217/782-2113

TITLE V - CLEAN AIR

ACT PERMIT PROGRAM (CAAPP) PERMIT

and

TITLE I PERMIT'.

PERMITTEE

The Premcor Refining Group, Inc. - Hartford

Distribution Center

Attn: Becky Malloy, Environmental Contact

2

01 East Hawthorne

Hartford,

Illinois 62048

Application No.: 96030082

I.D. No.:

119050AAA

Applicant's

Designation:

Date Received: March.7,

1996

Operation of:

Marine

Terminal

Date Issued: September 19, 2006

Expiration Date 2: September 19, 2011

Source Location: 201 East Hawthorne, Hartford, Madison

County

Responsible Official: Ed Jacoby, Vice

President of Wholesale, Marketing

and

Distribution

This permit is hereby granted to the above-designated

Permittee to OPERATE

a

Petroleum Bulk Storage and Loading Terminal, pursuant to

the above referenced

permit application. This permit is

subject to the conditions contained

herein.

If you have any questions concerning

this permit, please contact Sunil

Suthar

at 217/782-2113.

Donald E. Sutton, P.E.

Manager, Permit Section

Division of Air Pollution

Control

DES:SIS:psj

cc: Illinois EPA, FOS, Region

3

CES

Lotus Notes

1

z

This permit may contain terms and conditions which

address the applicability, and

compliance if determined applicable, of Title I of the CAA and

regulations promulgated

thereunder, including 40 CFR 52.21 -

federal PSD and 35 IAC Part 203 - Major

Stationary

Sources Construction and Modification. Any

such terms and conditions are identified

within

this permit.

Except as provided in Condition 8.7 of this permit.

EXHIBIT

1

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

TABLE OF CONTENTS

PAGE

1.0 SOURCE IDENTIFICATION

1.1 Source

1 .2 Owner/Parent

Company

1.3 Operator

1 .4 General Source

Description

2.0 LIST OF ABBREVIATIONS/ACRONYMS

USED

IN THIS PERMIT

5

3.0

INSIGNIFICANT ACTIVITIES

7

3 .1 Identification

of Insignificant Activities

3.2 Compliance with

Applicable Requirements

3.3 'Addition

of Insignificant

Activities

4 .0

SIGNIFICANT EMISSION

UNITS AT THIS SOURCE

9

5.0 OVERALL SOURCE CONDITIONS

11

5 .1

Source Description

5.2 Applicable Regulations

5.3

Non-Applicability of Regulations

of Concern

5 .4 Source-Wide

Operational and Production

Limits and Work

Practices-

5.5 Source-Wide

Emission Limitations

5.6 General Recordkeeping

Requirements

5.7

General Reporting Requirements

5.8 General

Operational Flexibility/Anticipated

Operating

Scenarios

5 .9

General Compliance Procedures

5.10 Special Permit

Shield

6 .0 NOT APPLICABLE

TO THIS PERMIT

17

7.0

UNIT SPECIFIC CONDITIONS

18

7.1 Unit 01: Vapor

Control System

Control: Thermal

Treatment Unit (Enclosed Flare)

7.2

Unit 02: River Dock (Marine

Vessel Loading)

Control:

Vapor Recovery Unit

7 .3 Unit 03: External

Floating Roof Storage

Tanks

Control: Floating

Roof, Double Seals and Submerged

Loading

7.4

Unit 04: Internal Floating

Roof Storage Tanks

Control:

Floating Roof and Seals,

Permanent Submerged

Loading

7 .5 Unit 05: Wastewater

Treatment System

Control: None

7 .6

Unit 06: Fugitive Emissions

- Paved and Unpaved Roadways

P ()1,

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

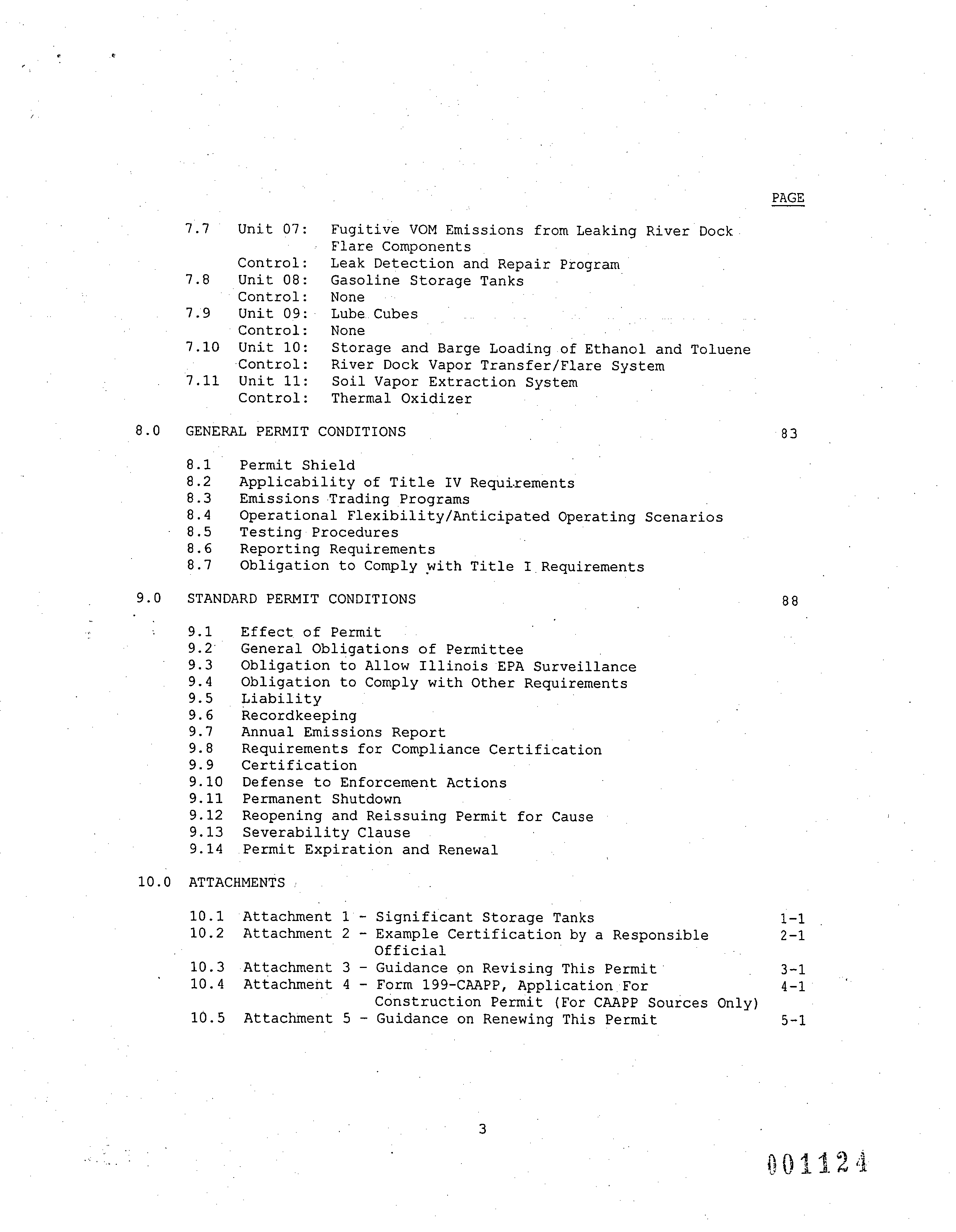

PAGE

7.7 Unit 07: Fugitive VOM

Emissions from Leaking River Dock

Flare Components

C ontrol: Leak Detection and Repair

Program

7.8 Unit

08: Gasoline Storage Tanks

Control: None

7 .9 Unit 09: Lube..Cubes

Control: None

7.10

Unit 10: Storage and Barge Loading.

of Ethanol and Toluene

-Control: River

Dock Vapor Transfer/Flare System

7.11 Unit 11: Soil Vapor Extraction

System

Control: Thermal Oxidizer

8 .0 GENERAL PERMIT CONDITIONS

83

8 .1 Permit Shield

8.2

Applicability of Title IV Requirements

8.3 Emissions-Trading

,Programs

8.4 Operational Flexibility/Anticipated

Operating Scenarios

8.5 Testing

Procedures

8.6 Reporting Requirements

8.7 Obligation to Comply with Title

I. Requirements

9 .0 STANDARD PERMIT CONDITIONS

88

9 .1 Effect,

of Permit

9.2' General Obligations of

Permittee

9.3 Obligation to Allow Illinois EPA

Surveillance

9.4 Obligation to

Comply with Other Requirements

9.5 Liability

9.6 Recordkeeping

9.7 Annual Emissions Report

9.8 Requirements for Compliance

Certification

9.9 Certification

9.10 Defense

to Enforcement Actions

9.11 Permanent Shutdown

9.12 Reopening and Reissuing Permit for

Cause

9.13 Severability

Clause

9.14 Permit Expiration

and Renewal

1 0.0 ATTACHMENTS

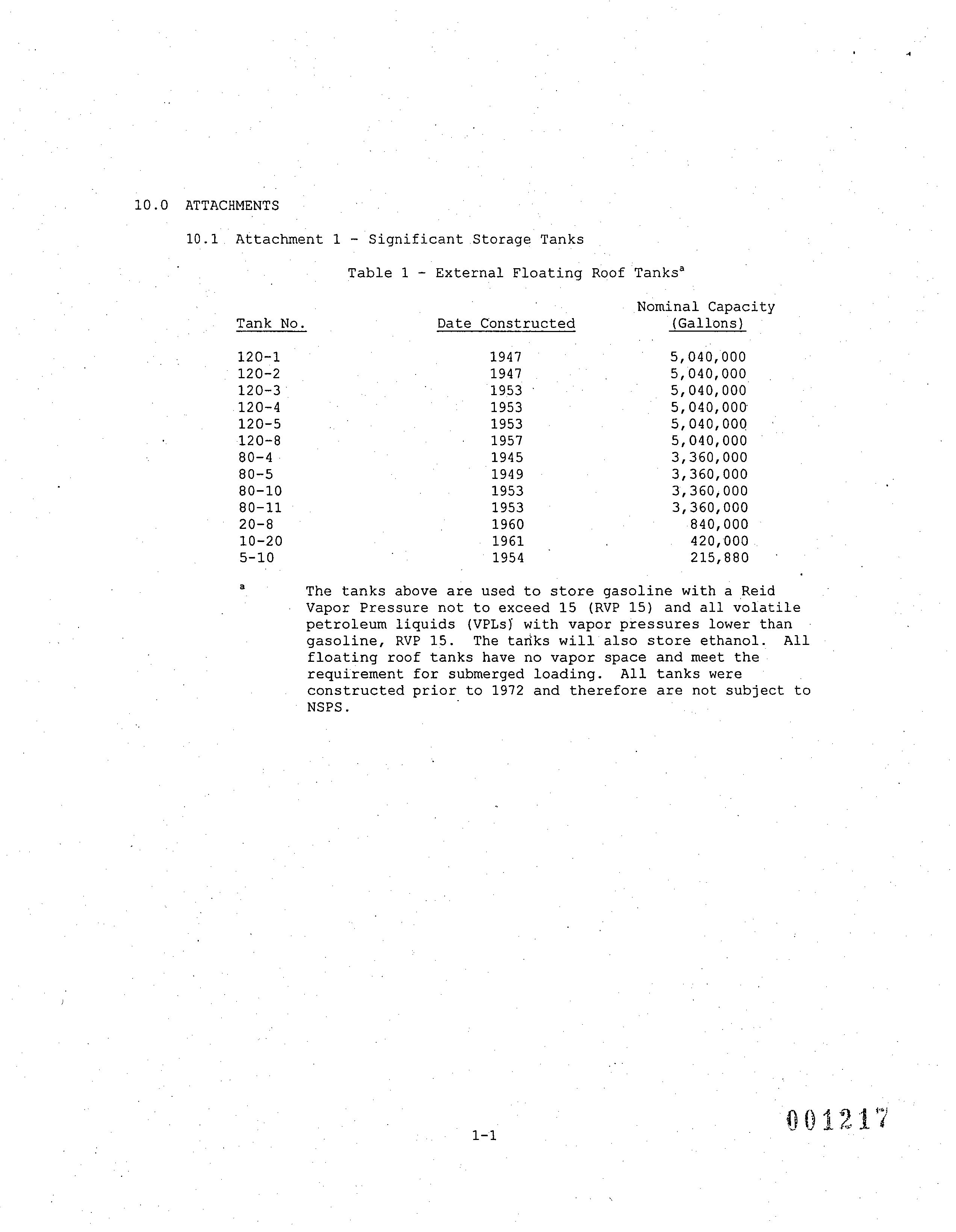

1 0.1 Attachment 1 - Significant

Storage Tanks

1-1

10.2 Attachment 2 - Example

Certification by a Responsible

2-1

Official

10.3 Attachment 3 - Guidance on Revising

This Permit'

3-1

10.4 Attachment

4 - Form 199-CAAPP, Application.For

4-1

Construction

Permit (For CAAPP Sources

Only)

10.5 Attachment

5 - Guidance on Renewing This Permit

5-1

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

.1.0 SOURCE

IDENTIFICATION

1 .1 Source

The Premcor Refining Group,.Inc. -Hartford Distribution Center

201 East

Hawthorne

Hartford, Illinois-

62048

I.D.

No.: 119050AAA

Standard

Industrial Classification.: 5171, Petroleum Bulk Storage

and Loading

1.2 '

Owner/Parent Company.

The Premcor Refining Group, ;Inc.

201 East Hawthorne

Hartford, Illinois

62048.

1.3 Operator

The Premcor Refining'Group, Inc

201 East

Hawthorne

Hartford, Illinois 62048

Bill Malloy,

Environmental Contact

618/254-7301 Ext. 261

1.4 General Source

Description

The Premcor

Refining Group, Inc. - Hartford Distribution Center

is located at 201 East Hawthorne, Hartford,

Illinois. The source

is engaged in petroleum storage and distribution operations.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

2.0

LIST OF ABBREVIATIONS/ACRONYMS

USED IN THIS PERMIT

Act

Illinois Environmental

Protection Act

[415 ILCS 5/1 et seq.]

AP-42

Compilation of Air Pollutant

Emission Factors, Volume

1,

Stationary Point and Other

Sources (and Supplements A

through F),

USEPA, Office of Air Quality

Planning and

Standards,

Research Triangle Park, NC 27711

B tu

British thermal unit

CAA

Clean Air Act

[42 U.S.C. Section 7401

et seq.]

CAAPP

Clean Air Act Permit Program

.

CAM

Compliance Assurance

Monitoring

C FR

Code of Federal Regulations

E RMS

Emissions Reduction

Market System

`F

d egrees

Fahrenheit

ft

cubic

feet

gal

gallon

'HAP

Hazardous

Air Pollutant

h p

horsepower

hr

hour

I AC

Illinois Administrative Code

I.D. No.

Identification Number

of Source, assigned by Illinois EPA

ILCS

Illinois Compiled

Statutes

Illinois EPA

Illinois Environmental Protection

Agency

'K

degrees Kelvin

K g

Kilogram

k Pa

Kilopascals

kW

kilowatts

1

liter

lb

pound

m

cubic meters

mmBtu

Million British thermal

units

m o

month

NESHAP

National Emission Standards

for Hazardous Air Pollutants

NO,,

Nitrogen Oxides

NSPS

New Source

Performance Standards

PM

Particulate Matter

PM10

P articulate

matter with an aerodynamic

diameter less than or

equal to a nominal

10 microns as measured

by applicable test

or monitoring methods

-PPM

parts per

million

P SD

Prevention of Significant

Deterioration

p sia

pounds per square

inch absolute

RMP

Risk Management Plan

RVP

Reid Vapor

Pressure

S02

S ulfur Dioxide

Tl

Title

I - identifies Title I conditions

that have been

carried over

from an existing permit

T1N

Title I New - identifies

Title I conditions that

are being

established in this permit

5

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

TIR

Title I Revised - identifies Title I conditions that have

been carried over from an existing permit and-'subsequently

revised

in this permit

USEPA

United States Environmental Protection Agency

VOL

Volatile

Organic Liquid

VOM

Volatile Organic Material

VPL

Volatile Petroleum

Liquid

wt.

weight

r -

ear

-001127

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

3.0 INSIGNIFICANT ACTIVITIES

3 .1 Identification of Insignificant

Activities

The

following activities at the

source constitute insignificant

activities

as specified in 35 IAC 201.210:

3.1.1 Activities determined

by the Illinois EPA to

be

insignificant activities, pursuant

to 35 IAC 201.210(a)(1)

and 201.211, as follows:

Chemical Storage

Tank

Chemical Storage

Drum

3.1.2 Activities

that are insignificant activities

based upon

maximum emissions, pursuant

to 35 IAC 201.210(a)(2)

or.

(a)(3), as follows:

None

3 .1.3

Activities that are insignificant

activities based upon

their type or character,

pursuant to 35 IAC

201.210(a)(4)

through (18), as follows:

Direct combustion

units designed and

used for comfort

heating purposes and fuel

combustion emission units

as follows:

(A) Units with a rated

heat input

capacity of less

than 2.5 mmBtu/hr that fire

only

natural gas, propane, or

liquefied petroleum gas; (B)

Units with

a rated heat input capacity

of less than

1.0 mmBtu/hr that fire

only oil or oil in

combination

with only natural gas, propane,

or liquefied

petroleum

gas; and (C) Units with

a rated heat input

capacity of less than

200,000 Btu/hr which never

burn

refuse, or treated or chemically

contaminated wood

[35 IAC 201.210(a)(4)].

Storage tanks of organic liquids

with a capacity of

less

than 10,000 gallons and an

annual throughput of

less than 100,000

gallons per year, provided

the

storage tank is not used

for the storage of gasoline

or any material listed as a

HAP pursuant to Section

112(b)

of the CAA [35 IAC 201.210(a)(10)].

Storage tanks of any

size containing virgin or

re-

refined distillate oil, hydrocarbon

condensate from

natural gas pipeline or

storage systems, lubricating

oil, or residual fuel oils [35

IAC 201.210(a)(11)].

Storage tanks of

any size containing exclusively

soaps, detergents, surfactants,

glycerin, waxes,

vegetable oils, greases,

animal fats, sweeteners,

corn syrup, aqueous salt

solutions, or aqueous

caustic

solutions, provided an

organic solvent has

7

0

11211

1

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

not

been

mixed with such materials [35 IAC

201.210(a)(17)].

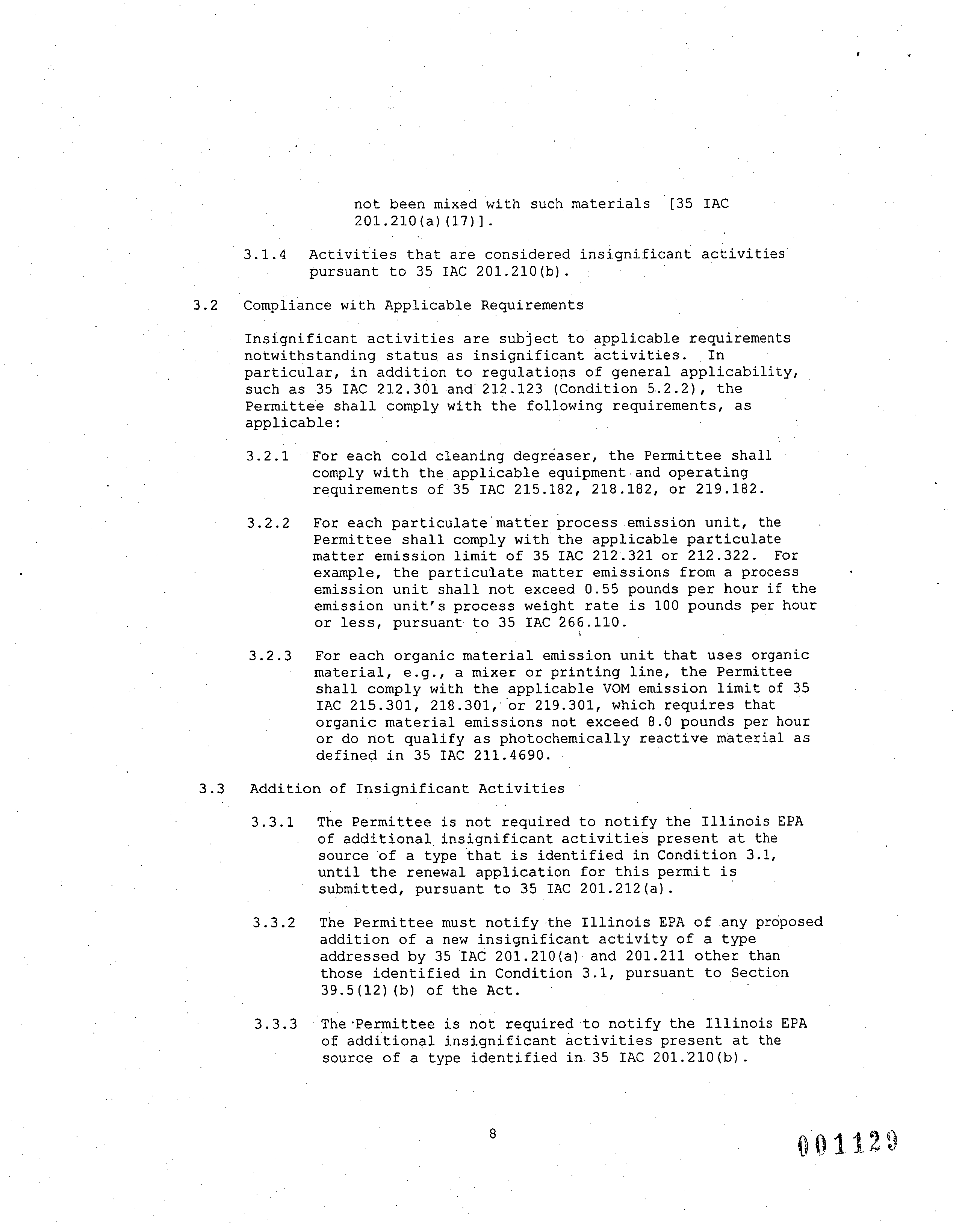

3 .1.4 Activities that are considered insignificant activities

pursuant to 35 IAC 201.210(b).

3.2 Compliance with Applicable Requirements

Insignificant activities are subject to

applicable requirements

notwithstanding status as insignificant activities. In

particular, in addition to regulations of general applicability,

such as 35 IAC 212.301 and 212.123 (Condition 5.2.2),

the

Permittee shall comply with the following

requirements, as

applicable:

3.2.1 For each cold cleaning degreaser,

the Permittee shall

comply with

the

applicable equipment and operating

requirements of 35 IAC 215.182, 218.182, or 219.182.

3.2.2 For each particulate matter process emission unit, the

Permittee shall comply with the applicable particulate

matter emission limit

of 35 IAC 212.321 or 212.322. For

example, the particulate matter emissions from a process

emission unit shall not exceed 0.55 pounds

per hour if the

emission

unit's

process

weight rate is 100 pounds per hour

or less, pursuant to 35 IAC 266.110.

3 .2.3 For each organic material emission unit that uses organic

material, e.g., a mixer or printing line, the

Permittee

shall comply with the applicable VOM emission limit of 35

IAC 215.301, 218.301, or 219.301, which requires

that

organic material emissions

not

exceed

8.0 pounds per hour

or do not qualify as photochemically reactive material as

defined in 35 IAC 211.4690.

3 .3 Addition of Insignificant Activities

3.3.1 The

Permittee

is not

required to notify the Illinois EPA

of additional. insignificant activities present at the

source of a type that is identified in Condition

3.1,

until the renewal application for this permit is

submitted, pursuant to 35 IAC 201.212(a).

3.3.2 The Permittee must notify the Illinois

EPA of any proposed

addition

of

a

new insignificant activity of a type

addressed by 35 IAC 201.210(a) and 201.211 other than

those identified in Condition 3.1, pursuant to Section

39.5(12)(b) of the Act.

3.3.3 The-Permittee is not required

to notify the Illinois EPA

of additional insignificant activities present at the

source of a type identified in 35 IAC 201.210(b).

8

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

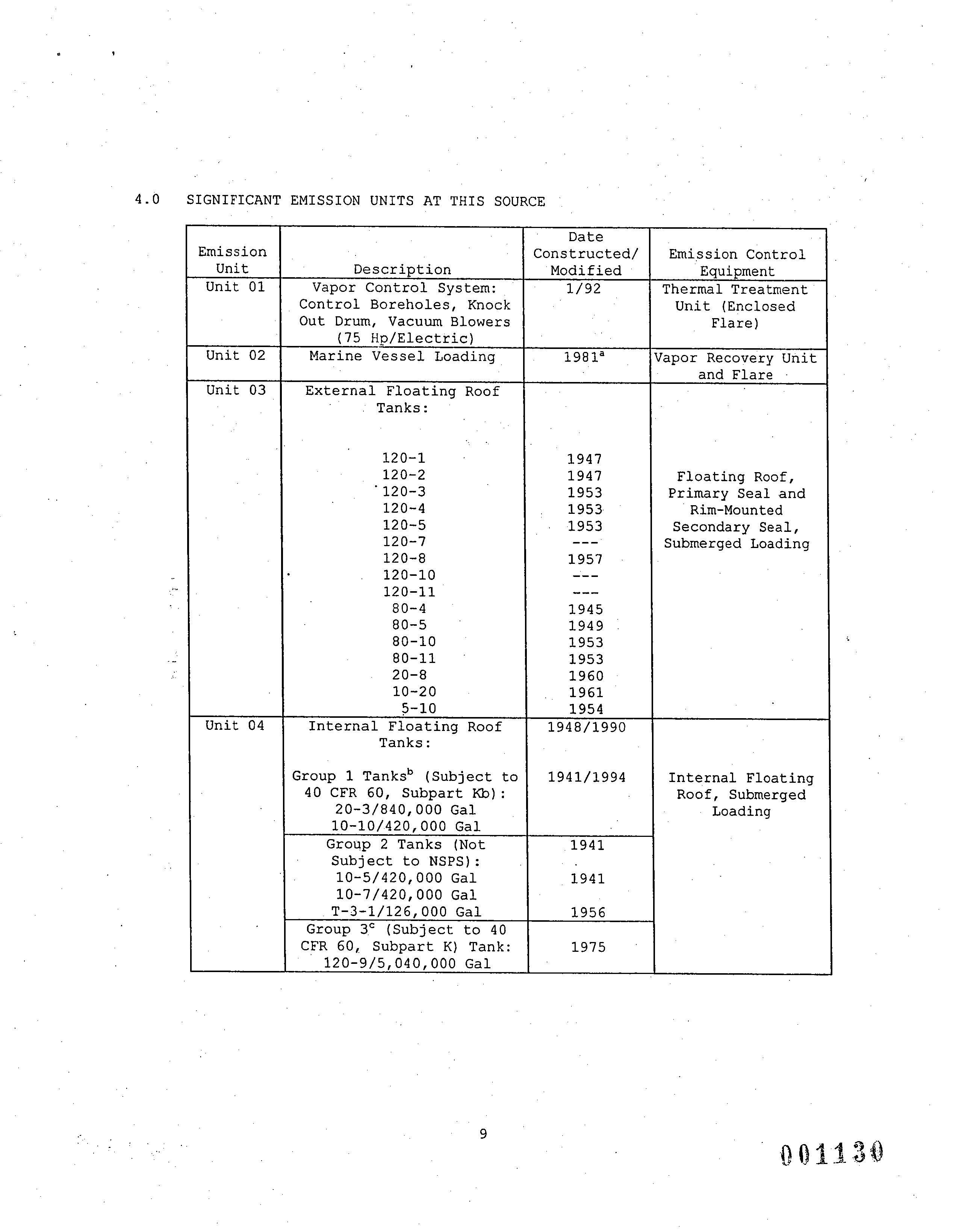

4.0 SIGNIFICANT

EMISSION UNITS AT THIS SOURCE

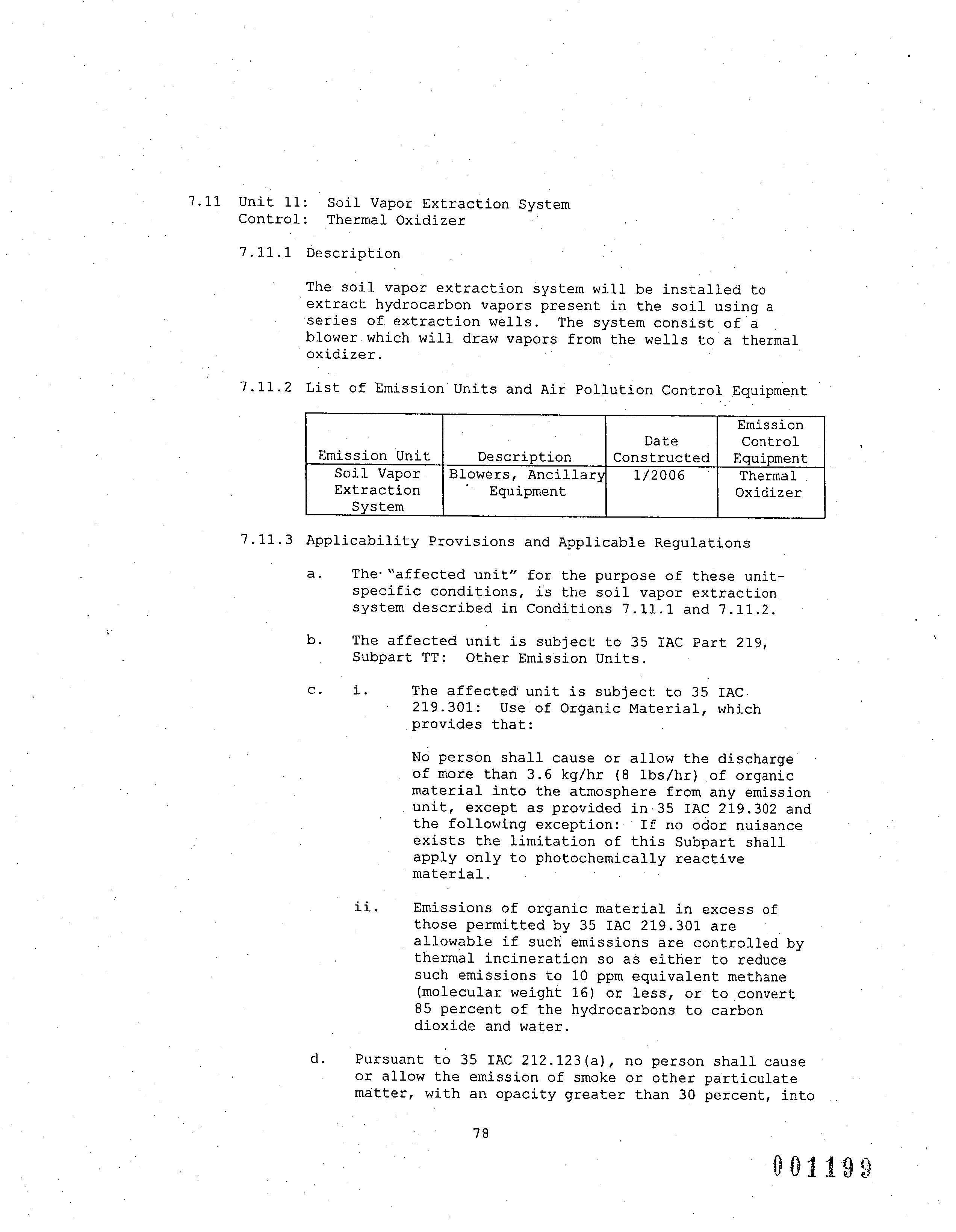

Date

E mission

Constructed/ Emission Control

Unit

Description

Modified

Equipment

Unit 01

Vapor Control

System:,

1/92

Thermal Treatment

Control Boreholes,

Knock

Unit (Enclosed

Out Drum, Vacuum Blowers

Flare)

( 75

Hp/Electric)

Unit 02

Marine Vessel Loading,

1981a

vapor Recovery

Unit

and Flare

Unit 03 External Floating

Roof

Tanks:

120-1

1947

120-2

1947

Floating Roof,

'120-3

1953

Primary Seal and

120-4

1953

Rim-Mounted

120-5

1 953

S econdary

Seal,

120-7

---

Submerged Loading

120-8

1957

120-10

---

120-11

---

80-4

1945

80-5

1949

80-10

1953

80-11

1953

20-8

1960

10-20

1961

5-10

1954

Unit 04

Internal Floating Roof

1948/1990

Tanks:

Group 1 Tanksb

(Subject to 1941/1994

Internal

Floating

40 CFR 60, Subpart

Kb):

Roof, Submerged

20-3/840,000 Gal

Loading

10-10/.420,000

Gal

Group 2 Tanks (Not

1941

Subject to NSPS):

10-5/420,000

Gal

1941

10-7/420,000

Gal

T-3-1/126,000

Gal

1956

'

Group

3.` (Subject to 40

CFR 60, Subpart K)

Tank:

1975

120-9/5,040,000 Gal

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

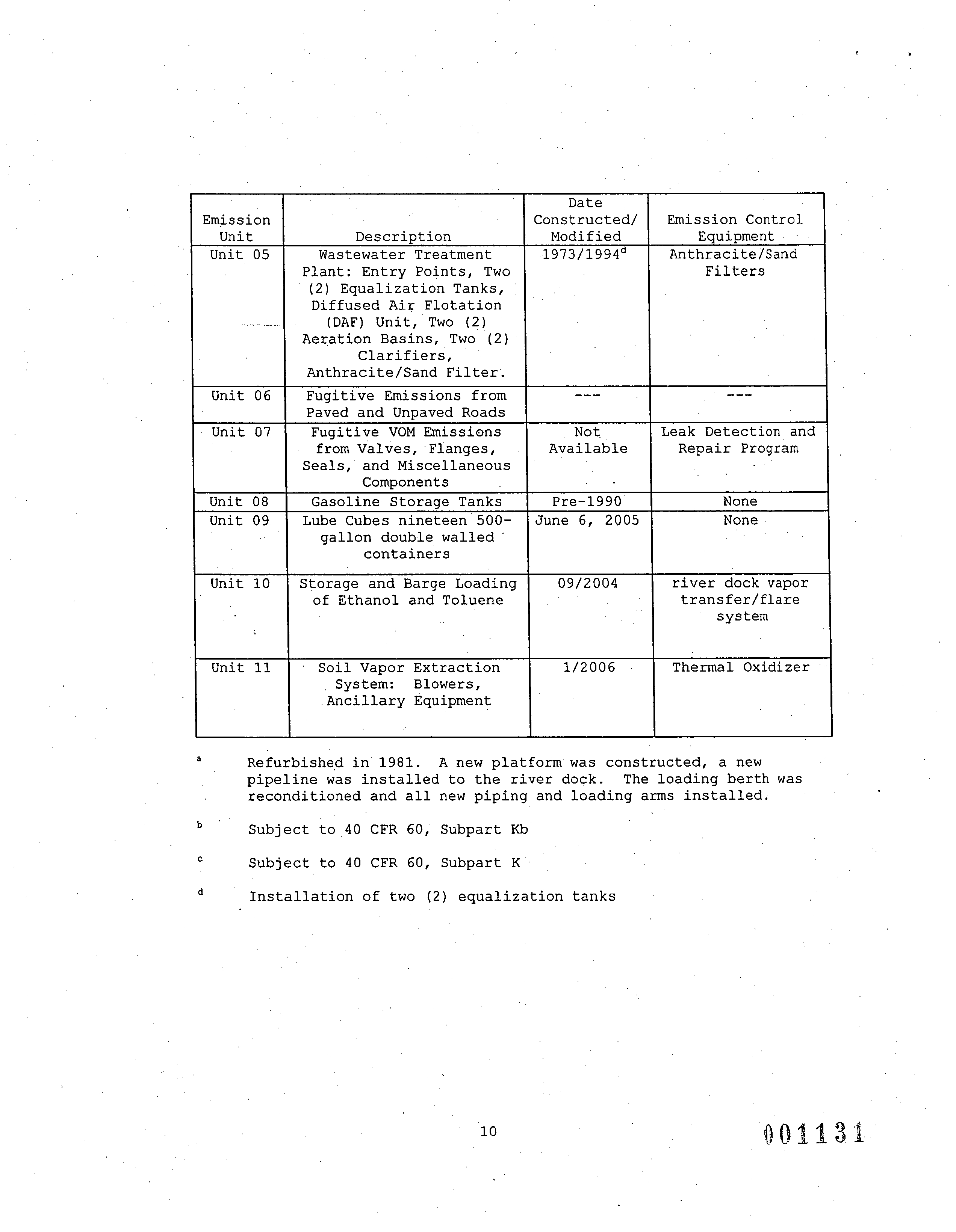

'

Date

E mission

Constructed/ Emission Control

Unit

Description

Modified

Equipment -

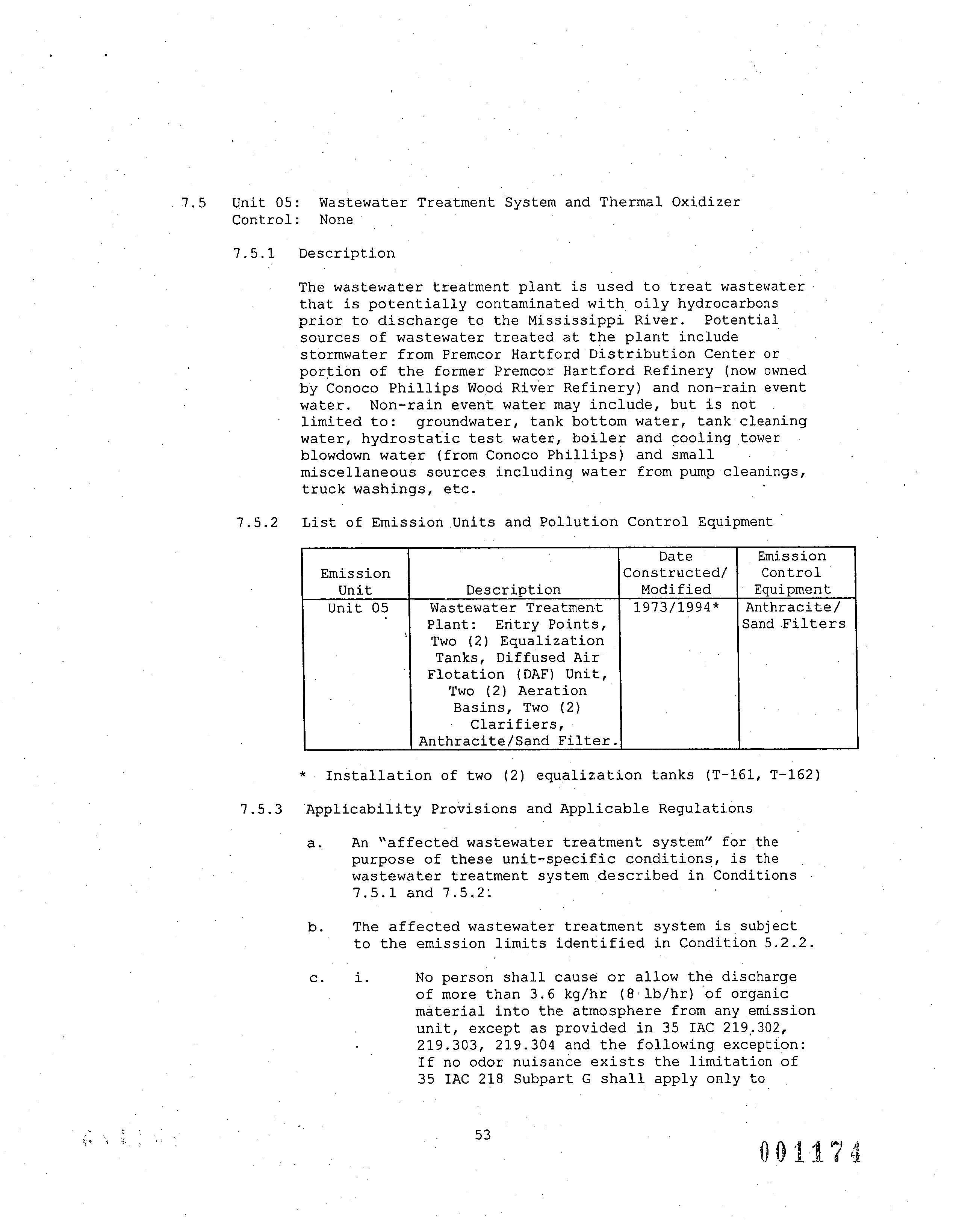

Unit 05

Wastewater Treatment

1973/1994°

Anthracite/Sand

Plant: Entry Points, Two

Filters

(2) Equalization Tanks,

Diffused Air Flotation

_-

(DAF)

Unit, Two (2)

Aeration Basins, Two (2)

.

Clarifiers,

Anthracite/Sand Filter.

Unit 06 Fugitive Emissions from

---

---

Paved and Unpaved Roads

Unit 07

Fugitive VOM Emissions

Not

Leak Detection. and

f rom Valves, Flanges,

Available

Repair Program

Seals, and Miscellaneous

Components

-

Unit 08

Gasoline

Storage Tanks

Pre-1990

None

Unit

09

Lube

Cubes

nineteen 500- June 6, 2005

None

gallon double walled '

containers

Unit 10 Storage and

Barge Loading

09/2004

river dock vapor

of Ethanol and Toluene

transfer/flare

.

system

Unit 11

Soil Vapor Extraction

1/2006

Thermal Oxidizer

System: Blowers,

Ancillary Equipment.

0

b

C

d

Refurbished in'1981. A new platform was constructed, a new

pipeline was installed to the river dock.

The loading berth was

reconditioned and all new piping and loading arms installed:

Subject to.40 CFR 60, Subpart Kb

Subject to 40 CFR 60, Subpart K

Installation of two (2) equalization tanks

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

5.0 OVERALL

SOURCE CONDITIONS

5.1 Source Description

5.1.1 This permit is

issued.based on the source

requiring a

CAAPP permit as

a major source of VOM,

and CO emissions.

5 .1.2 This permit

is issued based on

the source not being a

major source

of HAPs.

5.2 Applicable

Regulations

5.2.1 Specific

emission units at this

source are subject to

particular regulations

as set forth in Section 7

(Unit-Specific Conditions)

of this permit.

5.2.2 In addition,

emission units at

this source are subject to

the following regulations

of general applicability

a. No

person shall cause

or allow the emission of

fugitive

particulate matter from

any process,

including any material

handling or storage activity,

that is visible

by an observer looking

generally

overhead

at a point beyond the property

line of the

source unless the wind

speed is greater than

40.2

kilometers

per hour (25 miles

per hour), pursuant to

35 IAC 212.301

and 212.314.

Compliance

with this requirement

is considered to be

assured by the inherent

nature of operations

at this

source,

as demonstrated

by historical operation.

b. No person shall

cause or allow the emission of smoke

or

other particulate matter,

with an opacity greater than

30 percent,

into the atmosphere from

any emission unit

other than those

emission units subject to the

requirements of 35 IAC 212.122,

pursuant to 35 IAC

212.123(a),

except as allowed

by 35 IAC 212.123(b) and

212.124.

5.2.3 Ozone Depleting

Substances

The Permittee shall

comply with the standards

for

recycling

and emissions reduction

of ozone depleting

substances

pursuant to 40 CFR

Part 82, Subpart F, except

as provided

for motor vehicle air-

conditioners in Subpart

B of 40 CFR

Part 82:

a. Persons opening

appliances for maintenance,

service,

repair, or disposal

must comply with the required

practices

pursuant to 40

CFR 82.156.

b. Equipment

used during the maintenance,

service,

repair, or

disposal of appliances must

comply with

11

010113"

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

the standards for recycling and recovery equipment

pursuant to 40 CFR 82.158.

Persons performing maintenance, service, repair, or

disposal of appliances must be certified by an

approved technician certification program pursuant to

40

CFR 82.161.

5.2.4 Risk Management Plan

Should this

stationary source, as defined in 40 CFR

Section 68.3, become subject to the Accidental Release

Prevention regulations in 40 CFR Part 68, then the owner

or operator shall submit

[40 CFR 68.215(a)(2)(i) and

(ii)]:

a.

A compliance schedule for meeting the requirements of

40 CFR Part 68 by the date provided

in 40 CFR

68.10(a); or

b . A certification statement

that the source is in

compliance with all requirements of 40 CFR Part 68,

including the registration

and submission of the Risk

Management Plan (RMP), as part of the annual

compliance certification required by 40 CFR Part 70

or 71.

5.2.5 a. Should this stationary

source become subject to a

regulation under 40 CFR Parts 60, 61, or 63, or

35 IAC

after the date issued of this permit, then the owner or

operator shall, in accordance with

the applicable

regulation(s), comply with the applicable requirements

by the date(s) specified and shall certify compliance

with the applicable requirements of such regulation(s)

as part of the annual compliance certification, as

required

by 40 CFR Part 70

or

71.

b . No later than upon the submittal for renewal of this

permit, the owner or operator shall submit, as part

of an application, the necessary information

to

address either the non-applicability of, or

demonstrate compliance with all applicable

requirements of

any

potentially

applicable regulation

which was promulgated after the date issued

of this

permit.

5.2.6

Episode Action Plan

a. If the source is required to have an episode action

plan pursuant to 35 IAC 244.142, the Permittee shall

maintain at the source and have on file with the

Illinois EPA a written episode action plan (plan) for

reducing the levels of emissions

during yellow

alerts, red alerts, and emergencies, consistent with

12

0 01-3'

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

safe operating

procedures. The plan

shall contain

the information

specified in 35 IAC 244.144.

b. The

Permittee shall immediately

implement the

appropriate

steps described in this plan

should an

air pollution

alert or emergency be

declared.

c.

If a change occurs at the

source which requires a

revision

of the plan (e.g., operational

change,

change

in the source contact person),

a copy of the

revised plan

shall be submitted to the Illinois

EPA

for review within

30 days of the change. Such plans

shall be further revised if

disapproved by the

Illinois EPA.

d. For sources required to

have a plan pursuant to 35

IAC

244.142, a copy of the

original plan and any

subsequent revisions

shall be sent to:

i .

Illinois EPA, Compliance

Section; and

i i. For. sources located

in Cook County and outside

of the gity of Chicago: Cook

County

Department

of Environmental Control;

or

iii.

For sources located within

the city of

Chicago:

Chicago Department of Environmental

Control.

5.2.7 CAM Plan

T his stationary

source has a pollutant-specific

emissions

unit that is subject to

40 CFR Part 64, Compliance

Assurance

Monitoring (CAM) for Major

Stationary Sources.

As a result

of this application either not having

been

submitted or deemed complete

by April 20, 1998, the

source

is required to comply with the requirements

of 40 CFR Part

64 for large

pollutant-specific emissions units

in the

initial application

and CAAPP permit. The source

must

submit a CAM plan for all other

affected pollutant-

specific emissions

units upon application for

renewal of

the initial CAAPP

permit, or upon, a significant

modification to the

CAAPP permit for the construction

or

modification of a large pollutant-specific

emissions unit

which

has the potential post-control

device emissions of

the applicable

regulated air pollutant

that equals or

exceeds major

source threshold levels.

5.3 Non-Applicability

of Regulations

of Concern

None

13

0

13

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

5.4 Source-Wide Operational and Production Limits and Work

Practices

I n addition to

the source-wide requirements in the Standard

Permit Conditions in Section

9, the Permittee shall fulfill the

following source-wide operational and production

limitations

and/or work practice requirements:

None

5.5 Source-Wide

Emission Limitations

5 .5.1 Permitted Emissions for

Fees

The

annual emissions from the source, not considering

insignificant activities as

addressed by Section 3.0 of

this permit, shall not exceed the following limitations.

The overall source emissions shall be determined by adding

emissions from

all emission units. Compliance with these

limits shall be determined on a calendar year

basis.

These limitations (Condition 5.5.1) are set for the

purpose of

establishing fees and are not federally

enforceable.

P ermitted Emissions

of

Regulated

Pollutants

P ollutant

Tons/Year

Volatile

Organic Material (VOM)

230.30

Sulfur Dioxide (S02)

4.34

Particulate Matter (PM)

12.08

Nitrogen Oxides (NO.)

35.56

HAP,

not included in VOM or PM

.

----

Total

282.28

5.5.2 Emissions of Hazardous Air Pollutants

This permit is issued based on the

emissions of HAPs as

listed in Section 112(b) of the CAA not being equal to or

exceeding 10 tons per year of a single HAP or 25 tons per

year of any combination

of such HAPs, so that this source

is considered a minor source for HAPs.

5.5.3 Other Source-Wide

Emission Limitations

Other source-wide emission limitations are not set for

this

source pursuant to either the federal rules for

Prevention

of Significant Deterioration (PSD), 40 CFR

52.21, Illinois EPA rules for Major

Stationary Sources

Construction and Modification, 35

IAC Part 203, or Section

502(b)(10) of the CAA. However, there may be unit

specific emission.limitations set forth in Section 7 of

this permit

pursuant to these rules.

14

() ()

i-13

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

5.6 General Recoxdkeeping

Requirements

5.6.1 Emission Records

The Permittee

shall maintain re cords

,of

the following

items

for

the

source to demonstrate compliance.with

Condition 5.5..1, pursuant

to Section 39.5(7)(b) of the

Act:

Total

annual emissions on a calendar year

basis for

the emission

units covered by Section 7 (Unit

Specific Conditions)-of

this permit.

5.6.2

Records

for Operating Scenarios

N/A

5 .6.3 Retention and Availability

of Records

C a. All records and logs required

by this permit shall be

retained

for at least five years from the.date

of

entry (unless a longer

retention period is specified

by the particular recordkeeping provision

herein),

shall

be kept at a location at the source that is,

readily accessible to

the Illinois EPA or USEPA, and

shall be made available for inspection and

copying by

the Illinois EPA

or.USEPA upon request.

b.. The Permittee

shall retrieve and print,

on

paper

during normal source

office hours, any records

retained in an electronic format

*(e.g., computer) in.

response to an Illinois EPA or USEPA request for

records during the

course of a source inspection.

5.7 General Reporting Requirements

5.7.1 General Source-Wide 'Reporting Requirements

The Permittee shall.promptly

notify the Illinois EPA,

Compliance Section,, of deviations

of the source with the

permit requirements as follows, pursuant to Section

39.5(7) (f) (ii)

of the Act. Reports shall describe the

probable cause of such

deviations, and any corrective

actions or preventive measures taken.

5.7.2 Annual

Emissions Report,

The annual emissions

report required pursuant to Condition .

9.7 shall contain emissions information

for the previous

calendar year.

15

.

.

0 0113

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

5.7.3 Annual

Reporting of HAP Emissions

T h e

Permiftee shall submit an a nnual

-report to the

Illinois EPA,. Compliance

Section, on HAP emissions from

the

source, including the following

information, so as to

demonstrate.

whether the source

is being operated as a non-

major source

of HAP emissions. This report

shall be

submitted with the Annual

Emissions Report (Condition

9.7).

a. The annual

emissions of individual HAPs for

each

month of the previous

calendar year sufficient to

demonstrate compliance

with the 12 month running

total

of Condition 5.5.2, tons/year, (e.g.,

for the .

month of January,

the emissions from February of.

the

preceding.calendar year through

January; for the

month

of February, the emissions

from March of the

preceding

calendar year through February; 12

months .

in all); and

b. -The total

annual emissions of all HAPs combined for'

each month of the previous

calendar year. sufficient

to demonstrate

compliance with the 12 month

running

total of Condition

5.5.2, tons/year, (e.g., for the

month of January, the emissions

from February of the

preceding

calendar year through January; for

the

month of February, the

emissions from March of the

preceding

calendar year through February;

12 months

in all).

5.8

.General

Operational Flexibility/Anticipated"Operating

Scenarios

N/A

5 .9 General Compliance

Procedures

5.9.1

General Procedures for Calculating

Emissions

Compliance

with the source-wide emission

limits specified

in Condition 5.5

shall be based on the recordkeeping

and

reporting

requirements of Conditions

5.6 and 5.7, and

compliance procedures

in Section 7 (Unit.Specific

Conditions) of

this permit.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

6.0

NOT APPLICABLE TO THIS PERMIT

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

7.0

UNIT SPECIFIC CONDITIONS

7.1

Unit 01: Vapor Control System

Control: Thermal

Treatment Unit (Enclosed Flare)

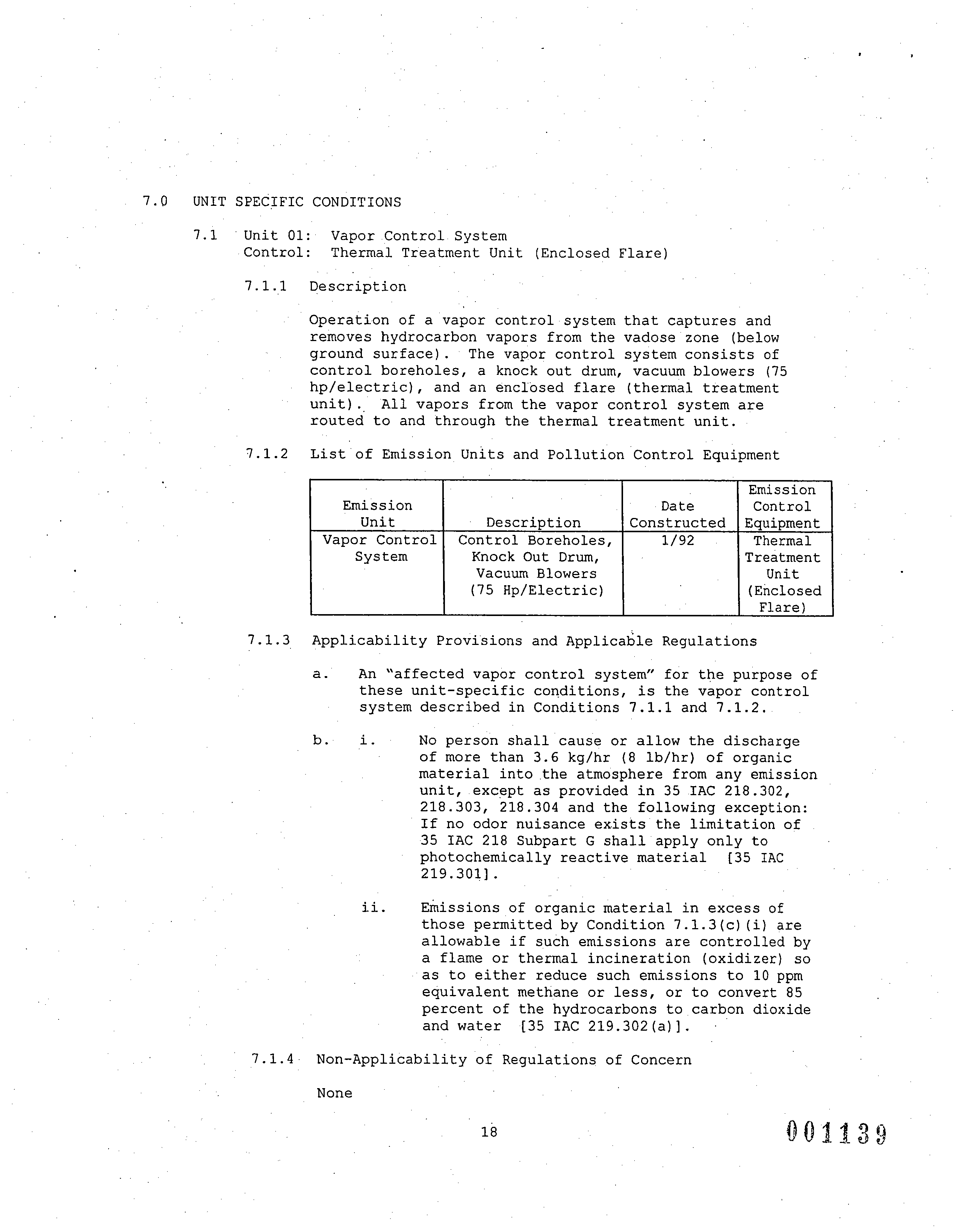

7.1.1 Description

Operation

of a vapor control system that captures and

removes hydrocarbon vapors

from the vadose zone (below

ground surface). The vapor control

system consists of

control boreholes, a knock out drum, vacuum blowers

(75

hp/electric),

and an enclosed flare (thermal treatment

unit). All vapors

from the vapor control system are

routed to and through the thermal treatment unit.

7 .1.2 List of Emission Units

and Pollution Control Equipment

Emission

Emission

Date

Control

U nit

Description

Constructed Equipment

Vapor Control Control Boreholes,

1/92

Thermal

System

Knock Out Drum,

Treatment

Vacuum

Blowers

Unit

( 75 Hp/Electric)

(Enclosed

F lare)

7.1.3. Applicability Provisions

and Applicable Regulations

a .

b .

An "affected vapor control system" for the purpose of

these unit-specific

conditions, is the vapor control

system described in Conditions 7.1.1 and 7.1.2.

ii.

No person shall cause

or

allow the discharge

of more than 3.6 kg/hr (8 lb/hr) of organic

material into.the atmosphere from any emission

unit, except as provided

in 35

IAC

218.302,

218.303, 218.304 and the following exception:

If no odor

nuisance exists the limitation of

35 IAC 218 Subpart

G shall apply only to

photochemically reactive material [35 IAC

219.301].

Emissions of organic material in excess

of

those permitted by Condition 7.1.3(c)(i)

are

allowable if such emissions are controlled by

a flame or

thermal incineration (oxidizer) so

as to either reduce such

emissions

to 10

ppm

equivalent methane or less, or to convert 85

percent of the hydrocarbons to carbon dioxide

and water [35 IAC 219.302(a)].

7 .1.4

Non-Applicability of Regulations of Concern

None

3 J

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

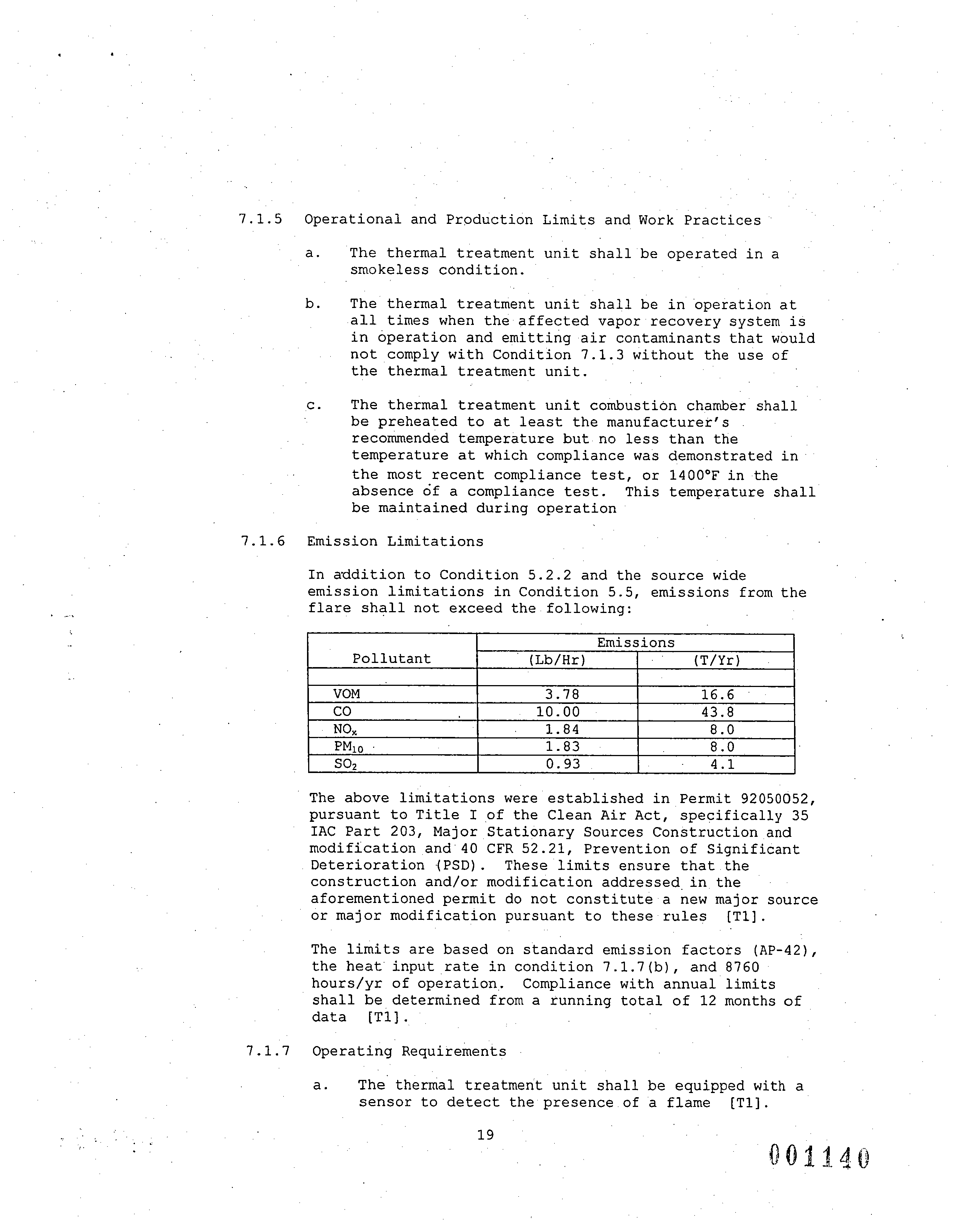

7.1.5 Operational and Production Limits and Work Practices

a.

b.

The thermal treatment

unit shall be operated in a

smokeless condition.

The thermal treatment unit shall be in 'operation

at

all times when

the affected vapor recovery system is

in operation and

emitting air contaminants that would

not comply with Condition 7.1.3 without

the use of

the thermal treatment unit.

'

The thermal

treatment unit combustion chamber shall

be preheated to at least the manufacturer's

recommended

temperature but no less than the

temperature

at which compliance was demonstrated in

the most recent compliance test, or 1400°F in the

absence of

a compliance test. This temperature shall

be maintained during operation

7.1.6 Emission Limitations

In addition to Condition 5.2.2 and the source wide

emission

limitations in Condition 5.5, emissions from the

flare shall not exceed the- following:

E missions

Pollutant

'

(Lb/Hr)

(T/Yr)

V OM

3.78

16.6

CO

10.00

43.8

NO,

1.84

8.0

P M10

1 .83

8.0

S02

0.93 .

4.1

The above limitations were

established in Permit 92050052,

pursuant to Title I of the Clean Air Act,

specifically 35

IAC Part 203, Major,' Stationary Sources Construction,

and

modification

,and,40

CFR 52.21, Prevention of Significant

Deterioration .(PSD).

These limits ensure that.the

construction and/or modification addressed in

the

aforementioned permit do not constitute a new major

source

or major modification pursuant to these rules [T1].

The limits are based on standard

emission factors (AP-42),

the heat input.rate in condition 7.1.7(b),

and 8760

hours/yr of operation.. Compliance with annual

limits

shall be determined from a running total of 12 months of

data [T1].

7.1.7 Operating Requirements

a. The thermal treatment unit shall be equipped with

a

sensor to detect the presence.of a flame [T1].

19

.

..

0®11,40

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

Total heat input to the thermal treatment unit,

including thermal

treatment unit gas and contaminated

air shall not exceed 27 inmBtu/hr [T1].

c.

Hydrogen Sulfide in the inlet to the thermal

treatment

unit shall not exceed.60 ppm [T1]'.

d. The capture.system and thermal treatment unit shall

be operated to reduce VOM emissions by 85% so as to.

comply with Condition 7.1.3(c)

and (d).

Flowrate of contaminated air to the thermal treatment

unit and hydrocarbons

in the air shall not exceed

1600 SUM and 1200 lb/hr [T1].

7.1.8 Monitoring

Requirements

The thermal treatment unit shall be equipped with a sensor

to

detect the presence of a flame [T1].

7.1.9

Recordkeeping Requirements

In addition to the records. required by Condition 5.6, the

Permittee shall maintain records.of the following items

for the affected vapor control

system to demonstrate

'compliance with Conditions 5.5.1, 7.1.3,. 7.1.5, 7.1.7, and

7.1.8, pursuant to Section

39.5(7)(b) of the Act:

Thermal oxidizer combustion chamber temperature

(continuous);

b . VOM and HAP emissions (lb/month);

and

c . Record of time periods when the flare flame is

extinguished. .

7.1.10

Reporting Requirements

a. The Permittee shall promptly notify the Illinois EPA,

Compliance Section, of deviations of the affected

vapor control system with

the permit

requirements

as.

follows, pursuant to

Section 39.5 (7)

(f) (ii)

of the

Act. Reports shall describe the probable cause of

such deviations, and any corrective actions or

preventive measures

taken.

b. The Permittee shall submit

an annual report of

emissions listed in Condition 7.1.6 with supporting

calculations. The report shall include a summary of

time periods when the thermal treatment unit flame

was extinguished.

20

0 01141

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

c. -The' Illinois EPA shall be. notified of permanent

shutdown of the system. Notifications shall

be sent.

to the Illinois

EPA's Regional office in.Collinsville

(see- Condition 8.6.4(ii)).

7.1.11

Operational Flexibility/Anticipated Operating

Scenarios

N/A

7.1.12

Compliance Procedures

Compliance with

the. requirements of Condition 7..1.3 (c) and

(d) (35 IAC 219.141 and 219.302)

is assured by compliance

with the operational requirements of Condition 7.1.5,

the

monitoring requirements of Condition 7.1.8 and the

recordkeeping requirements

in Condition 7.1.9.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

7.2

Unit 02: River Dock (Marine Vessel

Loading)

Control: Vapor Recovery Unit (for

Low-Vapor Pressure Materials)

and

Flare (for High-Vapor Pressure Materials)

7.2.1 Description

The

marine vessel loading terminal (river

dock) delivers

high-vapor pressure

materials (e.g. gasoline products,

naphtha, and rerun materials)

and low-vapor pressure

materials to marine vessels

that operate along the

Mississippi

River. The river dock consists

of two (2)

loading berths,

and can deliver product to a barge vessel

at each of the berths

simultaneously.

The loading

apparatus is equipped with a vapor recovery

hose positioned at

the marine vessel loading positions for

hook up to the flare.. The vapor hose

and associated

piping transports

the hydrocarbon-enriched air displaced

from the marine vessels

during loading to a liquid seal

knockout vessel and then

to the flare.

7 .2.2

List of Emission Units and Pollution

Control Equipment

*

Emission

Date

Emission Control

Unit

Description

Modified

Equipment

Unit 02

Marine Vessel Loading 1 981* Vapor

Recovery

Unit and Flare

Refurbished in 1981.

A new platform was constructed,

a new pipeline

was installed to the river

dock. The

loading berth was

reconditioned and all new piping

and loading arms installed.

7 .2.3 Applicability Provisions

and Applicable Regulations

a.

b .

The "affected

marine vessel loading operation" for

the purpose

of these unit-specific conditions, is the

operation as described in Conditions

7.2.1 and 7.2.2.

The.affected marine vessel

loading operation is

subject to 35 IAC Part 219, Subpart

GG: Marine

Terminals since the source is engaged

in delivering

high-vapor

pressure materials to marine. vessels.

7.2.4

Non-Applicability of Regulations

of Concern

a.

The affected marine vessel loading operation

is not

subject

to 35 IAC 219.122, which requires a submerged

loading pipe when

loading a volatile organic liquid

(VOL) with a vapor pressure

greater than 2.5 psia,

because the rule is only relevant to loading

operations for railroad tank car, tank truck,

trailer,

or stationary tank; the affected marine

22

0

C.'

1 1 4 3J

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

vessel

loading operation is only engaged in the

loading of

marine vessels.

b. The affected marine vessel loading not

subject to 35

Ill. Adm.

Code 219.120, Control Requirements

for

Storage

Containers of VOL per 35 Ill. Adm. Code

219.119, which

states that limitations of 35 Ill.

Adm. Code 219.120 do not apply

to

vessels

permanently

attached to trucks, railcars, barges,

or ships [35

Il1..Adm.

Code 219.119(d)].

c. The affected marine vessel

loading are not subject to

40 CFR 60, Subpart XX, Standards

of Performance for

Bulk Gasoline

Terminals, since the affected marine

vessel loading does not

deliver liquid product into

gasoline tank trucks as required

for applicability.

d. The affected

marine vessel loading operations

are not

subject to 40 CFR 63, Subpart

Y, National Emission

Standards for Marine. Tank Vessel Tank Loading

Operations,

since the facility has opted to

accept a

limit for total loading

of high-vapor pressure

materials

to marine vessels to no greater

than 9.5

million barrels per

year; the rule requires 10

million barrels or 200

million barrels per year for

applicability.

7 .2.5

Control Requirements and Operational Limitations

a . The affected marine vessel

loading operations shall

utilize vapor collection and control

system to

control VOM

emissions from the marine terminal while

loading gasoline and crude. oil,

so as to comply with

35 Ill. Adm. Code Part 219 Subpart

GG.

b. Pursuant to 35 Ill. Adm.

Code 219.762(a), this vapor

collection and control system shall meet the

following

requirements:

i.

Capture the vapors

displaced during the

loading event and reduce overall VOM emissions

by at least

95% by weight through the flare

[35 Ill.

Adm. Code 219.762(a)(1)].

ii. Be maintained and operated so that

it prevents

visible

liquid leaks, significant odors,

and

visible

fumes in the liquid transfer and

the

vapor

collection lines, and appurtenances

during loading [35

Ill. Adm. Code

219.762(a) (2)].

iii.

Be certified as required by Coast Guard

regulations found at 33 CFR 154 [35 Ill. Adm.

Code 219.762(a)(3)].

23

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

c. Pursuant to

35 Ill. Adm. Code 219-762(b), during the

regulatory control period, gasoline

or.crude oil

shall

only be loaded.into.marine vessels.that

are:

Equipped with vapor

collection equipment that

has been certified

as required by Coast Guard

regulations found at 46 CFR 39 [35 Ill.

Adm.

Code

219.762(b)(1)].

ii. Connected to.the vapor collection

system [35

Ill. Adm. Code 219.762(b)(2)]

iii. Vapor-tight as described

in 35 Ill.'Adm. Code

219.762 (b) (3) (A) , (b) (3) (B) , (b) (3) (C)

, or

(b)(3)(D)

[35 Ill. Adm. Code 219.762(b)(3)].

d. '

Total loading of high vapor pressure materials

to'

marine vessels

is limited to no greater than 9.5

million.barrels per year.

7.2.6 Emission Limitations.

There are no

specific emission limitations for this unit,

however, there

are source wide limitations in Condition

5.5 that include this unit.

7.2.7 Testing

and Monitoring Requirements

a. Pursuant to 35 Ill.

Adm. Code 219.766, the Permittee

shall comply with'the requirements regarding

detection

and repair of leaks of 35 Ill. Adm: Code

219.445 for.all equipment associated with

the vapor

collection

and control system, including (see

Section

7.7 for further

details):

i.

Develop

a monitoring program plan consistent

with

the provisions of 35 Ill. Adm. Code

219.446;

ii. Conduct

a monitoring program consistent with

the provisions.of 35

Ill.

Adm.

Code 219.447;

iii.

Record all leaking components which have

a

volatile

organic material.concentration

exceeding 10;000

ppm'consistent with the

provisions of 35 Ill. Adm.

Code 219.448;

iv.

Identify each component consistent with

the'

monitoring

program plan submitted pursuant to

35 Ill. Adm.

Code 219.446;

v.

Repair and retest the leaking

components as

soon as possible.within 22 days after

the leak

24

0 0114

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

is found, but no later than June 1 for the

purposes of 35 Ill. Adm. Code 219.447(a)(1),

unless the leaking components cannot be

repaired until the unit is shut down for

turnaround;

and

vi. Report to the Illinois EPA consistent with the

provisions

of 35 Ill. Adm. Code 219.449.

b. Compliance with 35 IAC

Section

219.762 (a) (2)

of this

Subpart shall be determined by visual inspection and

by the leak detection methods contained in Section

219.105(8) of this Part.

c. If the control device used to comply with 35 IAC

Section 219.762(a)(1) of this Subpart is a flare,

compliance shall

be determined by methods described

in 35 IAC Section 219.429(c).

d.

Compliance with

35 IAC Section 219.762 (b) (3) of this

Subpart shall be determined by one of the methods

described in this Section:

i.

A marine vessel loaded in accordance with 35

IAC Section 219.762(b)(3)(A) of this Subpart

through the use of

a

vacuum assisted vapor

collection system is assumed to be vapor=tight

for the purposes of this Subpart..

ii. A vapor-tightness test for marine vessels

shall be

conducted to

include

the

final

20

percent of loading of each product

tank of the

marine vessel, and it shall be applied to any

potential

sources

of vapor leaks

on the vessel

pursuant to Method 21 of 40 CFR 60, Appendix

A, incorporated by reference at 35 IAC Section

219.112 of this Part. A reading of 10,000

ppmv or greater as methane shall constitute

a

leak.

iii. As an alternative

to subsection

(d)(2)

of this

Section, an.owner or operator of a marine

terminal may use the vapor-tightness test

described in 40 CFR 61.304(f), incorporated by

reference at 35 IAC Section 219.112 of

this

Part.

f. When in the opinion of the Agency or USEPA it is

necessary to conduct testing to demonstrate

compliance

with

or

verify

effectiveness of the vapor

collection and control system required by 35 IAC

Section 219.762 (a), (c) (1),

or

(c)

(3) of this

Subpart, the owner or operator of a marine terminal

shall, at its own expense, conduct such tests in

25

0 011.46'

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

accordance with the applicable

test methods and

procedures

specified in subsections

(a), (b), or (c)

of this Section,

as applicable.

g .

An owner or operator of a marine

terminal planning to

conduct

a VOM emissions test to

demonstrate

compliance with

35 IAC Sections 219.762(a), (c)(1),

or (c)(3) of this Subpart

shall notify the Agency of

that

intent not less than 30

days before the planned

initiation

of the tests so that the Agency may

observe the

test

7.2.8 Inspection

and Monitoring Requirements

N one

7.2.9

Recordkeeping Requirements

a .

General Recordkeeping

The Permittee shall

maintain records of the following

for each

affected marine vessel loading

operations to

demonstrate compliance

with Conditions 5.5.1, 7.2.3,

and 7.2.6:

The identification

and properties of each

organic liquid distributed through

each

affected

loading rack, as related to emissions,

i.e., vapor pressure

and molecular weight;

ii. The amount of

each organic liquid distributed

through each affected loading rack,

gallons

per month

and gallons per year, with annual

records updated each

month by totaling the

throughput for that month plus

the preceding

11 months;

The number of components (i.e., valves,

pump

seals,

etc.) in light liquid, heavy liquid

or

gas service, as

applicable;

iv. Emissions

of VOM attributable to loading

of

petroleum products,

tons/month and tons/year,

with supporting calculations,

calculated

utilizing an approved USEPA methodology,

such

as

Section 5.2 of the AP-42 and the control

efficiency

of a VRU as demonstrated in the

most recent test,

with annual records updated

each month by totaling the

throughput for that

month plus the preceding 11 months

(See

Condition 7.1.12(c) for gasoline loading);

and

Emissions of VOM

attributable to fugitive

losses (valves, pump seals, etc.),

tons/month

26

0

011

47

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

and tons/year, with supporting calculations,

calculated utilizing an approved USEPA

methodology.

The owner or operator

of sources

complying with

35

IAC Sections 219.762 (a) and (b), or '(c)(1), or (c) (3)

of this Subpart shall maintain records regarding the

marine terminal, and each time a marine vessel is

loaded

during

the regulatory control period The

records shall include

but are

not limited to:

i.

The date(s) and the time(s) at which the

marine

vessel

was loaded from the marine

terminal;

ii. The name, type, identification number, and

owner of the vessel

loaded;

iii. The type and amount of liquid loaded into the

marine vessel;

iv. Records of any leaks found, repair attempts,

and the results of the required fugitive

monitoring and maintenance program, including

appropriate dates, test methods, instrument

readings, repair results,

and corrective

action taken as required by 35 IAC Sections

219.762(a)(2) and 219.766 of this Subpart;

A copy of the Coast Guard certification

demonstrating

that the marine terminal's vapor

collection and

control system has been

certified as required by Coast Guard

regulations found

at 33 CFR 154; and

vi. A copy of the Coast Guard certification

demonstrating that the marine vessel has been

inspected and certified as required by Coast

Guard regulations found at 46 CFR 39. If a

copy of the Coast Guard certificate is not

available at the time of loading, then the

date that the marine vessel was last inspected

and the authorization that the marine vessel

has functioning vapor control equipment must

be

recorded from

the certificate.

Further,

a

copy of the certificate must be obtained by

the owner or operator

of

the marine terminal

within 21 days after the loading event.

c. Owners or operators complying with 35 IAC Sections

219.762(b) (3) (B), (b) (3) (C), or (b) (3) (D) shall

additionally maintain the following records

concerning the vapor-tightness of the marine vessel:

27

0 01

-148

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

i.

Test

title;

ii.

Owner of the marine vessel

tested;

iii. The identification

number of the marine vessel.

tested;

i v. Testing

location

v .

Tester name and signature;

vi. Witnessing

inspector; name, signature,

and

affiliation;

and

vii. ;Test

results.

d. Owners or operators complying

with the requirements

of

35 IAC Section 219.762(c)(2) of

this Subpart shall

maintain records of daily

product volumes loaded to

demonstrate that the

applicable emission reduction

specified in Appendix E-of this Part

has been

achieved.

e. Owners

or operators certifying compliance under 35

IAC Section 219.764(c)

shall maintain the records

specified

in subsections (b)(1), (bj(2),

and (b)(3)

above.

'

f. All records

required by subsections (b), (c),

(d),

and (e) of this Section

shall be maintained for at

least

three years and shall be made

available to the

Agency upon.request..

9-

Total natural

gas usage for flare (ft3/mo)

7.2.10 Reporting

Requirements

7.2.11

The Permittee shall promptly

notify the Illinois. EPA,

Compliance

Section, 'of deviations

of the .affected marine

vessel loading

operations with the permit- requirements

as

follows, pursuant to Section

39.5(7)(f)(ii) of the Act.

Reports

shall describe the probable

cause of.such

deviations,

and any corrective actions

or preventive

measures taken.

Operational Flexibility/Anticipated

Operating.Scenarios

The Permittee

is authorized to make

the following physical

or operational change with

respect to an affected loading

rack without prior notification

to the Illinois EPA or

revision of this permit. This condition

does not affect

the

Per mittee's obligation to properly

obtain a

construction

permit in a timely manner for

any activity

28

0 01149

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

constituting construction

or modification of the ;source,

as defined in 35 IAC 201.102:

None

7 .2.12 Compliance Procedures

Compliance with the operational limitations of

Condition 7.2.5(a), shall-be demonstrated through, the

inspection/monitoring,

recordkeeping and reporting

requirements of Conditions 7.2.8,

7.2.9, and 7.2.10

and the compliance procedures in.7.2.12(c)

and (d).

b. Compliance.with

the control requirements of 7.2.5(a)

shall be demonstrated by

the inspection/monitoring,.

recordkeeping and reporting requirements of

Conditions 7.2.8, 7.2.9, and 7.2.10 and the fact that

compliance of loading rack

and associated vapor

recovery unit have previously

been demonstrated by

fulfillment of the test requirements of 40 CFR 60'.8

by measurement

of the total organic concentration(s)

in the effluent stream of the vapor recovery

system

pursuant to'40 CFR 60.503.

c. VOM and HAP emission from the loading shall

be

calculated

by use. of the following equations:

i.

Total VOM Emissions (lb) = Throughput

(gallons) x EF* X (1 - Control Efficiency of

Flare/100)

Where:

Throughput = Loading Rack Throughput as

Determined by the Records

Required in 7.2.9(a)

Control.Efficiency of Flare = 97 %

* Emission

Factors as provided in the Title

5 application

ii. HAP emissions = VOM emissions X EFi`

Material

Loaded

E mission Factor

lb/1000 Gallon

Gasoline

3.90

Distillate Fue1.Oi1

0.'012 -

** Emission

Factors as provided in the Title

5 application

29

0 01150

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

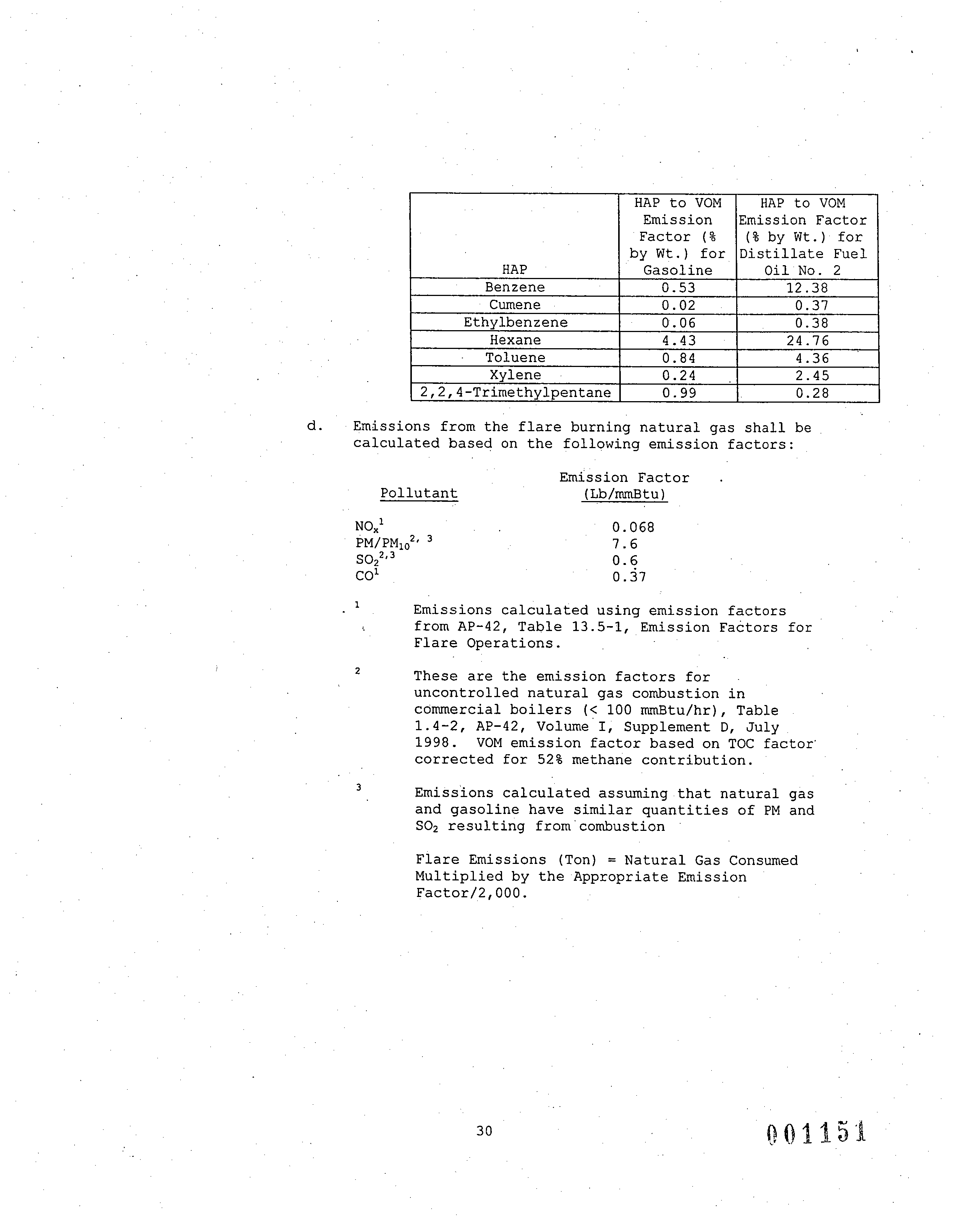

HAP

HAP to VOM

Emission

Factor ($

by Wt.)

for.

Gasoline

HAP to VOM

Emission Factor

($ by Wt.) for

Distillate Fuel

Oil

No. 2

Benzene

0.53

12.38

Cumene

0.02

0.37

Ethylbenzene

0.06

0.38

Hexane

4.43

24.76

Toluene

0.84

4.36

Xylene

0.24

2.45

2,2,4-Trimethylpentane

0.99

0.28

d. Emissions from the flare

burning natural gas shall be

calculated

based on the following emission

factors:

.

Emission

Factor

Pollutant

(Lb/mmBtu)

NO.'

0.068

PM/PMlo2,

3

7.6

S022,3

0.6

CO,

0.37

I

3

Emissions calculated

using emission factors

from AP-42, Table 13.5-1, Emission Factors for

Flare

Operations.

These

are the emission factors for

uncontrolled natural gas

combustion in

commercial boilers (< 100 mmBtu/hr),

Table

1.4-2,

AP-42, Volume I, Supplement D, July.

1998. VOM emission factor

based on TOC factor'

corrected for 52% methane contribution.

Emissions calculated

assuming. that natural gas

and gasoline have similar quantities of

PM and

S02 resulting from'combustion

Flare Emissions (Ton) = Natural Gas Consumed

Multiplied

by the Appropriate Emission

Factor/2,000.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

7.3 Unit 03: External Floating Roof, Storage Tanks

Control: Floating Roof, Double Seals and Submerged Loading

7.3.1 .-.Description

The terminal has a number of storage tanks used to store

gasoline (RVP 15); ethanol, and all VPLs with vapor

pressure lower than gasoline.

7.3.2 List of Emission Units and Air Pollution Control Equipment

Emission

Unit

Description

Date

C onstructed

Emission

Control

Equipment

Unit

03 External Floating

Roof Tanks:

120-1

1947

Floating Roof,

120-2

1947

Primary Seal

120-3

1953

and Rim-Mounted

120-4

1953.

. Secondary Seal,

102-5.

1953

Submerged

120-7

1957

Loading

120-8

1945

120-10

1949

120-11

1953.

80-4

1953

80-5.

1960

80-10

1961

80-11

1954

20-8

10-20'

5-10 .

7.3.3 Applicability Provisions

a. An "affected tank," for the purposes of these unit-

specific conditions, is a storage tank that is only

subject to the requirements of 35 IAC 219.121,.

219.122(b), 219.123, and 219.124. Each storage tank

with a capacity of 151.42 cubic meters (approx.

40,000 gallons) or more, storing volatile petroleum

liquid (VPL), equipped with an external

floating

roof

is subject to the requirements of

35 IAC

219.124(a)

unless it is exempted pursuant to 35 IAC 219.124(b).

A tank also may be exempt due to the current service,

features, or other circumstances associated with the

tank. A tank must comply with other rules if the

vapor pressure of the VPL is 86.19 kPa (12.5 psia) or

greater at

294.3°K (70°F)..

As of the "date issued" as shown.on page 1 of this

permit, the affected tanks. are identified in

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

Condition 7.3.2.

The status of 'all storage tanks-at

this

source, including

affected tanks that are

subject to

35 IAC 218.124(a), is

summarized.in

Attachment 1.

b. When

storing a volatile

organic liquid (VOL, e.g.

ethanol),

each tank is subject

to 35 IAC

219.120(a)(3)

which requires double seals.

Compliance with Condition

7.3.5, 7.3.7 and 7.3.8

shall

be deemed compliance with

this requirement.

7.3.4

Non-Applicable Regulations

None

7.3.5 Control

Requirements

Each affected tank

shall be equipped with

the following:.

a. A floating

roof which rests

on the surface of the VOL

that is equipped

with a primary seal [35

IAC

219.121(b)(1)];

b. A floating roof

that.is equipped with a continuous

' seal

extending from the floatirig.roof

to the tank

wall (rim mounted

secondary seal) [35

IAC

219.124(.a)(1)]'

(The Illinois

EPA has not approved

use of

other equivalent equipment in

lieu of a rim-

mounted secondary

seal.);

c. All drains.(for

drainage of rainwater,. also

know as

"stub drains") in the

floating roof deck shall be

provided

with slotted membrane

fabric covers or

equivalent covers

across at least 90 percent

of the

area

of the opening [35

IAC 219.124(a)(3)];

d. All openings

of the floating roof deck, other than

drains,

shall be equipped with

projections into the

tank which

remain below the liquid

surface at all

times except when

supported on the roof legs

and be

equipped with covers, lids or

seals [35 IAC

219.124(a)(4)];

and

e.. A permanent submerged

loading pipe [35 IAC

219.122(b)].

.

7.3.6

Emission Limitations

There

are no specific emission

limitations for this unit,

however,

there are source wide

emission limitations in.

Condition

5.5 that include this unit

. None

32

00115.3

.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

7.3.7 Operating Requirements

a. Each affected tank shall be operated so that the

floating roof 'including 'the seal closure devices meet

the following requirements:

i.

There shall be no-visible holes, tears,

or

other defects in the seal or'any seal fabric

or material of the floating roof [35 IAC

219.123

(b) (2)];

ii. The seal. is intact. and uniformly in place

.

around the circumference of the floating roof

between

the

floating roof

and tank

wall

[35

IAC 219.124.(a)(2)(A)];

iii. The accumulated area of gaps exceeding 0.32

centimeter (1/8 inch) in width

between the

secondary seal and .the tank wall shall not

exceed 21.2 square centimeters per meter of

tank

diameter (1.0 square inch per foot of

tank diameter) [35 IAC 219.124(a)(2)(B)]; and

iv. The

covers, lids or seals on openings of

.the

floating roof deck other than stub drains

shall be operated such that the following

requirements are met:

A.

The cover, lid or seal is in the closed

position at all times except when

petroleum liquid is transferred to or

from

the tank

[35 IAC

219.123 (b) (3) (A)];

B. .Automatic bleeder vents are closed at all

times

except

when

the

roof

is floated off

or landed on the roof leg supports [35

IAC 219.123(b)(3)(B)]; and

C. Rim vents, if provided, are

set to open

when the roof is being floated off the

roof

leg supports or.at the.

manufacturer's

recommended setting [35

IAC 219.123(b)(3)(C)].

b. No person shall cause or allow the emissions of air

contaminants into

the

atmosphere from

any gauging or

sampling devices attached'to an affected tank, except

during sampling or maintenance operations

[35 IAC

219.121 (b) (1)]..

7.3.8 Inspection Requirements

a. The

Permittee

shall. inspect each affected tank prior

to May 1 of each year, to insure compliance with the

33 .

.001154-

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

applicable control and

operating requirements (35

IAC 219.124 (a) (5)].

b. i.

The Permittee

shall measure the secondary seal

gap of each affected

tank prior to May 1 of

each year. This measurement

shall be

conducted in accordance with the methods

and

procedures

specified in 40 CFR 60, Subpart Kb

[35 IAC 219.124(4)(6)].

ii. .Prior notification for the above measurements

shall be given

to the Illinois EPA as

.specified in Condition

7.3.10(b).

c. The Permittee

shall perform a complete inspection of

the cover and seals of each

affected tank whenever..

the tank is emptied and degassed for any

reasons

other than

the transfer of liquid during the normal

operation of the tank, or whenever

repairs are made

that require degassing of the

tank as a result of. any

semi-annual

inspection or incidence of roof damage or

defect [35 IAC 219.123(b)(5)].

7.3.9 Recordkeep'ing Requirements

a. In addition

to the records required by Condition 5.6

(requiring records of throughput

and emissions), the

Permittee shall maintain records of the following

item's for each affected

tank, pursuant to 35 IAC

219.123 (b)(6).and 219.124 (a)(7):

i.

A list of the types

of

volatile

petroleum

liquid stored on a monthly basis;

ii. The maximum true vapor pressure

of each type

of

liquid as stored, psia;

iii. The results of any inspections

or measurements

required by the Condition 7.3.8 (a), (b)

and/or

(c), including:

A. Type of inspection;

B. When the inspection

and/or measurement

was performed.-

C.- Who performed the inspection and/or

measurement;

D. The method of inspection and/or

measurement.;

E.'

The observed condition of each feature

of

the external

floating roof (seals, roof

34

0

0 115)

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

deck and fittings) with raw data recorded

during the inspection and/or measurement;

and

F. Summary of compliance.

b. The Permittee

shall maintain records of the following

for each affected tank to demonstrate compliance with

Condition 7.3.8(c) (Cover and Seal Inspection) [35

IAC 219.123(b)(6)]:

Records that are sufficient

to

identify

whenever the tank is emptied and degassed for

any reason other than the transfer of liquid

during normal operation or whenever repairs

are made as a result of regular inspections or

incident of roof damage or defect.

7 .3.10 Reporting Requirements

a . The Permittee shall notify the Illinois EPA,

Compliance Section and Regional Field Office,

at,

least 30 days before the planned performance of seal

gap measurements, pursuant to Section 39.5(7)(f) of

the Act, so the Illinois EPA may

observe the

measurements.

b . The Permittee shall promptly notify the Illinois EPA,

Compliance Section of deviations with the control,

operating, or inspection

requirements, as follows

pursuant to Section 39.5(7)(f)(ii) of the Act:

i .

Any storage of VPL

in an affected tank that is

not in compliance with the control

requirements (due to absence of the features

required by Condition 7.3.5, e.g., "no rim-

mounted secondary seal,") within 5 days of

becoming aware of the non-compliance status.

This notification shall include a description

of the event, the cause for the non-

compliance, actions taken to correct the non-

compliance, and the steps to be taken to avoid

future

non-compliance.

ii. Any storage of VPL in an affected tank that is

out of compliance with the control

requirements (Condition 7.3.5) due to damage,

deterioration, or other condition of the tank,

within 30 days of becoming

aware of the non-

compliance status. This notification shall

include

.a

description of the event,

the cause

for the non-compliance, actions taken to

correct the non-compliance, and the steps to.

be

taken to avoid future non-compliance.

35

9;01_id_556'

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

7.3.11 Operational

Flexibility/Anticipated. Operating

Scenarios

The

Permittee is authorized

to make the following physical

or operational

change with respect

to an affected tank

without prior

notification to. the Illinois EPA

or revision

of this permit.

This condition does not affect the

Permittee's obligation to properly

obtain a construction

permit

in a timely manner for any

activity constituting

construction or

modification of the source, as defined

in

35 IAC 201.102:

a.

Changes in the material stored

in a tank, provided

the tank continues

to comply with the Conditions in

Section 7.3 ofthis permit..

The primary.

seals may. be replaced with

the same or a

different type.

Secondary seals may be replaced but

must be rim-mounted.

7.3.12

Compliance Procedures

a. Emissions from each

affected storage tank shall be

determined through the.use

of the TANKS program,

AP-42

upon which the Tanks Program is based, or

any

other method that

utilizes USEPA approved emission

factors for storage tank emissions.

b. For the purpose of estimating HAP

emissions from

equipment

at the facility, the vapor wt percent

(based on a 1992

USEPA survey or calculations based

upon the applicable MSDS for

the specific VOL) of

each HAP for each product

times the VOM emissions

contributed by that product

is acceptable. Other

means of estimating HAP emissions

utilizing USEPA

accepted methodologies

is also acceptable.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

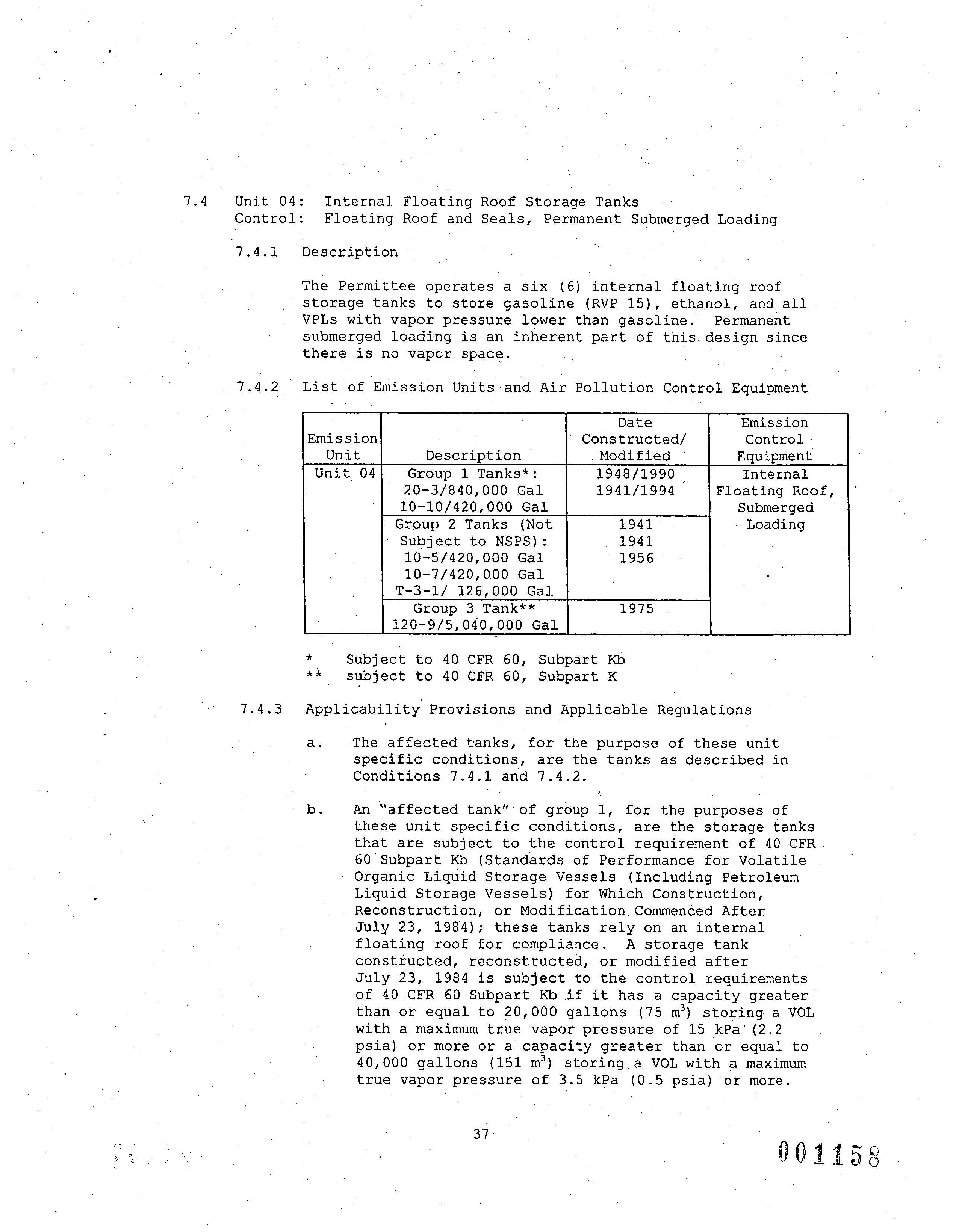

7.4 Unit 04: Internal Floating

Roof Storage, Tanks

Control: Floating Roof and

Seals, Permanent Submerged Loading

7.4.1 Description

The Permittee

operates a six (6) internal floating roof

storage tanks to store

gasoline (RVP 15), ethanol, and all .

VPLs with vapor pressure lower than gasoline.

Permanent

submerged loading is an inherent part of this. design since

there is no vapor

space.

7.4.2 ' List'of Emission Units -and Air Pollution

Control Equipment

Date

Emission

E mission

Constructed/

Control

Unit

Description

.Modified

Equipment

Unit.04 Group 1 Tanks*:

1948/1990

.

Internal

20-3/840,000 Gal

e

1941/1994

Floating- Roof,

10-10/420,000

Gal

Submerged '

Group 2 Tanks (Not

1941. .

Loading

Subject to NSPS):

1941

1 0-5/420,000 Gal

1956

10-7/420,0.00 Gal

.

T-3-1/ 126,000 Gal

Group 3 Tank**

1975

.

120-9/5,040,000 Gal

*

Subject to 40 CFR 60, Subpart Kb

subject

to 40 CFR 60, Subpart K

7.4.3 Applicability Provisions and Applicable Regulations

a.

b.

The affected tanks, for the purpose

of these unit

specific conditions, are the tanks as described in

Conditions 7.4.1

and

7.4.2.

An "affected tank'' of group 1, for the purposes of

these unit specific conditions, are the storage tanks

that are subject to the control

requirement of 40 CFR.

60 Subpart Kb (Standards of Performance for Volatile .

Organic Liquid Storage Vessels (Including Petroleum

Liquid

Storage Vessels).for Which Construction,

Reconstruction, or Modification.Commenced

After

July 23, 198'4); these tanks rely on an internal

.

floating roof for compliance. A storage tank

constructed, reconstructed, or modified after

July 23,

1984 is subject to the control requirements

of 40.CFR 60 Subpart Kb

.if it has a capacity greater

than or equal to 20,000 gallons (75 m3)

storing- a

VOL

with a maximum true vapor pressure of 15 kPa'(2.2

psia) or more of a capacity greater than or

equal

to

40,000 gallons (151 m3) storing.a VOL with a maximum

true vapor

pressure of 3.5 kPa (0.5 psia) or more.

37.

ELECTRONIC FILING, RECEIVED, CLERK'S OFFICE, DECEMBER 22, 2006

As of the "date issued" as shown

on page 1 of this

permit, the affected tanks are

identified in

Condition

7.4.2.

c . Each storage tank subject to

40 CFR 60 Subpart Kb is

hereby shielded from compliance

with 35 IAC 21,9.121.

This shield is issued

to streamline' the applicable

requirements for the source, based on the

Illinois

EPA's finding that compliance