| | - BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

- IN THE MATTER OF:

- PROPOSED NEW 35 ILL.ADM.CODE PART 225 CONTROL OF EMISSIONS FROM

- LARGE COMBUSTION SOURCES

- ) ) ) )

- PCB R06-25 Rulemaking - Air

- NOTICE OF FILING

- BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

- IN THE MATTER OF:

- PROPOSED NEW 35 ILL.ADM.CODE PART 225 CONTROL OF EMISSIONS FROM

- LARGE COMBUSTION SOURCES

- ) ) ) )

- PCB R06-25

- TESTIMONY OF PETER M. CHAPMAN, Ph.D.

- 1.0 Qualifications

- 2.0 Summary of Testimony

- 3.0 Mercury in the Environment

- Table 1

- Example of Physico-Chemical Processes Affecting Mercury Methylation

- Physico-Chemical Condition Methylation

- Enhanced ↑ Decreased ↓

- 4.0 Mercury in Illinois Water Bodies and Fish

- 5.0 Florida, Massachusetts and Ohio Studies: Relevance to Illinois

- 6.0 Conclusions

- Table 2

- Table 3

- COUNTY

- Total Mercury in Sediments (mg/kg

- dry weight)

- Total Mercury in

- Fish Tissue

- (mg/kg wet weight)

- Year Fish Data

- Collected

- Table 4

- Water Body Site Name Size

- Miles/

- Acres

- Impaired?

- Impaired?

- Could

- Reduction in Mercury

- Affect

- Impaired Listing?

- Table 4

- Water Body Site Name Size

- Miles/

- Acres

- Impaired?

- Impaired?

- Could

- Reduction in Mercury

- Affect

- Impaired Listing?

- Table 4

- Water Body Site Name Size

- Miles/

- Acres

- Impaired?

- Impaired?

- Could

- Reduction in Mercury

- Affect

- Impaired Listing?

- Figure 2 Mercury Methylation

- Figure 1

- The Mercury Cycle

- Experience:

- PROJECT RELATED EXPERIENCE – ECOTOXICOLOGY/TOXICITY TESTING

- Example Publications International Peer-Reviewed Literature

- PROJECT RELATED EXPERIENCE – ENVIRONMENTAL RISK ASSESSMENT

- Example Publications International Peer-Reviewed Literature

- Example Publications International Peer-Reviewed Literature

- PROJECT RELATED EXPERIENCE – EXPERT WITNESS AND PEER REVIEW

- Peer Reviewer USA, Canada, Australasia, Europe

- PROJECT RELATED EXPERIENCE – METALS AND METALLOIDS

- Example Publications International Peer-Reviewed Literature

- PROJECT RELATED EXPERIENCE – SEWAGE EFFLUENT AND TREATMENT

- Example Publications International Peer-Reviewed Literature

- JOURNAL PUBLICATIONS [* = Editorials or Letters to the Editor]

- CHAPTERS IN BOOKS

- LEARNED DISCOURSES

- Peter M. Chapman

- INTRODUCTIONS TO DEBATES/COMMENTARIES

- Peter M. Chapman

- EDITORIAL PUBLICATIONS

- Peter M. Chapman

- PUBLISHED PROCEEDINGS

- Peter M. Chapman

- Peter M. Chapman

- Peter M. Chapman

- Peter M. Chapman

- Peter M. Chapman

- PUBLISHED TECHNICAL REPORTS AND THESES

- Peter M. Chapman

- Peter M. Chapman

- CO-AUTHORED U.S. EPA SCIENCE ADVISORY BOARD (SAB) REPORTS

- Peter M. Chapman

- PUBLISHED ABSTRACTS

- Peter M. Chapman

- Peter M. Chapman

- Peter M. Chapman

- Peter M. Chapman

- Peter M. Chapman

- Peter M. Chapman

- Peter M. Chapman

- Peter M. Chapman

- Peter M. Chapman

- UNPUBLISHED MANUSCRIPTS AND REPORTS

- Peter M. Chapman

- Peter M. Chapman

- Peter M. Chapman

- Peter M. Chapman

- Peter M. Chapman

- Peter M. Chapman

- Peter M. Chapman

- Peter M. Chapman

- Peter M. Chapman

- Peter M. Chapman

- Exhibit 1

- Mercury

- Blood mercury concentration (μg per liter)

- 5% poorerperformancein Faroes

- Lower limit

- on 85

- 0.8 5.8

- EPA reference

- (women ofchildbearing

- 0 100

- 0.8 5.8

- Exhibit 4

- Blood mercurylevel comparison5.7% US

- women

- Hair mercury level (ppm)

- 5%increasein

- abnormalBoston

- NamingTest

- responses

- Faroe Islands

- Average

- EPAreference

- ge

- percentile

- Exhibit 5Hair mercury level

- comparison

- Japanese

- average

- ATSDR EPA RIVM WHO ICF/TERA

- Exposure

- Uncertainty

- Change assumption as per

- Relative source

- Resulting fish tissue

- concentration limit(mg/kg or ppm)

- BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

- IN THE MATTER OF:

- PROPOSED NEW 35 ILL.ADM.CODE PART 225 CONTROL OF EMISSIONS FROM

- LARGE COMBUSTION SOURCES

- ) ) ) )

- PCB R06-25 Rulemaking - Air

- EXECUTIVE SUMMARY

- A REVIEW OF

- THE STATUS OF MERCURY CONTROL TECHNOLOGY

- SECTION 1

- INTRODUCTION

- SECTION 2

- ILLINOIS PROPOSED RULE: WHAT DOES IT REALLY ASK?

- SECTION 3

- EVOLUTION AND COST OF ENVIRONMENTAL CONTROL TECHNOLOGY

- SECTION 4

- INHERENT MERCURY REMOVAL FROM ENVIRONMENTAL CONTROLS

- SECTION 5

- MERCURY SPECIFIC CONTROL TECHNOLOGIES

- (MW)

- FGD Type/SO2 Inlet

- Baseline Hg Removal vs. with Additive

- Hg Removal

- Test

- Duration

- Date

- Design Coal

- PresentCoal

- Initial/Final ESP SCA

- 2/kacfm)

- Description of ESP Upgrade

- ESP SCA, ft2/kacfm

- Hg removal, %

- (tons/year)

- ACI-Induced PM

- Emissions

- (tons/year at 98.3%

- efficiency)

- ACI-Induced PM

- Emissions

- (tons/year at 95% efficiency)

- SECTION 6

- PROCESS GUARANTEES

- SECTION 7

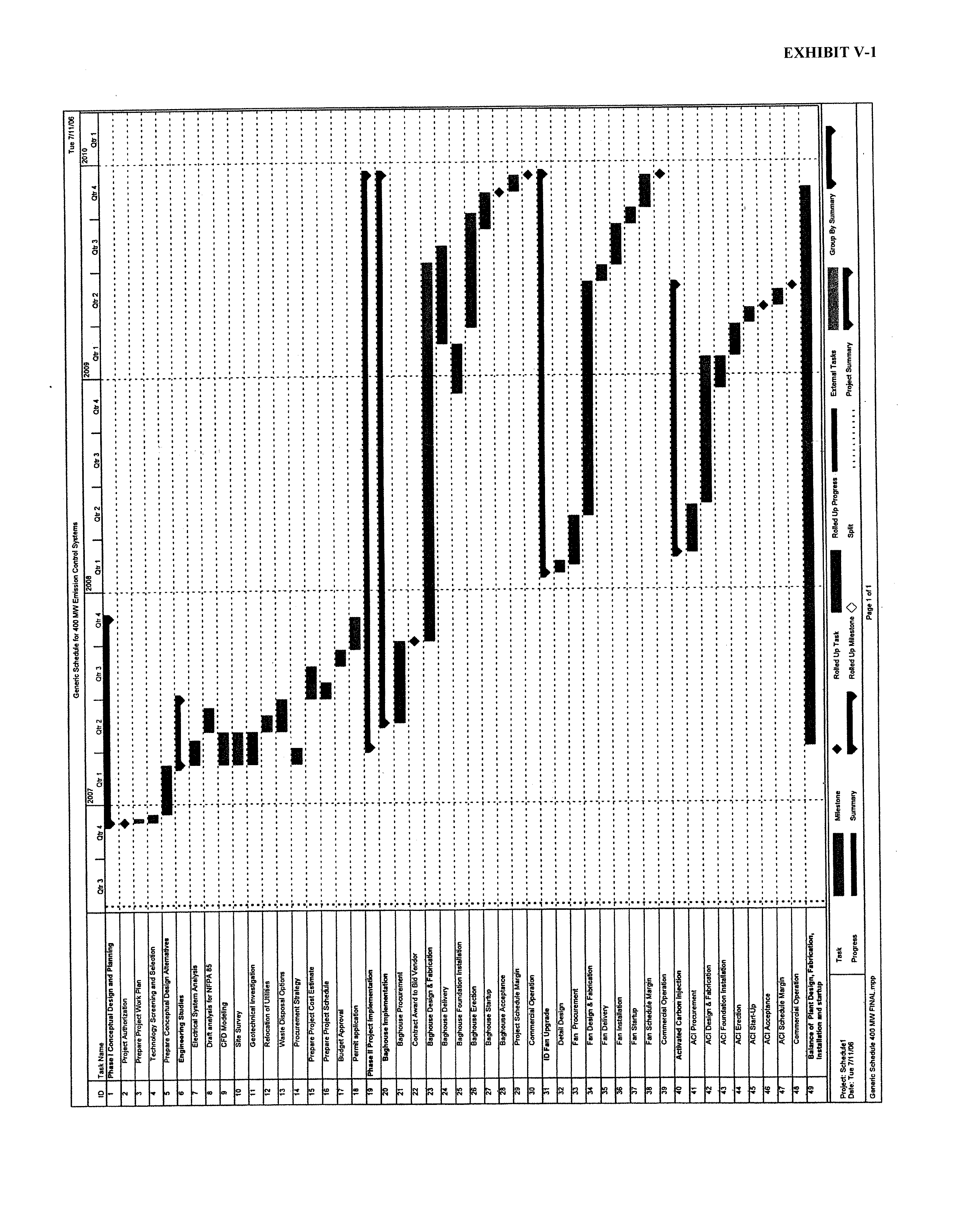

- SCHEDULE AND DEMONSTRATION PLANS

- SECTION 8

- CONCLUSIONS

- REFERENCES

- APPENDIX A

- SUMMARY OF ASSUMPTIONS DEFINING

- SECTION A-1

- INTRODUCTION

- SECTION A-2

- INHERENT REMOVAL AND BASELINE HG EMISSIONS

- Table A.2-1. EMF Recommendations

- Control Configuration Bituminous

- Coal

- Sub-bituminous Lignite

- Table A.2-2. Summary of Factors in the FBC Correlation

- SECTION A-3

- ACTIVATED CARBON INJECTION (ACI) IN PM CONTROLS

- SECTION A-4

- ACI/FABRIC FILTER

- SECTION A-5

- CARBON INJECTION: SPRAY DRYER ABSORBER (SDA)/FF

- Note 1 all ESP HACI 90% 6.5

- SECTION A-6

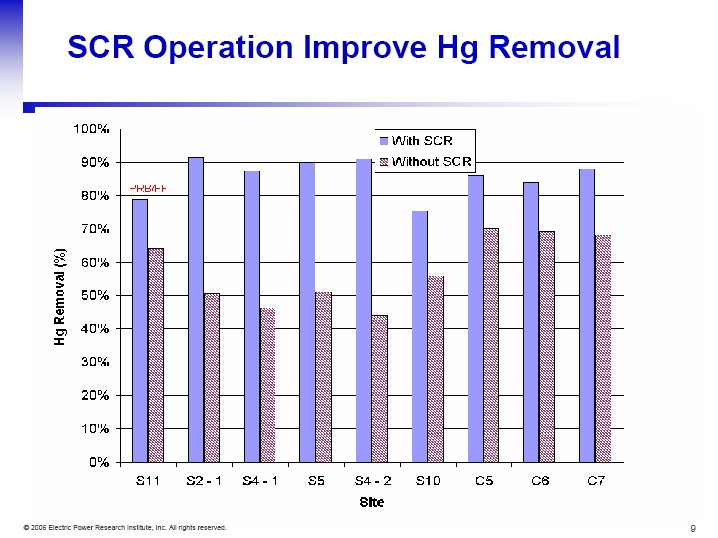

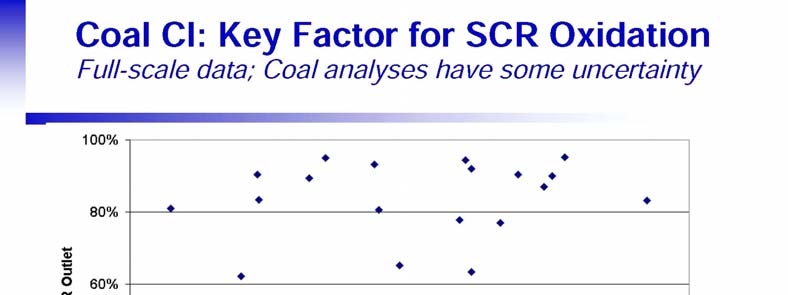

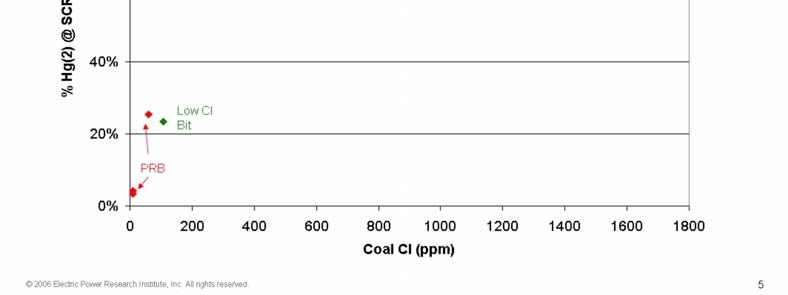

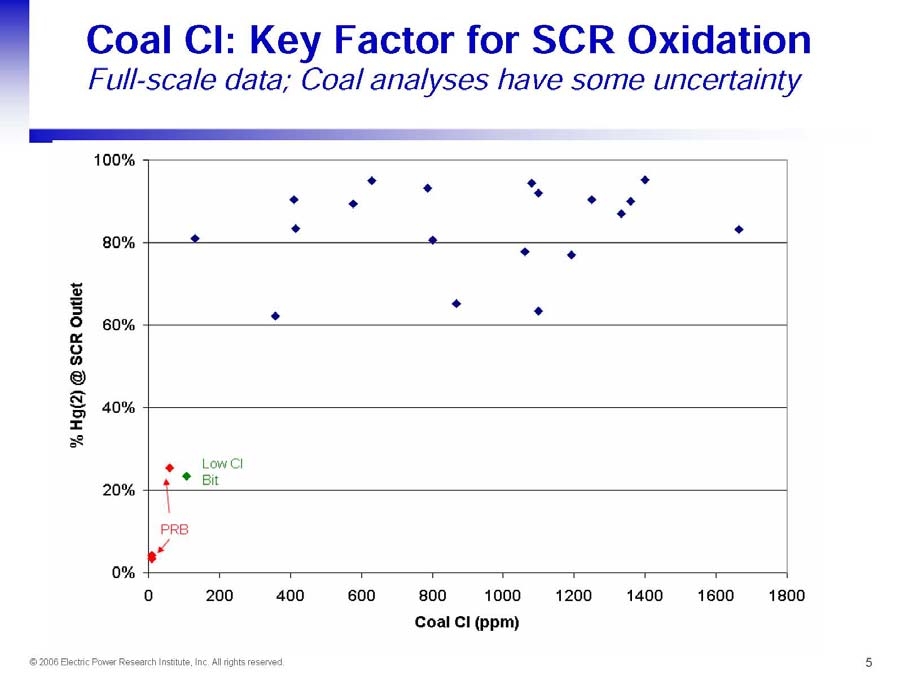

- SCR AND FGD HG REMOVAL

- SECTION A-7

- FLUID BED UNITS: ACI/FABRIC FILTER (COHPAC/TOXECON)

- APPENDIX A REFERENCES

- APPENDIX B

- ASSUMPTIONS DEFINING THE PERFORMANCE AND COST

- OF SO2, NOx, AND PARTICULATE MATTER FOR

- CAIR COMPLIANCE

- SECTION B-1

- INTRODUCTION

- SECTION B-2

- FLUE GAS DESULFURIZATION CONTROL TECHNOLOGY

- Table B-1 - Wet FGD Design and Operating Variables

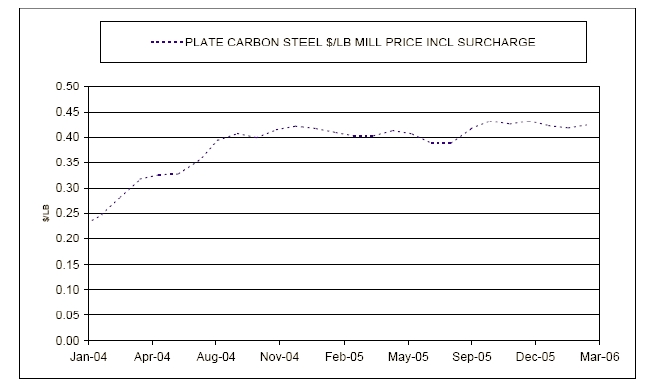

- Figure B-1 – Conventional Wet FGD Capital Cost Estimates

- Figure B-2 – Fixed O&M Costs: Conventional Wet and Dry FGD

- Figure B-3. Dry FGD Capital Cost

- Figure B-4. Dry FGD Fixed Operating Costs

- SECTION B-3

- NITROGEN OXIDES (NOx) CONTROL TECHNOLOGY

- Table B-3. SCR Fixed, Variable Operating Costs

- Coal Source Minimum NOx Outlet Rate

- (lbs/MBtu)

- SECTION B-4

- PARTICULATE MATTER CONTROL TECHNOLOGY

- SECTION B-5

- ACTIVATED CARBON INJECTION HARDWARE

- SECTION B-6

- ACI/FABRIC FILTER (COHPAC/TOXECON) for FLUIDIZIED BED UNITS

- APPENDIX B REFERENCES

- BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

- IN THE MATTER OF:

- PROPOSED NEW 35 ILL.ADM.CODE PART 225 CONTROL OF EMISSIONS FROM

- LARGE COMBUSTION SOURCES

- ) ) ) )

- PCB R06-25

- TESTIMONY OF MR. WILLIAM DEPRIEST

- I. INTRODUCTION

- II. DESIGN DECISION IMPACTS OF THE PROPOSED ILLINOIS

- 1. CAIR and CAMR emission reduction timelines were drafted to allow

- 2. If the phased mercury control approach of CAMR is eliminated, most

- III. RETROFIT DIFFICULTIES THAT AFFECT THE COSTS OF MERCURY

- CONTROL ON THE ILLINOIS COAL-FIRED POWER PLANTS

- 1. Capabilities of the Existing Electrostatic Precipitator (ESP) to

- 2. Fan Upgrades Required Due to Existing Fan Limitations

- 3. Electrical Distribution Upgrades Due to Existing Infrastructure

- Limitations

- 4. Infrastructure Limitations

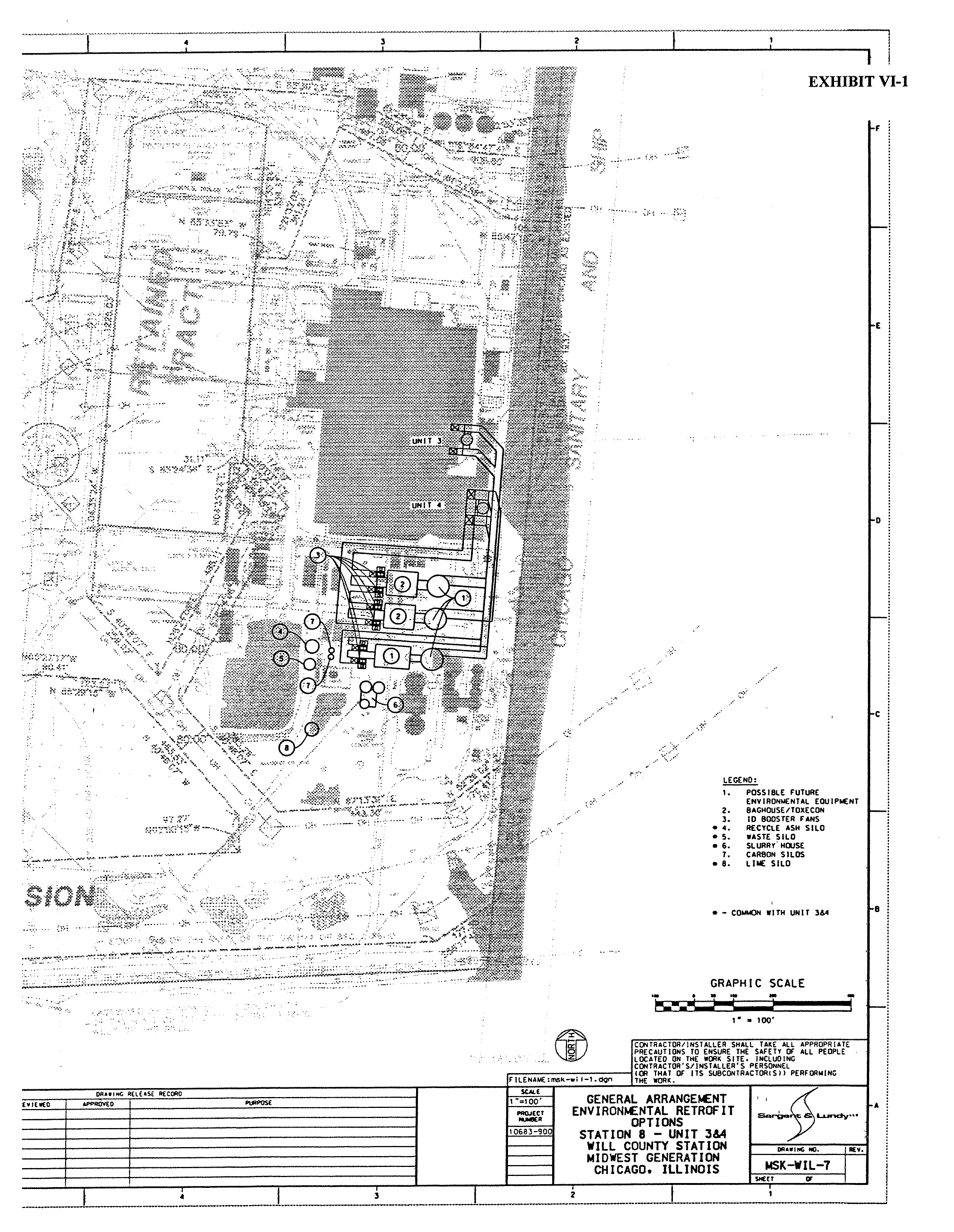

- 5. Physical Limitations of Existing ESPs, Existing Ductwork

- Configurations, and Existing Plant Layouts

- 6. Outage Limitations

- 7. Waste Disposal Limitations

- IV. CURRENT MARKET FACTORS THAT AFFECT THE COST AND

- SCHEDULE OF COMPLIANCE WITH THE PROPOSED ILLINOIS MERCURY RULE

- 1. Design and Manufacturing Capabilities

- 2. Labor Market

- 3. Seller’s Market

- 4. Steel and Alloy Market Volatility

- 5. Outage Costs and Impacts

- 6. Owner Resources and Contracting Approaches

- V. EXPECTED PROJECT IMPLEMENTATION SCHEDULES FOR

- MEASURES REQUIRED TO COMPLY WITH THE PROPOSED ILLINOIS MERCURY RULE

- VI. INSTALLED COST PROJECTIONS FOR RETROFITS EXPECTED TO

- MERCURY RULE

- 1. Cost Ranges for Sorbent Injection Alone

- 2. Cost Ranges for Polishing Fabric Filter Plus Sorbent Injection

- Unit Size

- Retrofit Complexity Moderate

- Retrofit Complexity

- Difficult

- Retrofit Complexity

- Severe

- 3. Cost Ranges For Full Pulse Jet Fabric Filter to be Used in

- Conjunction with Dry FGD and Sorbent Injection

- Two Stage Compliance ($/kw)

- Phase 1: Activated Carbon and Pulse Jet Fabric Filter

- Phase 2: Addition for Dry FGD

- Unit Size

- Retrofit Complexity

- Moderate

- Retrofit Complexity

- Difficult

- Retrofit Complexity

- Severe

- BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

- IN THE MATTER OF:

- PROPOSED NEW 35 ILL.ADM.CODE PART 225 CONTROL OF EMISSIONS FROM

- LARGE COMBUSTION SOURCES

- ) ) ) )

- PCB R06-25 Rulemaking - Air

- I. QUALIFICATIONS

- II. INTRODUCTION

- III. IL MERCURY RULE

- IV. METHODOLOGY AND CONTROL ASSUMPTIONS

- V. COMPARISON OF COMPLIANCE EFFECTS OF MEETING

- CAIR/CAMR AND CAIR/IL MERCURY RULE FOR IL GENERATORS

- TABLE 1

- IL COAL- & GAS/OIL-FIRED GENERATION: 2005 - 2018

- (GWh)

- TABLE 2

- SO2, NOx and MERCURY EMISSIONS FROM IL GENERATORS

- (SO2 & NOx in tons and Hg in pounds)

- TABLE 3

- CAPITAL INVESTMENT OF SO2, NOx AND MERCURY CONTROL

- TECHNOLOGIES: 2009 – 2018

- (billions of 2006 $)

- TABLE 4

- COMPARISON OF CUMULATIVE ANNUALIZED COMPLIANCE COSTS FOR

- SO2, NOx AND MERCURY CONTROLS: 2009-2018

- (billions of 2006 $)

- VI. SUMMARY OF COMPLIANCE ISSUES

- VII. COMPARISON OF COMPLIANCE COSTS

- TABLE 5

- COMPARISON FOR MERCURY CONTROL COMPLIANCE COSTS

- (in 2006 million dollars)

- MCH TSD ICF

- Capital Investment

- TABLE 6

- MCH AND TSD COMPARATIVE UNIT TECHNOLOGY COSTS: $/kW

- (in 2006 dollars)

- APPENDIX A

- METHODOLOGY AND INPUT ASSUMPTIONS

- TABLE A-1

- NOx UNIT ALLOCATION SCHEDULE UNDER CAIR

- TABLE A-2

- MERCURY UNIT ALLOCATION SCHEDULE UNDER CAMR

- TABLE A-3

- CAIR AND CAMR ALLOWANCE PRICES

- (2006 $)

- I. BACKGROUND AND QUALIFICATIONS

- II. ANALYSIS OF ELECTRICITY MARKET

- OPERATIONS

- Coal Description Heating Value

- (Btu/lb)

- SO2 Content (lbs/MMBtu)

- Hg Content (lbs/TBtu)

- Coal Type 2006 2008 2009 2010 2013 2015 2018

- Allowance Type 2006 2008 2009 2010 2013 2015 2018

- BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

- TESTIMONY OF RICHARD D. McRANIE

- Executive Summary

- Qualifications

- Introduction

- Brief Description of the Proposed Illinois Rule

- Overview Discussion of Hg Measurements Required

- General Discussion of the Probable Monitoring Issues

- Significant Figures

- Historical Perspective of Hg Emissions Monitoring

- Hg Monitoring Technology

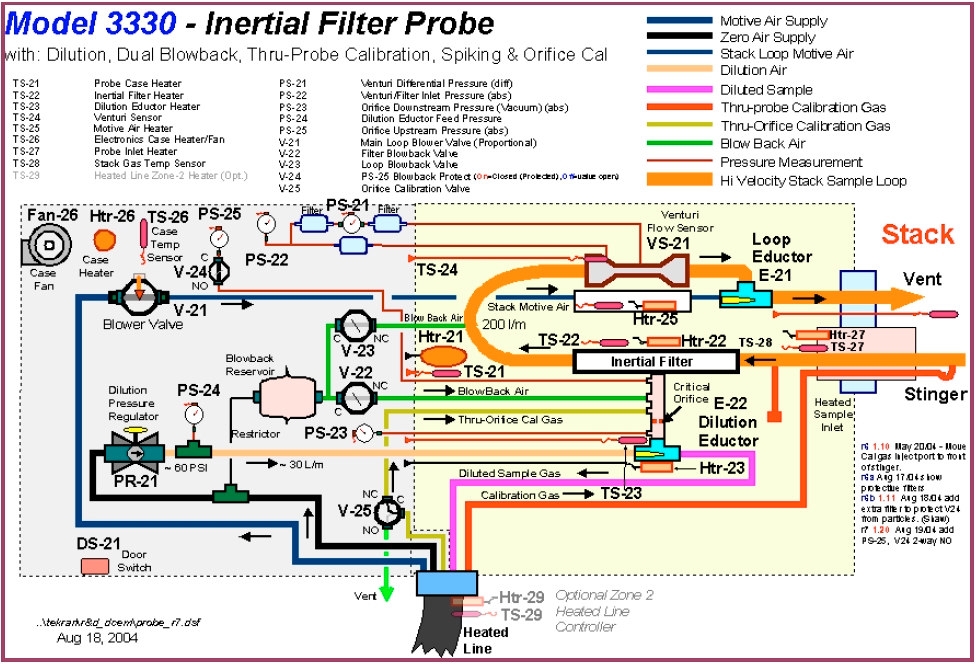

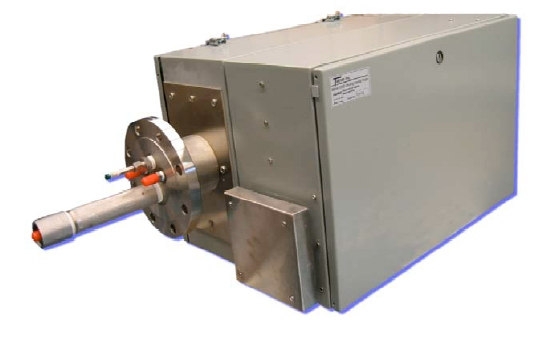

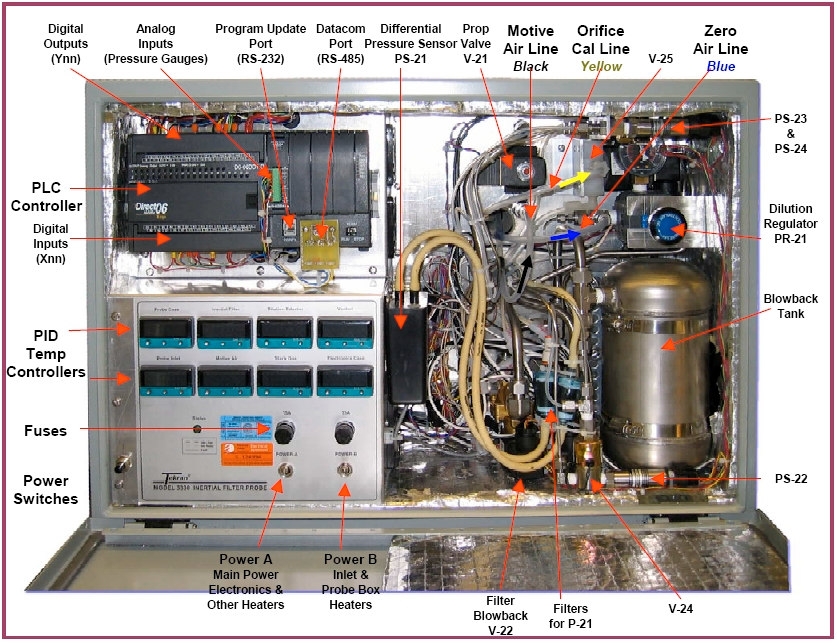

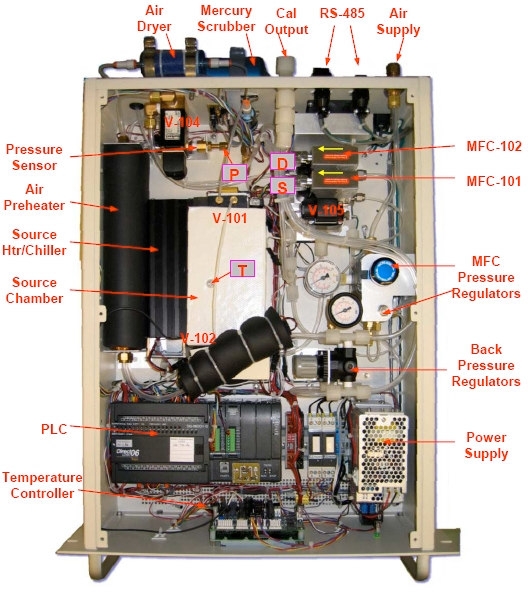

- Figure 1 – Tekran Hg CEMS Inertial Filter Probe

- Figure 2 – Tekran Probe Box

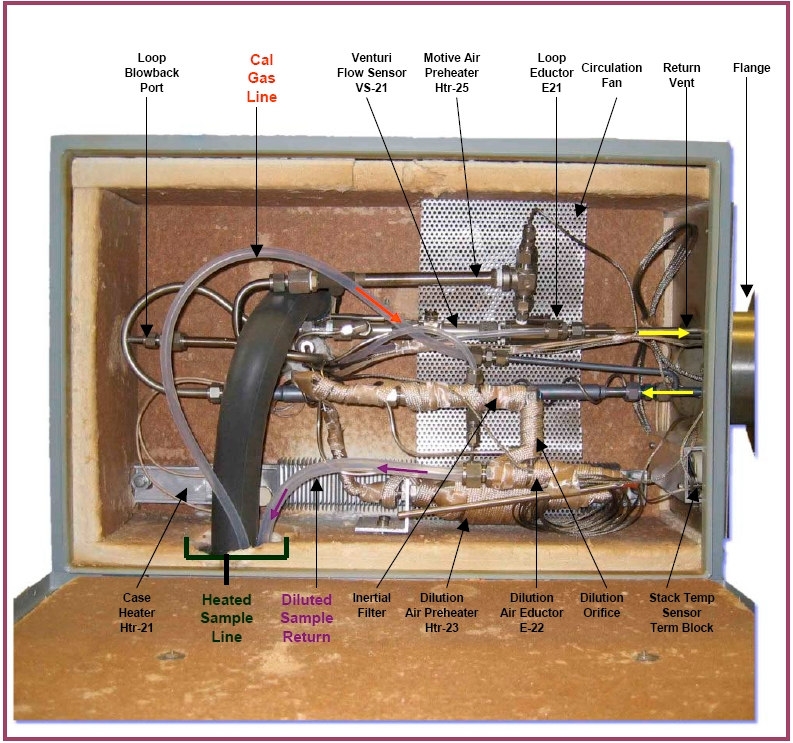

- Figure 3 – Tekran Probe Box - Hot-side

- Figure 4 – Tekran Probe Box – Cold Side

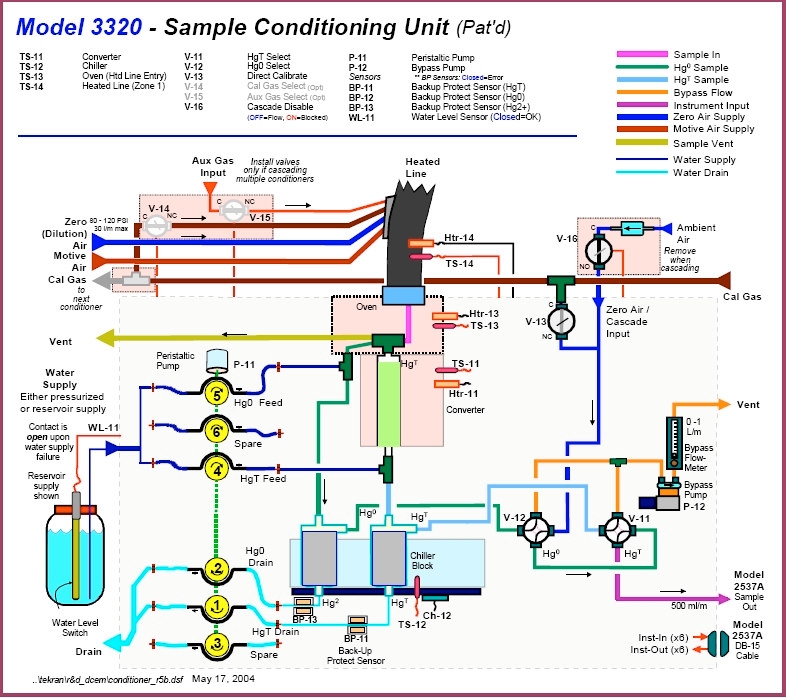

- Figure 5 – Tekran Sample Conditioning Unit

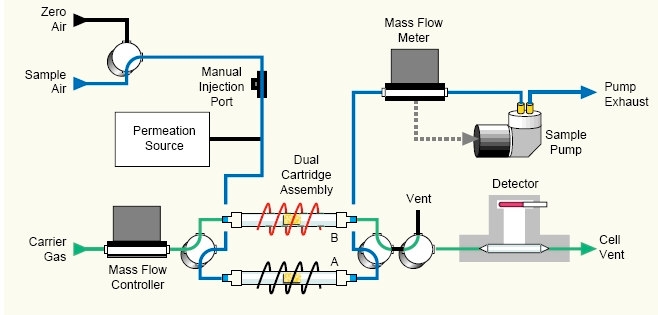

- Figure 6 – Tekran Hg Analyzer Flow Diagram

- Calibration Issues with Hg CEMS

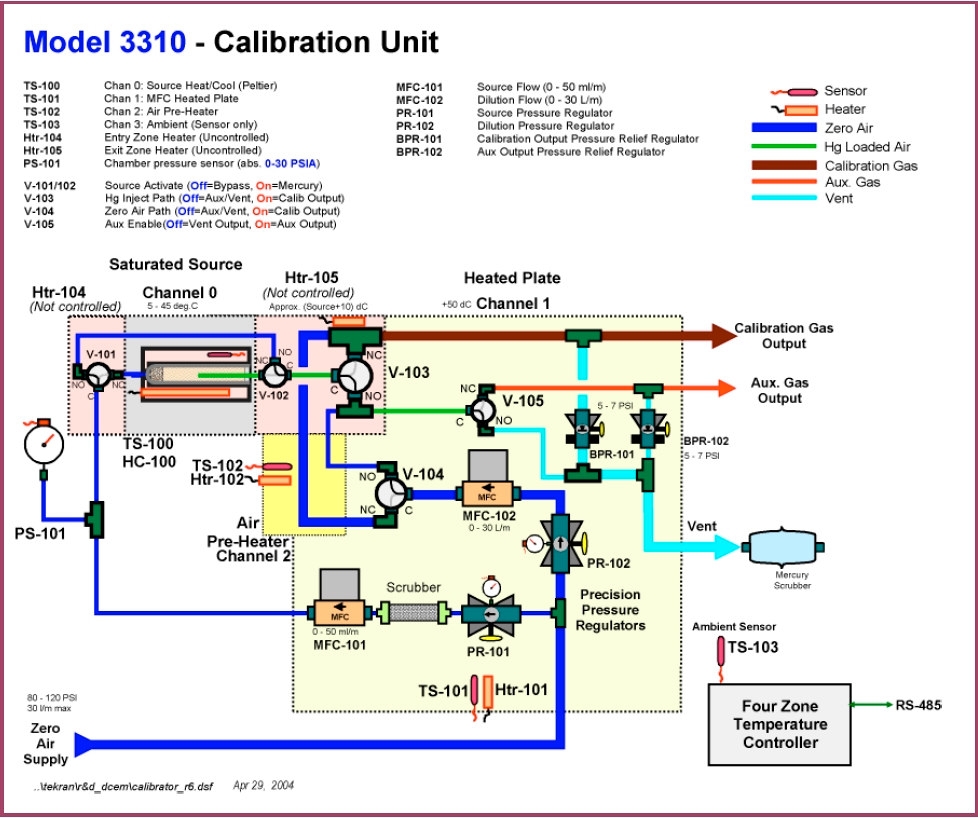

- Figure 7 – Tekran Elemental Hg Calibrator Flow Diagram

- Figure 8 – Tekran Calibrator Internal View

- Figure 9 – Oxidized Hg Calibrator Flow Diagram

- Figure 10 – HovaQuick Oxidized Hg Calibrator

- Measurement Characteristics

- Figure 11 – Example Normal Distribution

- Figure 12 – Example Log Normal Distribution

- Figure 13 - High accuracy but low precision

- Figure 14 - High precision but low accuracy

- Description of Hg Monitoring and Demonstration Research Projects

- Table 1 - RATA 1 Results From Trimble County

- RATA Criteria Tekran Thermo Horiba Forney

- Table 2 - RATA 2 Results From Trimble County

- RATA Criteria Tekran Thermo Opsis Durag

- EPRI Hg Monitoring Demonstration Project and Results

- Figure 13 – Inertial Probe Loop Exit Plugging

- Table 3. Calibration Error Test Results - CEMS X - April 2006

- Zero Error Span Response Error

- Date Response (% of Span) (Expected 9.8ug/m

- 3 ) (% of Span)

- Table 4. Calibration Error Test Results - CEMS X - May 2006

- Table 5. Calibration Error Test Results – CEMS Y - May 2006

- Missing Data Substitution

- Coal Sampling and Analysis Error Sources

- Propagation of Error

- Hg Data Discussion

- Figure 14 – Hg CEMS Readings – Trimble County

- Figure 15 – Hg CEMS Readings – Trimble County

- Figure 16 – Hg CEMS Readings – Trimble County

- Figure 17 – Hg CEMS Readings – Trimble County

- SCR damper opened

- NH3 injection began

- Conclusions

- Appendix 1

- Appendix 2

- Conversion Protocollb/GWh Hg to microgram/m

- Equation 1

- 10 Btu

- 0.80 10 lb Hg

- 10 Btu

- 0.80 lb Hg

- 10,000Btu

- 1 kW hr

- 1 10 kW

- GW hr

- 0.008 lbHg

- Equation 2

- EC F

- Equation 3

- 100

- 1,800

- 0.80 10C

- BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

- IN THE MATTER OF:

- PROPOSED NEW 35 ILL.ADM.CODE PART 225 CONTROL OF EMISSIONS FROM

- LARGE COMBUSTION SOURCES

- ) ) ) )

- PCB R06-25

- which is detrimental to its use in concrete.

- concrete.

- concrete.

- fly ash has been in contact with an activated carbon sorbent.

- Education:

- Current Employment

- February 2003 – present, University of Illinois at Chicago

- April 1998 – Present, Ish Inc.

- Previous Employment

- Business Experience

- Technical and Professional Experience

- National Committees Experience

- Publication and Presentations

- Current Service on University Committees

- Recently completed and ongoing projects on Coal Ash Management

- BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

- IN THE MATTER OF:

- PROPOSED NEW 35 ILL.ADM.CODE PART 225 CONTROL OF EMISSIONS FROM

- LARGE COMBUSTION SOURCES

- ) ) ) )

- PCB R06-25 Rulemaking - Air

- TESTIMONY OF KRISH VIJAYARAGHAVAN

- I. INTRODUCTION

- A. AER credentials

- B. Witness credentials

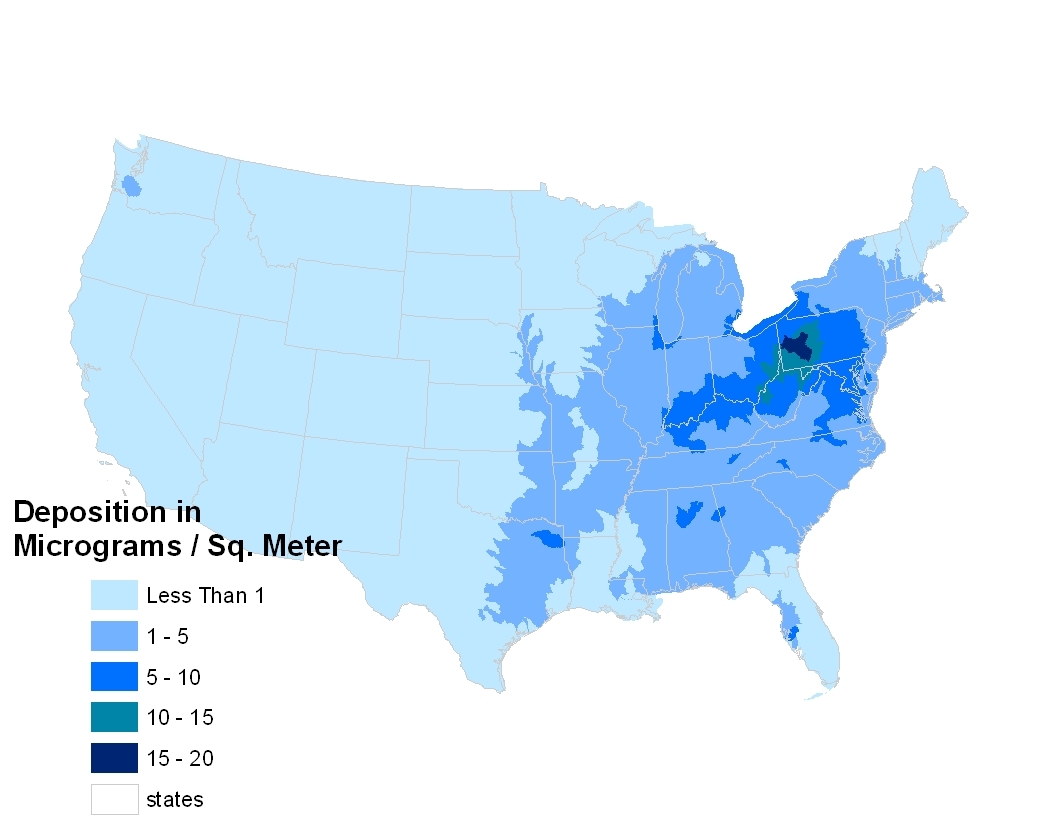

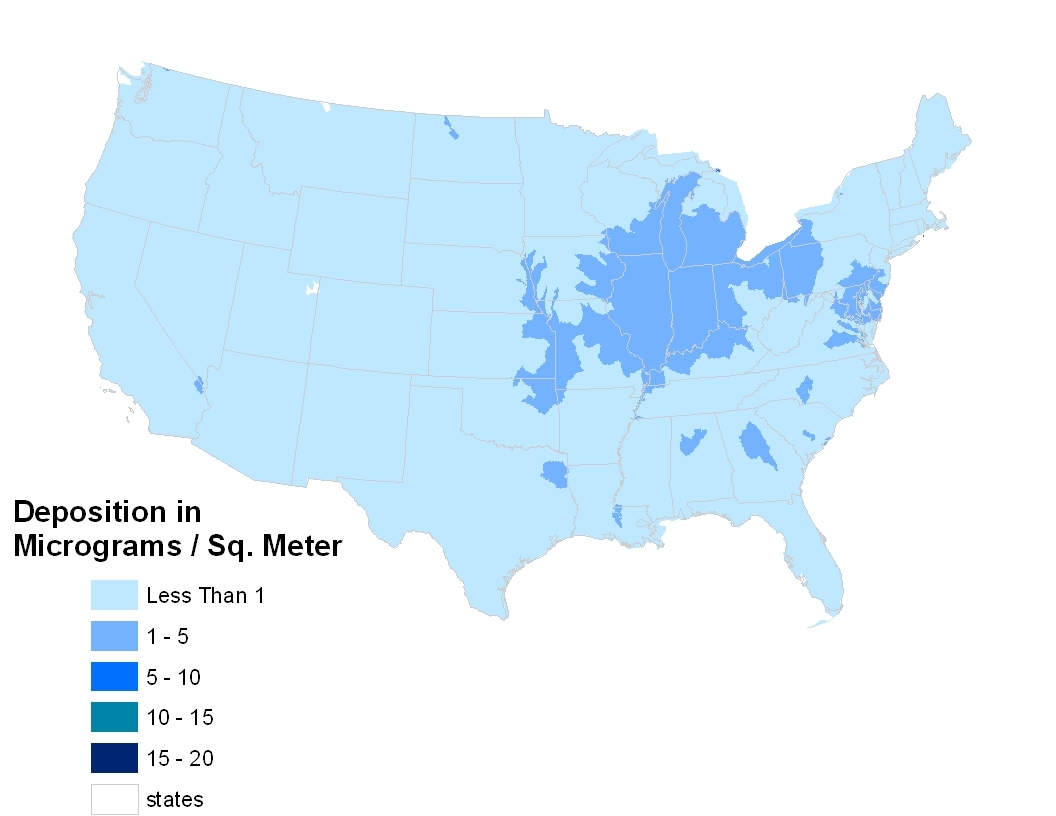

- II. ATMOSPHERIC MERCURY

- III. CHEMICAL TRANSPORT MODELS

- IV. THE TRACE ELEMENT ANALYSIS MODEL (TEAM)

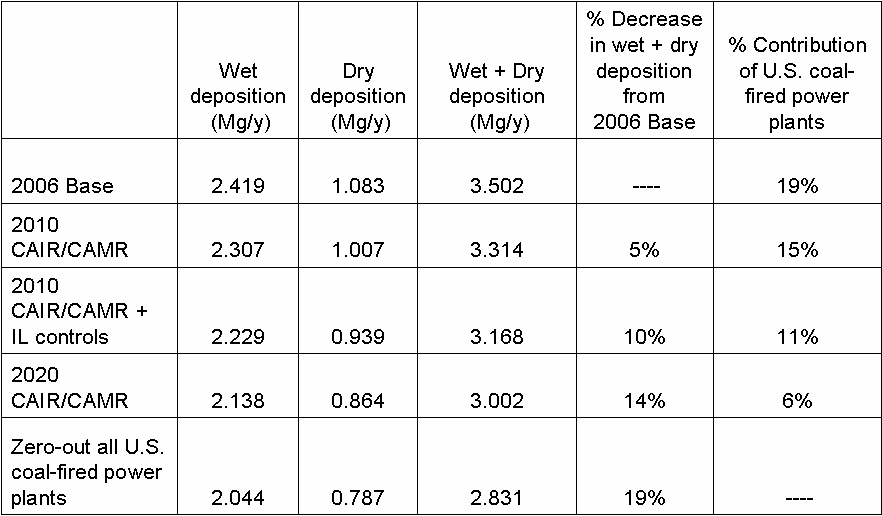

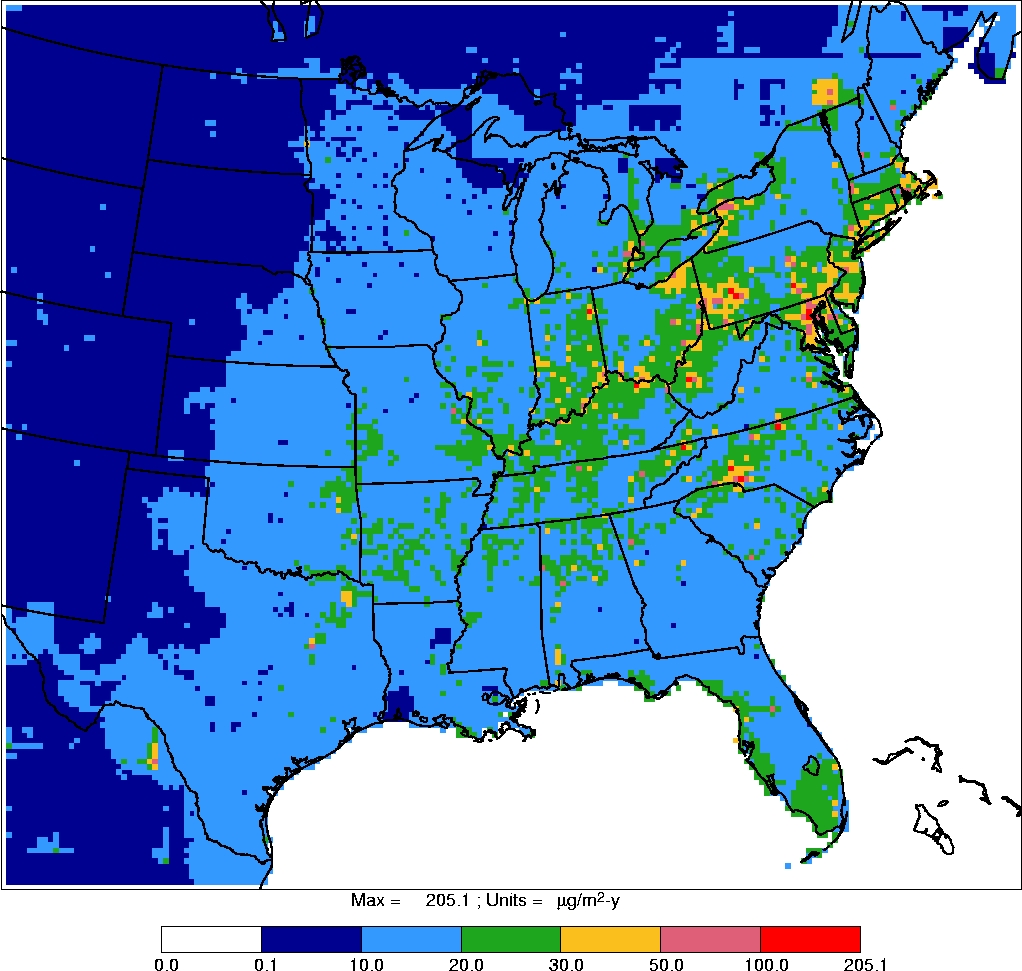

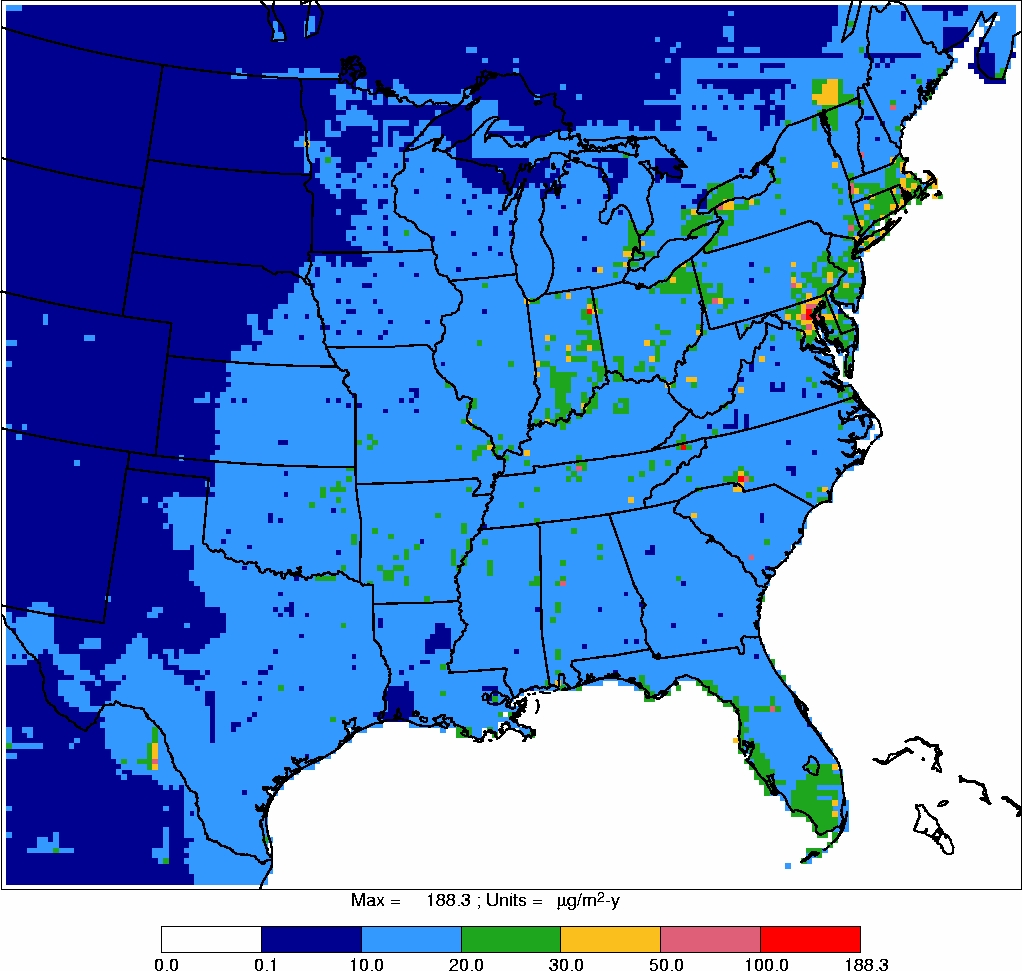

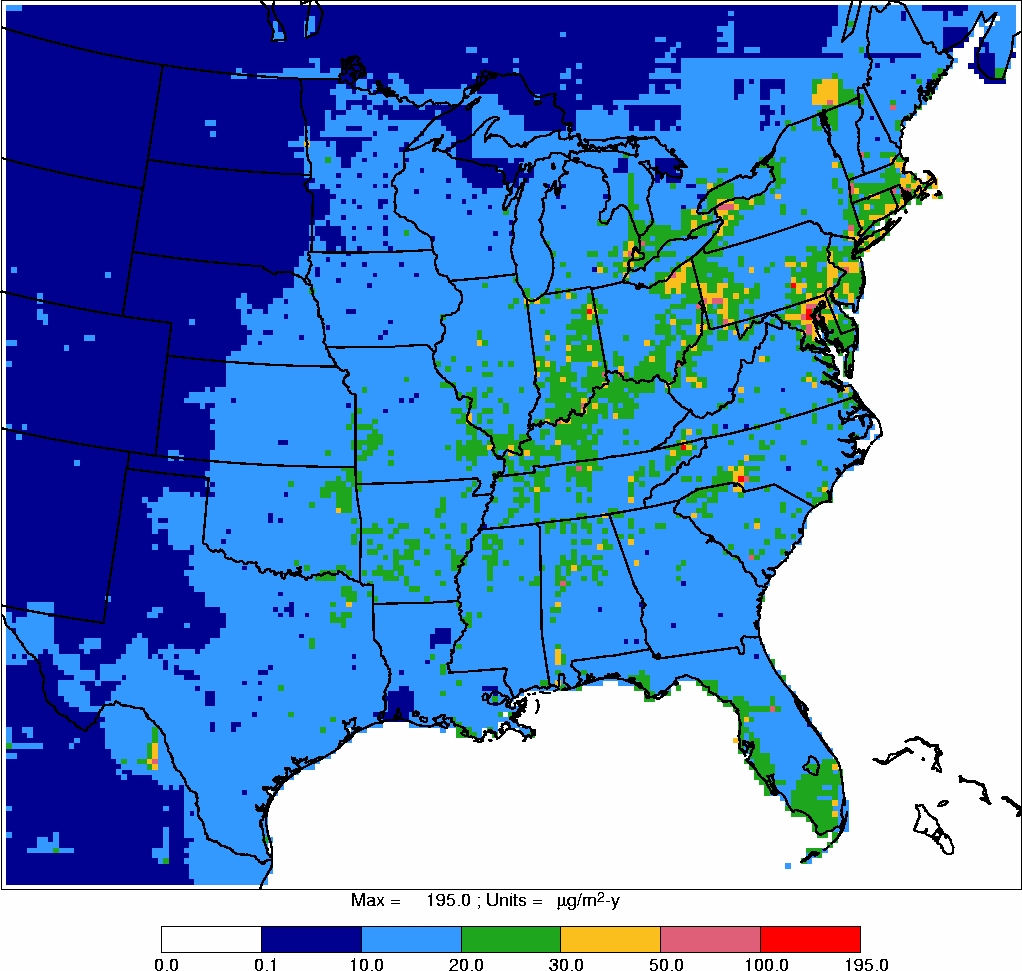

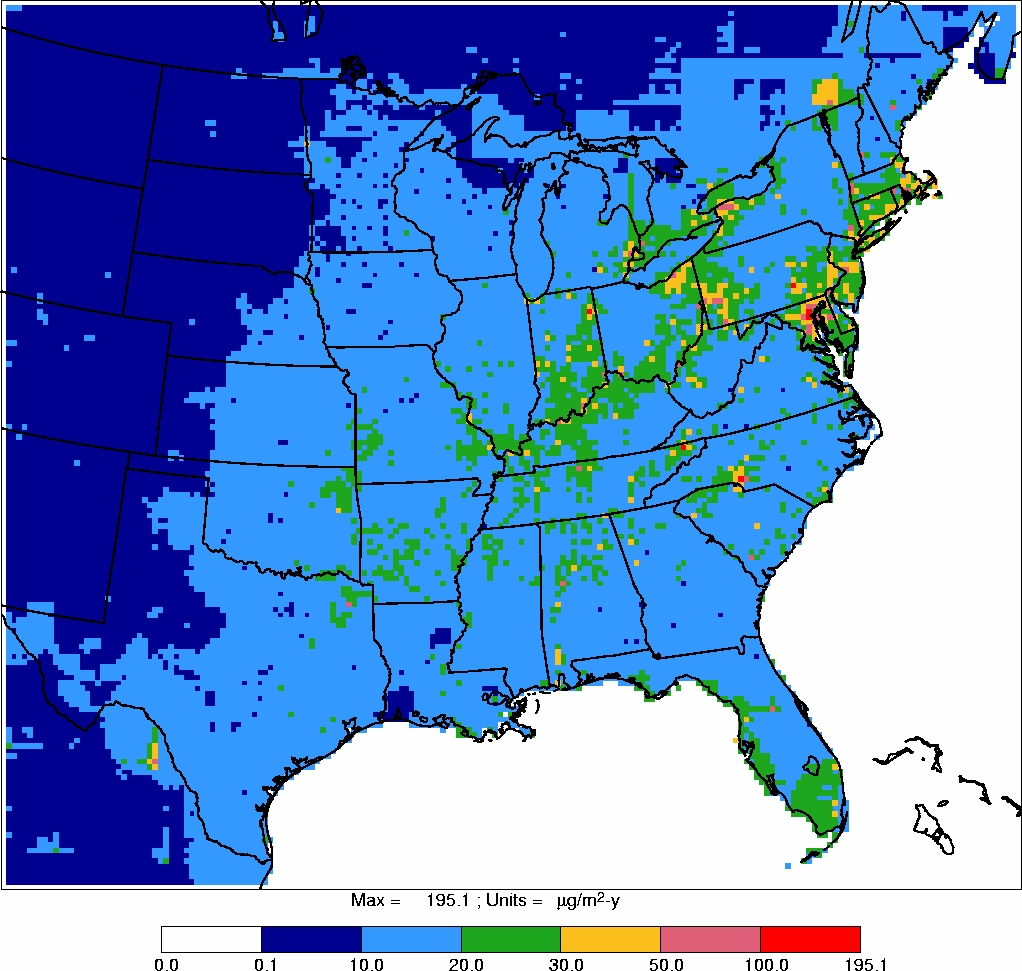

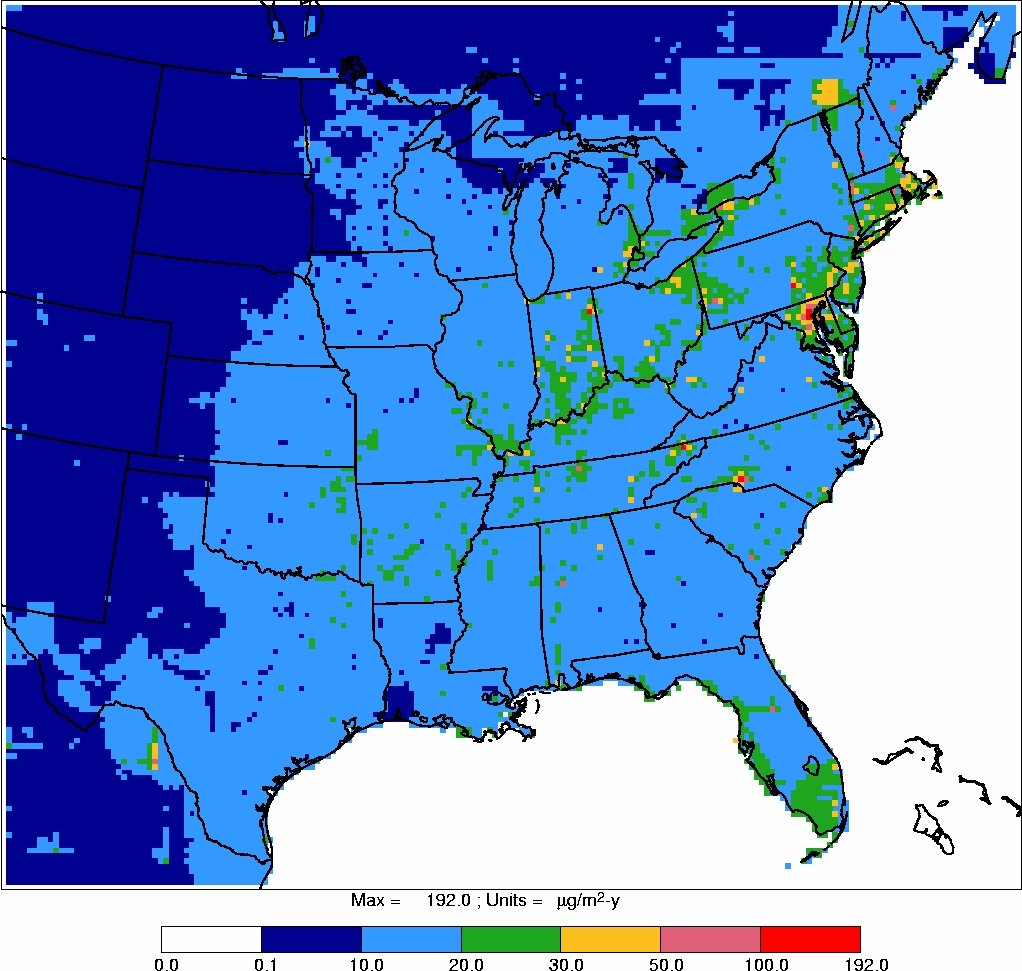

- VI. COMPARISON OF TEAM SIMULATION RESULTS WITH OTHER

- INFORMATION IN THE ILLINOIS PCB RECORD

- Mercury wet deposition in Steubenville, Ohio

- VII. OTHER COMMENTS ON INFORMATION IN THE ILLINOIS PCB

- RECORD

- Receptor-based models

- Meteorological analysis of Dr. Keeler

- Massachusetts analysis

- Florida analysis

- REFERENCES

- Attachment A

- KRISH VIJAYARAGHAVAN

- Atmospheric and Environmental Research, Inc. August 1997 - present

- Aspen Technology, Inc., Cambridge, MA

- I. BACKGROUND AND QUALIFICATIONS

- II. ANALYSIS OF ELECTRICITY MARKET OPERATIONS

- Coal Description Heating Value

- (Btu/lb)

- SO2 Content (lbs/MMBtu)

- Hg Content (lbs/TBtu)

- Coal Type 2006 2008 2009 2010 2013 2015 2018

- Allowance Type 2006 2008 2009 2010 2013 2015 2018

- CERTIFICATE OF SERVICE

- SERVICE LIST

- (R06-25)

- SERVICE LIST

- (R06-25)

|

BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

IN THE MATTER OF:

PROPOSED NEW 35 ILL.ADM.CODE PART 225

CONTROL OF EMISSIONS FROM

LARGE COMBUSTION SOURCES

)

)

)

)

)

PCB R06-25

Rulemaking - Air

NOTICE OF FILING

To:

Dorothy Gunn, Clerk

Illinois Pollution Control Board

James R. Thompson Center

Suite 11-500

100 West Randolph

Chicago, Illinois 60601

Persons included on the

ATTACHED SERVICE LIST

PLEASE TAKE NOTICE that we have today filed with the Office of the Clerk of the

Pollution Control Board the

Testimony

of the following witnesses, copies of which are herewith

served upon you:

Peter M. Chapman, Ph.D.; Gail Charnley, Ph.D., and Attached Exhibits;

J.E. Cichanowicz; William DePriest and Attached Exhibits; James Marchetti; Richard D.

McRanie; Ishwar Prasad Murarka, Ph.D.;

and

Krish Vijayaraghavan

.

/s/

Kathleen C. Bassi

Kathleen C. Bassi

Dated: July 28, 2006

Sheldon A. Zabel

Kathleen C. Bassi

Stephen J. Bonebrake

Joshua R. More

Glenna Gilbert

SCHIFF HARDIN, LLP

6600 Sears Tower

233 South Wacker Drive

Chicago, Illinois 60606

312-258-5500

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE JULY 28, 2006

Page 1

BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

IN THE MATTER OF:

PROPOSED NEW 35 ILL.ADM.CODE PART 225

CONTROL OF EMISSIONS FROM

LARGE COMBUSTION SOURCES

)

)

)

)

)

PCB R06-25

TESTIMONY OF PETER M. CHAPMAN, Ph.D.

Back to top

1.0 Qualifications

My name is Peter M. Chapman. I am an internationally recognized expert in the fields of

aquatic ecology, ecotoxicology, and environmental risk assessment, with particular

expertise and experience in the environmental fate and effects of metals including

mercury. I have published over 150 scientific journal articles and book chapters, written

over 200 technical reports, and made over 100 presentations at scientific meetings. I am

Senior Editor of the international peer-reviewed journal,

Human and Ecological Risk

Assessment

, a member of the Editorial Boards of two other international journals, editor

of a popular, on-going series of scientific discourses, and have held advisory

appointments with the National Research Councils of both Canada and the United States

as well as with the USEPA Science Advisory Board. In 2001 the Society of

Environmental Toxicology and Chemistry (SETAC) awarded me its Founders Award,

their most prestigious award for an outstanding career and contributions to the

environmental sciences. Since 1999 I have been part of the Natural Sciences and

Research Council (NSERC)-funded network of university researchers originally titled

“Metals in the Environment” [www.mite-rn.org] and now titled “Metals in the Holistic

Environment” [www.mithe-rn.org]. My role in the Network is to integrate the work done

by researchers and universities participating in the Network into a risk assessment

framework for decision-making. My specific focus in this regard is metals including

mercury in aquatic ecosystems. My curriculum vita is provided as Attachment 1.

Page 2

2.0 Summary of Testimony

My testimony initially explains what happens to mercury when it is deposited from the

atmosphere or other sources into aquatic environments. I then evaluate the possibility of a

linkage between mercury emissions from coal-fired power plants in Illinois and mercury

in fish in Illinois waters related to lifting impaired water restrictions.

The basis for Illinois EPA’s proposed mercury rule is well summarized in the testimony

of Jim Ross at page 5: "A key concept in understanding the need and methods for

mercury control is that although mercury air emissions are the target for reductions, the

ultimate goal is to reduce methyl mercury levels in water bodies and, hence, fish tissue."

Accordingly, the focus of my testimony is this “key concept”; specifically, my testimony

answers the following two key questions:

Question 1:

Will reducing inorganic mercury emissions from coal-fired power plants in

Illinois under the proposed rule reduce organic (methyl) mercury concentrations in fish

living in water bodies in Illinois to the same extent?

Question 2:

Will reducing inorganic mercury emissions from coal-fired power plants in

Illinois under the proposed rule ensure that impairment restrictions can be lifted for

water bodies where fish have elevated mercury concentrations?

The answer to both of these questions, as my testimony clearly demonstrates, is “No”.

The goal of the proposed rule, as summarized in Marcia Willhite’s written testimony at

page 4 (“In order to assure that 95% of largemouth bass in Illinois waters may be

consumed in unlimited quantities by sensitive subpopulations, a 90% reduction of

mercury in fish tissue is needed”), will not be achieved.

Page 3

3.0 Mercury in the Environment

The relationship between inorganic mercury emissions and organic mercury in the

environment including fish is complex

1

.

For instance, when mercury is emitted from

coal-fired power plants it is as an inorganic substance – typically elemental mercury

(Hg

0

), divalent mercury (Hg

2+

, also termed reactive gaseous mercury, or RGM), and

particulate mercury

2

, and can change form as it travels downwind

3

. Inorganic mercury is

also emitted from a wide variety of other sources including motor vehicles, incinerators,

crematoria, forest fires, deep sea vents, volcanoes, oceans, soils, etc

4

. Although estimates

vary, about half the mercury emitted to the atmosphere is natural, and about half is due to

human activities

5

. All states and countries have some level of mercury emissions; the

greatest current levels of human emissions appear to be from China related to its rapid

industrialization

6

.

Contamination due to mercury is a world-wide problem

7

.

Mercury in the atmosphere can be deposited onto land or water via either dry deposition

(e.g., dust) or wet deposition (e.g., rain, snow)

8

. Wet deposition can result in some forms

of mercury coming down closer to emission sources than others. But mercury deposited

to land or water may not remain there; mercury can be re-emitted back to the atmosphere

where it is transported further. For instance, Dr. Keeler (one of Illinois EPA’s witnesses)

and his co-workers have shown that re-emission of dissolved gaseous mercury from Lake

1

Eisler R. 2006. Mercury Hazards to Living Organisms. Published by Taylor and Francis, Boca Raton, FL,

USA.

2

Marcia Willhite’s verbal testimony on June 14, 2006: at page 32 of the transcript of that testimony.

3

Lohman K, Seigneur C, Edgerton E, Jansen J. 2006. Modeling mercury in power plant plumes. Environ

Sci Technol 40: 3848-54.

4

Eisler 2006, op. cit.; also, written testimony of Gerald Keeler at page 3, indicates that motor vehicle

sources contribute mercury to the atmosphere.

5

USEPA. 2005. Mercury emissions: The global context.

www.epa.gov/mercury/control_emissions/global.htm

; also, Landis MS, Vette AF, Keeler GJ. 2002.

Atmospheric mercury in the Lake Michigan basin: Influence of the Chicago/Gary urban area. Environ Sci

Technol 36: 4508-17.

6

Seigneur C, Vijayarghavan K, Lohman K, Karamchandani P, Scott C. 2004. Global source attribution for

mercury deposited in the United States. Environ Sci Technol 38: 555-69; also, Jiang G-B, Shi J-B, Feng X-

B. 2006. Mercury pollution in China. Environ Sci Technol 40: 3673-8; also, Gerald Keeler’s verbal

testimony on June 15, 2006: at page 17 of the transcript of that testimony.

7

Eisler 2006, op. cit.; also, Gerald Keeler’s verbal testimony on June 15, 2006: at page 17 of the transcript

of that testimony.

8

Dvonch JT, Graney JR, Keeler GJ, Stevens RK. 1999. Use of elemental tracers to source apportion

mercury in south Florida precipitation. Environ Sci Technol 33: 4522-7.

Page 4

Michigan is a process that significantly reduces net atmospheric deposition

9

. In fact, Dr.

Keeler in testimony before the U.S. House of Representatives stated, “…previously

deposited mercury can also undergo chemical transformations that convert it back to the

elemental form that readily leaves the earth’s surface (land and water) to re-enter the

global background of mercury”

10

. Similarly, Illinois EPA’s Technical Support Document

(the “TSD”) mentions mercury volatilizing from water back into the atmosphere. Thus,

once mercury enters the atmosphere, it becomes part of a global cycle of mercury

among land, water, and the atmosphere; past activities continue to affect current

atmospheric mercury concentrations

11

.

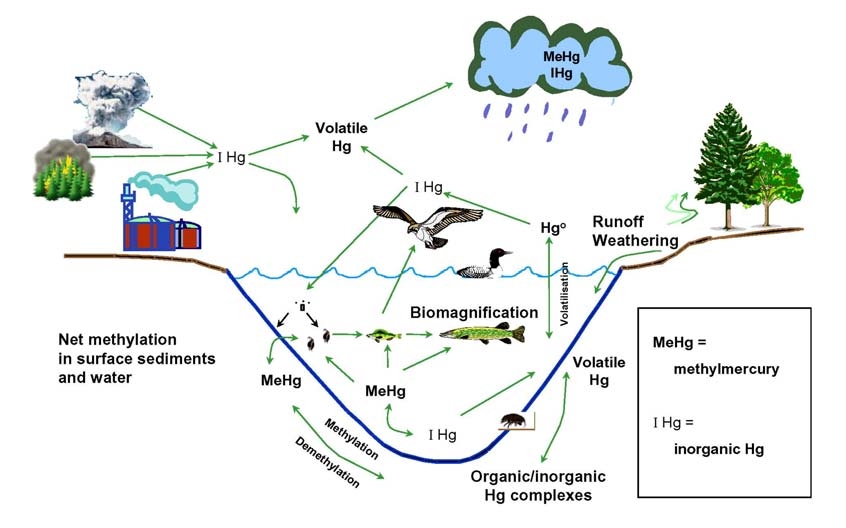

The inorganic mercury that remains in water bodies (either from the atmosphere or from

other sources) can undergo different biological and physico-chemical processes (Figure

1). The mercury cycle is a complex biogeochemical system involving both biotic and

abiotic transformations of the different forms of mercury. Inorganic mercury species that

are not reduced to form gaseous elemental mercury have an affinity for particulates and

organic matter and thus will tend, if not re-emitted, to sink down to and accumulate in the

sediments. The sediments of water bodies thus serve as both a sink and a reservoir for

mercury contamination. They can also be a source of potential mercury pollution

12

.

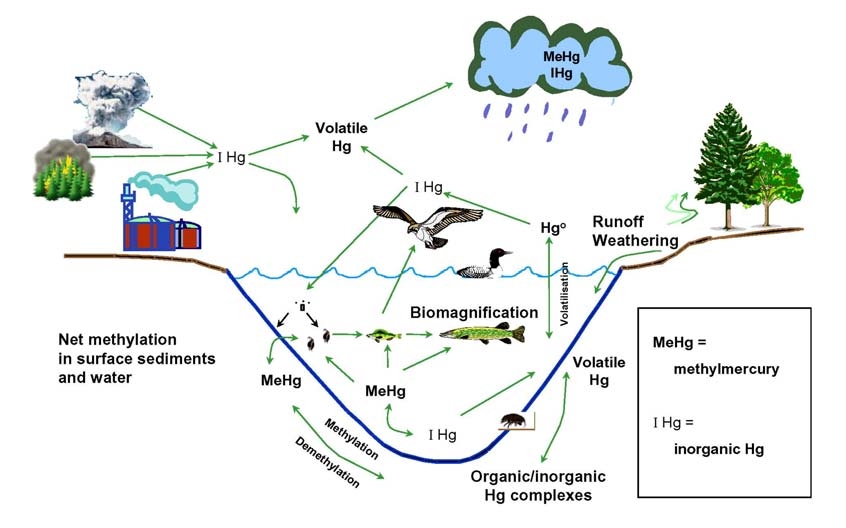

Although most inorganic mercury remains in this form in the sediments, a portion

13

of

that mercury can be converted to an organic form of mercury, methyl mercury. This

conversion occurs primarily by metabolism within sulphate- and iron-reducing bacteria

living in anaerobic sediments, i.e., sediments without oxygen

14

. Mercury methylation

9

Landis MS, Keeler GJ. 2002. Atmospheric mercury deposition to Lake Michigan during the Lake

Michigan mass balance study. Environ Sci Technol 36: 4518-24; Vette AF, Landis MS, Keeler GJ. 2002.

Deposition and emission of gaseous mercury to and from Lake Michigan during the Lake Michigan mass

balance study (July, 1994 – October, 1995). Environ Sci Technol 36: 4525-32.

10

Keeler GJ. 2001. The problem of mercury. Testimony for the U.S. House of Representatives Committee

on Science Hearing on Acid Rain: The State of the Science and Research Needs for the Future. May 3,

2001.

11

Eisler 2006, op. cit.

12

Eisler 2006, op. cit.

13

Marcia Willhite’s verbal testimony on June 14, 2006 states “it has been estimated that .7 to .0006 percent

of total mercury in sediment is methylmercury”: at page 40 of the transcript of that testimony.

14

Fleming EJ, Mack EE, Green PG, Nelson DC. 2006. Mercury methylation from unexpected sources:

Molybdate-inhibited freshwater sediments and an iron-reducing bacterium. Appl Environ Microbiol 72:

457-64; also, Jeremiason JD, Engstrom DR, Swain EB, Nater EA, Johnson BM, Almendinger JE, Monson

Page 5

generally cannot occur in aerobic (oxygenated) environments; in the water column it can

occur only when conditions are anoxic (there is no oxygen). Methyl mercury production

occurs not just in recently deposited surface sediments but also in much older, deeper

sediments where the mercury was deposited decades previously, even though “old”

inorganic mercury in sediments tends to be less biologically available than “new”

inorganic mercury in sediments

15

. Methyl mercury from these deeper sediments can reach

organisms living in shallower sediments by a process called diagenesis, which typically

occurs in sediments with low organic carbon content. There is a depth beyond which,

absent unusual disturbances, the mercury in the sediments will not reach animals or

plants, but burial to such a depth is typically a slow process under natural conditions. As

noted in the Florida study there is “slow mobilization of historically deposited mercury

from deeper sediment layers to the water column. Until buried below the active zone, this

mercury can continue to cycle through the system”

16

. Thus, even when emissions of

inorganic mercury are reduced, there will be a substantial lag phase before emission

reductions can result in reductions in methyl mercury concentrations in fish.

Production of methyl mercury in sediments is not a readily predictable process and can

be highly variable between water bodies

17

(Table 1). There is not a 1:1 relationship

between inorganic mercury released to the atmosphere and deposited in water bodies and

the level of methyl mercury found in water bodies and fish tissue. For instance, methyl

mercury produced in water bodies from inorganic mercury deposition can be augmented

by direct precipitation of methyl mercury from other sources, including: the atmosphere,

runoff from land, or inputs from other water bodies such as wetlands

18

.

BA, Kolka RK. 2006. Sulfate addition increases methylmercury production in an experimental wetland.

Environ Sci Technol 40: 3800-6.

15

Fleming et al. 2006, op. cit.

16

Florida Dept of Environmental Protection. 2003. Integrating atmospheric mercury deposition with

aquatic cycling in South Florida: An approach for conducting a total maximum daily load analysis for an

atmospherically derived pollutant: at page iii.

17

Marcia Willhite’s verbal testimony on June 14, 2006 notes that the characteristics that impact mercury

methylation are water body specific, can differ between water bodies, and that mercury methylation is

highly dependent on water chemistry and biology, in particular pH, dissolved oxygen, dissolved organic

carbon, nutrients, selenium concentrations, temperature, sulphate concentrations, drainage size to lake

volume ratio, percentage of wetland and watershed, conductivity and water level flucturations: at pages 45

to 47 of the transcript of that testimony. She made similar comments elsewhere in her verbal testimony:

e.g., at page 37 of the transcript of that testimony.

18

Eisler 2006, op. cit.

Page 6

Table 1

Example of Physico-Chemical Processes Affecting Mercury Methylation

19

Physico-Chemical Condition

Methylation

Enhanced

↑

Decreased

↓

Low dissolved oxygen

Yes

Low pH

Yes

(in water)

Yes

(in sediment)

Increased dissolved organic carbon

Yes

(in sediment)

Yes

(in water)

Increased conductivity or salinity

Yes

Increased nutrients

Yes

Increased selenium

Yes

Increased temperature

Yes

Increased sulphate or sulphide

Yes

Point and non-point source discharges continue to contribute mercury to water bodies.

For example, Marcia Willhite notes at page 144 of the transcript of her June 14, 2006

verbal testimony, that runoff may be a significant source of mercury in southern Illinois.

Interestingly, at page 118 of the transcript of that same testimony, Ms Willhite notes that

historical data suggest that the levels of mercury in fish are higher than expected in

waters in the far southern end of the State.

The TSD indicates (at pages 68 and 69, including Table 4.7) that, at “maximum”

discharge levels, the 137 wastewater point sources in Illinois would discharge

approximately 1.5 tons of mercury per year compared to 45 pounds at an “average”

discharge level. Marcia Willhite confirmed in her testimony (June 14, 2006, at pages 288-

290 of the transcript) that the “maximum” load or discharge level was based on actual

measured maximum flow and maximum mercury concentrations in the flow, which

would comprise approximately 1.5 tons, or about half of the mercury air emissions from

coal-fired power plants as indicated in the TSD (3 tons at page 60). Other un-measured

sources of mercury exist including combined sewer overflows, which Illinois EPA does

not sample for mercury but which contain mercury

20

. Thus other local sources of mercury

19

Developed based on information contained in Eisler 2006, op. cit.

20

Available data on mercury related to combined sewer overflow discharges for the Metropolitan Water

Reclamation District of Greater Chicago reviewed by Dr. Chapman suggest that inputs can be on the order

of tens of pounds per year.

Page 7

(as well as sources outside the State) will have inputs to different water bodies that likely

are, in some cases, greater than those from coal-fired power plants.

Similarly, production of methyl mercury in the sediments of water bodies is governed by:

microbial community composition, geochemical conditions that affect the activity of

methylating bacteria (e.g., availability of carbon, abundance of electron acceptors such as

sulphate), and availability of inorganic mercury in a suitable (bioavailable) form for

methylation. Availability of carbon and the cycling of sulphur are major constraints on

the process of mercury methylation. For instance, although sulphate is essential for the

methylation process, excessive amounts of sulphate can actually poison the mercury

methylation process by limiting the availability of mercury to methylating bacteria. The

key Florida study cited in the TSD notes, “Sulfate is an important influence on the

production of methylmercury, affecting not only mercury transformations, but also the

biological availability of mercury for uptake….[sulphate] is an important cofactor

controlling the severity of the mercury problem at any given site”

21

. Methyl mercury

concentrations in fresh water bodies in the U.S. may have increased historically due to

increases in atmospheric sulphate deposition.

Decreases in sulphate deposition alone,

with no change in mercury inputs, could result in lower methyl mercury levels in

freshwater fish

22

. It is thus entirely possible that reductions in sulphate deposition rates

resulting from the Acid Deposition Program were at least partly responsible for decreased

methyl mercury concentrations seen, for instance, in Massachusetts from 1999 to 2004.

In addition, demethylation can occur in sediments (Figure 2), also mediated by naturally

occurring microbes – possibly as a defense against mercury toxicity

23

. In most, but not all

anaerobic systems, mercury methylation rates are greater than demethylation rates.

However,

methyl mercury concentrations and production rates vary more than do

inorganic mercury deposition rates

. For instance, a simple change in bacterial activity

alone could “cause an increase in fish mercury concentrations even as atmospheric

21

Florida Dept of Environmental Protection 2003, op. cit., at page vi.

22

Jeremiason et al. 2006, op. cit.

23

Eisler 2006, op. cit.

Page 8

deposition [from industrial mercury emissions] decreases”

24

. Thus there can be, for

instance, freshwater systems containing relatively high concentrations of inorganic

mercury but relatively low concentrations of methyl mercury because conditions are

either less than optimum for mercury methylation, or demethylation is the predominant

process. And the reverse can also occur. Thus, it is not surprising that the TSD reports

that Illinois lakes with the highest mercury concentrations were not the same lakes as had

fish with the highest mercury concentrations.

When the organic form of mercury, methyl mercury, is present in a water body, this

organic form can biomagnify through food chains via the diet. Biomagnification is the

process by which a few organic chemicals (methyl mercury is one, PCBs are another)

increase in concentrations through successive levels of the food chain as a result of

dietary uptake. Fish absorb methyl mercury when they eat smaller aquatic organisms.

Larger and older fish absorb more methyl mercury as they eat other fish. Aside from the

concentrations of methyl mercury in the water body and sediment, which depend on the

factors discussed above, the level of mercury contamination in fish can be affected by

factors such as changing water levels

25

and dissolved organic matter

26

. In this way, the

amount of methyl mercury builds up as it passes through the food chain. Methyl mercury

generally reaches the highest levels in predatory (piscivorous [fish-eating]) fish at the top

of the aquatic food chain.

Some of the highest recorded mercury levels found in fish are in marine fish such as tuna

and swordfish, which are commonly found in supermarkets in Illinois

27

. Mercury levels

are also higher in older than in younger fish because older fish have had more time to

accumulate higher levels of mercury. In fresh water environments piscivorous fish such

as walleye and northern pike, found at the top of the food chain, tend to have the highest

24

Mason RP, Abbott ML, Bodaly RA, Bullock OR Jr, Driscoll CT, Evers D, Lindberg SE, Murray M,

Swain EB. 2005. Monitoring the response to changing mercury deposition. Environ Sci Technol 39: 14A-

21A.

25

Sorensen JA, Kallemeyn LW, Sydor M. 2005. Relationship between mercury accumulation in young-of-

the-year yellow perch and water-level fluctuations. Environ Sci Technol 39: 9237-43.

26

Ravichandran M. 2004. Interactions between mercury and dissolved organic matter – a review.

Chemosphere 55: 319-31.

27

Burger J, Gochfeld M. 2006. Mercury in fish available in supermarkets in Illinois: Are there regional

differences. Sci Total Environment: in press.

Page 9

mercury levels in their tissues. Most of the mercury in fish is in the form of methyl

mercury, which can be excreted by fish, but more slowly than inorganic mercury. Thus, if

fish are not exposed to new sources of methyl mercury in their diet they will begin to rid

themselves of the methyl mercury in their bodies. This is not a fast process, but it does

occur faster at higher temperatures than at lower temperatures

28

.

4.0 Mercury in Illinois Water Bodies and Fish

As noted at page 61 of the TDS “Mercury TMDLs are complicated. The mechanisms

controlling mercury accumulation in fish tissue are variable and difficult to model,

resulting in questionable values…sources may be outside the watershed, state or nation.”

However, the key issue related to the proposed rule is, as previously noted, the

relationship between inorganic mercury emitted from coal-fired power plants in Illinois

and organic (methyl) mercury in fish in Illinois waters.

As noted above, the pathway for inorganic mercury from the power plants reaching the

fish would be via atmospheric deposition into water bodies containing those fish. The

mercury would then have to accumulate in the sediments where some of it would be

transformed into the organic (methylated) form which would then accumulate in fish via

dietary uptake. Further, to have any possible health impact on an Illinois resident, that

resident would need to eat such fish. Whether or not consumption of fish with elevated

mercury concentrations will impact the health of human consumers requires

consideration of factors including the protective effects of selenium in tissues

29

.

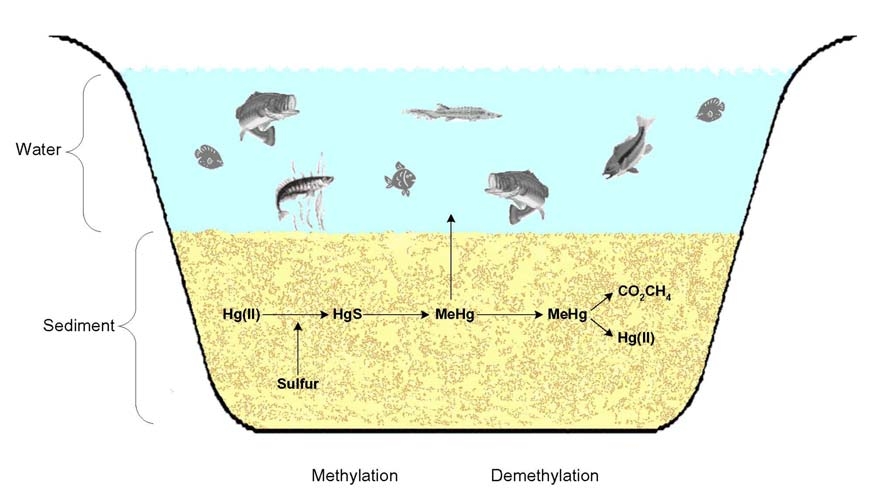

The relationship between the power plant mercury emissions and mercury in fish in

Illinois can be assessed using two key pieces of information: sediment mercury data, and

fish mercury data. To obtain this information, Illinois mercury sediment and fish tissue

data for the past 30 years were downloaded from the USEPA’s STORET data base. The

specific focus was on waters where fish had total mercury concentrations above threshold

values of 0.1 and 0.23 ppm (mg/kg wet weight). The State of Illinois uses an initial

28

Eisler 2006, op. cit.

29

Raymond LJ, Ralston NVC. 2004. Mercury:selenium interactions and health implications. Seychelles

Med Dental J 7: 72-7.

Page 10

threshold value of 0.06 ppm for advising no more than one meal per week of fish (range

of 0.06 to 0.22 ppm); however, because this value has been close to or below the

detection limits used by some chemical analytical laboratories, a value of 0.1 ppm was

used to provide more dependable data for comparison purposes

30

. Fish mercury values of

0.23 ppm and above are subject to the special mercury advisory

31

. Tables 2 and 3

summarize these data, and Figures 3 and 4 present these data in graphical form. The

mercury sediment concentrations were at times both higher and lower than the fish

concentrations.

Thus, there is no consistent relationship between total mercury

concentrations in sediments and mercury concentrations (primarily methyl mercury) in

fish tissues of impaired waters.

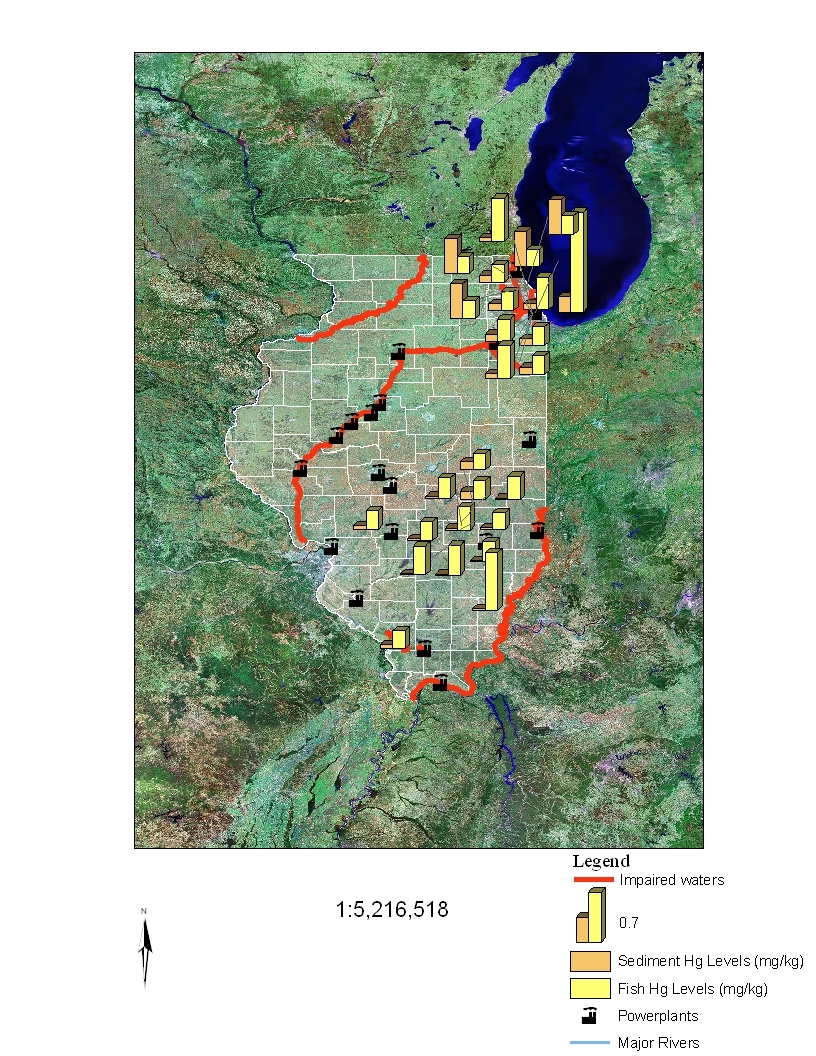

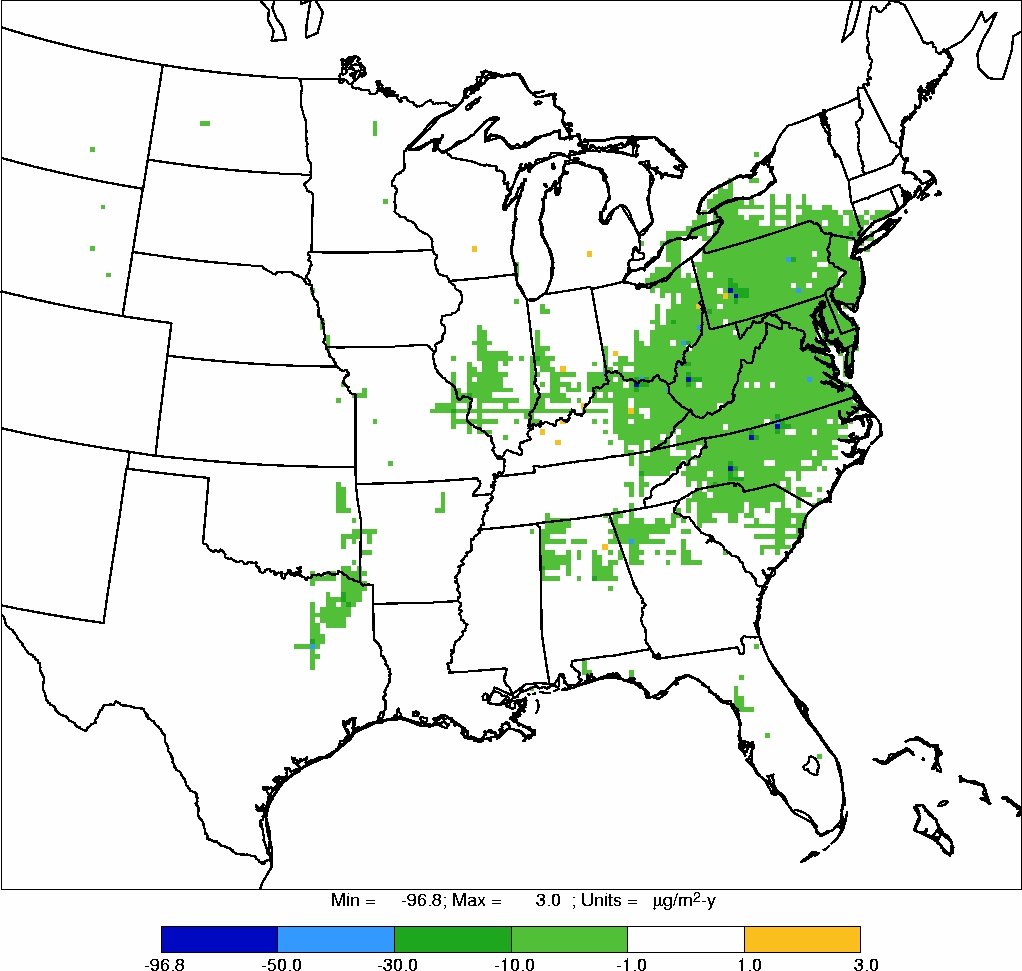

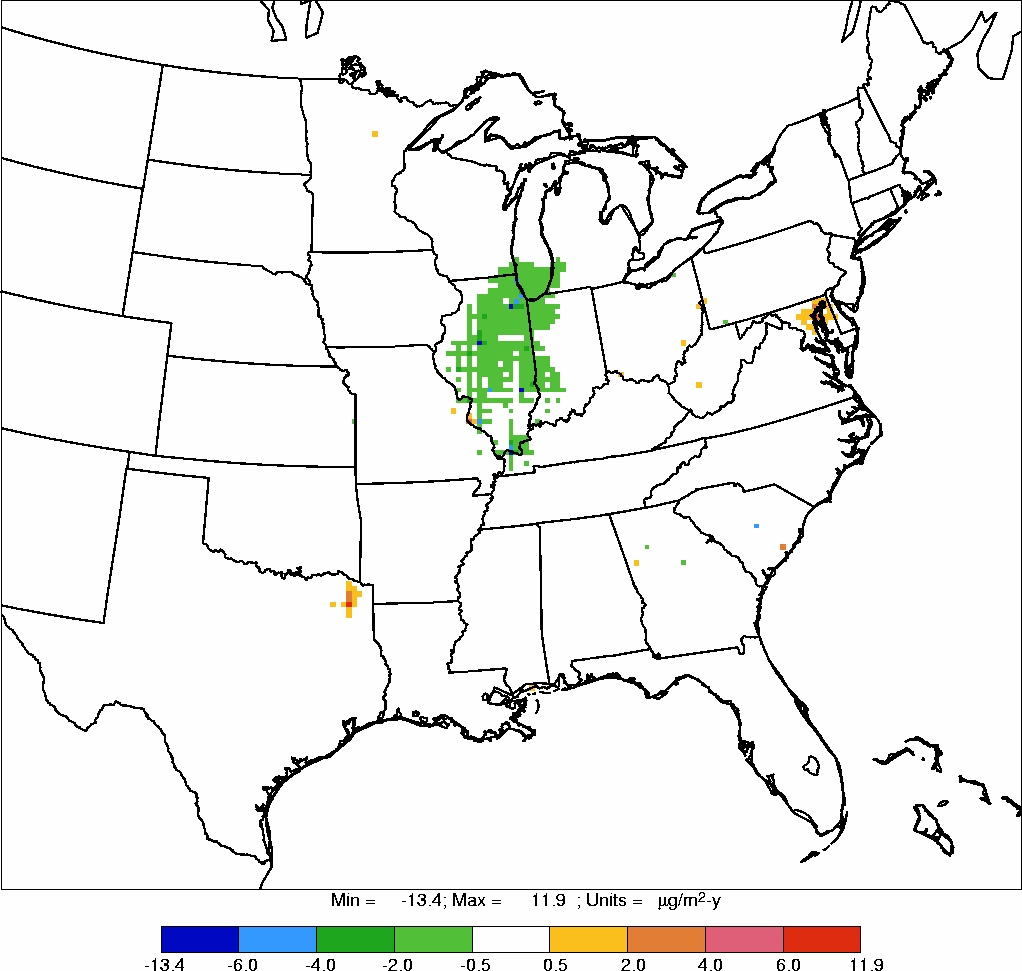

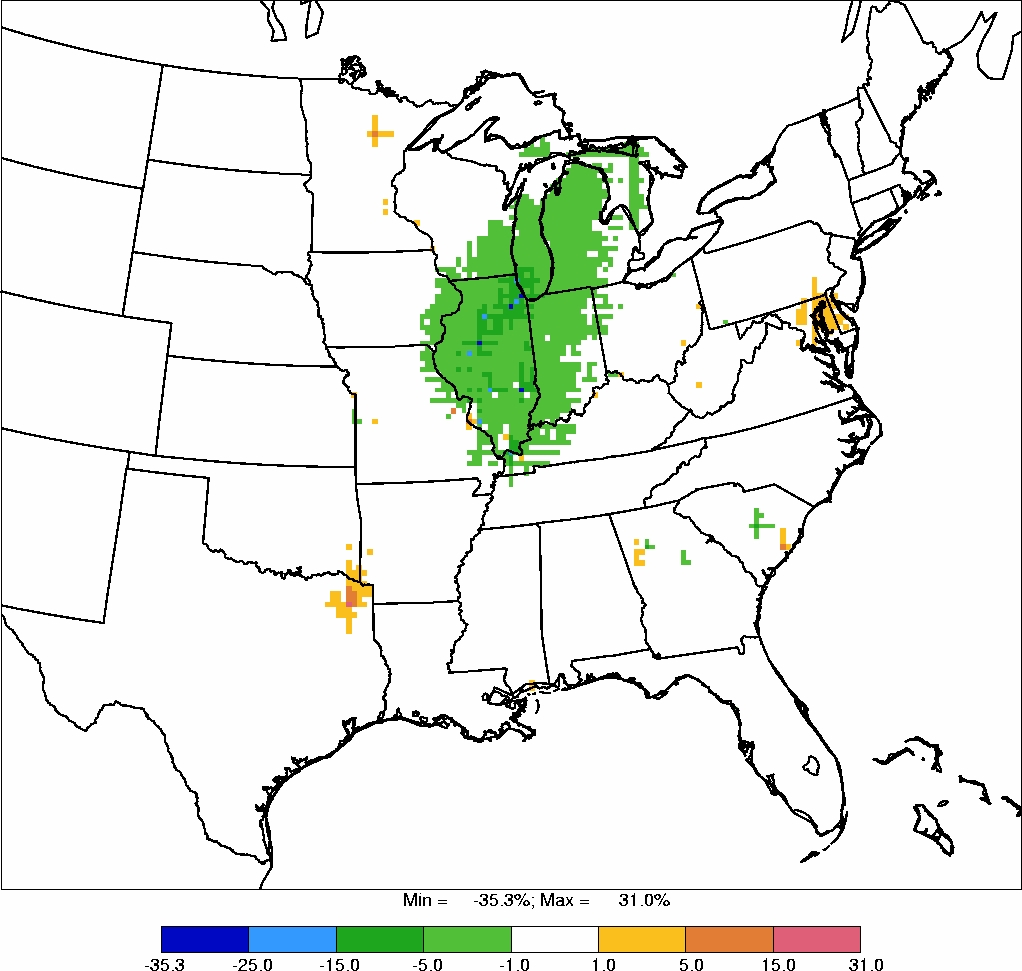

Power plant locations and Illinois impaired waters are also shown in Figures 2 and 3.

Exceedances of 0.1 and 0.23 ppm total mercury levels in fish were not always found at

sites in close proximity to power plants, nor were impaired waters always associated with

power plants. Moreover, given that the winds in Illinois are primarily south, southwest

and north, northwest in the winter

32

, emissions from power plants do not appear to be

responsible for all waters in Illinois impaired due to mercury (e.g., Rock River). Thus,

there is no clear and consistent relationship between Illinois coal-fired power plants

and methyl mercury concentrations in fish in Illinois waters.

This finding is not

unexpected given the complexity of the global mercury cycle. Although there is no

question that coal-fired power plants are significant sources of mercury to the

atmosphere, they are not the largest sources of mercury deposited in Illinois

33

. These

emissions cannot be directly related to mercury concentrations in fish collected from

30

Illinois EPA, in the TSD, assumes that if mercury is not detected, it is present at 50% of the detection

limits [cf Marcia Willhite’s verbal testimony of June 14, 2006: e.g., at pages 84-85 and pages 158-160 of

the transcript of that testimony]. However, this practice is questionable given that it means that mercury is

assumed to be present when it may not be. Better methods exist for dealing with values below detection

limits: e.g., Shumway RN, Azari RS, Kayhanian M. 2002. Statistical approaches to estimating mean water

quality concentrations with detection limits. Environ Sci Technol 36: 3345-53; also, Helsel DR. 2005.

More than obvious: Better methods for interpreting nondetect data. Environ Sci Technol October 15, 2005:

419A-23A.

31

Clarification regarding the 0.06 and 0.23 ppm mercury values was provided by Dr. Hornshaw in verbal

testimony on June 14, 2006: at pages 25 and 26 of the transcript of that testimony.

32

Gerald Keeler’s verbal testimony of June 15, 2006: at page 32 of the transcript of that testimony.

33

K Vijayaraghavan in his testimony at page 7 estimates “U.S. coal-fired power plants are calculated to

contribute 19% of mercury deposition in Illinois in 2006.”; also, see Section 3.0, page 4 of the present

document (Testimony of Peter M. Chapman)

Page 11

nearby water bodies. Further, Illinois’ proposed rule would only result in a 4% reduction

in depositions in Illinois from Illinois coal-fired power plant mercury emissions

compared to the CAMR

34

, which would likely not result in a measurable decrease in

mercury concentrations in fish in Illinois water bodies compared to the CAMR. As noted

at page 3 of Gerald Keeler’s testimony, “The relationship between the emissions of

mercury to the atmosphere from any one plant and the amount received at any receptor is

complex.” Interestingly, as noted by Thomas Hornshaw in his verbal testimony of

June 16, 2006 (at pages 84-85 of the transcript), Illinois fish tissue mercury levels are

lower than in some other Great Lakes States.

The discussion above explains the “no” answer to Question 1 (Section 2.0). The

discussion below explains the “no” answer to Question 2 (Section 2.0).

The Illinois 2004 Section 303(d) List

35

was reviewed, to identify water bodies considered

impaired by the State due to mercury and/or PCB concentrations. Table 4

36

summarizes

these sites, listing water body name, site name, and whether the site is impaired due to

levels of mercury and/or PCBs. Fifty-five of the 74 sites (74%) in Illinois listed as

impaired due to mercury would continue to be impaired even if full compliance with the

proposed rule were achieved and the projected fish mercury reductions were achieved.

The presence of PCBs renders the proposed rule ineffective at removing impairment

restrictions. Thus, even if fish mercury levels were to drop below the State mercury

threshold for impaired waters, which is highly unlikely as noted previously, the

classification of these sites as impaired would not change.

5.0 Florida, Massachusetts and Ohio Studies: Relevance to Illinois

We have found no published studies that specifically evaluate coal-fired power plant

mercury emissions and trends in methyl mercury levels in fish. The TSD relies on data

from Florida and Massachusetts to support its conclusion that reducing local coal-fired

power plant inorganic mercury emissions will similarly reduce local fish methyl mercury

34

Testimony of K. Vijayaraghavan at page 7.

35

Illinois Environmental Protection Agency, IEPA/BOW/04-005.

36

Source: Appendix A of the IEPA 2004 document.

Page 12

levels. A study in Ohio is also mentioned in testimony by IEPA witness Dr. Keeler,

however complete details of this study (i.e., the full report) have not been provided by

Dr. Keeler.

As noted in the TSD, Massachusetts has implemented mercury reduction programs, but

has not specifically focused on coal-fired power plants. The Massachusetts study

37

monitored mercury concentrations in Largemouth bass (LMB) and yellow perch (YP)

from 1999 to 2004. The authors noted at page viii that “Over this period consistent and

substantial statistically significant decreases in YP and LMB fish tissue mercury

concentrations occurred in most lakes sampled.” However, decreases did not occur in all

lakes (about 24% showed no decreases for YP and about 35% showed no decreases for

LMB), the level of decrease was variable, and there were some inconsistencies (e.g., at

page 7, “an apparent large temporal increase in tissue mercury concentrations between

1999 and 2004” in one lake and “a slight increase over the 1999 value” for 2004 fish

tissue data from another lake). It was estimated (at page viii) that mercury emissions in

the main deposition area identified in the TSD “decreased by about 87% between the late

1990’s and 2004 due to new pollution controls on municipal solid waste combustors

(MSWC) and the closure of medical waste incinerators (MWIs) and a MSWC in the

area.” But there was far from a 1:1 relationship between decreased emissions and

decreased methyl mercury concentrations in fish; in fact, the Massachusetts study

38

concluded that “…significant reductions from out-of-state mercury sources will likely be

needed to achieve water quality and public health objectives in Massachusetts.” The page

and a half in the TSD dedicated to the Massachusetts study provides an overly simplified

summary of this complex study, as does Marcia Willhite’s testimony.

Similarly, the TSD does not deal fully with the Florida study, which is a modeling study

that makes predictions that do not appear to be supported by available data. Marcia

Willhite, in her testimony, also simplifies the findings of the Florida study. Just a few of

37

Massachusetts Dept of Environmental Protection. 2006. Massachusetts Fish Tissue Mercury Studies:

Long-Term Monitoring Results, 1999-2004.

38

Massachusetts Dept of Environmental Protection. 2006. op. cit., at page viii.

Page 13

the caveats noted at page v of the Florida study report include

39

: the major assumption

that all mercury deposited via wet deposition was from local sources which cannot be the

case given global cycling of mercury; the acknowledgment that mercury cycling cannot

yet be fully modelled; and the fact that different areas might respond differently due to

site-specific differences (e.g., different habitat, food web dynamics and water quality). Of

note, Figure 5.7 in the TSD is labeled “Relation between Atmospheric Mercury Load and

Body Burden in Largemouth Bass”, whereas in the original Florida study (Figure 9, at

page 40) it is labelled “Predicted Hg concentrations in age 3 largemouth bass as a

function of different long term constant annual rates of wet and dry Hg(II) deposition.”

The fact this is a prediction rather than reality is not mentioned in the TSD.

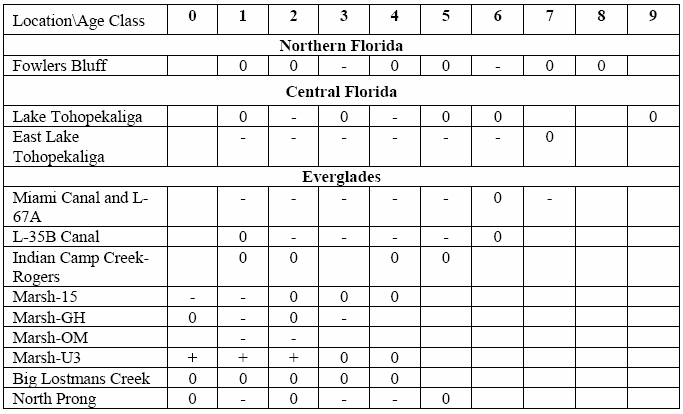

The actual field data reported in the Florida study do show some correlations between

reducing emissions and decreases in methyl mercury concentrations in some biota at

some locations, which is not unexpected. However, the actual data do not show a 1:1

relationship and in some locations show no correlation, which is also not surprising given

the simplifications made by the model which the authors of the Florida study

acknowledge but which the TSD does not mention. There are several examples in the

Florida study of differences between the 1:1 prediction and the reality. For example,

although emissions showed a declining trend from 1994 to 2000, mercury wet deposition

for this same time period remained relatively constant (Figure 24 at page 81 of the

Florida study report). The Florida study report at pages 81-82 assessed trends in mercury

concentrations in biota based on levels in Largemouth bass from 12 sites across Florida, 9

of which were in the Everglades and at least 3 of which were in the study area. There

were enough data in only a little over half of the available data sets to conduct statistical

tests for significance. The two sites with the most consistent declines are shown in the

TSD (Figure 5.5, basically the same figure as Figure 25, at page 83 in the Florida study

report). What is not mentioned in the TSD is that there were also examples of no declines

as well as of increases in fish methyl mercury concentrations. In fact, as noted in the

Florida study report (at page 81) and as confirmed by Gerald Keeler in his verbal

testimony on June 15, 2006 (at page 13 of the transcript), about half the cohorts in the

39

Florida Dept of Environmental Protection, op. cit.

Page 14

study area showed no change. The “bottom line” is that, although the Florida modeling

suggests a 1:1 relationship between inorganic mercury emissions and methyl mercury

concentrations in fish, this relationship is not supported by actual data and, given the

simplifications inherent in the model, is highly unlikely to reflect the “real-life” situation.

6.0 Conclusions

At the start of my testimony (Section 2.0) I asked and answered “no” to two key

questions, below:

Question 1:

Will reducing inorganic mercury emissions from coal-fired power plants in

Illinois under the proposed rule reduce organic (methyl) mercury concentrations in fish

living in water bodies in Illinois to the same extent?

Question 2:

Will reducing inorganic mercury emissions from coal-fired power plants in

Illinois under the proposed rule ensure that impairment restrictions can be lifted for

water bodies where fish have elevated mercury concentrations?

The reasons for my answers follow from my detailed testimony above. Reducing

inorganic mercury emissions from coal-fired power plants will result in a decreased level

of inorganic mercury deposition. However, even if reductions in mercury depositions

were to occur in Illinois, reductions in methyl mercury concentrations in local fish will

not occur to the same level as the emission reductions. Mercury is a global problem, not

just a local problem, and the pathways from inorganic mercury emissions to methyl

mercury in fish are complex and governed by site-specific differences that are not readily

predictable

40

. Generalizations such as a 1:1 relationship do not reflect reality.

The

amount of methyl mercury in fish is site specific, as confirmed by Marcia Willhite (see

footnote 18), and is not related simply to the amount of inorganic mercury that is

deposited to a water body.

Moreover, even if mercury levels in Illinois water bodies were

reduced below levels of potential concern, elevated levels of PCBs would still result in an

“impaired” designation for the vast majority of those water bodies.

40

Eisler 2006, op. cit.

Page 15

The goal of the proposed rule, as summarized in Marcia Willhite’s written testimony at

page 4 (“In order to assure that 95% of largemouth bass in Illinois waters may be

consumed in unlimited quantities by sensitive subpopulations, a 90% reduction of

mercury in fish tissue is needed”), will not be achieved.

Page 16

Table 2

Relationship between total mercury concentrations in sediments (mg/kg dry weight) and

fish tissues (mg/kg wet weight). Source: USEPA’s STORET data base. Values represent

sites with fish tissue mercury levels at or above 0.1 mg/kg wet weight. Fish data for the

year referenced; sediment data for samples collected within a 5-year period of the fish

tissue data collection date (2.5 years before and after the date of the tissue collection)

.

Sediment values shown are an average sediment concentration of these 5 years.

County

Total Mercury in Fish Tissue

(mg/kg wet weight)

Total Mercury in

Sediments (mg/kg dry

weight)

Year Fish Data Collected

Jackson

0.185

0.052

1986

Jackson

0.15

0.052

1990

Jackson

0.167

0.115

1988

Jackson

0.167

0.077

1988

Fayette

0.184

0.03

1978

Fayette

0.184

0.04

1978

Fayette

0.13

0.04

1979

Fayette

0.1

0.03

1980

Fayette

0.1

0.035

1980

Fayette

0.205

0.03

1981

Fayette

0.205

0.04

1981

Fayette

0.205

0.035

1981

Fayette

0.205

0.035

1981

Fayette

0.1

0.035

1983

Macoupin

0.26

0.048

1990

Coles

0.21

0.1

1991

Coles

0.1

0.1

1991

Champaign

0.16

0.215

1981

Kankakee

0.12

0.04

1978

Kankakee

0.12

0.05

1978

Kankakee

0.14

0.53

1988

Kankakee

0.14

0.08

1988

Henry

0.22

0.055

1981

La Salle

0.13

0.14

1988

La Salle

0.12

0.029

1990

Henry

0.143

0.037

1978

Henry

0.143

0.03

1978

Cook

0.15

0.331

1974

Cook

0.47

0.061

1990

Cook

0.47

0.1

1990

Cook

0.273

0.1

1991

Cook

0.1

0.221

1990

Cook

0.46

0.091

1991

Cook

0.19

0.49

1981

Page 17

Table 3

Relationship between total mercury concentrations in sediments (mg/kg dry weight) and

fish tissues (mg/kg wet weight). Source: USEPA’s STORET data base. Values represent

sites with fish tissue mercury levels at or above 0.23 mg/kg wet weight. Fish data for the

year referenced; sediment data for samples collected within a 5-year period of the fish

tissue data collection date (2.5 years before and after the date of the tissue collection)

.

Sediment values shown are an average sediment concentration of these 5 years.

COUNTY

Total Mercury in

Sediments (mg/kg

dry weight)

Total Mercury in

Fish Tissue

(mg/kg wet

weight)

Year Fish Data

Collected

Coles

0.113

0.23

1979

Coles

0.113

0.26

1979

Cook

0.49

0.24

1981

Cook

0.49

0.25

1981

Cook

0.49

0.27

1981

Cook

0.49

0.23

1981

Cook

0.061

0.61

1988

Cook

0.074

0.47

1990

Cook

0.1

0.26

1991

Cook

0.1

0.25

1992

Cook

0.1

0.31

1991

Cook

0.1

0.27

1992

Cook

0.221

1.4

1988

Cook

0.091

0.46

1991

Du Page

0.1

0.27

1998

Effingham

0.016

0.4

1989

Effingham

0.018

0.33

1989

Effingham

0.023

0.23

1989

Effingham

0.027

0.29

1989

Effingham

0.029

0.33

1989

Fayette

0.035

0.27

1978

Jackson

0.052

0.25

1986

Macoupin

0.048

0.26

1990

Clay

0.016

0.42

1989

Clay

0.024

0.81

1989

Clay

0.012

0.28

1989

Page 18

Table 4

Summary of current information on waters listed as impaired due to mercury, PCBs, or both as

documented in Appendix A of the Illinois 2004 303(d) List (IEPA/BOW/04-005). IEPA, 2004.

Illinois 2004 Section 303(d) List. Bureau of Water, Watershed Management Section, Planning

Unit. IEPA/BOW/04-005.

Water Body

Site Name

Size

Miles/

Acres

Hg

Impaired?

PCB

Impaired?

Could

Reduction

in Mercury

Affect

Impaired

Listing?

Des Plaines

IL_G-15

3.47 miles

NO

IL_G-22

4.14 miles

NO

IL_G-26

3.32 miles

NO

IL_G-28

8.82 miles

NO

IL_G-30

5.14 miles

NO

IL_G-32

6.08 miles

NO

IL_G-35

5.1 miles

NO

IL_G-36

6.92 miles

NO

IL_G-03

15.08 miles

NO

IL_G-11

5.17 miles

NO

IL_G-23

2.65 miles

NO

IL_G-39

11.12 miles

NO

IL_G-07

10.22 miles

NO

IL_G-08

0.77 miles

YES

IL_G-25

6.78 miles

YES

IL_G-26

3.32 miles

NO

IL_G-01

2.71 miles

NO

IL_G-12

8.35 miles

NO

IL_G-14

4.87 miles

NO

Chicago River

IL_HCB-01

2.56 miles

NO

Devils Kitchen

IL_RNJ

810 acres

YES

Little Grassy

IL_RNK

1000 acres

YES

Campus

IL_RNZH

40 acres

NO

Marquette Park Lagoon

IL_RHE

40 acres

YES

E. BR. DuPage R.

IL_GBL-08

5.53 miles

YES

IL_GBL-10

4.63 miles

YES

Salt Creek

IL_GL

11.19 miles

NO

IL_GL-03

10.38 miles

NO

IL_GL-09

11.78 miles

NO

IL_GL-10

3.64 miles

NO

IL_GL-19

3.1 miles

NO

Page 19

Table 4

Summary of current information on waters listed as impaired due to mercury, PCBs, or both as

documented in Appendix A of the Illinois 2004 303(d) List (IEPA/BOW/04-005). IEPA, 2004.

Illinois 2004 Section 303(d) List. Bureau of Water, Watershed Management Section, Planning

Unit. IEPA/BOW/04-005.

Water Body

Site Name

Size

Miles/

Acres

Hg

Impaired?

PCB

Impaired?

Could

Reduction

in Mercury

Affect

Impaired

Listing?

Cedar (Jackson)

IL_RNE

1800 acres

YES

Calumet-Sag Channel

IL_H-02

10.35 miles

NO

Little Calumet R. N.

IL_HA-05

5.06 miles

NO

Little Calumet R. S.

IL-HB-01

8.6 miles

YES

IL_HB-42

406 miles

YES

Arrowhead (Cook)

IL_RHZE

14 acres

YES

Midlothian Reservoir

IL_RHZI

25 acres

NO

Petticone Creek

IL_QA-C4

0.27 miles

NO

Lake-In-The-Hills 1W

IL_RTZZ

54 acres

YES

Rock River

IL_P-14

10.91 miles

NO

IL_P-20

13.62 miles

NO

IL_P-23

0.96 miles

NO

IL_P-15

21.19 miles

NO

IL_P-06

8.57 miles

NO

IL_P-21

18.36 miles

NO

IL_P-04

19.54 miles

NO

IL_P-06

8.57 miles

NO

IL_P-24

25.18 miles

NO

IL_P-25

15.13 miles

NO

IL_P-09

5.62 miles

NO

Illinois River

IL_D-31

25.49 miles

NO

IL_D-32

13.89 miles

NO

IL_D-16

6.58 miles

NO

IL_D-09

20.09 miles

NO

IL_D-01

35.09 miles

NO

IL_D-20

1.17 miles

NO

IL_D-23

10.52 miles

NO

IL_D-05

12.19 miles

NO

IL_D-10

9.38 miles

NO

IL_D-30

19.92 miles

NO

Page 20

Table 4

Summary of current information on waters listed as impaired due to mercury, PCBs, or both as

documented in Appendix A of the Illinois 2004 303(d) List (IEPA/BOW/04-005). IEPA, 2004.

Illinois 2004 Section 303(d) List. Bureau of Water, Watershed Management Section, Planning

Unit. IEPA/BOW/04-005.

Water Body

Site Name

Size

Miles/

Acres

Hg

Impaired?

PCB

Impaired?

Could

Reduction

in Mercury

Affect

Impaired

Listing?

Kankakee River

IL_F-01

11.54 miles

YES

IL_F-04

10.04 miles

YES

IL_F-12

1.76 miles

YES

IL_F-16

9.57 miles

YES

IL_F-02

13.46 miles

YES

IL_F-03

1.97 miles

YES

Kinkaid

IL_RNC

3475 acres

NO

Wabash River

IL_B-01

4.73 miles

NO

IL_B-06

7.51 miles

NO

IL_B-03

15.21 miles

NO

Monee Reservoir

IL_RFH

46 acres

YES

Big Bureau Creek

IL_DQ-03

5.31 miles

NO

Bracken

IL_SDZA

172 acres

NO

Page 21

Figure 2

Mercury Methylation

Figure 1

The Mercury Cycle

Page 22

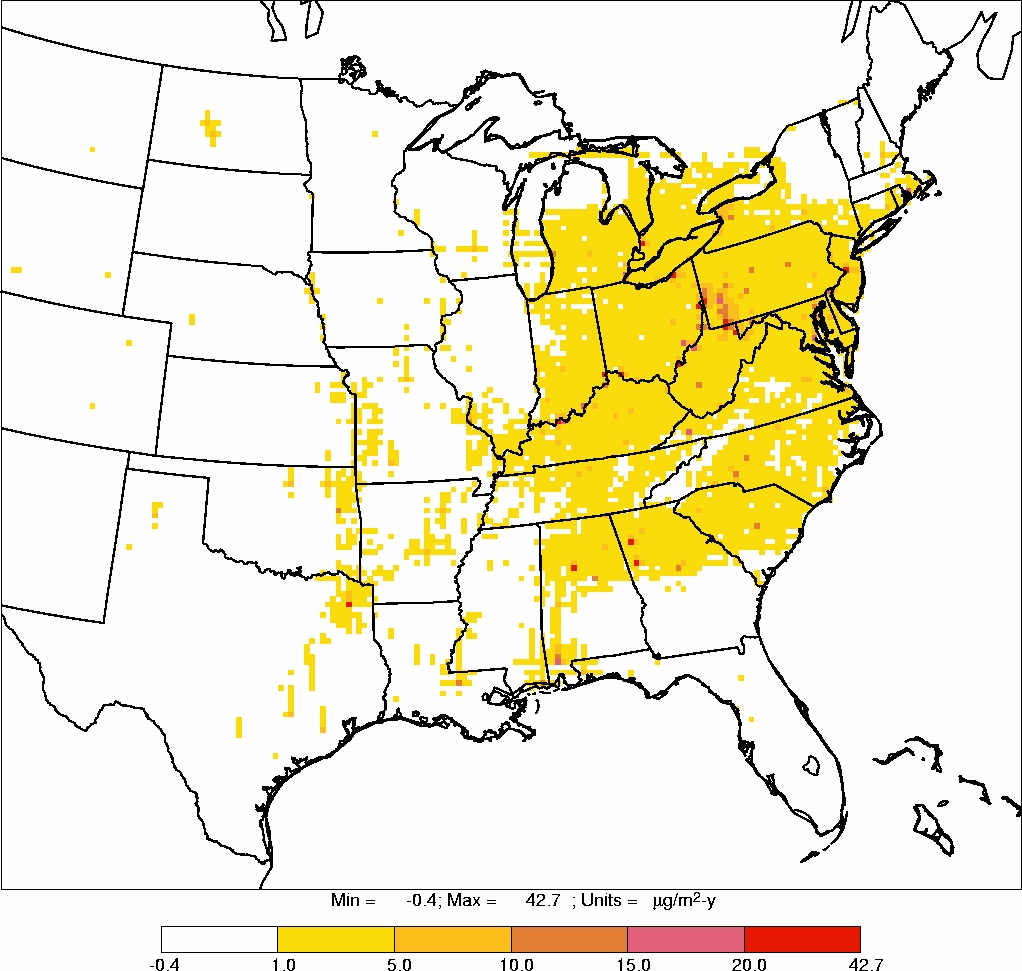

Figure 3

Relationship Between Total Mercury Concentrations in Sediments (mg/kg dry

weight) and Fish Tissue Concentrations (mg/kg wet weight) Greater Than or

Equal to 0.1 and Their Proximity to Listed Impaired Waters and Coal-Fired

Power Plants in Illinois.

Note: the information plotted comprises locations with

sediment and tissue data collected from the same site within a 5-year period.

Scale 1: 5,216,518

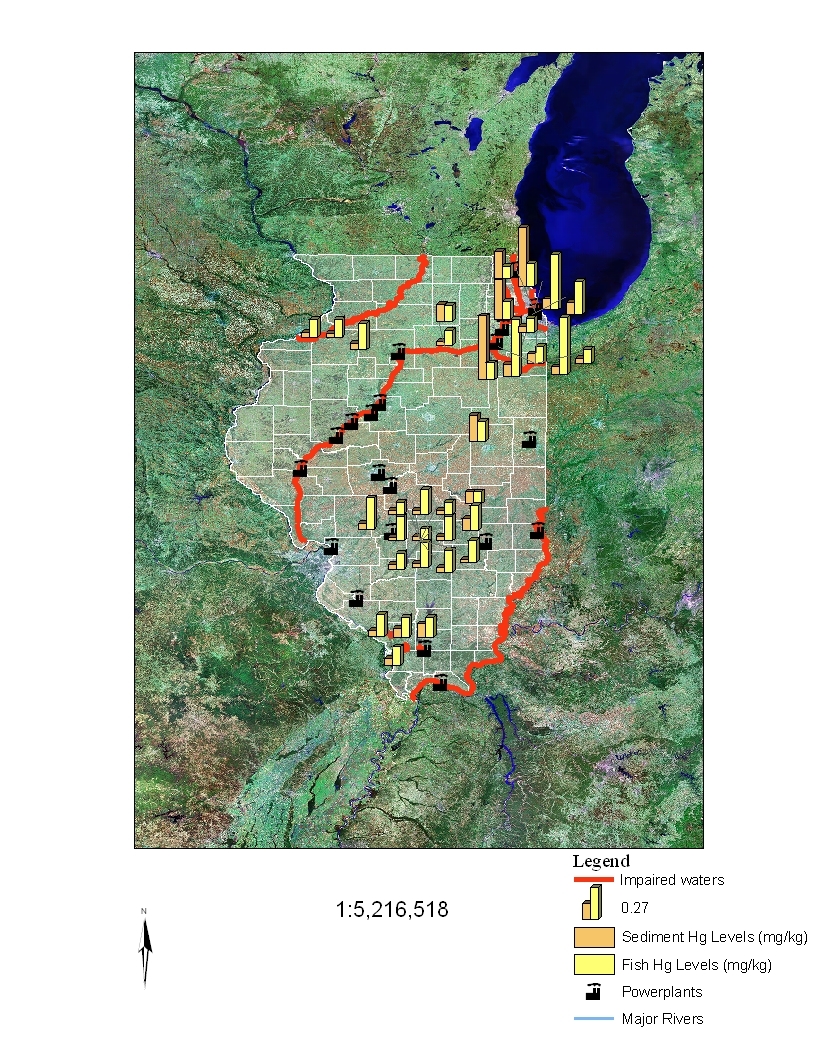

Page 23

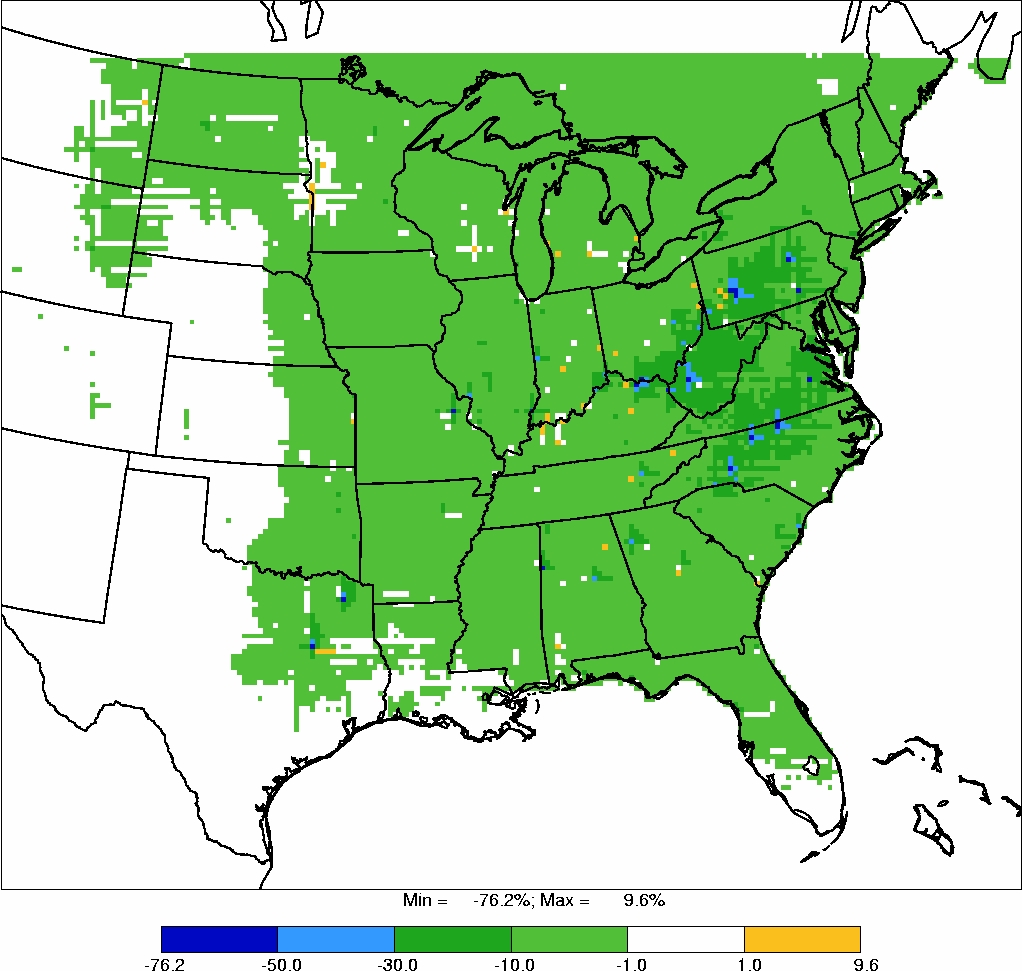

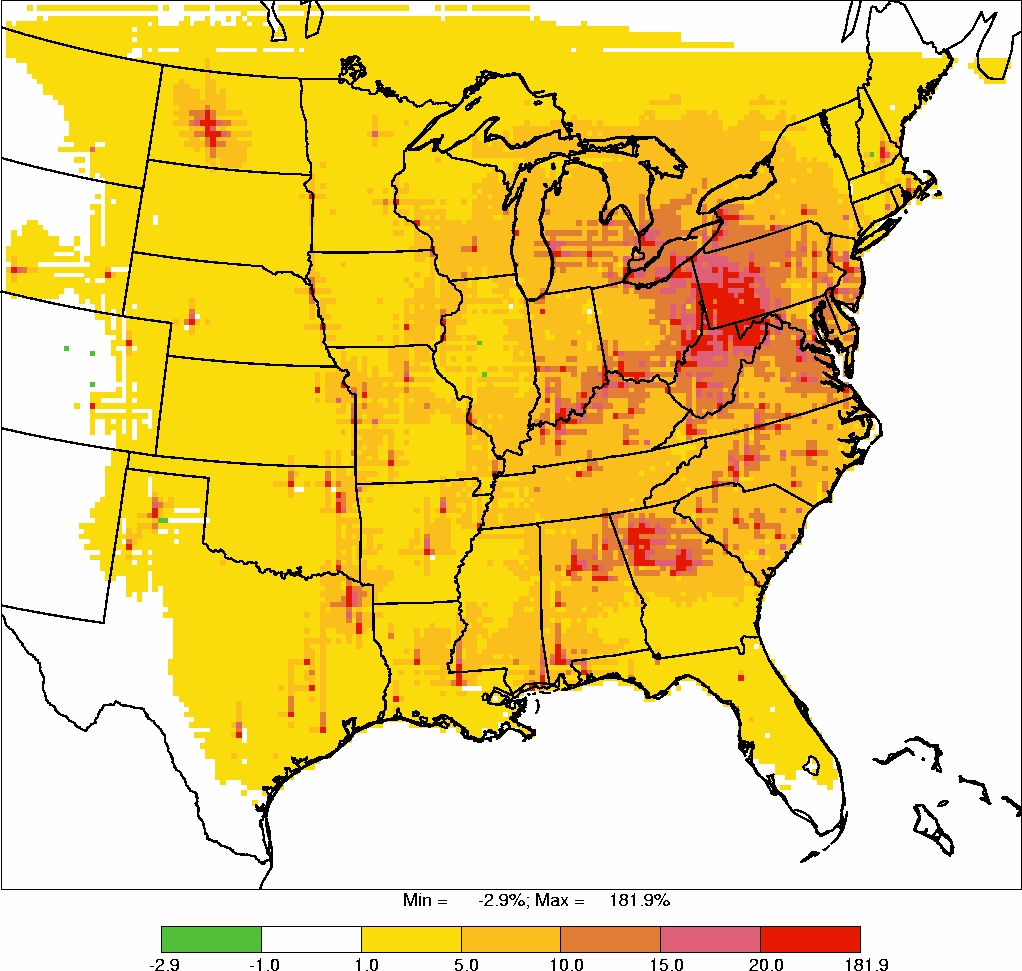

Figure 4

Relationship Between Total Mercury Concentrations in Sediments (mg/kg dry weight) and Fish

Tissue Concentrations (mg/kg wet weight) Greater Than or Equal to 0.23 and Their Proximity to

Listed Impaired Waters and Coal-Fired Power Plants in Illinois.

Note: the information plotted

comprises locations with sediment and tissue data collected from the same site within a 5-year period.

Scale 1: 5,216,518

Page 24

Education:

Ph.D., Benthic Ecology, University of Victoria, Victoria, BC, 1979

M.Sc., Biological Oceanography, 1976

B.Sc., Marine Biology, 1974

Affiliations:

Member, American Water Works Association

Member, North American Benthological Society

Member, American Society for Testing and Materials

Charter Member, Estuarine Research Federation

Member, Society of Environmental Toxicology and Chemistry (SETAC)

Member, Water Environment Federation

Awards:

Founders Award, Society of Environmental Toxicology and Chemistry, 2001

Region 10 award for resolving environmental issues, Port Valdez, Alaska, 1996

Languages:

English and Spanish

Publications:

Over 150 journal articles and book chapters

Over 200 technical reports

Over 100 presentations at meetings

Experience:

2004 – Present

Golder Associates Ltd.

North Vancouver, BC

Senior Environmental Scientist, Principal

Responsibilities include directing, designing, and managing environmental studies in

Arctic, temperate, and tropical ecosystems. Primary areas of expertise and

responsibilities are in ecotoxicology, risk assessment, and aquatic ecology. Areas of

specialisation include weight of evidence assessments and metals fate and effects,

especially selenium.

1979 – 2004

EVS Environmental Consultants

North Vancouver, BC

Senior Environmental Scientist/Principal

Responsibilities included directing, designing, and managing environmental studies in

Arctic, temperate, and tropical ecosystems. Primary areas of expertise and

responsibilities were ecotoxicology, risk assessment, and aquatic ecology. Areas of

specialisation included weight of evidence assessments and metals.

1977 – 1979

Environment Canada/Dept. Fisheries and Oceans

Victoria, BC

Independent Contractor

Conducted independent research on aquatic oligochaete distributions in the Fraser

River and assessed metal body burdens in aquatic benthos from various areas.

Published several papers and one book chapter based on this work.

1976 – 1979

University of Victoria

Victoria, BC

Teaching and Research Assistant

Prepared laboratories for undergraduate classes and provided lectures during

laboratory classes. Involvement in research activities included species collections

(terrestrial and aquatic), laboratory and field studies.

ECOTOXICOLOGY/TOXICITY TESTING Page 1 of 1

PROJECT RELATED EXPERIENCE – ECOTOXICOLOGY/TOXICITY

TESTING

Ecotoxicology

North and South America, Europe, Australasia

•

Directed development and source evaluation studies of chemical contaminants in water and

sediment.

•

Designed, directed and conducted studies involving sewage treatment plants, mining,

manufacturing, pulp and paper, wood processing, hazardous waste disposal, landfill operations, oil

and gas, smelting and food processing.

•

Conducted pioneering toxicity studies in Arctic, temperate, and tropical ecosystems.

Toxicity Testing

North and South America, Europe, Australasia

•

Nationally and internationally recognised expert in ecotoxicology.

•

Developed

and

verified

national

and

international

bioassessment

protocols

for

measuring/predicting toxicity and bioaccumulation.

Example Publications

International Peer-Reviewed Literature

Chapman, P.M. and J. Anderson. 2005. A decision-making framework for sediment contamination. Integr.

Environ. Assess. Manage. 1: 163-173.

Chapman, P.M. and M.J. Riddle. 2005. Toxic effects of contaminants in polar marine environments.

Environ. Sci. Technol. 38: 200A-207A.

Wang, F., R. Goulet, and P.M. Chapman. 2004. A critique of testing sediment biological effects with the

freshwater amphipod

Hyalella azteca

. Chemosphere 57: 1713-1724.

McDonald, B.G. and P.M. Chapman. 2002. PAH phototoxicity – An ecologically irrelevant phenomenon?

Mar. Pollut. Bull. 44: 1321-1326.

Chapman, P.M., H. Bailey, and E. Canaria. 2000. Toxicity of total dissolved solids (TDS) from two mine

effluents to chironomid larvae and early life stages of rainbow trout. Environ. Toxicol. Chem. 19:

210-214.

Wang, F. and P.M. Chapman. 1999. The biological implications of sulfide in sediment - a review focusing

on sediment toxicity. Environ. Toxicol. Chem. 18: 2526-2532.

Chapman, P.M. 1998. New and emerging issues in ecotoxicology - the shape of testing to come? Austral.

J. Ecotox. 4:1-7.

Chapman, P.M. 1997. Acid volatile sulfides, equilibrium partitioning, and hazardous waste site sediments.

Environ. Manage. 21: 197-202.

Chapman, P.M. 1990. The Sediment Quality Triad approach to determining pollution-induced degradation.

Sci. Tot. Environ. 97-8: 815-825.

ENVIRONMENTAL RISK ASSESSMENT

Page 1 of 2

PROJECT RELATED EXPERIENCE – ENVIRONMENTAL RISK

ASSESSMENT

Various Projects

North and South America, Europe, Australasia

•

Involved in ecological risk assessment since this process was formalised in the 1980s.

•

Conducted ecological risk assessments for government and industry.

•

Served, at the request of the U.S. Environmental Protection Agency Risk Assessment Forum, as a

peer reviewer for various agency guidance documents.

•

Published extensively on ecological risk assessment.

Global Experience

South America, Europe, Australasia

•

Senior Editor of the international peer-reviewed journal, Human and Ecological Risk Assessment.

•

Advisory and consulting services to the governments of Australia, Peru, Indonesia, Hong Kong,

ASEAN (Association of South East Asian Nations).

•

Helped set up the first Master’s degree in Ecotoxicology in Portugal.

•

Conducted pioneering toxicity testing studies in the Arctic, North Sea, and Venice lagoons.

•

Lectured, taught, and worked extensively in Europe, South East Asia, Australia, and South

America (fluent in Spanish).

•

Independent, external examiner for Ph.D. dissertations in Spain, Finland, Canada, the U.S.,

Denmark, and Australia.

•

Numerous lectures and presentations to the public, high school and university classes, business

and professional groups.

Large-Project Expertise

North and South America, Europe, Australasia

•

Responsible for synthesis of all studies conducted through NSERC (Natural Sciences and Engineering

Research Council) under the Metals in the Environment Research Network (MITE-RN; www.mite-

rn.org). MITE-RN ran for 5 years and involved 7 major Canadian Universities and over 20 Principal

Investigators from those Universities plus graduate students and other collaborators.

•

Currently providing similar services to the successor of MITE-RN, the Metals in the Holistic

Environment Research Network (MITHE-RN); www.mithe-rn.org

.

•

Directed regional-scale risk assessments in Alaska (Port Valdez), Papua New Guinea, Irian Jaya,

Chile, and Peru.

Example Publications

International Peer-Reviewed Literature

Campbell, P.G.C., P.M. Chapman, and B. Hale. 2006. Risk assessment of metals in the environment. pp

102-131, In: Hester, R. E. and R. M. Harrison (eds.), Chemicals in the Environment: Assessing and

Managing Risk. Issues in Environmental Science and Technology Volume 22, Royal Society of

Chemistry, Cambridge, UK.

Chapman, P.M., F. Wang, C. Janssen, R.R. Goulet, and C.N. Kamunde. 2003. Conducting ecological risk

assessments of inorganic metals and metalloids – Current status. Human Ecol Risk Assess 9: 641-697.

[This paper was selected as the Ecological Risk Assessment Paper of the Year 2003]

Chapman, P.M., B.G. McDonald, and G.S. Lawrence. 2002. Weight of evidence frameworks for sediment

quality and other assessments. Human Ecol. Risk Assess. 8: 1489-1515.

Chapman, P.M. 2002. Ecological risk assessment (ERA) and hormesis. Sci. Tot. Environ.288: 131-140.

ENVIRONMENTAL QUALITY MGT/AQUATIC ECOLOGY Page 1 of 2

PROJECT RELATED EXPERIENCE – ENVIRONMENTAL QUALITY

MANAGEMENT/AQUATIC POLLUTION ASSESSMENT

Environmental Quality

North and South America, Europe, Australasia, Arctic

•

Intimately involved in the process and methods for developing environmental quality guidelines,

both nationally and internationally.

•

Advisor to the federal governments of both the United States and Canada for environmental

toxicology and biomonitoring assessment policy and protocols.

•

Participated in and led aspects of international (South American, European, and Australasian)

monitoring development projects.

•

Published extensively on the subject of environmental quality guidelines.

•

Member of the International Standards Organization, representing Canada.

Pollution Assessment

North and South America, Europe, Australasia, Arctic

•

Developed the internationally recognised and accepted Sediment Quality Triad concept for

determining pollution-induced degradation in aquatic habitats.

•

Directed projects (for government and industry) for various studies involving biological

monitoring; assessment of toxicant levels (including Priority Pollutants) in tissues, sediments, and

water; ecological surveys; literature reviews for ranking environmental contaminants; and

bioassessment (e.g., toxicity testing).

Dredging/Sediment Projects

USA, Canada, and elsewhere

•

Peer reviewed the U.S. Environmental Protection Agency/Army Corps of Engineers

[USEPA/USACE] “Green Book” on ocean disposal.

•

Contracted author for the EPA/USACE Inland Testing Manual for Waters of the U.S.

•

Designed and implemented monitoring and assessment projects for aquatic dredging in fresh,

marine, and estuarine waters world-wide.

Example Publications

International Peer-Reviewed Literature

Chapman, P.M., W.S. Douglas, M.C. Harrass, R.M. Burgess, D.D. Reible, W.H. Clements, A.H.

Ringwood, C. Hogstrand, and W.J. Birge. 2005. Workgroup summary report on the role of SQGs and

other tools in different aquatic habitats. In: Wenning, R., C. Ingersoll, G. Batley, and M. Moore (eds.),

Use of Sediment Quality Guidelines (SQGs) and Related Tools for the Assessment of Contaminated

Sediments. SETAC Press, Pensacola, FL, USA.

Chapman, P.M., F. Wang, D.D. Germano, and G. Batley. 2002. Porewater testing and analysis: The good,

the bad and the ugly. Mar. Pollut. Bull. 44: 359-366.

Chapman, P.M. 2001. Utility and relevance of aquatic oligochaetes in ecological risk assessment.

Hydrobiologia 463:149-169.

Chapman, P.M., F. Wang, W. Adams, and A. Green. 1999. Appropriate uses of sediment quality values for

metals and metalloids. Environ. Sci. Technol. 33: 3937-3941.

Chapman, P.M., P.J. Allard, and G.A. Vigers. 1999. Development of sediment quality values for Hong

Kong Special Administrative Region: a possible model for other jurisdictions. Mar. Pollut. Bull. 38:

161-169.

EXPERT WITNESS AND PEER REVIEW

Page 1 of 1

PROJECT RELATED EXPERIENCE – EXPERT WITNESS AND PEER

REVIEW

Expert Witness

USA and Canada

•

Four trials with testimony.

•

Two trials with attendance but no testimony as cases settled.

•