IREC~llVED

CLERK’S OFFICE

BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

IN THE MATTER OF:

)

PROPOSED NEW

35111.

ADM. CODE 217, SUBPART U,

NOx CONTROL AND TRADING PROGRAM FOR

SPECIFIED Nox GENERATING UNITS, SUBPART X,

VOLUNTARY Nox EMISSIONS

REDUCTION PROGRAM,

AND AMENDMENTS TO 35111. ADM CODE 211

)

)

)

)

)

)

JI\N

1

1

2001

STATE OF ILLINOIS

Pollution Control Board

RO 1-17

(Rulemaking-

Air)

NOTICE OF FILING

TO:

Ms. Dorothy M. Gunn

Clerk of the Board

Illinois Pollution Control Board

James R. Thompson Center

100 West Randolph Street

Suite

11-500

Chicago, IL

60601

(VIA Certified U.S. MAIL)

Bobb A. Beauchamp, Esq

Hearing Officer

Illinois Pollution Control Board

James R. Thompson Center

100 West Randolph Street

Suite

11-500

Chicago, IL

60601

(VIA FAX)

PLEASE TAKE NOTICE that I have filed today with the Office of the Illinois Pollution

Control Board comments on behalfof the University of Illinois, a copy of which is herewith

served upon

you.

Respectfully submitted,

OFFICE FOR PLANNING AND BUDGETING

UNIVERSITY 0

ILLI

IS

By:

yle D.

Wachtel, P.E.

Dated:

January

8, 2001

Lyle D. Wachtel, P.E.

Director, Office for Planning and Budgeting

338 Henry Administration Building

506 South Wright Street

Urbana, IL 61801

(217) 333-0375

~TTV~T~~VV

The University, in

support of seeking relief to

the continuous emissions

requirements of the current NOx SIP Call, offers the following comments

to the Board•

for their thoughtful consideration.

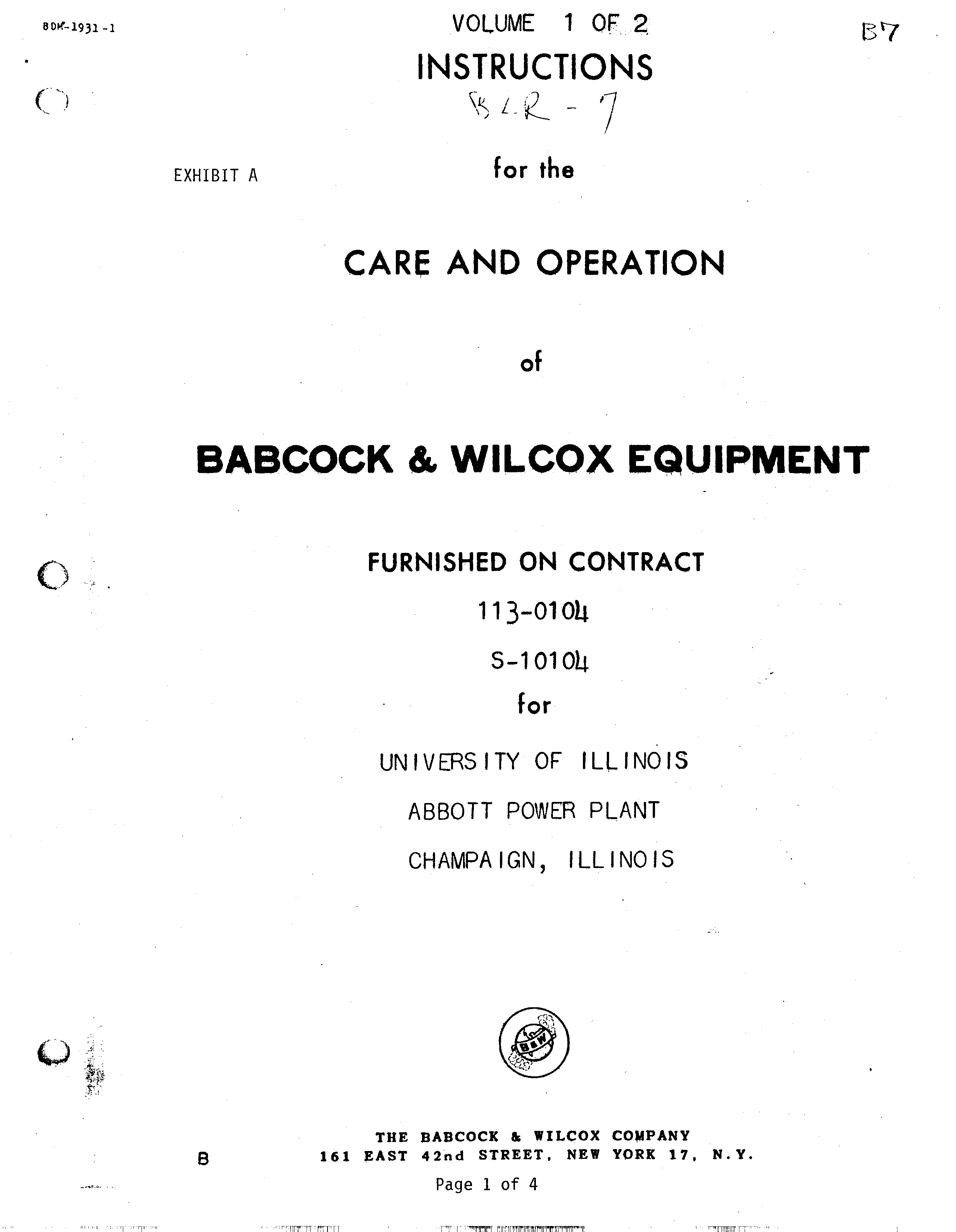

In September

1961, The Babcock and Wilcox Company (B & W), a manufacturer

of stoker boilers, responded to a bid solicited by

the Board of Trustees ofthe University

of Illinois.

This proposal was to furnish a 150 Mlb/Hr coal fired steam boiler for the

Urbana campus of the University of Illinois.

B & W also provided as an alternate bid, a

200 Mlb/Hr coal fired steam boiler.

These ratings were based on continuous operation.

The University selected the larger alternate and the boiler was installed at the

Abbott power plant in

1962.

As part of the installation, an owner’s manual that

documented the boilers specifications was provided.

Four pages of this manual have

been copied and are attached for reference as Exhibit A.

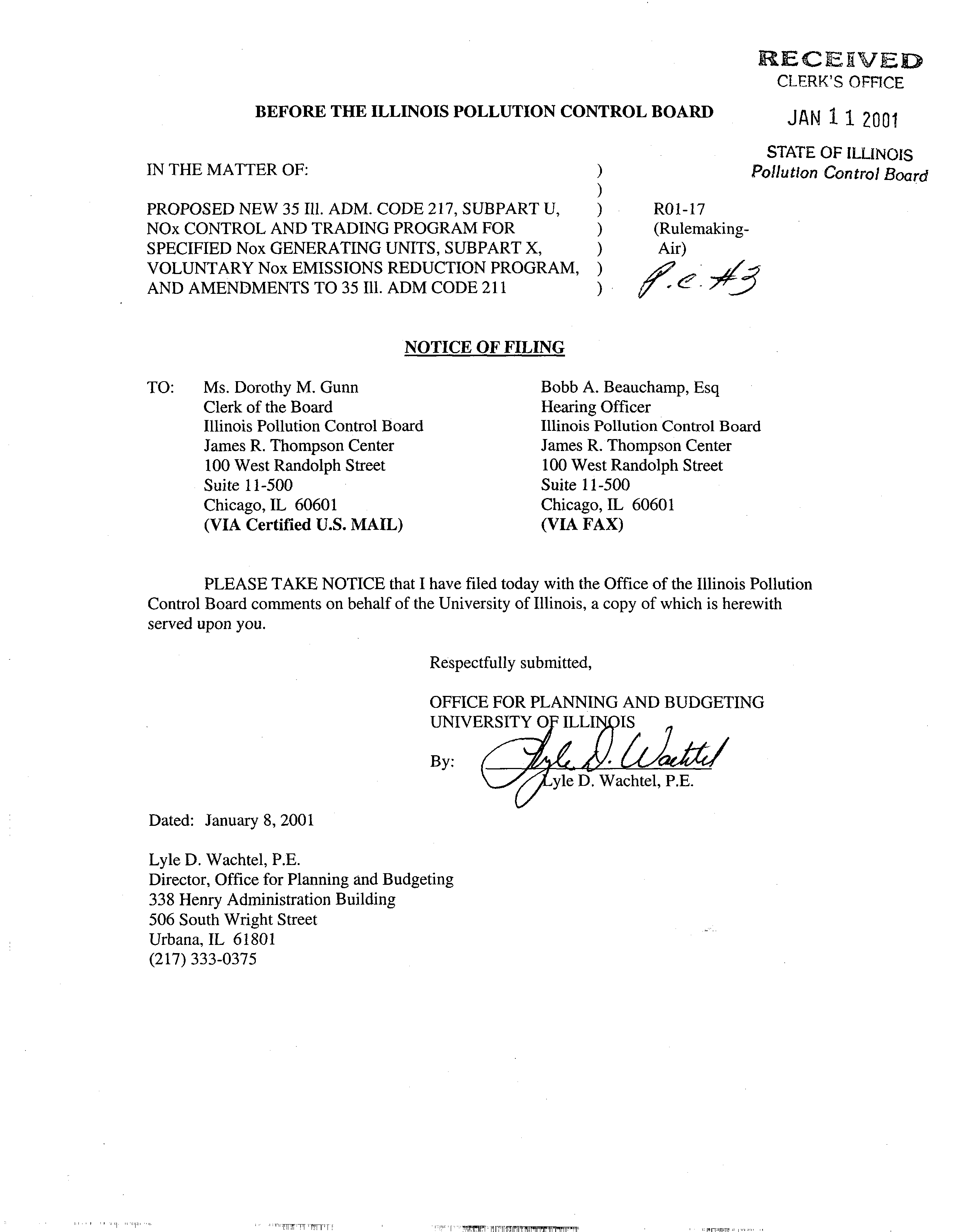

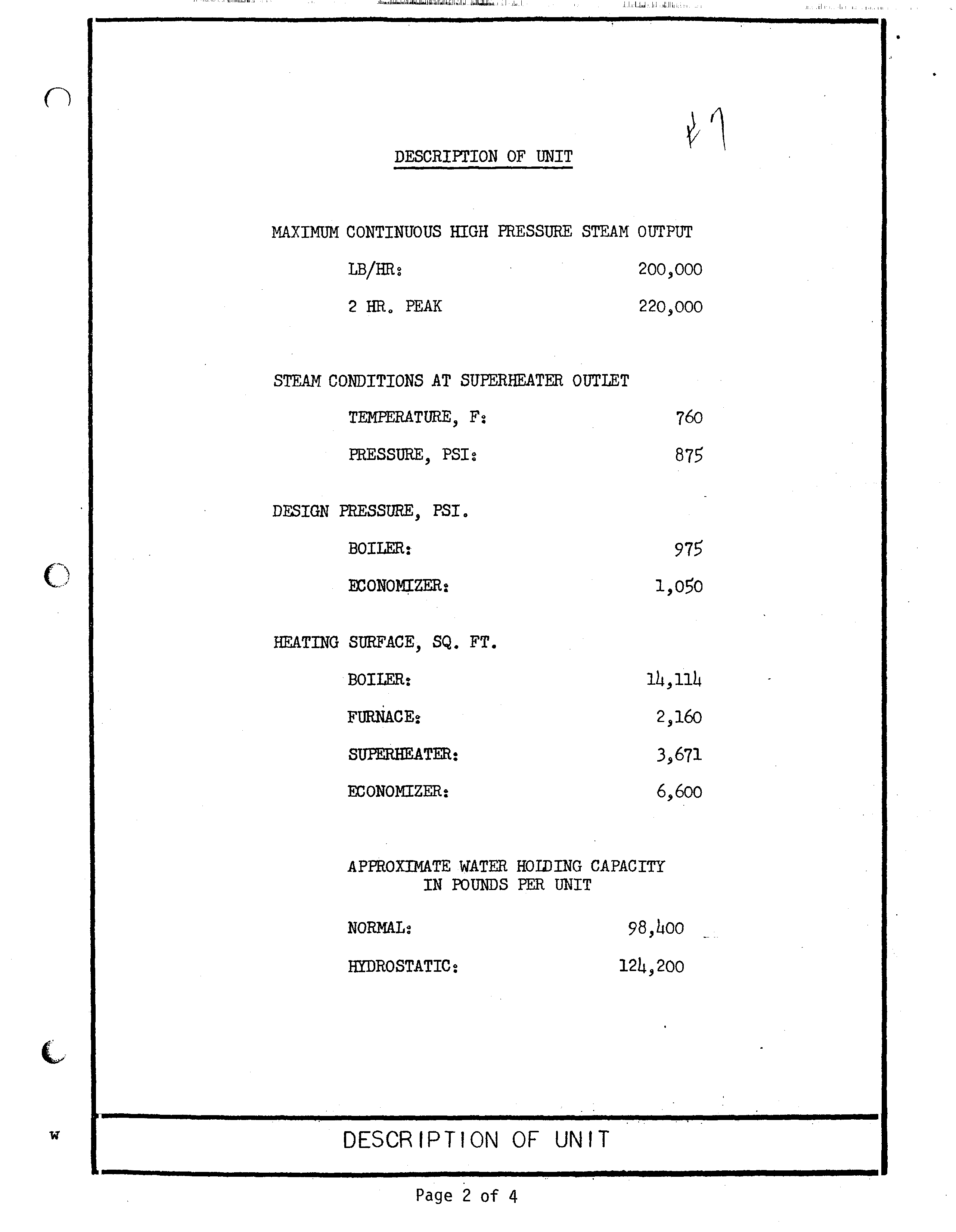

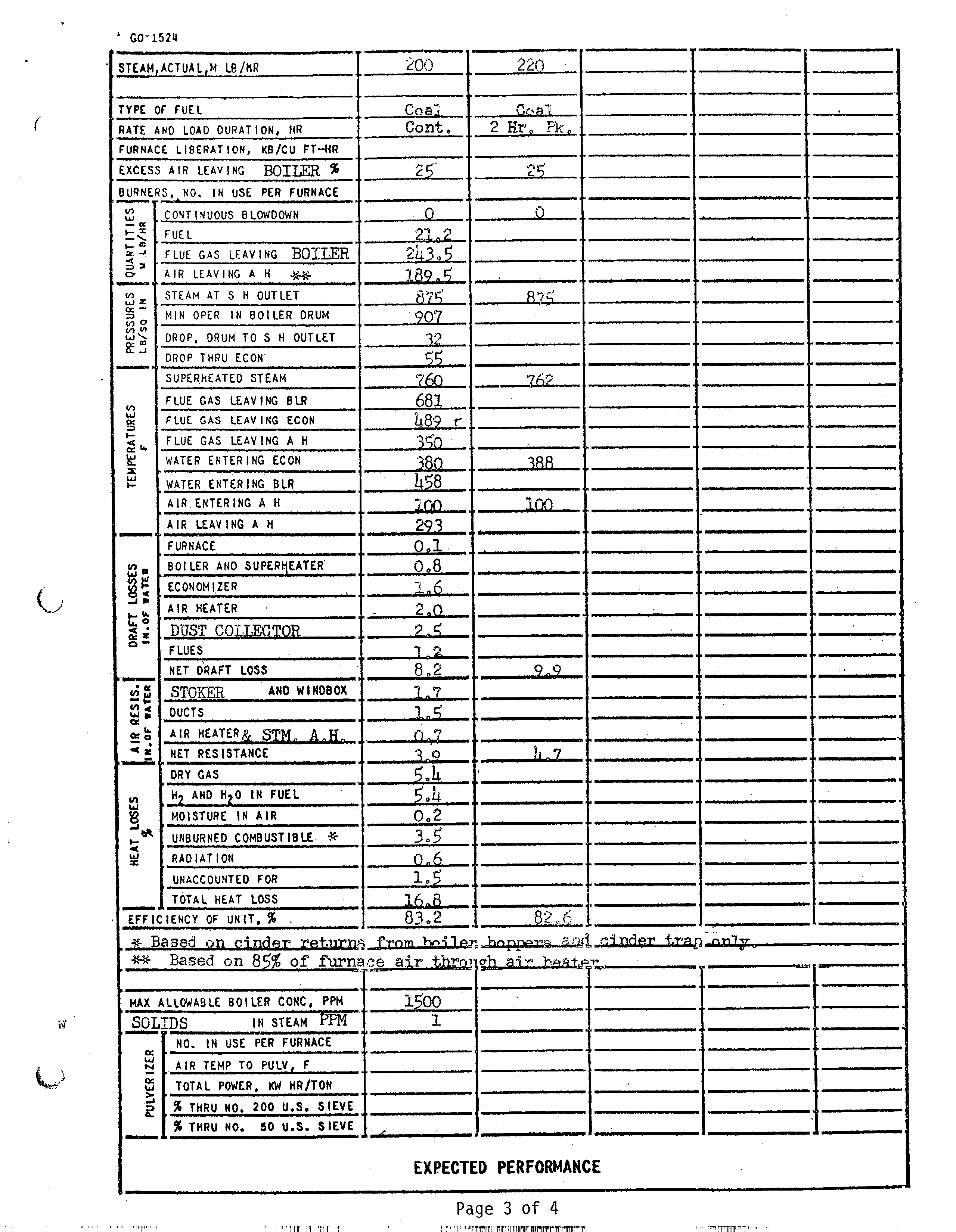

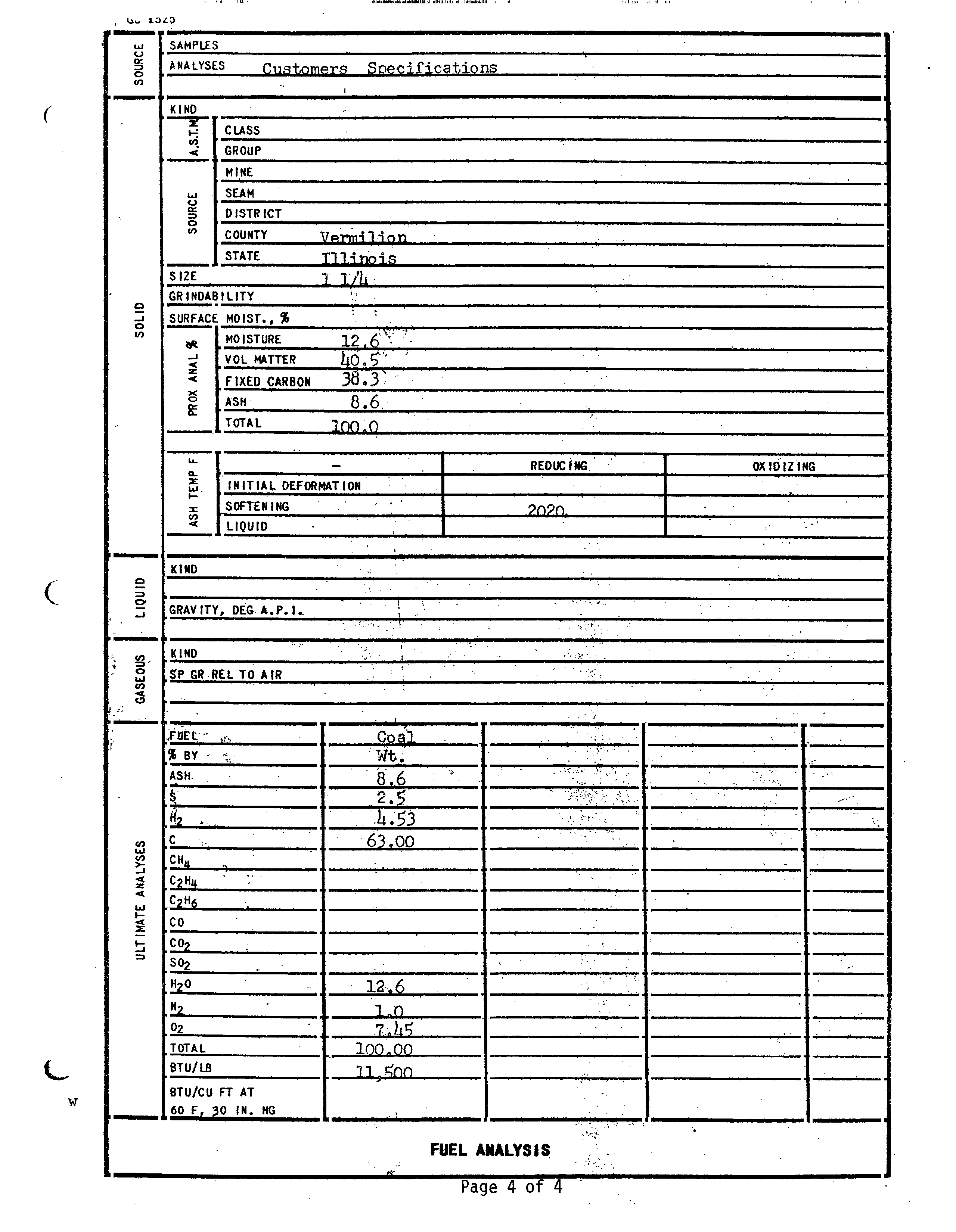

On page two of Exhibit A, two ratings are referenced forthe boiler operation:

a

two hour maximum peak rating of220 Mlb/Hr and a continuous rating of 200 MlbJLIr.

Using the continuous rating, the rating that the boiler was designed to operate over the

long term, the specifications indicate that a fuel quantity of 21,200 lbs of coal/hour

(Exhibit A, page 3, line 9) was the maximum rate of fuel input.

Furthermore, based on

the coal available from a mine in Vermillion County, Illinois, with a heat content of

11,500 BTU/lb (Exhibit A, page 4,

line

50),

the total heatinput of the boiler was designed

for 243.8 million BTU/Hr (21,200 lb/Hr X

11,500 BTU/lb).

This heat input is less than

the

250

million BTU required for inventory classification under the current NOx SIP

Call.

The Title V permit submitted to the Agency by the University was in error by

including the peak rating of the boiler as a nameplate

operation and not the continuous

rating as provided in the specifications.

If the Agency desires,

the University will submit

corrected documents reflecting this oversight to better reflect the true continuous heat

input of boiler #7.

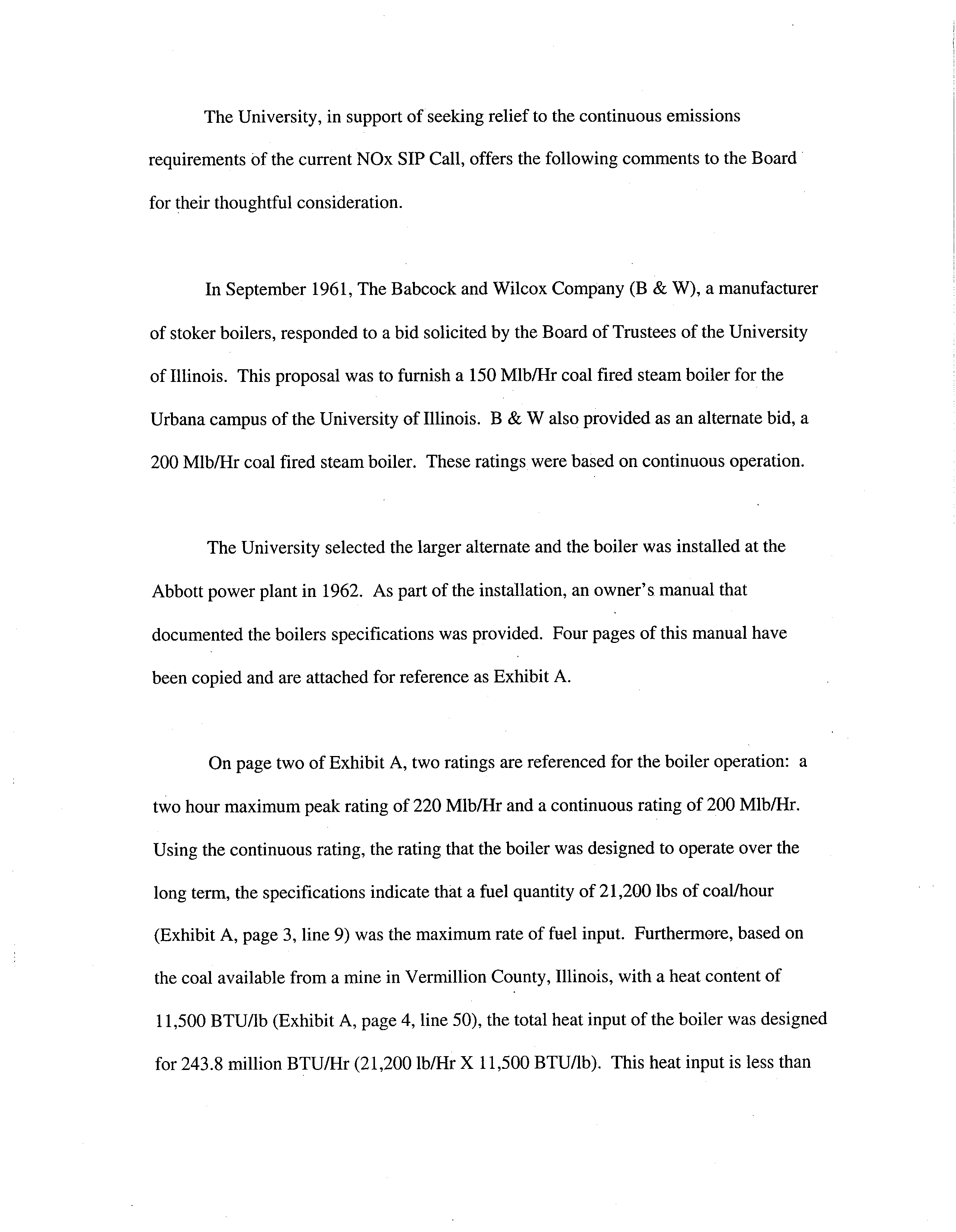

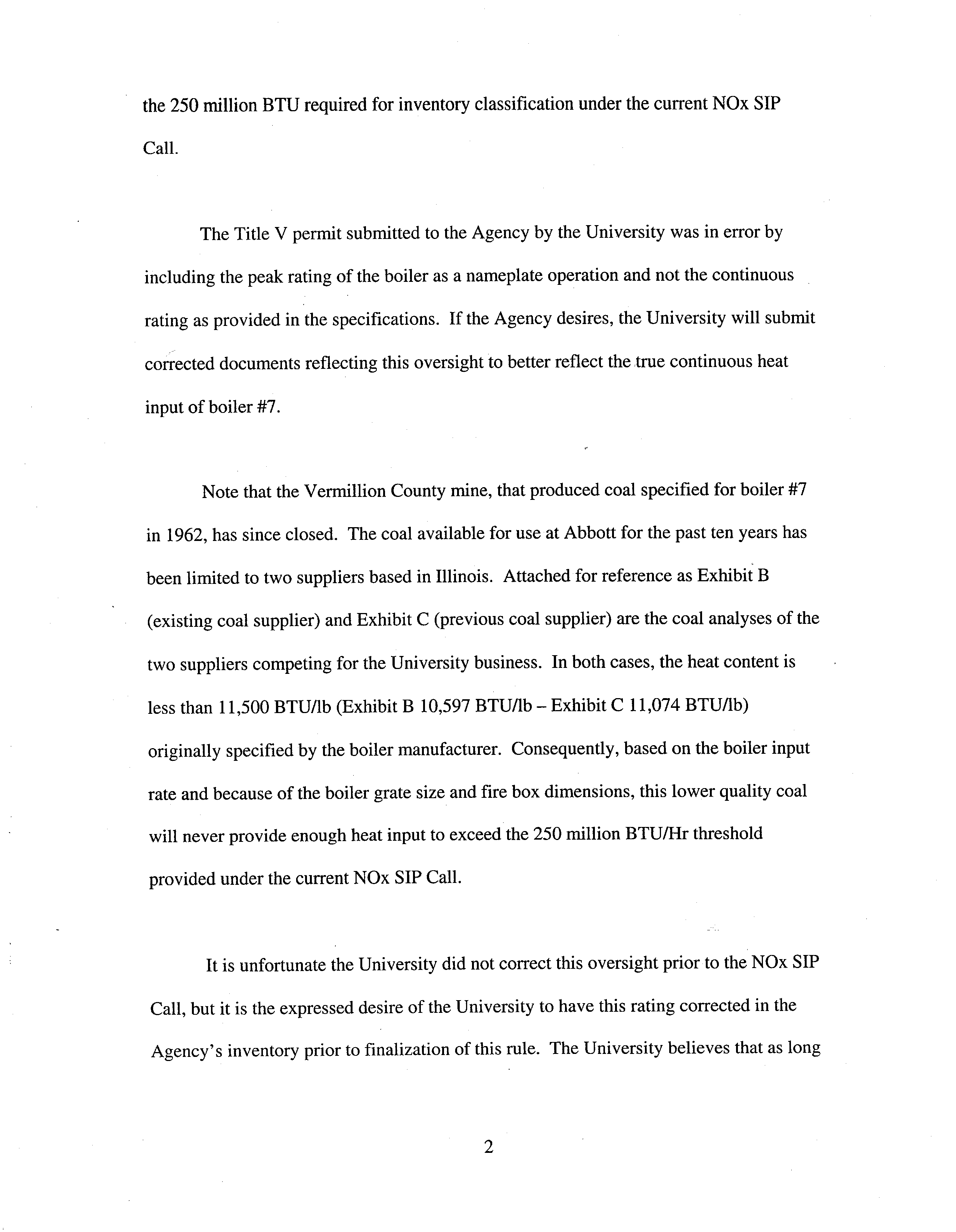

Note that the Vermillion County mine,

that produced coal specified for boiler #7

in

1962, has since closed.

The coal available for use at Abbott for the past ten years has

been limited

to two suppliers

based in Illinois.

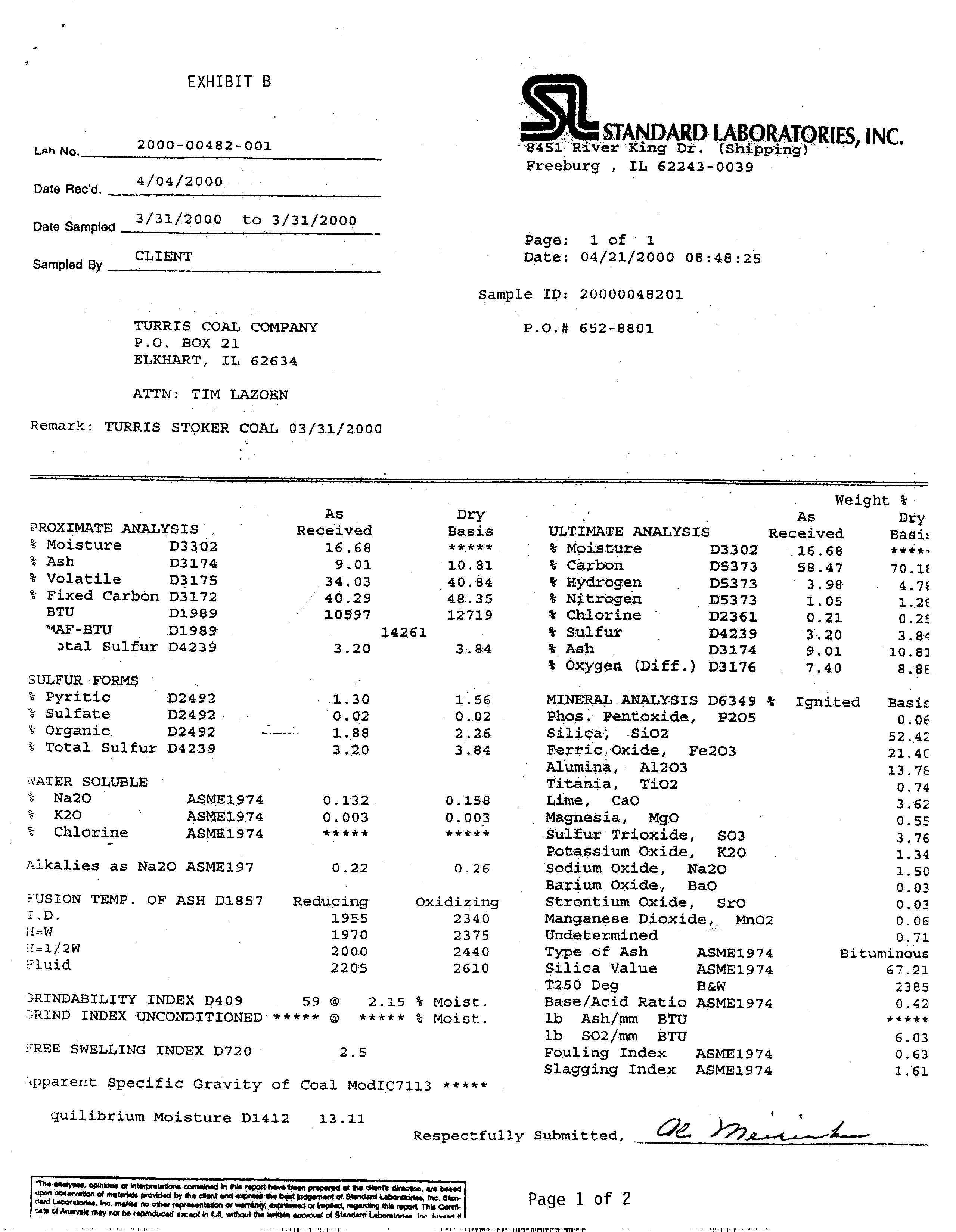

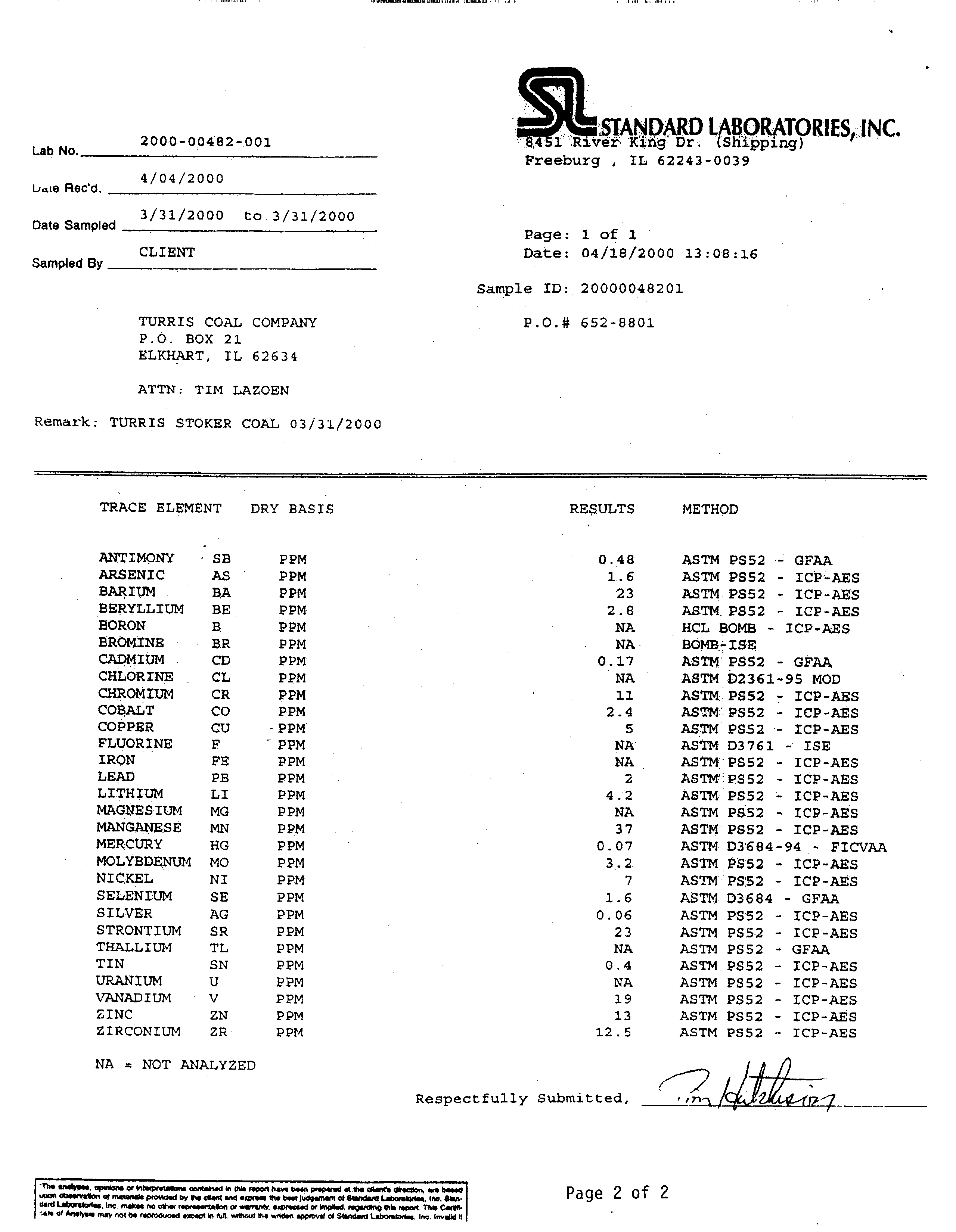

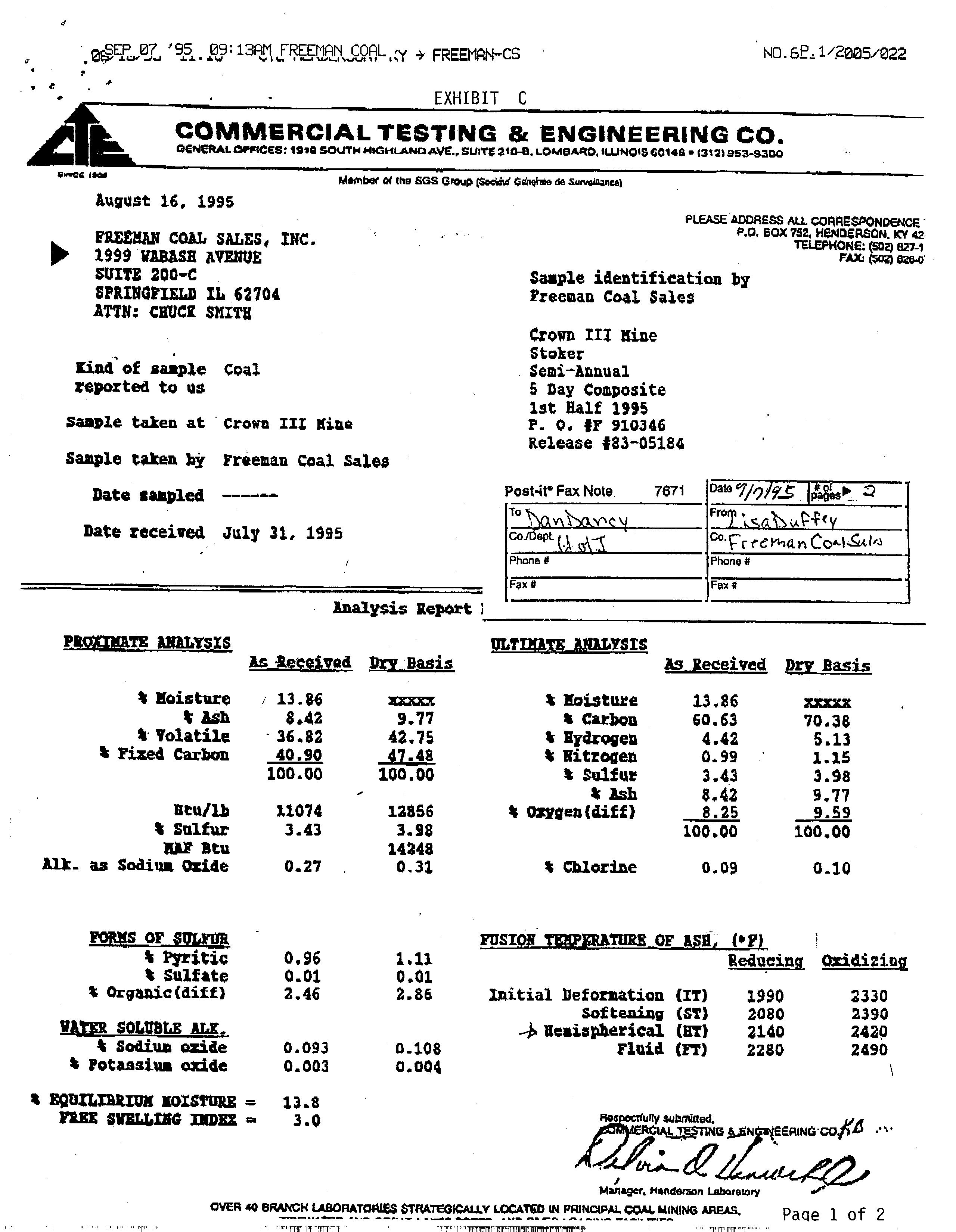

Attached for reference as Exhibit B

(existing coal supplier) and Exhibit C (previous coal supplier) are the coal analyses of the

two suppliers competing for the University business.

In both cases,

the heat content is

less than

11,500

BTU/lb (Exhibit B

10,597 BTU/lb

—

Exhibit C

11,074

BTU/1b)

originally specified by the boiler manufacturer.

Consequently,

based on the boiler input

rate and because of the boiler grate size and fire box dimensions, this lower quality coal

will never provide enough heat input to exceed the 250 million BTU/Jlr threshold

provided under the current NOx SIP Call.

It is unfortunate the University did not correct this oversight prior to the NOx SIP

Call,

but it is the expressed desire of the University to have this rating corrected in the

Agency’s inventory prior to finalization of this rule.

The University believes that as long

2

as the NOx budget of the State

is not affected, then this adjustment could be possible

pursuant to the precedent

set and described under the rule revision found in the Federal

Register (Dec. 21,

2000, Volume

65,

Number 246).

The Board has heard testimony of

another entity requesting additions to

the inventory and this adjustment provides an

opportunity

to

accommodate this entity.

Respectfully submitted,

UNIVERSITY OF ILLINOIS

By:

Office for Planning and Budgeting

Dated: January

8, 2001

Lyle D. Wachtel, P.E.

Director, Office for Planning and Budgeting

338 Henry Administration Building

506 South Wright Street

Urbana, IL

61801

(217) 333-0375

3

VOLUME

10F2

INSTRUCTIONS

EXHIBIT

A

\s

L ~

-7

for

the

CARE

AND

OPERATION

of

BABCOCK

& WILCOX

EQUIPMENT

FURNISHED

ON

CONTRACT

113-01014

S-i 01 014

for

UNIVERSITY

OF

ILLINOIS

ABBOTT

POWER

PLANT

CHAMPAIGN,

ILLINOIS

THE BABCOCK

& WILCOX COMPANY

161

EAST

42nd

STREET,

NEW YORK

17,

N.Y.

Page

1

of

4

8OI(—19~a

-a

8

i7~~~TlI

-~

DESCRIPTION

OF

UNIT

MAXIMUM

CONTINUOUS

HIGH

PRESSURE

STEAM

OUTPUT

LB/HR:

200,000

2 HR..

PEAK

220,000

STEAM CONDITIONS AT SUPERHEATER OUTLET

TEMPERATURE,

F:

760

PRESSURE, PSI:

87~

DESIGN

PRESSURE,

PSI.

BOILER:

97~

0

ECONOMIZER:

1,O~0

HEATING SURFACE, SQ. FT.

BOILER:

1-14,1114

FURNACE:

2,160

SUPERHEATER:

3,671

ECONOMIZER:

6,600

APPROXIMATE WATER HOlDING CAPACITY

IN

POUNDS

PER

UNIT

NORMAL:

98,1400

HYDROSTATIC:

1214,200

C

w

DESCRIPTION OF UNIT

Page

2

of

4

GO152~

STEAM,ACTUAL,M LB/hR

=00

220

TYPE OF FUEL

Coe~

RATE ANO

LOAD OURAT ION, HR

Cont,

2 Kr.

Fi,

FURNACE_LIBERATION,

KB/CU FT—HR

EXCESS

AIR

LEAVING

BOILER

j.....

~

BURNERS,

NO.

IN

USE

PER

FURNACE

~

CONTINUOUS BLOWDOWN

~

—N

FUEL

-

~

-J

FLUE GAS LEAVING

BOILER

2143~

AIR LEAVING

A

H

*~.

STEAM

AT

S

H

OUTLET

~5

—

MIN

OPER

IN

BOILER

DRUM

DROP,

DRUM TO S

H OUTLET

DROP THRU ECON

SUPERHEATED STEAM

~

FLUE GAS

LEAVING BLR

681

~

FLUE GAS

LEAVING ECON

I

FLUE GAS LEAVING A

H

—

~J

WATER ENTERING ECON

~

Li

,—

WATER ENTERING BLR

h~8

AIR ENTERING A

H

~

AIR LEAVING

A

H

•

FURNACE

0,1.

BOILER

AND

SUPERIjEATER

0,8

~

ECONOMIZER

-J

AIR

HEATER

~

DUST

COLLECTOR

~

FLUES

.

NET

DRAFT

LOSS

8,2

~

STOKER

AND

WINDOOX

Lib

DUCTS

~

AIR

HEATER&

STW

~

~

NET

RESISTANCE

3,

~j

DRY

GAS

~

H2ANOH2O

IN

FUEL

~

MOISTURE

IN

AIR

0,2

~..

UNBURNED

COMBUSTIBLE

*

~

RADIATION

UNACCOUNTED

FOR

TOTAL

HEAT

LOSS

8?

(

EFFICIENCY

OF

UNIT,

83,2

* Based on cinder ~

~

~

~

*~-

Ba~sed on 8

of furn~e

a. r

r

MAX

ALLOWABLE

BOILER

CONC.

PPM

1~OO

SOLIDS

IN

STEAM

PPM

1

AIR

TEMP

TO

PULV

F

~.i

TOTAL

POWER.

KW

HR/TON

~

TIIRU

NO.

200

U.S.

SIEVE

EXPECTED

PERFORMANCE

Page

3

of

4

F’

~“I~F

WF~’~’IT

(a

~

0

(12

SAMPLES

ANALYSES

Customers

Specifications

—

—a

0

(1)

KIND

~

~

CLASS

GROUP

Li

(~2

-~

0

~“

MINE

SEAM

DISTRICT

COUNTY

V~rmi1ton

STATE

Illinois

SIZE

1

1/h

GRINDABILITY

—.

SURFACE

MOIST.,

—

~

MOISTURE

12.6

—‘

VOL

HATTER

~

FIXED

CARBON

38.3~

ASH

8.6

TOTAL

—

a

a—

(1)

~

~

REDUCING

OXIDIZING

INITIAL

DEFORMATION

SOFTENING

LIQUID

•

•

~

KIND

GRAVITY,

DEG-A.P.L

~,,

~

C0

C,

KIND

SPGR.RELTOAIR

~

~,

L.J

~2

~

I-

~

FJ3EL

Co~1

Wt.

BY~

ASH.

8.6.

C

63.00

CHu

C2Hj~

-

C2H6

CO

CO2

N2

02

TOTAL

.

100.00

BTU/LB

11

£~np

F

FUEL

ANALYSIS

8TU/CU

FT

AT

60

F,

~O

IN.

HG

Page

4

of

4

(

(

C

w

EXHIBIT B

2000-00482-001

STANDARD LABORATORIES, INC.

River

King Dr.

(Shipping)

Freeburg

,

IL

62243-0039

4/04/2000

Date

Samplo4

3/231/2000

to

3/31/2000

Page.:

lofi

Date:

04/21/2000 08:48:25

TURRIS

COAL

COMPANY

P.O.

BOX

21

ELKHART,

IL

62634

Sample

ID: 20000048201

P.O.#

652-8801

ATTN:

TIM

LAZOEN

Remark:

TURRIS

STOKER

COAL

03/31/2000

PROXIMATE

ANALYSIS

—

~s

Moisture

D3302

D3174

D317S

D3172

D1989

Dl98-9

D423~

Ash

Volatile

Fixed Carbbn

BTU

“~AF-BTU

ztal

Sulfur

SULFUR

FORMS

~

Pyritic

~ Sulfate

~ Organic.

‘~

Tot-al Sulfur

WATER

SOLUBLE

-

~

Na2O

K20

Chlorine

D249=

D2492

-

D2492

P4239

A~ME.1974

ASME1974

ASM~1974

Alkalies

as

Na2O

ASMEl97

?USION

TEMP.

OF

ASH

D1857

I .D.

H=W

B~1/2W

Fluid

As

ReCeived

16 .68

9.01

34.03

40.29

10597

3 .20

•

.1.30

0

.

02

1.88

3.20

0.132

0.003

0.22

Reducing

1955

1970

20.00

2205

Dry

Basis

* *

*.*~*

10. 81

40. 84

48.35

12719

~4~6l

3.8-4

1.56

0 .02

2

.

2.6

3

.84

0.158

0. 003

0.26

Oxidizing

2340

2375

2440

2610

3RINDABILITy

INDEX

D409

59 @

2.15

9’

Moist.

3RIND

INDEX

UNCONDITIONED

~

o

*****

Moist.

tREE

SWELLING

INDEX

D720

2.5

~pparentSpecific Gravity of Coal

M0dIC7113

~

ULTIMATE

ANALYSIS

9’ Moisture

9’ Carbon

9’ Hydrogen

‘UNit rogen

9’ Chlorine

9’ Sulfur

9’A~h

9’ Oxygen (Diff.)

D3 302

D5373

D5373

1,5373

D2361

D4239

D3 174

D3176

MINERAL ANALYSIS D6349

Phos.

Pentoxide,

P205

Silica,

•5i02

Ferric

Oxide,

Fe2O3

Alumina,

A1203

Titania,

TiO2

L(ime,

CaO

Magnesia,

MgO

Sul~u~

Trioxide,

S03

Potassium Oxide,

K20

Sodium Oxide,

Na2O

Barium Oxide,

BaO

Strontium

Oxide,

SrO

As

Received

16.68

58.47

-

3.98-

1.05

0.21

3.20

9.01

-

7.40

*

Ignited

Manganese

Dioxide,

MnO2

Undetermined

Type -of Ash

A5ME1974

Silica Value

ASME1974

T250

Deg

B&W

Base/Acid Ratio

A5ME1974

lb

Ash/mm

BTU

lb

502/mm

BTU

Fouling Index

ASMEl974

Slagging

Index

A2ME1974

Weight

9’

Dry

Basis

7O.l~

4.

0.2E

3

.

10.82

8,

BE

BasiE

O

.

GE

52.42

21 .4C-

13 .76

0

.

74

3.62

0.55

3

.

76

1.34

1.50

0.03

0.03

O

-

06

0.71

Bituminous

~7.21

2385

0.42

6.03

0.63

1.61

guilibrium Moisture

D1412

13.11

Respectfully

Submitted,

Page

1 of 2

LAh

No.

Date

Rec’d.

Sampled

By

CLIENT

Th

fld~...

091,lIOflg

‘oqv.I.too.

oorn.Med Meg.,.po,t hay. be.,, prepw.d ~ V.. d~mnI~ dfrscIo,,. a,.

I

‘~

~~6on

~

~‘..di.

mo.ld.d

M’

V..

dm,tw.d

.~.me.

U.

by.4

g~w,~Iof S~ngud ~

~c

o~1...

~

2000--00462-oo1

~

LABORATORIES, INC.

Dr.

Shipping)

Freeburg

,

IL 62243-0039

4/04/2000

3/31/2000

to

3/31/2000

Page:

1

of

1

Date:

04/18/2000

13:08:16

CLIENT

Sample

ID:

20000048201

TURRIS COAL COMPANY

P.O.

BOX 21

ELKHART,

IL 62634

P.O.#

652-8801

ATTN;

TIM LAZOEN

Remark:

TURRIS STOKER COAL 03/31/2000

TRACE ELEMENT

DRY BASIS

RESULTS

ANTIMONY

ARSENIC

BARIUM

BERYLLIUM

BORON

BROMINE

CADMIUM

CHLORINE

CHROMIUM

COBALT

COPPER

FLUORINE

IRON

LEAD

LITHIUM

MAGNESIUM

MAGNESE

MERCtJ1~Y

MOLYBDENUM

NICKEL

SELENIUM

SILVER

STRONTIUM

THALLIUM

TIN

T.JRANIUM

VANAJJIUN

~ INC

ZIRCONIUM

SB

AS

BA

BE

B

BR

CD

CL

CR

CO

CU

F

FE

PB

LI

MG

MN

HG

MO

NI

PPM

PPM

PPM

PPM

PPM

PPM

PPM

PPM

PPM

PPM

-

PPM

PPM

PPM

PPM

PPM

PPM

PPM

PPM

PPM

PPM

0.48

1.6

-23

2.8

NA

NA

0.17

NA

11

2.4

5

NA

NA

2

4.2

NA

37

0.07

3.. 2

7

SE

PPM

AG

PPM

SR

PPM

TL

PPM

SN

PPM

U

PPM

V

PPM

ZN

PPM

ZR

PPM

1.6

0.06

23

NA

0.4

NA

19

13

12.

5

AETH

PS52

-

GFAA

ASTM P552

-

ICP-AES

ASTM PSS2

-

ICP-AES

ASTM PSS2

-

ICP-AES

HCL

BOMB

-

ICP-AES

BOMB-. ISE

ASTM PSS2

-

GFAA

ASTM

D2361-95

MOD

ASTM

PS52

-

ICP-AES

ASTM

P552

-

ICP-AES

ASTM PS52

-

ICP-AES

ASTM D3761

-

ISE

ASTM

P552

-

ICP-AES

ASTM

PS52

-

ICP-AES

ASTM

P552

-

ICP-AES

ASTM

PSS2

-

ICP-AES

ASTM

P552

-

ICP-AES

ASTM

D3684-94

-

FICVAA

ASTM P552

-

ICP-AES

ASTM PSS2

-

ICP-AES

ASTM

ASTM

ASTM

ASTM

ASTM

ASTM

ASTM

ASTM

ASTM

D3684

P552

P55-2

PS52

PSS2

PS52

PSS2

PS52

PS52

-

GFAA

-

ICP-AES

-

ICP-AES

-

GFA.A

-

ICP—AES

-

ICP-AES

-

ICP-AES

-

ICP-AES

-

ICP-AES

NA

NOT ANALYZED

Respectfully Submitted,

Lab No.

L,.ice

Recd.

Data

Sampled

Sampled

By

METHOD

Th. .n*u.s.

sp.neg.,

0

~eqq,rs~ass.w

osiofaSiad

~i

eve

,wwt

14w beal

9m9.r.d of 5,. d~.

~

SW

basedI

Asifl

SWVSIOn

of

~ASqUAs

PwAdd

by 5U

SUetai,d

•5ofu

ViaUe,

judgaYlaill ofSundaet

L.huuU,4.s.ISV

Viss.

I

Said

L~ab4a

lYlS

.‘iskSS

SO

,,d.si

~se.ta4..,

0

W,snty

a4ifwaad

0

impbd

i.gatdlng

Sib ispaut This

C.,W.

I

~4h

Si

Aflofpas

may

not

be

,ao~oou,sd ~0

V. Sd

ndVioof Si.

isSUe

•ppmM

ofSteodasi Labv~5~i,.s

Sio

innsvv

II

Page 2 of

2

95

09:

FREEMRN

13flM

,

•

FREEMAN—CS

NO. 6E.~1/.2~5/022

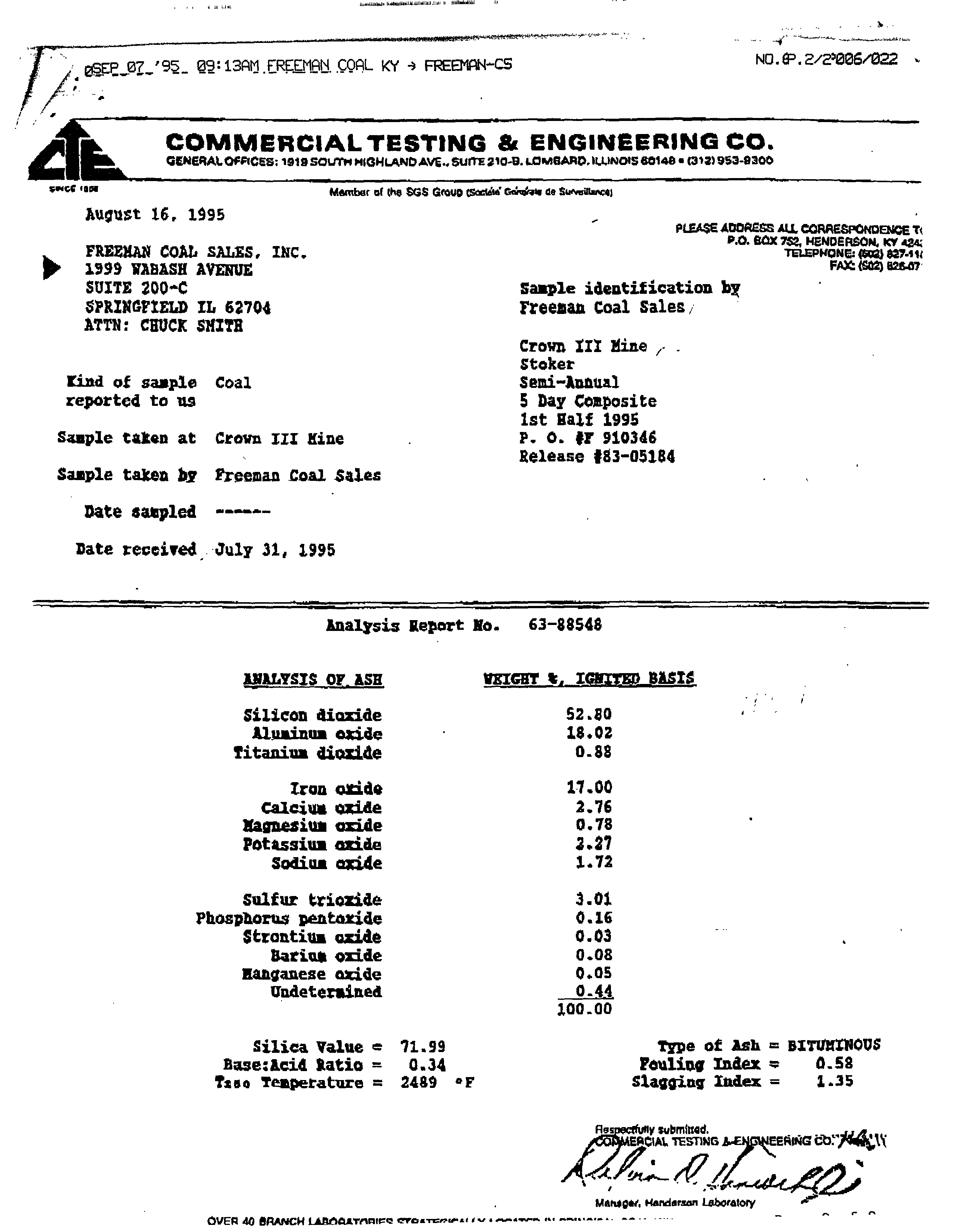

EXHIBIT

C

COMMURCIAL TESTING

&

~NGIN2ERING

CO.

•EPdERALOWICgS:as’s scum

IGHLANOAVE..SUITU

;io-n.

LOM6Ai~O. ILUNOIS60148

•

I3~OO

Member ol

thu 869

Group ($oddW Q4~tuJe de

Sur~iI~ncs)

PLEASE

ADDRESS AU.

QQE~PONoewE

P.O.

BOX752,

HENDeRSON.

ICY 42.

TEI-EPHONG:

(so~

827-1

FAX:

(~o~ eae~’

Sample

identification

by,

Freeman

CcaL

Sa1e~

Crown

III

line

Stoker

Semi—Annual

S

Day

Coaposite

lit

Half

1995

P.

0.

IF

910346

Release

#83—05184

Date

SaMpled

Date received

July

31,

1995

3.nalysi~

RepOrt

I

PosF4t Fax Note

7871

Oate7/47/~

I4Sbs’~

~

FrOT ~

~

Phona#

‘Phono#

F~xE

As

ie~Gj1~@d

Dry

Basis

1JLTINET~JUOLY8IS

As

Rec~ei¶ied

J~yI Basis

Moisture

~

Ash

~

Volatile

~

Fixed

Carbon

Den/lb

~ Sulfur

I~.F

Itu

Ilk,

as

Sodiu

Ozide

13.86

S

~42

-

36.82

40.90

100.00

11074

3

a

43

0.27

9.77

42.75

A7.48

100.00

12856

3.98

l4~43

0.32.

N.o~.sture

b

Carbon

~Iy4roge~a

~

Iit!OgB~1

t

~

Ash

~ Ozygea(diff)

~

chlorine

Pyritic

~

Sulfate

~.0r~anic

(dill)

VM’ER

SOLUaLE

ALL

Sodium

oxide

Fotassium

o~cidc

0.96

0.01

2.46

0. 093

0.003

1.11

o

.01

2.86

0.1.08

o

a

004

FUSIQ*I

TE~~RATEJRE

OF

A$U~

(•?)

Softeaing

(ST)

4

Ueai5pherical

(RY)

Fluid

(FY)

Redueing

Ozidizing

1990

2080

21.40

2280

2330

2390

~4ZP

2490

EgtIzTjuiux

KOIS1!~JRE

—

nil

SWELLING

DWEI

—

13.8

30

riq~oc~ufly

aj~mZtwd.

I/A

~

~

Si

#I.f

a~1~42.,

Manager.

Mendet~an

aha:~tory

A

Si—eSi i~

Aug’z~t

16,

1995

FaEZNAN

COAL

SALES ~ INC.

1999

V1B~SB

AVENUE

SUITE

200—C

SPRINGFIELD

IL

62704

ATYN:

CHUCK

S)ZITH

KiM

of

Sample

Coal

reported

to

us

Sample

taken at

Crown

III

Kina

Sample

taken

b~.g

Freeman

Coal

Sales

PRVCZM&TK

&NUYSIS

13.86

60.63

4.42

0..99

3.43

8•42

8.25

100.00

0.09

70.38

5.13

1.15

3.98

9.77

9.59

100.00

0-10

OVER

40SMNOH L4SOHATOI~$STRA

GICALLY LOCATEC IN

PPJNCAPAL ~AL

MINING ARSAS.

F

FFTT’TI

‘~‘F’’,

Pacie

1 of

2

NOA~.2/e~0~S/e22

09:

i3r4M FREEMRN COflL KY ~ Fi~8i~N~’-CS

I

p

COMMERCiAL TESTING

&

ENGINEERING CO.

GENERALO~FWC~S;

1913

SOUTh I4IGHLANbAVE.. SUITh

310-U.

LOMBARD.~WNOIS60140

a

(313)953-9300

—U—

;w~rA

~muw

M4mbuc

al t~’e EQS

Orogo

S~t~t~

Gah~,wI.

Ge

S’aNuEa.~4l

FRE~MAZ~

COA?j

SALES,

IE.

1999

WABASH

AVENIJI

SUITE

200-C

$flINOflELD

IL

62704

hTTN:

CHUCK

SUTh

Kind

o~

sample

reportc4 to us

Coal

Sample taken at

Cro’Ini 111 Mine

Sample taken

bii

Fr~enan

Coal Sales

PLEA$EAD0P.~SB

ALL C ~RE8PONDEIJCE

T4

P.O.

BOX 752, HENDERSON,

ICY 424~

TELEPI~QN~

~)

S27.It~

FA~

1S02) 825.87

Sample identification b~

fteeaan

Coal

Salea,

Crovn

XIZ

Hine

,•

Stoker

Semi—Annual

5

Day Composite

1st Half 1995

P. 0.

#1 910346

Release #83—05184

Date

6a~pled

Date

received

July

.31k

1995

ANALYSIS OF.. ASH

UWTE!U~

~,

T~!MTYET1

U~Y~

Silicon

dioxide

Aluminum

awie

Titanium diozide

Iran

a~ciua

Nagnesiua

Potassium

Sodium

oxide

arid.

azide

oxiAe

Sulfur ~iozi4e

Phospborii.~ peatoride

Zfzrantium oziae

Iah~aneBe ozide

~IndeteR~aiae&

Silica Value

e

Ease:Lcid latic

50

Temperature

=

71

99

0.34

2489

•F

Type of Ash

roul±~qIndex

SU~qing Index

=

DITIhrINQU$

~

0.59

=

1.35

Fj~p~cI~Ifly

ubmbuid.

.~..jj

a..

A0O1~AE~.CIAL

TEST)NS J..E~2ftiNG

~b.~P~I~VX\

MAIi*Qd’,

4a?gdfflzall

Lo~oeat

OVER

40

SPANcH LAO

)eA’rn~tI~

FOa.’I~~E

d

—

.~.

-

-

Analysis

Report

NOa

63—88548

S2

.80

18 •02

0-88

17.00

2.76

0.78

3.27

3.

a72

3.03.

0.16

0.03

0.08

0

•

05

0~44

~ao..oo