BEFORE

THE ILLINOIS

POLLUTION

CONTROL BOARD

IN TIlE MATTER

OF

RCRA DELISTING

ADJUSTED

STANDARD

PETITION

OF PEORIA

DISPOSAL

COMPANY

)

AS 08-10

)

(Adjusted Standard

— Land)

)

(RCRA Delisting)

)

To:

See

attached

Certificate

of Service

PLEASE

TAKE NOTICE that

on this date we filed

with

the Clerk

of the Illinois

Pollution

Control Board

the

attached COMMENTS

OF BAKER & MCKENZIE

LLP,

copies

of

which

are

attached hereto and

herby served upon

you.

Dated: September

12, 2008

• Respectfully

submitted,

fo)

Wats6n

‘aker

& McKenzie

LLP

One Prudential

Plaza,

Suite 3500

130

East Randolph Drive

Chicago,

IL 60601

NOTICE

OF FILING

THIS DOCUMENT

IS

FILED ON RECYCLED

PAPER

CERTIFICATE

OF

SERVICE

The undersigned certifies

that copies

of

the

COMMENTS

OF BAKER & MCKENZIE

LLP

were served

on

this

12

th

day

of

September,

2008.

Upon

the

following

by hand

delivery

(original and

nine copies):

John Therriault

Acting

Clerk of the

Board

Illinois

Pollution

Control Board

100

West Randolph

Street, Suite 11-500

Chicago,

IL 60601

And upon the following

by U.S. First Class

Mail:

Carol

Webb

Hearing

Officer

Illinois

Pollution Control

Board

1021

North Grand

Avenue East

P.O.

Box 19276

Springfield,

IL 62794

William

D.

Ingersoll

Illinois

Environmental

Protection

Agency

1021

North Grand

Avenue East

P.O.

Box

19276

Springfield,

IL 62794

Brian

Meginnes

Janaki Nair

Elias,

Meginnes,

Riffle &

Seghetti, P.C.

416 Main

Street, Suite 1400

Peoria,TL

61602

Claire Manning

Brown,

Hay

& Stephens,

LLP

205 South Fifth

Street,

Suite

700

Springfield,

IL 62701

BEFORE

THE ILLINOIS

POLLUTION

CONTROL

BOARD

IN THE MATTER

OF

)

)

AS 08-10

RCRA

DELISTING

ADJUSTED

)

(Adjusted

Standard

— Land)

STANDARD

PETITION OF

PEORIA

)

(RCRA Delisting)

DISPOSAL

COMPANY

)

COMMENTS

OF

BAKER & MCKENZIE

LLP

Baker & McKenzie

respectfully

submits

the following

comments in

response

to the

above-captioned

Petition

of Peoria

Disposal Company

(“PDC”) for

a RCRA delisting

adjusted

standard (the

“Petition”):

1.

If

PDC’s

Petition

is granted, the

delisting

should

include a

requirement that

re

treated electric

arc furnace

dust stabilized

residue

(“EAFDSR”)

be analyzed

for all

metals

constituents.

The Technical Support

Document

for the RCRA Delisting

Adjusted

Standard

Petition

for

PDC

EAF Dust Stabilized

Residue (hereinafter

“Technical

Support

Document”)

states:

When

analysis

of

samples following additional

chemical

reaction

time does

not

indicate compliance

with the delisting

levels prior to the

storage time

limit, or the

trend

in re-sample

analytical results makes

evident

to PDC that reduced

concentrations

with

additional curing time

are unlikely,

PDC

would

re-process

the

“failed”

EAF dust treatment

residue

in

the same

manner

as is described

above for

untreated EAF dust.

The re-treatment

recipe would

be

determined based

on the

metals

concentrations

and

final

extraction

pH of

the

most recent

resample.

Sample collection of

re-treated EAF dust

treatment residue

would be

identical

to

that

proposed above

for

samples

collected

after

additional

curing time.

Consistent

with

the

existing

IEPA

sampling and analysis

requirements

for WSF

treatment

residues,

re-treated LAFDSR

would

be

analyzedfor

only those constituents

that

did

not

meet the delisting levels

prior to re-treatment.

(Technical Support

Document,

at 3-20

(emphasis

added).)

If

additional chemical

reaction time

or re-processing

is necessary,

all constituents

should

be

reanalyzed

to determine compliance

with

the

delisting

levels,

not just

those

constituents

that

did not meet

the delisting levels prior to re-treatment. Typically,

laboratories

do not analyze

for

individual metals but rather

a suite

of

metals.

As such, no additional burden would

be imposed

by

reanalyzing

for all constituents,

given

that the data is already available.

The proposed

practice raises the question

why would

one

not

report

all

of the data if it is readily available.

The

use

of

additional reaction times and/or the necessity

of

adding

supplementary

reagents subsequent to initial

treatment

efforts indicate that the primary treatment

of

the electric

arc furnace dust has

failed

to attain delisting standards.

This

initial failure indicates that the

expected chemical reaction

mechanisms

responsible for chemical stabilization have not occurred

or

have been significantly retarded.

PDC

may elect to use

cure time

(supplementary reaction time) or additional reagents to

augment the initial

treatment regime to attain delisting standards.

To

verify

compliance

with

the

delisting,

it is being proposed that re-treated residue need only be analyzed for those constituents

that have failed

to meet delisting standards prior to re-treatment. The assumption being made

is

that cure time or

additional reagent enhancements will only have a positive effect

on

the overall

treatment process.

This

is

an incorrect assumption. Supplemental treatment

may also

have

negative

consequences

on

constituents

of

concern that were previously in compliance delisting

standards.

PDC

explains that it commonly operates its treatment process using “reagent proportions

known through

experience to be at the lower end of the effective range for a specific waste type.”

Technical

Support

Document, at 3-19. When considering the complexities associated with

delisting

fourteen distinct metals and differing solubility behaviors, subsequent treatment (cure

and/or

augmentation

using additional additives)

can

create

non-optimal conditions that may

cause

previously stabilized analytes to become leachable; even when starting

from

the “lower

2

end of

the

effective

range.”

In other

words,

cure

and/or

re-treatment

activities

can

create

an

environment

that

is

optimal

for

one

particular

analyte

of interest

while

creating

an environment

that is

deleterious

to

another.

Chemical

reactions

continue

to occur

and

the

final product

is

not

the

same as

the product

that

was

originally

tested.

Therefore,

this necessitates

that

every

constituent

of

concern

must be

reevaluated

when using

cure

and/or

re-treatment

options.

Additional

treatment

activities

(cure

and/or

re-treatment)

represent

an entirely

new

treatment

regime

that is

unproven

and

requires

a complete

assessment

of all

fourteen

metals

to ensure

that

this

new treatment

is effective

for

all constituents

of concern.

2.

If

approved,

the

Petition

should

be required

to demonstrate

that the

EAFDSR

has

a

complete

reaction

mechanism

prior

to landfill.

RMT,

Inc.,

the

consultant

utilized

by PDC

for

assistance

in preparation

of

the

Petition,

has

been

granted

many

patents

for

the stabilization

of

materials

including

EAFD.

While

it

is not

clear

if any

of

the patent

claims

have

been

utilized

in the

demonstration

for this

petition,

of

particular

concern

is

the

absence

of

a

reaction

which

is

acknowledged

in patent

#5,037,479

(attached

hereto

at

Appendix

A) and

other

similar

patents

held

by

RMT,

Inc..

The patent

states

that:

Dry

mixing

of

the agents

with

the solid

waste

does

not

necessarily

cause

the

reactions

which

convert

lead,

cadmium

and

zinc

into substantially

non-leachable

foims.

This

reaction

may

not

occur

until the

mixture

is

analyzed

using

the

Extraction

Procedure

Toxicity

Test

and will

result

in the

material

not being

classqIed

as

EP

toxic.

The reactions

may

also

not

occur until

the

waste

mixture

is

analyzed

using a

water

leach

test,

which

is

designed

to simulate

the leaching

conditions

present

in

an industrial

landfill.

In

the field,

the

reaction

will

probably

occur

slowly

as

the waste

is

wetted.”

(App.

A,

at 12

(emphasis

added).)

Only

when

the TCLP

extract

is analyzed

does

the

waste

sample

undergo

stabilization

such

that

it

passes

the

test for

the regulated

chemicals.

In other

words,

the TCLP

test

itself

3

causes the reaction leading to

stabilization;

the lest results do

not indicate

that the thy

combination ofKO6] waste and additives proposedfor deregulation are stabilized.

While the

Petition

and

the Technical

Support

Document report that water

is used in

the

process,

the following language does not indicate that water is being used to facilitate reactions:

As noted

earlier

in

this Document, the

addition of

treatment chemicals and make

up water, which

facilitates

mixing and will eliminate

the potential

for airborne

waste emissions when the EAFDSR

is

deposited at the landfill face, will increase

the

average bulk density of the

EAF

dust

by

approximately

50%

(Technical Support Document,

at

2-3; see also id. at

3-14 (table summarizing

same).) PDC fails

to

explain if sufficient water is added to provide a medium in

which

the reactions can occur. It is

simply

used to facilitate mixing and eliminate the

potential

for

airborne

waste

emissions.

All

reactions need a

driving mechanism. Most stabilization processes utilized water

as

a medium

in

which the

reactions can occur. Other driving forces are possible, such as the use of heat or

pressure, but

without

further information, it is not possible to know how the EAFDSR is created.

If

the delisting is

granted, it should require that a demonstration be made that the liquid added,

or

whatever mechanism utilized, is

sufficient

to

drive the reactions and produce

a

stabilized

product.

Showing that

this process has occurred in a relatively dry state is critical to prove that

the

proprietary technology

actually stabilized the waste. Otherwise, the petitioner

is

just gaming

the TCLP in a

clever if not inappropriate way in order

to evade the clear

intent

of the regulations.

3.

Finally, if the delisting is approved, to be consistent with delistings granted by

USEPA,

reopener

language similar

to that found in the Heritage Environmental Services, LLC,

at

Nucor Steel

facility in Crawfordsville, TN delisting for K06l (40 CFR 261 Appendix IX Table

2)

should

be incorporated into this delisting.

4

In conclusion,

if

the

Board grants

the

Petition

and approves

PDC’s

requested

delisting,

the

requirements

described

above

should

be

included

in the

approved

delisting.

Respectfully

submitted,

Jo

atson

B

er

& McKenzie

LLP

One

Prudential

Plaza,

Suite 3500

130 East Randolph

Drive

Chicago,

IL

60601

5

Appendix A: Patent #5,037,479

United States Patent

5,037,479

Stanforth

*

August

6, 1991

Method for reduction of heavy metal leaching

from

hazardous

waste under acidic

and

nonacidic conditions

Abstract

A method of treating solid hazardous wastes containing unacceptable levels

of leachable metals

such as lead, cadmium and zinc includes

mixing the solid waste with a buffering agent selected

from

the

group

consisting

of

magnesium

oxide, magnesium hydroxide, reactive calcium

carbonates

and

reactive

magnesium

carbonates, and with an additional agent which

is an acid

or

salt

containing

an anion that forms substantially nonleachable fonns

of

the

metals,

which

additional

agent is selected from the group consisting

of

triple superphosphate,

ammonium

phosphate,

diammonium phosphate, phosphoric acid, boric acid and metallic,

iron so that under

both

acidic and nonacidic leaching conditions the metals in the mixture will be converted

to

substantially nonleachabl e

forms.

Inventors: Stanforth; Robert R.

(Madison,

WI)

Assignee: RMT, Inc. (Madison, WI)

1*1

Notice: The portion of the term of this patent subsequent to December

26, 2006 has been

disclaimed.

Appl.No.:

512641

Filed:

April 20, 1990

Current U.S. Class:

‘

588/318; 75/746; 405/1 29.25; 423/92; 423/1 02;

423/659;

588/257; 588/407;

588/412

Intern’l

Class:

,

BO9B

003/00

Field of

Search:

405/129

423/35,55,305,659,DIG.

20,792,92,102

75/722,586,746

106/735,691 588/257 210/751

References Cited

IReferenced Byl

U.S.

Patent Documents

4356030

Oct.,

1982

Halpin

75/586.

4652381

Mar.,

1987

Inglis

423/35.

4671882

Jun., 1987

Douglas

423/305.

4764284

Aug.,

1988

Jansen

423/35.

4878944

Nov.,

1989

Rolle et al.

75/25.

4889640

Dec.,

1989

Stanforth

210/751.

4950409

Aug.,

1990

Stanforth

405/129.

Other

References

1985,

AFS

Transactions,

“Methods

to Treat EP

Toxic Foundry

Wastes and

Waste

Waters,”

vol.

93,

PP.

737-740.

California

Cast

Metals Association,

Feb.

1989, “Detoxifying

Foundry

Sand,” Report

to

Members.

Nagle,

D.

L.,

R.

R.

Stanforth,

P. E. Duranceau

and

T. P.

Kunes, 1983,

AFS

Transactions,

“Treatment

of

Hazardous

Foundry

Melting

Furnace

Dust

and

Sludges,”

vol.

91,

pp.

71 5-720.

Turpin,

P.

D., T.

R.

Sta]zenburg,

W.

A.

Stephens,

and

T. P.

Kunes.

Primary

Examiner:

Straub; Gary

P.

Assistant

Examiner:

Chen; C.

Robert

Attorney,

Agent

or Firm: Lathrop

&

Clark

Claims

What

is

claimed

is:

1. A method

of

treating

solid hazardous

waste containing

unacceptable

levels

of

leachable

metals

selected from

the group

consisting

of lead

and

cadmium,

the

method comprising

the steps

of

mixing the

solid waste

with

at least

one

first gent

selected from

the

group

consisting

of

magnesium

oxide and

magnesium

hydroxide,

and an

additional

agent

which is triple

superphosphate,

so

that

under both

acidic

and

nonacidic

leaching

conditions,

the

metals in

the

mixture

will

be

converted

to substantially

non-leachable

forms.

2.

The method

of claim

I wherein

the solid

waste and

agents are

mixed

into a mixture

with

sufficient quantities

of

each

of the

agents

so that

a random

100

gram sample

of the

mixture

will

have

sufficient

agents to

limit cadmium

extraction

to

below 1.0

mg!L

and

lead

extraction

to

below 5.0 mg/L

when

analyzed

by

the Extraction

Procedure

Toxicity

Test,

and cadmium

leaching

to below

0.01 mg/L

and lead

leaching

to

below

0.05

mg!L

when

analyzed

with a

water

leach

test.

3. A

non-hazardous

solid waste

mixture

which

may be

safely disposed

of

in a landfill,

comprising

a

solid

hazardous

waste

containing

unacceptable

levels

of

leachable

metals

selected

from

the group

consisting

of lead and

cadmium,

mixed

with at least

one

fist agent selected

from

thegroup

consisting

of

magnesium

oxide and

magnesium

hydroxide,

and

an additional

agent

which

is

triple superphosphate,

in quantities

sufficient

so that

under

both

acidic

and

nonacidic

leaching

conditions,

the

metals

will be converted

to

substantially

nonleachable

forms.

4. The non-hazardous

solid

waste

mixture

of

claim

3 wherein

there

is a sufficient

quantity

of

each

of the agents

incorporated

into

the mixture

so that

when a

random

100 gram

sample

of the

mixture is analyzed

by

the Extraction Procedure

Toxicity Test, cadmium

is

extracted

at a

level

below

1.0

mg/L and lead

is

extracted

at a

level below

5.0 mg/L, and when

a random 100 gram

sample

of

the mixture

is

analyzed

using a

water

leach test, cadmium will leach

at a

level

below

0.01 mgIL and

lead will

leach at a

level

below 0.05 mg/L.

5. A method of treating solid hazardous waste containing

unacceptable levels

of

leachable

metals

selected from the group consisting

of lead and cadmium, the method comprising the

steps of

mixing the solid waste

with

at least one

first

agent selected from the

group

consisting

of

magnesium oxide, magnesium hydroxide, reactive calcium carbonates

and

reactive

magnesium

carbonates, and at least one additional agent selected

from the group consisting of triple

superphosphate, ammonium phosphate,

diammonium phosphate,

phosphoric acid,

boric acid and

metallic

iron so

that under

both acidic and nonacidic leaching conditions,

the metals in the

mixture will be

converted

to substantially non-leachable forms.

6.

The method of claim 5 wherein the

solid

waste and agents

are mixed intQ a mixture with

sufficient

quantities of each

of

the agents

so

that

a

random

100 gram sample of the mixture

will

have

sufficient agents to limit cadmium extraction to below

1.0 mg/L and lead extraction to

below 5.0 mg/L when analyzed

by

the Extraction Procedure Toxicity

Test, and cadmium

leaching to below 0.01 mg/L and lead leaching to below 0.05

mg/L

when

analyzed with a water

leach test.

7. A

non-hazardous solid waste mixture which may

be safely disposed of in a landfill,

comprising a solid hazardous waste containing unacceptable levels

of

leachable

metals

selected

form the group

consisting

of lead and cadmium, mixed with at least one first agent selected

from

the group consisting of magnesium oxide, magnesium

hydroxide,

reactive

calcium carbonates

and

reactive

magnesium

carbonates, and at least one additional agent selected

from

the

group

consisting of triple superphosphate, ammonium phosphate,

diammonium phosphate, phosphoric

acid, boric acid, and metallic iron in quantities sufficient so that under both acidic

and nonacidic

leaching

conditions, the metals will be converted to substantially

nonleachable forms.

8. The

non-hazardous solid waste mixture specified

in

claim

7 wherein there is a sufficient

quantity

of each of the agents incorporated into the mixture

so

that when

a random 100 gram

sample of

the mixture is analyzed

by

the Extraction

Procedure

Toxicity Test, cadmium

is

extracted at a level below 1.0 mg!L and lead is extracted

at

a levelbelow

5.0 mg/L, and when

a

random 100 gram sample of the mixture is analyzed using a water leach test,

cadmium will leach

at a level

below 0.01 mg/L and lead will leach at

a

level

below 0.05 mg/L.

9.

A method of

treating solid hazardous waste

containing unacceptable levels

of

leachable

metals

selected

from the group

consisting

of lead and cadmium, the method comprising

the steps of

mixing

the solid waste with at least one first agent selected

from the group consisting

of

magnesium oxide, magnesium hydroxide, reactive calcium carbonates

and reactive magnesium

carbonates, and at least one additional agent selected

from the group consisting of triple

superphosphate,

ammonium

phosphate,

dianrmonium phosphate, phosphoric acid

and boric acid

so

that under

both acidic and nonacidic leaching

conditions, the metals in the

mixture will be

converted to

substantially

non-leachable forms.

10.

The

method

of claim

9

wherein

the

solid waste

and agents

are

mixed

into

a

mixture with

sufficient

quantities

of

each

of

the

agents

so

that

a random

100 gram sample

of the mixture

will

have

sufficient

agents

to limit

cadmium

extraction

to below

1

.0

mg!L and

lead

extraction

to

below

5.0 mg/L

when analyzed

by

the Extraction

Procedure

Toxicity

Test,

and cadmium

leaching

to below

0.01

mg/L

and lead

leaching

to

below

0.05

mg/L

when

analyzed

with a water

leach

test.

11. A non-hazardous

solid waste

mixture

which

may be safely

disposed

of

in a landfill,

comprising

a

solid

hazardous

waste

containing

unacceptable

levels

of leachable

metals

selected

from

the

group consisting

of

lead

and cadmium,

mixed

with at

least one

first agent

selected

from

the

group

consisting

ofmagnesium

oxide,

magnesium

hydroxide,

reactive

calcium

carbonates

and

reactive

magnesium

carbonates,

and at least

one

additional

agent

selected

from

the group

consisting

of

triple superphosphate,

ammonium

phosphate,

diammonium

phosphate,

phosphoric

acid

and boric

acid

in

quantities sufficient

so

that under

both

acidic

and nonacidic

leaching

conditions,

the

metals

will

be converted

to substantially

nonleachable

forms.

12. The

non-hazardous

solid

waste

mixture

of

claim

11

wherein

there

is

a

sufficient

quantity

of

each

of the agents

incorporated

into

the mixture

so

that when

a

random 100

gram sample

of

the

mixture

is analyzed

utilizing

the

Extraction

Procedure

Toxicity

Test, cadmium

is extracted

at

a

level

below 1.0

mgJL

and

lead

is extracted

at a

level

below 5.0

mg/L,

and

when

a

random 100

gram

sample

of the mixture

is analyzed

using

a

water leach

test,

cadmium

will leach

at a

level

below

0.01

mg/L and

lead

will leach

at a level

below

0.05 mg!L.

13. A

method

of treating

solid

hazardous

waste containing

unacceptable

levels

of

leachable

metals

selected

from the

group consisting

of lead

and cadmium,

the method

comprising

the

steps

of mixing

the

solid

waste

with at

least one

buffering

agent, and

further mixing

it

with at least

one

additional

agent

selected

from the

group

consisting

of triple

superphosphate,

ammonium

phosphate,

diammonium

phosphate,

phosphoric

acid,

boric acid

and metallic

iron

so that under

both

acidic

and

nonacidic leaching

conditions

the metals

in the

mixture will

be converted

to

substantially

nonleachable

forms.

14.

A nonhazardous

solid

waste

mixture

which

may be safely

disposed

of in

a landfill,

comprising

a solid

hazardous

waste

containing

unacceptable

levels

of

leachable

metals

selected

from

the

group

consisting

of lead and

cadmium,

mixed with

at least

one buffering

agent

and

further

mixed

with

at

least

one additional

agent

selected

from the

group

consisting

of triple

superphosphate,

ammonium

phosphate,

diammonium

phosphate,

phosphoric

acid, boric

acid,

and

metallic

iron

in

quantities

sufficient

so hat under

both acidic

and nonacidic

leaching

conditions,

the

metals

will

be

converted

to

substantially

nonleachable

forms.

15.

A

method

of

treating

solid

hazardous

waste

containing

unacceptable

levels

of leachable

metals

selected

from

the

group

consisting

of lead,

cadmium

and

zinc,

the

method

comprising

the

steps of

mixing the

solid

waste

with

at least

one

first

agent selected

from the group

consisting

of

magnesium

oxide,

magnesium

hydroxide,

reactive calcium

carbonates

and reactive

magnesium

carbonates,

and at least

one

additional

agent

selected

from the

group

consisting

of

triple

superphosphate,

ammonium

phosphate,

diammonium

phosphate,

phosphoric

acid,

boric acid

and

metallic

iron

so

that under

both

acidic

and nonacidic

leaching

conditions,

the

metals

in the

mixture

will be

converted

to substantially non-leachable

forms.

16. The method

of claim 15 wherein

the solid

waste

and agents are

mixed, into a mixture

with.

sufficient

quantities of each of the

agents

so

that

a random

100 gram sample

of

the

mixture will

have

sufficient agents to limit

cadmium

extraction to below

1 .0 mg/L and lead

extraction

to

below 5.0 mg/L

when

analyzed by the

Extraction Procedure

Toxicity Test,

and

cadmium

leaching to

below

0.01 mg!L and

lead leaching to

below 0.05 mg/L

when

analyzed

with a water

leach

test.

17. A non-hazardous

solid waste

mixture which may

be

safely disposed

of

in

a

landfill,

comprising

a solid hazardous

waste containing unacceptable

levels

of leachable

metals selected

from

the group consisting

of

lead,

cadmium

and zinc, mixed

with

at least

one first agent selected

from

the

group

consisting

of magnesium

oxide, magnesium

hydroxide,

reactive calcium

carbonates

and

reactive

magnesium

carbonates, and

at least

one

additional agent selected

from

the

group

consisting of

triple superphosphate,

ammonium

phosphate, diammonium

phosphate,

phosphoric

acid,

boric

acid, and metallic

iron

in

quantities

sufficient so that

under

both

acidic

and nonacidic

leaching

conditions,

the

metals will be converted

to substantially

nonleachable

forms.

1

8.

The non-hazardous

solid waste

mixture

of

claim 17 wherein there

is a sufficient

quantity

of

each

of

the agents incorporated

into the mixture

so that

when

a random

100

gram sample of

the

mixture

is analyzed by

the

Extraction Procedure

Toxicity

Test, cadmium is extracted

at a level

below

1.0 mg/L

and lead

is

extracted

at

a level below 5.0

mg/L, and when

a random

100

gram

sample

of

the mixture is

analyzed using

a

water

leach test,

cadmium will leach

at a level below

0.01 mg!L and lead

will

leach at a level

below 0.05 mgIL.

Description

FIELD OF

THE INVENTION

This

invention pertains

generally to the

field

of

treating

solid hazardous waste,

and particularly

to the chemical

treatment

of solid waste

containing

unacceptable

levels

of leachable metals,

such

as lead,

cadmium

and zinc to control leaching

under

both acidic and

nonacidic reaction

conditions.

BACKGROUND

OF THE INVENTION

Safe disposal

of hazardous waste is

an increasing societal

problem. Once

a

hazardous

waste

is

generated, disposal

and treatment of the

waste

is

heavily

regulated

by

the

United

States

Environmental

Protection

Agency

because

of the potentially

serious

consequences

of improper

disposal or

treatment.

Foundries

typically generate

large

quantities

of solid waste which

is collected

as baghouse

dust.

These

wastes

often contain leachable

heavy

metals, such as lead,

cadmium

and

zinc. If the levels

of

leachable

heavy

metals

are

high,

the

wastes

are

classified

as hazardous

wastes

by

U.S.

EPA

or

the

state

regulatory

agencies.

Disposal

of hazardous

wastes

containing

high

levels

of

leachable

heavy

metals,

such

as

lead

or

cadmium,

is

expensive.

In

addition

to the

business

cost of

completing

paperwork

associated

with

the

regulation

of

hazardous

waste,

tipping

fees

are

usually

more

than

$150

per

ton.

Transportation

costs

are also

high

Since

hazardous

waste

must

often

be transported

some

distance

for disposal

in

approved

facilities.

These

costs

will

undoubtedly

increase

with

the

U.S.

EPA

prohibition

on

land

disposal

of

untreated

hazardous

waste

beginning

on

May

8,

1990.

Therefore,

a

method

of

treating

hazardous

waste

to

render

it

nonhazardous

could

result

in

tremendous

cost

savings

for

generators

of

hazardous

waste,

such

as foundries.

Solid

wastes

are

classified

as

hazardous

by

U.S.

EPA

for

a number

of reasons.

Certain

wastes

are

classified

as

hazardous

because

they

contain

chemicals

which

are

listed

by

U.S.

EPA

as

hazardous.

Other

wastes

are

classified

as hazardous

because

of

characteristics

of

the

waste.

These

characteristics

include

ignitability,

corrosivity,

reactivity,

and

Extraction

Procedure

(EP)

Toxicity.

Extraction

Procedure

Toxicity

is determined

using

the

Extraction

Procedure

Toxicity

Test (EP.

Toxicity

Test)

contained

in

40

C.F.R.

Part

261,

Appendix

11,

(1989),

the

disclosure

of which

is

hereby

incorporated

by

reference.

In the

near

future,

the

Toxicity

Characteristic

Leaching

Procedure

(TCLP)

will

replace

the

EP

Toxicity

Test.

The

EP

Toxicity

Test and

TCLP

determine

whether

a solid

waste

has

unacceptable

levels

of hazardous

substances,

such

as heavy

metals,

which

can

be

leached

from

the

waste

by

infiltrating

water.

Wastes

containing

leachable

lead

and

cadmium

are

cuffently

classified

as EP

Toxic

Waste

if

the level

of

cadmium

extracted

in an

EP

Toxicity

test

is

above

1.0

mgIL

or

if the

level

of lead

extracted

is

above

5.0

mg/L.

The

upcoming

ban

on

disposal

of untreated

hazardous

waste

will

require

that

wastes

that

are

hazardous

for

lead

and/or

cadmium

leaching

not

be land

disposed

without

treatment.

Some

states,

notably

Michigan,

also

classify

wastes

which

leach

high

levels

of

zinc

as hazardous.

The

EP

Toxicity

Test

and

TCLP

are

designed

to simulate

a

worst-case

leaching

situation.

These

leaching

conditions

would

typically

be

found

in the

interior

of

an actively

degrading

municipal

landfill.

In such

landfills,

the leaching

medium

is slightly

acidic,

with

a

pH of

about

5.

Additionally,

the

leaching

medium

is

heavily

buffered

by

volatile

organic

acids

(e.g.,

acetic

acid)

produced

by

the

facultative

anaerobic

degradation

of organic

matter.

In

fact, many

industrial

wastes

are

not

disposed

of under

acidic

conditions.

The

actual

leaching

conditions experienced

by

these

wastes

in

an

industrial

landfill

may

be quite

different

from

the

worst-case

situation

simulated

by the

EP

Toxicity

and

TCLP

tests.

In

general,

high

volume

hazardous waste,

such

as

foundry

baghouse

dust,

is

disposed

of

in a

situation

where

it

is

not

exposed

to a

heavily

buffered

acidic

leachate,

but

rather

to

unbuffered

waters

such

as

rain.

Tests

are

available

which

simulate

the

more

typical

disposal

situation

for

hazardous

wastes

such

as

foundry

waste.

These

tests

utilize

a

relatively

unbuffered

solution,

e.g.,

deionized

water,

to

provide

a better

simulation

of

leaching

as

it actually

occurs

in

the

environment.

Examples

of

nonacidic

or

not

heavily

buffered

acidic

leach

tests,

commonly

referred

to as

water

leach

tests,

include

the Indiana Water Leach Test, which

is also called the EP Water

Test (Indiana

Administrative Code

Title

329, Article 2,

Solid Waste Management

Rule

9);

the

U.S. EPA

Multiple

Extraction Procedure

(U.S. EPA, 1986, Test Methods for Evaluating

Solid Waste,

Volume I C,

Method

1320); the American Society

.of

Testing

Materials

Test

(ATSM Standards,

method D3987-85); the American Foundrymans

Society Leach Test (Ham,

R. K., W. C. Boyle

and

T. P.

Kunes, J. Env.

Eng.

Div. Amer.

Soc. Civil Eng., 107 EEL,

pp.

155-170, 1981); and the

University

of

Wisconsin

SLT

Test

(Ham, R. K., M. A. Anderson, R. Stegmann

and

R.

R.

Stanforth,

EPA

600/2-79/109, 1979).

For wastes that are not disposed

of in

acidic

environments, two separate leach

tests need to be

run to determine whether

the

waste

is hazardous according to regulatory

standards, and to

determine whether the waste could pose an actual environmental

risk when exposed

to nonacidic

leachate in a disposal facility. The EP Toxicity

Test

or TCLP test will define

the regulatory

status

of

the waste. A water leach test will

provide an indication of the actual

leaching potential

of the waste in the environment.

It is important to utilize both types

of

tests

because lead and zinc are amphoteric

metals.

Therefore,

at alkaline pH values, lead will

solubilize and may leach from waste

at concentrations

that exceed the drinking water standards (maximum

contaminant

levels) established

under the

Safe

Drinking Water Act. Lead levels may even exceed

the hazardous waste standards

at alkaline

pH values. Because zinc is also an amphoteric metal, it would

be

expected

that zinc could

also

leach

from

waste at alkaline

PH

values,

at levels of environmental concern.

It should be noted

that cadmium is not an amphoteric metal except at extremely

high pH and leaching

of cadmium

from treated

waste

under

nonacidic leaching conditions has

not

been

observed.

These considerations are important because one

method

that

has been used for treating

hazardous

wastes containing leachable metals

is the addition of alkaline materials

to

control

the pH of the

EP Toxicity test so that the metals will not be extracted at

levels above the hazardous waste

standards

when the

waste is

analyzed using the EP Toxicity Test

or TCLP test. A number of

alkaline additives have been used which chemically react with

metals in the waste

and

control

the leaching

test

pH.

(See,

for

example,

Hickock, E. A., and Associates.

1984, “Foundry Waste

Stabilization:

Laboratory Testing and Conceptual Equipment

Design”, Report

to Participating

Foundry

Groups, 47 pages; California Cast Metals Association,

1989, “Detoxifiing Foundry

Sand”,

Report to Members; Nagle,

D.L., R. R. Stanforth, P. E. Duranceau and

T. P. Kunes, 1983,

AFS

Transactions, Vol. 91,

pp.

715-720; Turpin,

P.

D.,

T. R. Stolzenburg, W.

A.

Stephens,

and

T. P.

Kunes,

1985, AFS

Transactions,

Vol. 93,

pp.

737-740; and

U.S. Pat. No. 4,889,640 issued

Dec.

26,

1989 to Stanforth).

Hazardous wastes containing leachable metals that are

treated with alkaline additives

currently

meet regulatory

standards for

land disposal. However, the tests used

for regulatory purposes, the

EP

Toxicity Test and TCLP, do not necessarily simulate

actual environmental conditions.

Consequently,

it is possible to treat a waste

with

chemical

additives to reduce

leaching of metals

such as

lead

and

cadmium in the

EP Toxicity Test and TCLP to render

it nonhazardous from

a

regulatory standpoint,

while

at

the

same time increasing the

pH to the point where lead

is

solubilized when a water leach test is run. For wastes

containing

zinc, it would

also be

expected

that

zinc could leach

at levels

of

environmental

concern. Since the water

leach test simulates

common

disposal conditions

in

the environment,

this

indicates

that it

is

possible

to create

an

environmental

problem

in the

process

of

solving a

regulatory

problem.

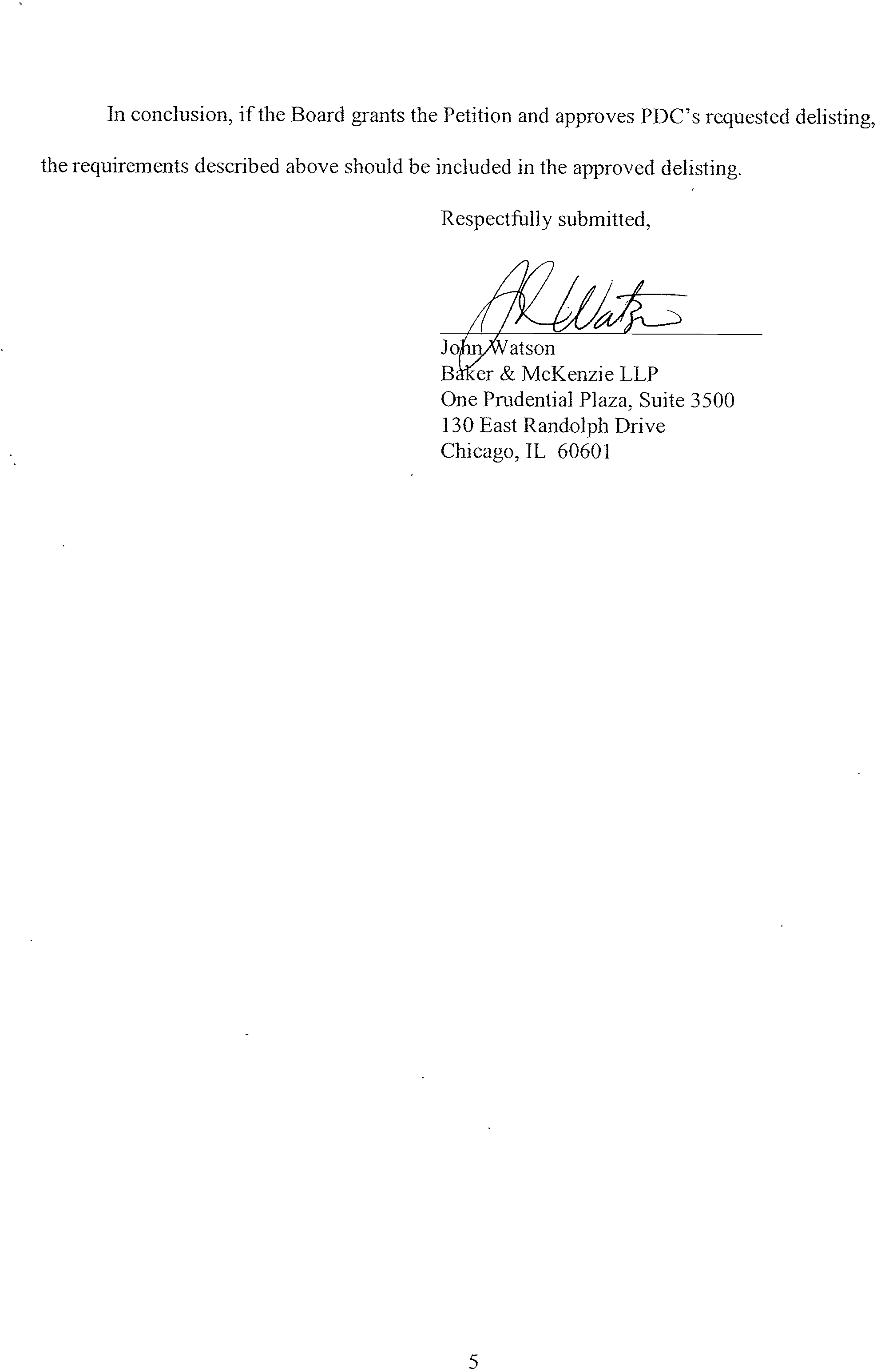

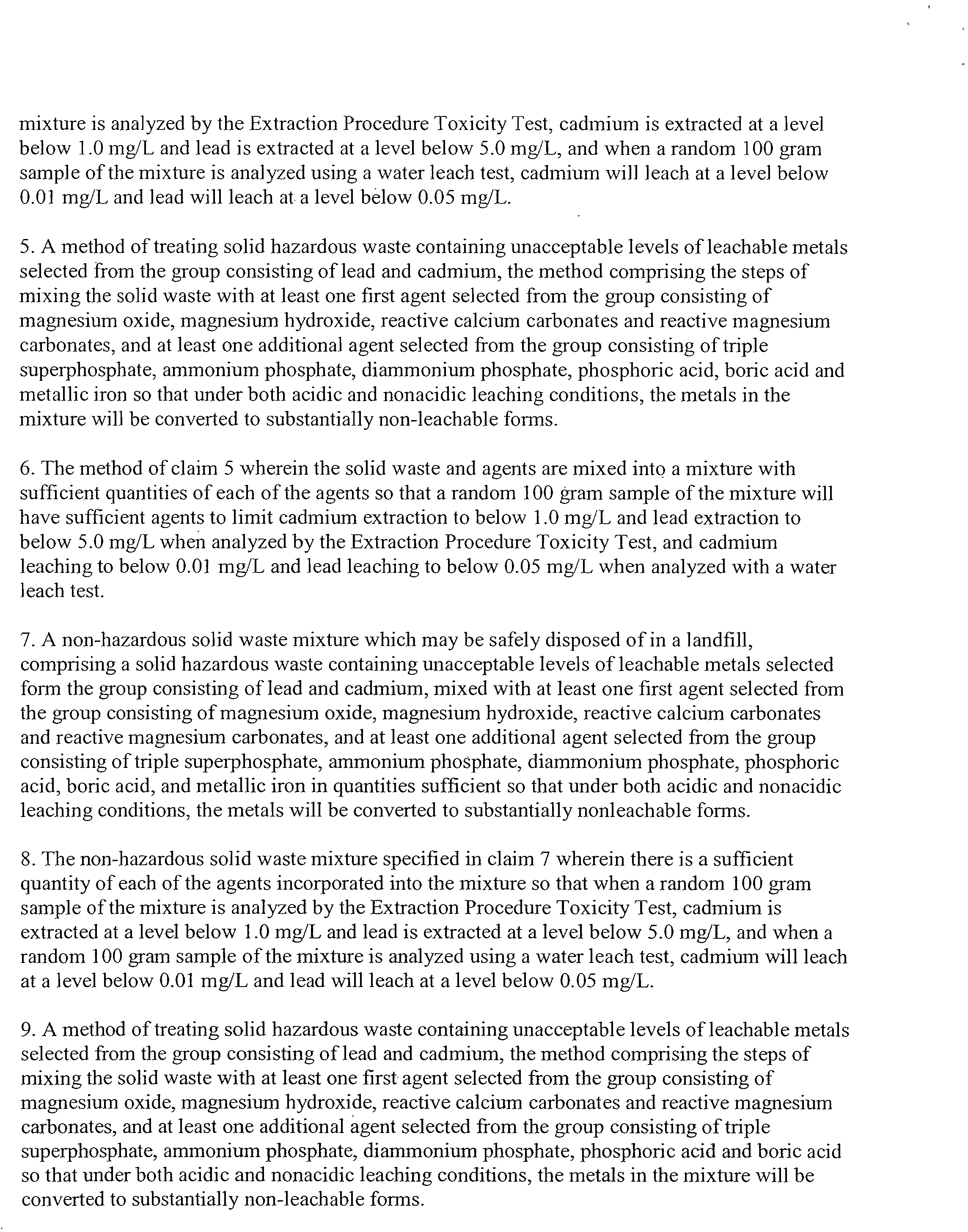

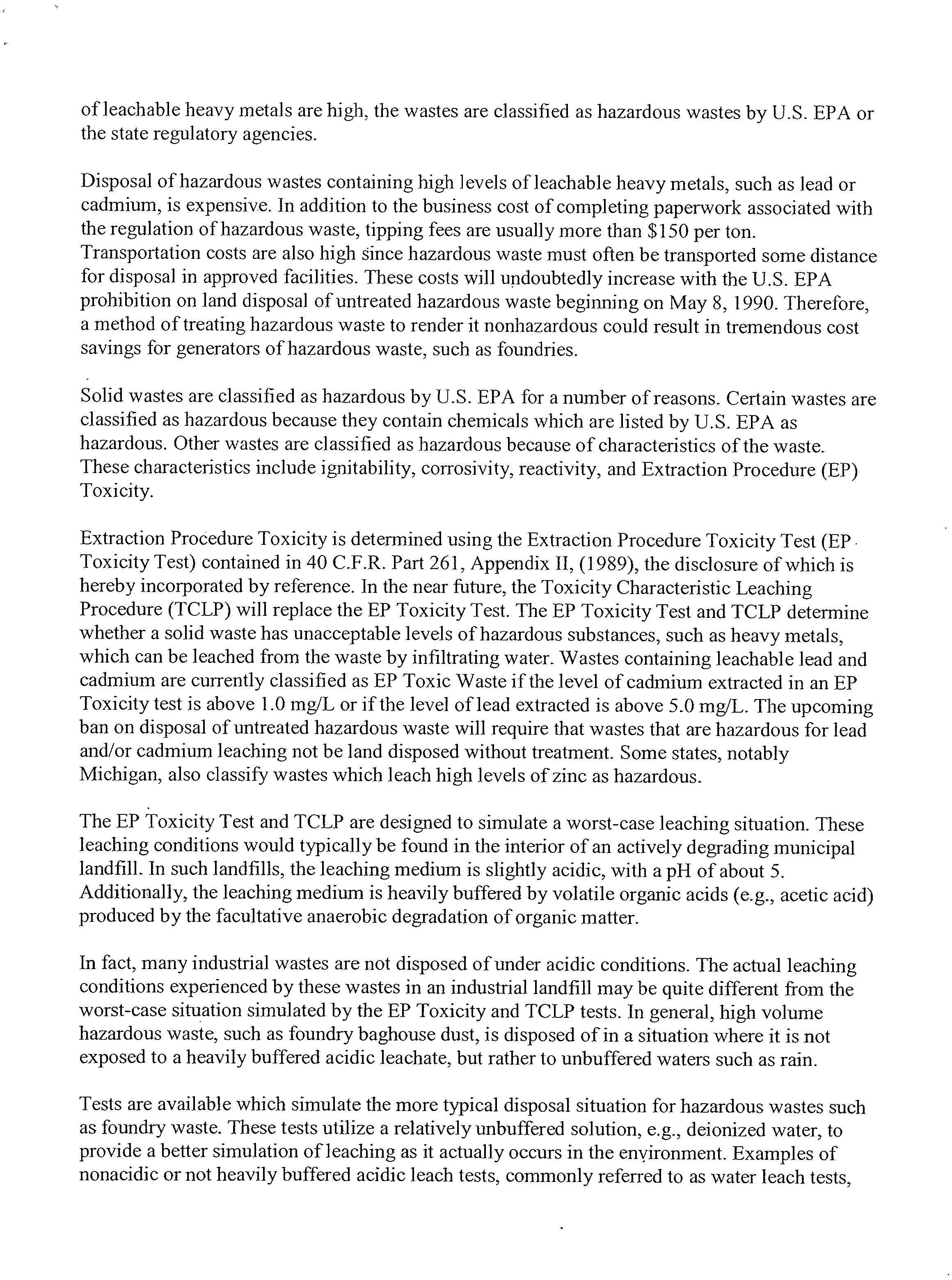

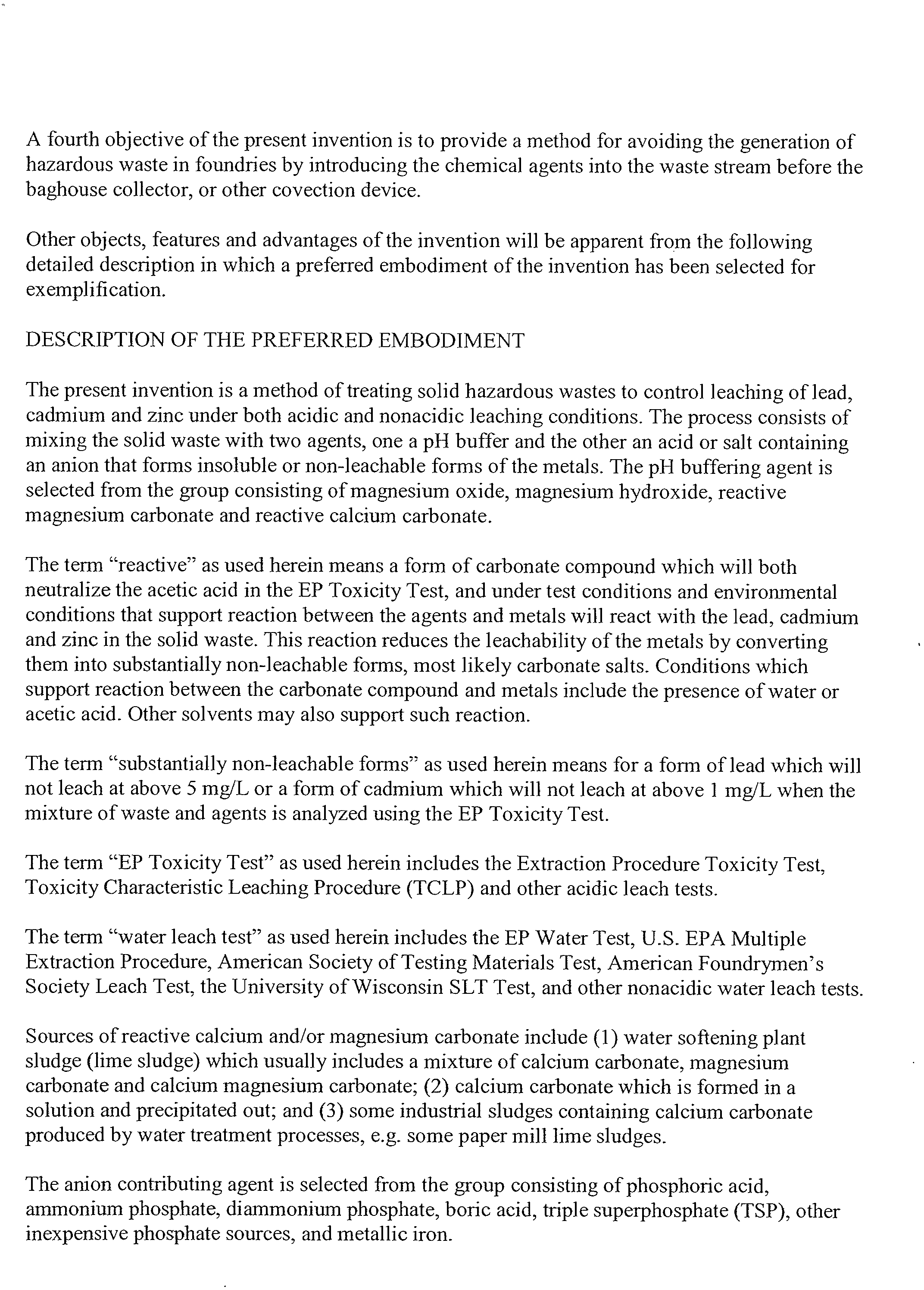

The

data

in Table I

show

the problem

with present

treatment

methods

which reduce

leaching

of

lead

and cadmium

when

a treated

waste

is analyzed

using an

acidic

leach test such

as the

EP

Toxicity

Test or

TCLP,

but simultaneously

increase

leaching

of lead

when treated

waste

is

analyzed

using

a water

leach

test.

Note

that some

of the additives,

particularly

cement,

are

commonly

thought

to

chemically

bind up

heavy

metals

(U.S.

EPA (1989),

“Stabilization

of

CERCLA

and RCRA

Wastes”,

publication

EPA 1625/6-89/022,

Cincinnati,

Ohio). As shown

in

Table 1,

the binding

was

not

sufficient to

immobilize

the

metals at alkaline

pH

values.

Untreated

Treated

with

Magnesium

Oxide

+7.5%

3.

5.1

9.2

Untreated

Treated

with

Calcium Oxide

+4%

6.9

16.0

+6%

8.9

5.5

+8%

9.7

8.8

+10%

10.0

8.6

+12%

11.0

8.6

EP Toxicity

Test Standards

Drinking

Water

Standards

(MCL5)

TABLE

1

TREATMENT

OF

EP TOXIC

WASTES

WITH

ALKALINE

ADDITIVES:

EP TOXICITY

AND

WATER

LEACH TEST

RESULTS

EP

Toxicity

Test

EP Water

Test

Final

Cd

Pb

Final

Cd

Pb

Sample

pH

mg/L

pH

mg/L

1.

5.6

8.8

Not Tested

Untreated

Treated

with

Cement

+20%

7.2

3.0

+30%

9.4

<0.005

2.

5.0

9.8

79

12

0.3

85.1

11.5

11.9

9.8

<0.005

12

<0.005

26

0.0034

9.7

0. 022

0.029

0.3 10.8

0.0003

1.3

9.7

6.5 6.8

3.4

-—

11.0

11.9

0.23

0.3 12.1

0.04

0.4

12.4

0.02

0.3

12.4

0.01

2.4

12.5

1.0

5.0

<0.01

<0.01

<0.01

<0.01

0.01

0.05

There are

single compound additives that can be used to control

leaching in both an EP Toxicity

Test and a

water leach test, that are not covered

by

this invention

disclosure,

for

example,

reactive calcium

carbonate

and

reactive

magnesium

carbonate as disclosed

in U.S.

Pat.

No.

4,889,640, which is incorporated herein by reference. However, a

problem with

reactive

calcium

carbonate is that it is less effective at preventing the leaching

of

lead

and cadmium, if the solid

waste

contains

high

levels

of

zinc, because zinc interferes with

the conversion of lead and

cadmium to

carbonate salts.

SUMMARY OF

THE INVENTION

In

accordance with the present

invention,

a method is disclosed for treating solid hazardous

waste containing unacceptable

levels

of leachable metals such as lead, cadmium

and

zinc,

which

includes the steps of mixing the solid waste with at least two additives, the

first a pH

buffering

agent and an additional agent which is an acid or salt containing an anion that

forms

insoluble

or

non-leachable forms of leachable metals such as lead, cadmium and zinc. The

pH

buffering

agent

is

selected

from

the group consisting of magnesium oxide, magnesium hydroxide, reactive

magnesium carbonate and

reactive calcium carbonate.

The anion contributing agent is selected

from the group consisting of

phosphoric

acid,

ammonium

phosphate,

diammonium phosphate,

boric acid, triple

superphosphate (TSP), other inexpensive

phosphate sources, and

metallic

iron.

The solid

waste and agents are mixed so that under both acidic and nonacidic leaching

conditions,

the metals will be converted to

substantially

non-leachable

forms.

Preferably,

the solid waste and agents are mixed into a mixture with a sufficient quantity of the

agents

so

that any 100

gram

sample of the

mixture has sufficient quantities

of

the

agents

to

limit

cadmium

extraction

to below 1.0 mg!L and lead extraction to below 5.0 mg/L when the sample

is

analyzed in accordance

with the

EP

Toxicity or TCLP Test, and at the

same

time, limit leaching

of lead to

below 0.05 mg!L and cadmium to

below

0.01 rngJL when analyzed with a water leach

test. This

method

would

also

be

expected to control zinc leaching under

both

acid and

nonacidic

conditions,

because like lead, zinc

is

an amphoteric metal.

Thus,

a primary

objective of the invention is to provide a method of treating solid hazardous

wastes containing

unacceptable levels of

leachable

metals

such as lead, cadmium and zinc to

reduce

the leaching of

lead,

cadmium,

and zinc and thereby render

the

waste

non-EP

toxic,

while

at

the same time

reducing lead and zinc leaching under the more typical nonacidic leaching

conditions

present

in the

environment.

A

second objective of the

invention

is

to make the treatment

method disclosed in U.S.

Pat.

No.

4,889,640 more

effective,

by overcoming the problem of zinc interfering with lead and cadmium

reaction

in wastes

which

also

contain zinc.

This

is accomplished

by

combining

the

reactive

calcium

carbonate

or reactive magnesium carbonate

with

an anion contributing agent.

A

third objective of

the invention is to provide a method

of

treating

solid

hazardous waste

containing

unacceptable

levels

of

leachable metals, such

as lead, cadmium and zinc, so

that

the

treatment

effectiveness does not decrease with the age of the treated waste.

A

fourth

objective

of

the

present

invention

is to provide

a method

for avoiding

the

generation

of

hazardous

waste

in

foundries

by

introducing

the

chemical

agents

into

the waste

stream

before

the

baghouse

collector,

or

other

covection

device.

Other objects,

features

and advantages

of the

invention

will

be apparent

from

the following

detailed

description

in which

a preferred

embodiment

of

the invention

has

been

selected

for

exemplification.

DESCRIPTION

OF

THE

PREFERRED

EMBODiMENT

The

present

invention

is

a method

of

treating

solid

hazardous

wastes

to

control

leaching

of lead,

cadmium

and zinc

under

both

acidic and

nonacidic

leaching

conditions.

The process

consists

of

mixing

the solid

waste

with

two

agents,

one

a

pH

buffer

and

the

other

an acid

or salt

containing

an anion

that

forms insoluble

or non-leachable

forms

of

the metals.

The

pH

buffering

agent

is

selected

from

the group

consisting

of magnesium

oxide,

magnesium

hydroxide,

reactive

magnesium

carbonate

and

reactive

calcium

carbonate.

The

term

“reactive”

as used

herein

means

a

form of

carbonate

compound

which

will

both

neutralize

the acetic

acid

in

the

EP

Toxicity

Test,

and

under

test

conditions

and

environmental

conditions

that

support

reaction

between

the

agents

and

metals

will

react

with the

lead,

cadmium

and zinc

in the

solid

waste.

This

reaction

reduces

the

leachability

of the

metals

by

converting

them into

substantially

non-leachable

forms,

most

likely carbonate

salts.

Conditions

which

support

reaction

between

the carbonate

compound

and

metals

include

the

presence

of

water

or

acetic acid.

Other

solvents

may

also

support

such reaction.

The term

“substantially

non-leachable

forms”

as used

herein

means

for a

form

of lead

which

will

not

leach

at above

5 mg/L

or a

form of

cadmium

which

will

not leach

at above

I mg/L

when

the

mixture

of waste

and agents

is

analyzed

using

the EP

Toxicity

Test.

The term

“EP

Toxicity

Test”

as

used

herein

includes

the

Extraction

Procedure

Toxicity

Test,

Toxicity

Characteristic

Leaching

Procedure

(TCLP)

and other

acidic

leach

tests.

The

term

“water

leach

test”

as

used herein

includes

the EP

Water Test,

U.S.

EPA

Multiple

Extraction

Procedure,

American

Society

of

Testing

Materials

Test,

American

Foundryrnen’s

Society

Leach

Test,

the University

of

Wisconsin

SLT

Test,

and other

nonacidic

water

leach

tests.

Sources

of reactive

calcium

and/or

magnesium

carbonate

include

(1)

water

softening

plant

sludge

(lime

sludge)

which

usually

includes

a

mixture

of calcium

carbonate,

magnesium

carbonate

and

calcium

magnesium

carbonate;

(2)

calcium

carbonate

which

is formed

in

a

solution

and

precipitated

out; and

(3) some

industrial

sludges

containing

calcium

carbonate

produced

by

water

treatment

processes,

e.g.

some

paper

mill

lime

sludges.

The

anion

contributing

agent

is

selected

from

the group

consisting

of

phosphoric

acid,

ammonium

phosphate,

diammonium

phosphate,

boric

acid,

triple

superphosphate

(TSP),

other

inexpensive

phosphate

sources,

and

metallic

iron.

In

the preferred embodiment,

solid waste

which

is

classified

as hazardous

due to

high

levels

of

leachable lead or

cadmium

is

treated

with a

combination

of magnesium

oxide

as a pH

buffer and

triple superphosphate (TSP) as an anion contributor. An appropriate mixture of these agents and

the solid waste will control leaching of the metals under both acidic and nonacidic conditions.

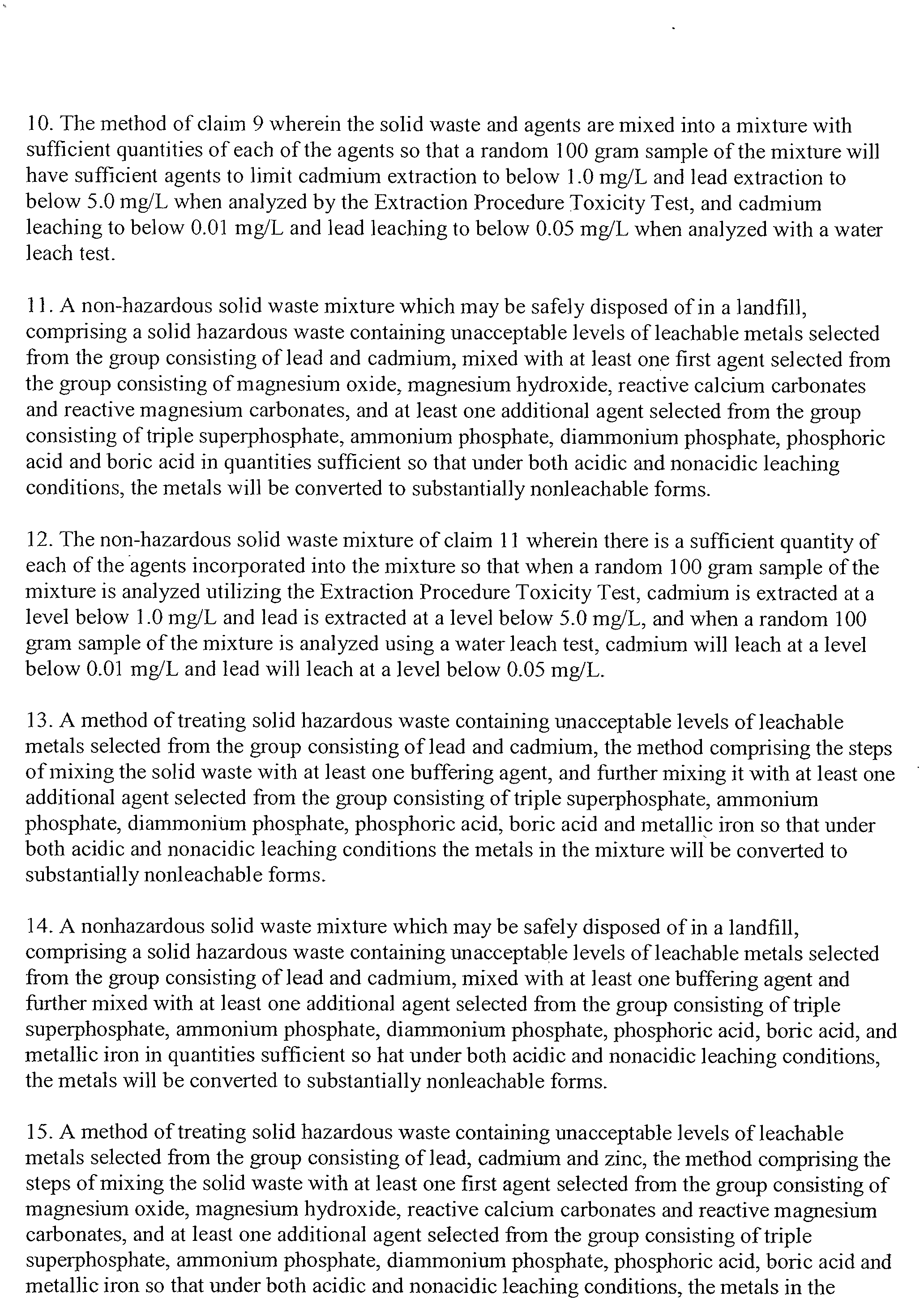

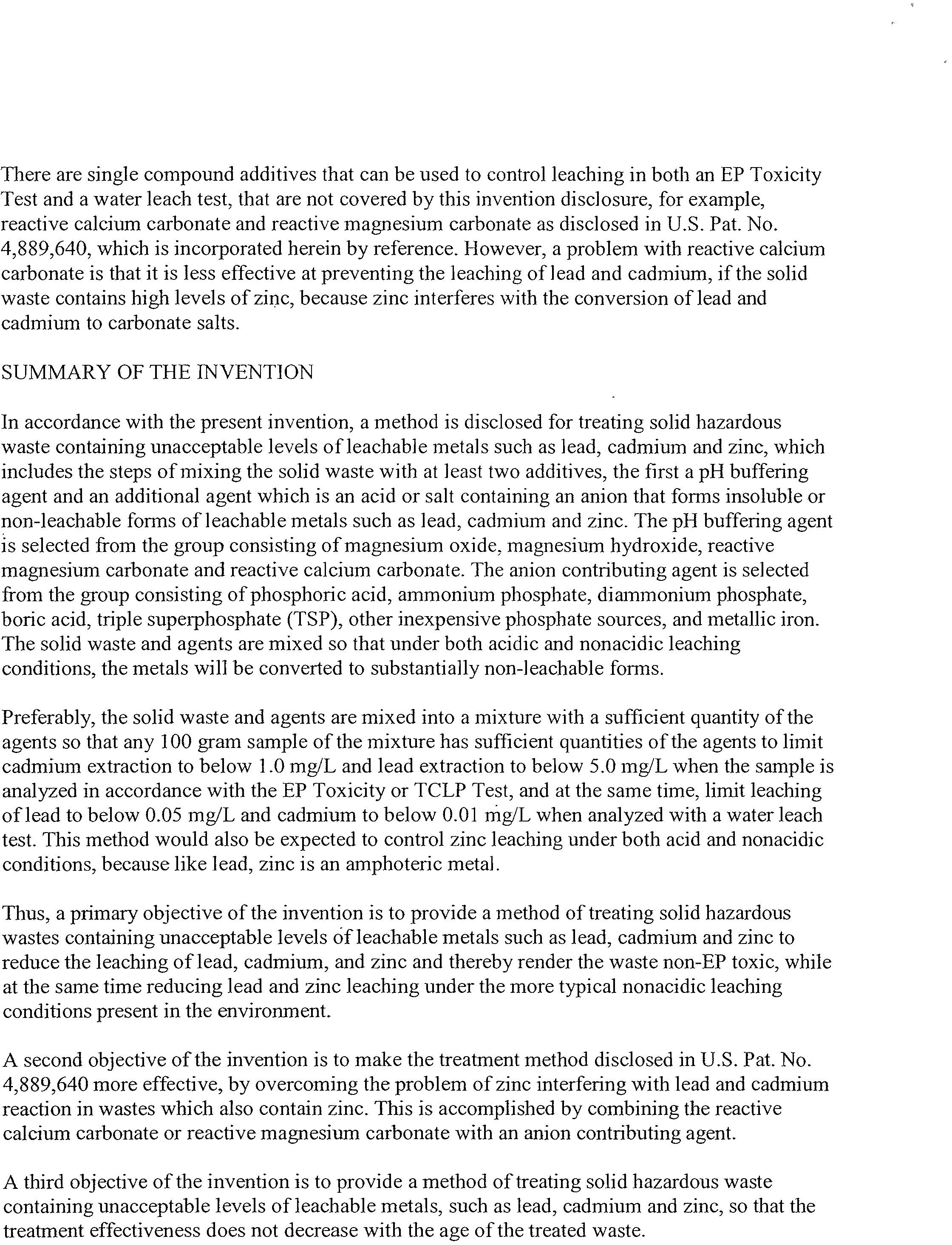

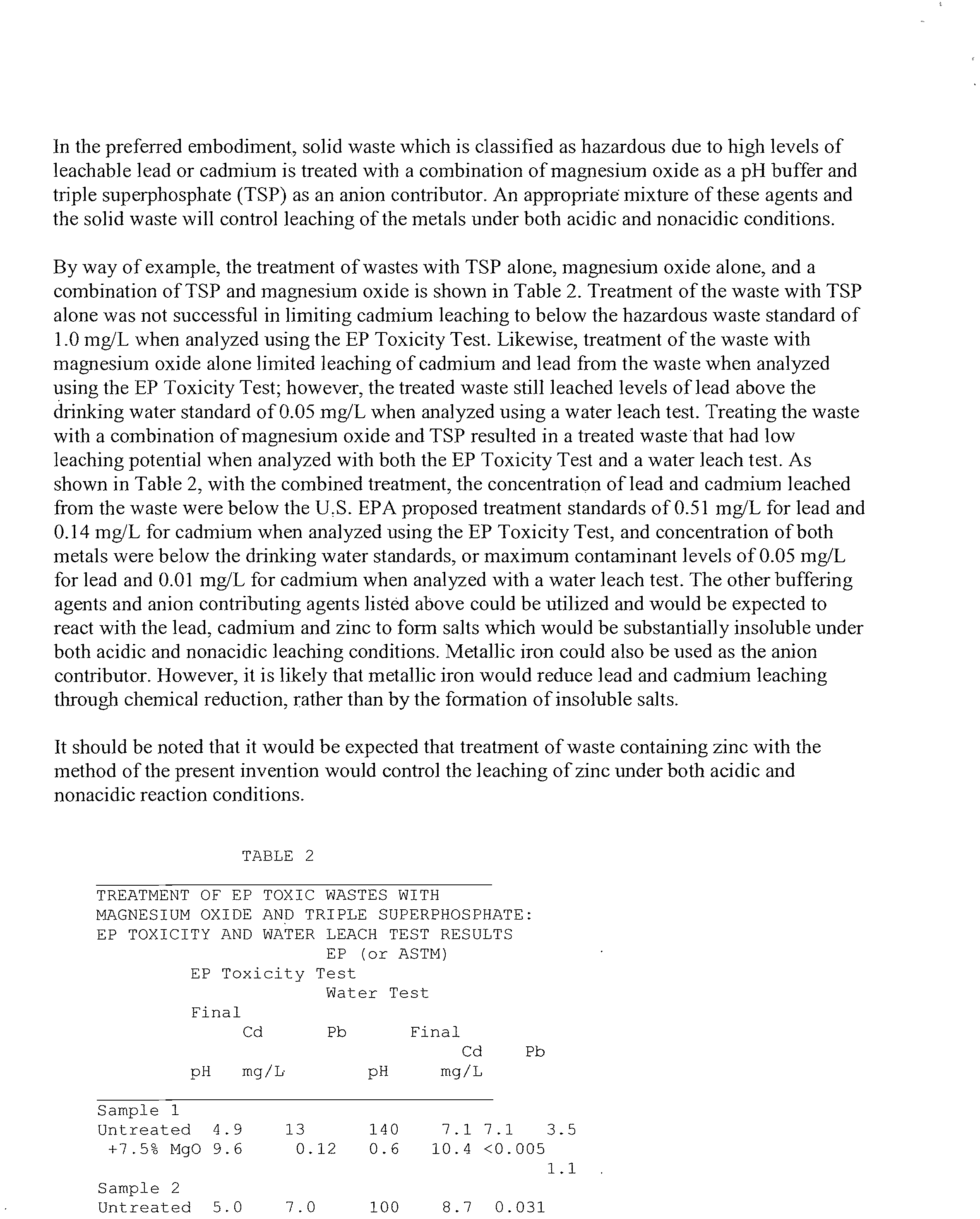

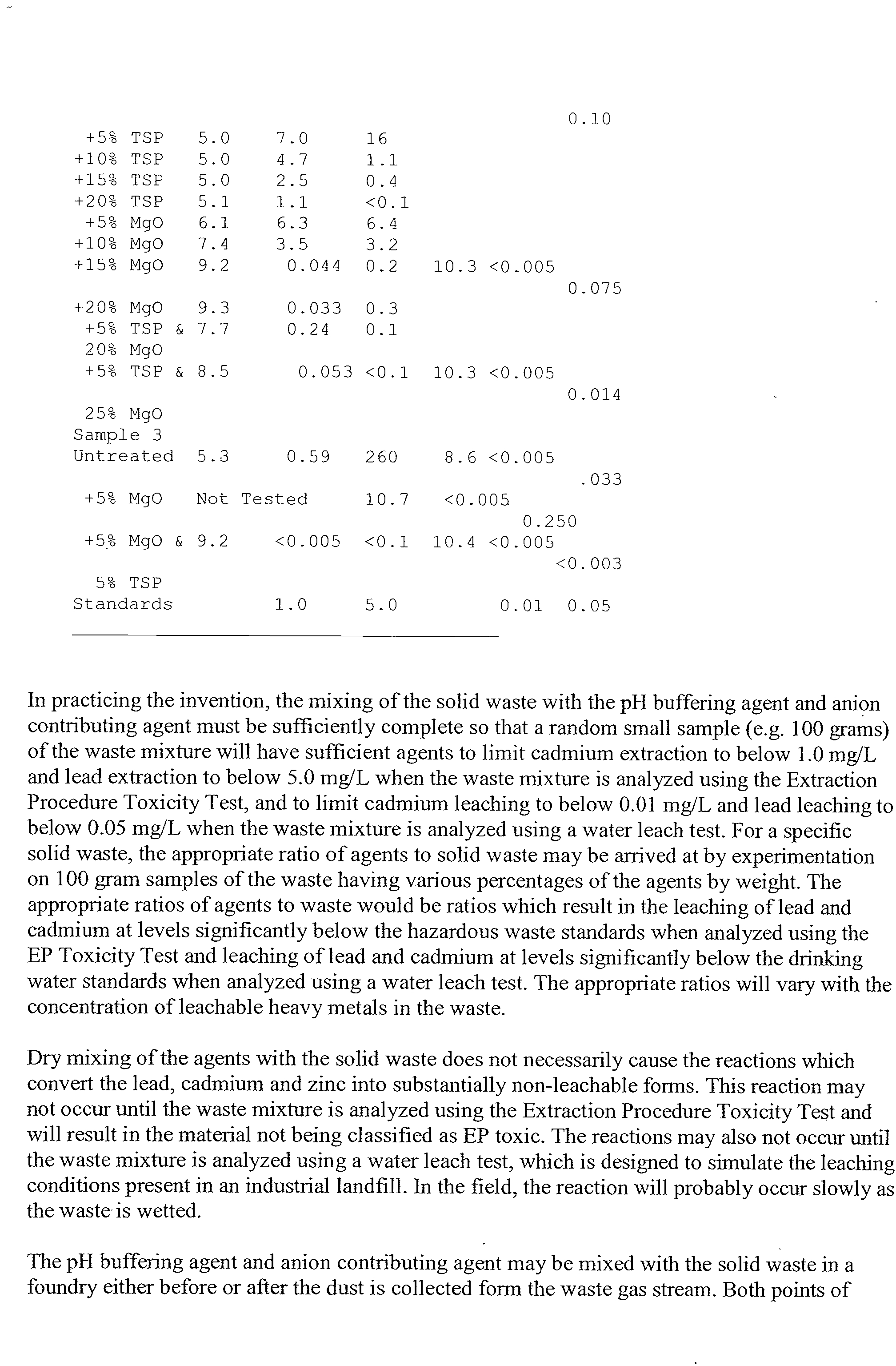

By

way

of

example, the treatment

of

wastes with

TSP

alone,

magnesium oxide

alone, and a

combination

of TSP and magnesium oxide is

shown

in Table 2. Treatment of

the waste with

TSP

alone was not successful in limiting cadmium leaching to below the hazardous waste standard of

1.0

mg/L

when analyzed using the EP Toxicity Test. Likewise, treatment

of

the waste with

magnesium

oxide alone limited leaching

of cadmium

and

lead from

the waste when analyzed

using the EP Toxicity Test;

however,

the treated waste still leached levels of lead above the

drinking water standard of 0.05 mg/L when analyzed using a water leach test. Treating the waste

with

a

combination of magnesium oxide and TSP resulted in a treated wastethat had low

leaching potential when analyzed with both the

EP

Toxicity Test and a water leach test. As

shown

in

Table 2, with the combined treatment, the concentration

of

lead and cadmium leached

from

the waste were below the

U.S.

EPA proposed treatment standards of 0.51 mg/L for lead and

0.14

mg/L

for cadmium when analyzed using the EP Toxicity Test, and concentration of both

metals were below the drinking water standards, or maximum contaminant levels of 0.05 mg/L

for lead and 0.01 mg!L for cadmium when analyzed

with

a water leach test. The other buffering

agents and anion contributing agents listed

above

could be utilized and would be

expected

to

react with

the lead, cadmium and zinc to

form

salts which would be substantially insoluble under

both acidic and nonacidic leaching conditions. Metallic iron could also be used as the anion

contributor.

However,

it

is

likely that metallic

iron

would

reduce

lead and cadmium

leaching

through

chemical reduction,

rather

than

by

the formation of insoluble salts.

It should be

noted that it would be expected that treatment

of

waste containing zinc with the

method of the present

invention

would control the leaching of

zinc

under both acidic and

nonacidic

reaction conditions.

TABLE 2

TREATMENT OF EP TOXIC

WASTES WITH

MAGNESIUM

OXIDE AND TRIPLE SUPERPHOSPHATE:

EP TOXICITY

AND WATER LEACH TEST RESULTS

EP

(or

ASTM)

EP Toxicity Test

Water

Test

Final

Cd

Pb

Final

Cd

Pb

pH

mg/L

pH

mg/L

Sample 1

Untreated

4.9

13

140

7.1 7.1

3.5

+7.5% MgO 9.6

0.12

0.6

10.4 <0.005

1.1

Sample 2

Untreated 5.0

7.0

100

8.7

0.031

0.10

25%

I’4g0

Sample

3

Untreated

5.3

0.59

260

8.6

<0.005

10.7

<0.005

0.250

+5%

MgO

&

9.2

<0.005

<0.1

10.4

<0.005

5% TSP

Standards

In

practicing

the invention,

the

mixing

of

the

solid

waste

with

the

pH

buffering

agent

and

anion

contributing

agent

must

be

sufficiently

complete

so

that

a

random

small

sample

(e.g. 100

grams)

of

the waste

mixture

will

have

sufficient

agents

to limit

cadmium

extraction

to below

1.0

mg/L

and

lead

extraction

to

below

5.0

mg/L

when

the

waste

mixture

is analyzed

using

the

Extraction

Procedure Toxicity

Test,

and

to limit

cadmium

leaching

to below

0.01

mg/L

and

lead leaching

to

below

0.05

mg/L

when

the

waste

mixture

is analyzed

using

a

water

leach

test.

For

a specific

solid

waste,

the

appropriate

ratio

of

agents

to

solid

waste

may

be arrived

at

by

experimentation

on

100

gram

samples

of the

waste

having

various

percentages

of the

agents

by

weight.

The

appropriate

ratios

of

agents

to

waste

would

be

ratios

which

result

in

the leaching

of

lead

and

cadmium

at levels

significantly

below

the

hazardous

waste

standards

when

analyzed

using

the

EP

Toxicity

Test

and

leaching

of

lead

and

cadmium

at levels

significantly

below

the

drinking

water

standards

when

analyzed

using

a water

leach

test.

The

appropriate

ratios

will

vary

with

the

concentration

of

leachable

heavy

metals

in

the waste.

Dry

mixing

of

the

agents

with

the

solid

waste

does

not necessarily

cause

the reactions

which

convert

the

lead,

cadmium

and

zinc

into substantially

non-leachable

forms.

This

reaction

may

not

occur

until

the

waste

mixture

is analyzed

using

the

Extraction

Procedure

Toxicity

Test

and

will

result

in the

material

not

being

classified

as

EP

toxic.

The

reactions

may

also not

occur

until

the

waste

mixture is

analyzed

using

a

water

leach

test,

which

is

designed

to simulate

the leaching

conditions

present

in an

industrial

landfill.

In

the

field,

the

reaction

will

probably

occur

slowly

as

the

waste

is

wetted.

The

pH

buffering

agent

and

anion

contributing

agent

may

be

mixed

with

the

solid

waste

in

a

foundry

either

before

or

after

the

dust

is

collected

form

the

waste

gas

stream.

Both

points

of

+5%

TSP

5.0

7.0

16

+10%

TSP

5.0

4.7

1.1

+15%

TSP

5.0

2.5

0.4

+20%

TSP

5.1

1.1

<0.1

+5%

MgO

6.1

6.3

6.4

+10%

MgO

7.4

3.5

3.2

+15%

MgO

9.2

0.044

0.2

10.3

<0.005

+20%

MgO

9.3

0.033

0.3

+5%

TSP

&

7.7

0.24

0.1

20%

MgO

+5%

TSP

& 8.5

0.053

<0.1

10.3

<0.005

+5%

MgO

Not

Tested

0.075

0.014

.033

<0.

003

1.0

0.01

0.05

5.0

addition

have

been

used

in

the past

for addition

of

materials

to foundry

wastes.

For

example,

injection

of

materials,

commonly

lime, into

foundry

ductwork

has

been

used

for

years

as

a

method

of

coating

baghouses

with

materials

to protect

against

sparks

and

improve

dust

collecting.

Such

mixing

may

be

accomplished

by

injection

of

the

pH

buffering

agent

and

anion

contributing

agent

into

foundry

ductwork

before

the baghouse.

This

is

a

preferred

application,

because

treatment

in

the

ductwork

prior

to dust

collection

may

eliminate

the

generation

of a

hazardous

waste

because

such

treatment

is considered

totally

enclosed

treatment

by

the

U.S.

EPA

and

does

not require

permitting.

Because

generators

of hazardous

waste

are subject

to

regulation,

it

is

an ad-vantage

to

avoid

generating

hazardous

waste

in

the first

place.

The

two

agents

used

in the preferred

embodiment

of

the invention,

magnesium

oxide

and triple

superphosphate,

are

both

dry

materials

that

can

be injected

into

ductwork.

Triple

superphosphate,

however,

would

need

to

be pulverized

before

being

injected.

It

is understood

that the

invention

is

not confined

to the

particular

process

disclosed

herein,

nor

to

the

materials

and

substances

described,

but embraces

such

modified

forms

thereof

as

come

within

the

scope

of

the

following

claims.