BEFORE THE ILLINOIS POLLUTION

CONTROL BOARD

THE PREMCOR

REFINING

GROUP INC.,

Petitioner,

v.

ILLINOIS ENVIRONMENTAL

PROTECTION AGENCY,

Respondent.

PCB 2007-030

(CAAPP Permit Appeal)

NOTICE OF FILING

T O: Ms. Dorothy M. Gunn

Clerk of the Board

Illinois Pollution Control Board

100 West Randolph

Street

Suite 11-500

Chicago, Illinois 60601

(VIA

ELECTRONIC MAIL)

C arol

Webb,

Esq.

Hearing

Officer

Illinois Pollution Control Board

1021 North Grand Avenue East

Post

Office

Box

19274

Springfield, Illinois 62794-9274

(VIA FIRST CLASS MAIL)

PLEASE TAKE NOTICE that I have today filed with the Office of the Clerk of

the Illinois Pollution

Control

Board

a MOTION FOR LEAVE TO FILE AMENDED

PETITION FOR REVIEW and AMENDED PETITION FOR REVIEW,

copies of

which are herewith served upon you.

Respectfully submitted,

D ated: December

22, 2006

K atherine D. Hodge

Monica T. Rios

HODGE DWYER ZEMAN

3150 Roland Avenue

Post Office Box 5776

Springfield, Illinois 62705-5776

(217) 523-4900

THE PREMCOR REFINING

GROUP INC.,

Petitioner,

By:/s/ Katherine D. Hodge

One of Its Attorneys

THIS FILING SUBMITTED

ON

RECYCLED PAPER

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

CERTIFICATE OF SERVICE

I, Katherine D. Hodge, the undersigned, certify that I have served the attached

MOTION FOR LEAVE TO FILE AMENDED

PETITION FOR REVIEW and

AMENDED PETITION FOR REVIEW upon:

Ms. Dorothy

M. Gunn

Clerk

of the Board

Illinois Pollution Control Board

100 West Randolph Street

Suite

11-500

Chicago, Illinois 60601

via electronic mail on December 22, 2006; and upon:

Carol Webb, Esq.

Hearing

Officer

Illinois Pollution Control Board

1021 North Grand Avenue East

Post Office Box 19274

Springfield, Illinois 62794-9274

Robb H. Layman, Esq.

Assistant Counsel

Division of Legal Counsel

Illinois Environmental Protection Agency

1021 North Grand Avenue East

Post Office Box 19276

Springfield, Illinois 62794-9276

by depositing said documents in the United States Mail in Springfield, Illinois, postage

prepaid, on December 22, 2006.

/s/ Katherine D. Hodge

Katherine D. Hodge

P REM-013Ti1WOF and COS - Motion for Leave, Amended Petition, Motion to Supplement

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

THE PREMCOR REFINING

)

GROUP INC.,

)

Petitioner,

)

v.

)

PCB 2007-030

(CAAPP

Permit Appeal)

ILLINOIS ENVIRONMENTAL

)

PROTECTION AGENCY,

)

Respondent.

)

MOTION FOR LEAVE TO FILE

AMENDED PETITION FOR REVIEW

NOW COMES Petitioner, THE PREMCOR REFINING GROUP INC.

(hereinafter "Premcor"), by

and through its attorneys, HODGE DWYER ZEMAN, and

for its Motion For Leave To File Amended Petition

For Review, states as follows:

1.

On September 19, 2006, the Illinois Environmental Protection Agency

("Respondent") granted a

final

Clean

Air Act Permit Program ("CAAPP") permit to

Premcor's Hartford Terminal, a petroleum bulk storage and loading terminal, located

in

Hartford, Illinois.

2.

On October

24, 2006, Premcor filed its Petition for Review ("Petition") of

the CAAPP permit based on the fact that the Respondent failed to incorporate comments

submitted by Premcor into the final CAAPP permit and, as such, the CAAPP permit does

not reflect the current applicable

requirements or the current operations of the Hartford

Terminal.

3.

On

November 27, 2006, the Respondent filed a Motion to Dismiss the

Petition ("Motion") arguing that the Petition

failed

"to

provide adequate specificity to

apprise either the Board or the Illinois EPA of the subject

matter

of

the

appeal."

Motion

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

to Dismiss, The Premcor Refining Groo Inc. v. Illinois EPA, PCB No. 07-03 at T5

(I11.Pol.Control.Bd.

Nov. 27, 2006) (requesting the Illinois Pollution Control Board

("Board") dismiss Premcor's petition or, in the alternative, require

the

filing

of an

Amended Petition for Review ("Amended Petition").

4.

On

December 13, 2006, Premcor filed

a

Motion

for Extension of Time

requesting an

additional

14

days, or until

December 26, 2006,

to

file

a

Motion

for

Leave

to File Amended Petition. On December 18, 2006, the Board Hearing Officer granted

Premcor's Motion.

5.

Counsel for Premcor has consulted with the Respondent regarding the

Respondent's concerns as described in the Motion. Based on these discussions, it is

Premcor's understanding that filing an Amended Petition reiterating in detail the

comments listed in Premcor's exhibits to the original Petition will resolve the

Respondent's

concerns.

6.

While Premcor does not concur with Respondent's position that Premcor's

original

Petition for Review is inadequate, Premcor is seeking leave to file this Amended

Petition in order to address the State's concerns.

7.

Premcor's Amended Petition would not change the bases of Premcor's

appeal, but rather simply restates those bases in a form more acceptable to

Respondent.

8.

For the reasons stated above, Premcor respectfully moves the Board to

grant Premcor leave to file the attached Amended Petition, and further moves the Board

to deem said Amended

Petition filed

as of the date of the

Board's

Order

granting this

Motion.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

WHEREFORE, Petitioner, THE PREMCOR

REFINING

GROUP

INC.,

respectfully moves the ILLINOIS POLLUTION CONTROL BOARD to grant it leave to

file an Amended Petition as set forth above, to deem the Amended Petition attached

hereto filed as of the date of the Board's Order granting this Motion, and to award it all

other relief just and proper in the premises.

Respectfully submitted,

THE PREMCOR REFINING GROUP INC.,

Petitioner,

By: /s/ Katherine D. Hodge

One of its Attorneys

Dated: December 22, 2006

Katherine D. Hodge

Monica T. Rios

HODGE DWYER ZEMAN

3150

Roland Avenue

Post Office Box 5776

Springfield, Illinois 62705-5776

(217) 523-4900

P REM-013\Fi1\Premcor Motion for Leave to File Amended

Petition

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

BEFORE THE ILLINOIS POLLUTION

CONTROL BOARD

THE PREMCOR REFINING

)

GROUP

INC.,

)

Petitioner,

)

v.

)

PCB 2007-030

(CAAPP Permit Appeal)

ILLINOIS ENVIRONMENTAL

)

PROTECTION AGENCY,

)

Respondent.

)

AMENDED PETITION FOR REVIEW

NOW COMES Petitioner, THE PREMCOR REFINING GROUP INC.

(hereinafter "Premcor"), by and through its attorneys, HODGE DWYER ZEMAN,

pursuant to Section 40.2 of the Illinois Environmental Protection Act (415 ILCS 5/40.2)

("Act") and 35111. Admin. Code § 105. Subpart C, and petitions the Illinois Pollution

Control Board ("Board") for review of the Clean Air Act Permit Program ("CAAPP")

permit granted to Premcor by the Illinois Environmental Protection Agency ("Illinois

EPA") pursuant to Section 39.5 of the Act on September 19, 2006. In support of

this

Petition, Premcor states as follows:

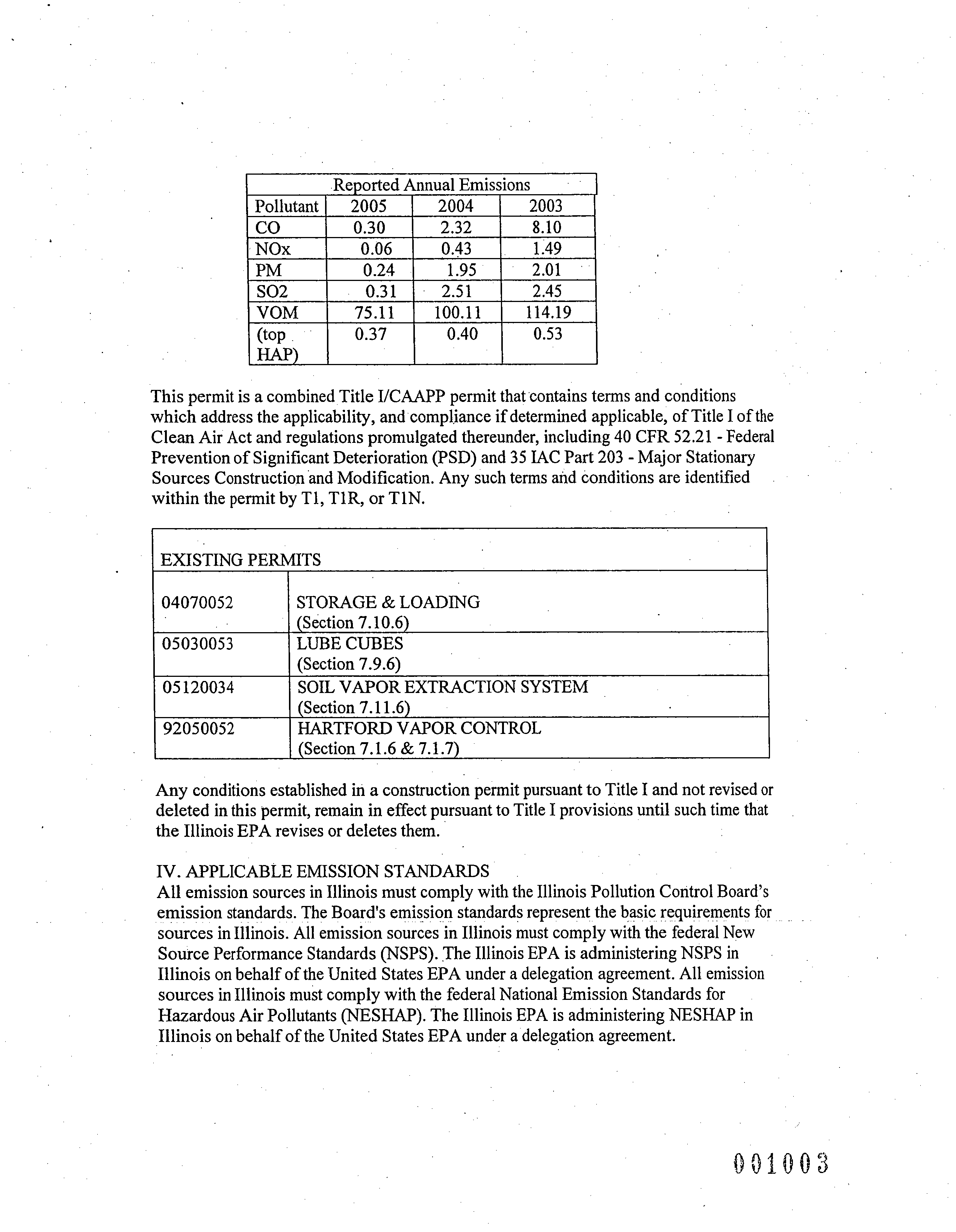

I. BACKGROUND

1.

Premcor owns and operates a petroleum bulk storage and loading terminal

in Hartford, Illinois ("Hartford

Terminal"),

which

is classified as a "major source" for

purposes of Title V of the federal Clean Air Act, 42 U.S.C. §§ 7401, et seq., and Section

39.5 of

the Act, 415 ILCS 5/39.5.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

2.

Pursuant to Section 504 of the Clean Air Act, 42 U.S.C. § 7661b(c), and

Section 39.5(5) of the Act, Premcor

submitted an application for a CAAPP permit for its

Hartford Terminal to Illinois EPA on March 7, 1996.

3.

On November 7, 2003, Premcor submitted comments (attached hereto as

Exhibit A)

to

Illinois EPA

on a draft CAAPP permit that Premcor had received from

Illinois EPA. Administrative Record at 503-507 ("R. at

").

4.

A draft CAAPP permit was issued by Illinois EPA on May 27, 2004, and

Illinois EPA honored a request for a public hearing that was received by Illinois EPA

during the ensuing public comment period. This public hearing was held on July 13,

2004; therefore, the public comment

period was extended until August 12, 2004. (R. at

586.)

5.

On August 2, 2004, during the above-referenced comment period,

Premcor submitted comments (attached hereto as Exhibit B) on the May 27, 2004 draft

permit.

R. at

942-945.

6.

Thereafter, on August 26, 2004, Premcor submitted a letter (attached

hereto as Exhibit C) intended to answer certain questions posed by the American Bottom

Conservancy regarding the May 27, 2004 draft permit. R. at 961-967.

7.

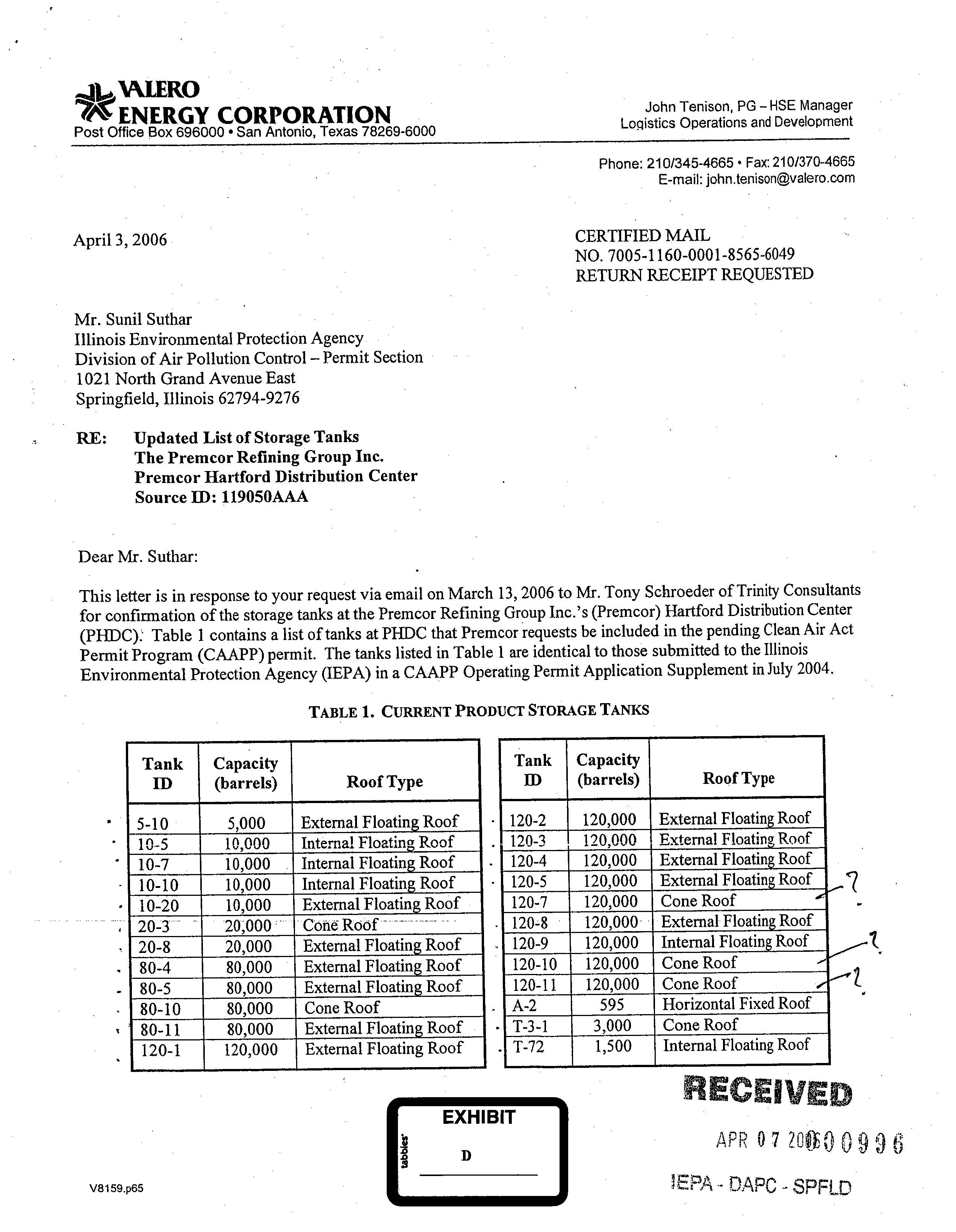

On April 3, 2006, Premcor further provided comments (attached hereto as

Exhibit D) in response to Illinois EPA's request for confirmation of

the

status

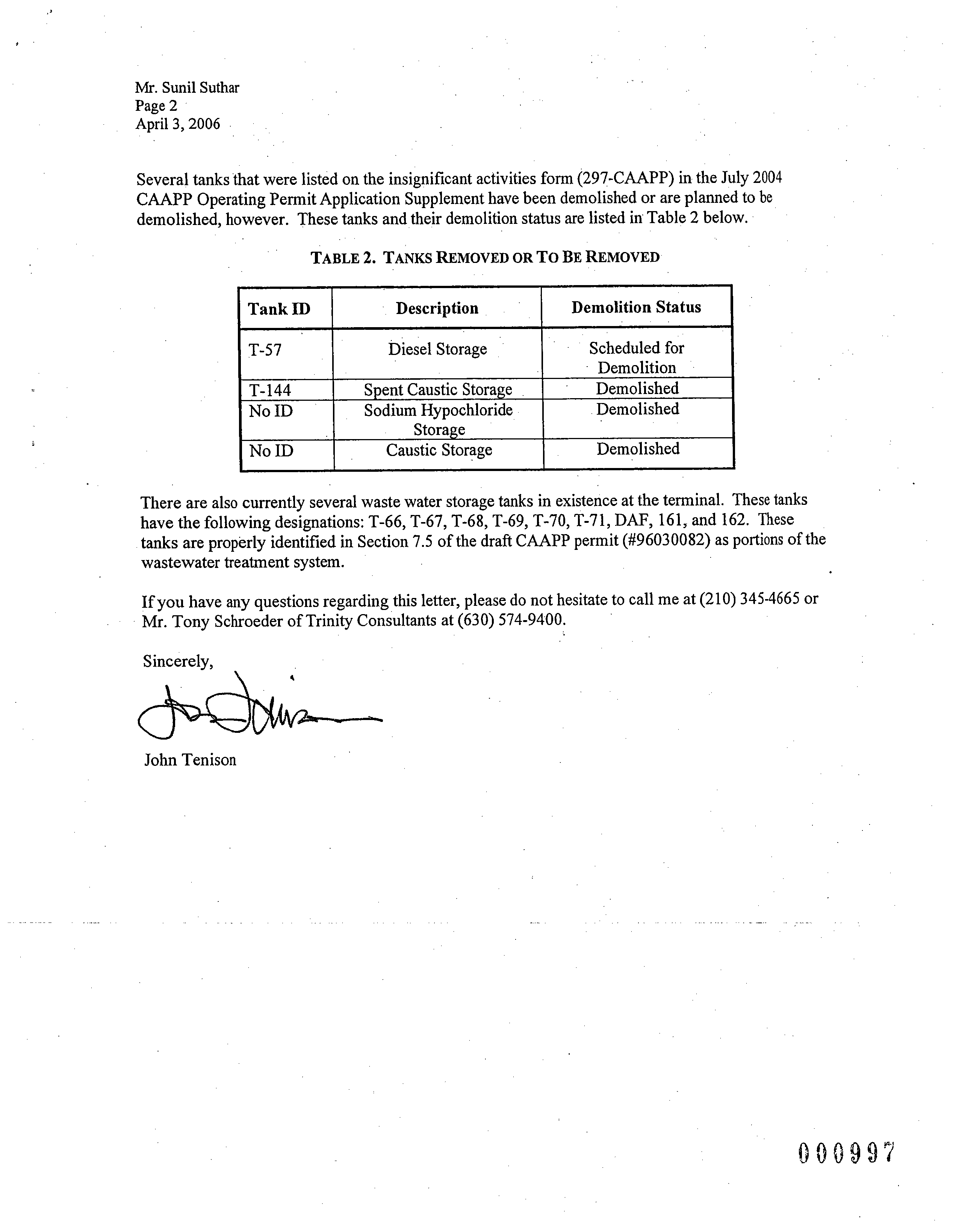

of

the

storage tanks at the Hartford Terminal. R. at 996-997.

8.

On August 3, 2006, Illinois EPA issued its "Project Summary for the Draft

Clean Air Act Program (CAAPP) Permit" ("Project Summary") (attached hereto as

Exhibit E)

for

the Hartford

Terminal. R. at 1000-1015. Illinois EPA

stated that

"[a]fter a

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

review of Premcor's application,... [it] made a preliminary determination that the

application met the standards for issuance of a CAAPP permit." R. at 1010. However,

Illinois EPA failed to address the comments that Premcor had submitted regarding

the

May

27, 2004 draft permit. See discussion infra.

9.

On or about August 3, 2006, Illinois EPA submitted a draft CAAPP permit

for the Hartford Terminal to the

United States

Environmental

Protection Agency

("USEPA") for its review. R. at 1016-1119.

10. In addition, during the time that elapsed between the issuance of the initial

draft CAAPP permit for the public comment period (May 2004) and the submission of a

subsequent draft permit (August 2006) to USEPA for review, Premcor applied for and

received several construction permits for the Hartford Terminal. Construction permit

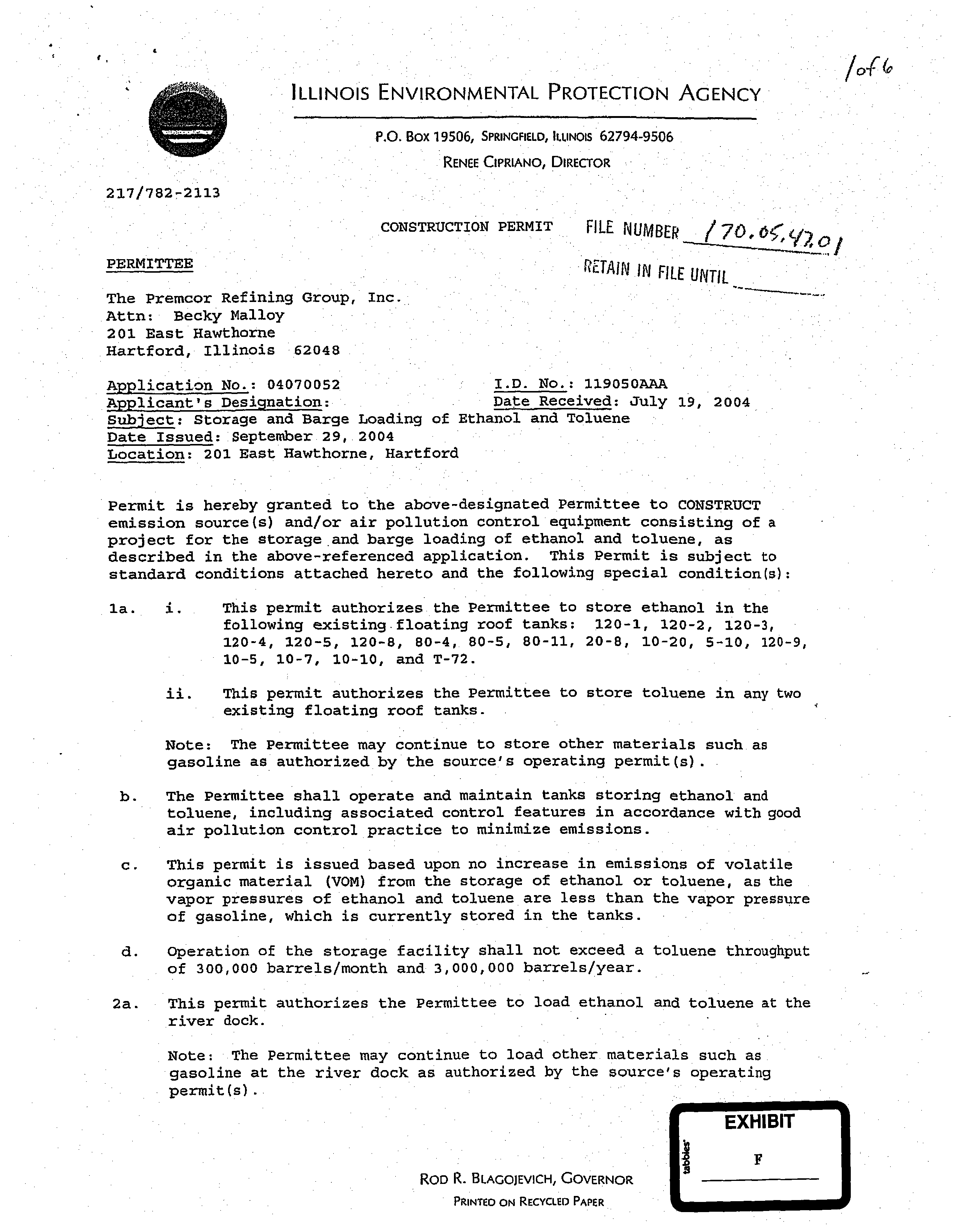

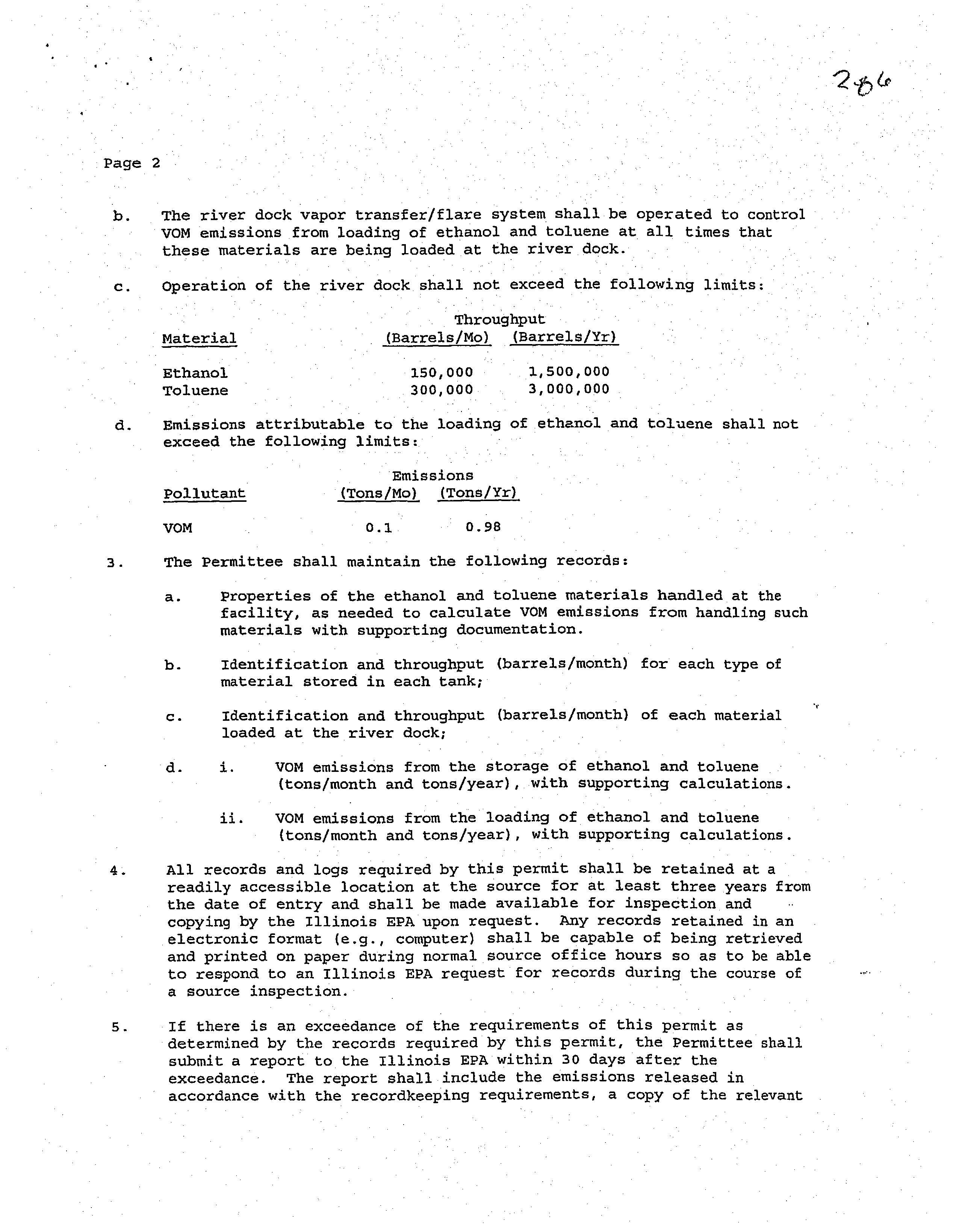

#04070052 (attached

hereto

as

Exhibit

F) allowed for the storage and loading of ethanol

and toluene at the terminal; permit #05030053 (attached hereto as Exhibit

G)

allowed for

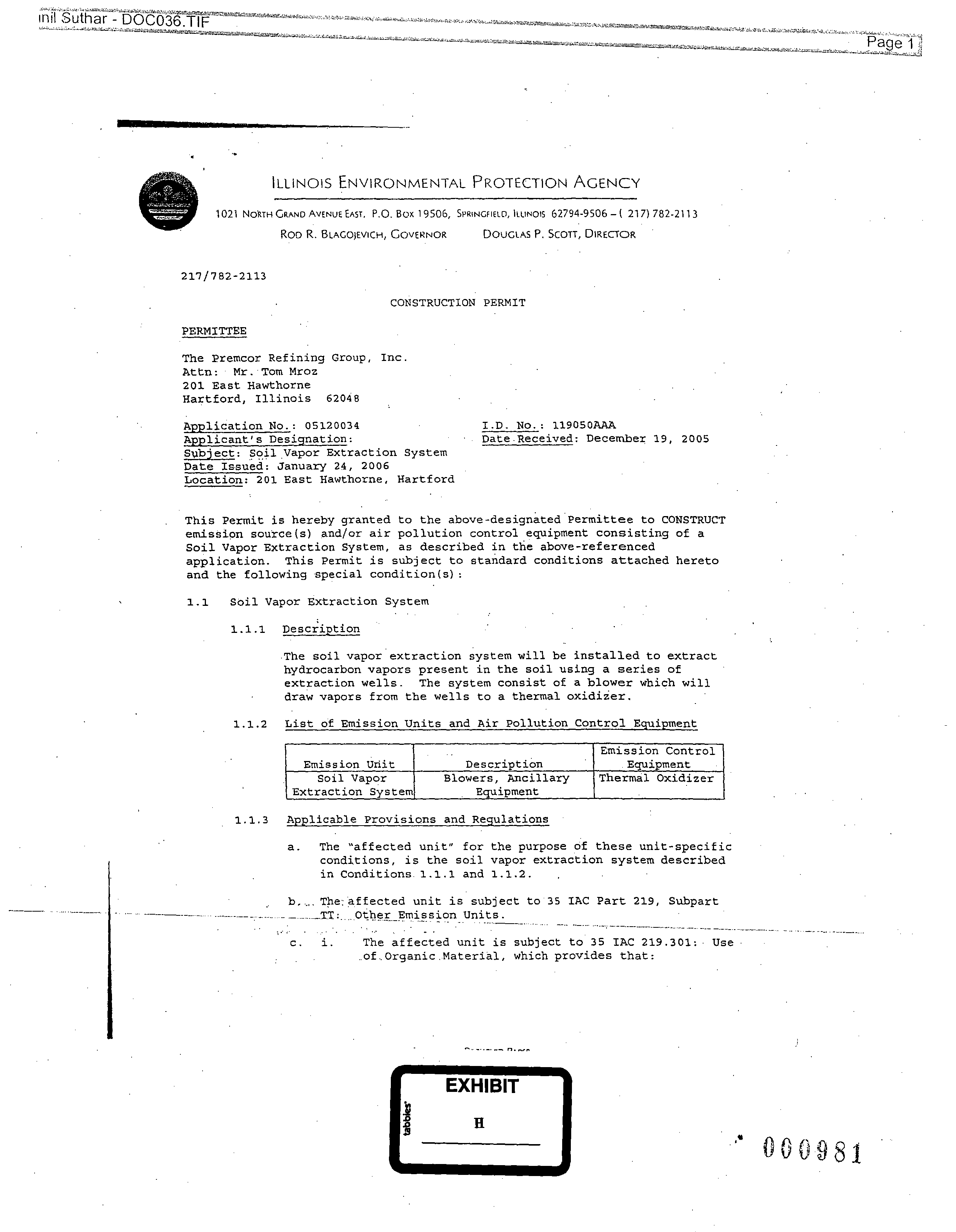

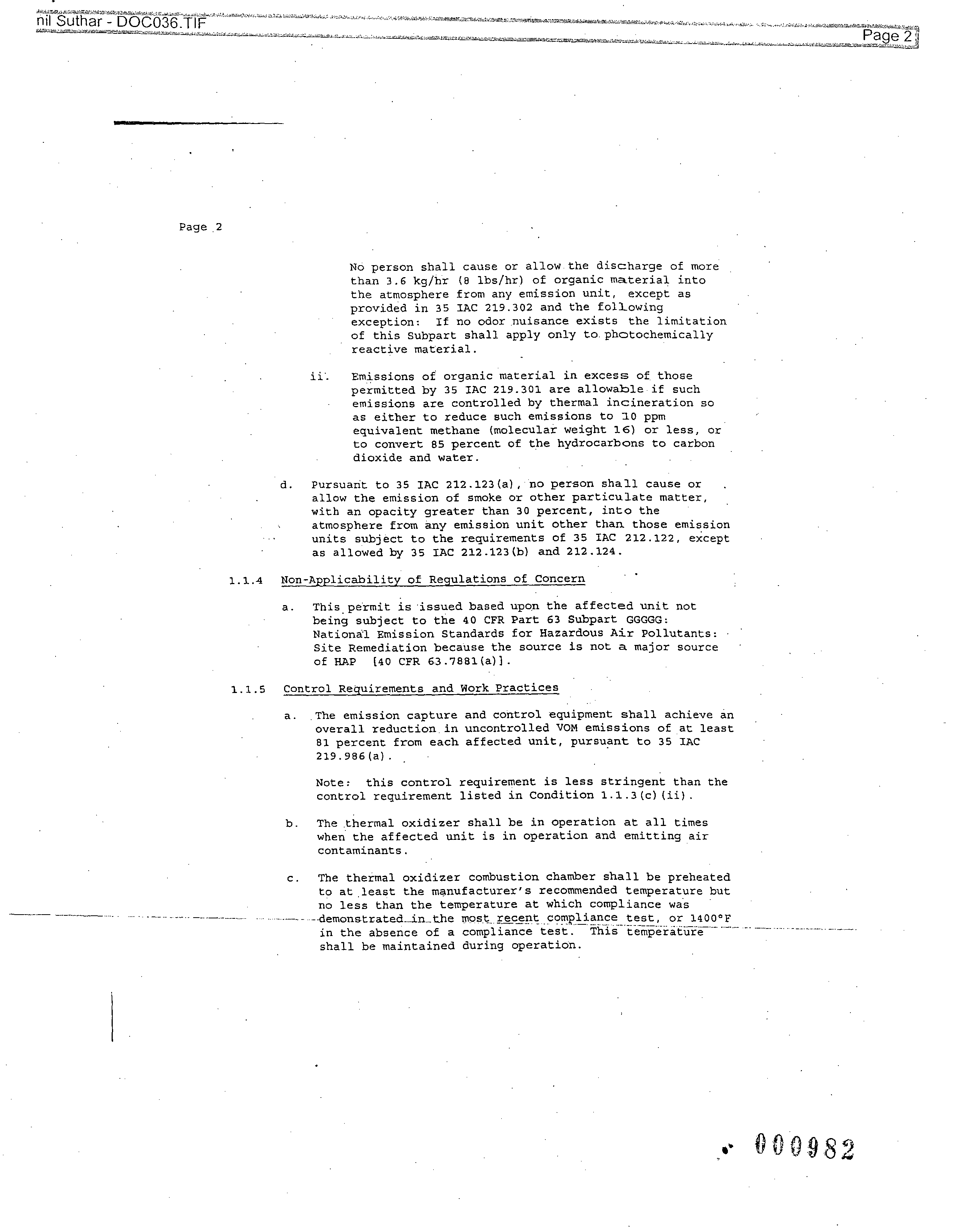

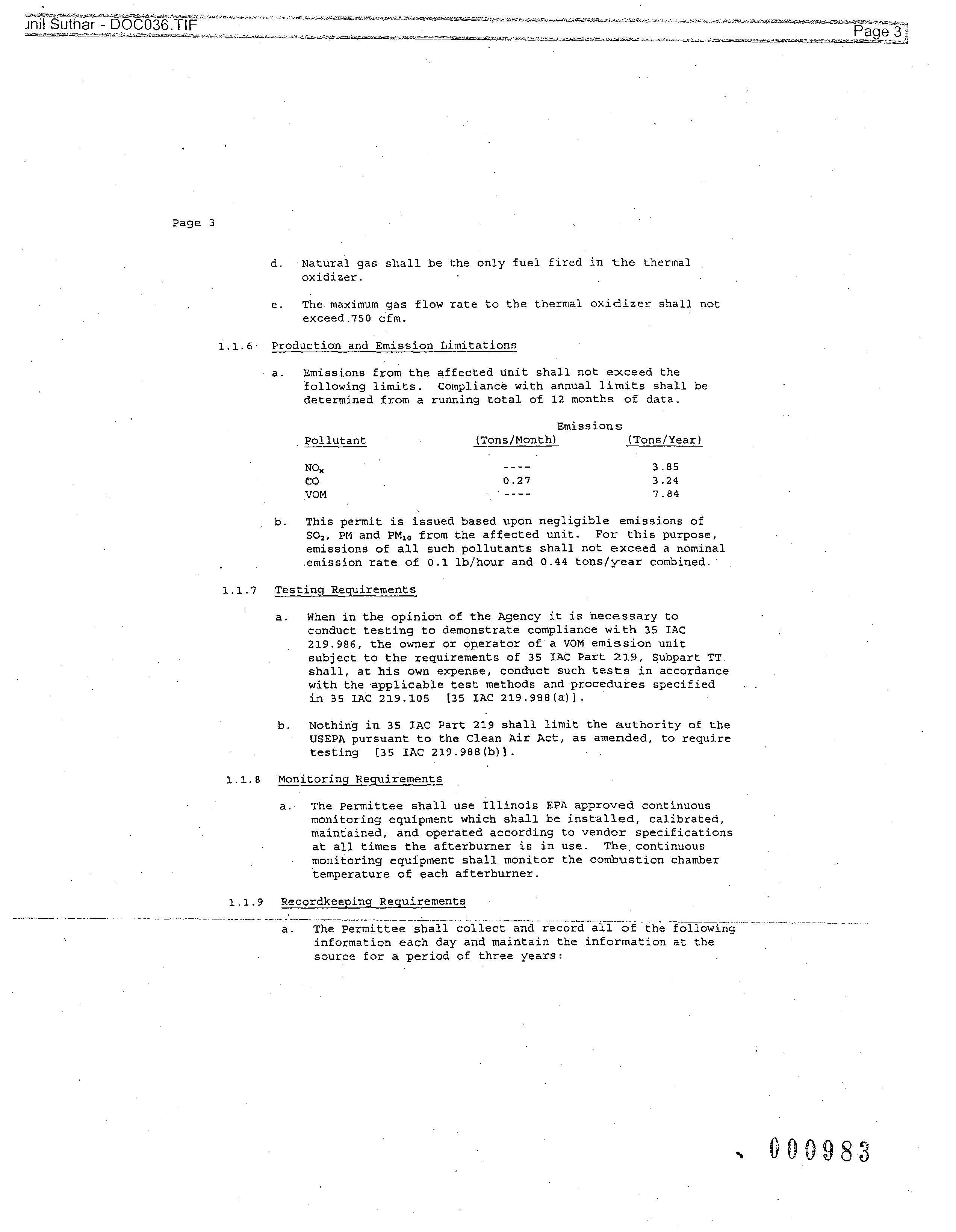

the installation of 19 Lube Cube containers; and permit #050120034 (attached hereto as

Exhibit H and R. at 981-988) allowed for the installation of an on-site Soil Vapor

Extraction

system.

I

11. On September 19, 2006, Illinois EPA granted a final CAAPP permit,

attached hereto as Exhibit 1, for the Premcor Hartford facility. R. at 1122-1225.

Although Premcor and Illinois EPA permit staff had discussions and have corresponded

regarding Premcor's concerns with the draft permit, Illinois EPA failed to make certain

changes to the CAAPP permit,

requested

by

Premcor prior

to September

19, 2006,

as set

forth more fully below.

I Certain

exhibits

to this Amended Petition for Review, including, but not limited to, Exhibit F and

G, were

omitted from the Administrative Record. Premcor intends to file a Motion to Supplement Administrative

Record in order to add these documents to the Administrative Record.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

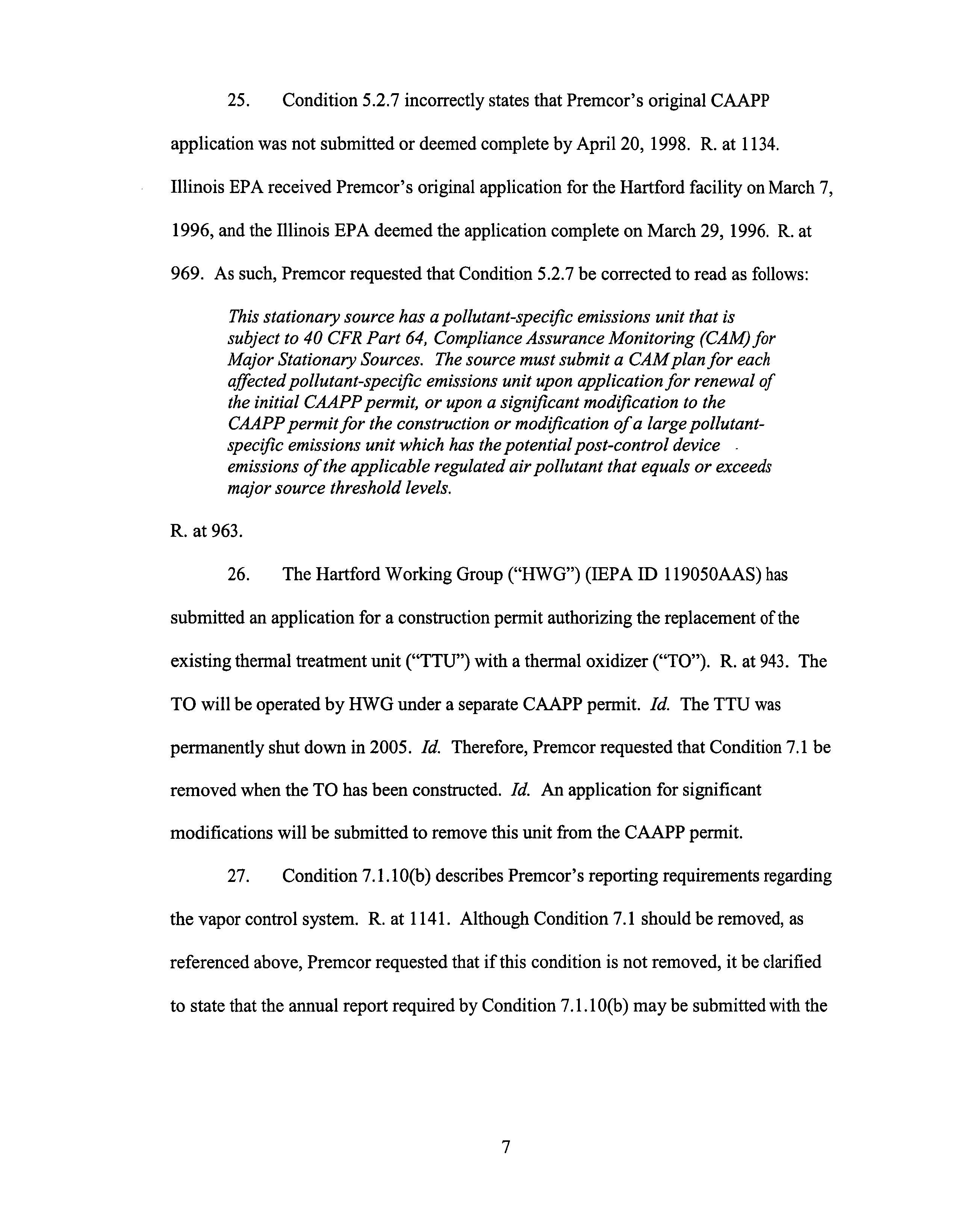

12. On October 24, 2006, Premcor filed its original Petition for Review

("Petition") of the CAAPP permit based on the fact that the Respondent failed to

incorporate comments submitted by Premcor into the final CAAPP permit and, as such,

the CAAPP permit does not reflect the current applicable requirements or the current

operation

of

the Hartford Terminal. Petition at JT10-12.

13. On November 27, 2006, the Respondent filed a Motion to Dismiss the

Petition ("Motion") arguing that the Petition failed "to provide adequate specificity to

apprise either the Board or the Illinois EPA of the subject matter of the appeal." Motion

to Dismiss at 15 (requesting the Board dismiss Premcor's petition or, in the alternative,

require the filing of an amended petition).

14.

Counsel

for Premcor has consulted

with

the Respondent regarding the

Respondent's concerns as described in its Motion. Based on these discussions, it is

Premcor's understanding that filing this Amended Petition reiterating in detail Premcor's

comments

regarding the issued CAAPP permit will resolve the Respondent's concerns.

II. COMMENTS RAISED BY PREMCOR PRIOR TO THE ISSUANCE OF

THE FINAL CAAPP PERMIT

15. The following concerns were raised by Premcor prior to the issuance of

the final CAAPP permit, but not incorporated by Illinois EPA into the final CAAPP

permit.

16. Condition 1.3 of the CAAPP

permit

incorrectly lists Premcor's

Environmental Contact as Bill

Malloy. R.

at

1125. In August 2004, Premcor

requested

that the name be corrected to list Becky Malloy as Premcor's Environmental Contact. R.

at 943.2

2

As discussed below, thereafter, Premeor's Environmental Contact changed to Massoud Modarres.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

17. In October 2005, Premcor submitted a notification (attached hereto as

Exhibit J) of change in the responsible official for the Hartford Terminal. Premcor

requested that the responsible official be changed

from Ed

Jacoby to

Paul Brochu,

Vice

President of Logistics, Operations, and Development.

18. Condition 3.1.1 pertains to "[a] ctivities determined by the Illinois EPA to

be insignificant activities, pursuant to 35 IAC 201.210(x)(1) and 201.211, as follows." R.

at 1128. Premcor requested the chemical storage tank and chemical storage

drum listed

in Condition 3.1.1 be removed since they are insignificant activities pursuant to 35 Ill.

Admin. Code § 201.210(x)(17) and

covered under Condition 3.1.3. R. at 943. Premcor

further requested that "Lube Cube Storage Tanks" be added to Condition 3.1.1.

Id.

Consequently, Condition 3.1.1 should read

3.1.1 Activities determined by Illinois EPA to be insignificant activities

pursuant to 35 IAC 201.210(x)(1) and 201.211, as follows:

Lube Cube Storage

Tanks

Id.

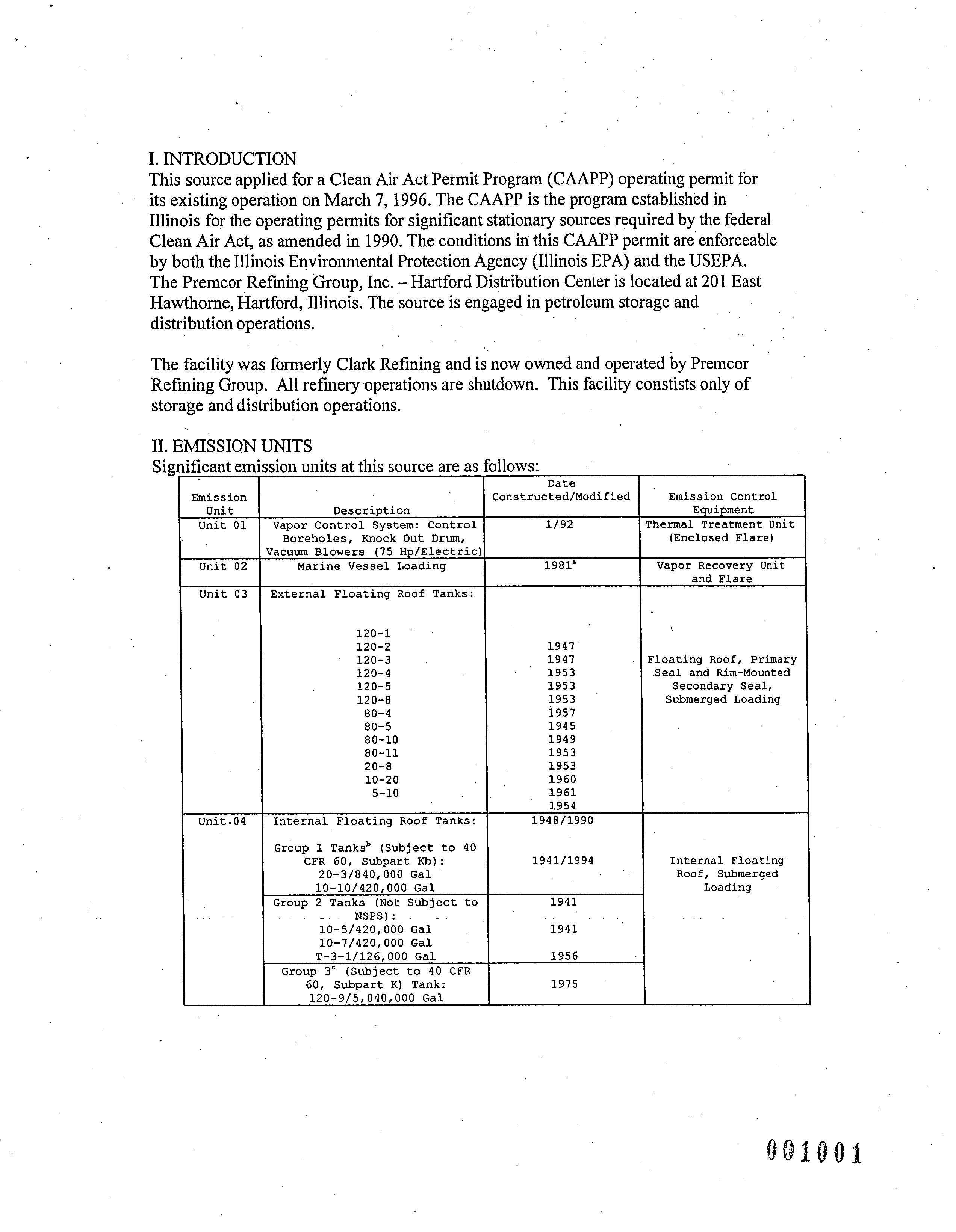

19. Condition 4.0 lists significant emission units at the

Hartford Terminal. R.

at 1130. Premcor requested that Tank 80-10, which is listed as part of Unit 03, be

removed from Condition 4.0 since it has a fixed

roof tank and only stores fuel oil #2. R.

at 943. It is, therefore, classified as an insignificant activity under 35

Ill. Admin.

Code

§ 201.210(x)(11) (Condition 3.1.3). For the same reasons, Premcor also requested that

Tank 20-3 and Tank T-3-1 be removed from Unit 04 of Condition 4.0. Id.

20. In addition,

Premcor requested that Tank T-72, which is an internal

floating roof tank, be added to Unit

04 of

Condition

4.0 since it will store gasoline and

other organic materials with vapor pressure less than gasoline. R. at 943.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

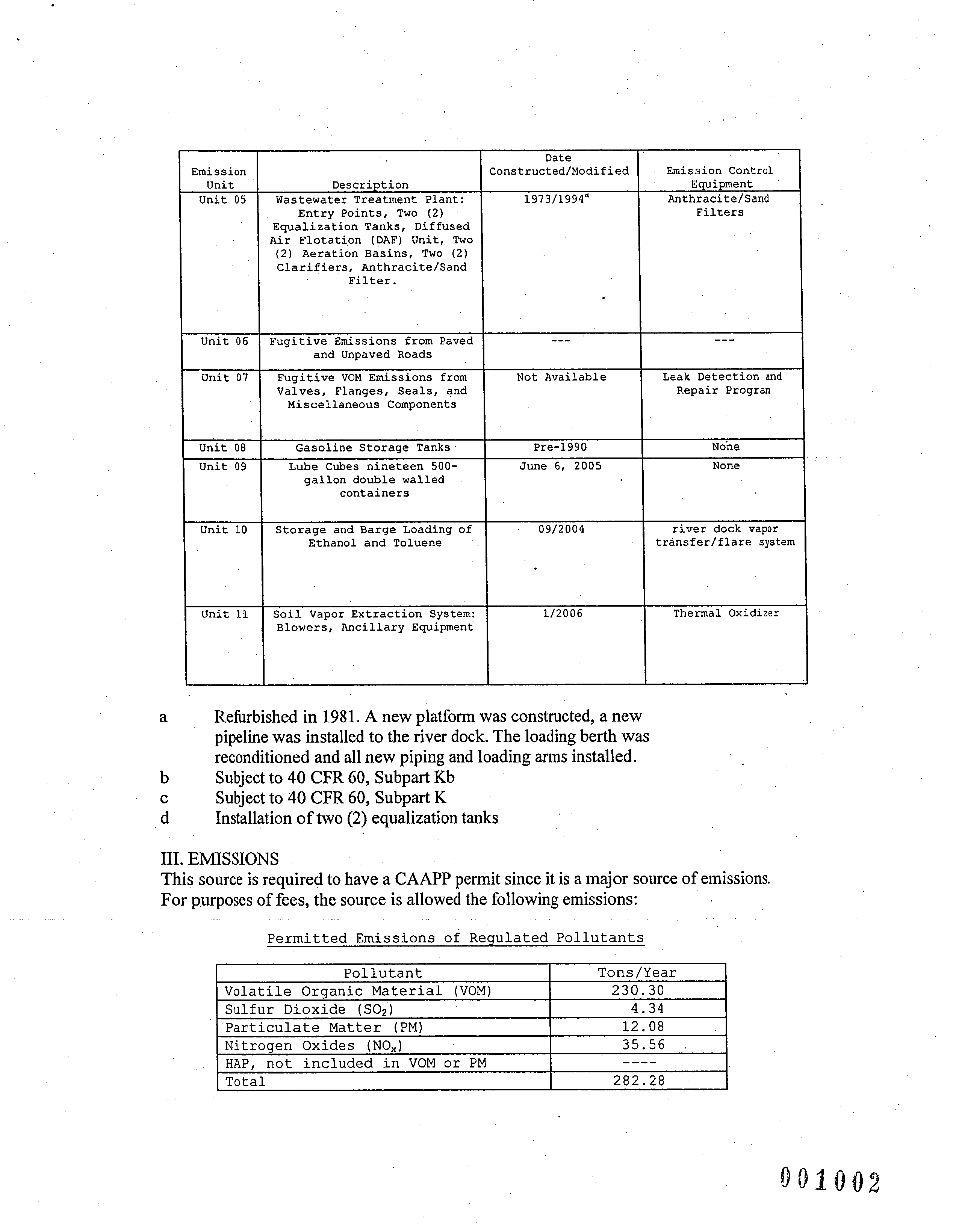

21. Premcor also requested that the Illinois EPA remove the anthracite/sand

filters from Unit 05 listed in Condition 4.0 because they are not air emission control

equipment. R. at 943. The anthracite/sand filters,

which

are part of the

wastewater

treatment plant, remove solids from the waste water stream. Id.

22. Because of the low level of road dust associated

with Unit 06,

Premcor

requested that "Fugitive Emissions From Paved and Unpaved Roads" be removed from

Condition

4.0. R. at

943, 945.

Due

to the

low level

of road dust associated with the

facility, Condition 5.2.5(a) of the permit should be adequate to regulate fugitive

dust

emissions from within the source. R. at 945.

23. Premcor also clarified in its comments that the "Gasoline Storage Tanks"

described as Unit 08 in Condition 4.0 were listed as insignificant activities in the original

CAAPP application and that all the gasoline tanks listed in Condition 7.8 of the draft

permit have

been

permanently removed from the facility,

with

the exception of the

Gasoline Tank Wells, which continue to be insignificant activities. R. at 943. Premcor,

therefore, requested that

Tank A-2

be added to Condition

4.0 and

that the description of

Unit 08 be changed to "Tank A-2" because as a small horizontal fixed roof storage tank,

which is used as a pressure relief tank, it is appropriately listed in Condition 4.0. Id.

24. Condition 5.5.1 includes a table entitled "Permitted Emissions of

Regulated Pollutants." R. at 1135. Premcor requested that the table be updated to reflect

the change in VOM emissions due to the reclassification of storage tanks. Id. The table

should be revised as follows: VOM "Tons/Year" from "230.30 tpy" to 212.69 tpy" and

the "Total Regulated Pollutant Emissions" from "282.28 tpy" to "264.67 tpy."

R.

at 943.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

25. Condition 5.2.7 incorrectly states that Premcor's original

CAAPP

application was not submitted or deemed complete by April 20, 1998. R. at 1134.

Illinois

EPA received Premcor's original application for the Hartford facility on March 7,

1996, and the Illinois EPA deemed the application complete

on March 29, 1996. R. at

969. As such, Premcor requested that Condition 5.2.7 be corrected to read as follows:

This stationary source has a pollutant-specific emissions unit that

is

subject to 40 CFR Part 64, Compliance Assurance Monitoring (CAM) for

Major Stationary Sources. The source must submit a CAMplan for each

affected pollutant-specific emissions unit upon application for renewal of

the initial CAAPP permit, or upon a significant modification to the

CAAPP permit for the construction or modification of a large pollutant-

specific emissions unit which

has the potential

post-control device

emissions of the applicable regulated air pollutant that equals or exceeds

major source threshold levels.

R . at 963.

2 6. The Hartford Working Group ("HWG") (IEPA ID 119050AAS) has

submitted an application for a construction permit authorizing the replacement of the

existing thermal treatment unit ("TTU") with a thermal oxidizer ("TO"). R. at 943. The

TO will be operated by HWG under a separate CAAPP permit. Id. The TTU was

permanently shut down in 2005.

Id. Therefore, Premcor requested

that Condition

7.1 be

removed when the TO has been constructed. Id. An application for significant

modifications will be submitted to remove this unit from the CAAPP permit.

27. Condition 7.1.10(b) describes Premcor's reporting requirements regarding

the

vapor

control system. R. at 1141. Although Condition 7.1 should be removed, as

referenced above, Premcor requested that if this condition is not removed, it be clarified

to state that the annual report required by Condition 7.1.10(b) may be submitted with the

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

Annual Emissions Report, which is required by Condition 5.7.2. R. at 944.

Premcor

suggested the following language:

The Permittee shall submit an annual report of emissions listed in

Condition 7.1.6 with supporting calculations. The report shall include a

summary of time periods, when the thermal treatment unit f ame was

extinguished.

This

annual

report may be submitted as a supplement to the

Permittee's Annual Emissions Report, which is required by Condition

5.7.2.

Id.

28. Condition 7.2.7(c) provides that if a flare is used as a control device to

comply with 35 Ill. Admin. Code § 219.762(a)(1), compliance will be "determined by the

methods described in Section 219.429(c)." R. at 1146. Premcor

requested

that Condition

7.2.7(c) be clarified by providing more detail regarding the requirements of 35 Ill.

Admin. Code § 219.429(c) and suggested the following language:

If the control device used to comply with 35 IAC Section

219.762(a)(1) of

this Subpart

is

a flare,

it shall:

1)

Be designed for and operated with no visible emissions, except

for

periods not

to exceed a total of 5 minutes during any 2 consecutive

hours as determined by U.S. EPA Method 22.

2)

Be operated with a pilot f ame present at all times and shall be

monitored with a thermocouple or any other equivalent

device to

detect the presence of the fame.

3)

Be steam-assisted, air-assisted,

or nonassisted.

4)

Be

used

only

with

the net heating value of the gas being combusted

being 11.2 MJ/scm (300 Btu/scf or greater if the f are is steam-

assisted or air-assisted; or with the net

heating

value

of the gas

being combusted being

7.45 MJ/scm (200 Btu/scf or greater if the

fare is nonassisted.

R. at 944.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

29. In order to maintain continuity of the permit condition numbering system,

Premcor requested

that Condition 7.2.7(d)(iii) be corrected to

read

"As an

alternative to

subsection (d)(ii) of this Section,..." as opposed to "As an alternative to subsection (d)(2)

of this Section,...." R. at 944.

30.

Premcor also requested that the following compliance option, as provided

in 35 Ill. Admin. Code §

219.762(b)(3)(B), be added to the permit as Condition

7.2.7(d)(iv):

As an alternative to subsections (d)(ii) and (d)(iii) of this Section, an

owner or operator of a marine terminal may obtain documentation as

described in 35 IAC 219.770(b) that the marine vessel

has been

vapor-

tightness tested within either the preceding 12 months or the preceding 14

months, if the test is being conducted as part of the Coast Guard's

reinspection of the vessel required under 46 CFR 31.10-17, using Method

21 of Part 60, Appendix

A,

incorporated by

reference at

Section

219.112

of this Part, as described in Section 219.768(b)

of this

Subpart.

R . at 944.

3 1. In order to maintain continuity of the permit condition numbering system,

Premcor requested that Condition 7.2.7(f) and 7.2.7(g) be

relabeled 7.2.7(e) and 7.2.7(f),

respectively. Id.

32. Premcor requested that Conditions 7.2.9(d) and 7.2.9(e) be

removed

because neither condition applies to the Hartford Terminal's

operations. Id. Premcor

does

not

use

the emissions reduction compliance option at the marine terminal as

described in Section 7.2.9(d), and the

requirement in

Condition

7.2.9(e) mandating initial

certification of marine terminal

operations was required, and complied with, in 1996. Id.

33. Condition 7.3.2 lists emission units and air pollution control equipment for

Unit 03. R. at 1152. Premcor requested that Tank 80-10 be removed from the list of

tanks included in Unit 03 because

it

is a

fixed roof tank and only stores fuel oil

#2.

Id. It

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

is, therefore, classified as an insignificant activity under 35

Ill. Admin.

Code

§ 201.210(a)(11)

(Condition 3.1.3). R. at 1152.

34. Condition 7.4.2

lists

emission

units and air pollution control equipment for

Unit 04. R. at 1158. Premcor requested that Tank 20-3 and Tank T-3-1 be removed from

the list of tanks included in Unit 04 because

they are fixed roof tanks that will only store

fuel oil

#2,

and are classified as insignificant activities under 35 Ill. Admin. Code

§ 201.210(a)(11) (Condition 3.1.3). R. at 944.

35. Premcor further requested that Tank T-72 be added to Unit 04 of

Condition

7.4.2 because it is an internal floating roof tank. Id.

36. Premcor also commented

regarding

Condition

7.5 that the HAP speciation

of VOM emissions from the wastewater treatment plant was updated in its supplement to

the CAAPP,

dated July 2004. R. at 945.

37. Premcor

requested that Illinois EPA remove Condition 7.5.5 from the

CAAPP

permit because, as previously discussed, the anthracite/sand filters are not air

emissions control equipment and should not be subject to periodic

inspections under the

CAAPP permit. Id.

38. As

referenced above, due to the low level of road dust associated with

paved and unpaved roadways at the Hartford Terminal, the requirement in Condition 7.6

regarding the annual calculation of emissions from road traffic

is

unnecessary

and over

burdensome.

Premcor, therefore, requested that Condition 7.6 be removed. R. at 945.

Condition 5.2.2(a) is adequate

to regulate fugitive dust emissions from roads at the

facility. Id.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

39. Premcor requested that references to "petroleum refineries" be removed

from Conditions 7.7.7, 7.7.8 and 7.7.9 in order to avoid confusion regarding the nature

of

Premcor's operations

under this permit. R. at 507. Condition 7.7.7 should read:

As prescribed by 35 IAC 219.766, affected Fugitive YOM Emissions from

Leaking River Dock Flare

Components are subject to 35 IAC 219.447,

which prescribes that an owner or operator of a marine terminal subject

to 35 IAC 219.445 of this Part shall, for the purpose of detecting leaks,

conduct a component monitoring program consistent with the following

provisions:

Condition 7.7.8 should read:

As prescribed applicable to marine terminals by 35 IA C 219. 766, affected

Fugitive VOMEmissions from Leaking River Dock Flare Components are

subject

to 35

IAC 219.446,

which

provides

that an owner or operator shall

prepare

a

monitoring

program which

contains,

at a

minimum:

a)

An identification of all marine terminal components and the period

in which each will be monitored pursuant to 35 IAC 219.447 X35

IA C Section 219.446(a)];

b)

The format for the monitoring log required by 35 IAC 219.448 (35

IA

C

Section 219.449(b)];

c)

A

description

of the monitoring equipment to be used pursuant to

35 IAC 219.447 of this Part X35 IAC Section 219.446(c)];

d)

A description of the methods to be used to identify all pipeline

valves, pressure

relief valves in gaseous service and all leaking

components, such that they are obvious to both terminal personnel

performing monitoring and Agency personnel performing

inspections X35

IA

C Section

219.446(d)].

Condition 7.7.9 should read:

As prescribed applicable to marine terminals by 35 IAC 219. 766, affected

Fugitive YOM Emissions from Leaking River Dock Flare Components are

subject to 35 IA C 219.448, which prescribes that an owner or operator

shall maintain a leaking component monitoring log which shall contain at

a minimum, the following information:

R. at 507.

11

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

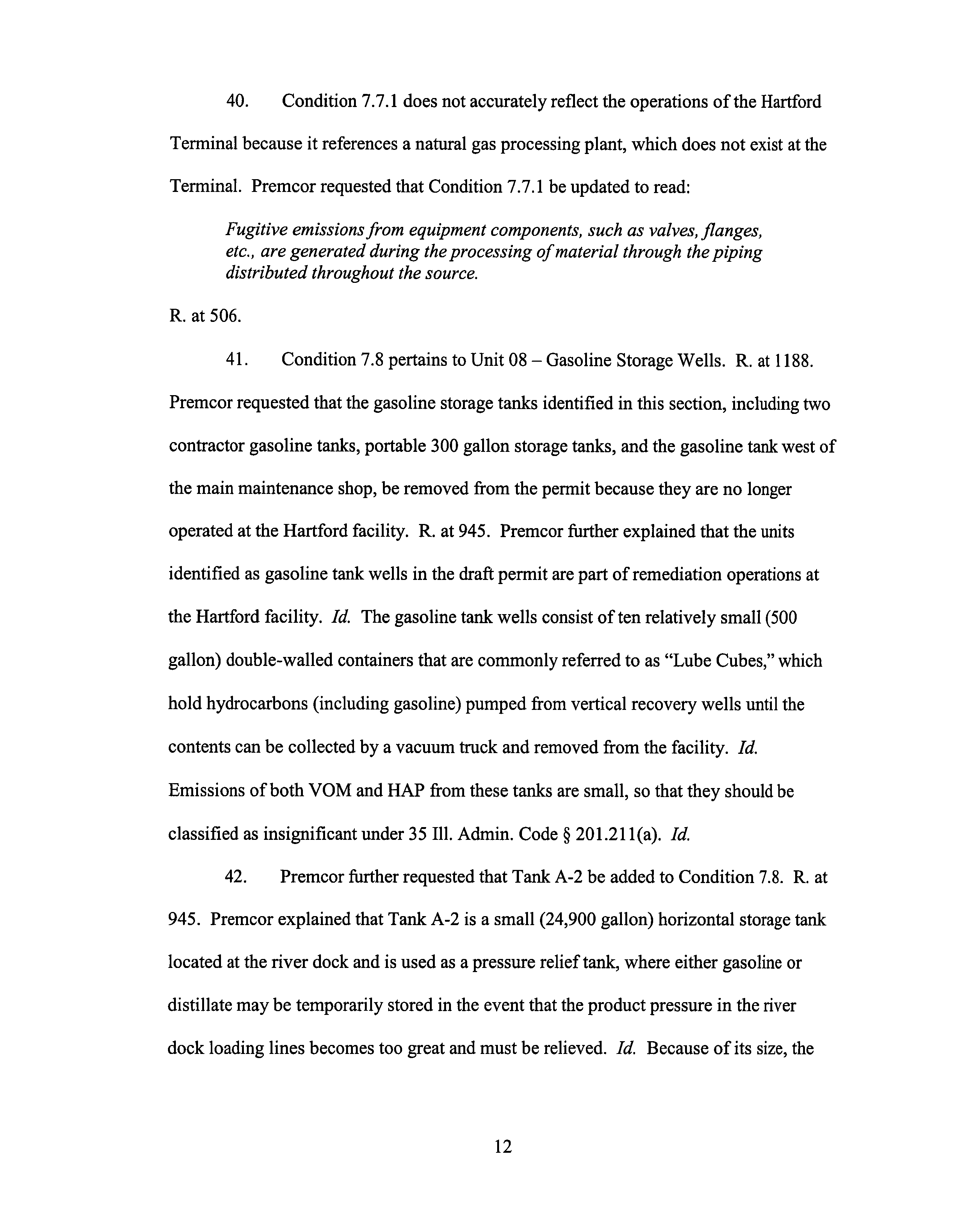

40.

Condition 7.7.1 does not accurately reflect the operations of the Hartford

Terminal because it references a natural gas processing plant,

which does

not

exist at the

Terminal. Premcor requested that Condition

7.7.1

be

updated to read:

Fugitive emissions from equipment components, such as valves, flanges,

etc., are generated

during the processing of material through the piping

distributed

throughout the source.

R. at 506.

41. Condition 7.8 pertains to Unit 08 - Gasoline

Storage Wells. R. at 1188.

Premcor requested that the

gasoline storage tanks identified in this section, including two

contractor gasoline tanks, portable 300 gallon storage tanks, and the gasoline tank

west

of

the main maintenance shop, be removed from the permit because they

are no longer

operated at the Hartford facility. R. at 945. Premcor further

explained that the units

identified as gasoline tank wells in the draft permit are part of remediation operations at

the Hartford facility. Id. The gasoline tank

wells consist of ten relatively small (500

gallon) double-walled containers that are commonly referred to as "Lube

Cubes," which

hold

hydrocarbons (including gasoline) pumped from vertical recovery wells until the

contents can be collected by a

vacuum

truck

and removed from the facility. Id.

Emissions of both VOM and HAP from these

tanks are small, so that they should be

classified as insignificant under 35 Ill. Admin. Code § 201.211(a). Id.

42. Premcor further requested that Tank A-2

be added to Condition 7.8. R. at

945. Premcor explained that Tank A-2 is a small (24,900

gallon) horizontal storage tank

located at the river dock and is used as a pressure relief tank, where either gasoline or

distillate may be temporarily stored in the event that the product pressure in

the river

dock loading lines becomes too great and must be relieved. Id. Because of its size, the

12

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

only control equipment necessary for the operation of this tank is submerged fill, as

required by 35 Ill. Admin. Code § 219.122(b). R. at 945. In addition, Premcor requested

that all references to "affected Tank Wells" in Condition 7.8 be changed to "affected

storage tank" to reflect the addition of Tank A-2 to Condition 7.8.

Id.

43. Premcor requested that the second paragraph of Condition 7.8.6 be

removed because it is entirely informational and does not contain any permit

requirements. Condition 7.8.6 should read as

follows:

7.8.6 Emission Limitations

There are no specific emission limitations

for this unit, however, there are

source wide

emission limitations in Condition 5.5 that include this unit.

Id.

4 4. As stated above, prior to the issuance of the final CAAPP permit, Premcor

requested all of the above changes to the permit

in

order

to

ensure

that the permit

accurately reflects the operation of the Hartford Terminal and the legal

requirements

applicable

to that operation. However, Respondent did not incorporate any of those

changes into the final permit.

III. ADDITIONAL COMMENTS FOR CONSIDERATION BY THE ILLINOIS

EPA

45. In addition to the comments above, Premcor has the following additional

comments on the final CAAPP permit.

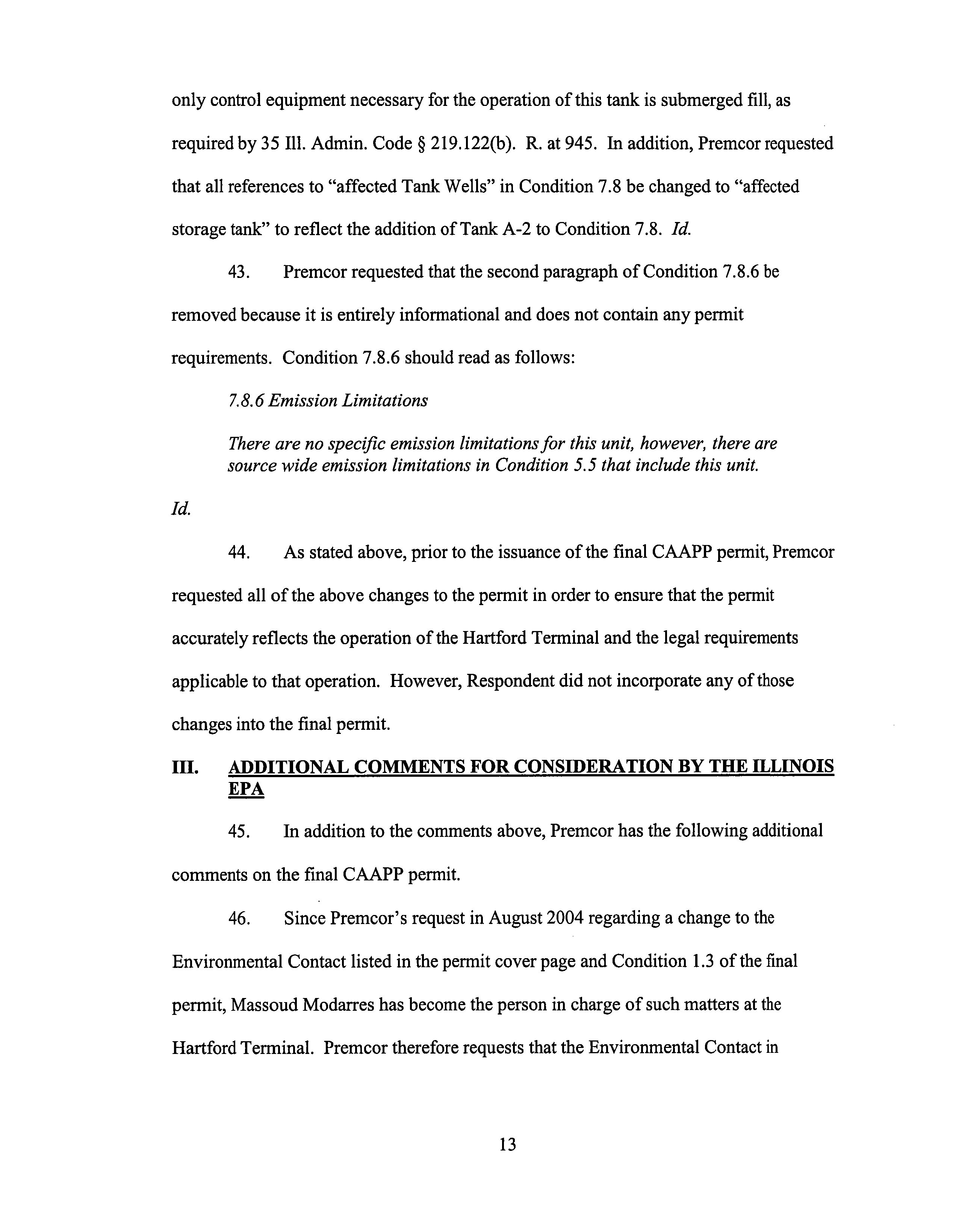

46. Since Premcor's request in August

2004 regarding a change to the

Environmental Contact listed in the permit cover

page and

Condition

1.3 of the final

permit, Massoud Modarres has become the person in charge of such matters at the

Hartford Terminal. Premcor therefore

requests that the Environmental Contact in

13

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

Condition 1.3 be changed to Massoud

Modarres, as well as updating the telephone

number

to (618) 255-5109. See Tl6 supra.

47. Because of the removal of "Fugitive

Emissions From Paved and Unpaved

Roads"

from Condition 4.0, Premcor requests that the unit number in

Condition 4.0 for

Fugitive VOM Emissions

be changed from Unit 07 to Unit 06. See R.

at

1130.

48. For consistency, Premcor requests

that the Illinois EPA update the unit

number for Gasoline Storage Tanks from

Unit 08 to Unit 07. See R. at 1130. In addition,

as more fully explained

below, Premcor requests that Unit 09 and Unit 10 be removed

from

the "Significant Emission Units" table, and consequently the unit number for

the

Soil Extraction System be updated from Unit 11 to Unit 08.

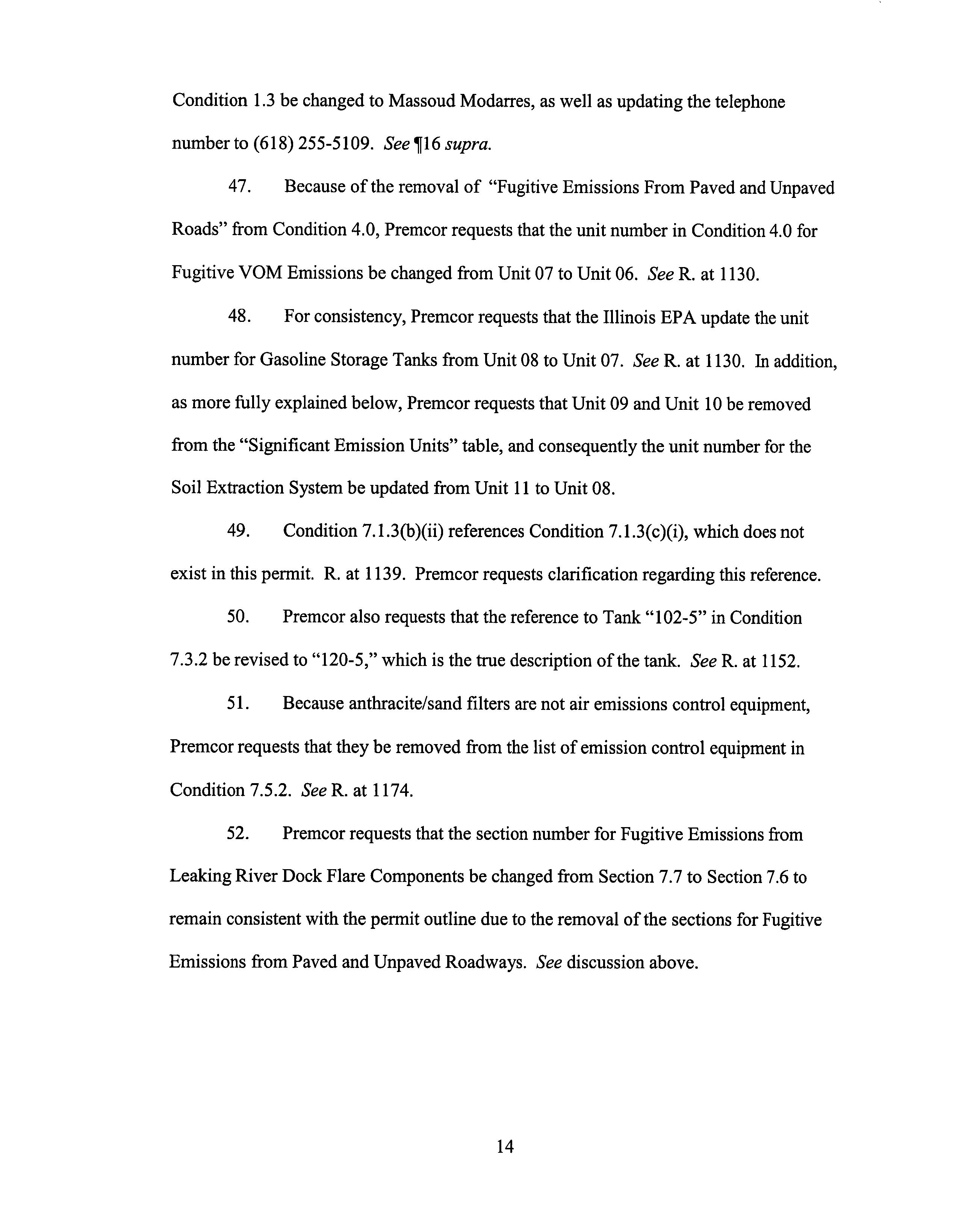

49. Condition 7.1.3(b)(ii) references

Condition 7.1.3(c)(i), which does not

exist

in

this permit. R. at 1139. Premcor requests clarification regarding

this

reference.

50. Premcor also requests that the reference

to Tank "102-5" in Condition

7.3.2 be revised to "120-5," which is the true description of the

tank. See R. at 1152.

51. Because

anthracite/sand filters are not air emissions control equipment,

Premcor requests that they be removed from

the list of emission control equipment in

Condition 7.5.2. See R. at 1174.

52. Premcor

requests that the section number for Fugitive Emissions from

Leaking River Dock Flare Components be changed from Section

7.7 to Section 7.6 to

remain consistent with the permit outline due to

the removal of the sections for Fugitive

Emissions from Paved and Unpaved Roadways. See discussion above.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

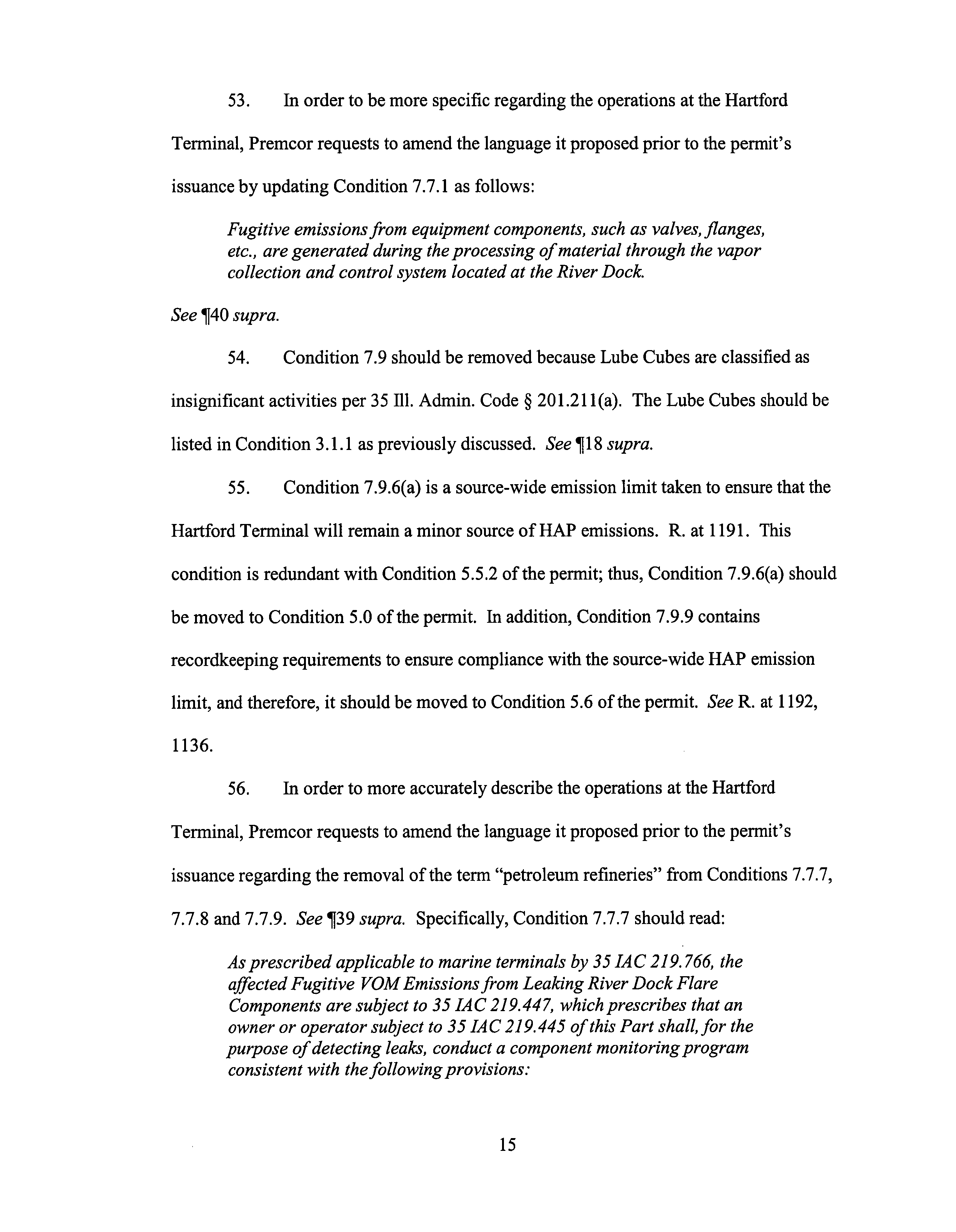

53. In order to be more specific regarding the operations at the Hartford

Terminal, Premcor requests to amend the language it proposed prior to the permit's

issuance by updating Condition 7.7.1 as follows:

Fugitive emissions from equipment components, such as valves, flanges,

etc., are generated during the processing of material through the vapor

collection and control system located at the River Dock.

See T40 supra.

54. Condition 7.9 should be

removed

because

Lube Cubes are classified as

insignificant activities per 35111. Admin. Code § 201.211(a). The Lube Cubes should be

listed in Condition 3.1.1 as previously discussed. See T18 supra.

55. Condition 7.9.6(a) is a source-wide emission

limit taken

to

ensure that the

Hartford Terminal will remain a minor source of HAP emissions. R. at 1191. This

condition is redundant with Condition 5.5.2 of the permit; thus, Condition 7.9.6(a) should

be moved to Condition

5.0 of the permit. In addition, Condition 7.9.9 contains

recordkeeping requirements to ensure compliance with the

source-wide HAP emission

limit, and therefore, it should be moved to Condition 5.6 of the permit. See

R. at 1192,

1136.

56. In order to more accurately describe the operations

at the Hartford

Terminal, Premcor requests

to amend the language it proposed prior to the permit's

issuance regarding the

removal of the term "petroleum refineries" from Conditions 7.7.7,

7.7.8 and 7.7.9. See x(39 supra. Specifically, Condition 7.7.7 should read:

As prescribed applicable to marine terminals by 35 IA C 219.766, the

affected Fugitive YOM Emissions from

Leaking River Dock Flare

Components are subject to 35

IA

C

219.447, which prescribes that an

owner

or operator subject to 35 IA C 219.445 of this Part shall, for the

purpose of detecting leaks, conduct a component

monitoring program

consistent with

the following provisions:

15

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

Condition 7.7.8 should read:

As prescribed applicable to marine terminals by 35 IA C 219.766, affected

Fugitive VOMEmissions from Leaking River Dock Flare Components are

subject to 35 IA C 219.446, which prescribes that an owner or operator

shall prepare a monitoring program which contains, at a minimum:

a)

An identification of all components and the period in which each

will be monitored pursuant to 35 IAC 219.447 [35 IAC

219.446(a)];

b)

The format for the monitoring log required by 35 IAC 219.448 [35

IAC' 219.446(b)];

c)

A description of the monitoring

equipment to be used pursuant

to

35

IAC 219.447 [35 IAC 219.446(c)];

d)

A description of the methods to be used to

identify all pipeline

valves, pressure

relief

valves

in gaseous service and all leaking

components such that they are obvious to both personnel

performing monitoring and Agency personnel performing

inspections [35

IAC 219.446(d)].

Condition 7.7.9 should read:

As prescribed applicable to marine terminals by 35 IA C 219.766, affected

Fugitive VOMEmissions from Leaking River Dock Flare Components are

subject to 35 IAC 219.448, which prescribes that an owner or operator

shall maintain a leaking components monitoring log which shall contain,

at a minimum, the following information:

57. Condition 7.10, as listed in the permit, contains alternate modes of

operation

for

emission

units that are already included in Sections 7.2, 7.3 and 7.4 of the

permit. See R. at 1195, 1143-1173. Section 7.10 mirrors construction

permit

#04070052,

which

permits the storage of alternate materials in existing storage tanks and loading of

alternate materials through the existing river barge dock

at the Hartford Distribution

Center. See Exhibit F. Premcor requests that the conditions from this section be

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

incorporated into Condition 7.2, 7.3 and 7.4 as appropriate.

Condition 7.10 should,

therefore, be removed.

58. Premcor requests that the section number for the Soil Vapor Extraction

System be updated from Condition 7.11 to Condition 7.8 to remain consistent

with

the

permit outline due to the removal

of the sections for "Lube Cubes" and "Storage and

Barge Loading of Ethanol and Toluene."

IV. CONCLUSION

59. For the above-referenced reasons, the CAAPP permit

does

not reflect

the

current applicable requirements or the current operations of the facility, and

thus

is not

"consistent with the Clean Air Act and regulations promulgated thereunder." 415 ILCS

5/39.5. Further, certain conditions discussed herein are not required to "accomplish the

purposes and provisions of this Act and to assure compliance with applicable

requirements." Id.

60. Accordingly, Premcor requests that the comments as detailed in this

Amended Petition be incorporated into a revised CAAPP permit issued for the Hartford

Terminal.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

WHEREFORE, Petitioner, THE PREMCOR REFINING

GROUP

INC.

petitions

the Illinois Pollution Control Board for a hearing on the Illinois Environmental Protection

Agency's action to issue this CAAPP permit in this fashion.

Respectfully submitted,

THE PREMCOR REFINING GROUP INC.,

Petitioner,

By:

/s/ Katherine D. Hodge

Katherine D. Hodge

Dated: December 22, 2006

Katherine D. Hodge

Monica T. Rios

HODGE DWYER ZEMAN

3150 Roland Avenue

Post

Office

Box 5776

Springfield, Illinois 62705-5776

(217) 523-4900

P REM-013TiMmended Petition for Review(3)

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

Surjil Sutha'r - Premcor Hartford

Draft Permit Comments

Page 1:

From:

<fpaterso@trinityconsultants.com>

.

To:

"Sunil Suthar"

<Sunii.Suthar@epa.state.il.us>

Date:

11/7/2003

9:56:23 AM

Subject:

Premcor Hartford

Draft Permit Comments

Sunil:

Tom Mroz (Premcor)

sent his comments on the draft CAAPP

permit for the Hartford Distribution

Center

to Mr. Brad Frost yesterday.

His comments are included in the attached document.

If you have

any questions regarding the comments,

please. give me a call at (630) 574-9400.

Thanks,

Fern Paterson

(See

attached file: Hartford Draft Permit Comments(r2).pdf)

The information transmitted

is intended only for the person

or entity to

which it

is addressed and may contain

confidential and/or privileged

material. Any review, retransmission,

dissemination or other use of, or

taking of

any action in reliance upon, this information

by persons or

entities other than the intended recipient

is prohibited. If you received

this in error, please

contact the sender and delete the material from

any

:computer.

m

EXHIBIT

A

0

005013

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

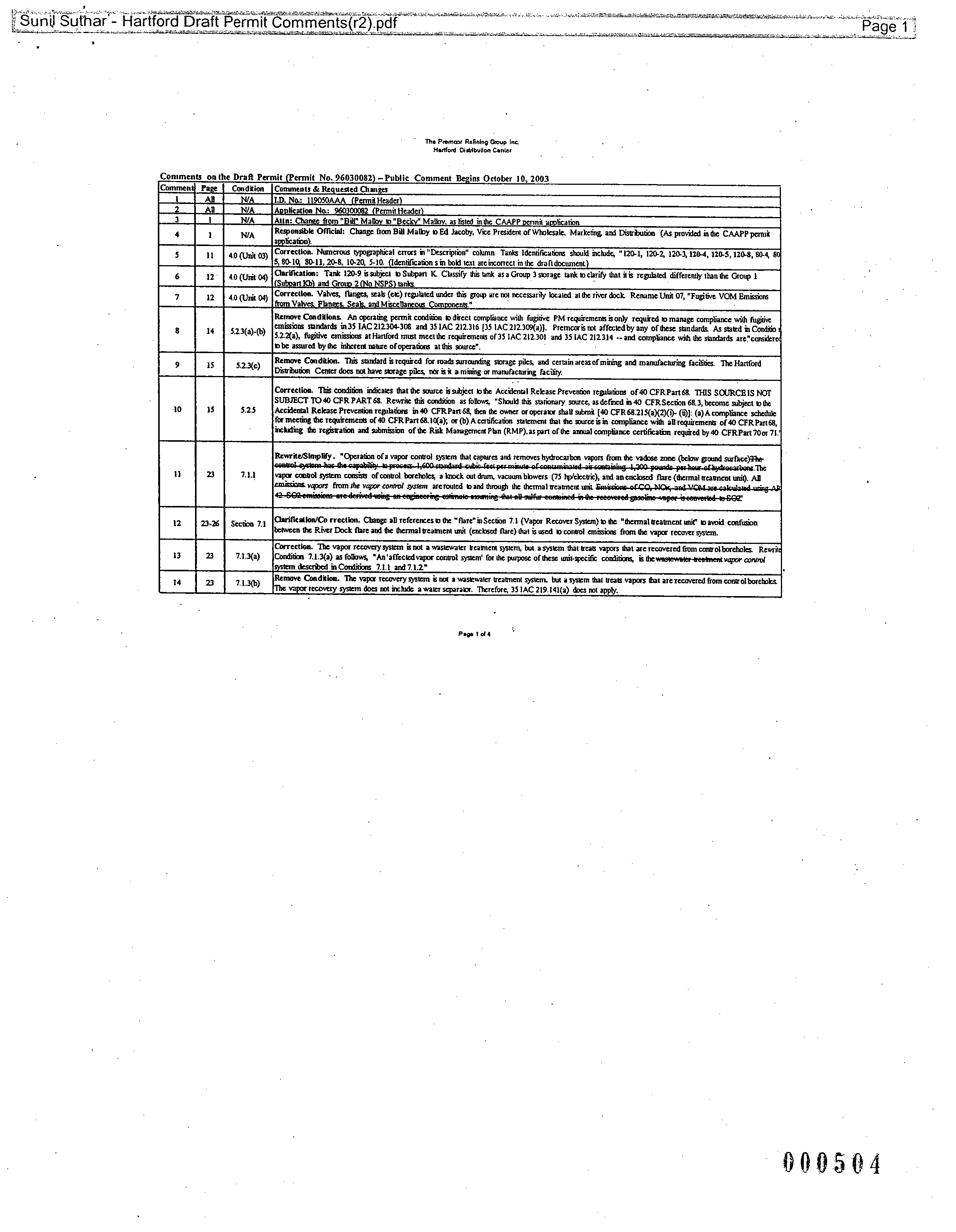

ýSuri4ý Suthar Hartford Draft

Peanut Comments(r2).pdf

Comment Pa

Conondi

ion

Comments & Re uested Char' et

1

AD

N/A

I.D.No.: 119050AAA PermdHeader

AD

N/A

A 8catf

No.: 9(0300082 PcrmitHeader

3

N/A

Atln: Cha e from "Bill" Ma b

"Becky" Mal . as listed inthe CAAPP rte a lication

4

1

N/A

Responsible Offncinl: Change frml Bill Malby o Ed Jacoby, Vice President

of Wholesale. Marketing and Distribution (As providod let due CAAPP pemri

application).

5

11

4.0 (Unit 03)

Correcion. Numerous typographical errors in"Description" cokann Tank

Identifications should ahchdc, "120.1, 120-2, 120.3,1204,

120.5,120-8, S" S

5 801 8011,

208, 1020, 5-10. Identification s tin boll text are incorrect in the dea fl docummc

6

12

4.0 (Unit 04)

ion: Tank 120-9 is subject b Subpart K Classify This tank as a Group, 3

storage lank to clarify that it is regulated differently than the

Croup 1

=9

1(b) and G 2 o N PS rants.

Correction. Valves, flange; seals (et) regulated under this group are not necesan

located at the river dock Rename Unit 07,

"Fugitive VOM Emissions

Remove Candillons. An operating permit condition b direct compliance wish fugitive PM requirements is

only required io manage compliance with fugitive

8

14

5.23(2)-(b)

emissions

standards in351AC212304-308 and 351AC 212.316 (351AC212.309(a)). Premcaisrot

affectedbyany of 0wse standards. As stated iaCondifio

5.2.2(2), fugitive emissions atHanfmd must meet dc requirements of35 IAC 212.301 and 351AC 212314

--and compliance with the sardards are."camidcro

IDbeassured byf htherentnature ofoperadom at this

source'.

9

15

5.2.3(c)

Remove Condition. This standard is required for roads surrounding storage piles, and certain

areas ofmming and manufacturing facilities. The Hartford

Distribution Center does nor have storage piles, nor

s it a mining or manufacturing facility.

Correction.

This condition indicates tat the source is subject b the Accidental Release Prevention

reilnbtiom of40 CFRPart69. TIES SOURCBIS NOT

SUBJECT TO 40 CPR PART 68. Rewriie this condition as

followz "Should 1hs satiorary sarce, as defmcd i n 40 CFRSecuon 68.3, become

mbject b the

10

15

5.2.5

Accidental

Release Prevention replatiors in 40 CFRPan68, men the owner or operator shall submit [40

CPR

68.215(ax2)(}

(b)]: (a)Acompliance schedule

for meetog the

requirements of 40 CPR Pan 68.10(2); a (b) A catificaton statement that the swan is m compliance with

all requiremens of 40 CFRPan68,

mckding do registration and submission of the Risk Management Plan (RMP),as

pan of do annual compliance certification respired

by 40 CFRPart70or 71.

RewritVSimplify. "Operation

ofa vapor control system that captives and removes

hydrocarbon

vapors

(torn this vadose cone (below ground soface}33te

11

23

7.1.1

The

vapor

caurtol system consists of control borehoks, a hock cot dnun, vacuum

blowers (75 Wckcbicý and an enclosed flare (thermal treatment unit).

AD

^"" vtpor8 from

the

vapor

Control system are routed b and through the da:mlal treatment lark

12

23.26 Section 7.1

Clanfication/Co rreclion.

Change

all references

b d¢ "flare" in Section 7.1 (Vapor Recover System) b

the

"dhentral

treatment unit b avoid confuson

between the River Dock flare and me thermal treatrnenn unit (enclosed

Dare) dot is used b control emissions from toe vapor recover

system.

Correction. The vapor recovery

system is not a wasmwatcr treament system, but a system that treats vapors that

are recovered from cam olboreh oks Rewru

13

23

7.1.3(2)

Cmdibm 7.1.3(x) as follows, "AnIaffected vapor control system' for

the purpose ofdKSeurtit-speci0c conditions, isdlewastewekrtentrnenrvgmrmruio7

nstem described

7.L1

and 7. 1.1"

1 4

23

7.1.3(b)

R emove

Condition. T he vapor r ecovery system is cot a wasicwatcr treatment

System. but a system dot treats vapors mat ate recovered from controlbortloks.

M -, ecovery *,stem does not iockde

a

water

separator. 11terefure, 351AC 219.141(2) does cot apply.

m . Pmmmr W nma G,o?v "t

M .m,m

G imbW -C.M a

Comments on the Draft Permit

emit No.96030082 -Public Comment Beggins October 10, 2003

P .gId4

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

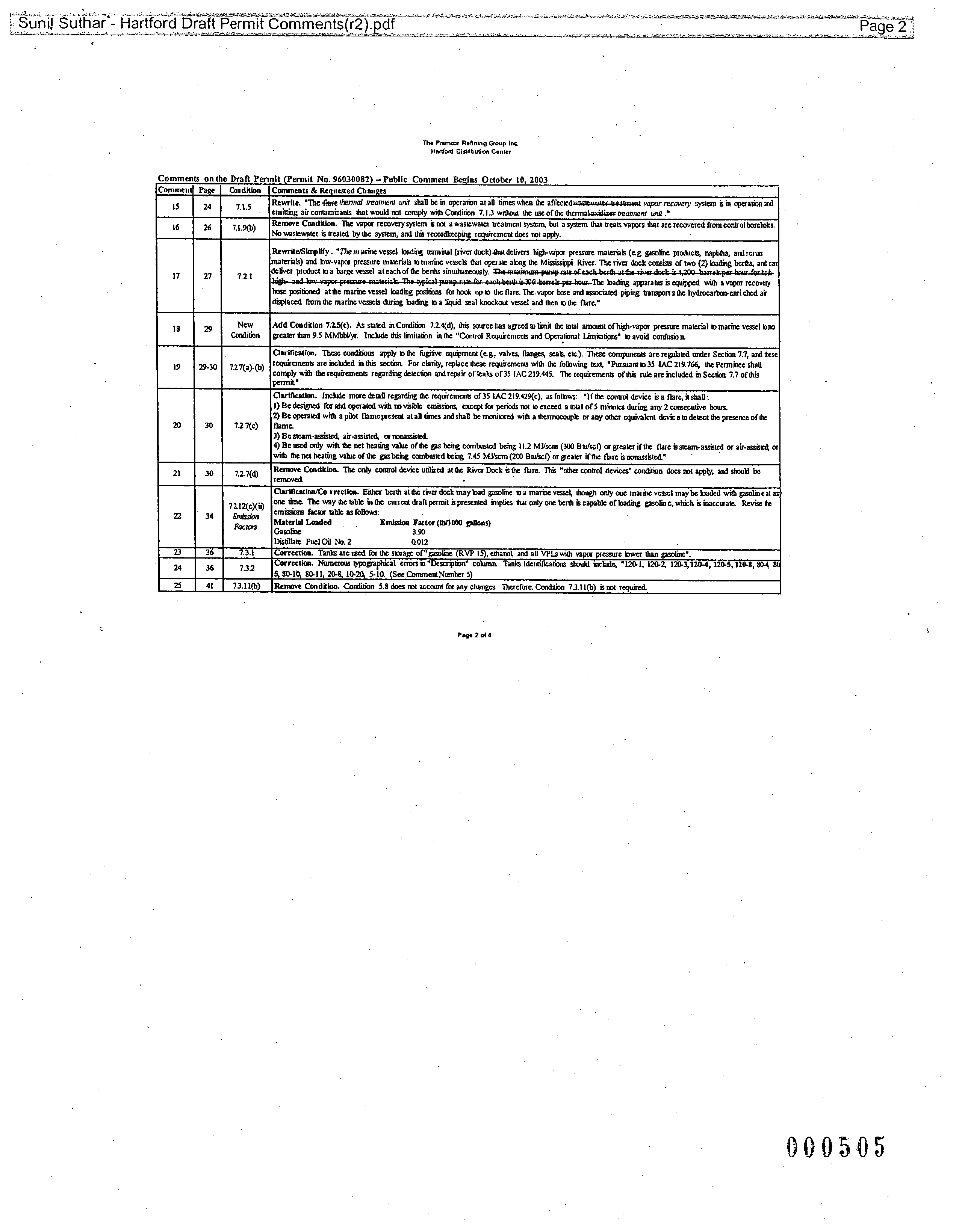

Suni!

Suthar Hartford

Draft Parm(t

Comments(r2).pdf

m. Pmmmr R.e.w¢ Grove 1"e.

H"do,4 Dim46mion

C-er

Comment!

Pa

Condition Comments & Requested Chart e5

I S

24

7 1 5

R ewrite. "Theflnmthenltd

Imomlent unit shall be tit operation

at all times when the affecledawkWal,FWait- vapor recover system s'vl operation and

. .

emitting ate contaminants that would not comply with Condition 7.1.3 without the use of to themlatexidiaa m8omow

.91 ."

16

26

7.1.9(b)

Remove Condition. The vapor recoverysystem s not a wastewater treauncnt system but a system tut treats vapors that

arerecovered tomconntrolboreboks

No wastwater is treated by the

system;

and this recurdkeeping

requirement does rot apply.

Rewrke/Simpify. "Then.arinevessel loading terminal (rim dock)daidefivers high-vapor pressure nulerials (cg gasoline profiles,

naphtha, andrenm

materials) and Imv-vapor pressure materials b marine vessels

that operate along the Masissppi River. The river dock consists of two (2) loading bcf and ca

17

27

7.2.1

deliver }eoduct b a barge vessel ateachofthe berths simuhtanemtsy.

' 4,200 b-I.Int;, W. IWWO.

ý.7be

loading

apparatus is equipped with a vapor recovery

base positioned at the marine vessel loading positions

for book up no the flaro. The. wpm best and associated piphg tiatuport a the hydrocarbon-enri shed au

displaced form the marine vessels during loading a a liquid seal knockout vessel and

dun a the flat."

i8

29

New

Add Condition 7.25(c). As stated in Condition 7.2.4(d), this sauce has agreed a ]unit

the iota] amount of-high-vapor pressure material to marine vessel bur

Condition greater dun

9.5 MMbbVyr. Include this Ii nitation in the "Control Requirements and Operatiorul Limitations" a avoid confusion

Clarification. These conditions apply a the fugitive equipment (e.&, valves, flanges, seas, em). These compouens are regulated

under Section 7.7, and these

19

29-30 727(a)-(b)

requucmens are included u this section For clarity,

replace these requirements with the following text "Pursuant a 35 IAC 219.766, the Pemamee shall

comply with the requirements regarding detection and repair of leaks of 35 IAC 219.445. The requirements of the role are included m

Section

7.7

of this

permit"

Clarification. Include more detail regarding the requirements of 35 IAC 219.429(c), as follows:

"If

the

control device is a Bare, i shall:

1) Be designed for and opmated with no visible

emssiom except fm periods rot a exceed a foul of 5 mutates during any 2 cmsecutive boas.

2) Be opttated with a pilot flamepresed air all times and shall be monitored wish a thermocouple or any

other equivalent device to detect the presence of du

20

30

7.2.7(c) flame.

3)Besteam-assisted, air-assisted, ornonassatd

4) Be used any with the net healing whit of de gas being combusted being 11.2 MLscm (300 B Wscl) or greater

if she five is sham-assisted or air-asssuo% m

with the net beating value of the gisbeing combatted

being

7.45

M.Vwm (20D Bbdxf) or greater iff fl ne is nonass'sted"

21

30

7.27(d)

Remove Condition. The only control device utilized at

the Rim

Deck

is

the

Rare. This "other control devices" condition does not apply, and should be

removed

Clarification/Co rrection. Either berth at she river

dock may load gasoline to a marine vesxk dough only one mat she vessel maybe loaded with psolme at a

7.212(exu)

'.

mne. The way -table m de current draft permit is presented unpfcs that only one berth is capable

of leading gawk e, which s inaccurate. Revise to

22

34

d'ndasion

emsimus factor table as follows:

Fairs

h1nterW loaded

.

Emission Factor(MI000 gp0ons)

Gasoline

3.90

Distillate Fuel Od tlo.2

Q012

23

36

7.3.1

Correction. Tanks are used for the storage of"g=lme

(RVP IS), ethanol, and all VPLs with wpm pressure Iowa than psolae".

24

36

7.3.2

Correct-. Numaous typographical errors a "Dcsmpton" column Tanks ldenubcauons should mckde, "1201,

120-2, 12P3,120-4, 120.5,120.8, 841,

5 80.1 8411, 248, 10- 5-IQ SeeCommenNumber

25

4l

7.3.11(b)

Remove Condit-. Condition 5.8 does not account fm any changes 11crefme. Condition 7.3.11(b) is nor required

Comments on the Draft

Permit emit No.96030082 -Public Comment Begins October 10, 2003

Pea.

2 .l4

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

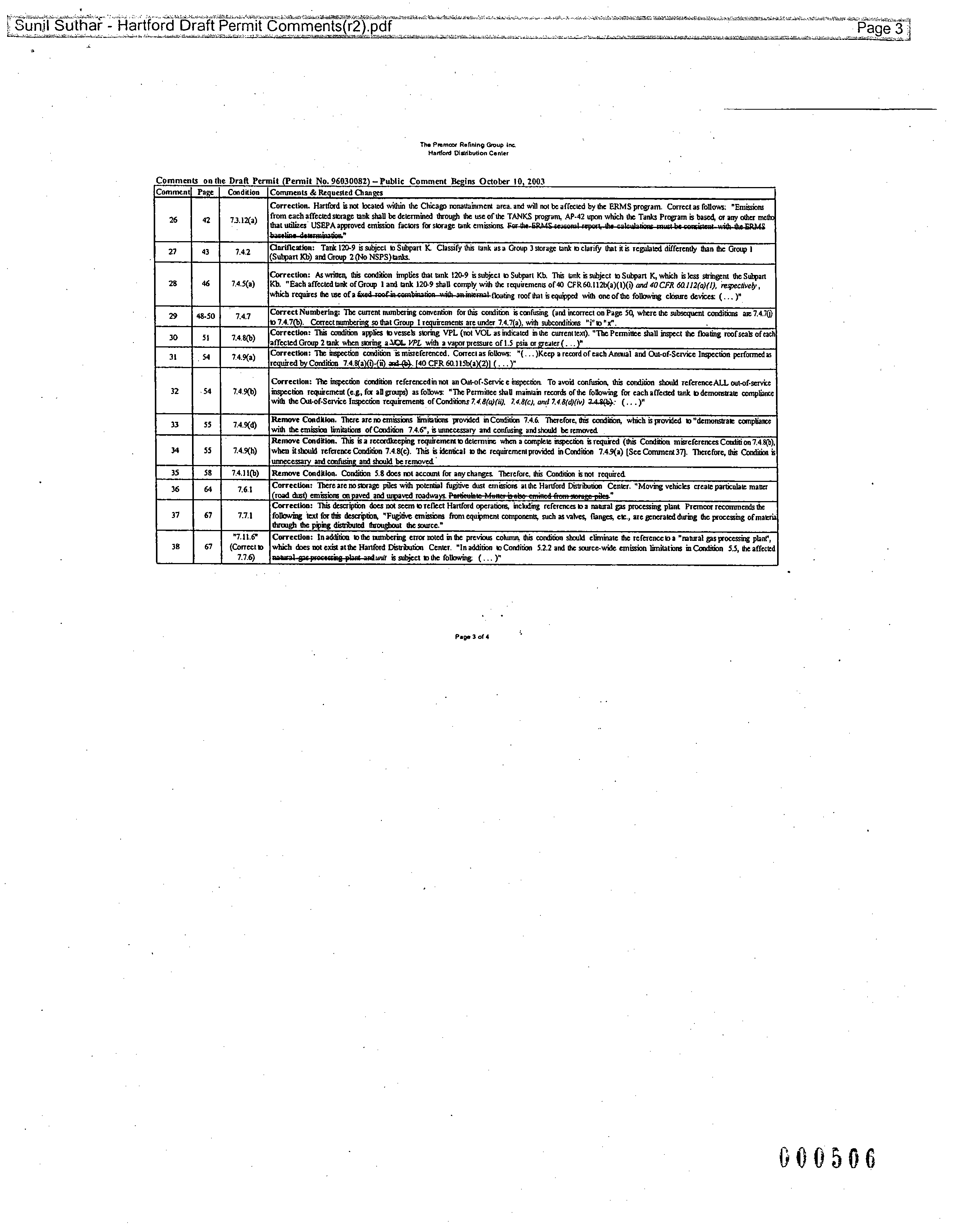

Sunil Suthar- Hartford Draft Permit Comments(r2).pdf

Comment Page Condition Continents&Requested Changes

Correction.

Hartford is not located

within

the Chicago nonarairnment area. and will not be affected by the ERMS program. Correct as follow:: "Emissions

26

42

73.12(a)

from each affected sponge tank shall be determined trough the use of the TANKS program

AP-42

upon which

the Tanks Program is based, or any other rated.

Oat utrdizes USEPA approved em ssion

i

factors for storage tank emissions

baflinr-d4ram6n64n"

27

43

7 4.2

Clarification: Tank 12(19

is

subject to

Subpart K Classify that tank as a Group 3 storage tank b clarify that d is regulated differently flan 0. Group 1

.

(Subpart Kb) and Croup 2 (No NSPS)tanks.

Correction: As written, this condition implies that tank 120.9 is subject b Subpart Kb. This tank s subject to Subpart K, which is kss

stringent the Subpart

28

46

7.4.5(a)

Kb. "Each affected tank of Group 1 and tank 1209 shall comply with the requvemens of 40 CFR60.112b(a)(1)() and 40 CAR 60112(q)(1),

respecivefy,

which requires the use of a 5xedraoLineanbiaauan-wi'Mawmurwlf

osfng roof dot s equipped with one of the following

closure

devices: (. .. )"

29

4&50

7.4.7

Correct Numbering:

The current numbering convention for this condition s confusing (and incorrect on Page 50, where dre subsequent conditions an 7.4.7(a

b 7.4.7(b). Cotratn mnbe i so shot Group I requirements are under 7.4.7(a). with subconditions "i"

b"x".

30

51

7,4.8(6)

Correction: This condition applies to much storing VPL (tat VOL as indicated tin the current text). "The Permince shall inspect the (baling

mofsah ofeach

affected Group 2 tank when shin 2A" VPL with a

wpm

essme of 1.5 sirs m eater

.

31

54

7.4.9(a)

Correction: The inspection condition is msreferenced. Correct as hollows: "( ... )Keep a record of each Annual and Out-of-Service

Inspection performed as

required Condition 7.4. a i - i

. 40 CFR 60.11 a 2

Correction: The inspection condition referencedin not an Out-of-Servic e bnNclion To amid confusion, this

condition should rferenecALL out of-service

32

54

74.9(6)

inspection

requirement (e.g, for all groups) as follows: "The Perminee shall maintain records ofthe following for each affected tank b demonstrate compliance

with

iheOut-of-ServiceInspection requirements ofCordidons248(Wfii), Z4.8(c),and1,4.8(d)(iv)IAA(b): (...)"

33

55

1.4.9(d)

Remove Condition. There are an emissions

limitations

provided

m Condition 7.4.6 Therefore, tln$ condition, which is provided b "demonstrate compliance

with the emission limitations of Condition 7.4.6", is umnecesnny and confusing and should be removed

Remove Condition. This is a raadkeeping requirement b determine when a compk¢ inspection is required (this Condition mincferences

Cwdifi on

7.4.8(6),

34

55

7.4.9(h) wheat it should reference Condition 7.4.8(c). This is identical b the rcquvcmcmprovided

in Condition 7.4.9(x) [See Comment 37). Therefore, this C*ndWm

is

unnecessary and cadmm and should be removed

35

58

7.4.11(6) Remove

Condition. Condition 5.8 does cot account for any changes Therefore, Ons Conditions not required

36

64

7.6.1

Correction: There are no storage piles with potential fugitive dust envisions

at the Hartford Disu-Lution Center. "Moving vehicles create particulate manor

road dust emýin- on avid aM

veil madwa

Correction: This description does not seem b reflect Hartford operations, including references b a

natural

gas

processing plant Premoor recommends the

37

67

7.7.1

folbtving text for this description, "Fugidve emissions boos equipment componens, such as vahts, Ranges, elf., are generated during

the,

processing

ofmatria

-

duasgh One piping

distributed

throughout

the source."

"7.11.6" Correction: In addition loth numbering enaanoted

in the previous

column

this condition should e8miate the reference toa "natural gas processing plant",

38

67

(Correct

b

which

does not exist at the Hartford Distribution Center. "In addition to Condition 5.2.2 and Oat source-wide emission limitations m

Condition 53, the affected

7.7.6)

utir

is subject

b due following ( ... )"

TM P- a.rMr,9 0w.p oK

M.ro.M

orrnn.uon C.m.,

Comments on the Draft Permit (Permit No.96030082 -Public Comment Begins October 10, 2003

Pas. 3 of 4

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

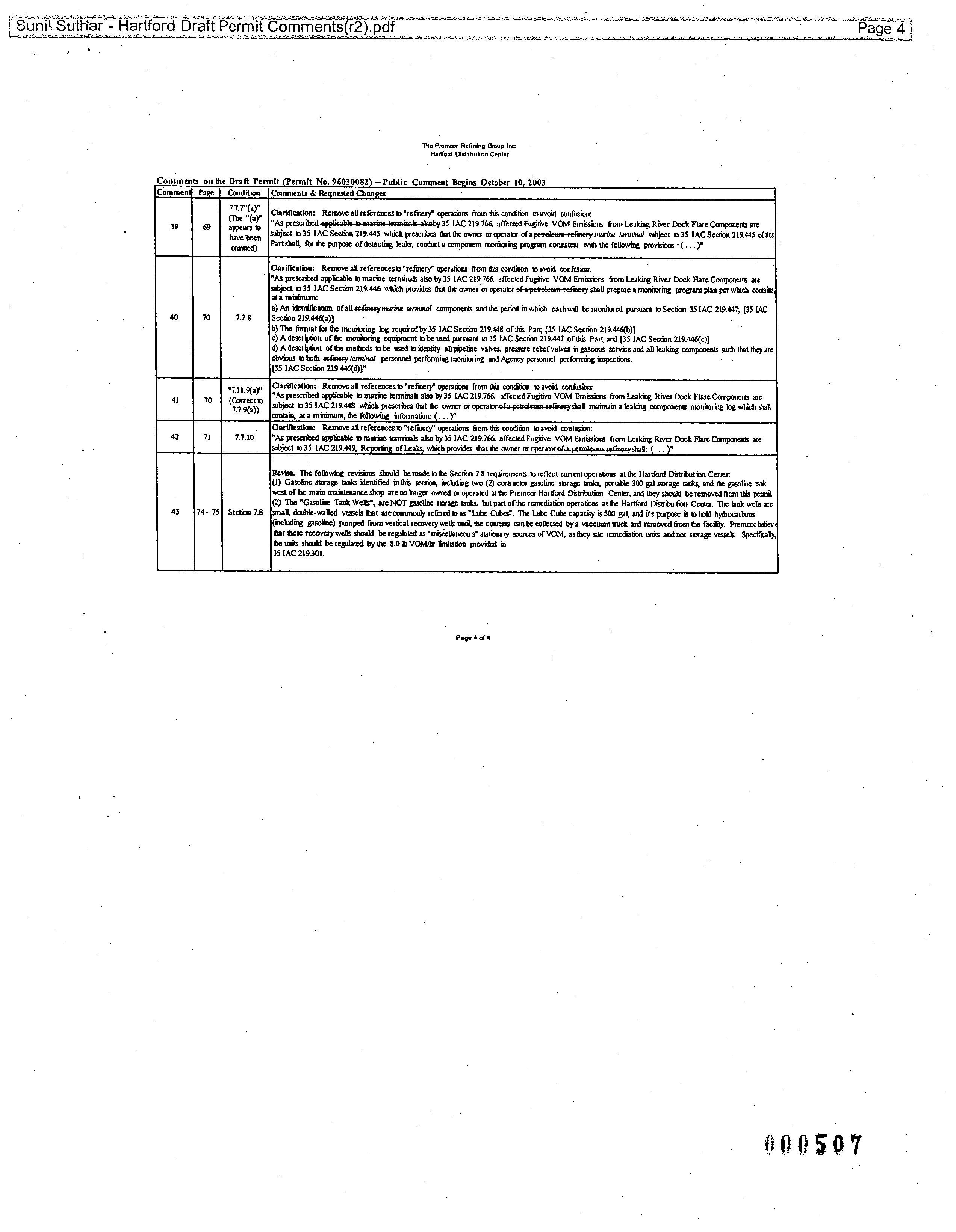

unik Suttiar Hartford Draft Permit

Gomments(rL)

---ý=-ý

Page

4

T he Pmmmr Reining Goup Ine

nedord OIadb"foa Cenlet

Commen1

P. R.

I Condition

Cwmnents & Re nested Chan es

71T'(a)-

(M.

"(a)"

Clarification: Remove all references

b"refinery' operations

from

thitcondition

to avoid

confusion:

3 9

69

appears

b

"As

pr

eswtbed

'

35 IAC 219.766. affteted Fugitive VOM Emissions from Leaking River Lock Flare

Components are

have been

sub

j

act b 35 I AC Section 219.445 which

prescribes

dot

the owner w

operator

ofapatrebmx-Feline ynrvine lenn6wl subject b351ACSection 219.445ofllds

milled)

Part shat, for the puspose of detecting leaks, conduct a component monitoring program consistent with the (allowing

provisions : (. . . )"

Clarification:

Remove all references to "refinery" operations from di codfuon b avoid confusion:

"As prescribed applicable b marine termmah also by 35 I AC 219.766 affected

Fugitive

VOM

Emotions from Leaking River Dock Flare Components are

subject b 35 IAC Section 219.446 which provides dal de owner or operator aFa petrelemsrreimry shall prepare a monitoring program plan per which onn tain

at a mihvnnnt:

a) An identification ofallssfiasoyrnarvre reminal components and the period in which each will

be

mcnibred pursuant

In Section 351 AC 219.447; (35 IAC

40

70

7.7.8

Section 219.446(x))

b) The formatfur the uonibing log requiedby 35 IAC

Section 219.448 of 0ii

Par; [35

IAC Section 219.446(b)]

c) A description of the monitoring equipment

to be

used pursuant to 35 IAC

Section

219.447

of dtis Part; and [35 IAC Section 219.446(c)]

d) Adescripton ofthe

methods to be used to idenAfy all pipeline valves, pressure reliefvalves en gaseous service and all leaking components

such

dot they arc

obvious toboth asfsaryremunaf personnel paRwmihgmonimilg and Agency personnel perfomninguopections.

.

[35 JAC Section 219.446(d)]"

"7.11.9(x)"

Clarillcallon: Remove all references to "refinery operations from No condition to avoid confusion:

41

70 ( Cmectta

" Asprescribed

applicable b marine temiah also by35 JAC219.766. affected Fugtive VOM Emission fronoLeaking River Dock

Flare Components tie

77.9(.))

subject b 35 SAC 219.448 which prescribes tat

the owner or operator afa.penolwna ;.ran, shall maintain a leaking components monitoring tog which stall

cooam, at a minimum, the following information: (. .. )"

Clarifkmion: Remove all

references to"tefmery' operations from dris condition to avoid confusion:

42

71

7.7.10 "As presenbed applicable b marine

terminals

akin by 35 IAC 219.766, affected Fugitive VOM

Emissions from Leaking River Dock Flare Components tie

object to 35 JAC 219.449,

Reporting of Leaks, which provides dot the owner or operator of a-petrýsha0: ( ... )"

Revise. The following revisions

should be made to the Section 7.8 requirements to reflect current operations at the Hartford Distrnbut ion Center.

(1) Gasoline stsrag Cnl6 identified it ti's

section, including two (2) contractor gasoline storage ranks, portable 300 ®1 storage ink; and the gasolne task

west

of de main maintenance shop are no longer owned or operated at the Premcnr Hartford Diorbution Center, and key

should be removed from this permit

(2) The "Gasoline Tank Wets", we NOT

dine sting tanks but part ofdhe rmedialion operations at the Hartford Distribution Ccntcr. The tank wells we

43

74. 75

Section

7.8

small double-walled vessels tat arecommonly, refued b as "Lobe Cubes". The Lobe Cube capacity is SW pal,

and ins purpose is b hold hydrocarbons

(including gasoline) pooped from vertical

recoveryvxlk send, the camera can be collected by a vaccuum truck and removed from the facility. Premcorbeliev

tat these recovery wells should be regulated as "miscellaneou s" stationary sources, of VOM, as they site remediaton units

and tow storage vessels Specifically,

the wits should be regulated by the 8.01b VOMdtr limitation

provided in

35

IAC 219.301.

Conlmelhts on the Draft Permit emit No. 96030082

-Public Comment Begins October 10, 2003

P ag. 4 .14

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

Premcor

Premier People,

Products

and Service

August 2,

2004

Mr. Sunil Suthar

Illinois

Environmental

Protection Agency

Division

of Air Pollution

Control

1021 North

Grand Avenue East

Springfield,

Illinois 62794

Comments

on Final Draft/Proposed

CAAPP Permit No. 96030082

The Premcor

Refining Group Incorporated, Hartford

Distribution Center

(Facility

ID No. 119050AAA)

D ear

Mr. Suthar:

The Premcor Refining Group, Inc.

Delaware City Refinery

P.O. Box 7000

Delaware City, DE 19706-7000

302/834-6000

On

May 27, 2004, the Illinois

Environmental Protection Agency (IEPA)

issued a public notice for the proposed

issuance

of a Clean Air Act Permit

Program (CAAPP) permit (Application

No. 96030082) for The Premcor

Refining

Group Inc.'s (Premcor's)

Hardford Distribution Center. As provided

in the public notice, /EPA is

accepting comments

on the proposed

CAAPP permit until August 12, 2004, which

is 30 days after the public

hearing date.

With this correspondence,

Premcor is providing

to IEPA comments to the Proposed

CAAPP permit as well as a

Supplement to

Premcor's September 2003

CAAPP application. Premcor's comments

are included in the letter

attachment. If

there are any questions regarding the attached

comments, please contact me at (618) 254-7301

ext.

261 or Mr. Tony

Schroeder of Trinity Consultants

at (630) 574-9400.

Sincerely,

THE

PREMCOR REFINING

GROUP INC.

Rebecca

Malloy

Environmental

Specialist

Enclosures:

Comments

on the Draft Permit

Supplement

to CAAPP Application

cc: Mr. Brad

Frost, IEPA

Mr. Ed Jacoby,

Premcor

Mr. Tony

Schroeder, Trinity Consultants

AUG

U

3

t6d4

EXHIBIT

B

0 e, 9 4

2

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

The Premcor Refir';.g Group Inc.

Hartford DislribL'on Center

u

L

Comments

oil the Draft Permit

Permit

No. 96030082 - Public Comment Begins Ma 27, 2004 anti Ends August 12, 2004.

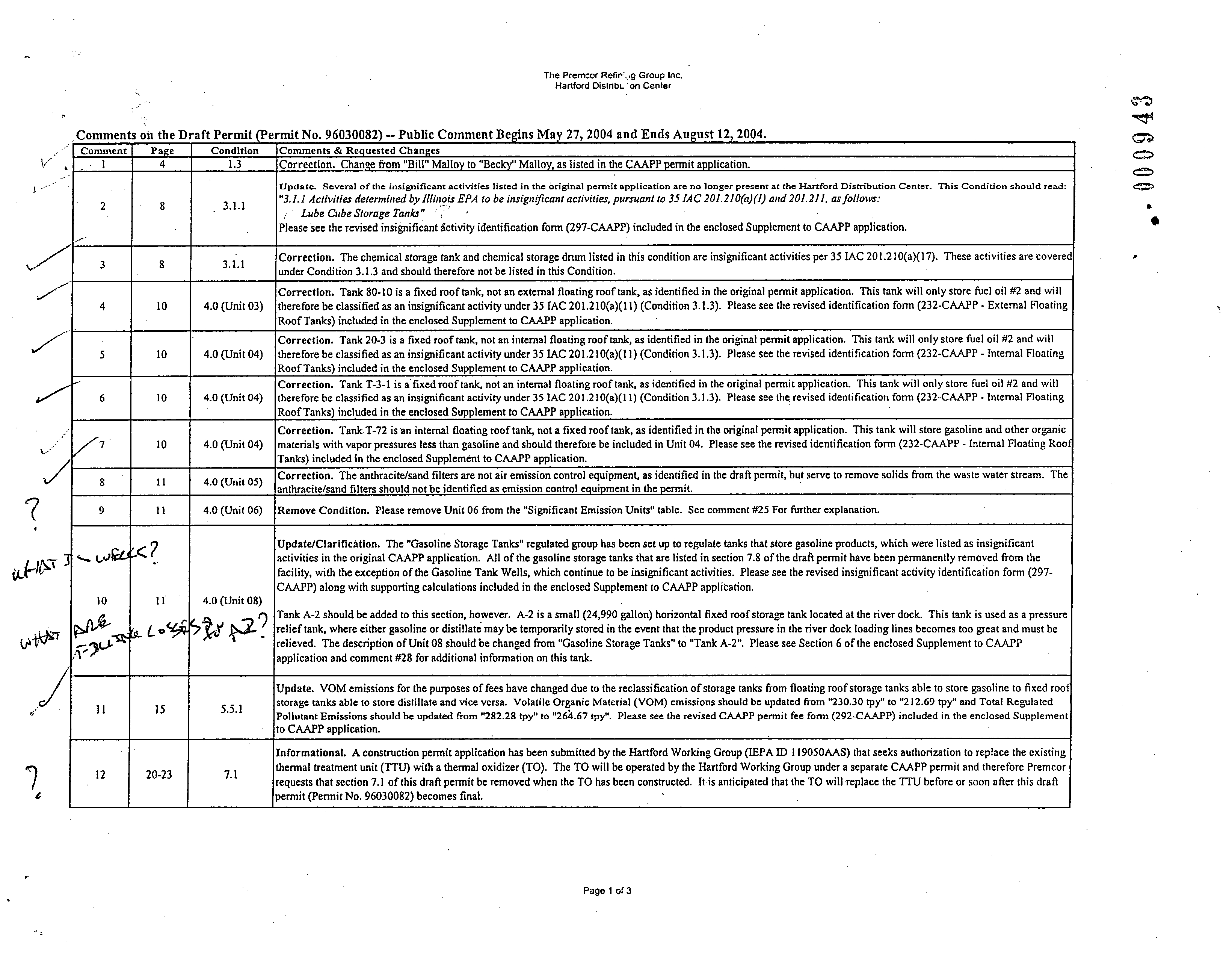

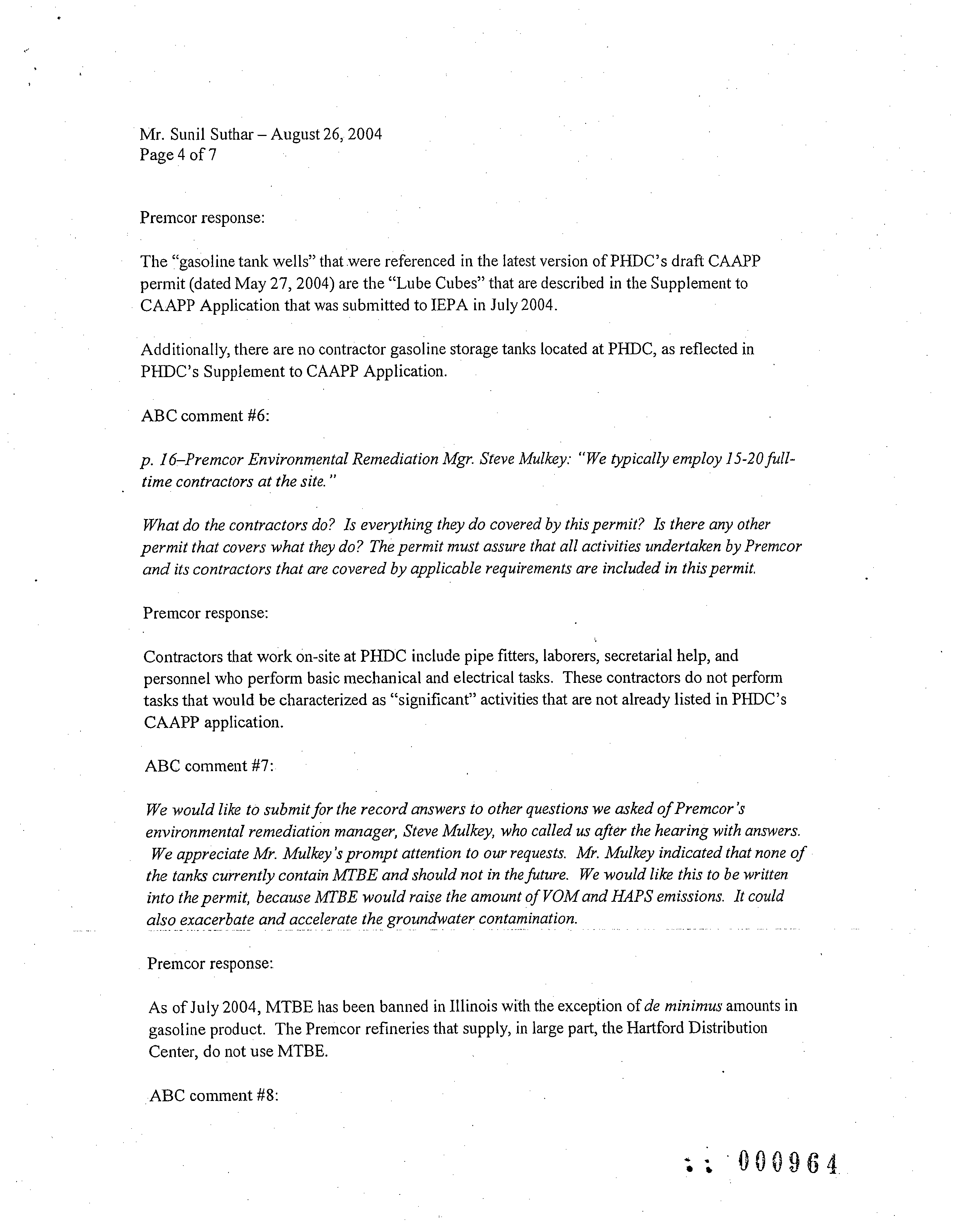

C omment rage

Condition Comments & Requested Changes

1

4

1.3

Correction. Chance from "Bill" Mallo to "Becky" Mallo , as listed in the CAAPP permit application.

Update. Several of the insignificant activities listed in the original permit application are no longer present at the Hartford Distribution Center. This Condition should read:

2

8

3.1.1

"3.1.1 Activities determined by Illinois EPA to be insignificant activities, pursuant to 35

IAC 201.210(a)(1) and 201.211, as follows:

Lube Cube Storage Tanks"

Please see the revised insignificant ictivity identification form (297-CAAPP) included in the enclosed Supplement to CAAPP application.

Correction. The chemical storage tank and chemical storage drum listed in this condition are insignificant activities per 35 IAC

201.210(a)(17). These activities are covered

3

8

3.1.1

under Condition 3.1.3 and should therefore not be listed in this Condition.

Correction. Tank 80-10 is a fixed roof tank, not an external floating roof tank, as identified in the original permit application. This

tank will

only

store fuel oil #2 and will

4

10

4.0 (Unit 03)

therefore be classified as

an insignificant activity under 35 IAC 201.210(a)(11) (Condition 3.1.3). Please seethe revised identification form (232-CAAPP - Extemal Floating

Roof Tanks) included

in

the

enclosed Supplement to CAAPP application.

Correction. Tank 20-3 is a fixed roof tank, not an internal floating

roof tank, as identified in the original permit application. This tank will only store fuel oil #2 and will

5

10

4.0 (Unit 04) therefore be classified as an insignificant activity under 35 IAC 201.210(a)(11) (Condition 3.1.3). Please seethe revised identification form (232-CAAPP

- Internal Floating

R oof Tanks) included in the enclosed Supplement to CAAPP application.

Correction. Tank T-3-1 is a fixed roof tank, not an internal floating roof lank, as identified in the original permit application. This tank

will only store fuel oil #2 and will

6

10

4.0 (Unit 04) therefore be classified as an insignificant activity under 351AC 201.210(a)(11)

(Condition 3.1.3). Please seethe revised identification form (232-CAAPP - Intemal Floating

R oofTanks) included in the enclosed Supplement to CAAPP application.

Correction. Tank T-72

is an internal floating roof tank, not a fixed roof tank, as identified in the original permit application. This tank will store gasoline and other organic

7

10

4.0 (Unit

04)

materials with vapor pressures less than gasoline

and

should

therefore be included in Unit 04. Please see the revised identification form (232-CAAPP - Internal Floating Roof

Tanks)

included in the enclosed Supplement to CAAPP application.

8

11

4.0 (Unit 05)

Correction. The anthracite/sand

filters are not air emission control equipment, as identified in the draft permit, but serve to remove solids from the waste water stream. The

a nthracite/sand filters should not be identified as emission control equipment in the permit.

9

11

4.0 (Unit 06)

Remove Condition.

Please remove Unit 06 from the "Significant Emission Units" table. See comment #25 For further explanation.

7

Update/Clarification. The "Gasoline Storage Tanks" regulated group has been set up to regulate tanks that store gasoline products, which were listed as insignificant

t?+2

activities in the original CAAPP application. All of the gasoline storage tanks that are listed in section 7.8 of the draft permit have been permanently removed from the

facility, with the exception of the Gasoline Tank Wells, which continue to be insignificant activities. Please see the revised insignificant activity identification form (297-

CAAPP) along with supporting calculations included in the enclosed Supplement to CAAPP application.

10

11

4.0 (Unit 08)

n

ý'

r

-

r

Tank A-2 should be added to this section, however. A-2 is a small (24,990 gallon) horizontal fixed roof storage tank located at the river dock. This tank is used as a pressure

relief tank where either

gasoline

or distillate may be temporarily stored in the event that the product pressure in the river dock loading lines becomes too great and must be

relieved. The description of Unit 08 should be changed from "Gasoline Storage Tanks" to "Tank A-2". Please see Section 6 of the enclosed Supplement to CAAPP

'3

application and comment #28 for additional information on this tank.

Update.

VOM emissions for the purposes of fees have changed due to the reclassification of storage tanks from floating roof storage tanks able to store gasoline to fixed root

1 1

15

55 1

storage tanks able to store distillate and vice versa. Volatile Organic Material (VOM) emissions should be updated from "230.30 tpy" to "212.69 tpy" and Total Regulated

. .

Pollutant Emissions should be updated from "282.28 tpy" to "264.67 tpy". Please see the revised CAAPP permit fee form (292-CAAPP)

included

in

the enclosed

Supplement

to CAAPP application.

Informational. A construction permit application has been submitted by the Hartford Working Group (IEPA ID 119050AAS) that seeks authorization to replace the existing

12

20-23

7.1

thermal treatment unit (TTU) with a thermal oxidizer (TO). The TO will be operated by the Hartford Working Group under a separate CAAPP permit and therefore Premcor

requests that section 7.1 of this draft permit be removed when the TO has been constructed. It is anticipated that the TO will replace the TTU before or soon after this draft

permit (Permit No. 96030082) becomes final.

'

Page 1 of 3

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

The Premcor Refining Group Inc.

Hartford Distribution Center

t.s

ý

J

fý

Comments

on the Draft Permit (Permit No. 96030082 - Public Comment Begins Ma 27, 2004 anti Ends August 12,

2004.

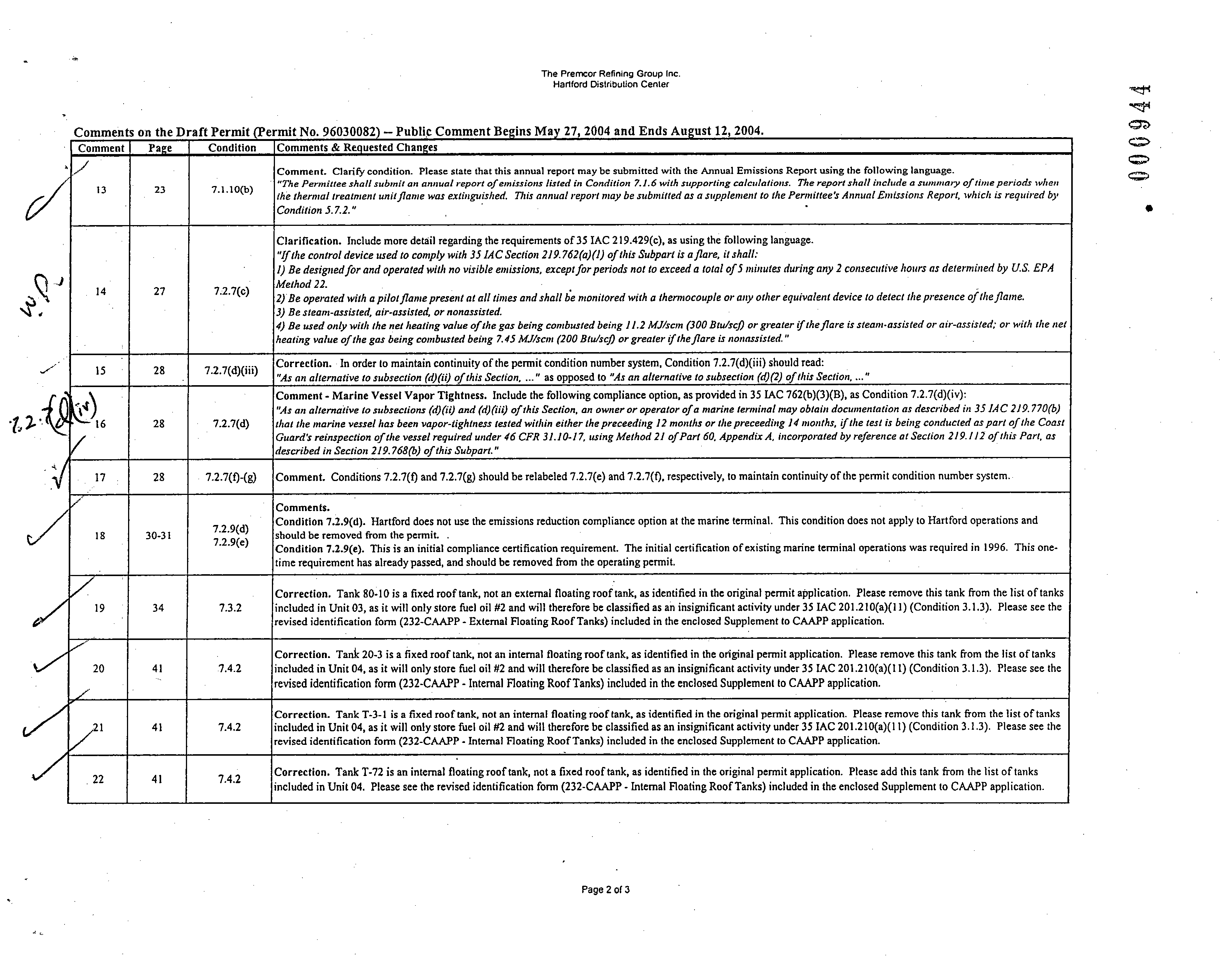

C omment Page

Condition Comments & Requested Changes

C omment. Clarify condition. Please state that this annual report may be submitted

with the Annual Emissions Report using the following language.

13

23

7.1.10(b)

"The Permittee shall submit an annual

report

ojeinissions listed in

Condition 7.1.6 with supporting calculations. The report shall include a srunmary of time periods when

the thermal treatment unit

flame

was extinguished.

This annual report may be submitted as a supplement to the Permittee's Annual Emissions Report, which is required by

Condition 5.7.1."

C larification. Include more

detail regarding the requirements of 35 IAC 219.429(c), as using the following language.

"If the control device used to comply

with

351AC

Section 119.762(a)(1) ojthis Subpart is a flare, it shall:

l) Be designed for and operated with no visible emissions, except for periods not to exceed a total of 5

minutes during any 2 consecutive hours as determined by U.S. EPA

14

27

7.2.7(c)

Method 12.

2) Be operated with a pilot flame present at all times and shall be monitored with a thermocouple or any other equivalent

device to detect the presence ojtlre flame.

3 ) Be steam-assisted, air-assisted, or nonassisted

4) Be used only with the net heating

value ojthe

gas being

conrbusJed being 11.2 MJ/snn (300 Btu/sc,0 or greater if the flare is steam-assisted or air-assisted; or with the net

heating value of the gas being combusted being 7.45 MJ/scm (100 Btu/scf) or greater ijthe flare is nonassisted "

C orrection. In order to maintain continuity of the permit condition number system, Condition 7.2.7(d)(iii)

should read:

15

28

7,2,7(d)(iii)

"its an alternative to subsection (d)(d) ojthis Section, ..." as opposed to "As

an alternative to subsection (d)(2) ojthis Section, ..."

Comment

- Marine Vessel Vapor Tightness. Include the following compliance option, as provided in 35 IAC 762(b)(3)(B), as Condition

7.2.7(d)(iv):

`1'

"As an alternative to subsections

(d)(if) and (d)()) ojthis Section, an owner or operator oja marine terminal may obtain documentation as described in 35 IAC 119.770(6)

1

6

28

7.2.7(d)

that the marine vessel has been vapor-lightness tested within either the preceedi» g 11 months or the preceedr rg 14 months,

ithe

j

test is

beingg

conducted as

part

ojthe Coast

Guard's reinspection of the vessel required under 46 CFR 31.10-17, using Method 11

ofPart 60, Appendix A, incorporated by reference at Section 219.112 ojthis Part, as

described

in Section 119.768(6) ojthis Subpart."

1 7 .

28

7.2.7(0-(g)

Comment.

Conditions 7.2.7(1) and 7.2.7(g) should be relabeled 7.2.7(e) and 7.2.7(f), respectively, to maintain continuity of the permit condition number system.

Comments.

Condition 7.2.9(4). Hartford does not use the emissions reduction compliance

option at the marine terminal. This condition does not apply to Hartford operations and

1 8

30-31

7.2.9(d)

7.2.9(e)

should be removed from the permit. .

C ondition 7.2.9(e). This is an initial compliance certification requirement. The initial certification of

existing marine terminal operations was required in 1996. This one-

time requirement has already passed, and should be removed from the

operating permit.

Correction. Tank 80-10 is a fixed roof tank, not an external floating roof tank,

as

identified

in the original permit application. Please remove this tank from the list of tanks

19

34

7.3.2

included in Unit 03, as it will only store fuel oil #2 and will therefore be classified as an insignificant activity under 35 IAC

201.210(a)(11) (Condition 3.1.3). Please see the

r evised identification form (232-CAAPP

- External Floating Roof Tanks) included in the enclosed Supplement to CAAPP application.

C orrection. Tank 20-3 is a fixed roof tank, not an internal floating roof tank, as identified in the original permit

application. Please remove this tank from the list of tanks

20

41

7.4.2

included in Unit 04, as it will only store fuel oil #2 and will therefore be classified as an insignificant activity under 35 IAC

201.210(a)(1 l) (Condition

3.1.3).

Please

see

the

revised identification form (232-CAAPP - Internal Floating Roof Tanks) included in the enclosed Supplement to CAAPP application.

C orrection. Tank T-3-1 is a fixed roof tank, not an internal floating roof tank, as identified

in the original permit application. Please remove this tank from the list of tanks

2 1

41

7.4.2

included in Unit 04, as it will only store fuel oil #2 and will therefore be classified as an insignificant activity under 35 IAC 201.2 10(a)(I 1) (Condition 3.1.3).

Please

see

the

revised identification form (232-CAAPP - Internal Floating Roof Tanks) included in the enclosed Supplement to CAAPP

application.

2

2

41

7.4.2

l

Correction. Tank T-72 is an internal floating roof tank, not a fixed roof tank,

as

identified

in

the original

permit application. Please add this tank from the list of tanks

included in Unit 04. Please see the revised identification form (232-CAAPP- Internal Floating RoofTanks) included in the enclosed Supplement to CAAPP application.

Page 2 of 3

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

The Premcor Refining Group Inc.

Hartford Distribution Center

c

Com ents on the Draft Permit (Permit

No. 96030082 - Public Comment Begins Ma

27, 2004 and Ends August 12, 2004.

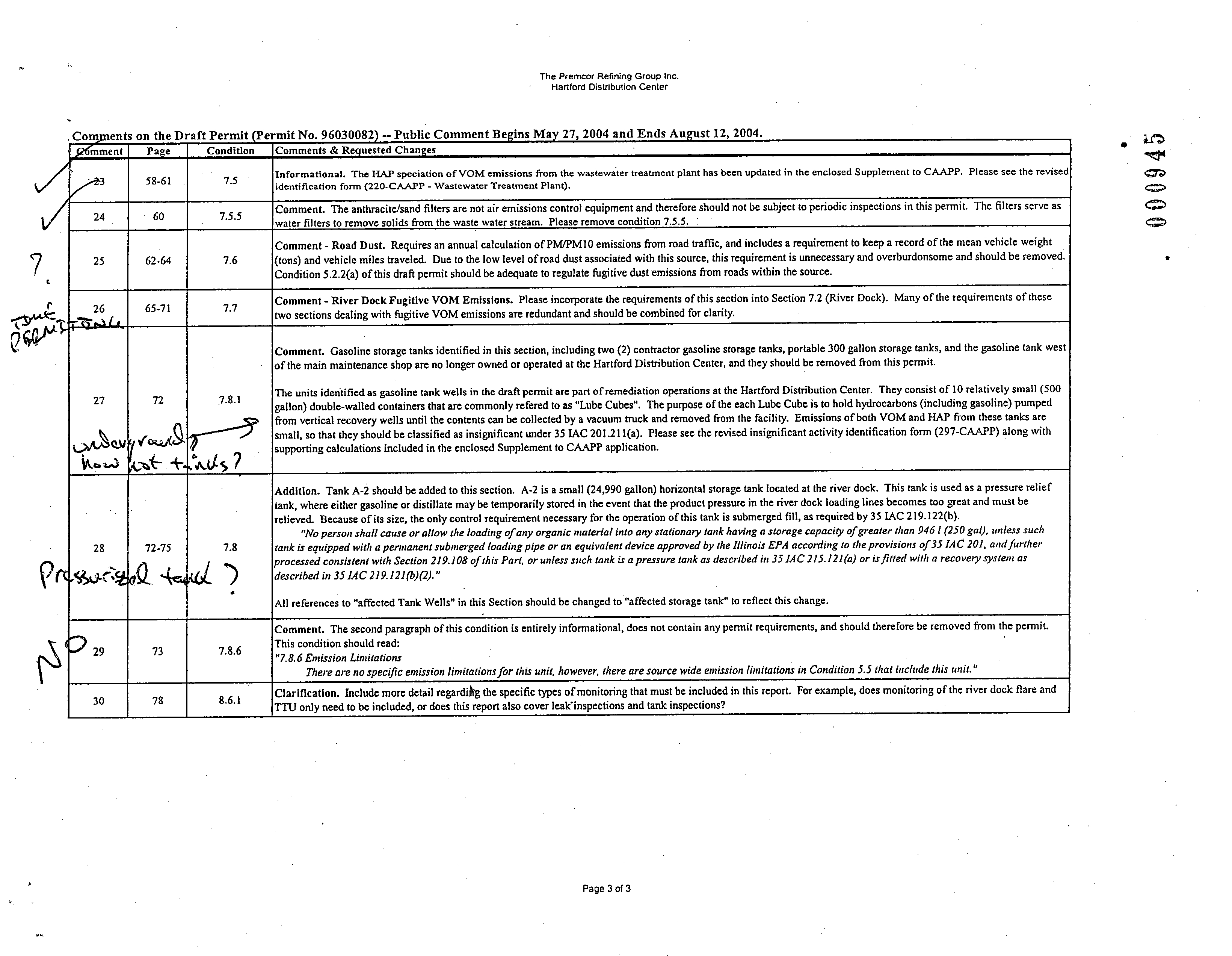

m ment Page

Condition Comments

&

Requested

Changes

3

58 61

75

-

Informational. The HAP speciation

of VOM emissions from the wastewater treatment plant has been updated

in the enclosed Supplement to CAAPP. Please see the revised

`

-

.

identification form (220-CAAPP - Wastewater Treatment Plant).

C omment.

The anthracite/sand filters are not air emissions control

equipment and therefore should not be subject to periodic inspections