1

ILLINOIS POLLUTION CONTROL BOARD

May 4, 2006

IN THE MATTER OF:

CLEAN-UP PART III AMENDMENTS TO 35 ILL. ADM. CODE PARTS 211, 218, AND 219 |

) ) ) ) ) |

R04-20 (Rulemaking - Air) |

______________________________________

IN THE MATTER OF:

TECHNICAL CORRECTIONS TO FORMULAS IN 35 ILL. ADM. CODE 214 “SULFUR LIMITATIONS” |

) ) ) ) ) |

R04-12 (Rulemaking - Air) (Consolidated) |

Adopted Rule. Final Order.

OPINION AND ORDER OF THE BOARD (by A.S. Moore):

In these consolidated rulemakings docketed as R04-20 and R04-12, the Board today adopts final rule amendments designed to clarify, correct, streamline, and update the Board’s air pollution control rules. The amendments appear in Parts 211, 214, 218, and 219 of Title 35 of the Illinois Administrative Code. On April 11, 2006, the Joint Committee on Administrative Rules (JCAR) issued certifications of no objection concerning the amendments proposed by the Board at second notice. The Board will now file the adopted amendments with the Secretary of State for publication in the Illinois Register as final rules.

The Board previously consolidated these two rulemakings for hearing. The Board has used docket R04-20 to address the rulemaking proposal filed by the Illinois Environmental Protection Agency (IEPA). IEPA proposed amending the Board’s rules at 35 Ill. Adm. Code Part 211 (definitions and general provisions), Part 218 (organic material emission standards and limitations for the Chicago area), and Part 219 (organic material emission standards and limitations for the Metro East area). Among other things, the adopted amendments in R04-20 allow additional methods for measuring the volatile organic material (VOM) “capture efficiency” of various emission control equipment. These changes are designed to increase regulatory flexibility, consistent with United States Environmental Protection Agency (USEPA) requirements.

Docket R04-12 has been dedicated to the Board-initiated rulemaking proposal to amend rules at 35 Ill. Adm. Code Part 214 (sulfur limitations). These changes correct typographical errors in formulas that appear to have occurred during re-codification of the Illinois Administrative Code.

In this opinion, the Board first provides the procedural history of the consolidated rulemaking. Next, the Board discusses the rule amendments adopted today and some of the issued raised by participants and resolved by the Board. The order following this opinion sets forth the Board’s adopted amendments to Parts 211, 214, 218, and 219 of the Board’s air pollution control rules.

PROCEDURAL HISTORY

On January 6, 2004, the Board received the proposal from IEPA to amend the Board’s air pollution rules at 35 Ill. Adm. Code 211, 218, and 219. In a January 22, 2004 order, the Board opened docket R04-20 for, and accepted for hearing, the IEPA proposal. In the same order, the Board opened docket R04-12 for its proposed amendments to 35 Ill. Adm. Code 214, and consolidated for hearing the IEPA proposal (R04-20) with the Board-initiated proposal (R04-12).

The Board held two public hearings in this consolidated rulemaking. The first took place in Chicago on March 18, 2004. One person testified at the first hearing: Gary Beckstead, Environmental Protection Engineer in the Air Quality Planning Section of IEPA’s Bureau of Air. The second hearing took place in Springfield on May 6, 2004. The following persons testified at the second hearing: Beckstead of IEPA; and David Bloomberg, Environmental Protection Engineer in the Ozone Regulatory Unit of the Air Quality Planning Section of IEPA’s Division of Air Pollution Control. Also participating at hearing were attorneys Charles Matoesian on behalf of IEPA and LaDonna Driver of Hodge, Dwyer, and Zeman on behalf of the Illinois Environmental Regulatory Group (IERG).

The transcripts of the Chicago and Springfield hearings were received by the Board on April 20 and May 17, 2004, respectively, and promptly placed in the Clerk’s Office On Line (COOL) on the Board’s Web site at www.ipcb.state.il.us . 1 Many other documents from this rulemaking are available through COOL, including Board opinions and orders, hearing officer orders, and public comments.

As required by Section 27(b) of the Act (415 ILCS 5/27(b) (2004)), the Board made the Department of Commerce and Economic Opportunity’s (DCEO) decision not to conduct an economic impact study (EcIS) available to the public at least 20 days before the second hearing. In letters of April 17, 2003 and April 2, 2004, DCEO declined to perform an EcIS, noting its limited financial resources. No one testified about either of DCEO’s letters. Tr.2 at 40-41.

The Board hearing officer entered two exhibits into the record at hearing. Hearing exhibit 1, which was entered on the hearing officer’s motion, is a group exhibit consisting of five Board orders that bear upon proposed amendments to equations in the rules: (1) May 25, 1978, in R75-5, R74-2; (2) December 14, 1978, in R75-5, R74-2; (3) February 15, 1979, in R75-5, R74-2; (4) February 24, 1983, in R80-22; and (5) April 20, 1995, R94-31. Hearing exhibit 2 was offered by IEPA and consists of an “Errata Sheet” that shows proposed changes to the rule language originally set forth in IEPA’s R04-20 proposal. 2

IEPA filed a public comment on June 18, 2004 (PC 1), as did IERG (PC 2). On

July 30, 2004, Jefferson Smurfit Corporation (U.S.) filed a public comment (PC 3). The Board adopted its first notice opinion and order on April 21, 2005. On May 27, 2005, the Illinois Register published first-notice of the Board’s proposed rule amendments (29 Ill. Reg. 7418 (Part 211), 7435 (Part 214), 7449 (Part 218), 7563 (Part 219) (May 27, 2005)). This began a 45-day period, concluding on July 11, 2005, during which any interested person could file with the Board a public comment on the proposed amendments. The Board received five additional public comments after first-notice publication. On June 30, 2005, the Printing Industry of Illinois/Indiana Association (PII) filed a public comment (PC 4). On June 28, 2005, the Specialty Graphic Imaging Association (SGIA) filed a public comment (PC 5). On July 7, 2005, Smurfit-Stone Container Enterprises, Inc. (Smurfit-Stone), successor by merger to Jefferson Smurfit Corporation (U.S.), filed a public comment (PC 6). On July 11, 2005, IEPA filed a public comment (PC 7). On July 11, 2005, IERG filed a public comment (PC 8).

On March 2, 2006, the Board adopted its opinion and order for second notice. On

April 11, 2006, JCAR issued certifications of no objection concerning the second-notice rule amendments to Parts 211, 214, 218, and 219. At JCAR’s request, the Board today makes only minor changes to the second-notice rules.

DISCUSSION

In this part of the opinion, the Board first provides background on the nature of the amendments being made in R04-20 and the regulatory framework within which they fit. The Board then discusses and analyzes some of the issues raised by participants in R04-20 and how the Board resolved those issues. Lastly, the Board addresses R04-12.

Background

In R04-20, the Board is amending its air pollution rules at 35 Ill. Adm. Code 211, 218, and 219. The amendments are designed to update, clarify, and correct provisions of the air rules, as well as ease regulatory burdens without allowing for increased emissions. 3 St. of Reas. at 1-2, 6-7. The rules focus on VOM emissions in the Chicago ozone nonattainment area and Metro-East St. Louis ozone area, as designated under the federal Clean Air Act, and as described in 35 Ill. Adm. Code 218.103 and 219.103, respectively. Id. at 2, 6.

The federal Clean Air Act (42 U.S.C. 7511a(b)(1)) required all moderate, serious, severe, and extreme ozone nonattainment areas to reduce VOM emissions 15% by 1996. St. of Reas. at 1. In Illinois, the Chicago area is classified as a severe nonattainment area and, until recently, the Metro-East St. Louis area was classified as a moderate ozone nonattainment area. 4 Accordingly, Illinois had to develop a plan to reduce VOM emissions in the Chicago and Metro-East areas. Id. In turn, Illinois, through Board rulemaking, adopted a 15% Rate of Progress (ROP) plan. Many of the provisions being amended in R04-20 were adopted as part of the 15% ROP plan. Id. at 1-2. The amendments are not expected to impact the overall air quality plans or goals of the Chicago nonattainment area or Metro-East ozone area. Id. at 2.

The R04-20 amendments are intended to:

| · | Update the test methods for capture efficiency; |

| · | Clarify the term “carbon adsorber”; |

| · | Clarify requirements for screen printers; |

| · | Clarify categories of sealers and topcoats; |

| · | Clarify provisions on monitoring, applicability, equations, recordkeeping, and reporting for lithographic printing operations; |

| · | Clarify that sources may turn off their natural gas fired afterburners outside the ozone season; |

| · | Delete the requirements applicable to perchloroethylene dry cleaning facilities; |

| · | Delete the requirement that auto finishing shops annually re-register with IEPA; |

| · | Delete the coating purchasing recordkeeping requirements; and |

| · | Correct miscellaneous grammatical and typographical errors. St. of Reas. at 2. |

Capture Efficiency (CE) Protocols

The Board will give background on capture efficiency (CE) before turning to the some of the issues raised by rulemaking participants concerning the CE protocols: CE protocols in enforcement cases; whether additional testing is required when establishing emission credits; whether the “Lower Confidence Limit” (LCL) protocol can be used to establish emission credits for trading; and the role of the LCL protocol and “Data Quality Objective” (DQO) protocol as “alternatives” to the “standard” enclosure protocols.

Background on CE Protocols

CE test methods are required by the federal Clean Air Act and included in the Chicago Federal Implementation Plan. Measuring CE is critical to determining the effectiveness of volatile organic compound (VOC) emission control systems. 5 St. of Reas. at 3.

On January 9, 1995, USEPA issued a guidance document entitled Guidelines for Determining Capture Efficiency (1995 Guidelines), which revised the existing USEPA approved “gas/gas” and “liquid/gas” CE test methods and introduced two new alternative CE test protocols. St. of Reas. at 3. The next month, in February 1995, John S. Seitz, Director, Office of Air Quality Control and Standards, USEPA, issued a memorandum entitled Revised Capture Efficiency Guidance for Control of Volatile Organic Compound Emissions (Seitz Memo) (id.), which transmitted the 1995 Guidelines to various USEPA regional directors (Seitz Memo at 1). On June 16, 1997, USEPA published a final rule in the Federal Register to update the CE test methods located in USEPA regulations at 40 C.F.R. 51, Appendix M (62 Fed. Reg. 32500

(June 16, 1997)). St. of Reas. at 3.

The four existing CE protocols, the so-called “standard” protocols, each require an enclosure of the VOM-emitting unit pursuant to USEPA’s Method 204, Appendix M, 40 C.F.R. 51. The two new “alternative” CE protocols do not. Tr.2 at 11, 27-28. Instead, the two new CE protocols are statistical “mass balance” approaches to determining CE and, as noted, are called the “Data Quality Objective” (DQO) and the “Lower Confidence Limit” (LCL):

USEPA developed the two alternative methods in order to provide additional regulatory flexibility and reduce compliance costs. *** These methods define sets of approval criteria which, when met by the data obtained from the measurement of applicable process parameters using USEPA approved procedures and protocols, may be used to determine VOC capture system compliance with a regulatory CE standard. St. of Reas. at 3.

Satisfying the DQO yields a result accurate to a 95% confidence level, and satisfying the LCL yields a result accurate to a 90% confidence level. PC 1 at 4, 5; Tr.1 at 10. The Seitz Memo generally described the DQO and LCL methods:

[T]hese alternatives offer additional flexibility in that they do not require specific testing procedures for measuring process parameters and for liquid and gas analyses; but only specify a limited set of guidelines on the data quality. The DQO and LCL methods are sets of approval criteria which, when met by the data obtained with any given protocol of process parameter measurement procedures, may be used to determine VOC capture system compliance with a CE standard. Seitz Memo at 3.

The R04-20 amendments to Parts 218 and 219 add the option for sources to use the DQO and LCL. St. of Reas. at 3 (see Sections 218.105(c), 219.105(c), 218.112, and 219.112). Part 218 applies to VOM emissions from stationary sources in the Chicago ozone nonattainment area, while Part 219 applies to VOM emissions from stationary sources in the Metro-East ozone area. Parts 218 and 219 are nearly identical, as are the amendments to the respective Parts. Accordingly, when the Board refers in this opinion to a provision of Part 218, it is also referring to that provision in Part 219, and vice versa.

Subsections (c)(1) of Sections 218.105 and 219.105 state that the requirements of the respective subsections (c)(2) (i.e., the CE protocols) apply to all VOM-emitting process emission units employing capture equipment (e.g., hoods, ducts), except in a few cases, such as when an emission unit is equipped with or uses a permanent total enclosure (PTE) that directs all VOM to a control device. See 35 Ill. Adm. Code 218.105(c)(1)(A), 219.105(c)(1)(A). Other than these exceptions, the CE of an emission unit must be measured using one of the CE protocols in subsection (c)(2). Before these amendments, subsection (c)(2) provided the four enclosure CE protocols (in subsections (c)(2)(A), (B), (C), and (D)): (1) gas/gas method using a temporary total enclosure (TTE); (2) liquid/gas method using TTE; (3) gas/gas method using the building or room enclosure in which the affected emission unit is located; and (4) liquid/gas method or room enclosure in which the affected emission unit is located. The DQO and LCL protocols, sometimes referred to as the “DQO/LCL protocol,” appear in new subsection (c)(2)(E) of Sections 218.105 and 219.105.

CE Protocols in Enforcement Cases

The participants in this rulemaking agreed that the LCL protocol alone cannot prove a violation because the LCL will tend to understate the actual CE. Because the actual CE is therefore likely to be greater than the LCL, a calculated LCL above the applicable CE standard demonstrates compliance. However, because the LCL is the “floor” for CE, a calculated LCL below the required CE does not demonstrate non-compliance.

As the Board discussed in its first-notice opinion, IERG and Jefferson Smurfit Corporation (U.S.) expressed concern that IEPA’s proposal suggested an improper shift of the “burden of proof” to the respondent source in an enforcement case. PC 2 at 3-4; PC 3 at 5. The Board agreed, finding that IEPA’s language indicated that a respondent would have the burden to prove it is in compliance. In an enforcement action, however, it is the complainant that has the burden of proving the respondent is not in compliance. See 415 ILCS 5/31(e) (2004).

In response, IEPA agreed that the burden of proof in enforcement cases is on the complainant. PC 7 at 5-6. However, IEPA states that if a source uses LCL and determines that its CE appears to be below the CE standard, the “burden the source has is providing the Agency with a solid number” using one of the other protocols. Id. at 6. IEPA emphasized that Section 201.282(a) (35 Ill. Adm. Code 201.282(a)) gives IEPA the ability to “require the owner or operator of the emission source or air pollution control equipment to conduct such tests in accordance with procedures adopted by the Agency.” Id. at 7.

IEPA explained that when the LCL is below the allowable CE limit, IEPA does not know whether a source is out of compliance:

[A]n LCL estimated CE value of 68% only means that the CE is at least 68%, but it may be 69% or 70%, or greater. If the standard of CE is 70% in a particular situation, the Agency doesn’t know if a source with an LCL estimated CE value of 68% is out of compliance or not. Further testing would be needed. PC 7 at 6.

IERG agreed that the DQO and the “standard” protocols (Section 218.105(c)(2)(A)-(D)) could be used to prove a violation. PC 8 at 3.

Indeed, the Board at first notice stated:

[I]f one of the CE protocols, say subsection (c)(2)(E), cannot be met, another protocol, i.e., (A), (B), (C), or (D), must be satisfied absent approval of an alternative under Section 218.108(b).

The Board recognized at second notice that the LCL will be the first protocol codified that, alone, cannot prove a CE violation. The Board added:

However, if a source uses the LCL and the LCL does not demonstrate CE compliance, IEPA in administering the air programs plainly can still require the source to demonstrate compliance with CE requirements using another protocol. If a source fails to do so, it would be subject to enforcement. Moreover, it is both self-evident and uncontested in this rulemaking that the CE protocols other than LCL can prove a violation of CE requirements.

To address the issue, the Board at second notice proposed the following addition (double-underlined) to the new Section 218.105(c)(2)(E):

In enforcement cases, the LCL protocol cannot confirm non-compliance; capture efficiency must be determined using a protocol under subsection (c)(2)(A), (B), (C) or (D) of this Section, the DQO protocol of this subsection (c)(2)(E), or an alternative protocol pursuant to Section 218.108(b) of this Part.

The Board adopts this language today as a final rule.

Emission Credits and Additional Testing

IERG expressed concern during the rulemaking that satisfying the DQO under IEPA’s proposal would necessarily require additional physical testing to establish emission credits for offsets, shutdowns, and trading. For example, IERG was concerned that more testing would be required when an emission unit is being shut down even though the unit, when originally permitted, established CE by testing. PC 3 at 3-4; Tr.2 at 29-31.

IERG and IEPA responded to the Board’s first-notice request for more comment on the issue of when additional testing is required for establishing emission credits. IERG stated that its position, based on discussions with IEPA, is as follows:

| · | where a source had originally performed testing at an emission unit using standard methods, and then later seeks emission credits for that emission unit, no additional testing will be required by this rulemaking to establish credits for that emission unit; | ||

| · | where a source had originally performed testing at an emission unit using the DQO, and then later seeks emission credits for that emission unit, no additional testing will be required by this rulemaking to establish credits for that emission unit; | ||

| · | where a source has not been required to perform testing at an emission unit, and then later seeks emission credits for that emission unit, no additional testing will be required by this rulemaking to establish credits for that emission unit; | ||

| · | where a source had originally performed testing at an emission unit, has relied upon the LCL, and then later seeks emission credits for that emission unit, additional testing will be required for that emission unit. PC 8 at 2-3, 8. | ||

IERG supported the Board’s rule language, as proposed at first notice, concluding that testing to establish emission credits would be required only when the source had previously conducted testing that relied upon the LCL. PC 8 at 3.

IEPA also supported the limitations on using LCL that the Board proposed at first notice. PC 7 at 11. The relevant sentence within Section 218.105(c)(2)(E) at first notice, which remains unchanged, reads:

Where capture efficiency testing is done to determine emission reductions for the purpose of establishing emission credits for offsets, shutdowns, and trading, the LCL protocol cannot be used for these applications.

IEPA reiterated that this restriction is necessary because the LCL would overestimate the unit’s emissions and provide too many credits to a source. PC 7 at 12.

IEPA interpreted the rule language “Where capture efficiency testing is done . . .” to mean any past CE testing, not just CE testing specifically for the shutdown. PC 7 at 11-12. In this way, IEPA pointed out, if a source tested at one point and then later decided to shut down, the source would not be required to do another test simply to determine emission credits, as long as the testing had not relied on the LCL. Id. at 13. Additionally, according to IEPA, the source would not have to do further testing if it did not wish to take emission credits from its shutdown. Id. at 12.

To further clarify the issue of CE testing and emission credits, the Board at second notice, as requested by IEPA and IERG, added a Board note after Section 218.105(c)(2)(E). The Board note appears in the final rules as follows, reflecting minor grammatical and capitalization changes at JCAR’s request:

| BOARD NOTE: Where LCL was used in testing emission units that are the subject of later requests for establishing emission credits for offsets, shutdowns, and trading, prior LCL results may not be relied upon to determine the appropriate amount of credits. Instead, to establish the appropriate amount of credits, additional testing may be required that would satisfy the protocol of Section 218.105(c)(2)(A), (B), (C) or (D), the DQO protocol of Section 218.105(c)(2)(E), or an alternative protocol pursuant to Section 218.108(b) of this Part. | ||

Emission Credits and Trading

As just discussed, the Board is adopting the following language for Section 218.105(c)(2)(E), closely tracking the Seitz Memo:

Where capture efficiency testing is done to determine emission reductions for the purpose of establishing emission credits for offsets, shutdowns, and trading, the LCL protocol cannot be used for these applications.

Regarding this language, the Board directed IEPA at first notice to specifically address the contention of Jefferson Smurfit Corporation (U.S.) that the LCL could be used to calculate actual seasonal emissions, just not the baseline for the VOM Emission Reduction Market System (ERMS) (35 Ill. Adm. Code 205).

Jefferson Smurfit Corporation (U.S.) had argued that the:

baseline emissions for determining emission credits should not be based on the LCL since this would overstate the baseline emissions and therefore give the facility emission credits above what it should obtain. *** However, once the baseline has been established, there is no reason why the facility should not be able to use the LCL capture efficiency to determine its actual ERMS seasonal emissions, especially since use of the LCL capture efficiency will overstate the VOM emissions that must be accounted for. Smurfit PC at 5.

Accordingly, Jefferson Smurfit Corporation (U.S.) took the position that “establishing emission credits for . . . trading” refers only to baseline calculations. Smurfit-Stone continues to interpret the first-notice language, taken from the Seitz Memo, as precluding the use of LCL for establishing an emission baseline, but allowing the use of LCL to calculate actual seasonal emissions. PC 6 at 3.

IEPA commented that the problem with Smurfit-Stone’s position is the word “actual.” PC 7 at 13. The relevant ERMS rule (35 Ill. Adm. Code 205.300(b)(1)) requires that sources must submit “[a]ctual seasonal emissions of VOM from the source.” Id. at 13-14. According to IEPA, because the LCL underestimates CE and overestimates emissions, the LCL does not result in the “actual seasonal emissions.” Id. at 13. IEPA stated that the integrity of the ERMS trading program is based on using actual seasonal emissions. IEPA concluded that if “sources overestimate their emissions, the integrity of the program could be jeopardized.” Id. at 14.

At second notice, the Board concurred with IEPA’s interpretation. The Board also noted that none of the participants had requested that the Board add any rule language concerning the ERMS baseline/seasonal emission issue, and the Board found no reason to do so at that time.

DQO/LCL as an “Alternative”

IEPA expressed concern during this rulemaking about the Board’s “concurrence with Smurfit that DQO/LCL should be on an ‘equal footing’ with the standard (enclosure) protocols.” PC 7 at 2. The “standard” protocols in Sections 218.105(c) and 219.105(c) use permanent total enclosure (PTE), temporary total enclosure (TTE), and building or room enclosures (BE). The DQO/LCL, IEPA emphasized, is a statistical analysis that measures CE without an enclosure. Id. at 4. IEPA maintained that “[t]his comparison is not of equals.” Id. at 2.

IEPA quoted USEPA’s 1995 Guidelines: “The [US]EPA continues to recommend the use of a PTE, TTE, or BE for determining CE.” PC 7 at 3. IEPA pointed out that the DQO/LCL is not included among USEPA’s recommended test methods, though USEPA guidance states that the DQO/LCL could be used as an alternative. Id. at 3. IEPA cautioned that the DQO and LCL are relatively new methods and have not yet been used frequently nationwide. Id. at 16. IEPA reiterated that the purpose of including the DQO/LCL is to provide flexibility as a courtesy to the regulated community, and that the Seitz Memo also cites reduced costs. Id. at 2-3.

At second notice, the Board recognized IEPA’s numerous points about the advantages of the enclosure protocols versus the DQO/LCL protocol. The Board noted, however, that the Board never stated that DQO/LCL is preferred to or more accurate than the enclosure protocols. The Board said at first notice:

The Board agrees with Smurfit’s sentiment that the DQO/LCL should be on “equal footing” with the standard (enclosure) protocols, i.e., that DQO/LCL should be available without the source having to first demonstrate that all standard protocols are “unsuitable.”

* * *

The Board agrees with Smurfit that these “alternative” protocols (DQO and LCL), now adopted by USEPA, should be on the same footing as the existing “standard” protocols, with the noted exceptions limiting the use of the LCL. To refer to DQO/LCL as an “alternative,” as IEPA proposes, even though the protocol will be codified and not require case-by-case approval for use, risks confusing it with this subsection (c)(2) language: “alternative capture efficiency protocol may be used, pursuant to the provisions of Section 218.108(b).” The Section 218.108(b) process is one by which other protocols (i.e., other than the codified enclosure and DQO/LCL protocols) may be proposed and approved on a case-by-case basis.

The Board at second notice stood by its statements: “The fact remains that, as permitted by USEPA guidance, the DQO/LCL is being added to the rules and can be used to demonstrate CE compliance. The proposed rules clearly set forth the limits on LCL use.” In its second-notice opinion, the Board declined IEPA’s suggestion to call DQO/LCL an “alternative” in the rules, noting:

IEPA appears to persist in proposing that DQO and LCL be labeled “alternatives” in the rules solely as a means to indicate that they lack the precision and “recommended” status of the enclosure protocols. PC 7 at 5. The Board finds this rationale for language changes unconvincing. The Seitz Memo and the 1995 Guidelines are being incorporated by reference and speak for themselves as to what is recommended.

Carbon Adsorbers

IEPA stated that industry was concerned that the term “carbon” in “carbon adsorbers” would limit the media that could be used in adsorbers to carbon. St. of Reas. at 3. IEPA proposed adding a definition of “carbon adsorbers,” which is based on the federally issued Control Technique Guidelines (CTG) document, and which would “reflect the changing technology in the field of adsorbers and the media used in them, such as aluminum and silicon oxides.” Id.

IEPA explained that other materials had recently been introduced claiming to be a more efficient adsorbent than carbon, though the “physical capturing of the VOM is the same basic process.” PC 1 at 3. IEPA reported, however, from its enforcement experience, that manufacturers of these new adsorbent materials maintain that “monitoring such devices pursuant to the requirements of Sections 218.105(d) and 219.105(d) is not required because these Sections refer only to ‘carbon’ adsorbers and not any other adsorber.” Id. Through its proposed definition, IEPA sought to “close that unforeseen loop hole” without causing any “undesired regulatory repercussions” that might arise from changing the term throughout Title 35. Id.

At first notice, the Board recognized IERG’s concern about potential confusion resulting from defining the term “carbon adsorber” to include non-carbon materials. The Board stated, however:

Not only is this term [“carbon adsorber”] commonly understood to refer to adsorbent technology generally, but now the term will be defined explicitly to include these other media. Compare 35 Ill. Adm. Code 211. 4470 (definition of “paper coating” refers not only to coatings applied to paper, but also to plastic film and metallic foil). Additionally, the Board notes that the term “carbon adsorber” is not just used in other Subparts of Parts 218 and 219 that are not open in this rulemaking, but also in other Parts of Title 35, such as Part 215, none of which are open in this rulemaking.

In the interest of proceeding most efficiently with this rulemaking, the Board declines to expand IEPA’s proposal to include such a large number of additional regulatory provisions in an effort to amend the term “carbon adsorber.” The Board, however, encourages IEPA to assess whether this definitional solution works as intended when the rule is implemented. If it does not work, the Board would invite IEPA to propose an omnimbus rulemaking to replace the term “carbon adsorber” throughout Title 35 with a term more accurate on its face.

With several clarifications to IEPA’s language, the Board proposed for first notice the following definition of “carbon adsorber” at Section 211.953:

“Carbon Adsorber” means a control device designed to remove and, if desired, recover volatile organic material (VOM) from process emissions where removal of VOM is accomplished through the adherence of the VOM onto the surface of highly porous adsorbent particles, such as activated carbon. The term “carbon adsorber” describes any adsorber technology used as a control device even though media other than carbon may be used as the adsorbent, such as oxides of silicon and aluminum.

IERG remained concerned that the definition of “carbon adsorber” still includes media besides carbon, such as oxides of silicon and aluminum. PC 8 at 4. IERG believed the stand-alone term “carbon adsorber” could be deceptive. Id. at 4. When reviewing monitoring requirements for “carbon adsorbers,” sources, IERG explained, might not be aware that the requirements for carbon adsorbers in Parts 218 and 219 would also extend to other types of adsorbers. Id. at 5.

According to IERG, IEPA concedes to having had difficulties in the past with sources believing that non-carbon adsorber technologies are not subject to the requirements for carbon adsorbers. PC 8 at 5. Although the Board at first notice requested that IEPA propose an omnibus rulemaking to replace the term “carbon adsorber” with a more accurate one if needed, IERG suspects that such a rulemaking would only be triggered after sources have suffered the enforcement consequences. Id. at 5. Rather than defining the existing term “carbon adsorber” to include all media and waiting for IEPA to propose an omnibus rulemaking, IERG suggested limiting the “carbon adsorber” definition to activated carbon. Id.

IEPA, on the other hand, concurred with the definition proposed by the Board at first notice. Further, IEPA offered that when processing permits, it can assist applicants with any questions they may have about the meaning of “carbon adsorber.” PC 7 at 16.

At second notice, the Board stated that when it promulgates regulations, the Board must assume that the regulations will be read by those regulated: “The Board anticipates that the regulated community does not consist of many, if any, “casual readers” of these regulations, but rather of sources that would be inclined to look up the definitions of defined terms.” The Board added that IERG or any other person may propose the omnibus rulemaking referred to by the Board. Further, the Board noted that IERG’s suggested definition would effectively exempt all non-carbon adsorbers from the requirements, which “runs directly counter to using this rulemaking to close the unforeseen compliance loophole mentioned at first notice.” The Board at second notice therefore declined to alter the definition of “carbon adsorber” proposed for first notice, which remains unchanged in these final rules.

R04-12

The Board in R04-12 is making technical corrections to formulas in 35 Ill. Adm. Code 214, the air pollution rules on sulfur limitations. The errors in the formulas appear to have occurred when the Illinois Administrative Code was re-codified. These changes were narrowly-tailored to make only the described technical corrections. IEPA identified several errors in the first-notice language of Part 214 ( PC 7 at 18-20, items 1, 2, 5, 6, 7), which the Board corrected at second notice.

CONCLUSION

The Board adopts final amendments to the following air pollution control rules: Part 211 (definitions and general provisions); Part 214 (sulfur limitations); Part 218 (organic material emission standards and limitations for the Chicago area); and Part 219 (organic material emission standards and limitations for the Metro East area). The amendments are needed to clarify, correct, streamline, and update the Board’s air pollution control rules, and are designed to be emissions neutral. The amendments include changes to give sources more flexibility in meeting VOM emission CE requirements.

Based on this record, the Board finds that the amendments adopted today are technically feasible and economically reasonable and will not have an adverse economic impact on the People of Illinois. See 415 ILCS 5/27(a), (b) (2004). The rule amendments in the order below reflect minor changes from second notice at JCAR’s request, none of which merit discussion. The Board directs the Clerk to submit the amendments in the order below to the Secretary of State for publication as final rules.

ORDER

The Board adopts the following amendments to Parts 211, 214, 218, and 219 of its air pollution control rules (35 Ill. Adm. Code 211, 214, 218, 219). The Board directs the Clerk to submit the amendments to the Secretary of State for publication in the Illinois Register as final rules.

| TITLE 35: ENVIRONMENTAL PROTECTION | |||||||||||||

| SUBTITLE B: AIR POLLUTION | ||||||||||||

| CHAPTER I: POLLUTION CONTROL BOARD | ||||||||||||

| SUBCHAPTER c: EMISSION STANDARDS AND LIMITATIONS FOR STATIONARY SOURCES | ||||||||||||

| PART 211 | ||||||||||||

| DEFINITIONS AND GENERAL PROVISIONS | ||||||||||||

| SUBPART A: GENERAL PROVISIONS | |||||||||

Section

211.101 Incorporations by Reference

211.102 Abbreviations and Conversion Factors

SUBPART B: DEFINITIONS

Section

| 211.121 | Other Definitions | |||||||

| 211.122 | Definitions (Repealed) | |||||||

| 211.130 | Accelacota | |||||||

| 211.150 | Accumulator | |||||||

| 211.170 | Acid Gases | |||||||

| 211.210 | Actual Heat Input | |||||||

| 211.230 | Adhesive | |||||||

| 211.240 | Adhesion Promoter | |||||||

| 211.250 | Aeration | |||||||

| 211.270 | Aerosol Can Filling Line | |||||||

| 211.290 | Afterburner | |||||||

| 211.310 | Air Contaminant | |||||||

| 211.330 | Air Dried Coatings | |||||||

| 211.350 | Air Oxidation Process | |||||||

| 211.370 | Air Pollutant | |||||||

| 211.390 | Air Pollution | |||||||

| 211.410 | Air Pollution Control Equipment | |||||||

| 211.430 | Air Suspension Coater/Dryer | |||||||

| 211.450 | Airless Spray | |||||||

| 211.470 | Air Assisted Airless Spray | |||||||

| 211.474 | Alcohol |

| 211.479 | Allowance | |||||||

| 211.484 | Animal | |||||||

| 211.485 | Animal Pathological Waste | |||||||

| 211.490 | Annual Grain Through-Put | |||||||

| 211.495 | Anti-Glare/Safety Coating | |||||||

| 211.510 | Application Area | |||||||

| 211.530 | Architectural Coating | |||||||

| 211.550 | As Applied | |||||||

| 211.560 | As-Applied Fountain Solution | |||||||

| 211.570 | Asphalt | |||||||

| 211.590 | Asphalt Prime Coat | |||||||

| 211.610 | Automobile | |||||||

| 211.630 | Automobile or Light-Duty Truck Assembly Source or Automobile or Light-Duty Truck Manufacturing Plant | |||||||

| 211.650 | Automobile or Light-Duty Truck Refinishing | |||||||

| 211.660 | Automotive/Transportation Plastic Parts | |||||||

| 211.670 | Baked Coatings | |||||||

| 211.680 | Bakery Oven | |||||||

| 211.685 | Basecoat/Clearcoat System | |||||||

| 211.690 | Batch Loading | |||||||

| 211.695 | Batch Operation | |||||||

| 211.696 | Batch Process Train | |||||||

| 211.710 | Bead-Dipping | |||||||

| 211.730 | Binders | |||||||

| 211.750 | British Thermal Unit | |||||||

| 211.770 | Brush or Wipe Coating | |||||||

| 211.790 | Bulk Gasoline Plant | |||||||

| 211.810 | Bulk Gasoline Terminal | |||||||

| 211.820 | Business Machine Plastic Parts | |||||||

| 211.830 | Can | |||||||

| 211.850 | Can Coating | |||||||

| 211.870 | Can Coating Line | |||||||

| 211.890 | Capture | |||||||

| 211.910 | Capture Device | |||||||

| 211.930 | Capture Efficiency | |||||||

| 211.950 | Capture System | |||||||

| 211.953 | Carbon Adsorber | |||||||

| 211.955 | Cement | |||||||

| 211.960 | Cement Kiln | |||||||

| 211.970 | Certified Investigation | |||||||

| 211.980 | Chemical Manufacturing Process Unit | |||||||

| 211.990 | Choke Loading | |||||||

| 211.1010 | Clean Air Act | |||||||

| 211.1050 | Cleaning and Separating Operation | |||||||

| 211.1070 | Cleaning Materials | |||||||

| 211.1090 | Clear Coating | |||||||

| 211.1110 | Clear Topcoat | |||||||

| 211.1120 | Clinker | |||||||

| 211.1130 | Closed Purge System | |||||||

| 211.1150 | Closed Vent System | |||||||

| 211.1170 | Coal Refuse | |||||||

| 211.1190 | Coating | |||||||

| 211.1210 | Coating Applicator | |||||||

| 211.1230 | Coating Line | |||||||

| 211.1250 | Coating Plant | |||||||

| 211.1270 | Coil Coating | |||||||

| 211.1290 | Coil Coating Line | |||||||

| 211.1310 | Cold Cleaning | |||||||

| 211.1312 | Combined Cycle System |

| 211.1316 | Combustion Turbine |

| 211.1320 | Commence Commercial Operation |

| 211.1324 | Commence Operation |

| 211.1328 | Common Stack |

| 211.1330 | Complete Combustion | |||||||

| 211.1350 | Component | |||||||

| 211.1370 | Concrete Curing Compounds | |||||||

| 211.1390 | Concentrated Nitric Acid Manufacturing Process | |||||||

| 211.1410 | Condensate | |||||||

| 211.1430 | Condensible PM-10 | |||||||

| 211.1465 | Continuous Automatic Stoking | |||||||

| 211.1467 | Continuous Coater | |||||||

| 211.1470 | Continuous Process | |||||||

| 211.1490 | Control Device | |||||||

| 211.1510 | Control Device Efficiency | |||||||

| 211.1515 | Control Period | |||||||

| 211.1520 | Conventional Air Spray | |||||||

| 211.1530 | Conventional Soybean Crushing Source | |||||||

| 211.1550 | Conveyorized Degreasing | |||||||

| 211.1570 | Crude Oil | |||||||

| 211.1590 | Crude Oil Gathering | |||||||

| 211.1610 | Crushing | |||||||

| 211.1630 | Custody Transfer | |||||||

| 211.1650 | Cutback Asphalt | |||||||

| 211.1670 | Daily-Weighted Average VOM Content | |||||||

| 211.1690 | Day | |||||||

| 211.1710 | Degreaser | |||||||

| 211.1730 | Delivery Vessel | |||||||

| 211.1750 | Dip Coating | |||||||

| 211.1770 | Distillate Fuel Oil | |||||||

| 211.1780 | Distillation Unit | |||||||

| 211.1790 | Drum | |||||||

| 211.1810 | Dry Cleaning Operation or Dry Cleaning Facility | |||||||

| 211.1830 | Dump-Pit Area | |||||||

| 211.1850 | Effective Grate Area | |||||||

| 211.1870 | Effluent Water Separator | |||||||

| 211.1875 | Elastomeric Materials | |||||||

| 211.1880 | Electromagnetic Interference/Radio Frequency Interference (EMI/RFI) Shielding Coatings | |||||||

| 211.1885 | Electronic Component | |||||||

| 211.1890 | Electrostatic Bell or Disc Spray | |||||||

| 211.1900 | Electrostatic Prep Coat | |||||||

| 211.1910 | Electrostatic Spray | |||||||

| 211.1920 | Emergency or Standby Unit | |||||||

| 211.1930 | Emission Rate | |||||||

| 211.1950 | Emission Unit | |||||||

| 211.1970 | Enamel | |||||||

| 211.1990 | Enclose | |||||||

| 211.2010 | End Sealing Compound Coat | |||||||

| 211.2030 | Enhanced Under-the-Cup Fill | |||||||

| 211.2050 | Ethanol Blend Gasoline | |||||||

| 211.2070 | Excess Air |

| 211.2080 | Excess Emissions |

| 211.2090 | Excessive Release | |||||||

| 211.2110 | Existing Grain-Drying Operation (Repealed) | |||||||

| 211.2130 | Existing Grain-Handling Operation (Repealed) | |||||||

| 211.2150 | Exterior Base Coat | |||||||

| 211.2170 | Exterior End Coat | |||||||

| 211.2190 | External Floating Roof | |||||||

| 211.2210 | Extreme Performance Coating | |||||||

| 211.2230 | Fabric Coating | |||||||

| 211.2250 | Fabric Coating Line | |||||||

| 211.2270 | Federally Enforceable Limitations and Conditions | |||||||

| 211.2285 | Feed Mill | |||||||

| 211.2290 | Fermentation Time | |||||||

| 211.2300 | Fill | |||||||

| 211.2310 | Final Repair Coat | |||||||

| 211.2330 | Firebox | |||||||

| 211.2350 | Fixed-Roof Tank | |||||||

| 211.2360 | Flexible Coating | |||||||

| 211.2365 | Flexible Operation Unit | |||||||

| 211.2370 | Flexographic Printing | |||||||

| 211.2390 | Flexographic Printing Line | |||||||

| 211.2410 | Floating Roof | |||||||

| 211.2420 | Fossil Fuel | |

| 211.2425 | Fossil Fuel-Fired | |||||||

| 211.2430 | Fountain Solution | |||||||

| 211.2450 | Freeboard Height | |||||||

| 211.2470 | Fuel Combustion Emission Unit or Fuel Combustion Emission Source | |||||||

| 211.2490 | Fugitive Particulate Matter | |||||||

| 211.2510 | Full Operating Flowrate | |||||||

| 211.2530 | Gas Service | |||||||

| 211.2550 | Gas/Gas Method | |||||||

| 211.2570 | Gasoline | |||||||

| 211.2590 | Gasoline Dispensing Operation or Gasoline Dispensing Facility | |||||||

| 211.2610 | Gel Coat | |||||||

| 211.2620 | Generator | |||||||

| 211.2630 | Gloss Reducers | |||||||

| 211.2650 | Grain | |||||||

| 211.2670 | Grain-Drying Operation | |||||||

| 211.2690 | Grain-Handling and Conditioning Operation | |||||||

| 211.2710 | Grain-Handling Operation | |||||||

| 211.2730 | Green-Tire Spraying | |||||||

| 211.2750 | Green Tires | |||||||

| 211.2770 | Gross Heating Value | |||||||

| 211.2790 | Gross Vehicle Weight Rating | |||||||

| 211.2810 | Heated Airless Spray | |||||||

| 211.2815 | Heat Input |

| 211.2820 | Heat Input Rate |

| 211.2830 | Heatset | |||||||

| 211.2850 | Heatset Web Offset Lithographic Printing Line | |||||||

| 211.2870 | Heavy Liquid | |||||||

| 211.2890 | Heavy Metals | |||||||

| 211.2910 | Heavy Off-Highway Vehicle Products | |||||||

| 211.2930 | Heavy Off-Highway Vehicle Products Coating | |||||||

| 211.2950 | Heavy Off-Highway Vehicle Products Coating Line | |||||||

| 211.2970 | High Temperature Aluminum Coating | |||||||

| 211.2990 | High Volume Low Pressure (HVLP) Spray | |||||||

| 211.3010 | Hood | |||||||

| 211.3030 | Hot Well | |||||||

| 211.3050 | Housekeeping Practices | |||||||

| 211.3070 | Incinerator | |||||||

| 211.3090 | Indirect Heat Transfer | |||||||

| 211.3110 | Ink | |||||||

| 211.3130 | In-Process Tank | |||||||

| 211.3150 | In-Situ Sampling Systems | |||||||

| 211.3170 | Interior Body Spray Coat | |||||||

| 211.3190 | Internal-Floating Roof | |||||||

| 211.3210 | Internal Transferring Area | |||||||

| 211.3230 | Lacquers | |||||||

| 211.3250 | Large Appliance | |||||||

| 211.3270 | Large Appliance Coating | |||||||

| 211.3290 | Large Appliance Coating Line | |||||||

| 211.3310 | Light Liquid | |||||||

| 211.3330 | Light-Duty Truck | |||||||

| 211.3350 | Light Oil | |||||||

| 211.3370 | Liquid/Gas Method | |||||||

| 211.3390 | Liquid-Mounted Seal | |||||||

| 211.3410 | Liquid Service | |||||||

| 211.3430 | Liquids Dripping | |||||||

| 211.3450 | Lithographic Printing Line | |||||||

| 211.3470 | Load-Out Area | |||||||

| 211.3480 | Loading Event | |||||||

| 211.3483 | Long Dry Kiln | |||||||

| 211.3485 | Long Wet Kiln | |||||||

| 211.3487 | Low-NOx Burner | |||||||

| 211.3490 | Low Solvent Coating | |||||||

| 211.3500 | Lubricating Oil | |||||||

| 211.3510 | Magnet Wire | |||||||

| 211.3530 | Magnet Wire Coating | |||||||

| 211.3550 | Magnet Wire Coating Line | |||||||

| 211.3570 | Major Dump Pit | |||||||

| 211.3590 | Major Metropolitan Area (MMA) | |||||||

| 211.3610 | Major Population Area (MPA) | |||||||

| 211.3620 | Manually Operated Equipment | |||||||

| 211.3630 | Manufacturing Process | |||||||

| 211.3650 | Marine Terminal | |||||||

| 211.3660 | Marine Vessel | |||||||

| 211.3670 | Material Recovery Section | |||||||

| 211.3690 | Maximum Theoretical Emissions | |||||||

| 211.3695 | Maximum True Vapor Pressure | |||||||

| 211.3710 | Metal Furniture | |||||||

| 211.3730 | Metal Furniture Coating | |||||||

| 211.3750 | Metal Furniture Coating Line | |||||||

| 211.3770 | Metallic Shoe-Type Seal | |||||||

| 211.3780 | Mid-Kiln Firing | |||||||

| 211.3790 | Miscellaneous Fabricated Product Manufacturing Process | |||||||

| 211.3810 | Miscellaneous Formulation Manufacturing Process | |||||||

| 211.3830 | Miscellaneous Metal Parts and Products | |||||||

| 211.3850 | Miscellaneous Metal Parts and Products Coating | |||||||

| 211.3870 | Miscellaneous Metal Parts or Products Coating Line | |||||||

| 211.3890 | Miscellaneous Organic Chemical Manufacturing Process | |||||||

| 211.3910 | Mixing Operation | |||||||

| 211.3915 | Mobile Equipment | |||||||

| 211.3930 | Monitor | |||||||

| 211.3950 | Monomer | |||||||

| 211.3960 | Motor Vehicles | |||||||

| 211.3965 | Motor Vehicle Refinishing | |||||||

| 211.3970 | Multiple Package Coating | |||||||

| 211.3980 | Nameplate Capacity | |||||||

| 211.3990 | New Grain-Drying Operation (Repealed) | |||||||

| 211.4010 | New Grain-Handling Operation (Repealed) | |||||||

| 211.4030 | No Detectable Volatile Organic Material Emissions | |||||||

| 211.4050 | Non-Contact Process Water Cooling Tower | |||||||

| 211.4055 | Non-Flexible Coating | |||||||

| 211.4065 | Non-Heatset | |||||||

| 211.4067 | NOx Trading Program | |||||||

| 211.4070 | Offset | |||||||

| 211.4090 | One Hundred Percent Acid | |||||||

| 211.4110 | One-Turn Storage Space | |||||||

| 211.4130 | Opacity | |||||||

| 211.4150 | Opaque Stains | |||||||

| 211.4170 | Open Top Vapor Degreasing | |||||||

| 211.4190 | Open-Ended Valve | |||||||

| 211.4210 | Operator of a Gasoline Dispensing Operation or Operator of a Gasoline Dispensing Facility |

| 211.4230 | Organic Compound | |||||||

| 211.4250 | Organic Material and Organic Materials | |||||||

| 211.4260 | Organic Solvent | |||||||

| 211.4270 | Organic Vapor | |||||||

| 211.4290 | Oven | |||||||

| 211.4310 | Overall Control | |||||||

| 211.4330 | Overvarnish | |||||||

| 211.4350 | Owner of a Gasoline Dispensing Operation or Owner of a Gasoline Dispensing Facility |

| 211.4370 | Owner or Operator | |||||||

| 211.4390 | Packaging Rotogravure Printing | |||||||

| 211.4410 | Packaging Rotogravure Printing Line | |||||||

| 211.4430 | Pail | |||||||

| 211.4450 | Paint Manufacturing Source or Paint Manufacturing Plant | |||||||

| 211.4470 | Paper Coating | |||||||

| 211.4490 | Paper Coating Line | |||||||

| 211.4510 | Particulate Matter | |||||||

| 211.4530 | Parts Per Million (Volume) or PPM (Vol) | |||||||

| 211.4550 | Person | |||||||

| 211.4590 | Petroleum | |||||||

| 211.4610 | Petroleum Liquid | |||||||

| 211.4630 | Petroleum Refinery | |||||||

| 211.4650 | Pharmaceutical | |||||||

| 211.4670 | Pharmaceutical Coating Operation | |||||||

| 211.4690 | Photochemically Reactive Material | |||||||

| 211.4710 | Pigmented Coatings | |||||||

| 211.4730 | Plant | |||||||

| 211.4740 | Plastic Part | |||||||

| 211.4750 | Plasticizers | |||||||

| 211.4770 | PM-10 | |||||||

| 211.4790 | Pneumatic Rubber Tire Manufacture | |||||||

| 211.4810 | Polybasic Organic Acid Partial Oxidation Manufacturing Process | |||||||

| 211.4830 | Polyester Resin Material(s) | |||||||

| 211.4850 | Polyester Resin Products Manufacturing Process | |||||||

| 211.4870 | Polystyrene Plant | |||||||

| 211.4890 | Polystyrene Resin | |||||||

| 211.4910 | Portable Grain-Handling Equipment | |||||||

| 211.4930 | Portland Cement Manufacturing Process Emission Source | |||||||

| 211.4950 | Portland Cement Process or Portland Cement | |||||||

| Manufacturing Plant | ||||||||

| 211.4960 | Potential Electrical Output Capacity | |||||||

| 211.4970 | Potential to Emit | |||||||

| 211.4990 | Power Driven Fastener Coating | |||||||

| 211.5010 | Precoat | |||||||

| 211.5015 | Preheater Kiln | |||||||

| 211.5020 | Preheater/Precalciner Kiln | |||||||

| 211.5030 | Pressure Release | |||||||

| 211.5050 | Pressure Tank | |||||||

| 211.5060 | Pressure/Vacuum Relief Valve | |||||||

| 211.5061 | Pretreatment Wash Primer | |||||||

| 211.5065 | Primary Product | |||||||

| 211.5070 | Prime Coat | |||||||

| 211.5080 | Primer Sealer | |||||||

| 211.5090 | Primer Surfacer Coat | |||||||

| 211.5110 | Primer Surfacer Operation | |||||||

| 211.5130 | Primers | |||||||

| 211.5150 | Printing | |||||||

| 211.5170 | Printing Line | |||||||

| 211.5185 | Process Emission Source | |||||||

| 211.5190 | Process Emission Unit | |||||||

| 211.5210 | Process Unit | |||||||

| 211.5230 | Process Unit Shutdown | |||||||

| 211.5245 | Process Vent | |||||||

| 211.5250 | Process Weight Rate | |||||||

| 211.5270 | Production Equipment Exhaust System | |||||||

| 211.5310 | Publication Rotogravure Printing Line | |||||||

| 211.5330 | Purged Process Fluid | |||||||

| 211.5340 | Rated Heat Input Capacity | |||||||

| 211.5350 | Reactor | |||||||

| 211.5370 | Reasonably Available Control Technology (RACT) | |||||||

| 211.5390 | Reclamation System | |||||||

| 211.5410 | Refiner | |||||||

| 211.5430 | Refinery Fuel Gas | |||||||

| 211.5450 | Refinery Fuel Gas System | |||||||

| 211.5470 | Refinery Unit or Refinery Process Unit | |||||||

| 211.5480 | Reflective Argent Coating | |||||||

| 211.5490 | Refrigerated Condenser | |||||||

| 211.5500 | Regulated Air Pollutant | |||||||

| 211.5510 | Reid Vapor Pressure | |||||||

| 211.5530 | Repair | |||||||

| 211.5550 | Repair Coat | |||||||

| 211.5570 | Repaired | |||||||

| 211.5580 | Repowering | |||||||

| 211.5590 | Residual Fuel Oil | |||||||

| 211.5600 | Resist Coat | |||||||

| 211.5610 | Restricted Area | |||||||

| 211.5630 | Retail Outlet | |||||||

| 211.5650 | Ringelmann Chart | |||||||

| 211.5670 | Roadway | |||||||

| 211.5690 | Roll Coater | |||||||

| 211.5710 | Roll Coating | |||||||

| 211.5730 | Roll Printer | |||||||

| 211.5750 | Roll Printing | |||||||

| 211.5770 | Rotogravure Printing | |||||||

| 211.5790 | Rotogravure Printing Line | |||||||

| 211.5810 | Safety Relief Valve | |||||||

| 211.5830 | Sandblasting | |||||||

| 211.5850 | Sanding Sealers | |||||||

| 211.5870 | Screening | |||||||

| 211.5880 | Screen Printing on Paper | |||||||

| 211.5890 | Sealer | |||||||

| 211.5910 | Semi-Transparent Stains | |||||||

| 211.5930 | Sensor | |||||||

| 211.5950 | Set of Safety Relief Valves | |||||||

| 211.5970 | Sheet Basecoat | |||||||

| 211.5980 | Sheet-Fed | |||||||

| 211.5990 | Shotblasting | |||||||

| 211.6010 | Side-Seam Spray Coat | |||||||

| 211.6025 | Single Unit Operation | |||||||

| 211.6030 | Smoke | |||||||

| 211.6050 | Smokeless Flare | |||||||

| 211.6060 | Soft Coat | |||||||

| 211.6070 | Solvent | |||||||

| 211.6090 | Solvent Cleaning | |||||||

| 211.6110 | Solvent Recovery System | |||||||

| 211.6130 | Source | |||||||

| 211.6140 | Specialty Coatings | |||||||

| 211.6145 | Specialty Coatings for Motor Vehicles | |||||||

| 211.6150 | Specialty High Gloss Catalyzed Coating | |||||||

| 211.6170 | Specialty Leather | |||||||

| 211.6190 | Specialty Soybean Crushing Source | |||||||

| 211.6210 | Splash Loading | |||||||

| 211.6230 | Stack | |||||||

| 211.6250 | Stain Coating | |||||||

| 211.6270 | Standard Conditions | |||||||

| 211.6290 | Standard Cubic Foot (scf) | |||||||

| 211.6310 | Start-Up | |||||||

| 211.6330 | Stationary Emission Source | |||||||

| 211.6350 | Stationary Emission Unit | |||||||

| 211.6355 | Stationary Gas Turbine | |||||||

| 211.6360 | Stationary Reciprocating Internal Combustion Engine | |||||||

| 211.6370 | Stationary Source | |||||||

| 211.6390 | Stationary Storage Tank | |||||||

| 211.6400 | Stencil Coat | |||||||

| 211.6410 | Storage Tank or Storage Vessel | |||||||

| 211.6420 | Strippable Spray Booth Coating | |||||||

| 211.6430 | Styrene Devolatilizer Unit | |||||||

| 211.6450 | Styrene Recovery Unit | |||||||

| 211.6470 | Submerged Loading Pipe | |||||||

| 211.6490 | Substrate | |||||||

| 211.6510 | Sulfuric Acid Mist | |||||||

| 211.6530 | Surface Condenser | |||||||

| 211.6540 | Surface Preparation Materials | |||||||

| 211.6550 | Synthetic Organic Chemical or Polymer Manufacturing Plant | |||||||

| 211.6570 | Tablet Coating Operation | |||||||

| 211.6580 | Texture Coat | |||||||

| 211.6590 | Thirty-Day Rolling Average | |||||||

| 211.6610 | Three-Piece Can | |||||||

| 211.6620 | Three or Four Stage Coating System | |||||||

| 211.6630 | Through-the-Valve Fill | |||||||

| 211.6650 | Tooling Resin | |||||||

| 211.6670 | Topcoat | |||||||

| 211.6690 | Topcoat Operation | |||||||

| 211.6695 | Topcoat System | |||||||

| 211.6710 | Touch-Up | |||||||

| 211.6720 | Touch-Up Coating | |||||||

| 211.6730 | Transfer Efficiency | |||||||

| 211.6750 | Tread End Cementing | |||||||

| 211.6770 | True Vapor Pressure | |||||||

| 211.6790 | Turnaround | |||||||

| 211.6810 | Two-Piece Can | |||||||

| 211.6830 | Under-the-Cup Fill | |||||||

| 211.6850 | Undertread Cementing | |||||||

| 211.6860 | Uniform Finish Blender | |||||||

| 211.6870 | Unregulated Safety Relief Valve | |||||||

| 211.6880 | Vacuum Metallizing | |||||||

| 211.6890 | Vacuum Producing System | |||||||

| 211.6910 | Vacuum Service | |||||||

| 211.6930 | Valves Not Externally Regulated | |||||||

| 211.6950 | Vapor Balance System | |||||||

| 211.6970 | Vapor Collection System | |||||||

| 211.6990 | Vapor Control System | |||||||

| 211.7010 | Vapor-Mounted Primary Seal | |||||||

| 211.7030 | Vapor Recovery System | |||||||

| 211.7050 | Vapor-Suppressed Polyester Resin | |||||||

| 211.7070 | Vinyl Coating | |||||||

| 211.7090 | Vinyl Coating Line | |||||||

| 211.7110 | Volatile Organic Liquid (VOL) | |||||||

| 211.7130 | Volatile Organic Material Content (VOMC) | |||||||

| 211.7150 | Volatile Organic Material (VOM) or Volatile Organic Compound (VOC) | |||||||

| 211.7170 | Volatile Petroleum Liquid | |||||||

| 211.7190 | Wash Coat | |||||||

| 211.7200 | Washoff Operations | |||||||

| 211.7210 | Wastewater (Oil/Water) Separator | |||||||

| 211.7230 | Weak Nitric Acid Manufacturing Process | |||||||

| 211.7250 | Web | |||||||

| 211.7270 | Wholesale Purchase - Consumer | |||||||

| 211.7290 | Wood Furniture | |||||||

| 211.7310 | Wood Furniture Coating | |||||||

| 211.7330 | Wood Furniture Coating Line | |||||||

| 211.7350 | Woodworking | |||||||

211.7400 Yeast Percentage

Appendix A Rule into Section Table

Appendix B Section into Rule Table

AUTHORITY: Implementing Sections 9, 9.1, 9.9 and 10 and authorized by Sections 27, 28 and 28.5 of the Environmental Protection Act [415 ILCS 5/9, 9.1, 9.9, 10, 27, 28 and 28.5].

SOURCE: Adopted as Chapter 2: Air Pollution, Rule 201: Definitions, R71-23, 4 PCB 191, filed and effective April 14, 1972; amended in R74-2 and R75-5, 32 PCB 295, at 3 Ill. Reg. 5, p. 777, effective February 3, 1979; amended in R78-3 and 4, 35 PCB 75 and 243, at 3 Ill. Reg. 30, p. 124, effective July 28, 1979; amended in R80-5, at 7 Ill. Reg. 1244, effective January 21, 1983; codified at 7 Ill. Reg. 13590; amended in R82-1 (Docket A) at 10 Ill. Reg. 12624, effective July 7, 1986; amended in R85-21(A) at 11 Ill. Reg. 11747, effective June 29, 1987; amended in R86-34 at 11 Ill. Reg. 12267, effective July 10, 1987; amended in R86-39 at 11 Ill. Reg. 20804, effective December 14, 1987; amended in R82-14 and R86-37 at 12 Ill. Reg. 787, effective December 24, 1987; amended in R86-18 at 12 Ill. Reg. 7284, effective April 8, 1988; amended in R86-10 at 12 Ill. Reg. 7621, effective April 11, 1988; amended in R88-23 at 13 Ill. Reg. 10862, effective June 27, 1989; amended in R89-8 at 13 Ill. Reg. 17457, effective January 1, 1990; amended in R89-16(A) at 14 Ill. Reg. 9141, effective May 23, 1990; amended in R88-30(B) at 15 Ill. Reg. 5223, effective March 28, 1991; amended in R88-14 at 15 Ill. Reg. 7901, effective May 14, 1991; amended in R91-10 at 15 Ill. Reg. 15564, effective October 11, 1991; amended in R91-6 at 15 Ill. Reg. 15673, effective October 14, 1991; amended in R91-22 at 16 Ill. Reg. 7656, effective May 1, 1992; amended in R91-24 at 16 Ill. Reg. 13526, effective August 24, 1992; amended in R93-9 at 17 Ill. Reg. 16504, effective September 27, 1993; amended in R93-11 at 17 Ill. Reg. 21471, effective December 7, 1993; amended in R93-14 at 18 Ill. Reg. 1253, effective January 18, 1994; amended in R94-12 at 18 Ill. Reg. 14962, effective September 21, 1994; amended in R94-14 at 18 Ill. Reg. 15744, effective October 17, 1994; amended in R94-15 at 18 Ill. Reg. 16379, effective October 25, 1994; amended in R94-16 at 18 Ill. Reg. 16929, effective November 15, 1994; amended in R94-21, R94-31 and R94-32 at 19 Ill. Reg. 6823, effective May 9, 1995; amended in R94-33 at 19 Ill. Reg. 7344, effective May 22, 1995; amended in R95-2 at 19 Ill. Reg. 11066, effective July 12, 1995; amended in R95-16 at 19 Ill. Reg. 15176, effective October 19, 1995; amended in R96-5 at 20 Ill. Reg. 7590, effective May 22, 1996; amended in R96-16 at 21 Ill. Reg. 2641, effective February 7, 1997; amended in R97-17 at 21 Ill. Reg. 6489, effective May 16, 1997; amended in R97-24 at 21 Ill. Reg. 7695, effective June 9, 1997; amended in R96-17 at 21 Ill. Reg. 7856, effective June 17, 1997; amended in R97-31 at 22 Ill. Reg. 3497, effective February 2, 1998; amended in R98-17 at 22 Ill. Reg.11405, effective June 22, 1998; amended in R01-9 at 25 Ill. Reg. 128, effective December 26, 2000; amended in R01-11 at 25 Ill. Reg. 4597, effective March 15, 2001; amended in R01-17 at 25 Ill. Reg. 5900, effective April 17, 2001; amended in R04-20 at _ Ill. Reg. _, effective _.

BOARD NOTE: This Part implements the Illinois Environmental Protection Act as of July 1, 1994.

Section 211.953 Carbon Adsorber

“Carbon Adsorber” means a control device designed to remove and, if desired, recover volatile organic material (VOM) from process emissions where removal of VOM is accomplished through the adherence of the VOM onto the surface of highly porous adsorbent particles, such as activated carbon. The term “carbon adsorber” describes any adsorber technology used as a control device even though media other than carbon may be used as the adsorbent, such as oxides of silicon and aluminum.

(Source: Added at _ Ill. Reg. _, effective _)

| Section 211.5880 | |

| Screen Printing on Paper | |

“Screen Printing on Paper” means a process that would otherwise be paper coating as defined in Section 211.4470 of this Part, except ink is passed through a taut screen or fabric to which a refined form of stencil has been applied. The stencil openings determine the form and dimensions of the imprint.

| (Source: Added at _ Ill. Reg. _, effective _) | |

TITLE 35: ENVIRONMENTAL PROTECTION

SUBTITLE B: AIR POLLUTION

CHAPTER I: POLLUTION CONTROL BOARD

SUBCHAPTER c: EMISSION STANDARDS AND LIMITATIONS FOR STATIONARY SOURCES

PART 214

SULFUR LIMITATIONS

SUBPART A: GENERAL PROVISIONS

Section

| 214.100 | Scope and Organization |

| 214.101 | Measurement Methods |

| 214.102 | Abbreviations and Units |

| 214.103 | Definitions |

| 214.104 | Incorporations by Reference |

SUBPART B: NEW FUEL COMBUSTION EMISSION SOURCES

Section

| 214.120 | Scope |

| 214.121 | Large Sources | |

| 214.122 | Small Sources | |

SUBPART C: EXISTING SOLID FUEL COMBUSTION EMISSION SOURCES

Section

214.140 Scope

| 214.141 | Sources Located in Metropolitan Areas |

| 214.142 | Small Sources Located Outside Metropolitan Areas |

| 214.143 | Large Sources Located Outside Metropolitan Areas |

SUBPART D: EXISTING LIQUID OR MIXED FUEL COMBUSTION EMISSION SOURCES

Section

| 214.161 | Liquid Fuel Burned Exclusively |

| 214.162 | Combination of Fuels |

SUBPART E: AGGREGATION OF SOURCES OUTSIDE METROPOLITAN AREAS

Section

| 214.181 | Dispersion Enhancement Techniques |

| 214.182 | Prohibition |

| 214.183 | General Formula |

| 214.184 | Special Formula |

| 214.185 | Alternative Emission Rate |

| 214.186 | New Operating Permits |

SUBPART F: ALTERNATIVE STANDARDS FOR SOURCES INSIDE METROPOLITAN AREAS

Section

| 214.201 | Alternative Standards for Sources in Metropolitan Areas |

| 214.202 | Dispersion Enhancement Techniques |

SUBPART K: PROCESS EMISSION SOURCES

Section

| 214.300 | Scope |

| 214.301 | General Limitation |

| 214.302 | Exception for Air Pollution Control Equipment |

| 214.303 | Use of Sulfuric Acid |

| 214.304 | Fuel Burning Process Emission Source |

SUBPART O: PETROLEUM REFINING, PETROCHEMICAL AND CHEMICAL MANUFACTURING

Section

| 214.380 | Scope |

| 214.381 | Sulfuric Acid Manufacturing |

| 214.382 | Petroleum and Petrochemical Processes |

| 214.383 | Chemical Manufacturing |

| 214.384 | Sulfate and Sulfite Manufacturing |

SUBPART P: STONE, CLAY, GLASS AND CONCRETE PRODUCTS

Section

| 214.400 | Scope |

| 214.401 | Glass Melting and Heat Treating |

| 214.402 | Lime Kilns |

SUBPART Q: PRIMARY AND SECONDARY METAL MANUFACTURING

Section

| 214.420 | Scope |

| 214.421 | Combination of Fuels at Steel Mills in Metropolitan Areas |

| 214.422 | Secondary Lead Smelting in Metropolitan Areas |

| 214.423 | Slab Reheat Furnaces in St. Louis Area |

SUBPART V: ELECTRIC POWER PLANTS

Section

| 214.521 | Winnetka Power Plant |

SUBPART X: UTILITIES

Section

| 214.560 | Scope |

| 214.561 | E. D. Edwards Electric Generating Station |

| 214.562 | Coffeen Generating Station |

| Appendix A | Rule into Section Table |

| Appendix B | |

| Section into Rule Table | |

| Appendix C | |

| Method used to Determine Average Actual Stack Height and Effective Height of Effluent Release | |

| Appendix D | |

| Past Compliance Dates | |

AUTHORITY: Implementing Section 10 and authorized by Section 27 of the Environmental Protection Act [415 ILCS 5/10 and 27].

SOURCE: Adopted as Chapter 2: Air Pollution, Rule 204: Sulfur Emission Standards and Limitations, R71-23, 4 PCB 191, filed and effective April 14, 1972; amended in R74-2 and R75-5, 32 PCB 295, at 3 Ill. Reg. 5, p. 777, effective February 3, 1979; amended in R74-2, R75-5, 38 PCB 129, at 4 Ill. Reg. 28, p. 417, effective June 26, 1980; amended in R78-17, 40 PCB 291, at 5 Ill. Reg. 1892, effective February 17, 1981; amended in R77-15, 44 PCB 267, at 6 Ill. Reg. 2146, effective January 28, 1982; amended and renumbered in R80-22(A), at 7 Ill. Reg. 42204219, effective March 28, 1983; codified 7 Ill. Reg. 1357913597; amended in R80-22(B), at 8 Ill. Reg. 6172, effective April 24, 1984; amended in R84-28, at 10 Ill. Reg. 9806, effective May 20, 1986; amended in R86-31, at 12 Ill. Reg. 17387, effective October 14, 1988; amended in R86-30, at 12 Ill. Reg. 20778, effective December 5, 1988; amended in R87-31 at 15 Ill. Reg. 1017, effective January 15, 1991; amended in R02-21 at 27 Ill. Reg. 12101, effective July 11, 2003; amended in R04-12 at _ Ill. Reg. _, effective _.

SUBPART D: EXISTING LIQUID OR MIXED FUEL COMBUSTION EMISSION SOURCES

| Section 214.162 | Combination of Fuels |

| a) | No person shall cause or allow the emission of sulfur dioxide into the atmosphere in any one hour period from any fuel combustion emission source burning simultaneously any combination of solid, liquid and gaseous fuels to exceed the allowable emission rate determined by the following equation: |

E = AX + BY + CZ

| E = SSHS + SdHd + SRHR | |

| b) | Symbols in the equation mean the following: |

E = allowable sulfur dioxide emission rate;

| solid fuel sulfur dioxide emission standard which is applicable; | |

| distillate oil sulfur dioxide emission standard determined from the table in subsection (d); | |

| residual fuel oil sulfur dioxide emission standard which is applicable; | |

XHS = actual heat input from solid fuel;

YHd = actual heat input from distillate fuel oil;

ZHR = actual heat input from residual fuel oil;

| c) | That portion of the actual heat input that is derived: |

| 1) | From the burning of gaseous fuels produced by the gasification of solid fuels shall be included in |

| 2) | From the burning of gaseous fuels produced by the gasification of distillate fuel oil shall be included in |

| 3) | From the burning of gaseous fuels produced by the gasification of residual fuel oil shall be included in |

| 4) | From the burning of gaseous fuels produced by the gasification of any other liquid fuel shall be included in |

| 5) | From the burning of by-product gases such as those produced from a blast furnace or a catalyst regeneration unit in a petroleum refinery shall be included in |

| d) | Metric or English units may be used in the equation of subsection (a) as follows: |

Parameter |

Metric |

English |

E |

kg/hr |

lbs/hr |

|

kg/MW-hr |

lbs/mmbtu |

|

0.46 kg/MW-hr |

0.3 lbs/mmbtu |

|

MW |

mmbtu/hr |

(Source: Amended at _ Ill. Reg. _, effective _)

SUBPART E: AGGREGATION OF SOURCES OUTSIDE METROPOLITAN AREAS

| Section 214.183 | General Formula |

| a) | The general formula is: |

E = A XB YC

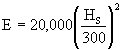

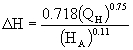

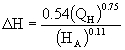

![]() (in English units)

(in English units)

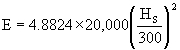

![]() (in Metric units)

(in Metric units)

| b) | Symbols used in the general formula mean the following: |

| E = | Total allowable emission of sulfur dioxide (in lbs/hr or kg/hr) into the atmosphere in any one-hour period from all fuel combustion emission sources owned or operated by such person and located within a 1.6 km (1 mile) radius from the center point of any such emission source. |

| Average actual stack height as determined by method outlined in Appendix C. | |

| Effective height of effluent release as determined by method outlined in Appendix C. | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(Source: Amended at _ Ill. Reg. _, effective _)

| Section 214.184 | Special Formula |

| a) | If the maximum total emissions of sulfur dioxide into the atmosphere in any one hour period from all fuel combustion emission sources owned or operated by any person and located within a 1 mile (1.6 km) radius from the center point of any such fuel combustion emission sources exceed, during normal cyclical variations in firing rate and fuel, the emissions allowed under Section 214.183 but, as of April 1, 1978, were in compliance with either the formula detailed below or a Pollution Control Board (Board) order, then the owner or operator of the emission sources shall not cause or allow such emissions to exceed the emissions allowed under Section 214.183 or the formula detailed below, whichever the owner or operator of the emission sources determines shall apply. |

| b) | |

E = 0.22222

(in English units)

(in English units)

(in Metric units)

(in Metric units)

H = P1 H1 + P2 H2 + ... Pn Hn

(Note: P1 + P2 ... Pn = 1)

| c) | As used in these equations, symbols mean the following: |

| E = | total emission of sulfur dioxide |

|

|

|

|

|

|

| Pi= | (for i=1, 2, . . ., n) percentage of total emissions E emitted from source i expressed as decimal equivalents (e.g., 21% = 0.21), and |

| Hi= | (for i=1, 2, . . ., n) physical height (in feet or meters) above grade of stack i. |

(Source: Amended at _ Ill. Reg. _, effective _)

SUBPART Q: PRIMARY AND SECONDARY METAL MANUFACTURING

| Section 214.421 | Combination of Fuels at Steel Mills in Metropolitan Areas |

| a) | Section 214.162 notwithstanding, no person shall cause or allow the emission of sulfur dioxide into the atmosphere in any one hour period from any existing fuel combustion emission source at a steel mill located in the Chicago or St. Louis (Illinois) major metropolitan area burning any solid, liquid or gaseous fuel, or any combination thereof, to exceed the allowable emission rate determined by the following equation: |

E = AW + BX + CY + DZ

E = SSHS + SdHd + SRHR + SGHG

| b) | Symbols in the equation mean the following: |

E = allowable sulfur dioxide emission rate;

| solid fuel sulfur dioxide emission standard which is applicable; | |

| distillate oil sulfur dioxide emission standard determined from the table in subsection (d); | |

| residual oil sulfur dioxide emission standard which is applicable; | |

| maximum by-product gas sulfur dioxide emissions which would result if the applicable by-product gas which was burned had been burned alone at any time during the 12 months preceding the latest operation, on or before March 28, 1983, of an emission source using any by-product gas. |

WHS = actual heat input from solid fuel;

XHd = actual heat input from distillate fuel oil;

YHR = actual heat input from residual fuel oil;

| actual heat input from by-product gases, such as those produced from a blast furnace. | |

| c) | That portion of the actual heat input that is derived: |

| 1) | From the burning of gaseous fuels produced by the gasification of solid fuels shall be included in |

| 2) | From the burning of gaseous fuels produced by the gasification of distillate fuel oil shall be included in |

| 3) | From the burning of gaseous fuels produced by the gasification of residual fuel oil shall be included in |

| 4) | From the burning of gaseous fuels produced by the gasification of any other liquid fuel shall be included in |

| d) | Metric or English units may be used in the equation of subsection (a) as follows: |

Parameter |

Metric |

English |

E |

kg/hr |

lbs/hr |

|

kg/MW-hr |

lbs/mmbtu |

|

0.46 kg/MW-hr |

0.3 lbs/mmbtu |

|

MW |

mmbtu/hr |

(Source: Amended at _ Ill. Reg. _, effective _)

APPENDIX C

Method used to Determine Average Actual Stack Height and Effective Height of Effluent Release

QH (Btu/sec) = Heat emission rate (in btu/sec or Kcal/sec) as determined by method outlined below.

| ∆H | Plume rise (in feet or meters). |

| H = | Physical height (in feet or meters) |

| T | Exit temperature of stack gases (in degrees Rankine or degrees Kelvin) from each source during operating conditions which would cause maximum emissions. |

| V | Exit velocity of stack gases (in feet/sec or meters/sec) from each source under operating conditions which would cause maximum emissions. |

D (feet) = Diameter of stack (in feet or meters).

| P = | Percentage of total emissions expressed as decimal equivalents emitted from each source. (Example: 21% = 0.21.) NOTE: The sum of P1 + P2 ... + Pn = 1. The emission values to be used are those which occur during operating conditions which would cause maximum emissions. |

| Average actual stack height (in feet or meters). | |

| Effective height of effluent release (in feet or meters). | |

STEP 1: Determine weighted average stack parameters utilizing the following formulae:

D = P1 D1 + P2 D2 + ... + Pn Dn

V = P1 V1 + P2 V2 + ... + Pn Vn

T = P1 T1 + P2 T2 + ... + Pn Tn

HAX = P1 H1 + P2 H2 + ... + Pn Hn

NOTE: P1, D1, V1, T1, P1, D1, V1, T1, and H1 H1 are the percentage of total emissions, stack diameter, exit velocity of gases, exit temperature of stack gases, and physical stack height, respectively, for the first source; P2, D2, V2, T2, P2, D2, V2, T2, and H2 H2 are the respective values for the second source; similarly, Pn, Dn, Vn, Tn, Pn, Dn, Vn, Tn, and Hn Hn are the respective values for the nth source, where n is the number of the last source.

| STEP 2: | Calculate heat emission rate utilizing the following formula and the weighted average stack parameters obtained in Step 1: |

Q + 7.54D2V (T - 515)

T

| (in English units) | |

| (in Metric units) | |

| STEP 3: | Calculate plume rise utilizing the appropriate formula given below and the total heat emission rate obtained in Step 2: |

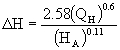

H = 2.58 (Q)0.6 for Q 6000 btu/sec.

(X)0.11

(in English Units for QH≥ 6000 btu/sec)

(in English Units for QH≥ 6000 btu/sec)

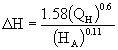

(in Metric Units for QH≥ 1500 kcal/sec)

(in Metric Units for QH≥ 1500 kcal/sec)

H = 0.718 (Q)0.75 for Q 6000 btu/sec.

(X)0.11

(in English Units for QH< 6000 btu/sec)

(in English Units for QH< 6000 btu/sec)

(in Metric Units for QH< 1500 kcal/sec)

(in Metric Units for QH< 1500 kcal/sec)

| STEP 4: | Calculate the weighted average facility effective height of effluent release utilizing the plume rise obtained in Step 3, the average stack height obtained in Step 1 and the formula given below: |

Y = X + H

| HE = HA + ∆H | |

| STEP 5: | Calculate the total facility hourly emission limitation utilizing the weighted actual stack height obtained in Step 1, the effective stack height given in Step 4, and the following formula: |

E = (X)0.11 (Y)2

128

![]() (in English units)

(in English units)

![]() (in Metric units)

(in Metric units)

(Source: Amended at _ Ill. Reg. _, effective _)

TITLE 35: ENVIRONMENTAL PROTECTION

SUBTITLE B: AIR POLLUTION

CHAPTER I: POLLUTION CONTROL BOARD

SUBCHAPTER c: EMISSIONS STANDARDS AND

LIMITATIONS FOR STATIONARY SOURCES

PART 218

ORGANIC MATERIAL EMISSION STANDARDS AND

LIMITATIONS FOR THE CHICAGO AREA

SUBPART A: GENERAL PROVISIONS

Section

| 218.100 | Introduction |

| 218.101 | Savings Clause |

| 218.102 | Abbreviations and Conversion Factors |

| 218.103 | Applicability |

| 218.104 | Definitions |

| 218.105 | Test Methods and Procedures |

| 218.106 | Compliance Dates |

| 218.107 | Operation of Afterburners |

| 218.108 | Exemptions, Variations, and Alternative Means of Control or Compliance Determinations |

| 218.109 | Vapor Pressure of Volatile Organic Liquids |

| 218.110 | Vapor Pressure of Organic Material or Solvent |

| 218.111 | Vapor Pressure of Volatile Organic Material |

| 218.112 | Incorporations by Reference |

| 218.113 | Monitoring for Negligibly-Reactive Compounds |

| 218.114 | Compliance with Permit Conditions |

SUBPART B: ORGANIC EMISSIONS FROM STORAGE AND LOADING OPERATIONS

Section

| 218.119 | Applicability for VOL |

| 218.120 | Control Requirements for Storage Containers of VOL |

| 218.121 | Storage Containers of VPL |

| 218.122 | Loading Operations |

| 218.123 | Petroleum Liquid Storage Tanks |

| 218.124 | External Floating Roofs |

| 218.125 | Compliance Dates |

| 218.126 | Compliance Plan (Repealed) |

| 218.127 | Testing VOL Operations |

| 218.128 | Monitoring VOL Operations |

| 218.129 | Recordkeeping and Reporting for VOL Operations |

SUBPART C: ORGANIC EMISSIONS FROM MISCELLANEOUS EQUIPMENT

Section