RECEIVED

CLERI-VS OFFICE

APR

2

5

2001

April

23, 2001

Ms.

Dorothy

M. Gunn, Clerk

Pollution Control Board

100

West

Randolph, Suite 11-500

James

R.

Thompson Center

Chicago,

IL 60601

Re:

Livestock Waste

Regulations

35

III. Adm.

Code 506

ROI-28 (Rulemaking-Land)

Dear Ms.

Gunn:

Enclosed with the letter please find and

original and nine (9)

copies of the following documents

for the above stated rulemaking:

Notice

of Filing

Testimony of the Illinois Stewardship Alliance

Service list

If you have any questions or concerns,

please do not hesitate to call me at 217-498-9707. Thank

you for your assistance

in this matter.

Sincerely,

Pam

Hansen

lndustrial

Agriculture Coordinator

Illinois Stewardship Alliance

P.O.

Box 6’wiochester,

STATE OF ILLINOIS

~

Pollution

Control Board

A

~625~

Phone 21 (-498-9!u7

-ax 211-4~8-9235

E-mail

ohilstew(Wfcii.net

Enclosures

ILLINOIS POLLUTION CONTROL BOARD

TN THE MATTER

OF;

)

)

AMENDMENTS TO LIVESTOCK

)

WASTE REGULATIONS

)

(35

ILL ADM.CQDE

506

)

RECEIVED

CLERICS

OFFICE

APR

2

5

2001

STATE OP ILLINOIS

Pollution Control Boord

ROl-28

(RULEMAKING-LAND)

TESTIMONY REGARDiNG AMENDMENTS To THE LIVESTOCK

WASTE REGULATIONS

My name

is Pam Hansen and I am employed by the Illinois Stewardship Alliance where I

am the Industrial Agriculture Coordinator.

As such, I work with rural residents and

farmers in their concerns about the seeming invasion of industrial sized livestock

operations. While most agree that farms are increasing in size, their concerns stem from

the degradation in their quality oflife and the potential health impacts and contamination

oftheir air and groundwater.

Our members are farmers, rural residents and urban citizens

who all share a concern for the production ofsafe, healthy food in a manner that is

sustainable for the environment.

When the first set of rules for the Livestock Management Facilities Act was being

promulgated, the Alliance brought before you some ofthese farmers and rural residents

to share their concerns.

Being in the midst ofplanting season, we regret we are unable to

bring these people back to you.

Rest assured their concerns have not changed. It is their

views I represent today.

The proposed

506

rule covering enhanced construction standards for large-scale animal

feeding operations appears to be a step forward in the protection of environmental quality

in the State of Illinois.

Members ofthe Livestock Advisory Committee and stakeholder

groups, including the Illinois

Stewardship Alliance, worked tirelessly to ensure the

rules

were both protective and fair.

The Board, in questions

submitted at it’s first hearingin Chicago April 2, 2001,

inquired

of the Department whether they were aware of any environmental problems associated

with livestock waste handling facilities located in karst areas.

The Department has

answered they were unaware ofany such problems and specifically referred to known

facilities in Illinois.

It should be noted that other states in the Midwest have been

-

experiencing problems with lagoons in karst areas.

Minnesota, for example, published

draft guidance documents concerning the siting oflagoons in karst areas after the

collapses ofseveral municipal waste lagoons located in karst.

While the size ofthose

lagoons were much larger than their average manure lagoon, they do note that the

contaminant concentrations of manure lagoons is often 100 times that ofa municipal

waste lagoon and would pose greater environmental consequences in the event of a

collapse.

In Kentucky, an estimated 1.

5

million gallons ofmanure drained into a karst aquifer.

The lagoon had a synthetic liner across the bottom and 4 feetup the sides, however the

collapse

occurred along the

side and above the liner which quickly expanded to

drain the

entire lagoon. Illinois’ construction standards are more stringent requiring that lagoon

structures constructed in karst be ofconcrete or rigidmaterials. We feel that to provide

protection, a portion ofthis concrete or rigid material should extend above grade to allow

for inspection ofcracks or other potential subsurface problems. The Kentucky report also

recommends that during a karst investigation a dye trace should be performedto identify

the receiving spring or springs in the event ofa leak.

The spring(s) should then be tested

periodically for groundwater contamination associated with the livestock waste.

The

draft guidance for Minnesota and the report ofthe manure lagoon collapse in Kentucky

are attached.

In addition facilities, constructed prior to the July 1999 amendment to the Livestock

Management Facilities Act requiring a site investigation for the presence ofkarst

material, should be identified and monitored for potential problems.

Utilizing the IDNR-

ISGS map

8 as referenced in Section 506.202, large-scale facilities located in known

areas ofkarst should be identified along with the potential receiving spring(s) or waters

and those waters tested routinely for the presence or increase in presence of contaminants

associated with livestock manure. The purpose here is not to identify and indict but to

prevent possible catastrophic contamination of groundwater.

In the previous information

submitted from Kentucky

and Minnesota, some lagoons had existed for

18 years before a

breech occurred.

An experience at a dairy facility recently pointed out the need for rulemaking in an area

that has not been addressed.

In attempts to make sure that administrative rules and

construction standards are protective of the environment and fair to the producer

regarding new facilities and new construction, existing large-scale facilities that may be

in need ofupgrades have been ignored. There may be large facilities that are not subject

to inspections because they predate the

1996 Livestock Management Facilities Act or the

most current amendments, and are potentially way behind the current standards for

livestock operations.

Rules should contain some minimum standards for identifying

existing facilities in order to prevent pollution.

For example, requirements making sure

lagoons have visual markers for liquid levels, making sure there is adequate freeboard of

2

feet 6 inches and adequate diversion of storm water along with secondary containment

in the event of a breech. All facilities should also have and maintain a waste

management plan regardless of age.

Again our intent is not to identify and indict, but to

prevent pollution.

Also missing are standards governing such items

as emergency/temporary lagoons as

recently approved for a large scale dairy in Elmwood Illinois. These two emergency,

temporary lagoons were allowed for a period of 6 months to allowthe owner! operator to

temporarily divert excess manure to avoid a repeat of illegal dumping. While that action

is commendable, we question by what authority did the Department approve such

facilities, and to what construction standards? As witnessed in television reports, these

emergency storage facilities appear to be depressions in the land with plastic thrown on

top.

While we are sure the Department ofAgriculture did what it thought was best at the time

in order to prevent further pollution, it points up the need for rules to govern such

situations. It is short sighted to think that the situation in Elmwood will never be repeated

Instead the Department and the LEPA as well as DNR and IDPH should work together to

develop a set ofstandards/rules concerning these type ofemergency situations

In conclusion the Alliance believes these rules are a step forward towards protecting

Illinois’ environment. Working around flaws in the statutory language, they appear to

cover many ofthe requirements necessary to adequately site a proposed new facility.

Thank you for the opportunity to comment and we look forward to implementation of

final rules.

LEAKAGE AND SiNKHOLE COLLAPSES UNDER HOG

WASTE LAGOONS IN KENTUCKY

Nicholas C. Crawford,

Ph.D.

Western Kentucky University

Surface ponding and concentration of water on

the ground surface is the leading

cause of sinkhole collapses in Kentucky (Figures

1

and 2, and Appendix

1).

Farm ponds

frequently

collapse

and

drain

into

karst

aquifers

in

a

matter

of

a

few

hours.

When

hazardous

waste

is

pumped

into

surface

lagoons,

the

leakage

can

be

very

serious.

Crawford

performed

a

dye

trace on

the

surface

lagoon

at

the

Rockwell

Site

in

Russellville, Kentucky.

Leakage from the lagoon into the groundwater was pumped into

a storm sewer by

a nearby

sump pump.

Groundwater contaminated

with PCBs traveled

through

the storm sewer into a ditch that leads to

Town Branch.

PCBs were carried by

Town Branch

into the Mudd

River.

The fish tested

in Mudd River and Town Branch had

levels of PCBs

as high as 300

ppm,

the highest levels

ever

found

in the

United

States.

This

problem

has

cost

Rockwell approximately

40

million

dollars

to

clean

up

the

contaminated

soils

and

groundwater

under the

site.

They

are

now

in

the

process of

cleaning up

soils along Town Branch for an estimated cost of 200 million dollars and a

successful lawsuit against Rockwell resulted in an additional 200 million dollar expense.

Hog

waste

lagoons

upon karst

terrain

appear

to

be

at

a

very high

risk

of

contaminating karst aquifers and surface streams downstream from springs.

Figure 3

is a

photograph taken

in.

1984 ofa sinkhole

collapse that occurred under a hog waste lagoon

in

southwest

Barren

County.

Figure 4

is a sinkhole

collapse of the,

secondary

lagoon

located downstream for the primary

lagoon

that collapsed

in

April

1990.

A

dye trace

performed after this collapse indicated that during both the

1984

and

1990

collapses, hog

waste flowed

into

Mammoth

Cave National Park

to

resurge

at

Turnhole spring on

the

Green River.

In

less

than

five

hours 2.4

million gallons of hog

waste

flowed

into

the

karst aquifer.

Figures

5,

6

and 7 are photographs ofsinkhole collapse under a hog waste lagoon

that occurred

in Warren County on January

6,

1.998.

The estimated loss

of settled hog

waste was approximately

15,000 gallons. The Kentucky Division of Water recommended

that a synthetic liner be placed under the lagoon.

Figures 8,

9

and

10 are photographs of

a sinkhole collapse under a hog waste lagoon that occurred in Logan County on April

29,

1991.

The

pond was

125 feet by

100

feet

and

12.8

feet

deep with

hog

waste when the

collapse

occurred.

The

entire

pond

drained

quickly into

the

karst

Aquifer

for

an

estimated loss of 1,050,000

gallons of hog

waste. This

pond

had a synthetic liner that

extended across the

bottom and

4 feet

up

the

sides. The

collapse

occurred

where

the

LEAKAGE AND SINKHOLE COLLAPSES UNDER HOG

WASTE LAGOONS IN KENTUCKY

August

5,

1998

Prepared For:

The Honorable Hank Graddy

103 Railroad Street

Midway, KY 40347

Prepared by:

Dr. Nicholas Crawford, Ph.D.

Center for Cave and Karst Studies

Department ofGeography and Geology

Western Kentucky University

Bowling Green, KY 42101

r

I

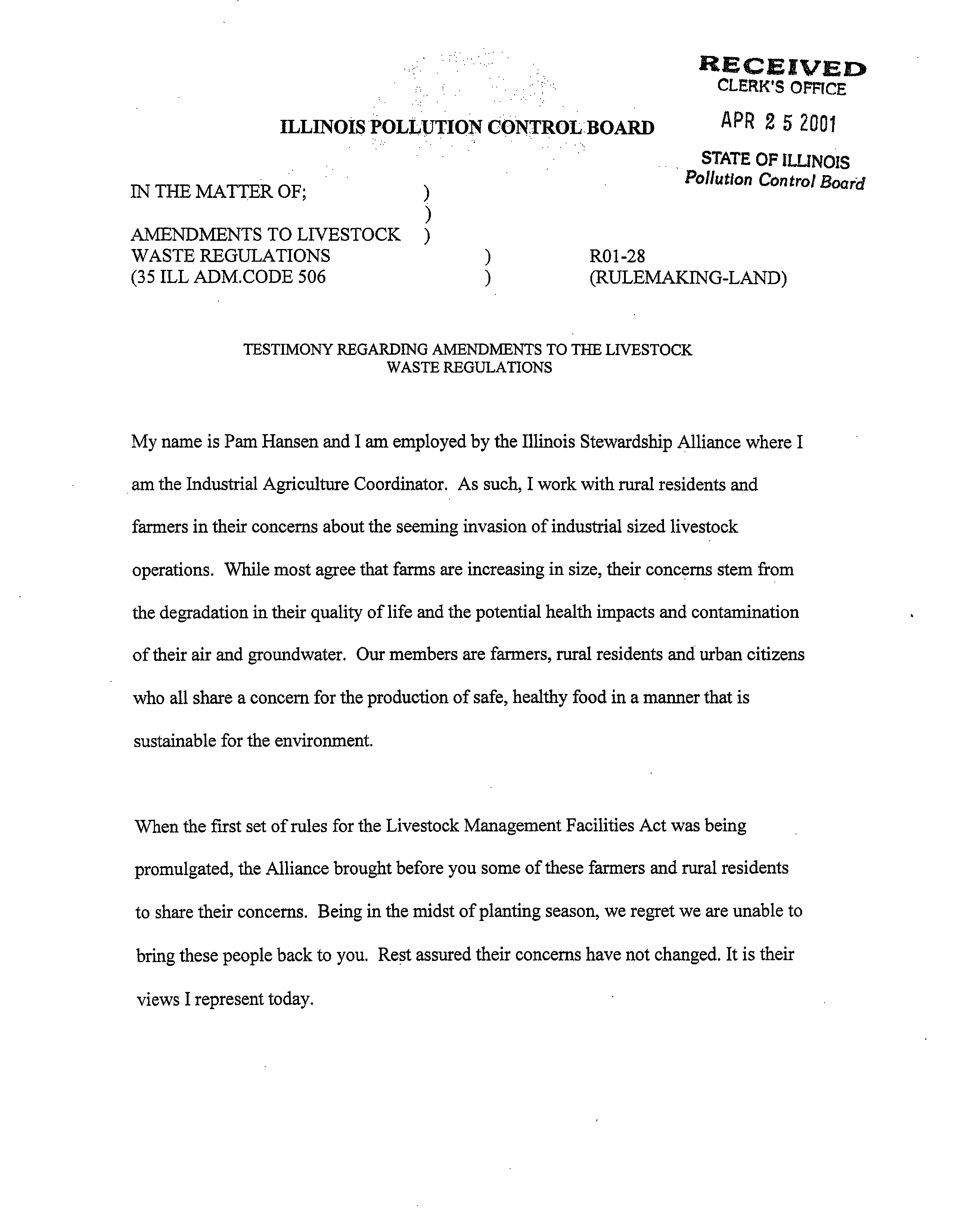

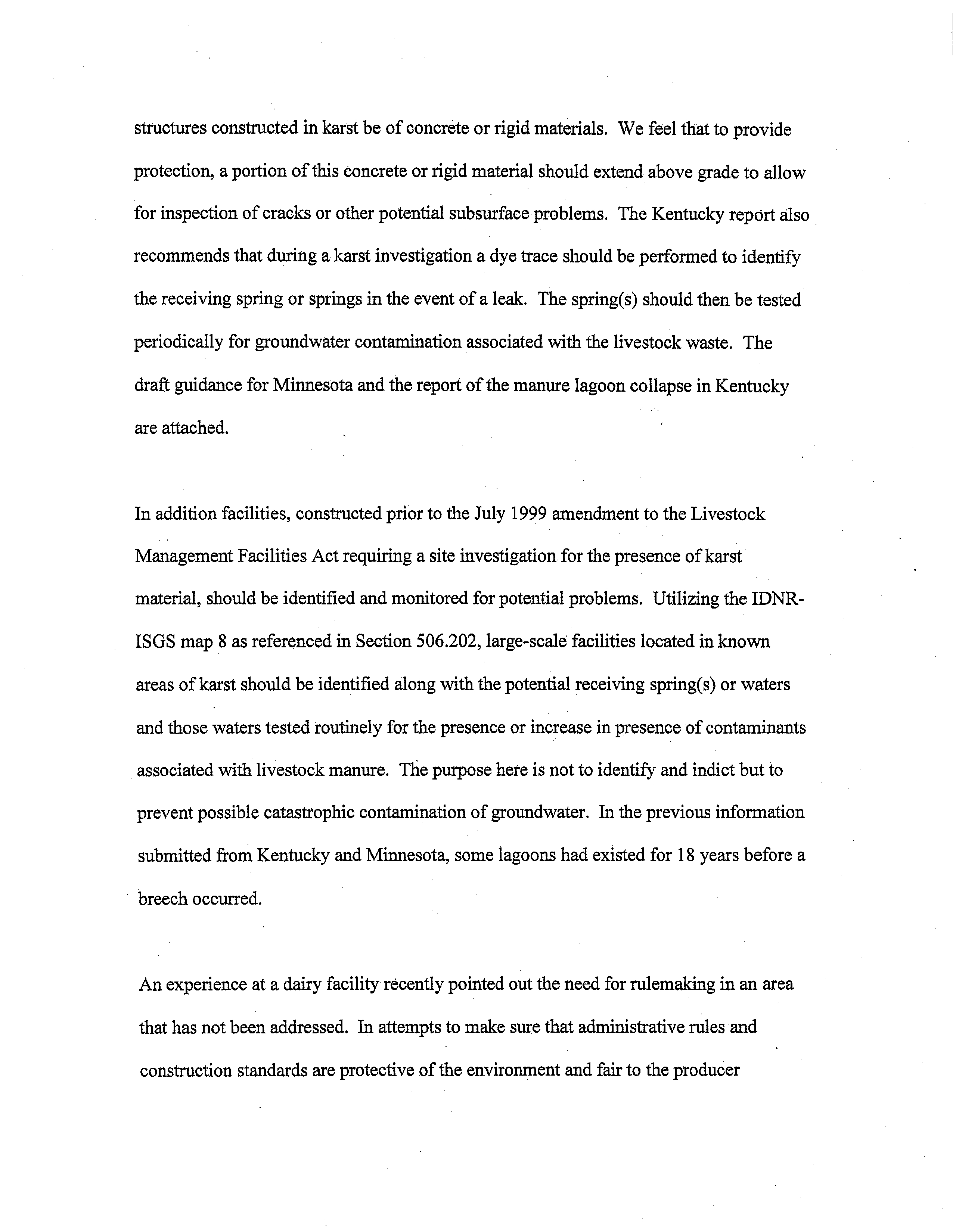

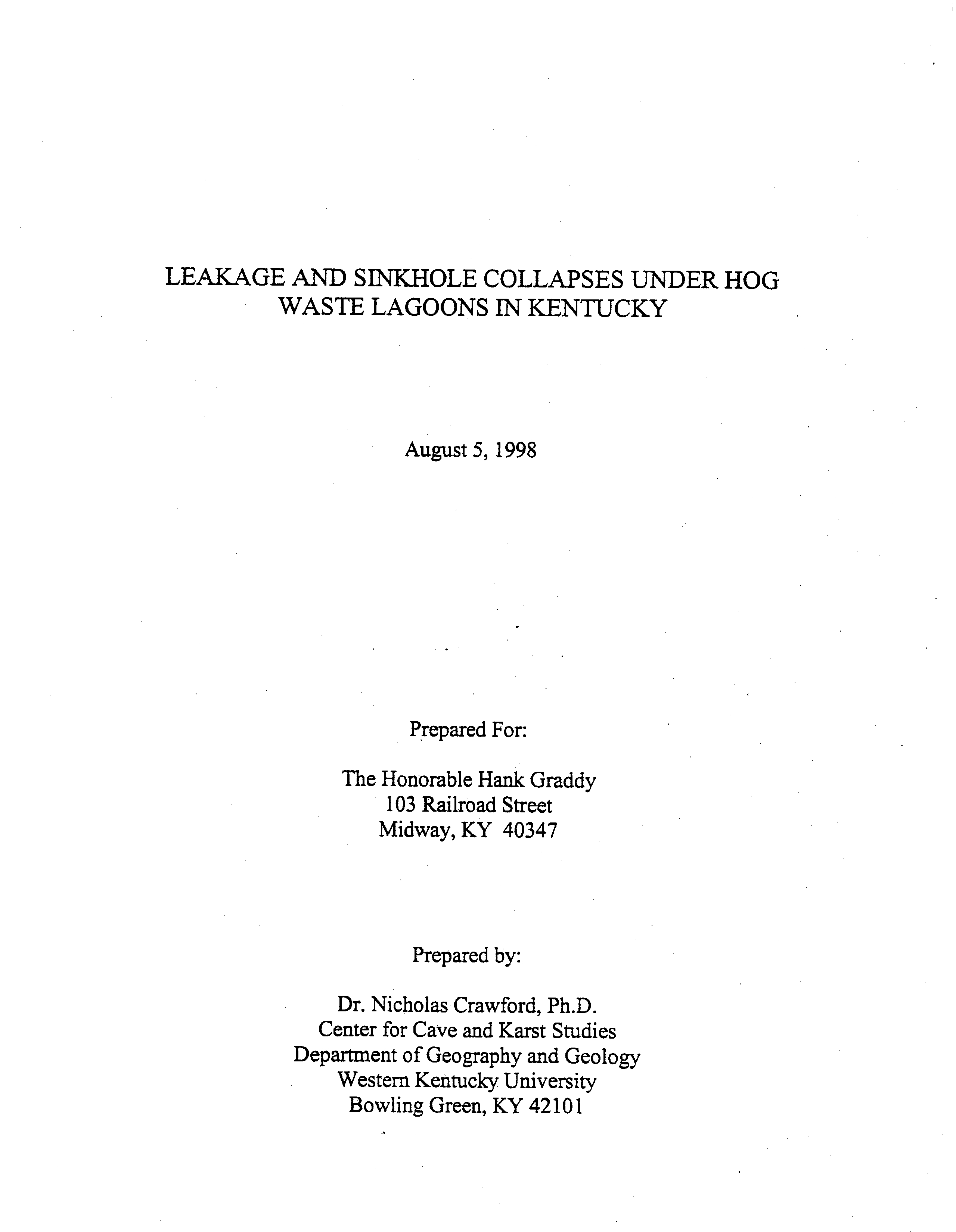

FIGURE 3.

Sinkhole collapse under hog waste lagoon in March

1984 on Barren County,

Kentucky.

Approximately 2.4 million gallons of hog

waste sank into

the

kArst aquifer in less than

5

hours.

Impoundment of water and concentration of surface runoff are the

leading causes of sinkhole collapses in

the

karst areas ofKentucky. Photograph by Kentucky Division of Water

vwwF

rwv

-pfv~

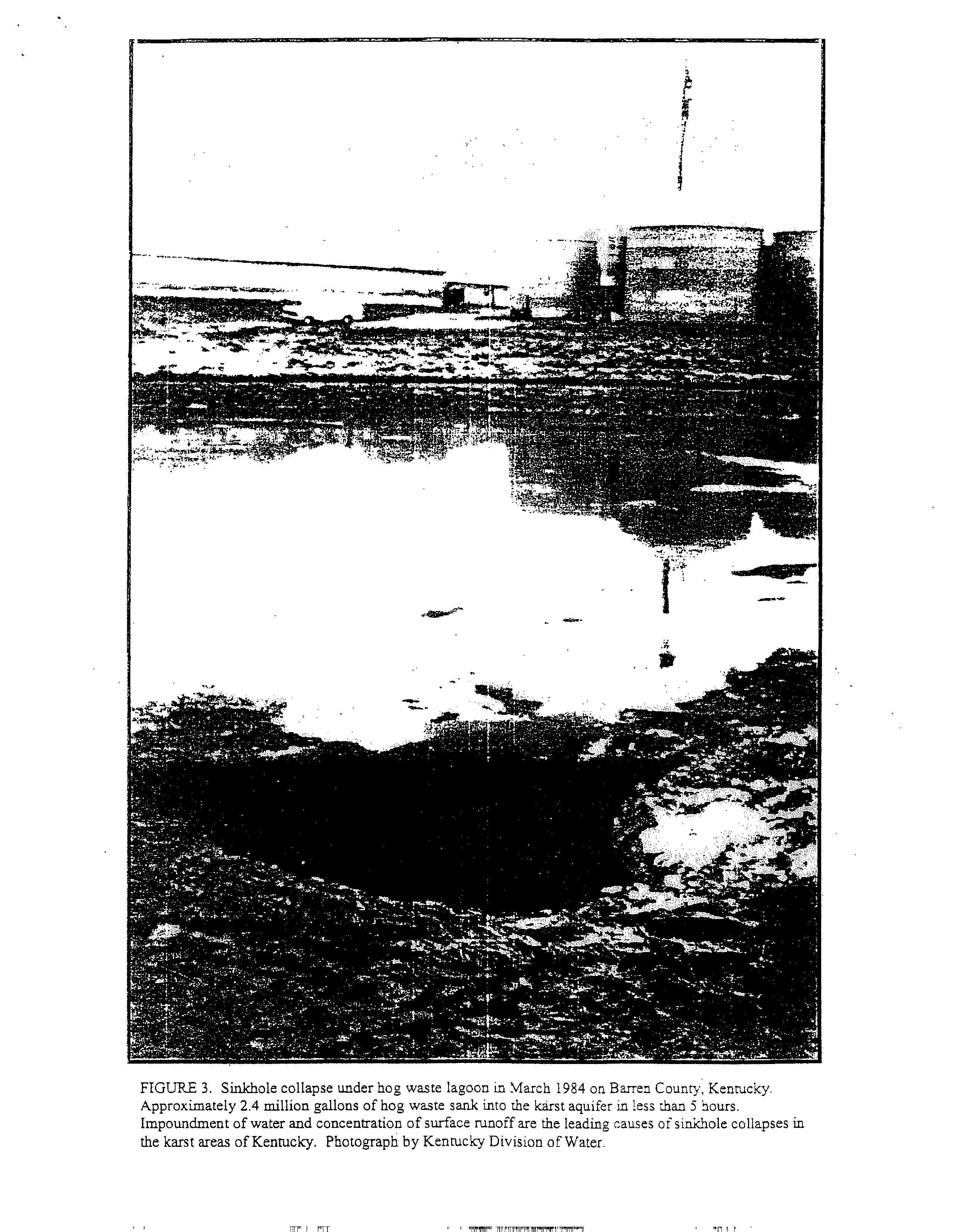

FIGURE 4.

Sinkhole

collapse

in

April

1990

of the

secondary

hog

waste

lagoon,

located

downslope

from

the primary

lagoon

that

collapsed

in

March

1984

(Figure 3).

A dye trace of this collapse indicated that hog waste

flowed into

mammoth Cave National

Park

to

discharge at Turnhole

Spring on the Green

River during both collapses.

Photograph by Kentucky Division of Water.

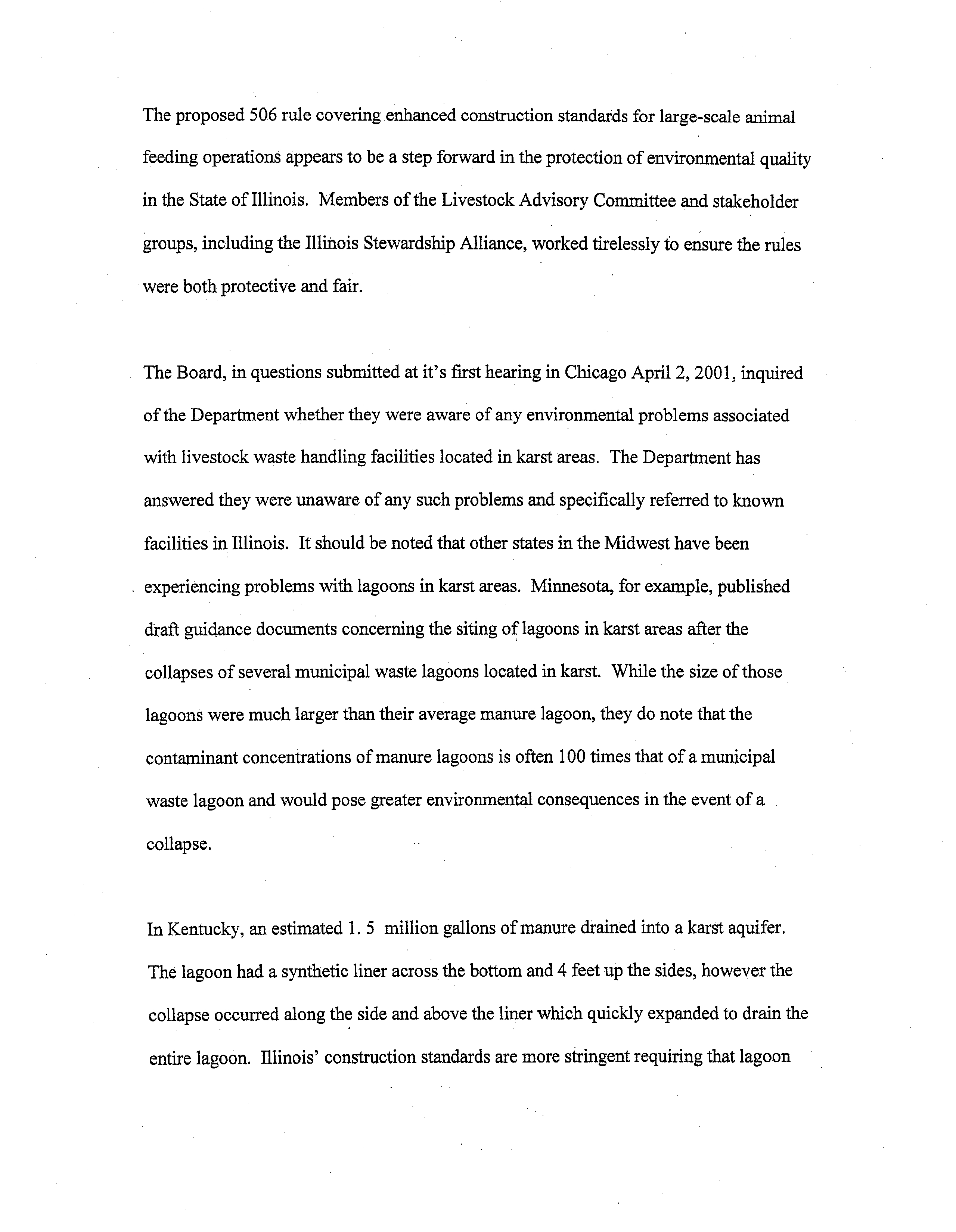

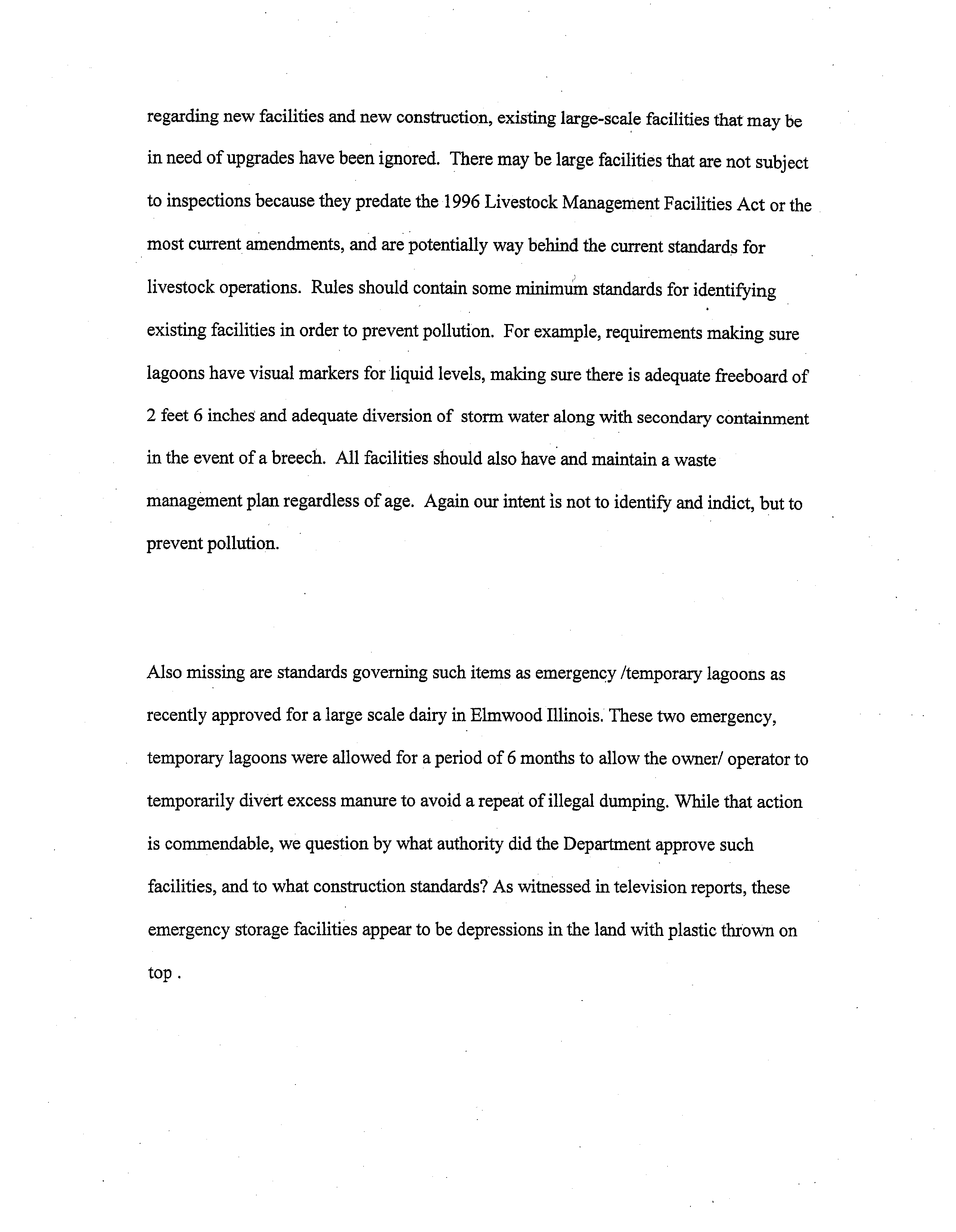

FIGURE

5.

Sinkhole collapse

under

a

hog

waste

lagoon

in

Warren

County,

Kentucky on January 6,

1998.

Photo by Kentucky Division of Water.

FIGURE

6.

Sandbags were

placed around the collapse

to

prevent additional

loss of

hog waste.

Photo by Kentucky Division of Water.

•1.

3.

..

FIGLRE

7

1998 Warren County

Sinkhole collapse.

Close up photo ofJanuary

6,

-.

—

~0w—

~

-

-.

.

—

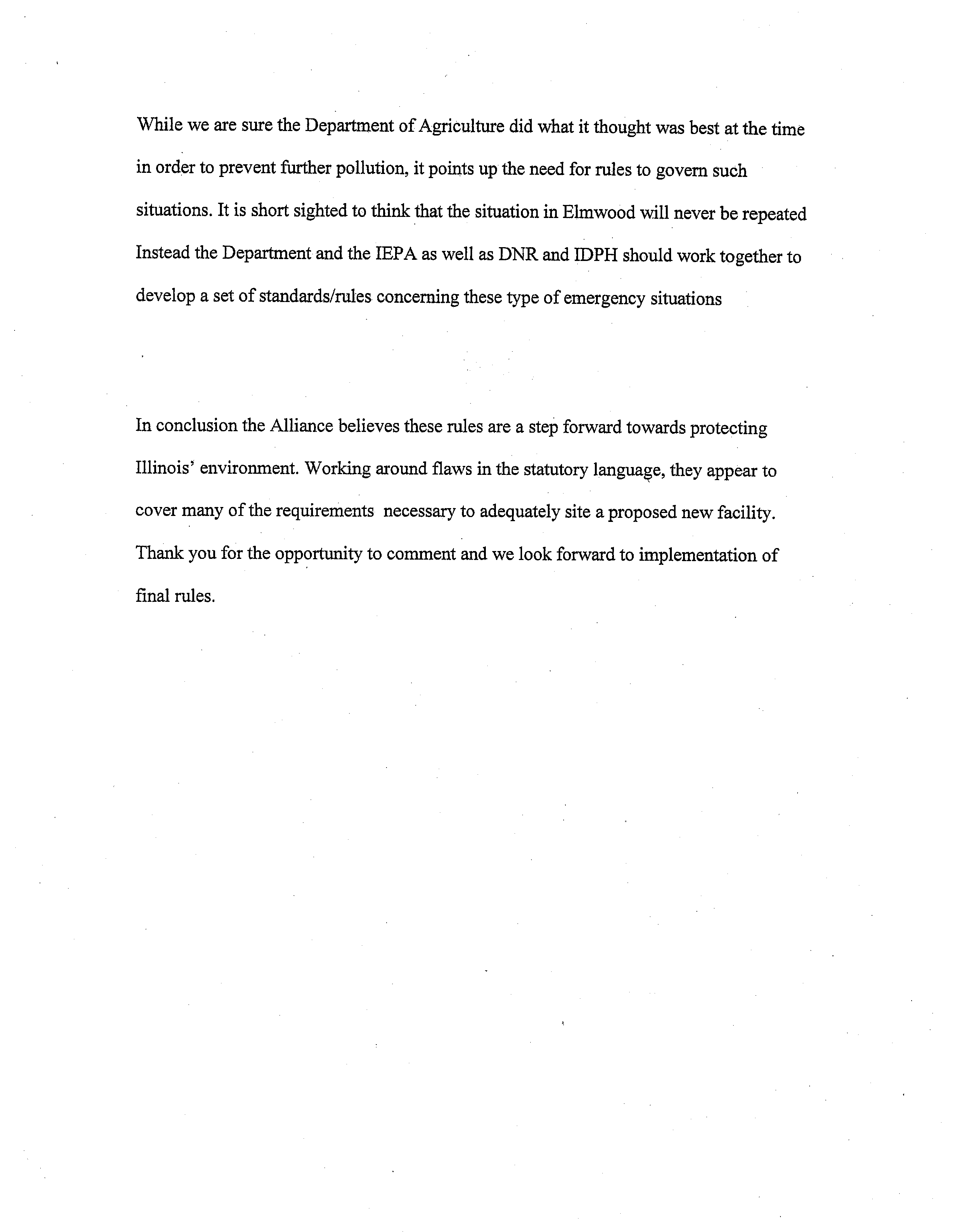

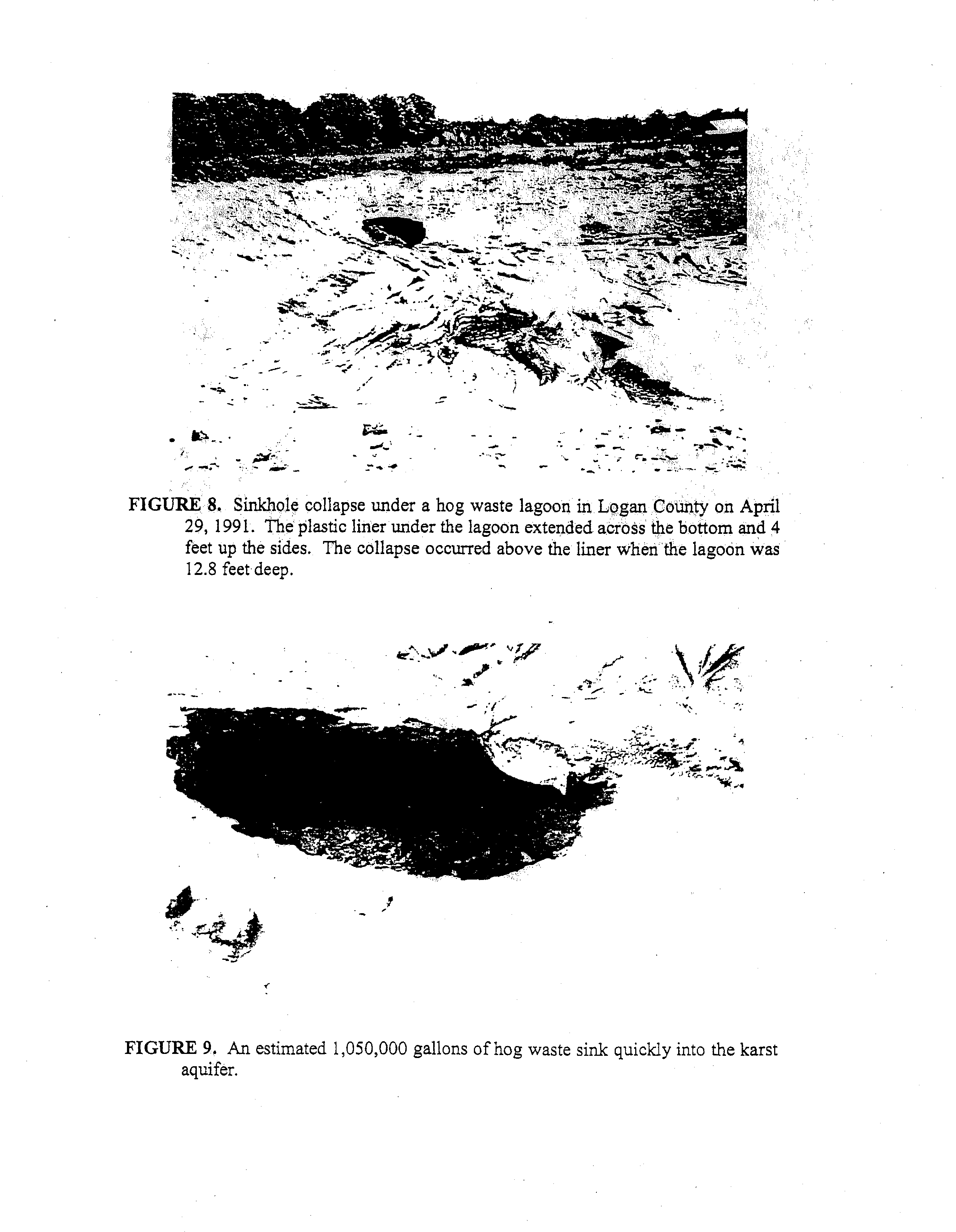

FIGURE

8.

Sinkhole collapse under

a hog waste lagoon in

Logan County on April

29, 1991.

The plastic liner under the lagoon extended across the bottom and 4

feet up the sides.

The collapse

occurred above the liner when the lagoon was

12.8 feet deep.

A

FIGURE 9.

An estimated 1,050,000

gallons ofhog waste sink quickly into the karst

aquifer.

—t

—

-•1

FIGURE

10.

A

Rhodamine WT dye trace

performed by the Kentucky Division of

Water was visually positive at the above spring on Sinking Creek.

pond was

12.8 feet deep along the side but above the liner.

The collapse then expanded

to

drain the entire pond.

A dye trace using Rhodamine WT

dye was

performed by the

Kentucky Division ofWater and visually observed at a nearby spring on Sinking Creek.

The

Kentucky Division ofWater recommended that the

hole

be repaired and that a .20

mu

or thicker liner be installed

to above the high water line ofthe pond.

Hog waste

lagoons

do

not have to

experience

catastrophic sinkhole collapses

to

contaminate karst

aquifers. Leakage

can

result

in contamination of karst

aquifers

and

surface

streams.

Figures

11

through

18

show

dye

traces

of two

leaking

hog

waste

lagoons

in

Logan

County,

Kentucky.

The

leakage from

surface lagoons

appears

to

be

through

macropores

(macrotubes).

These

tubes through the

soil

can

be

made

by

desiccation cracks, worms or tree roots which rot and leave

small tubes through the

soil.

If these tubes reach the epikarst, a very high permeability zone in the vicinity ofthe soil

-

bedrock

contact,

this

permits

water

to

drain rapidly through

the

low

permeability clay

subsoil into

the karst aquifer below. This

leakage through macrotubes may produce soil

piping that results in a sinkhole collapse. Also, the practice of excavating the soil for the

lagoon

tends

to

reduce

the

thickness

of soil

above

existing regolith

(unconsolidated

material above bedrock) arches.

This greatly increases the chances ofa sinkhole collapse

above an existing regolith arch.

There are thousands ofregolith arches per square mile in

most karst areas.

Plates

I

and 2

are maps of the karst

areas of Kentucky.

It shows that

over one half ofthe Commonwealth is underlain by carbonate rock with varying degrees

ofkarstification.

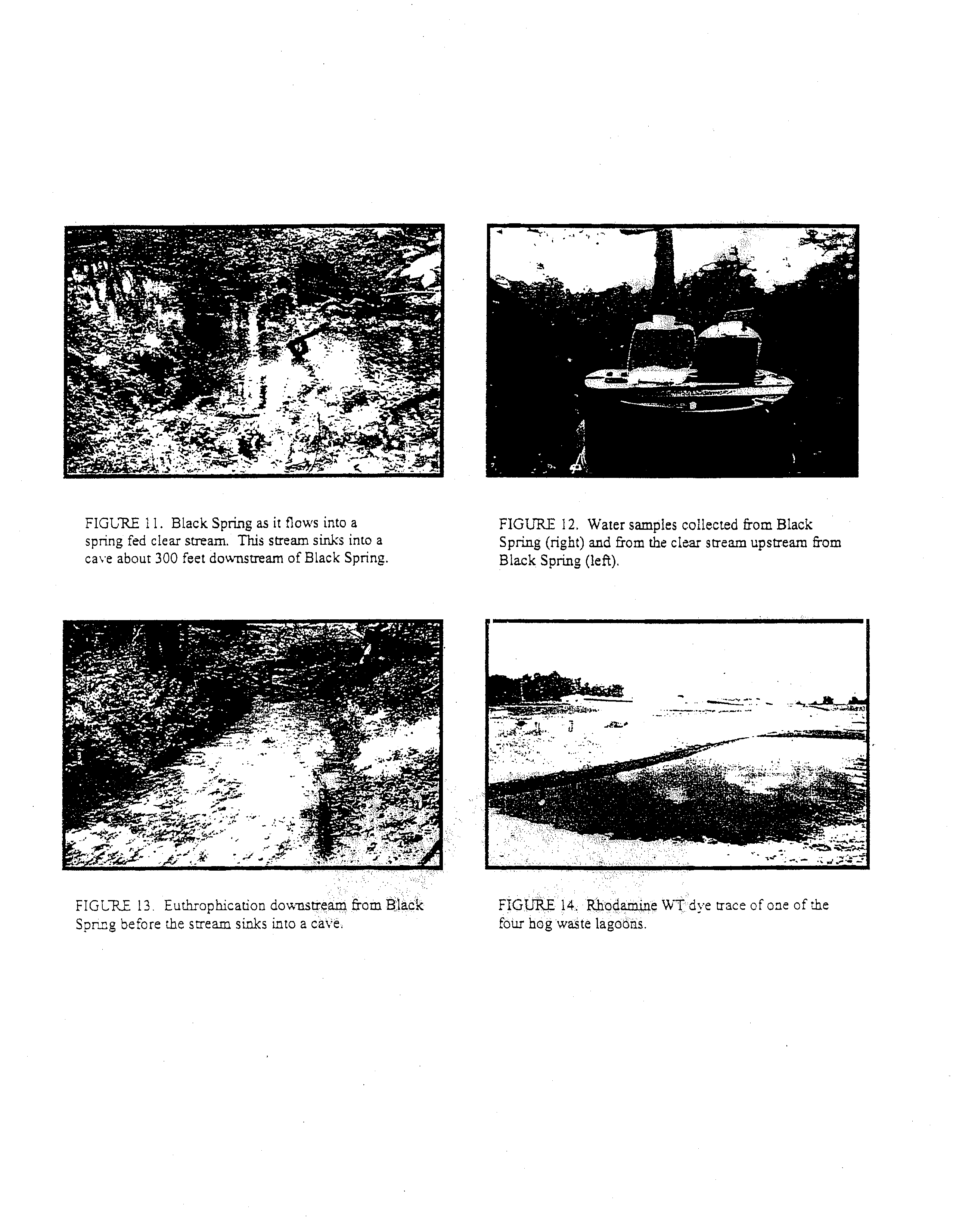

FIGURE

11.

Black

Spring as

it

flows

into

a

spring fed clear stream.

This stream sinks into

a

cave

about 300

feet downstream of Black

Spring.

FIGURE

12,

Water samples

collected

from Black

Spring (right) and

from

the

clear

stream upstream from

Black Spring (left).

I

FIGURE

13.

Euthrophication downstream from Black

Spnng before

the

stream sinks into

a cave.

FIGURE

14.

Rhodamine

WT dye trace of one of the

four hog

waste lagoons.

~UtU3~

FIGURE

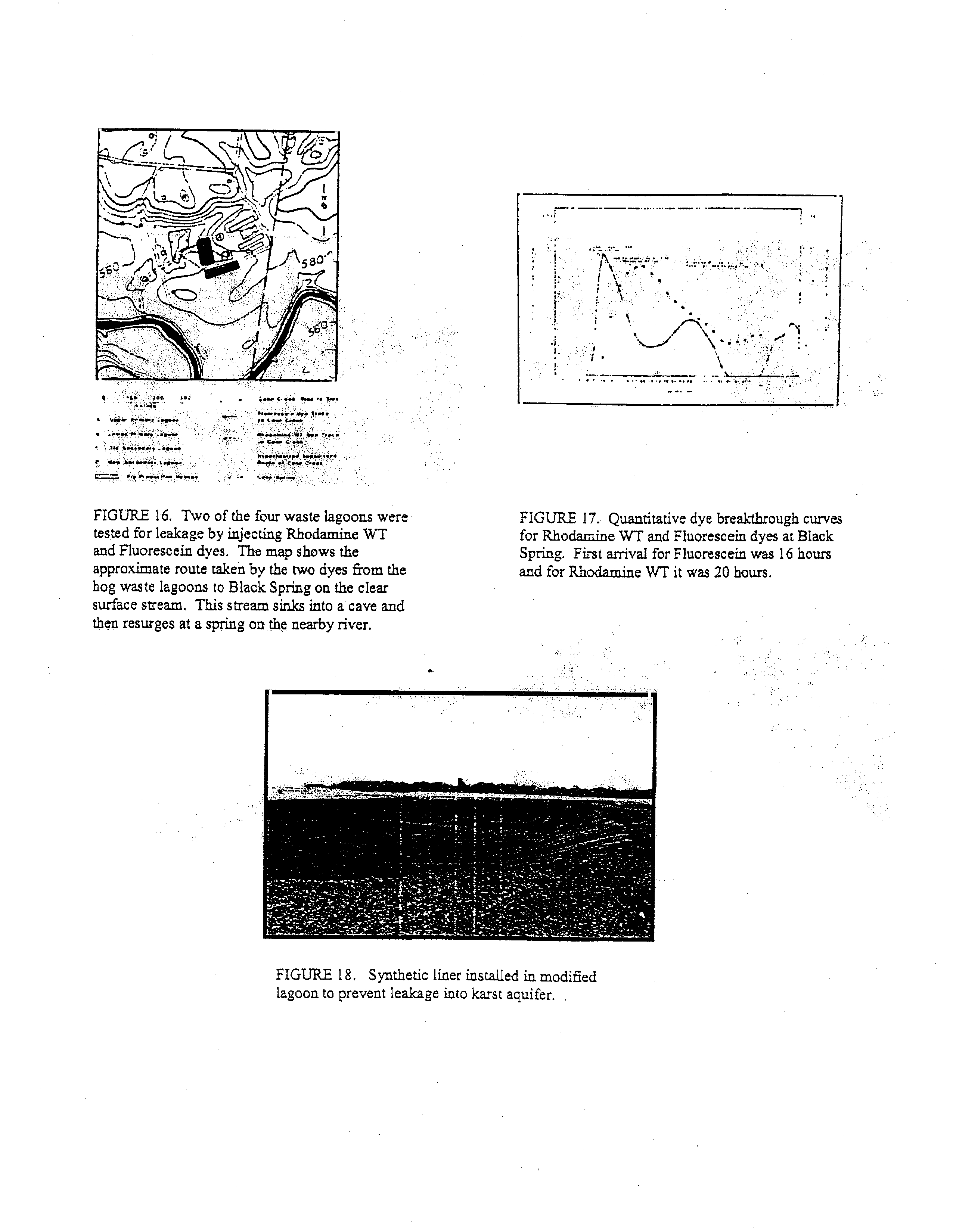

16.

Two of the four waste lagoons

were

tested for leakage

by injecting R.hodamine WT

and Fluorescein dyes.

The map shows

the

approximate route taken by the two dyes from the

hog waste lagoons

to Black Spring on

the clear

surface steam.

This sfleam sinks into a cave

and

then resurges at a spring on

the nearby river.

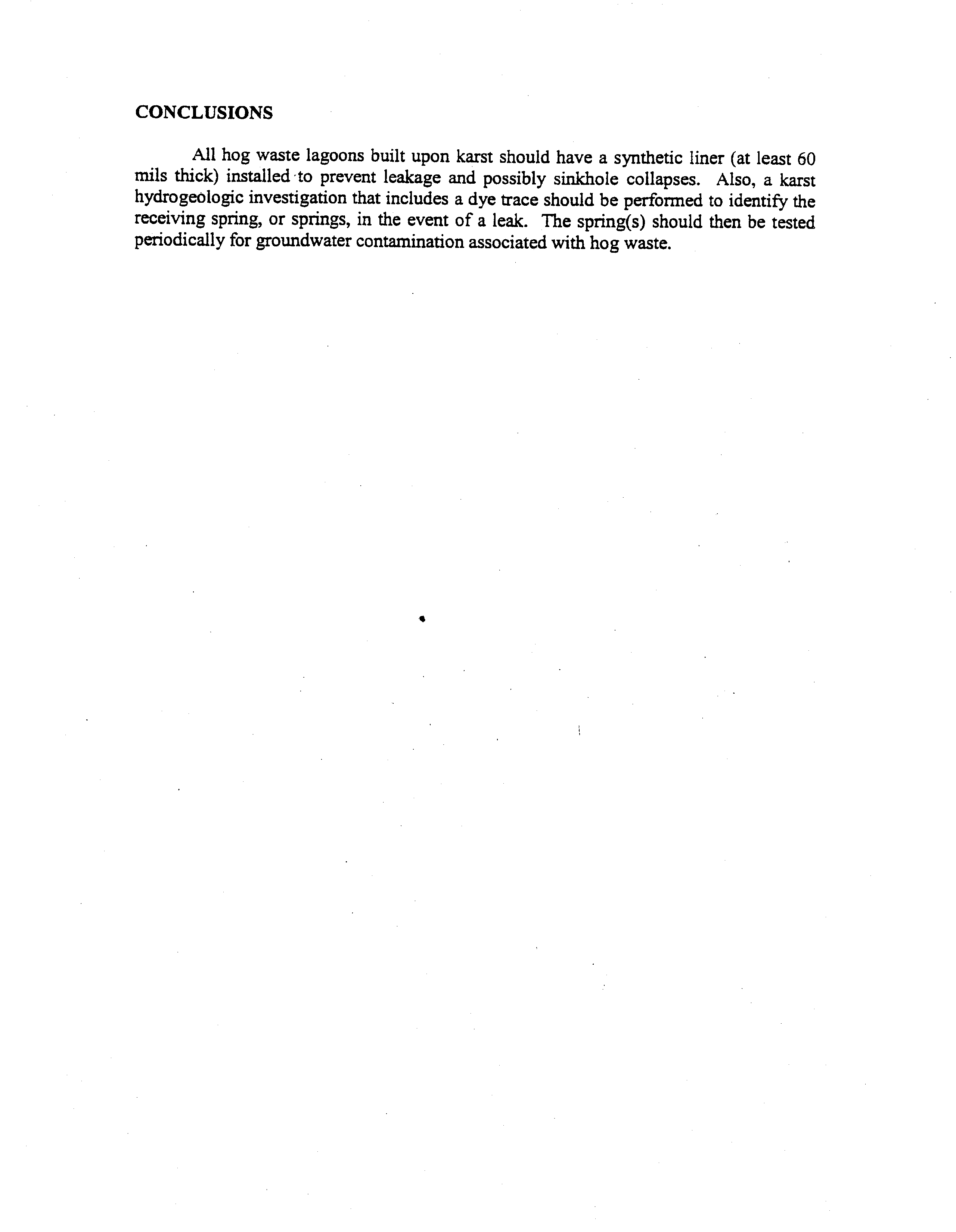

FIGURE

17.

Quantitative dye breakthrough curves

for Rhodanaine WT and Fluorescein dyes

at Black

Spring.

First arrival

for Fluorescein was

16

hours

and for Rhoda.mine WT it was 20

hours.

1

•

fl.

10~

•0:

•~c..*

I’

‘

/‘~•\

‘I

I

~

FIGURE

18.

S~thetic liner installed in modified

lagoon to prevent leakage into karst aquifer.

CONCLUSIONS

All hog waste

lagoons built upon karst

should

have a synthetic

liner (at least 60

mis

thick)

installed ‘to prevent leakage and possibly

sinkhole collapses.

Also,

a

karst

hydrogeologic investigation that includes a dye trace should be

performed

to identify the

receiving spring, or springs,

in the

event of a

leak.

The spring(s) should

then

be tested

periodically for groundwater contamination associated with hog waste.

S

CQNSTRUCTThJG NEW MANURE STORAGE SYSTEMS

IN THE KARST REGION

draft guidance document 2/8/99

Minnesota Pollution Control Agency

SUMMARY

Construction of large liquid

manure

storage

systems

has

greatly increased

during the

past

decade

in

the

karst region of southeastern Minnesota.

Soil subsidence

under

a liquid

manure storage system

could breach the integrity ofthe

liner, causing either a catastrophic

release of manure

to, ground water or a

slow

undetected manure

seepage

problem.

The

probability ofsoil subsidence varies greatly across this region ofthe state.

Construction of

new

liquid

manure storage

systems

in

higher

risk

areas for

sinkhole

formation creates

heightened

concerns

about

water quality protection. To minimize

the

risks of siting new

manure

storage

systems

in the

karst

region,

the

Minnesota

Pollution Control Agency

has

developed and

implemented

a policy

to

evaluate relative

risks of soil

subsidence prior

to

approving

feedlot construction

permits. Permitting decisions depend on

the

results of a

site-specific karst investigation, the proposed volume of manure to be stored and the type of

liner proposed

for the storage system. Precautionary measures required of some livestock

producers

have

included

one or

more of

the

following:

locating the

feedlot

in

a

less

vulnerable area, using less permeable liner materials, and rerouting roof runoff waters.

BENEFITS AND RISKS TO WATER QUALITY

Benefits ofLivestock andManure Storage Structures

Livestock agriculture has some water quality benefits in the karst region

that help to offset some of the

risks to water quality.

Manure applied to land planted to row crops

can reduce soil erosion.

Hay-land and

pasture

associated with

cattle

operations

results

in

very little soil erosion and pesticide

transport

in

this

region of steeply sloping soils.

The trends to

construct new and expanded

feedlot facilities and the

associated

liquid

manure storage

systems typically result in

further protection of surface water quality. Liquid

manure storage

structures

increase

management flexibility, making it easier to apply at proper rates and to avoid winter-time

manure

application. Also, may

of

the older

feedlot facilities

are

located

adjacent

to

streams

and do not

have

containment of manure or

manure-contaminated

runoff.

Most facilities with new liquid

manure storage

structures have total containment of manure such that there is

no manure discharge into

surface waters from

rainfall and snowmelt. Also, the liquid manure in containment structures

is usually injected below the soil

surface and is

less subject to surface runoff compared to the typical soil surface spreading practices of many

feedlot facilities without liquid manure storage.

Risks ofManure Storage Systems in Karst Regions

While there are a number ofwater quality benefits associated with

liquid manure storage systems, there

are also several heightened risks.

One possible risk

is

the failure of the walls of the manure storage system

to hold the manure with a resulting river of manure flowing down a valley and into a stream.

This has not

been known to occur in Minnesota, likely due in

part to engineering review and regulation of construction

activities.

What has occurred

in

Minnesota are

basin overflows

and

intentional discharges

from

manure

storage structures.

Enforcement of such

violations has increased

substantially

during recent

years

in

an

effort to curb blatantviolations and mismanagement.

-

Three potential water quality risks associated with liquid manure storage systems in the karst

region

include:

1)

seepage

of

contaminants

through the

liner

and underlying soil to

fractured

bedrock and

subsequently to

ground

water;

2)

soil subsidence below the structure which breaches-the

in4egrity of the

concrete,

geosynthetic or soil

liner, causing a slow and

perhaps

undetectable

leaking of manure from

the

storage system to ground water; and 3) a large

sinkhole forming below a manure storage system

leading to a

rapid flow

of manure

into

ground water or causing a

collapse

in

a basin sidewall

and a pouring

out

of

manure onto the ground surface.

Manure entering ground water will discharge into streams within a period of time ranging from hours to

decades

depending on

the site-specific hydrogeology. The karst region

of Minnesota maintains a

large

number of

high

quality trout

streams.

A rapid discharge of a large quantity of manure into a stream will

destroy

the

aquatic life for

a stretch

of the stream and also result in increased nutrient loading

into

the

receiving waters of the Mississippi River system.

Manure

which flows in the ground water

for a

longer

period before

discharging

into

streams will be more diluted and may

not destroy

aquatic

life,

but

will

threaten drinking water supplies

as

it

travels toward. the

stream,

and

contribute

to

stream pollution

upon

discharge.

Risks associated with slow seepage through the liner are reduced somewhat by Minnesota requirements

for

a minimum ten-foot separation distance between the bottom ofstandard reinforced concrete and earthen

manure storage structures and underlying bedrock.

If a composite liner or other nearly impermeable

liner

system is used, then the required miniipum separation distance

from bedrock is five feet. Requirements to

minimize

the risks associated with so~i subsidence

as new liquid

manure storage systems are constructed in

the karst region is the primary subject of these guidelines.

EVALUATING RISKS OF SOIL SUBSIDENCE

Learning experiences from sinkholesforming under municipal wastewater treatmentponds

Between

1974

and

1992,

sinkholes opened below three of the twenty-two municipal wastewater

treatmcnt ponds

in

Minnesota’.3 karst

region.

Sinkholes developed

in Altura’s ponds

in

1974

during

construction and in

1976 when it first filled to capacity (Alexander and Book,

1984).

A sinkhole developed

in a Lewiston pond in

1991

after eighteen years of use (Jannik et al.,

1992).

Several sinkholes developed

in

a Belichester pond

in

1992

after twenty-two years of use (Alexander et al.,

1993).

The amounts of partially

treated wastewater draining into sinkholes at the three respective sites was 3.7, 2.3, and 7.7 million gallons.

The ponds

were

constructed of earthen materials with a designed seepage rate not to exceed

3500

gallons

per acre per day. Several sinkholes

are

located within

about

a mile

from

all

three sites,

yet no

sinkholes

have been identified within a quarter of a mile from the sites.

These

failures clearly

demonstrate

the potential for sinkholes to

develop

in

southeastern

Minnesota

when

large quantities of liquids are stored

in sinkhole prone

areas with minimal barriers

between the liquid

and underlying materials.

Similar problems could develop when storing liquid manure on top of permeable

liner materials. However,

there are several

notable

differences between these failed municipal wastewater

treatment systems and manure storage systems currently being constructed. The maximum allowable design

seepage rate for manure storage systems

is

500

gallons/acre/day,

seven

times

less

than the

old

municipal

wastewater ponds.

These

design seepage rates assume that the ponds

remain

full

and they do

not

account

for seepage reductions

caused

by

the physical, chemical and biological sealing

which takes

place at the

2

manure/soil interface.

In

addition, the size of even the largest manure storage

systems

is

smaller than the

municipal ponds.

These differences between the failed municipal systems and manure storage structures are

worth recognizing, but they are not great enough to warrant complete disregard of

the risks

associated with

siting liquid manure

storage systems

in

sinkhole

prone areas.

It

is

also

important

to

note

that

the

contaminant concentrations in

manure

are

often over

100

times greater

than municipal

wastewater

pond

liquids, and thus the

environmental

consequences of a catastrophic

manure release could

be

much worse

than municipal

pond failures.

Sinkhole Probability Mappingand Research

Sinkhole mapping and research completed during the past two decades has made it easier to determine

the relative soil subsidence risks when siting new liquid manure storage

systems in Southeastern Minnesota.

Sinkhole probability maps

have

been

completed

for three counties

(Dalgleish

and

Alexander,

1984;

Alexander and Maki,

1988;

Witthuhn and Alexander,

1995) and additional

hydrogeologic investigation has

been conducted in

the

other

karst

areas.

The probability

of sinkhole formation has been

found

to

vary

tremendously across the region.

Some areas have

in excess of 50 sinkholes per square mile and other areas

have

no sinkholes.

Often

high density clusters of sinkholes are adjacent to areas with

scattered individual

sinkholes. Bedrock

composition, topographic position

in

the landscape and thickness

of glacial

materials

over bedrock have all

been found to affect the likelihocsd ofsinkhole formation.

Most sinkholes in southeastern Minnesota appear where there

is

less than 50

feet of surficial cover over

carbonate

and sandstone

bedrock.

The

proximity

of nearby sinkholes remain the single

best predictor of

new sinkhole development (Witthuhn and Alexander,

1995).

Magdalene and Alexander (1995)

concluded

that

on the

scale of several

kilometers,

new sinkholes

in

Winona County tend to

develop

in

the areas of

existing sinkholes,

especially near newl~’developed sinkholes.

The

risk of soil subsidence

has

generally

been found to

increase

in areas of po’~ided or intermittently

flowing water,

and

in

areas with

indications of

more extensive karstification, including

areas with disappearing streams,

caves,

dry

valleys,

springs and

solution cavities.

REGULATORY POLICY TO

MINIMIZE RISKS

Gverview

The

rapid

increase

in

the

construction

of

large liquid manure

storage

structures

in

southeastern

Minnesota,

coupled

with

experiences

of sinkhole development in

three

municipal

wastewater

treatment

ponds, prompted the Minnesota Pollution Control Agency (MPCA) to consider measures to

minimize risks

associated with construction of liquid or semi-solid manure storage structures in sinkhole prone areas.

Beginning in

1995, the MPCA has worked to develop and implement a policy to reduce

environmental

risks associated with construction of liquid manure storage systems in sinkhole

prone areas, yet maintain the

feasibility of constructing manure storage systems throughout much

of the karst

region..

These guidelines

were developed so that a general indication

of environmental risk can be readily evaluated in karst regions

and

precautionary measures

can

be taken.

The

information used to

evaluate

the

potential

for

sinkhole

formation,

and, in general, how this

information is

used

in making permitting decisions, is described on the

following pages. Specific

permitting

decisions are made

on

an individual

case-by-case

basis after

considering

numerous

factors. The

intent

of the

guidelines

is to allow the producers and their

technical

advisors to understand sinkhole risk considerations early in the planning and

site

selection process,

prior to

substantial investment of time and money.

3

Listed below are

three steps which producers are required to take when considering construction ofa liquid

or semi-solid manure storage system

in areas where sinkholes could potentially form

(e.g. areas mapped

with a sinkhole probability of “lowto moderate” or greater~ or unmapped areas with less than 50

feet to

bedrock).

Step

I

-

Conduct site investigation for sinkholes and other karst features.

Step 2

-

Submit site investigation to state and/or county officials so that the karst risk factor may be

determined.

Step

3

-

Determine manure storage system options

and requirements.

Step 1- Site Investigationfor Sinkholes and Karst Features

A site

specific investigation is used to gather information needed to evaluate the risks of soil subsidence

at a proposed manure storage site.

The following is required for the site investigation. A checklist of these

requirements is

included as attachment A.

•

Sinkhole

Maps

-

A copy of any published sinkhole location and/or probability maps showing the area

within

about 2 miles of the proposed facility.

If a sinkhole map shows the proposed manure storage site

location to be in an

area

designated

as

“low’~ or

“no~~

probability, then the other steps

for the

site

investigation need not be completed.

•

Field Inspection

-

a map of the proposed

site showing the location of all small and large depressions in

the landscape.

At a minimum, all land within a 700 foot radius of the

potential manure storage structure

location must be closely inspected.

The best period

of time to conduct this investigation is when crop-

cover, leaf cover, and snow-cover~e

minimal.

•

Sinkhole/depression

Characteristics

-

a description

of the

following for

all

sinkholes

and potential

sinkholes identified in steps I and 2: a) whether the sinkhole

is

currently open or has

been filled; b)

decade when formed, if known; c) position on landscape; d) depression diameter and depth, and e) other

possible explanations which may explain the hole or depression.

•

Other knrst features

-

a description of other notable

potential karst features located within

1

mile

of

the proposed facility, including disappearing streams, caves, dry valleys, springs or solution cavities.

•

Soil borings

or soil trench information

-

The minimum soil boring depth must be to a point

10

feet

below the bottom

of

the

proposed

manure

storage system. The

karst risk

factor (step

2) will be

determined by assuming that the bedrock elevation is

at the bottom of the shallowest boring. Deep soil

borings which extend beyond the minimum required depth are optional and can

be used to

demonstrate

a lower sinkhole risk potential. A minimum of four borings

are

required for the

first one-half acre

of

storage

system

surface area. A minimum of two additional borings shall

be taken

for each additional

one-half acre

of storage structure surface

area.

If the

borings

indicate an uneven bedrock surface or

highly

variable soil conditions,

additional

borings will

be

required.

PLEASE NOTE: The

minimum

soil thickness between manure and bedrock for all standard concrete and clay-lined structures is

10 feet.

If

a composite (compacted

cohesive

soil plus a geomembrane or

geosynthetic

liner) or

upgraded

concrete liner system is used,

the required

separation

distance between manure and bedrock

is

5

feet.

An

upgraded concrete liner includes steel

reinforced

floors and a waterstop or

water

sealant

in all

construction joints and control joints, including the joint between the sidewall and floor of the structure.

•

Other Potential

Diagnostic

Work

-

The

MPCA

may require

other work as deemed

necessary

by

agency

staff, possibly including: deeper borings to determine the characteristics of underlying bedrock,

4

ground

penetrating radar or other

geophysical

investigations to

better diagnose

subsurface conditions,

trenching,

or other karst investigative techniques.

The

following

additional

information

is

needed for

liquid

manure

storage

structures

proposed

in

counties where a sinkhole locationlprobability map has not been prepared:

•

Soils

Maps

and Aerial

Photos

-

topographic maps, soil survey maps and aerial. phot~

of all land

within

a one mile radius of the site.

All known open and filled sinkholes must be highlighted on

these

maps.

Closed depressions identified on topographic maps are to be identified and inspected.

•

Land

owner

interviews

-

a

list

of all

long-term

residents (living in area

at least

15

years) and

land

owners

in

the area who were interviewed and asked

about the location of existing and filled sinkholes

located within a

1

inile

radius of the proposed facility. All sinkholes

or potential

sinkholes (open or

filled) are to be

identified

1on amap or photo ofthe site.

•

Well Logs

-

Geologic

information from well logs within a 2 mile radius of the proposed site location

Step 2.

Determination ofKarst RiskFactor

Information obtained under Step

I

is

submitted to the MPCA or delegated county authority so that a

karst risk factor for the site under consideration may be estimated. The karst risk factor is

determined from

available sinkhole probability map information, along with site specific soils, landscape function, geology,

and sinkhole

information.

Karst experts from other organizations

may be

consulted

during the review of

more complex cases.

The

following site specific information is considered when determining the karst risk

factor:

a) density of sinkholes;

b)

the topographic and geologic setting which sinkholes are found;

c) patterns and characteristics of nearby sinkhole formation;

d) type and condition of first encountered bedrock;

~e) depth to bedrock;

f) soil and subsoil types;

g)

identification of other karst features (e.g. disappearing streams, blind valleys, dry valleys, caves,

springs, and karst features observed

in exposed bedrock along roadways); and

h)

proxiii’ityto nearest sinkhole

or karst feature.

Sinkhole characteristics

roughly representing various karst risk categories

are listed

below.

While these

general

descriptions largely

refer

to

proximity

to

sinkholes

and

sinkhole

densities,

the

other

site

specific

variables

noted

above

are

often

evaluated

for

proposed sites in

order

to

determine

the

most

fitting risk

category. The following descriptions are only intended to serve as general-guidelines.

•

NoRisk

-

Areas where the first encountered bedrock is not subject to sinkhole formation.

•

Low

Risk

-

Areas underlain

by

carbonate

bedrock,

but

in

which very few sinkholes are found. No

known sinkholes exist within a

1

mile radius of the proposed site, and the soils and geologic information

indicate that there is minimal risk of sinkhole formation at the site under consideration.

•

Moderately

Low Risk

-

No

sinkholes or

buried

sinkholes

are

known

within

a

1/2

mile radius of the

proposed

site.

However,

widely scattered sinkholes have been identified

in

the area and the depth to

bedrock

is

less

than about 50 feet.

5

•

Moderate Risk

-

No

sinkholes

or buried

sinkholes

are

known

within

a

1/4

mile

radius

of the

site.

However,

there are scattered sinkholes (e.g.

2

-

5

sinkholes in a

1

mile radius of proposed

site) and/or

other geologic factors that make the area susceptible to-sinkhole formation.

•

Moderately

High

Risk

-

Similar

sinkhole

densities

as

high

risk

zones,

but the

soils

and

other

information about karst features indicate that

the

specific site of construction has a lower sinkhole risk

than the high risk category.

a.

3~o

p4-.

•

High Risk

-

There is

typically

either

I

sinkhole

or

buried

sinkhole within a

1/4

mile

radius or 2-4

sinkholes or

buried

sinkholes

within

a

1/2

mile radius and the soils and

karst

feature

information

indicates minimal protection.

~24.

‘4~

~V)

•

Very

High

Risk

-

Sinkholes are common

in

the

area,

but sinkhole

densities

are less

than

in the

extremely high risk areas (e.g. 2 to 4 sinkholes in

a

1/4 mile radius or

5 or more sinkholes within a

1/2

mile radius).

•

Extremely High Risk

-

Sinkholes

are the dominant

landform, with typical sinkhole densities

exceeding

about 4 sinkholes in a

1/4 mile radius from any point.

Step

3. Determine Manure storage system options and requirenlents

MPCA requirements are that the proposed liquid or semi-solid manure storage systems be:

a) located as far as

possible from topographic lows, depressions or ravines;

b)

located as far as possible from existjn~ or historically filled sinkholes;

c) located in

an area with the greatest thickness of fine-textured-soils;

d)

constructed so as to minimize the amount of rainfall and roof runoff water infiltrating soils in the area of

the manure storage system;

e) not constructed when very large volume manure storage-systems-are-proposed

in high risk karst areas;

f) not constructed

when

soil

excavation

reveals

indications

of

historic or

potential

future

sinkhole

formation.

After the

sinkhole

risk

factor

and the combined storage capacity of

all

structures

on

site

has been

determined, Table

1

is used

as a general guideline for identif~’ingrecommended options for manure storage

structures and

associated

liners.

The

options

for manure storage

are

intended to be

guidelines only.

Best

professional judgment is

used when determining allowable manure storage system options.

Consideration

is

given when

a

new

manure

storage structure

is

designed to correct

existing surface

or

ground

water

pollution problems without a significant expansion in operation size. For example,

at existing operations,

it

can

be

better for the environment

to have a new liquid

containment structure built

in a sinkhole prone area

than to have direct feedlot runoff into streams or the continued use of an old structure that was

constructed

using

less stringent standards.

Other considerations include:

maximum

manure volume to be stored

in any

single manure storage structure,

site

history

and management, planned contingency

efforts,

and

specific

properties of cohesive soils.

6

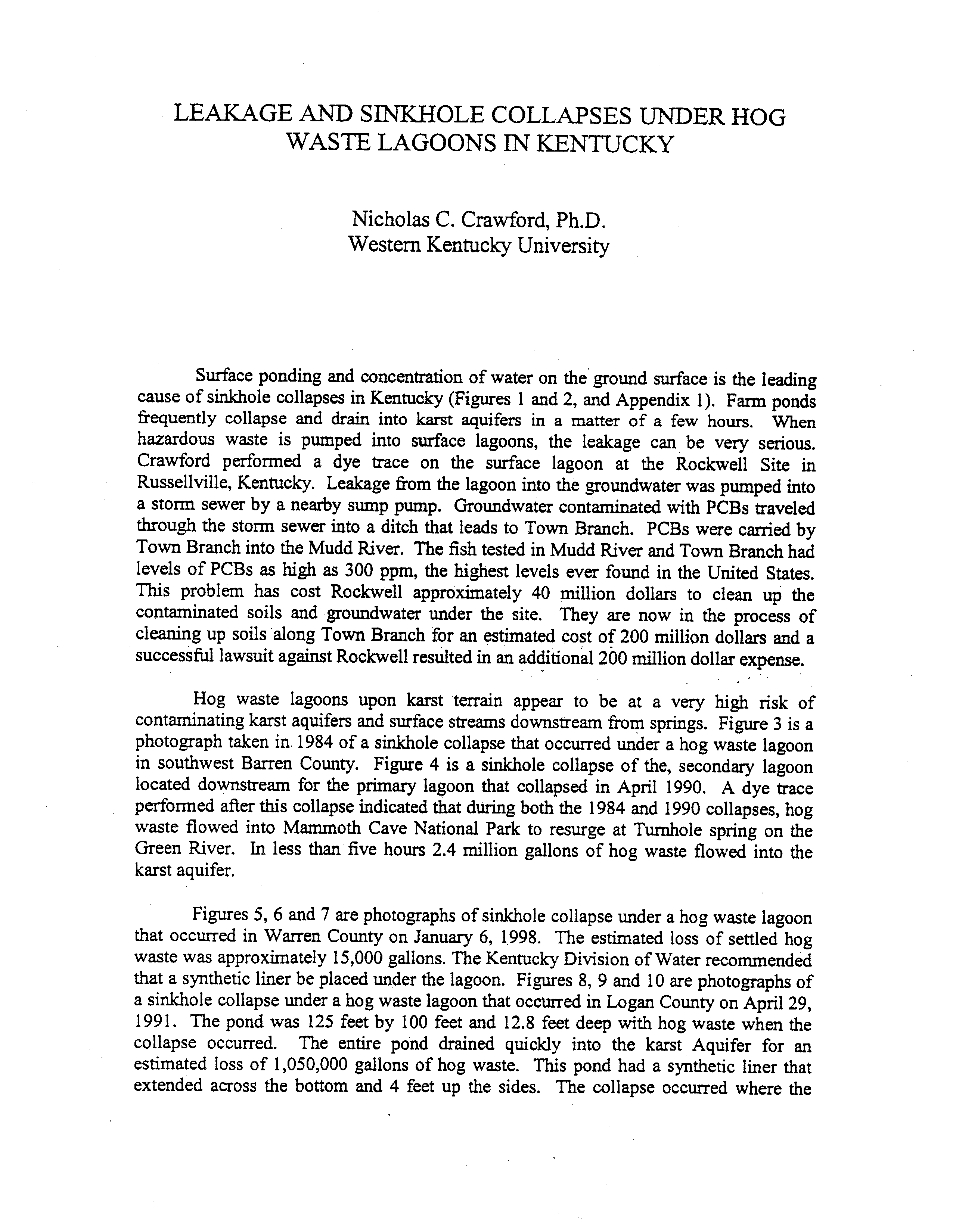

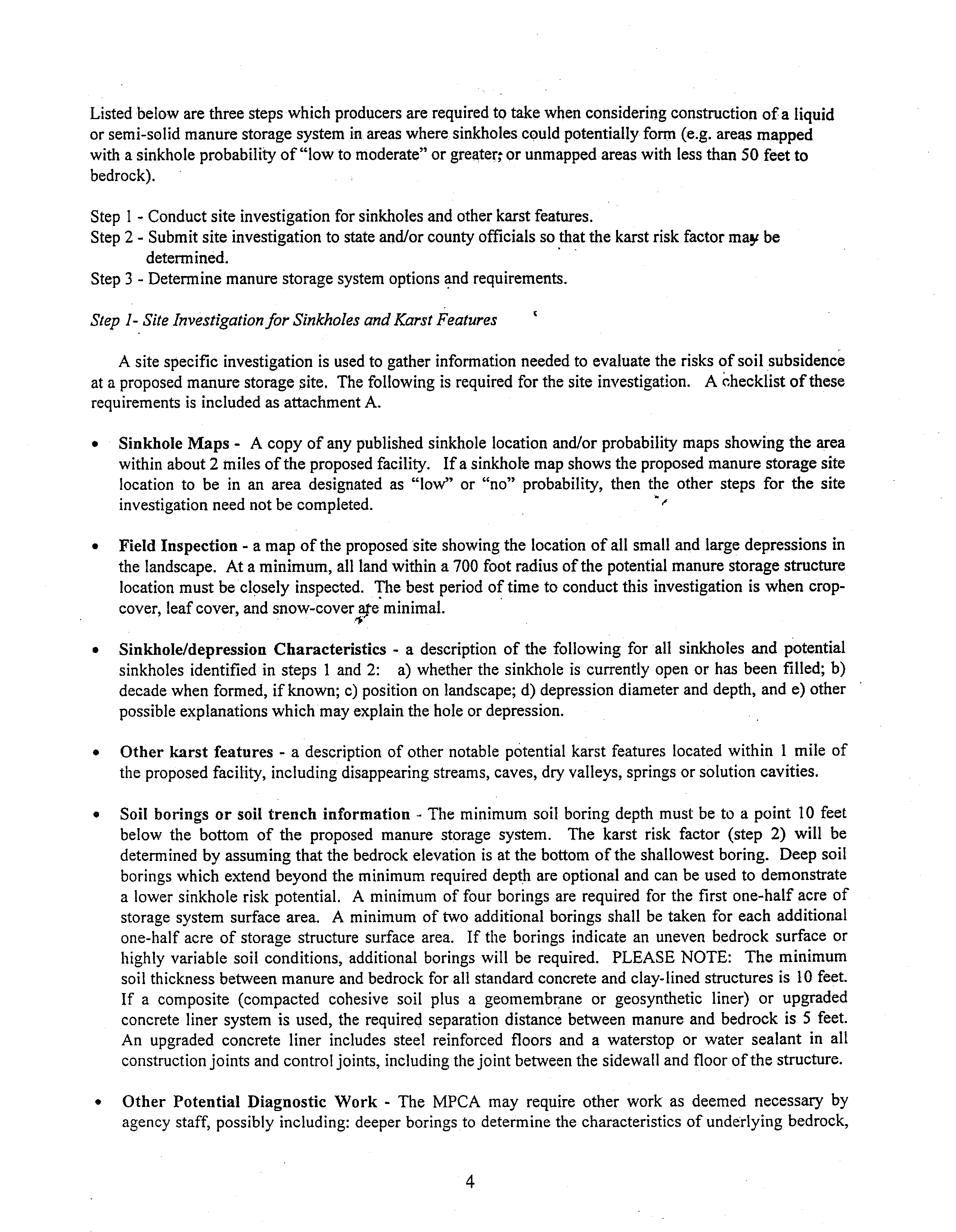

Table I.

General guidelines for manure storage system options in different karst risk zones.

The letters A-

G correspond with letters in the table. For example, a five million gallon storage structure proposed in a

moderate karst risk area could be constructed using options D, E, F, or G. Design capacity considers the

combined storage capacity of all manure storage structures on the property.

A. Cohesive soil liner designed/constructed to seep no more than 0.018” per daywhen full (of water) and a

designthicknessof2feetorgreater.

B.

Reinforced concrete structure constructed in accordance with MPCA standard requirements.

C.

Cohesive soil liner designed/constructed to seep no more than

0.0 12” per day when full (of water) and

with a liner thickness of 3

feet or greater.

D. Cohesive soil liner designed/constructed to seep no more than 0.0089” per day when full (of water) and

athickness of 4 ft or greater.

E.

Composite liner system or upgraded concrete liner. A composite liner system consists of a combination

of compacted clay covere~l by an approvable geomembrane or geosynthetic liner.

For concrete, an

upgraded system includes a steel reinforced floor and a waterstop or water sealant in all

construction

joints and control joints.

F. Above ground storage system.

G.

Solid manure handling systems only.

Design

capacity in millions ofgallons

KarstRisk

<0.25

0.25-

0.5-1

1-2

2-4

4-8

>8

0.5

No Risk or Low risk A-G A-G A-G A-G A-G A-G A-G

Moderately low risk

A-G~

A-G

A-G

A-G B-G

C-G C-G

Moderate risk A-G A-G A-G

B-G

C-G D-G E-G

Moderately high risk A-G A-G B-G

C-G

D-G E-G G

High risk

C-G C-G D-G E-G F-G G G

Very high risk

E-G E-G F-G G G G G

Extremely high risk E-G

G

G

G

G G

G

Other requirements

For all

sites constructed in areas considered as “Moderate Risk” orgreater the following additional

precautions must be met:

Subsoil Inspection

-

The MPCA must be notified at least 3 days prior to construction ofthe proposed

structure and be given the opportunity to inspect the soils during excavation. Also, atmany sites a soil

scientist or geologist will be required to be on-site following removal

ofthe soil B horizon to determine

whether there is any indication of potential sinkhole development observed in the soil (piping, voids,

channels, topsoil found at deeper depths or other indications of soil subsidence>.

When required, a subsoil

inspection report signed by the on-site soil scientist or geologist must be submitted to the MPCA

or

permitting authority.

If any indications of

potential sinkhole development are observed, the permittee must

notify the MPCA and the design engineer so that an evaluation can be made of whether the site must be

abandoned or if alternative measures can be

implemented to prevent sinkhole formation.

7

Rerouting roof runoffand site grading

-

The amount of water infiltrating soils in the area of the manure

storage system

must be minimized.

This can be accomplished by

sloping soils away from the manure

storage system, and routing all bam roof runoff and perimeter tile waters to a discharge point as far as

possible

from the manure storage system into a sloped runoff channel or to some other area where ponding

water will not occur.

Plans for rerouting facility runoff waters will

be required, for all permits

in sinkhole

prone areas.

CONCLUSIONS

There are

currently

many environmental protection ~demands surrounding

feedlots, including

enforcement of intentional

manure discharges, open

lot runoff problems, land application of manure

issues,

engineering

review for

new sites, hydrogen sulfide and

other

air emission

issues,

feedlot

abandonment

concerns, manure storage system construction problems, livestock access to public waters, manure stockpile

runoff,

silage liquids runoff, dead animal disposal, old

and poorly lined

manure storage systems, and other

problems

stemming

from

mismanagement

of manure. The

intent

of the MPCA

feedlot program

is

to

allocate limited

staff

resources

in

a

manner which balances addressing the issues

which

are causing

immediate environmental problems, with the need for taking preventative measures to minimize the chances

of catastrophic problems in the future.

Regulating the siting and designs of new manure storage systems in

areas

prone to sinkholes should help to

reduce the

chances of catastrophic and ~hronic problems

resulting

from

soil subsidence.

REFERENCES

Alexander, E. C.

Jr., and Book, P.R.,~i984. Altura Minnesota lagoon collapses.

in.

Beck, B.F. (ed.),

Proc. First Multidisciplinary Conf. on

Sinkholes,

Balkema, Boston.

p. 311-318.

Alexander, E.C., Jr., Brogerg, J.S., Kehren, A.R.,

Graziani, M.M. and Turn, W.L., 1993. Bellchester

Minnesota lagoon collapse.

in Beck, B.F. (ed.), Applied Karst Geology. Balkema, Rotterdam. p. 63 to

72.

Alexander, E.

C. Jr. and Maki, G.L.,

1988.

Sinkholes and sinkhole probability, Plate

7

of Balaban, N.H.

(ed.), Geologic Atlas Olmsted County, County Atlas Series C-3. Minnesota Geological Survey.

Dalgleish,

J..B. and Alexander, E.C., Jr.,

1984.

Sinkholes and sinkhole probability Plate

5 of Balaban, N.

H. and Olsen, B.M. (eds.), Geologic Atlas Winona County, County Atlas Series C-2. Minnesota

Geological Survey.

Magdalene, S. and Alexander, E.C., Jr.,

1995.

Sinkhole distribution in Winona County Revisited, in Beck

B.F. (ed.) Karst GeoHazards. Balkema, Rotterdam.

p. 43-Si.

Minnesota Pollution Control Agency.

1998.

MPCA Guidelines for design of cohesive soil liners for

manure storage structures.

Feb.

1998. draft.

28

pp.

Minnesota Pollution Control Agency.

1997.

Guidelines for concrete manure storage structures. Dec.

1997.

l

4pp.

Witthuhn, K. M. and Alexander, E.C. Jr.

1995.

Sinkholes and sinkhole probability, Plate

8 Geologic Atlas

Fillmore County, County Atlas Series C-8.

Minnesota Department ofNatural Resources and Minnesota

Geological Survey.

8

RO1-28 Service List

Livestock Waste Management

Monday April 23,02001

Cindy Bushur-Hallam

Department ofNatural Resources

524

S. Second SWeet

Springfield, IL

62701

Sheila H. Deely

Gardner Carton & Douglas

321 N. Clark Street, Suite 3400

Chicago, IL 60610

Terry Feldmann, P.E.

Feldmann & Associates

1191

Carolyn Ct.

East Peoria, IL

61611

Warren Goetsch

Illinois Department ofAgriculture

Division ofNatural Resources

PLO. Box

19281

Springfield, IL

62794

James T.

Harrington

Ross and Hardies

150 N. Michigan Ave., Suite 2500

Chicago, IL 6060 1-7567

Richard W. Davidson’

Illinois Pork Producers Association

2200 Greenside Dr.

Springfield,

IL 62704-3218

Cynthia I. Ervin

Chief Legal Counsel, Dept. of

Agriculture

Illinois State Fairgrounds

P.O. Box 19281

Springfield,

IL 62794

Scott Frank

Illinois Department Of Agriculture

Bureau ofEnvironmental Programs

P.O. Box 19281

Springfield,

IL 62794

Pam Hansen

Illinois Stewardship Alliance

P.O. Box 648

Rochester, IL 62563

Roy M. Harsch

Gardner, Carton & Douglas

321 N. Clark Street, Suite 3400

Chicago, IL 60610

Maralee M. Johnson

Illinois Beef Association

2060 W. Iles Ave., Suite B

Springfield, IL 62704

Carol Sudman

Illinois Pollution Control Board

600 5.

Second SWeet, Suite 402

Springfield, IL 62704

Dr. Bruce St. John

Illinois Citizens for Responsible

Practices

1620 Northedge Ct.

Dunlap, IL 61525

A.G. Taylor

IEPA

1021 North Grand Avenue East

P. 0. Box

19276

Springfield, IL 62794

Connie Tonsor

TEPA, Legal

Counsel Division

1021 North Grand Avenue East

P. 0. Box

19276

Springfield, IL

62794-9276