CHDB01 1285013.1 11-Jul-05 15:28

BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

IN THE MATTER OF: )

)

PROPOSED AMENDMENTS TO )

EXEMPTIONS FROM STATE )

PERMITTING REQUIREMENTS )

FOR PLASTIC INJECTION MOLDING ) R 05 -20

OPERATIONS )

(35 Ill. Admin. Code 201.146) )

PRE-FILED TESTIMONY

ON BEHALF OF THE

CHEMICAL INDUSTRY COUNCIL OF ILLINOIS

In response to questions posed at the first hearing in this matter on July 1, 2005,

CICI is herewith providing certain requested information. CICI witnesses, Lynne Harris,

Lisa Frede, and Patricia Sharkey, will be present to answer questions regarding these

responses at the July 15, 2005 hearing in Springfield.

1. Size of Facilities Exempted Under This Proposal

At the July 1, 2005 hearing, the Board asked how many PIM machines may be

located at a given PIM facility. CICI has not found any studies or data directly addressing

this question. However, CICI can state that its member facilities have between 4 and 70

machines.

Because the size of PIM machines varies, resin throughput is a better indicator of

the volume of emissions associated with a given facility. CICI member facilities have

annual PIM resin throughput ranging from 100 tons/yr to 3,250 tons/yr. Average facility

annual PIM resin throughput is approximately 500 tons/yr.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE JULY 11, 2005

2

CHDB01 1285013.1 11-Jul-05 15:28

2.

Estimated Volume of PIM Emissions Statewide in Illinois.

The Board asked what volume of emissions would be exempt from permitting

under this exemption. A broad estimate of the total volume of emissions generated by

PIM processes statewide can be derived by first multiplying the number of facilities in

Illinois by the average volume of resin processed per facility, and then multiplying that

number by an appropriate emission factor. As indicated in Mr. Harris’ testimony, a worst

case VOM emission factor is 0.4 lb/ton of resin processed. If we add to that a worst case

emission factor of 0.4 lb/ton of resin processed for the use of release or cleaning agent, as

discussed in Section 5 below, we arrive at a conservative overall VOM emission factor of

0.8 lb/ton of resin used.

Using the above information and the previous testimony that approximately 500

PIM facilities are located in Illinois, the formula for calculating statewide VOM

emissions associated with PIM is as follows:

500 facilities X 500 tons resin /yr = 250,000 tons resin /yr

250,000 tons/yr X 0.8 lb VOM /ton resin = 100 tons VOM /yr

CICI believes

100 tons per year

is a reasonable worst case estimate of the total

volume of VOM emissions generated statewide by PIM facilities in Illinois. We note that

this equates to

0.2 tons of VOM emissions per facility per year

. We further note that not

all of the approximately 500 PIM facilities in Illinois will be exempted from state

permitting under the proposal in this rulemaking. In response to the Board’s question

regarding the number of PIM facilities that have no other processes, such as coating, SPI

did a rough survey of its members and determined that approximately 80% of its

members in the PIM industry do not perform other processes at the their facilities. This

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE JULY 11, 2005

3

CHDB01 1285013.1 11-Jul-05 15:28

indicates that around 20% of the approximately 500 Illinois PIM facilities will not be

covered by this exemption. Thus total statewide emissions of VOM covered by this

exemption are actually likely to be on the order of 80 tons per year.

To answer any concern the Board may have that there may be larger volumes of

emissions involved, CICI has proposed in its Second Errata Sheet to limit the proposed

exemption to PIM facilities with no more than 5,000 tons/yr of resin processed. If every

facility in Illinois processed 5,000 tons of resin per year (an extraordinary assumption),

the total VOM emissions subject to this exemption would be 1,000 tons/yr. That equates

to approximately 2 tons of VOM per year per facility.

3. Location of PIM facilities in Illinois ( Attainment Areas/ Non-

Attainment Areas)

The Board asked about the location of PIM facilities in the State and whether they

were primarily located in Attainment or Non-Attainment Areas. To answer this question,

CICI reviewed the locations of the Illinois facilities listed in the Plastic News “2005

Survey of North American Injection Molders” and the locations of CICI member

facilities, and determined that 14% of those PIM facilities are located in Attainment

Areas and the remaining 86 % are located in Non-Attainment Areas. Of those located in

Non-Attainment Areas, all are located in areas which have been designated as Moderate

NAA under the new 8-hour ozone standard.

4. Estimated Emission from Resin Handling Operations: Loading,

Unloading, Conveying, Storage, Mixing, Grinding, Drying

As indicated at the July 1st hearing, CICI has attempted to find studies and other

sources of information on the volume and type of emissions generated by the various

activities associated with resin handling operations. We have found no studies directly

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE JULY 11, 2005

4

CHDB01 1285013.1 11-Jul-05 15:28

addressing or quantifying emissions from these activities. This is actually not surprising.

As indicated in Mr. Harris’ June 16, 2005 Pre-Filed Testimony, emissions from the

injection molding process as a whole had not been quantified prior to 1996. This lack of

quantitative information on emissions may also be explained by the nature of the

materials involved and the process. The resin and scrap are hardened plastic material at

ambient and low temperatures. Furthermore, these ancillary activities operate under

negative pressure, thus emissions from the movement of resin, the drying of the resin and

the grinding of scrap plastic are largely, if not entirely, drawn back into the process.

The following information on how and where emissions are formed in this

process may assist the Board in understanding that emissions from these ancillary

activities are minimal.

a. VOM and HAP Emissions

VOM and HAP emissions from plastic resin are directly related to temperature.

As found in the SPI studies accompanying Mr. Harris’ Pre-Filed Testimony (Group

Exhibit 3), “emission rates are directly correlatable with the melt temperature of the resin

involved.” (Group Exhibit 3, Harris Exhibit 3, p. 56.) Thermoplastic resins have melt

temperatures in the range of 300 F – 600 F. (Group Exhibit 3, Harris Exhibits 3 – 6.) The

SPI studies demonstrate that even at the melt temperatures reached in the extruder screw

VOM and HAP emissions are low. Thus, the brief drying of the resin at far lower

temperatures to remove moisture from the pellets can be presumed to generate only a

fraction of those emissions. The ancillary resin loading, conveyance and mixing at

ambient temperatures can be presumed to be even lower.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE JULY 11, 2005

5

CHDB01 1285013.1 11-Jul-05 15:28

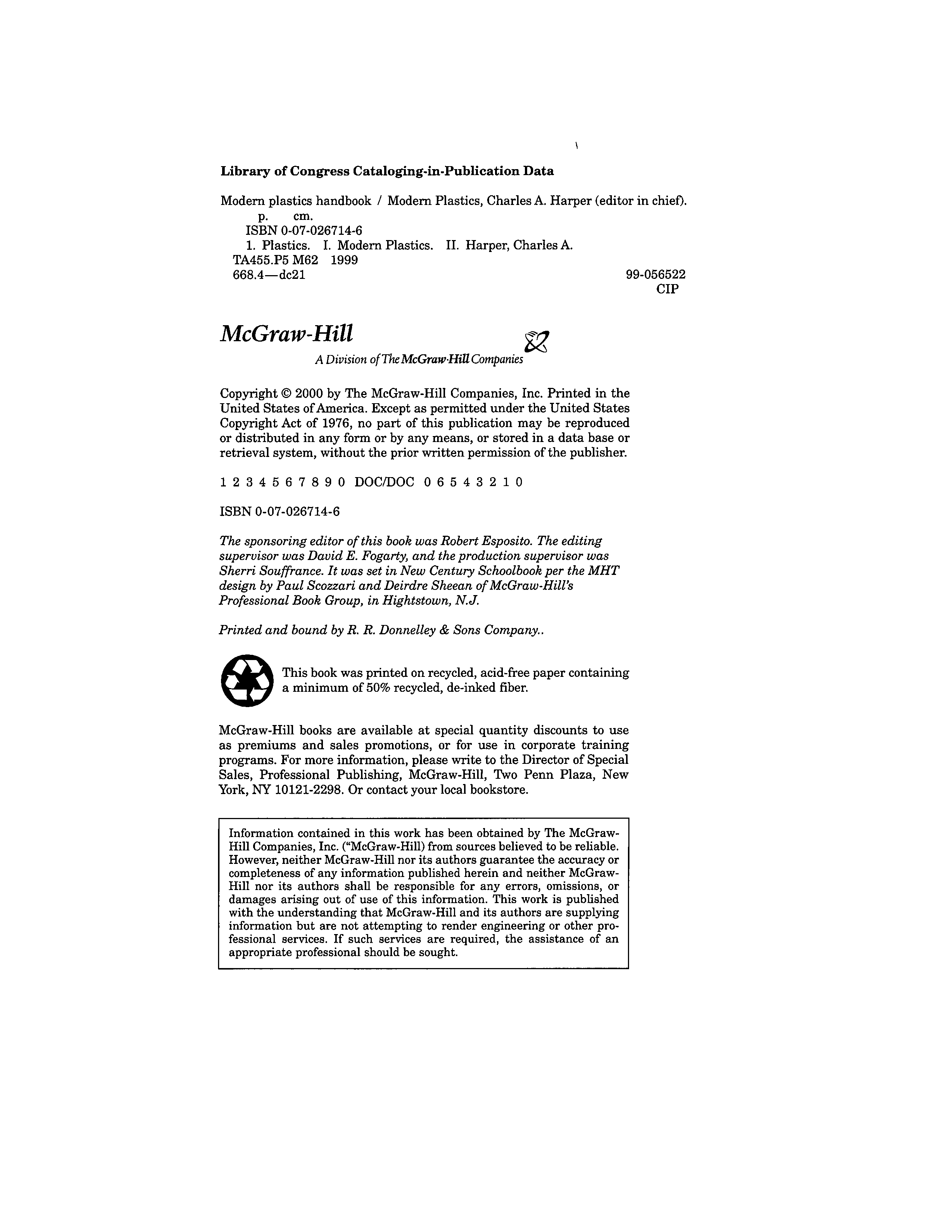

To a varying degree, all plastic resins take on moisture when exposed to relative

humidity. Even a minimal amount of moisture in many plastics can negatively affect

molding characteristics. Dryers operated at low temperatures are often utilized to remove

such moisture from plastic resin prior to the plastic injection molding process. The dryers

blow heated ambient air over the plastic resins. The temperatures used for drying plastic

resins are generally less than one half of the melting temperature of the plastic resin

involved. (See attached Table 5.1 from the

Modern Plastics Handbook.

) Although CICI

has not been able to find any data on emissions from dryers, emissions of VOM from

plastic resin at the relatively low temperatures used in the drying process can be

presumed to result in a small percentage of VOM or particulate emissions generated by

the overall process.

The conclusion that VOM emissions from resin pellets handled at ambient

temperatures are minimal is confirmed by the polyethylene study (Group Exhibit 3,

Harris Exhibit 5) which measured emissions of VOC from the hopper area and found that

emissions from this area accounted for less than 2% of the total VOCs measured. (Id.,

p. 577.)

b. Particulate Matter Emissions

There is an assumption that the movement of resin, even at ambient temperatures,

generates some level of particulate matter (“PM”). However, CICI has been unable to

find any EPA or industry studies of this subject.

To provide the Board with some perspective on the level of PM present at a PIM

facility, CICI Regulatory Affairs Director Lisa Frede visited one of its member facilities

on July 7, 2005. Ms. Frede will provide testimony at the July 15, 2005 hearing that she

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE JULY 11, 2005

6

CHDB01 1285013.1 11-Jul-05 15:28

found it to be exceedingly clean, with no dust or film on the floor or the equipment,

including the grinder or granulator, which is presumed to be the piece of equipment most

likely to produce PM. She will also testify that none of the employees in this workplace

wear respiratory protection, indicating the indoor particle levels meet OSHA standards

without such protection. One of the primary reasons that PM is so low in these facilities

is that product specifications require that foreign material not enter the process. Another

reason is that injection molding and the associated resin and scrap handling are almost

entirely enclosed operations which take place under negative pressure.

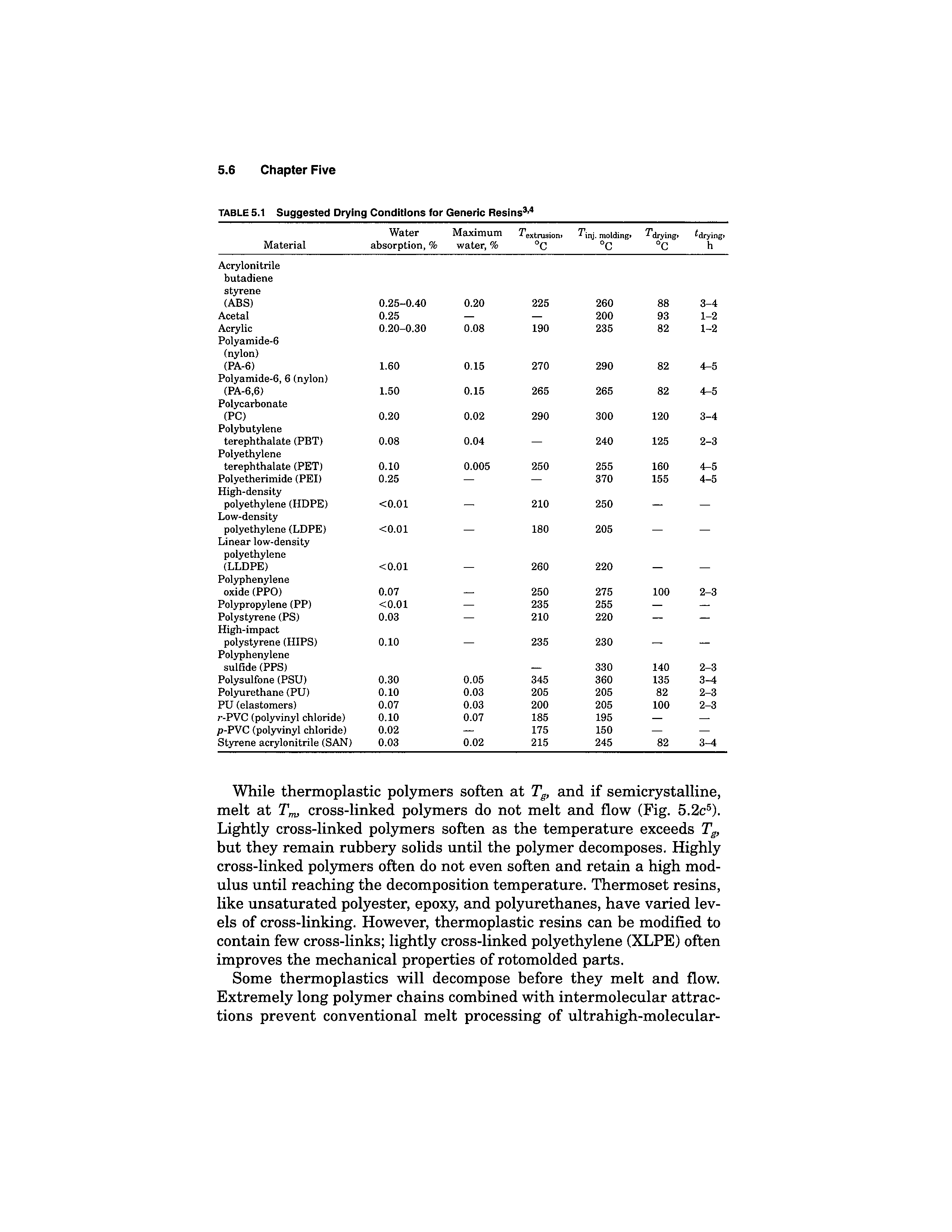

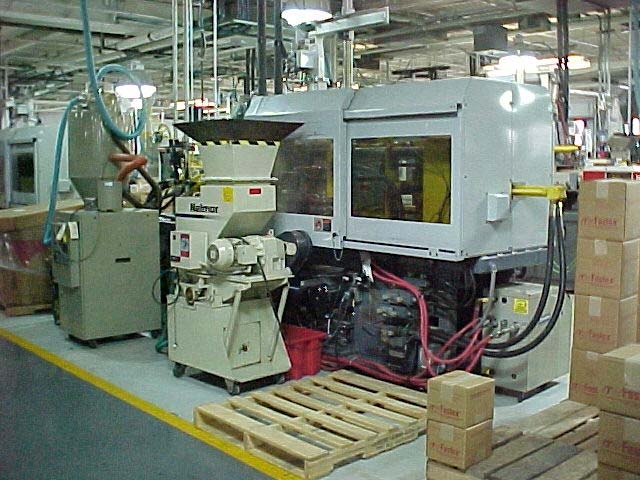

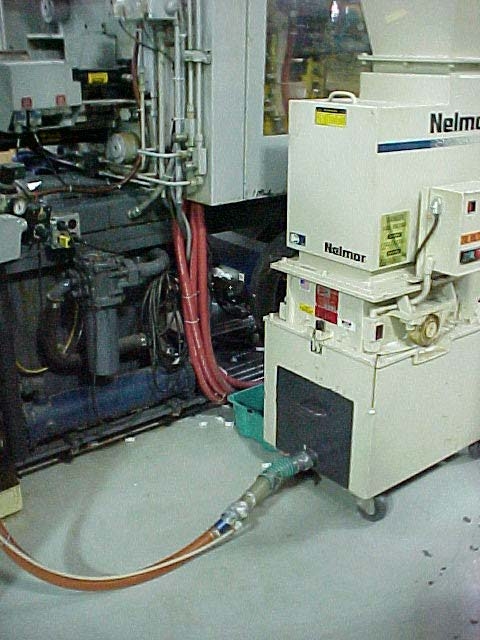

Ms. Frede will provide photographs and her observations on the injection molding

process. ( See attached Photos Nos. 1 – 9.) As can be seen from the attached photographs,

the resin is brought to the machine in a cardboard “gaylord” box and fed via vacuum hose

into the dryer and the hopper. The screw extruder and the mold are entirely enclosed

processes. When the mold opens, the product drops on to an open conveyor belt, which

can be seen to have little or no dust on it. Ms. Frede will testify that the plastic product

and plastic scrap leaving the mold are extremely clean. The scrap plastic “runners” and

“sprus” are removed from the mold by way of a robotic arm which drops the scrap into

the grinder or granulator. As can be seen from the attached photos, the grinder area has

little or no dust. Again, this is because the grinder operates under negative pressure and

both the scrap plastic and any associated dust are drawn into the grinder. Closing the

loop, the granulated plastic, while somewhat dusty, is fed directly from the grinder back

to the hopper to be reused in the process. This takes place by way of a vacuum hose.

Thus, the granulated plastic is never exposed to ambient air.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE JULY 11, 2005

7

CHDB01 1285013.1 11-Jul-05 15:28

Given the fact that these processes are so clean, there is little likelihood that PIM

machines would be vented outside the workplace. CICI’s survey of its member facilities

indicates that none of those facilities vent PIM machines outside the workplace. Thus

there is little likelihood of PIM emissions entering the outside environment. To the extent

that a PIM facility has emissions of concern within the workplace, they are subject to

OSHA standards and are not regulated under the Environmental Protection Act or air

pollution control permits issued under the Board’s rules.

At the July 15, 2005 hearing, Ms. Frede will be happy to answer any questions

regarding her observations at this facility. CICI will also provide samples of a typical

resin, typical “runner” and granulated scrap, and a typical PIM plastic product which Ms.

Frede observed being handled and processed at this facility.

5. Mold Release Agents and Cleaning Agents

Mold release agent and/or mold cleaner are sometimes used in the plastic

injection molding (PIM) process. Mold release agent leaves a very thin layer of a “non-

stick” substance on the surface of the mold to help parts fall from the mold as it opens at

the end of the cycle. Mold cleaner is used to remove built-up residue from the mold

surface. Some CICI member facilities have designed their molds to avoid use of mold

release altogether, but still use mold cleaner.

Historically, the volatile organic matter content of aerosol mold release agents and

mold cleaning products was in excess of 90%. However, mold release agents and mold

cleaning products are now available in water-based formulations and in formulations that

utilize non-photochemically reactive chemicals as carrier solvents.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE JULY 11, 2005

8

CHDB01 1285013.1 11-Jul-05 15:28

Both mold release agent and mold cleaner are generally used in 12- 16 ounce

aerosol cans. Based on data collected from CICI member facilities, VOM emissions

from mold release agent and/or mold cleaner range from less than 0.1 lbs/ton of resin

processed up to 0.4 lb/ton of resin processed. The combined usage of mold release

agents and mold cleaner at a PIM facility can be conservatively estimated to generate 0.4

lbs of VOM per ton of resin processed.

In general, facilities try to design molds to minimize the use of mold release

agents and mold cleaner because it is very inefficient to stop the PIM machine

periodically to apply either release agent or cleaner to the mold. Well-designed molds

require only a minimal amount of either substance. When possible, facilities try to apply

mold release agent or mold cleaner only at the beginning of a production shift.

6. Definitions of “Compression Molding” and “Transfer Molding”

In response to a question from the Board, CICI is providing the following

definitions which appear on The Society of the Plastics Industry, Inc. (“SPI”) website at

http://www.plasticsindustry.org.:

“Compression molding

is the most common method of forming thermosetting

materials. It is not generally used for thermoplastics.

“Compression molding is simply the squeezing of a material into a

desired shape by application of heat and pressure to the material in

a mold.

“Plastic molding powder, mixed with such materials or fillers as

woodflour and cellulose to strengthen or give other added qualities

to the finished product, is put directly into the open mold cavity.

The mold is then closed, pressing down on the plastic and causing

it to flow throughout the mold. It is while the heated mold is closed

that the thermosetting material undergoes a chemical change which

permanently hardens it into the shape of the mold. The three

compression molding factors -- pressure, temperature and time the

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE JULY 11, 2005

9

CHDB01 1285013.1 11-Jul-05 15:28

mold is closed -- vary with the design of the finished article and

the material being molded.”

“Transfer molding

is most generally used for thermosetting

plastics. This method is like compression molding in that the

plastic is cured into an infusible state in a mold under heat and

pressure. It differs from compression molding in that the plastic is

heated to a point of plasticity before it reaches the mold and is

forced into a closed mold by means of a hydraulically operated

plunger.

“Transfer molding was developed to facilitate the molding of

intricate products with small deep holes or numerous metal inserts.

The dry mold compound used in compression molding sometimes

disturbs the position of the metal inserts and the pins which form

the holes. The liquefied plastic material in transfer molding flows

around these metal parts without causing them to shift position.”

As stated in the first hearing, CICI is no longer proposing that these processes be

included in the proposed exemption and does not plan to provide additional testimony

regarding these processes.

Dated: July 11, 2005 Respectfully submitted,

CHEMICAL INDUSTRY COUNCIL OF ILLINOIS

By: /s/ Patricia F. Sharkey________

One of its Attorneys

Patricia F. Sharkey

Mayer, Brown, Rowe & Maw LLP

71 South Wacker Drive

Chicago, Illinois 60606-4637

(312) 782-0600

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE JULY 11, 2005

BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

IN THE MATTER OF: )

)

PROPOSED AMENDMENTS TO )

EXEMPTIONS FROM STATE ) R 05-20

PERMITTING REQUIREMENTS )

FOR PLASTIC INJECTION MOLDING )

OPERATIONS )

(35 Ill. Admin. Code 201.146) )

NOTICE OF FILING

TO: Ms. Dorothy M. Gunn

Clerk of the Board

Illinois Pollution Control Board

100 West Randolph Street

Suite 11-500

Chicago, Illinois 60601

(VIA ELECTRONIC FILING)

(PERSONS ON ATTACHED SERVICE LIST)

PLEASE TAKE NOTICE that on July 11, 2005, I filed with the Office of the Clerk of the

Illinois Pollution Control Board by electronic filing the SECOND ERRATA SHEET and PRE-

FILED TESTIMONY ON BEHALF OF THE CHEMICAL INDUSTRY COUNCIL OF

ILLINOIS, a copy of which is hereby served upon you.

Dated: July 11, 2005 Respectfully submitted,

CHEMICAL INDUSTRY COUNCIL OF ILLINOIS

By: /s/ Patricia F. Sharkey______

One of its Attorneys

Patricia F. Sharkey

Mayer, Brown, Rowe & Maw LLP

71 South Wacker Drive

Chicago, Illinois 60606-4637

(312) 782-0600

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE JULY 11, 2005

CERTIFICATE OF SERVICE

I, Patricia F. Sharkey, an attorney, hereby certify that I have served the Second Errata

Sheet and Pre-Filed Testimony on Behalf of the Chemical Industry Council of Illinois upon:

Ms. Dorothy M. Gunn

Clerk of the Board

Illinois Pollution Control Board

100 West Randolph Street

Suite 11-500

Chicago, Illinois 60601

(Electronic Mail)

Charles E. Matoesian

Division of Legal Counsel

Illinois Environmental Protection Agency

1021 North Grand Avenue East

Post Office Box 19276

Springfield, Illinois 62794-9276

(U.S. Mail and E-Mail)

Matthew Dunn, Chief

Division of Environmental Enforcement

Office of the Attorney General

188 West Randolph Street, 20

th

Floor

Chicago, Illinois 60601

(U.S. Mail)

Office of Legal Services

Illinois Department of Natural Resources

One Natural Resources Way

Springfield, Illinois 62702-1271

(U.S. Mail)

Donald Sutton

Manager, Permit Section

Division of Air Pollution

Bureau of Air

Illinois Environmental Protection Agency

1021 North Grand Avenue East

Post Office Box 19276

Springfield, Illinois 62794-9276

(U.S. Mail)

as indicated above, by e-mail and/or by depositing said document in the United States Mail,

postage prepaid, in Chicago, Illinois on July 11, 2005.

/s/ Patricia F. Sharkey

Patricia F. Sharkey

Patricia F. Sharkey

Mayer, Brown, Rowe & Maw LLP

190 South LaSalle Street

Chicago, Illinois 60603-3441

(312) 782-0600

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE JULY 11, 2005

Ms. Dorothy M. Gunn

Clerk of the Board

Illinois Pollution Control Board

100 West Randolph Street

Suite 11-500

Chicago, Illinois 60601

Charles E. Matoesian

Division of Legal Counsel

Illinois Environmental Protection Agency

1021 North Grand Avenue East

Post Office Box 19276

Springfield, Illinois 62794-9276

Matthew Dunn, Chief

Division of Environmental Enforcement

Office of the Attorney General

188 West Randolph Street, 20

th

Floor

Chicago, Illinois 60601

Office of Legal Services

Illinois Department of Natural Resources

One Natural Resources Way

Springfield, Illinois 62702-1271

Donald Sutton

Manager, Permit Section

Division of Air Pollution

Illinois EPA

Post Office Box 19276

Springfield, Illinois 62794-927

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE JULY 11, 2005

BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

IN THE MATTER OF: )

)

PROPOSED AMENDMENTS TO )

EXEMPTIONS FROM STATE )

PERMITTING REQUIREMENTS )

FOR PLASTIC INJECTION MOLDING ) R 05 -20

OPERATIONS )

(35 Ill. Admin. Code 201.146) )

CHEMICAL INDUSTRY COUNCIL OF ILLINOIS’

SECOND ERRATA SHEET

The Chemical Industry Council of Illinois (“CICI”), by its attorneys Mayer,

Brown, Rowe & Maw LLP, hereby submits the following corrections and amendments to

documents previously filed in this proceeding:

AMENDMENT TO PROPOSED REGULATORY LANGUAGE

CICI proposes to amend the text of its regulatory language, as proposed in its

original filing on April 19, 2005, as follows:

TITLE 35: ENVIRONMENTAL PROTECTION

SUBTITLE B: AIR POLLUTION

CHAPTER I: POLLUTION CONTROL BOARD

PART 201

PERMITS AND GENERAL PROVISIONS

Section

201.146 Exemptions from State Permit Requirements

Construction or operating permits, pursuant to Sections 201.142, 201.143, and 201.144 of

this Part, are not required for the classes of equipment and activities listed below in this

Section. The permitting exemptions in this Section do not relieve the owner or operator

of any source from any obligation to comply with any other applicable requirements,

including the obligation to obtain a permit pursuant to Sections 9.1(d) and 39.5 of the

Act, Sections 165, 173, and 502 of the Clean Air Act or any other applicable permit or

registration requirements.

* * *

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE JULY 11, 2005

hhh) Plastic injection, compression, and transfer molding equipment

with an annual

through-put not exceeding 5,000 tons of plastic resin

and associated plastic

resin handling,

loading, unloading, conveying, mixing,

storage, grinding,

granulating, and drying equipment

and associated mold release and mold

cleaning agents.

Respectfully submitted,

CHEMICAL INDUSTRY COUNCIL

OF ILLINOIS

By: /s/ Patricia F. Sharkey

One of Its Attorneys

Dated: July 11, 2005

Patricia F. Sharkey

Mayer, Brown, Rowe & Maw LLP

71 South Wacker Drive

Chicago, Illinois 60606-4637

(312) 782-0600

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE JULY 11, 2005

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE JULY 11, 2005

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE JULY 11, 2005

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE JULY 11, 2005

Robot

Transfers Runner / Spru

from Mold to Grinder

120 Ton Press

(Rear View)

Material Dryer

Material Dryer

Controller

Grinder

Grinds Runner / Spru

into pellets to be used

to mold parts.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE JULY 11, 2005

Material Gaylord

Material mixing

shovel

Plastic

Resin

purchased

in Gaylords

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE JULY 11, 2005

Plastic Resin Feed Hose

Transfers Resin from

Gaylord to Hopper

Material Gaylord

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE JULY 11, 2005

Hose from Grinder

(Regrind Runners)

Hose from

Gaylord

(Plastic Resin)

Material

Dryer

Dryer

Control Unit

Dryer

Supply &

Return

Hoses

Material is contained in

Hoses from Gaylord and

Grinder to the Molding

Press

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE JULY 11, 2005

Autoloader Filter Bag

Collects Material dust in

system

Supply Hose

from Grinder

Autoloader

Transfers Material

from Grinder and

Gaylord to Press

Material Hopper at

Molding Press

Supply Hose

from Gaylord

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE JULY 11, 2005

Robot

Transfers Runner /

Spru to Grinder

120Ton

Molding Press

(Front View)

Part Conveyor

Part Collection Bin

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE JULY 11, 2005

Mold

Part Conveyor

Molded Parts

Parts drop to

Conveyor when

Mold opens

Part Collection

Bin

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE JULY 11, 2005

Robot

Transfers Runner / Spru

from Mold to Grinder

Runner / Spru being

dropped into Grinder

Grinder

Grinds runner and

spru into plastic

pellets to be used to

mold parts

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE JULY 11, 2005

Grinder

Grinds runner and spru

into plastic pellets

that can be used to mold

parts.

Regrind

collection bin

Hose to feed

regrind to material

hopper

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE JULY 11, 2005