CONTROL BOARD

IIE SPECIFIC

RULE FOR CITY OF SPRINGFIELD,

OFFICE

OF PUBLIC

0 2.208( 8)

ROM 35 ILL. ADM. CODE

ecific Rulemaking --

100 West Randolph St

TRICT

60601

a

James R. Thompson Center

100 West Randolph, Suite 11-500

nois 60601

Ret

Ily submitted,

and

Date: November 21, 2008

By:

/s/ Chri

3150 Roland Avenue

Post Office Boy 5776

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

ION CONTROL BOARD

Light and Power ("CWLP") and Springfield Metro Sanitary

T -HEARING D OCU

N

OW COME the

Petitioners, City of Springfield, Illinois, Office of

rs"), by and through their attom

T".aI I u'-rI I,

I

C I ill;II

o

rt Documen

R09-8

c fit-enced

in the Technical

ioners, including:

al supply from

l. See especially,

pages

IV-1

as Attachrnen

through I

. The Report is attached hereto

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Sargent and Lundy, LLC, City Water Light & Power

Dallman &

Lakeside

Station Water Conservation Study

"Water

Conservation

Study"), April 2005, referenced

the TSD at page 6-5, regarding the inves

of a completely dry bottom

ash handling

system at the

CWLP Dallman Power Station. See especially, pages

3-4

onstrate anticipated

to as Attachmen

d.

Burns & McDonnell Engineering Co., Letter to Douglas

ing Boron Removal Using

"), May

18, 2007,

referenced in the TSD at page 6-10, regarding the capital

osts for removal of boron i

ate, pages 4 thro

D.

s

that CWLP supp

cotis

i I' lictlti in C O 'LP's

w a

i c'v1 gift,: I- SI I t"Im.

t

'

I

1k)\11 kit I\,

11

rI

Iir 1111ci'..',ove

mmental Cor

,Iýýtý1P(

ill d tl-,: Vl;:%

t

<G

I of Table 6-2 on page 6-1

explained at hearing and in the

of the TSD. As

dy

ý'l''dý,c.ný

2 008 Hearing, Petitioners noticed that

footnote

trator system. See, TSD

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

page

6-10 and Transcript of the Nove

of Table 6-2 of the TSD,

Water,

50-52. A corrected version

BEFORE,

Petitioners,

City

of

Springfield,

Illinois,

Office of

Public

Utilities,

ation and information

November 3, 2008 Hearing,

Order.

ld Metro Sanitary District respectfully sub

November 6, 2008 Hearing Officer

and

By:

ýAt omeys

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

OF SERVICE

I, Christine G. Zei

the undersigned,

ITTAL, upon:

James

100 Nest Randolph Street

Suite 1300

Suite

11-500

Chicago, Illinois 60601

Chicago, Illinois 60601

aettinger@elpc.org

via electronic mai

t

2008; and upon:

1021 North Grand Avenue East

F. Ettinger, Esq.

of Board

c/o Environmental Law and Policv Cent

K°,rd;on, Chief

i-mc.'ilt of Nawtal Resources

III II -Iý-),

F c ,-,tzrces Way

Jaiirc.,ý L. Thompson Center

of the

°r

IU ý .`v"w?',:ýtRand(,lrl1, Suite 11-500

lay depositing said

documents in the United States

By: /s/ Christine G. Zeman

Christine G.

Zeman

+;f)rj(Mý

1

h

eld,

Hearing, Doe Submittal

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

ATTACHMENT A

Phase II S02 Compliance Study Report

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

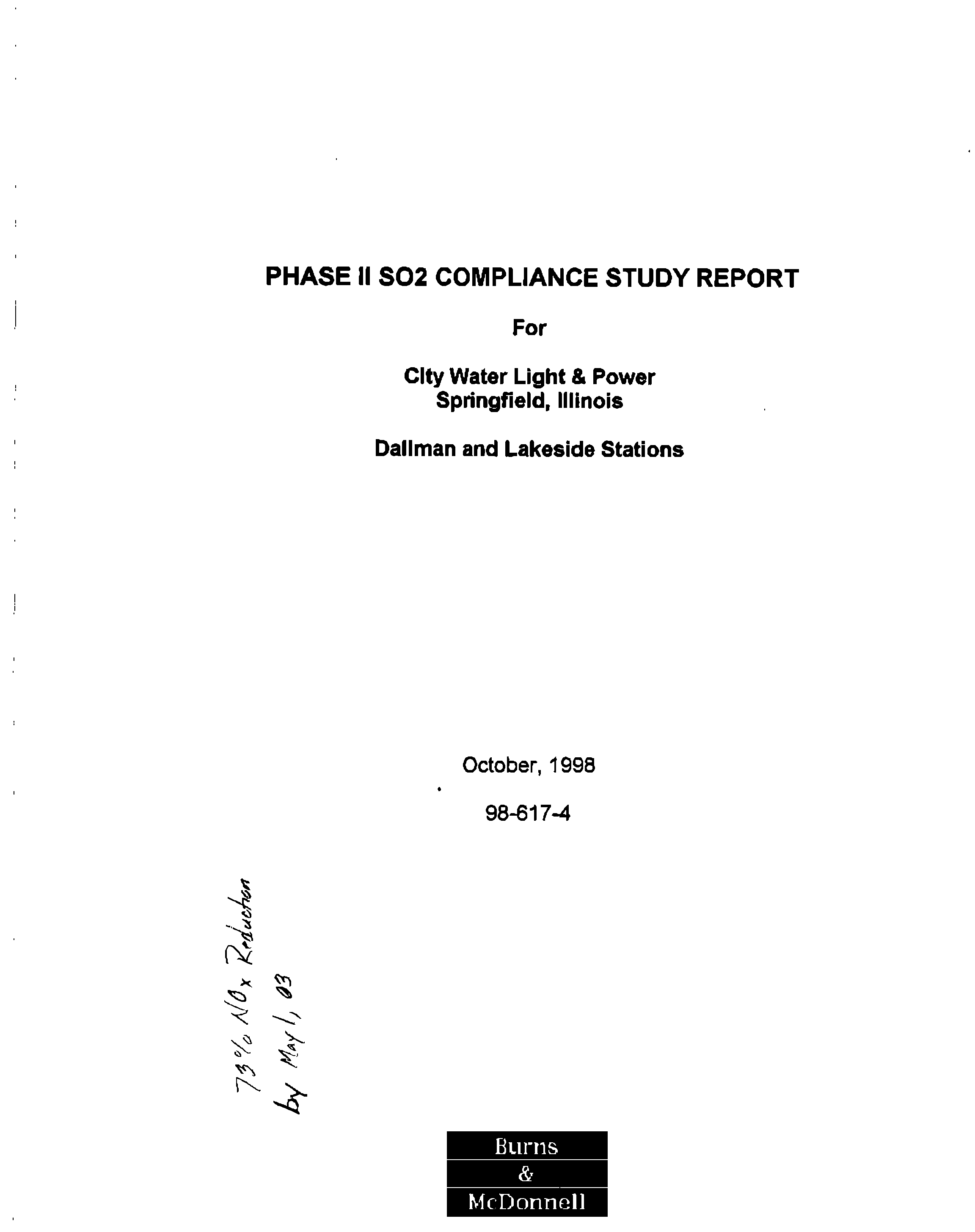

PHASE II S02 COMPLIANCE

STUDY REPORT

For

City Water Light & Power

Springfield, Illinois

Dallman and Lakeside Stations

October,

1998

98-617-4

c

h

ýO

u

a

W

BUI"I75

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

October 7, 1998

Mr. Jay Bartlett

City Water Light

& Power

3 100 Stevenson Drive

Springfield, IL 62757

Phase

11 S02 Compliance Study

Project

No. 98-617-4 (G)

Final Report

Dear

Mr. Bartlett:

Attached

are fifteen copies

of

the final report for the Phase II

S02 Compliance Study in

accordance with

our contract

for professional engineering

services (City of Springfield

purchase order

SCSCA99202021). This study investigated

and evaluated Phase

II 502

compliance options for the Dallman

and Lakeside Stations.

The report was revised

to include the comments received

from City Water Light &

Power

on the draft copy of information included

in the report. Submission of

this

report

and

completion

of the presentation of

study

results

scheduled for October 8, 1998

completes our work on this

project.

We appreciate this opportunity

to provide professional engineering

services to City

Water Light

&

Power

and would like to thank you

and

your

staff

for

your assistance in

providing information

used

in the performance

of the study and preparation of the report.

Brian

E. Basel, P.E.

Project

Manager

Attachments

M INERS " ARLNIRCIS " LONSULIANIS

9400 Word Pordway

N NnsasGly,

Aim,

64114-3319

Tel 816 333

9400

fnx:3163333690

hllp//ww,hummtdcon

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

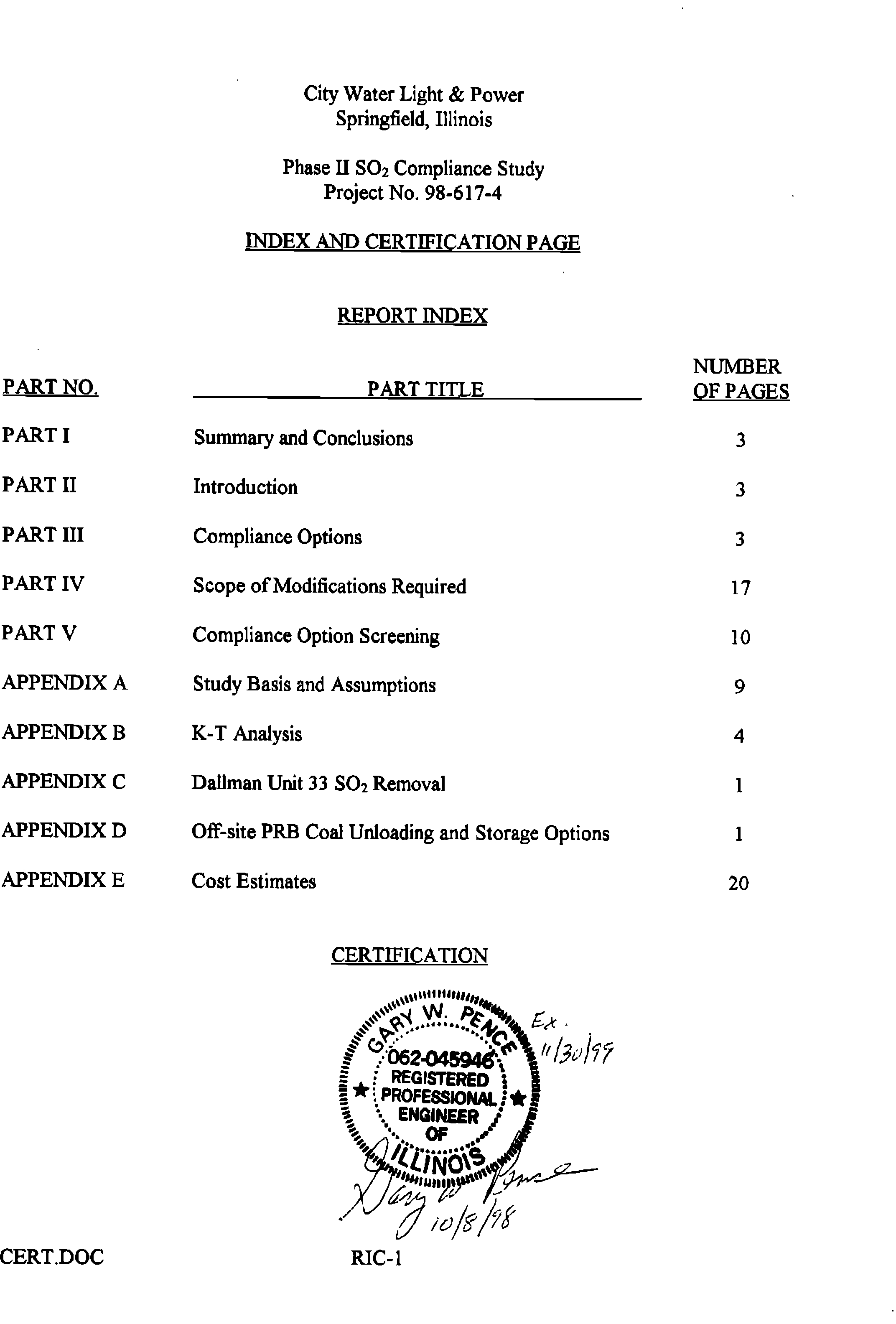

City

Water

Light & Power

Springfield, Illinois

Phase II S02

Compliance

Study

Project

No. 98-617-4

INDEX AND

CERTIFICATION PAGE

REPORTINDEX

NUMBER

PART NO

PART TITLE

OF PAGES

PART I

Summary and

Conclusions

3

PART

II

Introduction

3

PART III

Compliance Options

3

PART I V

Scope of Modifications

Required

17

PART

V

Compliance Option Screening

10

APPENDIX

A

Study

Basis

and

Assumptions

9

APPENDIX

B

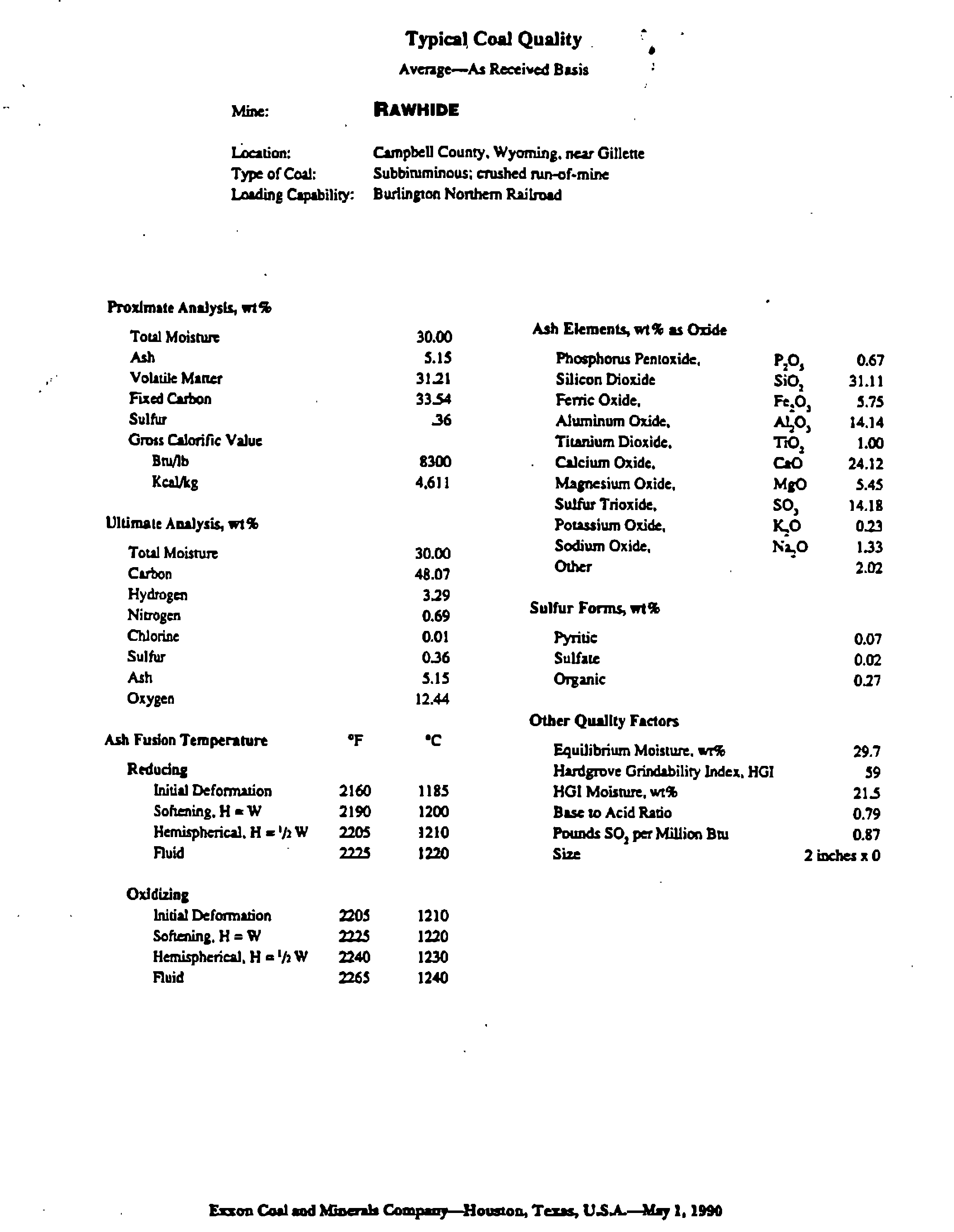

K-T Analysis

4

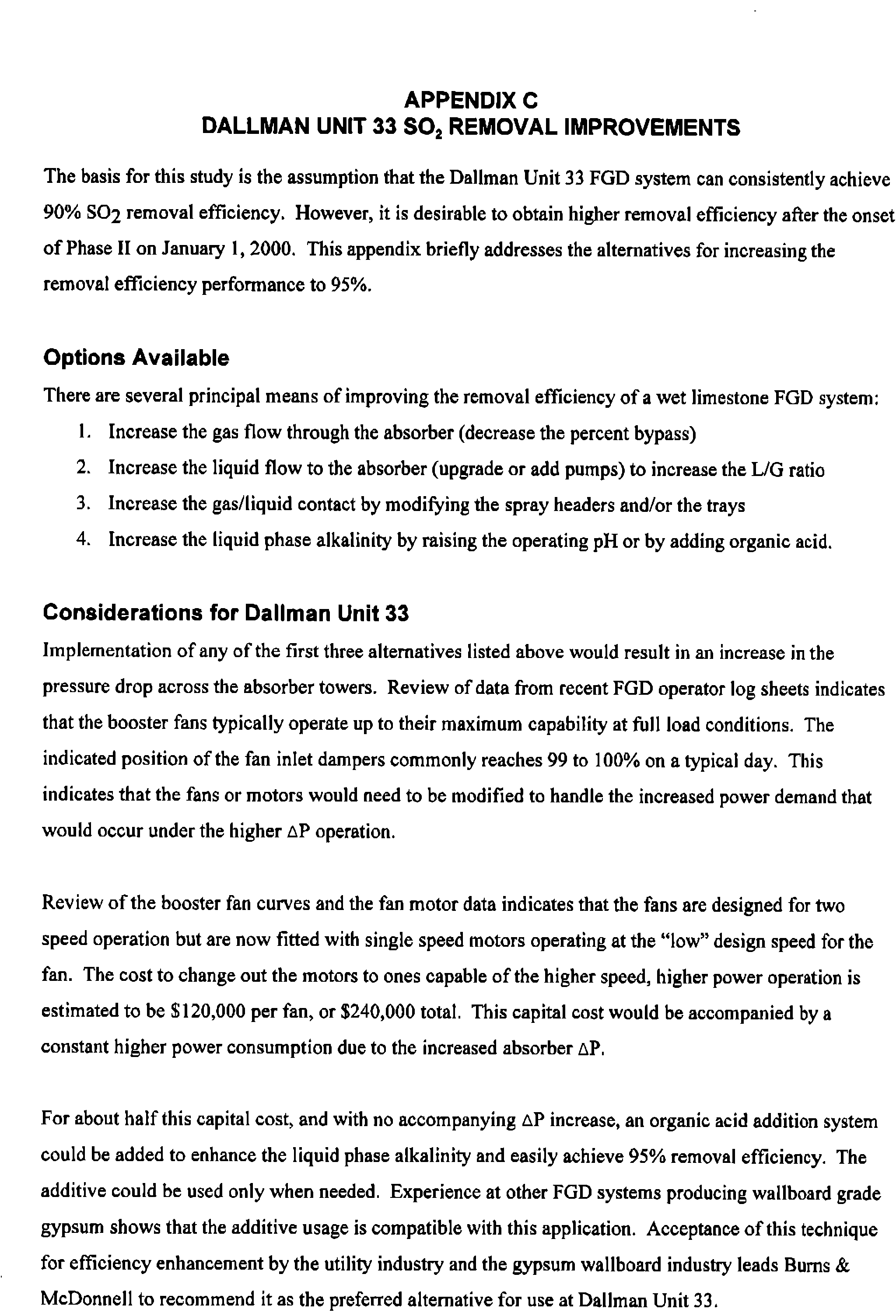

APPENDIX C

Dallman Unit 33

S02 Removal

1

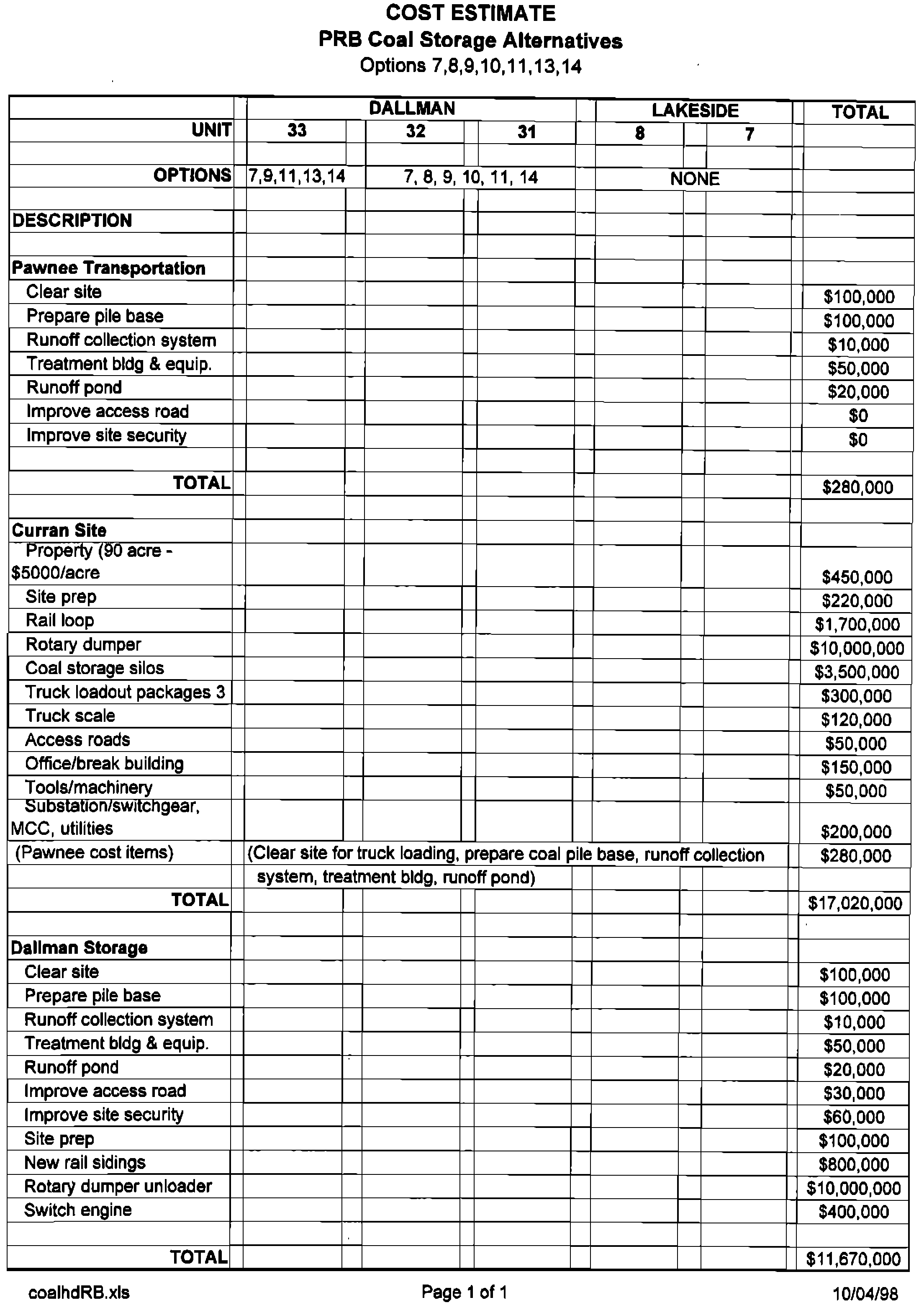

APPENDIX

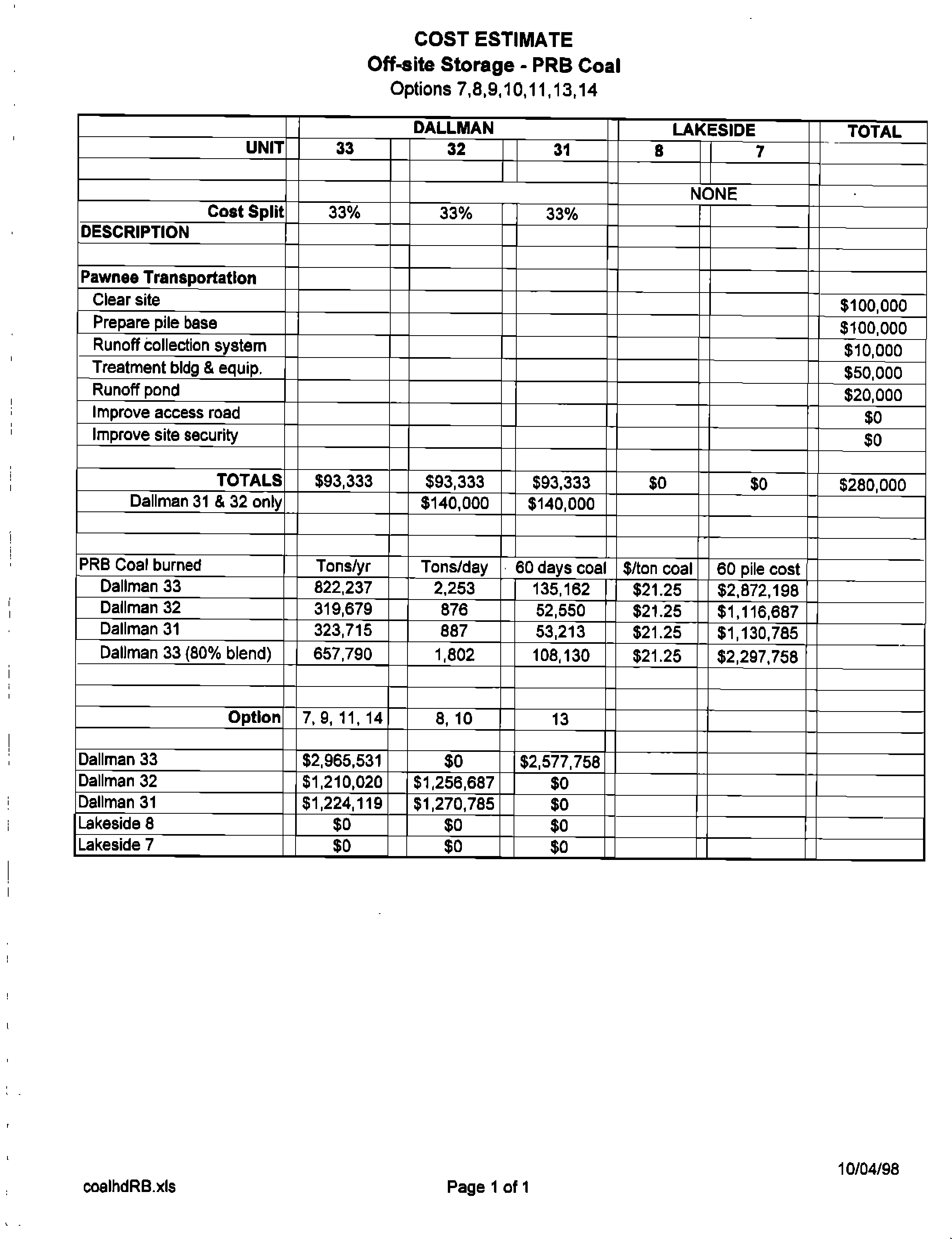

D

Off site PRB

Coal Unloading and Storage Options

1

APPENDIX E

Cost Estimates

20

CERTIFICATI

p 0-9

.

.......

\N. ýjN.

,

,

*i REGISTERED

I

=

i

P ROFESSIONAL.:*

-s

ENGINEER

,*

DP

/

'

.,

ý

uý`

'

1,'-'--7!7

, fý

10/5,/1

CERT.DOC

RIC-1

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

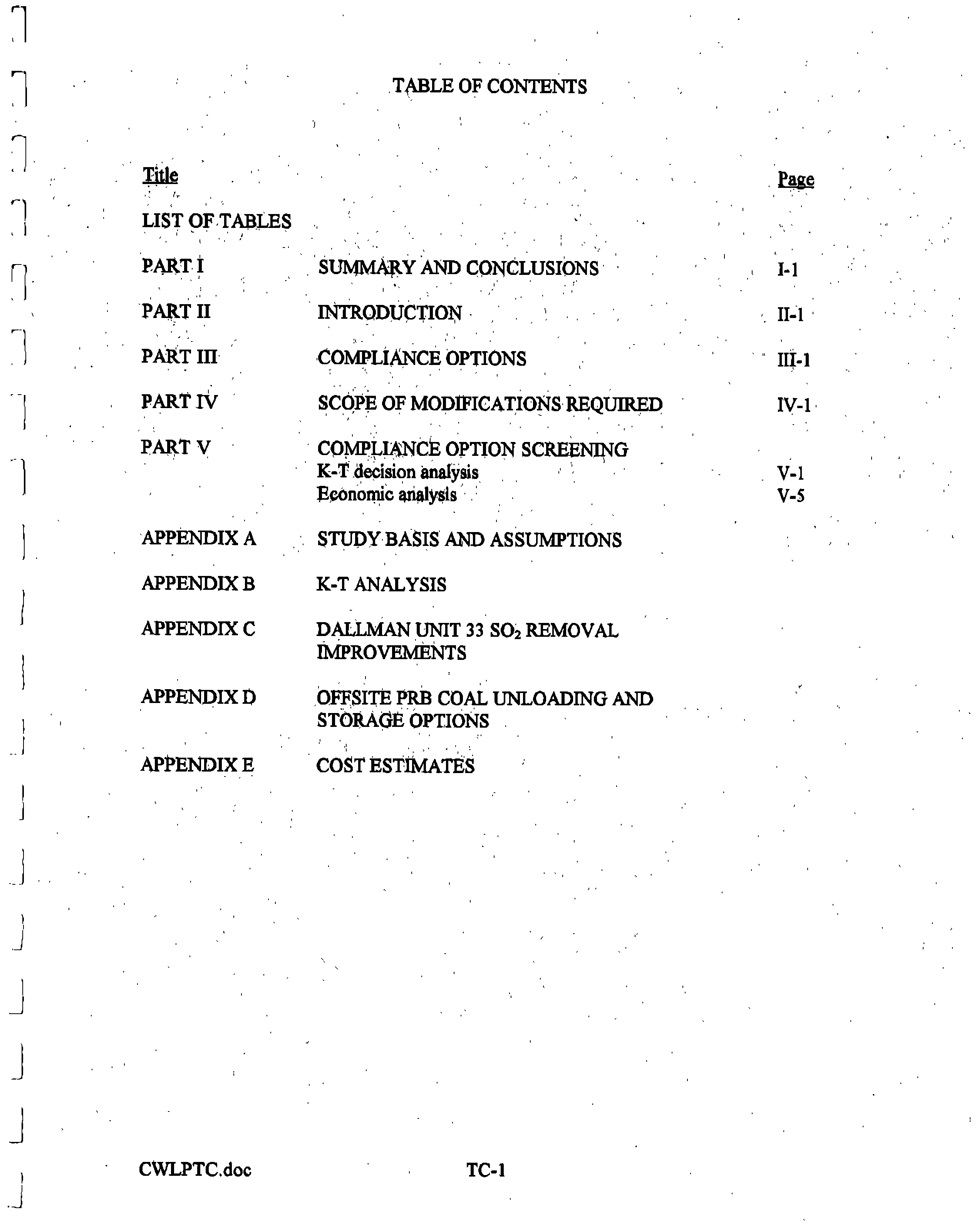

.TABLE OF CONTENTS

Title

Page

LIST OF, TABLES

PART I

SUMMARY AND

CONCLUSIONS

I-1

I1

I

J

I

INTRODUCTION

COMPLIANCE

OPTIONS

II-1

III-1

PART N

SCOPE OF MODIFICATIONS

REQUIRED

IV-1

PART V

COMPLIANCE OPTION

SCREENING

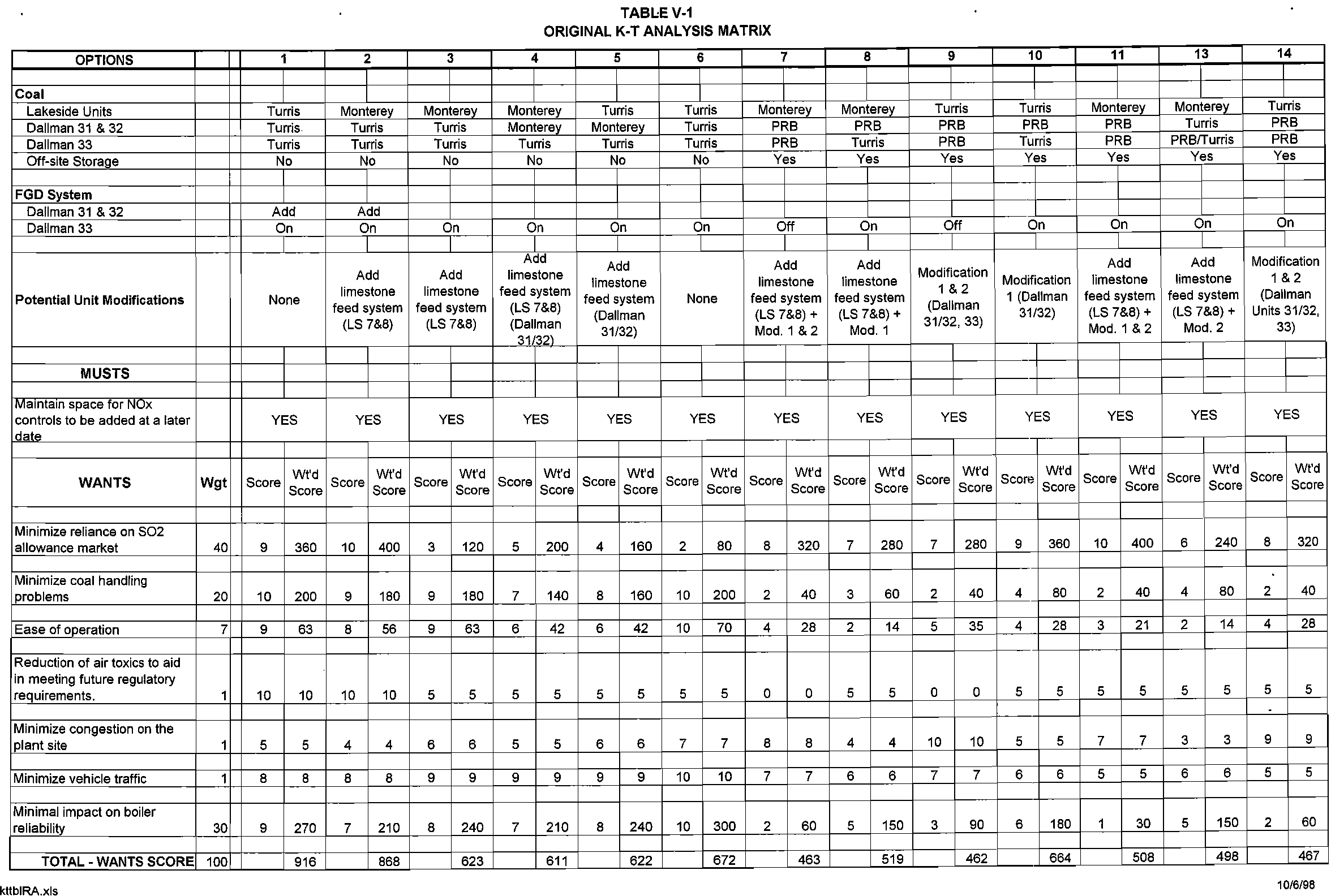

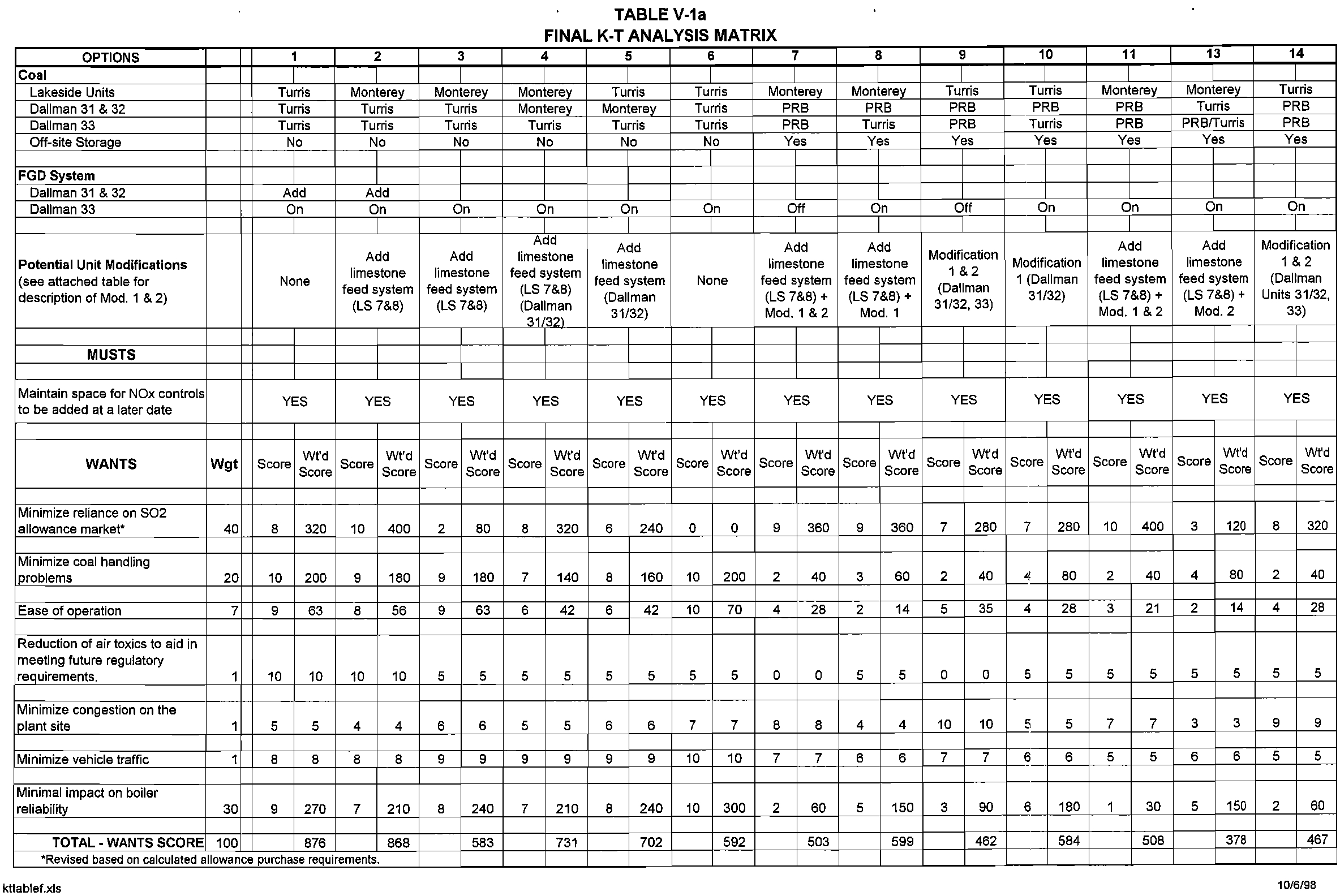

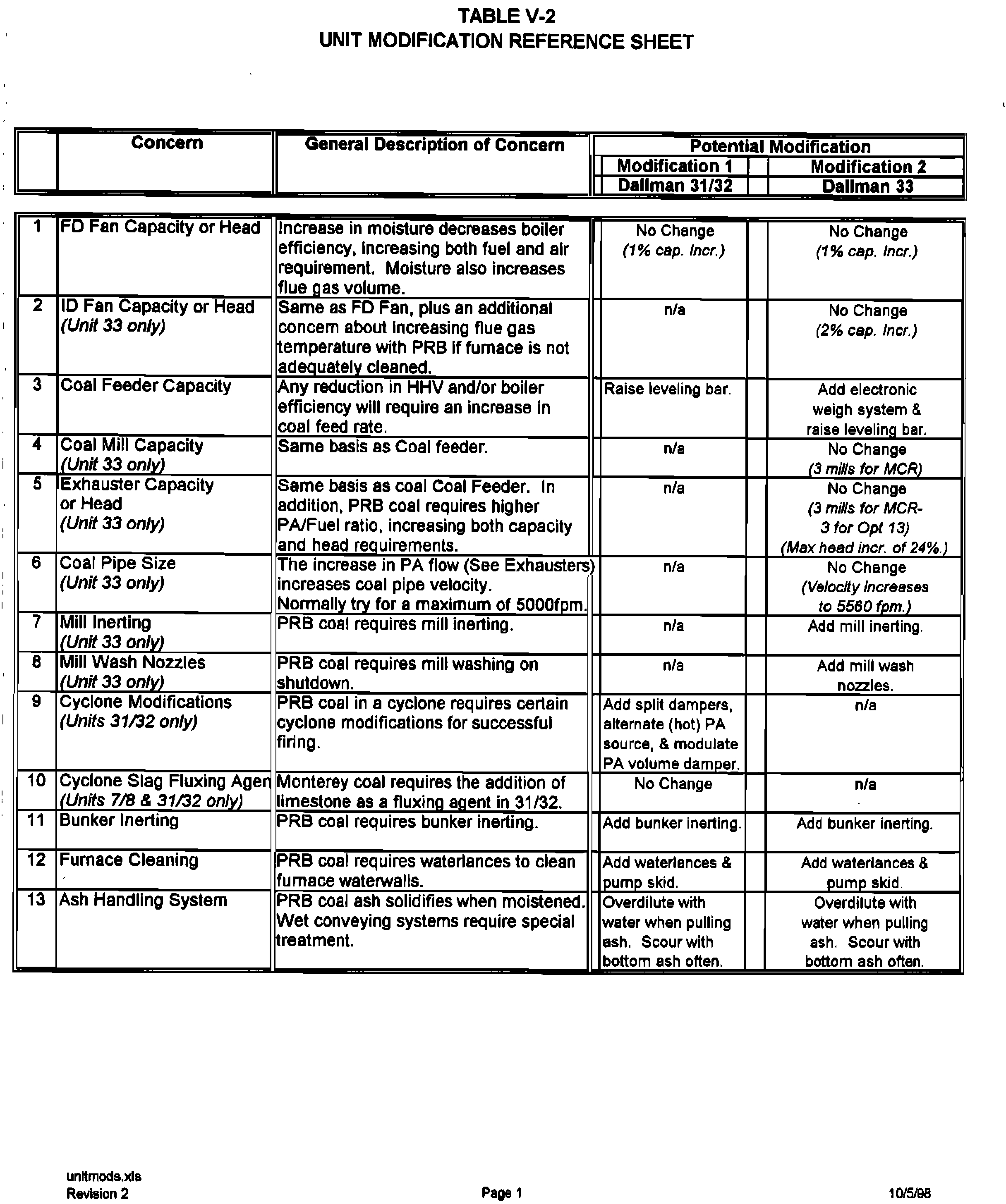

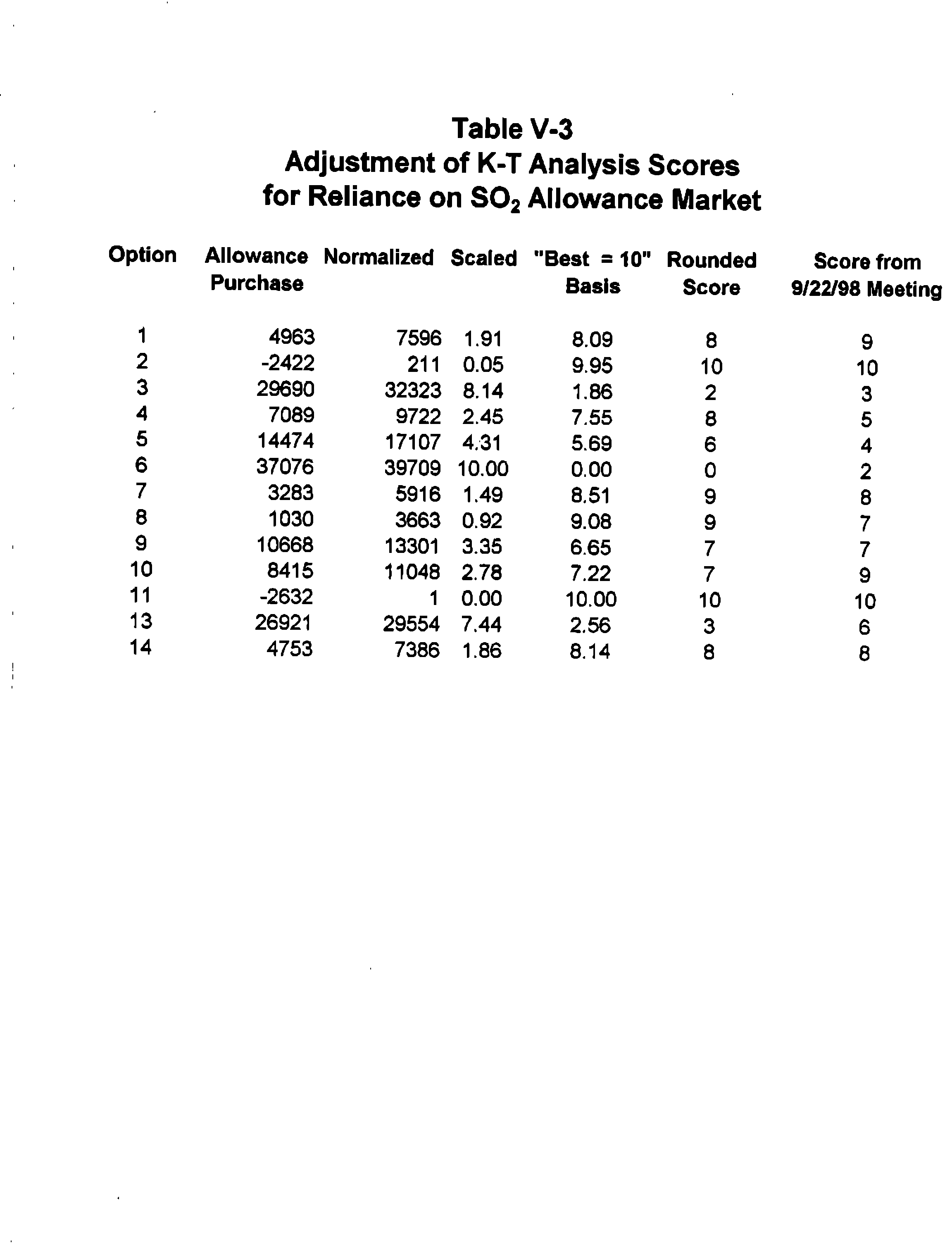

K-T decision

analysis,

V-1

Economic

§tialysis

V-5

APPENDIX A

STUDY

BASIS AND ASSUMPTIONS

APPENDIX B

K-T

ANALYSIS

APPENDIX

C

DALLMAN UNIT 33 S02

REMOVAL

IMPROVEMENTS

APPENDIXE

COST ESTIMATES

APPENDIX

D

OFFSITE PRB

COAL

UNLOADING AND

STORAGE

OPTIONS

CWLPTC.doc

TC-1

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

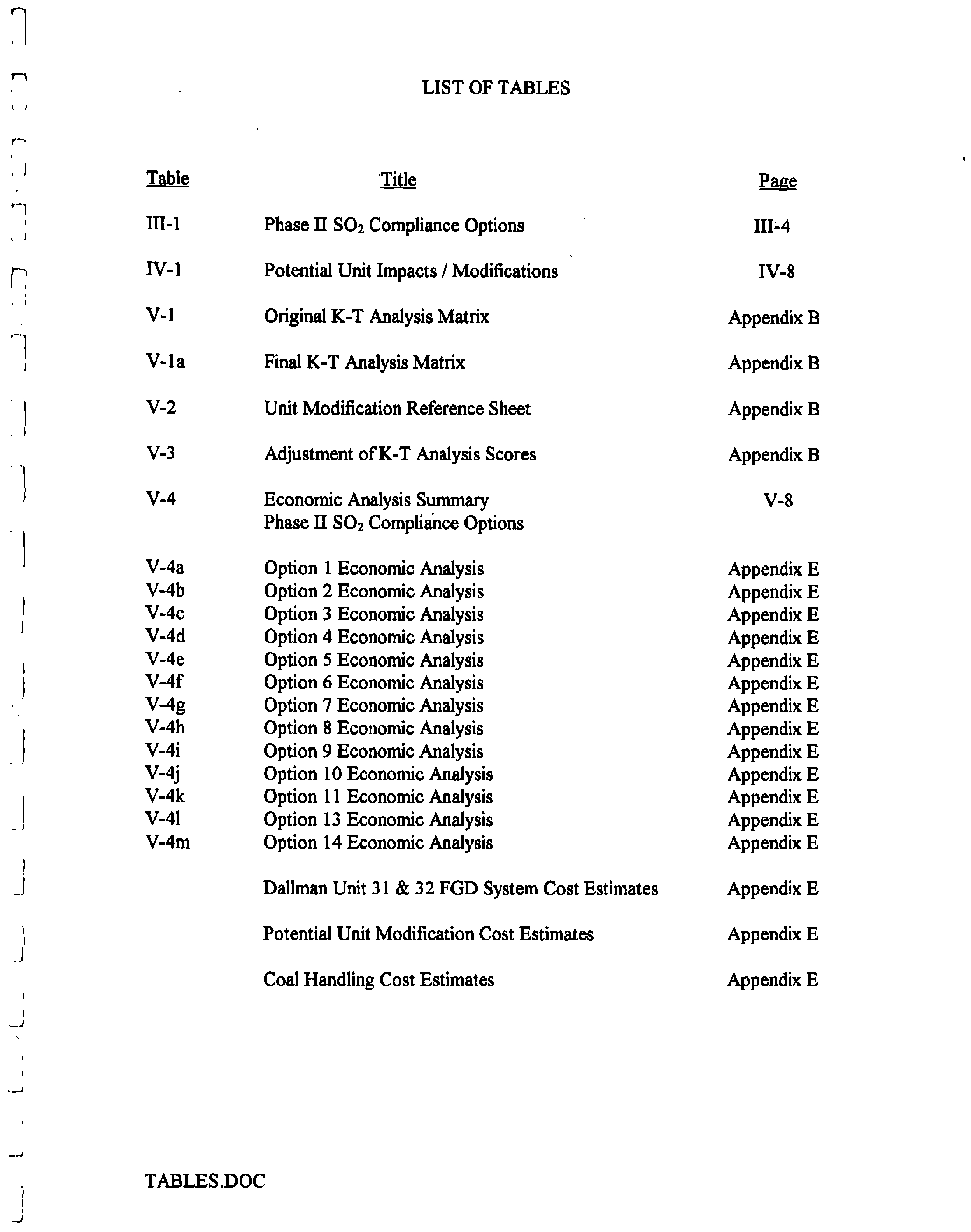

LIST OF TABLES

r-,

l

Table

TitLe

Page

III-1

Phase

II S02 Compliance options

III-4

N-1

Potential Unit Impacts

/

Modifications

IV-8

V-1

Original K-T Analysis Matrix

Appendix B

V-la

Final

K-T Analysis Matrix

Appendix B

V-2

Unit Modification Reference

Sheet

Appendix B

V-3

Adjustment of K-T Analysis Scores

Appendix B

V-4

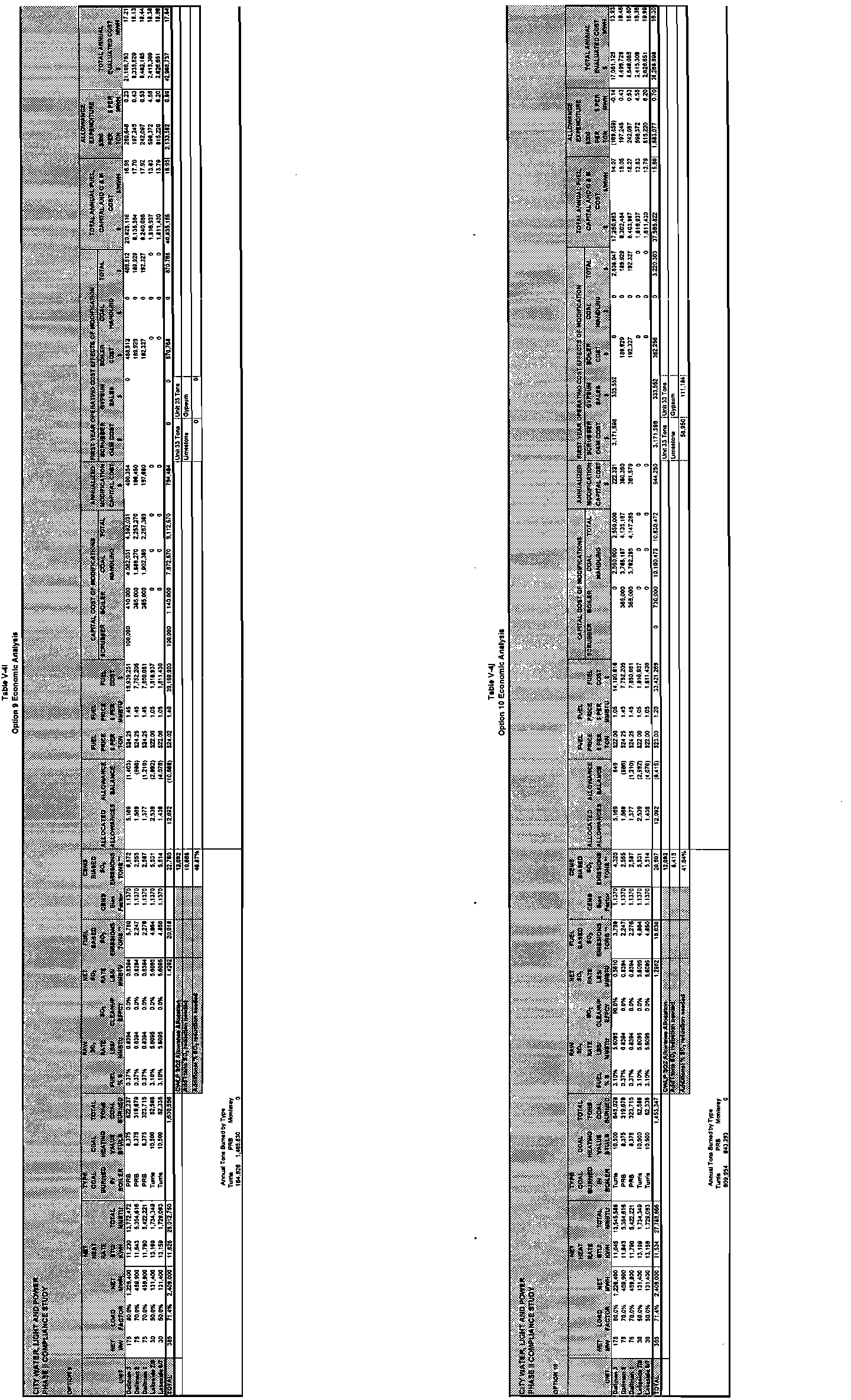

Economic

Analysis Summary

V-8

Phase

II S02 Compliance Options

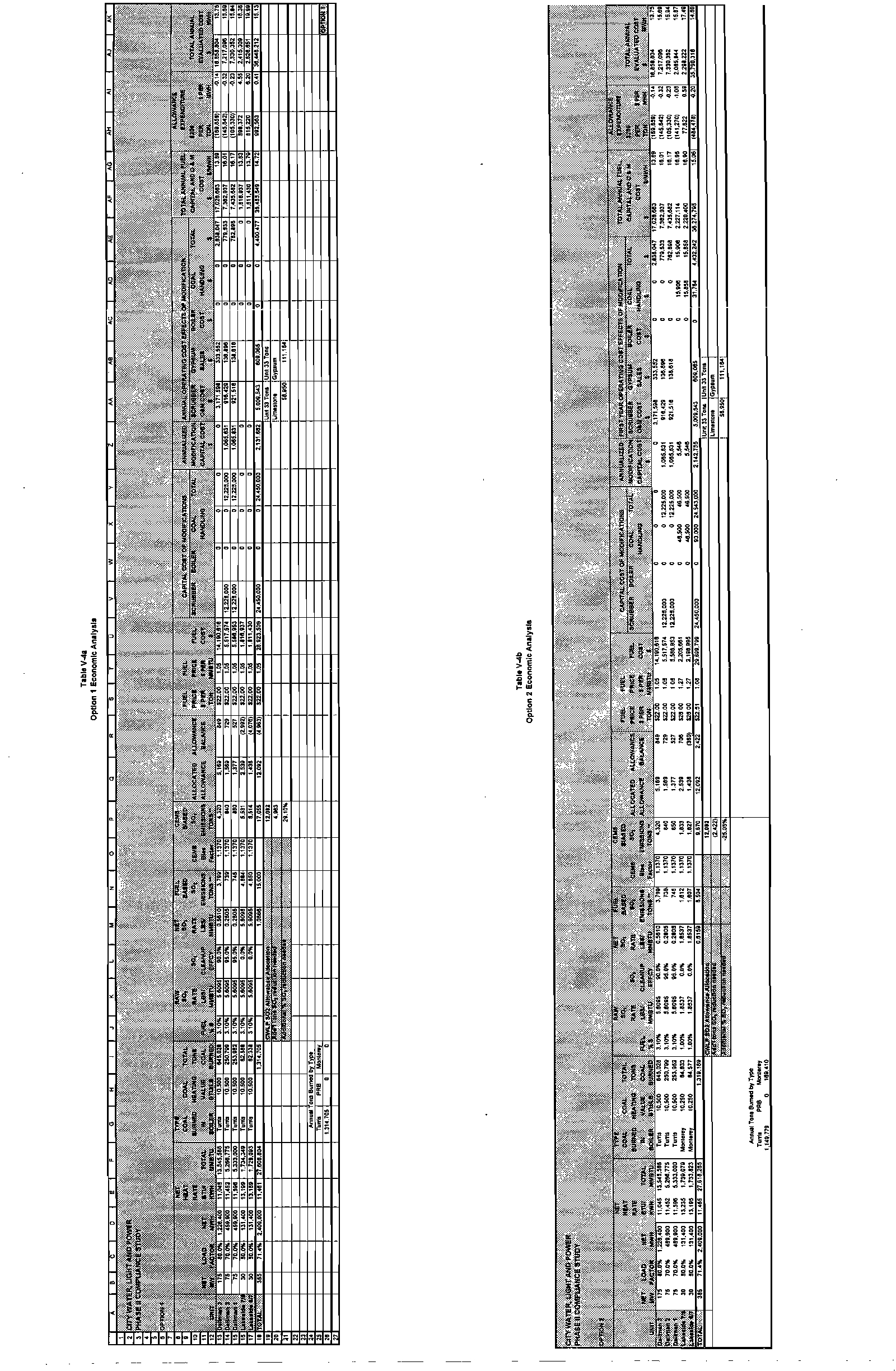

V-4a

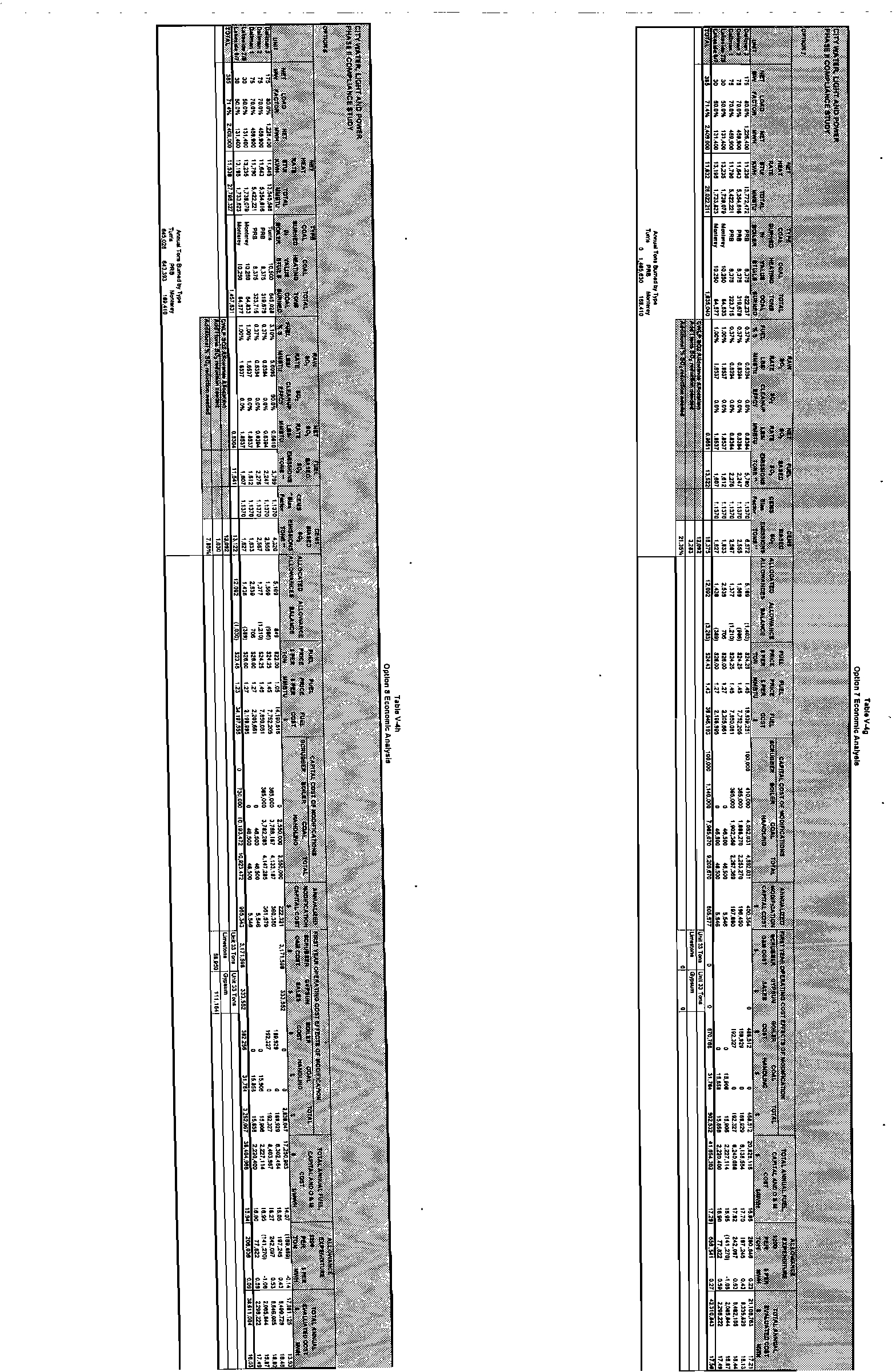

Option 1

Economic Analysis

Appendix E

V-4b

Option 2 Economic Analysis

Appendix E

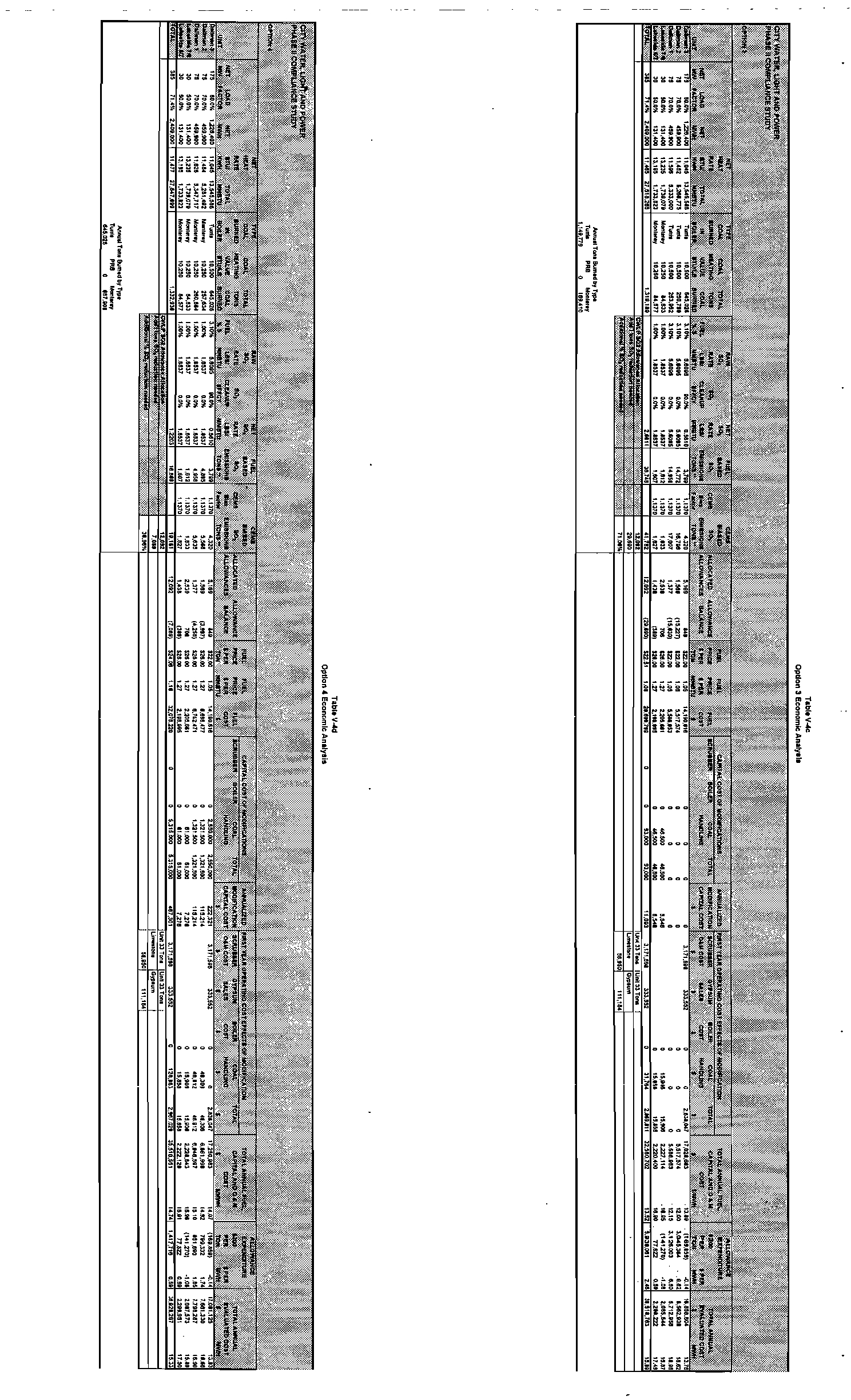

V-4c

Option 3 Economic Analysis

Appendix E

V-4d

Option 4 Economic Analysis

Appendix E

V-4e

Option 5 Economic

Analysis

Appendix E

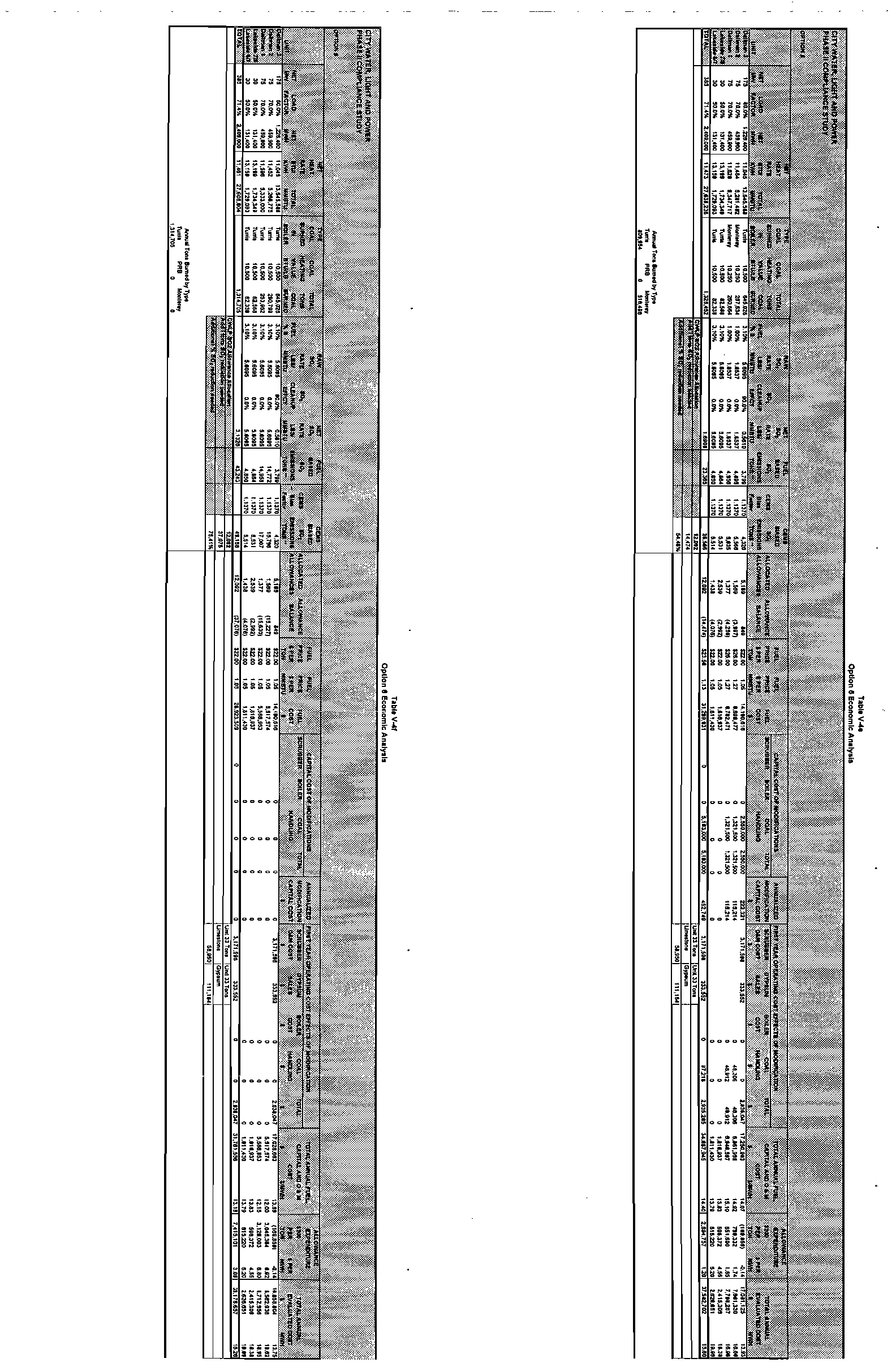

V-4f

Option 6 Economic Analysis

Appendix

E

V-4g

Option 7 Economic Analysis

Appendix E

V-4h

Option 8 Economic Analysis

Appendix E

V-4i

Option 9 Economic Analysis

Appendix E

V-4j

Option 10 Economic Analysis

Appendix E

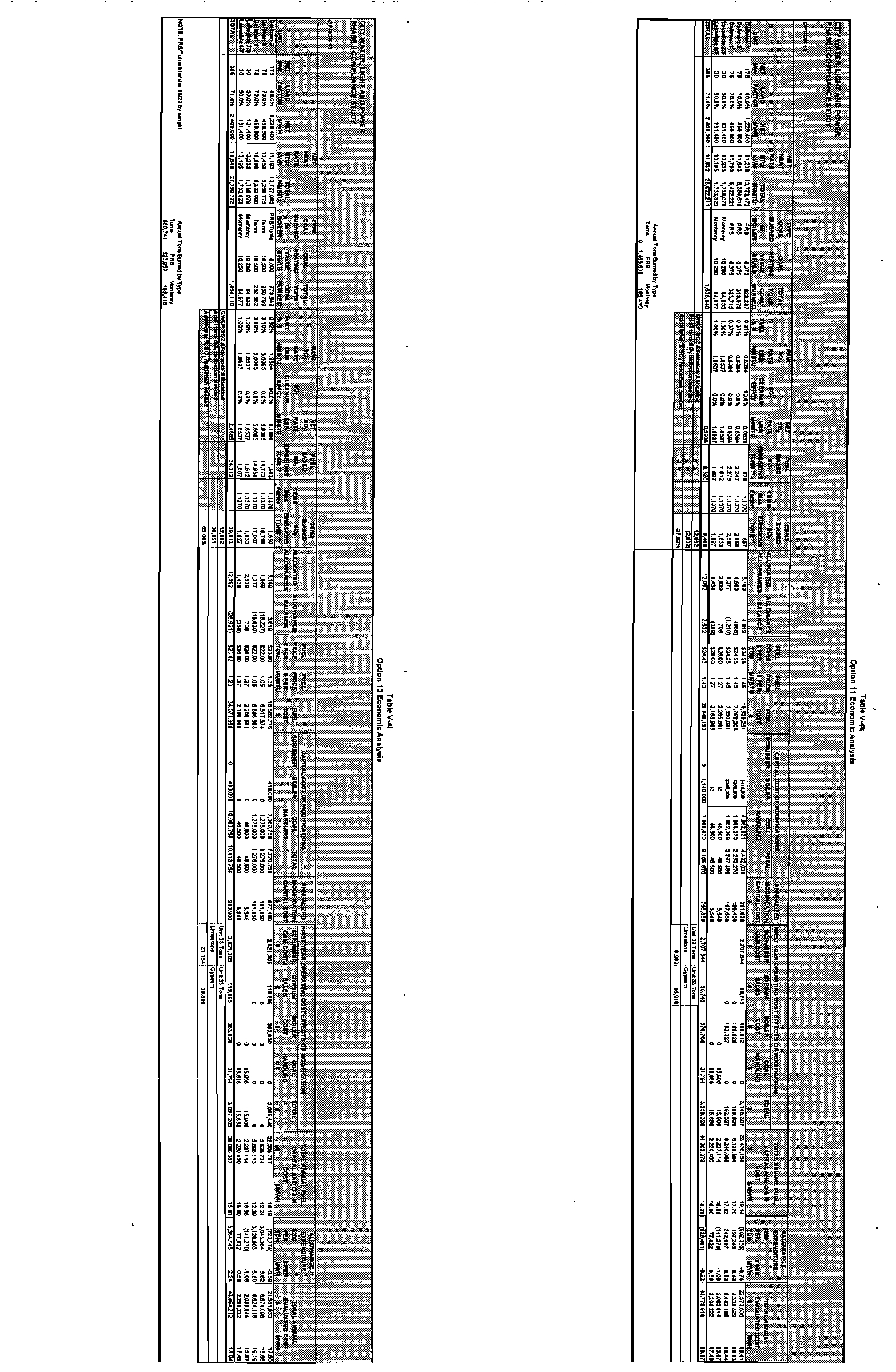

V-4k

Option 11 Economic Analysis

Appendix E

V-41

Option

13 Economic Analysis

Appendix E

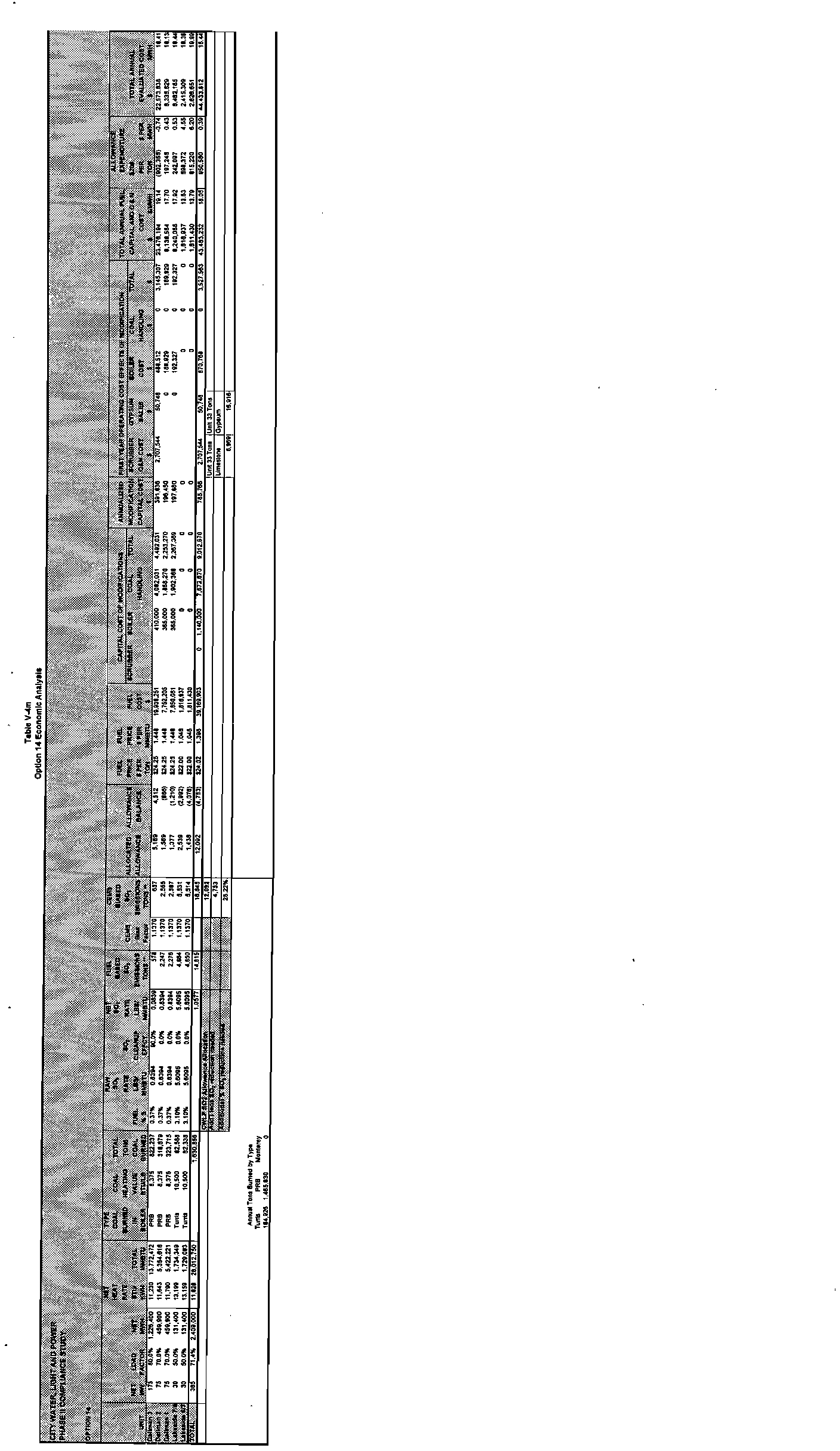

V-4m

Option 14 Economic Analysis

Appendix E

I

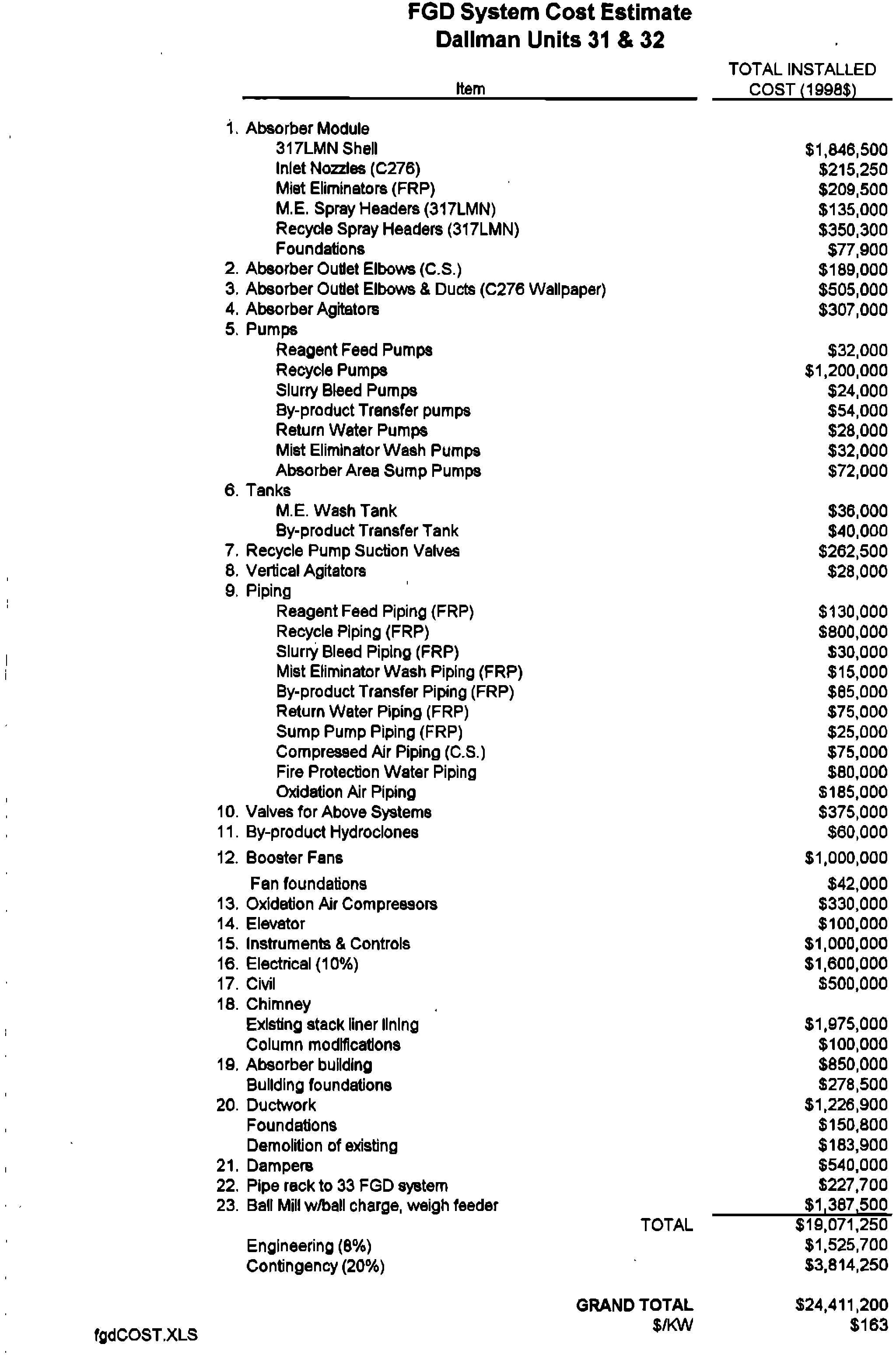

Dallman

Unit

31

&

32 FGD

System Cost Estimates

Appendix E

i

J

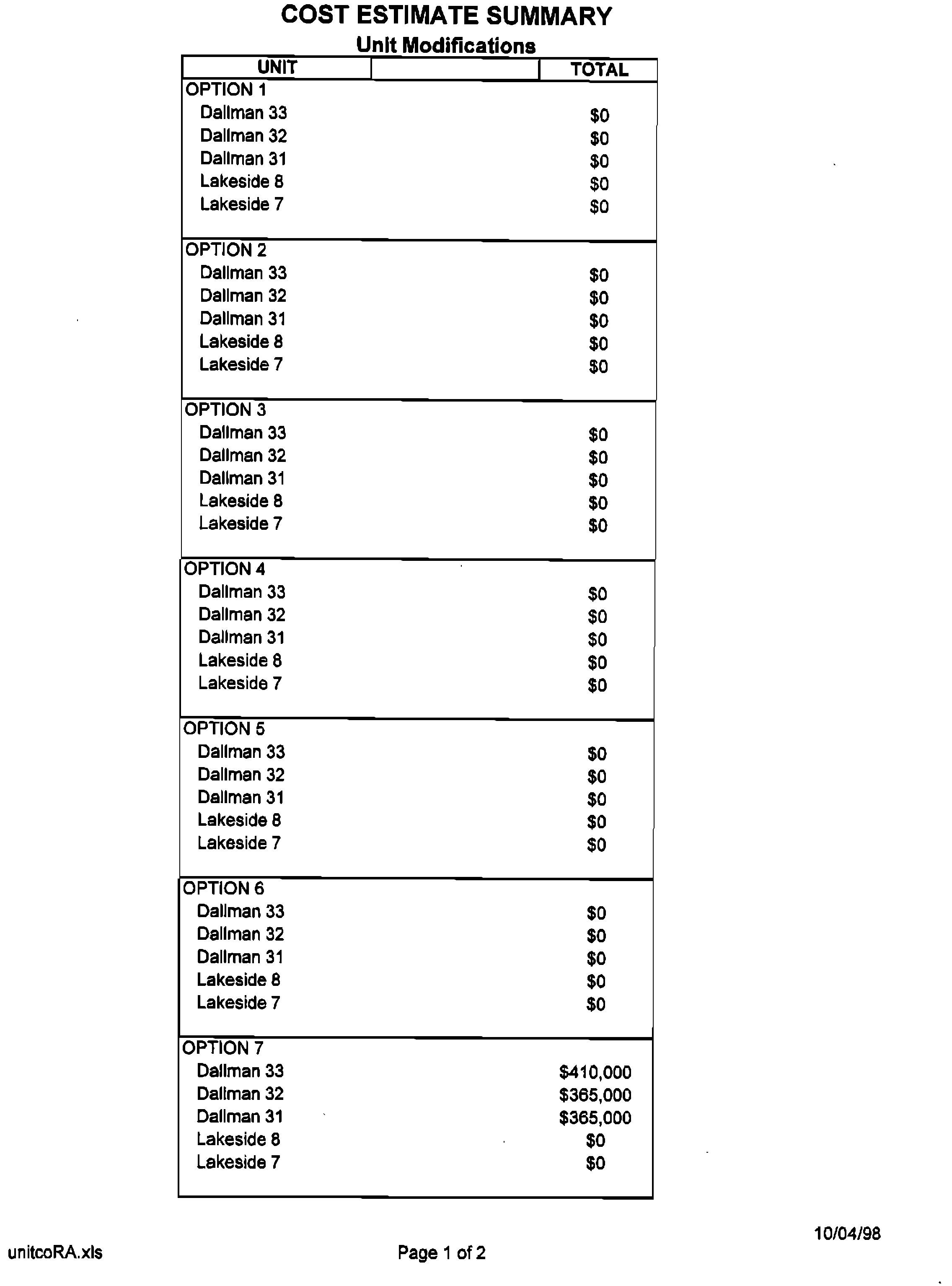

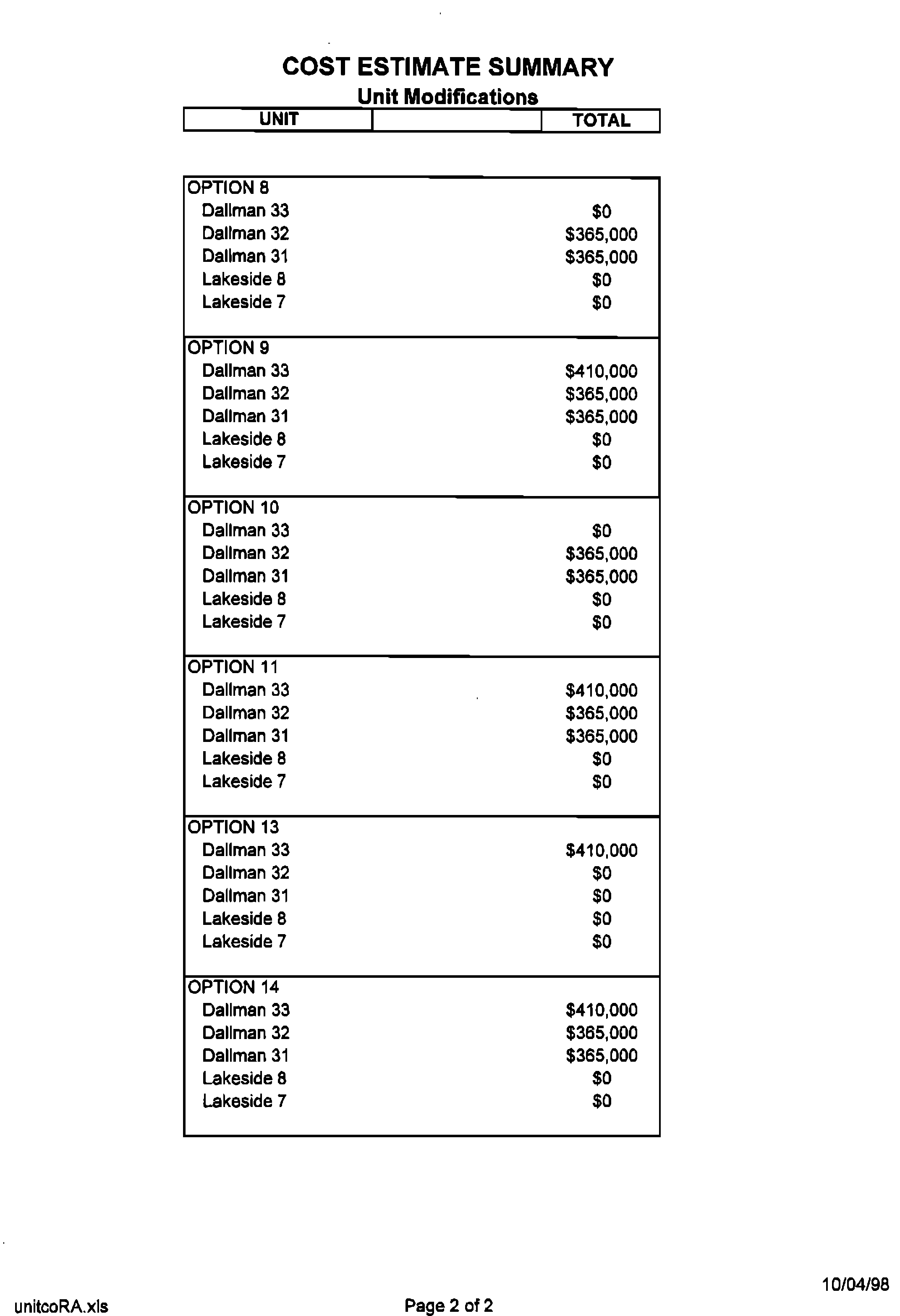

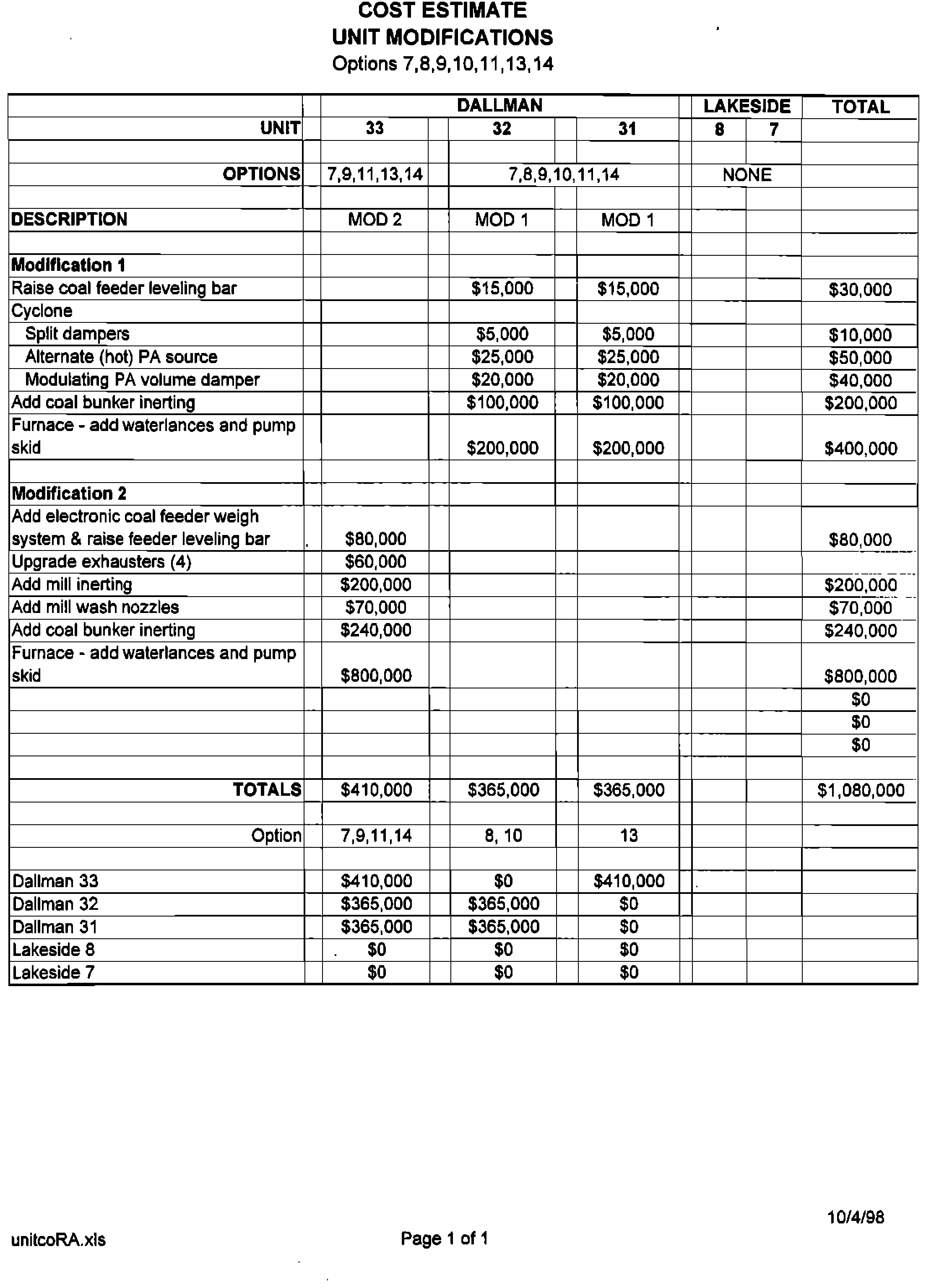

Potential Unit Modification Cost Estimates

Appendix E

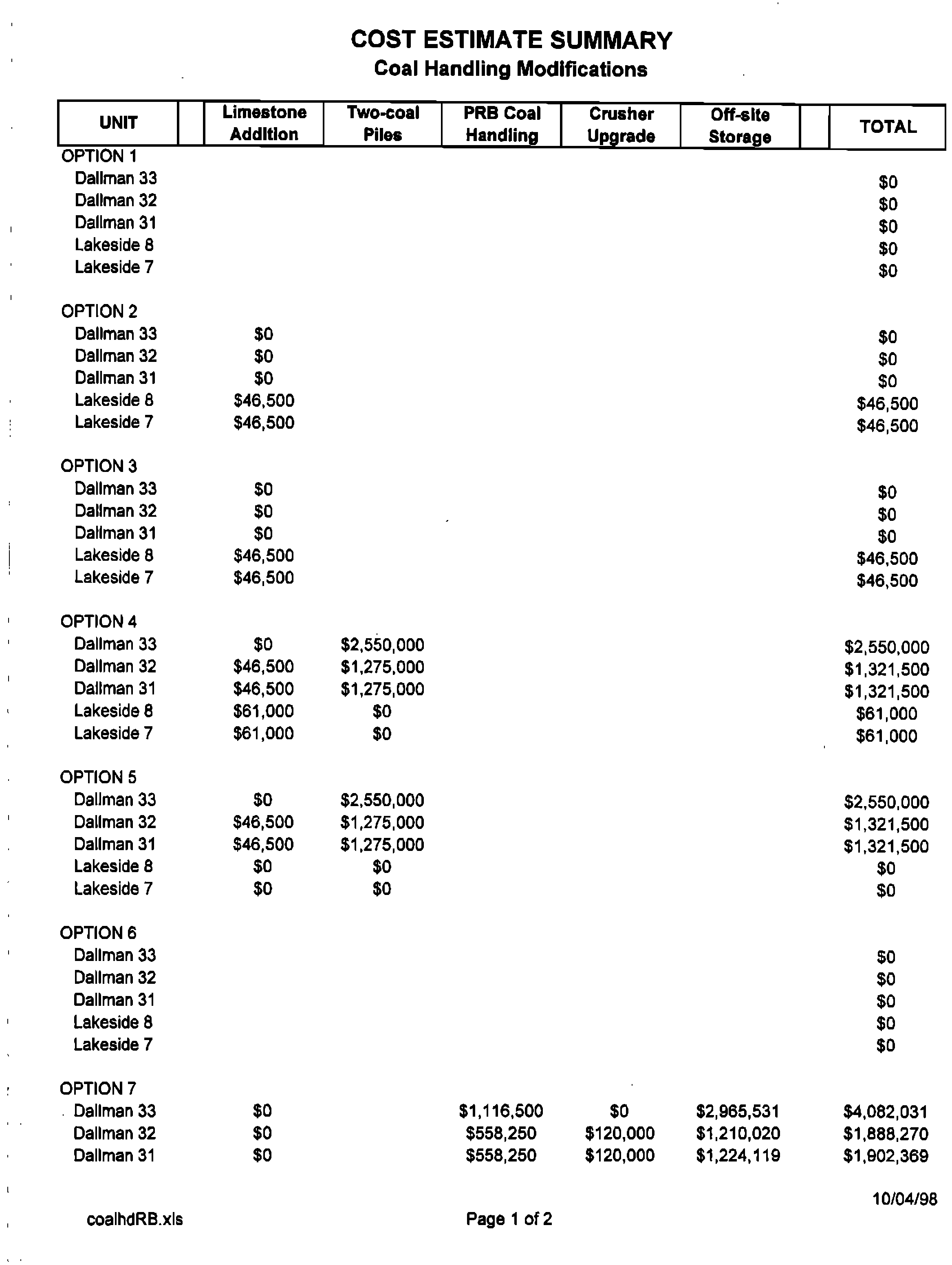

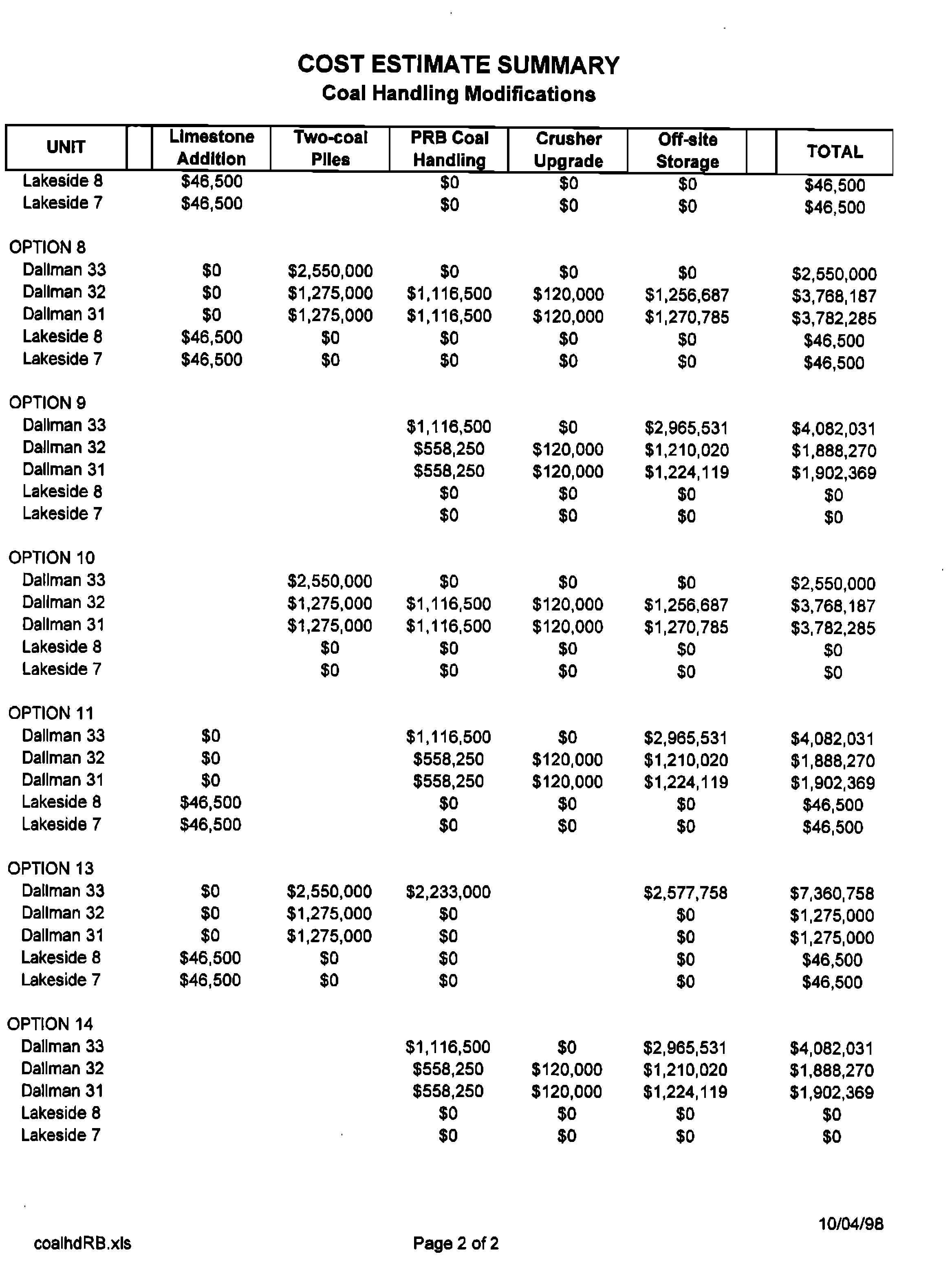

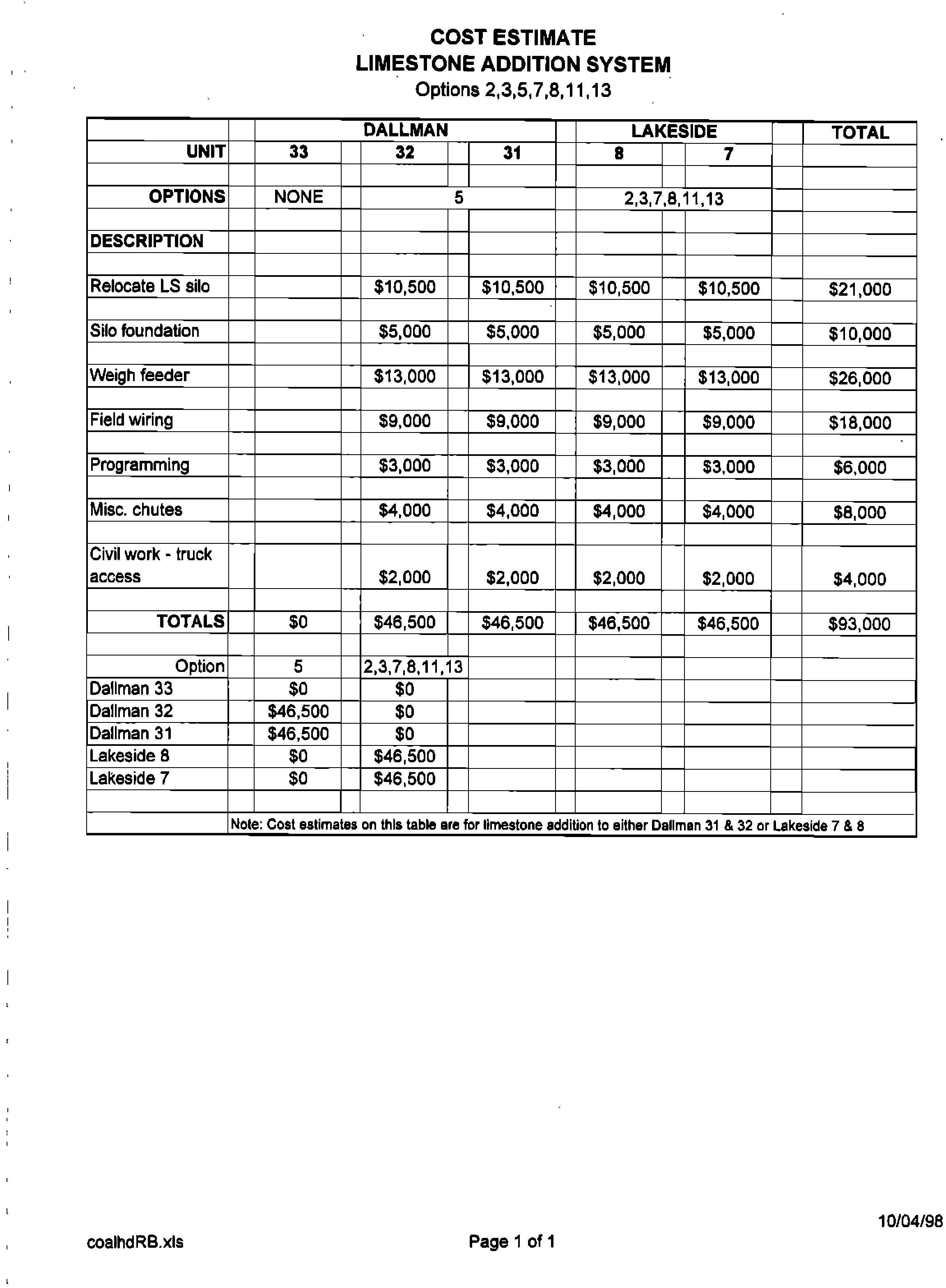

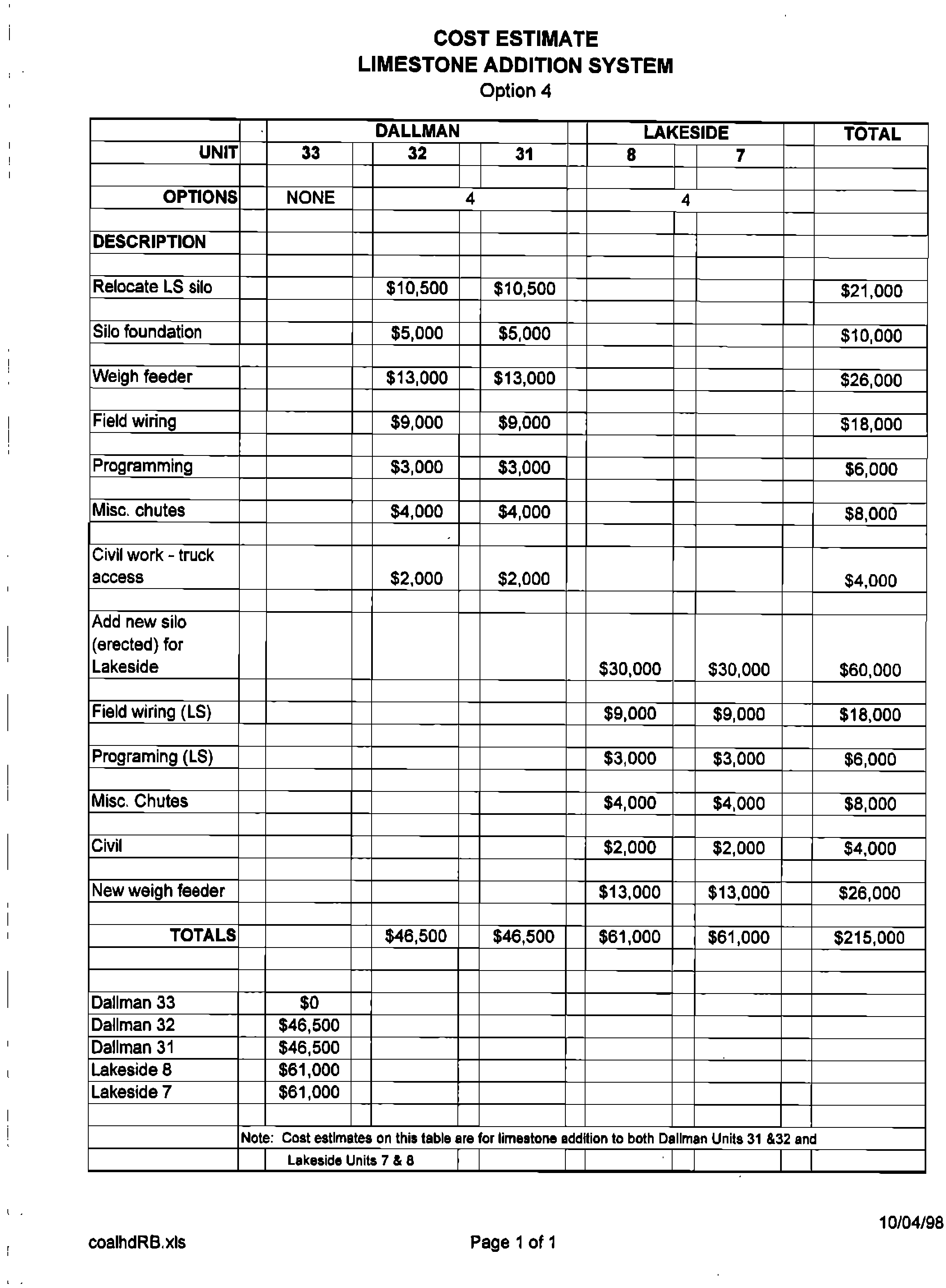

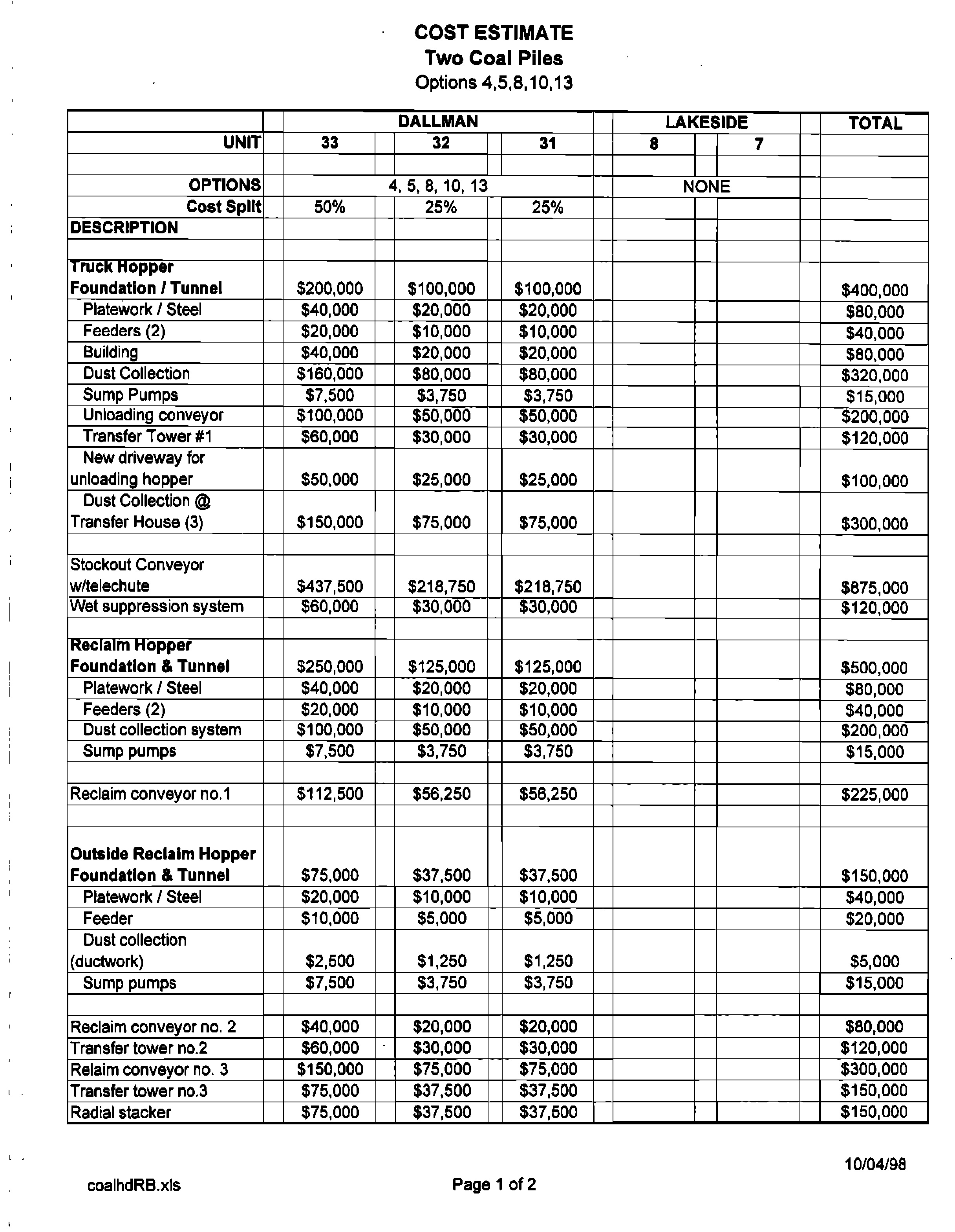

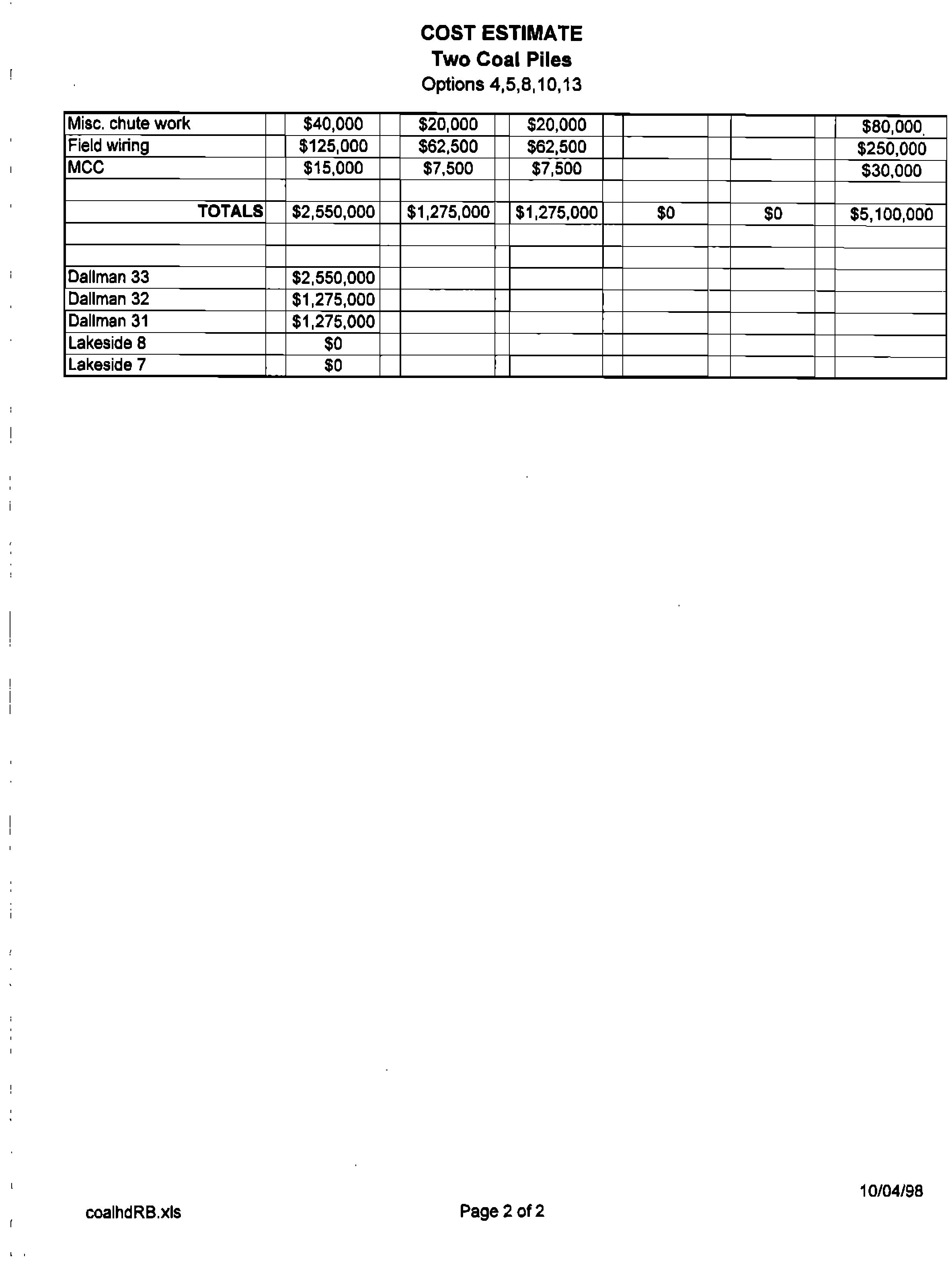

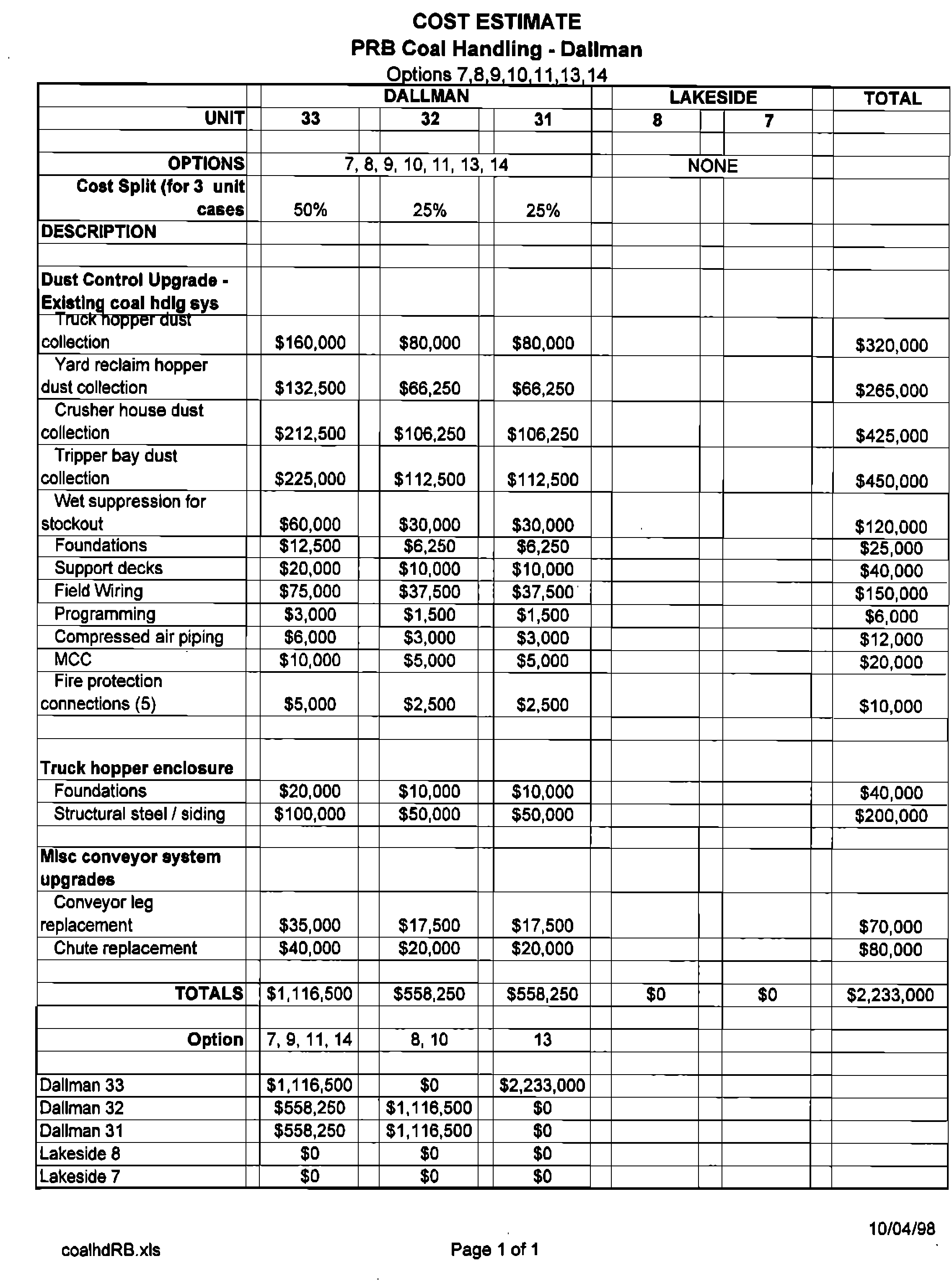

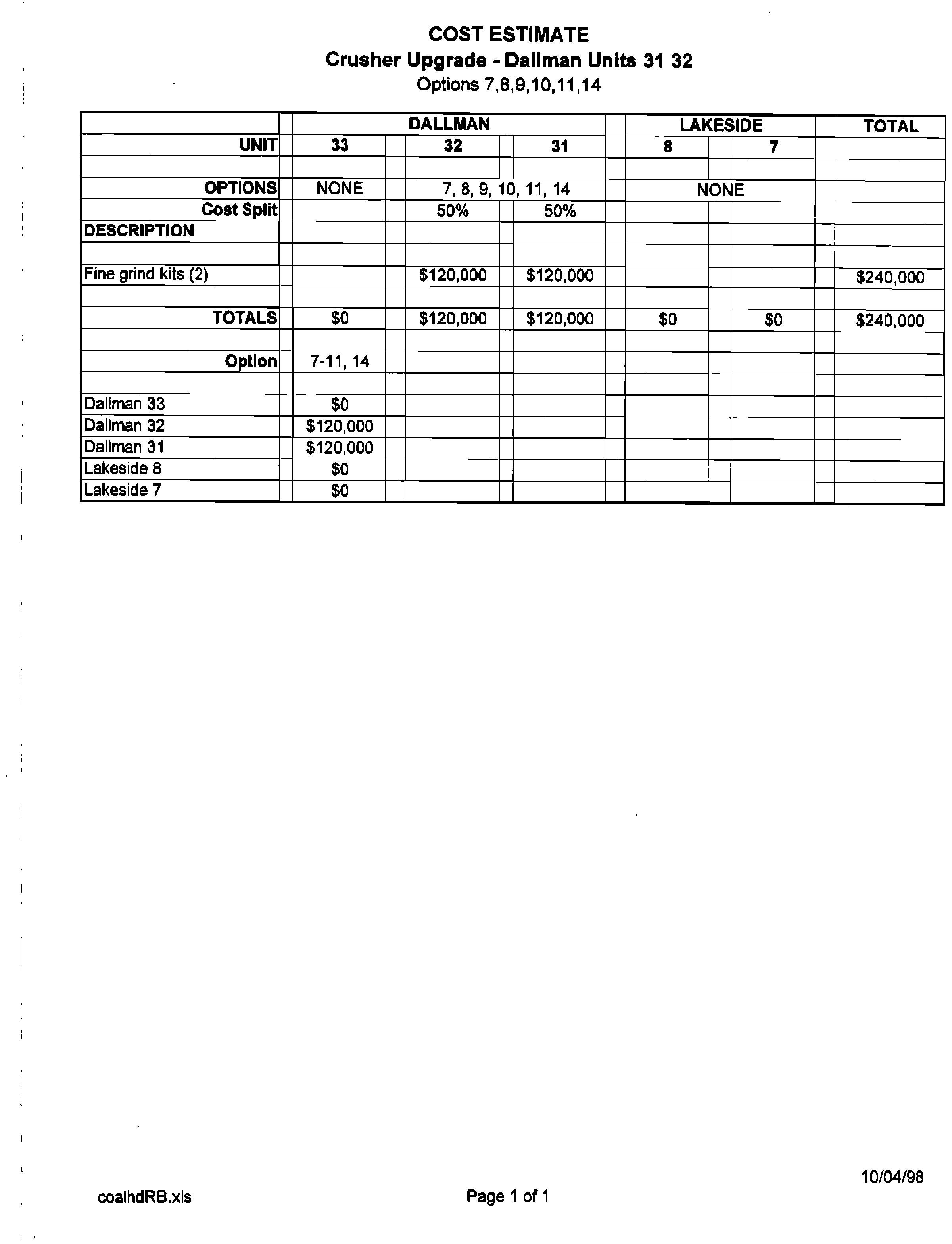

Coal Handling Cost Estimates

Appendix E

.

J

TABLESDOC

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

LIST OF FIGURES

Figure

Title

page

IV-1

Coal Handling

System Diagram

IV-3

Dallman

Two Coal Pile

IV-2

Preliminary FGD

System Flow Diagram

IV-12

Dallman

Station Units 31 & 32

IV-3

FGD System Plot Plan

-

Dallman

Units 31 & 32

IV-13

1

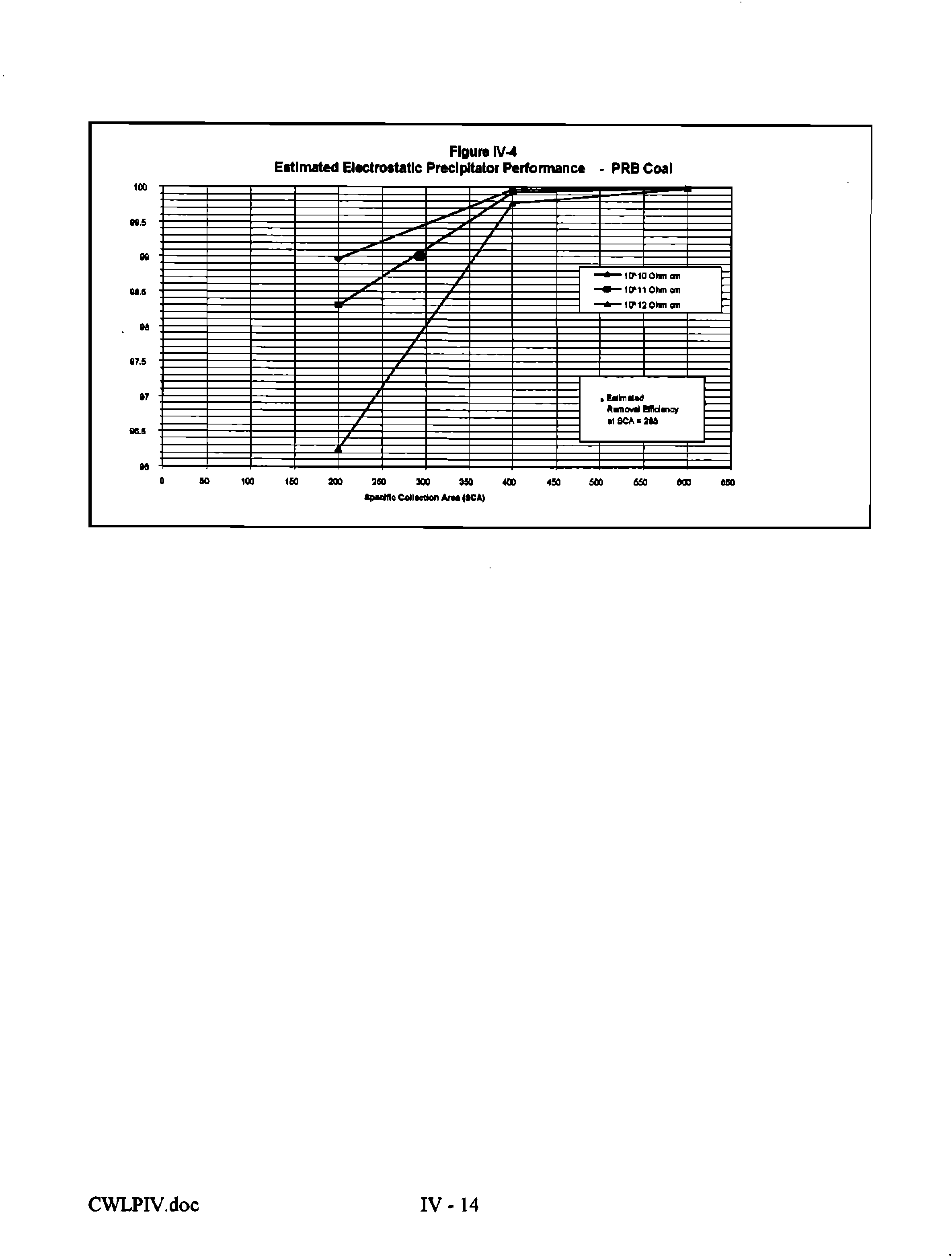

IV-4

Estimated Electrostatic Precipitator Performance

IV-14

1

- PRE Coal

i

I

l

J

FIGURES.DOC

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

PART I

SUMMARY

AND CONCLUSIONS

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

PART I

SUMMARY AND CONCLUSIONS

Bums & McDonnell performed

a study of Phase 11 SOz compliance

options as requested by City Water

Light & Power (CWLP) for

the

Dallman

and Lakeside Stations.

SUMMARY

CWLP has performed several previous

studies of options for compliance with the requirements

of

Phase

II

of the

Clean Air Act as amended in 1990. Bums

& McDonnell was contracted to provide professional

engineering

services to update and

expand the previous compliance option studies. The following

tasks

were accomplished

during this study:

" Compliance

options developed by CWLP were reviewed

and additional options were prepared

and included in the study.

" Each of the compliance options was

defined and agreed to by CWLP and Burns & McDonnell.

" A technical and economic screening

was performed of each option.

" This report

was prepared to document the activities that were

accomplished during the study.

" Three

meetings were held with

CWLP

personnel

to discuss the basis for the study, to review

the compliance options

and cost factors to use in the cost estimates, and to perform the

technical K-T

decision analysis.

A presentation of the final results of the

study

was made

to CWLP.

C ONCLUSIONS

As stated above,

both

a technical and an economic analysis were performed of potential compliance

options. Several conclusions

were made from

the

results

of these analyses.

Technical Analysis

The technical analysis of the

options

identified modifications

that might be required to the existing plant

based

on the option conditions. The modifications involve boiler and coal handling modifications that

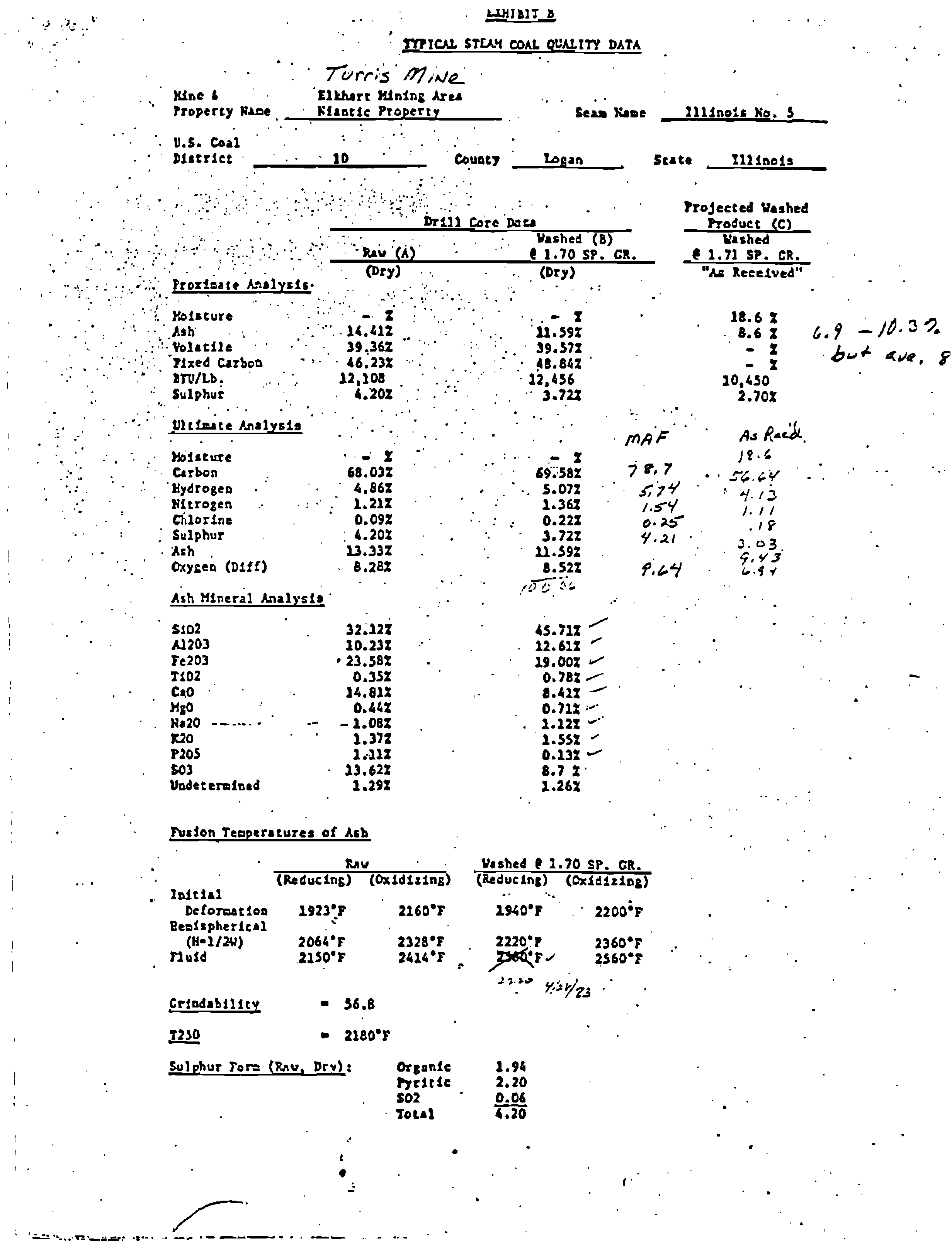

would be required for options involving a change in the coal from the Tunis coal presently being burned in

all of the Dallman and Lakeside units. Some of the options are based on the installation of FOD systems

on Dallman

Unit

31

and

32,

or taking the Dallman Unit 33 scrubber out of service. The modifications and

CWLPLdoc

I-1

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

FGD system impact

on several criteria were analyzed and scored

during a "K-T" analysis meeting attended

by both

CWLP and Bums & McDonnell personnel.

The highest ranked compliance

option is Option 1 based on the technical

analysis performed. The scope of

Option 1 includes

the addition of an FGD system to Dallman

Units

31

and

32.

Tunis coal would continue

to be burned in all Dallman

and Lakeside units for this option. The Dallmmm

Unit

33

scrubber would also

remain in service. Because

the coal supply does not change, no unit or coal handling modifications

would

be required for implementation

of this option.

Economic

Analysis

An economic analysis

similar to the analyses performed by CWLP for the previous studies was done for

each

of the options identified for this study. The capital

and operation and maintenance cost of each

modification that was

might be required for each option was estimated

and a total evaluated cost

calculated.

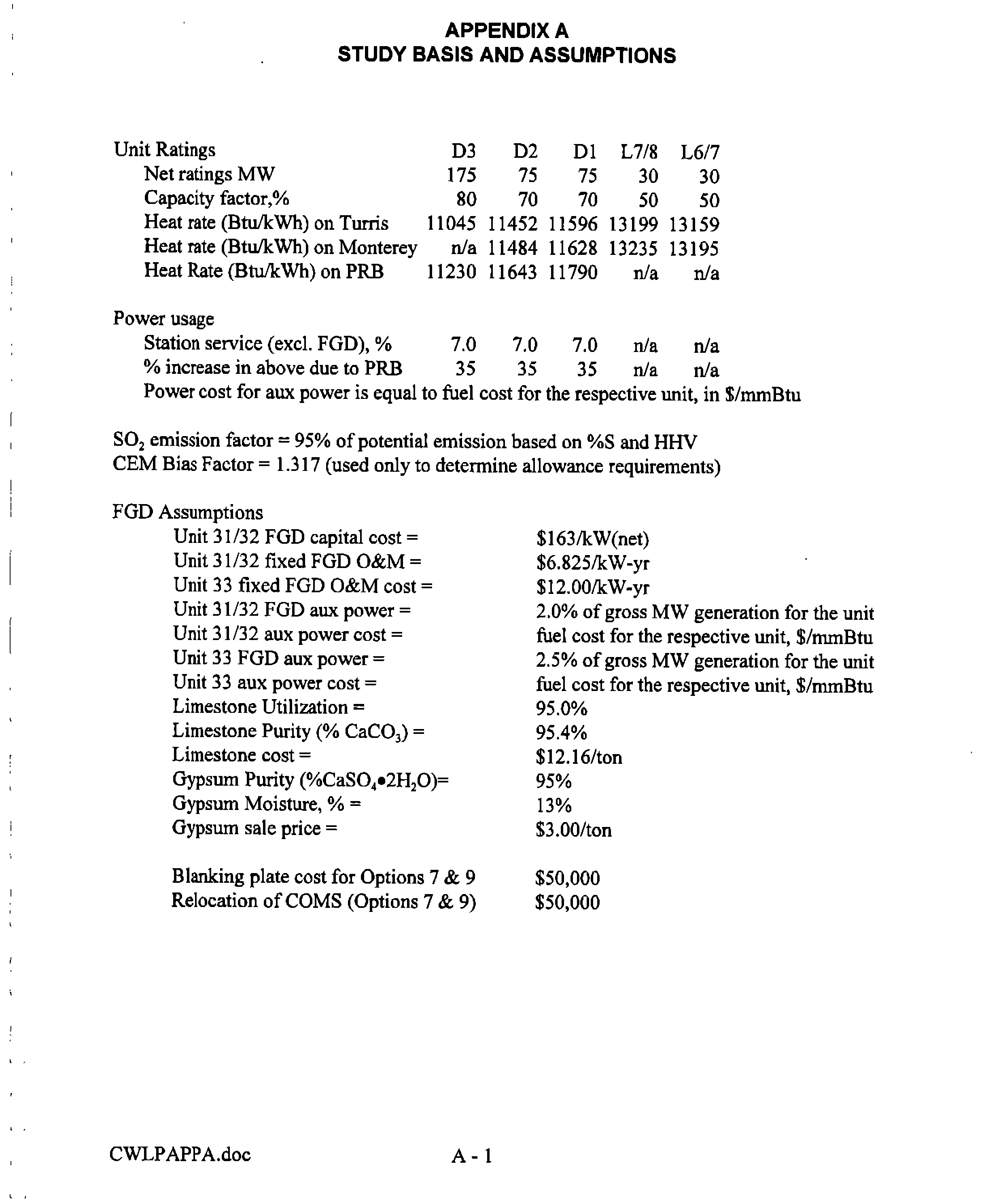

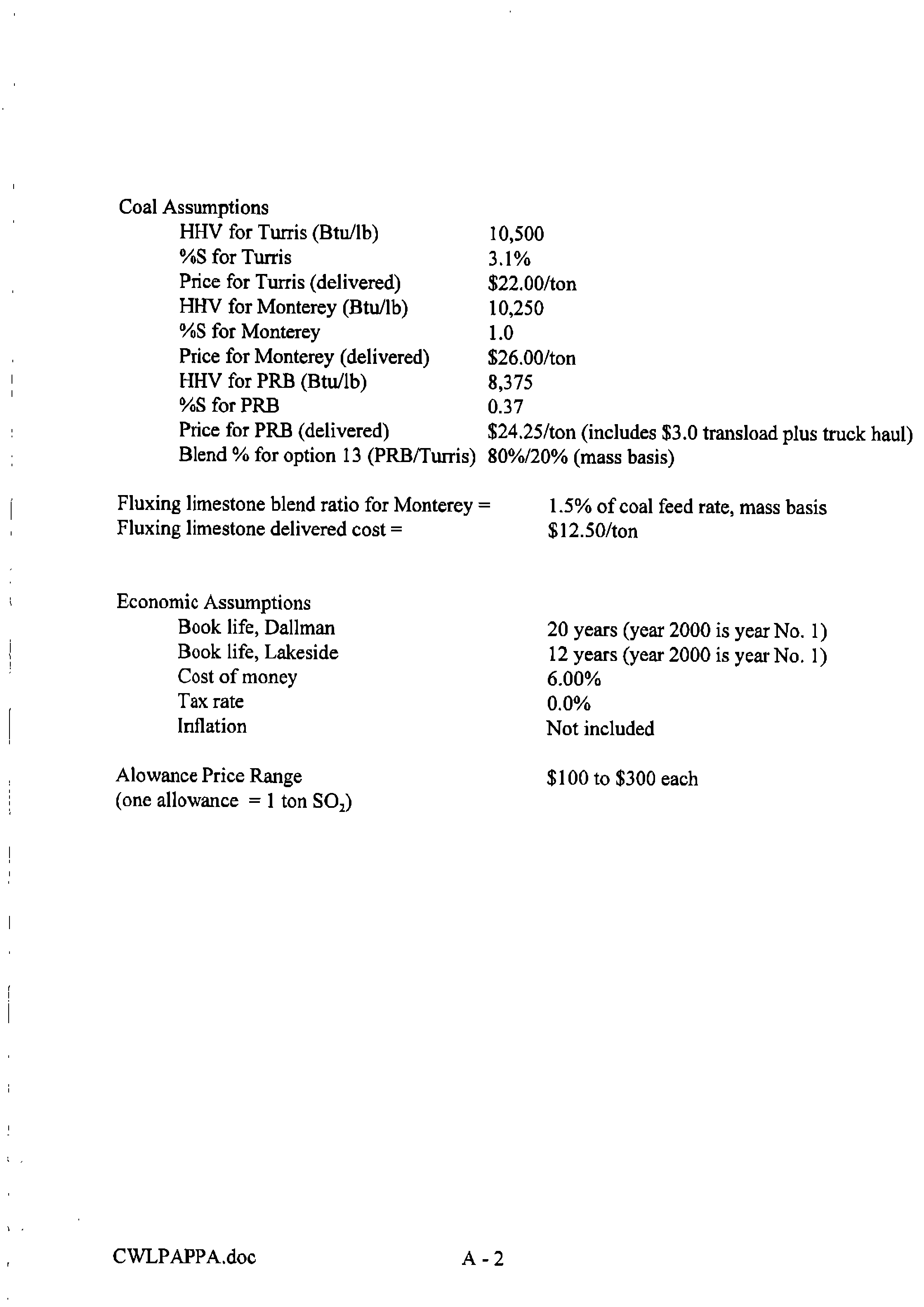

Key Assumptions: The

economic analysis was based on the following significant assumptions, many

of which parallel those made by

CWLP

in its

previous studies. These assumptions should be clearly

understood and considered in

interpretation of the reported economic analysis results:

" The

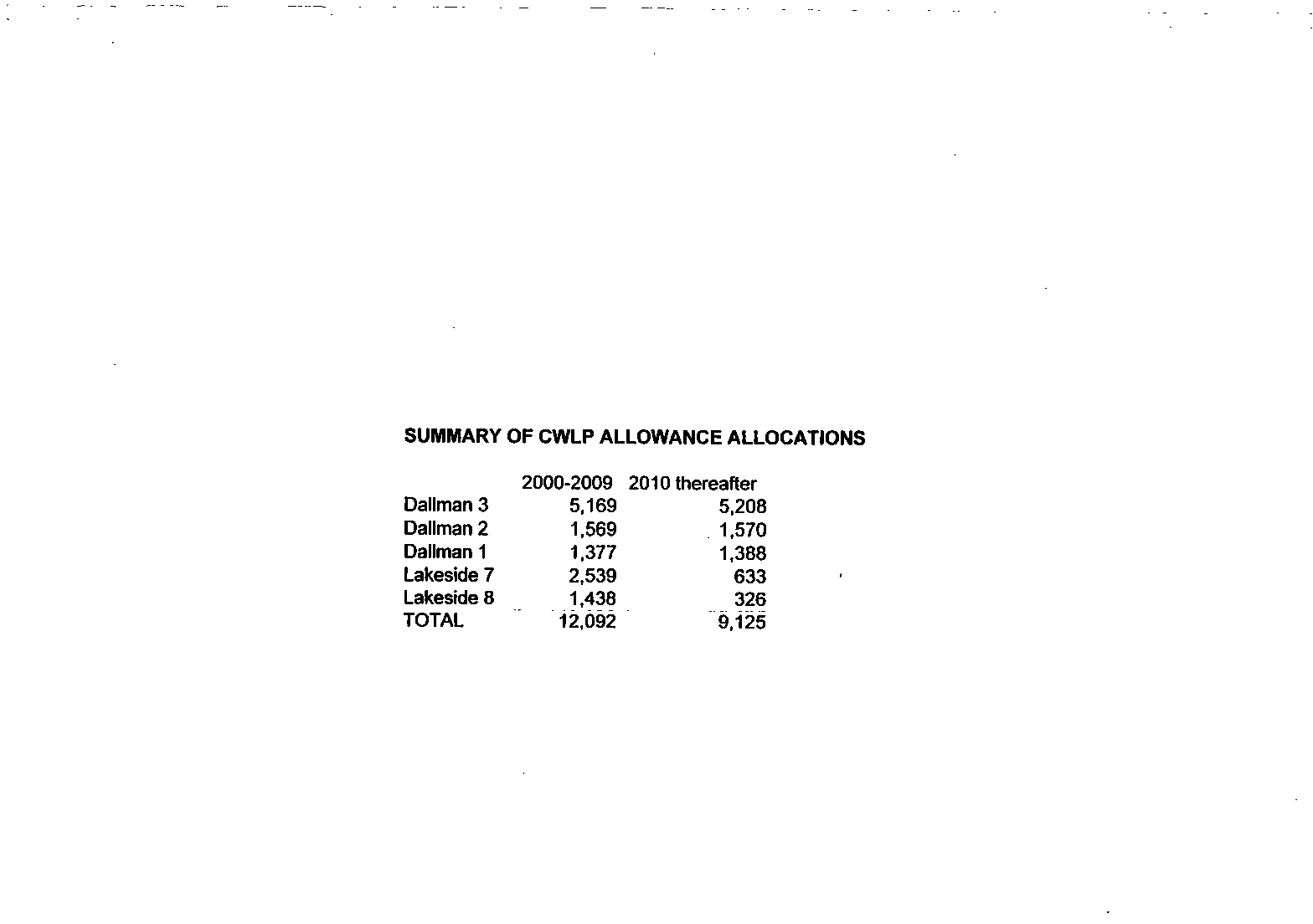

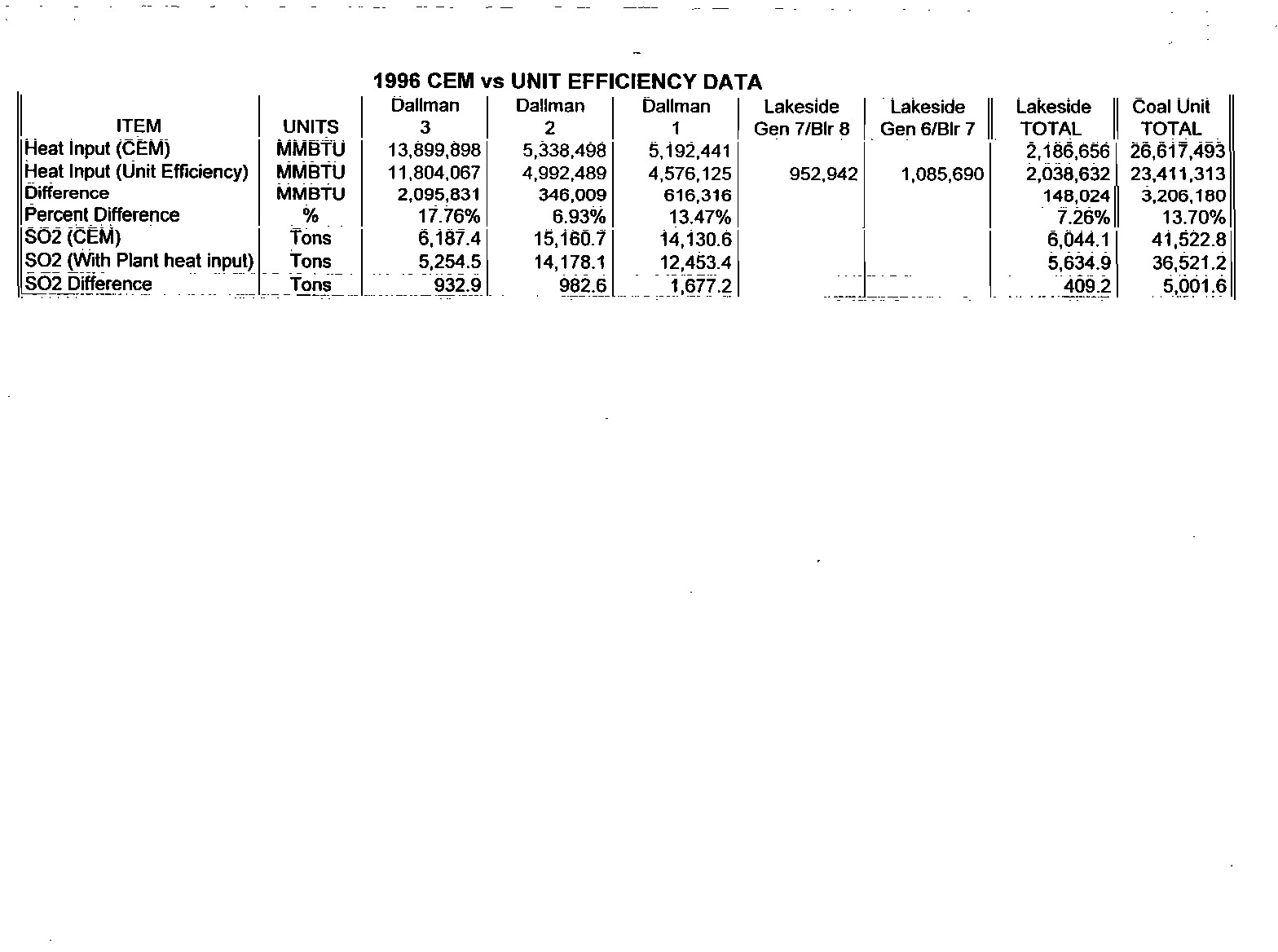

positive bias in S02 emissions due to the discrepancy between the CEMS-reported

and fuel-

based calculated emissions was included in

determination of allowances required.

" No banking of

SO,

allowances

was permitted. This includes the previous purchase of 27,000

allowances by

CWLP, which are not specifically accounted for in this analysis.

" The

significant reduction in the number of allowances available to the Lakeside units after the year

2009 was not

specifically accounted for. The results of the evaluation are therefore most relevant

for

the

first 10 years

of Phase II.

The analysis was based on assumed capacity factors that resulted in a total annual net generation

of 2,409,000 MWh. This is somewhat higher

than

historical generation levels.

The "best estimate" price

of

PRB

coal delivered to the plant site is equivalent to $1.45/mmBtu.

The "eval;uated costs" used in the analysis do not represent CWLP's full power production costs.

Even though some options evaluated would result in violation of the current Turris coal contract,

no cost or penalty which may result from such violation or dissolution of that contract are included.

CWLPI.doc

I-2

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

" Unit 33 FGD

0 & M costs are considered in

the evaluation of each option, including

the "base

case".

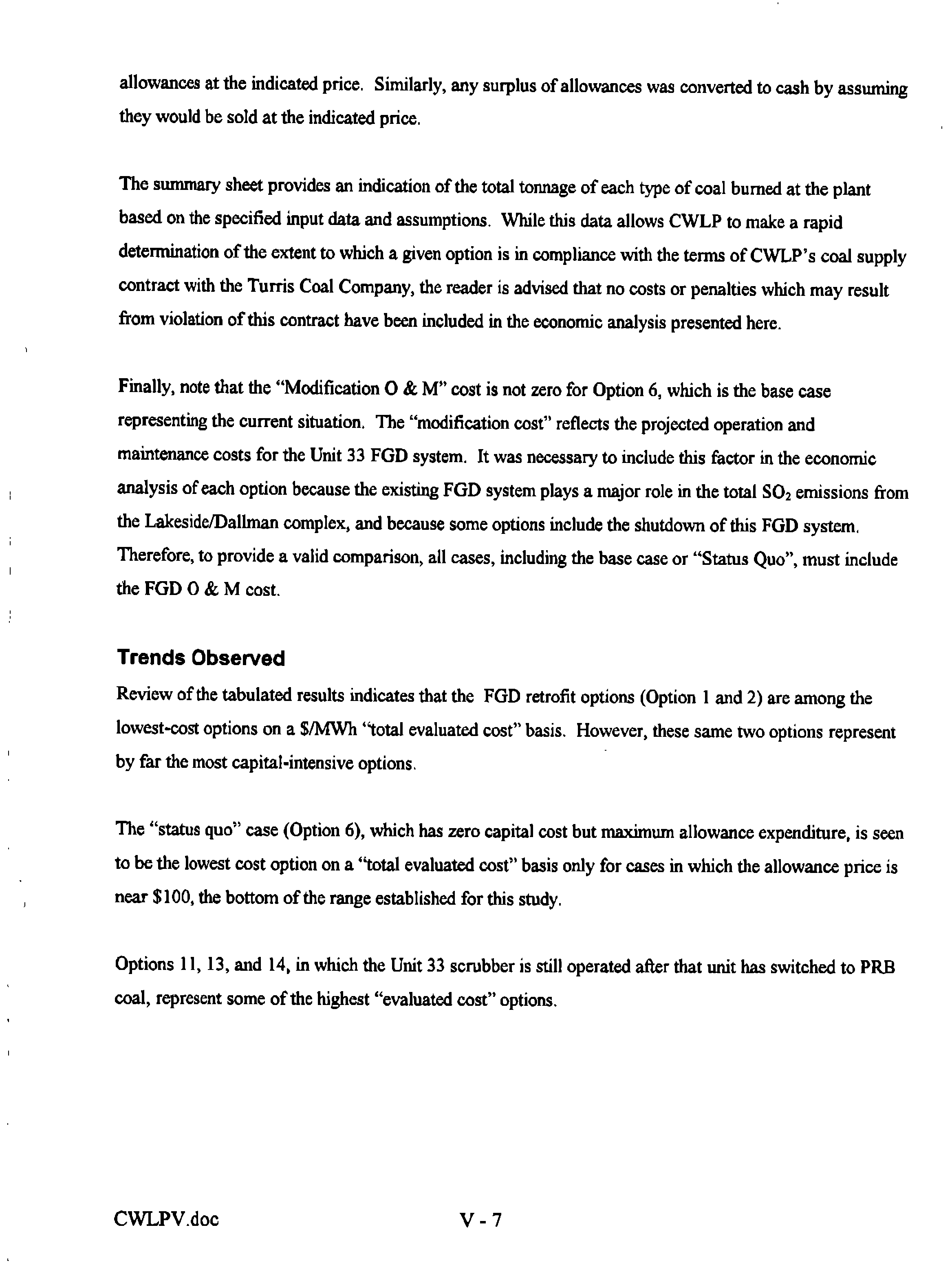

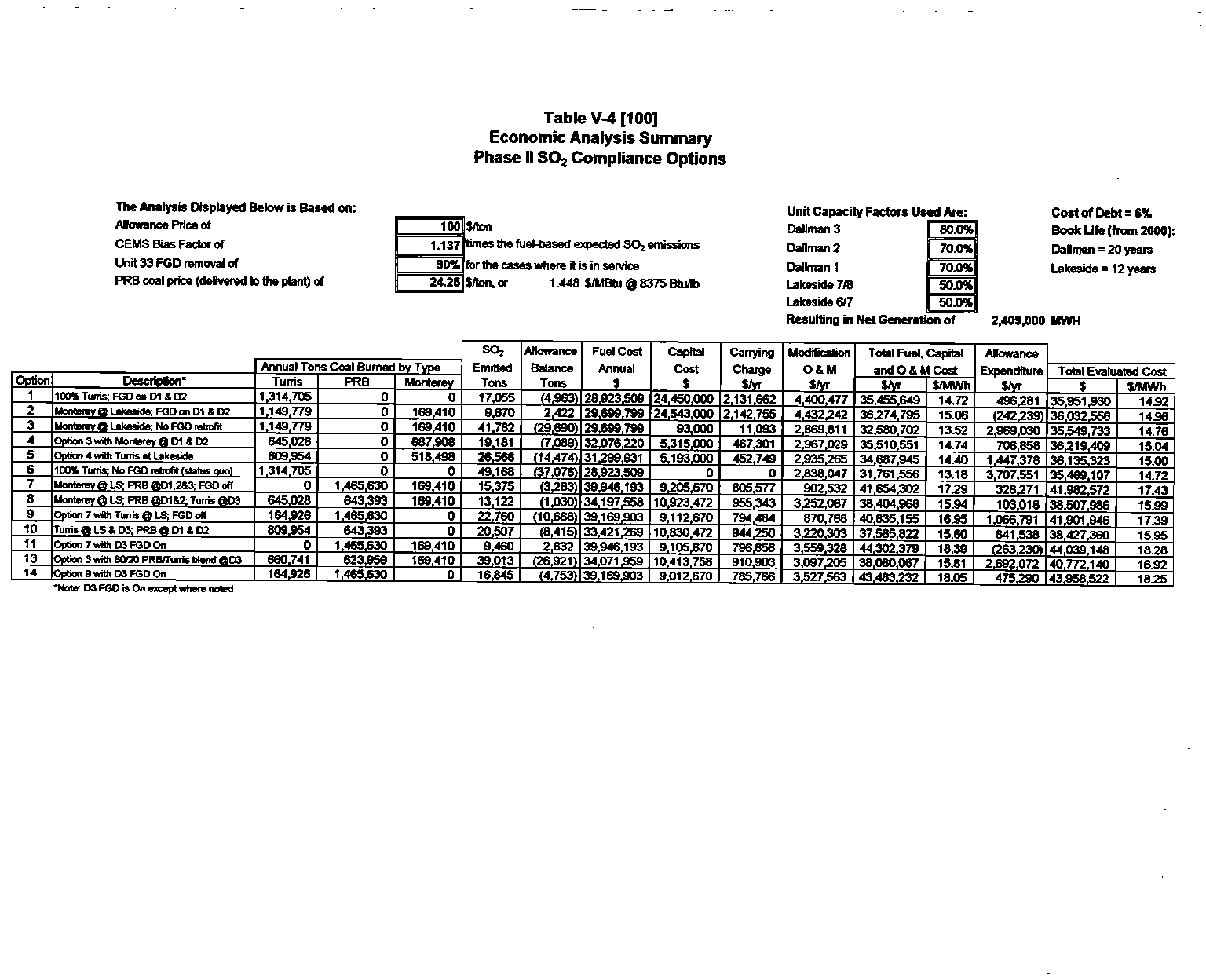

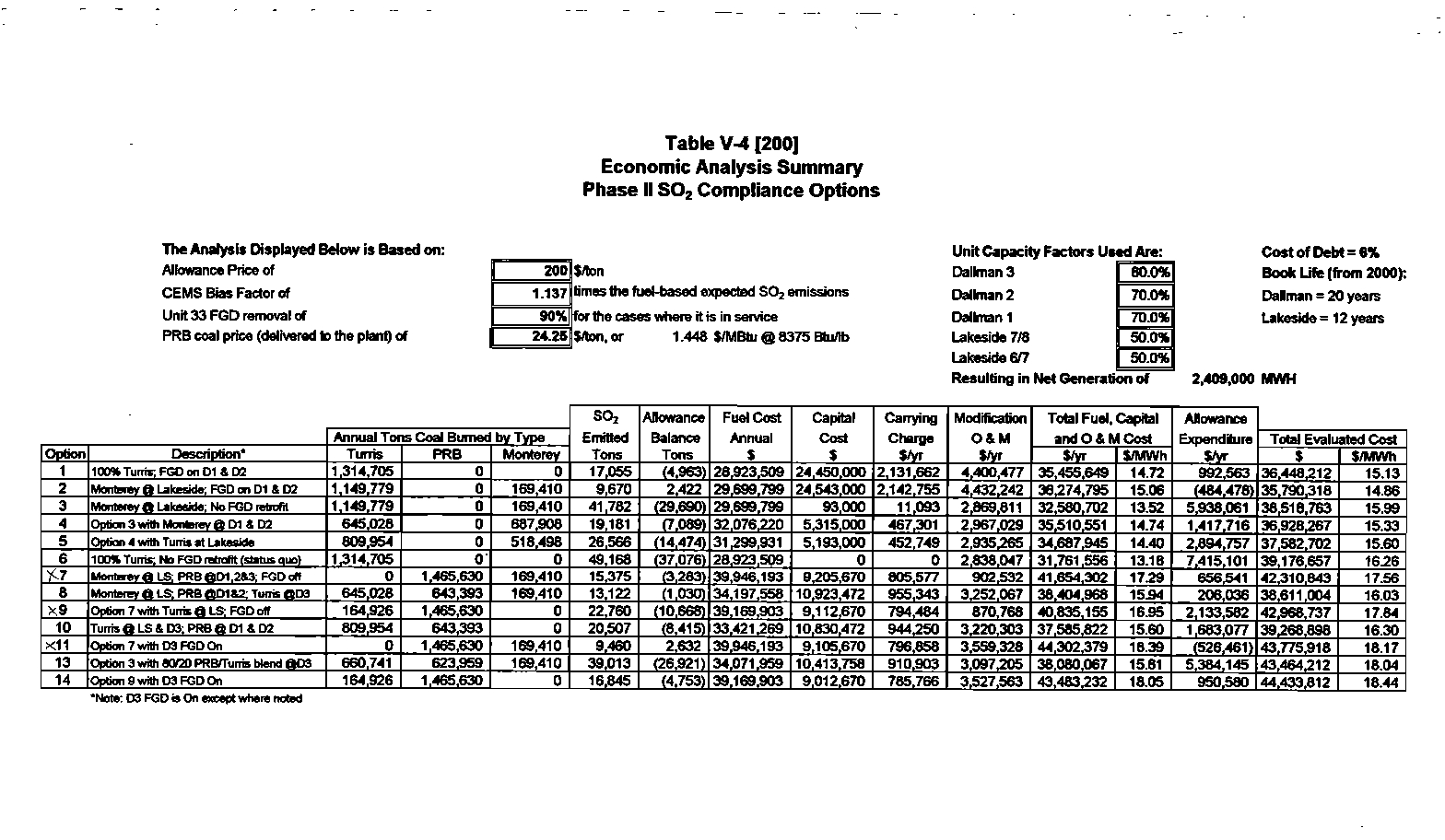

ReSUItS:

The lowest cost

option based on the evaluated life

cycle cost was Option 2, which is identical

to

Option 1

except that Monterey coal would

be burned in the Lakeside units. Options I

and 2 include the

addition

of an FGD system to Dallman

Units 31 and 32.

Although

Option 2 is the lowest evaluated

cost option, it has the highest capital

cost

requirement

of any

option evaluated.

This would require CWLP

to take on a substantial long-term debt burden. This may

make this option less

attractive to CWLP, depending

on the current financial condition and overall

cash

flow requirements of the

utility.

CWLPI.doc

1-3

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

PART

II

INTRODUCTION

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

PART II

INTRODUCTION

This report presents the results of the Phase II

S02 Compliance Study conducted

by Bums & McDonnell

for City Water

Light & Power (CWLP) of Springfield, Illinois.

BACKGROUND

Phase II refers to the second phase of sulfur dioxide

emission reductions under Title I V

of the Clean Air

Act as amended in 1990 (The Act). The specific

requirements for Phase II are provided in Section 405

of the Act. CWLP's Dallman

and Lakeside generating stations are affected

sources under Section 405,

and all coal-fired units at the two generating stations

are affected units. Section 405 requires

that,

beginning January l, 2000, these units are subject

to annual emission limitations for sulfur

dioxide

(SO2). Under the provisions of Section 403 of the Act, each

unit has been assigned an allowance

of a

certain number of tons of annual

S02 emissions based on the specific emission limitations

for that unit.

Beginning in calendar year 2000, the total actual S02

emissions (as determined by the continuous

emissions monitoring systems, or CEMS) from each of the affected

coal-fired units cannot exceed the

emission limitation unless the owner holds allowances to cover the

actual emissions. The U.S. EPA has

established an allowance trading system,

and holds annual auctions that help to set

the price of S02

allowances. Several brokerage firms also track and periodically

report the market value of allowances.

For any source subject to the Phase II S02 emission limitation requirements

of The Act, there are

basically three options for compliance:

1. Limit operation so as to insure that the total actual S02

emissions fall at or below the number of

allowances held.

2. Reduce S02 emission rates so that the total actual S02 emissions fall at or below

the number of

allowances held. This is typically done by some combination of switching

to coal with lower sulfur

content or retrofitting S02 emission control

equipment.

3. Procure additional allowances to cover the anticipated difference between actual emissions and the

base

number

of allowances granted by the U.S. EPA.

Various combinations of these compliance strategies are also possible.

C WLPILdoc

II - 1

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

CWLP has previously studied the situation with regard to

Phase II S02 compliance for

the Lakeside and

Dallman

stations. The previous CWLP studies

investigated the cost of switching

to low-sulfur Illinois

coal, the cost of retrofitting

a flue gas desulfurization (FGD)

system to Dallman Units

31 and 32, and the

cost of relying completely

on S02 allowance purchases for Phase II

compliance.

Since the

latest CWLP study was completed in

early 1996, several factors have

changed, and CWLP

determined

that it should update the study,

including expansion of the compliance options

to include

consideration

of switching to Powder River Basin (PRB)

coal. For this reason, CWLP retained

Bums &

McDonnell to complete the Phase

II S02 compliance study that is the subject

of this report.

PURPOSE

The purpose of the Phase

II S02 compliance study was to evaluate

options for compliance with the

S02

emission limitations which

will become effective for the Lakeside and Dallman generating

stations in the

year 2000. The six options covered

by the previous CWLP study in 1996 were revisited,

and four

additional options

that had been identified by CWLP for evaluation

were studied. In addition, Bums

&

McDonnell was

to identify and evaluate up to four additional

options which, in its opinion, would be

feasible additions to the range

of compliance optiuons previously identified.

The purpose of the study

was

to perform technical and economic evaluation

of all options, for the purpose of determining

the

preferred option.

Burns & McDonnell was tasked with

assessing the specific modifications required

for implementation of

the individual options at each coal-fired

generating unit at the Lakeside and Dallman

generating stations.

In doing so, our purpose was to identify the new and

modified equipment which would be necessary

to

maintain safe and reliable

operation of the plants. Bums & McDonnell has considerable

experience with

both coal

switching and FGD retrofit projects for Clean Air Act compliance,

and our goal was to bring

this experience to bear in the

assessment and evaluation of the compliance options for

CWLP.

SCOPE

The scope of the study included the following tasks:

1. An initial meeting at Dallman station with

CWLP staff to discuss the 10 options identified by CWLP

for consideration in the

study, and to clarify the scope and assumptions to be used for the study

parameters.

C WLPILdoc

11-2

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

2.

Identification of the four additional

options to complement those identified

by CWLP.

3. A meeting

at CWLP to finalize the list of

options to be evaluated in the study.

4.

Assessment of the equipment modifications

and additions required for,

and the operational effects of,

the implementation of each

option at each unit.

5. Performance of a Kepner-Tregoe

(K-T) decision analysis

to screen and rank each option

with regard

to its

ability to meet the needs and wants of CWLP.

Bums & McDonnell facilitated

this participative

decision analysis process at a meeting

at C WLP's Dallman station. This

allowed input from

CWLP's staff with regard to

the technical and operational factors judged

to be most important

to the

decision-making process.

6.

Preparation of cost estimates for the implementation

of each option at each unit. Estimates

prepared

included identification of expected capital costs

as well as assessment of equipment performance

and

operating cost effects.

7. Development

of an economic evaluation matrix,

in spreadsheet format, for use in the

economic

analysis of the various options.

8. Performance

of "sidebar" evaluations of possible

variations in the definition of certain

options.

These limited-scope

studies included:

" Location of off-site storage for PRB coal.

" Requirement for S02 removal

efficiency improvement for the Dallman

Unit 33 FGD system.

Preparation of this

final report.

10. Presentation of the results

of the study at a meeting with C WLP.

CWLPILdoc

11-3

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

PART III

COMPLIANCE

OPTIONS

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

PART III

COMPLIANCE OPTIONS

C WLP and

Bums

& McDonnell developed

the compliance options evaluated in this study. Ten

options

were presented by

CWLP as the basis for study. One of the initial tasks

of

this

study was to review these

ten

options and consider revisions or additions to the

base

list

of options. A maximum of four additional

options were to be added for

the study.

BASE COMPLIANCE

OPTIONS

The following ten compliance

options were identified by CWLP for this study. The

option

descriptions

define

the type of coal that would be burred in

each

unit,

changes in the operation of the Dalhnan Unit 33

scrubber and include the addition of scrubber to Dallnum Units 31 and 32.

1. Add

scrubber to Dallman Units 31 and 32, bum 100% Turris

coal in all units.

2. Add scrubber to Dallman Units 31

and

32,

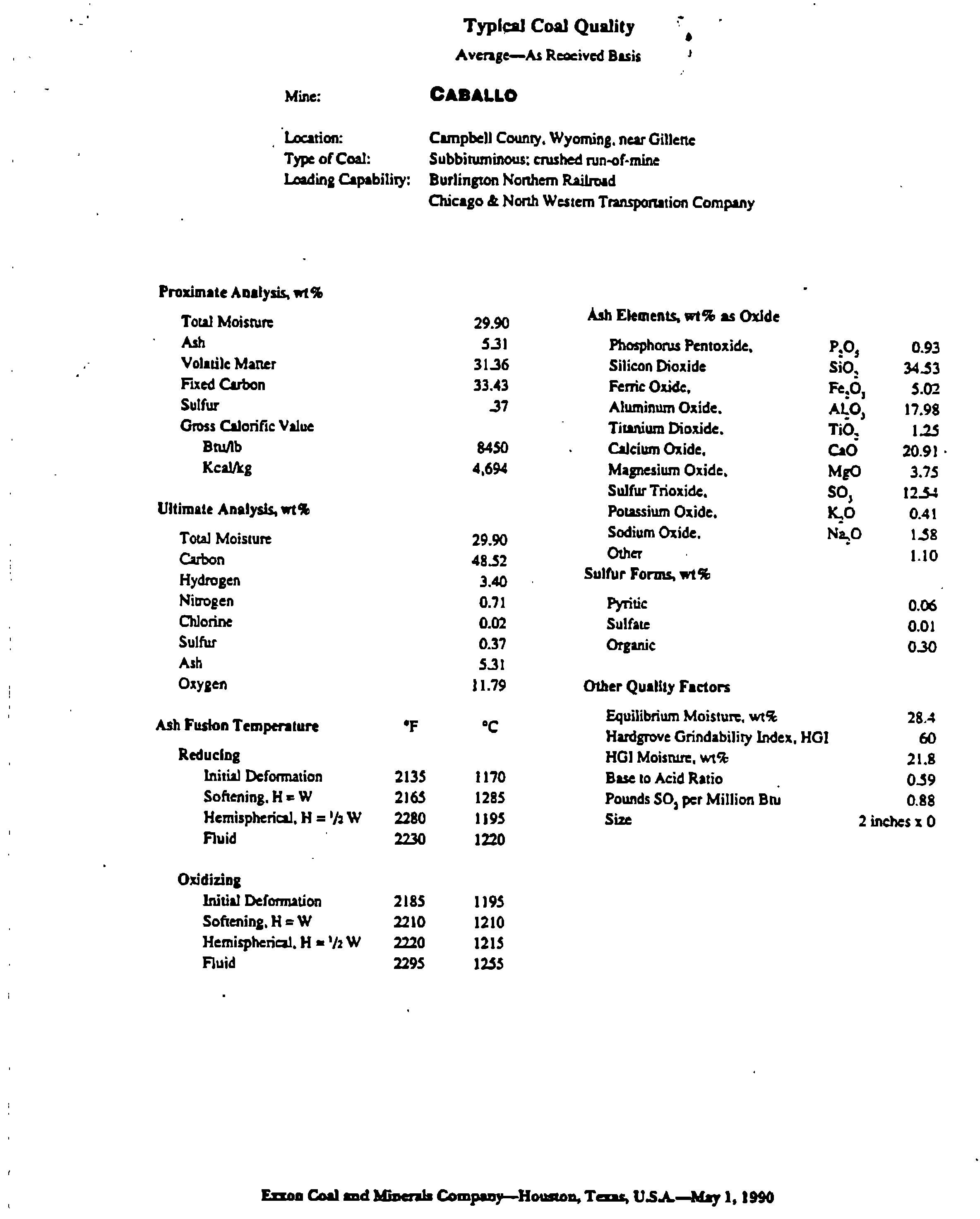

bum Tunis coal in Dalhnan units and bum Exxon

Monterrey coal in Lakeside

units (6 and 7).

3. Bum Exxon Monterrey

coal

in

Lakeside units, bum Turris coal in Dallman units.

4. Burn

Exxon Monterrey coal in Dallman Units 31, 32 and Lakeside

units, bum Turris coal in

Dallman Unit 33.

5. Bum Exxon Monterrey

coal

in Dallman

Units 31 and 32, bum Turris coal in Dallman Unit 33 and

Lakeside

units.

6. Bum 100% Turris coal in all Dallman and Lakeside

units.

7. Bum 100% Powder River Basin (PRB) coal in

Dallnum units, bum Exxon Monterrey coal in

Lakeside units,

shutdown Dallnum Unit 33 scrubber.

S. Bum PRB coal in Dallman Units 31 and 32, bum Turris coal in Dalhnan Unit 33,

and bum

Exxon

Monterrey coal in Lakeside units.

9. Bum 100% PRB

coal in Dallnum units, bum Tunis coal in Lakeside units, and shutdown

Dallnum

Unit

33

scrubber.

10. Bum PRB coal in Dallman Units 31 and 32, bum Turris coal in Dallman Unit 33 and in Lakeside

units.

CWLPIILdoc

III - 1

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

ADDITIONAL OPTIONS

F

ollowing review of these ten options, Bums & McDonnell identified four additional options, which were

submitted to CWLP on September 2, 1998. The

additional options were

initially

defined as

follows:

11. Bum Exxon Monterey coal in Units 31 and 32, and in the Lakeside units, and add scrubbers to

Unit 31 and 32.

12. No new

scrubber, bum a blend of PRB and

Exxon

Monterey coals

in

Units

31

and

32,

Turns coal

in Unit 33 and Exxon Monterey coal in Lakeside.

13.

No new scrubber, bum Exxon Monterey coal in Lakeside, Turris coal in Units 31 and

32,

and a

blend of PRB and Exxon Monterey coals in Unit 33. Unit 33 scrubber remains in service.

14. No new

scrubber, bum

Turns

coal

in

Units

31

and

32

and

in Lakeside, and bum 100% PRB coal

in Unit 33. Unit 33 scrubber remains in service.

Burns & McDonnell prepared a description of the coal and FGD status, potential new coal handling

equipment that could be required, Dallnum Unit 33 FGD system modifications and boiler modifications for

each of the ten base options and the four additional options. CWLP and Bums & McDonnell subsequently

discussed

the options at a

meeting

on September It, 1998 at the

Dallnum

Station. Several

changes were

made to the additional options, based

on

input received from CWLP personnel.

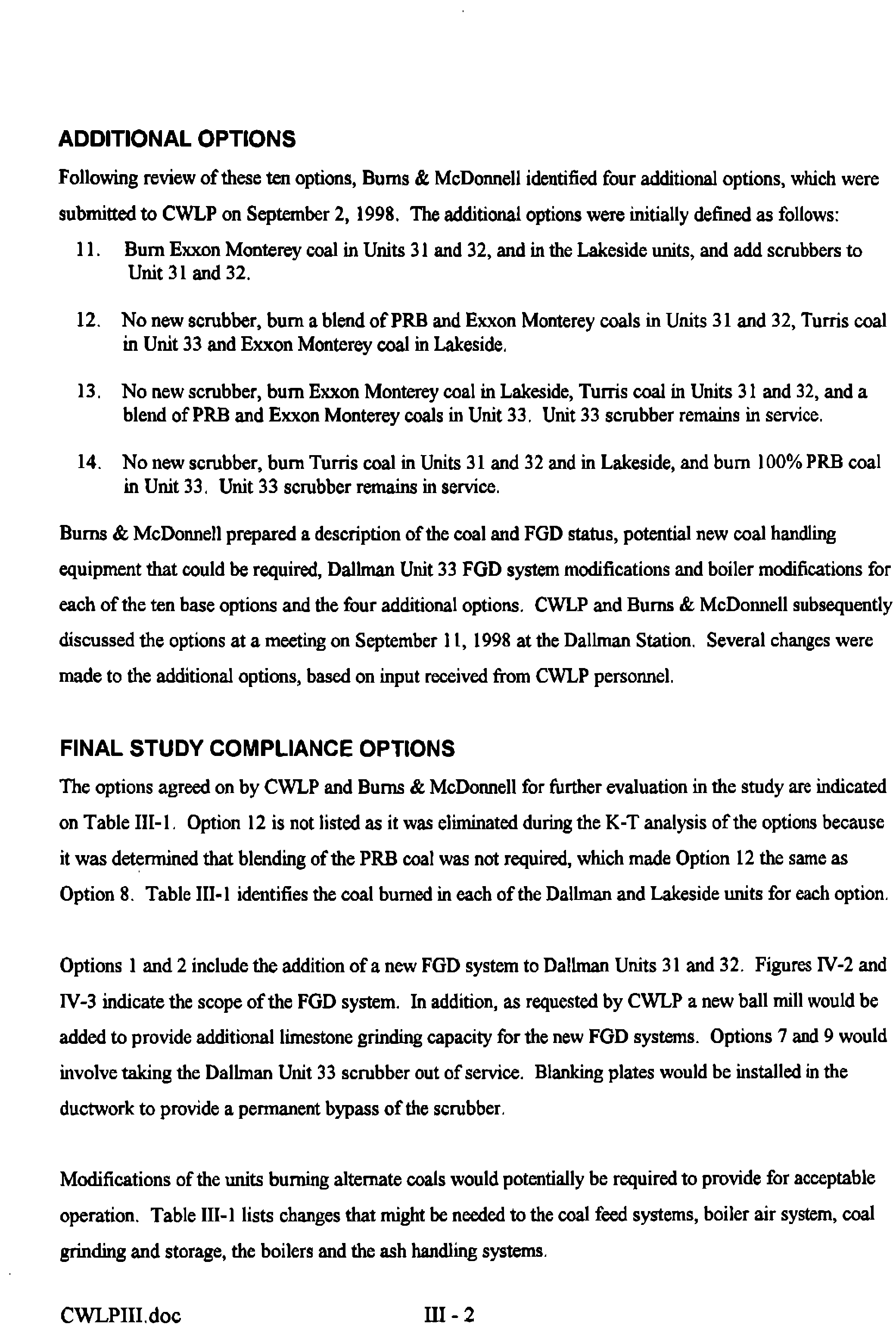

FINAL

STUDY

COMPLIANCE

OPTIONS

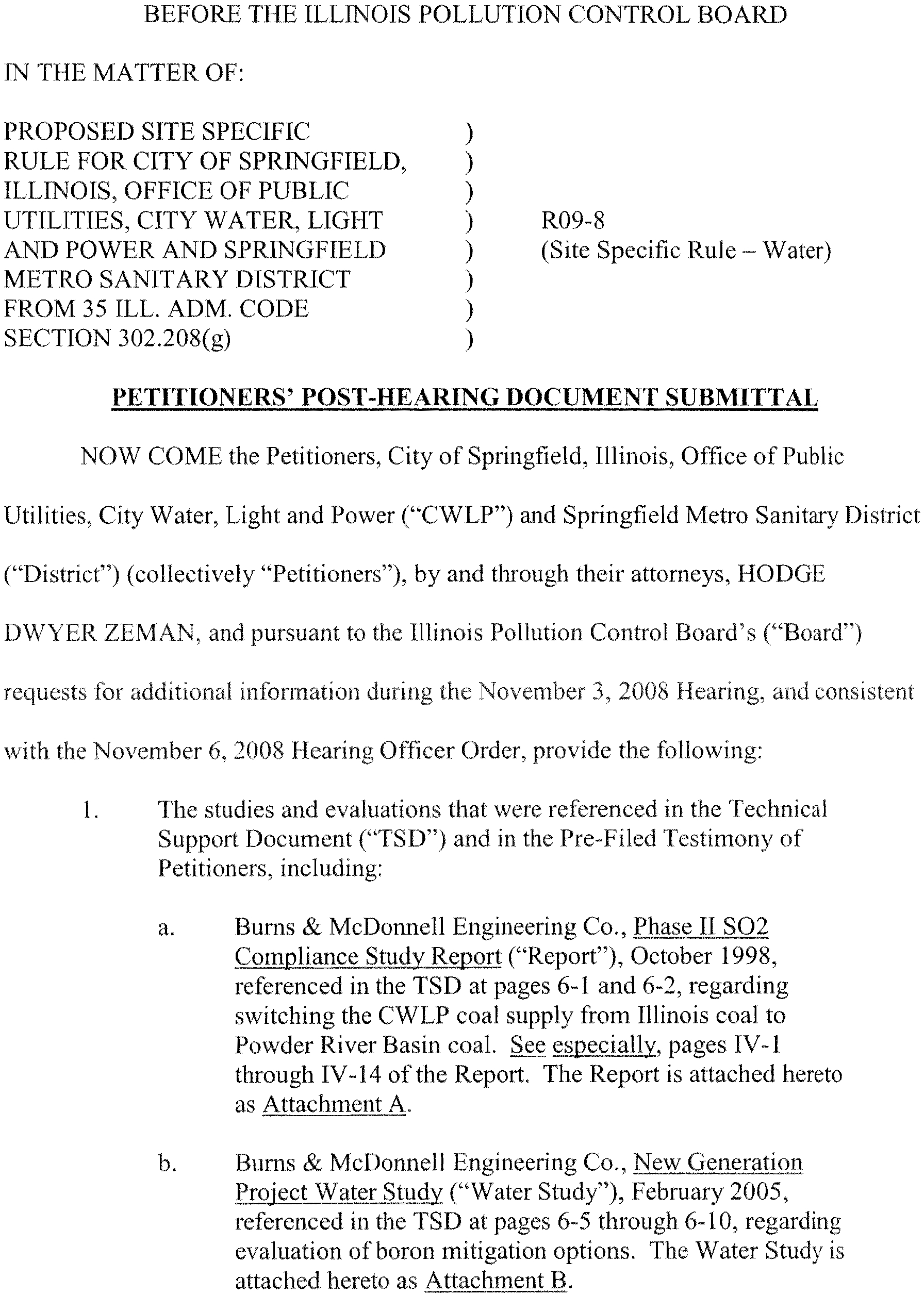

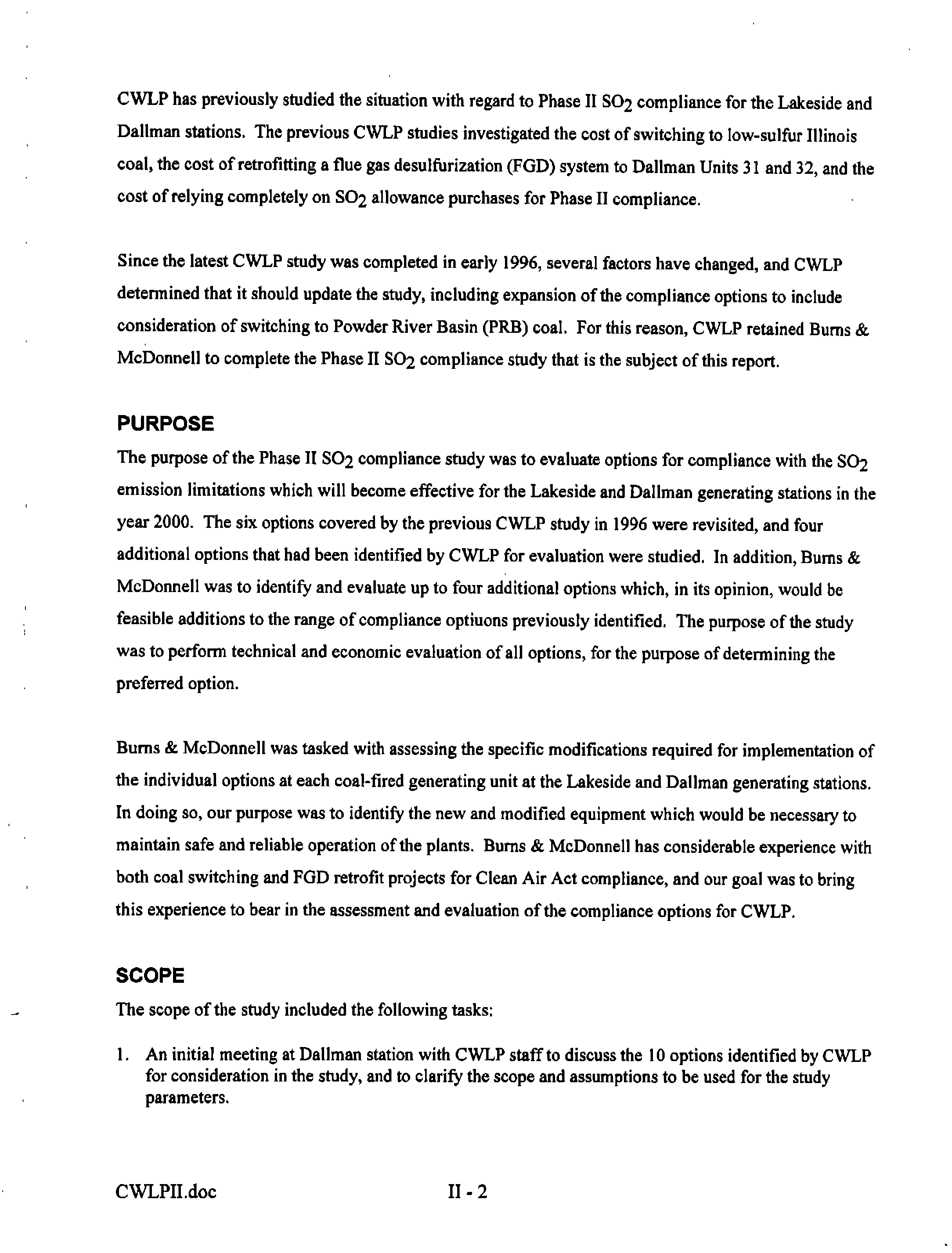

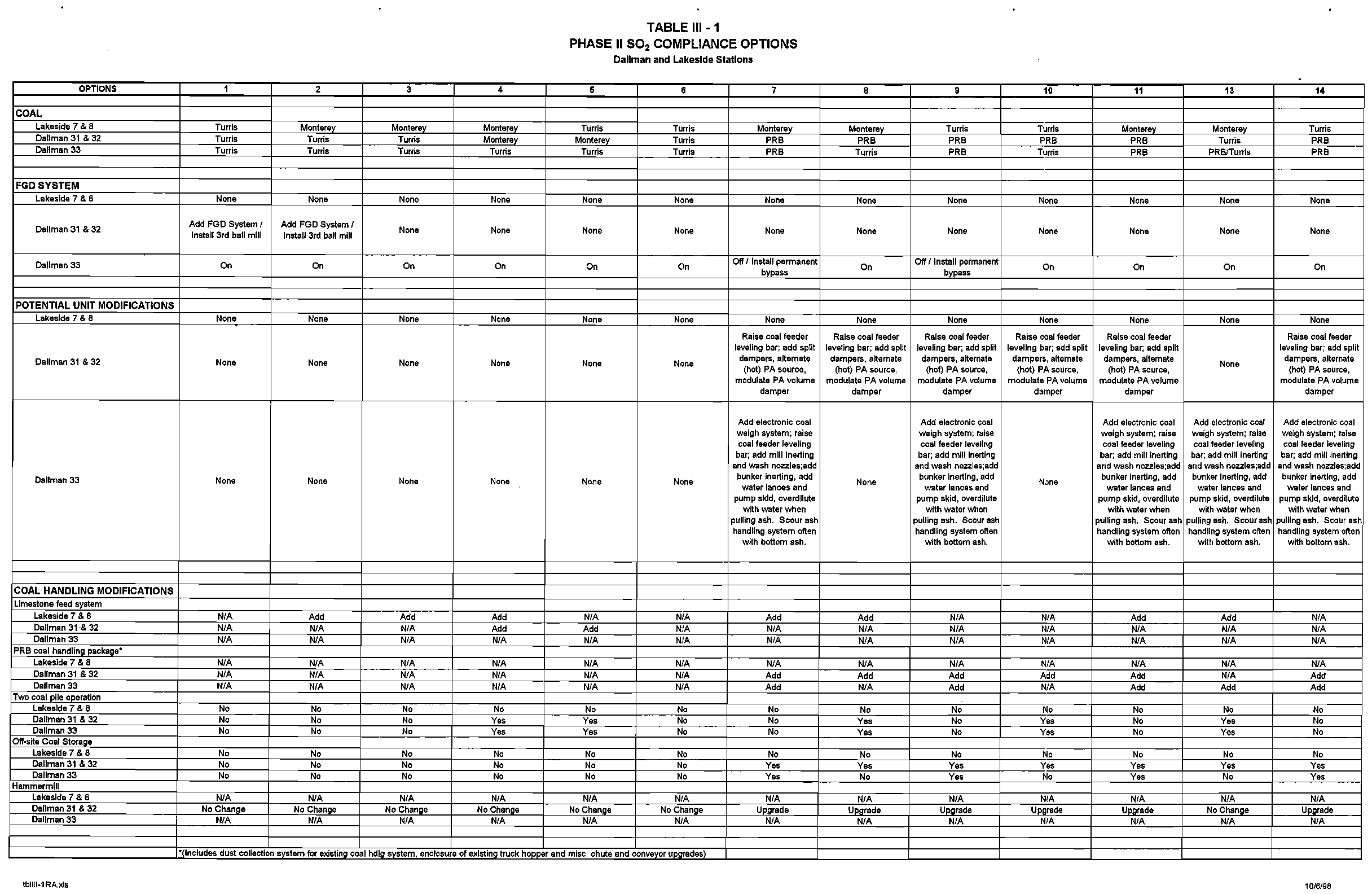

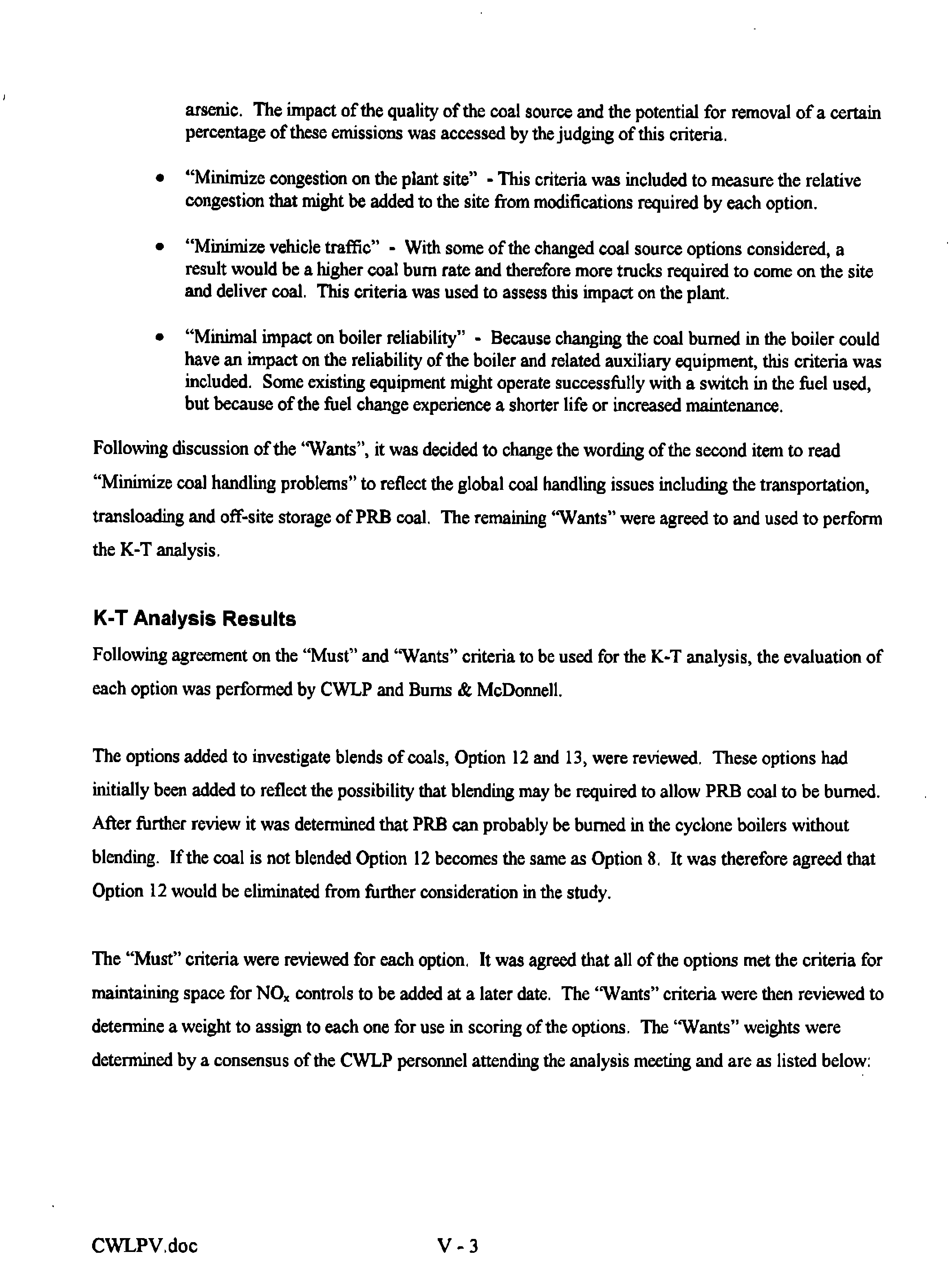

The options agreed on by CWLP and Bums & McDonnell for further evaluation in the study are indicated

on Table III-1. Option 12 is not listed as it was eliminated during the K-T analysis o£ the options because

it was determined that blending of the PRB coal was not required, which made Option 12 the same as

Option 8. Table III-1 identifies the coal burned in each of the Dallman and

Lakeside units for each option.

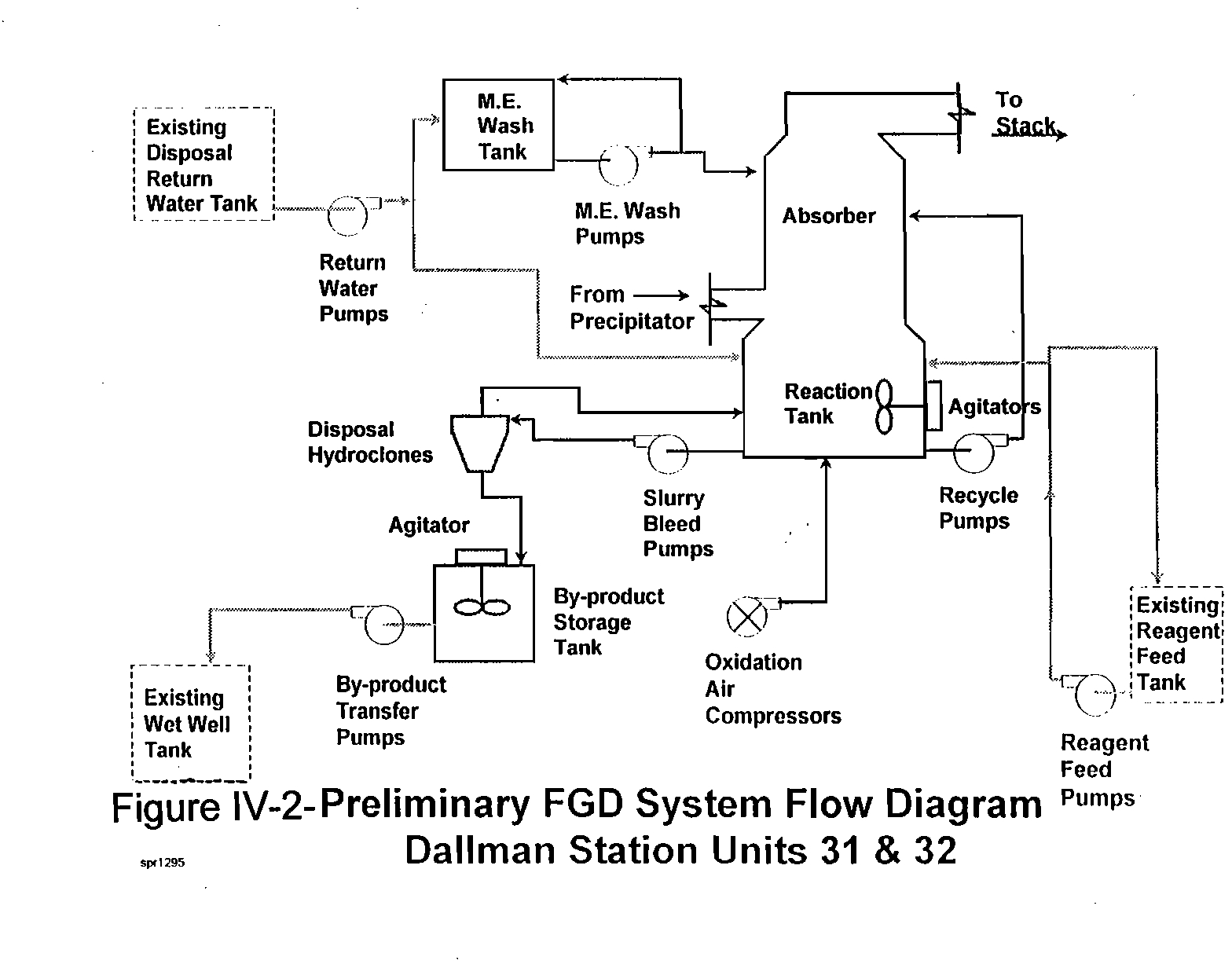

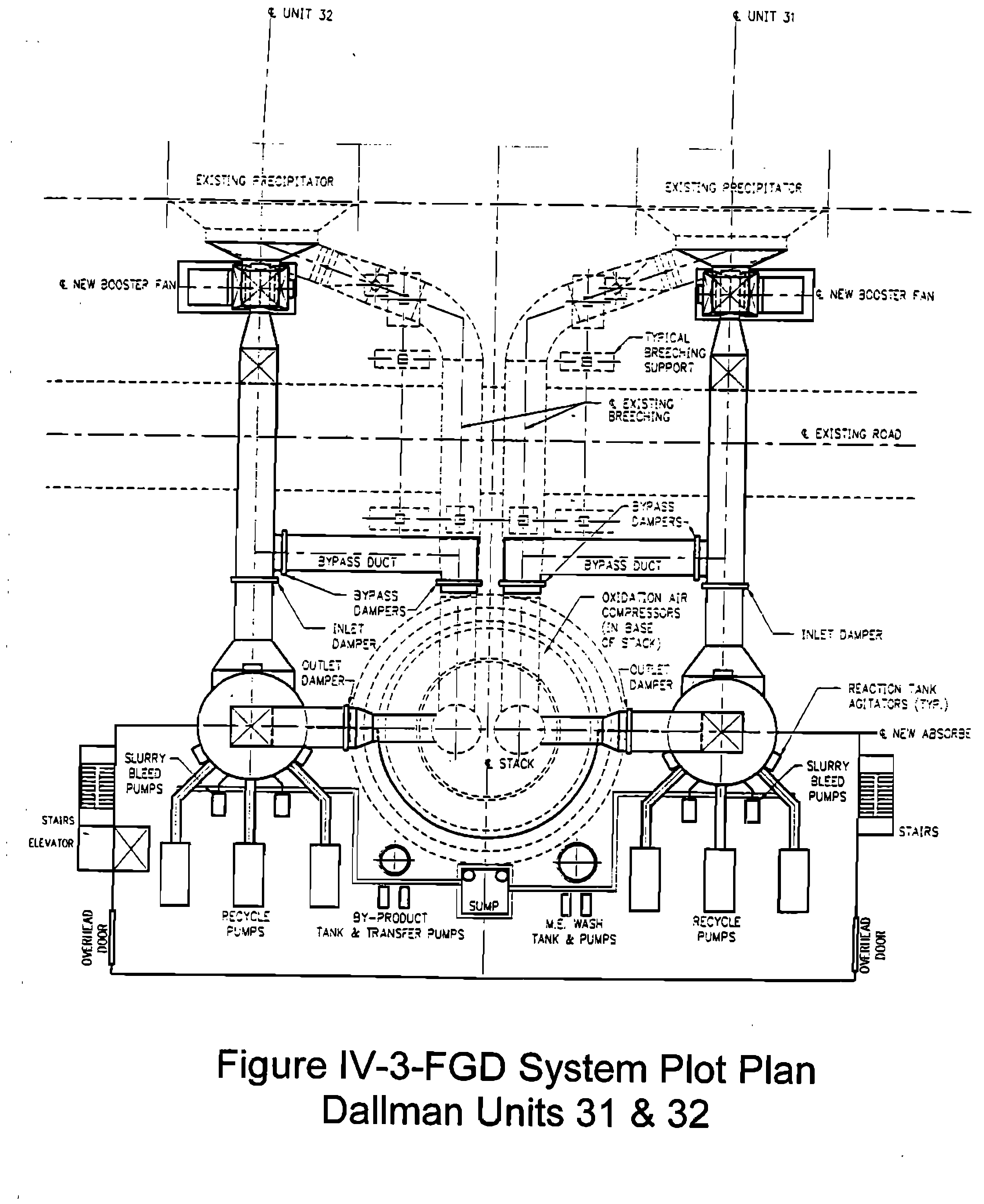

Options 1 and 2 include the addition of a new FGD system to Dallnum Units

31

and

32. Figures

IV-2 and

W-3 indicate the scope of the FGD system. In addition, as

requested

by

CWLP a new ball mill would be

added to provide additional limestone grinding capacity for the new FGD, systems. Options 7 and 9 would

involve taking the Dallman Unit 33 scrubber out of service. Blanking plates would be installed

in

the

ductwork to provide a permanent bypass of the scrubber.

Modifications of the units burning alternate coals would potentially

be required to provide for acceptable

operation. Table

III-1 lists

changes

that might be needed to the coal feed systems, boiler air system, coal

grinding and storage, the boilers and the ash handling systems.

CWLPIII.doc

III - 2

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

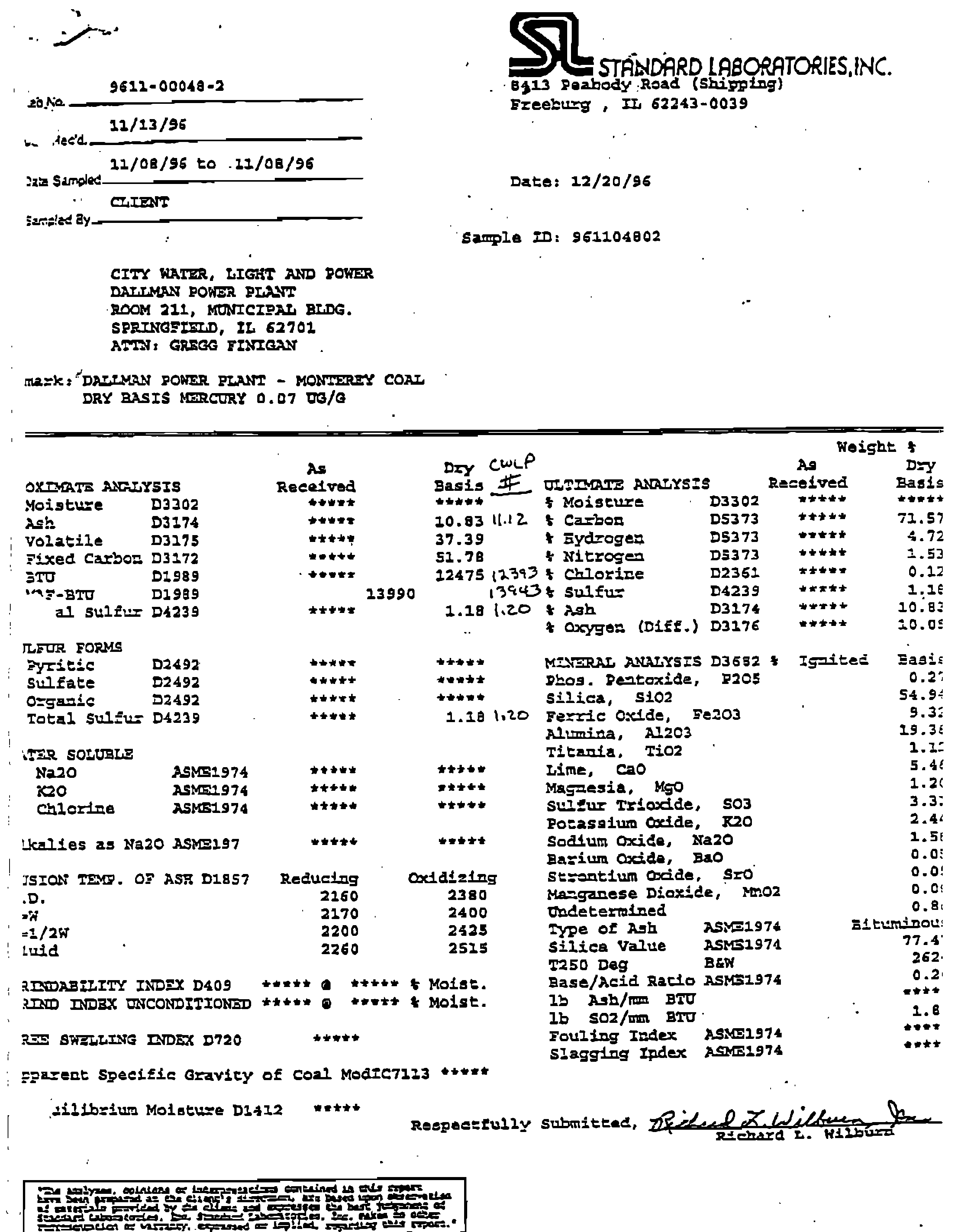

Special coal handling features were also

assumed to be required for the options involving units burning

alternative

coals. Based on experience gained by CWLP during a test bum

of the

Exxon

Monterey coal

performed in November 1996,

the analysis includes a feed system to provide limestone to the boiler

with

the coal. The

limestone is required to control slagging due to the high ash fusion

temperatures of the

Monterey

coal. PRB coal was assumed to require the addition of dust collection systems and

enclosure of

the existing truck unloading hopper

because of high potential for dusting. Because it may not be feasible to

provide rail

delivery of

PRB

coal to the Dallman plant site, off-site coal storage was evaluated. Upgrade

of

the existing hammermill crushers for Dallman

Unit

31

and 32 may also be required to handle PRB coal.

CWLPIII.doc

HI-3

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

TABLE III -1

P HASE II SO, COMPLIANCE OPTIONS

Dallman and Lakeside Stations

O PTIONS

1

2

3

6

8

8

7

8

9

10

11

13

10

COAL

Lakeside7&e

Turns

Monterey

Monterey

Monterey

Turns

Turns

Monterey

Monterey

Turns

Turrls

Monterey

Most .. y

Turns

Dellman 31 & 32

Turris

Tuns

Turds

Monterey

Montere

Turns

PRB

PRB

PRB

FPS

PRB

Turns

PRB

Dallmen33

Turns

Tuna

Turns

Turns

-Turns

Turns

PRB

Tuns

PRB

Tuns

PRB

Pfl Rurris

PRB

FGOSYSTEM

Lakeside 7

& 9

None

None

None

None

None

None

None - -

None

None

None

None

None

None

Dallman31&32

AddFGOSystem I

Insult 3rd bell mill

AddFGDSystem

/

Install 3N ball mill

None

None

None

None

None

None

None

None

None

None

None

Dallmen33

On

On

On

On

On

On

Off/ Insbypaaamanent

O

n

0a/Insallpermanent

On

On

On

On

POTENTIAL UNIT MODIFICATIONS

Lakeside 7 & B

None

Nor.

None

None

None

None

None

None

None

None

None

None

- None

Dellman 31 & 32

None

None

None

None

None

None

Raise

coal

feeder

leveling bar; add split

dampers,

aaemate

(hot) PA source,

modulate PA volume

damper

Raise coal feeder

leveling bar; add split

dampers, alternate

(hat) PA source,

modulate PA volume

damper

R.I.. coal feeder

leveling bar; add split

dampers, alternate

(hot) PA source,

modulate

PA

Valume

damper

Raise ..I feeder

leveling bar; add split

dampers, alternate

(hot) PA source,

modulate PA volume

damper

Raise coal feeder

leveling bar; add split

dampen, alternate

(hot) PA source,

modulate PA volume

damper

None

Raise coal feeder

leveling bar; add split

dampers, akernel.

(hot) PA source,

modulate PA volume

damper

Dellman 33

None

None

None

None

None

Non.

Add electronic coal

weigh system; raise

coal

feeder leveling

bar; add mill

Insuring

end wash

noules;add

bunker ineding, add

water lan... nd

pump skid. verdilut.

with water when

pullingesh. S...rash

handling system often

with

bottom ash.

N

one

A dd

electronic

coal

weigh system; flee

coal feeder leveling

bar;

add

mill

Ineding

and

wash noules;add

bunker

InertIng, add

water lances end

pump

-kid,overdilute

with waterwhen

pulling ash. Scour ash

handling

system aRan

Win bottom ash.

N

one

A ddelactronlccoal

weigh

system; raise

coal

feeder

leveling

bar;

add mill meting

end wash noaalaa.dd

bunker ineding, add

water lances and

pump

skid, overdllute

with water when

pulling ash. Scour ash

handling

system often

Win bottom ash.

Add electronic

ccal

weigh system; reiae

coal feeder leveling

bar; add mill

loaning

end

wash noazles;add

bunker

Ineding, add

water lances and

pump skid,

ovenilute

wkhvroterwhen

pullingesh. Scouresh

handling system often

with

bottom ash.

Add alectir.nic coal

weigh system; miss

coal feeder leveling

bar; add

mill losing

and

wash nosderadd

bunker Inenlng, add

water lances and

pump

skid,

overdilute

with

weterwher

pulling ash Swuresh

handling systemoRen

with bottom ash.

C OAL HANDLING MODIFICATIONS

Limestone feed system

Lakeside 7 & 8

NIA

Add

Add

Add

N/A

N/A

Add

Add

N/A

N/A

Add

Add

N/A

Dellman

31

&

32

N/A

N/A

NIA

Add

Add

NIA

NIA

N/A -

N/A

N/A

-

-

N/A

-

NIA

N/A

Dallmen33

N/A

NIA

NIA

N/A

N/A

-NIA

N/A

N/A

N/A

N/A

N/A

N/A

N/A

PRB coal handling packs a'

Lakeside 7 & e

NIA

NIA

N/A

N/A

NIA

N/A

N/A

NIA

N/A

N/A

N/A

NIA

NIA

Dallman31&32

N/A

NIA

N/A

N/A

NIA

NIA

Add

Add

Add

Add

Add

N/A

Add

Dallmen

33

N/A

N/A

NIA

N/A

N/A

NIA

Add

NIA -

Add

WA

Add

Add

Add

Two

coal

ire operation

-

Lakeside 7&B

No

No

No

No

No

No

No

No

No

No

No

No

No

Dallmen 31 & 32

No

No

No

Yes

Yes

No

No

Yes

No

Yes

No

Yes

No

Dellman 33

No

No

No

Yes

Yes

No

No

Yes

No

Yes

No

Yes

No

Ofhstte Coal Storage

Lakeslde7&8

No

No

No

Na

No

No

No

-

No

No

No

No --

No

No

Dallmen 31 & 32

No

No

No

No

No

No

Yea

Yes

Yes

Yes

Yes

Yes

Yes

Dallmen33

No

No

No

No

No

No

Yes

No

Yes

No

Yes

No

Yes

Hemmermlf

Lekeslds 7 & 8

N/A

NIA

NIA

NIA

NIA

NIA

NIA

- N/A -

NIA

NIA

NIA

N/A

NIA

Dallmen 31 & 32

No Change

No Chan e

No

Change

No

Change

No

Charge

No

Chan e

U grade

Upgrade

Upgrade

Upgrade

U red.

No Change

U rode

Dallmen

33

NIA

N/A

NIA

N/A

N/A

N/A

N/A

N/A

NIA

NIA

N/A

N/A

N/A

I

I' (Includes dust collection system

for existing coal hdlg system enclosure of existing truck hopper end mlac, chute end conveyor upgrades)

0

b11114RAMIs

10/&80

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

PART IV

SCOPE OF MODIFICATIONS

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

PART

IV

SCOPE OF MODIFICATIONS

REQUIRED

Bums & McDonnell reviewed

the existing systems and

equipment at the Lakeside and Dallman generating

stations to determine the modifications

required for the implementation

of each

Phase

II S02 compliance

option. Bums & McDonnell

engineers who specialize in the respective

disciplines of coal handling, coal

combustion

and air pollution control provided

input to this review and assessment. Data

gathered and

observations made during visits to the plant

site

were

considered. Discussions with CWLP personnel

provided

additional insight into

the

feasibility

of the required modifications and their effects

on operation of

the coal handling

system, boilers, electrostatic

precipitators and FGD system.

The following

sections provide a discussion of the important factors

considered by each discipline in the

assessment of

the

modifications

required. The basis for the estimates

of the costs of the modifications for

each option is described.

Where the modifications would result in equipment performance degradation

or

increased

operation and maintenance

costs, the basis for the estimation of those costs is

stated.

COAL HANDLING AND STORAGE

The

coal switch options under consideration

as part of the Phase II S02 compliance planning for the

Lakeside and Dallman

stations include:

" Switching from Tunis

coal to medium sulfur Illinois coal (from the Exxon Monterey mine) for

the

cyclone boilers

at Lakeside and Dallman; and

" Switching to low

sulfur

Wyoming

Powder River Basin (PRB) coal in units 1, 2 and/or 3 at the

Dallman

station.

Because

CWLP has conducted a test bum of Monterey coal in one unit each at Lakeside and Dallman, and

because of the physical

similarity between the Turris and Monterey coals, the modifications required

to

switch to Monterey coal are well

established, and minimal in extent.

Consequently, the majority of the assessment effort was

directed at the modifications required to receive,

store, transport, unload, convey and crush the PRB coal for use

at

Dallman

station.

A

switch to

PRB

coal

was not considered by CWLP for Lakeside

due to the

impending

retirement of the units in 2011.

CWLPIV.doc

IV-

1

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Handling PRB Coals-General

Considerations

There

are three major impacts on

coal handling operations when dealing with

Power River Basin

(PRE)

coals:

" Spontaneous combustion

" Fugitive dusting

" Higher bum rates

Spontaneous combustion

can occur with most

coals. The problem can be

significant with PRB coal.

Many utilities find they must

either bum PRB coal or compact it

in long term storage within 14

to 21 days

of

receipt,

to minimize the risk

of spontaneous combustion

depending on the weather

conditions. Putting

PRB coal into

storage requires

good stockpiling techniques.

The coal should be spread into

thin

layers

and

compacted.

Rubber tire dozers with

additional ballast can be used

to provide the required compaction

pressures. The

cost of a rubber tired

dozer was not included in

the cost estimates for this study because

of

the high cost and because

it would not be needed

often. Building the pile could

be performed using rented

equipment

or by subcontracting this work.

A

common characteristic of PRB

coals is the large amount

of fugitive dust created when it is handled. The

coal particles continually

break down with loss of moisture

and handling. Most PRB coal handling systems

use several types

of both active and passive dust

control. Dust that isn't controlled is

typically cleaned up

with

water wash down and

vacuum systems.

Because

PRB coals have a lower

BTU value than the Turris

coal currently used at Dallman, additional

coal must

be burned to provide the

same

heat

input to the boilers. At

CWLP, it is estimated that

approximately 25 percent more PRB

coal would be burned in the boilers (assuming the same

unit

ratings).

This

translates into longer operating hours for

the coal handling system.

Receiving

PRB Coal

Three alternatives were considered

for receiving rail shipments of PRB

coal

from

Wyoming. Technical

aspects

of these alternatives are discussed

below. Additional information regarding the

estimated scope and

cost of development

of the three alternatives is presented

in Appendix D.

Railcar Unloading at Dallman:

CWLP currently does not have

any

reliable

way to receive rail

delivered coal at the Dallman

and

Lakeside

power plants. The Lakeside track hopper is

abandoned and the

CWLPIV.doc

IV

- 2

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Dallman hopper no longer has rail

sidings connected to it. The plant site is not large enough for

any type of

true unit train coal

deliveries.

With

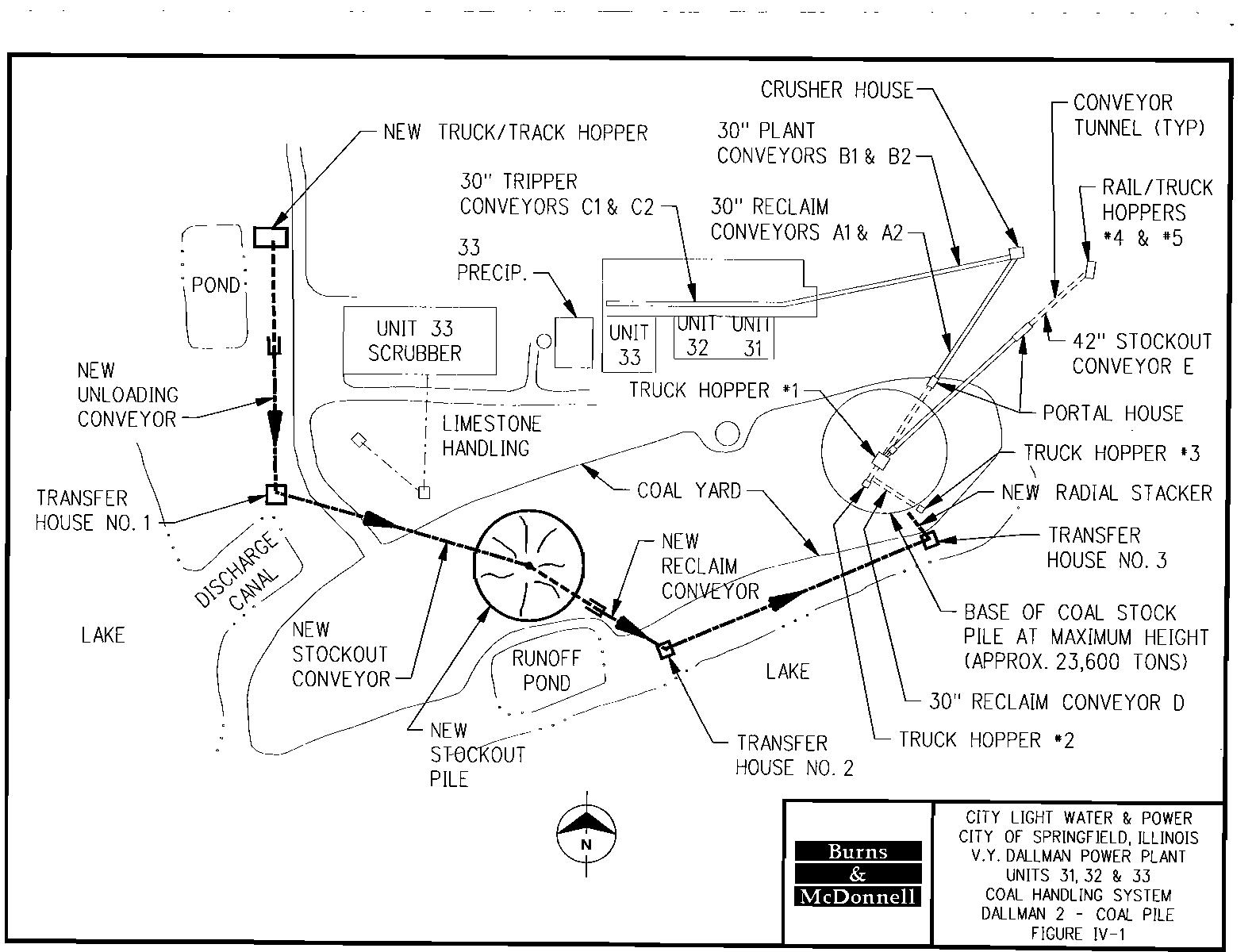

major modifications to the existing

mil sidings, limited rail unloading could be restored at Dallman

for delivery of PRB

coals. The location of the existing Dallman track/truck hopper

on

the

east side of the

plant would only allow

short strings of

railcars

to be unloaded. Unloading railcars on the existing hopper

would

interfere with truck unloading activities used by some

of the other options (where some Turris coal is

still burned at Dallman). For

this

reason,

the cost estimates for this study were based on a new track

hopper

and storage sidings on the west side of Dallman.

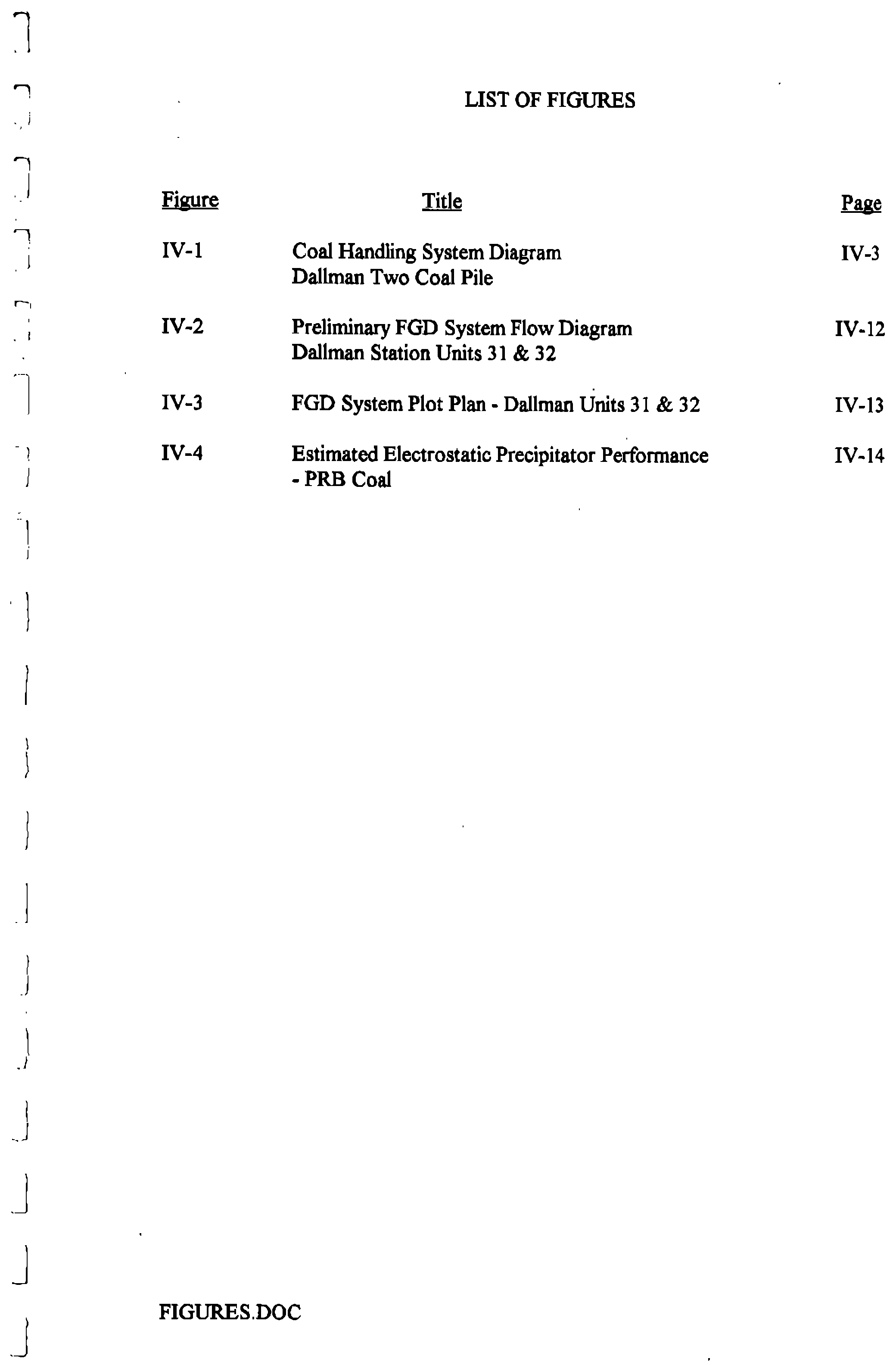

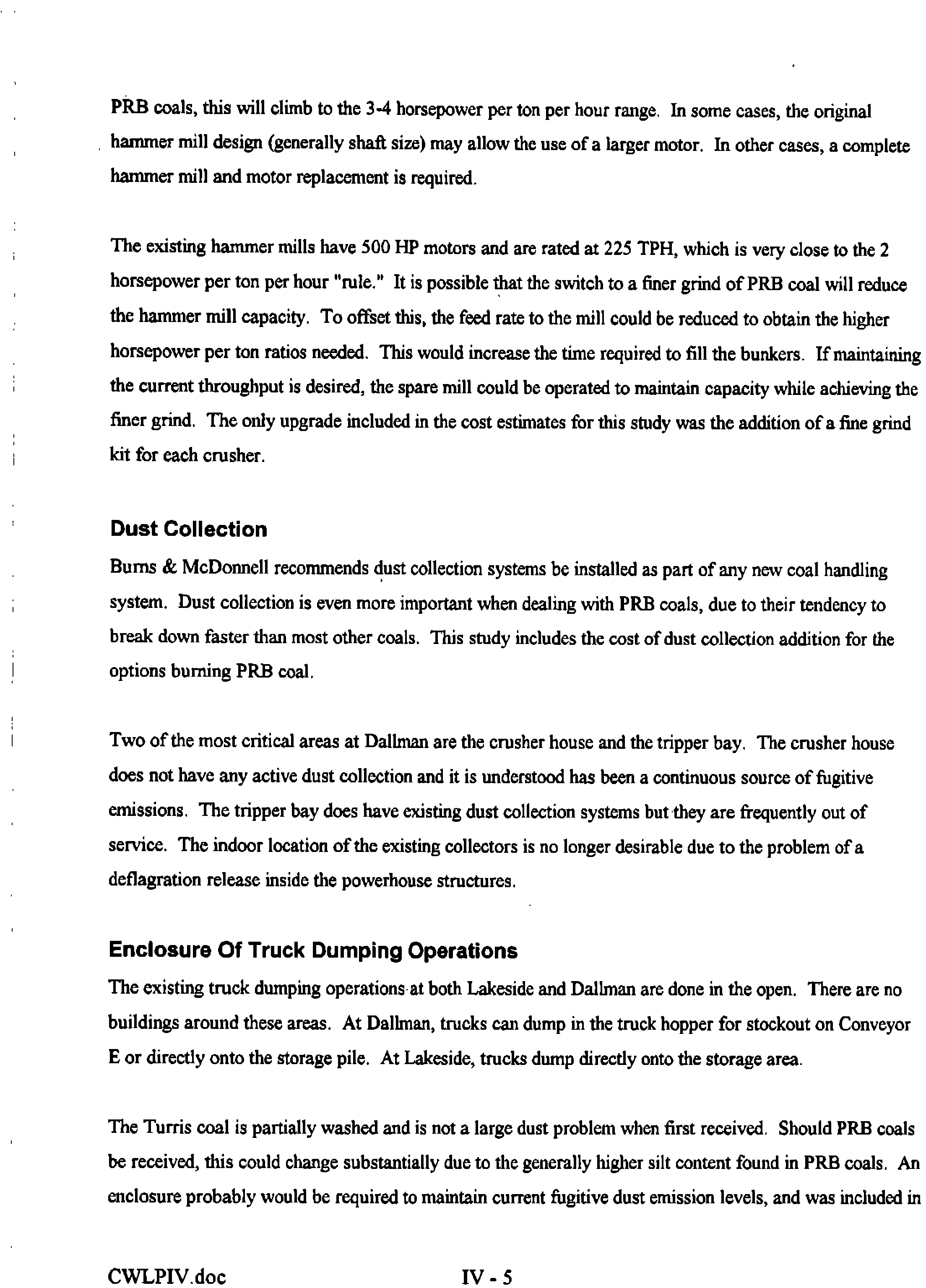

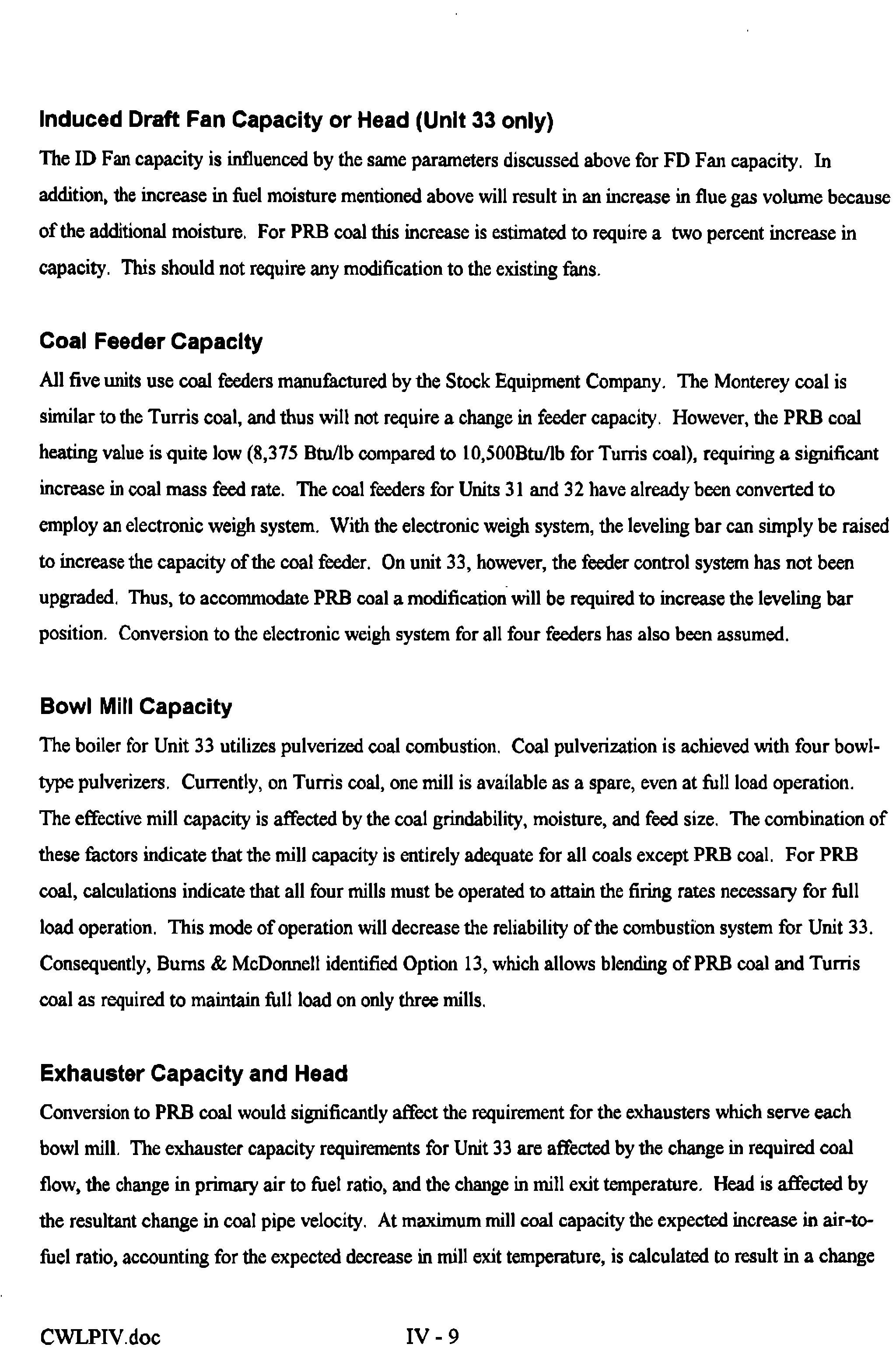

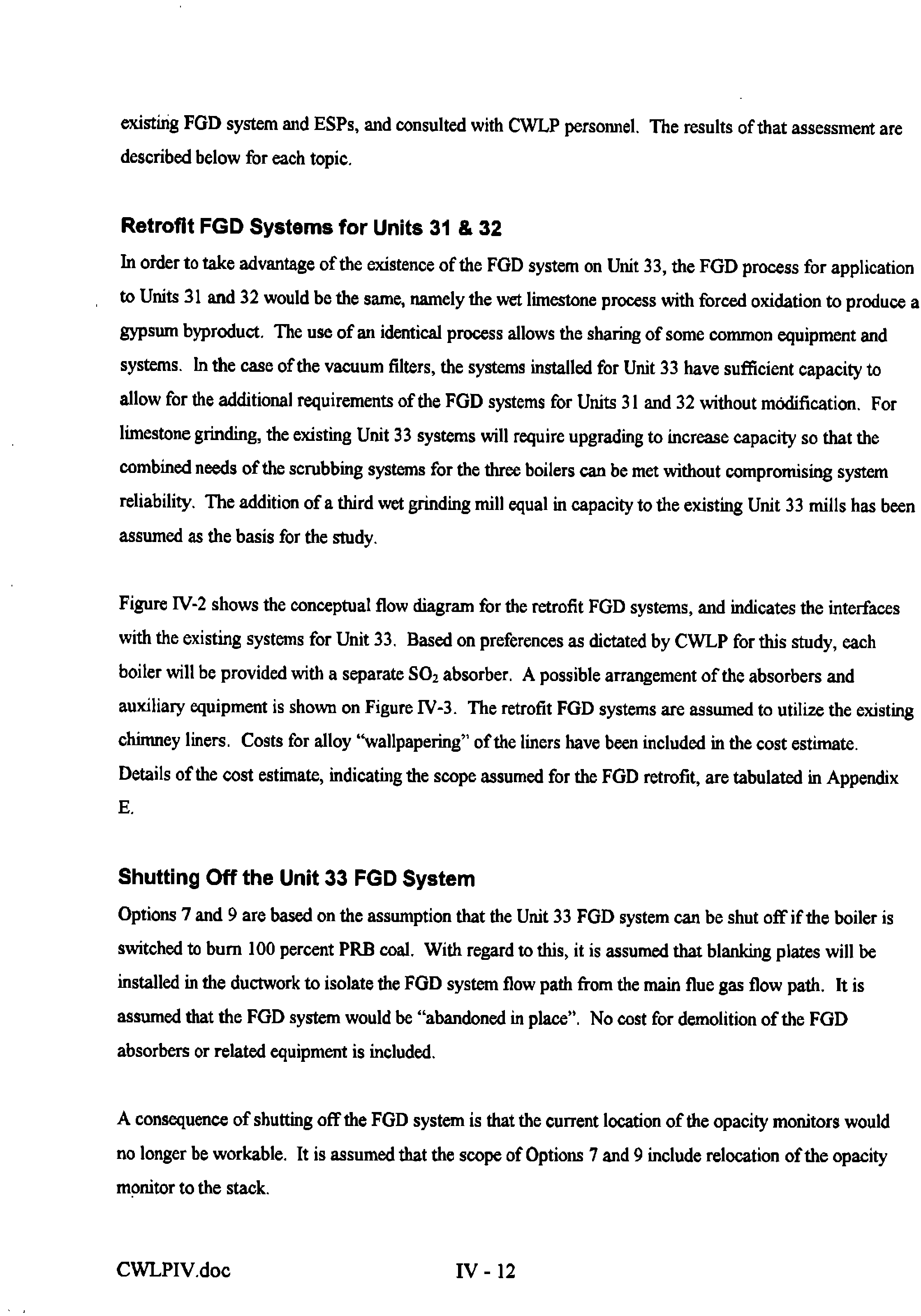

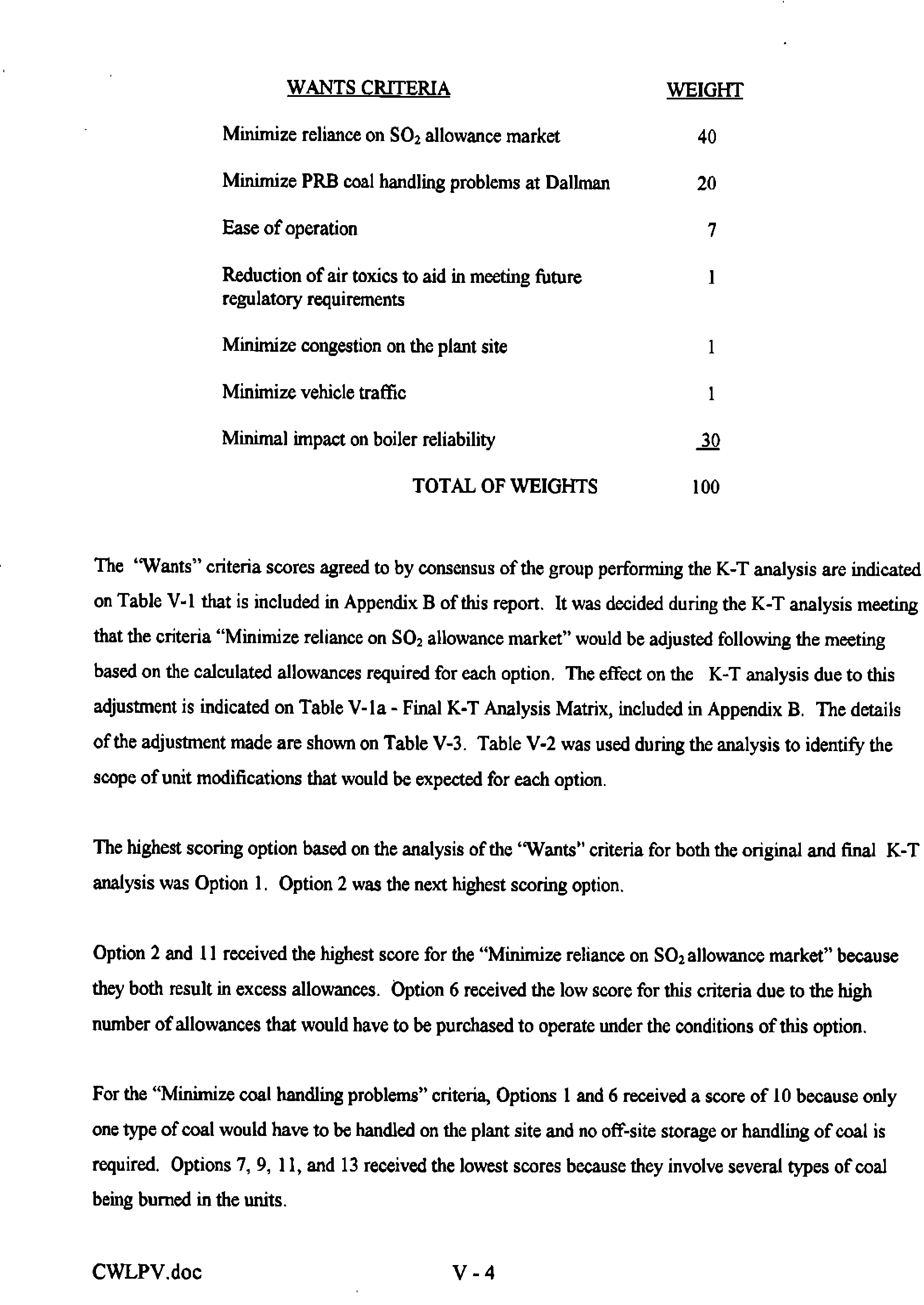

See Figure N-1 for a diagram of this

arrangement.

Under

the PRB rail delivery to Dallman alternative, PRB "unit trains" would

be delivered to a Springfield

railyard and then

broken up for delivery to Dallman. It should be possible to handle strings of 10-20 cars

for delivery

at

Dallnum.

The new track hopper would have a stockout conveyor that would build a new

pile in the western part of the Dallman

coal yard.

Off-Site Rail Delivery: Two

alternatives to on-site rail delivery were identified by CWLP for

consideration during this study. The first alternative would use the existing bottom dump

unloading system

operated by Pawnee Transportation, near Pawnee, Illinois. This unloading system currently receives

and

unloads trains for Dominion Energy's Kincaid station. The system can unload

rapid-discharge

hopper

cars

at a rate

of

1200 TPH.

They generally take all day to unload a unit train. No coal thaw facilities are

currently installed. Only limited area is now

available for on-site (Pawnee) coal storage.

A second alternative would be for CWLP to develop

a

new rail

unloading/truck

loadout facility. A

tentative site, Curran, was identified southwest o£ Springfield. The

Cousin

site was visited by Burns &

McDonnell and CWLP and

appears to be an

industrial

park with

rail

sidings.

Additional property may

be

available nearby that is currently in agricultural use. A new facility could be designed to unload either

rotary

dump or rapid discharge rail cars. An unloading rate of more than 3500 TPH should allow

unloading times less than four hours, which should qualify for lower freight rates. The additional

undeveloped area near the site may be large enough for storage for up to

60

days worth of

PRB

coal. The

cost estimates for this study were based on installing a rotary rail car dump unloader at the site.

CWLPIV.doc

IV-3

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

',POND;

ILJI

ý

i

I

N EW

i

U

NLOADING

C ONVEYOR--ý~ý

T RANSFER

HOUSE NO.1

LAKE

NEW

TRUCK/TRACK HOPPER

SC

UN

RUBBER

T

J10L _

U33T

-1 -

- TRUCK

HOPPER

L IMESTONE

ý

H ANDLING

ý ý`J

ý

Eý

3 0" TRIPPER

CONVEYORS C1& C2

33

3 0" PLANT

CONVEYORS B1&

B2

3 0" RECLAIM

CONVEYORS

Al & A2

r CONVEYOR

TUNNEL (TYP)

r

RAIL/TRUCK

H

OPPERS

"4 & °5

4 2" STOCKOUT

CONVEYOR

E

NEW RADIAL STACKER

TRANSFER

HOUSE NO.2

TRANSFER

HOUSE

NO.3

B ASE OF

COAL STOCK

PILE

AT MAXIMUM HEIGHT

(APPROX.23,600 TONS)

3 0" RECLAIM

CONVEYOR D

Burns

0

McDonnell

C ITY LIGHT WATER

& POWER

CITY OF SPRINGFIELD,

ILLINOIS

V.Y.DALLMAN POWER

PLANT

UNITS 31,

32 & 33

COAL HANDLING SYSTEM

DALLMAN 2 - COAL PILE

FIGURE IV-1

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

60-Day PRB Coal

Storage

D

ue to the uncertainty of PRB coal deliveries, CWL&P

directed that this study include storage of a 60-day

supply

of coal for the options using PRB

coal.

This

reserve supply could be stored on-site

or at either of

the two off site coal receiving

terminals (Pawnee Transportation

or Curran). Under the maximum PRB

bum rate

options (Nos. 7,9,11 & 14), approximately 238,000 tons would need

to be

in long

term storage.

Costs for this long-term

coal storage are presented in Part V

and

in Appendix

D.

The Pawnee Transportation

unloading site does not appear to include land for long term storage of coal. If

additional land is available, it would have

to be developed for PRB coal storage. This would include

a

prepared

pile base, coal pile runoff with treatment facility

and possibly a pile watering system for fugitive

dust control.

The proposed

Contain site would require all the same features listed above for

the

Pawnee Transportation

site in

addition to a milcar unloader and rail. It is anticipated

that the

60

days pile and its runoff pond

could be developed inside

the proposed rail loop.

For storage at the Dallman plant

site, part of the 60-day supply at maximum bum rate could be stored in

the existing

coal yard. It is estimated that approximately 150,000

to

175,000

tons could be stored in the

existing Dallman

coal yard located south o£ the plant. A potential location for additional storage

could be

developed across the plant's discharge canal. This

area

would need

to be cleared and developed similar to

the other

offsite storage areas. The PRB coal would be reclaimed by a wheel loader into trucks for

delivery

to Dallman as required. A conveyor reclaim

system could be considered in the future.

H ammer

Mill Upgrades

It is generally

recommended that cyclone boilers using PRB fuels use a 97.5% passing 4-mesh coal size.

This is usually

a

finer grind

than

is

used with bituminous coals. The existing Pennsylvania Crusher

reversible

hammer mills can be adjusted for the finer grind, however there are usually higher horsepower

requirements

(horsepower

per

ton per hour) to obtain this operation. The finer grind requirements will

shorten hammer and cage life. Pennsylvania Crusher has developed a "fine grind kit" for retrofitting older

hammer mills crushing PRB coals. The new cage

system

is

designed to prolong cage/screen bar

life

when

making the finer grinds. Grinding PRB coal may fimit the crusher capacity when fine grinding. Typical

grinds

with bituminous coals use approximately 11/2 to 2 horsepower per ton per hour. When fine grinding

CWLPIV.doc

IV - 4

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

PRB coals, this will

climb to the 3.4 horsepower per

ton

per hour

range. In some cases, the

original

hammier mill design (generally

shaft size) may allow the use of

a

larger

motor. In other cases, a complete

hammer mill and motor replacement is required.

The

existing hammer mills have 500 HP

motors and are rated m 225 TPH,

which is very close to the 2

horsepower

per ton per hour "rule." It is

possible that the switch to a finer grind

of

PRB

coal will reduce

the hammer mill capacity. To offset this,

the

feed

rate to the mill could be reduced to obtain

the

higher

horsepower per ton ratios needed.

This would increase the time required

to

fill

the bunkers. If maintaining

the

current throughput is desired, the spare mill

could be operated to maintain capacity while achieving

the

finer grind.

The only upgrade included in the cost estimates for this

study was the addition of a fine grind

kit for

each crusher.

Dust Collection

B

ums & McDonnell recommends dust collection systems

be

installed

as part of any new coal handling

system. Dust

collection is even mom; important

when dealing with PRB coals, due to their tendency to

break down faster than most

other coals. This study includes the cost of dust

collection addition for the

options burning PRB coal,

Two

of the most critical areas at Dallm m

are the crusher house and the tripper bay. The crusher house

does not have any active dust collection

and it is understood has been a continuous source of fugitive

emissions. The

tripper bay does have existing

dust collection systems but they are frequently out of

service. The indoor

location of the existing collectors is no longer

desirable due to the problem of a

deflagration release

inside the powerhouse structures.

E nclosure Of Truck Dumping

Operations

The existing truck dumping operations

at both Lakeside and Dallman are done in the open. Then; are no

buildings around

these areas. At Dallman, trucks can dump in the truck hopper for stockout on Conveyor

E or directly onto the storage

pile.

At Lakeside,

trucks dump directly onto the storage area.

The Turris coal is

partially

washed

and

is not

a large dust problem when first received. Should PRB coals

be received, this could change substantially due to the

generally

higher silt content found in PRB

coals. An

enclosure probably would be required to maintain current fugitive dust emission levels, and was included in

CWLPIV.doc

IV

- 5

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

the study cost estimates. Dust

collection and/or wet suppression is

often used to further reduce

unloading

emissions.

Coal Handling

Washdown and

Vacuum Systems

Any dust inside the coal handling

system that the active dust control systems

do

not

capture will eventually

have

to be cleaned up. Most coal handling

systems are equipped with at least

a partial water wash down

system.

A typical

system will have a header pipe

along the conveyor with hose stations at

approximately 100 feet

intervals. Hoses

are usually

11/2

inch diameter, though some

plants use fire hoses. "Start at the top, wash

to the bottom" is

the usual procedure. Water systems all have

me big drawback in northern climates -

freezing.

For this reason, many PRE

coal users also install a vacuum

system along the conveyors and

inside buildings.

One vacuum

system that works well for many

users is a rigid vacuum pipe in conveyors and buildings

with

vacuum hose

stations at 50-100ft intervals and

on each floor in buildings. Rather than use dedicated

vacuum producers

at each building, many

utilities use a truck or trailer mounted vacuum producer.

This

can be driven or towed

to the required building or conveyor, The

vacuum systems are not as neat or as

easy to use as water wash

down, but they solve the freezing problems in

the winter.

Limestone

Addition for Monterey

Coal

Previous

CWLP test bums with the low

sulfur

Monterey

coal demonstrated the need for the addition

of

11/2% by weight of limestone

to blend in the coal for use in any of the cyclone boilers (Lakeside and

Dallnran 31/32). A storage silo

and

feed

system would be needed for this purpose. At Lakeside, this would

be done by relocating

the existing unused sorbent silo to

a

location near

the coal conveyors. A new weigh

feeder would

meter the already crushed limestone onto

the coal belts prior to the crushing. This would

allow for some blending

of the limestone into the coal prior to bunkering. Limestone

would be delivered by

bulk tanker and unloaded pneumatically directly into the limestone

silo.

CWLPIV.doc

IV

- 6

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Handling Two Coals at Dallman

M

any of the S02 compliance options involving fuel

switching (4,5,8,10, & 13) would use

two types of coal

for fueling the Dallman

Station. Any of these options will present

a

number

of challenges to the existing

coal handling system including:

" There is

only one unloading hopper and stockout

conveyor, the E-belt.

" The two main reclaim hoppers

are located under the main stock pile

" The

only

"remote"

reclaim hopper ("D") is on the

extreme east end of the coal yard and has only

limited stockpile capacity over and

around

it.

" The existing

coal yard is long and narrow. Its growth is limited

by the Springfield Lake and the

plant structure.

The first requirement for a two-coal

receiving scenario would be to build a second truck dump hopper

and

a

new

stockout conveyor. The second

unloading/stockout system could be built in the southwest comer of

the

coal yard. Coal trucks could be routed

around the west side of Dallman m reduce traffic on the east

side. Having

two separate unloading and stockout locations would

allow simultaneous delivery of two

types of

coal.

Reclaim from the second

stockpile

has

a number of alternatives. The least expensive approach, based on

capital required, would be to doze coal from

the second pile to the "D" reclaim hopper. This would be a

long distance for everyday

dozing. A coal scraper or a Raygo carry dozer may be more practical than a

conventional dozer with a coal blade.

A more automated system would

add a reclaim

hopper

and conveyor to transport the coal back to the' D"

reclaim hopper. Both above ground and below ground

conveying systems could be used to tie into the

existing IA/B

or

D

conveyors. The reclaim hoppers could be arranged similar to the existing layout with

both under pile and outside of pile hoppers. The reclaimed coal could be discharged onto a small

radial

stacker that would discharge into the "D" reclaim hopper. The radial stacker could be swung out of the

way when not in use. This

system was included in the cost estimates for this study. Figure IV-1 provides

a diagram showing the equipment which would be required to implement the scheme for handling two coals

at the Dallman station.

CWLPIV.doc

IV - 7

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

COMBUSTION

SYSTEMS AND EQUIPMENT

F or purposes

of this study, the combustion systems

and equipment at the Lakeside and Dallman stations

were reviewed to determine the extent

of

modifications

required to accommodate the coal

switches being

considered

as options for Pbase II SOr

compliance. A total of 13 areas of concern were identified for

evaluation

o£ the adequacy of the existing equipment

and systems. In each area, the existing equipment

capacities

were reviewed. Calcuhdions were performed

to determine the relative need for equipment

upgrades or replacement.

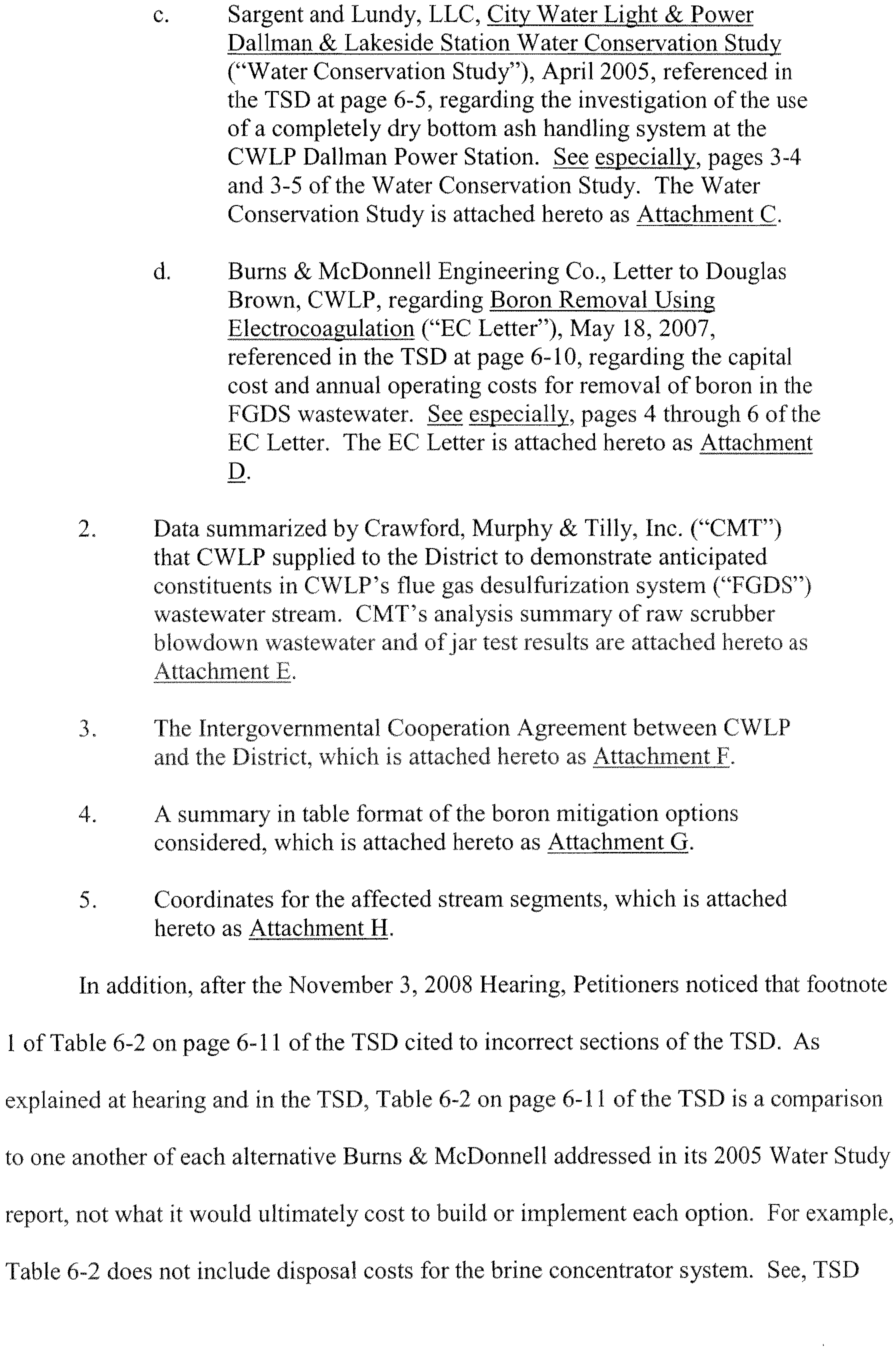

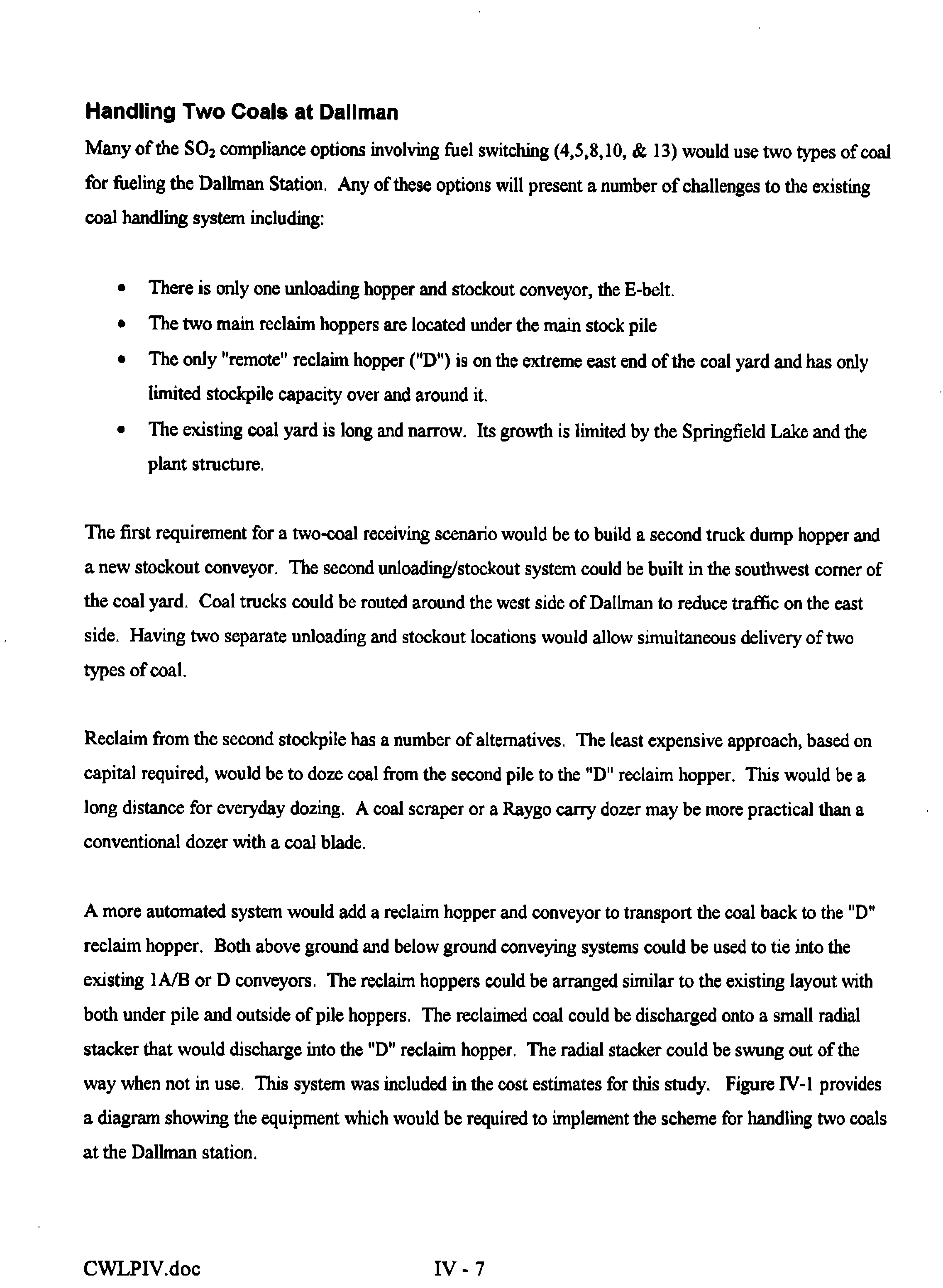

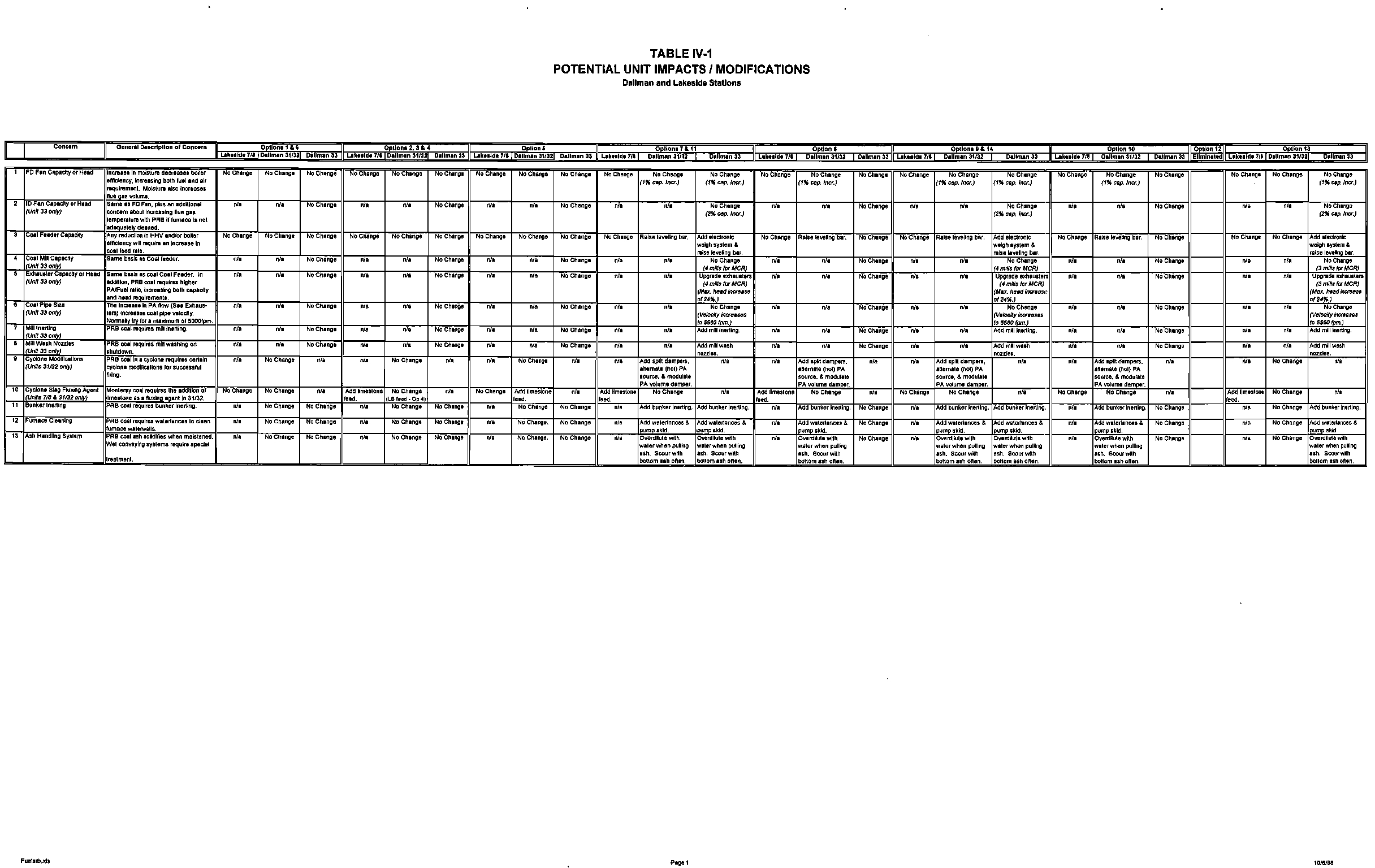

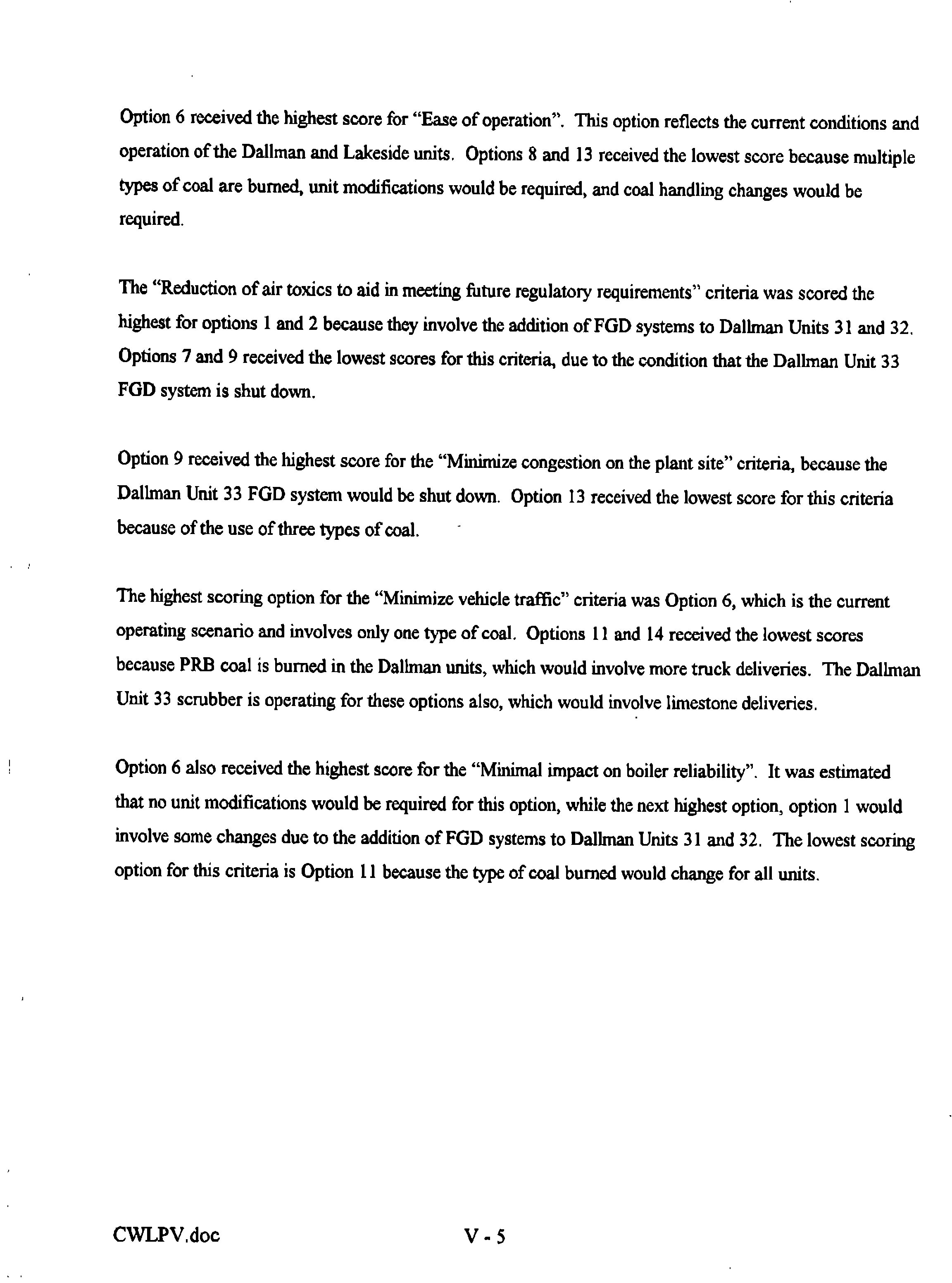

The results of this assessment

are displayed in Table IV-l. The table shows the determination of

modifications

required, if any, for each

boiler

under

the condition dictated by each of the 14 compliance

options described in Part III. Note that because there is no

coal switch for any unit under Options 1 and 6,

them will be no need to make any modifications.

Similarly, some options involve coal switches for two or

more of the five

boilers, but no change in the coal burned for the mmauting boilers.

The following

sections describe the considerations involved in the assessment

of equipment adequacy and

the need for modifications in each

of

the

areas of concern shown on the tabulation. They are presented in

the same order as displayed

on Table IV-1.

Forced Draft Fans

FD

Fm capacity is primarily

determined

by the

quantity of

heat

release, or carbon burned. Switching to a

coal with a higher or lower heating value

(HHV) will change the coal flow as required to maintain a

constant carbon input, but will not-in itself-change

air

flow. Air flow is matched

to carbon input.

However, switching

to a coal with a higher moisture content will deteriorate boiler efficiency, requiring

additional

carbon input (fuel flow) and a proportional increase in air flow. The only fuel in this study

which would

affect the

FD Fan

capacity is the switch to PRB coal. The increased moisture introduced into

the furnace by the switch to PRB coalmill

deteriorate boiler efficiency approximately one percent and thus

increase FD Fan capacity requirement

by approximately this same amount. Thus, no change

in FD

Fan

capacity or head is required. The degradation in unit heat rate due to the increased moisture content of the

coal is addressed in the economic analysis presented in Part V.

CWLPIV.doc

IV - 8

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

TABLE

IV-1

POTENTIAL UNIT IMPACTS I MODIFICATIONS

D ellman and Lakeside 9 lallons

II

..mm --I I

a.n.Nlw."ngln.nrcn...ý.

ol.n.,ap

nnn.x.u

Indd

o ..7 a a

o

Inn s

o

Ind.aa l.

MM..

n

Go

nd,x

-

YXnM.7l. w llmandl/U

w mur ex

YMWO/1 n l--.. .- wllm..»

-.."m o. IMnx

-.AA. dl Y m.7n o.m.. na wY...Y YY.a71 w.... Mr, w-m YY.ene A d. - IN Mwidd amn.xn ...Isp.mmma

I n^I d

m.n7e

A D ANNCM.gMel a

In-.,. 1.

MlMMMCNLMMnI

G .Me

CN,

PoCMmpe

II.nM

C dMge

CM

IxoCuse , CIIM'a.

C hid,

No CIIods.

N ocMnpe

No MmpN

M

G.

.

a

CNMIp.

CMIIM

CM.

NACMp. NdCXMIM

NdCMnM

MdenqMM.N,Mmhdid

Ad .11

i's Oglml

is

IAnsl

"d

"

a

Add. AM)

MN AM No.,

AM

I'M AM J

mm, go...IN-.

I

M .,*1-.ndnm.

M

N ..

CM

N.

N.

NoC.nMe

N.

Nd.O,

M

M

N.CMnp.

M

N.

Nd..rge

did

did

NA M.,

N.

Ne

NoCXmp

N.

nn

NI

nMX77

An,

e.

d- Ad,

Mvl

R.

Ma

, Inl

IxM w

-J

M.MM...aa..MAN.An

oI

med.

CddMANNV C,MMy

Md I

M in HNV IIIMIm

No Ompe NI

WCII.Me NOCMye

C e.dled

CM

E

No.MMe

c n.M,

C N.

I?Mdrd M

m dk

NoCMmM a.ReMMIMM,.

Po,

CI.Me

Main

lemlgpMir. Add eleMmW

nellnp, a.SaN.AIsM

C NNIPo

N nn.np.

N N,

Ad,

...N,

l

l....AMAMM

ANM Ny,I"ma

w,MM.ysbme

Add,

.yM.

-IMAM Nle

Made

Meln M

M

A

M

. C c.IMIeC.p.my

..Me MidI.MWNM.,

M

n M

H a nds.

N.

N.

CN,

N.

wm

N.

N.

N.cIMM

N.

nl.

Amp.

N.

N.

M

N.

CN.

N.

nn

NOCMnpe

.DAM

n.MMCa

(7.MMCa

epgyolNe.d a

And As Add. MIFdon,1,

M

n l.

, .MM

N.

N.

CMnPo

Ne

U m

N.

N.

c

M ý

M

N.

cn.

n

I

.

N.

IM

e

M

N.

N.

cn.nPo

N .

N.

. AM

M.

Ni

M

:w

:AIF MmM," MIN Mdn.MI,

I

IMn.MMMae..e

i.I

Nm.mbcw

IM-

.m

A..MV,mI.

.M IMcw

.M.

is

.

...

AI

Min IMANNNAMNM

N PI%.

NN%.

. I d.n.

e .IFIMNMe

-M1AmwIBnFMI.ue-

M

N.

CM

Ns

Ne

N dCA.Mo

ý

N e

did

Ms.

1h

n l.

Mind.

M

Na

Cn.npe

n/.

N .

Pion,....

N.

M

N.(M.n.

N.

MA

.

Nn C M

IMMYadnM

n7lnoemae.mdgimnm

IIMxpyNN".Me

IMM.M.Mq??,

IVeM"A'MMOn.

Nam. Iw.Mgmumo

N

MMMI

M1eep

Mnm

i

(ý-

MdM

IMIM mMIMAMNMIINd.niIp.

M

N.

nCd

.de.

did,

N.

CnmM

N.

did

MUenp.

nh

N.

mLInMMp-

N.

N.

CM

M

nl.

MdmYIM,niM,

N.

N.

CM.npe

N.

nl.

MIIMNInp.

N

MIIIW..MNwIM

aaam,MMmsmnwcnYMen

N.

N.

NACMIIp,

N.

N.

Nn MAMA

N.

Ne

G.

M

N.

w,eM

N.

n /.

C M

N.

N.

Ammll-.

N .

N.

i d,

N .

N. AmMIIweeX

ml

mule..

mu

4 .,MM MA IIm,

Iae n¢xq.mrmdlmuMln

N,

PoCnmpe

nl.

M

HnCNmp,

N

M

w.

N.

N. AddspXd.mPod

,

rve

M

d .M d.mgd.

And

N.

N,

nl.

m MIN Mm

M

N.

HoCMeye

Ne

ed".7Uex"

nd.n,MMIXMM.MINYCid"M

'.., AA

Ne1.AA

rMe17WFA

m"IM*PAA

M AI

A

.-. &

P

a.

o..

.

mmoNIe

M A m m.M

I

a m I mn

-M

. m .

e

P

r

F

C ygdd.NI,pFMpp.peM MMIemyn.I.YIM.

i e,

n.1

eMIIp.

CM

N.

M.-M

ym" r.

.

M

CMen Mdllmed

N.

nm

N,CMM,

M .

A dd

IIMNYM

n o n..a

N.

Cnen

didcNM.

N.

N ncnmpe N.enýp.

nl.

AmdM.dd,

Cn.

N.

x«m n?

I7u.

d

memnn m m . u

na

l "II". o.l

I.N.

M

end .

d o

d

Ne n . n.nmp.

N .

en.npe

xdcn.dp"

M

An.

en.

N,

cn.

en.

N.

Ann bonMaMI

And em.e.IneNM.

N.

MnK,Fw

Ch. M

in. A . dun.,NMr

E oIYmm.nM.

N .

MMMMiss. C n.n

rve

N ,Ch,n,

MmMdX,rln.nlne.

. M CI ...M

aaA did1.lm"wM,n,nM,MAA1

N

.

N ucn.pe

Cnm

N.

Cn.

M

nn,

N.

CM

cn.

N.

AddweLn.naeN A dd AMMMAM.

N.

A dd

aM"

N

w

c n.

N.

Add

mM a

w

, d

N.

A

iM.

n od

III a d

s

M m

Mw ,IE

m .hn

.xn.

N.mude Nr"LM

. IMd,ýendMlen..

. M.w-

s

N .

cn.

cnm

N.

ocn.M.

c n.M"

N .

w

Ndcn,

N.

N.

. - .In

Nncn.np"

N,

a.NlMMwnn

..m.In.wnn

N.

owm.I.......h

NA c n.np

"

N .

cn.n

N

rl

..N.IMm p.M"M AN

e .

w1.MI N m

I . ,is

l

I

meN

. nppllnp

I

-

.an.

I

l

I M

or M na..IM

. 11. 1

Win

N nnm , m.NMen.

O . Nmmwnn

mR N murwYN eNe Nm mIM

InNaulIM

MOdmNe Mm.

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

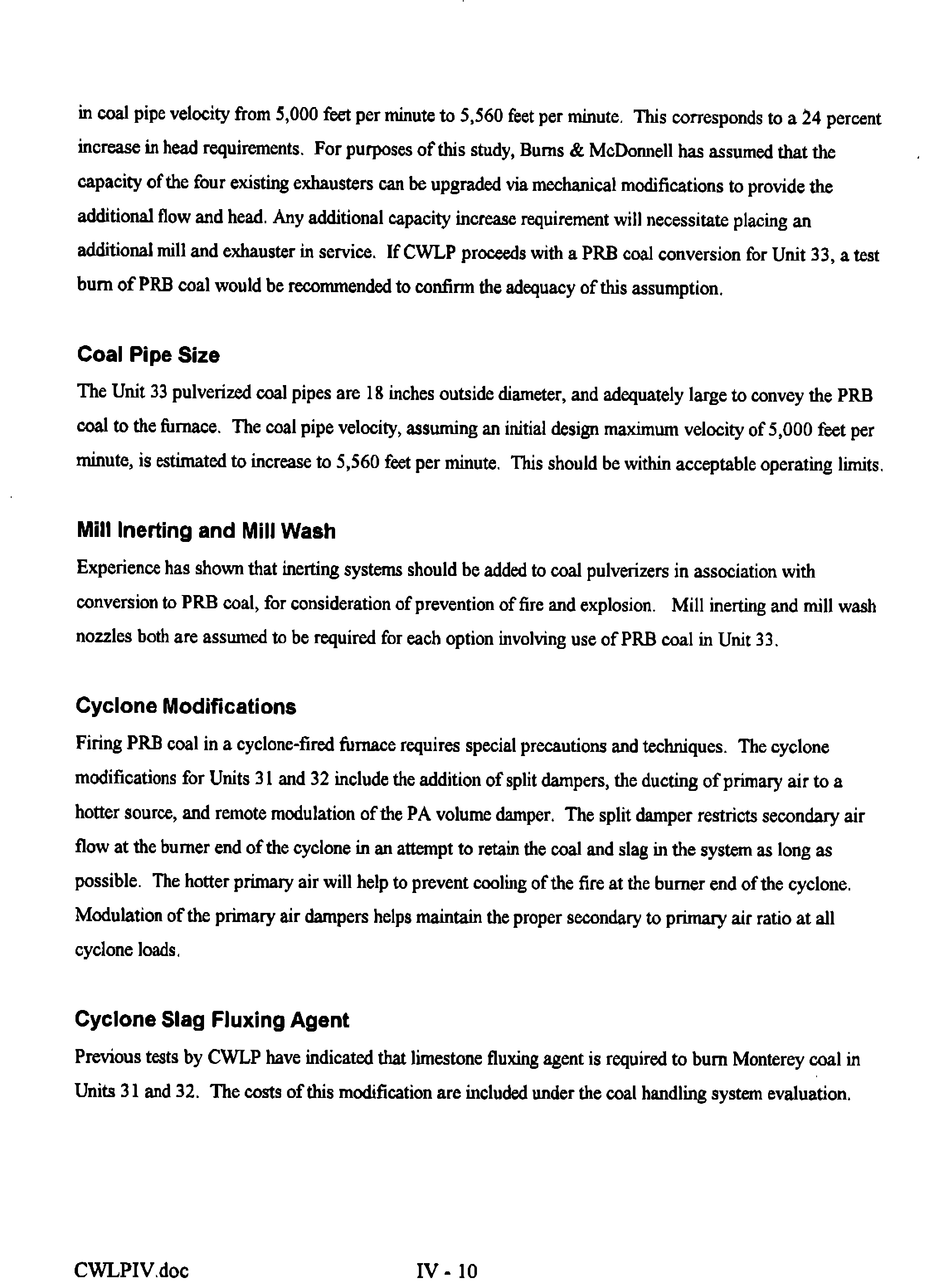

Induced Draft Fan

Capacity or Head (Unit 33 only)

T

he ID Fan capacity is influenced by the same parameters

discussed above for FD Fan capacity. In

addition,

the

increase

in fuel moisture mentioned above will result in an increase in flue

gas volume because

of the additional moisture. For PRB

coal this increase is estimated to require a two percent increase in

capacity. This should not require any modification to the existing fans.

C oal Feeder Capacity

A ll five units

use coal feeders manufactured by the Stock Equipment Company. The Monterey coal is

similar to the Turris

coal, and thus will not require a change in feeder capacity. However, the PRB coal

heating

value is quite low (8,375 Bm/Ib compared to 10,500Btu/Ib for Turns coal), requiring a significant

increase

in coal mass feed rate. The coal feeders for Units 31 and 32 have already been converted to

employ an electronic weigh system. With the electronic weigh system, the leveling bar can simply be raised

to increase

the capacity of the coal feeder. On unit 33, however, the feeder control system has not been

upgraded. Thus,

to accommodate PRB coal a modification will be required to increase the leveling bar

position. Conversion to the electronic weigh system for

all

four feeders has also been assumed.

Bowl Mill Capacity

The

boiler for Unit 33 utilizes pulverized coal combustion. Coal pulverization is achieved with four bowl-

type

pulverizers, Currently, on Turris coal, one mill is available as a spare, even at full load operation.

The effective mill capacity is affected by the coal grindability, moisture, and feed size. The combination of

these factors indicate

that the mill capacity is entirely adequate for all coals except

PRB

coal.

For PRB

coal, calculations indicate that all four mills must be operated to attain the firing rates necessary for full

load

operation.

This

mode of operation will decrease the reliability of the combustion system

for

Unit

33.

Consequently, Bums & McDonnell identified Option 13, which allows blending of PRB coal and Turns

coal as required to maintain full load on only three mills.

Exhauster Capacity and Head

C onversion to PRB coal would significantly affect the requirement for the exhausters which

serve

each

bowl mill. The exhauster capacity requirements for Unit 33 are affected by the change in required coal

flow,

the change

in primary

air to

fuel ratio,

and the

change in mill exit temperature. Head is affected by

the resultant change in coal pipe velocity. At maximum mill coal capacity the expected increase in air-to-

fuel ratio, accounting for the expected decrease in mill exit temperature, is calculated to result in a change

CWLPIV.doc

IV - 9

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

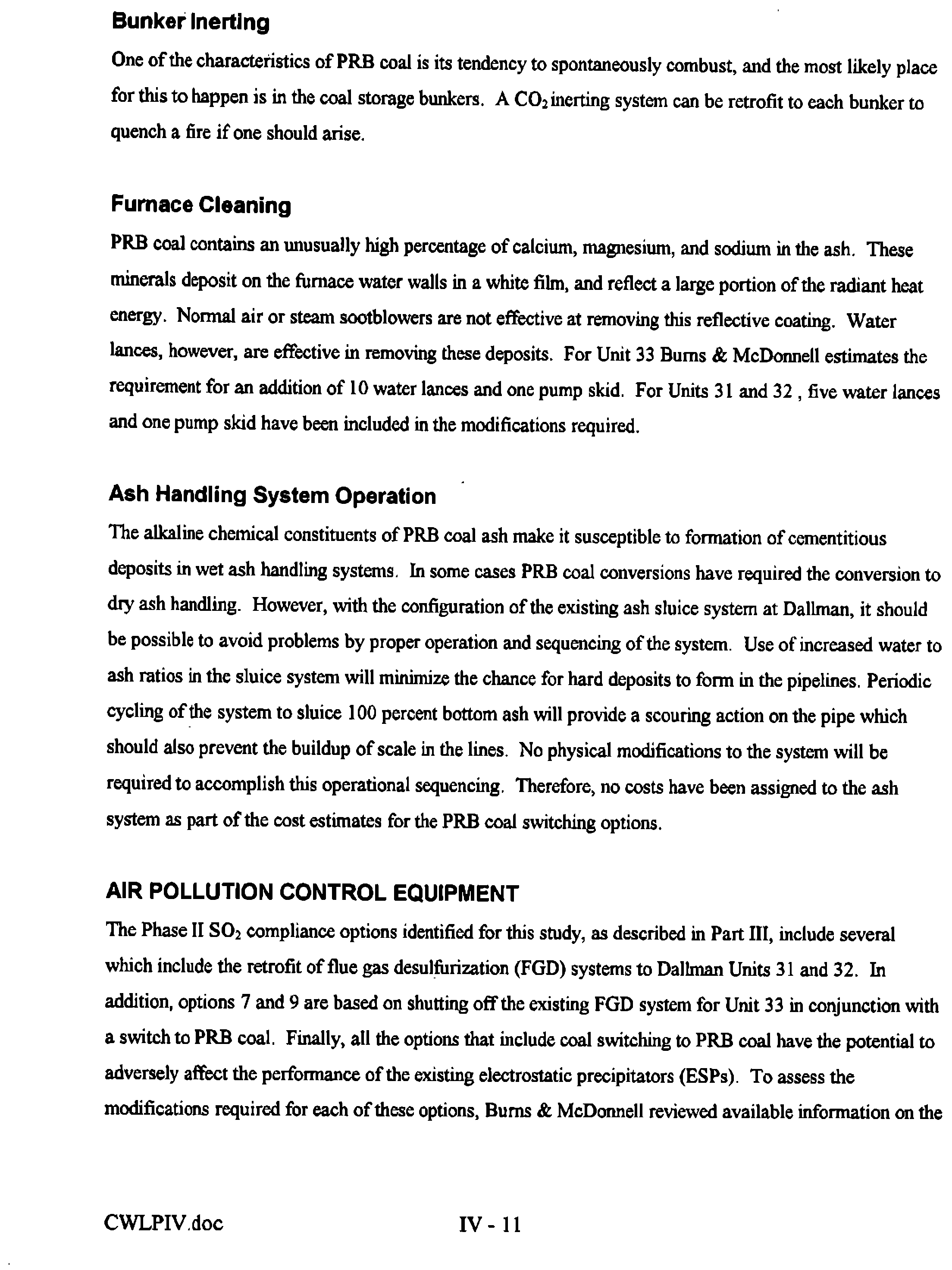

in coal pipe velocity from 5,000 feet

per minute to 5,560 feet

per minute. This corresponds

to a 24 percent

increase

in head requirements. For

purposes of this study, Bums

& McDonnell has assumed

that the

capacity

of the four existing exhausters

can be upgraded via mechanical modifications

to provide

the

additional flow and head. Any additional capacity

increase requirement will necessitate

placing an

additional mill

and exhauster in service. If

CWLP proceeds with a PRB coal

conversion for Unit 33, a test

bum of PRB coal

would be recommended to confirm

the adequacy of this assumption.

Coal Pipe

Size

The Unit 33 pulverized

coal pipes are 18 inches outside diameter,

and adequately large to convey the PRB

coal

to the furnace. The coal pipe

velocity, assuming an initial design maximum

velocity of 5,000 feet per

minute, is estimated to increase

to 5,560 feet per minute. This

should be within acceptable operating limits.

M ill

Inerting and Mill Wash

Experience has shown

that inerting systems should be added to coal pulverizers

in association with

conversion to PRB coal, for

consideration of prevention of fire and

explosion. Mill inerting and mill wash

nozzles both

are assumed to be required for

each option involving use of PRB coal in

Unit

33.

Cyclone

Modifications

F iring PRB

coal in a cyclone-fired furnace requires

special precautions and techniques. The cyclone

modifications for

Units 31 and 32 include the addition

of split dampers, the ducting of primary air to a

hotter

source, and remote modulation of the PA

volume damper. The split damper restricts

secondary air

flow at the burner

end of the cyclone hr an attempt to retain

the coal and slag in the system as long as

possible. The hotter primary air will help

to prevent cooling of the fire at the burner

end of the cyclone.

Modulation of the primary

air dampers helps maintain the proper secondary

to primary air ratio at all

cyclone loads.

Cyclone Slag Fluxing Agent

P revious tests by CWLP have indicated

that limestone fluxing agent is required to bum Monterey coal in

Units 31

and

32.

The costs of this modification are included

under the coal handling system evaluation.

CWLPIV.doc

IV - 10

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Bunkerlnertlng

One of the characteristics

of PRE coal is its

tendency to spontaneously combust,

and the most likely place

for

this to happen is in the

coal storage bunkers. A

COr inciting system

can be retrofit to each bunker

to

quench

a

fire

if one should

arise.

Furnace

Cleaning

PRB

coal contains an unusually

high percentage

of calcium, magnesium, and

sodium in the ash. These

minerals deposit on the furnace

water walls in a white film,

and reflect a large portion

of the radiant heat

energy.

Normal air

or steam soctblowers are not

effective at removing this

reflective coating. Water

lances,

however,

are effective in removing

these deposits. For

Unit 33 Bums & McDonnell

estimates the

requirement

for an addition of 10 water lances

and one pump skid. For

Units 31 and 32, five water lances

and one pump

skid have been included in

the modifications required.

Ash Handling System

Operation

T

he alkaline chemical

constituents of PRB coal

ash make it susceptible to formation

of cementitious

deposits in

wet ash handling

systems. In some cases PRB

coal conversions have required

the conversion to

dry ash handling. However,

with the configuration

of the existing ash

sluice system at Dallman, it should

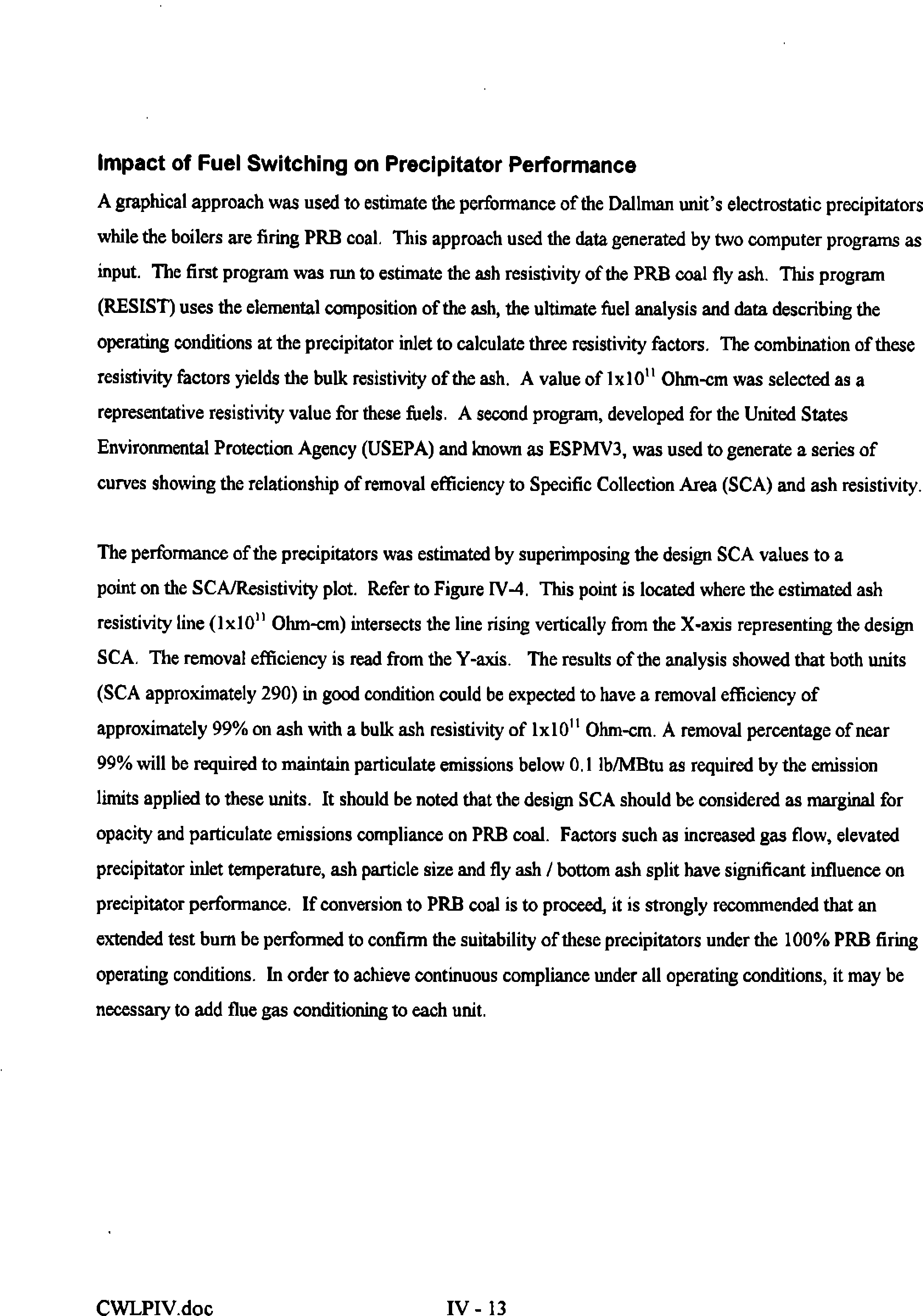

be possible