| | - RECEIVED

- NOTICE OF FILINGTO:

- )))))

- ~ECE~VED

- Introduction

- years ago.

- The second group ofproposed leathers, including one leather that was produced ma

- Section 102.202(a): The Language of theProposed Rules

- Proposed Rules

- Section 102.202(1): Justification for Inapplicability ofSections in 102.202

- Section 102.210(a): Language ofthe Proposed Site-Specific Rule

- Section 102.210(b): Reasons for the Rule Chance

- Section 102.2 10(d): Demonstration that the Board may Grant the Proposed Relief

- CERTIFICATE OF SERVICE

- LIST OF ATTACHMENTS

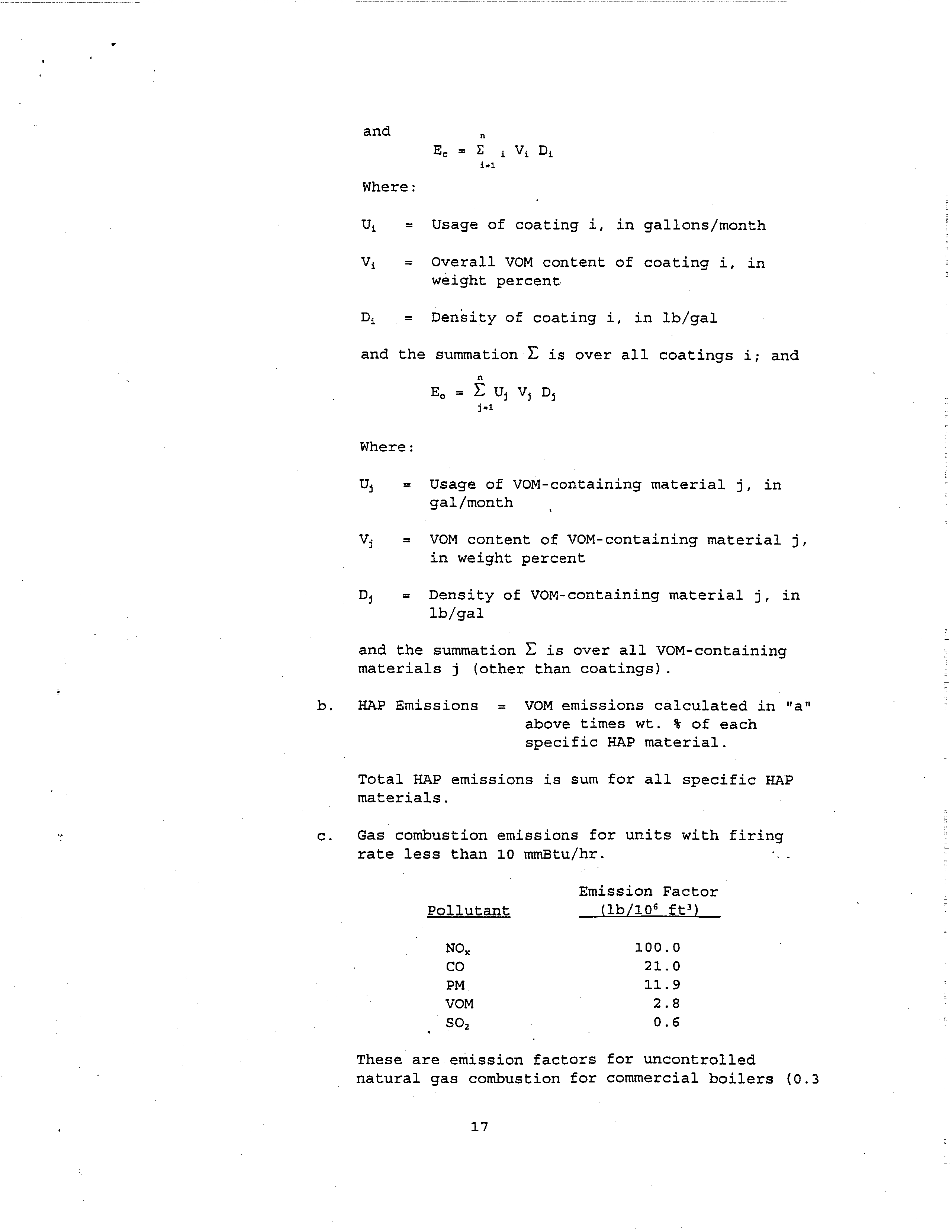

- YEARLY USAGE OF FINISHES CONTAINING VOM AND HAPS

- YEAR TONS OFVOM

- TONS VOM500 SIDESIWK!YR

- TONS HAP500. SIDESIWK!YR

- TONS VOMMAY-SEP

- TOTAL SIDES LBS OF VOMETHER HAPS FOOTAGE SHIPPED PER 1000 SQFT

- LBS OF GLYETHHAPS!1 000 SQ FT

- Cementable Finish APerformance Finish BHand Sewn Finish C

- 2.2641.2061.371

- TOTALS 14.374 9.534 4.840

- TONS VOMMAX* SIDES!WK!YR

- TONS HAPMAX* SIDES!WKIYR

- TONS VOMMAY-SEP

- Cementable Finish APerformance Finish BHand Sewn Finish C

- 16.5453.6524.249

- 22.6404.8222.738

- 84.844 54.645 30.1 9920 TON LIMIT** 20.000 12.881 7.119

- TONS VOM TONS HAPS ERMS ATU’S2000

- NEW PRODUCTION**40.980

- 20.00013.665

- 12.881192

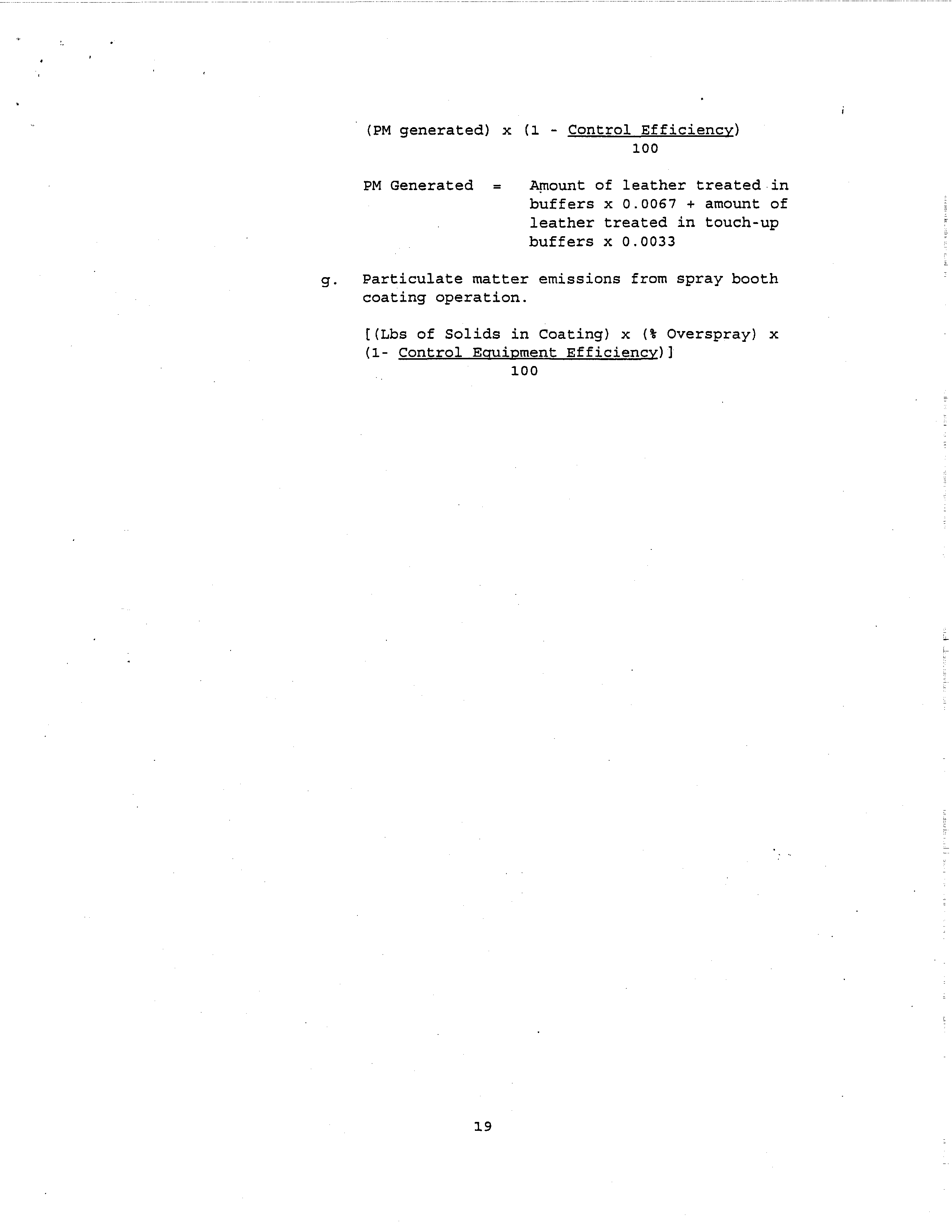

- TOTAL 1,414,250 1,305,262 1,229,831 1,213,167 1,098,863

- Unit- -$1,000,000SHOES &

- FranceGermanyItaly

- PortugalSpain

- UnitedKingdom

- ChinaHong KongIndia

- IndonesiaKorea

- PhilippinesSri LankaTaiwan

- ThailandVietnam

- Balanceof World

- ATTACHMENT 4

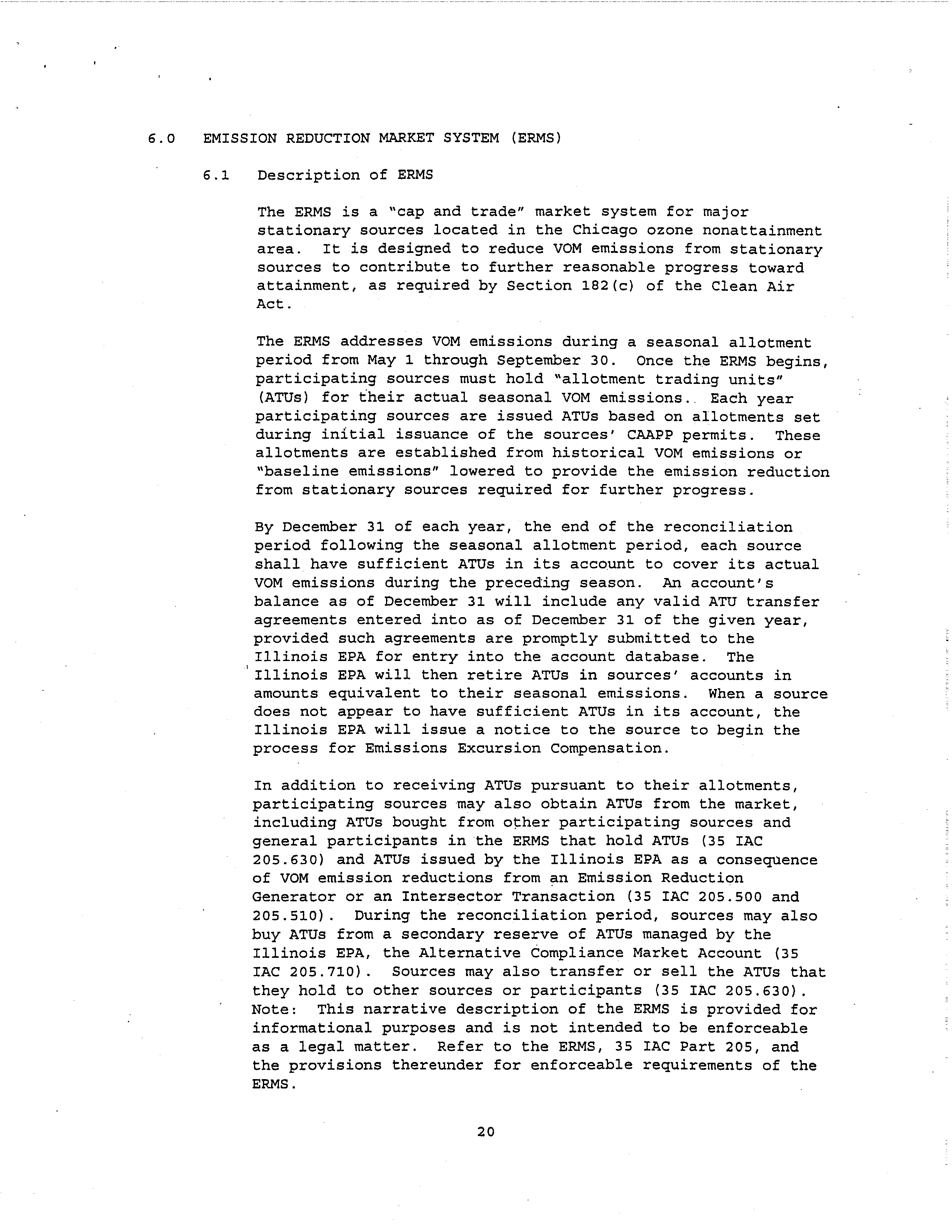

- NEWSOF THE MONTH

- Prime Tanning to ClosePlants, Release 550 Workers

- SaIz Tannery to CloseAfter 145 Years

- Dexter AnnouncesFactory Closing

- 114111630015

- 775•, 37

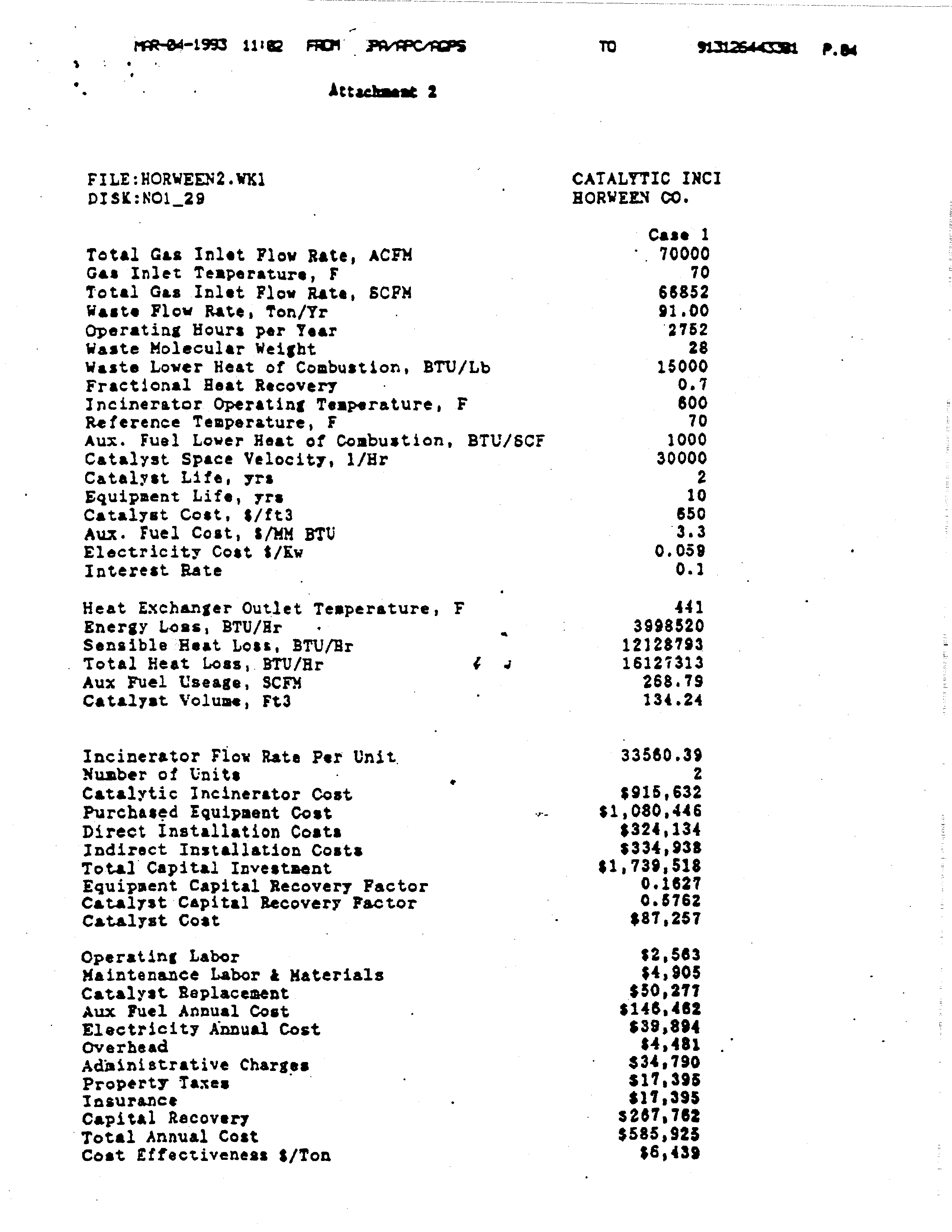

- 0.1627

- 0.l6~1

- $440, 7260.98

- Cue 170000

- 91.002752

- Attachaist 2

- Incinerator Operating Temperature, FReference Temperature, F

- $87,257

- 10650~3.3

- 0.0~ 90.1

- FILE:HORWEEN1.W~1D1SK:NOl_29

- ANALYSIS OF FLOW

- 66852.45

- Y’J~i,I,

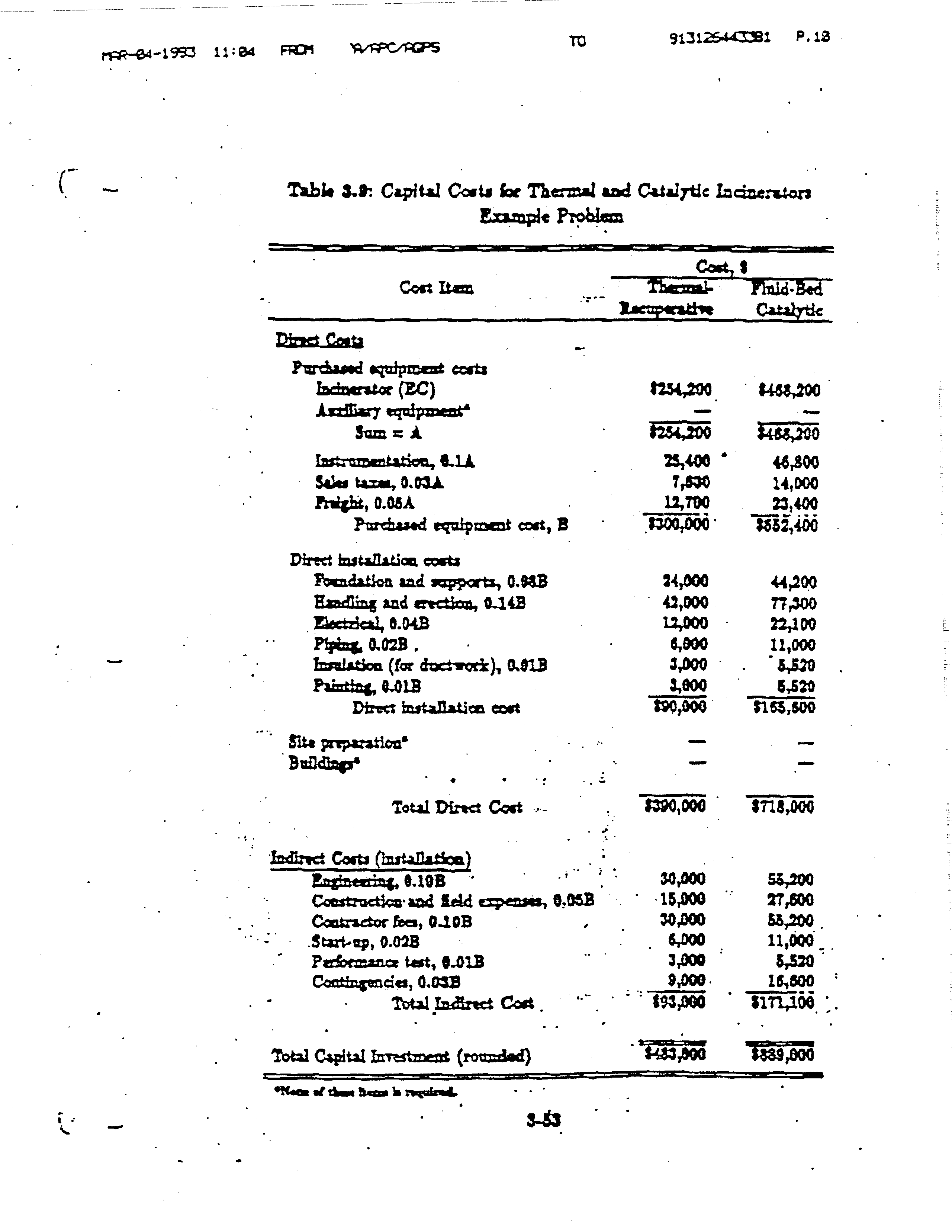

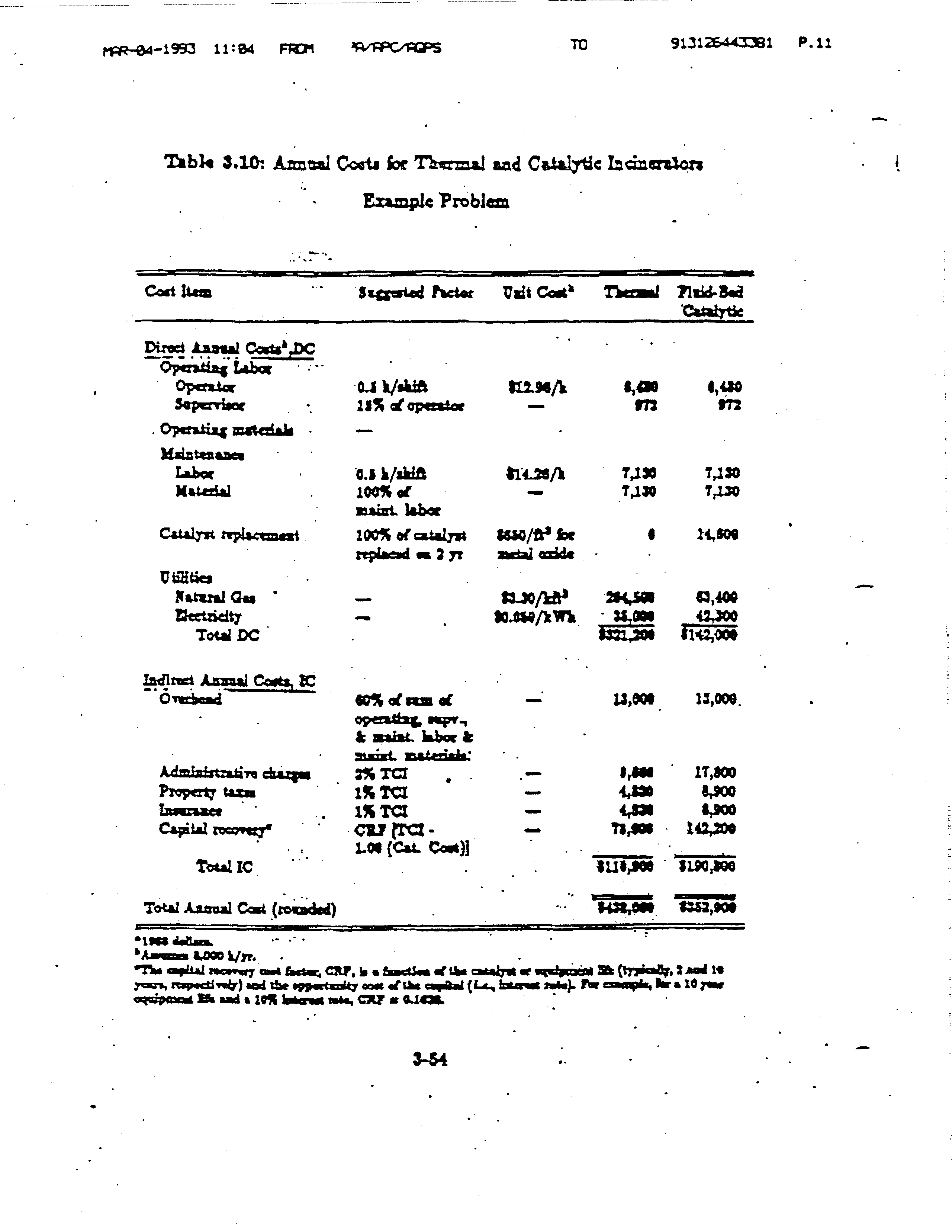

- Tot~1Dtr~ctCost

- i~4,SOQ

- TotaL IC

- $L9CZQO

- ADJUSTMENTS MADE TO DYE MtX

- ADJUSTMENTS MADE TO DYE MIX

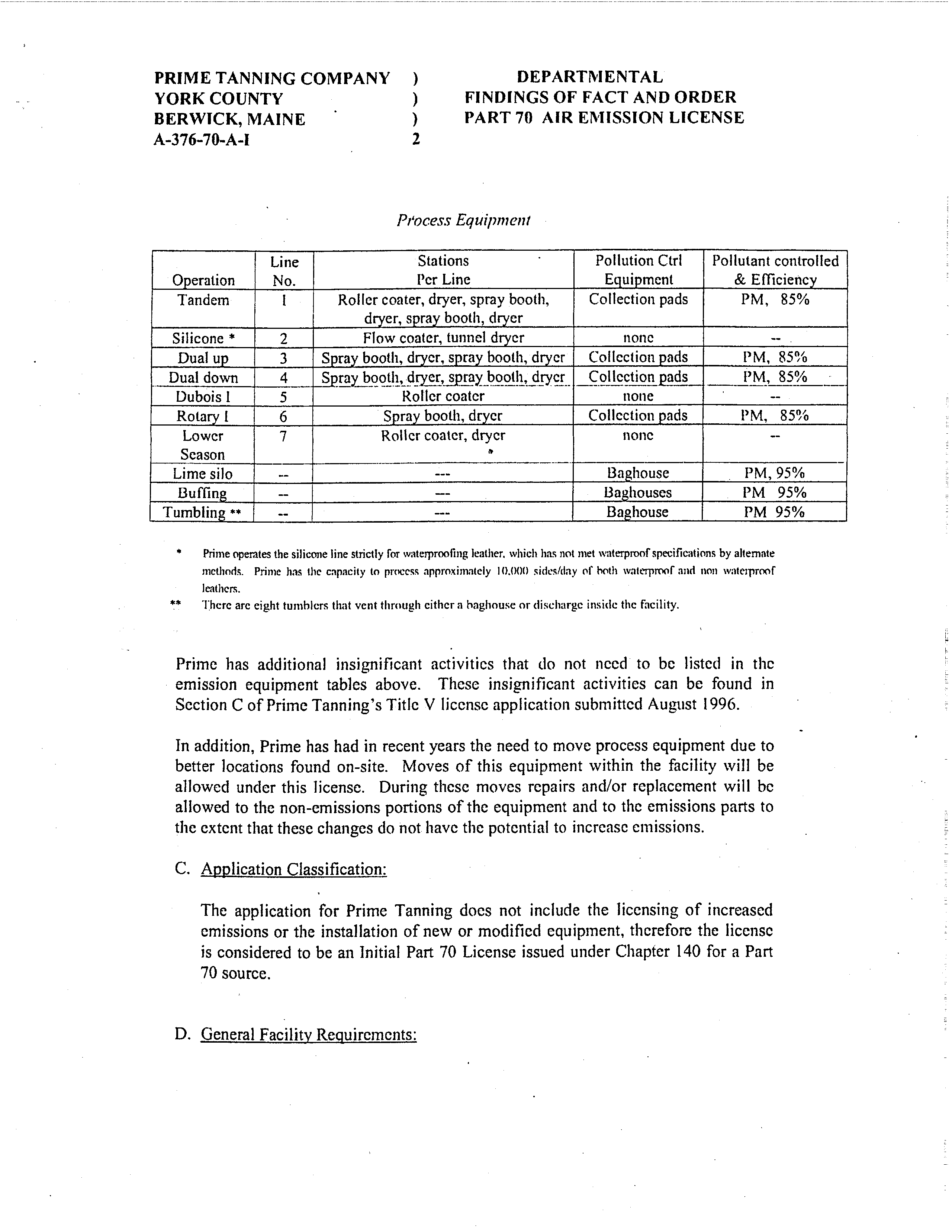

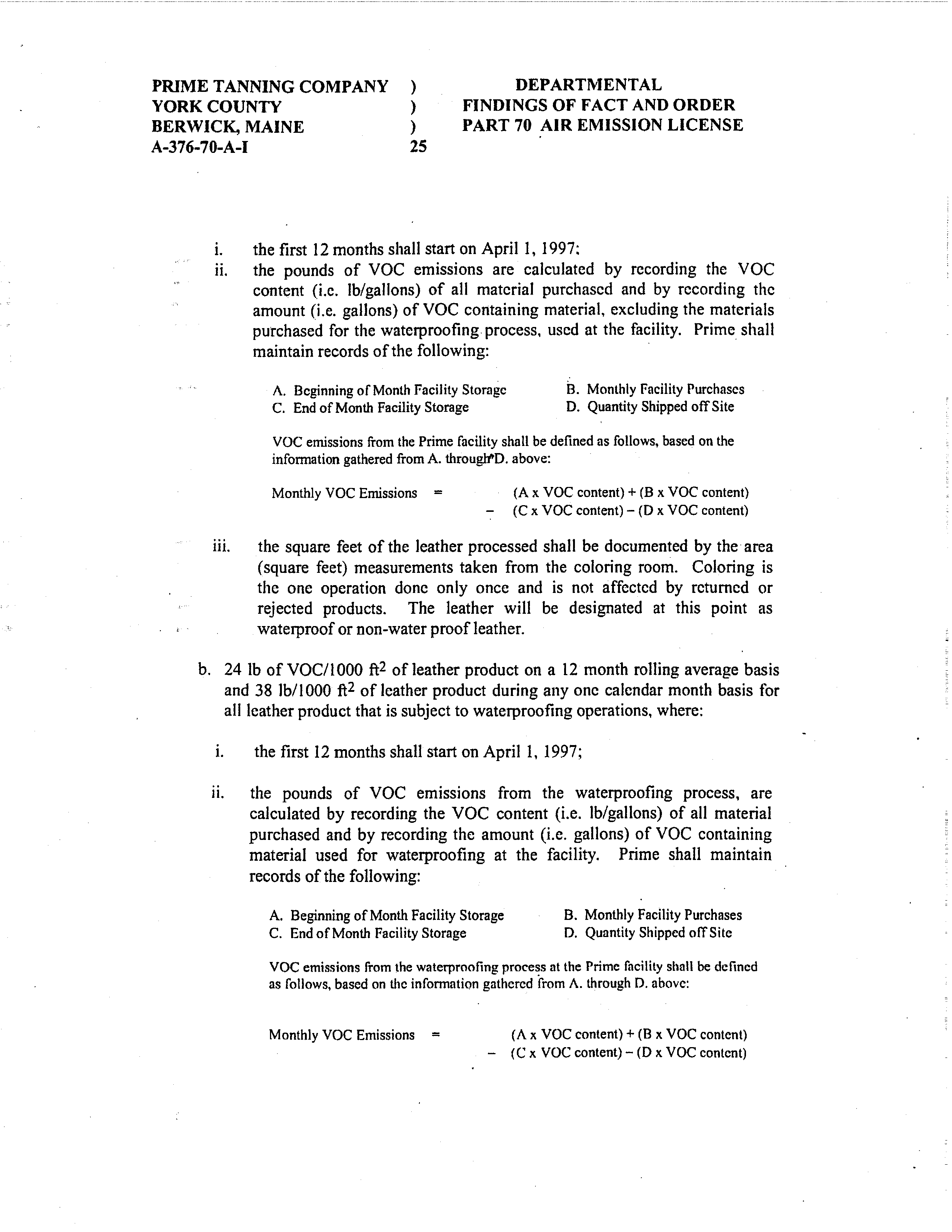

- PRIME TANNING COMPANYYORK COUNTY

- FINDINGSOFFACT ANDORDER

- PART 70 AIR EMISSIONLICENSE

-

- UNITTYPE

- BERWICK,MAINEA-376-70-A-I

- PRIME TANNINGCOMPANYYORK COUNTY

- DEPARTMENTALFINDINGSOF FACTANDORDER

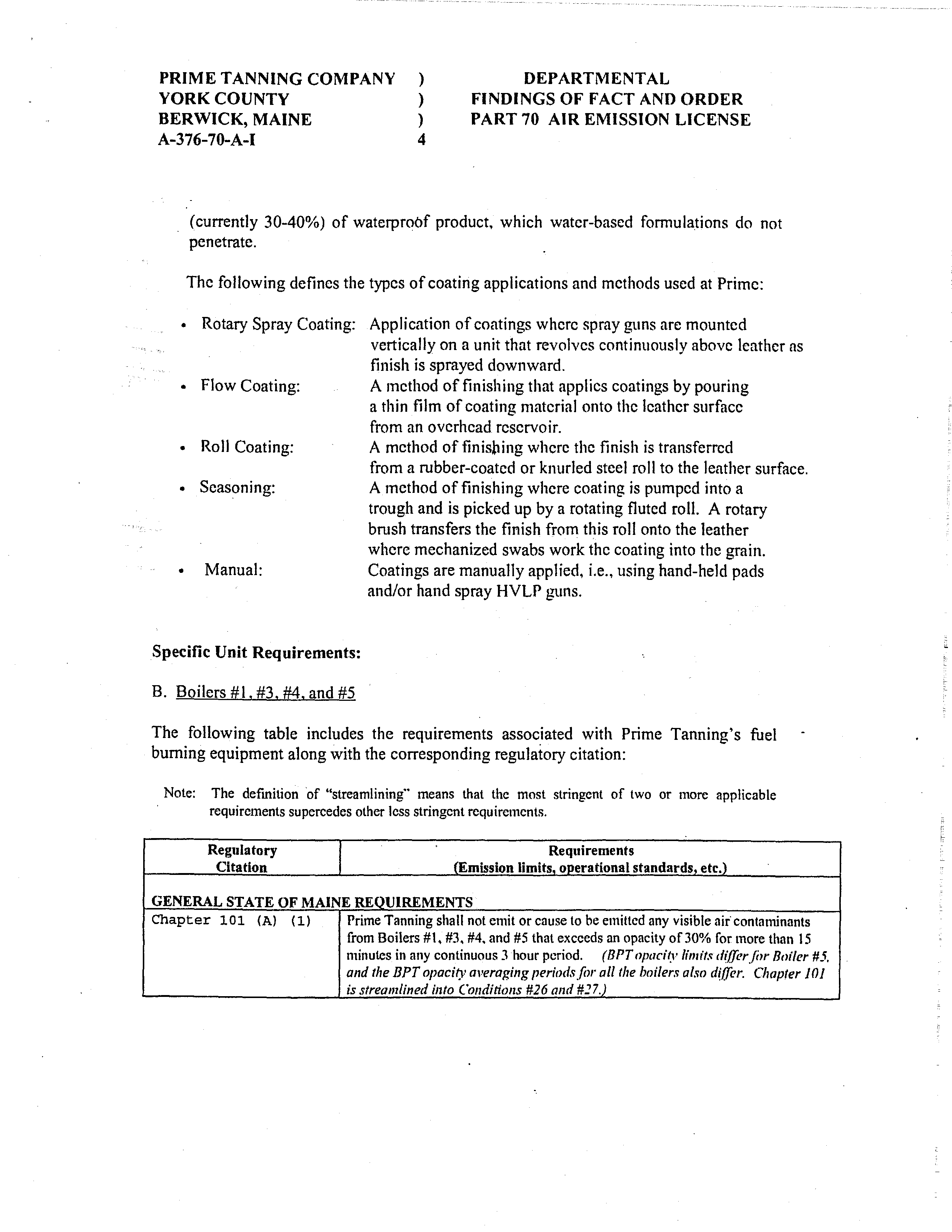

- Specific Unit Requirements:

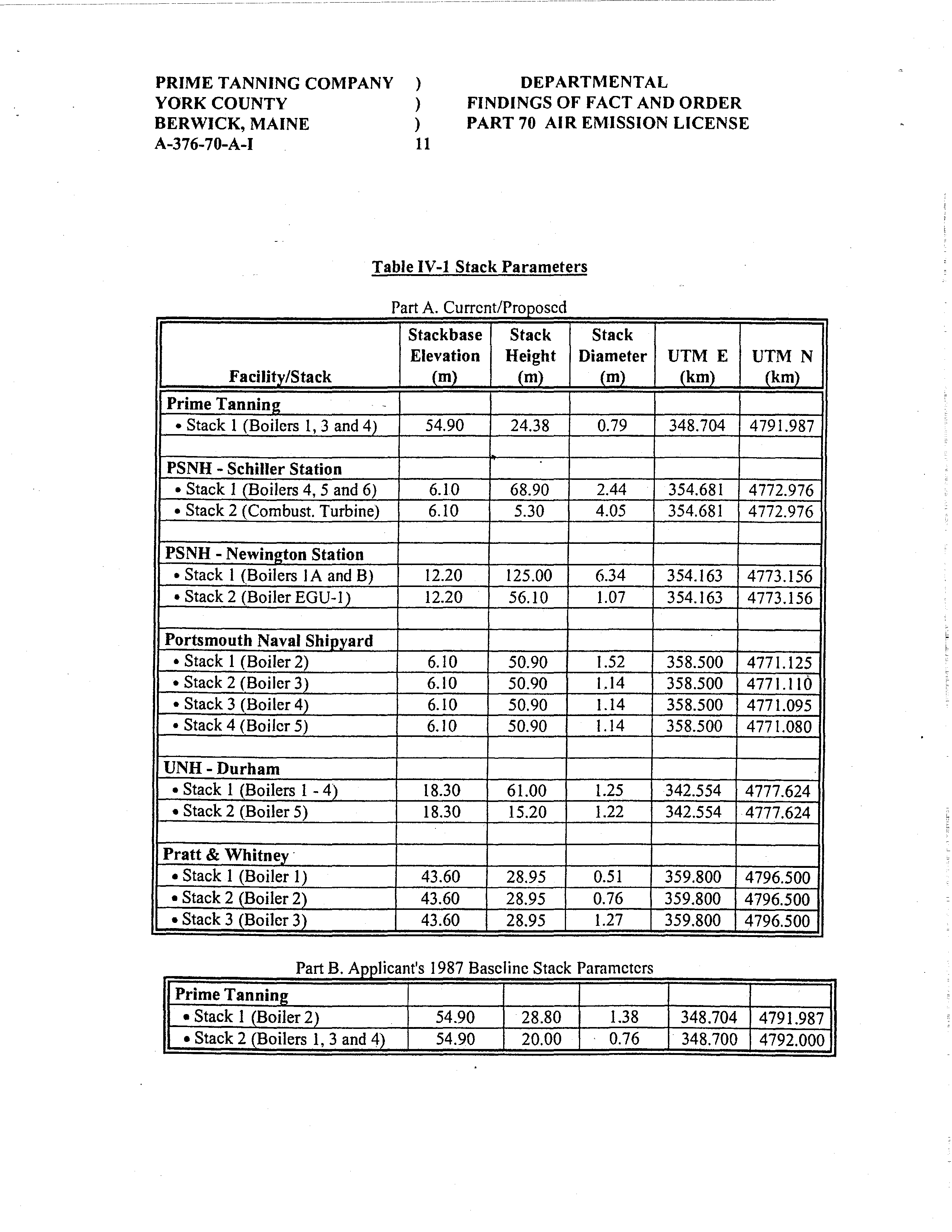

- PRIME TANNINGCOMPANYYORKCOUNTY

- BERWICK, MAINEA-376-79-A-I

- PRIME TANNINGCOMPANYYORK COUNTY

- PART 70 AIREMISSIONLICENSE

- PART 70 AIR EMISSION LICENSE

- III. AMBIENT AIRQUALITYANALYSIS

- Facility/Stack

- StackbaseElevation

- StackHeight(m)

- StackDiameter(m)

- UTM E(km)

- (km)

- PollutantAveraging

- PeriodISCST2

- RefinedCI-VM

- Impact BackgroundMax Total

- Averaging

- PeriodISCST2

- ImpactCI-YM

- Impact

- Class IiIncrementStandards

- STANDARD CONDITIONS

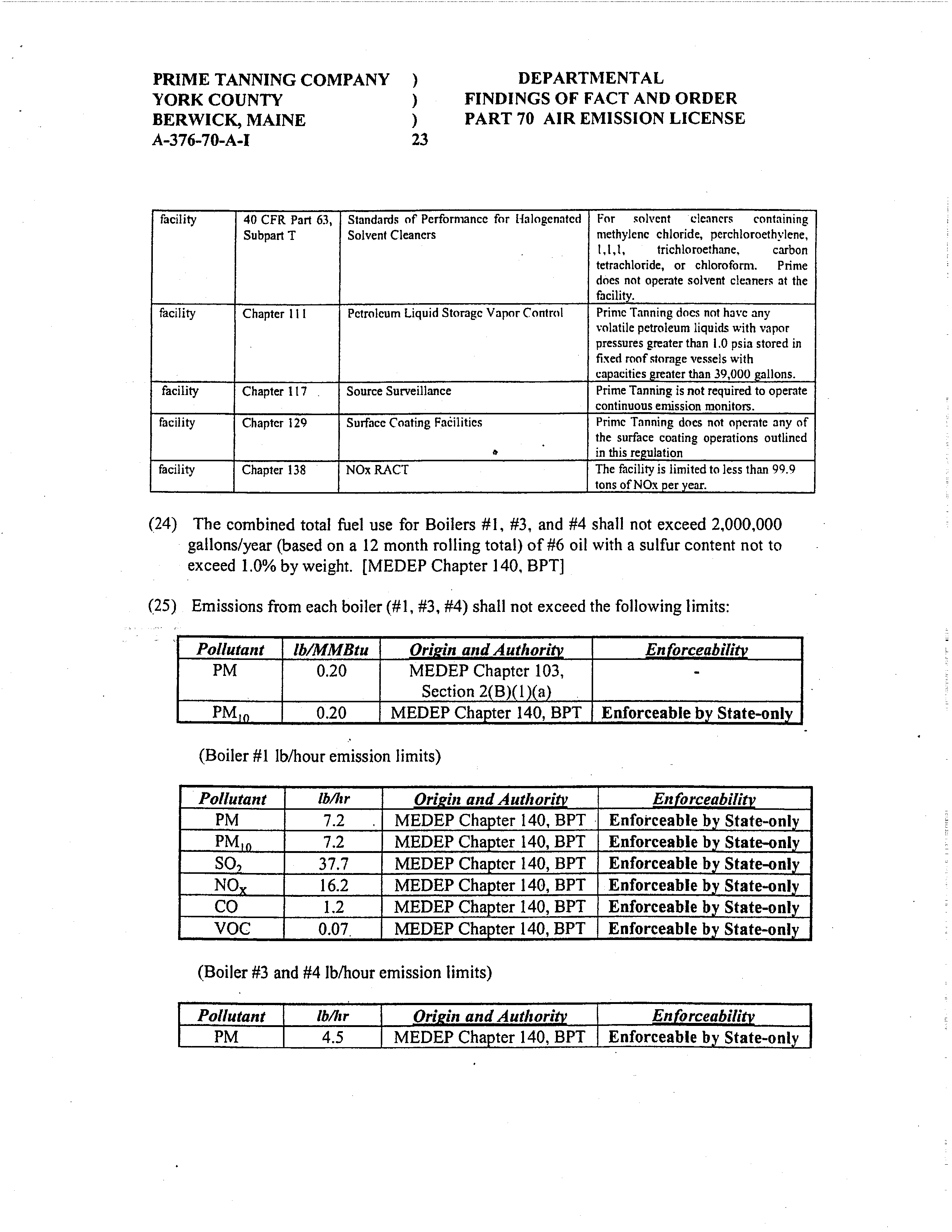

- Enforceable by State-only

- YORK COUNTY

- BERWICK, MAINEA-376-70-A-I

- SPECIAL CONDITIONS

- PRIME TANNING COMPANY

- YORK COUNTYBERWICK, MAINEA-376-70-A-I

- PRIME TANNING COMPANYYORK COUNTY

- BERWICK, MAINEA-376-70-A-I

- PRIME TANNING COMPANYYORK COUNTY

- BERWICK, MAINEA-376-70-A-I

- PRIME TANNING COMPANYYORK COUNTY

- BERWICK, MAINEA-376-70-A-I

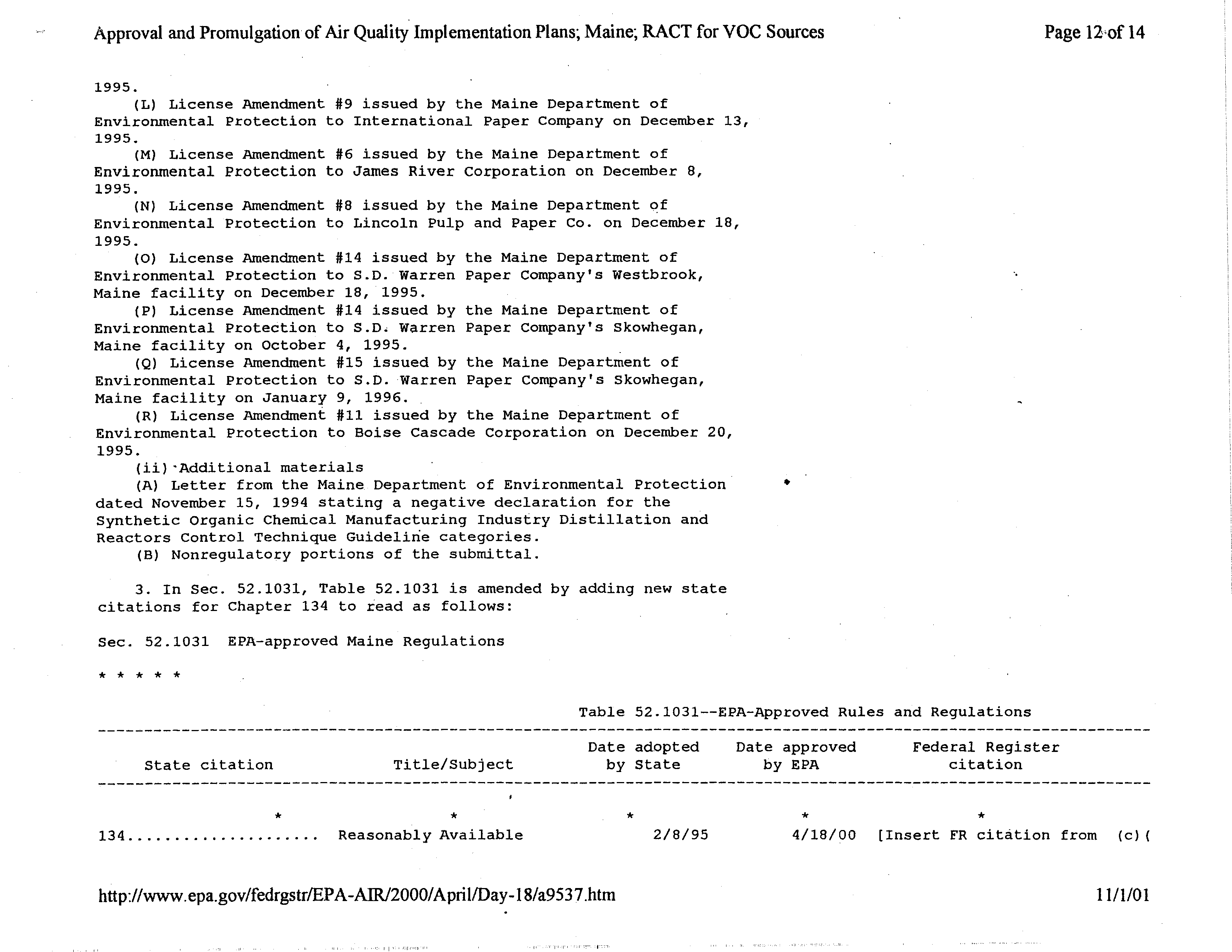

- Federal Register Document

- TOTAL HAPS

- TOTAL EGBE

- TOTAL HAPS WITHOUT EGBE

- IMPACT OF DELISTING OF EGBE2000 ANNUAL HAPS

- 13

- AFFIDAVIT OF ARNOLD HORWEEN, JR.

- AFFIDAVIT OF JULIE M. CHRISTENSEN

- ATTACHMENT 15

-

- HORWEEN LEATHER COMPANY

- December 1, 2000

- 1200 Pennsylvania Avenue, NWWashington, DC 20460

- Leather Finishing Operations

- Dear Sir or Madam:

- Comments:

- V. Conclusion

- //~?~~‘b~t/ ~

|

RECEIVED

(‘T

F~~5

OFFiCE

1

9

2002

bit~1h

01.:

ILLINOIS

iN THE

MATTER OF:

ttIOn

Control Boarj

PROPOSED

SITE SPECIFIC•

R02-

~2

AIR POLLUTION REGULATIONS

(Site-Specific Rulemaking

-

Air)

APPLICABLE TO HORWEEN

LEATHER COMPANY OF

CHICAGO, ILLiNOIS

35

Iii. Adm.

Code 211.6170

NOTICE OF FILING

TO:

Clerk, Illinois Pollution Control Board

Illinois Environmental

Illinois Department of

State of Illinois Center

Protection Agency

Natural Resources

100 West Randolph Street

1021 N. Grand Ave. East

524

South Second Street

Suite 11-500

Springfield,

IL

62702

Springfield, IL

62701-1787

Chicago, IL

60601

Illinois Attorney General

500

South Second Street

Springfield, IL 62706

PLEASE

TAKE

NOTICE

that on Tuesday, February 19,2002, we filed the attached

Petition for Site-Specific Rulemaking with the Clerk of

the

Illinois Pollution Control

Board,

a copy ofwhich is herewith served upon you.

Roy M. Harsch

Steven J. Murawski

GARDNER, CARTON & DOUGLAS

321 North Clark Street

Chicago, Illinois

60610

(312) 644-3000

II

BEFORE THE

ILLINOIS

)

)

)

)

)

)

)

submitted,

Attorneys

THIS FILING

IS SUBMITTED ON

RECYCLED PAPER

~ECE~VED

BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

~

orric~

FEB 19200

IN THE MATTER OF:

)

SThfE OF ILLINOIS

PROPOSED SITE SPECIFIC

)

R02-

~-D

Pollution

Control

Board

AIRPOLLUTION REGULATIONS)

(Site-Specific Rulemaking

-

Air)

APPLICABLE TO HORWEEN

)

LEATHER COMPANY OF

)

CHICAGO, ILLiNOIS

)

35111.Adm.Code2ll.6170

)

PETITION

FOR

SITE-SPECIFIC RULEMAKING

HorweenLeather Company (“Horween”) hereby petitions the Illinois Pollution Control

Board (“Board”) for a Site-Specific Rule pursuant to 35 III. Adm.

Code

Part

102,

Subpart B and

Sections 27 and 28 ofthe Illinois Environmental Protection Act,

415

ILCS

5/27-5/28

(“Act”).

Horween requests that the Board issue a site-specific rule from 35

III. Adm.

Code 211.6170 and

218.926 to change the controlrequirements as applied to a small amount ofnew specialty leathers

that Horweenwould like to produce.

The requested rule changewould allowHorweento

continue to produce its existing specialty leathers pursuant to the existing regulations, and

develop new specialty leatherproducts in compliance with environmental law pursuant to these

requested regulations.

Introduction

Horween is

submitting

this petition based on inherent technical restraints associated

with

making

newtypes of

specialty

leatherto meet customers’

demands

driven bythe

fhshion industry.

The severe economic

downturn

in theU.S.

leather

industry has greatly

reduced the productionof

leather and, as a result, the

viability

ofHorween’s

business.

In addition, there is a negligible

environmental impact in

allowing

Horween to produce these new

specialty

leather products.

In

reality, Horweenwould not exceed volatile organic

material

(““TOM”) emission levels of

five

years ago.

Horween, located in Chicago, Illinois, produces

specialty

leathers for a

small

niche of

customers

that

demand

quality.

It is extremely h

rtant that

Horweenbe

able to produce

additional “specialty-type” leathers to support its business.

Between

1995

and 2000, Horween

has experienced a marked reduction offootage shipped:

6,950,128

to 4,780,291, respectively.

See Attachment (“Attach.”) 1.

To remain a viable business, Horweenmust constantly change its

products to meet the demands ofits customers.

As part ofthe market-driven changes and in

order to continue to be

a viable entity, Horween needs to be able to

finish a larger variety of

specialty-type leathers including

cementable pull up, leathers designed for hand-sewn shoes, and

other performance leathers that were not considered in the existing ReasonablyAvailable Control

Technology (“RACT”) rule or the amendment to

the RACT rule that included the definition of

specialty leather and

established a separate RACT rule for such leather.

The rapid decline in the U.S. leather manufacturing industry has created

extreme economic

uncertainty for all tanneries in the U.S.

Since 1994,

over one-halfofthe side leather production in

this country has been lost.

See Attach. 2 and 3.

For

example, in

1999 only 120 million out of

1,767 billion shoes consumed were domestically produced.

As a result ofthe increasing offshore

leather production and the relocation ofleather customers overseas, the U.S. domestic

side

leather industry has been in the process ofrapid consolidation.

Since 1998, at least eight major

leather producers have closed or are closing.

The leather producers that have already closed

include A.L. Gebhardt, Pflster & Vogel, Whitehall Tanning, Salz Leathers, and Lackawanna

Tanning.

Additionally, this year, Midwest Tanning announced plans to move to China and

Blackhawk Tanning will be closing.

Finally, Irving Tanning, a direct competitor ofHorween, just

filed for Chapter

11 bankruptcy this summer,

Paul

Flagg Tanning is

for sale

and Prime Tanning

began ceasing domestic operations at the end ofthe 2001.

See Attach. 4.

The inherent production requirements ofleathers that use higher solvent-based finishes

were the subject ofIllinois’ original adoption ofamendments to the generally applicable RACT

leather coating rule.

See 35

III. Adm. Code

§~

218.926 and 211.6170; Board Order, PCB R.93-

14, January 6,

1994.

Horween worked extensively with the Illinois Environmental Protection

Agency (“JEPA” or “Agency”) in that procedure and testifiedbefore the Board.

The Board, after

thoroughly evaluating the required production needs ofspecialty leathers with a high grease, wax

2

and oil content, adopted a special

subcategoryfor this “specialty leather.”

~

35 Ill. Adm. Code

§~

218.926 and 211.6170.

The Illinois rule allows emission ofVOM in the amount of38 pounds

(“lbs.”) per 1,000 square feet and further provides an exemption for the stains used on leather.

35

Ill. Adm.

Code

§

2 18.926.

Furthermore, the rule specifically defines “specialty leather.”

35

III.

Adm.

Code

§

211.6170.

This particular rule was approved by the U.S.

Environmental Protection

Agency (“USEPA”) and included in the Illinois

State Implementation Plan (“SIP”).

59 Fed.

Reg.

46567

(Oct.

11,

1994).

During that rulemaking process, the IEPA and ultimately the Board

agreed that further solvent reductions and add-on control technology were not feasible and would

create an undue burden upon specialty leather manufacturers.

Thus, the Board enacted the

Specialty Leather Ruleto provide reliefto these manufacturers from the generally applicable

RACT

coating rules.

At the time the IEPA was developing the adjusted RACT

standards, Horween provided

IEPA with a substantial amount ofinformationto justil~’

the modified standards.

See Attach.

5.

Part ofthe information included the disclosure that products being developed by Horween may

change based on future customer demands and fashion changes.

Horween produces leathers to

meet the demand ofits customers who primarily produce shoes.

Fashion and the needs ofthe

shoe production process drive this demand.

To continue to

stay in business to provide high quality leather products and

compete with

internationalproducers ofleather products who are allowedto use a variety

of

finishes

not subject

to the same environmental constraints as those imposed in theUnited States, or even more

specifically, in Iffinois, Horween has recently explored the development ofnewleather products.

To date, Horween has identified two types ofwhat it believes to be “specialty leathers” that

would

allow Horween to replace a portion ofthe business it has lost.

The first group includes a

minor change to Horween’s existing CHROMEXCEL® specialty leather, and the second group,

performance leathers,

includes a leather previously made by a closed tannery.

This leather,

referred to by Horween as “GENTRY”

can be hand sewn and

ironed.

See

Attach. 6,

7

and

8.

3

Due to

changes

in

demand,

Horween now produces some CHROMEXCEL® Leathers

with less grease,

waxand oils

being

added to the mills during production;

however, through

combining hot stuffing

with roller coating, more than 25 percent

(““)

grease,

wax and oils are

added on a

dry weight basis.

Recently,

shoe

manufacturers have been requesting that Horween

produce

specialty leathers with less ofa

waxy

feel

than

the traditional CHROMEXCEL®

Leathers.

These new leathers

are intended to satisfy consumer demand for dressier looks that are

capable ofbeing used in a

different

type

ofshoe

making

system involving cementing soles to the

shoes, rather

than

sewing them.

Unfortunately, the traditional CHROMEXCEL® Leathers

are

not capable of

being

cemented because the high grease,

wax and oils content prevents any

cements from forming

a permanent bond.

Thus, Horween cannot produce these new leathers in

compliance with the current definition ofCROMEXCEL®

Leather because the formula for

producing

this

leather involves the use ofless

than

25

grease,

wax

and

oils

on a

dry weight

basis.

Furthermore, based on Horween’s experience, there would stifi be enough grease, waxand

oils present in these leathers to trigger the same technical problems which gave rise to the original

need for the Specialty Leather Exemption related to the inability ofwater-based dyes, finishes

or

other low solvent coatings to penetrate or adhere to the leathers during

the

finishing process.

These types

ofproblems

begin

to appear at grease, wax and

oils content of 12.

Therefore, the

newly proposed leathers with between 12

and 25

grease, wax and oils content cannot be

finished

with coatings that comply

with the generally applicable

3.5

lbs. per gallon RACT

coating

regulation

and

cannot

satisfy

the definition ofspecialty leather.

The second group ofproposed leathers, including one leather that was produced ma

tannery now closed in Wisconsin, was

designed for specialty performance for hand-sewn shoes

and

an extremely glossy, dressy look

and fine,

smooth

finish.

Fromthe

tanning

side,

changes

must be made so this

type

of specialty leather

will withstand soaking and

still be

pliable enough

that

the leather

and

the finish

shrink

together at a

consistent

rate, yielding a smooth surface

appearance.

Fromthe shoemaking side, the top

finish

ofthe leather must be able to withstand

ironing with high temperatures to give a

uniform,

smooth appearance.

The surface must

also be

4.

compatible with current

shoe

finishes usedto stain and antique the shoes to

give the desired

appearance.

Water-based finishes that comply with the

3.5

lbs.

per gallon RACT coating

regulation are

not

able to do

this.

While developing these new products, Horweenevaluated the existing RACT rules

to

review potential impacts on future

environmental compliance should these newproducts be

produced.

Consequently,

Horween realizedthat,

as written, Horween would not be

able to put

these new leathers into production and continue to comply with the existing Illinois

RACT rules.

However, even though the production ofthe newly proposed products cannot meet the current

RACT rules, there

is a negligible environmental impact from producing these newproducts.

The

production ofthe new specialty leathers at this facility

will

hopefully replace production that has

been lost since

1995

and

would not exceed the VOM emissions from 1995 with an additional 20

ton per year (“tpy”) cap on these new specialty leathers.

Horween would not exceed current

emission limits already in place

in the facility’s Title V permit

and

ERMS

baseline.

Thus,

any

environmental impact from production ofthe newproducts would be negligible.

Prior and subsequent to the amended RACT rule, Horweentested severalwater-based

leather finishes and continues

to be

unsuccessful in replacing solvent-based materials where finish

performance is an issue. While there are new stains that may be extended with water prior to

application, when the VOM content ofthese finishes is calculated, the water content must be

subtracted whencalculating VOM content.

See Attach. 9.

Therefore, the substitution ofthese

materials has

not resulted in compliance withthe generally applicable

3.5

lbs. ofVOM per gallon

RACT coating regulation.

However, Horweenreplaced solvent-based materials with water-based

materials

for all ofthe leathers

that

do not require special

finish performance or a dressier polished

look.

In addition, Horween continuously adjusts formulas to reduce VOM

and HAP emissions,

while maintaining

quality specialty leathers

that are

acceptable to customer’s

demands.

Based on the

above background and

the original justification for

amending the Illinois

RACT requirements

to

recognize “specialty

leather”

manufacturers, Horween

is proposing the

Board adopt the same

RACT

rule the USEPA recently approved as

part ofthe State ofMaine’s

5

SIP of 14.0

lbs.

VOC (VOM) per 1,000 square feet for non-waterproofleather, and 24.0

lbs.

VOC

(VOM) per

1,000 square feet for waterproofleather.

See Attach.10

and 11.

The two proposed groups ofspecialty leather will have both waterproofand non-

waterproof leathers depending upon the customer’s needs.

Generally speaking, the

difference

between our waterproof and non-waterproofleathers is the stuffing, oiling, and retannage; not the

top finishing coats.

The top finishing coats affect the final appearance as far as a natural and

casual, or a dressier more polished end-product.

The components ofthe finishes are also greatly

affected by the amount ofgrease, wax and oils used withthe leather.

In addition to the limitations ofthe Maine RACT rule, Horween proposes an emissions

cap of

20 tpy ofVOM for the emissions from the production ofthe above-described two new

leatherproduct groups of“specialty leathers” that would satisfy the parameters ofthe proposed

RACT rule.

Furthermore, the remaining leather production would remain subject to the existing

regulatory requirements.

These changes will allowHOrween to

continue to respond to

constant

changes in the “specialtyleather” market while continuing to operate its

facility in compliance

with environmental standards.

The specific information required in a petition for a site-specific

rulemaking pursuant to

35111.

Adam

Code §~102.202and

102.210 is set forth below.

Section 102.202

—

Petition

Content Requirements

Section 102.202(a): The Language of theProposed

Rules

The current coating regulations applicable to leather manufacturers can found in

35111.

Adm.

Code 211.6170 and 2 18.926.

Horweenhas been able to comply with these regulatory

provisions by carefully monitoring process materials in accordance the Illinois Rules and

Horween’s Title V permit requirements.

However, as explained throughout this petition, due to

market demand changes, inherent product manufacturing constraints, and the ability to stay well

within its Title V emissionlimits, Horwéen would like to manufacture new products without

raising any environmental concerns.

Accordingly, Horween requests that the Board make the

following changes to

Section 218.926:

6

Excent as nrovided in Section 218.929.

eE~very

owner or operator ofmiscellaneous

fabricatedproduct manufacturing process emission unit subjectto this Subpart shall

comply with the requirements ofsubsection (a), (b) or (c) ofthis Section:

Furthermore, Horween requests that the Board add Section 2 18.929 as follows:

Section 218.929

Cementable and

Dress

or Performance

Shoe Leather

a)

This

rule

anolies to a

leather

manufacturing facility located at 2015 North Elston

Avenue. Chicago.

Illinois 60614.

In addition to leathers nroduced in accordance

with

any

other rule, this facility shall

be allowed to oroduce the following types of

leather:

1)

Cementable Shoe Leather

~A

select grade ofchrome tanned. bark/nolvmer retanned leather:

Lb)

Hot stuffed. fat liauored or wet

stuffed to

over 12

but less than

25

by

weight grease, wax and oils measured by dryweight balance calculation. by

direct contact with suchmaterials in liuuelied form at elevated temperature:

and

Ic)

Finished with coating materials which adhere to the leather surface to

provide color and a rich visual luster while allowing a surface that feels

2)

Dress or Performance Shoe Leather

Ia)

A select grade ofchrome tanned. bark/r~olvmer

retanned leather;

(b)

Finished with coating materials containina water emulsified materials using

water miscible solvent materials to nrotect the leather and pigmented

coating: and

(c)

Used orimarilv in the manufacture of sewn shoes where the leather must be

canable ofsoaking

and/or

ironing ofthe

finished shoe to

smooth wrinkles:

or leathers with a fine. dressy finish that cannot meet the

3.5

lbs.

ner gallon

RACT coating regulation.

3’)

Does not meet the definition ofsnecialtv leather:

and

4)

Cannot meet the control reauirements in Section

2 18.926.

7

b)

The production of leather allowed under this

provision is subject to the following

limitations:

1)

The total VOM emissions

shall not exceed 24

lbs. VOM per 1.000 square feet

for waternroof leather based on a 12-month rolling averaQe:

2)

The total VOM emissions shall not exceed

14

lbs. VOM ner

1.000 sauare feet

for non-wateroroofleather based on a

12-month rolling average: and

3’)

The total annual VOM emissions shall not exceed 20 tons.

Section

102.202(b): Statement of

theReasons

Supporting the Proposal’

As stated throughout this petition, there are three main reasons that justify a site-specific

rule in this circumstance.

First, the rapid changes and deterioration ofthe U.S. leather industry

requires the limited number ofremaining U.S. specialty leathermanufacturers to create new

products to compete internationally orjointhe other recently failed leather manufacturers in

extinction.

Secondly, due to the technical and production limitations inherent in making specialty

leather products, Horween cannot produce the newly proposed products while complying with

the existing RACT rules.2

Finally, Horween’s production ofthe newly proposedproducts will not

result in a negative environmentalimpact when compared to prior operation at the facilityand the

continuing requirement to comply with existing emissionlimits in the

facility’s Title V permit.

The negative effects upon Horween ofmaintaining the status quo are readily apparent.

Since

1995,

because ofdrastic market changes to the leather manufacturing industry, Horween’s

use ofVOM has gone down along with its reduction ofleatherproduction and employees.

More

specifically, in

1995,

the facility used finishes containing 62.764 tons ofVOM and shipped

6,950,128

square feet ofproduct.

In 2000,

the usage dropped to 40.980 tons ofVOM and

Horween’s corresponding shipment ofproduct dropped to 4,780,291

square feet for a total of

over a 31

reduction in both areas.

See Attach.

1.

Consequently, Horweenwas forced to

reduce its workforce from 201

employees in 1995 to a current low of 151, almost a 25 percent

1

Also see the analysis for

Section

102.210(c)

which compliments this section.

2

The requested limitations are consistent

with

recently-approved

US-EPA

RACT

regulations adopted

by Maine.

8

loss ofemployment.

The cost ofcontinued compliance with the current regulations applicable to

Horween is the continued exponential decrease in annual market share ofthe leather producers’

market,

a continued decrease in production, and Horween’s eventual facility closure similar to the

previously mentioned leatherproducers that have closed or are in the process ofclosing.

During the Board’s decisionto recognize the unique emissions ofspecialty leather

manufacturers, it determined that add-on controls were technically infeasible.

Furthermore, the

Board concluded that the ability ofspecialty leather manufacturers to reformulate the solvents

used in the manufacturing process was technicallyimpossible based on the specific products

manufactured.

Finally, the Board determined that requiring add-on controls was economically

unreasonable based on the few existing specialty leathermanufacturing operations and the limited

productionat those facilities.

Therefore, the true cost ofcompliance and compliance alternatives

is eventual extinction ofspecialty leather manufacturing in flilnois and a continued

decimation of

U.S. leather manufacturing.

Furthermore, although the Horween facility is located in an area that has been designated

as a nonattainment area for ozone, the emissions from the new leather products that Horween

would like to produce are so small that

the impact on ambient air quality could not be measured at

the boundaries ofthe

site.

Moreover, the emissions from the facility resulting from the rule

change would not exceed the permitted limits

in the facility’s

existing TitleV permit.

The requested rule change would specifically apply to the product development for

cementablepull up, performance leathers and hand-sewn leathers which are currently estimated to

be from 500

sides per week to a maximum of2,000 sides per week depending on the limiting

factors.

See Attach.

1, 6, 7,

and

8.

At the maximumproduction rate ofthe new products, there

would be no physical changes necessary to be made to the facility.

Given the uncertainties in the

planning process, the fact that the leathers have yet to be produced, and the need to develop other

new products, Horween is proposing an emissions cap of20 tpy VOM for the total production of

these new leathers.

Furthermore, Horween is recommending the additional limitations that the

total VOM emissions shall not exceed 24

lbs. VOM per

1,000 square feet for waterproofleather,

9

and

14

lbs. VOM per 1,000 square feet for non-waterproofleather, based on a 12 month rolling

average.

These self-imposed constraints on emissions can easily be met and verified due to the

limited

size ofthe facility along with the specialized finishing equipment and processes used for

finishing this type ofspecialty leather. When comparing the increases in VOM and HAP emissions

to the recent VOM and HAP decreases due to Horween’s market share loss, allowing a rule

change so that Horween can produce the newproducts described above has a negligible impact

on compliance with existing emission limits and standards.

However, even without the recent

decreases in VOM and HAP, the emissions related to the change still do not

even come close to

the emission caps of99.12 tpy ofVOM and HAP

in Horween’s Title V permit and Horween’s

allotment of281 ATUs per season under the ERMS program.3

Finally, most ofthe finishing chemical HAPS are ethylene glycol n-butyl ether

(2-butoxyethanol) (“EGBE”) that should be delisted from the HAP list shortly.

The Chemical

Manufacturer’s Association (CMA) petitioned to have EGBE delisted in August 1999.

The

USEPA scientific study has been concluded, with the recommendation that EGBE should be

delisted.

EGBE

accounted for all but

2.5

tons ofHorween’s HAPS in 2000.

See Attach.

12.

Section 102.202(c): Synopsis ofAll Testimony

to be Presented atHearing

At hearing, Horween will be prepared to presenttestimony on thetechnical, economic and

environmental reasons why the Board should grant this petitionfor a site-specific rule.

The

general nature ofthe testimony to be provided has beendescribed in this petition in the

Introduction and

Section 102.202(b).

Two witnesses who are prepared to testify at a hearing have provided affidavits attesting

to the truth, accuracy and completeness ofthe information provided in this petition.

The

witnesses names, theirrelationship to Horween and their affidavits can be found in Attachment

13.

~The Title

V

permit source-wide emissions limitation

for HAP

are

included

within

the VOM

emissions limitation.

10

Section

102.202(d): Copies ofAny Material to be incorporated by reference within the

proposed rule pursuant to Section

7-75

ofthe IAPA ~5ILCS

100/5-75J

•

At

this time,

the Petitioner does not request that any information or material be

incorporated by reference within the proposed rule.

Section

102.202(e):

Proof of Service upon All Persons Required

to be Served Pursuant to

Section

102.422

Attached to

this petition is proof ofservice that the Petitioner satisfied the requirements

of 35 Ill.

Adm. Code

102.208 when filing this petition.

Should

the hearing officer orthe Board

create or modify a notice list during this regulatory proceeding pursuant to

35 Ill. Adm.

Code

102.422, the Petitioner will add those persons to the notice list and serve those persons as

required.

Section

102.202(f):

Petition

Signed by

at

least 200 Persons

Because the enactment ofthe proposed rule will not result in any negative environmental

impact when compared to historical production of specialty leathers at this facility and the

existing emission limitations in the facility’s Title V permit, the Petitioner believes that the

Board should waive the requirement to

submit a petition signed by at least 200 persons in

accordance with 35

Ill. Adm.

Code 102.202(f).

See Attach.

1.

Horween also believes that a

waiver ofthis requirement is further warranted based on the recent acceptance by USEPA and

Maine ofthe same RACT rule as the rule outlined in this petition.

Section

102.202(g): Agency

Proposal ofFederally Required Rule

This subsection does npt apply because the Petitioner is not the Agency.

Section

102.202(h): Verification

that the

Most

Recent Rule

is to be Amended

11

This statement certifies that the proposed changes to

35

Ill. Adm. Code 211.6170 and

218.926 outlined in this petition amend the most recent versions ofthe rules obtained from the

Board’s Web site.

Section 102.202(i):

IFor State Agencies) An Electronic Version ofThe Lanauaae ofthe

Proposed Rules

This subsection does not apply because the Petitioner is not a State agency.

Section 102.202(1): Justification for Inapplicability ofSections in 102.202

Please see descriptions under each subsection above forjustifications of inapplicability.

Section 102.210

—

Petition Content Requirements

Section 102.210(a): Language ofthe Proposed

Site-Specific Rule

For the language ofthe proposed site-specific rule, see the analysis for Section 102.202(a)

above.

Section

102.210(b): Reasons for the Rule Chance

For a description ofthe reasons for the rule change, see the analysis for Section

102.202(b) above.

In addition to the detailed descriptions above that support this petition,

Horween has also

included seventeen (17) attachments that justify the site-specific rule based on

technical, economic and environmental reasons.

Section

102.210(c): Description of the Site and the Area Affected by the Proposed Change4

Horween, a 96-year-old business, is located in the Elston Corridor Planned Manufacturing

District No. 2 at 2015 North Elston Avenue, Chicago, Cook County, Illinois.

It is zoned for

Heavy Manufacturing

and surrounded by manufacturing and commercial businesses.

See

Attach.

15.

The facility currently employees 151

people and primarily processes and finishes

specialty leatherfor a small niche ofhigh-end customers that demand quality.

Cattle hides

received are produced into both specialty leather and standard leather.

All cattle hides are

washed, limed,

de-haired, and chrome tanned to remove naturally occurring oils which must be

4Also see the analysis for Section 102.202(b) which compliments this

section.

12

replaced later in the process.

Oils

are replaced by hot stuffing, fat liquoring or wet stuffing.

Leather is then dried and may undergo buffing, staking

and splitting to prepare it for finishing.

In

the cattle leather finishing process, various types ofleather coatings or finishes are applied

depending upon the type ofleather being produced.

Coating operations include spraying,

machine brushing, roll coating, or hand brushing ofcoatings onto leather.

Drying techniques

involve gas-fired low heat cliyers, steam low heat dryers, vacuum drying, and hanging and

toggling in drying rooms.

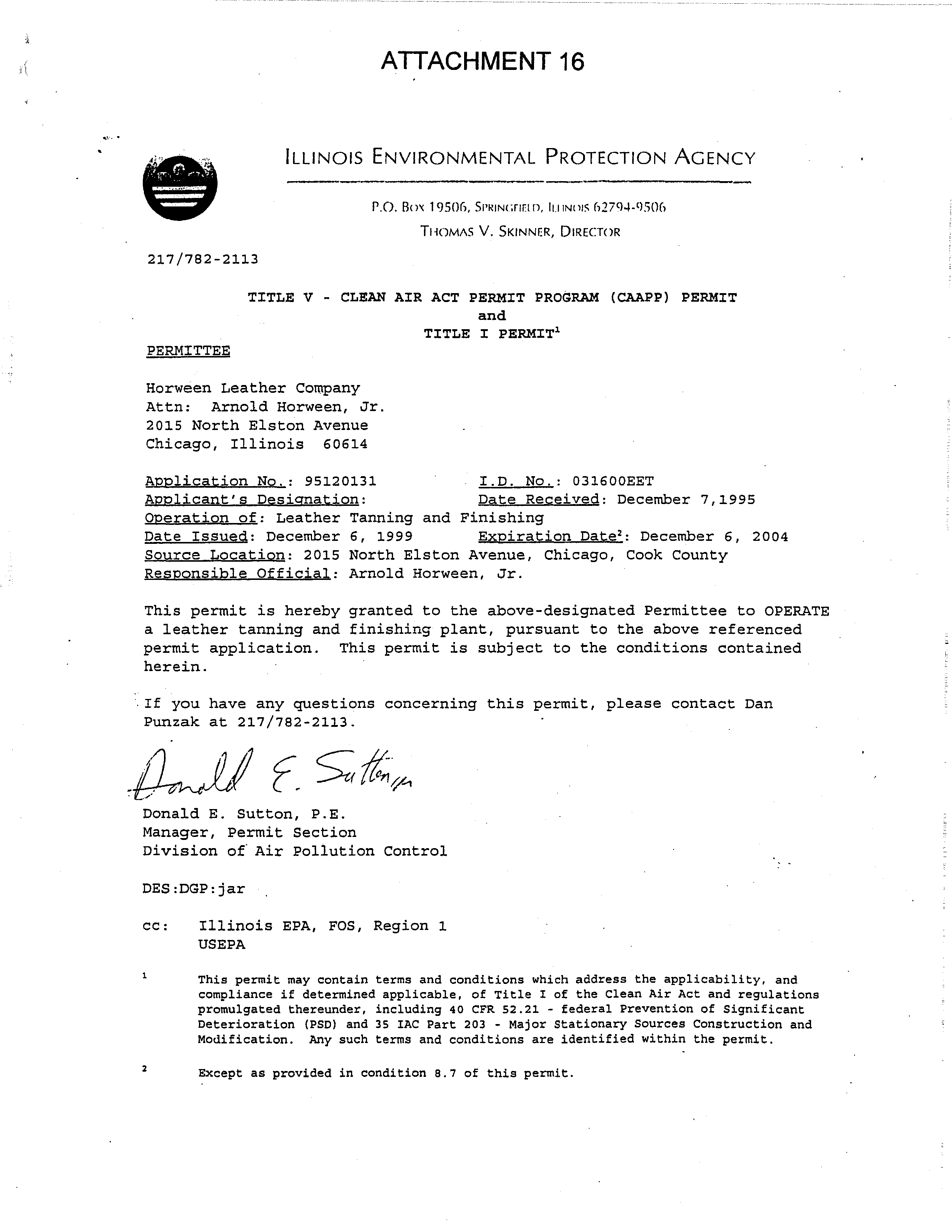

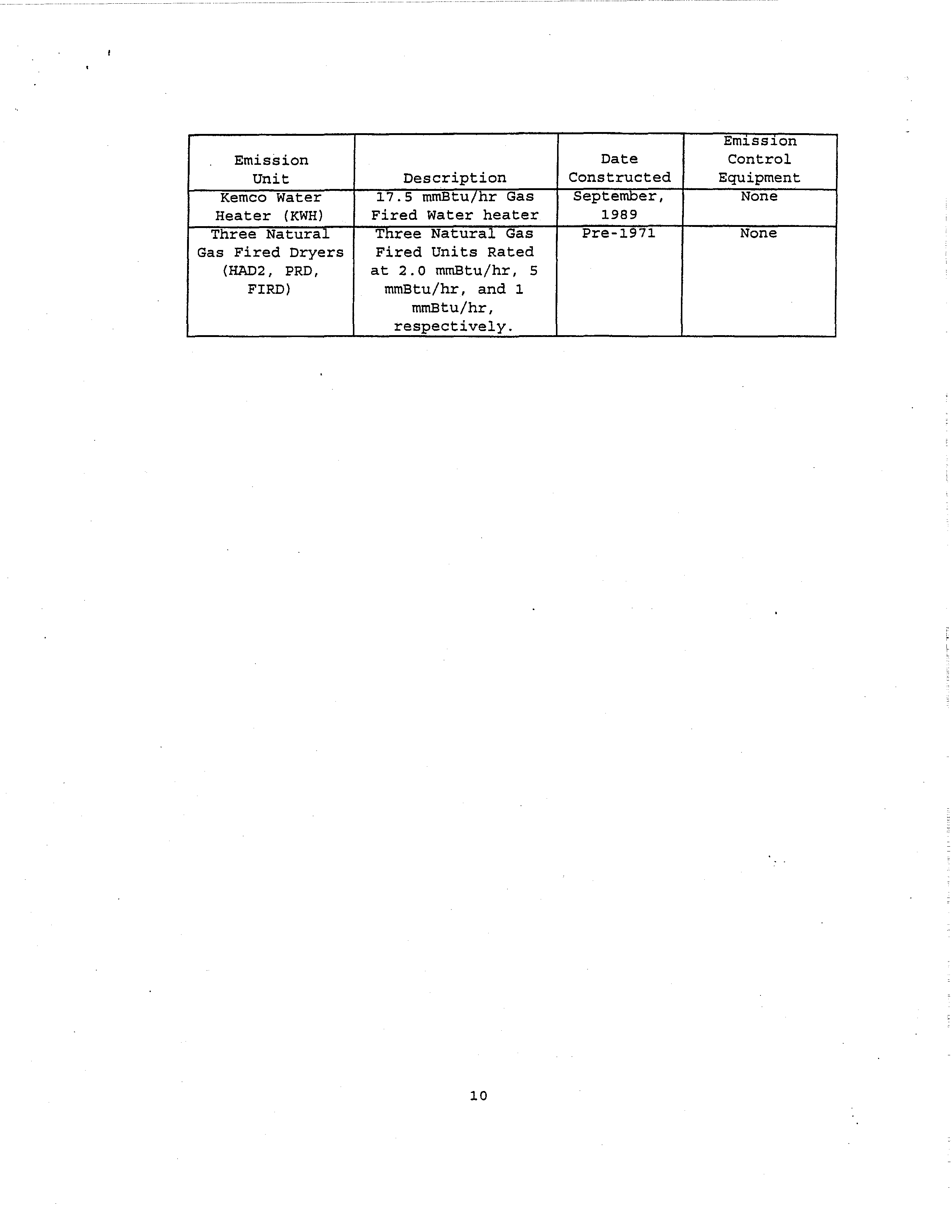

The facility currently has a Title V Clean Air Act Permit Program (CAAPP) Permit issued

by JEPA on December 6,

1999, because it is considered a major source ofVOM and Hazardous

Air Pollutant (“HAP”) emissions.

The facilityhouses 22 significant emission sources, excluding

emissions from miscellaneous/cleanup, that emit VOM, SO2, PM and NOX.

The permitted

emission limits, in tons per year, for these pollutants are 99.12,

3.58,

10.62 and

13.63,

respectively.

Seven ofthe sources have particulate matter pollution control equipment including

two built-in water curtains for the spray paint booths,

one baghouse forfour buffer units and a

whirl-wet dust collector for an additional buffer.

We also utilize electric eyes on our automatic

spray lines to eliminate the overspraying offinishes.

Work Practices, Compliance Procedures and

Recordkeeping Requirements are all outlined in Section

5.0

Overall Source

Conditions and

Section 9.0

Standard Permit Conditions of Horween’s Title V CAAPP

Permit.

See Attach.

16.

There are no treatment or control options that could avoid the Petitioner’s request for this

rule change.

First, no feasible add-on equipment currently exists to control VOM emissions from

the leather finishing process.

Additionally, as explained above, even though Horweenhas

invested heavily in the research and development ofutilizing different replacement finishes and

low VOM stain coats, no suitable substitute material has been satisfactorily developed to replace

the use ofsolvent-based coating on these types ofspecialty leathers.

Finally, material substitution

or process modification is not a viable alternative for tanneries producing this type ofspecialty

leather.

13

However, even though the use ofthe newly proposed specialtyleather coating cannot

meet the current rule, the environmental impact ofthe proposed change to the regulations

• allowing Horween to make thesenew specialty leather products is negligible.

More specifically,

Horween is asking for a 20 tpy limitation to ensure it does not exceed the Finishing VOM usage

from 1995.

See Attach.

5.

Constraints on emissions will also stem from the limited size ofthe

facility along with the

specialized finishing equipment and processes used for finishing this type of

specialty leather.

When comparing the increases in VOM and HAP emissions to the recent VOM

and HAP decreases due to Horween’s market share loss, the proposed standard has no impact on

compliance with existing emission limits and standards.

However, even without recent decreases

in VOM and HAP, the emissions related to the change

still do not even come close to the

emissioncaps in Horween’s Title V permit of99.12 tpy ofVOM and HAP in Horween’s Title V

CAAPP Permit.5

Section

102.2 10(d): Demonstration that the Board may Grant the Proposed Relief

The Board can grant the proposed relief consistent with federal law governing the subject

ofthe proposaL

In the

1990 amendments to the CleanAir Act,

Congress included provisions that

required states to

submit SIPs for moderate, serious, severe, and extreme ozone nonattainment

areas that imposed RACT on all major sources ofvolatile organic compounds.

~

42 U.S.C.

§

7511 a.

Chicago has been determined to be

located in a severe ozone nonattainment area.

40 C.F.R.

§

81.314.

Accordingly, Illinois submitted a SIP including RACT regulations for leather

coating.

As

originallyproposed by Illinois, Horween could not have met the RACT standards for

leather coating.

However, afler providing a substantial amount ofinformation about its unique

process oftanning leather and the air pollutant emissions relatedto

the process, IEPA agreed with

Horween’sposition and reflected its agreement by proposing a specialty leather emissions rule

•

that allowed VOM emissions in the amount of38

lbs. per

1,000 square feet and created the

~The Title

V

permit source-wide emissions limitation

for

HAP

are included within the

VOM

emissions limitation.

14

existing definition of“specialty leather.”

The amended RACT rule was approved by the Board

and USEPA as part ofits SIP under the Clean Air Act.

59

Fed. Reg. 46567

(Oct.

11,

1994).

With regard to Horween’s newly proposed products, the emission factors relating to

producing these products are substantially different from the factors relied upon by the Board in

adopting the general regulation.

As Illinois affirmed when originally amending the RACT rule for

specialty leather manufacturers, the unique treatment ofspecialty leather manufacturers is

necessary because oftheir limited number and minimal impact on the degradation of air quality.

Although the Horween facility is located in the Chicago metropolitan area, there will be a small

impact, if any, on the facility’s emissions ifthe requested rule change is granted.

Moreover, the

impact ofemissions will continue to be limited by the caps on Horween’s VOM emissions

proposed in this petition and the limits on its VOM and HAP emissions currently in its Title V

CAAPP Permit.

Thus, Horween’s introduction ofnew specialty leather products would not cause

or contribute to any violation ofthe national ambient air quality standards.

Additionally,

as set

forth above,

and perhaps most critical, no viable alternative currently exists to create the products

for which Horween is seeking this relief.

Accordingly, granting an amendment to the existing

Illinois RACT rules to

allow Horween to produce these new leather products is justified.

Because this petitionaffects the RACT rules established forthe Chicago Metropolitan

area and is not a proposal for an equivalent alternative control plan as identified in 35 Ill. Adm.

Code 218.926(c), the IEPA willhave to request a SIP revision to add this rule to Part 218.

However, for the reasons stated above, IEPA’s SIP revision request will likely be non-

controversial because ofthe negligible environmental impact of granting this proposed site-

specific rule and the recent acceptance by USEPA ofthe same rule as RACT in Maine.

~

65

Fed.

Reg. 20749 (Apr.

18, 2000).

See Attach.

10

and

11.

With regardto

other related federal laws, USEPA has published a proposed NESHAP

standard for Leather Finishing Operations that may affect Horween’s future HAP emissions, if

approved.

$~

65

Fed. Reg.

58702 (Oct. 2, 2000).

During the notice

and comment period,

Horween timely submitted comments to USEPA to explain its unique process ofmanufacturing

15

specialty leather products and requested USEPA recognize Horween’s unique operations in any

final NESHAP standard.

See Attach.

17.

On May

14, 2001, the USEPA announced that the

NESHAP standard was in its final stages and placed the NESHAP standard on the

list ofrules to

be promulgated within one year.

~

66 Fed. Reg. 26119 (May

14, 2001).

However, to date, the

NESHAP rule has not yet been issued; thus, Horween cannot comment on how the USEPA will

respond to Horween’s comments, change the proposed rule to recognize Horween’s unique

operations, or affect Horween’s operations.

Section 102.210(e): ~State Only Reguirementi Electronic Version

ofthe Proposal

This subsection does not apply because the Petitioner is not a State agency.

Section

102.210(f): Justification for Inapplicability of Sections

in

102.210

Please see descriptions under each subsection above.

WHEREFORE, Horween requests the Board grant a site-specific rule from compliance

with 35

III. Adni.

Code 211.6170 and 218.926 and add a newrule 218.929 so Horween can

continue to produce its existing specialty leathers and to develop new products in compliance with

environmental law.

Respectfully submitted,

President

HORWEEN

LEATHER COMPANY

Attachments

16

CERTIFICATE OF SERVICE

The undersigned certifies that a copy ofthe foregoing Notice of Filing and Petition

for Site-Specific Rulemaking was filed by hand delivery with the Clerk of the Illinois

Pollution

Control Board and served upon the parties to whom said Notice is

directed by

first

class mail, postage prepaid, by depositing~ the U.S.

au

at 321 Nort

i

Clark Street,

Chicago, Illinois on Tuesday, February

9, 20

.

CHOIll 2208868.1

-2-

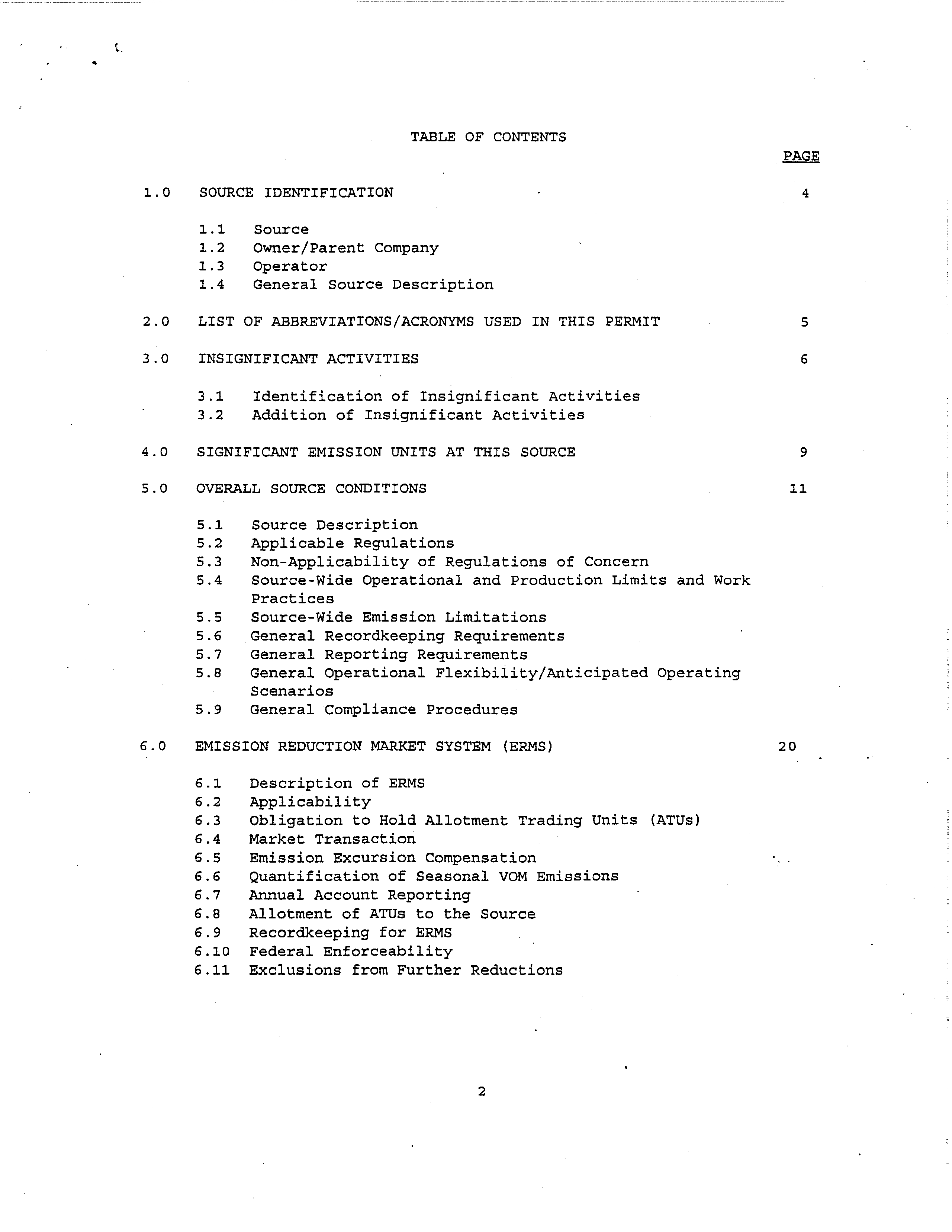

LIST OF ATTACHMENTS

I

YEARLY USAGE

OF

FINISHES CONTAINING VOM AND HAPS

2

US

NON-RUBBER SHOE MARKET

3

USFOREIGNTRADE

4

NEWS OF THE

MONTH,

American

Shoemaking,

October/November 2001

5

PREVIOUSLY SUBMITTED TECHNICAL SUPPORT DOCUMENT

6

CEMENTABLE

LEATHERS,

FINISH A

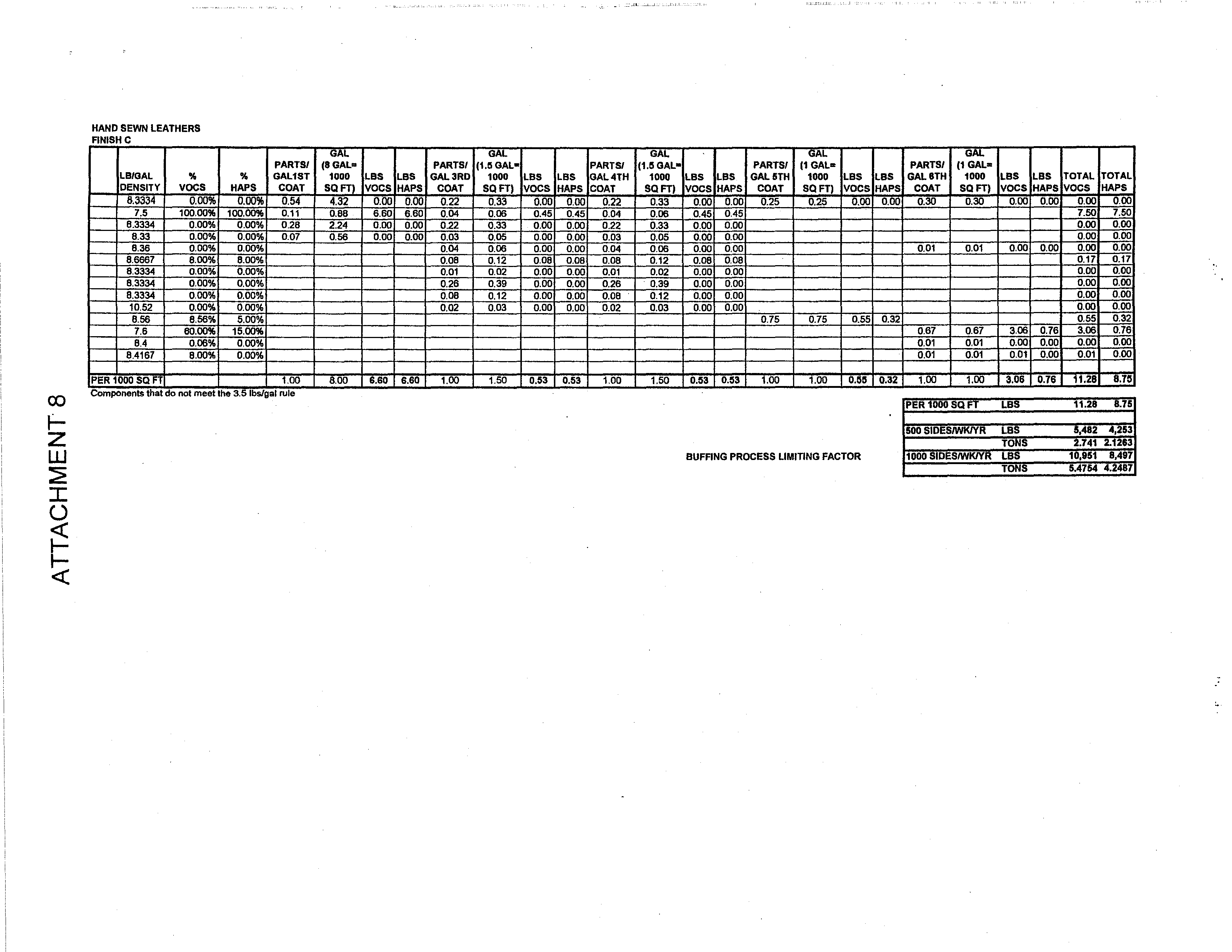

7

ADDITIONAL PERFORMANCE LEATHERS SAMPLE, FINISH B

8

HAND SEWN

LEATHERS,

FINISH C

9

ADJUSTMENTS MADE TO

DYE MIX

10

PRIME TANNING COMPANY, YORK COUNTY, BERWICK, MAINE,

PART 70

AIR EMISSION LICENSE

11

FEDERAL REGISTER DOCUMENT, 40 CFR PART 52, APPROVAL AND

PROMULGATION

OF AIR QUALITY IMPLEMENTATION

PLANS;

MAINE; RACT

FOR VOC

SOURCES

12

IMPACT OF DELISTING OF EGBE

13

AFFIDAVITS—ARNOLD HORWEEN, JR~,

JULIE

M.

CHRISTENSEN

14

NO ATTACHMENT

15

ELSTON CORRIDOR PLANNED MANUFACTURING

DISTRICT NO.2

16

TITLE V CAAPP

PERMIT

17

COMMENTS

REGARDING PROPOSED RULE, 40 CFR PART 63,

NESHAPS

FOR LEATHER FINISHING OPERATIONS

YEARLY USAGE OF FINISHES CONTAINING VOM AND HAPS

YEAR

TONS OFVOM

z

w

I

TONS VOM

500 SIDESIWK!YR

TONS

HAP

500. SIDESIWK!YR

TONS VOM

MAY-SEP

TONS OF GLYCOL

TOTAL SIDES

LBS

OF VOM

ETHER HAPS

FOOTAGE SHIPPED PER 1000 SQFT

1995

62.764

20.199

6,950,128

18.06

5.81

1996

49.239

16.861

5,435,611

18.12

6.20

1997

48.605

13.089

6,518,582

14.91

4.02

1998

42.773

12.598

5,030,894

17.00

5.01

1999

40.553

12.422

5,034,771

16.11

4.93

2000

40.980

13.665

4,780,291

17.15

5.72

LBS

OF GLYETH

HAPS!1 000 SQ FT

Cementable Finish A

Performance Finish B

Hand Sewn

Finish C

4.528

.

2.411

2.741

1.655

0.913

2.126

2.264

1.206

1.371

TOTALS

14.374

9.534

4.840

TONS VOM

MAX* SIDES!WK!YR

TONS HAP

MAX* SIDES!WKIYR

TONS VOM

MAY-SEP

Cementable Finish A

Performance Finish

B

Hand Sewn Finish C

45.279

9.644

5.475

16.545

3.652

4.249

22.640

4.822

2.738

TOTALS

84.844

54.645

30.1 99

20 TON LIMIT**

20.000

12.881

7.119

TONS VOM

TONS HAPS

ERMS ATU’S

2000

NEW PRODUCTION**

40.980

20.000

13.665

12.881

192

72

TOTALS

.

60.980

26.546

264

US NON-RUBBER SHOE MARKET

ATTACHMENT 2

US PRODUCTION

OF NON-RUBBER BOOTS & SHOES

Unit

-

-

1,000

Pairs

Dress &

Work

Men’s

Menus

Total

Dress

Work

1990

44,621

31,752

12,869

1991

39803

27,340

12,463

1992

41.185

28,959

12,226

1993

46,404

31,956

13,720

1994

41,313

27,641

13,672

1995

41,051

26,181

14,870

1996

36,646

21,795

14,851

1997

36,694

20,256

16,478

1998

34,845

22,644

12,201

1999

27,273

16,982

10,291

2000

Data

Not Available at

Time of PubHcation

*

Revised

Youth’s

& Boys’

1,205

807

801

1,203

1,528

1,289

553

403

*223

Chhldrens

5,611

5,263

4,332

3,939

4,084

3,871

2,737

1,612

.973

*963

Infants’

& Babies’

11,137

11,162

9,406

8,302

7,629

6,722

5,559

5,481

*4,213

1.788

Production

Production

Total

WlLeather

WlLeather

Production

Uppers

Only

Uppers &

Soles

184,568

88.944

27,287

167,386

85,865

26,693

168.451

79,451

24.275

171,733

93,228

26,802

163,000

99,845

26,194

147,559

83,801

27,072

127,315

77.562

25,962

124,444

66,296

21,767

*108.536

.

53,582

~18,622

78,870

34,680

10.406

US PRODUCTION NON-RUBBER SHOE MARKET

Unit

- -

1,000 Pairs

Women’s

Misses’

Athletic

Slippers

Other

1989

68,987

3,865

15,267

56,513

3,163

1990

63,082

1,985

9,532

44,718

2,677

1991

55,455

1,371

8.113

42,963

2,449

1992

57,185

1,736

8,157

43,735

1,914

1993

56,632

1,406

5,866

39.190

1.875

1994

49,849

836

6,146

43,265

2,754

1995

49,401

1,284

5.468

47,554

2,444

1996

49,889

686

•3405

40,696

*1,411

1997

43,364

796

~2,744

43,037

1.094

1998

22,478

~77

~3,737

40,189

**1

803

1999

~~13,630

~313

~32,235

~2,573

Excludes disposables

~Revised

US NON-RUBBER SHOE MARKET

Unit

-

-

1,000

Pairs

Total

US

US Population

Pairs

US

Imports

(July 1)

Per

Production

(Exc.

Disposables)

Total

(unit.

j,oao,eoo~

Capita

1990

184,568

897;532

1,082,100

249.9

4.33

1991

167,386

937,156

1,104,542

252.6

4.37

1992

168,451

974,224

1,142,675

255.4

4.47

1993

171,733

1.065,267

1,229.024

258.2

4.76

1994

163,000

1,101,268

1.257,980

260.6

4.83

1995

147,550

1,079,450

1,238,534

262.8

4.71

1996

127,315

1,098,064

1,241,822

265.3

4.68

1997

124,444

1,229,167

1,337,611

267.6

4.99

1998

*108,536

.

1,229,831

1,338,367

270.5

‘4.95

1999

78,870

1,305,262

1,384,132

273.1

5

2000

Not available

1,414,350

Not available

275.6

Not available

Revised

U.S. Leafher Industr/ Statistics,

Produced by Leather Industries of America

data taken from World Footwear Markets 2001

US FOREIGN

TRADE

TOTAL FOOTWEAR IMPORTS

Unit

1,000

Pairs

ATTACHMENT 3

Country

2000

1999

1998

1997

1996

TOTAL

1,414,250

1,305,262

1,229,831

1,213,167

1,098,863

US

BALANCE OF

TRADE

-

LEATHER

Unit- -$1,000,000

SHOES &

HIDES & SKINS

LEATHER

LEATHER PROUCTS*

NET

Imports

Exports

Imports

Exports

Imports

Exports

DEFICIT

1990

1991

1992

1993

1994

1995

1996

1997

1998

1999

2000

93

109

124

120

126

140

131

126

109

98

105

1,607

1,270

1,250

1,189

1,392

1,237

1,235

1,491

1,113

1,016

1,476

683

571

631

736

960

1,089

1,139

1,376

1,571

1,635

1,993

751

680

705

764

812

870

951

1,146

1,289

1,137

1,126

12,451

12,335

13,002

13,857

14,791

15,298

15,858

17,288

17,322

17,514

19,446

527

649

733

837

839

884

923

942

849

874

922

10,342

10,416

11,069

11,923

12,834

13,536

14,936

15,211

15,751

16,220

18,020

*Includes

leather and other materials

U.S. Leather Industry

Statistics,

Produced

by Leather Industries of

America

data taken from World

Footwear Markets 2001

Brazil

Canada

Dominican

Rep.

Mexico

France

Germany

Italy

Portugal

Spain

UnitedKingdom

China

Hong

Kong

India

Indonesia

Korea

Philippines

Sri Lanka

Taiwan

Thailand

Vietnam

Balance

of World

96,187

1,410

5,910

11,917

902

3,377

50,848

3,760

17,500

6,175

1,086,364

8,750

7,084

59,385

5,803

2,072

1,105

11,170

18,570

3,810

83,777

1,587

6,436

13,262

1,212

3,446

46,484

3,925

17,895

6,930

984,847

7,165

6,549

63,340

6,580

1,976

1,361

12,562

18,759

3,274

82,385

1,485

8,044

19,410

1,262

3,167

47,711

3,359

22,247

6,885

895,142

6,655

5,880

59,226

9,277

6,188

1,624

13,679

18,642

3,444

89,686

1,804

9,132

23,582

985

2,868

52,568

3,265

242,056

6,623

842,110

10,222

7,566

67,668

8,738

8,027

1,609

19,127

17,788

2,934

91,601

2,090

4,586

16,732

823

~2,356

49,528

3,215

21,764

4,533

750,944

7,946

7,254

67,129

10,066

8,397

1,738

17,845

17,620

808

11,888

12,151

13,395

14,119

12,659

ATTACHMENT 4

NEWS

OF THE

MONTH

Prime Tanning to Close

Plants, Release 550 Workers

Ken

Purdy,

president

of the

Prime

Tanning

Co.

of

Berwick,

ME,

has

announced

that

Prime

will

be

closing

its

plants

in

Berwick,

ME,

and

Rochester,

NH,

by

the end of

the

year. ‘rue

closing

will

mean

that 550 workers will he laid ott

In

n~akingthe

announcement,

Purdy

said

that

the

company

will

sell

its

Rochester,

NH,

facility

and

convert

its

Berwick plant

int(

a

production

develop-

ment

unit

employing

about

50 workers.

Purdy,

who

has

been

in

the tanning

business

fbr

scone

3() years,

said

that the

closing

was “the

most

difficult at~(l

sad-

dest

day

I’ve experienced.”

I Ic cited

the

continuing

trend

of U.S.

shoe

manulac—

tori

ng

cornpanics moving

tlici

r

pro-

duct

ion off

shore

f~r

cheaper labor costs.

‘l’his, he explained, made it impossible fir

Prime to

maintain

l)rofital)le production

levels.

He noted

that

969’o

of

the

shoc

sales

in this country

arc

now imports.

Pitrdy also

noted

that

l’rinie held

out

longer than

most other

tanneries, point-

ing out that

there

is

virtually

no

leather

industry left

in

this

country.

Jo

June

oF

this

year

Prime laid

oFF

70

workers

who

had been

employed

at

the

company

for fluir

months

or

less.

‘l’hcse

workcrs had heeti

hired

in .lnticipation

of

a sales increase that never materialized,

As of October

I

the company will stop

raking orders

and l)1i~

out l,ro(juction

over the next

three nionths.

‘J’he compa-

ny

expects

to

close

its

Berwick

plant

by

November

2,

Purdy

said,

with

the

Rochester plant closing

by

I)cceniber

I

When

the Bcrwick

facility

is

converted

to a product development center,

will also

house sales, marketing, customer service,

administration and corporate offices.

The

closing

of the

Maine

and

New

Hampshire

facilities

will

not

affect

the

wet

blue

operation

in

St.

Joseph,

MO.

‘Jhat

facility efliploys

some

300

wprkers.

No leather

is

finished

at that

plant.

‘Ihe

production

of wet

blues

will

be

sent

to

Prime’s

joint

ventures

in

China

and

Mexico, or to other Asia

tanneries.

Prime

Tanning

is a

fhmily—owned busi—

ness

that

began

tanning

leather

in

Massachusetts more than 90 years ago,

and nmved to its Maine site

in the

I 930s.

It was the last

of three major

tanneries in

thearea.

James

McMahon,

town

manager

of

Berwick, said he was “thinking about how

sad

it

is

that

after

70

years that

they

arc

stopping

production here

in

Maine.”

Charles

Myers,

president

of

Leather

Industries of America,

said

of the closing

that

“the

tanning

industry

in

the

United

States

is

gone. If it’s

labor

intensive,

it’s

not

going to

happen here

in

America.”

SaIz Tannery to

Close

After 145 Years

Salz

l.cathers

of

Santa

Crux, CA,

is

closing.

it

was announced

in

a

letter

to

customers

signed

by

Geoff’

Eisenberg,

CEo

of the

company.

According

to

Eiscnberg, the

company

will

win,

dowit

its

business

over

the next

two

or

three

months and

as

the

various

stages

of

production end,

workers

will

be

laid oft

l’he company presently

employs

Ill

workers.

Many

of the workers

had

been

with

the tanIi~ryfor 30

years.

l)turiitg

its

145

years

of existence,

the

company

has

survived

fires,

floods

and

earthquakes,

but

it cuuld

not survive

the

competition

from

China,

said

Norman

lain,

chairman

of the

company.

Over

the

pact

10

years,

he sakl,

the company

has

lost

over $10

million

as the industry

has

moved

to China wherelabor is cheap-

er

and

environmental

laws

are

less

stringent.

‘the

average

hourly

wage at

the

plant

was

$17,

compared

to

wages

in

(

hina ol $1

per hour.

I

ezin,

who

has

been

associated

with

Sal,. fir 53 years.

and

his

sons Jeremy

and

Matt

li;id

put

otFclosing the company

for

some

dine.

I e

said

that

he

should

have

closed the

f~iciliiy

10

years

ago

when

it

became

clear

that

globalization

was

changing huw

the industry

was taring.

Eisenbcrg said

that

during

this period

of

dosing

the

company

will

not

cumprit-

misc

its

quality

or

service

statidards, and

will

honor

all

clirren

t

ordcrs and

agree—

nietits.

lie noted

that

the company

is

financially

healthy

and

will

honor

its

obligations.

Each

employee

will

receive

one month’s p~yp1us

benefits,

and some

retraining

in

order

to

find

employment

elsewhere.

Bass Picks Sullivan

As

Vice

Chairman

(‘,.l-I.

Bass,

a

division

of

Philips-Van

Ileusen

Corp.,

has

announced~the

appointnient of

Diane

Sullivan

to

the

post

of

Vice

Chairman.

Sullivan,

most

recently

president

of

,Stride

Rite

brand,

will

divide

her

time

between

the

South

l’ortland,

ME,

offices

of

Bass

and

the

New

York

offices of Philip—Van

Iicusen.

Sullivan,

who

left

.~tri(lcRite

last

May,

replaces

Michael

Blitzer,

chairman and

CEO.

who

is

returning

to

New Jersey

where

lie

lived

prior

to

joining

Bass

as

president.

Mark

Weber,

president

and

CEo

1)1

Philips—Van

I leusen.

said

Stillivan

has

a

wealth of experience not

only

in

market-

ing

and

product

-

development,

but

in

administration as well:

He

tiored’that the

Bass

division

is

doing

well,

and

that

Sullivan’s appoititmenr

ccinies

at

a

time

when

Bass

is

looking

to expand

its

prod-

uct

depth.

Sullivan joined

Stride

Rite

as president

of’ the

brand

in

19

and

led

efbrts

to

rebuild

the

children’s

l,ttsiness.

She

was

promoted

to

group

presidetit,

licensed

brands, in

1998

when

s1te

helped

launch

the

‘lbmmy

I lilfiger

women’s

line.

She

became

president and

C(’)()

of

Stride

Rite

in

1999.

Dexter

Announces

Factory Closing

‘l’he I)exter Shoe Co. announced on

September

18

that

it

will

lie

closing

its

last f~ctory

in

Dexter,

ME,

by

the end

of

the

year.

When

the

company

closes,

it

will

release nearly

500 workers.

Owned

by

Berkshire

I lathaway

since

1993

and operated

by

the Ahlond

family,

the

c-omupany

produces

men’s

and worn—

AMERICAN SHOEMAKING

OCTOBER/NOVEMBER

2001

3

NEWS

en’s casuals and dress shoes,

golf

shoes,

boating

shoes

and a

line of

hiking

and

walking shoes.

Incorporated

in

1957

by

the

Harold

Alfond

family,

the

company

has

been

struggling

against

the

tide

of

imports

for

some

time,

and

within

a

year

has

closed

factories

in

Newport

and

Skow-

hegan, ME,

Ar one time the

company employed as

many as 3,000 workers.

Employeesof Dater are certified under

the Federal Trade Adjustment

Assistance

Program

for

extended

unemployment

benefits and job retraining funds.

Under

the

Trade

Adjustment

Assistance

Pro-

gram,

employees

of

those

companies

affected

by

foreign competition

are eligi-

ble for help,

SADESA new

processing

arrangement

in China

In

July

2001,

Sadesa launched

its

first

processing

arrangement

in

China.

The

plant,

Nanhai Mimosa

Leathers Ltd.,

is

located in Nanhai; 30

minutes drive from

the center of

Guangzhou.

This

arrange-

ment

will

complement

the

two

plants

already

operating

in

Thai-

land,

It

is

geared

to

supply

the

demands

of

Sadesa’s

China-based

customers in a

faster

way,

Focusing

mainly

in

performance

leathers,

with

the ability to

produce lifestyle

leathers as well.

As

the

first

step

towards

the

industrial expansion in Asia, Sadesa

inaugurated

in

May

1999

its

first

plant

outside

South

America. The

plant

is

located

in

Ayutthaya,

Thailand;

a

joint

venture

with

Bangkok

Rubber

Group

(BRG)

owned 85

by Sadesa.

In January 2001,

Sadesa increased

its output

in

Thailand

by

utilizing

the

finishing

capacity of

Pan

Asia

Leather

Co.

Led.,

a

tannery

also

part of BRG, located in

Kabinburi.

The

finished

leather

produced

at

this plant

is primarily focused to

the

performance

footwear

industry

in

Thailand,

Vietnam, and Indonesia.

Sadesa is one of the largestleather

manufacturers

in

the

world,

pro-

ducing

17

million

square

feet

of

quality

crust

and

finished

leather

per month

in

its

ten

industrial

facilities

and

employing 2,750 people. The com-

pany operates a global sales

network with

offices

and

commercial

alliances

in

18

countries

in

the

five

continents.

This

structure provides the means to serve cus-

tomers

wherever

required.

Its

worldwide

raw

material

sourcing

operates

irc

the

major hide

markets supplying raw mate-

rials that best match customers’

needs,

Two

Ten

Annual Meeting

Nov.

8

in

Boston

The

Two

Ten

International

Footwear

Foundation

will

hold

its Annual

Dinner

Meeting andSilent Auction on Thursday,

November 8,

Site of the event will

be the

Boston

Park

Plaza hotel.

This

will

be

an

opportunity

for

mem-

bers

to

meet

the

new president

oi

Two

Ten, Peggy

Kim

Meill.

On Friday November 9, Two Ten will

hold

its

annual

Leadership

Conference,

which will also be held at the Park

Plaza.

For

further

information

and

reserva-

tions

for

the

Annual

Meeting,

contact

Two Ten

by

telephone at 781-736-1500;

by fax at 781-736-1554; or contact Mary

Hehir by E-mail at mhehir@twoten.org.

Continued on

Page 32

Sadesa’s

New Processing Plant in

China.

Congrtitu(titious

American Slioemaktiuj

ouyour

100th.

tuiniwrstuy

he familial ties of Fred Moynihan to his son,

John, was

the

stimulus for the remarkable

growth

of American Shoemaking. John

and

his cohorts have taken this genesis to a well

respect-

ed and honorable institution of our industry—We

thank you for your excellence.

Your

friemLs at

Sfteefurn Sales

100 Cummings Center—Suite

12313,

Beverly,

MA 01915

Tel:

(978)

232-9680,

Fax: (978)

232-9684,

E-mail: sheehan@telcocom.com

4

OCTOBER/NOVEMBER

2001

AMERICAN SHOEMAKING

ATTACHMENT 5

HORWEEN LEATHER COMPANY

TECHNICAL

SUPPORT

DOCUMENT

1.0 INTRODUCTION

The Clean Air Act,

as amended

in 1990, ma~tdatesthat states

adopt

rules

to implement reasonable available control

technology

(R.ACT)

for all major sources of volatile organic

material

(VOM)

in nonattainment areas.

The Chicago

nonattainment area

is classified

as severe by National

Ambient Air Quality Standards;

therefore,

all major sources

with the potential

to emit greater than twenty—five

(25)

tons per year

are required to

have PACT.

For leather coating processes,

located

in the Chicago

nonattainment

area,

the current I1~linoisVOM regulations

define PACT for sources with ~ maximum theoretical emission

(MTE)

of

at

least one hundred

(100)

tons per year

(TPY).

Therefore,

the Illinois Environmental Protection Agency

(IEPA)

is proposing PACT regulations for sources

in this

category of emissions with the potential to emit

(PTE)

at

least twenty—five

(25)

tons per year of VOM emissions but

less than one hundred

(100)

tons per year MTE.

The proposed rule requires the use of leather coatings with

a VOM content of 3.5 pounds per gallon for all

leather

coatings with the exception of stain coatings and certain

specialty coatings.

For all coatings applied

to specialty

leather,

the proposed rule imposes

a limitation of

38 pounds

per 1,000 square foot of finished leather.

In

addition,

the VOC content

of stain coatings, other than

stain coatings applied

to specialty leather,

as

applied

at

the source may not exceed ten

(10)

tons in any twelve

(12)

month period.

This proposed rule

is necessary for

specialty coatings and stain coatings due

to inherent

difficulties

in controlling VOM éiñissions

that result when

certain specialty coatings

and stain coatings

are used.

Use of add—on controls, although technically feasible in

some instances,

is economically unreasonable.

2.0 GENERAL PROCESS DES~RIPTION

AND

SOURCES OF EMISSIONS

2.1

General Description of Leather Tanning

—

Industry

Pr act ice

In

the

production

of

most types of leather, certain

coatings are applied

to tanned leather in order to

provide protection,

cosmetic appeal and certain

specialty effects.

Prior

to the application of

coatings,

the leather

is produced by tanning raw hides

from cattle or horses.

Horse hides are the raw

material from which cordovan leather

is

produced.

This

leather

is produced through

a bark tanning

or

vegetable tanning process,

after which the cordovan

leather

is finished without the use of coatings

involving VOM.

Because the tanning and finishing

of

cordovan leather ‘does not

involve the emission of any

VOM,

the following discussion will not include

a

discussion of cordovan leather.

In the production of leather from cow hides,

the raw

hides

are first subjected to

a

series of processes

in

which the hides

are washed,

limed,

hair—removed and

then chrome

tanned.

This

initial process does not

utilize VOM and does not

result

in VOM emissions.

As

a result of this process,

all of the natural greases

and oils are

removed from the chrome—tanned hides.

In

order

to produce

a usable

leather, naturally occurring

oils must

be replaced so that the leather

is pliable.

This is normally accompl~.shedthroughout the industry

by the use of

a process known as

“fat liquoring,”

in

which oils

and greases are emulsified in

a water phase

and applied to the leather.

In the leather finishing process, various types

of

leather coatings, or “finishes,”

are applied,

depending upon the type of leather being produced and

the intended end use of the leather.

The different

types of finishes include:

“stains” or

“dyes,”

“pigments,”

“binders,”

and “top coats”

or

“sealer

coats.”

The terms “stain”