| | - BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

- NOTICE OF FILING

- SEE ATTACHED SERVICE LIST

- BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

- APPEARANCE

- BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

- TESTIMONY OF DIANNA TICKNER

- Specific Comments

- Ms. Laurel Kroack March 13,2006 Page 8

- Enclosure

- cc: Douglas P. Scott

- a~oroved by the Aeencv.)

- National Energy Tecbnohgy Laboratory

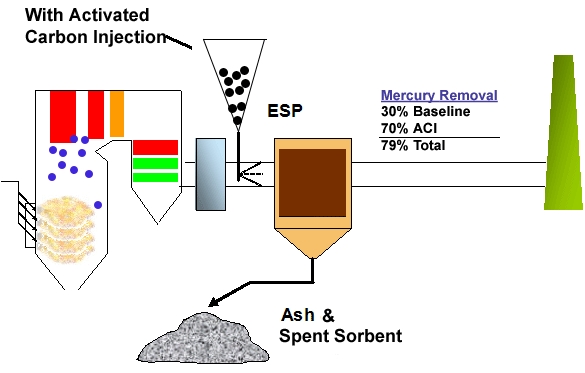

- Development Status of Mercury-Specific Control Technology

- Cost of Activated Carbon Injection

- Impacts of Mercury Control on Cost of Electricity

- U.S. DOE’s Hg Control Technology RD&D Program—

- Significant Progress, But More Work to be Done!

- Outline

- Mercury Control Technology Program

- Baseline (1999) Costs: $60,000 / lb Hg Removed

- 2000 Year

- NETL’s Hg Control Technology R&D

- rank coals more difficult to control due to lower Cl/higher element Hg content

- treated (e.g., halogenated) activated carbon (AC)

- Balance-of-Plant Issues/Lessons Learned

- TOXECON Retrofit for Hg and Multi-Pollutant Control

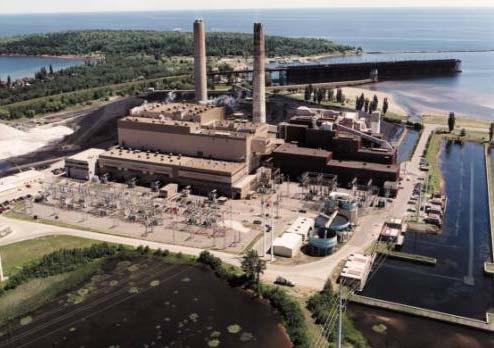

- Problem with Overheating Powdered Activated

- Carbon at Presque Isle

- all hoppers had embers

- heaters

- (welding, cutting, hopper heaters)

- Mercury Control Options for TXU’s

- Big Brown

- Side B ~ 300 MWSide B ~ 300 MW

- FF4 ~ 150 MWFF4 ~ 150 MW

- Upcoming NETL Field-Testing

- at Bituminous Units

- Quarter 2006ApproachLee Unit 3conditioning

- Gavin Station CS-ESP / Wet FGD Unknown TOXECON™ II 3.76

- Portland Unit 1 CS-ESP March 2006 Mer-Cure™ 2.01

- Conesville Unit 6 CS-ESP / Wet FGD March 2006 Enhanced ACI 3.00

- Amended 2.21Miami Fort Unit 6 CS-ESP 1stQuarter 2006Silicates™

- Lee Unit 1 CS-ESP November 2005 Enhanced ACI 0.77

- Yates Unit 1 CS-ESP / Wet FGD Fall 2005 Wet FGD additive 0.93

- Yates Unit 1 CS-ESP / Wet FGD November 2005 MerCAP™ 0.93

- Oxidation 0.93Yates Unit 1 CS-ESP / Wet FGD September 2005Catalysts

- Coal Sulfur Content (wt%)

- Mercury APCD Start DateControlConfiguration

- Bituminous

- Preliminary Results of Field Testing at Conesville

- Power Plant – Impact of High-S Coal

- (3.5-4%) bituminous coal equipped with ESP and wet FGD

- activated C yielded only 5-31%

- Hg removal @ 9-18 lb/MMacf

- on AC or otherwise compromise AC Hg removal capabilities

- DOE Hg Control RD&D Timeline in Sync with the

- Clean Air Mercury Rule (CAMR)

- DOE initiated field testing

- of technologies that

- mercury capture in

- early 2006

- 2005 2010 2018

- Complete field

- testing

- of technology

- capable

- of 50-70% Hg

- capture

- CAMR Phase I38 ton/year capvia Co-Benefit (NOx & SO2)

- Controls

- Issued

- CAMR Phase II15 ton/year capvia Hg Specific

- Controls

- Complete field

- testing

- of technology

- capable

- of 90%+ Hg capture

- Full-scale commercial

- demonstrations

- Commercial deployment

- Phase II Field Testing Economic Analysis

- Incremental Cost of 70% ACI Mercury Control

- Stanton #10

- Incremental Cost of Control,

- $/lb Hg Removed

- $10,000

- $20,000

- $30,000

- $40,000

- $50,000

- $60,000

- $70,000

- DOE 2007 Goal: ~$45,000/lb Hg Removed

- St. Clair

- Key Challenges to Continued/Increased

- By-Product Use

- meet CAIR (SO2) will increase volume

- of scrubber solids

- could negatively impact fly ash utilization due to increased carbon content

- from flue gas to fly ash and scrubber solids

- Fly Ash FGD By-product

- Mercury

- Projection of U.S. Coal-Fired Power Plant

- CUB Production

- Flyash Production

- FGD Solids Production

- 2004 2020

- Million Tons

- Coal-fired power generation projected to increase from

- 1,916 to 2,405 billion kWh from 2004 to 2020

- FGD capacity projected to increase from

- 100 to 231 GW from 2004 to 2020

- Wallboard Plant

- Wallboard production

- Home Construction

- Wallboard disposal

- Wallboard

- Wet FGD Scrubber

- FGD Gypsum Disposal

- FGD Gypsum:

- Pathways for Potential Mercury Release

- Incremental Cost of 70% ACI Mercury Control

- Stanton #10

- Incremental Cost of Control,

- $/lb Hg Removed

- $25,000

- $50,000

- $75,000

- $100,000

- $125,000

- $150,000

- DOE 2007 Goal: ~$45,000/lb Hg Removed

- Key Takeaways from Field Testing

- under “no by-product impact” scenario

- remain a “wild card”

- DOE/NETL Environmental and Water Resources

- (Innovations for Existing Plants Program)

- Re: Prairie State Energy Campus Hitachi Response (Hg 90% Removal)

- CERTIFICATE OF SERVICE

- SERVICE LIST

- (R06-25)

- SERVICE LIST

- (R06-25)

|

BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

IN THE MATTER OF:

)

)

R06-25

PROPOSED NEW 35 ILL. ADM. CODE 225

)

(Rulemaking – Air)

CONTROL OF EMISSIONS FROM

)

LARGE COMBUSTION SOURCES (MERCURY)

)

NOTICE OF FILING

TO:

Dorothy Gunn

Gina Roccaforte, Assistant Counsel

Clerk

Charles E. Matoesian, Assistant Counsel

Illinois Pollution Control Board

John J. Kim, Managing Attorney

James R. Thompson Center

Air Regulatory Unit,

100 W. Randolph St. , Suite 11-500

Division of Legal Counsel

Chicago, Illinois 60601-3218

Illinois Environmental Protection Agency

1021 North Grand Avenue, East

Marie E. Tipsord

P.O. Box 19726

Hearing Officer

Springfield, Illinois 62794-9276

Illinois Pollution Control Board

john.kim@epa.state.il.us

James R. Thompson Center

charles.matoesian@epa.state.il.us

100 W. Randolph, 100 W. Randolph

gina.roccaforte@epa.state.il.us

Chicago, Illinois 60601-3218

tipsorm@ipcb.state.il.us

SEE ATTACHED SERVICE LIST

PLEASE TAKE NOTICE that on July 28, 2006, I the undersigned caused to be

filed electronically with the Clerk of the Illinois Pollution Control Board the

APPEARANCE of Mary Frontczak on behalf of Prairie State Generating Company, LLC

and the attached TESTIMONY OF DIANNA TICKNER, copies of which are herewith

served upon you.

By:___[s]_Mary_Frontczak________________

Mary Frontczak (Reg. No. 6209264)

DATED: July 28, 2006

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

Mary Frontczak

Peabody Energy

701 Market Street

St. Louis, Missouri 63101-1826

(314) 342-7810

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

IN THE MATTER OF:

)

)

R06-25

PROPOSED NEW 35 ILL. ADM. CODE 225

)

(Rulemaking – Air)

CONTROL OF EMISSIONS FROM

)

LARGE COMBUSTION SOURCES (MERCURY)

)

APPEARANCE

I hereby file my appearance in this proceeding on behalf of Prairie State

Generating Company, LLC.

_[s]_Mary_Frontczak__________________

Mary Frontczak

Reg. No. 6209264

Peabody Energy

701 Market Street

St. Louis, Missouri

(314) 342-7810

DATED: July 28, 2006

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

IN THE MATTER OF:

)

)

R06-25

PROPOSED NEW 35 ILL. ADM. CODE 225

)

(Rulemaking – Air)

CONTROL OF EMISSIONS FROM

)

LARGE COMBUSTION SOURCES (MERCURY)

)

TESTIMONY OF DIANNA TICKNER

My name is Dianna Tickner. I am a Vice President of Prairie State Generating

Station, LLC (“Prairie State”) and I am here today to testify on its behalf. Prairie State is

directly affected by the proposed rule as it intends to construct a new 1500 megawatt

pulverized coal electric generating unit (“EGU”) facility in Washington County, Illinois.

The facility, Prairie State Generating Station, is being designed to burn high-sulfur

Illinois coal. In addition to my testimony, Prairie State will be providing detailed written

comments on the proposed rule.

Prairie State submitted comments to the Illinois Environmental Protection Agency

on the proposed rule on March 13, 2006. Those comments with minor corrections are

incorporated herein as part of my testimony (Attachment 1). As indicated in those

comments, Prairie State recommends that Illinois adopt the federal Clean Air Mercury

Rule (“CAMR”) as promulgated by the United States Environmental Protection Agency.

Prairie State has significant reservations on going beyond CAMR, which will be

elaborated on in the written comments. Specific to the Illinois proposed rule, Prairie

State expressed general concerns with the feasibility of 90% mercury removal efficiency

including the lack of any meaningful guarantees; the method for demonstrating

compliance with the 12-month rolling average standard, and the monitoring requirements.

Prairie State also identified concerns with specific provisions of the proposed rule.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

Prairie State also reviewed the Temporary Technology Based Standard (“TTBS”)

and provided comments to the Illinois Environmental Protection Agency on June 1, 2006.

Those comments were previously admitted as Exhibit 61 and are incorporated herein as

part of my testimony (Attachment 2). Prairie State believes the TTBS is a necessary

addition to the proposed rule to address any shortfalls in the capabilities of the

technologies. As expressed in the comments, Prairie State does have some concerns with

the current proposal, particularly for new generation.

In addition to the comments previously submitted, Prairie State is still concerned

about the long-term capabilities of the available technologies to control mercury

emissions from EGU flue gas. While there has been considerable testimony to date about

the capabilities of the available technologies (

see e.g.,

testimony of Dr. Staudt and Mr.

Nelson), that testimony appears to be based on several short term studies at facilities

burning low to medium sulfur coal. Mr. Nelson did identify one study that is currently

ongoing on a higher sulfur coal at Conesville Unit 6. As shown in Attachment 3, for coal

sulfur content of 3.5% to 4% the preliminary results indicate a mercury removal

efficiency of less than 20%. That removal efficiency is nowhere near the percent

removal that would be required to comply with the proposed rule. As discussed in our

March 13, 2006 comments, Prairie State to date has been unable to obtain a guarantee for

90% mercury removal on its high sulfur coal.

See

Attachment 4. Additionally, as the

studies have been short-term, there is no long-term information on the effect the available

technologies will have on balance of plant operations. Further study to assess high-sulfur

coals and the impact on plant operations is needed before imposing requirements that are

more stringent than CAMR.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

ATTACHMENT 1

TO

TESTIMONY OF DIANNA TICKNER

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

March 13,2006

Via Electronic Mail and Federal Express

Ms. Laurel Kroack

Bureau of Air

Illinois Environmental Protection Agency

1021 North Grand Ave. East

Post

Office Box 19276

Springfield,

l llinois 62794-9276

Re:

Comments on Draft Regulations for Control of Mercury Emissions

from

CoaCFired Electric Generating Units

Dear Laurel:

Prairie State Generating Company LLC is pleased to provide these comments on the

draft proposed regulations for Control of Mercury Emissions from Coal

-Fired Electric

Generating Units to be incorporated in 35 IAC 225. Prairie State

will be directly affected

by these regulations as

it is planning to construct a new coal-fired power plant in Illinois.

Provided below are our general observations and comments on the draft proposed

regulations followed by comments on specific provisions. In addition we are providing

suggested revisions and additions to the proposed regulations to address our concems.

General Observations and Comments

In general, Prairie State recommends that Illinois adopt regulations that are consistent

with the Clean Air Mercury Rule (

"CAMR

n

) promulgated by the United States

Environmental Protection Agency (

"EPA"). As to the draft regulations proposed, Prairie

State has three general concerns: (1) the

feasibilrty of 90% mercury removal efficiency;

(2) method for demonstrating compliance with the 12

-month rolling average standard;

and

(3) monitoring requirements.

MRIE STATE QEUaR1TIUO

-,

1U:

701 Market Street, Suite 781

St. his, Missouri 631

01

-1826

As will be explained in detail below, the requirement of a 90% removal efficiency is

beyond what has been proven in field studies to date. While Prairie State believes that

technology available in the future may be capable of controlling emissions at that

efficiency, such technology has not yet matured to the level that vendors are willing to

provide guarantees.

As

such the current proposed draft regulations could impair Prairie

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

Ms. Laurel Kroack

March 13,2006

Page

2

State's ability to finance and construct the facillty. Consequently, Prairie State has

proposed language that it believes meets the needs of all parties.

A

Reauirement of 90% Reduction is Not Feasible

As drafted, the regulations would require a 90% reduction in mercury emissions by

2009. This requirement appears to be based on a draft report titled

17echnology for

Controlling Mercury Emissions from Coal

-Fired Power Plants in Illinois

n

("Draft Mercury

Repor), which has been posted on the IEPA website. For the reasons set forth below

and in the enclosure to this letter, Prairie State believes that this requirement is not

technologically feasible or commercially feasible.

The

majonty of the Draft Mercury Report is a fair and balanced discussion of mercury

control. Where the Draft Mercury Report strays from basic scientific principles is when

it

optimistically predicts that a wide variety of control configurations can achieve 90%

mercury control. These claims rest on limited testing where 90% control was

occasionallv achieved. On close inspection of the performance during the tests, one

can make the case that 80

-85% control is achievable, but not 90%. Establishing the

standard at 90% would provide no margin of error and assumes continual operation at

the best (but unproven) control removal efficiency. That virtually assures non

-

compliance will occur.

In order for a

facillty to continuously comply with a 90% mercury control requirement, it

will normally need to operate at control levels around 95%. This margin is needed in

order to account for the routine variability in emissions regardless of how well controlled

a facility is. This higher control rate is needed to address excess emissions that occur

during

malfunctions, and process upsets. In developing CAMR, EPA evaluated

technological capabilities and determined that 90% was not feasible at this time.

Specifically, in discussing the use of activated sorbent injection in conjunction with

conventional technologies to achieve 90 percent or greater mercury removal, EPA

stated:

Although EPA is optimistic that such controls may be

available for use on some scale prior to 2018,

it does not

believe that such controls can be installed and operated on a

national scale before that date. Based on tests, ongoing

studies and discussions, we do not believe that the Hg

-

specific technologies have demonstrated an ability to

consistently reduce Hg emissions by 90 percent (or any

other level) at the present time.

70 Fed. Reg. 28606,2861 5 (May

18,2005).

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

Ms. Laurel Kroack

March 13,2006

Page

3

The Draft Mercury Report also overstates the long-term nature of the testing that has

occurred to date. In fact virtually all of the tests cited in the Draft Mercury Report have

been one month or less. It does not answer the question: what can these technologies

produce over the long term? Short term testing of technology does not mean

it will

perform at the levels observed during those tests over the long

-term or that the

technology is commercially available in any true sense. Nor does

it resolve all concerns

about balance

-of-plant effects. For example, the Draft Mercury Report tries to sweep

aside the greatest concern about brominated activated carbon injection

('ACI") -

namely whether it will cause corrosion or other maintenance and availability problems

over the long term. The Environmental Appeals Board recently reiterated that short

-

term data may not be suffi~cient

to be the basis for a limit that has to be achieved over

the long

-term.

See In

re

Newmont Nevada Energy Investment,

L. L.C., PSD Appeal No.

05

-04 (EAB Dec. 21,2005).

Finally, the Draft Mercury Report's discussion of vendor guarantees appears to have

been taken directly from the vendor's literature. The discussion is very misleading and

implies meaningful guarantees are readily available, which is not true. Prairie State has

not been able to obtain a 90% mercury control guarantee even though the project

includes an SCR and a wet FGD.

Of note, the Draft Mercury Report indicates that such

a technology configuration should easily be able to remove 90% of the mercury from

bituminous coal.

Id.

at 36. The Draft Mercury Report also states the

"liabillty to the

vendor

. . . .is related to the cost of the project."

Id.

at 30. In most cases the cost of the

"projectn

will be the cost of the sorbent injection system, which is in the $ 1 to 3 million

range per unit. This vendor

liabillty limit is typically much less than the costs the

Owner's

will experience if the mercury control guarantees are not met, including

shutting down a

facillty resulting in direct consequences of lost jobs and economic

benefit to the area as well as the indirect consequence of increased energy costs to

consumers. Moreover, the vendors generally are smaller companies that do not have

the financial wherewithal to ever make good on their extremely limited guarantees. In

essence, vendors are guaranteeing that

if their mercury controls don't work they will

give you another one just like

it. This doesn't help a power plant that is out of

compliance with a state regulation.

For more details on the concerns raised by the Draft Mercury Report, see the enclosed

letter from Steve Bjorklun of Bums and

McDonnell (March 10,2006). Given the above,

it is arbitrary for Illinois to include a 90% reduction requirement by 2009. Prairie State

believes that the Department of Energy ('DOE

n

) concurs with its position that the

technology is not yet mature. DOE has initiated twelve long

-term studies (12 to 36

months) to evaluate the viability of new and existing technologies with various coals.

DOE'S

goal is to have these technologies ready for commercial demonstration by 201 0,

which is after Illinois' proposed regulation would go into effect. Prairie State

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

Ms. Laurel Kroack

March 13,2006

Page

4

recommends that Illinois follow this effort and include a provision in the regulations to

incorporate

DOE's results. Regulations should not be based on predictions of what can

be achieved in the future as is the case here. They should be based on what has

actually been achieved and technology that is demonstrated and commercially feasible.

Discussions with vendors, lenders and equity participants in the project indicate that,

without an established, proven technology combined with suitable guarantees, the

project may have to be delayed or possibly not built at all. To address the fact that the

technology is not proven and vendors are unwilling to offer a viable guarantee that 90%

can

be achieved at all times or for the life of the facility, Prairie State is proposing the

following language to

be added as a new provision to 5225.237 to meet the needs of all

parties:

If a new EGU installs technology, at a minimum a particulate

matter collection device, a flue gas

desutfurization unit, a

selective catalytic reduction device, and

sorbent injection

(other material or combination of materials), and due to

technical shortfalls of such equipment, processes, or

systems is unable to achieve the emissions standards as set

forth in this regulation, the

EGU ownerloperator shall pursue

a corrective action plan in conjunction with the Illinois EPA to

determine alternative emissions standards for the EGU.

Such corrective action plan shall include a requirement to

determine the maximum practicable degree of mercury

removal that can

be continuously achieved with the installed

technology. During the pendency of the correction action

plan and the establishment of a site

-specific mercury

standard, the EGU

will be deemed in compliance with the

requirements of this regulation.

If Illinois is correct that 90% removal is continuously achievable, the above provision

would never need to

be implemented. Prairie State, however, believes that 90% is not

continuously achievable (for the reasons explained above and in Mr.

Bjorklun's letter)

and thus the provision is necessary. Absent such a provision, well

-controlled sources

unable to achieve the standard would be in a perpetual state of noncompliance or be

forced to shut down, leaving a significant void in the generation of needed power. Such

a provision would also bridge the gap pending the outcome of

DOE's studies.

Method of Assessing Compliance Could Lead to Anomalous Results

Assessing compliance over a 12

-month period as proposed is helpful, particularly given

the large variability in mercury emissions. Illinois' proposal to assess compliance on a

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

Ms. Laurel Kroack

March 13,2006

Page

5

monthly basis and then average those 12 months to determine compliance appears to

be based on the trading program established by EPA, which is not relevant to Illinois'

proposal.

It would be simpler to require plants to use the prior year of data to

demonstrate compliance with the limits, a true rolling annual limit. Such an approach

would avoid the adverse effects of anomalous months

(i.e., a few days of operation at

higher than normal mercury levels) and would not result in a finding of

non-compliance

for an entire month if a 12-month rolling average exceeded the mercury limits [see draft

§ 225.1301. Thus, Prairie State would suggest that a plant be required to report only its

twelve month rolling average based on the previous years worth of data.

Monitorina Reauirements Should be Consistent with CAMR

Currently, there are many questions about EPA's mercury monitoring requirements and

whether

CEMs will accurately measure mercury emissions under all conditions. EPA's

mercury monitoring requirements are currently being challenged in the D.C. Circuit. It

remains to be seen whether that challenge

will lead to revisions to EPA's monitoring

requirements but

it is highly likely that some changes will be made by EPA. The

question then arises: Does Illinois plan to revise its mercury monitoring requirements

if

EPA revises its regulations? The draft regulations incorporate some EPA requirements

by reference but they also include some specific mercury monitoring requirements.

Prairie State recommends that lllinois simply incorporate the EPA's monitoring

requirements by reference. This will avoid a situation where monitoring requirements in

Illinois are inconsistent with the remainder of the country leading to the potential

unavailability of monitors for facilities in lllinois.

Additionally, there are potential concerns with the methods (coal sampling as proposed,

or monitoring of inlet to control technology) for demonstrating compliance with the

percent removal standard. There is limited data available to confirm that these methods

would provide a consistent reliable measure of percent removal.

Specific Comments

Below are Prairie State's comments on specific provisions in the draft proposed

regulations.

5 225.130

-

definition of "electric generating unit":

An EGU is defined to include

"fossil fuel-fired" boilers and combustion turbines. Since EPA decided only to regulate

mercury emissions from coal

-fired units, wh the more inclusive definPnn9 Yote that

applies to coal-fired units

kRECTION

-

Dirregam

rn~

of electric generating unit is not in

the

proposed rule.]

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

Ms. Laurel Kroack

March 13,2006

Page 6

f 225.130

-

definition of "rolling 12month basis":

The definition implies that a 12-

month average is calculated based on monthly averages. The definition excludes

months when a boiler never operates. It presumably includes months when the boiler

operates as little as one day. This can lead to anomalous results. As noted above, a

better way to smooth results

would be to look at all data for the prior 12 months and

then calculate the average emission rate or percentage reduction making it a true

annual average. Emissions during periods of startup and shutdown should also be

excluded as technologies, such as SCR which aid in mercury removal, are not

operational during those periods. Such an exclusion would be consistent with the

NSPS.

f 225.140 and 225.202

- Standard Lab uses ASTM D6722-01 "Standard Test Method

for Total Mercury in Coal and Combustion Residues by Direct Combustion Analysis

" to

determine Mercury in coal for Draft Mercury Reporting under the MACT rule and other

Draft Mercury Reporting. The draft proposed regulations does not list ASTM D6722

-01

as an acceptable method. However, ASTM has obtained EPA acceptance of ASTM

D6722-01 as equivalent to all other required Mercury Determination methods. Per

ASTM, this acceptance is so stated in the Federal Register Volume 70 Number 209

(October 31,2005) (40 C.F.R. Part 63). This draft needs to include ASTM D6722

-01 as

an acceptable method.

f 225.210(e)

- Compliance should be judged at the source, not the unit level. If each

EGU must meet the stack limit, then

it follows that the source should be in compliance.

By requiring both the unit and source to

be in compliance, Illinois is effectively

assessing two violations if a unit fails to meet the emission limit.

f 225.220(~)(1)

- It is unclear what mercury requirements Illinois considers to be

"federally enforceable." Illinois' requirements go far beyond CAMR and as a result are

state standards, not federally enforceable limits.

f 225.230

- Given the definition of a 'rolling 12-month basis" there appears to be no

difference between compliance options (a) and (b).

5 225.230 (d)(3)

- This results in multiple violations when it may be only one unit that

has compliance issues.

f 225.232

- Averaging provisions appear to apply only to "existing" units. "New" units

should also have averaging provisions since the stringency of the limits Illinois proposes

to impose on new units is the same as existing units

- 90% control?

5 225.237

- The limits on new sources go beyond EPA's § 1 1 1

(b) mercury limits for

new coal

-fired power plants and are not federally enforceable.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

Ms. Laurel Kroack

March 13,2006

Page

7

It is unclear how the provisions of subsection (b) operate when the beginning of

compliance is delayed by 150 or

180 days. The regulations do not explain how this

delay works given the fact that compliance is judged on a 12

-month rolling basis.

5

225.240(b)

- EPA's regulations require all monitors to be certified by no later than

January 1,2009 and for compliance monitoring to begin on January 1,2009. The

Illinois regulations would require monitoring to be in

on MT-' 1, 2009. The

- -

drn4

regulations do not explain the timing difference.

I

IUN

-

IE

A

,-

essec

this comment in the proposed rule by requiring monitoring to begin on January

20091.1

Certifying a mercury monitor within 90 days of commercial operation will be next to

impossible. This is much shorter than the period allowed in NSPS for monitor

certifications. Considering that mercury emissions are a long

term not a short-term

issue, a more reasonable time to

certlfy the monitors should be allowed. Prairie State

would suggest an 180day period.

§

225.240 (c)(l)

- This is a particularly punitive provision considering the developmental

state of mercury monitors,

difficulties that can be expected in certifying the monitors and

the very short period allowed to

certrfy the monitors in 225.240 (b)(2).

§§

225.240(d) and 222.250(a)(2)(E)

- These provisions are premised on a level of

performance and dependability that mercury

CEMs have yet to demonstrate. As a

-enlr

thesa provisions may prove unworkable for

mercr lrv CEMs. ,[COPRECTIC

~e

referem to

§

222.250(m2)(~

r eq

~~~(~w~um

11

225.250 (a)(S)(D)(i), (ii) and (iii)

- The 120 days seem excessive considering the

facility is only being allowed 90 days to get the monitors certified. The review time adds

to the violation period

if the monitor certification is not approved.

We appreciate the opportunity to provide these comments. Should you have any

questions regarding our comments, please do not hesitate to contact me at (314) 342

-

7646 or (314) 651- 3665.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

Ms. Laurel Kroack

March 13,2006

Page 8

Enclosure

cc:

Douglas P. Scott

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

ATTACHMENT 2

TO

ONY OF DIANNA TICKNER

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

m

#WRIE

OEUERI~UO

coamux

uc

701 Market Street. Suite 781

St. Louis. M'iri 631

01

-1

826

June 1,2006

Federal Express

Electronic Mail

Laurel Kroack, Director

lllinois Environmental Protection Agency

1021 North Grand Ave. East

PO Box 19276

Springfield, Illinois 62794

-9276

Re: Comments on Temporary Technology

-Based Standard to be

Incorporated into Illinois' Draft Regulations for Control of Mercury

Emissions from Coal

-Fired Electric Generating Units

Dear Laurel:

Prairie State Generating Company,

LLC's is pleased to provide the following comments

on the proposed Temporary Technology

-Based Standard to be incorporated into Illinois'

draft proposed regulations for Control of Mercury Emissions from Coal

-Fired Electric

Generating Units to be incorporated in 35 IAC 225. Prairie State will be directly affected

by these regulations as

it is planning to construct a new coal-fired power plant in Illinois.

Prairie State's comments are focused on the provisions relating to new units, but

generally are equally applicable to those for existing units. In addition to the following

comments, Prairie State also has technical comments as indicated on the attached

markup of the proposed revision.

We appreciate the

opportunity to provide these comments. Should you have any

questions about our comments, please do not hesitate to

contact me.

Sincerely,

Dianna Tickner

Enclosures

cc:

Colin Kelly

Jim Ross

- IEPA

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

Questions on Illinois Proposed Mercury Standard

General comment - Why is eligibility for the technology based altemative tied to

the use a particular sorbent (halogenated activated carbon)? Such a linkage is

too restrictive and ignores new reagents and technologies that are being

developed that may be as or more effective than activated carbon. The rule

should not require an EGU to go through an alternative process to use other

sorbents. Instead, the rule should indicate that any sorbent approved by the

Agency may be used. This would afford the Agency the ability to consider and

approve the use of other products as they become available and are proven

effective without having to modify the rule or requiring an EGU to go through the

alternative process. To implement this concept, we would recommend replacing

'halogenated activated carbon

n

with 'sorbent or reagent approved by IEPA".

5

225.238(a)(I) - Does this section apply to sources commencing commercial

operation after January

1,2009? As currently drafted, this section read in

isolation is ambiguous and could be read to only apply to new sources that

commenced operation before January 1,2009. It might be better to word the

eligibility requirement in the positive (for sources at which the first EGU

commences operation after January

1,2009), rather than as a double negative.

§ 225.238(b)(I) - Is this reference to BACT for eligibility only or is it intended to

reopen a BACT determination made in the context of PSD permitting for a new

EGU? As currently drafted,

it can be read to mean that a new BACT

determination would have to be made for the EGU to be eligible.

5 225.238(b)(2) - Does IEPA intend that altemative rates of injection of

halogenated activated carbon may be included only in a federally enforceable

operating

permit? For new sources, this provision should also allow for similar

provisions to

be included in a federally enforceable construction permit. For

example,

Prairie State's permit includes provisions for determining the optimum

rate of sorbent injection. That provision should be acceptable as an alternative to

the default rates included in this provision.

What is the basis for the proposed injection rates? Do they effectively

consider

all the variables associated with mercury removal (e.g., chlorine and mercury

content of the coal, SCR catalyst and quantity, temperature of the gases going

through the air preheater, type of particulate collection device (cold or hot dry

ESP or baghouse), installation of additional down stream air pollution control

devices such as a wet ESP)? We believe a technology effectiveness evaluation

process more in line with the one defined in the PSD permit for Prairie State best

serves the intended purpose. Thus, we would ask that the Agency look at Option

B

(Condition 2.1 .Z(c)(ii)(A)(II)) in the Prairie State permit as a process for

evaluating mercury technologies.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

What is the basis for not including a provision similar to 5 225.234(b)(2)(D)

(allowing the use of lower injection rates if particulate matter emissions are

adversely impacted) in

5 225.238 for new EGUs? Prairie State recommends that

it be included and that =safety issuesn be added as a basis for lowering the

injection rate. Presique Island recently had a fire in their

TOXICON baghouse

due to excessive levels of carbon in the baghouse.

5 225.238(c)(2)(A) - What is the purpose for recording the activated carbon feed

rate on an hourly average basis? Does the Agency also intend to require

monitoring and recording of the mercury content of the coal and capture

efficiency on an hourly average basis, which Prairie State believes is

unnecessary7 Prairie State is concerned that this requirement

will eventually

translate the annual merwry limit into an hourly limit.

§ 225.238(d) - For new facilities whose construction permit already includes a

provision regarding

merwry control and the use of a sorbent, why is a new or

revised operating permit required? Could the source indicate in its initial

Title V

application that it is applying to operate under the Technology-Based Standard in

accordance with its PSD permit? A new facility that incorporated provisions

regarding mercury control should not have to go through further permit review

and public participation. Prairie State has a similar concern with respect to

5 225.238(6)(1

)(C).

There are some timing issues to be worked out. Under the proposed rule

(5 225.237), compliance with the mercury standard commences on the date of

the initial performance test. Application to use the Technology

-Based standard is

to be made at least three months before compliance with

5 225.237 would have

to be demonstrated and has to be included in a Title

V permit application.

However the initial

Title V application is not due within one year of commencing

operation. Theoretically, a facility would need to submit a Title

V permit to

comply with the Technology

- Based Standard three months after initial startup

and before the

compliance period is complete. One way to solve this problem is

to delink the application to use the technology Standard from the Title

V process,

i.e., include the requirement in the construction permit.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

Section 225.234

Temporary Technology

-Based Standard for EGUs at Existing Sources

General

At a source

with EGUs that commenced commercial operation on

or before December 3 1,2008, for an EGU that meets the eligibility

criteria in subsection

(b) of this Section,

as

an alternative to

compliance with the mercury emission

standards in Section

225.230 of this Subpart, the owner or operator of the EGU may

temporarily comply with the requirements of this Section, through

June 30,2015,

as

Wer provided in subsections (c), (d), and (e) of

this Section.

An EGU that is complying with the emission control requirements

of this Subpart by operating under this Section may not be

included in a compliance demonstration involving other EGUs

during the period that it is operating under this Section.

The owner or operator of an EGU

that is complying with this

Subpart by means of this Section is not excused from applicable

monitoring,

recordkeeping, and reporting requirements in Sections

225.240 through 225.290 of this Subpart.

Eligibility

To be eligible to operate an EGU under this Section, the following criteria

shall be met for the EGU:

The EGU is equipped and operated

with the air pollution control

equipment or systems that include injection of halogenated

activated carbon or other or

mercury control technolo~y

that is

mproved by the Agencv. and either (1) a cold-side electrostatic

precipitator or (2) a

fabrc filter. (The Agency shall

aaprove

atemate mercurv control technologies based on the effectiveness

and cost of the alternate technologv proposed.)

The owner or operator of the EGU is injecting halogenated

activated carbon in an optimum

manner

for control of mercury

emissions, which shall include injection of Alstrom, Norit, Sorbent

Technologies, or other halogenated activated carbon or other

mercury control technology

amroved bv the agency. that the

owner or operator of the EGU shows to have similar or better

effectiveness for control of mercury emissions, at least at the

following rates, [Activated

carbon iniection rates are a hction of

rnw variables. like chlorine in the coal. amount of

Hg

in the coal,

amount of SCR catalyst.

tye of catalyst.

tvw

of control equi-t

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

[ESP

or baghouse. wet or

dry

FGDMc..

setting

a bard injection

Fate is not wo~erl..

.

unless other provisions for injection of

halog&ted Avated carbon (or other mercury control

technolom)

are

established in a fededy enforceable operating

permit

issued for the EGU, with an injection

system

designed for

effective absorption of

mercury,

considering the configuration of

the EGU and its ductwork. For this purpose, flue gas flow rate

shall be

determined for the point of sorbent injection, provided,

however,

that this flow rate may be assumed to be identical to the

stack

flow rate

if

the gas

temperatures

at the point of injection and

the

stack

are

normally within

loo0

F, or may otherwise be

calculated

hm

the

stack

flow rate, corrected for the difference in

gas temperatures

For an EGU firing subbituminous coal,

5.0

pounds

per

million

actual

cubic feet.

For an EGU

firing bituminous coal,

10.0

pounds

per

million

actual

cubic feet.

I

For an EGU firing a blend of subbituminous and

bituminous coal, a rate that is the weighted average of the

above rates, based on the blend of coal being

fired.

A rate or rates set on a unit-specific basis that are lower

than

the rate specified above to the extent that the owner or

operator of the EGU demonstrates that such rate or rates are

needed so

that carbon injection would not increase

particulate matter emissions or opacity

so

as to threaten

compliance

with applicable regulatory requirements for

particulate matter or opacity,

does not effectively increase

mercury control or causes a safety issue.

The total capacity of the EGUs that operate under this Section does

not exceed the applicable value below:

For the owner or operator of more

than

one existing source

with EGUs,

25

percent of the total rated capacity, in

MW,

of

all

the EGUs at such existing sources that it owns or

operates, other

than

any EGUs operating pursuant to

Section

225.235

of this Subpart.

For the owner or operator of only a single existing source

with EGUs

(i.e., City, Water, Light

&

Power, City of

Springfield,

ID 1

67 12OAAO;

Eleceic Energy, Inc., ID

127855AAC;

Kincaid Generating Station,

ID 02 1 8

14AAB;

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

and Southern Illinois Power CooperativeIMarion

Generating Station, ID 199856AAC), 25 percent of the

total rated capacity, in

MW,

of the

all

the EGUs

at

such

existing

sources,

other than any EGUs operating pursuant

to Section 225.235 of this Subpart.

Compliance Requirements

Emission Control Requirements

The owner or operator of an EGU that is operating pursuant to this

Section shall continue to

maintain and operate the EGU to comply

with the criteria for eligibility for operation under this Section,

except during an evaluation of the current sorbent, alternative

sorbents or other techniques to control mercury emissions, as

provided by subsection (e) of this Section.

Monitoring and

Recordkeeping Requirements

In addition to complying with all applicable reporting requirements

in Sections 225.240 through 225.290 of this Subpart, the owner or

operator of an EGU operating pursuant to this Section shall also:

Through December 3

1,20

12, maintain records of the usage

of activated carbon, the exhaust gas flow rate

hm the

EGU, and the activated carbon feed rate, in pounds per

million actual cubic feet of exhaust gas at the injection

point, on a

weekly average.

Beginning January

1,20

13, monitor activated carbon feed

rate to the EGU, flue gas

temperature at the point of sorbent

injection, and exhaust gas flow rate

hm the EGU,

automatically recording this

data and the activated carbon

feed

rate, in pounds per million actual cubic feet of exhaust

gas

at

the injection point, on an hourly average. (Or

ather

a~oroved

by

the Aeencv.)

If a blend of bituminous and sub-bituminous coal is fired in

the EGU, records of the amount of each

type

or coal burned

and the required injection rate for injection of halogenated

activated carbon, on a weekly basis.

(Or

other

aporo~riate

parameters for the mercurv control technologv amroved by

the Agency.)

Notification and Reporting Requirements

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

In addition to complying with all applicable reporting requirements

in Sections 225.240

through

225.290 of

this

Subpart, the owner or

operator of an EGU operating pursuant to this Section shall also

submit the following notifications and reports to the Agency:

Written notification prior to the month in which any of the

following events will

occur:

the EGU will no longer be

eligible to operate under this Section due to a change in

operation; the

type

of coal

fired

in the EGU will change;

the mercury emission standard with which

the owner or

operator is attempting to comply for the EGU will change;

or operation under this Section will

be terminated.

Quarterly reports for the recordkeeping and monitoring

conducted pursuant to subsection

(c)(2) of this Section.

Annual reports detailing activities conducted for the EGU

to

f.urther

improve control of mercury emissions, including

the measures taken during the past year and activities

planned for the current year.

Applications to Operate under the Technology

-Based Standard

Application Deadlines

The owner or operator of an EGU that is

seeking to operate

the EGU under this Section shall submit an application to

the Agency no later

than three months prior to the date that

compliance with Section 225.230 of

this Subpart would

otherwise have to be demonstrated. For example, the

owner or operator of an EGU that is applying to operate the

EGU pursuant to this Section on June 30,2010, when

compliance with applicable mercury emission standards

must be

first

demonstrated, shall apply by March 3 1,201 0

to operate under this Section.

Unless the Agency finds that the EGU is not eligible to

operate under this Section or that the application for

operation under this Section does not meet the requirements

of subsection

(d)(2) of this Section, the owner or operator

of the EGU is authorized to operate the EGU under this

Section beginning 60 days after receipt of the application

by the Agency.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

The owner or operator of an EGU operating pursuant to this

Section must reapply to operate pursuant to this Section:

ii)

If it operated pursuant to this Section during the

period

of June 2010 through December 2012 and it

seeks

to operate pursuant to this Section during the

period

hm

January 2013 through June 2015.

If it is planning a physical change to or a change in

the method of operation of the EGU, control

equipment or practices for injection of activated

carbon that is expected to reduce the level of control

of mercury emissions.

Contents of Application

An application to operate pursuant to this Section shall

be

submitted as an application for a new or revised federally

enforceable operating permit for the EGU and include the

following:

A formal request to operate pursuant to this Section

showing that the EGU is eligible to operate pursuant to this

Section and describing the reason for the request, the

measures that have been taken for control of mercury

emissions, and factors preventing more effective control of

mercury emissions

hm

the EGU.

The applicable mercury emission standard in Section

225.23qa) with which the owner or operator of the EGU is

attempting to comply and a summary of relevant mercury

emission

data for the EGU.

If a unit-specific rate or rates for carbon injection are

proposed pursuant to subsection @)(2)

of this Section,

detailed

information to support the proposed injection rates.

An action plan describing the measures that

will

be taken

while operating under this Section to improve

control of

mercury emissions. This plan shall address measures such

as evaluation of alternative forms or sources of activated

carbon,

changes to the injection system, changes to

operation of the unit that

affect the effectiveness of

mercury absorption and

collection, changes to the

particulate matter control device to improve performance

and changes to other emission control devices. For each

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

measure contained in the plan, the plan shall provide a

detailed description of the specific actions that

are planned,

the reason that the measure is being pursued and the range

of improvement

in control of mercury that is expected, and

the factors

that affect the timing for carrying out the

measure,

with the current schedule for the measure.

Evaluation of Alternative Control Techniques for Mercury Emissions

During an evaluation of the effectiveness of the current sorbent,

alternative sorbent, or other technique to control mercury

emissions, the owner or operator of an EGU operating under this

Section need not comply with the eligibility criteria for operation

under this Section

as

needed to

carry

out an evaluation of the

practicality and effectiveness of such technique,

as

further

provided below:

The owner or operator of the EGU shall conduct the

evaluation in accordance

with a formal evaluation program

submitted to the Illinois EPA at least

30

days in advance.

The duration and scope of the evaluation shall not exceed

the duration and scope reasonably needed to complete the

desired evaluation of the alternative control technique,

as

initially addressed by the owner or owner in a support

document submitted

with the evaluation program.

Notwithstanding

35 Ill.

Adm. Code

20

1.146(hhh),

the

owner or operator of the EGU shall obtain a construction

permit for any new or modified

air

pollution control

equipment to be constructed

as

part of the evaluation of the

alternative control technique.

The owner or operator of the EGU shall submit a report to

the Illinois EPA no later

than

90

days after the conclusion

of the evaluation describing the evaluation that was

conducted and providing the results of the evaluation.

If the evaluation of the alternative control technique shows less

effective control of mercury emissions

Erom the EGU

than

achieved with the prior control technique, the owner or operator of

the EGU shall resume use of the prior control technique.

If the

evaluation of the alternative control technique shows comparable

effectiveness, the owner or operator of the EGU may either

continue to

use the alternative control technique in an optimum

manner

or resume

use

of the prior control technique. If the

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

evaluation of the alternative control technique shows more

effective control of mercury emissions, the owner or operator of

the EGU shall continue to

use the alternative wntrol technique in

an

optimum manner, if it continues to operate under

this

Section.

Section 225.238 Temporary Technology

-Based Standard for New Sources with EGUs

General

At a source

with EGUs that previously had not had any EGUs that

commenced commercial operation before January 1,2009, for an

EGU that meets the eligibility criteria in subsection

(b) of this

Section, as an alternative to compliance

with the mercury emission

standards in Section 225.2370f this Subpart, the owner or operator

of the EGU may temporarily comply

with the requirements of this

Section, through December 3 1,201 8,

as

further provided in

subsections (c), (d), and (e) of this Section.

EGU

that is complying with the emission control requirements

of this

Subpart by operating under this Section may not be

included in a compliance demonstration involving other EGUs at

the

source

during the

period that such standard is in effectk]

The owner or operator of an EGU that is complying with this

Subpart by means of this Section is not excused

from applicable

monitoring,

recordkeeping, and reporting requirements in Sections

225.240 through 225.290 of this Subpart.

Eligibility

To

be eligible to operate

an

EGU under this Section, the following criteria

shall be met for the EGU:

The EGU is subject to Best Available Control Technology (BACT)

for emissions of

sulfiu dioxide, nitrogen oxides and particulate

matter and is equipped and operated

with the air pollution control

equipment or systems specified below, as applicable to the category

of EGU:

For coal

-fired boilers, injection of halogenated activated

carbon,

OR OTHER MERCURY CONTROL

TECHNIQUE

APPROVED BY THE AGENCY.

For an EGU firing fuel gas produced by coal gasification,

processing of the raw fuel gas prior to combustion for

removal of mercury

with system a using activated carbon.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

For an EGU for which injection of

-

A

SORBENT

im

other meraw control techniaue) is required by

subsection

(MI) of this Section, the owner or operator of the EGU

is injecting

A SORBEN0 in an

optimum manner for control of mercury emissions, which

MAYddl include injection of Alstn,m, Norit, Sorbent

Technologies, or other SORBENT

0

that the owner or operator of the EGU shows to have similar or

better effectiveness for control of mercury emissions, at least at the

following

rates, unless other provisions for injection of

A

SORBENT lor other rnercurv control techniaue)

are

established in a federally enforceable

operating permit issued for the EGU, with

&

injection system

designed for effective absorption of mercury. For this purpose,

flue gas flow rate shall be determined for the point of sorbent

injection, provided, however, that this flow rate may be assumed to

be identical to the

stack

flow rate if the gas temperatures at the

point of injection and the

stack are normally within 100" F, or may

otherwise be calculated

from the stack flow rate, corrected for the

difference

in gas temperatures.

For an EGU firing

subbituminous coal, 5.0 pounds per

million

actual

cubic feet.

For

an EGU firing bituminous coal, 10.0 pounds per

million

actual

cubic feet.

For an EGU firing a blend of subbituminous and

bituminous coal, a rate

that is the weighted average of the

above rates,

based

on the blend of coal being fired.

Compliance Requirements

Emission Control Requirements

The owner or operator of

an EGU that is operating pursuant to this

Section shall continue to maintain and operate the EGU to comply

with the criteria for eligibility for operation under this Section,

except during an evaluation of the

cment sorbent, alternative

sorbents or other techniques to control mercury emissions, as

provided by subsection (e) of this Section.

Monitoring and

Recordkeeping Requirements

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

In addition to complying with

all

applicable reporting requirements

in Sections

225.240

though

225.290

of this Subpart, the owner or

operator of a new EGU operating pursuant to this Section shall

also:

Monitor activated carbon feed rate to the EGU, flue gas

temperature at the point of

sorbent injection, and exhaust

gas flow rate from the EGU, automatically recording this

data and the activated carbon feed rate, in pounds

per

million actual cubic feet of exhaust gas at the injection

point, on an hourly average.

If a blend of bituminous and sub-bituminous coal is fired in

the EGU, records of the amount of each

type

or coal burned

and the required injection rate for injection of halogenated

activated carbon, on a weekly basis.

Notification and Reporting Requirements

In addition to complying with all applicable reporting requirements

in Sections

225.240

through

225.290

of this Subpart, the owner or

operator of an EGU operating pursuant to this Section shall also

submit the following notifications and reports

to the Agency:

Written notification prior to the month in which any of the

following events will

occur:

the EGU will no longer be

eligible to operate under this Section due to a change in

operation; the

type

of coal fired in the EGU will change;

the mercury emission standard with which the owner or

operator is attempting

to comply for the EGU

will

change;

or operation under this Section

will be terminated.

Quarterly reports for the

recordkeeping and monitoring

conducted

pursuant to subsection

(c)(2)

of this Section.

Annual reports detailing activities conducted for the EGU

to

further improve control of mercury emissions, including

the measures taken during the past year and activities

planned for the current year.

Applications to Operate under the Technology

-Based Standard

Application Deadlines

The

owner or operator of an EGU that is seeking to operate

the EGU under this Section shall submit an application to

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

the Agency no later than three months prior to the date that

compliance

with Section 225.237 of this Subpart would

otherwise have to be demonstrated.

Unless the Agency

finds

that the EGU is not eligible to

operate under this Section or

that the application for

operation under this Section does not meet the requirements

of subsection

(dX2) of this Section, the owner or operator

of the EGU is authorized to operate the EGU under this

Section beginning

60 days after receipt of the application

by the Agency.

The owner or operator of an EGU operating pursuant to this

Section must reapply to operate pursuant to this Section if it

is planning a physical change to or a change in the method

of operation of the EGU, control equipment or practices for

injection of activated carbon that is expected to reduce the

level of control of mercury emissions.

Contents of Application

An application to operate pursuant to this Section shall be

submitted as an application for a new or revised federally

enforceable operating permit for the new EGU and include the

following:

A formal request to operate pursuant to this Section

showing

that the EGU is eligible to operate pursuant to this

Section and

describiig the reason for the request, the

measures that have been taken for control of mercury

emissions, and factors preventing more effective control of

mercury emissions

hm the EGU.

The applicable mercury emission standard in Section

225.237 with which the owner or operator of the EGU is

attempting to comply and a

summary

of relevant mercury

emission

data for the EGU.

If a unit-specific rate or rates for carbon injection are

proposed pursuant to subsection (b)(2) of this Section,

detailed information to support the proposed injection rates.

An action plan describing the measures that

will

be taken

while operating under this Section to improve control of

mercury emissions. This plan shall address measures such

as evaluation of alternative forms or sources of activated

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

carbon,

OR OTHER

MERCURY CONTROL

TECHNIQUE. changes to the injection

system,

changes to

operation of the unit

that affect

the effdveness of

mercury absorption and collection, and changes

to other

emission control devices. For each measure contained in

the plan, the plan

shall provide a detailed description of the

specific actions

that

are planned, the reason

that

the

measure is

being pursued and the range of improvement in

control of mercury

that

is expected, and the factors

that

affect

the timing for

carrying

out the measure, with the

current schedule for the measure.

Evaluation of Alternative Control Techniques for

Mercury

Emissions

During an

evaluation of the effectiveness of the current sorbent,

alternative sorbent, or other technique to control mercury

emissions, the owner or operator of an EGU operating under this

Section need not comply with the eligibility criteria for operation

under this Section

as

needed to carry out an evaluation of the

practicality and effectiveness of such technique,

as

further

provided below:

The owner or operator of the EGU shall conduct the

evaluation in accordance with a

formal evaluation program

submitted to the Illinois EPA at least 30 days in advance.

The duration and scope of the evaluation shall not exceed

the duration and scope reasonably needed to complete the

desired evaluation of the alternative control technique,

as

initially addressed by the owner or owner in a support

document submitted with the evaluation program.

Notwithstanding 35 Ill.

Adm.

Code 201.146(hhh), the

owner or operator of the EGU shall obtain a construction

permit for any new or modified

air pollution control

equipment to be constructed

as part

of the evaluation of the

alternative control technique.

The owner or operator of the EGU shall submit a report to

the Illinois EPA no later

than

90

days after the conclusion

of the evaluation describing the evaluation

that was

conducted and providing the results of the evaluation.

If the evaluation of the alternative control technique shows less

effective control of mercury emissions

hm the EGU

than

achieved with the prior control technique, the owner or operator of

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

the EGU shall resume use of the prior control technique. If the

evaluation of the alternative control technique shows comparable

effectiveness, the owner or operator of the EGU

may either

continue to

use the alternative control technique in

an

optimum

manner

or resume use of the prior control technique. If the

evaluation of the alternative control technique shows more

effective control

of

mercury

emissions, the owner or operator of

the EGU shall continue to

use the alternative control technique in

an

optimum manner, if it continues to operate

under

this Section.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

[s

I-

rates listed do not

make any

sense.

All testing

has

shown

tbat

AC injection is more ektive

(under similar cdions with similar

emission control

equip.) fa a unit firing bituminous coal

instead

of

subbituminous. Tbe required injedoa rate fa

bii

should

be

less

than

subbitumhus.

[~2]I'm

not

sure

what

they

are trying to accomplish. Roblems meeting

tbe

90% control requirement will

likely be

common

fa multiple uaits. It would be logical to demmtratc a technology on only

one

unit.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

U.

S. Department of Energy

National Energy Tecbnohgy Laboratory

April 25,2006

Clarification of the

U.S.

Department of Energy's Perspective on the

Status of Mercury Control Technologies for Coal-Fired Power Plants

On April 18, 2006 the Pennsylvania Federation of Sportsmen's Clubs (PFSC) issued a

press release through

PRNewswire that presented a somewhat inaccurate account of the

U.S. Department of Energy's perspective on the current status of mercury control

technologies for coal

-fired power plants. The press release was based on statements

made by Thomas

J. Feeley, 111, a technology manager at the Department's National

Energy Technology Laboratory

@OE/NETL), during an appearance on WPSU-TV's

public affairs program

--

Pennsylvania Inside

Out

--

that aired April

14&

in which Mr.

Feeley discussed mercury-related topics with the Secretary of the Pennsylvania

Department of Environmental Protection Kathleen

McGinty. Given the nature and

format of

Pennsylvania Inside OUZ

program, it is understandable that PFSC

may have misinterpreted the context of some of

Mr. Feeley's statements concerning the

commercial availability and cost of mercury controls. The following information is

provided to clarify

DOEMETL's perspective on the readiness of technologies for

controlling mercury emissions

fiom coal-fired power plants and their associated costs.

DOEINETL's Mercury Control Technology Research

&

Development Program

DOUNETL, in partnership with a number of key stakeholders, has been carrying out a

comprehensive research program focused on the development of advanced, cost

-effective

mercury control technologies since the mid

-1

990s. Considerable progress has been made

during that time in advancing our basic understanding of mercury in coal

-fired power

plant flue gas and what technologies could

be used to control power plant mercury

emissions. However, while DOE is very encouraged by the results of our mercury

control technology development efforts to date,

there remain a number of critical

technical and cost issues that need to be resolved through additional research before

these technologies can be considered commercially available for all US- co& and the

dgrerent coal-fled power plant configurations in operation in the United States.

Several key points related to the status and cost of mercury control technologies are

summarized below.

Development Status of Mercury-Specific Control Technology

Under DOEMETL's current field testing activity mercury-specific control

technologies such as activated carbon injection (ACI)

are being tested at a number

of coal

-fired power plants. These tests have yielded very promising results in

most cases. For instance, improved activated carbon

sorbents have been

developed and are being tested that

can capture the more difficult to remove

elemental form of mercury. Elemental mercury is the predominant species of

mercury formed when burning lower

-rank coals (subbituminous and lignite) that

have low chlorine content. The progress achieved under

DOEMETL's field

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

testing program has led to several recent announcements of sales of ACI systems

to the

electric-utility industry.

However, as alluded to above, one size does not fit all in regards to controlling

mercury fiom the broad range of coals burned by, and various pollution control

equipment installed on, today's coal

-fired power plants.

Higher-sulfur

bituminous coals

are a

case

in point. During combustion, plants burning medium

to high sulfur coal

can

produce acid gases, such as sulfur trioxide (SO

3

), that

compete with mercury for bonding sites on the activated carbon. Consequently,

the presence of

SO3 in coal combustion flue

gas

may limit the effectiveness of

mercury control via ACI. A recent

DOEMETL field test on a plant burning a

high

-sulfur Ohio coal has shown ACI to be relatively ineffective in capturing

mercury.

DOE/NETL has scheduled additional ACI field tests at five bituminous

coal

-fired units to address this concern.

Another technical performance issue that needs

firrther investigation relative to

ACI is the

type

of particulate control device installed on the power plant. The

majority of U.S. power plants

are

equipped with electrostatic precipitators (ESP)

to remove particulate matter

(i-e., fly ash) fiom the flue gas, while some use fabric

filters. Activated carbon is injected upstream of the particulate control device to

enable simultaneous capture of the mercury and removal of the spent carbon and

fly ash. The effect of continuous long

-term ACI operation on a power plant's

particulate control device is still under investigation.

DOEYNETL

field testing at

a

bituminous-find power plant equipped with an ESP with a relatively small

collection

area has shown that ACI

can

have a detrimental effect on ESP

performance and lead to carbon breakthrough

fiom the ESP which

can

effect

operations of the downstream

sulfk dioxide (Sa) emissions control equipment.

Therefore, further field testing is being

carried out to assess this and other

technical performance issues.

Finally,

DOEINETL's current mercury control field testing program has been

limited

to testing at 28 coal-fired units, representing about only 2.3% of the 1,165

coal-fired generating units in operation in the United States.

Co-Removal of Mercury in Flue

Gas

DesuI&rizahon Systems

Mr. Feeley stated that

"there is existing technology that

has

already proven to be

oble

to take mercury out [of

cod

combustion fie gas]."

This statement was

made in the context of Pennsylvania's proposed mercury control regulation

that is

based on the

co-removal of mercury in flue gas desulfkization systems (i.e., wet

scrubbers) designed to remove

S@.

Wet scrubbers have been employed by the

electric utility industry for more than

thii

years to meet ever increasingly

stringent

S@ regulations, thus, it is considered an "existing technology."

Recent data collected by DOEINETL, the U.S. Environmental Protection Agency,

and others indicate that wet scrubbers

are

also effective in capturing the oxidized

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, JULY 28, 2006

form of mercury. Oxidized mercury is the form of mercury most commonly

found when

combusting higher chlorine bituminous coals, such as those mined

and burned in Pennsylvania. This mercury is soluble and can be washed out in

the scrubber along with the

S@.

It is very important to note that the co-removal

of mercury across existing technology such as wet scrubbers will vary

significantly based on the chemical forms of mercury present. Recall above that

low

-rank coals tend to produce more elemental mercury, which is insoluble and

can not be removed in the scrubber. Bituminous

coals also produce some

elemental

mercury

that

will not be captured in the scrubber. And even for the

oxidized mercury, the level of removal across wet scrubbers has been shown to

range

hm

about

70%

to

90%.

Further complicating the overall effectiveness of

wet scrubbers in removing mercury is the fact that some of the mercury captured

by the scrubber may be re

-released through a yet-to-be completely understood

process in which the oxidized mercury is chemically reduced back to its elemental

form.

DOE/NETL

is carrying out research to better understand and control this

phenomenon.

Regarding

Mr. Feeley's statements concerning the cost of mercury control via

scrubbers, under the proposed Pennsylvania mercury regulation, mercury

reductions will result

hrn

the installation of wet scrubbers to meet the new

Federal Clean Air Interstate Rule that calls for

firrther cuts in

S@

(and nitrogen

oxide) emissions. Therefore, it

can

be

argued that the

cost

of mercury reduction is

"fiee,"

that is, it is a co-benefit of the cost of installing and operating the scrubber

for controlling

Sa.

However, there could be relatively significant fi~ture

costs

associated with the impact of mercury control on the management of the solid

byproducts produced by the scrubber that is discussed below.

Cost of Activated Carbon Injection

While mercury control via ACI is "relatively inexpensive" on a capital-cost basis,

the cost reported by

Mr. Feeley of

$5

-