UN

A

Department of Animal Sciences

College

ofAgricultural, Consumer

and Environmental Sciences

132 Animal Sciences Laboratory

1207 West Gregory Drive

Urbana, IL 61801

Is

I

RECEIVED

CLFRT=’s

OFFIrE

M/4Y

1

4

2001

STATE

OF ILLINOIS

Pollution

Control BoQrd

May 9, 2001

Dorothy M. Gunn

Clerk ofthe Board

Illinois Pollution Control Board

James R. Thompson Center

100

W. Randolph Street

Suite 11-500

Chicago, IL

60601

Dear Mrs. Gunn:

Enclosed is the original

and nine copies ofmy public comment and research report on the

proposed Livestock Waste Regulations,

Adm.

Code

506,

Construction

Standards.

Please

distribute this to the board members ofthe Illinois Pollution Control Board.

Thank you.

Sincerely,

/(#? /U

/4~e~&4&

Ken W

Koelkebeck

Assoclate Professor

KWK:nj d

Enc.

c:

R 01-28 Service List

Phone:

217-244-0195

Fax: 217-333-7861 E-mail: kkoelkeb@uiuc.edu

RECEIV2D

CLFRK’S(~FF1C’~

MAY

1

4

2001

ILLINOIS POLLUTION CONTROL BOARD

STATE OF

ILUNOIS

Pollution

Control Board

IN THE MATTER OF:

LIVESTOCK WASTE REGULATIONS

35 III. Adm. Code 506

Construction Standards

PUBLIC COMMENT

Members of the Illinois Pollution Control Board, I thank you for allowing me to

give public comment in regards to the proposed changes to the Livestock Waste

Regulations

—

Code

506

—

Construction Standards.

I’mKen Koelkebeck, Poultry

Extension Specialist and Associate Professor in the Department of Animal Sciences,

College ofAgriculture, Consumer, and Environmental Sciences at the University of

Illinois at Urbana-Champaign.

I also serve as an Advisory Board Member for the Illinois

State Turkey Growers Association and Executive-Secretary ofthe Illinois Poultry

Industry Council.

I have been in my current position for 14 years, and during that time, I

have worked closely with the turkey and egg producers on a number of issues of

importance to their industries.

Specifically, I would like to provide comment on the regulations

contained in

SUBPART

C ofAdm. Code

506 “Standards for the Design and Construction of

Livestock Waste Handling Facilities other than Lagoons

—

Sections 506.301 through

506.314 and any other sections that are closely related”.

It is my understanding that any

new facility or addition to

an existing facility which classifies it as a new facility which is

intended to house poultry (specifically turkey raising facilities and possibly laying hens)

has to conform to certain construction standards related to the floors ofthese facilities.

These proposed standards require that new facilities that are built must be constructed on

ground that has the hydrolic conductivity or permeability standards of 11 0~ cm/sec (sec.

506.304a. 1.).

Inthe event that a

1

x

10~ cm/sec cannot be attained the facility would

need to be

constructed with a concrete floor.

In addition, the producer or company must

obtain a soil sample to determine the presence or non-presence of aquafer containing

material within

5

ft.

(sec. 506.302a.l.) of the facility floor.

This regulation in addition to

others not specifically mentioned here would greatly affect producers and companies in

Illinois’ Poultry Industry, specifically the turkey industry and to some extent the laying

hen industry.

These regulations would also negatively affect the possible expansion of

the U.S. broiler industry looking to

expand their operations into the State ofIllinois.

More important to the immediate concern is the effect ofthese rulings on the existing

turkey industry in the state and the negative impactthese rulings would have on any

expansion ofthe current turkey industry.

In regards to these rulings, I was approached by an integrated turkey company

that contracts turkey production in SoutheasternIllinois about a year and a half ago.

This

company had several contractproducers

who were wanting to

expand their current turkey

growout facilities.

They were informed that they had to meet the construction guidelines

set forth in Section

506,

that being needing to demonstrate a

1

x

10~ cm/sec permeability

underneath and within the proposed facility.

The company then talked to the Department

of Agriculture and decided to obtain some scientific data on the permeability ofthe soils

and in

addition wanted to know the extent of leaching ofnutrients from the turkey

manure within the soils.

Therefore, the company contacted me to help them conduct a

field research study.

Thus, a year ago last fall, I helped the company design and conduct a research

study examining the degree of permeability and leaching of nitrogen, phosphorus, and

potassium in soils from earthen floors within several turkey barns in Southeastern

Illinois.

I have included a copy ofthis study.

For this project the company provided

financial support along with some funding from the Illinois Council on Food and

Agriculture Research (C-FAR) and the Department of Animal

Sciences.

We conducted

this study

during the months of December and January,

1999 and submitted a report of

our findings and gave a presentation to the Department of Agriculture on February 14,

2000.

In addition to this report, the findings of this study has been presented at the

Annual Poultry Science Association meeting last summer in Montreal, Canada and the

annual Midwest Poultry Federation meeting in St. Paul, Minnesota last month. A peer-

reviewed manuscript was

sent to

the Journal ofApplied Poultry Research on December

11, 2000 and is currently under review.

For this study, two turkey growout barns and one brooder barn were selected from

three commercial turkey farms in Southeastern Illinois to be sampled for the presence of

soil nutrients and permeability properties at specific depths.

The three barns had been in

existence housing turkeys for the past 10

to

12 years.

For each barn, nine

5

ft.

soil bores

were taken from the inside and three

5

ft. bores were taken from the outside.

The soil

bores taken from the outside ofthe barns served as controls and one of these bores went

an additional depth of28 ft. to determine the type ofsoil near each of the three turkey

barns. The soil bores were divided into five

1-ft. sections representing the top

5

ft. of

depth and sent to a private laboratory for the analysis of total Kjeldahl nitrogen (TKN),

nitrate nitrogen (N03-N), total phosphorus (P2), potassium (K), pH, and percent organic

matter (OM).

In addition, core samples at three depths (1 to 3, 5 to 7, and 9 to

11

in)

were taken to determine soil permeability.

The results ofthis study indicated that significantly greater concentration oftotal

TKN were present in the first

3 ft. of soil depth for the inside vs. outside (control)

samples for all farms.

However, no differences in total TKN concentration were found

between inside and outside samples at the 4- and 5-ft.

depths. Similar results were found

for N03-N and K concentrations as noted fortotal

TKN; however, total P2

concentrations were essentially the same between inside and outside samples for depths 2

to

5

ft.

This indicated that total P2 did not migrate in the soil.

The soil permeability

results indicated that lower permeability occurred for the inside vs. outside samples at the

1 to 3- and

5 to 7-in depths for all farms

averaged together.

The permeability data also

indicated that several inside permeabilities exceeded

1

x

10 minus 7 cm/sec.

Thus, this

study indicated that leaching ofsoil

nutrients essentially stopped at the 4- to

5-ft.

level

within these turkey barns, and in addition, soil permeability was lowered by the pr3sence

ofgrowing turkeys inside these facilities.

Since I’vebeen here at the University of Illinois, I have been actively engaged in

promoting the expansion ofthe poultry industry in the

State.

If the proposed changes

become law, it is my understanding that any further expansion of the turkey and layer

industry in the State will be

negatively affected.

Ifturkey producers are forced to build

new grow-out buildings that have to

have a concrete floor to meet permeability, the

additional cost of $25,000

to $30,000

will make it virtually impossible for the producer to

secure a building loan.

Also, when existing facilities depreciate in value and

can no

longer produce turkeys efficiently, total production volume in the State will decline

because construction of new facilities would be cost prohibitive.

Thus, in the end, the

State will lose

some 35

million dollars in net cash receipts that are generated per year.

In

addition, the money generated by the sale and consumption of nearly 3.5

million bushels

ofcorn per year would be lost.

Also, the State would not be able to receive any monetary

benefits from any broiler companies

looking to expand their production into

Illinois.

Finally, our research findings reported earlier seem to support the contention that

subsurface ground water would not be contaminated by the leaching of nutrients from

within turkey facilities particularly in the area of the State in which we conducted the

research. It is my opinion, based on our research findings, that new poultry (turkey and

layer) facilities be allowed to be constructed without a concrete floor.

Perhaps the

language ofthe permeability values needed for soil within these facilities be modified to

equal that ofexisting soil permeabilities obtained through present soil

geographical

measurements.

In addition, perhaps the language ofthe present documentation on

Livestock Waste Regulations further clarify the distinction between solid, semi-liquid,

and liquid waste handling facilities.

Perhaps some type of an exemption from the current

construction standards, i.e., soil permeability be made for solid or dry livestock waste

handling facilities, i.e., poultry (turkey, layer, and broiler houses).

Thus, as written, the

proposed construction standards would negatively affect expansion of the turkey and

layer industries in the State,

as well as prohibit any newpoultry (i.e., broiler companies)

from expanding into Illinois.

Respectively submitted

Ken W. Koelkebeck

Department of Animal Sciences

University of Illinois

The Degree of Permeability and Leaching ofNitrogen, Phosphorus, and Potassium in Soils

from Earthen Floors Within Turkey Barns in Southeastern Illinois

by

Ken W. Koelkebeck, Ph.D.

Department of Animal Sciences

University ofIllinois

Urbana, IL

61801

and

Scott Nally

Perdue Farms, Inc.

Washington, IN

47501

Financially Supported by:

Illinois Council on Food and Agriculture Research (C-FAR)

and

Perdue Farms, Inc.

Impact

Statement:

The impact ofthis research documents that soil permeability within a turkey

barn can be dramatically lowered by compaction produced by turkeys,

and shallow leaching of

possible harmful soil nutrients from turkey manure should not contaminate subsurface ground

water.

ABSTRACT

A

field study was conducted to determine the degree ofleaching of nitrogen, phosphorus,

and potassium, and permeability of soils from earthen floors within several turkey barns. Two

turkey grow out barns and one brooder barn were selected from three commercial turkey farms in

Southeastern Illinois to be sampled for the presence of soil nutrients and permeability properties

at specific depths.

The three barns had been in existence housing turkeys for the past

10 to

12

years.

For each barn, nine

5

ft.

soil borings were taken from the inside

and three 5

ft. bores were

taken from the outside.

The soil

bores taken from the outside of the barns served as controls and

one ofthese bores went to an additional depth of 28 ft. to determine the type ofsoil near each of

the three turkey barns. The soil bores were

divided into five

1-ft. sections representing the top

5

ft. ofdepth and sent to a private laboratory for the analysis of total Kjeldahl nitrogen (TKiN),

nitrate nitrogen (N0

3-N), total phosphorus

(P2), potassium (K), pH, and percent organic matter

(OM).

In addition to the

5-ft.

nutrient soil bores, a Uhland core sampling device was used to take

15 core samples (3” deep x 3” diameter cylindrical cores) from each barn to determine

permeability. Three core samples at three depths

(1-3”, 5-7”, 9-11

“)

were taken from the inside

and two

samples at the same three depths were taken from the outside of each barn.

Permeability

measurements were then determined on all

45 core samples at the University ofIllinois,

Department ofNatural Resources and

Environmental Sciences Laboratory.

The results ofthis field study indicated that significantly greater concentration of total

Kj eldahl nitrogen (TKN) were present in the first 3 ft. of soil depth for the inside vs outside

(control) samples for all farms.

However, no differences in total Kjeldahl nitrogen (TKN)

2

concentration were found between inside and outside samples for the 4- and 5-ft.

deep samples.

For nitrate nitrogen (N0

3-N), concentrations showed no differences between inside vs outside

samples at any

depth for farm B, however, inside vs outside samples differed at all depths for

farms A and C.

Similar results were found forpotassium (K) concentrations as noted fortotal

Kjeldahl nitrogen (TKN); however, total phosphorus (P2) concentrations were essentially the

same between inside and

outside samples for depths 2-5

ft.

This

indicated that total phosphorus

(P2) did not migrate in the soil.

The soil permeability results indicated that lower permeability

occurred for the inside vs outside samples at the

1-3” and

5-7”

depths for all farms averaged

together.

The permeability data also indicated that several inside permeabilities exceeded

1

x 10~ cm/sec.

In summary, the present study indicated that even though some soil nutrients leached

below the surface of the ground inside a turkey facility, leaching essentially stopped at the four

to five ft.

level.

In addition, the degree of soil permeability may be lowered by the presence of

turkeys inside a turkey grow out facility.

INTRODUCTION

In the past

10-15 years there has been considerable growth and expansion in the turkey

industry in the

State ofIllinois particularly in the counties ofRichland,

Crawford, and Lawrence.

Currently, about 1.3 million turkeys are raised per year in this part ofthe state.

This increased

production has brought about some concern by regulatory agencies over the possibility of

contaminating ground water by leaching ofnitrogen and phosphorus

from within a turkey house.

Studies

conducted previously have reported higher concentrations of nitrogen in soil samples

from beneath the floors ofpoultry houses than in soil samples from outside ofhouses where no

3

birds were raised (Lomax,

1995).

In addition, a report by Haberstroh (1997) found that nitrogen

concentrations were higher in soils under turkey barn floors to a depth offive feetthan in soils

outside the barns. Thus, the present study was conducted to determine the degree of leaching of

nitrogen, phosphorus, and potassium in the soil

from within several turkey barns as compared to

the nitrogen and phosphorus levels in the soil

outside the barns.

In addition, the degree of

permeability or hydrolic conductivity was determined in the first

11

in. ofsoil within the turkey

barns vs outside the barns.

BACKGROUND AND METHODS

Three turkey farms located in Lawrence and Crawford counties were selected for this

study.

On each farm, samples were taken for soil nutrient analysis and soil permeability from

earthen floors from one ofthe turkey barns.

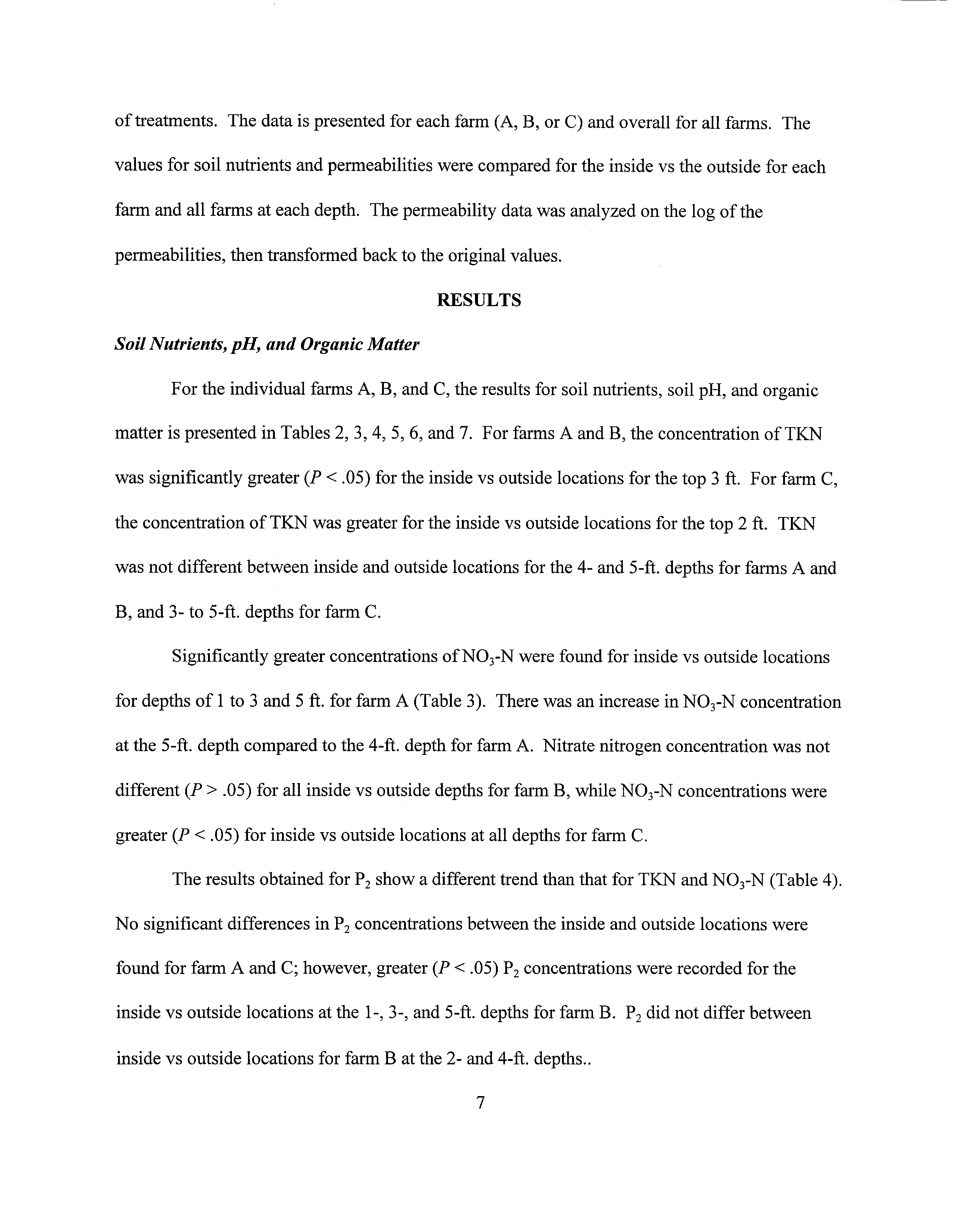

Figure

1

shows the location of soil borings for soil

nutrient analysis and permeability in and outside each barn.

The description ofeach farm

including information on the grow out

system is

described below.

The soil type, percent clay

and expected permeability for each farm is presented in Table

1.

These farms were picked for

sampling because they accurately represented the various sizes ofturkey barns and locations of

the most common soil types that typify those found in these counties in Southeastern Illinois.

Farm A

The first samples were taken from a farm located in Lawrence County, near Bridgeport,

IL.

Samples were taken from brooder barn number

1

(40 x 500 ft.).

The farm housing capacity

is 21,500

hens per flock and has been in existence since June

19,

1987.

Farm B

The second farm was located in Lawrence County, near the Illinois state line and

4

consisted ofthree barns (40 x

500 ft.) which has raised turkeys since July 25,

1987.

Samples

were taken from growout barn number 2.

The farm housing capacity is 21,500 hens per flock.

Farm C

Farm C was location in Crawford County, near Heathsville, IL.

This farm consisted of a

brooder barn built in 1986 and

a growout barn built in December of 1990.

Samples were taken

from growout barn number 2

(50 x

500 ft.).

The farm housing capacity is

13,500 hens per flock.

Soil Sampling Procedures and Technique

For each of the barns sampled on Farms A, B, and C there were a total of 12 soil borings;

nine soil

borings taken from within the barns and three soil borings taken from outside the barns.

For this procedure, an Illinois State Geological Survey Probe truck was used to collect the soil

bores.

Samples were taken from a S

x

10 ft.

rectangular area

1/3,

1/2

,

and 2/3 ofthe distance

from one end ofthe barn.

Samples were collected in this manner due to the ceiling height of

eachbarn.

In addition,

soil borings were taken in three locations

on the outside ofeach barn

approximately 20 ft. from the side and end wall.

For each bore,

the first

5

ft. ofdepth was

separated into five

1-ft. sections.

The initial bore took a 4-ft.

section, thenwent back in the same

bore hole and removed the next

1-ft. section.

Immediately after collecting the five 1-ft.

sections,

the separated soil bore samples were placed into pre-labeled plastic sample bags and transported

in a Styrofoam cooler twice a day to Alvey Laboratories, Belleville, IL

for analysis of soil

nutrients.

After the soil bore samples

were taken from a barn,

core samples for permeability were

taken. For soil permeability or hydrolic conductivity, a three inch diameter x three inch deep

cylindrical soil

core was taken using a Uhland core sampling device.

For each barn,

15

S

individual core samples were

taken at each location inside or outside ofthe barn (Figure

1).

Three core samples were taken at three depths (approximately

1-3”, 5-7”,and 9-11”)from the

inside and two

samples at the same depths were taken from the outside.

All samples were

carefully wrapped in aluminum foil to keep the sample intact and transported to Dr.

Bill

Simmons’ laboratory,Department ofNatural Resources and Environmental Sciences, University

ofIllinois to determine permeability or hydrolic conductivity.

In addition to the

soil bore samples for soil nutrients and core

samples for permeability, a

core sample was taken outside each barn to

a depth of about 28

ft.

Pictures were taken ofthis

core sample for each 4-ft.

section to

determine the type of soil (clay, sand, or clay/sand

combination) present.

Soil Nutrient and PermeabilityLaboratory Analysis

After all soil samples were taken, the soil bore samples were analyzed for several soil

nutrients and soil properties by Alvey Labs.

They analyzed the samples for total

Kjeldahl

nitrogen (TKN), nitrate nitrogen (N0

3-N), total phosphorus

(P2), potassium (K),

soil pH, and

percent organic matter (OM).

The TKN, N03-N, P2

and K values were presented in parts per

million concentration (ppm).

For the permeability or hydrolic conductivity values, the data are reported as cm/sec or

the rate at which water flowed through each core.

For each core sample, water was flushed

through the core three times, then the average permeability was recorded.

StatisticalAnalysis

Forthe

soil nutrient and permeability values presented, the data was analyzed by Analysis

ofVariance procedures consistent for a 3 x

2

x

5

(farm x location x depth) factorial arrangement

6

of treatments. The data is presented for each farm (A, B, or C) and overall for all farms.

The

values for soil nutrients

and permeabilities were compared for the

inside vs the outside for each

farm and all

farms at each depth.

The permeability datawas analyzed on the log of the

permeabilities, then transformed back to

the original values.

RESULTS

Soil Nutrients,pH, and Organic Matter

For the individual farms A, B, and C, the results for soil nutrients, soil pH, and organic

matter is presented in Tables 2, 3, 4,

5, 6, and

7.

For farms A and B, the concentration ofTKN

was significantly greater

(P

K

.05)

for the inside vs outside locations

for the top 3 ft.

For farm C,

the concentration ofTKN was greater for the inside vs outside locations for the top

2 ft.

TKN

was not different between inside and outside locations for the 4- and 5-ft. depths for farms A

and

B, and 3- to 5-ft. depths for farm C.

Significantly greater concentrations ofN0

3-N were found for inside vs outside locations

for depths of 1 to

3 and

5

ft. for farm A (Table 3).

There was an

increase in N03-N concentration

at the

5-ft.

depth compared to the 4-ft. depth for farm A.

Nitrate nitrogen concentration was not

different

(P>

.05) for all inside vs outside depths for farm B, while N03-N concentrations were

greater

(P

K

.05) for inside vs outside locations at all depths for farm C.

The results obtained for P2 show a different trend than that for TKN and N03-N (Table 4).

No significant differences in P2 concentrations between the inside

and outside locations were

found for farm A and C; however, greater

(P

<

.05) P2 concentrations were recorded forthe

inside vs outside locations at the

1-, 3-, and 5-ft.

depths for farm B.

P2 did not differ between

inside vs outside locations

for farm B at the 2- and 4-ft. depths..

7

Table

S

depicts the results for K for farms A, B, and

C.

These results are similar to those

shown for TKN in relation to the concentration of K at each depth for the inside vs outside

samples. The concentration of K was found to be

greater

(P

K

.05) for the top 2-ft. for the inside

vs outside locations

for farms A and

C, while

no difference in K concentration was noted

between the inside and outside locations at the 3- to 5-ft.

depths (Table 5). For farm B,

K

concentrations were greater

(P

K

.05) for the

1- to 3-ft. depths, while no differences in K

concentration was noted at the 4- and

5-ft.

depths for inside vs outside locations.

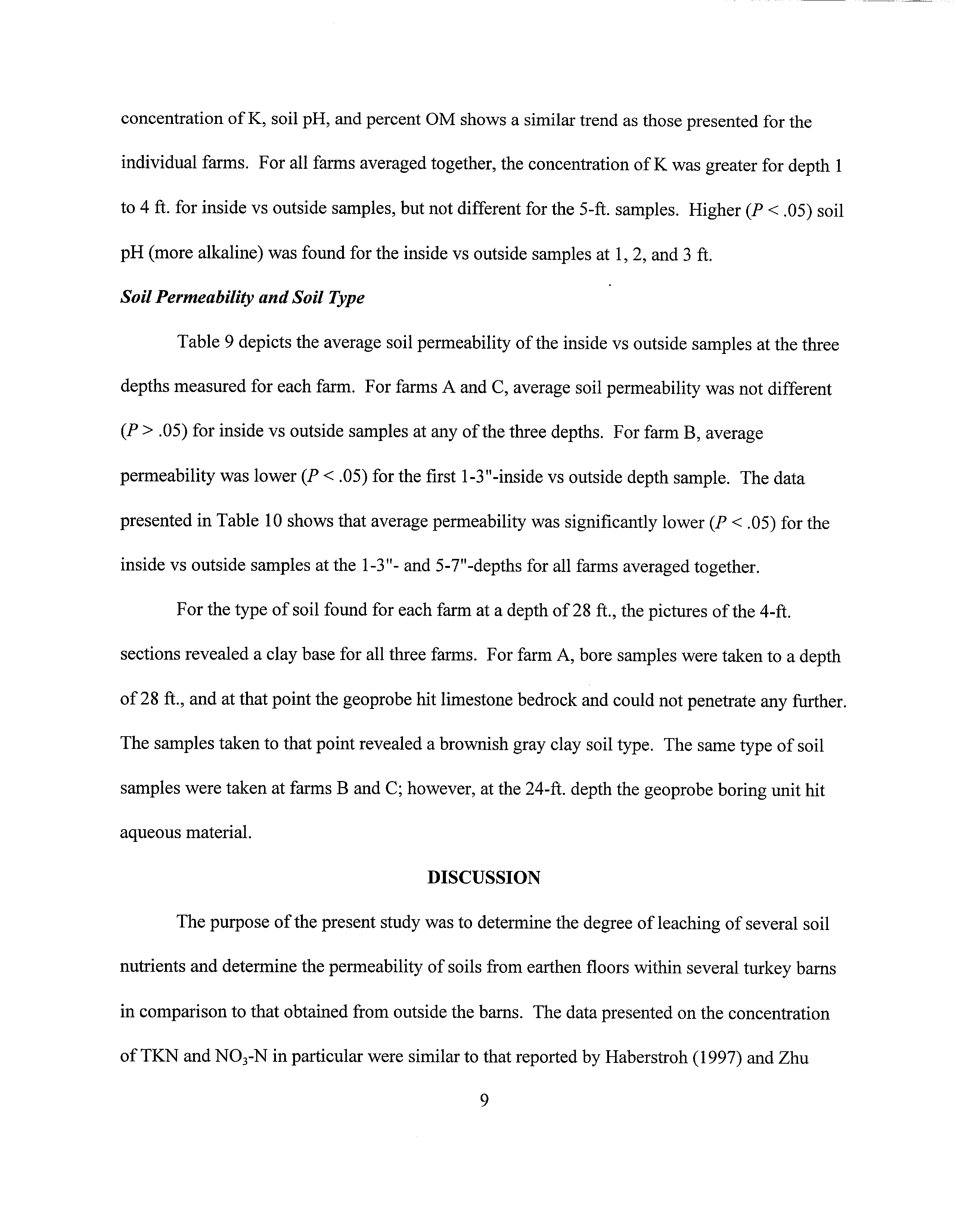

In addition to the soil nutrients measured, soil pH and OM were analyzed and are

depicted for each farm in Tables 6 and 7.

In general, soil pH for farms A and B were higher

(more alkaline) forthe inside vs outside samples at depths

1, 2, 3, and

1, 2, 3, and 4 ft.,

respectively for farm A and B

(Table 6).

For farm C, higher

(P

K

.05) pH soils were recorded at

the 3- and 4-ft. depths on the inside vs outside.

For percent OM, no consistent results were found

forthe inside vs outside samples at all depths for each farm (Table 7).

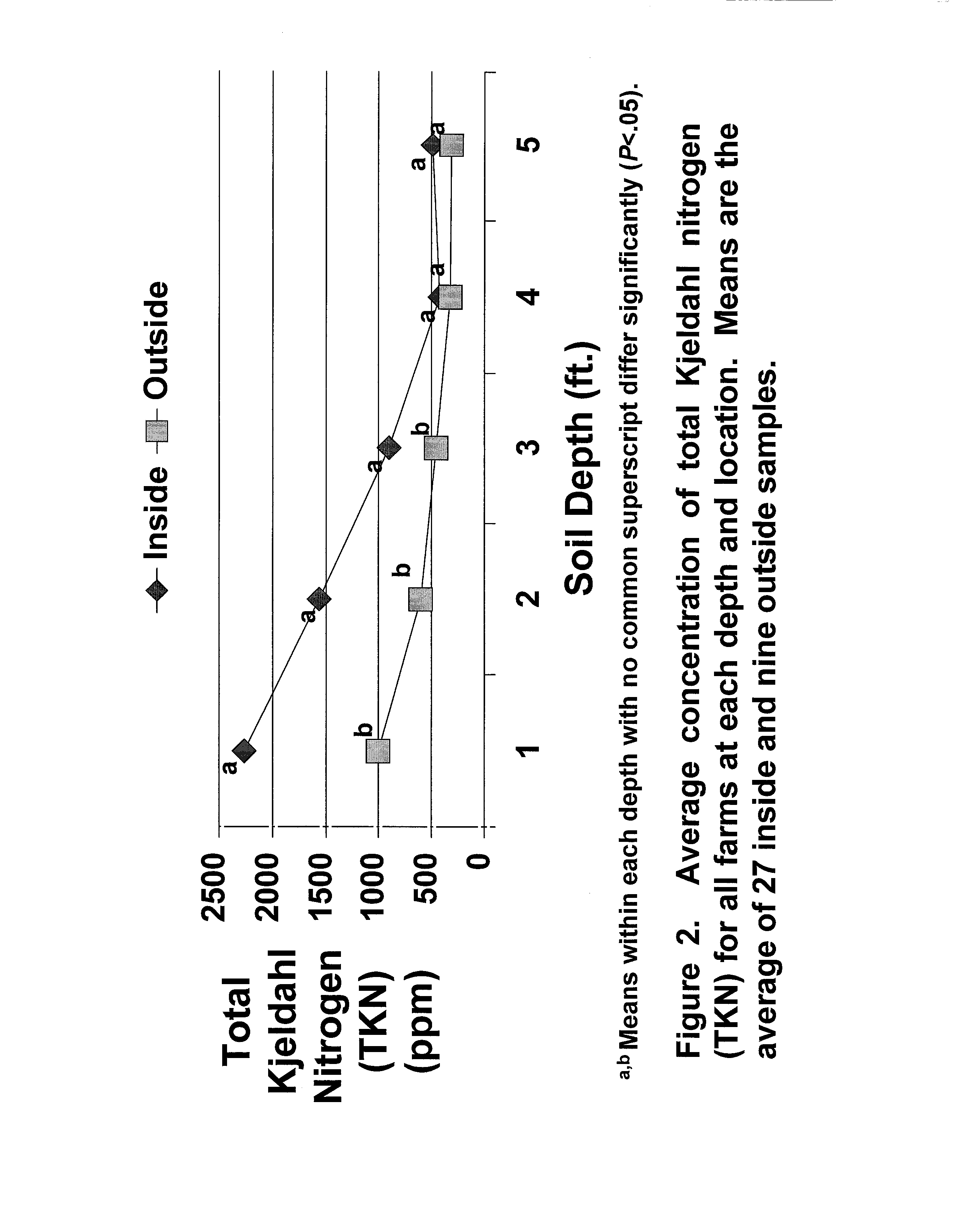

Figures 2, 3, and

4 and Table

8

depicts the results for soil nutrients, soil pH, and percent

OM for all three farms averaged together by

each soil

sample depth.

For the most part, the

results depicted in these figures and tables are similar to the data presented for the individual

farms.

In Figure 2, TKN concentration was greater

(P

K

.OS) for inside vs outside samples of soil

depths of 1, 2, and 3

ft., but not for the 4 and 5

ft. samples

(P>

.05).

In Figure 3, the results for

N0

3-N averaged

over all farms showed that greater

(P

K

.05) concentrations occurring for inside

vs outside samples at all depths (Figure 3).

However, the magnitude of differences was very

small at the 4- and 5-ft. depth compared to depths

1, 2, and

3

ft.

The results

for P2 (Figure 4)

closely follow that shown forthe individual farms.

The data presented in Table

8

for the

8

concentration of K, soil pH, and percent OM shows a similar trend as those presented for the

individual farms.

For all farms averaged together, the concentration ofK was greater for depth

1

to 4 ft. for inside vs outside samples, but not different for the 5-ft. samples.

Higher

(P

K

.05)

soil

pH (more alkaline) was found for the inside vs outside samples at 1, 2, and

3 ft.

Soil Permeability andSoil Type

Table 9 depicts the average soil permeability of the inside vs outside samples at the three

depths measured for each farm.

For farms A and C, average soil permeability was not different

(P>

.05) for inside vs outside samples at any ofthe three depths.

For farm B,

average

permeability was lower

(P

K

.05)

for the first

1-3 “-insidevs outside depth sample.

The data

presented in Table

10 shows that average permeability was significantly lower

(P

K

.05)

for the

inside vs outside samples at the

1-3”- and

5-7”-depths for all farms averaged together.

For the type of soil found for each farm at a depth of28 ft.,

the pictures ofthe 4-ft.

sections revealed a clay base for all three farms.

For farm A,

bore samples were taken to

a depth

of28

ft.,

and at that point the geoprobe hit limestone bedrock and could not penetrate any further.

The samples taken to that point revealed a brownish gray

clay soil type.

The same type of soil

samples were taken at farms B and C; however, at the 24-ft.

depth the geoprobe boring unit hit

aqueous material.

DISCUSSION

The purpose ofthe present study was to determine the degree of leaching ofseveral soil

nutrients and determine the permeability ofsoils from earthen floors within several turkey barns

in comparison to that obtained from outside the bams.

The data presented on the concentration

ofTKN and N0

3-N in particular were similar to that reported by Haberstroh (1997) and Zhu

9

(1999).

In our study, increased concentrations ofTKN were found for inside soil

samples for the

first 3-ft.

depth, but not for the 4- and 5-ft.

depth compared to outside samples.

This indicates

that over a 10 to

12 year period ofgrowing turkeys in these buildings, TKN only migrated about

4 ft. below the surface of the ground within the turkey bams.

The results for K were similar to

the TKN results.

The datapresented forN0

3-N revealed that this nutrient migrated about

5

or

more ft. below the surface of the inside of the turkey bams.

A possible reason that N03-N

seemed to migrate further in the soil

from within the turkey barns was because the sub-floor of

the inside ofthe barns were mixed with backfill (organically enriched) soil at the time ofbuilding

construction.

Further examination ofthe data presented for TKN, N03-N,

P2, and K indicated

that concentrations ofthese

soil nutrients actually tended to

increase from the 4- to

the 5-ft.

depth

both on the inside and outside.

The reason for this can be explained by the sampling method

used. Since the geoprobe truck probe unit could only take a 4-ft.

deep sample, the unit had to

extract that sample then re-enter the same bore to get the 5-ft.

sample.

Thus, some top soil

probably fell in the bore hole and contaminated the 5-ft.

sample.

The data presented for P2

indicated that this nutrient basically does not migrate in the soil like TKN and N03-N does.

In this study, the results presented for soil permeability indicate for the most part that the

compaction produced by the turkeys inside the barns helped to lower the permeability of soil

within the houses. This was particularly

evident for farms B and

C.

For farm B much lower

permeability values were found inside the turkey barn compared to the outside because a

considerable amount ofbackfill dirt was packed onto the turkey barn floor during construction of

the building.

In fact, a majority ofthe houses constructed by Perdue Farms utilizes backfill dirt

as a subbase for the bam floor.

The reason that permeability of soil samples from the inside

10

locations offarm A were the same as the outside may be

due to the fact that the turkey barn on

this farm was used mostly as a brooder, so the lighter birds would not have produced as much

compaction as on farms B and C.

It should also be noted that there were three inside

permeability core samples that did not allow water to penetrate through them while only one

outside sample did not allow the passage of water through it during the laboratory analysis.

Observation ofthe core samples that were taken from the 28-ft. cores showed that no

aqueous material was observed to be present up to 20 ft. or so.

These observations indicate that

the presence of aqueous containing soil seems to be a least 20

ft. below the surface of the ground.

CONCLUSIONS

In summary, the results ofthis study indicated that soil nitrogen (TKN) was shown to

leach below the surface of the ground inside turkey facilities to a depth of 4 ft.

Nitrate nitrogen

levels were found to penetrate a little

further, but were dramatically reduced at

5

ft. vs

1 ft.

inside

the turkey barns. The results for P

2 indicate that the soil nutrient did

not migrate in the

soil like

the results ofTKN and N03-N.

In addition, the raising of turkeys in these facilities seemed to

dramatically lower permeability of soil within the turkey barns.

Finally, since this study showed

that possible harmful nutrients from turkey manure leached below the surface ofthe soil within a

turkey barn just a few feet, it is highly unlikely that subsurface ground water would ever be

contaminated.

REFERENCES

Haberstroh, G.,

1997.

Nitrogen concentrations under turkey barn floors.

Water Quality

Division, North Dakota Department ofHealth, Bismark, ND.

Zhu, J.,

1999.

A preliminary study on seepage from deep bedded and poultry litter systems.

Minnesota Department of Agriculture,

St. Paul, MN.

11

~1)

0~

0

‘4-

ci~

Cl)

0

-Q

a

ci,’

~

—

—

=0w)

Cl)

L.

L

0

~

‘4—

cD

L

0

I

0~LC)

—

I

C~)

‘4-

100

LON~

II II

II

0

0

0

V

V

C/)

ci,

-c

E

0

‘4-

Cl)

0

0

0

-J

~Cl)

E

co~

C/:~2

.0

cDV

t30

TABLE

1.

Description of Soil Type, Percent Clay, and Permeability for Each Farm

1

Soil Type

Depth

Percent Clay

Permeability

(in)

(%) (in/hr)

FarinA

0-10

27-35

.6-2.0

10-24 22-33 .6-2.0

24-34

24-35

34-50

20-30 <.06

50-60 20-30

.2-.6

FarmB

12 Wynoose

silt loam

0-9

9-22

22-45

45-60

15-25

12-18

35-42

25-37

.6-2.0

.06-.2

<.06

.06-.2

14C2 Ava

silt loam

FarmC

214B Hosmer

0-6

siltloam

6-24

24-60

1Data were obtainedfromthe local Illinois State Geological

10-17

24-30

16-20

Survey Office.

.6-2,0

.6-2.0

<.06

13

TABLE 2.

Average Concentration of Total Kjeldahl Nitrogen (TKN) at Each Depth for Inside

and Outside Locations

1

Location

Farm

Inside

Outside

Depth

(ft.)

1

2

3

4

S

(ppm)

FarinA

2974a

1745a

448b

902a

394a 337a

433a 218a

FarmB

1

1663a

799b

2

1315a

3

1147a

4

546a

310a

5

683a 406a

FarmC

1

2172a

2

1628a

3

656a 622a

4

328a 311a

5

355a 319a

1Means are the average ofnine inside and three outside samples at each depth for farms A, B,

andC.

a,bMeans within a row and farm with no common superscript differ significantly

(P

<

.OS).

14

TABLE 3.

Average Concentration ofNitrate Nitrogen (N0

3-N) at Each Depth for Inside and

Outside Locations

1

Location

Farm

Inside

Outside

Depth

(ft.)

1

2

3

4

5

(ppm)

FarmA

425a

403a

153a

34a

7a

87a

FarmB

1

90a

65a

2

45a

57a

3

ha

45a

4

6a 9a

5

lOa

40a

FarmC

1

497a

18b

2

495a

3

431a

8b

4

185a

5

260a

1Means are the average of nine inside and three outside samples at each depth for farms A, B,

and C.

a,bMeans within arowandfarm withno common superscript differ significantly

(P

<

.05).

15

TABLE 4.

Average Concentration of Total Phosphorus

(P

2) at Each Depth for Inside

and

Outside Locations

1

Farm

Depth

Location

Inside

Outside

(ft.)

(ppm)

FarmA

1

108a

66a

2

44a

18a

3

39a

17a

4

14a

isa

5

36a 20a

FarmB

1

155a

2

51a

12a

3

61a

4

30a 17a

5

81a

FarmC

1

98a 64a

2 34a

77a

3

lOa

41a

4

ha

ba

5

29a

14a

1Means are the average of nine inside and three outside samples at each depth for farms A, B,

and C.

a,bMeans within arow andfarm withno common superscript differ significantly

(P

<

.0

5).

16

TABLE

5.

Average Concentration of Potassium (K) at Each Depth for Inside and Outside

Locations’

Farm

Depth

Location

Inside

Outside

(ft.)

(ppm)

FarmA

1

1645a

2

744a

3

217a

71a

4

52a 71a

5

lOla

54a

FarmB

1

2486a

2

1639a

3

563a

4

103a

31a

5

302a

27a

FarmC

92a

85a

57a

1

2203a

2

1157a

3

349a

4

75a

5

148a

1

Means are the average ofnine inside and three outside samples at each depth for farms A, B,

andC.

a,bMeans

within a row and farm with no common superscript differ significantly

(P

<

.05).

17

TABLE 6. Average SoilpH atEachDepth for Inside and Outside Locations

1

Location

Farm

Depth

Inside

Outside

(ft.)

(pH)

FarmA

1

6.3a

2

5.8a

3

5.8a

4

5.la

4.8a

5

5,la

5,la

FarmB

1

8.2a

2

79a

3

73a

4

6.2a

5

6.4a

5.2a

Farm C

1

6.2a

6.la

a

2

5.la

5.7

3

53b

6.3a

4

5.8a

5

49a

5.6a

1Means are the average ofnine inside and three outside samples at each depth for farms A, B,

and C.

a,bMeans within arowand farm withno common superscript differ significantly

(P

<

.05).

18

TABLE 7. Average PercentOrganic Matter (OM)of Soil at Each Depth for Inside and

Outside Locations’

Location

Farm

Inside

Outside

Depth

(ft.)

1

2

3

4

5

(%)

FarmA

1.7a

2.la

l.7a

l.2a

0.7a

0.6a

0.5a

0.5a

0.4a

FarmB

1

0.9a 1.Oa

2

1.6a

3

2.la

4

l.1a

5

0.8a

0.5a

FarmC

1

0.7a 1.5a

2

09b

l.8a

3

1.7a

4

0.4a 0.9a

5

0,4a

0.2a

1Means are theaverage ofnine inside and

three outside samples at each depth for farms

A, B,

andC.

a,bMeans within a row and farm with no common superscript differ significantly

(P

<

.0

5).

19

a)

(UO~ZE

~

Lr~

U

4-I

4-

a)

0

Co

0

V

‘I-I

Cu

C.)

II-

0)

U,

L.

o

II-

•0

0.

C.)

U,

1~

0

U,

0

E

E

0

C.)

0

4-’

0.

0

•0

C.)

Cu

0

4-’

U,

Cu

0

.0

00

I~L~

~cu

~U)

-ecu

Cu0

0

00

—

.

o~E

U)

000

4-14-I

~

Cu

0.0

~00

~.E~u

2

(U,

0Cu0

<N

Back to top

CU4-

L.O

(N0

L.

CU

0

-o

4-1

0

0

+

YE.

Back to top

0

0

00

00

0

0

00

0

0

If,0

If,

(N (N

‘-

t-

0

I-

If,

U

41

4-

a)

0

7

Co

(N

26’a

0

V

•1~

Cu

C.)

0)

U,

1~

a)

SI

II-

‘I-,

0.

C.)

U,

I-

a)

0.

U,

0

E

E

0

C.)

0

.6-I

a’-’

0.

a)

SO

C.)

Cu

a)

U,

Cu

a)

00

4-0

•CU

00

41

CU

Em

~CU

CU0

•

0O~

~CU0.

CU0CU

U)

0CU2

(U,

oo

2cU,~

OCU

LIU)

~

U—

LLCU(N

0

‘I-I

0

0

a)

41

0

•—

z

0

0 0

0

0

0

0 0

0

(N

YE

0

v

4-1

0

0

+

00

C0(D

C,,

o

o

0~

If)

U

‘I-I

‘I

-

4-I

a)

0

Co

(N

I0

0

V

4-’

Cu

C.)

0)

U,

L.

a)

SO

0.

C.)

U,

a)

0.

U,

0

E

E

0

C.)

0

4-’

45~

0.

a)

SO

C.)

Cu

a)

U,

Cu

a)

00

4-0

0CU

%LE

0

U)>

~CU

00

0.4-’

U)

0

L.

0CU

4-

0

“-1

4-1(U)

CUO

4-1

OCU

00.

oO

CU~

CU

~jU)

L.

0)~

S —

—

U-CU

u5

0

0.

E

CU

U)

0

“-1

0

0

CU

0

U)

S—

I~m

(N

Back to top

000

000

Back to top

q~.(N

‘- ‘- ‘-

Back to top

Cu

0

I-

—

—

‘-~

~

~

~0 c~

c~

I1-~

It) It)

It) It)

c~

c~ c~

c~

—

~t

~n

~

~

Li

-~

c~

00

~

00

~

Cl 00

~C ~O ~t

c~

—

0

‘~O

N

~

00

N

N

00

—

—

c~

—

Cl

.-

Cl

~

~r

0

0

0

0

0

-e

0

0

0

-o

0

0

-0

0

C.)

0

0

0

0

0

0

0

-0

0

0

0

0

0

0

-0

0

00

S

0

0

0

1-4

.4-i

0

0

0

0

1=

0

00

C.’

0

A~

0

it)

—

V

Qo

-oH

~

0

C.’)

0

0

—

ri)

CI) CI)

Ii

o

~

0

0

0

.5

~

.~ -~

~

c-I

~.

C~

-e

o

~

0

1~

0

0

~

~zi- C~

0

0

0

c,~

c~

C~

41-i

‘fl

•1-I

—

—

~—

—

r--

—

00

~

CO

CO

CO

—

—

—

0~

Cl

i—

~

~

r—

Li

CO

CO

Cl

m

N

—

—

~-4

z

x

i.0

~0

—

—

~-

00

—

,--4

—

CO CO

CO

N

00

~O

o

o

—

—

—

Q~

Lt)

~r)

It)

Cr) Cr)

Cr)

~—

—

I

I

—

CO

CO

CO

m

00

0

—

— —

z

It)

~r) ~

Cl Cl

—c-c

CO

CO

CO

N

kO

~

0

~

—

—

—

O~

Cr)

Cl

0

0~

it)

It)

—

~

Cr)

t~~-

—

I

I

—

0

.4-’

0

0

CI)

0

0

-0

CI)

,

N

0

0

CI)

‘- -,

0

0

I-

0

-0

CI)

I-

0

.4-’

0

0

0

1-4

0

CI)

0

0

-0

00

4-i

0

0

0

-0

C’)

0

0

0

0

0

0

4~I

0

I-

CI)

0

0

00

0

1-4

0

0

4-

0

4-

0

-0

0

0

C--

00

4-

0

,.-~

-~

It)

4-

0

CI)

-~

0

S

•S

I~

I-

0

0

0

•~

—

0

~)

00

0

00

-0

~

0

0

0

0

•~ •~

00

C.

—-0

0

c~

•-~

0

C~

1-~

00

0

~

-~

0

OLi

Cr)

~

I

I

—

~

—

It)

0

0

00

0

4-i

0

0

4-i

0

0

4-I

0

0

0

0

00

0

C

4-

0

0

0

bfl

1~4

0

H

0

,—~

~

Cl

;-

-0

0

~

-0

~

.4-i

4-1

0

C—

.4~I

~

-0

•~

0

CI)

00

—

0

00

1-4

0

0

5—

c~

0

00

~

0

0

•=

o

00

0

0

00

~

0

0

—

-~

00

4-i

0

4~I

0

0

4-

0

0

j

TABLE 10. Average Permeability of Soils at EachDepth for BothLocations for all Farms’

Depth

Location

Inside

Outside

(in)

1-3 “

2.07x iO~6a

(cmlsec)

6.31 x

5-7”

1.51x10

6a

5.57x104b

9-11”

7.40x iO~6a

139

10-5a

1Mean permeability values are the average ofnine inside

and six outside samples for each

depth for all three

farms averaged together.

For each individual value that makes up the

average value coresamples were flushed withwater three times, and the average permeability

value was calculated. Two coresamples were lost inthe laboratory analysis: 1) farm A, 9-11”

depth, inside; and 2) farmB, 5-7” depth, outside.

Statistical analysis wascomputed on the log

ofthe permeability values then transformed back to the original values.

a,bMeans within arow withno common superscript differ

significantly

(P

<

.05).

25