BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

IN

THE MATTER OF:

NITROGEN OXIDES EMISSIONS FROM

VARIOUS SOURCE CATEGORIES:

AMENDMENTS TO 35 ILL. ADM. CODE

PARTS

211 AND 217

)

)

)

)

)

)

R08-19

(Rulemaking - Air)

NOTICE

TO:

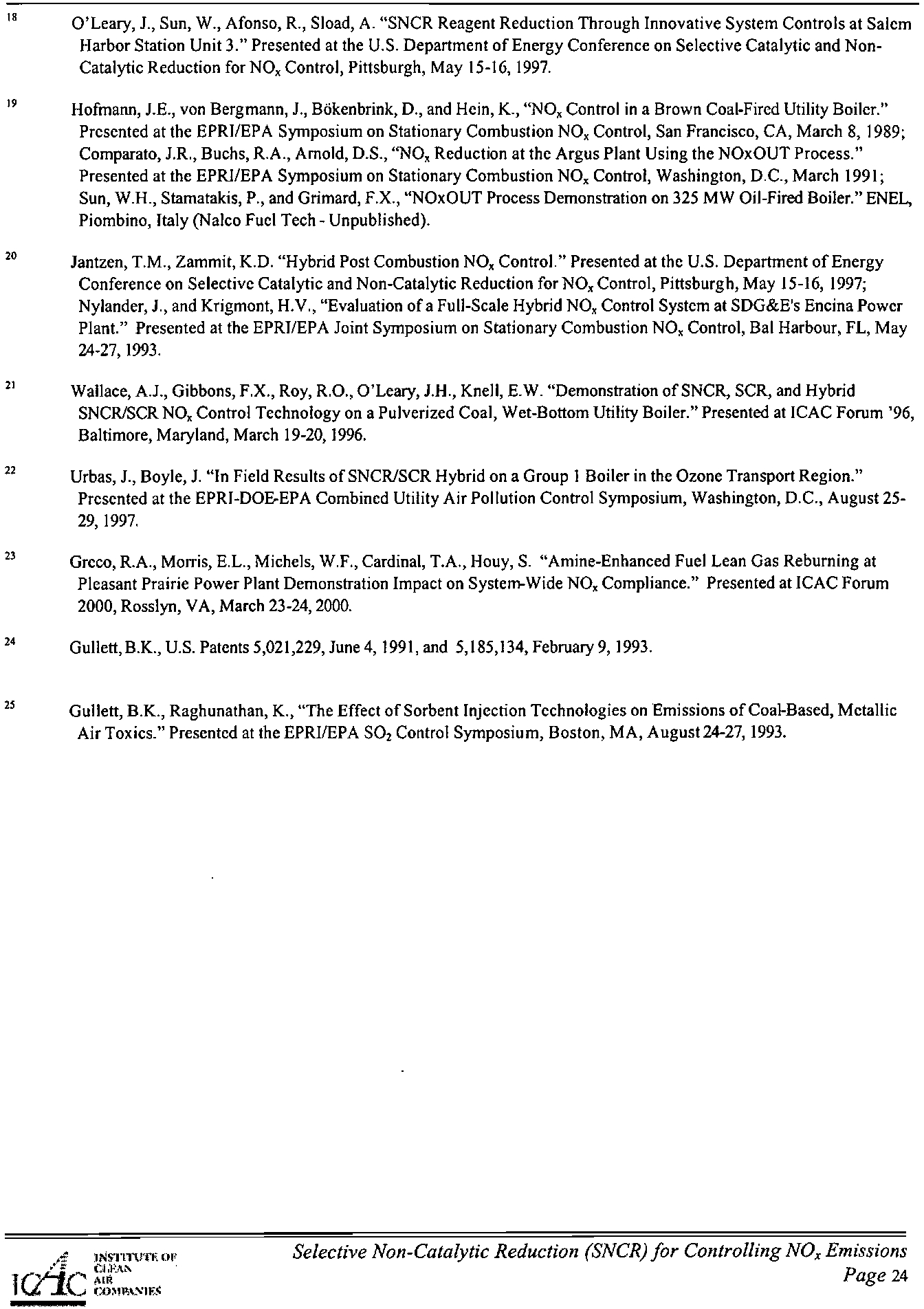

John Therriault

Assistant Clerk

Illinois Pollution Control Board

James

R. Thompson Center

100 West Randolph St., Suite 11-500

Chicago, IL 60601

SEE ATTACHED SERVICE LIST

PLEASE TAKE NOTICE that I have today filed with the Office of the Clerk ofthe

Illinois Pollution Control Board the ILLINOIS ENVIRONMENTAL PROTECTION

AGENCY'S ANSWERS TO PRE-FILED OUESTIONS

BY THE ILLINOIS

ENVIRONMENTAL REGULATORY GROUP, a copy

of which is herewith served upon you.

ILLINOIS ENVIRONMENTAL

PROT~7ION

AGENCY

By:r:j;}C

~

Gina Roccaforte

Assistant Counsel

Division

of Legal Counsel

DATED: September 30, 2008

1021 North Grand Avenue East

P.

O. Box 19276

Springfield, IL 62794-9276

217/782-5544

,

THIS FILING IS SUBMITTED

ON RECYCLED PAPER

Electronic Filing - Received, Clerk's Office, September 30, 2008

BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

IN THE MATTER OF:

NITROGEN OXIDES EMISSIONS FROM

VARIOUS SOURCE CATEGORIES:

AMENDMENTS TO

35 ILL. ADM. CODE

PARTS

211 AND 217

)

)

)

)

)

)

R08-19

(Rulemaking - Air)

THE ILLINOIS ENVIRONMENTAL PROTECTION AGENCY'S ANSWERS TO .PRE-

FILED QUESTIONS BY THE ILLINOIS ENVIRONMENTAL REGULATORY GROUP

NOW COMES the llIinois Environmental Protection Agency ("Illinois EPA"), by its

attorneys, and pursuant to the Hearing Officer's Order dated June 12,2008, respectfully submits

the Illinois EPA'sAnswers to the Pre-Filed Questions by the Illinois Environmental Regulatory

Group:

1.

The Technical Support Document, at page 5, and again at page 38, describes the NOx

reductions that could be achieved by switching to other fuels. In formulating its proposed

rule, did the Agency intend to force affected sources

to switch fuel sources to achieve

compliance?

It

is not the intent ofthe Illinois EPA to force affected sources to switch fuels. The

information provided on page 5 ofthe TSD is general information regarding NOx

emissions generated from the combustion

of different fuels.

a.

To what extent does the Agency expect fuel switching will be required to achieve

compliance?

Fuel switching is an option for industries to consider. The Illinois EPA

believes

that industries will determine the most cost effective approach to

compliance.

b.

To what extent did the Agency consider the availability of alternative fuels?

The Illinois

EPA considers the fuels mentioned on page 5 to generally be

available, although we have not performed a source-specific review.

c.

Does the Agency believe that it is technically and economically feasible for a

coal-fired boiler to be converted

to used oil or natural gas?

Such conversions

are technically feasible and have been implemented in

Illinois.

The feasibility of such conversions is an economic issue based on the

cost

of conversion and the relative costs of coal, natural gas, and oil.

Electronic Filing - Received, Clerk's Office, September 30, 2008

d.

Would such a converted boiler then be subject to the more stringent NOx

emissions limits applicable to oil and gas boilers?

That is not the Illinois EPA's intent. The converted boiler would be subject

to the emission limit based on the fuel used

prior to conversion, provided that

the conversion occurs after the effective date of this rule.

2.

Table 2-la of the Technical Support Document, at page 6, lists the "Emissions

Requirements

ofProposed Industrial and Small EGU Boilers RACT Rule." Has the

Agency made any determination

as to whether the Illinois units affected by this proposed

rule can achieve the emissions limits listed in this table?

The Illinois

EPA believes that control technologies needed to comply with this

proposal

are reasonably available and cost effective.

3.

Did the Agency consider the federally approved NOx RACT emission limits from other

states for similar affected units when it formulated its proposal?

Yes.

4.

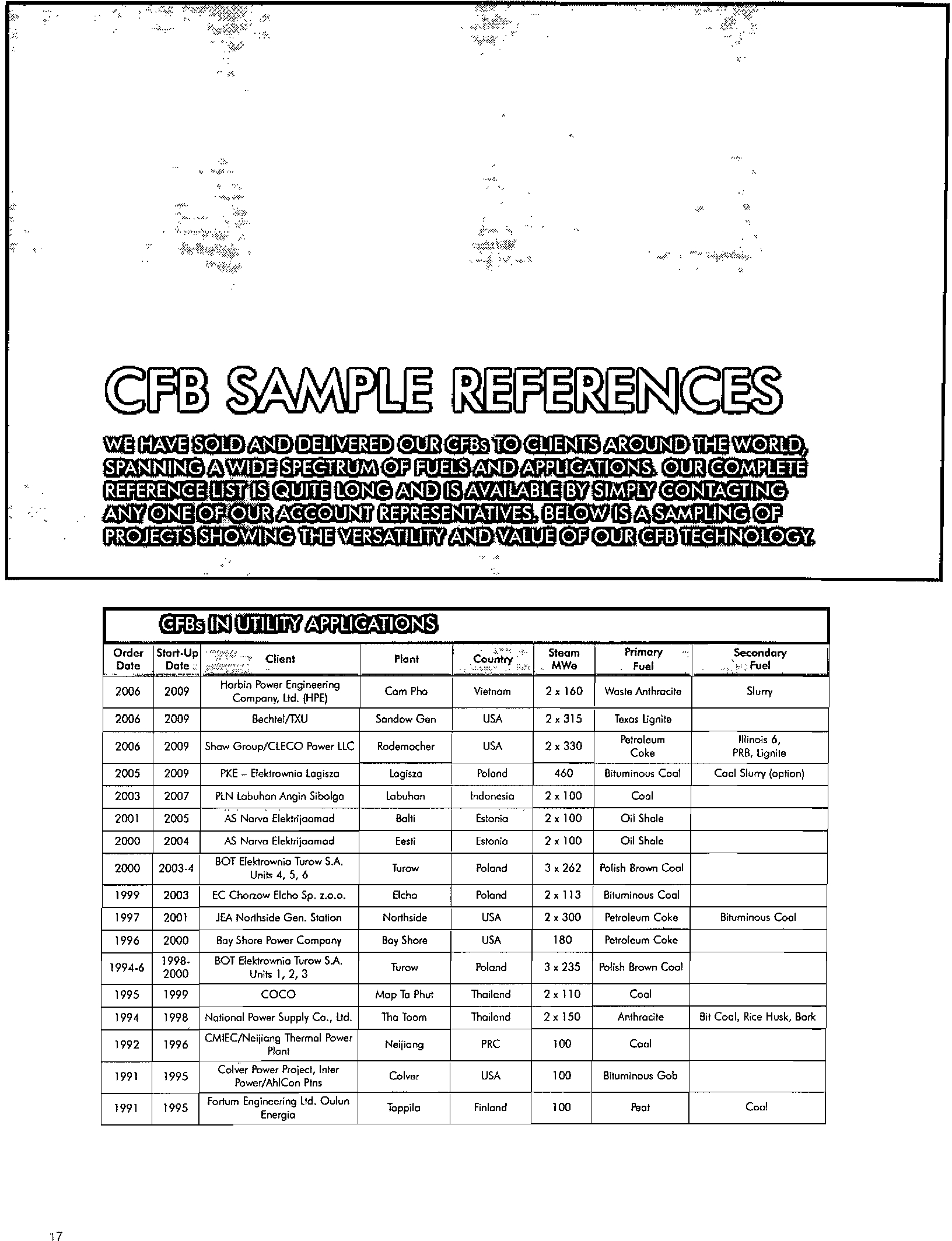

The Agency's Technical Support Document, at page 12, states that circulating fluidized

combustion boilers range in size

up to 1,075 mmBtu/hour. Is the Agency aware that the

largest such boiler affected by this rule is nearly twice that size, and that there are other

such boilers which are greater than 1,075 mmBtulhour?

The number being referred to was intended to describe "typical" sizes for industrial

boilers. As noted below on

that page, CFBs are larger, especially for utility boilers.

The largest CFB boilers in the world currently in operation

are on the order of 300

MW, or about 3,000 MMBtu/hr.

a.

Were the above mentioned large boilers considered in determining the emission

limits contained in the proposal?

Yes. CFBs, even large ones,

are capable of achieving under 0.10 IbIMMBtu.

5.

Table 2-2: Data from Cleaver-Brooks Study, on page 14 ofthe Technical Support

Document, provides information on NOx emission rates for gas-fired boilers

predominately in the size range

of 7 to 33 mmBtu/hour (one boiler had a size of 89

mmBtu/hour).

It

is IERG's understanding that the Agency is not proposing to establish

NOx emission limits for gas-fired boilers in the size range

ofless than, or equal to, 100

mmBtulhour.

Is this correct?

Yes.

a.

If so, how was the data in this table used to inform the Agency in the setting of

NOx limits for gas-fired boilers larger than 100 mmBtu/hour?

2

Electronic Filing - Received, Clerk's Office, September 30, 2008

The information on Tables 2-2 and 2-3 (from the same source) was not used

directly

to assist in forming an opinion on the emission limits for boilers

larger than 100 MMBtu/hr, because there is other data that refers to boilers

larger than 100 MMBtu/hr. However, the data in these tables aud in the

reference document has implications for such boilers (especially gas and oil

fired). Certainly,

it demonstrates that the emissions limits of the proposed

rule

are technically feasible. One of the units on Table 2-2 is of a size

approaching 100 MMBtu/hr. And, it

is generally more difficult to achieve

low emissions on a smaller boiler, as

there is often less space available for

modification of combustion controls. As shown on the table, the lowest

emissions

are achieved by the largest boilers. In fact, the reference cited has

a longer list

of retrofits than shown in the TSD, and includes a retrofit much

larger than 100 MMBtu/hr that achieves emissions levels below 0.01

IblMMBtu on gas (see #23 which is a retrofit

of a 184 MMBtu/hr boiler).

See, Attachment 8 to the TSD. So, this

data certainly demonstrates that the

emission limits in the rule are technically feasible.

In fact, as cited in this

reference document by

Mr. Willems, the Vice President of Product

Development for Cleaver Brooks, other locations have adopted emission

limits

far stricter than what is proposed in Illinois:

"Finally, the San Joaquin area air district in CA took this approach about two

years ago

and reduced their limits to

<9

ppm NOx (O.OllbIMMBtu) for boilers

over

20 MM BTUlhr and

<15

ppm NOx (0.02 IbIMMBtu) for boilers between

2MM BTUlhr and <20 MM BTUlhr. They malldated that

25%

ofthe boiler

population was required to comply with these

new regulations each year. They

are currently in year two

ofthis program with over (50) units completed and

ozone reductions have occurred. "

b.

What is the averaging time for the emission rates shown in Table 2-2?

These were stack tests.

c.

Does the emission data depicted

in

Table 2-2 represent stack test results? If so,

what was the load capacity

ofthe boilers at the time of testing?

Yes. Flowrates for each stack test

are shown on the table.

d.

How much flue gas recirculation was incorporated into each of the boilers listed

in Table 2-2?

As noted in the response to Question Sa, the Table

2-2 information is

referenced in the TSD. We do not have unit by unit information on FGR.

FGR was likely in use for most or all of the units at or below 12 ppm. But,

we cannot be certain

of this without additional information.

However, to comply with the emissions levels proposed in

the rule on gas

units - 0.080 Ib/MMBtu

(or about 60 ppm) - FGR should not be necessary.

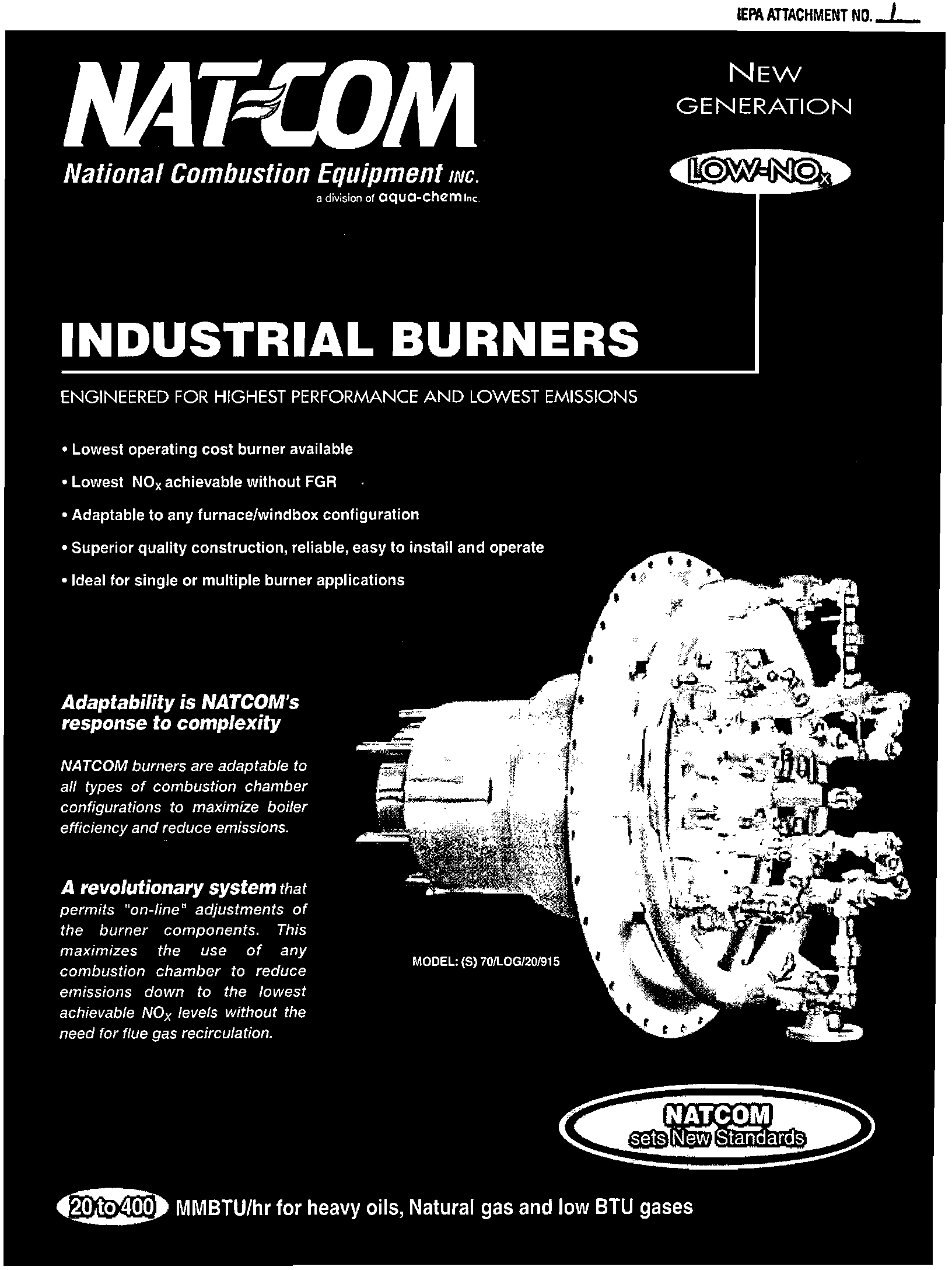

The NATCOM

burners that are referenced in Attachment 8 to the TSD are

3

Electronic Filing - Received, Clerk's Office, September 30, 2008

capable of under 0.05 lb/MMBtu without FGR, as shown in the attached

brochure (Attachment 1). This

is typical of the performance of burners from

other manufacturers as well.

e.

The paragraph that precedes Table 2-2 (the last paragraph on page 13 ofthe

Technical Support Document) states that Table 2-2 shows that low NOx levels

can be maintained through "proper planning

of boiler configuration." Since the

Agency'sproposed rule applies

to existing boilers, for which boiler configuration

modifications can be somewhat restricted, could

you please describe the boiler

configuration changes that were incorporated into the boilers shown in Table 2-2?

The retrofits included replacement

ofthe burner.

In

many cases the burner

quarl would need to be replaced or modified. Many of these burners have

induced FGR,

and therefore, may not require ductwork modifications. As

noted in the answer to Question 5d, more detailed information is not

available.

6.

Table 2-5, on page 18 of the Agency'sTechnical Support Document, is identified as

representing "uncontrolled" NOx emissions. Does the "Uncontrolled NOx Range"

include newer boilers with some NOx control incorporated

in

their design?

The table

is from the 1994 Alternative Control Techniques Document, NOx

Emissions from Industrial/CommerciaI/lnstitutional (ICI) Boilers,

and represents

uncontrolled emissions

as stated in that document. Due to the date of that document

(over 10 years ago), the "baseline" emissions would not represent the capabilities of

current low NOx burner technology even if the burners were called "low NOx

burners" at that time.

a.

How did the Agency utilize the "uncontrolled" ranges listed in Table 2-5 in

establishing its proposed RACT limits?

These are exemplary of "baseline" control levels

and might be useful in

providing baseline control emission rates when calculating cost

of control in

$/ton of NOx reduced.

b.

Has the Agency relied

on a percent reduction target from "uncontrolled" levels in

establishing its NOx RACT emission limits?

Yes and no. For post-combustion technologies, these are generally "percent

reduction" limited,

at least to a point. Combustion controls may be

characterized by percent reduction. However, they are probably best

characterized by their control level in

ppm or lblMMBtu thau

in

terms of

percent reduction. The emission rate targets were established by examining

what has been achieved

on similar units with technologies that are within the

cost range ofRACT.

In

most cases, combustion technology should be

adequate. However, it is understood

that in some cases post-combustion

technology may be determined

to be preferable or necessary.

4

Electronic Filing - Received, Clerk's Office, September 30, 2008

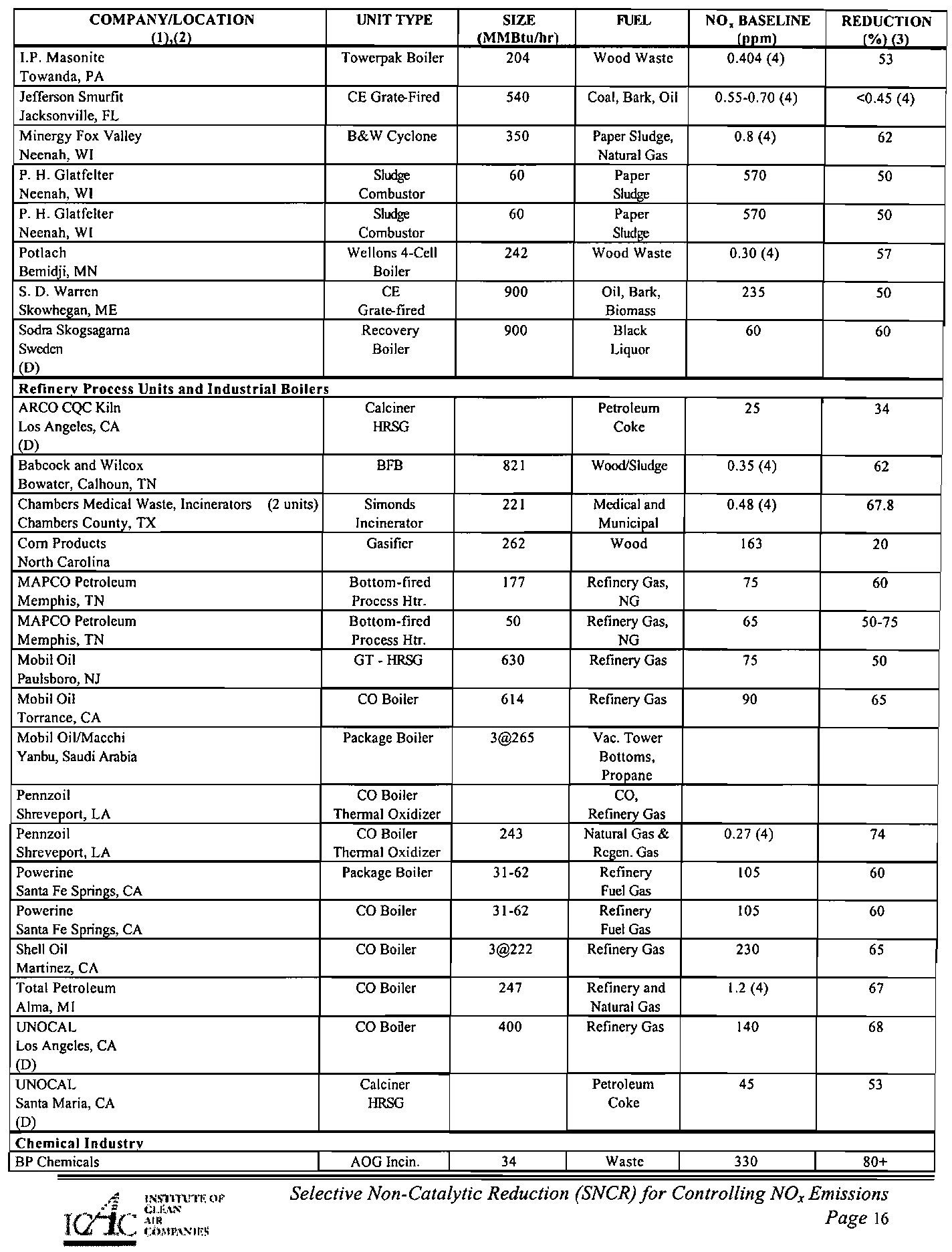

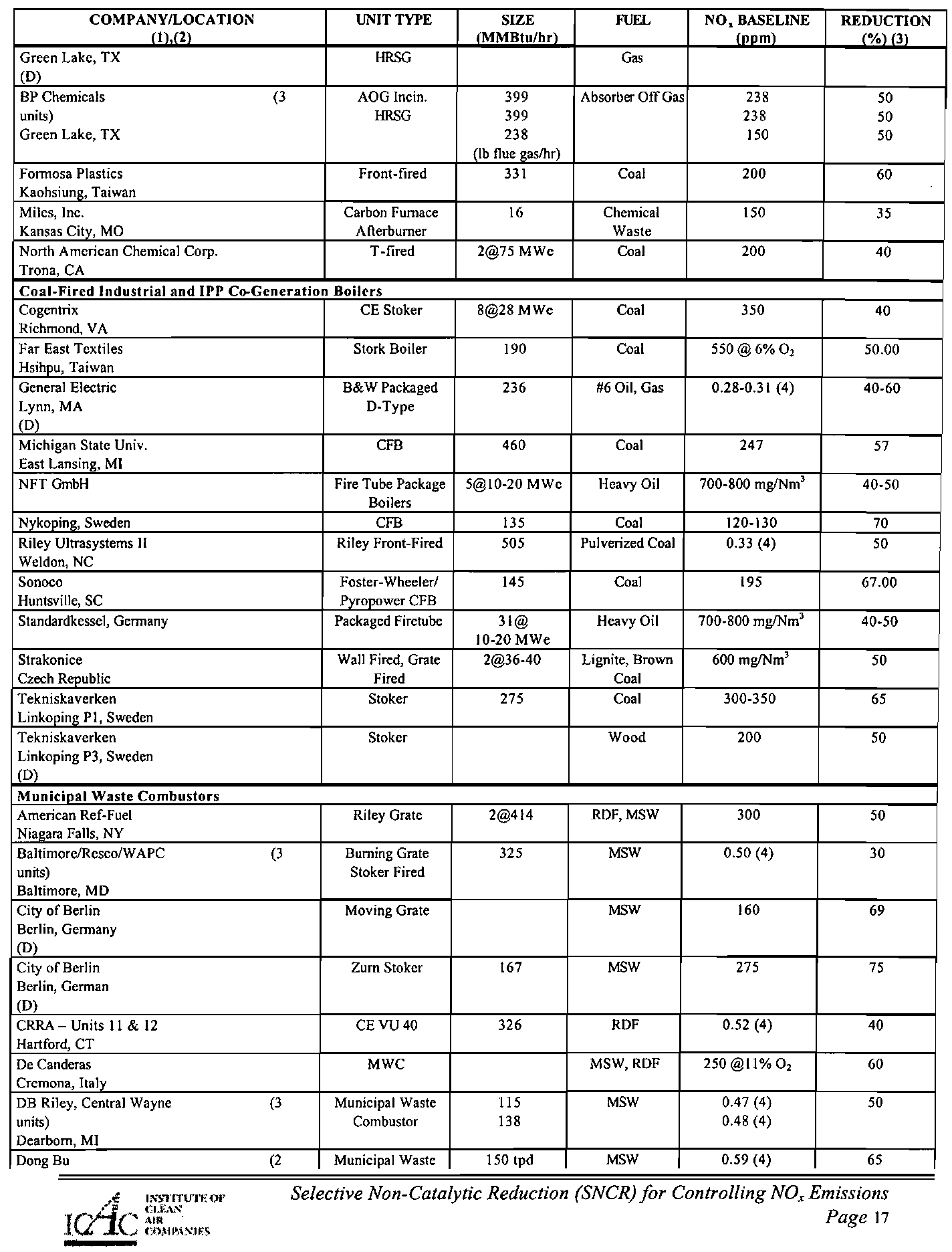

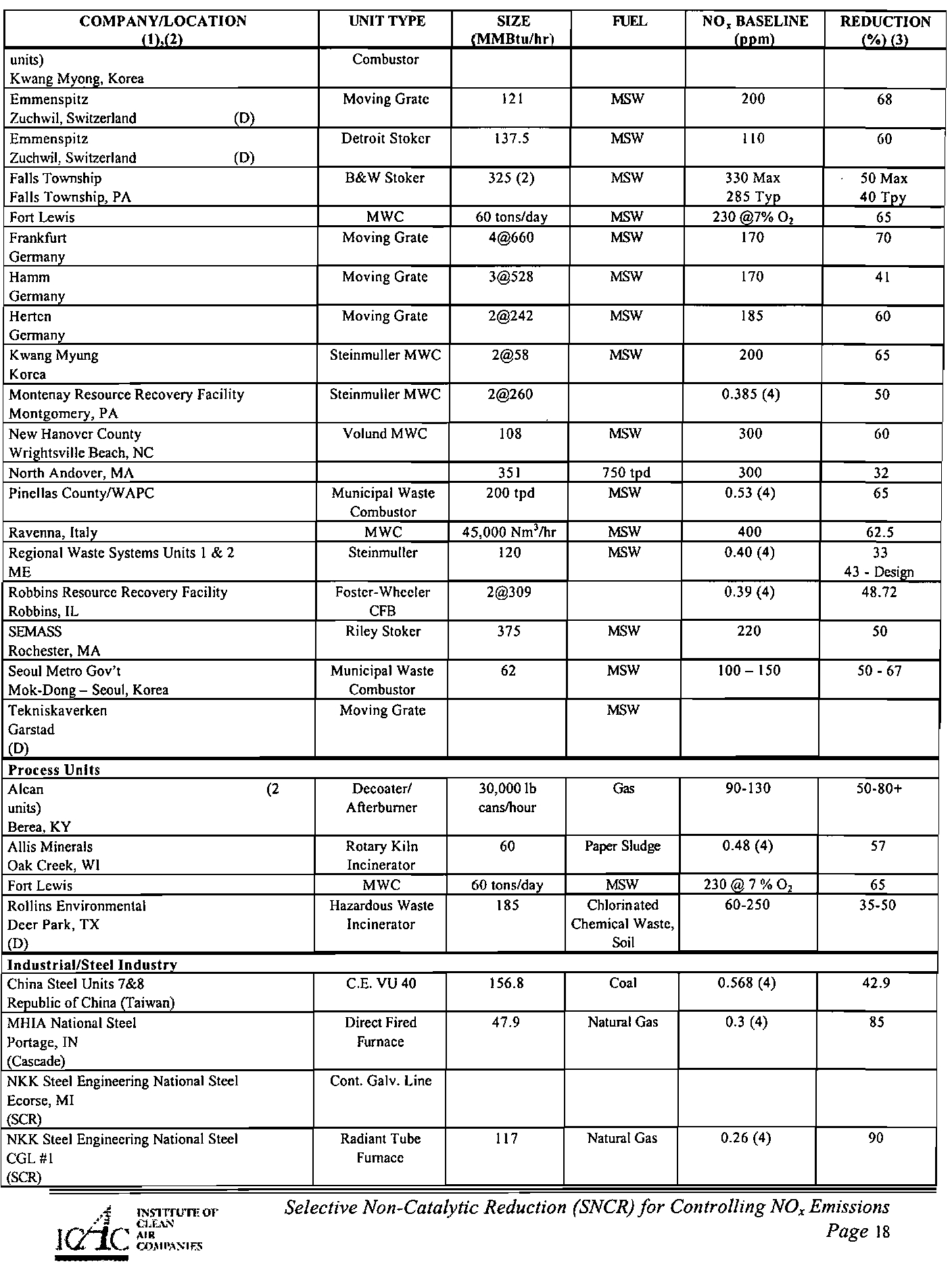

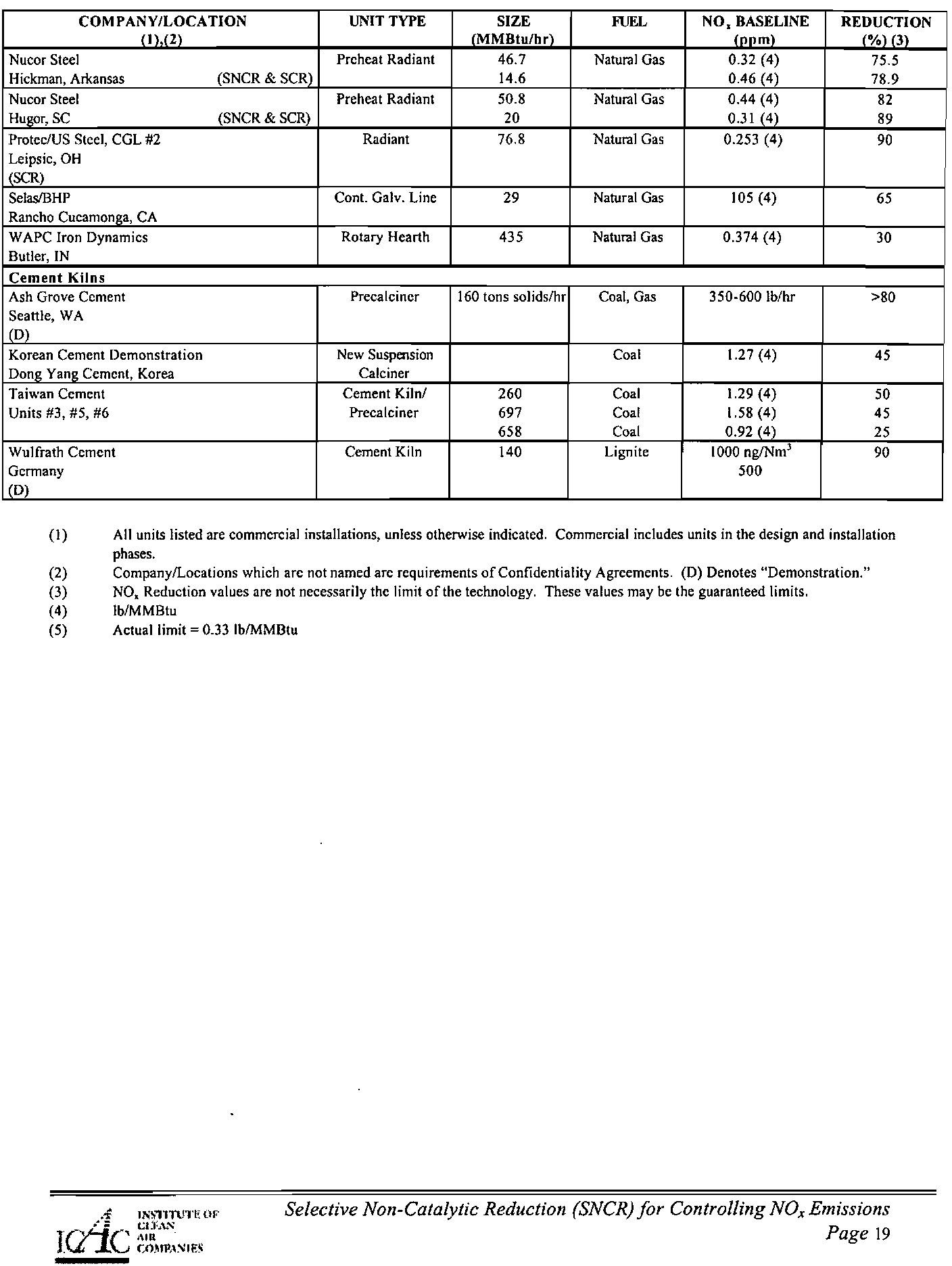

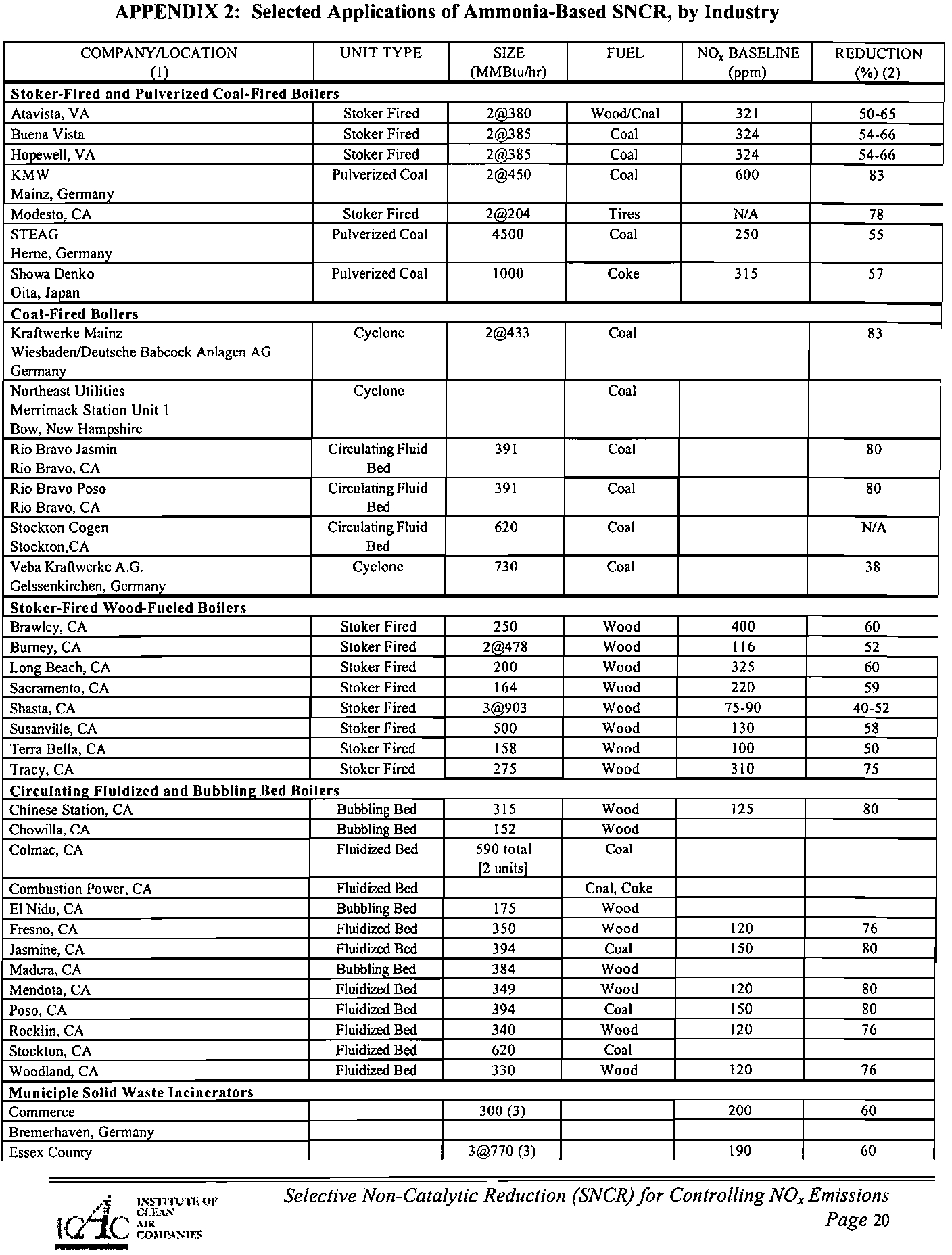

7.

Table 2-12b, on page 31 of the Technical Support Document, presents "Statistics

Regarding Performance

of Industrial Boiler Types Equipped with Ammonia SNCR." Has

the Agency evaluated the coal-fired stoker boilers used

in Illinois in relation to the

stokers included in Table 2-12b in terms

ofboiler design, fuel type, and ammonia slip in

order to evaluate their comparability?

Detailed review

of each boiler in Illinois was not done and was not viewed to be

necessary. SNCR has been shown to be effective on a large

number of stoker

boilers. Therefore, a "case-by-case" review was unnecessary.

8.

On page 33 of the Agency's Technical Support Document, the statement is made that"'"

SCR is viewed as technically feasible for nearly any coal application." Does the Agency

believe that SCR is technically feasible for fluid bed boilers?

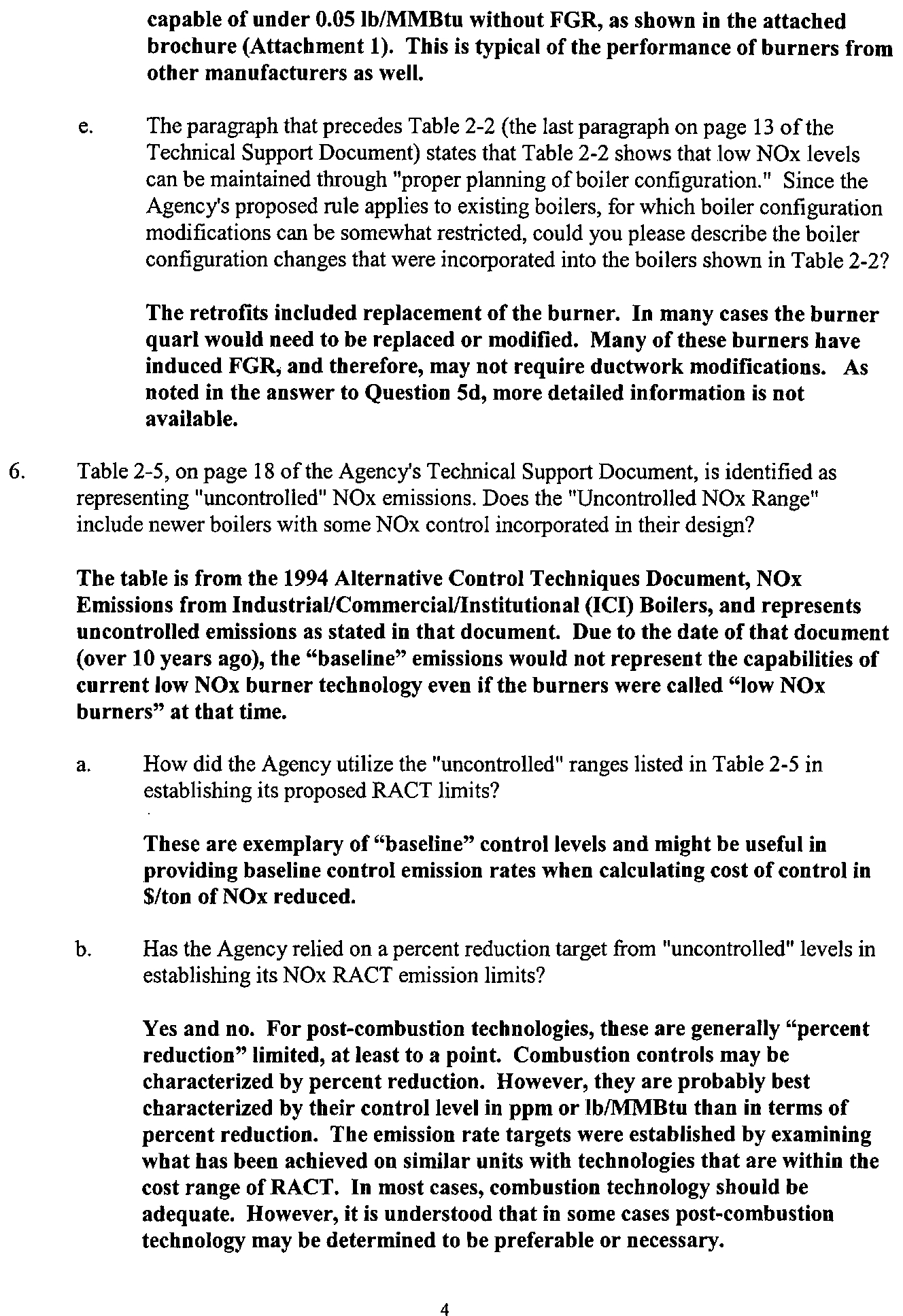

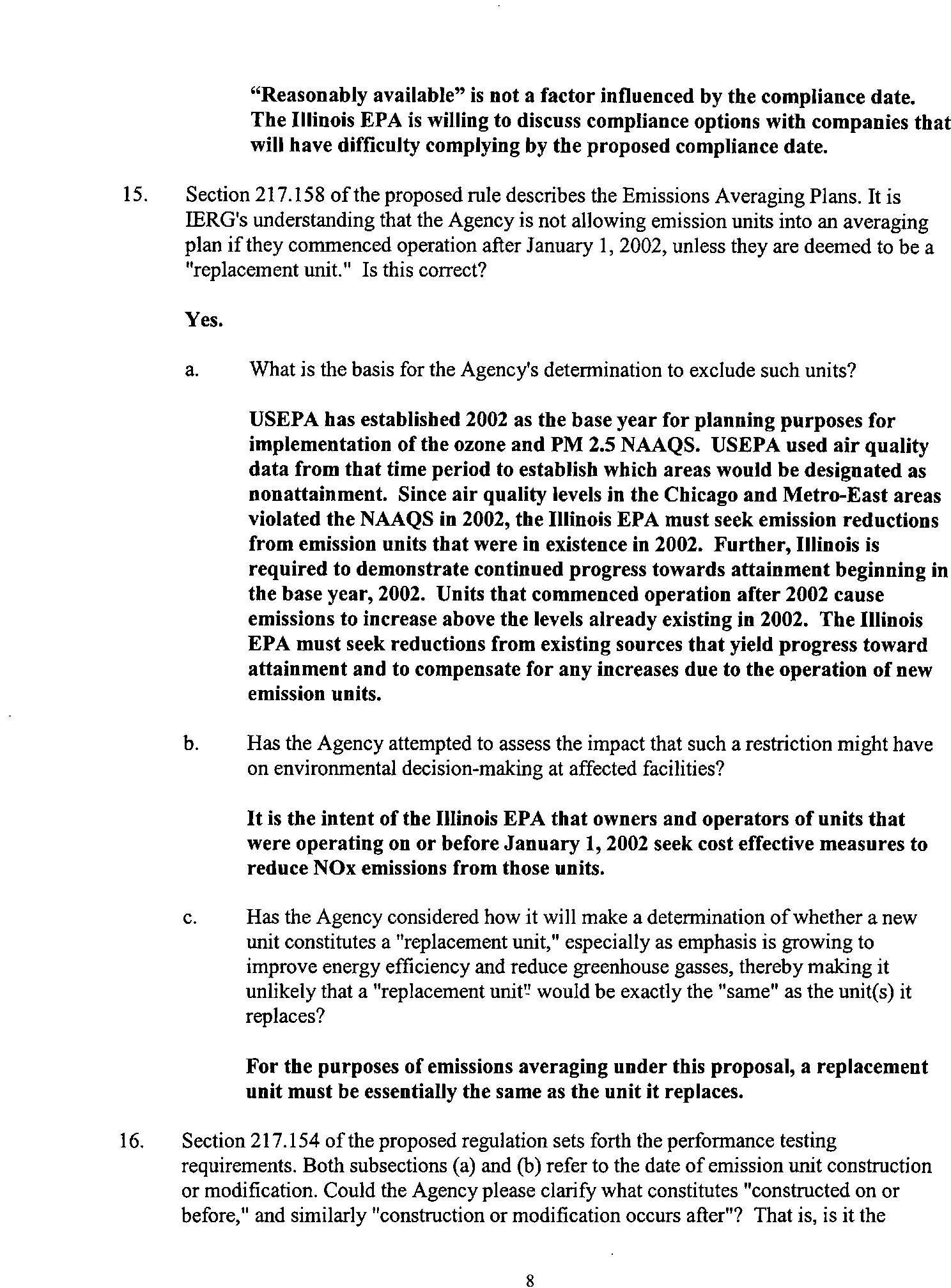

SCR is technically feasible on CFB boilers, but would be unnecessary for

compliance with this rule.

SCR is generally not used on CFB boilers because much

less expensive options

are available, such as SNCR, to comply with existing

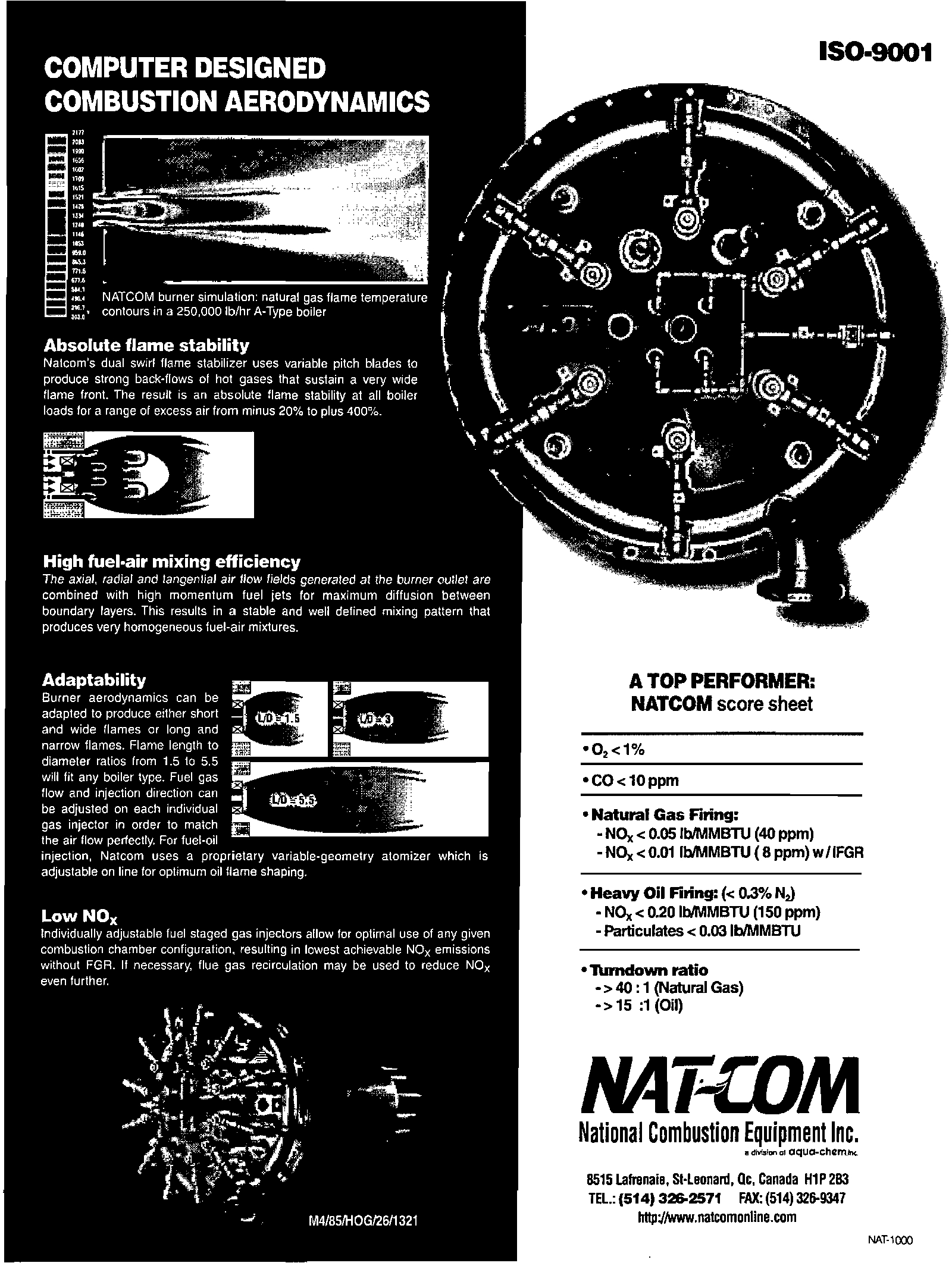

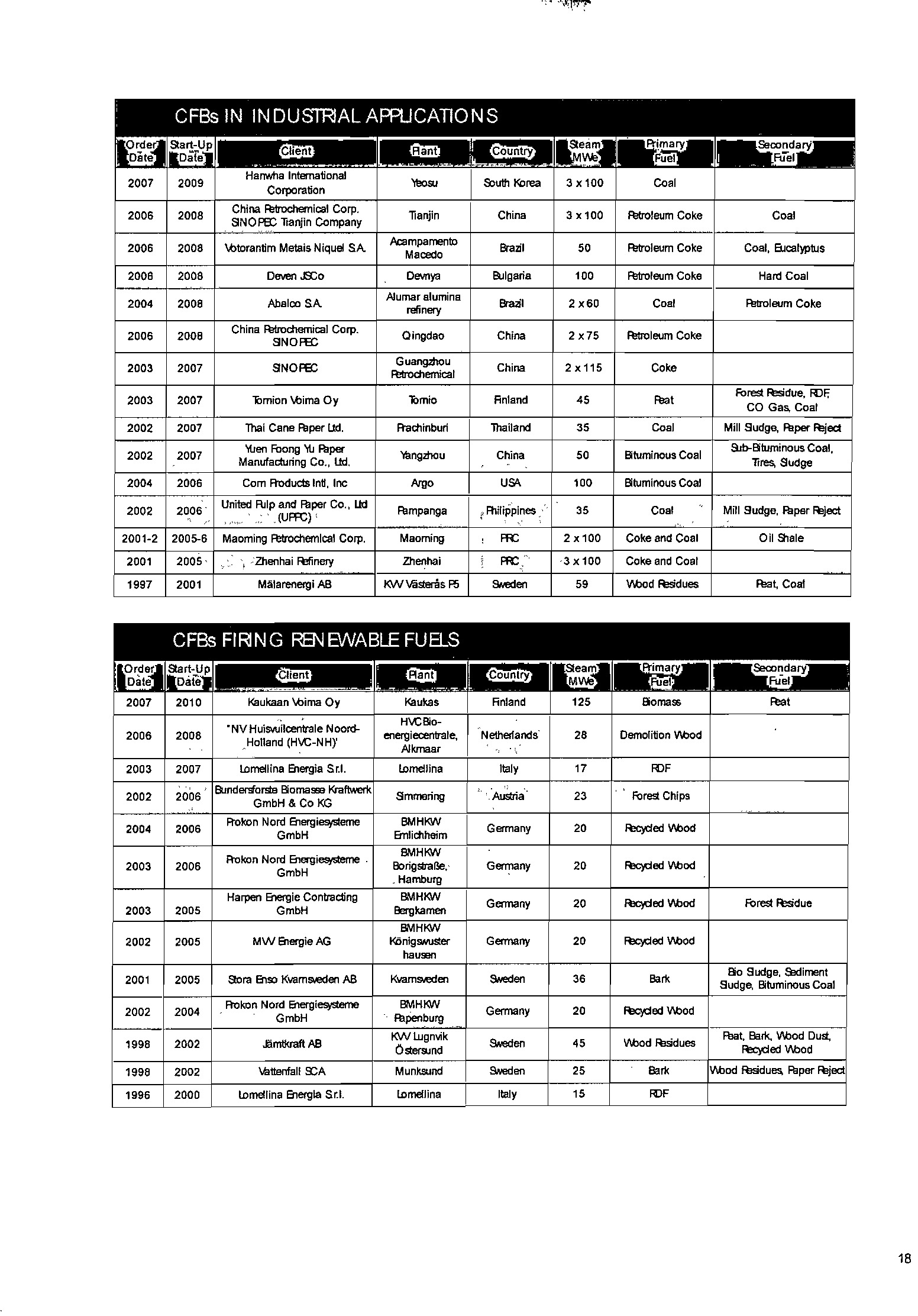

regulations. The figure set forth

at Attachment 2 is from a brochure by Foster

Wheeler - a manufacturer

of CFB boilers - that shows SCR installed on an

industrial CFB boiler. The complete brochure

is provided as Attachment 3.

a.

Does the Agency believe that SCR is feasible on all stoker boilers?

SCR is technically feasible on stoker boilers. However, it is generally not

used because, like CFB boilers, stoker boilers have much less costly options

for control.

b.

Do the Agency's proposed NOx emission limits for stoker boilers assume that

SCR is a feasible option?

We do not expect

that a stoker boiler would select SCR for compliance with

this rule because there

are less costly options, such as combustion controls

and SNCR. However, as noted in the answer to Question 8a,

SCR is

technically feasible on stoker boilers.

c.

What information did the Agency rely upon in determining that SCR is

technically feasible on a broad range of rCI boiler types and sizes?

It

is important to distinguish between technical feasibility and cost. SCR has

been applied to a

broad range of boiler types - coal, natural gas, oil. SCR

can be applied to any combustion source with an available temperature

range (or where the temperature range can be made available). However,

the cost

of applying SCR technology will vary by source type. The selection

of SCR or any other control technology for NOx reduction on a specific

source will depend upon the cost

of applying SCR to that source and the

costs

of other options that are available for that source. As a result, becanse

other less-expensive options

are available, SCR is not in use on some source

types although it is technically feasible to apply it to them,.

5

Electronic Filing - Received, Clerk's Office, September 30, 2008

9.

Has the Agency performed any analyses of Illinois facilities to determine the potential

cost of this rule?

A total cost was not estimated for tbe TSD. However, tbis rule was developed witb

tbe intent of keeping tbe cost of NOx reductions generally at or below $3000/ton.

10.

Has the Agency gathered or reviewed any information from the last 3 years for costs of

NOx retrofit controls for facilities in Illinois or similar to those in Illinois?

Yes, in fact escalation was applied to some of tbe cost estimates, particularly for

SCR as described on page 36 of tbe TSD.

11.

The Agency's Technical Support Document includes NOx emission limits for categories

of emission units that do not, or likely never will, exist in the area covered by this rule.

What is the purpose for including these limits?

Tbere is no basis for tbe claim tbat certain emission units "likely never will exist."

Tbe TSD acknowledges tbat tbere are no cement kilns in tbe current NAA

boundaries, and tbat tbe only aluminum melting furnace in tbe Cbicago area is not

currently operating. To our knowledge, tbe aluminum melting furnace bas not been

dismantled, so it is possible tbat tbe current, or a potential future owner, may intend

to operate the furnace in tbe future. Regarding cement kilns, it sbould be noted tbat

USEPA bas indicated tbat it will designate Massac County, wbere tbere is an

existing cement kiln, as non-attainment for PM2.5 in December 2008.

12.

Does the Agency intend its definition of "industrial boiler" (see Section 211.3 100, and

Sections 217.160 to 166 of the proposed rule) to include cogeneration units and/or heat

recovery steam generators that capture waste heat from turbines or engines?

Yes.

a.

If so, has the Agency performed any analysis to determine the technical feasibility

and cost for cogeneration units and/or heat recovery steam generators to comply

with its proposed rule?

No.

13.

Does the Agency intend its definition of "industrial boiler" (see Section 211.3 100, and

Sections 217.160 to 166 of the proposed rule) or "process heater" (see Section 211.5195,

and Sections 217.180 to 186 of the proposed rule) to include gas-fired chillers that

provide cooling for either processes or occupied spaces?

If

refrigerant is beated directly by gas firing, it is a process beater.

a.

If so, has the Agency performed any analysis to determine the technical feasibility

and cost for such gas-fired chillers to comply with its proposed rule?

6

Electronic Filing - Received, Clerk's Office, September 30, 2008

No separate analysis was performed, but the Illinois EPA believes that the

technical feasibility

and cost for gas-fired chillers should be similar to

process heaters

and industrial boilers.

14.

The Statement ofReasons, at pages 7-8, states that the NOx RACT State Implementation

Plan was required

to be submitted to the USEPA by September 15, 2006. And further,

that the date for affected sources to comply with the emissions limitations

in

the proposed

rule

is May 1, 2010.

a.

Based on the federal requirement for the NOx RACT SIP submittal, when does he

USEPA require that NOx RACT be implemented?

USEPA required

that NOx RACT be implemented no later than May 1,

2009.

b.

What is the basis for the Agency's selection of May 1,2010 as the compliance

date?

Given the delay in developing this proposal, and in response to concerns

expressed by stakeholders, the Illinois EPA has proposed to delay

implementation for one year after USEPA's required implementation date.

c.

In

the Agency's deliberations regarding the technical feasibility and cost of

compliance for this rule, was any consideration given to the amount oflead-time

necessary for various industries to plan, design, construct and test the emission

control technologies envisioned by this proposed rule?

The Illinois EPA believes

that stakeholders have already had ample time to

plan and design the control measures needed to comply with this proposal

since they have been aware

of it for several years. Depending on the

duration

ofthe rulemaking process, there mayor may not be sufficient time

to obtain the necessary permits and construct the control equipment. The

Illinois EPA

is willing to discuss specific hardships posed by the compliance

deadlines should they,

in

fact, occur.

d.

Does the Agency believe that the amount of time from rule promulgation to the

compliance date has a significant bearing on the ultimate cost and feasibility

of

compliance?

The Illinois EPA does not believe

that the compliance date will, in general,

impose a significant cost impact to most industries, although the Illinois EPA

is willing to discuss options with companies that are unduly impacted by the

proposed compliance date.

e.

Is the concept of "Reasonably Available" a factor of the compliance date such that

the technical options and economic cost for Reasonably Available Control

Technology would be dependent on the amount

of time between rule

promulgation and compliance?

7

Electronic Filing - Received, Clerk's Office, September 30, 2008

"Reasonably available" is not a factor influenced by the compliance date.

The Illinois EPA is willing to discuss compliance options with companies that

will have difficulty complying by the proposed compliance date.

15.

Section 217.158

ofthe proposed rule describes the Emissions Averaging Plans.

It

is

IERG's understanding that the Agency is not allowing emission units into an averaging

plan

ifthey commenced operation after January 1, 2002, unless they are deemed to be a

"replacement unit." Is this correct?

Yes.

a.

What is the basis for the Agency's determination to exclude such units?

USEPA has established 2002 as the base year for planning purposes for

implementation ofthe ozone and PM 2.5 NAAQS. USEPA used air quality

data from that time period to establish which areas would be designated as

nonattainment. Since air quality levels in the Chicago and Metro-East areas

violated the NAAQS in 2002, the Illinois EPA must seek emission reductions

from emission units that were in existence in 2002. Further, Illinois is

required to demonstrate continued progress towards attainment beginning in

the base year, 2002. Units that commenced operation after 2002 cause

emissions to increase above the levels already existing in 2002. The Illinois

EPA must seek reductions from existing sources that yield progress toward

attainment and to compensate for any increases due to the operation of new

emission units.

b.

Has the Agency attempted to assess the impact that such a restriction might have

on environmental decision-making at affected facilities?

It

is the intent of the Illinois EPA that owners and operators of units that

were operating on or before January 1,2002 seek cost effective measures to

reduce NOx emissions from those units.

c.

Has the Agency considered how it will make a determination ofwhether a new

unit constitutes a "replacement unit," especially as emphasis is growing to

improve energy efficiency and reduce greenhouse gasses, thereby making it

unlikely that a "replacement

unit~

would be exactly the "same" as the unites) it

replaces?

For the purposes of emissions averaging under this proposal, a replacement

unit must be essentially the same as the unit it replaces.

16.

Section 217.154 of the proposed regulation sets forth the performance testing

requirements. Both subsections (a) and (b) refer to the date

of emission unit construction

or modification. Could the Agency please clarify what constitutes "constructed on

or

before," and similarly "construction or modification occurs after"? That is, is it the

8

Electronic Filing - Received, Clerk's Office, September 30, 2008

beginning of construction, the completion of construction, the date of issuance of a

construction pennit?

The definitions contained in 35 Ill. Adm. Code

201 and 211 apply to Part 217. See,

35 Ill. Adm. Code 217.103. Accordingly, Section 201.102 defines the term

"construction" as "commencement

of on-site fabrication, erection or installation of

an emission source or of air pollution control equipment," and "modification" as

"any physical change in, or change in the method of operations of, an emission

source

or of air pollution control equipment which increases the amount of any

specified

air contaminant emitted by such source or equipment or which results in

the emission

of any specified air contaminant not previously emitted.

It

shall be

presumed

that an increase in the use of raw materials, the time of operation or the

rate of production will change the amount of any specified air contaminant emitted.

Notwithstanding any other provisions

of this definition, for purposes of permits

issued

pursuant to Subpart D, the Illinois Environmental Protection Agency

(Agency) may specify conditions

under which an emission source or air pollution

control equipment may be operated without causing a modification as herein

defined,

and normal cyclical variations, before the date operating permits are

required, shall not be considered modifications." See, 35 Ill. Adm. Code 201.102.

a.

If the tenns mean the beginning or completion of construction, please define what

constitutes beginning or completion.

See answer to Question 16.

17.

On page 6 of James Staudt'spre-filed testimony, the statement is made that SCR has been

widely used on boilers at industrial facilities.

a.

Could you please provide a representative list of such installations, including the

boiler type, and identify those that were retrofits?

According to my testimony,

"It has been widely used on utility boilers, turbines, diesel engines as well as

industrialfacilities. "

So, the question incorrectly characterizes my testimony. SCR has been used

in numerous gas-fired industrial boilers

and it has been used in refinery

process units, especially

CO boilers.

It

has also been retrofit on hundreds of

coal fired power plants. But, to my knowledge it has not been retrofit on any

solid fuel industrial boilers in the United States because lower cost

approaches

are available.

b.

Also, please identify those that used high-sulfur coal, and those that were stoker

fired boilers.

There

are numerous high sulfur boilers equipped with SCR in the electric

utility industry. In Illinois, the Duck Creek, Dallman,

and Marion plants all

9

Electronic Filing - Received, Clerk's Office, September 30, 2008

have units with SCR and burn high sulfur coal. Numerous other power

plants throughout the United States that fire high sulfur coal are also

equipped with SCR. USEPA's National Electric Energy Data System

(NEEDS) database,

that can be downloaded at

http://www.epa.gov/airmarktlprogsregs/epa-ipm/past-modeling.html.

includes a list of electric utility boilers equipped with both SCRs

and

scrubbers.

It

also shows units with SCR without scrubbers - some firing

high sulfur coal. Those units with wet scrubbers typically fire high

sulfur

coal. Therefore, there is extensive experience with SCR on high sulfur fueled

coal fired boilers.

I

am not aware of any stokers that are equipped with SCR, as stokers

generally have less expensive options to control NOx due to the lower

baseline NOx level, lower temperature combustion

and longer furnace

residence time than pulverized coal units. However,

if the owner of a stoker

boiler chose to use SCR to control NOx, there is no technical reason why they

couldn't,even

if they burned high sulfur coal. But, as previously mentioned,

a stoker boiler owner has other, less-expensive options to reduce NOx and,

therefore, would be very unlikely choose to use SCR.

18.

Does the Agency believe that a >250 mmBtulhour coal-fin;d boiler, using Illinois coal,

can meet a NOx limit

of 0.18 IbslMMBtu without SCR?

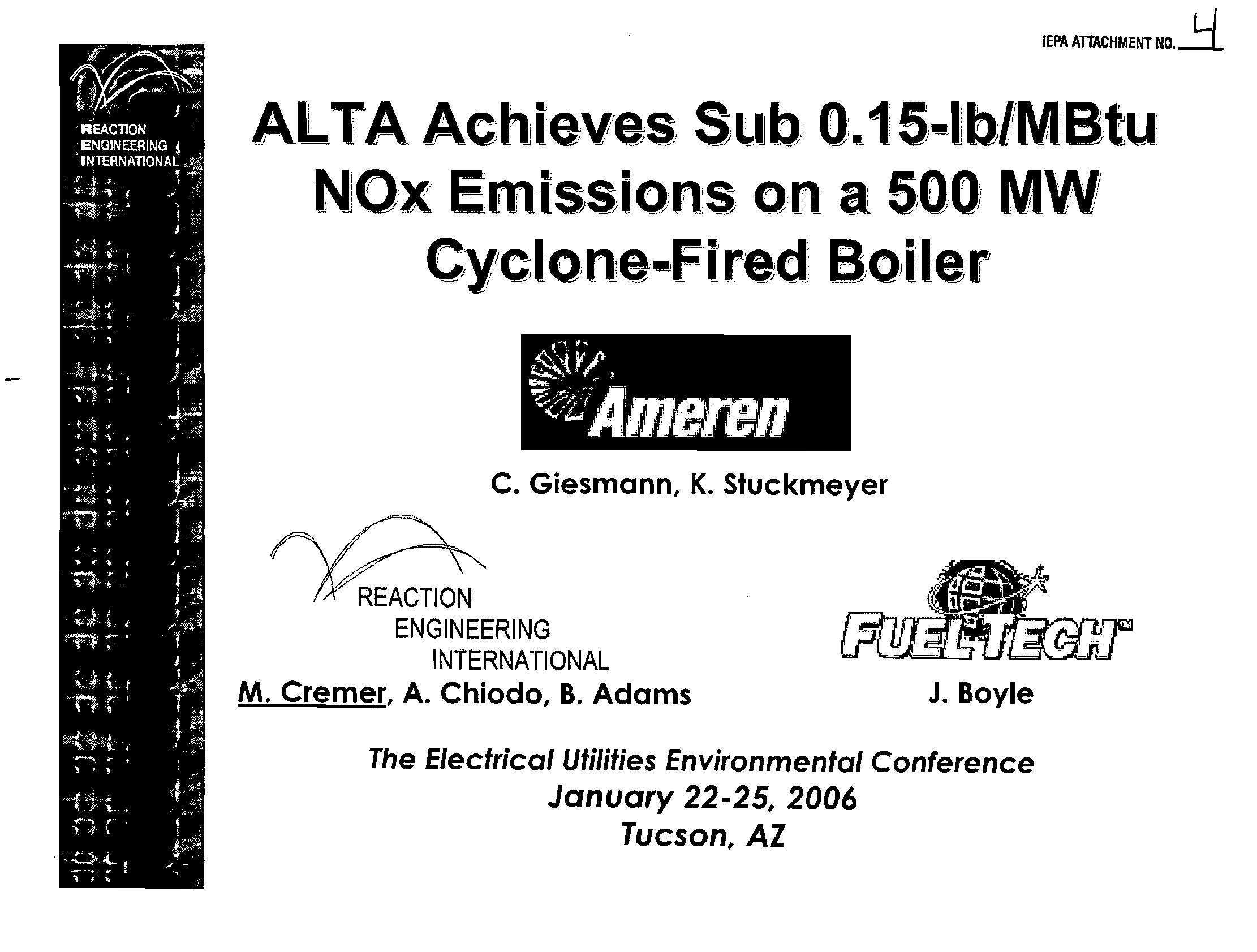

Yes, combinations

of combustion controls and SNCR have been shown to be capable

of providing emissions below 0.18 IbIMMBtu, as described in Section 2.3.6 of the

TSD. An example is Ameren's Sioux unit 1, which achieved

under 0.181b1MMBtu

while firing 100% Illinois bituminous coal, as presented

at the Electrical Utilities

Environmental Conference (EUEC),

January 22-25, 2006, in a presentation by

Giesmann, Stuckmeyer, Cremer, Chiodo, Adams,

and Boyle (See Attachment 4).

19.

On page 6 of James Staudt'spre-filed testimony, it is stated that "SCR can and has been

installed to provide NOx reductions

at costs below

$2,500/ton."

a.

What price was used for the cost of ammonia in making this calculation?

In the estimates in F.igures 2-17

and 2-18 of the TSD, $400/ton. Since 17

pounds

of ammonia removes 46 pounds of NOx, the effect of ammonia cost is

that a change in ammonia cost of $100/ton changes the cost of removing NOx

by $37/ton

of NOx. In other words, ifthe cost of ammonia were doubled

from $400/ton to $800/ton, the effect on Figure 2-17 would be to increase cost

by $150/ton

of NOx - a relatively modest shift.

b.

Does this cost include the cost ofreplacement of the boiler's air pre-heater?

Yes, the majority

ofthe boilers that have been retrofit with SCR were utility

boilers

and many of them replaced their air pre-heater.

c.

Does this cost include the cost of a wet electrostatic precipitator?

10

Electronic Filing - Received, Clerk's Office, September 30, 2008

No, because a wet ESP is not necessary. None of the hundreds of coal-fired

SCR retrofits in the United States have required a wet ESP.

20.

On page 6 of James Staudt's pre-filed testimony, he describes the SNCR technology. Is

the Agency aware of SNCR applications on industrial boilers using high-sulfur coal?

Yes, industrial and utility units that burn high sulfur coal (3 Ib/MMBtu of S02 or

greater) and have used SNCR on a commercial basis include:

•

AES Beaver Valley (PA)

•

AES Greenidge (NY)

•

BL England Station

(NJ)

•

Cinergy Miami Fort 6 (OR)

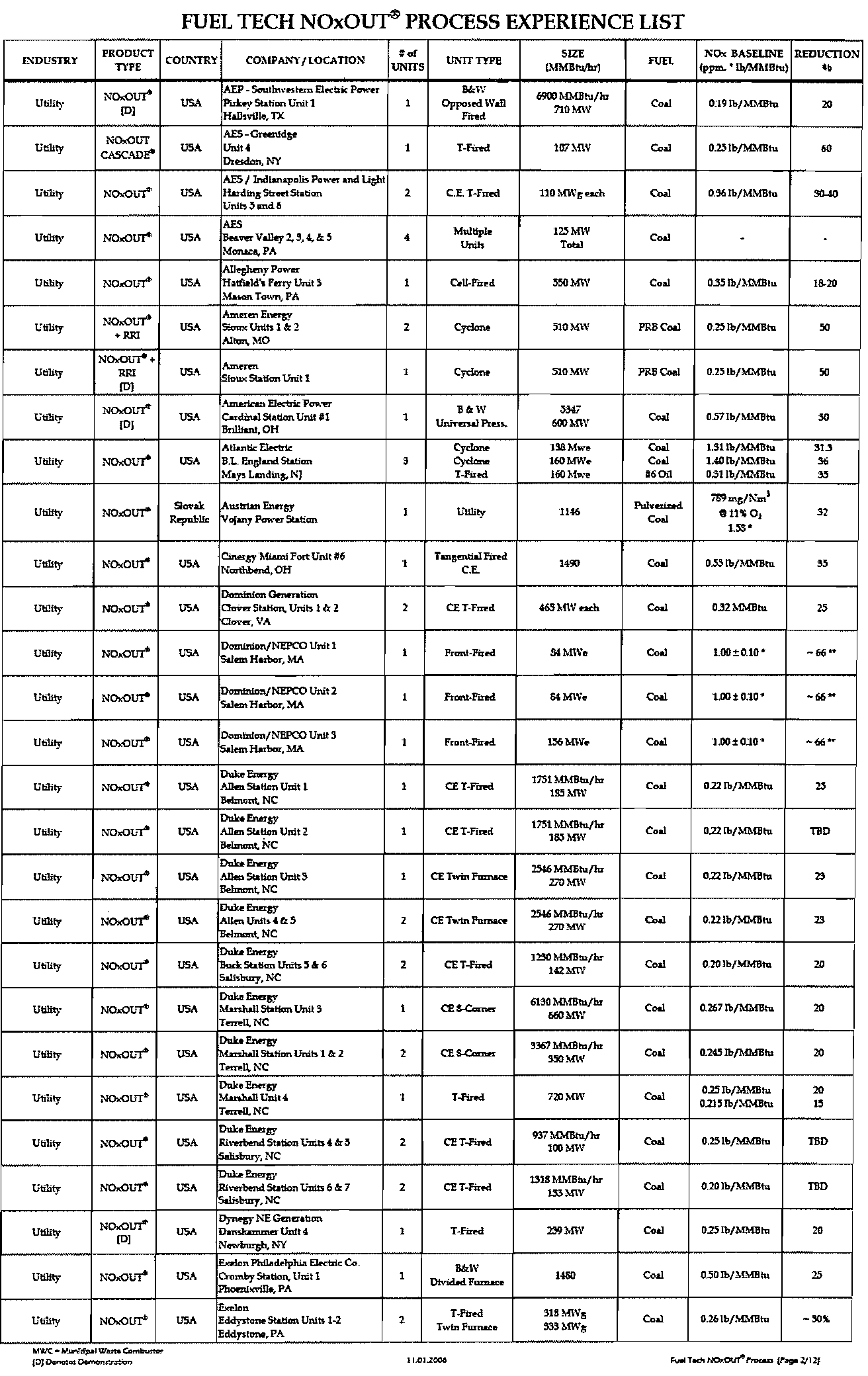

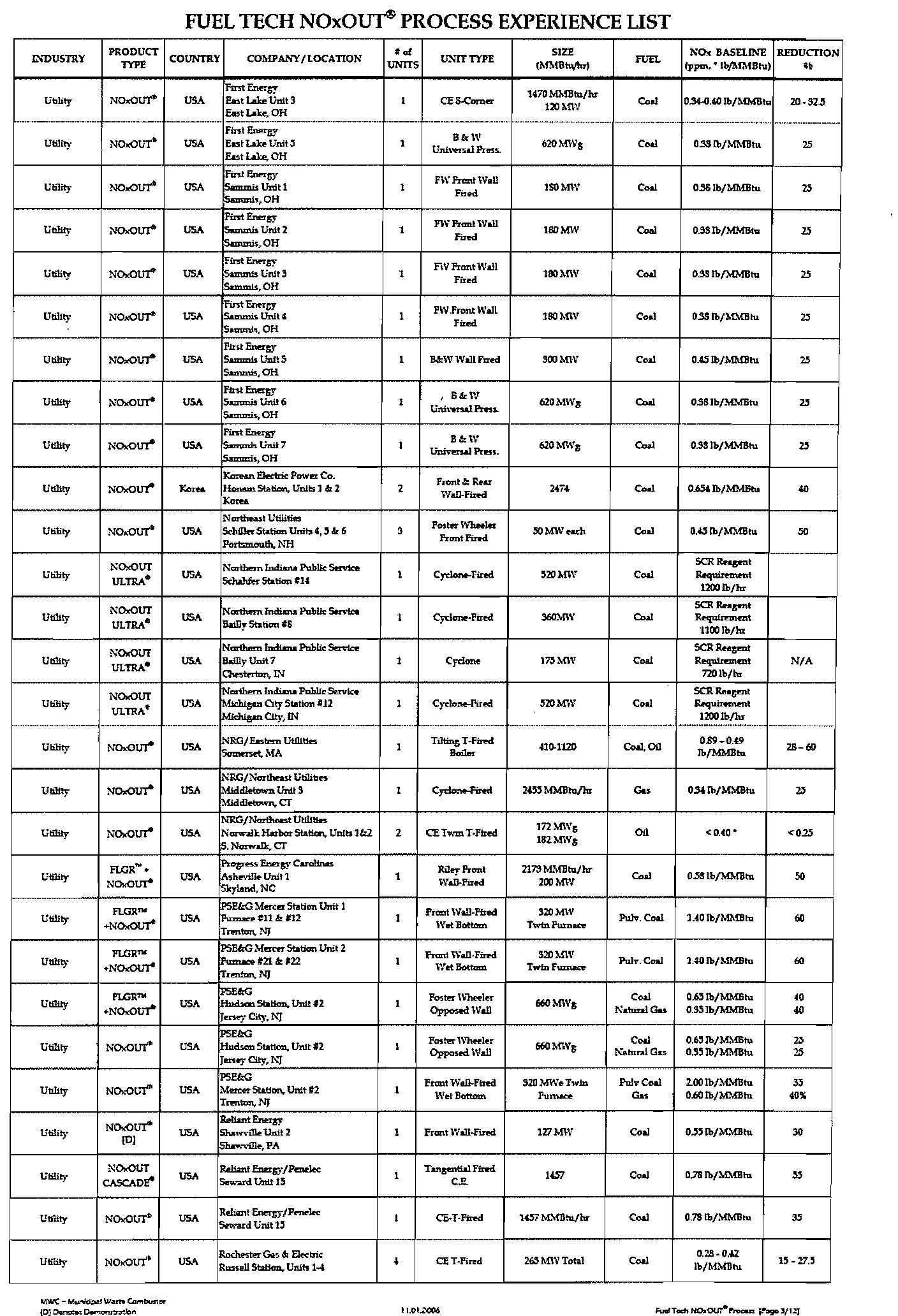

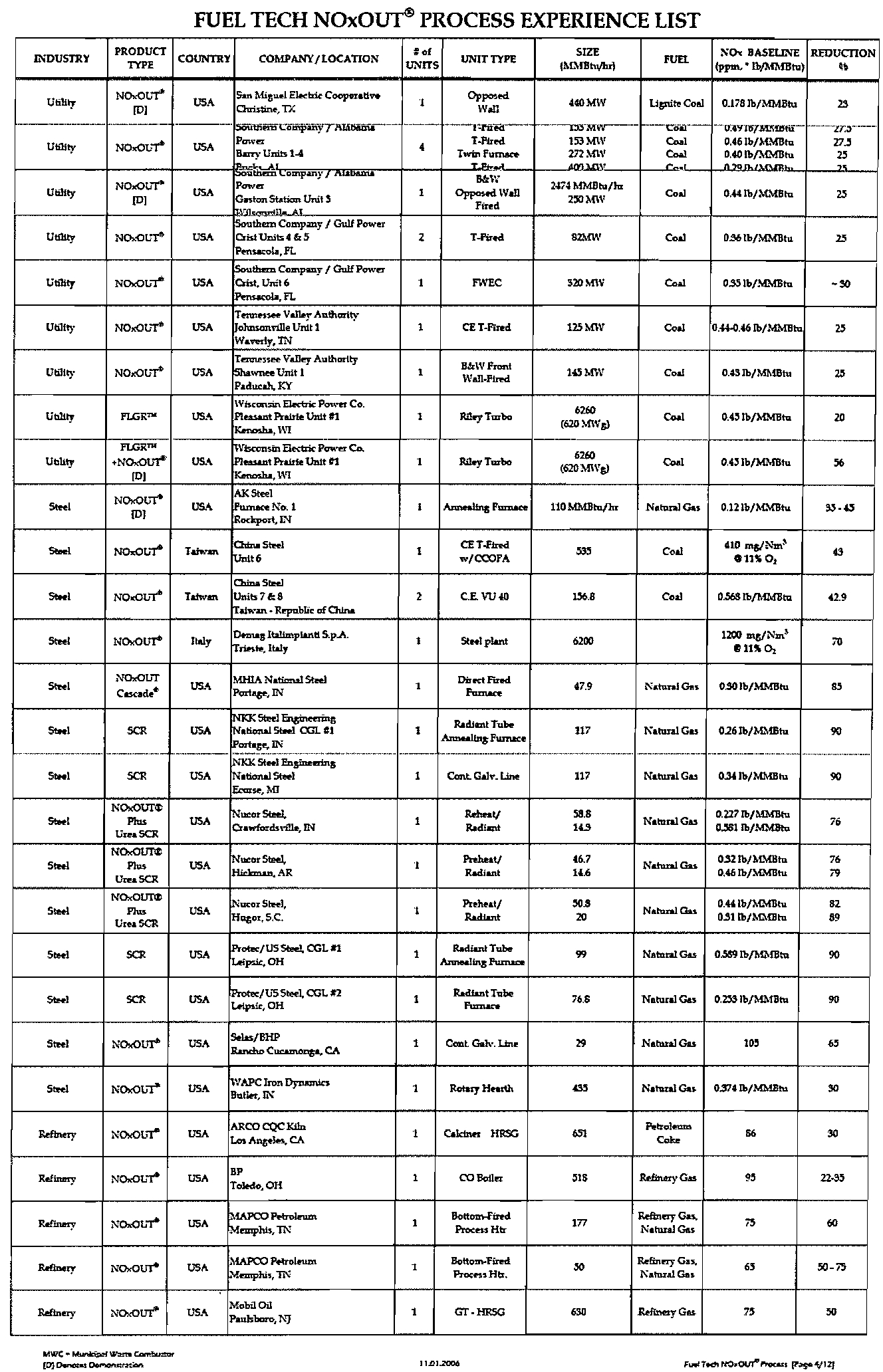

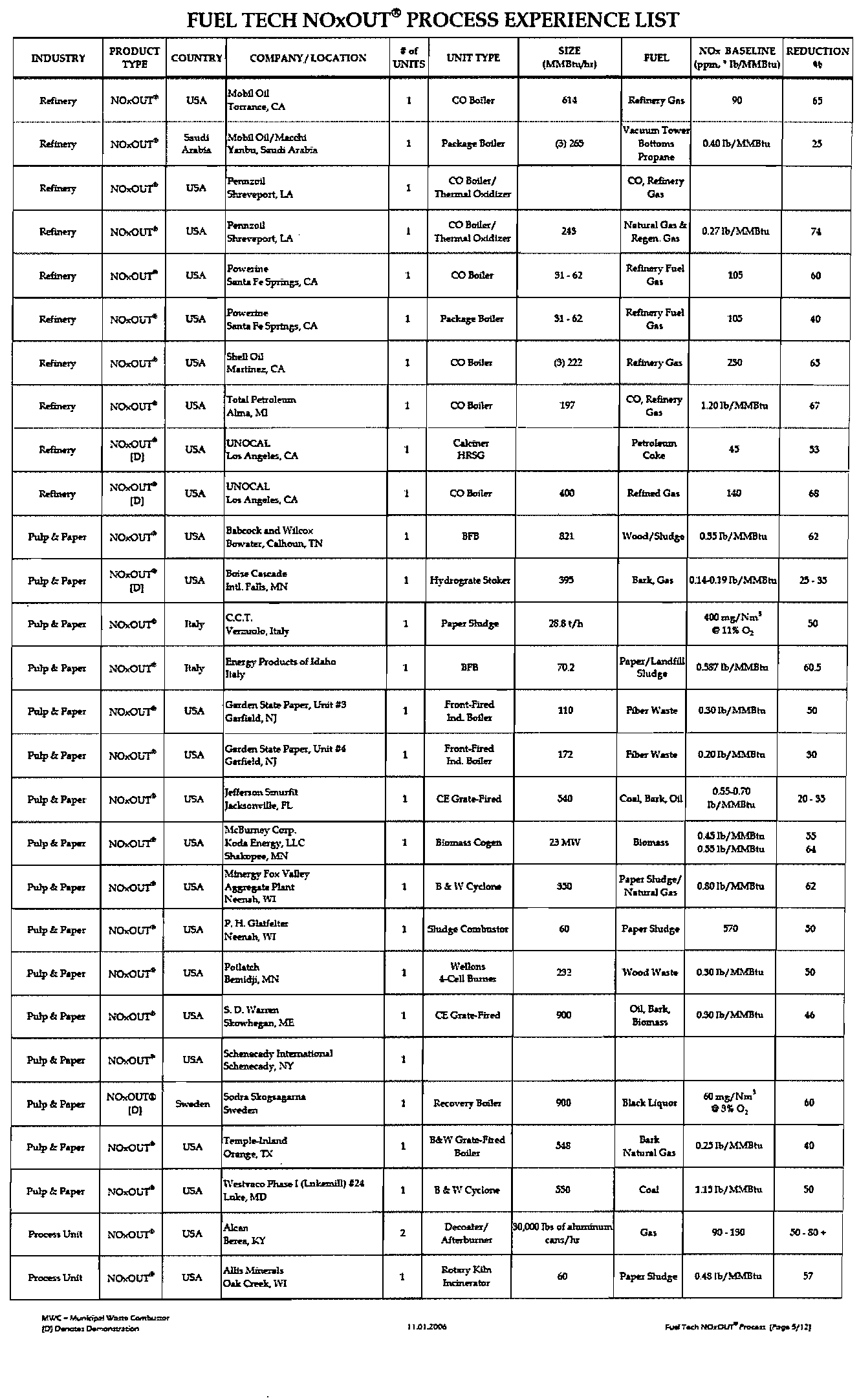

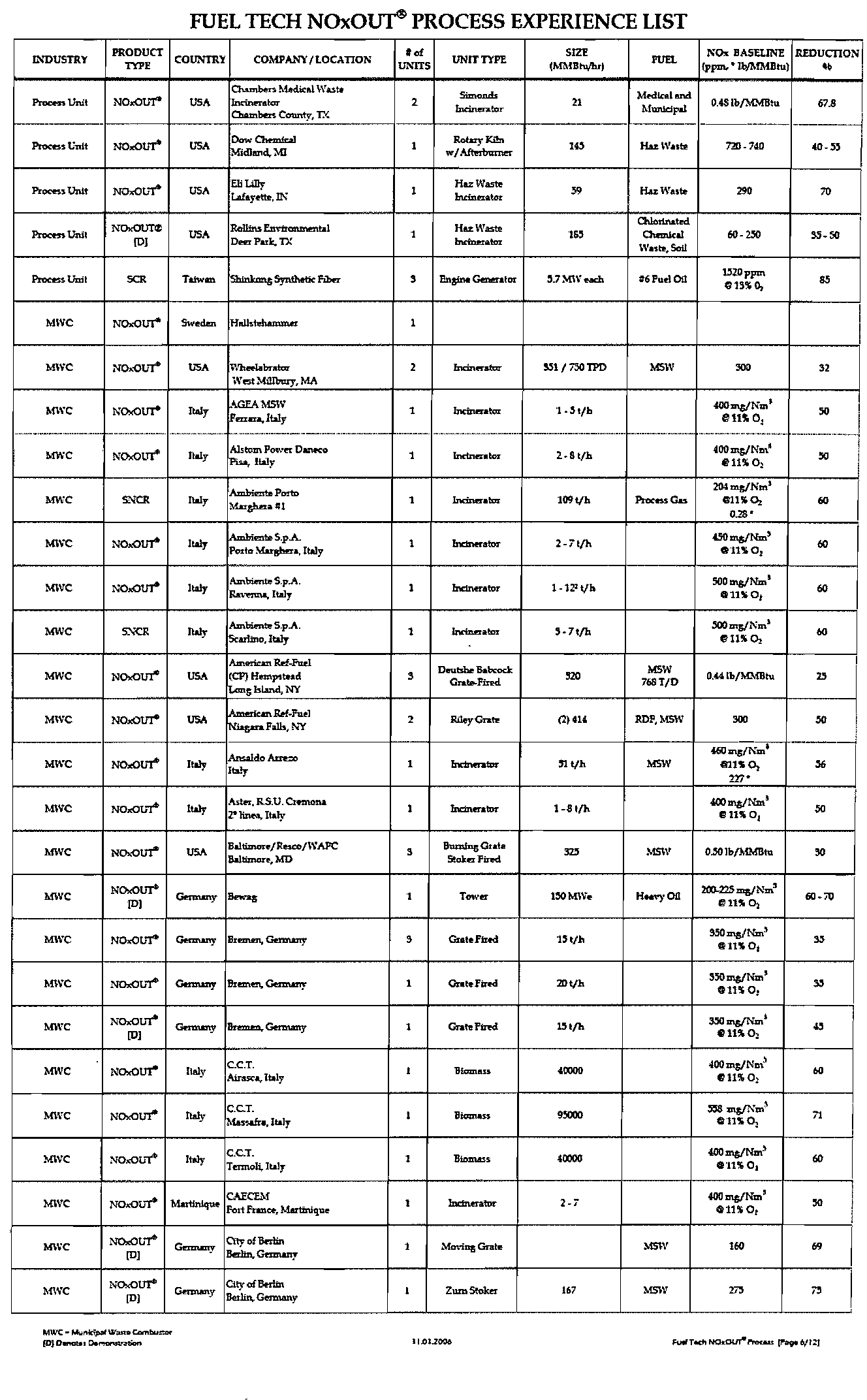

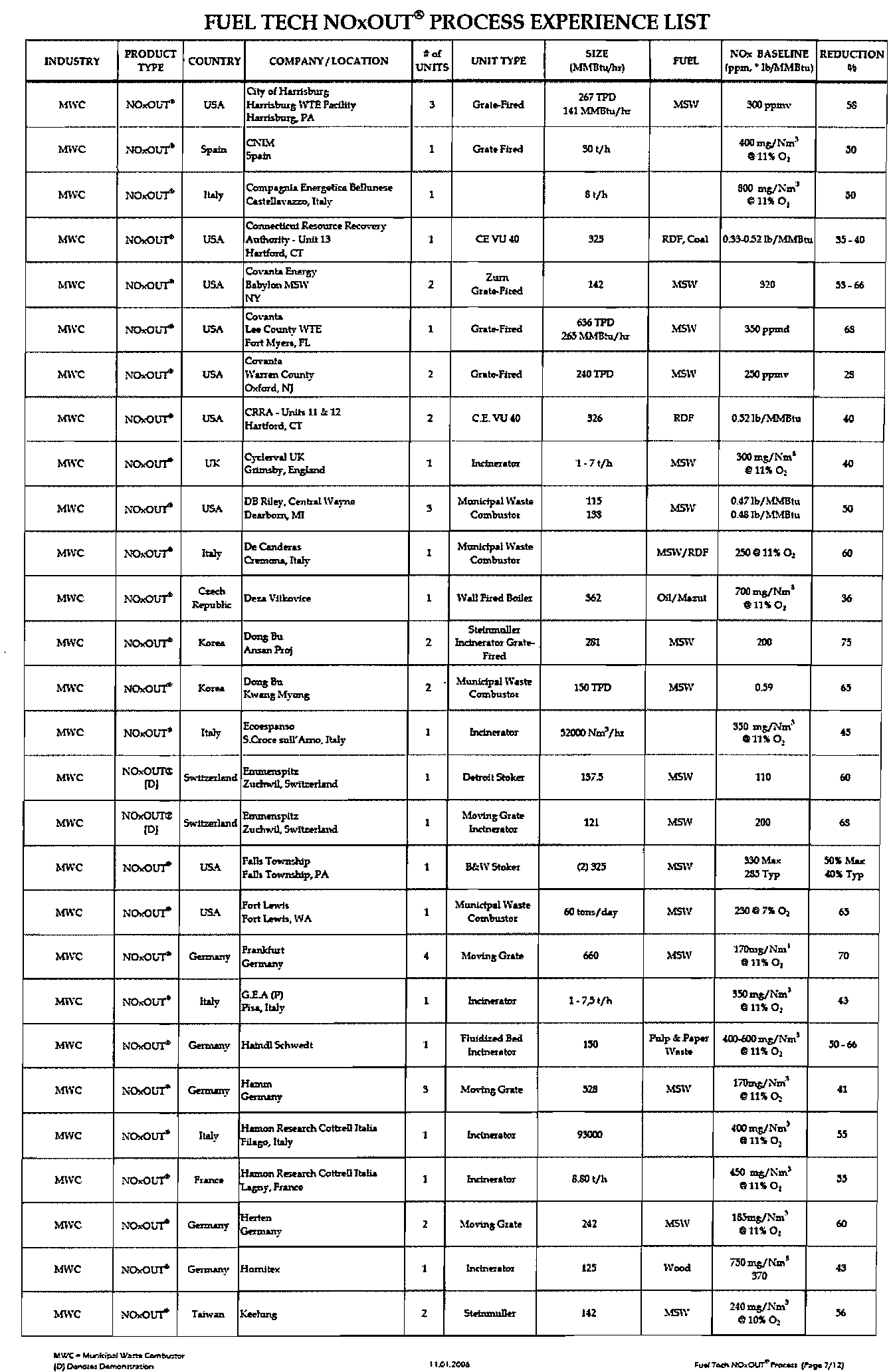

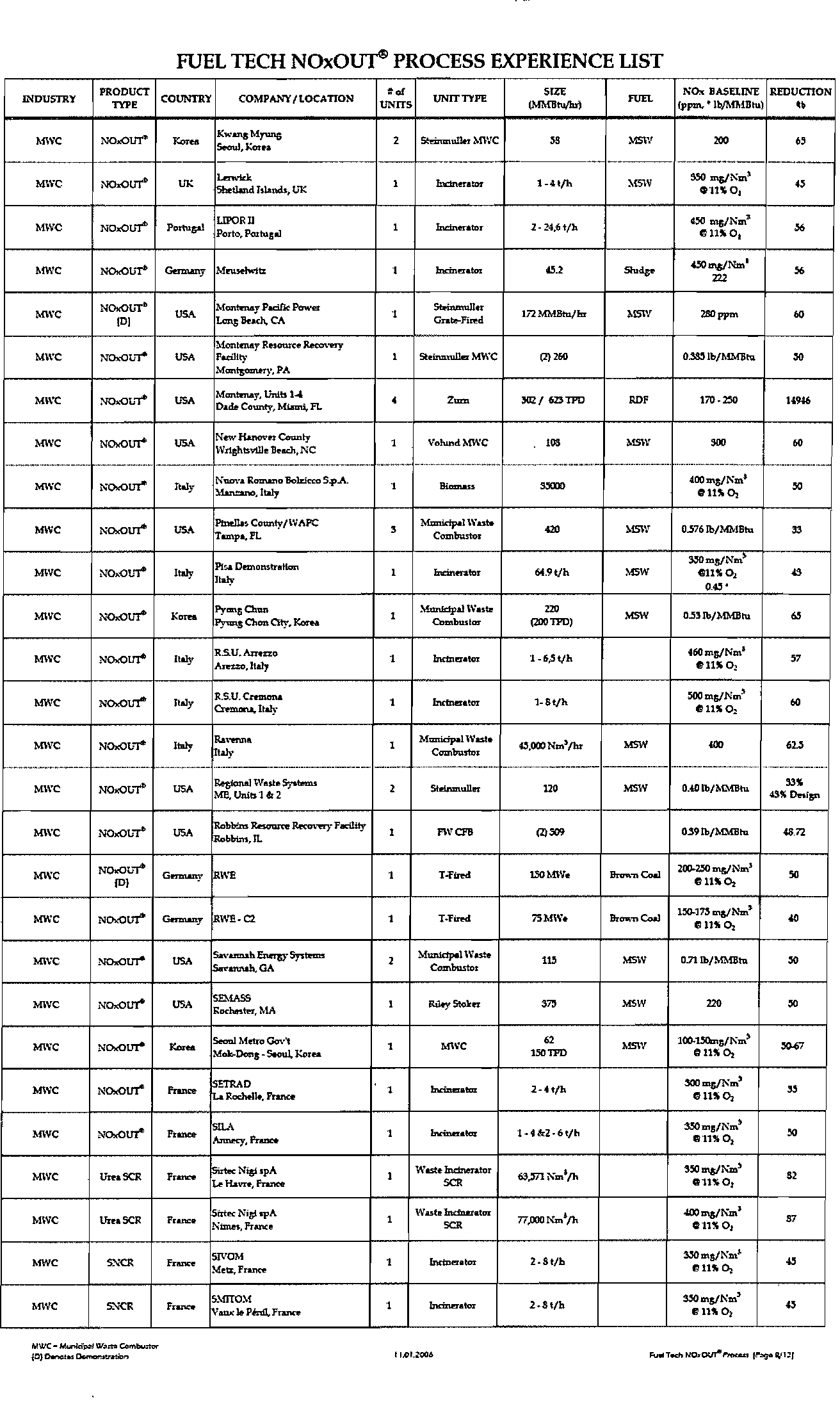

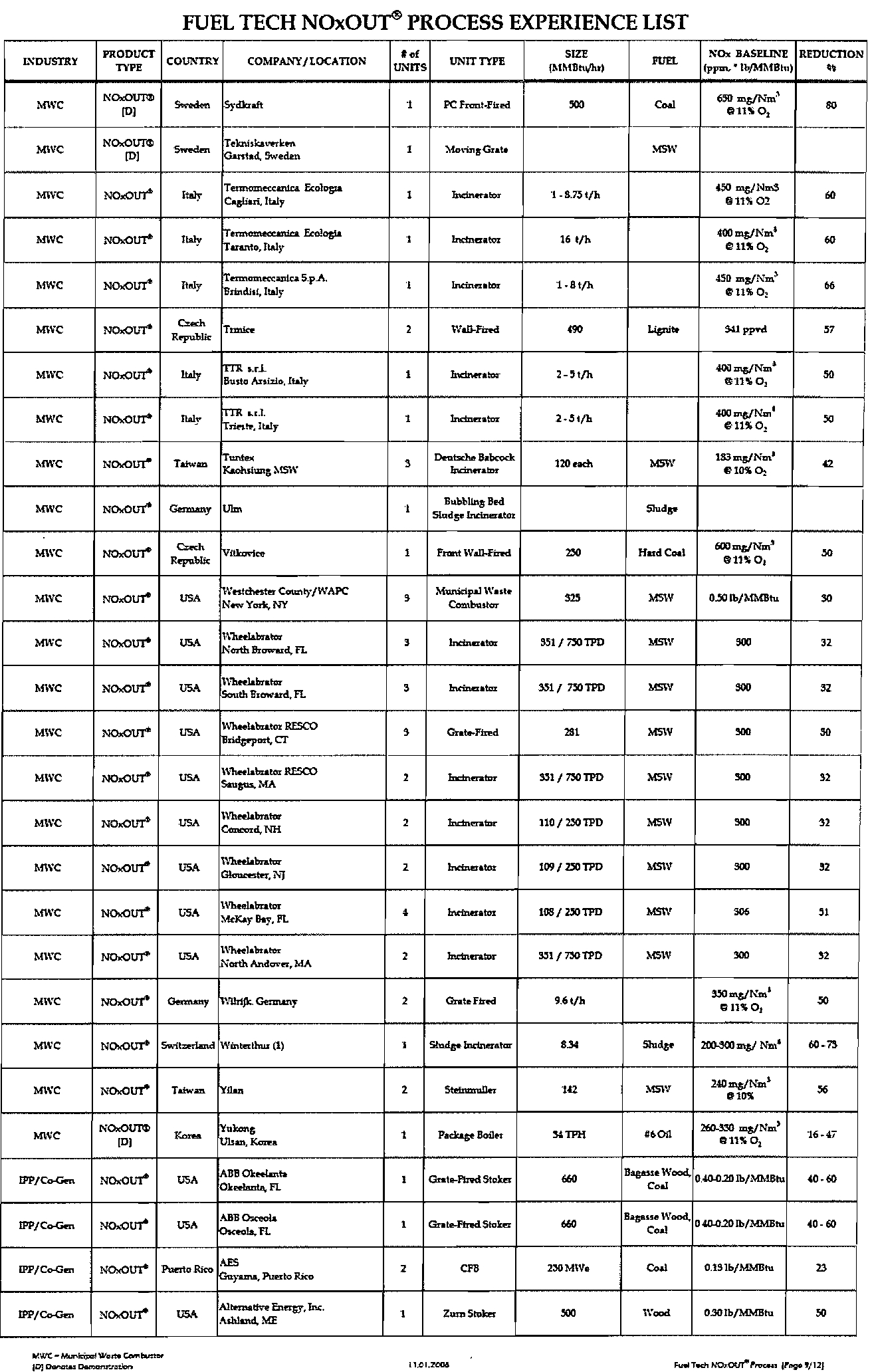

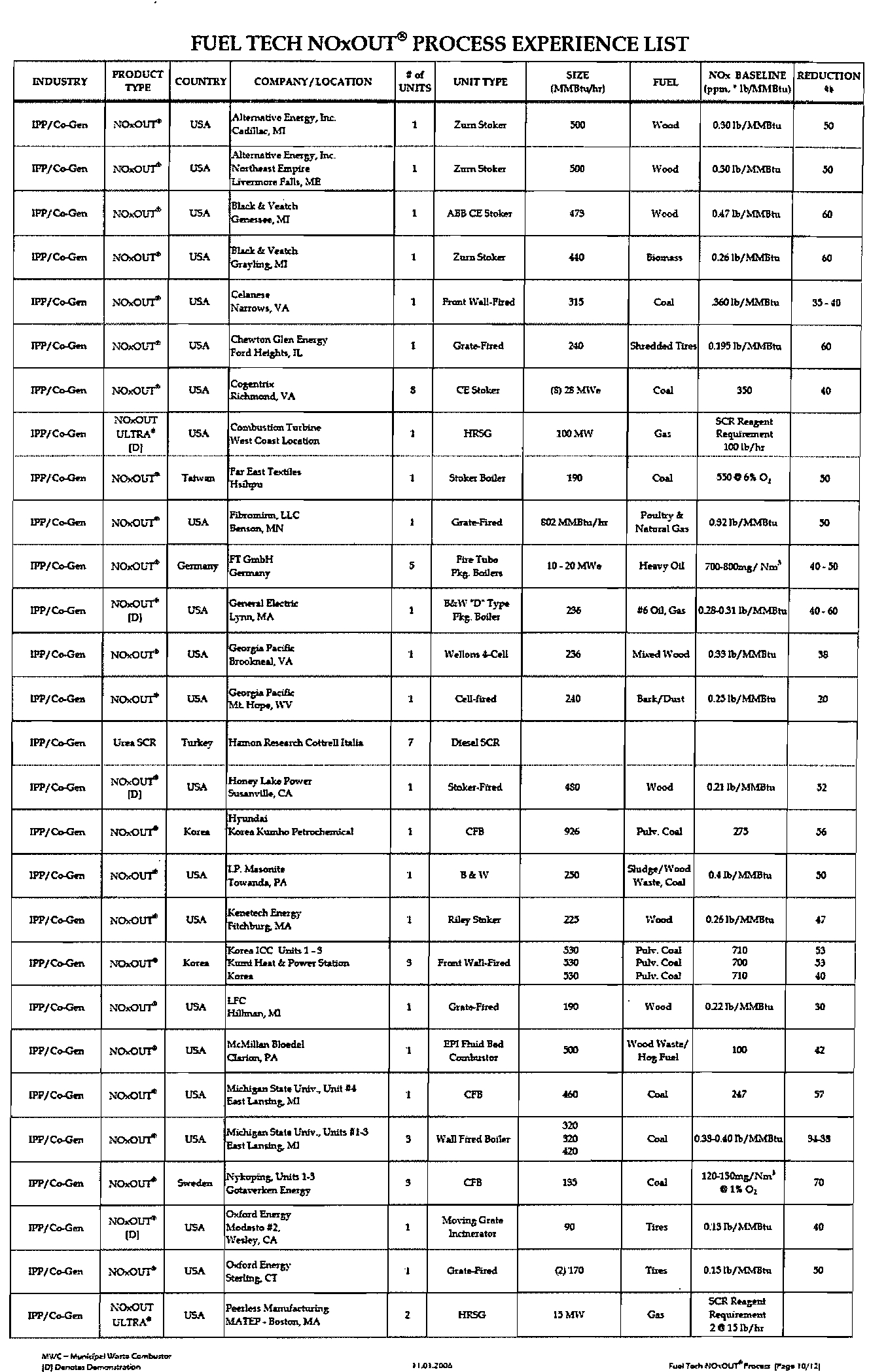

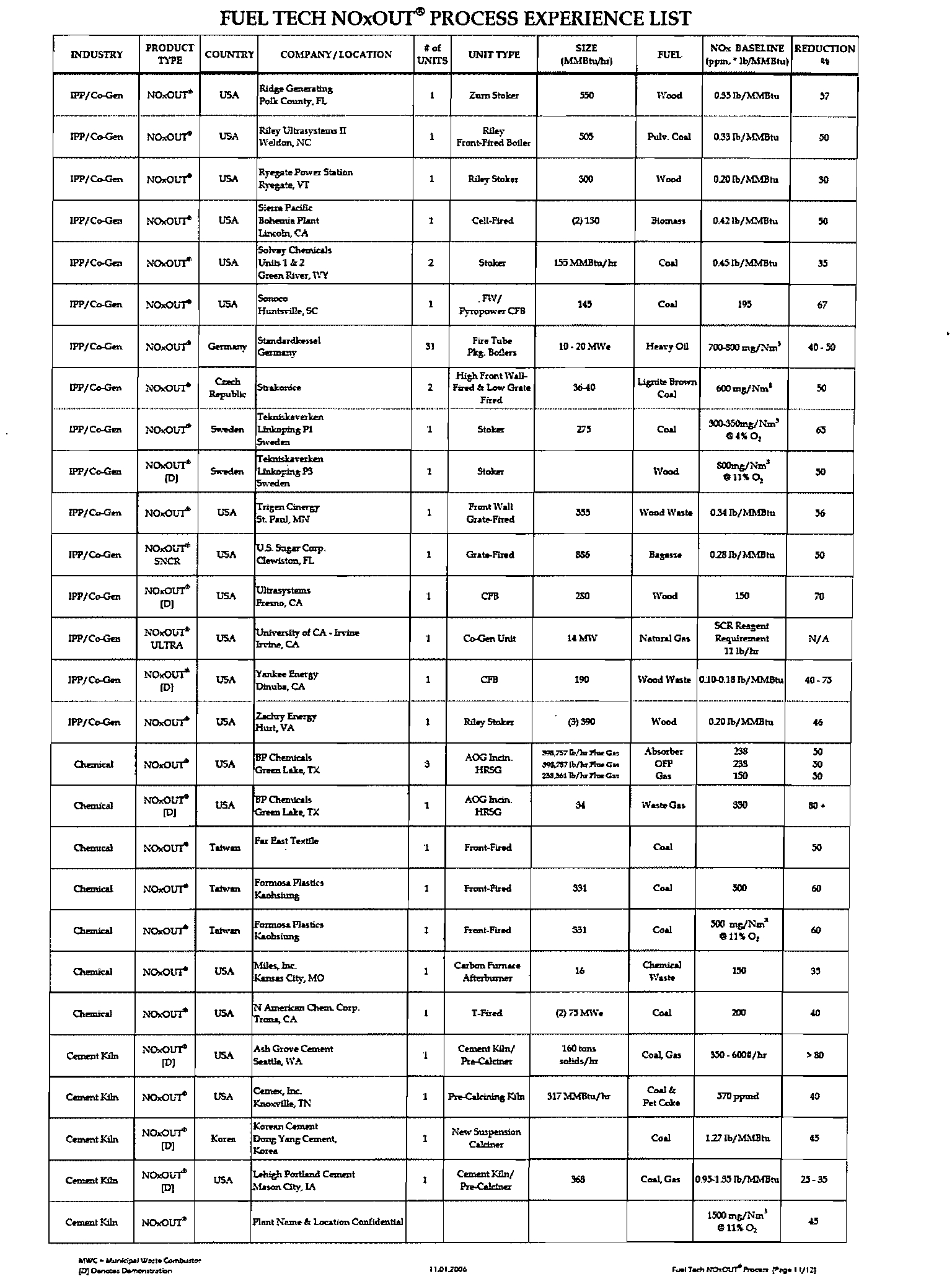

Also attached is the ICAC SNCR White Paper, as well as Fuel Tech's installation

list, to provide additional information regarding where SNCR has been applied (See

Attachments 5 and 6).

a.

Could you please describe how the formation of ammonium bisulfate is managed,

to avoid corrosion problems?

Ammonium bisulfate is primarily a concern for deposition on air preheater

surfaces.

It

is controlled by minimizing ammonia slip into the air preheater.

b.

What provisions need to be made to accommodate boilers with frequent load

swings?

More than one injection zone would likely be needed to ensure that the

reagent is injected into the proper temperature zone, and associated controls

would be necessary. This is a commonly included design feature in SNCR

systems that are expected to operate over a wide load range.

c.

How does SNCR affect the turn down ratio of the boiler?

SNCR should not affect turn down of the boiler if the SNCR system is

designed to cover the boiler's operating range. The most difficult load is

typically full load because temperatures are highest and gas flow is fastest

(treatment time is shortest). And, NOx emissions are often highest at full

load.

If

an owner wishes to operate the SNCR system at lower loads, then he

or she would normally design for injection zones and associated controls to

inject into the proper temperature location in the furnace at these lower

loads.

21.

Does the use ofSCR or SNCR affect the ability to beneficially re-use ash?

Potentially it does. However, this is normally avoided. The extent to which

ammonia slip can impact fly ash reuse will depend upon the level of ammonia slip,

the characteristics of the fly ash, the manner in which the fly ash is handled and how

II

Electronic Filing - Received, Clerk's Office, September 30, 2008

it is reused. But, if ammonia slip is maintained at sufficiently low levels, fly ash will

not be impacted.

Respectfully submitted,

ILLINOIS ENVIRONMENTAL

PROhAGENCY

By:

P

Gina Roccaforte

Assistant Counsel

Division ofLegal Counsel

DATED: September 30, 2008

1021 North Grand Avenue East

P.O. Box 19276

Springfield, IL 62794-9276

217/782-5544

12

THIS FILING IS SUBMITTED

ON RECYCLED PAPER

Electronic Filing - Received, Clerk's Office, September 30, 2008

STATE OF ILLINOIS

COUNTY OF SANGAMON

)

)

)

)

SS

CERTIFICATE OF SERVICE

I, the undersigned, an attorney, state that I have served electronically the attached

ILLINOIS ENVIRONMENTAL PROTECTION AGENCY'S ANSWERS TO PRE-

FILED OUESTIONS BY THE ILLINOIS ENVIRONMENTAL REGULATORY

GROUP, upon the following person:

John Therriault

Assistant Clerk

Illinois Pollution Control Board

James

R.

Thompson Center

100 West Randolph St., Suite 11-500

Chicago, IL 6060 I

and mailing it by first-class mail from Springfield, Illinois, with sufficient postage affixed

to the following persons:

SEE ATTACHED SERVICE LIST

ILLINOIS ENVIRONMENTAL

PROTECTION AGENCY,

Gina Roccaforte

Assistant Counsel

Division

of Legal Counsel

Dated: September 30, 2008

1021 North Grand Avenue East

Springfield, Illinois 62794-9276

(217) 782-5544

Electronic Filing - Received, Clerk's Office, September 30, 2008

SERVICE LIST 08-19

Timothy J. Fox

Hearing Officer

Illinois Pollution Control Board

100 W. Randolph St., Suite 11-500

Chicago, IL 60601

Virginia Yang

Deputy Legal Counsel

Illinois Department

of Natural Resources

One Natural Resources Way

Springfield, IL 62702-1271

Katherine D. Hodge

Monica T. Rios

Hodge Dwyer Zeman

3150 Roland Ave.

P.O. Box 5776

Springfield, IL 62705-5776

Matthew Dunn

Chief

Environmental Bureau North

Office

ofthe Attorney General

69 W. Washington St., Suite 1800

Chicago,

lL 60602

Kathleen

C. Bassi

Sheldon

A.

Zabel

Stephen

J. Bonebrake

SchiffHardin LLP

6600

Sears Tower

233

S. Wacker Drive

Chicago, IL

60606-6473

Alec M. Davis

General Counsel

Illinois Environmental Regulatory Group

215 E. Adams St.

Springfield, IL 62701

Electronic Filing - Received, Clerk's Office, September 30, 2008

IEPA ATIACHMENT

NO.--L-.

Electronic Filing - Received, Clerk's Office, September 30, 2008

150-9001

A TOP PERFORMER:

NATCOM

score sheet

oCO<10ppm

° Natural Gas

Firing:

• NO. < O.05lb1MMBTU (40 ppm)

• NO. < 0.01 IblMMBTU (8 ppm) w/IFGR

° Heavy Oil

Firing:

« 0.3% N,)

- NO. < 0.20 IblMMBTU (150 ppm)

- Particulates

< 0.03 IblMMBTU

o1\undown ratio

- > 40 : 1 (Natural Gas)

->15 :1 (Oil)

National

NAT-aJNI

Combustion Equipmenllnc.

R

diV!llion

01

oquo-chetm.",,-

8515 Lalrenaia, SHaonanl, Oc, Canada HiP 283

TEL.: (514) 3216-2511

FAX: (514) 326-9347

http~/www.nateomonline.com

NAT-1QCX)

Electronic Filing - Received, Clerk's Office, September 30, 2008

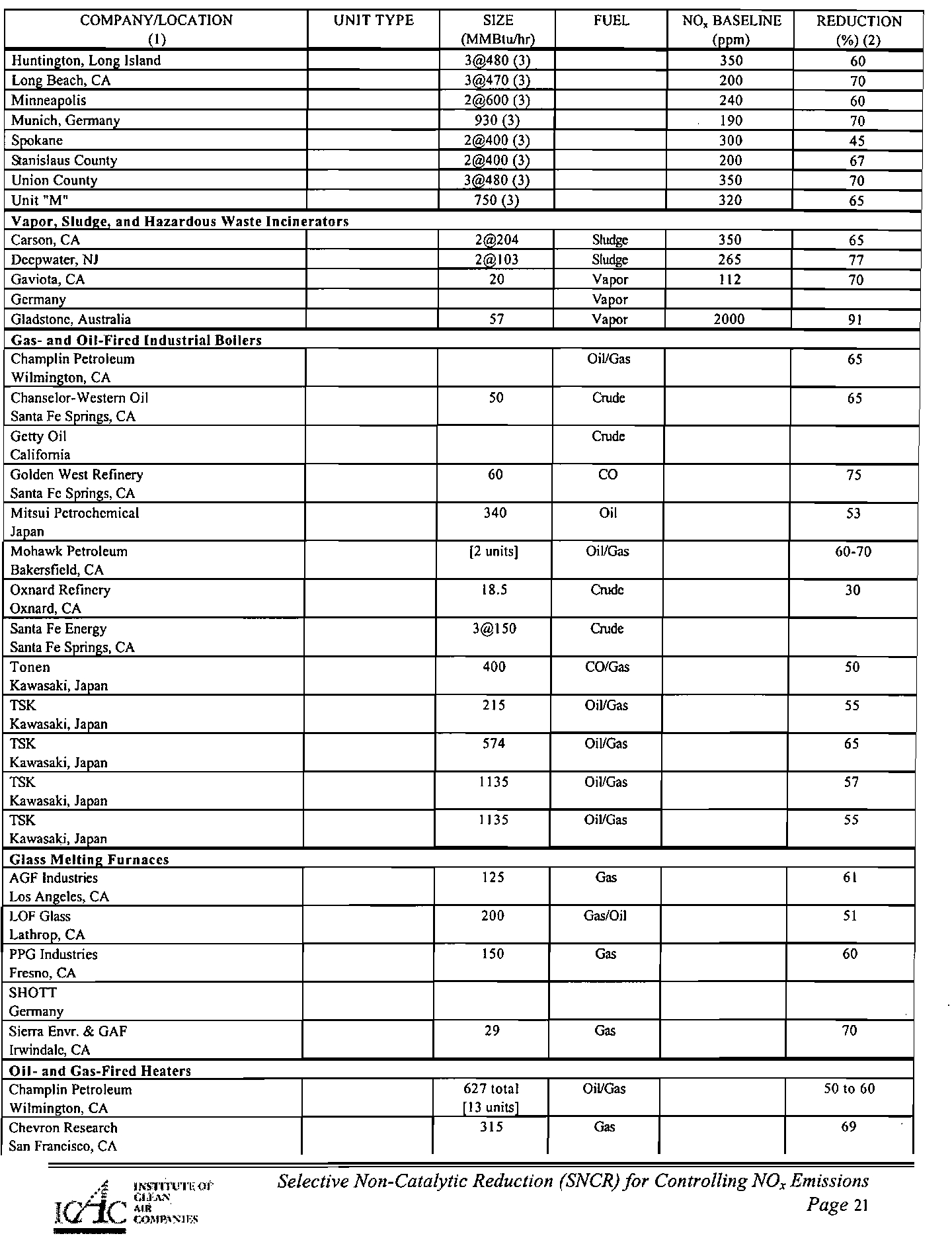

Integro1ed

WC~&:-cooled

solid

separate: and return leg for

compo'::: design and elimination

of f<Jrrloce-to-sepcrotor

expansion

icL'lls

Sloped supemem and

reheat

~ee.tion

for

r€duced mn build-up

PoSSlve ash collection

design fer reduced catalyst

and

bac?-pa~

foullng

lEPA ATTACHMENT NO

2-

Splil

economizer for

optimum SCR

perlormonce

SCR

cOlal~1

fo~

applicofions

requiring the to-west

NOx emissions

long-life fhin-'....olled cooled

refroetory used in lower

iumac~

and soHd separo:or

nstem for

ro-.•..

maintenance

and rapid sttllOS

Superheat and reheat

svrf.:ll:e con be located

in lNTREX"-' fluidized

bad heet exch::mger for

effident

h~t

transfer

and maximum

coillil~

RobuSI step.grid to

handle Ihe mOSl

difficult fuels

RelicblG

Io'r,o."

maintenance

grcvi:y fuel

feed

:;ystem

Tubular air heoter

for compad

de$ign

'Jnd no oir leokage

WE OFFER INNOVATIVE AND PROVEN DESIGN FEATURES

IN OUR INDUSTRIAL CFB UNITS

Electronic Filing - Received, Clerk's Office, September 30, 2008

IEPA ATIACHMENT

N~

3

Electronic Filing - Received, Clerk's Office, September 30, 2008

';f,

Electronic Filing - Received, Clerk's Office, September 30, 2008

P~ONlElERJNG

CFB

TECHNOLOGY

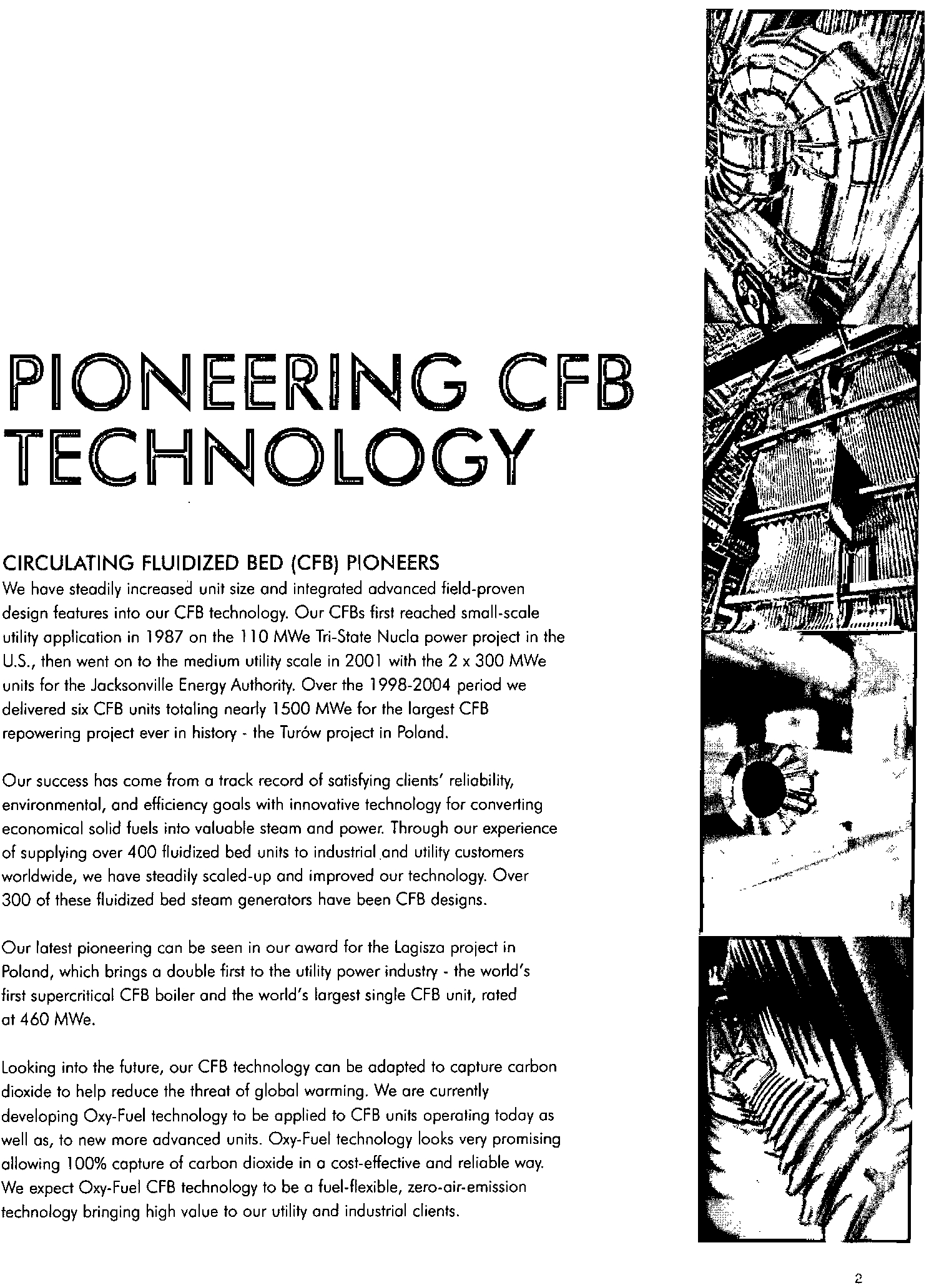

CIRCULATING FLUIDIZED BED (CFB) PIONEERS

We have steadily increased unit size and integrated advanced field-praven

design features into our

CFB technology. Our CFBs first reached small-scale

utility application

in 1987 an the 110 MWe Tri-State Nucla power project in the

U.S., then went on to the medium utility scale in 2001 with the 2 x 300 MWe

units for the Jocksonville Energy Authority. Over the

1998-2004 period we

delivered six CFB units totaling nearly 1500 MWe for the largest CFB

repowering project ever in history - the Tur6w project in Poland.

Our success has came fram a track record of satisfying clients' reliability,

environmental, and efficiency goals with innovative technology for converting

economical solid fuels into valuable steam and power. Through our experience

of supplying over 400 fluidized bed units to industrial.and utility customers

worldwide,

we hove steadily scaled-up and improved our technology. Over

300 of these fluidized bed steam generators have been CFB deSigns.

Our latest pioneering can be seen in our award for the Lagisza project in

Poland, which brings a double first to the utility power industry - the world's

first supercritical

CFB boiler and the world's largest single CFB unit, rated

at

460 MWe.

Looking into the future, our

CFB technology can be adapted to capture carbon

dioxide to help reduce

the threat of global warming. We are currently

developing Oxy-Fuel technology to

be applied to CFB units operating today as

well as, to new more advanced units. Oxy-Fuel technology looks very promising

allowing 100% capture

of carbon dioxide in a cost-effective and reliable way.

We expect Oxy-Fuel CFB technology to be a fuel-flexible, zero-air-emission

technology bringing high value to our utility and industrial clients.

2

Electronic Filing - Received, Clerk's Office, September 30, 2008

3

THINK GREEN

low emissions ore a key benefit of our CFB technology, allowing them to

meet the strictest environmental standards.

Our CFBs stage the combustion

process and operate at low combustion temperatures while giving the fuel

long burning times, resulting

in naturolly low nitrogen oxide (NOx) formation

and high combustion efficiency.

They can also capture the fuel's sulfur as the

fuel burns

by

using low-cost limestone and employing selective-nan-catalytic-

reduction (SNCR) to achieve very low NOx and sulfur oxide (SOx) emissions

in the most economical way, and in most cases, avoiding add-on pollution

control equipment.

The CFB advantage is particularly highlighted in repowering projects. SOx

and particulate emissions can often

be cut by over 90% and NOx emissions

by over 50%. Corban dioxide emissions ore often cut by 25% or more due to

the dramatic improvements in boiler and plant efficiency when older

equipment is replaced. For the lowest emissions, our supercritical, once.

through-unit (OTU) CFB technology can reduce all these emissions another

5-10%, due to

its ability to further increase overoll plant efficiency.

Electronic Filing - Received, Clerk's Office, September 30, 2008

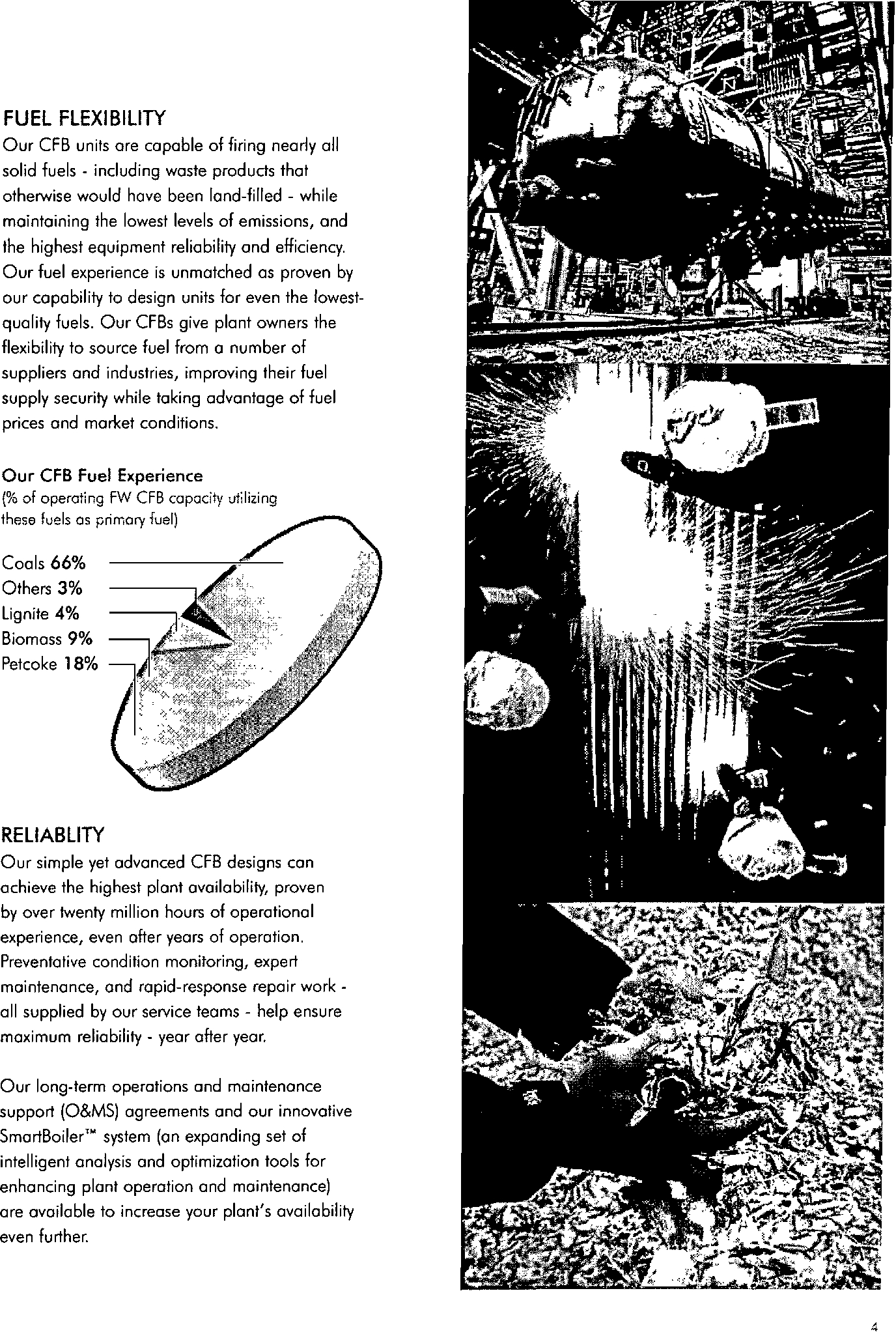

FUEL FLEXIBILITY

Our CFB units ore capable af firing nearly all

salid fuels - including waste products that

otherwise would have been land-filled - while

maintaining the lowest levels of emissions, and

the highest equipment reliability and efficiency.

Our fuel experience is unmatched as praven by

aur capability to design units for even the lowest-

quality fuels.

Our CFBs give plant owners the

flexibility to source fuel from a number

of

suppliers and industries, improving their fuel

supply security while taking advantage of fuel

prices and market conditions.

Our CFB Fuel Experience

(% of operating fW CFB capacity utilizing

these fuels as primary fuel)

Coals 66%

Others 3%

Lignite 4%

Biomass 9%

Petcoke 18%

RELlABLITY

Our simple yet advanced CFB designs can

achieve the highest plant availability, proven

by over twenty million hours of operotionol

experience, even ofter years of operation.

Preventative condition monitoring, expert

maintenance,

and rapid-response repair work -

all supplied by our service teams - help ensure

maximum reliability - year after year.

Our long-term operations and maintenance

support (O&MSI agreements and our innovative

SmartBoiler'.

system (an expanding set of

intelligent analysis and optimization tools for

enhancing plant operation and maintenance)

are available to increase your plant's availability

even further.

4

Electronic Filing - Received, Clerk's Office, September 30, 2008

5

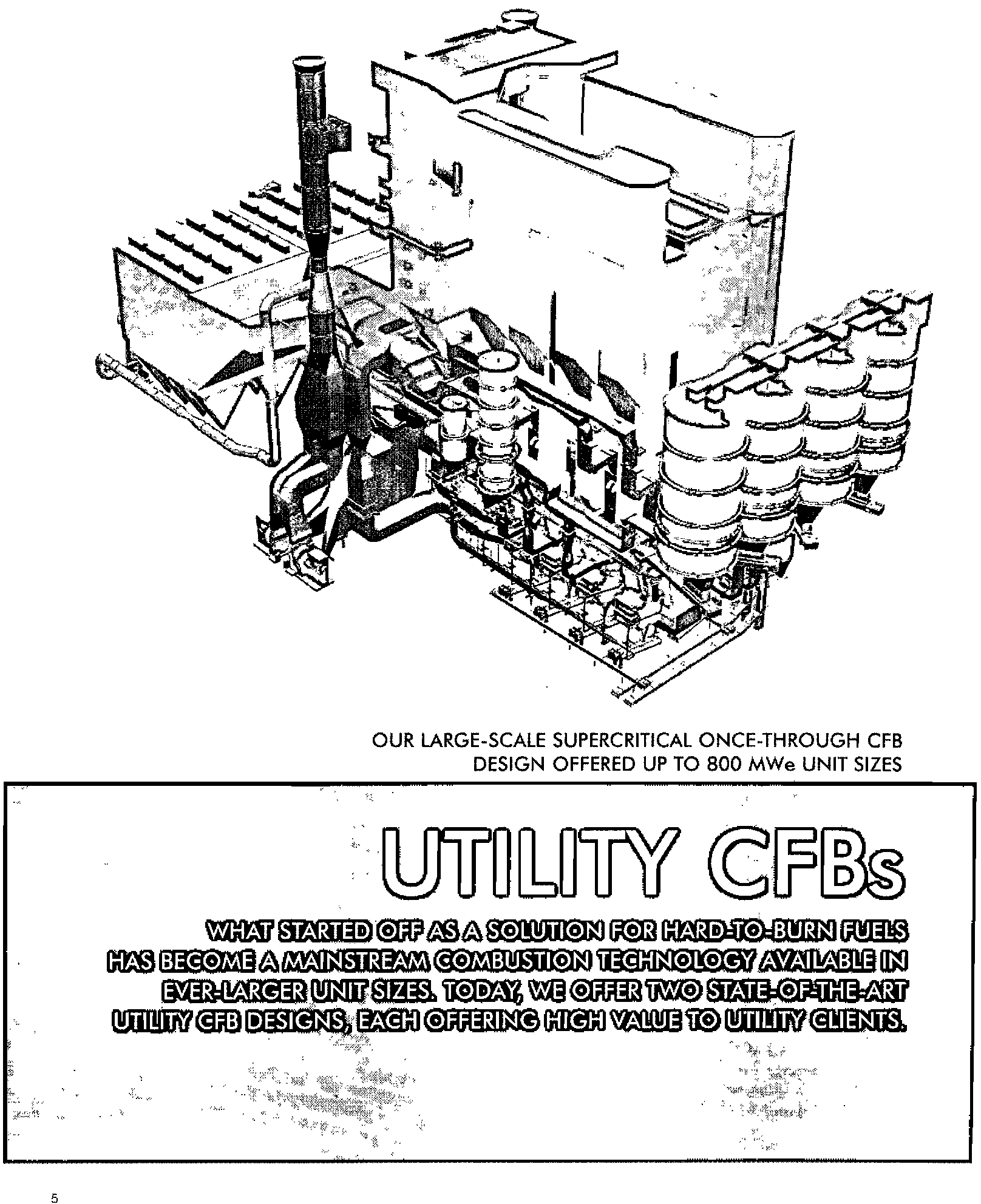

OUR LARGE-SCALE SUPERCRITICAl ONCE-THROUGH CFB

DESIGN OFFERED UP TO 800 MWe UNIT SIZES

Electronic Filing - Received, Clerk's Office, September 30, 2008

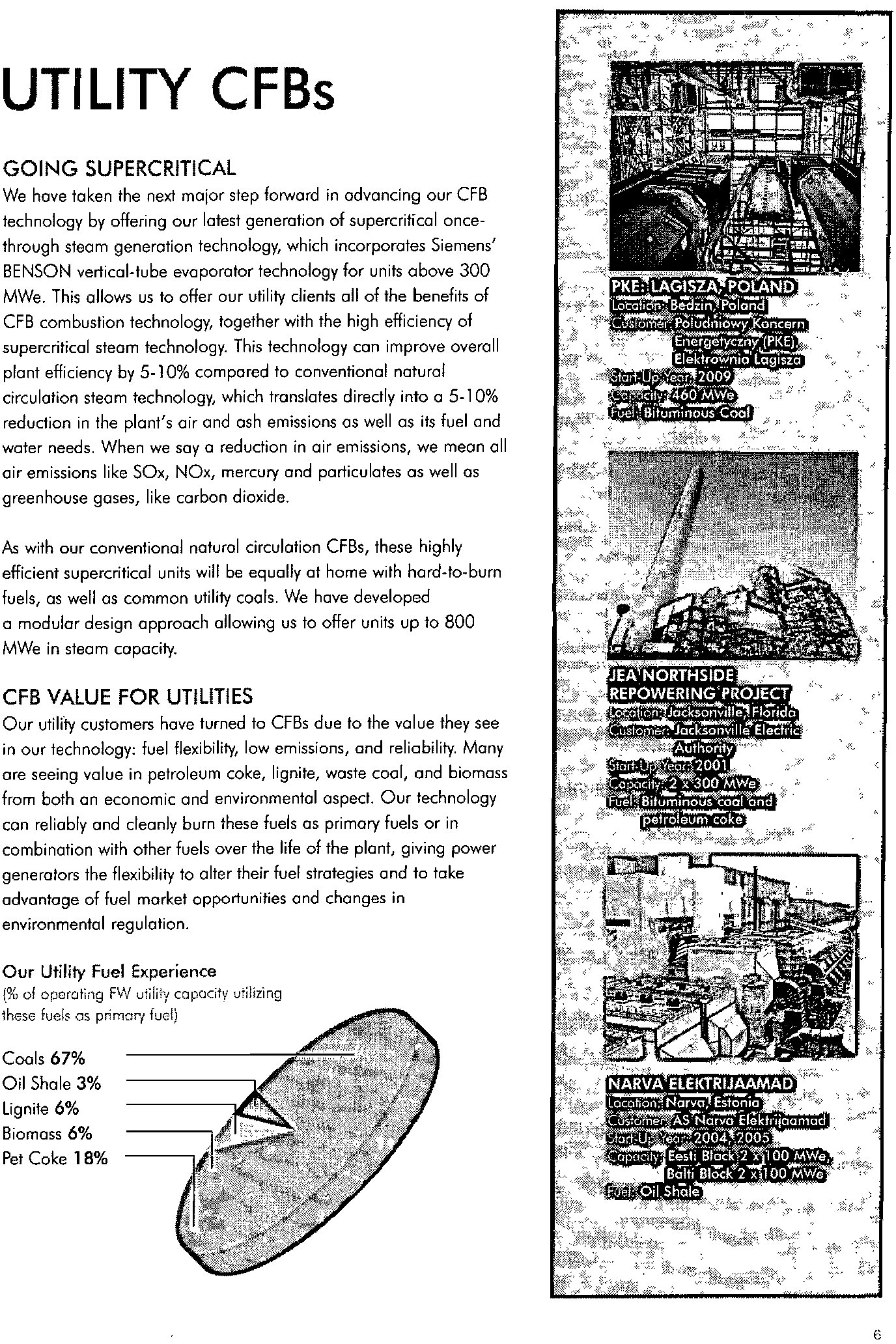

UTILITY CFBs

GOING SUPERCRITICAL

We have taken the next maior step forward in advancing our CFB

technology

by

offering our latest generation of supercritlcal once-

through steam generation technology, which incorporates Siemens'

BENSON vertical-tube evaporator technology for units above 300

MWe. This allows us to offer our utility clients all of the benefits of

CFB combustion technology, together with the high efficiency of

5upercritical steam technology. This technology can improve overall

plant efficiency by 5-10% compared to conventional natural

circulation steam technology, which translates directly into a 5-10%

reduction in the plant's air and ash emissions as well as its fuel and

water needs. When we say a redudion in air emissions, we mean all

air emissions like SOx, NOx

j

mercury and particulates as well as

greenhouse gases, like carbon dioxide.

As with our conventional natural circulation CFBs, these highly

efficient supercritical units will be equally at home with hard-to-burn

fuels, as well as cammon utility coals. We have developed

a modular design approach allowing us to offer units up to 800

MWe in steam capacity.

CFB VALUE FOR UTILITIES

Our utility customers have turned to CFBs due to the value they see

in our technology: fuel flexibility, law emissions, and reliability. Many

are seeing value in petroleum coke, lignite, waste coal, and biomass

from both an economic and environmental aspect. Our technology

can reliably and cleanly burn these fuels as primary fuels or in

combination with other fuels over the life of the plant, giving power

generators the flexibility to alter their fuel strategies and to take

advantage of fuel market opportunities and changes in

environmental regulation.

Our Utility Fuel Experience

(?-il

of operating

FW utiliiy

capclCity utilizing

1hese fuels os primary fuel)

Coals 67%

Oil Shale 3%

Lignite 6%

Biomass 6%

Pet Coke 18%

6

Electronic Filing - Received, Clerk's Office, September 30, 2008

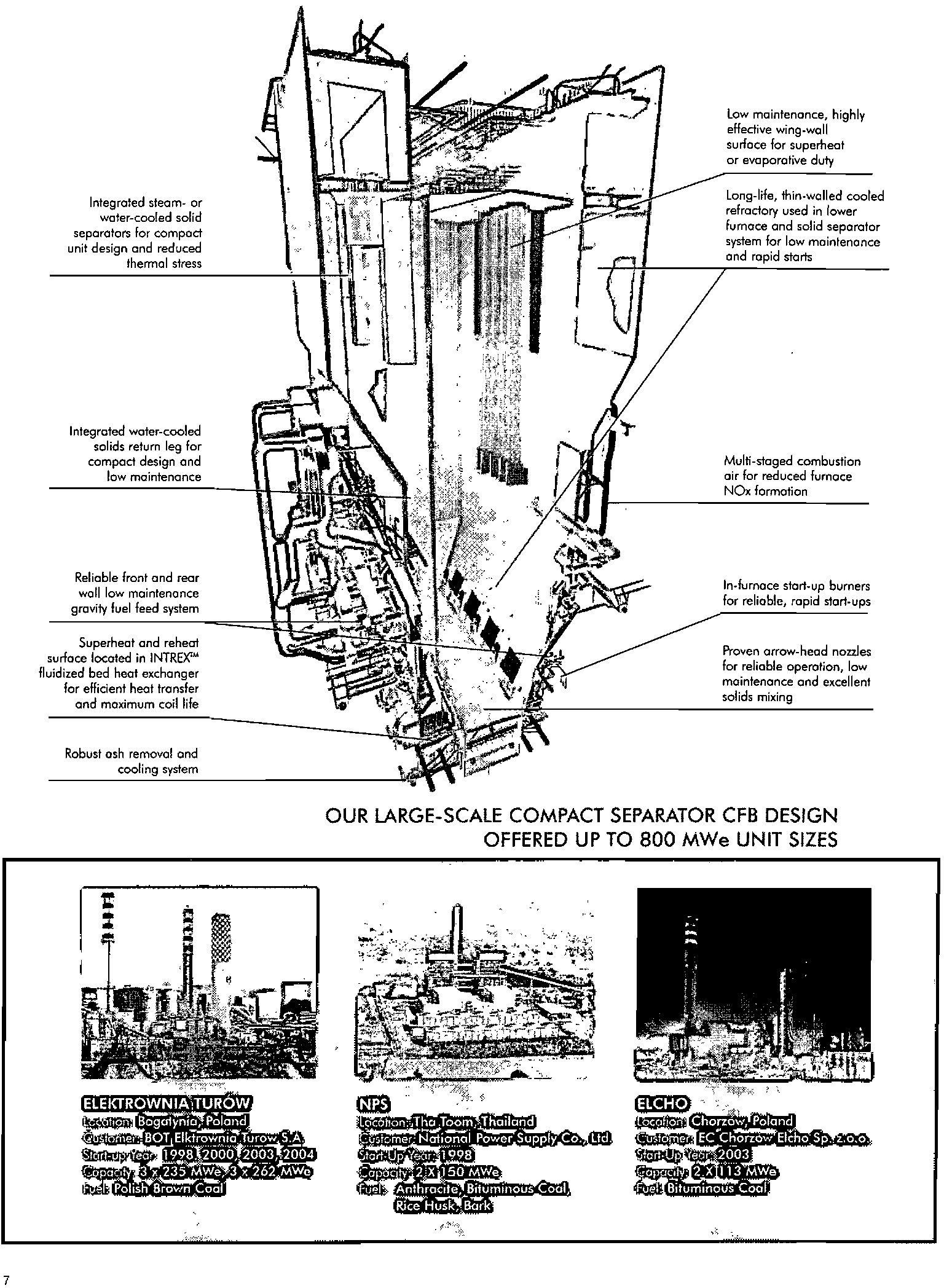

Integrated steam- or

wafer-coaled solid

separators for

compad

unit design and reduced

thermal

stress

Integrated water-cooled

solids return leg for

compact design and

low maintenance

Reliable front and rear

wall law maintenance

gravity fuel feed

system

Superheat and reheat

surface located in

INTRE)(IM

fluidized bed heat exchanger

for efficient heat transfer

and maximum coil life

Robust ash removal and

cooling

system

low maintenance, highly

effedive wing-wall

surface for superheat

or evaporative duty

Long-life, thin-walled cooled

refractory used in lower

furnace and solid separator

system for low maintenance

and rapid storts

Multi-staged combustion

air for reduced furnace

NOx

formation

In-furnace start-up burners

for reliable, rapid start-ups

Proven arrow-head nozzles

for reliable operation, low

maintenance and excellent

solids mixing

7

OUR LARGE-SCALE COMPACT SEPARATOR CFB DESIGN

OFFERED UP TO 800 MWe UNIT SIZES

Electronic Filing - Received, Clerk's Office, September 30, 2008

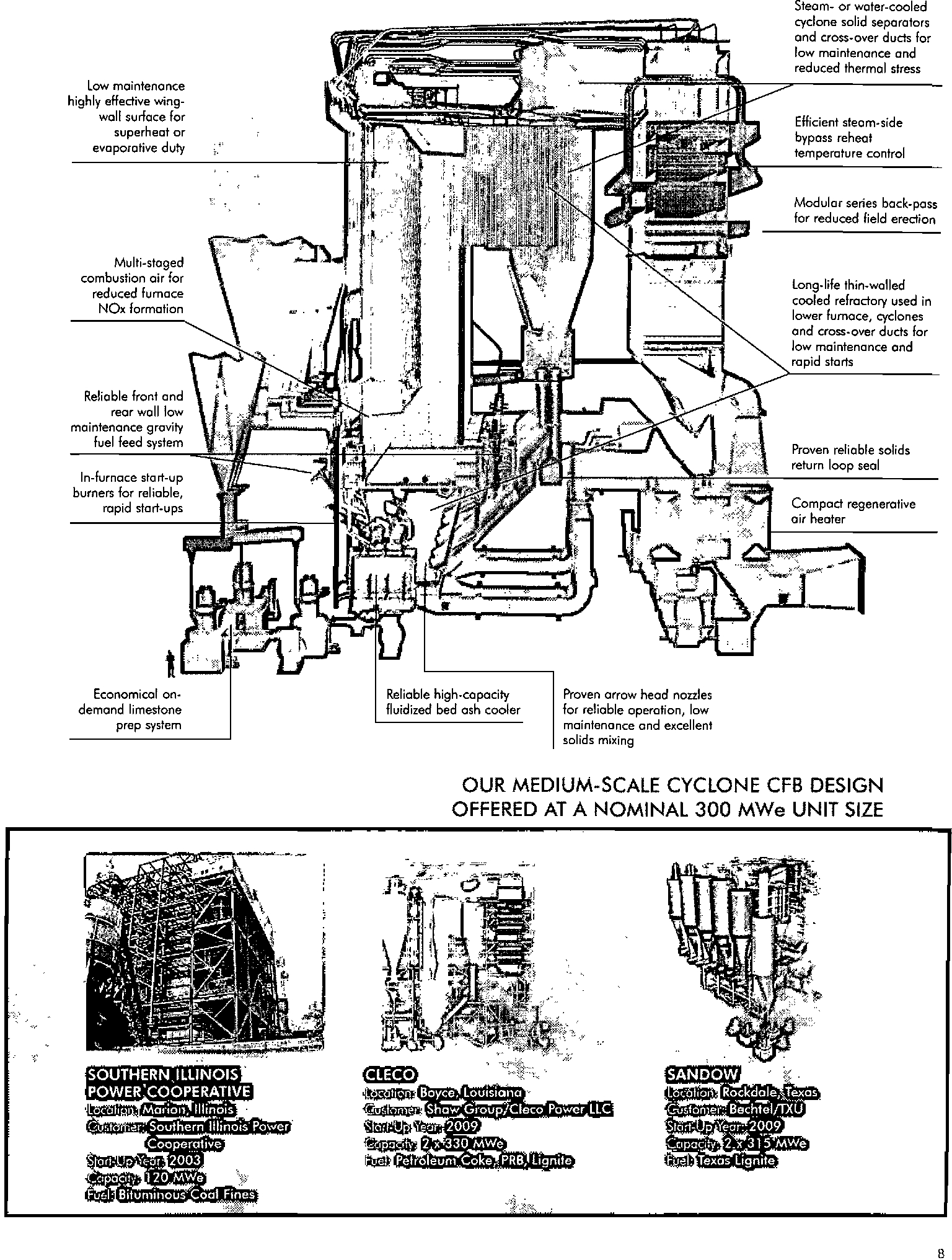

Low maintenance

highly effedive wing-

wall surface for

superheat

or

evaporative duty

Multi~staged

combustion air for

reduced furnace

NOx formation

Reliable front and

rear wall

low

maintenance gravity

fuel feed

system

In-furnace start-up

burners for reliable,

rapid

start~ups

Economical

on~

demand limestone

prep

system

Reliable high.capacity

fluidized bed ash cooler

Proven arrow head nozzles

for reliable operation, low

maintenance and excellent

solids mixing

Steam-

or water-cooled

cyclone solid separators

and cross-over ducts for

low maintenance and

reduced thermal

stress

Efficient steam-side

bypass reheat

temperature control

Modular series back-pass

for reduced field erection

long-life thin-walled

cooled refractory used in

lower furnace, cyclones

and cross-over ducts for

low maintenance and

rapid

storts

Proven reliable solids

return loop

seol

Compad regenerative

air heoter

,-

OUR MEDIUM-SCALE CYCLONE CFB DESIGN

OFFERED AT A NOMINAL 300 MWe UNIT SIZE

8

Electronic Filing - Received, Clerk's Office, September 30, 2008

9

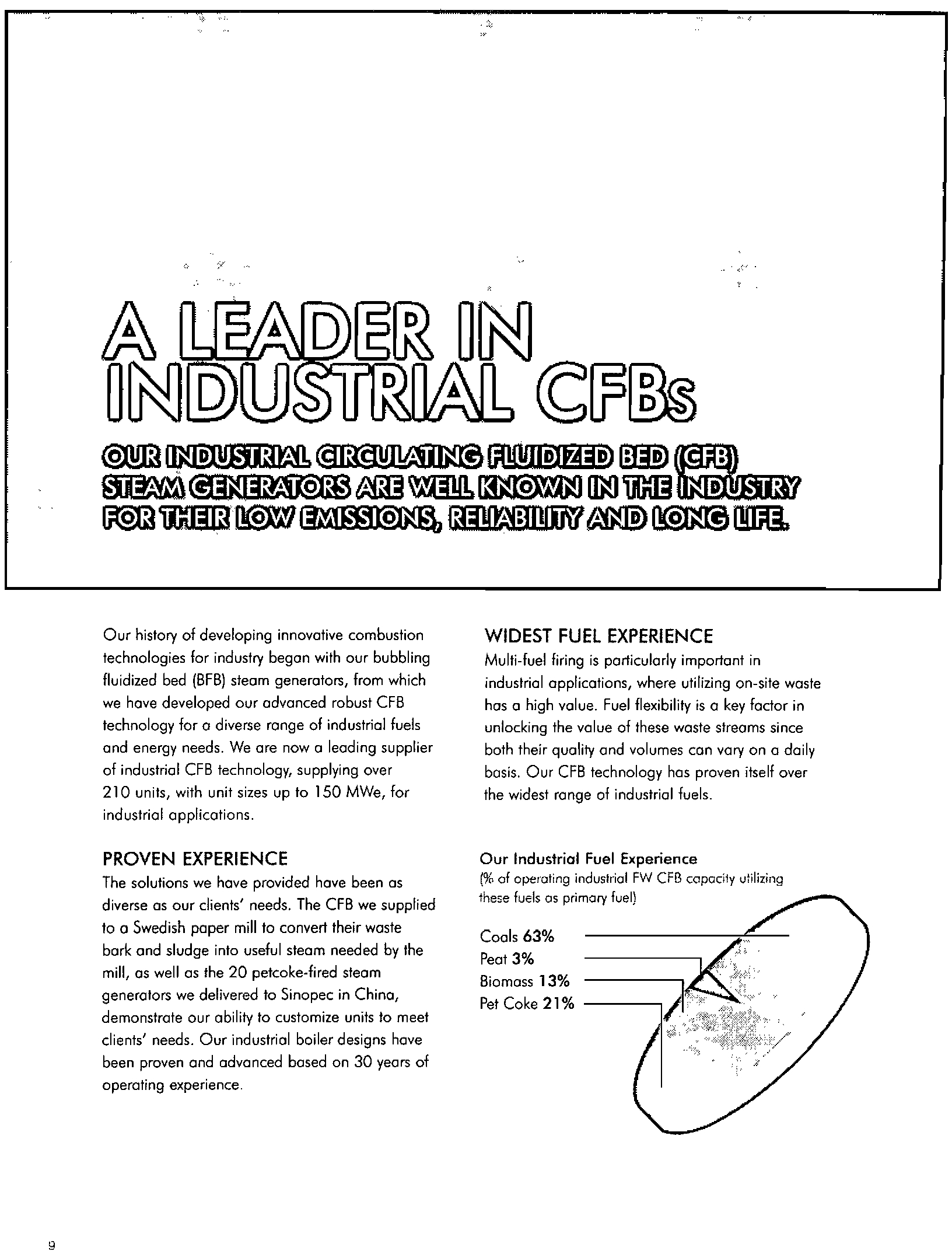

Our history of developing innovative combustion

technologies for industry began with our bubbling

fluidized

bed (BFB) steam generators, from which

we have developed our advanced rabust CFB

technology for a diverse range of industrial fuels

and energy needs.

We ore now a leading supplier

of industrial CFB technology, supplying over

210 units, with unit sizes up to 150 MWe, for

industrial applications.

PROVEN EXPERIENCE

The solutions we have provided have been as

diverse as our clients' needs. The CFB we supplied

to a Swedish paper mill to convert their

waste

bark and sludge into useful steam needed by the

mill, as well as the 20 petcoke-fired steam

generators we delivered to Sinopec in China,

demonstrate our ability to customize units to meet

clients' needs. Our industrial boiler designs have

been proven and advanced based on

30 years of

operating experience.

WIDEST FUEL EXPERIENCE

Multi-fuel firing is particularly important in

industrial applications, where utilizing on-site waste

has a high value. Fuel flexibility is a key factor in

unlocking the value of these waste streams since

both their quality and volumes can vary on a doily

basis. Our CFB technology has proven itself over

the widest range of industrial fuels.

Our Industrial Fuel Experience

(% of operating industrial FW CFB capodiy utilizing

these fuels as primary fuel)

Cools 63%

Peat 3%

Biomass

13%

Pet Coke

21

% -----,

Electronic Filing - Received, Clerk's Office, September 30, 2008

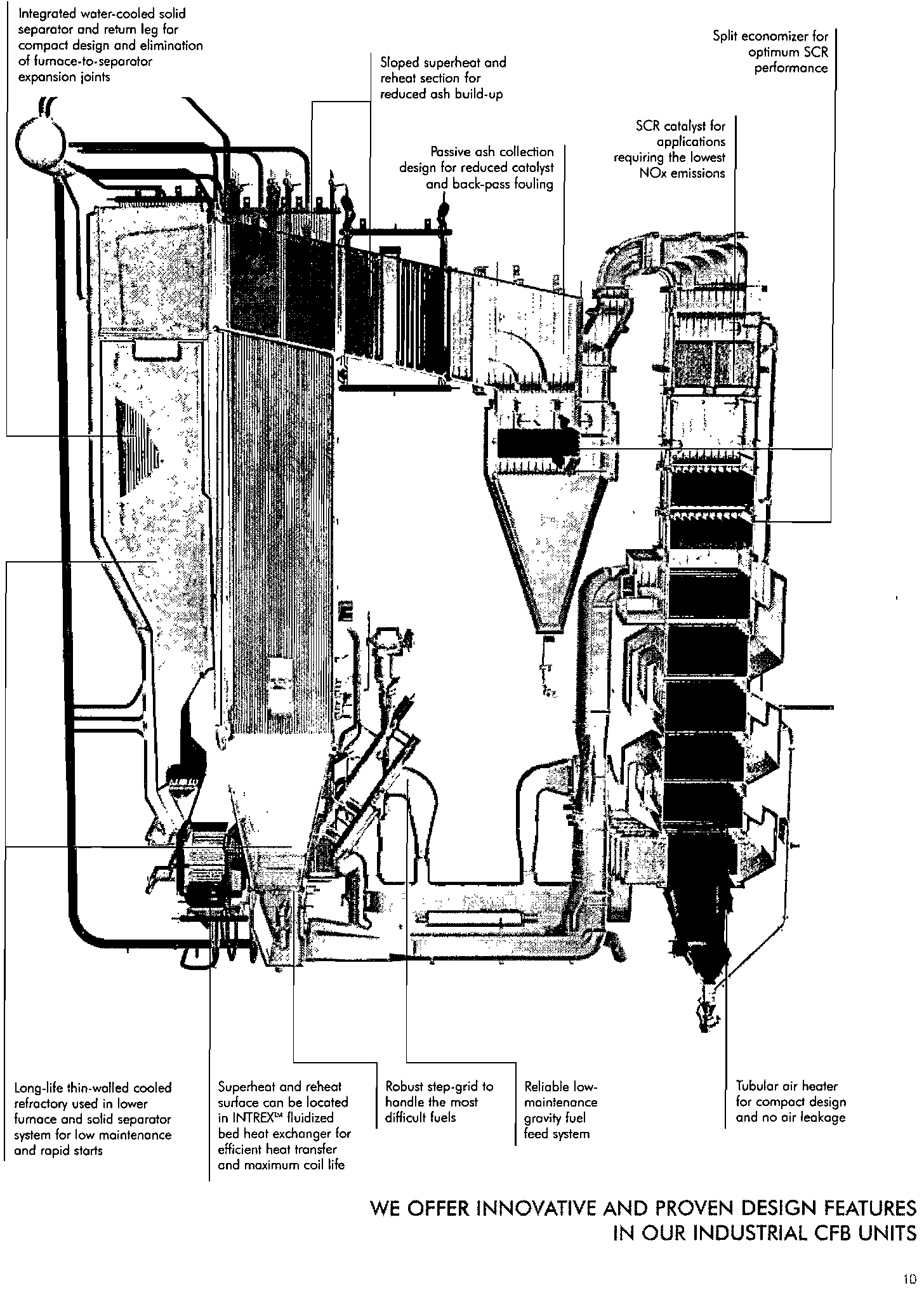

Split economizer for

optimum

SCR

performance

SCR catalyst for

applications

requiring the lowest

NOx emissions

Passive ash collection

design for reduced catalyst

and bock-pass fouling

Sloped superheat and

reheat section

for

reduced ash build-up

Integrated water-coaled solid

separator and refum leg for

compact design and elimination

of fumace-to-seporator

expansion joints

Long-life thin-walled cooled

refractory used in lower

furnace and solid separator

system for low maintenance

and rapid

starts

Superheat and reheat

surface can be located

in

INTRE)(l'IA fluidized

bed heat exchanger for

efficient heat transfer

and maximum coil life

Robust step-grid to

handle the most

diffiClllt

fuels

Reliable low-

maintenance

gravity fuel

feed system

Tubular air heater

for

compad design

and no air leakage

WE OFFER INNOVATIVE AND PROVEN DESIGN FEATURES

IN OUR INDUSTRIAL CFB UNITS

10

Electronic Filing - Received, Clerk's Office, September 30, 2008

r

-~

.~'

....

~0t:=

~"""

Electronic Filing - Received, Clerk's Office, September 30, 2008

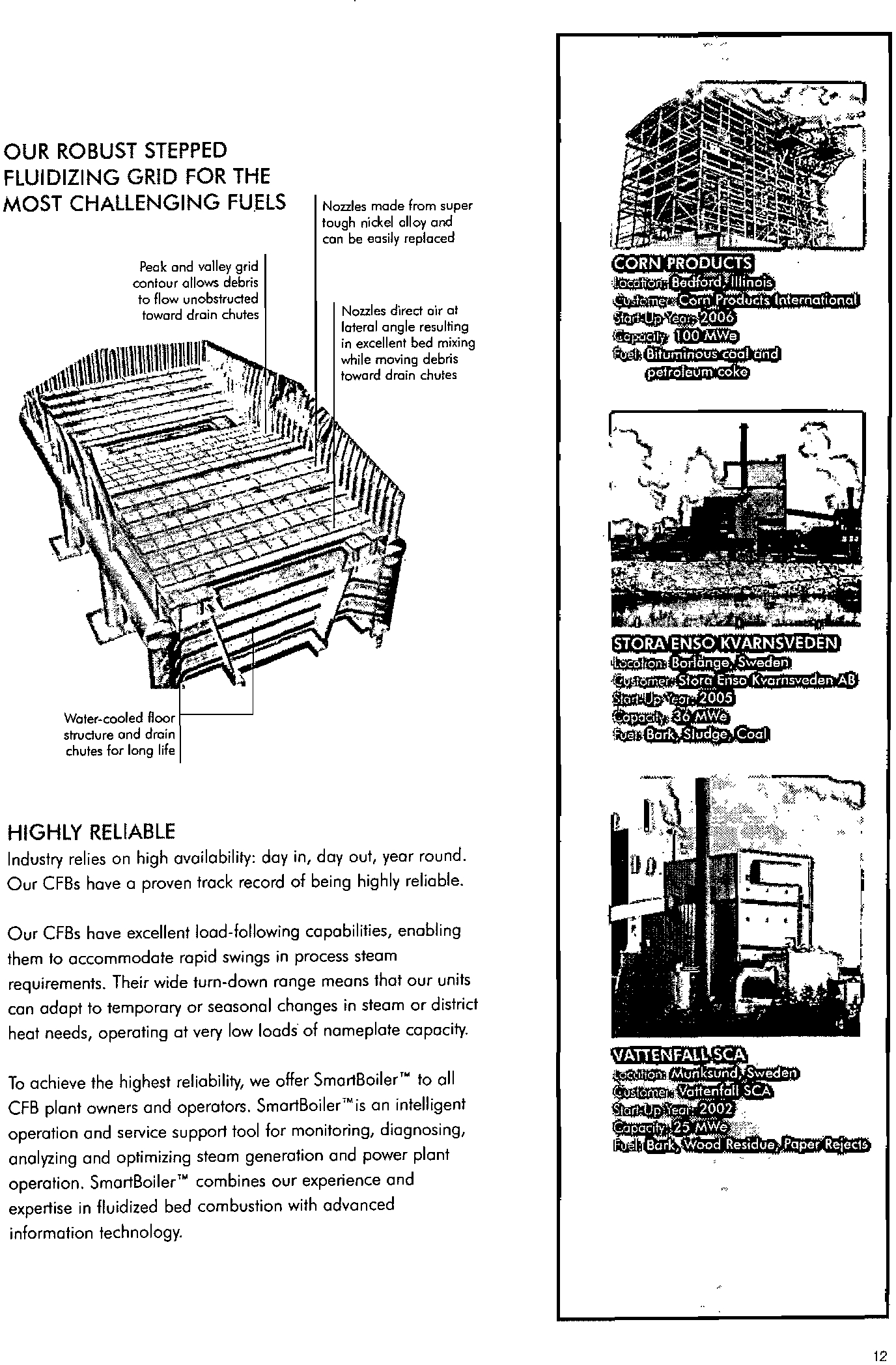

OUR ROBUST STEPPED

FLUIDIZING GRID FOR THE

MOST CHALLENGING FUELS

Peak and volley grid

contour allows debris

to flow unobstructed

toward drain chutes

Woter.cooled floor

1------'

structure and drain

chutes for long life

Nozzles made from super

tough nickel alloy and

can be easily replaced

Nozzles direct air

01

lateral angle resulting

in excellent bed mixing

while moving debris

toward drain chutes

HIGHLY RELIABLE

Industry relies on high availability: day in, day out, year round.

Our CFBs have a proven trock record of being highly reliable.

Our CFBs have excellent load-following capabilities, enabling

them to accommodate rapid swings in process steam

requirements. Their wide

turn-down range means that our units

can

adapt to temporary or seasonal changes in steam or district

heat needs, aperoting at very low loads of nameplote capacity.

To achieve the highest reliobility, we offer SmartBoiler'" to all

CFB plant owners and operators. SmartBoiler'"is an intelligent

operation and service support tool

for monitoring, diagnosing,

analyzing and optimizing steam generation and power plant

operation. SmortBoiler

Thl

combines our experience and

expertise in fluidized bed combustion with advanced

information technology.

12

Electronic Filing - Received, Clerk's Office, September 30, 2008

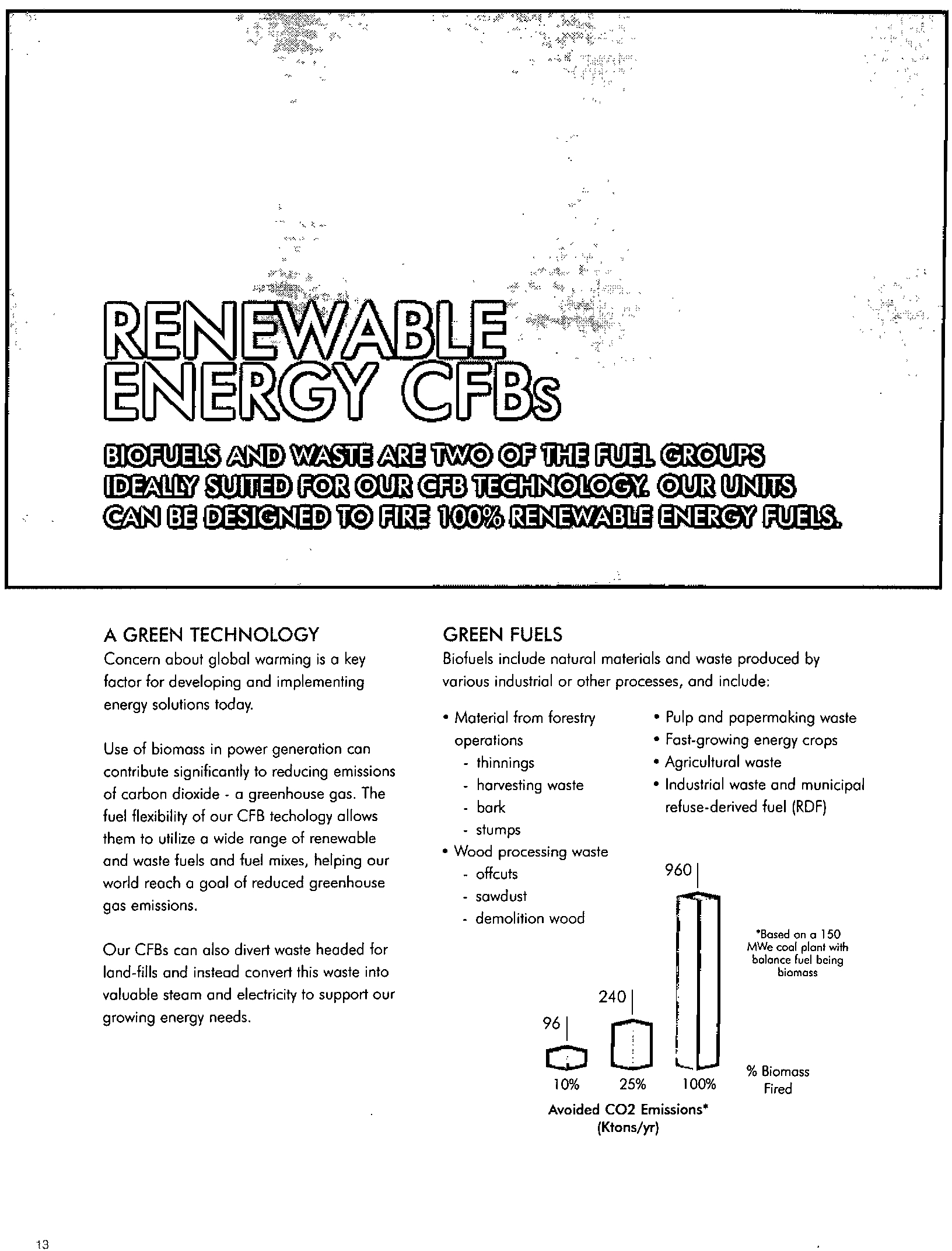

GREEN FUELS

Biofuels include natural materials and waste praduced by

various industrial or other processes, and include:

A

GREEN TECHNOLOGY

Concern abaut global warming is a key

factar for developing and implementing

energy solutions today.

Use of biomass in power generation can

contribute significantly to reducing emissions

of carbon dioxide - a greenhouse gas. The

fuel flexibility of our CFB techology allows

them to utilize a wide range of renewable

and waste fuels and fuel mixes, helping our

world reach a goal of reduced greenhause

gas emissions.

• MateriaI from forestry

operations

thinnings

harvesting waste

bark

stumps

• Wood processing waste

offcuts

sawdust

demolition wood

• Pulp and papermaking waste

• Fast-growing energy crops

• Agricultural waste

• Industrial waste and municipal

refuse-derived fuel (RDF)

960

1

Our CFBs can also divert waste headed for

land-fills and instead canvert this

waste into

valuable steam and electricity ta support

our

growing energy needs.

96

1

o

10%

240

1

QJ

25%

I

•

L.-.

100%

.Based on a 150

MWe coal plant

with

balance fuel being

biomass

%

Biomass

Fired

13

Avoided C02 Emissions.

(Ktons/yr)

Electronic Filing - Received, Clerk's Office, September 30, 2008

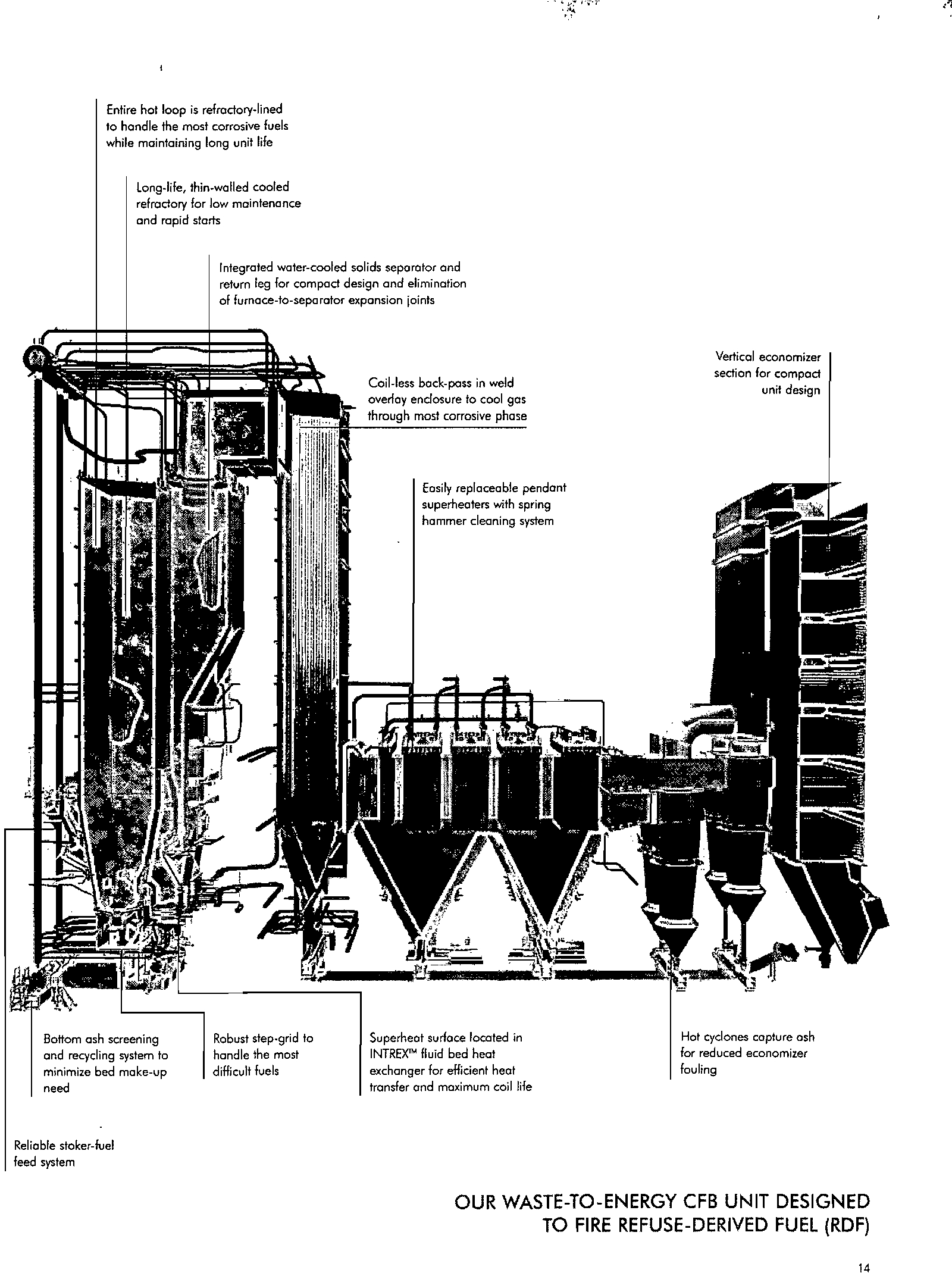

Entire hot loop is refractory-lined

to handle the most corrosive fuels

while maintaining long unit life

long-life, thin-walled cooled

refractory for low maintenance

and rapid storts

Integrated water-cooled solids separator

and

return leg for compad

design and

elimination

of furnace-fa-separator expansion

ioiots

Coil-less bock-pass in weld

overlay enclosure fa cool gas

through most corrosive phase

Easily replaceable pendant

superheaters

with

spring

hammer cleaning system

Vertical economizer

sedion for compad

unit design

"

Bottom ash screening

and recycling system to

minimize bed

make-up

need

Reliable stoker-fuel

feed

system

Robust step-grid to

handle the most

difficult fuels

Superheat surface located in

INTREJ<'M fluid bed heat

exchanger for efficient heat

transfer

and maximum coil life

Hot cyclones capture ash

for reduced economizer

fouling

OUR WASTE-TO-ENERGY CFB UNIT DESIGNED

TO FIRE REFUSE-DERIVED FUEL (RDF)

14

Electronic Filing - Received, Clerk's Office, September 30, 2008

}{,

\~:

.

.',

Electronic Filing - Received, Clerk's Office, September 30, 2008

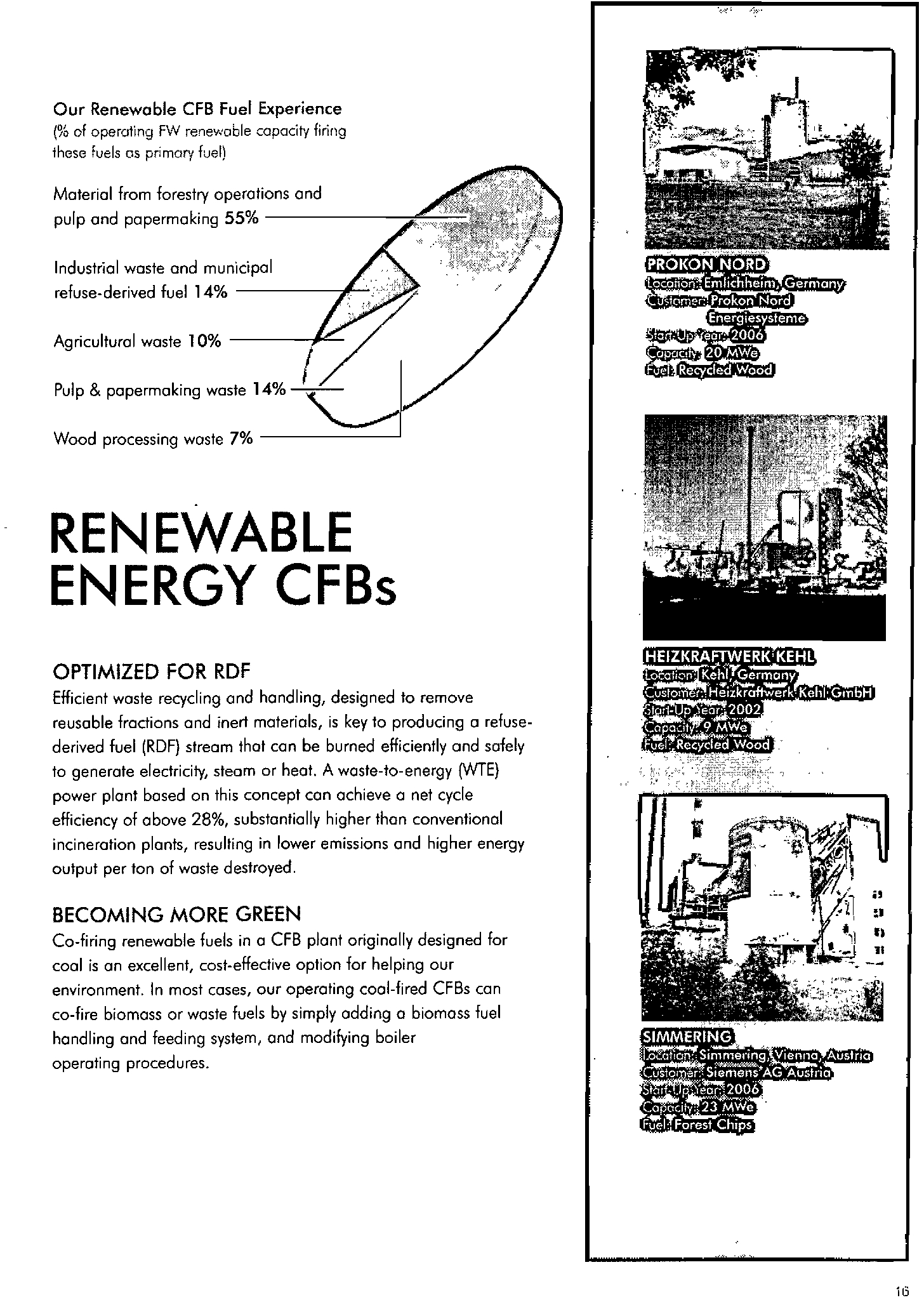

Our Renewable CFB Fuel Experience

(% of operating FW renewable capacity firing

these fuels os primary fuel)

Material from forestry operations and

pulp and papermaking

55% --------.;"=--

Industrial waste and municipal

refuse-derived fuel

14%

-----~=>

Agricultural waste 10%

----p.:...

Pulp & papermaking waste 14% -':"';;-"--

Wood processing

waste 7% ---------'

RENEWABLE

ENERGY CFBs

OPTIMIZED FOR RDF

Efficient waste recycling and handling, designed to remove

reusable fractions and inert materials, is key to producing a refuse-

derived fuel (RDF) stream that can be burned efficiently and safely

to generate eleetricily, steam or heat. A waste-to-energy

(WTE)

power plant based on this concept can achieve a net cycle

efficiency of above 28%, substantially higher than conventional

incineration plants, resulting in lower emissions and higher energy

output per ton of waste destroyed.

BECOMING MORE GREEN

Co-firing renewable fuels in a CFB plant originally designed for

coal is an excellent, cost-effective option for helping our

environment. In most cases, our operating cool-fired CFBs can

co-fire biomass or waste fuels by simply adding a biomass fuel

handling and feeding

system, and modifying boiler

operating procedures.

i15

Electronic Filing - Received, Clerk's Office, September 30, 2008

.).

.

.

,"-

9.

@liblOOlDiI!iii1~

Order Start.Up

,:::':"

~'

..

,

Steam

Primary

Secondary

Date

Date;.:

Client

Plant

..

7~i;~~

'.X<

MW.

Fuel

"

;~Fuel

-

-_.__

.-

2006

2009

Harbin Power Engineering

Cam Pho

Vietnam

2 x 160

Waste Anthracite

Slurry

Company, ltd. IHPE)

2006

2009

BechtellTXU

Sandow Gen

USA

2 x 315

Texas lignite

2006

2009

Shaw Group/ClECO Power LLC

Rademacher

USA

2x 330

Petroloum

Illinois 6,

Coke

PRB, lignite

2005

2009

PKE - Elektrawnia logisla

Lagiszo

I

Poland

460

Bituminous Cool

Coal Slurry (option)

2003

2007

PLN lobuhan Angin Sibolga

labuhan

Indonesia

2 x 100

Cool

2001

2005

AS Narva Eleklrijaamad

Bohi

Estonia

2 x 100

Oil Shale

2000

2004

AS Narva Elektrijoamad

Eesti

Estonia

2 x 100

Oil Shale

2000

2003-4

BOT Eleldrawnio Turow SA

Turow

Poland

3:c. 262

Polish Brown Cool

Units 4, 5,6

1999

2003

EC Chorzow Elcho Sp. Z.O.o.

Elcho

Poland

2 x 113

Bituminous Coal

1997

2001

JEA Northside Gen. Stotion

Northside

USA

2:c. 300

Petroleum Coke

Bituminous Cool

1996

2000

Bay Shore Power Company

Bay Shore

USA

180

Petroleum Coke

1994.6

1998-

BOT Elektrownia Turow SA

Turow

Poland

3 x 235

Polish Brown Coal

2000

Units 1, 2, 3

1995

1999

COCO

Mop To Phut

Thailand

2 x 110

Coal

1994

1998

National Power Supply Co., ltd.

Tho Toom

Thailand

2x 150

Anthracite

Bit Coal, Rice Husk, Bark

1992

1996

CM1EC/Neijiang Thermal Power

Neijiang

PRC

100

Coal

Plant

1991

1995

Colver Power Project, Inter

Colver

USA

100

Bituminous Gob

Power/AhICon Ptns

1991

1995

Fortum Engineering ltd. Oulun

Toppilo

Finland

100

Pool

Cool

Energio

Electronic Filing - Received, Clerk's Office, September 30, 2008

,

CFBsIN IN DUSTRlAL APPUCAllON S

rIfl~~~~~

2007

2009

HaITWha

In~tionm

""""

$:)uth

Korea

3

x

100

Coal

Corporation

2006

2008

China RWochemical Corp.

lianjin

China

3 x 100

Fetroleum Coke

Coal

SNOPEC lianjln Company

2006

2008

\Otorantim Metals Niquel SA

I'I::2mpamento

Bra~1

50

FIWoleum Coke

Coal, Eucalyptus

Macedo

2006

200S

Deven ..s::o

Oevn"

8Jlgaria

100

Fetroletlm Coke

Hard Coal

2004

2008

Abalco SA

AJumar alumina

Eira2i1

2 x60

Coal

Fetroleum Coke

"'"''''Y

2006

2008

China Rrlrodlemical Corp.

Qingdao

China

2 x75

Rm'oleum Coke

SNOF£C

2003

2007

SNOF£C

Guangmou

R:ltroc:hemicat

China

2 x 115

Coke

2003

2007

"ilmion \bima Oy

bmio

Roland

45

AlaI

FortS. R:Sdue, RJF,

CO Gas, Coal

2002

2007

Thai

Cane Riper Ud.

Rachinburi

Thailand

35

Coal

Mill Sudge, A:tper

~ec:t

2002

2007

'I1Jen Foong 'I1.J Riper

'tctngzhou

China

50

Bituminous Coal

9.lb-Efwminous Coal,

Manufacturing Co.,

lid.

..

Trres, $udge

2004

2006

Com R'oducts Inti, Inc

","0

US'<

100

Bituminous Coal

2002

2~06

United ,RJlp and Fbper Co., l1d

. (UFfC) •

Fampanga:

;:Fhilippines .'"

. ..

35

Coal

'.

Mill Sudge, RIper

Feject

2001~2

2005-6

Maoming Fttrochemlcal Corp.

Maoming

,

FRO

2 x100

Coke and Coal

Oil Slale

2001

2005,

.•

"

Zhenhai R:!finery

Zhenhai "

FRO.,'

-3 x 100

Coke and Coal

1997

2001

Malarenergl AB

KW\Fcisteras F5

s.wd",

59

W:lod RSdues

F83t, Coat

CFBs FIRING RENEWABLE FUaS

fWl~~QiiO~~~

2007

2010

Kaukaan \.bima Oy

Kaukas

Finland

125

Bomass

FOal

'NVHui~flcentrale

Noord-

H'vCBio-

2006

2008

energiecentrale,

Netherlands'

28

Demolition V\bod

....

~

Holland (H\A::-N H)'

A1kmaa,

.. " "

2003

2007

lomelHna Energia Sr.l.

lomellina

Italy

17

F<lF

2002

2006

'"

...

".',

B.mder'!forSeGmbHBiomasse

& Co KG

Kraflwerk

Austria'

Fore!i

Chips

Smmering

23

2004

2006

Rokon Nord Energie¥teme

BMHKW

Germany

20

_edVlbod

GmbH

Emlidlheim

Rokon Nord

Energiesysteme .

BMHKW

2003

2006

GmbH

BorigslJ'aBe.'

G~ny

20

_edVlbod

.Hamburg

Harpen 8lergie Contracting

BMHKW

Germany

20

_edVlbod

FareS:

fbdue

2003

2005

GmbH

"""ka""'"

BMHKW

2002

2005

MW Energie AG

KOnig9NUSl:er

Genna""

20

_edVlbOd

hau","

2001

2005

Sora En9:l Kwm9JE!den AB

Kwm~en

s.wd'"

36

sa"

Bio SOOge, S:ldiment

Sudge, Bituminous Coal

2002

2004

Rokon Nord

&lergi~

BMHKW

Germany

20

fU)ded

V\bod

GmbH

Rl.pen~urg

1998

2002

Jamtkraft AB

t\!Nlugnvik

s.wd",

45

\f1.bod R3Sdues

Feat, B3.rk,

Vlbod Dud,

6:&er'9Jnd

Fec)ded

V\bod

1998

2002

\attenfall 3;A

Munksund

s.wd",

25

sa"

Vo.bod

R:lsidu~

Faper R3ject

1996

2000

lomellina 81ergla Sr.I.

LDmellina

IlaJy

15

F<lF

18

Electronic Filing - Received, Clerk's Office, September 30, 2008

~

~~

=e:=~=.t~==:::r.~~Wt1

.,~

-,,'''.'i'* . .

_. _,".'. .

-

..... - . --,.c,,',

"

." . -

. >

o

o

o

.

:,

•

CONTACT US

CHINA

Units 12 to 26, 6th Aoor - To_ A

Beijing CO

FCO Aaza

NO.8 Janguomennei

Sreet

Beijing, Roople-s Fepublic

01

China 100005

T

+86(0)1065263480/81

8th Aoor, UC To_, 500 Fuman RJad

flJdong New

I'lea,

S1anghai, China 200122

T + 86 (0)

21 5058 2266

FINLAND

Metsanneidonkuja 8

R-02130 Espoo, Rnland

T + 358 (0) 10 393

11

RlIandennkatu 2, 78201 \/arkaus

1'0.8o<201,78201\/arkaus

T +358 (0) 10 39311

GERMANY

ElJrggrnlemlrnsse 5A

40545

Dusseldorf, Germany

T + 49 (0)

211 55024700

FOLAND

Aleja Jana PaYAa II 15

00-828

Warsaw, FOland

T + 48 (0) 22 697 6870

ul.

Sas1ica 31, 41-200 Eb"",";oo, FOland

T + 48 (0)32 368 1300

Website: www.fwc.com

SPAIN

Calle Gabnel Garda Marquez, 2

28230

UlS

RJzas - Madnd, spain

T + 34 (0)

91 336 2500

SWEDEN

UndOv1lgen 75, 602 28 NorrkOping

I'0, Ebx 6071, 600 06 Norr!<Oping

T +46 (0)11285330

THAILAND

9th ROOf, Maneeya BJilding

518/5 Roenchil RJad

wrJ1lini, FathUfTlINcm

Bangkok 10330, Thailand

T + 66 (0)

26520760

USA

~lIe

Corpornte Flux,

Clinton, New.e-sey

T + 1 (1) 908 730 4000

9780

Mt. F\<amid Court, $lite 260

8lglewood, CO 80112-7060

T

+ 1 (1)3037844880

Rinted on add

free

and environmental dllorine

free paper oontaining 50% rec:¥=led content

induding 25% pos: oon9Jmer waS-e.

Electronic Filing - Received, Clerk's Office, September 30, 2008

C. Giesmann, K. Stuckmeyer

IEPA ATTACHMENT ND•

...::L

,lrjIiJJ

b=oI~

J.

Boyle

r'

~1YI,

%:t:Alneren

The Electrical Utilities Environmental Conference

January

22-25,

2006

Tucson,

Al

Al

/ ,i

'

,

T'~A

,:-

A

:- C

h'

(ilieva,S,-,

III

S

,,-,U.II,

b

i

0

I;

1'5

~! ~ )~

Ib'

i

"M'!B't

=

""'....,-

-'"

~!!!!!!'7!!J

_=-"!ff~

_

(

i

"i

i ;-',

cu.,'

-

_

1.1

~

~IIJ

-.J

=--

- =-'....

_

.... _-'

NiO:

~ _._~~

v

E'm!is,

..... ='

Ill ..... '_

sloin;

!!!!!/'_)

~

'S;

~_;;'~

OIl

.... _

a~

~

i

5~O!O)

_

=--- =-'

M,

-'

;W;

.~.

_'

C

r

,Y/C,

/ __".

I0

~

n.,,'

"~

!~~Firj8dr!

_ 11 __

__~

'

Bo!iili8'r

~ -~

_ --'

_~

'"'"

~

/' \

'~EACTION

ENGINEERING

INTERNATIONAL

M. Cremer, A. Chiodo, B. Adams

Electronic Filing - Received, Clerk's Office, September 30, 2008

A

.__

ic~niO!\NII!e·dlgc

_."",,"~

~

__ .

~

~

le,m!e'nit~s~~:

~!!J!!J

_.

""' _

~

» The authors wish to thank the US DOE NETL

J

for providing funding for this program. The

authors would also like to acknowledge Bruce

Lani,

project officer for DOE NETL, and the

integral support of AmerenUE Sioux Plant

Manager, Bruce Bruzina, and his staff.

» "This presentation was prepared with the

support of the USDOE National Energy

Technology Laboratory's Innovations for

Existing Plants Program, under Award No. DE-

FC26-04NT42297. However, any opinions,

findings, conclusions, or recommendations

expressed herein are those of the author(s)

and do not necessarily reflect the views of the

DOE."

Electronic Filing - Received, Clerk's Office, September 30, 2008

vvv

OJ

V

~

"'U

OJ

n

m

m

...,

n

0

Ul

I

A

:::J

rt

~

lC

n

-

;:0

m

...,

Ul

0

0

c

m

rt

C

Ul

Ul

»

:::J

1<

_.

0

c

c.

d'

:::J

rt

-

n

Ul

rt

OJ

[2

Ul

_.

<

:::J

t

-.

~-

rt

C.

-'l'

-.

I

m

Ul

0

\-..I.

rr

m

rt

n

_.

Ul

<

m

Electronic Filing - Received, Clerk's Office, September 30, 2008

R

.'

h

R

t' I'.'

t.

-

~=-

JIIC,,"'1'

~.

.~.

~

Jeag-eJn

~ .~= ~

;

~!!!J ~~

i

__

~I

~

'n-

i',e.

;

_~

~c;

~ ':J~

1~IIQini

,

=--'"

~

=>

0=/

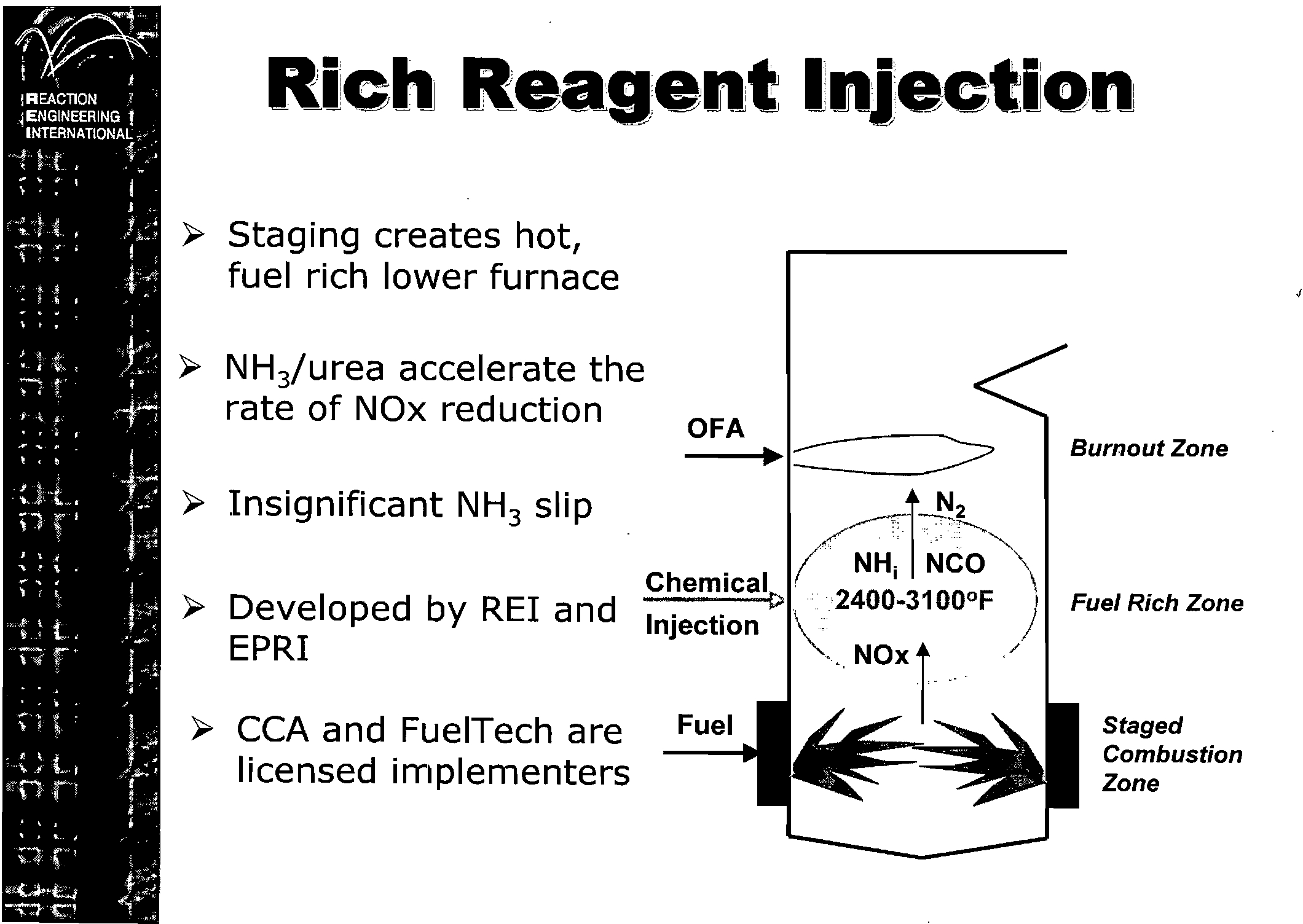

~

NHiurea accelerate the

rate of NOx reduction

J

Staged

Combustion

Zone

Fuel Rich Zone

Burnout Zone

OFA

~

I::::

=>

1

• _

N

2

Chemical

Injection I>

~'2400'31000F

~N~~"

)

", NOxt

/

Fuel -

~

-- r"

~

Developed

by

REI and

EPRI

~

CCA and FuelTech are

licensed implementers

~

Staging creates hot,

fuel rich lower furnace

~

Insignificant NH

3

slip

Electronic Filing - Received, Clerk's Office, September 30, 2008

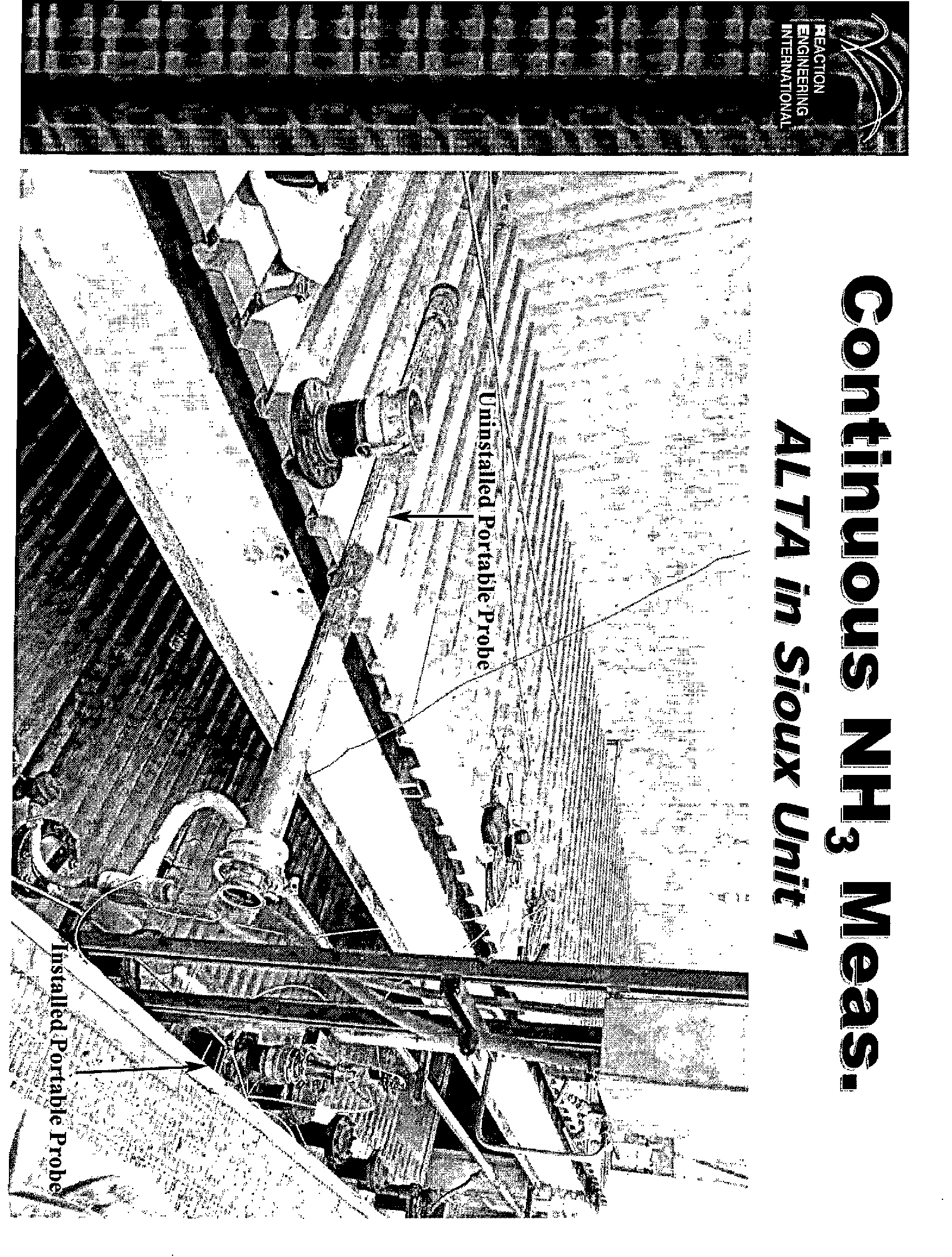

ALTA

=:

Adv'anced Layered

Techn

-

.~

_=--!"'!J ' =-'

1

Q,llo,g.y/

-~ ~

--

~/

,/

Ap'

---

-'~~!!!l=-'

;p

~~

.. )fo!achl

~

=-- ---

~

=

~

Deep staging

~

Rich Reagent Injection (RRI)

~SNCR

Electronic Filing - Received, Clerk's Office, September 30, 2008

ProJ,~!e,ctr

o'~

'b

l

~

!!!J

~

, _

~

~=

J)~!ectiY"

,,_

~ _~

/etS

~ ~

="

,

~'

,

~

NOx < 0.15 Ib/MBtu

~

Levelized cost below 75% that

of current state-of-the-art SCR

~

BOP impacts including LOI, slag

tapping, and NH

3

slip

Electronic Filing - Received, Clerk's Office, September 30, 2008

Project

Ti

eam

~

AmerenUE Sioux Plant - Host

~

REI - Project Lead

~

FuelTech - RRI and NOxOut SNCR

equipment supply and testing

~

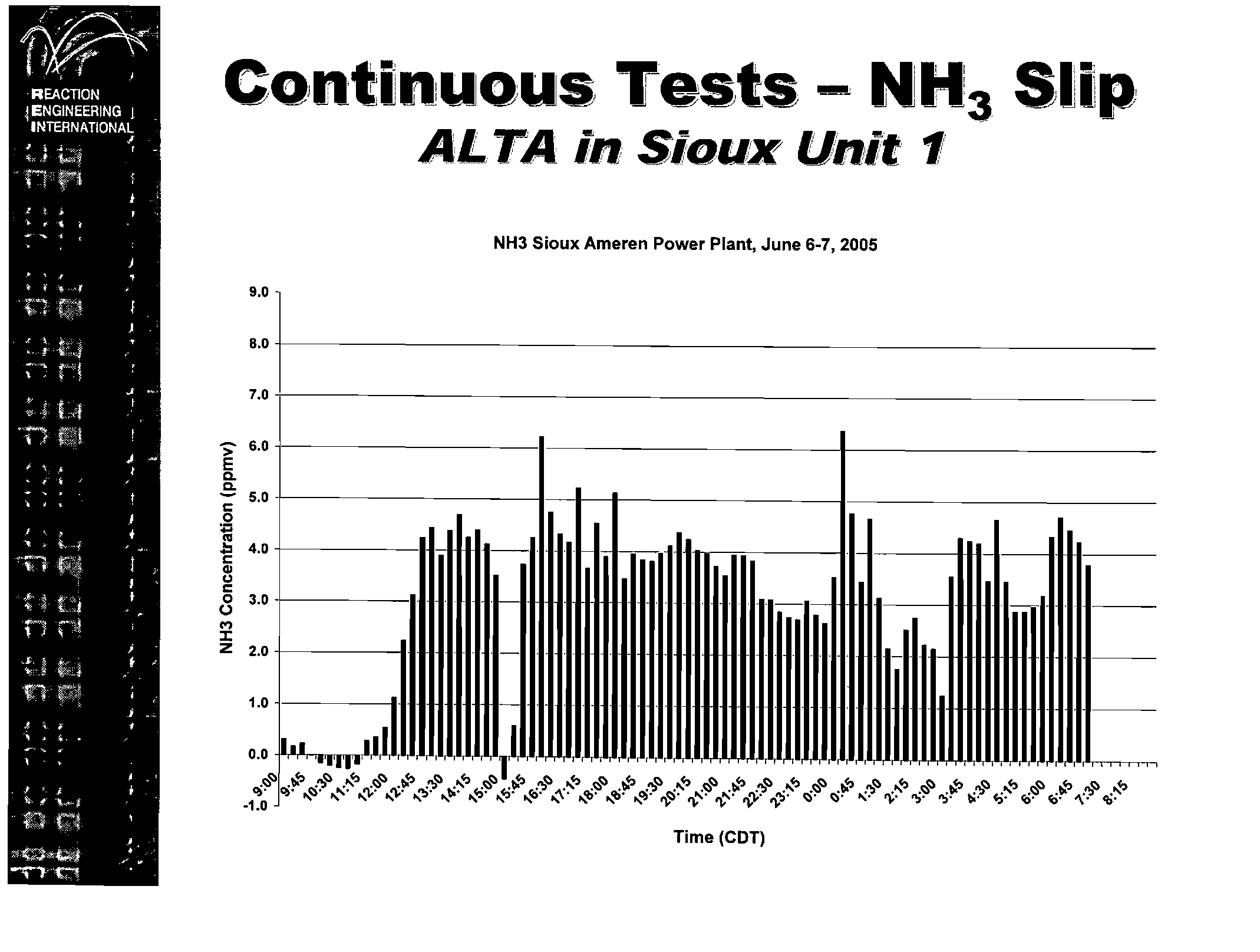

EPRI - Field support and

continuous NH

3

monitoring (UC-

Riverside)

Electronic Filing - Received, Clerk's Office, September 30, 2008

AnI:e..r'-Q,n'U'

=

,~=

"I

~

_!"

_~ _~

I

,IE's

~"~

S-IQU'

~ ~

__

'XI PI1a::

II !!!OJ

Int

_

~

Two Units -500 MW

each

~

Supercritical

~

10 cyclone barrels

~

85% PRB blend with

Illinois bituminous

~

FGR and GT for steam temperature control

~

Fine grind crushers

~

First application of OFA on cyclone in unit 2 in 1997

Electronic Filing - Received, Clerk's Office, September 30, 2008

C.FD:

=-'"'

J

Modlel

!!!!!l _

_~

_

Ap,.-

_;='"

:ipr

j __

)Fa,ach

~

__~ __

_~

-

-

Sio,ux Uniit 11

~

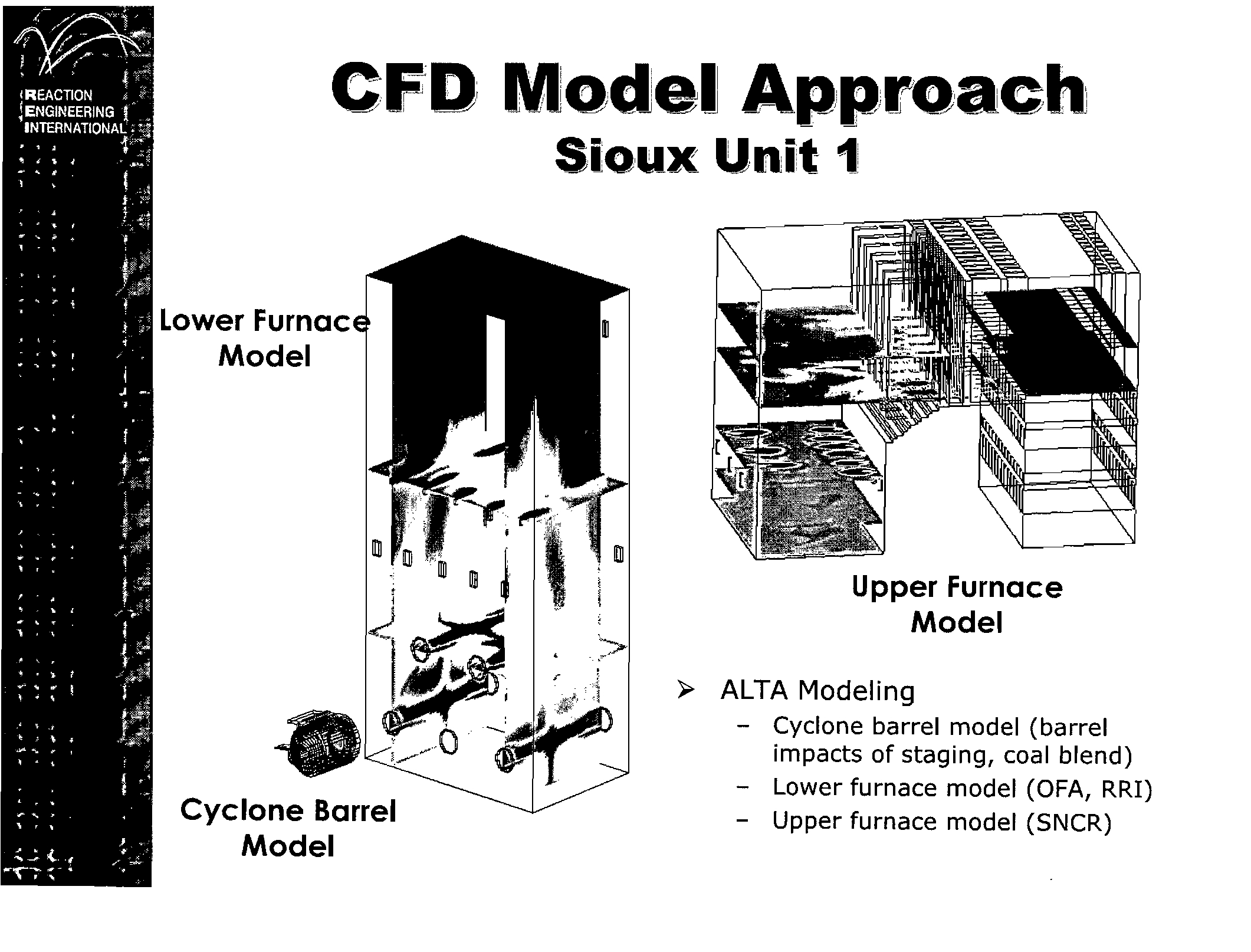

ALTA Modeling

Cyclone barrel model (barrel

impacts of staging, coal blend)

- Lower furnace model (OFA, RRI)

- Upper furnace model (SNCR)

Upper Furnace

Back to top

Model

Back to top

Cyclone Barrel

Back to top

Model

Lower Furnac

Back to top

Model

Electronic Filing - Received, Clerk's Office, September 30, 2008

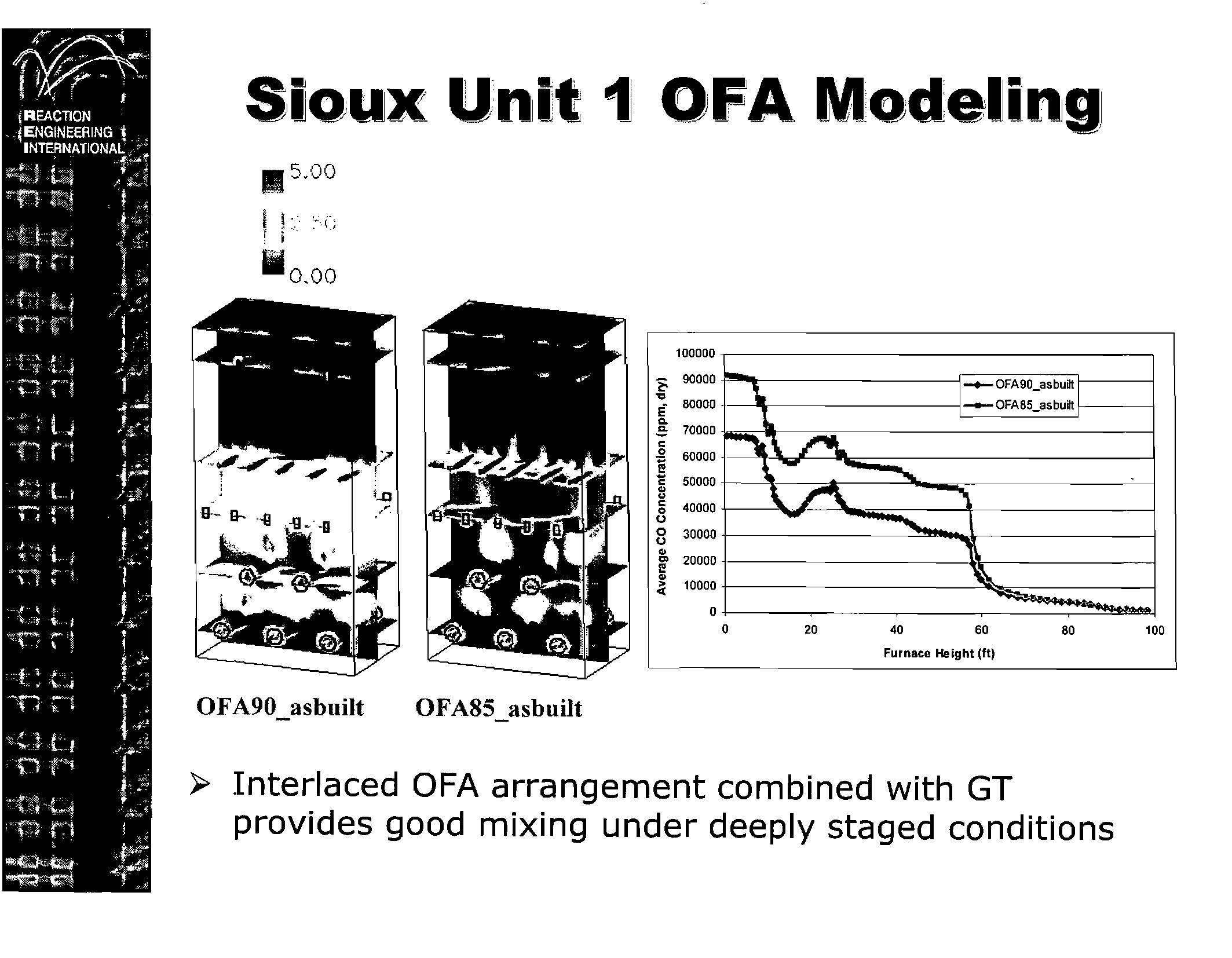

Sioux Unlit 1 OFA Modeling

~

Interlaced OFA arrangement combined with GT

provides good mixing under deeply staged conditions

40

60

80

100

Furnace Height (ft)

20

-

\.

I-+-

OFA90_aSbU~

I

\.

___ OFA85 asbuilt

1\.\ ............

~--

..,..

\~

--

""-

""'

.,

~

o

o

100000

F

90000

...

If

80000

Cl.

.e:

70000

c

0

60000

~

~

..

"

c

0

5000040000

U

u

0

..

0>

3000020000

..

!!

>

10000

'"

OFA85 asbuilt

.0.00

11

5

.

00

I !'

".C;

,

.

OFA90 asbuilt

Electronic Filing - Received, Clerk's Office, September 30, 2008

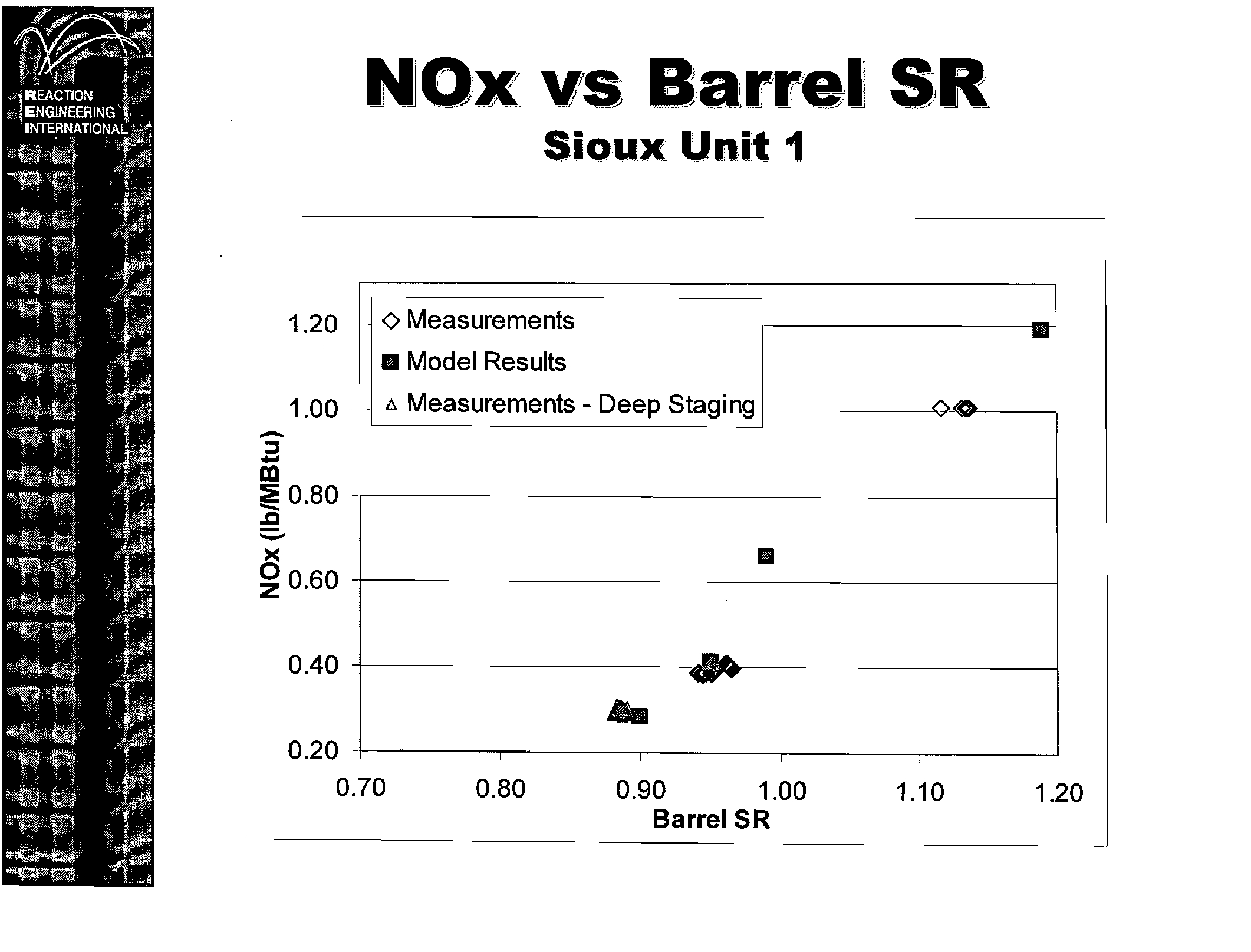

NOx

VIS Barre11 SiR

Sioux Unit 1

0.90

1.00

1.10

1.20

BarrelSR

0.80

II

<:> MeasurementsModelResults

-

f:,. Measurements - Deep Staging

0-

III

•

I

0.40

0.20

0.70

1.00

1.20

><

°060

z.

-

1XI

-

~

~

0.80

-

Electronic Filing - Received, Clerk's Office, September 30, 2008

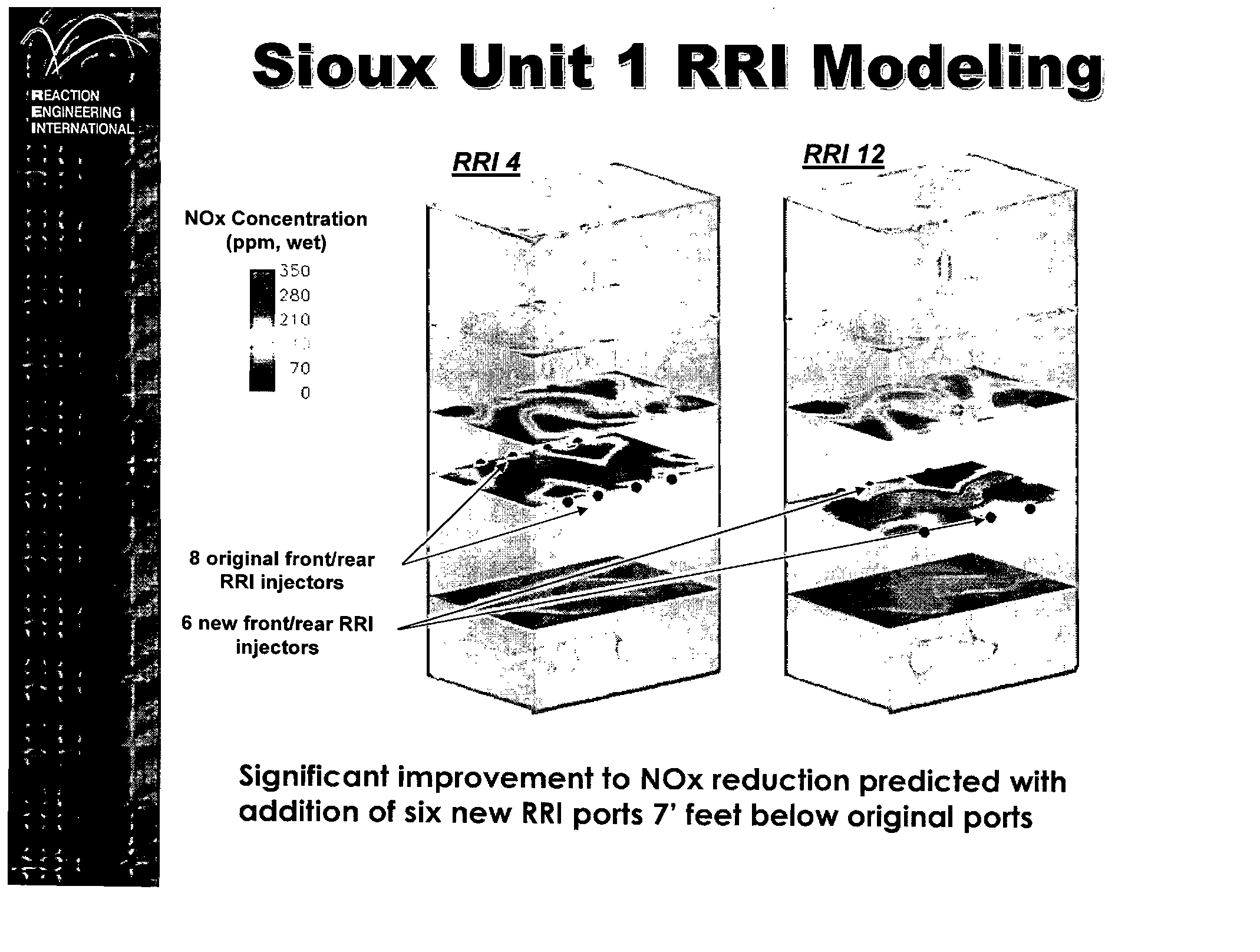

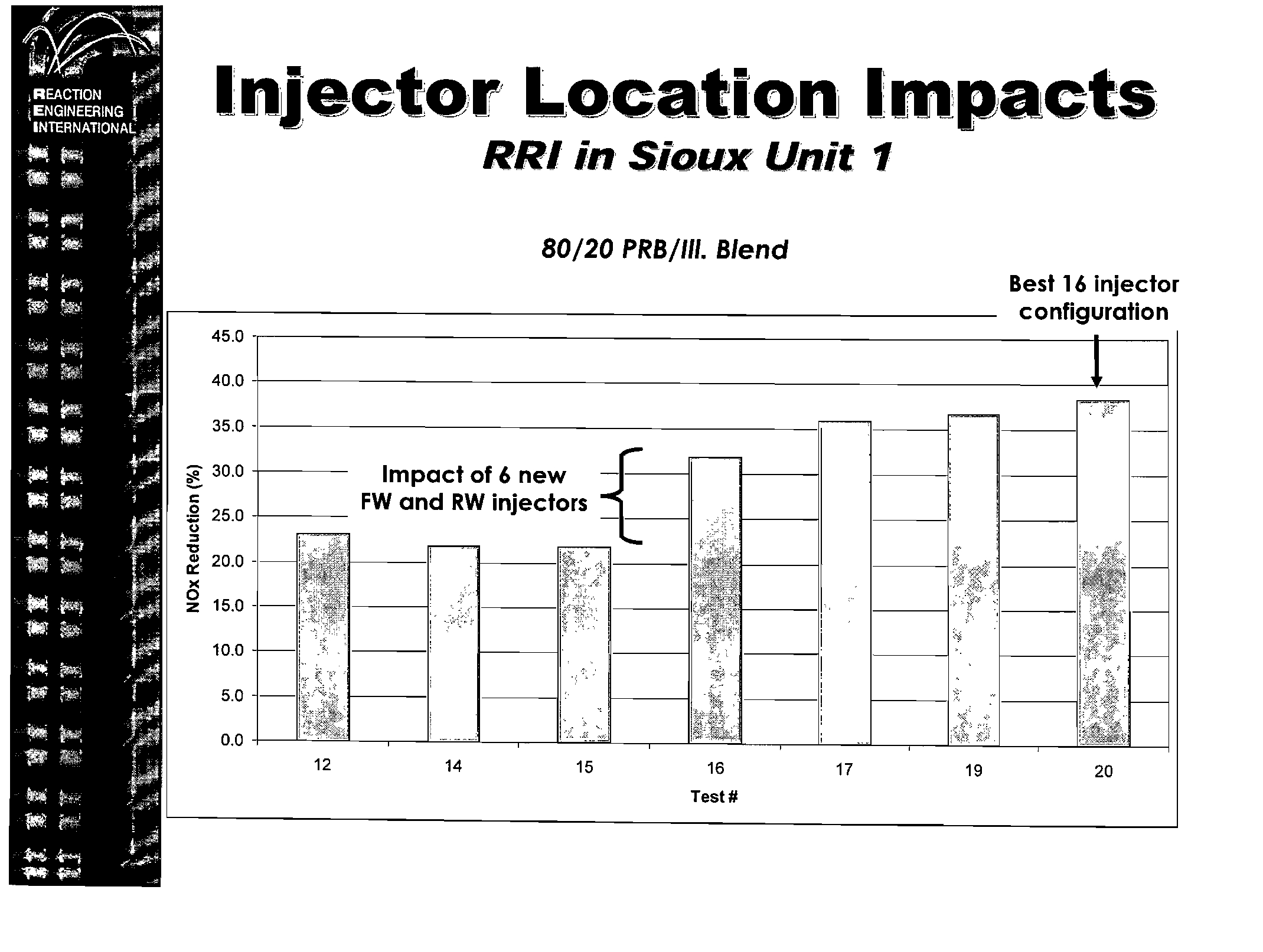

Significant improvement to NOx reduction predicted with

addition of six new RRI ports 7' feet below original ports

",'i"

~

...

-

.......

~

.

'rv~

_

..

~.

~\

q.,

.,~

..

-""....

""'..

, .....'

..., -.....................

---....,.:}<.:~"~,;~_.,,

RR/12

'~p

..

j:<-r-::~.J'«<'""

,-

RR/4

S

010JUX

~

u"

Jnl!

~t'

1!

v J

RR'I

:

~~- ~

,I,

.u.

,.,0

d!

~~e

I'~

ilng

117~

NOx Concentration

(ppm, wet)

_

35,0

280

21(1

8 original front/rear

RRI injectors

6 new front/rear RRI

injectors

Electronic Filing - Received, Clerk's Office, September 30, 2008

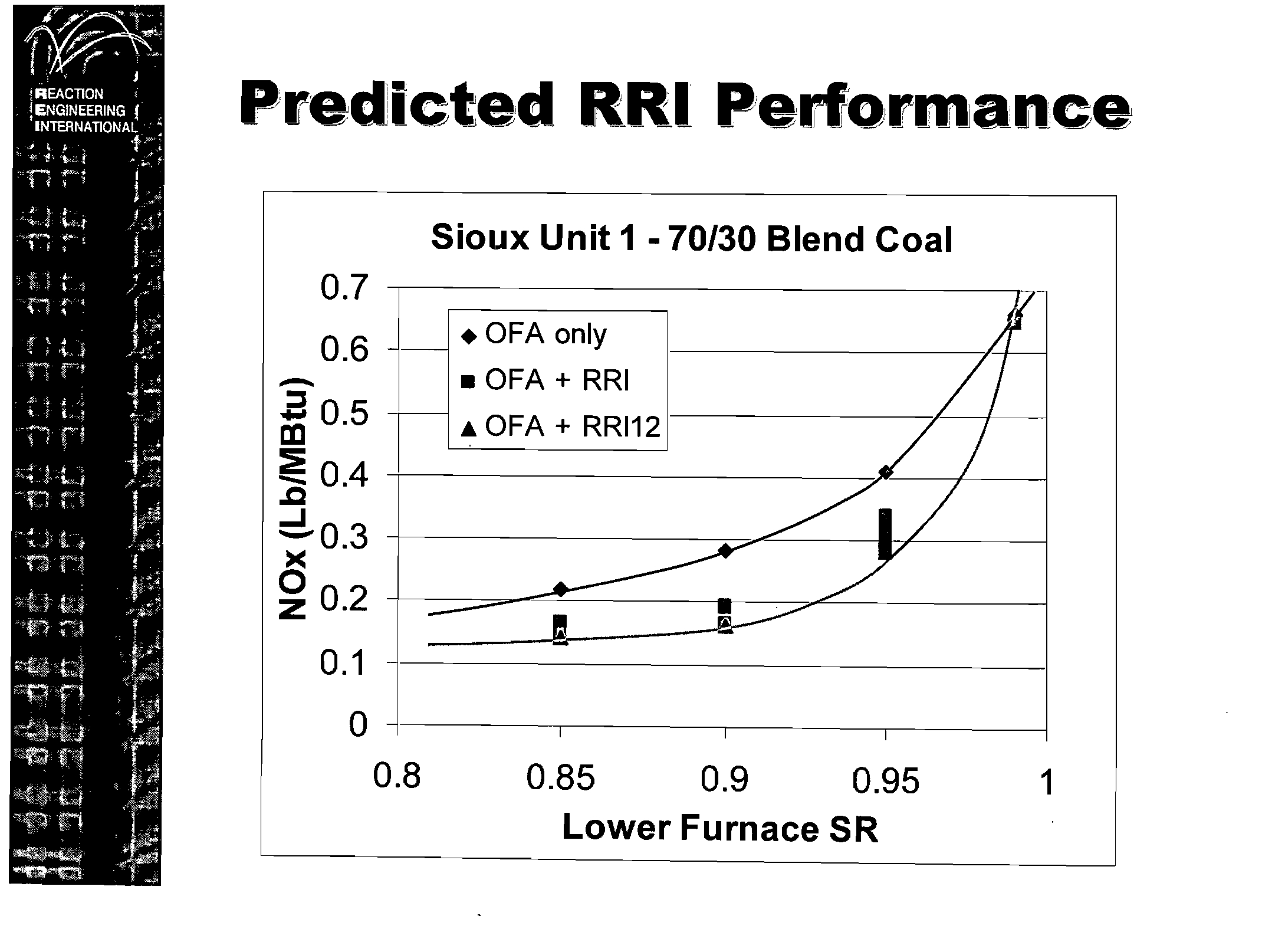

Predicted RRI Pe,rfolrmance

Sioux Unit 1 - 70/30 Blend Coal

• OFA only

)i

.&

• OFAOFA

++ RRI12

RRI

//

//

//

-.-~

/v

P.l

II

~

I

I

I

0.85

0.9

0.95

1

Lower Furnace SR

0.7

-

.a

0.60.5

m

~

0.4

.c

d.0.3

><

~

0.2

0.1

a

0.8

Electronic Filing - Received, Clerk's Office, September 30, 2008

S

~

~--')p_C

.I~

;r-.III!:n:-

, -'

,g,

~i

20'

-' -

,O_r;5'

~;r

GiU-

._~

-.~

ft'~ag-_!e,

~~

i

~

""'

--

~

Sioux Unit 1

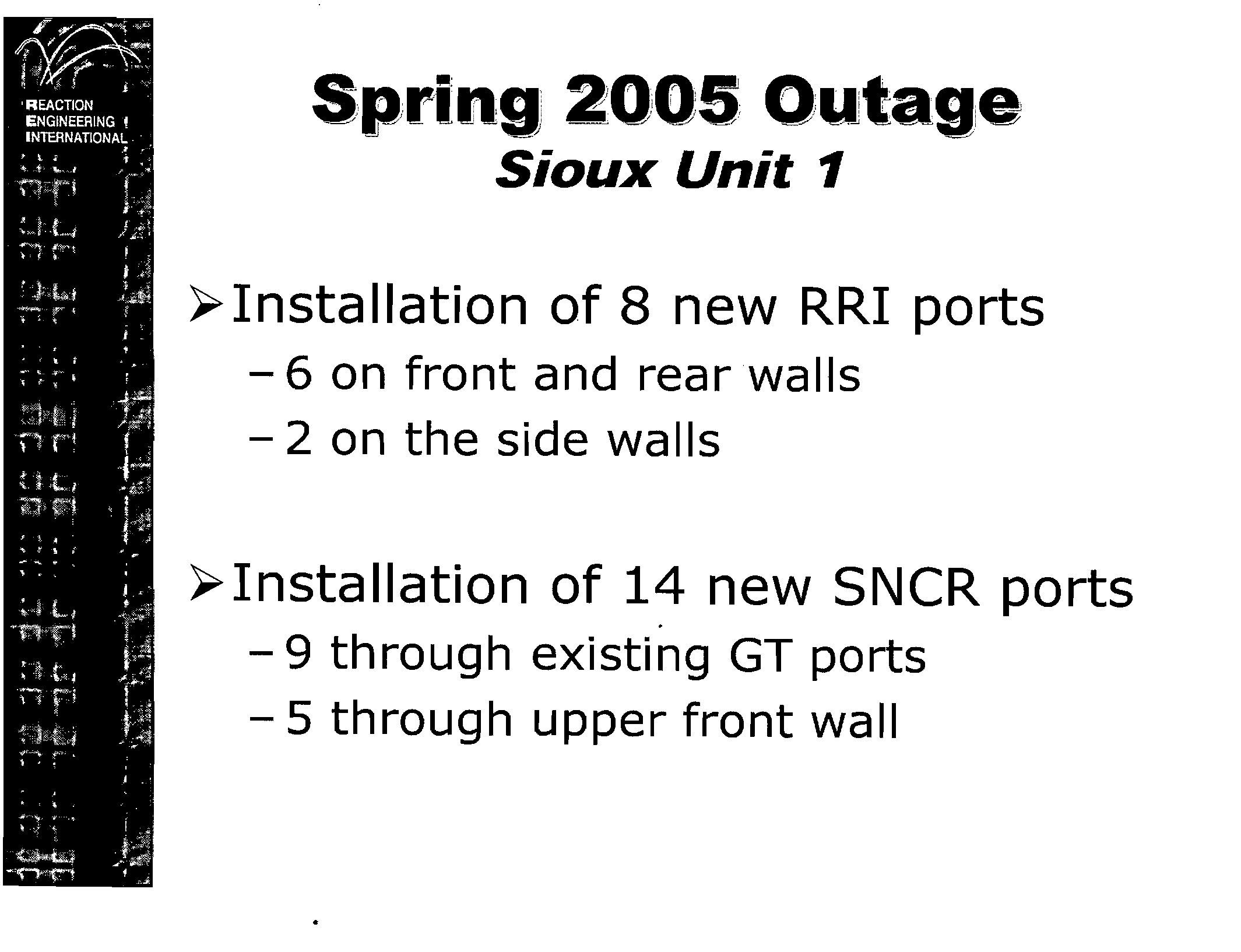

y Installation of 8 new RRI ports

-

6 on front and rear walls

-

2

on the side walls

y Installation of 14 new SNCR ports

-

9 through existing GT ports

-

5 through

upper front wall

•

Electronic Filing - Received, Clerk's Office, September 30, 2008

O

:~)y·

,

/e'"N'"

.

11~8'W'

;'

O,e

,f;

T~.-e·s,-·t·..:s'

~

/ ---:

/

I

~

/,.'

.':

!

_!!!!l .' ,'--

~~

:

~........;

.......i

=.I':;..'"

~=.;'

='

=

-

-

~~-_

...../

~

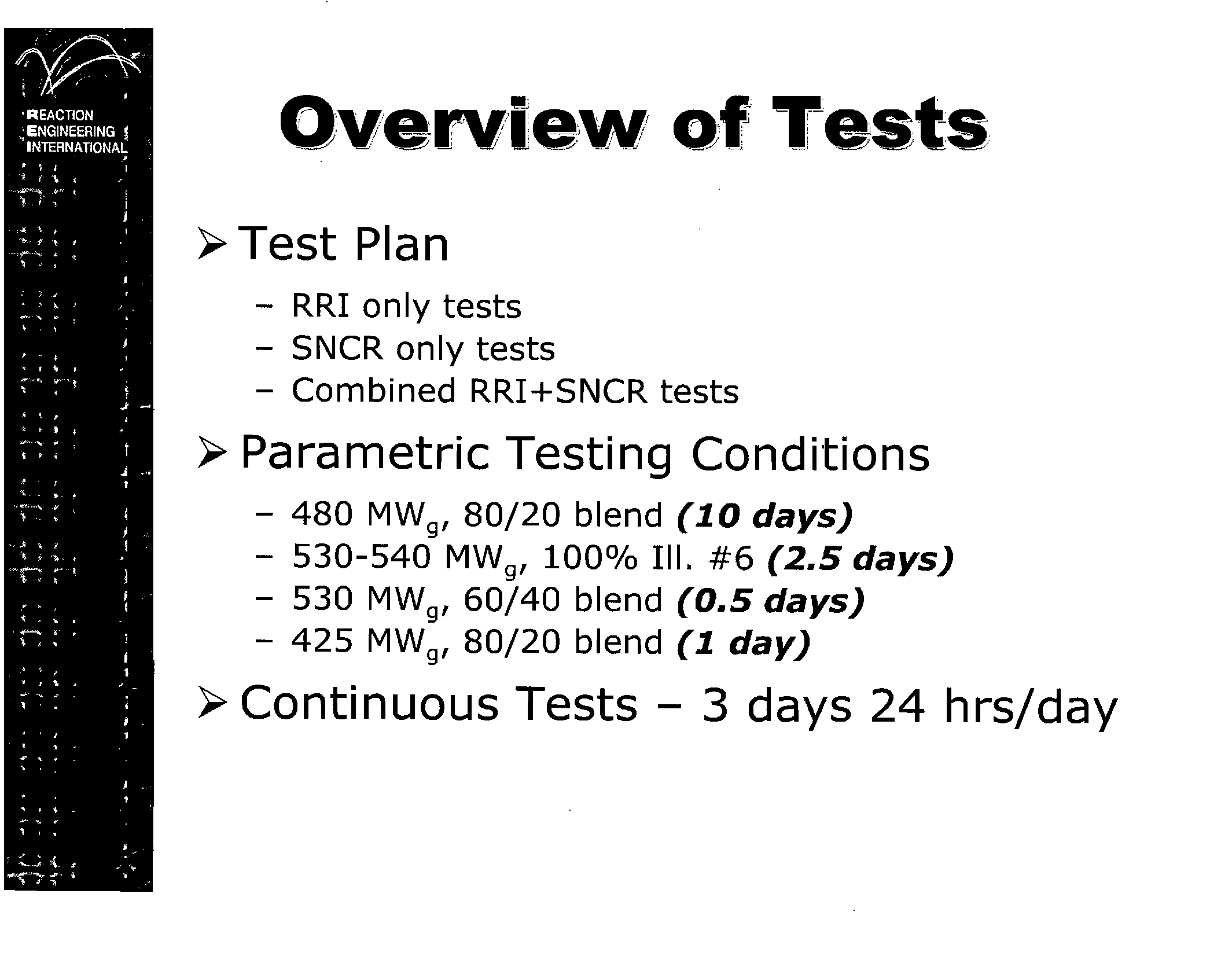

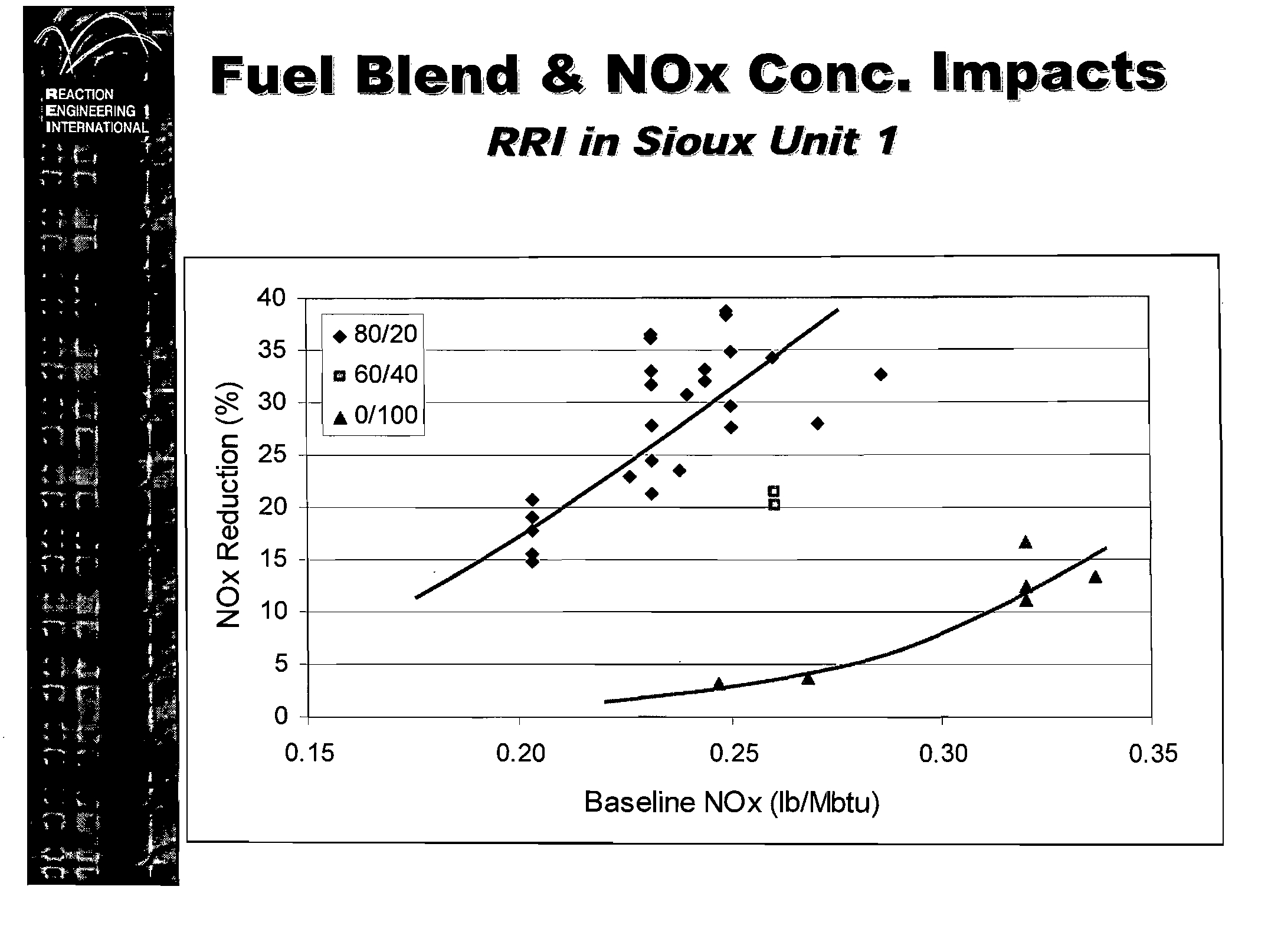

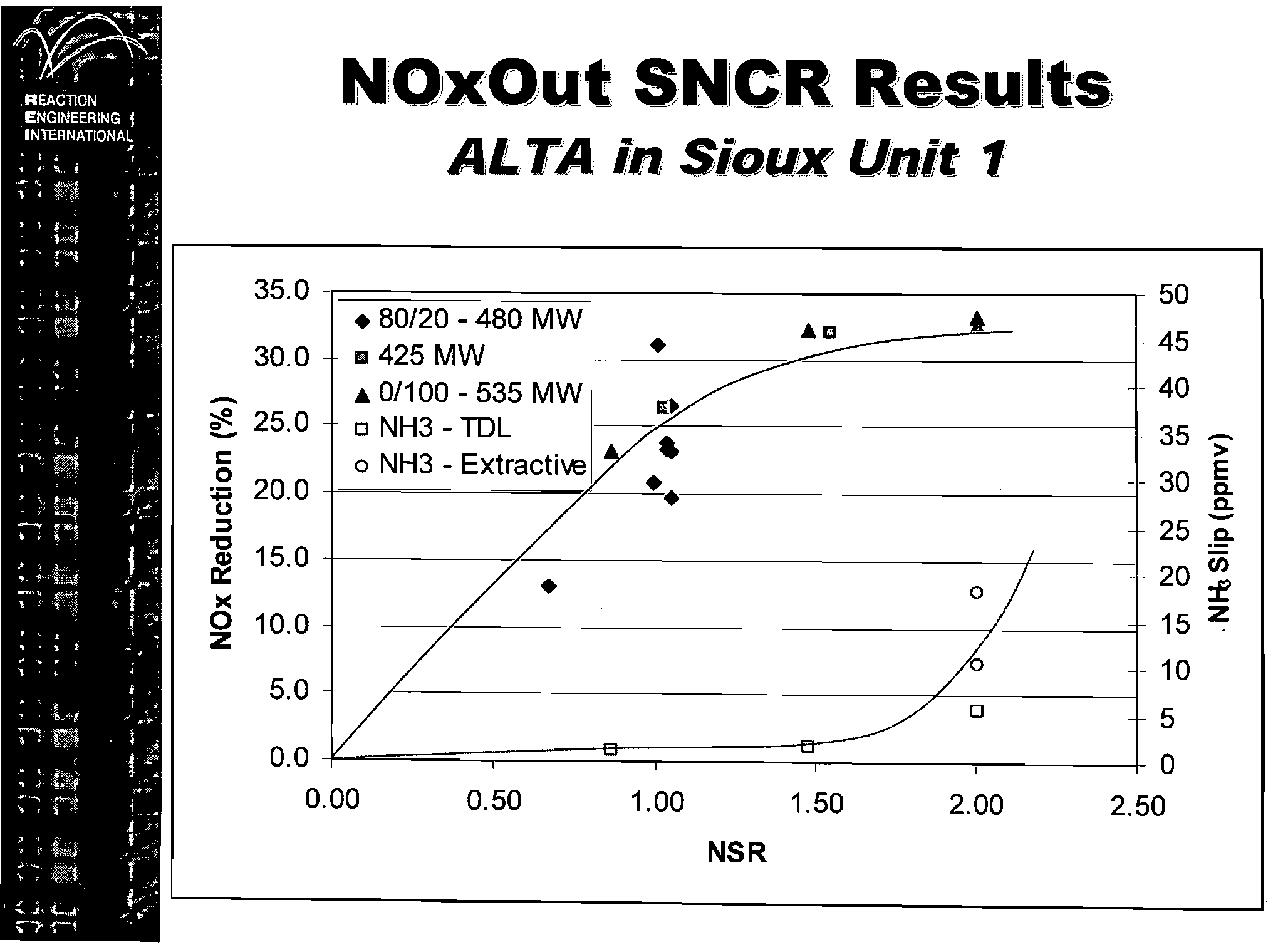

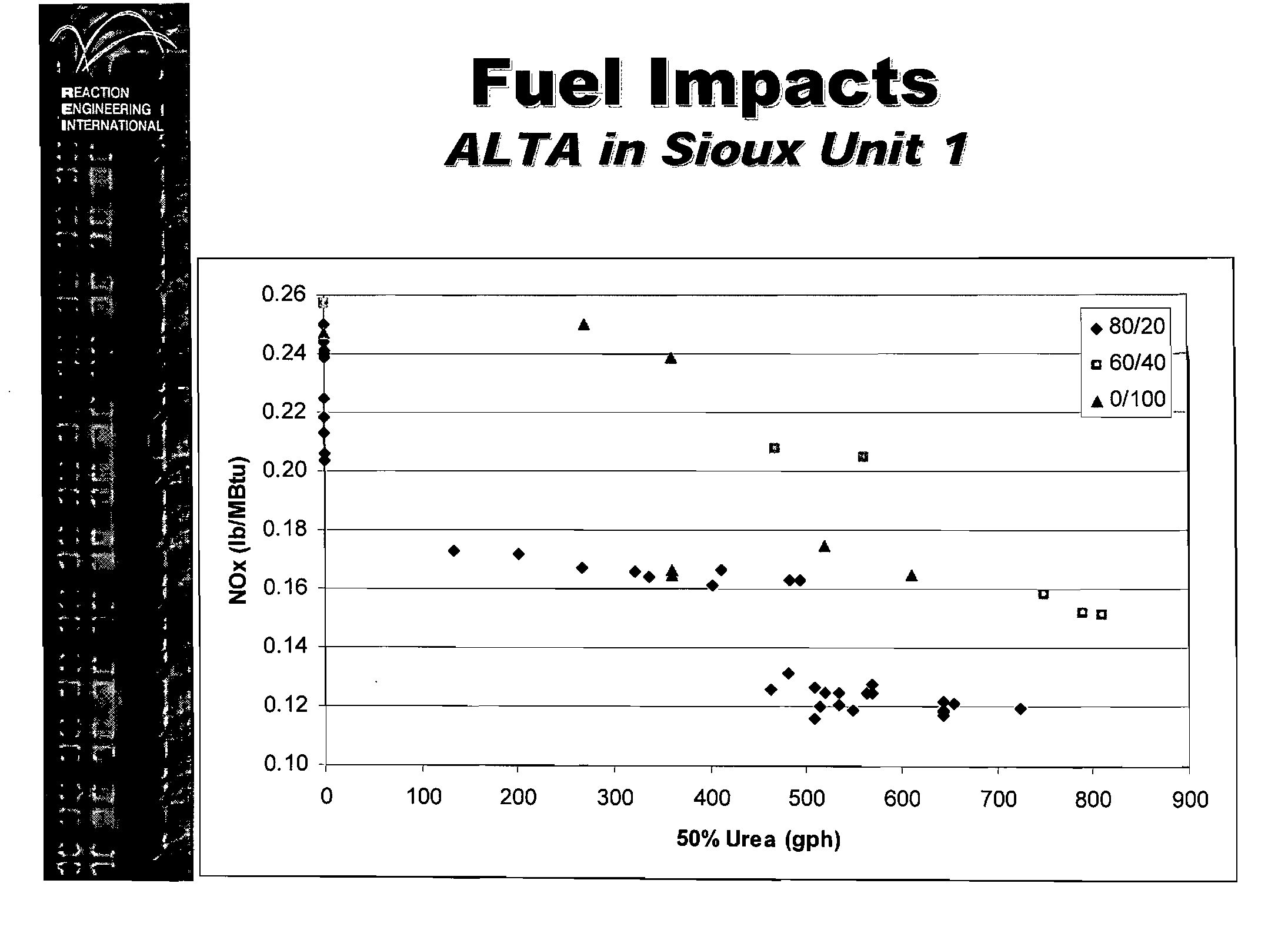

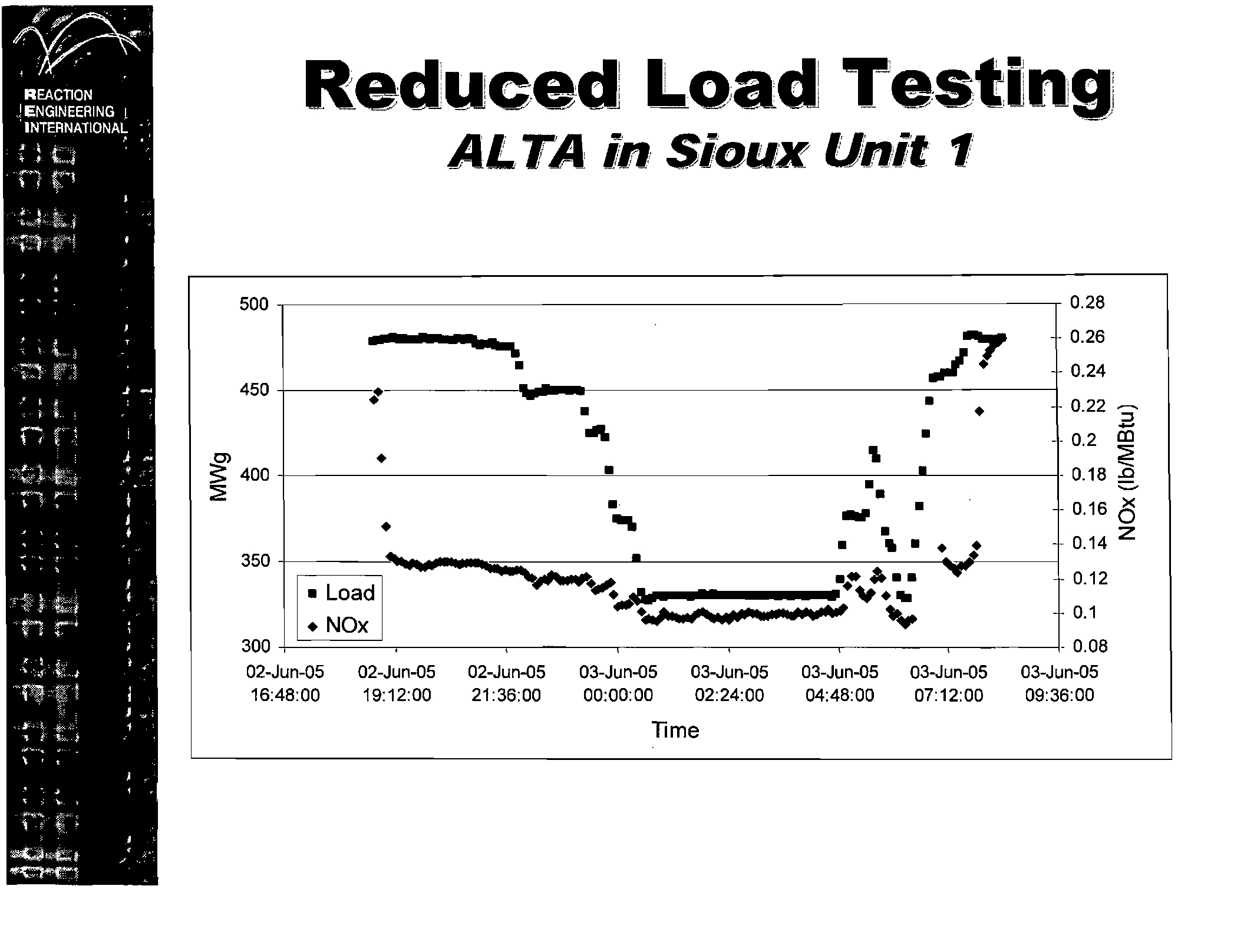

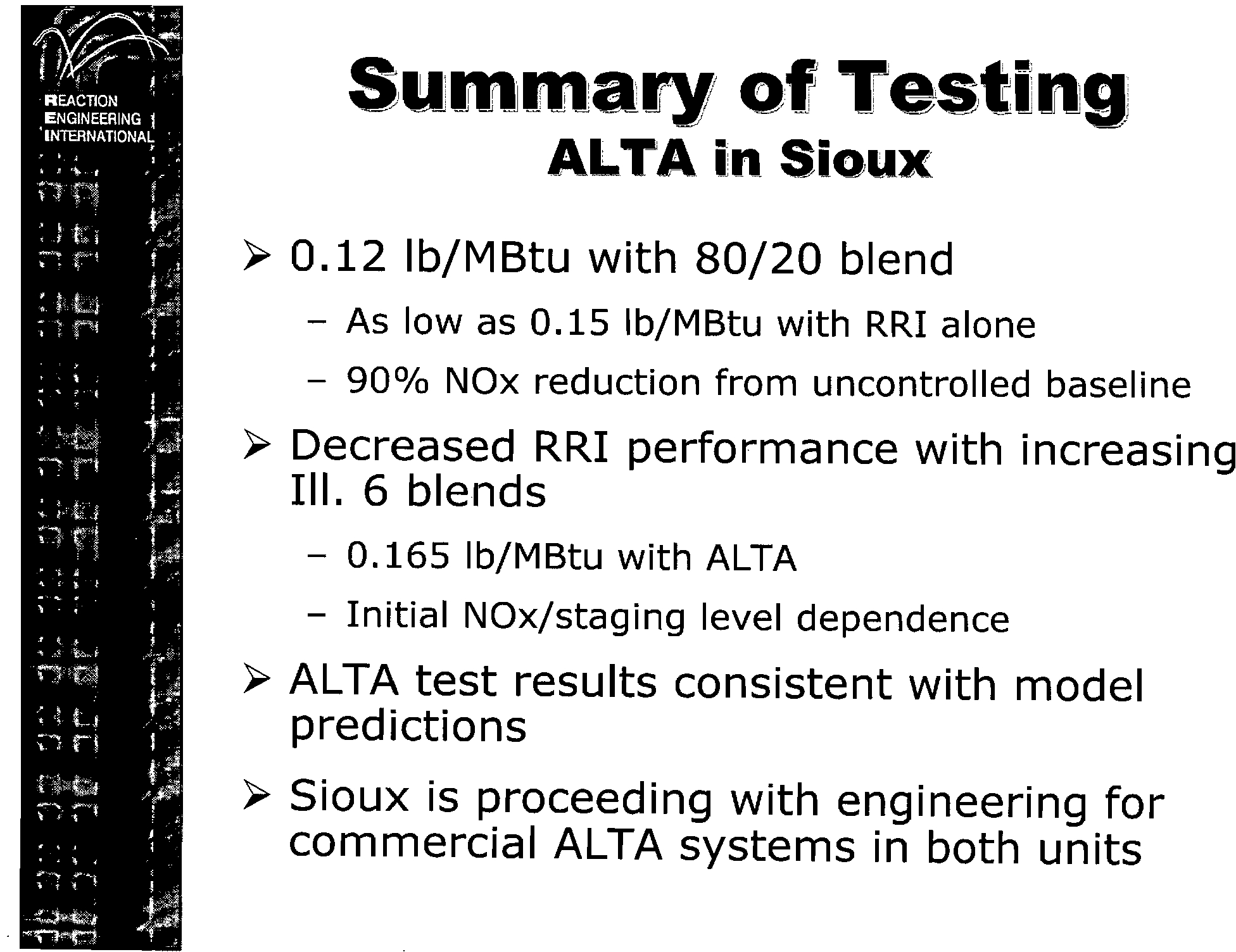

Test Plan

- RRI only tests

- SNCR only tests

- Combined RRI+SNCR tests

~

Parametric Testing Conditions

- 480 MWgf 80/20 blend

(10 days)

- 530-540 MW

gf

100% III. #6

(2.5

days)

- 530 MW

gf

60/40 blend

(0.5 days)

- 425 MW

gf

80/20 blend

(1

day)

~

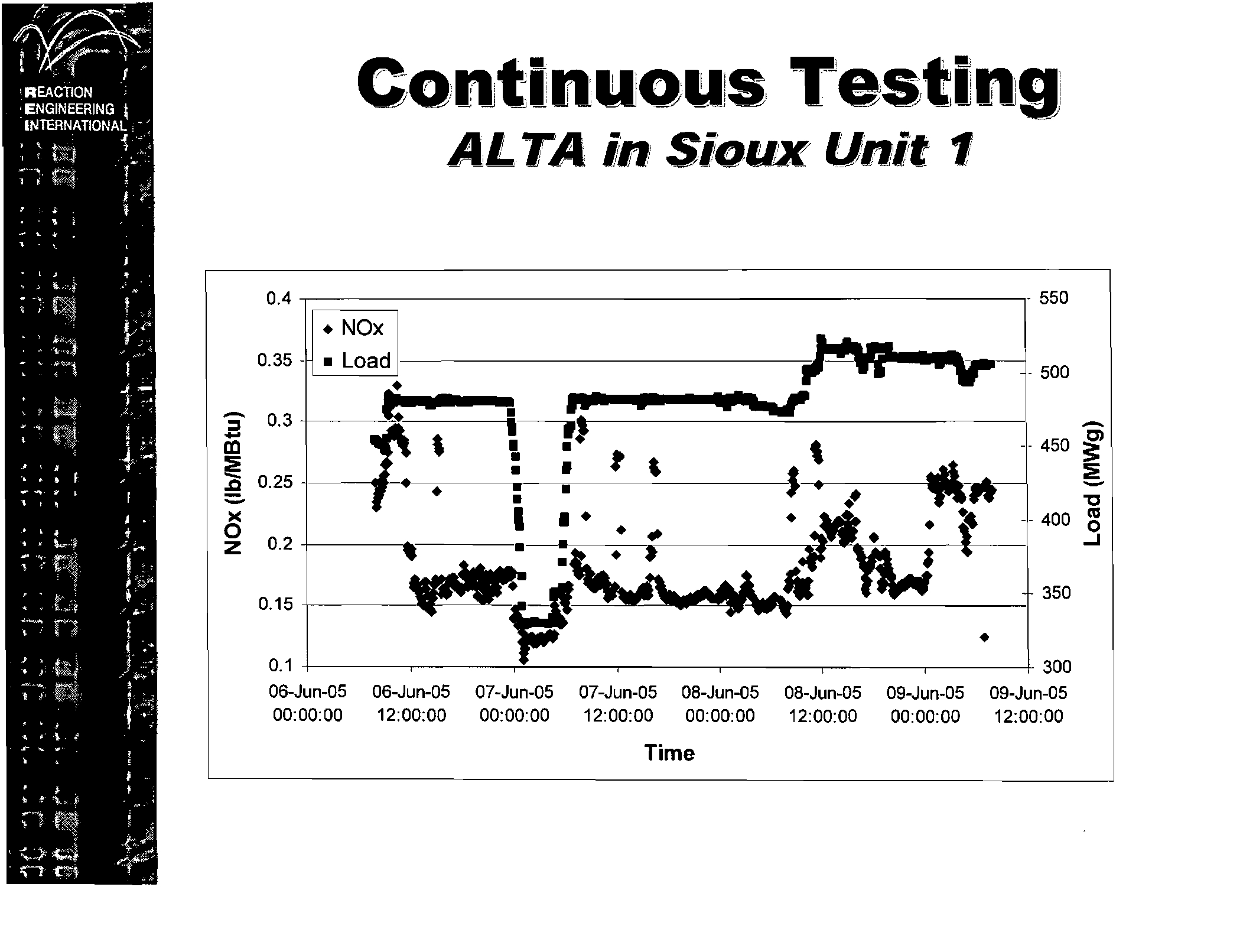

Continuous Tests - 3 days 24 hrsjday

Electronic Filing - Received, Clerk's Office, September 30, 2008

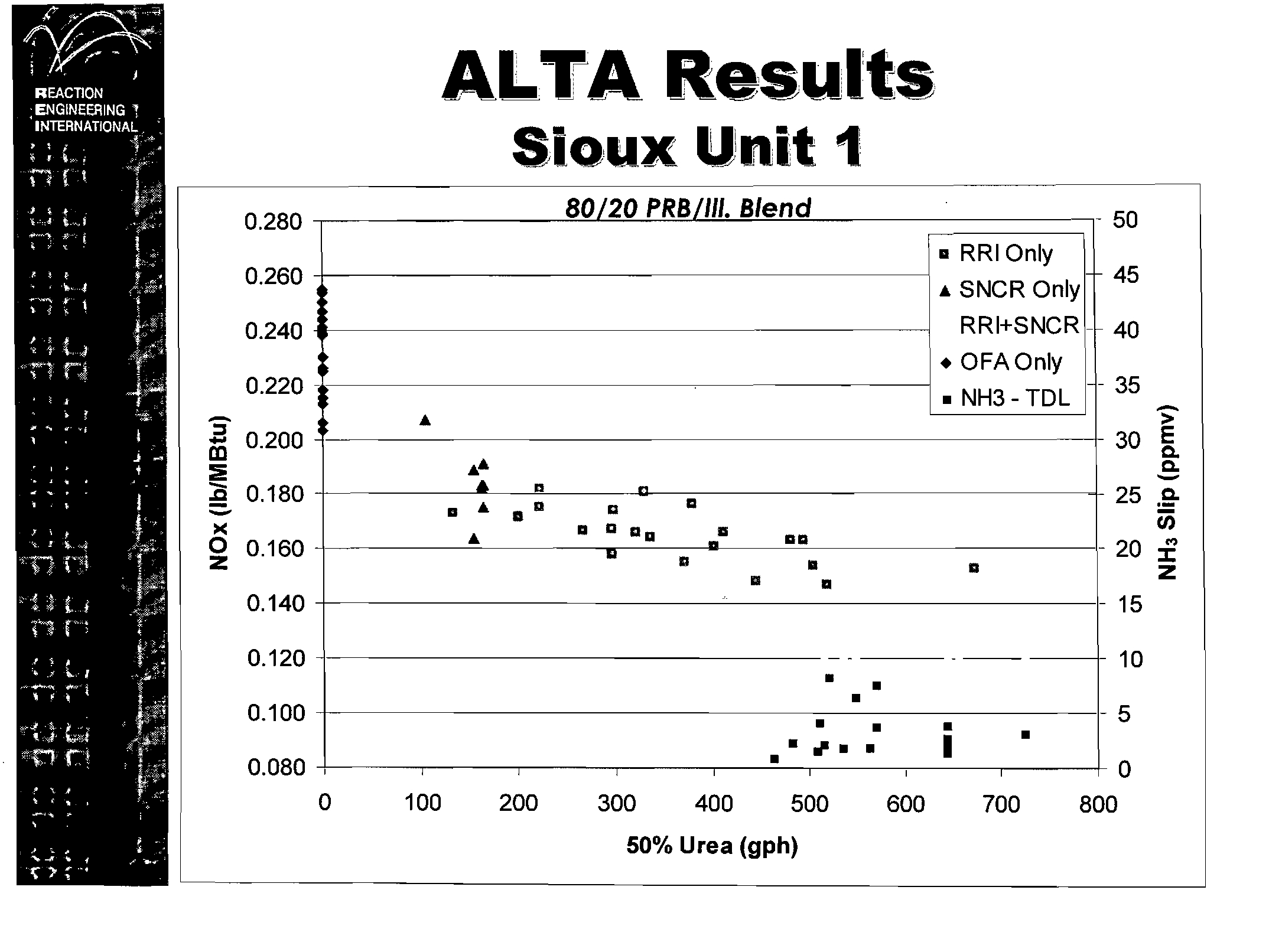

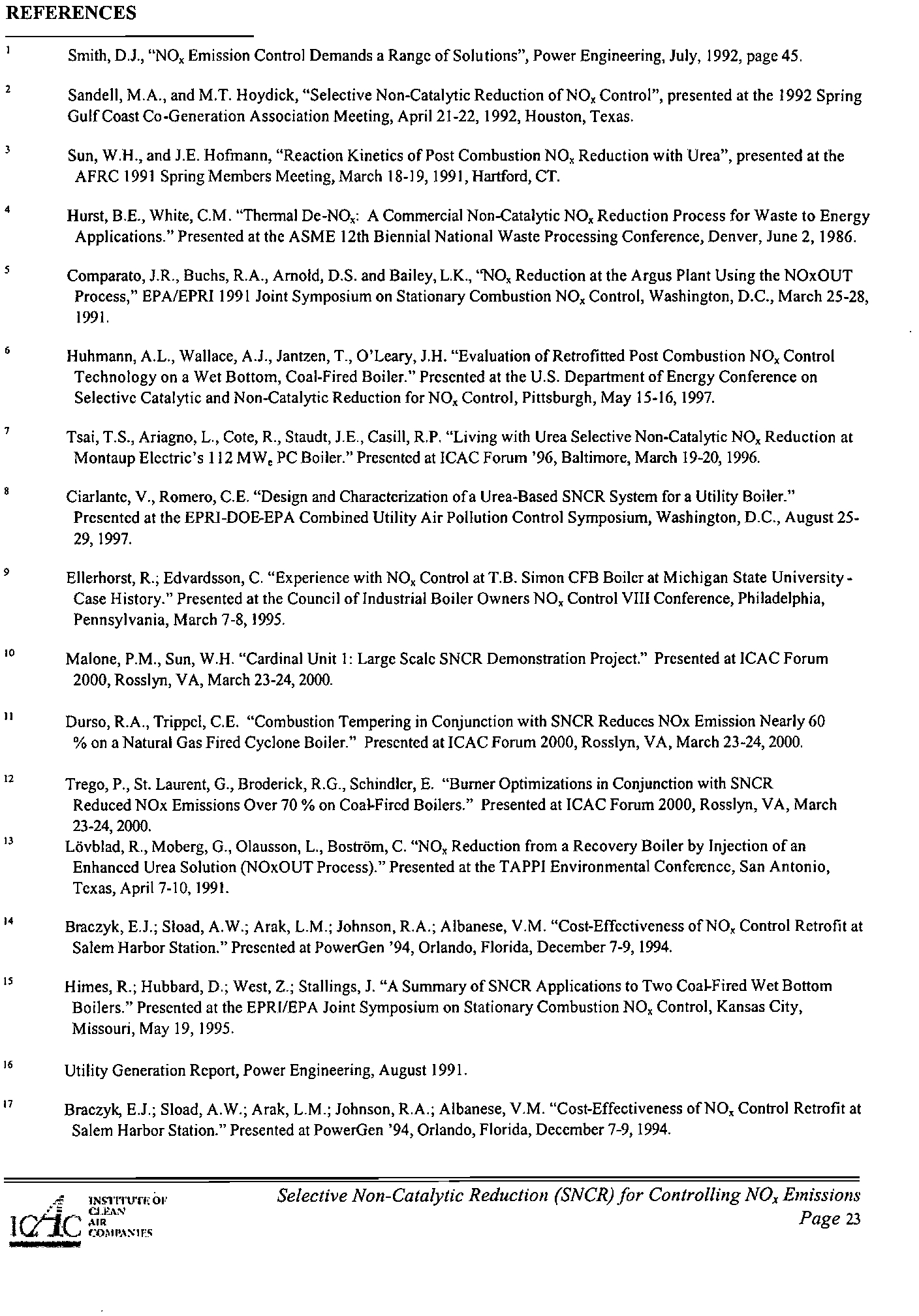

O

r

~

)Ve=--Jrraill

=.I

.'

'='-'"~

_

ReSU'llitS~-i

_

........

_

~

~

.,=r

~

'_"-'

ALTA

in

SiiQJux 1

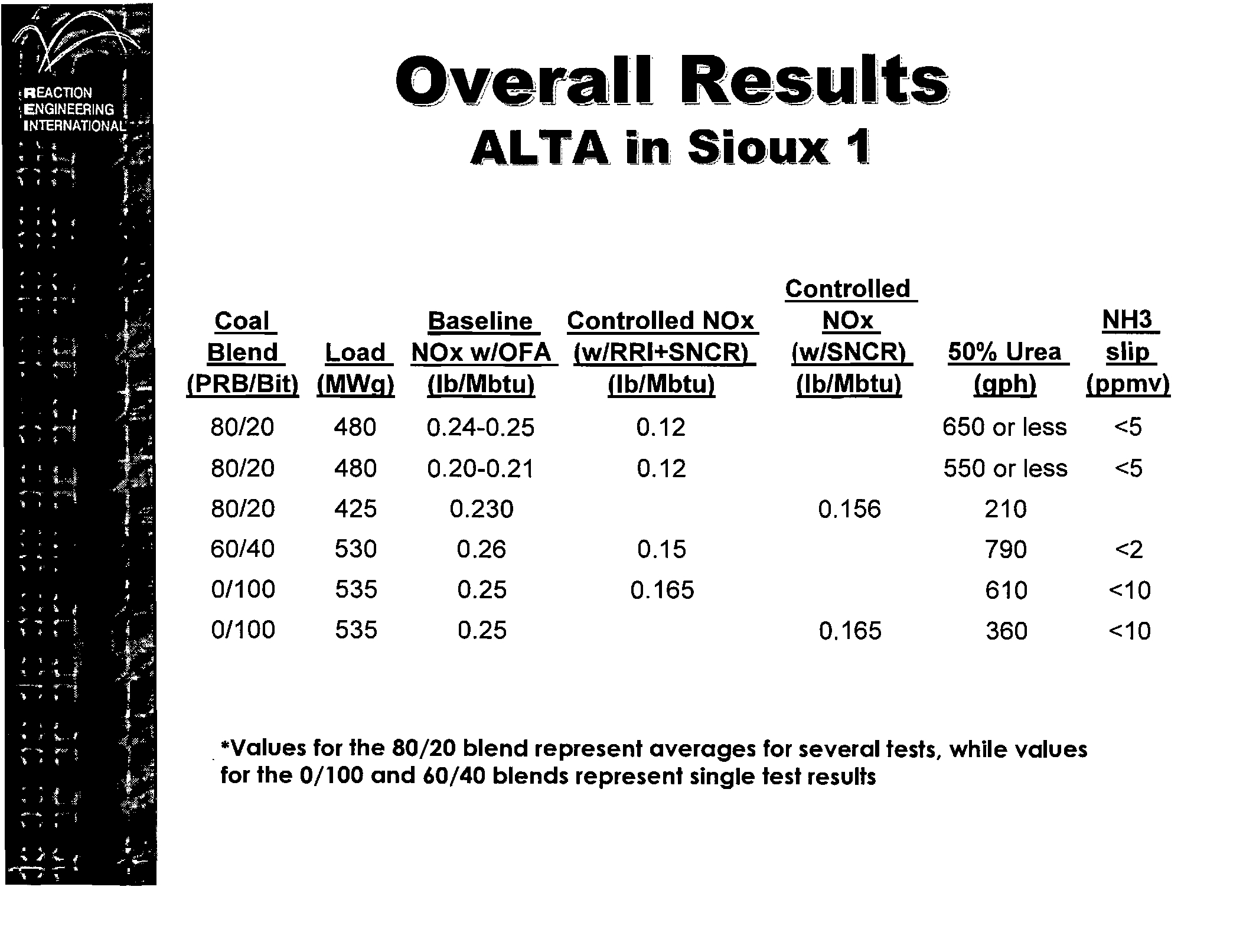

Controlled

Coal

Baseline

Controlled

NOx

NOx

NH3

Blend

Load

NOx w/OFA

~w/RRI+SNCRl

.(w/SNCRl

50% Urea

slip

lPRB/Bitl,

{MWg>. llb/Mbtul,

,(Ib/Mbtu>.

{lb/Mbtul

{gph>'

(ppmv>.

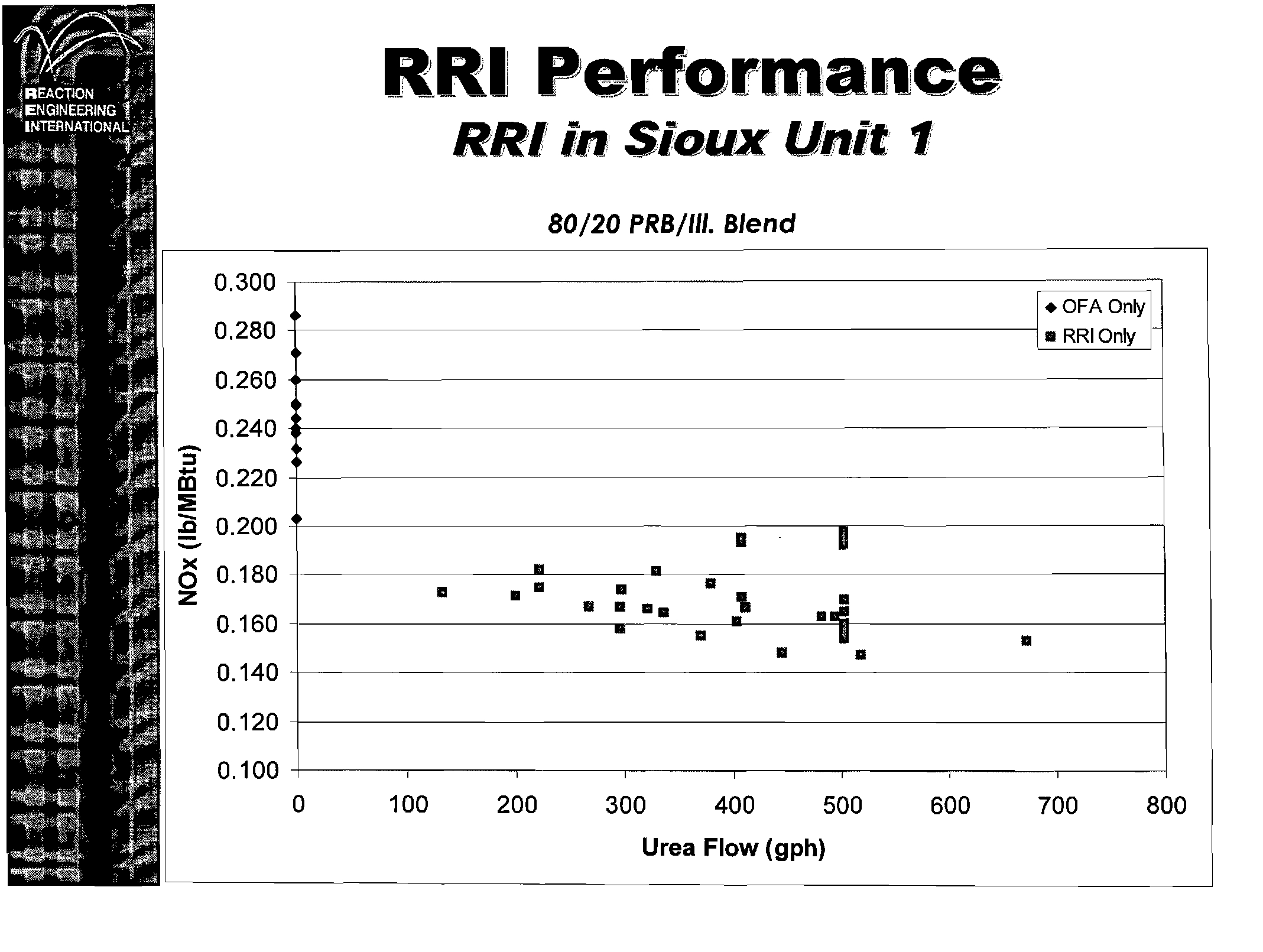

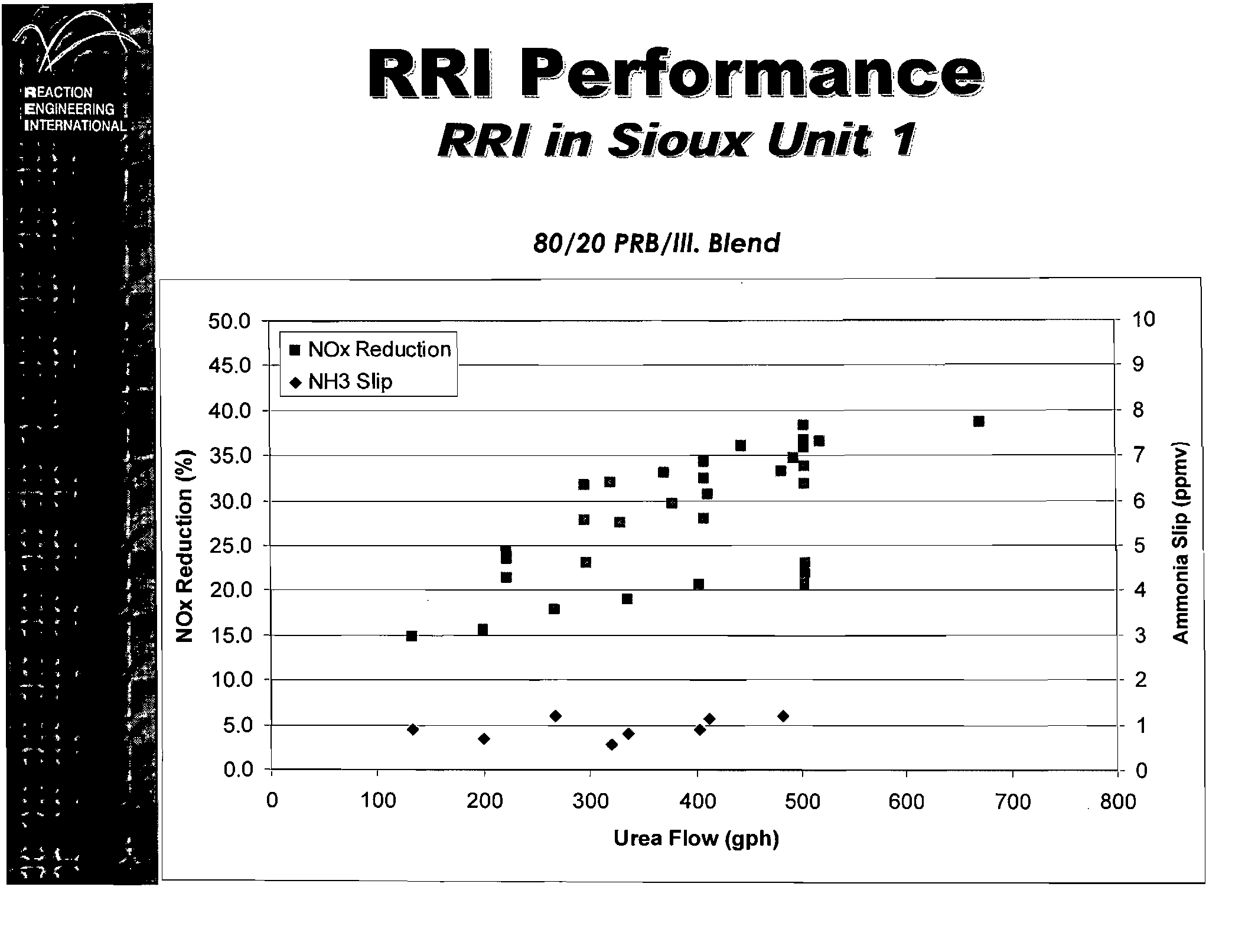

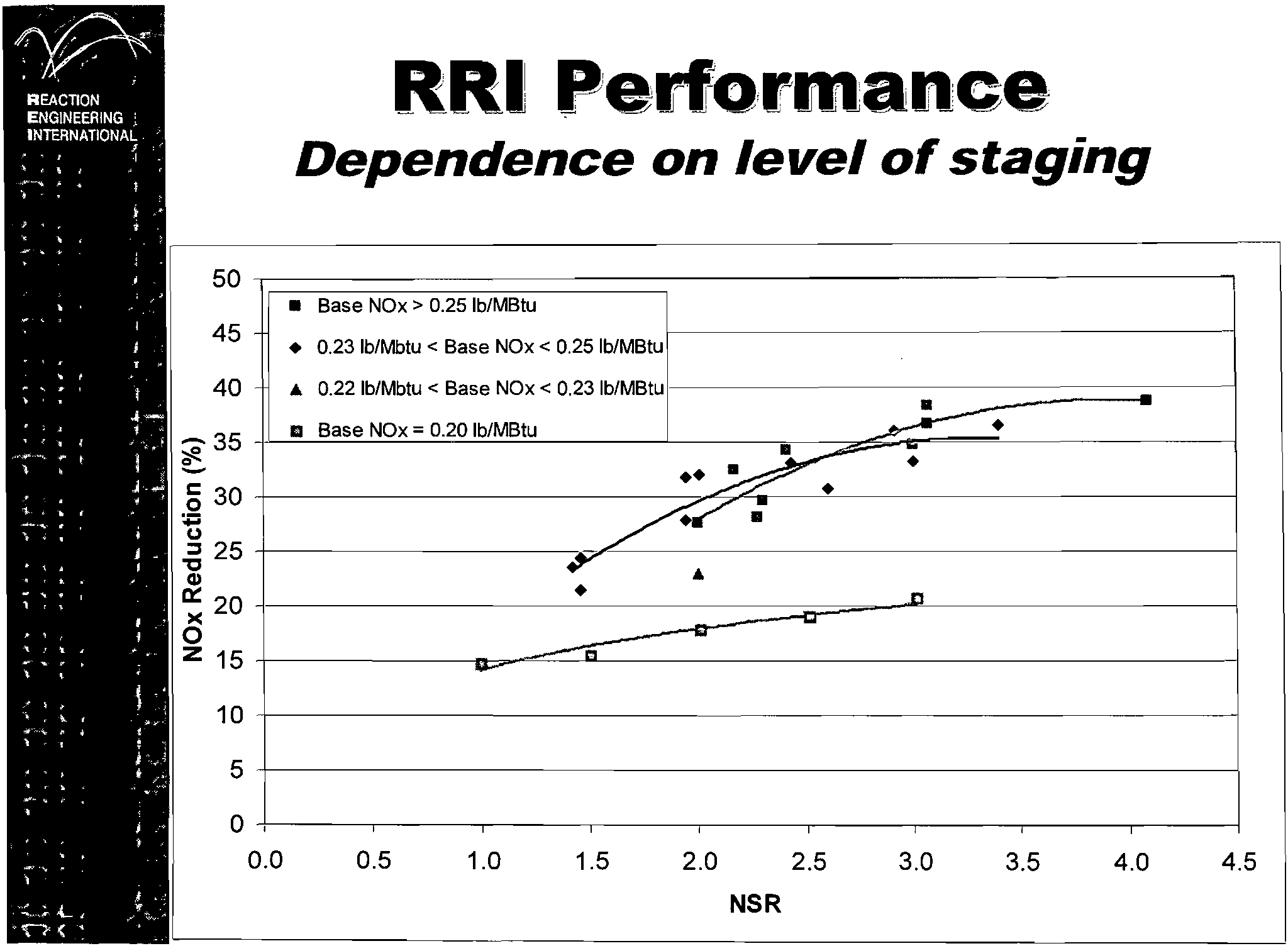

80/20

480

0.24-0.25

0.12

650 or less

<5

80/20

480

0.20-0.21

0.12

550 or less

<5

80/20

425

0.230

0.156

210

60/40

530

0.26

0.15

790

<2

0/100

535

0.25