ILLINOIS POLLUTION CONTROL BOARD

July

7,

1995

IN THE MATTER OF:

PETITION OF CONVERSION

)

AS 93-4

SYSTEMS,

INC.

FOR ADJUSTED

)

(Adjusted

St~ndard—L~nd)

STANDARD FROM 35 ILL.

ADM.

CODE PART 811

(Liner)

OPINION AND ORDER OF THE BOARD

(by C.A. Manning):

This matter

is before the Board on a petition for an

adjusted standard filed by Conversion Systems,

Inc.

(CSI)

on July

2,

1993.

CSI seeks adjusted standards from the requirements

of

35 Ill.

Adin. Code Part 811,

Standards for new solid waste

landfills, Sections 811.306,

811.314,

and 811.507,

as they apply

to its Poz—O—Tec® materials

(Poz—O-Tec).

These materials are

produced through

a patented stabilization process utilizing flue

gas desulfurization

(FGD)

sludges and ash produced by coal-

burning power generation facilities.

CSI seeks the adjusted

standard

in order to allow owners of chemical waste landfills

accepting only FGD sludges and coal combustion wastes to use Poz-

0—Tec as a liner and cap material.

Based upon the record before it and upon review of the

factors involved in the consideration of adjusted standards,

the

Board finds that petitioners have demonstrated that grant of an

adjusted standard is warranted.

Accordingly for reasons more

fully set forth below,

the Board hereby grants CSI an adjusted

standard from 811.306,

811.314,

and 811.507.

PROCEDURAL HISTORY

CSI originally filed

a petition for adjusted standard

concerning its Poz-O-Tec materials on August 24,

1992, which was

docketed as AS 92—9.

That petition was dismissed by the Board on

March

25,

1993,

pursuant to CSI’s request to voluntarily withdraw

the petition.

The petition before the Board in the present

proceeding was filed on July

2,

1993.

Concurrently with the

filing of this petition,

CSI filed a separate petition for

adjusted standard, docketed as AS 93—5, wherein CSI seeks relief

from the requirements

of 35

Ill.

Adin. Code Part 811 so as to

allow Poz-O-Tec materials to be disposed of in a monofill without

the

need

for

a

liner,

cap,

or

leachate

collection

system.

Also

on

July

2,

1993,

CSI

filed

a “Motion Regarding

Procedural Matters,” wherein CSI requested that it be allowed to

incorporate by reference the entire record from AS

92—9.

CSI

also requested that the Board rule

upon the

issue

of

whether

its

failure

to

include

site—specific

information

would

make

adjusted

standard relief unavailable.

On July 20,

1993, the Illinois

Environmental Protection Agency (Agency)

filed a response to this

motion

and

a

motion

to

dismiss,

and

CSI

filed

a

reply

to

the

2

Agency’s response.

The Board issued an order on July 22,

1993,

which granted CSI’s motion to incorporate the record in AS 92-9.

On August 26,

1993,

the Board issued an order, with two Board

Members dissenting, finding that CSI’s petition for adjusted

standard was an appropriate mechanism for seeking relief,

and

which accepted the petition for hearing.

(See Board Order of

August 26,

1993,

B.

Forcade and C.A. Manning dissenting.) In its

August 26,

1993 order, the Board expressed no opinion as to the

merits of the petition.

No appeal of that order was sought by

either the petitioner or the Agency.

The Agency filed two motions

for

extensions of time to file

its response in order to allow the Agency to substitute counsel,

and in order to allow negotiations between the parties.

The

Board granted both extensions of time,

the second of which

granted the Agency an extension until May 23,

1994 to file its

response.

The Board received CSI’s Certificates of Publication on

August

2,

1993, which indicated that notice of the proposed

adjusted standard was published in the State Journal-Register on

July 5,

1993, and in the Chicago Sun-Times on July

3,

1993.

No

requests for public hearing were received,

and no hearing was

held in this matter.

However,

on May 19,

1994,

the Board

assigned a hearing officer to this matter, and directed the

parties to hold a pre—hearing conference, which was held June 22,

1994.

Subsequently, because the parties wished to continue

negotiating, the hearing officer issued an order directing the

parties to file status reports on or before November

1,

1994.

The Agency filed

its response to the petition for adjusted

standard on November 3,

1994, recommending that the adjusted

standard be granted, subject to certain additions and amendments.

On November 14,

1994 CSI filed a motion for leave to file a reply

to the Agency response which the Board granted.

The reply

indicates that CSI is

in agreement with the Agency’s proposed

amendments to the adjusted standard.

On May 5,

1995, CSI filed a motion requesting that the Board

follow its August 26,

1993 order.

The Board finds the motion

moot for the reasons set forth below in the opinion.

THE ADJUSTED

STANDARD

PROCESS

-

SECTION 28.1 OF THE ACT

The Board’s responsibility in this matter arises from the

Environmental Protection Act

(Act)

(415 ILCS 5/1 et seq.).

The

Board is charged therein to “determine, define and implement the

environmental control standards applicable

in

the State of

Illinois” (Section 5(b)

of the Act)

and to “grant

.

.

.

an

adjusted standard for persons who can justify such an adjustment”

(Section 28.1(a)

of the Act).

More generally, the Board’s

responsibility in this matter is based on the system of checks

3

and balances integral to Illinois environmental governance: the

Board is charged with the rulemaking and principal adjudicatory

functions,

and the Agency is responsible for carrying out the

principal administrative and enforcement duties.

Section 28.1 of the Act provides that a petitioner may

request, and the Board may adopt an individual adjusted standard

different from the standard that would otherwise apply to

petitioner pursuant to a rule of general applicability.

Such a

standard is called an adjusted standard.

The general procedures

that govern an adjusted standard proceeding are found at Section

28.1 of the Act and within the Board’s procedural rules

at

35

Ill.

Adin.

Code Part 106.

Where,

as here, the regulation of general applicability does

not specify a level

of justification required for a petitioner to

qualify for an adjusted standard, the Act at Section 28.1(c)

specifies four demonstrations that must be made by a successful

petitioner:

1)

Factors relating to that petitioner are substantially

and significantly different from the factors relied

upon by the Board in adopting the general regulation

applicable to that petitioner;

2)

The existence of those factors justifies an adjusted

standard;

3)

The requested standard will not result in environmental

or health effects substantially and significantly more

adverse than the effects considered by the Board in

adopting the rule of general applicability; and

4)

The adjusted standard is consistent with any applicable

federal

law.

Instead of seeking relief that is specific to an individual,

or a site, CSI

is requesting that an adjusted standard be granted

from certain sections of Part 811,

so that those facilities which

produce FGD sludges and ash (approximately 45 coal burning power

generation facilities), may purchase CSI’s Poz—O-Tec process and

dispose of Poz-O-Tec material without having to comply with the

existing Part 811 liner and leachate requirements.

As stated previously the Board denied an Agency motion to

dismiss the instant petition and that of AS

93-5.

Since that

time, the Agency and CSI have come to agreement as to the

requirements that would be imposed on the purchasers of the Poz—

O—Tec process,

and the Agency has filed a recommendation to that

effect with the Board.

However,

in reviewing the language of the proposed adjusted

4

standard, the Board finds that it imposes requirements on the

purchasers and users of the Poz—O—Tec process, and not strictly

upon CSI, the individual company who sought and to whom we grant

this adjustment to the rules of general applicability. Therefore,

in order to ensure that the

users of the Poz—0—Tec materials for

which the adjusted standard is granted, clearly understand and

are legally and regulatorily committed to proper use of the Poz-

0-Tec process product, the Board will also open a rulemaking

docket to consider incorporating this adjusted standard into a

rule of general applicability governing the Poz-O-Tec process of

CSI, pursuant to Sections 27 and 28 of the Act.

The Board intends to use this docket to adopt the language

of the adjusted standard,

as agreed to and drafted by CSI and the

Agency,

as a new Part 816, entitled “New Utility Waste

Landfills.”

Additionally, we will propose amendments to Part

807,

810, and 811 in order to provide for consistency with a

proposed, new Part 816.

We also believe that it

is appropriate

for the Board, and we note that it is within our discretion, to

consider a rule of general applicability for the Poz—O--Tec

materials pursuant to Section

27 and 28 of the Act.

The following is the Board’s examination of the technical

merits of the requested adjusted standard.

APPLICABLE REGULATIONS FROM WHICH CSI

SEEKS AN ADJUSTED STANDARD

CSI seeks an adjusted standard from the requirements of

35

Ill.

Adm.

Code Sections 811.306,

811.314,

and

811.507.

These

rules are contained

in Subpart C of Part 811 of the Board’s

landfill rules.

Part 811 prescribes the standards applicable to

new solid waste

landfills,

and Subpart C of Part 811 prescribes

those standards specifically applicable to chemical and

putrescible waste

(chemical waste)

landfills.

Section 811.306

prescribes the liner requirements;

Section 811.314 prescribes the

final cover requirements,

including requirements for a

low

permeability layer or cap; and Section 811.507 prescribes

requirements for compacted earth liners,

including the

requirement that a test

liner be constructed.

Each of these is

discussed in greater detail below.

Section 811.306 prescribes the liner requirements applicable

to chemical waste landfills.

It contemplates use of two types of

liners:

compacted earth liners and geomembrane liners.

A

compacted earth liner must be at least

5 feet thick, with a

maximum hydraulic conductivity of 1x107 cm/sec., and must be

constructed in accordance with the quality assurance procedures

in 811.Subpart

E.

Geomembranes may be used only in conjunction

with

a compacted earth liner system,

and must meet certain

additional requirements specified in subsection 811.306(e).

A

5

leachate collection system must be used in conjunction with both

types of liners.

Alternatively, subsection 811.306(g)

specifies

that alternative technologies or materials may be used to serve

as liners if:

(1)

they provide equivalent or superior

performance;

(2)

the technology or material has been successfully

utilized in at least one other similar application; and

(3)

methods for manufacturing quality control and construction

quality assurance can be implemented.

Section 811.314 prescribes requirements for final cover

applicable to chemical waste

landfills.

It specifies that

chemical waste landfills must be covered by a final cover

consisting of a low permeability layer overlain by a final

protective layer.

The low permeability layer can consist of a

compacted earth layer at least three feet thick with

a

permeability

of

1xl07 cm/sec.,

or a geomembrane which provides

equivalent performance.

Subsection 811.314(3) (C)

allows

alternative techniques or materials to be used if they provide

equivalent or superior performance.

Section 811.507 requires that a test liner be constructed

prior to construction of

a full—scale compacted earth liner.

The

test liner must be constructed of the same design and materials

as the full

liner,

and must satisfy criteria specifying miniiiiuin

dimensions.

Subsection 811.507(b) (5)

specifies that the physical

properties of the test fill must be tested using field tests for

determining hydraulic conductivity,

and laboratory tests for

hydraulic conductivity and other engineering parameters,

including particle size distribution,

plasticity, water content,

and in-place density.

PROPOSED ADJUSTED STANDARD

In this petition,

CSI seeks an adjusted standard to allow

landfills which accept only coal combustion and FGD wastes to use

Poz—O-Tec materials for their liners and caps.

CSI’s Poz—O—Tec

materials are produced through

a patented stabilization process

which uses forced—oxidized flue-gas desulfurization scrubber

sludge and coal combustion ash as raw materials.

(Pet. at 1.)

The scrubber sludge is directed to

a scrubber blowdown tank,

and

then to primary and secondary dewatering systems.

(Pet.

at 7.)

The dewatered sludge is then directed to

a mixer where fly ash

and lime are added.

The materials

are mixed and then stabilized,

producing a highly impermeable monolithic mass

(Pet.

at 7),

with

a high unconrifled compressive strength and load-bearing capacity,

and the capability for autogenous healing of small cracks and

fissures

(Pet.

at 2-3).

The material continues to cure over a

period of years, becoming stronger.

The P02—0—Tee materials meet

the classification criteria

for inert waste, with the exception

of concentration of total dissolved solids

(TDS)

and sulfates in

the leachate produced.

(Pet.

at 2.)

6

Poz—O—Tec materials have been used since 1977 as bases

for

highways, parking lots and airport runways.

(Pet. at 3.)

They

have been used to construct aquaculture ponds, artificial ocean

reefs, and have been formed into construction blocks and used as

a substitute for aggregate or stone for the production of

concrete blocks.

(Pet.

at

3)

They have also been used to

prevent erosion along coastlines and railway embankments,

as a

monolithic fill material, and to reclaim strip mines from coal

mining.

(Pet.

at 3.)

CSI is seeking this adjusted standard in order to market the

Poz—O—Tec process to approximately 45 coal combustion power

generation facilities in Illinois.

There presently are no such

purchasers in Illinois

(Pet. at 4); however,

this may be because

such use may not be permitted pursuant to current Board

regulations, and due to the cost differential between surface

impounding and landfilling FGD waste subjected to the Poz-O-Tec

process pursuant to the chemical waste landfill rules.

CSI

asserts that this

is because surface impoundments are largely

unregulated under current law.

(Pet. at 4.)

In this petition,

CSI does not seek an adjusted standard

applicable to a specific site; rather,

it seeks to allow an

adjusted standard applicable to its Poz-O-Tec process when used

throughout the state.

CSI states that there are approximately 45

coal combustion facilities

in Illinois which could take advantage

of the Poz-O-Tec process.

(Pet.

at 6.)

These facilities have

baghouses or electrostatic precipitators, and would be required

to operate FGD systems in order to use the Poz—O—Tec process and

material made available by this adjusted standard.

(Pet.

at

6.)

The adjusted standard would not affect any of the other

requirements in the chemical waste landfill rules of Part 811

other than those rules from which CSI’s Poz—O-Tec process and

material is receiving an adjusted standard today in AS93-5.

Pursuant to the relief requested by CSI in the instant

petition and the related petition of AS 93-5,

facilities which

have decided to utilize the Poz-O-Tec process would have two

available disposal options: inonofilling pursuant to the relief

requested by CSI in AS 93—5,

or constructing a liner and cap of

Poz-O—Tec materials, pursuant to the relief requested in the

instant petition.

A facility’s decision as to which option to

use would be dependent upon the ratio of flyash and sludge in its

waste stream.

CSI asserts that most facilities will be able to

consistently produce high quality Poz-O-Tec materials with a

permeability less than or equal to lx107 cm/sec.

(Pet.

at 8.)

These materials could be disposed of in a monofill, which is the

subject

of

CSI’s adjusted standard petition in AS

93—5.

However, some facilities will not generate sufficient fly

ash to consistently produce materials with a permeability less

7

than or equal to 1x107 cm/sec.

(Pet.

at 8.)

These facilities

would produce a sufficient quantity of Poz-0-Tec materials to

construct a liner and cap meeting the lxlO7 cm/sec.

standard.

This would be accomplished by storing fly ash until an adequate

supply is available to produce high quality Poz—O—Tec materials

(Pet. at 8.)

The landfill would then be constructed and operated

in accordance with the chemical waste landfill rules.

The

adjusted standard proposed in the instant proceeding would allow

facilities to pursue this second option.

The proposed adjusted standard would allow facilities to use

a Poz-O-Tec liner which

is at least five feet

thick, which has a

permeability of

1x107 cm/sec. or less and an unconfined

compressive strength of 150 psi or greater.

The permeability and

unconfined compressive strength must be verified through the

construction and field testing of a test pad.

The landfill must

receive for disposal only FGD sludges and coal combustion wastes,

and must be constructed at least five feet above the water table.

The cap could be constructed of the same material as the liner,

and must be at least three feet thick.

Site owners would be

required to do site-specific contaminant modelling,

groundwater

modelling and assessment and remedial action.

JUSTIFICATION IN SUPPORT OF THE ADJUSTED

STANDARD

-

THE

SECTION

28.1(c) FACTORS

In support of its petition for adjusted standard,

CSI

asserts that the Board did not consider the specific properties

of the Poz-O-Tec materials when it adopted the liner rules.

(Pet. at 23.)

Additionally, although Section 811.306(g)

of the

Board’s landfill regulations specifies a procedure by which

alternative liner materials and technologies can be used,

CSI is

unable to use that procedure for liners constructed of its Poz—O—

Tec material.

Section 811.306(g)

specifies that when alternative

materials are used for

a landfill

liner, they are required to

show that they provide equivalent or superior performance to clay

or geotnembrane liners, that the technology or material has been

successfully utilized in at least one application similar to the

proposed application, and that manufacturing and construction

quality assurance can be implemented.

CSI believes that

it has demonstrated through its petition

that a Poz—O—Tec liner and cap would provide equivalent or

superior performance to a clay liner or geomembrane liner.

(Pet.

at 24.)

Though

CSI

cannot demonstrate the successful utilization

of Poz-O-Tec in at least one similar application,

this may be

because no such similar application yet exists.

(Pet.

at 25.)

Petitioner points out that, while Poz—O—Tec has not

been used as

the liner for a landfill,

it has been used successfully as the

liner for a surface runoff collection pond.

(Pet.

at 25.)

Although the materials used in that application were inferior to

8

those that would be required under the proposed adjusted

standard,

no leakage was reported over a period of nine years.

(Pet.

at

25.)

CSI further points out that the adjusted standard it seeks

would apply only to essentially inert

completely compatible with the liner.

contrast, the chemical waste landfill

applicable to a wide range of wastes,

of hazards to the environment.

(Pet.

requiring such landfills to install a

economically unreasonable burden upon

generation facilities.

(Pet.

at 23.)

the unreasonable burden,

CSI has also

alternatives available to coal burning power generation

facilities that produce FGD sludges and ash for disposal.

Compliance Alternatives

In its original petition in AS 92-9,

incorporated by

reference into this proceeding, CSI presented an analysis of

existing management alternatives for

FGI) by-products currently

available to coal burning power generation facilities.

This

analysis was based on a

study performed for CSI by Environmental

Resources Management

(ERM).

ERM investigated the following

management options for disposal of FGD by-products:

1) Wet Impoundment/Gypsum Stacking

—

This option consists of

directing the FGD slurry from

a scrubber system to

a

settling pond, where FGD solids are settled out.

Effluent

from the settling pond is either recycled into the scrubber

system or treated and discharged, while settled solids are

periodically removed.

The settled solids can be stacked

around the perimeter of the settling pond to increase its

height,

or

can be stored in

a

reclaim area for subsequent

landfill disposal;

2) Macroencapsulation

of Dewatered FGD Slud~e

—

This option

consists of dewatering the FGD sludge and placing

it into a

lined landfill.

The landfill would be capped upon closure.

The landfill could be used for either disposal of the FGD

sludge,

or co-disposal of the FGD sludge and fly ash;

3) Disposal of Dewatered FGD S1ud~ein an Unlined Cell

—

This option is

identical to option #2,

Ivlacroencapsulation or

Dewatered Sludge, with the exception that the materials are

disposed of in an unlined cell; and

4) Fixation and Stabilization of FGD Sludge

(Poz—0-Tec

process)

-

This option involves treating the FGD sludge with

the Poz—O-Tec process and disposing of

it in a lined or

unlined landfill.

wastes, which are

(Pet.

at 23.)

In

rules are generally

which pose a wide spectrum

at 23.)

CSI asserts that

clay liner would impose an

coal combustion power

As part of demonstrating

set forth the compliance

9

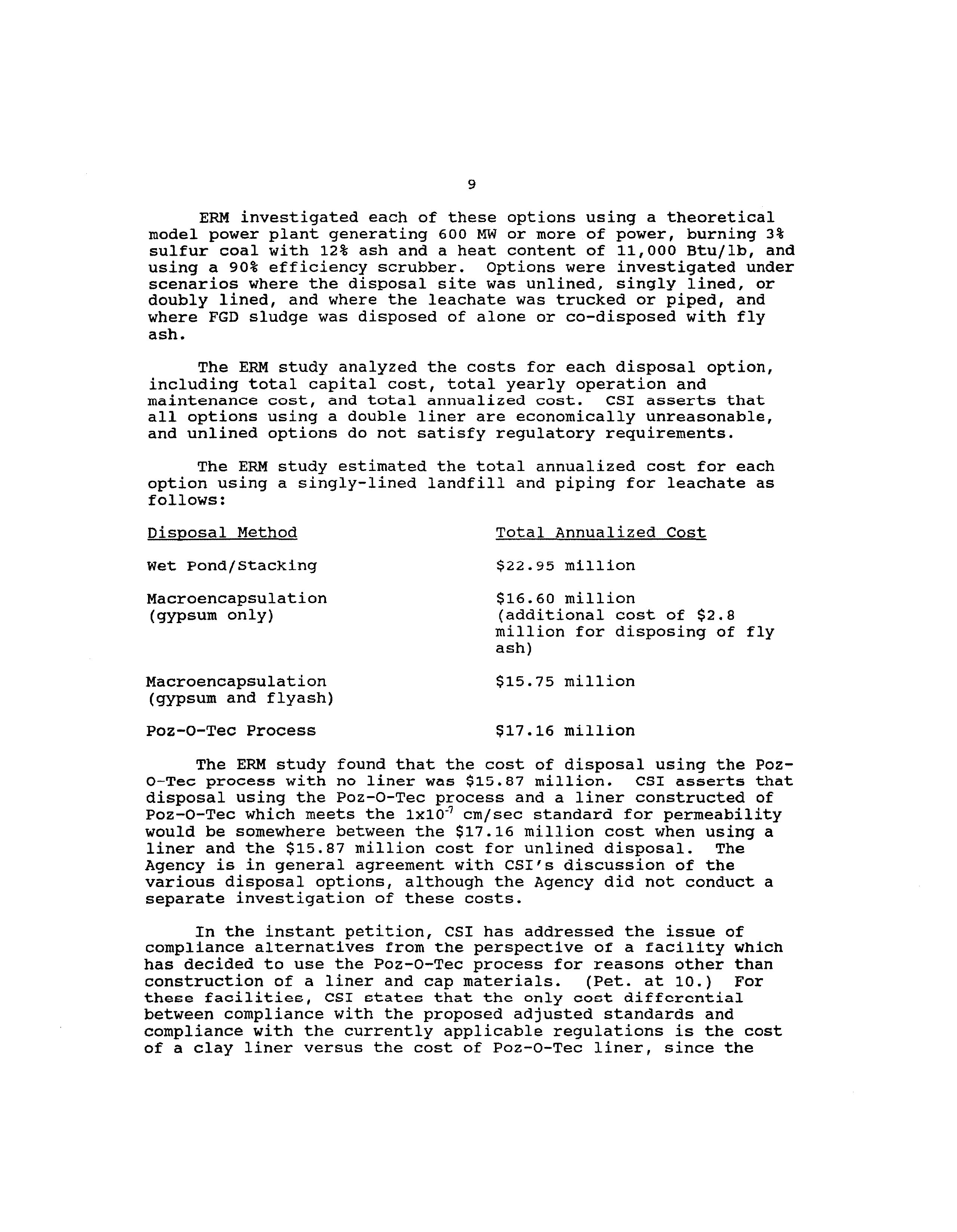

ERN

investigated each of these options using a theoretical

model power plant generating 600 MW or more of power,

burning 3

sulfur coal with 12

ash and a heat content of 11,000 Btu/1b,

and

using a 90

efficiency scrubber.

Options were investigated under

scenarios where the disposal site was unlined,

singly lined,

or

doubly lined,

and where the leachate was trucked or piped,

and

where FGD sludge was disposed of alone or co—disposed with fly

ash.

The ERM study analyzed the costs for each disposal

option,

including total capital cost, total yearly operation and

maintenance cost,

and total annualized cost.

C5I asserts that

all options using

a double liner are economically unreasonable,

and unlined options do not satisfy regulatory requirements.

The

ERN study estimated the total annualized

cost for each

option using a singly-lined landfill and piping for leachate as

follows:

Disposal Method

Total Annualized Cost

Wet Pond/Stacking

$22.95 million

Macroencapsulation

$16.60 million

(gypsum only)

(additional cost of $2.8

million for disposing of fly

ash)

Nacroencapsulation

$15.75 million

(gypsum and flyash)

Poz—O-Tec Process

$17.16 million

The ERN study found that the cost of disposal using the Poz-

0-Tec process with no liner was

$15.67

million.

CSI asserts that

disposal using the Poz—O-Tec process and a liner constructed

of

Poz—O-Tec which

meets the lxl0~cm/sec standard for permeability

would be somewhere between the $17.16 million cost when using a

liner and the $15.87 million cost for unlined disposal.

The

Agency is in general agreement with CSI’s discussion of the

various disposal options, although the Agency did not conduct a

separate investigation of these costs.

In the instant petition, CSI has addressed the issue of

compliance alternatives from the perspective or a facility which

has decided to use the Poz—O—Tec process for reasons other than

construction of a liner and cap materials.

(Pet.

at

10.)

For

these facilities,

CSI states that the

only cost differential

between compliance with the proposed adjusted standards and

compliance with the currently applicable regulations is the cost

of a clay liner versus the cost of Poz—O—Tec liner,

since the

10

cost to install either type of

liner would be similar.

(Pet. at

10.)

CSI estimates that for the ERN theoretical landfill,

a clay

liner and cap which meet the minimum requirements under the

regulations would cost $18 million.

(Pet.

at

11.)

In contrast,

for facilities which have decided to use the Poz—O—Tec process,

the cost of the additional materials needed to produce high

quality Poz-O-Tec for the liner and cap would be approximately

$2.7 million.

(Pet.

at

11.)

CSI thus estimates that these

facilities could save approximately $15.3 million.

Health and Environmental Effects

CSI asserts that liners

and caps made of Poz—O-Tec

materials,

when used at chemical waste landfills accepting only

FGD sludges and coal combustion wastes, will provide

environmental protection equivalent or superior to earthen or

geoxnembrane liners and caps.

(Pet.

at 29.)

CSI asserts that a

landfill using Poz—O-Tec materials will generate leachate which

is similar to that produced under any disposal option

investigated by ERN.

A landfill which uses Poz-O-Tec would

generate leachate which meet the Board’s inert waste standards,

except for total dissolved solids

(TDS)

and sulfates.

However,

a

landfill which uses Poz—O—Tec will generate significantly less

leachate than other disposal methods.

(Pet.

at 17.)

CSI asserts that the only difference between a clay liner

and a Poz—O—Tec liner concerning leachate production would result

from the ability of clay to attenuate contaminants.

(Pet. at

18.)

CSI asserts that many clays do not have such an ability,

and that such attenuation

is generally

not

applicable to TDS or

sulfates,

the only contaminants for which Poz—O-Tec leachate

exceeds the Board’s

inert waste standards.

Furthermore, CSI

points out that the landfill rules

do not require liners to

attenuate waste constitutents.

In its

petition,

CSI also addresses the

issue of cracking.

CSI asserts that while Poz-O-Tec materials are less plastic than

clay, they are far stronger.

CSI asserts that with an unconfined

compressive strength of greater than 150 psi as called for in the

proposed adjusted standard,

a Poz—O-Tec liner more than four feet

thick could span any void which may develop beneath

a landfill.

Furthermore, CSI asserts that if any small cracks or fissures

were to develop,

the autogenous healing properties of Poz—O—Tec

would heal

them.

Consistency with Federal Law

CSI

asserts

and the Agency

agrees that none of the

requirements from which relief

is sought were promulgated,

in

whole or in part, pursuant to federal requirements.

Therefore

the requested relief can be granted consistent with federal

law.

11

AGENCY RECOMMENDATION

In its response to the petition for adjusted standard, the

Agency states that it

generally agrees with the information

presented

in CST’s petition,

and r~comm~ndsthat the adjusted

standard be granted.

However,

the Agency raised concerns

regarding certain aspects of the proposed adjusted standard,

including curing of the test pad,

commencement of the full—scale

liner, and appropriate evaluation testing.

The Agency raised

these concerns to CSI and proposed amendatory language to address

them.

CSI has agreed to the inclusion of this amendatory

language in the adjusted standard.

The Agency proposed an amendment to the proposed adjusted

standard specifying additional criteria for construction of the

test liner.

The test liner must be completely constructed, such

that all that remains is curing,

before construction of the full—

scale liner can begin.

The test liner must be fully evaluated

and the results must be provided to the Agency.

If the liner

fails to meet the specified performance standards,

and if the

Agency so directs,

the user must excavate and properly dispose of

all Poz—O-Tec liners at the site,

and any waste deposited In and

around such liners.

The other amendments which the Agency proposed include a

requirement that the Poz-O-Tec liner material have an unconfined

compressive strength greater than or equal to

150 psi,

a

requirement that the user prepare an acceptable groundwater

impact assessment, and a requirement that the bottom liner and

low permeability layer of the cap be constructed according to a

quality assurance program in accordance with 35

Ill. Adm. Code

811. Subpart

E.

The Agency also proposes that the adjusted

standard include a provision specifying that the user comply with

the Act and 35 Ill.

Adm. Code to the extent not addressed by the

adjusted standard.

We find that the Agency’s proposed amendments clarify the

requirements applicable to those using the adjusted standard, and

we therefore will include them in the adjusted standard.

CONCLUSION

CSI

has demonstrated that there are factors relating to use

of the Poz-O—Tec materials for liners and caps at landfills

accepting only FGD and coal combustion wastes that are

substantially and significantly different from the factors relied

upon by the Board in adopting the regulation of general

applicability,

and that the

existence of those factors justifies

an adjusted standard.

Of course, CSI’s Poz—O—Tec process was not

considered by the Board when

it drafted the landfill rules since

CSI did not participate therein,

and while the landfill rules do

provide a procedure whereby alternative materials and

12

technologies can be used, that procedure cannot be relied upon

where,

as in the present case, there is not at least one other

similar application of the material or technology.

CSI has

demonstrated that use of Poz—O-Tec materials will provide

protection against environmental contamination as great or

greater than that provided by clay liners,

and that the proposed

adjusted standard may be granted consistent with any applicable

federal

law.

The Board hereby finds that petitioners have demonstrated

that an adjusted standard is appropriate in order to allow the

use of Poz—O—Tec materials for liners and caps at landfills which

contain solely FGD and coal combustion wastes.

Therefore, the

Board will adopt an adjusted standard for the use of CSI’s Poz—O-

Tec materials and process subject to the conditions agreed upon

by the Agency and CSI.

This opinion constitutes the Board’s conclusions

of law and

findings of fact

in

this

matter.

ORDER

The Board grants an adjusted standard pursuant to 415 ILCS

5/28.1,

to the Poz—0-Tec process and materials of Conversion

Systems,

Inc.

subject to the provisions and conditions set forth

below.

The Board directs the Clerk of the Board to open a

rulemaking docket to consider incorporating this adjusted

standard into a rule of general applicability.

Notwithstanding the liner and cap requirements set forth at

35

Ill. Adm.

Code 811.306, 811.314

(solely to the extent

that it may preclude

Poz—O—Tec

materials from being used as

a landfill cap)

and 811.507(a) (5),

FGD sludges and coal

combustion waste produced by coal combustion power

generating facilities utilizing

a

lime or limestone scrubber

system may be used for liner or cap construction for the

purposes of Subpart

C of Part 811 provided that:

1.

The materials have been processed using the Poz—O—Tec

stabilization process from Conversion Systems,

Inc.;

2.

The permeability of the liner material shall be

demonstrated to be less than or equal to

1xl07 cm/sec

after placement and curing based upon a geometric

average of the permeability testing results prior to

the placement of any waste upon the liner;

3.

The material has an unconfirmed compressive strength of

greater than or equal to

150

psi based upon an

arithmetic average of the strength testing results;

13

4.

The bottom liner shall have

a minimum thickness of five

feet but this thickness may be increased as necessary

to make the demonstrations required by 35

Ill.

Adin.

Code Parts 812 or 815;

5.

This base of the liner shall be constructed at least

five feet above the average historical groundwater

table;

6.

Only coal combustion wastes and FGD sludges. produced

from power generating facilities utilizing lime or

limestone scrubber systems

shall be placed into the

landfill;

7.

A final cover system shall be installed in accordance

with the requirements of

35 Ill. Adm.

Code

811.314

except that the low permeability layer of the cap shall

consist of Pox-O-Tec materials which are at least three

feet thick;

8.

The following material testing procedures will be

Implemented:

A.

Creation and Sampling of Test Pad

(1)

The owner/operator of the disposal site

shall

construct a test pad in accordance with

35

Ill.

Adm.

Code 811.507(a),

unless waived by

the Agency pursuant to subsection(b)

of that

section;

(2)

The test pad shall be allowed to cure for 56

days at

730

Fahrenheit

(or equivalent cure);

(3)

After curing,

fifty samples will be taken

using

a

4 inch diameter coring bit; and

(4)

The specimens will be trimmed to proctor

cylinder size utilizing an abrasive blade

masonry saw,

and tested for unconfined

compressive strength and coefficient of

permeability as described in subsection

C,

below.

Of the specimens taken from the pad,

twenty will be analyzed for their coefficient

of permeability and thirty will be analyzed

for their unconfined compressive strength.

B.

Collection of Production Samples

Samples will be collected from the production of

Poz—0-Tec in the following manner:

14

(1)

Utilizing a large scoop,

five gallon buckets

of freshly produced material will be

collected at uniform intervals during

construction of the test pad and shipped to a

laboratory for analysis.

(2)

Five proctor cylinder specimens will be

prepared from each bucket of freshly produced

material.

Three of these five cylinders will

be tested for unconfined compressive strength

and the other two will be tested for

permeability.

(3)

Additional uncured samples will

be taken as

necessary for preparation and testing to

determine criteria for moisture content,

lime

content,

the ratio of fly ash to sludge and

in-place density.

Testing for these

parameters shall be conducted in accordance

with standard test methods appropriate for

the particular parameter.

The criteria shall

be established

so as to reasonably ensure

that the material disposed of will achieve

the permeability and strength requirements

set forth in subsection E,

below.

C.

Strength and Permeability Testing

(1)

Uncured samples will be taken to a

laboratory,

placed into proctor cylinders,

compacted to simulate field conditions

(ASTM

method D-1557—9l), cured in sealed containers

for 56 days at

730

(or equivalent cure)

and

tested for coefficient of permeability and

unconfined strength using the following test

methods:

U.S.

Army Corp.

of Engineers Engineering

Manual 1110—2-1906 Appendix Vii,

Falling—Heal

Permeability Test with Perineameter Cylinder.

ASTM

Method 05102; Standard Method for

Unconfined Compressive Strength of Cohesive

Soils.

(2)

Field samples will be tested using the same

methods

as specified

in subsection C91),

above.

D.

Data Correlation

15

Laboratory data and field data will be compared to

determine any statistically significant

differences using standard statistical correlation

methodologies.

E.

Subsequent Testing

Upon completion of field verification,

as

described above,

the owner/operator of the

site

shall conduct QC/QA testing by taking monthly

samples of freshly produced Poz-O-Tec materials,

and sending those samples to a laboratory where

they will be formed into proctor cylinder

specimens for testing.

Two of those samples will

be tested for their coefficient of permeability,

three for unconfined compressive strength,

and one

each for the parameters set forth in subsection

B(3),

above.

Laboratory testing for permeability

and strength must be conducted

in accordance with

the test methods referenced in Section C(l)

of

these procedures.

Test results must demonstrate

a

coefficient of permeability of

less than or equal

to lxlo7 cm/sec using a geometric average of the

permeability testing results, and an unconfined

compressive strength of greater than or equal to

150 psi using an arithmetic average of the

strength testing results.

9.

The landfill shall be designed, constructed and

operated

in compliance with all applicable requirements

of 35 Ill.

Adm.

Code Parts 811,

812

and 815 other

than

Section 811.306, 811.324 and 811.507; and

10.

The bottom liner and low permeability layer of the cap

shall be constructed according to

a construction

quality assurance program in accordance with 35 Ill.

Adm.

Code 811, Subpart

E;

11.

The person or entity using the material

in this manner

shall prepare an acceptable groundwater impact

assessment pursuant to 35 Ill.

Adm. Code 811.317(b),

812.316,

813.304,

or 815.203,

as appropriate

for the

given facility;

12.

The person or entity using the material in this manner

shall construct a Poz-O-Tec test liner,

such that all

that remains is the curing of the test liner, before

construction

of

the actual full—scale Poz—O—Tec liner

may commence

in accordance with

35

Ill. Adm.

Code

8ll.407(a)(l—4).

The test liner must be fully

evaluated with the results provided to the Agency.

If

16

the test liner evaluation results indicate a failure of

the test liner to meet any of the requisite performance

standards,

and if the Agency so directs,

the user must

excavate and properly dispose of all Poz-O-Tec liners

at the site,

as well a~any waste deposited in and

around such liners; and

13.

The person or entity using the material

in this manner

complies with the Illinois Environmental Protection

Agency

(“the Agency”)

(415 ILCS 5/1 et seq.)

and 35

Ill.

Adin.

Code 811,

to the extent those provisions are

not otherwise addressed herein.

IT IS SO ORDERED.

Section 41 of the Environmental Protection Act

(415 ILCS

5/41

(1992)) provides for the appeal of final Board orders within

35

days of the date of service of this order.

The Rules of the

Supreme Court of Illinois establish filing requirements.

(See

also

35

Ill.

Adm. Code 101.246.

“Motions for Reconsideration”.)

~i.Theodore Meyer,

R.C. Fiemal and J.

Yi concurred.

I, Dorothy N.

Gunn, Clerk of the Illinois Pollution Control

Board, hereby certify that the above

pi ion and order was

adopted on the

‘7~

day of

..

,

1995,

by a

vote of

7—o

.

e

Dorothy M!/Gunn,

C~erk

Illinois 1~llutionControl Board