ILLINOIS POLLUTION CONTROL BOARD

December 20,

1995

IN THE MATTER OF:

)

15

ROP PLAN:

)

CLEAN-UP PART II:

)

R96-l3

AMENDMENTS TO 35

ILL. ADM.

)

(Rulemaking-Air)

CODE PARTS 218

AND

219

ProDosed Rule.

First Notice.

OPINION

AND

ORDER OF THE BOARD

(by J.

Theodore Meyer):

On December 13,

1995 the Illinois Environmental Protection

Agency (Agency)

filed this proposal for rulemaking.

In addition

to the proposal, the Agency filed a motion to waive certain

filing requirements.

Section 182(b) (1) of the Clean Air Act

(42

U.s.c.

7511(b) (1))

required Illinois to submit a plan by November 15,

1993,

for achieving a 15

reduction of volatile organic material

(VOM)

emissions in the Chicago and Metro—East ozone nonattainment

areas

(15

Rate—of-Progress

(ROP)

Plan).

Section 182(b)

of the

CAA

also required Illinois to submit fully adopted measures to

implement the ROP Plan.

Illinois submitted its 15

ROP plan

November 13,

1993, and thereafter proposed regulations to

implement the ROP Plan.

The Agency proposes seven

(7)

minor

amendments to 35 Ill. Adm.

Code Parts

218 and 219:

1)

Add identical

language found in Section 218.208(b)

regarding “equivalent alternative control plans” to

Section 219.108(b);

2)

Revise certain equations for vapor pressure

in Subpart

A;

3)

Clarify the applicable record keeping and reporting

requirements for coating operations using touch-up and

repair coatings in Subpart

F;

4)

Correct a Federal Register citation regarding Synthetic

Organic Chemical and Polymer Manufacturing Plants

(SOCMI)

and correct typographical errors in Subpart Q;

5)

Reflect the Illinois General Assembly’s repeal in

Public Law 89-79

of the bakery oven rules

in Subpart

FF;

6)

Amend the exemption for polyethylene manufacturing

operations in Subpart TT; and,

7)

Correct a typographical error in Appendix G.

As mentioned above,

the Agency also filed a motion to waive

certain filing requirements of 35

Ill.

Adm.

Code

102.

Specifically, the Agency requests a waiver of the nine

(9)

copy

filing requirement,

stating that, due to the length of the

2

proposal, it would be more feasible to file five

(5)

full copies

and four

(4)

partial copies with the Board.

The Agency also

requested relief from 35

Ill.

Adm.

Code 120 which requires that

the entire proposal be submitted to the Attorney General and the

Department of Natural Resources.

The Agency contacted

representatives of both departments who agreed that it would be

sufficient to be formally notified that a proposal has been made

and where it can be reviewed.

Finally, the Agency asked for

relief from providing copies of incorporated material to meet the

requirement of 35

Iii. Adm. Code 102.121(f).

The Board hereby

grants the Agency’s motion to waive the above described filing

requirements.

Today the Board acts to send this proposal to first notice

under the Illinois Administrative Procedure Act,

but without

commenting on the merits of the proposal.

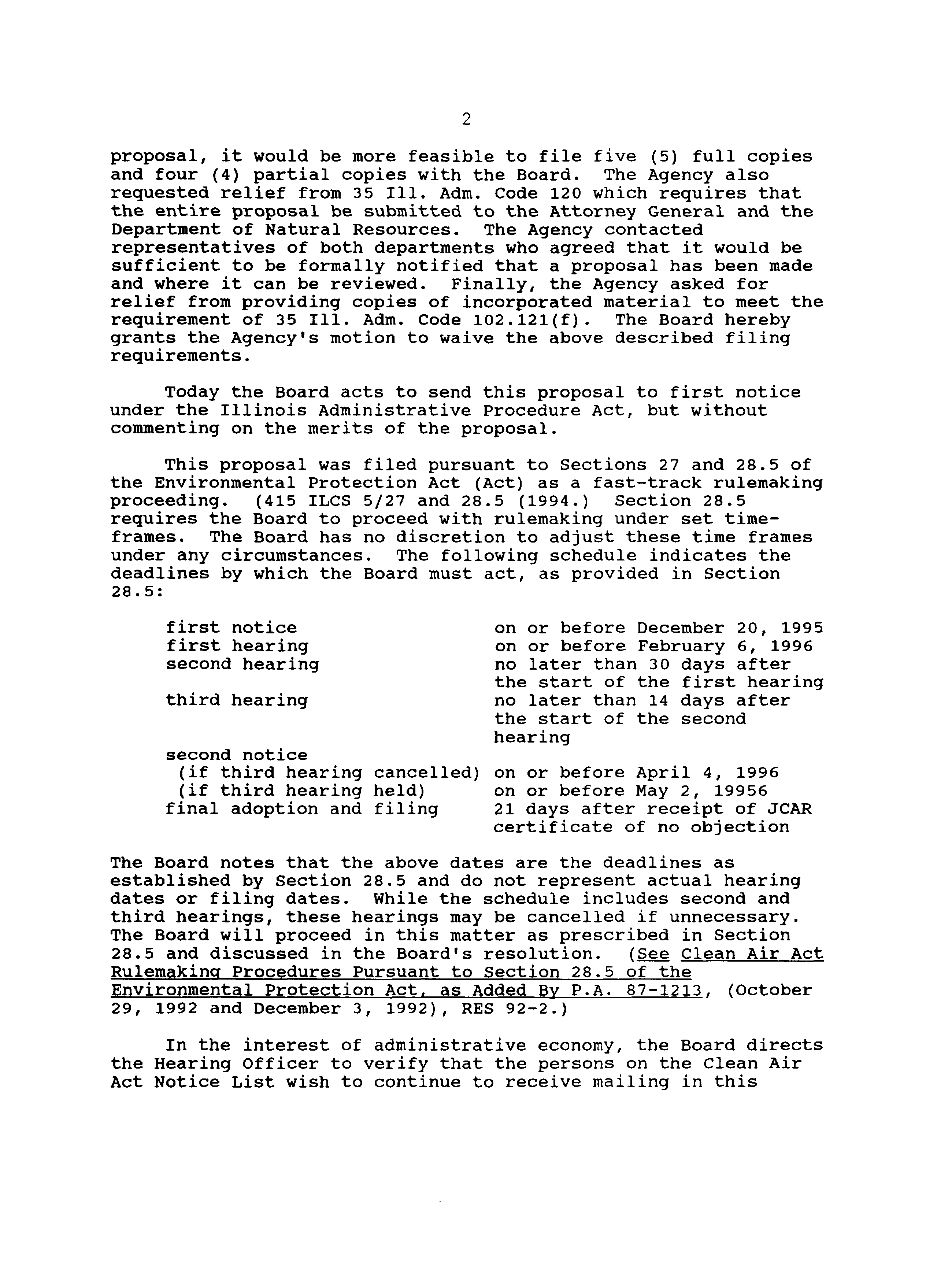

This proposal was filed pursuant to Sections 27 and 28.5 of

the Environmental Protection Act

(Act)

as a fast—track rulemaking

proceeding.

(415 ILCS 5/27 and 28.5

(1994.)

Section 28.5

requires the Board to proceed with rulemaking under set time—

frames.

The Board has no discretion to adjust these time frames

under any circumstances.

The following schedule indicates the

deadlines by which the Board must act, as provided in Section

28.5:

first notice

on or before December 20,

1995

first hearing

on or before February 6,

1996

second hearing

no later than 30 days after

the start of the first hearing

third hearing

no later than

14 days after

the start of the second

hearing

second notice

(if third hearing cancelled)

on or before April

4,

1996

(if third hearing held)

on or before May 2,

19956

final adoption and filing

21 days after receipt of JCAR

certificate of no objection

The Board notes that the above dates are the deadlines as

established by Section 28.5 and do not represent actual hearing

dates or filing dates.

While the schedule includes second and

third hearings,

these hearings may be cancelled if unnecessary.

The Board will proceed

in this matter as prescribed

in Section

28.5 and discussed in the Board’s resolution.

(~

Clean Air Act

Rulemaking Procedures Pursuant to Section 28.5 of the

Environmental Protection Act,

as Added By P.A.

87-1213,

(October

29,

1992 and December

3,

1992), RES 92—2.)

In the interest of administrative economy, the Board directs

the Hearing Officer to verify that the persons on the Clean Air

Act Notice List wish to continue to receive mailing

in this

3

proceeding.

ORDER

The Board directs the Clerk to cause publication of the

following amendments

in the Illinois Register for first notice:

TITLE 35:

ENVIRONMENTAL PROTECTION

SUBTITLE B:

AIR POLLUTION

CHAPTER

I:

POLLUTION CONTROL BOARD

SUBCHAPTER c:

EMISSIONS STANDARDS AND

LIMITATIONS FOR STATIONARY SOURCES

PART 218

ORGANIC MATERIAL EMISSION STANDARDS AND

LIMITATIONS FOR THE CHICAGO AREA

SUBPART A:

GENERAL PROVISIONS

Section

218. 100

218. 101

218. 102

218.103

218.104

218.105

218.106

218.107

218.108

218. 109

218.110

218

.

ill

218.112

218.113

218. 114

Introduction

Savings Clause

Abbreviations and Conversion Factors

Applicability

Definitions

Test Methods and Procedures

Compliance Dates

Operation of Afterburners

Exemptions, Variations, and Alternative Means of

Control or Compliance Determinations

Vapor Pressure of Volatile Organic Liquids

Vapor Pressure of Organic Material or Solvent

Vapor Pressure of Volatile Organic Material

Incorporations by Reference

Monitoring for Negligibly-Reactive Compounds

Compliance with Permit Conditions

SUBPART B:

ORGANIC EMISSIONS FROM STORAGE

AND LOADING OPERATIONS

Applicability for VOL

Control Requirements for Storage Containers of VOL

Storage Containers of VPL

Loading Operations

Petroleum Liquid Storage Tanks

External Floating Roofs

Compliance Dates

Compliance Plan (Repealed)

Testing VOL Operations

Monitoring VOL Operations

Recordkeeping and Reporting for VOL Operations

Section

218. 119

218.120

218.121

218. 122

218.123

218.124

218.125

218. 126

218.127

218.128

218.129

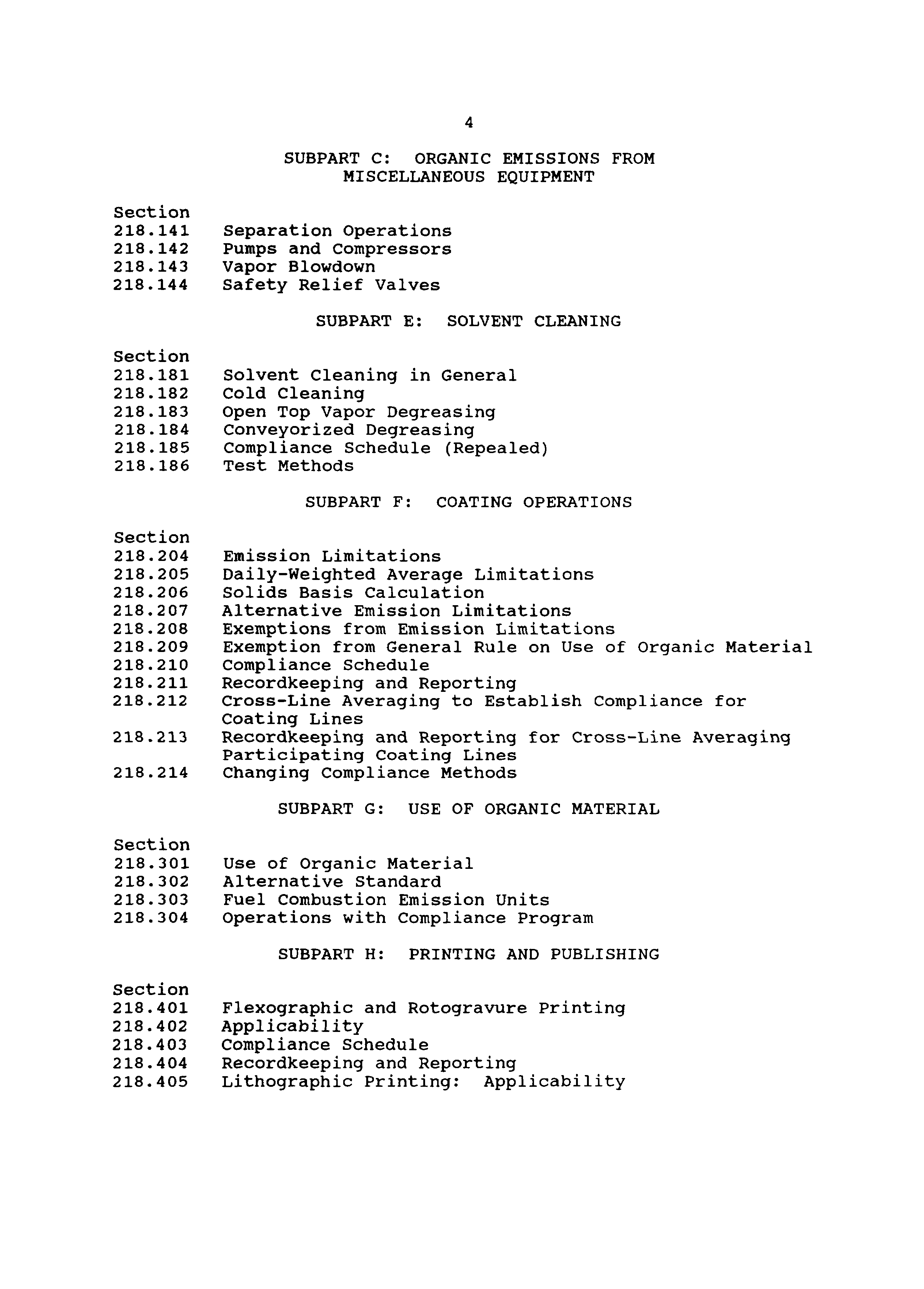

4

SUBPART

C:

ORGANIC EMISSIONS FROM

MISCELLANEOUS EQUIPMENT

Section

218.141

218.142

218.143

218.144

Separation Operations

Pumps and Compressors

Vapor Blowdown

Safety Relief Valves

SUBPART E:

SOLVENT CLEANING

SUBPART

F:

COATING OPERATIONS

Emission Limitations

Daily-Weighted Average Limitations

Solids Basis Calculation

Alternative Emission Limitations

Exemptions from Emission Limitations

Exemption from General Rule on Use of Organic Material

Compliance Schedule

Recordkeeping and Reporting

Cross-Line Averaging to Establish Compliance for

Coating Lines

218.213

Recordkeeping and Reporting for Cross—Line Averaging

Participating Coating Lines

218.214

Changing Compliance Methods

SUBPART

0:

USE OF ORGANIC MATERIAL

Use of Organic Material

Alternative Standard

Fuel Combustion Emission Units

Operations with Compliance Program

SUBPART H:

PRINTING AND PUBLISHING

Section

218.401

218.402

218.403

218.404

218.405

Flexographic and Rotogravure Printing

Applicability

Compliance Schedule

Recordkeeping and Reporting

Lithographic Printing:

Applicability

Solvent Cleaning in General

Cold Cleaning

Open Top Vapor Degreasing

Conveyorized Degreasing

Compliance Schedule

(Repealed)

Test Methods

Section

218.181

218.182

218.183

218.184

218.185

218.186

Section

218.204

218.205

218.206

218.207

218.208

218.209

218.210

218.211

218.212

Section

218.301

218.302

218.303

218.304

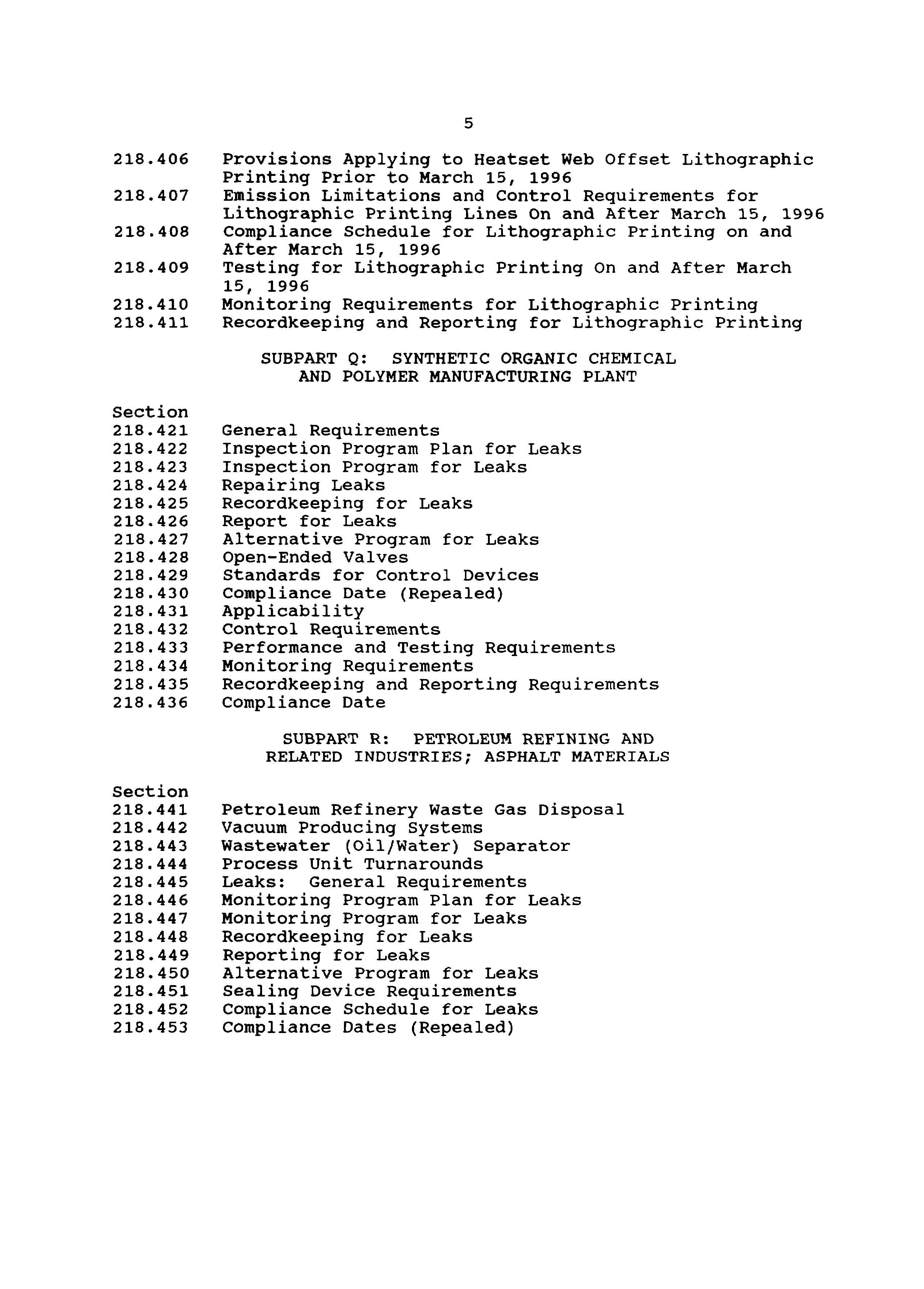

5

218.406

Provisions Applying to Heatset Web Offset Lithographic

Printing Prior to March

15,

1996

218.407

Emission Limitations and Control Requirements for

Lithographic Printing Lines On and After March 15, 1996

218.408

Compliance Schedule for Lithographic Printing on and

After March 15,

1996

218.409

Testing for Lithographic Printing On and After March

15,

1996

218.410

Monitoring Requirements for Lithographic Printing

218.411

Recordkeeping and Reporting for Lithographic Printing

SUBPART

Q:

SYNTHETIC ORGANIC CHEMICAL

AND

POLYMER

MANUFACTURING

PLANT

Section

218.421

218.422

218.423

218.424

218.425

218.426

2 18.427

218.428

218.429

218.430

218.43.

218.432

218.433

218.434

218.435

218.436

Section

218.441

218.442

218.443

218.444

218.445

218.446

218.447

218.448

218.449

218.450

218.451

218.452

218.453

General Requirements

Inspection Program Plan for Leaks

Inspection Program for Leaks

Repairing Leaks

Recordkeeping for Leaks

Report for Leaks

Alternative Program for Leaks

Open-Ended Valves

Standards for Control Devices

Compliance Date

(Repealed)

Applicability

Control Requirements

Performance and Testing Requirements

Monitoring

Requirements

Recordkeeping and Reporting Requirements

Compliance Date

SUBPART R:

PETROLEUM REFINING AND

RELATED INDUSTRIES; ASPHALT MATERIALS

Petroleum Refinery Waste Gas Disposal

Vacuum Producing Systems

Wastewater

(Oil/Water)

Separator

Process Unit Turnarounds

Leaks:

General Requirements

Monitoring Program Plan for Leaks

Monitoring Program for Leaks

Recordkeeping for Leaks

Reporting for Leaks

Alternative Program for Leaks

Sealing Device Requirements

Compliance Schedule for Leaks

Compliance

Dates

(Repealed)

6

SUBPART

5:

RUBBER

AND

MISCELLANEOUS

PLASTIC

PRODUCTS

Manufacture

of

Pneumatic Rubber Tires

Green

Tire

Spraying

Operations

Alternative

Emission

Reduction Systems

Emission Testing

Compliance Dates

(Repealed)

Compliance Plan

(Repealed)

SUBPART

T:

PHARMACEUTICAL MANUFACTURING

Section

218.480

Applicability

218.481

Control of Reactors,

Distillation Units,

Crystallizers,

Centrifuges and Vacuum Dryers

218.482

Control of Air Dryers, Production Equipment Exhaust

Systems and Filters

Material Storage and Transfer

In—Process Tanks

Leaks

Other Emission Units

Testing

Monitoring for Air Pollution Control Equipment

Recordkeeping for Air Pollution Control Equipment

SUBPART V:

BATCH OPERATIONS AND AIR

OXIDATION PROCESSES

Applicability for Batch Operations

Control Requirements for Batch Operations

Determination of Uncontrolled Total Annual Mass

Emissions and Average Flow Rate Values for Batch

Operations

218.503

Performance and Testing Requirements for Batch

Operations

Monitoring

Requirements

for

Batch

Operations

Reporting and Recordkeeping for Batch Operations

Compliance Date

Emission Limitations for Air Oxidation Processes

Definitions (Repealed)

Savings Clause

Compilance

Determination of Applicability

Emission Limitations for Air Oxidation Processes

(Renumbered)

218.526

Testing and Monitoring

218.527

Compliance Date

(Repealed)

Section

218.461

218.462

218.463

2 18.464

218.465

218.466

218.483

218.484

218.485

218.486

218.487

218.488

218.489

Section

218.500

218.501

218.502

218.504

218.505

2 18.506

218.520

218.521

218.522

218.523

218.524

218.525

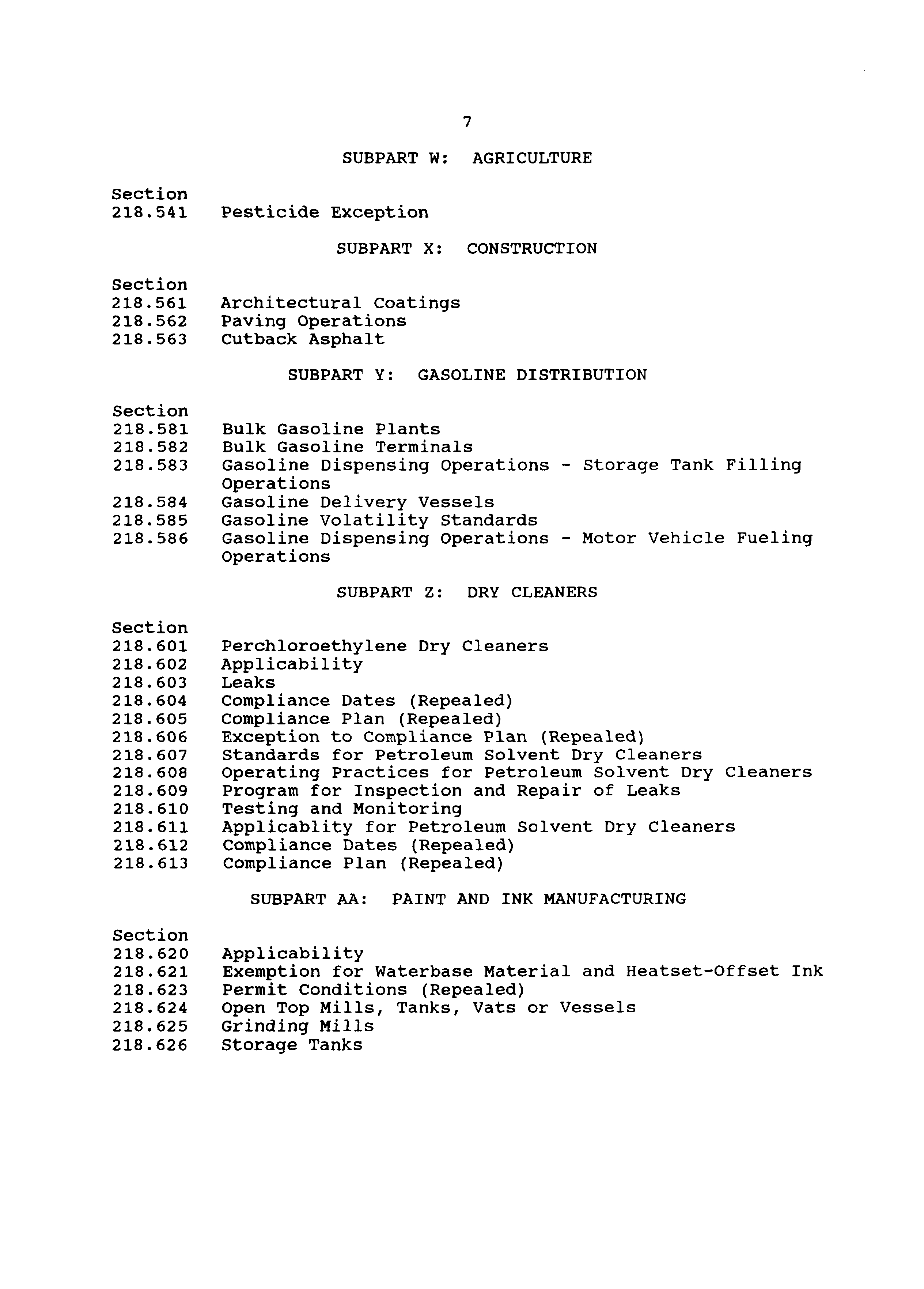

7

Section

218.54

1

SUBPART W:

Pesticide Exception

AGRICULTURE

Architectural Coatings

Paving Operations

Cutback Asphalt

Section

218.581

218.582

218.583

218.584

218.585

218.586

Bulk Gasoline Plants

Bulk Gasoline Terminals

Gasoline Dispensing Operations

-

Storage Tank Filling

Operations

Gasoline Delivery Vessels

Gasoline Volatility Standards

Gasoline Dispensing Operations

-

Motor Vehicle Fueling

Operations

SUBPART

Z:

DRY CLEANERS

Section

218.601

218.602

218.603

2 18.604

218.605

218 .606

218.607

218.608

218.609

218.610

218.611

218.612

218.613

Section

218.620

218.621

218.623

218.624

218.

625

218.626

Perchloroethylene Dry Cleaners

Applicability

Leaks

Compliance Dates

(Repealed)

Compliance Plan

(Repealed)

Exception to Compliance Plan (Repealed)

Standards for Petroleum Solvent Dry Cleaners

Operating Practices for Petroleum Solvent Dry Cleaners

Program for Inspection and Repair of Leaks

Testing and Monitoring

Applicablity for Petroleum Solvent Dry Cleaners

Compliance Dates

(Repealed)

Compliance Plan

(Repealed)

SUBPART AA:

PAINT AND INK MANUFACTURING

Applicability

Exemption for Waterbase Material and Heatset-Offset Ink

Permit Conditions

(Repealed)

Open Top Mills,

Tanks, Vats or Vessels

Grinding Mills

Storage Tanks

Section

218.561

218.562

218.563

SUBPART X:

CONSTRUCTION

SUBPART Y:

GASOLINE DISTRIBUTION

8

218.628

Leaks

218.630

Clean Up

218.636

Compliance Schedule

218.637

Recordkeeping and Reporting

SUBPART BB:

POLYSTYRENE PLANTS

Section

218.640

Applicability

218.642

Emissions Limitation

at Polystyrene Plants

218.644

Emissions Testing

SUBPART CC: POLYESTER RESIN PRODUCT

MANUFACTURING

PROCESS

Section

218.660

Applicability

218.666

Control Requirements

218.667

Compliance Schedule

218.668

Testing

218.670

Recordkeeping and Reporting for Exempt Emission Units

218.672

Recordkeeping and Reporting for Subject Emission Units

SUBPART DD: AEROSOL CAN FILLING

Section

218.680

Applicability

218.686

Control Requirements

218.688

Testing

218.690

Recordkeeping and Reporting for Exempt Emission Units

218.692

Recordkeeping and Reporting for Subject Emission Units

SUBPART FF:

BAKERY OVENS

(Repealed)

Section

218.720

Applicability

(Repealed)

218.722

Control Requirements

(Repealed)

218.726

Testing

(Repealed)

218.727

Monitoring

(Repealed)

218.728

Recordkeeping and Reporting

(Repealed)

218.729

Compliance Date

(Repealed)

218.730

Certification

(Repealed)

SUBPART GG:

MARINE TERMINALS

Section

218.760

Applicability

218.762

Control Requirements

218.764

Compliance Certification

218.766

Leaks

9

218.768

Testing and Monitoring

218.770

Recordkeeping and Reporting

SUBPART HH:

MOTOR VEHICLE REFINISHING

Section

218.780

218.782

2 18.784

218.786

218.787

2 18.788

218.789

218.790

218.791

218.792

218.875

218.877

218.879

218.881

218.883

218.886

Section

218.940

218.943

218.946

218.947

218.948

Section

218.960

218.963

218.966

Emission

Limitations

Alternative Control Requirements

Equipment Specifications

Surface Preparation Materials

Work Practices

Testing

Monitoring and Recordkeeping for Control Devices

General Recordkeeping and Reporting

Compliance Date

Registration

Applicability of Subpart BB

(Renumbered)

Emissions Limitation at Polystyrene Plants

(Renumbered)

Compliance Date

(Repealed)

Compliance Plan

(Repealed)

Special Requirements for Compliance Plan (Repealed)

Emissions Testing

(Renumbered)

SUBPART PP:

MISCELLANEOUS FABRICATED

PRODUCT MANUFACTURING PROCESSES

SUBPART QQ:

MISCELLANEOUS FORMULATION

MANUFACTURING

PROCESSES

Applicability

Permit Conditions

(Repealed)

Control Requirements

Compliance Schedule

Testing

SUBPART RR:

MISCELLANEOUS ORGANIC

CHEMICAL MANUFACTURING PROCESSES

Applicability

Permit Conditions

(Repealed)

Control Requirements

Section

218.920

218.923

218.926

218.927

218.928

Applicability

Permit Conditions

(Repealed)

Control Requirements

Compliance Schedule

Testing

10

218.967

Compliance Schedule

218.968

Testing

Exempt Emission Units

Subject Emission Units

Section 218.Appendix A:

Section 218.Appendix B:

Section 218.Appendix C:

Section 218.Appendix D:

Section 2l8.Appendix E:

Section 218.Appendix G:

Section 218.Appendix H:

List of Chemicals Defining Synthetic

Organic Chemical and Polymer

Manufacturing

VOM Measurement Techniques for Capture

Efficiency

Reference Methods and Procedures

Coefficients for the Total Resource

Effectiveness Index

(TRE)

Equation

List of Affected Marine Terminals

TRE Index Measurements for SOCMI

Reactors and Distillation Units

Baseline VOM Content Limitations for

Subpart F,

Section 218.212 Cross-Line

Averaging

AUTHORITY:

Implementing Section 10 and authorized by Section

28.5 of the Environmental Protection Act 415

ILCS 5/10 and

28.5.

SOURCE:

Adopted at R91-7 at 15 Ill.

Reg.

12231, effective August

16,

1991; amended in R91—23 at 16 Ill.

Reg.

13564, effective

August 24,

1992; amended in R91—28 and R91-30 at 16 Ill.

Reg.

13864, effective August 24,

1992; amended in R93-9

at 17

Ill.

Reg.

16636, effective September 27,

1993; amended in R93—l4 at 18

Ill. Reg. at

1945, effective January 24, 1994;

amended in R94-12

at 18 Ill. Reg.

at 14973, effective September 21,

1994;

amended

in R94—15 at

18 Ill. Reg.

16392, effective October 25,

1994;

amended in R94-16 at 18

Ill. Reg.

16950, effective November 15,

1994; amended in R94—2l,

R94—31 and R94—32 at 19

Ill.

Reg.

6848,

effective May 9,

1995; amended in R94—33 at 19 Ill. Reg.

7359,

effective May 22,

1995; amended at

_____

Ill. Reg.

effective

_____________________

Section

218.980

218.983

218.986

218.987

218.988

Section

218.990

218.991

SUBPART TT:

OTHER EMISSION UNITS

Applicability

Permit Conditions

(Repealed)

Control Requirements

Compliance Schedule

Testing

SUBPART UU:

RECORDKEEPING

AND

REPORTING

11

BOARD NOTE:

This Part implements the Environmental Protection

Act as of July

1,

1994.

SUBPART A:

GENERAL PROVISIONS

Section 218.110

Vapor Pressure of Organic Material or Solvent

a)

If the organic material or solvent consists of only a

single compound, the vapor pressure shall be determined

by ASTN Method D2879-86 (incorporated by reference in

Section 218.112 of this Part)

or the vapor pressure may

be obtained from a publication such as:

Boublik,

T.,

V. Fried and E. Hala,

“The Vapor Pressure of Pure

Substances,” Elsevier Scientific Publishing Co., New

York

(1973); Perry’s Chemical Engineer’s Handbook,

McGraw-Hill Book Company

(1984);

CRC Handbook of

Chemistry and Physics, Chemical Rubber Publishing

Company

(1986-87); and Lange’s Handbook of Chemistry,

John A.

Dean,

editor, McGraw-Hill Book Company

(1985).

b)

If the organic material or solvent is in a mixture made

up of both organic material compounds and compounds

which are not organic material,

the vapor pressure

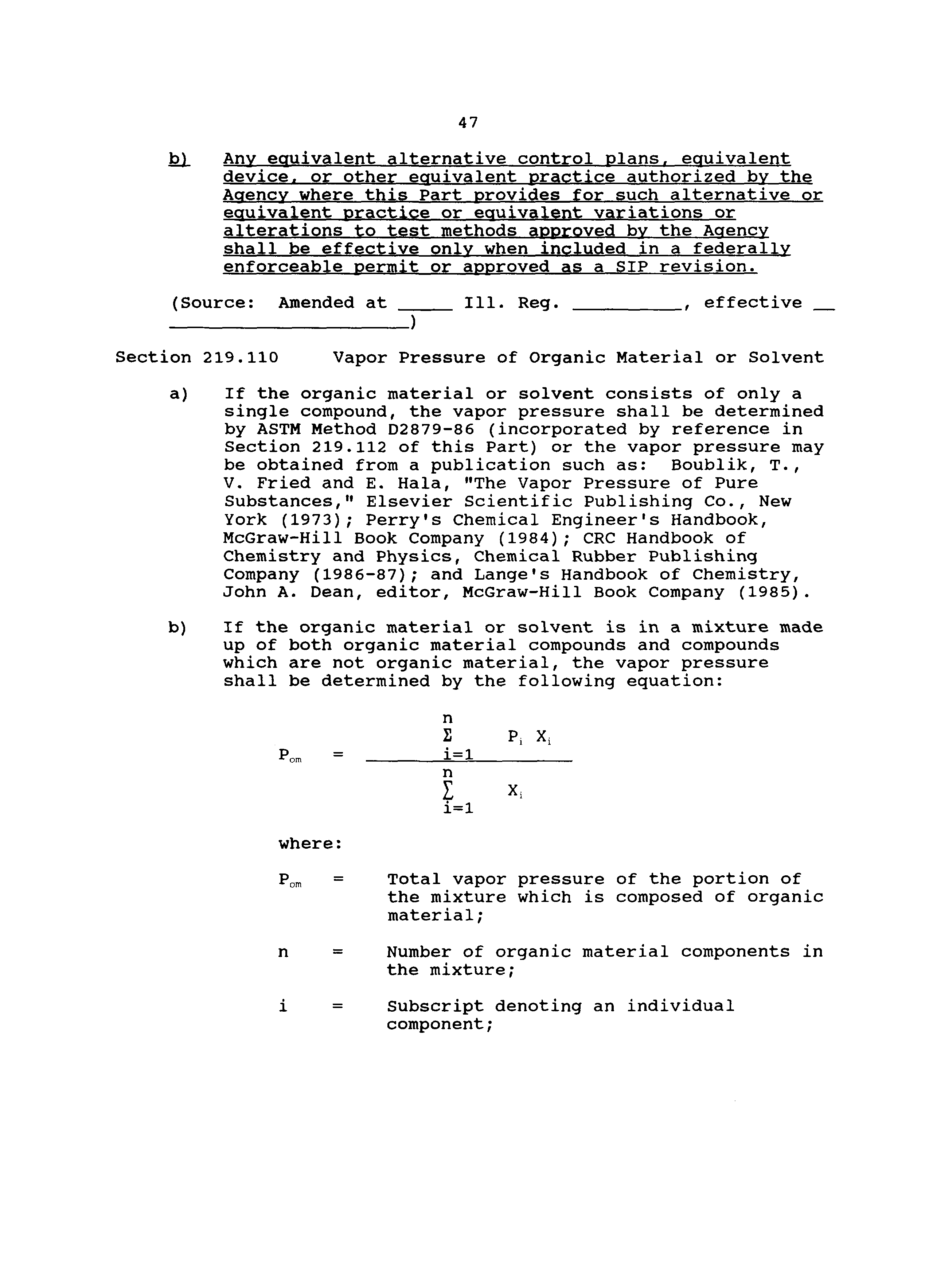

shall be determined by the following equation:

n

E

P,

X,

Pvom ~om

=

i=1

n

B

i=l

where:

Porn

=

Total vapor pressure of the portion of

the mixture which is composed of organic

material;

n

=

Number of organic material components

in

the mixture;

i

=

Subscript denoting an individual

component;

P1

=

Vapor pressure of an organic material

component determined

in accordance with

subsection

(a)

of this Section;

Xl

=

Mole fraction of the organic material

component of the total organic mixture.

12

c)

If the organic material or solvent is

in a mixture made

up of only organic material compounds, the vapor

pressure shall be determined by ASTM Method D2879-86

(incorporated by reference

in Section 218.112

of this

Part)

or by the above equation.

(Source:

Amended at

_____

Ill. Req.

__________,

effective

—

_______________________________________________________

)

Section 218.111

Vapor Pressure of Volatile Organic Material

a)

If the VON consists of only a single compound,

the

vapor pressure shall be determined by ASTM Method

D2879—86

(incorporated by reference

in Section 218.112

of this Part)

or the vapor pressure may be obtained

from a publication such as:

Boublik, T.,

V.

Fried and

E. Hala,

“The Vapor Pressure of Pure Substances,”

Elsevier Scientific Publishing Co., New York

(1973);

Perry’s Chemical Engineer’s Handbook, McGraw-Hill Book

Company

(1984); CRC Handbook of Chemistry and Physics,

Chemical Rubber Publishing Company

(1986-87); and

Lange’s Handbook of Chemistry,

John A.

Dean, editor,

McGraw-Hill Book Company

(1985).

b)

If the VOM is in

a mixture made up of both VOM

compounds and compounds which are not VOM, the vapor

pressure shall be determined by the following equation:

n

B

P,

X,

~vom

=

i=1

n

B

x,

1=1

where:

Pvom

=

Total vapor pressure of the portion of

the mixture which

is composed of VOM;

n

=

Number of VOM components

in the mixture;

i

=

Subscript denoting an individual

component;

P1

=

Vapor pressure of a VOM component

determined

in accordance with subsection

(a)

of this Section;

Xi

=

Mole fraction of the VOM component of

13

the total organic mixture.

c)

If the VOM is in a mixture made up of only VOM

compounds, the vapor pressure shall be determined by

ASTM Method D2879-86

(incorporated by reference in

Section 218.112

of this Part)

or by the above equation.

(Source:

Amended at

_____

Ill.

Reg.

_________,

effective

—

____________________________________________________________

)

SUBPART

F:

COATING OPERATIONS

Section 218.208

Exemptions From Emission Limitations

a)

Exemptions for all coating categories except wood

furniture coating.

The limitations of this Subpart

shall not apply to coating lines within a source,

that

otherwise would be subject to the same subsection of

Section 218.204

(because they belong to the same

coating category,

e.g.

can coating), provided that

combined actual emissions of VOM from all lines at the

source subject to that subsection never exceed 6.8

kg/day

15

lbs/day

before the application of capture

systems and control devices.

(For example, can coating

lines within a source would not be subject to the

limitations of Section 218.204(b)

of this Subpart if

the combined actual emissions of VON from the can

coating lines never exceed 6.8 kg/day

15

lbs/day

before the application of capture systems and control

devices.)

Volatile organic material emissions from

heavy off-highway vehicle products coating lines must

be combined with VOM emissions from miscellaneous metal

parts and products coating lines to determine

applicability.

Any owner or operator of a coating

source shall comply with the applicable coating

analysis test methods and procedures specified in

Section 218.105(a)

of this Part and the recordkeeping

and reporting requirements specified in Section

218.211(a)

of this Subpart if total VOM emissions from

the subject coating lines are always less than or equal

to 6.8 kg/day

15

lbs/day

before the application of

capture systems and control devices and,

therefore, are

not subject to the limitations of Section 218.204 of

this Subpart.

Once a category of coating lines at a

source is subject to the limitations

in Section 218.204

of this Subpart the coating lines are always subject to

the limitations in Section 218.204

of this Subpart.

b)

Applicability for wood furniture coating

14

1)

The limitations of this Subpart shall apply to a

source’s wood furniture coating lines if the

source contains process emission units,

not

regulated by Subparts B,

E, F (excluding Section

218.204(1)

of this Subpart), H (excluding Section

218.405 of this Part),

Q,

R,

5, T

(excluding

Section 218.486 of this Part),

V,

X,

Y, or BB of

this Part, which as a group both:

A)

Have a maximum theoretical emissions of 91 Mg

(100 tons)

or more per calendar year of VOM

if no air pollution control equipment were

used,

and

B)

Are not limited to less than

91 Mg

(100 tons)

of VON per calendar year

if no air pollution

control equipment were used, through

production or capacity limitations contained

in a federally enforceable permit or SIP

revision.

2)

The limitations of this Subpart shall apply to a

source’s wood furniture coating

lines,

on and

after March 15,

1996,

if the source contains

process emission units, which as

a group,

have a

potential to emit 22.7 Mg

(25 tons)

or more of VOM

per calendar year and have not limited emissions

to less than 22.7 Mg

(25 tons)

of VOM per calendar

year through production or capacity limitations

contained in a federally enforceable operating

permit or SIP revision,

and which:

A)

Are not regulated by Subparts B,

E,

F

(excluding Section 218.204(1)

of this

Subpart),

H,

Q,

R,

S, T

(excluding Section

218.486 of this Part),

V,

X,

Y,

Z

or BB of

this Part; and

B)

Are not included

in any of the following

categories:

synthetic organic chemical

manufacturing industry

(SOCMI)

distillation,

SOCMI reactors,

plastic parts coating

(business machines), plastic parts coating

(other), offset lithography,

industrial

wastewater, autobody refinishing, SOCMI batch

processing, volatile organic liquid storage

tanks and clean-up solvents operations.

3)

If a source ceases to fulfill the criteria of

subsection

(b) (1)

or

(b) (2)

of this Section, the

15

limitations of Section 218.204(1)

of this Subpart

shall continue to apply to any wood furniture

coating line which was ever subject to the

limitations of Section 218.204(1)

of this Subpart.

4)

For the purposes of subsection

(b)

of this

Section, an emission unit shall be considered to

be regulated by a Subpart if it is subject to the

limitations of that Subpart.

An emission unit is

not considered regulated by a Subpart

if it

is not

subject to the limits of that Subpart,

e.g.,

the

emission unit is covered by an exemption in the

Subpart or the applicability criteria of the

Subpart are not met.

5)

Any owner or operator of a wood furniture coating

line to which the limitations of this Subpart are

not applicable due to the criteria

in subsection

(b) of this Section shall, upon request by the

Agency or the USEPA,

submit records to the Agency

and the USEPA within 30 calendar days from the

date of the request that document that the coating

line is exempt from the limitations of this

Subpart.

C)

On and after March 15,

1996,

the limitations of this

Subpart shall not apply to touch—up and repair coatings

used by a coating source described by subsections

218.204(b),

(d),

(f),

(g),

(i),

(j),

(n) and

(0)

of

this Subpart; provided that the source-wide volume of

such coatings used does not exceed 0.95

1

(1 quart) per

eight—hour period or exceed 209 1/yr

55

gal/yr

for

any rolling twelve month period.

Recordkeeping and

reporting for touch—up and repair coatings shall be

consistent with Section 218.211(b) (4)

of this Subpart

subsection

(d)

of this Section.

d)

On and after March 15,

1996,

the owner or operator of a

coating line or a group of coating lines using touch—up

and repair coatings that are exempted from the

limitations of Section 218.204(b),

(d),

(f),

(g),

(i),

(j),

(n) and

(o)

of this Subpart because of the

provisions of Section 218.208(c)

of this Subpart shall:

1)

Collect and record the name,

identification

number, and volume used of each touch—up and

repair coating,

as applied on each coating line,

per eight-hour period and per month;

2)

Perform calculations on a daily basis,

and

16

maintain at the source records of such

calculations, of the combined volume of touch—up

and repair coatings used source—wide for each

eight-hour period;

3)

Perform calculations on

a monthly basis,

and

maintain at the source records of such

calculations, of the combined volume of touch-up

and repair coatings used source—wide for the month

and the rolling twelve month period;

4)

Prepare and maintain at the source an annual

summary of the information required to be compiled

pursuant to subsections

(c) (4) (A)

and

(c) (4) (B)

(d) (1)

and

(d) (2)

of this Section on or before

January 31 of the following year;

5)

Maintain at the source for a minimum period of

three years all records required to be kept under

this subsection and make such records available to

the Agency upon request;

6)

Notify the Agency in writing

if the use of touch-

up and repair coatings at the source ever exceeds

a volume of 0.95

1

(1 quart)

per eight-hour period

or exceeds 209 1/yr

-f-j55

gal/yr-J-j for any rolling

twelve month period within 30 days after any such

exceedance.

Such notification shall include a

copy of any records of such exceedance; and

7)

“Touch—up and repair coatings” means,

for purposes

of 35 Ill. Adm. Code 218.208, any coating used to

cover minor scratches and nicks that occur during

manufacturing and assembly processes.

(Source:

Amended at

_____

Ill.

Reg.

__________,

effective

SUBPART Q:

SYNTHETIC ORGANIC CHEMICAL

AND POLYMER MANUFACTURING PLANT

Section 218.431

Applicability

a)

The provisions of Sections 218.431 through 218.436 of

this Subpart shall apply to:

1)

Every owner or operator of any chemical

manufacturing process unit that manufactures, as a

primary product, one or more of the chemicals

17

listed in Appendix A of this Part and that

chemical manufacturing process unit causes or

allows any reactor or distillation unit,

either

individually or

in tandem,

to discharge one or

more process vent streams either directly to the

atmosphere or to a recovery system.

2)

All continuous distillation and reactor process

emission units not subject to Section 218.520

through 218.527 of this Part, and located within

Stepan Company’s Millsdale manufacturing facility,

Elwood, Illinois.

b)

Notwithstanding subsection

(a)

of this Section, the

control requirements set forth within Section 218.432

of this Subpart shall not apply to the following:

1)

Any process vent stream with

a total resource

effectiveness

(TRE)

index value greater than 10.

However,

such process vent stream remains subject

to the performance testing requirements contained

in Section 218.433 of this Subpart and the

reporting and recordkeeping requirements contained

in Section 218.435

of this Subpart;

2)

Any reactor or distillation unit that

is designed

and operated as a batch operation;

3)

Any reactor or distillation unit that

is part of a

polymer manufacturing operation;

4)

Any reactor or distillation unit that

is part of

the chemical manufacturing process unit with a

total design capacity of less than

1 gigagram

(1,100 tons) per year for all chemicals produced,

as a primary product, within that process unit.

However,

such operations remain subject to the

reporting and recordkeeping requirements contained

in Section 218.435(d)

of this Subpart;

5)

Any vent stream with a flow rate less than 0.0085

scm/mm

or a total VOM concentration of less than

500 ppniv,

less methane and ethane,

as measured by

Method 18, or a concentration of VOM of less than

250 ppmv as measured by Method 25A.

However, such

operations remain subject to the performance

testing requirement listed in Section 218.433 of

this Subpart,

as well as the reporting and

recordkeeping requirements contained in Section

218.435

of this Subpart; or

18

6)

Any reactor or distillation unit included within

an Early Reduction Program,

as specified in 40 CFR

63, and published

in

57

Fed.

Reg.

61970

(October

22,

1993) jDecember 29,

1992), evidenced by a

timely enforceable commitment approved by USEPA.

(Source:

Amended at

_____

Ill.

Reg.

_________,

effective

—

Section 218.434

Monitoring Requirements

a)

The owner or operator of a source subject to the control

requirements

in Section 218.432 of this Subpart that uses an

incinerator to comply with the VOM emission limitation

specified

in Section 218.432 (a) (1)

shall install, calibrate,

maintain,

and operate, according to manufacturer’s

specifications,

a temperature monitoring device equipped

with a continuous recorder and having an accuracy of ±1

percent of the temperature measured expressed

in degress

Celsius,

or ±0.5°C,whichever is greater.

1)

Where an incinerator other than a catalytic incinerator

is used,

a temperature monitoring device shall be

installed

in the firebox.

2)

Where a catalytic incinerator is used, temperature

monitoring devices shall be installed in the gas stream

immediately before and after the catalyst bed.

b)

The owner or operator of a source that uses

a flare to

comply with Section 218.432(a) (2)

of this Subpart shall

install, calibrate, maintain and operate, according to

manufacturer’s specifications,

a heat—sensing device,

such

as an ultraviolet beam sensor or thermocouple,

at the pilot

light to indicate continuous presence of a flame.

c)

The owner or operator of a source that uses a boiler or

process heater with a design heat input capacity less than

44 megawatts to comply with Section 218.432(a) (1)

of this

Subpart shall install, calibrate, maintain and operate,

according to the manufacturer’s specifications,

a

temperature monitoring device in the firebox.

The

monitoring device shall be equipped with a continuous

recorder with an accuracy of ±1percent of the temperature

being measured expressed in degrees Celsius or ±0.5°C,

whichever is greater.

Any boiler or process heater in which

all vent streams are introduced with primary fuel

is exempt

from this requirement.

d)

The owner or operator of

a process vent with

a TRE index

19

value of 4.0 or less that uses one or more product recovery

devices shall install either an organic monitoring device

equipped with a continuous recorder or the monitoring

equipment specified in subsections

(d) (1),

(d) (2),

(d) (3)

or

(d) (4)

of this Section, depending on the type of recovery

device used.

All monitoring equipment shall be installed,

calibrated and maintained according to the manufacturer’s

specifications.

1)

Where an absorber is the final recovery device in the

recovery system,

a scrubbing liquid temperature

monitoring device and a specific gravity monitoring

device,

each equipped with a continuous recorder,

shall

be used.

2)

Where a condenser is the final recovery device in the

recovery system,

a condenser exit

(product side)

temperature monitoring device equipped with

a

continuous recorder and having an accuracy of ±1

percent of the temperature being monitored expressed in

degrees Celsius or ±0.5°C,whichever

is greater.

3)

Where a carbon adsorber is the final recovery device in

the recovery system, an integrating regeneration Qtream

steam flow monitoring device having an accuracy of ±10

percent, capable of recording the total regeneration

strcam steam mass flow for each regeneration cycle;

and

a carbon bed temperature monitoring device having an

accuracy of ±1percent of the temperature being

monitored expressed in degrees Celsius of ±0.5°C,

capable of recording the carbon bed temperature after

each regeneration and within

15 minutes of completing

any cooling cycle.

4)

Where a scrubber is used with an incinerator,

boiler,

or,

in the case of halogenated vent streams,

a process

heater, the following monitoring equipment

is required

for

the

scrubber:

A)

A

pH

monitoring

device

equipped

with

a

continuous

recorder to monitor the pH

of

the

scrubber

effluent;

and

B)

Flow meters equipped with a continuous recorder at

the scrubber influent for liquid flow and the

scrubber inlet for gas stream flow.

e)

The owner or operator of a process vent using a vent system

that contains bypass lines capable of diverting a vent

stream away from the control device associated with a

20

process vent shall comply with either

(e) (1)

or

(e) (2)

of

this Section.

Equipment needed for safety purposes,

including, but not limited to, pressure relief devices, are

not subject to this subsection.

1)

The owner or operator shall install, calibrate,

maintain and operate a flow indicator that provides a

record of vent stream flow at least once every 15

minutes.

The flow indicator shall be installed at the

entrance to any bypass line that could divert the vent

stream away from the control device to the atmosphere.

2)

The owner or operator shall secure the bypass line

valve in the closed position with a car-seal or a

lock-and-key type configuration.

A visual inspection

of the seal or closure mechanism shall be performed at

least once every month to ensure that the valve is

maintained in the closed position and the vent stream

is not diverted through the bypass line.

f)

The owner or operator of a process vent may monitor by an

equivalent alternative means or parameters other than those

listed in subsections

(a) through

(d)

of this Section.

Any

equivalent alternative shall be approved by the Agency and

USEPA, and contained in the source’s operating permit as

federally enforceable permit conditions.

(Source:

Amended at

Ill. Reg.

_________,

effective

Section 218.435

Recordkeeping and Reporting Requirements

a)

Every owner or operator of a reactor or distillation unit

with a TRE index value of 4.0 or less shall keep records,

for a minimum of

3 years,

of the following parameters

measured during a performance test or TRE determination

required under Section 218.433 of this Subpart, and required

to be monitored under Section 218.434 of this Subpart.

1)

Every owner or operator of a source that seeks to

demonstrate compliance with Section 218.432 (a) (1)

of

this Subpart through the use of either a thermal or

catalytic incinerator shall maintain records of the

following:

A)

The average firebox temperature of the incinerator

(or the average temperature upstream and

downstream of the catalyst bed for a catalytic

incinerator), measured at least every 15 minutes

and averaged over the same time period of the

21

performance testing; and

B)

The percent reduction of VOM determined as

specified in Section 218.433(c)

of this Subpart

achieved by the incinerator,

or the concentration

of VOM (ppmv,

by compound)

determined as specified

in Section 218.433(c)

of this Subpart at the

outlet of the control device,

on a dry basis,

corrected to

3 percent oxygen.

2)

Every owner or operator of a source that seeks to

demonstrate compliance with Section 218.432 (a) (1)

of

this Subpart through the use of a boiler or process

heater shall maintain the records described below.

Any

boiler or process heater in which all vent streams are

introduced with primary fuel are exempt from these

requirements.

A)

A description of the location at which the vent

stream is introduced into the boiler or process

heater; and

B)

The average combustion temperature of the boiler

or process heater with a design heat input

capacity of less than 44 megawatt measured at

least every 15 minutes and averaged over the same

time period of the performance testing.

3)

Every owner or operator of a source that seeks to

demonstrate compliance with Section 218.432 (a) (2)

of

this Subpart through use of a smokeless

flare,

or flare

design

(i.e., steam—assisted,

air—assisted,

or

nonassisted), shall maintain records of all visible

emission readings, heat content determinations,

flow

rate measurements, and exit velocity determinations

made during the performance test,

continuous records of

the flare pilot flame monitoring, and records of all

periods of operations during which the pilot flame is

absent.

4)

Every owner or operator of a source that seeks to

demonstrate compliance with Section 218.432(b)

of this

Subpart shall maintain records of the following:

A)

Where an absorber is the final recovery device

in

the recovery system,

the exit specific gravity

(or

alternative parameter which is a measure of the

degree of absorbing liquid saturation,

if approved

by the Agency and USEPA, and average exit

temperature of the absorbing liquid measured at

22

least every 15 minutes and averaged over the same

time period as the performance testing

(both

measured while the vent stream is normally routed

and constituted);

B)

Where a condenser is the final recovery device in

the recovery system, the average exit

(product

side)

temperature measured at least every 15

minutes and averaged over the same time period as

the performance testing while the vent stream is

normally routed and constituted;

C)

Where

a carbon absorber is the final recovery

device in the recovery system,

the total strcam

steam mass or volumetric flow measured at least

every 15 minutes and averaged over the same time

period as the performance testing

(full carbon bed

cycle),

the temperature of the carbon bed after

regeneration

(and within 15 minutes

of completion

of any cooling cycle(s)),

and duration of the

carbon bed steaming cycle

(all measured while the

vent stream is normally routed and constituted);

D)

As an alternative to subsection

(a) (4) (A),

(a) (4) (B)

or

(a) (4) (C)

of this Section, the

concentration level or reading indicated by the

organic monitoring device at the outlet of the

absorber,

condenser,

or carbon absorber,

measured

at least every 15 minutes and averaged over the

same time period as the performance testing

(measured while the vent stream

is normally routed

and constituted);

or

E)

All measurements and calculations performed to

determine the flow rate,

VOM concentration,

heating value,

and TRE index value of the vent

stream.

b)

Every owner or operator of a reactor or distillation unit

with a TRE index value of less than 4.0 shall be subject to

the exceedance reporting requirements of the draft Enhanced

Monitoring Guidelines as published at 58 Fed.

Reg.

54648

(October 22,

1993).

c)

Every owner or operator of a source seeking to comply with

Section 218.432(b)

of this Subpart shall maintain records of

the following:

1)

Any changes in production capacity,

feedstock type,

catalyst type,

or of any replacement,

removal,

or

23

addition of recovery equipment or reactors and

distillation units; and

2)

Any recalculation of the flow rate, VON concentration,

or TRE index value calculated according to Section

(c)

of Appendix G of this Part.

d)

Every owner or operator of a source claiming a design

capacity of less than

1 gigagram (1,100 tons)

per year,

as

contained in Section 218.431(b)

of this Subpart, shall

maintain records of the design capacity or any changes

in

equipment or operations that may affect the design capacity.

e)

Every owner or operator of

a source claiming a vent stream

flow rate or vent stream concentration exemption level,

as

contained in Section 218.431(b) (5)

of this Subpart, shall

maintain records to indicate that the stream flow rate is

less than 0.0085 scm/mm

or the vent stream concentration

is

less than 500 ppmv.

(Source:

Amended at

_____

Ill.

Reg.

__________

,

effective

—

SUBPART FF:

BAKERY OVENS

(Repealed)

Section 218.720

Applicability (Repealed)

a)

The provisions of this Subpart shall apply to every

owner or operator of a source which operates a bakery

oven,

as defined at 35

Ill. Admin.

Code 2l1.C80, unless

tihc~

source bakes products only for on—site human

n-mntion or on—site retail sale.

~thatanding

~_~~on

(a) of this Section,

source

w

LLgulrcd to comply with the control

~

~

“dart

orL;

~

i

i

v

i

i

i. ii

c

ci

u r-

ci ci

h

z

~

th

ci

rcguiremefltci

cli-

iriii~

r.tirir

potential

to cmii~

~

i

my

(.z

LUflL~)

or

more of VON per

year,

in the aggregate,

from all emission units at the

source,

cxc lud.~....,.

1)

Emission units regulated by Subparts B,

E,

F,

H,

Q,

R,

C,

T

(excluding Section 218.486

of this

Part),

V,

X,

Y,

Z or BB of this Part;

and

2)

Emissi,.,., units that

...~

inc1~~.-L. ~

of the

following categories:

synthetic organic chemical

manufacturing industry

(COCHI)

distillation,

COCMI~

reactors, wood furniture coating, plastic parts

coating (business machines),

plastic parts coating

24

(other), offset lithography,

industrial

wastcwater,

autobody refinishing,

COCHI batch

processing,

volatile organic liquid storage tanks

~

~n—’~

oolvent~

operations.

Every owner or operator of a source which has limited

its i~ntcntialto emit below 22.7 Mg

(25 tons)

of VON

per year,

as specified in subsection

(b)

of this

Section, through federally enforceable permit

conditions

is not required to comply with this Subpart.

d)

Every

owner

or

CXCIU~L

irum

t~.nc

control

rcquircmcn-w

01

LfllB

~UD~UEt

because of the criteria in subsection

(b)

of this

Section remains ~ubjcct

to the rccordkccping and

reporting requirements of Section 218.728(b)

Subpart and the certification rcquircmcnto

in

of this

Scotion

.~it~.ii0(d)

of

this

Subpart.

(Source: Repealed at

_____

Ill. Reg.

__________,

effective

—

Section 218.722

Control Requirements

(Repealed)

~vcry

owner

nr

nn~r.~torof

a source subject to the

control requirements of this Subpart shall comply wi’cn

the requirements of subsection

(a) (1)

or

(a) (2)

of this

Section for each bakery oven with a rated heat input

capacity of at least

2 mmbtu/hr or at least 586

kW:

1)

Operate emissions capture and control equipment

which achieves an overall reduction

in

uncontrolled VON emissions of at least

n,-’rs-’r~ni

~‘-‘-

such

bakcry

~

2)

Provide

an

equivalent

alternative

c

suon

~akcry

ovens

at

tnc

source

wnion

nas

ucen

approves

oy

tnc

Agency

ana

UCEPA

tnrrillTn Icacrally

enforceable

permit

conai~.....

revision.

b)

An owner or operator of a source subject to the control

requirements of this Subpart may elect to exempt from

the control requirements

in subsections

(a) (1)

or

(a) (2) and

(c) (1)

or

(c) (2)

of this Section any bakery

oven with actual VON emissions

less than or equal to

15

TPY; provided that the total actual VON emissions from

all such exempt bakery ovens never exceed 25 TPY.

25

‘a~s

t~

.-Th#-n.-

—‘..—..~.

~——~..—.——‘.

~.a

‘as

~

ovens at the source which has been

approved

by

the Agency and UCEPA through federally

enforceable permit conditions or as a SIP

revision.

d)

Any bakery oven that becomes subject to the

requirements of this Subpart

at any time shall remain

subject to the requirements of this Subpart at all

times thereafter.

(Source: Repealed at

Ill.

Reg.

__________

,

effective

—

Section 218.726

Testing

(Repealed)

I

~--.4--’-.

4-----~~

(a)

of

..~.

this Section, until March

15,

1998,

only,

a

source

may

elect to comply with the control requirements

in

subsection

(c) (1)

or

(0)

(2)

of this Section, rather

than the control requirements

in subsection

(a) (1)

or

(a) (2)

of this Section,

if all emission units at the

source,

in the aggregate, excluding emission units

regulated by Subparts B,

E,

F, H (excluding Section

218.405 of this Subpart),

Q,

R,

5,

T (excluding Section

218.486 of this Subpart),

V,

X,

Y,

Z

or BB of this

Part, have maximum theoretical emissions of

less than

90.7 Mg

(100 tons)

of VON p~r

v~ar or

are limited to

1a”~i

th.,ri

r)fl7

Mg

(iflO

fcinr~i

rn-

vat

~mi’~ic1n’~

pm

in the

ak...~.......-e of ai

~l1uti...

-ee&’~’

~

through production or capacity limitati~.~

_c__,

._1,__

c______t1

__~!s..

_~__11s..1

in

~11I1CU

in

icacrui~ycniorocuuic

p~riu1Leoriuii~ion~

or

a SIP revision:

1)

Operate emissions capture and control equipment

which

achieves

an

overall

reduction

in

uncontrolled

VON emissions of at least

CO

percent

from each bakery oven with

a

rated heat input

capacity of at least

2 mmbtu/hr

or

at least 586

KW; or

2)

Provide

an equivalent alternative control plan for

suun

tests in accordance with the applicable test methods

and procedures specified

in Section 218.105(f)

of this

Part to demonstrate compliance with the control

requirements of this Subpart and shall:

1)

Notify the Agency 30 days prior to conducting such

26

tcsts~ and

2)

Submit all test

days of ccnduc1~

b)

Nothing in this Section shall limit the authority of

UCEPA pursuant to the Clean Air Act

(CAA)

to require

testing, or shall affect the authority of USEPA unde

Section

114 of the

CAA

(42

U.S.C.

7414

(1990)—)--

(Source: Repealed at

_____

Ill. Reg.

_________,

effective

—

Section 218.727

Monitoring

(Repealed)

a)

Every owner or operator of

a bakery oven subject to the

control requirements of this Subpart shall install and

operate at all times a device to continuously monitor

the following parameters for each type of control

device as

follow-si-

1)

For catalytic oxidizers,

the inlet and outlet

temperatures

of the oxidizer;

2)

For regenerative oxidizers,

the temperature in the

combustion chamber;

or

3)

For thermal incinerators,

the temperature in the

combustion chamber.

‘‘~‘

‘~“~ ‘~

~

may monitor with an alternative

“-~ametcrs if approved by the

enforceable permit

(Source: Repealed at

_____

Ill.

Reg.

__________,

effective

—

Section 218.728

Recordkeeping and Reporting

(Repealed)

a)

Every

owner

or

operator

of

a

bakery

oven

shall

maintain

the following records for the moot recent consecutive

3

year period for all bakery ovens subject

to the control

requirements of this Subpart.

Such records shall be

made available to the Agency immediately upon request.

.1

—F

methodo; ;;ni~~~

Agency

and

UCEPA

through

federally

conditions or as a SIP revision.

1)

Parameters for control devices as monitored

pursuant to Section 218.727 of this Subpart

27

2)

Hrs/day of operation of

each

bakery

ovcn-j-ET?1 w?144 736 m?473 736 l?S?BT?

3)

Factors necessary to calculate VON omissions for

all bakery ovens including, but not limited to,

type of dough used for each yeast-leavened baked

product,

initial yeast percentage for

ea-e1~i

product, total fermentation time for each product,

any additional percentage of yeast added,

and the

fermentation time of any additional yeas-ti

C~tlculateddaily VON cmiooi~~

-ef

~ch

bakery

expressed

as

lbs/day;

5)

Total

amount

of

each

type

of

yeast-l

product

produced

by

each

bakery

oven

lbs/day.

b)

Every owner or operator of a bakery oven which

is

exempt from the control requirements of this Subpart

because of the criteria

in Section 218.720(b)

of this

Subpart shall maintain records necessary to demonstrate

that its potential to emit is less than 22.7 Mg

(25

tons)

of VON per year,

as

218.720(b).

Such ret-!r~~d~

mos’-

-cacnt

~cified

in Ccct~-~

“~‘‘

l-~-~

maintained for ~-‘-e

-3-

period and shall

be

-~

available to the Agency immediately upon request.

1tt’-..’-—’—.

a)

Every owner

exempt from

or

the

operator

control

of a bakery

requirements

oven whic

of this

h is

Subpart

because of the criteria specified in Section 218.722(b)-

of this Subpart shall:

1)

ctua’

¶1f~1R

.1

~.-.-~_-

~

necessary

1r~

m~n~.i1r

th~i-

Fhi

~

from

exempt

bakery

or

equal

to

15

TPY

for

each

bakery

oven

and

less than or equal to 25 TPY from all

exempt

b~kcryovens combined.

Such records shall

be

maintained for the most recent consecutive

3 year

period and shall be made available to the Agency

immr~rii~fi—1~i

nnr~n

ir-~-~1-

2)

Notify

the

Agency

in

writing

if the actual VOM

xempt bak_~

-

~---.,.,

.~

.-.

~

~

~

a~mI .~3 ~

I ci

fl!~ r

r

iim

i fl

a.

1 S

TPV

r~r

ncir-li..

-

vciri

r’m

.~.

-.

.~

-

TPY,

within 30 ~e—a2~

the ~

Such notice shall include a copy of all records of

the

cxcccdance.

y

~-

i--a~-v nvcin

~-~Jr~ u

cixcir~r~i1

—

~

cxcmnt

baker”

“~

25

—

occurs

~&)

-~

l-~-_~

-‘

-~

1

28

controlling

emissions

as

provided

in

Section

218.722(c)

of this Subpart until March 15,

1998,

shall maintain

records necessary to demonstrate that its maximum

theoretical emissions as specified in Section

218.722(c)

arc less than 90.7 Hg

(100 tons)

of VON per

year.

Such records shall be maintancd for the most

recent consecutive

3 year period and shall be made

available to the Agency immediatley upon request.

(Source:

Repealed

at

_____

Ill.

Reg.

__________,

effective

—

Section 218.729

Compliance Date

(Repealed)

On and after March

15,

1996,

upon initial startup

or upon

modification,

every

owner or operator of a source

subject

to

this

Subpart shall comply with the requirements

of this Subpart.

(Source: Repealed at

Ill.

Reg.

__________,

effective

Certification (Repealed)

tor

of

a source subject to the

of

this

Subpart

shall

certify

r.~parton or before a

date

218.729 of this Subpart.

—

1

control requirements of this Subpart

of

compliance,

the

owner

or

pnrritnr

compliance with the reguirem

the alternative method upnn

compliance.

--

c)

All certifications

of compliance with this Subpart

shall

include

the

results

of

all tests and the

calculations

performed

~

~

that

each

::~p1ianccwith,

or is exempt from,

its of this Cubpa:~

i..

—

1 1

—

1 ..~

-~

4- K

~

1

1

~‘~‘ing

-

thr

~niirc~

i

:-~

i n

cimnr

the control

i—i--r~’i

rt

-

t~

1)

The name and identification number of each oven

and any associated capture and control dcvice;

2)

The maximum rated heat input of each oven;

3)

A eicissification of each oven as either a

“bakery

Section 218.730

.,

the method

shall _~rtify

ents o~~hio Subpart

f-.-.~

changi~ the method of

29

4)

The capture and control efficiency of each bakery

oven

control

device;

5)

Test reports, calculations, and other data

necessary to demonstrate that the capture and

control efficiency of each bakery

oven

control

device achieves an overall reduction

in

uncontrolled VON cmiss~-~n~i

of at least 81 per

-6)

The

date

each

bak

4-

~L1

.-.~

4

d)

On or before March

15,

1996,

or upon initial startup,

every owner or operator of a

bakery oven which

is

exempt from the control requirements of this Subpart

because of the criteria

in Section 218.720(b)

of this

Subpart shall certify that its potential to emit

is

lcs~than 22.7 Hg

(25 tons)

of VON per year,

as

specified

in

Section

218.720(b).

c)

—

1~

I

~

upon ~-~4-ialsta~tup,

.._.~

owner or

opcra...or

of

a

bakery

oven

which

is

exempt from the control requirements of this Subpart

because of the criteria specified

in Section 218.722(b)

of this Subpart shall certify that actual VON emissions

from any individual exempt bakery oven never exceed 15

TPY and that VON emissions from all exempt bakery

ovens,

in

the

aggregate,

never exceed 25 TPY.

f)

On

or

before

March

15,

1996,

or upon initial startup if

prior

to

March

15,

1998,

every

owner

or

operator

of

a

bakery oven which is controlling emissions

as provided

by Section 218.722(c)

of this Subpart shall certify

that its maximum theoretical emissions as specified

in

Section 218.722(c)

arc less than 90.7 Mg

(100 tons)

of

VOM

r~nrv~r.

--

-L

(Source: Repealed at

_____

Ill.

Reg.

__________,

effective

SUBPART TT:

OTHER EMISSION UNITS

Section 218.980

Applicability

d exclusively to bake non—y

.1

—

30

a)

Maximum theoretical emissions:

1)

A source is

subject

to

this Subpart if

it contains

process emission units not regulated by Subparts

B,

E, F (excluding Section 218.204(1)

of this

Part), H (excluding Section 218.405 of this Part),

Q,

R,

S, T

(excluding Section 218.486

of this

Part),

V,

X,

Y,

Z or BB of this Part,

which as a

group both:

A)

Have maximum theoretical emissions

of 90.7

Mg

(100 tons)

or more per calendar year of VOM,

and

B)

Are not limited to less than 90.7 Mg

(100

tons)

of VON emissions per calendar year in

the absence of air pollution control

equipment through production or capacity

limitations contained

in a federally

enforceable permit or a SIP revision.

2)

If a source

is subject to this Subpart as provided

in this Subpart, the requirements of this Subpart

shall apply to a source’s VOM emission units which

are not included within any of the categories

specified

in Subparts

B,

E,

F,

H,

Q,

R,

5,

T,

V,

X,

Y,

Z,

AA,

BB, PP, QQ, or RR of this Part or

which are not exempted from permitting

requirements pursuant to 35 Ill. Adm.

Code

201.146.

b)

Potential to emit:

1)

A source is subject to this Subpart

if it has the

potential to emit 22.7 Mg

(25 tons)

or more of VON

per year,

in aggregate,

from emission units,

other

than furnaces at glass container manufacturing

sources and VON leaks from components, that are:

A)

Not regulated by Subparts B,

E,

F,

H,

Q,

R,

5,

T,

(excluding Section 218.486

of this

Part),

V,

X,

Y,

Z,

or BB of this Part,

or

B)

Not included

in any of the following

categories:

synthetic organic chemical

manufacturing industry

(SOCMI)

distillation,

SOCMI reactors, wood furniture, plastic parts

coating (business machines),

plastic parts

coating

(other), offset lithography,

industrial wastewater,

autobody refinishing,

31

SOCMI batch processing,

volatile organic

liquid

storage

tanks

and

clean—up

solvents

operations.

2)

If a source is subject to this Subpart as provided

above,

the requirements

of this Subpart shall

apply to a source’s VOM emission units, which are:

A)

Not included within any of the categories

specified in Subparts B,

E,

F,

H,

Q,

R,

S,

T,

V,

X,

1,

Z,

AA,

BB,

CC, DD,

PP,

QQ

or RR of

this Part,

or which are not exempted from

permitting requirements pursuant to 35

Ill.

Adm. Code

201.146

(excluding Section

201.146(0)

and

(p)),

or

B)

Not included in any of the following

categories:

synthetic organic chemical

manufacturing industry

(SOCMI)

distillation,

SOCMI reactors, wood furniture, plastic parts

coating (business machines),

plastic parts

coating

(other), offset lithography,

industrial wastewater,

autobody refinishing,

SOCMI batch processing, volatile organic

liquid storage tanks and clean—up solvents

operations.

c)

If a source ceases to fulfill the criteria of

subsections

(a)

and/or

(b)

of this Section, the

requirements of this Subpart shall continue to apply to

an emission unit which was ever subject to the control

requirements of Section 219.986 of this Part.

d)

No limits under this Subpart shall apply to emission

units with emissions of VON to the atmosphere less than

or equal to 2.3 Mg

(2.5 tons)

per calendar year

if the

total emissions from such emission units not complying

with Section 219.986 of this Part does not exceed 4.5

Mg

(5.0 tons) per calendar year.

e)

For the purposes of this Subpart, an emission unit

shall be considered regulated by

a Subpart,

if it

is

subject to the limits of that Subpart.

An emission

unit is considered not regulated by

a Subpart

if

it is

not subject to the limits of that Subpart,

e.g., the

emission unit

is covered by an exemption in the Subpart

or the applicability criteria of the Subpart are not

met.

f)

The control requirements

in Subpart TT shall not apply

32

to

sewage treatment plants; vegetable oil extraction

and processing; coke ovens

(including by-product

recovery

plants);

fuel

combustion

units;

bakeries;

barge

loading

facilities;

jet

engine

test

cells;

production

of

polystyrene

foam insulation board

including

storage

and

extrusion

of

scrap

where

blowing

agent

is

added

to

the

polystyrene resin at the source,

but not including blending and preliminary expansion of

resin prior to molding where blowing agent

is

incorporated into the polystyrene resin by the producer

of the resin; production of polystyrene or polyethylene

foam

packaging

not including blending and preliminary

expansion of resin prior to molding where blowing agent

is

incorporated

into the polystyrene or polyethylene

resin by the producer of the resin,

and not including

storage and extrusion of scrap where blowing agent is

added to the polystyrene or polyethylene resin at the

source;

and iron and steel production; and furnaces at

glass

container

manufacturing

sources.

(Source:

Amended at

Ill.

Reg.

__________,

effective

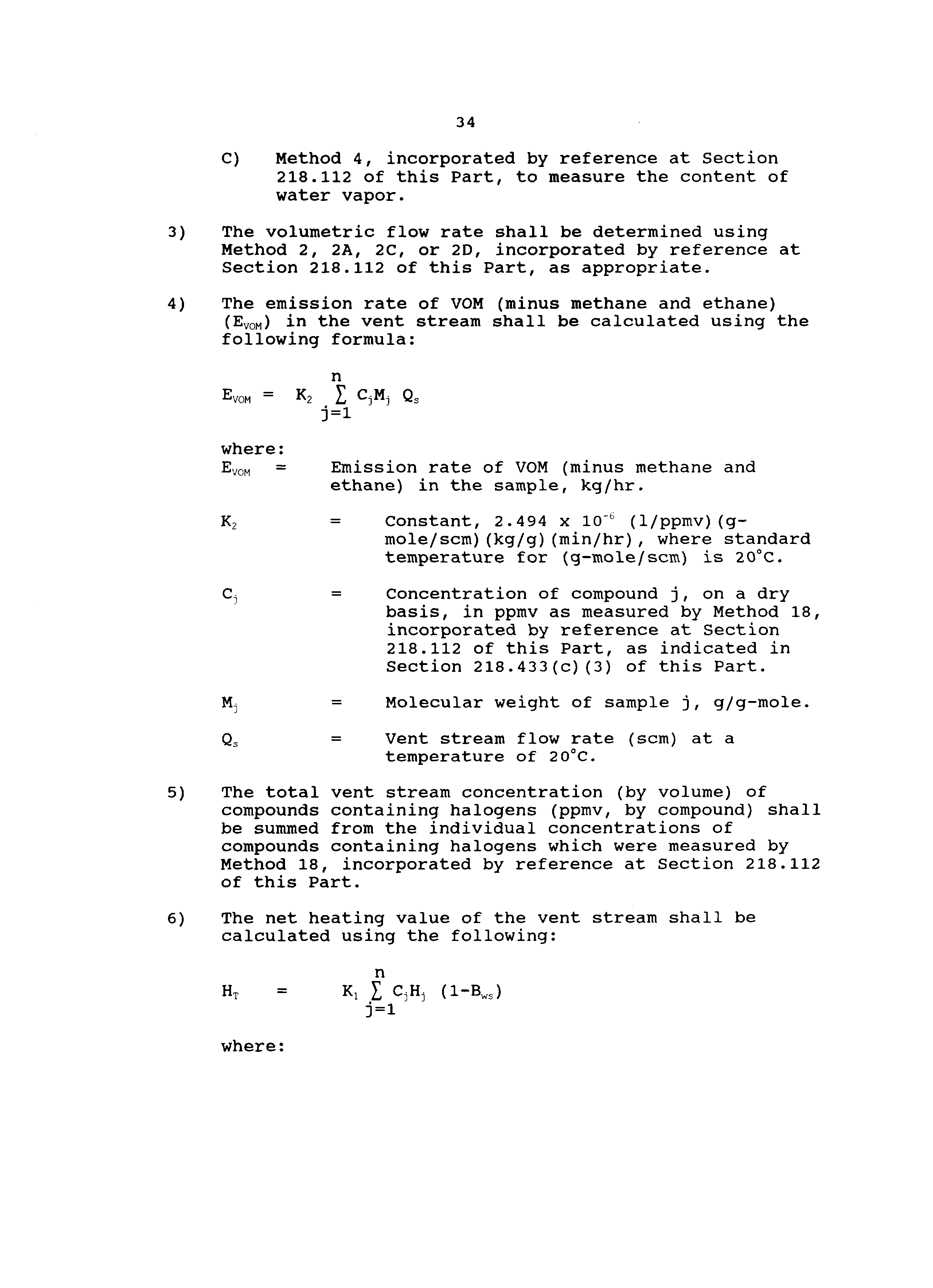

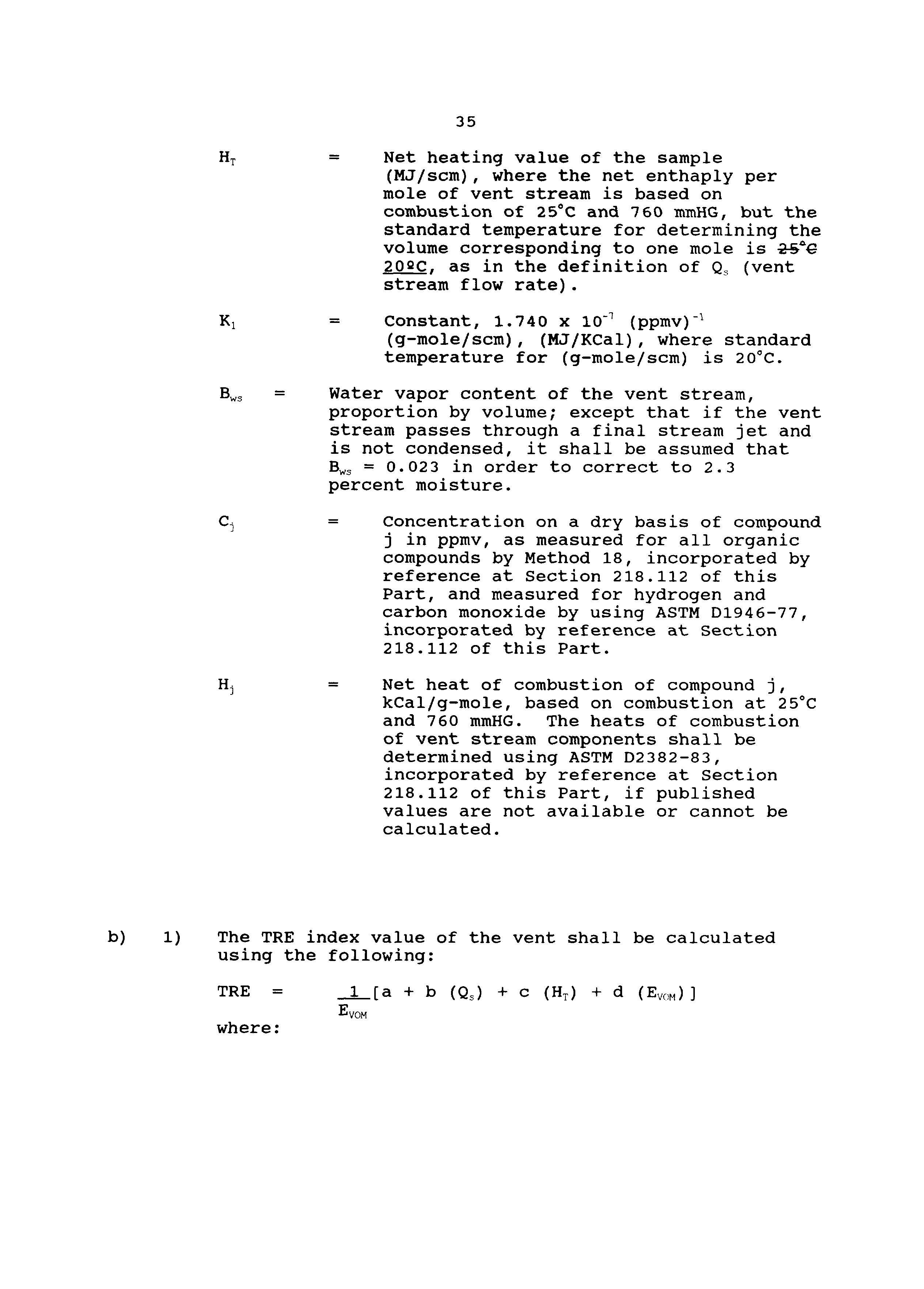

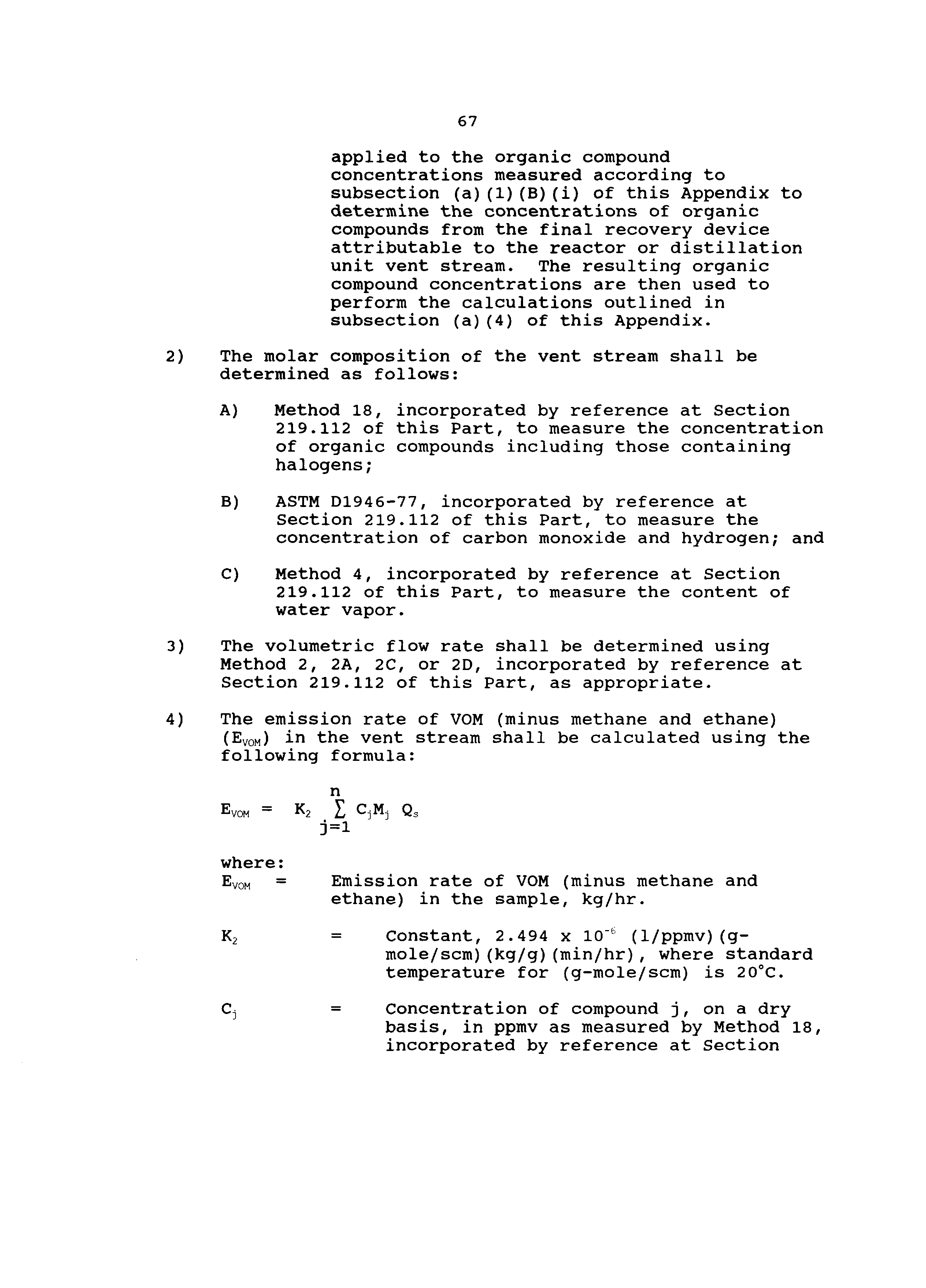

Section 218.Appendix G

TRE Index Measurements for SOCMI

Reactors and Distillation Units

For purposes of Subpart

Q,

Sections 218.431 through 218.435, the

following apply:

a)

The following test methods shall be used to determine

compliance with the total resource effectiveness

(“TRE”)

index value:

1)

Method

1 or

1A, incorporated by reference at Section

218.112 of this Part, as appropriate,

for selection of

the sampling site.

A)

The sampling site for the vent stream molar

composition determination and flow rate prescribed

in subsections

(a) (2)

and

(a)

(3)

of this Appendix

shall be, except for the situations outlined

in

subsection

(a) (1) (B),

after the final recovery

device,

if a recovery system is present, prior to

the inlet of any control device,

and prior to any

post-reactor or post-distillation unit

introduction of halogenated compounds into the

vent stream.

No traverse site selection method is

needed for vents smaller than

10 cm in

diameter.

33

B)

If any gas stream other than the reactor or

distillation unit vent stream is normally

conducted through the final recovery device:

i)

The sampling site for vent stream flow rate

and molar composition shall be prior to the

final recovery device and prior to the point

at which any nonreactor or nondistillation

unit vent stream or stream from

a nonaffected

reactor or distillation unit is introduced.

Method 18 incorporated by reference at

Section

218.112

of this Part,

shall be used

to measure organic compound concentrations at

this site.

ii)

The efficiency of the final recovery device

is determined by measuring the organic

compound concentrations using Method

18,

incorporated by reference at Section 218.112

of this Part,

at the inlet to the final

recovery device after the introduction of all

vent streams and at the outlet of the final

recovery device.

iii)

The efficiency of the final recovery device

determined according to subsection

(a) (1) (B) (ii) of this Appendix shall be

applied to the organic compound

concentrations measured according to

subsection

(a) (1) (B) (i)

of this Appendix to

determine the concentrations of organic