| TITLE 35: ENVIRONMENTAL PROTECTION | |

| SUBTITLE B: AIR POLLUTION |

CHAPTER I: POLLUTION CONTROL BOARD |

| SUBCHAPTER c: EMISSION STANDARDS AND LIMITATIONS FOR STATIONARY SOURCES |

| PART 225 | |

| CONTROL OF EMISSIONS FROM LARGE COMBUSTION SOURCES | |

| SUBPART A: GENERAL PROVISIONS | |

| Section | |

225.100 | |||

| Severability | |||

| 225.120 | |||

| Abbreviations and Acronyms | |||

| 225.130 | |||

| Definitions |

| 225.140 | Incorporations by Reference | ||||

| 225.150 | Commence Commercial Operation | ||||

| SUBPART B: CONTROL OF MERCURY EMISSIONS FROM COAL-FIRED ELECTRIC GENERATING UNITS | |

| Section |

225.200 | |||

| Purpose | |||

| 225.202 | |||

| Measurement Methods | |||

| 225.205 | |||

| Applicability | |||

| 225.210 | |||

| Compliance Requirements | |||

| 225.220 | |||

| Clean Air Act Permit Program (CAAPP) Permit Requirements | |||

| 225.230 | |||

| Emission Standards for EGUs at Existing Sources |

| 225.232 | Averaging Demonstrations for Existing Sources |

| 225.233 | Multi-Pollutant Standards (MPS) |

| 225.234 | Temporary Technology-Based Standard for EGUs at Existing Sources |

| 225.235 | Units Scheduled for Permanent Shut Down |

| 225.237 | Emission Standards for New Sources with EGUs |

| 225.238 | Temporary Technology-Based Standard for New Sources with EGUs |

| 225.239 | Periodic Emissions Testing Alternative Requirements |

225.240 | |||

| General Monitoring and Reporting Requirements | |||

| 225.250 | |||

| Initial Certification and Recertification Procedures for Emissions Monitoring | |||

| 225.260 | |||

| Out of Control Periods and Data Availability for Emission Monitors | |||

| 225.261 | |||

| Additional Requirements to Provide Heat Input Data | |||

225.263 | |||

| Monitoring of Gross Electrical Output | |||

| 225.265 | |||

| Coal Analysis for Input Mercury Levels | |||

| 225.270 | |||

| Notifications | |||

225.290 | |||

| Recordkeeping and Reporting | |||

| 225.291 | |||

| Combined Pollutant Standard: Purpose | |||

| 225.292 | |||

| Applicability of the Combined Pollutant Standard | |||

| 225.293 | |||

| Combined Pollutant Standard: Notice of Intent | |||

225.294 | |||

| Combined Pollutant Standard: Control Technology Requirements and Emissions Standards for Mercury | |||

| 225.295 | |||

| Combined Pollutant Standard: Emissions Standards for NOx and SO2 | |||

| 225.296 | |||

| Combined Pollutant Standard: Control Technology Requirements for NOx, SO2, and PM Emissions | |||

| 225.297 | |||

| Combined Pollutant Standard: Permanent Shut-Downs | |||

225.298 | |||

| Combined Pollutant Standard: Requirements for NOx and SO2 Allowances | |||

| 225.299 | |||

| Combined Pollutant Standard: Clean Air Act Requirements |

| SUBPART C: CLEAN AIR ACT INTERSTATE RULE (CAIR) SO2 TRADING PROGRAM | |

| Section | |

| 225.300 | Purpose |

| 225.305 | Applicability |

| 225.310 | |

| Compliance Requirements | |

| 225.315 | |

| Appeal Procedures | |

| 225.320 | |

| Permit Requirements | |

225.325 | |

| Trading Program | |

| SUBPART D: CAIR NOx ANNUAL TRADING PROGRAM | |

| Section | |

| 225.400 | Purpose |

| 225.405 | Applicability |

| 225.410 | Compliance Requirements |

| 225.415 | Appeal Procedures |

| 225.420 | Permit Requirements |

| 225.425 | Annual Trading Budget |

| 225.430 | Timing for Annual Allocations |

| 225.435 | Methodology for Calculating Annual Allocations |

| 225.440 | Annual Allocations |

| 225.445 | New Unit Set-Aside (NUSA) |

| 225.450 | Monitoring, Recordkeeping and Reporting Requirements for Gross Electrical Output and Useful Thermal Energy |

| 225.455 | Clean Air Set-Aside (CASA) |

| 225.460 | Energy Efficiency and Conservation, Renewable Energy, and Clean Technology Projects |

| 225.465 | Clean Air Set-Aside (CASA) Allowances |

| 225.470 | Clean Air Set-Aside (CASA) Applications |

| 225.475 | Agency Action on Clean Air Set-Aside (CASA) Applications |

| 225.480 | Compliance Supplement Pool |

| SUBPART E: CAIR NOx OZONE SEASON TRADING PROGRAM | |

| Section | |

| 225.500 | Purpose |

| 225.505 | Applicability |

| 225.510 | Compliance Requirements |

| 225.515 | Appeal Procedures |

| 225.520 | Permit Requirements |

| 225.525 | Ozone Season Trading Budget |

| 225.530 | Timing for Ozone Season Allocations |

| 225.535 | Methodology for Calculating Ozone Season Allocations |

| 225.540 | Ozone Season Allocations |

| 225.545 | New Unit Set-Aside (NUSA) |

| 225.550 | Monitoring, Recordkeeping and Reporting Requirements for Gross Electrical Output and Useful Thermal Energy |

| 225.555 | Clean Air Set-Aside (CASA) |

| 225.560 | Energy Efficiency and Conservation, Renewable Energy, and Clean Technology Projects |

| 225.565 | Clean Air Set-Aside (CASA) Allowances |

| 225.570 | Clean Air Set-Aside (CASA) Applications |

| 225.575 | Agency Action on Clean Air Set-Aside (CASA) Applications |

| SUBPART F: COMBINED POLLUTANT STANDARDS | |

| 225.600 | |

| Purpose (Repealed) | |

| 225.605 | |

| Applicability (Repealed) | |

| 225.610 | |

| Notice of Intent (Repealed) | |

225.615 | |

| Control Technology Requirements and Emissions Standards for Mercury (Repealed) | |

| 225.620 | |

| Emissions Standards for NOx and SO2 (Repealed) | |

| 225.625 | |

| Control Technology Requirements for NOx, SO2, and PM Emissions (Repealed) | |

| 225.630 | |

| Permanent Shut Downs (Repealed) | |

225.635 | |

| Requirements for CAIR SO2, CAIR NOx, and CAIR NOx Ozone Season Allowances (Repealed) | |

| 225.640 | |

| Clean Air Act Requirements (Repealed) | |

225.APPENDIX A | |

| Specified EGUs for Purposes of the CPS (Coal-Fired Boilers as of July 1, 2006) | |

| 225.APPENDIX B | |

| Continuous Emission Monitoring Systems for Mercury | |

| 225.EXHIBIT A Specifications and Test Procedures | |

| 225.EXHIBIT B Quality Assurance and Quality Control Procedures | |

| 225.EXHIBIT C Conversion Procedures | |

| 225.EXHIBIT D Quality Assurance and Operating Procedures for Sorbent Trap | |

| Monitoring Systems | |

| AUTHORITY: Implementing and authorized by Section 27 of the Environmental Protection Act [415 ILCS 5/27]. | |

| SOURCE: Adopted in R06-25 at 31 Ill. Reg. 129, effective December 21, 2006; amended in R06-26 at 31 Ill. Reg. 12864, effective August 31, 2007; amended in R09-10 at 33 Ill. Reg. 10427, effective June 26, 2009; amended in R15-21 at 39 Ill. Reg. 16225, effective December 7, 2015; amended in R18-20 at 43 Ill. Reg.9754, effective August 23, 2019. | |

SUBPART A: GENERAL PROVISIONS | |||||

| Section 225.100 | Severability | ||||

| If any Section, subsection or clause of this Part is found invalid, such finding must not affect the validity of this Part as a whole or any Section, subsection or clause not found invalid. | |||||

Section 225.120 Abbreviations and Acronyms | |||||

| Unless otherwise specified within this Part, the abbreviations used in this Part must be the same as those found in 35 Ill. Adm. Code 211. The following abbreviations and acronyms are used in this Part: | |

| Act | Environmental Protection Act [415 ILCS 5] | ||

| ACI | activated carbon injection | ||

| AETB | Air Emission Testing Body | ||

Agency | |||

| Illinois Environmental Protection Agency | |||

| Btu | British thermal unit | ||

| CAA | Clean Air Act [42 USC 7401 et seq.] | ||

| CAAPP | |||

| Clean Air Act Permit Program | |||

| CAIR | Clean Air Interstate Rule | ||

| CASA | Clean Air Set-Aside | ||

| CEMS | |||

| continuous emission monitoring system | |||

| CO2 | |

| carbon dioxide | |

| CPS | |

| Combined Pollutant Standard | |

| CGO | |

| converted gross electrical output | |

| CRM | |

| certified reference materials | |

| CUTE | |

| converted useful thermal energy | |

| DAHS | |

| data acquisition and handling system | |

| dscm | |

| dry standard cubic meters | |

| EGU | |

| electric generating unit | |

| ESP | |

| electrostatic precipitator | |

| FGD | |

| flue gas desulfurization | |

| fpm | |

| feet per minute | |

| GO | |

| gross electrical output | |

| GWh | |

| gigawatt hour | |

| HI | |

| heat input | |

| Hg | |

| mercury | |

| hr | |

| hour | |

| ISO | |

| International Organization for Standardization | |

| kg | |

| kilogram | |

| lb | |

| pound | |

| MPS | |

| Multi-Pollutant Standard | |

| MSDS | |

| Material Safety Data Sheet | |

| MW | |

| megawatt | |

| Mwe | |

| megawatt electrical | |

| MWh | |

| megawatt hour | |

| NAAQS | |

| National Ambient Air Quality Standards | |

| NIST | |

| National Institute of Standards and Technology | |

| NOx | |

| nitrogen oxides | |

| NTRM | |

| NIST Traceable Reference Material | |

| NUSA | |

| New Unit Set-Aside | |

| ORIS | |

| Office of Regulatory Information Systems | |

| O2 | |

| oxygen | |

| PM2.5 | |

| particles less than 2.5 micrometers in diameter | |

| QA | |

| quality assurance | |

| QAMO | |

| quality-assured monitor operating | |

| QC | |

| quality control | |

| RATA | |

| relative accuracy test audit | |

| RGFM | |

| reference gas flow meter | |

| SO2 | |

| sulfur dioxide | |

| SNCR | |

| selective noncatalytic reduction | |

| TTBS | |

| Temporary Technology Based Standard | |

| TCGO | |

| total converted useful thermal energy | |

| UTE | |

| useful thermal energy | |

| USEPA | |

| United States Environmental Protection Agency | |

| yr | |

| year | |

| (Source: Amended at 33 Ill. Reg. 10427, effective June 26, 2009) | |

Section 225.130 Definitions | |||||

| The following definitions apply for the purposes of this Part. Unless otherwise defined in this Section or a different meaning for a term is clear from its context, the terms used in this Part have the meanings specified in 35 Ill. Adm. Code 211. | |||||

| “Agency” means the Illinois Environmental Protection Agency. [415 ILCS 5/3.105] | |||||

“Averaging demonstration” means, with regard to Subpart B of this Part, a demonstration of compliance that is based on the combined performance of EGUs at two or more sources. | |||||

| “Base Emission Rate” means, for a group of EGUs subject to emission standards for NOx and SO2 pursuant to Section 225.233, the average emission rate of NOx or SO2 from the EGUs, in pounds per million Btu heat input, for calendar years 2003 through 2005 (or, for seasonal NOx, the 2003 through 2005 ozone seasons), as determined from the data collected and quality assured by the USEPA, pursuant to the 40 CFR 72 and 96 federal Acid Rain and NOx Budget Trading Programs, for the emissions and heat input of that group of EGUs. | |||||

| “Board” means the Illinois Pollution Control Board. [415 ILCS 5/3.130] | |||||

| “Boiler” means an enclosed fossil or other fuel-fired combustion device used to produce heat and to transfer heat to recirculating water, steam, or other medium. | |||||

| “Bottoming-cycle cogeneration unit” means a cogeneration unit in which the energy input to the unit is first used to produce useful thermal energy and at least some of the reject heat from the useful thermal energy application or process is then used for electricity production. | |||||

“CAIR authorized account representative” means, for the purpose of general accounts, a responsible natural person who is authorized, in accordance with 40 CFR 96, subparts BB, FF, BBB, FFF, BBBB, and FFFF to transfer and otherwise dispose of CAIR NOx, SO2, and NOx Ozone Season allowances, as applicable, held in the CAIR NOx, SO2, and NOx Ozone Season general account, and for the purpose of a CAIR NOx compliance account, a CAIR SO2 compliance account, or a CAIR NOx Ozone Season compliance account, the CAIR designated representative of the source. | |||||

“CAIR designated representative” means, for a CAIR NOx source, a CAIR SO2 source, and a CAIR NOx Ozone Season source and each CAIR NOx unit, CAIR SO2 unit and CAIR NOx Ozone Season unit at the source, the natural person who is authorized by the owners and operators of the source and all such units at the source, in accordance with 40 CFR 96, subparts BB, FF, BBB, FFF, BBBB, and FFFF as applicable, to represent and legally bind each owner and operator in matters pertaining to the CAIR NOx Annual Trading Program, CAIR SO2 Trading Program, and CAIR NOx Ozone Season Trading Program, as applicable. For any unit that is subject to one or more of the following programs: CAIR NOx Annual Trading Program, CAIR SO2 Trading Program, CAIR NOx Ozone Season Trading Program, or the federal Acid Rain Program, the designated representative for the unit must be the same natural person for all programs applicable to the unit. | |||||

“Coal” means any solid fuel classified as anthracite, bituminous, subbituminous, or lignite by the American Society for Testing and Materials (ASTM) Standard Specification for Classification of Coals by Rank D388-77, 90, 91, 95, 98a, or 99 (Reapproved 2004). | |||||

“Coal-derived fuel” means any fuel (whether in a solid, liquid or gaseous state) produced by the mechanical, thermal, or chemical processing of coal. | |||||

| “Coal-fired” means: | |||||

| For purposes of Subpart | |||||

| Except as provided above, combusting any amount of coal or coal-derived fuel, alone or in combination with any amount of any other fuel. | |||||

| “Cogeneration unit” means, for the purposes of Subparts C, D, and E, a stationary, fossil fuel-fired boiler or a stationary, fossil fuel-fired combustion turbine of which both of the following conditions are true: | |||||

| It uses equipment to produce electricity and useful thermal energy for industrial, commercial, heating, or cooling purposes through the sequential use of energy; and | |||||

| It produces either of the following during the 12-month period beginning on the date the unit first produces electricity and during any subsequent calendar year after that in which the unit first produces electricity: | |||||

| For a topping-cycle cogeneration unit, both of the following: | |||||

Useful thermal energy not less than five percent of total energy output; and | |||||

| Useful power that, when added to one-half of useful thermal energy produced, is not less than 42.5 percent of total energy input, if useful thermal energy produced is 15 percent or more of total energy output, or not less than 45 percent of total energy input if useful thermal energy produced is less than 15 percent of total energy output; or | |||||

| For a bottoming-cycle cogeneration unit, useful power not less than 45 percent of total energy input. | |||||

“Combined cycle system” means a system comprised of one or more combustion turbines, heat recovery steam generators, and steam turbines configured to improve overall efficiency of electricity generation or steam production. | |||||

| “Combustion turbine” means: | |||||

An enclosed device comprising a compressor, a combustor, and a turbine and in which the flue gas resulting from the combustion of fuel in the combustor passes through the turbine, rotating the turbine; and | |||||

If the enclosed device described in the above paragraph of this definition is combined cycle, any associated duct burner, heat recovery steam generator and steam turbine. | |||||

| “Commence commercial operation” means, for the purposes of Subpart | |||||

“Commence construction” means, for the purposes of Section 225.460(f), 225.470, 225.560(f), and 225.570, that the owner or owner’s designee has obtained all necessary preconstruction approvals (e.g., zoning) or permits and either has: | |||||

| Begun, or caused to begin, a continuous program of actual on-site construction of the source, to be completed within a reasonable time; or | |||||

| Entered into binding agreements or contractual obligations, which cannot be cancelled or modified without substantial loss to the owner or operator, to undertake a program of actual construction of the source to be completed within a reasonable time. | |||||

| For purposes of this definition: | |||||

| “Construction” shall be determined as any physical change or change in the method of operation, including but not limited to fabrication, erection, installation, demolition, or modification of projects eligible for CASA allowances, as set forth in Sections 225.460 and 225.560. | |

| “A reasonable time” shall be determined considering but not limited to the following factors: the nature and size of the project, the extent of design engineering, the amount of off-site preparation, whether equipment can be fabricated or can be purchased, when the project begins (considering both the seasonal nature of the construction activity and the existence of other projects competing for construction labor at the same time, the place of the environmental permit in the sequence of corporate and overall governmental approval), and the nature of the project sponsor (e.g., private, public, regulated). | |

| “Commence operation”, for purposes of Subparts C, D and E, means: | |

To have begun any mechanical, chemical, or electronic process, including, for the purpose of a unit, start-up of a unit’s combustion chamber, except as provided in 40 CFR 96.105, 96.205, or 96.305, as incorporated by reference in Section 225.140. | |

| For a unit that undergoes a physical change (other than replacement of the unit by a unit at the same source) after the date the unit commences operation as set forth in the first paragraph of this definition, such date will remain the date of commencement of operation of the unit, which will continue to be treated as the same unit. | |

| For a unit that is replaced by a unit at the same source (e.g., repowered), after the date the unit commences operation as set forth in the first paragraph of this definition, such date will remain the replaced unit’s date of commencement of operation, and the replacement unit will be treated as a separate unit with a separate date for commencement of operation as set forth in this definition as appropriate. | |

| “Common stack” means a single flue through which emissions from two or more units are exhausted. | |

| “Compliance account” means: | |

| For the purposes of Subparts D and E, a CAIR NOx Allowance Tracking System account, established by USEPA for a CAIR NOx source or CAIR NOx Ozone Season source pursuant to 40 CFR 96, subparts FF and FFFF in which any CAIR NOx allowance or CAIR NOx Ozone Season allowance allocations for the CAIR NOx units or CAIR NOx Ozone Season units at the source are initially recorded and in which are held any CAIR NOx or CAIR NOx Ozone Season allowances available for use for a control period in order to meet the source’s CAIR NOx or CAIR NOx Ozone Season emissions limitations in accordance with Sections 225.410 and 225.510, and 40 CFR 96.154 and 96.354, as incorporated by reference in Section 225.140. CAIR NOx allowances may not be used for compliance with the CAIR NOx Ozone Season Trading Program and CAIR NOx Ozone Season allowances may not be used for compliance with the CAIR NOx Annual Trading Program; or | |

| For the purposes of Subpart C, a “compliance account” means a CAIR SO2 compliance account, established by the USEPA for a CAIR SO2 source pursuant to 40 CFR 96, subpart FFF, in which any SO2 units at the source are initially recorded and in which are held any SO2 allowances available for use for a control period in order to meet the source’s CAIR SO2 emissions limitations in accordance with Section 225.310 and 40 CFR 96.254, as incorporated by reference in Section 225.140. | |

“Control period” means: | |

For the CAIR SO2 and NOx Annual Trading Programs in Subparts C and D, the period beginning January 1 of a calendar year, except as provided in Sections 225.310(d)(3) and 225.410(d)(3), and ending on December 31 of the same year, inclusive; or | |

| For the CAIR NOx Ozone Season Trading Program in Subpart E, the period beginning May 1 of a calendar year, except as provided in Section 225.510(d)(3), and ending on September 30 of the same year, inclusive. | |

| “Electric generating unit” or “EGU” means a fossil fuel-fired stationary boiler, combustion turbine or combined cycle system that serves a generator that has a nameplate capacity greater than 25 MWe and produces electricity for sale. | |

| “Excepted monitoring system” means a sorbent trap monitoring system, as defined in this S | |

| “Flue” means a conduit or duct through which gases or other matter is exhausted to the atmosphere. | |

| “Fossil fuel” means natural gas, petroleum, coal, or any form of solid, liquid, or gaseous fuel derived from such material. | |

| “Fossil fuel-fired” means the combusting of any amount of fossil fuel, alone or in combination with any other fuel in any calendar year. | |

| “Generator” means a device that produces electricity. | |

| “Gross electrical output” means the total electrical output from an EGU before making any deductions for energy output used in any way related to the production of energy. For an EGU generating only electricity, the gross electrical output is the output from the turbine/generator set. | |

| “Heat input” means, for the purposes of Subparts C, D, and E, a specified period of time, the product (in mmBtu/hr) of the gross calorific value of the fuel (in Btu/lb) divided by 1,000,000 Btu/mmBtu and multiplied by the fuel feed rate into a combustion device (in lb of fuel/time), as measured, recorded and reported to USEPA by the CAIR designated representative and determined by USEPA in accordance with 40 CFR 96, subpart HH, HHH, or HHHH, if applicable, and excluding the heat derived from preheated combustion air, recirculated flue gases, or exhaust from other sources. | |

| “Higher heating value” or “HHV” means the total heat liberated per mass of fuel burned (Btu/lb), when fuel and dry air at standard conditions undergo complete combustion and all resultant products are brought to their standard states at standard conditions. | |

“Input mercury” means the mass of mercury that is contained in the coal combusted within an EGU. | |

“Integrated gasification combined cycle” or “IGCC” means a coal-fired electric utility steam generating unit that burns a synthetic gas derived from coal in a combined-cycle gas turbine. No coal is directly burned in the unit during operation. | |

| “Long-term cold storage” means the complete shutdown of a unit intended to last for an extended period of time (at least two calendar years) where notice for long-term cold storage is provided under 40 CFR 75.61(a)(7). | |

| “Nameplate capacity” means, starting from the initial installation of a generator, the maximum electrical generating output (in MWe) that the generator is capable of producing on a steady-state basis and during continuous operation (when not restricted by seasonal or other deratings) as of such installation as specified by the manufacturer of the generator or, starting from the completion of any subsequent physical change in the generator resulting in an increase in the maximum electrical generating output (in MWe) that the generator is capable of producing on a steady-state basis and during continuous operation (when not restricted by seasonal or other deratings), such increased maximum amount as of completion as specified by the person conducting the physical change. | |

| “NIST traceable elemental mercury standards” means either: | |

| 1) | Compressed gas cylinders having known concentrations of elemental mercury, which have been prepared according to the "EPA Traceability Protocol for Assay and Certification of Gaseous Calibration Standards"; or |

| 2) | Calibration gases having known concentrations of elemental mercury, produced by a generator that fully meets the performance requirements of the "EPA Traceability Protocol for Qualification and Certification of Elemental Mercury Gas Generators," or an interim version of that protocol until such time as a final protocol is issued. |

| “NIST traceable source of oxidized mercury” means a generator that is capable of providing known concentrations of vapor phase mercuric chloride (HgCl2), and that fully meets the performance requirements of the "EPA Traceability Protocol for Qualification and Certification of Mercuric Chloride Gas Generators," or an interim version of that protocol until such time as a final protocol is issued. | |

| “Oil-fired unit” means a unit combusting fuel oil for more than 15.0 percent of the annual heat input in a specified year and not qualifying as coal-fired. | |

“Output-based emission standard” means, for the purposes of Subpart B of this Part, a maximum allowable rate of emissions of mercury per unit of gross electrical output from an EGU. | |

| “Potential electrical output capacity” means 33 percent of a unit’s maximum design heat input, expressed in mmBtu/hr divided by 3.413 mmBtu/MWh, and multiplied by 8,760 hr/yr. | |

| “Project sponsor” means a person or an entity, including but not limited to the owner or operator of an EGU or a not-for-profit group, that provides the majority of funding for an energy efficiency and conservation, renewable energy, or clean technology project as listed in Sections 225.460 and 225.560, unless another person or entity is designated by a written agreement as the project sponsor for the purpose of applying for NOx allowances or NOx Ozone Season allowances from the CASA. | |

| “Rated-energy efficiency” means the percentage of thermal energy input that is recovered as useable energy in the form of gross electrical output, useful thermal energy, or both that is used for heating, cooling, industrial processes, or other beneficial uses as follows: | |

| For electric generators, rated-energy efficiency is calculated as one kilowatt hour (3,413 Btu) of electricity divided by the unit’s design heat rate using the higher heating value of the fuel, and expressed as a percentage. | |

| For combined heat and power projects, rated-energy efficiency is calculated using the following formula: | |

| REE | = ((GO + UTE)/HI) ´ 100 |

| Where: | |

| REE | = | Rated-energy efficiency, expressed as percentage. |

| GO | = | Gross electrical output of the system expressed in Btu/hr. |

| UTE | = | Useful thermal output from the system that is used for heating, cooling, industrial processes or other beneficial uses, expressed in Btu/hr. |

| HI | = Heat input, based upon the higher heating value of fuel, in Btu/hr. |

| “Repowered” means, for the purposes of an EGU, replacement of a coal-fired boiler with one of the following coal-fired technologies at the same source as the coal-fired boiler: | |

| Atmospheric or pressurized fluidized bed combustion; | |

| Integrated gasification combined cycle; | |

| Magnetohydrodynamics; | |

| Direct and indirect coal-fired turbines; | |

| Integrated gasification fuel cells; or | |

As determined by the USEPA in consultation with the United States Department of Energy, a derivative of one or more of the technologies under this definition and any other coal-fired technology capable of controlling multiple combustion emissions simultaneously with improved boiler or generation efficiency and with significantly greater waste reduction relative to the performance of technology in widespread commercial use as of January 1, 2005. | |

| “Rolling 12-month basis” means, for the purposes of Subpart | |

“Sorbent Trap Monitoring System” means the equipment required by Appendix B of this Part for the continuous monitoring of Hg emissions, using paired sorbent traps containing iodated charcoal (IC) or other suitable reagents. This excepted monitoring system consists of a probe, the paired sorbent traps, an umbilical line, moisture removal components, an air tight sample pump, a gas flow meter, and an automated data acquisition and handling system. The monitoring system samples the stack gas at a rate proportional to the stack gas volumetric flowrate. The sampling is a batch process. Using the sample volume measured by the gas flow meter and the results of the analyses of the sorbent traps, the average mercury concentration in the stack gas for the sampling period is determined | |

| “Total energy output” means, with respect to a cogeneration unit, the sum of useful power and useful thermal energy produced by the cogeneration unit. | |

| “Useful thermal energy” means, for the purpose of a cogeneration unit, the thermal energy that is made available to an industrial or commercial process, excluding any heat contained in condensate return or makeup water: | |

| Used in a heating application (e.g., space heating or domestic hot water heating); or | |

| Used in a space cooling application (e.g., thermal energy used by an absorption chiller). | |

(Source: Amended at 33 Ill. Reg. 10427, effective June 26, 2009) | |||||

Section 225.140 Incorporations by Reference | |||||

| The following materials are incorporated by reference. These incorporations do not include any later amendments or editions. |

| a) | Appendices A-1 through A-8, subpart A, and Performance Specifications 2 and 3 of appendix B of 40 CFR 60 (2005). | ||||

| b) | 40 CFR 72.2 (2005). | ||||

| c) | 40 CFR 75 (2006), Sections 2.1.1.5, 2.1.1.2, 7.7, and 7.8 of Appendix A to 40 CFR 75, Appendix C to 40 CFR 75, Section 3.3.5 of Appendix F to 40 CFR 75 (2006). | ||

| d) | 40 CFR 78 (2006). | ||

| e) | 40 CFR 96, CAIR SO2Trading Program, subparts AAA (excluding 40 CFR 96.204 and 96.206), BBB, FFF, GGG, and HHH (2006). | ||

| f) | ||

| 40 CFR 96, CAIR NOx Annual Trading Program, subparts AA (excluding 40 CFR 96.104, 96.105(b)(2), and 96.106 | ||

| g) | ||

| 40 CFR 96, CAIR NOx Ozone Season Trading Program, subparts AAAA (excluding 40 CFR 96.304, 96.305(b)(2), and 96.306), BBBB, FFFF, GGGG, and HHHH (2006). | ||

| h) | |

| ASTM. The following methods from the American Society for Testing and Materials, 100 Barr Harbor Drive, P.O. Box C700, West Conshohocken PA 19428-2959, (610) 832-9585: |

| 1) | ||

| ASTM D388-77 (approved February 25, 1977), D388-90 (approved March 30, 1990), D388-91a (approved April 15, 1991), D388-95 (approved January 15, 1995), D388-98a (approved September 10, 1998), or D388-99 (approved September 10, 1999, reapproved in 2004), Classification of Coals by Rank. | ||

| 2) | ||

| ASTM D3173-03, Standard Test Method for Moisture in the Analysis Sample of Coal and Coke (Approved April 10, 2003). | ||

| 3) | ||

| ASTM D3684-01, Standard Test Method for Total Mercury in Coal by the Oxygen Bomb Combustion/Atomic Absorption Method (Approved October 10, 2001). | ||

| 4) | ||

| ASTM D4840-99, Standard Guide for Sampling Chain-of-Custody Procedures (Reapproved 2004). | ||

| 5) | ||

| ASTM D5865-04, Standard Test Method for Gross Calorific Value of Coal and Coke (Approved April 1, 2004). | ||

| 6) | ||

| ASTM D6414-01, Standard Test Method for Total Mercury in Coal and Coal Combustion Residues by Acid Extraction or Wet Oxidation/Cold Vapor Atomic Absorption (Approved October 10, 2001). | ||

| 7) | ||

| ASTM D6722-01, Standard Test Method for Total Mercury in Coal and Coal Combustion Residues by Direct Combustion Analysis (2001). | ||

| 8) | ||

| ASTM D6784-02, Standard Test Method for Elemental, Oxidized, Particle-Bound and Total Mercury in Flue Gas Generated from Coal-Fired Stationary Sources (Ontario Hydro Method) (Approved April 10, 2002). | ||

| 9) | ||

| ASTM D6911-03, Standard Guide for Packaging and Shipping Environmental Samples for Laboratory Analysis. | ||

| 10) | ||

| ASTM D7036-04, Standard Practice for Competence of Air Emission Testing Bodies. | ||

| i) | ||

| Federal Energy Management Program, M&V Guidelines: Measurement and Verification for Federal Energy Projects, US Department of Energy, Office of Energy Efficiency and Renewable Energy, Version 2.2, DOE/GO-102000-0960 (September 2000). | ||

| (Source: Amended at 33 Ill. Reg. 10427, effective June 26, 2009). | |||||

| Section 225.150 | Commence Commercial Operation | ||||

| Commence commercial operation means, for the purposes of Subparts C, D and E, with regard to a unit: | |||||

| a) | To have begun to produce steam, gas, or other heated medium used to generate electricity for sale or use, including test generation, except as provided in 40 CFR 96.105, 96.205, or 96.305, as incorporated by reference in Section 225.140. | ||||

| 1) | For a unit that is a CAIR SO2 unit, CAIR NOx unit, or a CAIR NOx Ozone Season unit pursuant to Sections 225.305, 225.405, and 225.505, respectively, on the date the unit commences commercial operation on the later of November 15, 1990 or the date the unit commences commercial operation as defined in subsection (a) of this Section and that subsequently undergoes a physical change (other than replacement of the unit by a unit at the same source), such date will remain the unit’s date of commencement of commercial operation, which will continue to be treated as the same unit. | ||||

| 2) | For a unit that is a CAIR SO2 unit, CAIR NOx unit, or a CAIR NOx Ozone Season unit pursuant to Sections 225.305, 225.405, and 225.505, respectively, on the later of November 15, 1990 or the date the unit commences commercial operation as defined in subsection (a) of this Section and that is subsequently replaced by a unit at the same source (e.g., repowered), such date will remain the replaced unit’s date of commencement of commercial operation, and the replacement unit will be treated as a separate unit with a separate date for commencement of commercial operation as defined in subsection (a) or (b) of this Section as appropriate. | ||||

| b) | Notwithstanding subsection (a) of this Section and except as provided in 40 CFR 96.105, 96.205, or 96.305 for a unit that is not a CAIR SO2 unit, CAIR NOx unit, or a CAIR NOx Ozone Season unit pursuant to Section 225.305, 225.405, or 225.505, respectively, on the later of November 15, 1990 or the date the unit commences commercial operation as defined in subsection (a) of this Section, the unit’s date for commencement of commercial operation will be the date on which the unit becomes a CAIR SO2 unit, CAIR NOx unit, or CAIR NOx Ozone Season unit pursuant to Section 225.305, 225.405, or 225.505, respectively. | ||||

| 1) | |

| For a unit with a date for commencement of commercial operation as defined in subsection (b) of this Section and that subsequently undergoes a physical change (other than replacement of the unit by a unit at the same source), such date will remain the unit’s date of commencement of commercial operation, which shall continue to be treated as the same unit. | |

| 2) | |

| For a unit with a date for commencement of commercial operation as defined in subsection (b) of this Section and that is subsequently replaced by a unit at the same source (e.g., repowered), such date will remain the replaced unit’s date of commencement of commercial operation, and the replacement unit will be treated as a separate unit with a separate date for commencement of commercial operation as defined in subsection (a) or (b) of this Section as appropriate. | |

| (Source: Added at 31 Ill. Reg. 12864, effective August 31, 2007) | |

| SUBPART B: CONTROL OF MERCURY EMISSIONS FROM COAL-FIRED ELECTRIC GENERATING UNITS | |

| Section 225.200 | Purpose | ||||

| The purpose of this Subpart B is to control the emissions of mercury from coal-fired EGU operating in Illinois. | |

| Section 225.202 Measurement Methods | |

| Measurement of mercury must be according to the following: | |

a) | ||

| Continuous emission monitoring pursuant to Appendix B to this Part or an alternative emissions monitoring system, alternative reference method for measuring emissions, or other alternative to the emissions monitoring and measurement requirements of Sections 225.240 through 225.290, if such alternative is submitted to the Agency in writing and approved in writing by the Manager of the Bureau of Air’s Compliance Section | ||

| b) | ASTM D3173-03, Standard Test Method for Moisture in the Analysis Sample of Coal and Coke (Approved April 10, 2003), incorporated by reference in Section 225.140. | |||

| c) | ASTM D3684-01, Standard Test Method for Total Mercury in Coal by the Oxygen Bomb Combustion/Atomic Absorption Method (Approved October 10, 2001), incorporated by reference in Section 225.140. |

| d) | ||

| ASTM D5865-04, Standard Test Method for Gross Calorific Value of Coal and Coke (Approved April 1, 2004), incorporated by reference in Section 225.140. |

| e) | ASTM D6414-01, Standard Test Method for Total Mercury in Coal and Coal Combustion Residues by Acid Extraction or Wet Oxidation/Cold Vapor Atomic Absorption (Approved October 10, 2001), incorporated by reference in Section 225.140. | |||

| f) | ASTM D6722-01, Standard Test Method for Total Mercury in Coal and Coal Combustion Residues by Direct Combustion Analysis (2001), incorporated by reference in Section 225.140. | |||

| g) | ASTM D6784-02, Standard Test Method for Elemental, Oxidized, Particle-Bound and Total Mercury in Flue Gas Generated from Coal-Fired Stationary Sources (Ontario Hydro Method) (Approved April 10, 2002), incorporated by reference in Section 225.140. | ||||

| h) | Emissions testing pursuant to Methods 29, 30A, and 30B in Appendix A-8 to 40 CFR 60. | ||||

| (Source: Amended at 33 Ill. Reg. 10427, effective June 26, 2009) | |||||

| Section 225.205 | Applicability | ||||

| The following stationary coal-fired boilers and stationary coal-fired combustion turbines, and the stationary boilers listed in Appendix A, regardless of the type of fuel combusted, are EGUs and are subject to this Subpart B: | |||||

| a) | Except as provided in subsection (b) of this Section, a unit serving, at any time since the start-up of the unit's combustion chamber, a generator with nameplate capacity of more than 25 MWe producing electricity for sale. | ||||

| b) | For a unit that qualifies as a cogeneration unit during the 12-month period starting on the date the unit first produces electricity and continues to qualify as a cogeneration unit, a cogeneration unit serving at any time a generator with nameplate capacity of more than 25 MWe and supplying in any calendar year more than one-third of the unit's potential electric output capacity or 219,000 MWh, whichever is greater, to any utility power distribution system for sale. If a unit qualifies as a cogeneration unit during the 12-month period starting on the date the unit first produces electricity but subsequently no longer qualifies as a cogeneration unit, the unit must be subject to subsection (a) of this Section starting on the day on which the unit first no longer qualifies as a cogeneration unit. | ||||

| (Source: Amended at 39 Ill. Reg. 16225, effective December 7, 2015) | |||||

| a) | |

| Permit Requirements. | |

The owner or operator of each source with one or more EGUs subject to this Subpart B at the source must apply for a CAAPP permit that addresses the applicable requirements of this Subpart B. | |

| b) | |

| Monitoring and Testing Requirements. | |

1) | |

| Except as otherwise indicated in this Subpart, the owner or operator of each source and each EGU at the source must comply with either the monitoring requirements of Sections 225.240 through 225.290 of this Subpart B, the periodic emissions testing requirements of Section 225.239 of this Subpart B, or an alternative emissions monitoring system, alternative reference method for measuring emissions, or other alternative to the emissions monitoring and measurement requirements of Sections 225.240 through 225.290, if such alternative is submitted to the Agency in writing and approved in writing by the Manager of the Bureau of Air's Compliance Section. | |

2) | |

| Except as otherwise indicated in this Subpart, the compliance of each EGU with the mercury requirements of Sections 225.230 and 225.237 of this Subpart B must be determined by the emissions measurements recorded and reported in accordance with either Sections 225.240 through 225.290 of this Subpart B, Section 225.239 of this Subpart B, or an alternative emissions monitoring system, alternative reference method for measuring emissions, or other alternative to the emissions monitoring and measurement requirements of Sections 225.240 through 225.290, if such alternative is submitted to the Agency in writing and approved in writing by the Manager of the Bureau of Air's Compliance Section. | |

| c) | |

| Mercury Emission Reduction Requirements | |

The owner or operator of any EGU subject to this Subpart B must comply with applicable requirements for control of mercury emissions of Section 225.230 or Section 225.237 of this Subpart B. | |

| d) | |

| Recordkeeping and Reporting Requirements | |

Unless otherwise provided, the owner or operator of a source with one or more EGUs at the source must keep on site at the source each of the documents listed in subsections (d)(1) through (d)(3) of this Section for a period of five years from the date the document is created. This period may be extended, in writing by the Agency, for cause, at any time prior to the end of five years. | |

1) | |

| All emissions monitoring information gathered in accordance with Sections 225.240 through 225.290 and all periodic emissions testing information gathered in accordance with Section 225.239. | |

2) | |

| Copies of all reports, compliance certifications, and other submissions and all records made or required or documents necessary to demonstrate compliance with the requirements of this Subpart B. | |

3) | |

| Copies of all documents used to complete a permit application and any other submission under this Subpart B. | |

| e) | |

| Liability. | |

1) | |

| The owner or operator of each source with one or more EGUs must meet the requirements of this Subpart B. | |

2) | |

| Any provision of this Subpart B that applies to a source must also apply to the owner and operator of such source and to the owner or operator of each EGU at the source. | |

3) | |

| Any provision of this Subpart B that applies to an EGU must also apply to the owner or operator of such EGU. | |

f) | |

| Effect on Other Authorities. No provision of this Subpart B may be construed as exempting or excluding the owner or operator of a source or EGU from compliance with any other provision of an approved State Implementation Plan, a permit, the Act, or the CAA. | |

| (Source: Amended at 39 Ill. Reg. 16225, effective December 7, 2015) | |

| Section 225.220 Clean Air Act Permit Program (CAAPP) Permit Requirements | |

| a) | Application Requirements. |

| 1) | Each source with one or more EGUs subject to the requirements of this Subpart B is required to submit a CAAPP permit application that addresses all applicable requirements of this Subpart B, applicable to each EGU at the source. |

| 2) | For any EGU that commenced commercial operation: |

| A) | on or before December 31, 2008, the owner or operator of such EGUs must submit an initial permit application or application for CAAPP permit modification that meets the requirements of this Section on or before December 31, 2008. |

| B) | after December 31, 2008, the owner or operator of any such EGU must submit an initial CAAPP permit application or application for CAAPP modification that meets the requirements of this Section not later than 180 days before initial startup of the EGU, unless the construction permit issued for the EGU addresses the requirements of this Subpart B. |

| b) | Contents of Permit Applications. |

In addition to other information required for a complete application for CAAPP permit or CAAPP permit modification, the application must include the following information: | |

| 1) | The ORIS (Office of Regulatory Information Systems) or facility code assigned to the source by the U.S. Department of Energy, Energy Information Administration, if applicable. |

| 2) | Identification of each EGU at the source. |

| 3) | The intended approach to the monitoring requirements of Sections 225.240 through 225.290 of this Subpart B, or, in the alternative, the applicant may include its intended approach to the testing requirement of Section 225.239 of this Subpart B. |

| 4) | The intended approach to the mercury emission reduction requirements of Section 225.230 or 225.237 of this Subpart B, as applicable. |

| c) | Permit Contents. |

| 1) | Each CAAPP permit issued by the Agency for a source with one or more EGUs subject to the requirements of this Subpart B must contain federally enforceable conditions addressing all applicable requirements of this Subpart B, which conditions must be a complete and segregable portion of the source’s entire CAAPP permit. |

| 2) | In addition to conditions related to the applicable requirements of this Subpart B, each such CAAPP permit must also contain the information specified under subsection (b) of this Section. |

(Source: Amended at 33 Ill. Reg. 10427, effective June 26, 2009) | |

| Section 225.230 Emission Standards for EGUs at Existing Sources | |

| a) | Emission Standards. |

| 1) | Except as provided in Sections 225.230(b) and (d), 225.232 through 225. 235, 225.239, and 225.291 through 225.299 of this Subpart B, beginning July 1, 2009, the owner or operator of a source with one or more EGUs subject to this Subpart B that commenced commercial operation on or before December 31, 2008, must comply with one of the following standards for each EGU on a rolling 12-month basis: |

| A) | An emission standard of 0.0080 lb mercury/GWh gross electrical output; or |

| B) | A minimum 90-percent reduction of input mercury. |

| 2) | For an EGU complying with subsection (a)(1)(A) of this Section, the mercury emission rate during quality-assured monitor operating (QAMO) hours of the EGU for each 12-month rolling period, as monitored in accordance with this Subpart B and calculated as follows, must not exceed the applicable emission standard: |

| Where: | |

| ER= | Mercury emissions rate of the EGU during QAMO hours for the particular 12-month rolling period, expressed in lb/GWh. | |

| Ei = | Mercury emissions of the EGU during QAMO hours, in lbs, in an individual month in the 12-month rolling period, as determined in accordance with the emissions monitoring provisions of this Subpart B. | |

| Oi = | Gross electrical output of the EGU during QAMO hours, in GWh, in an individual month in the 12-month rolling period, as determined in accordance with Section 225.263 of this Subpart B. | |

| 3) | For an EGU complying with subsection (a)(1)(B) of this Section, the actual control efficiency for mercury emissions achieved by the EGU for each 12-month rolling period, as monitored in accordance with this Subpart B and calculated as follows, must meet or exceed the applicable efficiency requirement: | |

| Where: | ||

| CE = | |

| Control efficiency for mercury emissions of the EGU during QAMO hours for the particular 12-month rolling period, expressed as a percent. | |

| Ei = | |

| Mercury emissions of the EGU, in lbs during QAMO hours, in an individual month in the 12-month rolling period, as determined in accordance with the emissions monitoring provisions of this Subpart B. | |

| Ii = | Amount of mercury in the fuel fired in the EGU during QAMO hours, in lbs, in an individual month in the 12-month rolling period, as determined in accordance with Section 225.265 of this Subpart B. Ii is determined by multiplying the amount of mercury in the fuel fired in the EGU in month i by the number of QAMO hours in that month, and dividing that product by the number of EGU operating hours in that month. |

| b) | Alternative Emission Standards for Single EGUs. |

| 1) | As an alternative to compliance with the emission standards in subsection (a) of this Section, the owner or operator of the EGU may comply with the emission standards of this Subpart B by demonstrating that the emissions of mercury from the EGU are less than the allowable emissions of mercury from the EGU on a rolling 12-month basis. |

| 2) | For the purpose of demonstrating compliance with the alternative emission standards of this subsection (b), for each rolling 12-month period, the emissions of mercury from the EGU, as monitored in accordance with this Subpart B, must not exceed the allowable emissions of mercury from the EGU, as further provided by the following formulas: |

|

| |

| Where: | |

| E12 = Mercury emissions of the EGU during QAMO hours for the particular 12-month rolling period. | |

| A12 = Allowable mercury emissions of the EGU during QAMO hours for the particular 12-month rolling period. | |

| Ei = Mercury emissions of the EGU during QAMO hours in an individual month in the 12-month rolling period. | |

| Ai = Allowable mercury emissions of the EGU during QAMO hours in an individual month in the 12-month rolling period, based on either the input mercury to the unit (AInput i) or the electrical output from the EGU (AOutput i), as selected by the owner or operator of the EGU for that given month. Ai is determined by multiplying the allowable mercury emissions based on either input mercury or electrical output in month i by the number of QAMO hours in that month, and dividing that product by the number of EGU operating hours in that month. | |

| AInput i = Allowable mercury emissions of the EGU in an individual month based on the input mercury to the EGU, calculated as 10.0 percent (or 0.100) of the input mercury to the EGU. | |

| AOutput i = Allowable mercury emissions of the EGU in a particular month based on the electrical output from the EGU, calculated as the product of the output based mercury limit, i.e., 0.0080 lb/GWh, and the electrical output from the EGU, in GWh. | |

| 3) | If the owner or operator of an EGU does not conduct the necessary sampling, analysis, and recordkeeping, in accordance with Section 225.265 of this Subpart B, to determine the mercury input to the EGU, the allowable emissions of the EGU must be calculated based on the electrical output of the EGU. |

c) | |

| If two or more EGUs are served by common stacks and the owner or operator conducts monitoring for mercury emissions in the common stacks, as provided for by Sections 1.14 through 1.18 of Appendix B to this Part, such that the mercury emissions of each EGU are not determined separately, compliance of the EGUs with the applicable emission standards of this Subpart B must be determined as if the EGUs were a single EGU. |

| d) | Alternative Emission Standards for Multiple EGUs. |

| 1) As an alternative to compliance with the emission standards of subsection (a) of this Section, the owner or operator of a source with multiple EGUs may comply with the emission standards of this Subpart B by demonstrating that the emissions of mercury from all EGUs at the source during QAMO hours are less than the allowable emissions of mercury from all EGUs at the source on a rolling 12-month basis. | |

| 2) | For the purposes of the alternative emission standard of subsection (d)(1) of this Section, for each rolling 12-month period, the emissions of mercury from all the EGUs at the source during QAMO hours, as monitored in accordance with this Subpart B, must not exceed the sum of the allowable emissions of mercury from all the EGUs at the source, as further provided by the following formulas: |

| Where: | ||

| ES = Sum of the mercury emissions of the EGUs at the source during QAMO hours. | ||

| AS = Sum of the allowable mercury emissions of the EGUs at the source during QAMO hours. | ||

| Ei = Mercury emissions of an individual EGU at the source during QAMO hours, as determined in accordance with subsection (b)(2) of this Section. | ||

| Ai = Allowable mercury emissions of an individual EGU at the source during QAMO hours, as determined in accordance with subsection (b)(2) of this Section. | ||

| n = Number of EGUs covered by the demonstration. | ||

| 3) | If an owner or operator of a source with two or more EGUs that is relying on this subsection (d) to demonstrate compliance fails to meet the requirements of this subsection (d) in a given 12-month rolling period, all EGUs at such source covered by the compliance demonstration are considered out of compliance with the applicable emission standards of this Subpart B for the entire last month of that period. | |

( Source: Amended at 33 Ill. Reg. 10427, effective June 26, 2009) | ||

Section 225.232 Averaging Demonstrations for Existing Sources | ||

| a) | Through December 31, 2013, as an alternative to compliance with the emission standards of Section 225.230(a) of this Subpart B, the owner or operator of an EGU may comply with the emission standards of this Subpart B by means of an Averaging Demonstration (Demonstration) that demonstrates that the emissions of mercury from the EGU and other EGUs at the source and other EGUs at other sources covered by the Demonstration are less than the allowable emissions of mercury from all EGUs covered by the Demonstration on a rolling 12-month basis. | |

| b) | The EGUs at each source covered by a Demonstration must also comply with one of the following emission standards on a source-wide basis for the period covered by the Demonstration: |

| 1) | An emission standard of 0.020 lb mercury/GWh gross electrical output; or |

| 2) | A minimum 75 percent reduction of input mercury. |

| c) | |

| For the purpose of this Section, compliance must be demonstrated using the equations in Section 225.230(a)(2), (a)(3), or (d)(2), as applicable, addressing all EGUs at the sources covered by the Demonstration, rather than by using only the EGUs at one source. | |

| d) | |

| Limitations on Demonstrations. | |

| 1) | The owners or operators of more than one existing source with EGUs can only participate in Demonstrations that include other existing sources that they own or operate. |

| 2) | Single Existing Source Demonstrations |

| A) The owner or operator of only a single existing source with EGUs (i.e., City, Water, Light & Power, City of Springfield, ID 167120AAO; Kincaid Generating Station, ID 021814AAB; and Southern Illinois Power Cooperative/Marion Generating Station, ID 199856AAC) can only participate in Demonstrations with other such owners or operators of a single existing source of EGUs. |

| B) | |

| Participation in Demonstrations under this Section by the owner or operator of only a single existing source with EGUs must be authorized through federally enforceable permit conditions for each such source participating in the Demonstration. | |

| e) | |

| A source may be included in only one Demonstration during each rolling 12-month period. | |

| f) | |

| The owner or operator of EGUs using Demonstrations to show compliance with this Subpart B must complete the determination of compliance for each 12-month rolling period no later than 60 days following the end of the period. | |

| g) | |

| If averaging is used to demonstrate compliance with this Subpart B, the effect of a failure to demonstrate compliance will be that the compliance status of each source must be determined under Section 225.230 of this Subpart B as if the sources were not covered by a Demonstration. | |

| h) | |

| For purposes of this Section, if the owner or operator of any source that participates in a Demonstration with an owner or operator of a source that does not maintain the required records, data, and reports for the EGUs at the source, or that does not submit copies of such records, data, or reports to the Agency upon request, then the effect of this failure will be deemed to be a failure to demonstrate compliance and the compliance status of each source must be determined under Section 225.230 of this Subpart B as if the sources were not covered by a Demonstration. | |

(Source: Amended at 33 Ill. Reg. 10427, effective June 26, 2009) | |

| Section 225.233 Multi-Pollutant Standards (MPS) | |

a) | |

| General | |

| 1) | |

| As an alternative to compliance with the emissions standards of Section 225.230(a), the owner of eligible EGUs may elect for those EGUs to demonstrate compliance pursuant to this Section, which establishes control requirements and standards for emissions of NOx and SO2, as well as for emissions of mercury. | |

| 2) | For the purpose of this Section, the following requirements apply: | ||

| A) | An eligible EGU is an EGU that is located in Illinois and which commenced commercial operation on or before December 31, 2004; and | ||

| B) | Ownership of an eligible EGU is determined based on direct ownership, by the holding of a majority interest in a company that owns the EGU or EGUs, or by the common ownership of the company that owns the EGU, whether through a parent-subsidiary relationship, as a sister corporation, or as an affiliated corporation with the same parent corporation, provided that the owner has the right or authority to submit a CAAPP application on behalf of the EGU. | ||

| 3) | The owner of one or more EGUs electing to demonstrate compliance with this Subpart B pursuant to this Section must submit an application for a CAAPP permit modification to the Agency, as provided in Section 225.220, that includes the information specified in subsection (b) and which clearly states the owner's election to demonstrate compliance pursuant to this Section 225.233. | ||

| A) | If the owner of one or more EGUs elects to demonstrate compliance with this Subpart pursuant to this Section, then all EGUs it owns in Illinois as of July 1, 2006, as defined in subsection (a)(2)(B), must be thereafter subject to the standards and control requirements of this Section, except as provided in subsection (a)(3)(B). Such EGUs must be referred to as a Multi-Pollutant Standard (MPS) Group. | ||

| B) | Notwithstanding the foregoing, the owner may exclude from an MPS Group any EGU scheduled for permanent shutdown that the owner so designates in its CAAPP application required to be submitted pursuant to subsection (a)(3), with compliance for such units to be achieved by means of Section 225.235. | ||

| 4) | Notwithstanding any contrary provision in this subsection (a), on and after January 1, 2019: | ||

| A) | The following EGUs shall be merged into a new MPS Group: Baldwin Units 1, 2, and 3; Coffeen Units 1 and 2; Duck Creek Unit 1; E.D. Edwards Units 2 and 3; Havana Unit 9; Hennepin Units 1 and 2; Joppa Units 1, 2, 3, 4, 5, and 6; and Newton Unit 1. If one or more of the above EGUs are transferred to a different owner, such EGU or EGUs will become a separate MPS Group on and after the date of transfer. For purposes of this Section, "transfer" means sale, conveyance, transfer, or other change in ownership of an EGU; and | ||

| B) | No other EGUs except for those listed in subsection (a)(4)(A) are subject to the requirements of this Section. | ||

| 5) | When an EGU is subject to the requirements of this Section, the requirements apply to all owners or operators of the EGU. | ||

| b) | Notice of Intent | ||

| The owner of one or more EGUs that intends to comply with this Subpart B by means of this Section must notify the Agency of its intention by December 31, 2007. The following information must accompany the notification: | |||

| 1) | The identification of each EGU that will be complying with this Subpart B by means of the multi-pollutant standards contained in this Section, with evidence that the owner has identified all EGUs that it owned in Illinois as of July 1, 2006 and which commenced commercial operation on or before December 31, 2004; | ||

| 2) | If an EGU identified in subsection (b)(1) is also owned or operated by a person different than the owner submitting the notice of intent, a demonstration that the submitter has the right to commit the EGU or authorization from the responsible official for the EGU accepting the application; | ||

| 3) | The Base Emission Rates for the EGUs, with copies of supporting data and calculations; | ||

| 4) | A summary of the current control devices installed and operating on each EGU and identification of the additional control devices that will likely be needed for the each EGU to comply with emission control requirements of this Section, including identification of each EGU in the MPS group that will be addressed by subsection (c)(1)(B), with information showing that the eligibility criteria for this subsection (b) are satisfied; and | ||

| 5) | Identification of each EGU that is scheduled for permanent shutdown, as provided by Section 225.235, which will not be part of the MPS Group and which will not be demonstrating compliance with this Subpart B pursuant to this Section. | ||

| c) | Control Technology Requirements for Emissions of Mercury | ||

| 1) | Requirements for EGUs in an MPS Group | ||

| A) | For each EGU in an MPS Group other than an EGU that is addressed by subsection (c)(1)(B) for the period beginning July 1, 2009 (or December 31, 2009 for an EGU for which an SO2 scrubber or fabric filter is being installed to be in operation by December 31, 2009), and ending on December 31, 2014 (or such earlier date that the EGU is subject to the mercury emission standard in subsection (d)(1)), the owner or operator of the EGU must install, to the extent not already installed, and properly operate and maintain one of the following emission control devices: | ||

| i) | A Halogenated Activated Carbon Injection System, complying with the sorbent injection requirements of subsection (c)(2) of this Section, except as may be otherwise provided by subsection (c)(4), and followed by a Cold-Side Electrostatic Precipitator or Fabric Filter; or |

| ii) | If the boiler fires bituminous coal, a Selective Catalytic Reduction (SCR) System and an SO2 Scrubber. |

| B) | An owner of an EGU in an MPS Group has two options under this subsection (c). For an MPS Group that contains EGUs smaller than 90 gross MW in capacity, the owner may designate any such EGUs to be not subject to subsection (c)(1)(A). Or, for an MPS Group that contains EGUs with gross MW capacity of less than 115 MW, the owner may designate any such EGUs to be not subject to subsection (c)(1)(A), provided that the aggregate gross MW capacity of the designated EGUs does not exceed 4% of the total gross MW capacity of the MPS Group. For any EGU subject to one of these two options, unless the EGU is subject to the emission standards in subsection (d)(2), beginning on January 1, 2013, and continuing until such date that the owner or operator of the EGU commits to comply with the mercury emission standard in subsection (d)(2), the owner or operator of the EGU must install and properly operate and maintain a Halogenated Activated Carbon Injection System that complies with the sorbent injection requirements of subsection (c)(2), except as may be otherwise provided by subsection (c)(4), and followed by either a Cold-Side Electrostatic Precipitator or Fabric Filter. The use of a properly installed, operated, and maintained Halogenated Activated Carbon Injection System that meets the sorbent injection requirements of subsection (c)(2) is defined as the "principal control technique." |

| 2) | For each EGU for which injection of halogenated activated carbon is required by subsection (c)(1), the owner or operator of the EGU must inject halogenated activated carbon in an optimum manner, which, except as provided in subsection (c)(4), is defined as all of the following: |

| A) | The use of an injection system designed for effective absorption of mercury, considering the configuration of the EGU and its ductwork; |

| B) | The injection of halogenated activated carbon manufactured by Alstom, Norit, or Sorbent Technologies, Calgon Carbon's FLUEPAC CF Plus, or Calgon Carbon's FLUEPAC MC Plus, or the injection of any other halogenated activated carbon or sorbent that the owner or operator of the EGU has demonstrated to have similar or better effectiveness for control of mercury emissions; and |

| C) | The injection of sorbent at the following minimum rates, as applicable: |

| i) | For an EGU firing subbituminous coal, 5.0 lbs per million actual cubic feet or, for any cyclone-fired EGU that will install a scrubber and baghouse by December 31, 2012, and which already meets an emission rate of 0.020 lbs mercury/GWh gross electrical output or at least 75 percent reduction of input mercury, 2.5 lbs per million actual cubic feet; |

| ii) | For an EGU firing bituminous coal, 10.0 lbs per million actual cubic feet for any cyclone-fired EGU that will install a scrubber and baghouse by December 31, 2012, and which already meets an emission rate of 0.020 lbs mercury/GWh gross electrical output or at least 75 percent reduction of input mercury, 5.0 lbs per million actual cubic feet; | ||

| iii) | For an EGU firing a blend of subbituminous and bituminous coal, a rate that is the weighted average of the above rates, based on the blend of coal being fired; or | |

| iv) | A rate or rates set lower by the Agency, in writing, than the rate specified in any of subsections (c)(2)(C)(i), (c)(2)(C)(ii), or (c)(2)(C)(iii) on a unit-specific basis, provided that the owner or operator of the EGU has demonstrated that such rate or rates are needed so that carbon injection will not increase particulate matter emissions or opacity so as to threaten noncompliance with applicable requirements for particulate matter or opacity. | |

| D) | For the purposes of subsection (c)(2)(C), the flue gas flow rate shall be the gas flow rate in the stack for all units except for those equipped with activated carbon injection prior to a hot-side electrostatic precipitator; for units equipped with activated carbon injection prior to a hot-side electrostatic precipitator, the flue gas flow rate shall be the gas flow rate at the inlet to the hot-side electrostatic precipitator, which shall be determined as the stack flow rate adjusted through the use of Charles' Law for the differences in gas temperatures in the stack and at the inlet to the electrostatic precipitator (Vesp = Vstack x Tesp/Tstack, where V = gas flow rate in acf and T = gas temperature in Kelvin or Rankine). |

| 3) | The owner or operator of an EGU that seeks to operate an EGU with an activated carbon injection rate or rates that are set on a unit-specific basis pursuant to subsection (c)(2)(C)(iv) must submit an application to the Agency proposing such rate or rates, and must meet the requirements of subsections (c)(3)(A) and (c)(3)(B), subject to the limitations of subsections (c)(3)(C) and (c)(3)(D): |

| A) | The application must be submitted as an application for a new or revised federally enforceable operating permit for the EGU, and it must include a summary of relevant mercury emission data for the EGU, the unit-specific injection rate or rates that are proposed, and detailed information to support the proposed injection rate or rates; and |

| B) | This application must be submitted no later than the date that activated carbon must first be injected. For example, the owner or operator of an EGU that must inject activated carbon pursuant to subsection (c)(1)(A) must apply for unit-specific injection rate or rates by July 1, 2009. Thereafter, the owner or operator of the EGU may supplement its application; and |

| C) | Any decision of the Agency denying a permit or granting a permit with conditions that set a lower injection rate or rates may be appealed to the Board pursuant to Section 39 of the Act; and |

| D) | The owner or operator of an EGU may operate at the injection rate or rates proposed in its application until a final decision is made on the application, including a final decision on any appeal to the Board. |

| 4) | During any evaluation of the effectiveness of a listed sorbent, an alternative sorbent, or other technique to control mercury emissions, the owner or operator of an EGU need not comply with the requirements of subsection (c)(2) for any system needed to carry out the evaluation, as further provided as follows: | |

| A) | The owner or operator of the EGU must conduct the evaluation in accordance with a formal evaluation program submitted to the Agency at least 30 days prior to commencement of the evaluation; | ||

| B) | The duration and scope of the evaluation may not exceed the duration and scope reasonably needed to complete the desired evaluation of the alternative control technique, as initially addressed by the owner or operator in a support document submitted with the evaluation program; | ||

| C) | The owner or operator of the EGU must submit a report to the Agency no later than 30 days after the conclusion of the evaluation that describes the evaluation conducted and which provides the results of the evaluation; and | ||

| D) | If the evaluation of the alternative control technique shows less effective control of mercury emissions from the EGU than was achieved with the principal control technique, the owner or operator of the EGU must resume use of the principal control technique. If the evaluation of the alternative control technique shows comparable effectiveness to the principal control technique, the owner or operator of the EGU may either continue to use the alternative control technique in a manner that is at least as effective as the principal control technique, or it may resume use of the principal control technique. If the evaluation of the alternative control technique shows more effective control of mercury emissions than the control technique, the owner or operator of the EGU must continue to use the alternative control technique in a manner that is more effective than the principal control technique, so long as it continues to be subject to this subsection (c). |

| 5) | In addition to complying with the applicable recordkeeping and monitoring requirements in Sections 225.240 through 225.290, the owner or operator of an EGU that elects to comply with this Subpart B by means of this Section must also comply with the following additional requirements: |

| A) | For the first 36 months that injection of sorbent is required, it must maintain records of the usage of sorbent, the flue gas flow rate from the EGU (and, if the unit is equipped with activated carbon injection prior to a hot-side electrostatic precipitator, flue gas temperature at the inlet of the hot-side electrostatic precipitator and in the stack), and the sorbent feed rate, in pounds per million actual cubic feet of flue gas, on a weekly average; |

| B) | After the first 36 months that injection of sorbent is required, it must monitor activated sorbent feed rate to the EGU, gas flow rate in the stack, and, if the unit is equipped with activated carbon injection prior to a hot-side electrostatic precipitator, flue gas temperature at the inlet of the hot-side electrostatic precipitator and in the stack. It must automatically record this data and the sorbent carbon feed rate, in pounds per million actual cubic feet of flue gas, on an hourly average; and |

| C) | If a blend of bituminous and subbituminous coal is fired in the EGU, it must keep records of the amount of each type of coal burned and the required injection rate for injection of activated carbon, on a weekly basis. |

| 6) | Until June 30, 2012, as an alternative to the CEMS or excepted monitoring system (sorbent trap system) monitoring, recordkeeping, and reporting requirements in Sections 225.240 through 225.290, the owner or operator of an EGU may elect to comply with the emissions testing, monitoring, recordkeeping, and reporting requirements in Section 225.239(c), (d), (e), (f)(1) and (2), (h)(2), (i)(3) and (4), and (j)(1). |

| 7) | In addition to complying with the applicable reporting requirements in Sections 225.240 through 225.290, the owner or operator of an EGU that elects to comply with this Subpart B by means of this Section must also submit quarterly reports for the recordkeeping and monitoring conducted pursuant to subsection (c)(5). |

| d) | Emission Standards for Mercury | |

| 1) | For each EGU in an MPS Group that is not addressed by subsection (c)(1)(B), beginning January 1, 2015 (or such earlier date when the owner or operator of the EGU notifies the Agency that it will comply with these standards) and continuing thereafter, the owner or operator of the EGU must comply with one of the following standards on a rolling 12-month basis: |

| A) | An emission standard of 0.0080 lb mercury/GWh gross electrical output; or |

| B) | A minimum 90-percent reduction of input mercury. |

| 2) | For each EGU in an MPS Group that has been addressed under subsection (c)(1)(B), beginning on the date when the owner or operator of the EGU notifies the Agency that it will comply with these standards and continuing thereafter, the owner or operator of the EGU must comply with one of the following standards on a rolling 12-month basis: |

| A) | An emission standard of 0.0080 lb mercury/GWh gross electrical output; or |

| B) | A minimum 90-percent reduction of input mercury. |

| 3) | Compliance with the mercury emission standard or reduction requirement of this subsection (d) must be calculated in accordance with Section 225.230(a) or (d), or Section 225.232 until December 31, 2013. | |

| 4) | Until June 30, 2012, as an alternative to demonstrating compliance with the emissions standards in this subsection (d), the owner or operator of an EGU may elect to comply with the emissions testing requirements in Section 225.239(a)(4) and (b), (c), (d), (e), (f), (g), (h), (i), and (j). | |

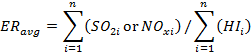

| e) | Emission Standards for NOx and SO2 | |

| 1) | NOx Emission Standards | |

| A) | Beginning in calendar year 2012 and continuing through calendar year 2018, for the EGUs in each MPS Group, the owner and operator of the EGUs must comply with an overall NOx annual emission rate of no more than 0.11 lb/mmBtu or an emission rate equivalent to 52 percent of the Base Annual Rate of NOx emissions, whichever is more stringent. | |

| B) | Beginning in the 2012 ozone season and continuing through the 2018 ozone season, for the EGUs in each MPS Group, the owner and operator of the EGUs must comply with an overall NOx seasonal emission rate of no more than 0.11 lb/mmBtu or an emission rate equivalent to 80 percent of the Base Seasonal Rate of NOx emissions, whichever is more stringent. | |

| C) | Except as otherwise provided in subsections (f), (g), and (h), beginning in calendar year 2019 and continuing in each calendar year thereafter, the owner and operator of the EGUs in an MPS Group must not cause or allow to be discharged into the atmosphere combined annual NOx emissions in excess of 19,000 tons from all EGUs. | |

| D) | Except as otherwise provided in subsections (f), (g), and (h), beginning in calendar year 2019 and continuing in each calendar year thereafter, from May 1 to September 30 the owner and operator of the EGUs in an MPS Group must not cause or allow to be discharged into the atmosphere combined NOx emissions in excess of 11,500 tons from all EGUs. | |

| E) | On and after January 1, 2019, the owner and operator of any of Baldwin Units 1 and 2, Coffeen Units 1 and 2, Duck Creek Unit 1, E.D. Edwards Unit 3, and Havana Unit 9 must comply with the following: | |

| i) | Operate each existing selective catalytic reduction (SCR) control system on each EGU in accordance with good operating practices and at all times when the unit it serves is in operation, provided that such operation of the SCR control system is consistent with the technological limitations, manufacturers' specifications, and good engineering and maintenance practices for the SCR control system. During any such period in which the SCR is not operational, the owner and operator must minimize emissions to the extent reasonably practicable. All NOx emissions from each EGU, regardless of whether the SCR is operational or non-operational, must be included in determining compliance with the emission standards set forth under subsections (e)(1)(C), (e)(1)(D), (f)(1), (g)(1), and (h)(1), as applicable. | |

| ii) | From May 1 through September 30, comply with a combined NOx average emission rate of no more than 0.10 lb/mmBtu. Averaging is only allowed among EGUs in the same MPS Group. | |

| 2) | SO2 Emission Standards | |

| A) | Beginning in calendar year 2013 and continuing in calendar year 2014, for the EGUs in each MPS Group, the owner and operator of the EGUs must comply with an overall SO2 annual emission rate of 0.33 lb/mmBtu or a rate equivalent to 44 percent of the Base Rate of SO2 emissions, whichever is more stringent. | |

| B) | Beginning in calendar year 2015 and continuing through calendar year 2018, for the EGUs in each MPS Group, the owner and operator of the EGUs must comply with an overall annual emission rate for SO2 of 0.25 lbs/mmBtu or a rate equivalent to 35 percent of the Base Rate of SO2 emissions, whichever is more stringent. | |