TITLE 35: ENVIRONMENTAL PROTECTION

SUBTITLE G: WASTE DISPOSAL

CHAPTER I: POLLUTION CONTROL BOARD

SUBCHAPTER d: UNDERGROUND INJECTION CONTROL AND UNDERGROUND STORAGE TANK PROGRAMS

PART 730

UNDERGROUND INJECTION CONTROL OPERATING REQUIREMENTS

SUBPART A: GENERAL

Section

730.101 Applicability, Scope, and Effective Date

730.102 Laws Authorizing Regulations

730.103 Definitions

730.104 Criteria for Exempted Aquifers

730.105 Classification of Injection Wells

730.106 Area of Review

730.107 Corrective Action

730.108 Mechanical Integrity

730.109 Criteria for Establishing Permitting Priorities730.110 Plugging and Abandoning Wells

SUBPART B: CRITERIA AND STANDARDS APPLICABLE TO CLASS I NON-HAZARDOUS WASTE INJECTION WELLS

Section

730.111 Applicability

730.112 Construction Requirements

730.113 Operating, Monitoring, and Reporting Requirements730.114 Information to be Considered by the Agency

SUBPART C: CRITERIA AND STANDARDS APPLICABLE TO CLASS II INJECTION WELLS

Section730.121 Adoption of Criteria and Standards Applicable to Class II Injection Wells by the Illinois Department of Natural Resources, Office of Mines and Minerals

SUBPART D: CRITERIA AND STANDARDS APPLICABLE TO CLASS III INJECTION WELLS

Section

730.131 Applicability

730.132 Construction Requirements

730.133 Operating, Monitoring, and Reporting Requirements730.134 Information to be Considered by the Agency

SUBPART F: CRITERIA AND STANDARDS APPLICABLE TO CLASS V INJECTION WELLS

Section

730.151 Applicability730.152 Inventory and Assessment (Repealed)

SUBPART G: CRITERIA AND STANDARDS APPLICABLE TO CLASS I HAZARDOUS WASTE INJECTION WELLS

Section

730.161 Applicability and Definitions

730.162 Minimum Criteria for Siting

730.163 Area of Review

730.164 Corrective Action for Wells in the Area of Review

730.165 Construction Requirements

730.166 Logging, Sampling, and Testing Prior to New Well Operation

730.167 Operating Requirements

730.168 Testing and Monitoring Requirements

730.169 Reporting Requirements

730.170 Information to be Evaluated

730.171 Closure

730.172 Post-Closure Care730.173 Financial Responsibility for Post-Closure Care

SUBPART H: CRITERIA AND STANDARDS APPLICABLE TO CLASS VI WELLS

Section

730.181 Applicability

730.182 Required Class VI Injection Well Permit Information

730.183 Minimum Criteria for Siting

730.184 Area of Review and Corrective Action

730.185 Financial Responsibility

730.186 Injection Well Construction Requirements

730.187 Logging, Sampling, and Testing Prior to Injection Well Operation

730.188 Injection Well Operating Requirements

730.189 Mechanical Integrity

730.190 Testing and Monitoring Requirements

730.191 Reporting Requirements

730.192 Injection Well Plugging

730.193 Post-Injection Site Care and Site Closure

730.194 Emergency and Remedial Response730.195 Alternative Class VI Injection Well Depth Requirements

AUTHORITY: Implementing Sections 7.2, 13, and 22.4 and authorized by Section 27 of the Environmental Protection Act [415 ILCS 5/7.2, 13, 22.4, and 27].

SOURCE: Adopted in R81-32 at 6 Ill. Reg. 12479, effective March 3, 1984; amended in R82-19 at 7 Ill. Reg. 14426, effective March 3, 1984; recodified at 10 Ill. Reg. 14174; amended in R89-2 at 14 Ill. Reg. 3130, effective February 20, 1990; amended in R89-11 at 14 Ill. Reg. 11959, effective July 9, 1990; amended in R93-6 at 17 Ill. Reg. 15646, effective September 14, 1993; amended in R94-5 at 18 Ill. Reg. 18391, effective December 20, 1994; amended in R95-4 at 19 Ill. Reg. 10047, effective June 27, 1995; amended in R00-11/R01-1 at 24 Ill. Reg. 18680, effective December 7, 2000; amended in R06-16/R06-17/R06-18 at 31 Ill. Reg. 1281, effective December 20, 2006; amended in R11-14 at 36 Ill. Reg. 1661, effective January 20, 2012; amended in R17-14/R17-15/R18-12/R18-31 at 42 Ill. Reg. 24145, effective November 19, 2018.

SUBPART A: GENERAL

Section 730.101 Applicability, Scope, and Effective Date

a) This Part sets forth technical criteria and standards for the Underground Injection Control (UIC) Program. This Part must be read in conjunction with 35 Ill. Adm. Code 702, 704, and 705, which also apply to the UIC program. 35 Ill. Adm. Code 702 and 704 prescribe the regulatory requirements for the UIC permit program. 35 Ill. Adm. Code 704 further outlines hazardous waste management requirements and sets forth the financial assurance requirements applicable to Class I hazardous waste injection wells and requirements applicable to certain types of Class V injection wells. 35 Ill. Adm. Code 705 describes the procedures the Agency must use for issuing UIC permits.

b) Any underground injection that is not authorized by rule or by permit is unlawful.

c) Electronic Reporting. The filing of any document pursuant to any provision of this Part as an electronic document is subject to 35 Ill. Adm. Code 720.104.

BOARD NOTE: Subsection (c) is derived from 40 CFR 3 and 145.11(a)(33) (2017).

(Source: Amended at 42 Ill. Reg. 24145, effective November 19, 2018)

Section 730.102 Laws Authorizing Regulations

The laws authorizing these regulations and all other UIC program regulations are included in the Environmental Protection Act, as amended.

(Source: Amended at 42 Ill. Reg. 24145, effective November 19, 2018)

Section 730.103 Definitions

The following definitions apply to the underground injection control program.

“Abandoned well” means a well whose use has been permanently discontinued or that is in a state of disrepair such that it cannot be used for its intended purpose or for observation purposes.

“Act” means the Solid Waste Disposal Act, as amended by the Resource Conservation and Recovery Act of 1976 (P.L. 94-580, as amended by P.L. 95-609, 42 USC 6901).

“Administrator” means the Administrator of the U.S. Environmental Protection Agency or the Administrator’s designee.

“Agency” means the Illinois Environmental Protection Agency.

“Application” means the Agency forms for applying for a permit, including any additions, revisions, or modifications to the forms. For RCRA, application also includes the information required by the Agency pursuant to 35 Ill. Adm. Code 703.182-703.188 and 703.200 (contents of Part B of the RCRA application).

“Aquifer” means a geologic formation, group of formations or part of a formation that is capable of yielding a significant amount of water to a well or spring.

“Area of review” means the area surrounding an “injection well” described according to the criteria set forth in Section 730.106 or, in the case of an area permit, the project area plus a circumscribing area the width of which is either 402 meters (one-quarter mile) or a number calculated according to the criteria set forth in Section 730.106.

“Casing” means a pipe or tubing of appropriate material, of varying diameter and weight, lowered into a borehole during or after drilling in order to support the sides of the hole and thus prevent the walls from caving, to prevent loss of drilling mud into porous ground or to prevent water, gas, or other fluid from entering or leaving the hole.

“Catastrophic collapse” means the sudden and utter failure of overlying “strata” caused by removal of underlying materials.

“Cementing” means the operation whereby a cement slurry is pumped into a drilled hole or forced behind the casing.

“Cesspool” means a “drywell” that receives untreated sanitary waste containing human excreta and which sometimes has an open bottom or perforated sides.

“Confining bed” means a body of impermeable or distinctly less permeable material stratigraphically adjacent to one or more aquifers.

“Confining zone” means a geologic formation, group of formations, or part of a formation that is capable of limiting fluid movement above an injection zone.

“Contaminant” means any physical, chemical, biological, or radiological substance or matter in water.

“Conventional mine” means an open pit or underground excavation for the production of minerals.

“Director” means the Director of the Illinois Environmental Protection Agency or the Administrator’s designee.

“Disposal well” means a well used for the disposal of waste into a subsurface stratum.

“Drywell” means a well, other than an improved sinkhole or subsurface fluid distribution system, that is completed above the water table so that its bottom and sides are typically dry except when receiving fluids.

“Environmental Protection Act” means the Environmental Protection Act [415 ILCS 5].

“EPA” or “USEPA” means the United States Environmental Protection Agency.

“Exempted aquifer” means an “aquifer” or its portion that meets the criteria in the definition of “underground source of drinking water” but which has been exempted according to the procedures of 35 Ill. Adm. Code 704.123, 704.104, and 702.105.

“Existing injection well” means an “injection well” other than a “new injection well”.

“Experimental technology” means a technology that has not been proven feasible under the conditions in which it is being tested.

“Facility or activity” means any HWM facility, UIC injection well, or any other facility or activity (including land or appurtenances thereto) that is subject to regulation under the “State” RCRA or UIC program.

“Fault” means a surface or zone of rock fracture along which there has been displacement.

“Flow rate” means the volume per unit time of the flow of a gas or other fluid substance that emerges from an orifice, pump or turbine or which passes along a conduit or channel.

“Fluid” means material or substance that flows or moves, whether in a semisolid, liquid sludge, gas, or any other form or state.

“Formation” means a body of rock characterized by a degree of lithologic homogeneity that is prevailingly, but not necessarily, tabular and is mappable on the earth’s surface or traceable in the subsurface.

“Formation fluid” means fluid present in a formation under natural conditions as opposed to introduced fluids, such as drilling mud.

“Generator” means any person, by site location, whose act or process produces hazardous waste identified or listed in 35 Ill. Adm. Code 721.

“Groundwater” means water below the land surface in a zone of saturation.

“Hazardous waste” means a hazardous waste as defined in 35 Ill. Adm. Code 721.103.

“Hazardous waste management facility” or “HWM facility” means all contiguous land, and structures, other appurtenances and improvements on the land used for treating, storing, or disposing of hazardous waste. A facility may consist of several treatment, storage, or disposal operational units (for example, one or more landfills, surface impoundments, or combination of them).

“HWM facility” means Hazardous waste management facility.

“Illinois” means the State of Illinois.

“Improved sinkhole” means a naturally occurring karst depression or other natural crevice that is found in volcanic terrain and other geologic settings that have been modified by man for the purpose of directing and emplacing fluids into the subsurface.

“Injection well” means a well into which fluids are being injected.

“Injection zone” means a geologic formation, group of formations, or part of a formation receiving fluids through a well.

“Lithology” means the description of rocks on the basis of their physical and chemical characteristics.

“Owner or operator” means the owner or operator of any facility or activity subject to regulation under RCRA, UIC, or the Environmental Protection Act.

“Packer” means a device lowered into a well that can be expanded to produce a fluid-tight seal.

“Permit” means an authorization, license, or equivalent control document issued by the Agency to implement the requirements of this Part and 35 Ill. Adm. Code 702 through 705. Permit does not include RCRA interim status (Subpart C of 35 Ill. Adm. Code 703), UIC authorization by rule (Subpart C of 35 Ill. Adm. Code 704), or any permit that has not yet been the subject of final Agency action, such as a draft permit or a proposed permit.

“Plugging” means the act or process of stopping the flow of water, oil, or gas into or out of a formation through a borehole or well penetrating that formation.

“Plugging record” means a systematic listing of permanent or temporary abandonment of water, oil, gas, test, exploration, and waste injection wells, and may contain a well log, description of amounts and types of plugging material used, the method employed for plugging, a description of formations that are sealed and a graphic log of the well showing formation location, formation thickness, and location of plugging structures.

“Point of injection,”, for a Class V injection well, means the last accessible sampling point prior to waste fluids being released into the subsurface environment through the well. For example, the point of injection of a Class V septic system might be the distribution box—the last accessible sampling point before the waste fluids drain into the underlying soils. For a dry well, it is likely to be the well bore itself.

“Pressure” means the total load or force per unit area acting on a surface.

“Project” means a group of wells in a single operation.

“Radioactive Waste” means any waste that contains radioactive material in concentrations that exceed those listed in Table II, column 2 in appendix B to 10 CFR 20 (Water Effluent Concentrations), incorporated by reference in 35 Ill. Adm. Code 720.111.

“RCRA” means the Solid Waste Disposal Act, as amended by the Resource Conservation and Recovery Act of 1976 (42 USC 6901 et seq.).

“Sanitary waste” means liquid or solid wastes originating solely from humans and human activities, such as wastes collected from toilets, showers, wash basins, sinks used for cleaning domestic areas, sinks used for food preparation, clothes washing operations, and sinks or washing machines where food and beverage serving dishes, glasses, and utensils are cleaned. Sources of these wastes may include single or multiple residences, hotels and motels, restaurants, bunkhouses, schools, ranger stations, crew quarters, guard stations, campgrounds, picnic grounds, day-use recreation areas, other commercial facilities, and industrial facilities, provided the waste is not mixed with industrial waste.

“SDWA” means the Safe Drinking Water Act (42 USC 300(f) et seq.).

“Septic system” means a well that is used to emplace sanitary waste below the surface and which is typically comprised of a septic tank and subsurface fluid distribution system or disposal system.

“Site” means the land or water area where any facility or activity is physically located or conducted, including adjacent land used in connection with the facility or activity.

“Sole or principal source aquifer” means an aquifer that has been designated by the Administrator pursuant to section 1424(a) or (e) of SDWA (42 USC 300h-3(a) or (e)).

“State” means the State of Illinois.

“Stratum” (plural strata) means a single sedimentary bed or layer, regardless of thickness, that consists of generally the same kind of rock material.

“Subsidence” means the lowering of the natural land surface in response to: earth movements; lowering of fluid pressure, removal of underlying supporting material by mining or solution of solids, either artificially or from natural causes; compaction due to wetting (hydrocompaction); oxidation of organic matter in soils; or added load on the land surface.

“Subsurface fluid distribution system” means an assemblage of perforated pipes, drain tiles, or other similar mechanisms intended to distribute fluids below the surface of the ground.

“Surface casing” means the first string of well casing to be installed in the well.

“Total dissolved solids” or “TDS” means the total dissolved (filterable) solids, as determined by use of the method specified in 40 CFR 136.3 (Identification of Test Procedures; the method for filterable residue), incorporated by reference in 35 Ill. Adm. Code 720.111.

“UIC” means the Underground Injection Control program under Part C of the Safe Drinking Water Act (42 USC 300h through 300h-8), including the approved Illinois program.

“Underground injection” means a “well injection”.

“Underground source of drinking water” or “USDW” means an aquifer or its portion is not an exempted aquifer, as defined in this Section, and of which the following is true:

It supplies any public water system; or

It contains a sufficient quantity of groundwater to supply a public water system; and

It currently supplies drinking water for human consumption; or

It contains less than 10,000 mg/ℓ total dissolved solids.

“USDW” means underground source of drinking water.

“Well” means a bored, drilled, or driven shaft whose depth is greater than the largest surface dimension; a dug hole whose depth is greater than the largest surface dimension; an improved sinkhole; or a subsurface fluid distribution system.

“Well injection” means the subsurface emplacement of fluids through a well.

“Well monitoring” means the measurement, by on-site instruments or laboratory methods, of the quality of water in a well.

“Well plug” means a watertight and gastight seal installed in a borehole or well to prevent movement of fluids.

“Well stimulation” means several processes used to clean the well bore, enlarge channels, and increase pore space in the interval to be injected, thus making it possible for wastewater to move more readily into the formation, and includes surging, jetting, blasting, acidizing, and hydraulic fracturing.

BOARD NOTE: Derived from 40 CFR 146.3 (2017).

(Source: Amended at 42 Ill. Reg. 24145, effective November 19, 2018)

Section 730.104 Criteria for Exempted Aquifers

An aquifer or a portion of an aquifer that meets the criteria for an “underground source of drinking water” in Section 730.103 is an “exempted aquifer” for a Class I, Class III, or Class V injection well if the Board determines pursuant to 35 Ill. Adm. Code 704.123 that the aquifer meets the criteria of either subsections (a) and (b) or (a) and (c). For a Class VI injection well, the Board must determine that the well meets the criteria of subsection (d).

a) The aquifer does not currently serve as a source of drinking water.

b) The aquifer cannot now and will not in the future serve as a source of drinking water because one or more of the following is true of the aquifer:

1) The aquifer is mineral, hydrocarbon, or geothermal energy producing, or a permit applicant can demonstrate, as part of a permit application for a Class II or III injection well, that the aquifer contains minerals or hydrocarbons that are expected to be commercially producible considering their quantity and location;

2) The aquifer is situated at a depth or location that makes recovery of water for drinking water purposes economically or technologically impractical;

3) The aquifer is so contaminated that it would be economically or technologically impractical to render that water fit for human consumption; or

4) The aquifer is located over a Class III injection well mining area subject to subsidence or catastrophic collapse.

c) The total dissolved solids content of the groundwater in the aquifer is more than 3,000 and less than 10,000 mg/ℓ, and the aquifer is not reasonably expected to supply a public water system.

d) The areal extent of an aquifer exemption for a Class II enhanced oil recovery or enhanced gas recovery well is expanded for the exclusive purpose of Class VI injection for geologic sequestration pursuant to 35 Ill. Adm. Code 704.123(d) if the Agency determines that the aquifer meets the following criteria:

1) The aquifer does not currently serve as a source of drinking water;

2) The total dissolved solids content of the ground water in the aquifer is greater than 3,000 mg/ℓ and less than 10,000 mg/ℓ; and

3) The aquifer is not reasonably expected to supply a public water system.

BOARD NOTE: Derived from 40 CFR 146.4 (2017).

(Source: Amended at 42 Ill. Reg. 24145, effective November 19, 2018)

Section 730.105 Classification of Injection Wells

Injection wells are classified as follows:

a) Class I Injection Wells. A Class I injection well is any of the following:

1) A Class I hazardous waste injection well that is used by a generator of hazardous waste or an owner or operator of a hazardous waste management facility to inject hazardous waste beneath the lowermost formation containing an underground source of drinking water within 402 meters (one-quarter mile) of the well bore.

2) An industrial or municipal disposal well that injects fluids beneath the lowermost formation containing an underground source of drinking water within 402 meters (one-quarter mile) of the well bore.

3) A radioactive waste disposal well that injects fluids below the lowermost formation containing an underground source of drinking water within 402 meters (one-quarter mile) of the well bore.

b) Class II Injection Wells. A Class II injection well is one that injects any of the following types of fluids:

1) Fluids that are brought to the surface in connection with conventional oil or natural gas production and which may be commingled with wastewaters from gas plants that are an integral part of production operations, unless those waters are classified as a hazardous waste at the time of injection;

2) Fluids that are used for enhanced recovery of oil or natural gas; and

3) Fluids that are used for storage of hydrocarbons that are liquid at standard temperature and pressure.

c) Class III Injection Wells. A Class III injection well is one that injects fluid for extraction of minerals, including one used in any of the following activities:

1) Mining of sulfur by the Frasch process;

2) In situ production of uranium or other metals. This category includes only in situ production from ore bodies that have not been conventionally mined. Solution mining of conventional mines, such as stopes leaching, is included in Class V; or

3) Solution mining of salts or potash.

BOARD NOTE: Class III injection well would include a well that is used for the recovery of geothermal energy to produce electric power, but would not include a well that is used in heating or aquaculture that falls under Class V.

d) Class IV Injection Wells. A Class IV injection well is any of the following:

1) A well used by a generator of hazardous waste or of radioactive waste, by an owner or operator of a hazardous waste management facility, or by an owner or operator of a radioactive waste disposal site to dispose of hazardous waste or radioactive waste into a formation that contains an underground source of drinking water within 402 meters (one-quarter mile) of the well.

2) A well used by a generator of hazardous waste or of radioactive waste, by an owner or operator of a hazardous waste management facility, or by an owner or operator of a radioactive waste disposal site to dispose of hazardous waste or radioactive waste above a formation that contains an underground source of drinking water within 402 meters (one-quarter mile) of the well.

3) A well used by a generator of hazardous waste or an owner or operator of a hazardous waste management facility to dispose of hazardous waste that cannot be classified pursuant to subsection (a)(1), (d)(1), or (d)(2) (e.g., wells used to dispose of hazardous wastes into or above a formation that contains an aquifer that has been exempted pursuant to Section 730.104).

e) Class V Injection Wells. A Class V injection well is any not included in Class I, Class II, Class III, Class IV, or Class VI. Specific types of Class V injection wells include the following:

1) Air conditioning return flow wells used to return the water used in a heat pump for heating or cooling to the supply aquifer;

2) Cesspools, including multiple dwelling, community, or regional cesspools, or other devices that receive wastes that have an open bottom and sometimes have perforated sides. The UIC requirements do not apply to single family residential cesspools or to non-residential cesspools that receive solely sanitary wastes and have the capacity to serve fewer than 20 persons a day;

3) Cooling water return flow wells used to inject water previously used for cooling;

4) Drainage wells used to drain surface fluid, primarily storm runoff, into a subsurface formation;

5) Dry wells used for the injection of wastes into a subsurface formation;

6) Recharge wells used to replenish the water in an aquifer;

7) Salt water intrusion barrier wells used to inject water into a fresh water aquifer to prevent the intrusion of salt water into the fresh water;

8) Sand backfill and other backfill wells used to inject a mixture of water and sand, mill tailings, or other solids into mined out portions of subsurface mines whether what is injected is a radioactive waste or not;

9) Septic system wells used to inject the waste or effluent from a multiple dwelling, business establishment, community, or regional business establishment septic tank. The UIC requirements do not apply to single family residential septic system wells, or to nonresidential septic system wells that are used solely for the disposal of sanitary waste and which have the capacity to serve fewer than 20 persons a day;

10) Subsidence control wells (not used for the purpose of oil or natural gas production) used to inject fluids into a non-oil or gas producing zone to reduce or eliminate subsidence associated with the overdraft of fresh water;

11) Radioactive waste disposal wells other than Class IV injection wells;

12) Injection wells associated with the recovery of geothermal energy for heating, aquaculture, or production of electric power;

13) Wells used for solution mining of conventional mines such as stopes leaching;

14) Wells used to inject spent brine into the same formation from which it was withdrawn after extraction of halogens or their salts; and

15) Injection wells used in experimental technologies.

f) Class VI Injection Wells. A Class VI injection well is any of the following:

1) An injection well that is not experimental in nature and which is used for geologic sequestration of carbon dioxide beneath the lowermost formation containing a USDW;

2) An injection well that is used for geologic sequestration of carbon dioxide and which has been granted a permit that includes alternative injection well depth requirements pursuant to Section 730.195; or

3) An injection well that is used for geologic sequestration of carbon dioxide and which has received an expansion to the areal extent of an existing Class II enhanced oil recovery or enhanced gas recovery aquifer exemption pursuant to Section 730.104 and 35 Ill. Adm. Code 704.123(d).

BOARD NOTE: Derived from 40 CFR 146.5 (2017).

(Source: Amended at 42 Ill. Reg. 24145, effective November 19, 2018)

Section 730.106 Area of Review

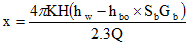

The area of review for each injection well or each field, project, or area in Illinois must be determined according to either subsection (a) or (b). The Agency may solicit input from the owners or operators of injection wells within Illinois as to which method is most appropriate for each geographic area or field. Zone of Endangering Influence 1) The zone of endangering influence must be the applicable of the following: A) In the case of an application for a well permit pursuant to 35 Ill. Adm. Code 704.161, that area the radius of which is the lateral distance in which the pressures in the injection zone may cause the migration of the injection or formation fluid into an underground source of drinking water; or B) In the case of an application for an area permit pursuant to 35 Ill. Adm. Code 704.162, the project area plus a circumscribing area the width of which is the lateral distance from the perimeter of the project area, in which the pressures in the injection zone may cause the migration of the injection or formation fluid into an underground source of drinking water. 2) Computation of the zone of endangering influence may be based upon the parameters listed below and should be calculated for an injection time period equal to the expected life of the injection well or pattern. The following modified This equation illustrates one form that the mathematical model may take.

where:

r = Radius of endangering influence from injection well (length) k = Hydraulic conductivity of the injection zone (length/time) H = Thickness of the injection zone (length) t = Time of injection (time) S = Storage coefficient (dimensionless) Q = Injection rate (volume/time) hbo = Observed original hydrostatic head of injection zone (length) measured from the base of the lowermost underground source of drinking water hw = Hydrostatic head of underground source of drinking water (length) measured from the base of the lowest underground source of drinking water SpGb = Specific gravity of fluid in the injection zone (dimensionless) p = 3.14159 (dimensionless) 3) The above equation is based on the following assumptions: A) The injection zone is homogenous and isotropic; B) The injection zone has infinite area extent; C) The injection well penetrates the entire thickness of the injection zone; D) The well diameter is infinitesimal compared to “r” when injection time is longer than a few minutes; and E) The emplacement of fluid into the injection zone creates instantaneous increase in pressure. b) Fixed Radius 1) In the case of an application for a well permit pursuant to 35 Ill. Adm. Code 704.161, a fixed radius around the well of not less than 402 meters (one-quarter mile) may be used. 2) In the case of an application for an area permit pursuant to 35 Ill. Adm. Code 704.162, a fixed width of not less than 402 meters (one-quarter mile) for the circumscribing area may be used. 3) In determining the fixed radius, the following factors must be taken into consideration: the chemistry of injected and formation fluids; the hydrogeology; the population and groundwater use and dependence; and historical practices in the area. c) If the area of review is determined by a mathematical model pursuant to subsection (a), the permissible radius is the result of such calculation even if it is less than 402 meters (one-quarter mile). (Source: Amended at 42 Ill. Reg. 24145, effective November 19, 2018) Section 730.107 Corrective Action

In determining the adequacy of corrective action proposed by the applicant pursuant to 35 Ill. Adm. Code 704.193 and in determining the additional steps needed to prevent fluid movement into underground sources of drinking water, the following criteria and factors must be considered by the Agency: The nature and volume of injected fluid; b) The nature of native fluids or by-products of injection; c) Any potentially affected population; d) Geology; e) Hydrology; f) The history of the injection operation; g) Any completion and plugging records; h) Any abandonment procedures in effect at the time the well was abandoned; and i) Any hydraulic connections with underground sources of drinking water. (Source: Amended at 31 Ill. Reg. 1281, effective December 20, 2006) Section 730.108 Mechanical Integrity

a) The owner or operator must demonstrate mechanical integrity when required by other Sections. An injection well has mechanical integrity if both of the following conditions are fulfilled:

1) There is no significant leak in the casing, tubing, or packer; and

2) There is no significant fluid movement into an underground source of drinking water through vertical channels adjacent to the injection bore.

b) One of the following tests must be used to demonstrate the absence of significant leaks pursuant to subsection (a)(1):

1) Following an initial pressure test, monitoring of the tubing-casing annulus pressure with sufficient frequency to be representative, as determined by the Agency, while maintaining an annulus pressure different from atmospheric pressure measured at the surface; or

2) A pressure test with liquid or gas.

c) One of the following methods may be used to determine the absence of significant fluid movement pursuant to subsection (a)(2):

1) The results of a temperature or noise log;

2) For Class III injection wells where the nature of the casing precludes the use of the logging techniques prescribed at subsection (c)(1), cementing records demonstrating the presence of adequate cement to prevent migration; or

3) For Class III injection wells where the Agency elects to rely on cementing records to demonstrate the absence of significant fluid movement, the monitoring program prescribed by 35 Ill. Adm. Code 730.113(b) must be designed to verify the absence of significant fluid movement.

d) The Agency may allow the use of a test to demonstrate mechanical integrity other than those listed in subsections (b) and (c). To obtain approval, the owner or operator must submit a written request to the Agency that sets forth the proposed test and all technical data supporting its use. The Agency must approve the request if the test will reliably demonstrate the mechanical integrity of wells for which its use is proposed.

e) In conducting and evaluating the tests enumerated in this Section or others to be allowed by the Agency, the owner or operator and the Agency must apply methods and standards generally accepted in the industry. When the owner or operator reports the results of mechanical integrity tests to the Agency, it must include a description of the test and the method used. In making its evaluation, the Agency must review monitoring and other test data submitted since the previous evaluation.

f) The Agency may require additional or alternative tests if the results presented by the owner or operator pursuant to subsection (e) are not satisfactory to the Agency to demonstrate that there is no movement of fluid into or between USDWs resulting from the injection activity.

(Source: Amended at 42 Ill. Reg. 24145, effective November 19, 2018)

Section 730.109 Criteria for Establishing Permitting Priorities

In determining priorities for setting times for owners or operators to submit applications for authorization to inject pursuant to the procedures of 35 Ill. Adm. Code 704.161, the Agency must base these priorities upon consideration of the following factors:

a) Any injection wells known or suspected to be contaminating underground sources of drinking water;

b) Any injection wells known to be injecting fluids containing hazardous contaminants;

c) The likelihood of contamination of underground sources of drinking water;

d) Any potentially affected population;

e) Any injection wells violating existing Illinois requirements;

f) Coordination with the issuance of permits required by other State or federal permit programs;

g) The age and depth of the injection well; and

h) The expiration dates of existing Illinois permits, if any.

(Source: Amended at 31 Ill. Reg. 1281, effective December 20, 2006)

Section 730.110 Plugging and Abandoning Wells

a) Requirements for Class I, II, and III injection wells.

1) Prior to abandoning a Class I or Class III injection well, the well must be plugged with cement in a manner that will not allow the movement of fluids either into or between underground sources of drinking water. The Agency may allow Class III injection wells to use other plugging materials if it is satisfied that such materials will prevent movement of fluids into or between underground sources of drinking water.

2) Placement of the cement plugs must be accomplished by one of the following means:

A) The Balance Method;

B) The Dump Bailer Method;

C) The Two-Plug Method; or

D) An alternative method approved by the Agency in the permit that will reliably provide a comparable level of protection to underground sources of drinking water.

3) The well to be abandoned must be in a state of static equilibrium with the mud weight equalized top to bottom, either by circulating the mud in the well at least once or by a comparable method prescribed by the Agency, prior to the placement of the cement plug.

4) The plugging and abandonment required in 35 Ill. Adm. Code 704.181(f) and 704.188 must also demonstrate adequate protection of USDWs in the case of a Class III injection well that underlies or is in an aquifer that has been exempted pursuant to Section 730.104. The Agency must prescribe aquifer cleanup and monitoring where it deems it necessary and feasible to insure adequate protection of USDWs.

b) Requirements for Class IV injection wells. Prior to abandoning a Class IV injection well, the owner or operator must close the well in accordance with 35 Ill. Adm. Code 704.145(b).

c) Requirements for Class V injection wells.

1) Prior to abandoning a Class V injection well, the owner or operator must close the well in a manner that prevents the movement of fluid containing any contaminant into an underground source of drinking water if the presence of that contaminant may cause a violation of any primary drinking water regulation pursuant to 35 Ill. Adm. Code 611, may cause a violation of any of the ground water quality standards of 35 Ill. Adm. Code 620, or may otherwise adversely affect the health of persons. Closure requirements for motor vehicle waste disposal wells and large-capacity cesspools are listed at Section 704.289.

2) The owner or operator must dispose of or otherwise manage any soil, gravel, sludge, liquids, or other materials removed from or adjacent to the well in accordance with all applicable federal, State, and local regulations and requirements.

(Source: Amended at 31 Ill. Reg. 1281, effective December 20, 2006)

SUBPART B: CRITERIA AND STANDARDS APPLICABLE TO CLASS I NON-HAZARDOUS WASTE INJECTION WELLS

Section 730.111 Applicability

This Subpart B establishes criteria and standards for underground injection control programs to regulate Class I non-hazardous waste injection wells.

BOARD NOTE: Derived from 40 CFR 146.11 (2005).

(Source: Amended at 31 Ill. Reg. 1281, effective December 20, 2006)

Section 730.112 Construction Requirements

a) All Class I injection wells must be sited in such a fashion that they inject into a formation which is beneath the lowermost formation containing, within 402 meters (one-quarter mile) of the well bore, an underground source of drinking water.

b) All Class I injection wells must be cased and cemented to prevent the movement of fluids into or between underground sources of drinking water. The casing and cement used in the construction of each newly drilled well must be designed for the life expectancy of the well. In determining and specifying casing and cementing requirements, the following factors must be considered:

1) The depth to the injection zone;

2) The injection pressure, external pressure, internal pressure, and axial loading;

3) The hole size;

4) The size and grade of all casing strings (wall thickness, diameter, nominal weight, length, joint specification, and construction material);

5) The corrosiveness of injected fluid, formation fluids, and temperatures;

6) The lithology of the injection and confining intervals; and

7) The type or grade of cement.

c) A Class I injection well, except a municipal well injecting non-corrosive wastes, must protect underground sources of drinking water against movement of fluids from the injection zone upward through the well. An operator may do this by injecting fluids through tubing with a packer set immediately above the injection zone, or tubing with an approved fluid seal as an alternative. The tubing, packer, and fluid seal must be designed for the expected service.

1) The use of other alternatives to a packer may be allowed with the written approval of the Agency. To obtain approval, the operator must submit a written request to the Agency that sets forth the proposed alternative and all technical data supporting its use. The Agency must approve the request if the alternative method will reliably provide a comparable level of protection to underground sources of drinking water. The Agency may approve an alternative method solely for an individual well; however, the Agency may promulgate criteria approving alternatives pursuant to 35 Ill. Adm. Code 702.106.

2) In determining and specifying requirements for tubing, packer, or alternatives the following factors must be considered:

A) The depth of setting;

B) Characteristics of the injection fluid (chemical content, corrosiveness, and density);

C) The injection pressure;

D) The annular pressure;

E) The rate, temperature, and volume of injected fluid; and

F) The size of the casing.

d) Appropriate logs and other tests must be conducted during the drilling and construction of new Class I injection wells. A descriptive report interpreting the results of such logs and tests must be prepared by a knowledgeable log analyst and submitted to the Agency. At a minimum, such logs and tests must include the following information:

1) Deviation checks on all holes constructed by first drilling a pilot hole, and then enlarging the pilot hole by reaming or another method. Such checks must be at sufficiently frequent intervals to assure that vertical avenues for fluid migration in the form of diverging holes are not created during drilling.

2) Such other logs and tests as may be needed after taking into account the availability of similar data in the area of the drilling site, the construction plan, and the need for additional information, that may arise from time to time as the construction of the well progresses. In determining which logs and tests must be required, the following logs must be considered for use in the following situations:

A) For surface casing intended to protect underground sources of drinking water, the following:

i) Resistivity, spontaneous potential, and caliper logs before the casing is installed; and

ii) A cement bond, temperature, or density log after the casing is set and cemented.

B) For intermediate and long strings of casing intended to facilitate injection, the following:

i) Resistivity, spontaneous potential, porosity, and gamma ray logs before the casing is installed;

ii) Fracture finder logs; and

iii) A cement bond, temperature, or density log after the casing is set and cemented.

e) At a minimum, the following information concerning the injection formation must be determined or calculated for new Class I injection wells:

1) Fluid pressure;

2) Temperature;

3) Fracture pressure;

4) Other physical and chemical characteristics of the injection matrix; and

5) Physical and chemical characteristics of the formation fluids.

(Source: Amended at 31 Ill. Reg. 1281, effective December 20, 2006)

Section 730.113 Operating, Monitoring, and Reporting Requirements

a) Operating Requirements. Operating requirements must, at a minimum, specify the following:

1) That, except during stimulation, injection pressure at the wellhead must not exceed a maximum that must be calculated so as to assure that the pressure in the injection zone during injection does not initiate new fractures or propagate existing fractures in the injection zone. In no case must injection pressure initiate fractures in the confining zone or cause the movement of injection or formation fluids into an underground source of drinking water;

2) That injection between the outermost casing protecting underground sources of drinking water and the well bore is prohibited; and

3) That, unless an alternative to a packer has been approved pursuant to Section 730.112(c), the annulus between the tubing and the long string of casings must be filled with a fluid approved by permit condition, and a pressure prescribed by permit condition must be maintained on the annulus.

b) Monitoring Requirements. Monitoring requirements must, at a minimum, include all of the following:

1) The analysis of the injected fluids with sufficient frequency to yield representative data of their characteristics;

2) Installation and use of continuous recording devices to monitor injection pressure, flow rate, and volume, and the pressure on the annulus between the tubing and the long string of casing;

3) A demonstration of mechanical integrity pursuant to Section 730.108 at least once every five years during the life of the well; and

4) The type, number, and location of wells within the area of review to be used to monitor any migration of fluids into and pressure in the underground sources of drinking water, the parameters to be measured, and the frequency of monitoring.

c) Reporting Requirements. Reporting requirements must, at a minimum, include:

1) Quarterly reports to the Agency on each of the following:

A) The physical, chemical, and other relevant characteristics of injection fluids;

B) The monthly average, maximum, and minimum values for injection pressure, flow rate and volume, and annular pressure; and

C) The results of monitoring prescribed pursuant to subsection (b)(4).

2) Reporting the results, with the first quarterly report after the completion of each of the following:

A) Periodic tests of mechanical integrity;

B) Any other test of the injection well conducted by the permittee if required by permit condition; and

C) Any well work over.

d) Ambient Monitoring

1) Based on a site-specific assessment of the potential for fluid movement from the well or injection zone and on the potential value of monitoring wells to detect such movement, the Agency must require the owner or operator to develop a monitoring program. At a minimum, the Agency must require monitoring of the pressure buildup in the injection zone annually, including at a minimum, a shut down of the well for a time sufficient to conduct a valid observation of the pressure fall-off curve.

2) When prescribing a monitoring system the Agency may also require:

A) Continuous monitoring for pressure changes in the first aquifer overlying the confining zone. When such a well is installed, the owner or operator must, on a quarterly basis, sample the aquifer and analyze for constituents specified by permit condition;

B) The use of indirect, geophysical techniques to determine the position of the waste front, the water quality in a formation designated by permit condition or to provide other site-specific data;

C) Periodic monitoring of the ground water quality in the first aquifer overlying the injection zone;

D) Periodic monitoring of the ground water quality in the lowermost USDW; and

E) Any additional monitoring necessary to determine whether fluids are moving into or between USDWs.

BOARD NOTE: Derived from 40 CFR 146.13 (2017).

(Source: Amended at 42 Ill. Reg. 24145, effective November 19, 2018)

Section 730.114 Information to be Considered by the Agency

This Section sets forth the information that must be considered by the Agency in authorizing a Class I injection well. For an existing or converted new Class I injection well, the Agency may rely on the existing permit file for those items of information listed below which are current and accurate in the file. For a newly drilled Class I injection well, the Agency must require the submission of all the information listed below. For both existing and new Class I injection wells, certain maps, cross-sections, tabulations of wells within the area of review, and other data may be included in the application by reference, provided they are current, readily available to the Agency (for example, in the Agency’s files) and sufficiently identified to be retrieved.

a) Prior to the issuance of a permit for an existing Class I injection well to operate or the construction or conversion of a new Class I injection well, the Agency must consider the following:

1) Information required in 35 Ill. Adm. Code 702.120 through 702.124 and 704.161(c);

2) A map showing the injection well for which a permit is sought and the applicable area of review. Within the area of review, the map must show the number, or name, and location of all producing wells, injection wells, abandoned wells, dry holes, surface bodies of water, springs, mines (surface and subsurface), quarries, water wells, and other pertinent surface features including residences and roads. The map should also show faults, if known or suspected. Only information of public record is required to be included on this map;

3) A tabulation of data on all wells within the area of review that penetrate into the proposed injection zone. Such data must include a description of each well’s type, construction, date drilled, location, depth, record of plugging or completion, and any additional information the Agency may require;

4) Maps and cross-sections indicating the general vertical and lateral limits of all underground sources of drinking water within the area of review, their position relative to the injection formation, and the direction of water movement, where known, in each underground source of drinking water that may be affected by the proposed injection;

5) Maps and cross-sections detailing the geologic structure of the local area;

6) Generalized maps and cross-sections illustrating the regional geologic setting;

7) Proposed operating data, including the following information:

A) The average and maximum daily rate and volume of the fluid to be injected;

B) The average and maximum injection pressure; and

C) The source and an analysis of the chemical, physical, radiological, and biological characteristics of injection fluids;

8) A proposed formation testing program to obtain an analysis of the chemical, physical, and radiological characteristics of and other information on the receiving formation;

9) A proposed stimulation program;

10) The proposed injection procedure;

11) Schematic or other appropriate drawings of the surface and subsurface construction details of the system;

12) Contingency plans to cope with all shut-ins or well failures so as to prevent migration of fluids into any underground source of drinking water;

13) Plans (including maps) for meeting the monitoring requirements in Section 730.113(b);

14) For wells within the area of review that penetrate the injection zone but are not properly completed or plugged, the corrective action proposed to be taken pursuant to 35 Ill. Adm. Code 704.193;

15) Construction procedures including a cementing and casing program; logging procedures; deviation checks; and a drilling, testing, and coring program; and

16) A certificate that the applicant has assured, through a performance bond or other appropriate means, the resources necessary to close, plug, or abandon the well as required by 35 Ill. Adm. Code 704.189.

b) Prior to granting approval for the operation of a Class I injection well, the Agency must consider the following information:

1) All available logging and testing program data on the well;

2) A demonstration of mechanical integrity pursuant to Section 730.108;

3) The anticipated maximum pressure and flow rate at that the permittee will operate;

4) The results of the formation testing program;

5) The actual injection procedure;

6) The compatibility of injected waste with fluids in the injection zone and minerals in both the injection zone and the confining zone; and

7) The status of corrective action on defective wells in the area of review.

c) Prior to granting approval for the plugging and abandonment of a Class I injection well, the Agency must consider the following information:

1) The type and number of plugs to be used;

2) The placement of each plug including the elevation of the top and bottom;

3) The type and grade and quantity of cement to be used;

4) The method for placement of the plugs; and

5) The procedure to be used to meet the requirements of Section 730.110(c).

(Source: Amended at 31 Ill. Reg. 1281, effective December 20, 2006)

SUBPART C: CRITERIA AND STANDARDS APPLICABLE TO CLASS II INJECTION WELLS

Section 730.121 Adoption of Criteria and Standards Applicable to Class II Injection Wells by the Illinois Department of Natural Resources, Office of Mines and Minerals

The criteria and standards for Class II injection wells will be adopted by the Illinois Department of Natural Resources, Office of Mines and Minerals pursuant to Section 1425 of the SDWA (42 USC 300h-4).

BOARD NOTE: This Section corresponds with subpart C of 40 CFR 146 (2011).

(Source: Amended at 36 Ill. Reg. 1661, January 20, 2012)

SUBPART D: CRITERIA AND STANDARDS APPLICABLE TO CLASS III INJECTION WELLS

Section 730.131 Applicability

This Subpart D establishes criteria and standards for underground injection control programs to regulate Class III injection wells.

(Source: Amended at 31 Ill. Reg. 1281, effective December 20, 2006)

Section 730.132 Construction Requirements

a) A new Class III injection well must be cased and cemented to prevent the migration of fluids into or between underground sources of drinking water. The Agency may waive the cementing requirements for a new well in existing projects or portions of existing projects if it has substantial evidence that no contamination of underground sources of drinking water would result. The casing and cement used in the construction of each newly drilled well must be designed for the life expectancy of the well. In determining and specifying casing and cementing requirements, the following factors must be considered:

1) The depth to the injection zone;

2) The injection pressure, external pressure, internal pressure, axial loading, etc.;

3) The hole size;

4) The size and grade of all casing strings (wall thickness, diameter, nominal weight, length, joint specification, and construction material);

5) The corrosiveness of injected fluids and formation fluids;

6) The lithology of injection and confining zones; and

7) The type and grade of cement.

b) Appropriate logs and other tests must be conducted during the drilling and construction of a new Class III injection well. A descriptive report interpreting the results of such logs and tests must be prepared by a knowledgeable log analyst and submitted to the Agency. The logs and tests appropriate to each type of Class III injection well must be determined based on the intended function, depth, construction, and other characteristics of the well; the availability of similar data in the area of the drilling site; and the need for additional information that may arise from time to time as the construction of the well progresses. Deviation checks must be conducted on all holes where pilot holes and reaming are used, unless the hole will be cased and cemented by circulating cement to the surface. If deviation checks are necessary, they must be conducted at sufficiently frequent intervals to assure that vertical avenues for fluid migration in the form of diverging holes are not created during drilling.

c) If the injection zone is a formation that is naturally water-bearing, the following information concerning the injection zone must be determined or calculated for a new Class III injection well or project:

1) The fluid pressure;

2) The fracture pressure; and

3) The physical and chemical characteristics of the formation fluids.

d) If the injection formation is not a water-bearing formation, the information in subsection (c)(2) must be submitted.

e) If injection is into a formation that contains water with less than 10,000 mg/ℓ TDS, monitoring wells must be completed into the injection zone and into any underground sources of drinking water above the injection zone that could be affected by the mining operation. These wells must be located in such a fashion as to detect any excursion of injection fluids, process by-products, or formation fluids outside the mining area or zone. If the operation may be affected by subsidence or catastrophic collapse, the monitoring wells must be located so that they will not be physically affected.

f) If injection is into a formation that does not contain water with less than 10,000 mg/ℓ TDS, no monitoring wells are necessary in the injection stratum.

g) If the injection well penetrates a USDW in an area subject to subsidence or catastrophic collapse, an adequate number of monitoring wells must be completed into the USDW to detect any movement of injected fluids, process by-products, or formation fluids into the USDW. The monitoring wells must be located outside the physical influence of the subsidence or catastrophic collapse.

h) In determining the number, location, construction, and frequency of monitoring of the monitoring wells the following criteria must be considered:

1) The population relying on the USDW affected or potentially affected by the injection operation;

2) The proximity of the injection operation to points of withdrawal of drinking water;

3) The local geology and hydrology;

4) The operating pressures and whether a negative pressure gradient is being maintained;

5) The nature and volume of the injected fluid, the formation water, and the process by-products; and

6) The injection well density.

(Source: Amended at 42 Ill. Reg. 24145, effective November 19, 2018)

Section 730.133 Operating, Monitoring, and Reporting Requirements

a) Operating Requirements. Operating requirements prescribed must, at a minimum, specify each of the following:

1) That, except during well stimulation, the injection pressure at the wellhead must be calculated so as to assure that the pressure in the injection zone during injection does not initiate new fractures or propagate existing fractures in the injection zone. In no case must injection pressure initiate fractures in the confining zone or cause the migration of injection or formation fluids into an underground source of drinking water; and

2) That injection between the outermost casing protecting underground sources of drinking water and the well bore is prohibited.

b) Monitoring Requirements

1) Monitoring requirements must, at a minimum, specify the following information:

A) Monitoring of the nature of injected fluids with sufficient frequency to yield representative data on its characteristics. Whenever the injection fluid is modified to the extent that the analysis required by Section 730.134(a)(7)(C) is incorrect or incomplete, the owner or operator must provide the Agency with a new analysis as required by Section 730.134(a)(7)(C);

B) Monitoring of injection pressure and either flow rate or volume semimonthly, or metering and daily recording of injected and produced fluid volumes, as appropriate;

C) Demonstration of mechanical integrity pursuant to Section 730.108 at least once every five years during the life of the well for salt solution mining;

D) Monitoring of the fluid level in the injection zone semi-monthly, where appropriate, and monitoring of the parameters chosen to measure water quality in the monitoring wells required by Section 730.132(e) semi-monthly; and

E) Quarterly monitoring of wells required by Section 730.132(g).

2) A Class III injection well may be monitored on a field or project basis, rather than on an individual well basis, by manifold monitoring. Manifold monitoring may be used in cases of facilities consisting of more than one injection well operating with a common manifold. Separate monitoring systems for each well are not required provided the owner or operator demonstrates that manifold monitoring is comparable to individual well monitoring.

c) Reporting Requirements

1) Reporting requirements must, at a minimum, include the following information:

A) Quarterly reporting to the Agency on required monitoring; and

B) Results of mechanical integrity and any other periodic test required by the Agency reported with the first regular quarterly report after the completion of the test.

2) Monitoring may be reported on a project or field basis rather than individual well basis where manifold monitoring is used.

(Source: Amended at 42 Ill. Reg. 24145, effective November 19, 2018)

Section 730.134 Information to be Considered by the Agency

This Section sets forth information that must be considered by the Agency in authorizing a Class III injection well. Certain maps, cross-sections, tabulations of wells within the area of review, and other data may be included in the application by reference provided they are current, readily available to the Agency (for example, in the Agency’s files) and sufficiently identified to be retrieved.

a) Prior to the issuance of a permit to operate an existing Class III injection well or area or for the construction of a new Class III injection well, the Agency must consider the following:

1) The information required in 35 Ill. Adm. Code 702.120 through 702.124 and 704.161(c);

2) A map showing the injection well or project area for which the permit is sought and the applicable area of review. Within the area of review, the map must show the number or name and location of all existing producing wells, injection wells, abandoned wells, dry holes, public water systems, and water wells. The map may also show surface bodies of waters, mines (surface and subsurface), quarries and other pertinent surface features including residences and roads, and faults if known or suspected. Only information of public record and pertinent information known to the applicant is required to be included on this map;

3) A tabulation of data reasonably available from public records or otherwise known to the applicant on wells within the area of review included on the map required pursuant to subsection (a)(2) that penetrate the proposed injection zone. Such data must include a description of each well’s type, construction, date drilled, location, depth, record of plugging and completion, and any additional information the Agency may require. In cases where the information would be repetitive and the wells are of similar age, type, and construction the Agency may elect to only require data on a representative number of wells;

4) Maps and cross-sections indicating the vertical limits of all underground sources of drinking water within the area of review, their position relative to the injection formation and the direction of water movements, where known, in every underground source of drinking water that may be affected by the proposed injection;

5) Maps and cross-sections detailing the geologic structure of the local area;

6) Generalized map and cross-sections illustrating the regional geologic setting;

7) Proposed operating data, as follows:

A) The average and maximum daily rate and volume of fluid to be injected;

B) The average and maximum injection pressure; and

C) Qualitative analysis and ranges in concentrations of all constituents of injected fluids. The applicant may request confidentiality as specified in 35 Ill. Adm. Code 101.107. If the information is proprietary an applicant may, in lieu of the ranges in concentrations, choose to submit maximum concentrations that must not be exceeded. In such a case the applicant must retain records of the undisclosed concentrations and provide them upon request to the Agency as part of any enforcement investigation;

8) A proposed formation testing program to obtain the information required by Section 730.132(c);

9) A proposed stimulation program;

10) The proposed injection procedure;

11) Schematic or other appropriate drawings of the surface and subsurface construction details of the system;

12) Plans (including maps) for meeting the monitoring requirements of Section 730.133(b);

13) Expected changes in pressure, native fluid displacement, direction of movement of injection fluid;

14) Contingency plans to cope with all shut-ins or well failures so as to prevent the migration of contaminating fluids into underground sources of drinking water;

15) A certificate that the applicant has assured, through a performance bond or other appropriate means, the resources necessary to close, plug, or abandon the well as required by 35 Ill. Adm. Code 704.189; and

16) The corrective action proposed to be taken pursuant to 35 Ill. Adm. Code 704.193.

b) Prior to granting approval for the operation of a Class III injection well, the Agency must consider the following information:

1) All available logging and testing data on the well;

2) A satisfactory demonstration of mechanical integrity for all new wells and for all existing salt solution pursuant to Section 730.108;

3) The anticipated maximum pressure and flow rate at which the permittee will operate;

4) The results of the formation testing program;

5) The actual injection procedures; and

6) The status of corrective action on defective wells in the area of review.

c) Prior to granting approval for the plugging and abandonment of a Class III injection well, the Agency must consider the following information:

1) The type and number of plugs to be used;

2) The placement of each plug including the elevation of the top and bottom;

3) The type, grade, and quantity of cement to be used;

4) The method of placement of the plugs; and

5) The procedure to be used to meet the requirements of Section 730.110(c).

(Source: Amended at 42 Ill. Reg. 24145, effective November 19, 2018)

SUBPART F: CRITERIA AND STANDARDS APPLICABLE TO CLASS V INJECTION WELLS

Section 730.151 Applicability

This Subpart F sets forth criteria and standards for underground injection control programs to regulate all injection not regulated in Subparts B, D, and E. A Class II injection well, however, is not regulated by this Subpart F.

a) Generally, a well covered by this Subpart F injects non-hazardous fluids into or above formations that contain underground sources of drinking water. It includes all wells listed in Section 730.105(e) but is not limited to those types of injection wells.

b) It also includes a well not covered in Class IV that injects radioactive materials listed in table II, column 2 in appendix B to 10 CFR 20 (Water Effluent Concentrations), incorporated by reference in 35 Ill. Adm. Code 720.111(b).

(Source: Amended at 42 Ill. Reg. 24145, effective November 19, 2018)

730.152 Inventory and Assessment (Repealed)

(Source: Repealed at 18 Ill. Reg. 18391, effective December 20, 1994)

SUBPART G: CRITERIA AND STANDARDS APPLICABLE TO CLASS I HAZARDOUS WASTE INJECTION WELLS

Section 730.161 Applicability and Definitions

a) This Subpart G establishes criteria and standards for underground injection control programs to regulate Class I hazardous waste injection wells. Unless otherwise noted, this Subpart G supplements the requirements of Subpart A and applies instead of Subpart B to a Class I hazardous waste injection well.

b) Definitions. The following definitions apply for the purposes of this Subpart G:

“Cone of influence” means that area around the well within which increased injection zone pressures caused by injection into the hazardous waste injection well would be sufficient to drive fluids into a USDW.

“Existing well” means a Class I hazardous waste injection well that had a UIC permit or UIC permit by rule prior to August 25, 1988, or a well that has become a Class I hazardous waste injection well as a result of a change in the definition of the injected waste which would render the waste hazardous pursuant to 35 Ill. Adm. Code 721.103.

“Injection interval” means that part of the injection zone in which the well is screened, or in which the waste is otherwise directly emplaced.

“New well” means any Class I hazardous waste injection well that is not an existing well.

“Transmissive fault or fracture” is a fault or fracture that has sufficient permeability and vertical extent to allow fluids to move between formations.

BOARD NOTE: Derived from 40 CFR 146.61 (2017).

(Source: Amended at 42 Ill. Reg. 24145, effective November 19, 2018)

Section 730.162 Minimum Criteria for Siting

a) All Class I hazardous waste injection wells must be sited such that they inject into a formation that is beneath the lowermost formation containing, within 402 meters (one-quarter mile) of the well bore, a USDW.

b) The siting of a Class I hazardous waste injection well must be limited to an area that is geologically suitable. The Agency must determine geologic suitability based upon its consideration of the following:

1) An analysis of the structural and stratigraphic geology, the hydrogeology, and the seismicity of the region;

2) An analysis of the local geology and hydrogeology of the well site, including, at a minimum, detailed information regarding stratigraphy, structure, and rock properties; aquifer hydrodynamics; and mineral resources; and

3) A determination that the geology of the area can be described confidently and that limits of waste fate and transport can be accurately predicted through the use of models.

c) Class I hazardous waste injection wells must be sited such that the following is true:

1) The injection zone has sufficient permeability, porosity, thickness, and area extent to prevent migration of fluids into USDWs; and

2) The confining zone is as follows:

A) It is laterally continuous and free of transecting, transmissive faults, or fractures over an area sufficient to prevent the movement of fluids into a USDW; and

B) It contains at least one formation of sufficient thickness and with lithologic and stress characteristics capable of preventing vertical propagation of fractures.

d) Alternative Injection Zone Demonstrations

1) The owner or operator must demonstrate one of the following alternatives:

A) That the confining zone is separated from the base of the lowermost USDW by at least one sequence of permeable and less permeable strata that will provide an added layer of protection for the USDW in the event of fluid movement in an unlocated borehole or transmissive fault;

B) That, within the area of review, the piezometric surface of the fluid in the injection zone is less than the piezometric surface of the lowermost USDW, considering density effects, injection pressures, and any significant pumping in the overlying USDW; or

C) There is no USDW present.

2) The owner or operator of a site that does not meet the requirements in subsection (d)(1), (d)(2), or (d)(3) may petition the Board for an adjusted standard pursuant to Subpart D of 35 Ill. Adm. Code 104. The Board may grant an adjusted standard approving such a site if it determines that because of site geology, nature of the wastes involved, or other considerations; abandoned boreholes; or other conduits would not cause an endangerment of USDWs. A petition for an adjusted standard pursuant to this subsection (d)(4) must include the following components:

A) Those portions of a permit application for the particular injection activities and site that are relevant to the Board’s determination; and

B) Such other relevant information that the Board may by order require pursuant to 35 Ill. Adm. Code 104.228.

BOARD NOTE: Derived from 40 CFR 146.62 (2017).

(Source: Amended at 42 Ill. Reg. 24145, effective November 19, 2018)

Section 730.163 Area of Review

For the purposes of Class I hazardous waste injection wells, this Section applies instead of Section 730.106. The area of review for a Class I hazardous waste injection well must be a two-mile radius around the well bore. The Agency may specify by permit condition a larger area of review in the UIC permit if it determines in writing that the larger area is necessary based on the calculated cone of influence of the well.

BOARD NOTE: Derived from 40 CFR 146.63 (2005).

(Source: Amended at 31 Ill. Reg. 1281, effective December 20, 2006)

Section 730.164 Corrective Action for Wells in the Area of Review

For the purposes of a Class I hazardous waste injection well, this Section applies instead of 35 Ill. Adm. Code 704.193 and Section 730.107.

a) The owner or operator of a Class I hazardous waste injection well must, as part of the permit application, submit a plan to the Agency outlining the protocol used to accomplish both of the following:

1) Identify all wells penetrating the confining zone or injection zone within the area of review; and

2) Determine whether wells are adequately completed or plugged.

b) The owner or operator of a Class I hazardous waste injection well must identify the location of all wells within the area of review that penetrate the injection zone or the confining zone and must submit both of the following, as required in Section 730.170(a):

1) A tabulation of all wells within the area of review that penetrate the injection zone or the confining zone; and

2) A description of each well or type of well and any records of its plugging or completion.

c) For wells that the Agency determines are improperly plugged, completed, or abandoned or for which plugging or completion information is unavailable, the applicant must also submit a plan consisting of such steps or modification as are necessary to prevent movement of fluids into or between USDWs. Where the plan is adequate, the Agency must incorporate it into the permit as a condition. Where the Agency’s review of an application indicates the permittee’s plan is inadequate (based at a minimum on the factors in subsection (e)), the Agency must do the appropriate of the following:

1) It must require the applicant to revise the plan;

2) It must prescribe a plan for corrective action as a condition of the permit; or

3) It must deny the application.

d) Requirements

1) Existing Injection Wells. Any permit issued for an existing Class I hazardous waste injection well requiring corrective action other than pressure limitations must include a compliance schedule pursuant to 35 Ill. Adm. Code 702.162 requiring any corrective action accepted or prescribed pursuant to subsection (c). Any such compliance schedule must provide for compliance no later than two years following issuance of the permit and must require observance of appropriate pressure limitations pursuant to subsection (d)(3) until all other corrective action measures have been implemented.

2) New Injection Wells. No owner or operator of a new Class I hazardous waste injection well may begin injection until all corrective actions required pursuant to this Section have been taken.

3) The Agency may require pressure limitations instead of plugging. If pressure limitations are used instead of plugging, the Agency must require as a permit condition that injection pressure be limited so that pressure in the injection zone at the site of any improperly completed or abandoned well within the area of review would not be sufficient to drive fluids into or between USDWs. This pressure limitation must satisfy the corrective action requirements. Alternatively, such injection pressure limitation may be made part of a compliance schedule pursuant to 35 Ill. Adm. Code 702.162 and may be required to be maintained until all other required corrective actions have been implemented.

e) The Agency must consider the following criteria and factors in determining the adequacy of corrective action proposed by the applicant pursuant to subsection (c) and in determining the additional steps needed to prevent fluid movement into and between USDWs:

1) The nature and volume of injected fluid;

2) The nature of native fluids or byproducts of injection;

3) Geology;

4) Hydrology;

5) The history of the injection operation;

6) Any completion and plugging records;

7) The closure procedures in effect at the time the well was closed;

8) Any hydraulic connections with USDWs;

9) The reliability of the procedures used to identify abandoned wells; and

10) Any other factors that might affect the movement of fluids into or between USDWs.

BOARD NOTE: Derived from 40 CFR 146.64 (2017).

(Source: Amended at 42 Ill. Reg. 24145, effective November 19, 2018)

Section 730.165 Construction Requirements

a) General. All existing and new Class I hazardous waste injection wells must be constructed and completed to accomplish each of the following:

1) Prevent the movement of fluids into or between USDWs or into any unauthorized zones;

2) Permit the use of appropriate testing devices and workover tools; and

3) Permit continuous monitoring of injection tubing and long string casing as required pursuant to Section 730.167(f);

b) Compatibility. All well materials must be compatible with fluids with which the materials may be expected to come into contact. The owner or operator must employ any compatibility testing method specified by permit condition. The owner or operator may otherwise refer to “Technical Assistance Document: Corrosion, Its Detection and Control in Injection Wells”, USEPA publication number EPA-570/9-87-002, incorporated by reference at 35 Ill. Adm. Code 720.111.

c) Casing and Cementing New Wells

1) Casing and cement used in the construction of each newly drilled well must be designed for the life expectancy of the well, including the post-closure care period. The casing and cementing program must be designed to prevent the movement of fluids into or between USDWs, and to prevent potential leaks of fluids from the well. The Agency must consider the following information as required by Section 730.170 in determining and specifying casing and cementing requirements:

A) The depth to the injection zone;

B) The injection pressure, external pressure, internal pressure, and axial loading;

C) The hole size;

D) The size and grade of all casing strings (well thickness, diameter, nominal weight, length, joint specification, and construction material);