BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

IN THE MATTER OF:

)

)

PROPOSED NEW CAIR SO

2

, CAIR NO

x

)

R06-26

ANNUAL AND CAIR NO

x

OZONE

)

(Rulemaking – Air)

SEASON TRADING PROGRAMS, 35 ILL.

)

ADM CODE 255, CONTROL OF EMISSIONS

)

FROM LARGE COMBUSTION SOURCES,

)

SUBPARTS A, C, D, AND E

)

Notice of Filing

To:

See Attached Service List

PLEASE TAKE NOTICE that on January 5, 2007, we filed with the Clerk of the Illinois

Pollution Control Board the attached POST-HEARING COMMENTS a copy of which is

attached hereto and hereby served upon you.

Faith E. Bugel

Staff Attorney

Environmental Law & Policy Center

Representing the American Lung Association of Metropolitan Chicago

Keith Harley

Chicago Legal Clinic

Representing Environment Illinois

Bruce Nilles

Sierra Club

Dated: January 5, 2007

1

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

IN THE MATTER OF:

)

)

PROPOSED NEW CAIR SO

2

, CAIR NO

x

)

R06-26

ANNUAL AND CAIR NO

x

OZONE

)

(Rulemaking – Air)

SEASON TRADING PROGRAMS, 35 ILL.

)

ADM CODE 255, CONTROL OF EMISSIONS

)

FROM LARGE COMBUSTION SOURCES,

)

SUBPARTS A, C, D, AND E

)

Post-Hearing Comments

NOW COMES Participants the Environmental Law & Policy Center (“ELPC”), by itself and on

behalf of American Lung Association of Metropolitan Chicago (“ALAMC”); Environment

Illinois, by and through its attorneys the Chicago Legal Clinic; and the Sierra Club (collectively,

“Environmental Advocates”). Pursuant to Hearing Officer’s Order of December 20, 2006, the

following post-hearing comments are submitted to the Illinois Pollution Control Board. Through

these comments, the Environmental Advocates urge that the Illinois Environmental Protection

Agency’s (“IEPA”) proposed Clean Air Interstate Rule (“CAIR”) rule be amended in the

following three ways. The renewable energy and energy efficiency set-asides should be

increased so as to better meet its own renewable energy goals. Secondly, Clean Air Set Aside

(“CASA”) proposed for circulating fluidized bed boilers (“CFBs”) should be removed, as CFBs

are not a clean coal technology. Finally, the fuel weighting factors should be eliminated, as they

discourage the use of cleaner fuels in energy production.

Along with these comments, we are also providing documents requested at the hearing of

November 28, 2006 during the testimony of Charles Kubert.

I.

The Energy Efficiency and Renewable Energy Set Aside Should Be Increased.

2

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

In order to best meet the pollution reduction goals of CAIR and the Governor’s own

renewable energy plan, the renewable energy and energy efficiency (“RE/EE”) set asides in the

IEPA’s CAIR rule proposal must be increased. Encouraging RE/EE projects through allowance

set-asides directly contributes to the stated goals of the CAIR. Specifically, RE/EE allow

replacement and reduction of a portion of the energy need that is currently being delivered to

Illinois consumers through the burning of fossil fuels. This replacement and reduction will result

in a decrease in the burning of fossil fuels, leading to a decrease in Illinois’ emissions of NO

x

and SO

2

.

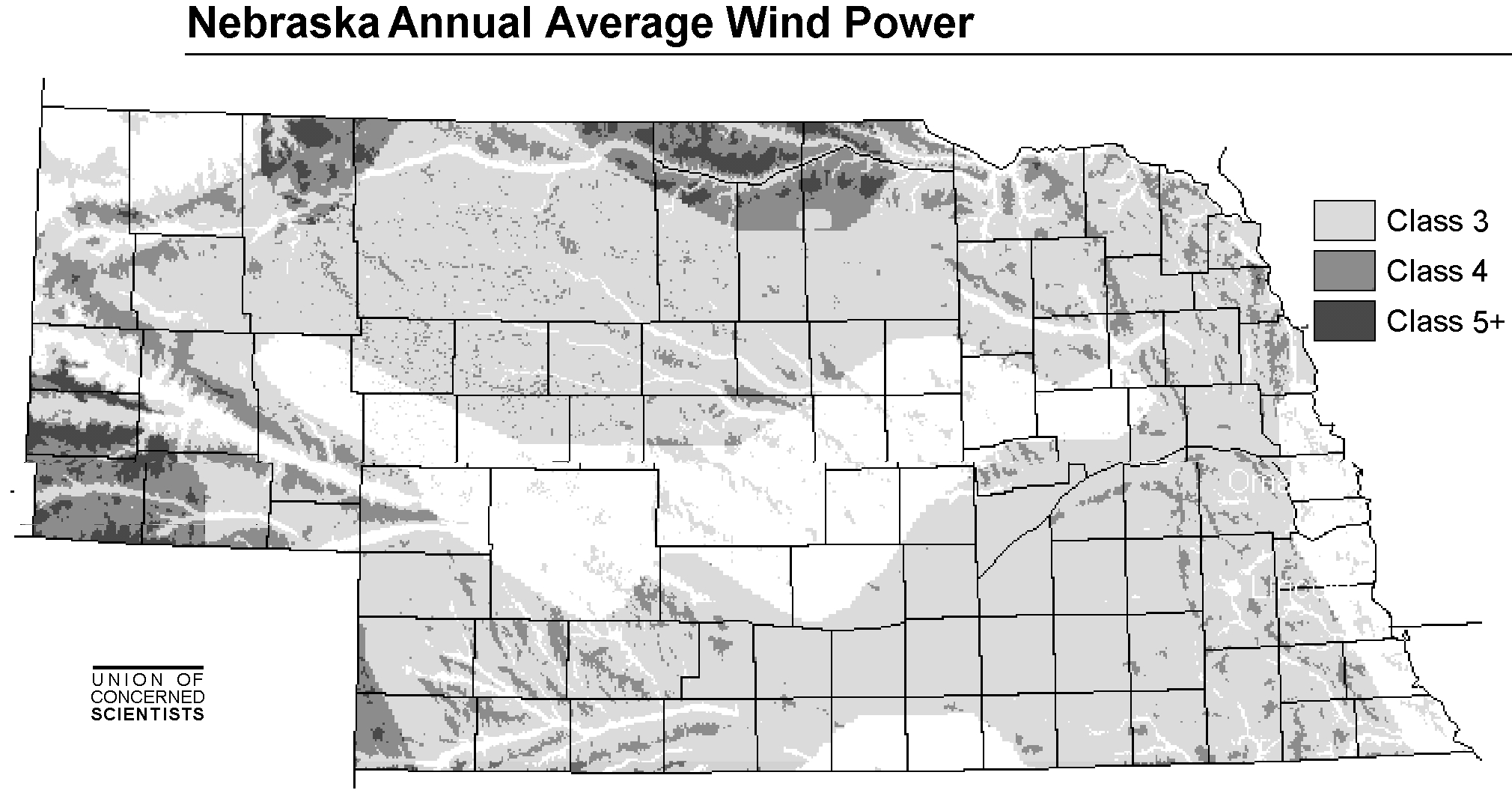

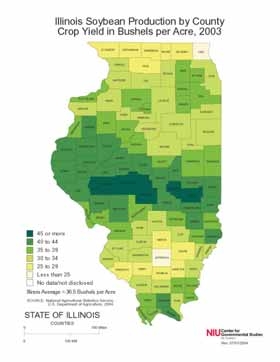

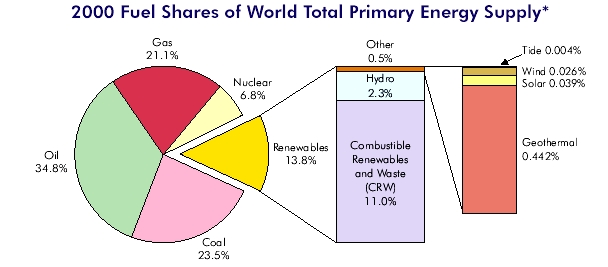

Illinois has great potential for the production of renewable energy from wind, solar

power, and biofuel. Renewable energy production projects will benefit from assignment of

allowances corresponding to the amount of energy they produce. IEPA has acknowledged that

while the Governor’s plan calls for 10% of Illinois energy to come from renewable sources by

2015, the current CAIR proposal will only lead to an offset of 5-8% of future need. (Cooper

10/12/2006 Tr. at 95-97). The renewable energy and energy efficiency set asides included in

CASA, currently set at 12%, should be raised to 15%, with an annual increase of 1% to a

maximum of 20%. This will best allow the Illinois CAIR rule to work toward both the

Governor’s plan and its own goals. (Kubert 11/29/2006 Tr. at 179;

see also

, Kubert 11/28/2006

Am. Test. at 7).

In response to requests made during the November 29, 2006 hearing, documents are

attached to this comment as exhibits. Exhibit 1 (in response to request on 11/29/2006 Tr. at 156)

is a Department of Defense study on the effects of wind turbines on radar. The study concludes

that with proper planning and site selection, any conflict between radar technology and wind

turbines may be mitigated.

3

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

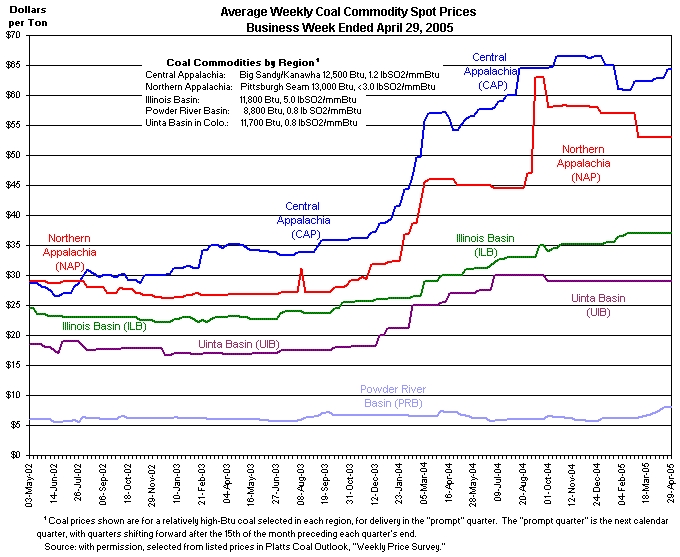

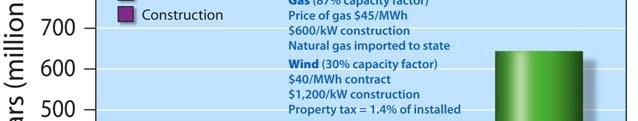

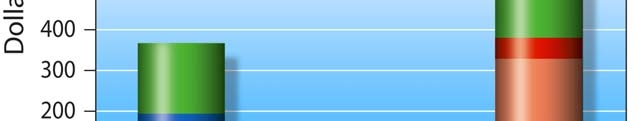

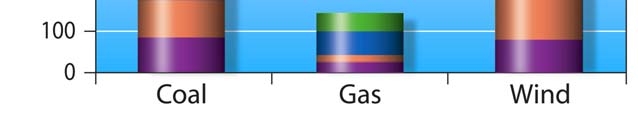

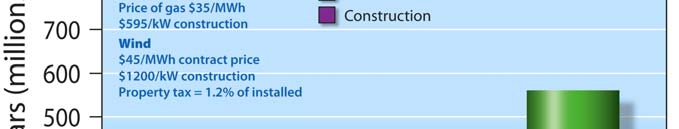

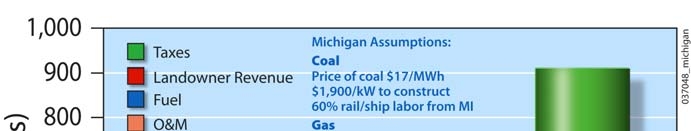

Exhibits 2 and 3 (in response to request on 11/29/2006 Tr. at 158-9) are relevant to the

subject of the economic impact on wind power versus coal power. Exhibit 2 is a report

published by the National Renewable Energy Laboratory. The study concludes that “adding new

wind power can be more economically effective than adding new gas or coal power and that a

higher percentage of dollars spent on coal and gas will leave the state.” Exhibit 3 is a study by

the Union of Concerned Scientists. The study shows that developing wind power instead of coal

and natural gas power can have a net benefit to a state’s economy.

Exhibit 4 (in response to request on 11/29/2006 Tr. at 172-3) includes the press release

and presentation by the office of Governor Blagojevich of his plan for the future development of

energy in Illinois. This plan calls for meeting 10% of Illinois’ electricity needs with renewable

resources by 2015.

Exhibit 5 (in response to request on 11/29/2006 Tr. at 157) is a document from the

Energy Information Administration comparing the generation costs of wind power, new coal,

and natural gas, among other energy sources and shows that the generation costs of RE/EE are

competitive with coal.

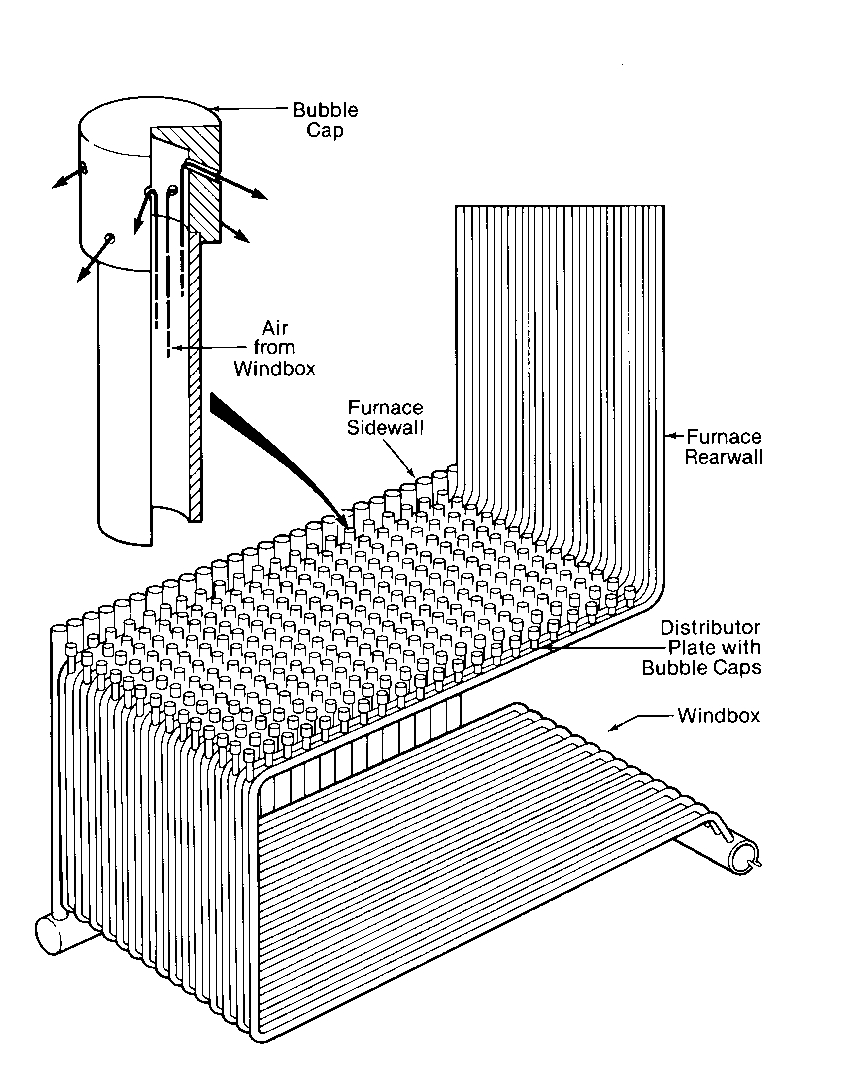

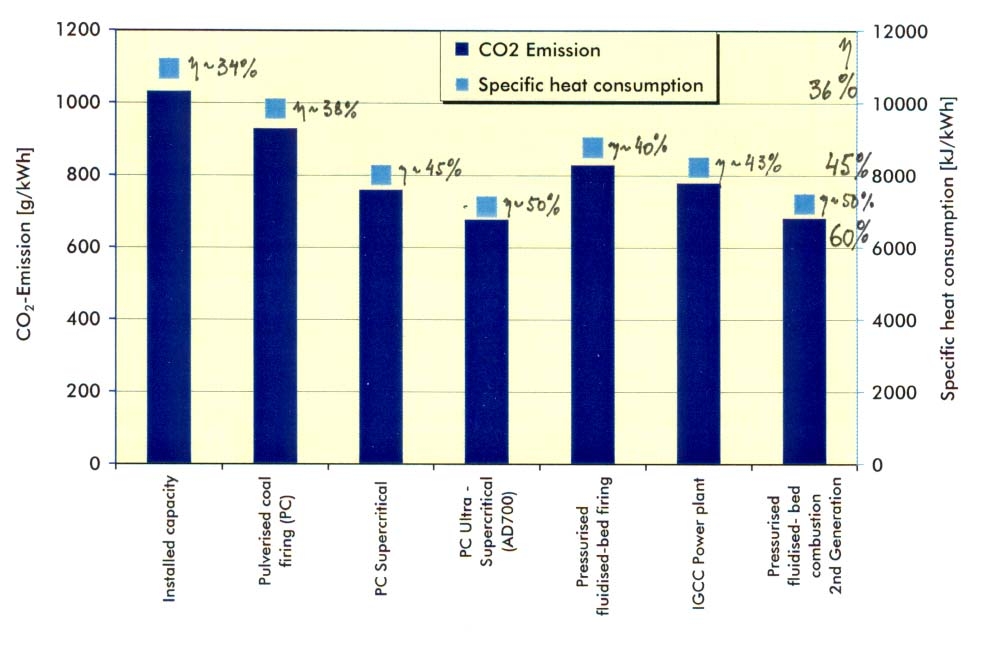

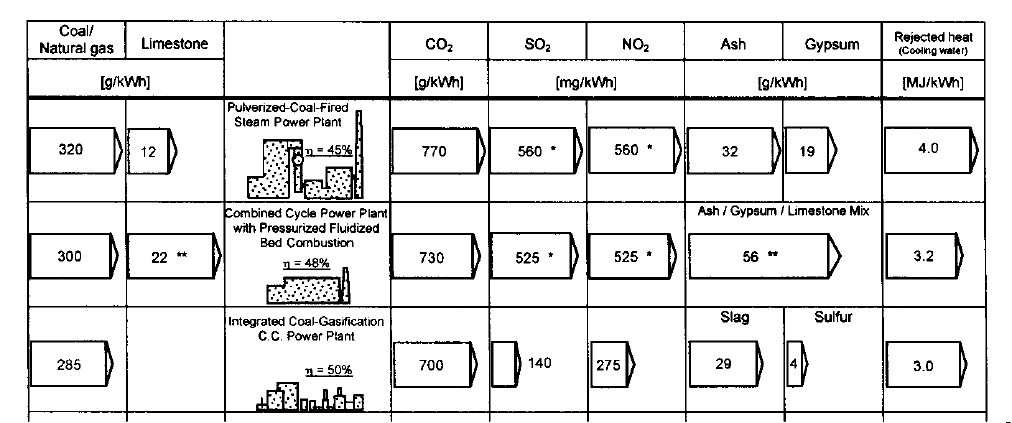

The Rule Should Not Provide Incentives for Circulating Fluidized Bed Boilers.

Circulating fluidized bed boilers (“CFBs”) should not receive CASA credits. Why?

•

Controlled CFBs are not lower in NO

x

emissions than controlled pulverized coal (“PC”)

boilers;

•

CFBs do not achieve the low NO

x

emissions that IGCC plants do; and

•

CFBs emit more greenhouse gases than PC boilers.

IEPA’s explanation of its reason for including CFBs in the CASA makes clear the lack of

justification for CFBs receiving CASA credits. Aside from the unsubstantiated assertions that

4

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

CFBs “result in very low pollutant emissions,” and “very low emission that can be achieved”

with CFBs, the Technical Support Document for IEPA’s proposed rule (“TSD”) contains no

support for giving incentive credits to CFBs. (TSD at 112.) IEPA was apparently merely

responding to concerns of “the coal-fired power plants for fluidized bed boilers” and “listened to

concerns there, that there should be some set-asides available to them, and, in fact, we [IEPA] do

provide some set-asides to fluidized bed boilers.” (Ross, 10/10/2006, 9:00 A.M., Tr. at 46-47.)

In addition, these concerns apparently came from an existing CFB because the IEPA “in

particular, for the fluidized bed boilers . . . decided for a look back until 2001 to give some level

of credit to companies that undertook what we [IEPA] would consider a clean technology, clean

coal project.” (Ross, 10/11/2006, 1:00 P.M., Tr. at 135.) However, companies undertook these

projects independent of any consideration of the availability of credits or other financial rewards

or incentives under the CASA. Clearly, the economics of installing the technology were such

that no credit or reward was needed and it makes no sense to provide one retroactively. Because

IEPA puts forward no persuasive reason for including CFBs in the CASA, and because CFBs

emit more NO

x

and greenhouse gases than controlled PC boilers and IGCC plants, CFBs should

be removed from the CASA.

a. CFBs do not lead to reduced NO

x

emissions compared to PC boilers.

When looking at real-world operations, CFBs do not emit less NOx than PC boilers. In

fact, the opposite is the case. While CFBs may be lower emitting than PCs when looking at

uncontrolled emissions, CFBs are not lower emitting once controlled. By focusing on what “can

be achieved” with CFBs or the “result[ing] . . . emissions” from CFBs, IEPA underscores what

should be considered—the end point, not the starting point. (TSD at 112.) Air quality impacts

are the reason for this rulemaking. Consequently, real world operations and actual emissions

5

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

impacts on air quality should be considered when deciding categories worthy of incentives. In

this day and age, new coal fired power plants are all built with controls. Therefore, it is

emissions from controlled CFBs compared to emissions from controlled PC boilers that should

be considered because that is demonstrative of what the actual emissions will be.

Historically, new CFBs have not been required to install the most effective NO

x

controls—SCR—while PC boilers have.

See, e.g.

, Babcock & Wilcox Report at 3 (Ex. 6).

Therefore, PC boilers achieve lower NO

x

emissions levels and have lower NO

x

permit levels

than CFBs. CFB permit levels for NO

x

have generally been in the 0.07 to 0.08 lb/MMBtu range.

See, e.g.

, Indeck, Spurlock, and Highwood Permits (Ex. 7, 8, 9). PC boilers, however, have been

permitted in the 0.04-0.05 lb/MMBtu range.

See, e.g.

, Trimble Permit (Ex. 10). In fact, there are

at least thirty PC units in the US operating with ozone season SCRs emitting less than 0.05

lb/MMBtu NO

x

as measured by an hourly average.

See

Erickson Paper at 8 (Ex. 11).

In sum, new PC boilers, which generally use the most modern NO

x

controls, achieve

approximately 30% lower NO

x

emissions than CFBs, which generally are built without the best

performing NO

x

controls. Consequently, there is no justification for offering incentives for

CFBs if in real world operations they do not achieve lower emission levels than PC boilers.

b. CFBs do not achieve emissions levels comparable to IGCC.

Furthermore, the CASAs categorize IGCC plants with CFB plants for the same “Clean

Coal Technology” incentive and also opened the category up to additional similar projects.

IEPA Proposed Rule, § 225.460(e). The TSD discusses the eligibility for other projects to

receive credits under this section for the “Clean Coal Technology” incentive and states that

projects that use “technologies that achieve comparable emission rates” to IGCC or CFBs may

be eligible for the set aside. (TSD at 112.) This further highlights the inappropriateness of

6

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

allowing CFBs to receive credits as a “Clean Coal Technology” because CFBs and IGCC

projects themselves do not achieve comparable NO

x

emissions rates.

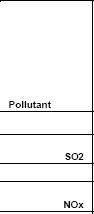

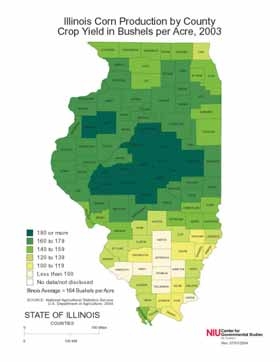

As pointed out above, CFB permit levels for NO

x

have generally been in the 0.07 to 0.08

lb/MMBtu range.

See, e.g.

, Indeck, Spurlock, and Highwood Permits (Ex. 7, 8, 9). Contrast

such levels to expected NO

x

emissions levels for recently proposed IGCC plants which average

.039 lb/MMBtu, resulting upwards of 45% lower NO

x

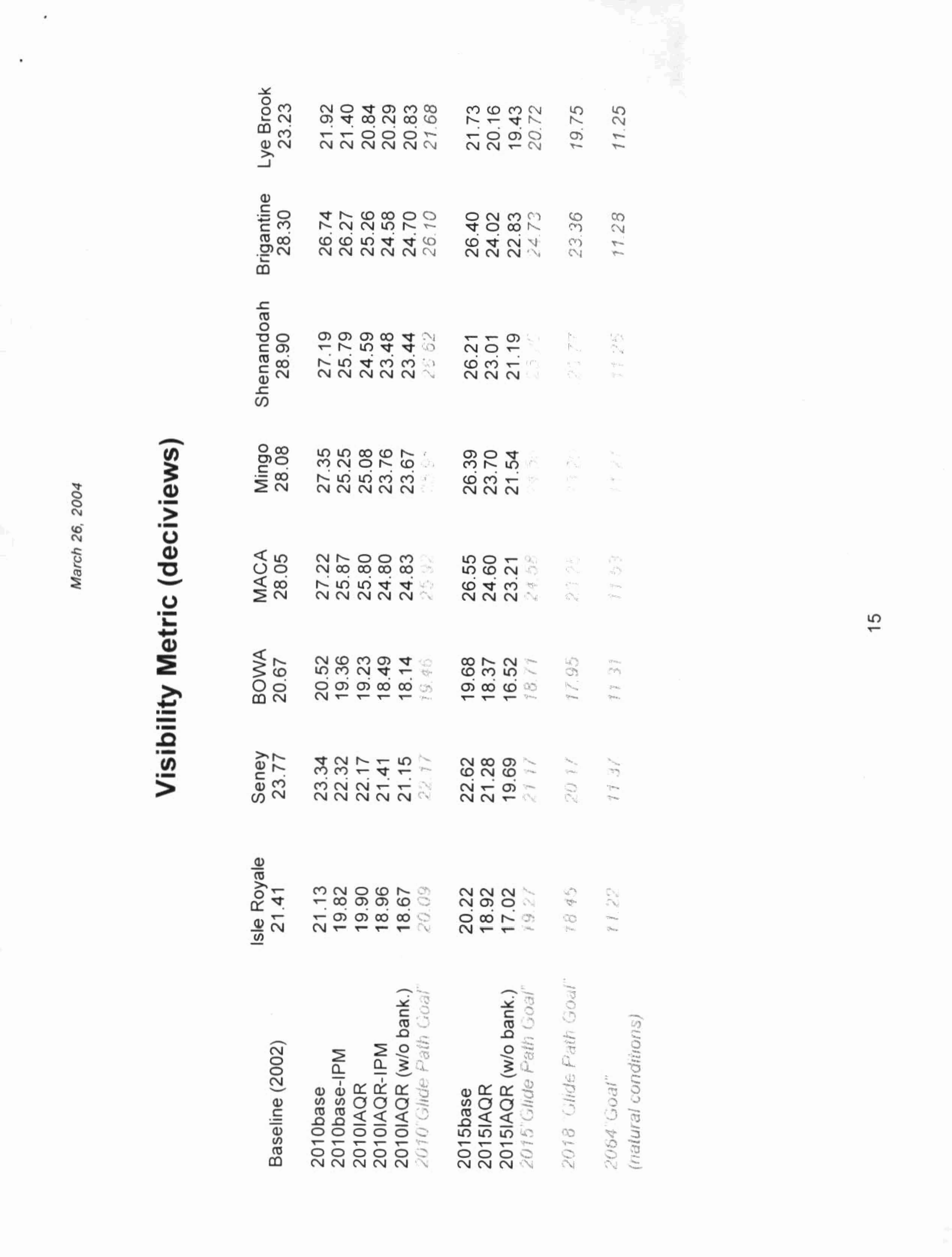

emissions. See Table 1 (Ex. 12). Since

CFBs do not perform nearly as well as IGCC, they should not be included in the same category

of incentives.

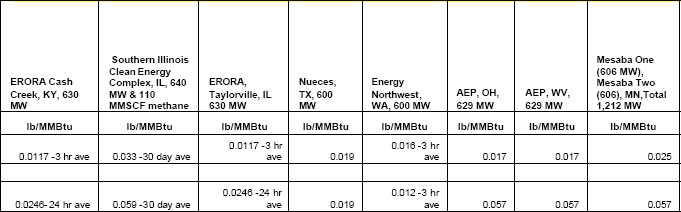

Table 1

1

Consequently, not only do CFB NO

x

emissions levels not come close to being as low as

IGCC NO

x

emissions levels but it would also be impossible to determine what other projects

ought to be eligible under the clean coal technologies category. The IEPA is required to

determine whether a project is “similar in its effects as the projects specifically listed in section

225.460 (c).” § 225.460(e). If the two projects listed in section 225.460(c), are not similar in

their effects—that is, similar in their emissions rates as articulated in the TSD—there is no

1

Taken from “Comments on EPA’s Proposed Construction Permit for Sithe Global Power to Construct the Desert

Rock Energy Facility,” submitted to Robert Baker by Dine Citizens Against Ruining our Environment et al., at 35

(Nov. 13, 2006) (Ex. 12).

7

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

clarity on what emissions rates new projects ought to be achieving in order to receive clean coal

technology credits. For these reasons, CFBs should be removed from the CASA.

c. CFBs emit 15% more greenhouse gases.

Finally, and perhaps most egregiously, not only are CFBs emitting more NO

x

than

controlled PC boilers and IGCC plants, but CFBs pose a very serious additional environmental

and health concern: CFBs emit more N

2

O, a potent greenhouse gas, than PC boilers.

Comparatively, CFBs emit approximately 15% more global warming pollutants than PC boilers.

N

2

O has a GWP (Global Warming Potential) 296 times that of CO

2

. Because of

its long lifetime (about 120 years) it can reach the upper atmosphere, depleting the

concentration of stratospheric ozone, an important filter of UV radiation. N

2

O is

emitted from fluidized bed coal combustion; global emissions from FBC units are

0.2 Mt/year, representing approximately 2% of total known sources. N

2

O

emissions from PC units are much lower. Typical N

2

O emissions from FBC units

are in the range of 40-70 ppm (at 3% O2). This is significant because at 60 ppm,

the N

2

O emission from the FBC is equivalent to 1.8% CO

2

, an increase of about

15% in CO

2

emissions for an FBC boiler. Several techniques have been proposed

to control N

2

O emissions from FBC boilers, but additional research is necessary

to develop economically and commercially attractive systems.

2003 National Coal Council Report "Coal-Related Greenhouse Gas Management Issues" at 7

(Ex. 13). In fact, SNCR, the NO

x

controls most commonly used on CFBs, increase the amount

of N

2

O.

Once again, this weighs against providing a CASA incentive for CFBs. Creating an

incentive for a technology that emits 15% more global warming pollutants than the alternatives is

contrary to both state and IEPA goals. Both the Governor and IEPA Director Doug Scott have

publicly stated that reducing global warming pollutants is a state priority. The Governor is

committed to a “long-term strategy by the state to combat global climate change, and builds on

steps the state has already taken to reduce greenhouse gas (GHG) emissions, such as enhancing

the use of wind power, biofuels and energy efficiency.” Press Release, “Governor Launches

8

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

Global Warming Initiative,” Office of the Governor (Oct. 5, 2006). In launching his Global

Warming Initiative, Governor Blagojevich stated

We’ve worked hard in Illinois to become a national leader in reducing toxic

pollutants like mercury, sulfur dioxide and nitrogen oxide. The next front is

greenhouse gases. The impact of global warming from greenhouse gases in

Illinois and around the globe could be devastating. We can’t wait for the federal

government to act because experts have warned that if we don’t address global

warming within the next decade, it may be too late to avoid serious and

irreversible consequences.

Id

. Similarly, IEPA Director Scott chairs the Illinois Climate Change Advisory Group.

Regarding global warming, he has stated, “By acting now we can take important steps to reduce

our greenhouse gas emissions and realize the economic development benefits that strategies to

confront climate change can offer.”

Id

. Consequently, by endorsing CFBs and providing

incentives for them, IEPA and the state are acting completely contrary to state policy on global

warming. For that reason, CFBs should be removed from the CASA.

In sum, incentives for CFBs are inappropriate because CFBs emit more NO

x

than

controlled PC boilers, emit significantly more NO

x

than other technologies receiving the same

“clean coal” incentives (IGCC), and emit 15% more global warming pollutants than PC boilers.

It is incumbent upon the IPCB to correct the course of this rule and remove “clean coal”

incentives for CFBs.

II.

Illinois Should Adopt A Fuel Neutral Approach In Allocating NO

x

Allowances To

Specific Sources In Order To Encourage The Use of Cleaner Fuels and Modern,

Well-Controlled Electric Generating Units.

The original federal CAIR proposal was fuel neutral, meaning it did not include an

adjusted fuel-weighting calculation to determine NO

x

emission credit allowances. 69 Fed. Reg.

4610 (2004). Fuel neutrality has generally been the approach taken for NO

x

allocation under the

9

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

NO

x

SIP call.

Alternative

NO

x

Allowance Allocation Language for the Clean Air Interstate Rule,

prepared by State and Territorial Air Pollution Program Administrators (STAPPA) and the

Association of Local Air Pollution Control Officials (ALAPCO), August 2005, at 5. According

to STAPPA and ALAPCO, a fuel neutral allocation system that does not differentiate between

coal and non-coal units "…even[s] the playing field by treating all units the same. Among other

things, this allows the trading program to do a more effective job of determining the most cost

effective compliance mix."

Id

.

U.S. EPA received several comments in opposition to the fuel neutral approach to

determine NO

x

emission credit allowances. Predictably, virtually all of the comments in

opposition were submitted by the operators of coal-fired electric generating units or their trade

associations. For their part, states which commented on CAIR focused on other issues. For

example, Illinois EPA's comments of March 30, 2004 were largely supportive of CAIR, except

that Illinois EPA asserted that CAIR as originally proposed did not go far enough or fast enough

to protect public health and to achieve attainment with NAAQS (Ex. 14). From the perspective

of Illinois EPA, further reductions of emissions from fossil fuel fired power plants were

practicable, warranted, cost effective and long overdue. Illinois EPA did not object to the fuel

neutral approach in allocating NO

x

emission credit allowances.

When CAIR was promulgated in final form, it was no longer fuel neutral, and included

an adjustment factor of 1.0 for coal, 0.4 for gas and 0.6 for oil. 70 Fed. Reg. 25231 (2005). The

adjustment factor functioned in two ways. First, U.S. EPA used the adjustments in order to

establish the final NO

x

statewide budgets.

Id

. By virtue of the application of the fuel adjustment

factors, Illinois' statewide budget actually increased when compared with its budget under the

original CAIR proposal. The Illinois budget for 2009-2014 grew from 73,613 tons to 76,230

10

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

tons of NO

x

.

See

Table V-2 at 70 Fed. Reg. 25231 (2005) and Table VI-10 at 69 Fed. Reg. 4620

(2004). The budget for 2015 and thereafter grew from 52,973 to 63,525 tons of NO

x

.

Id

.

Illinois, which had argued for deeper reductions, now found itself with more NO

x

allowances by

virtue of the elimination of fuel neutrality.

However, having given Illinois additional NO

x

allowances, CAIR in its final form

explicitly does not require Illinois or any other state to use the fuel allocation factors in

distributing allocations to individual sources. This is the second way that fuel allocation factors

can be used. For U.S. EPA, it was entirely left to individual states to decide whether to use a fuel

neutral or fuel weighted system in making allocations to individual sources. 70 Fed. Reg. 25231

(2005). In the words of U.S. EPA:

It is important to note that the methodology by which the

NO

x

State budgets are determined need not be used by

individual States in determining allocations to specific sources.

As discussed in section VIII of this document (Model Trading

Rule), EPA is offering States the flexibility to allocate

allowances from their budgets as they see fit.

Id

. According to U.S. EPA, any differences between the model federal rule and state rules in

allocating NO

x

allowances "…are possible without jeopardizing the environmental and other

goals of the [CAIR] program."

Id

. at 25278. Simply, Illinois is free to allocate NO

x

credits in a

fuel neutral manner. A fuel neutral allocation is the approach to which IEPA had no objection in

the initially proposed CAIR, and the approach which will achieve the deeper, faster reductions it

seeks. The Environmental Advocates urge the Illinois Pollution Control Board to eliminate or

modify the fuel weighting component of the proposed Illinois rule.

In making this recommendation, the Environmental Advocates are not alone among

Illinois stakeholders. In the fuel weighted system that is now a component of the proposed

11

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

Illinois rule, coal-fired power plants are the clear beneficiaries by comparison to their oil- and

especially gas- fired counterparts. Coal-fired power plants are allocated NO

x

allowances on a

1:1 to basis, oil-fired power plants receive a 0.6:1 allocation and gas-fired EGUs receive only a

0.4:1 allocation. Because Illinois will freely distribute initial credits, coal-fired power plants will

receive a significant asset by comparison to their non-coal competitors. Because they will

receive proportionately greater credits, the market will be designed to perpetuate this arbitrary

advantage.

The immediate losers as a result of this market inefficiency are unmistakably identified in

the IEPA's Technical Support Document. According to IEPA, there are 229 existing generating

units that will be subject to the CAIR NO

x

Annual, the CAIR SO

2

, and the CAIR NO

x

Ozone

Season trading programs. (TSD at 25.) Of these units, the losers are the 170 gas and oil fired

boilers and combustion turbines identified by IEPA.

Id

. The winners are 59 coal-fired power

plants. The IEPA's reasoning for using a fuel weighted system that benefits one sector at the

expense of others has been consistent throughout these proceedings, and it is twisted. According

to IEPA, coal-fired EGUs have an "inherently higher emission rate" by comparison to their

cleaner EGU counterparts, and therefore deserve an advantage in the form of a disproportionate

allocation of credits. (TSD at 35.) In other words, oil- and gas-fired EGUs are being punished

for using an inherently cleaner fuel. This is twisted because it disadvantages an EGU that

generates an equivalent unit of energy with lower emissions by comparison with a coal-fired

unit. It moves Illinois farther from, not closer to, IEPA's stated objective of promoting cleaner,

sustainable energy alternatives.

Id

.

Many oil and gas fired EGUs are also being punished by virtue of operating more

modern, well-controlled facilities than their coal-fired counterparts. This is clear in the

12

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

testimony of Jason Goodwin. In his testimony, Mr. Goodwin repeatedly called attention to the

fact that under the Illinois allocation scheme, many gas-fired units will receive

disproportionately fewer credits not only because they use cleaner fuel, but also because they

were constructed with modern pollution control equipment. Mr. Goodwin noted this was

particularly unfair for "…those that have undergone control technology review within the recent

past and have demonstrated compliance with best available control technology requirements."

(Goodwin 11/28/2006 Tr. at 21). Goodwin states "…the reduction in terms of allocations that

are available to gas-fired units ignores the basis and understanding that the facilities that we're

talking about…represent…not only the best available emission and technology threshold, but it

also satisfies the most available emission rate technology for similar sized facilities throughout

the country."

Id

. at 22. For Mr. Goodwin, one particularly worrisome consequence of

allocating disproportionately fewer credits to well-controlled gas-fired units is that if they

operate at a greater capacity than their baseline years, they may be forced to purchase credits

from older, poorly controlled coal-fired competitors. Because the facilities already employ state-

of the-art emission controls, Mr. Goodwin noted, "There really is no option for us to make any

sort of additional reductions at the facility itself."

Id

. at 26. Putting modern, well-controlled and

cleaner facilities at such disadvantage is a far cry from IEPA's stated objective. In the Technical

Support Document, the Agency asserts "…Illinois EPA believes that is good environmental

policy to provide more allowances to sources that operate more efficiently, install air pollution

control equipment, and upgrade their equipment. (TSD at 35.)

Perhaps just as importantly, Mr. Goodwin also testified that the new Illinois allocation

system represents a change in the approach under the existing NO

x

seasonal trading system. Mr.

Goodwin testified, "We see this as an unfortunate departure from the NO

x

trading program,

13

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

which has been in effect and operational within Illinois for several years. We view the past

experience with the trading program as being highly successful and question the basis for

deviating from that concept." (Goodwin 11/28/2006 Tr. at 21-22.) In light of the success of the

fuel neutral NO

x

seasonal trading program and the IEPA's stated policy to provide more

allowances to efficient, modern facilities, why has IEPA proposed a fuel weighted system? Mr.

Goodwin's explanation is succinct, "Clearly, Illinois is strongly oriented to coal generation."

(

Id

. at 27.) On the issue of fuel weighting or fuel neutrality, the Illinois rulemaking proposal

may be politically savvy, but is not reasonably related to the stated purposes of encouraging

cleaner energy generation.

Illinois would not be alone among states in establishing a more fuel neutral system for

allocating NO

x

allowances. Several states at various stages of the rulemaking process have

decided a more fuel neutral allocation would be a better option. According to Jason Goodwin,

Alabama and Arkansas propose fuel neutral allocation systems. (Goodwin 11/28/2006 Tr. at 92).

At preliminary stages in the rule development process, both Massachusetts and Virginia have

indicated an intention to propose fuel neutrality. Wisconsin's proposed rule is fuel neutral.

2

Other states have modified the fuel allocation system to a two-tier system. South

Carolina has adopted fuel weighting but with only two fuel factors, 1.0 and 0.6. South Carolina

stated the following:

The Department presently supports the language in the Federal rule that allocates

allowances adjusted for fuel type. The reason for our support is because this

system recognizes the fact that coal combustion devices have inherently higher

NO

x

emissions than oil or natural gas sources. Thus, a fuel neutral allocation

system would provide a disproportionately larger share of NO

x

allocations to oil

and gas fired units. However, the Department recognizes that such a system may

tend to promote higher-emitting fuels. Furthermore, we acknowledge that a fuel-

neutral allocation system would be much easier to implement. Currently, the

2

http://www.dnr.state.wi.us/org/aw/air/HOT/8hrozonestd/cairbart/CAIRNOxallocations060605.pdf Last accessed

21 December, 2006

14

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

information needed to calculate the ratios of fuel types to heat input for facilities

using different fuels is not available or is difficult to obtain. Also, the calculations

of adjusted heat input would probably be more complicated and time consuming.

Thus, we are continuing to look into our options regarding this issue and

appreciate further input. The Department is proposing modified fuel adjustment

language that allocates allowances adjusted for fuel type at two levels instead of

three as proposed in the Federal rule. The Department believes this represents a

compromise between those stakeholders that support fuel-adjusted allocations in

recognition of the fact that coal combustion devices have inherently higher NO

x

emissions and those stakeholders that believe that such a system provides a

subsidy for dirtier fuels. Under this proposal, the Department is proposing to use a

fuel adjustment factor of 1.0 for all sources that are permitted to burn any amount

of coal. For sources that are not permitted to burn coal, the unit’s heat input

would be subject to a fuel adjustment factor of 0.6.

3

A similar fuel neutral approach has been proposed in Texas. Finally, as noted, STAPPA

and ALAPCO have developed a model rule for state CAIR implementation that eliminates fuel

weighting, a copy of which is attached to these comments.

Alternative NO

x

Allowance

Allocation Language for the Clean Air Interstate Rule

, prepared by State and Territorial Air

Pollution Program Administrators (STAPPA) and the Association of Local Air Pollution Control

Officials (ALAPCO), August 2005.

IEPA's stated goals for CAIR are to allocate more credits to sources that operate

efficiently and install effective pollution control equipment. Throughout the CAIR process,

IEPA pressed for faster, deeper reductions through practicable, warranted, cost effective and

long-delayed pollution control upgrades at poorly controlled facilities. When measured against

its own goals, the fuel weighting system IEPA proposes fails. Fuel weighting rewards operators

of poorly controlled facilities and facilities that use inherently higher polluting fuel. IEPA

rewards these operators by freely allocating credits that are in inverse proportion to its

3

http://www.scdhec.gov/eqc/baq/pubs/CAIR/BAIICAIRCAMR.pdf#xml=http://www.scdhec.gov/cgi-

in/texis.exe/Webinator/search/xml.txt?query=CAIR&pr=page&rorder=500&rprox=500&rdfreq=500&rwfreq=500&

rlead=500&sufs=1&order=r&cq=&id=44ff994a2a last accessed: 21 December 2006.

15

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

objectives. This not only benefits historically dirtier facilities, it punishes facilities that already

employ cleaner fuels and modern pollution control equipment. Fuel weighting is not mandated

by U.S. EPA, it is a retreat from the successful NO

x

seasonal trading program, and it is not a

feature of the STAPPA and ALAPCO model rule. The Illinois Pollution Control Board should

address the contradiction between IEPA's stated goals and its proposed allocation system by

eliminating or significantly modifying the fuel weighting component of the rule.

For all of the above reasons, it is recommended to the Illinois Pollution Control Board

that the IEPA’s proposed CAIR rule be amended to increase the renewable energy and energy

efficiency set-asides, remove any allowance incentives granted to fluidized boilers, and eliminate

the included fuel weighting factors.

Faith E. Bugel

Staff Attorney

Environmental Law & Policy Center

Representing the American Lung Association of Metropolitan Chicago

Keith Harley

Chicago Legal Clinic

Representing Environment Illinois

Bruce Nilles

Sierra Club

16

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

CERTIFICATE OF SERVICE

I, Faith Bugel, hereby certify that on January 5, 2007 I filed the attached

POST-HEARING

COMMENTS. An electronic version was filed with the Illinois Pollution Control Board and

copies were served via United States Mail to those individuals included on the attached service

list.

Faith E. Bugel

Staff Attorney

Environmental Law & Policy Center

Representing the American Lung Association of Metropolitan Chicago

Keith Harley

Chicago Legal Clinic

Representing Environment Illinois

Bruce Nilles

Sierra Club

Dated: January 5, 2007

Environmental Law and Policy Center

35 East Wacker Drive, Suite 1300

Chicago, IL 60601

(312) 673-6500

17

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

REPORT TO THE CONGRESSIONAL DEFENSE

COMMITTEES

The Effect of Windmill Farms On Military Readiness

2006

Office of the Director of Defense Research and Engineering

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

EXECUTIVE SUMMARY

SECTION 358, NATIONAL DEFENSE AUTHORIZATION ACT FOR FISCAL

YEAR 2006 (PUBLIC LAW 109-163)

REPORT ON EFFECTS OF WINDMILL FARMS ON MILITARY

READINESS.

Not later than 120 days after the date of the enactment of this Act, the Secretary of

Defense shall submit to the Committee on Armed Services of the Senate and the

Committee on Armed Services of the House of Representatives a report on the effects

of windmill farms on military readiness, including an assessment of the effects on the

operations of military radar installations of the proximity of windmill farms to such

installations and of technologies that could mitigate any adverse effects on military

operations identified.

Overview

There is growing public and private sector interest in generating electrical power

using wind energy. According to the Department of Energy, over 60,000 megawatts of

wind power capacity is in operation worldwide with over 10,000 megawatts installed in

the United States. These systems are largely comprised of installations of up to several

hundred wind turbines with rotating blades reaching to heights of up to 500 feet. The

numbers, height and rotation of these wind turbines present technical challenges to the

effectiveness of radar systems that must be carefully evaluated on a case-by-case basis to

ensure acceptable military readiness is maintained. For many cases, processes are in

place to allow responsible federal authorities to complete determination of acceptability

of wind turbine impacts on military readiness. However, since wind energy use in the

United States is dramatically increasing, research and interagency coordination is

warranted to enhance capability for completing timely determinations and developing

measures for mitigating readiness impacts. This report focuses on the effects of wind

farms on air defense and missile warning radars and the resulting potential impact on

military readiness. Its scope is limited to these specific subjects and is based on the

current level of understanding regarding interactions between such defense systems and

state-of-the-art wind turbines.

The report begins with a brief introduction of the key principles of radar systems,

describes in what circumstances wind farms might cause problems for the Department

and under what circumstances such wind farms would not cause problems. Radar test

results from multiple flight trials near wind farms performed by the United Kingdom

Ministry of Defence are discussed. The results from those flight trials documented that

state-of-the-art utility-class wind turbines can have a significant impact on the operational

capabilities of military air defense radar systems. The results demonstrated that the large

radar cross section of a wind turbine combined with the Doppler frequency shift

produced by its rotating blades can impact the ability of a radar to discriminate the wind

turbine from an aircraft. Those tests also demonstrated that the wind farms have the

potential to degrade target tracking capabilities as a result of shadowing and clutter

effects.

2

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

The Department sponsored a testing campaign as a part of this study to establish a

technical database on the radar cross section and Doppler behavior of a modern utility-

class wind turbine that can be used to support development of future mitigation

approaches. This testing was performed using the state-of-the-art Air Force Research

Laboratory Mobile Diagnostic Laboratory (MDL) which is certified to perform radar

measurements to the most stringent national standards. The test procedures, samples of

the experimental test data, and calibration methodology have been documented in a

report. The full data set has been made available to U.S. radar contractors and

government-sponsored researchers.

The report discusses a number of mitigation approaches that might be employed

to reduce the impact wind turbines can have on an air defense radar. Only three methods

so far have been proven to be completely effective in preventing any impairment of

primary radar systems. Employment of these or other approaches that could produce

marginal, but acceptable, impacts on defense capabilities need to be assessed on a case-

by-case basis.

The report discusses potential wind farm impacts on Department test and training

capabilities, security on and around defense installations, through introduction of

electromagnetic noise in special electronic system testing areas, and the general

environment.

The Department recognizes that wind energy use is dramatically increasing in the

United States. Development of additional mitigation technologies is important to enable

robust expansion of wind generation capacity to continue while concurrently maintaining

defense capabilities for our Nation. The also describes exploratory development efforts

initiated by the Department to advance the state of maturity of other mitigation

approaches that could be employed in the future are also described in the report.

Appendices are provided describing the policies employed in several NATO

countries to govern wind farm development and how wind farms can impact the

performance of U.S. Comprehensive Test Ban Treaty monitoring systems.

Conclusions and Recommendations

Given the expected increase in the U.S. wind energy development, the existing

siting processes as well as mitigation approaches need to be reviewed and enhanced in

order to provide for continued development of this important renewable energy resource

while maintaining vital defense readiness. The Department of Defense strongly supports

the development of renewable energy sources and is a recognized leader in the use of

wind energy. As one of the largest consumers of energy, the Department is keenly aware

of the budgetary pressures that recent increases in the cost of energy have created for all

Americans and continues to invest in the development of alternative energy sources.

However, the Department is also mindful of its responsibility to maintain its capabilities

to defend the nation.

Consequently, the Department, as a result of this study, makes the following

conclusions and recommendations regarding the challenges and areas for further

attention, in coordination with other Federal agencies, to allow for construction of wind

turbines while maintaining defense readiness capabilities:

3

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

!

Although wind turbines located in radar line of sight of air defense radars can

adversely impact the ability of those units to detect and track, by primary radar return,

any aircraft or other aerial object, the magnitude of the impact will depend upon the

number and locations of the wind turbines. Should the impact prove sufficient to

degrade the ability of the radar to unambiguously detect and track objects of interest

by primary radar alone this will negatively impact the readiness of U.S. forces to

perform the air defense mission.

!

The mitigations that exist at present to completely preclude any adverse impacts on

air defense radars are limited to those methods that avoid locating the wind turbines

in radar line of sight of such radars. These mitigations may be achieved by distance,

terrain masking, or terrain relief and requires case-by-case analysis.

!

The Department has initiated efforts to develop additional mitigation approaches.

These require further development and validation before they can be employed.

!

The analysis that had been performed for the early warning radar at Cape Cod Air

Force Station was overly simplified and technically flawed. A more comprehensive

analysis followed by development of appropriate offset criteria for fixed-site missile

early warning radars should be performed on an expedited basis.

!

Wind turbines in close proximity to military training, testing, and development sites

and ranges can adversely impact the “train and equip” mission of the Department.

Existing processes to include engagement with local and regional planning boards

and development approval authorities should be employed to mitigate such potential

impacts.

!

Wind turbines located in close proximity to Comprehensive Test Ban Treaty

monitoring sites can adversely impact their ability to perform this mission by

increasing ambient seismic noise levels. Appropriate offset distance criteria should be

developed to mitigate such potential impacts.

!

The Federal Aviation Administration (FAA) has the responsibility to promote and

maintain the safe and efficient use of U.S. airspace for all users. The Department

defers to the FAA regarding possible impacts wind farms may have on the Air Traffic

Control (ATC) radars employed for management of the U.S. air traffic control

system. The Department stands prepared to assist and support the FAA in any efforts

the FAA may decide to undertake in that regard.

!

The National Weather Service (NWS) has the primary responsibility to provide

accurate weather forecasting services for the nation. The Department defers to the

NWS regarding identification of impacts wind farms may have on weather radars and

development of appropriate mitigation measures. The Department stands prepared to

work with the NWS in this area on NWS identified mitigation measures that have the

potential to benefit Department systems.

4

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

Table of Contents

1. Introduction

Focus of Study

Brief History of the Development of Wind Energy Systems

Fundamentals of Radar

2. Types of Radar Systems

Primary Surveillance Radar

Secondary Surveillance Radar

Missile Early Warning Radar

Weather Radar

3. General Principles of Operation

Use of Clutter Cells and Background Averagers

Moving Target Indication/Moving Target Detection Principles

Target Declaration and Tracking

4. Characteristics of Wind Turbines Applicable to Radars

DOD-Sponsored Field Testing of an SOA Wind Turbine

5. Observations of Impacts on Radar Systems

United Kingdom Flight Trials and Analyses

Observations of Wind Turbine Impacts on U.S. Operational Radars

Testing Performed at King Mountain, TX

Testing Performed at Tyler, MN

Other Observations About U.S. Radar Systems

Comments Regarding Air Traffic Control and Weather Radars

6. Potential Mitigation Approaches

Line of Sight Mitigation Techniques

Wind Turbine Radar Signature Suppression Concepts

Concepts for Radar Hardware/Software Modifications

Concepts for Gap Filler Mitigation Approaches

Testing and Verification Factors

7. Other Potential Impacts on DOD Readiness

Overflight and Obstruction

Security

Signature

Environment

Summary of Potential Mitigation Approaches

8. Summary

Air Defense Radars - Shadowing

Air Defense Radars - Clutter

Missile Early Warning Radars

Air Traffic Control Radars

Weather Radars

Other Potential Impacts on DOD Readiness

Treaty Compliance Sites

9. Conclusions

5

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

References

Appendix 1: Policies Employed by Select NATO Countries

Appendix 2: Impacts on Treaty Compliance Systems

6

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

List of Figures

1.

Scientific American

illustration of the 1888 Brush Windmill in Cleveland, Ohio

2. Illustration of a basic radar system

3. Notional main, side, and back lobes of a 2-D radar

4. Geometric approximation to estimate radar line of sight

5. Regions of partial and complete blockage of radar illumination

6. Effect of a diffraction grating on a propagating wave

7. RCS values for several common objects

8. RCS values for C-29 aircraft as a function of view angle

9. Two common types of 3-D radar

10. Notional elevation side lobe for fifth beam of the Figure 9b phased-array radar

11. PSR and SSR antennas of the UK Watchman ATC radar

12. Upgraded Early Warning Radar at Beale AFB, CA

13. First NEXRAD WSR-88D radar, Norman, OK

14. Clutter cell example

15. Relationship between clutter and resolution cells

16. Picture of SOA wind turbines located in Wales, UK

17. AFRL Mobile Diagnostics Laboratory measuring wind turbines at Fenner, NY

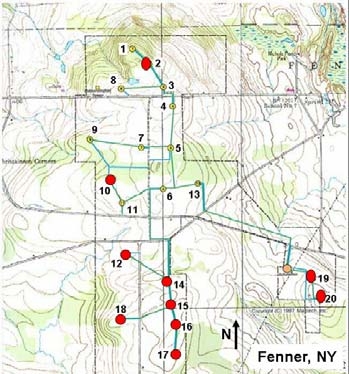

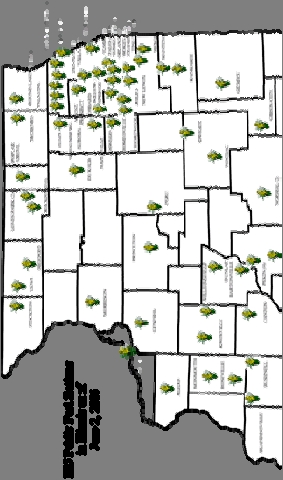

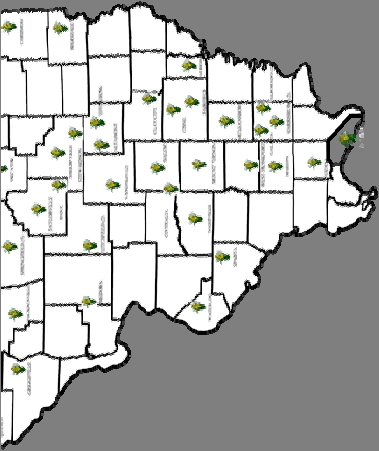

18. Layout of the wind farm at Fenner, NY, and locations of the turbines tested

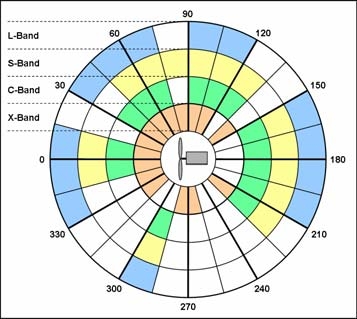

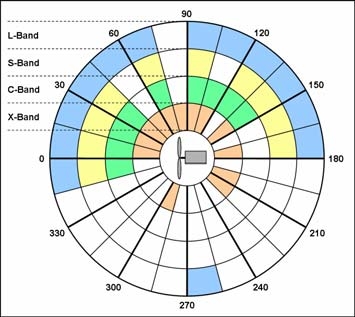

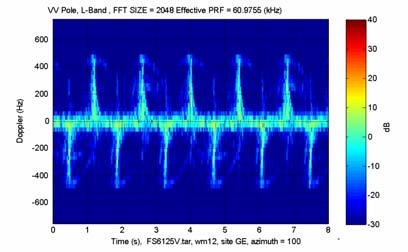

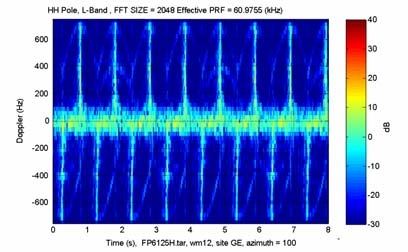

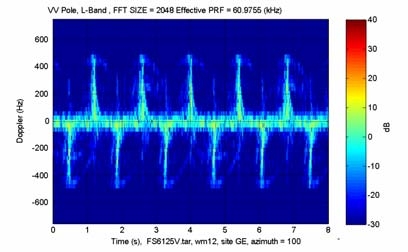

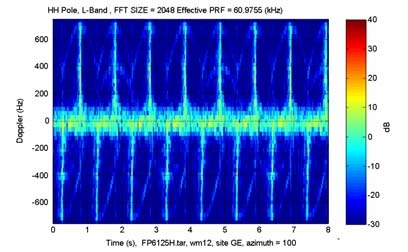

19. Graphical representation of data obtained during field tests at Fenner, NY

20. Example of Doppler characteristics of a wind turbine at L-band

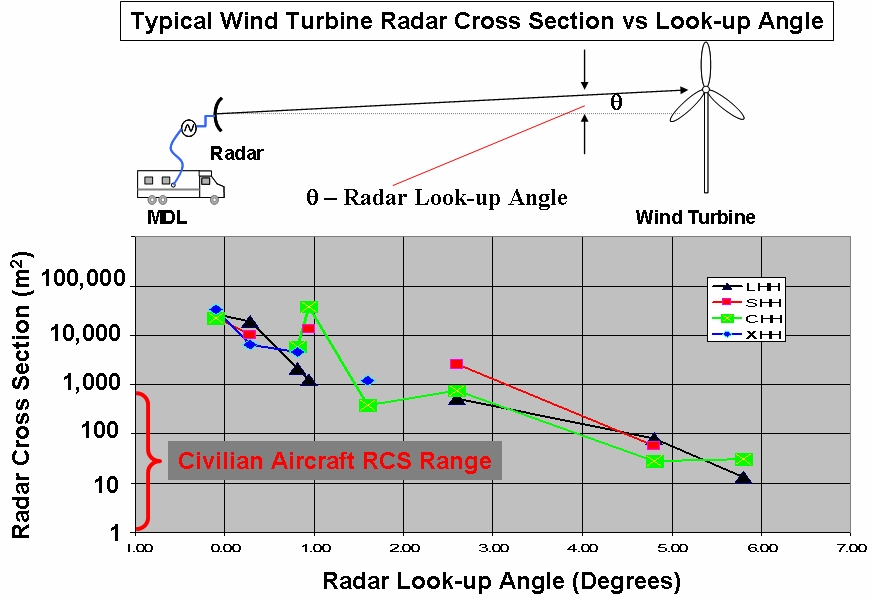

21. Graphical summary of RCS measurements for L-, C-, S-, and X-bands

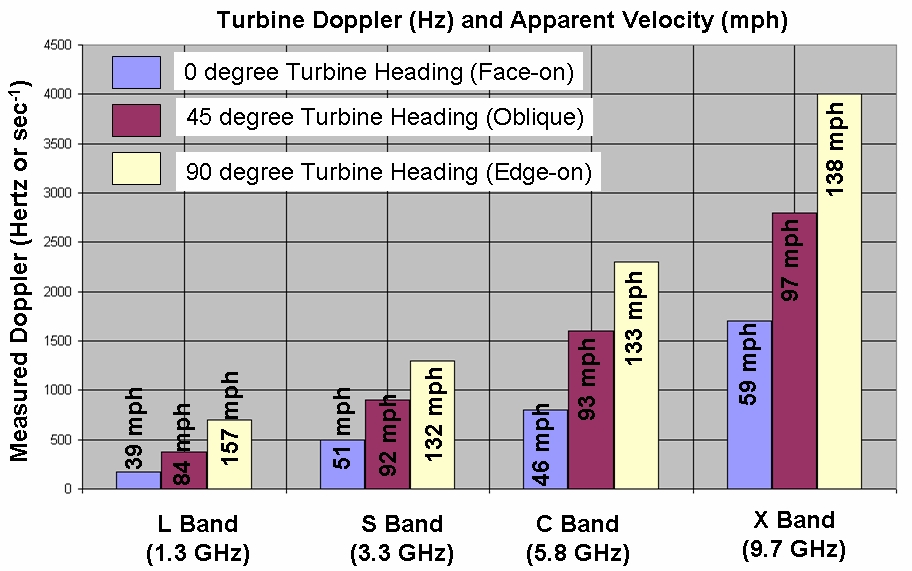

22. Doppler frequencies and derived tip velocities from measurements at L-, C-, S-, and

X-band frequencies

23. Commander AR327 - Type 101 air defense radar

24. Example of data obtained during Fall 2004 flight trial

25. Sector of clutter cells superimposed on flight trial data obtained during Spring 2005

flight trial

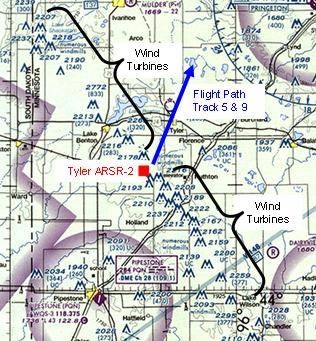

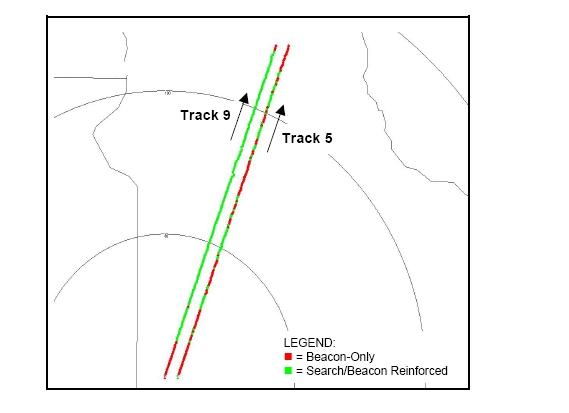

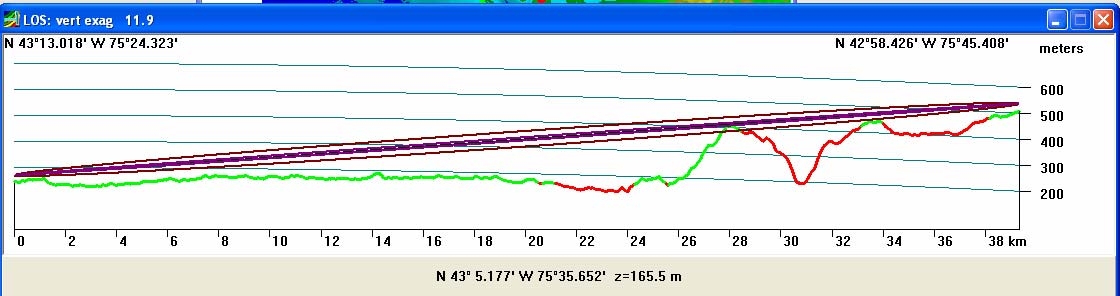

26. Location of wind turbines with respect to ARSR-4 radar at King Mountain

27. Picture of wind turbines and ARSR-2 radar at Tyler, MN

28. Location of wind turbines with respect to ARSR-2 radar at Tyler

29. Tracking performance of ARSR-2 radar over wind farm at Tyler, MN

30. Illustration of “bald earth” line of sight mitigation approach

31. Illustrative results of line of sight distance offsets using a “bald earth” approach

32. Illustration of “terrain masking” line of sight mitigation approach

33. Illustration of “beam propagation” analysis to evaluate “terrain masking”

34. Overlapping radar coverage example

List of Tables

1. Physical data for representative SOA turbines

2. Decibel (dB) equivalents for some common numerical ratios

3. Approximate primary beam elevations for an Early Warning Radar

7

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

1. INTRODUCTION

Focus of Study

This report has been prepared in response to Section 358 of the National Defense

Authorization Act for Fiscal Year 2006 concerning the impacts wind farms may have on

U.S. military readiness, to include an assessment on operation of military radar

installations and technologies that could mitigate any adverse effects identified. The

intent is to ensure that the accelerating development of wind energy systems within the

United States will occur in a manner that also preserves the capability of U.S. military

forces to protect the homeland.

This report specifically discusses how megawatt (MW) class state-of-the-art

(SOA) wind turbines can impact domestically sited U.S. air defense and missile warning

radar systems. Wind turbines of this size are typically considered to be “bulk-power

utility-scale” units often employed in “wind farms” to provide electricity for local or

regional power grids. Within the context of this report, the term “wind farm” will be

employed to denote a collection of two or more megawatt class wind turbines within a

geographical area that may range in size from a few acres to hundreds of acres.

The report does not attempt to consider impacts that could occur from small

“homeowner” type wind turbine systems. Modern versions of such units are relatively

small in physical size, with generating capacities in the low kilowatt (kW) range. They

are not anticipated to have significant impact unless located directly adjacent to a

domestic defense system. This is not considered to be a highly probable occurrence since

land directly adjacent to domestic defense systems is generally under the positive control

of the federal government.

The report describes existing as well as possible future mitigation techniques that

could be employed to mitigate impacts for megawatt wind turbines. Finally, it describes

science and technology efforts already being pursued to develop additional future

mitigation approaches.

Brief History of the Development of Wind Energy Systems

According to the history page of the Danish Wind Industry Association

(www.windpower.org), the first automatically operated windmill employed to generate

electricity was built in Cleveland, Ohio, in 1888. Figure 1 provides an illustration of this

system that appeared on the front page of the 20 December 1890 edition of

Scientific

American.

While physically large, the 17 m diameter rotor was only able to generate 12

kW of power.

For the next 40 years a variety of low-power wind turbine designs were

developed. Some were employed to provide power to local electrical grids or at remotely

located farms not connected to electrical grid networks. The development of bulk power

utility-scale turbines, units with generating capacities on the order of 100 kW or more,

appears to have begun in earnest in the 1930s in multiple nations but this did not lead to

the development of any major commercially operated “wind farms” for bulk power

8

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

generation. Subsequent advances in turbine technologies during the 1960s and 1970s did,

however, provide the technical basis for current approaches.

Figure 1.

Scientific American

illustration of the 1888 Brush Windmill

in Cleveland, Ohio

One of the earliest large wind farms in the United States was built, starting in

1982, in the Altamont Pass area of California. The wind farm is actually a collection of a

number of different turbine designs owned and operated by several different

organizations. The Altamont Pass Wind Farm currently consists of more than 4700 units;

the vast majority being older 100 kW capacity units with, in 2003, a reported combined

net generating capacity on the order of 494 MW [1]. The significantly greater per-unit

generating capability of current SOA turbines means that far fewer, but physically much

larger, turbines can be employed to generate this level of power. For size comparison

purposes, note that a typical 1980s vintage 100 kW capacity wind turbine, such as those

at Altamont Pass, has a blade length on the order of 8 m and is mounted on towers 24 to

30 m high. In contrast, a SOA 1.5 MW unit may have blades on the order of 35 to 40 m

in length mounted on support towers 60 to 80 m or more high.

In terms of future trends, a recent report by the European Wind Energy

Association [2] discussed the numerous technical factors related to growth in turbine

sizes and capacities over the past several years. While it was expected that rotor sizes and

rated capacities may continue to increase as higher strength materials are employed in

fabrication of turbine blades and other components, it also indicated that economic and

operational factors could exert limitations. Consequently, the report concluded that

significant growth in size beyond the 5 MW class units currently in development would

not be automatic. Table 1 provides typical dimensions for SOA megawatt class turbines

currently available from two manufacturers. Similar size/capacity units are also produced

by a number of other firms.

9

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

Table 1. Physical data for representative SOA turbines

Manufacturer & Data

Source

Rated Capacity

(MW)

Rotor Diameter

(m)

Rotor Speed

(rpm)

Tower Height

(m)

GE

(www.gepower.com)

1.5

77

10-20

65-100

GE

(www.gepower.com)

3.6

104

8.5-15

Site dependent

Vestas

(www.vestas.com)

1.65

82

11-14

59-78

Vestas

(www.vestas.com)

4.5

120

10-15

Site dependent

Fundamentals of Radar

*

Radar systems are widely employed for many commercial and defense

applications. In its simplest form (Figure 2), a radar is a sensor system utilizing

electromagnetic radiation in the radio frequency (rf) spectral region, spanning from

approximately 3 MHz to around 100 GHz, and consisting of a transmitter, an antenna, a

receiver, and a processor. The transmitter emits pulses of energy in the form of rf waves

that propagate through the atmosphere. An object, typically referred to as the target, in

this radar beam will reflect some of this energy back to the radar. This reflected energy is

collected by a receiving antenna for processing. The basis of operation of a specific radar

sensor system is determined by the content of the information contained in the reflected

radiation and how it is processed.

The degree of difficulty encountered in processing the radar reflection from the

target of interest depends upon the strength and variability of the signal at the receiver

relative to other sources. For example, the strength of the reflected signal received by the

radar will depend on the power of the transmitter, the distance to the target, atmospheric

effects, the radar cross section (RCS) of the target, the possible presence of intervening

physical objects, and the antenna geometry. The radar may also receive reflected

radiation from other objects such as trees, buildings, vehicles, and hills, as well as direct

radiation emitted by other natural and man-made rf sources, such as the atmosphere, cell

phone towers, television and radio antennas, and electrical generators.

Signal variability can occur due to motion of the target and changes in the

intervening physical environment, such as those caused by rain or hail, as well as

reflections from wind-blown trees. A number of other effects arising from the inherent

thermal electronic noise in the radar sensor, the physics of antenna systems, the

atmosphere and intervening objects on the propagation of electromagnetic radiation also

*

The term “RADAR” was an American acronym created in 1941, with the letters selected from the words

ra

dio

d

etection

a

nd

r

anging. The use of this acronym has become so prevalent that it is now generally

accepted as a common word in English and rarely capitalized.

10

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

must be taken into account in determining the performance fidelity of a radar sensor

system.

Reflected Energy

Transmitted Energy

Antenna

Target

Processor

Radar

Electronics

Display

Reflected Energy

Transmitted Energy

Antenna

Target

Processor

Radar

Electronics

Display

Figure 2. Illustration of a basic radar system

The term “clutter” has been established to encompass any unwanted reflected

signal that enters the radar receiver and can interfere with the determination of the desired

attributes of the target of interest. Discussions in following sections of this report will

provide examples of the effects of clutter that interfere with resolving behavior, such as

detecting the presence of a valid target, discriminating between two closely spaced

targets, and subsequently tracking the motion of all targets of interest.

At the most basic level, the ability to successfully process the reflected radiation

depends on the strength of this signal relative to the background noise inherent in the

radar electronics. This is characterized as the signal-to-noise ratio (SNR). Increasing the

radar-to-target distance dramatically decreases the intensity of the received signal. For

example, if the distance between the radar and the target is doubled, the signal returned

decreases by a factor of 16. Since a design goal for a defense radar is to detect targets at

the maximum range possible, the ability to sense very low signal strengths is essential.

At the extreme, the absolute minimum level of noise that can occur in a system is

fundamentally limited to the thermally induced noise in the sensor electronic components

and thermal radiation from the atmosphere. However, the actual level of noise, to include

clutter effects, that a radar sensor must deal with are significantly greater than this

theoretical limiting case.

Many of the attributes characterizing a radar system involve values spanning

many orders of magnitude. For example, the SNR for a radar system can vary by more

than 1 million during operation. The decibel (dB), a logarithmic ratio of two quantities,

is used to describe these ratios in terms of smaller numerical values. For example, an

SNR value of -30 dB means that the signal strength is 1/1000 of the strength of the noise.

Similarly, for a value of 10 dB, the signal would be 10 times greater than the noise. The

dB unit will be used frequently in the sections to follow. For convenience to the reader,

Table 2 provides examples of the conversion of dB to the equivalent factor.

11

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

Table 2. Decibel (dB) equivalents for some common numerical ratios

dB

-50 dB

-30 dB

- 10 dB

-3 dB

0 dB

3 dB

10 dB

30 dB

Factor

1/100,000 1/1,000

1/10

½

1

2

10

1,000

Due to the finite size and shape of an antenna, the emitted power is distributed in

a lobe-shaped pattern. The center (or main) lobe contains the majority of the radar

power, but the secondary, tertiary, etc., lobes (side lobes) can have sufficient energy to

introduce clutter into the system. Figure 3 illustrates the main, side, and back lobes for a

2-dimensional (2-D) radar. Figure 3a provides a range versus elevation plot of the -3 dB

(half power) point of the beam relative to the peak power level. Figure 3b provides an

azimuth beam shape plot, where power level as a function of azimuth angle is plotted

relative to peak main lobe power.

90°

0°

30°

60°

300°

120°

150°

180°

210°

240°

270°

330°

Range

A

l

t

i

t

u

d

e

Main Lobe

1

st

Side Lobe

Back Lobe

90°

0°

30°

60°

300°

120°

150°

180°

210°

240°

270°

330°

90°

0°

30°

60°

300°

120°

150°

180°

210°

240°

270°

330°

Range

A

l

t

i

t

u

d

e

Range

A

l

t

i

t

u

d

e

Main Lobe

1

st

Side Lobe

Back Lobe

0 dB

-10 dB

-20 dB

a. Main lobe as function of

b. Main, side, and back lobe amplitudes

range and altitude

as a function of azimuth angle

Figure 3: Notional main, side, and back lobes of a 2-D radar

Multiple side lobes can exist in both the vertical and azimuth directions with

respect to the axis of the main lobe. In a well-designed radar system, the power level of

the side lobes will be significantly below that of the main lobe.

Radars can detect sufficiently strong reflections from objects located in the

antenna side lobes. Side lobe suppression methods have been developed to reduce the

influence of such signals. The ultimate effectiveness of the side lobe attenuation provided

will depend significantly upon the power level of the side lobe beam and the strength of

the reflected signal in comparison to the primary signal of interest.

12

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

The range of an optical viewing systems is ultimately limited by the optical or

“geometric” horizon. For radar systems, the electromagnetic radiation propagating

through the atmosphere is refracted (effectively bent), with the result that a radar beam

can be reflected by an object beyond the geometric horizon. Analysis of this refraction

effect has indicated that for radar frequencies, the radar horizon can be reasonably

approximated by employing a “4/3 earth model.” In this approximation, a geometric line

of sight is calculated, but using an “effective” radius for the earth equal to the actual

radius of the earth multiplied by the factor 1.33, as illustrated in Figure 4.

Radar Line of Sight

(4/3)R

earth

= 4587 nMi

H

Radar Line of Sight

h

(4/3)R

earth

= 4587 nMi

Hh

Figure 4. Geometric approximation to estimate radar line of sight

Objects in the path of an electromagnetic wave affect its propagation

characteristics. This includes actual blockage of wave propagation by large individual

objects and interference in wave continuity due to diffraction of the beam by individual

or multiple objects. The effect caused by either of these is often termed to cause

“shadowing” of the radar beam.

The presence of a single tall building within the radar field of view provides a

typical example for blockage. Since a tall building effectively blocks all propagation of a

radar rf wave, the zone immediately behind the building will not be illuminated by the

radar. If the building is close to the radar there will be zones of complete and partial

shadowing. This is illustrated in Figure 5.

In the region where the radar wave is completely blocked it is impossible to detect

any object in that region. In contrast, detection is still possible in the zone of partial

blockage but with greater difficulty. In this region both the level of illumination from the

radar and the reflected signal from the target will be weakened by the partial blockage.

This is one form of the shadowing effect.

The second form of disruption occurs because of a phenomenology referred to as

“diffraction.” Near-field and far-field diffraction effects were first studied by the Danish

physicist Christian Huygens and the French physicist Augustin-Jean Fresnel. As

illustrated by Figure 6, whenever a traveling wave encounters a line of objects, the

objects will disrupt the propagation of the wave in that locale. This phenomena can be

illustrated as propagation of spherical waves from each of the objects. These waves will

combine constructively and destructively on the far side of the objects. In the zone of the

13

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

disrupted waves the reflection of the radar signal is significantly different from areas

where it has not been disturbed. These differences include variations in intensity and

phase angle and are a function of original frequency and the spacing of the objects

causing disruption.

Antenna

Radar

Electronics

O

B

J

E

C

T

T

O

T

A

L

S

H

A

D

O

W

P

A

R

T

I

A

L

S

H

A

D

O

W

Antenna

Radar

Electronics

O

B

J

E

C

T

T

O

T

A

L

S

H

A

D

O

W

P

A

R

T

I

A

L

S

H

A

D

O

W

Figure 5. Regions of partial and complete blockage of radar illumination

Radar Pulse

Wind Turbines

Interference

Waves

Shadowed

Region

Radar Pulse

Wind Turbines

Interference

Waves

Shadowed

Region

Figure 6. Effect of a diffraction grating on a propagating wave

These disruption effects will occur both for the original transmitted wave and the

wave reflected back to the radar by a target. As such, the ability to detect a target in this

zone will be degraded. This is the form of shadowing that has been raised as a concern in

relation to wind farms since the spacing of turbines over a field of view can create this

type of diffraction effect for a radar.

The strength of the reflected signal, whether the object is illuminated by the main

lobe or by one or more side lobes, depends not only upon the power level of that

illumination but how “large” a reflector of radar energy the object is. This “size” factor is

commonly referred to as its radar cross section (RCS). Objects with a large RCS will

14

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

reflect, proportionately, a larger amount of radar energy than an object with a lower RCS

and thus be easier to detect. RCS is normally expressed in terms of “decibel square

meters” (dBsm), a logarithmic expression of an object’s radar reflecting surface area.

Figure 7 provides typical RCS values, in terms of both square meters and dBsm, for a

number of common items, including that of a 1.5MW SOA wind turbine. Unlike the

other objects depicted in Figure 7, the RCS for the wind turbine is a combination of a

near-zero Doppler reflecting surfaces consisting of the tower and nacelle and variable

Doppler reflecting surfaces consisting of the turbine blades. The near-zero Doppler

portion of the reflected signal generally will not cause a problem in a well designed radar.

However, the broadly spread variable Doppler portion of the reflected signal from the

wind turbine can often exceed that produced by an aircraft.

1.5MW WIND TURBINE

LARGE A/C (747)

CONVENTIONAL

AIRCRAFT (C-29)

IMPROVED

CONVENTIONAL AIRCRAFT

CONVENTIONAL

CRUISE MISSILES

BIRDS

MAN

CARS/TRUCKS

INSECTS

RCS

dB

= 10 log RCS

m

2

dBsm

.0001

.001

.01

.1

1

10

100

1000

10000

-40

-30

-20

-10

0

10

20

30

40

Square Meters

SPACE SHUTTLE

& BOOSTERS

(ENGINE VIEW)

Figure 7. RCS values for several common objects

The magnitude of the RCS of an object is dependent upon the angle, both in

bearing and elevation, from which it is observed by the radar. Figure 8 illustrates how the

RCS value for the C-29 “business jet” included in Figure 7 varies as a function of bearing

angle, where observing the airplane from a nose-to-tail perspective is denoted as a 0-

degree bearing angle. These values were measured at 2.9 GHz, with a “look down” angle

from the vertical of 15 degrees. Modifying the viewing angle or changing the frequency

band used for the measurement will change the measured RCS characteristics.

Radar systems have been designed and deployed for a wide variety of applications

and missions. These include air defense radars, air traffic control (ATC) radars, missile

warning radars, and weather radars. The design of each of these radar sensor systems

depends on the mission requirements, the phenomenology to be exploited, and the

C-29

747

1.5MW WIND TURBINE

LARGE A/C (747)

CONVENTIONAL

AIRCRAFT (C-29)

CONVENTIONAL

AIRCRAFT (C-29)

IMPROVED

CONVENTIONAL AIRCRAFT

CONVENTIONAL

CRUISE MISSILES

BBIIRRDDSS

MMAANN

CCAARRSS//TTRRUUCCKKSS

IINNSSEECCTTSS

RCS

dB

= 10 log RCS

m

2

dBsm

.0001

.001

.01

.1

1

10

100

1000

10000

-40

-30

-20

-10

0

10

20

30

40

Square Meters

dBsm

.0001

.001

.01

.1

1

10

100

1000

10000

-40

-30

-20

-10

0

10

20

30

40

Square Meters

SPACE SHUTTLE

& BOOSTERS

(ENGINE VIEW)

C-29

747747

15

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

available technology. For example, current generations of weather radar systems exploit

the Rayleigh scattering properties of precipitation, i.e., scattering of radiation having

wavelengths, on the order of 10 cm, much larger than the characteristic size of rain, hail,

and snow particles. The computational schemes employed are designed to reduce the

effects of “clutter” to obtain the desired weather information. Surveillance radars, in

addition to having a capability to sense weather-related phenomena as just described,

exploit the scattering properties of objects much larger than the wavelength of the radar.

They also employ computational schemes specifically tailored to produce desired

surveillance information. The mission challenges introduced by clutter to the

performance of radar systems are discussed in the following sections of this report.

Figure 8. RCS values for C-29 aircraft as a function of view angle

Advances in electronics, processor, and computational technologies have enabled

a number of radar system performance enhancements. A key capability provided by

these advances and employed in virtually all modern radar systems today is the capacity

to sense pulse-to-pulse phase differences, thus enabling the Doppler effect to be

exploited.

The Doppler effect, specifically the shift in frequency of the reflected signal that

occurs when an object is moving, was first discovered by Christian Doppler. It applies to

all propagating waves and is particularly useful for radars. This Doppler shift results

from the fact that the frequency of a signal received by an observer will depend upon

whether the source of that signal is stationary, moving toward, or moving away from the

observer. For radar applications, the “source” of the signal is the radar wave reflected by

the target. If the target is moving away from the radar, the frequency of the reflected

16

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JANUARY 5, 2007

* * * * * PC #7 * * * * *

signal will be lower than the originally transmitted frequency. Conversely, if the object is

moving toward the radar the frequency will be higher. Additionally, the magnitude of the

signal frequency shift is directly proportional to the radial velocity between the object

and the radar. Only objects that are stationary or moving perfectly tangentially to the

radar wave will not produce a Doppler shift.

The development of high-performance processing capability, along with

innovative computational techniques tailored to extract desired information from the

massive amounts of data available, has provided desired radar enhancements, particularly

for defense capabilities.

2. TYPES OF RADAR SYSTEMS

Primary Surveillance Radar

Air defense radars typically operate in what is termed a “Primary Surveillance”

mode. When operated in that manner they are referred to as a “Primary Surveillance

Radar” (PSR). A PSR will send out rf waves (radar energy) focused by the antenna to

provide an “illuminated” volumetric region of coverage. For a radar with a single

transmitting element, the characteristics of this volume of coverage will be governed

primarily by the shape of the antenna and whether or not the antenna can be rotated about

one or two axes.

Figure 3 illustrated a radar coverage pattern where the antenna has been shaped to

produce an illuminated area that is broad in altitude and radial distance (range) but rather

narrow in width in terms of azimuth angle coverage. This type of radar is generally

rotated about a vertical axis to extend the volume of coverage. The angle of rotation may

be as little as a few degrees to observe a small sector or up to 360 degrees to cover the

entire airspace surrounding the radar. Alternatively, the antenna may oscillate back and

forth over a small angle to cover only a sector of airspace. Systems of this type able to

rotate a full 360 degrees can often be observed in use around airports.

Radars of the type illustrated in Figure 3 are often referred to as 2-D radars since

they are able to determine the position of an aircraft in terms of range and bearing angle

(angular position of the aircraft with respect to north) but are unable to determine the

height at which the airplane is above the surface of the earth. In contrast, most radars

designed to inherently determine aircraft range, bearing, and altitude employ multiple

beams. Radars able to determine all three aircraft parameters are typically referred to as

being three-dimensional (3-D) radars. Figure 9 illustrates two different types of