BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

IN THE MATTER OF:

)

)

R06-25

PROPOSED NEW 35 ILL. ADM. CODE 225

)

(Rulemaking – Air)

CONTROL OF EMISSIONS FROM

)

LARGE COMBUSTION SOURCES (MERCURY)

)

NOTICE OF FILING

TO:

Dorothy Gunn

Gina Roccaforte, Assistant Counsel

Clerk

Charles E. Matoesian, Assistant Counsel

Illinois Pollution Control Board

John J. Kim, Managing Attorney

James R. Thompson Center

Air Regulatory Unit,

100 W. Randolph St. , Suite 11-500

Division of Legal Counsel

Chicago, Illinois 60601-3218

Illinois Environmental Protection Agency

1021 North Grand Avenue, East

Marie E. Tipsord

P.O. Box 19726

Hearing Officer

Springfield, Illinois 62794-9276

Illinois Pollution Control Board

john.kim@epa.state.il.us

James R. Thompson Center

charles.matoesian@epa.state.il.us

100 W. Randolph, 100 W. Randolph

gina.roccaforte@epa.state.il.us

Chicago, Illinois 60601-3218

tipsorm@ipcb.state.il.us

SEE ATTACHED SERVICE LIST

PLEASE TAKE NOTICE that on September 20, 2006, I the undersigned caused

to be filed electronically with the Clerk of the Illinois Pollution Control Board the

attached POST-HEARING COMMENTS, copies of which are herewith served upon you.

By:_[s]

Mary Frontczak__________________

Mary Frontczak (Reg. No. 6209264)

DATED:

September 20, 2006

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

IN THE MATTER OF:

)

)

R06-25

PROPOSED NEW 35 ILL. ADM. CODE 225

)

(Rulemaking – Air)

CONTROL OF EMISSIONS FROM

)

LARGE COMBUSTION SOURCES (MERCURY)

)

PRAIRIE STATE’S POST-HEARING COMMENTS

NOW COMES Participant PRAIRIE STATE GENERATING COMPANY, LLC,

by and through its attorney, MARY FRONTCZAK, pursuant to 35 Ill. Adm. Code

§ 102108, and offers the following POST-HEARING COMMENTS in the above-

captioned proposed rule:

I.

THE PROPOSED RULE WITHOUT A TECHNOLOGY BASED

STANDARD WILL NEGATIVELY IMPACT NEW GENERATION

BURNING ILLINOIS COAL SUCH AS PRAIRIE STATE GENERATING

STATION.

A.

Technology has not been sufficiently tested on high sulfur coals (e.g., 9

lb. SO

2

/mmBtu) such as Illinois Seams 5 and 6

Illinois Seams 5 and 6 coal have sulfur content on the order of 9 lb sulfur dioxide

(SO

2

) per million Btu or approximately 4% sulfur. This is classified as a high sulfur coal.

As discussed in Prairie State’s testimony at the hearing, there is very little information on

the efficacy of mercury control technologies when high-sulfur coal is burned. Exhibit 80;

Ms. Tickner, Hearing Transcript at 456 (August 15, 2006). That testimony is supported

by the TSD and other witnesses, including those for IEPA.

See, e.g.

, TSD at 128 (“There

is currently no test data on units with sulfur levels as high as those of Illinois coals.”); Dr.

Staudt, Hearing Transcript at 73 (June 22, 2006); Mr. DePriest, Hearing Transcript at

2

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

1230-31 (August 18, 2006). Mr. Nelson even suggested that technology may not be

commercially available for high sulfur coals:

It is commercial at least in the type of coals and the type of

systems, like perhaps not a Conesville situation, but

certainly in those types of systems that they have had

successful demonstrations on.

Hearing Transcript at 73 (June 22, 2006).

1

The control of mercury emissions at coal-fired power plants is extremely difficult

for numerous reasons including the minute amount of mercury in stack gas. To date,

short-term testing of mercury controls has occurred at only 28 coal-fired units -- those

plants comprise about 2.3% of the coal-fired units in operation in the U.S. Despite the

millions of dollars that DOE and industry have spent on this testing, DOE recently

concluded that:

while DOE is very encouraged by the results of our mercury

control technology development efforts to date,

there remain a

number of critical technical and cost issues that need to be

resolved through additional research before these technologies

can be considered commercially available for all U.S. coals and

the different coal-fired power plant configurations in operation

in the United States.

Exhibit 55 at p. 1 (emphasis in original). DOE plans to continue its mercury control

technology testing program through at least 2009. EPA reached a similar conclusion

about the state of mercury controls when it stated in the preamble of CAMR:

We do not believe that such full scale [mercury] technologies can

be developed and widely implemented within the next 5 years;

however, it is reasonable that this can be accomplished over the

next 13 years.

1

Conesville is a facility in Ohio that burns high (3 to 4%) sulfur coal.

3

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

70 Fed. Reg. 28,619. Thus, there is no technical basis for assuming that 90% control of

mercury is achievable at all coal-fired plants. This is particularly true for mercury control

of high sulfur coals like those that will be burned by Prairie State.

Witnesses for IEPA and industry also concur that mercury removal from high

sulfur coal is difficult.

See, e.g.

, Dr. Staudt, Hearing Transcript at 73, 98 (June 22, 2006);

Mr. DePriest, Hearing Transcript at 1230 (August 18, 2006). As Dr. Staudt testified:

And let me just state, in the case of the high sulfur

situation, that is a situation that I've acknowledged is a

difficult one both in the TSD and in my testimony,

Hearting Transcript at 73 (June 22, 2006). The apparent reason is sulfur trioxide (SO

3

)

interference. Dr. Staudt Hearing Transcript at 98 (June 22, 2006); Mr. DePriest, Hearing

Transcript at 1230 (August 18, 2006).

Dr. Staudt did offer his unsupported opinion that the technology on new units will

make it possible for them to meet the proposed standards. Hearing Transcript at 156

(June 21, 2006 pm). The limited available data actually suggests otherwise. In the one

study to date on high sulfur coal at Conesville, preliminary data indicate that less than

50% mercury removal is achievable, around 30%. Exhibit 80, Attachment 3 (discussing

Conesville study). The removal efficiency was even worse when brominated carbon was

used (i.e., less than 25% mercury removal).

Id.

The experience at Conesville may not be

directly transferable to what will be achievable at Prairie State due to different control

technologies but it is the only test that is available to provide some insight into the impact

high sulfur coal will have on mercury removal. Conesvillle has an ESP and wet FGD,

while Prairie State will have an SCR, ESP, wet FGD and WESP. To Prairie State’s

knowledge, there are no data on mercury removal using all the above technology on high

sulfur coal. Such lack of knowledge is why Prairie State believes the inclusion of a

4

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

technology-based standard is necessary. That belief appears to be shared by Dr. Staudt at

least for existing units. Hearing Transcript at 65 (June 21, 2006 pm); Hearing Transcript

at 86-87 (June 22, 2006).

B.

Guarantees are not available for 90% mercury

control at new facilities

As indicated in Prairie State’s testimony at the hearing, meaningful guarantees for

mercury removal of 90% are not readily available, especially for use with high sulfur

coals. Exhibit 80; Ms. Tickner, Hearing Transcript at 444-45, 465-69 (August 15, 2006).

Prairie State has been working with Engineering, Procurement, and Construction (EPC)

contractors for the past 3 years to determine the capabilities of the available technologies

to reduce mercury emissions. Part of that effort has included ascertaining what

guarantees are available for a new facility with respect to mercury removal.

The EPC contractors based on information from the vendors of the proposed

technologies have indicated a willingness to guarantee around 84% mercury removal for

Prairie State. Ms. Tickner, Hearing Transcript at 471 (August 15, 2006). Based on the

mercury content of the Illinois coal to be burned at Prairie State (average of 0.09 ppm and

worst case of 0.13 ppm), that removal efficiency is insufficient to meet either of the

proposed standards.

As Mr. DePriest testified, guarantees are important to a prudent company because

they “protect the owner from the investment he’s making in that particular technology.”

Mr. DePriest, Hearing Transcript at 1150 (August 18, 2006). That is precisely what the

owner of a new facility such as Prairie State is seeking from its EPC contractor —

protection from its investment in all the control technology installed to control air

emissions.

5

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

Unlike with retrofit applications of technology where a guarantee is limited to the

equipment being installed, a new facility is looking for a guarantee from the EPC

contractor to cover the cost of the facility — on the order of $2 to 3 billion dollars — if

the control technologies do not perform as designed. The EPC contractor will wrap the

various guarantees offered by the individual technology vendors into one overall

guarantee to cover the scope of the project.

See

Excerpts from EPC Agreement

(Attachment 1). The wrap is necessary in order to get financing for the project because

lenders are unwilling to accept any risk related to the plant’s inability to operate.

See

Mr. Romaine, Hearing Transcript at 162 (June 20, 2006) (indicating risk adverse

investors as one of the reasons IEPA proposed the TTBS for new units). If an EPC

guarantee cannot be obtained, it would be because the technology is not commercially

available or proven. No one, neither banks nor equity owners, will build a $2 to 3 billion

dollar plant and

hope

the control technology works. While activated carbon vendors may

be willing to guarantee their product will achieve 90% removal (but only after they have

had an opportunity to assess its effectiveness), their limited guarantee of $ 1 to 2 million

is basically meaningless when compared to the overall cost of the facility. Moreover,

given the preliminary results at Conesville discussed above, it is doubtful that activated

carbon vendors will guarantee 90% removal on high sulfur coal.

II.

TRADING SHOULD BE ALLOWED

Prairie State is concerned that IEPA’s proposed rule creates future regulatory

uncertainties for coal-fired power plants in Illinois. For new plants, these uncertainties

are particularly problematic because they can affect the availability of capital to finance

the project. One way to eliminate much of the regulatory uncertainty from the proposed

6

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

rule would be for IEPA to adopt EPA’s CAMR model trading rule and then layer the

Illinois-specific provisions of the proposed rule on top of the model trading rule.

CAMR imposes a hard cap on nationwide mercury emissions. From 2010 to

2017, the cap is 38 tons per year; for 2018 and thereafter, the cap is reduced to 15 tons

per year. CAMR requires that the mercury emissions from new coal-fired generating

plants must be offset by reductions somewhere else in the U.S. either as the result of a

decrease in emissions at an existing unit or by the retirement of a unit. EPA has allocated

CAMR’s nationwide cap among the states by establishing state mercury budgets based on

the heat input of the coal-fired power plants in each state during the period 1998 to 2002.

If a state opts out of the federal mercury cap-and-trade program, then CAMR mercury

budget for that state becomes a hard cap on annual emissions from that state.

2

Prairie State is concerned that at some point in the future, perhaps after 2018,

utilities in Illinois will be in compliance with the requirements of IEPA’s proposed rule

yet the total emissions for the State would exceed Illinois’ mercury budget. If that were

to happen, Illinois would have to require further mercury reductions from coal-fired

power plants in the State since plants would not be able to purchase allowances from

outside the State to show compliance with the federal limit.

3

2

In a recent set of comments on the New Mexico Environment Department’s

CAMR proposal, EPA Region 6 noted that if a state finalizes a rule with a “no trading”

provision, then “it will actually be up to [the State] to ensure and demonstrate to EPA that

you have met your State budget versus the utilities demonstrating to EPA that they have

met the allowance provided to them by the State since they are not participants in the

Federal cap-and-trade program.”

See

Attachment 2.

3

In fact, if Illinois were to allow trading, then in all likelihood coal-fired power

plants in the State would probably bank sufficient allowances to avoid needing to

purchase additional allowances in the event total Illinois emissions exceeds the state

budget.

7

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

One way that Illinois emissions may exceed the state mercury budget is if

mercury control technologies do not perform as advertised. As discussed above, this is of

particular concern with mercury control of high sulfur coals like those to be burned by

Prairie State.

A recurring theme whenever a trading program is discussed is that “hot spots”

may be created. In the case of mercury, this claim is at the forefront of the trading

debate. A central problem with the debate about mercury “hot spots” is that the term is

rarely defined, and when it is, the definitions vary widely. Many who claim that “hot

spots” will result from a mercury cap-and-trade program fail to offer any evidence that

“hot spots” are being created by emissions from coal-fired power plants or plausible

explanations of how mercury “hot spots” would be created by a mercury trading program.

The evidence presented before the Illinois Pollution Control Board demonstrates

that a mercury cap-and-trade program will not create mercury “hot spots.” The main

modeling work on possible mercury “hot spots” presented by the IEPA is that of Dr.

Gerald Keeler. Dr. Keeler used a receptor model to attempt to identify the sources of

mercury in wet deposition he measured near Steubenville, Ohio. Dr. Keeler admitted

during questioning that receptor models cannot be used to make future predictions.

See,

e.g.

, Hearing Transcript at 204 (June 15, 2006). Thus, Dr. Keeler’s work cannot answer

the critical question of how mercury deposition changes at a given location because of the

implementation of CAMR or for that matter IEPA’s proposed rule.

The only presentation in the record that attempts to predict the future mercury

deposition that will result from various regulatory approaches is that offered by Krish

Vijayaraghavan on behalf of Dynegy and Midwest Generating. Exhibit 126. That work

8

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

shows that the full implementation in 2020 of CAIR and CAMR will lead to less mercury

deposition in Illinois than the implementation of IEPA’s proposed rule, except for three

grid cells where increases in mercury deposition of less than 3% are predicted.

Id.

Thus,

adding EPA’s CAMR model rule to the IEPA’s proposed rule would not produce

mercury “hot spots” in Illinois, in fact, it would probably reduce mercury deposition in

the state.

For all these reasons, the proposed rule should be revised to include the CAMR

model trading rule.

III.

IEPA’S RULE HAS NOT CONSIDERED THE SIGNIFICANT

COMPLIANCE ISSUES THAT WILL ARISE IF ADOPTED AS

PROPOSED.

Currently, there are many questions about EPA’s mercury monitoring

requirements and whether available continuous emissions monitoring systems (CEMS)

can accurately measure mercury emissions, particularly at the levels necessary to

demonstrate compliance. Exhibit 132;

see, e.g.,

Mr. McRanie, Hearing Transcript at

1692 (August 22, 2006). As discussed at the hearing by Mr. McRanie, there are serious

doubts whether the currently available CEMS can accurately monitor at the level required

to show compliance with CAMR, much less the more stringent Illinois proposed rule.

See, e.g.,

Mr. McRanie, Hearing Transcript at 1753-54 (August 22, 2006). Imposing a

more stringent limit only exacerbates those concerns.

See

Mr. Romaine, Hearing

Transcript at 227 (June 19, 2006) (concurring that for a standard equal to 0.8 μg/m

3

and a

CEMS with an accuracy of plus or minus one μg/m

3

it would be impossible to determine

compliance with the standard as a practical matter).

Additionally, EPA’s mercury monitoring requirements are currently being

challenged in the D.C. Circuit. It remains to be seen whether that challenge will lead to

9

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

revisions to EPA’s monitoring requirements but it is likely that some changes will be

made by EPA. The proposed regulations incorporate some EPA requirements by

reference but they also include specific mercury monitoring requirements. Prairie State

recommends that Illinois simply incorporate the EPA’s monitoring requirements by

reference. This will avoid a situation where monitoring requirements in Illinois are

inconsistent with the remainder of the country leading to the potential unavailability of

CEMS for facilities in Illinois.

As explained by Mr. Roberson in the attached assessment of mercury CEMS for

Prairie State (Attachment 3), mercury CEMS continue to be a work in progress. They

continue to have technical difficulties including: the sampling probe, transporting the

sample long distances, reliable and affordable calibration standards, and the lack of an

instrumental reference method (IRM) for mercury. While mercury CEMS will continue

to improve, it is important that their current limitations be considered in this rulemaking.

IV.

A TECHNOLOGY BASED STANDARD MUST BE ADOPTED IF IPCB

STANDARDS ARE MORE STRINGENT THAN CAMR.

A.

Technology Based Standard (TBS) is needed to address potential

shortfalls in technology.

There was substantial testimony during the hearings regarding the capabilities of

technology to reduce mercury emissions to the levels required by the proposed rule. One

theme that was heard throughout is the lack of long-term data. That short-coming is why

a technology-based standard is needed to bridge the gap between what technologies are

capable of achieving by 2009 versus 2018. While the short-term tests may be promising,

they are not sufficient to conclude that levels required by the proposed rule can be

sustained day in and day out over the life of the facility. As noted above, those ACI tests

cannot even be said to be promising for high sulfur bituminous coal, such as Illinois coal.

10

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

The utility industry will undoubtedly rise to the challenge and build a better

mousetrap to meet the requirements as it has done in the past (e.g., SCR for NO

x

),

assuming those requirements are physically achievable. The real question is timing.

EPA took this into account in establishing the timing for CAMR; IEPA did not. A rule

requiring compliance in 2009 will necessarily have to be based on technology available

today given the time necessary to procure and install the technology and to get the

necessary permits in place. If that technology proves incapable of achieving the levels

required, a facility will have no option other than to shut down absent a technology based

standard as the proposed rule does not allow trading to make up for any shortfall in the

technology.

If IEPA is correct in its view that the technologies are capable of achieving 90%

removal, adopting a technology-based standard poses little impact as it would never need

to be used. However, if IEPA is incorrect, which Prairie State believes based on its

investigation into the capabilities of technology for its new units, without a technology

based standard, facilities would be required to shutdown, greatly curtail operations, or

face enforcement actions as they would have no way to comply with the requirements. A

technology-based standard would alleviate this concern and would also bridge the gap

pending the outcome of ongoing DOE studies. Moreover, IEPA’s technology expert, Dr.

Staudt, has indicated he supports the inclusion of a technology-based standard. Dr.

Staudt, Hearing Transcript at 87 (June 22, 2006).

B.

The proposed TTBS is not sufficient.

Prairie State is pleased that IEPA has proposed a temporary technology-based

standard (“TTBS”) for the reasons discussed above. However, the TTBS proposed by

IEPA needs improvement.

11

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

First, eligibility should not be tied to the use a particular sorbent (halogenated

activated carbon).

This linkage is too restrictive and ignores new reagents and

technologies that are being developed that may be as or more effective than halogenated

activated carbon. Moreover, the preliminary data on high sulfur coal indicates that

halogenated activated carbon may be less effective than other activated carbons. Exhibit

80, Attachment 3. The rule should not require an EGU to go through an alternative

process to use other sorbents. Instead, the rule should indicate that any sorbent approved

by the Agency may be used. This would afford the Agency the ability to consider and

approve the use of other products as they become available and are proven effective

without having to modify the rule or require an EGU to go through the alternative

process. To implement this concept, Prairie State recommends replacing “halogenated

activated carbon” with

“sorbent or reagent approved by IEPA.”

Second, the TTBS should allow an optimization study to determine the optimum

injection rate such as the one included in Prairie State’s construction permit. Prairie

State’s permit includes detailed provisions for determining the optimum rate of sorbent

injection (Attachment 4). Those provisions consider all of the variables that affect

mercury removal (e.g., halogen, sulfur and mercury content of the coal; SCR catalyst

type and quantity; temperature of the flue gas passing through the air preheater; type of

particulate collection device; installation of additional downstream control devices such

as a wet electrostatic precipitator). It is unclear whether the proposed TTBS considered

such variables in arriving at the default injection rates.

The provisions in Prairie State’s permit should be acceptable as an alternative to

the default rates included in the proposed TTBS without the need for further permitting

12

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

activities. For new facilities like Prairie State whose construction permit already includes

a provision regarding mercury control and the use of a sorbent, the TTBS should not

require a new or revised operating permit as indicated in § 225.238(b)(2) and

§ 225.238(d). A new source should be allowed to indicate in its initial Title V application

that it is applying to operate under the TTBS in accordance with its construction permit.

A new facility that incorporated provisions regarding mercury control should not have to

go through duplicative review and public participation when those provisions have

already been subject to such requirements. Prairie State has a similar concern with

respect to proposed § 225.238(e)(1)(C).

There is a significant cost associated with the default injection rate. As indicated

in Prairie State’s testimony, the cost for compliance with the TTBS at the designated

injection rate of activated carbon is $25 million per year just for the activated carbon

itself. That cost is based on a cost of $1 per pound of activated carbon (Sid Nelson,

Hearing Transcript at 116 (June 21, 2006 am) times 10 pounds per actual cubic foot (acf)

of flue gas times the Prairie State flue gas flow of 2,700,000 acfm per unit. This high

cost is not justifiable as there is currently no evidence that supports an injection rate of 10

lb/million acf.

Third, Prairie State recommends that a provision similar to § 225.234(b)(2)(D),

which allows existing units to lower the injection rate if particulate matter emissions are

adversely impacted, be included in § 225.238 for new EGUs. While new units should not

have the same particulate control device size concerns as discussed at the hearing, they

nevertheless may experience unforeseen problems given the lack of long-term experience

with how activated carbon will impact facility operations. Prairie State also recommends

13

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

that “safety issues” be added as a basis for allowing the injection rate to be lowered. For

example, as discussed at the hearing, Presque Isle recently had a fire in their TOXECON

baghouse due to overheating the carbon in the baghouse. Dr. Staudt, Hearing Transcript

at 91 (June 21, 2006 pm).

Fourth, Prairie State does not understand the requirement, as proposed in

§ 225.238(c)(2)(A), to record the activated carbon feed rate on an hourly average basis.

There does not appear to be any rational basis for requiring a facility to average its

activated feed rate hourly. As the mercury content of the coal cannot feasibly be

monitored and recorded on an hourly average basis, knowing the injection rate on an

hourly basis will provide no useful information with respect to the facility’s mercury

control effectiveness.

Finally, there are some potential timing issues in the proposed TTBS that need to

be worked out. Under § 225.237 of the proposed rule, compliance with the mercury

standard commences on the date of the initial performance test. Application to use the

TTBS must be made at least three months before compliance with § 225.237 would have

to be demonstrated and has to be included in a Title V permit application. The initial

Title V application, however, is due within one year of commencing operation.

Theoretically, a facility would need to submit a Title V permit application to comply with

the TTBS three months after initial startup and before the compliance period is complete.

It is Prairie State’s understanding based on Mr. Romaine’s testimony at the hearing that a

Title V permit application would not have to be submitted prematurely. Mr. Romaine,

Hearing Transcript at 259-60 (June 20, 2006). Prairie State recommends the rule be

clarified on this point.

14

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

Prairie State is providing a markup of the proposed TTBS with its recommended

changes (Attachment 5.

C.

The Proposed Multi-Pollutant Standard Could Negatively Impact

New Sources

In addition to the TTBS, IEPA in conjunction with certain utilities has proposed a

multi-pollutant standard (MPS) that addresses sulfur dioxide (SO

2

) and nitrogen oxide

(NO

x

) emissions in addition to mercury. While the proposal is directed towards existing

facilities, it may have serious consequences on new facilities within the state. The

primary concern for new facilities with the proposed MPS is the effect it will have on the

availability of SO

2

allowances for new units. As proposed, existing units must relinquish

their allocated unused allowances as a result of the MPS to IEPA, who in turn will retire

them. If the majority of existing units elect to sign up for the MPS, it will reduce the pool

of available allowances making it difficult, if not impossible, for Prairie State or any

other new unit to purchase allowances for its emissions. There is a potential solution. To

alleviate potential shortfalls in the availability of allowances, IEPA should make the

allowances relinquished to it under the MPS available to new units for purchase.

V.

CHANGES TO THE PROPOSED RULE ARE NECESSARY IF IPCB

ELECTS TO GO BEYOND CAMR.

While inclusion of the TTBS revised as suggested will address most of the

concerns Prairie State has with the proposed rule, a few issues remain.

First, Prairie State recommends that ASTM D6722-01 "Standard Test Method for

Total Mercury in Coal and Combustion Residues by Direct Combustion Analysis" to

determine mercury in coal be added to § 225.140 and § 225.202 of the proposed rule as

an acceptable method. ASTM has obtained EPA acceptance of ASTM D6722-01 as

equivalent to all other required mercury determination methods. Per ASTM, this

15

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

acceptance is so stated in the Federal Register Volume 70 Number 209 (October 31,

2005) (40 C.F.R. Part 63).

Second, compliance should be judged at the unit level, not on a both unit level

and source level as specified in § 225.210(e) of the proposed rule. If each EGU must

meet the stack limit, then it follows that the source should be in compliance. By

requiring both the unit and source to be in compliance, Illinois is effectively assessing

two violations if a unit fails to meet the emission limit.

Proposed provision

§ 225.230(d)(3) also could result in multiple violations when only one unit may be

having compliance issues.

Finally, averaging provisions should be provided for both “existing” and “new”

units. Section 225.232 appears to apply only to “existing” units. “New” units should

also have averaging provisions since the stringency of the limits Illinois proposes to

impose on new units is the same as existing units -- 90% control.

16

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

CERTIFICATE OF SERVICE

I, Mary Frontczak, certify that I served electronically the attached POST-HEARING

COMMENTS upon the following this 20

th

day of September, 2006:.

Dorothy Gunn

Marie E. Tipsord

Clerk

Hearing Officer

Illinois Pollution Control Board

Illinois Pollution Control Board

James R. Thompson Center

James R. Thompson Center

100 W. Randolph St. , Suite 11-500

100 W. Randolph, 100 W. Randolph

Chicago, Illinois 60601-3218

Chicago, Illinois 60601-3218

tipsorm@ipcb.state.il.us

Gina Roccaforte, Assistant Counsel

Charles E. Matoesian, Assistant Counsel

John J. Kim, Managing Attorney

Air Regulatory Unit

Division of Legal Counsel

Illinois Environmental Protection Agency

1021 North Grand Avenue, East

P.O. Box 19726

Springfield, Illinois 62794-9276

john.kim@epa.state.il.us

charles.matoesian@epa.state.il.us

gina.roccaforte@epa.state.il.us

and electronically to the persons listed on the

ATTACHED SERVICE LIST

.

_[s] Mary Frontczak__________________

DATED: September 20, 2006

Mary Frontczak

Reg. No. 6209264

Peabody Energy

701 Market Street

St. Louis, Missouri 63101-1826

(314) 342-7810

17

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

SERVICE LIST

William A. Murray

Special Assistant Corporation Counsel

Office of Public Utilities

800 East Monroe

Springfield, Illinois 62757

bmurray@cwlp.com

N. Ladonna Driver

Katherine D. Hodge

Hodge Dwyer Zeman

3150 Roland Avenue, P.O. Box 5776

Springfield, Illinois 62705-5776

nldriver@hdzlaw.com

Christopher W. Newcomb

Karaganis, White & Mage, Ltd.

414 North Orleans Street, Suite 810

Chicago, Illinois 60610

cnewcomb@k-w.com

Bill S. Forcade

Katherine M. Rahill

Jenner & Block

One IBM Plaza, 40

th

Floor

Chicago, Illinois 60611

bforcade@jenner.com

krahill@jenner.com

Faith E. Bugel

Howard A. Lerner

Meleah Geertsma

Environmental Law and Policy Center

35 East Wacker Drive, Suite 1300

Chicago, Illinois 60601

fbugel@elpc.org

Keith I. Harley

Chicago Legal Clinic

205 West Monroe Street, 4

th

Floor

Chicago, Illinois 60606

kharley@kentlaw.edu

David Rieser

Jeremy R. Hojnicki

James T. Harrington

McGuire Woods LLP

77 West Wacker, Suite 4100

Chicago, Illinois 60601

drieser@mcguirewoods.com

jharrington@mcguirewoods.com

S. David Farris

Manager, Environmental, Health and

Safety

Office of Public Utilities, City of

Springfield

201 East Lake Shore Drive

Springfield, Illinois 62757

dfarris@cwlp.com

Bruce Nilles

Sierra Club

122 West Washington Avenue, Suite 830

Madison, Wisconsin 53703

bruce.nilles@sierraclub.org

18

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

SERVICE LIST

(R06-25)

Sheldon A. Zabel

Kathleen C. Bassi

Stephen J. Bonebrake

Joshua R. More

Glenna L. Gilbert

Schiff Harden, LLP

6600 Sears Tower

233 South Wacker Drive

Chicago, Illinois 60606

szabel@schiffhardin.com

kbassi@schiffhardin.com

sbonebrake@schiffhardin.com

jmore@schiffhardin.com

ggilbert@schiffhardin.com

James W. Ingram

Senior Corporate Counsel

Dynegy Midwest Generation, Inc.

1000 Louisiance, Suite 5800

Houston, Texas 77002

Jim.Ingram@dynegy.com

Daniel McDevitt

General Counsel

Midwest Generation, LLC

440 South LaSalle Street, Suite 3500

Chicago, Illinois 60605

19

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

•

•

EXCERPTS FROM THE

•

ENGINEERING, PROCUREMENT AND CONSTRUCTION AGREEMENT between

PRAIRIE STATE MANAGEMENT COMPANY, LLC (PSMC)

•

and

•

(Contractor)

•

dated as of [October 31], 2005

•

8.1.1.7

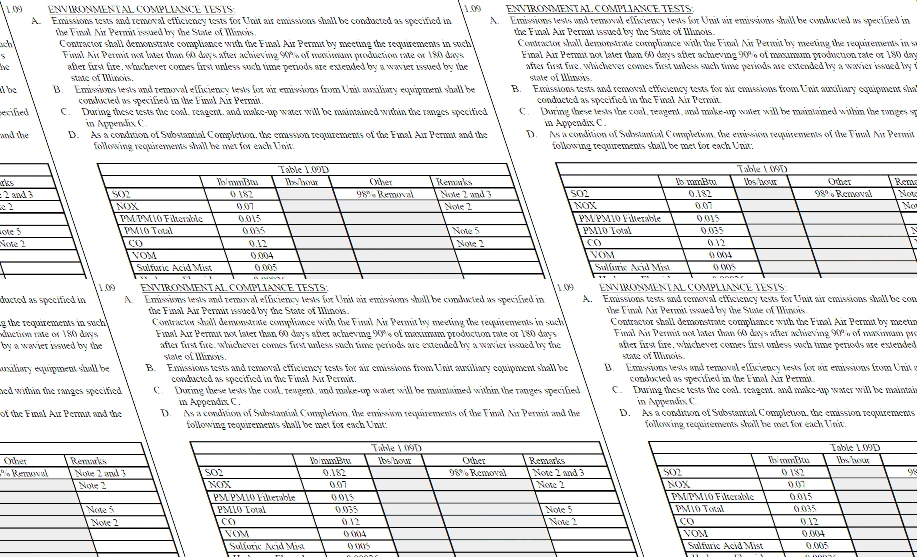

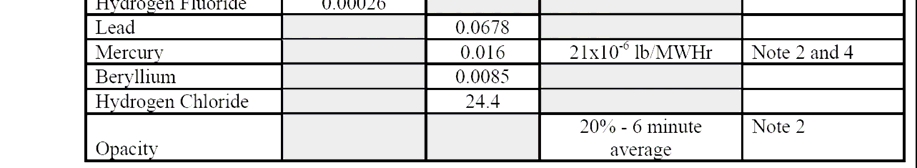

Environmental Compliance Guarantee. Contractor guarantees that each Unit and

the Facility shall comply with all requirements of the Permits during the entirety of the

Performance Tests including the Facility Reliability Test (the “Environmental Compliance

Guarantee”). Contractor further guarantees that each Unit and the Facility shall meet the

Environmental Compliance Guarantee at the loads with the fuels specified in Appendices C and E.

A description of certain Permit levels that adjust over time that are required to be achieved to

satisfy the Performance Guarantees are set forth in Appendix E. Article 16

LIMITATIONS OF LIABILITY

16.1 Aggregate Limitation of Contractor’s Liability

.

•

16.1.1

To the fullest extent permitted by law, the total cumulative monetary

liability of Contractor for payments in respect of Contractor’s failure to cause Mechanical

Completion to occur or failure to cause the Facility to achieve the Environmental Compliance

Guarantee or to achieve the Minimum Performance Guarantees or for violations of Applicable

Legal Requirements by Contractor, its Affiliates, Subcontractors or Personnel shall not exceed an

amount equal to the Contract Price; provided, however, that (i) the foregoing limitation shall not

limit Contractor’s liability arising out of any Claims for which Contractor has an indemnification

obligation under this Agreement, and (ii) the aggregate amount of Contractor’s liability under this

Agreement shall not be reduced by any proceeds of the insurance described in

Appendix Q

that

are received by Contractor or paid to PSMC or any Owner.

5.1

Contract Price

. As full consideration for the full and complete

performance of the Work by Contractor and Contractor’s other obligations hereunder and all

costs incurred in connection therewith, PSMC shall, subject to

Sections 5.2

and

5.3

, pay to

Contractor the firm fixed lump sum amount of $__,___,___,___.__, inclusive of all Contractor

Taxes (the

“Contract Price”

)

2.2

Work to be Performed

. Except as otherwise expressly set forth in

Article 3

as being the responsibility of PSMC, Contractor shall, in accordance with the

Agreement, perform or cause to be performed all acts or actions required or necessary in

connection with the design, engineering, permitting (with respect to Contractor Permits),

procurement, equipping, supplying, manufacturing, construction, installation, training,

commissioning, start-up, demonstration, testing, operation, care, custody and control, and

completion of the Facility (whether at the Facility Site or elsewhere) until Final Completion and

satisfaction of Contractor’s warranty obligations during the Warranty Period (collectively, the

“Work”

) all on a lump sum, turnkey, basis and in accordance with this Agreement.

•

1/3

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

•

2/3

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

•

3/3

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

EPA REGION 6 COMMENTS ON NMED CAMR PROPOSAL

Regulatory Comments:

20.2.85.2

– Should the scope be changed to apply to only coal-fired electric

generating units?

20.2.85.50

- What is meant by the effective date being Nov. 17, 2006? Is this

date the date EGUs need to begin complying with the rules, or just the

approximate date that NMED expects the rule to be final?

20.2.85.7

- A definition you may want to include is "sequential use of energy" to

deal with the potential for a future cogeneration units being constructed in New

Mexico. We also encourage NMED to adopt the June 9, 2006 definition of

"electric generating unit" to include the exclusionary language on solid waste

incineration units in the definition of electric generating units. Other definitions

that should be considered for adoption include continuous emission monitoring

system (CEMS), control period, emissions, excess emissions, mercury budget

permit.

20.2.85.101 A

. - We suggest that you add a calendar year reference to the last

sentence of the paragraph......."No electric generating unit regulated under this

part shall emit a quantity of mercury greater than the number of annual mercury

allowances the electric generating unit has been allocated under 20.2.85.103

NMAC beginning in calendar year 2010.”

20.2.85.101 B

. - We suggest that you also show the state's budget in ounces for

the corresponding budget years.

20.2.85.102

- We do not believe this paragraph is needed in the rule. If the State

finalizes a rule with "no trading" provisions, the State is basically creating a State

run program that differs from EPA's regulatory approach. Therefore, it will

actually be up to New Mexico to ensure and demonstrate to EPA that you have

met your State budget versus the utilities demonstrating to EPA that they have

met the allowance provided to them by the State since they are not participants

in the Federal cap-and-trade system.

20.2.85.103

– EPA has several questions/comments:

1. Since New Mexico is considering a no-trading type program, has New

Mexico considered a larger new unit set aside in the event that new units

are built in future years, or would New Mexico redistribute the utilities

mercury allowances to accommodate a new unit?

2. Were lower allowance levels considered for the existing units to provide a

buffer for New Mexico to stay within its State mercury budget?

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

3. How will NM address the possibility of an electric generating unit

exceeding its allocation of allowances? Will an enforcement action result?

EPA is concerned about the possible implications of a State with a no-

trading approach exceeding its State budget and the State should clearly

demonstrate in its Section 111(d) plan what safeguards are in place to

prevent the State from exceeding its assigned State budget.

4. What if a utility exceeds its allowance, what type of penalty and

enforceable restoration to the State’s allowance and budget system will be

made? Any potential restoration requirements need to be incorporated

into an enforceable permit for the unit.

20.2.85.104

- Would higher fees for mercury allowances provide a disincentive to

electric generating units to exceed its allocation of allowances? Has some type

of escalating fee system been considered based upon the number of allowances

needed by an EGU?

20.2.85.105

- What is the process for new units to request and receive

allowances from NMED? What if there are not enough allowances available for

the new source to start operation? We are concerned about the implications for

both existing and new units if there are not sufficient allowances for a new unit to

start operation in New Mexico, or the potential for an existing unit’s NMED

assigned allocation of allowances to be impacted without sufficient time to install

any necessary pollution controls to make room for a new unit’s emissions.

20.2.85.106

- We suggest revising the regulatory text to state: "Sources subject

to this part are required to comply with all requirements of 40 CFR Part 75

concerning determinations of mercury mass emissions."

General Comments:

- A provision requiring compliance with 60.4170(a), (b), (c), (d) is needed in the

regulations. Please note that CEMS units for existing units need to be certified

by January 1, 2009. There needs to be a definitive requirement in the State

rules for monitoring and reporting by the units.

- There are no CAMR permit requirements in the regulatory language. The

State should clearly outline the CAMR permit requirements in the regulatory text.

Does the State intend for these rules to function as a permit-by-rule type

program?

- Will NMED specify that the companies or operators that own the San Juan

power station or Escalante power stations designate an individual as mercury

designated representative to report to NMED.

- NMED should outline in the regulatory proposal what the EGUs will need to

provide NMED to demonstrate an increment of progress as discussed at 60.21

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

and 60.24(e). NMED will need to ensure that it’s section 111(d) submittal

satisfies the requirements of 40 CFR part 60 – Subpart B.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

STATUS OF MERCURY

CONTINUOUS EMISSION MONITORING SYSTEMS

September 2006

Prepared for

Dianna Tickner, Vice President

Prairie State Generating Company, LLC

Prepared by

Ralph L. Roberson, P.E.

RMB Consulting & Research, Inc.

Raleigh, North Carolina

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

2

REGULATORY BACKGROUND

On May 18, 2005, EPA published in the Federal Register the Clean Air Mercury Rule (CAMR)

designed to reduce mercury emissions from coal-fired electric generating units (EGUs). CAMR

creates a cap-and-trade program that will be implemented in two phases. Phase 1 caps mercury

emissions at 38 tons per year (tpy) in 2010 and phase 2 caps mercury emissions at 15 tpy in

2018. CAMR requires existing units to begin to continuously monitor mercury emissions with a

certified system no later than January 1, 2009. CAMR recognizes two options for obtaining

continuous mercury emission data: (1) sorbent trap monitoring systems and (2) mercury

continuous emission monitoring systems (CEMS).

EPA developed CAMR pursuant to the Agency’s authority under section 111(d) of the Clean Air

Act (CAA). Section 111(d) authorizes EPA to promulgate standards of performance that States

must adopt through the State Plans, which requires State rulemaking action followed by review

by EPA. If a State fails to submit a satisfactory plan, EPA has authority to prescribe a plan for

the State. States are not required to adopt and implement EPA’s proposed mercury emission

trading rule, but States are required to be in compliance with their statewide mercury emission

budgets.

The State of Illinois has proposed to opt out of the federal trading program and instead impose

unit/facility specific mercury emission limits or percent mercury removal requirements.

Specifically, the Illinois Environmental Protection Agency (IEPA) has proposed to add new

regulations to 35 Illinois Administrative Code Part 225, Control of Emissions from Large

Combustion Sources. These regulations would control mercury emissions from coal-fired EGUs

located in the state. Beginning July 1, 2009, the regulations would require existing EGUs to

meet either (1) an emission limit of 0.0080 lb Hg/GWh gross electrical output, or (2) achieve a

90 percent reduction of input mercury.

1

MERCURY MONITORING ISSUES

Mercury CEMS continue to be plagued by slower than expected development and a limited

number of viable suppliers. The potential limited number of mercury CEMS suppliers tends to

make the electric utility industry want to start the procurement process sooner rather than later.

On the other hand, reports of continued technical difficulties with mercury CEMS cause the

utility industry to want to proceed cautiously. Significant technical issues include: the sampling

probe, transporting the sample long distances, reliable and affordable calibration standards, and

the lack of an instrumental reference method (IRM) for mercury. Each of these technical issues

is discussed in more detail below. Moreover, the Illinois proposed mercury EGU rule presents

mercury monitoring challenges above and beyond those posed by EPA’s CAMR. Illinois-

specific issues are also discussed below.

1

For the purpose of this rule,

existing

EGUs are those in commercial operation on or before December 31, 2008.

Also,

input mercury

means the mass of mercury that is contained in the coal.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

3

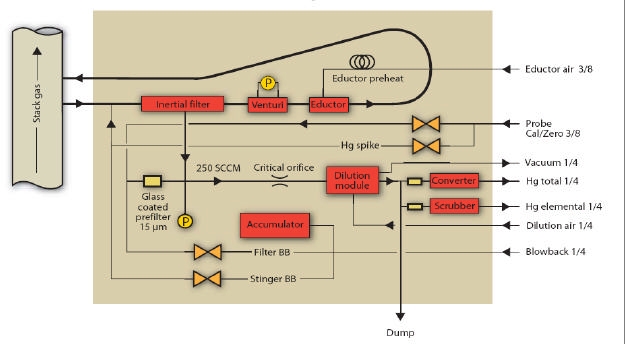

Sampling Probes

Most of the leading Hg CEMS vendors use an inertial dilution probe. These probe assemblies

are bulky and quite complicated. To illustrate the point, a schematic of a typical inertial

sampling probe is shown in Figure 1.

2

Figure 1

Thermo Electron Inertial Mercury Probe

Dilution helps minimize the deleterious effects of acid gases and selenium on analyzer

components, especially catalytic converter systems. Dilution sampling also means the sample

will be analyzed on a wet basis, which means the Hg concentration can be simply (without need

for moisture correction) multiplied times stack volumetric flow rate to yield Hg mass emissions

(ounces per hour). However, these probes have been especially problematic on wet stacks (e.g.,

units with wet flue gas desulfurization systems) and appear to be the root cause of poor

reliability. The dilution probes withdraw a relative large volume of gas from the stack, albeit

only a small sub-sample is ultimately delivered to the analyzer. However, when the water from

the saturated flue gas is evaporated by the probe heat, scrubber solids tend to get deposited in

critical openings and bends. Also, the dilution probe’s inertial filter has also proven, at times, to

be a challenge to get the calibration gases through. This problem appears to be mitigated by

humidifying the calibration gas prior to injection.

2

Figure 1 is reproduced from a Thermo Electron brochure. The probe box is 10.5 inches wide x 18.5 inches high x

approximately 3 feet in length and weighs about 80 pounds. The fractions (i.e., 1/4 and 3/8) on the figure denote the

respective tube diameters (inches).

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

4

Calibration Standards

Two forms of gas are needed for the calibration of Hg CEMS: elemental (Hg

0

) and oxidized

(Hg

+2

) mercury. The calibration gases can be generated on site for both species of mercury (Hg

0

and Hg

+2

), or supplied in compressed gas cylinders (only Hg

0

). EPA’s Part 75 rule requires

affected sources to use both Hg

0

and Hg

+2

standards, which must be NIST traceable.

3

To date,

no such NIST traceable standards exist or can be purchased. We understand from discussions

with EPA staff that NIST is close to having a protocol available to use for characterizing

vendors’ gas generators or gas cylinders. Perhaps by the end of 2006, vendors will have NIST

research grade materials (RGMs) for Hg

0

. Vendors would then follow a yet-to-be-developed

EPA protocol, using the RGMs, to mass produce either Hg gas generators or Hg calibration gas

cylinders.

RMB’s experience with Hg

0

gas cylinders has not been good. First, Hg

0

cylinder gas is very

expensive relative to the cost of SO

2

and NO

x

cylinder gases. Second, the cylinders do not last

as long as the SO

2

and NO

x

calibration gases, apparently because of the large calibration gas

volumes required to “flood the probe” for each calibration cycle. Lastly, we have actually

experienced a change in concentration during the life of a cylinder. We believe that during one

cold December night a bit of the Hg apparently condensed, lowering the effective Hg gas-phase

concentration in the cylinder. Once the cylinder returned to a more normal temperature, the

condensed Hg evaporated and, in effect, increased the cylinder concentration above the

“certified” value. For these reasons, RMB has stopped purchasing Hg cylinder gases for our Hg

CEMS Demonstration projects. The foundation of any successful CEMS program has always

been the availability of reliable and accurate calibration standards; thus, there is need for

considerable improvement in Hg calibration materials

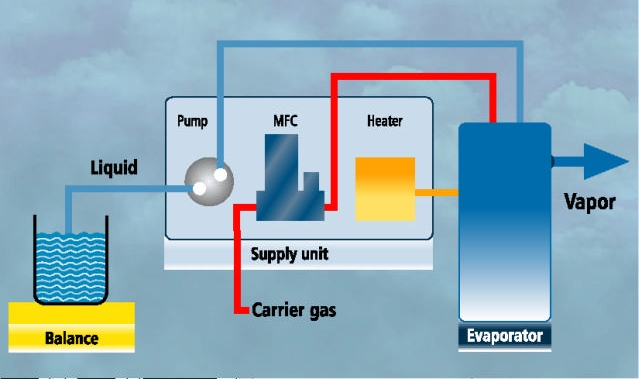

The chemical properties of Hg

+2

compounds preclude them from being compressed into gases.

Thus, Hg

+2

gas cylinders cannot be manufactured. HoVaCal and MerCal gas generators can

produce HgCl

2

(oxidized Hg) gas. EPA and NIST are purportedly working on a traceability

protocol and ways to characterize the uncertainty for oxidized mercury gas generators.

Unfortunately, in the previously referenced conversation with EPA, Agency personnel

acknowledged that NIST is far behind schedule in developing RGMs for Hg

+2

. To date, we

believe only the HoVaCal device has been used in the field for Hg

+2

. The HoVaCal principal of

operation is based on using a high temperature evaporator (see Figure 2) to convert a liquid

HgCl

2

solution into a gas-phase mixture with nitrogen carrier gas. Using the HoVaCal is a

manual, labor-intensive process and requires considerable analytical chemistry skills because the

accuracy with which the liquid solutions are prepared basically control the accuracy of the

calibration standards.

3

See, for example, 40 C.F.R. §75.20(c) and Appendix A, §5.1.9.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

5

Figure 2

Schematic of HoVaCal Illustrating Principles of Operation

Sample Transport

This remains an area of uncertainty. At one of the EPA mercury CEMS evaluation sites, the

analyzers are located in a trailer, but the sample transport distance is less than 150 feet. At a

second mercury CEMS evaluation site, all the analyzers are located at the sampling elevation,

which is over 400 feet above grade. Unfortunately, most stack sampling locations are +300 feet

above grade but, unlike the second evaluation site, do not have adequate space to accommodate a

mercury CEMS. So, the questions are: can mercury be transported in excess of 300 feet in well-

heated (+350º F) sampling lines without losing any Hg, and if so, how maintainable are these

high technology sample lines.

Instrumental Reference Method

Historically (and CAMR is no different), EPA requires each installed CEMS to be “certified”

before the CEMS is used to collect compliance and/or allowance tracking data. The linchpin of

EPA’s CEMS certification process is the relative accuracy test audit (RATA). In simplest terms,

a RATA describes the process of collecting data with the appropriate EPA reference method and

simultaneously collecting data with the CEMS. The relative accuracy of the CEMS is then

calculated from the required minimum of nine valid paired runs. Relative accuracy is a statistic

designed to provide a measure of the systematic and random errors associated with the data from

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

6

the CEMS – when compared to the EPA reference method. CAMR specifies the Ontario Hydro

Mercury (OHM) method

4

as the mercury reference method and is to be used to conduct a RATA.

The OH method is complicated and expensive to perform. Moreover, a very high level of

experience and attention to detail is required to obtain consistent results. In several field studies,

EPA contractors have consistently had difficulty achieving the required precision between paired

OH runs to be used in the RATA calculations. As stated above, CAMR requires a minimum of

nine valid paired runs for each RATA test. EPA contractors have typically conducted 12 paired

runs, but once the analysis are completed, find that less than nine runs are valid. But time is the

real enemy of the OH method. It has taken as along as 2 months to receive some of EPA’s

RATA results. Granted, this may not be indicative of the time required fo r utility companies to

receive results given the apparent EPA/EPA contractor bureaucracy. However, RMB expects

that many utility companies, which use outside laboratories for OH sample analysis, will find

that 3 to 4 weeks are required to obtain RATA results.

Clearly, there is a major need for EPA to quickly develop a mercury IRM. Without a mercury

IRM, RMB does not believe the electric utility industry has any chance of certifying mercury

CEMS in any reasonable timeframe or at any reasonable cost. One of the primary reasons utility

companies have experienced high CEMS availability and excellent CEMS accuracy under EPA’s

Acid Rain program is the advent of instrumental reference methods for SO

2

and NO

x

. RATA

results are available before the testing contractor leaves the plant. Thus, if there is a problem,

corrective action can be taken, and the RATA can be repeated – often without having to

reschedule the testing contractor. EPA is just beginning to field test the elaborate procedures

specified in the Agency’s conceptual IRM. Given the progress made to date, RMB does not

believe that EPA’s Hg IRM can be promulgated in time for the initial round of Hg CEMS

certification tests.

Mercury CEMS Accuracy

While on the subject of RATA testing, there is definitely a problem with EPA’s “alternative”

acceptance criterion. EPA’s alternative RATA criterion is if the mean reference method (RM)

concentration is less than 5.0 μg/m

3

, RATA results are acceptable if the absolute value of the

mean difference between the RM and CEMS values does not exceed 1.0 μg/m

3

.

5

While the

alternative criterion may be reasonable when the mean RM concentration is around 5 μg/m

3

, it

does not seem appropriate when the mean RM concentration is say, 1 μg/m

3

. In this example,

the potential error is effectively ±100 percent of the RM-determined emission concentration. We

believe the alternative criterion is important, but probably too lenient in its current form. The

major question is how much this “loophole” can be tightened while remaining reasonably

achievable.

4

The Ontario Hydro Mercury method is codified as ASTM D6784-02.

5

40 C.F.R., Part 75, Appendix B, Figure 2.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

7

SPECIAL CHALLENGES POSED BY ILLINOIS MERCURY PROPOSAL

States, such as Illinois, who are proposing mercury emission standards more aggressive than

CAMR are making unsupported assumptions with respect to the status of cont inuous mercury

monitoring technology. These States apparently assume that if mercury monitoring technology

is advanced enough to support EPA’s cap-and-trade program, then it is sufficient for their more

aggressive command-and-control regulations. There are at least two problems with this

assumption. First, EPA is not contending that Hg CEMS technology is 100 percent ready for

CAMR. For example, consider the following quote from a recent EPA report.

6

It is apparent through the results from each subsequent field evaluation that the

reliability and accuracy of Hg CEMS continues to improve. However, some

issues such as probe and umbilical operation continue to affect the reliability of

CEMS systems on wet stacks.

The Illinois proposed mercury rule will be impacted by the alternative RATA criterion discussed

above. RMB examined the mercury content of both eastern bituminous and western

subbituminous coals, and we observed nominal uncontrolled Hg emission concentrations in the

range of 6-10 micrograms per dry standard cubic meter (μg/dscm). Therefore, when 90%

reduction is applied as suggested by the Illinois proposed mercury rule, the expected stack

concentration will be in the 0.6-1.0 μg/dscm range. The Illinois proposed alternative Hg

emission limit of 0.0080 lb Hg/GWh gross electrical output is (assuming a gross heat rate of

approximately 9,500 Btu/kW-hr) equivalent to 0.84 lb/10

12

Btu. For coal-fired boilers, 0.84

lb/10

12

Btu converts to a flue gas concentration of approximately 0.81 microgram per wet

standard cubic meter (μg/wscm). It is important to convert the proposed Illinois Hg limit to

concentration units because many important Part 75 monitoring criteria are expressed in the units

of μg/dscm. For example, if stack gas Hg concentration is less than 5 μg/dscm during a RATA,

the continuous Hg monitoring system achieves EPA’s alterative RATA criterion if the mean

difference between the reference method and the monitor is ± 1μg/dscm. The Part 75

specification for daily calibration error checks is 5 percent of span or ± 1μg/dscm. In other

words, Part 75 permissible Hg monitoring tolerances are on the order of 1.23 (i.e., 0.81 x 1.23 =

1.0) times Illinois’ proposed Hg limit. Thus, the uncertainty of Hg measurements at the Illinois

proposed levels is, and is expected to remain, quite large. Although the proposed Hg emission

limitation is a few years away, it is too soon for IEPA to begin thinking about developing an

enforcement discretion policy, considering the likely uncertainty in the Hg monitoring data at

these very low concentrations. There is very little experience in measuring mercury emissions at

these low levels. There is a very real question whether such low mercury concentrations can be

measured reliably, accurately and precisely.

A second problem, which has already been alluded to, is that stringent Illinois Hg limit can result

in much lower and more difficult to measure Hg concentrations than will CAMR. EPA’s Part 75

monitoring requirements were designed for the SO

2

cap and trade program and as such includes

components such as missing data substitution, which are needed to accurately track emissions

during all operating hours. Some of those components may not be appropriate for tracking

6

“Mercury Emissions Monitoring Program for Coal-Fired Boilers under the Clean Air Mercury Rule Status

Report,” U.S. Environmental Protection Agency, Clean Air Markets Division, Washington, DC, February 2006.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

8

compliance with the Illinois proposed Hg emission rate limit. In particular, the missing data

substitution procedures implicit in the Illinois proposed rule are very problematic from two

different perspectives. First, although EPA’s Part 75 missing data procedures have worked well

to maintain high levels of SO

2

and NO

x

data availability, Hg CEMS technology is not as mature

as are those technologies. We expect that there will be much more missing data with the Hg

monitors and, as a result, that the punitive penalties for data substitution will be used more often.

Second, under an emission trading program, if a facility is plagued with significant missing

CEMS data, which produces emission estimates that are biased high, the facility can enter the

market and purchase additional allowances to offset the over-reporting. However, there are no

such alternatives with the Illinois proposed Hg emission standards. Moreover, EPA specifically

excludes substituted data for determining compliance with emission limits.

7

Therefore, we

strongly recommend that the IEPA develop compliance calculations that do not include

substituted data.

As previously discussed, as of today, there are no NIST traceable gas standards at all for mercury

and not likely to be any at the low levels contemplated by the Illinois proposed rule. The only

NIST traceable standards that are available are liquid standards in the oxidized mercury form,

and a special device (i.e., HoVaCal) is needed to use those standards on gas analyzers. In

addition, EPA’s current reference method for mercury (i.e., OHM Method) was not developed to

measure these low concentrations, and the method’s performance (e.g., precision, accuracy, and

bias) has never been evaluated at concentrations below approximately 3 μg/dscm. In short, there

are numerous issues associated with measuring mercury in the range of 1 μg/dscm. As the

reader should surmise, mercury CEMS have a ways to go before electric utility users can expect

to have reliable and accurate continuous measurement of mercury emissions.

CONCLUSIONS

Hg CEMS technology continues to be a “work in progress.” In addition to the EPRI Hg CEMS

Demonstration project, a number of utility companies are currently conducting their own field

evaluations of Hg CEMS from multiple vendors. Progress in operability is being reported,

although it is slow and not without setbacks. RMB is cautiously optimistic that time and market

demand will improve the quality and availability of Hg calibration materials. In the meantime,

States such as Illinois that are embarking on aggressive Hg emission regulations need to

recognize that measurement uncertainties are inherent at these low Hg concentrations.

Prevailing political considerations may drive the Hg limits quite low; however, the accuracy of

low-level Hg measurements is relatively non-partisan.

7

See, for example, §40 C.F.R. 60.49a(p)(4)(ii) – EPA’s Subpart Da emission monitoring provisions for new electric

utility steam generating units.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

ATTACHMENT 4:

DETERMINING THE SORBENT INJECTION RATE FOR CONTROL OF MERCURY EMISSIONS FROM

THE COAL-FIRED BOILERS

1.

Purpose

This attachment contains the requirements for the sorbent injection

systems for control of mercury emissions from the coal-fired boilers

if the boilers are subject to Condition 2.1.2(c)(ii)(A) and the

Permittee elects to comply with Permit Option B, i.e., use of a

control system for mercury emissions. Among other matters, this

attachment defines the process by which the applicable injection rate

of sorbent for such systems will be determined. These requirements

are included as an attachment to this permit, rather than in the body

of the permit, due to the detailed nature of the requirements and the

likelihood that these requirements will never take effect, as the

emissions of mercury from the coal-fired boiler are subject to

requirements adopted by USEPA pursuant to the Clean Air Act.

2.

General Requirements

a. The sorbent injection systems, including the selected sorbent(s)

shall be designed, constructed and maintained in accordance with

good air pollution control practices. For this purpose,

sorbent(s) shall be used, such as treated activated carbon, that

have been demonstrated to have high levels of effectiveness in

similar boiler/control device applications (or pilot tests on an

affected boiler). The systems shall have ample capacity to

handle and inject such sorbent(s), and the location, number and

type of injection ports designed for effective distribution of

sorbent in the flue gas. The Permittee shall submit a

demonstration to the Illinois EPA showing that the proposed

sorbent injection systems meet these criteria, for review and

approval by the Illinois EPA.

b. i. The sorbent injection systems shall each be operated to

inject sorbent at a rate, in lb/million Btu or lb/scf of

flue gas, that is at least at the rate that has been

determined to represent the maximum practicable degree of

removal for mercury, as previously established pursuant to

an evaluation of the effectiveness of the sorbent for

control of mercury conducted in accordance with Condition 3

or 4, below. This rate shall be maintained while coal is

being fired in the boiler, including periods of startup and

shutdown of the boiler.

ii. Notwithstanding the above, for purposes of evaluating the

performance of sorbent(s), the Permittee may operate without

the sorbent injection system in service or at low rates of

sorbent injection as necessary to (1) to prepare for the

formal evaluation of a sorbent, i.e., flushing residual

sorbent from the boiler and control train, and (2) determine

the “performance curve”, provided that the number and duration

of such operation is minimized to the extent reasonably

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

necessary for this purpose. (Refer to Paragraph 5(a), below,

for the definition of the performance curve.) The Permittee

may also conduct pilot tests to confirm suitability of a

potential sorbent prior to a detailed evaluation, with prior

notification to the Illinois EPA describing such tests and the

available data indicating the suitability of the sorbent

material for effective control of mercury.

3.

Initial Evaluation of the Effectiveness of Sorbent Injection and

Establishment of the Optimum Sorbent Injection Rate

a. The Permittee shall perform an evaluation of the effectiveness of

injecting sorbent(s) for control of mercury in accordance with a

plan submitted to the Illinois EPA for review and comment.

i. The Permittee shall submit the initial plan to the Illinois

EPA no later than 180 days after initial start-up of a

boiler.

ii. The Permittee shall promptly begin this evaluation after a

boiler demonstrates compliance with all applicable short-

term emission limits as shown by emission testing and

monitoring. At this time, the Permittee shall submit an

update to the plan that describes its findings with respect

to control of mercury emissions during the shakedown of the

boilers, which highlights possible areas of interest for

this evaluation.

iii. This evaluation shall be completed and a detailed written

report submitted to the Illinois EPA within two years after

the initial startup of a boiler. This report shall include

proposed injection rate limit(s) for mercury emissions.

(See Condition 3(d)(i), below.)

iv. This deadline may be extended by the Illinois EPA for an

additional year if the Permittee submits an interim report

(1) demonstrating the need for additional data to

effectively evaluate sorbent injection and (2) includes an

interim limit for mercury injection that provides effective

control of mercury.

b. i. If the Permittee is conducting monitoring for mercury

emissions with a continuous method, the plan shall provide

for systematic review of mercury emissions as related to

variation in operation of the boiler, within the normal

range of boiler operation, including the effect of (1)

boiler load and combustion settings, including excess

oxygen, (2) operating data for the SCR system, including

the level of uncontrolled NO

x

before the SCR, as predicted

from boiler operating data, (3) operating data for the

scrubber, including pH of the scrubbant, and (4) operating

data for the wet WESP. As an alternative to reliance on

the measurements from a continuous monitoring system, the

Permittee may also supplement its monitoring with semi-

continuous monitoring, as provided below.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

ii. If the Permittee is conducting monitoring for mercury

emissions with a semi-continuous method, the sampling

periods shall be of an appropriate duration to cover a

representative selection of operation of the boiler.

c. In conjunction with such measurements of mercury emissions, the

Permittee shall sample and analyze the fuel supply to the boiler

so that representative data for the mercury content of the fuel

supply is available that correlates with emission measurements.

d. i. Unless the Permittee elects to conduct a supplementary

investigation, as provided below, the maximum practicable

degree of removal shall be injection of sorbent at a rate

that is twice the rate at the “transition point” from the

performance curve. (Refer to Paragraph 5(b), below, for

the definition of the transition point.) The sorbent

injection systems shall be operated at this rate.

ii. The Permittee may elect to conduct a supplemental

investigation of the effectiveness of injection of

sorbent(s) to determine whether effective control of

mercury, as generally required, is achieved with lower (or

higher) injection rates considering the operating rate or

other relevant operating parameters of the boilers or

control train, excluding periods of startup and shutdown of

boilers. For this purpose, the Permittee shall conduct

additional measurements and develop additional performance

curves for the control of mercury emissions for the boilers

under such operating conditions. In the report for the

evaluation, the Permittee shall explain why such operating

conditions affect the control of mercury emissions, provide

the criteria for identification of such operating

conditions, and identify the rates at which the sorbent

injection system must be operated during such conditions,

determined as twice the rate at the “transition point” on

the applicable performance curve.

4.

Subsequent Evaluation of the Effectiveness of Sorbent Injection and

Adjustment of the Optimum Sorbent Injection Rate

a. The Permittee shall repeat the evaluation described in

Condition 3, above, in the following circumstances:

i. If the initial evaluation of sorbent injection does not

demonstrate that 90 percent or more overall control of

mercury will be achieved, a new evaluation shall be

commenced two years after the initial evaluation was

completed.

ii. If the Permittee undertakes significant changes to the

mercury control system, e.g., use of a different sorbent or

changes in the location or type of injection ports, at the

conclusion of such changes.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, SEPTEMBER 20, 2006

* * * * * PC #6294 * * * * *

iii. If the Permittee undertakes significant changes to other

devices in the control train, e.g., use of a different

catalyst in the SCR or changes in the chemistry of the

scrubber which would generally act to reduce the

effectiveness of those devices in controlling or

facilitating the control of mercury emissions, at the

conclusion of such changes.

iv. If requested by the Illinois EPA for purposes of periodic

confirmation of the effectiveness of sorbent injection,

which request shall not be made more than once every five

years.

v. If the Permittee elects to perform such evaluation,

provided, however that the Permittee shall explain why such

an evaluation is being undertaken if it is less than two

years after completion of the last evaluation.

b. For the purpose of subsequent evaluation, the plan shall be

submitted to the Illinois EPA for review and approval at least 45

days before undertaking changes that trigger the need to perform

such an evaluation and the evaluation shall be completed in one

year, with opportunity for a 6-month extension.

c. As a subsequent evaluation reassesses the continuing operation of

the boilers or addresses the future operation of the boilers, the

results of the evaluation shall supersede the results of the

preceding evaluation and thereafter govern the operation of the

sorbent injection systems. For example, if the subsequent

evaluation was performed for a new sorbent material and the

boilers continue to be operated with such sorbent, operation

shall be governed by the results of the subsequent evaluation.

If the new sorbent will not continue to be used, operation shall

be governed by the results of the preceding evaluation for the

sorbent material that will be used.

5.

Definition of Terms As Related to Sorbent Injection for Control of

Mercury Emissions

For the purpose of these conditions, the following terms shall apply: