BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

PEOPLE OF WILLIAMSON COUNTY

dx rel.

STATE'S ATTORNEY CHARLES GARNATI,

and THE WILLIAMSON COUNTY BOARD,

Petitioners,

v.

KIBLER DEVELOPMENT CORPORATION,

MARION RIDGE LANDPILL, INC., and

ILLINOIS ENVIRONMENTAL PROTECTION

AGENCY,

No.

el

?‘...

k

k 0°

(6A)

(Permit Appeal - Land)

LERK'S

iceive

.co

OFFICE

MAY

2 9 2008

Pollution

STATE

OF

Control

ILLI

NO/S

Board

Respondents.

Is= g's

To:

Doug/as Scott, Director

Envirownental Protection Agency

1021 North Guild Avenue East

Springfield

•

, Illinois 62701

Melanie Jarvis

Illinois Environmental Protection Agency

1021 North Grand Avenue East

P.O. Box 19276

Springfield, Illinois 62794-9276

Kibler Development Corporation

do Registered Agent, Stephan Chodera

290 South Main Plane #101

Carol Stream. Illinois 60188

Marion Ridge. Landfill, Inc.

c/o Registered Agent, Stephan Chodera

290 South Main Place

Carol Stream, Illinois 60188

Patrick

Mazza,

President

Kibler Development Cinporation

Marion Ridge Ltaidfill,

Inc.

290 South Main Place

Carol Stream, Illinois 60)88

Stephen Iledinger

liedinger Law Office

2601 South Fifth Street

Springfield, Illinois 62703

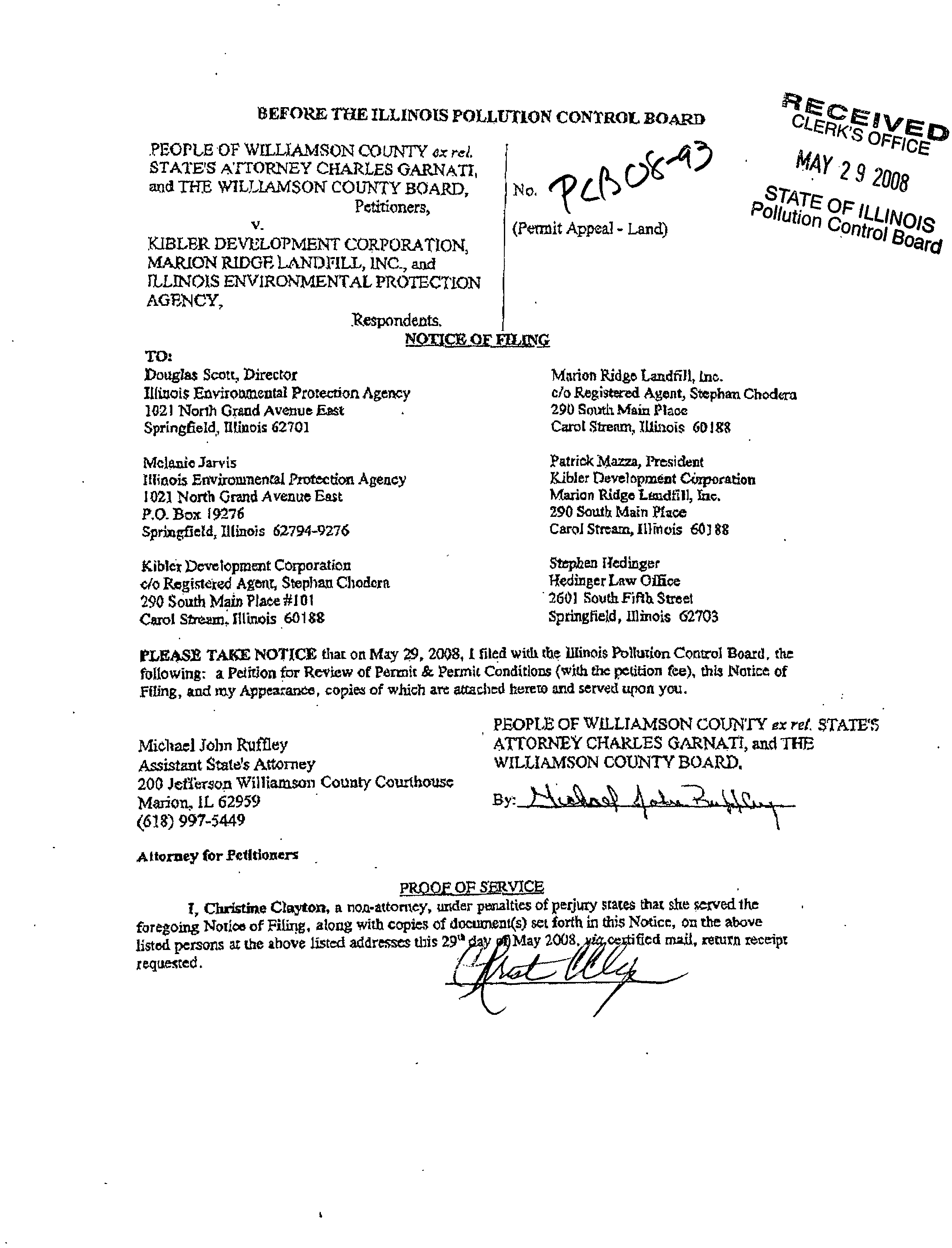

PLEASE TAKE NOTICE

that on May 29, 2008, I filed with the Illinois Pollu

t

ion Control Board, the

following: a Petition for Review of Permit & Permit Conditions (with the petition fee), this Notice of

Filing, and ray Appearance, copies of which are attached hereto and served upon you.

PEOPLE OF

WILLIAMSON COUNTY

ax re(

STATE'S

AITORNEY CHARLES

GARNATI, and THE

WILLIAMSON COUNTY BOARD,

By

Jt-&A IVAr'\94j

Attorney for

Petitioners

PR.00E OF SERVICE

I, Christine Clayton, a non-attorney, under penalties of perjury states that site served the

foregoing Notice of FiliTsg, along with

copies of document(s) set forth in this Notice, on the

above

listed persons at the above listed addresses this 29'

?

May 2008. "fled

?

return receipt

requested.

Mioliael John Ruffley

Assistant State's Attorney

200 Jefferson Williamson County Courthouse

Marion, IL 62959

(018) 997-5449

BEFORE THE ILLINOIS POLLUTION CONTROL BOAR))

(24,1)0%1,1'5

(Permit Appeal -

Land.)

RECEIVED

CLERK'S OFFICE

MAY 2 9 2008

STATE OF ILLINOIS

Pollution Control Board

PEOPLE OF WILLIAMSON COUNTY

ex

ref

STATE'S ATTORNEY CHARLES CARNATI,

and THE WILLIAMSON COUNTY BOARD,

Petitioners,

v.

KIBLER DEVELOPMENT CORPORATION,

MARION RIDGE LANDFILL,

me.,

and

ILLINOIS

ENVIRONMENTAL PROTECTION

AGENCY,

Respondents.

No.

APPEARANCE,

I

hereby file my appearance in this proceeding on belialf of Petitioners, People of

Williamson County

cc rel. States

Attorney Charles Oaniati and. the Williamson County Board.

Assistant States tt ey Michaei JolaARtney

Name

Attorney for

Address •

City

Telephone

Michael John Ruffley, Assistant State's Attorney

Petitioners

200 Jefferson Williams= County Courthouse

M461741,

IL 62959

(618) 997-5449

BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

PEOPLE OF WILLIAMSON COUNTY

ex rel.

STATE'S ATTORNEY CHARLES GARNATI,

and THE WILLIAMSON COUNTY BOARD,

Petitioners,

v.

KIBLER DEVELOPMENT CORPORATION,

MARION RIDGE LANDFILL, INC., and

ILLINOIS ENVIRONMENTAL PROTECTION

AGENCY,

Respondents.

No. p6 66 °I -5

(Permit Appeal - Land)

RECEIVED

CLERK'S OFFICE

MAY 2 9 2008

STATE OF ILLINOIS

Pollution Control Board

PETITION FOR REVIEW OF PERMIT & PERMIT CONDITIONS

NOW COME

Petitioners PEOPLE OF WILLIAMSON

COUNTY and the

WILLIAMSON COUNTY BOARD, by and through the Williamson County State's Attorney

and Assistant State's Attorney Michael John Ruffley, and file this Petition for a review of the

decision of the Illinois Environmental Protection Agency ("Illinois EPA") granting with

conditions the application for a permit to modify Permit, No. 2000-199-LF. In support of this

Petition, Petitioners state as follows:

1. This Petition is filed pursuant to Section 5/3-90Q5(a)(1) of the Illinois Counties Code

and Sections 105.204(f) of the Illinois Pollution Control Board Regulations. (55 ILCS 5/3-

9005(a)(1), 35 IAC 105.204(f)).

2.

This Petition is filed by the State's Attorney of Williamson County, Charles Garnati,

in his official capacity, on behalf of the People of Williamson County and the Williamson

County Board. This Board and Illinois Court have acknowledged the particular duties of State's

Attorneys' embodied in the Illinois Counties Code that give them standing in actions that,

ordinarily, other third-parties lack. E.g.,

Land and Lakes Co. v. PCB,

245 I11.App.3d 361, 616

N.E.2d 349, 354-355 (3

rd

Dist. 1993)(State's Attorney allowed to intervene in permit appeal);

Pioneer Processing Inc. v. EPA,

102 I11.2d 119, 464 N.E.2d 238 (S.Ct. 1984)(Attorney General

allowed to seek review of a Board decision in a landfill permit appeal);

AFSCME v. Ryan, et al.,

347 Ill.App.3d 732, 807 N.E.2d 1235 (5

th

Dist. 2004)(without specific statutory authority under

the Illinois Health Facilities Planning Act, State's Attorney allowed to enjoin closure of state

mental health facility and require it to follow procedures of that act);

Saline County v. IEPA,

PCB 02-108 (April 18, 2002)(State's Attorney intervened in permit appeal).

3.

The State's Attorney is a constitutional officer whose duties and powers largely

parallel those of the Attorney General.

People ex rel. Kunstman v. Nagano,

389 Ill. 231, 249, 59

N.E.2d 96, 104 (1945). One important duty of the State's Attorney is to "commence and

prosecute all actions, suits, indictments and prosecutions, civil and criminal, in the circuit court

for his county, in which the people of the State or county may be concerned." 55 ILCS 5/3-

9005(a)(1). There is a strong public interest in a healthful environment.

See,

Ill. Const. 1970, art.

XI, sec. 1. The Williamson County State's Attorney has the duty and authority to represent the

interests of the people of Williamson County and the County Board to, among other things,

protect their interest in a healthful environment. As discussed further below, the grounds for this

petition, including but not limited to the conditions by Illinois EPA allowing a landfill to be

developed that is not what the County Board approved pursuant to Section 39.2 of the Illinois

Environmental Protection Act ("Act"). (415 ILCS 5/39.2).

4.

Although this Board has also held in the past that third-parties have no standing under

Section 40(a)(1) of the Illinois Environmental Protection Act to file a petition for review of

Illinois EPA municipal solid waste landfill permit decisions, that precedent is not applicable as it

has not involved a State's Attorney's petition for review. E.g.,

City of Waukegan, et al. v. IEPA,

et al.,

PCB 02-173 (May 2, 2002),

citing, Landfill Inc. v. PCB,

74 I11.2d 541, 387 N.E.2d 258

(1978).

2

5.

The subject of the application for a permit to modify is the Kibler Development

Corporation and Marion Ridge Landfill, Inc. facility located in Williamson County, Illinois.

Interestingly, the application sought to resolve two pending permit appeals and was approved

with conditions by Illinois EPA nearly two weeks in advance of Illinois EPA's regulatory

deadline for review. The first appeal (PCB 05-35) involves permit approval with conditions,

among other things, correctly limiting the development of the facility until it complied with FAA

setback requirements. The second appeal (PCB 07-43) involves a permit denial of proposed

modifications to the permit by Kibler Development Corporation and Marion Ridge Landfill, Inc.

that would, in essence, change the type of waste allowed to be accepted at the landfill (essentially

limiting it to non-putrescilble waste).

6.

The subject permit approval with conditions, among other things, changes the type of

waste allowed to be accepted at the landfill to non-putrescible waste, unless the FAA approves

the non-applicability or a variance from its setback requirements. However, for this, and the

other reasons identified below, Illinois EPA has modified the permit to allow a landfill that was

not sited by Williamson County. Thus, it is in the public interest of Williamson County to seek

the review of the subject peunit approval with conditions, to, among other things, ensure that the

siting decision of the County is honored by Illinois EPA and that a facility which was not the

subject of the public site location hearing is permitted by Illinois EPA in derogation of the

County Board's decision making authority and due process, and of the public's interest to

participate in such a proceeding.

7.

The Illinois EPA approved with conditions the subject pellnit modification on April

25, 2008 (the decision deadline was June 8, 2008. Pursuant to Section 105.210(a), a copy of the

permit is attached to this Petition as

Exhibit

A.

3

8. Pursuant to Section 105.210(c), the following subparagraphs set forth the grounds for

this petition.

a.

Illinois EPA modified the development permit of the subject landfill to extend and

change the boundaries of what was approved by the Williamson County Board,

including but not limited to changing the type of waste accepted at the facility.

These changes have potential impacts to Criterion 1, 2, 5, 6 and 8 of Section 39.2

of the Act.

b.

Although the required notification form is referenced in the subject permit

application by Kibler Development Corporation and Marion Ridge Landfill, Inc.

as being sent to the County and State's Attorney, on information and belief,

neither the County nor State's Attorney received that application from Kibler

Development Corporation, Marion Ridge Landfill, Inc. or its agents.

c.

The permit allows development of a facility over a public roadway for which

Kibler Development Corporation and Marion Ridge Landfill, Inc. have not sought

vacation from the County, that has not been vacated and, at this time, may not be

feasible to vacate. Moreover, if that public roadway is not vacated, it requires a

substantially different design, construction and operational plans, changes the

facility capacity, and likely different traffic patterns, impacting Criterion 2, 3, 5,

and 6 of Section 5/39.2 of the Act.

d.

The Illinois EPA in approving with conditions the permit modification had

deviated from its precedent to deny modification to permits outside the scope of

the sited boundaries.

4

e.

The Illinois EPA wrongfully determined that siting approval was "not applicable"

for a request to modify a development permit and failed to seek confirmation

from Williamson County Board whether the applicants' requested modifications

were or were not a deviation from the sited facility, depriving the Petitioners of

their rights to participate in that process.

f.

The Illinois EPA's issuance of the permit modification with conditions was

arbitrary, unreasonable, and lacks any basis in law or fact.

g.

The Illinois EPA has no authority or jurisdiction over to issue a development

permit for a facility other than what received site location approval.

h.

The Petitioners reserve the right to raise additional bases for review as they

become apparent and reserve their right to bring a jurisdictional dispute to Circuit

Court.

WHEREFORE, Petitioners, People of Williamson County

ex rel.

Charles Garnarti and

the Williamson County Board respectful request the Board enter an order allowing this Petition

and reversing Illinois EPA's approval with conditions of the subject permit modification and

denying that permit modification. If this Board finds that the Petitioners herein do not have

standing based on the precedent referenced in Paragraph 4, above, the Petitioners respectfully

request that the Board clearly and specifically acknowledge the jurisdictional ground of standing

being the sole reason for the denial, as was done, for example, in

City of Waukegan, et al. v.

IEPA, et al.,

PCB 02-173 (May 2, 2002), and allowing for the future enforcement or other action

by the State's Attorney or County Board.

5

Dated; May 29, 2008

Respectfully submitted,

PEOPLE OF WILLIAMSON COUNTY

ex

rel.

STATE'S ATTORNEY CHARLES GARNATI, arid

THE WILLIAMSON COUNTY BOARD,

Michael John Ruff:ley

By:

Assistant State's Attorney

200 Jefferson Williamson County Courthouse

Marion, IL 62959

(6

IS

997-5449

6

iStlize

t.)

ILLINOIS ENVIRONMENTAL PROTECTION AGENCY

1021 NORTH

GRAND AVENUE EAST, P.O.

Box 19276,

SPRINGFIELD, ILLINOIS

62794-9276 - ( 217) 782-3397

JAMES R. THOMPSON

CENTER, 1 00 WEST RANDOLPH, SUITE

11-300.

CHICAGO,

IL 60601 - (312) 814-6026

ROD

R.

BLAGOJEVICH, GOVERNOR DOUGLAS

P. SCOTT, DIRECTOR

217/524-3300

April 25, 2008

?

C ertified M ail

7007 0220 0000 0039 5001

7007 0220 0000 0040 2518

Owner

Operator

Kibler Development Corporation

Marion

Ridge Landfill, Inc.

Attn: Mr. Patrick Mazza

Attn: Mr. Patrick Mazza

290 South Main Place

290 South. Main Place

Carol Stream, Illinois 60188

Carol Stream, Illinois 60188

Re:

1990555136 -- Williamson County

Marion Ridge Landfill

Peunit No. 2000-199-LF

Modification No. 1

Log No. 2008-090

Expiration Date: July 15, 2009

Pennit Landfill 811 File

Permit Approval

Dear Mr. Mazza:

RELEASABLE

Mu

1 5 2008

RE\AEVVER MD

Permit was hereby granted to Kibler Development Corporation as owner and Marion Ridge

Landfill, Inc. as operator, allowing modification of the above referenced existing municipal solid

waste and non-hazardous special waste landfill all in accordance with the application and plans

identified as Log No. 2000-199. Final plans, specifications, application, and supporting

documents, as submitted and approved, shall constitute part of this permit and are identified in

the records of the Illinois Environmental Protection Agency (Illinois EPA), Bureau of Land,

Division of Land Pollution Control by the permit number designated in the heading above.

Permit No. 2000-199-LF approved:

A.

The development of this landfill in accordance with the requirements of Title 35,

Illinois Administrative Code (hereinafter 35 IAC), Subtitle G, Parts 811 and 812,

pursuant to 35 IAC, Section 813.107;

B.

The development of a new MSWLF unit consisting of an approximately 358 acre

facility with 189 acres for disposal with an "in-place" disposal capacity of

approximately 37,152,000 cubic yards, including daily and intermediate cover,

but excluding final cover. The maximum final elevation shall be approximately

640 feet above mean sea level;

C.

The lower waste boundaries and the waste footprint approved by this permit are

shown on the drawing entitled "Sheet 6: Liner – Leachate collection system".

The final contours approved by this permit are shown on the drawing entitled

ROCKFORD -

4302 North Main Street, Rockford, IL 61103 - (815) 987-7760 •

DES PLAINES - 9511 W. Harrison St., Des Plaines, IL 60016 - (847) 294-4000

ELGIN -

595 South State, Elgin, IL 60123 - (847) 608-3131 ?• PEORIA -

5415 N. University St., Peoria, IL 61614 - (309) 693-5463

BUREAU OF LAND -

PEORIA - 7620 N. University St., Peoria, IL 61614 - (309) 693-5462 •

CHAMPAIGN - 2125 South First Street, Champaign, IL 61820 - (217) 278-5800

SPRINGFIELD -

4500 S. Sixth Street Rd., Springfield, IL 62706 - (217) 786-6892 •

COWNSVILLE -

2009 Mall Street, Collinsville, IL 62234 - (618) 346-5120

MARION - 2309 W. Main St., Suite 116, Marion, IL 62959 - (618) 993-7200

PRINTED ON

RECYCLED PAPER

EXHIBIT

Page 2

"Sheet 8: Final site conditions"; furthermore, the upper waste boundaries

approved by this permit are defined by the final contours within the waste

footprint minus the design thickness of the final cover system (i.e. 4.5 feet). Both

sheets are in the August 30, 2002 addendum to Permit Application Log No. 2000-

199; and

D.

Acceptance of special waste streams without individual special waste stream

authorizations, upon obtaining a permit allowing waste disposal, in accordance

with the special conditions listed in Part III of this permit.

Modification No. 1 to Permit No. 2000-199-LF is hereby granted to Kibler Development

Company as owner and Marion Ridge Landfill, Inc. as operator, approving a modification of an

existing municipal solid waste and non-hazardous special waste landfill, all in accordance with

the application prepared by Steven F. Hedinger, esq., and signed and sealed by Michael W.

Rapps, P.E., signature dated March 6, 2008.

The application, Illinois EPA Log No. 2008-090, was dated and received March 10, 2008.

Specifically, Modification No. 1 approves revisions to the permit's special conditions as

proposed by the permittee to settle two permit appeals, Illinois Pollution Control Board Case

Nos. PCB05-35 and PCB07-43.

Additionally, the Illinois EPA is modifying the permit pursuant to 35 Ill. Adm. Code Section

813.201(b)(1)(D) in response to Illinois Pollution Control Board rulemaking Docket No. R2007-

008 and Permit Section procedures: Condition 1.12 was modified to require use of GRI

standards for geomembrane testing; condition V.10 was added requiring submittal of compliance

with Section 39(i) of the Act; and the leachate monitoring section was revised to comply with the

new regulations.

Docket No. R2007-008 is available online at

http ://www.ip cb . state 11.us/Cool/External/Cas eVi ew2. asp ?referer=co olsearch &cas e=13041

The compliance form for 39(i) certification is at http://w\

Yvw.epa.state.il.us/land/regulatory-

pro grams/p ermits-and-man ag em ent/forms/index.html

Except for the changes described in the following table, the special conditions in the penult letter

for Modification No. 1 to Permit No. 2000-199-LF are identical to the special conditions in the

pelinit letter for Permit No. 2000-199-LF, issued July 23, 2004.

Condition in Permit No.

Condition in Modification

Description of change

2000-199-LF

No. 1

1.12

1.12

Revised to require use of

GRI standards for

geomembrane testing

Page 3

N/A

11.25

New condition requiring

FAA approval or exemption

before accepting MSW

V.9

V.9

Revised to note permission

is only required for

inhabited structures in place

before permitting

N/A

V.10

New condition requiring

submittal of 39(i)

compliance forms

VII.3

N/A

Deleted obsolete condition

requiring adding parameters

found to groundwater

sampling lists

VII.4

VII.3

Renumbered, added note

about points not yet

constructed

VII.5

VII.4

Renumbered, Revised lists

Ll and L2, and deleted list

L3.

VII.6

VII.5

Renumbered, revised

sampling schedule

VII.7

N/A

Deleted obsolete condition

requiring quarterly

monitoring for 8 quarters

N/A

VII.6

New condition that used to

be a note on the sampling

schedule requiring

electronic submittal of

leachate monitoring data

Please be aware that 49 United States Code ("U.S.C.") Section 44718(d)(1) states: "No person

shall construct or establish a municipal solid waste landfill (as defined in section 258.2 of title

40, Code of Federal Regulations, as in effect on the date of the enactment of this subsection) that

receives putrescible waste (as defined in section 257.3-8 of such title) within 6 miles of a public

airport that has received grants under chapter 471 and is primarily served by general aviation

aircraft and regularly scheduled flights of aircraft designed for 60 passengers or less unless the

State aviation agency of the State in which the airport is located requests that the Administrator

of the Federal Aviation Administration exempt the landfill from the application of this

subsection and the Administrator determines that such exemption would have no adverse impact

on aviation safety." At their closest points, Marion Ridge Landfill's facility boundaries and the

runways of the Williamson County Regional Airport appear to be separated by approximately

2.2 miles. If the Marion Ridge Landfill and the Williamson County Regional Airport meet the

Page 4

criteria described in Section 44718(d)(1) of 49 U.S.C., to demonstrate compliance with Section

44718(d)(1), the landfill operator would need to be able to prove that the Illinois Department of

Transportation/Division of Aeronautics requested an exemption for the landfill and the

Administrator of the Federal Aviation Administration granted the exemption, before construction

of the landfill began. The above paragraph is not intended to create an enforceable duties or

obligations under this permit, but rather is merely an identification of federal law which the

Illinois EPA believes may be, or may become, relevant to this facility.

Pursuant to Section 39(a) of Illinois Environmental Protection Act (Act) [415 ILCS 5/39(a)] and

35 IAC, 813.104(b), this permit is issued subject to the development, operating and reporting

requirements for non-hazardous waste landfills in 35 IAC, Parts 810, 811, 812, and 813, the

standard conditions attached hereto, and the following special conditions. In case of conflict

between the permit application and these conditions (both standard and special), the conditions

of this pelinit shall govern.

I.

CONSTRUCTION QUALITY ASSURANCE

1.

All necessary surface drainage control facilities shall be constructed prior to other

disturbance in any area.

2.

No part of the unit shall be placed into service or accept waste until an acceptance

report for all the activities listed below has been submitted to and approved by the

Illinois EPA as a significant modification pursuant to 35 IAC, Sections

811.505(d) and 813.203.

a.

Preparation of the subgrade and foundation to design parameters;

b.

Installation of the compacted earth/synthetic liner;

c.

Installation of slurry trenches or cutoff walls;

d.

Installation of the leachate drainage, collection and management systems;

e.

Placement of final cover;

f.

Installation of gas control facilities; and

g.

Construction of ponds, ditches, lagoons and berms.

3.

The permittee shall designate an independent third party contractor as the

Construction Quality Assurance (CQA) Officer(s). The CQA Officer(s) shall be

an Illinois Certified Professional Engineer who is independent from and not under

the control or influence of the operator, any employee of the operator, or any

Page 5

other corporation, company or legal entity that is a subsidiary, affiliate, parent

corporation or holding corporation associated with the operator.

4.

Except as provided below, the CQA Officer(s) designated pursuant to Condition

1.3. shall personally be present during all construction and testing that is subject to

CQA certification pursuant to 35 IAC, Section 811.503(a). If the CQA Officer(s)

is unable to be present as required, then a written explanation and signed

statement must be provided for each absence pursuant to 35 IAC, Section

811.503(b).

5.

The clay liner shall be tested for density and moisture content a minimum of five

tests per lift per acre.

6.

A minimum of one laboratory permeability test shall be performed for every

10,000 cubic yards of liner soil placed.

7.

If the clay portion of the liner is exposed to freezing conditions, it must be

recertified. The designated CQA Officer(s) shall then certify that the clay portion

of the liner and all necessary repairs to the leachate drainage layer meet the

required design standards. This certification must be provided to the Illinois EPA

prior to disposal of waste on the subject portion of the liner. If operating

authorization has not yet been issued for that area, the recertification shall be

included in the application for Significant Modification of Permit to obtain

Operating Authorization for that area.

8. Pursuant to 35 IAC, Section 811.505(d), upon completion of construction of each

major phase, the CQA Officer(s) shall submit an acceptance report to the Illinois

EPA. The acceptance report shall be submitted before the structure is placed into

service and shall contain the following:

a.

A certification by the CQA Officer(s) that the construction has been

prepared and constructed in accordance with the engineering design;

b.

As-built drawings; and

c.

All daily summary reports.

9.

Applications for operating authorization shall not be made for areas

. of less than

1.5 acre increments of constructed liner.

10.

All stakes and monuments marking the facility boundary and the permitted

disposal area shall be maintained, inspected annually and surveyed no less

Page 6

frequently than once in five years by a professional land surveyor. Any lost or

damaged monuments shall be replaced.

11.

All standards for testing the characteristics and performance of materials,

products, systems and services shall be those established by the American Society

for Testing and Materials (ASTM) unless otherwise stated in the permit

application.

12.

Effective upon issuance of Modification No. 1 (Log No. 2008-090), all

conformance testing of the geomembrane used shall meet the requirements in the

Geosynthetic Research Institute's Test Method GM 13 with the following

exceptions: For the geomembrane used in the bottom liner, the minimum

thickness must be within 5% of nominal for all samples, i.e. 60 mil liner must be

at least 57 mil; and UV resistance testing is not necessary unless the

geomembrane is exposed for more than 30 days.

II. OPERATING CONDITIONS

1.

Pursuant to 35 IAC, Sections 811.107(a) and 811.107(b), throughout the operating

life of this landfill, waste shall not be placed in a manner or at a rate which results

in unstable internal or external slopes or interference with construction, operation

or monitoring activities.

2.

The operator of this solid waste facility shall not conduct the operation in a

manner which results in any of the following:

a.

refuse in standing or flowing waters;

b.

leachate flows entering waters of the State;

c.

leachate flows exiting the landfill confines (i.e., the facility boundaries

established for the landfill in a permit or permits issued by the Illinois

EPA);

d.

open burning of refuse in violation of Section 9 of the Illinois

Environmental Protection Act (Act);

e.

uncovered refuse remaining from any previous operating day or at the

conclusion of any operating day, unless authorized by permit;

f.

failure to provide final cover within time limits established by Board

regulations;

Page 7

g.

acceptance of wastes without necessary permits;

h.

scavenging as defined by Board regulations;

i.

deposition of refuse in any unpermitted (i.e., without an Illinois EPA

approved significant modification authorizing operation) portion of the

landfill;

J

.

acceptance of a special waste without a required manifest and

identification record;

failure to submit reports required by permits or Board regulations;

1.

failure to collect and contain litter from the site by the end of each

operating day.

m.

failure to submit any cost estimate or any financial assurance mechanism

for the facility as required by the Act or Board regulations.

3.

Moveable, temporary fencing shall be used to prevent blowing litter when the

refuse is above the natural ground line.

4.

At the end of each day of operation, all exposed waste shall be covered with:

a.

Clean soil at least six (6) inches thick (i.e., conventional daily cover); or

b.

An alternate cover as described below.

5.

Geotextile fabric, plastic panels, degradable plastic sheeting, Sanifoani, Rusmar

Foam, and ConCover-Foam are approved as alternate daily cover pursuant to 35

IAC, Sections 811.106(b) and 812.111(b). Use of alternate materials as daily

cover shall be subject to the following conditions:

a.

If any alternate daily cover other than those approved by this permit are

to be used, their use must be approved by the Illinois EPA through the

permit process.

b.

At any one time, the total area, using alternate daily cover, shall be no

more than 2,500 square yards. Beyond this maximum, daily cover soil

shall be used on all areas where waste has been disposed and to which

intermediate or final cover has not been applied.

Page 8

c.

Areas upon which alternate daily cover has been used must be covered

with either conventional cover or additional waste within six days.

d.

Conventional daily cover in accordance with 35 IAC 811.106(a) shall be

used if weather or other conditions adversely affect the ability of the

alternate daily cover to prevent problems with blowing litter, fire, odors,

or vectors.

e.

Geotextile fabric, plastic panels, and degradable plastic sheeting shall be

anchored adequately to prevent wind damage. If the alternate daily cover

is torn during or after placement they must be repaired immediately or the

damaged area must be covered with six inches of daily cover soil. If tires

are used as weights for the alternate daily cover, they shall be converted

tires, in accordance with 35 IAC, Part 848: Management of Used and

Waste Tires.

f.

A continuous layer of a minimum of one inch thickness of SaniBlanket, 3

inches thickness of Rusmar Foam, or a quarter-inch thickness of

ConCover Foam shall be applied to the top of the waste. Application of

foam during inclement weather is not allowed unless the foam cover

installed meets these requirements. The foams shall only be used when

the temperatures are within the manufacturer's recommended range.

g.

When an alternate daily cover is applied, the operator shall keep a record

including a description of the weather conditions, the type of alternate

daily cover used and its performance. A summary of this information

shall be provided with this facility's annual reports.

h.

Any alternate daily cover which has been used for daily cover may not be

reused for any purpose (including road underlayment and erosion control)

outside of permitted disposal boundaries.

6.

No later than 60 days after placement of the final lift of waste in any area, the area

shall receive a final cover system meeting the design specifications approved in

this permit application. The low permeability layer shall consist of an 18 inch

layer of soil covered with a 40-mil geomembrane. The final protective layer shall

consist of either a 12 inch drainage layer of with a hydraulic conductivity > 10-3

cm/sec covered with 18 inches of soil and 6 inches of topsoil, or a geo-composite

layer covered with 30 inches of soil and 6 inches of topsoil. At a minimum, the

top six inches of the protective soil must be capable of supporting vegetation.

The total thickness of the final protective layer shall not be less than three feet.

Page 9

7.

All waste not covered within sixty days of placement with additional waste or

final cover shall have an intermediate cover of compacted clean soil with a

minimum thickness of one foot applied to it.

8.

The operator shall implement a load checking program that meets the

requirements of 35 IAC, Section 811.323. If regulated hazardous waste is

discovered, the Illinois EPA shall be notified no later than 5:00 p.m. the next

business day after the day it is detected. The load checker shall prepare a report

describing the results of each inspection. A summary of these reports shall be

submitted to the Illinois EPA as part of this facility's annual report.

9.

Asbestos debris from construction-demolition shall be managed in accordance

with the National Emission Standards for Hazardous Air Pollutants (NESHAPS)

regulations.

10.

Managemel

la

r)ri,?

waste

—andscape waste found to be mixed

with

?

wa„:° will be

removed the same day and transported

to c:

facility that is opel ‘,

in

accordance with the Act, Title V, Section 21.

b.

Lead-acid batteries will be removed the same day and transported either

to a drop-off center handling such waste, or to a lead-acid battery retailer.

c.

Potentially infectious medical waste (PIMW) found to be mixed with

municipal waste shall be managed in accordance with 35 IAC, Subtitle

M.

d.

Tires found to be mixed with municipal waste shall be removed and

managed in accordance with 35 IAC, Part 848.

e.

White good components mixed with municipal waste shall be removed

and managed in accordance with Section 22.28 of the Act.

f.

This facility is prohibited from disposing any waste containing

polychlorinated bi-phenyls (PCBs) in concentration greater than allowed,

pursuant to the Toxic Substance Control Act (TSCA).

g.

No liquid waste (special or non-special) as determined by the Paint Filter

Test shall be disposed unless the waste is from a household or is in a

small container similar in size to that normally found in household waste

and the container was designed for use other than storage. The

prohibition applies to on-site generated wastes except for leachate or gas

Page 10

condensate that is specifically approved by permit for recirculation into

the landfill. However, minor amounts of liquid resulting from

precipitation (rain, sleet, hail or snow) during transport and disposal

operations shall not be construed as a violation of this condition.

h.

In accordance with Section 21.6 of the Act, beginning July 1, 1996, no

owner or operator of a sanitary landfill shall accept liquid used oil for

final disposal that is discernable in the course of prudent business

operation.

After the unauthorized waste has been removed, a thorough cleanup of

the affected area will be made according to the type of unauthorized -

waste managed. Records shall be kept for three (3) years and will be

made available to the Illinois EPA.

11.

Operating hours are those hourE

which „ 2 --;te

may be accepted. For this

the operating

IA,?

ot: iniLLu"

?

AM to 6:00 PM, Monday

-r-?

r

-:

o:00 AM to 2:00 PM on Saturday.

';21-i.ing

shall be

provided

to.

adoor activities at the landfill occurring before sunri

sunset.

12.

If it is required for the facility to be open beyond normal operating hours to

respond to emergency situations, a written record of the date(s), times and reason

the facility was open shall be made part of the operating record for the facility.

The Illinois EPA-FOS Marion Regional Office, and when applicable, the county

authority responsible for inspections of this facility per a delegation agreement

with the Illinois EPA shall be notified no later than 5:00 p.m. the next business

day following the acceptance of waste outside the specified operating hours.

13.

Road building materials used to construct roads at the facility that are not solid

waste may be stockpiled on-site in the amount estimated to be needed within the

next construction season provided they are managed in accordance with 35 IAC,

Section 811.108(c)(1).

14.

Equipment shall be maintained and available for use at the facility during all

hours of operation to allow proper operation of the landfill. If breakdowns occur

that would prevent proper facility operation, back-up equipment shall be brought

onto the site.

15.

All utilities, including but not limited to heat, lights, power, communications

equipment and sanitary facilities necessary for safe, efficient and proper operation

of the landfill shall be available at the facility at all times.

Page 11

16.

Waste shall be deposited at the fill face and compacted upward into the fill face

unless precluded by extreme weather conditions or for reasons of safety.

17.

The operator shall implement methods for controlling dust so as to prevent wind

dispersal of particulate matter off-site.

18.

The facility shall be constructed and operated to minimize the level of equipment

noise audible outside the facility. The facility shall not cause or contribute to a

violation of 35 IAC, Parts 900 through 905.

19.

The operator shall implement measures to control the population of disease and

nuisance vectors.

20.

The operator shall institute fire protection measures in accordance with the

proposed fire safety plan.

21.

The operator shall implement methods to prevent tracking of mud by hauling

vehicles onto public roadways.

22.

Access to the active area and all other areas within the boundaries of the facility

shall be controlled by use of fences, gates and natural barriers to prevent

unauthorized entry at all times.

23.

A permanent sign shall be maintained at the facility entrance containing the

information required under 35 IAC, Section 811.109(b)(1) through (5).

24.

This permit is for development only. No waste shall be accepted until the Illinois

EPA issues a significant modification to operate.

25.

a.

As an express condition of this permit, the landfill at no time may accept

for disposal any putrescible waste (within the meaning of that term as

used by 49 U.S.C. 44718(d)(1)) until such time that the landfill owner

and/or operator received either (i) the exemption by the Administrator of

the Federal Aviation Administration described in 49 U.S.0 44718(d)(1),

or (ii) a court order or written agreement by the Federal Aviation

Administration stating that 49 U.S.C. 44718(d)(1) does not apply to this

landfill for any reason, including grandfathering described in 49 U.S.C.

44718(d)(2).

b.

This condition may also be included in any operating permit that may be

issued for this facility if neither of the documents described in paragraphs

(a)(i) or (a)(ii) above have been received prior to issuance of the

operating permit.

Page 12

c.

At such time, if ever, the landfill owner and/or operator receives one of

the documents described in paragraphs (a)(i) or (a)(ii) above, the landfill

owner and/or operator shall forward the document to the Illinois EPA,

Bureau of Land, Permit Section, for review and inclusion with the

facility's permit file. Thirty days following submittal of the document to

the Illinois EPA, the landfill may begin to accept putrescible waste for

disposal and to operate as a putrescible waste landfill in a lined area in

which the Illinois EPA has approved a CQA (Construction Quality

Assurance) Acceptance Report.

III. SPECIAL WASTE

1.

The permittee is authorized to accept non-hazardous special waste that meets the

definition of industrial process waste or pollution control waste as found in

Sections 3.235 and 3.335, respectively, of the Illinois Environmental Protection

Act, in accordance with the following requirements:

a.

The waste is analyzed in accordance with the requirements described

below and complies with the acceptance criteria in the approved waste

analysis plan;

b.

The waste is delivered by an Illinois licensed special waste hauler or an

exempt hauler as defined in 35 IAC, Section 809.21 1; and

c.

The waste, is accompanied by a manifest, if required.

2.

The permittee shall obtain a completed Special Waste Preacceptance Form

(enclosed) and a preacceptance analysis from each generator for each waste to be

accepted. In addition, the Annual Generator Special Waste and Recertification of

for Disposal of Special Waste form, which certifies the waste has not changed

since the last analysis, must be completed and included in the operating record. A

complete laboratory analysis must be provided with the exceptions listed below.

Analysis shall be conducted using SW-846 test methods. The waste shall be

reanalyzed at least every five years and must identify the actual concentration of

each chemical constituent and state of each physical parameter. In all cases, a

copy of the lab analysis (on lab letterhead and signed by a responsible party such

as the person conducting the analysis or his/her supervisor) must be included in

the operating record with the Special Waste Preacceptance Form (Profile

Identification Sheet). The analysis may not be greater than one year old at the

time. A new analysis is required if the composition of the waste changes (normal

variations in waste composition are expected and are not included in this

requirement). All waste must be analyzed as follows:

Page 13

a.

The permittee shall obtain the following lab analyses to determine the

concentrations of the following parameters.

Paint Filter Test

Flash point

Sulfide (reactive)

Cyanide (reactive)

Phenol (total)

pH

Toxicity Characteristic Constituents

b.

The permittee shall obtain analysis for reactive sulfides (H2S) and

cyanides (HCN). Waste containing

.

250 ppm or greater reactive cyanide

or 500 ppm or greater reactive sulfide is presumed to be hazardous waste

pursuant to 35 IAC, Section 721.123(a)(5) unless specific information to

show it does not present a danger to human health or the environment is

provided. Analysis for total sulfide and/or cyanide may be substituted for

reactive concentrations if they are equal to or less than 10 ppm. For

wastes containing greater than 10 ppm reactive cyanide or reactive

sulfide, the permittee shall not accept the waste unless the generator

provides a signed and dated statement indicating the following:

i.

The waste has never caused injury to a worker because of H2S

and/or HCN generation;

ii.

That the OSHA work place air concentration limits for H

2

S and/or

HCN have not been exceeded in areas where the waste is

generated, stored or otherwise handled; and

iii.

That air concentrations of H

2

S and/or HCN above 10 ppm have not

been encountered in areas where the waste is generated, stored or

otherwise handled.

c.

The permittee shall obtain analysis for phenols. If the total phenol

concentration is greater than 1000 ppm, the waste will be required to be

drummed and labeled, unless justification that this precaution is not

necessary is provided. The justification must demonstrate skin contact is

unlikely during transport or disposal.

d.

The permittee shall obtain metals and organics analysis. Either procedure

may be utilized (i.e., total or TCLP), but any constituent whose total

concentration exceeds the TCLP limit specified in 35 IAC, Section

721.124 must be analyzed using the TCLP test and the results reported,

Page 14

unless an alternative test has been approved by the Illinois EPA. TCLP

test methods must be in accordance with SW 846-1311.

e.

EXCEPTIONS:

The generator may certify that the eight pesticides (D012, D013,

D014, D015, D016, D017, D020 and D031) would not reasonably

be expected to be present in the waste based on the nature of the

process generating the waste.

ii.

Petroleum contaminated media and debris from LUST sites subject

to corrective action regulation under 35 IAC, Parts 731 and 732 are

temporarily exempt from complete TCLP analysis and the

generator may limit analyses to flashpoint, paint filter test and

TCLP lead.

iii.

For off-specification, unused or discarded commercial or chemical

products, an MSDS to determine the hazardous constituents

present may be provided in lieu of analytical results.

f.

CLARIFICATIONS:

Notwithstanding the exception for manufactured gas plant waste

contained in 35 IAC 721.124(a), no manufactured gas plant waste shall

be disposed in a non-hazardous waste landfill, unless: i) the waste has

been tested in accordance with subsection (d) of this special condition,

and ii) the analysis has demonstrated that the waste does not exceed the

regulatory levels for any contaminant given in the table contained in 35

IAC 721.124(b).

g.

Pursuant to 35 IAC 722.111, the generator of a solid waste is required to

determine if the waste is hazardous and comply with all applicable

hazardous waste regulations. For any waste that has been determined to

be hazardous, the results of quality assurance testing for the treatment

program, taken at an appropriate frequency to demonstrate the waste is no

longer hazardous, must be obtained. Verification that the waste meets the

land disposal restrictions must also be documented. These requirements

are in addition to the other standard special waste test requirements.

3.

An individual waste stream permit is no longer required by the Illinois EPA for

this facility. Therefore, a waste stream permit number will no longer be required

on the manifest when shipping waste to this facility as authorized by this permit.

Page 15

4.

Special waste generated due to an emergency situation may be disposed without

complete TCLP analysis if:

a.

The permittee receives authorization from the Emergency Response Unit

of the Illinois EPA at 1-217-782-3637;

b.

The permittee ensures that the generator has received an incident number

from the Illinois Emergency Management Agency at 1-800-782-7860

within Illinois, or 1-217-782-7860 outside of Illinois; and

c.

The waste is analyzed for the chemical constituents required by the

Emergency Response Unit.

5.

The permittee shall conduct the following analyses for waste received in labeled

containers in lab packs, including commingled wastes:

a.

Compatibility review in accordance with the procedures identified in

USEPA document EPA-600/2-80-076; and

b.

MSDS review to determine the hazardous constituents present and

appropriate USEPA hazardous waste class.

6.

RCRA empty containers received as a special waste are subject to the following

conditions:

a.

Containers have a rated capacity of less than 110 gallons only.

b.

Containers which formerly held 'P' listed hazardous waste or TSCA

regulated quantities of PCBs or empty compressed gas cylinders are not

included under this pea

nut.

c.

All containers must meet the definition of empty as described in 35 IAC,

Section 721.107(b).

d.

Additionally, where possible, a copy of the material safety data sheets for

products last present in the container shall obtained and kept on file.

e.

For drums, at least one end must be removed and the drums must be

crushed flat.

7.

The Special Waste Preacceptance Form shall be utilized for the special waste

profile identification requirements of 35 IAC, Section 811.404(a).

Page 16

8.

The Annual Generator Special Waste Recertification for Disposal Special Waste

foul1 shall be utilized for the special waste recertification requirements of 35 IAC,

Section 811.404(b).

9.

The operator shall retain all special waste records until the end of the post-closure

period in accordance with 35 IAC, Section 811.405.

IV. RECORDKEEPING

1.

Information developed by the operator but not yet forwarded to the Illinois EPA

in a quarterly or annual report shall be kept at or near the facility for inspection by

the Illinois EPA upon request during normal working hours.

2.

Information and observations derived from load checking inspections shall be

recorded in writing and retained at the facility for at least three years.

3.

Every person who delivers special waste to a special waste hauler, every person

who accepts special waste from a special waste hauler and every special waste

hauler shall retain a copy of the special waste transportation record as a record of

each special waste transaction. These copies shall be retained for three years and

shall be made available at reasonable times for inspection and photocopying by

the Illinois EPA pursuant to Section 4(d) of the Act.

4.

The operator shall retain copies of any special waste profile identification sheets,

special waste recertifications, certifications of representative samples, special

waste laboratory analyses, special waste analysis plans, and any waivers of

requirements, at the facility until the end of the closure period and thereafter at the

site office until the end of the post-closure care period.

5.

Inspections of the closed landfill shall be conducted in accordance with the

approved post-closure care plan. Records of field investigations, inspections,

sampling and corrective action taken are to be maintained at the site and made

available to Illinois EPA personnel. During the post-closure care period, those

records are to be maintained at the office of the site operator.

6.

The owner or operator shall record and retain near the facility in an operating

record or in some alternative location specified by the Illinois EPA, the

information submitted to the Illinois EPA pursuant to 35 IAC, Parts 812 and 813,

as it becomes available. At a minimum, the operating record shall contain the

following information, even if such information is not required by 35 IAC, Part

812 or 813:

Page 17

a.

Any location restriction demonstration required by 35 IAC,

Sections 811.302, 812.109, and 812.303;

Inspection records, training procedures, and notification procedures

required by 35 IAC, Section 811.323;

c.

Gas monitoring results and any remediation plans required by 35 IAC,

Sections 811.310 and 811.311;

d.

Any MSWLF unit design documentation for placement of leachate or gas

condensate in a MSWLF unit required by 35 IAC, Section 811.107(m);

e.

Any demonstration, certification, monitoring results, testing, or analytical

data relating to the groundwater monitoring program required by 35 IAC,

Sections 811.319, 811.324, 811.325, 811.326, 812.317, 813.501 and

813.502;

f.

Closure and post-closure care plans and any monitoring, testing, or

analytical data required by 35 IAC, Sections 811.110, 811.111,

812.114(h), 812.115 and 812.313; and

g.

Any cost estimates and financial assurance documentation required by 35

IAC Part 811, Subpart G.

V.

GENERAL CONDITIONS

1.

The issuance of this permit does not release the permittee from compliance with

other applicable statutes and regulations of the United States, of the State of

Illinois, or with applicable local laws, ordinances and regulations, including, but

not limited to, the Ford Act.

2.

This permit is issued with the expressed understanding that no process discharge

to Waters of the State or to a sanitary sewer will occur from these facilities except

as authorized by a permit issued by the Bureau of Water Pollution Control.

3.

It should be noted that the issuance of this permit does not relieve the Permittee of

the responsibility of complying with the provisions of the State of Illinois Rules

and Regulations, 35 IAC, Subtitle B, Air Pollution Control, Chapter 1. The

Illinois EPA's - Bureau of Air - Division of Air Pollution Control has determined

that this project requires both a Construction and Operating permit in accordance

with 35 IAC Section 201. If you have any questions regarding this requirement,

contact the Illinois EPA's Bureau of Air, Division of Air Pollution Control, Permit

Section at 217-782-2113.

Page 18

4.

If changes occur which modify any of the information the permittee has used in

obtaining a permit for this facility, the peunittee shall notify the Illinois EPA.

Such changes would include but not be limited to any changes in the names or

addresses of both beneficial and legal titleholders to the herein-permitted site.

The notification shall be submitted to the Illinois EPA within fifteen days of the

change and shall include the name or names of any parties in interest and the

address of their place of abode; or, if a corporation, the name and address of its

registered agent.

5.

Pursuant to 35 IAC, Section 813.201(a), any modifications to this permit shall be

proposed in the form of a permit application and submitted to the Illinois EPA.

6.

Pursuant to 35 IAC, Section 813.301, an application for permit renewal shall be

filed with the Illinois EPA at least ninety days prior to the expiration date of this

permit.

Current, valid Prior Conduct Certification pursuant to 35 IAC Part 745 is required

for all operators of landfills that require a permit.

8.

Landfill Operator Certification pursuant to 68 IAC Part 870 is required for

operation of a landfill.

9.

The operator shall conduct a survey of the waste boundaries and adjacent

properties before starting construction of the liner. No part of a unit may be

located closer than 152 meters (500 feet) from an occupied dwelling, school, or

hospital that was occupied on the date when the operator first applied for a permit

to develop the unit or the facility containing the unit, unless the owner of such

dwelling, school, or hospital provides permission to the operator, in writing, for a

closure distance. 35 IAC 811302(d)

10.

Effective upon issuance of Modification No. 1 (Log No. 2008-090), the

permittee(s) shall submit a 39(i) certification and supporting documentation

within 30 days of issuance of Modification No. 1 and thereafter within 30 days of

any of the following events:

a.

The owner or officer of the owner, or operator, or any employee who has

control over operating decisions regarding the facility has violated federal,

State, or local laws, regulations, standards, or ordinances in the operation

of waste management facilities or sites; or

b.

The owner or operator or officer of the owner, or operator, or any

employee who has control over operating decisions regarding the facility

has been convicted in this or another State of any crime which is a felony

under the laws of this State, or conviction of a felony in a federal court; or

Page 19

c.

The owner or operator or officer of the owner, or operator, or any

employee who has control over operating decisions regarding this facility

has committed an act of gross carelessness or incompetence in handling,

storing, processing, transporting, or disposing of waste.

d.

A new person is associated with the owner or operator who can sign the

application form(s) or who has control over operating decisions regarding

1 -- -

i-nrtrate officer or a delegated employee.

VI.

SURFACE WATER CONTROL

1.

Runoff from disturbed areas to Waters of the State shall be permitted by the

Illinois EPA in accordance with 35 IAC, Part 309, and meet the requirements of

35 IAC, Part 304 unless permitted otherwise.

2.

All surface water control structures other than temporary diversions for

intermediate phases shall be operated until the final cover is placed and erosional

stability is provided by the final protective layer of the final cover system.

3.

Runoff from-undisturbed areas resulting from precipitation events less than or

equal to the 25-year, 24-hour precipitation event shall be diverted around

disturbed areas where possible and not commingled with runoff from disturbed

areas.

4.

Site surface drainage, during development, during operation and after the site is

closed, shall be managed in accordance with the approved drainage control plan

detailed in Permit Application Log No. 2000-199. Stormwater management

structures shall be constructed prior to disturbing any portion of a drainage area

identified in Application Log No. 2000-199.

VII.

LEACHATE MANAGEMENT/MONITORING

1.

Pursuant to 35 IAC, Section 811.309(h)(3), leachate from this MSWLF landfill

shall be collected and disposed beginning as soon as it is first produced and

continuing for at least 30 years after closure except as otherwise provided by

811.309(h)(4) and (h)(5). Collection and disposal of leachate may cease only

when the conditions described in 35 IAC, Section 811.309(h)(2) have been

achieved. The leachate recirculation plan proposed in Log No. 2000-199 is

approved. Note that the leachate recirculation in each area must cease before final

cover is installed in that area. Leachate removed from this landfill shall be treated

at a permitted facility in accordance with the leachate management plan proposed

in Permit Application Log No. 2000-199.

Page 20

cover is installed in that area. Leachate removed from this landfill shall be treated

at a permitted facility in accordance with the leachate management plan proposed

in Permit Application Log No. 2000-199.

2.

Pursuant to 35 IAC, Sections 811.307(a) and (b), 811.308(a) and (h), and

811.309(a), leachate shall be pumped from the side slope riser sump(s) before the

level of leachate rises above the invert of the collection pipe(s) at its lowest

point(s). Leachate removal as such shall he performed througnout me period that

the leachate (.--:--11,-,..-.ti,..)11,1 Management system must be operated in accordance with

Permit Application Log No. 2000-199.

3.

The following monitoring points are to be used in the Leachate Monitoring

Program for this facility:

Leachate Monitoring Points

Applicant Designation

Leachate Manhole 1

Leachate Manhole 2

Leachate Manhole 3

Leachate Manhole 4

Leachate Manhole 5

Leachate Manhole 6

Leachate Manhole 7

*G99L

Illinois EPA Designation

@L301

@L302

@L303

@L304

@L305

@L306

@L307

@*L308

@ indicates leachate monitoring points not yet placed into service.

*In the event that monitored concentrations in L308 constitute a significant

increase as defined in VIII.13.c.or d., the operator shall follow the resampling

and/or assessment procedures of VIII.14 and VLII.15.

4.

Pursuant to 35 IAC, Sections 811.309(g), 722.111 and 721, Subpart C, leachate

monitoring (i.e., sampling, measurements and analysis) must be conducted in

accordance with the permit for this facility. The concentrations or values for the

parameters contained in List LI (below) shall be determined on a semi-annual

basis and submitted with the quarterly groundwater reports.

Each year, the permittee shall collect a representative leachate sample and have it

tested for the parameters contained in List L2.

Page 21

LIST LI

Leachate Monitoring Parameters

STORET

pH (S.U.)

00400

Elevation Leachate Surface (ft. MSL)

71993

Bottom of Well Elevation (ft. MSL)

72020

1.eachate Level irorn measuring 1

(Cr

72109

arsenic (total)

01002

T)----4,1 m

(total)

01007

Cadmium (iuL

“ :,

01027

Iron (total)

010=;

Ammonia Nitrogen – N (mg/L)

00610

Bacteria (Fecal Coliform) (FCBR/100 mL)

31616

Biochemical Oxygen Demand (BOD5) (mg/L)

00310

1, 1,1,2- Tetrachloroethane

77562

1,1,1 -Tri chloro eth ane

34506

1,1,2,2-Tetrachloroethane

34516

1,1,2-Trichloroethane

34511

1, 1 -Di chloro ethane

34496

1,1 -Dichloroethylene

34501

1,1-Dichloropropene

77168

1,2,3-Trichlorobenzene

77613

1,2,3-Trichloropropane

77443

1,2,4-Trichlorobenzene

34551

1,2,4-Trimethylbenzene

77222

1,2-Dibromo-3-Chloropropane

38760

1,2-Di chloro ethane

34531

1,2-Dichloropropane

34541

1,3,5-Trimethylbenzene

77226

1,3-Dichloropropane

77173

1,3-Dichloropropene

34561

1,4-Dichloro-2-Butene

73547

1-Propanol

77018

2,2-Dichloropropane

77170

2,4,5-tp (Silvex)

39760

2,4,6-Trichlorophenol

34621

2,4-Dichlorophenol

34601

2,4-Dichlorophenoxyacetic Acid (2,4-D)

39730

Page 22

LIST LI

Leachate Monitoring Parameters

STORET

2,4-Dimethylphenol

34606

2,4-Dinitrotoluene

34611

2,4-Dinitrophenol

34616

2,6 l^irucrotoiu^;

."4526

2-Chloroethyl Vinyl Ether

34576

2-Chloronaphthalene

3/15SI

2-Chlorophenol

34586

2-Hexanone

77103

2-Propanol (Isopropyl Alcohol)

81310

3,3 -Dichlorob enzi dine

34631

4,4-DDD

39310

4,4-DDE

39320

4,6-Dinitro-O-Cresol

34657

4-Bromophenyl Phenyl Ether

34636

4-Chlorophenyl Phenyl Ether

34641

4-Methyl-2-Pentanone

78133

4-Nitrophenol

34646

Acenaphthene

34205

Acetone

81552

Alachlor

77825

Al dicarb

39053

Aldrin

39330

Alpha – BHC

39337

Aluminum

01105

Anthracene

34220

Antimony

01097

Atrazine

39033

Benzene

34030

Benzo (a) Anthracene

34526

Benzo (a) Pyrene

34247

Benzo (b) Fluoranthene

34230

Benzo (ghi) Perylene

34521

Benzo (k) Fluoranthene

34242

Beryllium (total)

01012

Beta – BHC

39338

Page 23

LIST LI

Leachate Monitoring Parameters

STORET

(ing/L, as LaCo..;,

OU425

.123i s (2- Chloro -1-Methyl ethyl) Ether

73522

Bis (2-Chloroethoxy) Methane

34278

Bis (2-Chloroethyl) Ether

34273

Bis (2-Ethylhexyl) Phthalate

39100

B i s (Chloromethyl) Ether

34268

Boron

01022

Bromobenzene

81555

Bromochloromethan e

77297

Bromodichloromethane

32101

Bromoform

32104

Bromomethane

34413

Butano I

45265

Butyl Benzyl Phthalate

34292

Calcium (mg/L)

00916

Carbofuran

81405

Carbon Disulfide

77041

Carbon Tetrachloride

32102

Chemical Oxygen Demand (COD) (mg/L)

00335

Chlordane

39350

Chloride (mg/L)

00940

Chlorobenzene

34301

Chloroethane

34311

Chloroform

32106

Chloromethane

34418

Chromium (total)

01034

Chrysene

34320

Cis- 1,2-Dichloro ethylene

77093

Cobalt (total)

01037

Copper (total)

01042

Cyanide (mg/L)

00720

DDT

39370

Delta – BHC

46323

Di-N-Butyl Phthalate

39110

Di-N-Octyl Phthalate

34596

Page 24

LIST LI

Leachate Monitoring Parameters

?

STORET

Dibenzo (a,h) Antliracene

?

34356

Dibromochloromethane

?

32105

Dibromomethane?

77596

Di chloro di fluoromethane

?

34668

Dichloromethane

?

34423

Dieldrin?

39380

Diethyl Phthalate?

34336

Dimethyl Phthalate

?

34341

Endosulfan I?

34361

Endosulfan II

?

34356

Endosulfan Sulfate

?

34351

Endrin?

39390

Endrin Aldehyde?

34366

Ethyl Acetate

?

81585

Ethylbenzene

?

78113

Ethylene Dibromide (EDB)

?

77651

Fluoranthene?

34376

Flourene?

34381

Fluoride (mg/L)?

00951

Heptachlor Epoxide

?

39420

Heptachlor

?

39410

Hex achlorob enzene

?

39700

Hexachlorobutadiene

?

39702

Hexachlorocyclopentadiene?

34386

Hexachloroethane?

34396

Ideno (1,2,3-cd) Pyrene?

34403

Iodomethane?

77424

Is oprop ylb enzene

?

77223

Lead (total)

?

01051

Lindane?

39782

Magnesium (total) (mg/L)?

00927

Manganese (total)?

01055

Mercury (total)

?

71900

Methoxychlor

?

39480

Methyl Ethyl Ketone?

81595

Page 25

LIST LI

Leachate Monitoring Parameters

STORET

Naphthalene

34696

Nickel (total)

01067

Nitrate-Nitrogen (mg/L)

00620

Nitrob enzene

34447

Oil. Hexane Soluble (or Equivalent) (mg/L)

00550 or

00552

Parathion

39540

Pentachlorophenol

39032

Phenanthrene

34461

Phenols

32730

Phosphorous (mg/L)

00665

Polychlorinated Biphenyls

39516

Potassium (mg/L)

00937

Pyrene

34469

Selenium

01147

Silver (total)

01077

Specific Conductance (umhos/cm)

00094

Sodium (mg/L)

00929

Styrene

77128

Sulfate (mg/L)

00945

Temperature of Leachate Sample (°F)

00011

Tert-Butylbenzene

77353

Tetrachlorodibenzo-p-Dixoins

34675

Tetrachloroethylene

34475

Tetrahydrofuran

81607

Thallium

01059

Tin

01102

Toluene

34010

Total Organic Carbon (TOC) (mg/L) 00680

Total Dissolved Solids (TDS) (mg/L)

70300

Total Suspended Solids (TSS) (mg/L)

00530

Toxaphene

39400

Tr ans-1 ,2-Dichloro ethyl ene

34546

Trans-1,3-Dichlorpropene

34699

Trichloroethylene

39180

Page 26

LIST LI

Leachate Monitoring Parameters

STORET

Trichlorofluoromethane

34488

Vinyl Acetate

77057

Vinyl Chloride

39175

Xylene

81551

Zinc (total)

01092

m-Dichlorobenzene

34566

m+p-Xylene

61283

n-Butylbenzene

77342

n-Nitrosodimethylamine

3443 8

n-Nitrosodiphenylamine

34433

n-Nitro sodipropyl amine

34428

n-Propylbenzene

77224

o-Chlorotoluene

77275

o-Dichlorobenzene

34536

o-Nitrophenol

34591

o-Xylene

77135

p-Chlorotoluene

77277

p-Cresol

77146

p-Dichlorobenzene

34571

p-Isopropyltoluene

77356

sec-Butylbenzene

77350

LIST L2

RCRA Parameters for Leachate and Condensate

RCRA PARAMETERS

STORETS

Ignitability

Flashpoint, Pensky-Martens Closed Cup

00497

(°F)

Corrosivity

pH (S.U.)

00400

Page 27

LIST L2

RCRA Parameters for Leachate and Condensate

RCRA PARAMETERS

STORETS

Reactivity

Reactive Cyanide

Reactive Sulfide

99040

99042

Toxicity

Total

TCLP

conc.

conc.

(ug/l)

(mg/L)

Arsenic

1002

99012

Barium

1007

99014

Cadmium

1027

99016

Chromium

1034

99018

Lead

1051

99020

Mercury

71900

99022

Selenium

1147

99024

Silver

1077

99026

Endrin

39390

99028

Lindane

39782

99030

Methoxychlor

39480

99032

Toxaphene

39400

99034

2,4-D

39730

99036

2,4,5-TP Silvex

39760

99038

Benzene

34030

99128

Carbon tetrachloride

32102

99050

Chlordane

39350

99148

Chlorobenzene

34301

99096

Chloroform

32106

99149

o-Cresol

77152

99150

m-Cresol

77151

99151

p-Cresol

77146

99152

Cresol

79778

99153

1,4-Dichlorobenzene

34571

99154

1,2-Dichloroethane

34531

99155

Page 28

LIST L2

RCRA Parameters for Leachate and Condensate

RCRA PARAMETERS

STORETS

1,1-Dichloroethylene

34501

99156

2,4-Dinitrotoluene

34611

99157

Heptachlor (and its epoxide)

39410 and

99158

39420

Hexachlorobenzene

39700

99159

Hexachloro-1,3-Butadiene

39702

99160

Hexachloroethane

34396

99161

Methyl Ethyl Ketone

81595

99060

Nitrobenzene

34447

99062

Pentachlorophenol

39032

99064

Pyridine

77045

99066

Tetrachloroethylene

34475

99068

Trichloroethylene

39180

99076

2,4,5-Trichlorophenol

77687

99078

2,4,6-Trichlorophenol

34621

99080

Vinyl Chloride

39175

99162

Notes for all leachate monitoring parameters:

a.

The test methods for leachate monitoring shall be those approved in the

USEPA's Test Methods for Evaluating Solid Waste, Physical/Chemical

Methods (SW-846), Third Edition or the equivalent thereof.

b.

All parameters shall be determined from unfiltered samples.

c.

The monitoring results should be reported in ug/I units unless otherwise

indicated.

Notes for List L2 parameters:

a.

Flashpoint shall be reported in degrees Fahrenheit. The parameters for

reactivity and toxicity shall be reported in parts per million.

b.

The permittee shall obtain metals and organics analysis. For List L2

parameters, either procedure may be utilized (i.e., total or TCLP), but any

constituent whose total concentration exceeds the TCLP limit specified in

Page 29

35 IAC, Section 721.124 must be analyzed using the TCLP test and the

results reported, unless an alternative test has been approved by the Illinois

EPA. TCLP test methods must be in accordance with SW 846-1311.

5.

The schedule for leachate sample collection and submission of monitoring data is

illustrated below:

Sampling Period

Sampling Points

Lists

Report Due Date

Oct-Nov 2008

L301

Ll

January 15, 2009

April-May 2009

L301

LI

July 15, 2009

LREP

L2

Oct-Nov 2009

L301

Ll

January 15, 2010

April-May 2010

L301

Ll

July 15, 2010

LREP

L2

Oct-Nov 2010

L301

Ll

January 15, 2011

April-May 2011

L301

Ll

July 15, 2011

LREP

L2

Oct-Nov 2011

L301

Li

January 15, 2012

April-May 2012

L301

LI

July 15, 2012

LREP

L2

Oct-Nov 2012

L301

Ll

January 15, 2013

April-May 2013

L301

Ll

July 15, 2013

LREP

L2

6.

The leachate monitoring data must be submitted in an electronic format. The

information is to be submitted, as fixed-width text files formatted as found in

Attachment A. Additional guidance regarding the submittal of the information in

an electronic format can be found at ww-w.epa.state.il.us/land/waste-

mgmt/groundvvater-monitoring.html .

VIII. GROUNDWATER MONITORING

1.

The groundwater monitoring program must be capable of determining

background groundwater quality hydraulically upgradient of and unaffected by

the units and to detect, from all potential sources of discharge, any releases to

groundwater within the facility. The Illinois EPA reserves the right to require

installation of additional monitoring wells as may be necessary to satisfy the

requirements of this permit.

Page 30

2.

The groundwater monitoring wells shall be constructed and maintained in

accordance with the requirements of 35 Ill. Adm. Code, 811.318(d) and designs

approved by the Illinois EPA.

3.

Groundwater monitoring wells shall be installed in the locations shown in

Attachment L of the permit application, Log No. 2000-199 and screened in the

constructed subgrade layer (equivalent to the Herrin No. 6 coal) and the

Springfield-Harrisburg No. 5 coal identified as potential contaminant pathway(s)

within the zone of attenuation. All wells as listed in Condition V.9 must be

installed prior to application for operating authorization.

4.

Within 60 days of installation of any groundwater monitoring well, boring logs

compiled by a qualified geologist, well development data and as-built diagrams

shall be submitted to the Illinois EPA utilizing the enclosed "Well Completion

Report" form. For each well installed pursuant to this permit, one form must be

completed.

5.

Groundwater monitoring wells shall be easily visible, labeled with the Illinois

EPA monitoring point designations and fitted with padlocked protective covers.

6.

In the event that any well becomes consistently dry or unserviceable and therefore

requires replacement, a replacement well shall be installed within ten (10) feet of

the existing well. The Illinois EPA shall be notified in writing at least 15 days

prior to the installation of all replacement wells. A replacement well that is more

than ten feet from the existing well or which does not monitor the same geologic

zone is considered to be a new well and must be approved via a significant

modification permit.

7.

All borings, wells and piezometers not used as monitoring points shall be

abandoned in accordance with the standards in 35 Ill. Adm. Code 811.316, and

the decommissioning and reporting procedures contained in the Illinois

Department of Public Health's (IDPH) Water Well Construction Code, 77 Ill.

Adm. Code, Part 920 (effective 1/1/92). In the event specific guidance is not

provided by IDPH procedures, the enclosed Illinois EPA monitoring well