Illinois Environmental Protection Agency

Exhibit List

Title or Description of Exhibit

Exhibit No

.

Simple cycle gas turbine application diagram.

1

"Section 3.1 Stationary Gas Turbines" Supplement F to Compilation of Air Pollutant

2

Emission Factors, Volume 1: Stationary Point and Area Sources Volume 1:

Stationary Point and Area Sources

, July 1993, AP-42.

Letter dated May 16, 2000, to Mr. Francis X. Lyons, Regional Administrator,

3

USEPA Region 5 from Thomas V. Skinner, Director, Illinois EPA.

Letter dated June 15, 2000, to Thomas V. Skinner, Director, Illinois EPA from

Francis S. Lyons, Regional Administrator, USEPA Region 5.

"Alternative Controls Technology Document-NOx Emissions from Stationary Gas

4

Turbines", USEPA Office of Air and Radiation Emission Standards Division,

January 1993, EPA-453/R-93-007.

Existing Power Plants with key (table).

5

Table: Existing Fossil Fuel Fired Boilers.

6

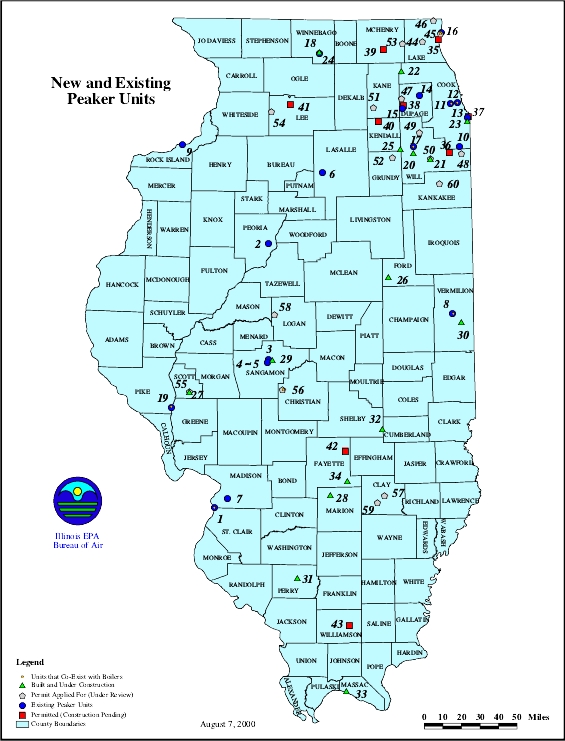

New and Existing Peaker Units map with key (table).

7

Existing Peaker Power Plant table.

8

Table: New Large EGU Peak Units.

9

Table I Natural Ambient Air Quality Standards and PSD Increments

10

Table 2 Maximum impact from Peakers Compared to Class II PSD Increments

Table 3 Maximum impacts from Peakers Compared to the National Ambient Air

Quality Standards.

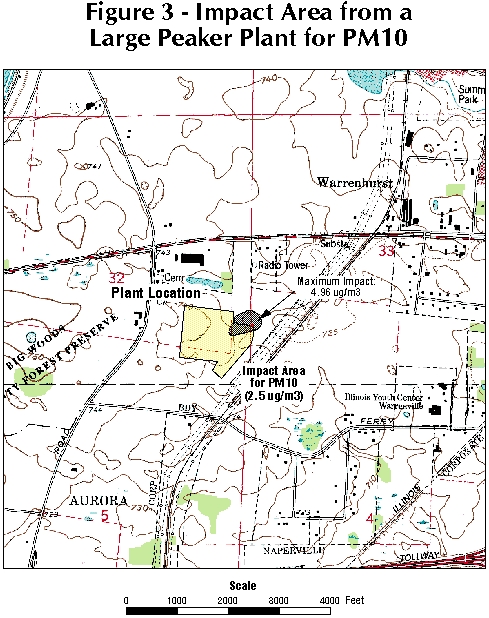

Figure I - Significant Impact Area from a Large Peaker Plant for NOx

11

Figure 2 - Impact Area from a Large Peaker Plant for CO

Figure 3 - Impact Area from a Large Peaker Plant for PM 10

Figure 4 - Impact Area from a Large Peaker Plant for S02.

Figure 5 10 Year Trend of I -Hour Ozone Design Values in the Lake Michigan Area.

12

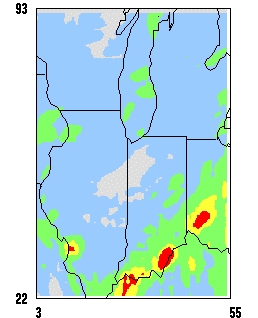

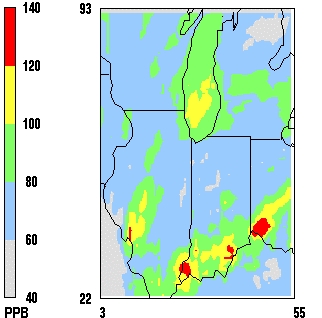

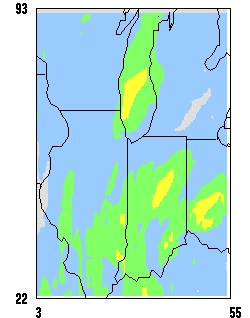

Peak 1 -Hour Ozone Concentrations Assuming CAA Controls.

13

Title or Description of Exhibit

Exhibit No.

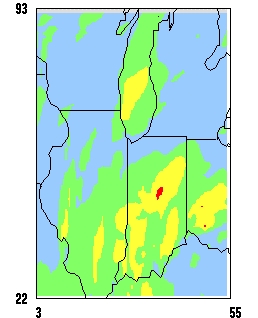

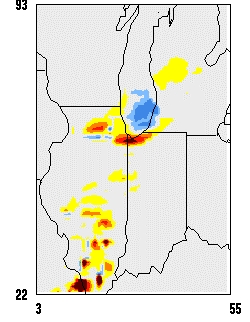

Peak I-Houre Ozone Concentrations Assuming SIP Call Controls.

14

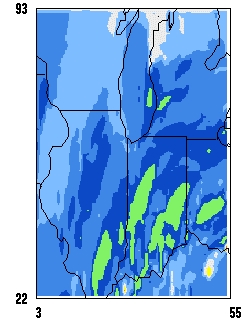

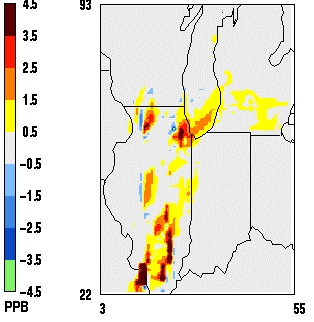

Effect on 2007 CAA Ozone Concentrations due to SIP Call Controls.

15

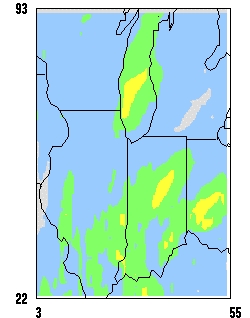

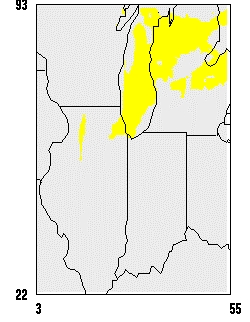

SIP Call 1 -Hour Ozone Concentrations with "Peakers".

16

Effect on SIP Call 1 -Hour Ozone from Peakers in Illinois.

17

Overview of Applications for Permits Received by the Illinois EPA's Bureau of

18

Water as of July 20, 2000.

Noise Pollution Clearinghouse, "Good Neighbors Keep Their Noise to Themselves".

19

Peaker Plant Fact Sheet of the Illinois Environmental Protection Agency Office of

20

Community Relations.

3.1 Stationary Gas Turbines

3. 1.1 General'

Gas turbines, also called "combustion turbines", are used in a broad scope of applications including electric power generation,

cogeneration, natural gas transmission, and various process applications. Gas turbines are available with power outputs ranging in size

from 300 horsepower (hp) to

2

over 268,000 hp, with an average size of 40,200 hp. The primary fuels used in gas turbines are natural

gas and distillate (No. 2) fuel

oil.3

3.1.2 Process Description,2

A gas turbine is an internal combustion engine that operates with rotary rather than reciprocating motion. Gas turbines are

essentially composed of three major components: compressor, combustor, and power turbine. In the compressor section, ambient air is

drawn in and compressed up to 30 times ambient pressure and directed to the combustor section where fuel is introduced, ignited, and

burned. Combustors can either be annular, can-annular, or silo. An annular combustor is a doughnut-shaped, single, continuous

chamber that encircles the turbine in a plane perpendicular to the air flow. Can-annular combustors are similar to the annular; however,

they incorporate several can-shaped combustion chambers rather than a single continuous chamber. Annular and can-annular

combustors are based on aircraft turbine technology and are typically used for smaller scale applications. A silo (frame-type)

combustor has one or more combustion chambers mounted external to the gas turbine body. Silo combustors are typically larger than

annular or can-annular combustors and are used for larger scale applications.

The combustion process in a gas turbine can be classified as diffusion flame combustion, or lean-premix staged combustion.

In the diffusion flame combustion, the fuel/air mixing and combustion take place simultaneously in the primary combustion zone. This

generates regions of near-stoichiometric fuel/air mixtures where the temperatures are very high. For lean-premix combustors, fuel and

air are thoroughly mixed in an initial stage resulting in a uniform, lean, unburned fuel/air mixture which is delivered to a secondary

stage where the combustion reaction takes place. Manufacturers use different types of fuel/air staging, including fuel staging, air

staging, or both; however, the same staged, lean-premix principle is applied. Gas turbines using staged combustion are also referred to

as Dry Low NOx combustors. The majority of gas turbines currently manufactured are lean-premix staged combustion turbines.

Hot gases from the combustion section are diluted with additional air from the compressor section and directed to the power

turbine section at temperatures up to 2600'F. Energy from the hot exhaust gases, which expand in the power turbine section, are

recovered in the form of shaft horsepower. More than

50 percent of the shaft horsepower is needed to drive the internal compressor

and the balance of recovered shaft horsepower is available to drive an external load.

2

Gas turbines may have one, two, or three shafts

to transmit power between the inlet air compression turbine, the power turbine, and the exhaust turbine. The heat content of the exhaust

gases exiting the turbine can either be discarded without heat recovery (simple cycle); recovered with a heat exchanger to preheat

combustion air entering the combustor (regenerative cycle); recovered in a heat recovery steam generator to raise process steam, with

or without supplementary firing (cogeneration); or recovered, with or without supplementary firing, to raise steam for a steam turbine

Rankine cycle (combined cycle or repowering).

4/00

Stationary Internal Combustion Sources

3.1-1

Illinois EPA

Exhibit No. 2

The simple cycle is the most basic operating cycle of gas turbines with a thermal efficiency ranging from 15 to 42 percent. The

cycle thermal efficiency is defined as the ratio of useful shaft energy to fuel energy input. Simple cycle gas turbines are typically used

for shaft horsepower applications without recovery of exhaust heat. For example, simple cycle gas turbines are used by electric utilities

for generation of electricity during emergencies or during peak demand periods.

A regenerative cycle is a simple cycle gas turbine with an added heat exchanger. The heat exchanger uses the turbine exhaust

gases to heat the combustion air which reduces the amount of fuel required to reach combustor temperatures. The thermal efficiency of

a regenerative cycle is approximately 35 percent. However, the amount of fuel efficiency and saving may not be sufficient to justify the

capital cost of the heat exchanger, rendering the process unattractive.

A cogeneration cycle consists of a simple cycle gas turbine with a heat recovery steam generator (HRSG). The cycle thermal

efficiency can be as 84 percent. In a cogeneration cycle, the steam generated by the HRSG can be delivered at a variety of pressures

and temperatures to other thermal processes at the site. For situations where additional steam is required, a supplementary burner, or

duct burner, can be placed in the exhaust duct stream of the HRSG to meet the site's steam requirements.

A combined cycle gas turbine is a gas turbine with a HRSG applied at electric utility sites. The gas turbine drives an electric

generator, and the steam from the HRSG drives a steam turbine w1iich also drives an electric generator. A supplementary-fired boiler

can be used to increase the steam production. The thermal efficiency of a combined cycle gas turbine is between 38 percent and 60

percent.

Gas turbine applications include gas and oil industry, emergency power generation facilities, independent electric power

producers (IPP), electric utilities, and other industrial applications. The petroleum industry typically uses simple cycle gas turbines

with a size range from 300 hp to 20,000 hp. The gas turbine is used to provide shaft horsepower for oil and gas production and

transmission. Emergency power generation sites also utilize simple cycle gas turbines. Here the gas turbine is used to provide backup

or emergency power to critical networks or equipment. Usually, gas turbines under 5,000 hp are used at emergency power generation

sites.

Independent electrical power producers generate electricity for resale to larger electric utilities. Simple, regenerative, or

combined cycle gas turbines are used at IPP; however, most installations use combined cycle gas turbines. The gas turbines used at IPP

can range from 1,000 hp to over 100,000 hp. The larger electric utilities use gas turbines mostly as peaking units for meeting power

demand peaks imposed by large commercial and industrial users on a daily or seasonal basis. Simple cycle gas turbines ranging from

20,000 hp to over 200,000 hp are used at these installations. Other industrial applications for gas turbines include pulp and paper,

chemical, and food processing. Here, combined cycle gas turbines are used for cogeneration.

3.1.3 Emissions

The primary pollutants from gas turbine engines are nitrogen oxides (NOx), carbon monoxide (CO), and to a lesser extent,

volatile organic compounds (VOC). Particulate matter (PM) is also a primary pollutant for gas turbines using liquid fuels. Nitrogen

oxide formation is strongly dependent on the high temperatures developed in the combustor. Carbon monoxide, VOC, hazardous air

pollutants (HAP), and PM are primarily the result of incomplete combustion. Trace to low amounts of HAP and sulfur dioxide (S02)

are emitted from gas turbines. Ash and metallic additives in the fuel may also contribute to PM in the exhaust. Oxides of sulfur (SOX)

will only appear in a significant quantity if heavy oils are fired

3.1-2

EMSSION FACTORS

in the turbine. Emissions of sulfur compounds, mainly SO2, are directly related to the sulfur content of the fuel.

Available emissions data indicate that the turbine's operating load has a considerable effect on the resulting emission levels.

Gas turbines are typically operated at high loads (greater than or equal to 80 percent of rated capacity) to achieve maximum thermal

efficiency and peak combustor zone flame temperatures. With reduced loads (lower than 80 percent), or during periods of frequent

load changes, the combustor zone flame temperatures are expected to be lower than the high load temperatures, yielding lower thermal

efficiencies and more incomplete combustion. The emission factors for this sections are presented for gas turbines operating under high

load conditions. Section 3.1 background information document and emissions database contain additional emissions data for gas

turbines operating under various load conditions.

Gas turbines firing distillate oil may emit trace metals carried over from the metals content of the fuel. If the fuel analysis is

known, the metals content of the fuel ash should be used for flue gas emission factors assuming all metals pass through the turbine.

If the HRSG is not supplementary fuel fired, the simple cycle input-specific emission factors (pounds per million British

thermal units [lb/MMBtu]) will also apply to cogeneration/combined cycle systems. If the HRSG is supplementary fired, the emissions

attributable to the supplementary firing must also be considered to estimate total stack emissions.

3.1.3.1 Nitrogen Oxides -

Nitrogen oxides formation occurs by three fundamentally different mechanisms. The principal mechanism with turbines firing

gas or distillate fuel is thermal NOX, which arises from the thermal dissociation and subsequent reaction of nitrogen (NO and oxygen

(02)

molecules in the combustion air. Most thermal NOX is formed in high temperature stoichiometric flame pockets downstream of

the fuel injectors where combustion air has mixed sufficiently with the fuel to produce the peak temperature fuel/air interface.

The second mechanisrn, called prompt NOX, is formed from early reactions of nitrogen molecules in the combustion air and

hydrocarbon radicals from the fuel. Prompt NOX forms within the flame and is usually negligible when compared to the amount of

thermal NOX formed. The third mechanism, fuel NOX, stems from the evolution and reaction of fuel-bound nitrogen compounds with

oxygen. Natural gas has negligible chemically-bound fuel nitrogen (although some molecular nitrogen is present). Essentially all NOx

formed from natural gas combustion is thermal NOX. Distillate oils have low levels of fuel-bound nitrogen. Fuel NOX from distillate

oil-fired turbines may become significant in turbines equipped with a high degree of thermal NOX controls. Otherwise, then-nal NOX

is the predominant NOx formation mechanism in distillate oil-fired turbines.

The maximum thermal NOX formation occurs at a slightly fuel-lean mixture because of excess oxygen available for reaction-

The control of stoichiometry is critical in achieving reductions in thermal NOx. Thermal NOx formation also decreases rapidly as the

temperature drops below the adiabatic flame temperature, for a given stoichiometry. Maximum reduction of thermal NOX can be

achieved by control of both the combustion temperature and the stoichiometry. Gas turbines operate with high overall Levels of excess

air, because turbines use combustion air dilution as the means to maintain the turbine inlet temperature below design limits. In older

gas turbine models, where combustion is in the form of a diffusion flame, most of the dilution takes place downstream of the primary

flame, which does not minimize peak temperature in the flam; and suppress thermal NOX formation.

4100

Stationary Internal Combustion Sources

3.1-3

Diffusion flames are characterized by regions of near-stoichiometric fuel/air mixtures where temperatures are very high and

significant thermal NOX is formed. Water vapor in the turbine inlet air contributes to the lowering of the peak temperature in the

flame, and therefore to thermal NOX emissions. Thermal NOX can also be reduced in diffusion type turbines through water or steam

injection. The injected water-steam acts as a heat sink lowering the combustion zone temperature, and therefore thermal NOX. Newer

model gas turbines use lean, premixed combustion where the fuel is typically prernixed with more than 50 percent theoretical air which

results in lower flame temperatures, thus suppressing thermal NOX formation.

Ambient conditions also affect emissions and power output from turbines more than from external combustion systems. The

operation at high excess air levels and at high pressures increases the influence of inlet humidity, temperature, and pressure.

4

Variations of emissions of 30 pe cent or greater have been exhibited with changes in ambient humidity and temperature. Humidity acts

to absorb heat in the primary flame zone due to the conversion of the water content to steam As beat energy is used for water to steam

conversion, the temperature is the flame zone will decrease resulting in a decrease of thermal NOx formation. For a given fuel firing

rate, lower ambient temperatures lower the peak temperature in the flame, lowering thermal NOX significantly. Similarly, the gas

turbine operating loads affect NOX emissions. Higher NOx emissions are expected for high operating loads due to the higher peak

temperature in the flame zone resulting in higher thermal NOX.

3.1.3.2 Carbon Monoxide and Volatile Organic Compounds -

CO and VOC emissions both result from incomplete combustion. CO results when there is insufficient residence time at high

temperature or incomplete mixing to complete the final step in fuel carbon oxidation. The oxidation Of CO to C02 at gas turbine

temperatures is a slow reaction compare

U-1

to most hydrocarbon oxidation reactions. In gas turbines, failure to achieve CO burnout may

result fruit, quenching by dilution air. With liquid fuels, this can be aggravated by carryover of larger droplets from the atomizer at the

fuel injector. Carbon monoxide emissions are also dependent on the loading of the gas turbine. For example, a gas turbine operating

under a full load will experience greater fuel efficiencies which will reduce the formation of carbon monoxide. The opposite is also

true, a gas turbine operating under a light to medium load will experience reduced fuel efficiencies (incomplete combustion) which will

increase the formation of carbon monoxide.

The pollutants commonly classified as VOC can encompass a wide spectrum of volatile organic compounds some of which

are hazardous air pollutants. These compounds are discharged into the atmosphere when some of the fuel remains unburned or is only

partially burned during the combustion process. With natural gas, some organics are carried over as unreacted, trace constituents of the

gas, while others may be pyrolysis products of the heavier hydrocarbon constituents. With liquid fuels, large droplet carryover to the

quench zone accounts for much of the unreacted and partially pyrolized volatile organic emissions.

Similar to CO emissions, VOC emissions are affected by the gas turbine operating load conditions. Volatile organic

compounds emissions are higher for gas turbines operating at low loads as compared to similar gas turbines operating at higher loads.

3.1.3.3 Particulate Matter

13

PM emissions from turbines primarily result from carryover of noncombustible trace constituents in the fuel. PM emissions

are negligible with natural gas firing and marginally significant with distillate oil firing because of the low ash content. PM emissions

can be classified as "filterable" or "condensable" PM. Filterable PM is that portion of the total PM that exists in the stack in either the

solid or liquid state and

3.14

EMISSION FACTORS

4/00

can be measured on a EPA Method 5 filter. Condensable PM is that portion of the total PM that exists as a gas in the stack but

condenses in the cooler ambient air to form particulate matter. Condensable PM exists as a gas in the stack, so it passes through the

Method 5 filter and is typically measured by analyzing the impingers, or "back half'of the sampling train. The collection, recovery,

and analysis of the impingers is described in EPA Method 202 of Appendix M, Part 51 of the Code of Federal Regulations.

Condensable PM is composed of organic and inorganic compounds and is generally considered to be all less than 1.0 micrometers in

aerodynamic diameter.

3.1.3.4 Greenhouse Gases

5-11 -

Carbon dioxide (C02) and nitrous oxide (N20) emissions are all produced during natural gas and distillate oil combustion in

gas turbines. Nearly all of the fuel carbon is converted to C02 during the combustion process. This conversion is relatively independent

of firing configuration. Methane (CH4) is also present in the exhaust gas and is thought to be unburned fuel in the case of natural gas

or a product of combustion in the case of distillate fuel oil.

Although the formation of CO acts to reduce C02 emissions, the amount of CO produced is insignificant compared to the

amount of C02 produced. The majority of the fuel carbon not converted to C02 is due to incomplete combustion.

Formation of N20 during the combustion process is governed by a complex series of reactions and its formation is dependent

upon many factors. However, the formation of N20 is minimized when combustion temperatures are kept high (above 1475*F) and

excess air is kept to a minimum (less than 1 percent).

3.1.3.5 HAP Emissions -

Available data indicate that emission levels of HAP are lower for gas turbines than for other combustion sources. This is due

to the high combustion temperatures reached during normal operation. The emissions data also indicate that formaldehyde is the most

significant HAP emitted from combustion turbines. For natural gas fired turbines, fonnaldehyde accounts for about two-thirds of the

total HAP emissions. Polycyclic aromatic hydrocarbons (PAH), benzene, toluene, xylenes, and others account for the remaining

one-third of HAP emissions. For No. 2 distillate oil-fired turbines, small amount of metallic HAP are present in the turbine's exhaust in

addition to the gaseous HAP identified under gas fired turbines. These metallic HAP are carried over from the fuel constituents. The

formation of carbon monoxide during the combustion process is a good indication of the expected levels of HAP emissions. Similar to

CO emissions, HAP emissions increase with reduced operating loads. Typically, combustion turbines operate under full loads for

greater fuel efficiency, thereby minimizing the amount of CO and HAP emissions.

3.1.4 Control Technologies

12

There are three generic types of emission controls in use for gas turbines, wet controls using steam or water injection to reduce

combustion temperatures for NOX control, dry controls using advanced combustor design to suppress NOX formation and/or promote

CO burnout, and post-combustion catalytic control to selectively reduce NOX and/or oxidize CO emission from the turbine. Other

recently developed technologies promise significantly lower levels of NOX and CO emissions from diffusion combustion type gas

turbines. These technologies are currently being demonstrated in several installations.

Emission factors in this section have been determined from gas turbines with no add-on control devices (uncontrolled

emissions). For NOX and CO emission factors for combustion controls, such as water-steam injection, and lean pre-mix units are

presented. Additional information for controlled

4/00

Stationary Internal Combustion Sources

3.1-5

emissions with various add-on controls can be obtained using the section 3.1 database. Uncontrolled, lean-premix, and water

injection emission factors were presented for NOx and CO to show the effect of combustion modification on emissions.

3.1.4.1 Water Injection -

Water or steam injection is a technology that has been demonstrated to effectively suppress NOX emissions from gas turbines.

The effect of steam and water injection is to increase the thermal mass by dilution and thereby reduce peak temperatures in the flame

zone. With water injection, there is an additional benefit of absorbing the latent heat of vaporization from the flame zone. Water or

steam is typically injected at a water-to-fuel weight ratio of less than one.

Depending on the initial NOX levels, such rates of injection may reduce

NOx

by 60 percent or higher. Water or steam

injection is usually accompanied by an efficiency penalty (typicality 2 to 3 percent) but an increase in power output (typically 5 to 6

percent). The increased power output results from the increased mass Dow required to maintain turbine inlet temperature at

manufacturer's specifications. B-NI, CIO and VOC emissions are increased by water injection, with the level of CO and VOC

increases. dependent on the amount of water injection.

3.1.4.2 Dry Controls -

Since thermal NOx is a function of both temperature (exponentially) and tune (linearly), the

basis

of dry controls are to either

lower the combustor temperature using lean mixtures of air and/or fuel staging or decrease the residence time of the combustor. A

combination of methods may be used to reduce NOX emissions such as lean combustion and staged combustion (two stage lean/lean

combustion or two stage rich/lean combustion).

Lean combustion involves increasing the air-to-fuel ratio of the mixture so that the peak and average temperatures within the

combustor will be less than that of the stoichiometric mixture, thus suppressing thermal NOx formation. Introducing excess air not only

creates a leaner mixture but it also can reduce residence time at peak temperatures.

Two-stage lean/lean combustors are essentially fuel-staged, premixed combustors in which each stage bums lean. The

two-stage lean/lean combustor allows the turbine to operate with an extremely lean mixture while ensuring a stable flame. A small

stoichiometric pilot flame ignites the premixed gas and provides flame stability. The NOx emissions associated with the high

temperature pilot flame are insignificant. Low NOX emission levels are achieved by this combustor design through cooler flame

temperatures associated with lean combustion and avoidance of localized "hot spots" by premixing the fuel and air.

Two stage rich/lean combustors are essentially air-staged, premixed combustors in which the primary zone is operated fuel

which and the secondary zone is operated fuel lean. The rich mixture produces lower temperatures (compared to stoichiometric) and

higher concentrations of CO and H2, because of incomplete combustion. The rich mixture also decreases the amount of oxygen

available for NOX generation. Before entering the secondary zone, the exhaust of the primary zone is quenched (to extinguish the

flame) by large amounts of air and a lean mixture is created. The lean mixture is pre-ignited and the combustion completed in the

secondary zone. NOX formation in the second stage are minimized through combustion in a fuel lean, lower temperature environment.

Staged combustion is identified through a variety of names, including Dry-Low NOx (DLN), Dry-Low Emissions (DLE), or

SoLoNOx.

3.1-6

EMISSION FACTORS

4/00

3.1 A.3 Catalytic Reduction Systems -

. Selective catalytic reduction (SCR) systems selectively reduce NOx emissions by injecting ammonium (NH3) into the exhaust

gas stream upstream of a catalyst. Nitrogen oxides, NH3, and 02 react on the surface of the catalyst to form N2 and H20. The exhaust

gas must contain a minimum amount of 02 and be within a particular temperature range (typically 450OF to 8500F) in order for the

SCR system to operate properly.

The temperature range is dictated by the catalyst material which is typically made from noble metals, including base metal oxides

such as vanadium and titanium, or zeolite-based material. The removal efficiency of an SCR system in good working order is typically

from 65 to 90 percent. Exhaust gas temperatures greater than the upper limit (850*17) cause NOX and NH3 to pass through the catalyst

unreacted. Ammonia emissions, called NH3

Slip,

may be a consideration when specifying an SCR system

Ammonia, either in the form of liquid anhydrous ammonia, or aqueous ammonia hydroxide is stored on site and injected into the

exhaust stream upstream of the catalyst. Although an SCR system can operate alone, it is typically used in conjunction with water-steam

injection systems or lean-premix system to reduce NOx emissions to their lowest levels (less than 10 ppm at 15 percent oxygen for SCR

and wet injection systems). The SCR system for landfill or digester gas-fired turbines requires a substantial fuel gas pretreatment to

remove trace contaminants that can poison the catalyst. Therefore, SCR and other catalytic treatments may be inappropriate control

technologies for landfill or digester gas-fired turbines.

The catalyst and catalyst housing used in SCR systems tend to be very large and dense (in terms of surface area to volume ratio)

because of the high exhaust flow rates and long residence times required for NOx, 02, and NH3, to react on the catalyst. Most catalysts

are configured in a parallel-plate, "honeycomb" design to maximize the surface area-to-volume ratio of the catalyst. Some SCR

installations incorporate CO catalytic oxidation modules along with the NOX reduction catalyst for simultaneous CO/NOX control.

Carbon monoxide oxidation catalysts are typically used on turbines to achieve control of CO emissions, especially turbines that

use steam injection, which can increase the concentrations of CO and unburned hydrocarbons in the exhaust. CO catalysts are also being

used to reduce VOC and organic HAPs emissions. The catalyst is usually made of a precious metal such as platinum, palladium, or

rhodium. Other formulations, such as metal oxides for emission streams containing chlorinated compounds, are also used. The CO

catalyst promotes the oxidation of CO and hydrocarbon compounds to carbon dioxide (COD and water (H20) as the emission stream

passes through the catalyst bed. The oxidation process takes place spontaneously, without the requirement for introducing reactants. The

performance of these oxidation catalyst systems on combustion turbines results in 90-plus percent control of CO and about 85 to 90

percent control of formaldehyde. Similar emission reductions are expected on other HAP pollutants.

3.1.4.4 Other Catalytic Systems

14,15

New catalytic reduction technologies have been developed and are currently being commercially demonstrated for gas turbines.

Such technologies include, but are not limited to, the SCONOX and the XONON systems, both of which are designed to reduce NOx and

CO emissions. The SCONOX system is applicable to natural gas fired gas turbines. It is based on a unique integration of catalytic

oxidation and absorption technology. CO and NO are catalytically oxidized to C02 and N02. The N02 molecules are subsequently

absorbed on the treated surface of the SCONOX catalyst. The system manufacturer guarantees CO emissions of I ppm and NOX

emissions of 2 ppm. The SCONOX system does not require the use of ammonia, eliminating the potential of ammonia slip conditions

evident in existing SCR system. Only limited emissions data were available for a gas turbine equipped with a SCONOX system This data

reflected HAP emissions and was not sufficient to verify the manufacturer's claims.

4/00

Stationary Internal Combustion Sources

3.1-7

The XONON system is applicable to diffusion and lean-premix combustors and is currently being

demonstrated with the assistance of leading gas turbine manufacturers. The system utilizes a flameless

combustion system where fuel and air reacts on a catalyst surface, preventing the formation of NOX while

achieving low CO and unburned hydrocarbon emission levels. The overall combustion process consists of the

partial combustion of the fuel in the catalyst module followed by completion of the combustion downstream

of the catalyst. The partial combustion within the catalyst produces no NOX, and the combustion downstream

of the catalyst occurs in a flameless homogeneous reaction that produces almost no NOX. The system is

totally contained within the combustor of the gas turbine and is not a process for clean-up of the turbine

exhaust. Note that this technology has not been fully demonstrated as of the drafting of this section. The

catalyst manufacturer claims that gas turbines equipped with the XONON Catalyst emit NOx levels below 3

ppm and CO and unburned hydrocarbons levels below 10 ppm. Emissions data from gas turbines equipped

with a XONON Catalyst were not available as of the drafting of this section.

3.1.5 Updates Since the Fifth Edition

The Fifth Edition was released in January 1995. Revisions to this section since that date are

summarized below. For further detail, consult the memoranda describing each supplem

I p

ent or the

background report for

this

section. These and other documents can be found on the new EFIG home page

(http://www.epa.gov/ttn/chief).

Supplement A, February 1996

For the PM factors, a footnote was added to clarify that condensables and all PM from oil and

gas-fired turbines are considered PM-10.

In the table for large uncontrolled gas turbines, a sentence was added to footnote "e" to

indicate that when sulfur content is not available, 0.6 lb/106 ft' (0.0006 lb/MMBtu) can be

used.

Supplement B, October 1996

Text was revised and updated for the general section.

Text was added regarding firing practices and process description.

Text was revised and updated for emissions and controls.

All factors for turbines with SCR-water injection control were corrected.

The C02 factor was revised and a new set of N20 factors were added.

Supplement F, April 2000

Text was revised and updated for the general section.

All emission factors were updated except for the S02 factor for natural gas and distillate oil

turbines.

3.1-8

EMISSION FACTORS

4/00

Turbines using staged (lean-premix) combustors added to this section.

Turbines used for natural gas transmission added to this section.

Details for turbine operating configurations (operating cycles) added to this section.

Information on new emissions control technologies added to this section (SCONOX and

XONON).

HAP emission factors added to this section based on over 400 data points taken from over

60 source tests.

PM condensable and filterable emission factors for natural gas and distillate oil fired

turbines were developed.

NOx and CO emission factors for lean-premix turbines were added.

Emission factors for landfill gas and digester gas were added.

4/00

Stationary Internal Combustion Sources

3.1-9

Table3.1-1. EMISSION FACTORS FOR NITROGEN OXIDES (NOX) AND

CARBON MONOXIDE (CO) FROM STATIONARY GAS TURBINES

Emission Factors'

Turbine Type

Nitrogen Oxides

Carbon Monoxide

Natural Gas-Fired Turbines

b

(lb/MMBtu)

c

Emission Factor

(104MBtu)

c

Emission Factor

(Fuel Input)

Rating

(Fuel Input)

Rating

Uncontrolled

3.2 E-01

A

8.2 E-02

d

A

Water-Steam Injection

1.3 E-01

A

3.0 E-02

A

Lean-premix

9.9 E-02

D

1.5 E-02

D

Distillate Oil-Fired Turbines

c

(lb/MMBtu)

f

Emission Factor

(lb/MMBtu)

F

Emission Factor Rating

(Fuel Input)

Rating

(Fuel Input)

Uncontrolled

8.8 E-01

C

3.3 E-03

C

Water-Steam injection

2.4 E-0 I

B

7.6 E-02

C

Landfill! Gas-Fired Turbines

g

(1b/MM13tu)

h

Emission Factor

(lb/MMbtu)

h

Emission Factor Rating

(Fuel Input)

Rating

(Fuel Input)

Uncontrolled

1.4 E-01

A

4.4 E-01

A

Digester Gas-Fired Turbines

i

(lb/MMBtu)

k

Emission Factor

(lb/MMBtu)

k

Emission Factor Rating

(Fuel Input)

Rating

(Fuel Input)

Uncontrolled

1.6 E-01

D

1.7 E-02

D

a

Factors are derived from units operating at high loads ( 80 percent load) only. For information on units operating at other

loads, consult the background report for tWs chapter (Reference 16), available at " www.epa.gov/ttn/chief

'.

b

Source Classification Codes (SCCs) for natural gas-fired turbines include 2-01-002-01, 2-02-002-01, 2-02-002-03,

2-03-002-02, and 2-03-002-03. The emission factors in this table may be converted to other natural gas heating values by

multiplying the given emission factor by the ratio of the specified heating value to this average heating value.

c

Emission factors based on an average natural gas heating value (HHV) of 1020 Btu/scf at 60'F. To convert from

(lb/MMBtu) to (lb/1 0

6

scf), multiply by 1020.

d

It is recognized that the uncontrolled emission factor for CO is higher than the water-steam injection and lean-premix

emission factors, w1iich is contrary to expectation. The EPA could not identify the reason for this behavior, except that the

data sets used for developing these factors are different.

e

SCCs for distillate oil-fired turbines include 2-01-001-01, 2-02-001-01, 2-02-001-03, and 2-03-001-02.

f

Emission factors based on an average distillate oil heating value of 139 NIMBtu/103 gallons. To convert from

(lb/MMBtu) to (lb/ 103 gallons), multiply by 139. SCC for landfill gas-fired turbines is 2-03-008-01.

h

Emission factors based on an average landfill gas heating value of 400 Btu/scf at 60'F. To convert from lb/MMBtu), to lb/

0

6

SCf) multiply by 400. SCC for digester gas-fired turbine is 2-03-007-01.

k

Emission factors based on an average digester gas heating value of 600 Btu/scf at 60'F. To convert from (lb/MMBtu) to

(lb/1 06

SCf)

multiply by 600.

3.1-10

EMISSION FACTORS

4/00

Table 3.1-2a.

EMISSION FACTORS FOR CRITERIA POLLUTANTS AND GREENHOUSE

GASES FROM STATIONARY GAS TURBINES

Emission Factors

a

- Uncontrolled

Natural Gas-Fired Turbines

b

Distillate Oil-Fired Turbines

d

Pollutant

(lb/MMbtu)c

Emission Factor

(lb/MMBtu)

e

Emission Factor

(Fuel Input)

Rating

(Fuel Input)

Rating

C0

2

f

110

A

157

A

N

2

0

0.0032

E

ND

NA

Lead

ND

NA

1.4 E-05

C

S0

2

0.94S

h

B

1.01S

h

B

Methane

8.6 E-03

C

ND

NA

VOC

2.1 E-03

D

4.1 E-04

j

E

TOC

k

1. 1 E-02

B

4.0 E-03

i

C

PM (condensable)

4.7 E-03

i

C

7.2 E-03

i

C

PM (filterable)

1.9 E-03

i

C

4.3 E-03

i

C

PM (total)

6.6 E-03

i

C

1.2 E-02

i

C

a

Factors are derived from units operating at high loads ( 80 percent load) only. For information on units

operating at other loads, consult the background report for this chapter (Reference 16), available at

"www.epa.gov/ttn/chief'. ND = No Data, NA = Not Applicable.

b

SCCs for natural gas-fired turbines include 2-01-002-01, 2-02-002-01 & 03, and 2-03-002-02 & 03.

c

Emission factors based on an average f e natural gas heating value (HHV) of 1020 Btu/scf at 60'F. To

convert from (lb/NIMBtu) to (lb/10 scf), multiply by 1020. Similarly, these emission factors can be

converted to other natural gas heating values.

d

SCCs for distillate oil-fired turbines are 2-01-001-01, 2-02-001-01, 2-02-001-03, and 2-03-001-02.

e

Emission factors based on an average distillate oil heating value of 139 NlMBtti/103 gallons. To convert

from (lb/MMBtu) to (lb/ 103 gallons), multiply by 139.

f

Based on 99.5% conversion of fuel carbon to C02 for natural gas and 99% conversion of fuel carbon to

C02 for distillate oil. C02 (Natural Gas) [lb/MMBtu] = (0.0036 scf/Btu)(%CON)(Q(D), where %CON

= weight percent conversion of fuel carbon to C02, C = carbon content of fuel by weight, and D =

density of fuel. For natural gas, C is assumed at 75%, and D is assumed at 4.1 E+04 lb/l 06 scf For

distillate oil, C02 (Distillate Oil) [lb/MMBtu] = (26.4 gaVMMBtu) (%CON)(C)(D), where C is assumed

at 87%, and the D is assumed at 6.9 lb/gallon.

Emission factor is carried over from the previous revision to AP-42 (Supplement B, October 1996) and is

based on limited source tests on a single turbine with water-steam injection (Reference 5).

h

All sulfur in the fuel is assumed to be converted to S02. S = percent sulfur in fuel. Example, if sulfur

content in the fuel is 3.4 percent, then S = 3.4. If S is not available, use 3.4 E-03 lb/MMBtu for natural

gas turbines, and 3.3 E-02 lb/MMBtu for distillate oil turbines (the equations are more accurate).

VOC emissions are assumed equal to the sum of organic emissions.

k

Pollutant referenced as THC in the gathered emission tests. It is assumed as TOC, because it is based on

Emission factors are based on combustion turbines using water-steam injection.

4/00

Stationary Internal Combustion Sources

3.1-11

Table 3.1-2b. EMISSION FACTORS FOR CRITERIA POLLUTANTS AND GREENHOUSE

GASES FROM STATIONARY GAS TURBINES

a

Factors are derived from units operating at high loads ( 80 percent load)

only.

For information units operating

at other loads, consult the background report for

this

chapter reference 16), available at www.epa.gov/ttn/chief.

ND = No Data, NA = Not Applicable.

b

SCC for landfill gas-fired turbines is 2-03-008-01.

c

Emission factors based on an averafe landfill gas heating value (HHV) of 400 Btu/scf at 60T. To convert

from (lb/MMBtu) to (lb/ 10

6

scf), multiply by 400.

d

SCC for digester gas-fired turbine include 2-03-007-01.

e

Emission factors based on an average digester gas heating value of 600 Btu/scf at 60'F. To convert from

(lb/MMBtu) to (lb/I 06

SCf),

multiply by 600.

f

For landfill gas and digester gas, C02 is presented in test data as volume percent of the exhaust stream (4.0

percent to 4.5 percent). Compound was not detected. The presented emission value is based on one-half of the

detection limit.

h

Based on adding the formaldehyde emission to the NMHC.

Emission Factors

a

- Uncontrolled

Landfill Gas-Fired Turbines

b

Digester Gas-Fired Turbines

d

Pollutants

(lb/MMBtu)

c

Emission Factor

(lb/MMBtu)

e

Emission Factor

Rating

Rating

C0

2

f

50

D

27

C

Lead

WD

NA

< 3.4 E-06

D

PM-10

2.3 E-02

B

1.2 E-02

C

S0

2

4.5 E-02

C

6.5 E-03

D

VOC

h

1.3 E-02

B

5.8 E-03

D

3.1-12

EMISSION FACTORS

4/00

Emission Factors

b

- Uncontrolled

Pollutant

Emission Factor

Emission Factor Rating

(lb/MMBtu)

c

1,3-Butadiene

d

< 4.3 E-07

D

Acetaldehyde

4.0 E-05

C

Acrolein

6.4 E-06

C

Benzene

e

1.2 E-05

A

Ethylbenzene

3.2 E-05

C

Formaldehyde

f

7.1 E-04

A

Naphthalene

1.3 E-06

C

PAH

2.2 E-06

C

Propylene Oxide

d

< 2.9 E-05

D

Toluene

1.3 E-04

C

Xylenes

6.4 E-05

C

a

SCC for natural gas-fired turbines include 2-01-002-01, 2-02-002-01, 2-02-002-03, 2-03-002-02, and 2-

03-002-03. Hazardous

Air Pollutants as defined in Section 112 (b) of the

Clean.&r.4ct.

b

Factors are derived from units operating at high loads ( 80 percent load) only. For information on units

operating at other loads, consult the background report for this chapter (Reference 16), available at

44

www.epa.gov/ttn/chief'.

c

Emission factors based on an average natural gas heating value (HHV) of 1020 Btu./scf at 60'F. To

convert from (lb/MMBtu) to (lb/l

06

scf), multiply by 1020. These emission factors can be converted to

other natural gas heating values by multiplying the given emission factor by the ratio of the specified

heating value to this heating value.

d

Compound was not detected. The presented emission value is based on one-half of the detection limit. '

e

Benzene with SCONOX catalyst is 9.1 E-07, rating of D.

f

Formaldehyde with SCONOX catalyst is 2.0 E-05, rating of D.

Table 3.1-3. EMISSION FACTORS FOR HAZARDOUS AIR POLLUTANTS

FROM NATURAL GAS-FIRED STATIONARY GAS TURBINES

a

Table 3.14

.

EMISSION FACTORS FOR HAZARDOUS AIR POLLUTANTS

FROM DISTILLATE OIL-FIRED STATIONARY GAS TURBINES

a

Emission Factors

b

- Uncontrolled

Pollutant

Emission Factor

Emission Factor Rating

(lb/MMBtu)

c

1,3-Butadiene

d

< 1.6 E-05

D

Benzene

5.5 E-05

C

Formaldehyde

2.8 E-04

D

Naphthalene

3.5 E-05

C

PAH

4.0 E-35

C

a

SCCs for distillate oil-fired turbines include 2-01-001-Ol-, 2-02-001-01, 2-02-001-03., and 2-03-001-02.

Hazardous Air Pollutants as defined in Section 112 (b) of the

Clean Air Act.

b

Factors are derived fiom units operating at high loads ( 80 percent load) only. For information on units

operating at other loads, consult the background report for this chapter (Reference 16), available at www.

epa.gov/ttn/cheif

c

Emission factors based on an average distillate oil heating value (HIP,/)

of 139

MMMBtu/l0

3

convert from

lb/MMBtu) to (lb/10

3

gallons), multiply by

139.

d

Compound was not detected. The presented emission value is based on one-half of the detection limit.

3.1-14

EMISSION FACTORS

4/00

Table 3.1-6. EMISSION FACTORS FOR HAZARDOUS AIR POLLUTANTS

FROM LANDFILL GAS-FIRED STATIONARY GAS TURBINES

a

Emission Factors

b

- Uncontrolled

Pollutant

Emission Factor (lb/MMBtu)

c

Emission Factor Rating

Acetonitrile

d

< 1.2E-05

D

Benzene

2. 1 E-05

B

Benzyl Chloride

d

< 1.2 E-05

D

Carbon Tetrachioride

d

< 1.8 E-06

D

Chlorobenzene

d

< 2.9 E-06

D

Chioroform

d

< 1.4 E-06

D

Methylene Chloride

2.3 E-06

D

Tetrachloroathylene

d

< 2.5 E-06

D

Toluene

1.1 E-04

B

Trichloroethylene d

< 1.9 E-06

D

Vinyl Chloride d

< 1.6 E-06

D

Xylenes

3.1 E-05

B

a

SCC for landfill gas-fired turbines is 2-03-008-01. Hazardous Air Pollutants as defined in Section 112 (b) of

the Clean Air Act.

b

Factors are derived from units operating at high loads ( 80 percent load) only. For information on units

operating at other loads, consult the background report for this chapter (Reference 16), available at

"www.epa.gov/ttn/chief'.

c

Emission factors based on an average landfill gas heating value (HHV) of 400 Btu/scf at 60'F. To convert

from (lb/MMBtu) to (lb/ 10

6

scf), multiply by 400.

d

Compound was not detected. The presented emission value is based on one-half of the detection limit.

3.1-16

EMISSION FACTORS

4/00

I#1VV

Table 3.1-7. EMISSION FACTORS FOR HAZARDOUS AIR

POLLUTANTS

FROM DIGESTER GAS-FIRED STATIONARY GAS TURBINES'

Emission Factors

b

- Uncontrolled

Pollutant

Emission Factor (lb/MMBtu)

c

Emission Factor Ratings

1,3-Butadiene

d

< 9.8 E-06

D

1,4-Dichlorobenzene

d

< 2.0 E-05

D

Acetaldehyde

5.3 E-05

D

Carbon Tdrachloride

d

< 2.0 E-05

D

Chlorobenzene

d

< 1.6 E-05.

D

Chloroform

d

< 1.7 E-05

D

Ethylene Dichloride

d

< 1.5 E-05

D

Formaldehyde

1.9 E-04

D

Methylene Chloride

d

< 1.3 E-05

D

Tetrachloroethylene

d

< 2.1 E-05

D

Trichloroethylene

d

< 1.8 E-05

D

Vinyl Chloride

d

< 3.6 E-05

D

Vinylidene Chloride

d

< 1.5 E-05

D

a

SCC for digester gas-fired turbines is 2-03-007-01. Hazardous Air Pollutants as defined in Section

112 (b) of the

Clean Air Act.

b

Factors are derived from units operating at high loads ( 80 percent load) only. For information on

units operating at other loads, consult the background report for this chapter (Reference 16),

available at "www.epa.gov/ttn/chief".

c

Emission factors based on an averafe digester gas heating value (HHV) of 600 Btu/scf at 60’f. To

convert from (lb/MMBtu)) to lb/10

6

scf), multiply by 600.

d

Compound was not detected. The presented emission value is based on one-half of the detection

limit.

Table 3.1-8. EMISSION FACTORS FOR METALLIC HAZARDOUS AIR

POLLUTANTS

Emission Factors

b

- Uncontrolled

Pollutant

Emission Factor (lb/MMBtu)

c

Emission Factor Rating

Arsenic

d

< 2.3 E-06

D

Cadmiwn

d

< 5.8 E-07

D

Chromium

d

< 1.2 E-06

D

Lead

d

< 3.4 E-06

D

Nickel

2.0 E-06

D

Selenium

1.1 E-05

D

a

SCC for digester gas-fired turbines is 2-03-007-01. Hazardous Air Pollutants as

defined in Section 112 (b) of the

Clean Air Act.

b

Factors are derived from units operating at high loads (80 percent load) only. For

more information on units operating at other loads, consult the background report for

this chapter (Reference 16), available at “www.epa.gov/ttn/chief”.

c

Emission factor based on an average digester gas heating value (HHV) of 600

Btu/scf at 60

!

F. To convert from (lb/MMBtu) to (lb/10

6

scf), multiply by 600.

d

Compound was not detected. The presented emission value is based on one-half of

the detection

0

3.1-18

EMISSION FACTORS 4/00

References For Section 3.1

1

.

Alternative Control Techniques Document - NOX Emissions from Stationary

Gas Turbines,

EPA 453/R-93-007, January 1993.

2.

C. C. Shih,

et al., Emissions Assessment Of Conventional Stationary Combustion Systems,

Vol. II: Internal Combustion Sources,

EPA-600/7-79-029c, U. S. Environmental Protection

Agency, Cincinnati, OH, February 1979.

1

3.

Final Report - Gas Turbine Emission Measurement Program,

GASLTR787, General Applied

Science Laboratories, Westbury, NY, August 1974.

4.

Standards Support And Enivronmental Impact Statement, Volume 1:

Proposed Standards Of

Performance For Stationary Gas Turbines,

EPA450/2-77-017a, U. S. Environmental Protection

Agency, Research Triangle Park, NC, September 1977.

5.

L. P. Nelson,

et al., Global Combustion Sources Of Nitrous Oxide Emissions,

Research Project

2333-4 Interim Report, Sacramento: Radian Corporation, 1991.

6.

R. L. Peer,

et al., Characterization Of Nitrous Oxide Emission Sources,

U. S

.

Environmental

Protection Agency, Office of Research and Development, Research Triangle Park, NC, 1995.

7.

S. D. Piccot,

el al., Emissions And Cost Estimates For Globally Significant Anthropogenic

Combustion Sources Of NO

X

, N

2

0, CH

4

, CO, And C0

2

,

U. S

.

Environmental Protection Agency,

Office of Research and Development, Research Triangle Park, NC, 1990.

8.

G. Marland and R. M. Rotty,

Carbon Dioxide Emissions From Fossil Fuels: A Procedure For

Estimation And Results For 1951-1981,

DOE/NBB-0036 TR-003, Carbon Dioxide Research

Division, Office of Energy Research, U. S. Departrnent of Energy, Oak Ridge, TN, 1983.

9.

G. Marland and R. M. Rotty,

Carbon Dioxide Emissions From Fossil Fuels: A Procedure For

Estimation And Results For 1950-1982,

Tellus 36B:232-261, 1984.

10

.

Inventory Of U. S. Greenhouse Gas Emissions And Sinks: 1990-1991,

EPA-230-R-96-006,

U. S. Environmental Protection Agency, Washington, DC, November 1995.

11

IPCC Guidelines For National Greenhouse Gas Inventories Workbook,

Intergovernmental Panel

on Climate Change/Organization for Economic Cooperation and Development, Paris, France,

1995.

12.

L. M. Campbell and G. S. Shareef,

Sourcebook- NQ,, Control Technology Data,

Radian Corp.,

EPA-600/2-91-029, Air and Energy Engineering Research Laboratory, U. S. Environmental

Protection Agency, Research Triangle Park, July 199 1.

13.

In-stack Condensible Particulate Matter Measurement and Permitting Issues for Maryland

Power Plants,

Maryland Department of Natural Resource, Prepared by Versar, INC, January

1998.

4/00

Stationary Internal Combustion Sources

3.1-19

14

.Catalysts for Power Generation, The

SCONOX

System.

Goal Line Environmental Technologies,

www.glet.com/gl_prod_SCONOX.htm, March 1998.

15.

Information form Chuck Solt of Catalytica Combustion Systems, Inc., to EPA, XONON Flameless

Combustion, January 1996.

16.

Emission Factor Documentation of AP-42 Section 3. 1, Stationary Combustion Turbines,

EPA.

Contract No. 68-D7-0070, Alpha-Gamma Technologies Inc., Raleigh, North Carolina, April 2000.

3.1-20 EMISSION FACTORS

4/00

ILLINOIS ENVIRONMENTAL PROTECTION AGENCY

1021 North

Grand Avenue East, P.O. Box 19276, SPRINGFIELD, ILLIMNS 62794-9276

THOMAS V. SKINNER, DIRECTOR

217/782-9540

May 16, 2000

Mr. Francis X. Lyons

Regional Administrator

U.S. Environmental Protection Agency, Region 5

R-19J

77 West Jackson Boulevard

Chicago, Illinois 60604-3507

Re:

New Peaker Power Plants in the Chicago Area

Dear Frank:

On behalf of Governor Ryan, 1 am writing to request the assistance of the United

States Environmental Protection Agency (US EPA) with regard to an issue that has

developed recently in Illinois. The Illinois Environmental Protection Agency (Illinois

EPA) has received a number of permit applications (over twenty to date) for new natural

gas-fired electrical generation units (EGUs), commonly referred to as "peaker plants," in

the northern Illinois area. We understand that other states are also receiving an increased

number of permit applications, but it appears that the number coming into Illinois

exceeds those of our neighbors by a. rather significant amount.

A number of members of the Illinois General Assemblv. local environmental

groups, and citizens (some whose homes are near the sites chosen by the new EGU

permit applicants), have raised concerns regarding air quality and health issues associated

with the operation of these new plants, In permitting the new EGU.s, we have followed

the federal new source review rules

for prevention of significant deterioration (PSD),

except in the Metro-East ozone nonattainment area where nonattainment New Source Review

applies.

A number of parties have raised questions regarding the federal PSD rules.

Specifically, they question the applicability of an annual emission threshold of 250 tons,

to peaker plants that will operate primarily during the summer months (the peakers' 250

tons likely will be emitted within a three-month period -- and perhaps within a lesser

period, since peakers operate only when demand is highest, which we estimate to be less

than 20 days during the summer).

Illinois EPA

GEORGE H. RYAN,

GOVERNOR

Exhibit No. 3

Printed on Recycled Paper

Page 2

Letter to: Francis X. Lyons

May 16, 2000

Furthermore, these new EGUs have. been limiting their proposed emissions to just below the

PSD threshold, thus avoiding required application of best available control technology (BACT).

As Illinois implements the federal program only, avoiding PSD means that such plants may be

subject only to the new source performance standards (NSPS), which as you are aware are

somewhat.less stringent.than BACT for these types of sources. This is being characterized as a

“loophole” in the. PSD rules.

Our own air quality analyses of these proposed plants, performed as we receive

the permit applications, indicate that their emissions will not cause violation of any of

the relevant national ambient-air quality standards (NAAQS). While we do not model

for ozone (it would be impossible, both physically and in terms of resources, to perform

the necessary photochemical modeling for each of these permit.applications), we do not

believe that the nitrogen oxides (NOx) emitted by these plants will result in violation of

the ozone standard, particularly with anticipated reductions, of NOx downstate and

regionally.

However, as we continue to analyze the developing peaker situation, we would

appreciate hearing U.S. EPA's perspective, particularly with regard to the federal PSD rules

and the alleged loophole. For example, does U.S. EPA agree with our interpretation of PSD?

Does it agree that these plants should not significantly impact air quality or cause violations?

T'here is some urgency to this request, as we generally must act on applications for new

EGUs within 180 days.

Thank you in advance for your assistance. Please contact either me or Dennis

Lawler of my staff with any questions.

Sincerely,

Thomas V. Skinner

Director

cc: The Honorable George H. Ryan

minor sources in the Clean Air Act or U.S. EPA regulations. Minor

sources subject to Illinois current State Implementation Plan

(SIP) need not apply BACT.

Your letter also raises concerns that these sources will operate

primarily in the summer. We understand that your Agency will soon be

submitting a plan which will demonstrate how selected emissions

management strategies will enable Chicago to attain the ozone

standard within the required time frames. When our office reviews

this demonstration, we will look for evidence that the size of the

total nitrogen oxides (NOx) emissions inventory will not compromise

the effectiveness of these strategies. We hope, as you do, that the

forthcoming restrictions on statewide sources of NOx will make great

strides toward this goal.

Also regarding summertime NOx emissions, the Illinois Environmental

Protection Agency assures protection of the NAAQS by including short

term, hourly emissions limits in its permits. This practice is

consistent with the Illinois SIP, at 35 IAC 201.160, requiring

applicants to submit proof that their project will not cause a

violation of the Illinois Environmental Protection Act. One tool that

applicants may use to submit this proof is dispersion modeling. You

are to be commended for requesting that dispersion modeling be

included for these minor sources as a means to quantify the potential

impacts of NOx

,

and to set suitable hourly and other short term limits

as a result.

We hope this letter addresses your concerns, and we would like to

offer two additional thoughts. First, after applicants receive their

initial permits to operate these peaker plants, some may submit

subsequent applications to construct new units or expand operation

of their existing units. Certain changes may bring potential

emissions above major source thresholds, and consequently may cause

either the new project or the entire source to be subject to PSD,

including any applicable BACT analyses. one example of this type of

change is a request to relax a previously imposed limit such as

operating hours. Another example is a proposal to install additional

capacity, where such expanded operation was anticipated as part of

the original design. We encourage your staff to inform applicants of

these consequences and regularly assess the relationship between

requested changes to an existing plant and the initially permitted

project.

Secondly, we encourage your Agency to continue to solicit public

comments and conduct public hearings on these projects. This valuable

process allows the people of Illinois to gain a full and meaningful

understanding of your analysis of these projects.

We appreciate this opportunity to address your concerns. If you

wish to discuss any of these issues further, feel free to call me,

or Lauren Steele, of my staff, at (312) 353-5069.

Sincerely,

Francis X. Lyons

Regional Administrator

Existing Boiler Power Plants (8/7/00)

MAP NUMBER ID NUMBER

NAME

COUNTY

STREET ADD

CITY TOWN

FUEL

UTM EAST

1

033801AAA

Hutsonville (Ameren)

Crawford

14281 E 1900th Av

Hutsonvill

Coal boilers

442498.9 4

2

077806AAA

Grand Tower (Ameren)

Jackson

Ferry Rd

Grand Towe

Coal boilers

278413.4

3

079808AAA

Newton (Ameren)

Jasper

6725 N 500th Rd

Newton

Coal boilers

395503.4

4

119105AAA

Venice (Ameren)

Madison

701 Main St

Venice

Gas/oil boilers 745681.3

5

135803AAA

Coffeen (Ameren)

Montgomer

134 CIPS Lane

Coffeen

Coal boilers

292044.9

a

137805AAA

Meredosia (Ameren)

Morgan

800 S Washington St.

Meredosia

Coal & oil boilers 708571.3

7

057801AAA

Duck Creek (Central Illinois Light)

Fulton

17751 N Cilco Rd

Canton

Coal boilers

247925.5

a

143805AAG E. D. Edwards (Central Illinois Light)

Peoria

7800 CILCO Lane

Bartonvill

Coal boilers

274651.8

9

167120AAO

Lakeside/Dallman (CWLP)

Sangamon

3100 Stevenson Drive

Springfiel

Coal boilers

277154.9

10

127855AAC

Electric Energy

Massac

2100 Portland

Joppa

Coal boilers

334996.3

11

119020AAE

Wood River (IP)

Madison

I Chessen Lane

East Alton

Coal boilers

748805.5

12

125804AAB

Havana (IP)

Mason

N Highway 78

Havana

Coal & oil boilers 748460.9

13

155010AAA

Hennepin (IP)

Putnam

Rural Route

Hennepin

Coal boilers

305886.4

14

157851AAA

Baldwin (IP)

Randolph

10901 Baldwin Rd

Baldwin

Coal boilers

249933.2

15

183814AAA

Vermilion (IP)

Vermilion

Power Plant Rd

Oakwood

Coal boilers

436712.4

16

021814AAB

Kincaid Generation

Christian

Route 104 West

Kincaid

Coal boilers

285467.4

17

031600AIN

Crawford (Midwest Generation)

Cook

3501 S. Pulaski Rd

Chicago

Coal boilers

439978.8

Is

031600AMI

Fisk (Midwest Generation)

Cook

1111 W Cermak Rd

Chicago

Coal boilers

445750.6

19

063806AAF

Collins (Midwest Generation)

Grundy

4200 E Pine Bluff Rd

Morris

Gas/oil boilers 386926.6

20

097190AAC

Waukegan (Midwest Generation)

Lake

401 E Greenwood Ave.

Waukegan

Coal boilers

433310.2

21

179801AAA

Powerton (Midwest Generation)

Tazewell

13082 E Manito Rd

Pekin

Coal boilers

273149.6

22

197809AAO

Joliet (Midwest Generation)

Will

1601 S Patterson

Joliet

Coal boilers

406601.5

23

197810AAK

Will County (Midwest Generation)

Will

529 E Romeoville Rd

Romeoville

Coal boilers

411386.5

24

199856AAC

Southern Illinois Coop

Williamso 10825 Lake of Egypt Rd

Marion

Coal boilers

3

25

149817AAB

Pearl (Soyland Power Coop)

Pike

South Highway 100

Pearl

Coal boilers

705250.8

Existing Boiler Power Plants (8/7/00)

MAP NUMBER ID NUMBER

NAME

COUNTY

STREET ADD

CITY TOWN

FUEL

UTM EASTING !'UTM NORTHING

1

033801AAA

Hutsonville (Ameren)

Crawford

14281 E 1900th Av

Hutsonvill

Coal boilers

442498.9 4331575.3

2

077806AAA

Grand Tower (Ameren)

Jackson

Ferry Rd

Grand Towe

Coal boilers

278413.4

4170609.6

3

079808AAA

Newton (Ameren)

Jasper

6725 N 500th Rd

Newton

Coal boilers

395503.4

4305976.9

4

119105AAA

Venice (Ameren)

Madison

701 Main St

Venice

Gas/oil boilers 745681.3

4283086.4

5

135803AAA

Coffeen (Ameren)

Montgomer

134 CIPS Lane

Coffeen

Coal boilers

292044.9

4325821.7

a

137805AAA

Meredosia (Ameren)

Morgan

800 S Washington St.

Meredosia

Coal & oil boilers 708571.3

4410688.5

7

057801AAA

Duck Creek (Central Illinois Light)

Fulton

17751 N Cilco Rd

Canton

Coal boilers

247925.5

4482695.1

a

143805AAG E. D. Edwards (Central Illinois Light)

Peoria

7800 CILCO Lane

Bartonvill

Coal boilers

274651.8

4497090.2

9

167120AAO

Lakeside/Dallman (CWLP)

Sangamon

3100 Stevenson Drive

Springfiel

Coal boilers

277154.9

4403468.3

10

127855AAC

Electric Energy

Massac

2100 Portland

Joppa

Coal boilers

334996.3

4119492.0

11

119020AAE

Wood River (IP)

Madison

I Chessen Lane

East Alton

Coal boilers

748805.5

4305373.1

12

125804AAB

Havana (IP)

Mason

N Highway 78

Havana

Coal & oil boilers 748460.9

4462712.1

13

155010AAA

Hennepin (IP)

Putnam

Rural Route

Hennepin

Coal boilers

305886.4

4574644.9

14

157851AAA

Baldwin (IP)

Randolph

10901 Baldwin Rd

Baldwin

Coal boilers

249933.2

4232179.8

15

183814AAA

Vermilion (IP)

Vermilion

Power Plant Rd

Oakwood

Coal boilers

436712.4

4447574.4

16

021814AAB

Kincaid Generation

Christian

Route 104 West

Kincaid

Coal boilers

285467.4

4385488.1

17

031600AIN

Crawford (Midwest Generation)

Cook

3501 S. Pulaski Rd

Chicago

Coal boilers

439978.8

4630755.7

Is

031600AMI

Fisk (Midwest Generation)

Cook

1111 W Cermak Rd

Chicago

Coal boilers

445750.6

4631357.2

19

063806AAF

Collins (Midwest Generation)

Grundy

4200 E Pine Bluff Rd

Morris

Gas/oil boilers 386926.6

4V8588.7

20

097190AAC

Waukegan (Midwest Generation)

Lake

401 E Greenwood Ave.

Waukegan

Coal boilers

433310.2

4692596.0

21

179801AAA

Powerton (Midwest Generation)

Tazewell

13082 E Manito Rd

Pekin

Coal boilers

273149.6

4491024.2

22

197809AAO

Joliet (Midwest Generation)

Will

1601 S Patterson

Joliet

Coal boilers

406601.5

4593915.5

23

197810AAK

Will County (Midwest Generation)

Will

529 E Romeoville Rd

Romeoville

Coal boilers

411386.5

4609585.6

24

199856AAC

Southern Illinois Coop

Williamso 10825 Lake of Egypt Rd

Marion

Coal boilers

3

4165199.7

25

149817AAB

Pearl (Soyland Power Coop)

Pike

South Highway 100

Pearl

Coal boilers

705250.8

4369098.7

Table 1: Existing Fossil-Fuel Fired Electric Utility Boilers

Operation: All Coal-fired boilers are base-loaded except at Havana which is cyclic and all Gas/oil-fired boilers operate as Peakers except Collins 1-5 which are cyclic units

Acid Rain NOx Limits (lb/mmBtu): T-fired Boilers: 0.45 (Ph.

1),

0.40 (Ph.11); W-Fired Units: 0.50 (Ph.

1).

0.46 (Ph.

11).

C-Fired Units >155 MW (0.86). Soyland Power <25 MW and hence no NOx limit.

Abbreviations:

C-

Cyclone;

T-

Tangential;

W-

Wall; Cty - County; A.R - Acid Rain; NAA - Non. Attainment Area

F: qprof EGU-nu-old Peakersl.xls/ 8-15-2000 Original in F:wp/existing power plants2.xis/sheeti/ 8-7-2000

Company Name

UnitName

Street Address

City/

Town

County

ID No.

Area

Designation

Primary

Fuel

No.

of

Boilers

Type

of

Boller

Total

MW

A.Rain

Nox Control

Applicability

1998 Nox

Emissions

TonslYr

Midwest Generation (Com Ed)

Crawford 7,8

3501

S.

Pulaski Rd

Chicago

Cook

031600AIN

Chicago NAA

Coal

2

2-T

542

Yes

4778

Chicago

Cook

031600AMI

Chicago NAA

Coal

I

I-T

321

Yes

3,095

Morris

Grundy

063806AAF

Chicago NAA

Coal

5

&V

2794

Yes

4019

. rw kegan 6,7.8 401 E Greenwood Ave

Waukegan

Lake

097190AAC AA

Chicago NAA

AA

Coal

3

I-C,

2-T

790

Unit 6-No, 7& 8-yes

9627

Joliet

will

197809AAO Chica

goN A

Coal

5

1 -C, 2-T

1328

Yes

18565

4

2-C, 2- T

1094

Yes

12659

Dynegy Midwest Group (1P)

Wood River 4,5

2

2-T

501

Yes

6496

Wood River 1-3

1

Chessen Lane

Cast Alton

M

dison

119020AAE

Metro East NAA

Gas/oil

3

3

153

No

87

[H.l.onville 3,4

14281 E 1900th Ave

Venice

Hutsonville

Madison

Crawford

119105AAA

033801AAA

Metro East NAA

Downstate

Cly

Gas/oil

Coal

a

2

8

2-T

474

150

No

Yes

180

1283

,Grand Tower 7,8

Ferry Rd

Grand Tower

Jackson

077806AAA

Downstate Cty

Coal

3

3-W

177

Yes

2080

lNew1on 1,2

6725 N 500th Rd

~ewton

Jasper

079808AAA

Downstate

Cly

Coal

2

2-T

1267

Yes

8778

Imereclosia 1,2,3

~e2ta 4

M r _

800

S

Washington St

800

S

Washington St

Coffeen

Mereclosia

Meredosia

Morgan

Morgan

Nontgomor

135803AAA

137805AAA

137805AAA

Downstate Cty

Downstate Cty

Downstate Cty

Coal

Coal

Gas/oil

2

5

1

2-C

5-T

1

1005

355

210

Yes-

Yes

No

24813

3248

3

139

1

9

AES

C/o

CILCO

r3l

Canton

Fulton

057801AAA

Downstate Cty

Coal

I

1-W

416

Yes

5

6

7156

7

Peo,

eoria

14380SAAG

Downstate Cty

Coal

3

3-W

786.5

Yes

10003

3

0

0

0

rLakeside 7,8; Dallman 1-2 13100 Stevenson Drive

Spqingfield

Sangamon

167120AAO

Downstate Cty

Coal

4

4-C

235

No

6366

11

11-T

200

Yes

2249

Joppa 1-6

2100 Portland

Joppa

Massac

127855AAC

Downstate Cty

Coal

6

6-T

1086

Yes

9509

Dynegy Midwest Group (1P)

Havana 6

N Highway 78

Havana

Mason

125804AAB

Downstate

Cly

Coal

I

I-W

429

Yes

1

5

4

Havana 1-5

N Highway 78

Havana

Mason

125804AAB

Downstate Cty

Gastoil

a

8

230

No

244

Hennepin 1,2

Rural Route

Hennepin

Putnam

155010AAA

Downstate Cty

Coal

2

2-T

300

Yes

5111

Baldwin

Randolph

157851AAA

Downstate

Cly

Coal

3

2-C,

1-T

1774

Yes

62711

Oakwood

Vermilion

183814AAA

Downstate Cty

Coal

2

2-T

177

Yes

1980

Kincaid

Christian

021814AAB

Downstate Cty

Coal

2

2-C

1108

Yes

32534

Pcywerton 5,6

13082 E Manito Rd

Pekin

Tazewell

179801AAA

Downstate Cty

Coal

4

4-C

1598

Yes

33633

SIPCO

IMarion 1-4

ISoyland Power Coop

10825 Lake of Egypt Rd

Marion

Williamson

199856AAC

Downstate Cty

Coal

4

4-C

272

1.2,3 -No/ 4-yes

11731

Soyland

South Highway

100

Pearl

Pike

149817AAB

Downstate Cty

Coal

I

I-W

24

No

749.9

Total

90

19,797

288,139

Illinois EPA

Exhibit No. 6

New and Existing Peaker Units (8/7/00)

MAP-NUMBER ID-NUMBER

NAME

CITY-TOWN

UTM EASTING UTM NORTHING

1

119105AAA

Venice (Ameren)

745681.3

4283086.4

2

143065AMW

Sterling Ave (Central Illinois Light)

Peoria

277836.4

4513075.8

3

167120AGQ

Factory Street (CWLP)

Springfield

274942.7

4411680.3

4

167120AHJ

Reynolds Street (CWLP)

Springfield

273820.3

4409338.9

5

167120AHJ

Ridgely Road (CWLP)

Springfield

273820.3

4409338.9

6

099816AAB

Oglesby (IP)

Oglesby

326214.2

4573401.9

7

119813AAC

Stallings (IP)

Stallings

756778.1

4290905.2

8

183814AAA

Vermilion (IP)

436712.4

4447574.4

9

161045AAV

Moline (Midamerican Energy)

Rock Island

705879.1

4598058.3

10

031045AAR

Bloom (Midwest Generation)

Chicago Heights

446760.6

4593291.8

11

031600AIN

Crawford (Midwest Generation)

439978.8

4630755.7

12

031600AMI

Fisk (Midwest Generation)

445750.6

4631357.2

13

031600AW

Calumet (Midwest Generation)

Chicago

454662.8

4618156.6

14

043804AAA

Lombard (Midwest Generation)

Lombard

413239.1

4638248.6

15

043805AAM

Electric Junction (Midwest Generation)

Eola

397596.6

4627536.6

16

097190AAC

Waukegan (Midwest Generation)

433310.2

4692596.0

17

197809AAO

Joliet (Midwest Generation)

406601.5

4593915.5

18

201030AXQ

Sabrooke (Midwest Generation)

Rockford

327027.5

4677411.6

19

149817AAB

Pearl (Soyland Power Coop)

705250.8

4369098.7

20

197808AAC

Peoples Gas

Elwood

406200.0

4588200.0

21

197811AAH

Desplaines Greenland/Enron

Manhattan

421000.0

4582750.0

22

089425AAC

Dynegy/Rocky Rd

E.Dundee

397560.0

4660075.0

23

031600GHA

Calumet Energy Team LLC

Chicago

453691.0

4614679.0

24

20103OBCG

Indeck-Rockford

Rockford

326506.0

4678385.0

25

093808AAD

LS Power*

Minooka

394944.0

4592616.0

26

053803AAL

Ameren CIPS/LIE