Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

CITY WATER LIGHT & POWER

DALLMAN

& LAKESIDE STATION

WATER CONSERVATION STUDY

Report SL-008254

Revision 2

L ""ncfyLL°

55 East

Monroe

Street

Chicago, IL 60603

PROJECT NO. 11319-005

April

23, 2004

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

D.,ilrri::!i ,. Lakeside Station

4 1,T cc;j ,ý.ý. iVati

C

ITY WATE

April 23, 2004

A pproved by:

S eal;

w

(I

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

City

V-I;-'r U

I };4tttrrý ýi

watc;-

(', rkigc

t_!

.

.1

1 lid, Si

ES

I

-.,. ccrtive

urnmary........,....,...........?.,..,...,..............................................................------ES-1

1 .

J ztraclta tic,r7...................,.............................,..........,....,.......,...........................,............,......,...,.

A.

of Sources Used to Develop Water Balance.,. .,........,...............................................2-1

............,.... 2-1

if !,tii -i,

of Alternatives ..

A .

I:,

C3.

1V

V

V1.

A,

[:

....,......,......,............,................,.....3-1

....................... ........

....,..,..,............3-1

i,

I.

,',nsn k rb\kfaca f

\U,4r''i

P

19-005

ýc

at

ar ,

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Ciiý Water Light & Power

4

III

. a.xr

..,

.

.

y

i

l'Irn;,1

& Lakeside Station

SL-()08254

i , ý`:onservation

11-1

P,?ý-'[s

!',r

C lo

ý:,i

t ,>op Recircula

11-3

!, 1- Consumption

Dry Bottom Ash

Creek F .Ii',t

Effluent Verses h?:,l

ater.l'ýal:, ,ýý..

Lltnpti,

-,i

F :'

1;uý

Ct>nccntrat

IV-2

V

11-1

11-2

1V-1

ý, s

ý,

ir rri

Load

Metering

C;

B

alance

Flo

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

""j, , , I: w,,ly

u ý

I m \f,

V

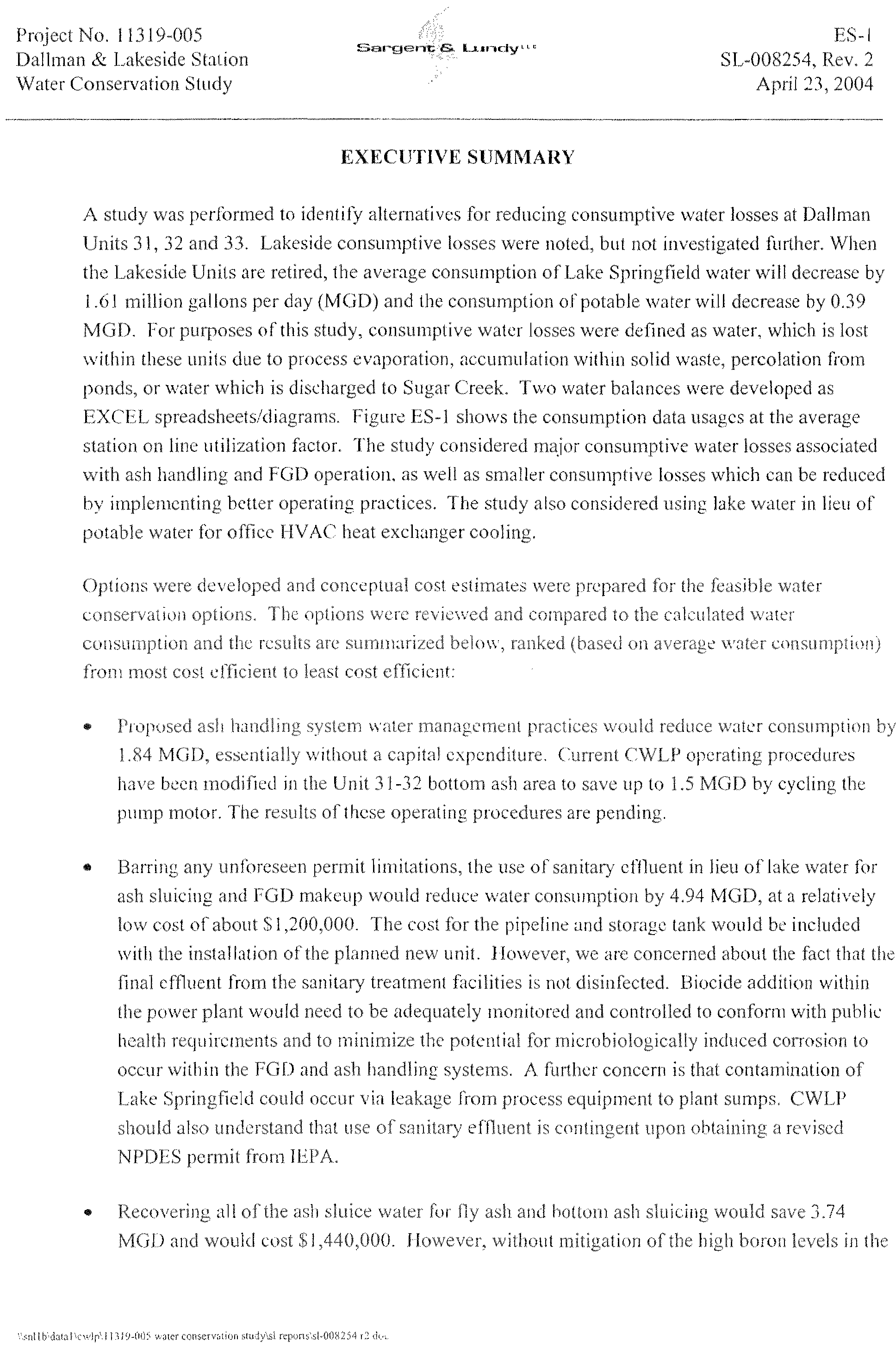

U nits 31, .ý,

7

and

rr.,- Hgure i

shows the c ot1SUMPrrI

tor. The stuck= considered naayjor consurrrpov

t-;,,

ration, as well as smaller consumptive I--

seen 'p..

r: ýýit

limitations, the,

I

Lake

Spring'fieId ý,;ý

i

will r1{

ri

)f

notable watt r 'w I I I

r; ;t:,( bN,

r t from the sanitary treani!--ýZt

J ..cilities i

ES-1

SL,-008254, Rev. 2

ed about 11i:

t:-

r

that the

i , . E3io

b e i rir ?udcd

at c,r,: imination of

e,

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

n

P1 -005

ES- 2

l

c S tation

sere; 1! ()n

waste sii, :.1 1:

c

mitering

the

ponds,

this option would cause

1

u, 1wr ti

he, Unit 31/32 slag handling sy>ij .i

to

a

closed loop recircula

r discharged

dewat(ring

)sins appear to offer a good balance of

water

saved

versus installer) cost. "flee Unit 33

l

.

(1

l..

The recovery-r!

e i1) 1., -iltir,, pump seal water would save 0.07

expenditu

SIT; " l

levels

r -4 system to a d r y s ystem would

s ave ot

of

i 1l

orb"

III ý,

rnr)Vpr::ý, t'f'1"

th,- Unit 33 bo'i

l

"''1'

its

apl

appro 1.ýr;ý

-ly (

).V

MGD il the root cause(s) cý

I ')

i ons in the come?

-f the: current and ! u i u

":rtption from

lake .-.j

h

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

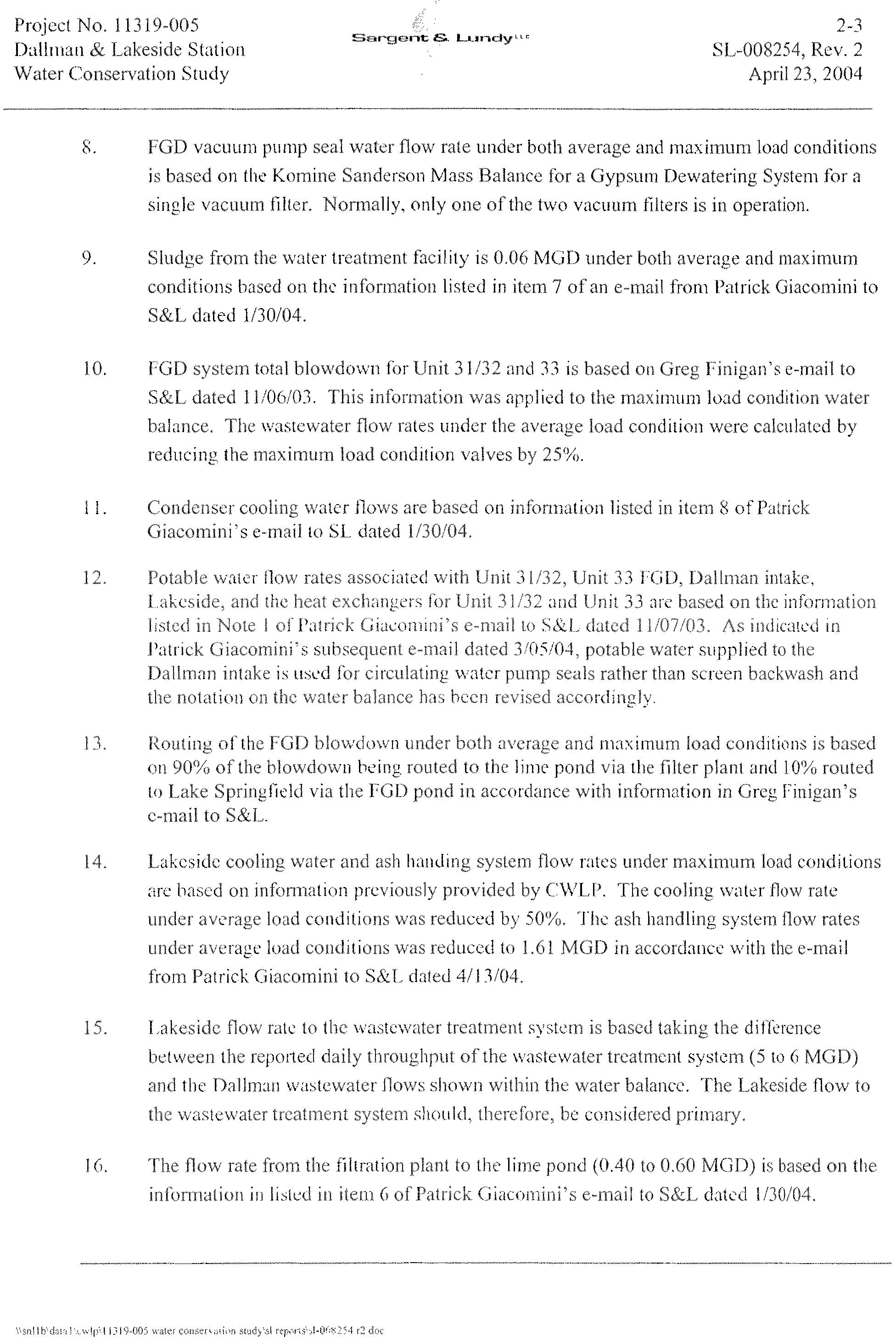

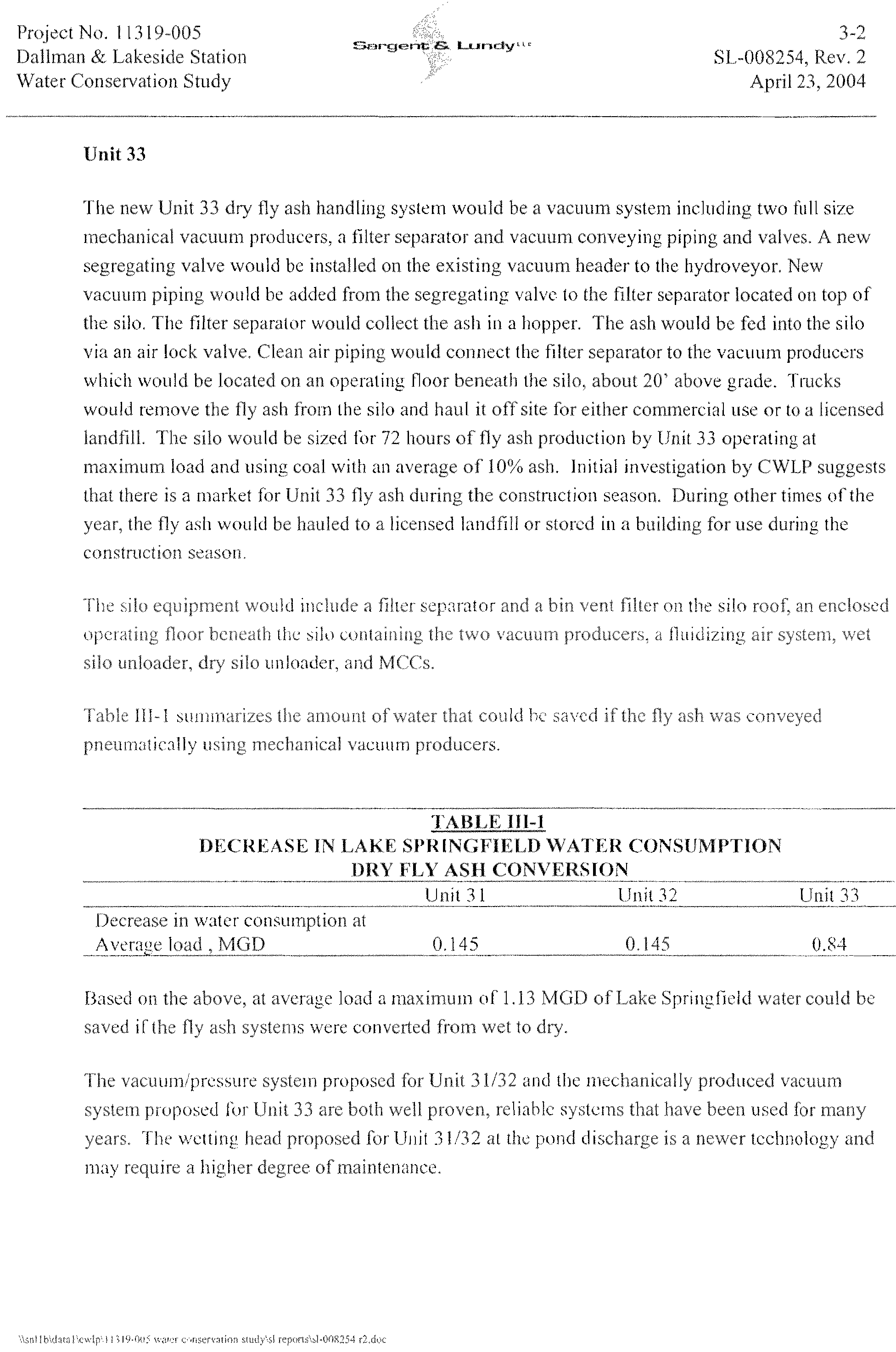

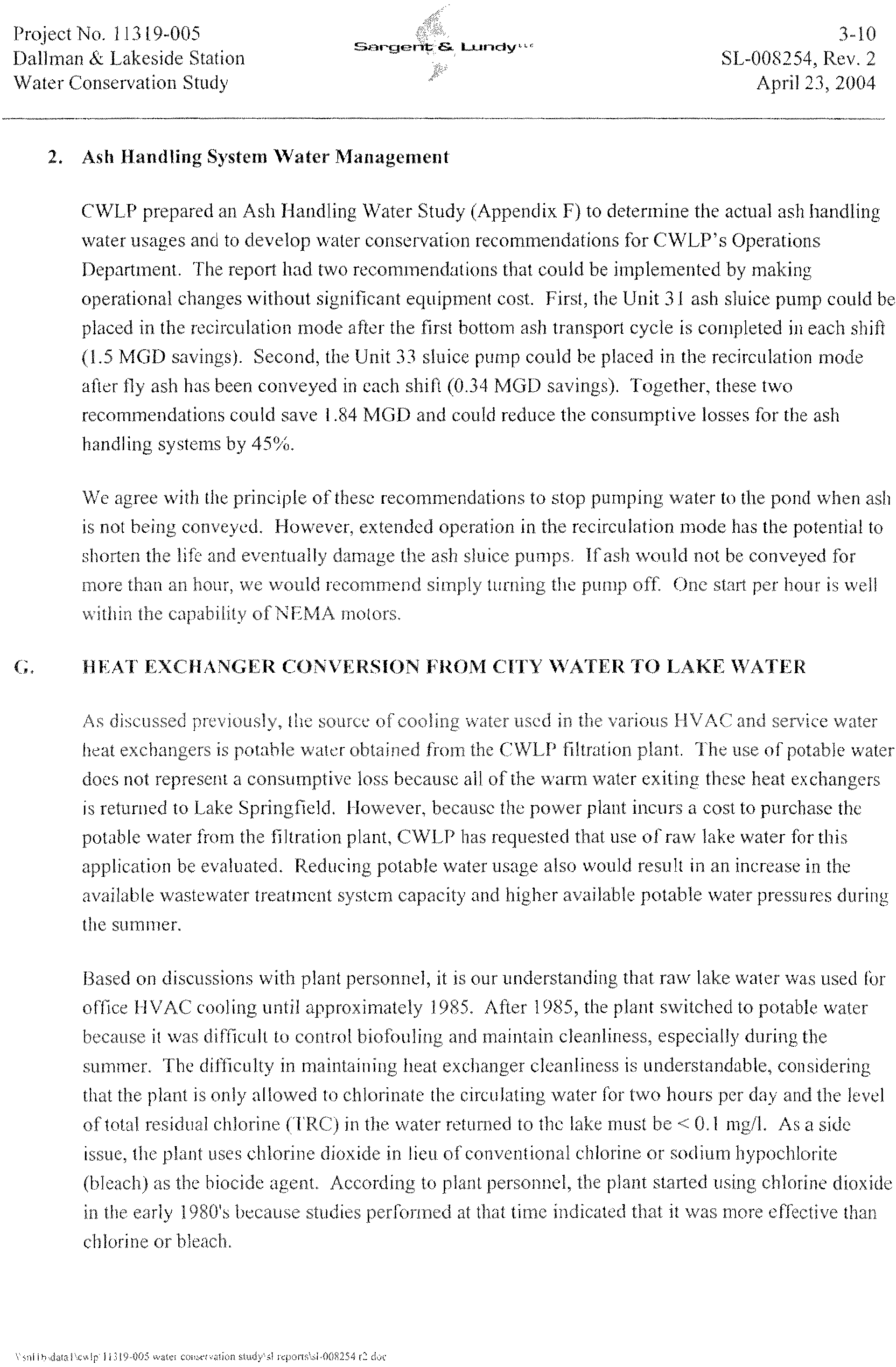

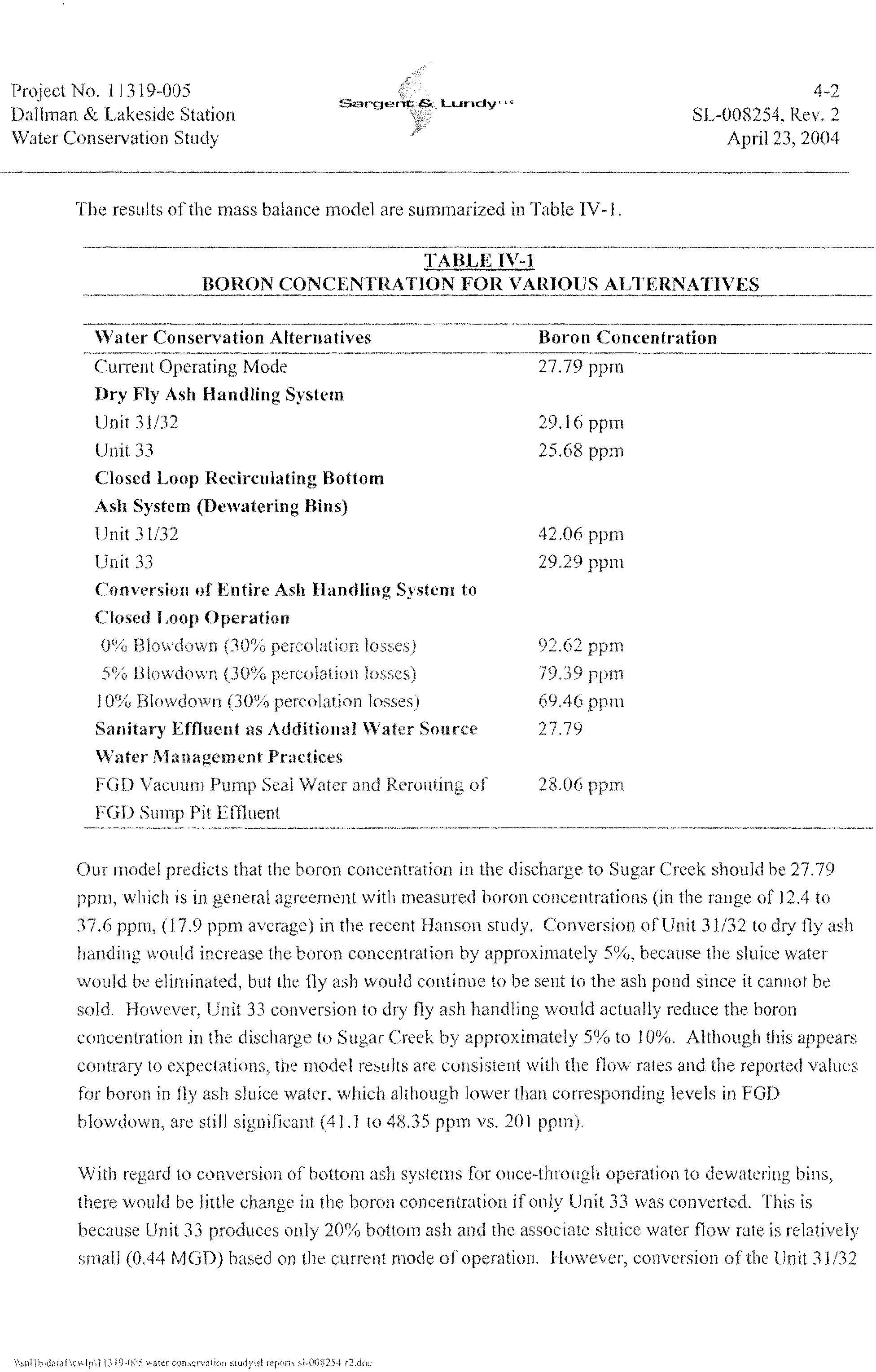

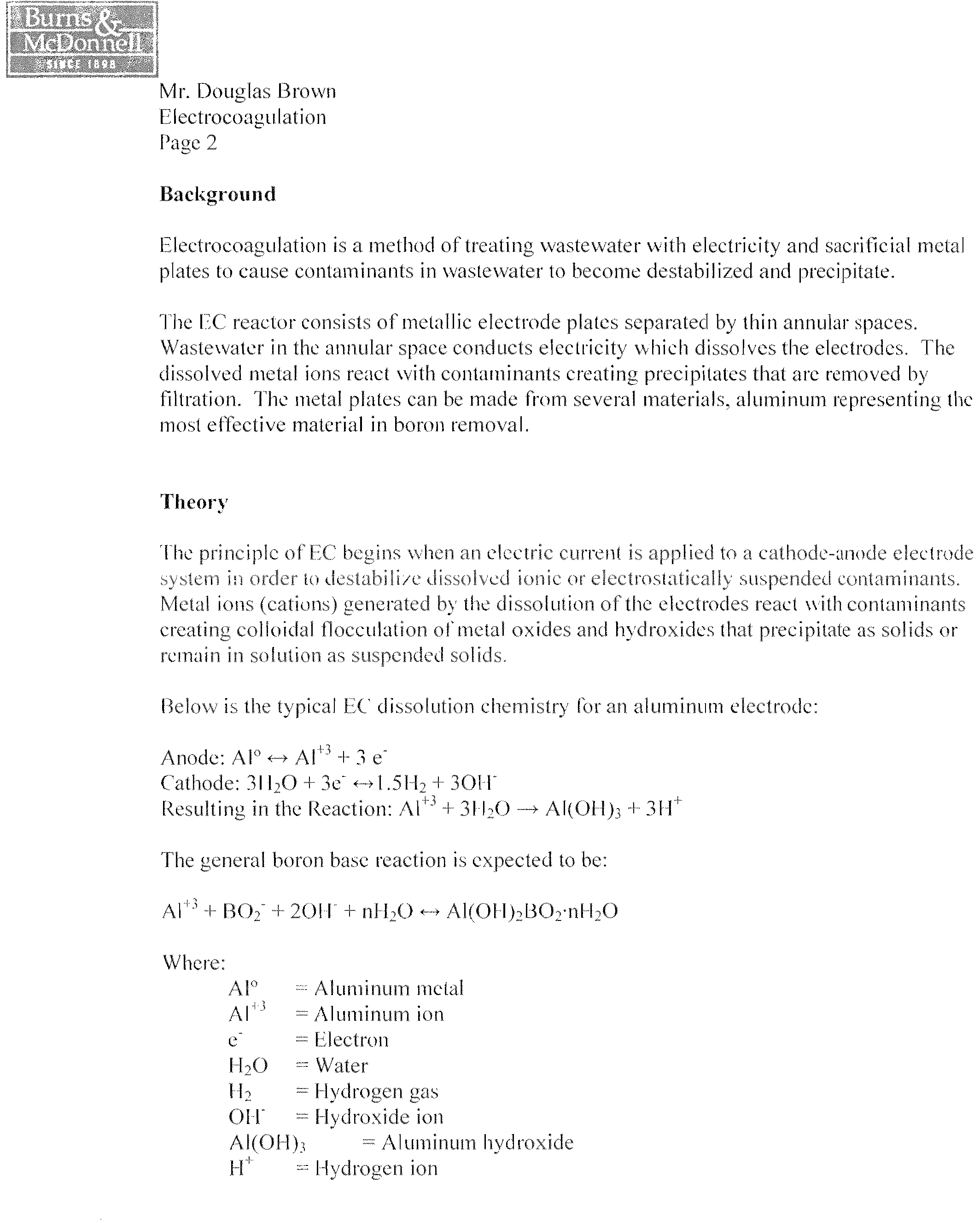

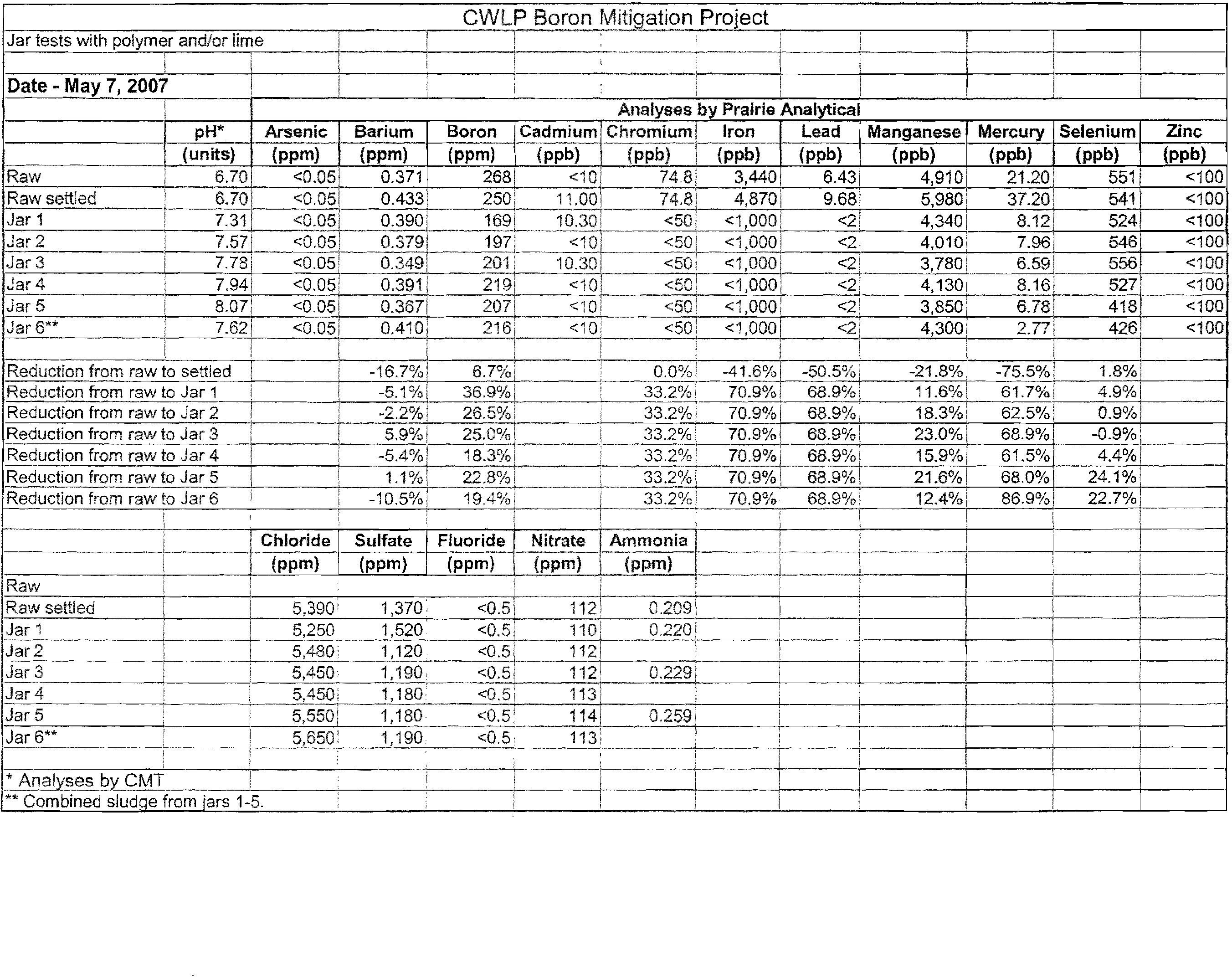

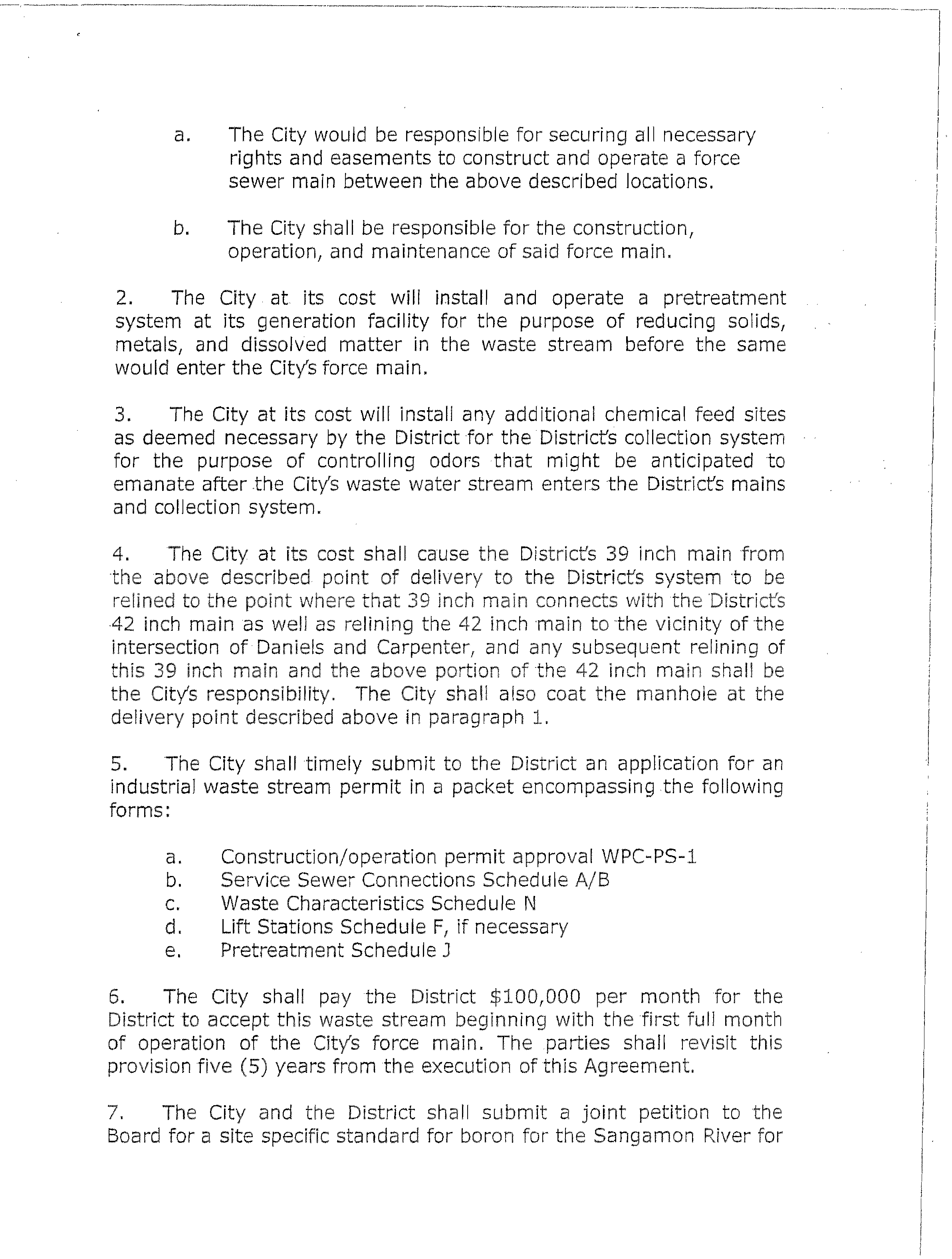

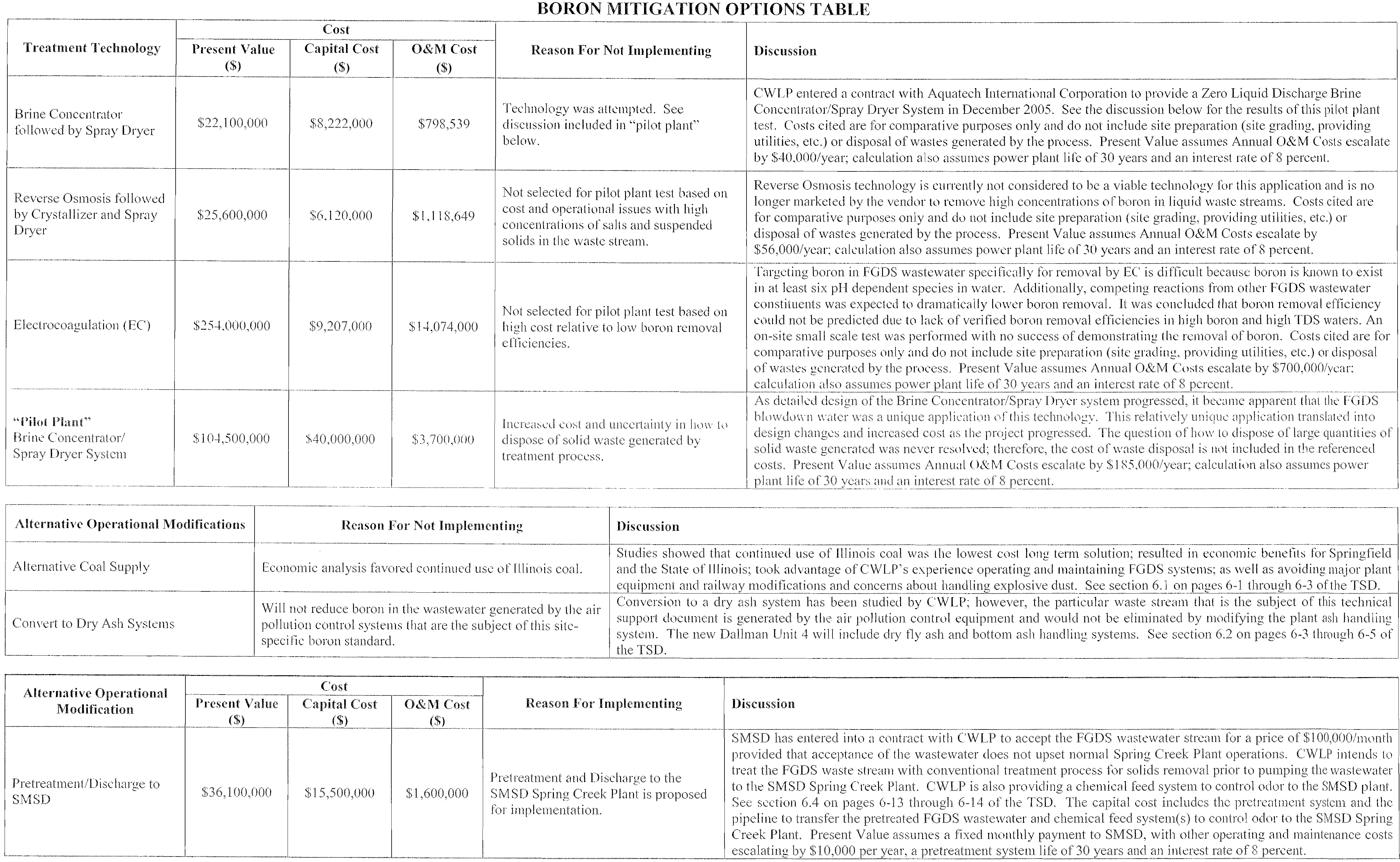

Other 0.10

Waste Water

Plant Blowdown

0.06

Dallman FGD Biowdown 0.09

Dallman FGD

Vac Pump 0.07-1

U31132133

Ash Tank

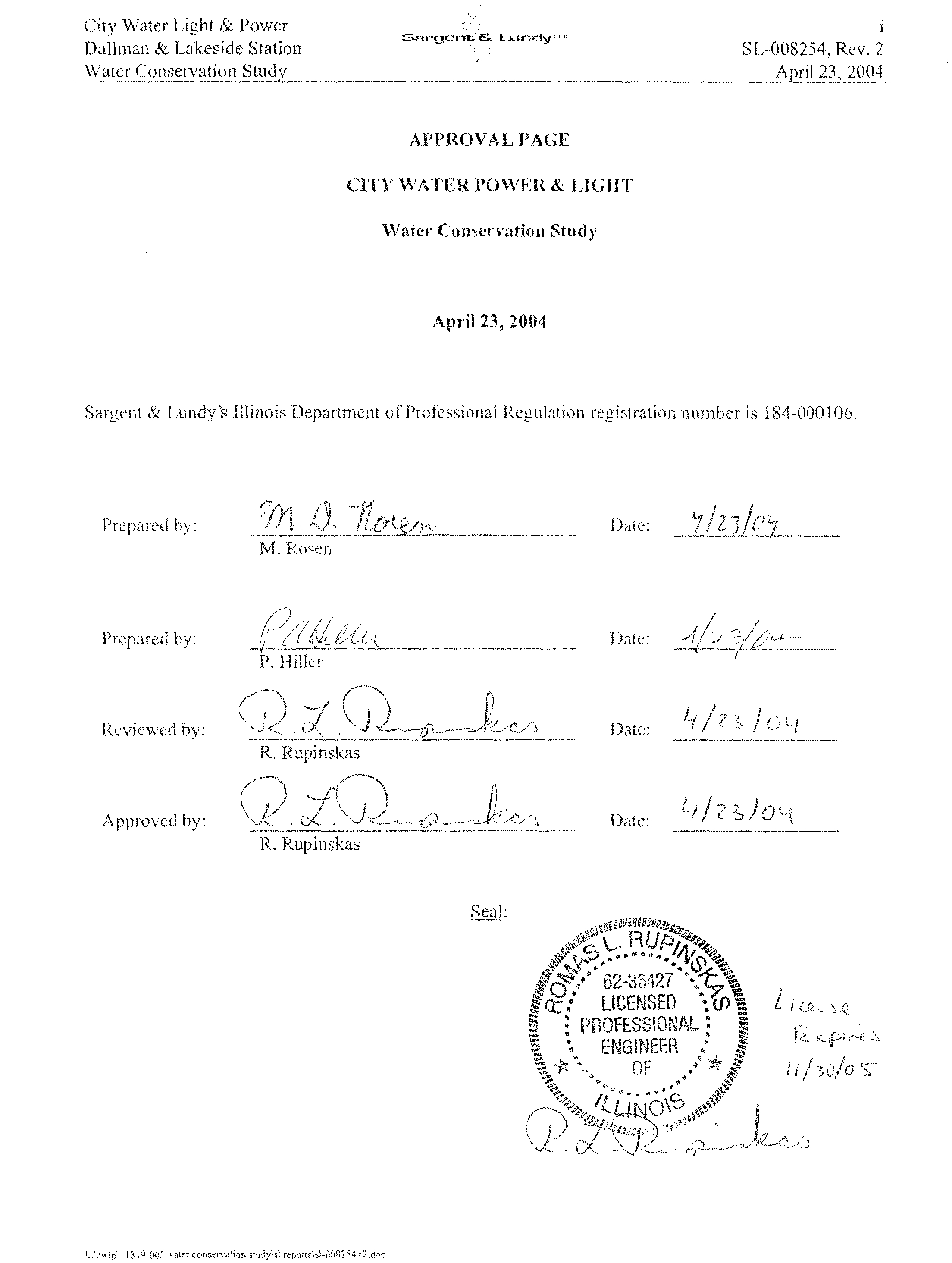

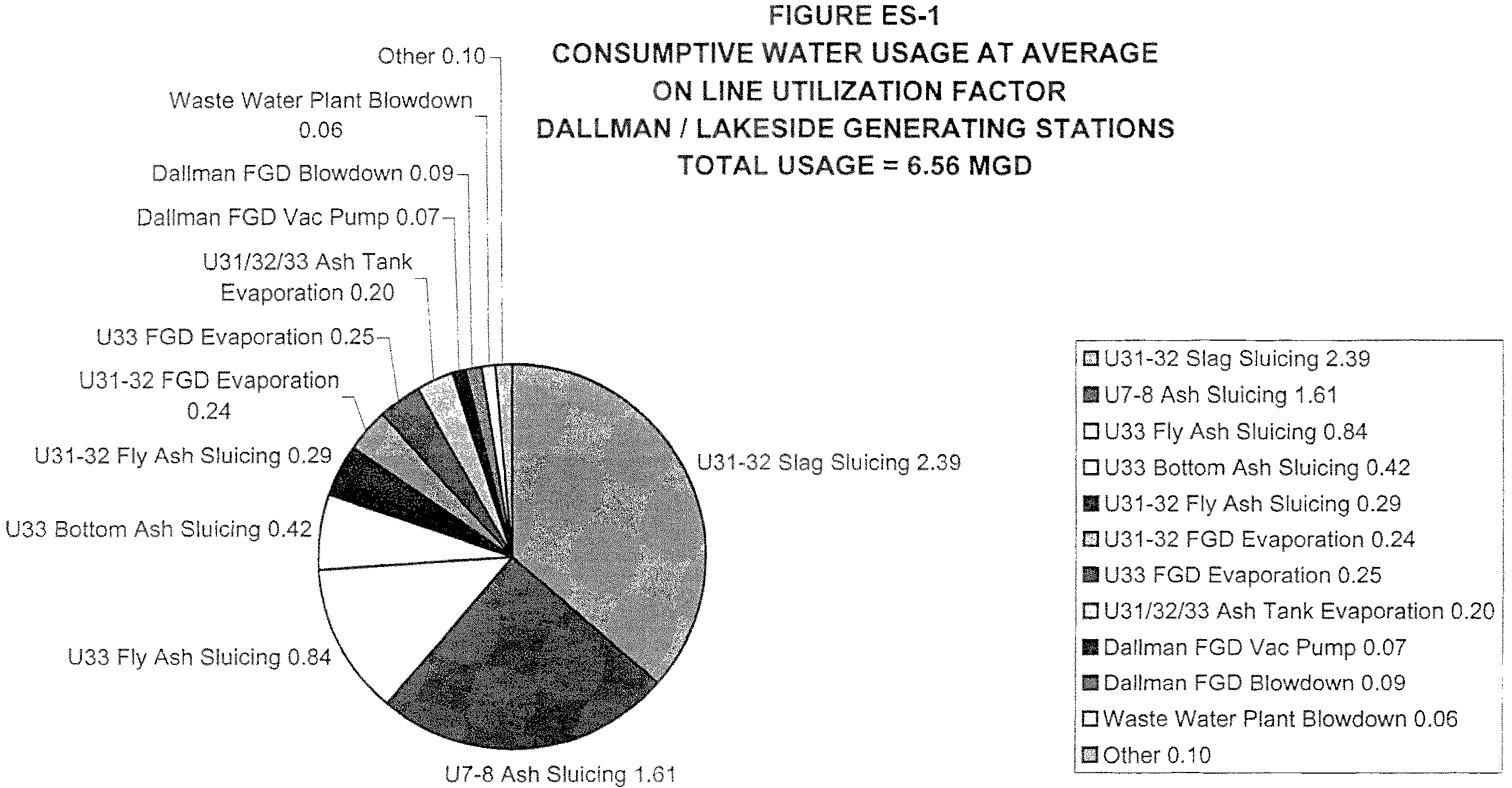

FIGURE ES-1

CONSUMPTIVE

WATER USAGE

AT AVERAGE

ON

LINE UTILIZATION

FACTOR

DALLMAN

/ LAKESIDE

GENERATING STATIONS

TOTAL USAGE = 6.56 MGD

U

33 FGD Evaporation

0.25

U31-32 FGD

Evaporation

0.24

U31-32

Fly Ash Sluicing 0.29

U33 Bottom Ash Sluicing 0.42

U31-32 Slag Sluicing 2.39

U33 Fly Ash Sluicing 0.84

® U31-32

Slag

Sluicing 2.39

" U7-8 Ash Sluicing

1.61

0 U33

Fly Ash Sluicing 0.84

0

U33

Bottom Ash Sluicing 0.42

" U31-32

Fly Ash Sluicing 0.29

®

U31-32

FGD Evaporation 0.24

" U33 FGD

Evaporation 0.25

0

U31132133

Ash Tank Evaporation 0.20

" Daliman FGD Vac Pump 0.07

" Daliman FGD

Blowdown 0.09

Waste Water Plant Blowdown

0.06

®

Other

0.10

U7-8 Ash Sluicing 1.61

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Projý- :-¢ No. 11319-005

t akeside

Sta

1-1

33 is rate(] for 19

(iii

w c l irrel

each and are scheduled for

r ,. rir: 1n

;, ?t

i

7 I t, kill- S

are

m

I :;I.eside

Statioik i;

iii-

"

,'I

be elh

rt^ot1s

are

located

on the same sitýý ;ýi the'

rlorthem shore of

It, d by the

Lal-

air

Stalions. Opt ,

ris

N. wre developed and ev=al

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

c;_

1,

: ii:c-ide

S tation

w ,-f,-r, w',,ich is last,

within the units

losses" within [tic t-

2-1

SL-008254,

Rev. 2

April 23, 2404

e r1,1iit

can then be evaluated.

,

_,I-;1.,

ýned

and "'c)ws the rapid

e r;lhiati

f [cffirýýxrn

by

ý 'fI

C OnsWu>, five

I tem mi g s

tations.

ý

3liStITllptF.

,ý

lý r.

:,t

' l.

41 _ I l i i

I on various d °°-vi.

,;;1y 1-ii;tl;,

which i

data and p-(.,

B. W ATER BALANCE 1 °

c c u rrent site water b alance,., bas

EP\ C t'

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

sn, rtgcýe , c.

T y1>1 Cý Ilrl_..__

ned in the fol

Two water balances have been developed associ;uý-?

«

i

6 .

n ,43d to the nearest (x.01

MCrD.

L .Gx"rlyI

s

1 1,ONV'S

USED 1N

1 i

F -R

water balances is expla

P.,11

1 11,

individual flow rate nder avera-e

and rrý:ý=

I,.

results

1 1'., -port prepared by

Patrick Giiacomznini of

% for U nit

1

as

L akeside. ... --- .....

', ()

(ý .; ti,IL_.t, a within these

two

0%

Under

1):)t

(iWns

ru°e

based on the

valt;es b y 2

1 .t. ;12 1' GD wastewatcx flow rate

c+ i sons are based can C

-112,

v( re (;J. : (',

red

by

rolu,.

7 _u

it

3 3) FGD

=.,d L b`dac

1

repay

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

'I'eS

i

_c,\,_ition

Study

z=xr°c ý ýý ýt. e:.: L-jnciy-

is based on the Konr

FGD vacuum purrip weal water flew

rate

under both average

and ma

under both

^ýer,:, and ma

conditions based on the information listed in itecri 7 of an e-mail froiiý

I';iric

/f)4.

It.

14.

l ,_.ducin

2004

t/3' and

33 is based ors G i

,

,,

dlh

=>a

were calcltlated

by

1 is load

conditions

r Fý:rrrnat ,,previously p,,vided by CWLI'.

i.rn

2

_;

ý

4 , Rev. 2

r -,Iiim

.

between

11,111;

1

Lakeside

flow j-:

ý

to the

bases! on the

t ed 1/30!04.

ý ý5n1

;I9-605 watel

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

water

makeup treatment svster; j

I",

d to

2-4

sses.

q!talit ity

I I

i:^*,-.y

focus of the

a CCOL' IC

11", :Ash

(i.e. miter backwash,

It() reject and

demineralizer

gfeld and are,

thý: rcfore, not considered

consurnf

4.4`;%, (0.29

M

t_T,-if, 33 bottom ash

M

ý,1 I . At t,-, the

! h

j) seal water consumption

11 ly r ind water tr,

°I ::

total consumptive',

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

,"Ix-i-1-

Station

ý

,11

Study

( ',)1

tI

i;

i

e m 4

any additional consnrn

er the past three N,,. ý i i .

2 -5

SL-0 08254, Rev. 2

A

pril

22, 2004

W ýi'=i j)1o=litc

a continuous average basis.

m ými

I-II,, J,i :t

for de

on water

m ent plant serves the three Dallcnan and two I 1l.

I t `.,;%C and service

'die"

II [II

, ,,

C 1', IT filtration plant,

asses. v Iiich are significant o r would be cons

W 35.4 e2.Jcc

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

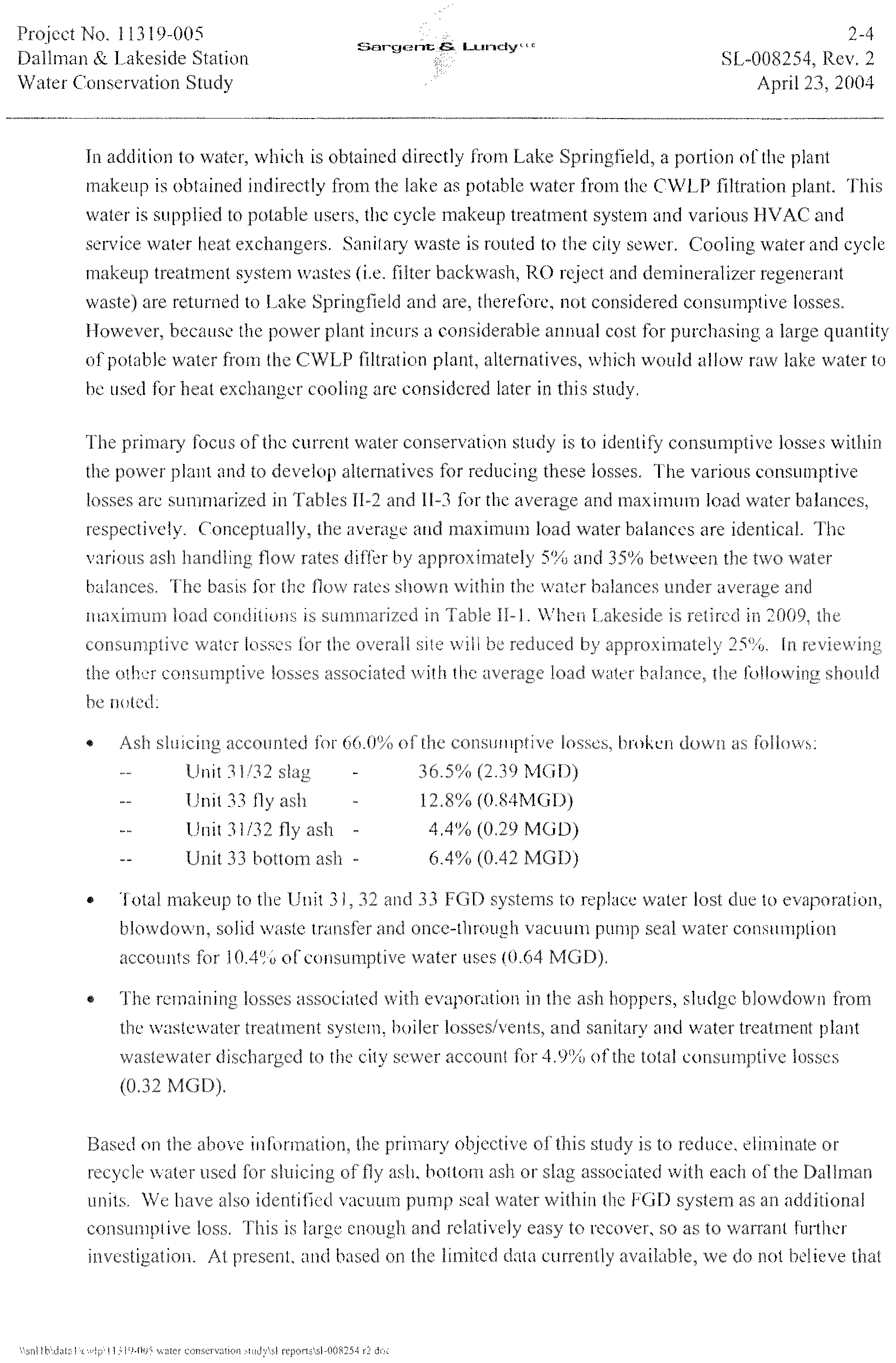

2-G

n Unit 31132

Dallman Unit 33

1/32

Unit 33

T )ý

I

;

1

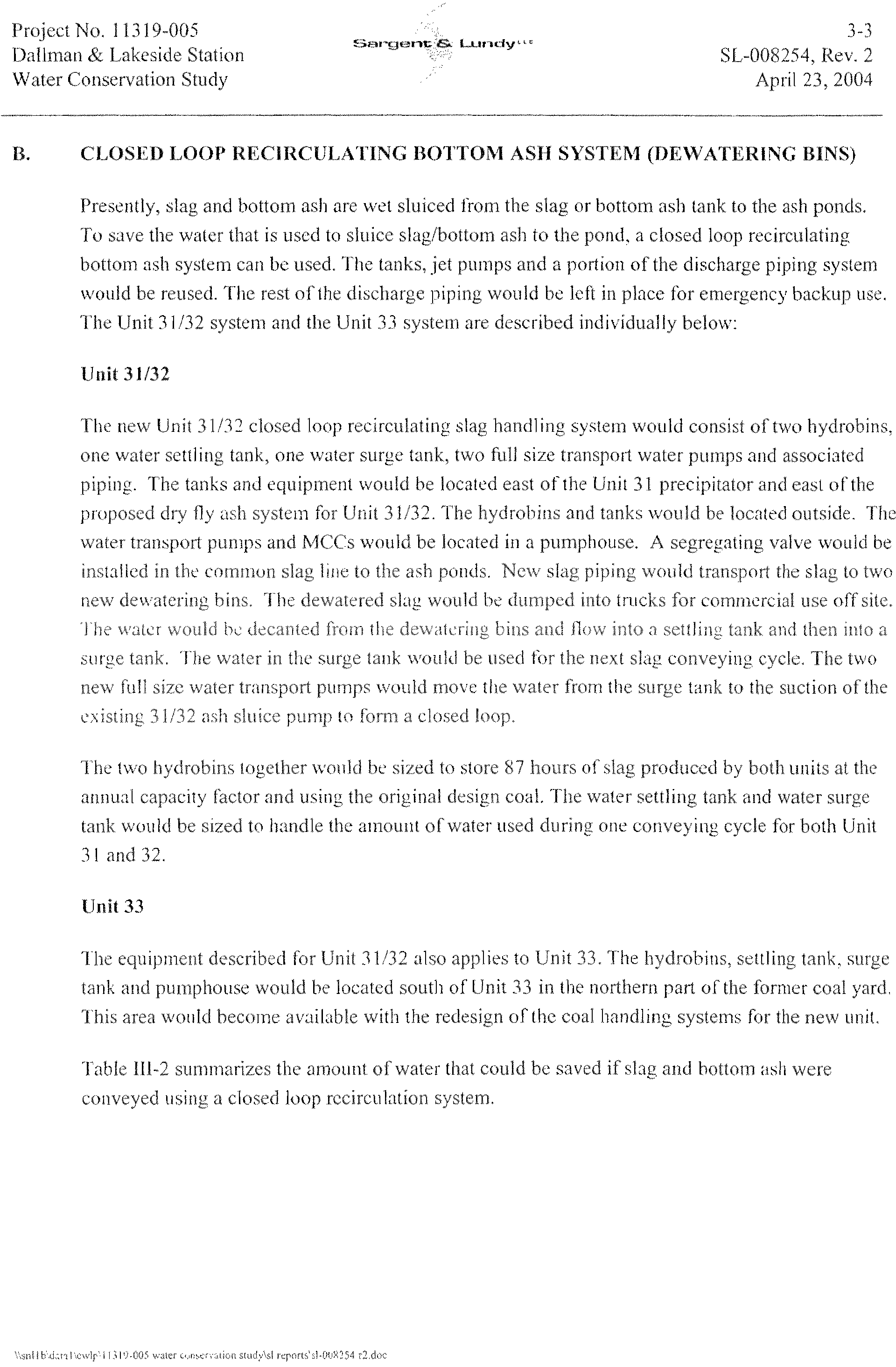

_I1-2

SUMMARY OF CON'Ai"li'TINT

LO'-1-11'S

11N AVERAGE

LWJ) W,`.TLR It

SYS"LEM

pP,-()

r

Slag

Fly Aslr

Bottom

Ash

Fly Ash

W:j 1' ý1r1p

4.4

3.7

01.20

OF T(ITAL

2.39

36.5

1.61

24.6

84

0 ,25

0 .06*

().05

O's

O.()4

11.6

Losses

to

C}.(?1

1).2

TOTAL

6,55

Bl«wclcnvn

0.09*

1.4

Wastewater

Clarifier

Treatment

lowdown

-down and vaccturn

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

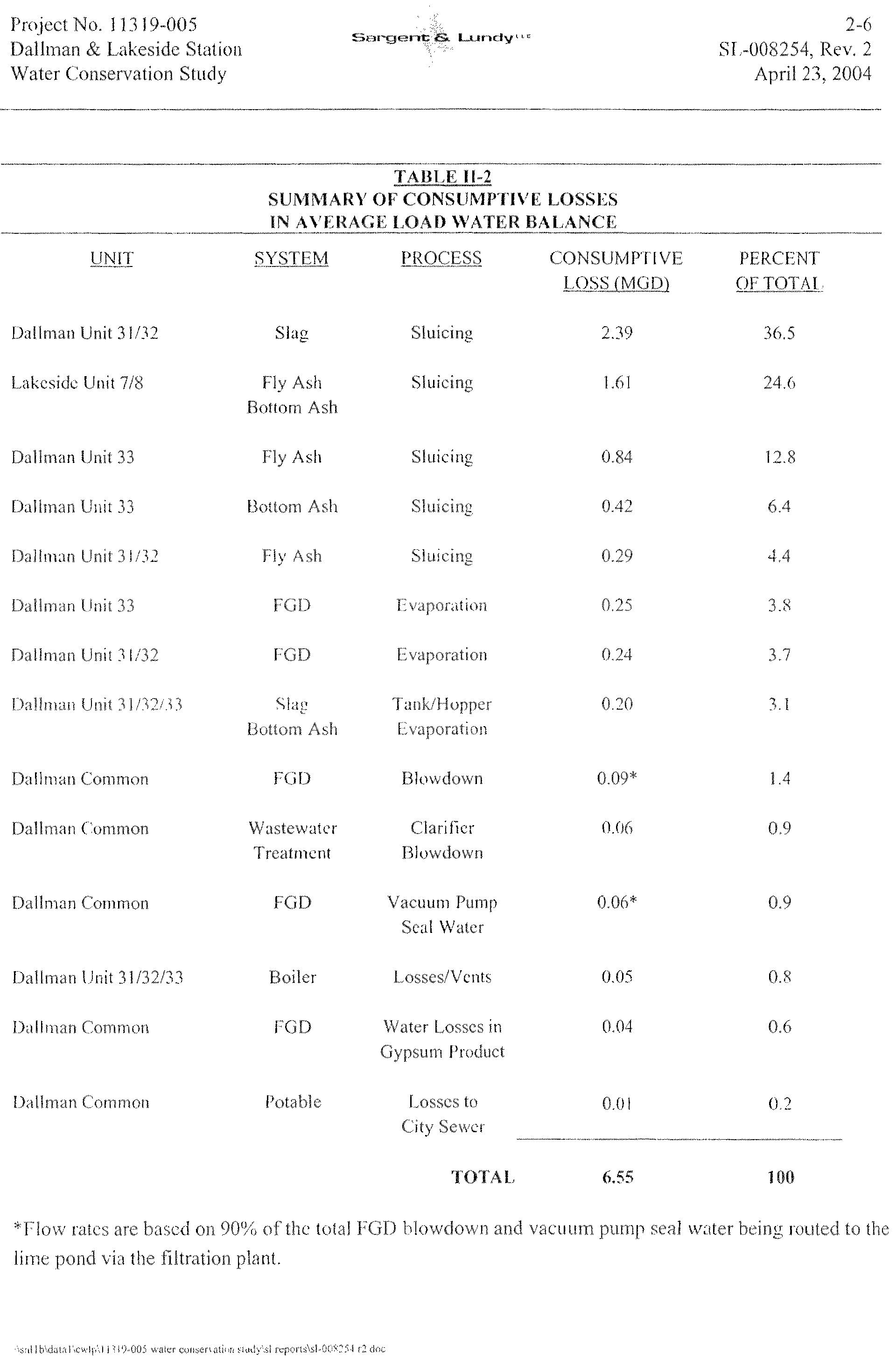

Project

No. 11319-005

2-7

Dallrnan

& Lakeside; Station

`""* "`"`

tv ý_ýý

4Q

SL.-OOS254 Rev.

2

Water Conservation Study

April

23,

2004

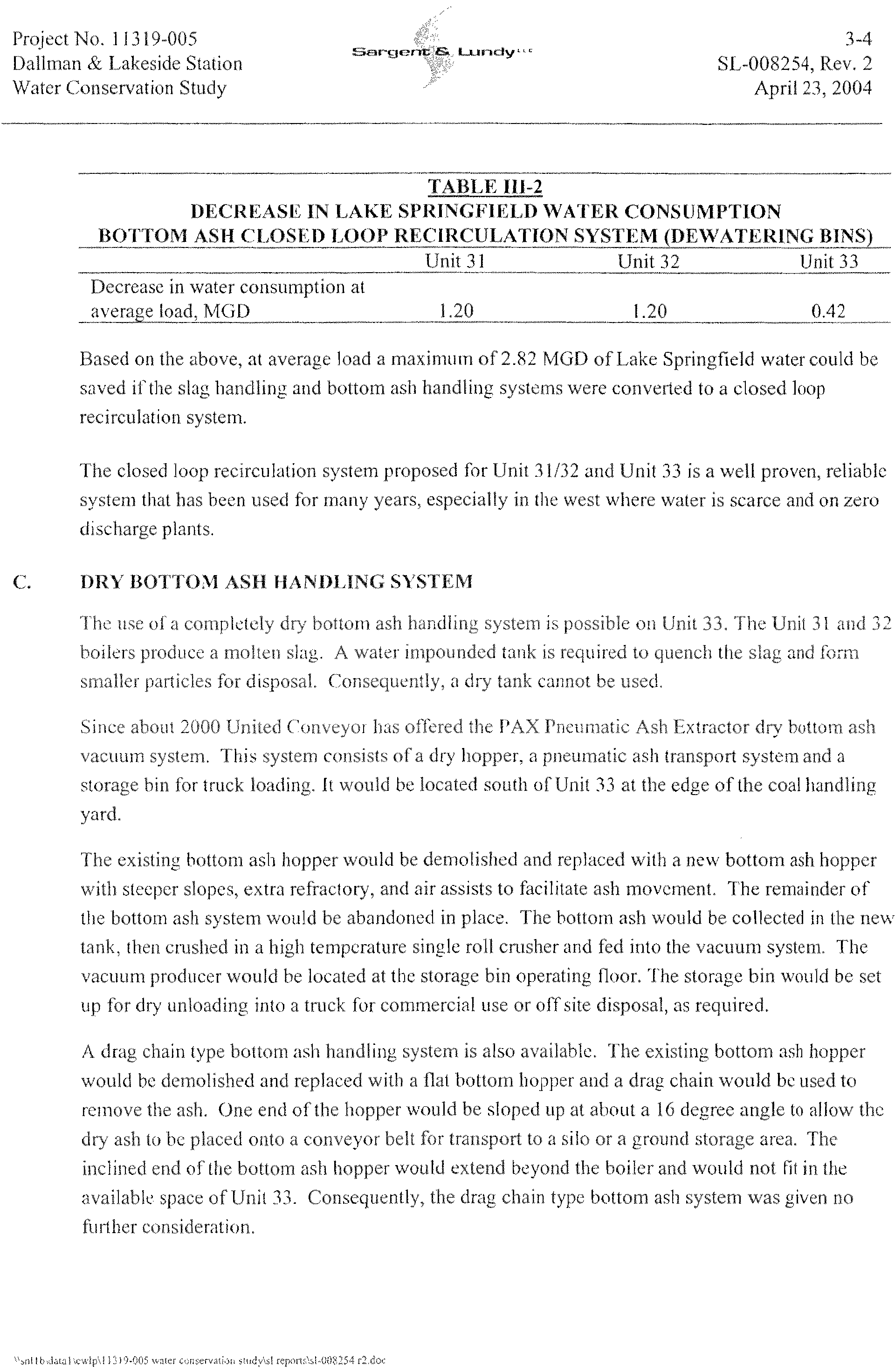

l E Ii-3

It-3

CSI' CONSUMPTIV

M

I()AD

WATER

Dallman

Unit

31132

Dallman Um( 33

i32

SYSTEM

Slat

Fly Ash

Fly Ash

Bottom Ast1

FCD

E.aj

09.33

4.3

ý--rjt)

I

vapcri«ýaon

0.32

4.2

sh

2.53

33.01

2.05

261.7

( i,iClýl

01.9

11.7

0.52

6.8

01.44

5.7

O.l1*

1.4

Blowdown

t` ,;?, :

L.osse0Vents

0.0}9

1.2

I-)

Vac,ý,irn Pump

Q.06*

0.8

Gypsum I', oduct

1' c,

01.7

1(1[3

\ \srdkb:datki'v.,[p\ 11314- C#G5 ,3mconserv2m¢»as:a-

I

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

I,

,

IIY

l

III

l g-(In S

3-l

1;31.11

W

ater Conservation

Study

ar,lr

ý;.

fly ash systems use a

wet

fly ash

Ii,rndfng system to remove the fly ash from

the

sy>;i ý i, [ c,)nsists of hydroveyors that use water

to create a

u

and slurry the ash to an

ash pond.

system is dry from the

hopper discharge

tip to the hydroveyor, In order to save the water that

i

use=

of a

t i : :;li-+o rt b lo'.IvG1z, :::1f

rld he installed it the.

I re

wý-,=ying air strearrr and

collect the

a<,)

ire

a hopper under

t],.

lie;

t!. «:,

f,

rrerl from the filter

separator uc,l+, i 1;,ý"t,2rr21 and

foci I; to

r.,

"-

r

loci.

!

,,

J

r; beneath the hopper.

Two fLill ý.i1:-

1

from

rhc ; i;r lock feeders to the ash

pond

is a r<

-w 4

,ý,spu

t r ;1,

h , ical vacuum

-130' x

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Unit

33

mc,:

kinical

vacuum

producers, a filter separator and vacuum conveying

i

.

i'irv

ti-+,`u

world be

ti )g vacuum header to the hydroveyor, New

A pril 23, 200

vaý: utmi P 111111",

1,-1-)uld

ý

b e added from the

s e,-rc: ý,

Ive to the filter separator located on top of

l ili

ý e

separator

would collect the , ý

d coi:ur ct the filter separator to the vacuum producers

O h thes

h

aul

it ý,fi

about 20` above grade. Trucks

al rise or to a

oiýrs ofby ash production by Unit 33 operat

% ash. Initial invest,

s, A new

n to the silo

ng at

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

t No. 11319-005

3-3

Presently,

slag, and bottom ash are

wet sluiced from the slag

)EWA,TER

°'ag/bottom ash to the pond, a closed loop

recirculating

bottom

ash system can be used. T1i,: 1;,;

ýl.ý:.

jet pumps and a portion of the

discharge

pipin

w ould be reused. The rest of 0,

c- ,II - ]1,r: piping would be left in place for emergency

backup use.

U

nit 31/32 system and the Unit

,,

.y-item are described individually below:

Unit 31132

t ank

C be ,,I,

anno: l

I

l f- cbins.

i i l,e Unit 31 precipitator acrd east,

I

!he

i i i ýg slag ha

t : 1, L,

two

Tire i

-.ý.v

Unit 31/3?

c1-

-

-,.,

a,1,".

rl.A

durin

This

area would

b: ,one available with the redesi

tank and purnplivý-

;Id be located south

of

n i¬

dy

f andle t

he

amount

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

D,illi ri-n & Lakeside Star

V!';a,x Conservation

Study

ICJZV

kSE

I

ý Ill'I I_11-?

l'11:1

ll W

\S11 CI.OSED

LOOP RECIRC:

Tb,-

c'lose(l

3oý:,

sv: i ;,I

d: .J:,.

zI

a

maxin

ýi,ld boaorn ash

handling systems were converted to a closed

loop

1,,.-

-,vould

b e

demo

1r;:u;.ory, and a

ir

a

tile

'Lotiw:3 <dsh system

.would

L)e abandoned

in place. TI

te

bottom ash would be collected in

the crew

c iiirl1ci -cnd

vacuum producer would

be loc, i .:d at the , tc,i;, 1,1.E

cl'e

into the vacuum system.

l,jr =-onlmercýý :

I L!:-

or off

i ( a 16 degree angle to allow the

nd

stc ; e area. The

acrd

wi

;

r

,

ýý

lire

wall-

[ fl 1l

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

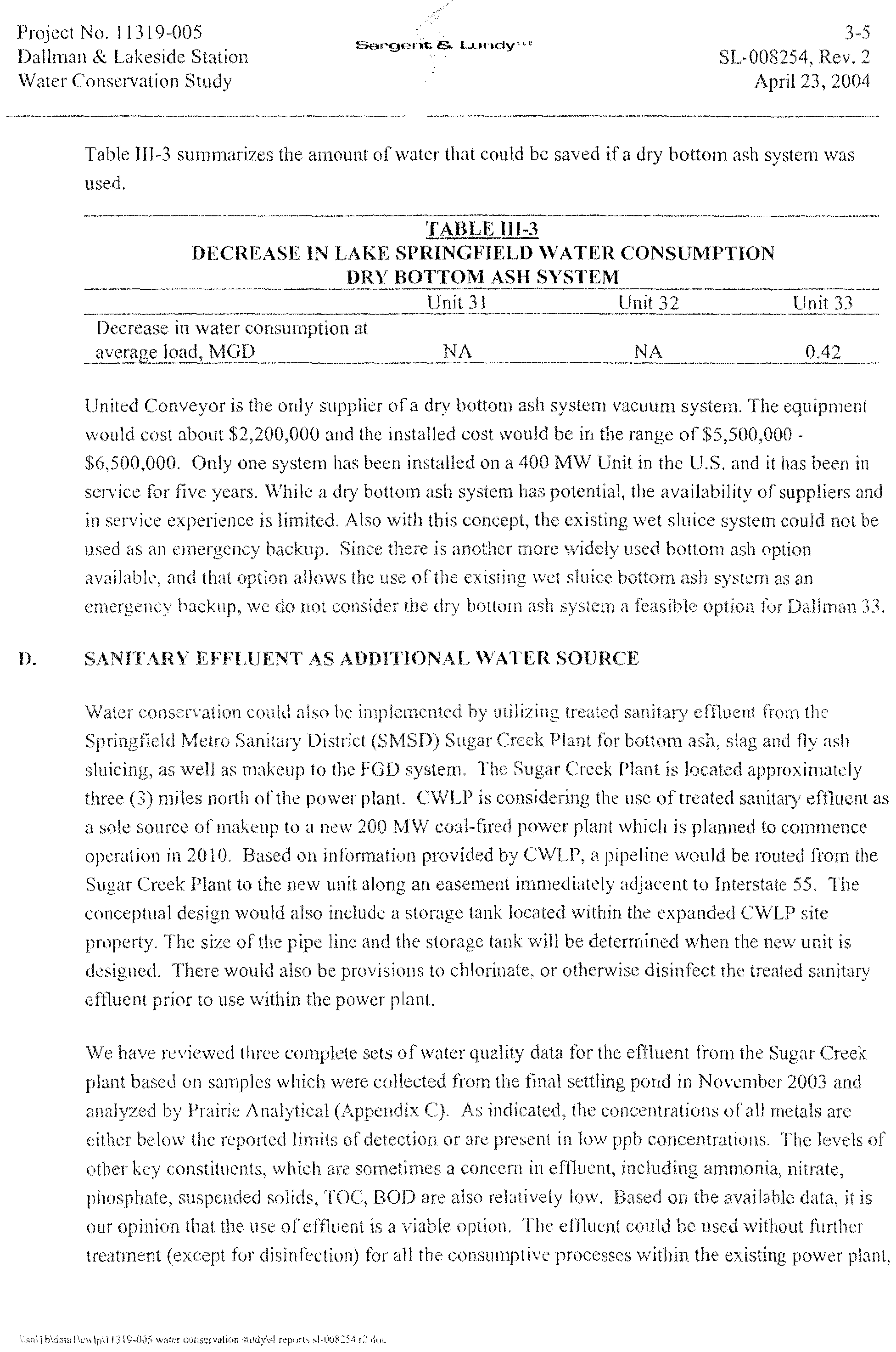

Table, III-3 suiiilII°

used.

water crl it ,;,;-I

d

United Conveyor

is the only suppl

w ould cost about

$2,200,000

acrd

the installed cost would be in the range of

$5,500,

i Icl;i

-,,Ilich

is planned to comru,iice

Iii;.

r-,i:,te

5 5.

The

n1;

I

-

-at. \i within the e xpanded

3 -5

s ystem vacuurn system, The equipmen

(,iii was

c ir h r;.; .rý ý;hr systernhaspotential, the availability

of

suppli_-r:, and

1 this Cýt7Cý"'.ýt,

t1?,

'i°ri"`. wet slt'1C`E`

sx'ntein

could iiot be

i_ n? hýýý b,-n installed on a 400

1

;,ýrr,r_:rrrce

is

limo:-rl

otherwise

disinfect

til - tl,.%w .

J. :

lwt:

ry

,1 t1 i

cc complete sets o`' v -titer quality data for- th,.

f; ý ý

ý

nt

`tiliý;

f

t;,,,

Ii

riI sevlýn:

-

i <I

i

j

I i

be determined when

the i i.

,,

,

! ute use oi clfluent is a viaiOle upi.IO'',

T11 ti

i I b`alnra l \ewlpl I 1319-005 wat+:.r cu.scrvrdic?n swdylsl rerun-1-008354

r3,ýtýe.

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

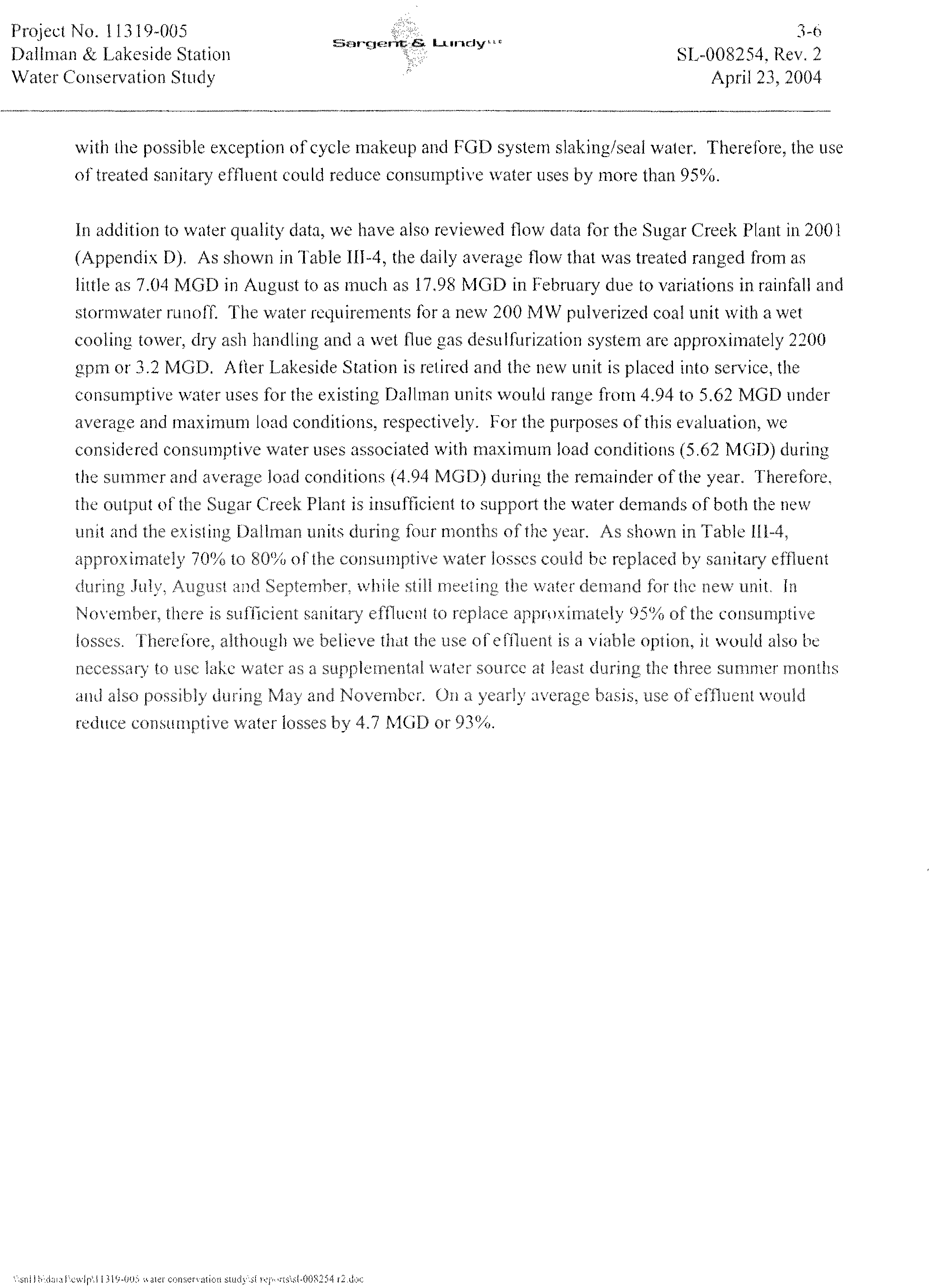

the

possible exec

F : t.x nIcly-

:1-6

iiur. Therefore, the use

I,,in 95?ý.

little as 7.04Iý-lGIJ in August to as i;o,wh

as

17.98 TVIGD

us (4.94

co, it Id, i ý-d , onsutnpU water uses assoc

a

vera

-, 4I;-y

ash handling and a

wet flu( ;-,:Is desu'lfurization system are apl

4C'rD.

After Lakcsiah

Station

is I, i I

ri , i

., nd the new unit is placed in

water uses far

if.,:

ing Dalhrl,Aii Units WOUld range from 4.94 to

maximum toad conditions,

respectively. For the ptarpor

-s of this ev

f ated with maximum look'

k i,Tions

(5

A)

(ry'da,a

l c, tP., 1319-005

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

roJect No. 11319-005

ide Station

SL-008254, Rev. 2

Water Conservation Study

April 23, 2(104

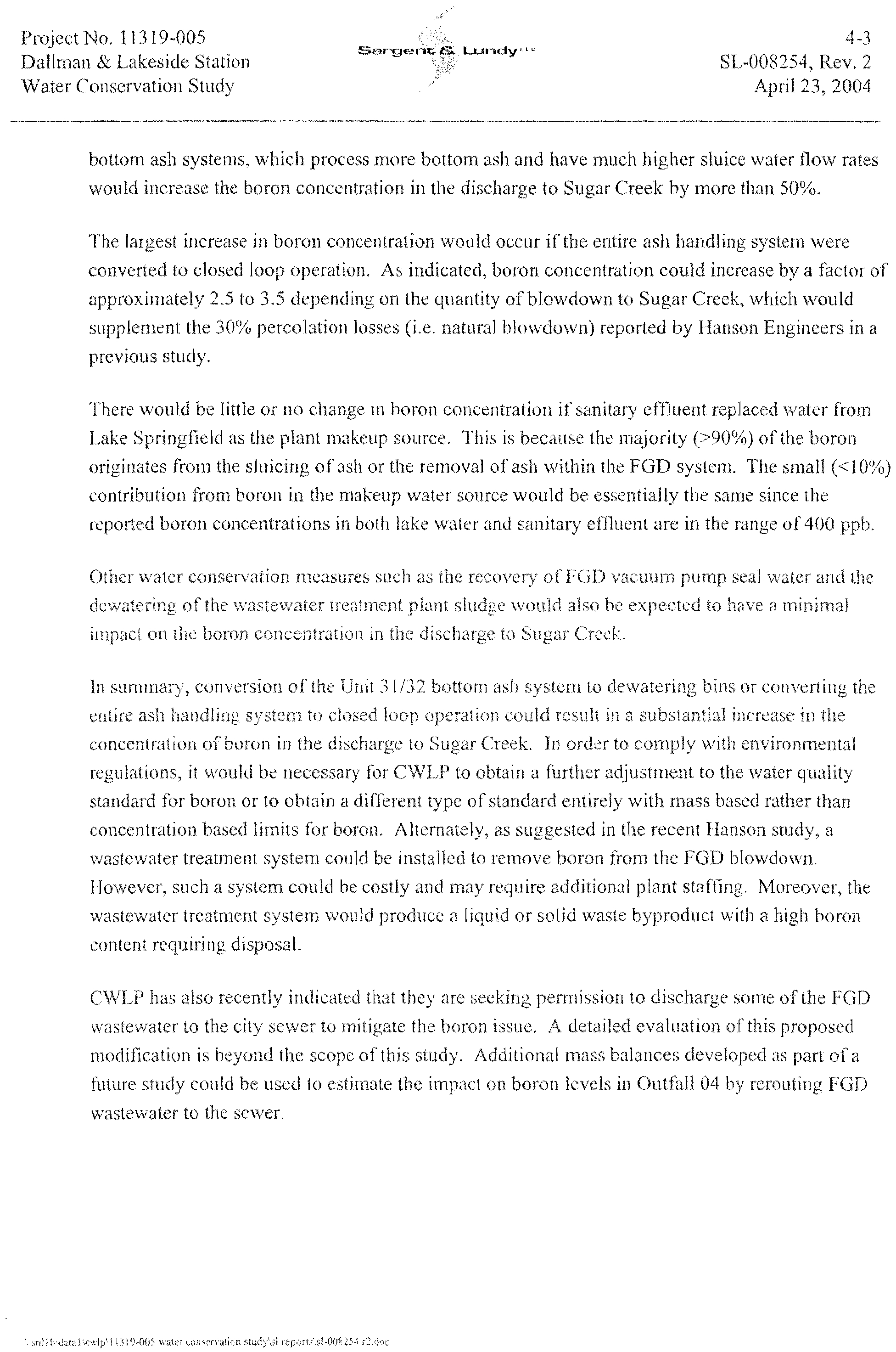

C OMPARISON

OF SUGAR CREEK PLANT SANITARY EFFLUENT

3.2

s.94

7.22

1001

3

.2

4 .94

I . ss

1 00

1 0.42

Mar-0 I

r-0 I

3.2

4.94

3.2

4.94

5 .19

5.62

5.51

7.05

3.2

5.62

3-

S'

7.04

J-01

7.15

3.2

4.94

3.95

10.94

3.2

4.94

7.74

Nov-01

'7.93

3.2

4.14

4.73

3>3

3.2

4.94

t , r

l t'H

c onsumptive

losses f T,:.

could occur 6

Ll

fi

nal i i I; ý, rrt ronr the Stioar Creek. Plant

is

not

dis

effluent

is riot

p-

1,

o-1,

,i, ii is

received at the,

,power

plant. We believe drat Ml(

I-

Dallrnan

e nt

ý mn.ptive

Available for C onsuwj,

r

1,1

i,ý4uced ca i_ ;r; `,I1()

within ii,r

ash

handling

and 1.

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

1rý, f ý,n. _ u ,,e of effluent within the power p1

itLin the ash handlIM

so because. the

operating temperatures within the ash handling an

100°I 1ý1 140°F) may he opt

I I jcrr,' MI populations are being kept under control, and

is not occurring.

ri:'

ý' it l \. I;1

ti,,,,

W i,

li, ;,I,!

u ltimrtrly

di,ých;u

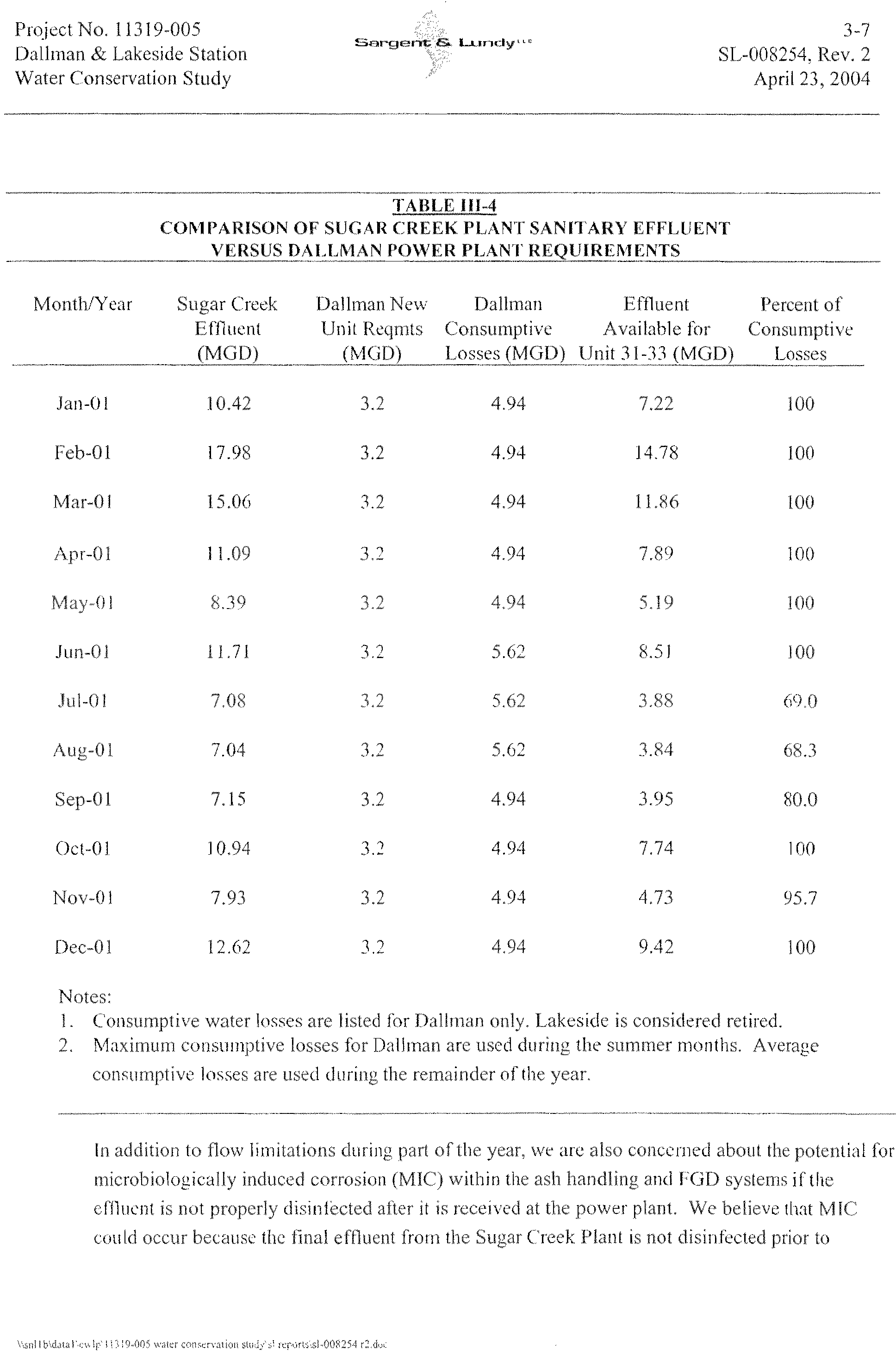

Afler

pumps to o , the flow

1-1ik at

,,l r1

u

;he water

from

Id be waved

if al I the, ash slu

i; tnk to the inlet of

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

3-e)

-008254. Rev. 2

'floe ash sluiri v..,(cr recovery system proposed

would

consists

result in

ground water stand.,r,?, he

i:i:,

pumps and new

cent lo

iI,, existing ash .handing systems requirc,

some rel

iý,( -ý , there are adverse environmental

nnp.:ici

,,ssociated

r evio: i,

,,,

<.

(r :'audy performed by Hanson

iII11tt1 , i l.itlSl i;-'

w e leave ;,I ý>

i S(i ti+t'aI \ Vater act

l ily,?

Ftl

FGD Sump Pit

E

tll1S£'it

"t it,.-

I

u' )

r,

, i

-

:y

,' um

falter vacuum purr i . eal

water i

.

jowl,,.

The wastewater (oV--i-I

in t,-ie su

Tilt atiorr ;ý!ant, but is also

occasional:

N,

tT..ake

Sr.? n.

1'(3D pond and the;

2 ti

I ii

II) waste ,i (er being routed

to the lime pond and

1G'%a being routed to LaL

sl

ý_'t

water to

tank.

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

1'r, Ijcci

No. 11

llm;in&La

2. Ash Handling

System Water Management

o mmen

ti ! i

1) ,ý: tier c onservation

recommeT

ificant equ

l-,,,

ý,<<fý (I

an Ash ll;Indling Water Study (Appen

e els by

45%.

I II

G a

ýI }

al,l,1ý.cation be evaluated.

R,

available

wastewater treatrn+

the

sunnner.

:3-10

;_ LL. 11owever, because

t1,

l),

_ ,,,i.

plant, CahILP has rep- ;

water for

this

?

j III-1r"Pd. However, ¬-:-.ý_

nded o1,,-r.:r

l %I F1

.,

l ";(-II4.."¬ ;ý I? ( t)",1 t Ct 10 "-1 l i?( )NICITY A

T F1t Iii LAKE

W;I"9 I

is--

I-vel

e1tcd

to

potable water

;j;ýýi&,ble, consi&ring

ash handling

ions

,1, it

is

ur understandin

o

i ý ,w l3

until apprr,--i,-,1

;,t,,

I,,

Cie

h iring

;;II ;

:mni 1 b data PC, IP,11 3 f 9-04$

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

ý,lltt-,l

-5z,,), ý p -t. 1-.. L.x..ynclyýýý'

on

Suit Iv

lieu

of

potable

water

for heat exchanger cooling

i

I ý io

Fouling k

- 1Ild

be adequately controlled. This could be accomplish. J

by

feeding biocide to the

1 ýc:. t c ýwchI,j;:,-, ý

I's

sand dechlorinat

permit.

Un l; -ý-unately, the configuration of these heat excll:-ýItýýý

r.

is aci orally twelve separate

to the common italet and

outl¬

i 1:

water to th(, - I I : ;I

i,ýr Unil 31/32 and Unit 33, wl, i, II

II,'-li.ac these heat exch.tli_ t. r r<< t,.vorl<s inclu k

r-(ý;

<!-

rtt facilities, and also proviid,,, the source; of pi iii

:' I , .ive piping and/or eqn 1, itnent modifica

ý ..ter. Based on then ,

,

-

r

r; id,

rations,

a complete

°, h r,-.:

ctical.

\

.,nlItr'.ýw;3lct,[P1I

I3 t9-00h

v.ate,

consrra

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

SECTION 4

i .i i1,-ril ;:,

curren

,

,_

I.erize

the sources of

boroji %,ý,,ithin

the power plant, the lji her f,i

c,ri

levels

nay be due to arnnior

a SCR operation.

-,i('1_

<

iýpecific

reasons for

these levels.

n , r.;,i:;,a! i ,easures co

i luent available Fr

s tudy.

I lovaev(

ntly collected by CWL,

-2) to

estini ,. e the

increase

i`

!,!

trate

order,

t'

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

9-

sic

servation Study

Unit 33

A l3 f (' IV-I

M ing System

Unit 31/32

29.16

ppm

1'0 12

VARIOUS A LTFRNA'

1 /32 to dry fly ash

1

:i

s old.

Howeverjf,4 33 cow-

i,I boron in

fly

ash sluice water, v.

(h

th

r

,

\nsistent

with the flow rates anti the reported

v.; l{.,

1-11

r:

1,

t he boron

coni ,. Irt1 t!Icri ii

only

I

i,Ln

vs. 201

4-2

SL,-008254,

Rev. 2

April

23, 20014

o converse,

it of'bott.onr ash

..: ,i

3,,

fý,.rr°

onc_ -throu-h

,

1:i-

r t,

of

-I,r=ration.

L

\ \.'nIIbda¢aI\cw-Ip%133[9-P0awaterco"Crvationstudyt;.L.

t

.4tIciuc

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

would i .r .

"the largest it

converted to closed

loofa I

_:

ration. As indicated, boron concentration

could

i( lý._ýtding on the quantity of blowdown

to Sugar Creek, which would

supplement tyre 30%

perch d_-lion losses

ýi-i;,a ,iom boron in the makeup

wqt¬ i sojjrc;f, woilliki

l

ýý _sential

,116

iiiuRý,t sire in the ran,!,,, of"4i)()

w !, 11f ,s^t-ni cc,rldb

= ýh << >ystetn

< ý:,ild

be costly

. nt 11 -C.i ,,;1 study. ;:

'

'

also recently indi

f

ion in the di>:_C:.u

ch higher slui

I,)

Sugar Creek

by

more than SU%,

MnO

it 1 i011 1

I ioik of this proposed

.h;veloped as part

of

a

r, Outfall 04 by re

wastewater

to the sewer.

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

C+-,t

,

n

I , ,r,clyýIý

W ater Conservation SGrrdy

systems,

which would result in a conversion to closed

moth

st

1!}

i

c lahorat,

ý::p

I

1

s

of

actual plant

wastewater

to the model sysi, ;i1 as well as

gtion and/or blowdown. Daily st,niples were collected

T t

1,

Id

the

scope

it was c- [eluded drat convers

qw

4-4

r of water quality parameters.

I,,ýrJI b; at least a two-fold to

three-fold

increas

; ;t7 1 1o

s ome water

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

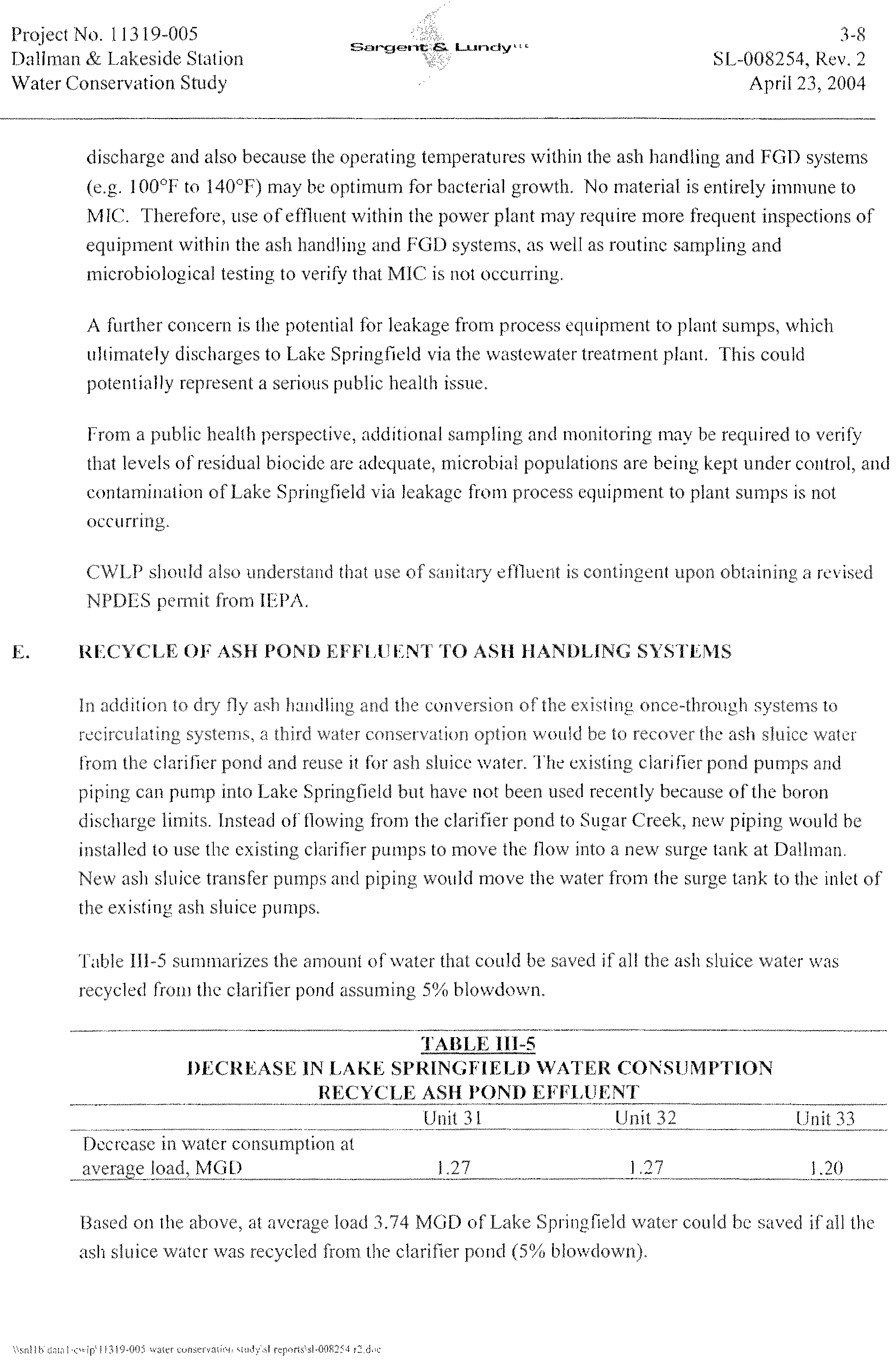

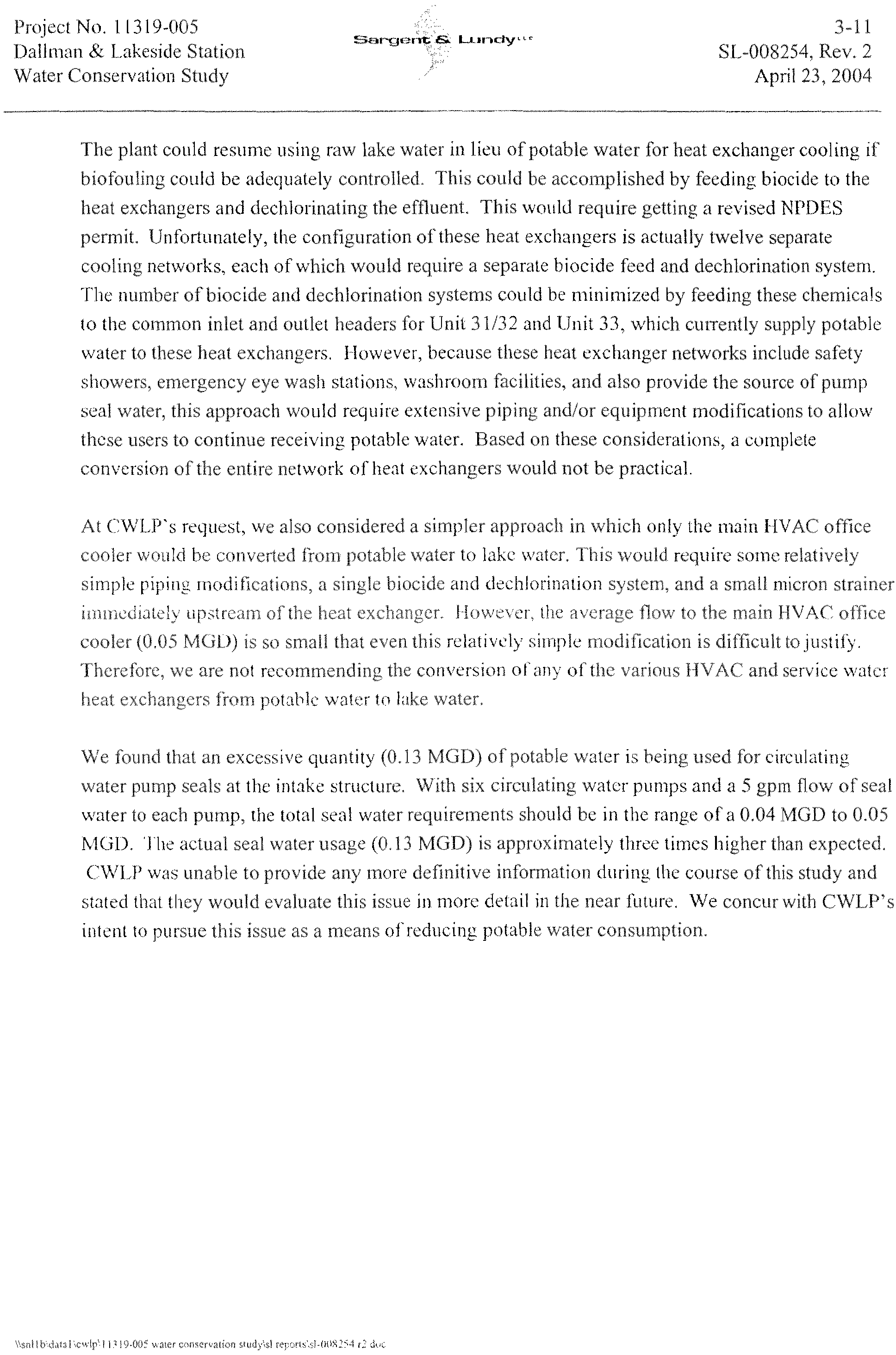

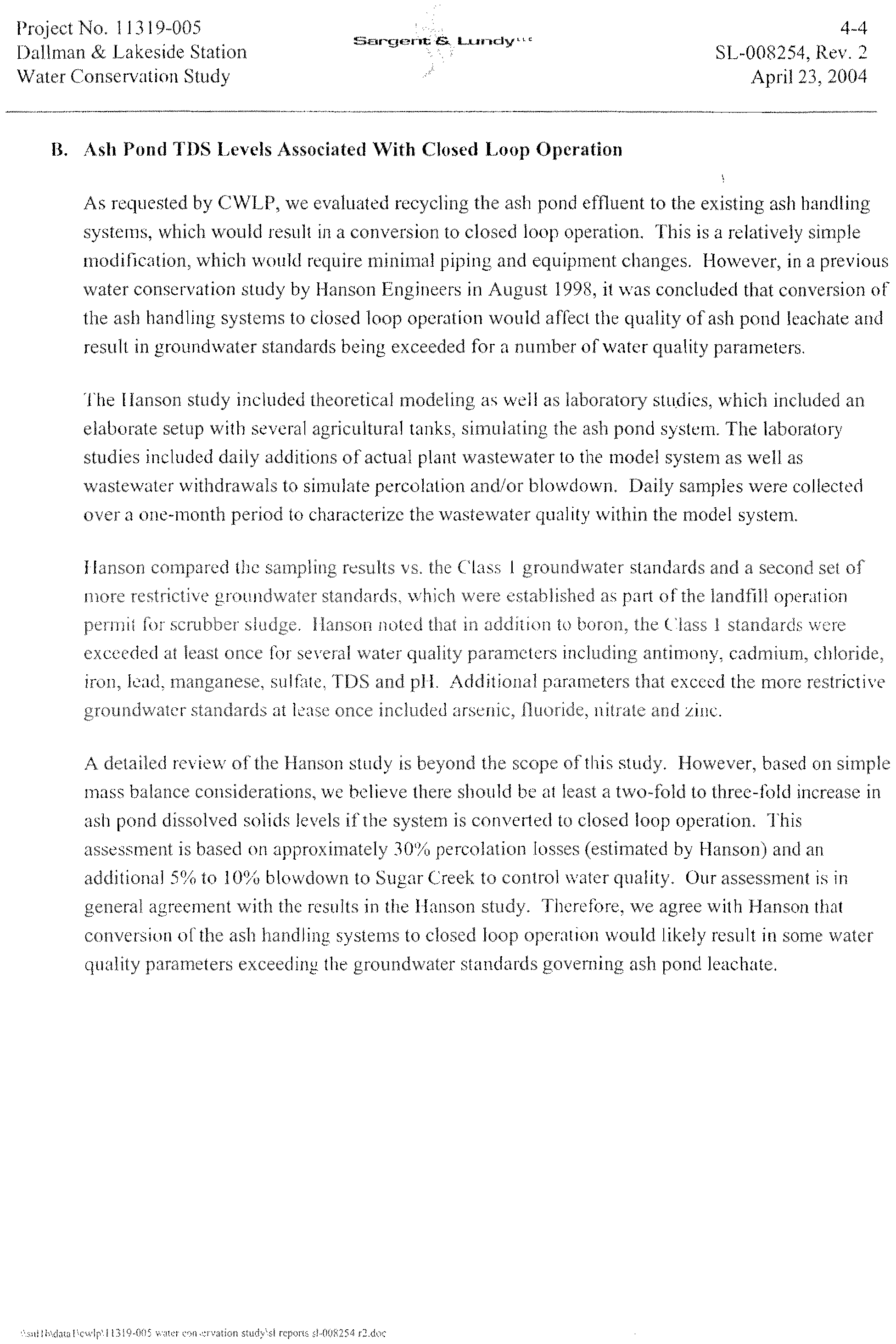

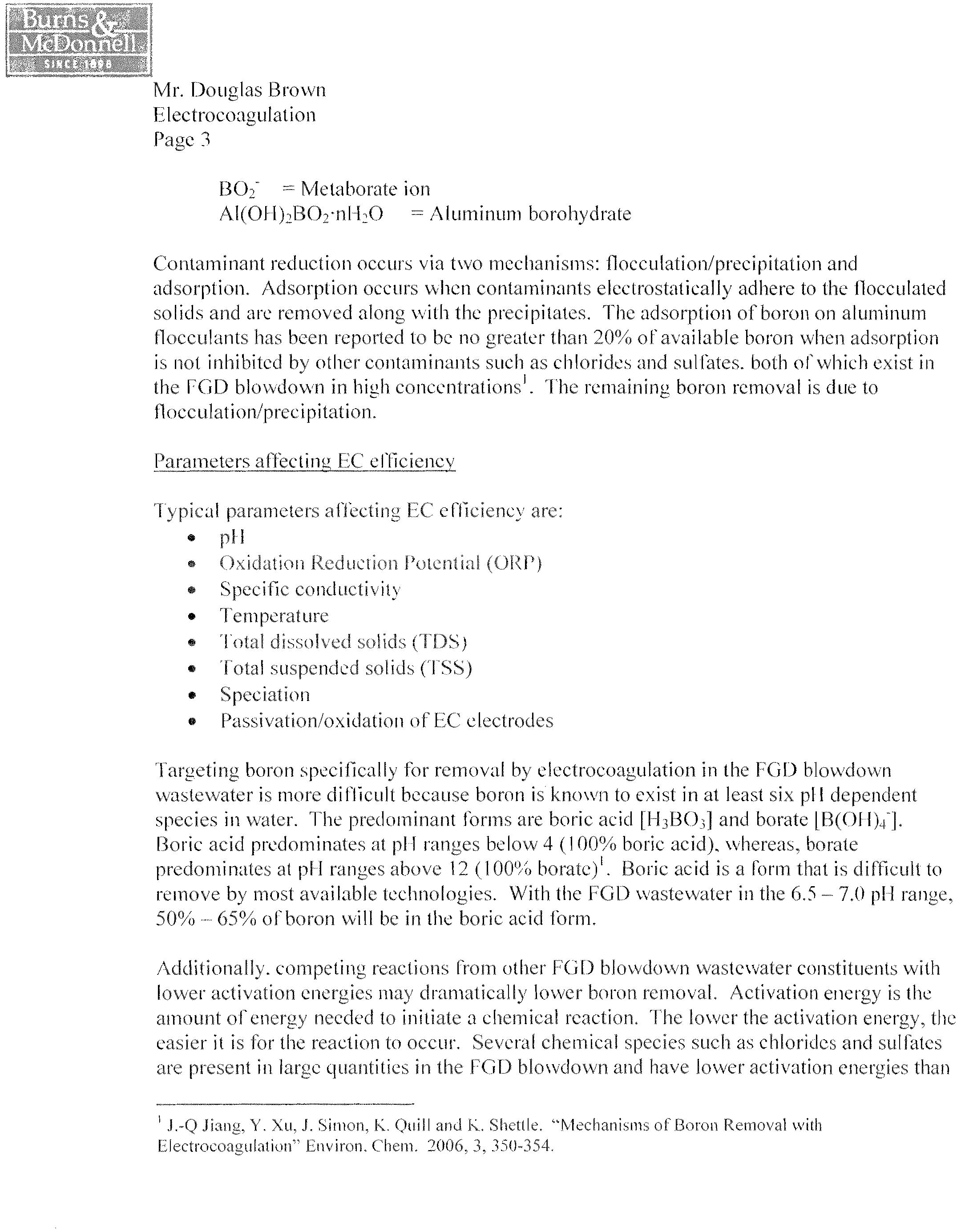

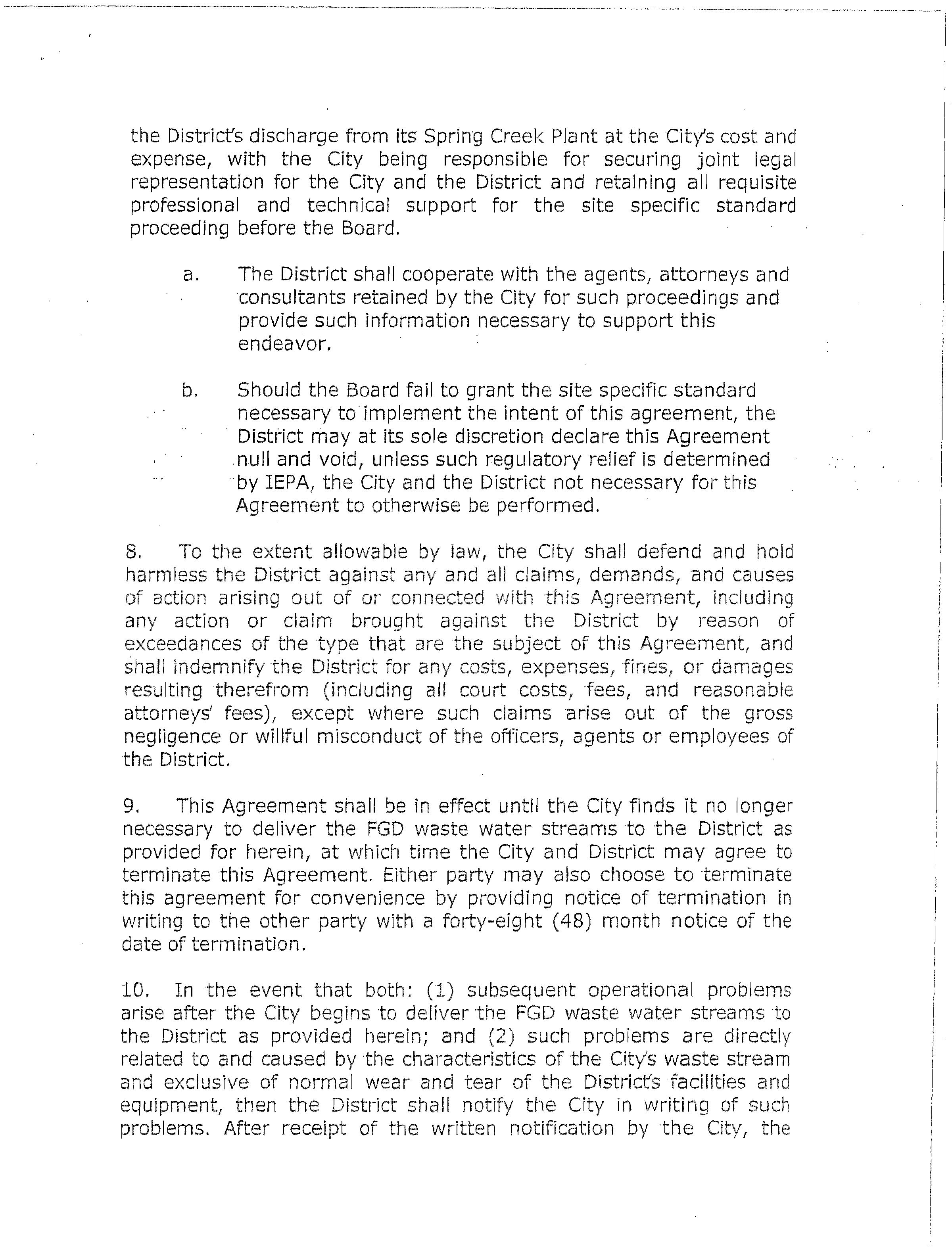

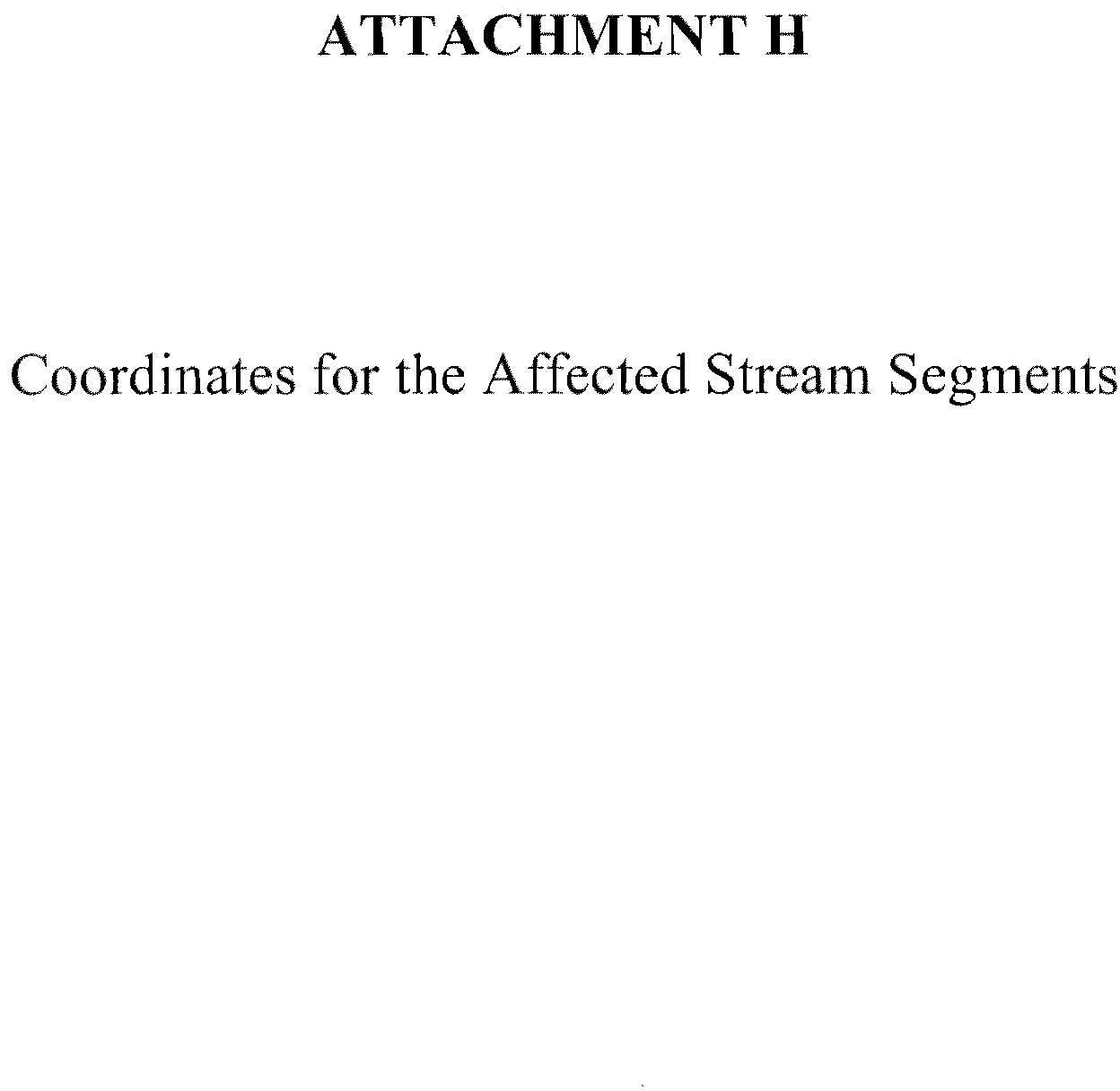

City Water Light &

Power

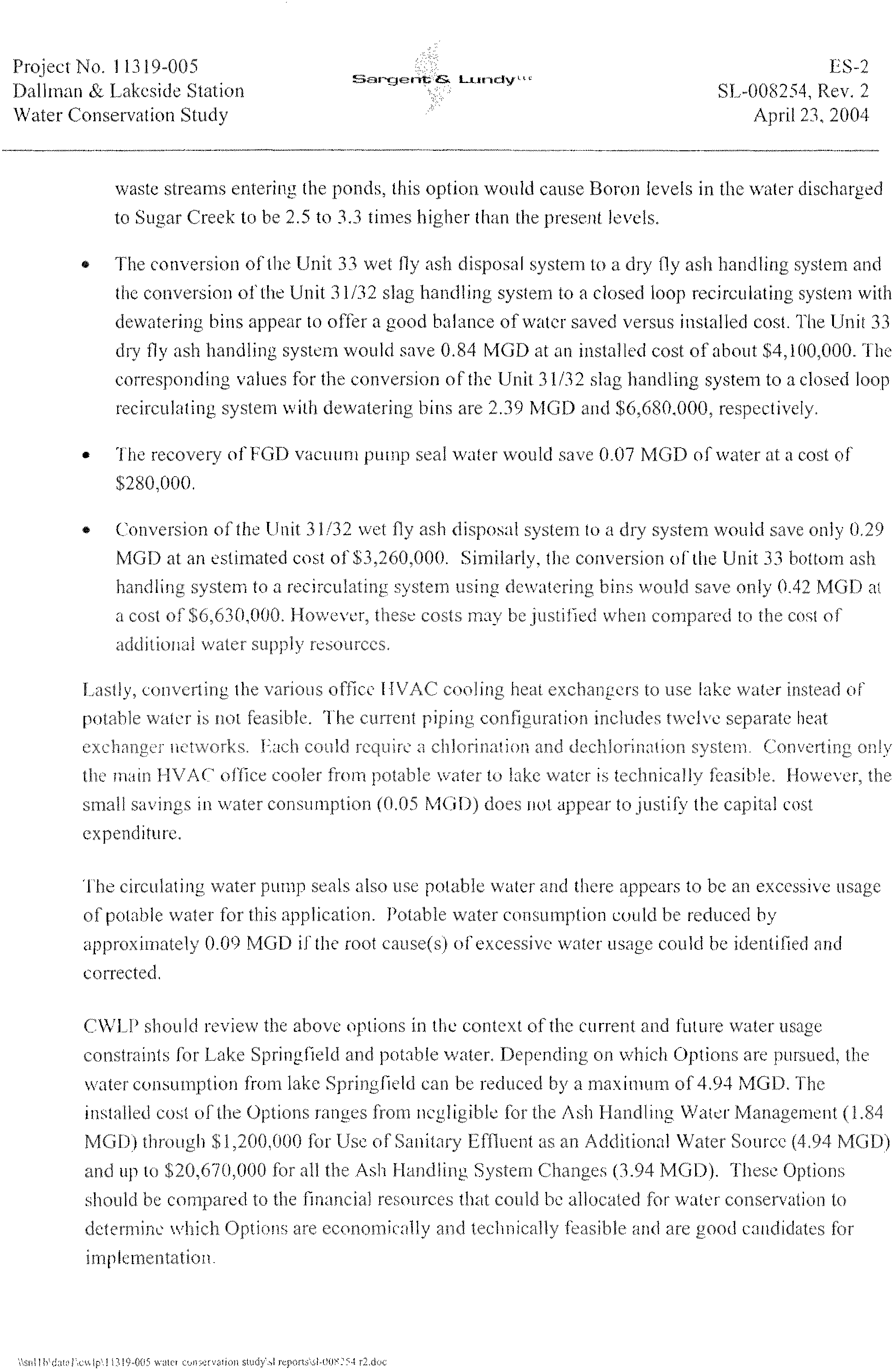

Figure IV-1

-

Mass

Balance Model for Boron

Sargent

& Lundy LLC

Dallman Power Station

Prep'd

MR

Water Conservation

Study

Rvw'd

PAH

App'd RLR

Rev 2 04/23104

Q 33FAC33FA

Unit 33 Fly Ash Sluice Water

033BAC330A

Unit

39132 Fly Ash Sluice Water

Unit 33 Bottom Ash Sluice

Water

Unit 31132

Slag Sluice

Water

QFCP

QFGDCFGD

QswapCs".

Q FntCFnt

New

C-----4

Surge

I--------I"

Tank

Optional Recycle to

Power Plant

Percolation

FGD Blowdown

WWTS Sludge

Filtration Plant

Sludge

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

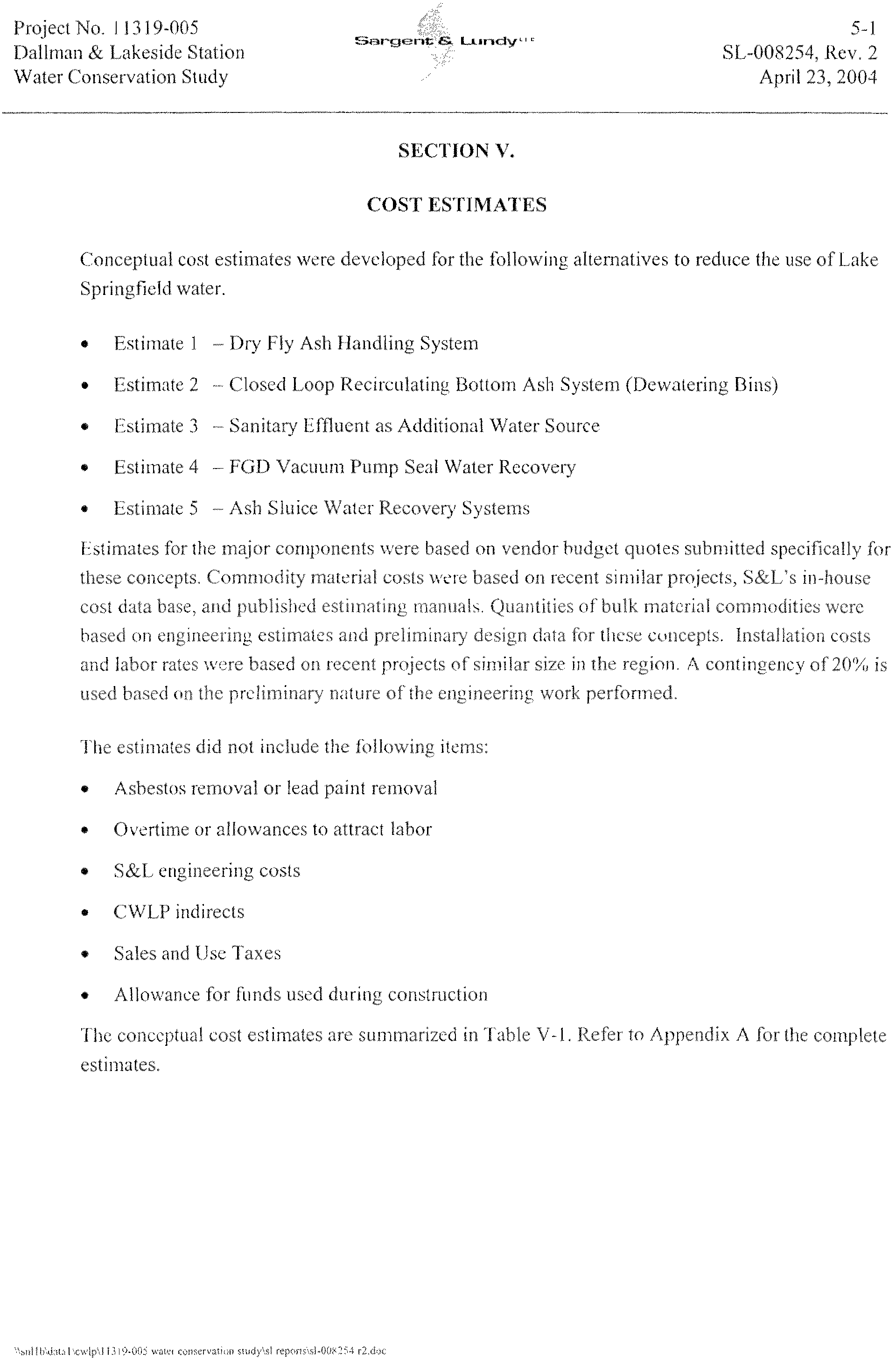

SECTION V.

Conc

_

ptýl;it east

es,

i En,,

rate 1

I t

the fottc»jin

i

rCUlating

Bottom Ash System

,

1

[fluent

as

Additional

Water Source

ý stos remc

e°d during construe

e

summarize

` =mri`b' entaI`m=Ip°d(3I£-00f

«-,atay cvnýerva;Cetn seud ý; ,tpim'A-008254

2,d,c

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

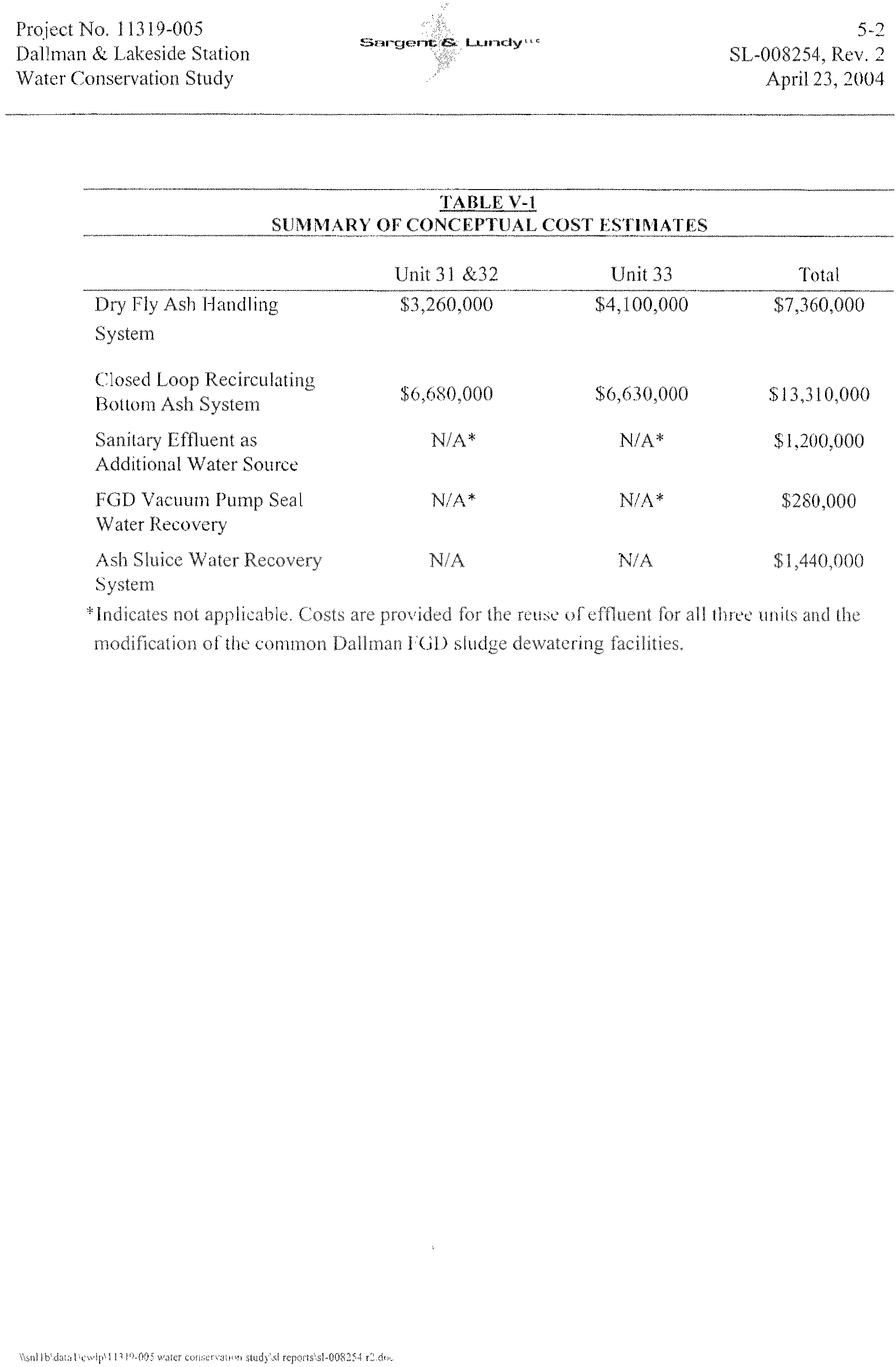

-2

N/A*

1 11. ',;I,

Wat(r 1'ý--very

N /A*

N/A

*

P ,ýrlW.a: at`-c ipl

.'.dot,

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

6-I

D4ill;rn;°iz &'

I ahr

ýruion Study,.,._.

SUM

ý t ilt l ,& CON(

I IrSIONS

terms of reduced water consurn

The alternatives that were reviewed

, ,n

d ( -. ))eri

, 1

their

installe

iý:),

1,: 1,.-A

1, op operr

cannot use , dry tank. A dry

bottom ash sys`

l :iridlin ofters

I

rd to water r ,::111 -, ý_ ir,°ir

[i fi

It should be no!;

1

t1!: it.

regardless of whether tiny of the above,.',

. . ý,,; ar

is

, rent

f.

Units 7 &

8 in 2009 will reduce cowls

i ;,ii water losse " :,proximate

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

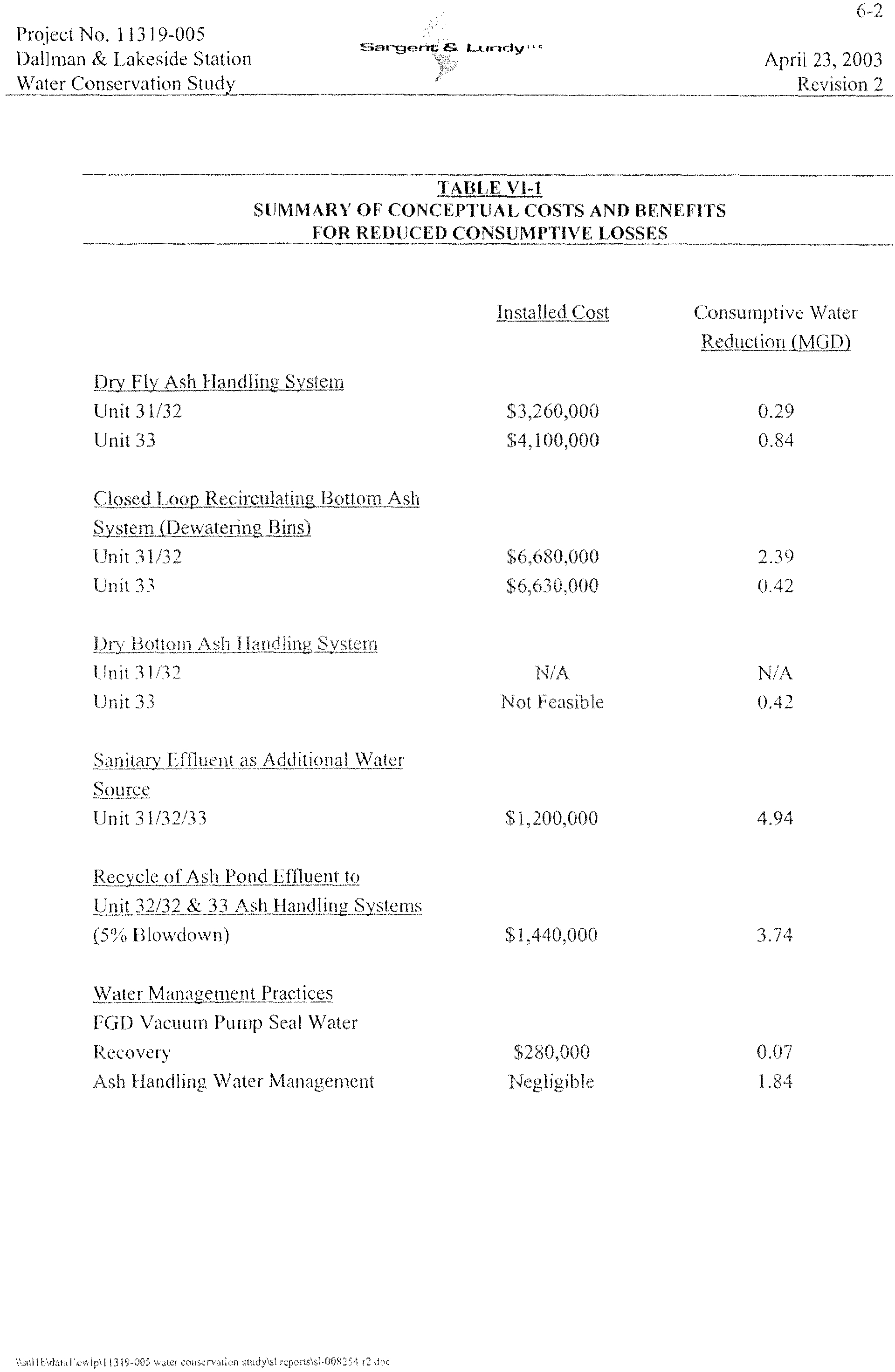

Il

R <11nixi & Lakeside Sta

S CIMNIAR1'

Q

1M.,

U nit 31/32

Installed

Cost

54,100,000

1 _Init 31/. "

Unit 33

ý n

r 1()

i.ruý V

U nit 3 3

0 .29

2.39

N/A

1Juit 31/32/33

$1,200,000

4.94

ý

0 -

1 h l 1

fi

11:;nr

A '

a;

I landlin

o 1 'urnp Se: T Water

W ater

,,'I ,

t

3 .74

1.84

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

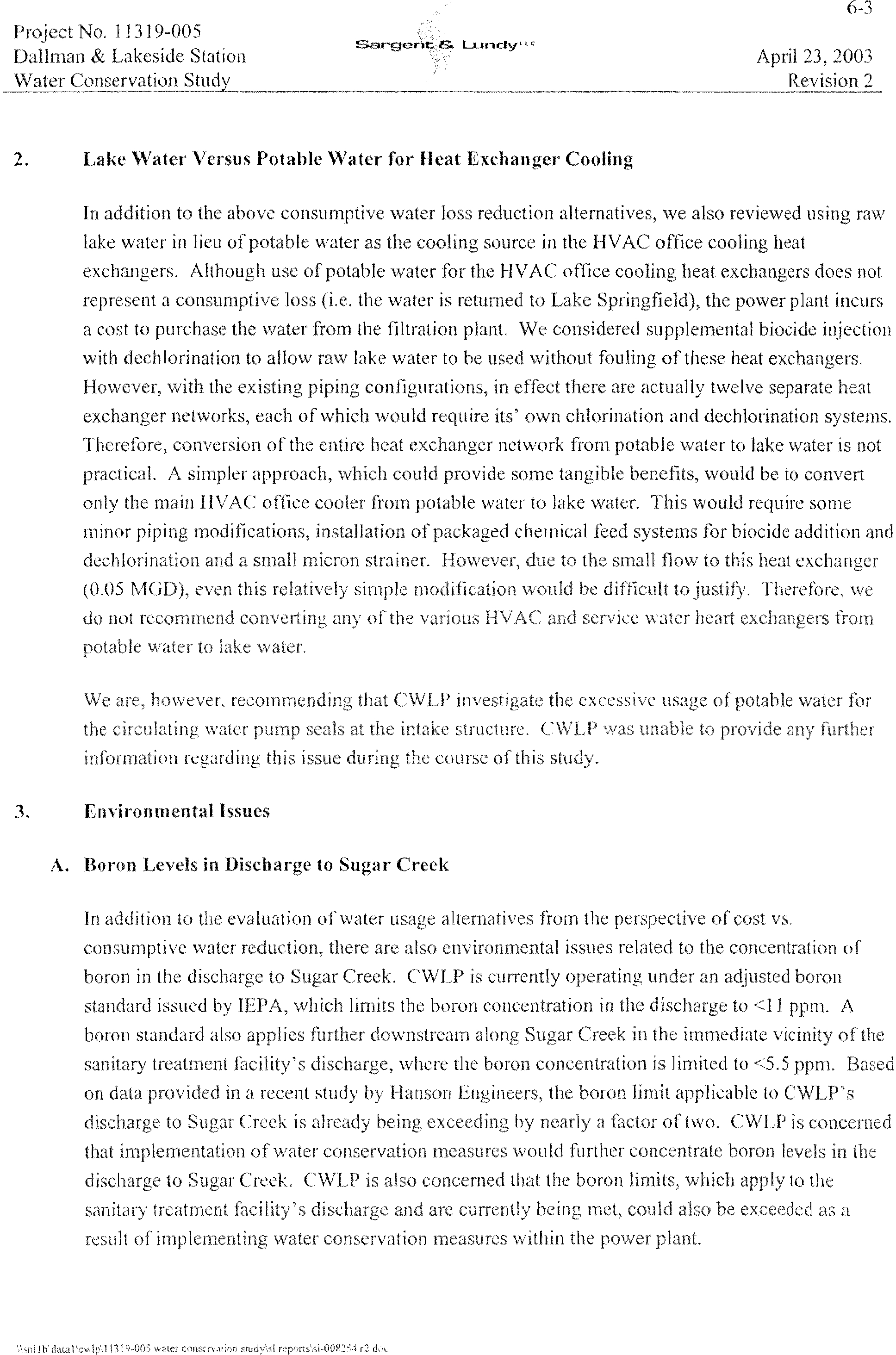

6-3

ater

Versus Potable

the water is retained to Lake Springfield), the power plant incurs

addition to the above consump

loss reduction alterna

e cooling source in the HVAC" office coolin

-i

ii)n

and dechlorination sy <GLrns.

,i:, ble water to take water i ,,, n ot

r -, actually twelve separ,,r<,

-,-lýit?r

cckuld provide sor"n

i1);;

b_ me

z I I ý a potr?'Ir.

.?-!Aer

tv a

allatin

ion of the eat

exchanger networks, each of which would n--

I

ý i i

rc

a cost to purchase the ý,, aik

i

Ilom

the

filtration plant. We considered supplemental biocide it

rimrIItJ l ,.ms

I I i" in

1 1%,('

((,

Su

to addition

to

the

evaluation

ref water i

borcri

sr:ý 0:ýrd

also

-,r

n-..:i

f vc- ;

from the

issues

related to the concentrati

A ýnI r h ':data I -y

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Water Conservation

iýý,

data in the

Hanson study, we developed a simp

re, n

i

(,rut

with the actual bor

e

i

mate

3 '1132 17ouw;i

,::1r

sluice systems

to

r ecircu

( fr, )

ý

I 127.79 pprn to 42.01:

r,.,_ i,r ýI !,Iting operatirr.:

27.'79

pprn to 29,'

in

boron

concentration wo ýId occur if wastewater

I it ýr I c1

the ash

i,iandfng

systerrr

rrivel

i c J

to closed

the

boron

con-

"it-

II , II irr

,`,ill`iýi-C

;'CE`f.'It, fr;I'ij

I[CkT

I', CU

II. I'I K 'vets,

I

r,

ict:-

i

`Lai i1rr

1"ýýriý)I2

Concentration

I I,'(i

i

I I

ash sluice system to

',I

l l . ,

I

r."h

c ontrary

to

"1l boror.r ý,tiri,

tli, 1 ,)n-

1,1'

h -

: ý I:.-

recently indicat-- l i hat

1 .,_ 1 ' ;D wastewa..

[to

the. city sewer as a means

1 1T 1:a:_ýy 5 E'

T 1,ý :

largest in,

'

.\,{r,!

I

nýa?;ý,

I I

s

I s

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

B.

b:ý3,and the scope of dais study,

we agree with their basic cone

1,1,'y were based on the resuI(.,

G

_

iýh;r sludge landf il I operating permit,

tlh,, E

i;0

I

ding this ssue.

f low meter.

I ýw

zazozai

d iii dzr,

sh han

urnptiv(

'

, 'v, . i ý at the Dalllnan anal Lakeside stations are z,

l)ouph v ý,t directly,

6-S

i s

ý

1 -I-pti

included theoretical modeling and laboratory

operation.

In addition to boron, I-

al '

::Sný 1 ý';\trtRUF t ýt ý'. ýF ý F ý [ x,T-UOS 1:34t".F eGRS

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

,T: t Lxxrrcay-

A pril 23, 2003

r

rvatiou Study

Revisi

either be implemented

or ev,Ai;tted in furthcr dl.

ý

A ->i `benefit analysis

for the various

alternatives considered

is beyond the scope of this study.

The r,: fore, we cannot

provide

recommendations v.rith regard

to s7r:.°cific alternatives, which

should

i- r lo,.ses or the ccr -is for implement

w_ý c

will need 1..1

establish

specific

water usage constraints for Lake

Sprul.ý, k, lei and determine the

financi.

A r : x ,1;1-, ý:s which can

be allocated

for water conservation.

,yond the scope

of this study.

ý1 ?lj:ý- i;:-,, rrts in surface and groundwater standards

14ý,a9 Liner`s iuak(;ý.1

i

"s 14-t1fiS

war6=r con?crw.

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Project No. 11319-005

Dallman

&

Lakeside Station

Water Conservation Study

Appendix A -

Appendix B -

Appendix C -

Appendix

D -

Appendix E -

Appendix F

Appendix G

W ndy

ý. .

A PPENDICES

Cost

Estimates

CWLP

Water Metering Points

Effluent

Data

Sugar Creek Plant 2001 Flow Data

Demineralized Water Consumption

Ash Handling

Water

Study Draft Report

FGD Water Flow

A-1

April 23, 2004

Revision 2

:+snlIWdatal'.c.lp,11319-005

water conservation study'sl reports\sl-008254 rldoc

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

ell Engineering

Co.

Letter

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

May 18, 2007

Mr. Douglas Brown

City

Water Light & Power

3 100 Stevenson Drive

Springfield,

IL 62703

City Water Light

& Power

Wastewater Treatment Facility

Burns & McDonnell Project

39600

Wastewater

Treatment Equipment (ENVIR)

Electrocoagulation

Dear

Mr. Brown:

This

letter was prepared to assist in

City Water Light & Power's

(CWLP) efforts to evaluate

boron removal using electrocoagulation

(EC).

Introduction

The Illinois Environmental Protection

Agency (IEPA) has

requested that CWLP evaluate

pre-treating the Flue

Gas Desulphurization (FGD)

scrubber blowdown wastewater

from

Dallman

31, 32 and 33 generating

facilities using electrocoagulation

(EC), prior to

discharge.

Boron

in FGD scrubber blowdown is derived

from naturally occurring

compounds found in

coal. The boron is carried in

the flue gas after combustion

and is ultimately dissolved

in the

FGD wastewater.

Boron removal

by electrocoagulation from FGD wastewaters

has not been verified

by the

EPA. Verification

studies by the EPA

and the Department of Energy (DOE)

have focused

on

contamination in

such waters as drinking water

and radionuclides in wastewater.

Contamination

removal efficiencies

(CRE) calculated in these studies

indicate that boron

removal by EC ranges

from 3% - 71 %. Research papers

on EC also indicate that

EC can

remove boron

from solution depending on its

form or speciation. The range

of boron CRE is

explained by studies indicating

that EC works by creating

stable precipitates from

contaminants

in waters based on the oxide/hydroxide

activation energies.

EPA-DOE results

also indicate that EC is unreliable

for inorganic contaminants

that do not

form

precipitates or do not absorb

to solids. Certain forms of boron

are among these

contaminants.

9 400 Ward Parkway

Kansas

City, lrirssouri 64114-3319

Tel: 816 33.3-9400

Fax:

816 333-3690

vArrv.barnsmcd.com

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Mr. Douglas

Brown

Electrocoa

Pale 2

Electro<;-nýýul.Ltion is

a method of treati

ists of metallic, electrode pla ic,,

Plates to

cause contaminants in wastewater to

became destabilized a

The l;

W ,3: ý,:,t i

in the annular space conducts

electsi_

i

dissolved wci.il il ins react

with contaminants crew

filtration.

T

sacrificial metal

lar s pýi

r(-?-

f

r ecipitates

that are remo\,.

, l by

n

w[ ,1l plates (,;n be made from

several materials, aluminum

r, pi .c._ý:ntin

ii a1ci i,.l in

boi,ii r,movaL

I Ii!1ý,

Id hydroxides

that preC

i4;i'; ýi , ,

!id:

or

±,-)r an aluminum

electrodc:

al boron base rear

Where:

--

l-l

,

11

-= Electron

-= Water

= Flvdl,,,,,. II

, lui1jiituln

llyd;,

-1- > l 1

Ion

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Mr.

Douglas

Brown

c oagulation

Aluminum borohydrate

Contaminant reduction occurs via

two ýncrh:+ni=;m;: flocculationfprccil,ii:itioii

and

itarriiii;nif ,

electrostatically

adhcrý, to the flocculated

>n on alum

b e no greater

!h ,ii

'U"/o of avaihd,l,ý, boron when

ads;,i

ption

other contaminants

such as chl, rides and sul1:1i,. :,..

both of whiA (ý..i .i i11

I

- -1 11

flocculation/precipitation.

:

+1C r 1

f,,rms

are boric acid

1,": low d (100% b

' (100% borate) 1. 1-3

s p"ý-,.i,, in v,; ic. r.

The predom

Boric acid p

wdoii+ina(,,

,

at

pll vin;:

prcdorniw;.tc

ýýi pill

r

emove by roost avail:,N,

ýý ý l

GD blowdown

;ýý,

I

,iý.

pt

-I

dependent

id),r,N!i :r,:,- 1,;rate

id is a forii; that

,;i

,1

_'\,:;ter

in the

50%-- 65% u1 boron

\%ill

(,c

10ý'-ý''t

,

ti ion

I

from other FGD (lowdown

w.ýste rr iý.: i cony

a tically lows. ; l :oron

rcmoval_ '; ,. ' i ; ;, '

i,-,ii

cnergy

I

'111-.

lo,-

-l.

th,. :,ýAivation

enem..

(he

h,

+iiý .ýl ; l,

I!--h

as chlorides an"l n ll;fi

ý l[lant

ý ;

ý

ru-tý,i,

lli

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

I'Io,t

rocoa

b oron.

boron.

n,

t-ý.

onauctor

not e,I:,Ily (, -. id ized to a c?; npoun

ith these

other chemical

c lý:,iý,ý_

raid t hus wiII n est

r ;;ic(

,with t he

al

urI inum

ions readily as anions such as

chlorides

I I.ates.

,t1 id is c,Itr,

i.k re

(

,ýý',

f1,ý1

(ýtrr11

n

-..

11-_

11

in

t h.- I-

;

r ecipit

gyred

alu1ninum

borate and

other

I h ý ,

l

r,i-ý'niI

t d ).A

s

olid. <

reated is 49,000lbs/day

:,f

4`'

,; Is

c ontent t,c a 11(o, r;ii,. i,!'

N

_II-,ni. I ,uclt:tted

sbi_1, .foes not include

pr,. ý-.

ihit:,u-ýýt1

1, :1,.- tions

with

other con,,(itucr!t-, itt

!-.

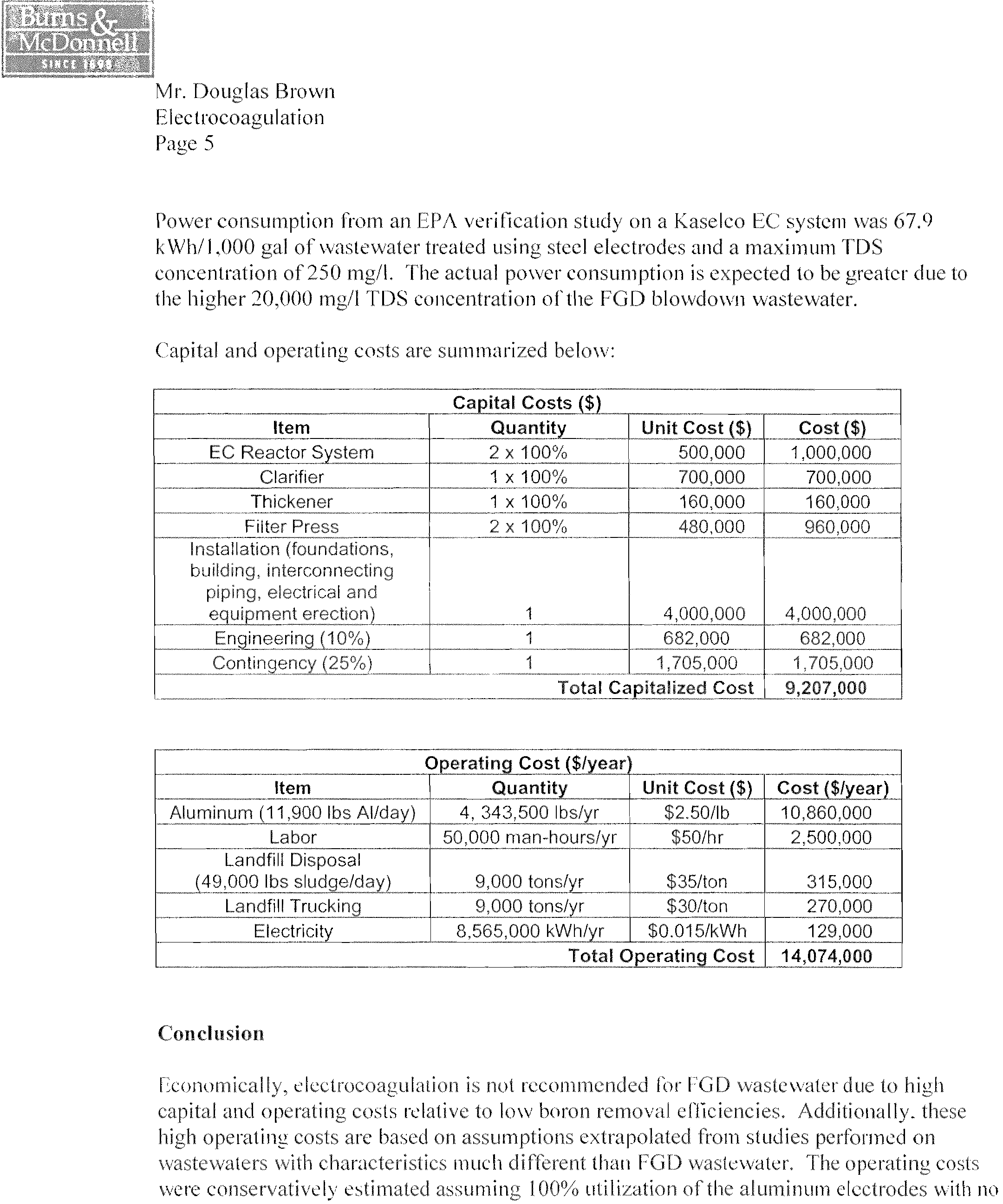

C

ost

E

stimate

,;,t,`,.

,~tssaciated with the

Dalltrtan cAt-truct

I (:itt.',

l

i{!(1111 d

oes not have a s trong toni c

e r Systems. Inc.

its 10 ft x 1.5 ft x I l<`; i n,. 1, i 11g(_ k.

poun.1

hasis

for

alumitti!n)

-

this equates to 26.5 lbs per slot, or

5,'750 Ibs total. V.'ith an

irr!:tcoilt.ur,,I

-Itio!ý ýIT:ý1,.:,ut 1 1,900 Ibs

Al/day, there, would U,, !r!,cwe than

two coUtpl

II 1-Y 1.-

100% Utilization, res,!?i!ýý

!.'l!-

int

. ,ý-wi

1. K. Quid art 1

f

o

t :J t`!Ainum

electrodes in,

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

El cctrocoaguIation

r option from an 1 F ý, wriliý :,ti.Fn

study on a Kaselco FC:' systern w,

k Wh/1,000)

!.,al

of wastewatcr trc,rilcd

stcel electrodes and

a maximurn IDS

concentration of 250 m /l.

'11)c,

.wwli I I}ov=.-cr

consurnption is expected to he

the h igher 2 0,0}00 mg/ l

T DS conccntr:ý.fiýýn o f the FGD blowdown w

astý:itCI- .

0 p'),

,' ! : 1

. C1n',

( . C? S ýS

i< nti!y

)[;ii

i ,ius,

F;con, , f

ul-,i[ :ýI ý]

h i"1

O n itýCost

? .50/Ib

/hr

111CI

ilw-tl

c il

ia

i, ilý i C

-D I 4i,1

(I I' .I, )hi,

u ra il l i'

4 , 34:_':,00 Ibs/yr

.

50,000 miA;ours/yr

u Inti

___

f ý()()

tens/Y-ý.___

u '^000 kWh/yr

i

I

d

i l

i,,

w

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

l Icctrocoa

ulation

h og

ý-,,

rcntov.i' cffccicnc

incttlio consurn

T DB v

,

,

;1

\l ;!Iý.,

: ! -;t cwatcr,

criliý_c-i boron

:1L

cffici

to b e d r!!r,ý (iý:,,T' dcýiC;!`-ý'ý-l

from thci,i,,-JC;iI

d41e tO cornpe

1 .'

ý

ie

ctroco;l','tiL;l

l

IoiT p roce` s,

l f'you have an,, questions

on the above, please

c c:

E`.! trc

, i.

G, co

I

iandling,

associated

w

cl,!rica

i ncy canna

n hiý_I, I),(ý,;,Ji

and

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

ATTACHMENT

E

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

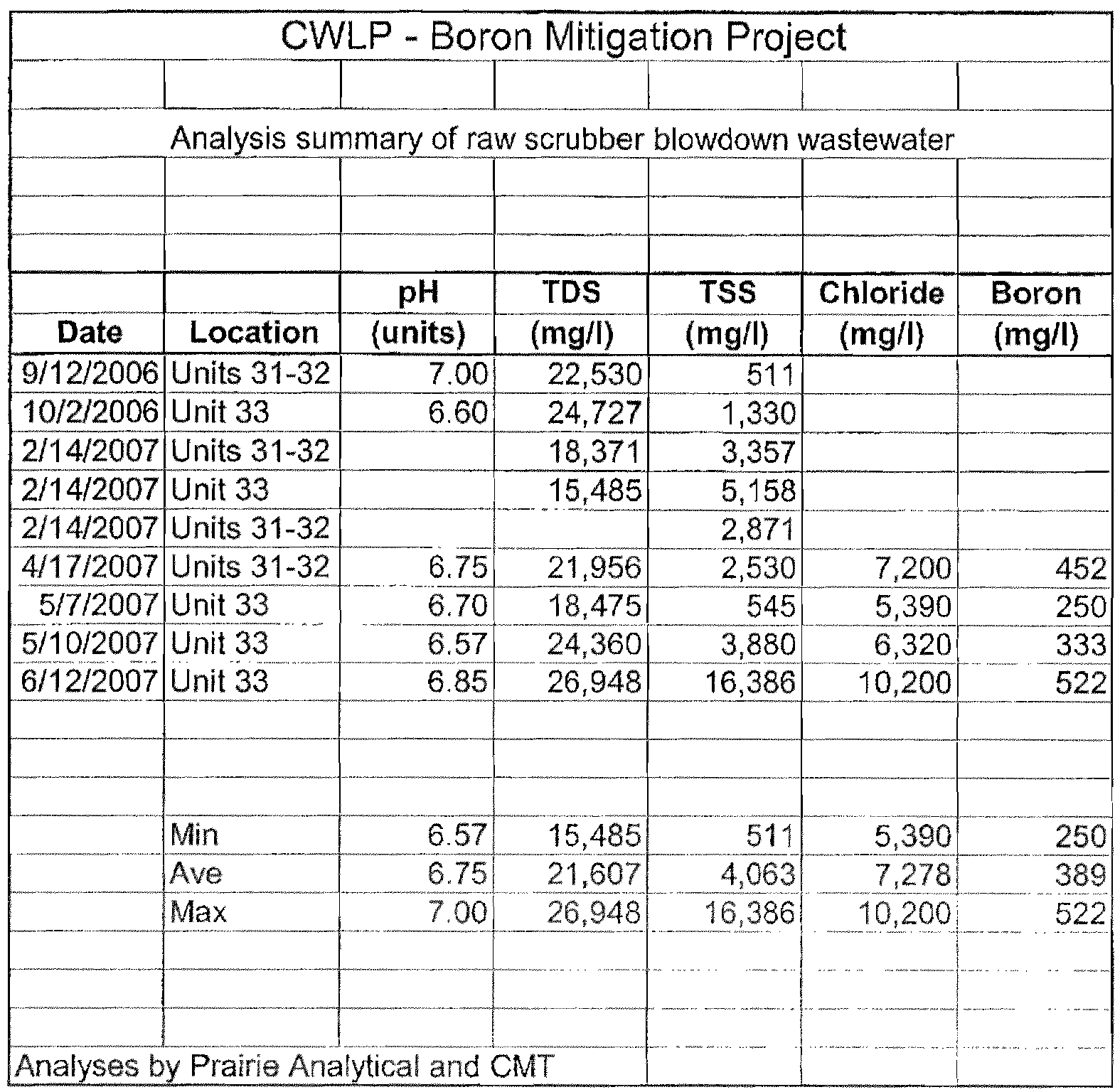

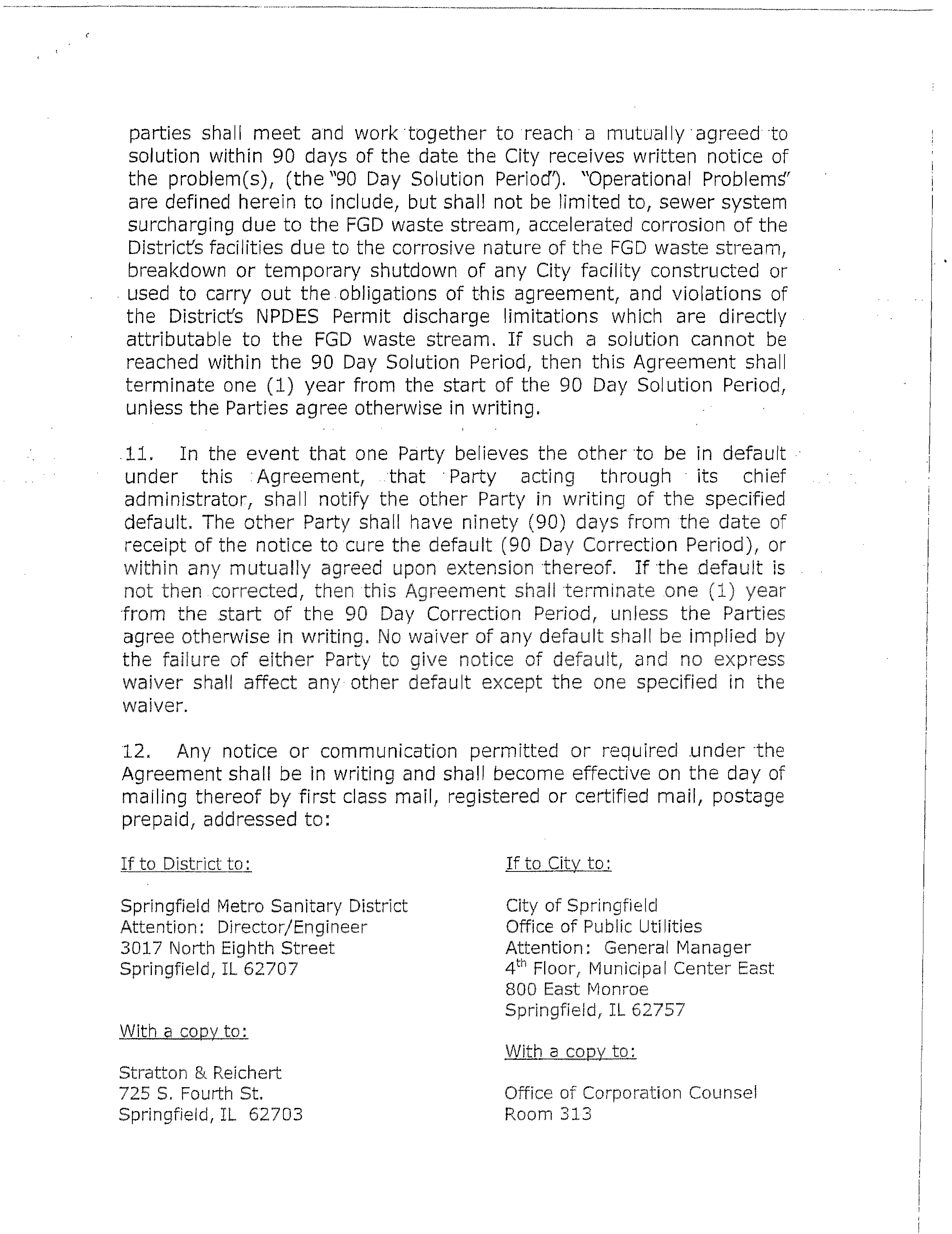

CWLP - Boron

Mitigation Project

A nalysis summa of raw scrubber

blowdown wastewater

pH

TDS

TSS Chloride

Boron

Date Location

(units)

(mg/1)

(mgll) (mg/1) (mg/1)

911212006 Units 31-32

7.00 22,530

511

101212006 Unit 33

6.60 24,727

1,330

211412007

Units 31-32

18,371

3,357

211412007 Unit 33

15,485

5 ,485

5,158

211412007

Units 31-32

-

_

---- _

2,871

4/17/2007 Units 31-32

6.75

_

21,956

2,530

7,200

452

5/7_/2007 Unit 33

6.70

18,475

_

545

5,390

250

_5/1_0/2007

...,

Unit 33

.

-

6.57

24,360

3,880

6,320

333

6/1212007

Unit 33

6.85

26,948 16,386

_

10,200

522

Min

6.57

15,485

511

5,390

250

Ave

6.75 21,607

4,063

7,278

_

3 89

Max

7.00

26,948 16,386

10,200'

__ _

522

,Analyses by Prairie Ana lytical

and CMT

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

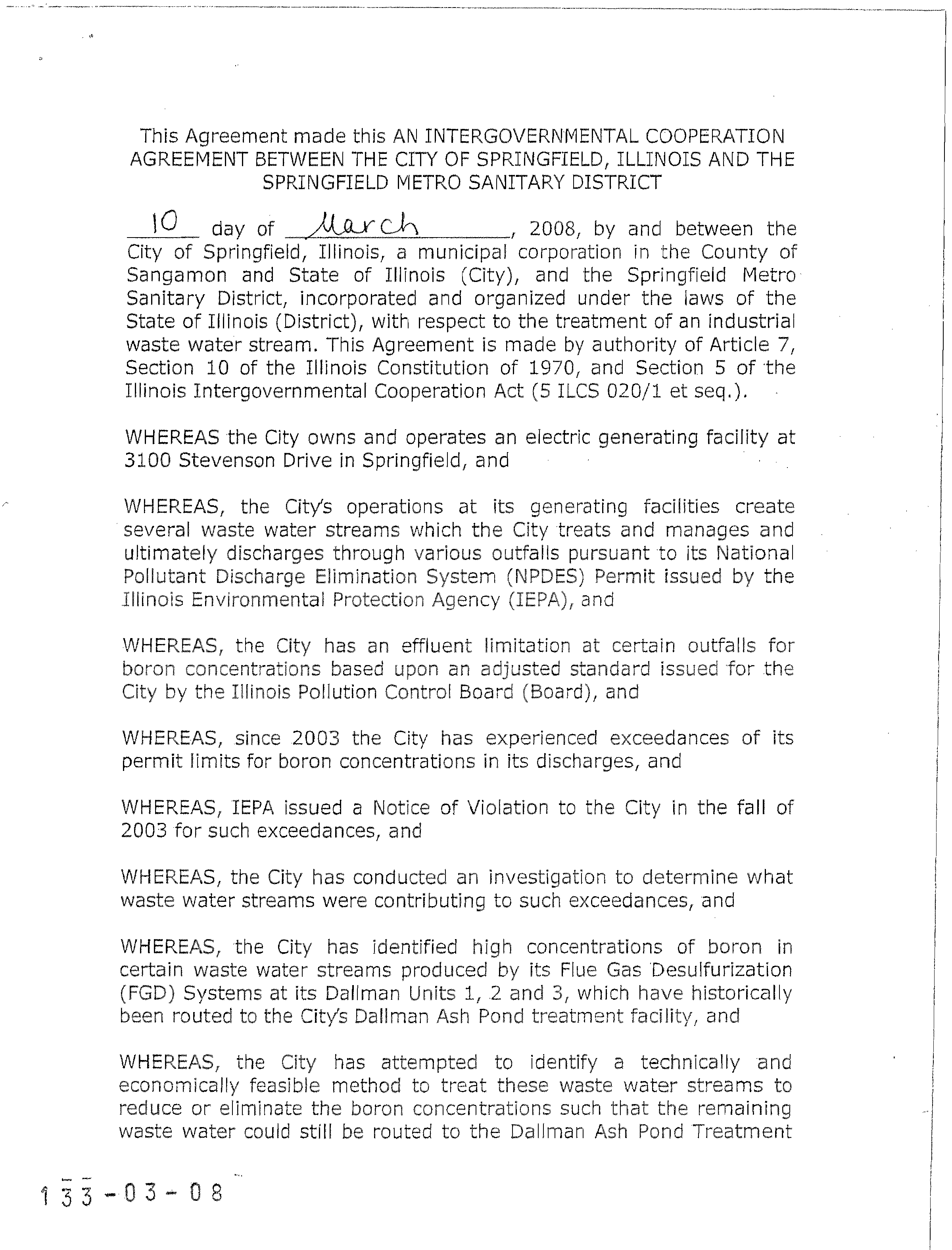

CW .P

Foron ýý'ilic;aflc?1i Project

J ar tests with polymer and/or lime

---

4

Date

° I Y1

A nalyses b Prairie Analytical

pH" Arsenic Barium Boron

c

admium C " romium Iron

Lead Manganese

Mercury

Selenium

Zinc

(

units)

(

ppm)

{Ppm)

pphi

.j

h

r)

_-

{ppb}

_

(ppb)

(

ppb)

{pPb}

{ppbj

ppb)

;

Raw

7; j

<0

5

Raw

settled

6.7t}

t'ý1

0 4 3

1

=

; -

3,440

4,870

1

A3ýi

1 9.6'

4,910

5,980

21.20

37.201

551

j

541

<100ý

<100ý

Jar 1

1

7.31

<0 0,51

a

9

-

<

-

<1,000ý

<2

4,340

8.12 ?

524

<100

Jar 2

e

7.571

.

<0.0 0 .379

;

-

< .

-,

.

<1,000 ,

<21

4,010

7.90 1

546

<100'ý

Jar3

?-

7.78!

<0.05E

0

10

_

-, <1,000 i

<2E

3,780'

_

6.59

556

<100i

Jar 4

;

7.94

<U5ý

0 91_

_

< <

Cý'

--

<11,000ý

<

4,130

8.16

-

1

527

<1001

J ar 5

807

< 0.05i

0.367;

<

101

.

rt _-`

<1,000 1

<21

3,850-

6.78 1

418

<10C )l

;,' r6

*

7.62``

<0,05 i

<1,000

< 2!

'

4,300

2.77E

426s

<100

Reduction from raw to settled 1

[ -16,7010

1

r;. ?

0 ( -41.60/6 -50ý5%1

-21.8% -75.5°14

8

Reduction from raw to Jar 1

3

I

-5.1010

- ^

__ -` 7 0.9010

r 3 .ý?3

1

1.6%

61.7010;

4.9°141

Reduction from raw to jar 2 3

-2.2°10 1 2:'

_

70.00,0 ! 6&c-

18.3°/a ý 62,5% 1

0.9°14ý

Reduction

from raw to

Jar

3

5.9%n

;

3 I 7 0.9:: 68,9°

23.0°/aý

68.9°10

-0.9°10'

Reduction from raw to Jar 4

-5:

- '

13.. 4

1

-

_

6

8.9°101

1 5.9010

6 1.5%

4.4%

Reduction from ra w

to

Jar 5 i

1 '

_

_

_

7)

=

21.60101 68.0%

24-1010

Reduction from

raw

to

Jar

6 !

-

1

3

6 8.9-/.l

12.4010

86,9010

22.7°10'

1

Chloride

Sulfate Fluoride

Citrate ( Ammonia

{Ppm}

{Ppm} {ppm

{Ppm}

{Ppm)

_

i

j

Raw

Rata settled

i

i

5 ,390'

1,370;

1121

_

0.2091

Jar

11

i

5,250

_

_

1,520

1101

0.220r

,

Jar 2

5,480.

1,120

:

<0

t-'

Jar 3

#

5,4513.

1,190

- -

11L,

02291

Jar 4

1 5.450'

1 ,180 -_ý -

-

1 ;

ý-

ý

_

J ar 5

I

5,53C'

1,18 0

--

11='

0.259!

!

Jar 6**

5.5

r-

1,184_

< Fý

1 1ý

,'"` Combined sludge from jars 1-5.

r

!

1

ý

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

H

1

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

This Agreement made this AN

INTERGOVERNMENTAL COOPERATION

AGREEMENT BETWEEN THE CITY OF

SPRINGFIELD, ILLINOIS AND THE

I()

d ay of

C

City

of Springfield,

Illinois, a municipal

c orpo ration in the County of

Sanga mon a nd State of Illinois (Ci t y ), a

nd the Springfield Metro

Sanitary

District, incorporated and organized

under the laws of the

State of

Illinois (District), with respect to the

treatment of an industrial

is Agreement is made by authority

of Article

7,

Section LQ of

the Illinois Constitution of 1970, and

Section 5 of the

31DO Stevenson Drive

g field, and

nd

operates an electric generating

facility at

f acilities

create

e liminate the baron concentrations

suc

w aste water could still be routed to

the Dallman Ash Pond

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Facility with that discharge

again meeting

the

perm

c oncentration limitations,

without success

S , the City has approached

the District

regarding a proposal

ste

water streams

to the District for

WHEREAS, the City proposed

such

a

cility, and

a chieve compliance

with the

exceedances for

which

tion

t

he District

g iven an

effluent limitation for

concentration of boron

in its

discharge based upon

the Board's general

water quality standard

for

boron

and the data

further suggested

the

District's discharge

would not

ly meet

this proposed effluent limitation,

and

REAS,

the

District is willing to

accept the Citys F D waste

water

streams in accordance

with the following

terms and conditions

of its

Agreement,

WS:

1.

The C ity w ill install

at i

o posal

to

IEPA to direct

es necessary

to

deliver

t he

FGD waste water stream

from its

facili

above des

facility to the

District

the District

has a

k

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

The City wo u ld be r esp o nsib

le for securing a ll n ecessary

n d easements to

construct and operate a farce

locati

2.

The City at

its cost will install and operate

a pretreatment

at its generation

facility for the purpose

of reducing solids,

3.

ste stream

before the same

for

the purpose

e manate after

.the Ci tys was

4 . The Cir_v

at its cost

ubsequent relining of

shall be

forms

a .

b.

L ift

Stations

Schedule F,

if ne

e .

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

professi

p roceeding

before the Board.

of this agreement,

the

a t its

sole discretion declare

this Agreement

t he site

specific standard

I

ischarge from its Spring

Creek Plant at the City's

cost and

w ith the City being responsible

for se

i reLamirly

dii r tL4ulý,ILt

ed by

the

City for such proce

site specific standard

The

District shall cooperate

with the agents, attorneys

and

ity and

the District n

otherwise

be performed.

9,

terminate this

Agreement. Either

party

may also

choose to ten

this agreement

for convenience

by

providing n

a

forty-eight (48)

month notice of the

the District

as provided herein;

and (2) such problems

are directly

related to and

caused

b

a nd exclusive of

normal wear and

the City an

istrict shall

notify the Ci

ritten

notification by

the

City

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

parties shall meet and work together to

reach

a mutually, agreed -to

solution within 90 days of the date the City

receives written

n

the problem(s), (the "90 Day Solution

PeriodD. "Operational

Problems'

are

defined herein

to include, but shall not be limited to,

sewer

system

surcharging

due to the FGD waste stream, accelerated

corrosion of the

Districts

facilities due to the corrosive nature of the FGD

waste stream,

own of any City facility constructed or

D

ay

Solution

Period, then this Agreement shall

r from the start of

the 90 Day Solution Period,

in

writi

11.

under

this

a

dmin

a nd violations of

ieh are directly

default.

The other

Partv shall have

n

r are

the defa..lt

A ny

Agreement s

mailing thereof by

i1,

registered or certif

ýf to City to:

i liti

G eneral

Manager

icipal Center

nroe

Stratton

Reichert

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Municipal Center East

800 East Monroe

1 5.

S pringfi

n the successors and ass

bodies,

a mended

except by means of

15.

igned by authorized

t shall

be deemed dated and beco

he Parties signs i

it

duly authorized representatives.

Date:

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

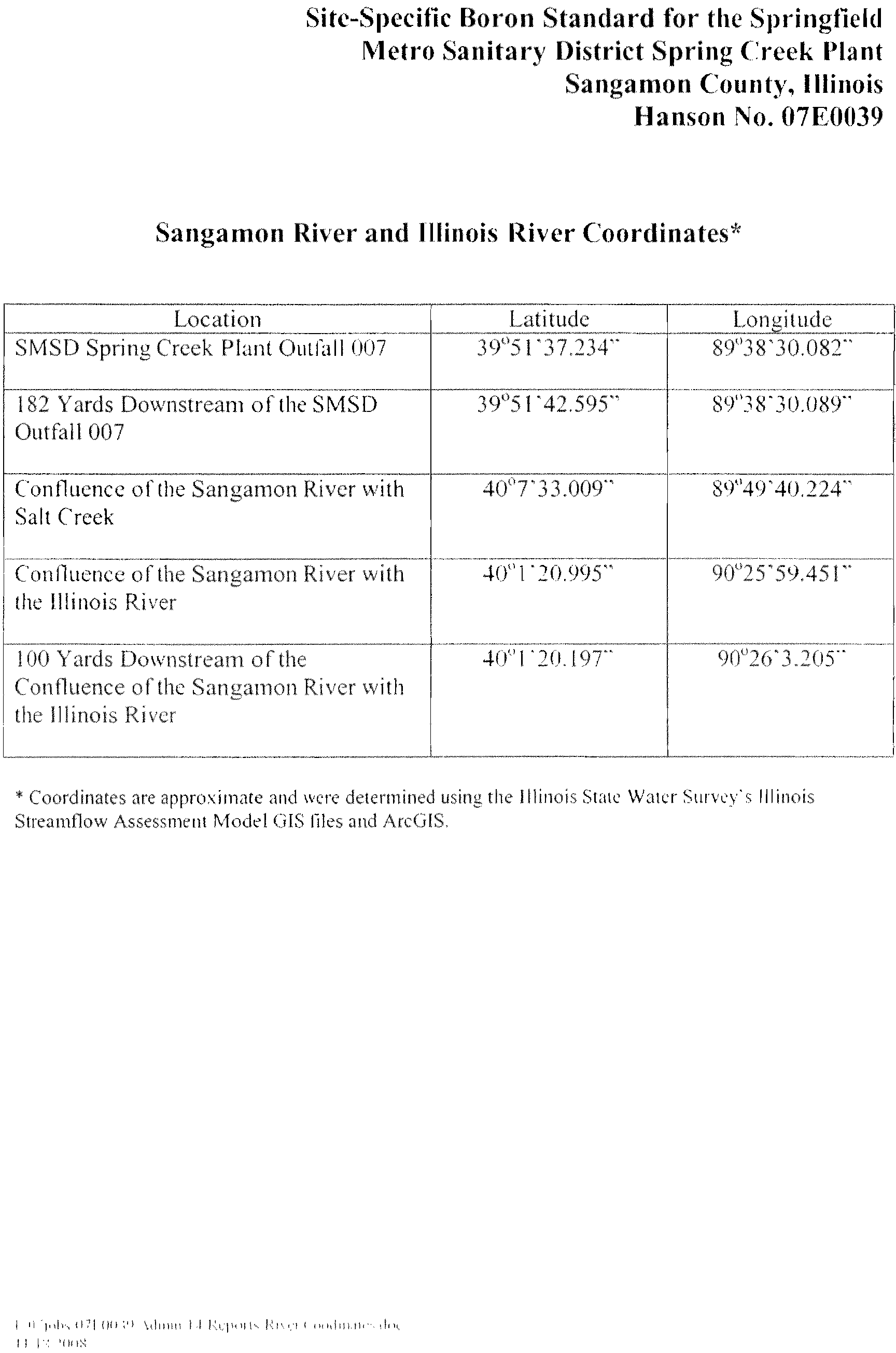

BORON

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

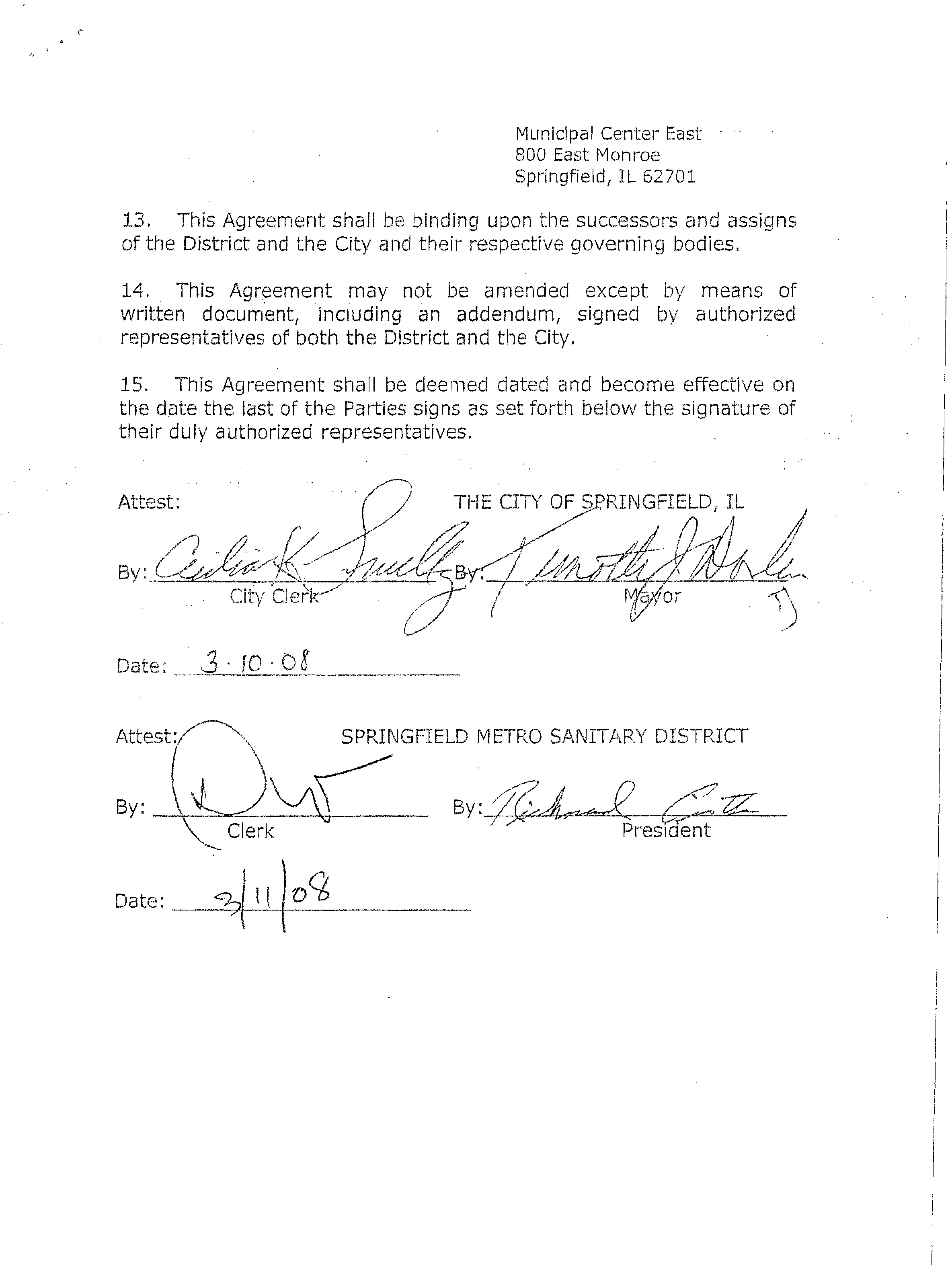

TIONS 'I'

---

Cast

ýý

----------____..

--- -

---.

_.

--

-

-.

Tre;rtnrr ?t Technology

Present Value

Capital

Cast

ChM Cost

Reason Far Not Implementing

Discussion

ýý)

(ý}

(S}

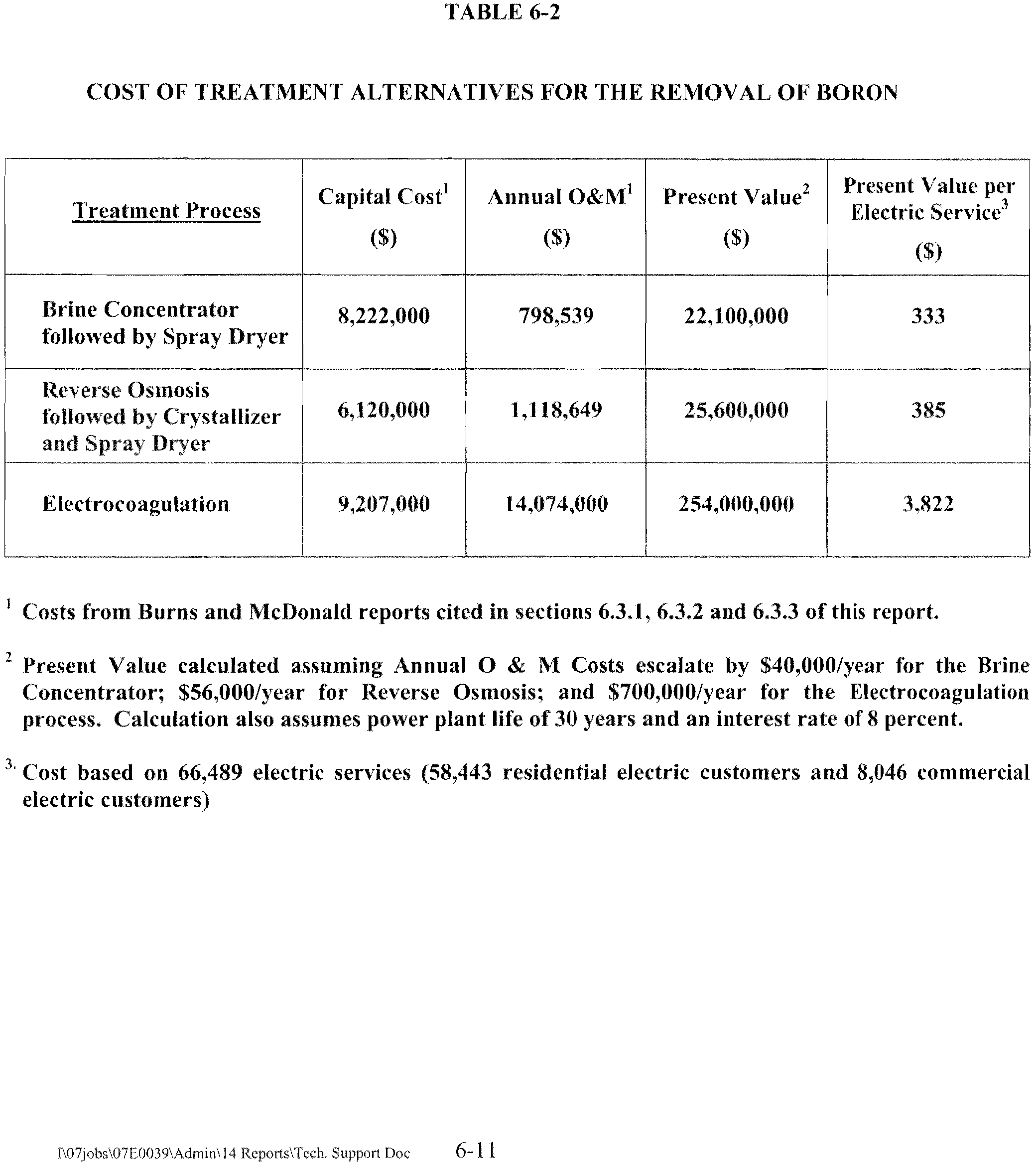

CWLP entered a contract with Aquatech lit, l -I uti,,aal Corporation to provide a Zero Liquid Discharge

Brine

Brine Concentrator

"r echnology was attempted. See

Concentrator/Spray Dryer System in Decemb,.

r

2005. See the discussion below

for the results of this pilot plant

followed by Spray Dryer

$22,100'000

$8,222,000

$798,539

discussion in cluded

i

tr

"

plat plant" "

test. Casts cited are for comparatr e

,ee

e'

purposes only and l1o

. not

include

site pi, ,

ý; r

tion

(

s ite grading, p roviding

v

below.

utilities, etc.) or disposal of wastes generated by the hroc, Ss. Present Value asslrrues Annual O&M

Costs escalate

by $40,000/year; calculation also assumes power plant

IIic

of 30 years and

an interest rate of 8 percent.

Reverse Osmosis technology is currently not considered

to be a viable technology for this application and is no

1'

. r., Osmosis followed

Not

selected for pilot plant test based Oil

1

1

longer marketed

by

the \, lulor to remove high concentrations o 'boron in liquid waste streams. Costs

cited are

I,Y t r-

si;:rlfzer

and Spray

$25,600,000

$6>12O,UU(

)

$1,118,649

cost and operational issues with high

_

for comparaU ý

ýýe

e'

L,urpc r t,_ oý, ly and do

7

not include site prep,-,

r,rti, u l (.,ite

grading,

ý

providing utilities etc.) or

D1'

C C}nCeniratlons of still . and Suspended

disposal of wastes g, uw,;

I fly

the process.

Present

Value uý :[I,uu:ý Animal 0&M Costs

escý,i;lt` by

solids in the waste

$56,000/year; calculatic <! , ,.sumcs power plant life of 30

a,°,irs

and ;

n interest rate of 81,,1, ,111.

`targeting boron ia FCiDS v, , I ,r

r, ,11,

1 sj

,-i1

I,Jl_

for removal by LC is (I I' t1ý,1 t bc,_a [° L.uron is known to exist

in

at

least

six

ptl

dependent p, I; s in

I'-r.

l 11t ,rally, competing r,,reti,i,s from

her FGDS wastewater

constituents was expected to d,;

oratically

lower boron removal,

It was c(included drat boron removal efficiency

l

Nat selected for pilot plant test based on

,

could not be

predicted

drr, to lack of

verified

boron removal ,. l I,. I,. ilcies

ill

k

_Ir l,,nron

an, high TDS

waters.

An

I

Elect roeaagrrlation (EC)

$254,000,000

$9,207ý000

$14,074,000

high cost relative to low boron removal

ry ,

or) - ý;.

II1 1l :

b i

,

p,

rformed will,. u o,c

iii

m;arating

the Inovai

cýf 1 ,;ý-I. Costs cited are for

efficiencies.

cqul, and do

not in, luý k_ i, tar ,. °. u, (,ite Rrading_ providiw, utrl l,

i,_,

ctc.) ordisposal

I

I

t!.,

process. Pi.1

0,1M Costs esr;l,[c by,io700,000/year;

I -)wen pi

l

,

ý ý

11

till, O S

" Pilo

In

rine

i

,.$,1 04,x())f ,

t

) (1( i

J 0 ),c0)J

t f

$ 3,-/ 1) ':

,

I

.

ý,ý

dr

I1,

L

II

r

l

l

c''

Spray L)r.

`

,

m

I

i

ý

! t l

,

i

I

,

I

,,

l -

?

, ý

I

I

I. I, -1

5,0('`,/ý

i.nl-1ý r

's;,

zý

I

of ;Illinois coal.

Studies showed that continued use of Illinois coal was the lowe,l

,,;ost long term solution; resulted in I..?iIari, bene

and

the State of Illinois, tool: advrntlae of CWLP's experiencý° cpý_I iting and maintaining FCiDS sy

^tF,III ., x.,11 rrs avc

equipr,', art and railw¬ry modifi,-ýati,

i .

and concerns about Iran/11`-ý.

plosive

dust. Sce

section-6.1 rm

I

e, 1

I,r,.,nrrh

f

Con,,,-

1-ii to a dry ash s,tsi, m I, been studied by CWLP h

c:v,cr,

the particular

vast- !r,_ urn tlr'i is t1 -dj,__t of this

si andard.

crael,

ý,

d by fire air Pollution control egi,,ja,l,:nt

and would not be ehmin,,[, d by rnodifyin4 the plant as

Vi-It

include dry fly ash and b0i-m ash handling systems.

Alternative Operational

Modification

---.-.._°-ý

Present

Value

($

Cast

°--

Capital Cost

(ý

-------_..._

CI&M Cost

Reason Far Implementing

Discussion

--..._-_ --__ ------ --

--

-------

-_-------

SMISD 1

_l into a contract with CWLP

to accept the FGDS wastewater stream for ; price of $100,000/%l

,nth

provided tli,:

ceptano

4

the wastewater clot . rot upset normal Spring Creek

Plant ,. , --uc. rs. CWLP iii; l

treat the FCiDS wasi,-

'II,

,with conventio, -il 11, ltnrent process

for

soli,i ; r,

n-

rval prior 1, L,[IiniýinAr thewasi, ,.:r1 r

P retreatment/l)lsclý, i

n

t rnent

and

Discharge

to the

ý,

.

,

ý'

,

,

, .

.

°

.

,

_

to

ill; ,ýhlcOSllrrlý

?,

,

,?m.

,,

CtyLtrs.

1

l

?

l

r, ,1,>ýý,ýý

_Irrlgacbeini f

'I,,

c o rrtr,rl?,I

?f ý.ýS

M5

,

D

I, Izt.

S MSI)

$.16,100,000

$15,500,000

$1,600,000

ý,

,: ''1 SD Spring Creek Plant is proposed

.

cF.

,

ýI?ýý

.;,

,di

drc

i,t

.ystcm ý'III.

,

?I"

;

,r-13

through 6 , a

Tbý c.t?i,?

,

for inr,lalecrrentati°n.

.

ý,Lt,;I

r?tý:uý

ntreatedFCiDSý[_,r:''Irdcheni ,II,'- sa

Iý,,_(-)tocontrol

o,?ýriý the ,SNISI)`,"r

Cr, ý k

I I ,'r .I

i,

It Value assun, a

l

1

,

.1

Il,, lrilily

p ayment to SMSD, with other operatir-

r'jj,I maintenance cc-Is

esc, 1

:, by $'1.0,000 l- y IT,,

.

pi, !,; I,_, ur ý.ystern

life of 30 years.and

an

interest rate of

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

ATTAC

is

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

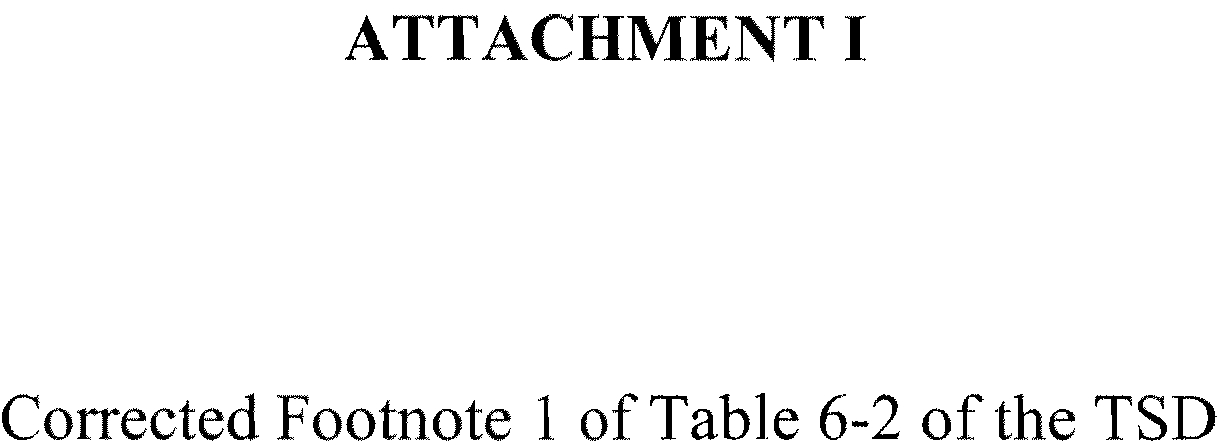

Site-Specific Boron Standard for the

Metro

Creek

Sangamon River and

Illinois

7

C

ýrýý4titrlt

ins:Ovc:k k'lWlt

Outfall

007

ards

L7owt!

,

u ý..rm

,

* Coordin

St eanlflow

,t> ,_ .

raent

M-1, ( r r1;, h1 ýs

and Fire

ii

U '1.+hý, rf:'1 (In

;'w

lJuuii i.4 6:ý;1}ýnp.. Idi,.cr

c

ý,?,lirr.rrý-_

( 1 I'ý 'ItrrC;

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

Corrected Footnote 1

of

Table

6-2 of the TSD

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *

TABLE 6-2

,3 of this report.

Concentrator; $56

alculat

by $40,000!

for the

Electrocoagulation

ial electric customers

and 8,046 commercial

1\07joN II

f

ii(i

ýAJýnin\l4 Reports\Tcch. Support Doe

Electronic Filing - Received, Clerk's Office, November 21, 2008

* * * * * PC #1 * * * * *