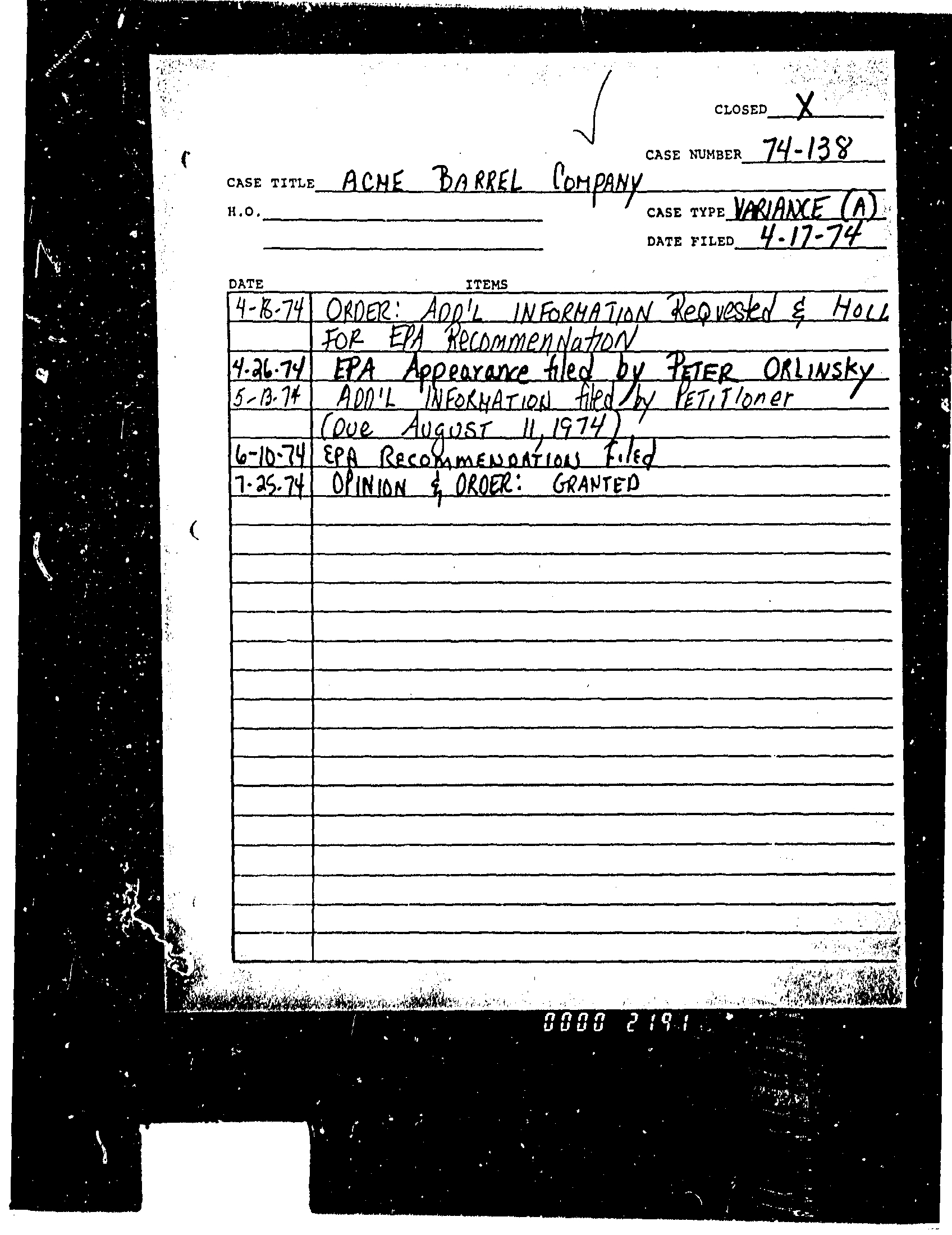

CASE TITLE

ACHE

IA

RREL

bHfAN/

H .O .

DATE

ITEMS

5-~ ~~`

RDO'L I Fo~CjArloi

~P+

'ETi 1 lop gr

e-ia

q

9

EP

Rpco o VA ; kiAATIat

1 •$.7'f

Of1N1AN

4

ORORZ :

GRANTED

I

nnnn

ACM! BARREL

tfrAlwxm

COMPANY

1694

2300 W. 13th STREET

TEL to 'LOR 9 .3838

CHICAGO, ILLINOIS 60608

Illinois Pollution Control Board

209 West Washington Street

Chicago, Illinois 60606

Gentlemen :

Re : Cnsc No .

r

PDtlUTIOH COH11C1 DZRRD

April 15, 1974

.1;

~FYe0{I_INM

n

PPA

7'-138

At the present time our company Is continuing to operate under the terms of

the settlement and variance which was granted on December 18, 1973 . This

variance was granted in order to allow us to have a drum draining system

designed and constructed in order to remove moat if not all of the combustible

materials from the insides of our open head drums prior to feeding them Into

our Incinerator .

Due to a number of problems relating to the necessity for redesigning the

system somewhat from the original proposal and clue to an unbclivable time

in getting prices and deliveries from various contractors that were consulted

and called upon, we arc not going to be able to conform to the original dead-

line set forth by the Board .

Digitali Do Not Remove

Ost a basis of the problems of getting prices and deliveries we arc requesting

that the Board give us an extension of six months so that we can fabricate this

equipment ourselves and install It with our own forces

.

You will note by review of the reports submitted by our company that we have

been making diligent efforts to got prices and to get this work Initiated, How-

ever, we have been unsuccessful In obtaining quotations and do not as of the

date of this submission have any proposals in writing from any of the people

to whom we submitted request for bids,

r

i

'

We have been advised that most of the steel which would be required for con-

struction of this equipment would be available to us within 60 to 75 days after

we place an order . We would thus anticipate that we could begin fabrication

within 75 days and would hope to have the equipment fabricated In another 75

days with Installation occurring during the last month of our requested vari-

ance extension

.

Ji'/cJ

0, 0

STATE OF ILLINOIS )

) SS :

PORM0

COUNTY OF COOK

)

APR 2 6 1974

,BEFORE

TE ILLINOIS POLLUTION OCNIADL BOARD

POLLUTION

,

CONTROL BOARD

AODE BARREL CCI4'ANY,

)

Petitioner,

)

V.

PCB 74-138

ENVIROUWNTAL PROTECTION AGENCY,

Respondent . )

APPEARANCE

The undersigned,

as one

of its attorneys, hereby enters an Appearance

on

behalf of Respondent, the ENVII ¢NTAL PROTSCTICN AGENCY

.

ENVIRONDENTAL ?RCIECTICN AGENCY

STATE OF ILLINOIS

By :(ftL 6 , ~ ~

Peter E . Orlinsky, Attorney

Enforcement Services Section

Division of Air Pollution Control

Dated

: April 24, 1974

309 West Washington

Chicago, Illinois 60606

312/793-3875

iF .

nnnn n to

M1

4

STATE OF ILLINOIS

)

SS .

COUNTY OF S.ANWON

)

dIF

Aw

p

PROOF OF SERVICE

I, the undersigned, being duly sworn on oath, depose and

state that I have served the attached document(s) upon the

person to whom said document(s) is/are directed, by placing a

copy of same in an envelope addressed to Jordan Peariman, Vice

President, Acme Barrel Company, 2300 W

. 13th Street, Chicago, Illinois 60608

and mailing same with sufficient postage affixed, certified

mail, return receipt requested

; said envelope being deposited

in the United States mail, Springfield, Illinois, on

Sill

24

,

1974

.

SUBSCRIBED AND SWORN TO BEFORE ME

this

24th

day of April

i/Ir.i

. •/

i .fr.1

J

'/(totary

L'ublic

My Commission expires October 31, 1976

.

,

1974 .

, )a .M .Qii I CN4'

f.yf

+ t`J,4Y

b

MAY 13 1974

POLLUTION

COnOL BOAR

.

1 . Open burning has been alleged, In order to minimize this the company has

installed hoses to quench fires as they might occur

. The ompany Is draining drums

prior to incineration to reduce the possibility of open burning

. Estimated possible

emission from open burning is less than one pound per hour of particulate and 1/2

pound per hour of CO .

2

. During late 1973 and early 1974 a building was removed to allow for drainer

Installation, An existing conveyor has been rerouted to allow installation of the

proposed equipment, long lead time Items ( drive motor and gear box, chain etc .)

have boon ordered

. Request for quotations for drainer and fabrication went out on

Feb . 27, 1974 to three (3) contractors . Verbal responses in early April Indicated

"no bids" were to be obtained . On April 10, 1974 drawings were again submitted

to three (3) other contractors who Indicated they would bid by mid May, 1974

.

On a basis of bids being received by May 20, 1974, the company will place

orders for fabrication and Installation by Juno 3, 1974,

We estimate lubrication will take 14 to 16 weeks . Parts machining (shafts,

sprockets etc .) will take 16 to 20 weeks . Fan will take 18 to 20 weeks, therefore

we can expect installation to begin November 1, 1974 and be complete February 1,

1975

.

3 . 11ie company is a major reclaimer of steel drums used to ship oils, adhesives,

paints . foodstuffs etc . The company supplies reprocessed drums to such users as

Texac , Mobil, Standard Oil, Proctor & Gamble, Campbell Soup, Schwartz Pickle and

Corn Products .

With the present tight steel supply if these drums are not reclaimed the com-

panies dependent on Acme Barrel would be unable to ship all their requirements .

Beyond this, Acme would be forced to lay off 115 hourly people during the

period it was not permitted to run the "open head" line

.

4

. The effect on the environment has been minimized by steps taken by the company

to pre-drain drums which contain excess combustibles and to promptly quench any fires

which occur in the incinerator vestibule,

The plant operates 40 to 46 hours per week

. It is set up to shut clown in the event

of an Air Pollution Episode . Operations occur during daylight from 7

:30 A

.M . to 4

:00

P .M

. which minimizes any danger of night time or early morning inversions creating

local neighborhood problems .

'U

UULU C

.

u

1,1

q .

v

(VP-12)

ILLINOIS ENVIRONMENTAL

2200 Churchill Road

62706

Dr

. Richard H

. Briceland, Director

June 6, 1974

Nis . Christan L

. Moffett

Clerk

Illinois Pollution Control Board

309 West Washington Street

Chicago, Illinois 60606

Re

: Petition for Variance of

: Acme Barrel

PCB 74-138

Dear Ms . Moffett

Enclosed please find the original and nine copies of

the Agency's Recommendation for filing with regard to the

above-captioned matter .

Enclosures (10)

cc

: Docket Control (w/attachment)

Enforcement Suction Manager (w/attachment)

(2) Variance Section (w/attachment)

B

. Sidlor

file

S

Very truly yours,

J

/,d

bntorrYcem nt

s'ecti h

Attor

Division of Air Polluti

SN

0

PROTECTION AGENCY

Springfield, Illinois

Phone :

312/Nginala7Do

Not Rernove

JUN 10 1974

LUTT if ( ",'~

~( B

:w

AUd

Control

STATE OF ILLINOIS

)

SS .

COUNTY OF COOK

)

BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

ACNE BARREL

- PANY, INC.,

)

Petitioner ,

)

PCB 74-138

vs .

)

ENVIRONMENTAL PROTECTION AGENCY,

)

Respondent .

)

N 0 T I C E

TO : Acne

Jordan

Barrel

Pearlman

CompanyVice

President

Chicago,

2300 Rest

Illinois

13th Street60608

PLEASE TAKE NOTICE that I have today filed in the Office

of the Clerk of the Pollution Control Board, the

Recommendation

of the Environmental Protection Agencv, a

copy of which is herewith served upon you .

ENVIRONMENTAL PROTECTION AGENCY

OF THE STATE OF ILLINOIS

By :

Enforcement

Kathryn

' S

. Nesburg,

%Section

..yJ,

Attorney

1llc'k1.4

Division of Air Pollution Control

DATED : June 6, 1974

2200 Churchill Road

Springfield, Illinois 62706

312 - 793 - 3875

Now comes the ENVIRONMENTAL PROTECTION AGENCY (herein-

after Agency) and for its report of investigation and recommen-

plant is located at 2300 West 13th Street, Chicago, Illinois .

The plant is engaged in the reclamation and reconditioning of

steel barrels

. The plant receives the used drums from various

s

r

a

-2-

3 . The Petitioner receives 4000 barrels each day which

contain residues of undercoating, tar, oils, animal fats,

varnish, p

.u nt, glue, printing ink, chemicals, etc . Both

open-head and tight-head barrels are reconditioned

. The

Petitioner is equipped with two drum incinerators, one cover

incinerator, eight paint spray booths, four curing ovens and

five steel shot blasting units, each of which is equipped with

a baghouse .

4 . Petitioner is seeking a Variance from the Board Order

in PCB 72-404 . Petitioner requests an extension of six months

from the May 1, 1974 deadline set out in the Board Order so

that it can refabricate its drum draining system itself and

install it with its own forces . A grant of the Petition for

Variance would extend the deadline until November 1, 1974 .

HISTORICAL BACKGROUND

5 . The Agency filed a complaint against Acme Barrel Company,

Inc, on October 13, 1972,

(PCB 72-404) .

The complaint alleged that during the period beginning on

or before January 26, 1972, and continuing at least to the date

of the filing of the complaint, Acme Barrel operated its

salamanders, Its barrel prohoating process and the collection

of waste materials from the prohoated barrels in such a manner

as to violate Section 9(a) of the Environmental Protection Act

[I11 . Rev, Stat „ ch . 111 1/2, Section 1009(n), 1971], The

complaint further alleged that during the same period Acme

Barrel caused or allowed the burning of refuse in pits located

Environmental Protection Act . The complaint further alleged

that on or subsequent to July 1, 1970, Acme Barrel installed

pollution control equipment without first having obtained a

permit from the Agency in violation of Section 9(b) of the Act

.

A hearing was held on March 17, 1973

. This hearing was

fired heaters . It also agreed to undertake a program to

eliminate the possibility of any smoke emanating from the area

in front of the incinerators, Acme Barrel also agreed to

undertake the following additional work and installation of

equipment

: to establish a program for eliminating the possibility

of any smoke emanating from the area in front of the incinerators ;

f

C

F

f

uuuu

[a t~U

1

I

material from this process by means of an in-plant special

incinerator at some future date ; the installation of a now

wnter spray booth for the external paint line ; and a program

of proper maintenance of both filters on the existing spray

booth and of the existing baghouse . Schedules were submitted

in detail for the program for drum cleaning and disposa : of

drum drainage .

INVESTIGATION :

7 . Petitioner applied for operating permits but was

denied them

. At the time Petitioner applied for rermits, it

acknowledged that smoke emissions from the charge end of

drum incinerators are not controlled .

8 . Petitioner is installing a now baghouse and stool

shot blasting units . According to the purchase order submitted

to the Agency, the baghouse and blasting units cost approximately

$200,000

.

9, Petitioner has already purchased conveyor, gearbox,

chain and pumps, otc ., for the drum drain system . The purchase

receipts have boon submitted to the Agency .

10 . Petitioner informed the Agency's representative that

Petitioner did not receive quotations for the fabrication and

installation system because of the unavailability of stool and

previous commitments of the construction companies . The Agency

investigator verified this claim with the construction companies

by phone on May 8, 1974 .

VV

reconditioning can be in progress without affecting production .

12 . Petitioner requests six months to complete installation

of the drum drain system . The Agency finds that this is sufficient

time to complete the system .

13 . Petitioner has submitted monthly progress reports

to the Agency as required by Paragraph $ of the Board Order

.

Pollution Control, state that there is still an odor problem

but that it is improving

. Those people work at 2121 West Taylor

Street, Chicago, which is close to Petitioner's facility .

a . Petitioner shall continue to pursue

vigorously its investigations and imple-

mentation of alternatives

regarding

dis-

posal of drum drainings .

b .

Petitioner shall maintain a high degree of

maintenance on its paint booth filters and

on its shotblast baghouse .

c . Petitioner shall apply for all necessary

Agencypermits.

from the Environmental Protection

d . Petitioner should submit monthly

reports

to :

Environmental Protection Agency

ControlDivision

2200 ChurchillProgramof

Air

RoadCoordinatorPollution

Control

Springfield, Illinois 62706

The monthly reports should include the

progress of the installation of the

drum drain system .

The

Agency reserves the right to amend its Recommendation

pending the close of the record in this case .

Acme Barrel v, EPA

PCB 74-138

-6-

ENVIRONMENTAL PROTECTION AGENCY

STATE OF ILLINOIS

)

SS .

COUNTY OF

SANGAMON

)

PROOFOPSERVICE

I, the undersigned,

being duly sworn on oath, depose and

state that I have served the attached document(s) upon the

person to whom said document(s) is/are directed, by placing a

copy of same in an envelope addressed to

Jordan Pearlman, Vice-

President, Acme Barrel Co ., 2300 W . 13th St ., Chgo, IL 60608

and mailing same with sufficient postage affixed, certified

mail,

return receipt

requested ; said envelope being deposited

In

the United States mail, Springfield, Illinois, on

L'

I

Qtc (,

,

197.4 .

SUBSCRIBED AND SWORN

TO

BEFORE

HE

this ~~ ~ydny

of

1974 .

,~

p

G ~

(! 1 t---rf

et

Public