REC8VED

STATE OF ILLINOIS

)

FEB

251994

COUNTY OF GRUNDY

)

STAFE OF

ILLINOIS

POLLUTION

CONTROL

BOARD

BEFORE THE ILLINOIS POLLUTION CONTROL

BOARD

AKZO Chemicals Inc.

)

PCB 94-

~1

(a

)

(Variance)

Petitioner,

)

)

v.

)

)

ILLINOIS ENVIRONMENTAL PROTECTION

)

AGENCY,

)

)

Respondent.

)

NOTICE OF FILING

TO:

Ms.

Lisa Moreno

Illinois Environmental Protection Agency

2200 Churchill Road

Springfield,

IL

62794

PLEASE

TAKE

NOTICE

that on February

25,

1994, I have filed with the Office ofthe

Clerk ofthe Pollution Control Board the Petition for Variance, a copy ofwhich is attached hereto

and herewith served upon you.

BY:)~

~

Roy M. Harsch

Mark Latham

GARDNER, CARTON &

DOUGLAS

321 N. Clark Street

Suite 3400

Chicago IL

60610

(312) 644-3000

THIS FILING IS

SUBMITTED ON REYCLED PAPER

~C.E~~~/E1D

STATE OF

ILLINOIS

)

FEB

2 51994

COUNTY OF GRUNDY

~

pOLLUTION 00

oLBOARD

BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

AKZO Chemicals Inc.

)

PCB 94-

~\

(c~

)

(Variance)

Petitioner,

)

)

v.

)

)

ILLINOIS ENVIRONMENTAL PROTECTION

)

AGENCY,

)

)

Respondent.

)

PETITION FOR VARIANCE

AKZO

Chemicals Inc.

(“AKZO”), through its attorneys, Gardner, Carton &

Douglas, hereby

submits this petition for variance.

AKZO respectfully requests a variance from 35 Ill. Adm.

Code

304.105

as it applies to the discharge of total dissolved

solids (“TDS”),

chloride, sulfate and boron

from AKZO’s Morris, Illinois facility.

AKZO

further requests a variance from 35 Ill. Adm.

Code

302.208 as it applies to those discharges.

AKZO requests that this variance be retroactive to

October 27,

1993, and terminate the earliest of:

(1) three years from the date the variance is

granted

or (2) modification of AKZO’s NPDES permit to include the adjusted standard relief sought in AS

93-8.

I.

BACKGROUND

On August 20,

1993, AKZO filed a petition with the Board seeking adjusted standard

relief from the sections previously cited and forthe same constituents noted above.

Pursuant to a

Board Order dated September 9,

1993, AKZO filed an amended adjusted standard petition on

November

12,

1993, to address the four factors set forth in Section 28.1(c) ofthe Illinois

Environmental Protection Act (“Act”).

AKZO filed a second amendment to the adjusted

standard petition on February 2,

1994.

This second amendment solely revised the language of

the proposed adjusted standard sought in AS 93-8.

AKZO’s NPDES permit required AKZO to achieve compliance with TDS and boron by

October 27,

1993.

A copy ofAKZO’s NPDES permit is

attached as Exhibit

1.

Because

compliance was economically unreasonable, AKZO consulted the Illinois Environmental

Protection Agency (“Agency”) to determine whether the Agency could recommend a course of

action.

Following consultation with the Agency, AKZO pursued adjusted standard relief as

suggested by the Agency.

AKZO requested modification ofthe compliance

deadline in its

NPDES permit on August 3,

1992, to allow sufficient time to

obtain adjusted standard relief.

On

August 13,

1993, AKZO again requested modification ofthe compliance deadline to allow

sufficient time for Board action on the amended adjusted standard.

The United States

Environmental Protection Agency (“U.S. EPA”) objected to the second request on ground that

the Agency may only grant one modification ofa compliance deadline set forth in a NPDES

permit.

Accordingly, AKZO now seeks a variance from the Board pursuant to 35 Ill. Adm.

Code

104.121

and Sections 35 to 38 ofthe Act.

II.

SECTION

104. 121 INFORMATIONAL REQUIREMENTS

A.

Section

104.121(a):

Relief Sought

AKZO seeks a variance from 35

Ill. Adm.

Code 302.208 and 304.105

as they apply to the

discharge ofTDS, chloride, sulfate and boron from AKZO’s Morris, Illinois facility.

B.

Section 104.121(b):

Description ofActivity

AKZO owns and operates a plant in Morris, Illinois.

At that facility, AKZO produces fatty

acid nitrogen derivatives that are used primarily as surfactants in agricultural products, personal care

products and detergents.

In addition, the fatty acid nitrogen derivatives are used as surfactants in a

wide variety ofother industrial processes including the food, chemical,

highway paving, metal

processing, mining, petroleum, paint, ink, paper, pharmaceutical, rubber and polymer processing

industries.

-2-

C.

Section 104.121(c):

Materials Used

The major raw materials used to produce fatty acid nitrogen derivatives at the AKZO Morris

facility include water, tallow, coconut oil,

soybean oil, ammonia, hydrogen, methyl chloride,

acrylonitrile, isopropyl alcohol, ethanol and formaldehyde.

Finished products include glycerine,

fatty acid, nitrile, amines and quaternary. amines.

D.

Section 104.121(d):

Discharge Description

The production ofsurfactants results in the generation ofseveral wastewater streams which

AKZO treats by differing means prior to discharge.

Main process wastewater is collected,

biologically treated and stored in a concrete reservoir.

The reservoir water .is then used for crop

irrigation.

Through an underdrain system lying beneath the spray field, excess water from crop

irrigation is collected and discharged through outfall 001

to Aux Sable Creek.

Wastewater from steam generating boilers, water softener regeneration operations and

stormwater runofffrom the facility is discharged through outfall 002 to Aux Sable Creek.

A pH

adjustment station was installed on the discharge line from the boiler house to outfall 002 in

1984 to

adjust the pH to within the 6 to 9 limit imposed by AKZO’sNPDES permit.

Aux Sable Creek

discharges to the Illinois River approximately ito

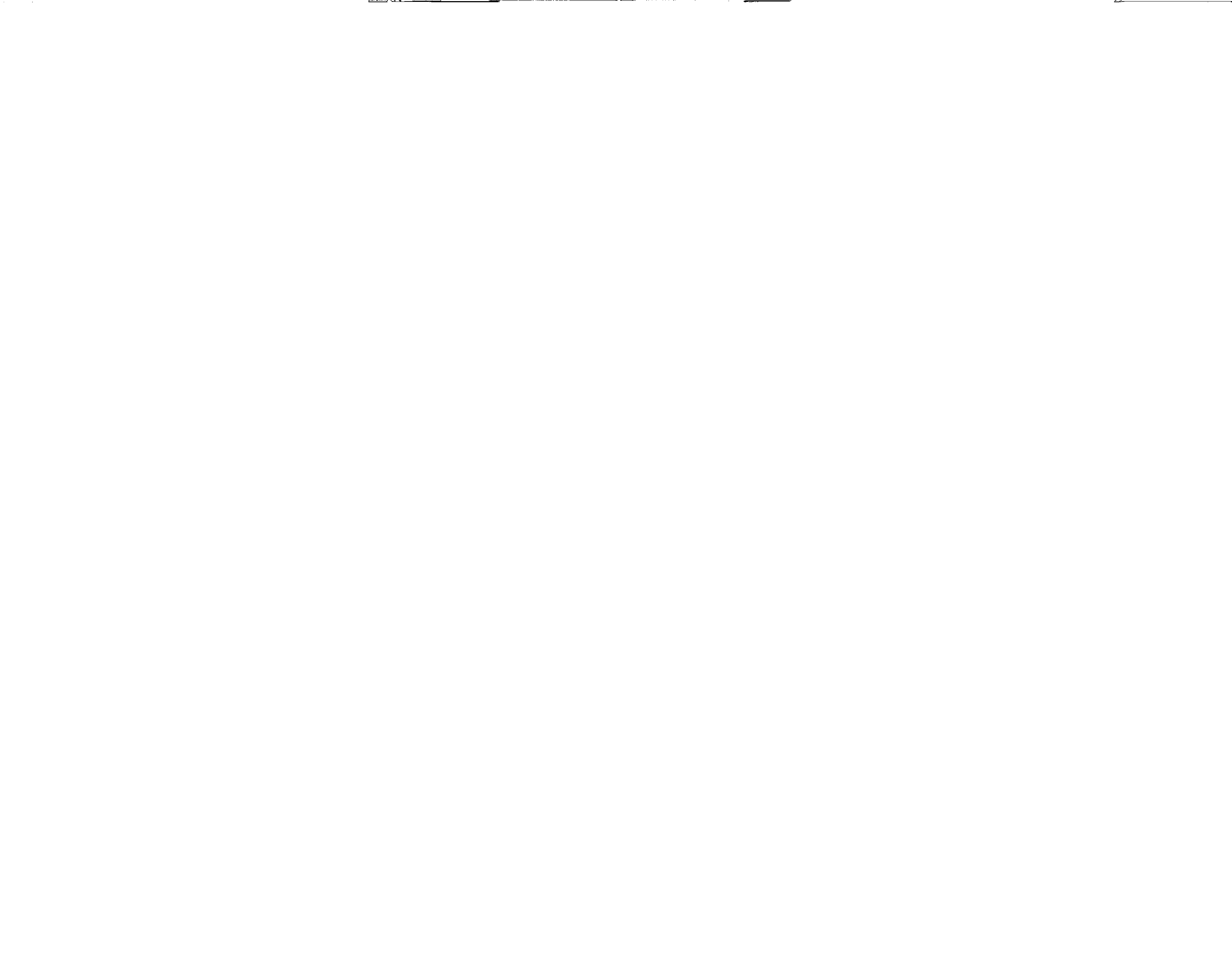

2 miles downstream ofoutfall 002.

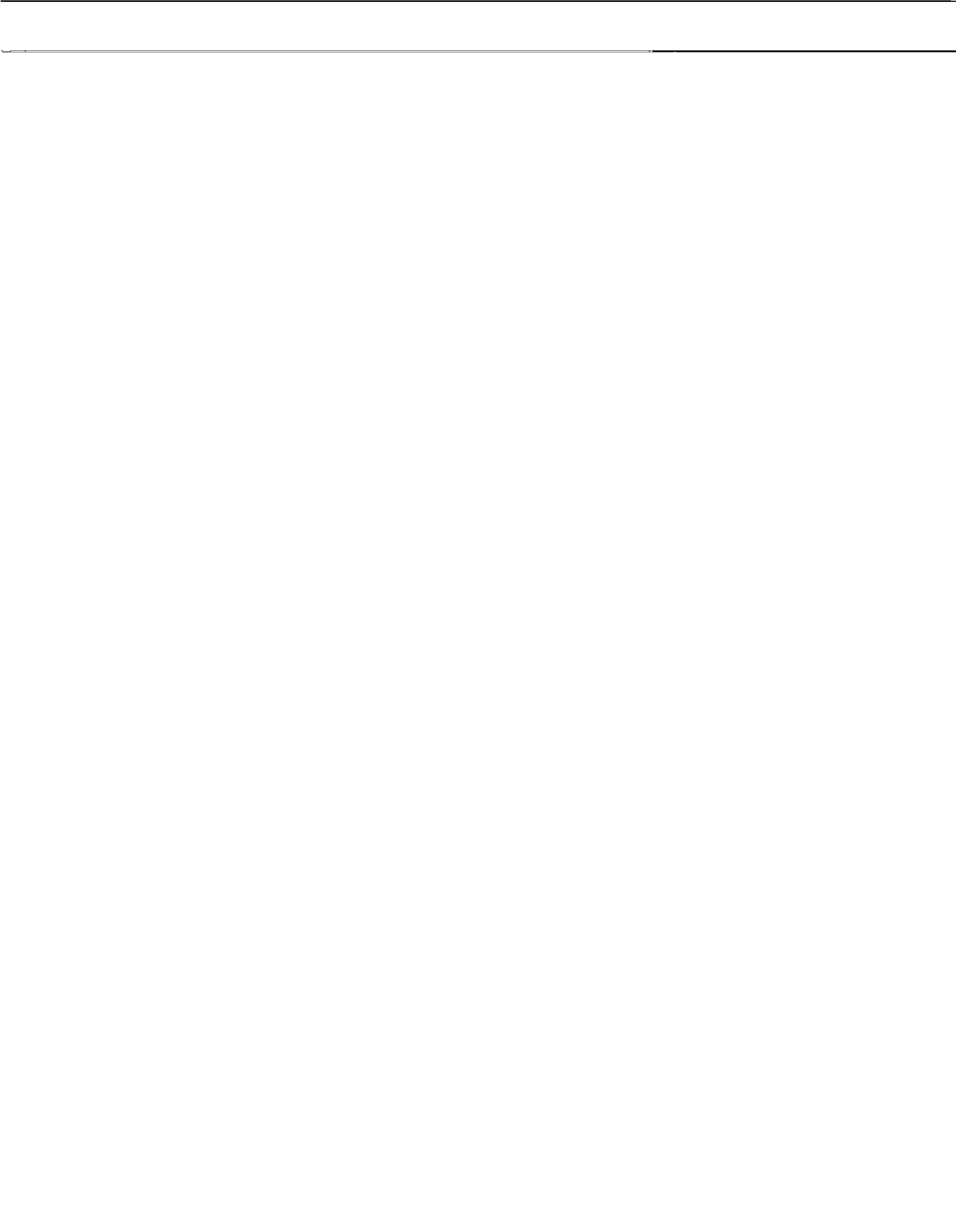

A map

showing the locations of outfalls

001

and 002 and the receiving stream is presented in Exhibit 2.

The primary sources ofTDS, chloride, sulfate and boron in the discharge from outfall 002

are boiler blowdown and a water softenerregenerant stream.

As part ofthe renewal ofAKZO’s

NPDES

permit in 1990, the Agency imposed discharge limitations on outfall 002 equivalent to the

water quality standards for TDS and boron.

The Agency also

included a compliance schedule for

those

constituents as a Special Condition ofAKZO’s NPDES

permit.

After consultation with the

Agency regarding the need for an adjusted standard, the permit was modified on November 24,

1992, to provide AKZO additional time to comply with the TDS and boron limitations.

-3-

E.

Section 104.121(e):

Non-Compliance With

Standards

The

boron contained in AKZO’s discharge is naturally occurring, and no boron is

added by

AKZO’s processes.

However, the boron is concentrated as a result ofthose processes.

The well

water supplied to the Morris facility, which is used for all potable uses, process uses, cooling water

make-up and boiler feed, contains on the order of0.5 mg/l ofboron.

No boron-containing

compounds are utilized in the boiler pretreatment softening, corrosion control orblowdown pH

adjustment.

The boron is concentrated in the boiler through

steam losses and consumptive steam

uses.

No treatment is provided for boron.

The average daily level ofboron discharged over the last

28 months has been 0.78 mg/I, with a maximum of 1.4 mg/i, and eight readings of 1.0

mg/l or more.

Thus,

periodically the wastewater discharged through outfall 002 exceeds the

1.0 mg/l limit for

boron contained in the Morris facility’s NPDES permit.

Boiler water treatment, blowdown pH adjustment and water softening, which are all

necessary for proper boiler operation and compliance with permitted pH limits for direct discharge,

add TDS, chloride and sulfate to that naturally present in the well water.

Similar to boron, the TDS,

chloride and sulfate ions present in the boiler feed water are concentrated as a result ofsteam losses

and consumptive steam uses.

The average daily TDS discharge concentration over the last 28 months was approximately

3,000 mg/l, with a maximum of6,180 mg/l, and

15

readings ofgreater than 3,000 mg/i.

The

average TDS discharge concentration, however, is less than 3,000 mg/i.

According to recent sample results chloride levels averaged

1,566 mg/I and sulfate levels

averaged 286 mg/l at the 002 flume, with a maximum of 2,960 mg/l and 574 mg/l,

respectively.

In four sets ofinstream samples which were taken, the stream levels for chloride upstream and

downstream ofoutfall 002 are well below the 500 mg/i stream standard.

Additionally, the

instream sampling demonstrated that sulfate levels upstream and downstream ofoutfall 002 were

also well below the 500 mg/I stream standard.

A detailed analysis ofthe boron and TDS

-4-

concentrations in the wastewater discharged through outfall 002

is presented in Exhibit 3.

Sample results obtained for chloride and sulfate are presented in Exhibit 4.

F.

Section 104.121(1):

Control Methods

As discussed below, AKZO has instituted certain measures to reduce the TDS, boron,

chloride and sulfate in its discharge.

In addition, as required by Special Condition

9 of its NPDES

permit,

AKZO has investigated several compliance alternatives discussed below in Sections

11.1.

G.

Section 104.121(g):

Environmental Impact

AKZO has made no formal assessment ofthe effect of this requested variance upon the

environment.

In 1986,

however, the Agency conducted a stream survey in the vicinity ofAKZO’s

discharge.

This study (Exhibit

5)

concluded that there was

“no apparent adverse impact in the

vicinity ofAKZO” within Aux Sable Creek as a result ofAKZO’s wastewater discharge.

AKZO

agrees with the conclusion ofthe Agency’s study and believes that it is valid today since AKZO’s

operations and processes at its Morris facility have not changed significantly

sincethe Agency’s

1986

study.

Further, AKZO incorporates by reference the result ofthe literature search conducted by it in

AS

93-8.

Based on the results ofthat literature

search, AKZO believes that sufficient data exists to

support the conclusion that the requested variance for TDS, chloride and sulfate will not harm

aquatic life.

The literature search revealed data demonstrating that fresh water fish survived for

several days to several weeks in levels ofchloride, sulfate and TDS at levels much higher than those

discharged by AKZO.

The Agency study and the results ofthe literature

search in AS 93-8

demonstrate that a grant ofthis variance will have little, if any, adverse environmental impact.

AKZO is requesting this variance to continue its present discharge to Aux Sable Creek while

it pursues an adjusted standard that the Agency has recommended be granted.

The Agency did raise

some concerns in its recommendation.

To address those concerns, AKZO filed a second amended

adjusted standard in which it agreed to perform toxicity testing and agreed to conduct a stream

survey within six months ofthe granting ofthe adjusted standard relief.

The stream survey will be

-5-

repeated in

5

years.

AKZO is confident that the toxicity testing and stream survey will show that

AKZO’s discharge will have no adverse environmental impact.

H.

Section 104.121(h):

Past Compliance Efforts

AKZO’s NPDES permit did not contain any limits for TDS, boron, chloride or suifate until

reissued on September 20,

1990.

As discussed below, however, AKZO has expiored a number of

compliance alternatives in an attempt to comply with the permit limits.

I.

Section 104.121(i):

Compliance Alternatives

As required by Special

Condition 9 ofits NPDES permit, AKZO has reviewed the Morris

facility’s processes to determine whether any feasible compliance

alternatives exist.

AKZO has

evaluated a number ofcompliance alternatives.

Based upon that evaluation, AKZO has concluded

that compliance is not technically feasible nor economically reasonable.

Therefore, AKZO is

pursuing an adjusted standard to obtain relief.

The compliance alternatives

evaluated by AKZO are

set forth below.

1.

Operation ofthe Boiler at an Abnormally High B lowdown Rate

Operation ofthe boiler at an abnormally high blowdown rate was determined to be an

unreasonable compliance alternative because it would greatly increase the consumption ofnatural

gas by the rate of0.14 million cubic feet per day or 51

million cubic feet per year in order to

compensate for the heat lost in the excessive blowdown water.

Such an increase in fuel

consumption would not only waste a non-replenishable natural resource but also result in

significantly

higher operating costs.

In addition, increased

operation ofthe boiler in such a manner

would contribute to boiler wear requiring additional maintenance and also result in the increased use

and discharge ofboiler water treatment chemicals.

The increased maintenance and chemical usage

would further increase the cost ofthis compliance alternative.

The costs of additional maintenance

and boiler wear are unknown at this time.

This alternative, however, would increase boiler

operating costs in the magnitude of $155,000 annually.

-6-

2.

Installation ofa Reverse Osmosis Treatment System with Offsite

Disposal ofBrine

The installed cost ofa reverse osmosis treatment system, including multimedia filters,

would be approximately $140,000 for boiler biowdown alone and would be an additional

$500,000 to $700,000

for softening ofthe larger boiler feed water stream.

Installation of such a

system would result in a treated discharge comprising approximately 67

to

75

ofthe influent

to the system.

The remaining

25

to 33

ofthe discharge would be

a wastewater containing

concentrated dissolved solids which would require offsite disposal since the TDS, chioride,

sulfate and boron levels would be even more eievated thanthe levels in the existing blowdown.

Based on daily boiler blowdown flows ofapproximately 48,700 gallons per day (“gpd”) and

daily boiler water feed ofapproximately 180,000 gpd, this 25

to 33

concentrated brine

discharge would range from 12,000 to

16,000 gpd (4.4 to

5.8

million gallons per year) for boiler

blowdown and 45,000 to 59,000 gpd (16.4 to 21.5 milliongallons per year) for boiler feed water.

Using offsite disposal costs on the order of $1.00 per gallon, the offsite disposal ofthe

reverse osmosis concentrated brines from the treatment ofboiler biowdown and boiier feed water

would range from $4.4 to $5.8 million per year and $16.4 to

$21.5

million per year, respectively.

The current boiler water softener generates approximately 2,000

gpd ofhigh TDS wastewater.

Disposal offsite, rather than discharge into Aux

Sable Creek, would cost $2,000 per day or

$0.73

millionper year.

Thus,

softening is much more cost effective than treating the boiler feed

water by reverse osmosis.

The total offsite disposal costs for the softener regenerant stream and

the brine stream from reverse osmosis ofthe blowdown could, however, still reach

$5.1

to $6.5

million per year.

Consequently, offsite disposal of such a large volume ofwastewater is

prohibitively expensive.

3.

Reverse Osmosis System with Evaporation

Evaporation, instead ofoffsite disposal, ofthe boiler softener water and reverse osmosis

concentrate was also considered as a compliance alternative.

An evaporator would cost

approximately $500,000

to $1.0 million installed, assuming that installation is only a 1.25 to

1.5

-7-

multiplier ofcapitai cost.

Therefore, the purchase and installation ofan evaporator is not an

economically reasonable compliance option.

4.

Combination of Outfalls 001

and 002

AKZO also evaluated combining the wastewaters which discharge to outfall 001

and

outfall 002 and uitimateiy discharging the combined stream to the concrete reservoir.

Once in

the reservoir, the wastewater would be discharged through the existing

irrigation system onto the

spray field.

The additional wastewater, however, could hydraulically overload the system.

Further, such a system would threaten the long term viability of the spray field as a result ofthe

addition ofapproximately 2,400 pounds of salt to the field daily, based on an average of96,000

gpd containing

3,000 mg/l of TDS.

Application ofthat amount ofsalt could result in the

inhibition ofbiological activity in the

soil.

Therefore, combining the discharges from outfall 001

and outfall 002 and discharging the combined stream onto the spray field is not a feasible

compliance alternative on a long-term basis.

Diversion ofoutfaii 001

to outfall 002 for combination downstream ofthe spray field was

also

considered.

Unfortunately, outfall 001

does not provide a continuous discharge ofwater

with which to combine the outfall 002 discharge.

Outfall 001

discharges an estimated 154 days per year, when the groundwater table under

the spray field is high.

During the summer, there is little discharge from the field to outfall 001,

even during spraying.

During the winter, there

is no spraying oftreated process wastewater to

the spray field, and there is no discharge from the spray field to outfall 001

except during a

sustained thaw.

These are typically periods of high TDS discharge from outfall 002, since there

is little runoffcontribution to outfall 002.

There is usually a more consistent discharge from the

spray field to outfall 001

during the spring and autumn seasons when there is frequent rainfall.

These latter periods,

however, coincide with periods of high stormwater runoff flow from outfall

002, when TDS levels would be expected to be reiatively low.

Combination ofoutfalls

001

and

002 would not, therefore, allow consistent compliance with discharge standards.

-8-

AKZO also considered diverting several wastewater streams from outfall 001

to outfali

002.

Among the streams that were considered were cooling water and condensate streams.

Although neither stream directiy contacts process materials, the current discharge to

outfall 001

provides attenuation and treatment in the event that a leakin a heat exchanger would

contaminate these sources with process material.

AKZO believes that it is important to maintain

the extra safety factor that

is built into the current system rather than to allow even a remote

possibility ofprocess contamination ofthe outfall 002 discharge.

This alternative was, therefore,

not pursued ftirther.

5.

Optimization ofExisting Sodium Zeolite System and Recycle ofthe Most

Concentrated Rinse Streams

The brine and slow rinse (regeneration) streams from the sodium zeolite system are the

most concentrated TDS streams generated at the Morris plant.

The existing softener regeneration

system could be modified to allow isolation ofthese streams for one oftwo options.

The first

option is

AKZO’s preferred aiternative for achieving compliance with the proposed TDS limit at

outfall 002.

This option involves optimization ofthe existing sodium zeolite system and

pollution prevention through recycling a portion of the brine rinse and slow rinse streams to

reduce the salt usage and the quantity ofwastewater for disposal, followed by trucking ofthe

remainder ofthe brine and slow rinse streams offsite to the Morris POTW.

This option will not

achieve compliance with the existing

standards for TSD, boron, chloride or sulfate.

It will,

however, allow AKZO to comply with the standards proposed in the pending adjusted standard

petition.

The existing regeneration procedures have been fine-tuned to increase the salt

concentration and reduce the volume ofwater introduced into the zeolite bed.

The amount ofsalt

introduced during each regeneration cycle is being more carefully controlled to minimize the

excess salt which must be disposed following regeneration.

Piping changes have been made to allow isolation and collection ofthe brine rinse and

slow rinse wastewater streams (approximately 2,000 gallons per day) which follow the

-9-

regeneration cycle.

AKZO has determinedthat,

after evaluation and consultation with water

treatment experts, the last third of the brine rinse and first two-thirds ofthe slow rinse stream can

be

effectively recycled for use in regeneration ofthe sodium zeolite, resulting in the recycle of

approximately 900 pounds per day ofTDS.

The system has been tested forthe last four months

and was fuiiy implemented earlier this month.

The first two-thirds ofthe brine rinse stream would contain high concentrations of

magnesium and calcium hardness, which the sodium zeolite system was designed to remove

from boiler feed water.

It wouid not, therefore, be feasible to recycle this stream.

The last third

ofthe slowrinse stream would contain a relativeiy dilute salt concentration and,

as a result,

would not be feasible to recycle.

These streams contain approximately 900 pounds ofTDS, and

AKZO is now transporting these streams offsite for treatment at th~

Morris POTW.

The remaining flow to outfall 002 after segregating, recycling and disposing ofthese two

streams is expected to contain approximately 3,000

mg/i of TDS.

On occasion, however, even

after initiating the above steps, the

level ofTDS might exceed the 3,000 mg/l limit which was

proposed in AKZO’s adjusted standard petition.

In order to insure compliance with this limit, a

smaii volume ofweli water would be used for dilution.

This well water would be added

automatically based on continuous measurement ofthe specific conductance, which is directly

proportional to the TDS concentration, in the wastewater upstream ofoutfall 002.

6.

Isolation and Evaporation of High TDS Streams

The second alternative involving isolation of the softener regenerant brine and slow rinse

streams is isolation followed by evaporation.

This alternative would utilize an evaporator to

evaporate approximately

1,800 gpd of water, leaving approximately

1,800 pounds ofsalt and 200

gallons of waterper day

for offsite disposal.

The capital cost for the evaporator,

although substantially lower than that required for

reverse osmosis with evaporation, would be approximately $300,000, plus $115,000 in annual

operating costs,

which is still a significant amount.

-10-

This option, moreover, would result in the same TDS concentration at outfaii 002 as

optimization ofthe existing

sodium zeolite system but at a substantially greater cost and without

any recycling ofthe

salt.

Further, this option would still require some portion ofdilution with

well water to assure consistent compliance with the 3,000 mg/i TDS limit which is proposed in

AKZO’s pending adjusted standard.

7.

Discharge to Chemical Plant’s 16” or 10”

Pipe

AKZO investigated possible discharge into one of two discharge~pipesfrom the

neighboring chemical plant to the Illinois River.

The Illinois River could accept the current

discharge from outfall 002 and stay within the regulated stream standards for TDS, boron,

chloride and sulfate due to its

large flow and its non-zero 7-day,

10-year low flow value.

The

estimated cost for this alternative was on the order of $100,000, plus $5,000 to $10,000 per year

for pipe maintenance.

In response to AKZO’s proposal to use one ofthe two available discharge

pipes, the neighboring chemical plant has made a policy decision not to allow any outside

facilities to use its discharge pipes.

Accordingly, this alternative is not a feasible option.

8.

Pipeline to the Illinois River

This alternative is similar to

dischargingto the neighboring chemical plant’s discharge

pipe, but AKZO would install its own discharge line over a much longer distance.

The capital

cost for this alternative was estimated at $400,000 with $35,000 annual operating costs.

it is also

worth noting that this solution does not incorporate any ofthe pollution prevention measures that

would be instituted by optimizing the existing sodium zeolite system and is much more costly.

9.

Reverse Osmosis ofBoiler Feed Water Followed by Direct Discharge

This alternative

is similar to reverse osmosis treatment ofthe boiler feed water stream

with offsite disposal ofthe reverse osmosis concentrate.

With this alternative, however, the

reverse osmosis concentrate stream, which comprises 25 to 33

of the feed stream and contains

all ofthe concentrated dissolved solids, would be discharged to outfall 002.

—11—

The concentration ofTDS in outfall 002 would be ciose to 3,000 mg/l, the approximate

concentration ofthe boiler blowdown stream and the approximate concentration-atoutfall 002

that would be achieved by optimizing the existing sodium zeolite system, which is the alternative

preferred by AKZO.

In order to reduce hardness to the levels required for high pressure boiler

operation, the entire volume of boiler feed water would have to be treated through the reverse

osmosis unit followed by treatment through the sodium zeolite system.

The latter would require

less frequent regeneration than it would without pretreatment ofthe feed waterthrough the

reverse osmosis system.

The estimated capital cost for a reverse osmosis unit is $500,000 to $700,000 pius annual

operating costs of$90,000 to $100,000.

This option is quite costly and is not as economically

feasible as other alternatives considered by AKZO.

10.

Demineralization ofBoiler Feed Water

Demineralization is a process that

is used to generate ultra-high purity water.

There are

two

ion exchange resins through which the boiler feed water would pass prior to use, a cation

exchanger and an anion exchanger.

The sodium zeolite system which is currentiy being used is

only a cation exchanger that exchanges sodium ions for the cations in the boiler feed water.

Demineralizers require regeneration with an acid for the cation exchange resin and a base

(typically caustic) for the anion exchange resin.

Handling ofthe acid and caustic streams

introduces an additionai hazard to the operation and wouid require piping ofthe regenerant

streams to the existing pH neutralization system and modifications to the system to permit

neutralizationofthe acid stream.

The TDS concentration in the regeneration water would likely

be on the same order ofmagnitude as that from the sodium zeolite system, but would depend on

the magnitude ofexcess acid and caustic required for regeneration.

The cost ofa demineralizer, excluding any required modifications to the neutralization

system, is approximately $600,000 to $750,000 plus annual operating costs on the order of

-12-

$50,000 to $140,000.

AKZO does not believe that a demineraiizer would substantially reduce

the TDS levei at outfaii 002, and the cost would be prohibitively expensive.

J.

Section

104.121(j):

Impact Minimization

As discussedpreviously, AKZO has optimized its existing

sodium zeolite system and is

recycling a portion ofthe brine rinse and slow rinse streams to reduce salt usage and the volume of

wastewater.

The portion ofthe brine rinse stream and siow rinse stream which is not recycled is

sent offsite to the Morris POTW for treatment.

As noted earlier, this will not allow AKZO to meet

the current standard for TDS, boron, chloride

or sulfate but will ailow AKZO to meet the standard

proposed in its pending adjusted standard petition.

AKZO will also

continue its present testing to

determine the level of TDS and boron in its discharge from outfall 002.

K.

Section 104.121(k):

Arbitrary or Unreasonable Hardship

AKZO believes that the denial ofa variance would constitute an arbitrary orunreasonable

hardship

since the grant ofthe variance will cause little, if any,

adverse environmental impact.

Denial ofthe variance would cause AKZO to incur hundreds ofthousands ofdollars, orperhaps

millions, in pursuing a compliance alternative which would confer little environmental benefit.

III.

CONSISTENCY WITH FEDERAL LAW

The Board may grant the requested relief from 35 Ill. Adm. Code Sections 302.208 and

304.105 consistent with the Clean Water Act, 33

U.S.C.

§~

1251

to

1387.

As explained above, the

requested relief is predicated solely upon potential violations ofthe TDS, chloride, sulfate or boron

water quality standards.

No federal or state TDS, chloride, sulfate or boron effluent standards are

applicable.

Under federal law:

A water quality standard defines the water quality goals ofa waterbody,

or portion thereof, by designating the use, and by setting

criteria necessary

to protect public health or welfare, enhance the quality ofwater and serve

the purposes ofthe Clean Water Act (the Act).

Serve the purposes ofthe

Act (as defined in sections i01(a)(2) and 303(c) ofthe Act) means that

water quality standards should, where ever attainable, provide water

quality forthe protection and propagation of fish,

shellfish and wildlife

and for recreation in and on the water and take into consideration the use

-13-

.

.

..

and value ofpubiic water suppiies, propagation offish, shellfish, and

wildlife, recreation in and on the water, and agricultural, industrial, and

other purposes including

navigation.

40 C.F.R.

131.2.

Under 40 C.F.R.

131.4 “states are responsible for reviewing, establishing and

revising water quality standards.”

Inturn,

pursuant to 40 C.F.R.

131.5,

“EPA is to review and to

approve or disapprove the State-adopted water quaiity standards.”

These standards are to be

protective ofthe designated uses

(~

131.5(b))

and, where those uses are not protected, this must

be

supported by “appropriate technical and

scientific data and analyses.”

(~

13

1.5(d)).

A state is

allowed to remove a designated use, which is not an existing use, if it “can demonstrate that

attaining the designated use

is not feasible” because ofseveral enumerated causes.

(~

131.10(g)).

In the case of Aux Sable Creek in the vicinity of AKZO, the creek is used for transportation

and recreation.

The granting ofthe adjusted standard will not impair any beneficial use ofthe

receiving stream.

As such, no need for federal review exists.

This has been established by the study

which has been conducted by the Agency and which has been attached to this petition as Exhibit

5.

IV.

WAIVER OF HEARING

AKZO hereby waives its right to a hearing in this matter.

WHEREFORE, AKZO

respectfully requests the Board to grant it a variance from 35 Ill.

Adm.

Code Sections 302.208 and 304.105 to the extent those rules are applicable to its discharge

from outfall 002.

Respectfully submitted,

AKZO Chemicals Inc.

BY:

_________

One ofIts Attorneys

-14-

Roy M. Harsch

Mark Latham

GARDNER, CARTON & DOUGLAS

321

N. Clark Street

Chicago, IL

60610-4795

(312) 644-3000

-15-

30012789.1

Exhibit List

--

AKZO Variance Petition

1.

NPDES Permit

2.

Location of outfalls

001

and 002

3.

Boron and TDS concentrations

4.

Chloride and sulfate sample results

5.

Agency study of Aux Sable Creek

6.

Affidavit ofWalter G. Dion

30014853.1

Illinois

Environmental

Protection

Agency

P.

0.

Box

19276.

Springfield.

IL

62794-92Th

21 7/782—061

0

November

24,

1992

Akzo

Chemicals,

Inc.

300

South

Riverside

Plaza

~

~

L

~

~

Chicago,

Illinois

60606

Re:

Akzo

Chemicals,

Inc.

NPDES

Permit

No.

1L0026069

Modification

of

NPDES

Permit

(After

Public

Notice)

Gentl emen:

The

Illinois

Environmental

Protection

Agency

has

reviewed

the

request

for

modification

of

the

above-referenced

NPDES

Permit

and

issued

a

public

notice

based

on

that

request.

The

final

decision

of

the

Agency

is

to

modify

the

Permit

as

follows:

Revise

the

compliance

schedule

for

boron

and

total

dissolved

solids.

Enclosed

is

a

copy

of

the

modified

Permit.

You

have

the

right

to

appeal

this

modification

to

the

Illinois

Pollution

Control

Board

within

a

30

day

period

following

the modification

date

shown

on

the

first

page

of

the

permit.

Should

you

have

any

question

or

coments

regarding

the

above,

please

contact

Fred

Rosenblum of

my

staff.

Very

truly

your’

iomas

G

McSwiggin,

P.E.

Manager,

Permit

Section

Division

of

Water

Pollution

Control

TGM:TK:jab/2798r/41

Attachment:

Modified

Permit

cc:

USEPA

5WQP

Facility

EXHIBIT

1

NPDES Permit

No. 1L0026069

Illinois Environmental Protection Agency

Division of Water Pollution Control

2200 Churchill Road

P.O.

Box

19276

Springfield, IllInois

62794—9276

NATIONAL POLLUTANT DISCHARGE ELIMINATION

SYSTEM

Modified (NPOES) Permit

Expiration Date:

October

1.

1994

Issue Date:

September 27.

1990

Effective Date:

October 27.

1990

Modification Issue Date: November 24, 1992

Modification Effective Date: November 24,

1992

Name and Address

of Permittee:

Facility

Name

and Address:

Akzo Chemicals,

Inc.

Akzo Chemicals,

Inc.

300

S. Riverside Plaza

Tabler Road

Chicago, Illinois

60606

Post Office Box

310

Morris, Illinois

60450

(Grundy County)

Discharge Number

and Name:

Receiving Waters

001 Treated Spray Field

Underdrain

Aux Sable Creek

002

Stormm.iater Runoff. Boiler

Aux

Sable Creek

Blowdown

and Softener

Regeneration Stream

OO1A Treated Domestic Waste

Internal Waste

Stream

In compliance with the provisions of the

Illinois Environmental Protection Act, Subtitle

C and/or

Subtitle

0 Rules and Regulations of the Illinois Pollution Control

Board, and the Clean Water Act.

the above—named permittee

is hereby authorized

to discharge at the above

location to the

above—named receiving stream in accordance with the standard conditions

and attachments

herein.

Permittee

is not authorized to discharge after the above expiration

date.

In order to receive

authorization

to discharge beyond the expiration date,

the permittee shall

submit

the proper

application

as required by the Illinois Environmental Protection

A enc

(IEPA)

not later

than 180

days prior to the expiration date.

omas

G.

cSwiggin. P.E.

Manager.

Permit Section

Division

of Water Pollution Control

TGM: FLR:dl 5/3586k. sp

Page

2

ModIfication Date: November 24,

1992

NPDES Permit No. 1L0026069

Effluent Limitations and Monitoring

LOAD LIMITS

CONCENTRATION

lbs/day

LIMITS mall

30 DAY

DAILY

30 DAY

DAILY

SAMPLE

SAMPLE

PARAMETER

AVG.

MAX.

AVG.

MAX.

FREQUENCY

TYPE

1. From the effective date of this permit

until

the expiration

date,

the effluent of the following

discharge(s)

shall

be monitored and limited at all

times as follows:

Outfall(s):

001

Flow (MCD)

Shall

be reported

as 3D day Avg. and Daily Max.

Measure When

Monitoring

BOD,

30

60

1/Week

Composite

Total

Suspended

Solids

30

60

.

1/Week

Composite

Amonia

April

through October

1.5

1/Month

Grab

Nitrogen

(as

N) November through March

4.0

1/Month

Grab

Fats,

Oil

and

Grease

15

30

1/Week

Grab

pH

See Special

Condition

1.

1/Week

Grab

See 40 CFR 414.91 LIst on pages

3 and 4

Outfall:

OO1A

See Special Condition

11.

Outfall:

002

Flow (MCD)

Shall

be reported as 30 day Avg. and Daily Max.

Measure When

Monitoring

pH

See Special

Condition

1.

1/Month

Grab

Temperature

See Special

Condition

2.

1/Month

Grab

Total

Dissolved

Sollds~

1000

1/Month

Composite

Boron~

1.0

1/Month

Composite

Asiinonia

April through October

1.5

1/Month

Grab

Nitrogen

(as N) November through March

4.0

1/Month

Grab

Total Copper*

0.031

0.052

1/Month

Composite

Total

Lead*

0.1

1/Month

Composite

~Limitationsshall

become effective two years

from

the effective date of this permit.

See

Special

Condition 9.

~Limitatlons shall

become effective three years from the effective date of this permit.

See

Special Condition

10.

Page

3

Modification Date:

November 24,

1992

NPDES

Permit No. 1L0026069

Effluent Limitations and Monitoring

Outfall

001

40 CFR 414.91 LIst

PARAMETER

LOAD LIMITS

lbs/day

30 DAY

DAILY

AVG.

MAX.

CONCENTRATION

LIMITS ma/l

30 DAY

DAILY

AVG.

MAX.

SAMPLE

FREQUENCY

SAMPLE

TYPE

Acenaphthene

0.019

0.051

0.022

0.059

l/Year~

Composite

Acrylonitrile

0.084

0.211

0.096

0.242

1/Years

Grab

Benzene

0.032

0.118

0.037

0.136

1/Yearn

Grab

Carbon

Tetrachioride

0.016

.

0.033

0.018

0.038

1/Year*

Grab

Chlorobenzene

0.013

0.024

0.015

0.028

1/Year*

Grab

1,2,4—

Trichlorobenzene

0.059

0.122

0.068

0.140

1/Year*

Grab

Hexachlorobenzene

0.013

0.024

0.015

0.028

1/Years

Grab

1,2—Dichioroethane

0.059

0.183

0.068

0.211

1/Years

Grab

1.1,1—Trlchloroethane 0.018

0.047

0.021

0.054

1/Years

Grab

Hexachioroethane

0.018

0.047

0.021

0.054

1/Years

Grab

1.1 Dlchloroethane

0.019

0.051

0.022

0.059

1/Years

Grab

1,1,2 Trichloroethane 0.018

0.047

0.021

0.054

1/Year~

Grab

Chloroethane

0.090

0.233

0.104

0.268

1/Year’

Grab

Chloroform

0.018

0.040

0.021

0.046

1/Year’

Grab

2—Chlorophenol

0.027

0.085

0.031

0.098

1/Year’

Grab

1,2-Dichlorobenzene

0.067

0.142

0.077

0.163

1/Year’

Grab

1,3—Oichlorobenzene

0.027

0.038

0.031

0.044

1/Year’

Grab

1,4—Dlchlorobenzene

0.013

0.024

0.015

0.028

1/Year’

Grab

1,1—Dichioroethylene

0.014

0.022

0.016

0.025

1/Year’

Grab

1 .2-Trans—

Dichloroethylene

0.018

0.047

0.021

0.054

1/Year’

Grab

2.4—Dichlorophenol

0.034

0.097

0.039

0.112

1/Year’

Grab

1.2—Dichloropropane

0.133

0.200

0.153

0.230

1/Year’

Grab

1 .3—

Dichloropropylene

0.025

0.038

0.029

0.044

1/Year’

Crab

2,4—Dimethylphenol

0.016

0.031

0.018

0.036

1/Year’

Composite

2,4—Dinltrotoluene

0.098

0.248

0.113

0.285

1/Year’

Composite

2.6—Dinltrotoluene

0.222

0.558

0.255

0.641

1/Year’

Composite

Ethylbenzene

0.028

0.094

0.032

0.108

1/Year’

Grab

Fluoranthene

0.022

0.059

0.025

0.068

1/Year’

Composite

Page

4

Modification Date: November

24,

1992

NPDES Permit

No. IL0O26069

Effluent Limitations

and Monitoring

Outfall

001

40 CFR 414.91 LIst

LOAD LIMITS

CONCENTRATION

lbs/day

LIMITS

mall

30 DAY

DAILY

30 DAY

DAILY

SAMPLE

SAMPLE

PARAMETER

AVG.

MAX.

AVG.

MAX.

FREQUENCY

TYPE

Methylene Chloride

0.035

0.077

0.040

0.089

1/Year’

Grab

Methyl

Chloride

0.075

0.165

0.086

0.190

1/Year’

Grab

Hexachlorobutadiene

0.017

0.043

0.020

0.049

1/Year’

Composite

Naphthalene

0.019

0.051

0.022

0.059

1/Year’

Composite

Nitrobenzene

0.023

0.059

0.027

0.068

1/Year’

Composite

2—Nltrophenol

0.036

0.060

0.041

0.069

1/Year’

Composite

4—Nltrophenol

0.063

0.108

0.072

0.124

1/Year’

Composite

2.4—Dlnitrophenol

0.062

0.107

0.071

0.123

1/Year’

Composite

4,6—Dinitro—o—cresol

0.068

0.241

0.078

0.277

1/Year’

Composite

Phenol

0.013

0.023

0.015

0.026

1/Year’

Composite

Bis( 2—ethylhexyl)

phthalate

0.090

0.243

0.103

0.279

1/Year’

Composite

Di—n—butyl phthalate

0.023

0.050

0.027

0.057

1/Year’

Composite

Diethyl phthalate

0.070

0.177

0.081

0.203

1/Year’

Composite

Dimethyl phthalate

0.017

0.041

0.019

0.047

1/Year’

Composite

Benzo(a)anthracene

0.019

0.051

0.022

0.059

1/Year’

Composite

Benzo(a)pyrene

0.020

0.053

0.023

0.061

1/Year’

Composite

3.4—

Benzofluoranthene

0.020

0.053

0.023

0.061

1/Year’

Composite

Benzo(k)fluoranthene

0.020

0.053

0.022

0.059

1/Year’

Composite

Chryserte

0.019

0.051

0.022

0.059

1/Year’

Composite

Acenaphthylene

0.019

0.051

0.022

0.059

1/Year’

Composite

Anthracene

0.019

0.OS1

0.022

0.059

1/Year’

Composite

Fluorene

0.019

0.051

0.022

0.059

1/Year’

Composite

Phenanthrene

0.019

0.051

0.022

0.059

1/Year’

Composite

Pyrene

0.022

0.058

0.025

0.067

1/Year’

Composite

Page

5

Modification Date:

November 24,

1992

NPDES Permit No.

1LO026069

Effluent Limitations and Monitoring

Outfall

001

40 CFR 414.91

LIst

LOAD LIMITS

CONCENTRATION

lbs/day

LIMITS mo/i

30 DAY

DAILY

30 DAY

DAILY

SAMPLE

SAMPLE

PARAMETER

AVG.

MAX.

AVG.

MAX.

FREQUENCY

TYPE

Tetrachloroethylene

0.019

0.049

0.022

0.056

1/Year’

Grab

Toluene

0.023

0.070

0.026

0.080

1/Year’

Grab

Trichloroethylene

0.018

0.047

0.021

0.054

1/Year’

Grab

Vinyl

Chloride

0.090

0.233

0.104

0.268

1/Year’

Composite

Total

Chromium

0.87

1.74

1.0

2.0

4/Year”

Composite

Total

Copper

0.139

0.226

0.16

0.26

4/Year”

Composite

Total Cyanide

0.023

0.096

0.026

0.11

4/Year”

Composite

Total

Lead

0.174

0.35

0.2

0.4

4/Year”

Composite

Total

Nickel

0.87

1.74

1.0

2.0

1/Month

Composite

Total

zinc

0.87

1.74

1.0

2.0

1/Month

Composite

‘Sampling results shall

be submitted with June DMR

“Sampling results

shall

be submitted with March,

June,

September and December DMRS

Page 6

ModificatIon Date:

November

24,

1992

NPDES Permit No.

1L0026069

Soecial Conditions

SPECIAL CONDITION 1.

The

pH shall

be

in the range 6.0 to

9.0.

The monthly minimum and monthly

maximum values

shall

be reported on the DMR form.

SPECIAL CONDITION

2.

DIscharge of wastewater

from this facility must not alone or

in combination

with other sources cause

the receiving stream to violate the following thermal limitations at the

edge of the mixing zone which

Is defined by Section 302.211. IllInois Administration Code.

Title

35. Chapter

1, SubtItle

C. as amended:

A.

Maximum temperature rise above natural

temperature must not exceed 5°F(2.8°C).

B.

Water temperature at representative locations in the main river shall

not exceed the maximum

limits

In the following table

during more than one

(1) percent of the hours

in the

12—month

period ending with any month.

Moreover, at no

time

shall

the water temperature at such

locations exceed the maximum limits

In the following table by more than 3°F(1.7°C).

(Main river temperatures are temperatures of those

portions of the

river essentially similar

to and following the same thermal regime as the temperatures of the main flow of the river.)

~

~

~

APL2.

~

~

~1.uix Ajj.g.,.

Seot,

~

~

~

°F

60

60

60

90

90

90

90

90

90

90

90

60

°C

16

16

16

32

32

32

32

32

32

32

32

16

C.

The monthly maximum value shall

be reported on the DMR form.

SPECIAL CONDITION

3.

Outfall 002

shall be relocated from its present position

to a point

approximately

100

ft. north of containment dam

in surface ditch tributary to Aux Sable Creek.

SPECIAL CONDITION 4.

Samples taken

in compliance with the effluent monitoring requirements for

outfalls 001 and 002 shall

be taken

at a point representative of the discharge

but

prior to entry

into the Aux Sable Creek.

SPECIAL CONDITION

5.

The use

or operation of this facility shall

be by or under

the supervision

of

a Certified Class K operator.

SPECIAL CONDITION 6.

If an applicable effluent standard or limitation

is promulgated under

Sections 3O1(b)(2)(C) and

(0).

304(b)(2).

and 307(a)(2)

of the Clean Water Act

and

that effluent

standard or limitation

is more stringent than any effluent limitation

in the permit

or controls

a

pollutant not limited

in the NPDES

Permit,

the Agency shall revise or modify the

permit

in

accordance with the more stringent standard or prohibition

and shall

so notify the

permittee.

SPECIAL CONDITION

7.

The permittee shall record monitoring results

on Discharge Monitoring

Report

Forms

using one

such form for each discharge each month.

The completed Discharge Monitoring

Report

forms

shall

be submitted to IEPA no later

than the

15th day of the following month, unless otherwise specified by the permitting authority.

Discharge Monitoring Reports

shall

be mailed to the IEPA at the following address:

Illinois Environmental Protection Agency

Division of Water Pollution Control

2200 Churchill Road

P.O.

Box

19276

Springfield,

Illinois

62794—9276

Attention:

Compliancq Assurance Section

SPECIAL CONDITION 8.

Within one year of the effective date of the

permit, outfall 002 shall

be

monitored,

and the discharge analyzed for

the organic pollutants

listed

in 40 CFR 414.91, using

the

sampling procedures

set forth

in

a promulgated storm water regulation under 40 CFR

122.21.

In

the absence

of final

regulation, the sampling procedure

set forth

in the proposed regulation

53

F.R. 49464

(December 7.

1988)

shall

be used.

The results

shall

be submitted to the Agency either

as part of storm water application or as an addendum to

a D.M.R.

After review of the submitted

data,

the Agency may modify the permit

to require additional

monitoring or to incorporate effluent

limitations

for parameters

of concern.

Page

7

Nodlfication Date:

November

24,

1992

NPDES Permit

No.

1L0026O69

Soeclal Conditions

SPECIAL CONDITION 9.

The following parameter monitorIng and limitations

at Outfall

002 shall

become effective two years from the effective date of this permit.

Total

Copper

Total

Lead

Compliance

shall

be achieved

In accordance with the following schedule:

1.

Proposal to achieve compliance.

including

plans and specifications

for treatment facility

if necessary

9 months from effective date

2.

Interim report

16 months from effective date

3.

Complete construction,

if necessary

22 months from effective date

4.

Obtain operational

level

24 months from effective date

Compliance

dates

set out

In this Permit may be superseded or supplemented by compliance

dates in

judicial orders. Pollution Control Board orders.

This permit may be modified, with Public Notice.

to include such revised compliance dates.

REPORTING

The permittee shall

submit a report no later than fourteen (14)

days following the completion

dates

indicated for each numbered Item in the compliance

schedule, Indicating,

a) the date the

item was completed, or

b) that the item was not completed,

the reasons for non completion and the

anticipated completion date.

SPECIAL CONDITION

10.

The following parameter monitoring and limitations (Daily Maximum) at

Outfall 002 shall

become effective three years from the effective date of this permit.

Total

Dissolved

Solids

Boron

Compliance

shall

be achieved in accordance with the following schedule:

1.

Proposal to achieve compliance,

including

plans

and specifications

for treatment facility

if necessary

9 months from effective date

2.

InterIm report

16 months from effective date

3.

Complete construction,

If necessary

22 months from effective date

4.

Interim Report

27 months from effective date

5.

Obtain operational

level

36 months from effective date

Compliance

dates

set out in this Permit may be superseded

or supplemented by compliance

dates in

judicial

orders. Pollution Control Board orders.

Th~ispermit may be modified, with Public Notice,

to include such revised compliance dates.

REPORTING

The permittee shall

submit

a report no later

than fourteen

(14) days following the completion

dates

indicated for each numbered

Item in the compliance

schedule, indicating,

a) the date the

item was

completed,

or b) that the item was not completed,

the reasons for non completion and the

anticipated completion

date.

SPECIAL CONDITION

11.

No limitations

or monitoring requirements are imposed by this permit for

Outfall

DO1A.

8

ATTAC$MENT

Pt

MI

isteiste di. ~no.e

E,wvorvnersal

P

,teci.on Act.

Ct.

III

t~2m Re.

Stat.

Sec

1001.

1061 ii

Amar.dsd

A,ency “..a.~it..

~tois

Inwti.......ntal P.ot.ct.ci, Agency

S.erd awe.,,

lt.e

Iimo.s Polute.,

Control SoniC

Cloast

Wet.,

Act Iform..ly

r,f erred

to

as

the

F.d.raJ Wat.r

Podut,ori

Control

Act)

meant

Pm~L

92.500.

a.

amended

33

u.s

C.

1251

at

e.g

NPO?*

Sfat.on.t

Polutant

D.sct.arg. Elerenat.or Sy,i.m)

means

It..

nai,onal

program

br

4*s~i0_.

moófyutc_. r,vole,g arid rartsuew

I.rni.uatW~.

trioretoreig

and enforcing p.rm.tt. and

enoosaig and

enforcing plutrntnwmn reptarern~ntt.under

S.ct.ons 307. 402. 318 and

405

of

the Clean Water

Act

UILPA insan, thi

Ursted States Enveorirnental

P,ot.cl.ori

Agency

Dfly

Dtac*.ai1.

mean,

the

d.scha,ge of a polt,..tant measur.d

during $ Calendar day or any

24.hoit

pertod

thai

reasonably

reo,etarit$

the

calendar

Cly for

Purposal of

sa.mpl.ng

~or

polutanis

with Mm.tabon*

e.pr.ss.d

a.

tests of

mast.

the

‘de.ly

diScharge

ri

Calculated

at

the

total

mass

of

It..

poeulant

drscharg.d

aser

tt,.

day

Foi

pollutants

w,tti

bn.taf,on~

•.pross.d a.

other

awls

of

,.aturemenu,.

the

defy

discharge”

is

catculat.d

as

the ann9.

m.asurernerit

of

the pOlutent

ow.,

the

day

Maxbeum Daily

Dfecharge t.kn.tatlo.,

lda.ly ma.wiiumi

moans

the higheit

allowable

daily

discharge

Avsrage

Monthly

Dfach.rge

LenltaIloel

30

day

average)

tiwant

(hi

h.ghesf

allowable

guer.q. ef

daily

d.scharges

son

$

calendar

mOnth.

CalcutaiId

Is

the

stem

of

as

deft

thechar9.s

measca.d

dunng

a

cal.nda,

mont.

d.nded

by It..

number

of

daily

olscharges

mea,ur.d dunng that

month

Average

Wabty

Discharge

LimitatIon

(7

day

average)

mean,

It..

h.ghest

alowabi.

averag,

of

daily d.schargei over

a

cal.nder

weal.

calculated

as ft..

stem

ot Se

daily discharges

tii.aesNed during

a

calendar week divided by the flna,tber

of

daily di5CPterg.t

measured

dtw.ng

that

weal.

S..I

Mawageniefit

PractIce.

IBMP5)

means

schedules

of

aCt.rli.SI.

prot..b.t.orww

of

practice., ,mtae,i.rwancs proCidte.,, and oih~mflanag.rfl.nt pract,css

to

present or reduce

fit.

poIut,on

of

wat.rs

of

the

Stat.

IMPs

also

e,ck.de

treatment

r.aua.ments.

operating

procedures,

InC

pract.CS5

to

control

plant

site

runoff.

50.11.9.

or

leaks,

sludge

or

waste

ósposal,

or pla.nag

from

raw malarial

storage

Ailguot

m.ans a sampi.

of

sp.c.f..d

wolurn. uled to male

up a total

comoos.ta sample

Grab Saul.

rt..ans

an

a.d.v,dual

,.ampl.

of

at

basf

¶00 milhl.t.rs coflsct.d

eta

randomly.

s.l.ct.d

tans

ov.r a

period not e.ceeding

I

S m.nutes

24

Ifos,,

ComposIte Sample

means. comb,nat.orl

of

at

least

8

sampl. $l.Quoti

Of it bait

tOO m.a.ksars. colf.ct.d

at periodic

a.f.r’.als dsetnq

the op.rat.ng hours

at a

fac.lltyorera

24.

hote period

•

Hour Composite Sarnpl. moans

a

combliat.On

ol

51 bait

3 s.amOi~

abyuois

of at

least

tOO

miajiters,

colected

at

periodic

,nt.rrals during

th.

op.r.t.rig hours

of a

facaip, ~

an

period.

Plate Propontionaf

compoalta

Saul.

means

a

cOmbnat,Orl

of

Sample

alquots

~f at

least

tOO rmwldit.ri coe.ct.d

at p.nod.c

ritanvali

such that either

the

fly,.

aileryaf betwe..

each

abauot or

the voltanie

of ..crt

sbquot

is

proport.onal

to

either

the

strsann

flow at the

nine of

tampw.g or the

total

stream

flow twice

the coa.ctor

of

the

previous

akouof

(1)

Duty

to

comply

The

p.rnn.tI.s

must

comply

with a~Cond.f.on,

of

this

permit

Any

perm,t

noncompliance corwtrtutes a n.olat.on

of it..

Act

aria

is grids

tar

er.forcarn,ertt

acl.ori.

perrmwt

ier,nin.t.omt,

revocation

and

.wssuanc.

mod,fc.t.on,

or

for

denial

of

a

p.rlTwt

i.r..wal

appl.cation

ihe

p.rm.tt.e

sisal

comply

,ith

sffluenf

standards

or

profsb.t.ons

sstableJi.d und.r Sact.on

3071.4

of

the

Clean

Wat

Ac?

for

10cc

po8utants

.r,thr,

It.. tine

PrOvided

an

th.

neg.ilat.orns

that

establish

Ih.sa

standards

or

prOlwb.t.oin. ever

it

tt~ePermit

Pat

not

yet

bean

mod.t..d to

etcorporat. the

reg.w.rrtert

12)

Duty

to

reapefy

If

the parasIte.

ansi,., to contawae an

activity

tegulaf SC

by

tt..s

permit after

the

espeat,or date

of

mlvi

permit

the

p.rnvtt.,

must

apply for

and

obtain a mew

p.rn’vt flit,. perirwlt.e

si~nttsa

proper

appl.cat.on

as

rapured

by

the Agencyno

later

than 150days prior to

the

eapaat.on

date.

five

pemsi

,hae

contosia

it

full force and effect iwila the few,) Agency decision on the

appecatior

ii..

bean

made.

13)

Need

to

halt a

r.dscc. actIvity

item

a

defense

ft

sp.ai not

be

a

defer,,.

tori

,.....athi.

in ar

eiiforcerment action that

4

would have

been

necessary

to

fwait or

rs~ac.it..

permitted act.

,

..

urea to maantaet compleanc. wit?,

pie co.~t.on,

of It.,

pemwt

14)

Duty I.

mitigate

The

permits..

thai

tale

SC

reasonable

step,

to

rnewis.re

or

prevent erty ~charge

it

.iolai,on

of

pa,

permntt

which

has a

reasonable

hIelewood

of

adversely affecting

l’sanari

heant. or the enveomvrwiit

(5)

Proper

operatIon

and

mawitaissec.

The

perir.tiee

thai

ii

ai

ma.,.,

proper,,

Operate

and

ma.nta

ii

t.cat4$

arid

systems

of

treatment

and

control

land

related appuoerw,ncesf

which

we

a’,staa.d

or

used

by

the

permits..

to

ache.

complancu ,..th th. conditions

of Ibis

permit

Proper operator

arid

mr,aante.w,ce

includes effect,,, performance.

adequate Iundrng.

adequate

operator statIaig

and

tra.ne’tg,

arid

adeguall

Laboratory

and

process

controls

.ncludang

appropriate

Quality assurance proC.duros

Tit., provision

reoures

the

operation

of bact.up

or

ausil.ary

facibt.,,

or

51,1gw

systems

only

.1w.,

n,cr.aary

In

ach,r,,

t’..n.plianrr

wtth

the

t’oeid.t,om,,

o(

11w

prrnrtl

~)

Permit actions

The

pemif may

be

mod.f..d_,

rewolad and

reissued,

or isr’rnewisd

for cause

by the Agency pursuant to 40Cye ¶22 62

The tV.g

of a

mop.iasl

by SW

~

for

a p.wet

,,.,d.f.cabo.t,

rewocafion and

rwe.ss~~,

or bnne’..bor.,

or

a

rot.fcabor

of

plarvied

changes

or witicipated norwompgwce.

does ape

stay

sPy

penhe co~ben

(1)

Pvoperty rights

The

panret

does

not corn’.y any

property

ogistiof

wry

tori.

or

any •.clus.ve prisdege

(SI

Duty

to proaiie lm.$ormatloit

The

perrrsflee thai

turn..?’

to the Agency

within

a

rsesonaob

time,

any

istormnat.on

which

the

Agency i~aymqueet

to

delarme..

wfwetjW

curia

e.*ts

for modifying,

revol.w.g

end

rsis.si.arrg.

Or tW..wiat.ig

Itte

pernit,,

or

to

deter,,..,. compliance

with

the

p.i~rwL The

par’mr.ttae

thai

also

turn.,?’ to the Agency, upon ruquost cop.es

of

records requeed to

be 1501

by this

(9)

Inepection and

enny

The parasIte. thai alp..

an authorized r.preeentabv,

of

the

Agency, upon

the presentation

Of

cr,der,f,als arid other docterisnia ia niway

be

requeed

by law,

to

l&)

Enter upon

the penrettee’t premises

where a regulated

facrl,ty or activity

is

located or conducted,

or where r.cordl insist

be

ks(tt under tire Cor.d,t,Oli.

ot

this

permit,

lsl

Nasa

access to

and

copy,

at

reasonable

tames,

any r.cordt

Itsat

must

be

kept

under the

COnd.t,ons of

ttws

permit,

Ic)

lirspect

am

reasonable sines

any faced..,,

equprn,ert

l.nclod.ng rmwori,oreig

arid

control

pe,.,plnwerru,

pract.ces,

or

operet.orss

regulated

or

r.qured

under the

permit,

and

Id)

Sample

or monitor

at reasonable tar,.,,

for If.. purpose of

assuring

perl’rwt

compliatce.

or

at

ot’,erw.s,

authoried

by It..

Act,

airy

nubstancit

or

paramefer,

at any

location

110)

Monitoring and

racorde

Ia)

Samples

and measurements taken for the purpose

of

mnonrtoratg thai I.

.epres.ntatrae

of

the

monitored activity

b

The

perrndtee

shea

retain records

of

all moniloraig .inI

o,mat,oe~wickid.ng

SC

caimat.ow

and

ma.ntenance

records,

arid

SI

original

say

that

mecord.nge for continuous moriitonrtg

r.sW’umwitaboln, copes of

SC reports

requied

by

this

permit.

end

records

of

SC

data

used

to

corr~te tt’ie

applicat,on

to,

this permit,

to,

a period

Of at least 3

years

f

rout the

dale

of

Its,

pernuf,

measurement

report

or

acplicat,o.i.

Tfvs

period

may

be

e.t.rided

by reguost of

ihe

Agency

at

any

mate.

Ic)

Records

of mometorwig

.nformat,on

sIsal .tclcide.

It)

The date.

aaact

place,

and tilt.

of sarirpl.ng

or

meat.aarnsnts,

(2)

The

eid.v,dualtt(

who

performed

the

s.ernpl,ng

or measurements,

13)

The date(s)

analyses

were

performed,

14)’

The itdmridual)a)

who performed

the

~il’ys.s,

IS)

The

analytical

i.ctin,Qu.t

or

methods used,

and

IS)

The r$sufts

of

such analyses

IC)

Monitoring

must

be

Conducted

accorde’ig

to

test

procedures

approved

,aider 40 CPA

Pat

138. unlau

other test procedures hays beer

sp.crfiad

an this

permit

Where no

test procedure under 40

CPA

Part

¶36

has been

approved.

(tie

perm.ttae

must

submit

to

Iii.

Agency

a

test method

tar

approval

Th.

permrtteu

shall

cal.bmata

and

perform

mentenance

procedures on

SC

morstonsig

InC

analytical

e’btrurnentation

al ento’v$li

to

..wure

accuracy

of

measureriwints.

Ill)

SIgnatory requirement

AS

appf.cat.oni,

reports

or

,r.tormat,or. subin,rtad

to

the

Agency

sIteS

be

signed

and can,f.ed

(a)

Apobcatsomt

AS

pa.nrtl

applications

shae

be signed as

foSows

ftI

Par

e canporatloel

by

a

principal

esecutwe

officer

of

at

least

the

level

Of

rica

president

or

a

person

or

pOsatior

ha’,,,Q

overal

r,spon$t,alyy

for smwecrwnerital mater,

for the corporawi.,,

(2)

For

a pertitereltig.,

sole

piepriotarelmig

by a

general

partner

or

the

proprietor. respeclerely, a

(3)

Pa

a issuisticlp&ity.

Itata.

Federal,

a

oUter public

agency

by

either a

prmcipat e.ecutwe

officer ci raribeig

elected official

aj(

Reports

Al reports r,qswed by

permits, or Other

enforir.at,on neatreif ad by

the Agency sisal

be

signed by a person described

er

paagnspfl

(a)

or by

a

dcli

suthorued repres.ntatm~

of thet person

A person

isa

duly authonied

reprelantatme

OmWyil

Ii)

The

autteruatioml

a

riled.

a.

wntr.g

by

I

person

described

it

paragraph Ill,

and

(2)

The

authorrzat,On

sp.c.f4$

e.th.r

am

atdrmid.aal

or

a

position

responsibl,

for

the

overal operathan

of ft.. facet,,

from

which

the

discharge

or.gesat.’s.

such

as

a

plant

manager.

f.upenint.nOent

or

p.riorl

of

equivalent

respons.ba.ty.

arid

(3)

The wrrtfen authorniatiorn

.s

submitted to

lii.

Agency

DRTNIED

OP~

~EDVCLEO

PAPEP

r:~:

__

___

-

-

-

~

Ii?

5.

—

‘5

-

I

~.

_

~

~

~-r

I

‘

~

•‘~.

~U.de..

.

‘:

-

p

‘!-1~)-

-~4~:

~

~

2~

‘~

.L7~’

_~7y~’-T~::

-_

-

e*~~

LL~J

,9

~

~L•

.i~i

~

.,,•,~

1.~

~

‘~

a’~2

—

~

a—

-

~

~

in

•~ç

~Y

if~

-~

~/

I

i

)~L1~

~

~‘~e

j

_

5.~L

~—~‘

e

‘resss~.

;

~~y—

~

r~

_____

IlL

~

~

~

~y

tt

C&o~.caI

Ssi’~v~y

and USC~

omt~”.d

from

lertel ps~fo(rapM

ph

~SIulsfy5j9~J-~954

____________________________

(rUt kinvc.n

dJtusn

‘Oil

C000dinlfI System,

a

—

EXHIBIT

2

‘isa ifercafer

•r.4 t.clii,

;.4

fail,

a,’ If cs3!:4’i~ns

~3f

f.e14 c,C i,4

yt

cr0

...

,rtir,y,

o.ra

ecc,’.i

es

•r

Ct—ta a

s_to,

‘CO.

Cr

yr

a,,..

‘a

Ii

sc~

CONTOt.j

hI(~vll,,

0

‘(Er

O*rw.

.5

-~

SLa

ilil$

eraP

COMPtrCS

ar..

s.

e—.es

~

FOR

$Af,(

IV

U.

S

G(0(O~at

s5a’.r’

~

LIsa

•y

Tff(

STAT( CCOt~s,

S,,e’.fv

as.’

~

vo.,ote

ecsCI’I~O

tn.OCae.,..

—

..~

—a

t...ao~5

c

1/SI’—.

Ii’::

il

:8

I

—

Month

TDS, mg/L

Boron, mg/L

September 1990

3,270

October 1990

6,110

1.0

November 1990

6,180

1.2

3,680

1.2

December 1990

3,280

0.75

January 1991

2,760

0.77

February 1991

2,390

0.30

3,910

0.56

March 1991

2,440

0.46

April 1991

1,680

0.25

May 1991

2,730

0.92

June 1991

3,360

1.0

July 1991

4,690

1.2

August 1991

5,080

1.4

September 1991

1,150

0.7

October 1991

2,200

0.6

November 1991

1,000

0.43

December 1991

3,030

0.61

January 1992

3,810

0.92

February 1992

4,770

0.83

March

1992

3,760

1.0

April 1992

4,330

0.90

May 1992

2,060

0.97

June 1992

4,230

0.82

July 1992

1,910

0.83

August 1992

485

1.2

September 1992

912

0.4

October

1992

1,750

0.6

November 1992

607

0.34

December 1992

1,820

0.57

Average

2,979

0.78

Maximum

6,180

1.4

—

EXHIBIT

3

Total

Dissolved

Solids

mg/i

Date

12/27/91