©~II~~AL

BEFORE THE

ILLINOIS POLLUTION CONTROL BOARD

RECEIVED

CLERcS

OF~1’E

APR

2

4

2001

STATE OF

ILLINOIS

Pollution

Con

tról

BoOr(1

IN THE MATTER

OF:

AMENDMENTS

TO LIVESTOCK

WASTE REGULATIONS

(35

ILL.

ADM. CODE 506)

)

)

)

)

R01-28

)

(Rulemaking-Land)

)

NOTICE OF

FILING

Dorothy M.

Gunn, Clerk

flhnois Pollution Control Board

James R. ThompsonCenter

100 West Randolph Street, Suite.

11-500

Chicago, Illinois 60601

Carol Sudman,

Hearing Officer

Illinois Pollution Control Board

600 South Sixth Street,

Suite

402

Springfield, Illinois 62704

AND TEE ATTACHED SERVICE LIST

(Via U.

S. Mail)

PLEASE

TAKE

NOTICE

that I have today filed

with

the

Office of the Clerk of the

Pollution Control

Board the Appearance of the Illinois Environmental Protection Agency, a Motion to fileTestimony and the

TestimonyofDaniel L. Heacock, a copy of which is herewith served upon you.

DATED: April

23, 2001

Illinois Environmental ProtectionAgency

1021 North Grand Avenue East

Post Office Box 19276

Springfield, Illinois

62794-9276

(217) 782-5544

ENVIRONMENTAL PROTECTION AGENCY

OF

THE

STATE OF ILLINOIS

By:

Connie L. Tonsor

Associate Counsel

Division of Legal Counsel

THIS

FILING

IS

SUBMITTED ON

RECYCLED

PAPER

,,,,,,~“

~

,~

-

-

RECEIVED

CLERK’S

OFFICE

BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

APR

2 4

2001

IN THE MATTER OF:

)

STATE

OF

ILLINOIS

Pollutjo~

Control Board

)

AMENDMENTS

TO LIVESTOCK

)

WASTE

REGULATIONS

)

R01-28

(35

ILL.

ADM.

CODE

506)

)

(Rulemaking-Land)

)

APPEARANCE

The

undersigned,

as one ofits attorneys, hereby enters her Appearance on behalfofthe

Illinois Environmental Protection Agency.

ILLINOIS

ENVIRONMENTAL

-

PROTECTION AGENCY

By:

(t~~’C74~

Connie L. Tonsor

Associate Counsel

Division ofLegal Counsel

DATED: April 23, 2001

Illinois Environmental Protection Agency

1021 North Grand Avenue East

Post Office Box 19276

Springfield, Illinois 62794-9276

(217)

782-5544

THIS FILING

IS

SUBMiTTED

ON RECYCLED PAPER

RECEIVED

CLERK’S

OFFICE

BEFORETHE

APR

2

4

2001

ILLINOIS POLLUTION CONTROL BOARD

STATE OF

ILLINOIS

Pollution

Control

Boarr

IN

THE MATTER OF:

AMENDMENTS TO LIVESTOCK

)

-

WASTE REGULATIONS

)

R01-28

(35 ILL. ADM. CODE 506)

)

(Rulemaking-Land)

MOTION TO FILE

TESTIMONY

Now

comes

the Illinois Environmental

Protection Agency (illinois EPA”) by one of its

attorneys,

Connie L. Tonsor and moves that the Illinois Pollution Control

Board (“Board”)

accept the attached

testimony of Daniel

L. Heacock in the above encaptioned matter.

1.

On January 22, 2001, the Illinois Department of Agriculture filed proposed rules concerning the

design and construction of livestock waste handling facilities.

2.

On

February 21, 2001, the Board set the matter forhearing and established dates for the pre-

filing of testimony.

3.

On

March 27, 2001, the Hearing Officer set April

30,

2001 as the second hearing date.

The order

set April

23,

2001

as the date for pre-flIed

testimony.

WHEREFORE, for the reasons set forth

above, the Illinois EPA respectfully moves that the Board

accept the attached

testimony of Daniel

L.

Heacock.

Respectfully submitted,

-

ILLINOIS

ENVIRONMENT

L

PROTECTION AGENCY

By:__________

Connie L. Tonso~

Associate Counsel

DATED:

April

23, 2001

1021

North Grand Ave.

E.

P.O. Box 19276

Springfield Illinois 62794-9276

217/782-5544

PRINTED

ON RECYCLED PAPER

1

RECEIVED

CLERK’S

(~F~

APR

24

2001

ILLINOIS POLLUTION CONTROL BOARD

STATE OF

ILLINOIS

-

Pollution Control Boar,i

IN

THE MATTER

OF:

-

)

)

AMENDMENTS TO LIVESTOCK

)

WASTE REGULATIONS

)

R0I-28

-

(35

ILL. ADM.

CODE 506)

)

(Rulemaking-Land)

-

)

TESTIMONY OF DAN HEACOCK

OUALIFICATIONS

My

name

is

Dan

Heacock. I am employed by the Illinois Environmental Protection

Agency (“Agency”) as the manager of the Facility Evaluation Unit in the Watershed Management

Section ofthe Bureau of Water. The duties

of the Facility Evaluation Unit include reviewing

NPDES applications and

providing technical assistance forthe livestock waste

management

program

administered by the Illinois

EPA. I have been employed-in-the

permit programs-of the

Bureau of Water or Division of Water Pollution Control since

1985. My experiencewith the

livestock waste

management programs of the Agency began with my employment with the

Agency. I have participated in the Livestock Management Advisory Committeemeetings during

the development of the proposed amendmentsto

Part

506

and

the Illinois Department of

Agriculture’s

Part

900 rules. I am a graduate ofthe University ofIllinois

in Agricultural

Engineering. I am a registered professional engineer in Illinois.

INTRODUCTION

The Agency participated in the developmentofthis proposal through the~Livestock

Management Advisory Committee

and

appreciates the opportunity to further that participation by

offering comments

and this testimony concerning the proposed revision of 35

Ill. Adm. Code

506.

My testimony will: (1) discuss

two

areas of substantive concern regarding the detection of

voids and construction in karst areas,

and

the installation and operation ofperimeter drainage

tubing; (2) seek clarification of one area; and

(3) address other matters

that mayrequire

clarificatioq due to typographical errors or other reasons.

REGULATORY REViEW

Section 506.103

-

The provision for species other than listed in the proposed regulation requires the

Departmentto detennine mature animal weight. Immature livestockshuuldbe included in the

calculation of animal units at a livestock management facility.

Section 506.104

The

ASAE standard for anaerobic lagoons

was

revised in December

1998

and is now

referenced

as ASAE EP 403.3

DEC98. The ASAE standard for manure

storages was revised in

December

1998

and is now referenced

as ASAE EP 393.3 DEC

9-8.

The regulations should

be

revised to referencethe most current standards for manure lagoons and manure storages.Section

I 3(b)(2) and (b)(3) of the Livestock Management Facilities Actrequires use of the updated

standards for manure storages,

Section

506.204

The

ASAE publishes

all of its standards

annually in a single volume, resulting in changes

to -the page numberingof unchanged standards, as new standards are added or modified. The

section numbers of the standards remain the same unless the standard

is revised and issued with a

new standard number. Therefore,

the Agency recommends that references to page numbers, used

in

the

regulations, be changed to section numbers of the standards to eliminate ambiguity

regarding the standard referenced.

-

Section

506.2O4(g)(3)

The ASAE EP 403.3 DEC98 “Design of AnaerobicLagoons for Animal

Waste

Management” clarifies the method of determining the totalvolume of the lagoon by

specifically

including runoffand precipitation generated between manure removal events. The proposed

regulations do not specifically list this runoffand precipitation as additional

volumes, although

2

the runoffand precipitation generated, which are tributary to a lagoon for a storage period of 270

days, should be accounted for in the calculation of the

amount of

waste generated in

the same

270-clay

period. The

illinois EPA- suggests that for clarity, these volumes be listed in the proposed

regulation.

We recommend that Section

506.204(g)(3)(C) be replaced with:

“Runoff and wash

down volumes generated during a 270-day period including all runoffand precipitation from lots,

roofs and other surfaces where collected precipitation is directed into the

lagoon, plus all the

washdown liquids that are directed into the lagoon. In no case shall this volume

be

less than the

precipitation and runoff

generated by a 25-year, 24-hour

storm

event

and directed to the

lagoon;

and”

Section

506.205(a)

Proposed Section

506.205(a) adds a cross-reference to Section

506.203(d) and deletes a

cross-reference to Section 506.204(d). The Agency proposes removing the deletion of Section

506.204(d). Section

506.203(d) is shown as repealed in the proposed regulations,

and

the stricken

reference, Section

506.204(d), appears to be the correct reference.

Section 506.206(a)

Proposed

Section 506.206(a) adds a cross-reference to Section

506.203(d) and deletes a

cross-reference to Section

506.204(d).

The Agency proposes removing the deletion of Section

506.204(d). Section 506.203(d)

is

shown as repealed in

the proposed regulations, and the stricken

reference, Section 506.204(d), appears to be the correctreference.

Section

506.207(b)

This provision

requiring rigid construction materials should be appficabletolagoons

constructed on

the

land

surfacenot just to lagoons constructed below the We-construction land

surface in karst areas. A non-rigid lagoon could be constructed on the land surface. Requiring a

rigid structure will provide additional

assurance that a collapse

causing groundwater

contamination will not occur.

3

Section

506.208(d)

Section 506.208(d) concerns

groundwater-monitoring wells. The referenceto Section

506.205

Liner Standards appears that it should be replaced with a reference-to -Section 506.206

Groundwater Monitoring.

Section

506.303

-

The last sentence of 506.303(a) should

be revised for clarity to include the term

“volume”

as follows, “In

addition,

the

design volume of livestockwaste storage structuresthat handle the

waste in liquid or semi-solid form shall include the following:”

The regulations do not specifically list as an additional volume~therunoff

and

precipitation generated and

tributary

to the livestock waste

handling facility for a period of 150

days. This runoff

and

precipitation is livestock waste

and

should be included in the calculation of

the livestock waste

volume generated during a period of 150 days

and

listed in the regulations for

th~

calculation of the total volume ofthe livestock waste handling facilities. The Illinois EPA

suggests that for clarity,this volume be added to the list of additional

volumes in the proposed

-

regulation andrecommends that Section

506.303(a) (1)and (2)be replaced with:

“(1)

Runoffvolumes generated during a 150-day period including all runoff

and

precipitation from lots, roofs and other surfaces where collected precipitation

is

directed into the storage. In no case shall this volume be

less

than

the precipitation

and runoff generated by a 25-year, 24-hour storm event

and

directed to the livestock

waste handling facility;

and

(2)the volume of all washdown liquids generated during the

150-day period that are

directed

into the livestockwaste handling facility.”

Section

506.304(c)

The Agency recommends that this subsection be revised to include:

•

Specifications for the maximum allowable horizontal separation between the perimeter

drainage tubing and the -livestock waste

handling facility. The drainage tubing must be

4

located nearthe structure to effectively lower the water

table

-below The livestock waste

handling facility to prevent floatation. The

following language should be added:

“The perimeter drainage tubing must be located at a horizontal distance that

provides sufficientdrainage to maintain the water table elevation below the bottom

-

of the livestock waste handling facility.”

•

A required sampling port. The drainage tubing mayreceive and transport livestock waste

that has leaked from the nearby livestock waste storage structure. A subsurface drain

discharge may be discovered discharging livestock wastewith several possible sources of

livestock waste upstream. A sampling port located on-site immediately

downstream

of

the subsurface drain around the livestock waste handling facility, would provide

easy

access for sampling and inspection to determine ifthe particular facility

is or is not

causing the discharge of livestock waste.

Additionally, early detection of such a

discharge

by sampling or

inspection of the sampling port would provide the facility a

better opportunity to initiate actions to contain the livestock waste

or prevent a discharge

to waters ofthe state.

•

A reference to howthe “seasonal high water table” may be determined (this may require

the addition of a definition in Section 506.103). If the water table rises

above the

livestock waste handling facility bottom, the livestock waste handling facility

can be

damaged by floatation, possibly causing a discharge. Therefore,

it is critical to know

accurately the seasonal high water table elevation when no subsurface drainage is

installed.

-

•

A provision forthe diversion of livestockwaste that may be discharged from the drainage

tubing, away from surface waters, to a field or collection area,

pending collection and

appropriate disposal. Ifthe subsurface drainage tubing receives

livestock waste, a means

to contain the waste and

prevent discharge to waters of the- state-would-need-to be

implemented.

5

Section 506.310(c)(3)

This Section requires

the certification by the Licensed ProfessionalEngineer of the liners

for livestock facilities locatednear aquifer materials.

Does this provision require certification of

Sections 506.3 10

and

506.304 requirements for liners?

The Agency is uncertain from the

language of the proposal

and

recommends that the certification

by the Licensed Professional

Engineer include both Sections 506.310

and

506.304 requirements because the provisions ofboth

sections are important to the prevention of groundwater-contamination by

livestock waste.

Section

506.3 12(b)

This provision requiring rigid construction materials should be applicable to livestock

waste handling facilities constructed on the land surface not justto livestock-waste handling

facilities constructed below the pre-construction land surface in karst areas. A non-rigid livestock

waste handling facility could be constructed on

the land surface. Requiring a rigid structure will

-

provide additional assurance that a collapse

causing groundwater contamination will

not occur.

Sections 506. 207

and 506.312

-

These sections regard

the

construction of lagoons and non-lagoons in karst areas. The

Agency

is concerned that ifa single boring is made to a maximum depth of 20 feet below the

waste handling structure bottom elevation,

as

is proposed in these new sections of Part 506, a

void maybe present below the proposed livestock waste handling structure

and

still be

undetected.

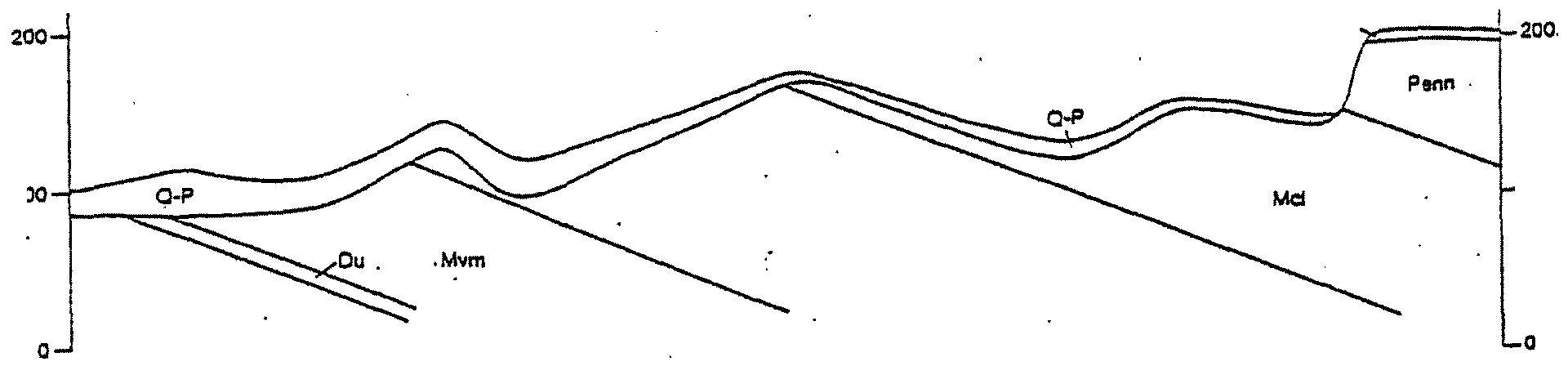

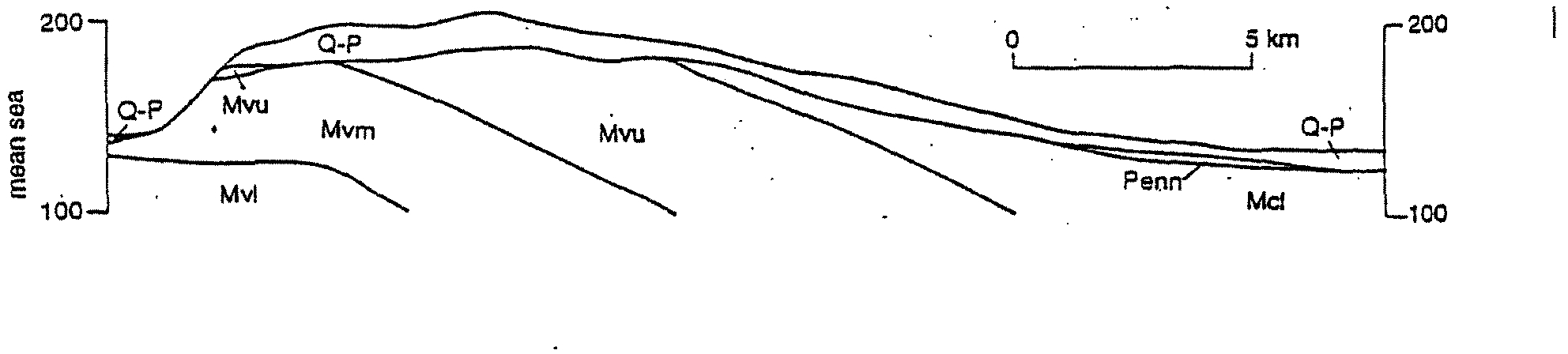

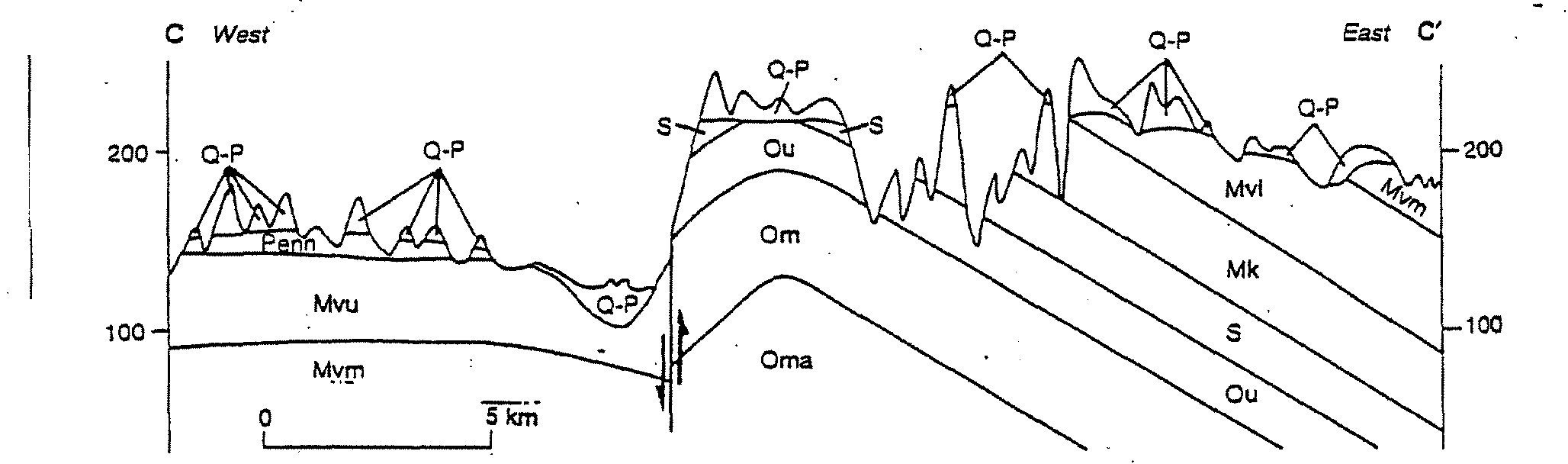

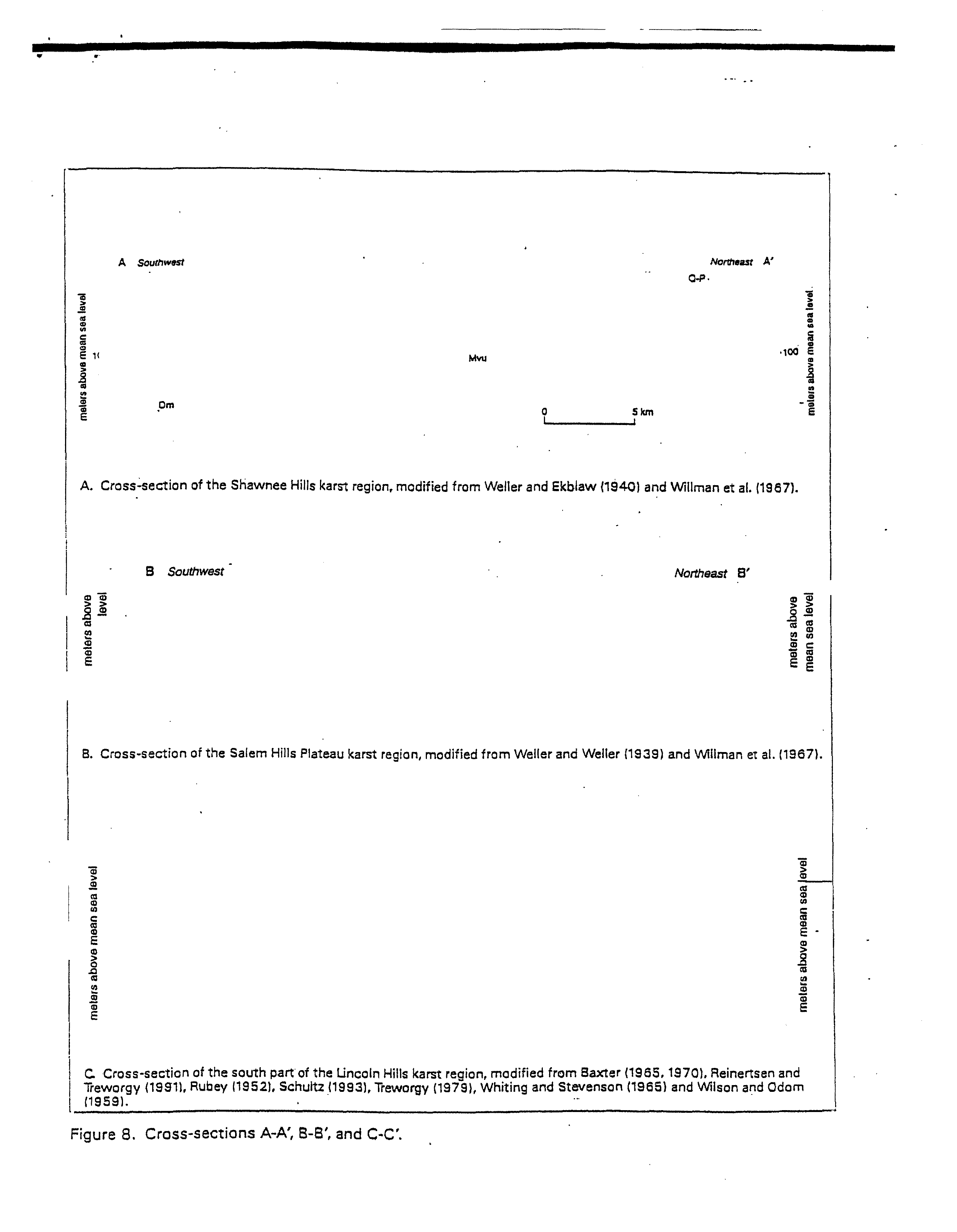

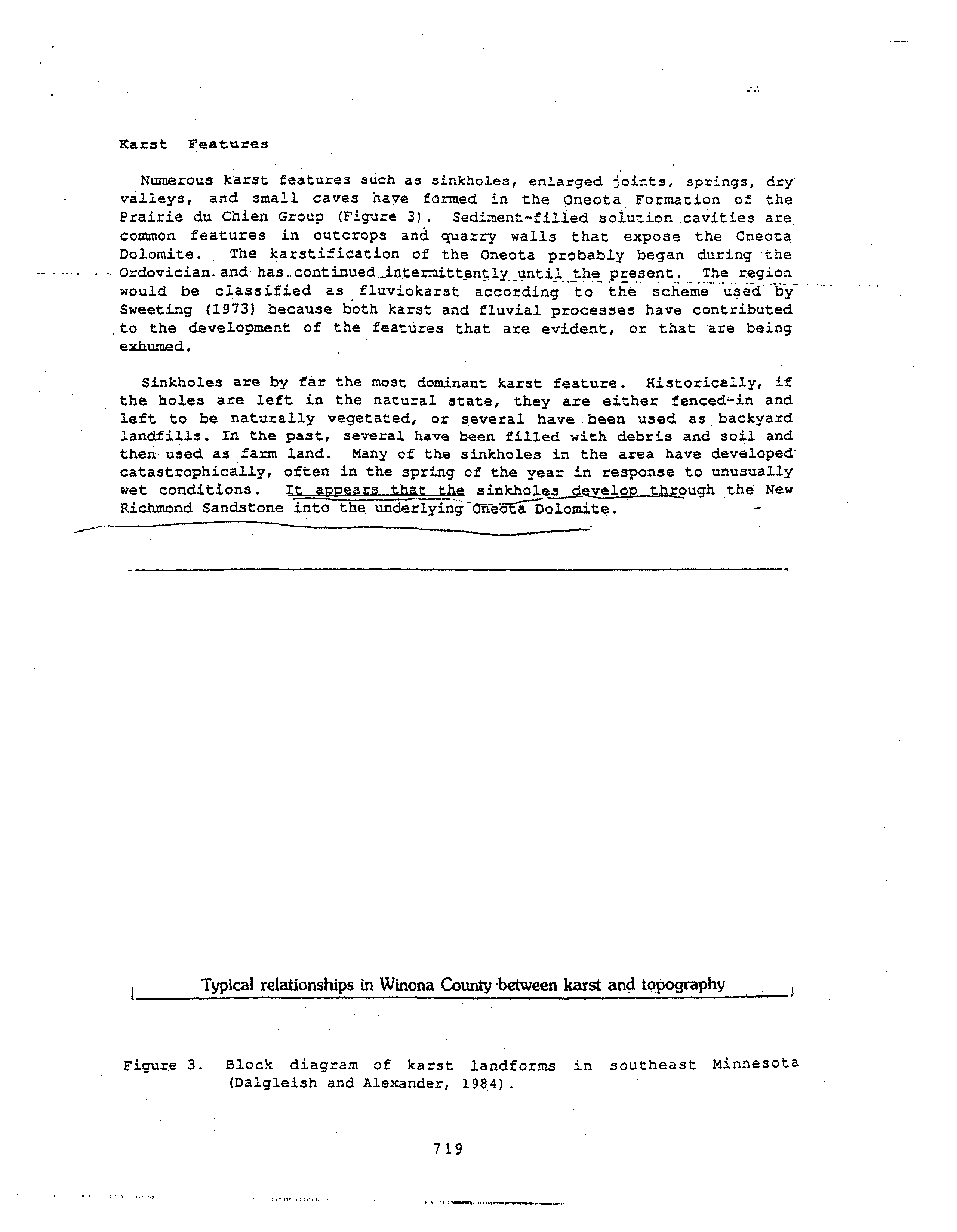

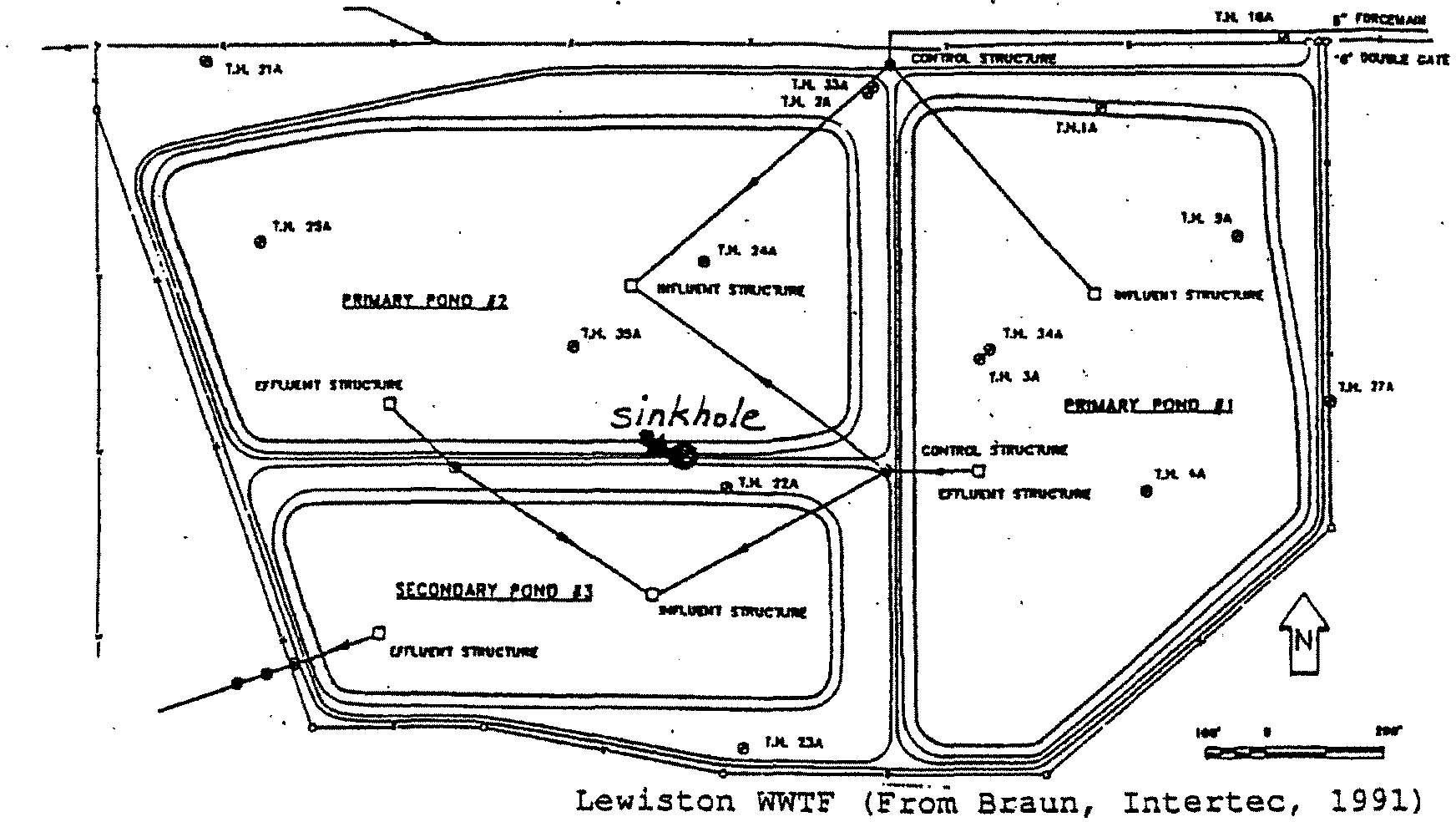

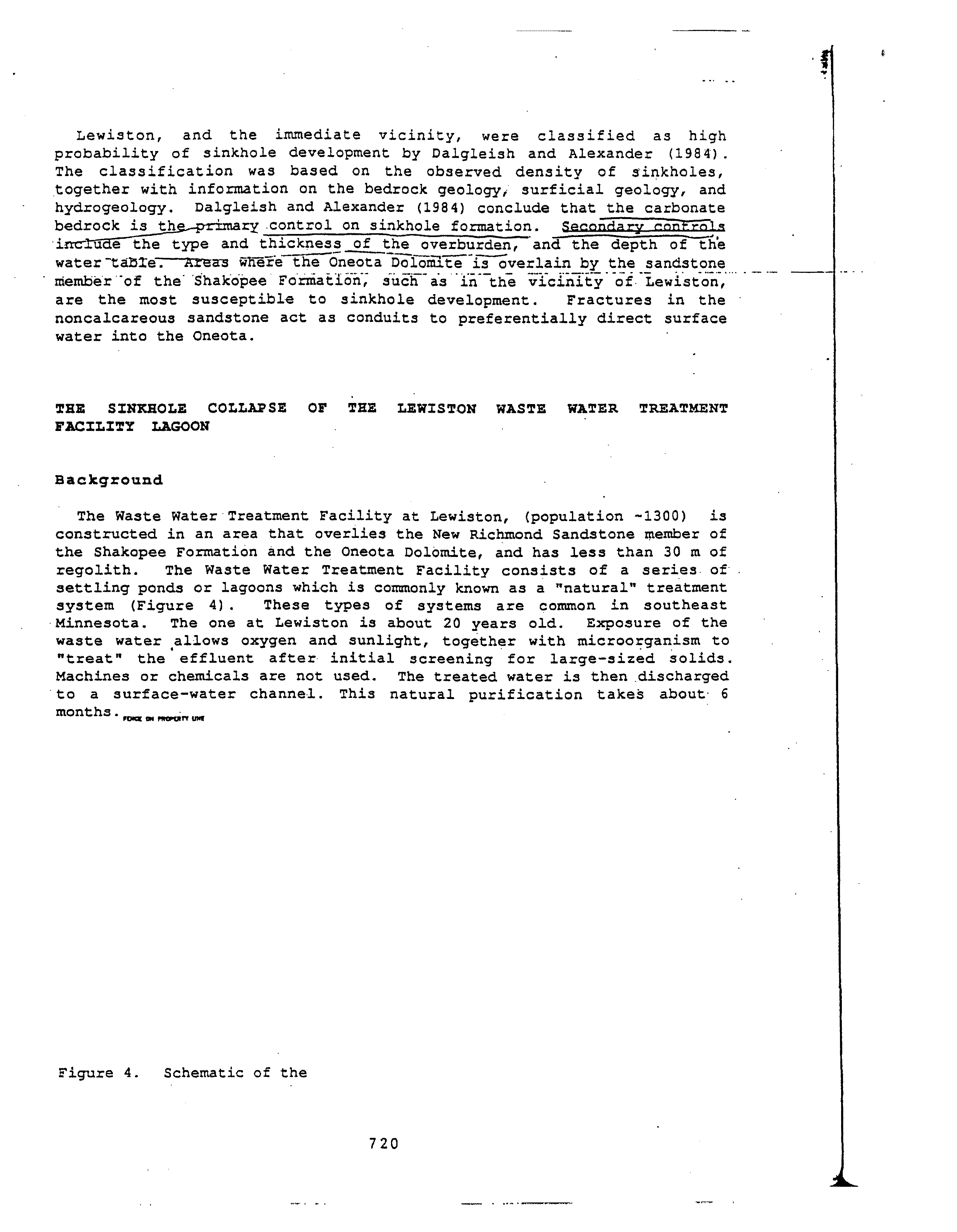

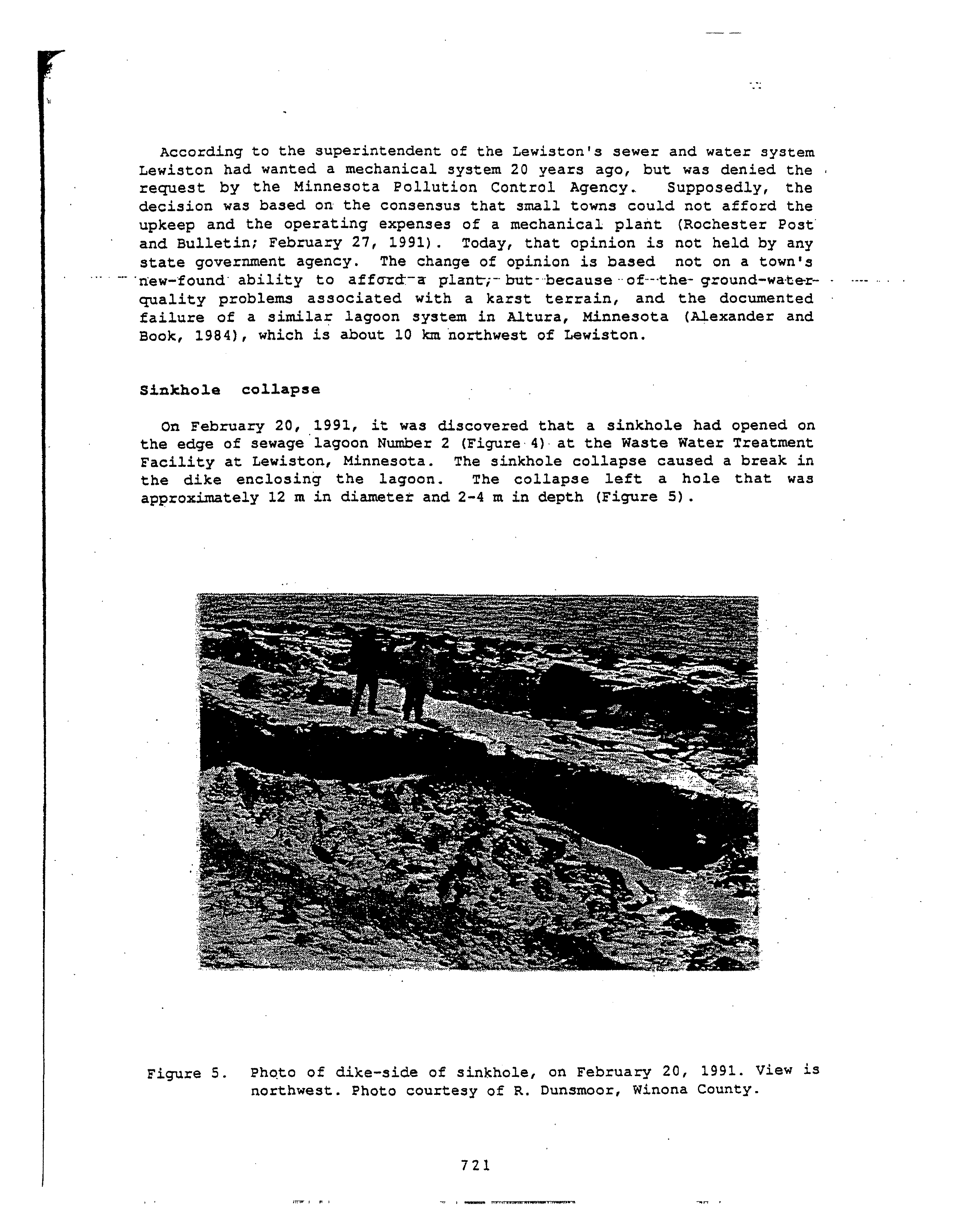

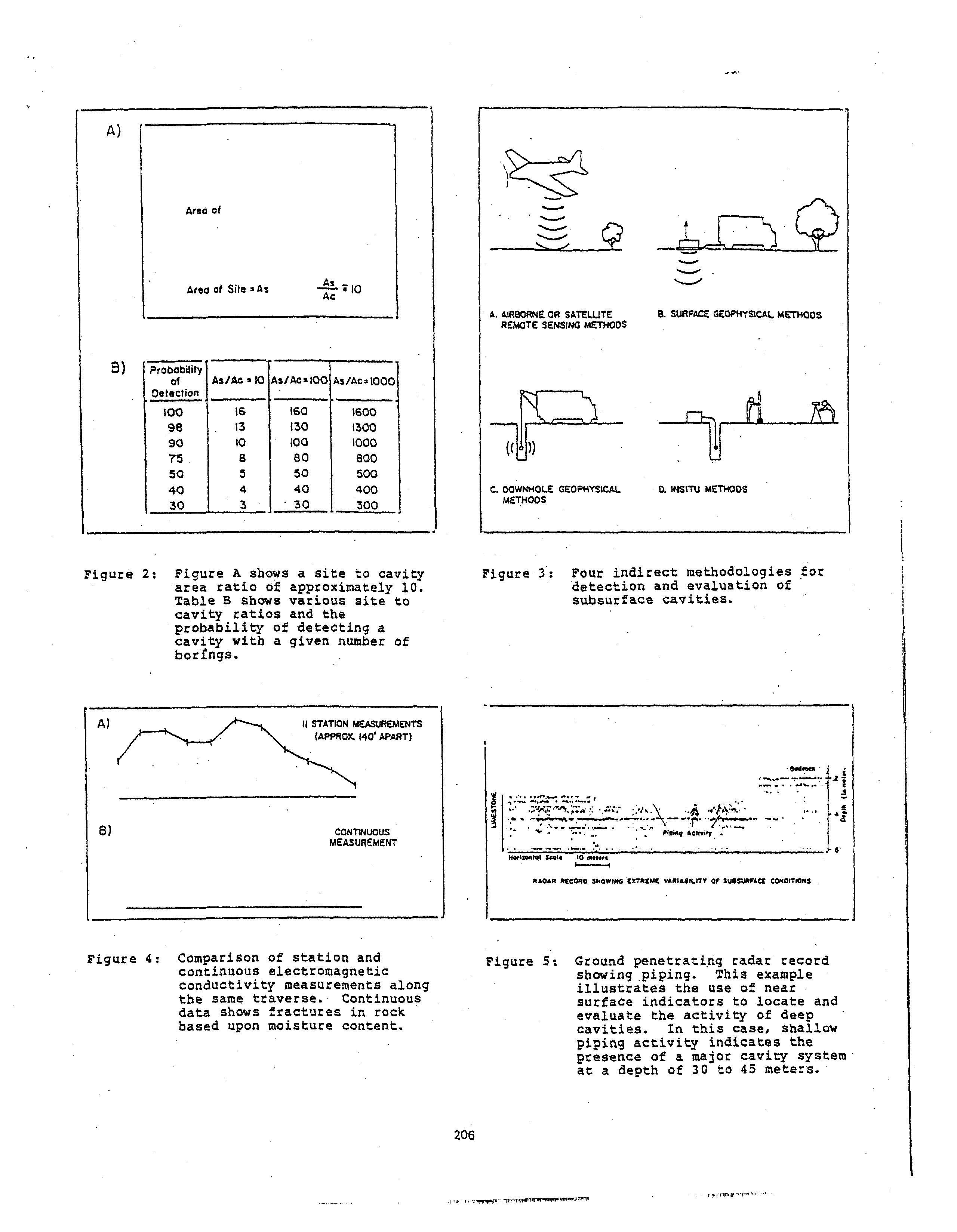

Agency research has revealed the following:

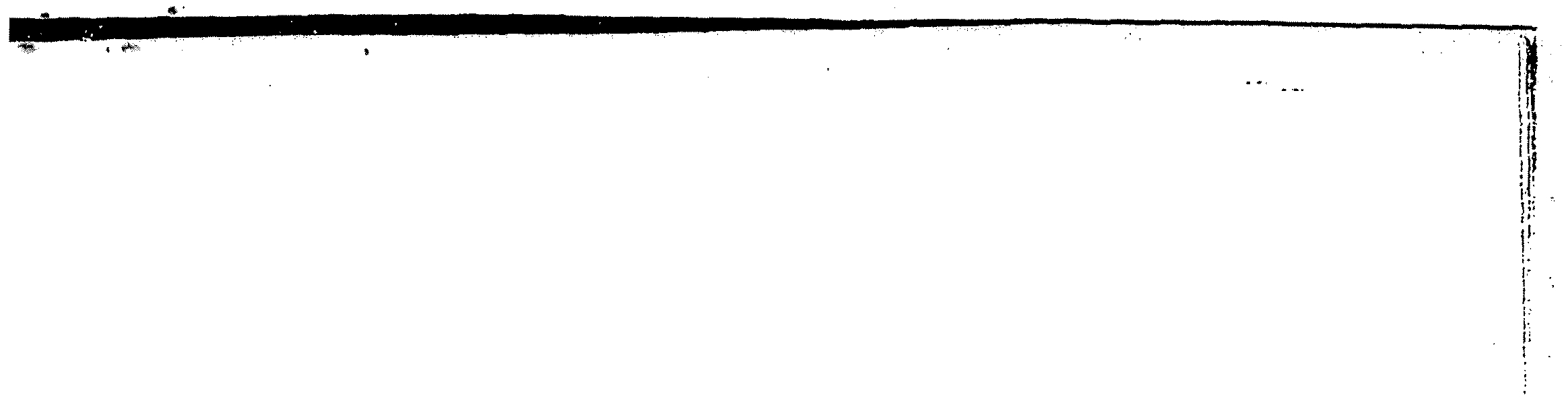

Jannick, et al., 1992, reported that of 14 wastewater lagoon sites in southeastern

Minnesota located over karstic bedrock and with 30 meters

or less of overburden soil or till

over the bedrock, 2 had failed in the twentyyears preceding

1992.

An interim guidance

document titled “ConstructingNew Manure Storage Systems in the Karst Region”

(Minnesota Pollution Control Agency, March 2000), reports that 3 of 22 municipal

-

wastewater treatmentponds failed in the karst region of southeast Minnesota between 1974

6

and 1992. The report also

indicates that one manure storage system had manure seepage into

fractured bedrock occurring

so rapidly that the storage system did not ever

need

to be

pumped.

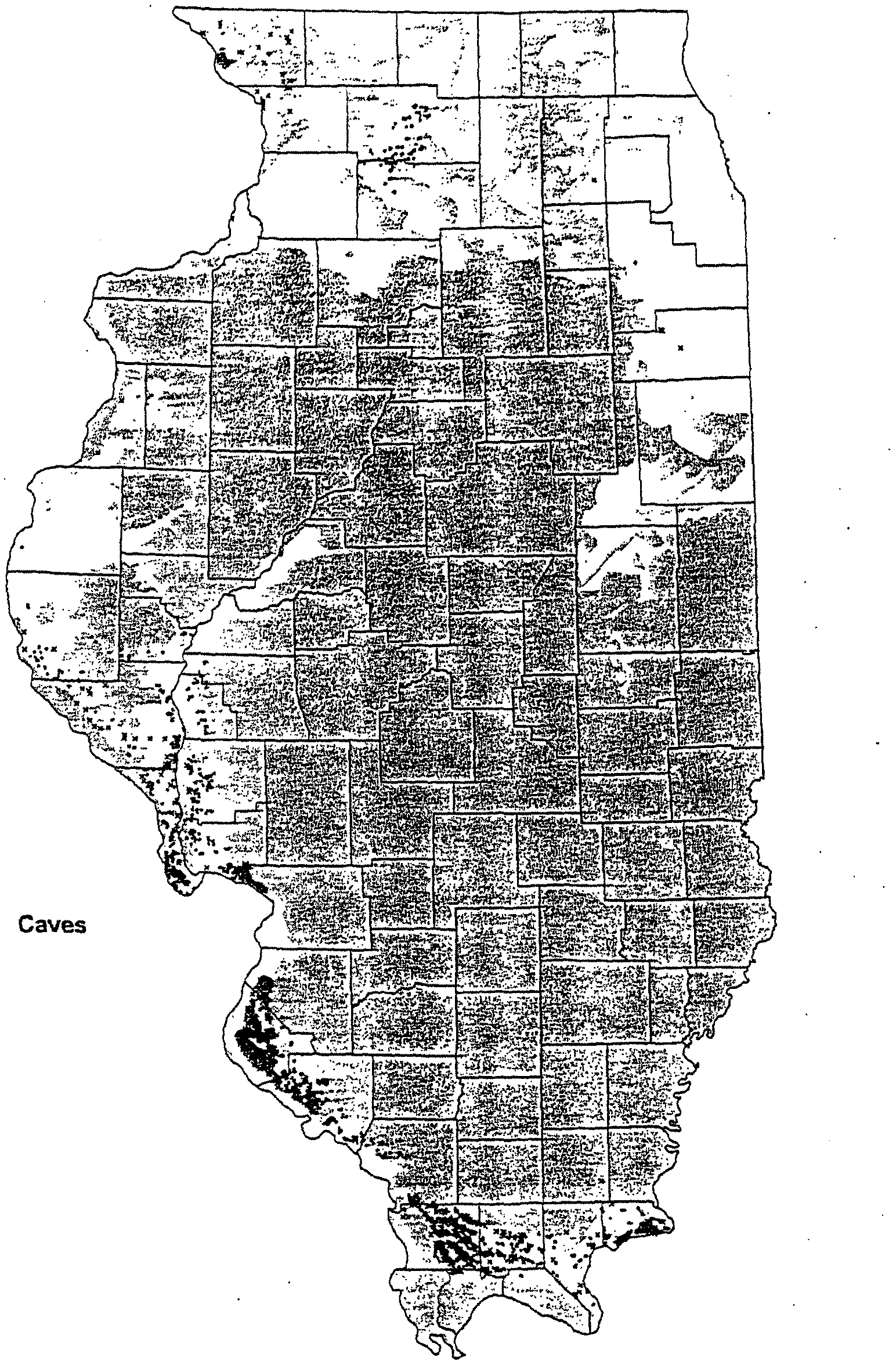

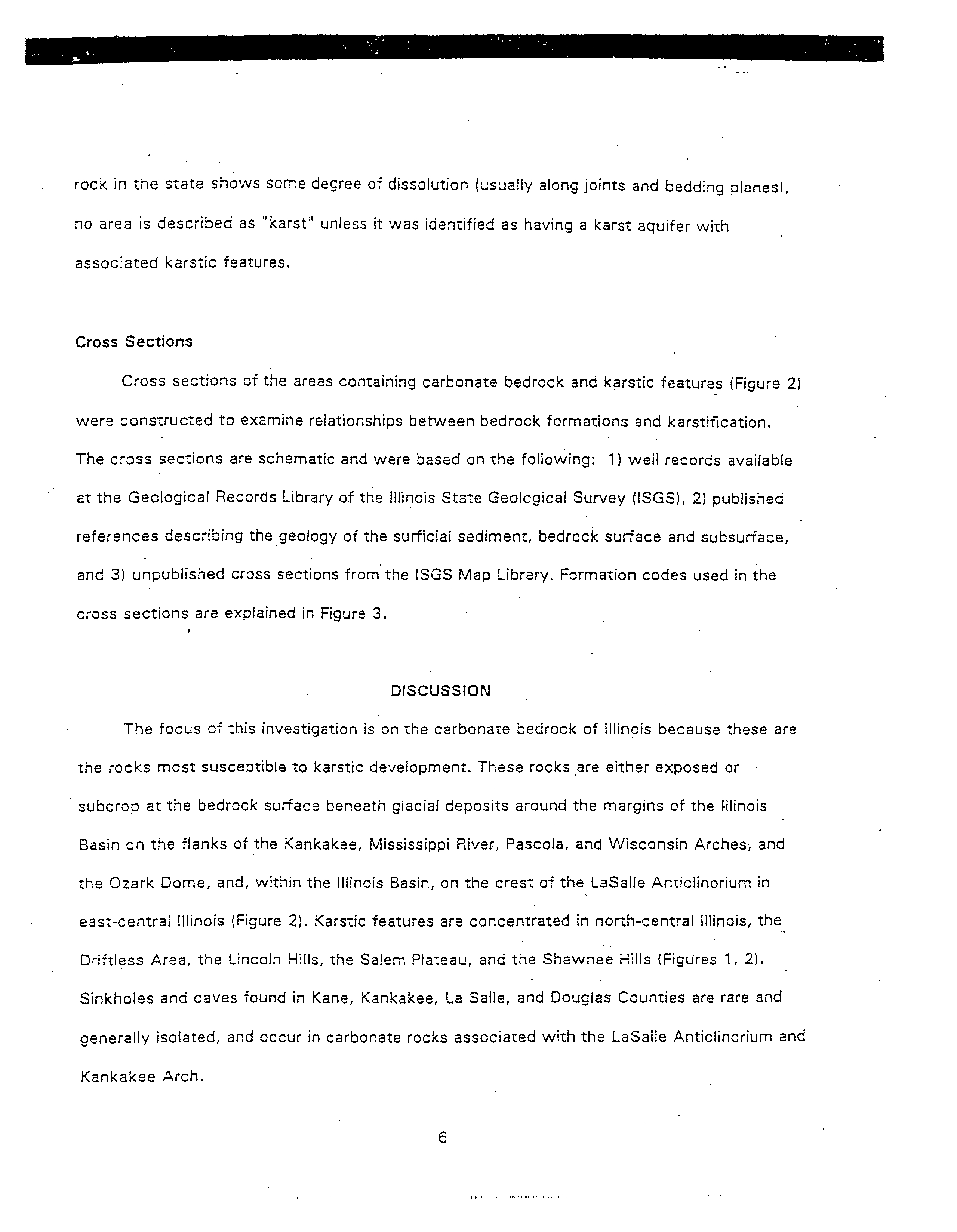

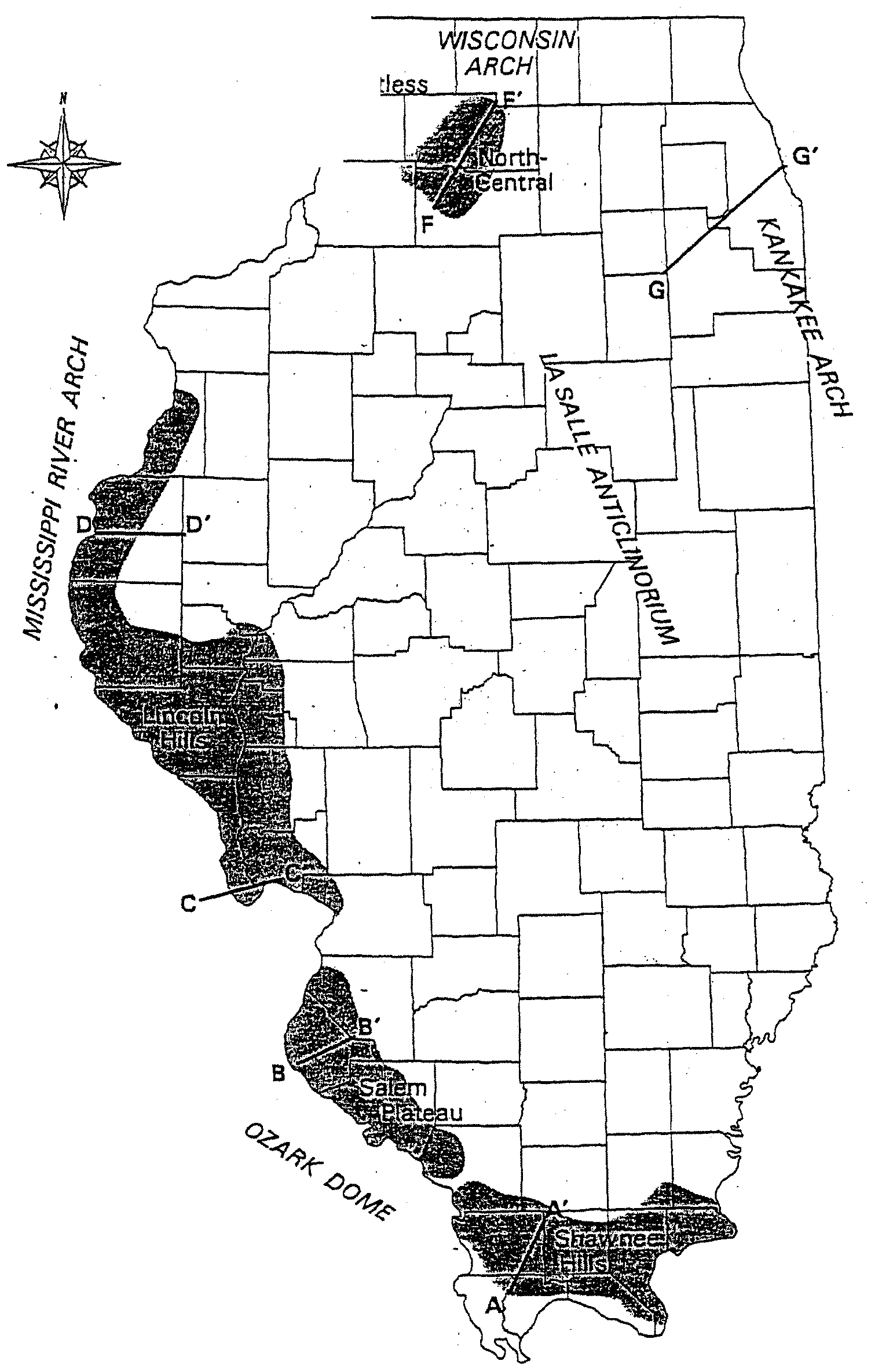

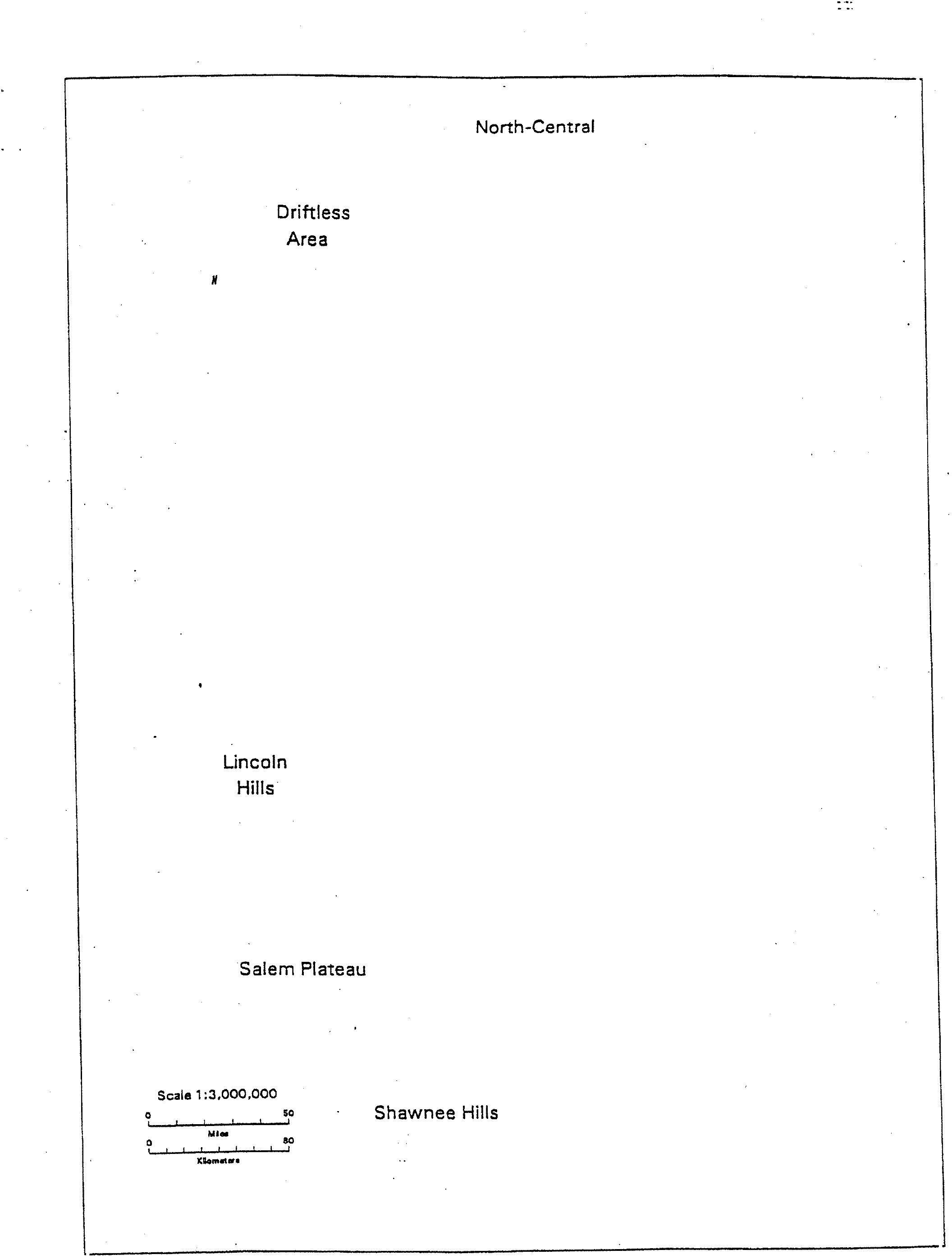

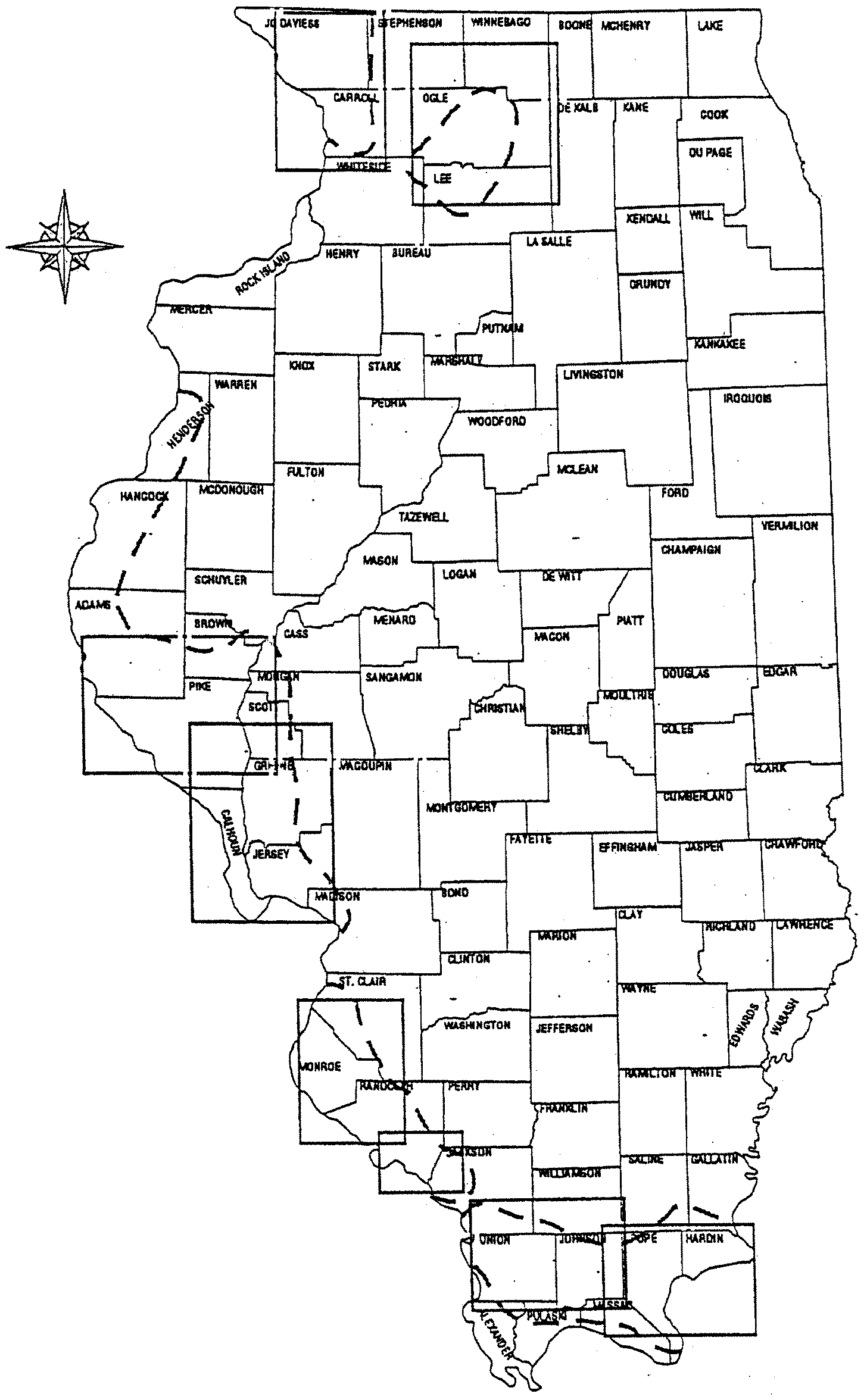

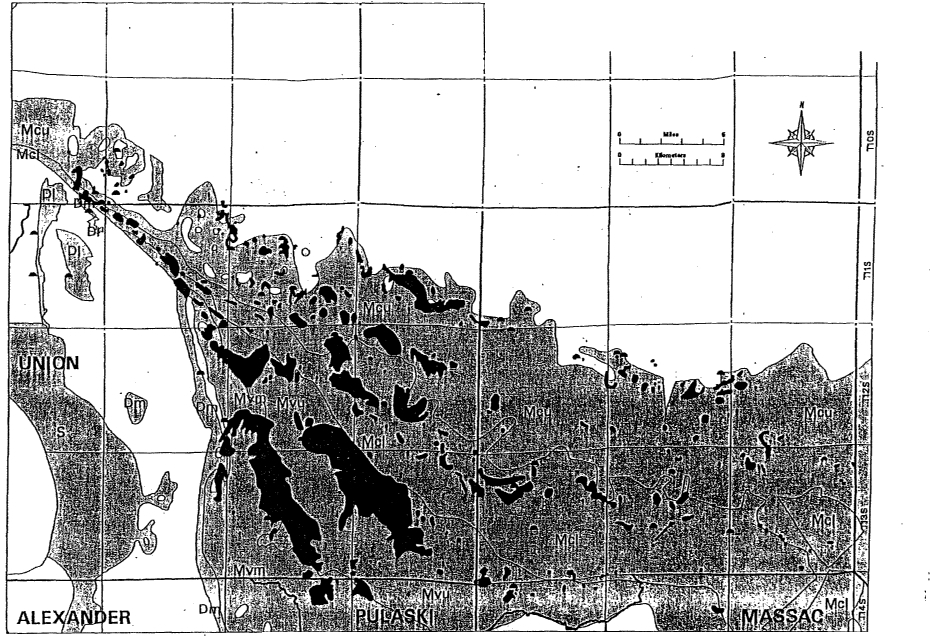

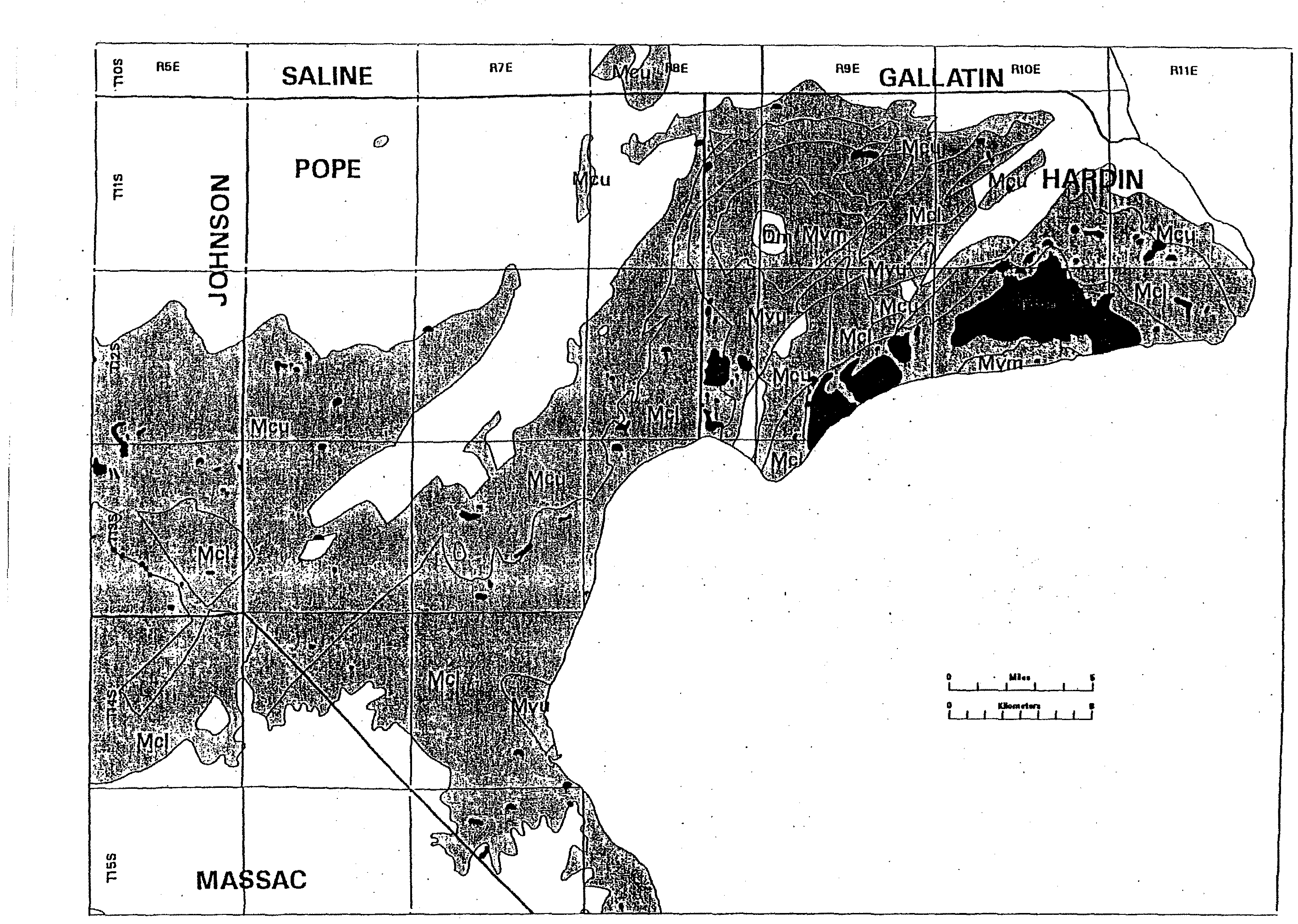

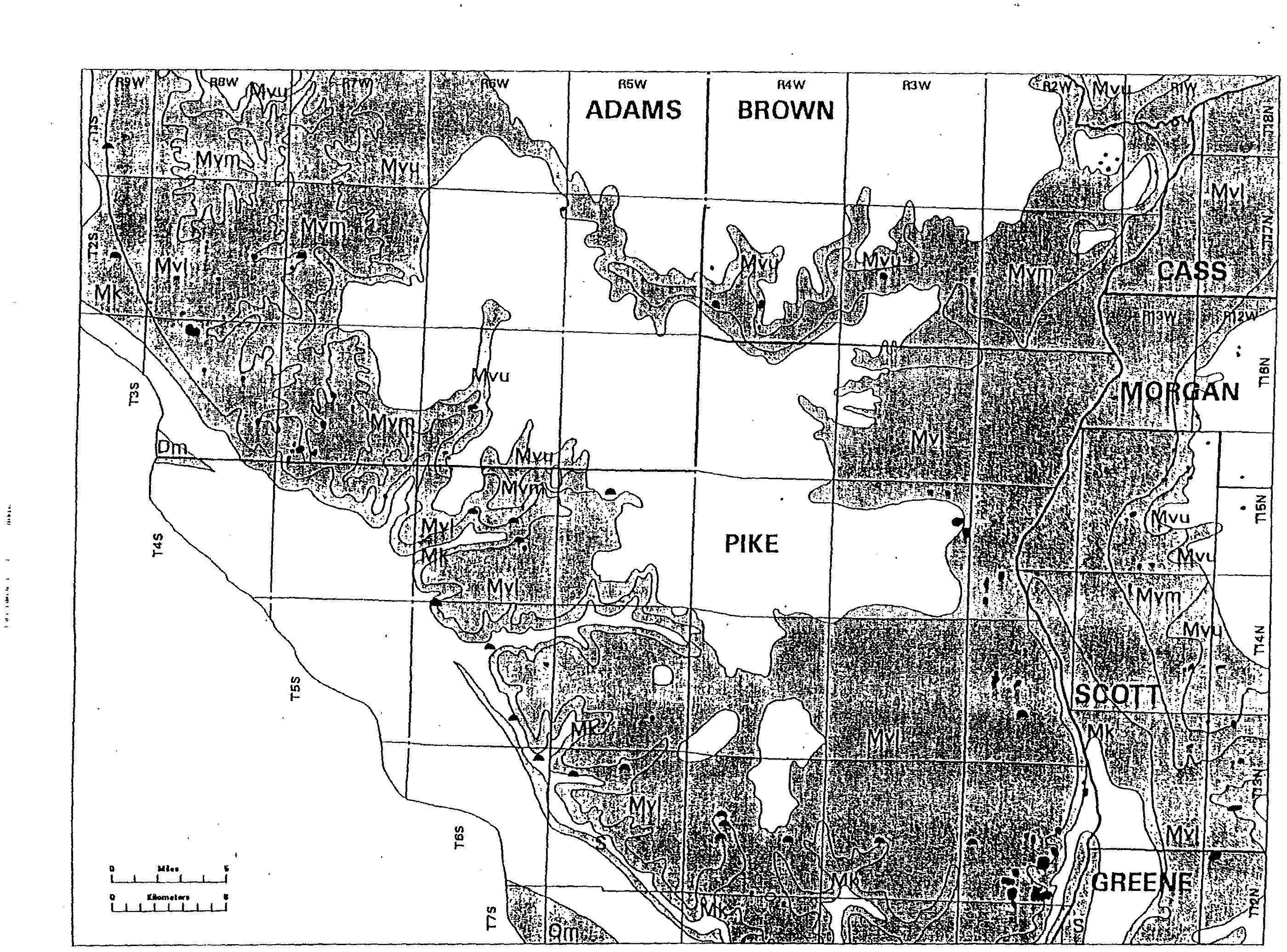

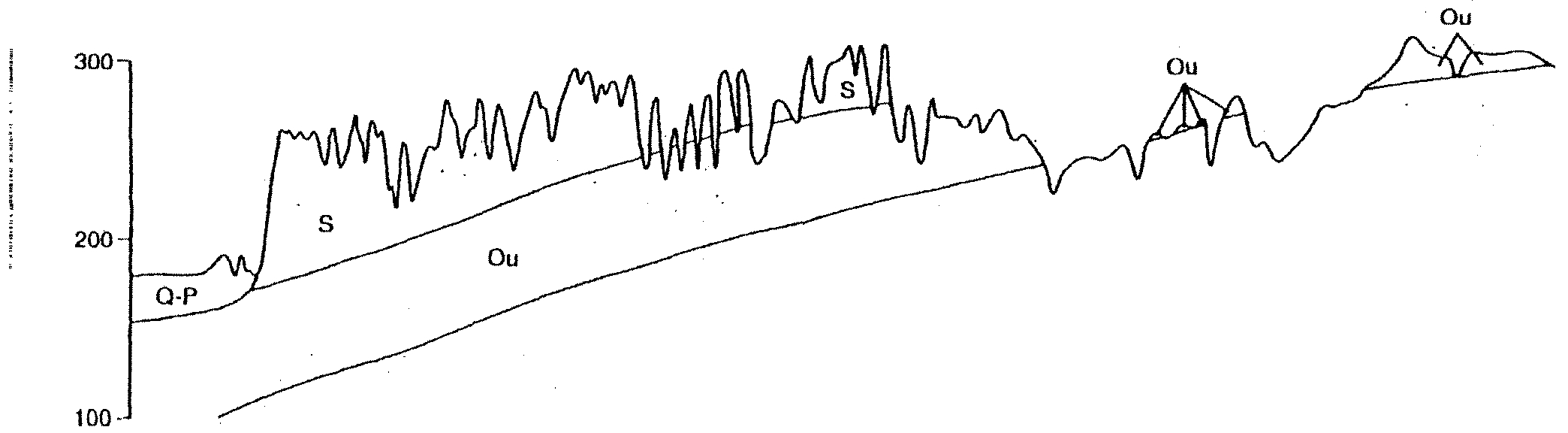

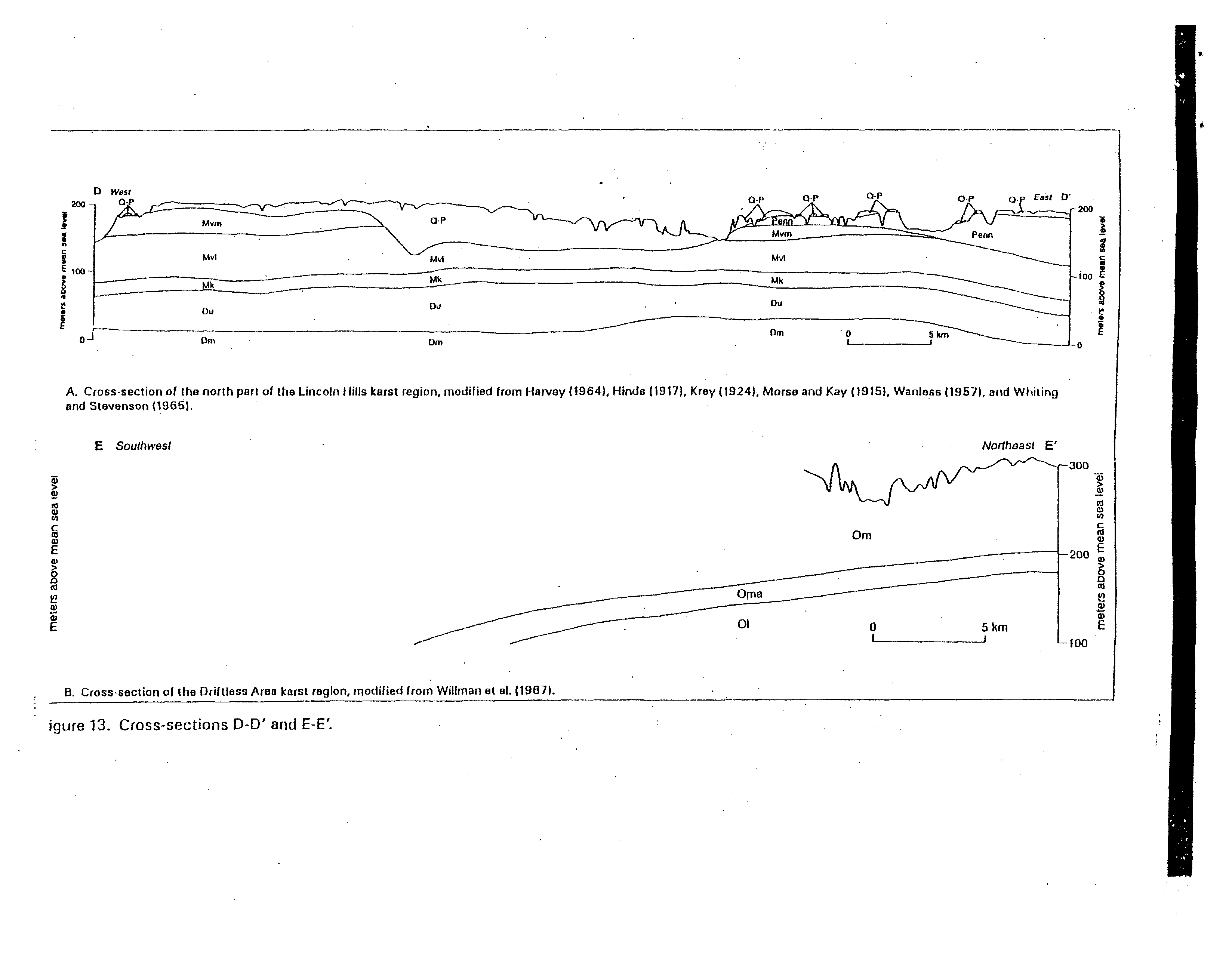

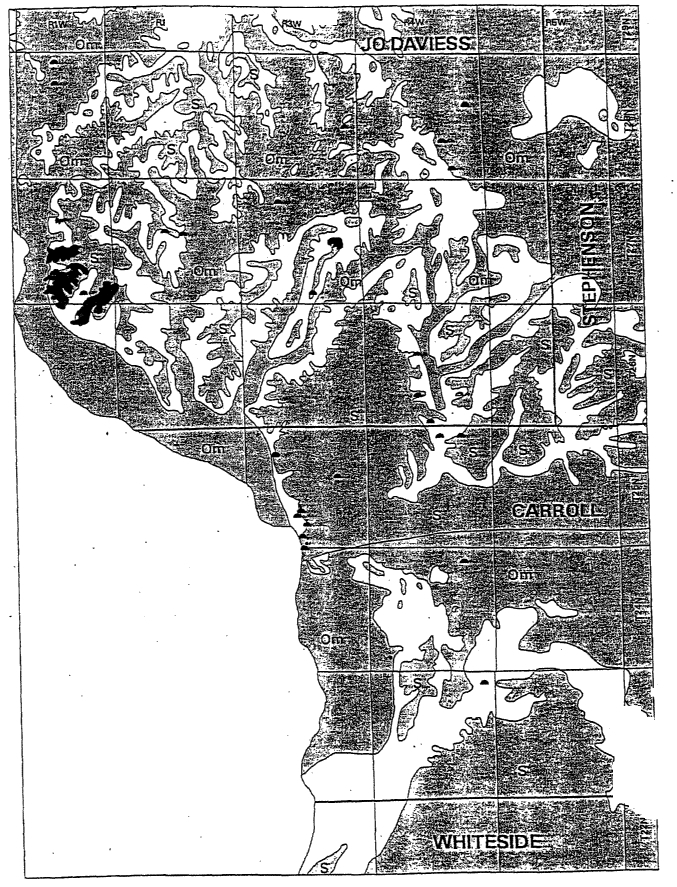

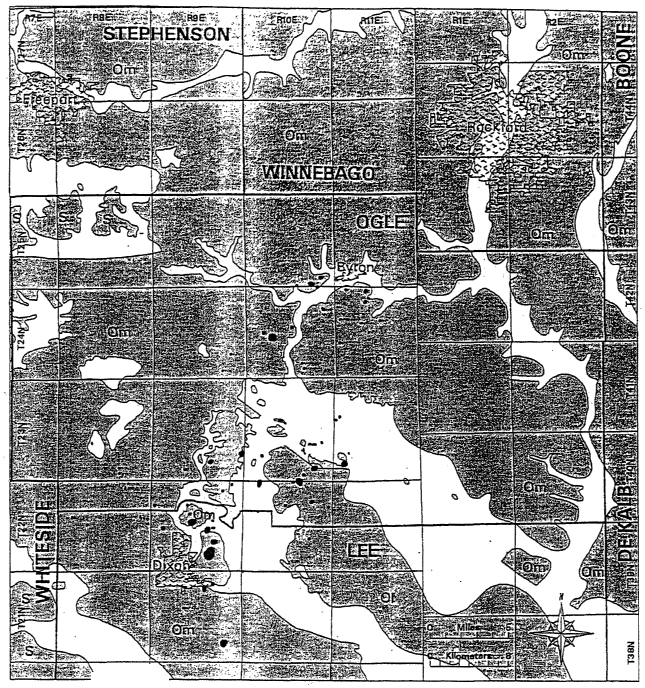

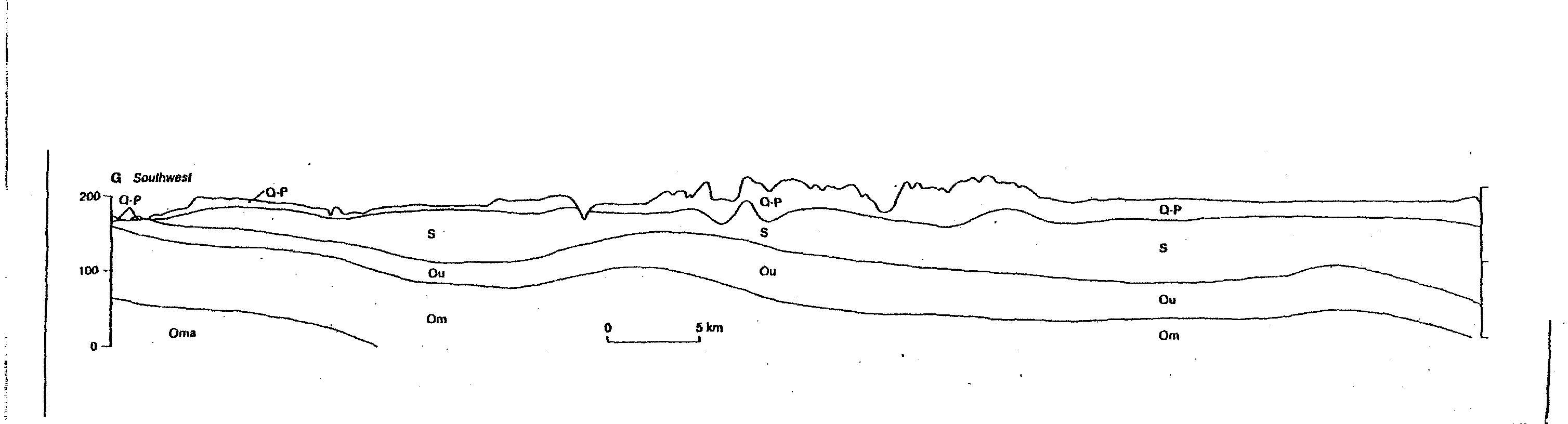

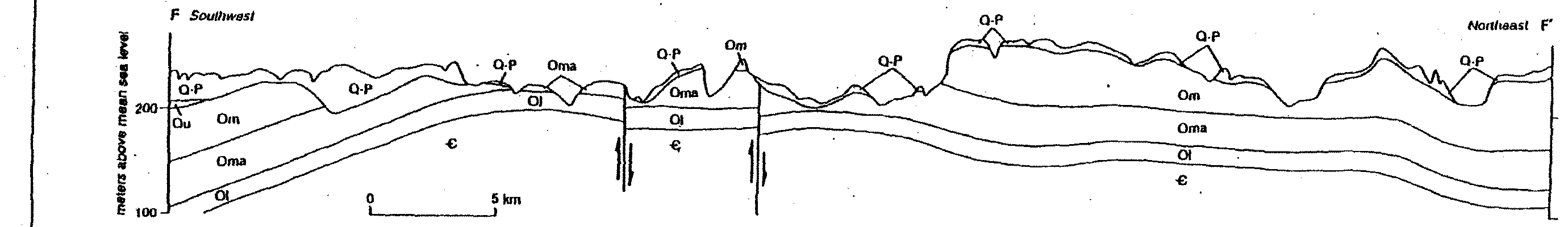

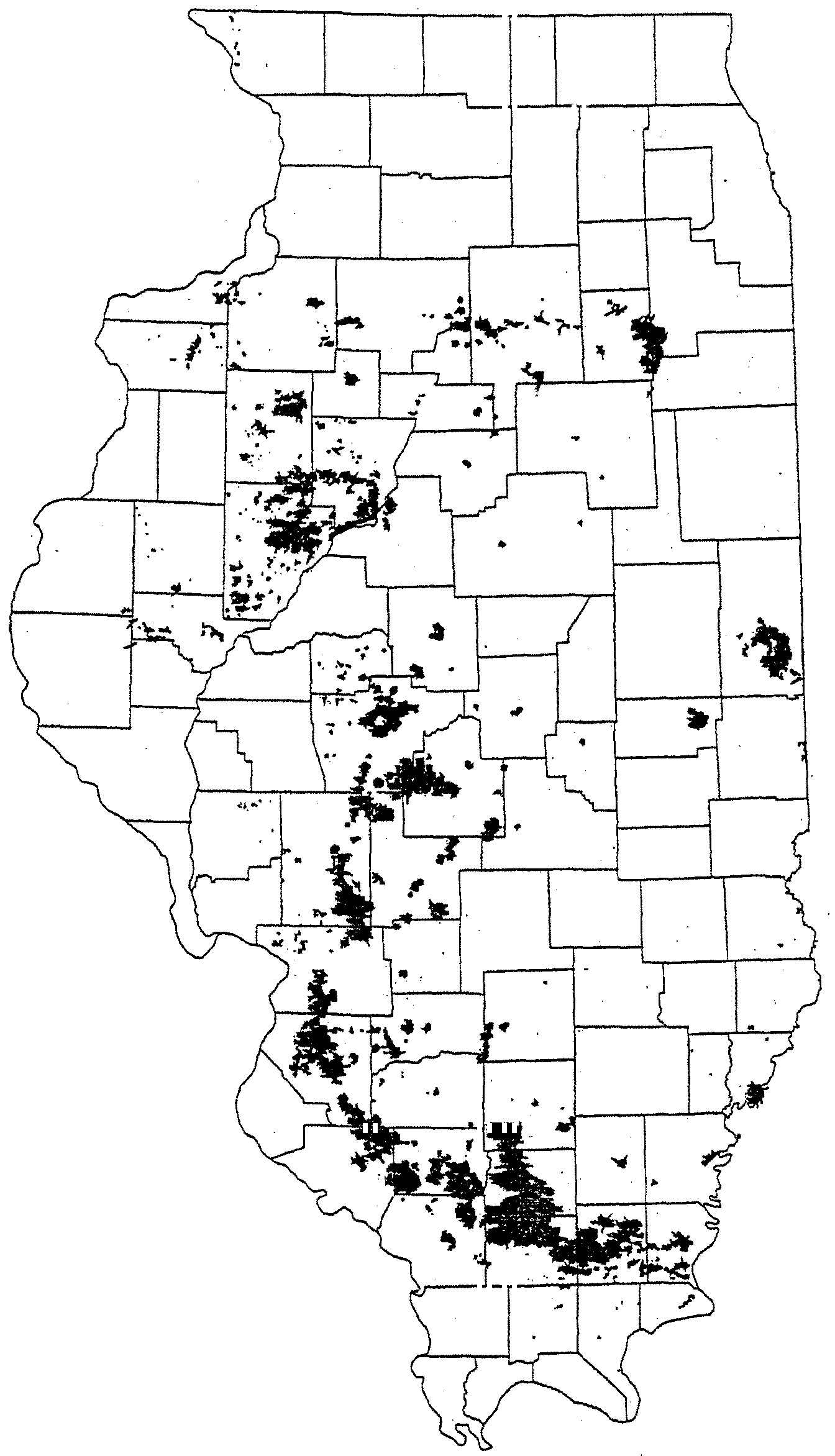

The IDNR- ISGS Illinois Map

8

“Karst Terrains and Carbonate Rocks of Illinois,”

incorporated by reference in Section

506.

104(a)(3), shows that karst areas with sinkholes exist in

areas with drift over the bedrock of 50

feet or

less.

Small areas of the Salem Plateau and Lincoln

Hills karst areas are shown on the map to have sinkholes in areas where drift thickness is greater

than 50 feet over the bedrock.

In the report “Karst Regions of Illinois” by Panno, et a! (1997) for

the Salem Plateau karst area,

the bedrock is reported to be typically less than

15

meters (or

approximately 49

feet) belowthe surface, although some areas exceed this depth.

In the Lincoln

Hills karst region the report indicates that many of the sinkholes in this region occur in “relatively

thick bess deposits.”

Most sinkholes form

in driftthickness of less than 20 feet below the

surface in the North Central Karstregion according to the report by Panno. The formation of

sinkholes appears to occur in areas with depth to bedrock up to 50

feet or more in Illinois. Benson

and La Fountain,

1984, state that 1000

borings conducted on agrid would be needed for a 90

probability to detect a void of2.3 meters

in size on a one acre site.

-

The

Agency concludes, therefore, that ifa single boring is made to a maximum depth of

20 feet below awaste handling structure bottom elevation a void-may be-present below the

proposed structure and still be undetected.

The

Agency recommends a more comprehensive

investigation based on several sources of data.

Such systems are described below from

-

information on programs in Minnesota and Missouri.

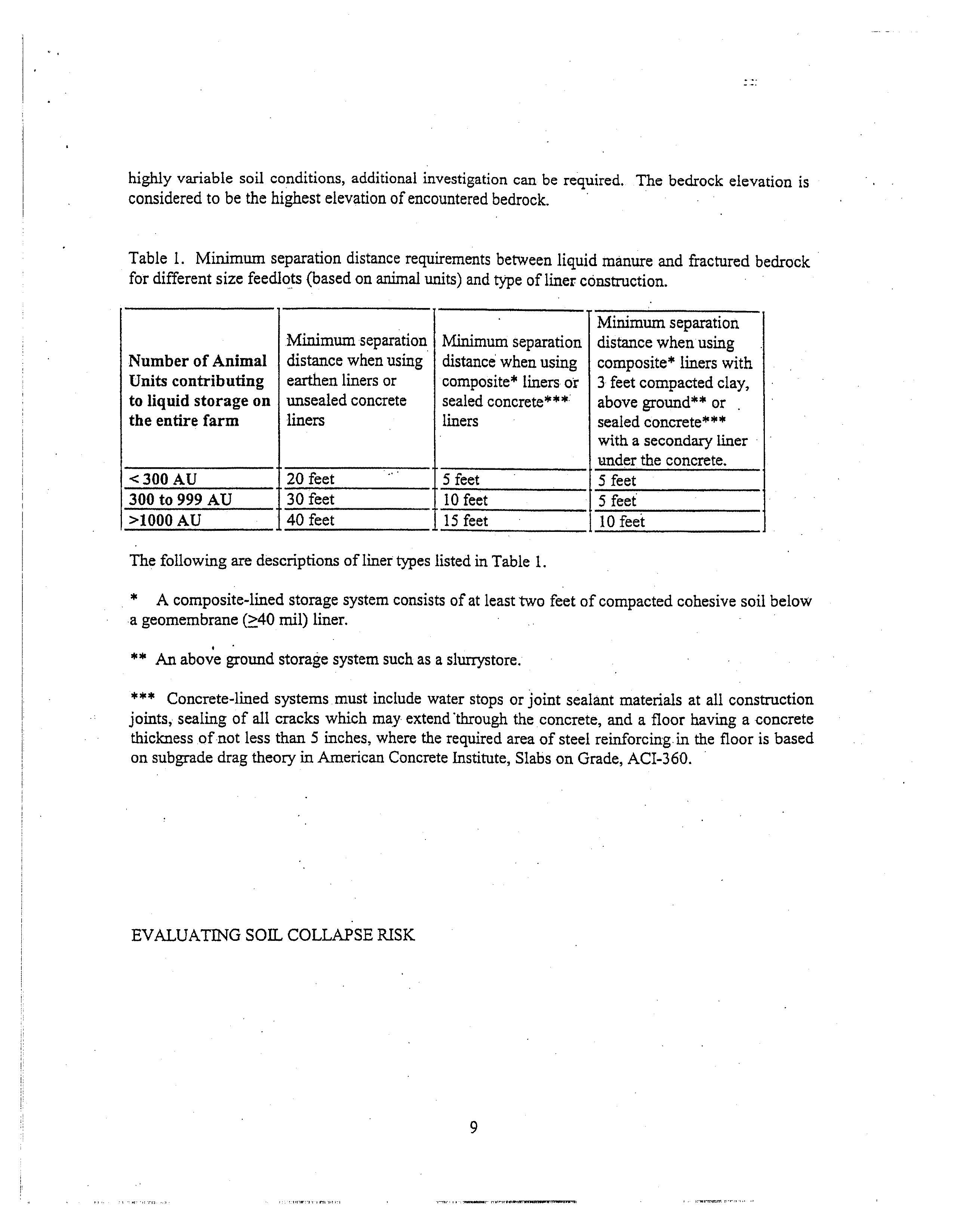

The State ofMinnesota adopted regulations in October,

2000 regarding the location of

manure storage structures in karst areas. The regulations as adopted require that certain facilities:

•

have aminimum separation

from bedrock of twentyto forty feet for earthen liners,

based

on the size of operation

and type

of structures,

•

use rigid structures or

composite

earthen/synthetic liners,

7

•

limit the size of manure storage structuresto 250,000 gallons,

•

prohibit manure storage structures if

the

bedrock is within

5

to

15

feet of the livestock

waste handling structure bottom, or

•

relocate away from the karst features.

Minnesota also convened a workgroup of engineers that were not state regulatory

personnel to determinewhat should

be required for livestock facilities located in karst areas

(Minnesota Pollution Control Agency, 2000, Minnesota

Pollution

Control Agency, 2001).

The

report from that workgroup indicates

the following:

-

•

that in

5

instances earthen manure storage structures have failed due-to- sinkhole

development in states other than Minnesota,

•

Minnesota

and

other states also have had non-livestockwastewater treatmentponds fail

due to sinkhole development,

-

•

In

all cases

the failures have occurred when there is no

liner or the liner is designed to

seep at greater than the Minnesota requirements for earthen soil liners. The seepage rate

-

requirement is

1156th

inch per day. l/56~’

inch per day

is equivalent to a 2 feet thick

liner

with ahydraulic conductivity of

1

x

10~

cm/sec with an operating depth of livestock

waste of 8.6 feet.

-

The Minnesota workgroup issued the

report

“Recommendations of the Technical

-

Workgroup-Liquid Manure Storage Structures in the KarstRegion”

on

December 20, 2000. The

report concludesthat the following be required:

•

no new earthen manure storages located in areas where carbonate bedrock is

less than 5-0

feet from the ground surface and the upper bedrock

is fractured or other geologic strata

where soil collapse or sinkhole formation occurs,

•

construction of manure storage structure is not allowed if voids

are

encountered

in

the

construction of

the

structure

or soil inspection,

8

•

minimum bedrock separation of five feet for concrete tanks, dual lined basins, composite

lined

basins

and

above-ground tanks with concrete floors,

•

a secondary liner with a leachate collection system if bedrock separation is less than

5

feet,

-

-

•

soil inspections during construction,

•

diversion of fresh water away from the perimeter of manure storages,

•

annual liner inspections,

•

monitor manure levels,

and

•

emergency response plans.

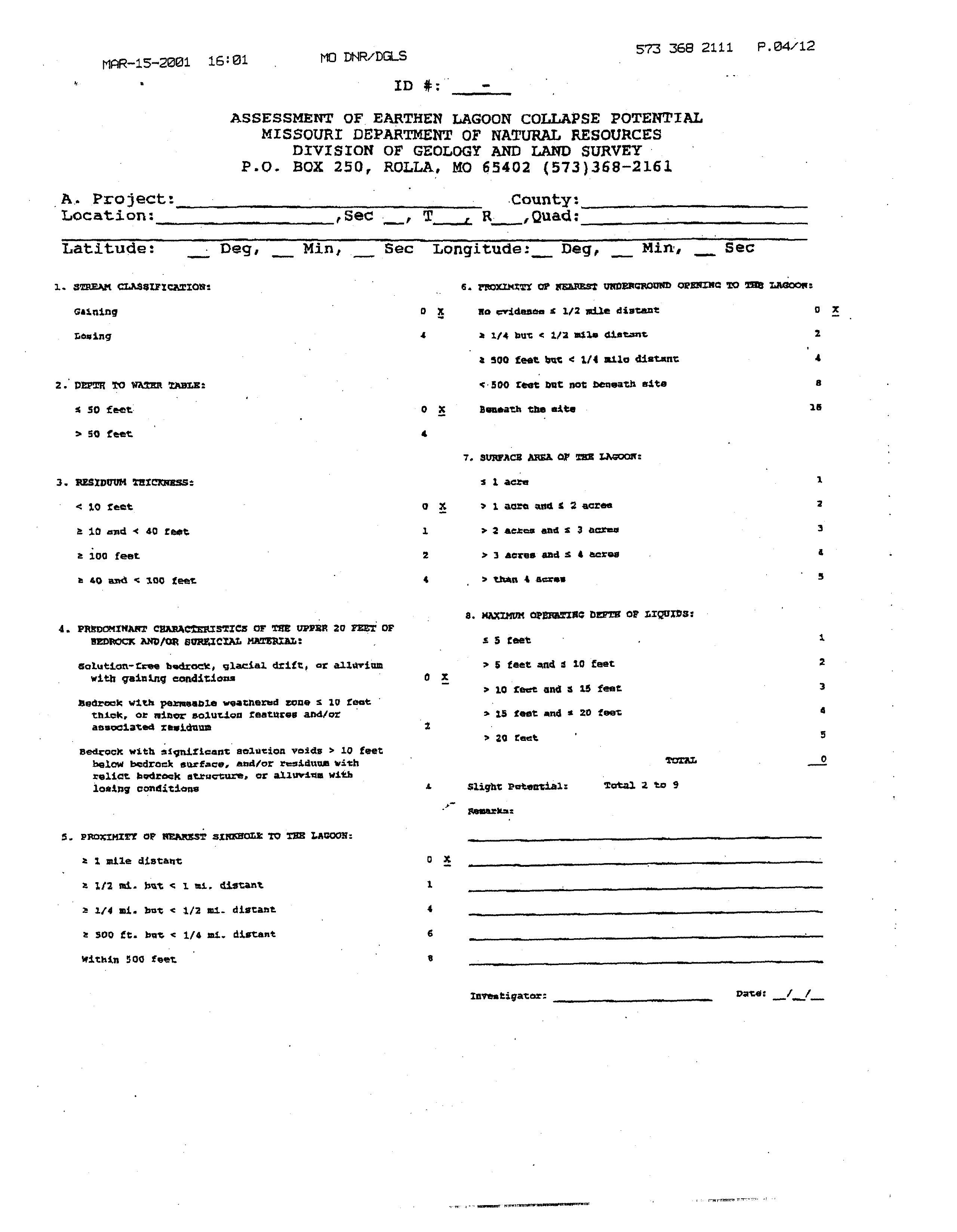

The

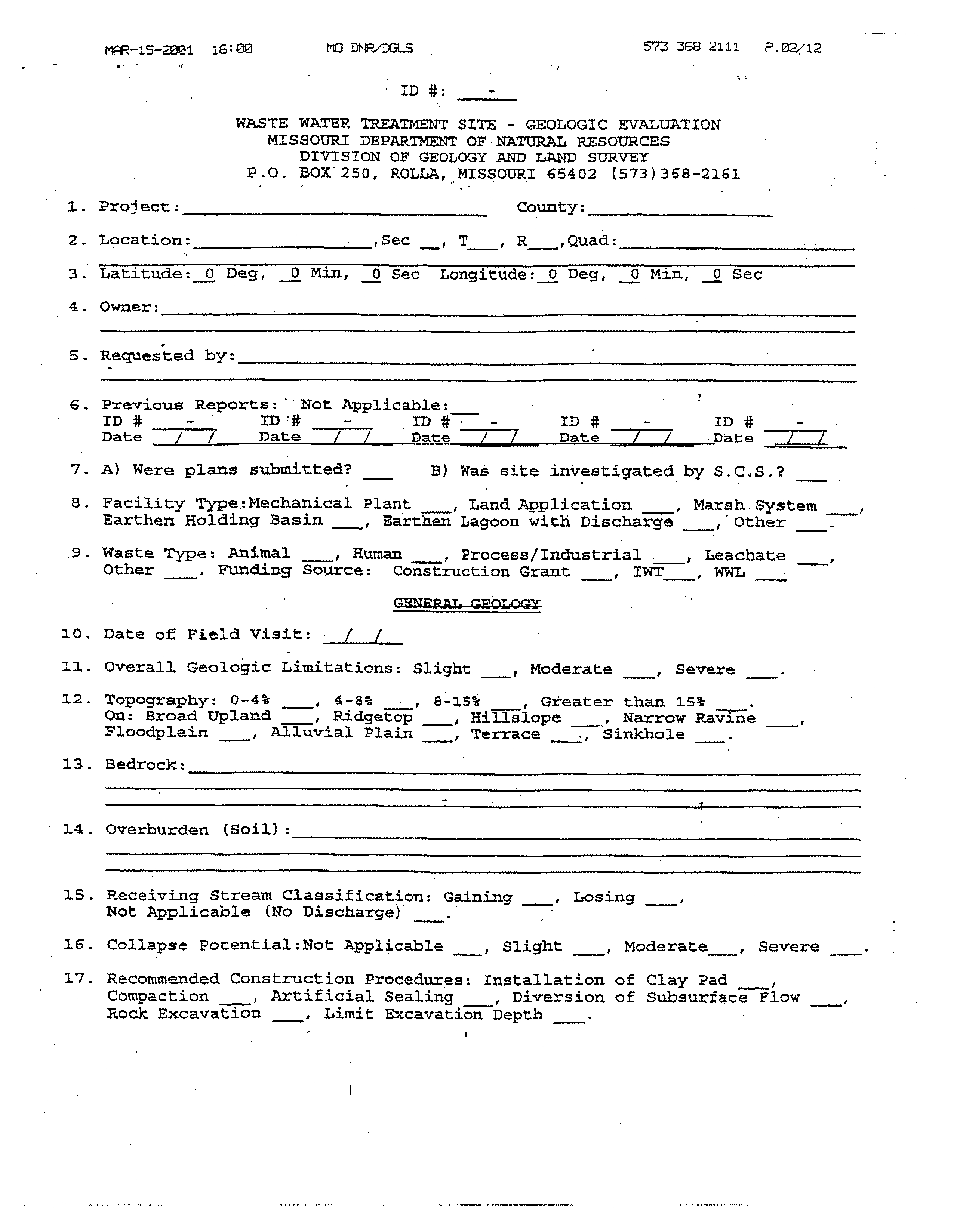

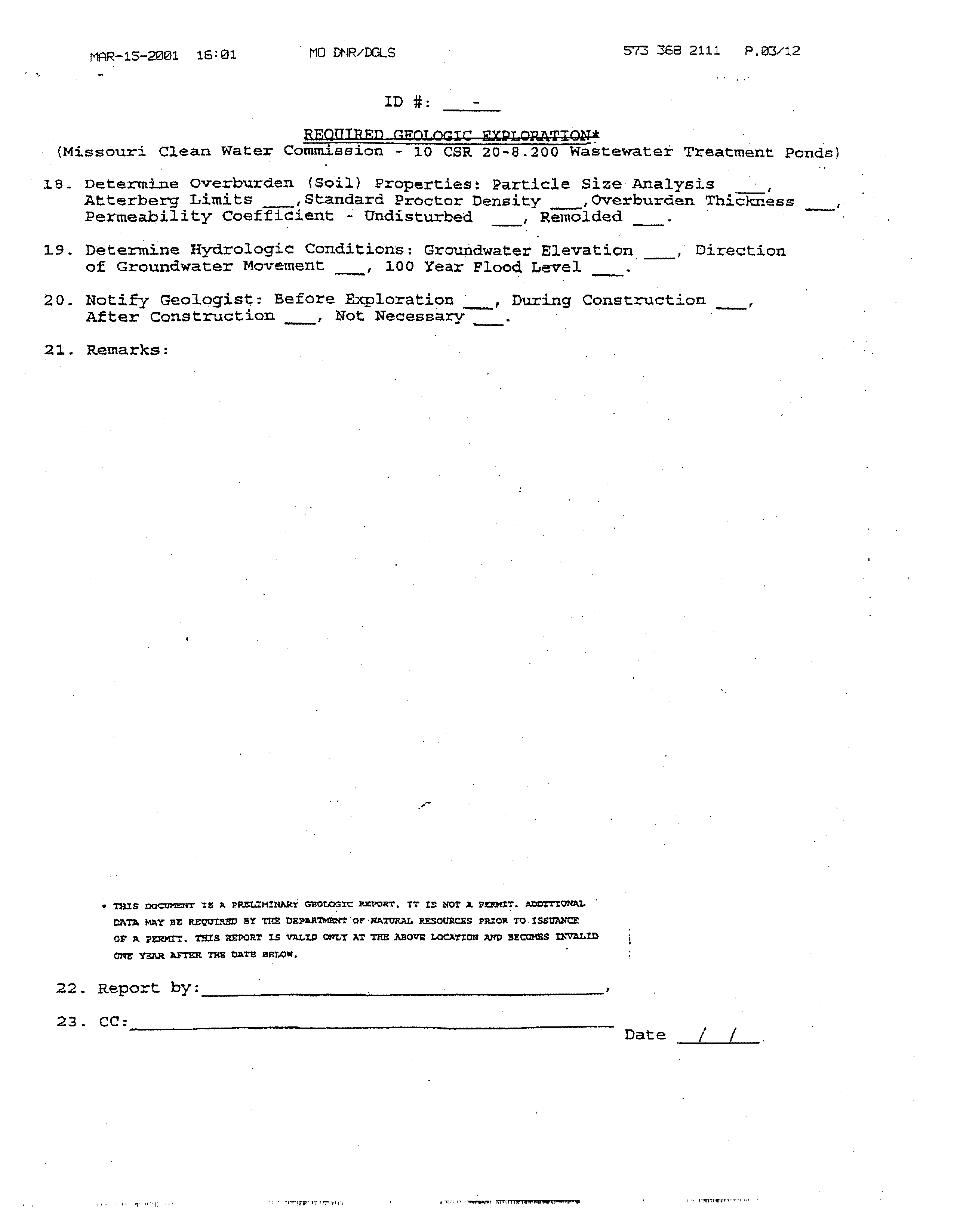

Missouri Department ofNatural Resources regulations~

require that each site for a

earthen wastewater pond, including livestock waste

facilities, be subject to a geological

evaluation. These evaluations are conducted by the Missouri

DepartmentofNatural Resources. If

the facility has severe geological

limitations,the wastewater pond

(i.e., livestock waste lagoon or

holding pond) may be prohibited unless liner technology-and/ormore detailed investigation and

analysis can demonstrate that the proposed pond will not cause groundwater contamination. If the

geological evaluation indicates high collapse

potential, then

the

ponds are generally prohibited

(Missouri Code of State Regulations,

1999).

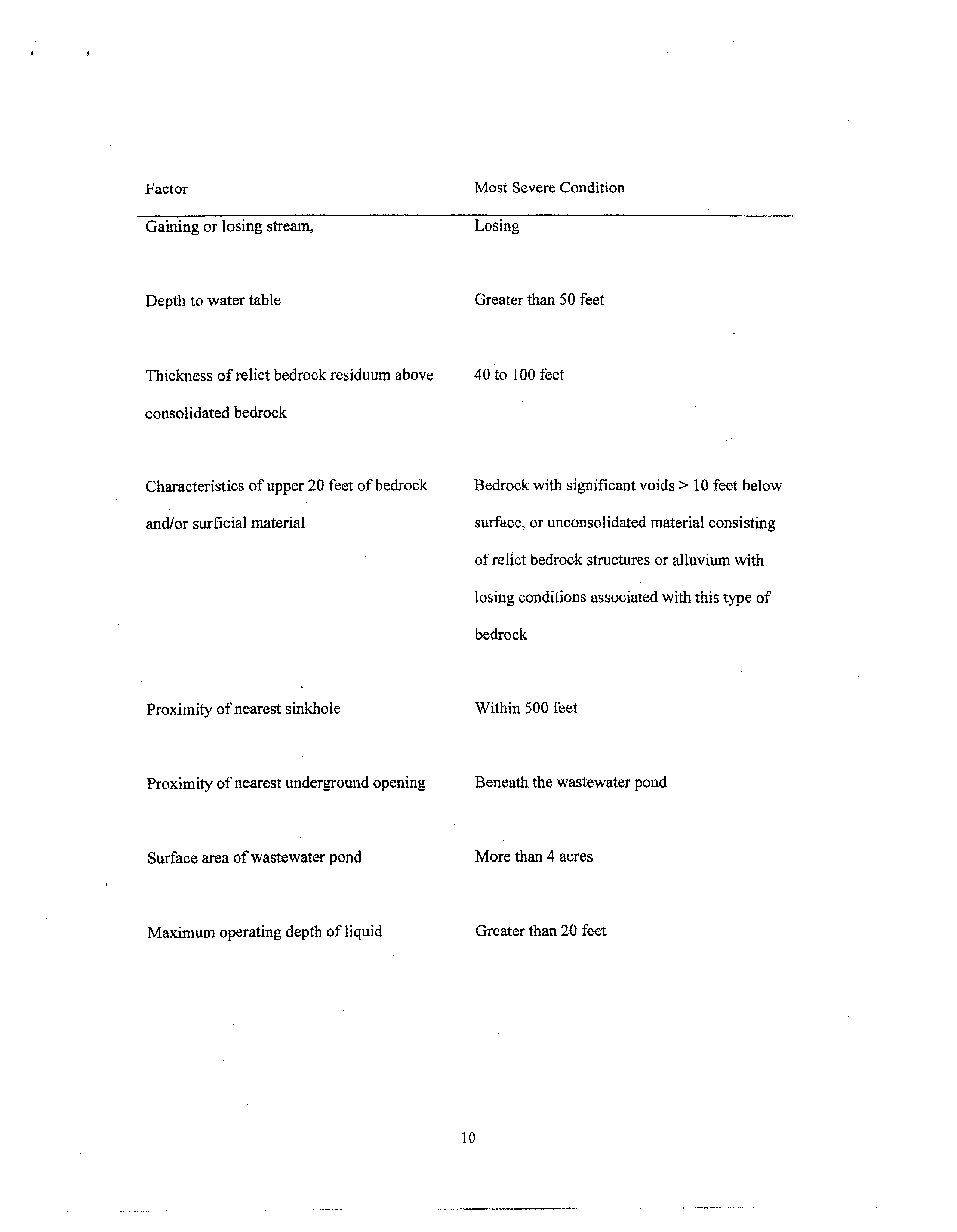

The Missouri

system provides for the evaluation

and

designation of a score for the

followingeight factors in making an assessment of

the

earthen lagoon collapse potential of a site.

A site

is scored if greater than 50

of the top twenty feet ofbedrock is limestone, dolomite

or

calcareous sediments and the wastewater pond bottom is underlain by

less than 20 feet of

unconsolidated material

on top of the bedrock. A site is not scored for an assessment of

earthen

lagooncollapse potential ifthe

earthen

lagoon bottom is underlain by 20 feet or more of

unconsolidated material (other than relict bedrock residuum or alluvium). Listed with each

factor

is the conditionthat is scored the highest for potential wastewater pond

collapse as shown below:

9

Factor

Gaining or losing stream,

Depth to water table

Most Severe Condition

Losing

Greaterthan 50 feet

Thickness

ofrelict bedrock residuum above

consolidated bedrock

Characteristics of upper 20

feet of bedrock

and/or surficial material

Proximity ofnearest sinkhole

Proximity of nearest underground opening

Surface area of wastewater pond

Maximum operating depth of liquid

4Oto

100 feet

Bedrock with significant voids

10 feet below

surface, or unconsolidated material

consisting

of relict bedrock structures or alluvium with

losing conditions associated

with this type of

bedrock

Within 500 feet

Beneath the wastewater pond

Morethan 4 acres

Greater than 20

feet

10

Section

2.5 of the report “Recommendations of the Technical Workgroup- Liquid Manure

Storage in the Karst Region” provides a summary ofthat workgroup’s reviewof requirements of

manure storage structures located in karst areas often states with karst geology. The factors or

restrictions used

by Florida, Pennsylvania, Indiana, Ohio, Missouri, Kentucky, Wisconsin, Iowa

and two other unidentified states surveyed included:

-

•

size-of the manure storage structure,

-

•

use of rigid materials, above ground storage or impermeable liners,

•

liner permeability requirements,

-

•

prohibition of earthen liners,

•

setbacks from sinkholes of 150 to 500 feet,

•

site assessment to determinerelative risk, and

-

•

depth to bedrock

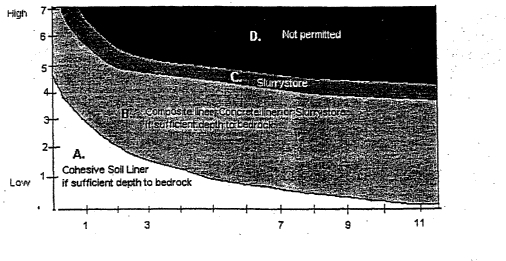

I have attached a chart comparing the Part 506 proposal with the Minnesota and Missouri

regulations and workgroup report.

-

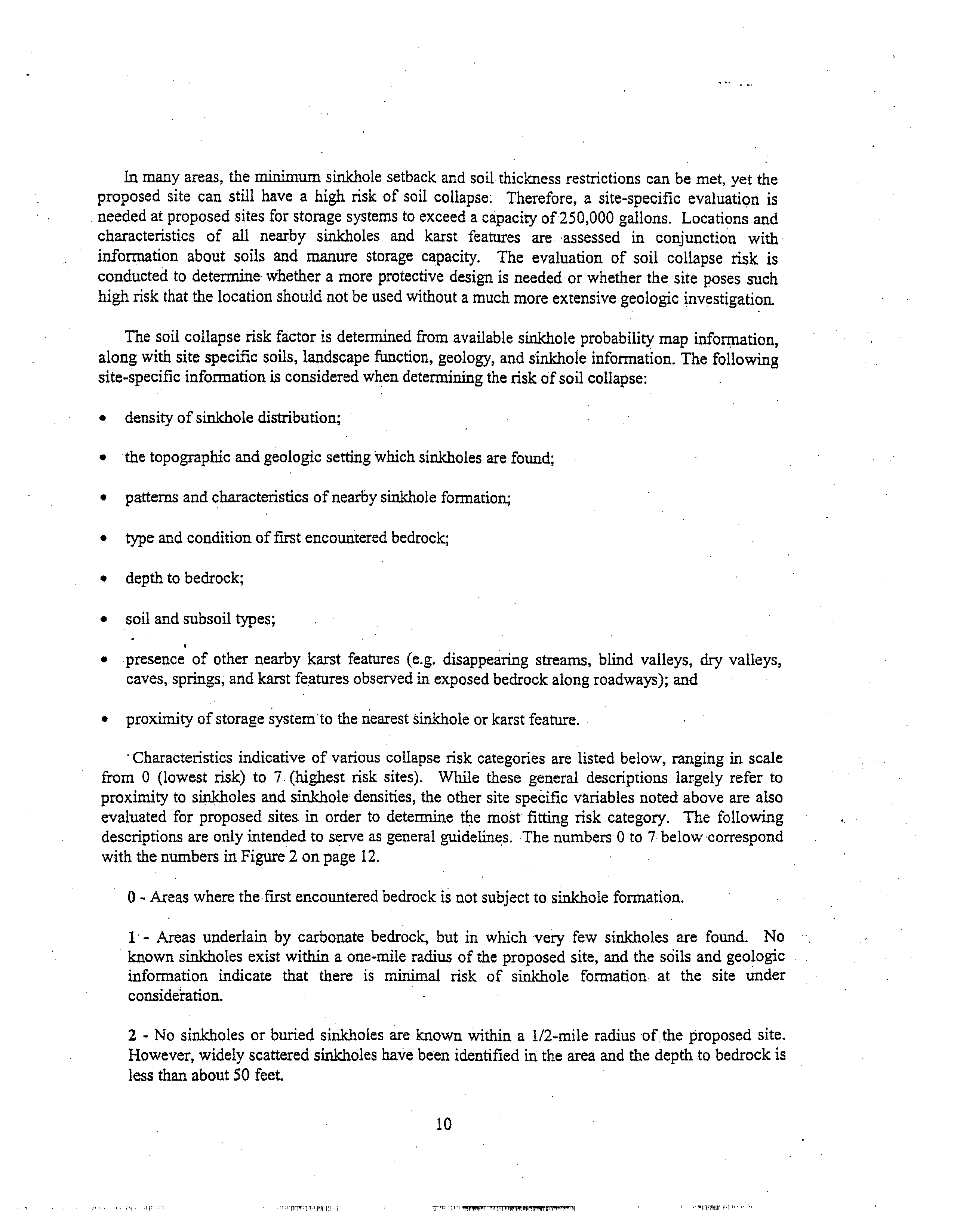

The presence of voids below the structure presents the greatest threat in karst areas to the

integrity of the waste storage structure. Based on the above information regarding

karst, a single

soil boring to a depth of 20 feet will not be sufficient to reliably detect voids located near the

manure storage structure that can cause failureof manure storage structures. Additional borings

would provide more assurancethat voids are not present. Multiple borings should be conducted to

a depth of at least 50 feet or to the bedrock to detect the presence of voids.

Alternatively, ifa single boring to 20 feet or to bedrock

is used

as proposed, additional

requirements would provide methods to prevent groundwater contamination due to failures of

manure storage structures into fractured bedrock. Examples of these additional

requirements are:

preventing the location of manure storage structures or requiring-the -use ofsecondaryliners with

leachate

collection in areas of shallow soils over bedrock, requiring material and liners based

on

11

depth to bedrock, limitations on the

size of manure storage structures, diversion of fresh water

away from manure storage areas, and prohibitions

based

on detection of voids during

construction.

-

I have used the following materials, which will

be offeredas exhibits in thisproceeding:

‘Benson,

R.

C. andLa Fountain, L. J.,

1984.Evaluation of subsidence or collapse potential dueto

subsurface cavities. Proceedings of the First Multidisciplinary Conference on

Sinkholes. Orlando,

Florida

-

•Jannick, N. 0.

,

Alexander, E. C., and Lanherr, L. J.,

1992.

The

Sinkhole Collapse of the

Lewiston, Minnesota Waste Water Treatment Facility Lagoon. Proceedings of the Third

Conference on

Hydrogeology, Ecology, Monitoring and Management of Ground Water in Karst

Terranes, National Groundwater Management Association.

‘Minnesota Pollution Control Agency, March 20, 2000. Constructing Manure Storage Systems in

the Karst Region. Interim Guidance

Document. Minnesota Pollution Control Agency, Saint Paul,

MN.

•Minnesota Pollution Control Agency, December 20, 2000. Recommendations of the Technical

Workgroup- Liquid Manure Storage in Karst Region To the Minnesota Senate and House

Agriculture and Rural Development Committees. Minnesota Pollution Control Agency, Saint

Paul, MN.

-

‘Minnesota Pollution Control Agency, January

17, 2001. Karst Workgroup Recommendations-

Legislative Fact Sheet. Minnesota Pollution Control Agency, Saint Paul, MN.

‘Missouri Code of State Regulations,

1999. 10

CSR 20-8.200 Division 20-Clean Water

-

Commission, Secretary of State, State of Missouri.

‘Missouri DepartmentofNatural Resources, Division of Geology and Land Survey. Waste Water

Treatment Site

-

Geologic Evaluation. Rolla, Missouri.

12

‘Missouri Department of Natural Resources, Division of Geology and Land Survey. Assessment

of Earthen Lagoon Collapse Potential. Rolla, Missouri.

‘Missouri Department ofNatural Resources, Division of Geology and Land Survey, August

15,

1994.

Guidelines for Assessment of Earthen Lagoon Collapse Potential. Rolla, Missouri.

‘Panno, S. V., Weibel,

C. P. and Li, W.

1997. Karst Regions of Illinois, Open File Series

1997-2.

Illinois Department of Natural Resources-Illinois

State Geological Survey.

•Panno,

S. V.

and Weibel,

C.

P.

1997. Karst Terrains and Carbonate Rocks ofIllinois.

Illinois

Department of Natural Resources-Illinois

State Geological-Survey.

‘State of Minnesota. Minnesota Rules, Chapter 7020.

http://www.revisor.leg.state.mn.us/arule/7020/2100.html

This concludes my testimony, I would be happy to answer any questions that you may

have.

By:

~

/

Daniel

L. Heacock

April 23, 2001

Illinois Environmental Protection Agency

1021

North Grand Avenue East

-

P.O. Box 19276

Springfield,

Illinois 62794-9276

13

F

cqis-Iativg.

FACT~J-S-HEE.T

-

____

Minnesota Pollution

Control

Agency

Karst

Workgroup

recommendations

Introduction

-

Due

to its unique karst geology (fractured limestone

bedrock overlaid with shallow soil, often with

sinkholes), much of southeastern Minnesota

represents a sensitive environment for containmation

of ground water and surfacewaters.

One of the

environmental concerns about karst geology is the

potential forsinkholes to form below wastewater- or

manure-storage structures, causing contaminants to be

channeled directly into

the ground water.

Sinkholes

have formed below three poorly lined municipal

wastewater-treatrnent ponds

in Minnesota and at

several poorly lined wastewater and liquid manure

storage areas in other states.

Ground water

contamination problems have also resulted from

chronic seepage of liquid manure into cracks in the

bedrock that are directly connected

to aquifers.

Background

-

Recognizing the environmental sensitivity of the karst

region, the Minnesota Pollution Control Agency

(MPCA) recently incorporated into rule (Chapter

7020) several

standards for construction of liquid

manure-storage systems in areas prone to sinkhole

development.

In response to the rule

changes, the

Legislature requested that a workgroup be convened

to review and propose standards relatedto this topic

according

to the requirements in section

13 of 2000

Session Laws, Chapter435.

-

-

The MPCA convened a workgroup consisting of 10

engineers, none of whom are employed by state

regulatory agencies, in accordance with the guidelines

set forth by the Legislature, which specified that

engineers in the workgroup be from the private sector.

At

the requestof the workgroup, two or more

hydrogeologises

experienced in the karst region were

present at each meeting to advise on issues pertaining

to karst geology,

soils andhydrogeology.

The

workgroup met over eight days between August and

November.

The workgroup did not build from

existing MPCA policy,

but rathertook a fresh look at

standards needed for the karst region.

The

workgroup considered areas “susceptible to soil

collapse

or sinkhole formation,” to include all

land

where the depth to carbonatebedrock is less than 50

-

feet, and the uppermost bedrock

is fractured carbonate

materials or other bedrock where soil collapse

or

sinkhole formation occurs.

karst Workgroup recommendations

Following considerable study oftechnical information

from Minnesota

and other states, the workgroup

developed

several standards forthese areas.

Location restrictions

•

Maintain a 300-foot setback from sinkholes.

•

Relocate site if subsoil inspections during

excavation indicate soil subsidence

or sinkhole

development.

•

Avoid construction over mapped caves that

become

registered with the state.

Design specifications

-

a

Use

dual liners, -concrete liners or above-ground,

-

glass-fused metal tanks.

•

Limit maximum

capacity

ofa single cell to three

million gallons (no total-capacity limit per

farm

and no restrictions based on

animal-unit

numbers).

-

a

Maintain a five-foot minimum separation between

manure and bedrock, with some exceptions.

January17,

2001

Minnesota Pollution

Control Agency,

520 Lafayette

Road

North, Saint Paul, MN

55155-4194

(651) 296-6300,

toll-free (800) 657-3564,

TTY (651)282-5332 or (800) 657-3864

This material

can

be

made

available

in

alternative formats

for people with

disabilities.

®

Printed on recycled

paper containing at least

30

percent fibers from paper

recycled

by consumers.

Minnesota

Pollution

Control Agency

-.

Convey

roof and site runoff waters away from the

manure-storage area.

-

Identifying and responding to failures

•

Monitor manure levels regularly and conduct an

annual inspection of the liner.

•

Develop an emergency response plan.

The

workgroup recommended that the proposed

standards replace existing MPCA rules pertaining to

design standards in areas

susceptible

to sinkhole

formation.

It also suggested that

these

-

recommendations

be reviewed

and refined after

furthersinkhole-formation studies are

completed.

Similarities between recommendations

and existing regulations

-

Many similarities can be found when comparing

current Minn. R.

ch.

7020

and workgroup

recommendations for

areas susceptible to soil collapse

or sinkhole formation.

For example, both the existing

rules and

workgroup recommendations:

•

establish 300-foot setbacks from sinkholes.

•

include major restrictions foruse of cohesive soil

liners alone.

•

allow for use of concrete-lined, dual-lined and

above-ground storage.

•

establish a similar minimum soil thickness needed

above bedrock foruse of concrete, composite and

above-ground

liners at small to moderate-size

feedlots.

-

-

Differences between recommendations

and existing

regulations

•

Current rules forminimum

separation-to-bedrock

restrictions vary from five to

15

feet for concrete

pits, dual-lined basins and above-ground tanks,

depending on the type of liner and the number of

animal units on the farm.

The workgroup

recommends that separation to bedrock be a

-

minimum offive

feet, except fortwo types of

designs

where. separation

to bedrock can

be less

than five

feet.

•

MPCA rules allow cohesive soil liners alone

where there is a substantial soil thickness (e.g.,

20

to 40 feet). between manure and bedrock

The

workgroup recommends that no

cohesive soil

liners be used alone without another liner in areas

with less than 50

feet from ground surface to

-

Page2

carbonate bedrock until further geologic study

identifies the areas with less than 50

feet to

-bedrock that have a low potential for soil collapse

or sinkhole formation.

•

MPCA rules

set a 250,000-gallon limit per storage

cell in areas where there are four or more

sinkholes within

1,000 feet.

No other storage-

capacity limits

are set in rules.

The workgroup

recommends a three-million-gallon limit in all

areas susceptible to sinkhole formation

Recommendations for additions to

existing regulations

Other recommendations that the workgroup made are

consistent with MPCA policy and past permit

-

conditions, but

are not currently established in rule for

all new liquid-manure-storage facilities in sinkhole-

prone

areas.

The workgroup proposes that the

following be added to state rules for areas susceptible

to sinkhole formation:

•

-

inspections of subsoil during construction,

•

diverting freshwater away from the

manure-storage area,

•

annual liner inspections,

•

monitoring of manure levels and

-

•

emergency response plans.

What’s next?

The

MPCA intends to implement workgroup

recommendations in the following ways:

1)

Study technical information from the workgroup

proposals as a basis for future rule

revisions.

2)

Issue permits with the workgroup standards until

the rule

can be revised (where an equivalent level

-

-

-

of environmental protection is achieved).

3)

Modify MPCA guidelines

to reflect workgroup

proposals.

4)

Discuss with other agencies how and when to

implement recommendations for further study.

For more -information

If you have any questions or would like more

information about the Karst Workgroup’s

-

-

recommendations, call David Wall at

(651)

296-8440

or e-mail

him at david.wall@pca.state.mn.us.

Recommendations

of the

Technical Workgroup

Liquid Manure Storage in the Karst Region

To the

Minnesota Senate and House

Agriculture and Rural Development Committees

-

December 20,

2000

Convened by the Minnesota Pollution Control Agency

Printed

on recycled

paper containing at

least 20

fibers from paperrecycled by consumers.

AcknowIed~ements

We extend our sincere thanks to the dedicated technical workgroup members who gave a

considerable amount of time and effort to attend numerous meetings and review materials.

The

Minnesota Pollution Control Agency (MPCA) gratefully acknowledges private sector engineers

that voluntarily contributed -their time and attention through this unfunded directive.

The

workgroup and MPCA gratefullyacknowledge

the public sector staff from the NaturalResources

Conservation Service, University of Minnesota, Minnesota Department of Health, Minnesota

Extension Service, Minnesota Department of Natural Resources, Minnesota Geological

Survey

andIowa Geological Survey who-participated in this endeavor.

The workgroup would like to

express their sincere thanks to those who traveled great distance to supply information and

testimony to the workgroup.

-

Table of

Contents

Chapter

1

-

Introduction

1

1.1

Workgroup Charge and Scope

....

1

1.2

Workgroup Members

1.3

Workgroup process and principles

3

Chapter 2

-

Background

5

2.2

Historical record of failed and successful waste storage systems in karst regions

7

2.3

Benefits of livestock agriculture in the karst region

S

2.4

Minnesota policy on liquid manure storage in karst areas

8

2.5

Other states’ standards for liquid manure storage in karst areas

9

Chapter 3:

Workgroup Recommendations

~.

3.1

Defining areas susceptibleto soilcollapse or sinkhole formation

11

3.2

Recommended standards for areas potentially susceptible to soil coJJ.apse orsinkhole

-

formation

..

3.2.1

Location restrictions

.~.

...

~l-2

3,2.2 Design

Specifications

~

3.2.3

Identifying andresponding to failures

..

14

Chapter 4:

Comparison of workgroup recommendations with

15

current Minnesota policy

4.1 Comparison overview

4.2 Workgroup proposed additions to MPCA rules

17

4.3 Recommended alternative standards to MPCA

rules

~-1

8-

4.3.1

Storage cell capacity limits

~

153-

4.3.2

separation to bedrock requirements

..

4.4 Proposals for further study

~

20

Chapter 5:

Workgroup Considerations and Justification

5.1

Location Restrictions

5.2

Areas with similar water quality risks as the rest of the state

~22

5.3

LinerTypes

~.23

5.4

Separation to bedrock

25

5.5

Feedlot size andstorage capacity

26

5.6

Diverting surface

runoff

~

28

5.7

Construction requirements

~.

2&

5.8

Monitoring

..

29

5.9

Emergency Response Plan

~

29

Chapter 6

-

Recommendations forfurther study

~1l

-

Attachment A

—

Information about Workgroup Members

-

Attachment B

—

Bibliography

-

Attachment C

—

Minnesota Rules

ch.

7020.2005 and

7020.2100

Attachment D

—

ConstructingNew

Manure Storage Systems

in the

Karst Region

Executive Summary

Much of the karst region of southeastern Minnesota represents a sensitive -environment for

contamination of ground water and surface waters, due largely to:

•

shallow soils

above highly fractured bedrock;

-

•

rapid transport of water into and through the subsurface;

-

•

sinkholes and other openings to the fractured bedrock;

•

hydrogeology that is highly variable and difficult to predict; and

-

•

an interconnected system ofsurface water andground water.

One of the environmental concerns in karst regions

is the potential for sinkholes to form below

wastewater- or manure storage structures, causing contaminants to be directly channeled into the

ground water.

Excessive seepage from liquid impoundments

can cause underlying soil to wash

into bedrock fractures, leading to an eventually soil collapse

or sinkhole formation.

Low

-

permeability liners reduce the

likelihood of sinkhole formation below liquid storage areas.

Sinkholes have developed under three poorly lined municipal wastewater treatment ponds in the

karst region, draining several million gallons of wastewater into the ground water below.

In

addition,

several cropland runoffretention ponds establishedfor erosion control have also failed

when sinkholes developed under the ponds.

No

liners of any sort were used for construction of

these runoff retention ponds.

Sinkhole developmentbelow liquid manure storage systems has

-

not been known to occur atthe hundreds of structures in southeastern Minnesota, but has

occurred in at least five instances in other states with karst geology.

Other

karst

states have also

had failures ofwastewater treatment ponds into sinkholes.

All failures in Minnesota and other

-

states have been associated with

earthen

storage ponds having either no liner, or a soil liner

designed to seep more than current Minnesota requirements forcohesive soil liners.

-

-

Ground water contamination problems can also result from chronic seepage of liquid manure

moving into fractured bedrock (without sinkhole

formation).

Well water was severely

-

contaminated at one southeasternMinnesota fa.rmwhen liquidmanure continuously leaked

through a soil liner into

the fractured bedrock immediately below the

earthen basin.

Long-term

-

chronic seepage into fractured bedrock can add bacteria, viruses

and other potential contaminants

to the uppermost bedrock aquifers.

-

Recognizing

the potential for both chronic and catastrophic

failure of liquid manure storage

systems in the karst region, the Minnesota Pollution Control Agency (MPCA or Agency)

established guidelines for construction of liquid manure storage systems in areas susceptible to

soil collapse

or sinkhole formation.

The

agency encourages producers and design engineers to

-

follow these guidelines.

Some ofthe standards in the guidelines were incorporated into MPCA

proposed revisions to Minn. R.

ch. 7020, governing animal feedlots andthe

l1llllfl~E,

lflMlSPOlTllll~R~l

llllLllllillltl

of manure.

Prior to going into effect on October 23, 2000, the revised rule underwent an

-

extensive public review process involving oversight by an Administrative Law Judge.

The

MPCA made several changes

to the rules in response to comments from the

public and the

Judge.

In addition, the Minnesota Legislature reviewed the proposed rules and passed legislation

requiring changes

to several parts ofthe proposed rules (2000 Session Laws, Chapter

435).

No

changes were made by the MPCA or the Legislature to proposed rules pertaining to manure

storage in areas susceptible to sinkhole formation.

However, the Legislature requested that a

workgroup be conyened to review and propose standards related to this topic.

The legislation in

section

13

of2000

Session Laws,

Chapter

435,

states:

“The commissioner of the Pollution Control Agency shall convene a workgroup consisting of

representatives

from Natural Resources Conservation Services andprivate sector licensed

professional engineers, including individuals with expertise in hydraulics, structural systems,

and geology, to review and propose design standards for liquid manure storage facilities in

areas susceptible to soil collapse and sinkhole formation.

This review shall include an

evaluation ofwhether such standards should be volume based or animal unit based.”

The MPCA responded

to the legislationby convening a workgroup consisting often engineers

with collective backgrounds in structural engineering; hydraulics; geology; design and

-

construction ofliquid manure storage systems in the karst region; assessing seepage through

manure storage system liners; geotechnical evaluation; alternative liners for liquid containment;

and liner reinforcement.

All workgroup recommendations were made by the ten engineers

forming the workgroup, none of whom are employed by

state regulatory agencies.

At the

request of the workgroup,

two or more hydrogeologists experienced in the karst region were

present at each meeting to advise on

issues pertaining to karst geology,

soils and hydrogeology.

The workgroup was specifically asked by the legislature to target standards for liquidmanure

storage in areas “susceptible to soil collapse or sinkhole formation.”

The workgroup

considered

areas “susceptible to soil collapse or sinkhole formation,”

tO include all land where the depth to

-

carbonate bedrock is less than 50

feet, and the uppermost bedrock is fractured carbonate

materials

or other geologic strata where soil collapse

or sinkhole formation occurs.

In areas not

susceptible to soil collapse or sinkhole formation, the workgroup recommends that the same rules

should apply for liquid manure storage design, construction and operation as throughout the rest

of the state.

-

-

A shortcoming noted by the workgroup with existing information is the

lack of geostatistical

analyses indicating the likelihood of soil collapse to occur in a given area.

The Minnesota

Geological Survey, University ofMinnesota andDepartment ofNatural Resources are currently

examining the relationship between the presence of karst features and associated geologic

conditions.

The recommended measures in this report are intended to serve

as interim standards

until the studyis completed and the standards can be revised to more specifically reflect a

geostatistical evaluation of sinkhole formation.

-

The workgroup did not build from existing MPCA policy, but rather took a fresh look atneeded

-

standards for the karst region.

ExistingMPCA policy was only briefly considered during the

workgroup process.

Workgroup recommendations made in this report reflect

the best

professionaljudgement of the workgroup members made after considerable study and discussion

of available information on this topic.

11

The workgroup recommends the followingprotective measures for areas susceptible

to soil

collapse

or sinkhole

formation.

These measures are meant to be used in addition to the existing

protective measures required by the MPCA throughout the state.

These standards pertain to

1)

location restrictions, 2) design, and 3) identifying andresponding to failures.

The standards can

be summarized as follows:

Location restrictions

-

-

•

Maintain a 300-foot setback from sinkholes;

-

•

Relocate site if subsoil inspections during excavation indicate soil subsidence or sinkhole

development;

-

-

•

Avoid construction over mapped caves that become registered with the State;

-

-

-

Design spec~flcations

•

Use dual-liners, concrete liners or above ground glass-fused metal

-

•

-

Limit maximum capacity of a single cell to three million gallons (no total capacity limit per

farm and no restrictions based on animal unit numbers);

-

-

•

Maintain a five-foot minimum separation between manure and bedrock, with some

exceptions;

•

Convey roof and site runoff waters away from the storage area;

Identifying and responding to failures

-

-

-

-

-.

Monitor manure levels regularly and conductan annual inspection of the liner; and

•

Develop an emergency response plan.

-

-

The workgroup recommends that the proposed standards in this report replace existing MPCA

rules pertaining to design standards in areas susceptible to -sinkhole formation.

They also suggest

that these recommendations be reviewed and relmed after completing further study of the

likelihood of sinkhole formation under various geologic conditions.

Many similarities can be foundwhen comparing Minn.

R.

ch.

7020 and workgroup

recommendations for areas susceptible to soil collapse

or sinkhole formation.

For example, both

the rules and the workgroup recommendations:

-

•

establish setbacks from sinkholes of 300 feet;

-

•

include

mnajor restrictions on use of cohesive soil liners alone;

-

•

allow for use of concrete lined, dual-lined and above ground storage; and

•

establish a similar minimum soil thickness needed above bedrock foruse of concrete,

composite and above ground liners at small to moderate-sized feedlots;

Yet, the specific criteria for some of the recommendations

are different.

Current MPCA rules for

separation

to bedrock restrictions vary from five

to fifteen feet for concrete pits, dual-lined basins

and above ground tanks,

depending on the type of liner and the numberof animal units on the

farm.

Whereas, the workgroup recotumends that separation to bedrock be a minimum of five-

feet, except for two types of designs where separation to bedrock can

be less than five feet.

MPCA rules allow cohesive soil liners alone where there is a substantial

soil thickness between

111

~_~:—

~

-

*

~

manure and bedrock (e.g., 20

to 40 feet).

The workgroup recommends no cohesive soil liners to

be used alone without another liner

in areas with less than-50 feet from ground surface to

carbonate bedrock until further geologic study identifies the areas with less than 50 feet to

bedrock that have a low potential for soil collapse

or sinkhole formation.

-

Other workgroup recommendations, such

as inspections of subsoil during construction and

diverting freshwater away from the manure storage area,

are not stated in MPCA rules but are

consistent with MPCA guidelines.

The MPCA requires manure storage system designs

to

include plans forperiodic

inspection of the liner.

This is consistent with, but not as specific

as

workgroup recommendations

to require regular monitoring of manure

levels and annual liner

-

inspections.

The workgroup recommended emergency response plan requirements for all new

liquid manure storage systems constructed in areas susceptible to sinkhole formation.

Emergency response plans are currently required by MPCA rules at feedlots with 1000 or more

animalunits.

Another difference between current MPCA policy and workgroup recommendations

relates to

storage capacity limits.

MPCA rules set a250,000 gallon limit per storage cell in areas with four

or more sinkholes within

1000 feet.

No other storage capacity limits

are set in rules; however,

recommended guidelines suggest limits that vary with the

liner type and geologic conditions.

The workgroup recommends a three million gallon limit in all areas susceptible to sinkhole

formation, regardless ofproximity of karst features

(with the exception ofthe 300 foot setback

requirement from sinkholes).

The workgroup emphasized that further work is needed

to:

•

Determine the geostatistical probabilities

of soil collapse in different types of geologic

settings;

-

-

•

Study pathogen transport through soils below liquidmanure storage systems in the karst

region;

•

Develop generic emergency response plans that can then be tailored for specific feedlot

operations;

-

•

Conduct research and demonstration projects on alternative manure management approaches

-

that do not rely on liquid storage;

-

-

•

Conduct regular monitoring and inspections of existing liquid manure storage systems; and

•

Collect, manage, analyze, interpret and map geologic and hydrogeologic information needed

-

for engineers designing liquid storage basins in karst areas.

iv

Chapter

1

*

Introduction

ii

Work~rounChar2e

and

Scone

In December

1999, the Minnesota Pollution Control Agency (MPCA) proposed revisions to rules

(Minn.

R.

ch. 7020) governing animal feedlots and the

S!UU(E, 1RfiISP~MflflUII~ilII

~II1IlliTI~

of manure.

The

rule

revision updated the 20-year old rules and modified the approach to permitting feedlots.

The rule

revision also added technical standards for such activities as land application of manure, manure

transportation, open lot discharges, manure storage closure, stockpiling, and construction of

-

liquid storage systems.

Several new requirements specificallyaddressed construction of liquid

manure storage systems in areas susceptible to sinkhole formation.

Prior to going into effect

on October 23, 2000, the revised rule underwent an extensive public

review process involving oversight by an Administrative Law Judge.

The MPCA made several

changes

to the rules in response to comments

from the public and the Judge.

In addition, the

Minnesota State Legislature reviewed the rules and passed legislation requiring further changes

to the proposed feedlot rules (2000 Session Laws, Chapter

435).

No changes were made to the

rules pertaining to manure storage in areas susceptible to sinkhole formation.

However,

the

legislature requested that a workgroup be convened to review and propose standards related to

this topic.

The legislation in section

13

of2000

Session Laws, Chapter 435, states:

“The commissioner of the Pollution Control Agency shall convene a workgroup consisting of

representatives from Natural-Resources Conservation Services and private sector licensed

professional engineers, including individuals with expertise in hydraulics, structural systems,

and geology, to review and propose design standards for liquid manure storage facilities in

areas susceptible to soil collapse and sinkhole formation.

This review shall include an

evaluation of whether such standards should be volume

based or animal unit based.

The

commissioner shall submit the fmdings and recommendations

ofthe workgroup

to -the Senate

and House Agriculture and Rural Development Committees by October 31, 2000.”

In response, the MPCA convened a technical workgroup to address the specific issues required in

the legislation.

The workgroup focused

on standards forwater quality protection thatare directly

related to the design and construction of liquid manure storage systems

in areas susceptible to

soil collapse or sinkhole formation.

Several issues were considered to be beyond the scope of the

workgroup, including in-depth analysis about economics and affordability, extensive

investigation of current water quality throughout southeastern Minnesota, and the socio-political

ramifications of implementing these recommendations

as state law.

Risks associated with

manure application to fields, liquid manure spills and air emissions were also considered to be

beyond the scope and charge of the workgroup (yet these issues are linked to manure storage

techniques).

This document discusses workgroup recommendations made for new liquidmanure storage areas

andmaj or modifications made to existing structures. The workgroup did not address standards

for existing liquid manure storage systems currently operating in the karst region.

1

The MPCA requested and was

granted an extension of the report deadline from October 31,

2000, to January 4, 2001.

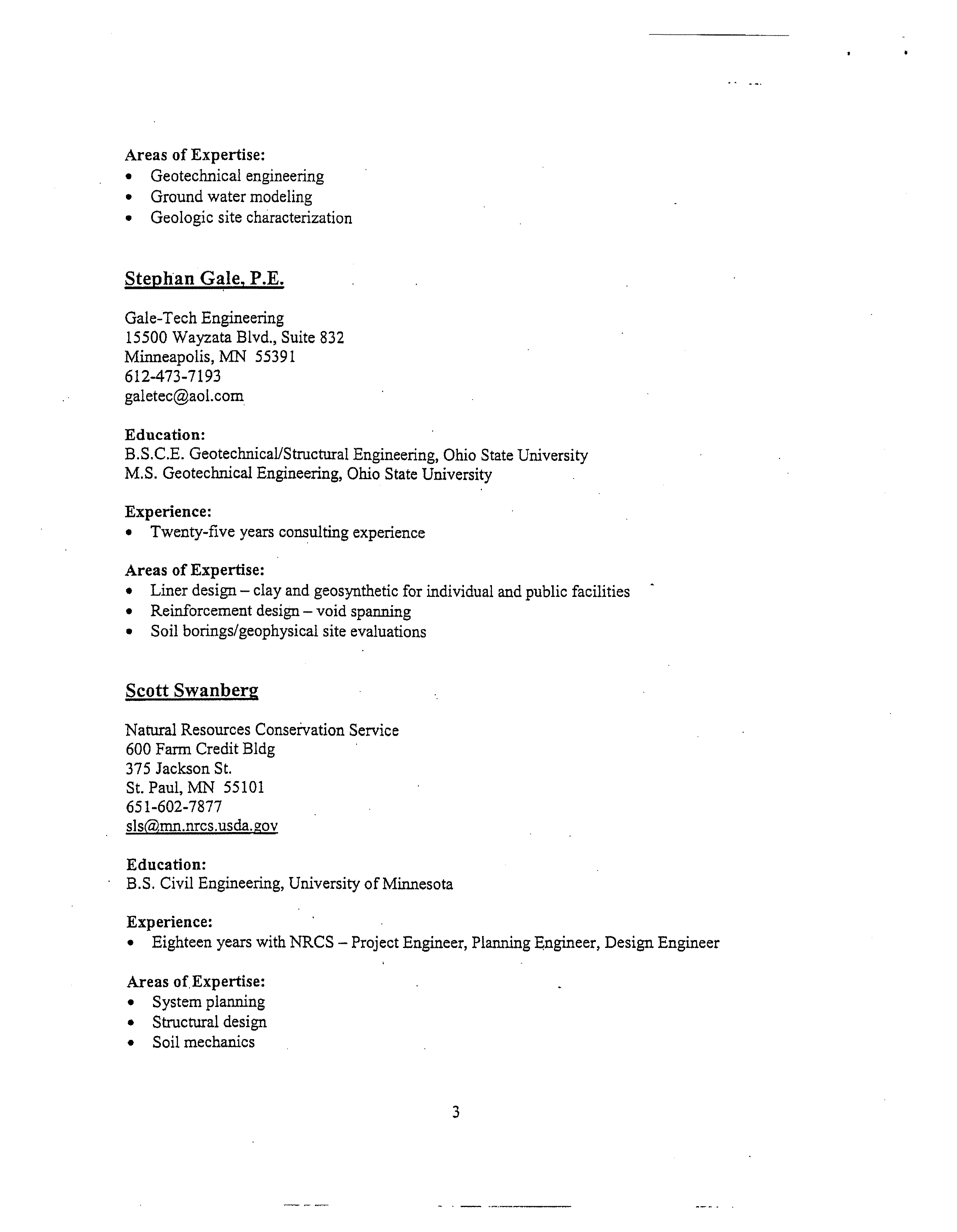

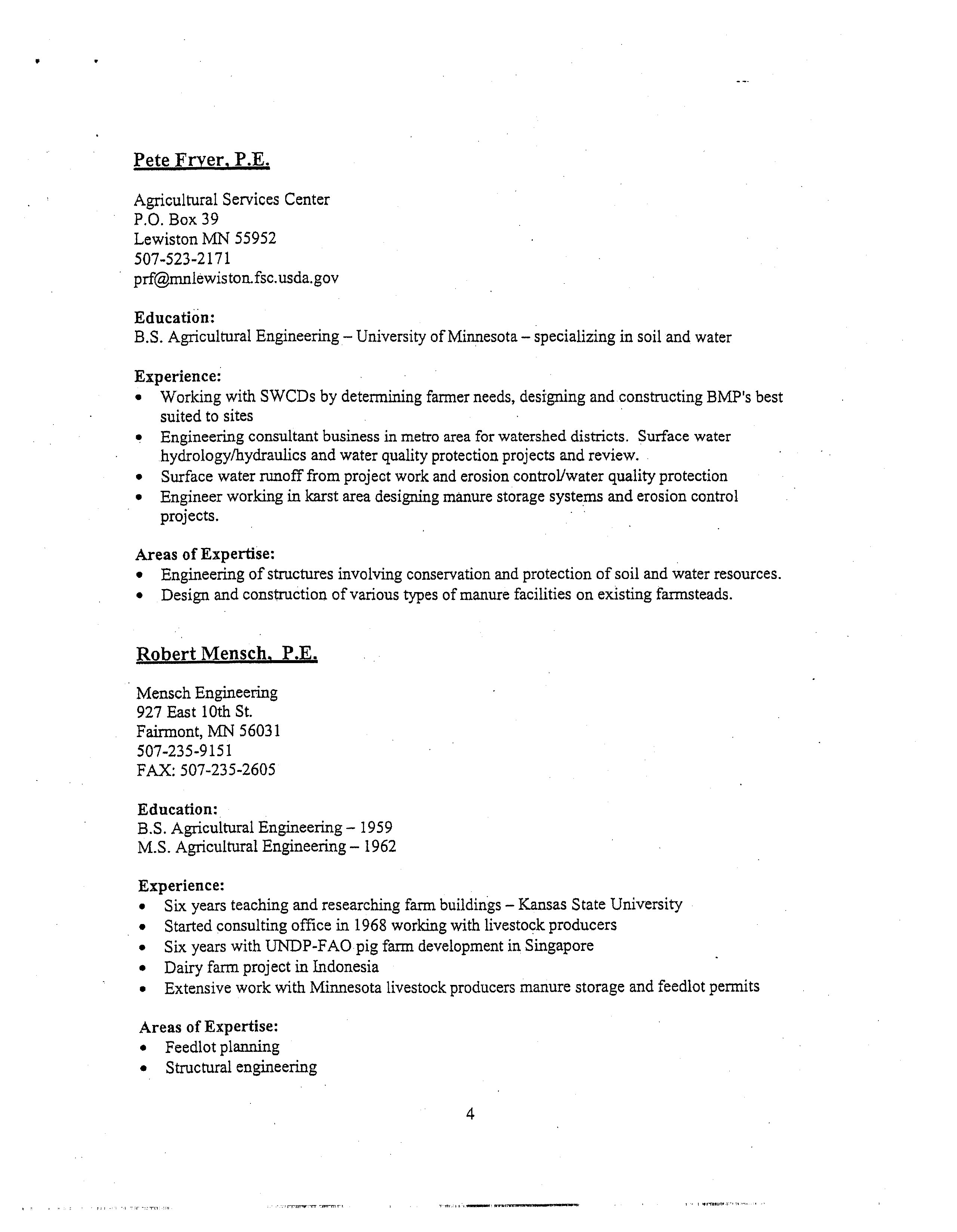

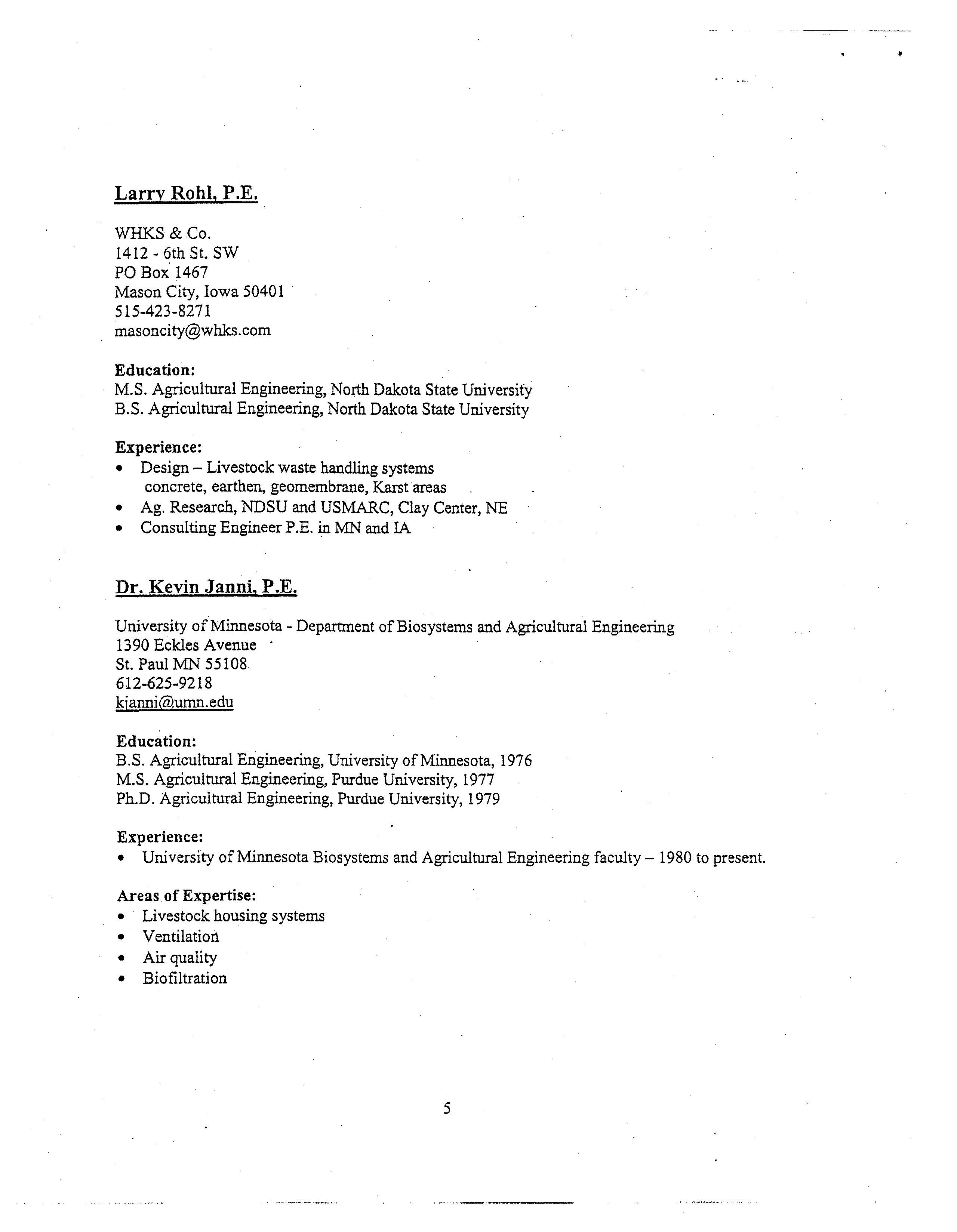

1.2

Workgroup Members

-

The MPCA convened a workgroup consisting of individuals who collectively, met the

requirements of the legislation.

The group

includes engineers with expertise in the areas of

structural engineering, hydraulics, and geology.

In addition, engineers were

selected who have

-

experience in the following areas: a) designing and constructing liquid manure storage systems in

the karst region, b) studying seepagethrough manurestorage system liners, c) evaluating

geotechnical information,

and d) using alternative liners and liner reinforcement for liquid

containnient systems.

-

The

ten engineers in the workgroup are listed below.

Their education, experience,

expertise,

-

addresses and phone/e-mail

is includedin Attachment A.

Dr. Randal Barnes, P.R.

-

University of Mintiesota, Department of Civil Engineering

Dr. Chuck Clanton, P.R., P.S.S. (alternate Dr. Kevin Janni, P.R.)

-

University of Minnesota,

Department of Biosystems and Agricultural Engiiieering

Mr. Pete Fryer, P.E.

-

Joint Powers Board, working in association with NRCS

and SWCDs

Mr. Stephan Gale, P.E.

-

Gale-Tech Engineering

-

-

Mr. Art Kaimnes, P.R.

*

Polaris Group

Mr. Robert Mensch, P,.E.

-

Mensch Engineering

-

Mr. Larry Roehi, P.E.

-

WHKS & Co.

-

Mr. Rob-Romocki, P.R.

-

Natural Resources Conservation Service

Mr. Scott Swanberg, P.R.

-

Natural Resources Conservation Service

Mr. Colby Verdegan, P.R.

-

Chosen Valley Testing

-

The MPCA understood the intent of the legislation was for the recommendations to be made

by

the people

from organizations specified in the legislation. All workgroup recommendations

included in this report were made by the ten workgroup engineers.

The recommendations

in this

report were not made by— the state

agency regulatory staff participating in this process.

This is

very different from a rule-making process where state agencies, local government, private

organizations and the public at large provide input into the environmental regulation

development process.

The workgroup engineers requested that hydrogeologists experienced in the karst region be

present at all meetings.

A minimum of two hydrogeologists experienced in the karst region were

present at each meeting to advise on issues pertaining to karst geology, soils-and hydrogeology.

The hydrogeologists included:

Mr. Jeff Green, P.G.

*

Minnesota Departthentof Natural Resources

Mr. Bruce Olsen, P.G.

-

Minnesota Department of Health

Mr. Dave Wall, P.S.S., P.G.

-

Minnesota Pollution Control Agency

-

In addition, five

other geologists and hydrogeologists withkarst expertise were invited to attend

one of two meetings held on September

7 and October 2, 2000.

These individuals included:

Dr. Calvin Alexander

-

University of Minnesota, Dept. of Geology and Geophysics

Mr. Robert Libra

-

Iowa Geological Survey

-

Dr. Tony Runkel

-

Minnesota Geological Survey

Mr.

Robert Tipping

-

Minnesota Geological Survey

-

-

Dr. Mike Trojan

-

Minnesota Pollution Control Agency

-

Mr. Roger Steinberg, Minnesota Extension

Service, assisted with meeting facilitation.

Mr. Dave Wall, Minnesota Pollution Control Agency, coordinated workgroup activities and

developed the report

as directed by the workgroup.

1.3

Workgroup process and

~rinciules

-

The workgroup did not build from existing MPCA policy, but,rather took a fresh look at needed

standards for the karst region.

Existing MPCA policy was

only briefly considered during the

workgroup process.

-

-

The workgroup held all-day meetings on eight days between August 10 and November 27, 2000.

Notes

from each meeting were incorporated into written summaries that were reviewed arid

refined by workgroup members following each meeting.

Written resource materials were handed

out to workgroup members as supplemental information forreview and consideration during

development of the recommended standards (see Bibliography in Attachment B).

The following background topics were studied by the workgroup-during the first four meetings:

•

Mechanisms potentially icading to chronic andcatastrophic failure when operating liquid

manure storage systems in the karst region;

•

Environmental consequences of manure storage failures in karst areas;

•

Environmental consequences of unachievable standards;

-

-

-

-

•

Standards for liquidmanure storage in karst areas outside of Minnesota;

•

Historical record of failed and successful waste storage systems in karst regions;

•

Minnesota’s karst-related standards for other types of contaminant containment;

-

•

Ground water impacts from liquid manure storage systems;

-

•

Site characterization techniques; and

-

-

-

-

-

•

Perspectives from MPCA, Minnesota Department of Health, Minnesota Department of

Natural Resources;

Prior to the

development of recommended standards, the workgroup spent considerable time

discussing the criteria and principles to use as a basis for developing the standards.

The

workgroup agreed that the standards should protect the environment from both chronic problems

resulting from seepage out ofthe

liquid manure storage system, and from catastrophic problems

resulting from a soil collapse

below the storage system.

The workgroup decided that the design

3

Karst conditions represent a sensitive environment forcontamination of the upper aquifers and

surface waters.

Some of the heightened environmental concerns

characteristic—of--karst’ areas

include:

1.

Shallow soils above bedrock

—

reducing the chance for treatmentand attenuation of

contaminants introduced at the land surface;

2.

Highlyfractured bedrock

-

potentially leading to rapid contaminant transport to other

underground locations or streams, and making

it very difficult to collect, remove arid treat

contaminants after moving into

bedrock;

3.

Soil collapse/sinkhole development

-

that can lead to failure of liquid impoundment

structures;

4.

Existing Sinkholes and other openings into

the ground—that

can funnel contaminants in

surface runoff directly into

the ground water;

5.

Interconnected system of

suiface and groundwater

—

so that contaminants entering

ground

water can be rapidly transported to surface waters, and visa-versa;

6.

Steeply sloping landscapes

—

accelerating surface runoff and erosion;

7.

Large number ofwells in the uppermost bedrock

aquifer

so that many private domestic

water sources and some public water sources are vulnerable to contamination;

8.

Highly variable and unpredictable geology

—

leading to a lower

level of certainty regarding

contaminant transport.

Several concerns have been raised in recent years regarding the construction and operation of

-

liquid manure storage systems in Minnesota’s karst region.

Fourpotential water quality risks

-

associated with liquid manure storage systems in the karat region

are described below.

The

first

and second risks could lead to long-term chronic problems, whereas- the third risk is a

catastrophic failure.

-

-

1.

Seepage of contaminants through the storage facility and underlyingsoil to fractured bedrock

and subsequently to ground water;

-

-

-

2.

Soil subsidence below the structure which breaches the integrity of the liner, causing slow

continuous leaking ofmanure from the storage system to ground water; and

-

3.

A sinkhole forming below a pianure storage system causing either a rapid flow of manure

directly into

ground water, or a collapse in a basin sidewall resulting in arelease of manure

onto the ground surface where it could then flow to streams.

-

4.

Surface runoff of liquid manure from the storage area to sinkholes, blind valleys, Losing

streams or areas with very thin

soils above bedrock (e.g. resulting from a spill,

overflow, or

sidewall failure).

Manure entering

ground water will threaten drinking water supplies as

it travels toward streams.

Most of the people in southeastern Minnesota rely on ground water for drinking water supplies.

Manure entering

ground water will ultimately discharge

into streams within a period oftime

ranging from hours to decades depending on the site-specific hydrogeology.

The karst region of

Minnesota maintains a large number of high quality trout streams.

A rapid discharge of a large

quantity of manure into a stream will destroy the aquatic life for a stretch of the

stream until the

stream

is rejuvenated.

Ultimately the discharge will

also

increase

contaminant loading into

the

6

receiving waters of the Mississippi River system.

Manure that travels in the

ground water for a

longer period before

discharging into streams will be more diluted and may not

destroy aquatic

life, but can still contribute to stream pollution upon discharge into -the- stream.

-

Basin overflows and discharges from manure storage structures have been problems at some

facilities in Minnesota.

Another potential water quality-risk from liquidmanure storage systems

is a failure of earthen basin sidewalls to hold liquid manure.

This type ofrisk appears to be

-

minimal with systems permitted

in Minnesota, given that sidewall failures are not known to have

occurred in Minnesota at any ofthe over 2500 earthen basin facilitiespermitted by

the MPCA,

2.2

Historical record of failed and successful waste stora2e sYstems

in karst regions-

-

-

Hundreds of manure storage systems have beenconstructed in the karat region in Minnesota and

have been in operation for-several years

to several decades.

The Natural Resources Conservation

Service (NRCS)

and Soil and Water ConservationDistricts

(SWCDs), which provided assistance

with the design and construction of many of these systems, is not aware of anycatastrophic

failures of liquid manure storage systems into

sinkholes in Minnesota.

-

However, the NRCS and

SWCDs are aware of several cropland runoff retentionponds for erosion control that have failed

into sinkholes.

Runoff retention ponds are typically constructedwithout any sort of a liner and

are not designed to minimize seepage.

-

-

-

-

The MPCA is aware ofone instance

in Fillmore County,

Minnesota, where manure seepage

through a soil liner into fractured bedrock occurred at such arapid rate that the storage system

did not ever need to be pumpedand the farmer’s well was severely contaminated.

During the

original construction of the earthen basin, the soil was reportedly excavated to depths exceeding

-

those in the approved- design plan.

A new well and installation ofa synthetic liner corrected the

problem for that producer.

There have been few farms -with ongoing monitoring or

documentation ofmanure levels throughout southeastem Minnesota to

gain an understanding of

how frequently excessive seepageproblems occur in areas with shallow soils above bedrock.

-

-

The

workgroup

contacted-people in ten other states with karst geology to find-out ifthere have

been any sinkholes forming below liquid manure storage systems

in these-other

states.

-

Sinkholes

-

-

have developed below four earthen hog manure storage systems in Kentucky, as reported in

Crawford,

1998.

In Florida, a sinkhole developed in a new storage system after the basin was.

filled with water to check forproblems.

No other known sinkhole-related manure storage

failures were reported by the other states formanure storage.

-

Sinkholes have formedbelow municipal wastewater treatment ponds in Minnesota.

Between

1974 and

1992, sinkholes openedbelow three of the twenty-two municipal wastewater treatment

ponds

in Minnesota’s karst region.

Sinkholes developed in Altura’s ponds in 1974 during

construction and in

1976 when it firstfilled to

capacity (Alexander and Book,

1984).

A sinkhole

developed in a Lewiston pond in

1991

after eighteen years ofuse (Jannik et al.,

1992).

Several

sinkholes

developed in a Beilchester pond in 1992

after twenty-two years ofuse (Alexander et

al.,

1993).

The amounts of partiallytreatedwastewater draining into sinkholes at the three

7

respective sites was

3.7, 2.3, and 7.7 million gallons.

The ponds were

constructed of earthen

materials with a designed seepage-rate not to exceed 3,500 gallons per acre per day(note that the

current minimum design standard formanure storage with soil liners is

500

gal/ac/d and is

50 gal/ac/d forcomposite

liners).

Several sinkholes are -located within-about a mile from all

-

three sites, yet no sinkholes were mapped within about a quarter of a mile from the sites.

The

-

environmental consequences of these failures were not thoroughly studied.

Sinkholes have also

formed below municipal wastewater treatment ponds in Missouri (Aley-et al.,

1972) and

-

Pennsylvania (Bachir et al.,

1999);

-

These failures clearly demonstrate the potential for sinkholes to develop in southeastern

Minnesota when large quantities of liquids are stored in sinkhole prone areas with minimal

barriers between the liquid and underlying materials.

Similar problems can develop when storing

liquidmanure above permeable liner materials.

It should be noted that allowable design seepage

rates for cohesive-soil lined manure storage systems in Minn. R.

cli. 7020

is -more protective than

the standards used forthe failed municipal wastewater pond construction.

It is also importantto

consider that the contaminant concentrations in manure are often over 100 times greater than

municipal wastewater pond liquids.

Thus, the environmental consequences -ofa catastrophic

manure release will be much worse than a-similar

release from a municipal pond failure.

-

2.3

Benefits of livestockagriculture in the karst reaion

Livestock agriculture and liquidmanure storage can benefit water quality in the karst region,

helping to offset some ofthe risks to water quality.

For example, manure application to land in

row crop production can enhance

soil properties and reduce soil erosion.

Hayland and

-

pastureland associated with dairy and beefcattle operations result in little losses ofsediment,