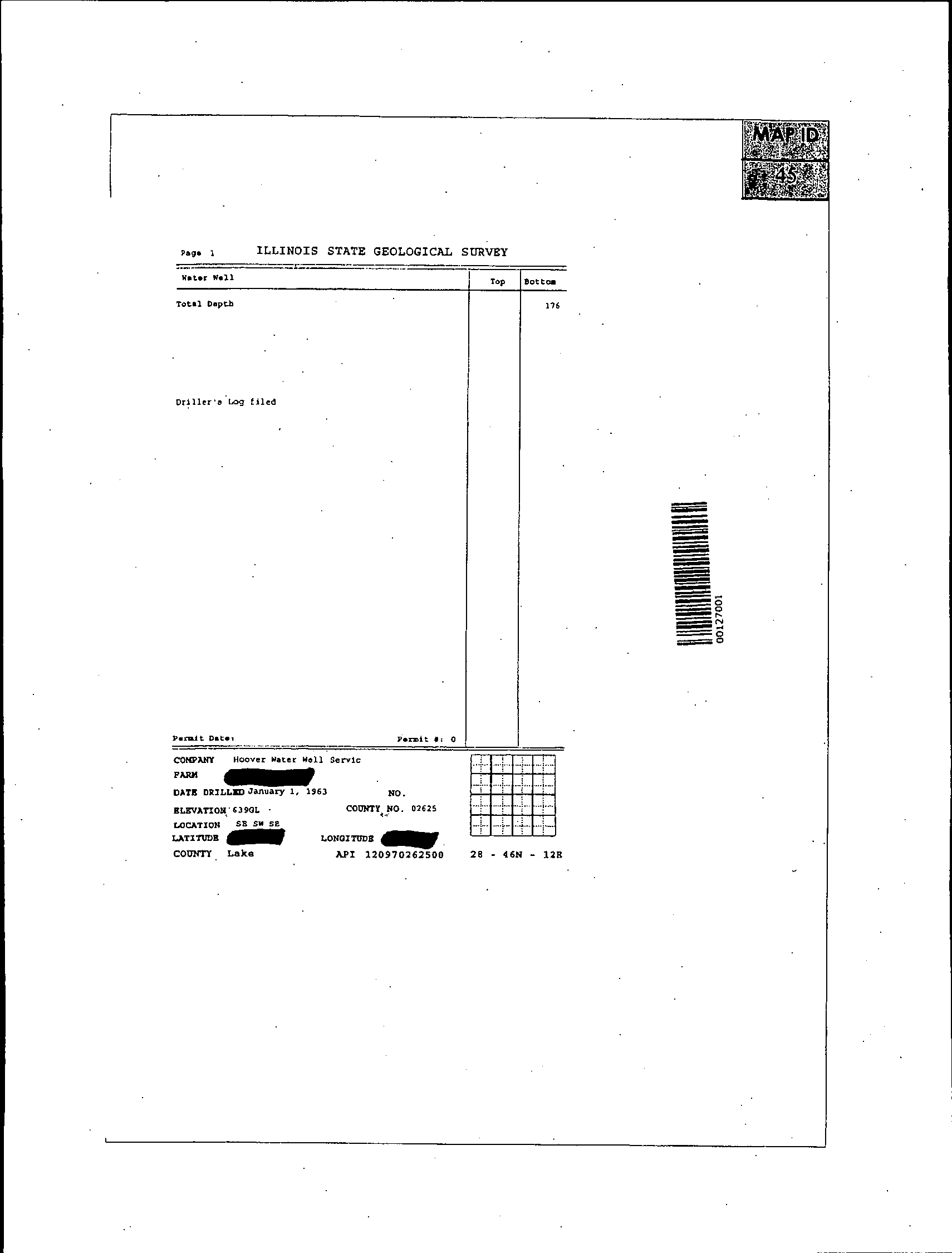

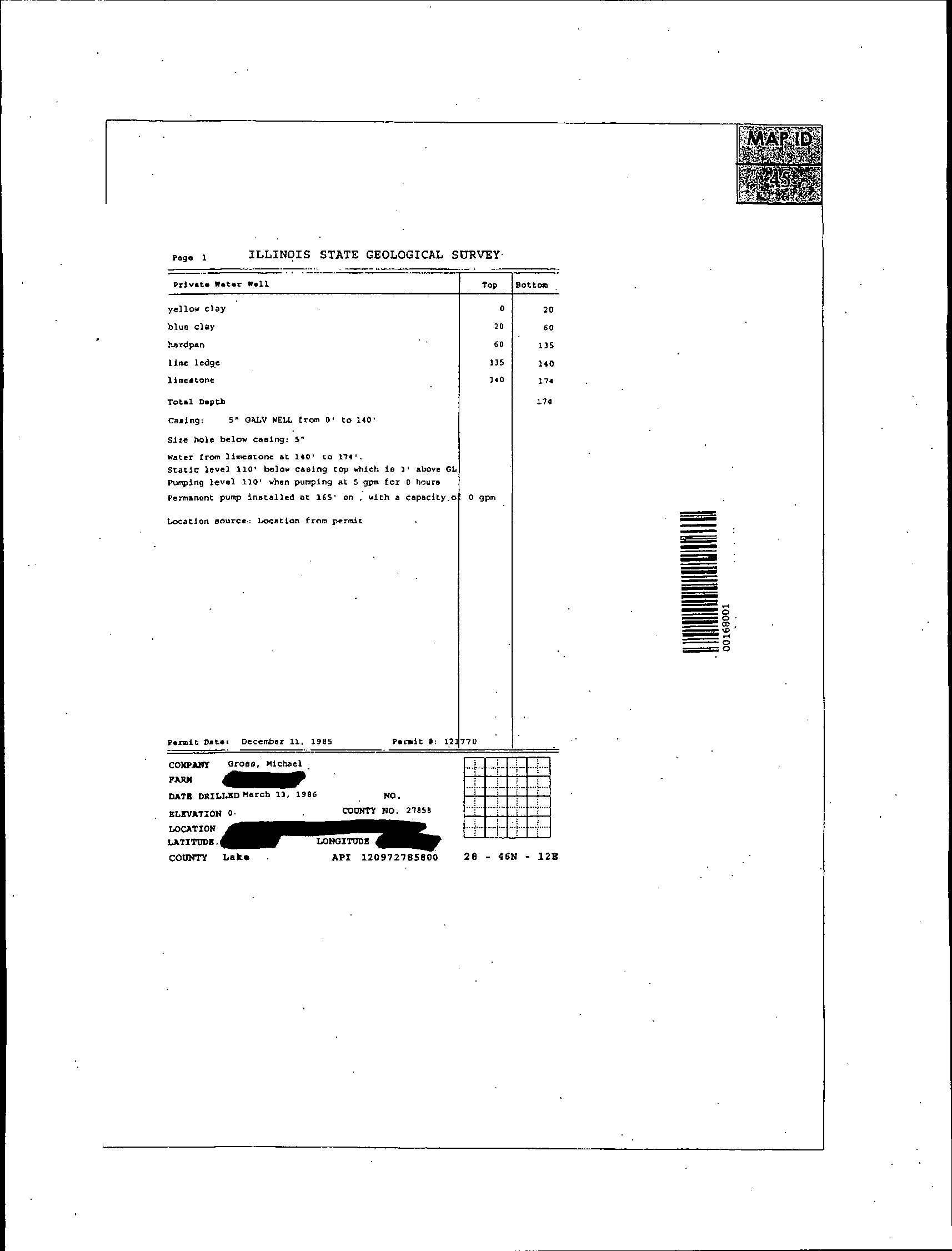

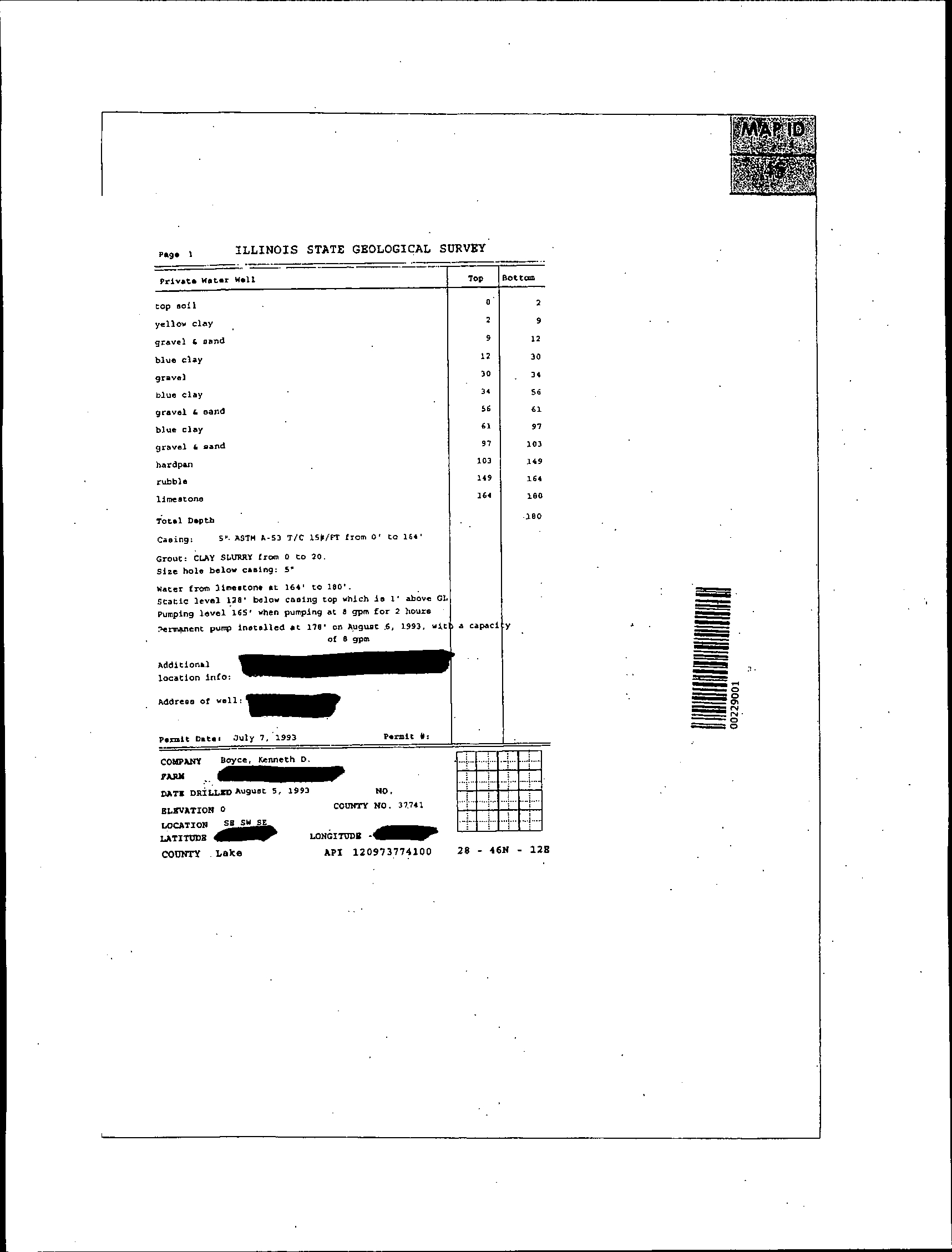

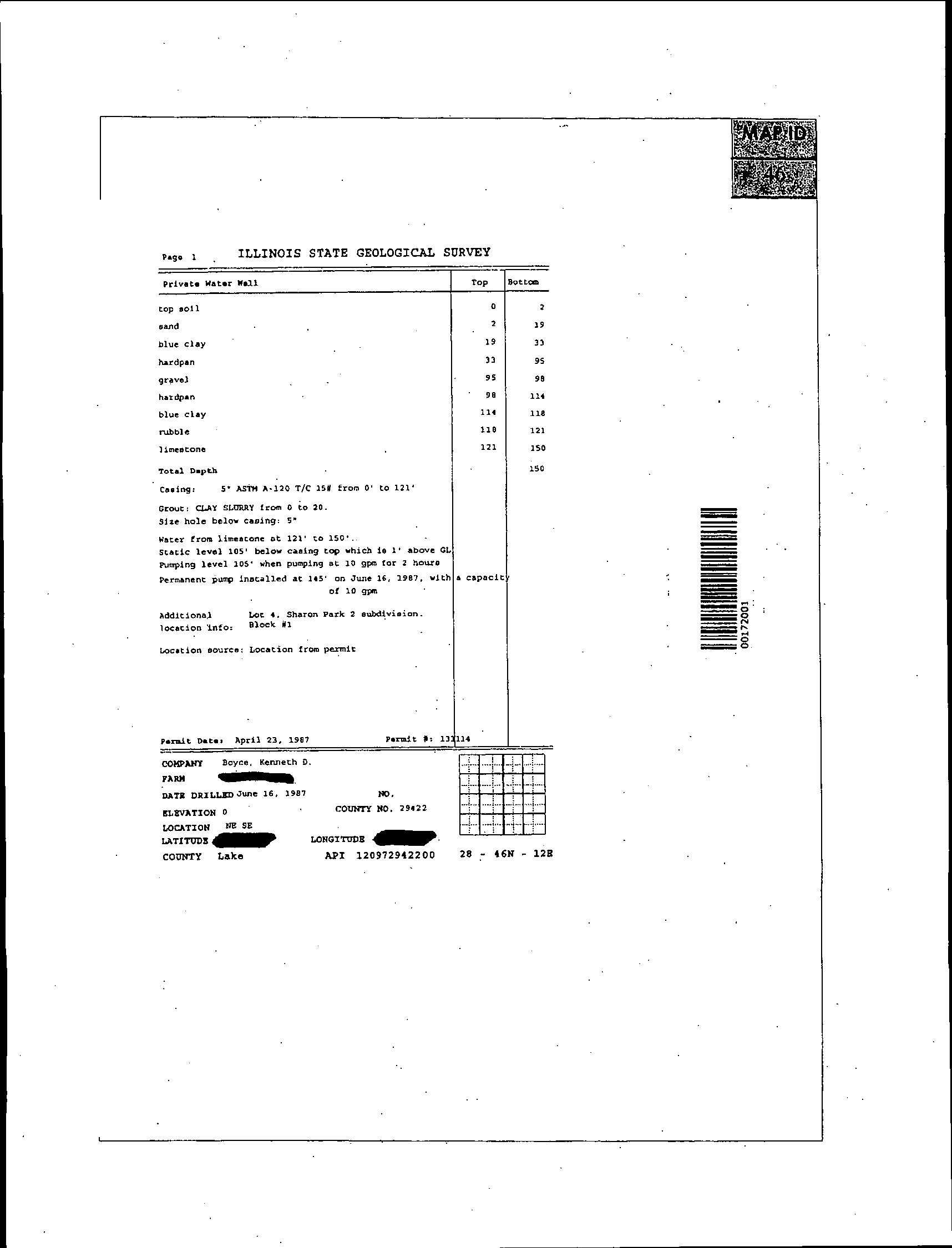

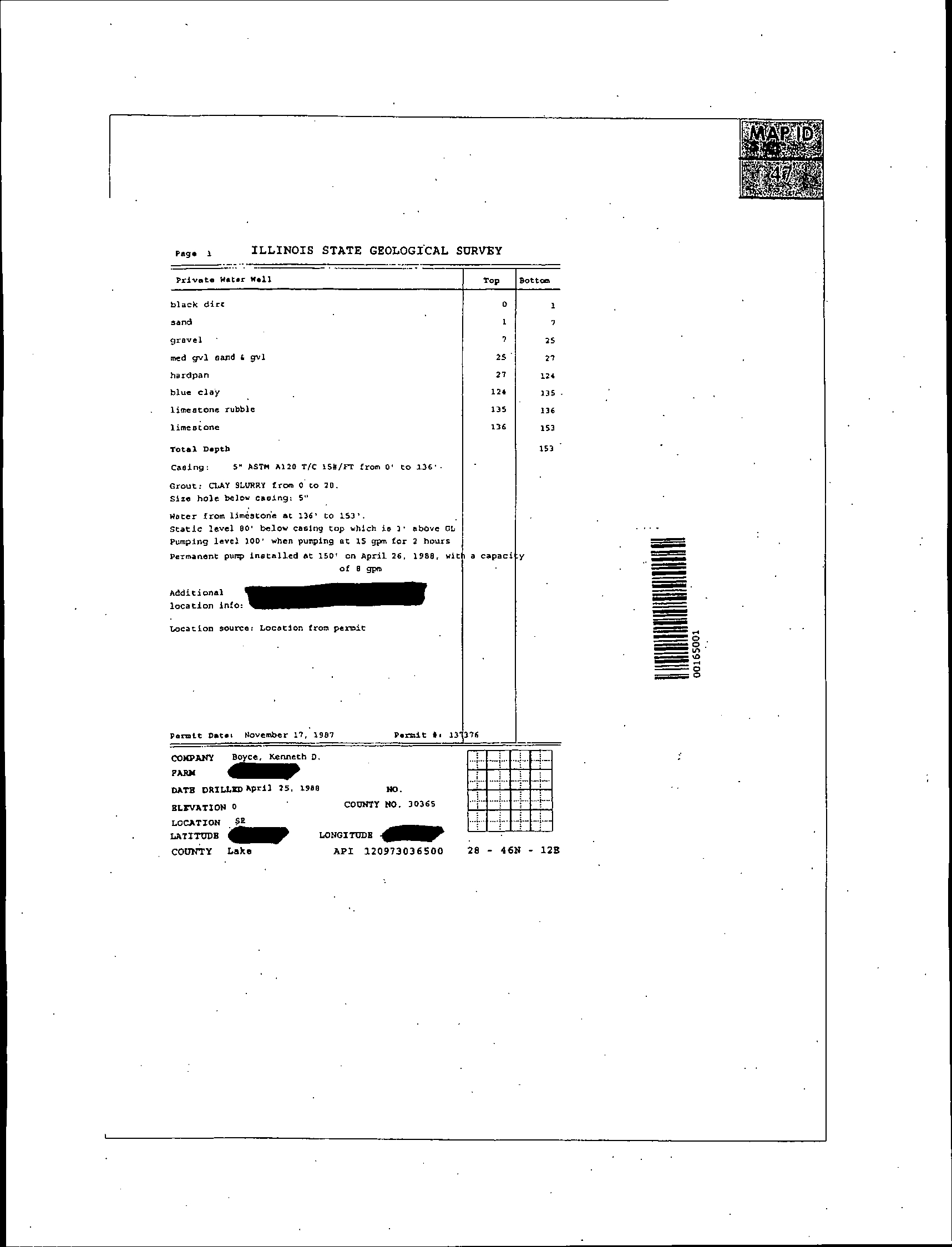

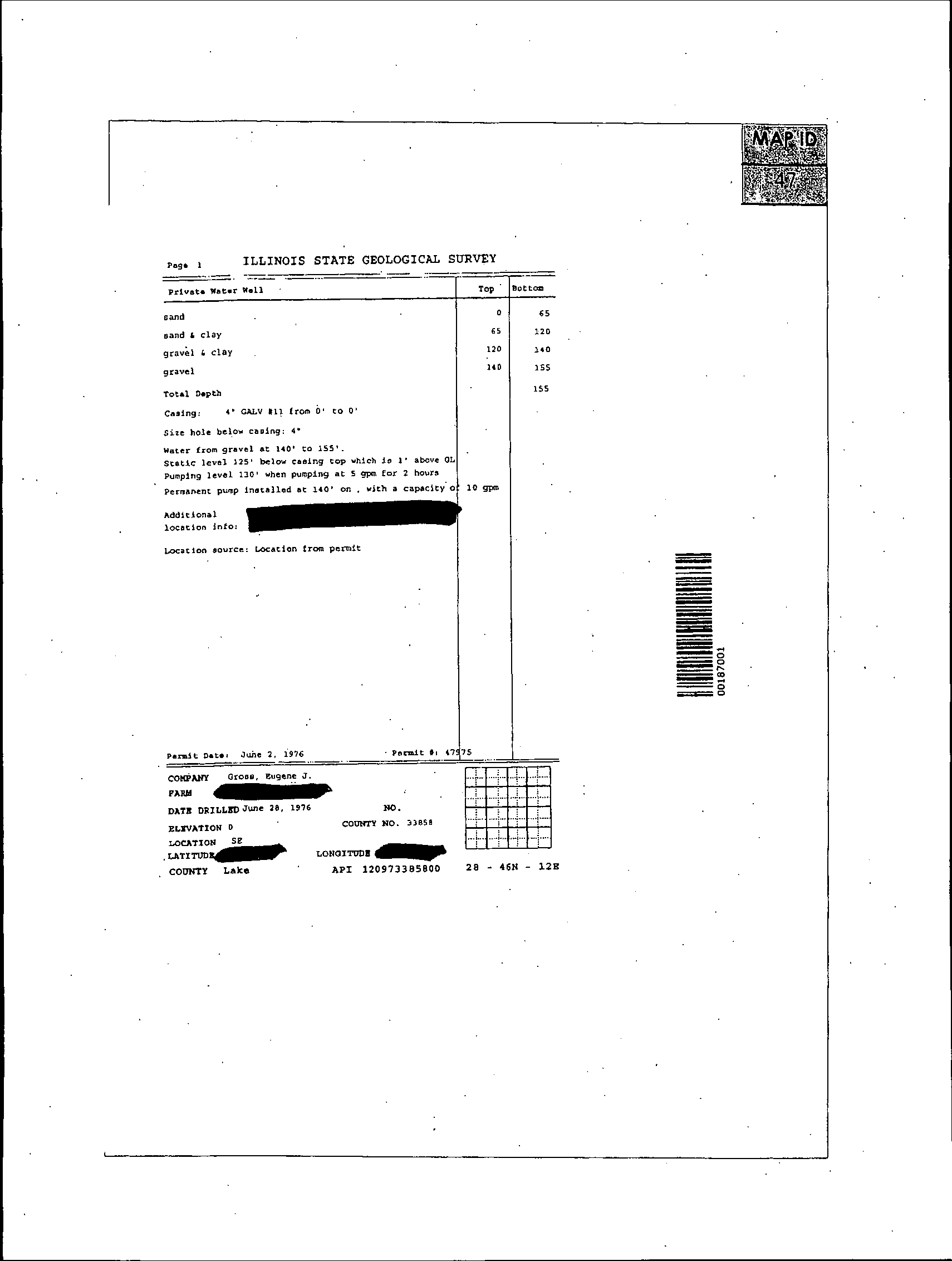

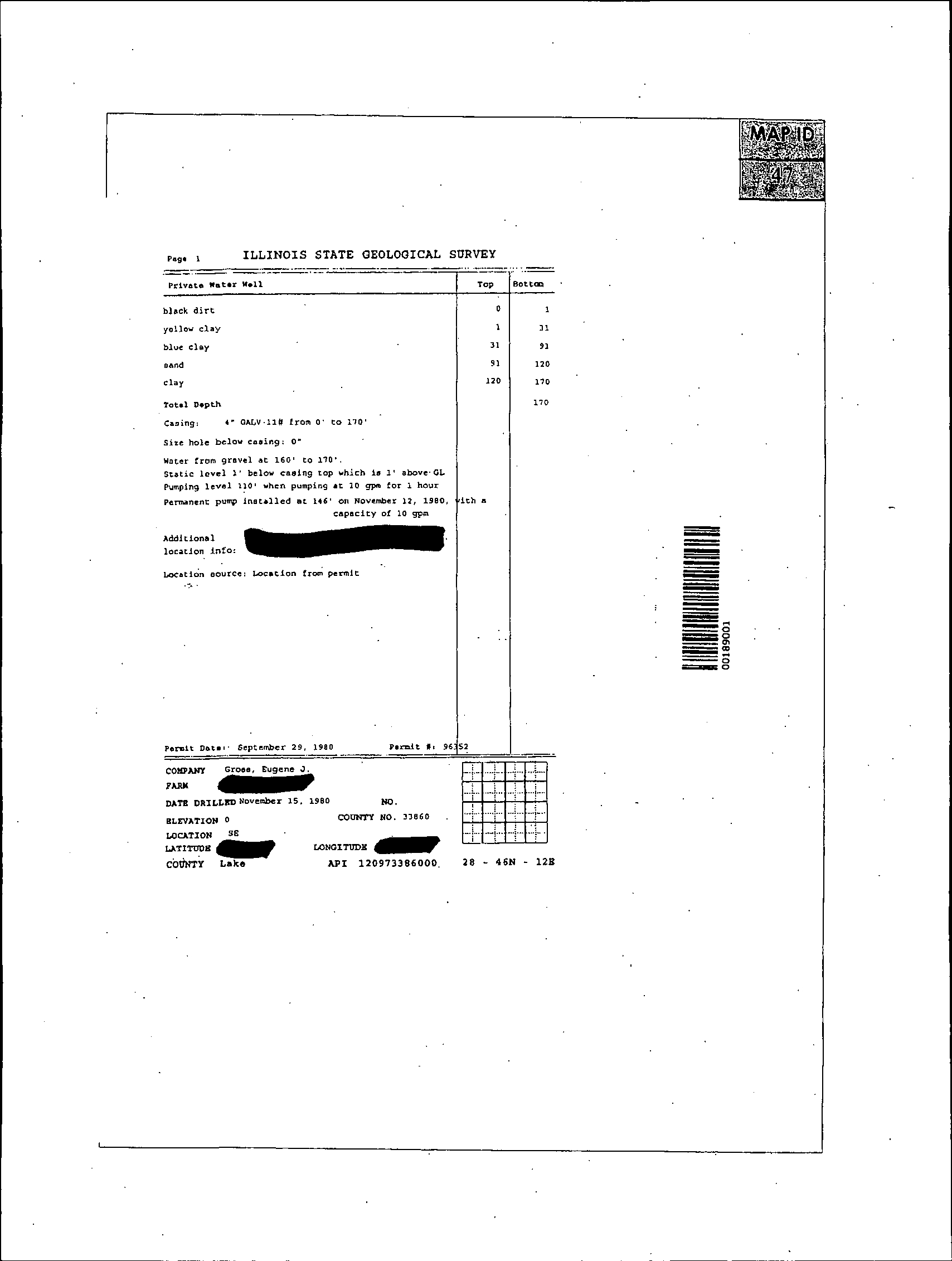

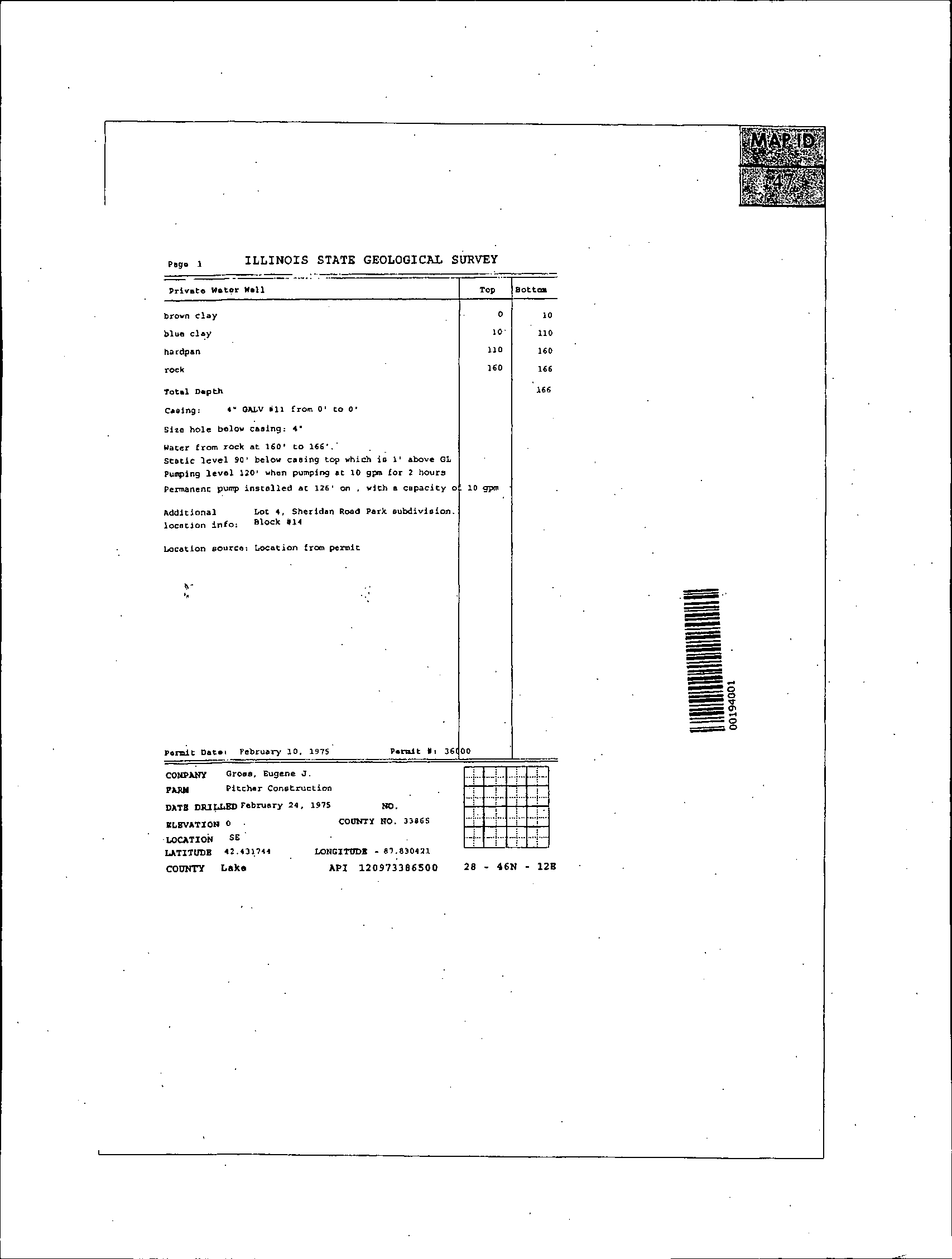

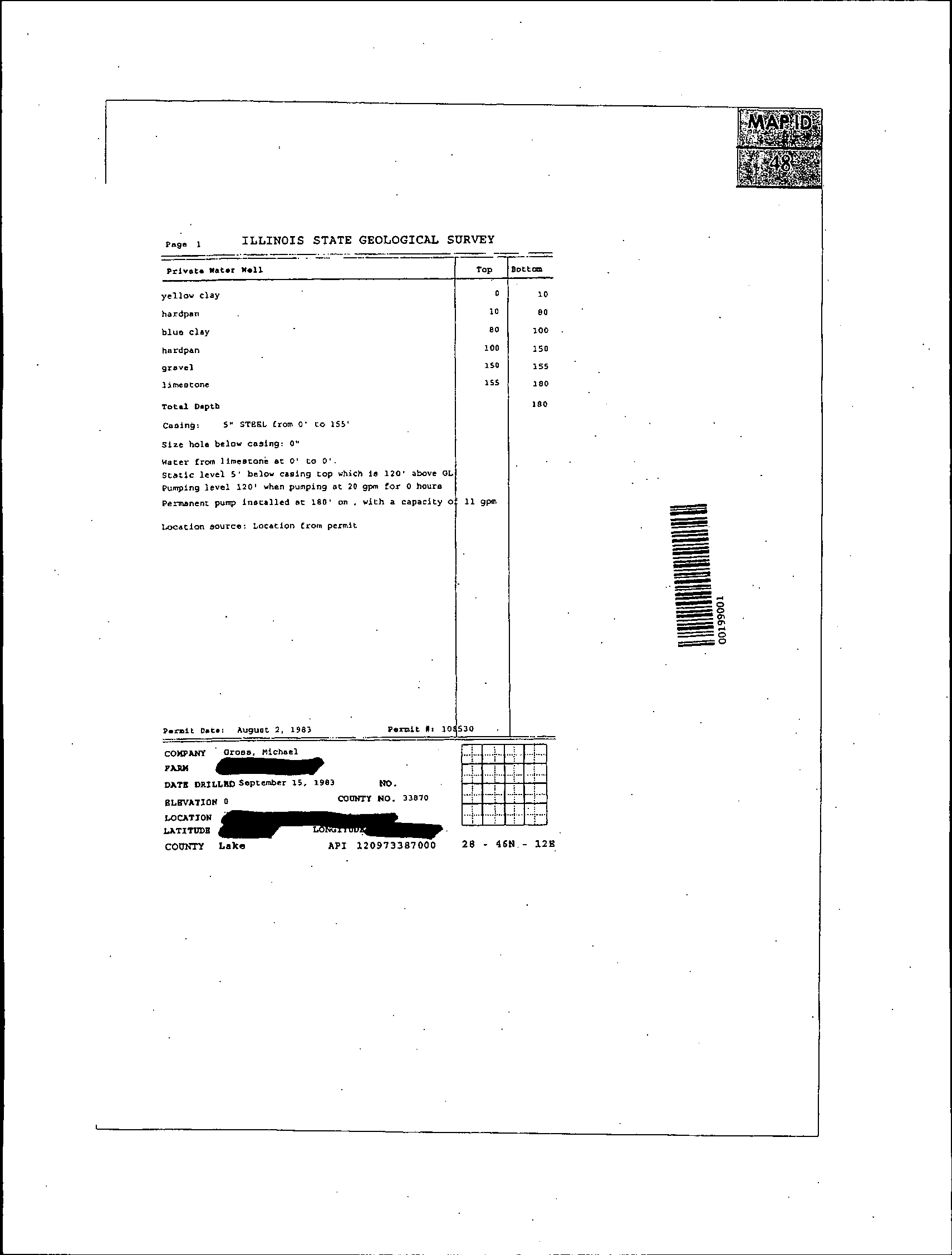

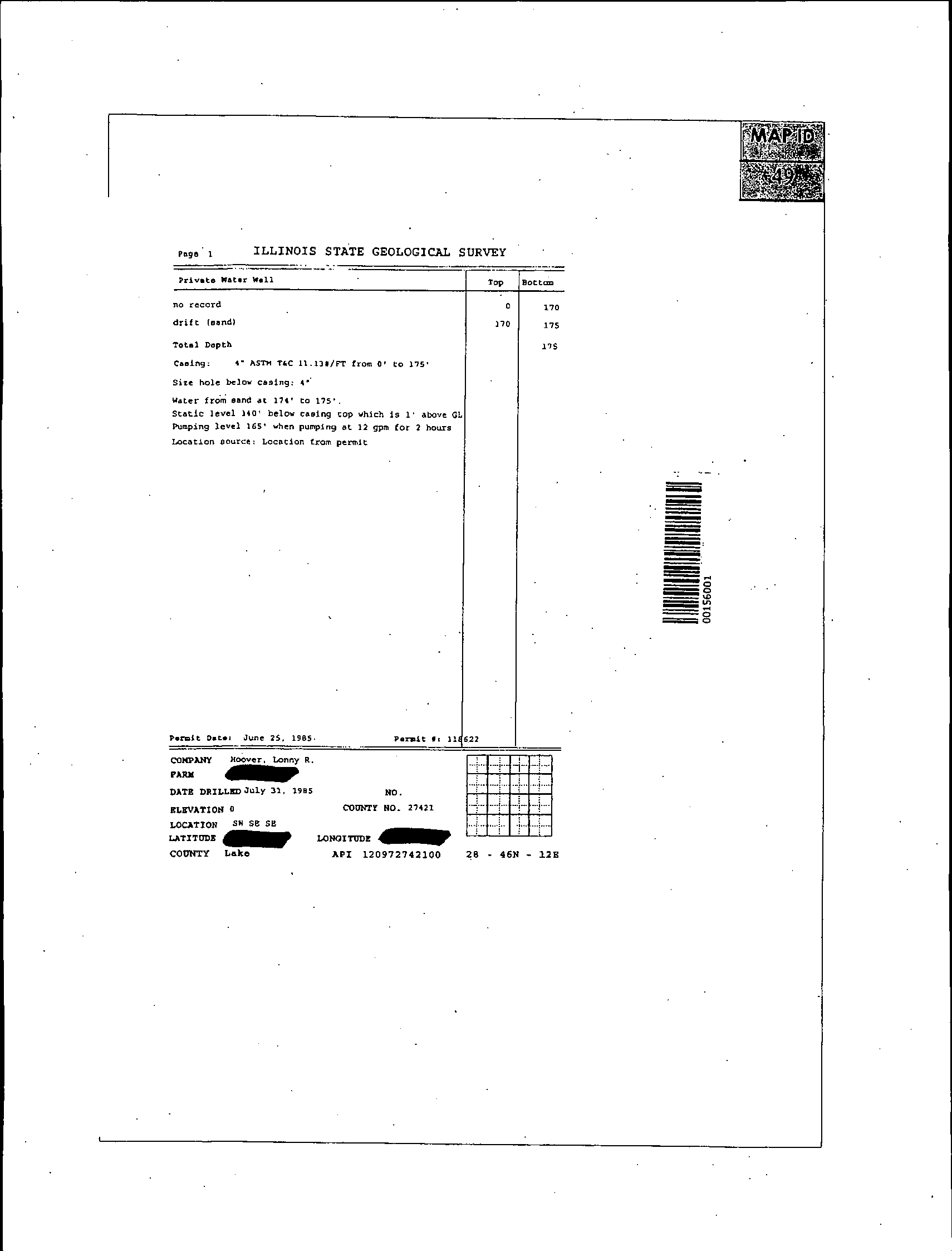

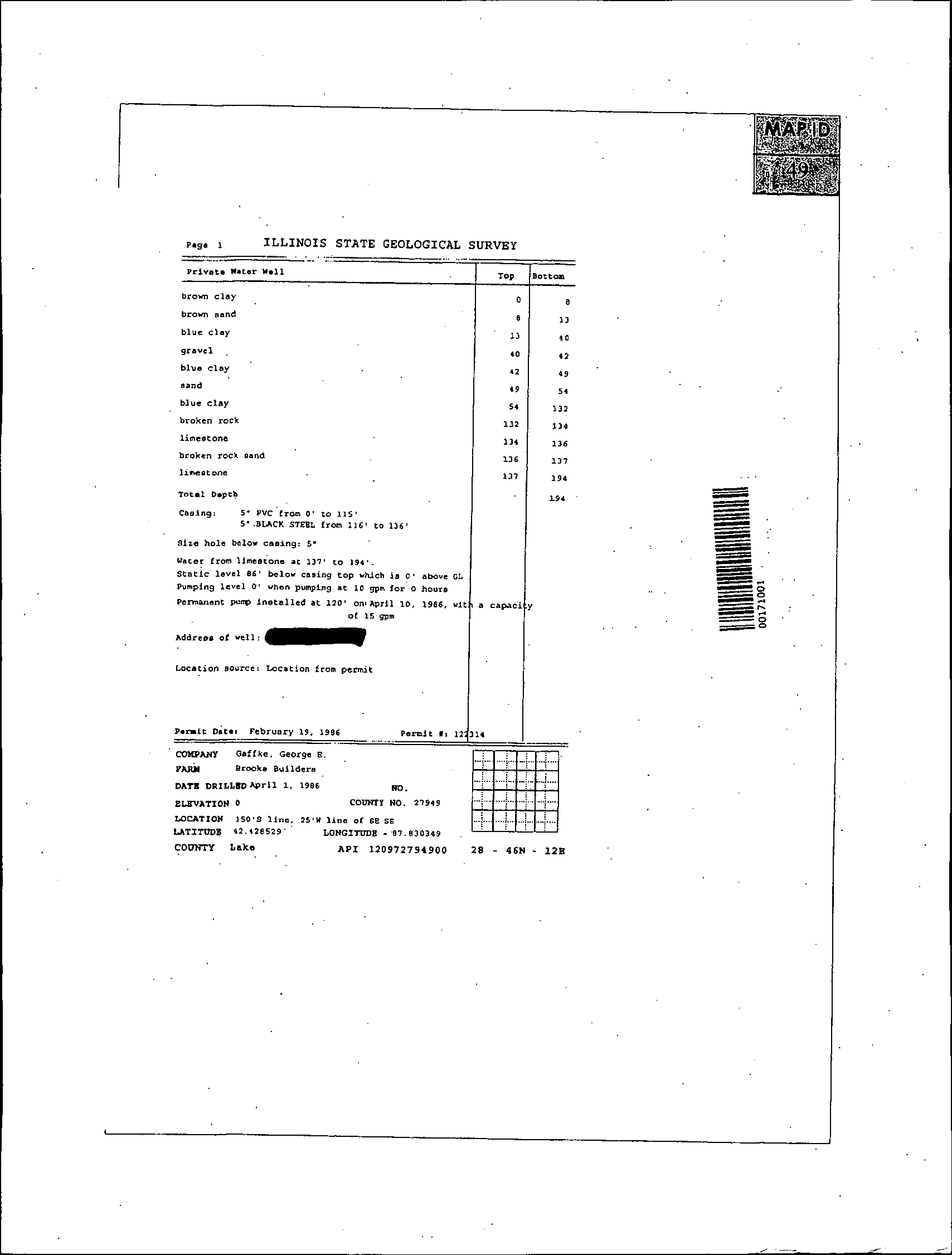

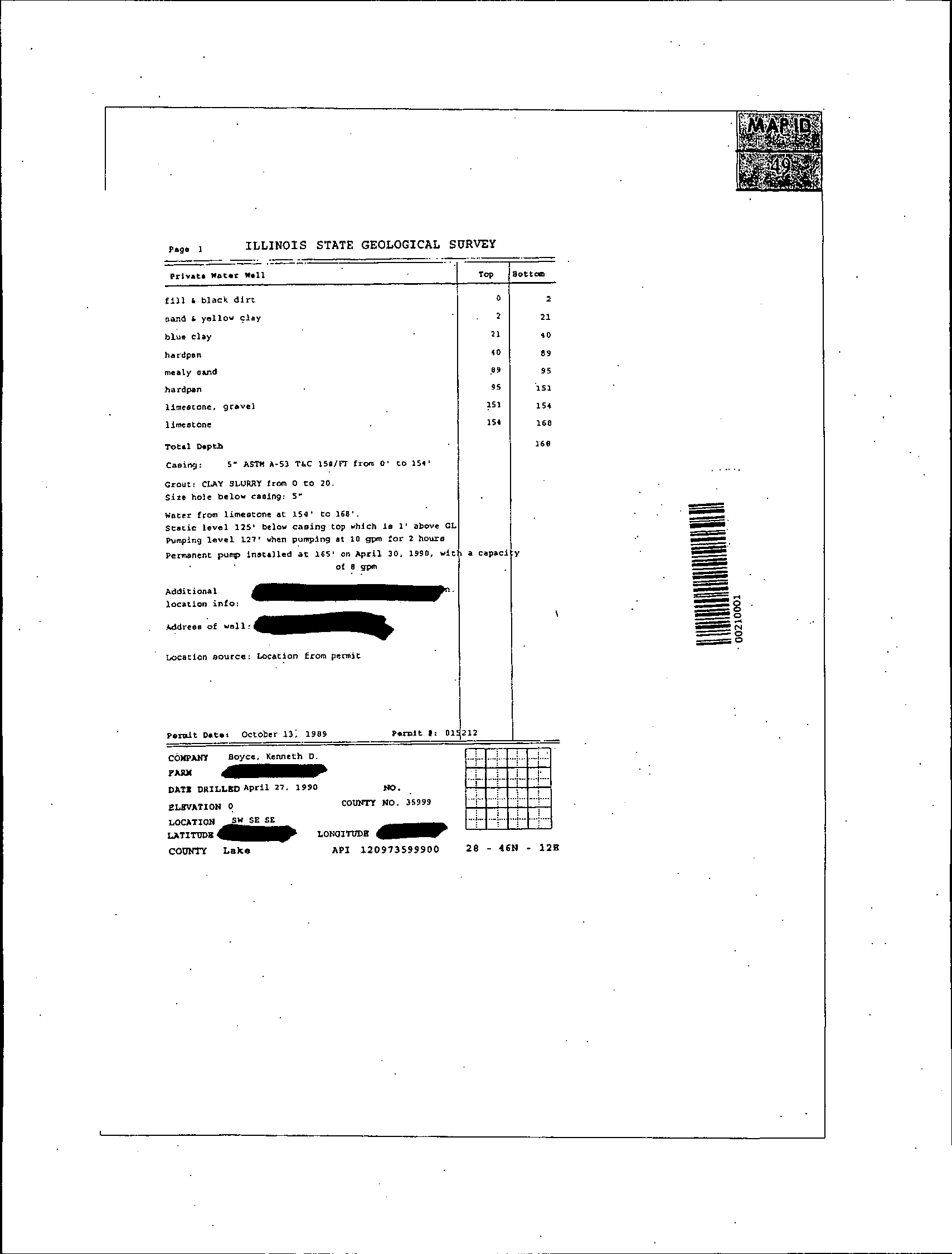

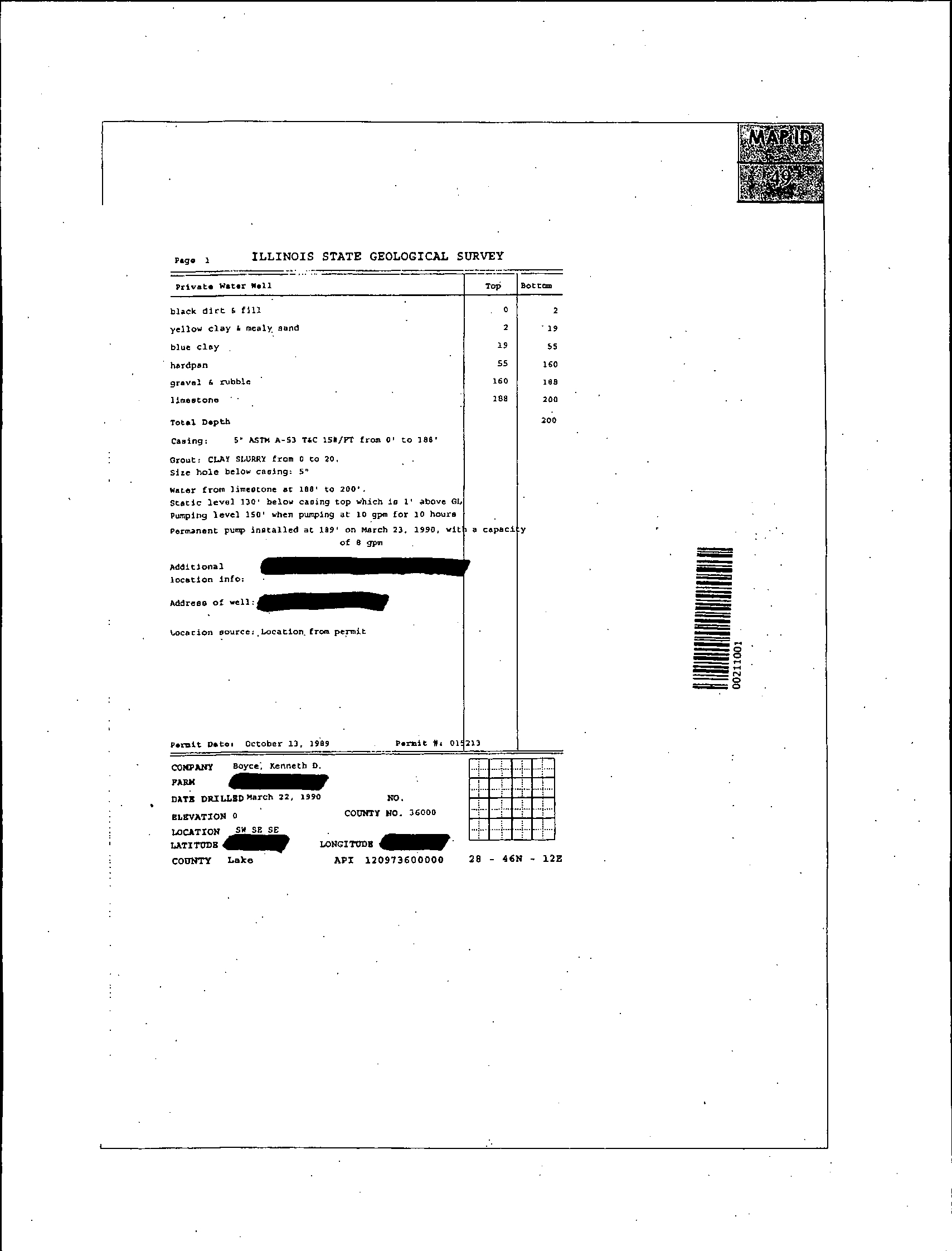

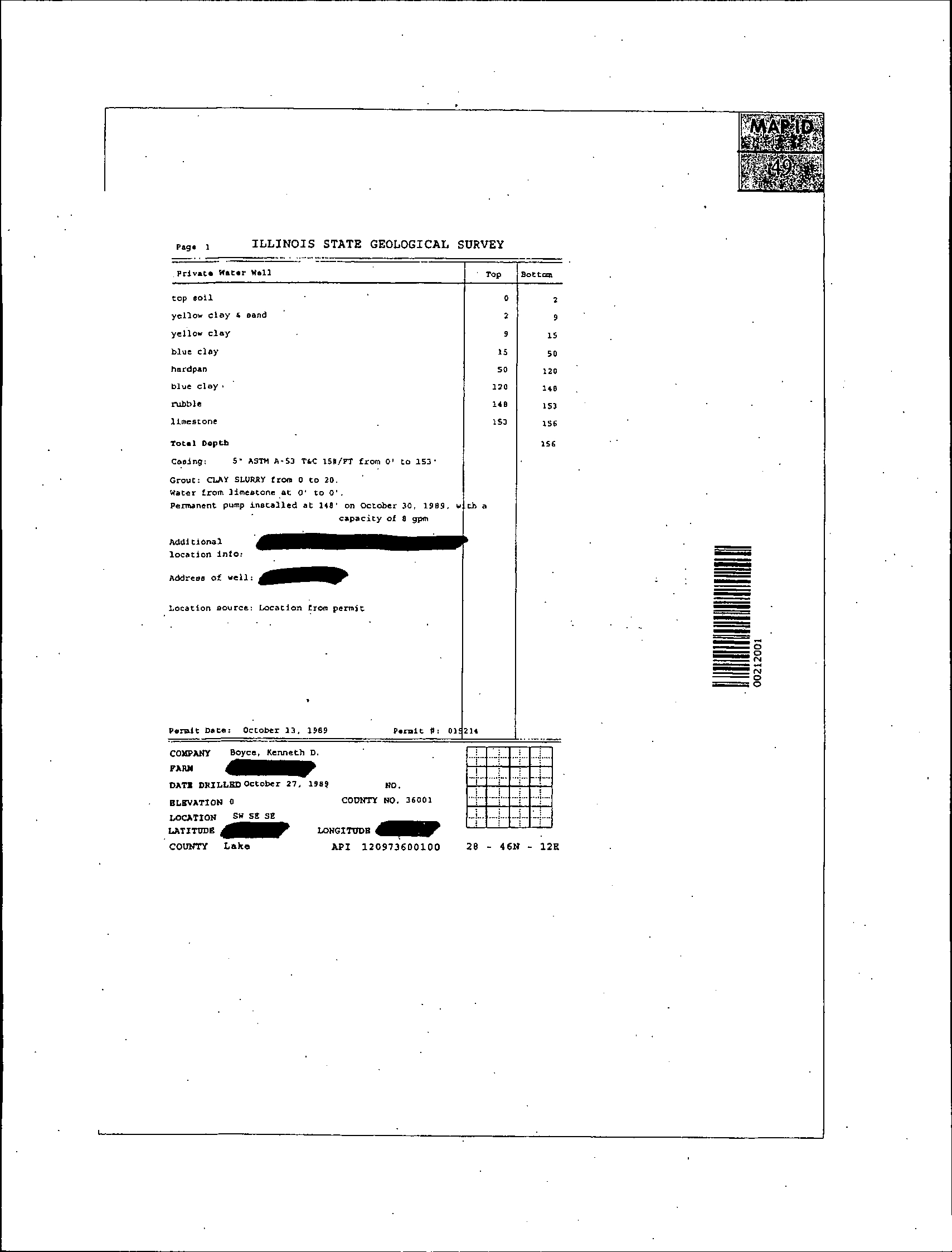

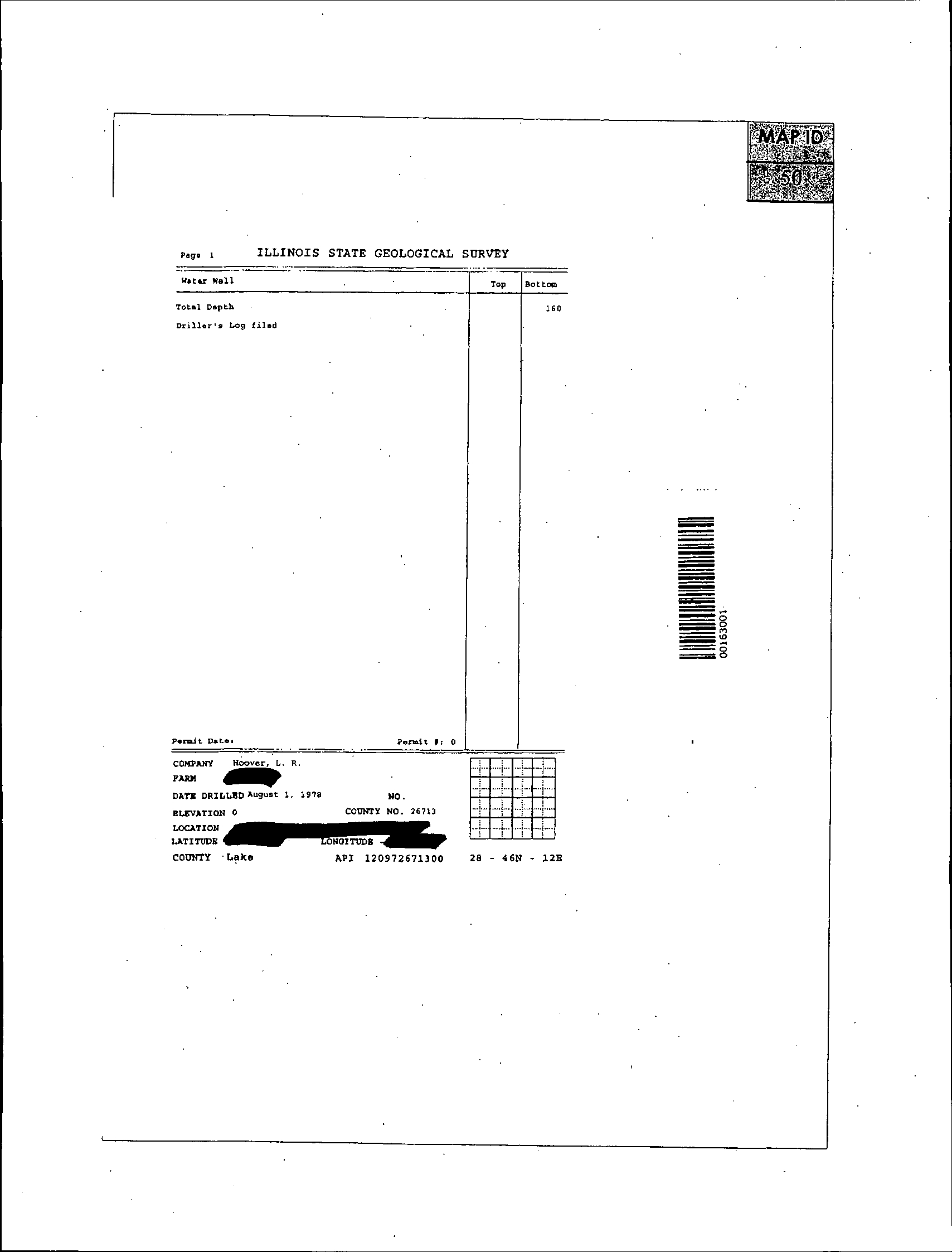

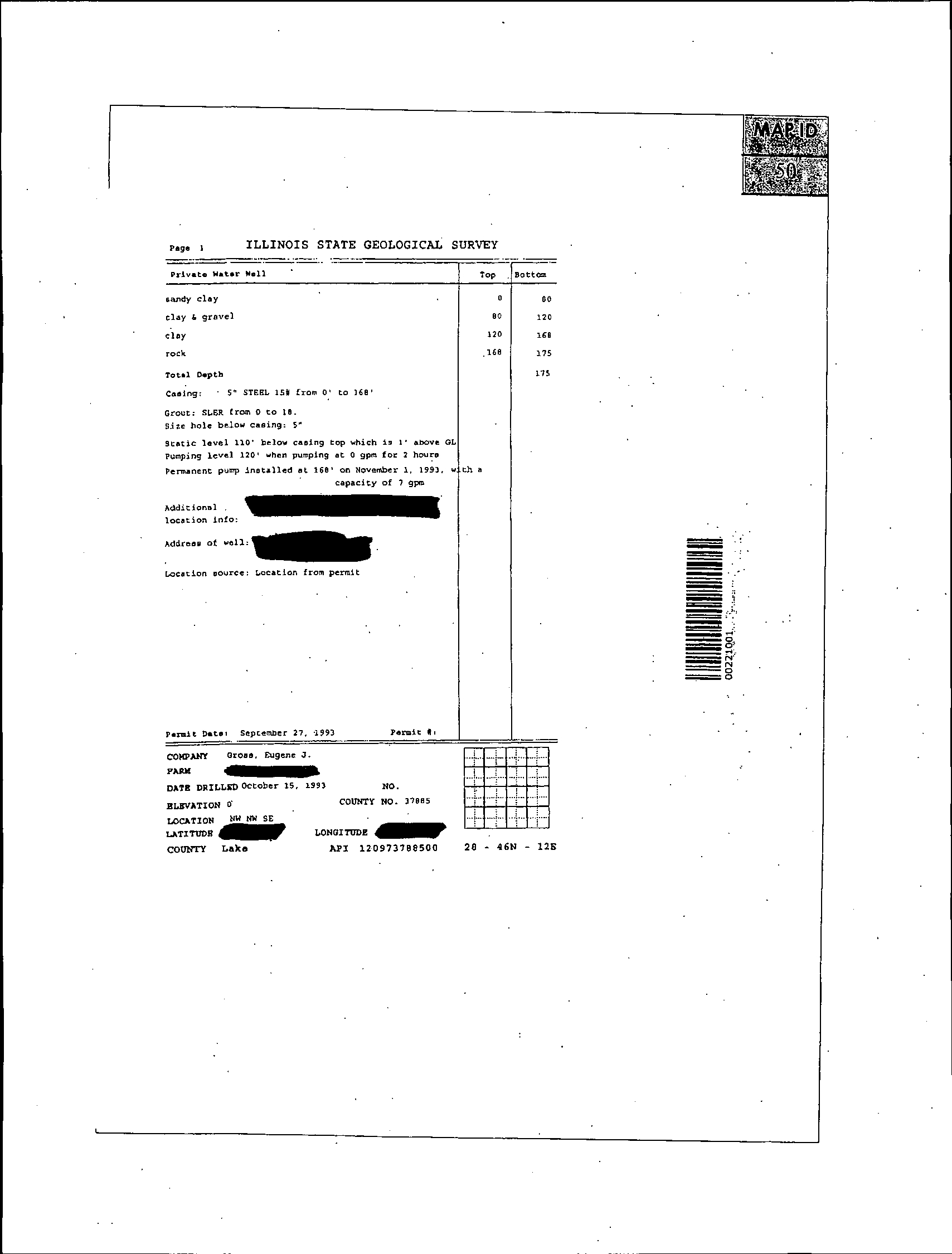

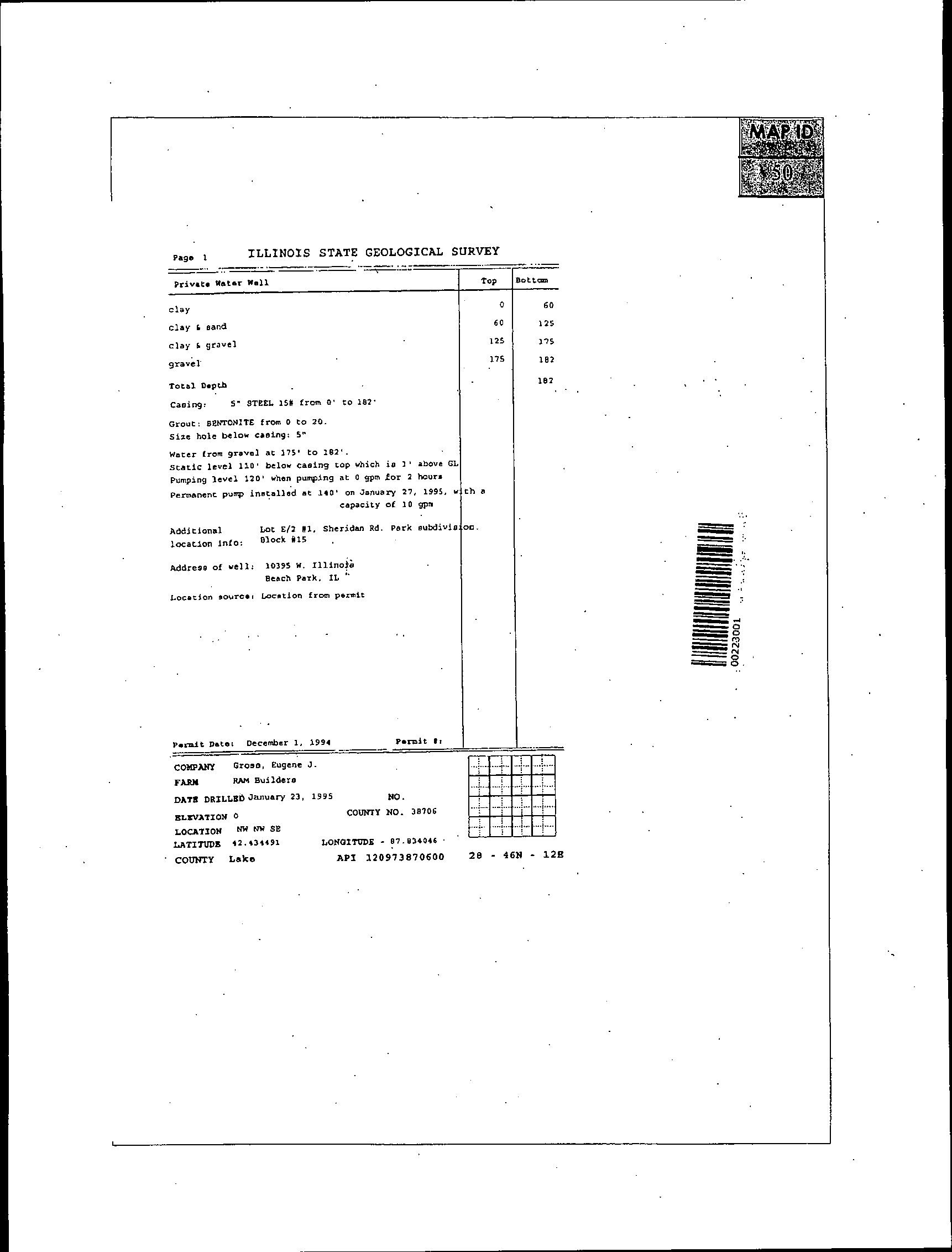

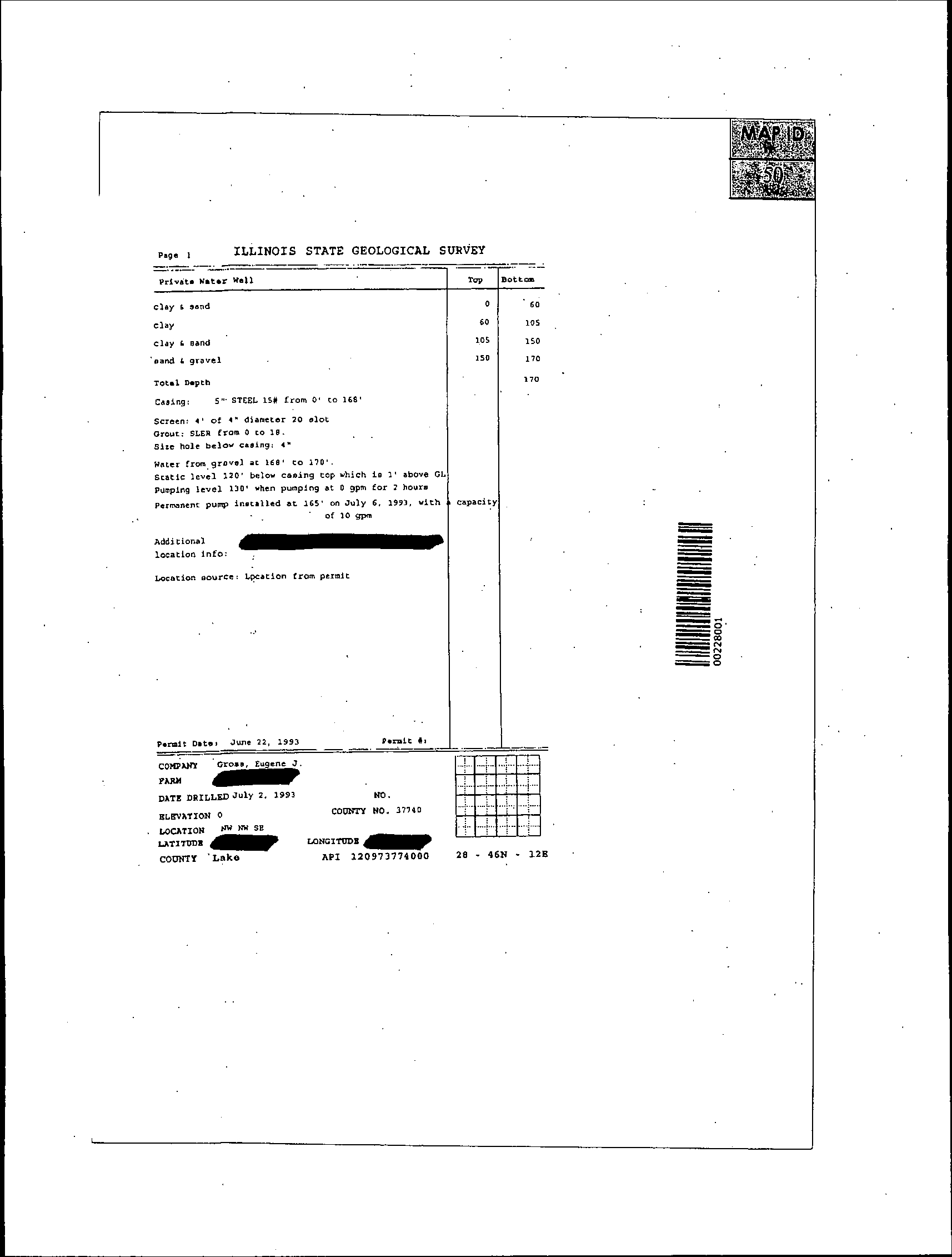

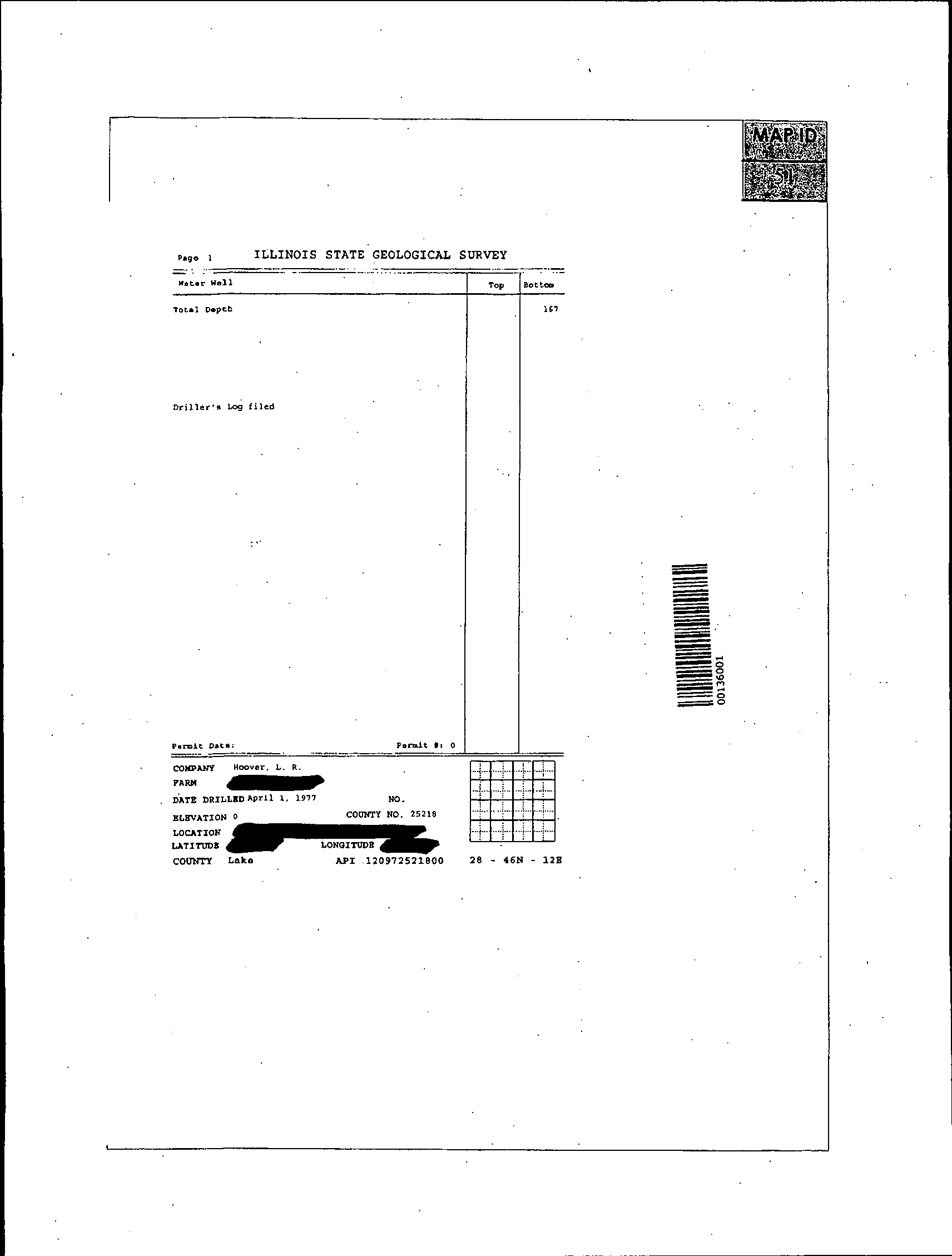

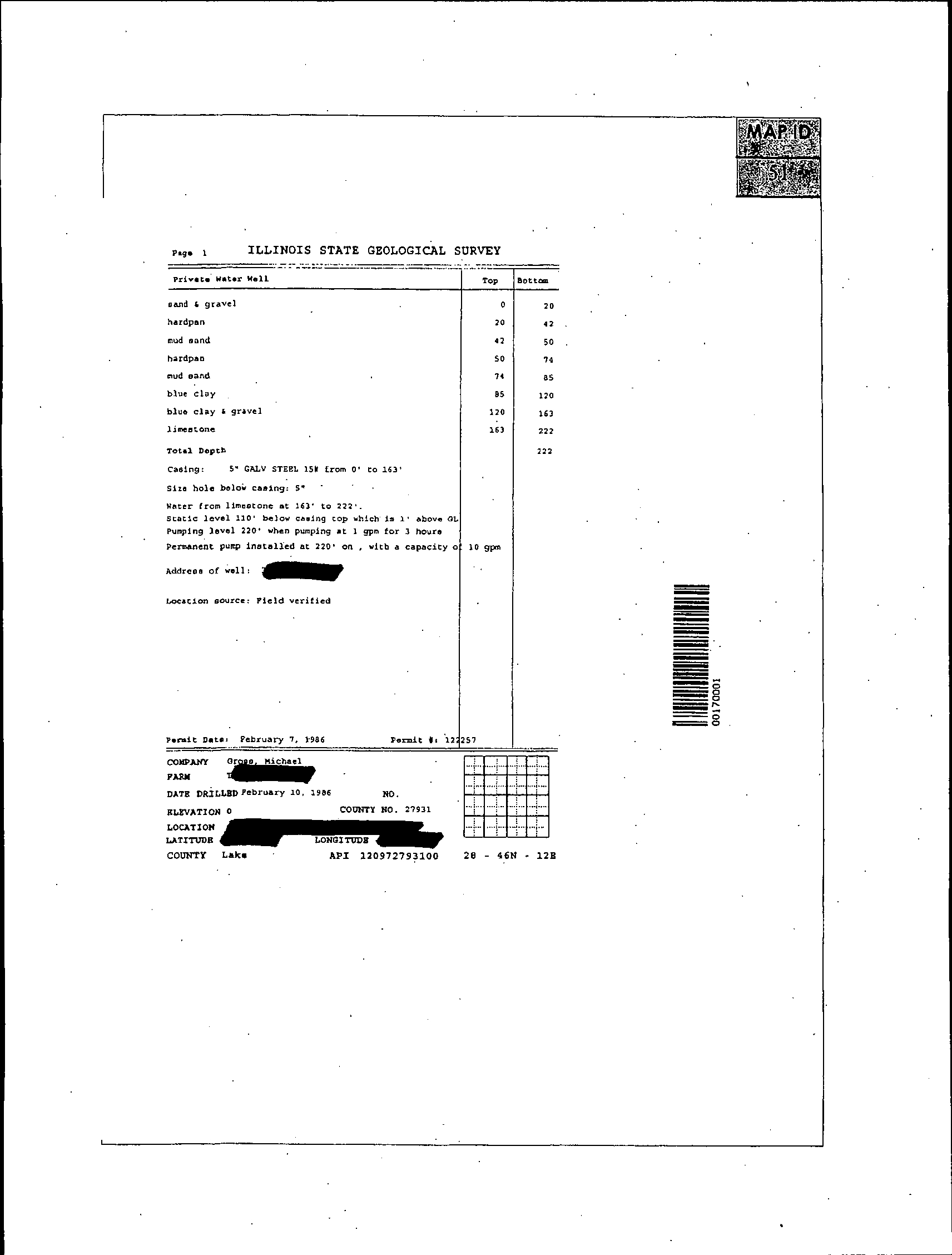

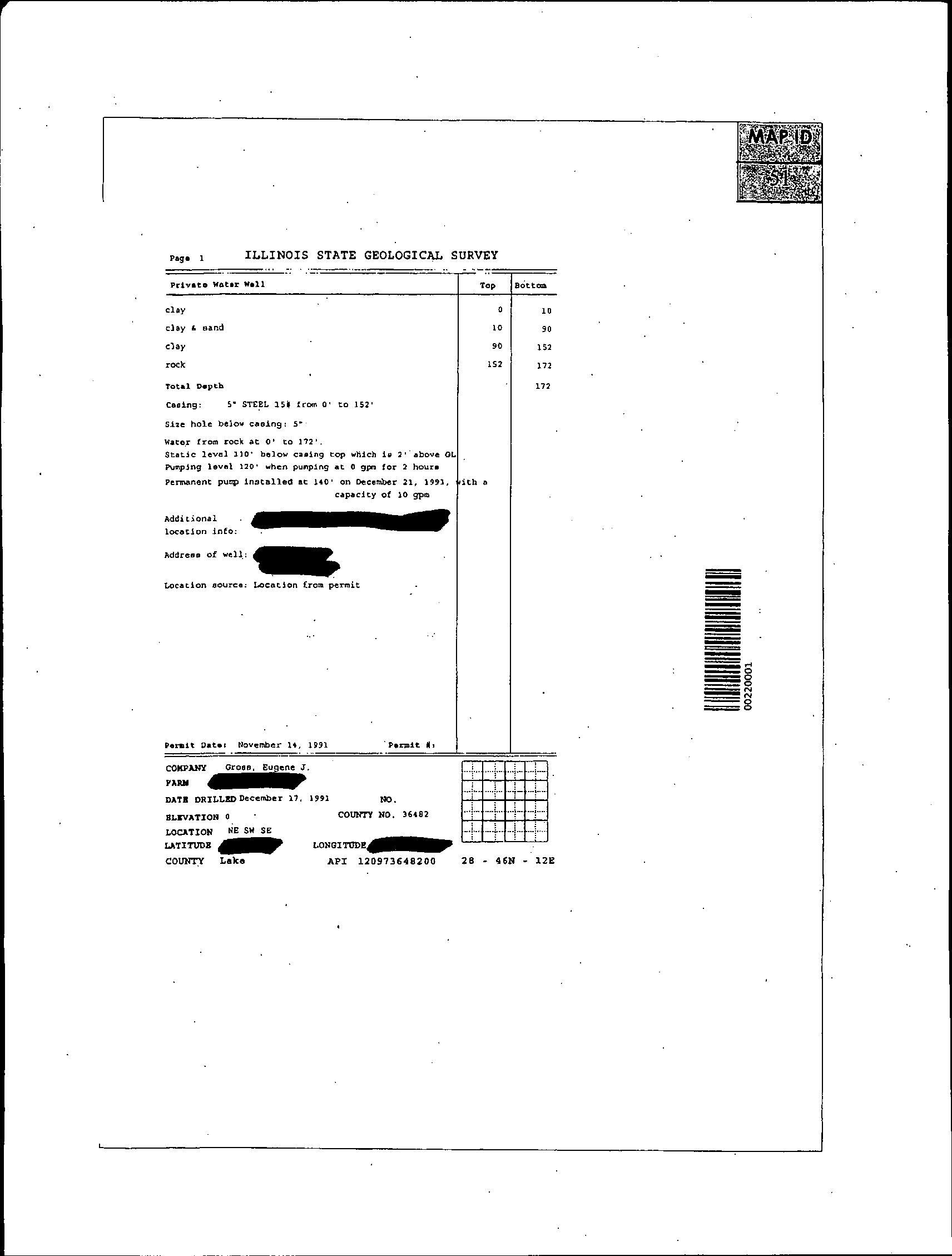

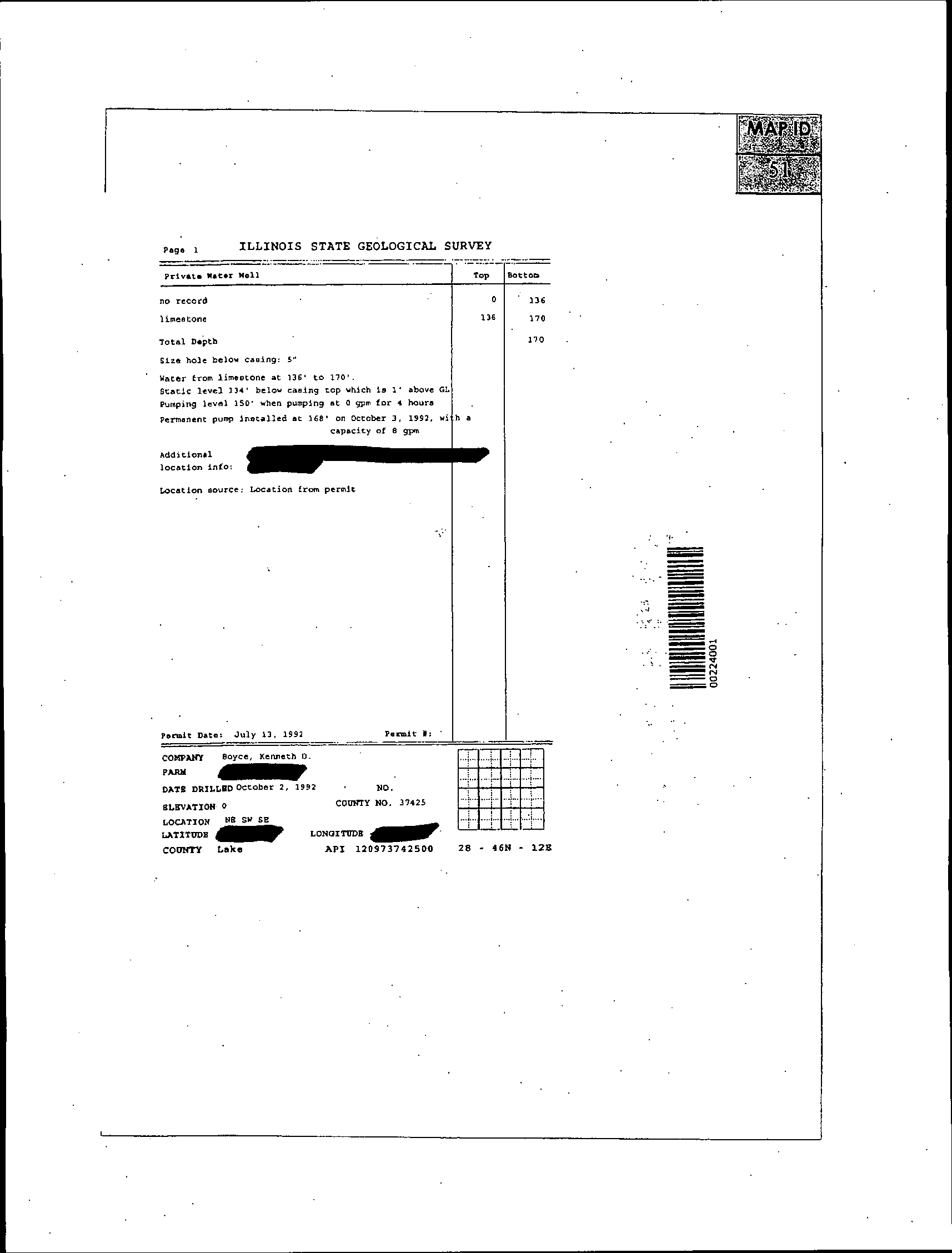

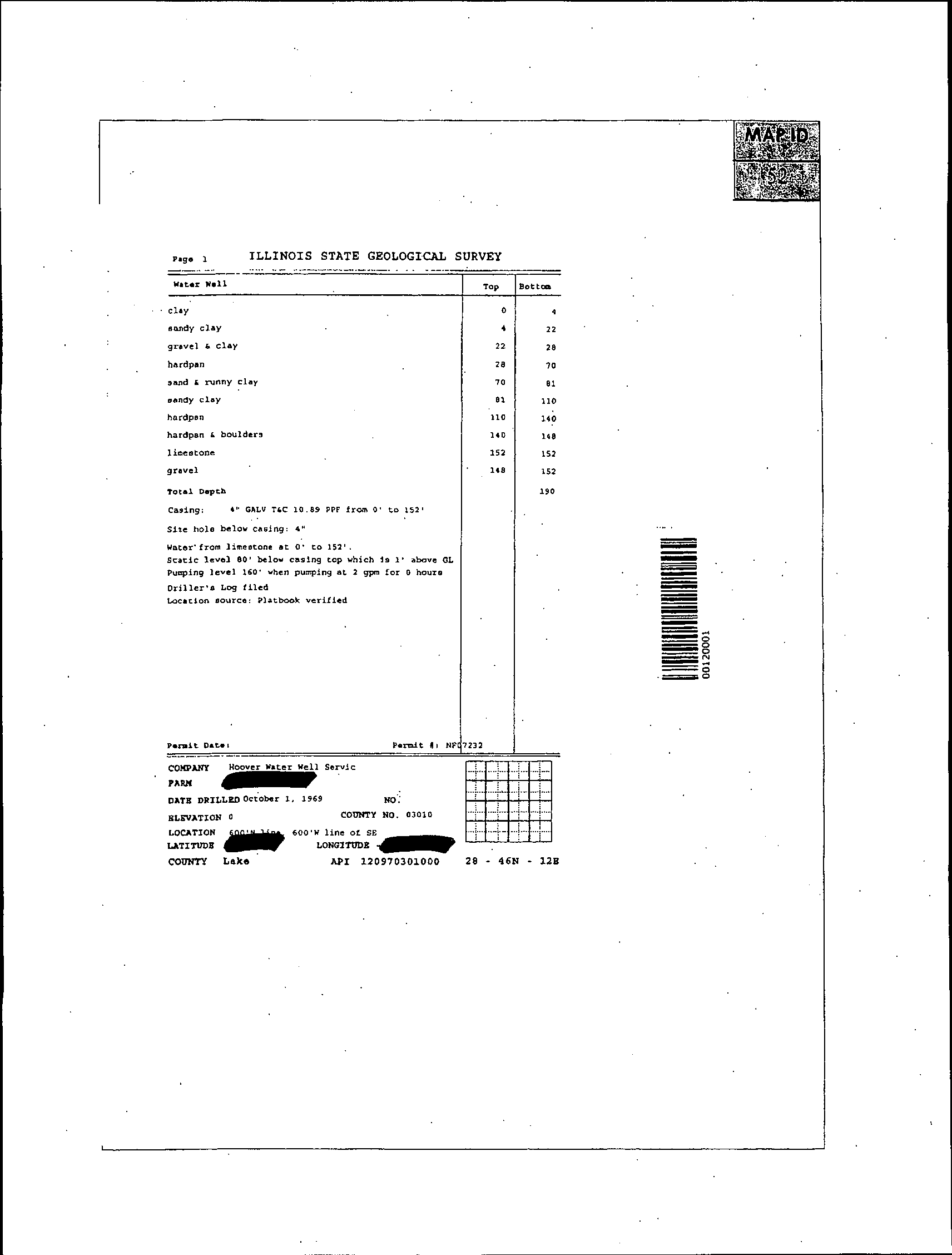

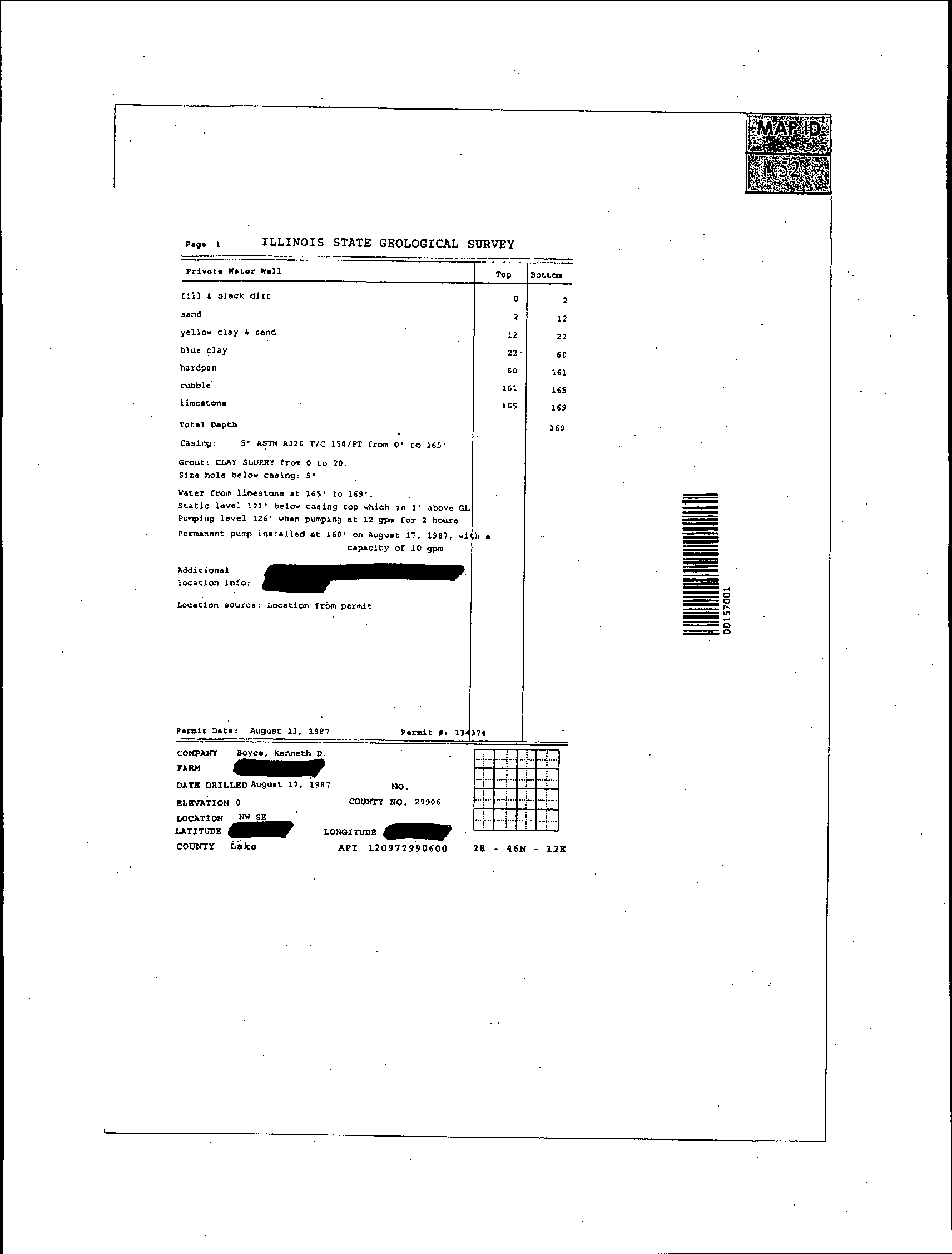

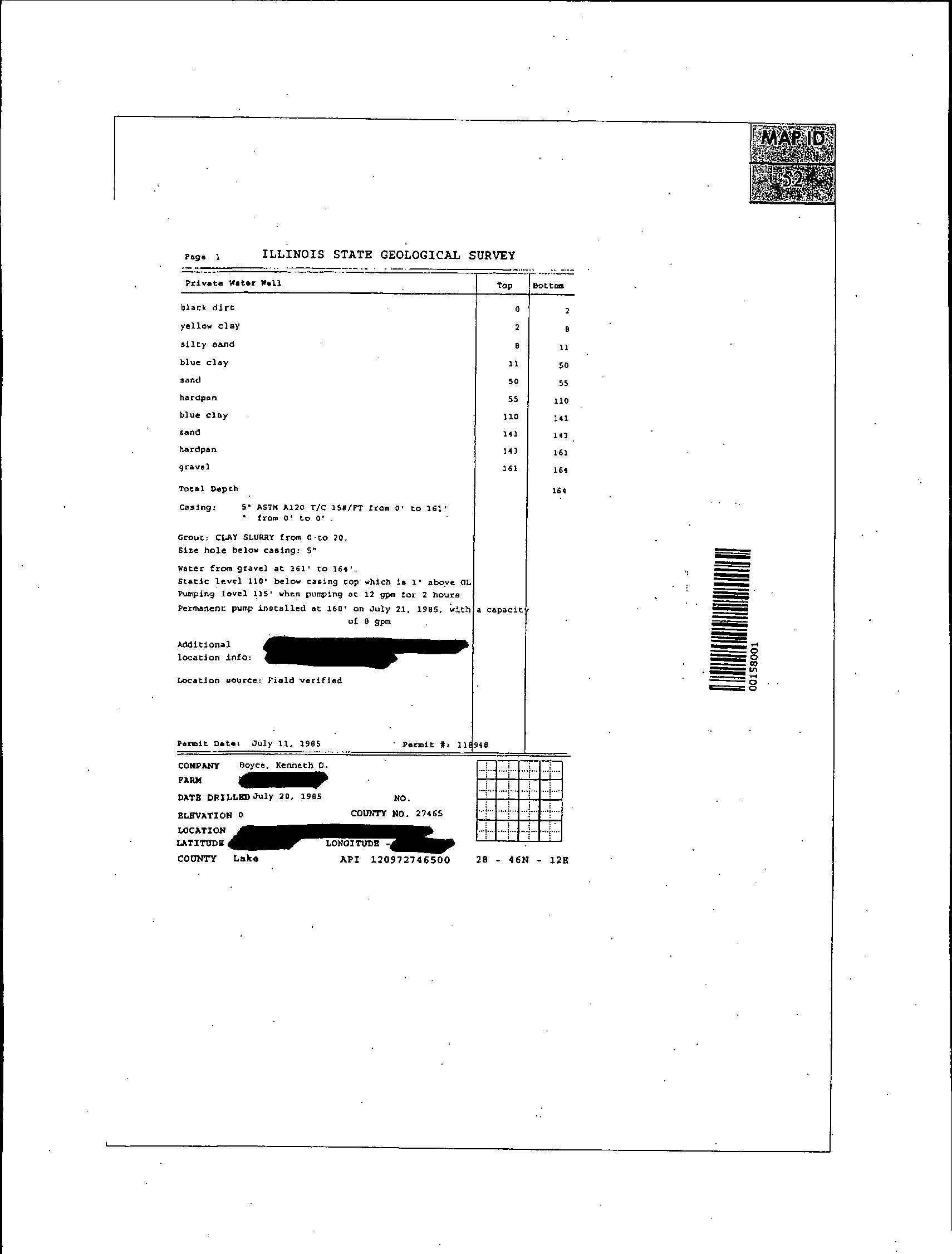

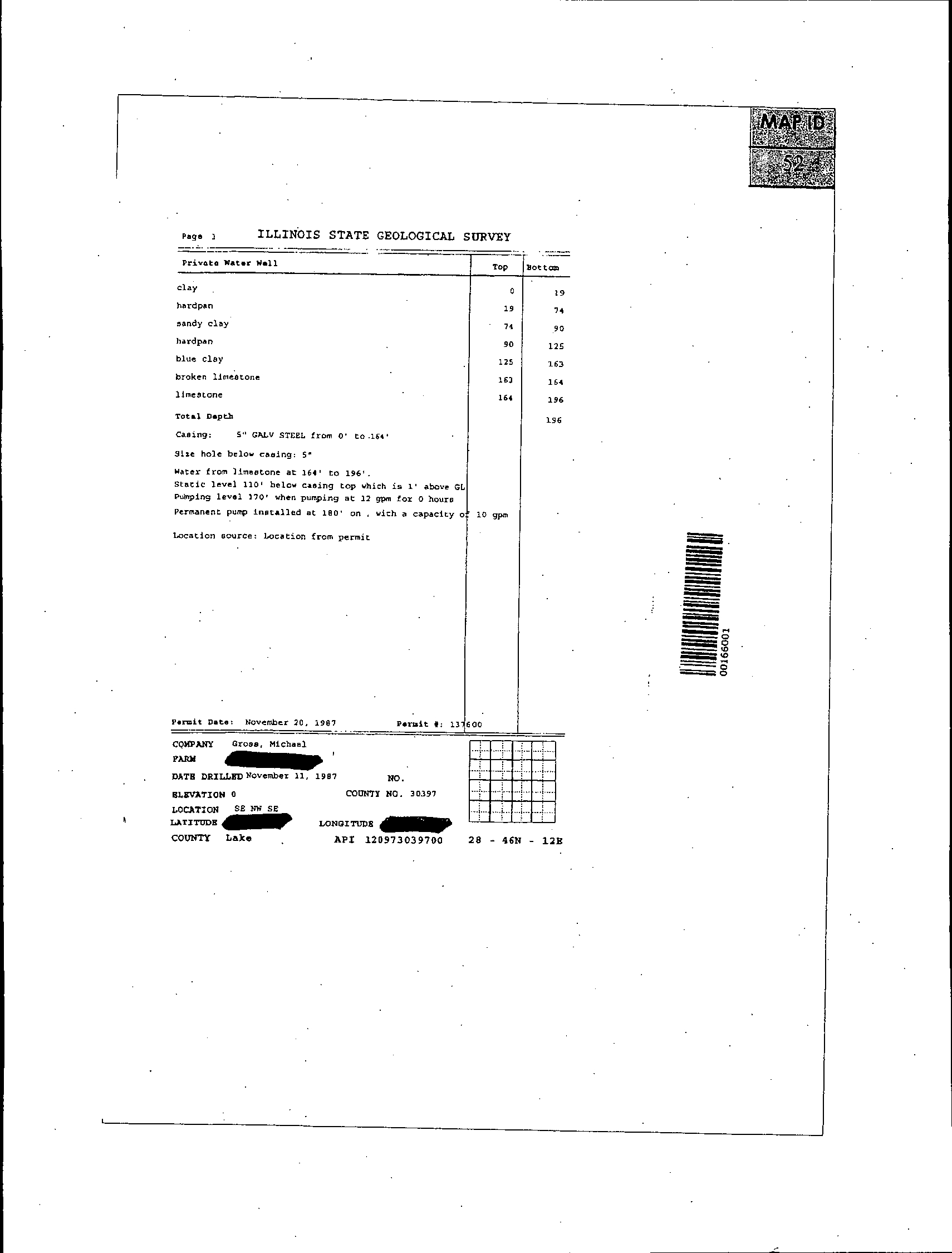

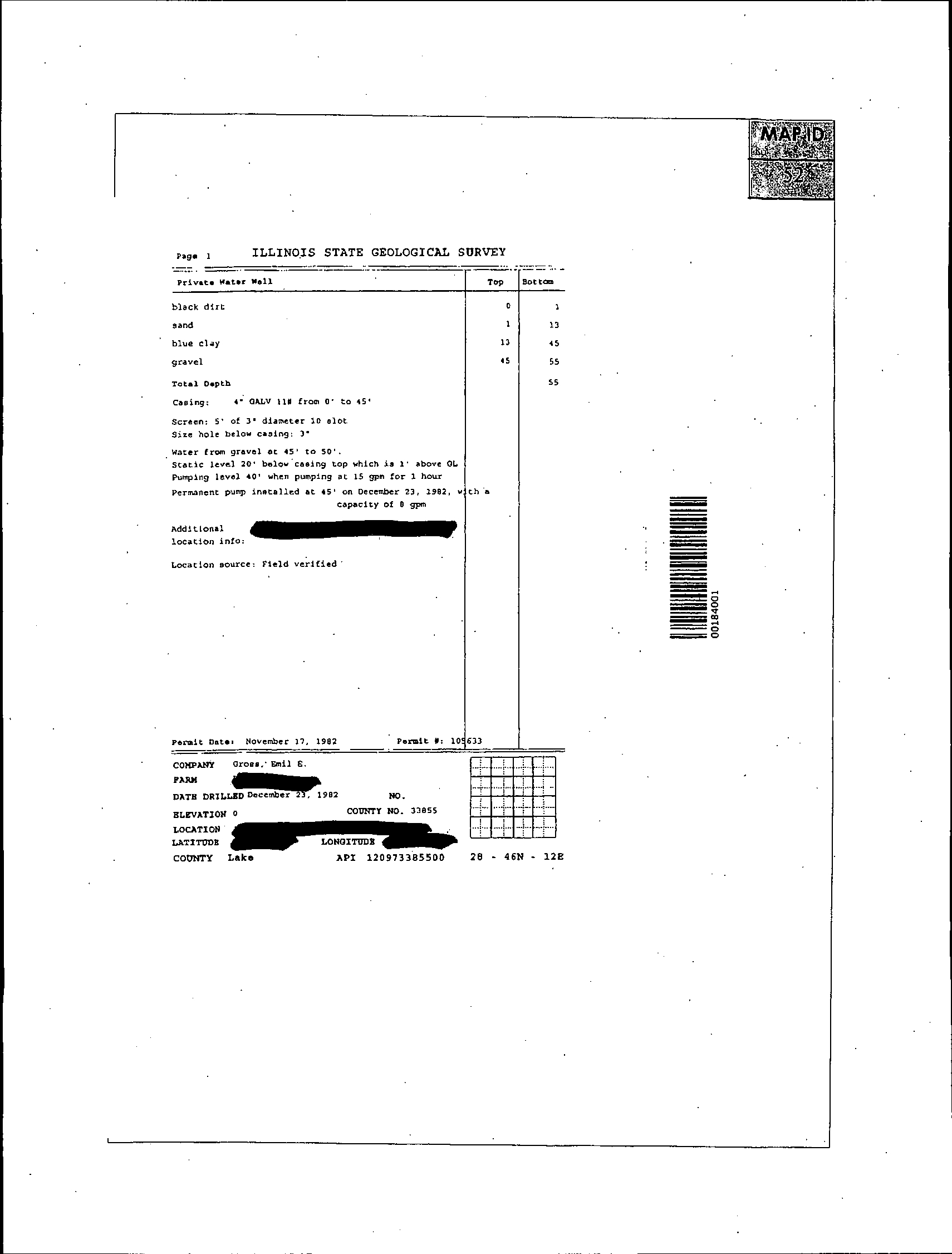

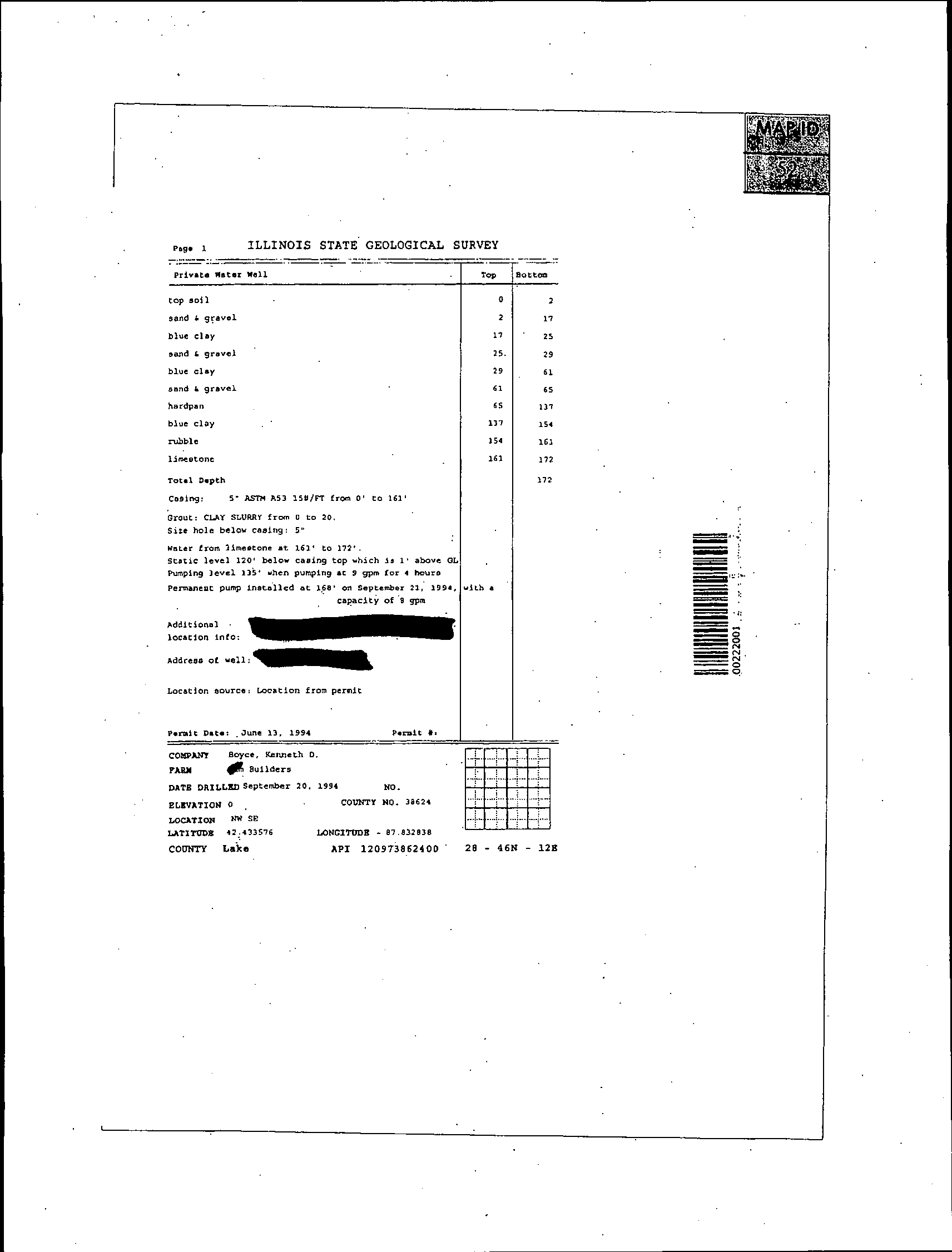

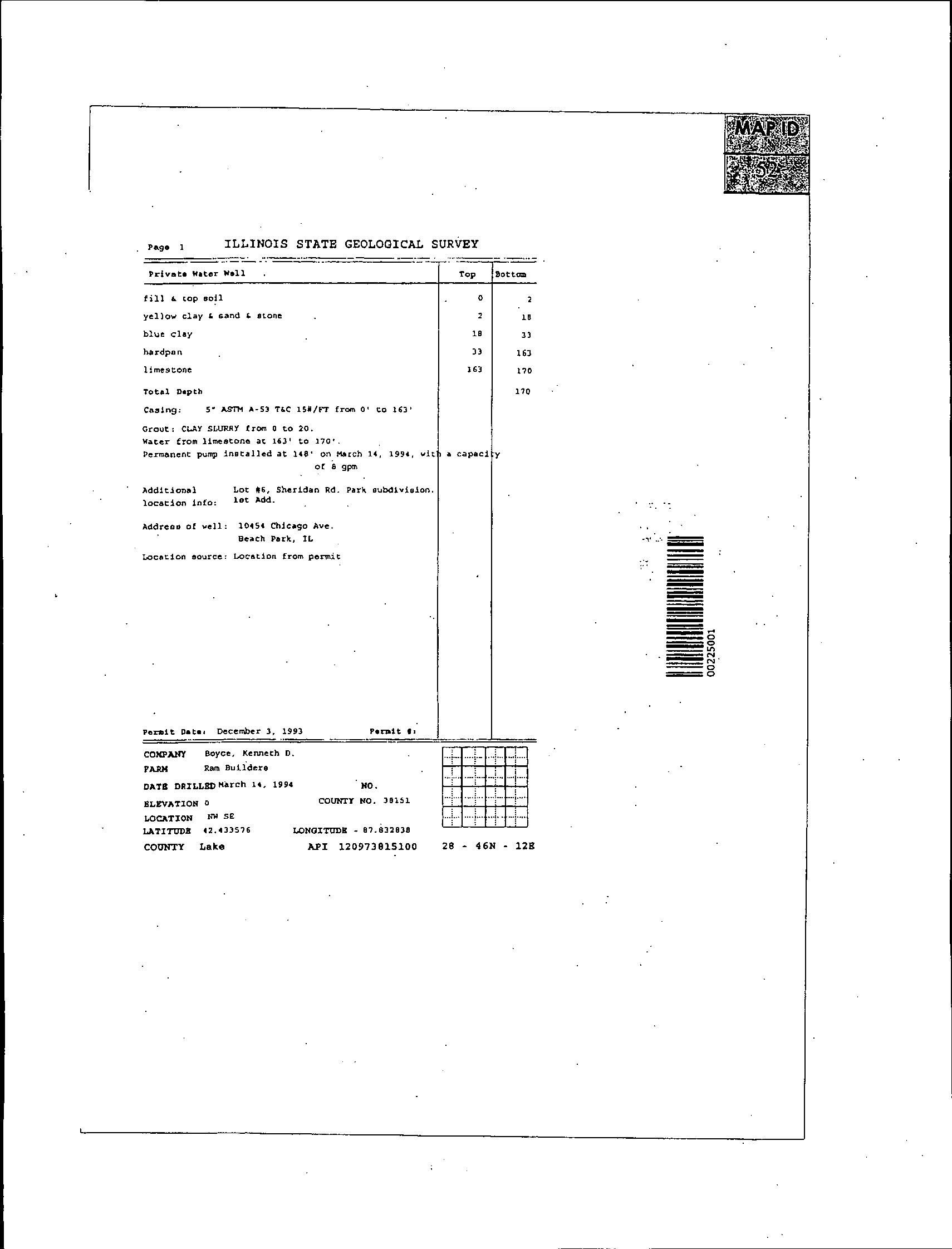

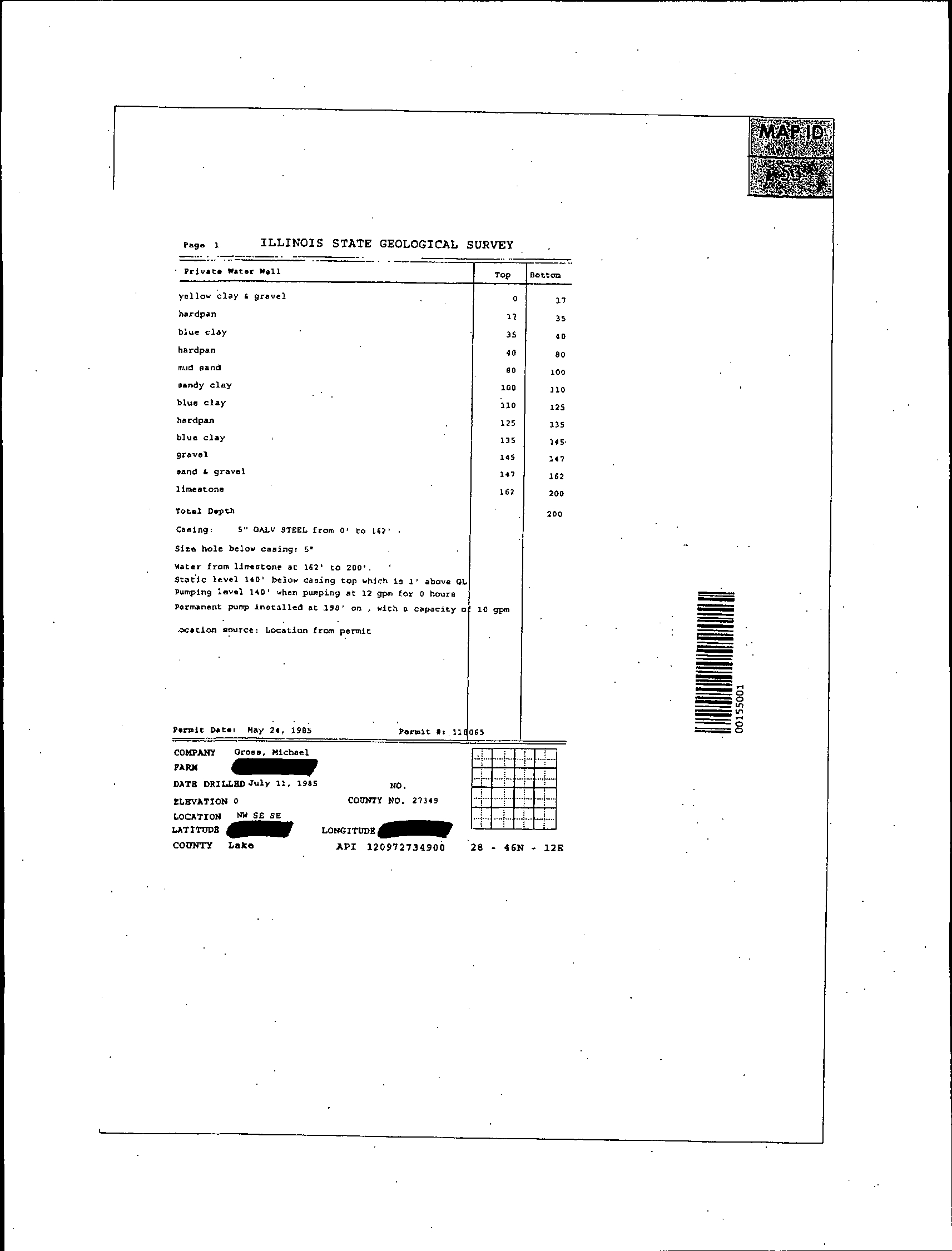

A water well inventory compiled as part of this investigation indicates a number of

wells located (or formerly located) near the Station. The locations of wells in the vicinity

of the Station are provided on Figure 2.4. A water well report was prepared using

Illinois water well databases and associated well logs, and is provided in Appendix A.

The well records for locations nearest to the Station (map identifiers 5, 6, and 10) are

mis-located (Map Id. 5

1

), not a water well (Map Id. 6

2

), or no longer exist (Map Ids. 6

and 10

3

). With the exception of Map Ids. 6 and 10, the wells identified in the water well

report have not been field verified and it is expected that many of the wells listed have

been abandoned.

The City of Zion provides municipal water to the City residents and the surrounding

area. The City purchases water from the Lake County Public Water District (LCPWD).

The LCPWD obtains its water from Lake Michigan by means of an intake pipe located

approximately 1.1 mile north of the Station and extending 3,000 feet into the Lake. The

City of Zion municipal code requires all improved properties to be connected to the

City's water supply. It is "unlawful for any person to construct, permit or maintain a

private well or water supply system within the City which uses groundwater as a

potable water supply" (City of Zion, 2004). The only exception is for existing wells

constructed prior to March 2, 2004 at properties located more than 100 feet from the

municipal supply system, which must: 1) enter into an agreement with the City, and

2) demonstrate that the well water is unlikely to contain any contaminant at

concentrations exceeding the United States Environmental Protection Agency (USEPA)

drinking water standards (City of Zion, 2004).

The Station is connected to the Zion municipal water supply and does not use

groundwater in its operations. The Illinois Beach State Park is serviced by municipal

water.

1

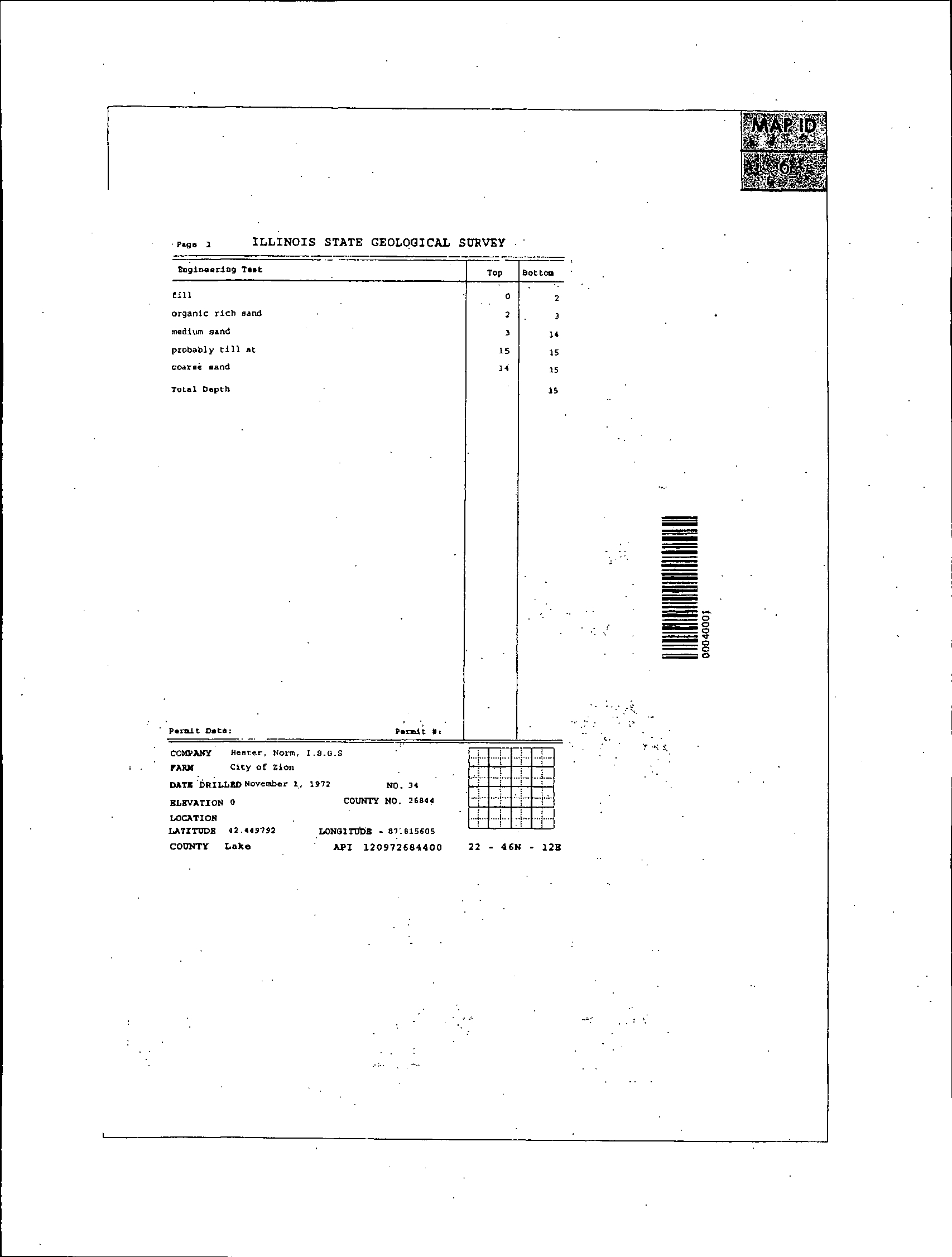

Map ID 5 is a private water well at Lot #1, Beach Homeland subdivision, Beach Park, Illinois.

The latitude and longitude listed in the ISWS database is inconsistent with the address listed in

the well log (Beach Park is located between Zion and Waukegan).

2

Map ID 6 is an engineering test hole installed by Norm Hester of the ISGS on November 1, 1972.

The total depth was 15 feet. This boring was installed as part of a study documented in Fraser

and Hester (1974).

045136 (22) Zion Station

8

CONESTOGA-ROVERS & ASSOCIATES

3

Map ID 10 is a water well installed by F H Ferguson at 'Zion Estates' at an unknown date. The

total depth of the well was 138 feet. The location specified in the well record (42.446046N,

87.800889W) indicates that this well was located on the eastern edge of what is now the Zion

Station. 'Zion Estates' may have been part of the Hosah Beach subdivision (see Bannon-Nilles

2003) which was purchased by ComEd in about 1967. This well is not currently present at the

Zion Station.

Revision 1

3.0

AREAS FOR FURTHER EVALUATION

CRA considered all Station operations in assessing groundwater quality at the Station.

During this process, CRA identified areas at the Station that warranted further

evaluation or "AFEs". This section discusses the process by which AFEs were selected.

CRA's identification of AFEs involved the following components:

•

Station inspection on March 22 to 23, 2006;

•

interviews with Station personnel;

•

evaluation of Station systems;

•

investigation of confirmed and unconfirmed releases of radionuclides; and

•

review of previous Station investigations.

CRA analyzed the information collected from these components combined with

information obtained from CRA's study of hydrogeologic conditions at the Station to

identify those areas where groundwater potentially could be impacted from operations

at the Station.

CRA then designed an investigation to determine whether any confirmed or potential

releases or any other release of radionuclides adversely affected groundwater. This

entailed evaluating whether existing Station groundwater monitoring systems were

sufficient to assess the groundwater quality at the AFEs. If the systems were not

sufficient to adequately investigate groundwater quality associated with any AFE,

additional monitoring wells were installed by CRA.

The following sections describe the above considerations and the identification of AFEs.

The results of CRA's investigation are discussed in Section 5.0.

3.1

SYSTEMS EVALUATIONS

Exelon launched an initiative to systematically assess the structures, systems and

components that store, use, or convey potentially radioactively contaminated liquids.

Maps depicting each of these systems were developed and provided to CRA for review.

The locations of these systems are presented on Figure 3.1. The Station identified a total

of 17 systems that contain or could contain potentially radioactively contaminated

liquids. The following presents a list of these systems.

045136 (22) Zion Station

9

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

System Identification

Description

AD

Auxiliary Drains

AX

Auxiliary Steam

BD

Blowdown System

CF

Cavity Fill

CW

Circulating Water

VC

Chemical and Volume Control

CC

Component Cooling

CD/SC

Condensate and Condensate Storage

MS

Main Steam

PW

Primary Water

RR

Resin Removal

SI

Safety Injection

SW

Service Water

SF

Spent Fuel

TD

Turbine Building Drains

WD

Waste Disposal

WT

Waste Water

After these systems were identified, Exelon developed a list of the various structures,

components and areas of the systems (e.g., piping, tanks, and process equipment) that

handle or could potentially handle any radioactively contaminated liquids.

The

structures, components, and areas may include:

•

aboveground storage tanks;

•

condensate vents;

•

areas where confirmed or potential historical releases, spills, or accidental discharges

may have occurred;

•

pipes;

•

pools;

•

sumps;

•

surface water bodies (i.e., basins, pits, ponds, or lagoons);

•

trenches;

•

underground storage tanks; and

•

vaults.

045136 (22) Zion Station

10

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

The Station then individually evaluated the various system components to determine

the potential for any release of radioactively contaminated liquid to enter the

environment.

Each structure or identified component was evaluated against the

following seven primary criteria:

•

location of the component (i.e., basement or second floor of building);

•

component construction material (i.e., stainless steel or steel tanks);

•

construction methodologies (i.e., welded or mechanical pipe joints);

•

concentration of radioactively contaminated liquid stored or conveyed;

•

amount of radioactively contaminated liquid stored or conveyed;

•

existing controls (i.e., containment and detection); and

•

maintenance history.

System components, which were located inside a building or that otherwise had some

form of secondary containment, such that a release of radioactively contaminated liquid

would not be discharged directly to the environment, were eliminated from further

evaluation. System components that are not located within buildings or did not have

some other form of secondary containment were retained for further qualitative

evaluation of the risk of a release of radioactively contaminated liquid to the

environment and the potential magnitude of any release.

Exelon's risk evaluation took into consideration factors such as:

•

the potential concentration of radionuclides;

•

the volume of liquid stored or managed;

•

the probabilities of the systems actually containing radioactively contaminated

liquid; and

•

the potential for a release of radioactively contaminated liquid from the system

component.

These factors were then used to rank the systems and system components according to

the risk for a potential release of a radioactively contaminated liquid to the environment.

The evaluation process resulted in the identification of structures, components, and

areas to be considered for further evaluation.

045136 (22) Zion Station

11

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

3.2

HISTORICAL RELEASES

CRA also reviewed information concerning confirmed or potential historical releases of

radionuclides at the Station, including reports and documents previously prepared by

Exelon and compiled for CRA's review. CRA evaluated this information in identifying

the AFEs. Any historical releases identified during the course of this assessment that

may have a current impact on Station conditions are further discussed in Section 3.4.

3.3

STATION INVESTIGATIONS

CRA considered previous Station investigations in the process of selecting the AFEs for

the Station. This section presents a summary of the pre-operational radiological

environmental monitoring program (pre-operational REMP), past station investigations,

and the radiological environmental monitoring program (REMP).

3.3.1

PRE-OPERATIONAL RADIOLOGICAL

ENVIRONMENTAL MONITORING PROGRAM

A pre-operational REMP was conducted to establish background radioactivity levels

prior to operation of the Station. The environmental media sampled and analyzed

during the pre-operational REMP were surface water, well water, air particulates, milk,

locally grown vegetables, and aquatic plants and animals (ComEd, 1971). The results of

the monitoring were detailed in the report entitled, 1971 Zion Station Final Safety

Analysis Report, December 1971.

The pre-operational REMP report noted that surface water was sampled at five public

water intakes. Generally, the gross beta radioactivity of Lake Michigan was less than

10 picoCuries per liter (pCi/L) with typical concentrations between 3 pCi/L to 6 pCi/L.

Gross alpha radioactivity was typically less than 3 pCi/L (ComEd, 1971).

Tritium levels in Lake Michigan water were studied in the vicinity of Zion Station

throughout 1970. The concentration of tritium in the surface water samples from the

Lake at Zion ranged from approximately 311

±

20 pCi/L to 374

±

34 pCi/L and averaged

340 pCi/L. There was no statistical difference in average tritium concentrations among

the stations (eight stations from Kenosha to Waukegan) (ComEd, 1971).

045136 (22) Zion Station

12

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

1973 Aerial Radiological Measuring System

An Aerial Radiological Measuring System (ARMS) survey was conducted at the Station

prior to the startup of the reactors in 1973. The ARMS survey was conducted using

small aircraft flying at an altitude between 300 and 500 feet.

Ground-based

measurements were obtained from two locations as part of the study.

Tritium

measurements were not included in the ARMS survey (ComEd, 1999).

The ARMS survey showed that cosmic ray exposure rate was substantially less than the

northern Illinois background radiation level (ComEd, 1999).

Soil samples contained small concentrations of uranium-238 and thorium-232.

Cesium-137 activity in soil samples ranged from 0.276 to 0.40 picoCuries per gram

(pCi/g) (ComEd, 1999).

3.3.2

RADIOLOGICAL ENVIRONMENTAL MONITORING PROGRAM

The REMP at the Station was initiated in 1973. The REMP includes the collection of

multi-media samples including air, surface water, groundwater, fish, sediment, and

vegetation. The samples are analyzed for beta and gamma-emitting radionuclides,

tritium, iodine-131, and/or strontium as established in the procedures developed for the

REMP. The samples are collected at established locations, identified as stations, so that

trends in the data can be monitored.

An annual report is prepared providing a description of the activities performed and the

results of the analysis of the samples collected from the various media. The latest report

generated was prepared by Station personnel and is entitled Final Monthly Progress

Report to Exelon Nuclear, Radiological Environmental Monitoring Program – 2005. This

report concluded that the operation of the Station had no adverse radiological impact on

the environment. The annual report is submitted to the NRC.

Prior to the cessation of power generation in 1998, surface water samples were collected

at the following six locations along Lake Michigan:

•

Kenosha, Wisconsin (intake located 10 miles north of the Station);

•

Lake County Public Water District (intake located 1.1 miles north of the Station);

•

Waukegan, Illinois (intake located 6 miles south of the Station);

•

North Chicago, Illinois (intake located 10 miles south of the Station);

045136 (22) Zion Station

13

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

•

Great Lakes NTS (intake located 13 miles south of the Station); and

•

Lake Forest, Illinois (intake located 16.5 miles south of the Station).

After 1998, surface water samples were collected at the following four locations along

Lake Michigan:

•

Kenosha, Wisconsin (intake located 10 miles north of the Station);

•

Lake County Public Water District (intake located 1.1 miles north of the Station);

•

Waukegan, Illinois (intake located 6 miles south of the Station); and

•

Lake Forest, Illinois (intake located 16.5 miles south of the Station).

Lake Michigan surface water data are collected as part of the REMP.

Tritium

concentrations in surface water samples from Lake Michigan ranged from

non-detect to 660 pCi/L.

3.3.3

DEFUELED SAFETY ANALYSIS REPORT

In October 2004, Exelon updated the Defueled Safety Analysis Report (DSAR). The

DSAR discusses the overall adequacy of the Station for safety, storing, and handling of

fuel and radioactive waste, and to monitor potential radiological effluent release paths.

It provides information on Station and local characteristics such as geography,

demography, meteorology, geology, and hydrogeology.

The DSAR states that intermittent liquid effluents from the Station will not affect

groundwater supplies in the adjacent area in excess of concentrations in 10 CFR 20 due

to local drainage patterns, release rates, and specific features of the sources of water

supplies.

The DSAR also states that the Station's radioactive liquid waste generated is collected,

treated and either recycled or discharged. Discharged liquid wastes are monitored to

assure compliance with 10 CFR 20. Radioactivity levels should not exceed permissible

concentrations at the cooling water outlet in Lake Michigan. The two closest municipal

water intakes are the LCPWD (approximately 1 mile north) and the Waukegan

Waterworks (approximately 6 miles south). The February 2005 REMP report indicates

that there have been no tritium concentrations detected in surface water samples at

concentrations exceeding the lower limit of detection (LLD) of 200 pCi/L.

045136 (22) Zion Station

14

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

3.3.4

WISCONSIN DEPARTMENT OF HEALTH AND

FAMILY SERVICES MONITORING

The Wisconsin Public Health Statutes 254.41 mandates the Department of Health and

Family Services (DHFS) to conduct environmental radiation monitoring around the

nuclear power facilities that impact Wisconsin.

The Station is included in this

monitoring due to its proximity to the Wisconsin border.

In the 2004 Zion

Environmental Radioactivity Survey, the Wisconsin DHFS concluded:

•

air particulate analysis shows no evidence of influence by the Station on air quality;

•

the average yearly exposure of ambient gamma radiation is at background levels

and is comparable to other areas within Wisconsin;

•

the surface water samples showed no unusual concentrations of gross beta, gross

gamma, tritium, and strontium;

•

the gamma isotopic analysis for surface water indicated radioisotopes below their

respective minimum detectable concentration;

•

the gamma isotopic analysis on vegetation detected only a small amount of the

naturally occurring elements potassium-40 and beryllium-7;

•

the gamma isotopic analysis for soil detected potassium-40 and cesium-137. These

were also detected in previous years and are naturally occurring (potassium-40) or

attributable to fallout from previous atmospheric nuclear tests (cesium-137); and

•

doses of radiation as a result of gaseous and liquid effluent are less than the limits

allowed for an average individual as stated in Federal Regulations.

3.4

IDENTIFIED AREAS FOR FURTHER EVALUATION

CRA used the information presented in the above sections along with its understanding

of the hydrogeology at the Station to identify AFEs, which were a primary consideration

in the development of the scope of work in the Work Plan. The establishment of AFEs is

a standard planning practice in hydrogeologic investigations to focus the investigation

activities at areas where there is the greatest potential for impact to groundwater.

Specifically, AFEs were identified based on these six considerations:

•

systems evaluations;

•

risk evaluations;

•

review of confirmed and/or potential releases;

045136 (22) Zion Station

15

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

•

review of documents;

•

review of the hydrogeologic conditions; and

•

Station inspection completed on March 22 and 23, 2006.

Prior to CRA completing its analysis and determination of AFEs, Station personnel

completed an exhaustive review of all historic and current management of systems that

may contain potentially radioactively contaminated liquids.

CRA reviewed the systems identified by the Station, which have the potential for the

release of radioactively contaminated liquids to the environment, and groundwater flow

at the Station. This evaluation allowed CRA to become familiar with Station operations

and potential systems that may impact groundwater. CRA then evaluated information

concerning historic releases as provided by the Station. This information, along with a

review of the results from historic site investigations, was used to refine CRA's

understanding of areas likely to have the highest possibility of impacting groundwater.

Where at risk systems or identified historical releases were located in close proximity or

were located in areas which could not be evaluated separately, the systems and

historical releases were combined into a single AFE. At times, during the Station

investigation, separate AFEs were combined into one or were otherwise altered based on

additional information and consideration. This HIR details the AFEs investigated.

Finally, CRA used its understanding of known hydrogeologic conditions (prior to this

investigation) to identify AFEs. Groundwater flow was an important factor in deciding

whether to combine systems or historical releases into a single AFE or create separate

AFEs. For example, groundwater beneath several systems that contain radioactively

contaminated liquids that flows toward a common discharge point were likely

combined into a single AFE. The AFEs were created based on known groundwater flow

conditions prior to the work completed during this investigation.

Based upon its review of information concerning confirmed or potential historical

releases, historic investigations, and the systems at the Station that have the potential for

release of radioactively contaminated liquids to the environment combined with its

understanding of groundwater flow at the Station, CRA has identified four AFEs (see

Figure 3.1).

045136 (22) Zion Station

16

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

AFE-Zion-1: Main Complex Area

This area was identified to evaluate the main area of the facility, which includes the two

containment structures, the Fuel Building that contains spent fuel, the Auxiliary

Building, and the Turbine Building.

AFE-Zion-2: Unit 1 (Southern) Aboveground Storage Tank (AST) Area

This area was identified to evaluate the quality of groundwater in the area around the

Unit 1 systems including the primary water storage tank, the secondary condensate

tank, oil separator, discharge tunnel, and discharge outfall. This AFE was established

based on information regarding the storage, handling, and historical releases in this

area.

AFE-Zion-3: Unit 2 (Northern) AST Area

This area was identified to evaluate the quality of groundwater in the area around the

Unit 2 systems including the primary water storage tank, secondary condensate tank, oil

separator, discharge tunnel, and discharge outfall. This AFE was established based on

information regarding the storage, handling, and historical releases in this area.

AFE-Zion-4: Wastewater Treatment Plant Area

This area comprises the Wastewater Treatment Plant in the northeast corner of the

Station. Groundwater monitoring was initiated in this area of the Station to evaluate the

wastewater treatment and associated systems.

045136 (22) Zion Station

17

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

4.0

FIELD METHODS

The field investigations completed for this HIR were completed in May to July 2006.

CRA supervised the installation of monitoring wells and a staff gauge, and collected

samples from the newly-installed monitoring wells and the surface water location. The

field investigations were completed in accordance with the methodologies presented in

the Work Plan (CRA, 2006).

The scope of work presented in the Work Plan included the installation and sampling of

nine permanent monitoring wells and the collection of a surface water sample. Based on

the concentrations of tritium detected in monitoring well MW-ZN-01S, additional

investigative activities were recommended by CRA, and implemented in June and

July 2006. The additional investigative tasks included a second round of sampling at

MW-ZN-01S and the installation and sampling of two permanent and four temporary

monitoring wells. The additional investigative activities provided plume delineation

and additional hydraulic information cross-gradient and down-gradient of MW-ZN-01S.

The groundwater sampling events undertaken as part of the investigation are:

•

May 24-26, 2006 sampling of MW-ZN-01S through MW-ZN-09S;

•

June 28, 2006 sampling of MW-ZN-01S (second round);

•

July 17, 2006 sampling of TW-ZN-100 through TW-ZN-103; and

•

July 28, 2006 sampling of MW-ZN-10S and MW-ZN-11S.

4.1

STAFF GAUGE INSTALLATION

Figure 4.1 presents the location of the staff gauge installed as part of this investigation.

CRA installed staff gauge SG-ZN-01, which is a notch in a bridge within the Intake Crib.

The Intake Crib is hydraulically connected to Lake Michigan via the intake tunnel that

extends approximately 1/2 mile into Lake Michigan.

4.2

GROUNDWATER MONITORING WELL INSTALLATION

Prior to completing any ground penetration activities, CRA completed subsurface utility

clearance procedures to minimize the potential of injury to workers and/or damage to

subsurface utility structures.

The subsurface clearance procedures consisted of

completing an electronic survey within a minimum of 10-foot radius of the proposed

location utilizing electromagnetic and ground penetrating radar technology.

045136 (22) Zion Station

18

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

Additionally, a vacuum soft dig was used to verify utilities were not present at the

proposed location to a depth to 10 feet bgs.

Fifteen new monitoring wells were installed for the fleetwide hydrogeologic

investigation, including 11 permanent and 4 temporary monitoring wells. Monitoring

well construction logs are provided in Appendix B. Figure 4.1 presents the location of

the 15 new monitoring wells. These locations were selected based on a review of all data

provided, the hydrogeology at the Station, and current understanding of identified

AFEs, and modified based on conditions encountered during the investigation.

Table 4.1 summarizes the well installation details.

Specific installation protocols for the permanent monitoring wells are described below:

•

the borehole was advanced to the target depth using 4.25-inch inside diameter

hollow-stem augers (HSA);

•

a nominal 2-inch diameter (No. 10 slot) PVC screen, 10 or 20 feet in length, attached

to a sufficient length of 2-inch diameter schedule 40 PVC riser pipe to extend to the

surface, was placed into the borehole through the augers;

•

a filter sand pack consisting of silica sand was installed to a minimum height of

2 feet above the top of the screen as the augers were removed;

•

a minimum 2-foot thick seal consisting of 3/8-inch diameter bentonite pellets or

chips was placed on top of the sand pack and hydrated using potable water;

•

the remaining borehole annulus was sealed to within 3 feet of the surface using pure

bentonite chips (the soft-dig portion of the borehole was backfilled with a mixture of

soil and bentonite); and

•

the remaining portion of the annulus was filled with concrete and a 6-inch diameter

protective above-grade casing. The well head was fitted with a water-tight lockable

cap.

Specific installation protocols for the temporary monitoring wells are described below:

•

the borehole was advanced to the target depth using a 2-inch direct push technology

(DPT) drill rig;

•

a nominal 1-inch diameter (No. 10 slot) PVC screen, 15 or 20 feet in length, attached

to a sufficient length of 1-inch diameter schedule 40 PVC riser pipe to extend to the

surface, was placed into the borehole through the DPT casing;

•

a filter sand pack consisting of silica sand was installed to a minimum height of

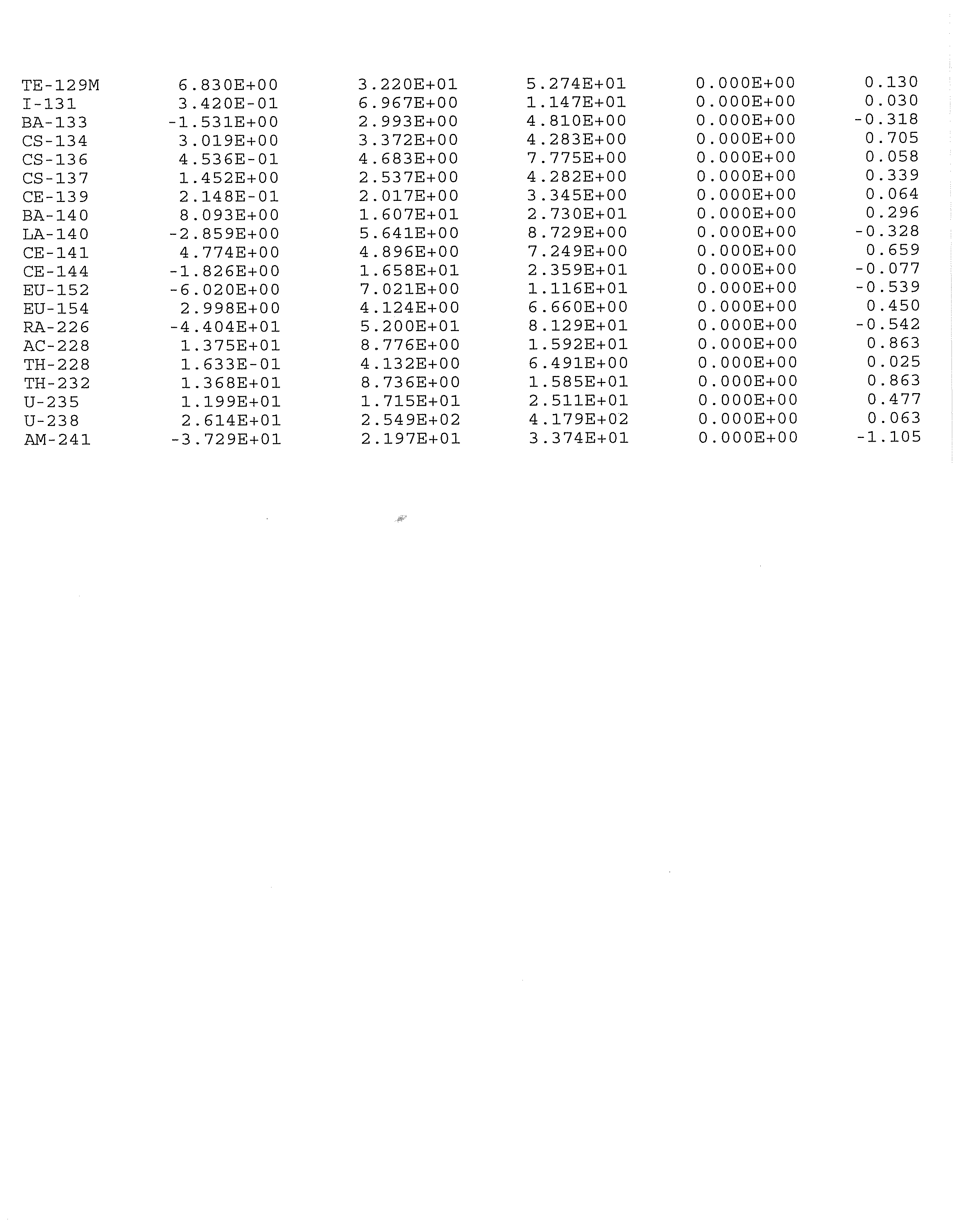

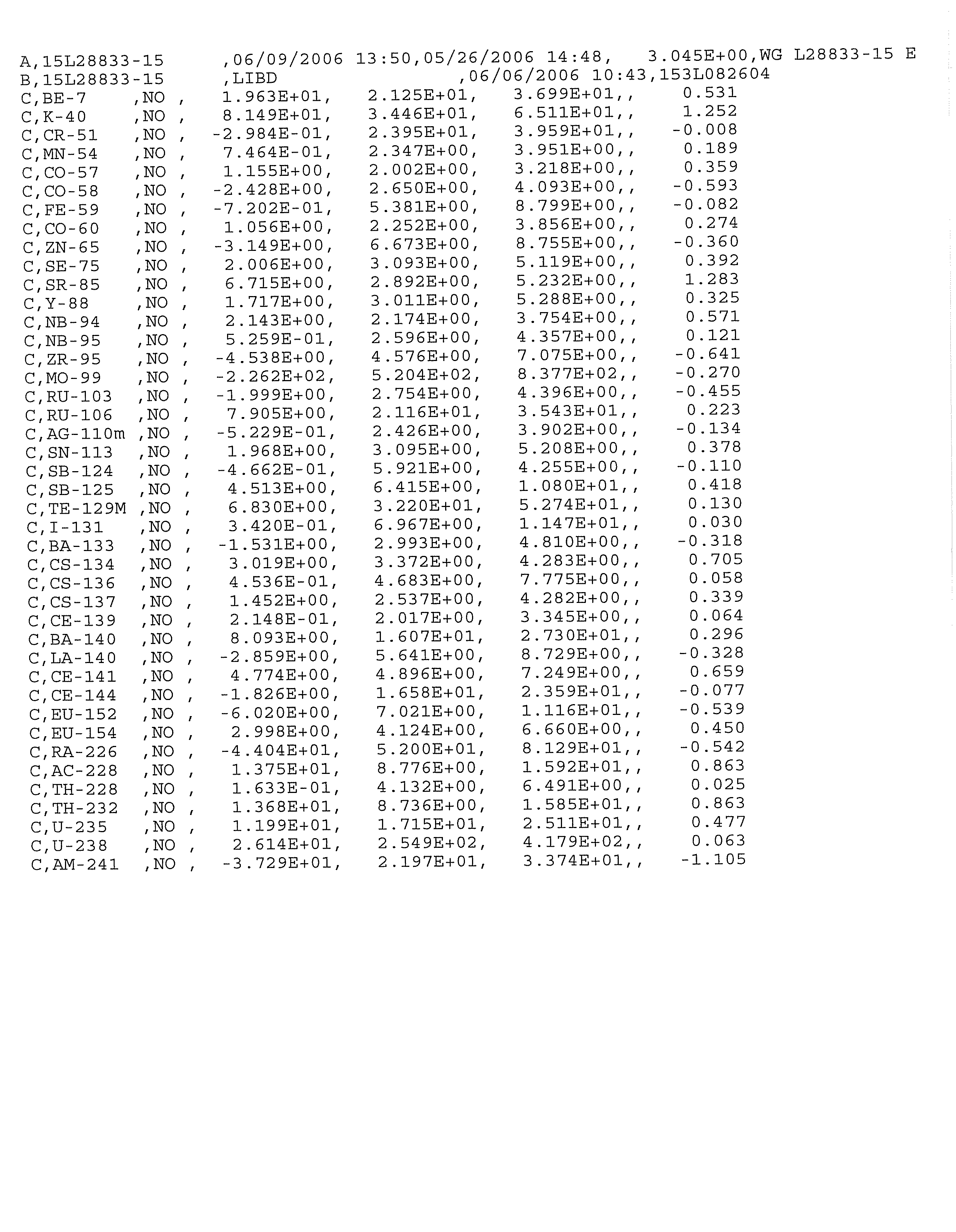

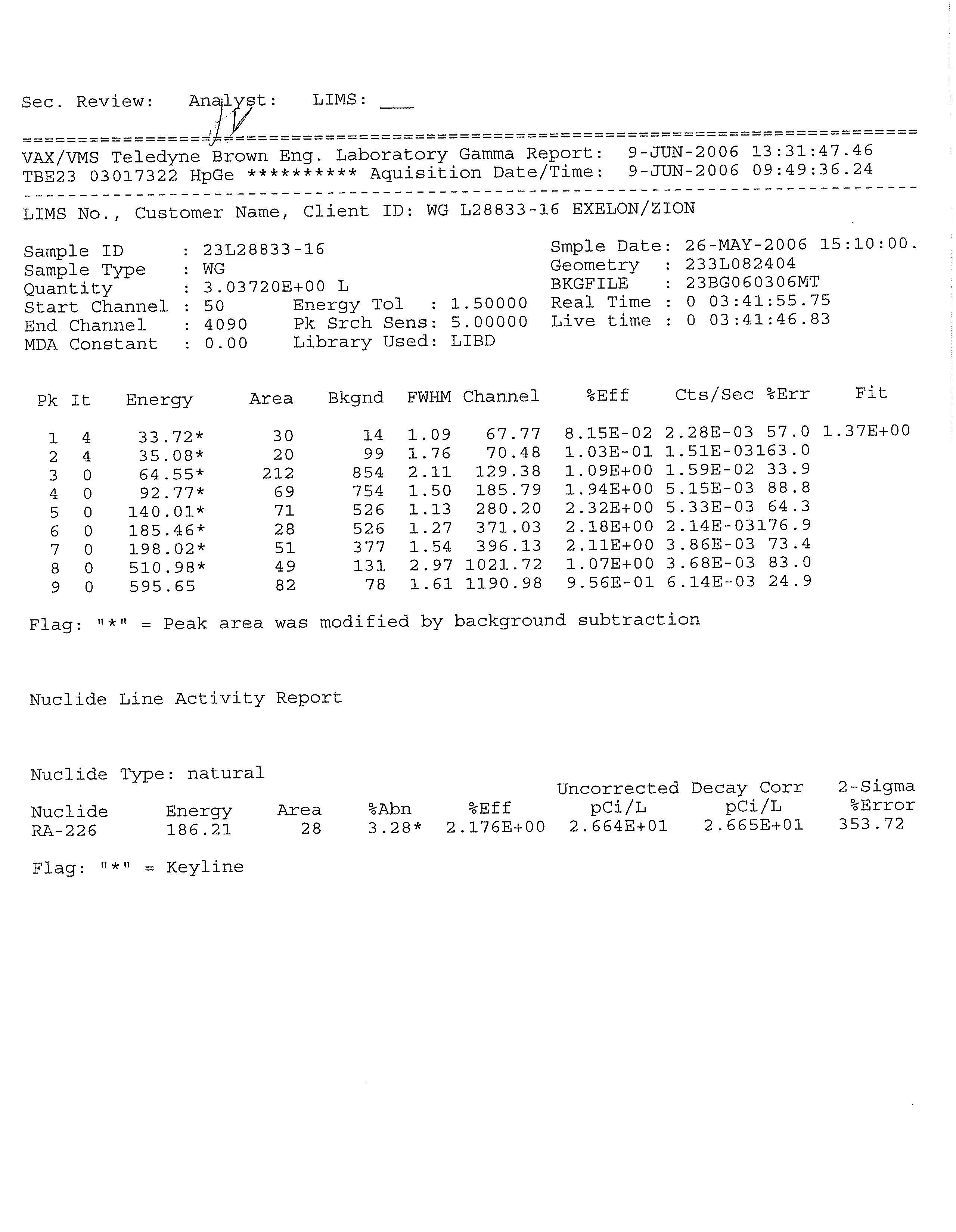

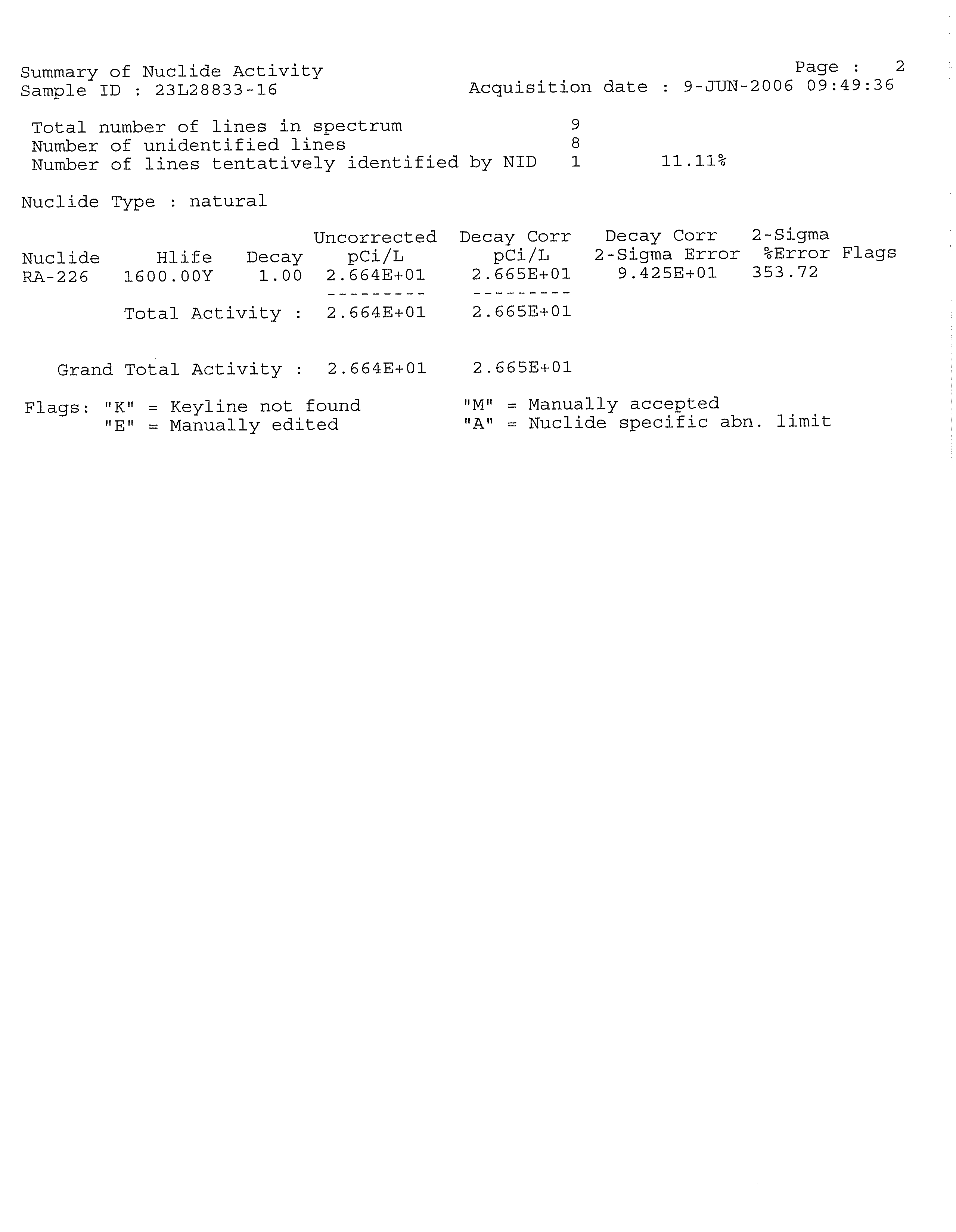

2 feet above the top of the screen as the augers were removed;

045136 (22) Zion Station

19

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

•

a minimum 2-foot thick seal consisting of bentonite powder was placed on top of the

sand pack; and

•

the remaining borehole annulus was sealed at the surface using bentonite powder or

chips.

The shallow soil borings completed in unconsolidated materials that were to be used for

monitoring well installation were installed using either DPT or 4.25-inch inside diameter

HSA drilling techniques. The borehole depths ranged from 19 to 45 feet bgs. During the

subsurface utility clearance activities described above, the borehole was periodically

examined and the soil types documented. A description was added to each monitoring

well construction log. The overburden soils were classified using the Unified Soil

Classification System (USCS).

4.3

GROUNDWATER MONITORING WELL DEVELOPMENT

To establish good hydraulic communication with the aquifer and reduce the volume of

sediment in the permanent monitoring wells, well development was conducted in

accordance with the procedure outlined below:

•

monitoring wells were surged using a pre-cleaned bailer for a period of at least

5 minutes;

•

a minimum of one well volume of water was purged using a submersible pump;

•

the monitoring well was surged for 5 minutes again;

•

water was purged from the monitoring well using an electric submersible pump;

•

groundwater was collected at regular intervals and the pH, temperature, and

conductivity were measured using field instruments. These instruments were

calibrated daily according to the manufacturer's specifications.

Additionally,

observations such as color, odor, and turbidity of the purged water were recorded;

and

•

development continued until the turbidity and silt content of the monitoring wells

were significantly reduced and three consistent readings of pH, temperature, and

conductivity were recorded, or a minimum of ten well volumes was purged.

A summary of the monitoring well development parameter measurements is presented

in Table 4.2.

045136 (22) Zion Station

20

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

4.4

SURVEY

The 15 monitoring wells and surface water gauge were surveyed to establish reference

elevations relative to mean sea level. The top of each well casing was surveyed to the

nearest 0.01 foot relative to the National Geodetic Vertical Datum (NGVD), and the

survey point was marked on the well casing. The survey included the ground elevation

at each well to the nearest 0.10 foot relative to the NGVD, and the horizontal well

location to the nearest 1.0 foot. A reference point was also marked on the concrete at the

surface water elevation measuring location.

The Lake Michigan shoreline was surveyed at the Station using a handheld Global

Positioning System (GPS) with an estimated accuracy of ± 12 feet. The GPS survey was

conducted on June 30, 2006.

4.5

GROUNDWATER AND SURFACE WATER

ELEVATION MEASUREMENTS

On May 23, 2006 and July 27, 2006, CRA collected water level measurements from the

monitoring wells and the staff gauge at the Station in accordance with the Work Plan.

Based on the measured depth to water from the reference point and the surveyed

elevation of the reference point, the groundwater or surface water elevation was

calculated. A summary of groundwater and surface water elevations is provided in

Table 4.3.

Prior to the water level measurements, the wells and staff gauges were identified and

located. Once the wells were identified, CRA completed a thorough inspection of each

well and noted any deficiencies. Water level measurements were collected using an

electronic depth-to-water probe accurate to

±

0.01 foot. The measurements were made

from the designated location on the inner riser or steel casing of each monitoring well

and reference point on the staff gauge. The water level measurements were obtained

using the following procedures:

•

the proper elevation of the meter was checked by inserting the tip into water and

noting if the contact was registering correctly;

•

the tip was dried, and then slowly lowered into the well or surface water body until

contact with the water was indicated;

•

the tip was slowly raised until the light and/or buzzer just began to activate. This

indicated the static water level;

045136 (22) Zion Station

21

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

•

the reading at the reference point was noted to the nearest hundredth of a foot;

•

the reading was then re-checked; and

•

the water level was then recorded, and the water level meter decontaminated prior

to use at the next location.

Surface water measurements for Lake Michigan were obtained from the National

Oceanic and Atmospheric Administration (NOAA) gauging stations at Milwaukee,

Wisconsin (Station 9087057), and Calumet Harbor, Illinois (Station 9087044) for the date

and time when the water levels in monitoring wells were measured (NOAA, 2006).

Station

Time Period

Median Lake Elevation

9087057 Milwaukee

May 23, 2006 8:00-13:00

577.99

9087044 Calumet Harbor

May 23, 2006 8:00-13:00

577.94

May 23, 2006 8:00-13:00 Average

577.97

9087057 Milwaukee

July 27, 2006 9:15-11:10

577.91

9087044 Calumet Harbor

July 27, 2006 9:15-11:10

577.96

July 27, 2006 9:15-11:10 Average

577.93

4.6

GROUNDWATER AND SURFACE WATER SAMPLE COLLECTION

CRA conducted one round of groundwater sampling during the hydrogeologic

investigation, with additional samples collected from monitoring well MW-ZN-01S. A

total of 15 monitoring wells were sampled between May 24, 2006 and July 28, 2006.

Eleven new permanent monitoring wells were installed. The sampling was scheduled to

allow for 2 weeks to elapse between well development and groundwater sample

collection. Four temporary monitoring wells were installed and sampled in July 2006.

At the monitoring well locations, CRA conducted the sampling using peristaltic pumps

and dedicated polyethylene tubing to employ low flow purging techniques, as described

in Puls and Barcelona (1996).

For permanent monitoring wells with 20-foot screen lengths (MW-ZN-01S through

MW-ZN-08S, MW-ZN-10S and MW-ZN-11S), separate samples were collected from the

lower portion and the upper portion of the screened interval. The lower sampling

interval targets potential releases from deep structural features such as the basement of

the Auxiliary Building. The upper sampling interval targets potential surface and near

surface releases such as spills from the primary cooling water ASTs.

045136 (22) Zion Station

22

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

The groundwater in the monitoring wells was sampled by the following low-flow

procedures:

•

the wells were located and the well identification numbers were verified;

•

a water level measurement was taken;

•

the well was sounded by carefully lowering the water level tape to the bottom of the

well (so as to minimize penetration and disturbance of the well bottom sediment),

and comparing the sounded depth to the installed depth to assess the presence of

any excess sediment or drill cuttings;

•

the pump or tubing was lowered slowly into the well and fixed into place such that

the intake was located at the mid-point of the well screen, or a minimum of 2 feet

above the well bottom/sediment level;

•

the purging was conducted using a pumping rate between 100 to 500 milliliters per

minute. Initial purging began using the lower end of this range. The groundwater

level was monitored to ensure that a drawdown of less than 0.3 foot occurred. If this

criterion was met, the pumping rate was increased dependent on the behavior of the

well. During purging, the pumping rate and groundwater level were measured and

recorded approximately every 10 minutes;

•

the field parameters [pH, temperature, conductivity, oxidation-reduction potential

(ORP), dissolved oxygen (DO), and turbidity] were monitored during the purging to

evaluate the stabilization of the purged groundwater. Stabilization was considered

to be achieved when three consecutive readings for each parameter, taken at

5-minute intervals, were within the following limits:

pH

±

0.1 pH units of the average value of the three readings,

Temperature

±

3 percent of the average value of the three readings,

Conductivity

±

0.005 milliSiemen per centimeter (mS/cm) of the average value

of the three readings for conductivity <1 mS/cm and

±

0.01 mS/cm of the average value of the three readings for

conductivity >1 mS/cm,

ORP

±

10 millivolts (mV) of the average value of the three readings,

DO

±

10 percent of the average value of the three readings, and

Turbidity

±

10 percent of the average value of the three readings, or a final

value of less than 5 nephelometric turbidity units (NTUs);

•

once purging was complete, the groundwater samples were collected directly from

the pump/tubing directly into the sample containers; and

045136 (22) Zion Station

23

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

•

in the event that the groundwater recharge to the monitoring well was insufficient to

conduct the low-flow procedure, the well was pumped dry and allowed to

sufficiently recharge prior to sampling.

All groundwater samples were labeled with a unique sample number, the date and time,

the parameters to be analyzed, the job number, and the sampler's initials. The samples

were then screened by the Station for shipment to Teledyne Brown Engineering Inc.

(Teledyne Brown).

A sample key is presented in Table 4.4; field measurements for the hydrogeologic

investigation are presented in Table 4.5.

CRA containerized the water purged from the monitoring wells during the sampling, as

well as the water purged from all of the wells during the hydrogeologic investigation.

The water was placed into 55-gallon drums, which will be processed by the Station in

accordance with its NPDES permit.

One surface water sample was collected on May 26, 2006 from Lake Michigan at station

SW-ZN-1, adjacent to the Station. The surface water sampling location is presented on

Figure 4.1.

The surface water sample was collected by directly filling the sample container from the

composite sampler at the determined location until completely filled. A sample key is

presented in Table 4.4.

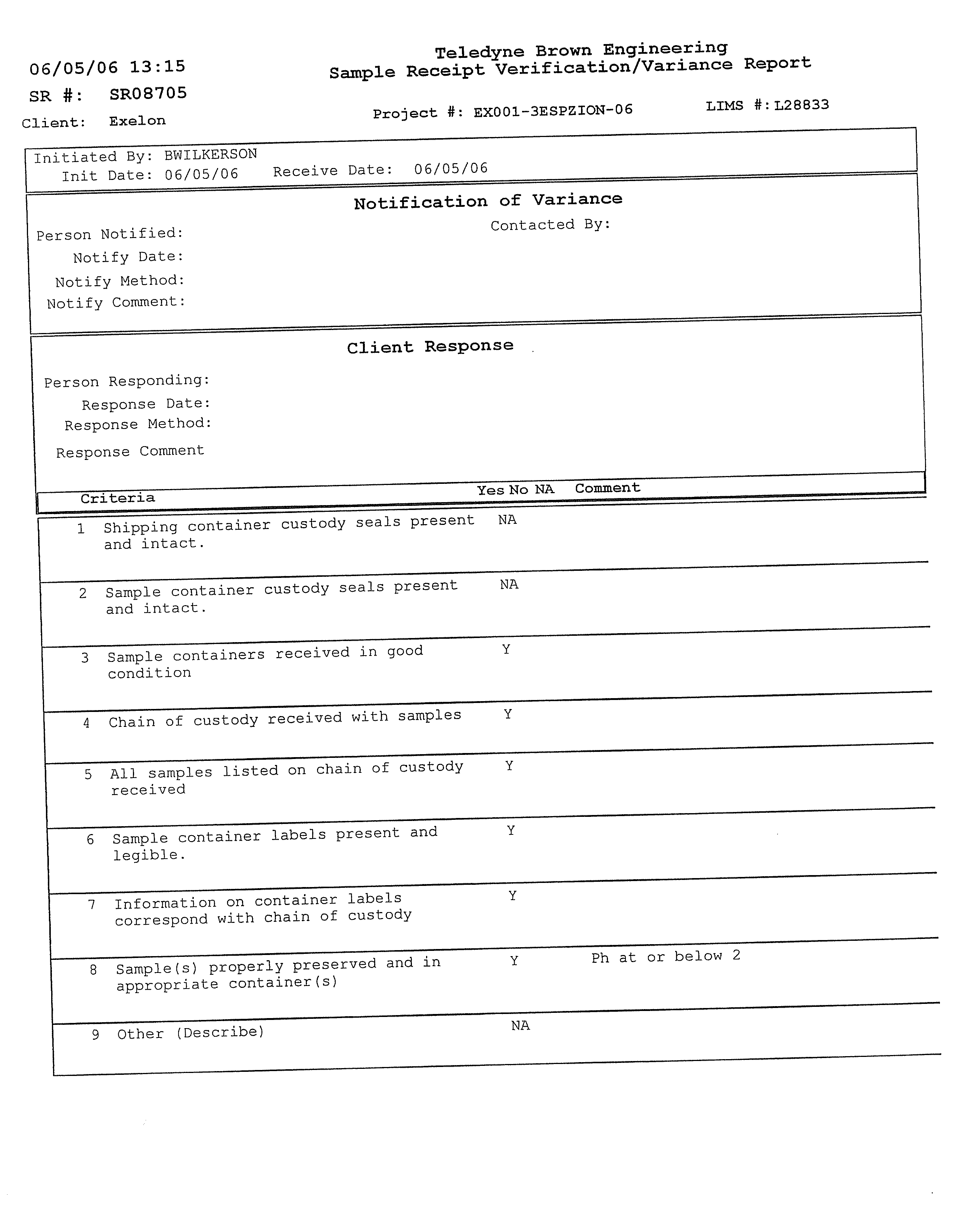

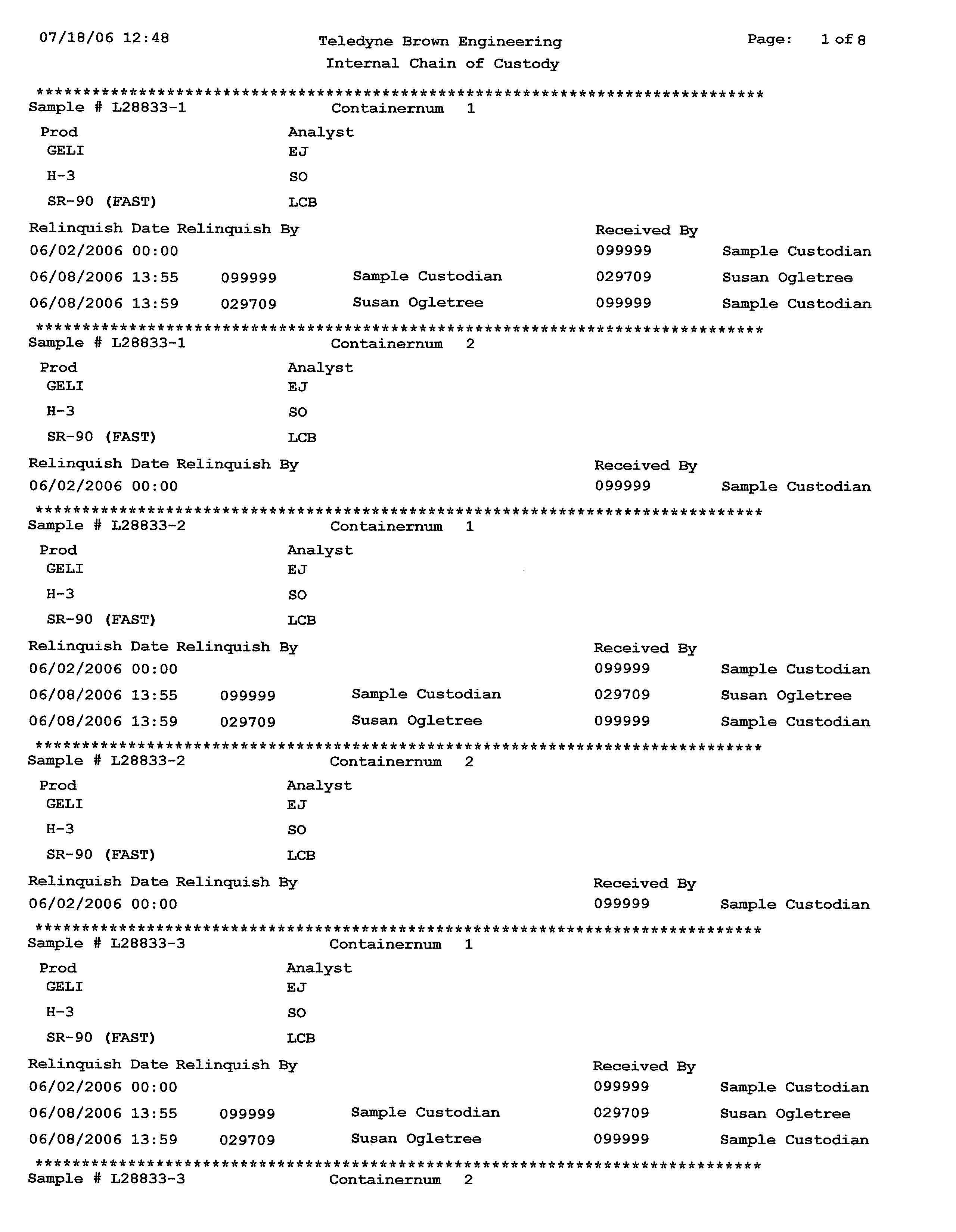

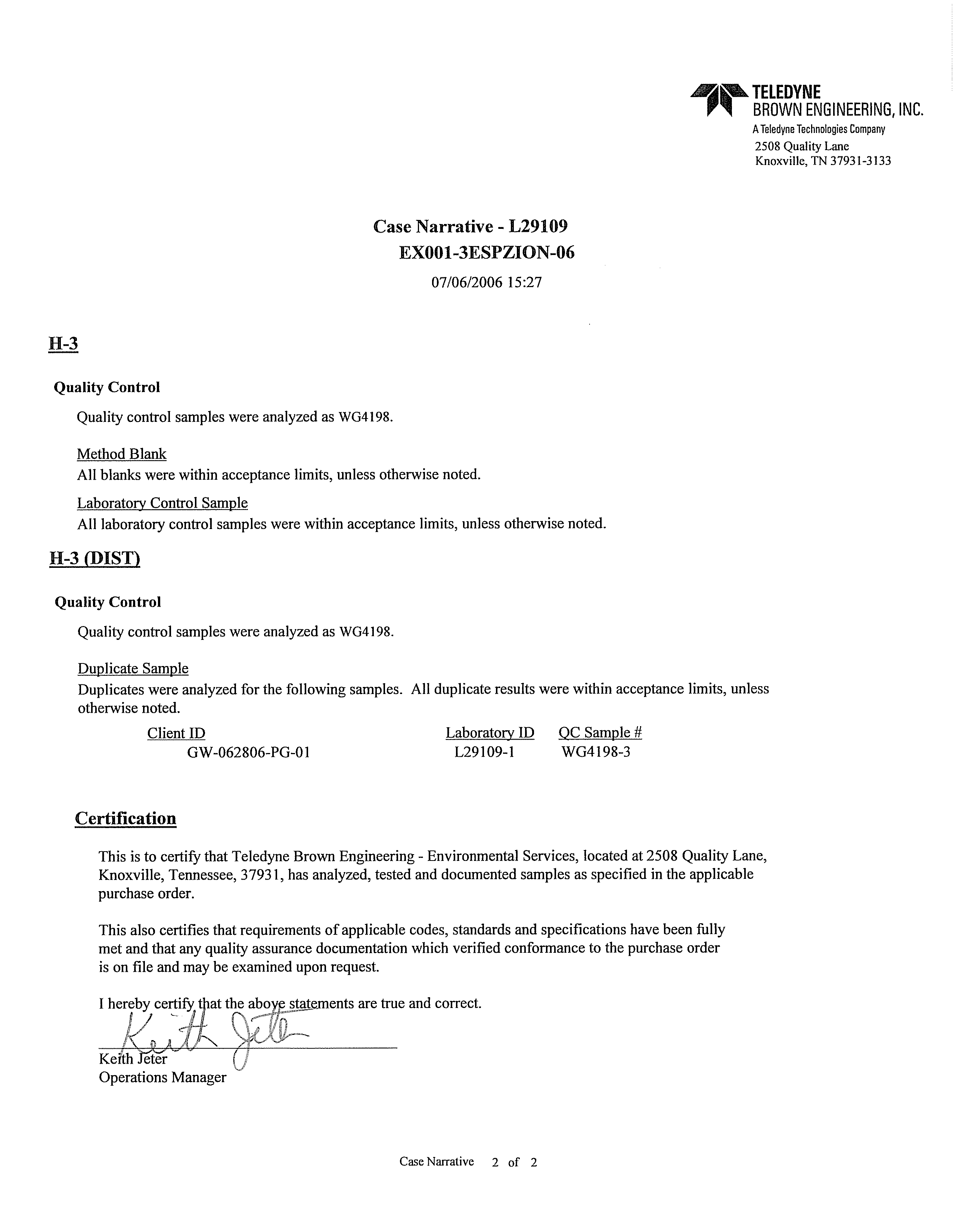

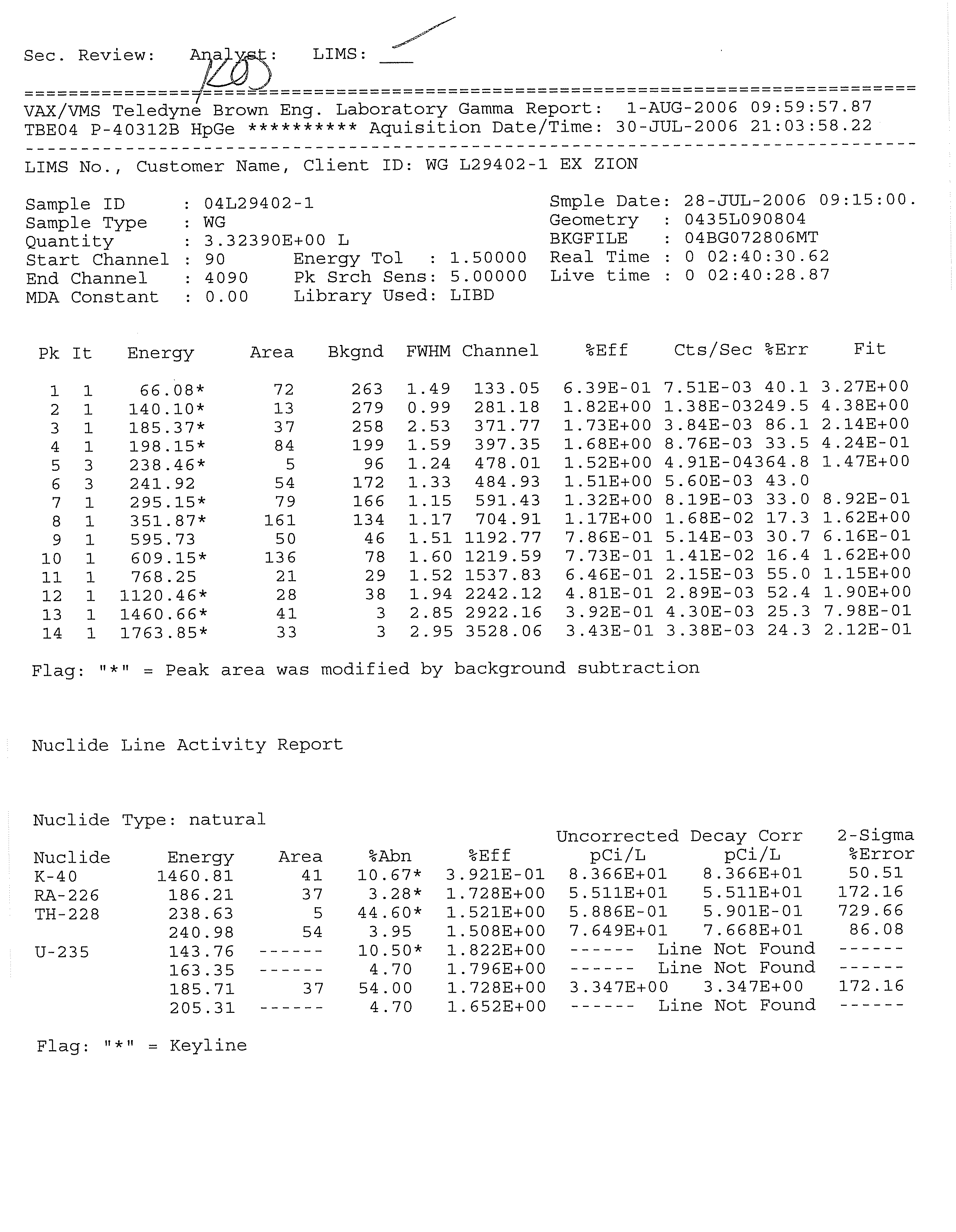

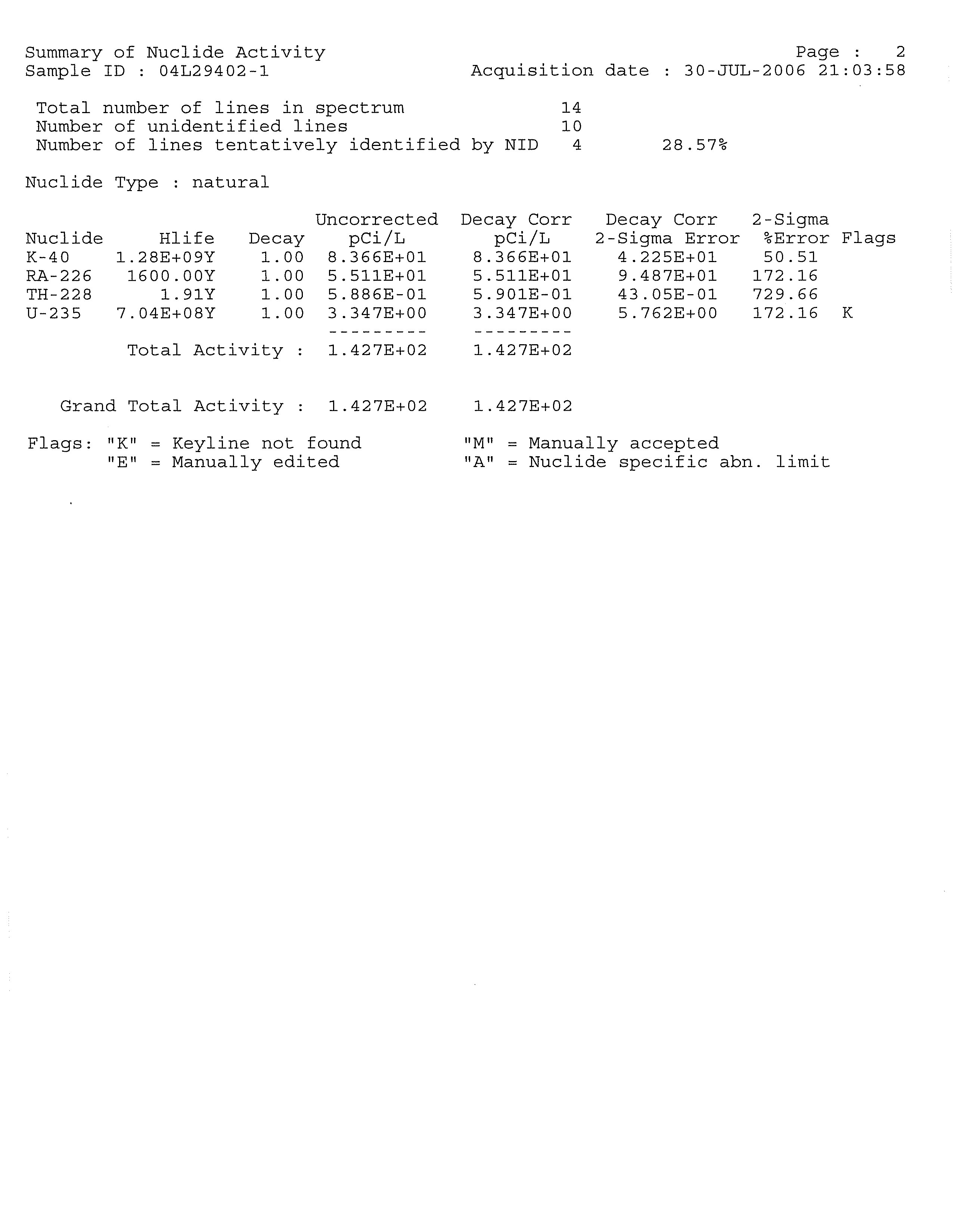

4.7

DATA QUALITY OBJECTIVES

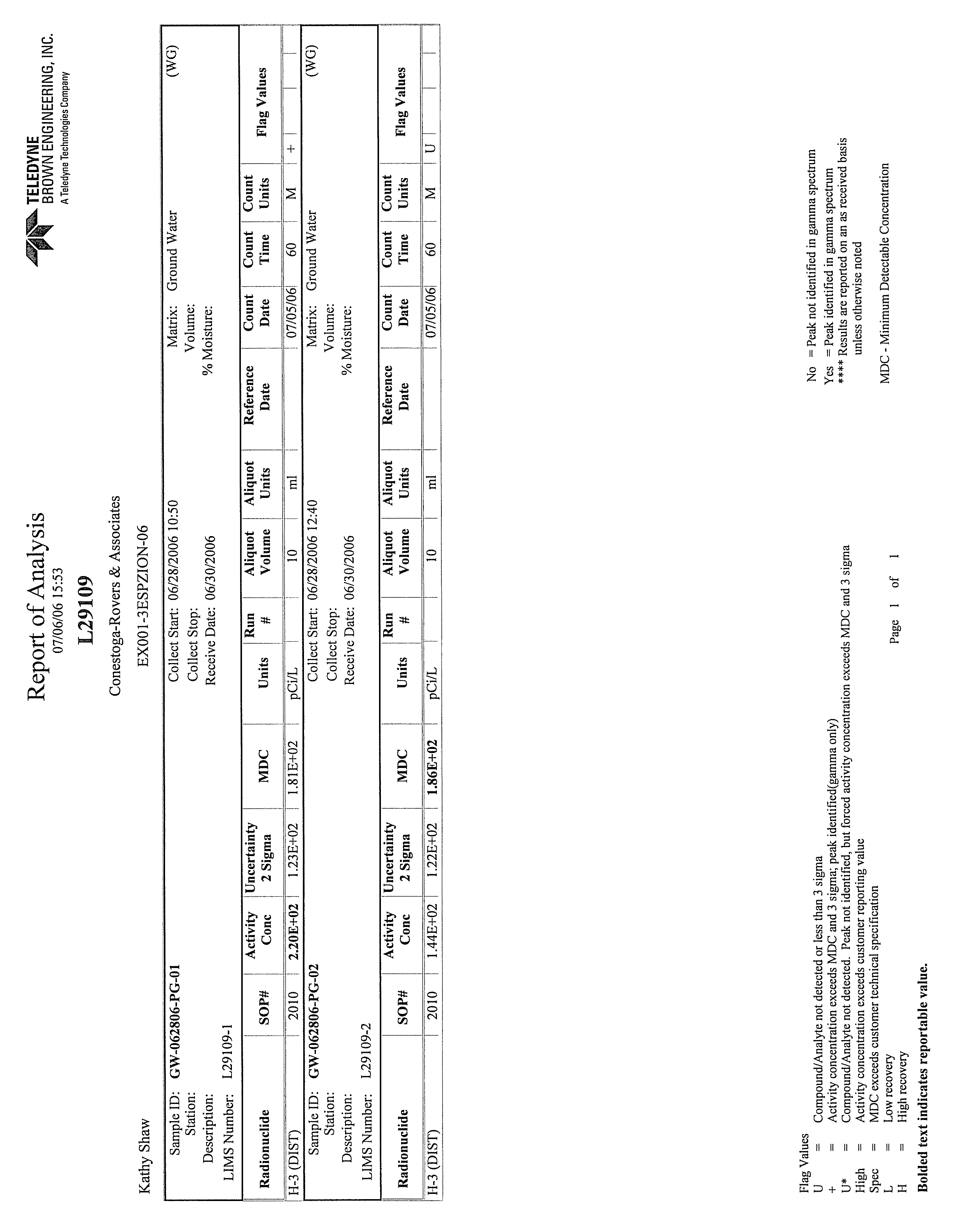

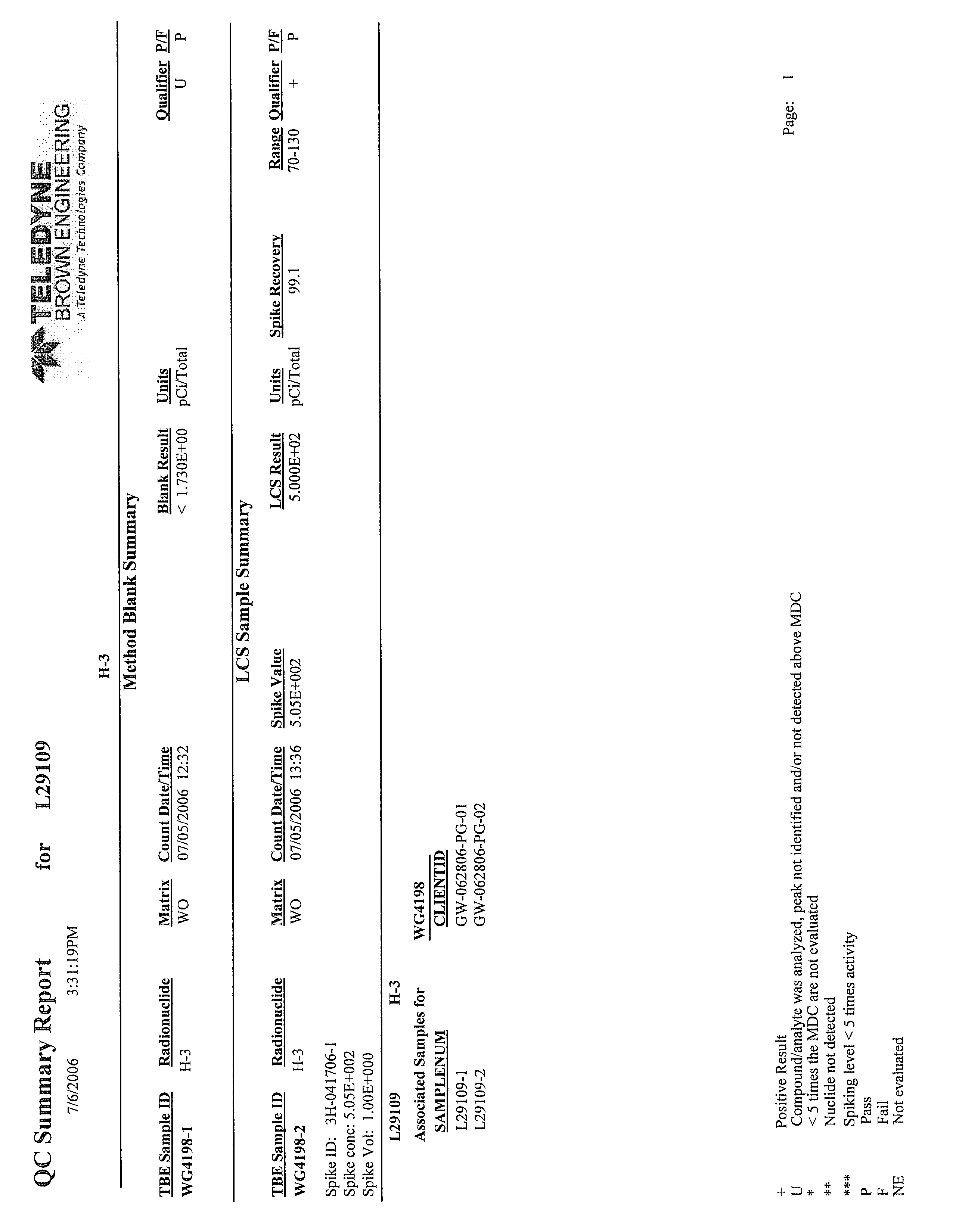

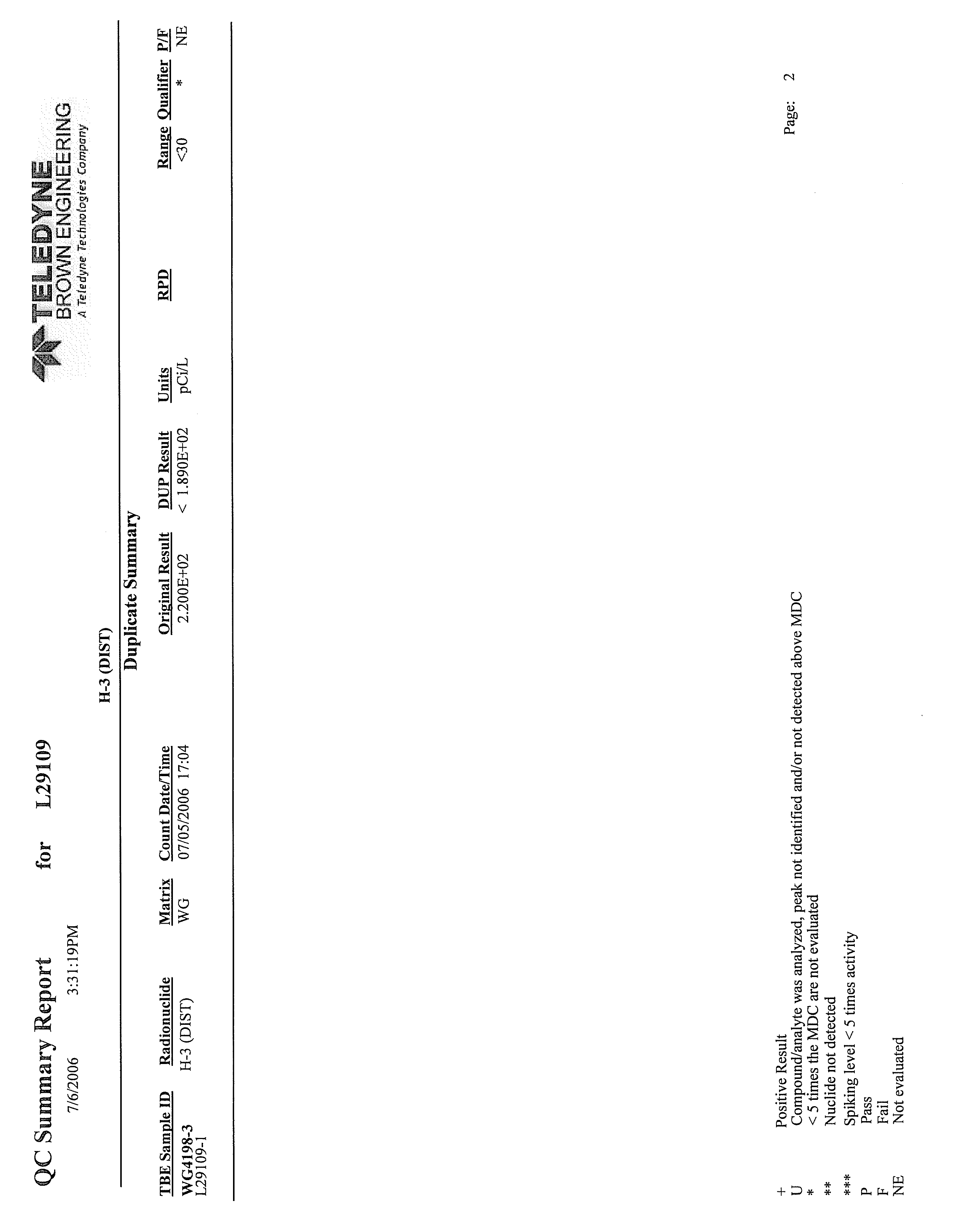

CRA has validated the analytical data to establish the accuracy and completeness of the

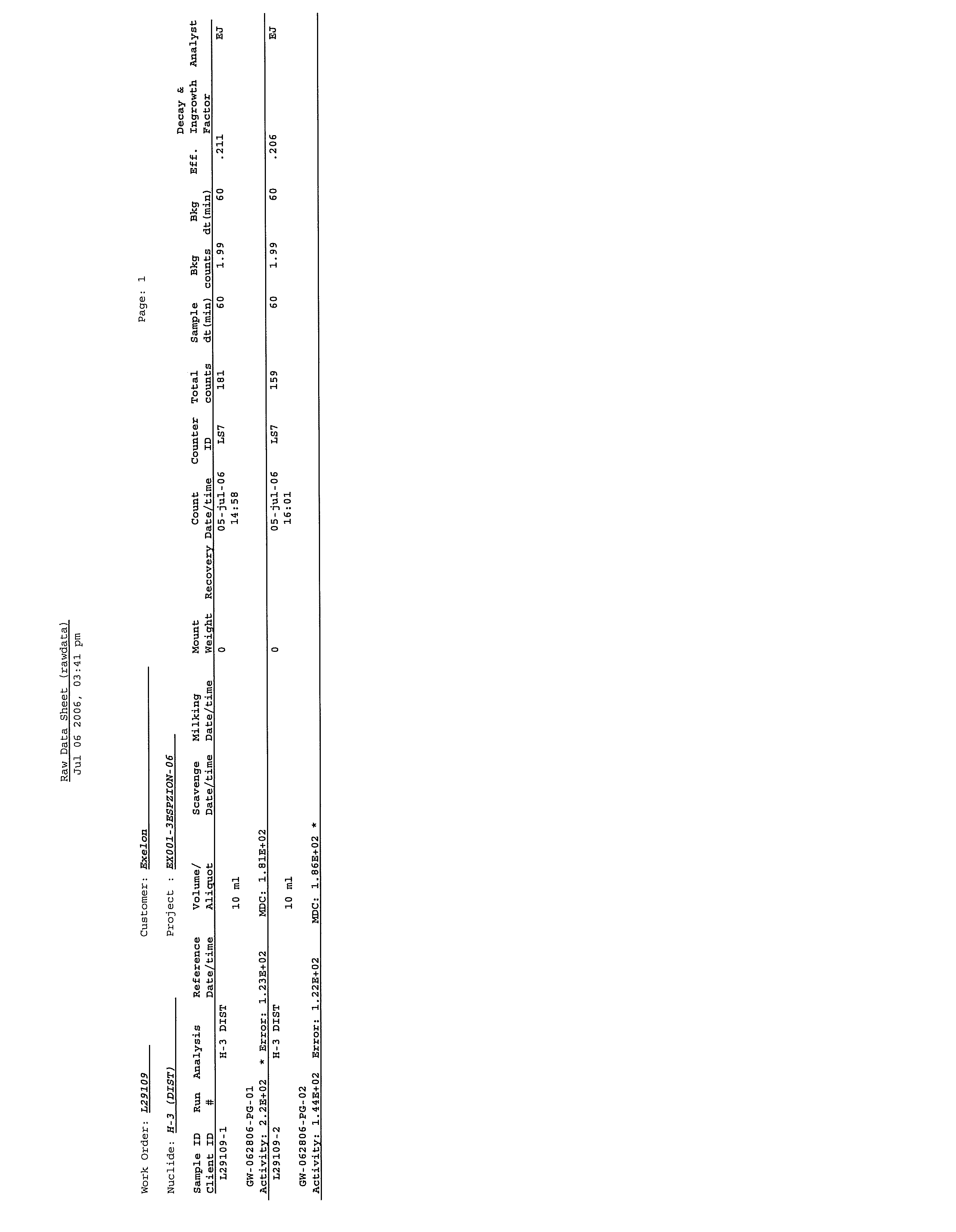

data reported. Teledyne Brown provided the analytical services. The Quality Assurance

Program for the laboratory is described in Appendix C.

Analytical data for

groundwater and surface water samples collected in accordance with the Work Plan are

presented in Appendix D. Data validation reports are presented in Appendix E. The

data validation included the following information and evaluations:

•

sample preservation;

•

sample holding times;

•

laboratory method blanks;

•

laboratory control samples;

045136 (22) Zion Station

24

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

•

laboratory duplicates;

•

verification of laboratory qualifiers; and

•

field quality control (field blanks and duplicates).

Following the completion of field activities, CRA compiled and reviewed the geologic,

hydrogeologic, and analytical data.

The data were reviewed using the following techniques:

•

data tables and databox figures;

•

hydrogeologic cross-sections; and

•

hydraulic analyses.

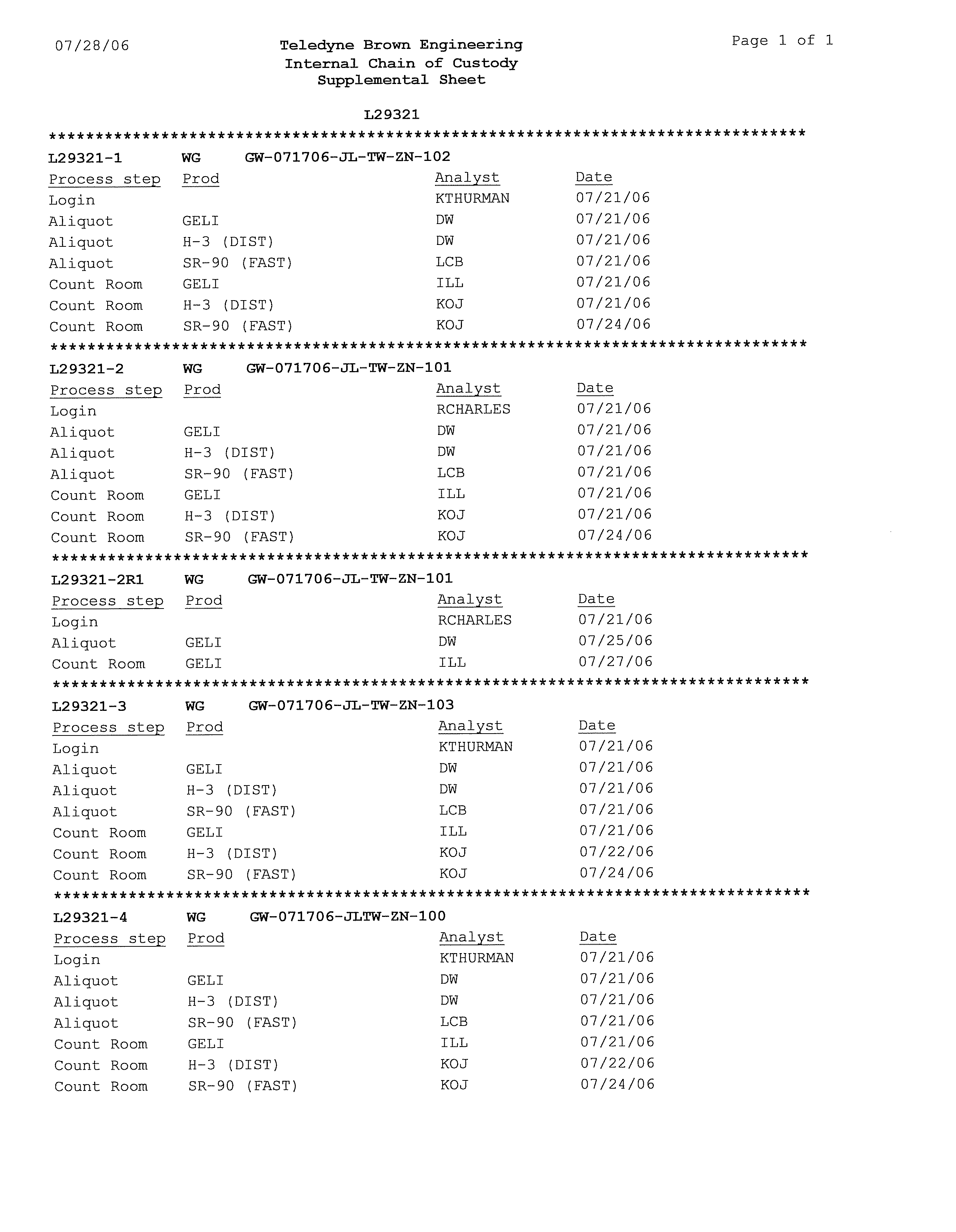

4.8

SAMPLE IDENTIFICATION

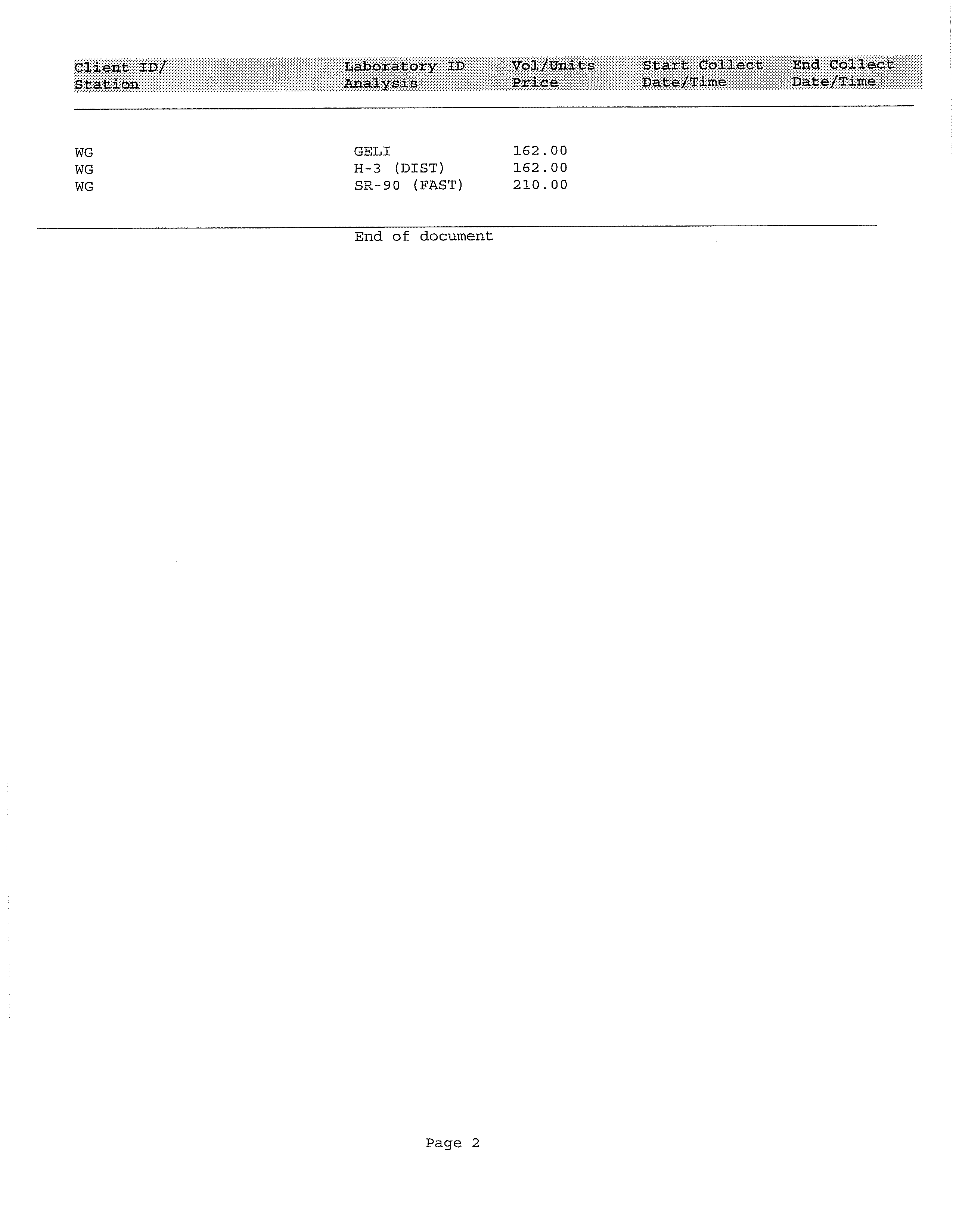

Systematic sample identification codes were used to uniquely identify all samples. The

identification code format used in the field was: WG - Zion – MW-8L – 052406 -

MS - 001. A summary of sample identification numbers is presented in Table 4.4.

WG

-

Sample matrix -groundwater

WS

-

Sample matrix - surface water

Zion

-

Station code

ZN

-

Station code

MW-8L -

Well location

052406

-

Date

MS

-

Sampler initial

001

-

Sample number

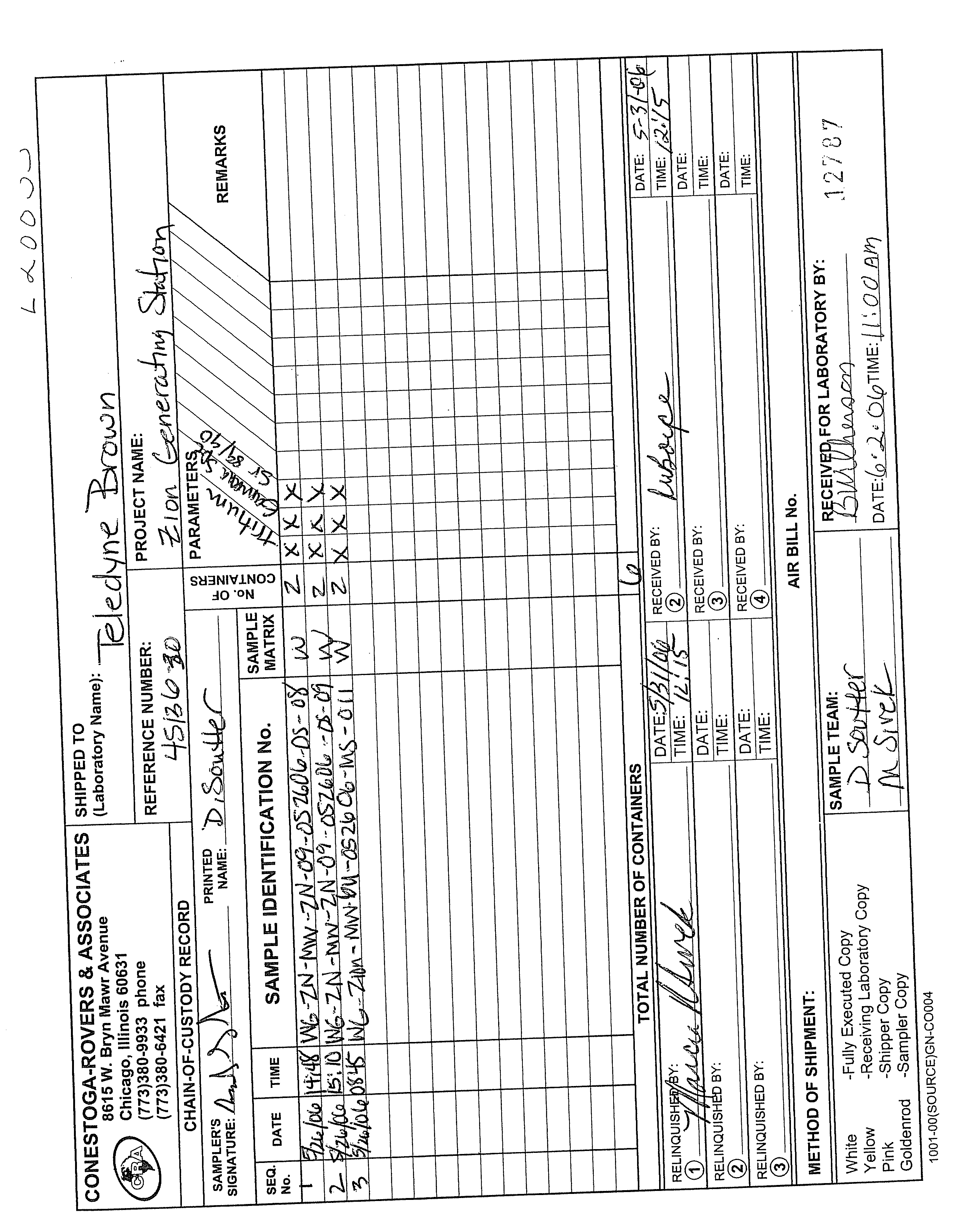

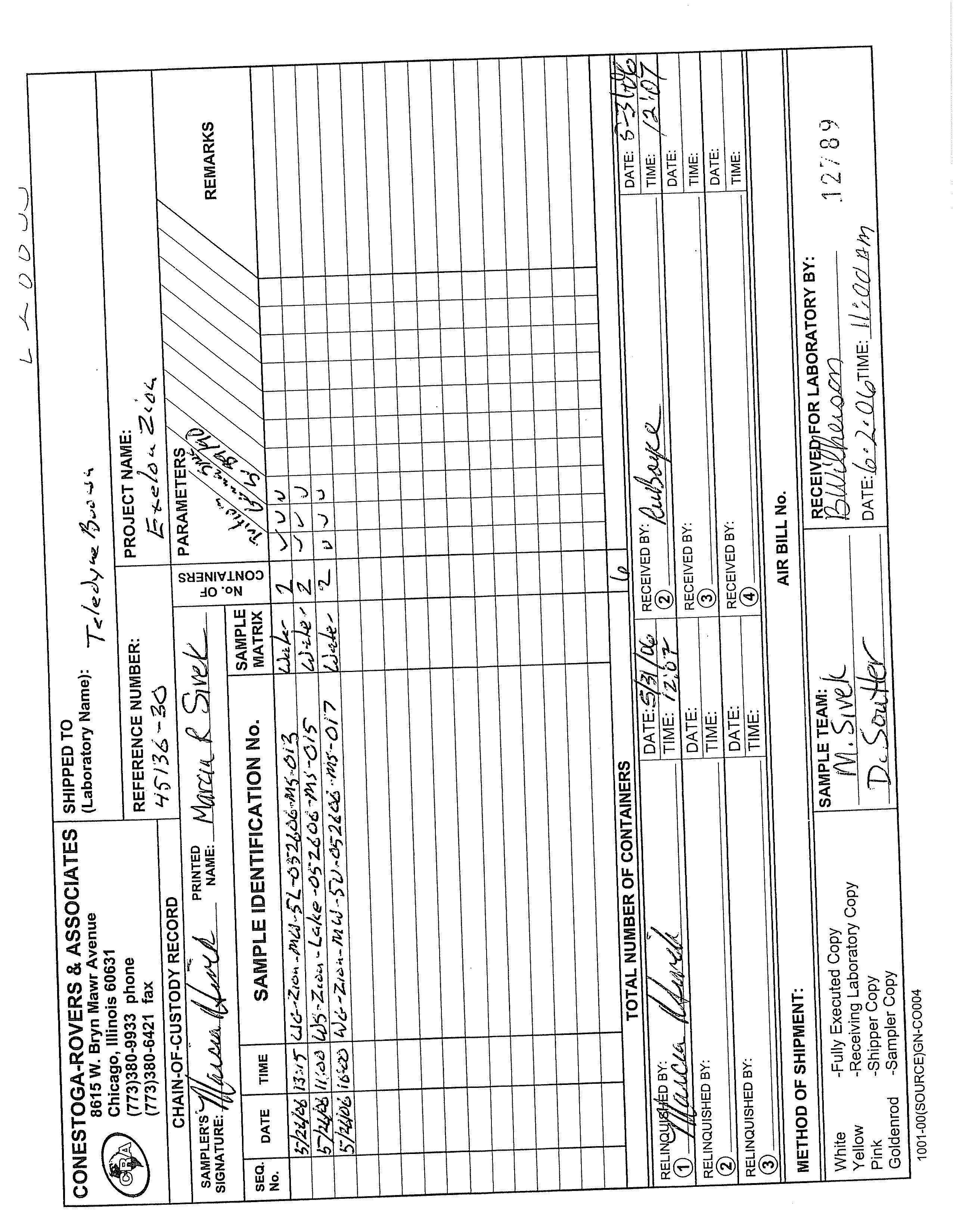

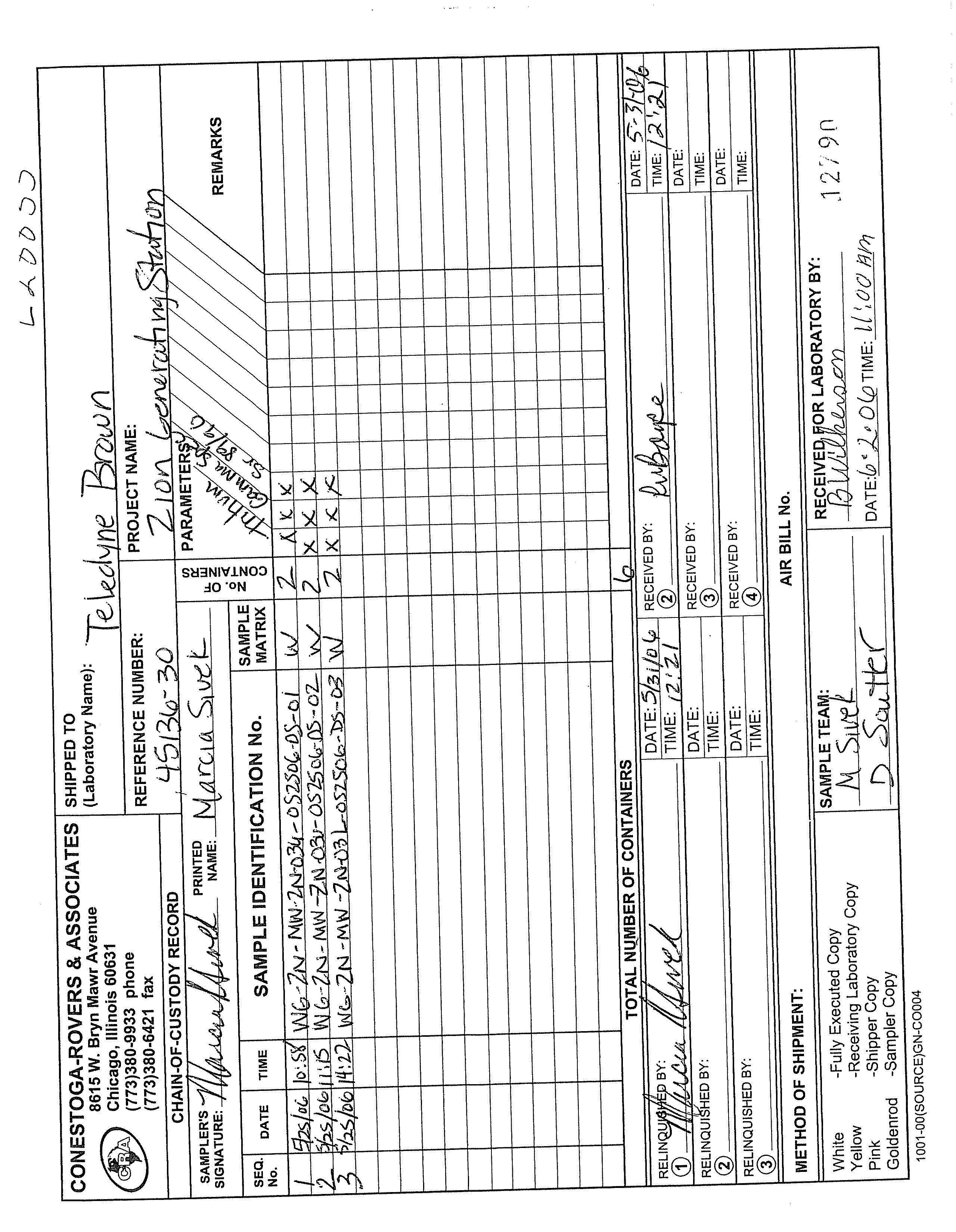

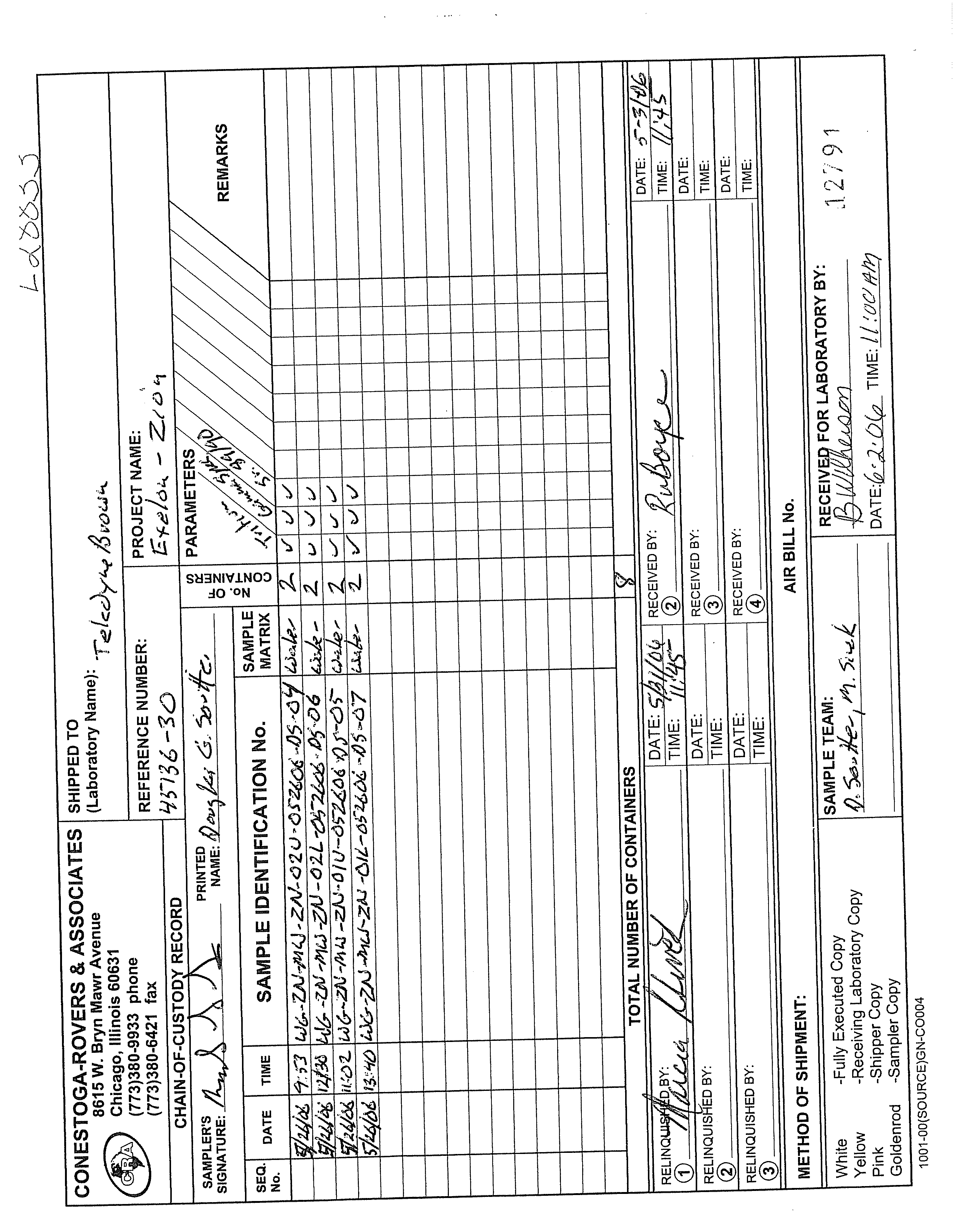

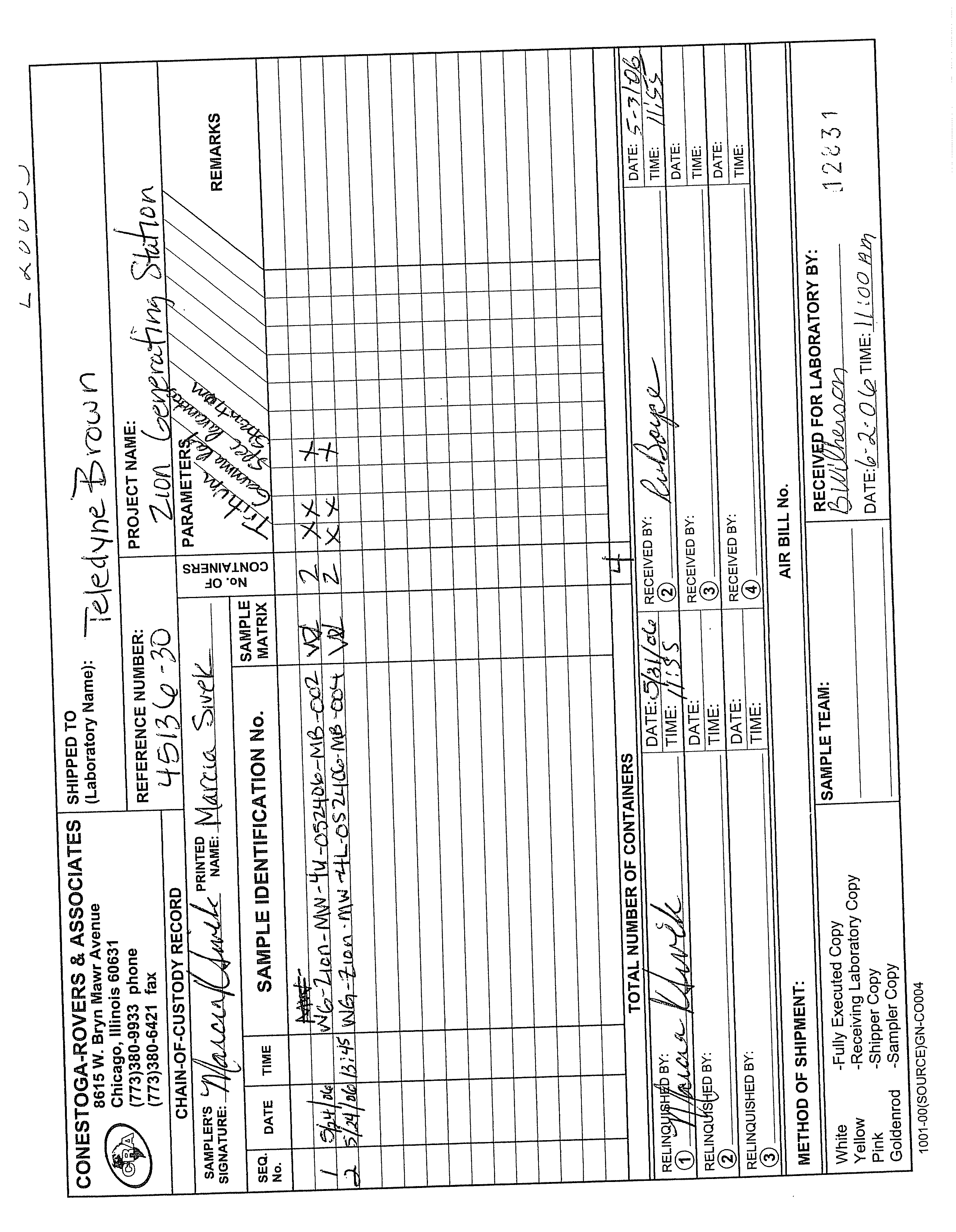

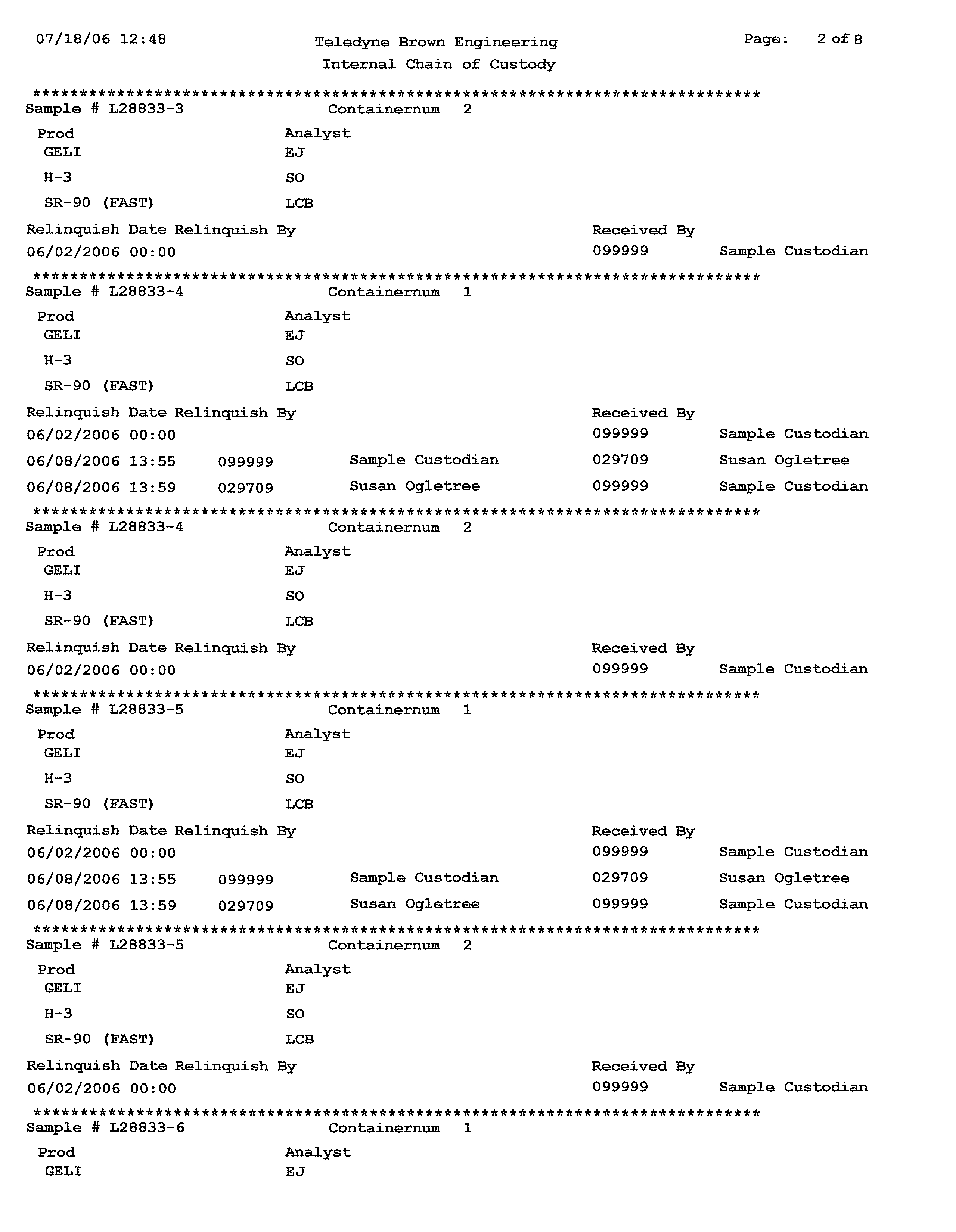

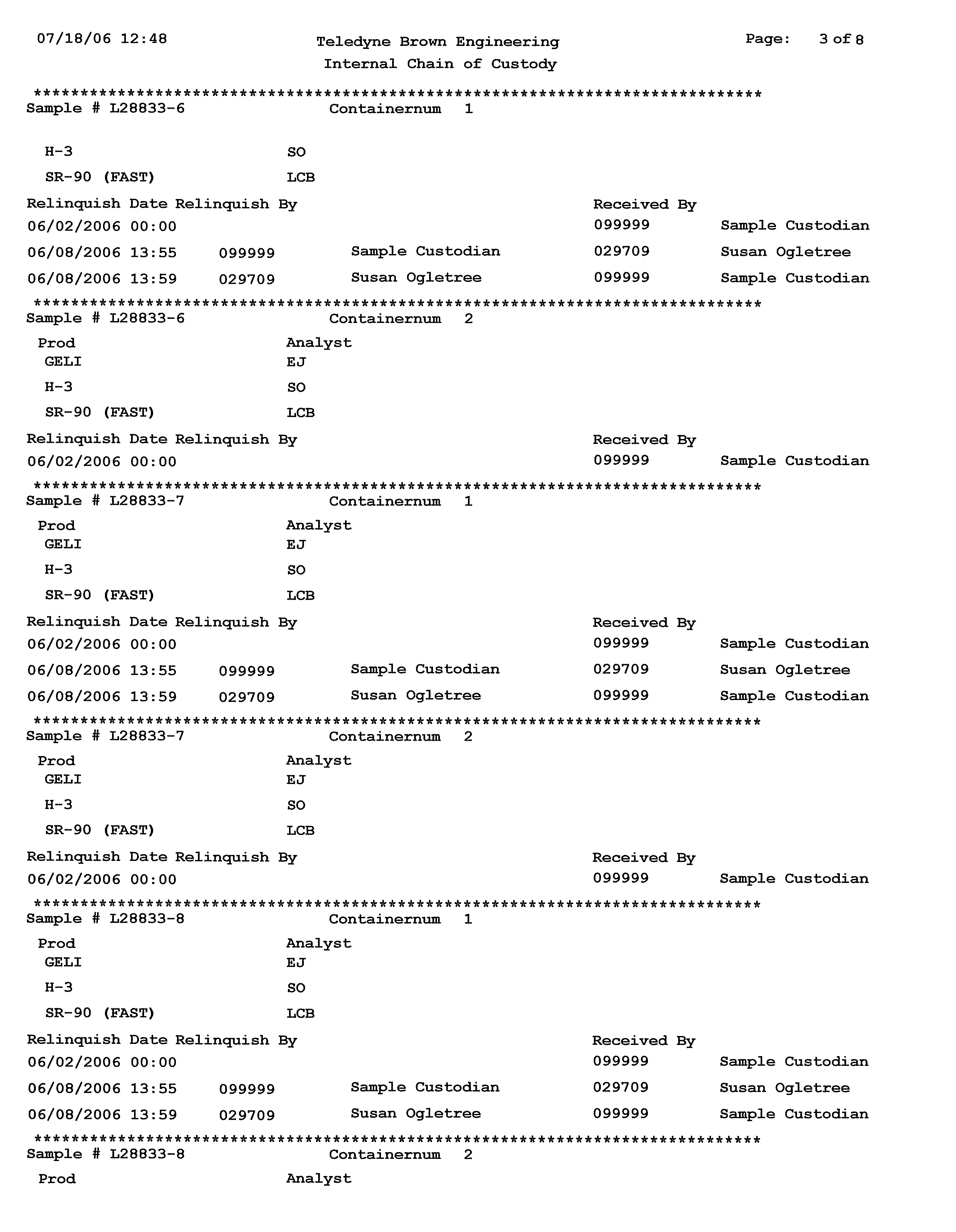

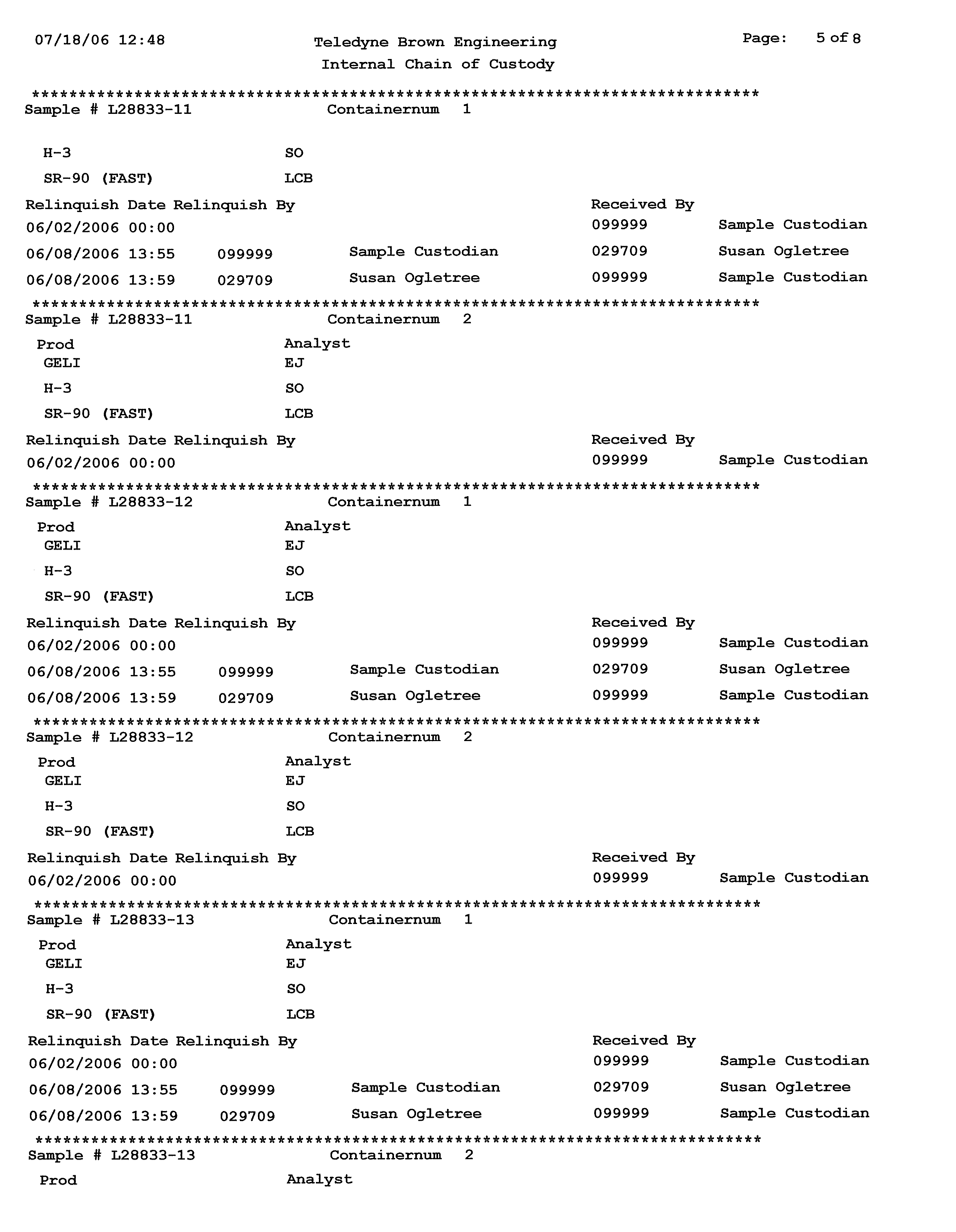

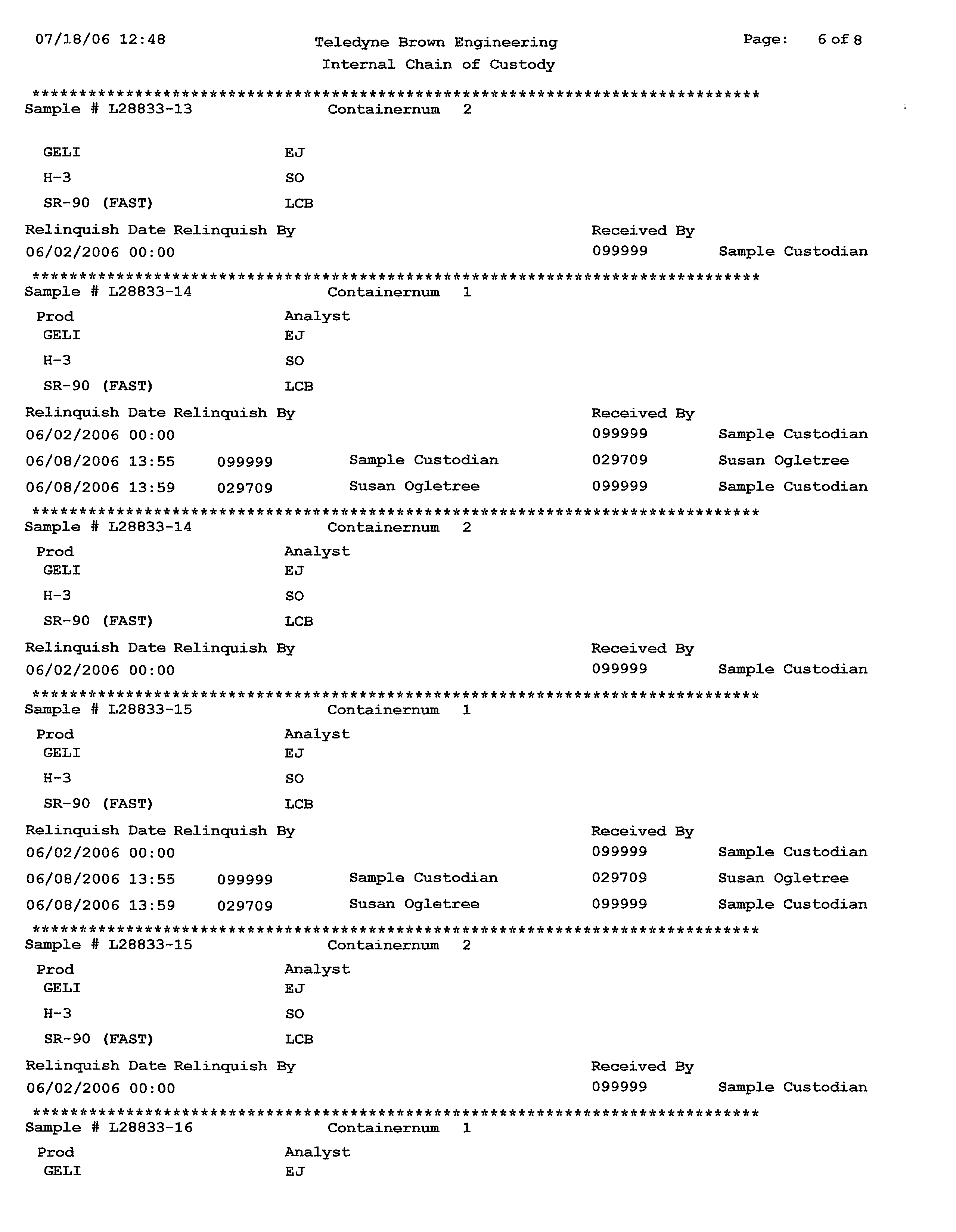

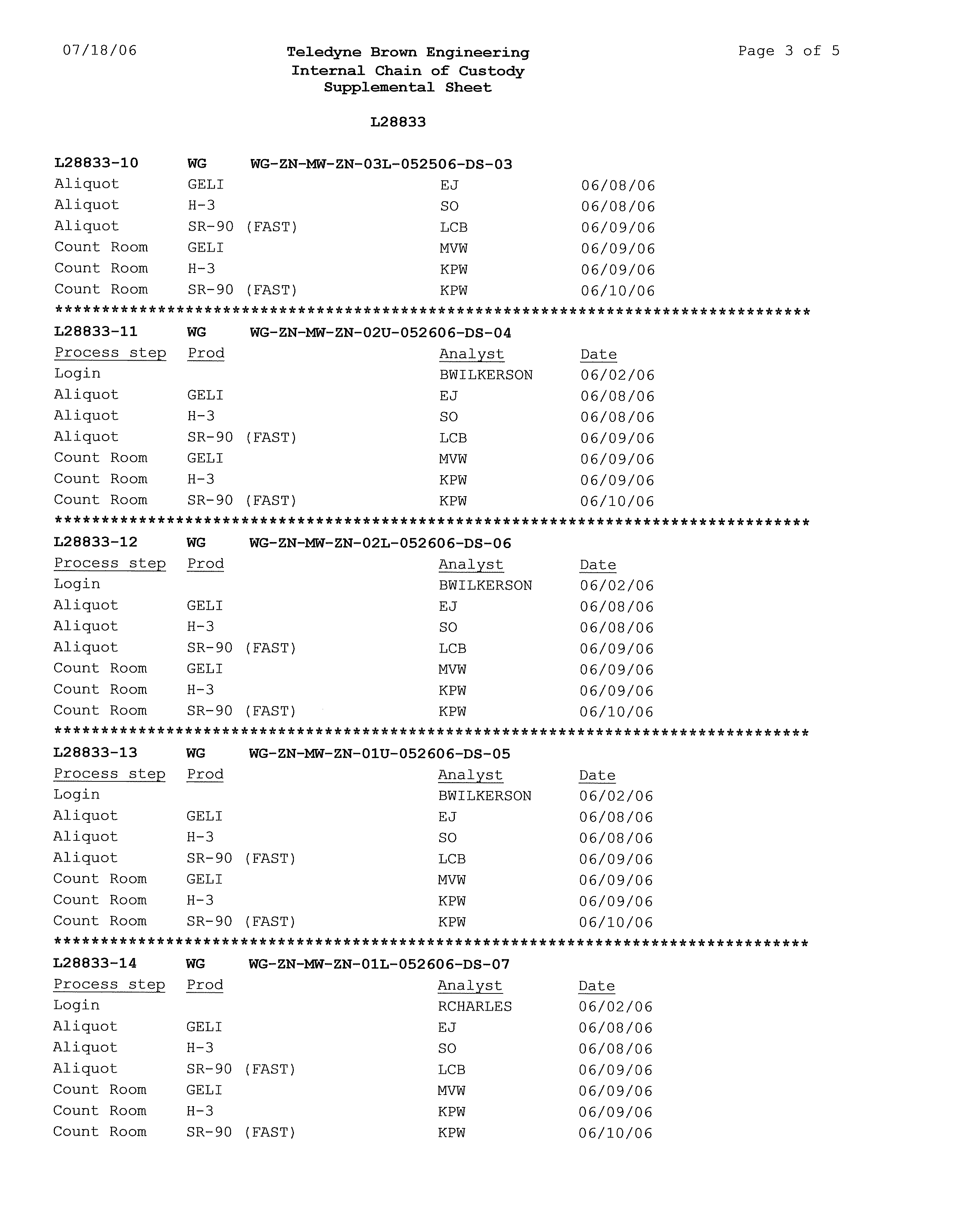

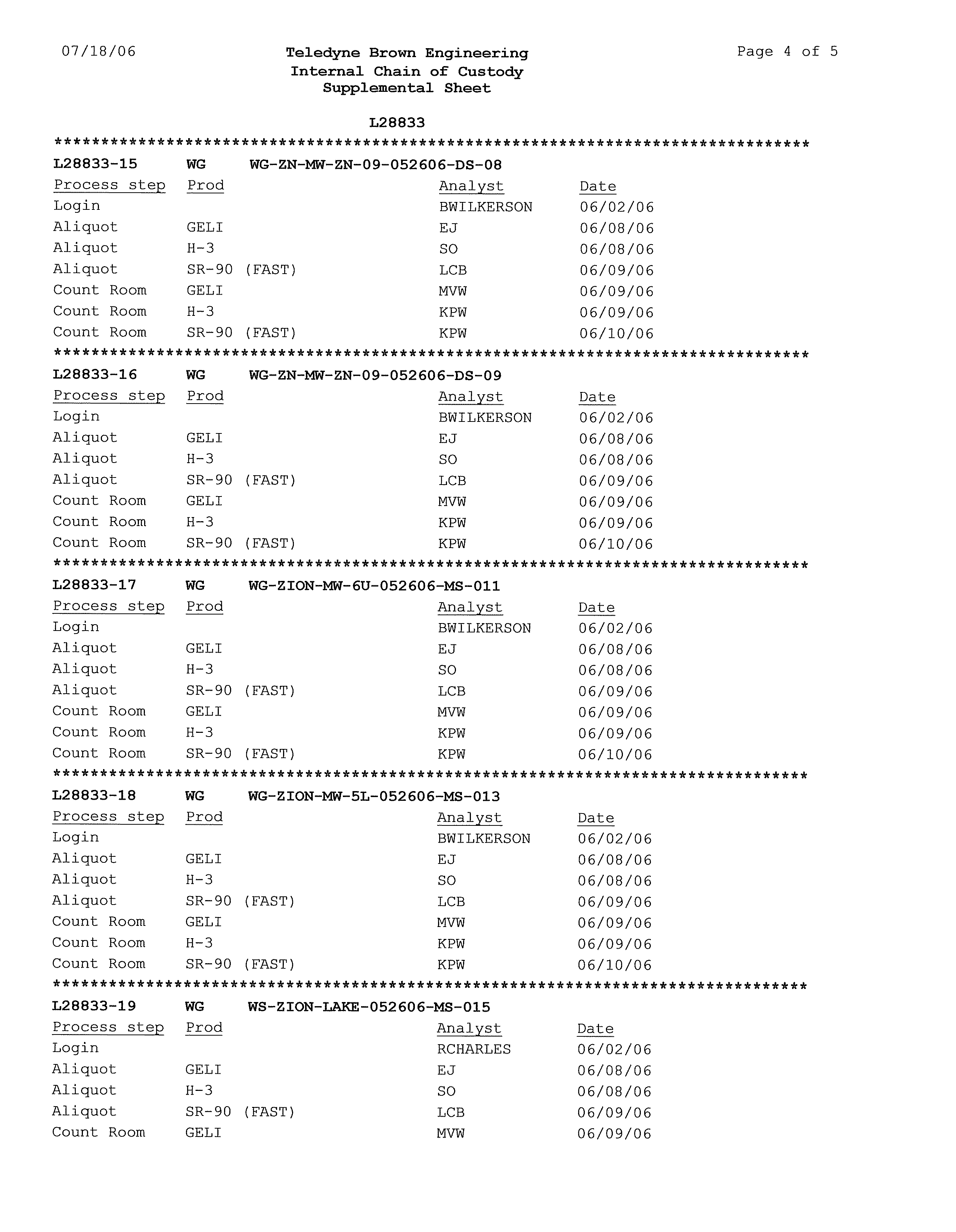

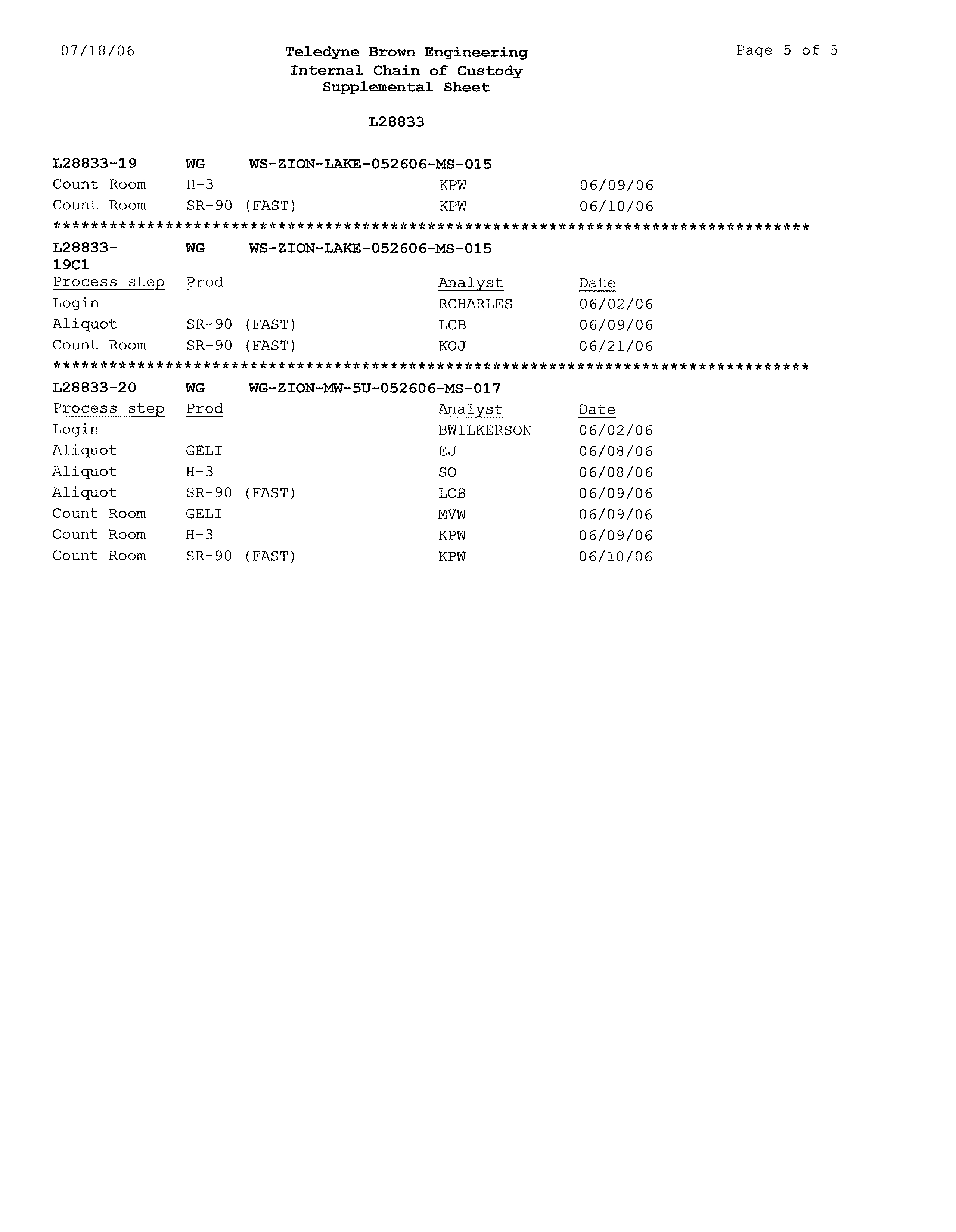

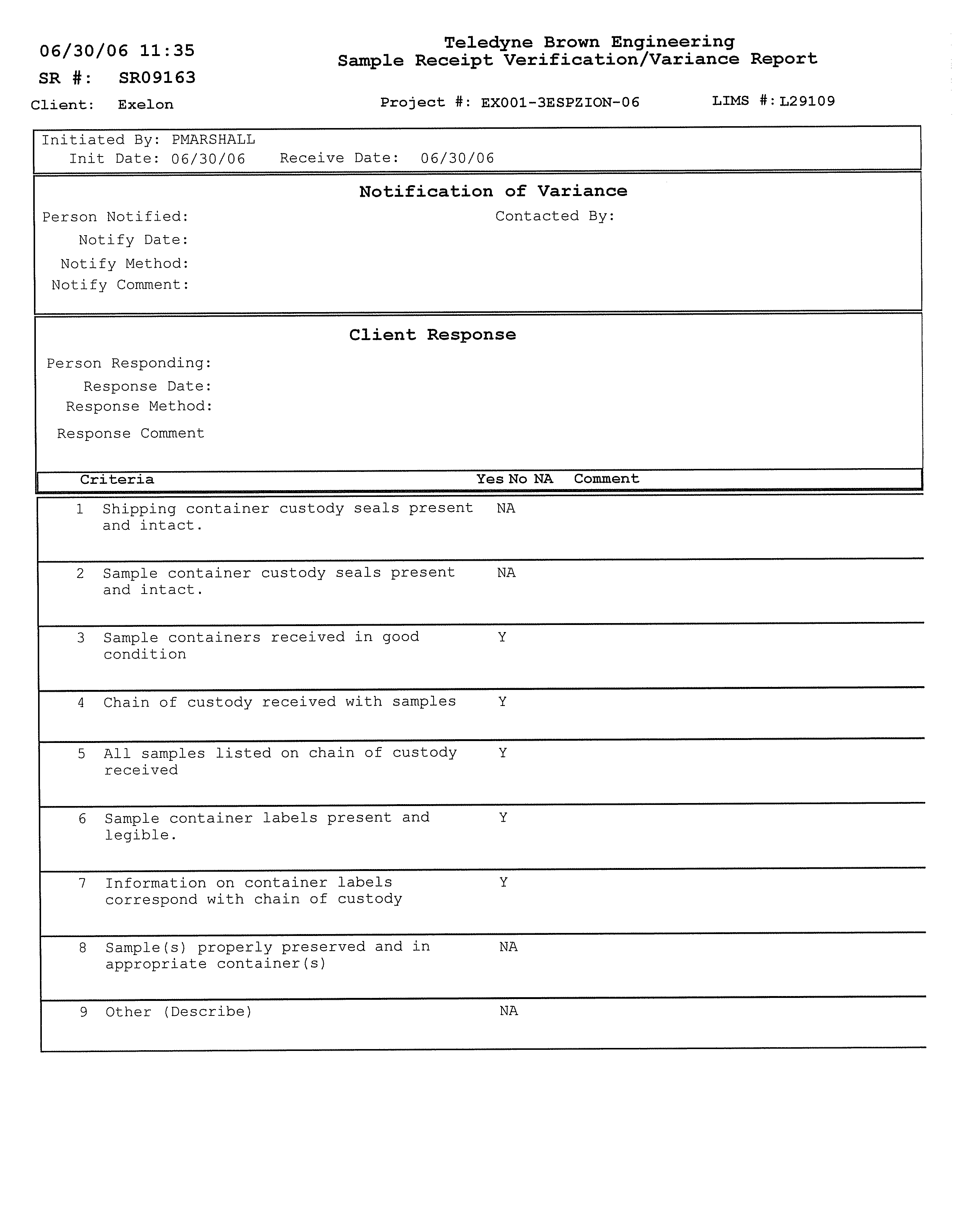

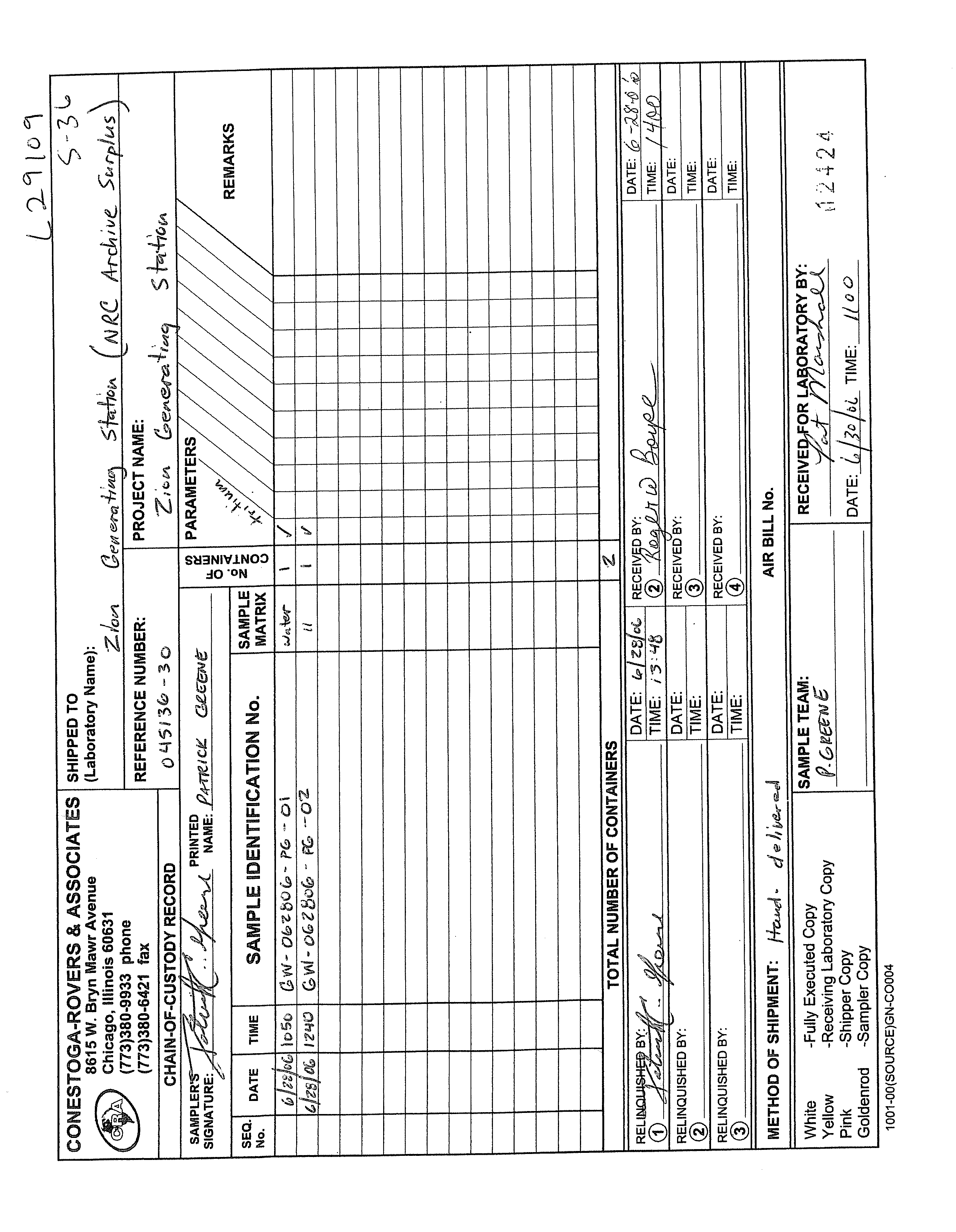

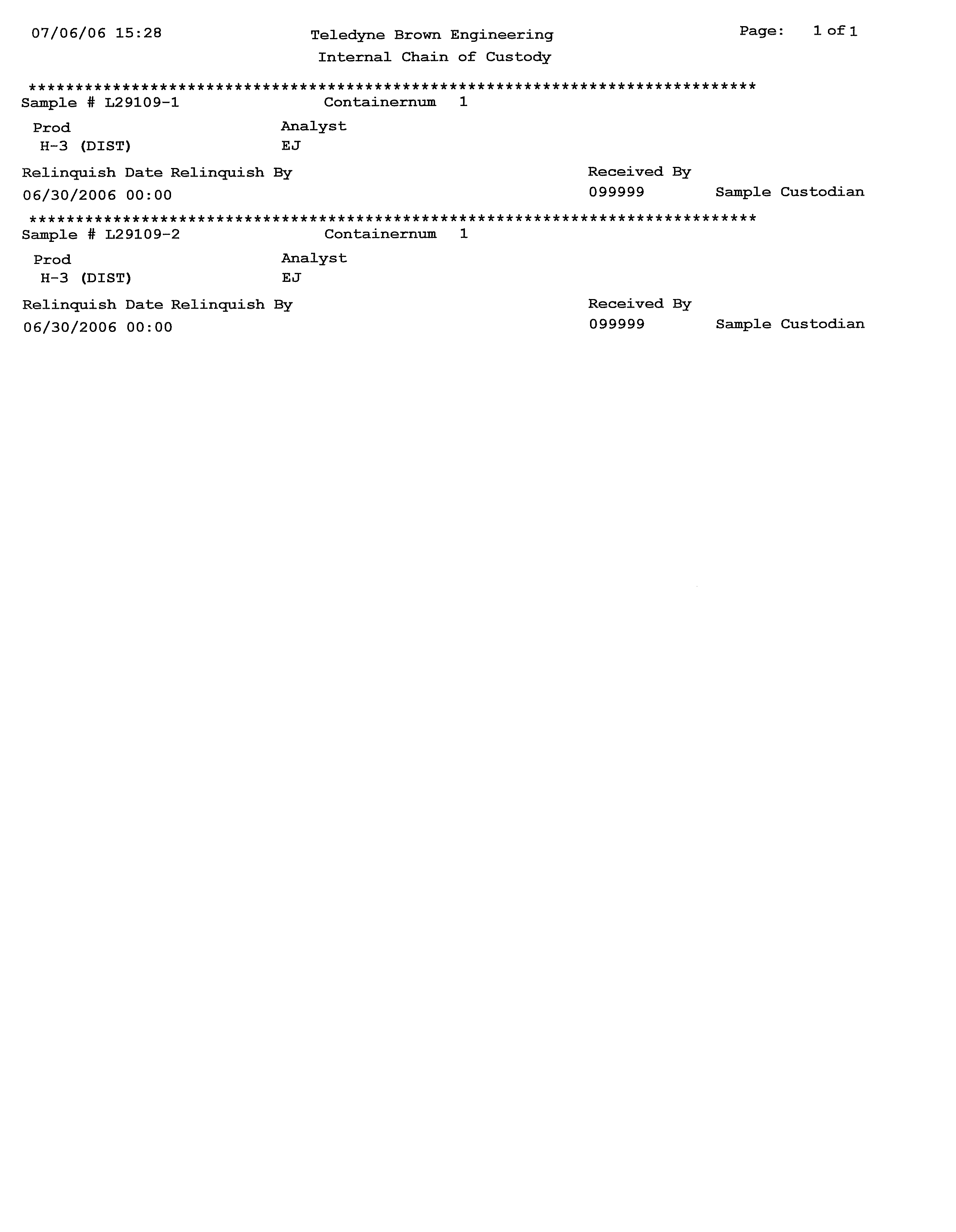

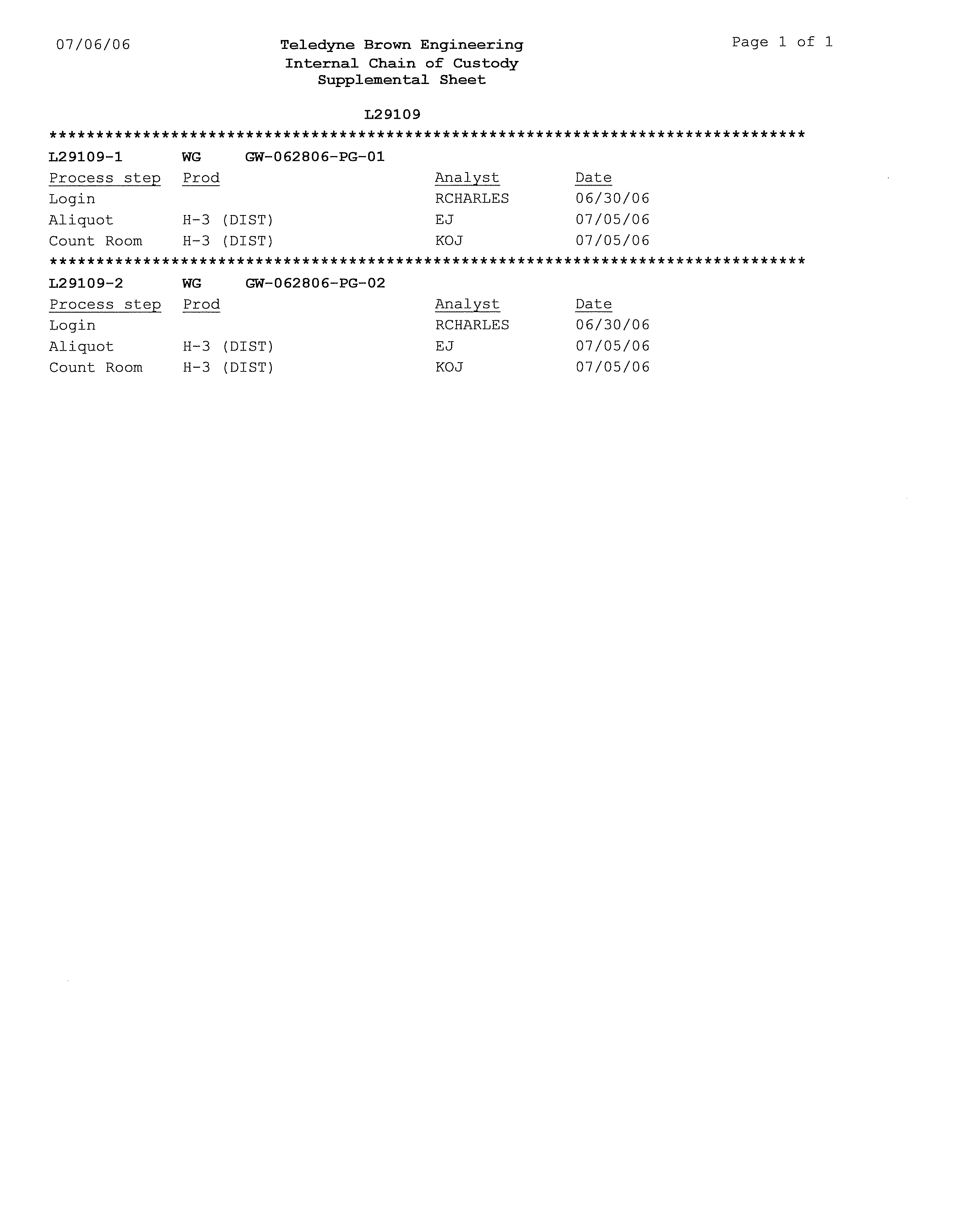

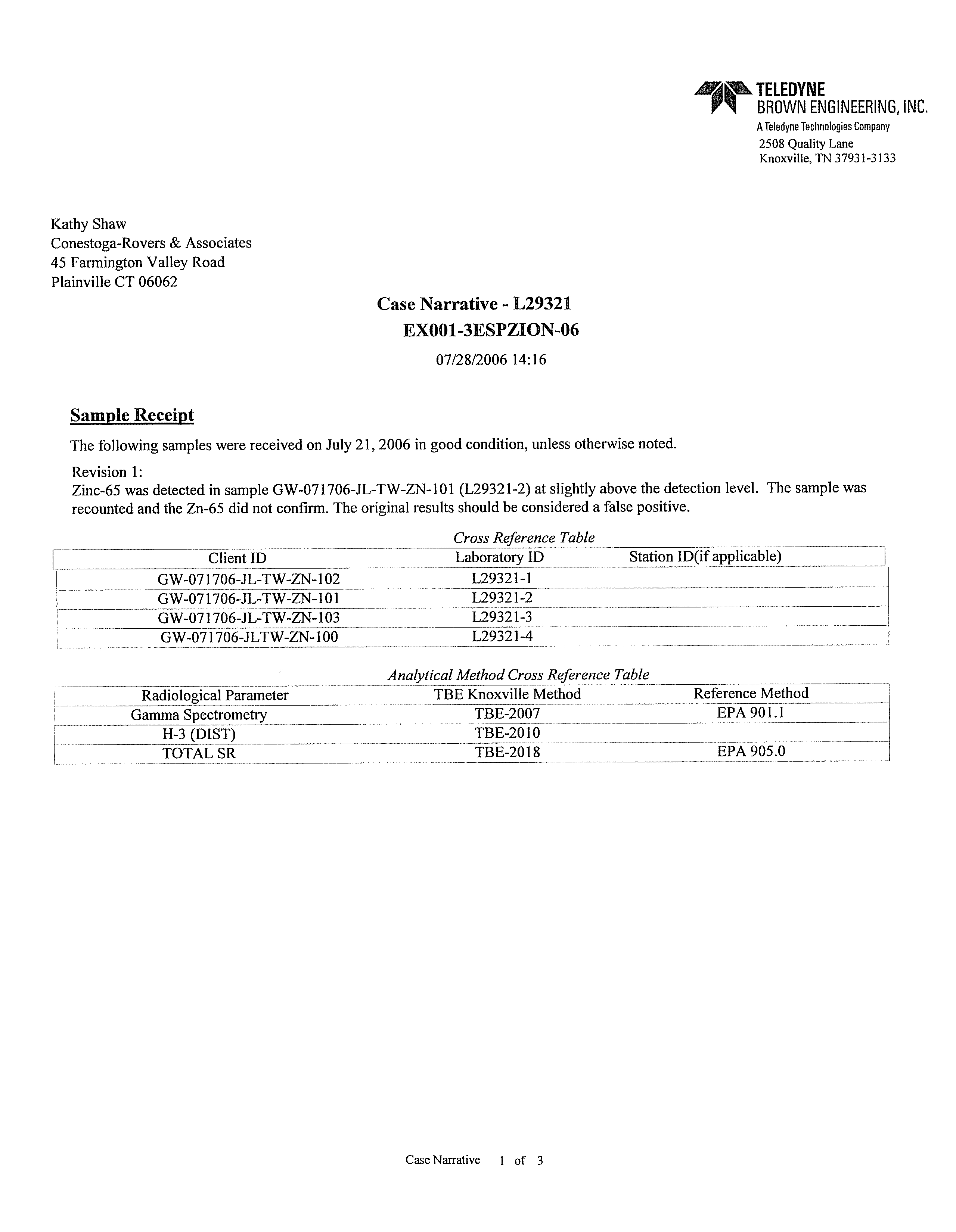

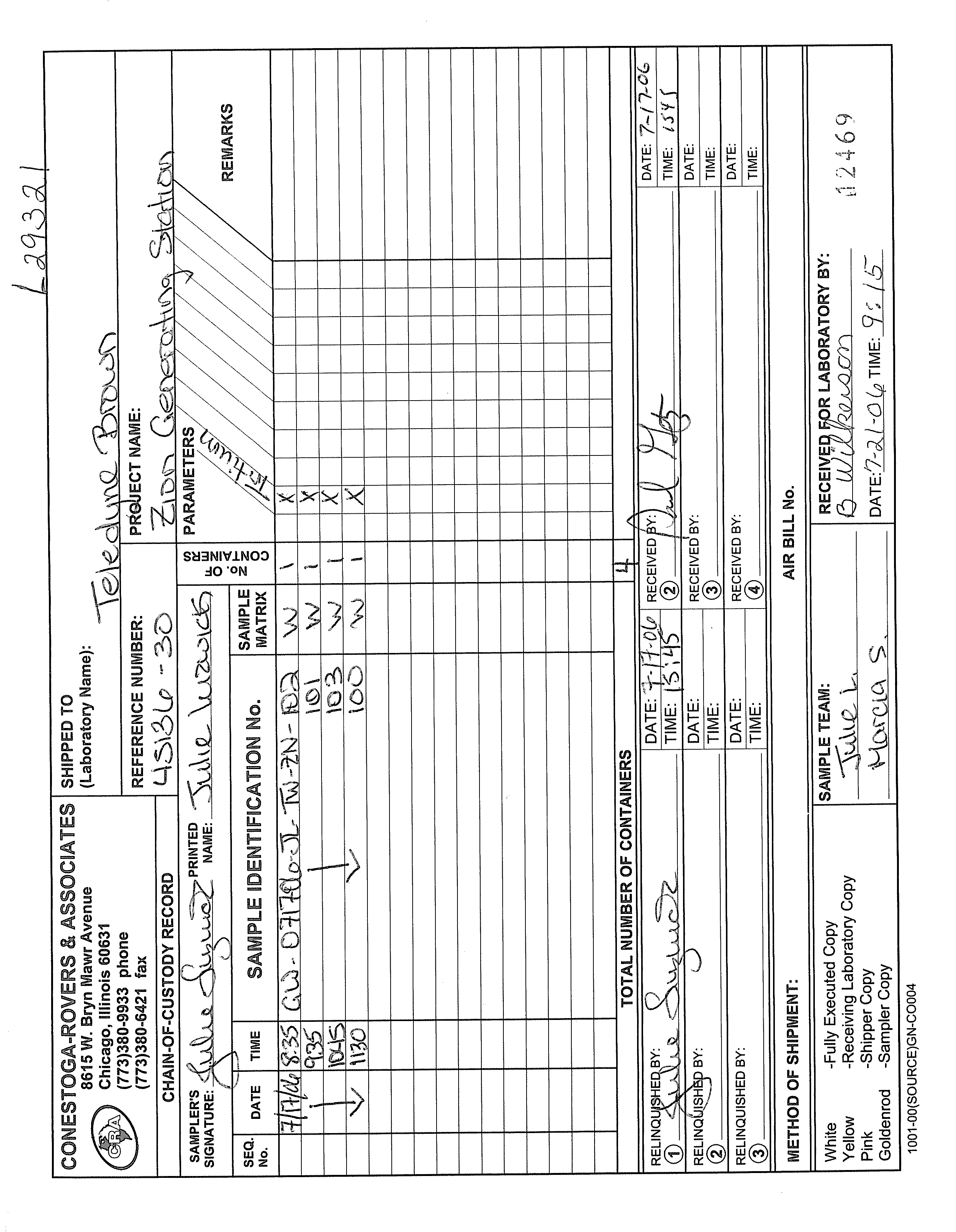

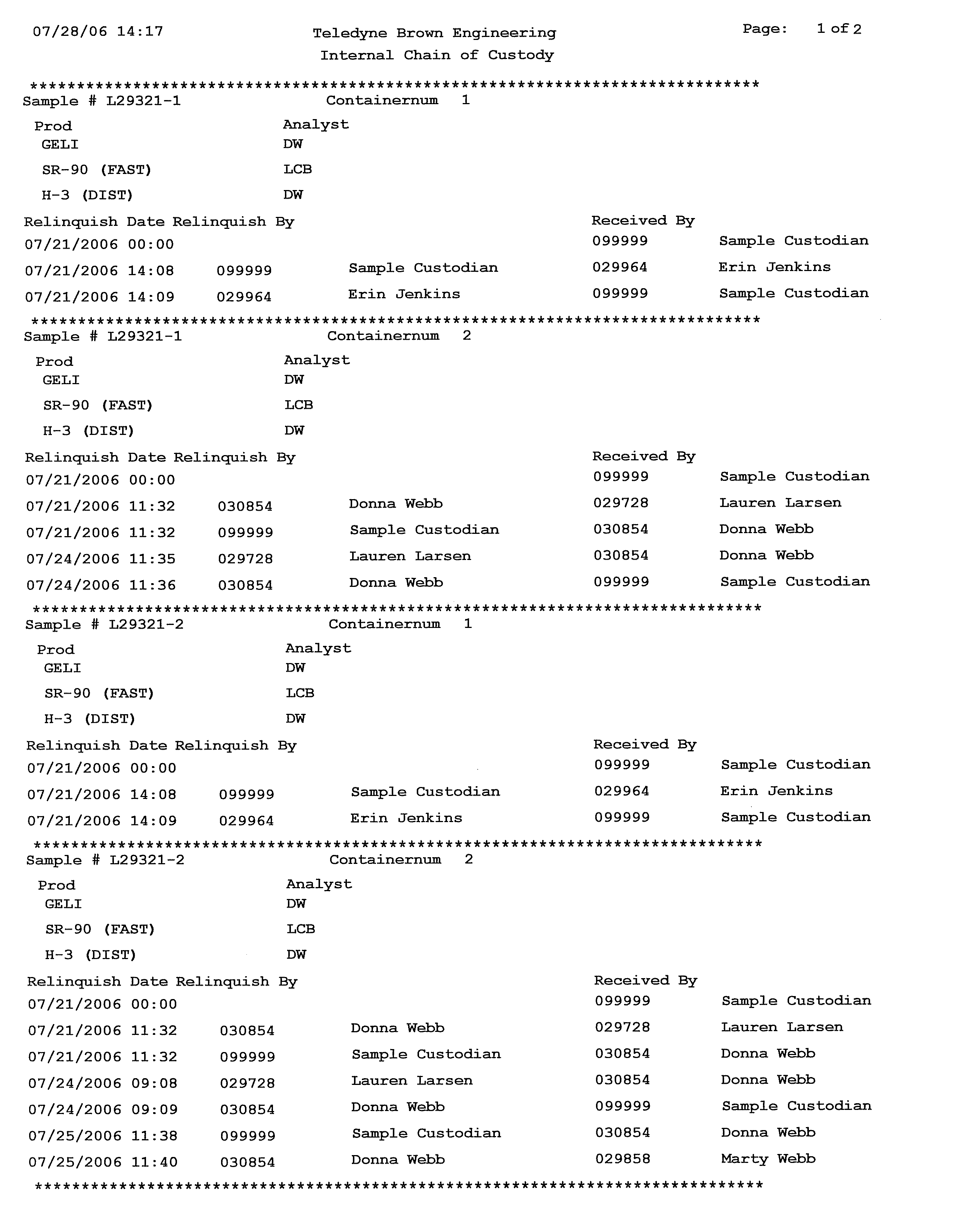

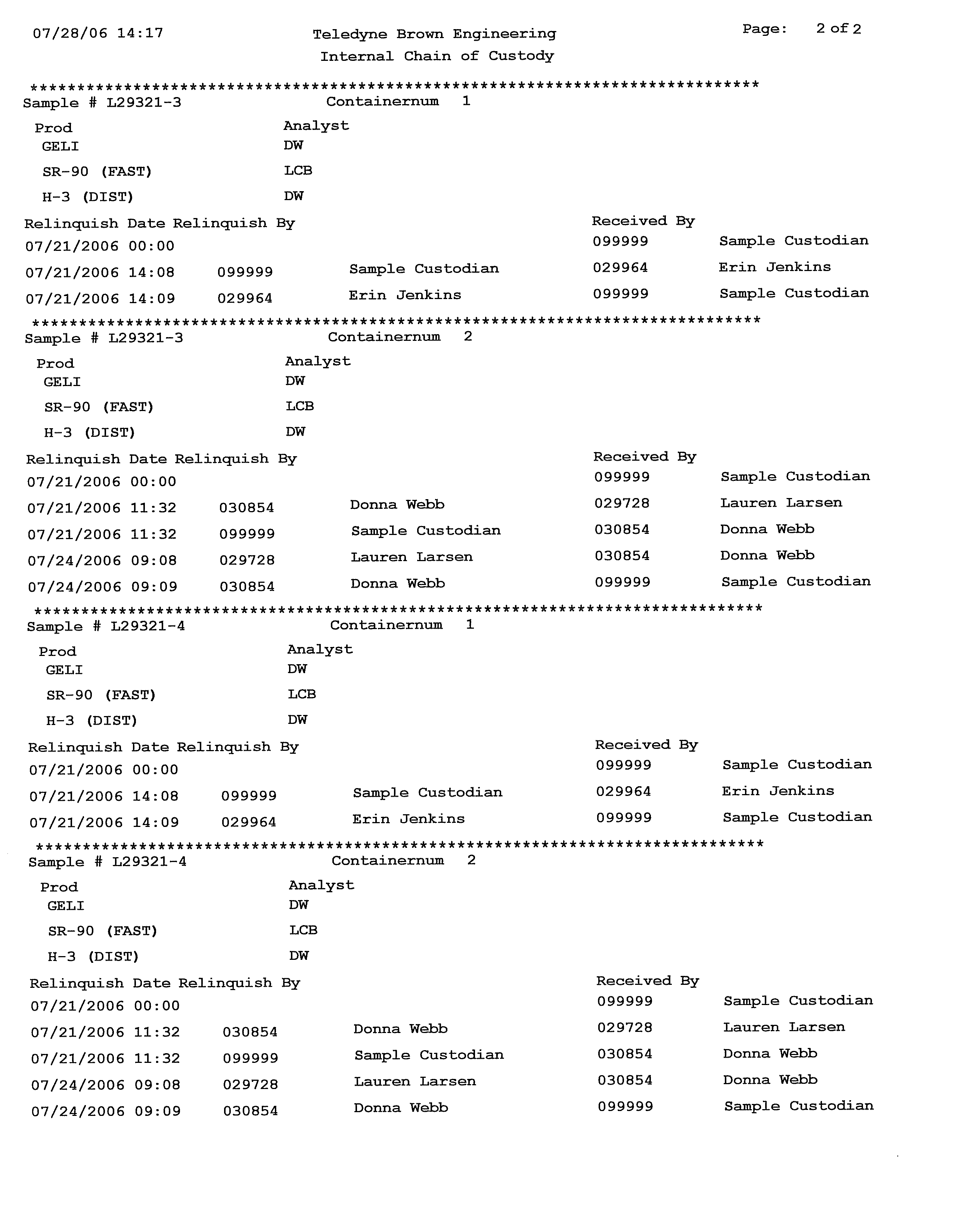

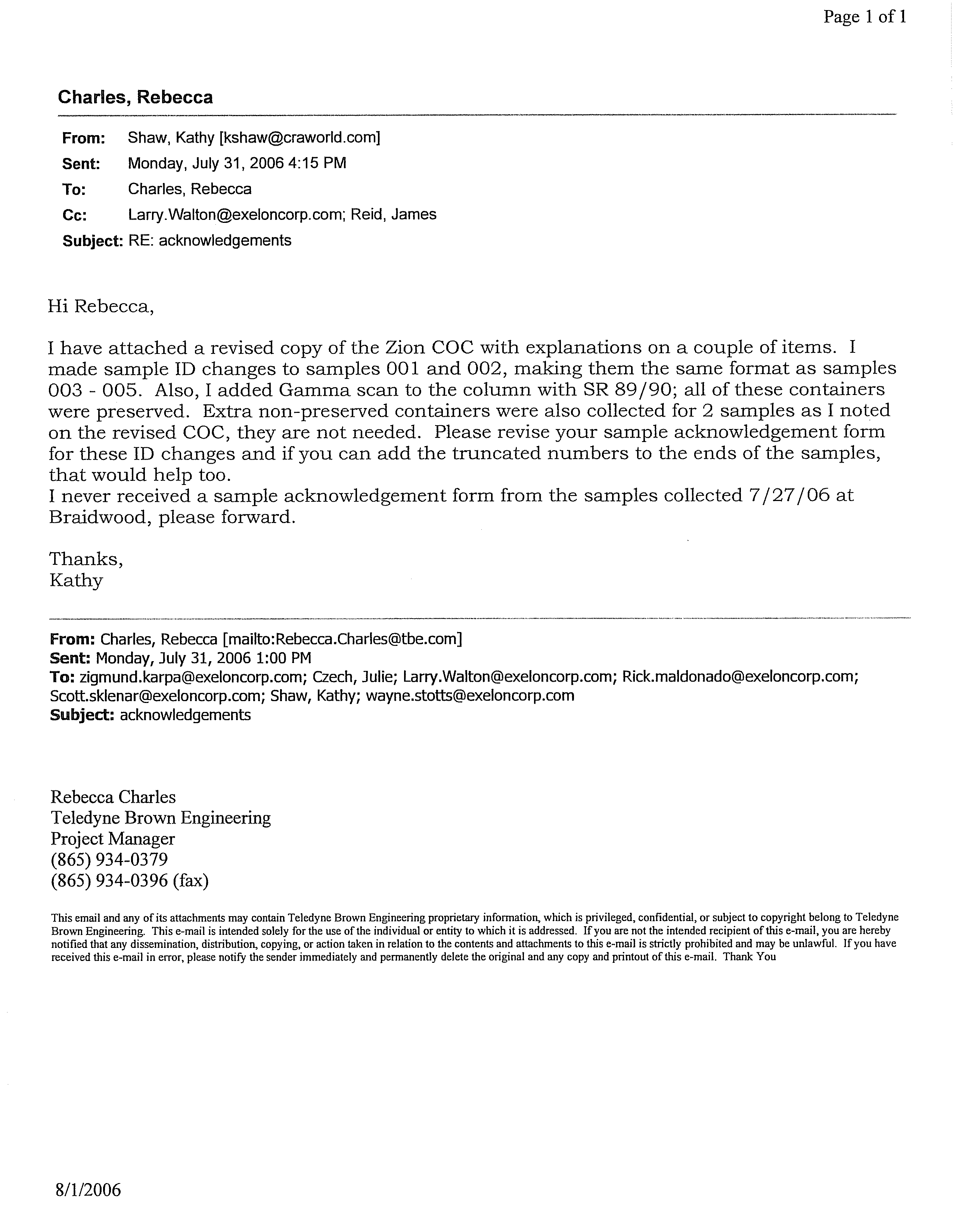

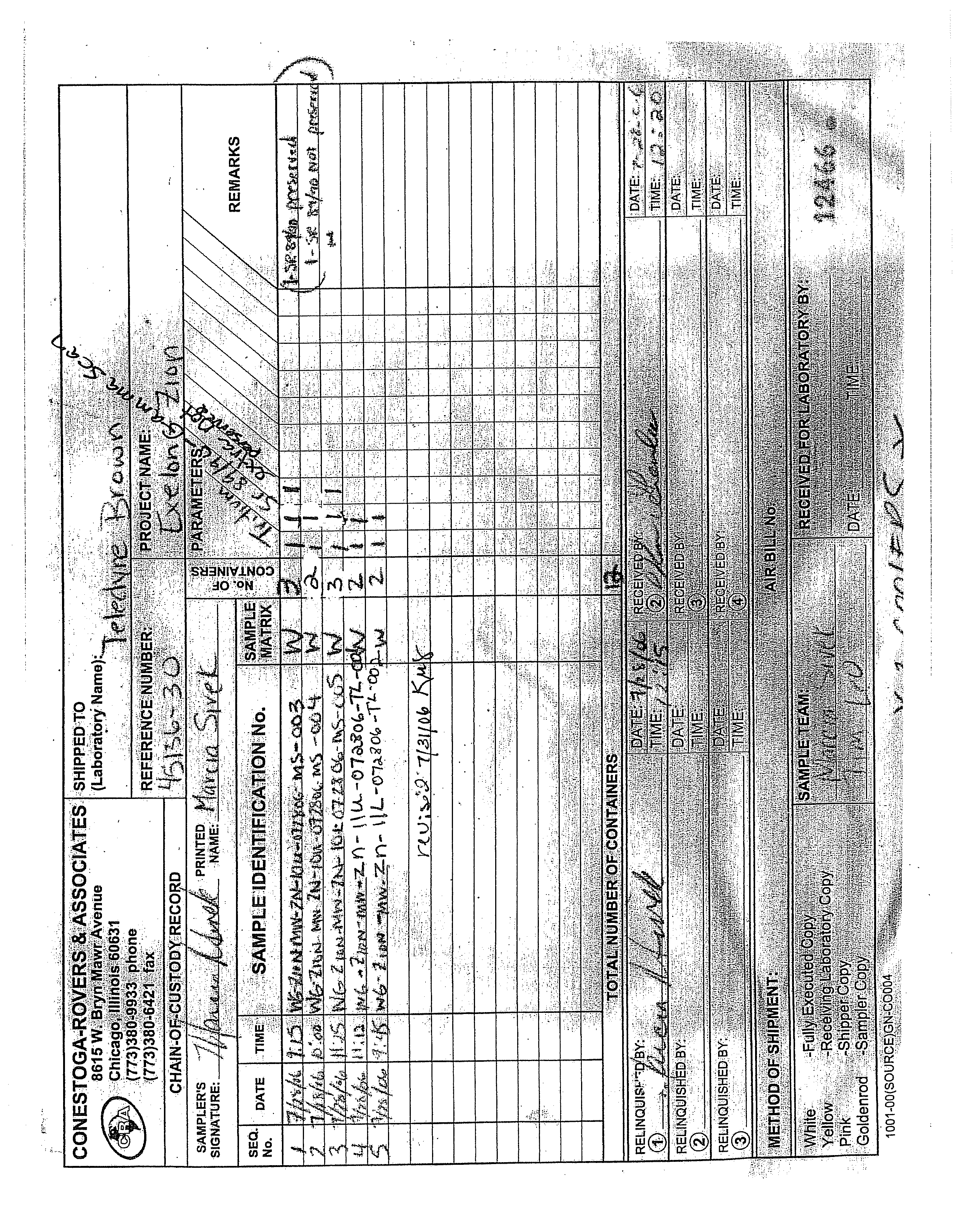

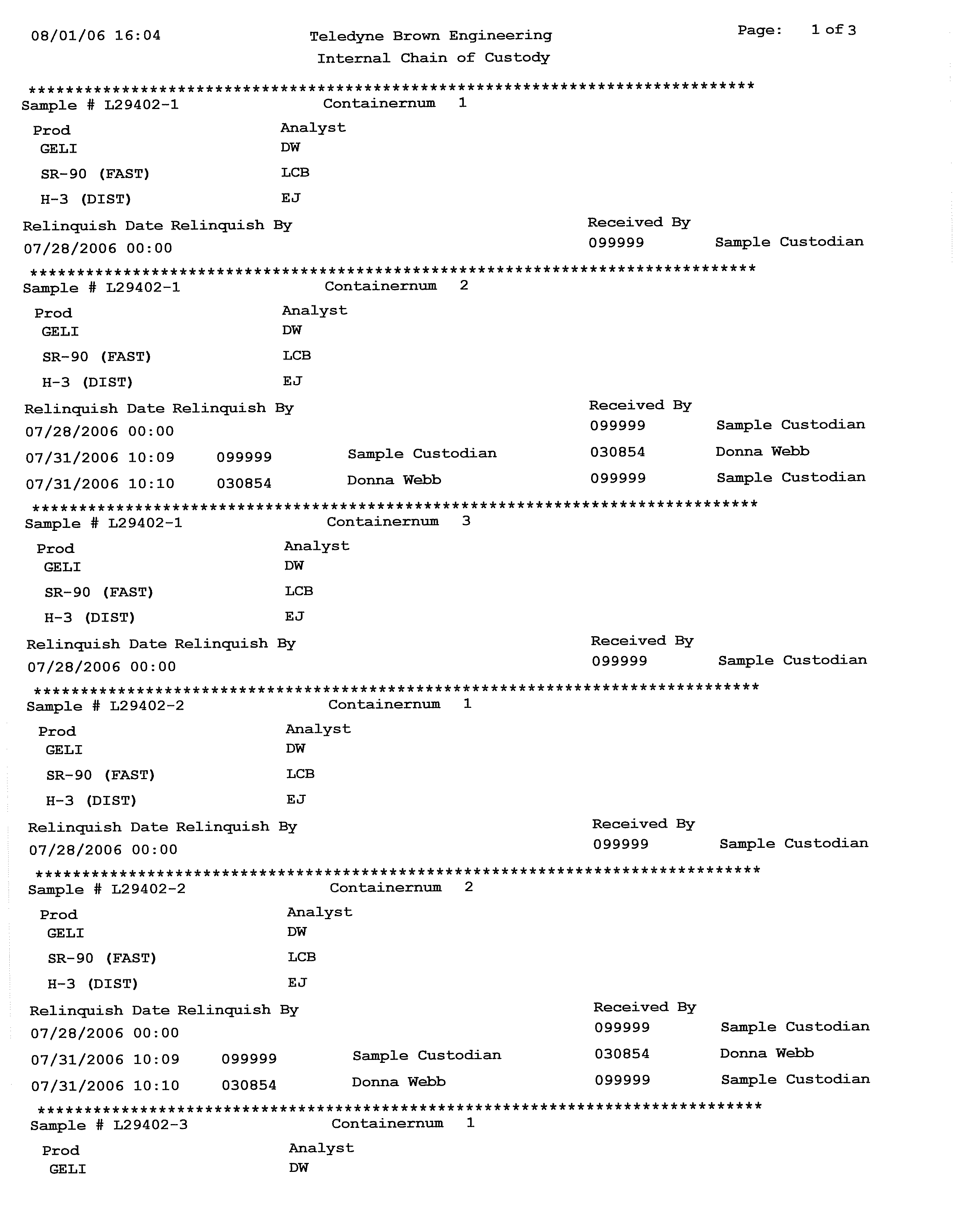

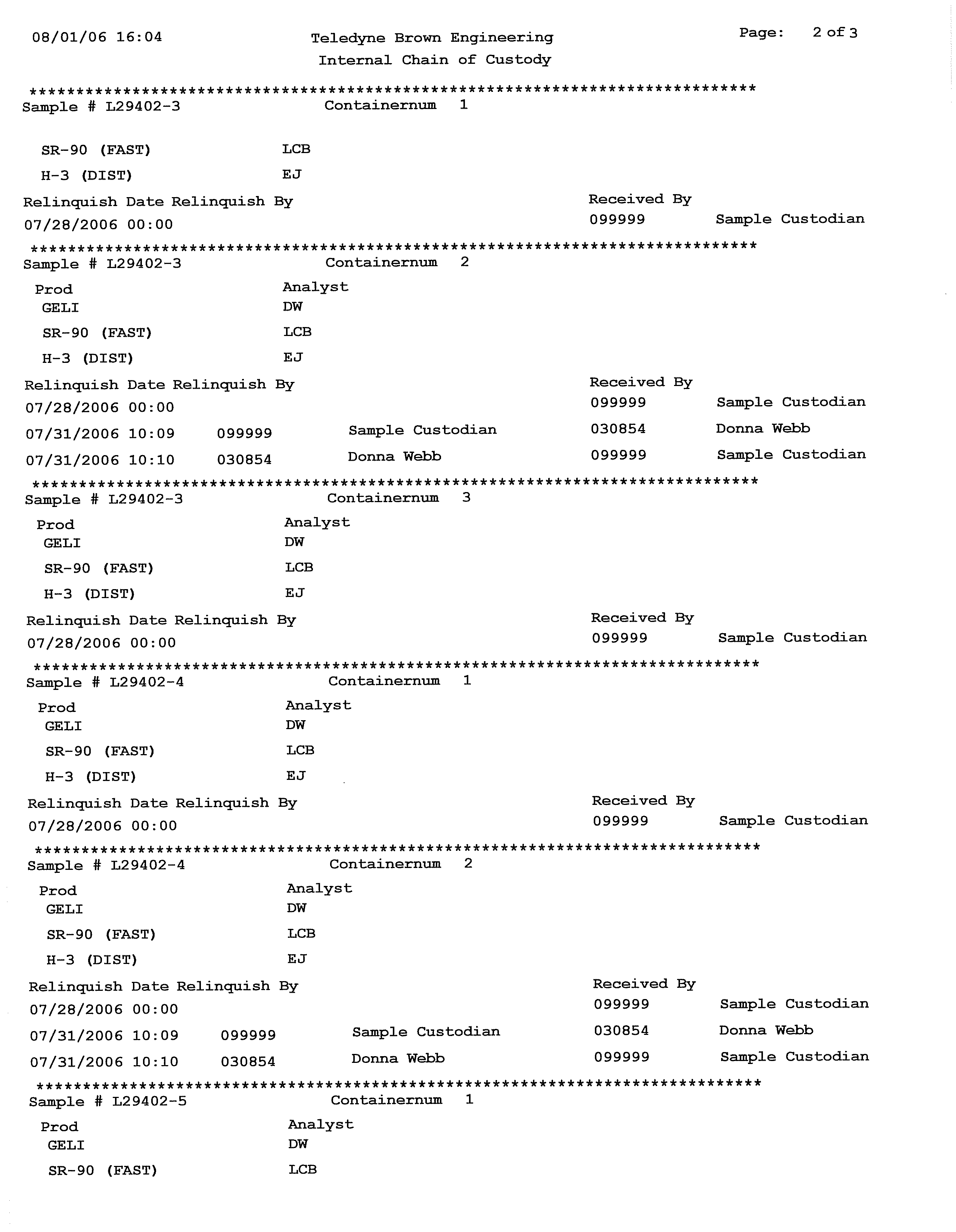

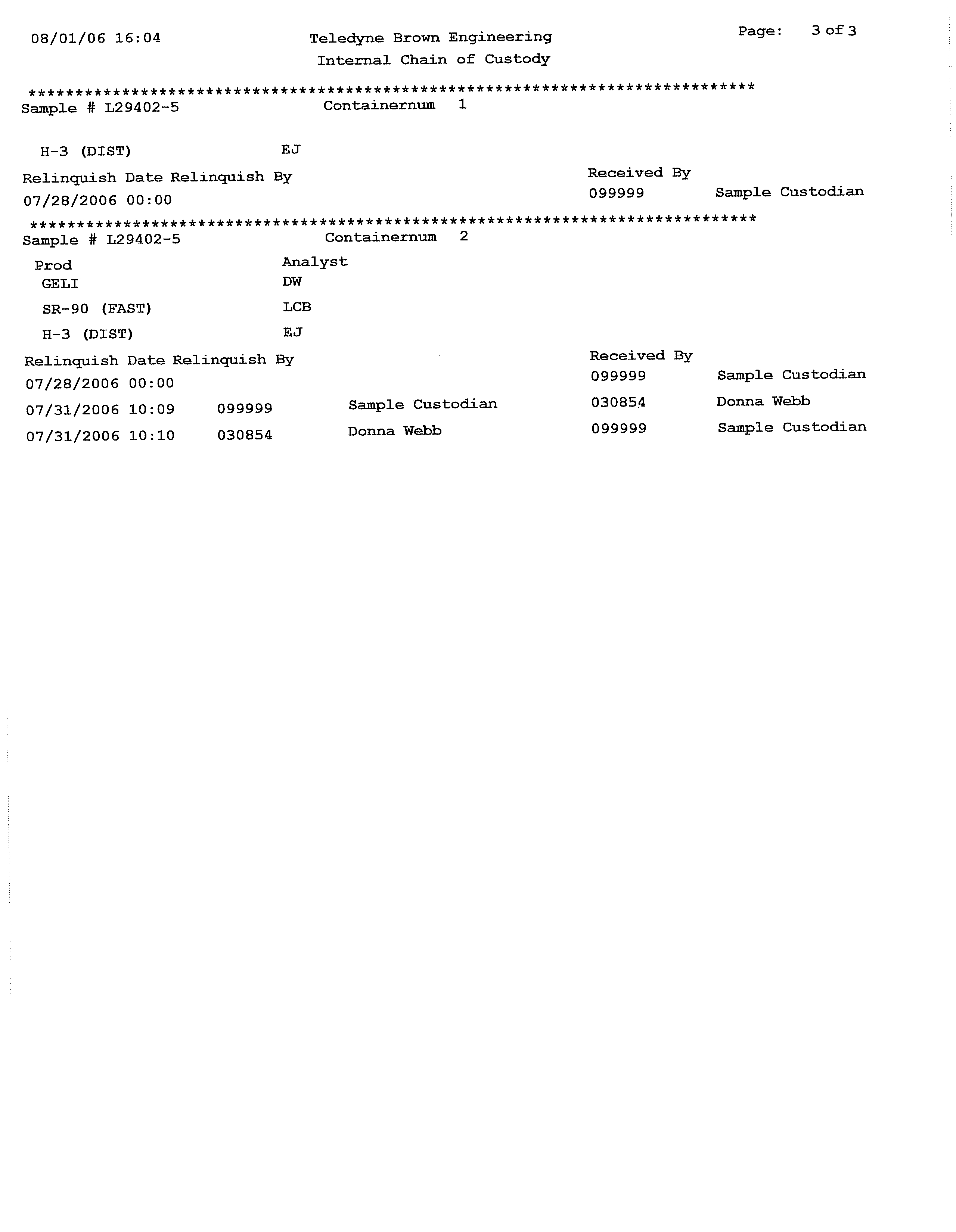

4.9

CHAIN-OF-CUSTODY RECORD

The samples were delivered to Station personnel under chain-of-custody protocol.

Subsequently, the Station shipped the samples under chain-of-custody protocol to

Teledyne Brown for analyses.

045136 (22) Zion Station

25

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

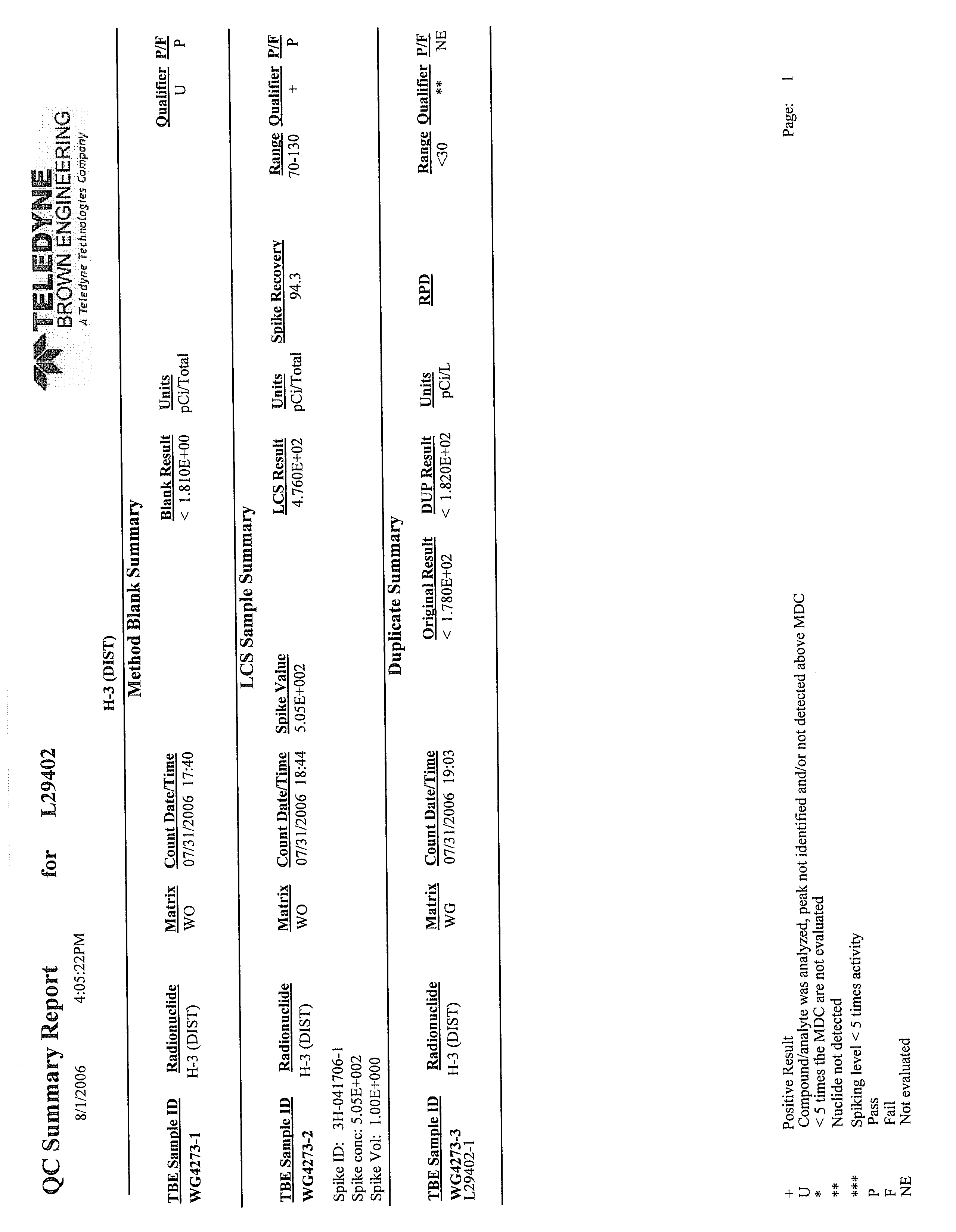

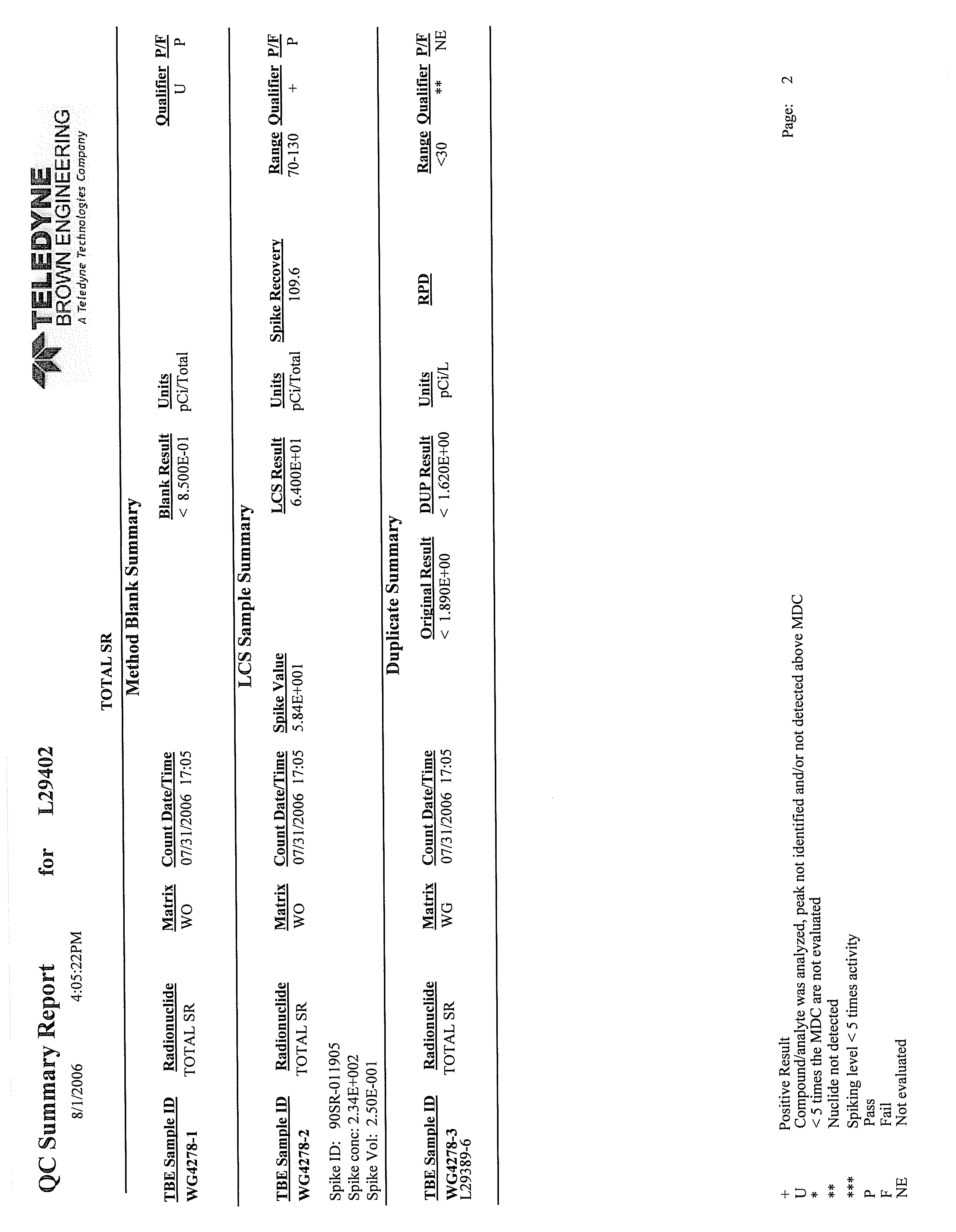

4.10

QUALITY CONTROL SAMPLES

Quality control samples were collected to evaluate the sampling and analysis process.

Field Duplicates

Field duplicates were collected to verify the accuracy of the analytical laboratory by

providing two samples collected at the same location and then comparing the analytical

results for consistency. Field duplicate samples were collected at a frequency of one

duplicate for every ten samples collected. A total of three duplicate samples were

collected. The locations of duplicate samples were selected in the field during the

performance of sample collection activities. The duplicate samples were collected

simultaneously with the actual sample and were analyzed for the same parameters as

the actual samples.

Split Samples

Split samples from permanent monitoring wells and surface water were collected for the

NRC for tritium simultaneously with the actual sample at every sample location. Split

samples were delivered to the Station personnel and (if requested) made available to the

NRC. Split samples from the temporary monitoring wells were collected directly by the

NRC and the Illinois Emergency Management Agency (IEMA).

4.11

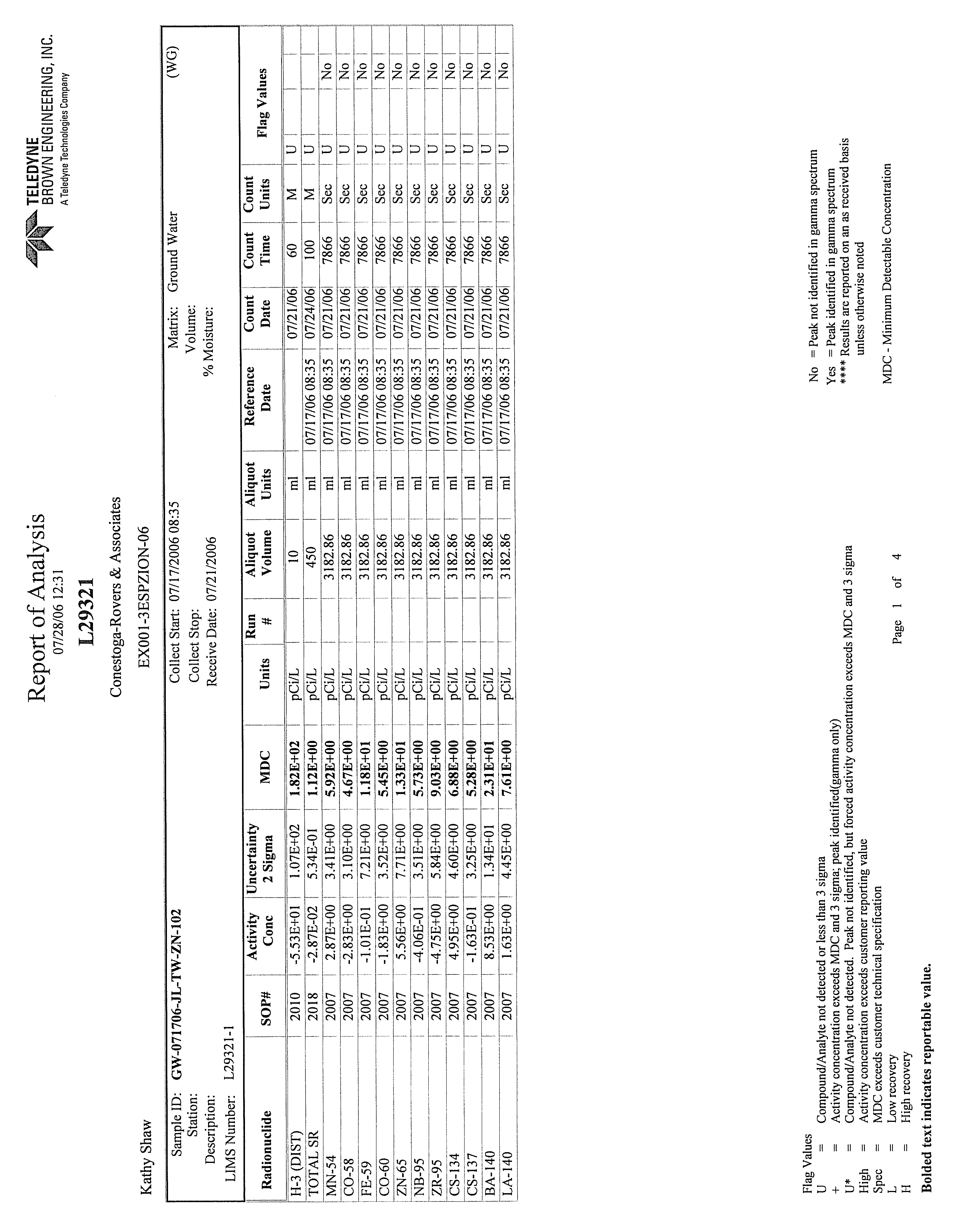

ANALYSES

Groundwater and surface water samples were analyzed for tritium and gamma-emitting

radionuclides as

listed in NUREG-1301, and strontium-89/90 as

listed 40 CFR 141.25.

045136 (22) Zion Station

26

CONESTOGA-ROVERS & ASSOCIATES

Revision 1

5.0

RESULTS SUMMARY

This section provides a summary of Station-specific geology and hydrogeology, along

with a discussion of hydraulic gradients, groundwater elevations, and flow directions in

the vicinity of the Station. This section also presents and evaluates the analytical results

obtained from activities performed in accordance with the Work Plan.

5.1

STATION GEOLOGY

Geologic cross-sections in both a south-north and east-west profile have been developed.

Figure 5.1 displays the cross-section locations across the Station and the cross-sections

are provided on Figures 5.2 and 5.3. These cross-section locations were chosen because

of their close proximity to the AFEs and structures potentially influencing groundwater

flow patterns.

The Station is underlain by overburden deposits and a regionally extensive sequence of

consolidated sedimentary deposits as discussed in Section 2.4.3. In descending order,

the following overburden stratigraphic units have been identified and characterized

during the various Station investigations:

•

Upper Sand Unit: Dense to very dense granular soils which range in gradation from

very fine sand to fine to coarse sand, and which contains some gravel and occasional

cobbles and boulders. Depth ranges from the ground surface to an elevation of

approximately 555 feet AMSL.

•

Silt-Clay Unit: Hard silt, silty clay, clayey silt, and sandy silt, which contain some

sand and gravel and occasional cobbles and boulders.

Depth ranges from

approximately 525 feet to 555 feet AMSL.

•

Lower Sand Unit: Dense to very dense sands and silty sands which contain some

gravel, occasional cobbles and boulders, and layers of hard silty clay, clayey silt, and

sandy silt.

Depth ranges from approximately 480 feet to 525 feet AMSL

(ComEd, 1969).

The Upper Sand Unit includes the surficial deposits of the Zion beach-ridge plain and

consists of sand and gravel of the Lake Michigan Formation. The Lake Michigan

Formation

describes

Holocene

shallow-water,

near-shore

beach

sediments

predominantly consisting of medium-grained sand with local lenses of sandy gravel,

and containing beds of silt.

045136 (22) Zion Station

27

CONESTOGA-ROVERS & ASSOCIATES

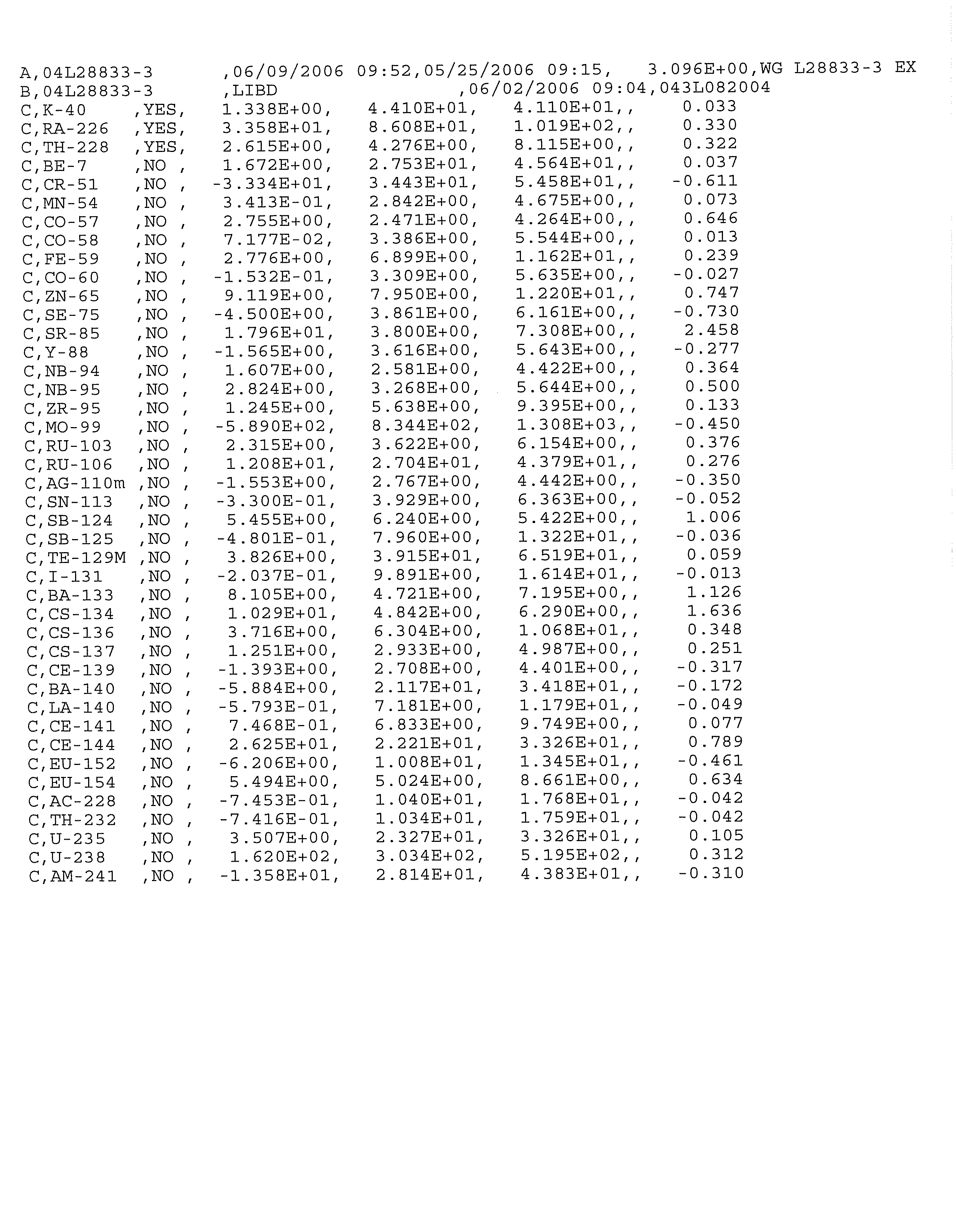

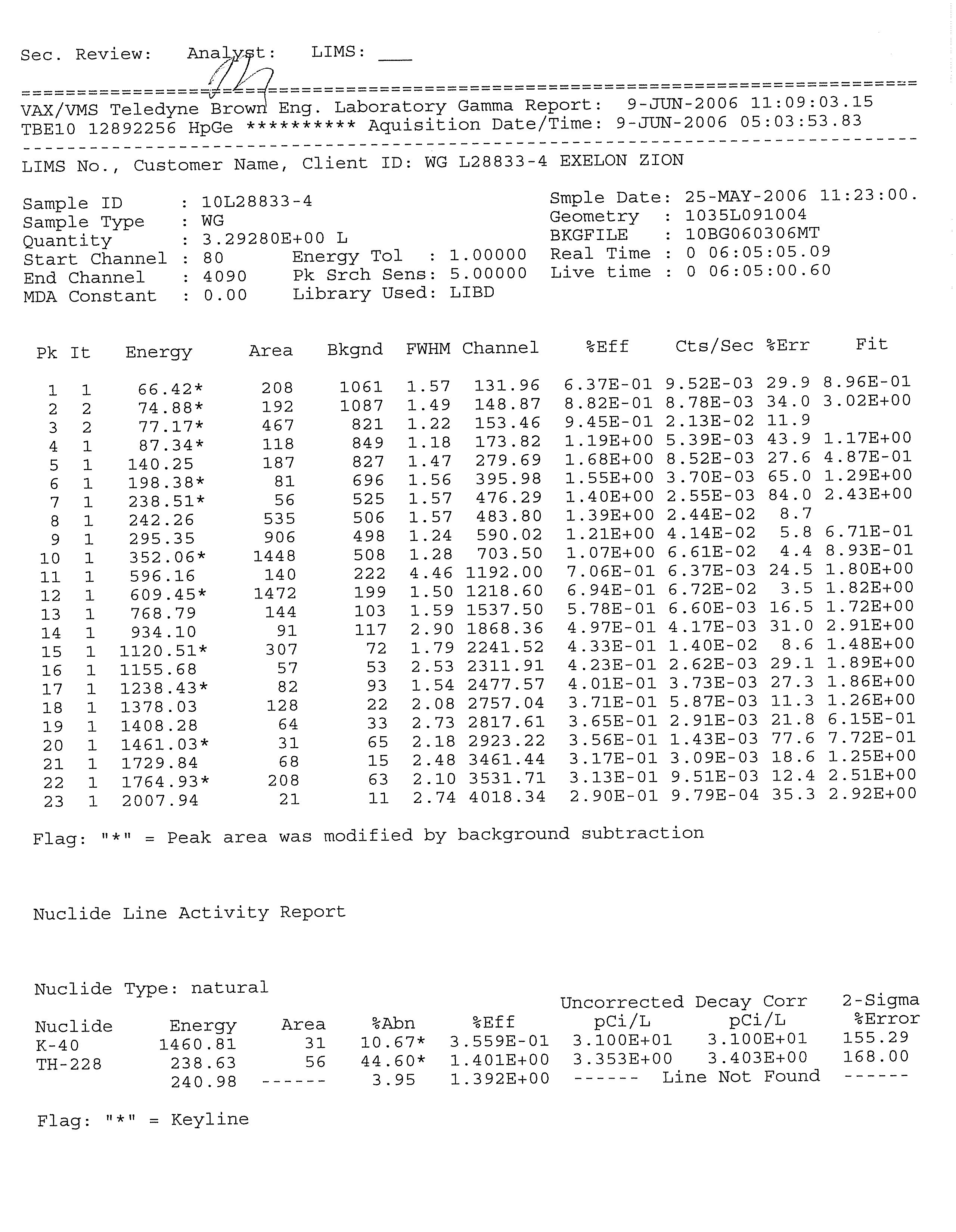

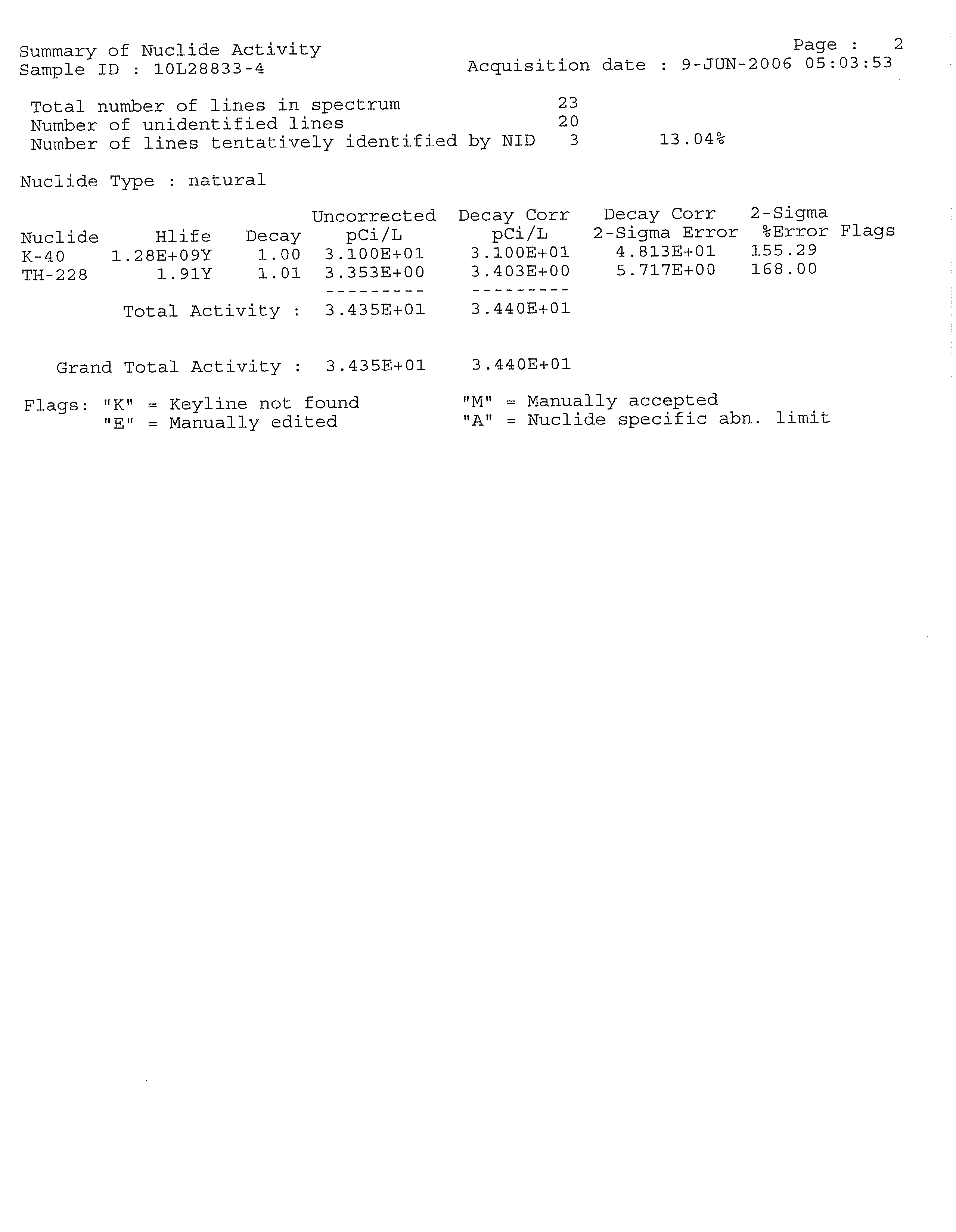

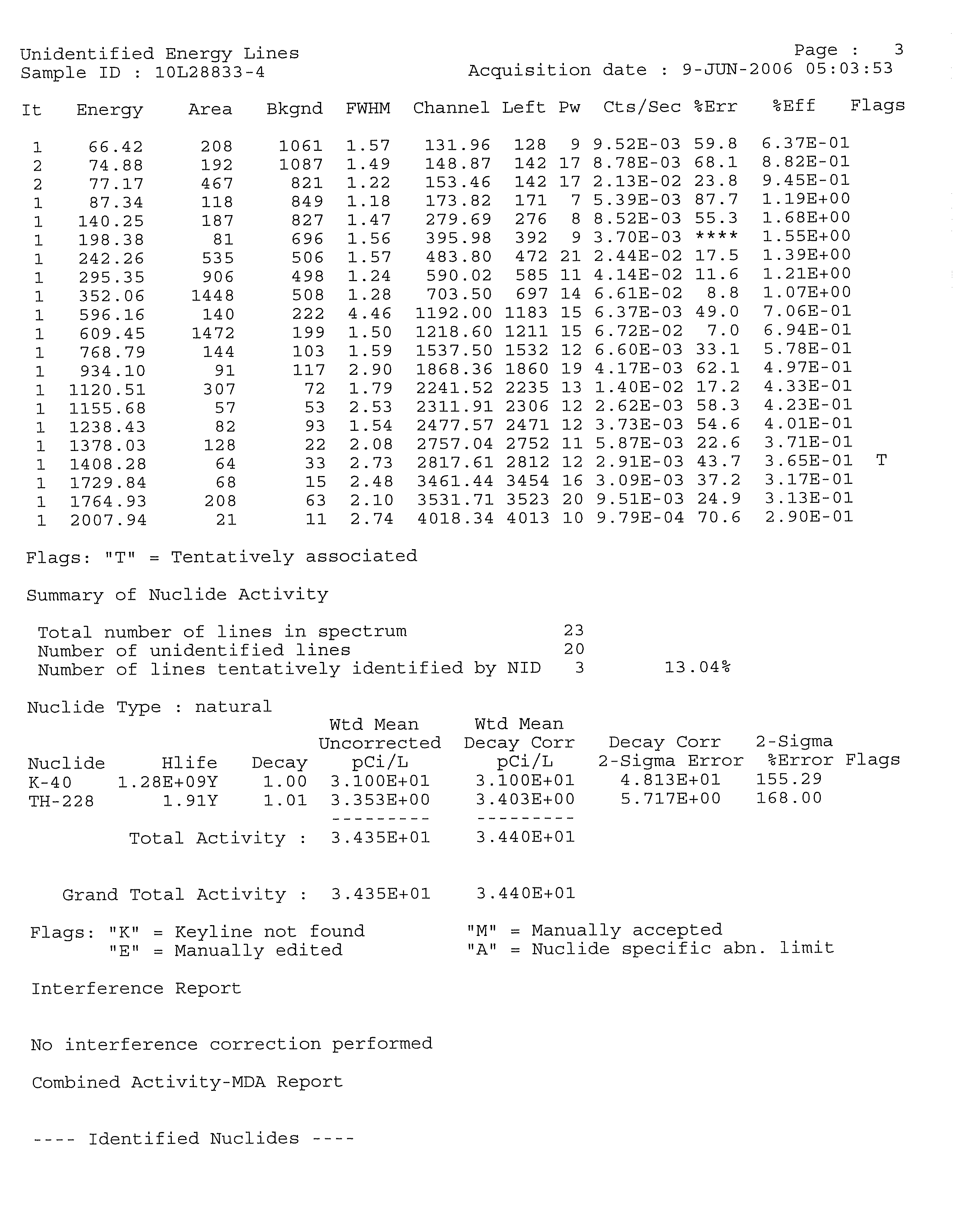

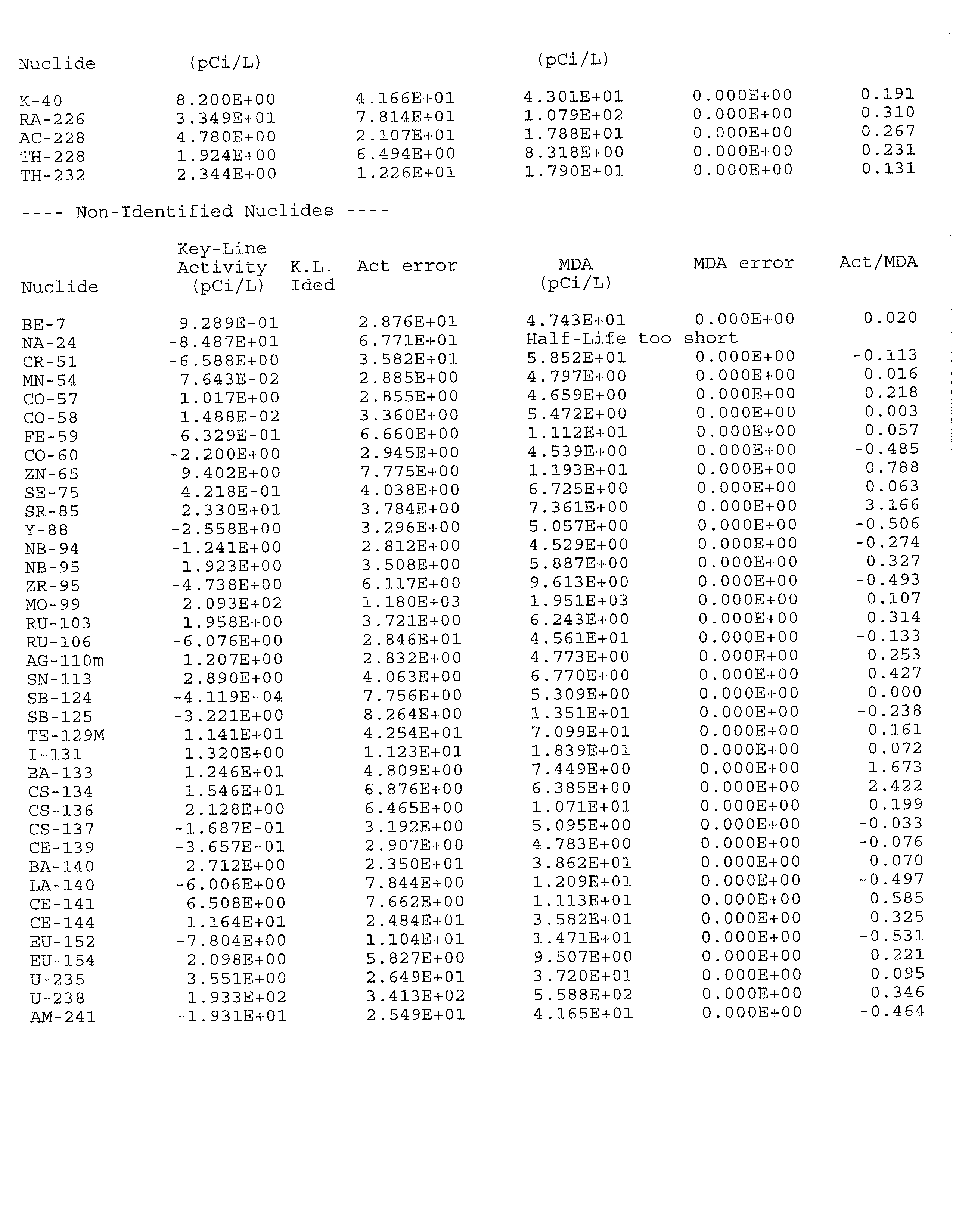

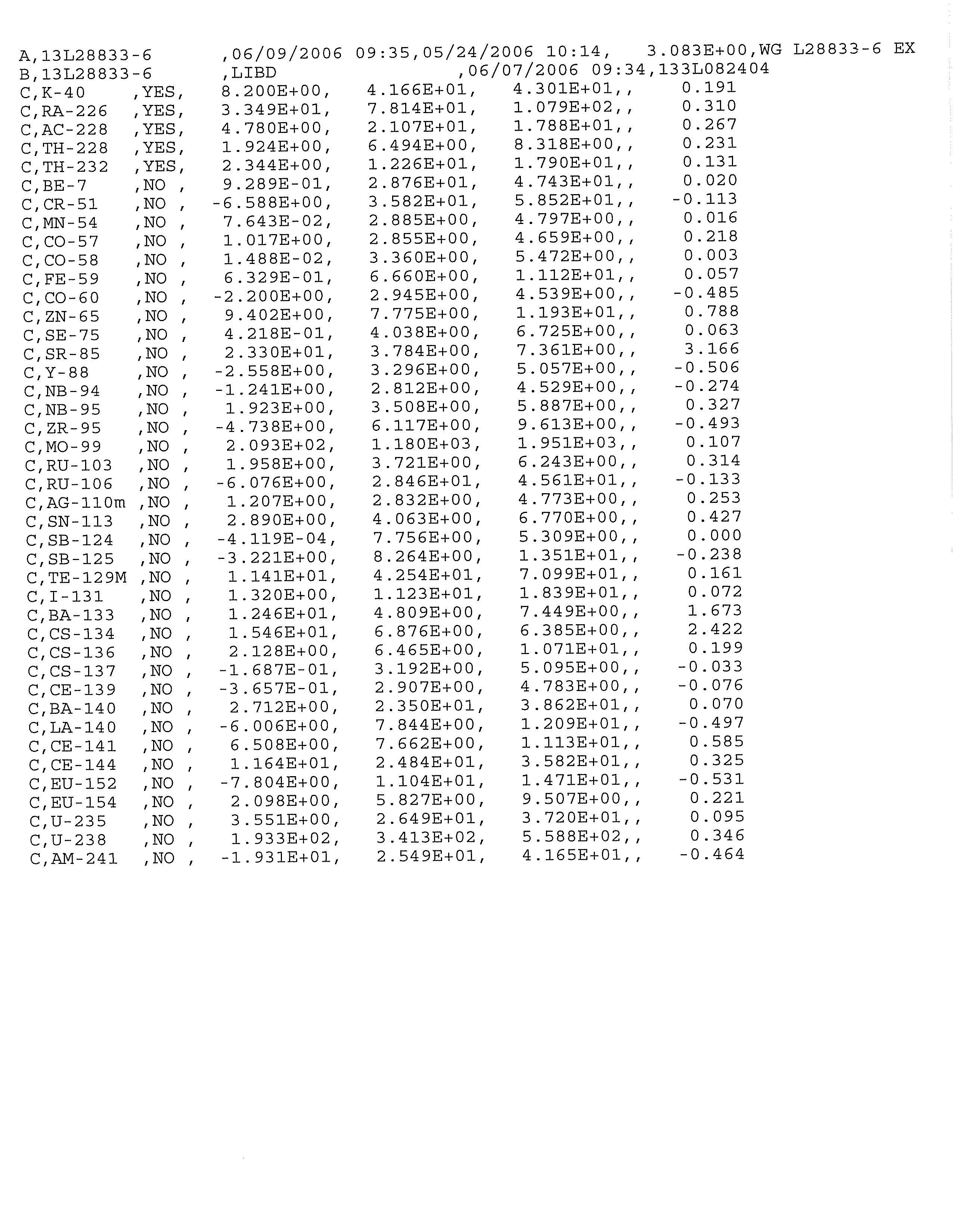

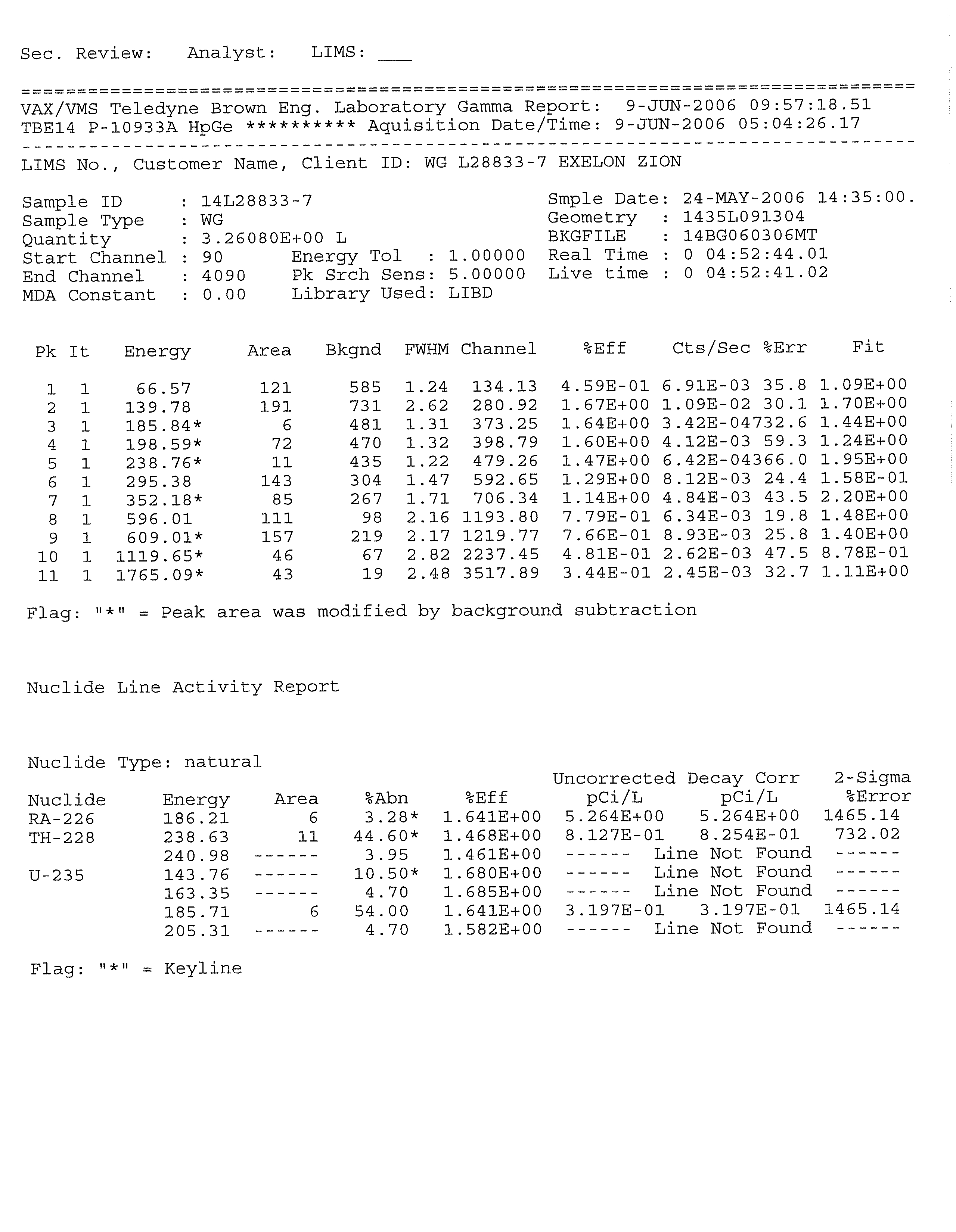

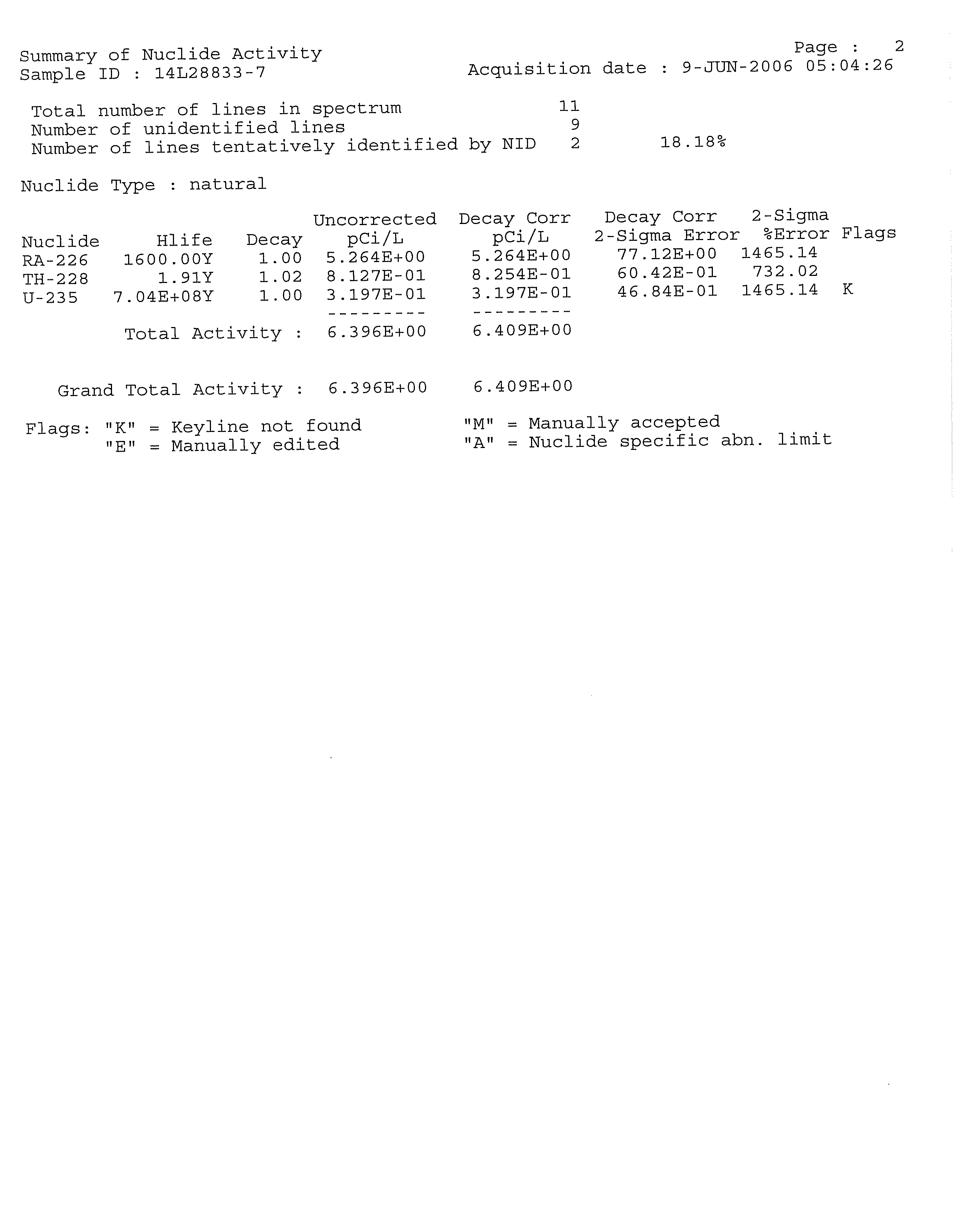

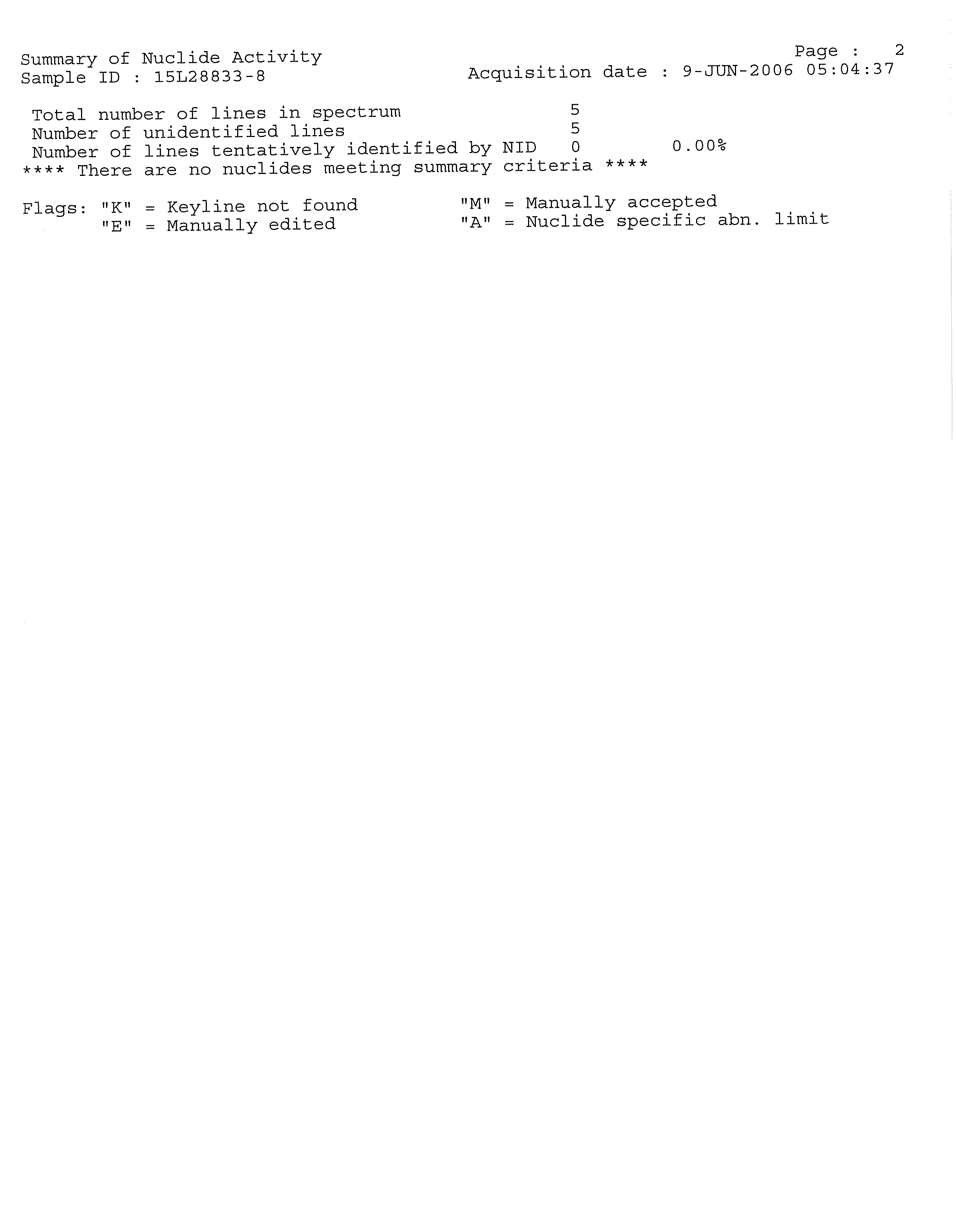

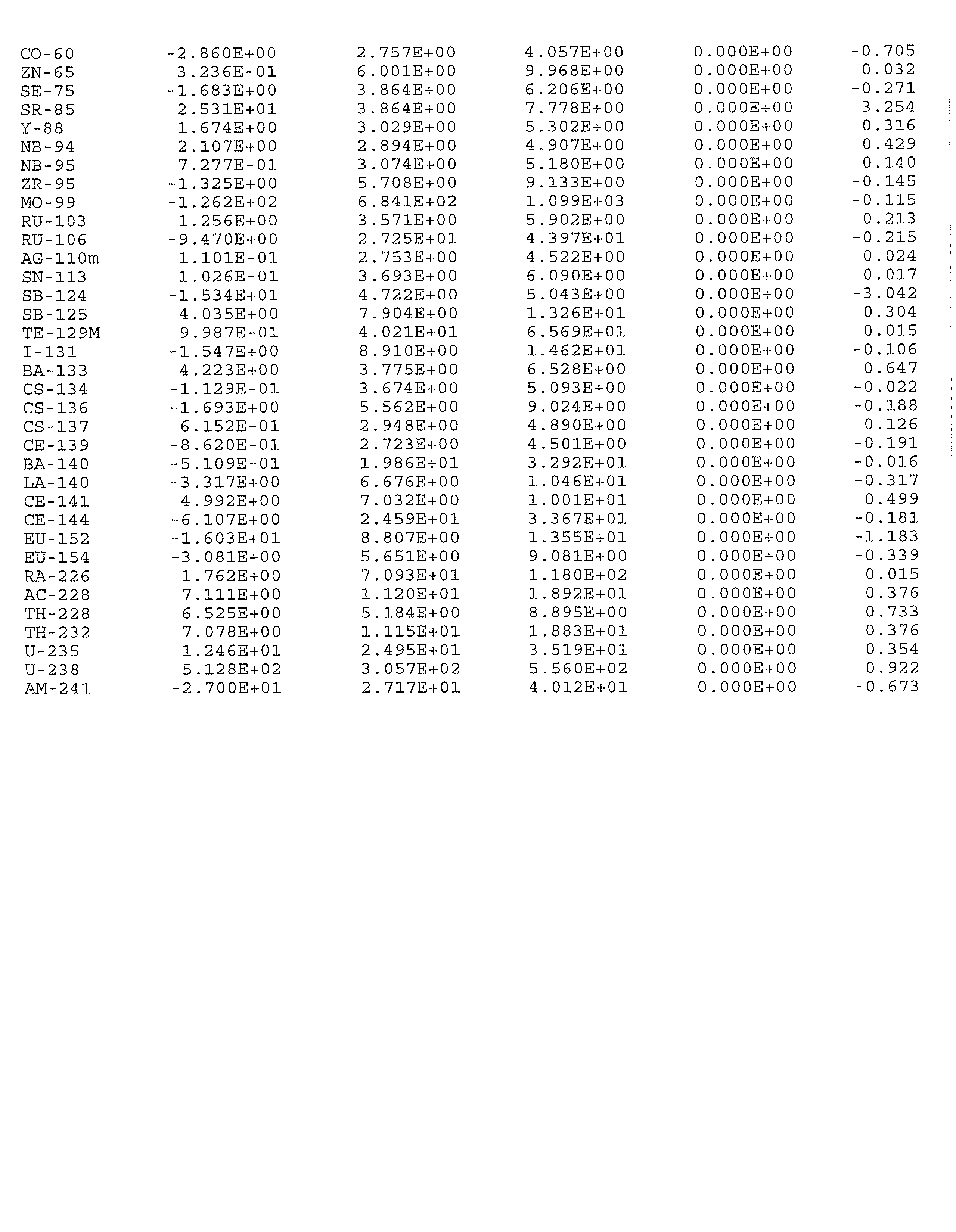

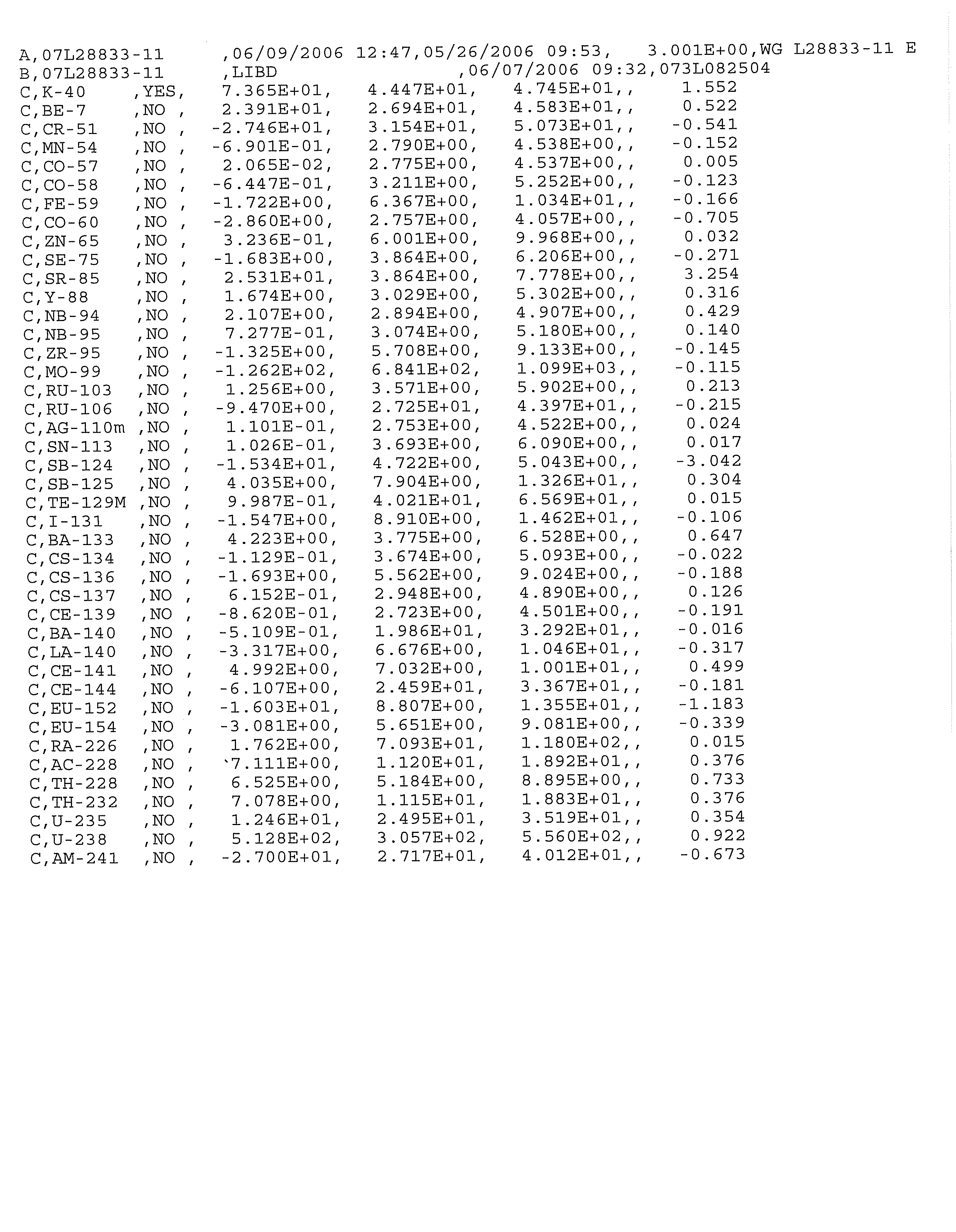

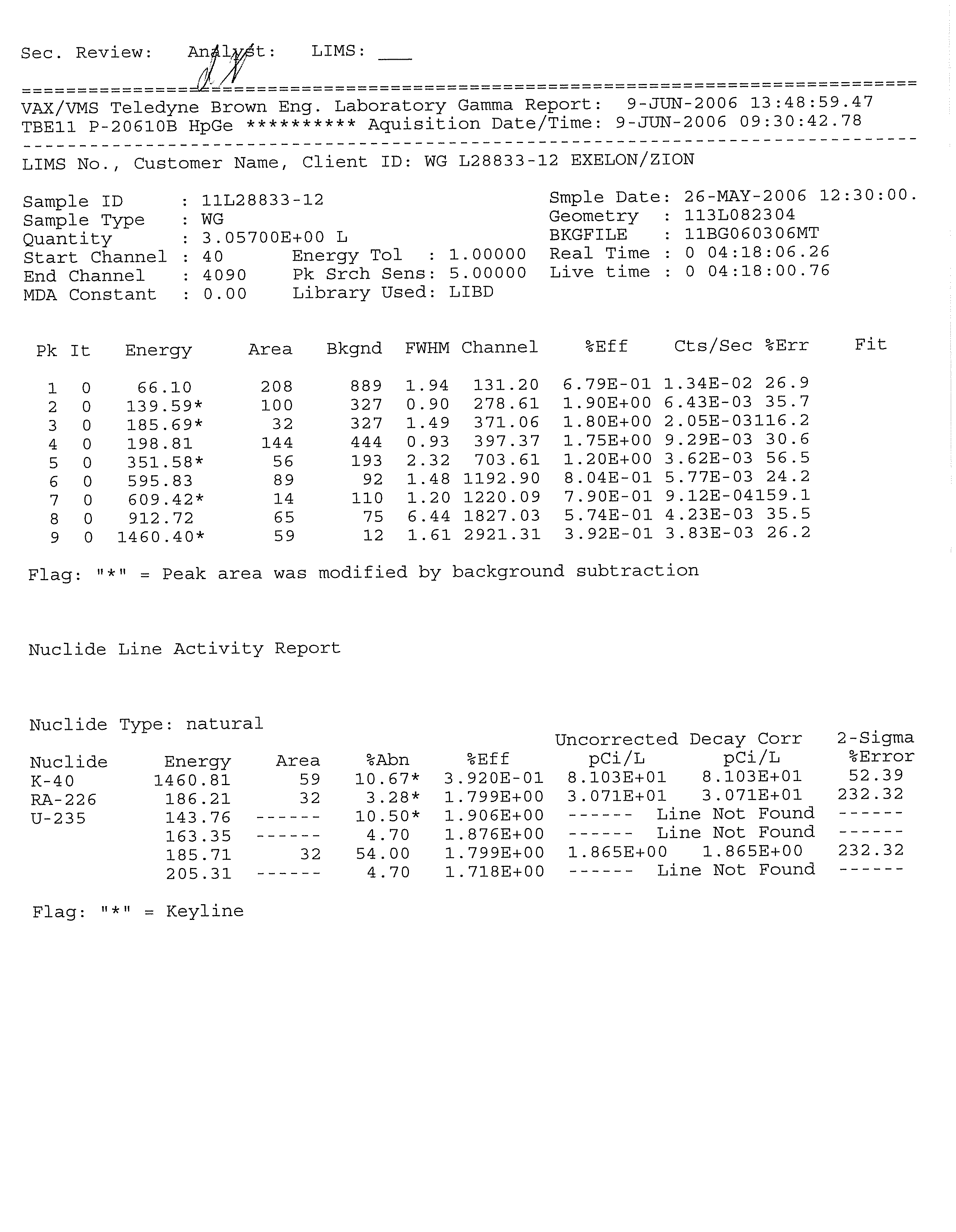

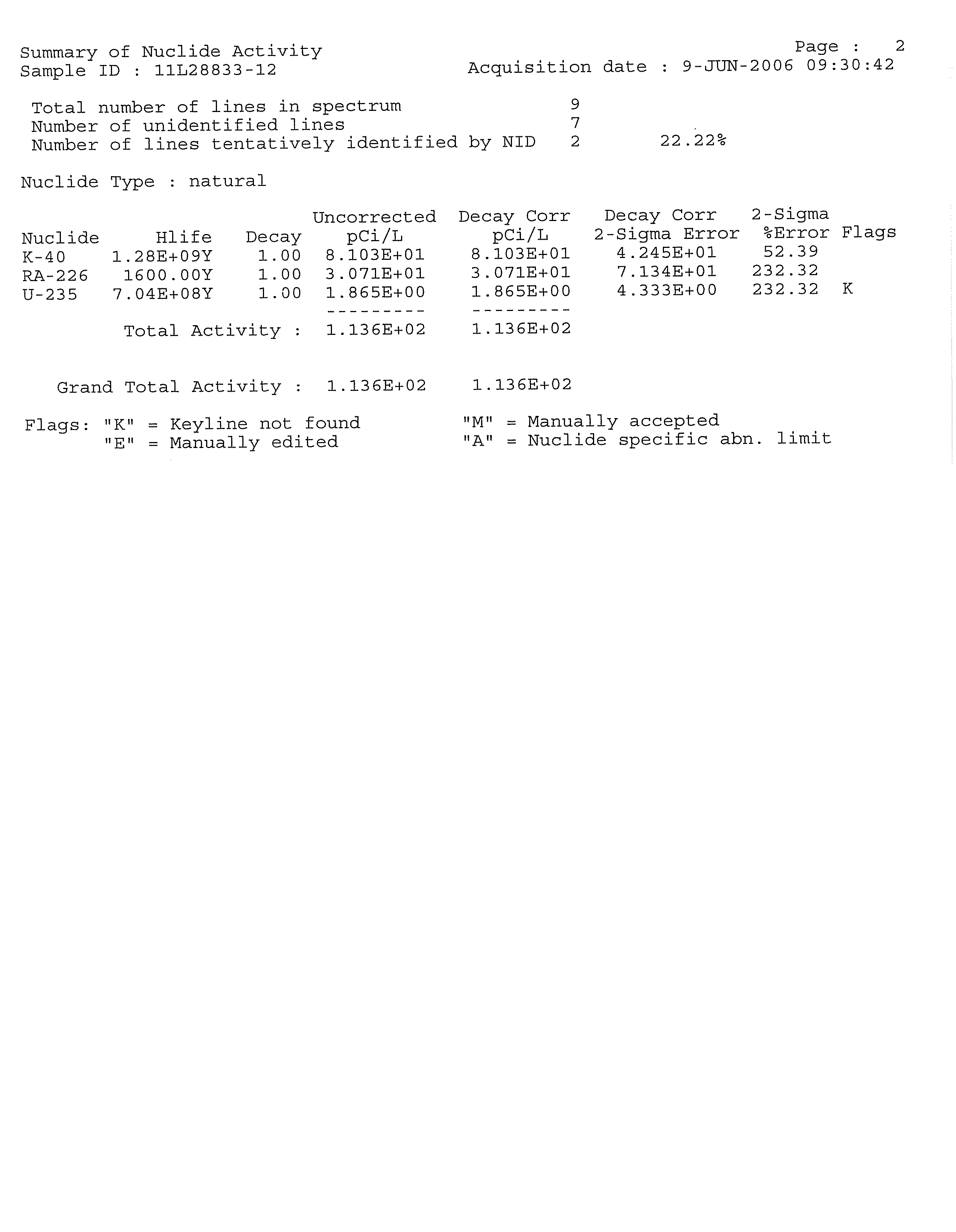

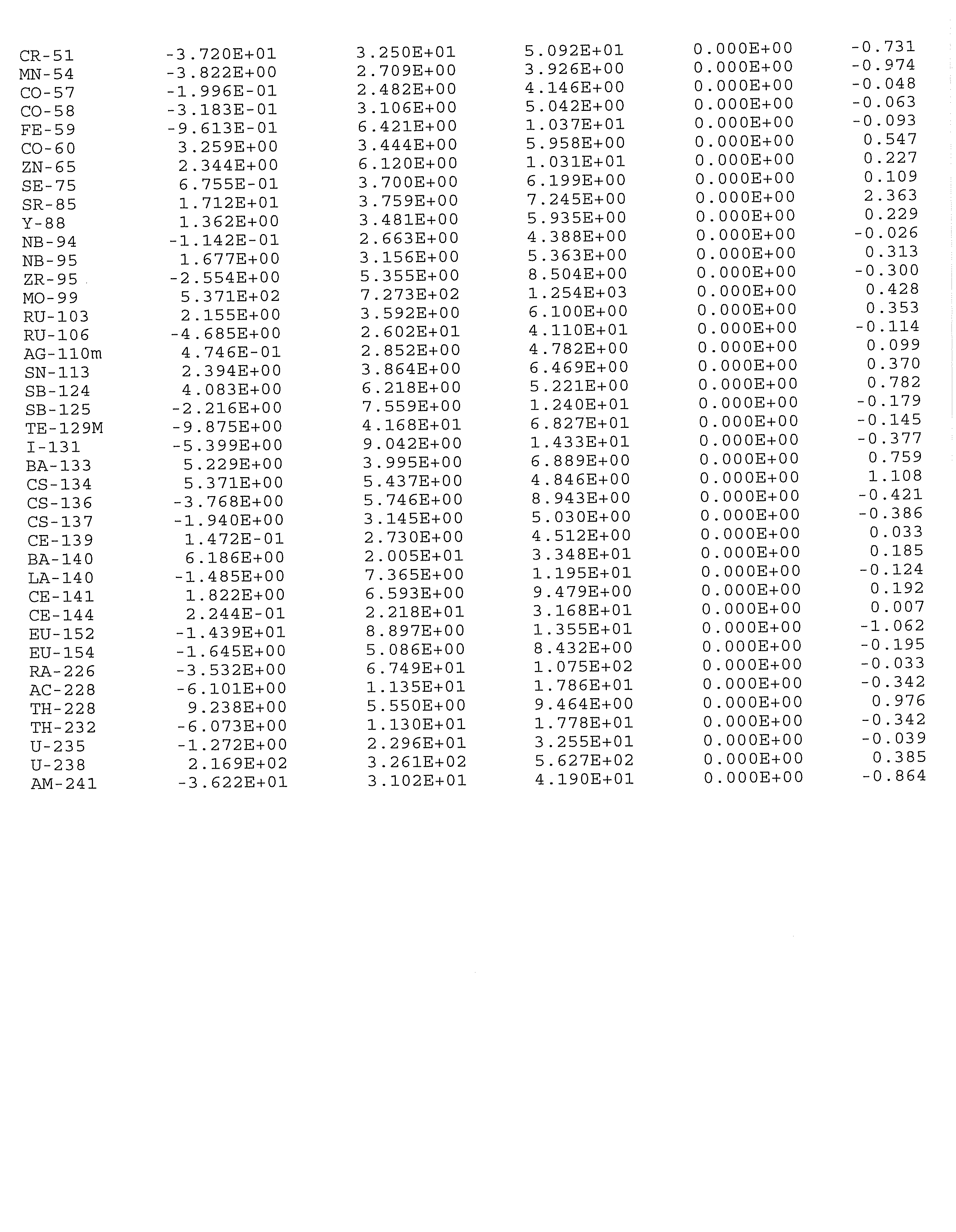

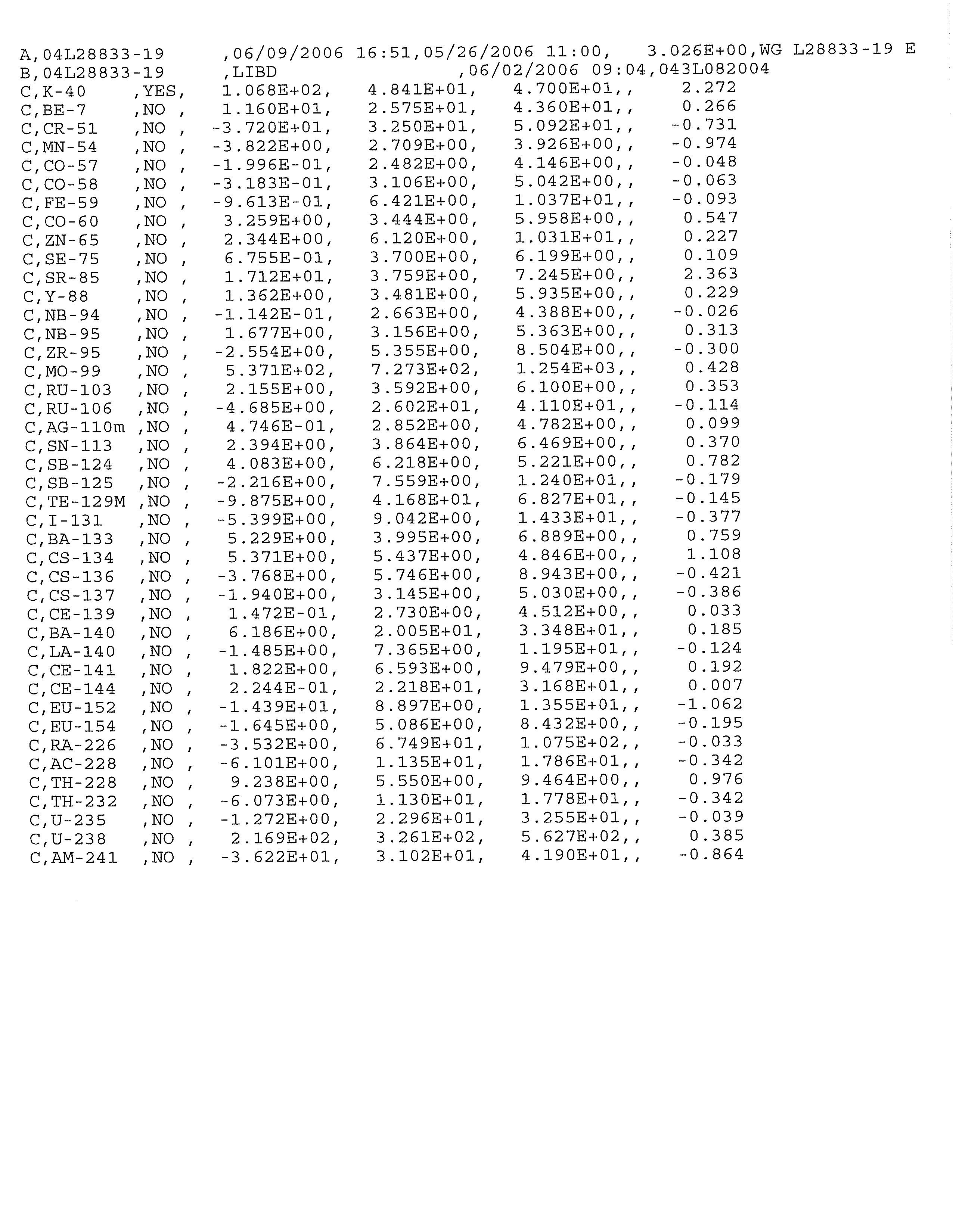

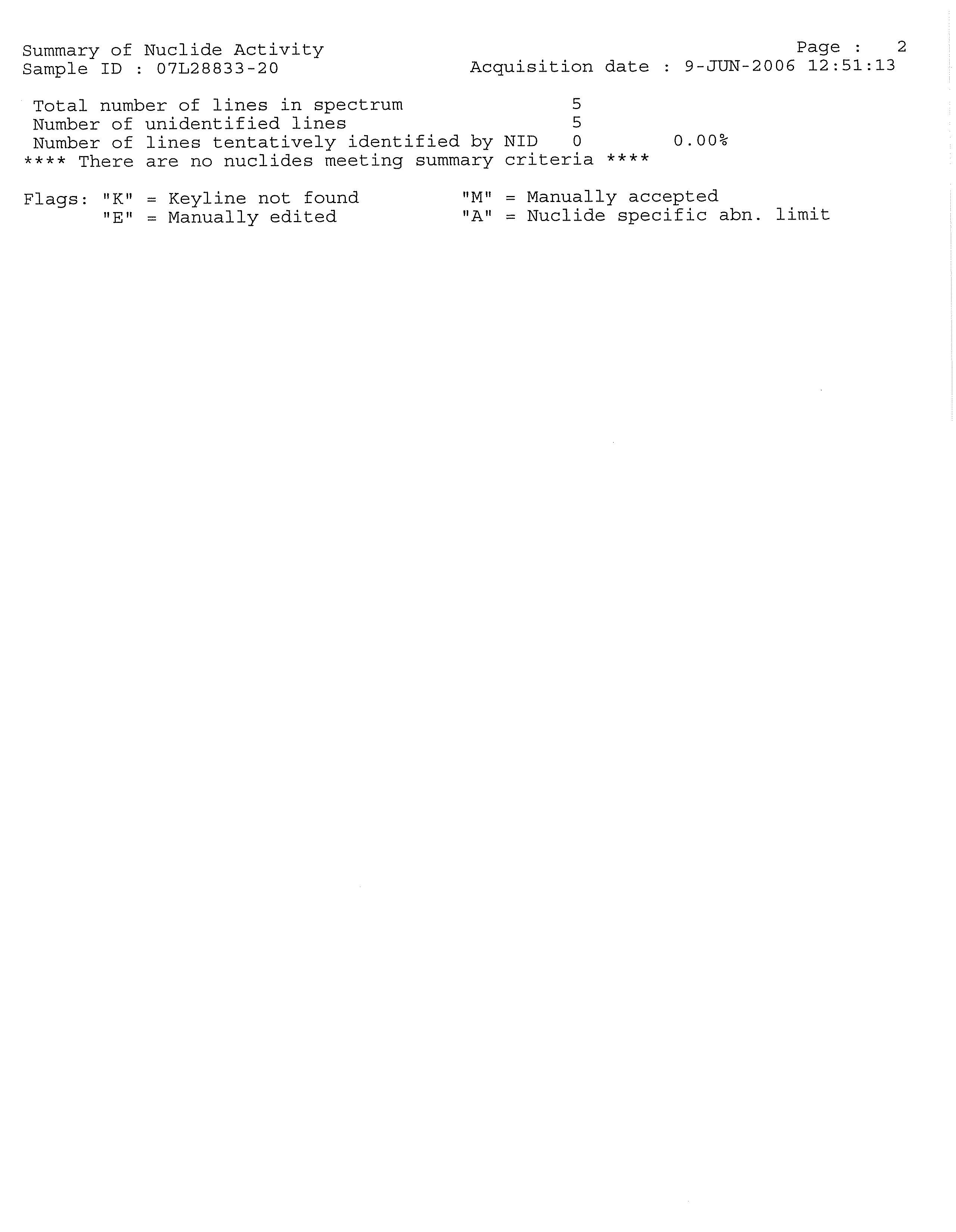

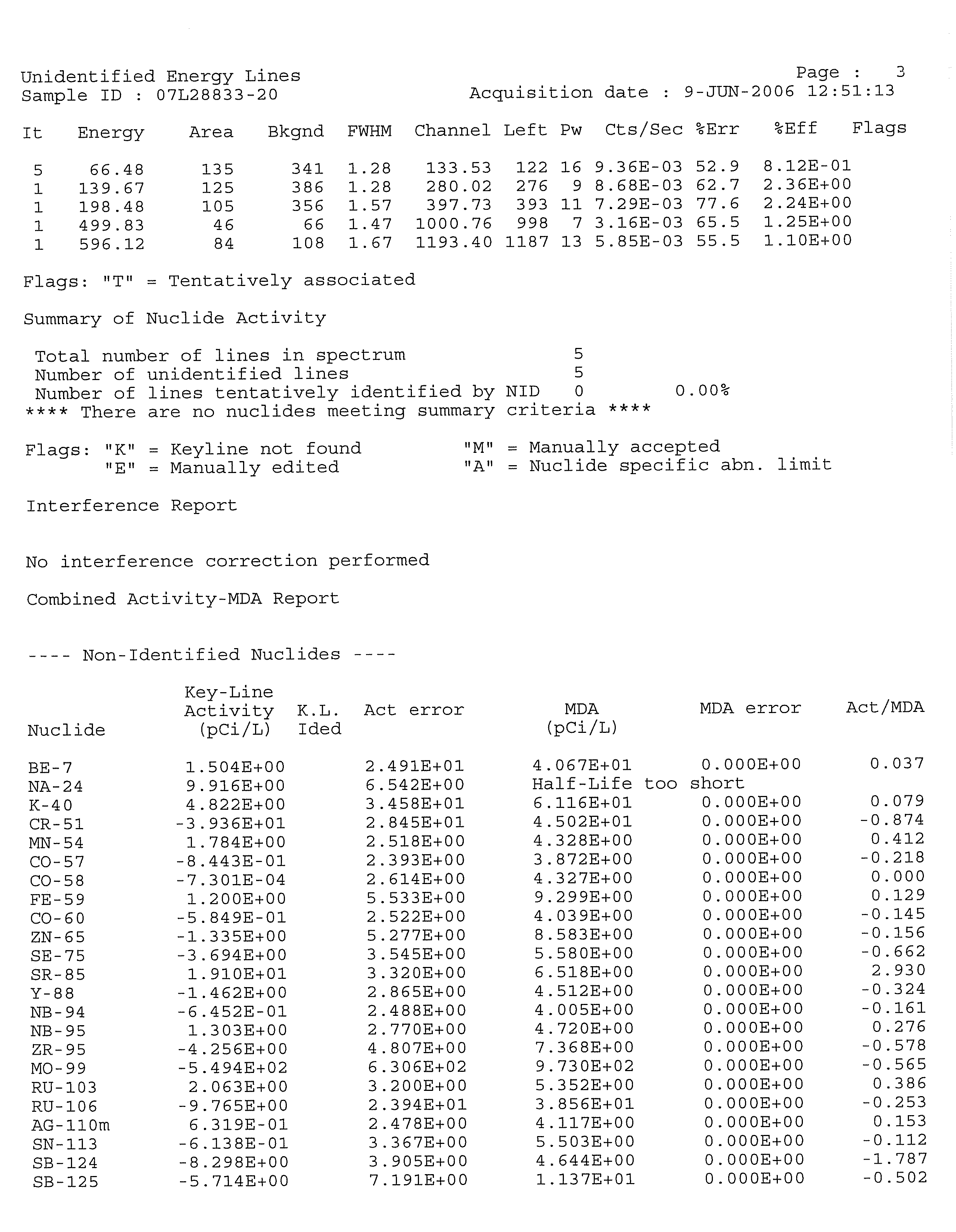

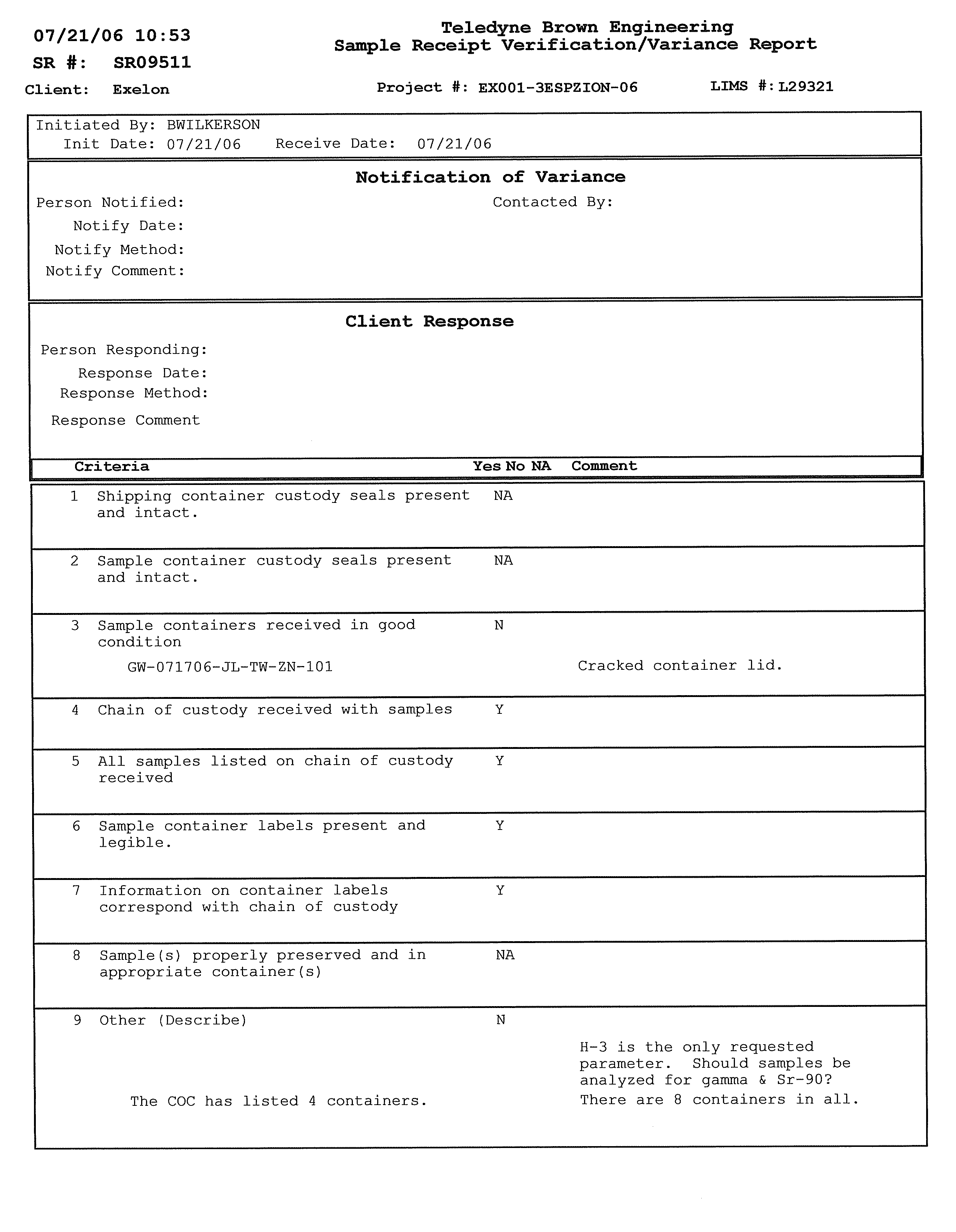

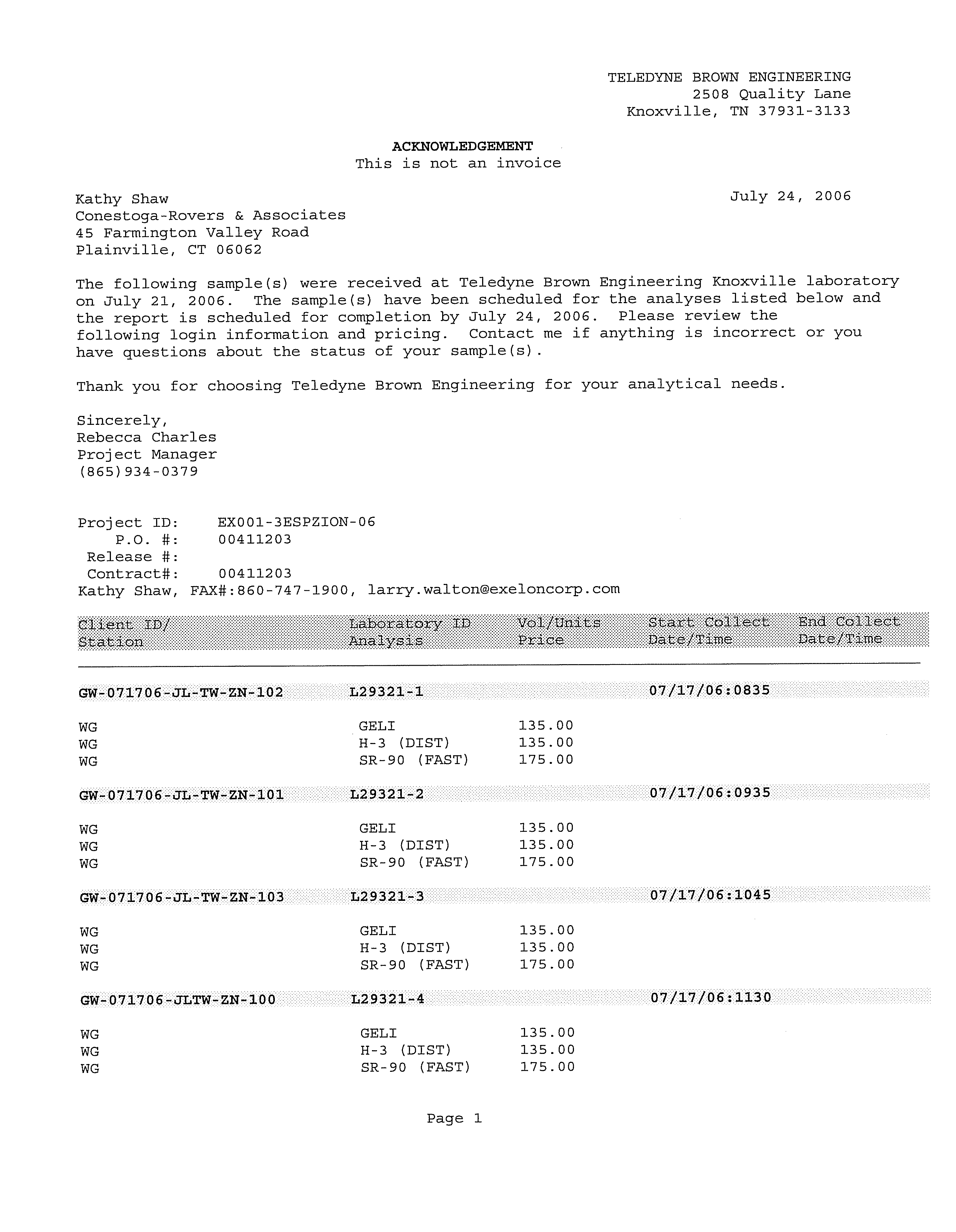

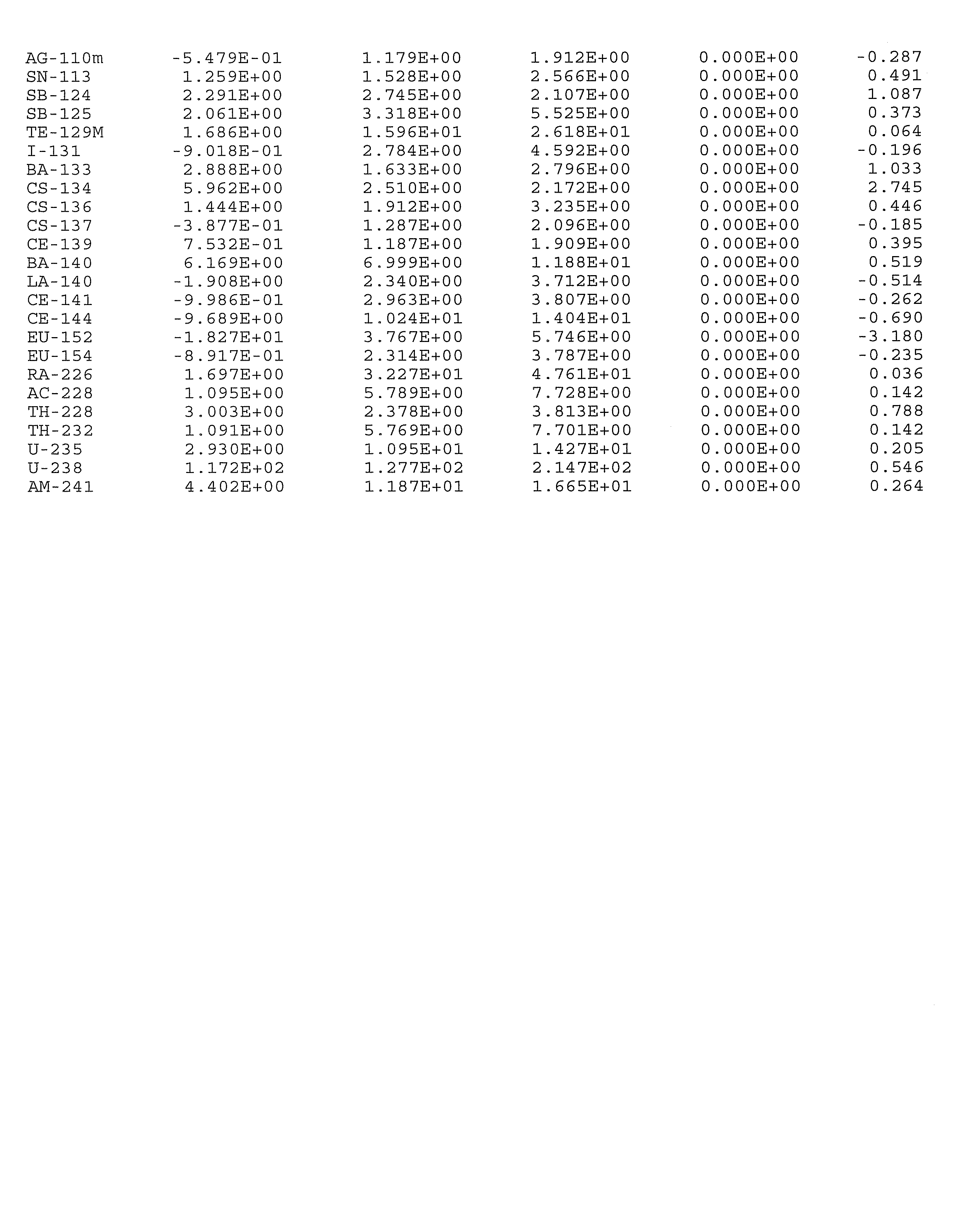

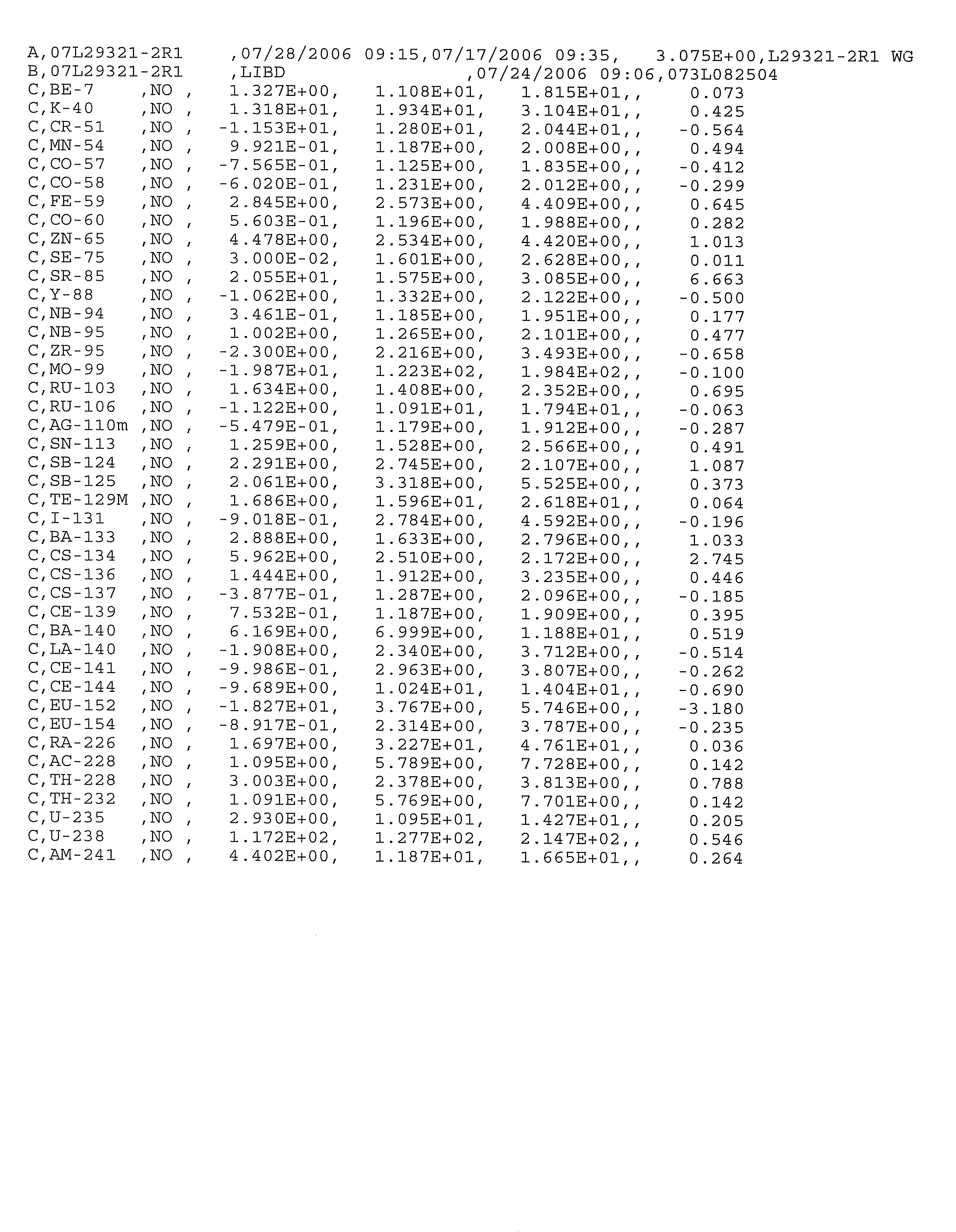

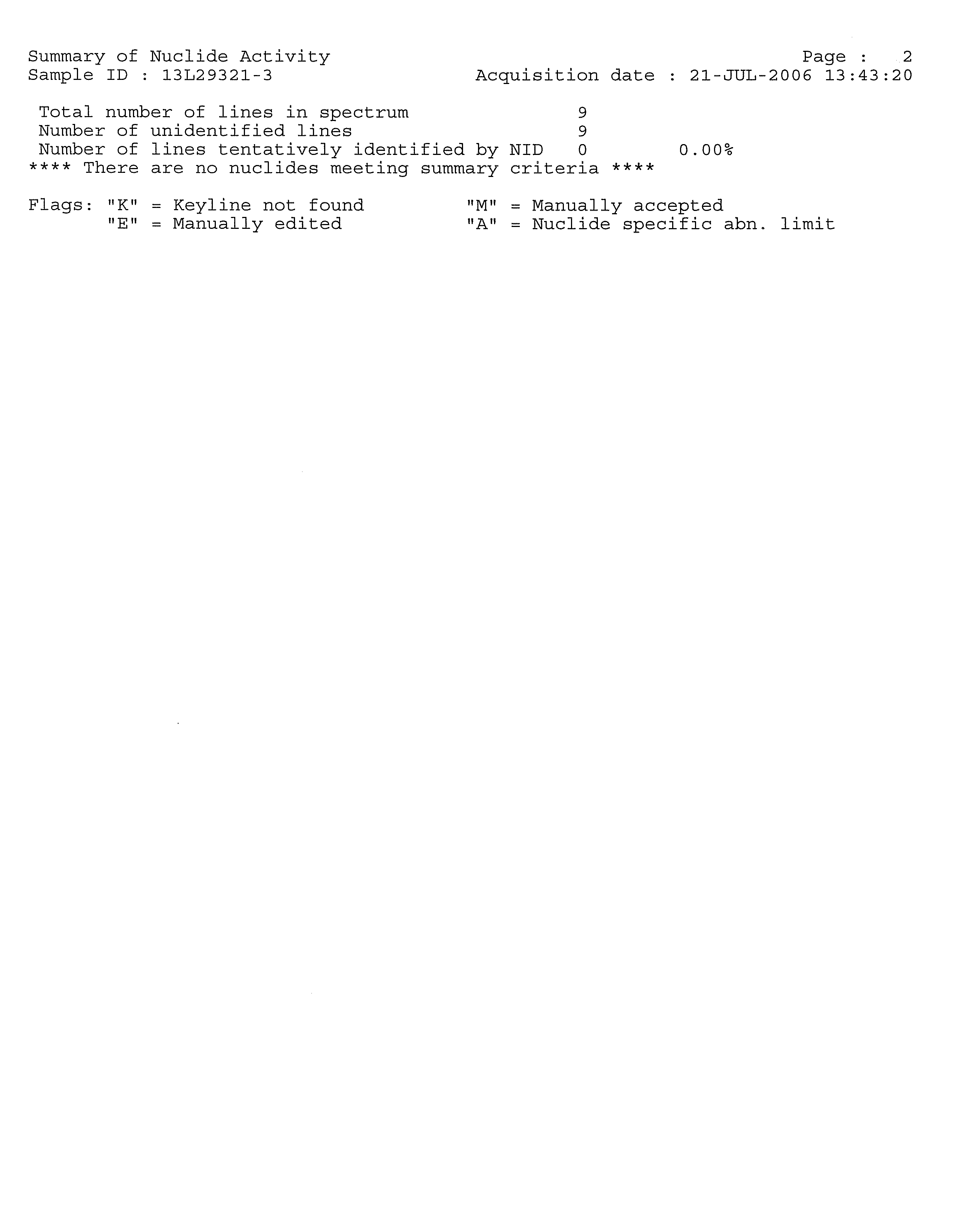

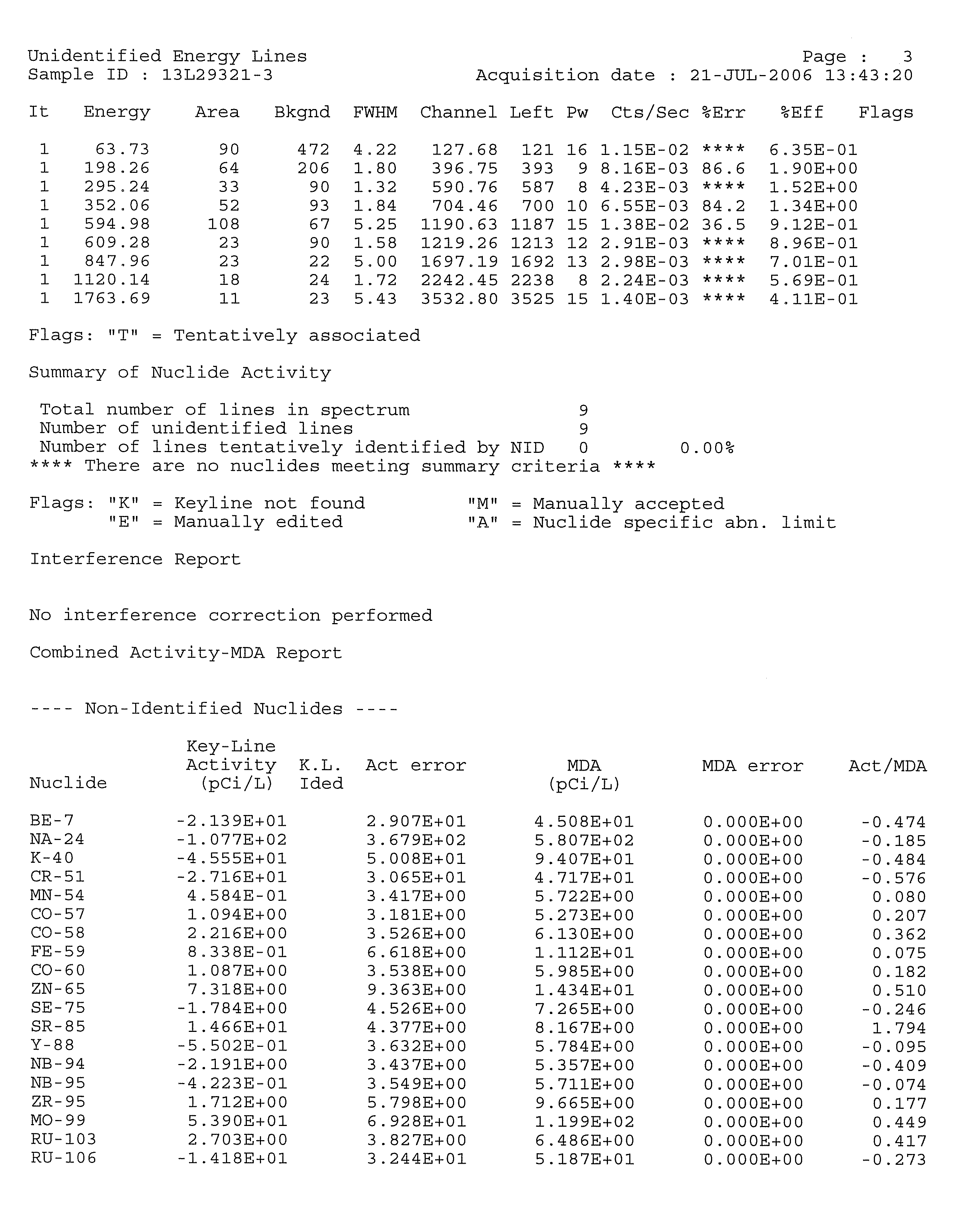

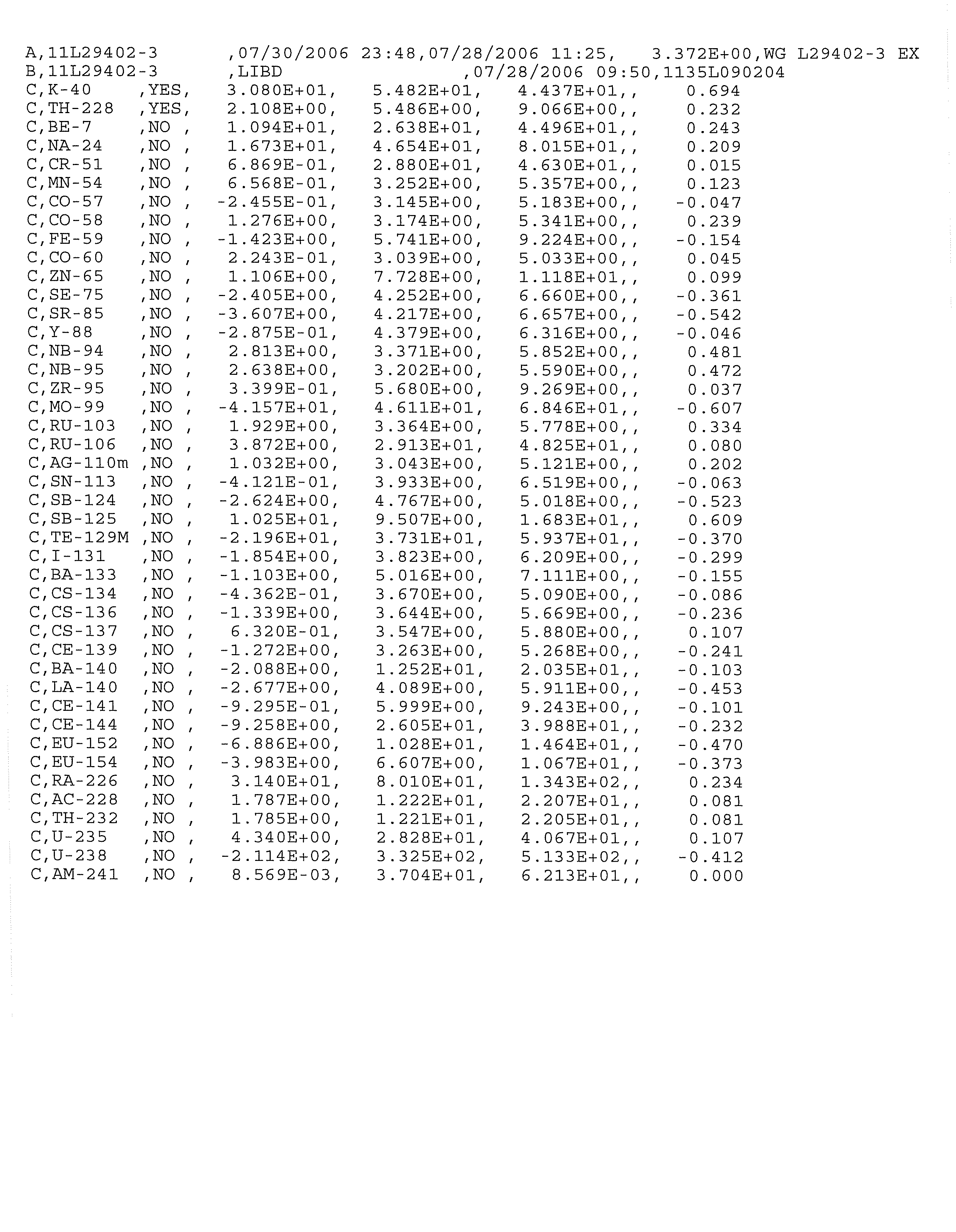

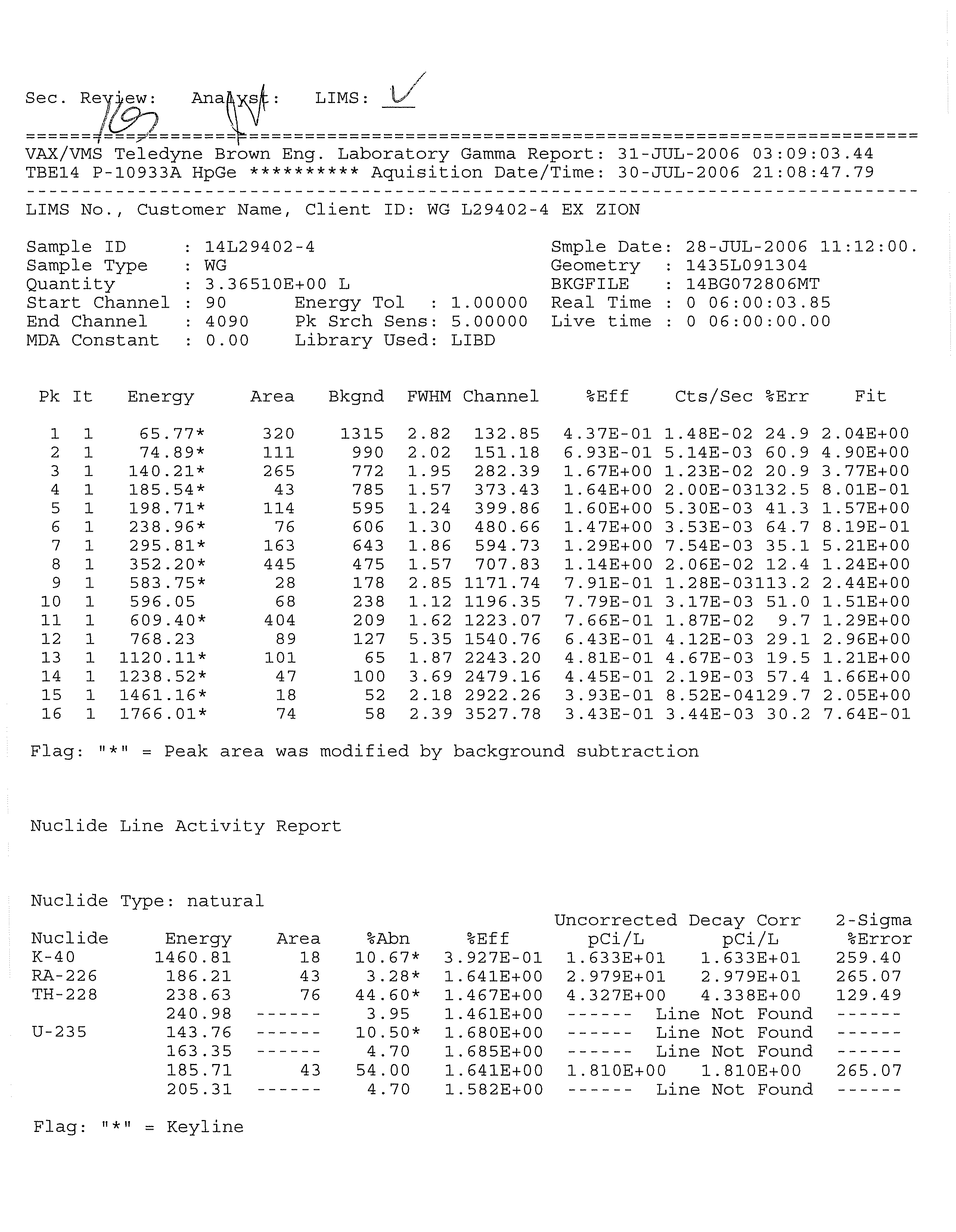

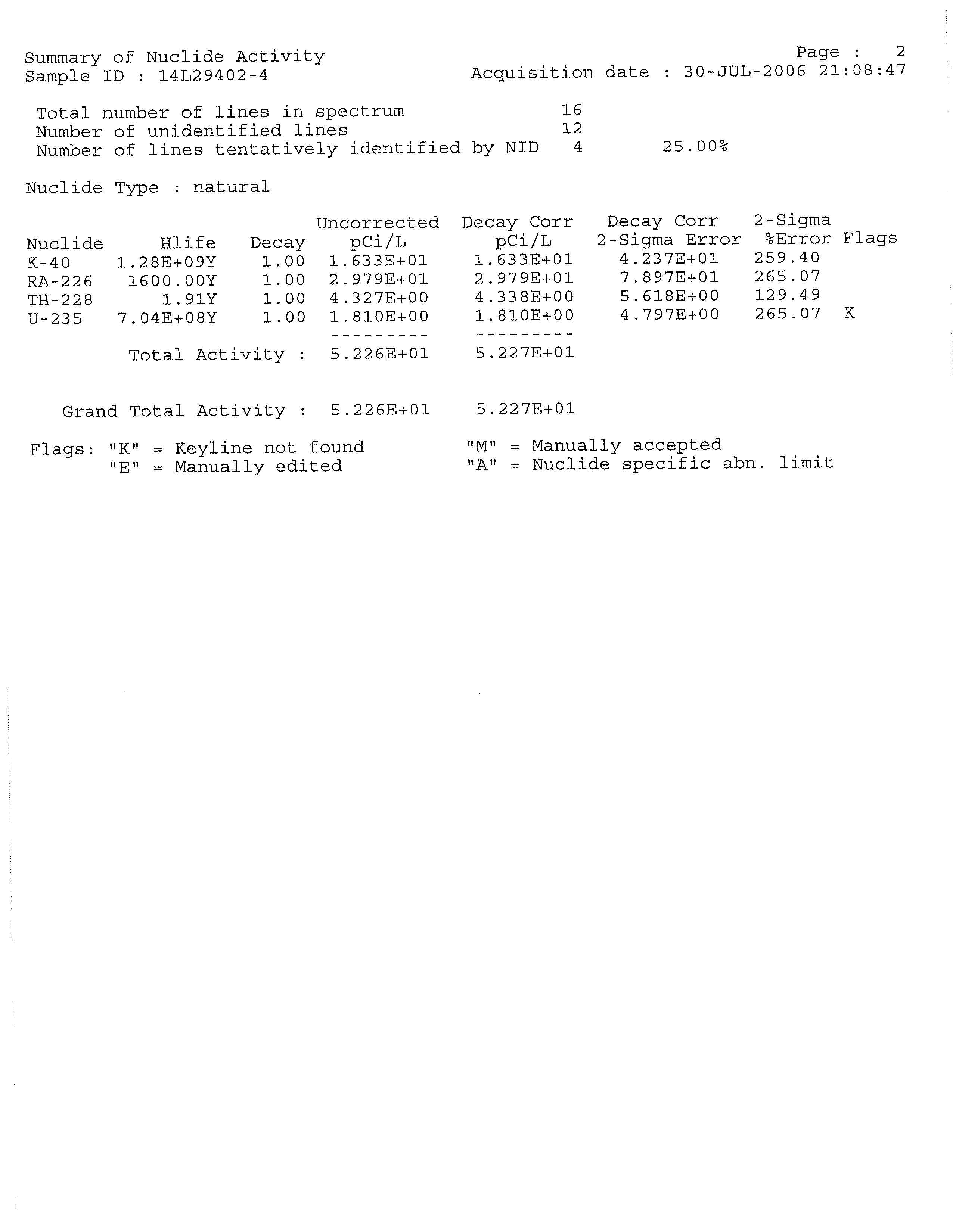

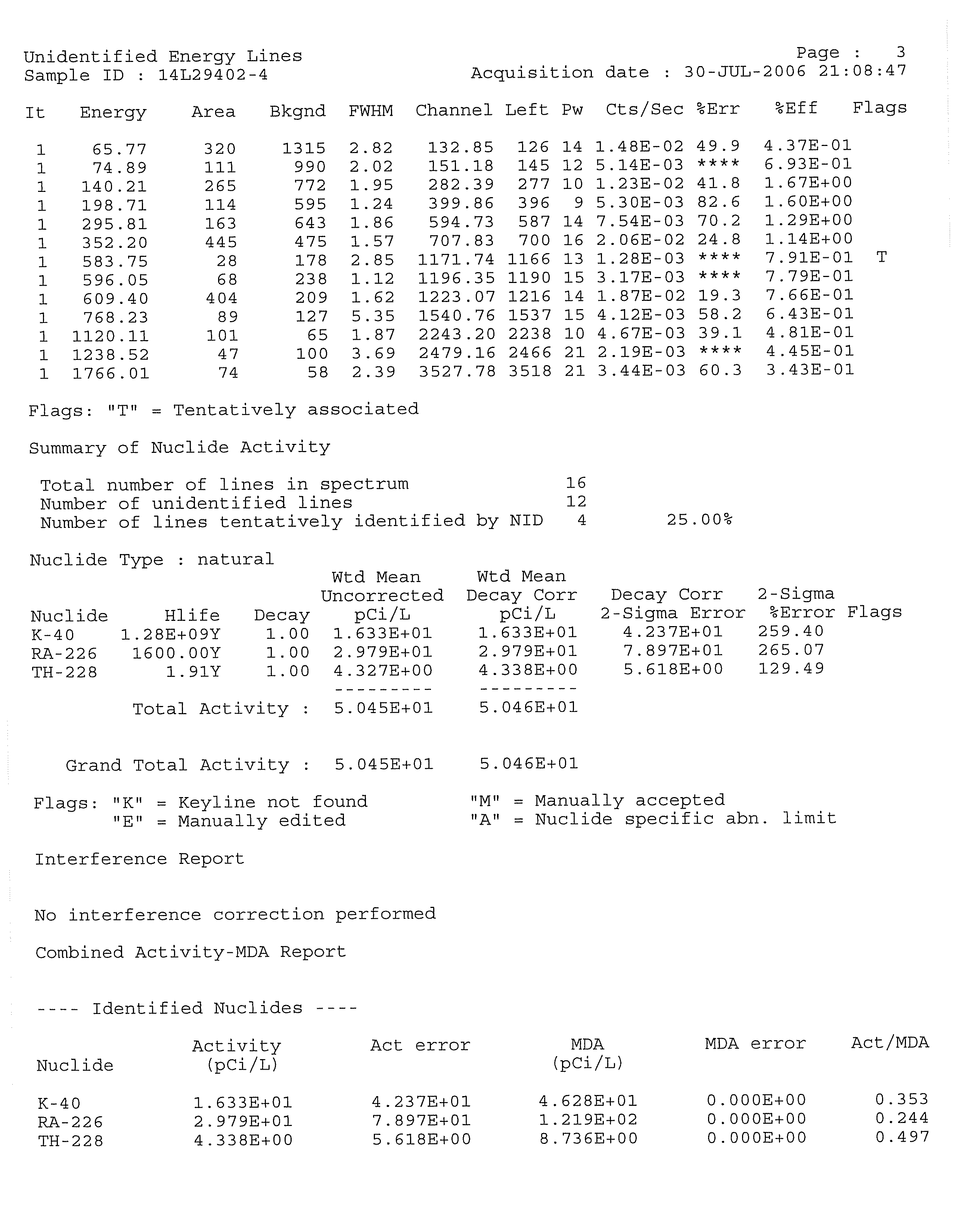

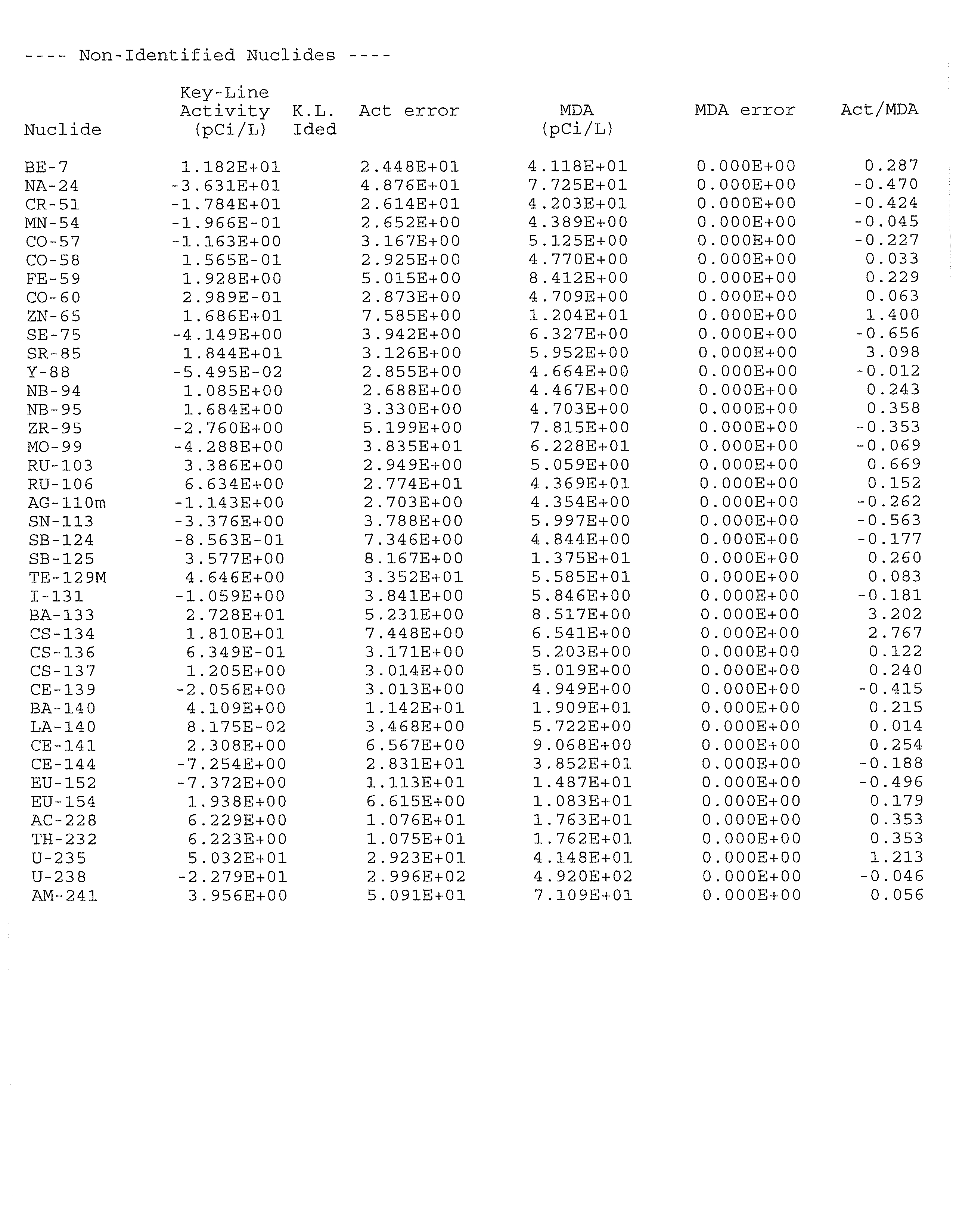

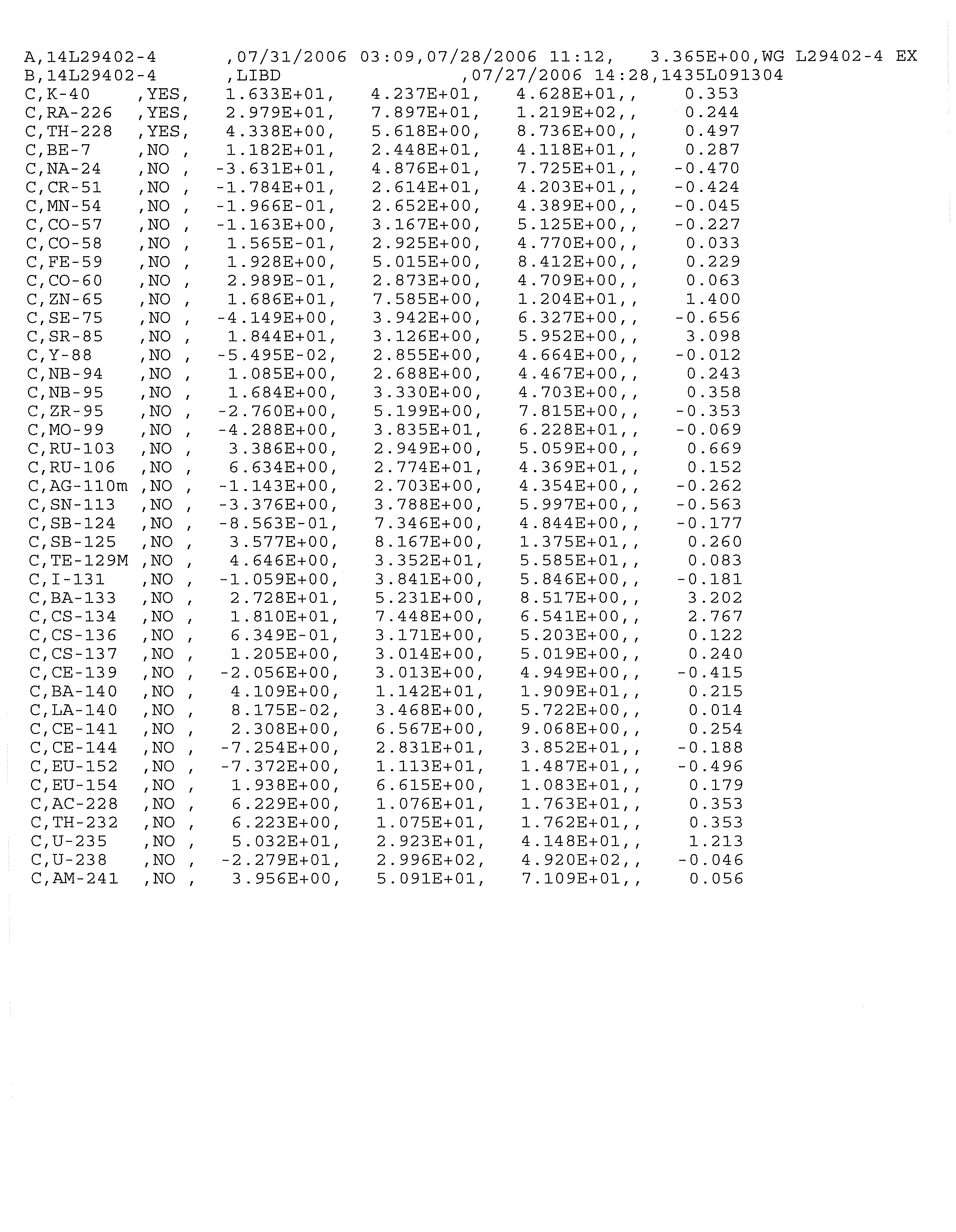

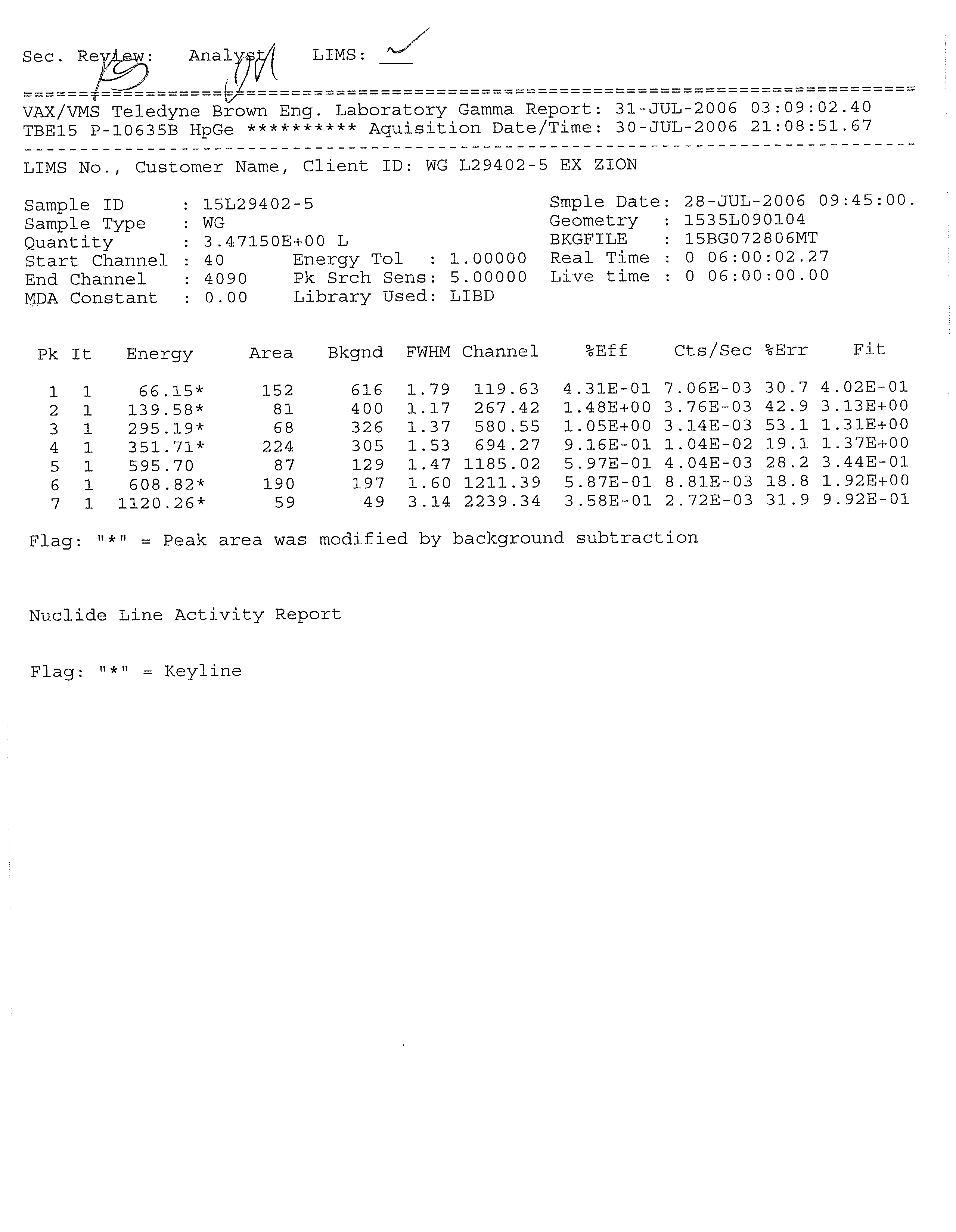

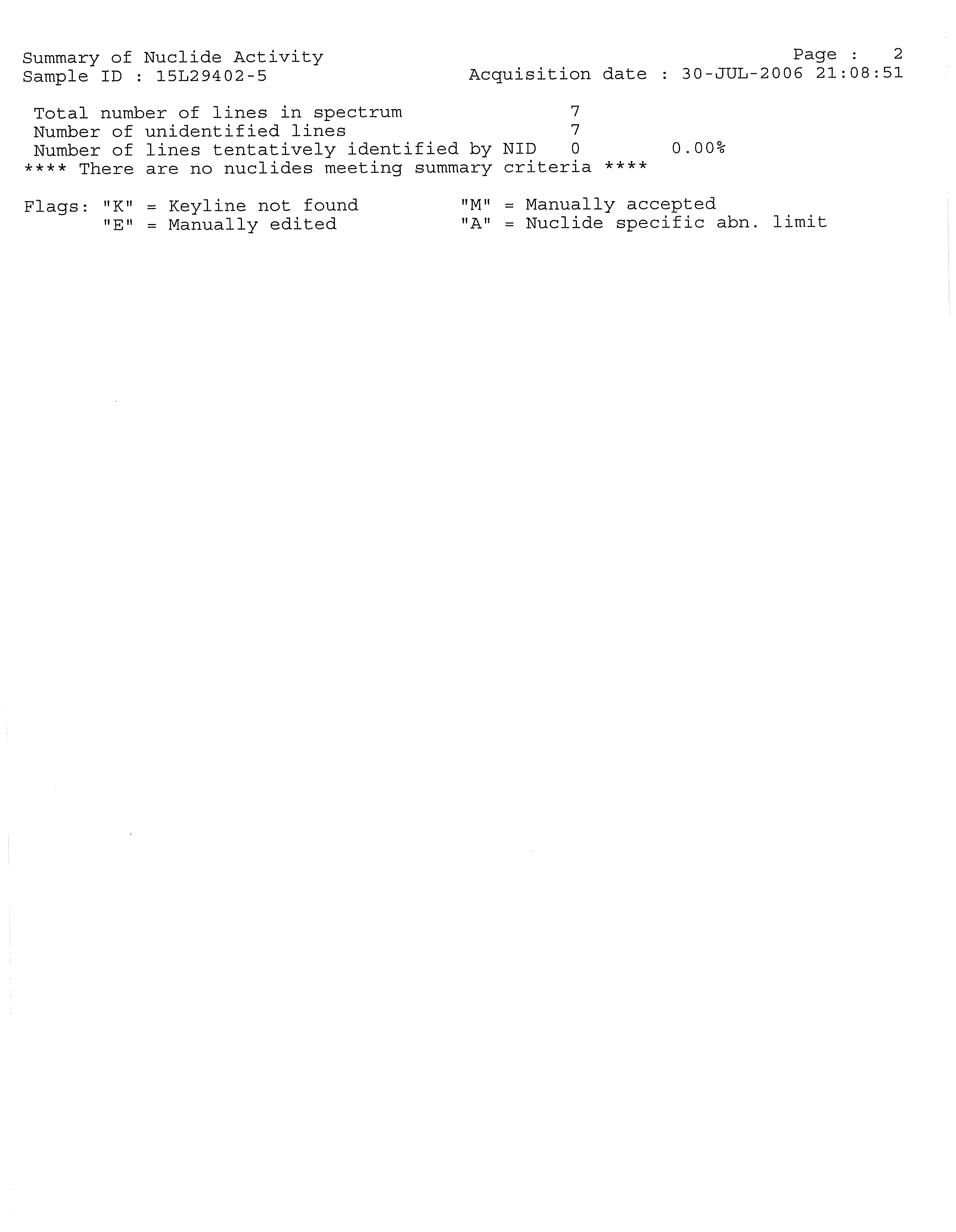

Revision 1