BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

IN THE MATTER OF:

NITROGEN OXIDES EMISSIONS FROM

VARIOUS SOURCE CATEGORIES:

AMENDMENTS TO 35 ILL. ADM. CODE

PARTS

211 AND 217

)

)

)

)

)

)

R08-19

(Rulemaking - Air)

NOTICE

TO:

John Therriault

Assistant Clerk

Illinois Pollution Control Board

James

R.

Thompson Center

100 West Randolph St., Suite 11-500

Chicago,IL 60601

SEE ATTACHED SERVICE LIST

PLEASE TAKE NOTICE that I have today filed with the Office

ofthe Clerk ofthe

Illinois Pollution Control Board the ILLINOIS ENVIRONMENTAL PROTECTION

AGENCY'S ANSWERS TO MIDWEST GENERATION'S QUESTIONS

FOR AGENCY

WITNESSES, a copy

of which is herewith served upon you.

ILLINOIS ENVIRONMENTAL

PROTECTION AGENCY

BY:~~

G

~occaforte

Assistant Counsel

Division

of Legal Counsel

DATED: September 30, 2008

1021 North Grand Avenue East

P.

O. Box 19276

Springfield,

IL 62794-9276

217/782-5544

TillS FILING IS SUBMITTEO

ON RECYCLED PAPER

???????????

??????? ?? ??????????

???????? ???????? ??????????

???? ????

BEFORE THE ILLINOIS POLLUTION CONTROL BOARD

IN THE MATTER OF:

NITROGEN OXIDES EMISSIONS FROM

VARIOUS SOURCE CATEGORIES:

AMENDMENTS TO

35 ILL. ADM. CODE

PARTS 211 AND 217

)

)

)

)

)

)

R08-19

(Rulemaking - Air)

THE ILLINOIS ENVIRONMENTAL PROTECTION AGENCY'S ANSWERS TO

MIDWEST GENERATION'S QUESTIONS FOR AGENCY WITNESSES

NOW COMES the lllinois Environmental Protection Agency ("Illinois EPA"), by its

attorneys, and pursuant to the Hearing Officer'sOrder dated June 12,2008, respectfully submits

the Illinois EPA'sAnswers to Midwest Generation's Questions for Agency Witnesses:

Questions for Mr. Kaleel

1.

Please explain the relationship between these proposed rules establishing reasonably

available control technology ("RACT")/reasonably available control measures ("RACM")

for the current ozone and fine particulate matter ("PM2.5") national ambient air quality

standards ("NAAQS") and what may be required for the revised ozone and PM2.5

NAAQS.

Unless USEPA issues new guidance regarding NOx control technology, we expect

that this RACT proposal will satisfy requirements to implement NOx RACT under

the revised NAAQS for the source categories and geographic areas to which this

proposal applies. The Illinois EPA has not yet determined the emissions reduction

measures needed to attain the revised ozone and PM

2.5 NAAQS.

It

may be

necessary to implement more stringent measures, however,

if additional measures

are necessary for attainment.

2.

What distinction, in the definitions or use, between industrial boilers, fossil fuel-fired

boilers, and electric generating units ("EGUs") does the Agency make or intend in this

rule?

EGU boilers are used primarily to generate electricity to sell on the electricity grid.

Industrial boilers are used primarily to generate power (steam

or electricity) for use

at the source. Both types of boilers may use fossil fuels, coal, oil, or gas.

3.

Ifthere are no cement kilns in the nonattainrnent areas, why are cement kilns included in

this rulemaking? Likewise, ifthere are no aluminum melting furnaces affected, why does

the rule include that sector?

There is an aluminum melting furnace in the Chicago non-attainment area (NAA),

although it has not operated for several years. To the best of

our knowledge, the

emission unit has not been torn down,

so it is possible that the company, or a future

???????????

??????? ?? ??????????

???????? ???????? ??????????

???? ????

owner, will seek to operate the furnace in the future. There are no cement kilns in

the

current NAAs, although there is a cement kiln in Massac County, which USEPA

intends to designate as nonattainment for the 24-hour PM2.5 NAAQS.

The attached

letter shows USEPA's inteut regarding Massac County. See, Attachment 1.

4.

How will the limitation of a unit to only one emissions averaging plan in this rule interact

with the averaging plan provisions

of other rules? That is, is it the Agency's intent for this

rule

to preclude participation or inclusion of a unit that is in an averaging plan under this

rule from participating in averaging plans under other rules and vice versa?

It

is the Illinois EPA's intent that an emission unit be included

in

only one seasonal

and one annual averaging plan. Units affected by Subpart Q (Engine Rule) can be

included in an averaging plan with units affected by this proposal.

5.

In Section 217.150(a)(2), the regulatory language uses the word "emits." How will the

Agency determine whether a unit is subject to the rule? That is, how will the Agency

determine whether a unit emits, as opposed

to having the potential to emit, at the

threshold levels?

In general, the Illinois EPA intends to rely on Annual Emission Reports submitted

by owners/operators

of emissions sources.

6.

Applicability ofSubpart M and the nonapplicability of Subpart D are premised upon the

applicability

of the Part 225, Subparts C, D, and E ("the Illinois [Clean Air Interstate

Rule] CAIR") to electric generating units ("EGUs"). However, the federal rule

underlying the Illinois CAIR has been overturned (assuming that the D.C. Circuit Court

issues the mandate for its decision in appeal

ofthe rule), thus invalidating the Illinois

CAIR. Therefore, it appears that EGUs, which the Agency apparently intended to cover

in Subpart M

ofthis rulemaking, are covered by Subpart D. Does the Agency intend to

amend the language in Subpart M?

If

so, how?

The Illinois EPA does not agree with the Underlying premise

of this question;

however, the Illinois

EPA is amenable to amending Sections 217.340, 217.342,

211.3100,

and 217.160 as set forth in the response to Question 20, below.

7.

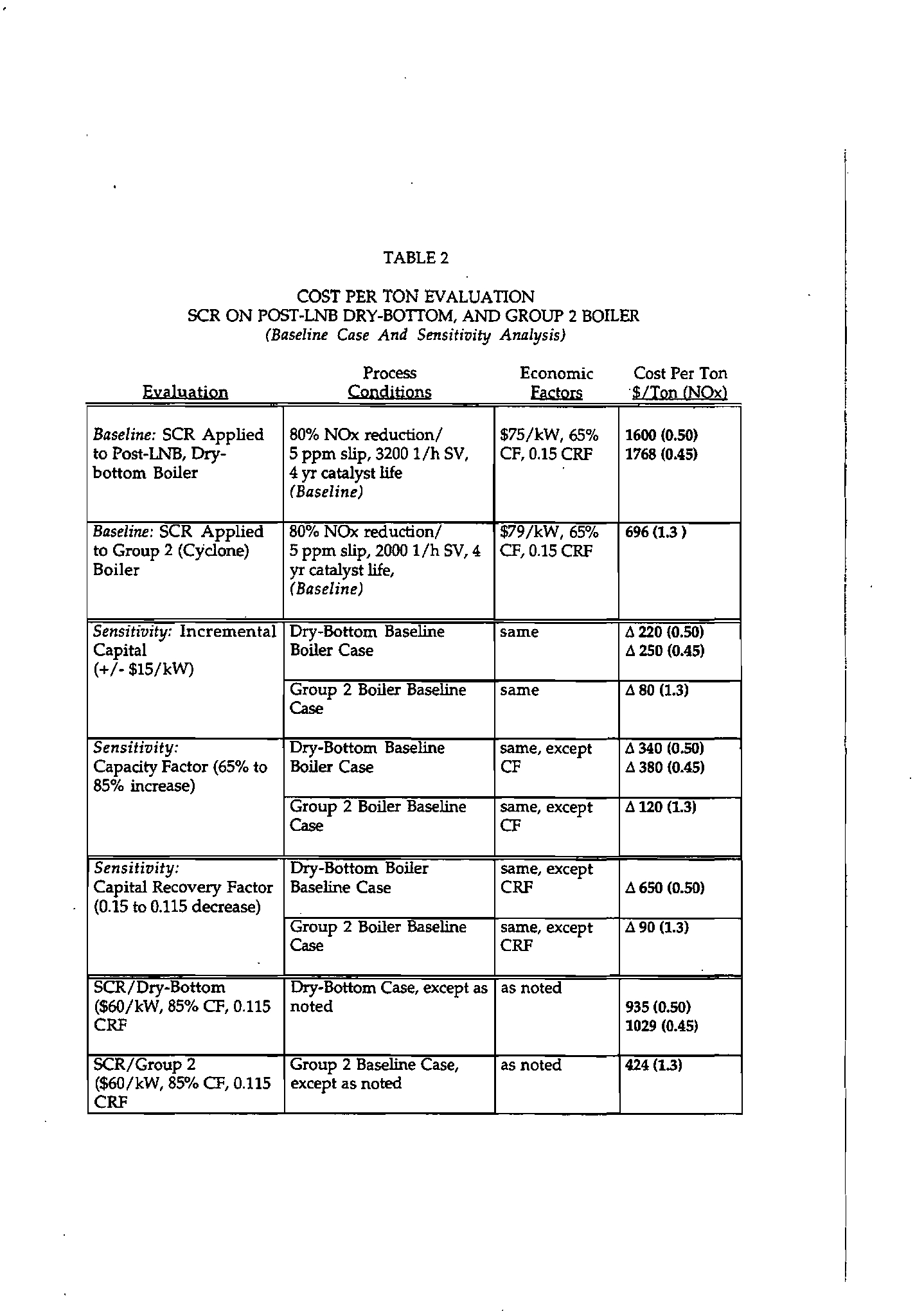

What does the Agency consider to be the nominal cost per ton for RACT for nitrogen

oxides ("NOx")?

The USEPA and the Illinois EPA have not established a specific cost threshold for

RACT, although the Illinois EPA has used $2500 to $3000

per ton as a range for cost

effectiveness.

8.

Does a load shaving unit (Section 211.3475) include a peaker power plant?

Yes.

9.

Section 217.150(a) says, "The provisions of this Subpart and Subparts D, E, F, G, H, and

M" ofthis Part apply to ... 1) All sources.... " (Emphasis added.) Is it the Agency's intent

2

???????????

??????? ?? ??????????

???????? ???????? ??????????

???? ????

that all of these subparts actually apply to all sources in the specified geographic areas?

Isn't actually the Agency's intent that only one subpart will apply

to a unit or units at

threshold sources, as determined by the characteristics

of the unit?

It

is the Illinois EPA's intent that each respective Subpart apply to sources that meet

the applicability criteria and individual emission units

at such sources that meet the

applicability criteria, i.e., the provisions

of a respective Subpart apply to the extent a

source includes emission units

of the type covered under that Subpart.

10.

The "all industrial boilers" language in Section 217.160(a) and similar language in the

other subparts could be construed

to expand the scope of Section 217.150(a)(2), which

refers to "any industrial boiler [and other types

of emission units] that emits NOx in an

amount equal

to or greater than 15 tons per year and equal to or greater than five tons per

ozone season." Is it the Agency's intent to expand the applicability

ofthe rule in this

way?

The Illinois EPA's intent is that each Subpart apply to all of the affected emission

units

at an affected source, e.g., "any" emission unit that meets the applicability

criteria.

1I.

Is it the Agency's intent that the proposed rule applies to areas designated nonattainment

for either ozone or PM2.5?

Yes.

12.

What comprises the second compliance period ifthe first is May 1, 2010, through April

30,2011, and then is subsequently on a calendar year basis?

See

Section 217.152.

January 1, 2011, through December 31, 2011.

13.

How is the second sentence of Section 217.152(b) ("The owner or operator of an

emission unit that is subject to Subpart D, E, F,

G, H, or M must operate such unit in a

manner consistent with good air pollution control practice to minimize NOx emissions."

related to the compliance date?

There is no relation.

14.

Can the recordkeeping systems that sources already have in place comprise the "Iogs"

required at Sections 217.156(b)(8) and (9), assuming all

of the information required by

the rule is included?

Yes, as long as all ofthe required information under the rule is included.

15.

What is an "applicable compliance period" referred to in Section 21 7. I56(g)?

The annual or ozone season compliance period.

3

???????????

??????? ?? ??????????

???????? ???????? ??????????

???? ????

16.

Does Section 217.156(k), which requires compliance certifications, recordkeeping, and

reporting for Subpart M units pursuant to 40 CFR Part 96, supersede the other

recordkeeping and reporting requirements

of Section 217.156?

The Illinois EPA's intent is that electric generating nnits subject to Subpart M

comply with

the compliance certifications, recordkeeping, and reporting

requirements

pursuant to 40 CFR Part 96, in conjunction with the other

recordkeeping and reporting requirements under Section 217.156, to the extent the

requirements

are not duplicative.

17.

Does the Agency have information confirming that the stacks at affected units that are

typically small can be tested safely, as required by Section 217.1517

No.

18.

Section 21 7.158(b) requires that averaging plans be submitted by May 1, 2010. What if

a source decides in 2010 that it does not want to average, but in 2015 it decides that it

does want to average?

Is that source precluded from establishing an averaging plan? Is

this a "once out/always out" provision?

Averaging plans can be amended once per year at the discretion of the

owner/operator. Units not previously included in an averaging plan can

be included

at a date later than May 1, 2010.

It

is not the Illinois EPA's intent to establish a

"once out/always

out" provision.

19.

What is the Agency's basis for establishing a rate ofO.08Ib/mmBtu rate for gas-fired

industrial boilers greater than 100 mmBtu? (Section 217.164(a))

The basis for this limit is set forth in the TSD, at page 43, specifically, Table 2-17a:

Cost Effectiveness

Data for Natural Gas-Fired ICI Boilers.

20.

Based upon the proposed applicability language in Subpart M, Section 217.340, assuming

the D.C. Circuit Court issues the mandate implementing its decision in the appeal

ofthe

CAIR, EGUs would be subject to the provisions

of Subpart D. Is the Agency amenable

to amending Sections 217.340, 217.342, 211.3100, and 217.160, as follows:

Section 217.340

Applicability [Subpart M)

Notwithstanding Subpart V or W

ofthis Part, the provisions of Subpart C of this

Part and this Subpart apply to all fussil fuel firee statienary beilers s\fbjeet te the

CAIR

1>10)(

Traeing Pregrams \fneer 81!llpart D er E efPart 225 any fossil fuel-

fired stationary boiler serving a generator that has a nameplate capacity greater

than

25 MWe and produces electricity for sale, excluding any units listed in

Appendix D

ofthis Part, located at sources subject to this Subpart pursuant to

Section 217.150

of this Part.

Section 217.342

Exemptions

4

???????????

??????? ?? ??????????

???????? ???????? ??????????

???? ????

a)

Notwithstanding Section 217.340 ofthis Subpart, the provisions ofthis

Subpart do not apply to a fossil fuel-fired stationary boiler operating under

a federally enforceable limit

of NOx emissions from such boiler to less

than

15 tons per year and less than five tons per ozone season.

b)

Notwithstanding Section 217.340

ofthis Subpart, the provisions ofthis

Subpart

do not apply to a coal-fired stationary boiler that commenced

operation before January 1,2008, that is complying with Part 225.Subpart

B through the multi-pollutant standard under Section 225.233

of Part 225

or the combined pollutant standards under Subpart F

ofPart 225.

Section 211.3100

Industrial Boiler

"Industrial boiler" means, for purposes

ofPart 217, an enclosed vessel in which

water is heated and circulated either as hot water or as steam for heating or for

power, or both. This term does not include boilers serving a generator that has a

nameplate capacity greater than

25 MWe and produces electricity for sale, and

cogeneration units, as that term

is defined in Section 225.130 ofPart 225, if sueh

bailers

ar eageaeratiaauaits are subjeet ta the CAlR

~IOl(

TFaBiag Pragrams

uaBer Subpart

Dar II afPart 225.

Section 217.1

60

Applicability [Subpart D]

b)

The provisions ofthis Subpart do not apply to boilers serving a generator

that has a nameplate capacity greater than

25 MWe and produces

electricity for sale, and cogeneration units, as that term

is defined

in

Section 225.230 of Part 225, ifsueh bailers ar eageaeratiaauaits are

slllJjeet ta the CAlR

~IOl(

TraBiag Pragrams llI1Ber Subpart D ar II afPart

m.

The lIIinois EPA is amenable to amending Sections 217.340, 217.342, 211.3100, and

217.160 as follows:

Section 217.340

Applicability [Subpart

M]

Notwithstanding Subpart V or W of this Part, the provisions of Subpart C of

this Part and this Subpart apply to all fessil fuel fired stationary boilers

subjeet to the

CAIR NOx Trading Programs under Subpart D or E of Part

m any fossil fuel-fired stationary boiler serving at any time a generator that

has a nameplate capacity greater than 25 MWe and produces electricity for

sale, excluding any units listed in Appendix D

of this Part, located at sources

subject to this

Subpart pursuant to Section 217.150 of this Part.

Section 217.342

Exemptions

a)

Notwithstanding Section 217.340 of this

Subpart, the provisions of

this Subpart do not apply to a fossil fuel-fired stationary boiler

operating

under a federally enforceable limit of NOx emissions from

5

???????????

??????? ?? ??????????

???????? ???????? ??????????

???? ????

such boiler to less than 15 tons per year and less than five tons per

ozone season.

b)

Notwithstanding Section 217.340

ofthis Subpart, the provisions of

this Subpart do not apply to a coal-fired stationary boiler that

commenced operation before January 1, 2008, that is complying with

Part 225.Subpart B through the multi-pollutant standard under

Section 225.233 ofPart 225 or the combined pollutant standards

under Subpart F of Part 225.

Section 211.3100

Industrial Boiler

"Industrial boiler" means, for purposes

of Part 217, an enclosed vessel in

which water

is heated and circulated either as hot water or as steam for

heating

or for power, or both. This term does not include boilers serving a

generator

that has a nameplate capacity greater than 25 MWe and produces

electricity for sale,

and eogeneration units, as dlat term is defiBed in Seetion

22S.HO of Part 22S, if such boilers or eogeneration units are subjed to meet

the applicability criteria

under Subpart M of Part 217 the

CUR NOll:

Trading Programs under Subpart D or E of Part 22S.

Section 217.160

Applicability [Subpart

D]

b)

The provisions ofthis Subpart do not apply to boilers serving a

generator

that has a nameplate capacity greater than 25 MWe and

produces electricity for sale, and eogeneration units, as dlat term is

defined

in

Seetion

22S.2~O

of Part 22S, if such boilers or eogeneration

units

are subjeet to meet the applicability criteria under Subpart M of

Part 217 die CAIR

NOll:

Trading Programs under Subpart

D

or

E

of

Part 22S.

21.

What is the basis for determining that the O.091b/mmBtu rate at Section 217.344(a) is

RACT?

The technologies to control utility boilers to below 0.09 Ib/MMBtu

are certainly

available

as evidenced by the number of utility boilers in Illinois and throughout tbe

United States

that currently control to that level or less. Emissions data for over 100

coal units equipped with SCRs and other low NOx technology were examined in a

comprehensive study by Erickson and Staudt with the results presented

at the EPA-

DOE-EPRI Combined Power Plant Air Pollution Control Symposium (the MEGA

Symposium) in 2006. See, Attachment

29 to the TSD, Selective Catalytic Reduction

System Performance

and Reliability Review, the 2006 MEGA Symposium, Paper

#121, by Clayton A. Erickson and James E. Staudt. Without a doubt, coal-fired

units have demonstrated

that emissions under 0.09 Ib/MMBtu are possible using

combustion controls, post-combustion controls,

or combinations of the two. In fact,

Illinois' own Baldwin Unit

#3 achieves below 0.091b1MMBtu using only combustion

control.

Otber units in Illinois achieve under 0.09 Ib/MMBtu using SCR.

6

???????????

??????? ?? ??????????

???????? ???????? ??????????

???? ????

So, from the perspective of RACT, the only remaining question is whether or not the

technology is reasonable in cost. As a benchmark of what is reasonable, the United

States Environmental Protection Agency (USEPA) determined in its Clean Air

Interstate Rule analysis, which motivated installation of SCRs,

that

The EPA's analysis indicates that emissions reductions from electric

generating units (EGUs) are highly cost effective,

and EPA encourages States

to adopt controls for EGUs.

See, 70 Fed. Reg. 25162, 25165 (May 12, 2005).

Further, in describing

what is "highly cost effective" USEPA stated:

(II) Determination

of Highly Cost-Effective Amount

The EPA determined the dollar amount considered to be highly cost effective

by reference to the cost effectiveness

of recently promulgated or proposed

NOX controls. The EPA determined

that the average cost effectiveness of

controls in the reference list ranged up to approximately $1,800 per ton of

NOX removed (1990$), on an annual basis. The EPA considered the controls

in the reference list to be cost effective.

See,

70 Fed. Reg. 25162, 25173 (May 12, 2005).

It

is widely recognized that combustion controls are reasonable in cost. However,

SCR also provides NOx reductions

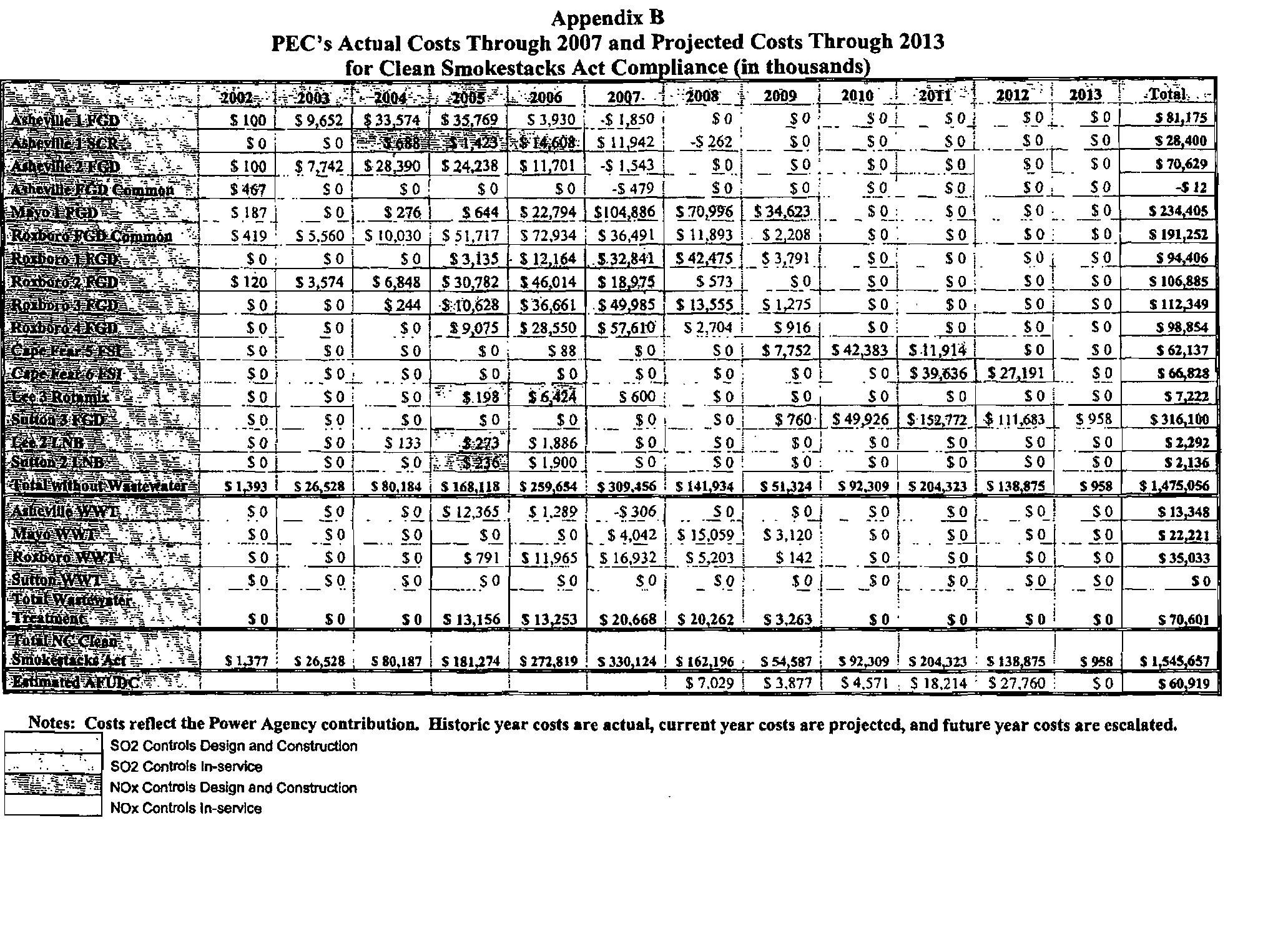

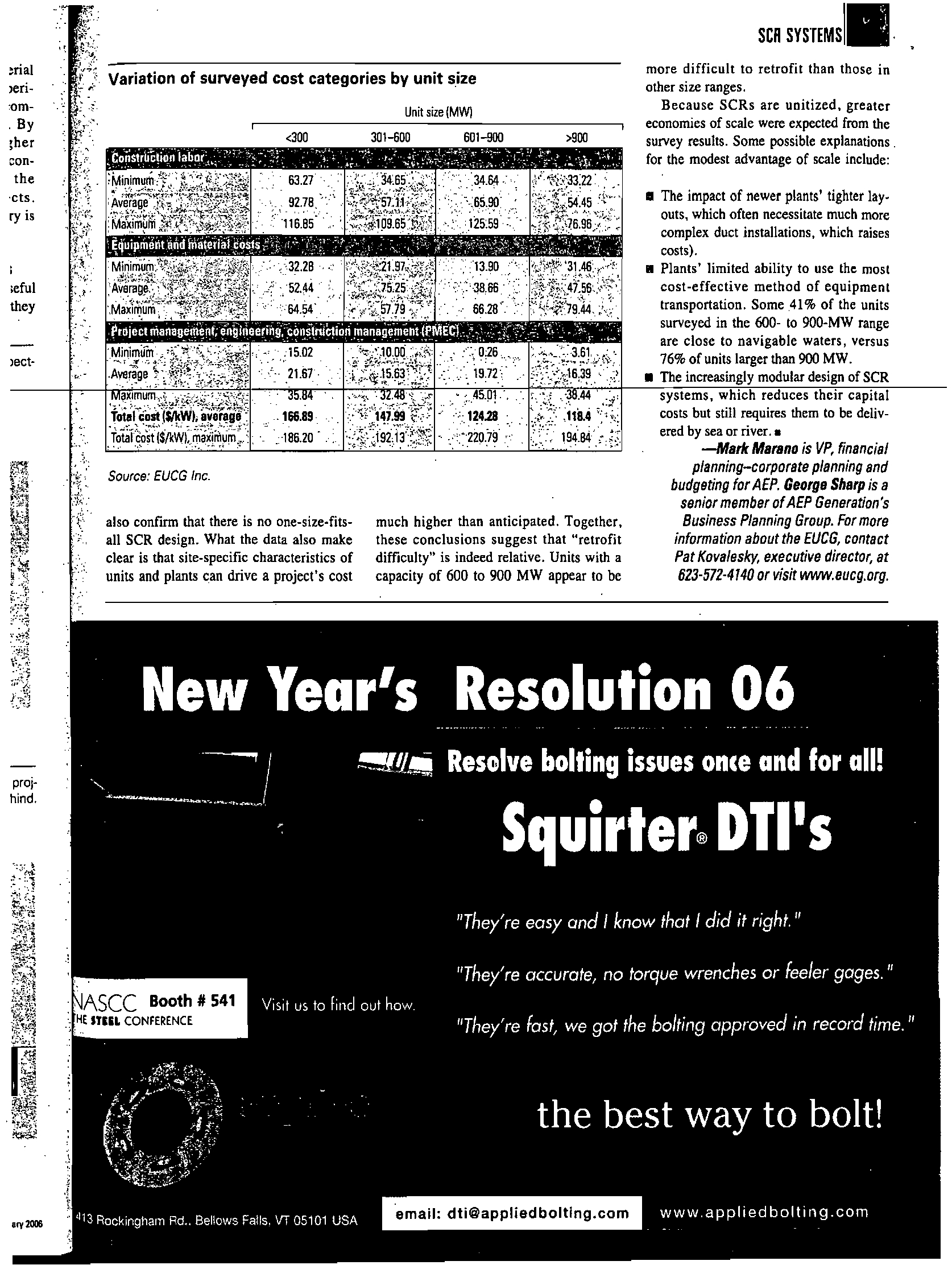

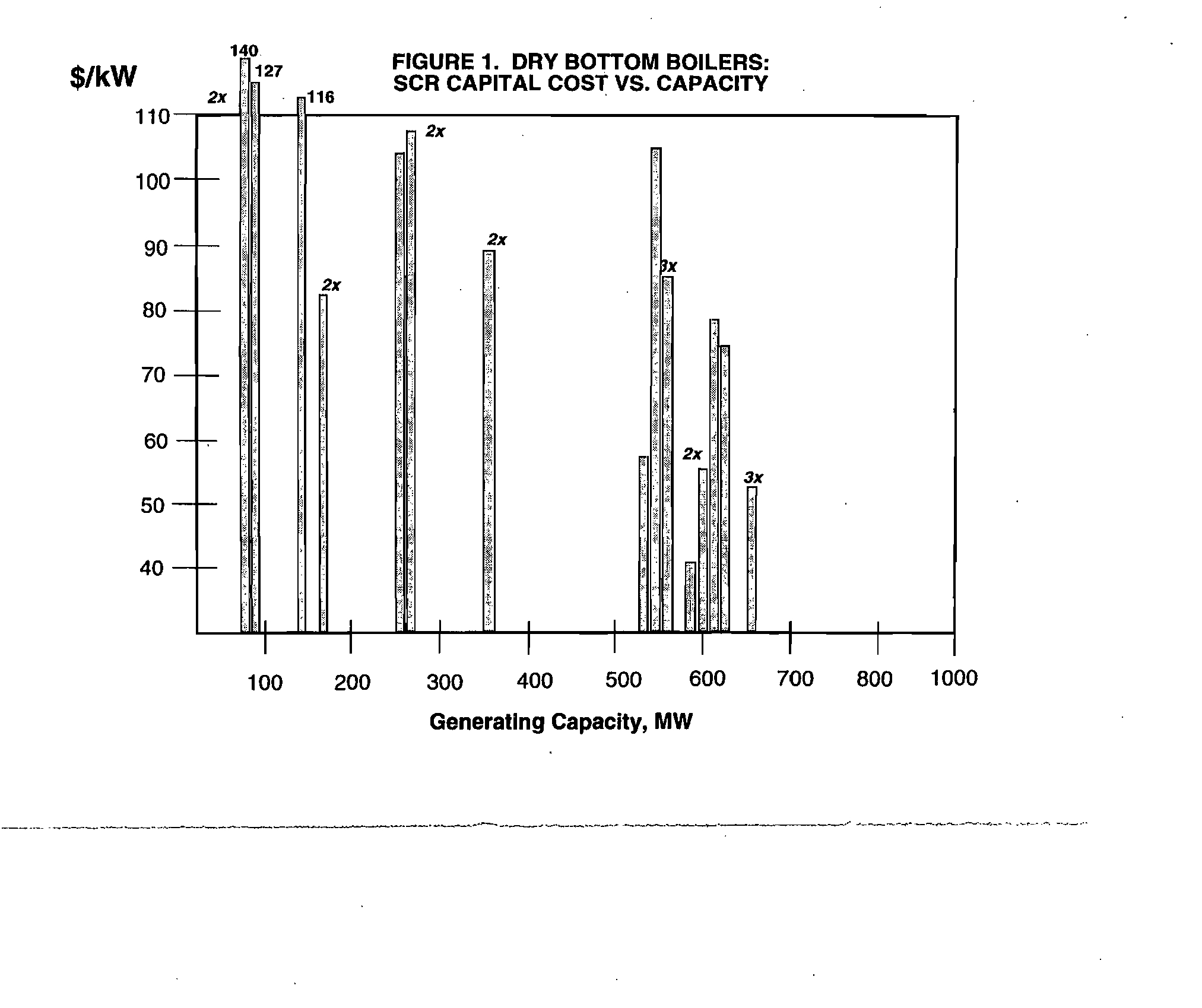

at reasonable costs. Figure 2-17 from the TSD

can be used to make this point. A capital cost of

$200/KW

is near the high end of

what a utility SCR retrofit would typically be expected to cost and this translates

roughly to $20,000IMMBtulbr, assuming a heat rate on the

order of 10,000

Btu/kWhr.

Using Figure 2-17 and an assumed uncontrolled NOx level of 0.50

IbIMMBtu, one arrives

at $2000/ton of NOx removed. Uncontrolled units would

typically have an emissions rate

of at least 0.50 IbIMMBtu. But, even at

uncontrolled NOx levels of 0.40 IbIMMBtu, the cost is estimated at about $2500/ton.

For more typical capital cost numbers in the range of $100/KW to

$150/KW

(roughly $10,000-$15,00 OIMMBtu/hr on Figure 2-17), the cost of NOx reduction

would be below $2000/ton. Companies typically do not publish their cost data. But,

fortunately, cost data is available for some SCR retrofits.

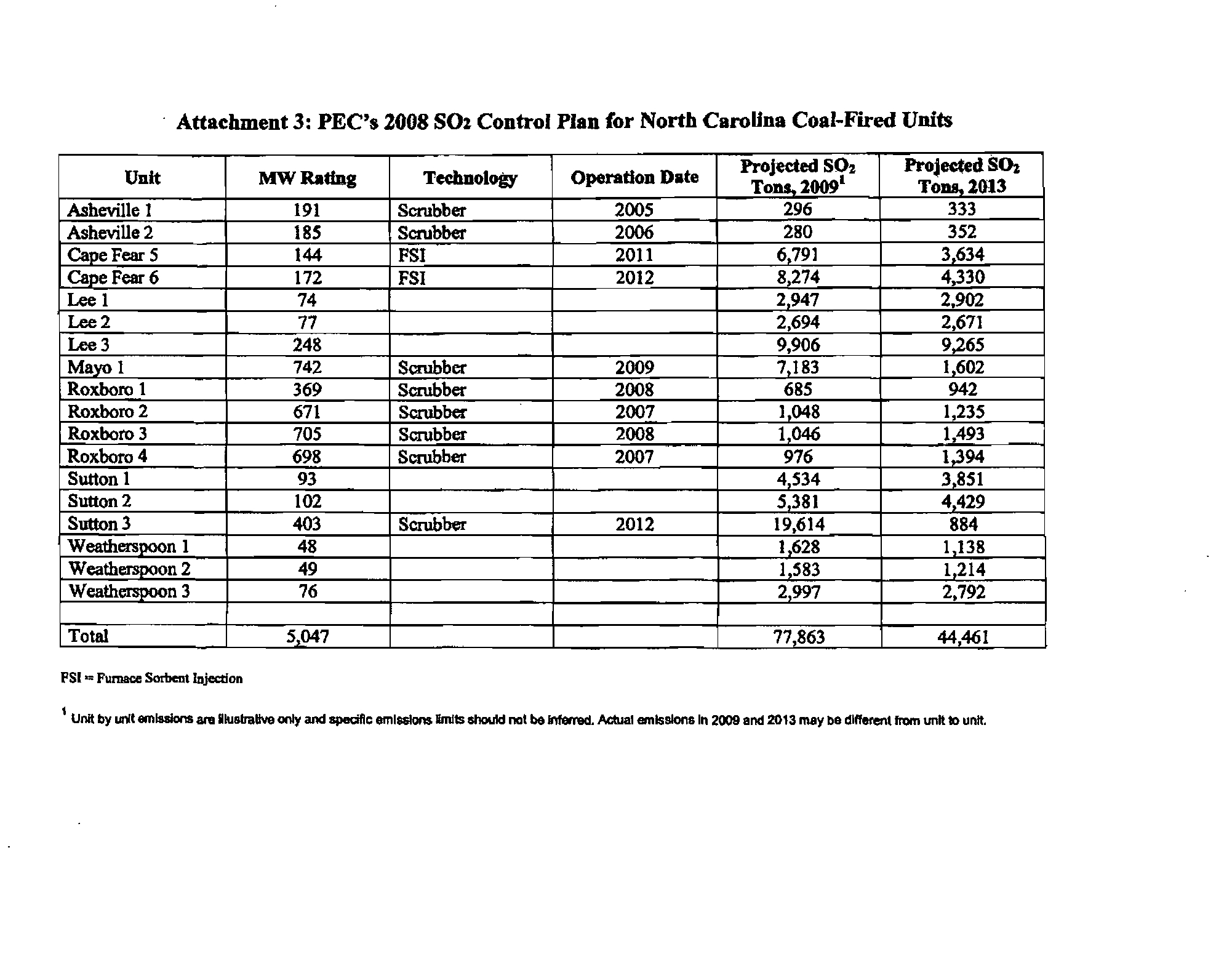

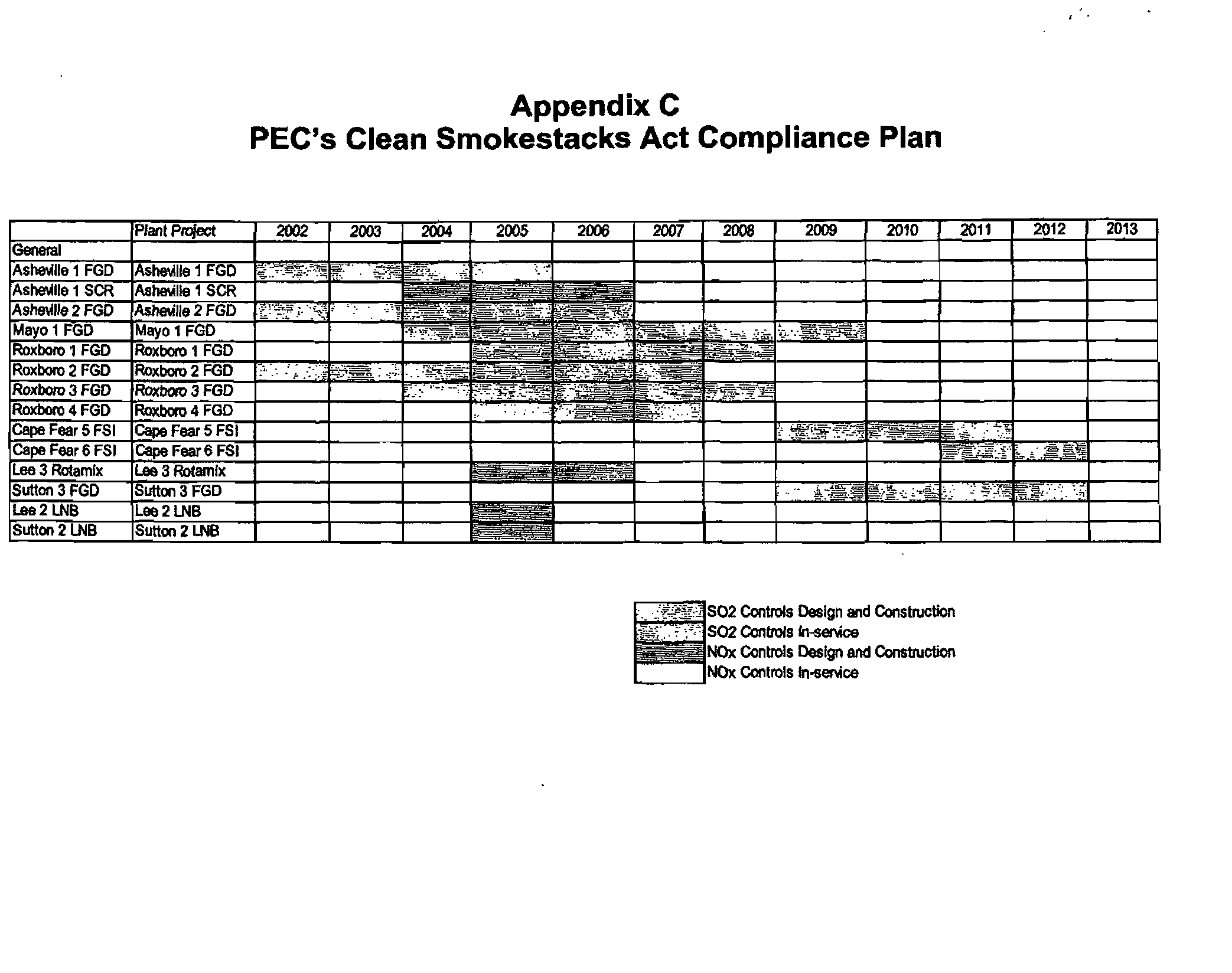

As shown in the attached

report submitted by Progress Energy to the North Carolina Public Utilities

Commission, the Asheville Unit 1 SCR retrofit cost

$28 million on the 191 MW unit

- $149/KW.

See, Attachment 2. And, as reported in Power Engineering Magazine,

(http://pepei.pennnet.com/display_

article/162367/61

ARTCL/none/none/l/SCR-=-

Supremely-Complex-Retrofitl), in an article titled

"SCR =Supremely Complex

Retrofit), Duke Power'stwo Belews Creek Units

(2 times 1120 MW) were retrofit

for $325 million,

or $145/KW. See, Attachment 3. Thus, a "Supremely Complex

Retrofit" cost $145/KW.

According to a study of SCR costs published by Murano and

Sharp in February

2006, (http://findarticles.com/p/articles/mi_qa5392/is_200602lai_n21409717)

7

???????????

??????? ?? ??????????

???????? ???????? ??????????

???? ????

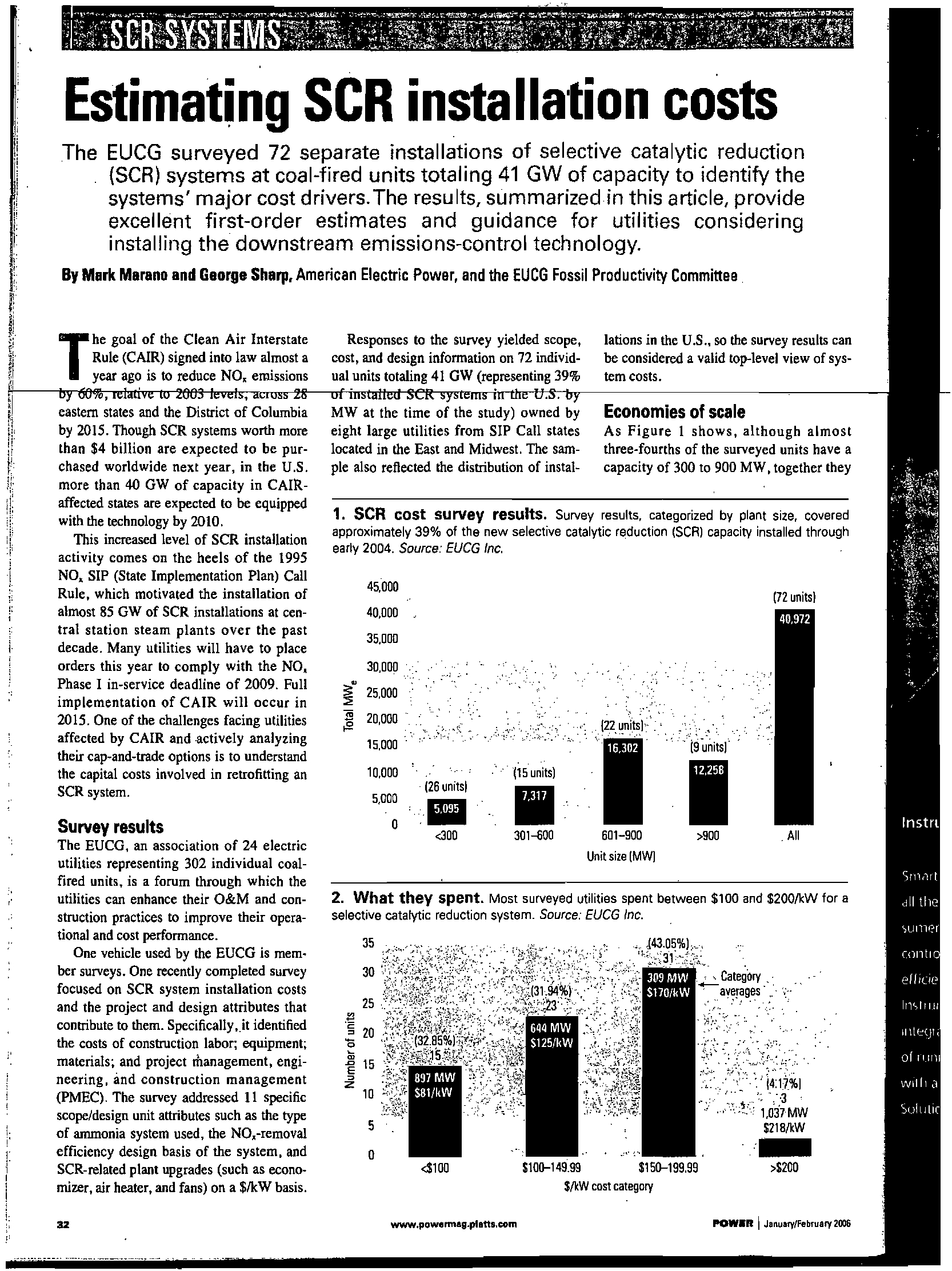

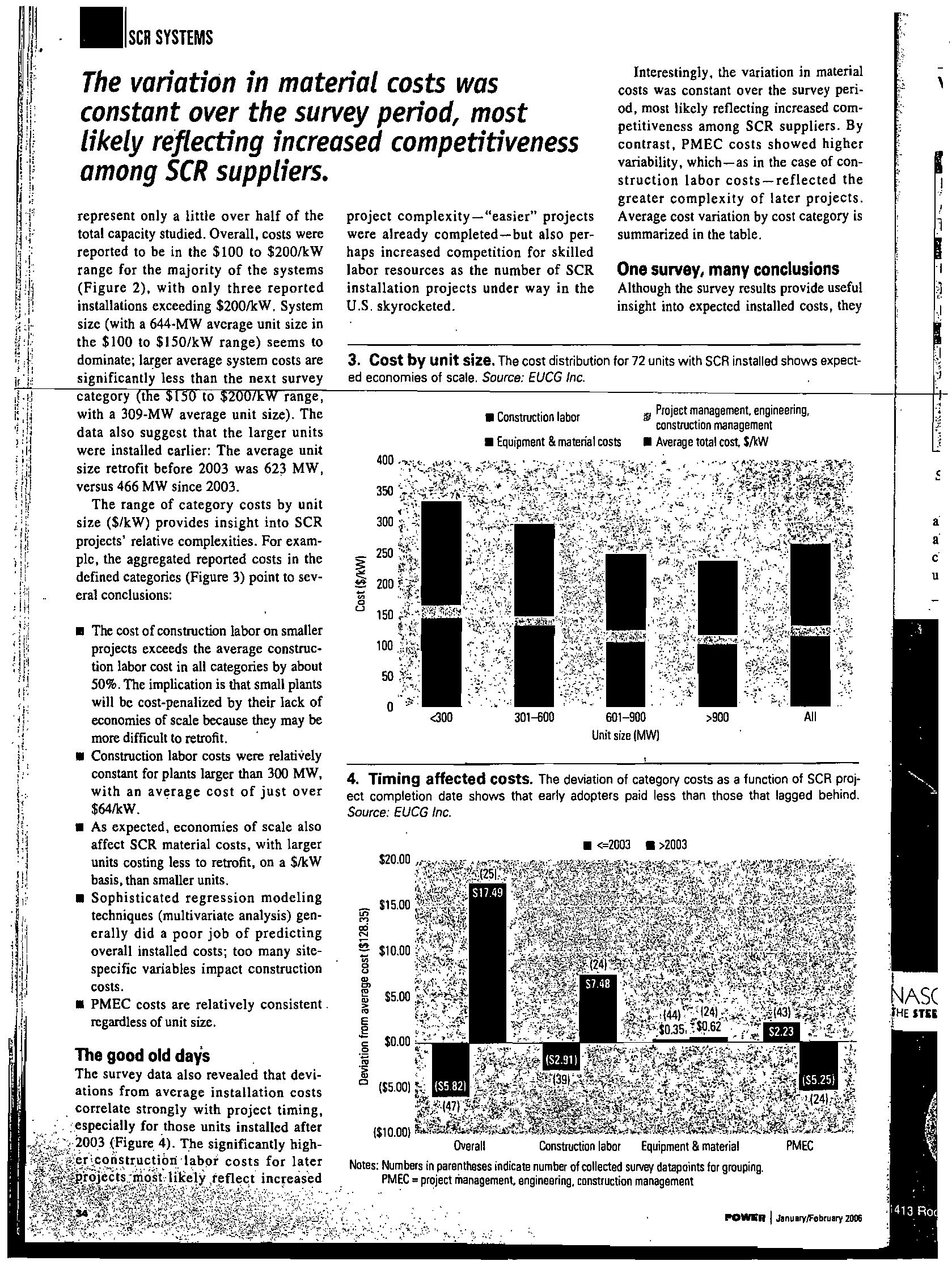

"Overall, costs were reported to be in the $100 to $200/kW range for the

majority

of the systems (Figure 2), with only three reported installations

exceeding $200IkW. System size (with a 644-MW average unit size in the

$100 to $1501kW range) seems to dominate; larger average system costs

are

significantly less than the next survey category (the $150 to $200/kW range,

with a 309-MW average unit size)."

See, Attachment

4. As a result, multiple studies have affirmed the cost of SCR to be

in a capital cost range where they

are shown to provide reductions below the "highly

cost effective" level established by USEPA.

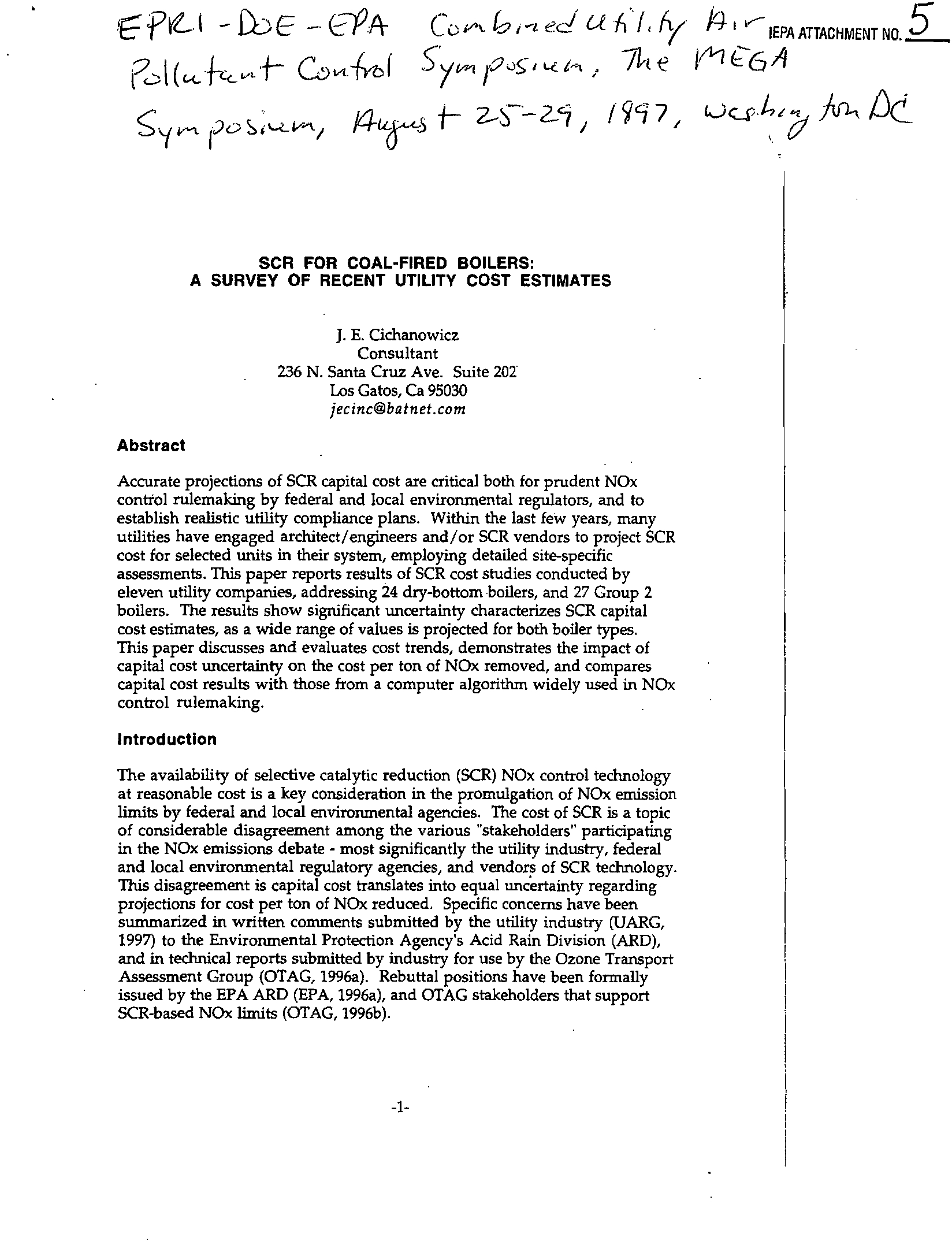

Earlier studies using capital costs in the range of

$70-$90/KW

determined that NOx

could be controlled from

SCR at costs in the range of

$400-$17681

ton. See,

Attachment 22 to the TSD,

and Attachment 5, Cichanowicz, "SCR for Coal-Fired

Boilers: A Survey

of Recent Utility Cost Estimates," EPRl-DOE-EPA Combined

Power Plant Air Pollutant Control Symposium, the MEGA Symposium, August 25-

29, 1997, Washington, DC. This

is below the

$1800/ton

(in 1990$) that USEPA

determined to be "highly cost effective." However, SCR costs have gone

up faster

than inflation. But, even doubling

that cost range to

$800-$3536/ton

of NOx

reduced to account for escalation

of SCR costs, keeps the cost in the range of what

USEPA determined to be "highly cost effective" except

at the very highest end.

22.

The Technical Support Document ("TSD") indicates on page 130 that there are a total of

12 industrial boilers subject to the NOx SIP call affected by this proposed rule while the

Statement

ofReasons on page 10 states that there are 80 industrial boilers affected by the

proposed rule. Are these additional

50 industrial boilers all less than 250 mmBtu?

The additional

68 industrial boilers are less than 250 mmBtu and are not subject to

the NOx SIP Call.

23.

The TSD claims there are a total of 18 EGUs subject to the rule, while the Statement of

Reasons says there are 20 "fossil fuel-fired stationary boilers" subject to the rule. Are

there fossil fuel-fired stationary boilers that are not EGUs that

are subject to the rule?

No, there are 20 EGU boilers. Table E-l of the TSD Appendices lists units;

however, there

are two instances in which one unit is comprised of two boilers (see,

Midwest Generation LLC, Joilet 29: Unit 7, Boilers

71 and 72, and Joliet 29: Unit 8,

Boilers 81 and 82).

Ouestions for Dr. Staudt

24.

Are NO and N0

2

the only components ofNOx?

Yes, however, they are reported on a mass basis as if they were all in the form of

NO

z•

For boilers, the majority of the NOx is in the form of NO as it leaves the stack.

However, the NO subsequently oxidizes to

NO

z

in the atmosphere.

8

???????????

??????? ?? ??????????

???????? ???????? ??????????

???? ????

25.

Explain oxy-combustion. In your testimony, you say that NOx is reduced by reducing

the amount

of oxygen available for the nitrogen to combine with, yet oxy-combustion

appears to provide even more oxygen in the combustion chamber.

Oxycombustion

is described in my testimony as a nitrogen-depletion approach.

Normally, nitrogen comprises 79%

of combustion air. By having an enriched

oxygen environment, nitrogen

is depleted in the combustion air to much lower

amounts. One benefit

of this is that there is less nitrogen available to oxidize at high

temperature to NO

or N02.

26.

Your testimony suggests there are other post-combustion controls besides SCR and

SNCR. What are those other types

of post-combustion controls?

Other approaches include oxidation of the NO to water soluble oxides using ozone,

peroxide,

or with an electric barrier discharge reactor, and then scrubbing them out

with a wet scrubber, and injection of Trona. Duct injection of Trona (sodinm

sesquicarbonate) will remove some NOx as well as S02. However, SNCR and SCR

are the most widely used post-combustion controls.

27.

Is SCR RACT? Or is it beyond RACT?

SCR can be RACT.

In fact, the first retrofit of SCR on a coal fired utility boiler was

at Public Service Company of New Hampshire'sMerrimack Unit #2 in 1995, and

this was in response to

New Hampshire'sNOx RACT rule that was implemented at

that time. SCR has been retrofit on several other coal fired boilers in response to

the Ozone

Transport Commission NOx budget rule (PSNH Merrimack 1) and on a

number of Group 2 boilers in response to regulations enacted under Title IV of the

Clean

Air Act. Both of these regulations were ostensibly intended to impose NOx

controls

at a cost ($/ton of NOx) similar to low NOx burners, which are widely

regarded

as within RACT.

If

$2500-$3000/ton is to be the guide for what is RACT,

Figure 2-17

of the TSD demonstrates that SCR is capable of being RACT. However,

having said that, I do not believe

that SCR is likely to be necessary under the

proposed rule. I expect

that less expensive controls or combinations of less

expensive controls

are most likely to be used.

28.

Would a wet scrubber intended to reduce S02 be a NOx scrubber as well if the NOx were

first oxidized?

See

Section 1.2.2, page 4 of the TSD.

Yes,

if the NOx were both oxidized to a water-soluble form and subsequently

captured in the scrubber.

29.

What does the following mean: nNOx emissions from residual oil-fire boilers can be

controlled level by using residual

fuel oil. ...n (Emphasis added.)

See

Section 2.1, page 5

ofthe TSD.

The term "level"

is a typographical error. Once you remove that, the sentence

should make sense. But, to explain, reducing fuel nitrogen

is a way of controlling

NOx emissions.

9

???????????

??????? ?? ??????????

???????? ???????? ??????????

???? ????

30.

Is it the case that there are currently no wood-fired boilers that would be subject to the

proposed rule?

That is my understanding.

31.

Does the fact that pulverized coal is used in wall-fired boilers contribute to the NOx

levels?

See

Section 2.2.1, page 9

ff.

of the TSD.

Yes, coal contains significant levels of fuel nitrogen, which contributes to NOx.

32.

Page

13 ofthe TSD says that Cleaver Brooks illustrates that with proper control, NOx

emissions can be reduced, and page 15 ofthe TSD says that Cleaver Brooks illustrates

that with proper retrofits, NOx emissions can be reduced. What are those "proper"

controls and retrofits? How are they effective

in reducing NOx? Who is Cleaver

Brooks?

The

"proper" retrofits referred to are low NOx burners. The effectiveness of these

controls in reducing NOx is shown in Tables

2-2 and 2-3 of the TSD, wbich are from

Cleaver Brooks

and referenced in a letter, dated May 19, 2006, submitted by Daniel

J. Willems of Cleaver Brooks to the New Hampshire Division of Environmental

Services (see, Attachment 8 to the TSD). The data in these tables demonstrate

that

these burners are capable of achieving emission rates at extremely low levels - well

below the proposed limits.

As noted in the TSD, at page 13, Cleaver Brooks is the

largest producer of hot water

and steam boilers in the United States.

33.

How do excess air and complete combustion affect safety?

See

Section 2.3.1, page 20 of

the TSD.

Reducing excess

air too far can make the flame unstable or even extinguish it. In

this case there is a risk

of high combustible levels remaining in the gas that can

affect safety.

In a worst-case scenario there is risk of a boiler explosion. However,

operating limitations and control devices prevent these conditions from occurring.

As excess air is reduced, operating limitations on CO emissions or high unburned

carbon in the case of coal-fired boilers will be reached well before unsafe conditions

are reached, preventing the operator from reducing excess

air further. Also, boilers

have flame monitors as

part of their controls that also assure safety by alerting the

operator to a problem with the flame. So, a boiler is capable

of operating at low

excess

air to reduce NOx while also operating in a safe manner.

34.

Page 22 of the TSD refers to 100-600 hp boilers. How large are these boilers in terrns of

mrnBtu heat input capacity?

One

hp is 2524 Btu/hr. So, 100-600 hp boilers are in the range of 252,000 Btulbr to

about 1.5 million Btu/br. The specific reference you have identified is in the section

on combustion tuning (mostly

of interest for small boilers) and relates to the cost of

oxygen

trim systems in the range of $6000-$7000 for boilers of that size. And, as

noted in the TSD, for larger boilers the cost would be somewhat higher.

Of course,

10

???????????

??????? ?? ??????????

???????? ???????? ??????????

???? ????

100-600 hp boilers are well below the size of boilers that are subject to emissions

limitations. However, small boilers may be subject to the combustion tuning

requirement, depending upon the emissions

ofthe boiler.

35.

Please describe the combustion tuning training requirement and where companies may

obtain such training.

This is described in the TSD. Boiler manufacturers

and private companies offer

such training. The American Boiler Manufacturer'sAssociation website

(www.abma.comltraining.html) lists training courses

that are available.

36.

Regarding SNCR, the TSD says that there need to be several injection points to inject the

reagent

at proper temperatures for large boilers. What happens ifthe reagent is injected at

an improper temperature?

See

page 30 of the TSD.

The injectors

are placed in locations on the boiler designed to inject the reagent into

a temperature zone where the desired chemical reactions occur. The

proper

temperature zone changes as boiler conditions, such as load, change. So, multiple

injection zones may be needed. SNCR systems have control systems to determine

the

proper injectors to use for a given load snch that the reagent is injected in the

correct location (and therefore, the correct temperature)

at all times. Since there

are hundreds of SNCR systems installed on industrial and utility boilers, this is

something that engineers have good experience with.

If

the reagent were not

injected in the

proper location (where the correct temperature is), then poor NOx

reduction

or high ammonia slip would result.

37.

Why would the cost ofSNCR on a wood-fired boiler be about the same as for a coal-fired

boiler

ofthe same size?

The capital cost

of an SNCR system depends primarily on the number of injectors,

which

is largely related to the boiler size and heat input, and the amount of reagent

used (which determines the size

of the storage tank). So, for solid fuel boilers of

similar heat input and similar NOx levels, you would expect similar costs.

38.

Looking at Table 2-12a, what is a "Wood Fired IPP"?

In

this same column, the table says

that the fuels are "Biomass Wood/Coal." What does this mean?

A "Wood fired

IPP" is an Independent Power Producer that has a boiler that burns

wood. Fuels "Biomass Wood /Coal" mean

that the boiler fires those fuels - and may

fire combinations

of these fuels.

39.

Page 30 of the TSD states, "For EGU's SNCR capital cost is in the range of about

$15/KW, and in most cases NOx reductions in the rage

of about 30% are possible." How

does this translate

to dollars per ton ofNOx removed?

Figures 2-14a

and 2-14b of the TSD, which are data for

Industrial/Commercial/Institutional (ICI) boilers,

are also useful for getting a sense

ofthe cost for utility boilers if you look at the far right where the information for

11

???????????

??????? ?? ??????????

???????? ???????? ??????????

???? ????

large ICI boilers is shown. As shown in Figure 2-14b, the capital cost is about

$1500/MMBtu for large ICI boilers, which is roughly equivalent to $15/KW. And,

as shown in Figure 2-14a, the $/tou

of NOx reduced is in the range of about

$1500/ton on an annual basis.

40.

On page

36 ofthe TSD is a discussion of the cost of SCR; the TSD appears to essentially

argue that a cost expressed

in dollars per mmBtu is a better measure of RACT because an

expression in dollars per ton removed depends upon baseline NOx. Please explain.

This does not argue for

or even suggest a different measure for RACT. The reason

the cost in $IMMBtu is showu

is to give the cost in terms offuel use, which may be

useful for industrial boiler owners in the same sense

that $/MWhr would be of

interest to a power plant owner.

41.

Have the cost calculations for industrial/commercial/institutional ("ICI") boilers included

retrofit issues?

Yes

42.

It

appears that the TSD includes a number of evaluations of cost-effectiveness of

proposed rule from a number of different sources. What is the bottom line,

i.e.,

the

Agency'sdetermination

of the cost-effectiveness ofthe proposed rule, in at least 2006

dollars?

See

TSD pages 41-42.

The bottom line is as stated in my prefiled testimony.

"Fortunately, for each

of the source categories affected there are available controls

that can be used to provide the NOx reductions required by the rule at costs

envisioned to be within the expectations for RACT."

43.

What is the significance

ofthe statement on page 126 of the TSD that "the [USEPA cost]

model does not allow for differences

in stack height, or explicitly distinguish between

Part 60 and Part

75 systems"?

The significance of this statement is that the model used was developed primarily

for utility boilers, which generally have taller stacks

than industrial boilers and Part

75 systems. Therefore, I would expect that an industrial boiler continuous emissions

monitoring system's(CEMS) costs would likely be less since the stacks

are smaller

and also they would likely have a Part 60 CEMS.

44.

The TSD

at page 126 suggests that opacity monitoring is required by this rule where a

source, because

of the size ofthe affected unit, must employ Part 75 monitoring. Is it the

intent

of this rule to require opacity monitoring? If so, why is opacity monitoring part of

a NOx RACT rule?

No.

45.

What is a "point source"?

See

TSD page 130. Is the term defined in the rule?

12

???????????

??????? ?? ??????????

???????? ???????? ??????????

???? ????

A point source is an individual stationary emission unit. No, the term is used in the

TSD, but is not defined in the rule.

46.

The TSD states on page 131, "The NOx inventory was generated through the use of year

2005 annual emission reports submitted pursuant to 35

Ill.

Adm. Code Part 234. For our

purpose, year 2005, instead of year 2002, was selected because some sources have been

either shut down or modified since 2002." What is the significance of 2002 that the TSD

would explain using 2005 data instead?

USEPA'simplementation rules for ozone and PM2.5 require the use of 2002 as the

base year for emissions inventories and determining reasonable further progress.

The I1Iinois EPA used 2005 emissions data to identify potentially affected units

because 2005 data are more current.

47.

Please explain the difference between Tables H-I and I-I. Appendix pages 31 and 33.

Table

0-1

sorts all sources by the ID number, whereas Table

1-1

groups them by

emission category and nonattainment area.

48.

In

Appendix A, Table A-4, what does "703" in the first column mean?

It

means uncontrolled emissions are 703 tons per year for the gas fired refinery

boiler that was being evaluated in Table A-4.

Respectfully submitted,

ILLINOIS ENVIRONMENTAL

PRO~ON

AGENCY

BY:~

Gina Roccaforte

Assistant Counsel

Division of Legal Counsel

DATED: September 30,2008

1021 North Grand Avenue East

P. O. Box 19276

Springfield, IL 62794-9276

217/782-5544

13

THIS FILING IS SUBMITTED

ON RECYCLED PAPER

???????????

??????? ?? ??????????

???????? ???????? ??????????

???? ????

STATE OF ILLINOIS

COUNTY OF SANGAMON

)

)

)

)

SS

CERTIFICATE OF SERVICE

I, the undersigned, an attorney, state that I have served electronically the attached

ILLINOIS ENVIRONMENTAL PROTECTION AGENCY'S ANSWERS TO

MIDWEST GENERATION'S OUESTIONS

FOR AGENCY WITNESSES, upon the

following person:

John Therriault

Assistant Clerk

Illinois Pollution Control Board

James

R. Thompson Center

100 West Randolph St., Suite 11-500

Chicago,IL 60601

and mailing it

by first-class mail from Springfield, Illinois, with sufficient postage affixed

to the following persons:

SEE ATTACHED SERVICE LIST

ILLINOIS ENVIRONMENTAL

PROTECTION AGENCY,

Assistant

G~

Counsel

Division

of Legal Counsel

Dated: September 30, 2008

1021 North Grand Avenue East

Springfield, Illinois 62794-9276

(217) 782-5544

???????????

??????? ?? ??????????

???????? ???????? ??????????

???? ????

SERVICE LIST 08-19

Timothy

J. Fox

Hearing Officer

Illinois Pollution Control Board

100

W. Randolph St., Suite 11-500

Chicago, IL 60601

Virginia Yang

Deputy Legal Counsel

Illinois Department

ofNatural Resources

One Natural Resources Way

Springfield,

IL

62702-1271

Katherine D. Hodge

Monica

T. Rios

Hodge Dwyer Zeman

3150 Roland Ave.

P.O. Box 5776

Springfield,

IL

62705-5776

Matthew Dunn

Chief

Environmental Bureau North

Office

ofthe Attorney General

69

W. Washington St., Suite 1800

Chicago, IL 60602

Kathleen

C. Bassi

Sheldon A. Zabel

Stephen

J. Bonebrake

SchiffHardin LLP

6600 Sears Tower

233

S. Wacker Drive

Chicago, IL 60606-6473

Alec M. Davis

General Counsel

Illinois Environmental Regulatory Group

215

E. Adams St.

Springfield, IL 62701

???????????

??????? ?? ??????????

???????? ???????? ??????????

???? ????

IEPA ATTACHMENT No.l

UNITED STATES ENVIRONMENTAL PROTECTION AGENCY

REGION 5

77 WEST JACKSON BOULEVARD

CHICAGO, IL 60604.3590

AUG 1 82008

REPLY TO THE ATIENTION OF'

R-19J

The Honorable Rod Blagojevich

Governor of Illinois

Springfield, Illinois

62706

Dear

Governor Blagojevich:

Thank

you for your recommendations on the status of fine particle (PMZ,5) pollution

throughout

D1inois. As you know, fine particle pollution represents one of the most significant

baniers to clean air facing our

nation today. Health studies link these tiny particles - about

I130

1h

the diameter of a human hair - to serious human health problems including aggravated

asthma, increased respiratory symptoms

like coughing and difficult or painful breathing, chronic

bronchitis, decreased

lung function, and even premature

death

in people with heart and lung

disease. Fine particle pollution

can remain suspended in the air for long periods of time and

create public health problems

far away from emission sources. Reducing levels of fine particle

pollution

is an important part of our nation'scommitment to clean, healthy air.

We have reviewed the December 18, 2007, and June 2,2008, letters from Laurel

L.

Kroack, Chief of the Bureau of Air, D1inois Environmental Protection Agency, and the August 6,

2008, letter from Douglas Scott, Director, D1inois Environmental Protection Agency, submitting

the

D1inois recommendations on air quality designations for the 2006 24-hour PM

Z

.5 standards.

We have also reviewed the technical information submitted to support the D1inois

recommendations. We appreciate the effort your State has made to develop this supporting

information. Consistent

with the Clean Air Act, this letter is to inform you that the U.S.

Environmental Protection Agency intends to make modifications to the designations and

boundaries recommended

by D1inois.

We have enclosed a detailed description of areas where EPA intends to modify your state

recommendations, and

the basis for such modifications. Your Environmental Director will also

receive a copy

of this letter and the enclosure. Should you have additional information that you

wish EPA to consider in this process, please provide it to us by October 20, 2008.

EPA has taken steps to reduce fine particle pollution across the country, such as the Clean

Diesel Program, which

we expect to dramatically reduce emissions from highway, non-road and

stationary diesel engines.

In addition, State programs to attain the 1997 PM

z

.5 standards will

help to reduce unhealthy levels of fine particle pollution.

RecycledlRecyciable • Pnnted with Vegetable Oil eased Inks 00 100% Recycled Paper (50% Poslconsurner)

???????????

??????? ?? ??????????

???????? ???????? ??????????

???? ????

We intend to make final designation decisions for the 2006 24-Hour PM2.S standards by

December

18. W08. Please also be aware that EPA plans to publish a notice in the Federal

Register

in the near future in order to solicit public comments on our intended designation

decisions. If

you have any questions. please do not hesitate to contact me. We look fOlward to a

continued dialogue

with you as we work together to implement the PM2.S standards.

Sincerely,

~r.:-0uJJ

Regional Administrator

Enclosure

cc: Douglas P. Scott

Director

D1inois Environmental Protection Agency

2

???????????

??????? ?? ??????????

???????? ???????? ??????????

???? ????

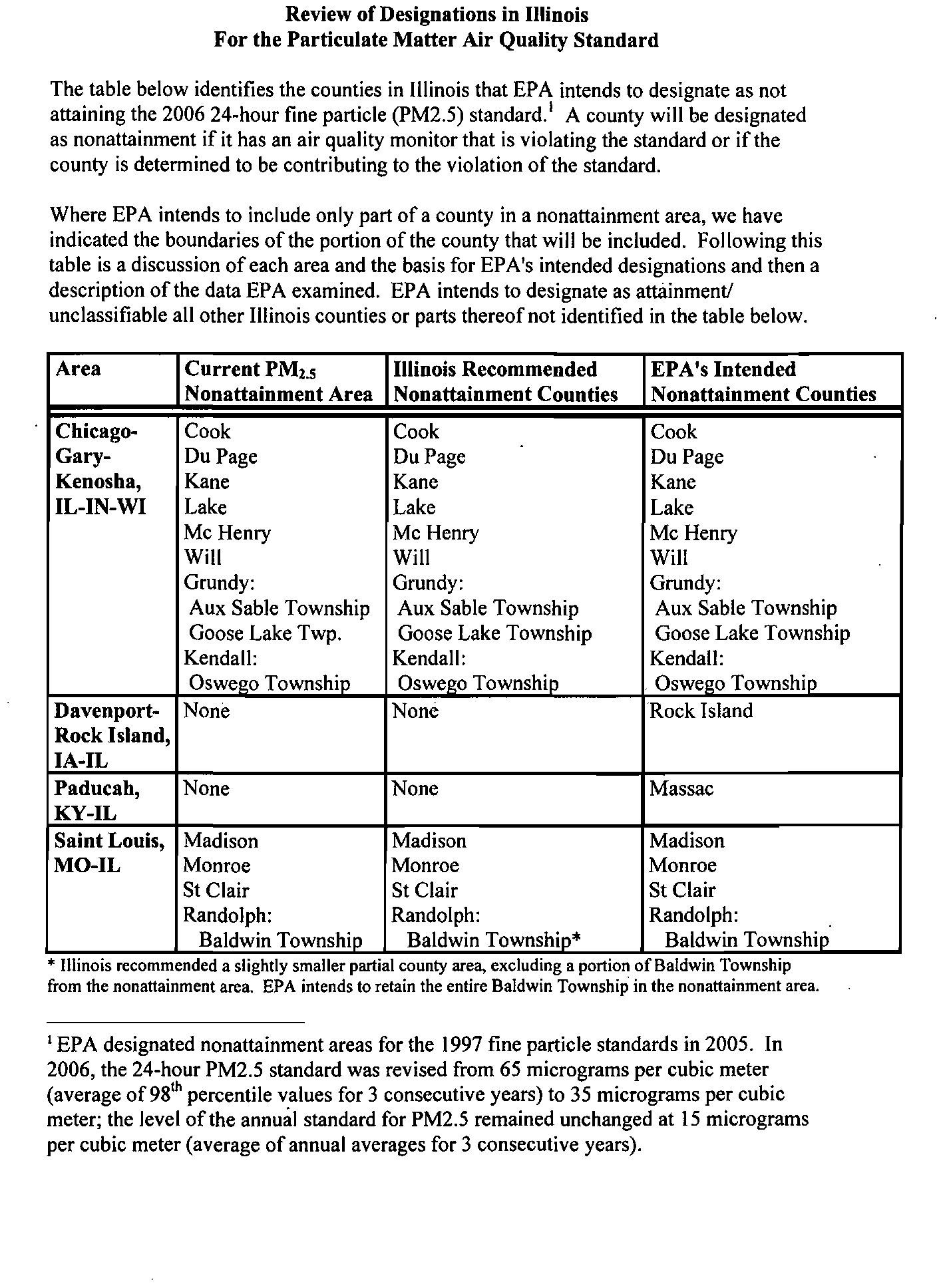

Review of Designations in Illinois

For the Particulate Matter Air Quality Standard

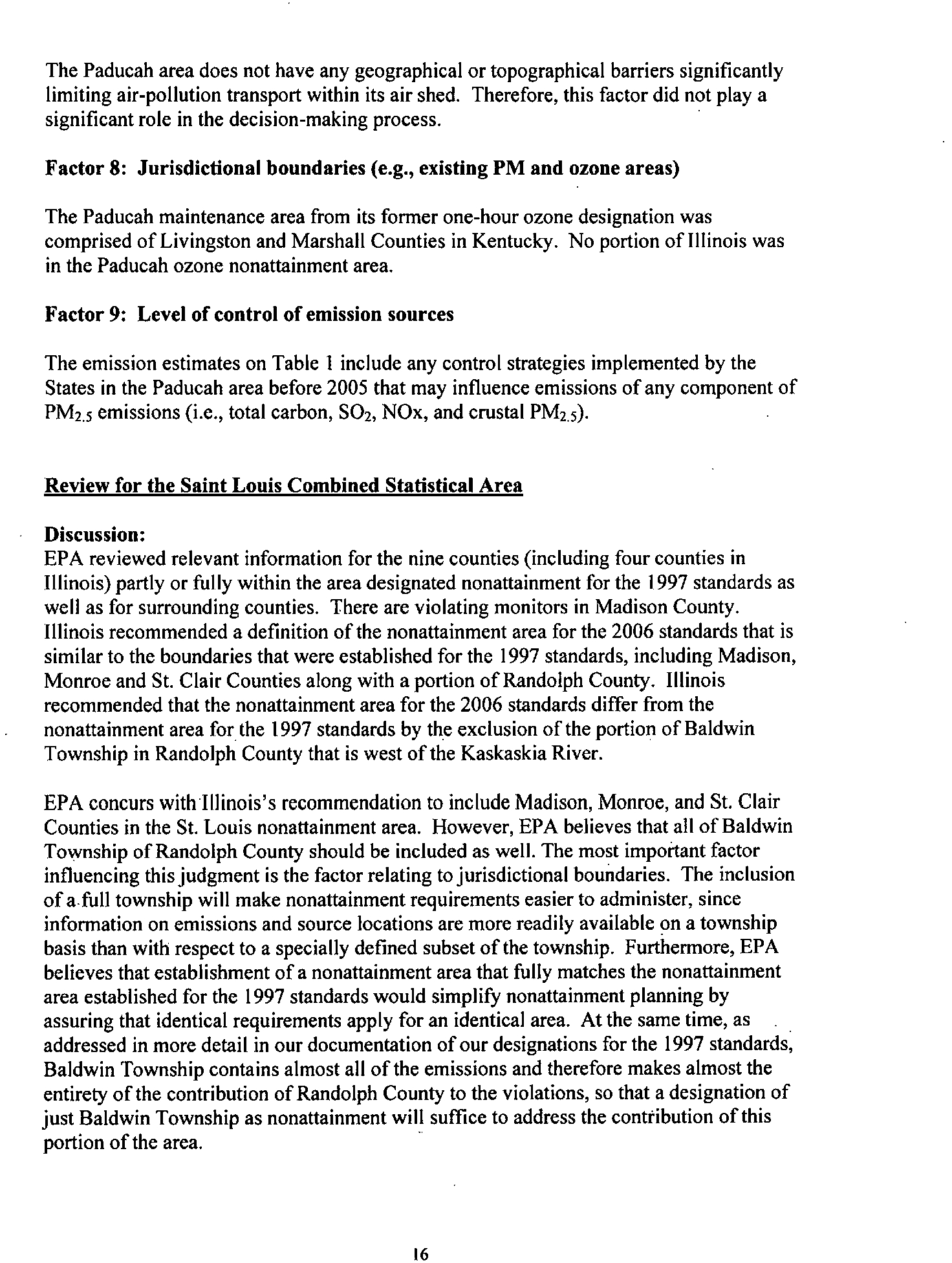

The table below identifies the counties in l1linois that EPA intends to designate as not

attaining the 2006 24-hour fine particle (pM2.5) standard.' A county will

be designated

as nonattainment

if it has an air quality monitor that is violating the standard or if the

county

is determined to be contributing to the violation of the standard.

Where EPA intends to include only part

of a county in a nonattainment area, we have

indicated the boundaries

of the portion of the county that will be included. Following this

table

is a discussion of each area and the basis for EPA's intended designations and then a

description

of the data EPA examined. EPA intends to designate as attainment!

unclassifiable all other l1linois counties or parts thereof not identified

in the table below.

Area

Current PMZ.5

Illinois Recommended

EPA'sIntended

Nonattainment Area Nonattainment Counties

Nonattainment Counties

Chicago-

Cook

Cook

Cook

Gary-

DuPage

DuPage

Du Page

Kenosha,

Kane

Kane

Kane

IL-IN-WI

Lake

Lake

Lake

Mc Henry

Mc Henry

Mc Henry

Will

Will

Will

Grundy:

Grundy:

Grundy:

Aux Sable Township

Aux Sable Township

Aux Sable Township

Goose Lake Twp.

Goose Lake Township

Goose Lake Township

Kendall:

Kendall:

Kendall:

Oswel!o Townshio

Oswel!o Townshio

Oswel!o Townshio

Davenport-

None

None

Rock Island

Rock Island,

IA-IL

Paducah,

None

None

Massac

KY-IL

Saint Louis, Madison

Madison

Madison

MO-IL

Monroe

Monroe

Monroe

St Clair

St Clair

St Clair

Randolph:

Randolph:

Randolph:

Baldwin Townshio

Baldwin Townshio*

Baldwin Township

• IllInOIS recommended a slightly smaller partIal county area, excludmg a portIon of Baldwm TownshIp

from the nonattainment area. EPA intends to retain the entire Baldwin Township'in the nonattainment area.

1 EPA designated nonattainment areas for the 1997 fine particle standards in 2005. In

2006, the 24-hour PM2.5 standard was revised from 65 micrograms per cubic meter

(average

of9S

th

percentile values for 3 consecutive years) to 35 micrograms per cubic

meter; the level

ofthe annwil standard for PM2.5 remained unchanged at 15 micrograms

per cubic meter (average

of annual averages for 3 consecutive years).

???????????

??????? ?? ??????????

???????? ???????? ??????????

???? ????

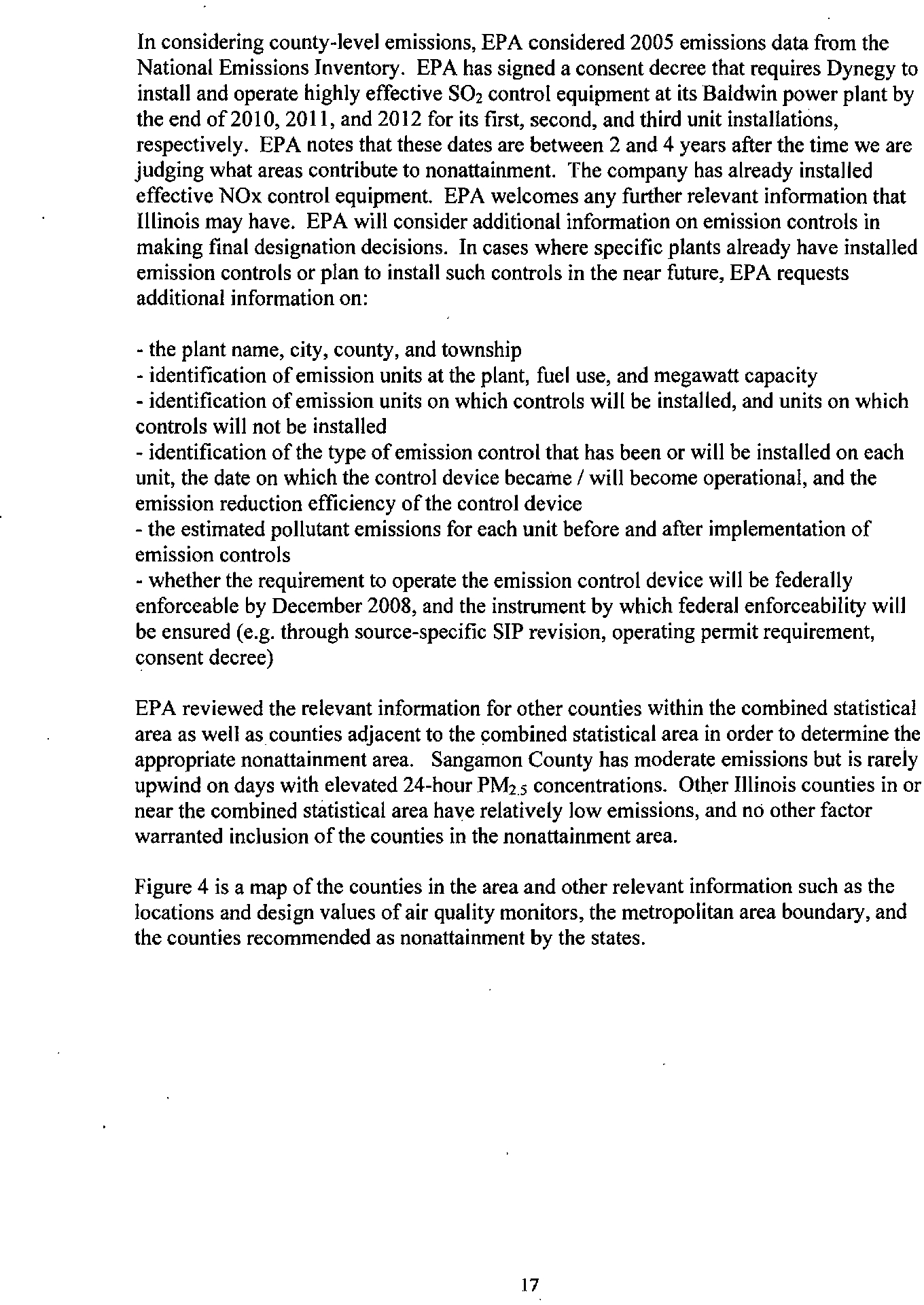

On June 8, 2007, in a memorandum from Robert Meyers to the EPA Regional

Administrators, EPA issued guidance on a timetable for designation

of areas violating the

PM2.5 air quality standards promulgated in 2006 and factors that EPA urged states to

consider as they prepared recommendations for nonattainment area boundaries. This

guidance was sent to the Governor

of Illinois as an attachment to a letter dated July 9,

2007, requesting the State'srecommendations.

Pursuant to section 107(d) of the Clean Air Act, EPA must designate as nonattainment

those areas that violate the NAAQS and those areas that contribute to violations. The

technical analysis for each area identifies the counties with monitors that violate the 24-

hour PM2.5 standard and evaluates the counties that potentially contribute

to fine particle

concentrations

in the area. EPA has evaluated these counties based on the weight of

evidence of the following nine factors recommended in EPA guidance and any other

relevant information:

- pollutant emissions

- air quality data

- population density and degree

of urbanization

- traffic and commuting patterns

- growth

- meteorology

- geography and topography

- jurisdictional boundaries

- level of control of emissions sources

Additional background information on each

of the nine factors can also be found in the

background section below.

EPA also computed a Contributing Emissions Score (CES) for each county. The CES is

a metric that takes into consideration emissions data, meteorological data, and air quality

monitoring information

to provide a relative ranking of potential impacts of counties in

and near an area on violating monitors. While this metric provides a useful synthesis of

important relevant information, including weighting the emissions ofvarious pollutants

according

to estimates of the relative importance of each pollutant, the CES is not the

exclusive variable EPA uses to consider these factors. A summary

of the CES is included

in the background section, and a more detailed description can be found at

http://www.epa.gov/ttn/naags/pm/pm252006techinfo.html#C.

Review for the Illinois Portion of the Chicago-GaIT-Kenosha. IL-IN-WI

Metropolitan Area

Discussion:

EPA reviewed relevant information for the ten counties (including eight counties in

Illinois) partly or fully within the area designated nonattainment for the 1997 standards as

well as for surrounding counties. There are violating monitors in Cook and Will

Counties and

in Lake County, Indiana. Illinois recommended a definition ofthe

2

???????????

??????? ?? ??????????

???????? ???????? ??????????

???? ????

nonattainment area for the 2006 standards that reflects the same boundaries within

Illinois as were established for the 1997 standards, including (within Illinois) Cook, Du

Page, Kane, Lake, Mc Henry, and Will counties, Aux Sable and Goose Lake Townships

in Grundy County, and Oswego Township

in Kendall County. EPA agrees with this

recommendation.

EPA also examined information for other counties within and adjacent to the Combined

Statistical Area as well as for adjacent counties. The bulk

of emissions and population

are captured without including DeKalb, Grundy, Kankakee and Kendall Counties, since

these counties have limited emissions and population. Nevertheless, we support the

recommendation by the Illinois EPA to include the three townships

in Grundy and

Kendall counties in the nonattainment area to maintain consistency with the ozone

designations and the prior PM

25

designations and thereby facilitate planning, as well as to

include slightly more emissions

in the planning area.

Emissions for other surrounding counties are relatively low, and no other factor

warranted designating these other counties nonatlainment.

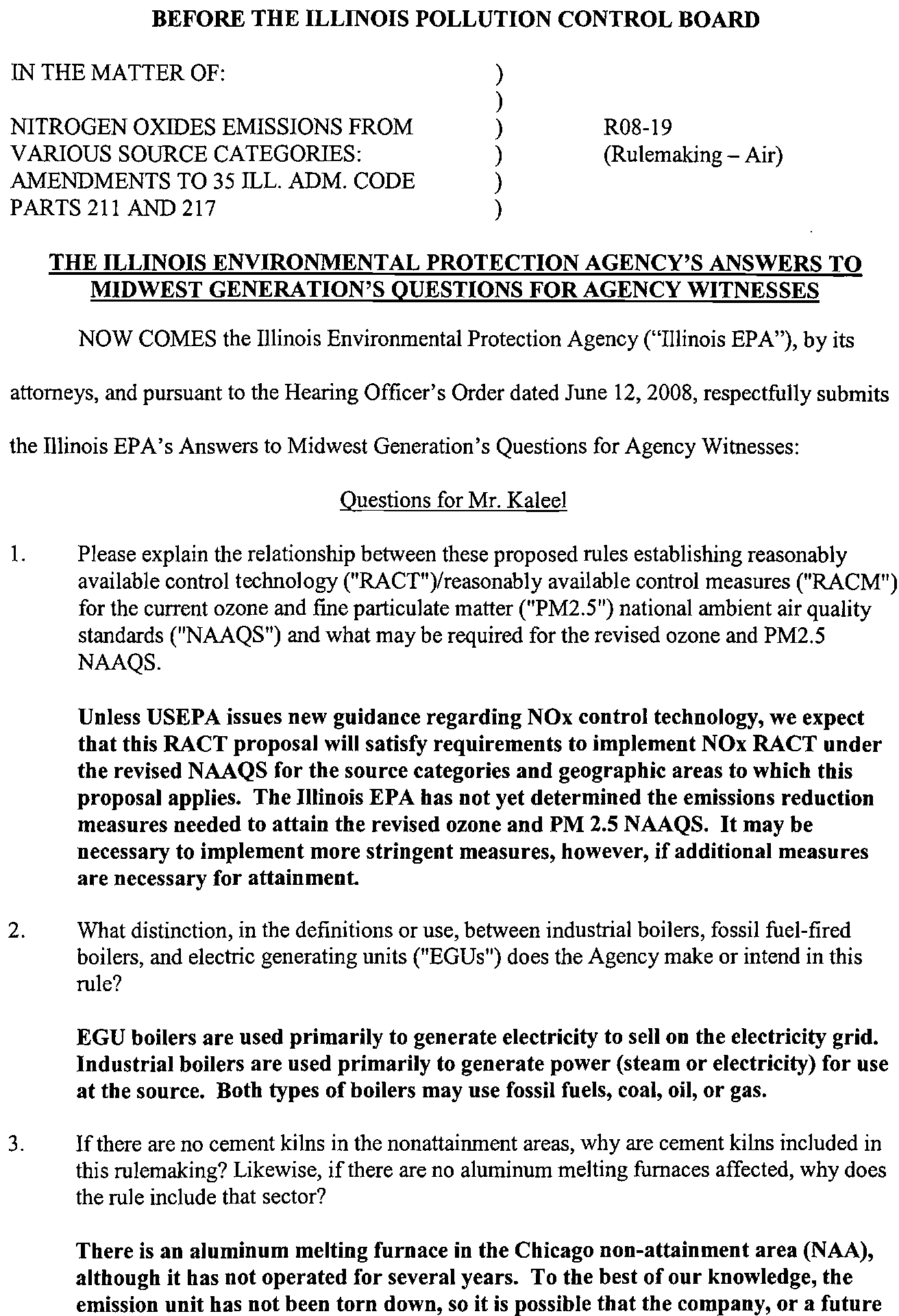

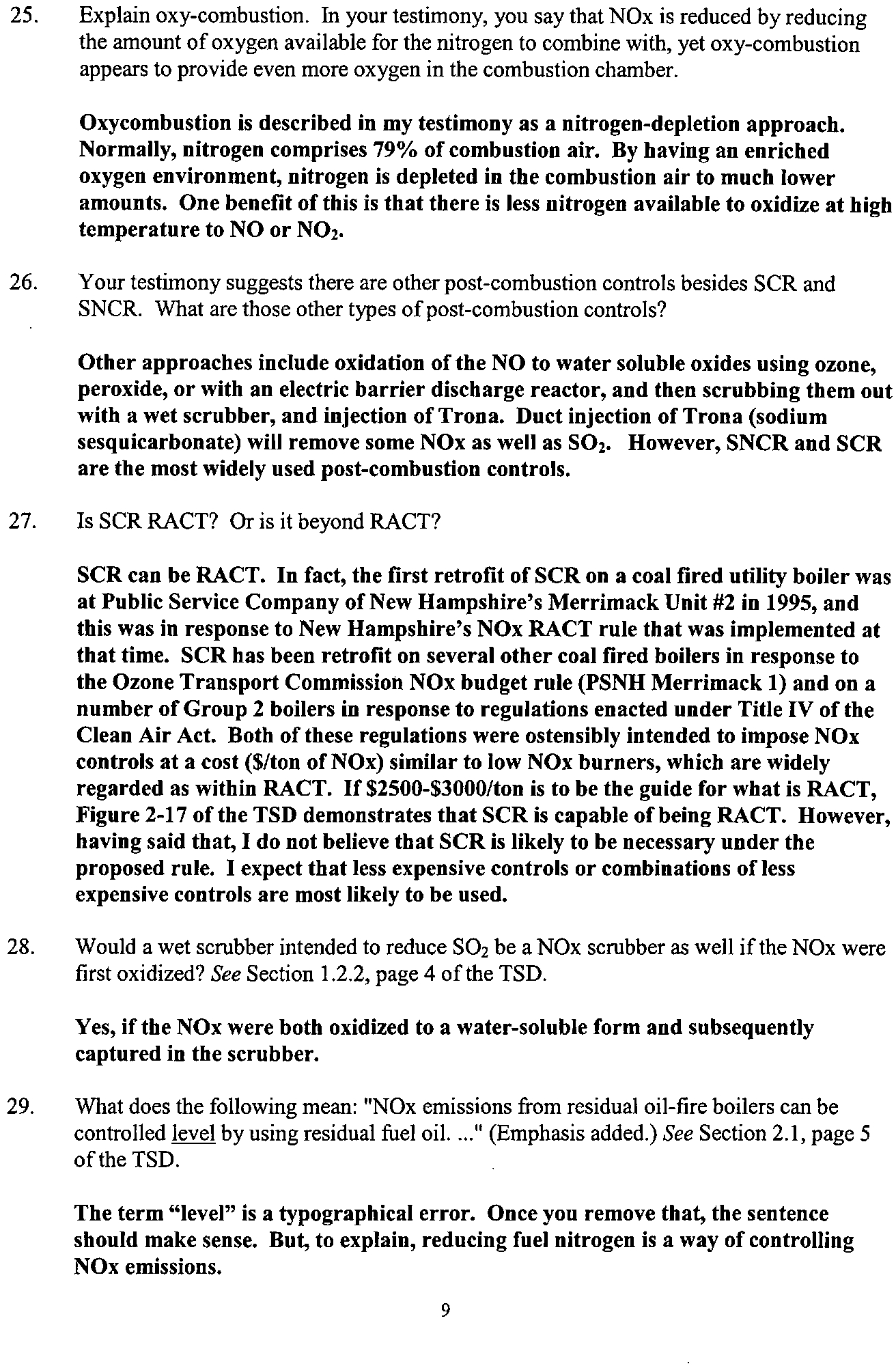

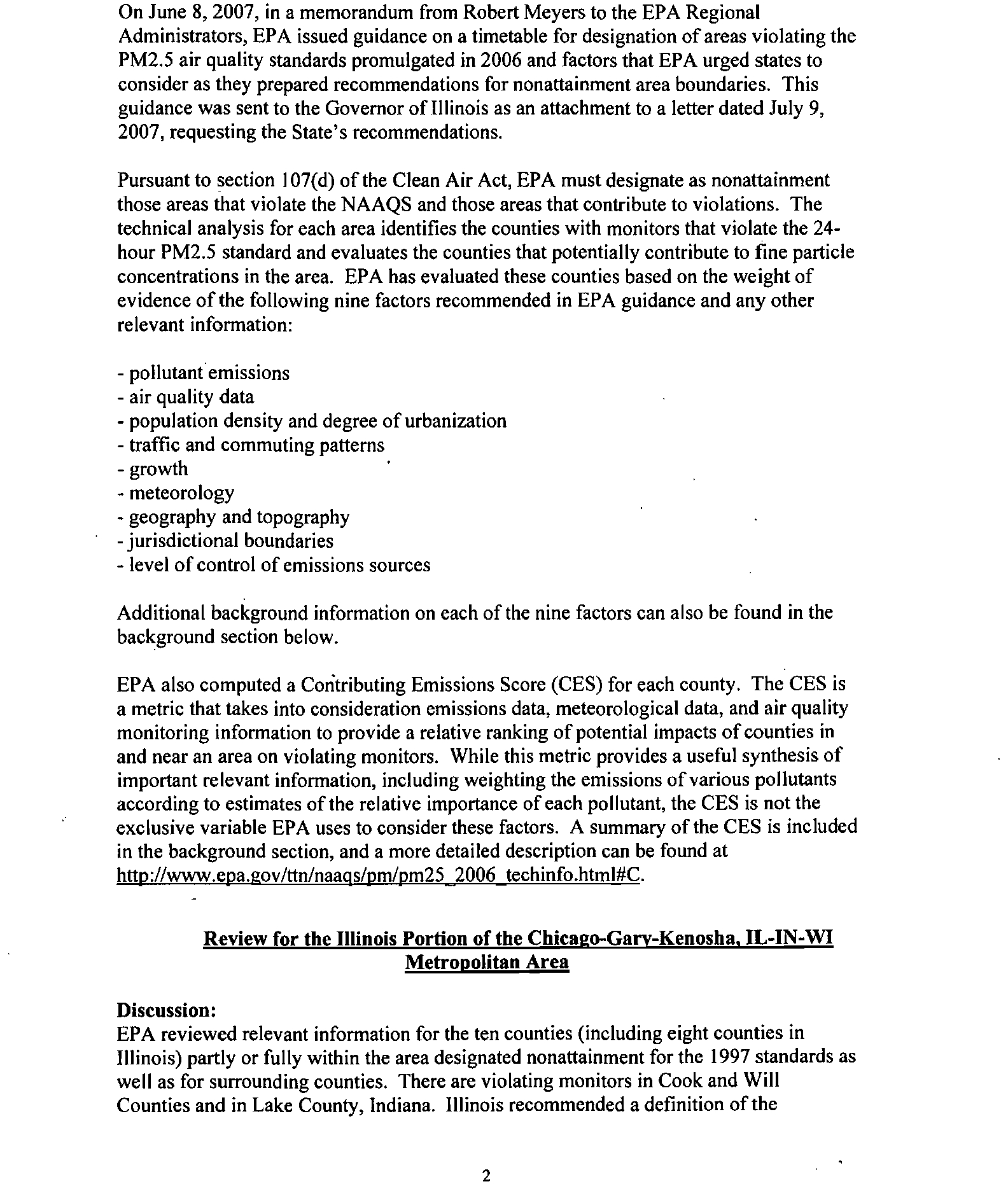

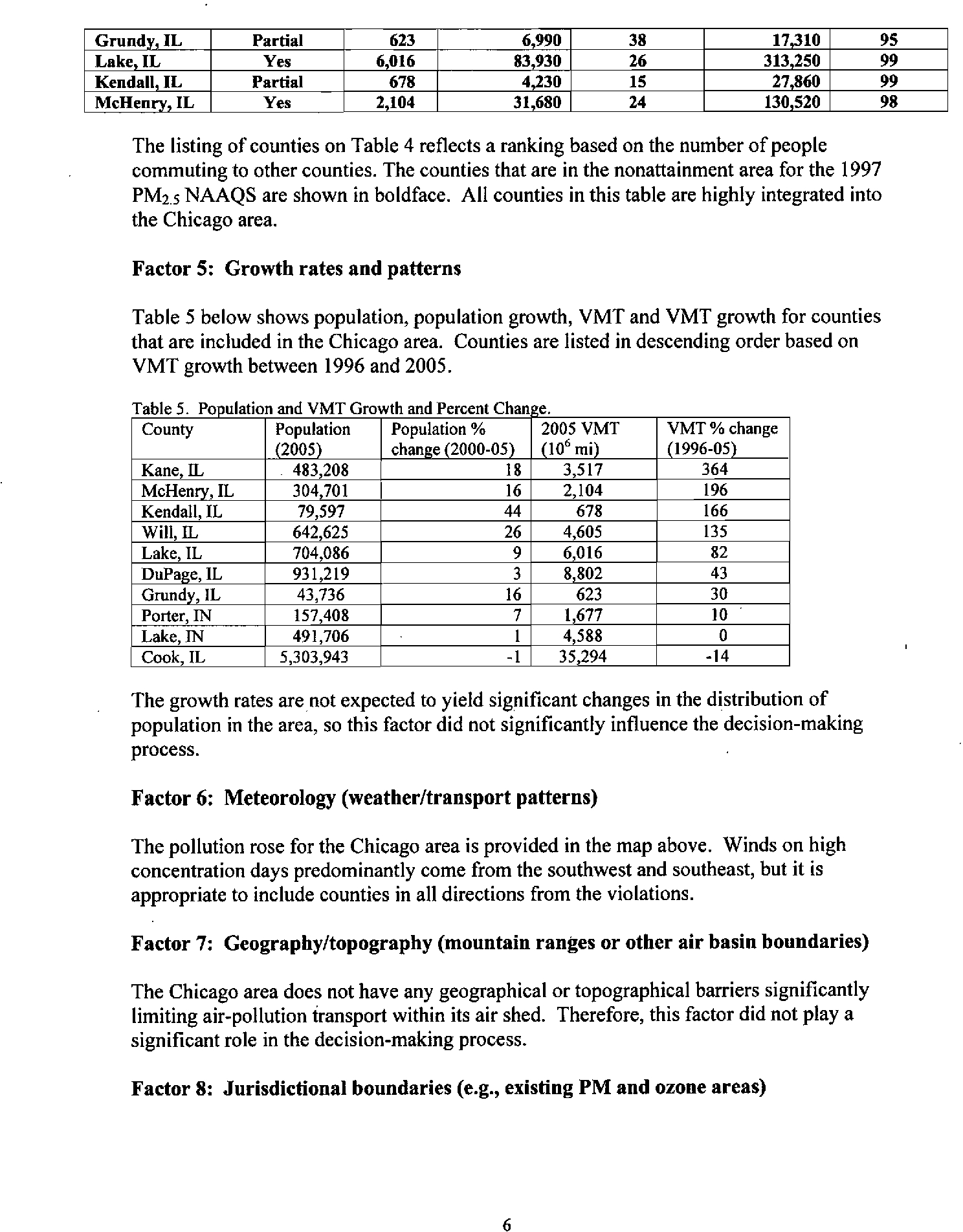

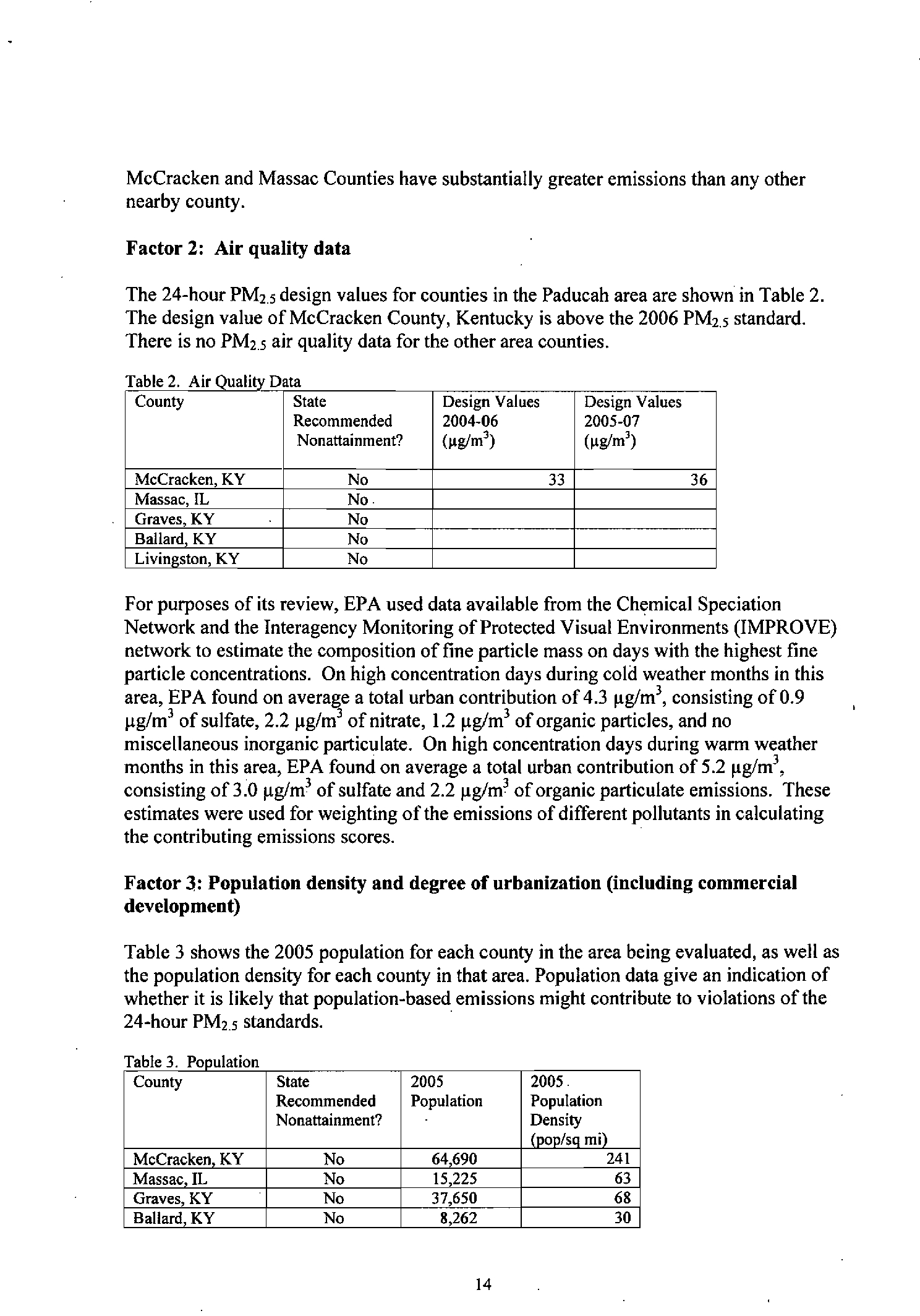

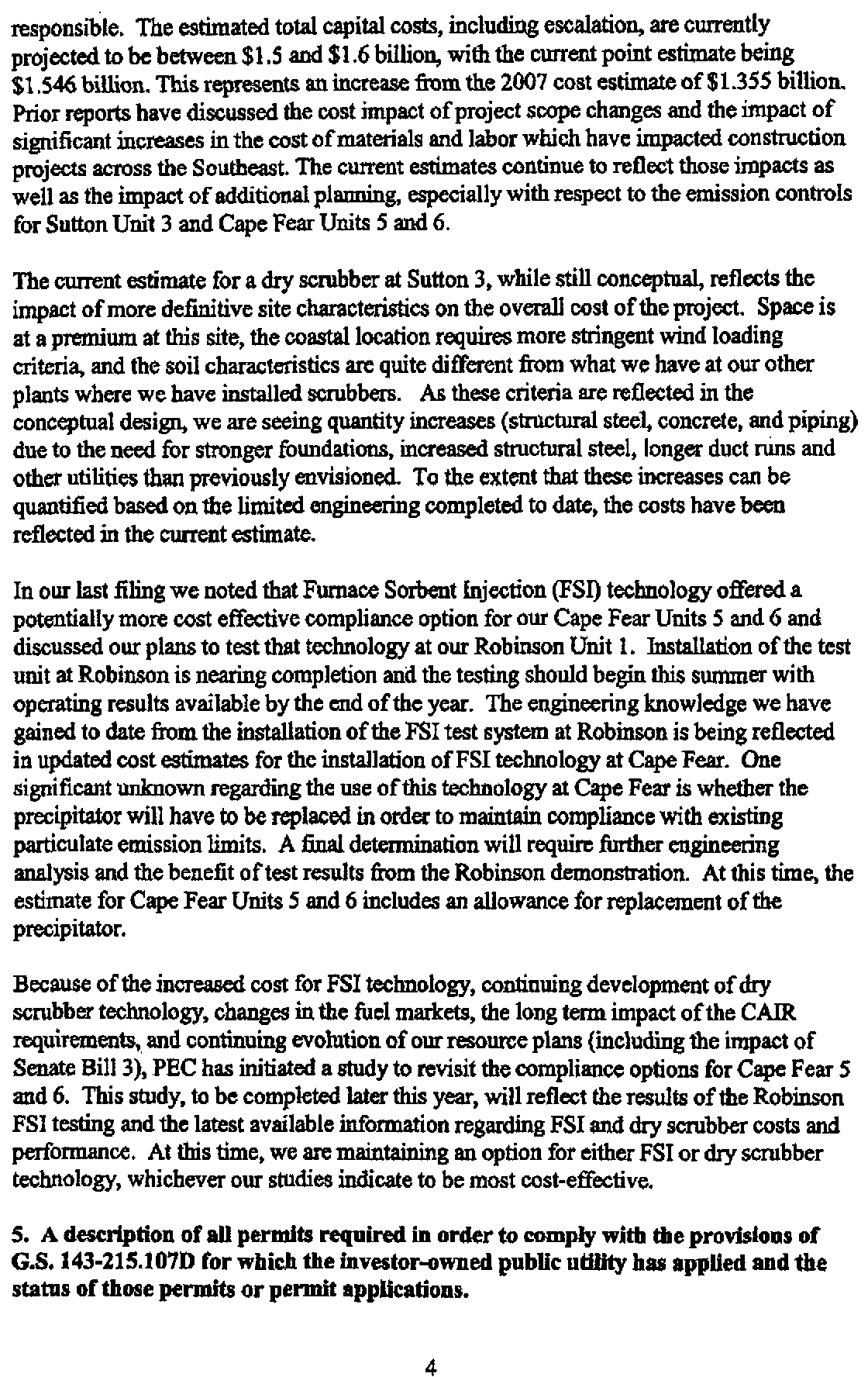

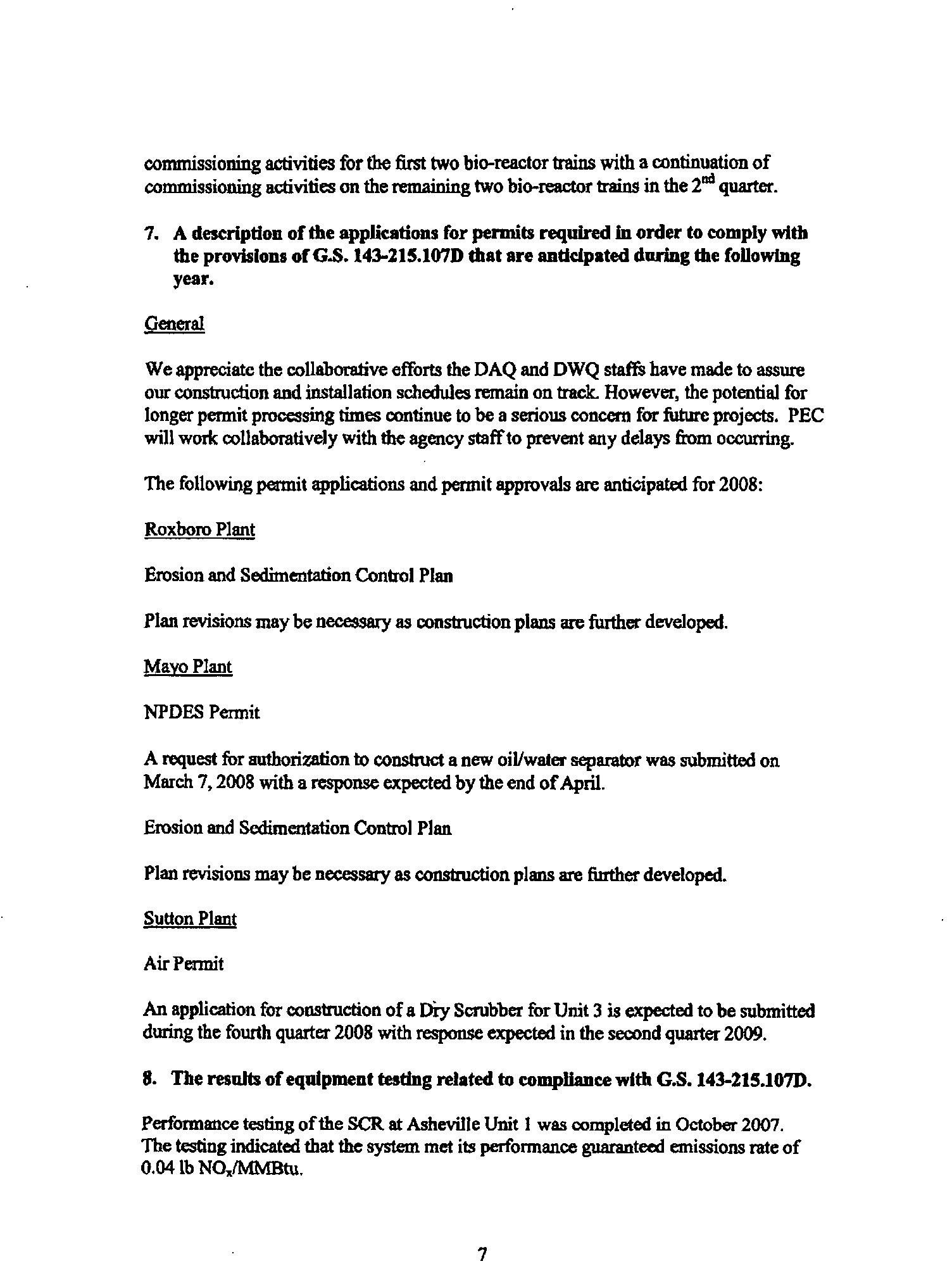

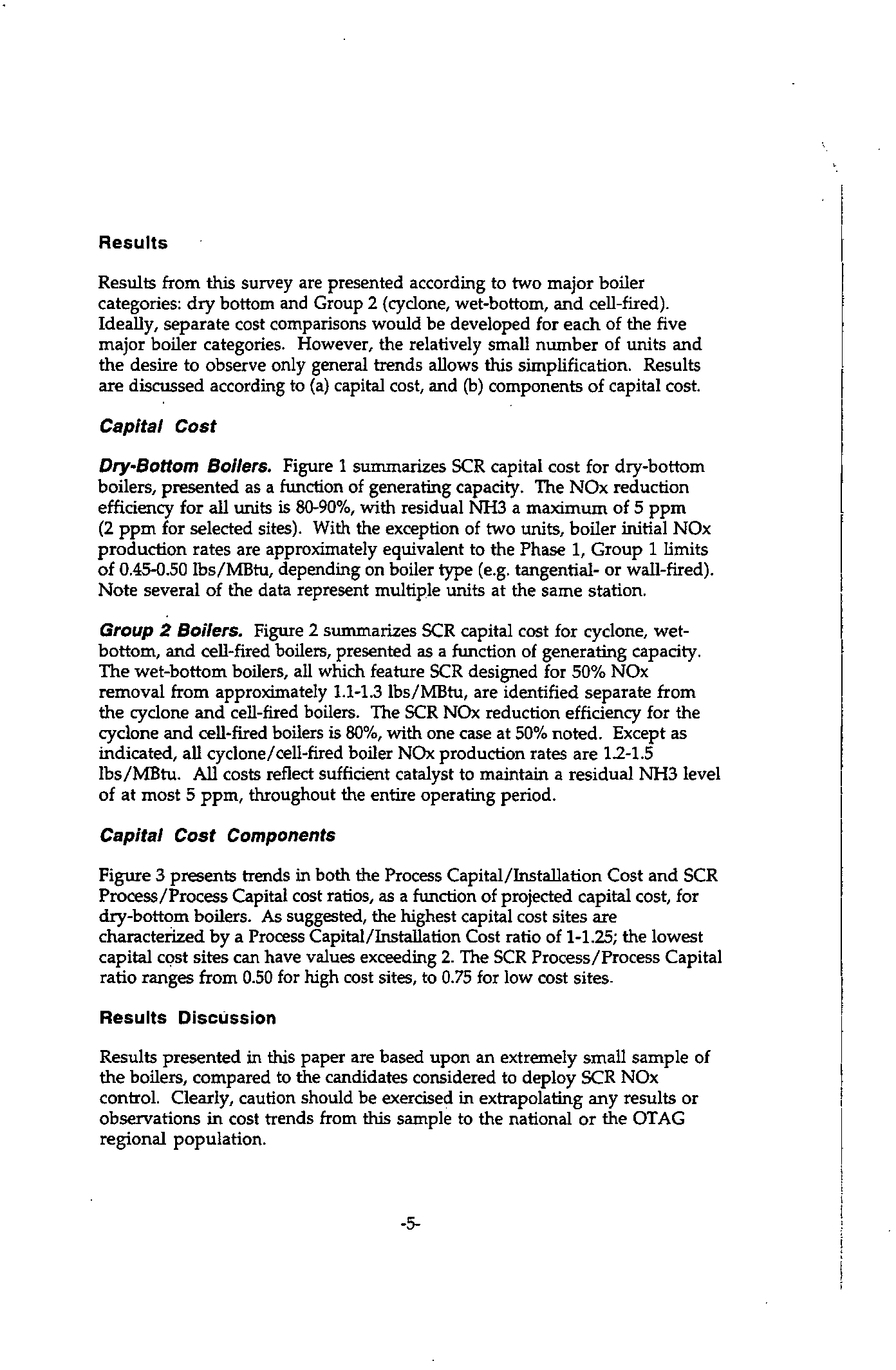

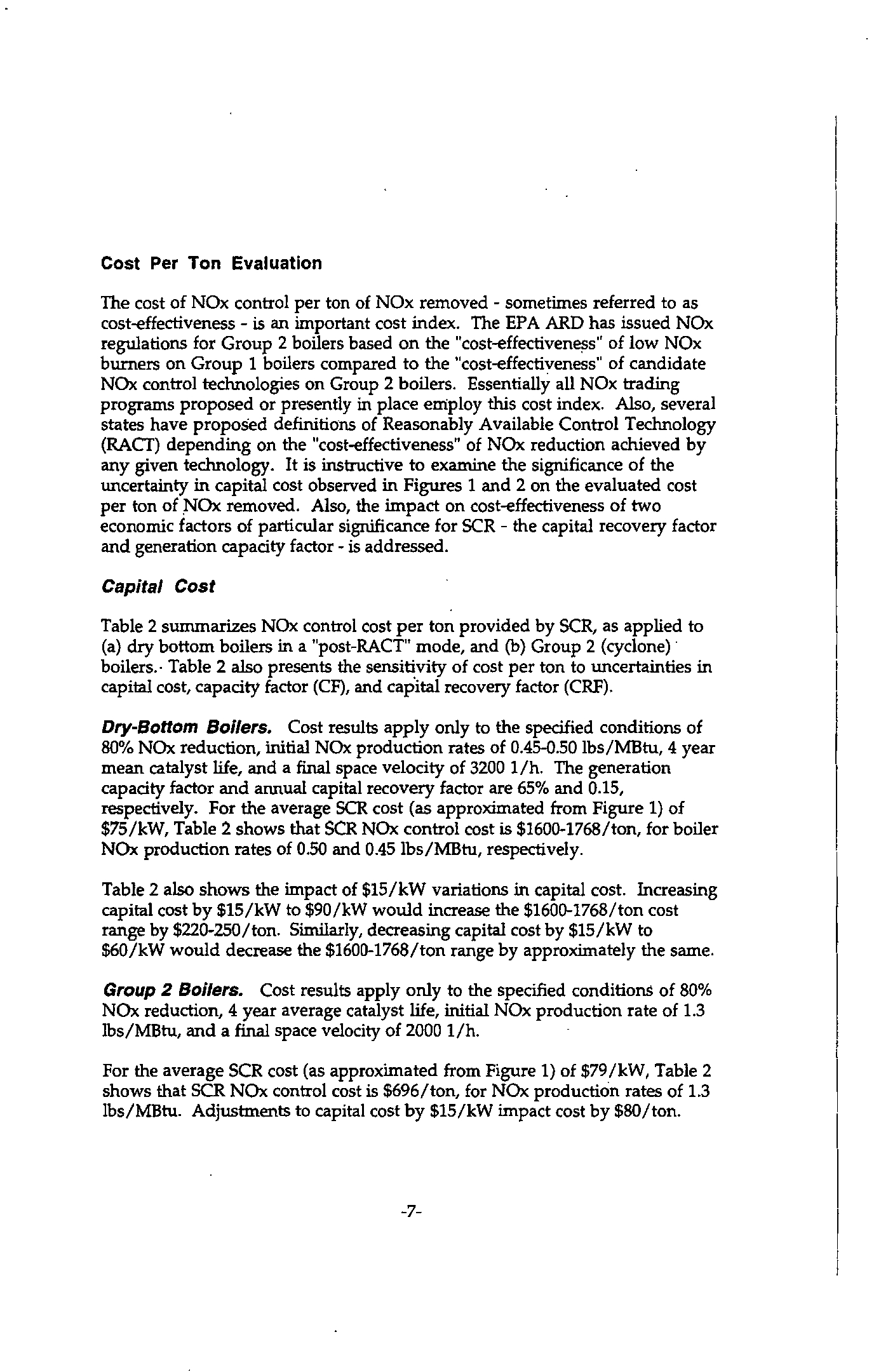

Figure I is a map of the counties in the area and other relevant information such as the

locations and design values

of air quality monitors, the metropolitan area boundary, and

counties recommended as nonattainment by the States.

sin

ROf'

~

<1"

I!!>

l!"

Illinois

.

.,

o

Stlle

1~1Idaton

!Of I'ICI"l3tl!inment

-34,

0

Sl.r.ereoJmleMatcmforparbal oonattalmntll1

SII:e retOll\'Tlel1daSOllIOta (ilfe{enz rr:t1tO area

Mo&.or Yiola:ing 24-tlr PU2.S NAAQS

(pre'imin.

2005.2001

design

'ti1!Ues)

Mi.

M~r.rairl'ng24-IlrPM2.5NMas

lpre"min. 2005-2001 des'gn va:t.les)

M~\'IoIating

24.flr PM2.S NMOS

Iprl!rrmln_ 2005-2007 incomplete

~I!sig:l ~arues)

National higllway$

c::J 2006 Combined

Sla~cal

Area

'~

PM2.SNoniIlIainmentArea

(1997 NMOS)

JiI

~~,..---

r::::::I

All 1'1.'2.5 NonattainmentAleas

11991 NMOS).

r-t--1

NonallaM1tim'Ma~enantIJ

Atea

......... for 8-1W Olone

~

EGUnilh!IUJCAP

emissiOns>

5.000

tDllSr'year in

2002

@

o:tlef

Point

Source

with total CAP

emissions>

5.000

tDf15fYUr

il2002

.-

Com~~~_~(49~1

Indiana ••

,

Figure 1- Note: Map produced prior to Indiana's nonattainment recommendation for Lake County, Ind.

3

???????????

??????? ?? ??????????

???????? ???????? ??????????

???? ????

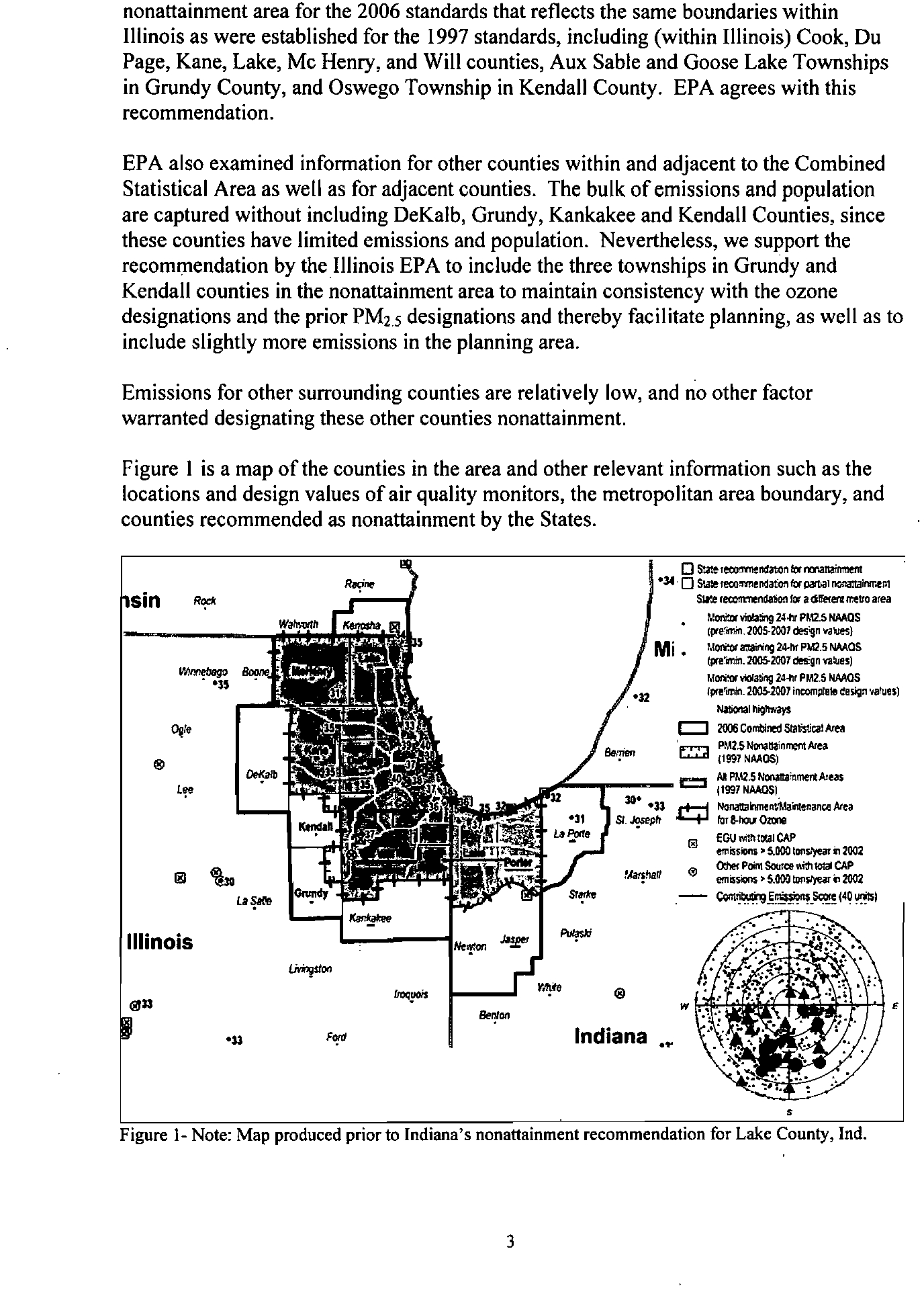

Factor 1: Emissions data

Table 1 shows emissions of PM2.5 components (given in tons per year) and the CESs for

potentially contributing counties in the Chicago area. Counties that are part

ofthe

Chicago nonattainment area for the 1997 PM

2

.

5

NAAQS are shown in boldface. Counties

are listed

in descending order by CES.

Tbl

a e 1. PM

~"

24h

- our Comt anent EmISSions an

d

CESs.

County

State

CES

PM"

PM,.,

PM,.,

SO,

NOx

VOCs

NH,

Recommended

emissions

emissions

emissions

(tpy)

(tpy)

(tpy)

(tpy)

Nonattainment?

total

carbon

other

(tnv)

(tnv)

(tnv)

Cook

IL

Yes

100

10081

5407

4674

35.354

175.267

152288

4550

Lake IN.

No

100

7079

1219

5861

39500

54.203

24679

3784

Will IL

Yes

95

5432

1.236

4195

78792

46028

19886

1407

Porter IN

No

41

3901

719

3183

24458

29930

9795

909

DuPa2e

IL

Yes

16

2075

1259

816

2013

36880

29541

1.385

Jasper, IN

No

14

2641

280

2360

40723

20,104

3,367

2,929

Kankakee, IL

No

9

1,660

419

1242

366

7,351

6,830

1699

Kane

IL

Yes

4

1997

733

1263

1037

16528

15578

1293

Grundy, IL

Partial

3

1105

248

857

362

4057

4223

1027

Lake

IL

Ves

3

2,657

1070

1587

14719

29478

32778

747

Kendall,IL

Partial

2

811

230

581

351

3697

3693

753

MeHenry,IL

Ves

1

2102

634

1,468

592

9493

10596

1224

Kenosha WI

No

I

1489

460

1,030

33,988

15967

7,857

647

Within lIlinois, emissions are highest in Cook, Will, DuPage, Lake, Kane, and McHenry

Counties. Emissions are moderate in Kankakee, Grundy, and Kendall Counties.

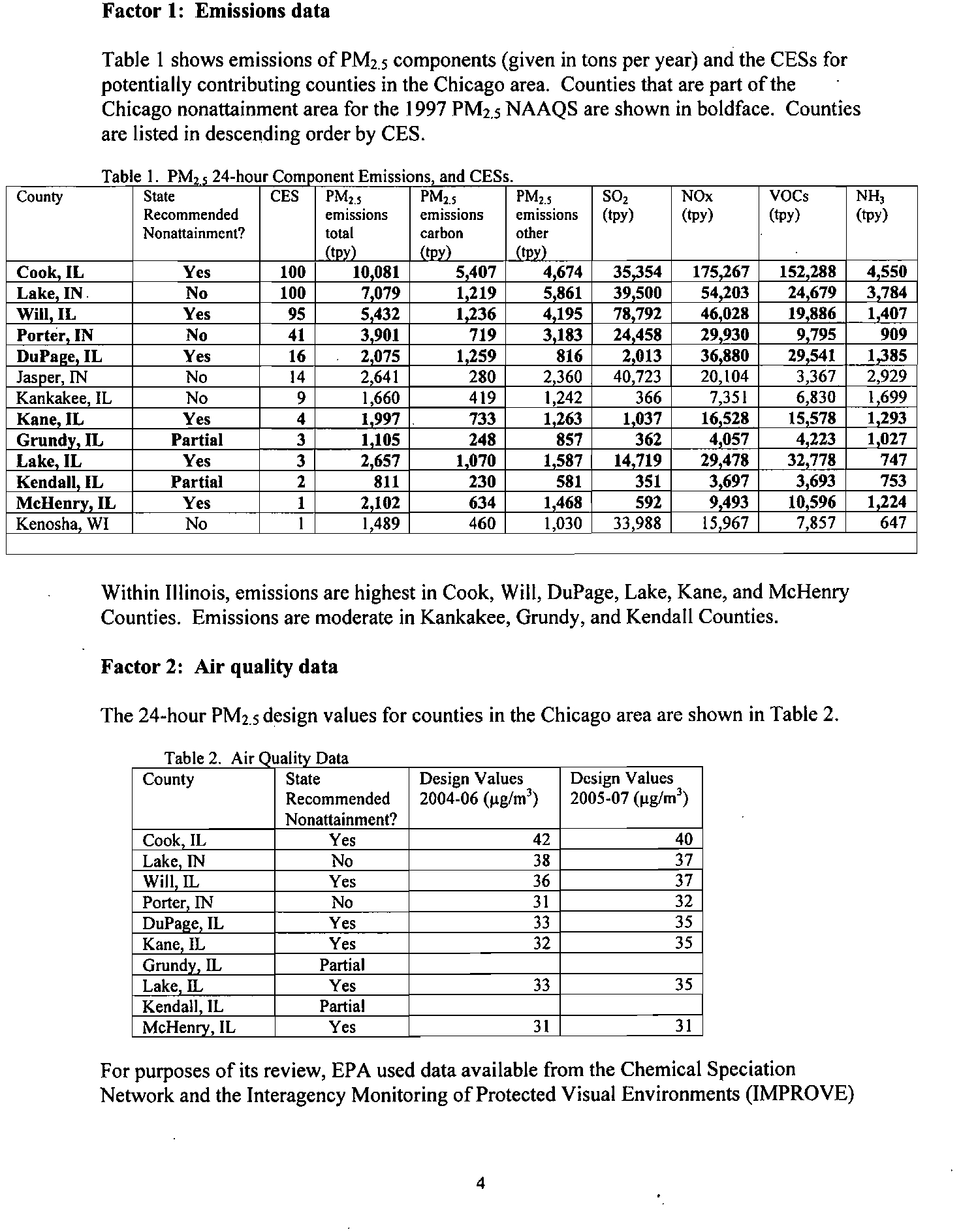

Factor 2:

Air

quality data

The 24-hour PM2.5 design values for counties in the Chicago area are shown in Table 2.

Table 2. Air Oualitv Dala

County

State

Design Values

Design Values

Recommended

2004.06 (j.tglm')

2005.07 (j.tglm')

Nonattainment?

Cook IL

Yes

42

40

Lake IN

No

38

37

Will IL

Yes

36

37

Porter IN

No

31

32

DuPa2e IL

Yes

33

35

Kane IL

Yes

32

35

Grundv. IL

Partial

Lake IL

Yes

33

35

Kendall IL

Partial

McHenry,IL

Yes

31

31

For purposes of its review, EPA used data available from the Chemical Speciation

Network and the Interagency Monitoring

ofProtected Visual Environments (IMPROVE)

4

???????????

??????? ?? ??????????

???????? ???????? ??????????

???? ????

network to estimate the composition of fine particle mass on days with the highest fine

particle concentrations. On high concentration days during cold weather months in this

area, EPA found on average a total urban contribution

of 8.8 flg/m

3

,

consisting of

004

flg/m

3

of sulfate, no nitrate,

804

flg/m

3

of organic particles, and no miscellaneous

inorganic particulate. On high concentration days during warm weather months

in this

area, EPA found on

avera~e

a total urban contribution of3.9 flg/m

3

, consisting of 0.5

flg/m

3

of sulfate, 3.1 flg/m of organic particles, and 0.3 flg/m

3

of miscellaneous

inorganic particulate. These estimates were used for weighting

of the emissions of

different pollutants in calculating the contributing emissions scores.

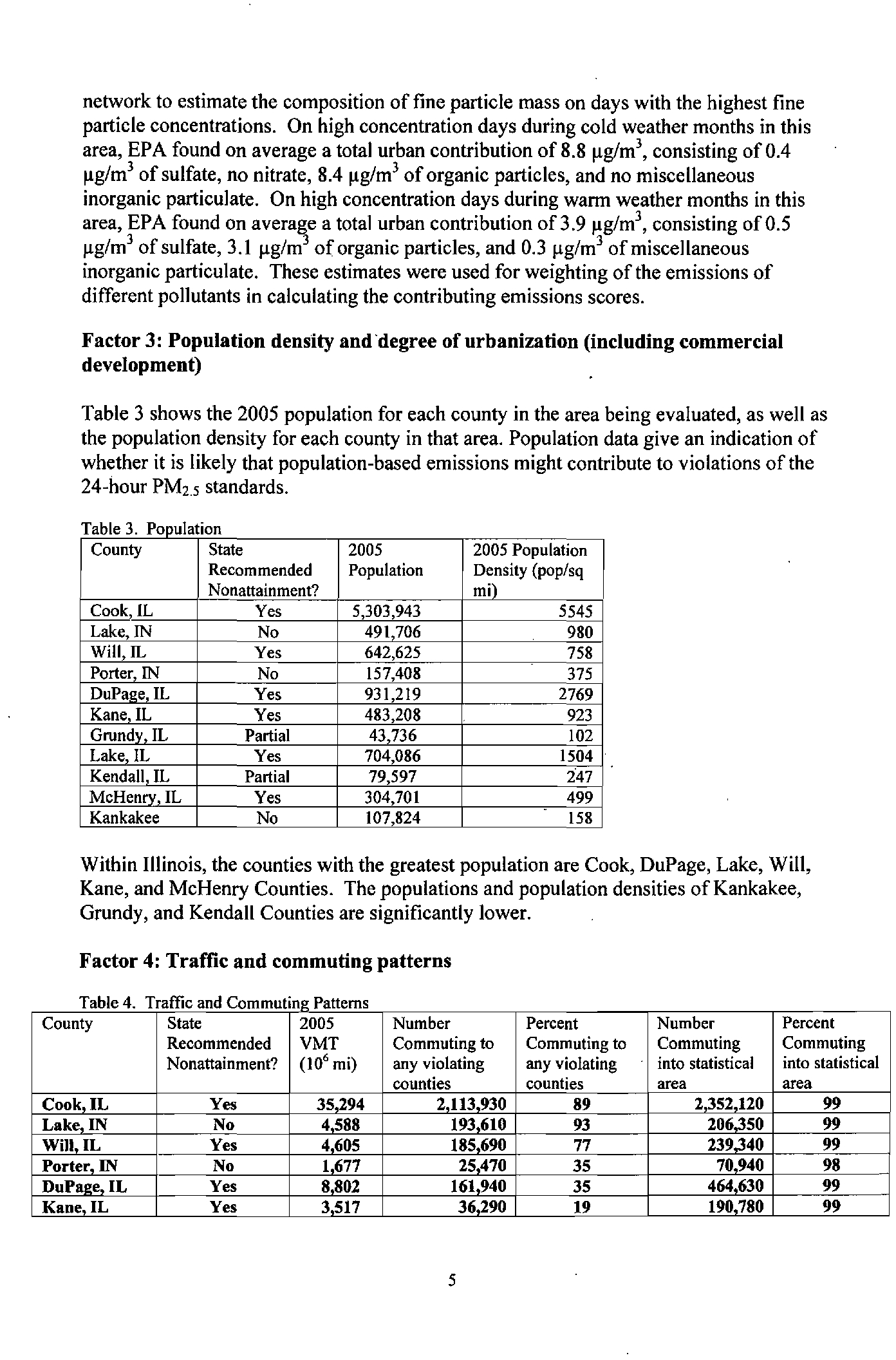

Factor 3: Population density and 'degree of urbanization (including commercial

development)

Table 3 shows the 2005 population for each county in the area being evaluated, as well as

the population density for each county in that area. Population data give an indication

of

whether it is likely that population-based emissions might contribute to violations of the

24-hour

PM25 standards.

Table 3. Ponulation

County

State

2005

2005 Population

Recommended

Population

Density (pop/sq

Nonattainment?

mil

Cook,IL

Yes

5,303,943

5545

Lake, IN

No

491706

980

Will, IL

Yes

642,625

758

Porter IN

No

157,408

375

DuPaoe IL

Yes

931,219

2769

Kane IL

Yes

483,208

923

Grundv IL

Partial

43736

102

Lake lL

Yes

704,086

1504

Kendall IL

Partial

79,597

247

McHen~

IL

Yes

304,701

499

Kankakee

No

107,824

158

Within Illinois, the counties with the greatest population are Cook, DuPage, Lake, Will,

Kane, and McHenry Counties. The populations and population densities

of Kankakee,

Grundy, and Kendall Counties are significantly lower.

Factor 4: Traffic and commuting patterns

Table 4. Traffic and Commutino Patterns

County

State

2005

Number

Percent

Number

Percent

Recommended

VMT

Commuting to

Commuting to

Commuting

Commuting

Nonattainment?

(10' mil

any violating

any violating

into statistical

into statistical

counties

counties

area

area

Cook

IL

Yes

35294

2.113930

89

2.352.120

99

Lake:" IN

No

4588

193610

93

206."50

99

Will IL

Yes

4.605

185.690

77

239-l40

99

Porter. IN

No

1.677

25.470

35

70940

98

DuPa~e

IL

Yes

8.802

161.940

35

464 630

99

Kane IL

Yes

3.517

36.290

19

190780

99

5

???????????

??????? ?? ??????????

???????? ???????? ??????????

???? ????

Grundy.IL

Partial

623

6.990

38

I7--nO

95

Lake.IL

Yes

6016

83.930

26

313 250

99

Kendall

IL

Partial

678

4,230

15

27860

99

McHenry,IL

Yes

2104

31.680

24

130520

98

The listing of counties on Table 4 reflects a ranking based on the number ofpeople

commuting to other counties. The counties that are in the nonattainment area for the 1997

PM25 NAAQS are shown in boldface. All counties in this table are highly integrated into

the Chicago area.

Factor 5: Growth rates and patterns

Table 5 below shows population, population growth, VMT and VMT growth for counties

that are included in the Chicago area. Counties are listed in descending order based on

VMT growth between 1996 and 2005.

Table

5. PoouIatlon

.

and VMT Growth and Percent Chan e.

County

Population

Population %

2005 VMT

VMT%change

(2005)

chanee (2000-05)

00'mil

0996-05\

Kane, IL

483,208

18

3,517

364

McHenry,IL

304701

I

16

2,104

196

Kendall,IL

79597

44

678

166

Will, IL

642,625

26

4,605

135

Lake,IL

704,086

9

6016

82

DuPaee,IL

931,219

3

8802

43

GrundV,IL

43,736

16

623

30

Porter,

IN

157,408

7

1,677

10

Lake,IN

491,706

I

4588

0

Cook,IL

5,303,943

-1

35,294

-14

The growth rates are not expected to yield significant changes in the distribution of

population in the area, so this factor did not significantly influence the decision-making

process.

Factor 6: Meteorology (weather/transport patterns)

The pollution rose for the Chicago area is provided in the map above. Winds on high

concentration days predominantly come from the southwest and southeast, but it

is

appropriate to include counties in all directions from the violations.

Factor 7: Geography/topography (mountain ranges or other air basin boundaries)

The Chicago area does not have any geographical or topographical barriers significantly

limiting air-pollution iransport within its air shed. Therefore, this factor did not

playa

significant role in the decision-making process.

Factor 8: Jurisdictional boundaries (e.g., existing PM and ozone areas)

6

???????????

??????? ?? ??????????

???????? ???????? ??????????

???? ????

The Chicago Area Transportation Study (CATS) Policy Committee is the Metropolitan

Planning Organization (MPO) for the northeastern Illinois region. CATS webpage:

http://www.catsmpo.coml.

The Illinois portion

of the Chicago ozone nonattainment area consists of the following

counties: Cook, Du Page, Kane, Lake, Mc Henry, Will,

Aux Sable and Goose Lake

Townships in Grundy County, and Oswego Township in Kendall County. Designating a

nonattainment area matching these boundaries will facilitate planning.

Factor 9: Level of control of emission sources

The emission estimates on Table 1 include any control strategies implemented by the

States in the Chicago area before 2005 that may influence emissions

of any component of

PM2.5 emissions (i.e., total carbon, S02, NOx, and crustal PM2.s).

Review for the Davenport-Moline-Rock Island Metropolitan Statistical Area

Discussion:

The Davenport-Moline-Rock Island area is currently designated attainment for PM2.5. A

monitor in Davenport (Scott County) is showing violations

of the standard. Illinois

recommended including no part

of Illinois in the nonattainment area. EPA reviewed

relevant information for the four counties in

the metropolitan statistical area and for

surrounding counties.

EPA believes that the nonattainment area should include Rock Island County in Illinois.

Rock Island County has moderate emissions that commonly are blown toward the

violating monitor is Scott County. We also believe

that sufficient commuting occurs

between Rock Island County and Scott County that Rock Isiand County must

be

considered an integral part of the Davenport area.

EPA recognizes that emissions in close proximity to the monitor may make an important

contribution to the violations. Indeed, EPA recognizes the possibility that reduction

of

the emissions close to the monitor may suffice to address the violation. Nevertheless, our

obligation under Clean Air Act section 107 in defining a nonattainment area is to identify

the area that is violating the standard and the area that is contributing to the violation.

The area that contributes to the violation is then included in the planning area evaluated

for measures for attaining the standard. Even

if the state already suspects that its control

strategy will focus on sources in the immediate vicinity

of the violating monitor, EPA

must apply a nonattainment designation to the entire area that contributes to the violation,

such that the SIP planning will address the entire contributing area.

Furthermore, the available evidence suggests that local emissions contribute only a

fraction

of the concentrations in Davenport. A much larger fraction of the concentrations

in Davenport arise from emissions farther from the monitor. EPA believes that

an

important component of these concentrations arises from a contribution from emissions

throughout the Quad Cities area. While the impact

of Rock Island County appears to be

7

???????????

??????? ?? ??????????

???????? ???????? ??????????

???? ????

less than that of Scott Counties, Iowa, the impact nevertheless appears sufficiently

substantial to include Rock Island County in the nonattainment area.

EPA also examined information for Henry and Mercer Counties as well as for nearby

counties outside the metropolitan area.

EPA found that these other counties have

relatively low emissions, and no other factor warranted inclusion

of the counties in the

nonattainment area.

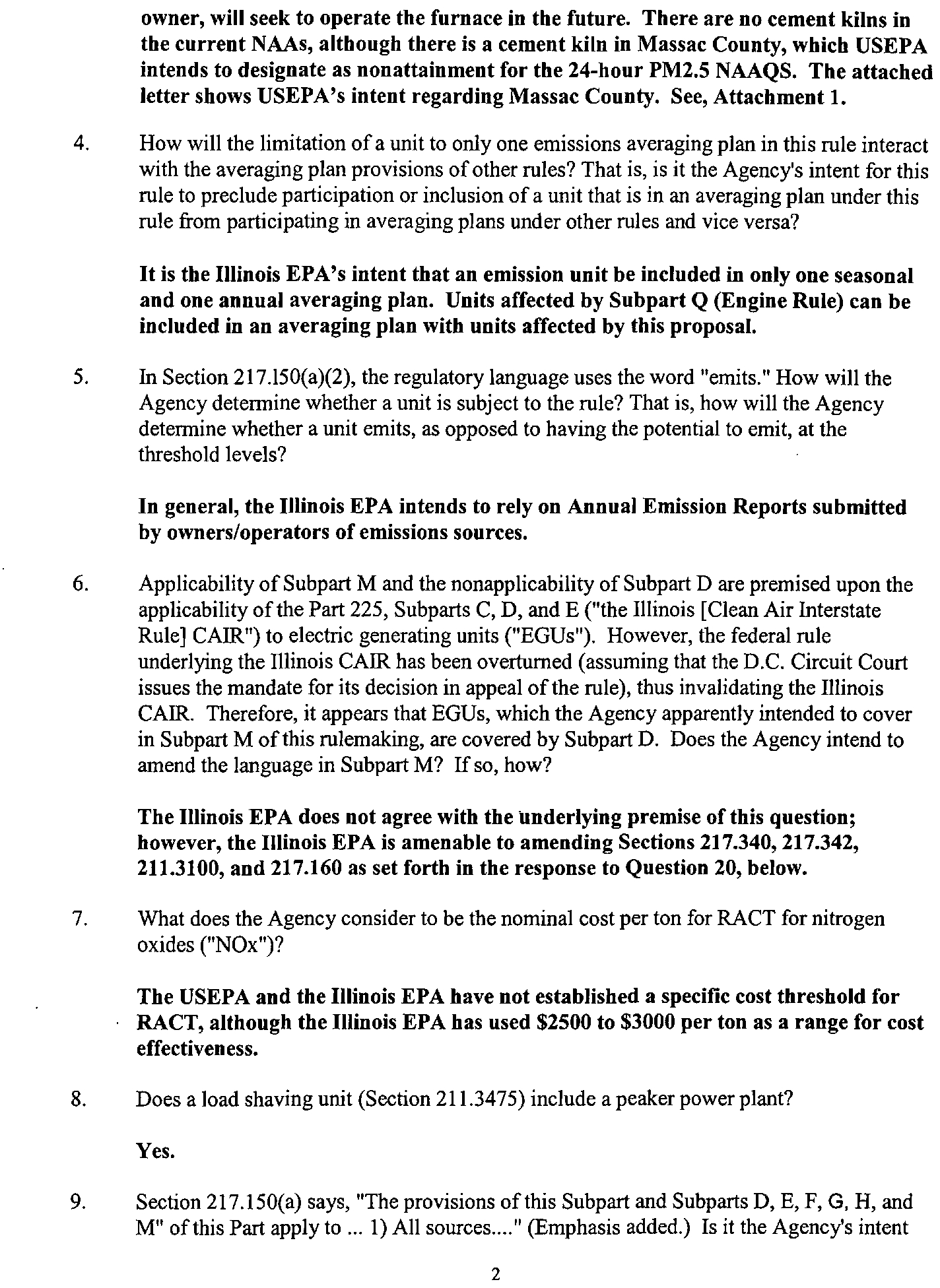

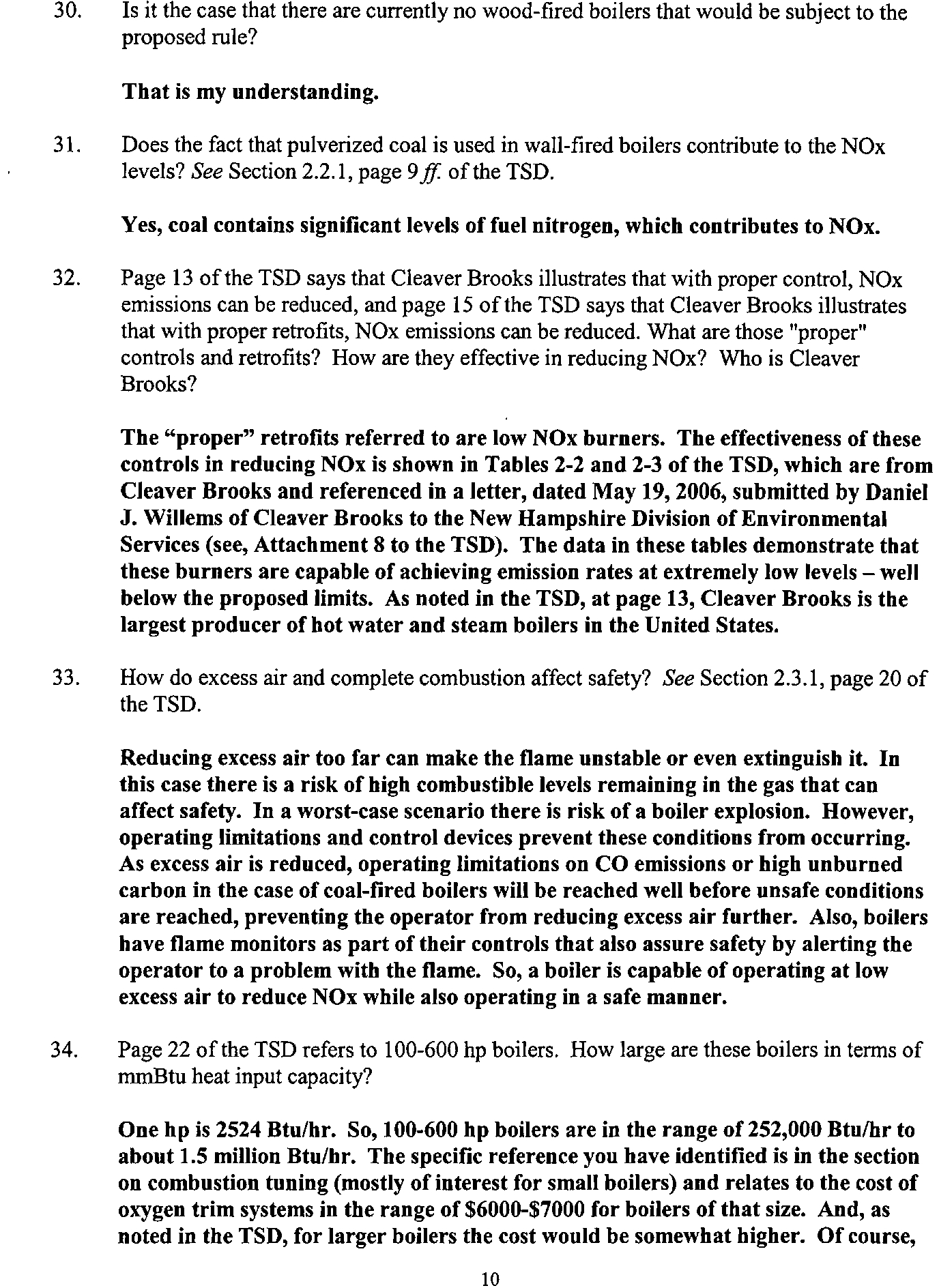

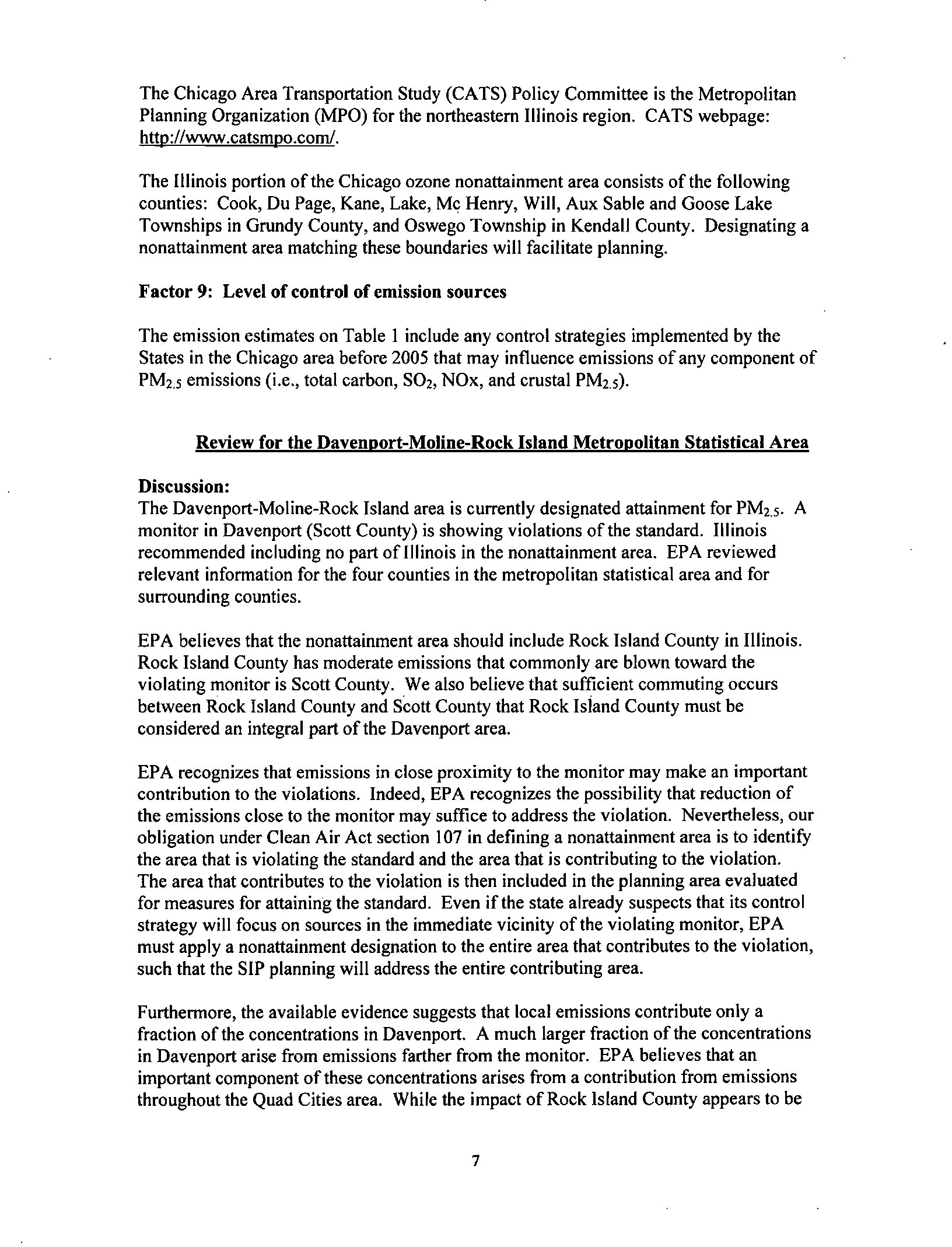

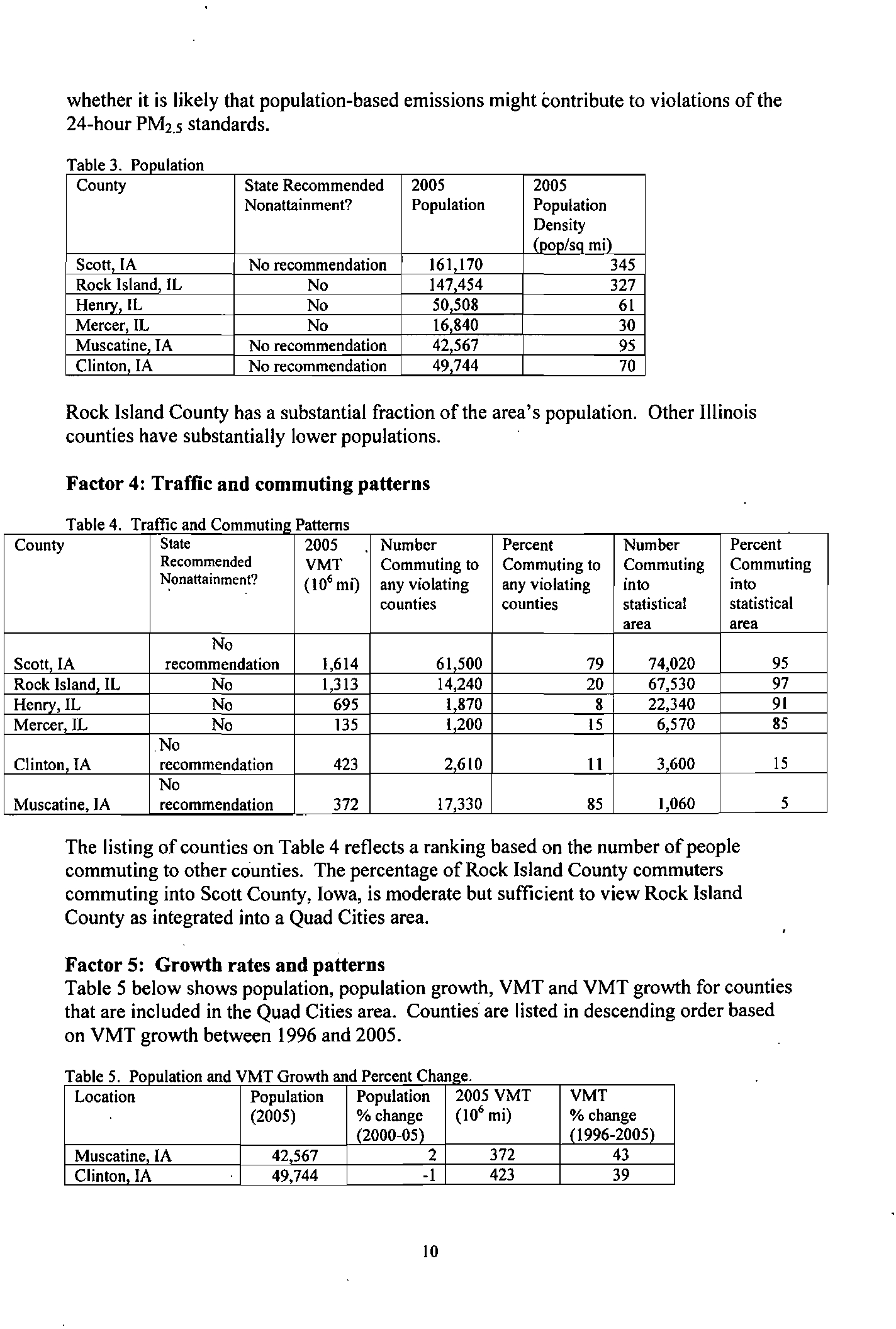

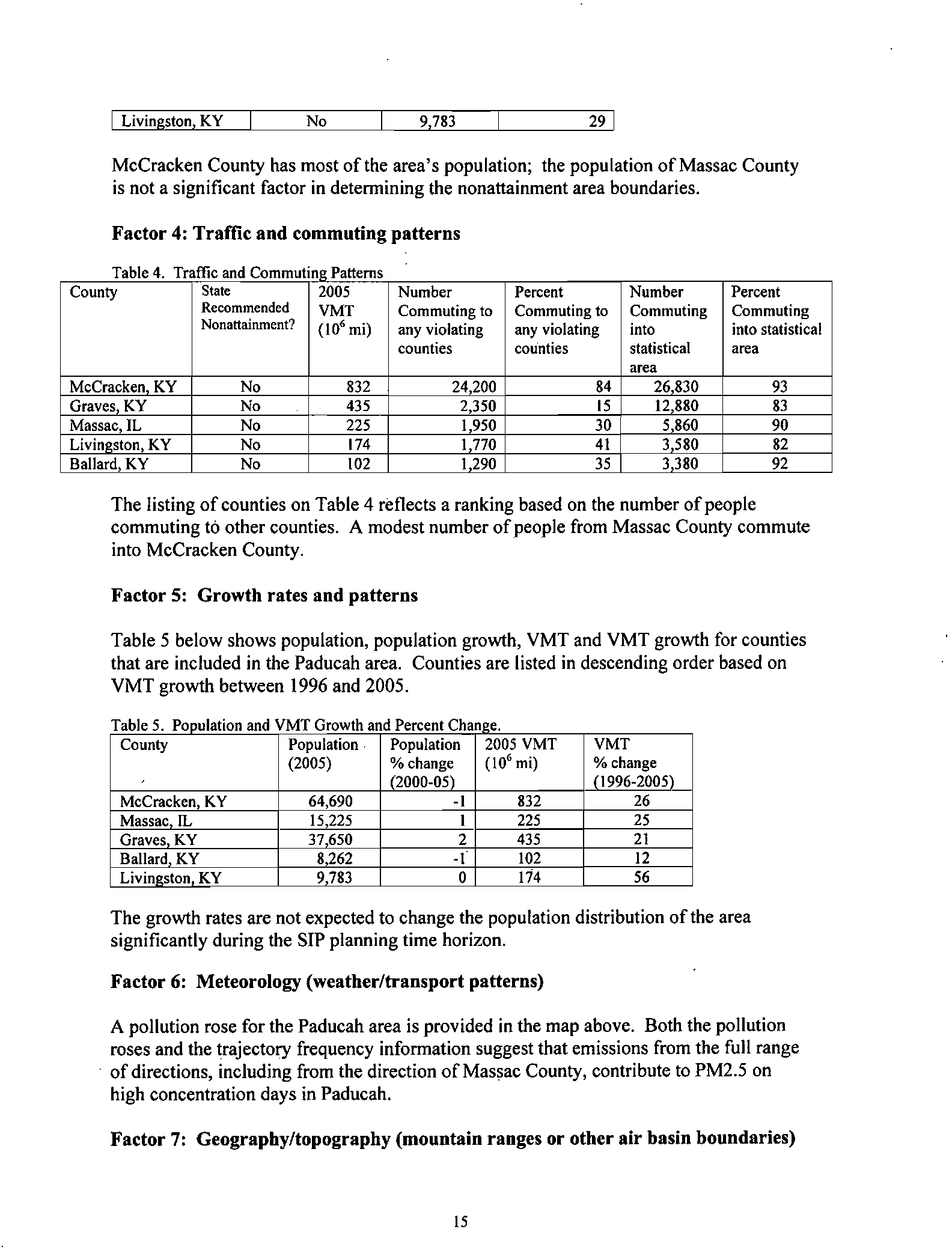

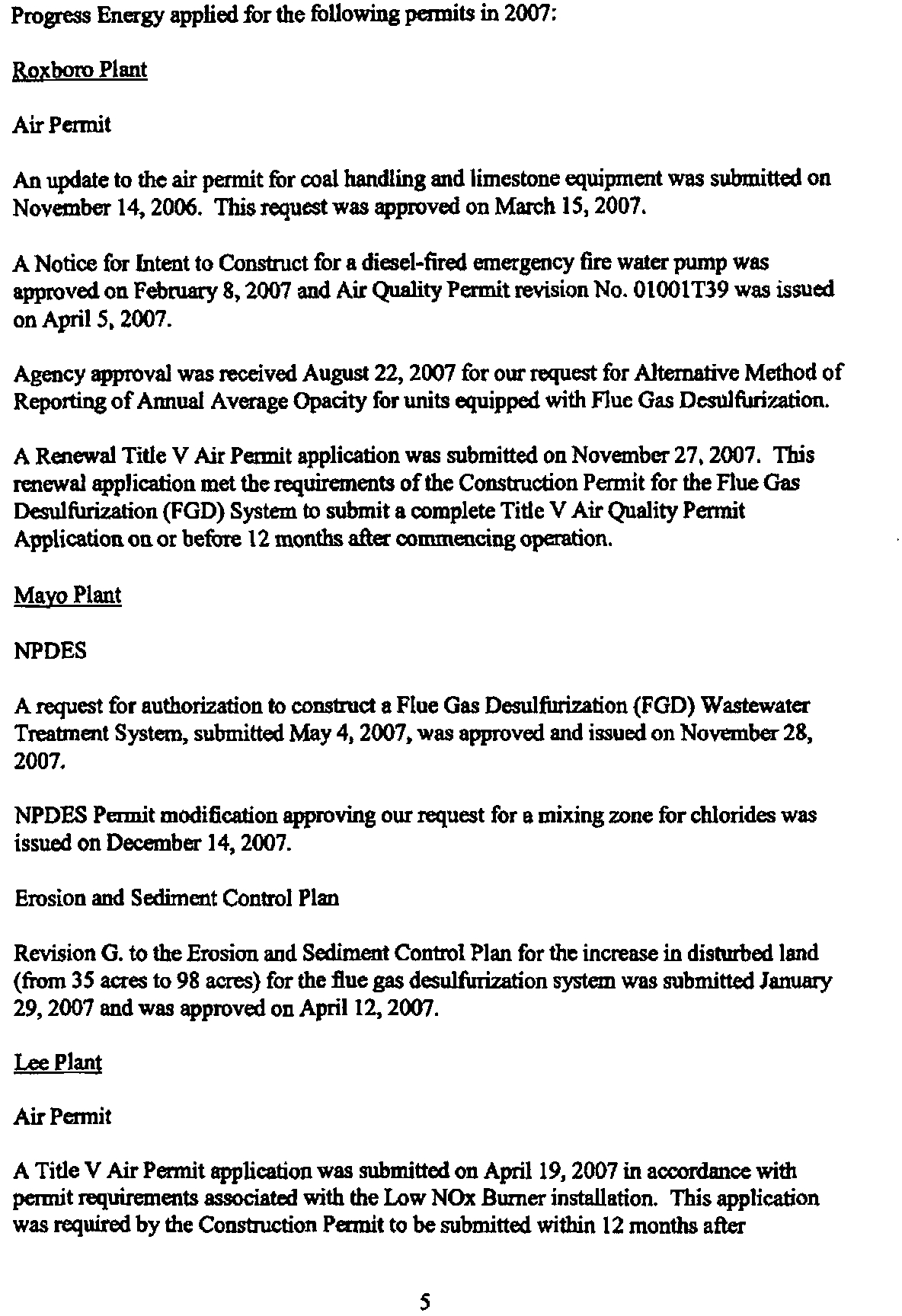

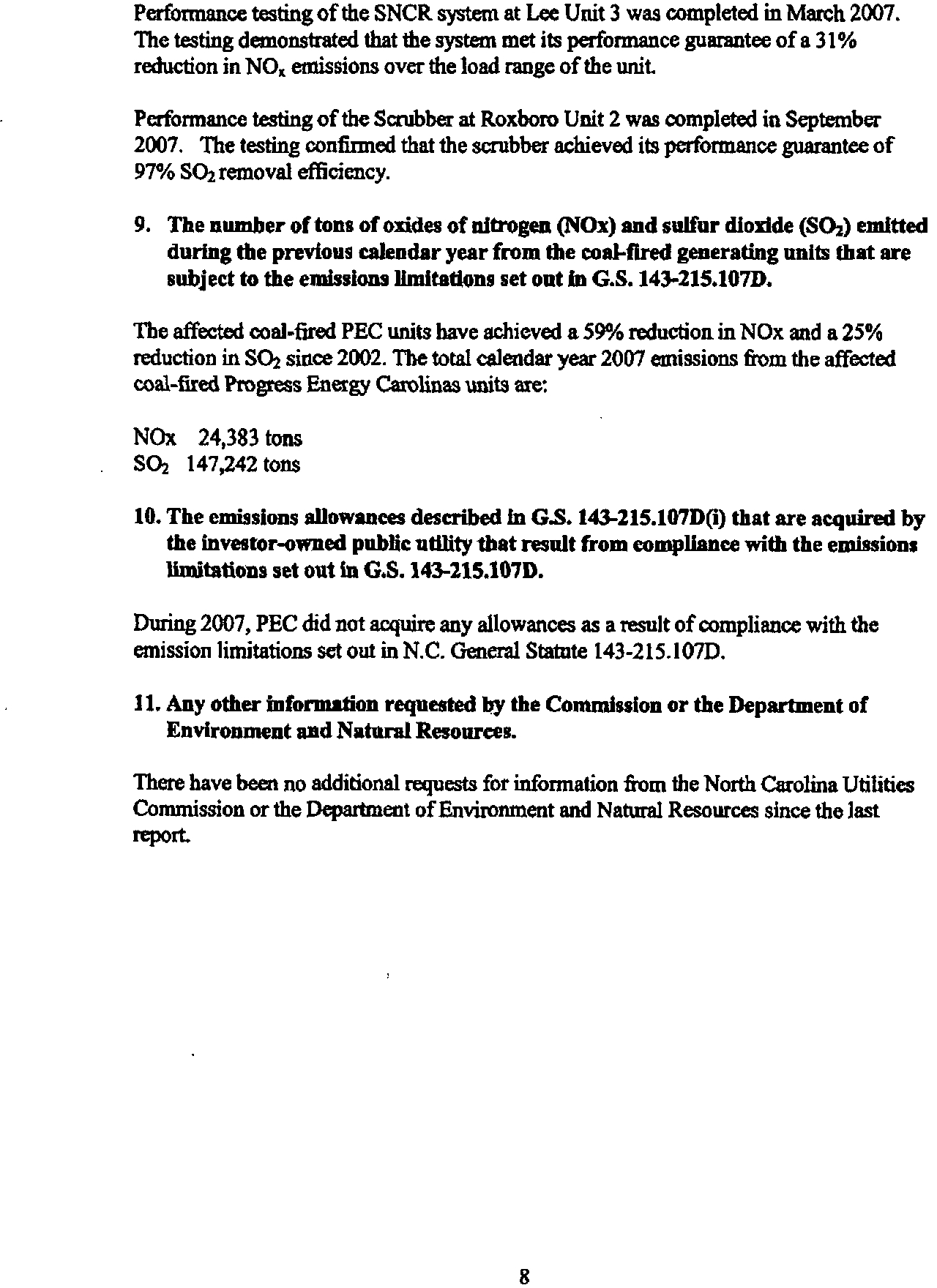

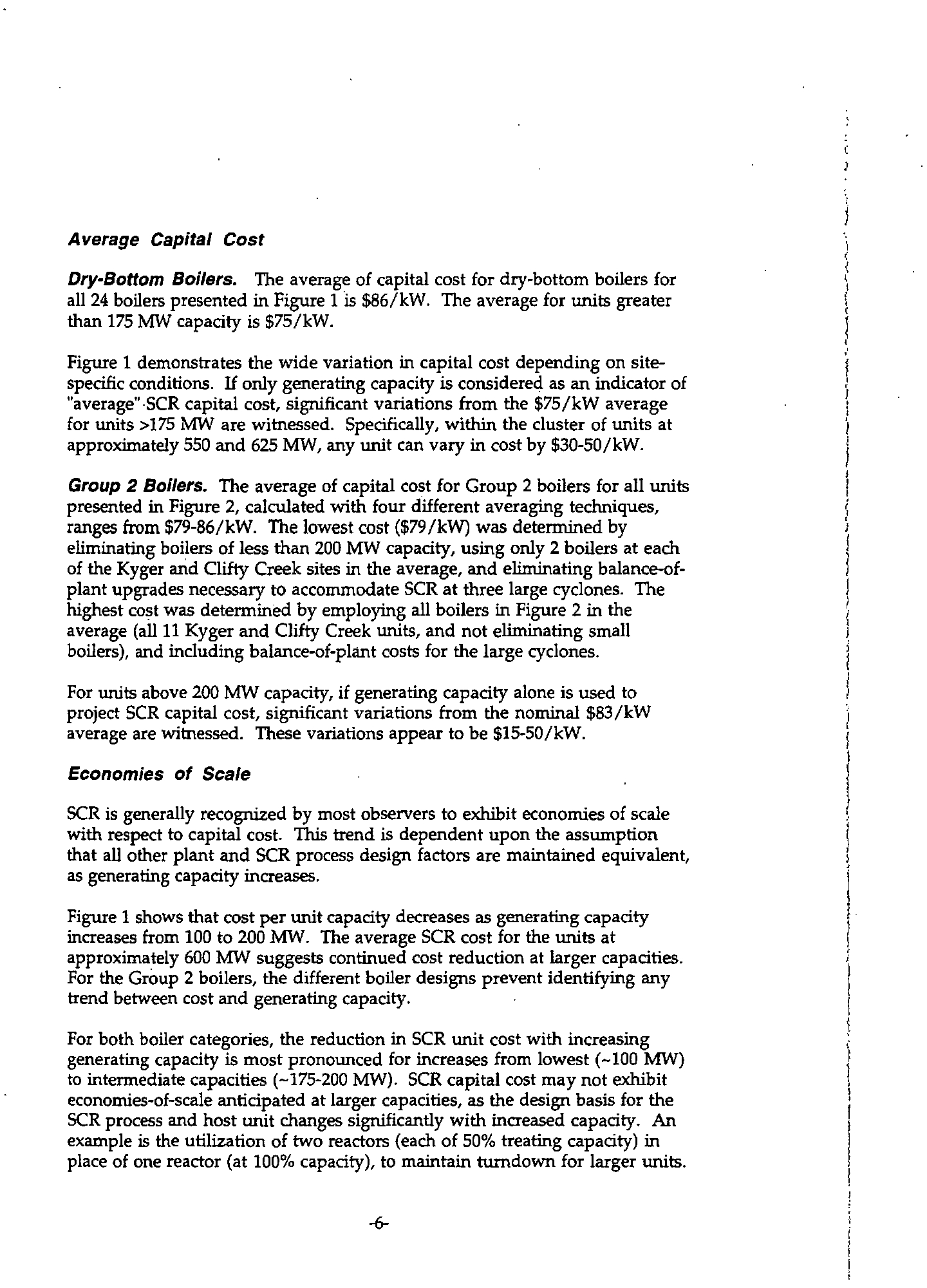

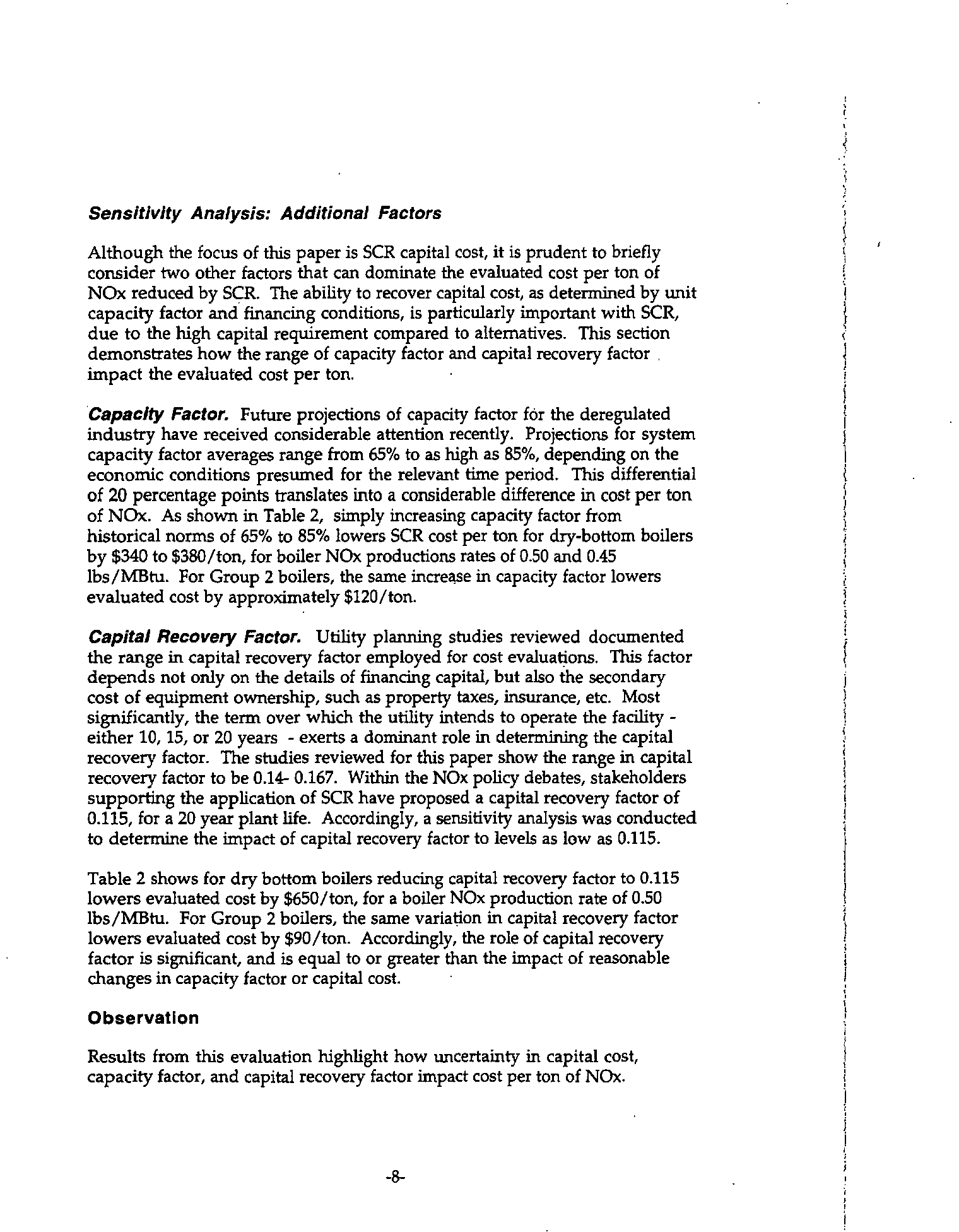

Figure 2

is a map of the counties in the area and other relevant information such as the

locations and design values

of air quality monitors, the metropolitan area boundary. Iowa

did not make formal recommendations, and Illinois recommended that no Illinois

counties be included, so this map shows no state recommended nonattainment area.

Iowa

o Sla:le'lecommerclalion for nc::l3t1amme:nt

o

Slale recommendation for partial nonattal.'lmell1

St.alll recomnendatiofl for ad:trerent metro area

MCritot

~iOIali'ltl24·llf

pt12.5 NMOS

~

12

@

ipretmin. 2005-2007 dMign vah.e!l1

Whir~

Mcrli::l!' atIi'nng2U!r PM2,5I'WtOS

IllttIini'l.2005-2007 des9'lvalles}

C<!"

Mcnilor ¥0Iali'.g2+lu Pt.l2.5 NMOS

Iprelinn. 200S-2001 irlcetnll!etB desi;n ..-alias)

Nalionalllighl'l1)'$

c:J 2006

Co'! Based

Stitistita1

Area

""

~

PM2.5f\>Onor.ai'mentArea

~

(1997 NAAQS)

:::::I

AI PP.l2.5 Nonatl21M::ent

Areas

(l997NAAOSI

.

He~1Y

J:!:+j

~~"JI:a

8I1t~au

br

UlOUr Otone

.,

EGUwllhlolalCAP

l~

em;sslons;>

5.«01ons.')'earin2002

f.t8f..

cer

"

OtIler Polnl Source

\mt1latalCN'

em:ssiOns > S,COO lQnSfyeal in

2002

St!fk

.-

COrr:rtutin9E~l!"1401,lrt\$)

~

illinois

~"'"

w

...

........

".

s

Figure 2

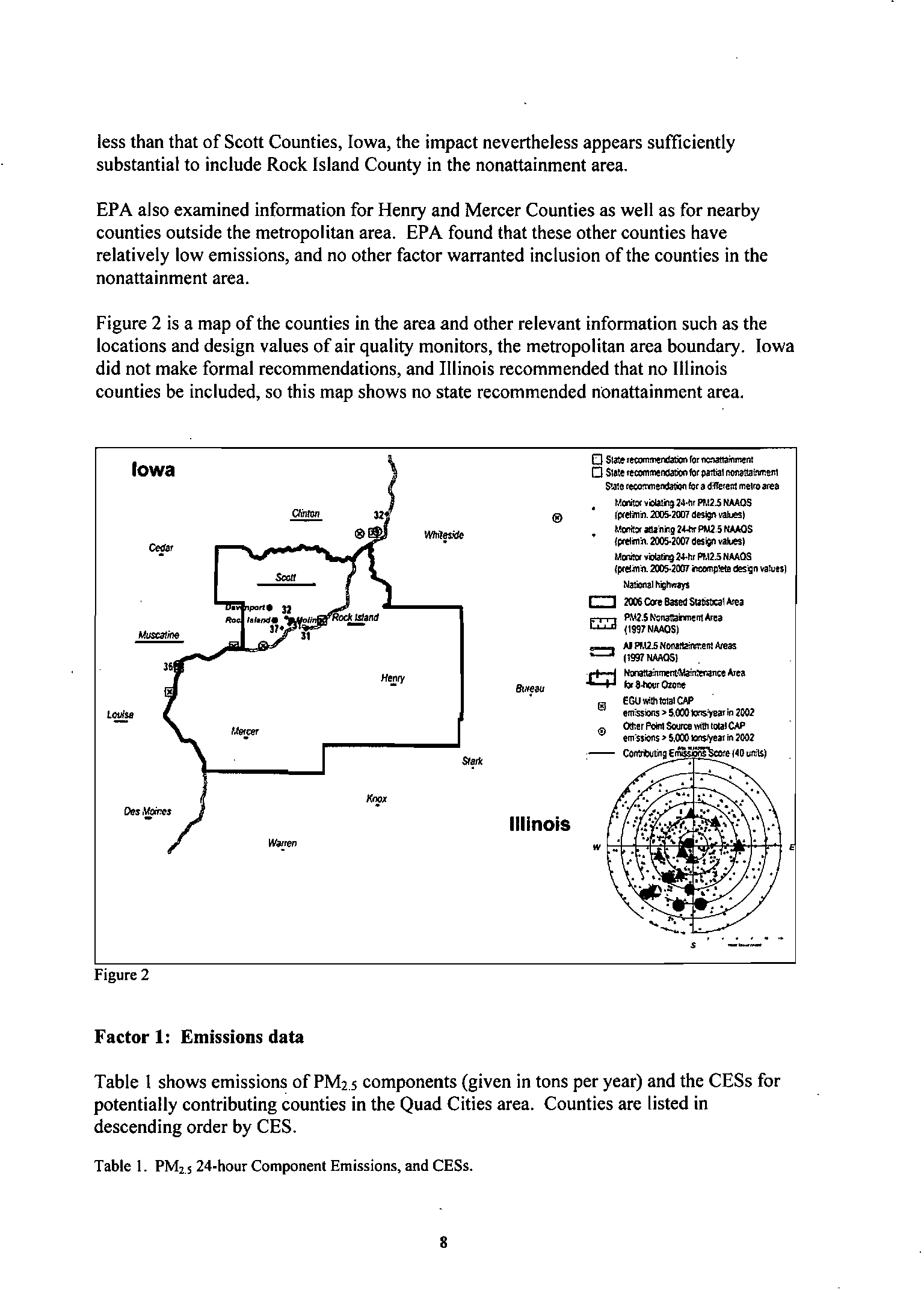

Factor 1: Emissions data

Table I shows emissions of PM25 components (given in tons per year) and the CESs for

potentially contributing counties in the Quad Cities area. Counties are listed in

descending order by CES.

Table 1. PM,s 24.hour Component Emissions, and CESs.

8

???????????

??????? ?? ??????????

???????? ???????? ??????????

???? ????

County

State

CES

PM"

PM"

PM"

SO,

NOx

VOCs

NH,

Recommended

emissions

emissions

emissions

(tpy)

(tpy)

(tpy)

(tpy)

Nonattainment?

total

carbon

other

(tDV)

(tDV)

(tDV)

No

Scoll IA

recommendation

100

2,034

395

1639

9 173

11 317

9323

1986

No

Muscatine

IA

recommendation

80

1702

283

1419

27020

10717

4910

1083

Clinton. IA

No

52

2,711

354

2357

II 506

13217

11 503

4870

Rock Island IL

No

27

932

269

663

2 169

6 140

7359

664

Henrv. IL

No

7

1,273

252

1021

268

6,648

3,431

2805

Mercer IL

No

4

793

149

644

133

1,120

1,469

1026

Rock Island County has a substantial fraction of the area's emissions.

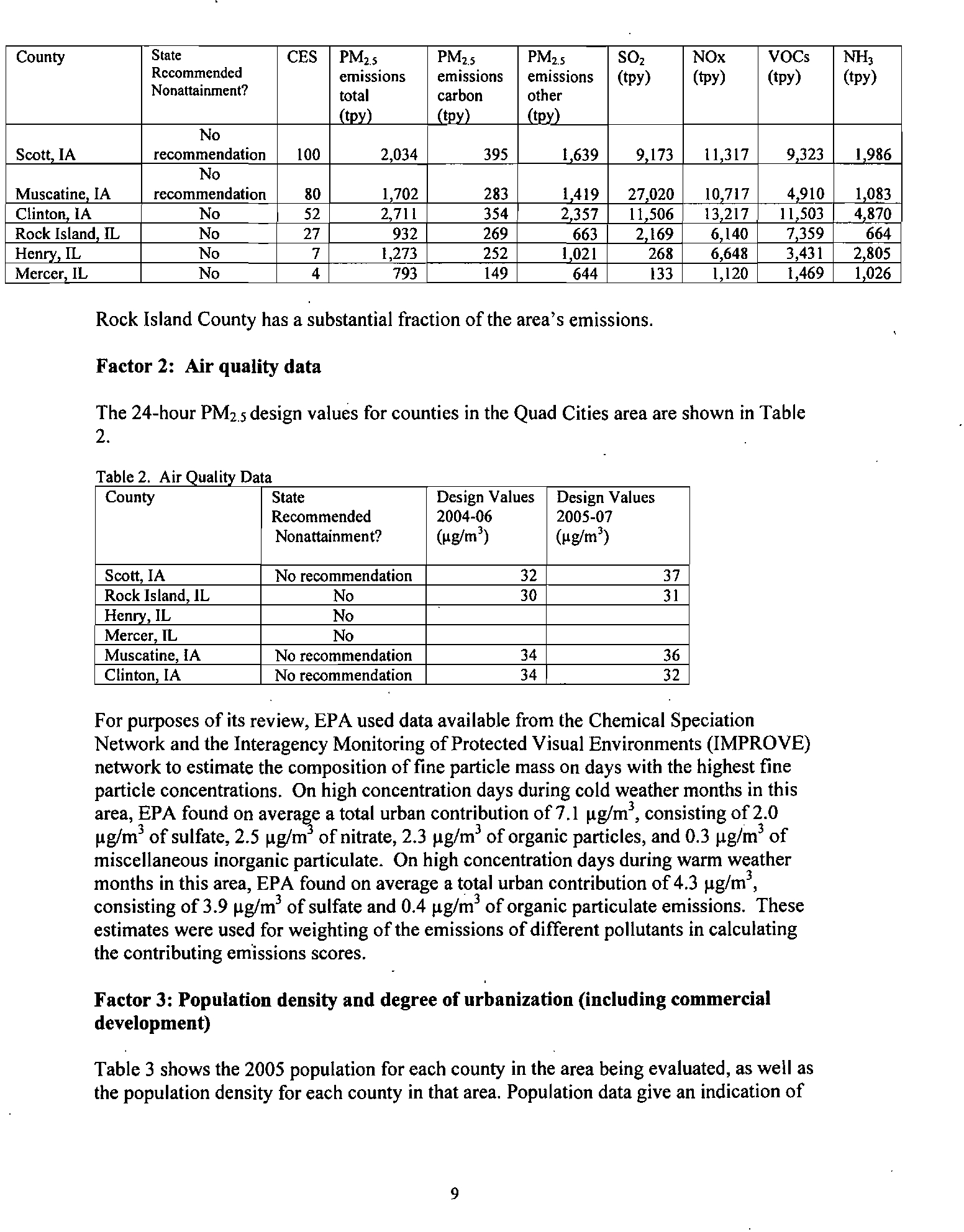

Factor 2: Air quality data

The 24-hour PM

25

design values for counties in the Quad Cities area are shown in Table

2.

Table 2. Air Oualitv Data

County

State

Design Values

Design Values

Recommended

2004-06

2005-07

Nonaltainment?

(~glm')

(~glm')

Scott,IA

No recommendation

32

37

Rock Island, IL

No

30

31

Henrv,IL

No

Mercer IL

No

Muscatine,

IA

No recommendation

34

36

Clinton

IA

No recommendation

34

32

For purposes of its review, EPA used data available from the Chemical Speciation

Network and the Interagency Monitoring

of Protected Visual Environments (IMPROVE)

network to estimate the composition

of fine particle mass On days with the highest fine

particle concentrations. On high concentration days during cold weather months

in this

area, EPA found

On

avera~e

a total urban contribution of7.1

~glm3,

consisting of2.0

~glm3

of sulfate, 2.5

~glm

of nitrate, 2.3 j!glm

3

of organic particles, and 0.3 j!g/m

3

of

miscellaneous inorganic particulate. On high concentration days during warm weather

months

in this area, EPA found On average a total urban contribution of 4.3 j!g/m

3

,

consisting of 3.9

~glm3

of sulfate and 0.4 j!glm

3

of organic particulate emissions. These

estimates were used for weighting

of the emissions of different pollutants in calculating

the contributing em'issions scores.

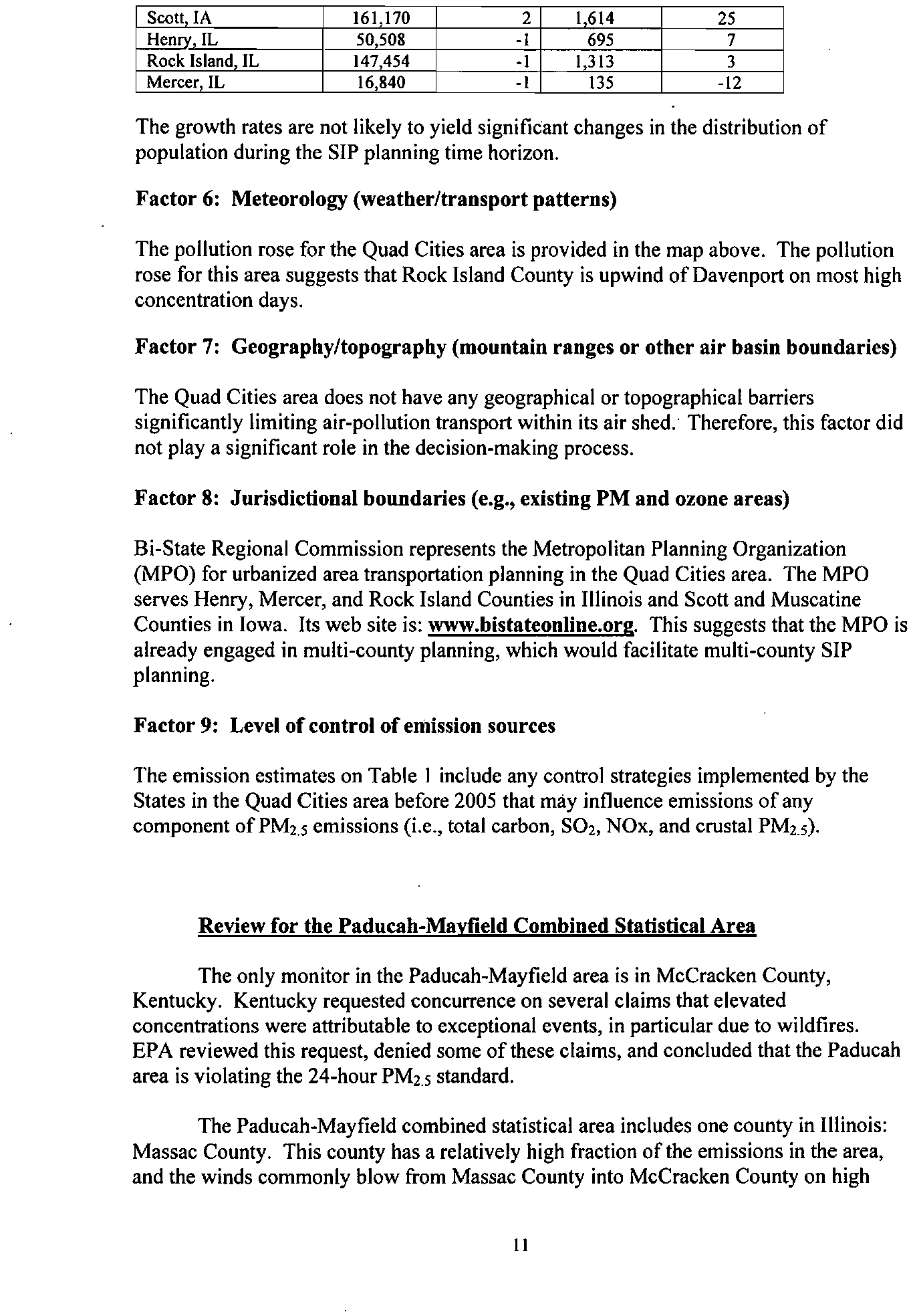

Factor 3: Population density and degree of urbanization (including commercial

development)

Table 3 shows the 2005 population for each county in the area being evaluated, as well as

the population density for each county in that area. Population data give an indication

of

9

???????????

??????? ?? ??????????

???????? ???????? ??????????

???? ????

whether it is likely that population-based emissions might contribute to violations ofthe

24-hour PM

2

.5 standards.

T

a

bl

e

3

.

Popu

I'

atmo

County

State Recommended

2005

2005

Nonattainment?

Population

Population

Density

(DoD/sa mil

Scott

[A

No recommendation

161 170

345

Rock [sland IL

No

147454

327

Henrv.

[L

No

50508

61

Mercer IL

No

16840

30

Muscatine [A

No recommendation

42567

95

Clinton IA

No recommendation

49744

70

Rock Island County has a substantial fraction of the area'spopulation. Other Illinois

counties have substantially lower populations.

Factor 4: Traffic and commuting patterns

Tbl4Tffi

a e

fa Ie an

dC

ommutmg

P

attems

County

State

2005

Number

Percent

Number

Percent

Recommended

VMT

Commuting to

Commuting to

Commuting

Commuting

Nonattainment?

(10'mil

any violating

any violating

into

into

counties

counties

statistical

statistical

area

area

No

Scott IA

recommendation

[,614

61500

79

74,020

95

Rock [sland IL

No

1,313

14,240

20

67,530

97

Henrv,IL

No

695

1870

8

22,340

91

Mercer IL

No

135

1200

15

6570

85

.No

Clinton IA

recommendation

423

2610

\I

3600

15

No

Muscatine,

[A

recommendation

372

17330

85

1,060

5

The listing of counties on Table 4 reflects a ranking based on the number ofpeople

commuting to other counties. The percentage

of Rock Island County commuters

commuting into Scott County, Iowa, is moderate but sufficient to view Rock Island

County as integrated into a Quad Cities area.

Factor 5: Growth rates and patterns

Table 5 below shows population, population growth, VMT and VMT growth for counties

that are included in the Quad Cities area. Counties are listed

in descending order based

on VMT growth between 1996 and 2005.

Table 5.

PI'

opu atlon and VMT

Growlh

andP

ercent

Ch

anl!c.

Location

Population

Population

2005 VMT

VMT

(2005)

% change

(10'mil

% change

(2000-05)

11996-2005)

Muscatine [A

42,567

2

372

43

Clinton [A

49,744

-1

423

39

10

???????????

??????? ?? ??????????

???????? ???????? ??????????

???? ????

Scott IA

161 170

2

1614

25

Henrv.IL

50508

-1

695

7

Rock Island IL

147454

-I

1 313

3

Mercer IL

16,840

-I

135

-12

The growth rates are not likely to yield significant changes in the distribution of

population during the SIP planning time horizon.

Factor 6: Meteorology (weather/transport patterns)

The pollution rose for the Quad Cities area is provided in the map above. The pollution

rose for this area suggests that Rock Island County

is upwind of Davenport on most high

concentration days.

Factor 7: Geography/topography (mountain ranges or other air basin boundaries)

The Quad Cities area does not have any geographical or topographical barriers

significantly limiting air-pollution transport within its air shed. Therefore, this factor did

not

playa significant role in the decision-making process.

Factor 8: Jurisdictional boundaries (e.g., existing PM and ozone areas)

Bi-State Regional Commission represents the Metropolitan Planning Organization

(MPO) for urbanized area transportation planning in the Quad Cities area. The MPO

serves Henry, Mercer, and Rock Island Counties in Illinois and Scott and Muscatine

Counties

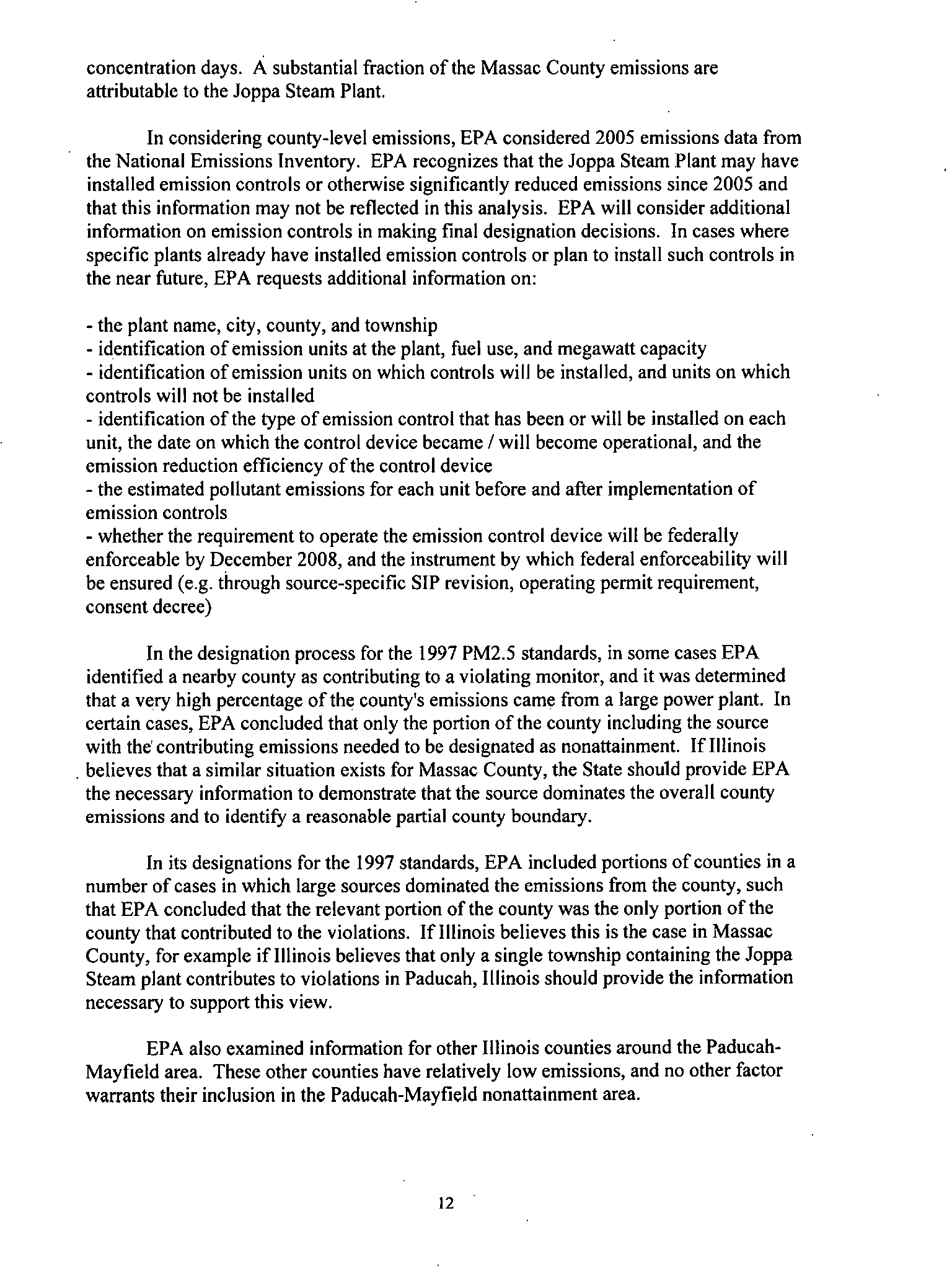

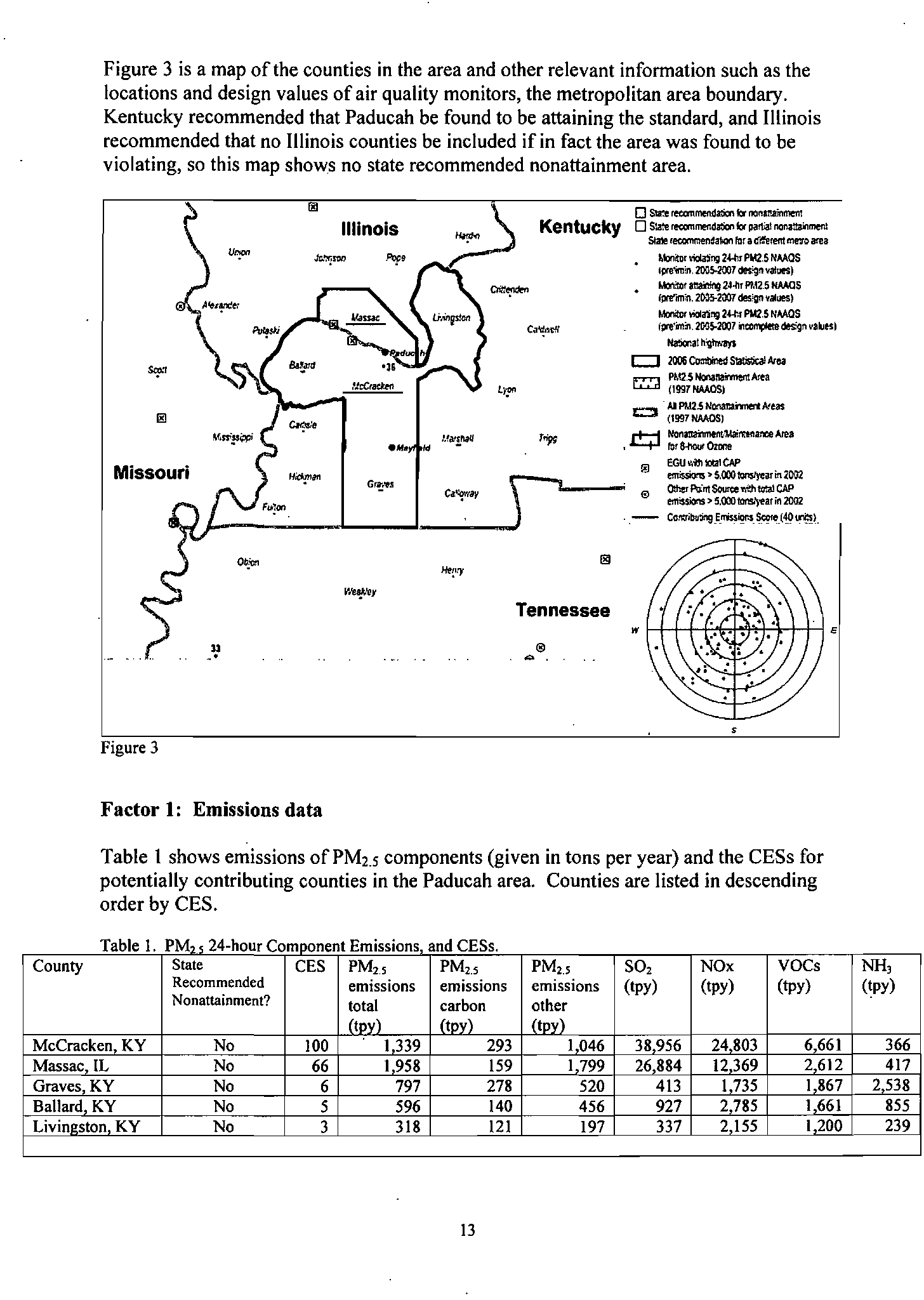

in Iowa. Its web site is: www.bistateonline.org.This suggests that the MPO is