BEFORE THE POLLUTION CONTROL BOARD

OF THE STATE OF ILLINOIS

RECEIVED

CLERK'S OFFICE

JUN 2

31997

STATE OF ILLINOIS

POLLUTION CONTROL BOARD

IN THE MATTER OF :

)

R97-28

SITE SPECIFIC PETITION OF

)

(Water

- Regulatory)

MOBIL OIL CORPORATION FOR

)

RELIEF FROM 35 ILL . ADM

. CODE 304.122,

)

AMMONIA NITROGEN EFFLUENT STANDARDS

)

NOTICE OF FILING

To: Ms

. Dorothy Gunn

Margaret P . Howard, Esq .

Clerk

Illinois Environmental Protection Agency

Pollution Control Board

2200 Churchill Road

100 West Randolph, Suite 11-500

Springfield, Illinois 62794

PLEASE TAKE NOTICE that this day I have filed with the Illinois Pollution

Control Board the

TESTIMONY OF LILLIANA GACHICH, JAMES E . HUFF AND

JOHN H. KOON

on behalf of Mobil Oil Corporation

. Copies are attached and served upon

you .

Respectfully submitted,

Dated: June 23, 1997

ROSS & HARDIES

James T. Harrington, Esq

.

David L. Rieser, Esq

.

David A. Piech, Esq .

150 North Michigan Avenue

Suite 2500

Chicago, Illinois 60601

(312) 558-1000

THIS FILING IS SUBMITTED ON RECYCLED PAPER

1

Refinery

. Specifically, I am responsible for the NPDES Permit administration and all other water

related issues

. My education background consists of a Bachelor's Degree in Chemistry and a

Master's Degree in Organic Chemistry . I have been employed by Mobil Oil for nineteen years,

thirteen years at the Joliet Refinery and six years at the Beaumont Refinery in Texas . Prior to

assuming my current duties as an Environmental Advisor, I held the position of Supervisor of the

Laboratories at both Joliet and Beaumont

. During my employment with Mobil Oil, I have participated

in a number of environmental projects and, most recently, I was the team leader for the Joliet

Refinery Waste Water Treatment Plant Nitrification Optimization Study and Upgrade project . I also

helped prepare the PETITION FOR SITE-SPECIFIC RELIEF FROM 35 ILL . ADM

. CODE 304 .122 and

am hereby stating that the facts contained in the petition and its attachments are all true and

correct .

On March 3, 1994 the Illinois Pollution Control Board (PCB) granted Mobil a four year variance from

Section 304 .122(b) (

PCB 93 -151) with a monthly average effluent ammonia concentration of 13

mg/I and a daily maximum of 26 mg/I . Subsequently, the variance was extended by one year .

During the term of the this variance, Mobil was to perform an extensive investigation to identify

means by which Mobil can come into compliance with Section 304

.122(b), submit six month

progress reports detailing the investigation findings, and ultimately submit a compliance plan with

Section 304 .122(b) or seek a Site Specific relief

.

The purpose of my testimony today is to describe the WWTP historical performance, its current

configuration and Mobil's efforts during last three years to minimize ammonia concentration in its

effluent

. The testimony will describe the findings of the Nitrification Optimization Study, the actual

mechanical upgrades of the WWTP and the current WWTP Performance .

WASTE WATER TREATMENT PLANT CONFIGURATION

An average of about 1900 gallons per minute (gpm) of process wastewater and contaminated

surface run-off is processed through the Refinery WWTP, shown in Figure I

. This is mainly

accomplished by a program to increase cooling tower recycling and in-plant water reuse, thereby

lessening water discharge to the sewer

. The modern design features, such as separation of the

storm water and the process water systems and extensive water reuse enable Mobil to achieve an

effluent discharge rate of only 14 gallons per barrel of crude oil refined .

In comparison, under the BAT guidelines, the discharge rate for a refinery of Joliet's size and

configuration would be about 5200 gpm, which translates to about 38 gallons of effluent per barrel

of crude oil refined . However, the conservation efforts inevitably result in more concentrated

effluent

. In the case of Mobil, the multiple between BAT guideline discharge rate and the actual

rate is 2 .7 (38 gal/bbl : 14 gal/bbl)

. If a similar concentration effect were applied to the existing

NH, -

N effluent standard, it would result in an "equivalent" increase from 3 .0 mg/I to 8.1 mg/I .

Or conversely, because of the additional water available for dilution, Mobil's 1996 annual average

NH3

- N effluent concentration would have been 1 .4 mg/I instead of 3 .9 mg/I .

THIS FILING IS SUBMITTED ON RECYCLED PAPER

RECEIVED

STATE OF ILLINOIS)

CLERK'S OFFICE

COUNTY OF WILL )

BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

JUN 2

31997

IN THE MATTER OF :

)

STATE OF ILLINOIS

PETITION OF MOBIL OIL

1

POLLUTION CONTROL BOARD

TO AMEND

)

R 97-28

REGULATIONS

1

PERTAINING TO

1

WATER POLLUTION

1

TESTIMONY OF LILLIANA GACHICH

My name is Lilliana Gachich . I am an Environmental Advisor for Mobil Oil Corporation, Joliet

The Waste Water Treatment process consists of :

•

Sour Water Stripper

•

Desalter

•

TK 103

•

Benzene Air Stripper

•

Diversion Basin

•

Dual Channel Preseparation Flume

•

API Oil Separator

•

Dissolved Air Flotation

•

Equalization Biological Treatment Unit

2

o Primary removal of ammonia and sulfides

•

Partial removal of phenolics and in- plant

water reuse

•

Primary equalization

•

Removal of benzene, sulfides, and volatile

organics

•

Basin used for hydraulic overflow during

wet weather

•

Primary solids removal

•

Primary Oil separator

•

Residual oil and solids removal

o Secondary equalization, aggressive phenolic

removal and partial COD removal

•

Two Aeration Basins

o Conventional activated sludge system for

(with diffused air)

for ammonia, organics, cyanide, and other

pollutant removal

o Two Clarifiers

o Bio solids settling/removal

•

Guard Basin o Final retention basin

•

Aeration Cone o Saturation with oxygen

WASTE WATER TREATMENT PLANT HISTORICAL PERFORMANCE

As shown in Table I and further detailed in Exhibit I, the performance of the WWTP has progressively

improved from start up in 19973 to the present . From March, 1994 to May, 1997, the monthly limitation

of 13 mg/I was exceeded only in January, 1995 and March and April, 1996 . During the same period,

the maximum daily limitation of 26 mg/I was exceeded in April, 1996 and May, 1997

. The 1995

exceedance was directly attributable to an incursion of spent caustic from the Merox Gasoline Treating

Unit into Process Water system

. Since this incident, to prevent recurrences of a similar incident, Mobil

has installed a caustic free Merox Gasoline Treating Unit . The 1996 exceedances occurred when 100

gallons of diethanol amine IDEA) was drained to a process sewer instead of a holding tank . Maintenance

procedures were reviewed and revised to ensure that this event would not recur

. The 1997 exceedance

was caused by an undetermined amount of oily water influx into the activated sludge system prior to

API Oil separation . This bypass around the API separator occurred due to the plugging of the line leading

to the primary treatment portion of the WWTP

. The plugged line has been cleaned and will be subject

to a routine inspection in order to prevent a recurrence of a similar event

.

3

YEAR

TABLE I

RANGE

REFINERY AMMONIA DISCHARGE HISTORY (mg/L)

ANNUAL

AVERAGE

1973

77

27- 236

1974

55

4 -

191

1975

42

12 - 100

1976

36

9 - 120

1977

17

1 - 69

1978

9

1 - 30

1979

13

1 - 38

1980

17

0-53

1981

13

0-40

1982

15

0-66

1983

4

0 - 27

1984

3

0 -

19

1985

3

0 - 25

1986

4

0-32

1987

2

0 - 13

1988

1

0- 12

1989

0.2

0 - 3

1990

0.3

0 - 5

1991

0 .4

0-7

1992

3.2

0 - 22

1993

4.0

0-22

1994

4.9

0 - 19

1995

6.3

2 - 13

1996

3.9

0 - 27

1997(5mos)

2 .6

0 - 33

RESULTS OF NITRIFICATION OPTIMIZATION STUDY

Broadly speaking, Mobil's investigative efforts pursuant to 1994 Variance were divided into the following

categories :

•

Pollution Source Survey/Nitrification Inhibition Study

•

Removal of Inhibitors of Biological Nitrification

•

WWTP Respiration Studies

As shown in Exhibit II, Mobil has submitted six progress reports detailing the outcome of the above

activities

. In order to avoid restating the information which already has been submitted

the Agency, I will

summarize the most significant findings :

•

Pollution Source Survey/Nitrification Inhibition Study confirmed Mobil's contention that

the installation of the Benzene Reduction Unit (BRU) increased toxicity of the WWTP

influent resulting in the less efficient ammonia removal

.

The BRU was installed in

September of 1990 as required by RCRA and NESHAPS regulation

.

•

Spent caustic solution containing phenolic and sulfidic compounds generated in the

Refinery Gasoline Caustic Treaters was also found to be highly inhibitory to the WWTP

ammonia removal process .

•

A strong correlation between the residual Chemical Oxygen Demand (COD)

concentration and the degree of nitrification inhibition indicated that some biodegradation

products are toxic to the nitrifying bacteria

. By comparison, the correlation between

the

degree of nitrification inhibition and the influent COD concentration is much weaker, thus

further indicating that the biodegradation process itself generates major contributors to

the nitrification inhibition

. Subsequently, it can be concluded that the activated sludge

process is self limiting or autoinhibitive

. Exhibits III

and IV are graphic representation of

these findings .

•

An upstream removal of inhibitory substances may not result in commensurate

decrease in the degree of nitrification inhibition at the WWTP due to the autoinhibitive

nature of the process

.

•

WWTP respiration study indicated that the activated sludge system was air deficient

under peak loadings

. Furthermore, the existing mechanical aerators were not delivering

the air to the system in an uniform fashion

. The combination of these factors

seriously affected the WWTP ammonia removal capability

.

WASTE WATER TREATMENT PLANT MECHANICAL UPGRADES

The intent of the mechanical upgrades was to improve the efficiency of the WWTP by optimizing

both

the upstream, as well as, the downstream processes

.

•

The replacement of the caustic Merox Gasoline Treaters with caustic free treaters was an

upgrade designed to eliminate an entire stream from the refinery byproduct inventory

.

This project was implemented, in spite of the inhibition study finding indicating that

due to the autoinhibition in the activated sludge system, an upstream control may not be

very effective

. Fortunately, this upstream process change not only precluded direct

upsets of the WWTP by spent phenolic caustic, it also partially offset the increase in

toxicity resulting from RCRA mandated installation of the BRU unit

. Exhibit V shows the

toxicity increase across the BRU unit and an overall decrease in toxicity subsequent to

the installation of the Caustic Free Merox Gasoline Treaters

.

4

o The installation of the fine bubble diffusers, the replacement of the clarifier internals and

the changes made to the Dissolved Air Flotation (DAF) unit were changes directly

intended to enhance the performance of the WWTP itself

. Of these changes, only the

installation of the air diffusers was found to be required as per the finding indicating

shortage and maldistribution of air in the activated sludge system

. All other changes

were implemented in order to more closely align the WWTP with current technology

.

CURRENT WWTP PERFORMANCE

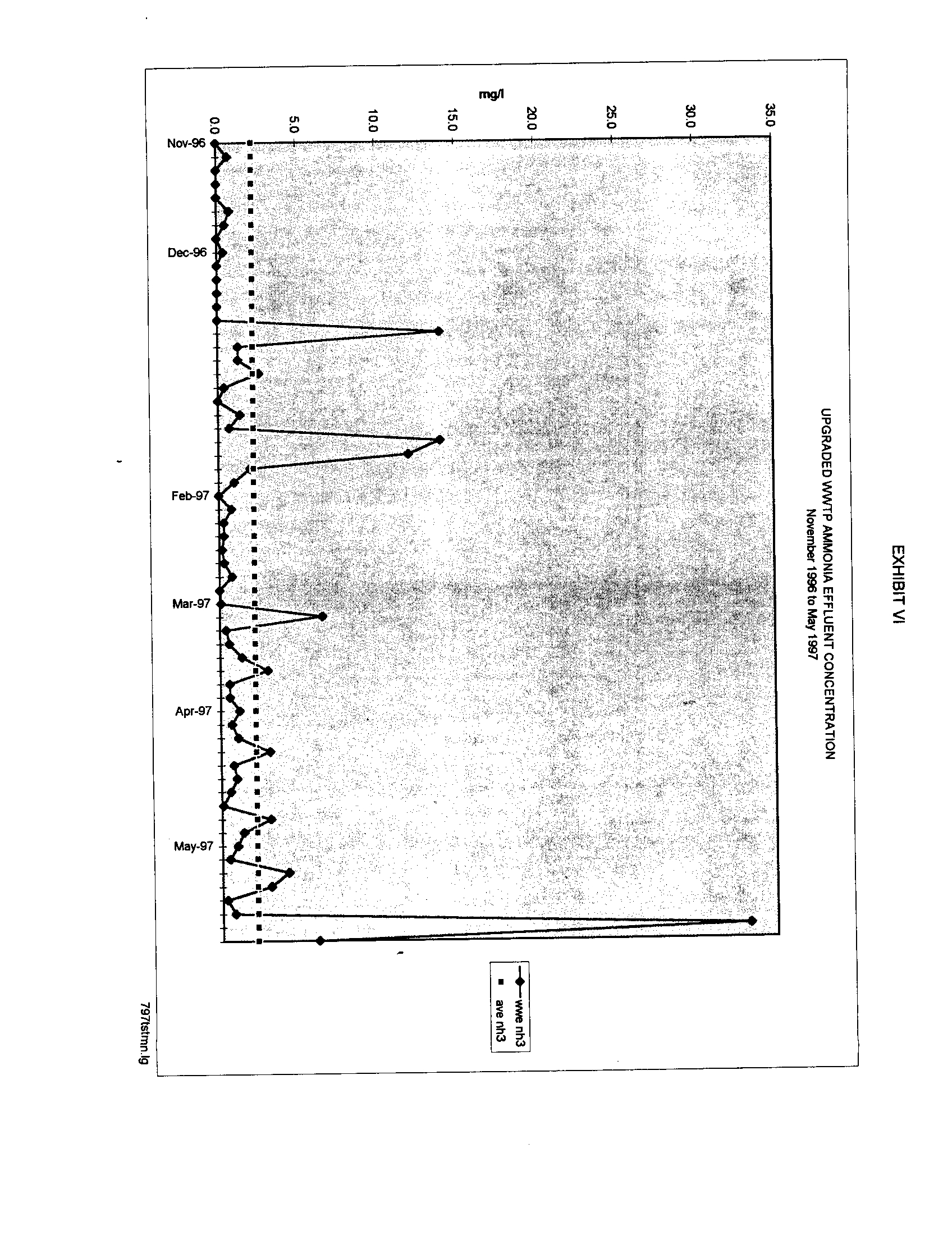

As shown in Exhibit VI, the performance of the upgraded WWTP has been very good

. Between

November, 1996 and May, 1997, the average ammonia effluent concentration was about

2 .2 mg/I

.

However, on several occasions and as explained in the WWTP historical performance review, the

daily maximum ammonia effluent concentration has reached levels

as high as 33 mg/I

. Some upsets

were associated with a known cause and for some no obvious cause

could be found . However,

all have been of short duration

. Such quick recovery of the WWTP

indicates that the recent

upgrades are effective and that the a good prospective performance

can be expected .

Nevertheless, even when the explainable high concentrations are removed from the upgraded WWTP

performance chart, as shown in Exhibit VII, an 8

.5% of the effluent samples are still not in

compliance with the Sate daily maximum effluent standard of 6 mg/I

. Since the WWTP was

upgraded less than one year ago, at the existing rate of non compliance, the annual

non

compliance rate with the same standard could easily be as high as 15%

.

Not all upsets can be associated with a preventable cause and probably most are directly associated

with the Refinery crude oil mix variability

. Exhibit VIII

shows various crudes processed in 1996 and

the substantial changes in both the crude mix and its nitrogen content

. The changes represented

here are based on monthly averages

. In reality, the crude mix changes every several days

. In

addition to the crude mix change, the refinery product mix may be changing due to the market

demands

. As more sulfur and nitrogen are removed from the crude oil

, the composition of the waste

water also changes

. This constant flux in the waste water composition, in spite of Mobil's large

equalization capacity, can easily cause an upset of the WWTP

.

In summary, the improved and the robust operation of the WWTP shows a

strong commitment by

Mobil to comply with Section 304 .122(b)

. Since completing the WWTP upgrades in November,

1996 Mobil has achieved a 40% reduction in ammonia discharge

. However, in spite of having spent

a large amount of money to upgrade its WWTP, a technically feasible and cost effective solution

resulting in consistent compliance with the State effluent standards has not been found

. Further,

Mobil's ammonia discharge has an insignificant effect on the ammonia concentration of the Des

Plaines River

. Requiring compliance now would not result in any measurable lowering of ammonia

concentration in the receiving waters

. For that reason, Mobil is seeking this Site Specific relief from

Section 304

.122(b) or it would otherwise suffer an arbitrary and unreasonable hardship

.

TABLE II

Mobil Oil Joliet Refinery Ammonia Compliance vs Section 304

.122(b)

Annualized Average in mg/I

Average in mg/I Nov 1, 96 to May 31, 97

2 .2

This completes my prepared remarks and I thank you for your attention

. I will be pleased to answer any

questions you may have

.

5

1994

1995

1996

1997

4.9

6 .3

3 .9

2 .6

un on01o0 of

SIN3MIUIN

NOWWV

1Y.AL731q

i

3HnDi3

I

MID ox

lM LN31VLV3N1

31SVM AW103YS

HSW NOIIW3V

1V0000'00!

NW NOUVVW

7V01fl w9

mm

ONsv3111

7 010010NNOLYOW

4

A 1

BINS S3MVId S30

-$ 013omlGsn03LM3WOA9

---w 93MYM930

L

003 01 1144--

01

N31VM

SS3000d

AMM33N

N3LVM

HSD1VNN

HR-MM

F

U3ddMLS

N31VM

U31VMUnOS

4- 1Y109AU3NU3N

EXHIBIT I

MOBIL OIL CORPORATION

JOLIET REFINERY

AMMONIA DISCHARGE HISTORY

MARCH 1994-MAY 1997

mgA

M2nt

Influent-Avenge

Influent-Ranw

Effluent-Average

Effluent-Range

X Average CenvM Ion

Mar-94

34

26-30

4 .9

1 .4-14 .9

86

Apr-94

37

31 -

43

1

.6

0.7-3 .5

96

May-94

32

26-40

3.7

0.4-12 .9

88

Jun-94

37

35-39

8 .1

1 .7-16 .6

78

Jul-94

43

34-58

3.7

0.8-14.3

91

Aug-94

37

30-43

6.0

2.4-10.8

84

Sep-94

23

7-35

9.9

5 .0-16.

57

Oct-94

30

3 .43

1 .2

0 .0 .3.0

96

Nov-94

31

27-38

3.5

0 .4-8.0

89

Dec-94

22

12-30

12.2

5 .5-19.2

45

Jan-95

22

17 .26

13.7

8 .7 .19 .1

38

Feb-95

17

14-21

7.2

0.6-20.4

58

Mar-95

33

30-38

1 .8

0 .4-3.7

95

Apr-95

34

31 - 38

6 .6

2

.4-13 .9

81

May-95

30

8-39

7 .5

4

.1 -10

.8

75

Jun-95

30

6-40

12 .2

0

.3-22 .9

59

Jul-95

43

35-49

0.4

0 .1-0.8

99

Aug-95

41

24-73

2 .0

0 .2-5 .8

95

Sep-95

59

37-73

2 .2

0 .5-5 .7

96

Oct-95

31

13-52

2 .7

0.2-7

.2

91

Nov-95

40

30-44

8 .1

0 .2-19 .0

80

Dec-95

40

31-49

11 .0

6 .0-25 .5

73

Jan-96

28

22-35

8 .5

2 .6-16 .9

70

Feb-96

25

14-38

5 .3

0-21 .4

79

Mar-96

24

11 -

30

9 .2

0-27.4

62

Apr-96

33

21 - 49

14 .9

0 .6-21 .1

55

May-96

37

28-55

1 .3

0-4 .2

96

Jun-96

37

32 - 42

3 .6

0-13 .7

90

Jul-96

43

37-56

1 .3

0-4.2

97

Aug-96

40

25-45

0 .3

0-0 .7

99

Sep-96

29

16-40

0 .3

0-1

.7

99

Oct-96

32

25-44

0 .1

0-0.2

100

Nov-96

38

34-45

0.3

0.0.8

99

Dec96

40

36-42

1 .6

0-14

96

Jan-97

35

33 - 36

3 .8

0-14

89

Feb-97

27

11 - 35

0 .3

0-0.8

99

Mar-97

36

22-48

1 .3

0 .1-6 .5

96

Apr-97

34

28-39

1 .3

0.1-3.1

96

May-97

31

24 -28

6 .2

0.3-33 .3

80

Period Average

,}¢

41

93

Period Minimum

0 .1

38

9497var.plc

Period Maximum

14.9

100

varrpt.6th

EXHIBIT 9

AMMOMA REMOVAL OPIRQATION ACIMIE3

ACTIVITY

NATURE

COST I COST e

COST iR COST tot

I at report 3l3ler-913/94

i a

investigative activity

Refinery Sour Water Pollutant Survey

I

$ 10M

$

10.4

e s equipment change or upgrade

Activated Sludge System Aeration Capability Engineering Analysis

W WTP API and DAF System Assessment

SWSTULaboratory Investigation -Phase 1

I

I

I

$ SM

$

6M

3 25M

$ SM

$

6M

m -

miscellaneous upgrade

$ 25M

Ind report 913194913196

Envirex . Inc

. Activated Sludge System Field Analysis

5

4M

$

4M

SWSTU Laboratory Investigation

- Phase 2

$ 25M

5 25M

Upgrade Crude Unit Desalter Controls

e

$

100M

$ 100M

Constructed Caustic Free Merox Treaters

e

$ 3M.1

$

3h9A

3rd retort 313195-913196

SWSTU Laboratory Investigation- Phase 3

$ 25M

$

25M

SWSTU Pilot Plant Study

$ 30M

$

30M

MCROTOX/Nitrifcation Inhibition Study

$120M

$ 120M

Upgraded West Side of Activated Sludge System

a

$1

.75M.I

$1

.751.9.1

Replaced West Clarifier Internals

e

$ 225M

$ 225M

Mg(Ot02 Addition Facilities

e

$

25M

$

25M

Bioaugmentation

m

S 65M $

65M

Mg(OH)2 Addition

a

$ 40M

$ 40M

4th report 913195313196

- Pendlnq

Upgrade East Side of Activated Sludge System

Upgrade East Clarifier Internals

Complete W WTP Laboratory

Complete DAF Controls Upgrades

Perform W WTP Post Mechanical Upgrade Optimization

6th report 3!3196-913196-Completed S Pendlnq

e

e

e

e

m

cwnoleeon dara

Upgraded East Side of Activated Sludge System

Junae

a

$1.75MA

51.751.9.1

Completed WWTP Laboratory

s

.l•a

s e

$

100M

$ loom

Completed DAF Controls & Recycle Upgrades

s.pf e

$

143M

$

143M

Install Liquid Nutrient (Phosphate) Addition System

Pending

Perform W WTP Post Mechanical Upgrade Optimization

Pending

6th report 913196-313197-Completed & Pending

e

m

, ..Ia,Wn diva

Upgrade East Clarifier Internals

Nov-4 0

$

225M

$

225M

Perform In-Stream Water Quality Data Collection

$ 33M

octae

I

Install Liquid Nutrient (Phosphate) Addition System

P.ndlng m

$ 25M

$ 25M

Perform W WTP Post Mechanical Upgrade Optimization

Pending

$ 33M

$ 45M $ 45M

TOTAL

5 283 M 5

7.363 M 5116M

S 7.776 MM

250 -

0

0)M

EXHIBIT III

ECL Inhibition vs Residual COD r = 0 .5

eclinbr.cod

i

Lo

1o

d'

a

w

00

N

N

In

LO

00

N

a)

Ln

(0

N

IN

C)

0

-N

N

N

N

N

M

C)

C)

C)

M

a

7

LO

LO

1o

LO

0

r

00

00

% Inhbition

300 -

200

-

100

-

0

EXHIBIT IV

ECL Inhibition vs Influent COD r = 0 .2

(n

W

4

11 (O W N N In

Ln W N T

Lc)

(o

N

N M

0

IN

1 N N N N C) M M

%

M

Inhibition

C)

a a W (()

Ln Lo to N W W

eclinhi. cod

0-C

ID

0

0x

h--

25-Apr -

2-May

-` ;

9-May

16-May

23-May -

30-May

6-Jun -

13-Jun

19Jun

-

23-Jun

30-Jun

11Jul

18-Jul -

25-Jul

V

2

a2

f

cm

c

co

m

C

7

C

N

X

c

m ep=

rn

CYI

0

N

3m

-4

0

x_n

co

J

m

0

5j-

rm(n

m

OD1

7-Feb

14-Feb -

21-Feb

-

m

D

v

0

28-Feb

V0

7-Mar

0'CDm

14-Mar21-Mar--

EXHIBIT VII

UPGRADED WWTP AMMONIA EFFLUENT CONCENTRATION

November 1996 to May 1997

exclusive of May 27, 1997 high value

-6 wwe nh3

a ave nh3

797tstmn .lg

Gentlemen :

As required by Special Condition No

. 16 of the above captioned NPDES Permit, the average crude

feedstock nitrogen concentration was 1571 mg/I for the period from January 1, 1996, to December

31, 1996

.

Very truly yours,

EXHIBIT VIII

Mobil Oil Corporation

File : 1006 .15

Joliet Refinery

Facility I

.D . 197800AAA

MOBIL OIL CORPORATION

OIL

FEEDSTOCK NITROGEN

CONCENTRATION REPORT

NPDES PERMIT NO . IL0002861

MFDWEE' AE3 :D, Dr , -E

P C BOX r'

JOLIET I .LJPOISeW 08-1

James M

. Kenna

Refinery Production Manager

LG1mmm

96ntg .rpt

cc -.

Mr .

Adolfo Gonzalez . Jr . - IEPA

. Maywood

Certified Mail

January 24, 1997

Illinois Environmental Protection Agency

Division of Water Pollution Control

Compliance Assurance Section

2200 Churchill Road

P .O . Box 19276

Springfield, Illinois 62794-9276

1996

I

1996

FEB

Crude Source

N2

WPPM BBLS API

CRUDE N2

MLBS , MLBS

BBLS API

RUDE

MLBS

N2

12

600879

92010,083.511 3135.0.0 280,8253,002

2472 925,250 31.6

281,2320

MLBS2470

780,540BBLS

API32.2

43

600570

56,739 31.0 17,3100

100

54,263 36.9

15,9740

100

3,339 36.9

5

5,000

00

00

2527261823242221201912171610151114138769

4,2003,3001,4522,1002,0001,3642,3001,4292,1001,84011,1621,3131.000.9008937003939966001703000

1,433,611265,041224,759114,078229,499106,385457,388410,628269,346729,187456,482455,33950,14682,07757,952

232333233923232234282526302923.5.2.0.5.3.8.0.1.4.2.7.6.0.5.3

441,708146,573131,503233,975146,105146,00032,65667,65279,15314,53825,39986,37072,56036,69918,1490000000

440269491616100173336477952104899000000070

1,435,828291,811256,559215,754251,391262,238297,143116,968136,199350,156298,294883,9517,670

25232726292623232323283423.5.8.2.6.3.1.0.6.3.2.5.7.7

442,116110,848283,26882,00493,33242,78883,76595,59034,86980,50891,95267,6532,399000000000

39222044015117515159510661359700000000001

1,403,739234,159146,128309,110260,099111,050111,787532,314585,339394,010283,489338,507139,640

23232323283222292523342723.3.1.2.8.3.8.9.2.7.3.6.3.6

00

00

N2,

TOTALWPPM

6,329,251

1,980,177 3,027,528

5,783,475

1808,299

1,4822

.681

5,633,250

1996

Crude Source

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

AR

APR

MAY I

(_JUN,/

WPPM

CRUDE

N2

MLBS MLBS BBLS

CRUDE

API MLBS

N2

MLBS BBLS , API

R DE N2

MLBS MLBS BBLS

RUDE

N2

API MLBS

MLBS

879 236,378

208

980,430 276 305,496 269 710,069 31.1 216,491

190 1,275,793 31.4 388,257

341

600

0

0

0 0 95,791 35.0 28,521

17 22,339 35.0 6,651 4

600

983

1

00 0

0 00

570

0

0

0 0 96,843 31.0 29,544

17 22,339 31.0 6,815 4

5,000

0

0 00 0

0 00

2,300 98,801

227 599,403 23.4 191,835 441 512,335 23.2 164,181

378 566,215

22.7 182,036 419

1,364 107,024

146 342,963 25.0 108,641 148 175,739 25.0 55,669

76 108,119 23.9 34,491

47

1,900 87,672

167 112,843 28 .8 34,898

66 69,034 28.8 21,350

41 180,140

28.4 55,850 106

2,100 187,576

394 490,316 23.1 157,227 330 395,653 22.6

127,283

267

806,867 22.5 259,741 545

1,840 170,473

314 388,234 23.2 124,412 229 544,867 23.0 174,832

322 619,707

22 .5 199,492 387

1,162 83,350

97 266,130

22.8 85,504

99 144,737 22.5

46,593

54 189,862 22 .0 61,318

71

1,429 44,865

64 117,181 22.5 37,722

54 113,982 22.2 36,764

53 113,746 21 .8 36,784

53

300

0

0

00

0

0

00

1,313 74,989

98

197,365 22.9 63,370

83 55,188 22.4 17,777

23 354,717 22 .4 114,262

150

4,200 125,938

529 365,582 24.5 116,177 488 240,252 23.3 76,941

323 443,289

22 .8 142,442 598

996 431,164

429

1,344,191 30.5 411,344 410 1,095,087 27.8 340,794

339 1,189,159

29 .3 366,618 385

393 45,676

18 139,959 26.9 43,803

17 54,544 26.4 17,125

7

9,225

27.0

2,885

1

2,000

0

0

00

0

0

00

0 33,610

0

137,344 33.7 41,215

0 144,161 37.1 42,389

0

164,255 36.5 48,470

0

600

0

0

00

0

0

00

1,000 33,344

33 181,800 34 .8 54,195

54 241,222 34 .6 71,996

72 142,858

34 .2 42,741

43

700

0

0

00

0

0

00

893

0

0

00

0

0

00

170

0

0

00

0

0

00

2,100

0

0

00

0

0'

0 0

1,452

0

0 52,329 30.5 16,014

23 46,109 30 .1 14,145

21

81,636 30.0

25,059

38

3,300

0

0

00

0

0 12,536 21 .8

4,054

13

0

0

00

0

0

00

TOTAL 1,761,843

725 5,716,070

1,791,854

?,712

4,735,611

1,482,395 2,199 6,302,802

1,977,965

N2, WPPM

5471

1,514

484~~ _ _

(1,600

1996

TOTAL

N2, WPPM

JUL,-

CRUDE N2

BBLS API

MLBS MLBS_

445,207 31 .0

135,821

119

0

0

54,512 36 .9

16,048

10

548,723 31 .0

167,402

95

0

0

697,993 22 .3

224,985

517

15,988 25

.0

5,065

7

36,752 28

.0 11,423

22

727,724 21

.9 235,180 494

747,623 22

.0 241,454

444

315,475 22

.0 101,886

118

236,366 22

.1

76,288

109

58

.170 32 .1 17,627

5

193,254

21 .8 62,495

82

472,463 22

.3 152,290

640

1,540,975 28

.8 476,565

475

0

0

0

0

74,883 31 .8

22,733

0

0

0

102,578

34 .2

30,690

31

0

0

0

0

30,023 46

.8

8,348

1

0

0

307,017

30.0

94,243

137

0

0

0 0

6,605,726

2,080,541

3 07

.589

(~AUG-

SEP

BBLS

CRUDE

N2

MLBS BBLS

UDE

API

MLBS

N2

API

MLBS

MLBS BBLS

API

643,539 30 .7 196,6910

, 1730 348,074

30:4----106,5820

940 579,461

33.6

10,552 36.9

3,106

2

0

0

785,773 31.0 239,7200 1370

667,764

31.0 203,7180 1160 189,339

31.0

585,00828,520 2133.8.0 189,1828,5950

435160 423,75368,717

2922.9.2

136,6780 3140 632,602169,438

2225.0.3

406,519 23.2

130,272 274 431,786

22.1

21 .107

40

218,312 27.2

529,698 22.0 171,072

315

517,753 22.1

139,360 293

567,428 21 .8

212,460 21 .6

68,796

80 235,597

21 .7

167,106

307 597 .141 21

.7

194,009 21 .9

62,698

90 59,433

22.1

76,238

89

191,459

21 .6

202,6509,290 2132.1.5

65,6622,815

861 166,813

22.1

19,1820

270 150,828 22.1

411,494

22.6 132,379 556

144,299 21 .9

53,839

71 410,330

21 .8

1,484,26850,211

2928.1.5

459,88815,499 4586

1,417,1946,340 3029

.1.2

434,48946,633

433196 1,652,250512,820

2822.2.5

1,957

1

163,313

48 .3 45,0290

00

84,053 49 .1

0

0

61,018

34.6 18,2120

180

282,016 33.8

23,0730

00

72,635 49.2

0

0

84,5790

850

208,367 34.5

636,65250,029 2846.5.8 197,26113,9100

41420

440,822108,817

4628.5.8 122,5660

210

375,458

46.8

6,532,070113,918(46,851)

2130.8.0

2043,249(14,382)36,8390 3.548122(21630

.246,191842,960

21.8

1,943,422272,599?3,71600

3,0569007100

6,617,59389,725

21.8

F-

I

N2

Crude Source

WPPM

1

879

2

600

3

600

4

570

5

5,000

6

2,300

7

1,364

8

1,900

9

2,100

10

1,840

11

1,162

12

1,429

13

300

14

1,313

15

4,200

16

996

17

393

18

2,000

19

0

20

600

21

1,000

22

i

700

23

893

24

170

25

2,100

26

1,452

27

3,300

Lt

9Z

St

*Z

EZ

ZZ

13

OZ

61

81

LL

91

St

*t

E1

Z1

LL

OL

6

9

L

9

S

4

Z

L

aamoS apni3

9661

119`1

~

*89699' .)

16S't

WddM'31

1*9'*90'£3 L99'099'EL

ZED£ 919'160'3

9£9'819'9 916 £ 899'9*O'3

400'094'9 9 £ 9£9'010'3

IViOl

0

0

0

00

00

00

OEL't

909'Z*E 6£1'690'1 0

0

0

0

96

9L0'63

00£'£

got

**3

LL6'0£Z9£L'L91

939'9*S69*'S*L

00

00

00

00

00

00

001'ZZS*'t

3*

LLZ'6*Z Z€€'969 0

0

0

0

9L

£6£'M

011

901

SEE , lZl

6E6'OL* 90L SEE'IZL

*9E 6£6'Ot*• 0

0

0

0

E68

0t

8£9'41

941'09

0

0

0

0

0

0

OOL

9ES

90*'9E5

OZS'96L'1 E

OtL'3

B'*€ 691'6

3Z

*19'13 9'*€ 90L'ZL Z9

LZ3'39

000'1

0

0

0

00

00

00

009

0

61 L'SZ*

9060**' L 0

06E' L t 1'6* 96*' 14 0

6L6' L

0'6* *OZ'L

0

LZ6'61 0

0

0

0

0

0

0

0

0

0

000'3

99

*6*'L*1

6Z0'ZL* 0

0

0

0

0

0

£6t

Sot's

999'SOZ'S ZL*'*89'91 OZ* *39'13* 9'63 611'01€'1 99*

Z13'L9* S'6Z LE£'L1S'l OLS 9E6'LlS 966

99*'9

SS€'6£9'1

LOV961'* 919 OS0'*61 1'E3 191'909 919 *61'1*1 L'ZZ Z*9'LS* 969

90*'S9L OOZ*

61Z'L

3*£'836 090'489'3 *9

4£9'9* LZZ ELZ'191' BOL 609'38

VZZ *8Z'99Z *LL *69'Z£L EL€'l

9

3**'OZ

09*'L9

0

0

0

0

0

0

OOE

SZ9

99E'LLS 496'061'1 Z6 999'*9 9ZZ EEE'LOZ 001 013'01 S'ZZ 691'913

OL 099'9* 6Z*'t

**1'L

*01'496

L9L'SS0'E 031. EZ3'EOl 9'ZZ *98'OZE S*1 *90'931

VZZ *6*'L9£ ZL

966'19 391'1

669'€

£93'611'Z LS 1'885'9 9** 99*'Z*3 0'EZ 9*9'SSL 09€

1IL'903 9'ZZ ££1'Z*9 99€ L£Z'E6t O*8'L

SZt'S

91£'O**'Z 969'999'1 OES t9*'ZSZ 9'33 191'*8L 9ZS 9LVOSZ

VZZ *90'911 SSE L6*'E8L 001'3

990'1

903'199 599'319'1 Ott 914'99 l'6Z L€9'IZZ 931 883'99

*'9Z L08'ElZ OEL 961'99 006'1

*33'1

OSZ'L68 SZ9'1t9'Z 913 Z1E'99L

8'*3 931'66* 09Z 996'061 9'*Z 990'309 £L ELVES *9£'1

Z*9'*

391'910'Z *91'613'9 69* 90*'661 0'EZ OS*'LZ9 LZ* SLVSBL

6ZZ,t,Z99'LLS 69* 906'EOZ 00€'3

96

SL9'61

810' L9

0

0

96

SL9'61 VZZ ' 910' 19 0

0

000'5

009

6*Z'ZSO'1 191'6**'E ZOL 660'811 0'L£ 69L'€99 LB

618'191 0'1£ Z*9'16* EE

E9L'LS OLS

ZZ

111'9£

999'ZZL

0

0

0

0

0

0

009

£3

SLL'9£

£LZ'831 0

0

0

0

0

0

009

031'3

9Z9't1VZ

*34'306'1

LZ S85'OE 9ZE 0*3'101 ZS

*14'69 8'BZ OI£'Z61 ESt 966'ELL 619

S8IW SBIW

S188 SBIW S8IW

IdV I S188 S8IW

S8IW

IdV S188 S8IW S8111

WddM

ZN

30f1N3

ZN 3Of1

ZN

3Of1 3

ZN 30f83 -. ZN

101

33

AON __

13"1 1

BEFORE THE POLLUTION CONTROL BOARD

OF THE STATE OF ILLINOIS

IN THE MATTER OF :

)

SITE SPECIFIC PETITION OF

)

MOBIL OIL CORPORATION FOR

)

(Water - Regulatory)

RELIEF FROM 35 ILL ADM

. CODE 304.122

)

AMMONIA NITROGEN EFFLUENT STANDARDS

)

TESTIMONY OF JAMES E. HT JFF

My name is James E

. Huff, and I am Vice President and part owner of Huff & Huff, Inc

., an

environmental consulting firm founded in 1979

. I received a Bachelor of Science in Chemical

Engineering in 1970 from Purdue University and was awarded a Masters of Science in Engineering

from the Environmental Engineering Department at Purdue University in 1971

. I am a registered

Professional Engineer in Illinois

as well as

in New Jersey

. My work experience includes two years

with Mobil Oil as

an Advanced Environmental Engineer during the construction and start-up of the

Joliet Refinery

. My responsibilities at the Joliet Refinery included the following

:

•

Construction oversite of some of the wastewater treatment facilities

•

Preparation of Operation & Maintenance Manual for the wastewater treatment

facilities

•

Training the wastewater treatment operators

•

Technical support for the wastewater treatment facilities, including sampling

coordination, trouble shooting, and discharge monitoring reports

•

Operations of the wastewater treatment facilities for a 6 week period

•

Oil spill response program development

From the above responsibilities, I am familiar with the refinery, its wastewater treatment

system, as well as the receiving waterway, the Des Plaines River

.

R97-28

CLERICS

RECEIVEDOFFICE

JUN 2 3 1997

STATE OF ILLINOIS

POLLUTION CONTROL BOARD

I

THIS FILING SUBMITTED ON

RECYCLED PAPER

After leaving Mobil in the fall of 1973, I was employed for three years at IIT Research

Institute in the Chemical Engineering Department, working on advanced wastewater treatment

projects including catalytic oxidation of cyanide in petroleum wastewaters

. I then spent four years

with the Armak Company, now called Akzo Nobel Chemicals

. I was the Corporate Manager of

Environmental Affairs responsible for regulatory compliance and engineering design of

environmental systems at nine manufacturing facilities in the United States and Canada

. Three of

these chemical plants were fatty amines manufacturers, where ammonia was utilized as a raw

material and was a major component in the wastewater

. For the last 17 years at Huff & Huff, Inc

.,

I have been involved in over 20 environmental impact studies associated with the impact of

wastewater discharges on receiving streams throughout the United States

. Many of these studies

have involved ammonia nitrogen impacts, including those for the City of Lockport, the Uno-Ven

Refinery and its predecessor Union Oil, the Galesburg Sanitary District, and Modine Manufacturing

.

I was Project Manager on a year long Fox River Ammonia Study on behalf of most of the municipal

discharges on the Fox River below the Chain-of-Lakes

. I was an active participant in the recent

ammonia water quality proceedings (R94-1 b), on behalf of six communities and also Indian Refining

Corporation .

In addition, I have designed nitrification facilities for both industrial and municipal

wastewater treatment plants

. Most recently, after a nine month pilot study on nitrification of

anaerobic digester supernatant, I designed a batch biological system that will take influent ammonia

levels from above 300 mg/e to less than 1 mg/e

. This system is currently under construction

.

I was retained by Mobil to evaluate the environmental impact of Mobil's discharge on the

Des Plaines River and ensure that the effluent standards recommended are protective of stream uses

and consistent with water quality goals and standards

. The report included as Exhibit VIII was

prepared under my supervision and direction

. The purpose of my testimony is to summarize this

report .

2

Background

The Mobil refinery is located in Will County approximately 10 miles southwest of Joliet,

Illinois, on the south side of the Des Plaines River, just upstream of the Interstate 55 bridge . The

Des Plaines River is approximately 600

ft

wide at the location of the outfall . The Des Plaines River

above the 1-55 Bridge is designated as a Secondary Contact Water under 35 Ill Adm . Code 303

.441 .

The ammonia water quality standard for Secondary Contact Waters is 0 .1 mg/P un-ionized ammonia .

Mixing Zone Determination

The available dilution within the mixing zone and Zone of Initial Dilution are important in

establishing the potential impacts of a discharge on water quality . Based upon field measurements

and both U .S

. EPA and IEPA policies, the Zone of Initial Dilution or ZID, and the full mixing zone

were determined . Factoring in the mixing of once through cooling water, which is discharged

through the same effluent channel, as well as the stream mixing, the available dilution within the

ZID is 4 .2 to 1 . The overall available dilution within the mixing zone was determined to be 63 to 1 .

At the 1-55 Bridge, the Des Plaines River is designated as a "General Use" waterway . The

winter un-ionized ammonia standard becomes 0 .025 mg/P below the 1-55 Bridge, or four fold more

restrictive than the 0 .1 mg/P Secondary Contact Water Quality Standard . The extent of mixing

achieved by the 1-55 Bridge was also determined as part of the field work, as one of our tasks was

to ensure that the recommended effluent standards would be protective of the "General Use"

waterway below the 1-55 Bridge . Further dilution from the edge of the mixing zone to the 1-55

Bridge was found to be 4 fold

. Thus, if the edge of the mixing zone achieves 0.1 mg/P un-ionized,

the Des Plaines at the 1-55 Bridge will achieve 0

.025 mg/P, ignoring any ammonia removal processes

such as plant uptake, volatilization, and nitrification

. Thus, effluent limits protective of the

Secondary Contact Water Quality Standard (0

.1 mg/P un-ionized ammonia) will also assure

compliance with the General Use Water Quality winter un-ionized standard (0

.025 mg/P). As the

General Use Water Quality Summer un-ionized standard is 0

.057 mg/P, the summer standards will

also be achieved .

3

Derivation of Effluent Limits

Appropriate effluent limits can be derived based on water quality considerations, existing

effluent quality, as well as existing permit limits under IEPA and U .S

. EPA policies . The most

restrictive of the three approaches is the appropriate methodology

. Using the 0.1 mg/Q un-ionized

ammonia water quality standard, with the 75th percentile stream temperature and pH, the equivalent

total ammonia water quality level can be derived

. Then factoring in the available dilution within the

mixing zone, the water quality based ammonia effluent limits for Mobil are back calculated as

follows

:

Summer

70 mg/Q monthly average

Winter

243 mg/Q monthly average

U.S

. EPA's methodology for statistically deriving effluent limits based upon existing effluent

quality was also utilized, as typically determined by IEPA at permit renewals . With the recent

wastewater treatment upgrades, the representative monthly average database was limited from

November, 1996 to March, 1997 . However; short term upsets can still occur, independent of the

upgrade

. Therefore, for deriving a daily maximum effluent limit, a larger database is appropriate .

The daily values from 1992 through 1996 were utilized for deriving a daily maximum limit

. The

results of this statistical analysis are as follows

:

Monthly Limit

9 mg/9

Daily Maximum

23 mg/Q

The present variance from Section 304

.122 limits Mobil's ammonia effluent to 13 mg/Q

monthly average and 26 mg/p daily maximum

. Unless a discharger can not meet existing effluent

limits derived using best professional judgement, Section 404 of the 1987 Clean Water Act

amendments prohibits less stringent effluent limits in renewal permits

.

4

The appropriate effluent limits then become the most restrictive of the above three described

effluent limits, which are as follows :

Monthly Effluent

Ammonia Limit

9 mg/e

Daily Maximum

Effluent Limit

23 mg/e

These limits reflect a 31 percent reduction from the current monthly average limit and a 12

percent reduction from the current daily maximum limit

. The larger reduction in the monthly limit

reflects the greater improvement the expanded treatment will have on the average ammonia

achieved ; however, shorter term upsets still have the potential to occur .

In summary, the proposed effluent limits are more restrictive than the existing effluent limits,

reflecting the improvements from $7

.8 million in expenditures . The proposed limits will readily

result in maintaining ammonia water quality in the Des Plaines River, both upstream of the 1-55

bridge (Secondary Contact) and downstream of the 1-55 Bridge (General Use) .

5

Education :

1966-1970

Purdue University, West Lafayette, Indiana

B.S. in Chemical Engineering

1970-1971

Purdue University, West Lafayette, Indiana

M.S.E . in Environmental Engineering

1974-1976

University of Chicago

Graduate School of Business . Part time

Honors :

Omega Chi Epsilon (Chem . Engr. Honorary)

President's Academic Award

Graduated with Distinction

Fellowship from the Federal Water Quality Admin .

Thesis :

"Destabilizing Soluble Oil Emulsions Using Polymers with Activated

Carbon," Major Professor, Dr . J . E . Etzel

Experience :

Since 1980, Mr . Huff has been vice president of Huff & Huff, Inc . responsible for projects pertaining

to wastewater treatment, hazardous waste management, ground water and soil remediation, and

compliance assessments

. A significant portion of his time has been devoted to assisting clients on day-

to-day environmental issues ; from permitting and reports to setting up programs for compliance .

Mr. Huff has designed industrial wastewater treatment plants ranging in size from less than one thousand

gallons per day to five million gallons per day . These designs have ranged from foundries, plating,

metal working, and printed circuit boards to the organic chemical industry . Mr. Huff has also directed

ten municipal wastewater treatment design projects and four country club on-site wastewater systems

over the past fifteen years

. Two novel in-stream aeration systems, using high-purity oxygen on a

shallow Illinois stream, were designed and installed . Mr. Huff was retained by a community to direct

(contract O&M) the operations of a new 1

.5 mgd tertiary treatment plant until the system was lined out

and a superintendent hired .

In the area of Water Quality Analysis, Mr. Huff has completed a variety of projects, including both

biological and chemical assessments . Mr

. Huff has directed studies for two of the Quad Cities to assess

the environmental impact of water treatment plant discharges on the Mississippi River

. These studies

have included evaluating various locations along the Mississippi for the presence of mussel beds, the

potential presence of endangered species, primarily the Lampsilis

higginsi, and whether the areas were

important for fish spawning

. The scope-of-work for the mussel surveys developed by Mr . Huff were

reviewed and approved by U .S

. Fish & Wildlife, IDOC, IEPA, and the Illinois Natural History Survey .

Approval for both of the outfalls was secured .

ATTACHMENT I

JAMES E . HUFF, P.E .

J. E. Huff, P .E . - Resume

On the Fox River, Mr

. Huff was project manager for a group of municipal dischargers on a project to

collect and analyze weekly water quality samples along the river, its tributaries, and outfalls at over 30

locations to establish a better database than currently exists . Mr

. Huff has directed fish and benthic

surveys for industrial, storm water, and municipal wastewater discharges located on the following

waterways

: Cedar Creek, Deep Run, Thom Creek, North Kent Creek, Chicago Sanitary & Ship Canal,

and Casey Fork Creek .

In the hazardous waste field, over sixty industrial plants have relied on Mr

. Huffs expertise for

complying with the regulations . Mr

. Huff has provided the required RCRA and DOT training, prepared

inspection plans, contingency plans, training plans, and waste minimization plans

. Mr. Huff directs

H&H's underground storage tank (UST) closure and remediation projects for a variety of clients

. Both

petroleum and solvent tank releases have required regulatory reporting and remediation

. Tank systems

have varied in size from single units to 50 USTs .

Remediation designs, many associated with underground storage tank releases, are a major portion of

Mr. Huff s activities

. He has designed and implemented landfarming, soil vapor extraction, air sparging,

ground water pump and treat systems utilizing batch biological reactors, activated carbon, air strippers,

and in situ enhanced bioremediation. Mr

. Huff has completed treatability studies at a Federal Superfund

site for cyanide and thiocyanate destruction in ground water, including operation of a 4,000 gpd pilot

reactor at the site and was the lead engineer for a feasibility study for a major chlorinated solvent release

at a state superfund site . Mr

. Huff has directed over fifteen hazardous waste closures of TSD facilities,

ranging from drum storage areas to the complete clean-up of a 27-acre abandoned manufacturing

facility

. This abandoned manufacturing site included plating solutions, cyanide bearing sludges, oils,

and over 20,000 gallons of virgin chemicals requiring placement

.

Compliance assessment is a significant part of Mr

. Huff s work

. Over 100 environmental audits of

manufacturing firms have been conducted by Mr

. Huff over the last fifteen years

. These audits have

included potential acquisitions as well as on-going industrial operations

. Mr. Huff has also been

involved in siting and permitting of new industrial facilities, including a mining operation

.

From 1987 through 1990, Mr

. Huff was a part-time faculty member, teaching the senior level

environmental courses in the Civil Engineering Department at IIT-West in Wheaton, Illinois

.

From 1976 to 1980, Mr

. Huff was Manager of Environmental Affairs for the Armak Company (now

Akzo Nobel Chemicals), a diversified industrial chemical manufacturer

. At Armak, Mr . Huff was

responsible for all environmental activities at eight plants located throughout the United States and

Canada

. Technical work included extensive biological and chemical treatability studies as well as

designing new facilities, including two wastewater pretreatment facilities, a land application system, and

an incinerator system .

Previously, Mr

. Huff was an Associate Environmental Engineer in the Chemical Engineering Section

at IIT Research Institute (IITRI)

. The work included extensive testing of wet scrubbers for odor control

in the rendering industry as well as carbon adsorption evaluations

. Also Ozone/UV was tested as a

treatment method for cyanide, PCB's, RDX, HMX, and TNT

. At Mobil Oil's Joliet refinery Mr

. Huff

was employed as an Advanced Environmental Engineer during the construction and start-up of the

grassroots refinery

. Mr

. Huff was responsible for wastewater, water supply, solid waste, and noise

abatement issues at the refinery from 1971 to 1973

.

J . E. Huff, P .E. - Resume

Membership

Water Environment Federation Member

Illinois Water Environment Federation

National Water Well Association

Certified Class 2 and Class K Sewage Treatment Works Operator in Illinois

Licenses

:

Registered Professional Engineer, Illinois and New Jersey

Papers:

"Ozone-U.V . Treatment of TNT Wastewater," E .G. Fochtman and J .E. Huff, International Ozone

Institute Conference, Montreal, May 1975 .

"Characterization of Sensory Properties" Qualitative, Threshold, and Supra-Threshold," J .E. Huff and

A. Dravnieks, American Water Works Assoc . Seminar, Minneapolis, MN, June 1975 .

"Optimizing Wet Scrubber Systems for Odor Control in the Rendering Industry," R .H. Snow, J .E. Huff,

and W

. Boehme, Purdue Air Quality Conference, Lafayette, IN, November 1975

.

"Control of Rendering Plant Odors by Wet Scrubbers

: Results of Plant Tests," R .H. Snow, J .E. Huff,

and W

. Boehme, APCA Conference Boston, MA, June 1975 .

"Asbestos Manufacturing Waste Disposal and Utilization," P . Ase, J.E. Huff, L.L. Huff, C .F. Harwood,

and D. Oestreich, Mineral Waste Utilization Symposium, Chicago, IL, April, 1976 .

"Alternative Cyanide Standards in Illinois, a Cost-Benefit Analysis," L .L. Huff and J .E. Huff, 31st

Annual Purdue Industrial Waste Conference, Lafayette, IN, May 1976 .

"Cyanide Removal from Refinery Wastewaters Using Powdered Activated Carbon," J

.E. Huff, J.M.

Bigger, and E.G

. Fochtman, American Chemical Society Annual Conference, New Orleans, LA, March

1977

. Published in Carbon Adsorption Handbook, P.N. Cheremisinoff and F . Ellerbusch, Eds ., Ann

Arbor Science Publishers, Inc ., 1978.

"Industrial Discharge and/or Pretreatment of Fats, Oils and Grease," J .E. Huff and E .F. Harp, Eighth

Engineering Foundation Conference on Environmental Engineering, Pacific Grove, CA, February, 1978.

"A Review of Cyanide of Refinery Wastewaters," R .G

. Kunz, J .E. Huff, and J .P. Casey, Third Annual

Conference of Treatment and Disposal of Industrial Wastewater and Residues, Houston, TX, April 1978

.

Published as : "Refinery Cyanides

: A Regulatory Dilemma," Hydrocarbon Processing, pp 98-102,

January, 1978

.

"Treatment of High Strength Fatty Amines Wastewater - A Case History," J.E. Huff and C.M.

Muchmore, 52nd Conference

- Water Pollution Control Federation, Houston, TX, October 1979 .

Published JWPCF,

Vol. 54, No . 1, pp 94-102, January, 1982 .

J. E. Huff, P.E. - Resume

"An Overview of Environmental Regulations," E .F. Harp and J.E. Huff, Soap & Detergent Association

Annual Meeting, Boca Raton, FL, January 1980 .

"A Proposal to Repeal the Illinois Pollution Control Board's Construction Permit Water Regulations,"

J.H. Russell and J .E. Huff, Chicago Bar Record, Vol. 62, No. 3, pp 122-136, Nov.-Dec., 1980

.

"Disinfection of Wastewater Effluents in Illinois-A Cost

:Benefit Analysis," L

.L

. Huff and J

.E

. Huff,

Illinois Water Pollution Control Association 2nd Annual Conference, Kankakee, IL, May 20, 1981 .

"Measurement of Water Pollution Benefits - Do We Have the Option?" L .L. Huff, J .E. Huff, and N .B.

Herlevson, IL Water Pollution Control Assn 3rd Annual Conference, Naperville, IL, May 1983

.

"Evaluation of Alternative Methods of Supplementing Oxygen in a Shallow Illinois Stream," J.E. Huff

and J.P. Browning, Illinois Water Pollution Control Assn Sixth Annual Meeting, Naperville, IL, May

7, 1985

.

"Environmental Audit for Wastewater Compliance," J

.E

. Huff, Federation of Environmental

Technologists Environmental '86 Seminar, Milwaukee, WI, March 5, 1986.

"Technical and Economic Feasibility of a Central Recovery Facility for Electroplating Wastes in Cook

County, IL," J .E. Huff and L.L. Huff, 1986 Governor's Conference on Science and Technology in

Illinois, Rosemont, IL, Sept

. 3, 1986 .

"Hazardous Waste Closure Procedure," J .E

. Huff, Federation of Environmental Technologists Seminar,

Rockford, IL, Dec . 17, 1986.

"Training & Contingency Plan Requirements Under the Hazardous Waste/Right-To-Know/OSHA

Regulations," J .E

. Huff, Federation of Environmental Technologists Environment'88, Milwaukee, WI,

March 9, 1988

.

"Biomonitoring/Bioassay," J .E. Huff, Federation of Environmental Technologists Seminar, Harvey, IL,

December 11, 1989 .

"Storm Water Discharges," J.E. Huff, Federation of Environmental Technologists Environment '90

Seminar, Milwaukee, WI, March 7, 1990.

"Cleanup Standards-Past, Present and Future," J .E

. Huff and D.O'Neill, Chicago Bar Association's

Environmental Law Seminar "Underground Tanks

: Down and Dirty," Chicago, IL, June 8, 1993 .

"Engineering Aspects of Individual Wastewater System Design," J

.E . Huff, 22nd Annual Northern

Illinois Onsite Wastewater Contractors Workshop, St

. Charles, IL, February 27, 1995 .

C

:\ I DOC\MOBIL\PETITION\TESTIMONDOC

107715-I

BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

IN THE MATTER OF:

)

)

SITE SPECIFIC PETITION OF

)

MOBIL

RELIEF FROM

OIL

35 ILL .

CORPORATION

ADM

. CODE 304.122,

FOR ))

AMMONIA NITROGEN EFFLUENT STANDARDS

)

TESTIMONY OF JOHN H . KOON, Ph.D., P.E.

INTRODUCTION

My name is John H . Koon and I am affiliated with Parsons Engineering Science,

Inc. (Parsons ES)

. I have been working with Mobil Oil Corporation (Mobil) in evaluating

Mobil's Joliet refinery's wastewater treatment plant (WWTP) with regard to achieving the State

of Illinois ammonia discharge limitation

. A copy of our full report is included as Exhibit VII

to Mobil's petition

. This exhibit accurately reflects our analysis and conclusions .

Parsons ES was retained by Mobil to provide a technical evaluation of the

refinery's WWTP and treatment process modifications that have been made or investigated with

specific regard to the removal of ammonia

. Our specific tasks were to :

Evaluate the design, operation, and performance of the existing

wastewater treatment system, paying special attention to any

circumstances that would interfere with biological nitrification

.

Determine if changes in the treatment system operation would

improve ammonia removal .

Determine if the present wastewater treatment system meets the

United States Environmental Protection Agency (USEPA) Best

Available Technology (BAT) economically achievable criteria .

THIS FILING IS SUBMITTED ON RECYCLED PAPER

RECEIVED

CLERICS

OFFICE

JUN 2 3 1997

POLLUTION

STATE

CONTROL

OF

ILLINOISBOARD

R97-28

Determine how recent changes in the Resource Conservation and

Recovery Act (RCRA) regulations have adversely impacted the

ammonia removal performance of the system .

Review the evaluation of alternative ammonia removal technologies

performed by Mobil, evaluate any additional technologies, as

appropriate, and develop current cost estimates for the construction

of applicable technologies .

We began our study in October of 1996

. We conducted a two-day site visit to

inspect the treatment plant and review operating procedures and data . Mobil also provided us

with extensive treatment plant operating data and information on capital improvement projects

and previous investigations . We used this information to form our opinions and conclusions .

I was the lead technical resource for this investigation and the report was prepared

under my supervision and direction

. Christopher Donohoe, a junior engineer, gathered most of

the information and conducted the initial analysis

. Gregory M

. Gibbons, P .E. worked with Mr .

Donohoe in the information analysis and was a primary author of the report .

I have over 27 years experience in the environmental field . My educational

background includes a B .E . in Civil Engineering, a M .S . in Environmental Engineering from

Vanderbilt University, and a Ph .D . in Environmental Engineering from the University of

California, Berkeley .

I have specialized in the area of industrial water pollution control and have

worked with numerous industries with regard to biological nitrification and nitrogen control .

A detailed list of projects is included in the attached biographical information .

WASTEWATER TREATMENT PLANT DESCRIPTION

Mobil owns and operates a 200,000 barrels per day (bbl/day) refinery on the

Des Plaines River in Joliet, Illinois . Process wastewater and contact storm-water runoff are

-2-

treated in the facility's WWTP

. The facility is a conventional activated sludge treatment plant

with solids and oil removal as primary treatment

. Major unit process include :

Sour Water Stripper

- Primary removal of ammonia and sulfide

.

This treatment unit is located in the refinery process area .

Desalter - Partial removal of phenolics and in-plant water reuse

.

This unit is located in the refinery process area

.

TK 103 -

Wastewater flow equalization . This unit is located in the

refinery process area .

Benzene Removal Unit -

An air-stripping process for removal of

benzene, sulfide, and volatile organic compounds

. This unit is

located in the refinery process area

.

Diversion Basin -Basin used for hydraulic overflow during wet

weather. .

API Oil/Water Separator -

Parallel basin process for the oil

removal of gravity separable oil

.

Dissolved Air Flotation - Parallel basin process for the removal of

suspended oil

. The DAF system was modified/upgraded in 1996

with enhanced air injection features .

Equalization Biological Treatment Unit (EBTU)

- Secondary

equalization with surface aerators for phenolic and other chemical

oxygen demand (COD) oxidation

. The EBTU normally receives

treated sanitary wastewater and effluent from the dissolved air

flotation units (DAF) .

Aeration Basins -

Parallel activated sludge basins for ammonia,

organic, cyanide and other pollutant removal

. The aeration basins

were upgraded in 1996 with the installation of a fine bubble air

diffuser system and new aeration blowers .

Clarifiers - Parallel clarifiers for solids removal/sludge settling

.

The settled sludge and surface skimming mechanisms in the

clarifiers were replaced to improve separated solids removal from

the units .

Guard Basin

- Effluent retention prior to discharge

.

-3-

The facility also has a biological-sludge thickening tank, where waste activated

sludge is gravity settled and stabilized . Waste bio-sludge is then hauled to the on-site coker for

recycling .

The nominal design capacity of the treatment plant is 2,500 gallons per minute

(gpm) . Current throughput is 1,900 gpm .

Mobil has implemented a number of capital improvement projects to optimize the

W WTP processes, including enhancement of ammonia removal. Mobil has conducted laboratory

studies to pinpoint inhibition to the nitrification/denitrification process . Mobil has also evaluated

further improvements to the WWTP to improve ammonia removal . These actions were

considered in our evaluation .

WASTEWATER TREATMENT PLANT MODIFICATIONS

Since 1990, Mobil has made the following modifications:

Installed a benzene removal unit (BRU) .

Converted an equalization basin to an aerated biological

pretreatment unit, the equalization biological treatment unit

(EBTU) .

Switched to a caustic-free Merox gasoline treating unit .

Upgraded to diffused aerators in the activated sludge basins

.

Upgraded the WWTP clarifiers .

Made extensive modifications to the DAF system

.

The BRU was installed in September of 1990 to meet the requirements of RCRA

(40 CFR 261) and the National Emission Standards for Hazardous Air Pollutants (NESHAPS-40

CFR 61) regulations at a cost of $2

.1 million. Mobil constructed and operates the unit to

remove benzene, other volatile hydrocarbons, and a substantial amount of sulfide from a major

-4-

portion of their process wastewater . Similarly, in 1991, upon the listing of F037 and F038

sludges, Mobil converted an equalization basin to the EBTU through the addition of surface

aerators

. The EBTU is an aggressive biological treatment unit.

The nitrification performance of the treatment system has deteriorated since 1991

.

This is most likely attributable to increases in some chemical inhibitory substance in the BRU

or the EBTU . A nearly identical conclusion was made at the UNO-VEN refinery in Lemont,

Illinois, in a 1993 petition to the IL PCB (R 93-8) .

In June of 1995, Mobil began operating a newly constructed caustic-free Merox

gasoline treating unit (Merox unit)

. The nature of the new Merox unit is such that its operation

precludes a recurrence of WWTP upsets caused by incursion of the phenolic spent caustic into

the wastewater system thus, at least removing one source of known inhibitory substances

.

Mobil also upgraded the WWTP's activated sludge basins and clarifiers to enhance

nitrification

. To promote more efficient oxygen transfer and to increase the dissolved oxygen

(DO) levels in the aeration basins-creating a more suitable environment for nitrifiers-Mobil

replaced the mechanical aerators of the west and east basins with fine bubble diffusers

(November 1995 and June 1996, respectively)

. Mobil spent $3

.5 million in modifying the

activated sludge basins

. Moreover, Mobil replaced the east and west clarifier internals by

removing the suction-riser-pipe and installing bottom-suction-header equipment in each clarifier

costing . These changes cost $450,000

.

Mobil made upgrades to the DAF recycle system to increase the efficiency of the

air saturation system

. This also improved operability and reliability over the original system

.

This upgrade to the recycle system cost $143,000 .

-5-

LABORATORY STUDIES

Mobil performed the following studies per IPCB order in PCB 93-151 .

SOUR-WATER STRIPPER TAIL UNIT PROCESS

Mobil suspected that the stripped sour water stream was the most likely source

of substances inhibitory to nitrification

. As a result, Mobil conducted investigations to pinpoint

and possibly remove inhibitors, including the installation of a sour water stripper tail unit

(SWSTU) . Mobil's SWSTU evaluation activities consisted of a refinery sour water pollutant

survey, three phases of laboratory investigations, and a pilot-scale study .

The objective of the investigations was to determine the most probable cause of

inhibition and to identify a promising treatment technology

. Mobil researchers suspected phenol

to be a major cause of inhibition and developed a nickel-tungsten catalyst bonded to activated

carbon (Ni/W-AC) to remove phenol by catalytic oxidation

. Laboratory investigations with the

catalyst yielded positive results

. However, pilot-scale testing with the Ni/W-AC process

between March and September 1995 was less successful . Mobil researchers observed that

phenol was removed by adsorption to the activated carbon, not by catalytic oxidation, and

concluded that adsorption was not a commercially viable option for phenol removal from sour

water

. Mobil spent in excess of $100,000 for the multiple phases of the SWSTU investigation

.

MICROTOX STUDY

Using MICROTOX technology, Mobil performed a toxicity identification study

elucidating toxic inputs to the WWTP . This study concluded

:

Toxicity increases across the BRU-supporting Mobil's contention

that the operation and performance of the WWTP has become less

reliable after the BRU installation

.

-6-

Commissioning of the new Merox unit led to an overall decrease

in toxicity .

AMMONIA INHIBITION STUDY SUMMARY

Mobil conducted a nitrification inhibition study from October 1981 through

January 1983

. This study was summarized in Mobil's May 1, 1984, proposal to the Board

(adopted rule PCB R84-16) .

Results from this study indicated that factors inhibitory to

biological nitrification in Mobil's wastewaters were recurring and unpredictable

.

In 1995 Mobil contracted with Nalco Chemical Company (Nalco) to conduct a

second ammonia inhibition study on input streams to the WWTP

. The work involved laboratory

testing and a general review of the wastewater generation and treatment processes

. Nalco

conducted their study to assess the degree of nitrification inhibition of 15 wastewater influent

component streams and the overall contribution of these influent streams to the quality of the

final effluent .

Nalco also attempted to correlate measured nitrification inhibition to such

parameters as pH, ammonia, residual COD following biological treatment, cyanide, sulfide,

phenols, conductivity (dissolved salts), nitrates, and process unit variability

. The principal

finding of the study was that inhibition to the nitrification process was caused by biological

degradation products produced in the activated sludge process

. Thus, by accomplishing its

primary objective, i.e

.,

the oxidation of degradable organics, the biological treatment process

appeared to be creating conditions that prevented it from achieving high levels of nitrification

.

Mobil spent a total of $120,000 for the MICROTOX and the Nalco nitrification

inhibition studies.

-7-

All together, Mobil has spent nearly $10,000,000 on upgrades to the WWTP and

studies investigating further enhancements to the facility's performance

. A summary of these

costs is presented in Table 1

.

The Mobil Joliet refinery WWTP has a history of varying ammonia removal due

to inhibition of nitrification in the treatment plant

. Nitrification is a sensitive process that can

be affected by many factors . Mobil has been able to identify some causes for reduced

nitrification, e .g.,

increased WWTP influent toxicity resulting from the installation of the BRU

and EBTU

; incursion of the phenolic spent caustic into the wastewater system

; and varying

ammonia levels in the raw crude oil

. However, even after installing the caustic free Merox unit

and totally upgrading the WWTP, Mobil is unable to consistently meet the state effluent

standard .

WASTEWATER TREATMENT PLANT OPERATION EVALUATION

Parsons ES evaluated the operation of the WWTP to assess if (1) the facility was

well run, (2) operating conditions were favorable to nitrification, and (3) the facility meets or

exceeds BAT requirements .

EVALUATION OF CURRENT OPERATION

Following a thorough inspection of the Mobil WWTP and operating data, Parsons

ES concludes that Mobil properly operates their treatment facility

. Removal efficiency data for

major parameters of concern are shown in Table 2

. This performance data are indicative of an

exemplary treatment plant, evidenced by BOD

5 , TSS, and phenolics data

. Although the facility

design promotes conditions well within the range for nitrification, the WWTP does not

consistently achieve levels of nitrification necessary to meet Illinois regulations

. Studies have

8

indicated that this inconsistency can be attributed to inhibitory agents resulting from

RCRA and

NESHAP mandated upgrades to the WWTP . Therefore, it is the opinion of Parsons

ES that

ammonia levels above the Illinois ammonia effluent standard do not result from poor facility

operation .

Furthermore, it is unlikely that significant additional removal of organics and

ammonia could be achieved through operating or equipment modifications .

COMPARISON TO INDUSTRY PRACTICES AND GUIDELINES

A comparison of Mobil's treatment plant practices with BAT requirements are

presented in Table 3 . Mobil meets or exceeds all BAT

treatment plant process requirements .

Parsons ES compared the Mobil Joliet refinery's WWTP effluent with the

BAT effluent

guidelines

. This comparison is presented in Table 4 . The Joliet refinery WWTP effluent is

significantly below the USEPA BPT and BAT

ammonia effluent limitations (daily maximum of

2,215 lb/day and daily average of 1,007 lb/day) . The facility also has operated at flow rates

significantly lower than the BPT

average flow rate, due to water conservation and stream

segregation

. These water conservation and segregation practices may, in a sense, hinder Mobil's

efforts to meet the Illinois concentration-based effluent limit

. The net result of discharging less

water is that wastewater constituents are concentrated in the reduced flow

.

ALTERNATIVE TREATMENT TECHNOLOGY EVALUATION

Mobil has evaluated a number of alternative treatment technologies to further

enhance ammonia removal

. These have included :

Pre-ICPB 93-151 Variance Petition

From 1979 through 1982 Mobil operated a two-stage pilot

treatment system.

-9

Addition of rotating biological contactors (RBCs) for second-stage

secondary treatment .

Addition of a trickling filter as second-stage treatment .

Addition of a third aeration basin and clarifier in parallel to the

existing activated sludge system .

Technology Assessment Associated with ICPB Variance Petition

Breakpoint chlorination .

Addition of powdered activated carbon (PACT) to the aeration basins

.

Selective ion exchange .

Mobil has experimented with and performed engineering evaluations on a number