NOTICE

TO:

John

Therriault

Assistant

Clerk

Illinois

Pollution

Control

Board

James

R.

Thompson

Center

100

West

Randolph

St.,

Suite

11-500

Chicago,

IL

60601

SEE

ATTACHED

SERVICE

LIST

PLEASE

TAKE

NOTICE

that

I

have

today

filed

with

the

Office

of

the

Clerk

of

the

Illinois

Pollution

Control

Board

TESTIMONY

OF

ROBERT

KALEEL,

TESTIMONY

OF

MICHAEL

KOERBER,

TESTIMONY

OF

JAMES

E.

STAUDT,

Ph.D.,

MOTION

TO

CORRECT

TRANSCRIPTS,

and

DRAFT

ATTAiNMENT

DEMONSTRATION

FOR

THE

1997

8-HOUR

OZONE

NATIONAL

AMBIENT

AIR

OUALITY

STANDARD

FOR

THE

CHICAGO

NONATTAINMENT

AREA,

AOPSTR

08-07,

AN])

RELATED

DOCUMENTS,

a

copy

of

which

is

herewith

served

upon

you.

ILLiNOIS

ENVIRONMENTAL

PROTEC

‘ION

AGENCY

By:________

Gina

Roccaforte

Assistant

Counsel

Division

of

Legal

Counsel

DATED:

January

20,

2009

1021

North

Grand

Avenue

East

P.

0.

Box

19276

Springfield.

IL

62794-9276

THIS

FilING

IS

STJRMTTTFJ’

2

17/782-5544

ON

RECYCLED

PAPER

* * * Replacement for Authorized Fax Filing for Clarity and Color * * *

TESTIMONY

OF

ROBERT

KALEEL

My

name

is

Robert

Kaleel.

I

am

the

Manager

of

the

Air

Quality

Planning

Section

in

the

Bureau

of

Air

at

the

Illinois

Environmental

Protection

Agency

(Illinois

EPA).

I

have

previously

testified

in

this

rulemaking.

My

testimony

today

is

intended

to

update

the

Board

on

recent

developments

affecting

or

related

to

this

proposal.

The

Illinois

EPA

has

continued

to

work

with

potentially

affected

industries

to

address

some

of

the

concerns

and

issues

raised

at

the

previous

hearing.

The

Illinois

EPA

anticipates

a

motion

to

amend

its

proposal

prior

to

the

public

hearing

scheduled

on

February

3,

2009,

to

address

concerns

raised

at

the

previous

hearing

or

to

reflect

agreements

between

the

Illinois

EPA

and

stakeholders.

I

will

highlight

some

of

the

expected

amendments

to

the

proposal.

In

response

to

several

comments

that

the

proposed

implementation

date

of

May

1,

2010

would

not

allow

enough

time

for

industries

to

reasonably

comply

with

the

requirements

of

the

rule,

the

Illinois

EPA

is

recommending

three

changes.

First,

the

Illinois

EPA

recommends

that

the

compliance

date

in

Sections

217.152,

217.155,

217.164,

217.184,

217.204,

217.224,

217.244,

and

217.344

of

Part

217

be

extended

until

January

1,

2012,

to

allow

industries

enough

time

to

plan

and

implement

the

measures

needed

to

comply.

Second,

recognizing

the

unique

role

of

petroleum

refineries

in

the

region’s

economy,

the

Illinois

EPA

is

recommending

that

the

compliance

date

for

refineries

coincide

with

already

planned

maintenance

turnarounds

to

avoid

unplanned

shut-downs

and

potential

disruptions

to

the

region’s

fuel

supply.

Third,

in

response

to

concerns

about

the

availability

of

continuous

emissions

monitoring

system

(CEMS)

equipment,

the

Illinois

EPA

recommends

extending

the

compliance

date

for

CEMS

for

a

period

of

three

years

after

the

effective

date

of

this

rule.

For

refineries

with

potentially

later

compliance

dates,

CEMS

would

be

required

by

the

compliance

date

for

the

emissions

limitations

contained

in

the

rule.

For

other

industries

with

ArcelorMittal

USA

regarding

concerns

about

the

emission

limits

for

its

reheat

furnace.

We

are

discussing

with

Saint-Gobain

Containers,

Inc.,

the

appropriate

regulatory

language

to

address

its

comment

provided

to

the

Board

prior

to

the

last

hearing.

It

is

our

understanding

that

Saint-Gobain

Containers,

Inc.,

will

either

comply

with

the

requirements

of

this

proposal

by

the

compliance

date

recommended

by

Illinois

EPA,

or

agree

to

more

stringent

requirements

to

be

implemented

by

2014.

We

hope

to

agree

on

the

revised

regulatory

provisions

prior

to

the

third

hearing

to

allow

Saint-Gobain

Containers,

Inc.,

the

flexibility

to

comply

with

the

more

stringent

requirement

at

the

later

date.

The

Illinois

EPA

is

also

working

with

Midwest

Generation

and

ConocoPhillips

to

try

to

resolve

some

of

the

concerns

raised

during

this

rulemaking.

Again

it

is

hoped

that

these

issues

will

be

resolved

prior

to

the

next

hearing.

I

would

also

like

to

update

the

Board

on

some

recent

developments

that

have

been

mentioned

during

this

rulemaking.

On

December

16,

2008,

the

Illinois

EPA

held

a

public

hearing

to

take

comments

on

its

draft

attainment

demonstration

for

Chicago

for

the

1997

8-

hour

ozone

standard,

and

its

draft

maintenance

plan.

The

maintenance

plan

is

intended

to

provide

continued

attainment

of

the

ozone

standard

after

the

area

has

been

redesignated

to

attainment.

Per

the

Board’s

request,

the

Illinois

EPA

is

filing

the

associated

documents,

in

conjunction

with

this

testimony,

as

part

of

this

rulemaking.

Since

the

primary

technical

support

for

the

attainment

demonstration

was

prepared

by

the

Lake

Michigan

Air

Directors

Consortium

(LADCO),

the

Illinois

EPA

requested

that

LADCO’s

Executive

Director,

Mr.

Michael

Koerber,

provide

testimony

and

appear

at

hearing

to

discuss

the

key

findings

contained

in

the

LADCO

technical

support

document.

The

Illinois

EPA

continues

to

maintain,

however,

that

modeling

did

not

play

a

role

in

the

development

of

this

NOx

RACT

proposal.

2

deficiencies

Call

have

been

replaced

by

the

CAIR.

Since

the

Board

has

already

adopted,

and

USEPA

has

approved,

regulations

that

comply

with

CAR

for

electric

generating

units

(EGUs)

in

Illinois,

the

Illinois

EPA

is

developing

revisions

to

the

Illinois

CAR

rule

to

sunset

the

provisions

of

the

NOx

SIP

Call.

These

revisions

will

be

submitted

to

the

Board

in

the

near

future.

Illinois

must

also

correct

its

CAIR

rule

to

ensure

that

non-EGUs

affected

by

the

NOx

SIP

Call

meet

the

emissions

budget

contained

in

the

NOx

SIP

Call

even

though

Illinois

did

not

opt

to

include

non-EGUs

in

the

CAIR

trading

program.

The

Illinois

EPA

is

also

developing

a

regulatory

proposal

to

resolve

this

deficiency

and

hopes

to

submit

this

proposal

to

the

Board

in

the

near

future.

On

December

22,

2008,

the

USEPA

designated

areas

throughout

the

United

States,

including

areas

in

Illinois,

as

nonattainment

for

the

24-hour

PM2.5

air

quality

standard

established

in

2006.

Areas

in

Illinois

that

have

been

designated

as

nonattainment

include

both

Chicago

and

the

Metro-East,

the

same

areas

designated

previously

as

nonattainment

for

the

annual

PM2.5

standard.

Illinois

must

develop

an

attainment

plan

and

adopt

control

measures

needed

to

attain

the

24-hour

PM2.5

standard

within

three

years

of

the

effective

date

of

U.S.

EPA’s

decision,

and

Illinois

must

attain

the

standards

within

five

years

of

the

date.

On

December

16,

2008,

the

Illinois

EPA

held

a

public

meeting

in

Chicago

to

present,

and

take

comments

on,

its

recommendation

for

establishing

nonattainment

area

boundaries

for

the

2008

8-hour

ozone

standard.

A similar

meeting

is

planned

for

the

Metro-East

area

on

January

22,

2009.

The

Illinois

EPA’s

initial

proposal

is

for

Illinois

to

recommend

to

USEPA

to

establish

nonattainment

boundaries

for

the

2008

standard

that

generally

match

the

boundaries

already

established

for

the

1997

ozone

standard.

Illinois

must

provide

recommendations

to

USEPA

no

later

than

March

12,

2009.

USEPA

is

expected

to

finalize

the

nonattainment

designations

in

2010,

initiating

a

new

cycle

of

planning

and

regulatory

3

requirements

to

implement

RACT

for

the

newstandards.

4

TESTIMONY

OF

MICHAEL

KOERBER

My

name

is

Michael

Koerber.

I

am

the

Executive

Director

for

the

Lake

Michigan

Air

Directors

Consortium

(LADCO).

I

have

a

Bachelor

of

Science

degree

in

Environmental

Engineering

from

the

University

of

Illinois

at

Chicago,

and

a

Master

of

Science

degree

in

Meteorology

from

the

Pennsylvania

State

University.

I

have

worked

at

LADCO

for

over

19

years,

and

have

been

in

my

present

position

since

1997.

Previously,

I

worked

as

the

Regional

Meteorologist

at

USEPA,

Region

V.

In

that

capacity,

I

was

responsible

for

reviewing,

overseeing,

and

conducting

air

quality

studies

for

new

source

permits,

state

implementation

plans,

and

other

purposes.

As

Executive

Director

for

LADCO,

I

am

responsible

for

overseeing

and

managing

the

day-to-day

operations

of

the

organization.

The

main

purposes

of

LADCO

are

to

provide

technical

assessments

for

and

assistance

to

our

member

states

(Illinois,

Indiana,

Michigan,

Ohio,

and

Wisconsin)

on

problems

of

air

quality,

and

to

provide

a

forum

for

our

member

states

to

discuss

air

quality

issues.

LADCO

is

committed

to

an

open

and

public

process,

as

exemplified

by

our

long-standing

actions

to

share

data

and

information,

conduct

regular

public

meetings,

and

welcome

participation

by

outside

parties (e.g.,

industry

and

citizen

groups)

on

our

committees.

During

my

career

at

LADCO,

I

have

managed

the

identification

and

evaluation

of

emissions

control

strategies

to

address

1-hour

ozone

nonattainment

in

the

Lake

Michigan

region

as

part

of

the

Lake

Michigan

Ozone

Study

(LMOS),

ozone

transport

problems

in

the

eastern

half

of

the

U.S.

as

part

of

the

Ozone

Transport

Assessment

Group

(OTAG),

visibility

impairment

in

Class

I

areas

across

the

country

as

part

of

the

Regional

Planning

Organization

(RPO)

process,

and

8-hour

ozone

nonattainment,

PM2.5

nonattainment,

and

* * * Replacement for Authorized Fax Filing for Clarity and Color * * *

the

Michigan,

Ohio,

and

Wisconsin.

The

analyses

include

preparation

of

regional

emissions

inventories

and

meteorological

modeling

for

two

base

years

(2002

and

2005),

evaluation

and

application

of

regional

chemical

transport

models,

and

analysis

of

ambient

monitoring

data.

The

results

of

these

analyses

are

summarized

in

LADCO’s

report,

“Regional

Air

Quality

Analyses

for

Ozone,

PM2.5,

and

Regional

Haze:

Final

Technical

Support

Document”,

April

25,

2008.

This

document

is

included

in

the

Illinois

Environmental

Protection

Agency’s

attainment

demonstration

for

ozone,

and

which,

I

believe,

has

already

been

submitted

to

the

Illinois

Pollution

Control

Board

in

this

rulemaking.

As

described

in

the

report,

the

first

step

in

the

technical

analyses

was

to

review

ambient

monitoring

data

to

provide

a

conceptual

understanding

of

the

air

quality

problems.

Key

findings

of

the

data

review

are

as

follows.

Ozone

Based

on

monitoring

data

for

the

period

2005-2007,

there

were

about

20

sites

in

violation

of

the

1997

8-hour

ozone

standard

of

85

parts

per

billion

(ppb)

in

the

upper

Midwest,

including

eight

sites

in

the

Lake

Michigan

area.

Based

on

the

preliminary

monitoring

data

for

the

period

2006-2008,

there

is

only

one

site

in

the

Lake

Michigan

area

in

violation

of

the

1997

8-hour

ozone

standard

(i.e.,

Holland,

Michigan).

Historical

ozone

data

show

a

steady

downward

trend

over

the

past

15

years,

especially

since

200

1-2003,

due

likely

to

federal

and

state

emission

control

programs.

2

* * * Replacement for Authorized Fax Filing for Clarity and Color * * *

some

areas

far

from

population

or

industrial

centers.

As

I

discuss

below,

the

source

region

with

the

largest

contribution

on

high

ozone

days

in

Holland,

Michigan

is

northeastern

Illinois.

M2.5

Based

on

monitoring

data

for

the

period

2005-2007,

there

were

30

sites

in

violation

of

the

current

(1997

version)

annual

PM25

standard

of

15

Ig/m

3

in

the

upper

Midwest,

including

five

sites

in

the

Chicago

area.

Nonattainment

sites

are

characterized

by

an

elevated

regional

background

(about

12

—

14

j.tg/m

3)

and

a

significant

local

(urban)

increment

(about

2

—

3

.tg/m

3).

Historical

PM2.5

data

show

a

slight

downward

trend

since

deployment

of

the

PM2.5

monitoring

network

in

1999.

PM2.5

concentrations

are

also

influenced

by

meteorology,

but

the

relationship

is

more

complex

and

less

well

understood

compared

to

ozone.

On

an

annual

average

basis,

PM2.5

chemical

composition

consists

mostly

of

sulfate,

nitrate,

and

organic

carbon

in

similar

proportions.

The

second

step

in

the

technical

analyses

was

to

apply

air

quality

models

to

support

the

regional

planning

efforts.

The

modeling

was

conducted

in

accordance

with

USEPA’s

air

quality

modeling

guidance.

Two

base

years

were

used

in

the

modeling:

2002

and

2005.

Basecase

modeling

was

conducted

to

evaluate

model

performance

(i.e.,

assess

the

model’s

ability

to

reproduce

observed

concentrations).

This

exercise

was

intended

to

build

confidence

in

the

model

prior

to

its

use

in

examining

control

strategies.

3

demonstration

based

on

the

primary

(guideline)

modeling

and

supplemental

analyses

(i.e.,

other

modeling,

examination

of

historical

trends

in

emissions

and

monitored

data,

and

special

data

analyses).

Such

a

“weight

of

evidence”

approach

for

the

attainment

demonstration

is

recommended

by

USEPA’s

modeling

guidance.

It

should

be

noted

that

among

the

other

modeling

analyses

considered

for

inclusion

in

our

weight

of

evidence

demonstration

was

modeling

conducted

by

a

contractor

for

the

Five

States

Stakeholders,

which

includes

the

Midwest

Ozone

Group

(a

consortium

of

Midwest

utilities).

Because

this

analysis

relied

on

several

assumptions

that

were

counter

to

USEPA’s

modeling

guidance

(and,

as

such,

would

not

be

acceptable

to

USEPA

as

part

of

a

valid

modeled

attainment

demonstration),

we

were

unable

to

include

this

other

modeling

in

our

weight

of

evidence

demonstration.

Based

on

the

modeling

and

supplemental

analyses,

the

LADCO

report

provides

the

conclusions.

First,

existing

controls

are

expected

to

produce

significant

improvement

in

ozone

and

PM25

concentrations.

Second,

the

choice

of

the

base

year

affects

the

future-year

model

projections.

A

key

difference

between

the

base

years

of

2002

and

2005

is

meteorology.

Both

are

technically

valid,

although

2002

was

more

ozone

conducive

than

2005.

The

choice

of

base

year

as

the

basis

for

the

SIP

is a

policy

decision

(i.e.,

how

much

safeguard

to

incorporate).

4

“Western

Michigan

Ozone

Study.”

The

report

is

expected

to

conclude

that

the

1997

8-hour

ozone

standard

will

be

met

at

most,

but

not

all,

sites

in

western

Michigan

by

the

applicable

attainment

date

(i.e.,

by

2009)

—

the

one

site

projected

to

remain

in

nonattainment

is

Holland.

Shoreline

areas

in

western

Michigan,

such

as

Holland,

are

affected

by

inter-regional

transport

and

intra-regional

transport,

especially

from

Illinois

(e.g.,

modeling

estimates

that

1/4

of

the

high

ozone

concentrations

in

Holland

are

from

northeastern

Illinois

emissions).

Fourth,

modeling

suggests

that

most

sites

are

expected

to

meet

the

current

annual

PM2.5

standard

by

the

applicable

attainment

date,

except

for

sites

in

Detroit,

and

Granite

City.

The

regional

modeling

for

PM2.5

does

not

include

air

quality

benefits

expected

from

PM2.5

controls

from

local

industries.

States

are

conducting

local-scale

analyses

and

will

use

these

results,

in

conjunction

with

the

regional-scale

modeling,

to

support

their

attainment

demonstrations

for

PM25

.

These

findings

of

residual

nonattainment

for

ozone

and

PM2.5

are

supported

by

monitoring

data

for

the

period

2005

—

2007,

which

show

significant

nonattainment

in

the

region

(e.g.,

peak

ozone

design

values

on

the

order

of

90—

93

ppb,

and

peak

PM2.5

design

values

on

the

order

of

16

-

17

jig/rn3).

Because

existing

controls

will

not

provide

sufficient

emission

reductions

in

the

next

couple

of

years,

additional

emission

reductions

are

necessary

to

provide

for

attainment

at

all

sites.

Attainment

at

most

sites

by

the

applicable

attainment

date

is

dependent

on

actual

future

year

meteorology

(e.g.,

if

the

weather

conditions

are

similar

to

[or

less

5

and

the

version)

ozone

standard

will

not

be

met

at

several

sites

in

the

Lake

Michigan

region,

even

by

2018,

with

existing

controls.

6

contrib

—

NOX

—

VOC

—

lagion

Ohio

Michigan

Indiana

Illinois

Wisconsin

Ill

Chi

NA

Ind

ChiNA

WisNA

Detroit_NA

Cl

eve

NA

Kentucky

Was

tVirgin:a

Missouri

VISTAS

MANE-VU

GAPWFAP

IA1%IN

Canada

20

30

40

53

60

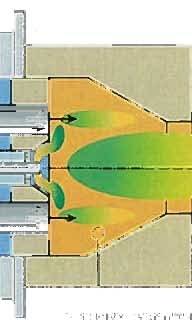

Figure

15.

Model-based

ozone

source

apportionment

results

for

Holland,

Michigan

Note:

BC

represents

the

contribution

from

the

boundary

conditions

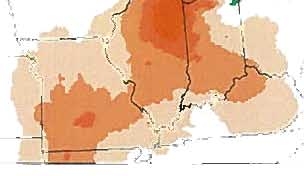

Figure

12.

Monitor-based

back

trajectory

plot

for

high

ozone

days

in

Holland,

Michigan

Note:

darker

shading

represents

higher

frequency

(e.g.,

air

is

most

likely

to

have

passed

through

areas

with

dark

orange

shading

—

I

I

.

—

—

I

0

Percent

PARTS211AND217

)

TESTIMONY

OF

JAMES

E.

STAUDT,

Ph.D.

I,

James

E.

Staudt,

have

been

retained

by

theIllinois

Environmental

ProtectionAgency

(“Illinois

EPA”)

as

an

expert

in

this

nitrogen

oxides

(“NOx”)

rulemaking

addressing

various

source

categories

and

Reasonably

Available

Control

Technology

(“RACT”).

I

have

previously

testified

regarding

this

rulemaking

in

both

pre-filedtestimony

and

in

person

on

October

14,

2008.

I

have

also

examined

the

testimony

of

witnesses

for

industries

affected

by

the

proposed

rule

during

the

hearing

on

December

9

and

10,

2008.

In

response

to

this

testimony

by

industry,

I

have

prepared

the

followingrebuttaltestimony.

Summary

of

Testimony

It

is

my

opinion

thatConocoPhillips

and

United

States

Steel

(“US

Steel”)

werenot

convincing

in

theirarguments

to

increase

the

emissions

rates

proposed

in

the

rule.In

support

of

their

argument

for

higher

emission

limits,

ConocoPhillips

cited

costs

estimated

from

Ultra

Low

NOxBurner

(“ULNB”)

projects

associatedwith

ConocoPhillips’ConsentDecree

that

are

far

above

the

costs

(about

15

to

20

times)

reported

for

similar

technology

by

numerous

independent,

publicly

available

studies.

However,

to

date,

none

of

thesupporting

information

for

these

cost

estimates

has

beenmade

available

for

examination

and

ConocoPhillips

couldnot

provide

many

important

details

on

these

estimates

when

asked

at

the

December

9

hearing.

Withregard

to

US

Steel,

information

it

provided

was

found

to

have

errors

and

contradictions

and

was

missing

key

pieces

of

information,

as

I

willdescribe

in

more

detail

in

thefollowingtestimony.

Using

more

informationthey

did

provide.

This

information

was

requested

at

the

hearing,but

has

not

yet

been

provided

(Transcript

of

December

10,

2008,

hearing,

(“12/10/08

TR”)p.

31,

lines

11-20).

Forthese

reasons

I

do

not

believe

either

ConocoPhillips

or

US

Steel

provided

convincing

information

in

support

of

theirarguments

for

higher

NOx

emission

rates.

Comments

on

ConocoPhillips

Testimony

ConocoPhillips’

argument

largely

relies

on

Mr.

Dunn’sassertion

that

the

costs

of

NOx

controls

that

could

meet

the

proposed

limits

are

well

above

the

cost

range

targeted

by

the

rule.

Mr.

Dunn

stated

that

as

a

result

of

the

proposed

emission

rates

ConocoPhillips

is

“looking

at

least

at

low

NOxburners

probablywith

FGR,

flue

gas

recirculation,

or

ultra

low

NOx

burners”

(Transcript

of

December

9,

2008,

hearing

(“12/9/08

TR”),

p.

144,

lines

5-7).

Mr.

Dunn

testified

that

the

proposed

emission

rates

are

well

above

what

is

achievable

with

ULNB

(12/9/08

TR,

p.

146,

lines

2-13;

p.

148,

lines2-21).

Mr.

Dunn

also

testifiedthat

the

proposed

rule

does

not

require

ULNB(12/9/08

TR,

p.

143,

lines

9-13).

Moreover,

according

to

the

technical

support

document

(“TSD”),

emissions

limits

are

consistent

with

thoseachievable

with

low

NOxburners,

and

as

noted

above,

Mr.

Dunncited

low

NOx

burners

as

a

possibility.

So,

facility

ownershave

moreoptions

than

just

ultra

low

NOx

burners.

Mr.

Dunn

also

admitted

that

ULNB

could

be

used

on

a

large

unit

to

allowsmaller

units

to

average

in

with

littleor

no

effort

(12/9/08

TR,

p.

148,

line

22

through

p.

149,

line

5).

So,

this

is

not

a

question

of

whether

or

not

the

emissions

rates

2

removed.

ULNB

are

reported

in

theTSD

to

cost

in

the

range

of

about

$1000/ton

of

NOx

removed

(TSD

pages

43,

64,

65).

Tn

his

pre-filed

testimony,

Mr.

Dunn

used

a

cost

estimate

of

burnersinstalled

pursuant

to

a

ConsentDecree

to

argue

that

ULNB

are

more

expensive

—

inthe

range

of

$15,000

to

$20,000/ton

of

NOx

removed

(Pre-filed

Testimony

of

David

Dunn,

p.

7-12).

However,

Mr.

Dunn

couldnot

explain

why

the

cost

effectiveness

estimate

ConocoPhillips

developed

for

ULNB

retrofits

was

so

much

higherthan

what

is

widelyreported

in

literature

from

LADCO,

USEPA,

and

others,

and

as

documented

in

theTSD

(12/9/08

TR,

p.

153,

lines

15-20).

It

is

important

to

point

out

that

a

dollar

per

ton

of

NOx

removedestimate

entails

many

assumptions

that

can

greatly

skew

the

estimate

in

one

direction

or

another.

There

are

assumptionsregarding

what

shouldbe

included

in

the

capital

cost,

the

amortization

of

that

cost

to

a

yearly

capital

charge,

what

is

assumed

as

the

initial

versus

the

final

emissions

levels,

how

and

if

overhead

shouldbe

accounted

for,

insurance

costs,

taxes,

assumptions

for

allowance

for

spare

parts,

maintenance,

the

cost

of

other

routine

maintenance

that

may

be

performed

at

the

same

time

as

the

project,

etc.

Many

of

these

are

outlined

in

USEPA’sAir

Pollution

Control

Cost

Manual

(http://www.epa.gov/ttnlcatc/products.html#cccinfo).

As

a

result,

by

adjusting

the

assumptions,

it

is

possible

to

arrive

at

a

wide

range

of

dollar

per

ton

of

NOxremoved

cost

estimates

for

any

given

project.

Because

of

this,

examination

of

the

assumptions

is

important

for

interpreting

such

a

cost

estimate.

3

in

Mr.

Dunn’s

pre-filed

testimony.

TheIllinois

EPA

attempted

to

learn

whatwould

account

for

this

difference

during

hearing,

such

as

inclusion

of

other

“routinemaintenance”

items

or

what

assumptions

were

used

to

craft

thisestimate

of

dollar

per

ton.

When

askedabout

assumptions

of

the

cost

effectiveness

estimate,

Mr.

Dunn

admitted

that

the

costestimate

included

significant

indirect

costs.

Furthermore,

he

could

not

describe

many

of

the

key

underlyingassumptions

used

to

craft

the

dollar

per

tonestimate

(12/9/08

TR,

p.

159,

lines

2-20;

p.

161,

lines

8-1

1).

The

underlying

costanalysis

has

not

beenprovided

to

the

Board

to

date.

In

addition,

due

to

claims

that

the

“detailed”

cost

estimate

is

privileged,

it

is

not

clear

whether

the

Illinois

EPA

canallow

me,

as

an

IllinoisEPAcontactor,

to

examine

and

comment

on

it

(12/9/08

TR,

p.

151,

lines

4-10;

p.

154,

lines

18-20).

ConsideringthatConocoPhillips’

cost

estimates

are

so

inconsistentwith

numerous

independent

estimates

that

have

beenwidely

published,

and

that

the

company

will

notsubject

the

data

to

public

scrutiny,

it

is

myopinion

that

the

company’s

cost

information

should

not

be

considered.The

Illinois

EPA

has

relied

on

independent

and

publicly

verifiable

estimates,

as

documented

in

theTSD,

and

this

information

demonstrates

that

the

proposed

emissions

limits

are

achievable

with

available

technology

at

a

cost

that

is

within

the

range

of

RACT.

4

available.

Moreover,

there

are

errors

and

inconsistencies

in

the

data

presented.

In

justifying

its

conclusions,

US

Steel

made

several

assertions

without

any

supporting

dataor

calculations.

Upon

examination

I

found

these

assertions

to

be

erroneous.

In

the

following

paragraphs

I

will

examine

these

assertions

as

well

as

errors

or

inconsistencies

in

calculations

that

were

presented.

Assertions

by

US

Steel

Found

to

be

Erroneous

US

Steel’s

consultant,

Mr.

Stapper,

ruled

outlow

NOx

burners

and

selective

non-

catalytic

reduction

(“SNCR”)

as

viable

NOx

control

options,

although

he

made

no

effort

to

contactsuppliers

of

these

technologies

to

determine

the

suitability

of

these

technologies

(12/10/08

TR,

p.

39,

line

16

through

p.

40,

line

3;

p.

48,

line

19

through

p.

49,

line

17).

Despite

having

no

information

from

burner

suppliers,

Mr.

Stapper

testified

thatthere

were

no

low

NOx

burnersthat

wouldapply

to

the

multi-fuel

application

of

Boilers

11

and

12

(12/10/08

TR,

p.

19-

20,

39).

Moreover,

he

testified

thatburners

would

cause

dangerous

conditions

that

could

result

in

furnace

explosions

(12/10/08

TR,

p.

20,

lines

14-17).

These

assertions,

as

will

be

demonstrated,

are

incorrect.

While

there

are

challenges

to

cofiring

low

BTU

fuels

such

as

Blast

Furnace

Gas

with

Natural

Gas

or

other

higher

BTU

fuels,

this

canand

has

been

done.

Mr.

Stapper

relied

solely

on

his

own

experience

withoutconsulting

any

burner

suppliers

or

boiler

manufacturers.

Mr.

Stapper

made

it

clear

that

it

is

URS’snormalpractice

not

to

contact

technology

suppliers

for

information

(12/10/08

TR,

p.

49,

lines

8-17).

As

a

result,

it

is

uncertain

whether

Mr.

Stapper

is

5

have

since

contacted

burner

suppliers

to

evaluate

Mr.

Stapper’s

assertions.

In

contrast

to

Mr.

Stapper’s

testimony,BloomEngineering,

North

American

Burner,

Coenand

Hamworthy

Peabody,

all

reputable

burner

suppliers,have

stated

that

they

supply

burners

that

are

capable

of

safely

reducing

the

NOx

from

US

Steel’s

boilersfor

thefuel

conditions

that

US

Steel

projected.

As

for

specificemissions

rates,

they

could

not

confirmemission

rates

without

a

more

careful

examination

of

the

boiler.

However,

some

of

them

provided

ranges

based

upon

the

burners

that

they

offer.

Information

from

these

companies

is

provided

in

Exhibit

1

and

as

attachments

to

this

testimony.

These

companies

haveexperience

in

supplying

such

burners

on

other

steel

mill

and

mixed

fuel

applications.

In

fact,

multi-fuel

burners

are

not

as

rare

as

Mr.

Stapper

asserted

in

his

testimony

and

are

commonly

used

in

the

steel

industry

as

well

as

in

the

refining

industry.

Refinery

coking

processes

can

also

produce

low

BTU

gases

that

are

fired

at

the

refinery.

According

to

the

Handbook

of

Petroleum

Processing,’

edited

by

D.

S.

J.

Jones

and

Peter

R.

Pujado,

Exxon

Mobil’s

Flexicoke

processproduces

a

low

BTU

gas

with

a

lower

heating

value

of

127

Btu/SCF

that

is

similar

to

the

heating

value

of

Blast

Furnace

Gas.

This

gas

is

fired

at

the

refinery

once

sulfurbearingcompounds

are

cleaned

from

the

gas.

Mr.

Stapperfurther

testified

thatinstalling

a

circular

low

NOx

burner

on

the

tangentially

fired

(also

referred

to

as

“corner

fired”)

Boiler

number

11

would

require

complete

reconstruction

‘http://books.google.com/books?id=D6pb

1YnOvYoC&dg=Handbook+of+Petro1eum+Processing&printsec=frontcov

er&soceb1&otsXW2zZa1

Qct&sig=nKh8rkyzFJmKLTXO

WZ7cmGB8_s&hl=en&sa=X&oi=book

result&res

num8&ctresult#PPA453

,M

1

6

conducted

a

simple

Google

search

for

“Tangential

Low

NOx

Burners”

(see

http://www.coen.com/i

html/pdf/TFireLowNoxOilRef.pdf,

which

was

the

first

item

to

come

up

on

such

a

search).

Coen,

as

well

as

other

companies,

sell

low

NOxburners

or

burner

modifications

for

tangentially

fired

boilersthat

fire

gas.

These

are

burners

that

are

installed

in

the

existingcorner

burner

areaand

do

notrequire

reconstruction

of

the

boiler.

In

response

to

my

request

for

information,

the

Coen

Company

stated

that

they

couldsupply

low

NOxburners

for

this

application

(Boilers

11

and

12).

Mr.

Stapper

also

testifiedthat

there

would

be

risks

of

furnace

explosions

with

the

use

of

Low

NOxburners

(12/10/08

TR,

p.

20,

lines

11-17)

andstated

that

“There

are

no

low

NOx

burners

that

could

safely

be

installed

on

boiler

12

to

burn

blast

furnace

gas

and

Cokeoven

gas”

(12/10/08

TR,

p.

39,

lines

13-15).

He

did

not

provide

any

data

or

calculations

to

support

this

assertion

and

didnot

contact

any

burner

suppliers

to

check

onthis.

(12/10/08

TR,

p.

39,

lines

16-

20)

There

is

always

a

risk

of

a

boiler

explosion,

regardless

of

the

burner

type

or

fuel.

Because

a

boiler

explosion

is

such

a

catastrophic

event,

under

the

National

Fire

Protection

Association

PA)

codes,

all

boilers

must

be

equipped

withinstrumentation

and

controls

to

avoid

such

events,

which

is

why

these

events

are,

thankfully,

so

rare.

In

contrast

to

Mr.Stapper’

s

assertion

that

such

burners

are

dangerous,

which

he

didnotsupport

with

any

information

from

technology

suppliers

or

with

any

engineering

calculations,

four

reputable

burner

suppliers

have

stated

that

they

cansupply

low

NOxburners

for

this

application.

7

suppliers

of

this

technology

haveshown

in

the

hundreds

of

industrialinstallations

that

the

technology

is

available

and

works

in

multi-fuelindustrial

boiler

applications,

as

well

as

a

wide

array

of

other

applications,

which

is

supported

by

theTSD

and

supporting

documents

inthe

original

submittal.

Mr.

Stapper

admitted

that

he

did

notcontact

a

single

supplier

of

SNCR

technology

for

technical

input,

and

that

URS

has

never

supplied

an

SNCRsystem

(12/10/08

TR,

p.

47,

line20

through

p.

48,

line

4).

As

a

result,

his

testimony

regarding

SNCR,

likehis

testimony

regarding

lowNOx

burners,

amounts

only

to

hisassertions

without

adequate

supporting

data.

In

Mr.

Stapper’s

hearing

testimony,

he

discussed

the

John

Zink

RapidMix

Burner

(12/10/08

TR,

p.

51,

line

6

through

p.

53,

line

17).

He

testified

that

the

Rapid

Mix

Burner

achieves

0.01

lb/MMBtu

and

that

it

“works

only

in

a

very

narrow

niche

of

industrial

boiler

applications”

(12/10/08

TR,

p.

52,

line

8-10).

However,

as

he

stated,this

technology

is

not

required

by

the

rule

(12/10/08

TR,

p.

54,

line

11-12).

Moreover,

theIllinois

EPA’s

proposed

limits

for

boilers

are

eijiht

times

the

emission

ratethat

Mr.

Stapper

testified

the

Rapid

Mix

Burner

is

capable

of.

Therefore,the

Rapid

Mix

Burner,

or

otherultra

low

NOxburners

from

other

manufacturers,may

be

used

to

complywith

the

proposed

rule

where

the

owner

deems

this

the

appropriate

technology.

However,

because

the

proposed

limits

are

far

in

excess

of

whatultra

low

NOx

burners

are

capable

of,

facility

ownershave

many

moreoptions

at

their

disposal

than

the

Rapid

Mix

Burner

to

achievethe

proposed

emission

rates.

8

US

Steel

did

not

provideback

up

for

the

assumptions

that

underlie

its

recommended

emission

rates

for

Boilers

11

and

12

that

are

shown

in

Exhibit

A

to

Mr.

Siebenberger’s

pre-filed

testimony.

US

Steeldid

not

provide

any

test

data

or

other

supporting

information.Calculations

werenot

shown

to

explainthe

largedifference

between

the

presumed

emission

rate

for

coke

oven

gas

(COG)

versusthat

of

natural

gas

(NG).

Supporting

information

for

Exhibit

A

was

requested,but

to

date

has

not

yet

been

provided.

(12/10/08

TR,

p.

28,

line

22

-

p.

29

line

7)

The

principal

reason

coke

oven

gashas

higherNOx

emissions

thannatural

gas

is

the

hydrogen

cyanide

(“HCN”)

present

in

the

gas

(Pre-filed

Testimony

of

Larry

Siebenberger,

p.

5),

shown

on

the

gas

analysis

provided

by

US

Steel

to

the

Illinois

EPA

as

0.185%

(moleweighted)

without

the

COG

scrubber

and

0.0

13%

(mole

weighted)

with

the

COG

scrubber.

2

However,

even

if

itis

conservativelyassumed

that

100%

of

the

nitrogen

in

the

HCN

of

the

COG

is

oxidized

to

form

NOx,

it

wouldnot

explain

the

increased

NOx

TIRS

assumed

for

scrubbed

COG

over

NG.

URS

assumed

in

Exhibit

A

to

Mr.

Siebenberger’s

pre-filedtestimonythatwith

the

COG

scrubber

in

service,

NG

produces

emissions

of

0.084

lb/MMBtu

and

COG

produces

0.144

lb/MMBtu,

a

difference

of

0.06

lb/MMBtu.

No

basis

for

theseemission

estimates,such

as

test

2

Fuelanalysis

provided

by

US

Steel

to

the

Illinois

EPAshows

that,on

a

mole

weight

basis,

COG

has

52%

hydrogen,

26%

methane,

5%

CO,

2%

ethylene

and

most

of

the

rest

are

incombustibles

(nitrogen,

water,

CO

2

).

Pure

hydrogen

would

potentially

increase

the

flame

temperature

and

the

NOx

relative

to

natural

gas.

But

for

COG,

which

contains

significant

amounts

of

moisture

and

non-combustibles,

and

only

52%

hydrogen,

we

would

not

expect

an

increase

in

thermal

or

promptNOx

generation

over

natural

gas,

likely

even

a

decrease.

This

is

supported

by

data

generated

by

Waibel

and

others

on

NOx

generationfrom

gas

mixtures.

ADVANCED

BURNER

TECHNOLOGY

FOR

STRiNGENTNOxREGULATIONS,

R.

T.

WAIBEL,

PHD

.,

D.

N.

PRICE

AND

P.

S

.

TISH,

M.L.

HALPR[N,PRESENTED

AT

THE

AMERICAN

PETROLEUM

INSTITUTEMIDYEAR

REFINING

MEETING

JOINTMEETING

OF

THE

SUBCOMMITfEE

ON

HEAT

TRANSFER

EQUIPMENT,

ORLANDO,

FL,

MAY

8,

1990,

www.johnzink.com/elibraiy/DownloadFile.

aspx?fileguid=8e219961-ec78-4]

Of-bb6754dd87]d2d4

7

9

COG

fuel

analysis,

I

estimate

that

if

all

of

the

nitrogen

in

the

HCN

in

the

cleaned

COG

oxidized

to

NOx,

this

would

increase

NOx

by

only

about

0.03

lb/MMBtu

—

half

that

estimated

by

URS

for

US

Steel

(see

Table

1,

attached).

Furthermore,

in

actual

practice,

significantly

less

than

100%

of

the

fuel

bound

nitrogen

actually

gets

converted

to

NOx,

particularly

if

low

NOxburners

or

other

combustion

controls

are

used.

So,

the

difference

in

theemission

rate

should

be

less

than

the

0.03

lb/MMBtucontributed

by

100%

HCN

oxidation.

Additionally,

IJRS’s

estimate

in

Exhibit

A

of

Mr.

Siebenberger’s

pre-filed

testimony

shows

a

difference

between

NG

and

COG

without

the

scrubber

to

be

0.252

lb/MMBtu

(0.336-0.084

lb/MMBtu),

roughly

59%

of

what

is

theoretically

predicted

for

100%

conversion

of

fuel

bound

nitrogen

to

NOx

(0.252/0.422

-

see

Table

1

for

estimate

of

fuel

bound

NOx

from

unscrubbed

COG).

It

appears

that

IJRS

has

overestimated

theemissions

level

of

scrubbed

COG.

Therefore,

URS

may

have

made

a

mistake

in

its

calculations

for

NOx

from

the

various

gases,

which

it

has

not

yet

provided

for

the

Illinois

EPA

or

the

Board

to

review.

Mr.

Siebenberger

also

testified

that

there

is

an

error

in

Exhibit

A

of

his

pre-filed

testimony.

Exhibit

A

of

his

pre-filed

testimony

does

not

have

the

correct

mix

of

gases

for

conditions

where

the

blast

furnace

is

out

of

service

(12/10/08

TR,

p.

28,

line

17-21).

Instead

of

firing

60%

COG

and

40%

NGwhen

the

BlastFurnace

is

not

in

service

as

stated

on

page

2

of

Exhibit

A,

the

boilers

would

fire

60%

NG

and

40%

COG.

Since

this

error

overestimates

the

3

10

Mr.

Siebenberger’

s

pre-filed

testimony

using

the

assumptionsthat

are

shownin

that

exhibit

and

his

testimony.

I

arrived

at

different

results

for

both

tons

of

NOx

emitted

and

the

emission

rate.

The

Controlled

case

calculations

were

performed

two

ways:

one

assuming

60%

COG

and

40%

NG

during

the

Furnace

Down

period

(see

Table

2,

attached),

andone

assuming

40%

COG

and

60%

NGduring

the

Furnace

Down

period

(see

Table

3,

attached).

Neither

case

produced

results

that

corresponded

with

the

annual

NOx

emissions

rate

or

total

NOx

shown

in

Exhibit

A.

I

was

able

to

reproduce

the

“Base

Case”

calculations

for

emissions

(see

Table

4,

attached),

soit

appears

that

I

am

using

the

same

approach

as

used

by

US

Steelin

Exhibit

A.

Therefore,while

theIllinois

EPA

is

notstating

that

it

agrees

with

the

assumptions

of

US

Steel’s

analysis,

the

assumptions

that

US

Steel

uses

do

not

appear

to

produce

the

results

shown

in

Exhibit

A

for

the

controlled

case.

The

rate

that

US

Steel

requests

of

0.113

lb/MMBtu

that

was

developed

from

these

assumptions

does

correspondwith

the

estimated

OzoneSeason

emission

rate

using

the

original

assumptions

stated

in

Mr.

Siebenberger’

s

pre-filed

testimony.

However,

this

higher

NOx

emission

rate

for

the

OzoneSeason

is

an

anomaly

of

the

assumption

to

shut

down

the

COG

scrubberduringtheOzone

Season

and

the

fact

that

he

overstated

theamount

of

COG

fired

when

BFG

was

unavailable.

In

light

of

the

importance

of

keepingNOx

emissions

low

during

the

Ozone

Season,

it

would

certainly

make

more

sense

to

have

the

COG

scrubber

serviced

at

other

times.

The

annual

totalNOxemissions

and

therate

that

I

calculated

in

attempting

to

reproduced

11

because

the

assumptions

are

incorrect.

As

Mr.

Siebenberger

statedon

page

4

of

his

pre-filed

testimony,

Boilers

1-10

will

be

shut

down

as

part

of

the

Cogen

project

improvement.

This

will

causemore

COG

to

be

burned

in

Boilers

11

and

12.

So,

the

historical

baseline

NOxemissions

for

Boilers

11

and

12

are

not

as

great

as

assumed

in

the

Baseline

calculation

for

Exhibit

A.

More

importantly,

US

Steel

did

not

take

into

account

in

their

Baseline

calculation

thefact

that

the

COG

desulfurization

system

would

be

in

operation.

US

Steel

should

certainly

have

assumed

the

reduced

COG

NOx

level

for

the

COG

resulting

from

the

desulfurization

system,

because

this

is

definitely

going

to

be

thecase

regardless

of

the

proposed

NOx

RACT

rule.

Since

US

Steel

assumed

in

its

Baseline

the

higher

NOx

levels

for

COG

withoutdesulfurization

at

all

times,

its

estimate

of

the

Baseline

is

grossly

overstated

and

the

reduction

in

emissionsshown

on

Exhibit

A

is

therefore

grossly

overstated.

Moreover,

the

COG

usagewill

likely

be

less

fortheboilers

than

assumed

in

Exhibit

A

due

to

limitations

on

availability

of

COG.

According

to

a

January

8,

2009,

e-mail

sentfrom

Mr.

Siebenberger

to

Mr.

Kaleel,

the

available

COG

is

3,830,400

million

Btu/yr.

US

Steel

did

not

provide

information

on

how

much

COG

is

fired

in

the

reheat

furnaces,

except

that

its

emission

rate

for

the

reheat

furnaceswas

based

on

the

“maximum

combusted

blend

of

desulfurized

coke

oven

gas

and

non-desulfurized

cokeoven

gas.”The

reheat

furnaces

have

the

heat

input

capacity

to

accept

100%

of

the

COG.

If

US

Steel

opted

to

use

all

of

the

available

COG

in

the

reheat

furnaces,

then

none

of

it

would

be

available

to

boilers

11

and

12.

If

it

is

assumed

that

the

reheat

12

appears

to

havebeen

assumed

by

US

Steelin

developing

Exhibit

A

of

Mr.

Siebenberger’s

pre

filed

testimony.

This

is

a

significant

overestimate

of

theamount

of

COG

that

is

actually

available,

which

results

in

a

significant

overestimate

of

the

amount

of

NOxgenerated

from

this

fuel.

It

is

likely

that

the“excess”

COG

wouldhave

to

be

replacedwith

natural

gas,

which

would

further

reduce

emissions,

since

natural

gas

has

a

lower

NOx

content

than

COG.

As

a

result,

US

Steel

has

overstated

the

controlled

NOx

emission

rate.

I

re-estimated

the

rateusing

US

Steel’s

assumptions,

but

corrected

per

Mr.

Siebenberger’s

testimony

and

corrected

to

account

for

the

actual

availability

of

COG

and

40%

COG

firing

in

the

reheat

furnaces

(making

COG

firing

in

the

boilers

less

than

40%).

The

results

are

shown

in

Table

6,

attached.

As

shown,

using

US

Steel’s

estimates

for

emissions

rates,

which

as

discussed

earlier

are

probably

high

for

COG,

I

arrive

at

an

annual

rate

of

0.091

lb/MMBtu

—

which

is

less

than

the

rate

recommended

by

US

Steel.

Correcting

the

COG

NOx

rate

for

the

maximum

amount

of

fuel

NOx

results

in

an

annualrate

of

0.084

lb/MMBtu

—

very

close

to

the

Illinois

EPA’s

proposed

rate

(see

Table

7,

attached).

It

is

possible

that

all

of

the

COG

could

be

used

in

the

reheat

furnaces,

leaving

none

for

the

boilers,

sincethe

available

COG

has

roughly

53%

of

the

heat

input

available

for

the

reheat

furnaces.

As

shown

in

Table

8,

attached,

if

all

of

the

COG

is

fired

in

the

reheat

furnaces,

leavingnone

for

Boilers

11

and

12,

the

annualemission

rate

is

0.075

lb/MMBtu,

which

is

less

than

the

proposed

rule.

13

that

US

Steel

provided

in

its

fuel

analysis

and

testimony

show

inconsistencies,

and

no

back

up

calculations

or

test

datawereprovided.

I

have

shown,

by

reproducing

US

Steel’scalculations,

that

US

Steel

apparentlymade

severalerrors

in

assumptions

and

in

calculations.

Therefore,

US

Steel’s

emissionestimates

for

Boilers

11

and

12

should

be

regarded

with

caution,

and

the

Board

should

not

consider

them

until

such

time

as

more

reliable

information

is

available

from

US

Steel.

US

Steel

claims

that

its

approach

for

NOx

control

on

Boilers

11

and

12

was

the

result

of

an

optimization

study.

This

study

was

requested

for

examination

at

hearing

(12/10/08

TR,

p.

41,

lines

12-23).To

date,

this

has

not

yet

beenproduced

for

the

Illinois

EPA

or

Board

to

examine.

US

Steel’s

emissionrates

for

the

reheat

furnacewere

also

providedwithout

any

supporting

backup.The

IllinoisEPA

requested

this

additional

information

at

thehearings,

On

page

7

of

his

pre-filedtestimony,

Mr.

Siebenberger

stated

that

the

limit

was

“based

on

the

burner

manufacturer’s

warranty

andthe

maximum

combustedblend

of

desulfurized

cokeoven

gas

and

non-desulfurized

coke

oven

gas

(during

desulfurized

maintenance

outage)

with

natural

gas.”

Exhibit

A

states

that

these

are

developed

by

BloomManufacturing

andMr.

Siebenberger

testified

that

he

believedthat

they

were